Patents

Literature

175results about How to "Uniform air intake" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

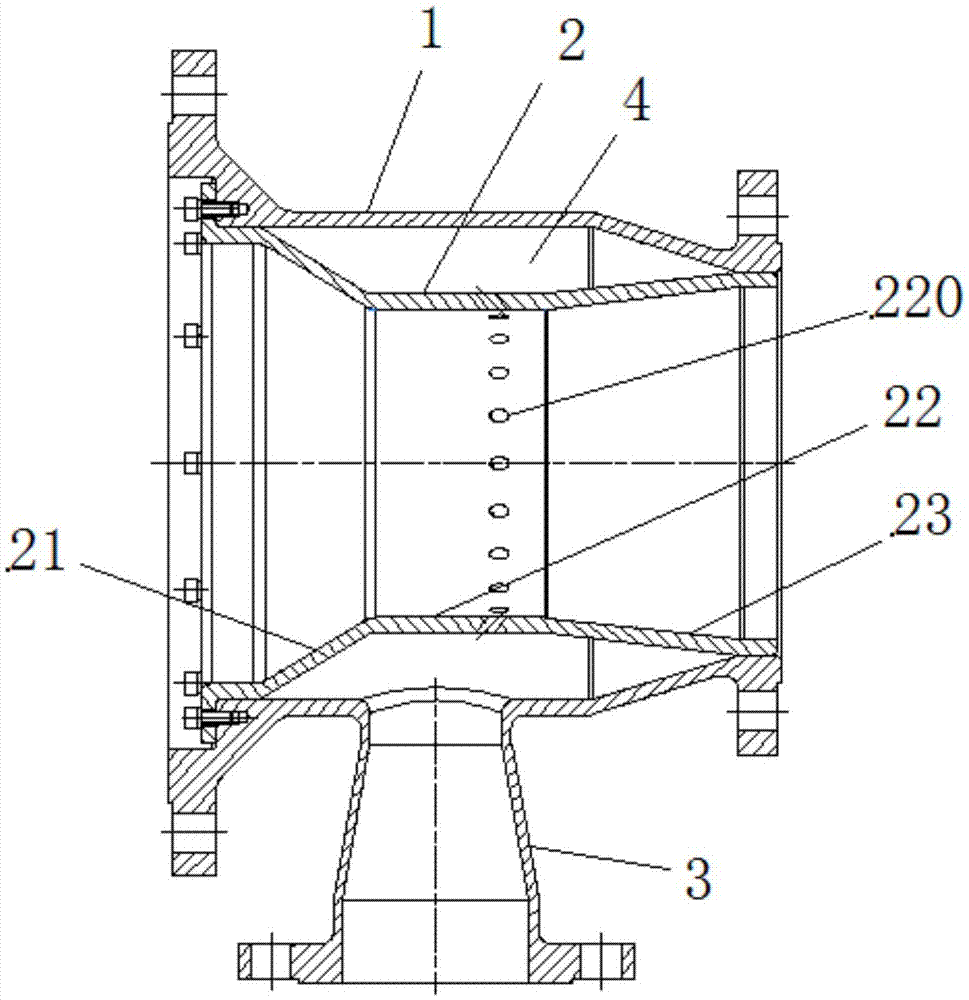

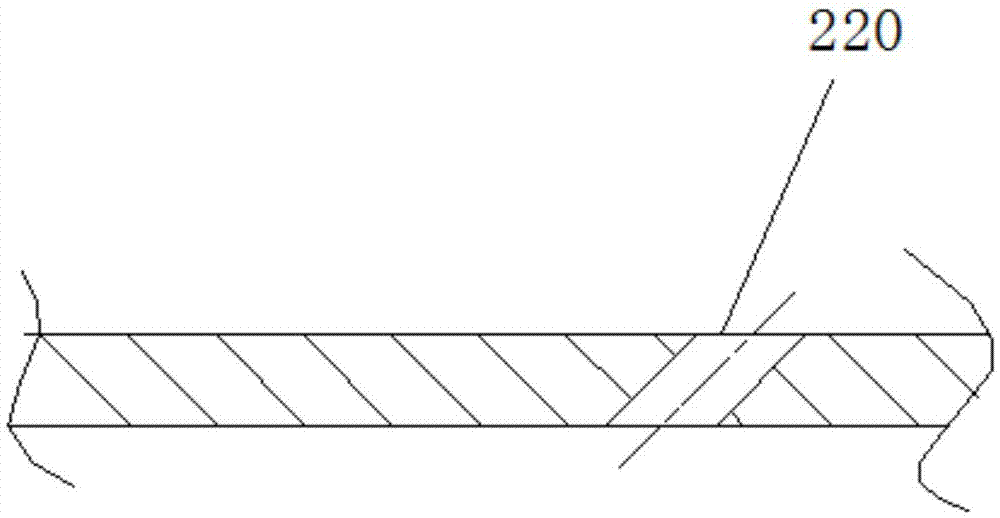

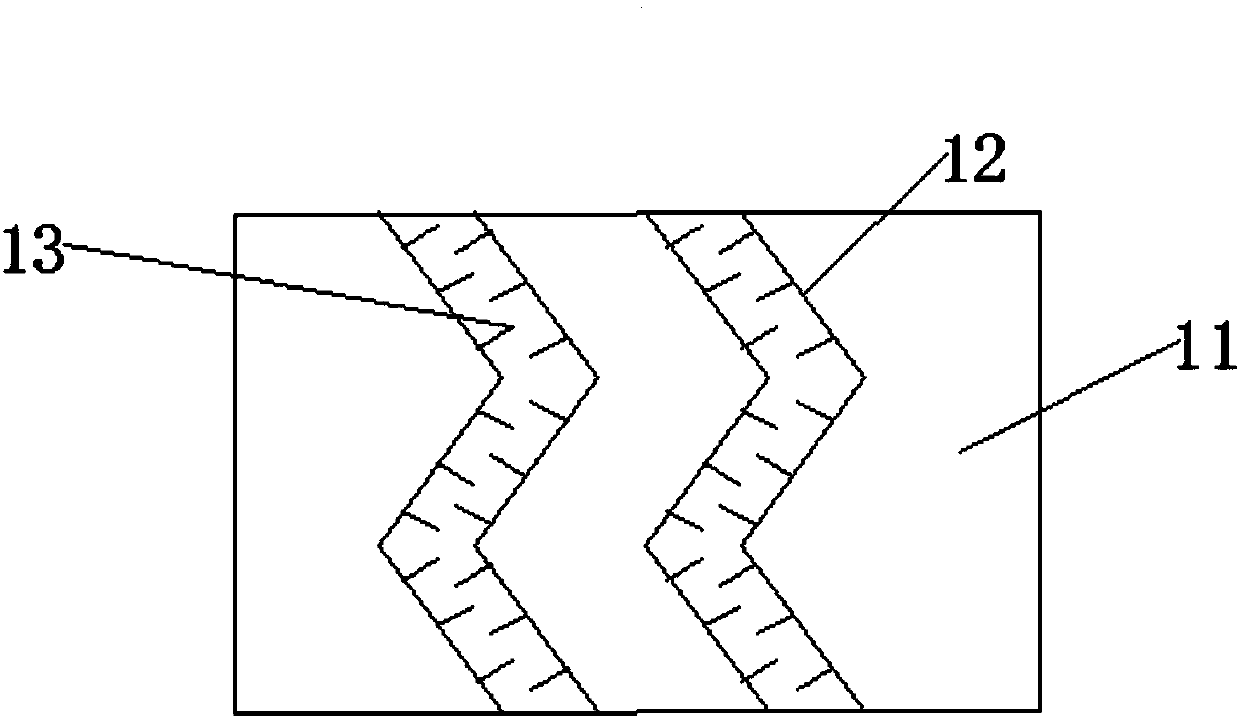

Gas distributor for uniform gas emission

InactiveCN101949007ASimple structureEasy to processChemical vapor deposition coatingGas phaseProcess engineering

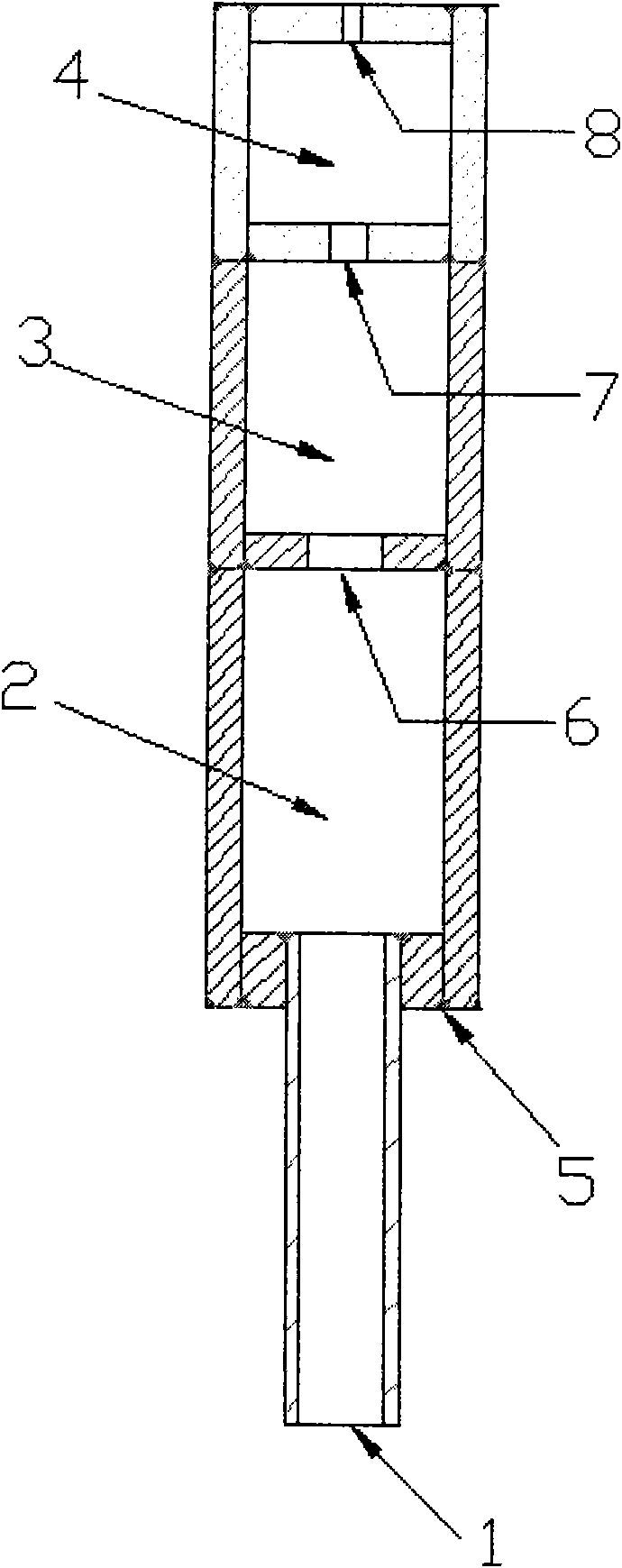

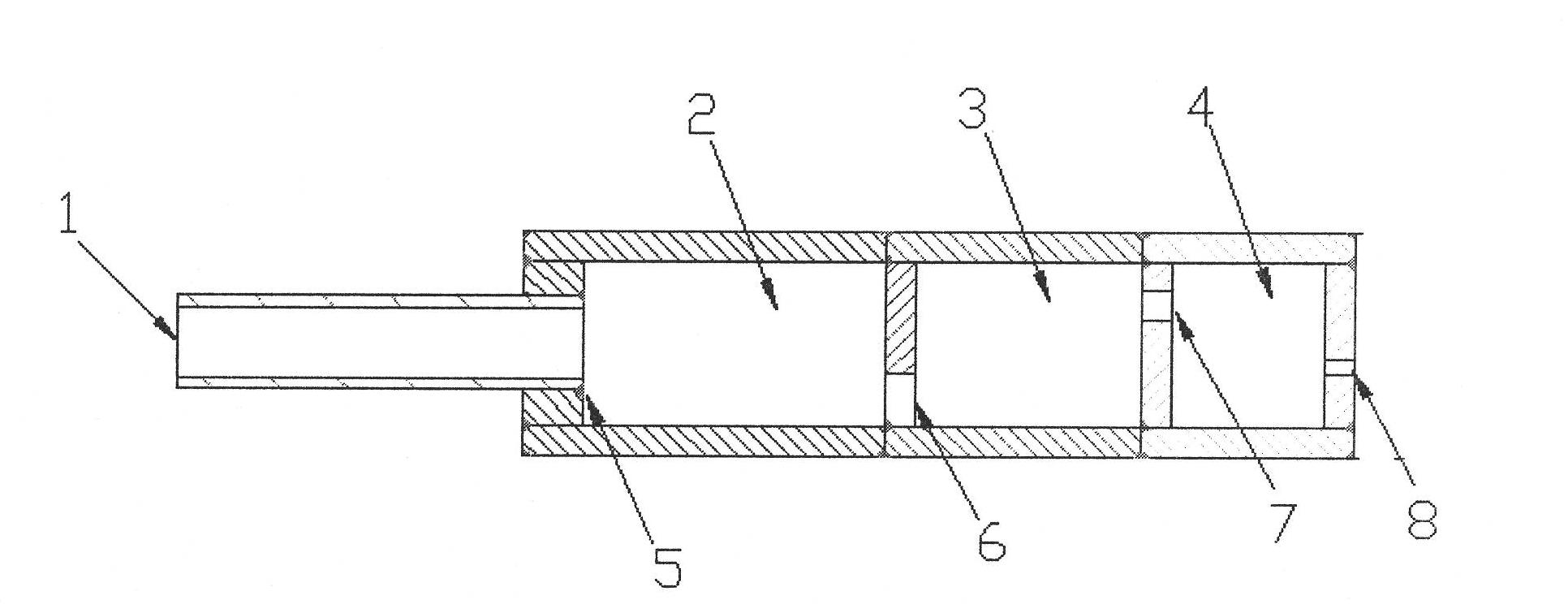

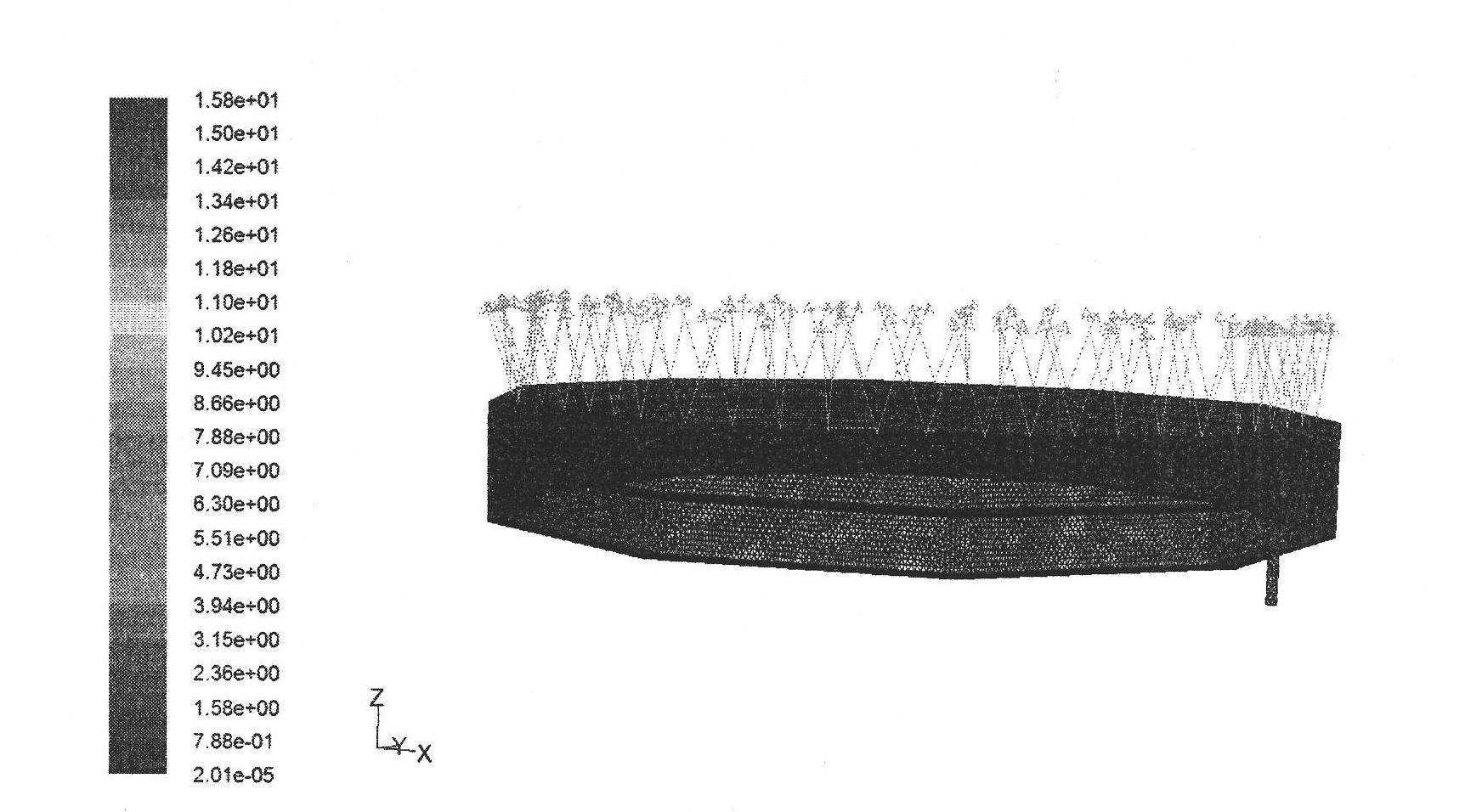

The invention relates to a gas distributor for uniform gas emission. The gas distributor is generally arranged on a gas inlet section on a chemical vapor deposition device and used for providing uniform inlet gas for a reaction chamber. The gas distributor comprises at least one gas inlet pipe and over two closed gas distribution cavities, which are intercommunicated; the gas inlet pipe and the gas distribution cavities are fixedly connected in turn along the running direction of gas flow; the adjacent two gas distribution cavities are mutually spaced by a connecting wall; and over one gas distribution hole is distributed on the connecting wall. The final outlet gas flow speeds are equal by adjusting the heights or the lengths of the gas distribution cavities and adjusting the arrangement position and aperture size of the gas distribution hole on each connecting wall. The gas distributor has the advantages of simple structure, easy processing, convenient assembly and maintenance and low cost, can provide uniform inlet gas for the reaction chamber, ensures the uniformity and consistency of the inlet gas of the chemical vapor deposition device, and is favorable for uniform growth of a film.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

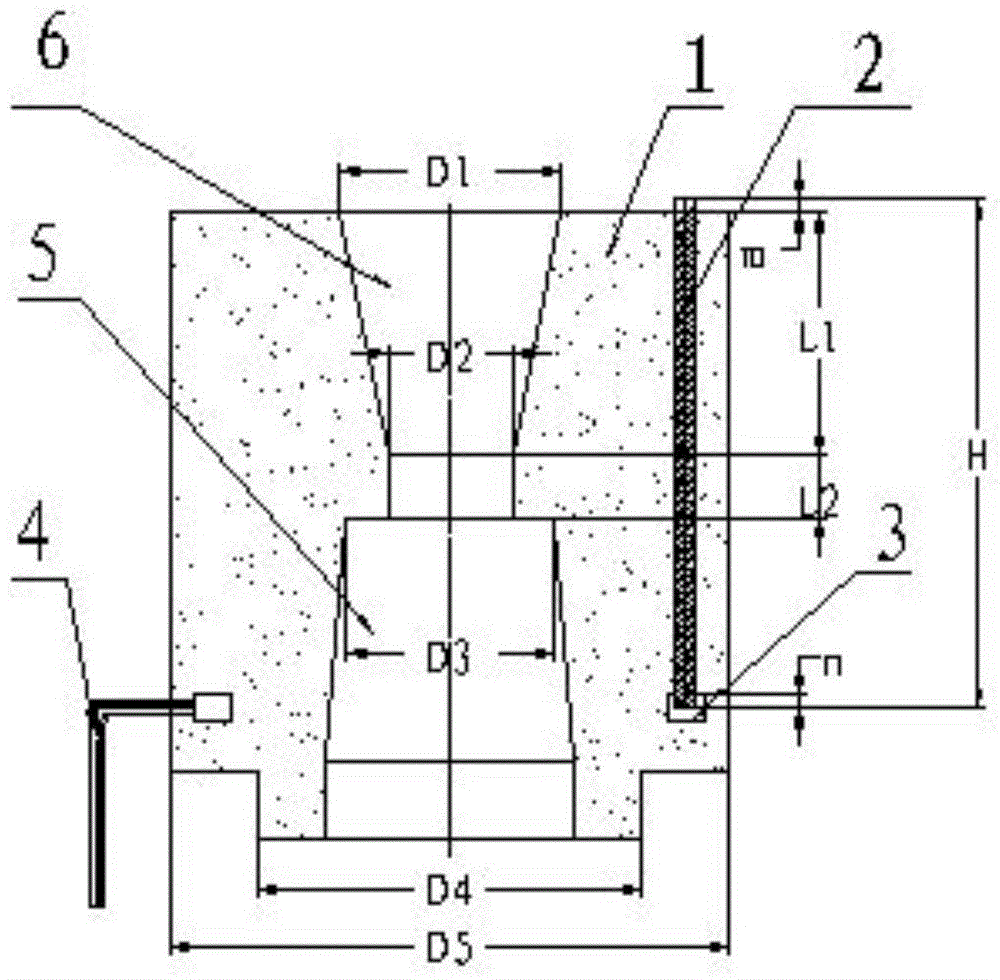

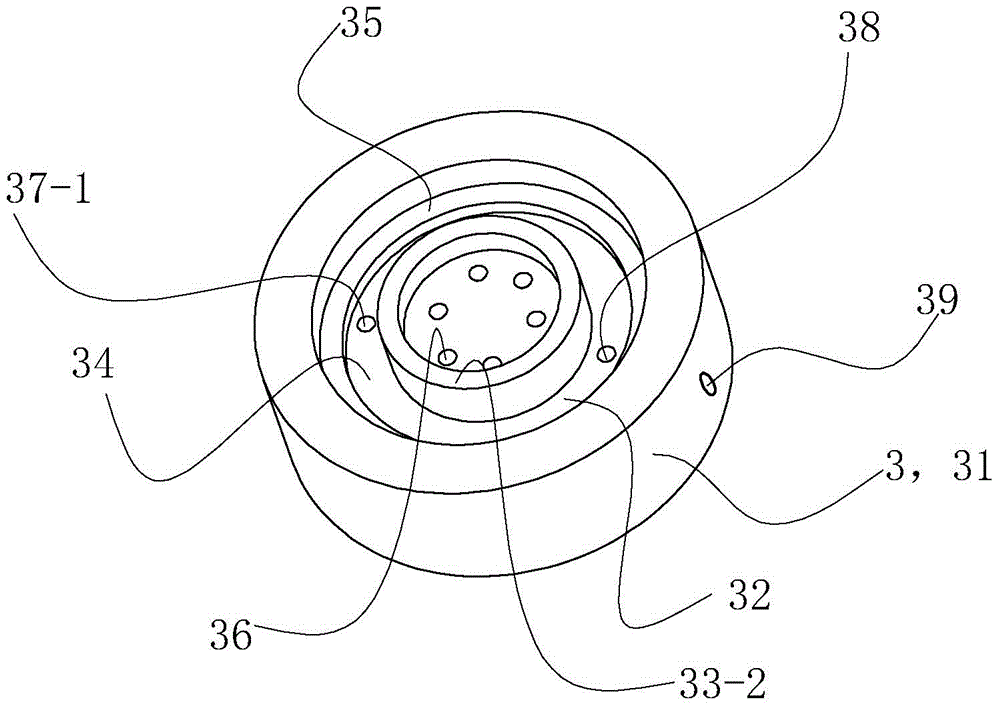

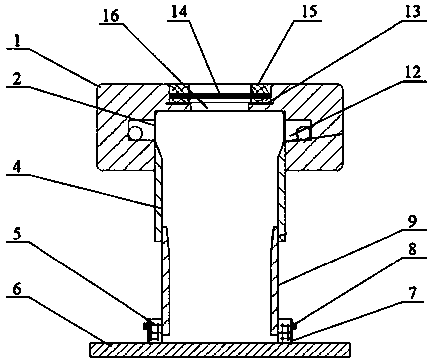

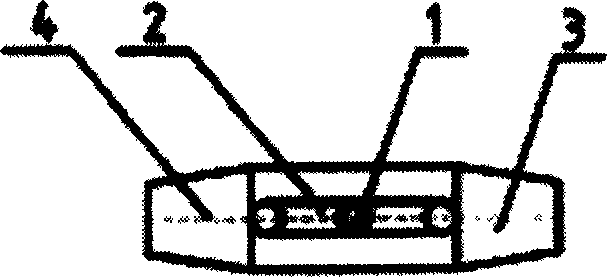

Ladle breathable upper nozzle seat brick and method for controlling nozzle slag entrainment

The invention relates to a ladle ventilating upper nozzle seat brick and a method for controlling nozzle slag volume, which comprises a ladle upper nozzle seat brick body, a ventilating ceramic rod and an air chamber box, the air chamber box is located at the bottom of the ventilating ceramic rod and connected with the ventilating ceramic rod Connected, there are a plurality of breathable ceramic rods, which are evenly arranged in the body of the upper nozzle block in a ring around the flow steel hole. The top of each breathable ceramic rod protrudes from the upper surface of the upper nozzle block body. A plurality of slots for fixing the air-permeable ceramic rods are provided, and the bottom end of each air-permeable ceramic rod extends into the slot of the air intake chamber box. When the molten steel in the ladle is at a low level, argon gas is blown in from the inlet pipe to form a ring-shaped air curtain barrier around the upper nozzle of the ladle to wash the molten steel that is about to enter the upper nozzle. The problem of eddy current slag entrainment at the nozzle not only improves the cleanliness of molten steel, but also reduces the amount of molten steel in the ladle injection surplus, a year-on-year decrease of more than 30%.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

