Adjustable type electromagnetic damping vibration absorption boring bar

A technology of electromagnetic damping and electromagnetic damper, which is applied to boring bars and other directions, can solve the problems of difficult and complicated manufacturing, and the structure of vibration-absorbing boring bars is easy to fail, and achieves the effect of simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

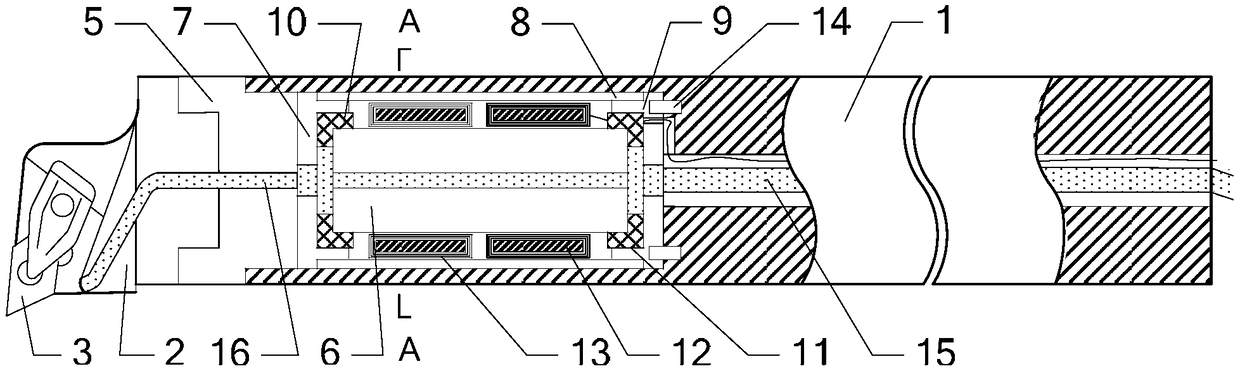

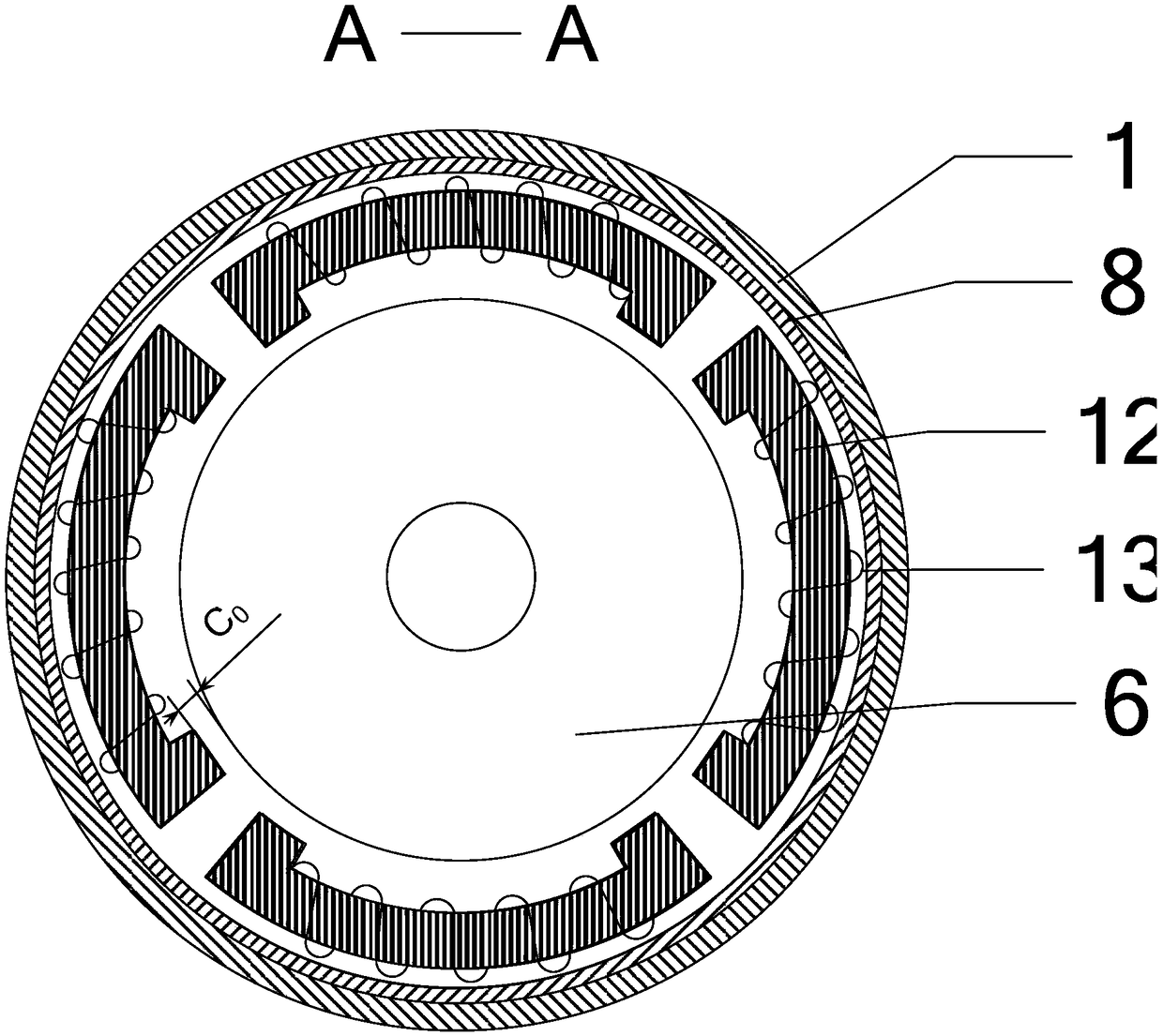

[0039] Embodiment: combine below Figure 1 to Figure 6 This embodiment will be described in detail.

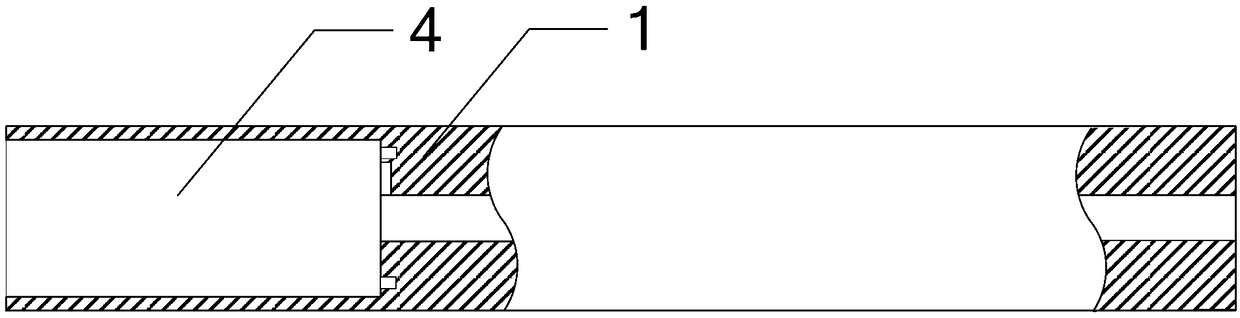

[0040] The adjustable electromagnetic damping and damping boring bar described in this embodiment includes a rod body 1, and a cutter head 2 is arranged at the front end of the rod body 1, and the cutter head 2 is used for clamping a boring tool 3;

[0041] The damping boring bar also includes a main controller, an excitation current source and an electromagnetic damper;

[0042] The master controller pre-stores the corresponding relationship table between the combination of process parameters and the optimal excitation current. Each combination of process parameters includes the rotational speed, feed rate, back engagement, workpiece material and geometric parameters of the boring tool;

[0043] The electromagnetic damper can minimize the radial vibration of the rod body 1 under the corresponding process parameter combination under the excitation of the optimal excitation cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com