Noise reduction type high speed small size axial flow fan

A small-sized axial flow fan technology, applied in the direction of axial flow pumps, electromechanical devices, mechanical equipment, etc., can solve the problem of poor air intake uniformity of axial guide vanes, few studies on fan guide structure, and influence on the outflow of impeller blades and other problems, to achieve the effects of slowing static and dynamic interference, excellent aerodynamics, and reducing radial vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

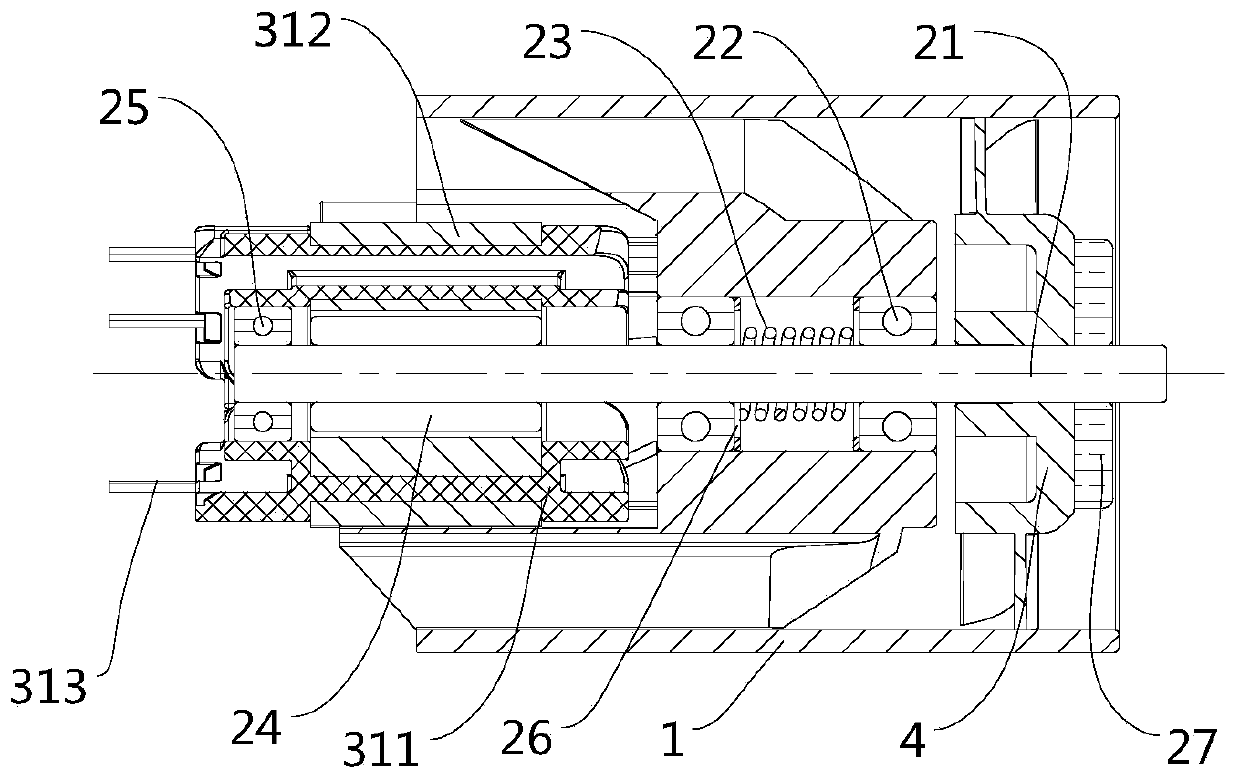

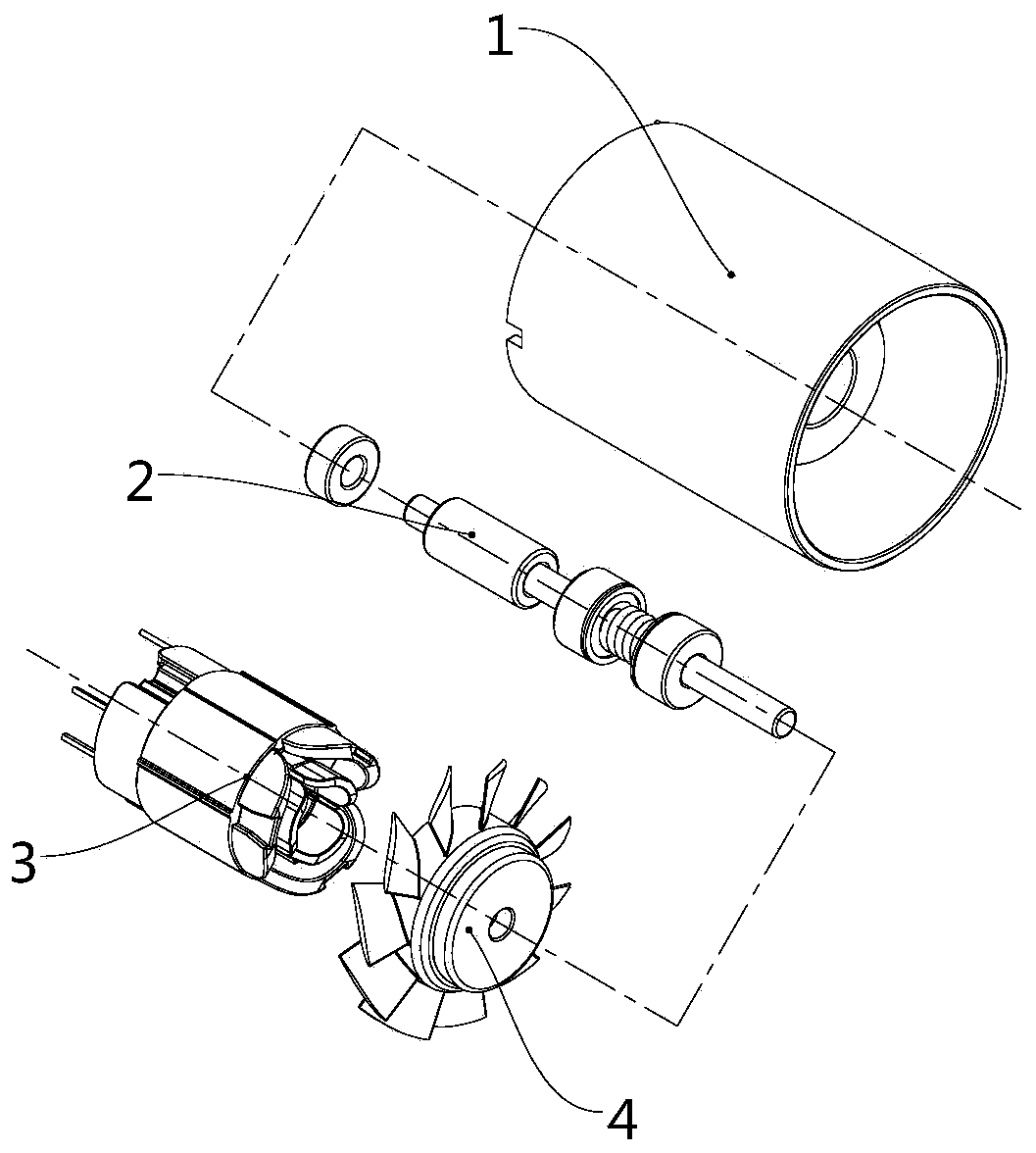

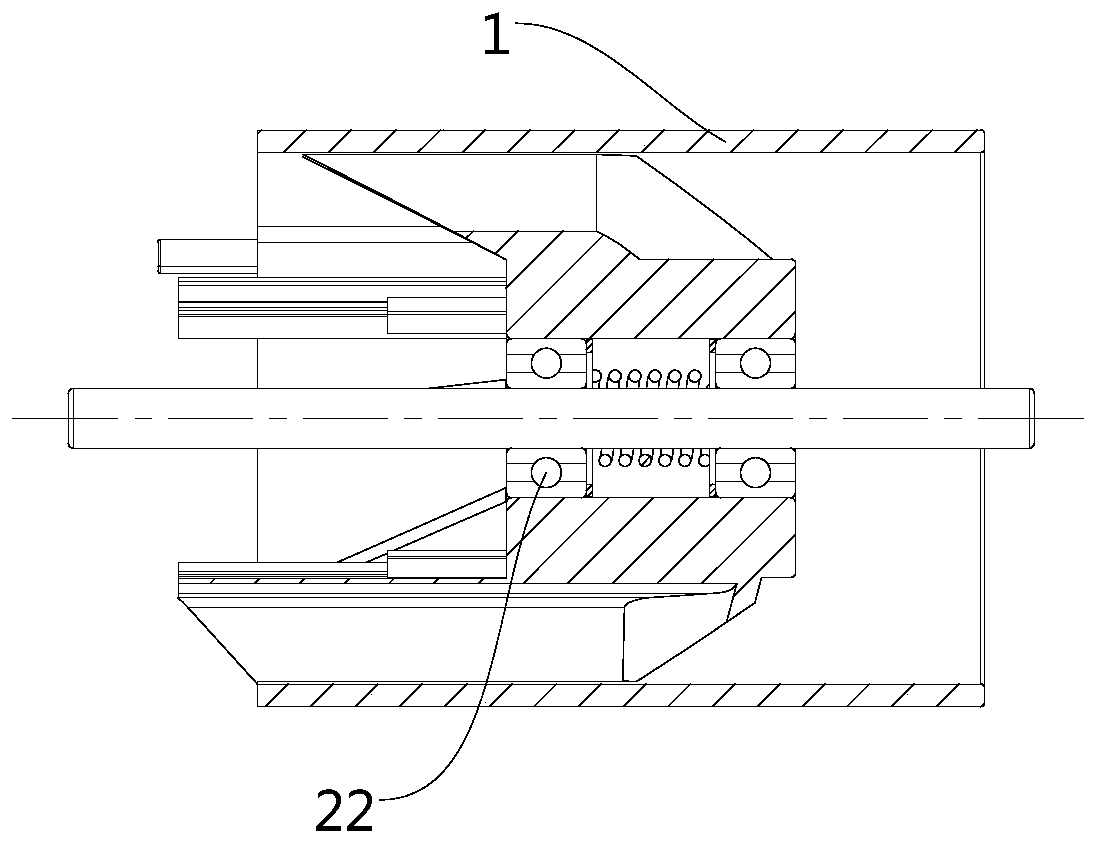

[0035] Embodiment: Noise-reducing high-speed small-size axial flow fan, the structure is as follows Figure 1 to Figure 11 As shown, the air cylinder 1 is included, the air cylinder 1 is provided with a rotor assembly 2 and a stator assembly 3, the air inlet end of the air cylinder 1 is provided with an impeller 4 connected with the rotor assembly 2, and the rotor assembly 2 includes a rotating shaft 21, the rotating shaft A pair of support bearings 22, a magnetic steel 24 and an auxiliary bearing 25 are arranged in sequence along the direction of the fan inflow on the top 21, and a pair of support bearings 22 are connected with the steel sleeve in the blower 1, and a spring 23 is arranged between the pair of support bearings 22 , the auxiliary bearing 25 is connected with the stator assembly 3 .

[0036] The stator assembly 3 includes three sets of stator units 31 connected end-to-end. The stator unit 31 is an integral injection molding structure of a skeleton 311 and an iron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com