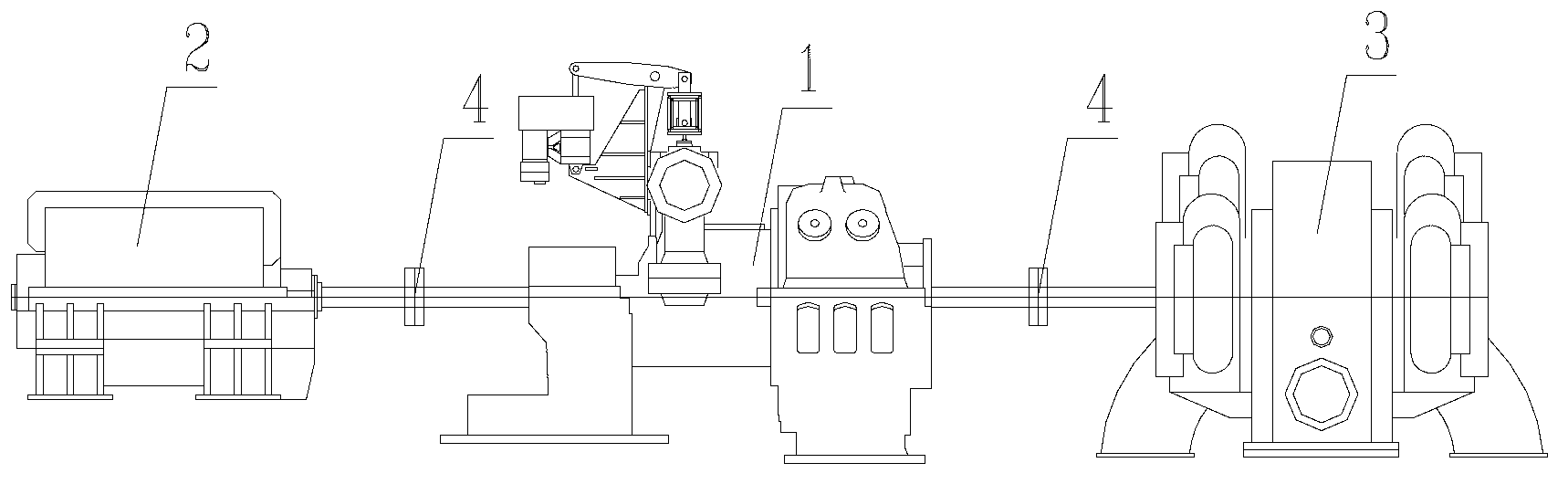

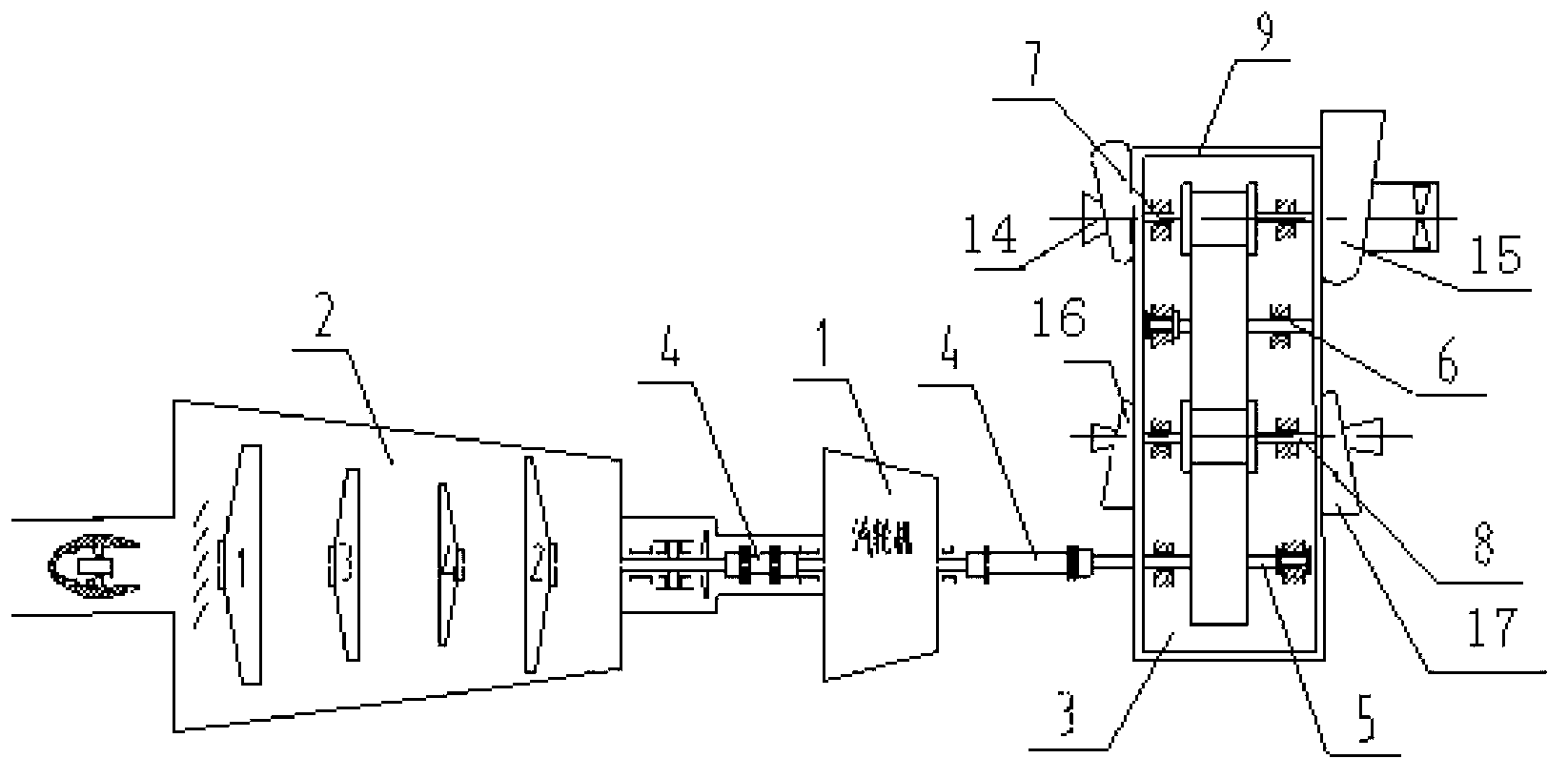

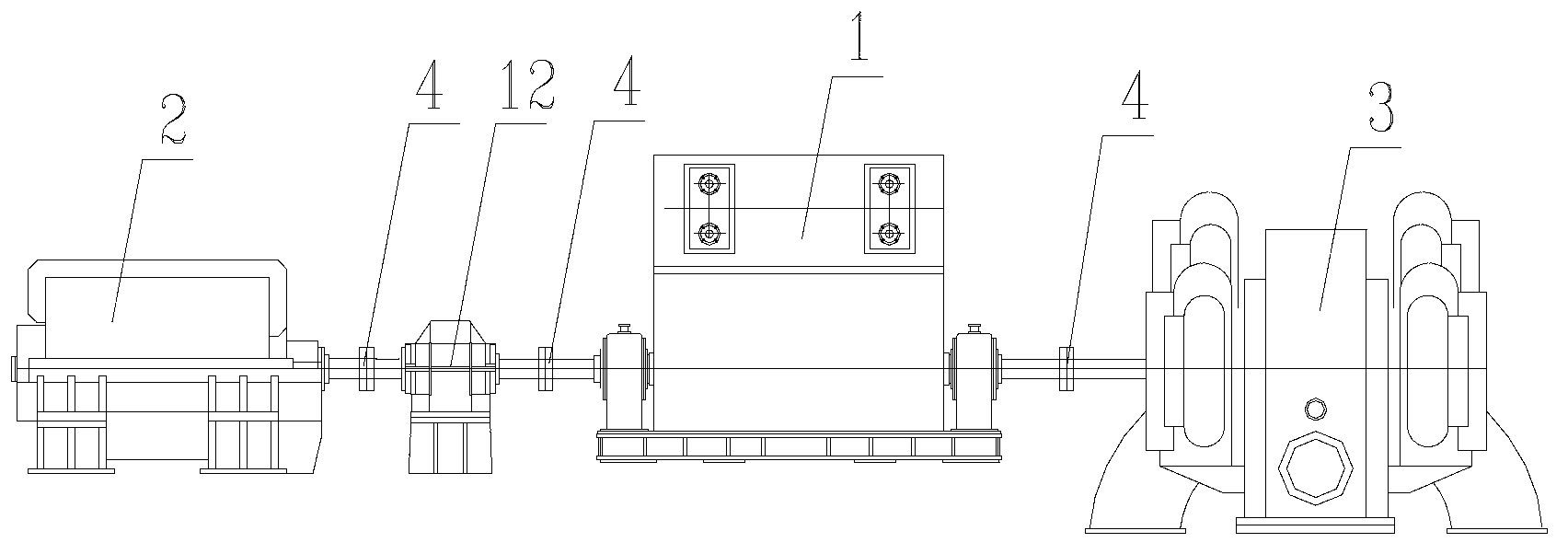

Single-shaft plusing multiple-shaft type carbon dioxide gas centrifugal compressor unit

ActiveCN102979751ADetermine the numberSingle stage pressure ratio highPump installationsNon-positive displacement fluid enginesProcess systemsCoupling

A single-shaft plusing multiple-shaft type carbon dioxide gas centrifugal compressor unit comprises a double extended shafts type driving device. A diaphragm coupling which is used for a left extended shaft of the double extended shafts type driving device is directly connected with a single-shaft type low pressure cylinder. The diaphragm coupling which is used for a right extended shaft of the double extended shafts type driving device is connected with a multiple-shaft type high pressure cylinder. Carbon dioxide gas enters into a first stage impeller of the single-shaft type low pressure cylinder, after four stage compression, the carbon dioxide gas flows out through a back outlet pipeline of a fourth stage of the low pressure cylinder and then enters into a first stage impeller of the multiple-shaft type high pressure cylinder. After another four stage compression, the carbon dioxide gas is discharged from a fourth stage impeller of the multiple-shaft type high pressure cylinder 3 and enters into subsequent process system. The single-shaft plusing multiple-shaft type carbon dioxide gas centrifugal compressor unit can save energy by over 10 % compared with the existing single-shaft plusing multiple-shaft type device and is high in security and stability compared with the multiple-shaft type carbon dioxide gas compressor in foreign.

Owner:西安赛尔机泵成套设备有限责任公司

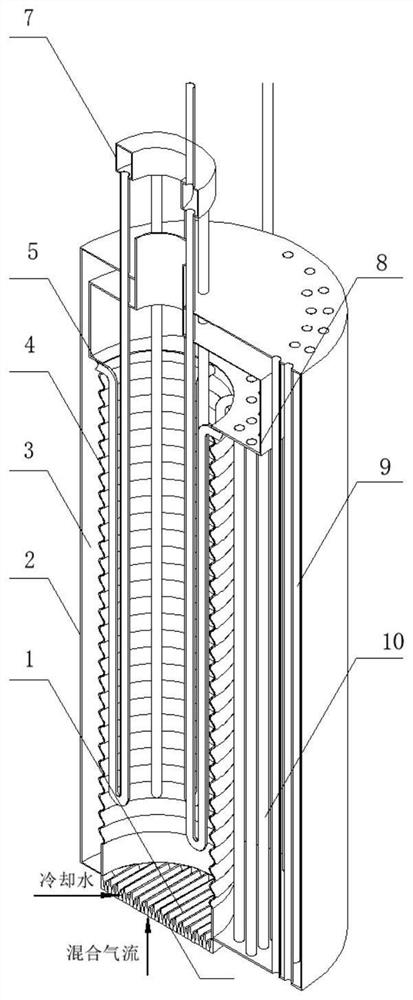

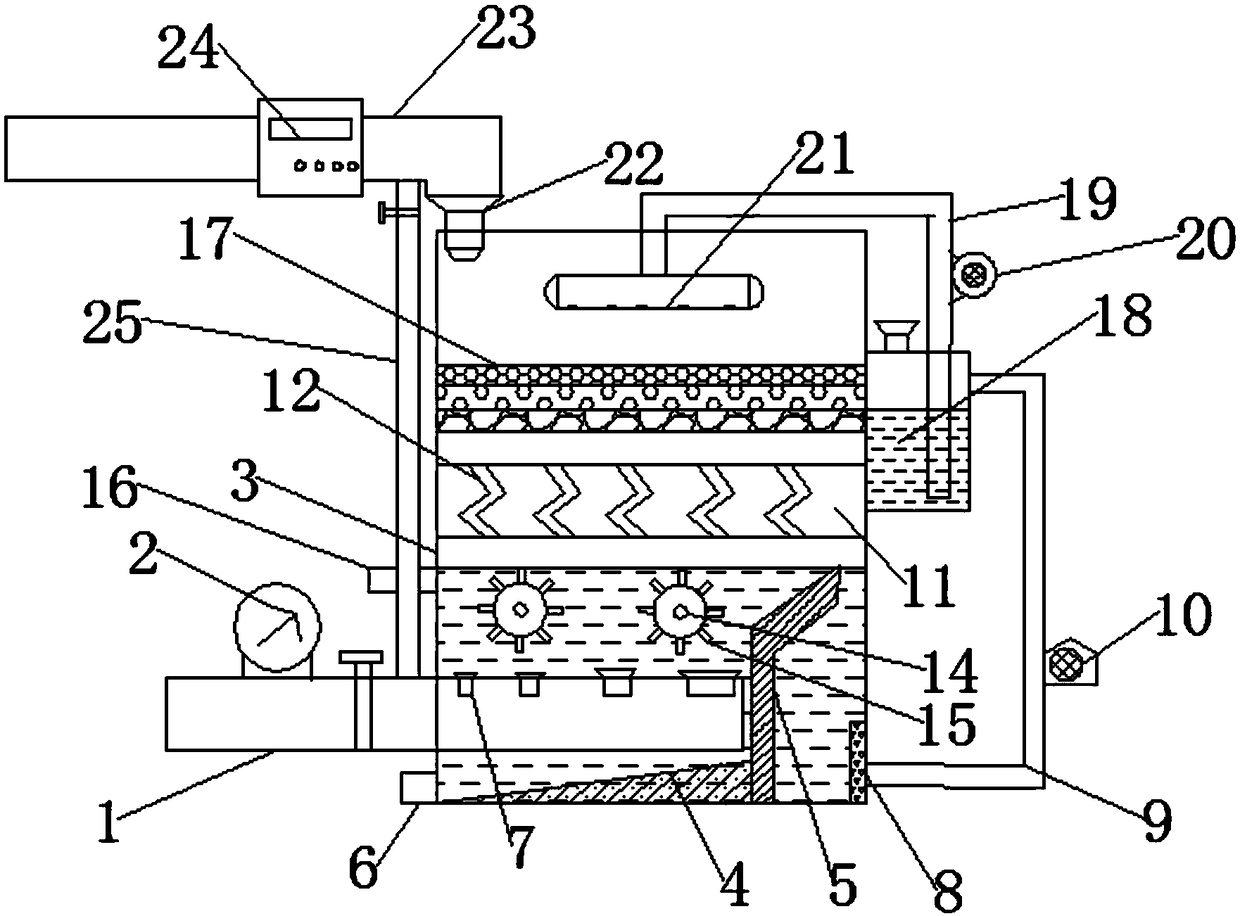

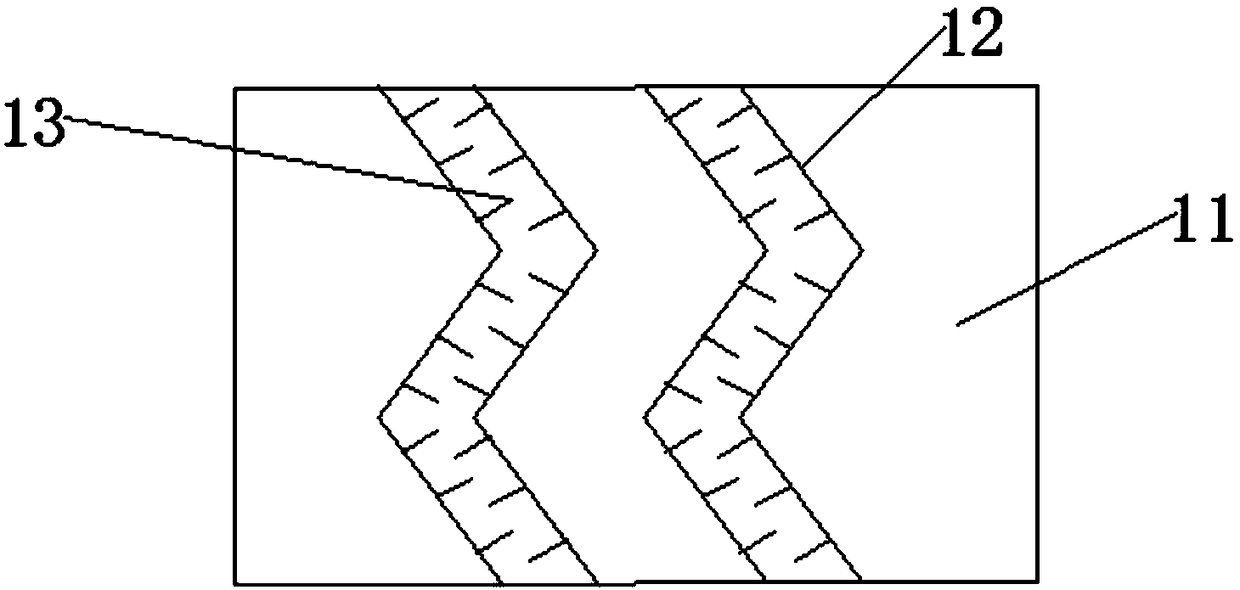

Hearth and combustor cooling type surface cold flame premixing gas boiler

The invention discloses a hearth and combustor cooling type surface cold flame premixing gas boiler. The boiler comprises a hearth, a water cooling combustor is installed at the position of an inlet of the hearth, an outlet of the hearth is connected to a reversal chamber, U-shaped water cooling components are evenly arranged in the hearth in the circumferential direction, inlets of the U-shaped water cooling components are evenly connected to an annular pipeline in the circumferential direction, and water outlets of the U-shaped water-cooling components and a water outlet of the water coolingcombustor are connected to a boiler water tank. According to the hearth and combustor cooling type surface cold flame premixing gas boiler, by the adoption of the water cooling combustor, uniform gascombustion can be achieved, the flame root combustion temperature is reduced while a local high-temperature area is not generated, generation of thermal NOx at the flame root is reduced, and meanwhile, a hearth cooling system is adopted, a U-shaped pipeline cooling structure is arranged, the compact structure and manufacturing economy of the boiler are achieved while the uniform low-temperature atmosphere in the boiler is guaranteed, and generation of the NOx during gas fuel combustion is further remarkably reduced.

Owner:XI AN JIAOTONG UNIV

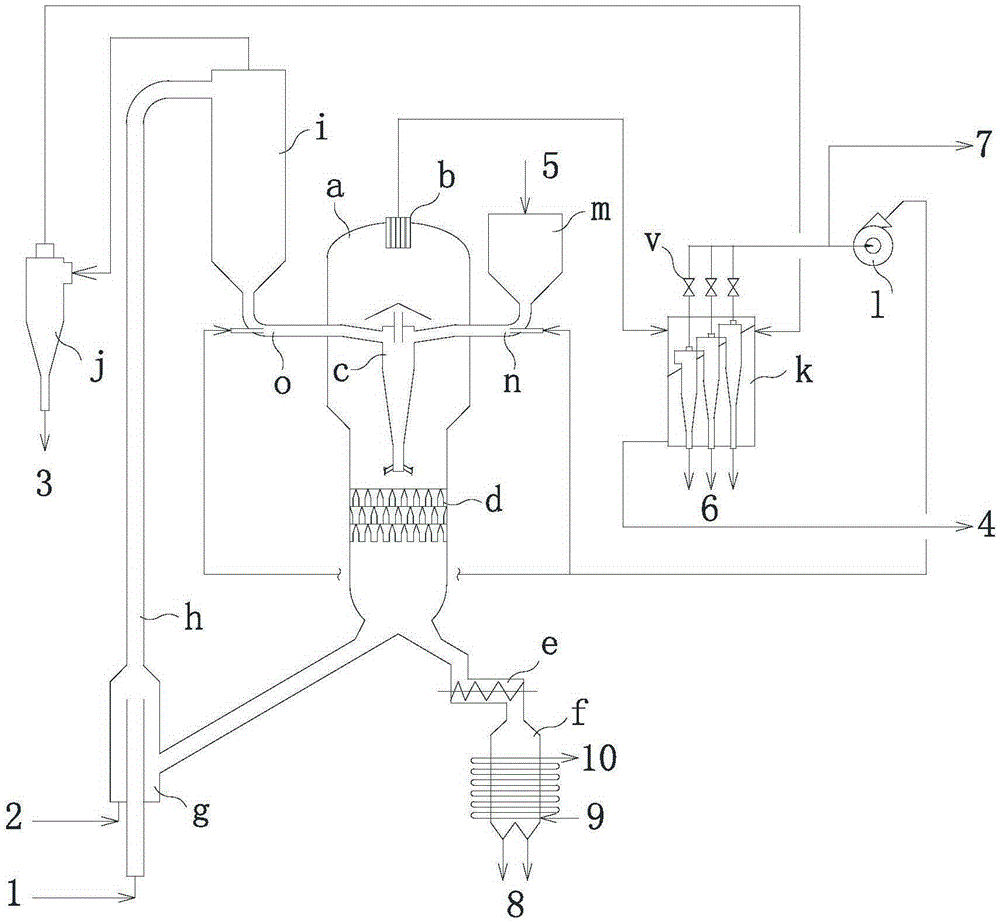

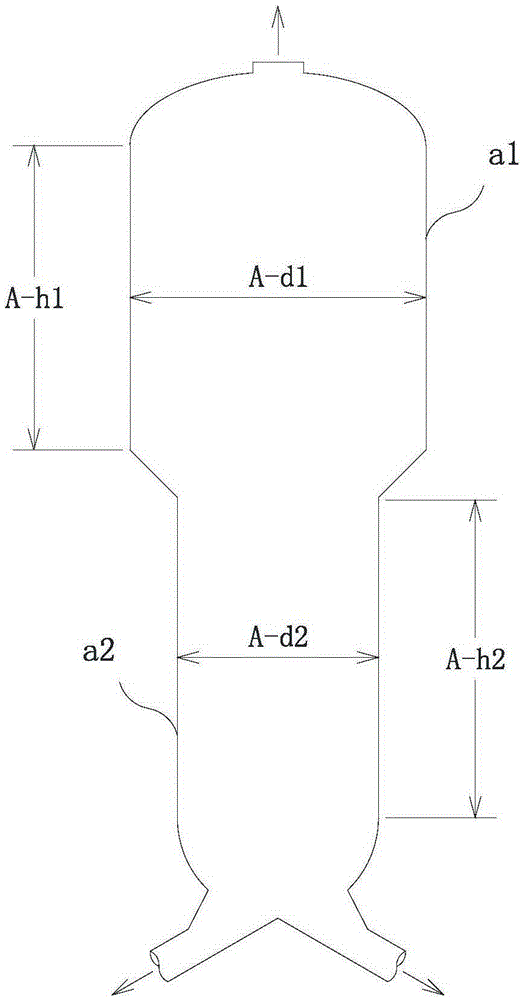

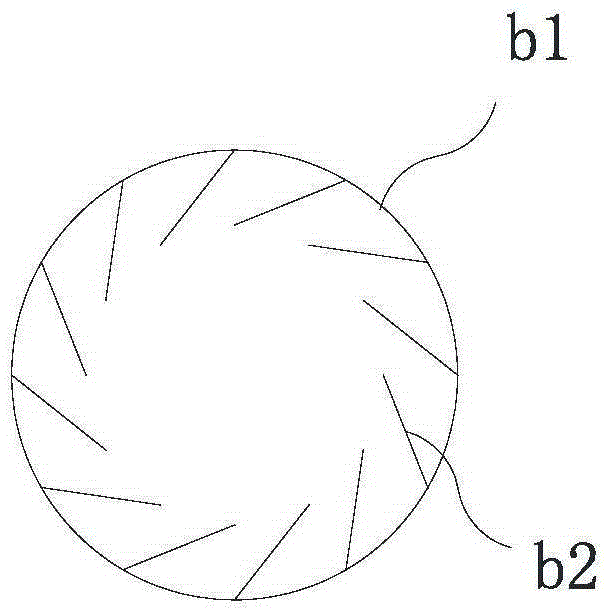

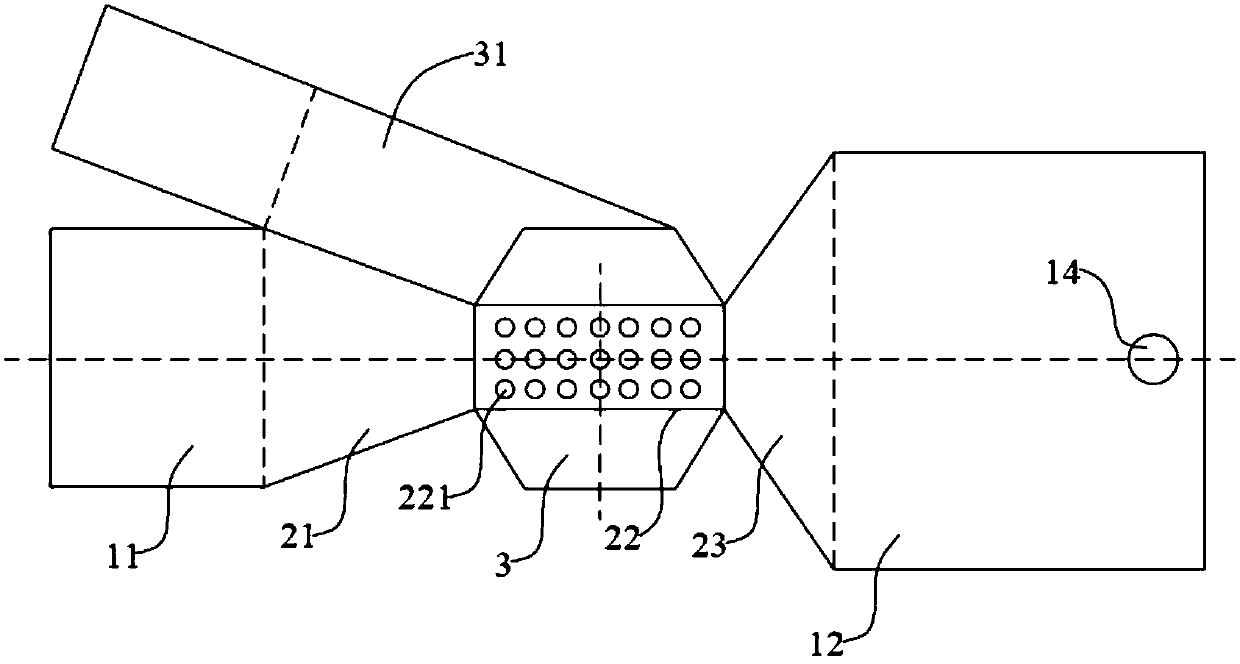

Gas-solid mixed heat carrier quick pulverized coal pyrolysis process and device

InactiveCN105238425AAvoid entrainmentPush breakSpecial form destructive distillationCycloneHeat carrier

The invention discloses a gas-solid mixed heat carrier quick pulverized coal pyrolysis process and a device. The device includes a diameter variable pyrolysis reactor, the top outlet of the pyrolysis reactor is provided with a pyrolytic oil gas collector, a vortex mixer is hidden in the middle part, a breathable heat storage layer is arranged at the lower part, two hot semicoke outlets are arranged at the bottom, one outlet is used for discharging hot semicoke, and the other outlet is connected to a tobacco pipe type refeeder, the tobacco pipe type refeeder is connected to a simple separator through a combustion lift pipe, the bottom of the simple separator is provided with an L-shaped high temperature semicoke control valve, the bottom of a dry raw material coal bunker is equipped with an L-shaped dry raw material coal control valve, outlets of the two valves are respectively connected to two inlets of the vortex mixer, the pyrolytic oil gas collector is in connection with an oil gas inlet manifold box of a box type multi-tube cyclone dust collector, the outlet of the box type multi-tube cyclone dust collector is connected to a high temperature centrifugal fan, the outlet of the high temperature centrifugal fan is connected to the L-shaped dry raw material coal control valve and the L-shaped high temperature semicoke control valve. Therefore, disadvantages of the prior art are overcome.

Owner:SHAANXI MEISILIN ENERGY SCI & TECH RES INST

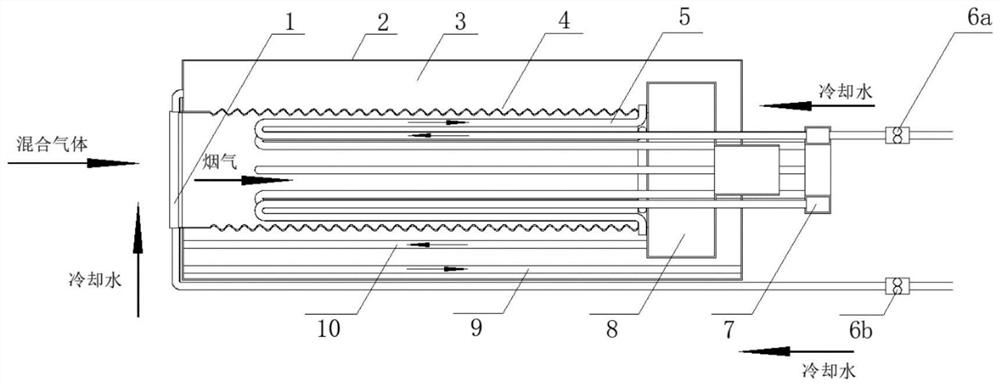

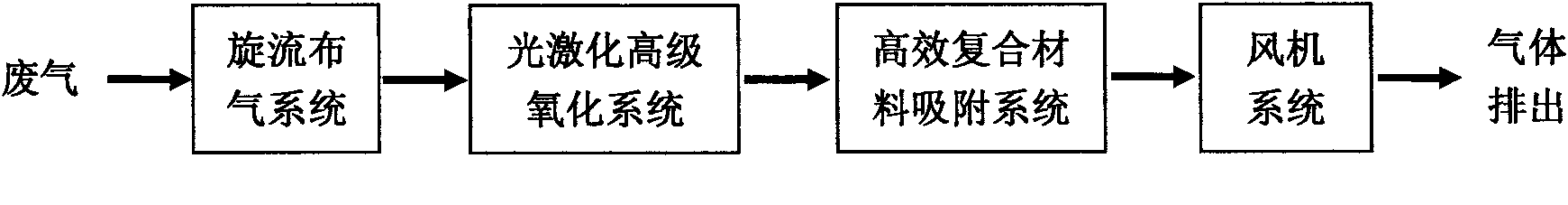

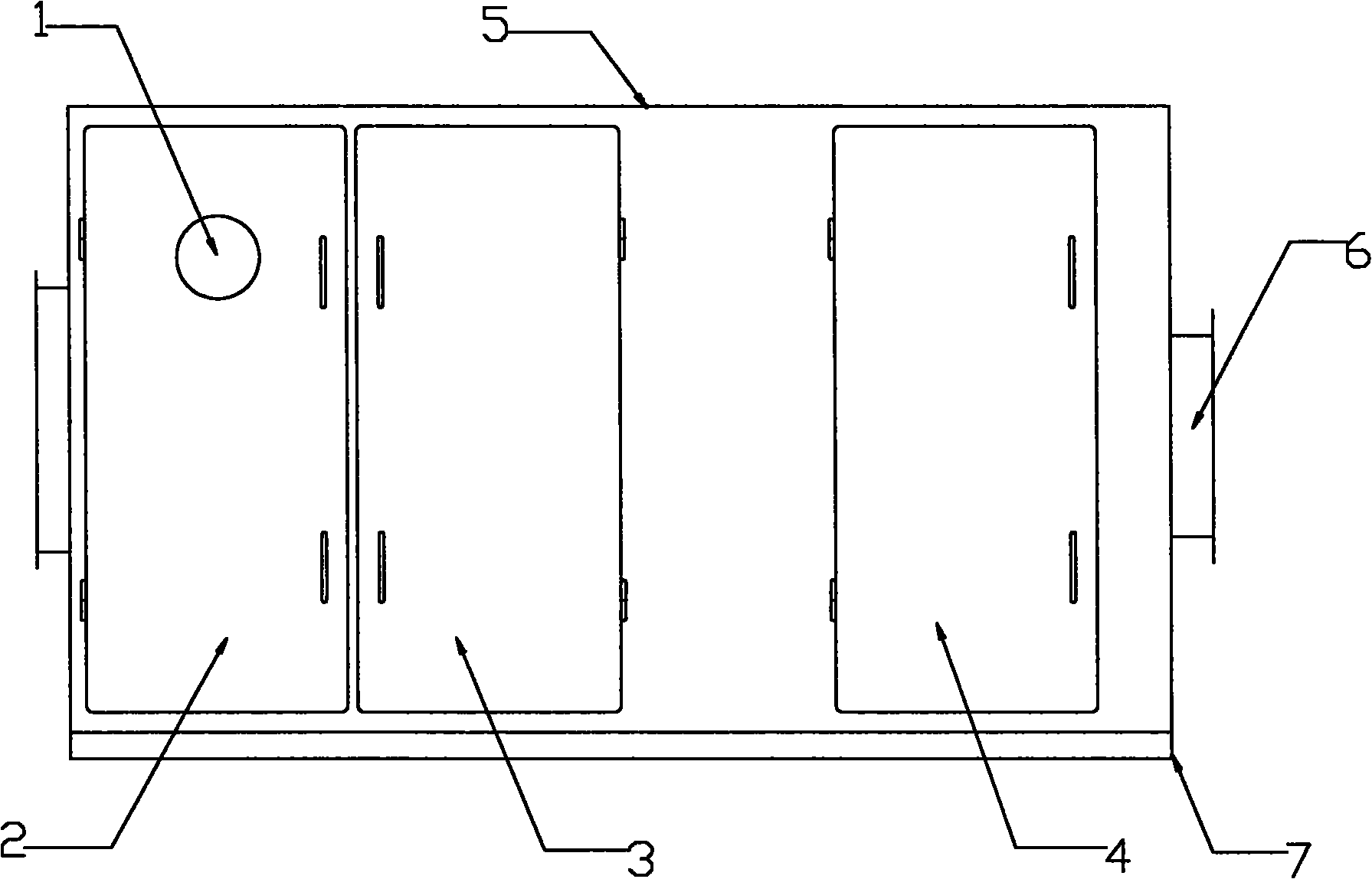

Method and device for treating volatile organic waste gas

InactiveCN101791512AReasonable designCompact structureDispersed particle separationLight activationDecomposition

The invention discloses a method and device for treating volatile organic waste gas. In the method, the volatile organic waste gas firstly enters into a flow rotating and gas distributing system containing a rotating flow tray which is provided with a plurality of cyclone vanes, then the gas which is subdivided by the flow rotating and gas distributing system subsequently enters into a light activation and advanced oxidation system to be irradiated by high power ultraviolet lamps, while radiation-induced decomposition is carried out on part of the waste gas, reactive oxygen is generated to oxidize the organics in the waste gas, after that, the waste gas uniformly passes through a high efficiency composite material adsorption system to be adsorbed by the high efficiency composite materials, and finally the waste gas is discharged from the waste gas outlet via an explosion-proof fan system. By the method, the efficiency and the rate of treating the volatile organic waste gas are improved, the harm of the waste gas to human health and the environment is weakened, the health of the experimental personnel is further protected and the working environment is improved.

Owner:中洁环淼(江苏)环境科技有限公司

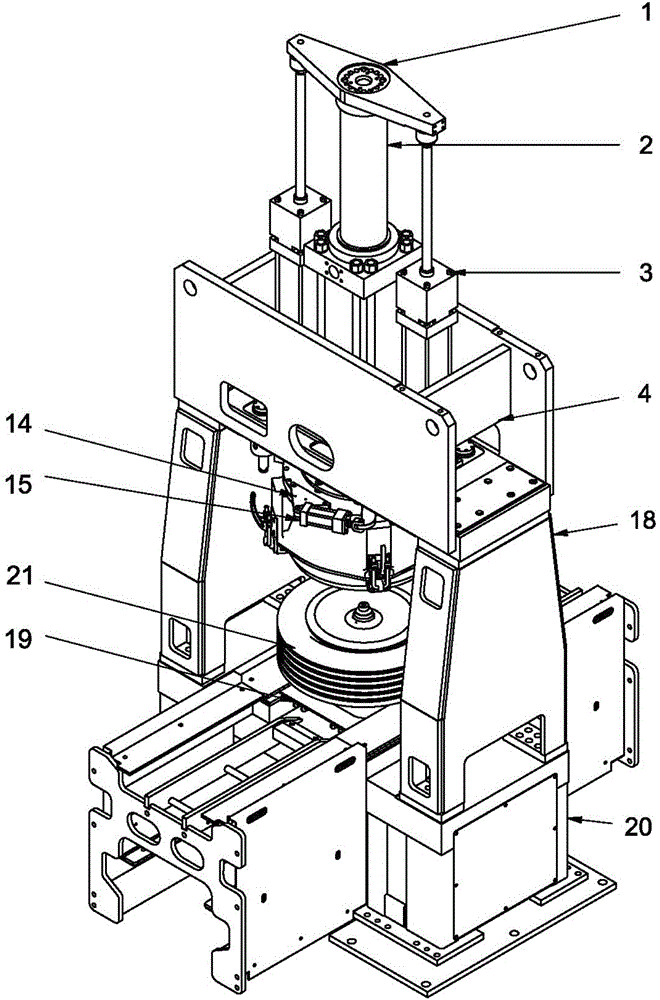

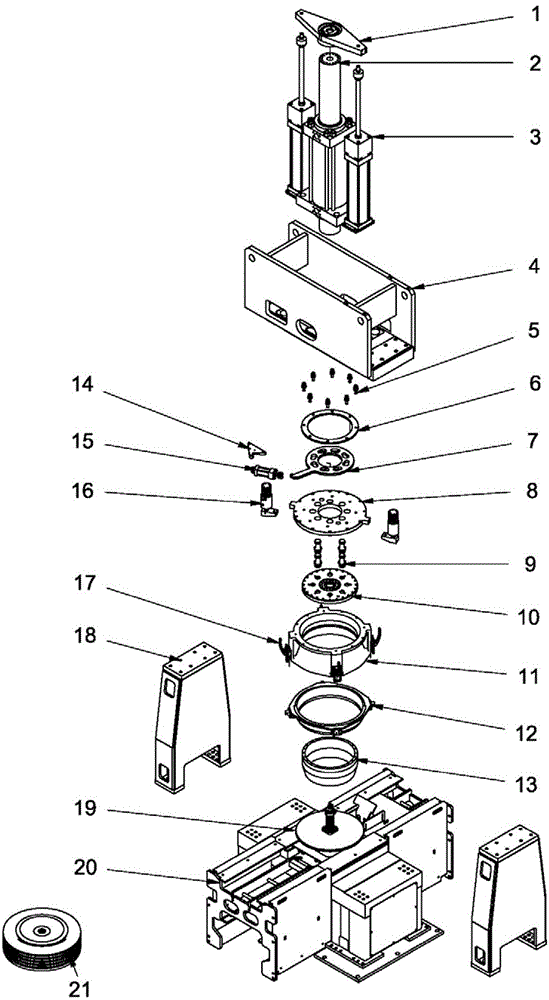

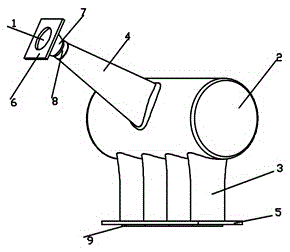

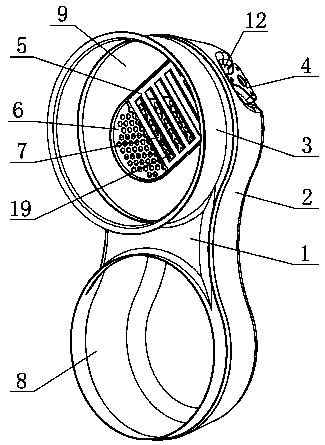

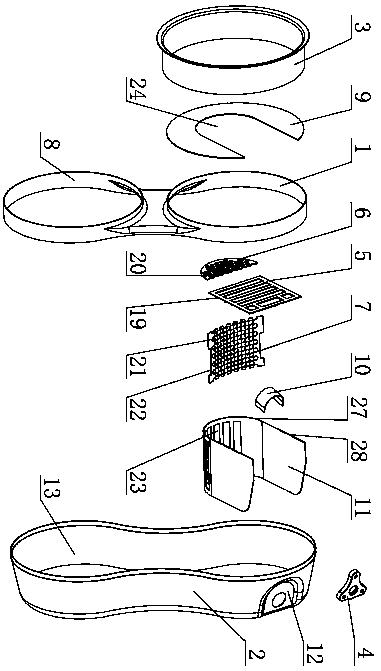

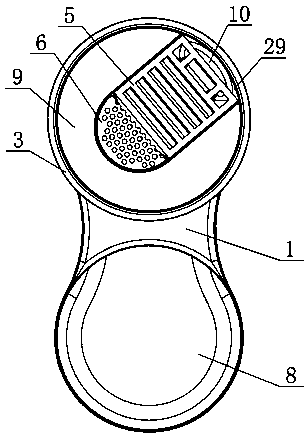

Jacking type tire inflation machine

InactiveCN104386039AEasy maintenanceQuick inflationVehicle servicing/repairingPulp and paper industryDouble ring

The invention discloses a jacking type tire inflation machine, which comprises a base, wherein the two sides of the base are respectively provided with a support seat, the top part of each support seat is provided with a connecting seat, a tire support disc is arranged on the base, a lifting driving mechanism is arranged on the connecting seats, the bottom end of the lifting driving mechanism is connected with an inflation ring, the inflation ring corresponds to the tire support disc, and comprises an inflation outer ring and an inflation inner ring, and the inflation inner ring is arranged in the inflation outer ring. The jacking type tire inflation machine has the advantages that by adopting the jacking type inflation design, the maintenance of the inflation ring and the inflation machine is convenient; the inflation ring squeezes out a wheel hub of the tire and the lip edge of the tire to directly complete the inflation, the inflation is quick, the efficiency is high, the air can enter the interior through the wheel hub of the tire and the lip edge of the tire, and the air intake is uniform; the inflation ring adopts the double ring design of the inflation outer ring and the inflation inner ring, so the tires with different sizes can be inflated, and the application range is wide.

Owner:宝克(无锡)测试设备有限公司

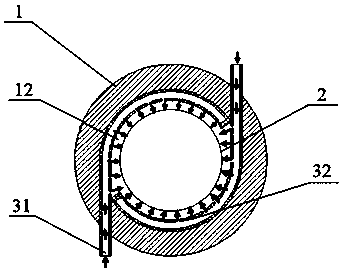

Venturi mixer with drainage function

InactiveCN105435669APlay a drainage roleStable differential pressureFlow mixersTransportation and packagingPressure stabilizationInlet channel

The invention discloses a venturi mixer with a drainage function. The venturi mixer comprises an outer pipeline, an inner pipeline and a fuel gas inlet channel which is vertically arranged on the outer pipeline, wherein a closed circuit chamber is formed between the outer pipeline and the inner pipeline; the inner pipeline comprises a contracting section, a throat section and a flaring section; gas inlets are uniformly formed on one circle along the circumferential direction of the throat section; the gas inlets are formed in an inclined form along the wall of the inner pipeline; the fuel gas inlet channel is arranged as a gradual reducing pipeline. The fuel gas firstly enters into the closed circuit chamber through the fuel gas inlet channel, and then enters into a main runner through a circle of gas inlets uniformly distributed on the throat section, and mixes with air entering from the inlet of the main runner, so that the smooth entering of the fuel gas is ensured while the uniform gas entering along the circumference of the throat section is realized, the buffering and pressure stabilization for the fuel gas are realized, the stable differential pressure between the fuel gas inlet channel and the main runner is formed and the uniform stable running field of the main runner is maintained, and furthermore, the gas inlets are formed in the inclined form on the throat section, so that the fuel gas can form the confluence at a certain degree, the influence on air entering is reduced and the air flow collision loss is reduced.

Owner:CHONGQING PUSH MECHANISM

An environment-friendly efficient flue gas spraying and dust removing device

An environment-friendly efficient flue gas spraying and dust removing device is disclosed. The device includes a gas feeding pipe, a treatment tank, a separating plate, a gas filtration plate, air holes, brush hairs, a stirring blade, an activated carbon filtration plate assembly, a water tank, a water spraying pipe, a spraying row and a gas discharging pipe. The bottom side wall of the treatmenttank is communicated with the gas feeding pipe. The gas filtration plate is disposed in the treatment tank. The bottom surface of the treatment tank is provided with the separating plate. A water filtration screen is disposed between a backflow pipe and the bottom side wall of the treatment tank. An output shaft of a stirring motor is connected to a rotating shaft. The rotating shaft is provided with the stirring blade. The activated carbon filtration plate assembly is disposed in the treatment tank. The water tank is provided with the water spraying pipe. An outlet end of the water spraying pipe is provided with the spraying row. The spraying pipe is provided with a booster pump. The top of the treatment tank is provided with the gas discharging pipe. The device facilitates subsequent flue gas treatment. Flue dust and water mist condense together and drop down under the function of gravity and dust particles in the flue gas are further removed. The working efficiency and effects are increased. Water flows back and is recycled, thus saving resources. The device is simple in structure, convenient to use and prone to popularization.

Owner:ZHENGZHOU YUANRAN BIOLOGY TECH CO LTD

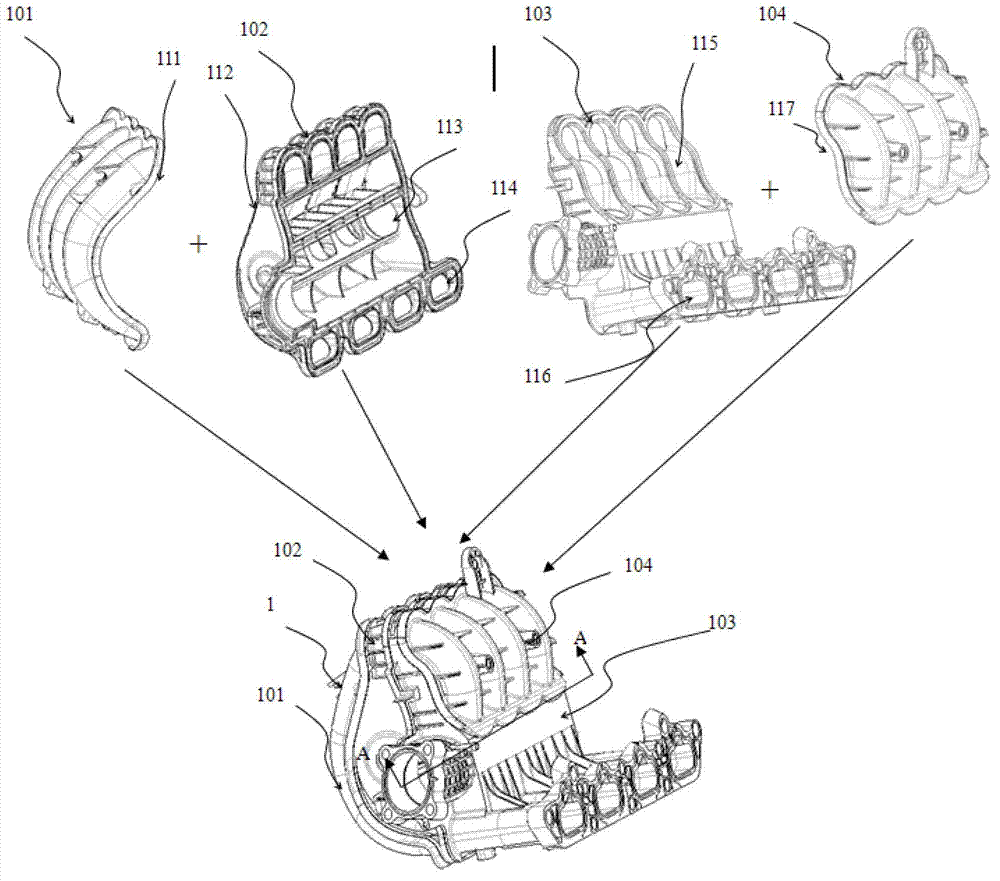

Variable air inlet manifold for gasoline engine

ActiveCN102808709AImprove performanceUniform air intakeCombustion-air/fuel-air treatmentEngine controllersGasolineMechanical engineering

The invention discloses a variable air inlet manifold for a gasoline engine. A short air passage and a long air passage which are communicated with each other are arranged in an air passage of the air inlet manifold, wherein a switching part which is used for opening or closing the short air passage is arranged at the air inlet of the short air passage. The switching part is a rotary drum capable of being in fixed-axis rotation, and a flow passing through hole is formed in the rotary drum along the direction vertical to the middle axis of the rotary drum; when the flow passing through hole in the rotary drum is enabled to be connected with the air inlet of the short air passage by rotating the rotary drum, the short air passage is in an opening state; and when the flow passing through hole in the rotary drum is enabled to be divorced from the air inlet of the short air passage by rotating the rotary drum, the short air passage is blocked and is in a closed state. The variable air inlet manifold for the gasoline engine has the advantages that the long air passage and the short air passage designed in the variable air inlet manifold are switched, and all air inlet branches are differently designed structurally, so that the uniformity of inlet air can be ensured, and the performance of the engine is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

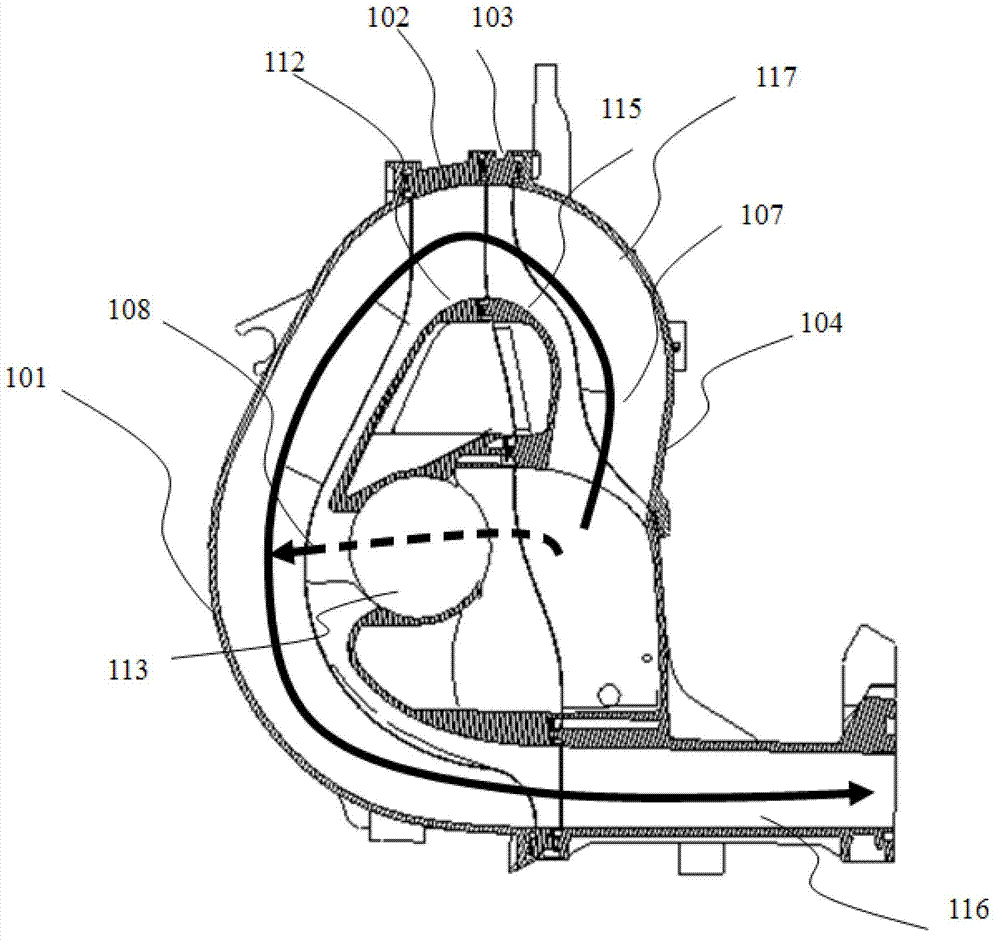

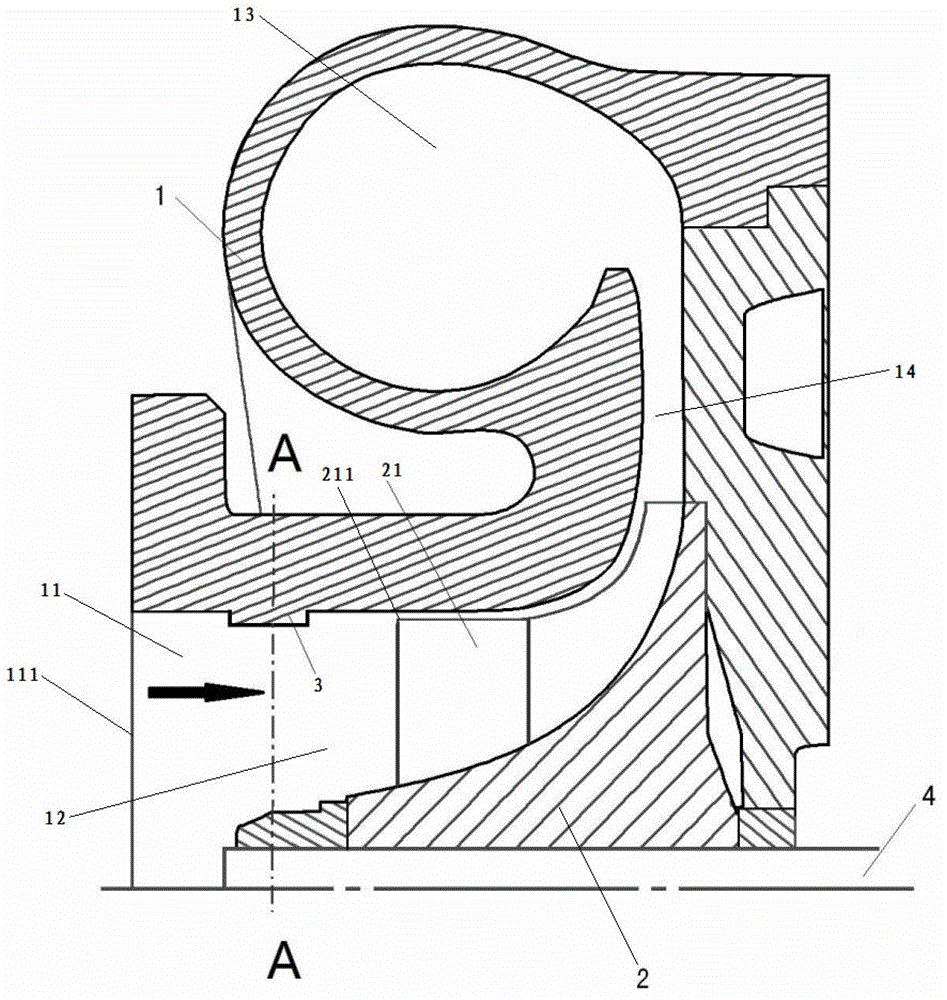

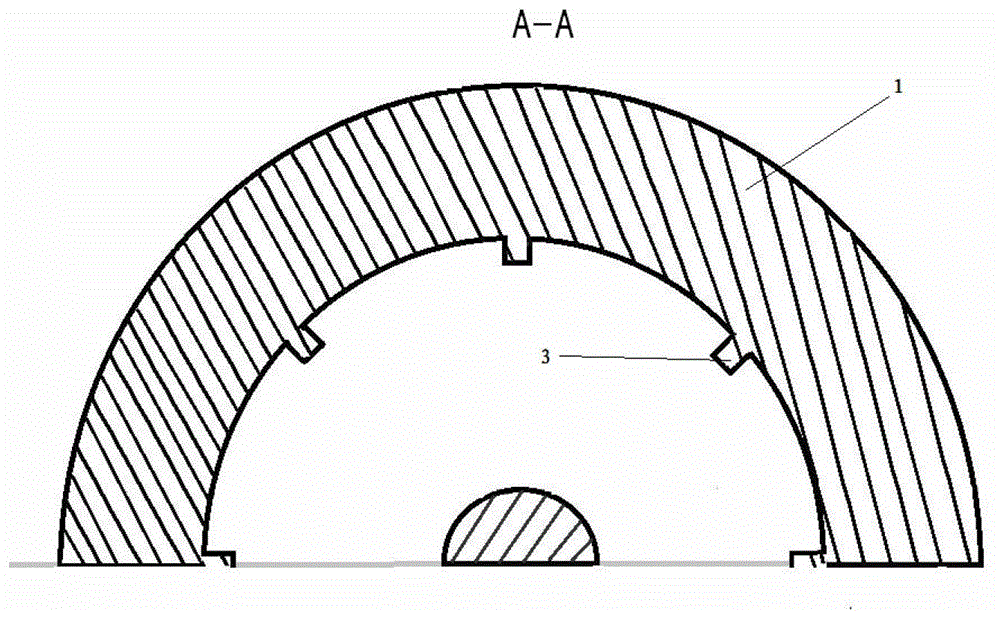

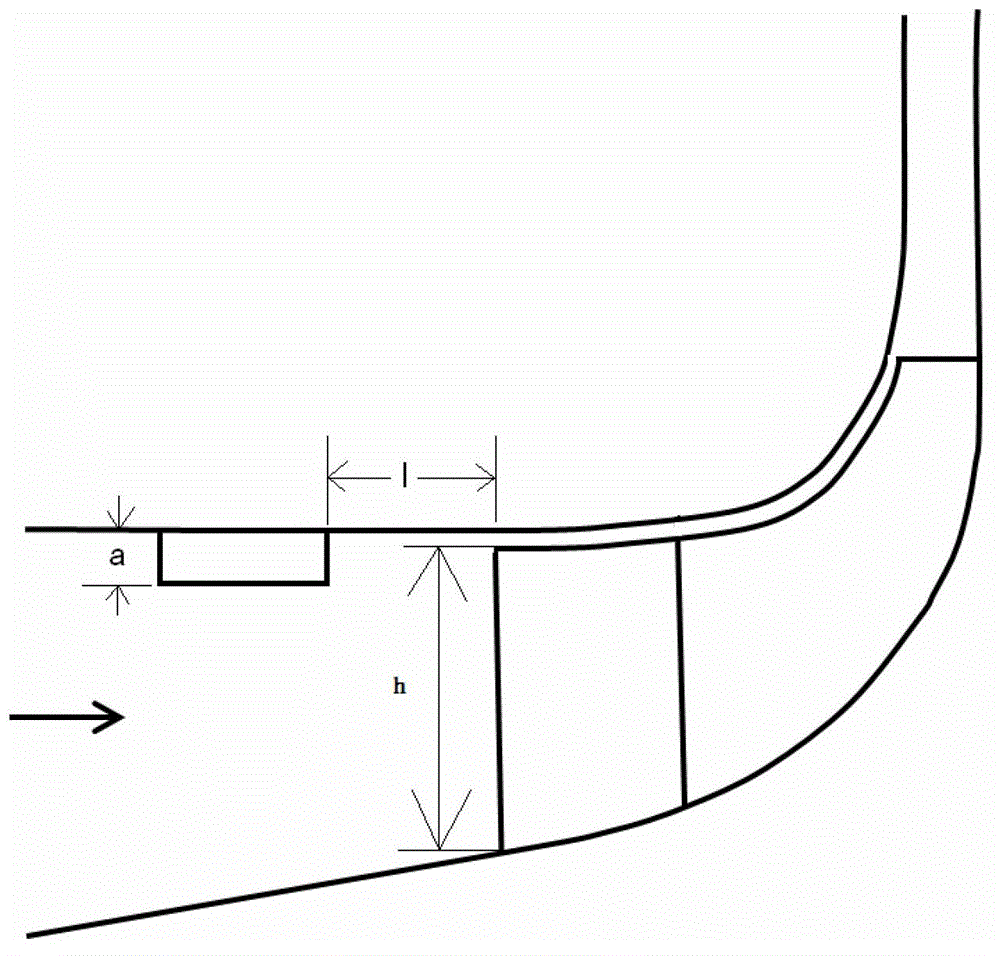

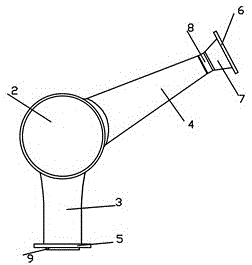

Centrifugal compressor with inlet guide blades and turbocharger

ActiveCN103148021AImprove performanceReduce peripheral speedEngine manufacturePump componentsInlet channelTurbocharger

The invention discloses a centrifugal compressor with inlet guide blades and a turbocharger. The centrifugal compressor comprises a volute, an impeller and guide blades, wherein an air inlet channel, an impeller mounting space and an air outlet channel are defined in the volute, the impeller mounting space is respectively communicated with the air inlet channel and the air outlet channel, and the air inlet channel is provided with an air inlet and the air outlet channel is provided with an air outlet; the impeller can be rotationally arranged in the impeller mounting space by surrounding around a revolving shaft and is provided with a plurality of blades; and guide blades are arranged on a peripheral wall of the air inlet channel. According to the centrifugal compressor provided by the invention, the peripheral speed of fluid such as air in the air inlet channel is reduced by the fact that the guide blades are mounted, so that air inflows at the tips of the blades can be more uniform; and moreover, and the sudden change of the peripheral speed can be reduced, so that the increasing ranges of thermal charges at the tips of the blades can be reduced, the property of the centrifugal compressor can be further improved, especially, the property can be remarkably improved under the small flow working condition.

Owner:TSINGHUA UNIV

Quasi-molecular ultraviolet radiation and plasma coupling integrated waste gas degrading device

ActiveCN104014233ALower breakdown voltageIncrease profitDispersed particle separationPlasmonic couplingChemical reaction

Owner:赛瑞意(江苏)生物设备有限公司

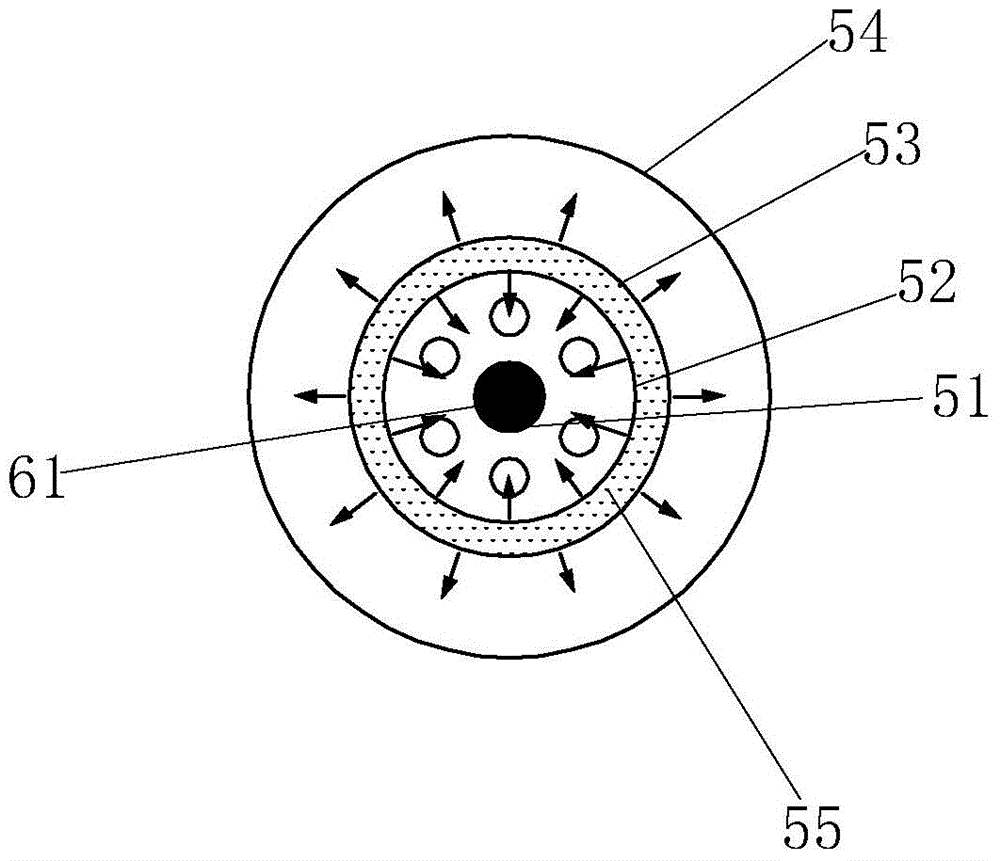

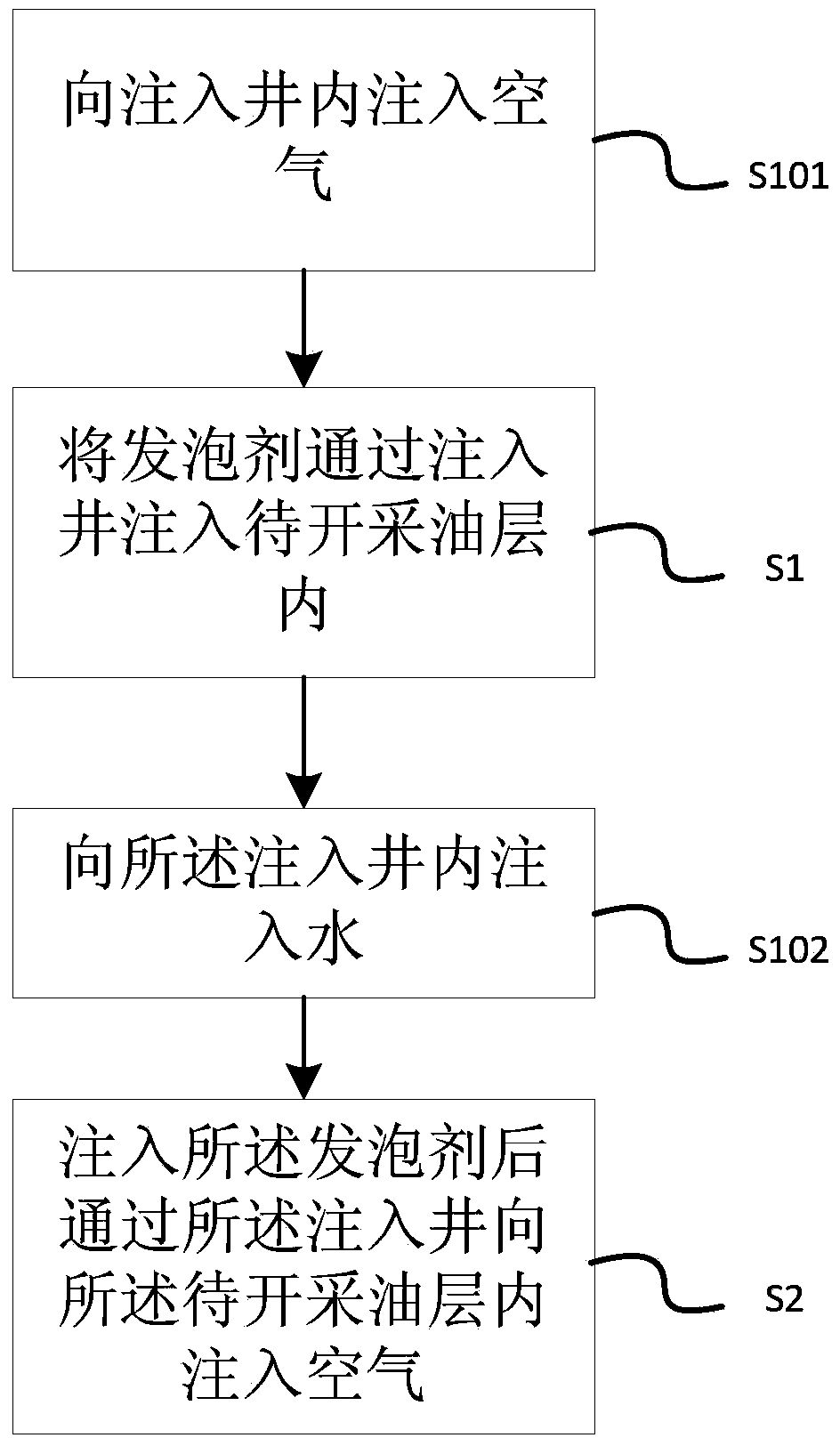

Oil layer gas injection method

The invention discloses an oil layer gas injection method. The oil layer gas injection method comprises the following steps: injecting a foaming agent water solution into an oil layer to be mined through an injection well; injecting air into the oil layer to be mined through the injection well after the foaming agent water solution is injected, wherein the injection speed of the foaming agent water solution is 150-300 cubic meters per hour, the injection time of the foaming agent water solution is 2-5 hours, and the injection speed of the air is that 200-300 normal cubic meters of air is injected into the oil layer with the thickness of every one meter every day; stopping injection of the air when the volume ratio of the air injected inside the oil layer to be mined to the combusted crude oil is 200-500. Through the oil layer gas injection method provided by the invention, the producing extent of each oil layer is balanced during multi-layer burning.

Owner:PETROCHINA CO LTD

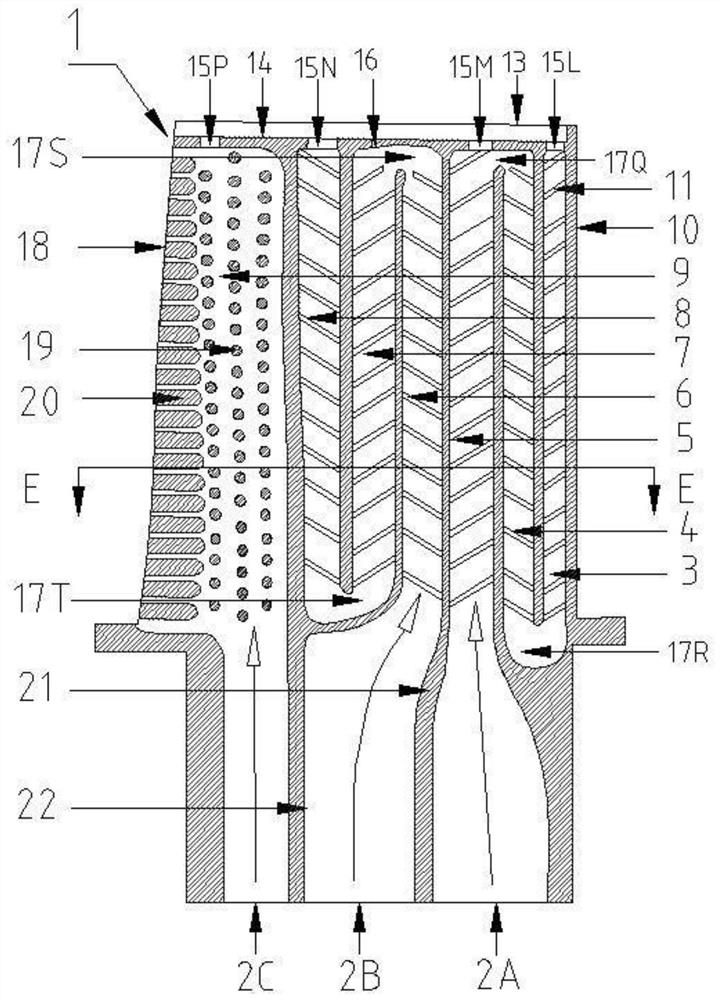

Cooling structure of high-pressure moving blade of turbine of gas turbine

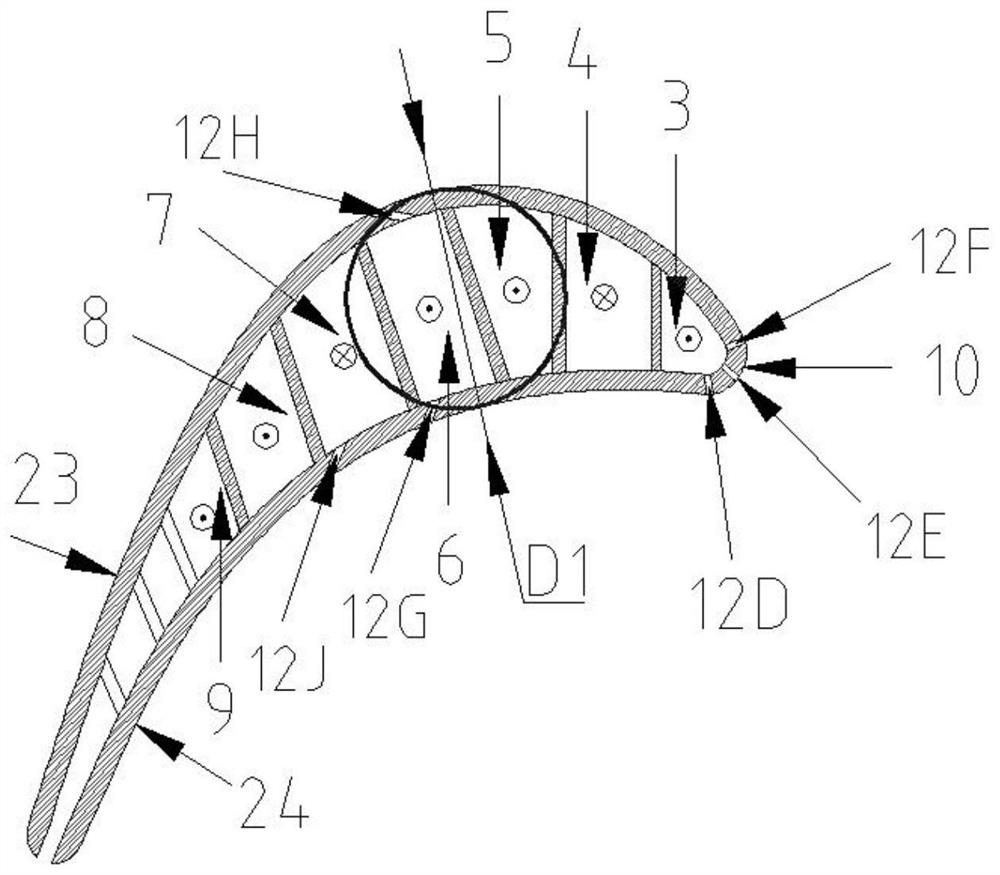

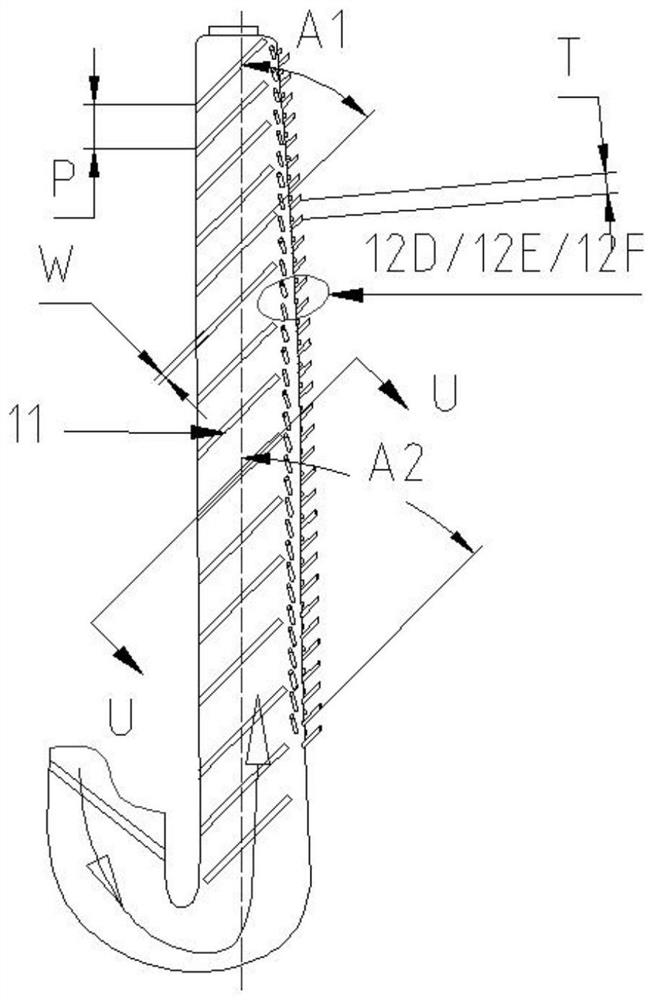

ActiveCN113236370ACool enoughPrecision Cooling StructureBlade accessoriesEfficient propulsion technologiesSurface coolingSuction force

The invention provides a cooling structure of a high-pressure moving blade of a turbine of a gas turbine, and belongs to the technical field of gas turbines. The cooling structure is characterized in that seven channels including a first channel, a second channel, a third channel, a fourth channel, a fifth channel and a sixth channel are sequentially formed in the blade from the front edge of the blade to the tail edge of the blade; the first channel, the second channel, the third channel, the fourth channel, the fifth channel and the sixth channel are provided with turbulent flow ribs, the third channel, the second channel and the first channel are sequentially connected with one another to form a snakelike channel, U-shaped spaces are formed at joints of the adjacent channels, the fourth channel, the fifth channel and the sixth channel are sequentially connected with one another to form a snakelike channel, and U-shaped spaces are formed at joints of the adjacent channels; a first gas inlet, a second gas inlet and a third gas inlet are formed in the bottoms of the third channel, the fourth channel and the seventh channel; a plurality of split seams are formed in the tail edge of the blade, and gas can be exhausted via the split seams; a blade top groove is formed in a blade top, and cooling holes and process holes are formed in the blade top groove; and blade top pressure surface cooling holes are formed in a blade top pressure surface. The cooling structure has the advantages that the front edge of the blade, a suction surface of the blade, the blade top and the like can be sufficiently cooled, accordingly, uniform blade root temperature fields can be guaranteed, the temperature of a blade body can be reasonably distributed, and the cooling structure is low in cold gas flow.

Owner:HANGZHOU TURBINE POWER GRP

High-efficiency and environmentally-friendly flue gas dust removing equipment

InactiveCN108854380AEasy to handleEasy to condenseCombination devicesParticle suspension analysisActivated carbon filtrationFlue gas

The invention discloses high-efficiency and environmentally-friendly flue gas dust removing equipment, comprising a gas inlet pipe, a treatment box, a gas filter plate, rotating drums, turnover plates, an activated carbon filter plate group, a water tank and an exhaust pipe, wherein the side wall of the bottom end of the treatment box is communicated with the gas inlet pipe; one end of the gas inlet pipe is connected with an external flue gas pipe; a spacer plate is arranged on the bottom face of the treatment box; a guide plate is arranged at the bottom end of the spacer plate in an inclinedway; the side wall of the bottom end of the treatment box is communicated with one end of a return pipe, and the other end of the return pipe is communicated with the water tank; a flotage discharge pipe is arranged on the side wall of the treatment box; the treatment box is internally provided with the rotating drums, and the turnover plates are evenly arranged on the outer edge walls of the rotating drums; the gas filter plate is arranged in the treatment box; the treatment box is internally provided with the activated carbon filter plate group; a gas pressure reducing valve is arranged at the top end of the treatment box and is connected with the exhaust pipe. The high-efficiency and environmentally-friendly flue gas dust removing equipment can conveniently remove dust particles in fluegas, improves the working efficiency and effect, and enables water to flow back for continuously recycling so as to save resources; the equipment is simple in structure, convenient to use and beneficial to popularization.

Owner:湖南图强科技开发有限公司

Garbage combustion furnace high in combustion efficiency

The invention discloses a garbage combustion furnace high in combustion efficiency. Household garbage is put into a furnace chamber of the combustion furnace from the top of the combustion furnace, and air is fed into the furnace chamber from the bottom, so that the garbage is combusted from bottom to top, and waste residues are discharged through a residue discharging port in the bottom. Final tail gas of garbage combustion is exhausted from the lower portion of the furnace chamber after being combusted sufficiently, so that the temperature inside the furnace chamber is decreased gradually from bottom to top. According to the garbage combustion equipment which is optimized in design and is high in gas circulation efficiency, the lower portion of a furnace body can be effectively cooled through an annular cooling chamber arranged outside the furnace body; meanwhile, on one hand, the air is preheated after flowing through the periphery of the upper portion of the furnace body and then enters the furnace chamber, so that the situation that cold air enters the furnace chamber, and consequently the temperature in the furnace chamber and the combustion efficiency in the furnace chamber are influenced is avoided; on the other hand, the air enters the furnace chamber uniformly from the bottom of the furnace chamber, so that uniform combustion in the furnace chamber is guaranteed, the air utilization rate is greatly increased, the treatment temperature in the furnace chamber is guaranteed, and the combustion efficiency in the furnace chamber is greatly improved; and furthermore, the tail gas is exhausted after being cooled through the cooling chamber, and accordingly the subsequent tail gas treatment is facilitated.

Owner:湖南未名环保科技有限公司

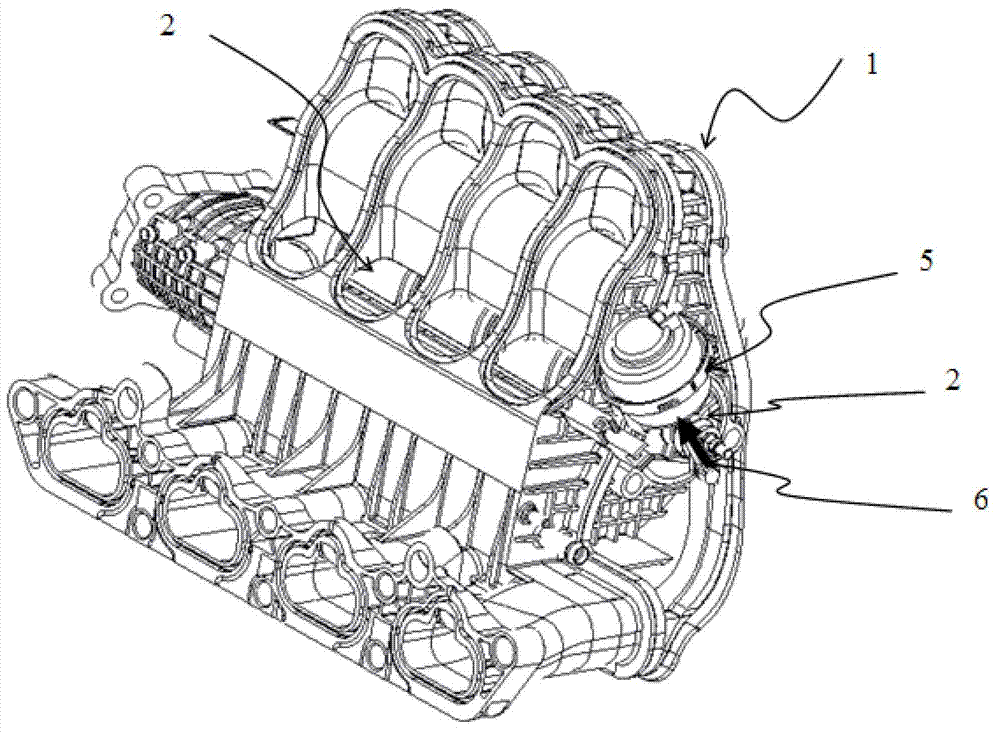

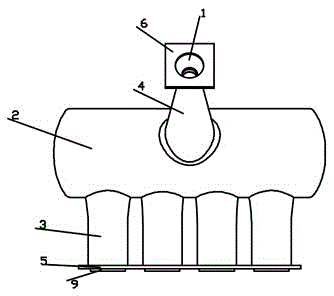

Air inlet cavity of FSAE racing car

InactiveCN105626331AUniform air intakeMake up for the lack of air intakeInternal combustion piston enginesAir intakes for fuelEngineeringLow-pressure area

The invention discloses an air inlet cavity of an FSAE racing car. The air inlet cavity comprises an air inlet pipe, a pressure stabilizing cavity, air inlet manifolds and a manifold mounting surface, wherein one end of the air inlet pipe is connected with the pressure stabilizing cavity; the tops of the four air inlet manifolds which are parallel to one another are connected with the bottom of the pressure stabilizing cavity; the bottoms of the air inlet manifolds are connected with the manifold mounting surface; the manifold mounting surface is used for be assembled with an engine; the air inlet pipe comprises a throttle valve mounting surface, a compression pipe, a flow-limiting valve and a diffusion pipe; the throttle valve mounting surface is arranged at one end of the compression pipe; the other end of the compression pipe is connected with one end of the flow-limiting valve; one end of the diffusion pipe is connected with the other end of the flow-limiting valve; the other end of the diffusion pipe is connected with the pressure stabilizing cavity; and the throttle valve mounting surface is used for being assembled with a throttle valve. According to the air inlet cavity disclosed by the invention, by enlarging openings of two air inlet manifolds at the outer side, the air inflow is more uniform, and the defect that the air inflow of the two air inlet manifolds positioned at the outer side is insufficient is overcome; a low-pressure area and vortex at the flow-limiting valve and a corner are reduced, and the induced resistance of a connected part is reduced; the phenomenon of blow-by of various cylinders is inhibited; and meanwhile, the lengths of the air inlet manifolds are also increased.

Owner:NANJING UNIV OF SCI & TECH

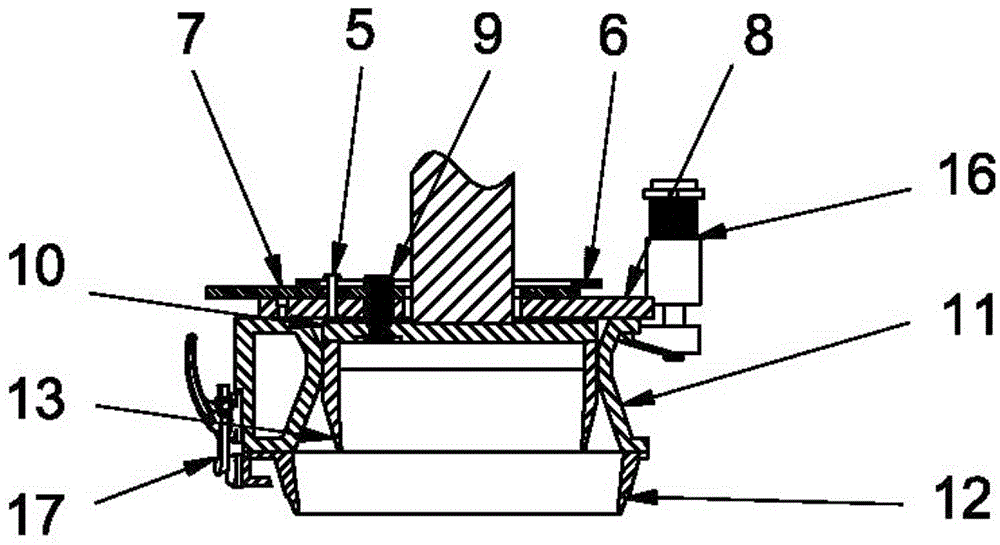

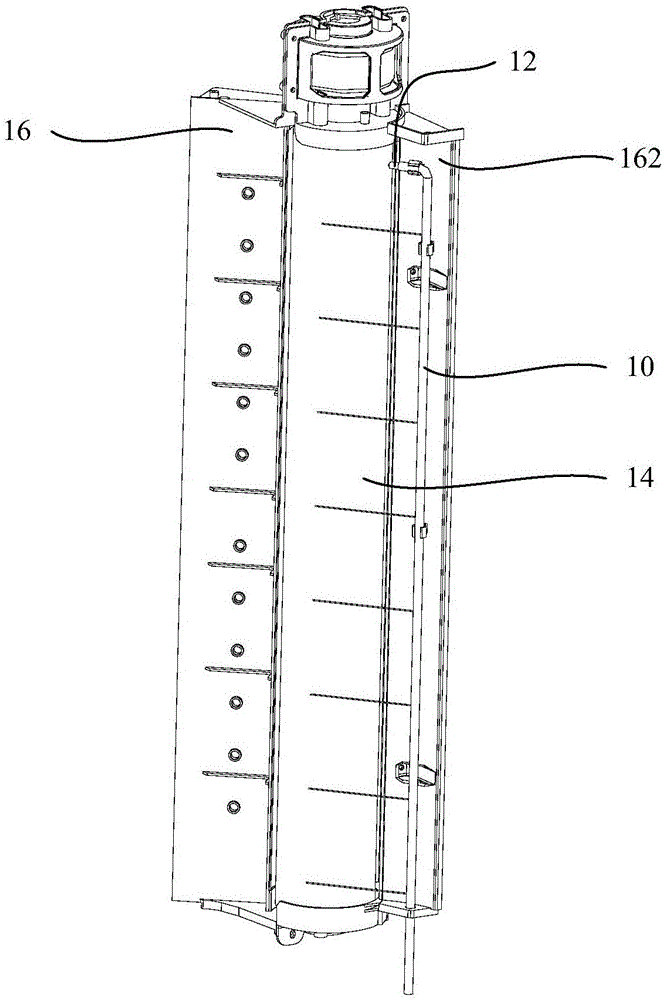

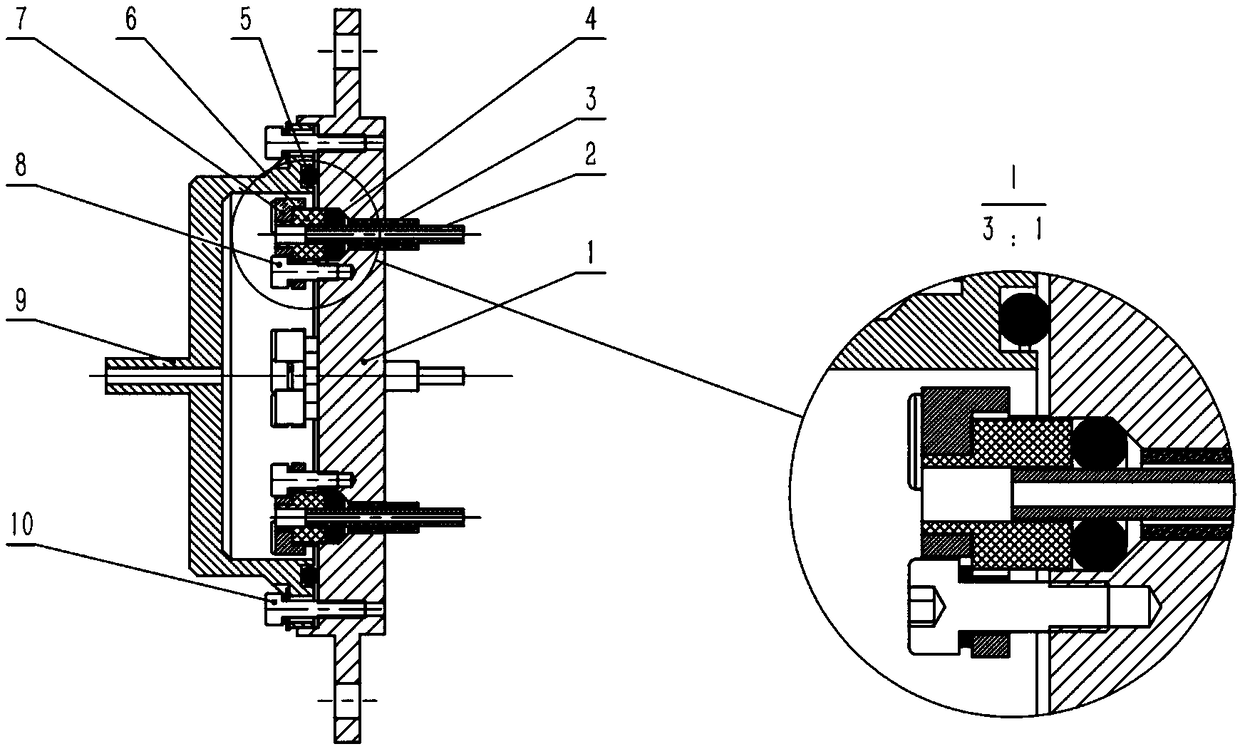

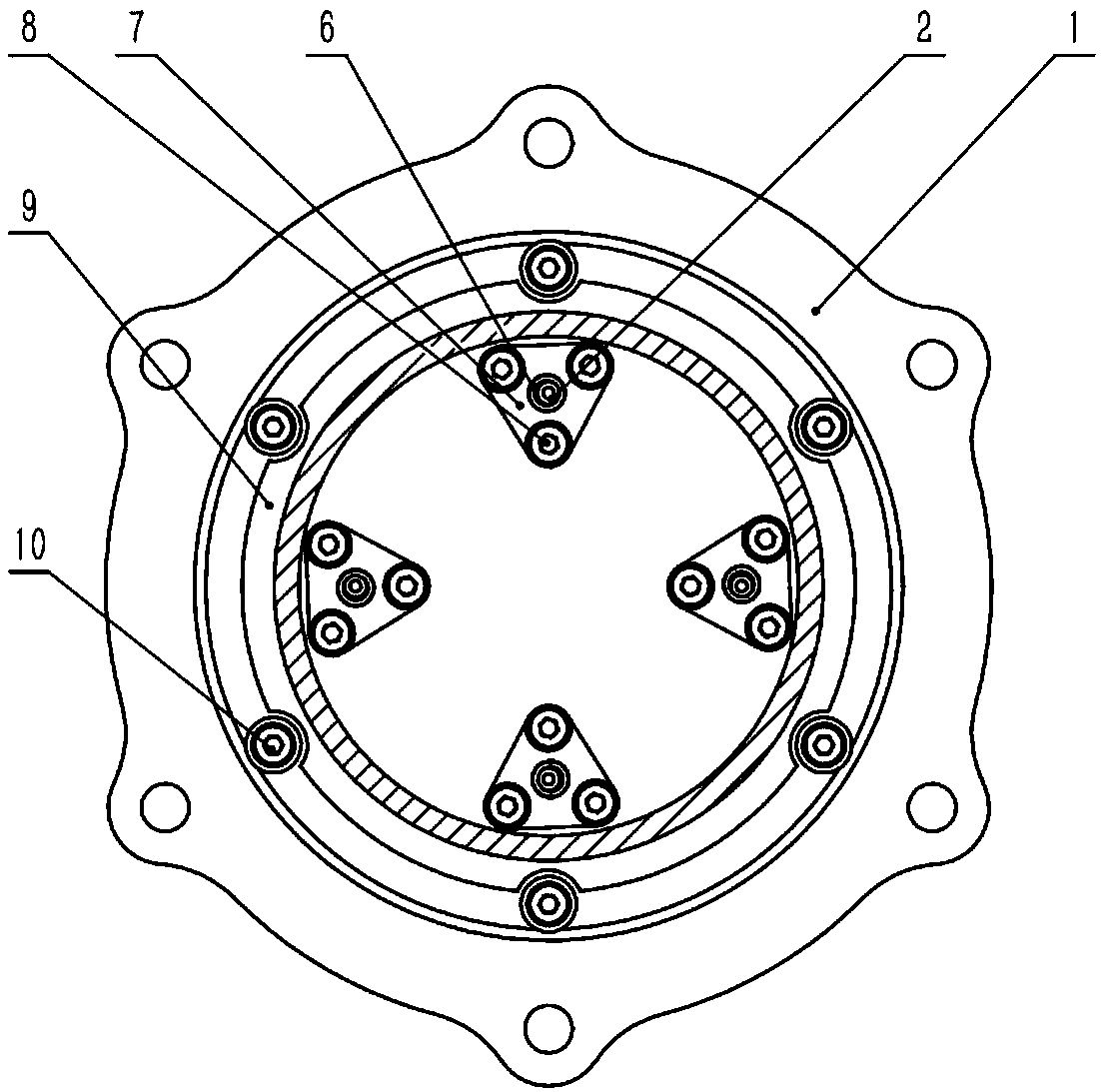

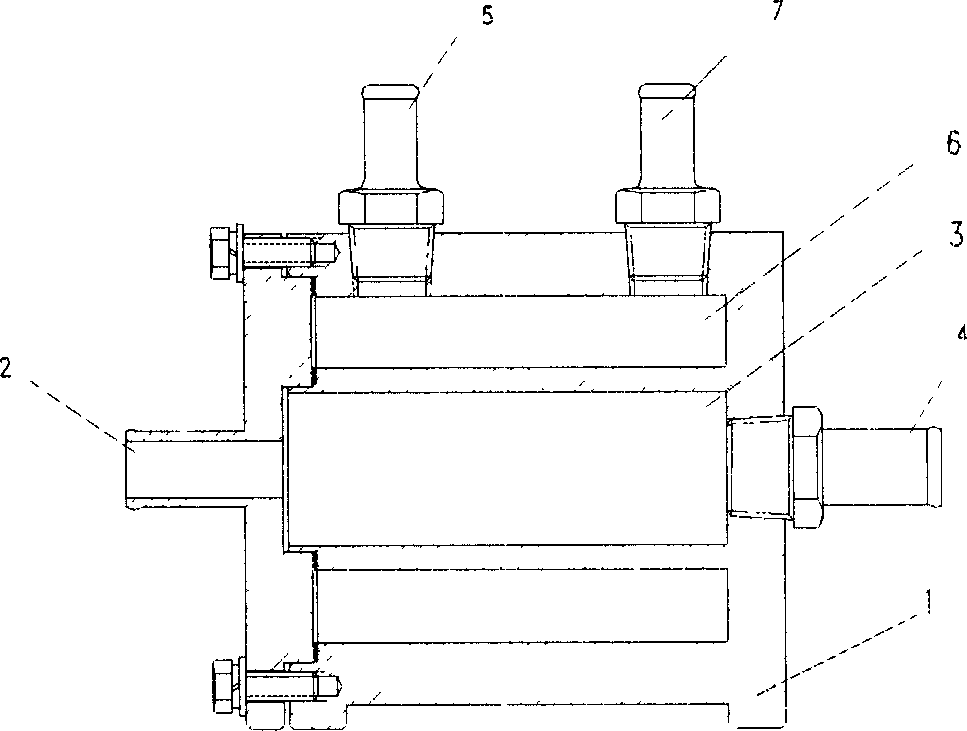

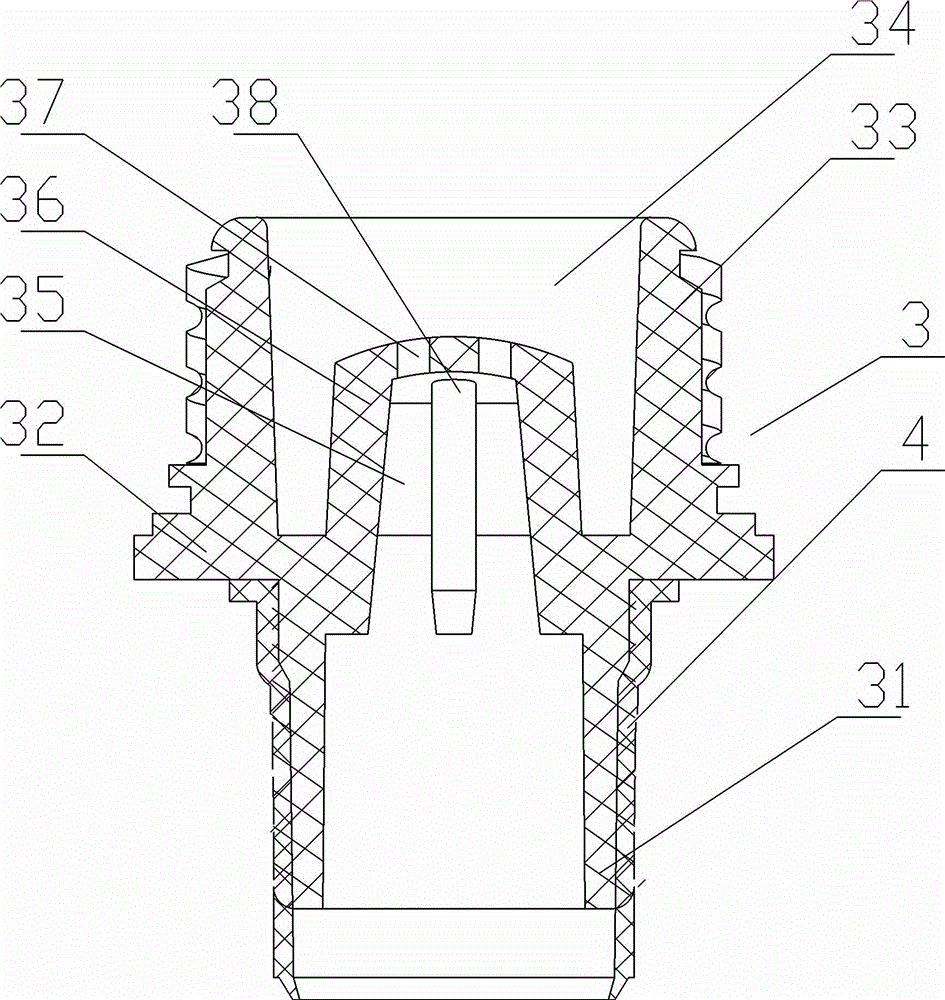

Drainage device used for underwater laser welding and using method thereof

InactiveCN107931872AUniform air intakeSimple structureLaser beam welding apparatusEngineeringWater environment

The invention discloses a drainage device used for underwater laser welding. The drainage device includes an upper end cover, a distance adjusting shell, a drainage shell and a drainage sealing pad. The upper end cover is provided with anti-reflection glass, an anti-reflection glass frame, an anti-reflection glass arrangement groove, a sealing ring, a drainage air hole, an air buffer slot, and a metal sieving net. The distance adjusting shell is connected with inner threads of the upper end cover through outer threads. The drainage shell is connected with the distance adjusting shell through outer threads. The drainage sealing pad is connected with the bottom of the drainage shell through a clamping hoop. The drainage device is simple in structure arrangement, convenient to operate, economical and practical; a stable local drying space can be formed on the surface of an underwater workpiece to be welded; the problem that underwater laser welding is influenced by water environment is effectively solved; and underwater laser welding is achieved.

Owner:HARBIN INST OF TECH AT WEIHAI

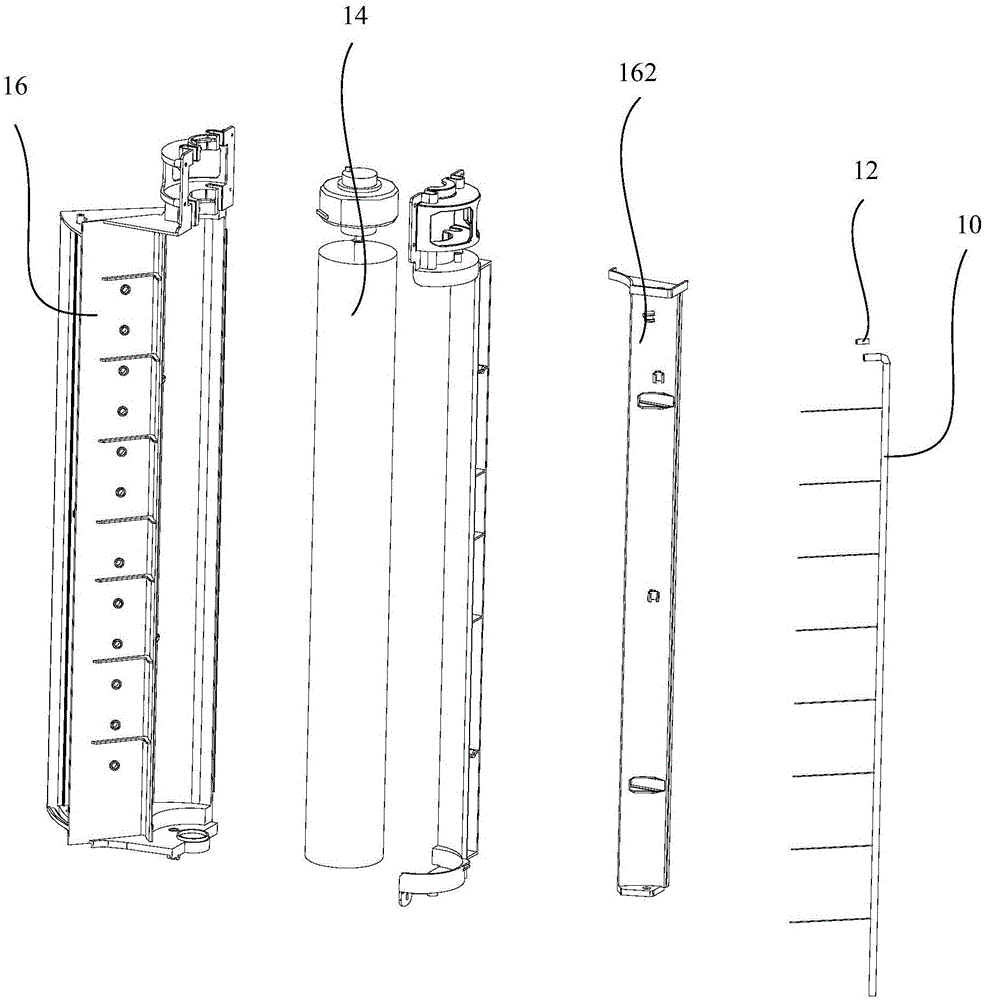

Cleaning device and air conditioner

PendingCN106839356AAvoid situations where cleaning is not possibleEasy to cleanLighting and heating apparatusSpace heating and ventilation detailsEngineeringMechanical engineering

The invention provides a cleaning device. The cleaning device is used for cleaning a wind wheel and an air channel of an air conditioner, and comprises a liquid supply assembly and a cleaning assembly, wherein the cleaning assembly comprises a cleaning pipe; the cleaning pipe is a hollow pipe; a spray head is arranged at the top end of the cleaning pipe; the bottom of the cleaning pipe is communicated with the liquid supply assembly; a plurality of liquid spraying holes are formed in the cleaning pipe; the hole diameter of each liquid outlet hole of the spray head is more than that of each liquid spraying hole; and the spray head and the plurality of liquid spraying holes are arranged by facing towards blades of the wind wheel. Cleaning liquid is sprayed on the wind wheel through the spray head and the liquid spraying holes simultaneously, and a large amount of cleaning liquid is sprayed by the spray head at the top end to wash the wind wheel, so that one part of cleaning liquid can flow towards the bottom of the wind wheel and dust is taken away; and the cleaning liquid sprayed by the liquid spraying holes is used for impacting the wind wheel, so dust in the wind wheel and the air channel is effectively removed and the cleaning effect of the air conditioner is improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

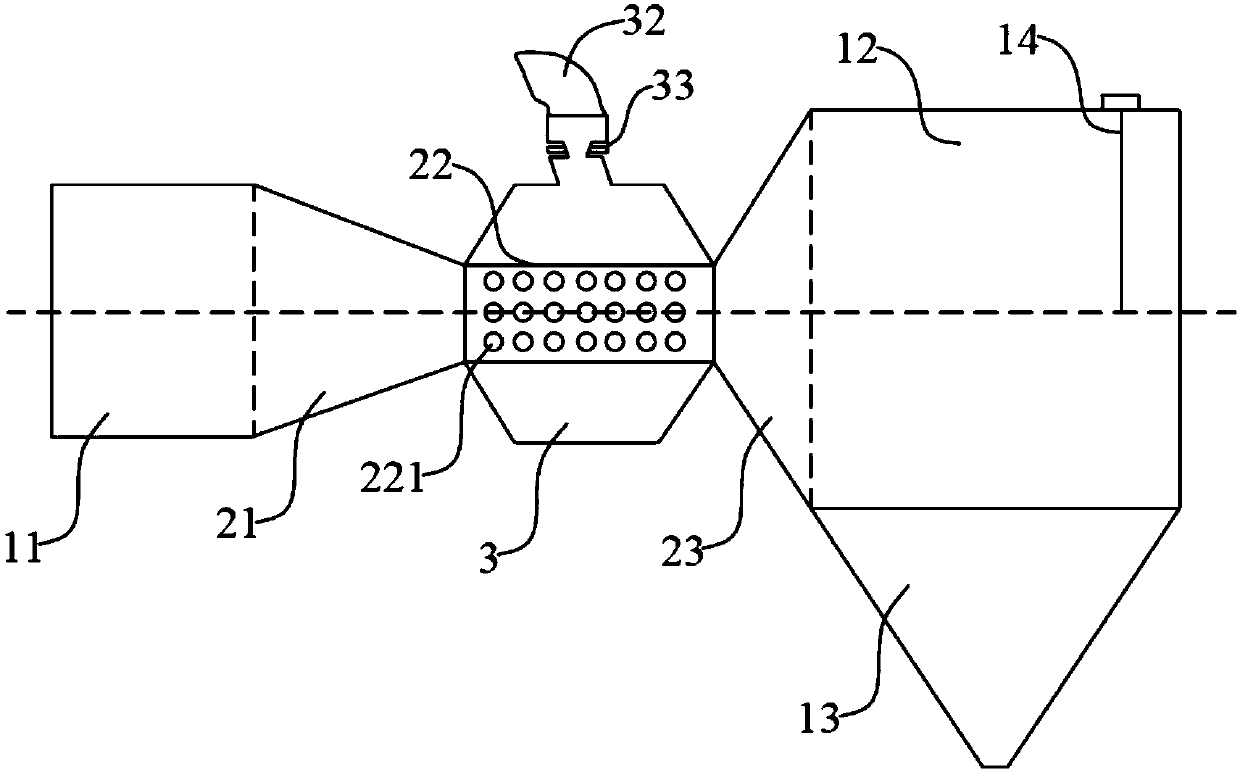

Flue gas mixing device and method

ActiveCN108014667ASolve the problem of energy consumptionPlay a drainage roleFlow mixersTransportation and packagingFlue gasHigh energy

The invention discloses a flue gas mixing device and method and relates to the technical field of gas mixing. The flue gas mixing device comprises a flue inlet section, a throat section and a flue outlet section which are sequentially communicated, wherein multiple gas inlet holes are circumferentially formed in the side wall of the throat section, and an annular channel cavity is formed in the periphery of the throat section and connected with an annular cold waste gas branch pipe. The main body of the flue gas mixing device is designed into a venture tube structure, so that circulating fluegas can accelerate and guide annular cold waste gas when flowing into the throat section, the annular cold waste gas can be fully mixed without being boosted by an annular cold fan to enter a circulating flue, the annular cold waste gas passes through an annular channel cavity and the gas inlet holes sequentially and can also guide the circulating flue gas, and the problems of high energy consumption and poor flue gas mixing effect of existing flue gas mixing devices are solved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

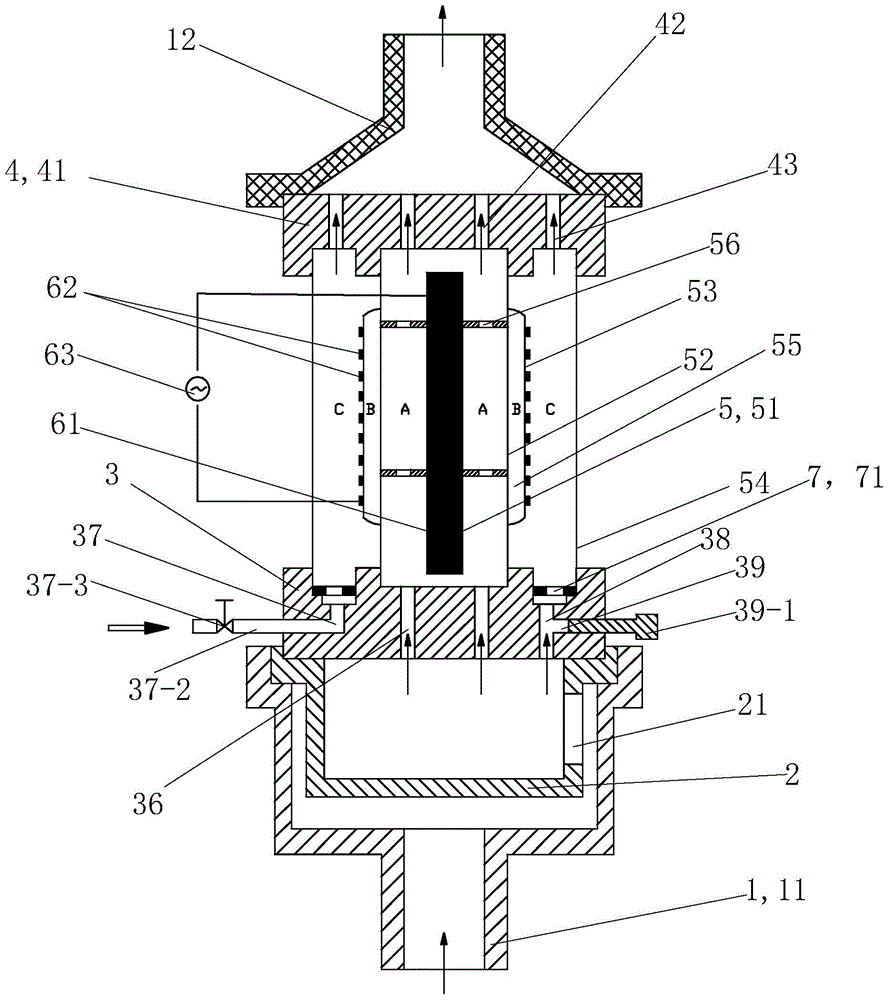

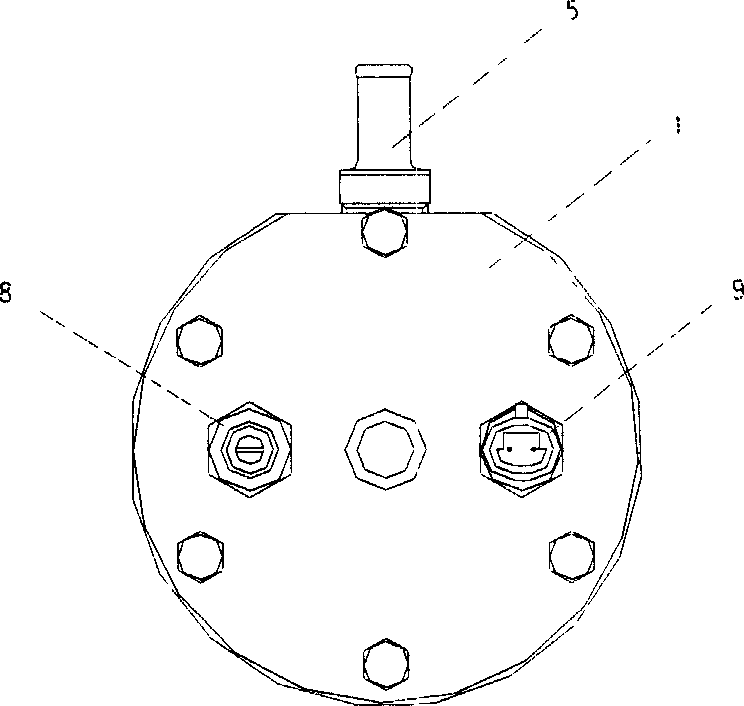

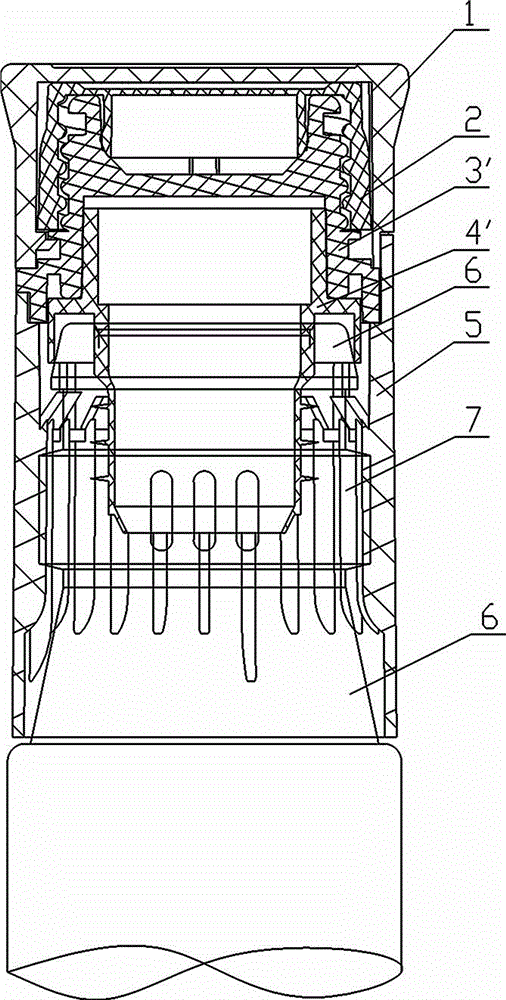

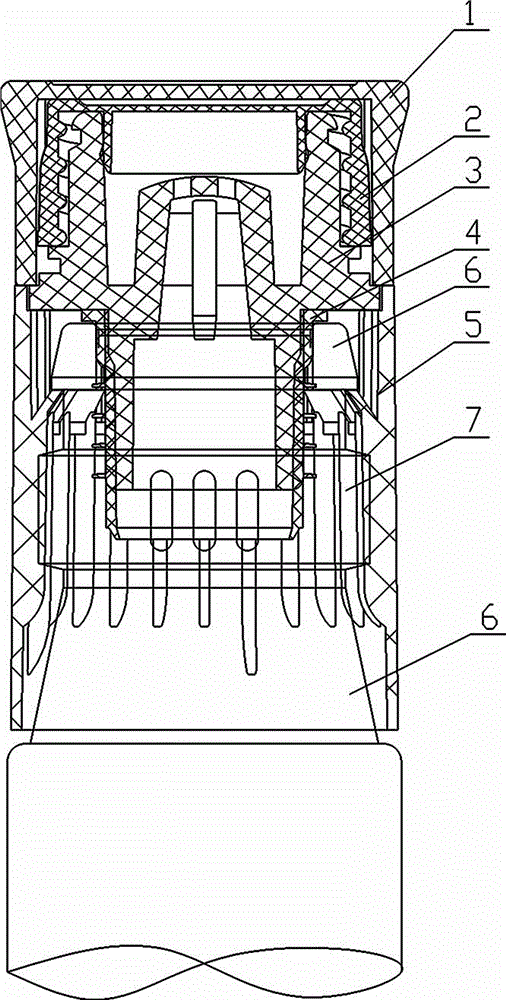

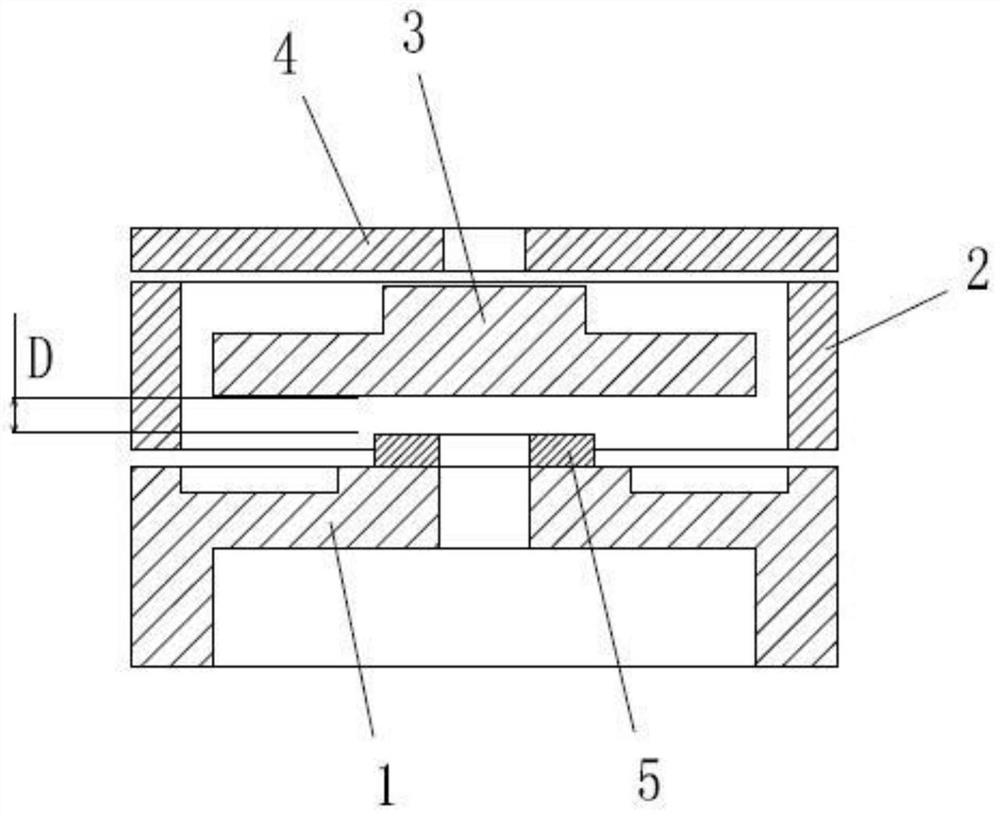

Air inlet structure of electric propulsion engine

ActiveCN109404240ASealed and compactSimple and convenient detachableMachines/enginesUsing plasmaElectricityWorking temperature

The invention provides an air inlet structure of an electric propulsion engine, relates to the problem of propellant supply of the electric propulsion engine, and belongs to the field of electric propulsion. The volume of the electric propulsion engine body is greatly reduced, and a propellant supply structure of the engine becomes more complicated. Because an engine gas distributor air inlet pipeline has a high discharge voltage and is in a relatively high working temperature range, a propellant supply pipeline outside the engine is difficultly in direct connection with a gas distributor, otherwise the engine is short-circuited. In order to solve the problem, an electric propulsion engine air inlet structure with sealing and insulating functions is designed. Conical surface extrusion is carried out on a gas distributor pipeline-sealing ring, and an air inlet cavity is formed between an air inlet flange and an engine body flange, so that the one-to-four connection mode between an external propellant pipeline and the engine gas distributor pipeline is achieved, and simultaneously the sealing and insulation requirements on the outer wall surface of the gas distributor pipeline and the engine body flange are met.

Owner:BEIHANG UNIV

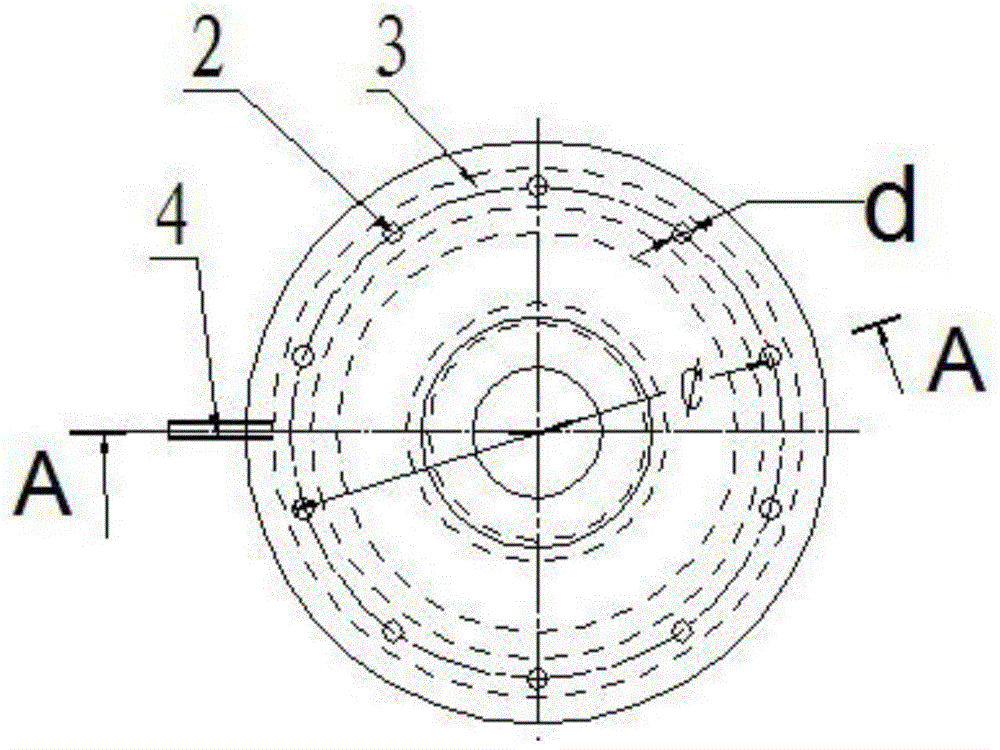

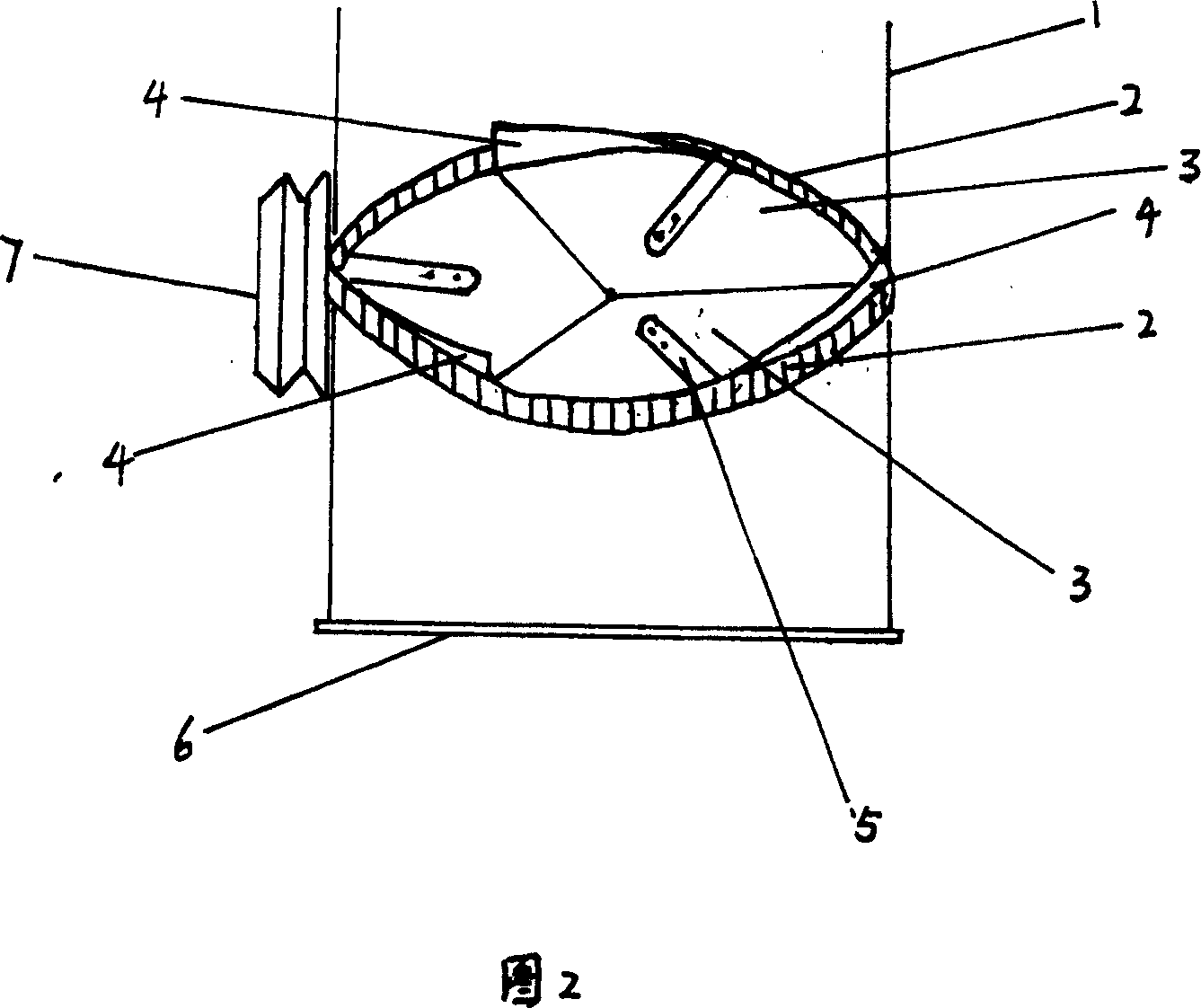

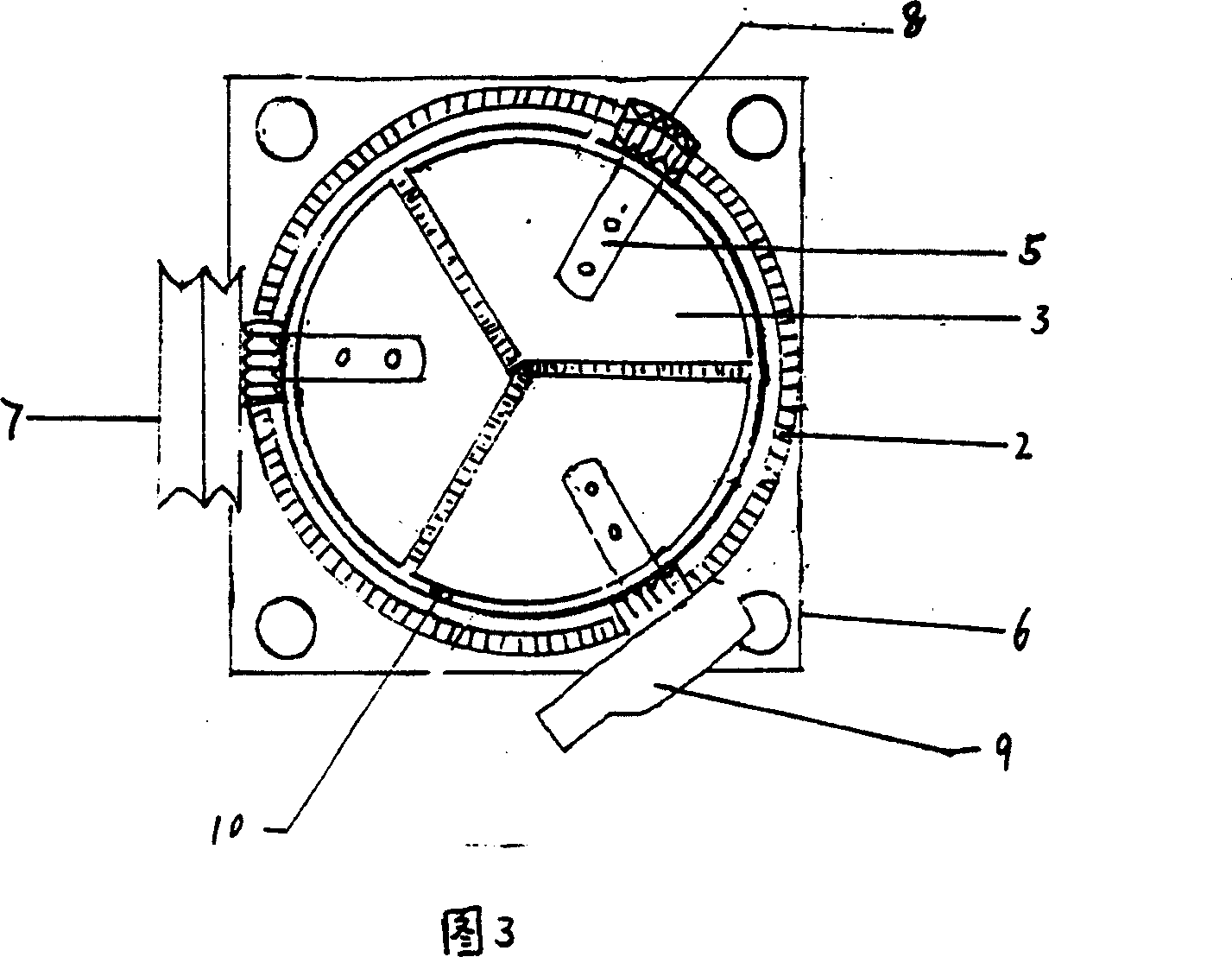

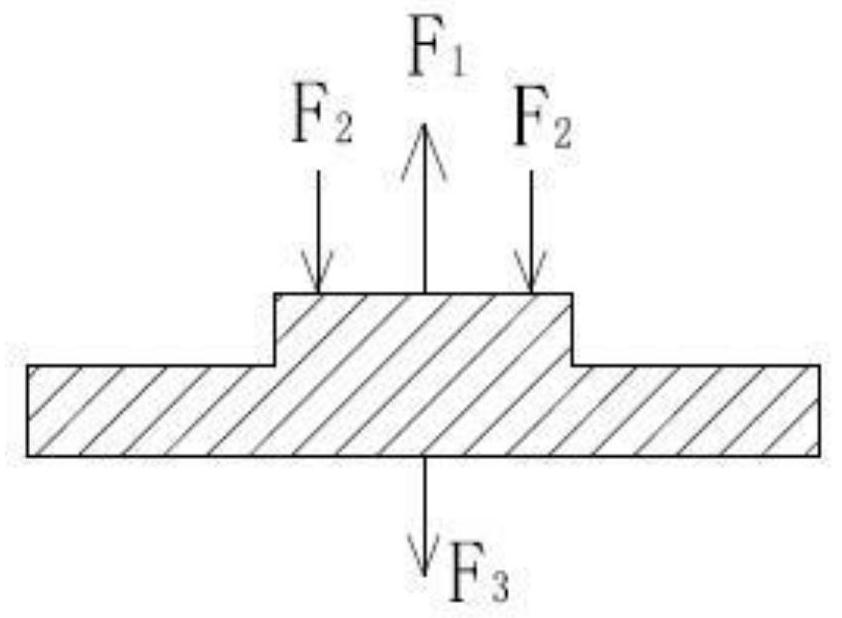

Disc shaped variable vortex throttle piston for automobile engine, internal combustion engine

InactiveCN1303315CFast flowHigh horsepowerEngine controllersMachines/enginesCircular discEddy current

The invention relates to a disk shaped variable eddy current restrictor of automobile engine and internal combustion engine. The disk is divided into more than three same sectorial restrictor 3, each sectorial restrictor 3 is fixed on the restrictor shaft 5, and rotate driven by restrictor driving disk 7. When the restrictors are opened simultaneously, under the action of engine negative pressure, airflow will flow in along the incline with flow guiding leaf of each restrictor, and generate eddy, and increase the intake airflow and intake pressure, for making oil combust completely, and improving the engine torsional moment and the throttle sensitivity in slow or medium speed. The invention can shorten the air intake pipe of existing engine for decreasing the intake resistance of engine working under the maximum load.

Owner:王萍

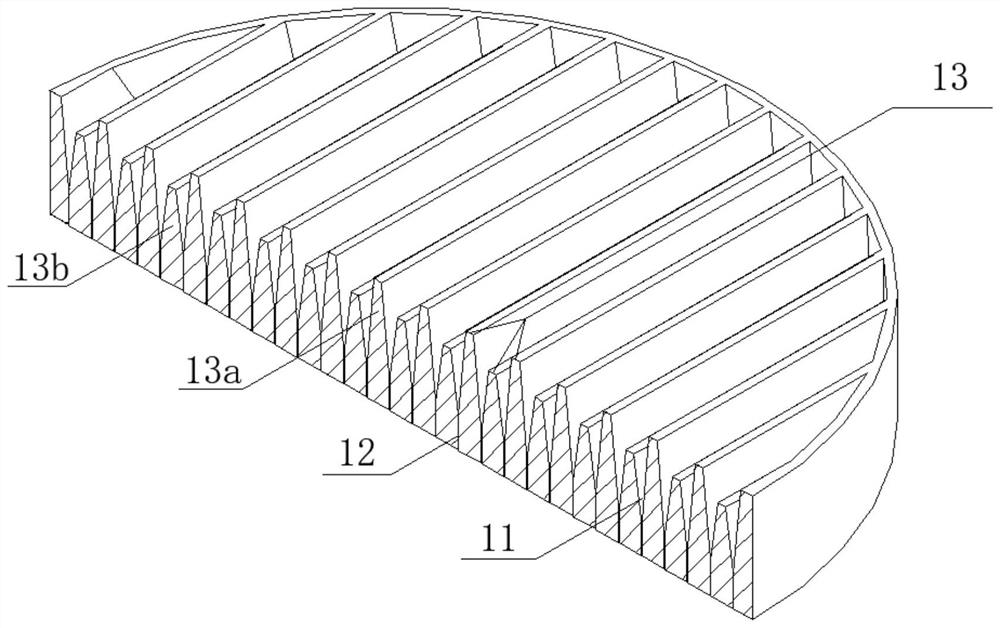

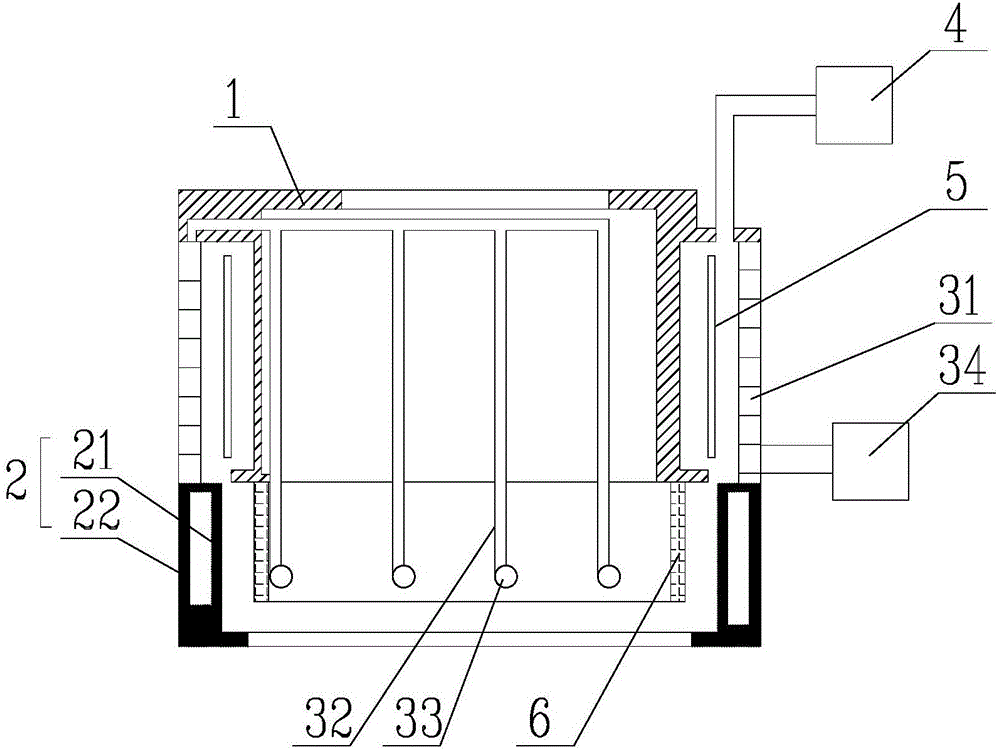

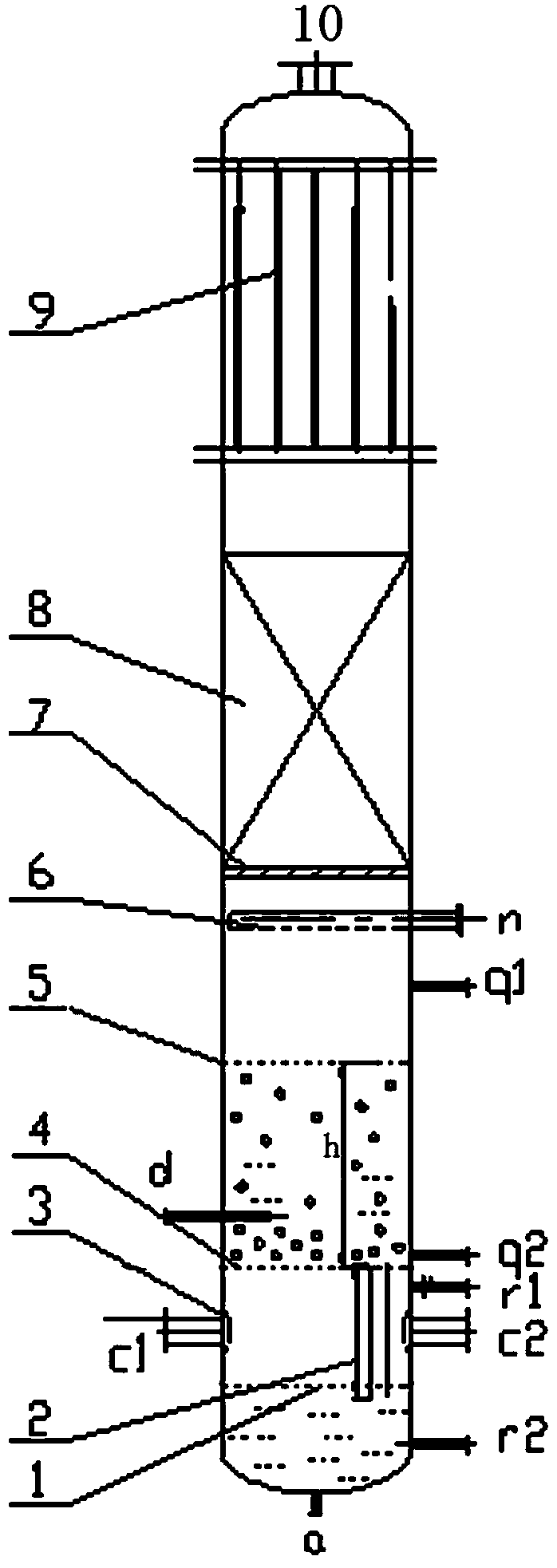

Reaction rectification reactor

ActiveCN103706309AUniform air intakeReduce volatilityLiquid-gas reaction processesFractional distillationGas phaseSolvent

The invention discloses a reaction rectification reactor. The reaction rectification reactor comprises a reaction section, a rectification section and a reflux condensation part from bottom to top, wherein a liquid outlet, a gas inlet and a gas distribution plate are arranged on the reaction section from bottom to top; a downspout and the gas distribution plate are arranged in the reactor; the upper end of the downspout is fixed on the gas distribution plate; a liquid inlet is formed in the reactor side wall between the reaction section and the rectification section; holes are evenly formed in the gas distribution plate. Compared with the prior art, the reaction rectification reactor has the beneficial effects that (1) a gas feeding manner of a gas phase is even, the amplitude of fluctuation of a reaction liquid level is small, the liquid level is easily controlled, and the problems of difficult connection between a large-diameter gas inlet pipeline and a gas distributor and processing difficulty of the gas distributor are avoided; (2), one part of reaction heat can be removed by gas carrying a gasified solvent, the temperature is controlled to be stable, and the problems of overheating locally and removing the reaction heat difficultly are avoided; (3), the rectification section and a condenser are capable of better separating certain components which are difficulty separated.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

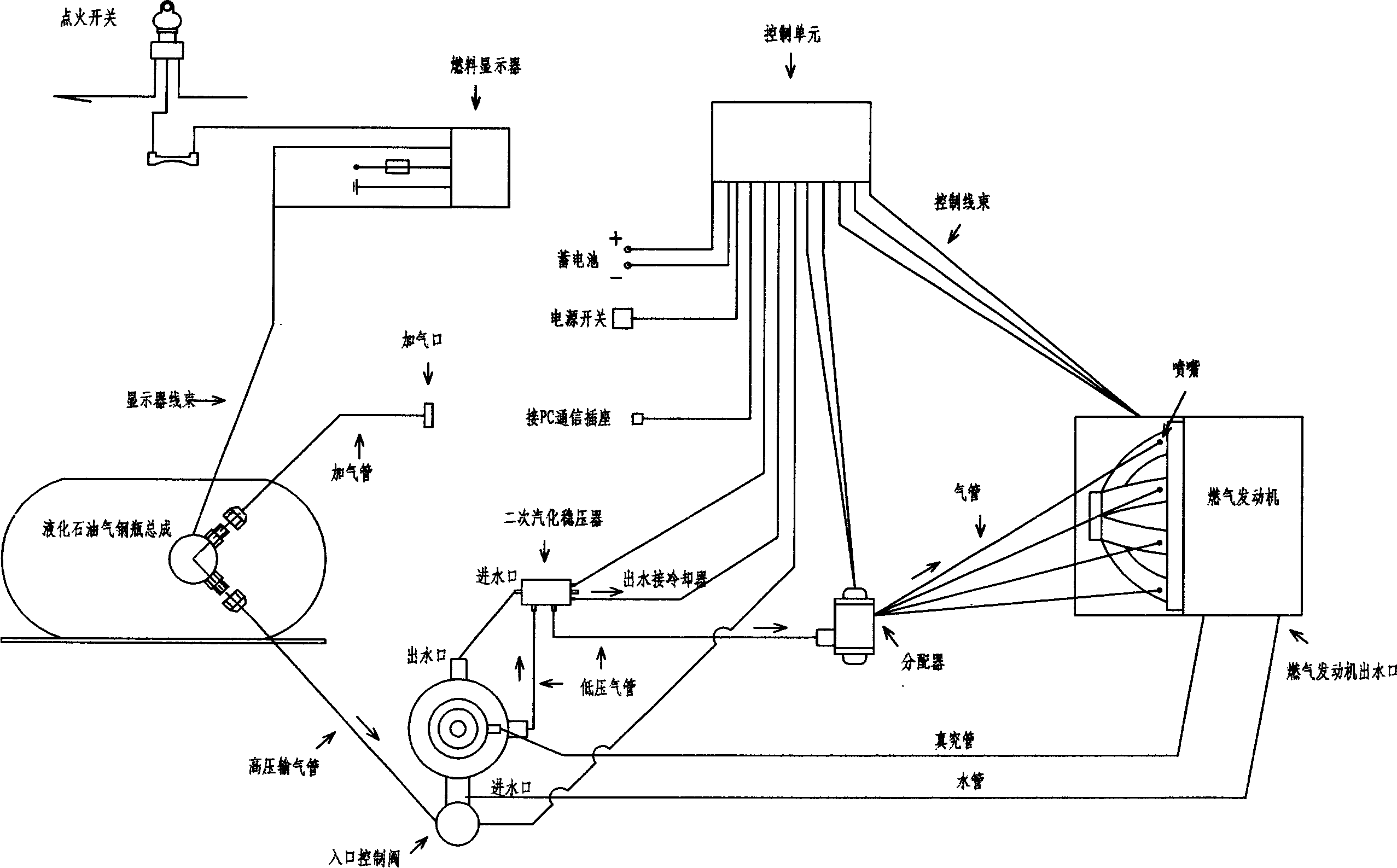

Gas engine

InactiveCN1746476AUniform air intakeSpeed up vaporizationInternal combustion piston enginesFuel supply apparatusReducerProcess engineering

A gas engine using LPG or natural gas as fuel supply has a secondary vaporizer in between the reducer and distributor. The secondary vaporizer is comprised by a sealed water pipe and a sealed gas pipe which are connected side by side. On the secondary vaporizer may install a heating system and temperature sensor. The engine of this kind of structure is characterized of balanced gas distribution in each cylinder and stable running.

Owner:吕国怀 +2

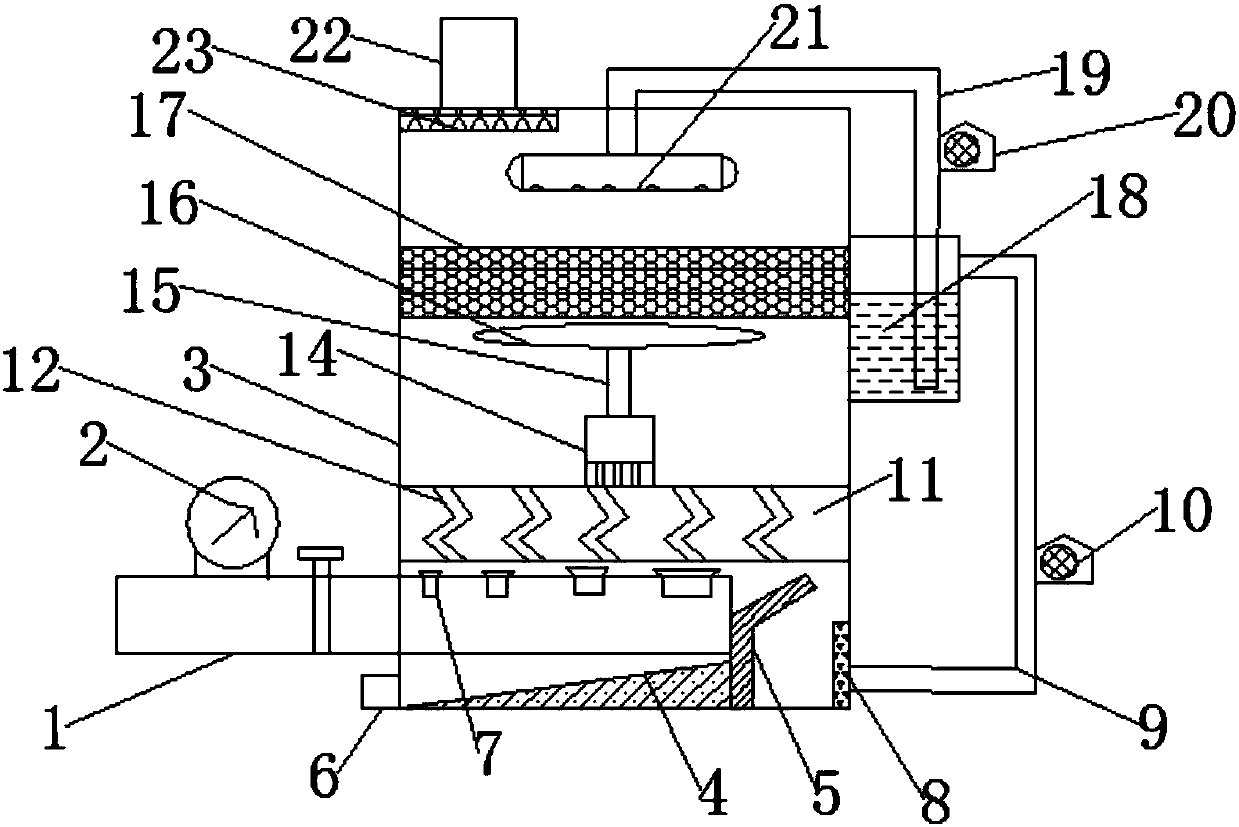

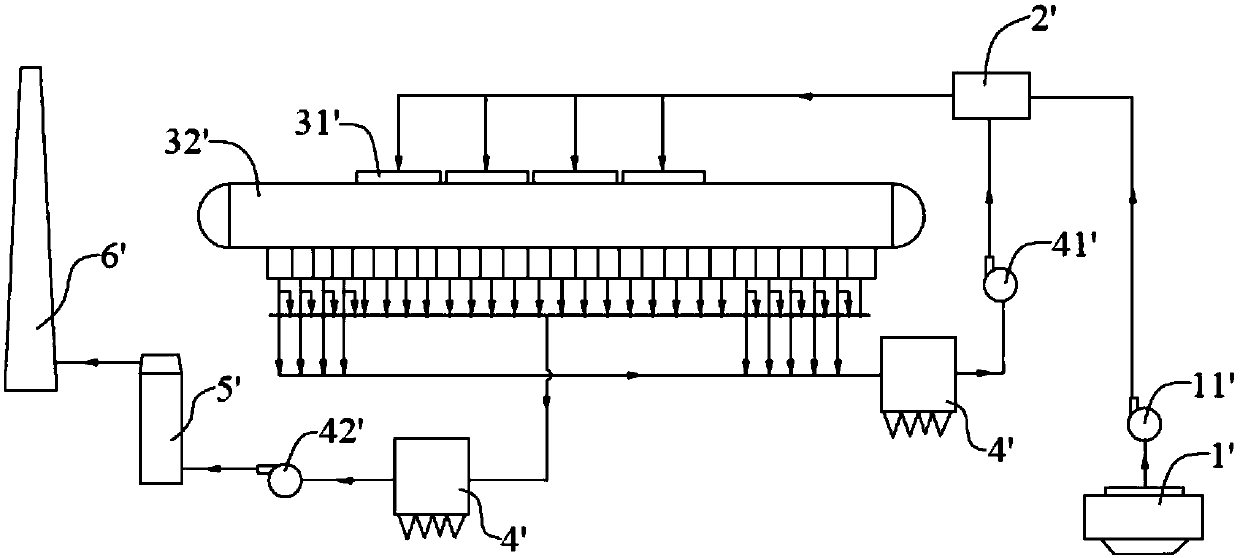

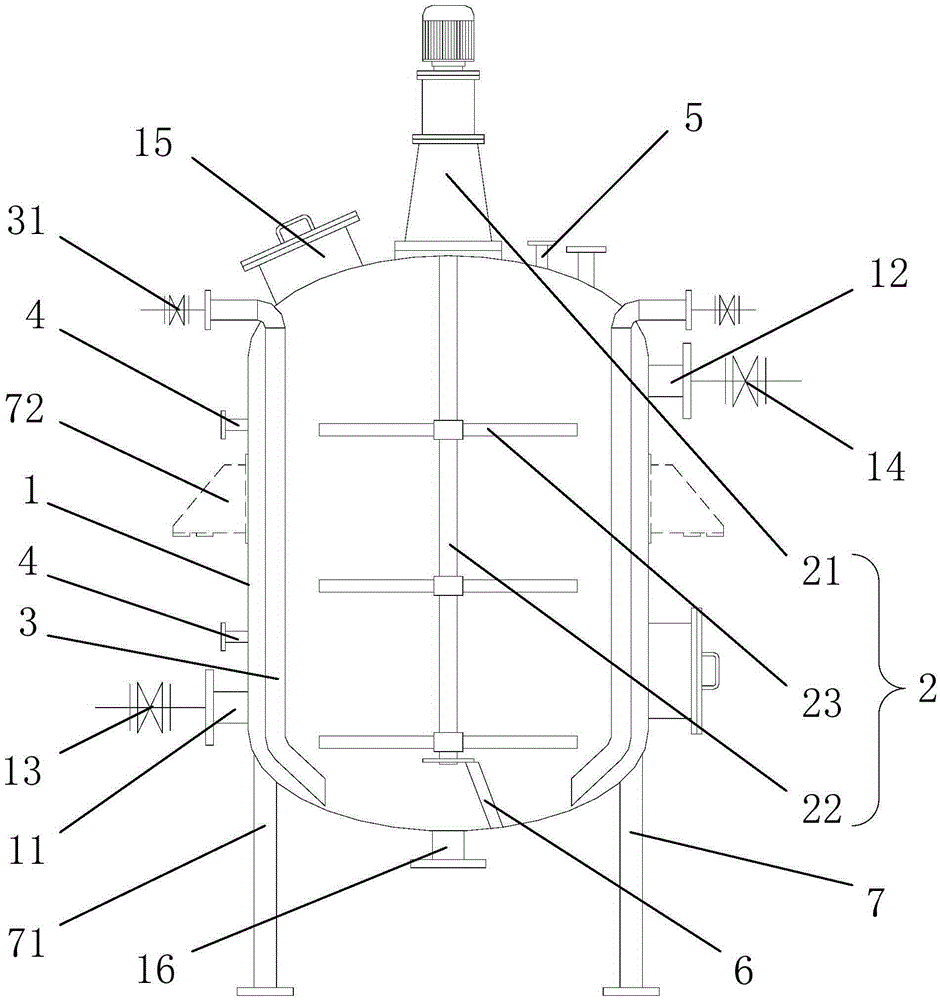

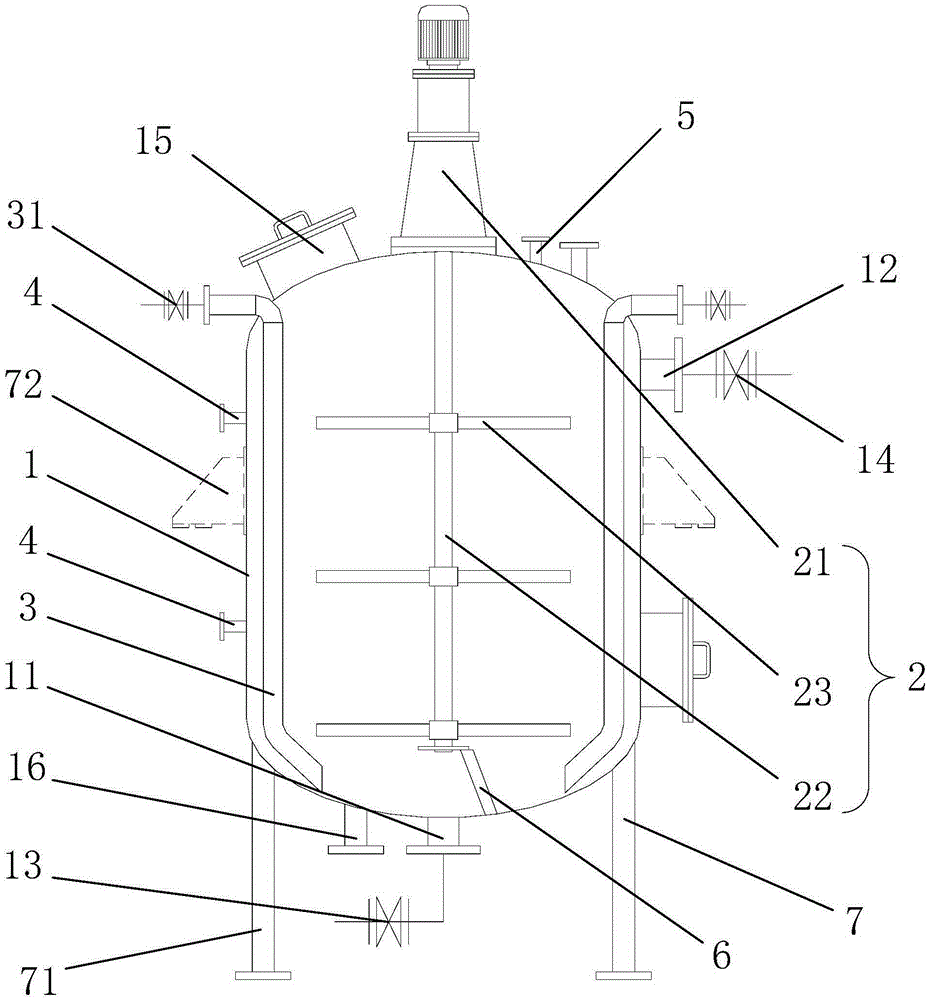

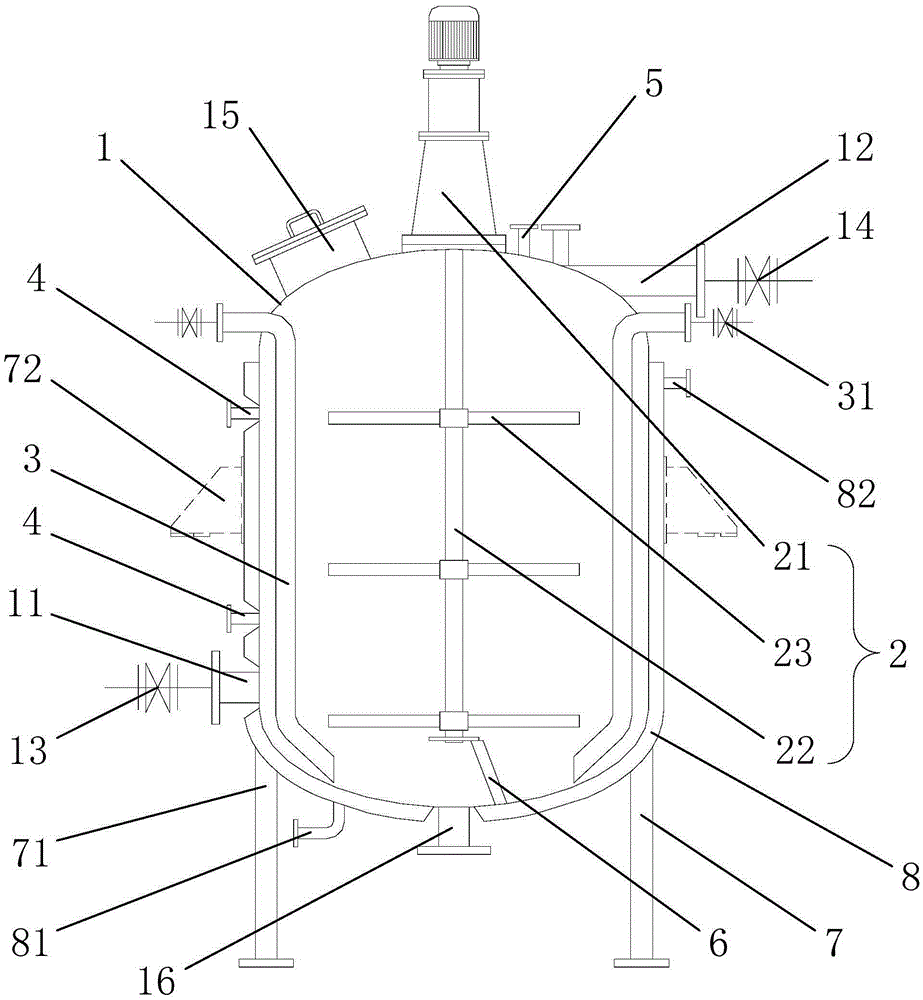

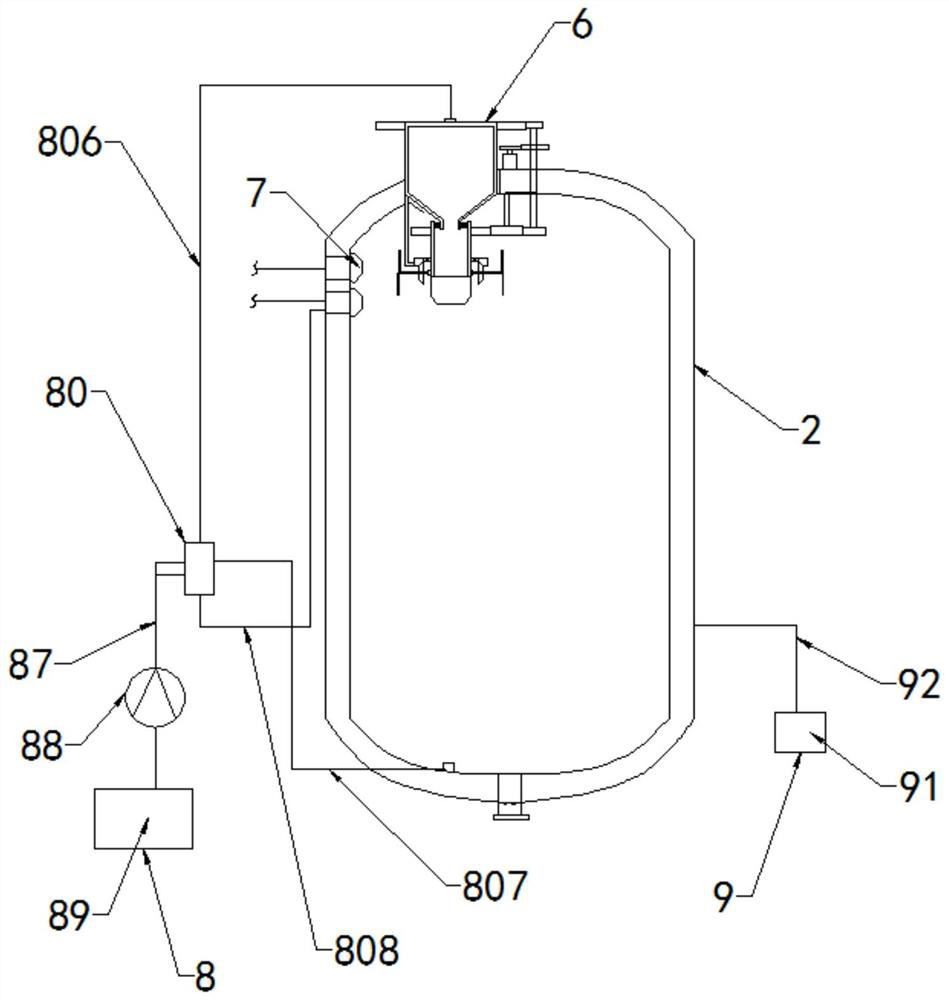

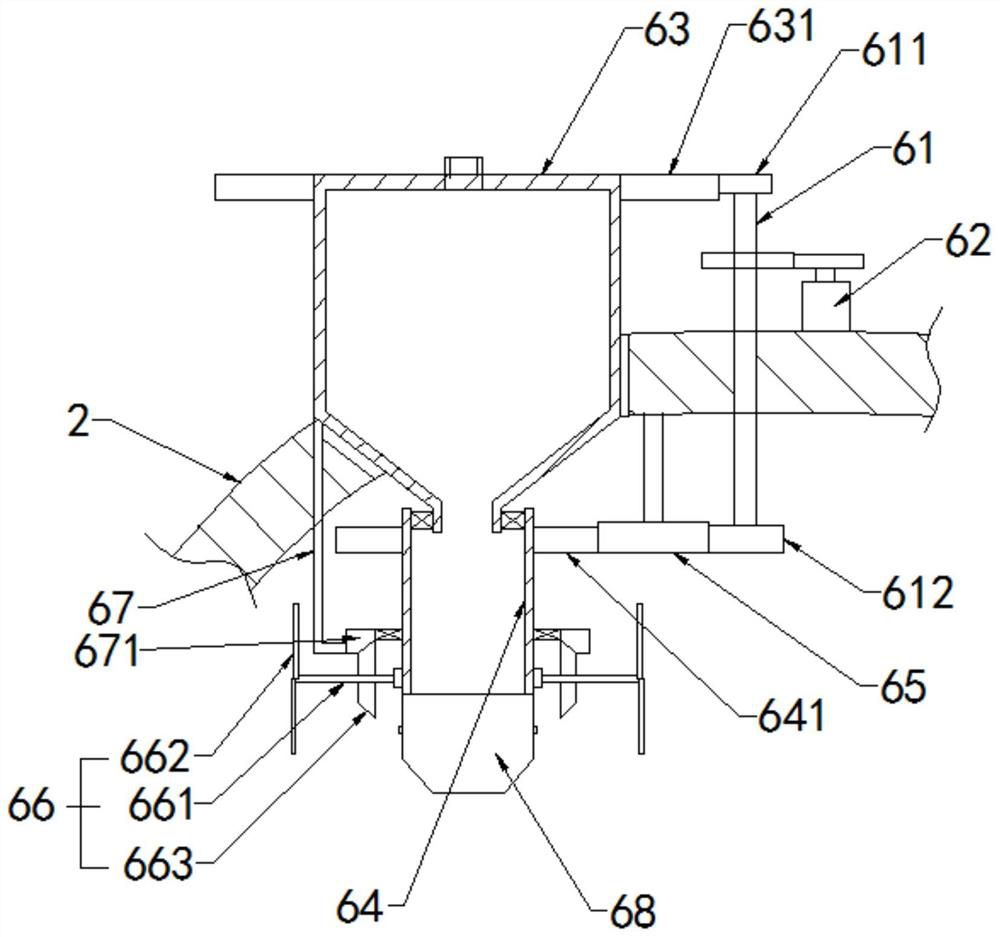

Continuous sludge thermo-hydrolysis device and use method thereof

InactiveCN105417922AFully hydrolyzedAdaptableSludge treatment by de-watering/drying/thickeningRotary stirring mixersSludgeHydrolysis

The invention relates to a continuous sludge thermo-hydrolysis device and a use method thereof. The device comprises a tank body, a stirring device arranged in the tank body, a steam pipeline penetrating through the tank body from the top of the tank body and extending to the bottom of the tank body along the inner wall of the tank body, temperature detection devices arranged at the upper part and the lower part of the side wall of the tank body respectively and a pressure detection device arranged at the top of the tank body, wherein a feed port is formed in the bottom of the tank body or the lower part of the side wall of the tank body; a discharge outlet is formed in the upper part of the side wall of the tank body; a feed valve and a discharge valve are arranged at the feed port and the discharge outlet respectively; a steam valve is arranged at an inlet of the steam pipeline. According to the continuous sludge thermo-hydrolysis device, materials are fed into the tank body from the lower part of the tank body and discharged from the upper part of the tank body; the stirring device with multiple layers of paddles is arranged, the materials are continuously conveyed for thermo-hydrolysis treatment, the treatment process is simple, operation is convenient, the treatment efficiency is improved, and a new approach is provided for large-scale application of the sludge thermo-hydrolysis process.

Owner:BEIJING JIELV ENVIRONMENTAL TECH CO LTD

Urea mixing device

PendingCN110848007AReduce breakageCompletely brokenInternal combustion piston enginesExhaust apparatusEngineeringMechanical engineering

The invention discloses a urea mixing device. A partition is arranged between a front housing and a rear housing, a breaking plate is fixed to the partition, a front baffle is arranged on the front end part of the partition, an opening is formed in a part corresponding to the partition, of the front baffle, a flow guide plate and a hole plate are arranged on the opening, and an intake port is formed between the flow guide plate and an inner wall surface corresponding to the front housing; a blade opened inwards and towards an injection cavity is formed in the flow guide plate; a plurality of first through holes are formed in the hole plate; grating openings are formed in a wall surface facing the breaking plate, of the partition; and the rear housing is provided with a waist-reducing part.According to the urea mixing device, the plurality of grating openings are formed in the part facing the breaking plate, of the partition, and play a role of secondary breaking on urea drops, and more thorough atomization and volatilization for the urea drops are ensured, so that adequate mixing for mixed gas flow is much benefited, and higher mixing uniformity is achieved. The rear housing is provided with the waist-reducing part, and the flowing speed of the mixed gas flow while passing through the waist-reducing part, is increased, so that a better mixing effect and higher mixing uniformity are achieved.

Owner:无锡亿利环保科技有限公司

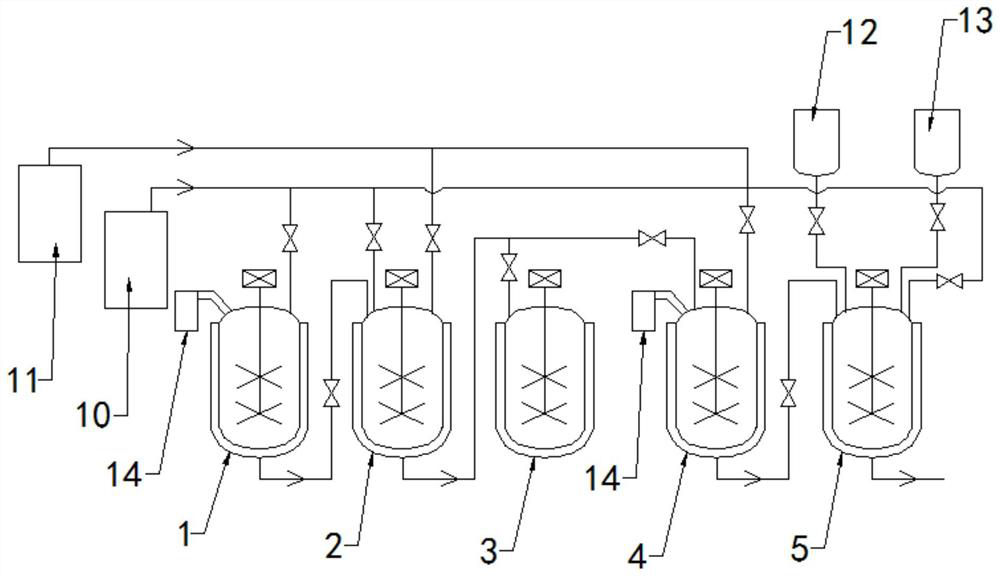

Polycarboxylic acid high-performance water reducing agent production and synthesis device and production process thereof

InactiveCN113058532AHigh polymerization activityGood mud resistanceChemical/physical/physico-chemical stationary reactorsFeed devicesPtru catalystEthylene oxide

According to the technical scheme, a polycarboxylic acid high-performance water reducing agent production and synthesis device is characterized by comprising a polyether primary pre-reaction kettle, a polyether primary reaction kettle, a polyether secondary pre-reaction kettle, a polyether secondary reaction kettle and a water reducing agent reaction kettle which are connected in sequence; the device further comprises a 4-hydroxybutyl vinyl ether storage tank and an ethylene oxide and epoxybutane storage tank; the water reducing agent reaction kettle is further provided with an unsaturated monocarboxylic acid monomer solution storage tank and an initiator and chain transfer agent solution storage tank, and the polyether primary pre-reaction kettle and the polyether secondary pre-reaction kettle are provided with continuous catalyst feeders; and a first feeding mechanism for dispersing and feeding materials and a second feeding mechanism for atomizing and feeding ethylene oxide, epoxybutane and 4-hydroxybutyl vinyl ether are arranged on a feeding hole of the polyether primary reaction kettle. The device has the beneficial effects that the efficiency of producing and synthesizing the polycarboxylate water reducing agent is high, the mixing is sufficient, and the quality of the produced polycarboxylate water reducing agent is good.

Owner:浙江衢州鼎盛建材有限公司

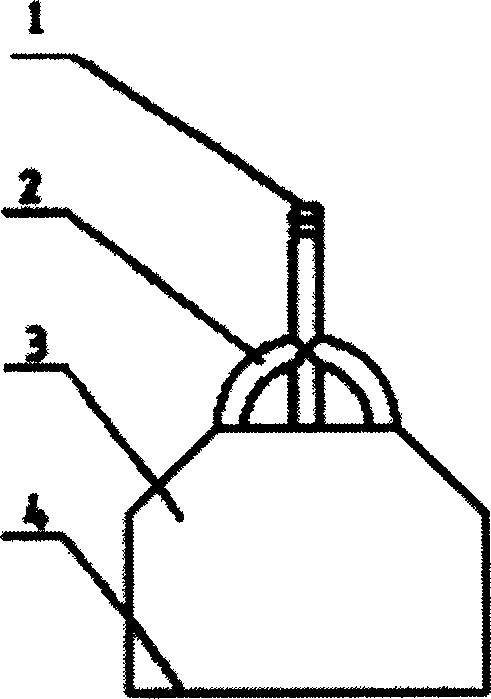

Leak-proof bottle cap

A leak-proof bottle cap comprises a lower cap fixed at a bottle opening of a bottle body and an inner plug arranged in the bottle opening. A through hole is formed in the inner plug. An extending portion of the lower portion of a bottle neck extends into the inner plug. A step portion is formed in the middle of the bottle neck, and a connecting portion is arranged on the upper portion of the bottle neck. An outer thread is formed on the outer wall of the connecting portion. A wine through is formed in the bottle neck. An upper inner cap is connected with the connecting portion through an inner thread and fixedly connected with an upper cap through a fastener. The bottle neck with the extending portion extending into the through hole of the inner plug is adopted and made of hard plastic so as to support the inner plug. According to the arrangement, after long-term storage, the inner plug and the bottle neck are free of deformation, thus excellent sealing effect between the bottle plug and the bottle body is guaranteed to avoid leakage of wine.

Owner:宜昌崟锦包装有限责任公司

Micro flow valve control mechanism

PendingCN111623163AGuaranteed tightnessNo skewOperating means/releasing devices for valvesLift valveSuction forceSolenoid valve

The invention discloses a micro flow valve control mechanism. The micro flow valve control mechanism comprises an electromagnetic coil, a base, a ring seat, a rotor plate and an elastic sheet. The elastic sheet is located above the base. The ring seat and the rotor plate are located between the base and the elastic sheet. The rotor plate is located on the inner side of the ring seat. The base is provided with a sealing ring matched with the rotor plate. The electromagnetic coil is located on the upper side of the elastic sheet. A valve intake control structure is optimized. The ring seat achieves the guide effect on ascending and descending of the rotor plate to some extent. It is ensured that the rotor plate cannot defect in the intake process so that uniform air intake on an outer ring of the lower side of the rotor plate can be realized, and the operation stability of a solenoid valve is ensured. The electromagnetic coil generates upward suction force to the rotor plate, and the elastic sheet generates downward elastic force to the rotor plate; the height of the rotor plate can be slightly adjusted through current change of the coil, and then the opening degree of the valve is changed. The sealing ring on the base can ensure the airtightness of the valve after power-off of the coil.

Owner:SUZHOU RAYONTECH TECH CO LTD

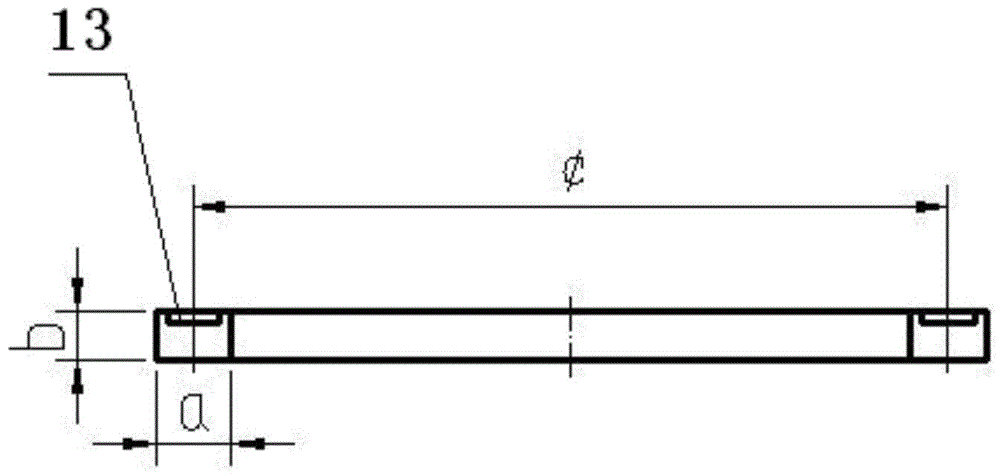

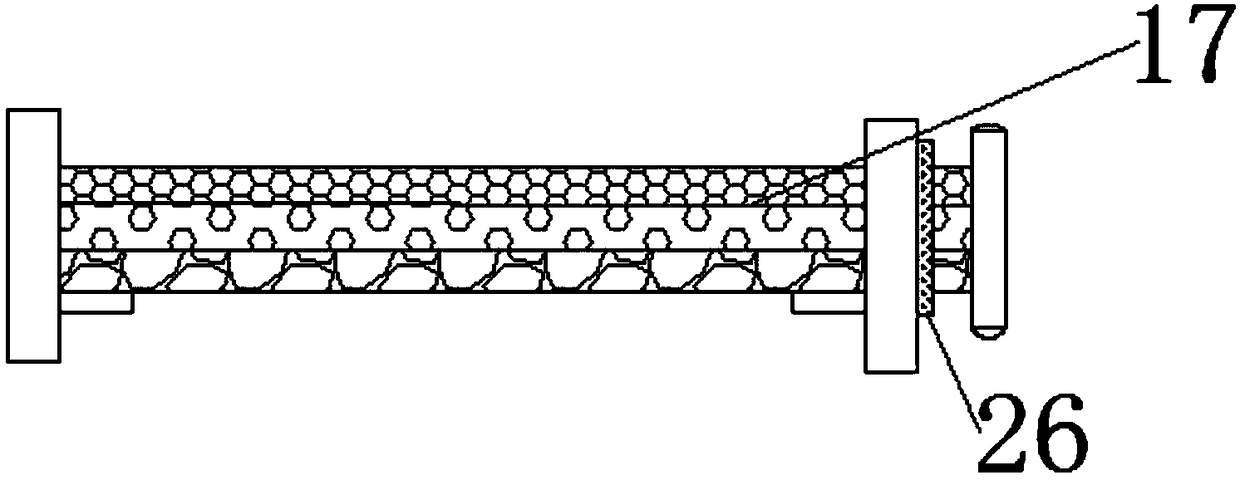

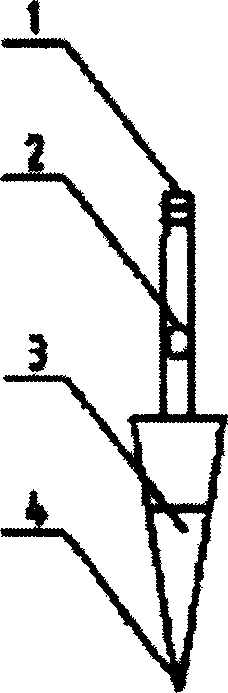

Nozzle specially used for preparing transparent conductive film by using ultrasonic quick precipitation method

InactiveCN1692987ASimple structureEasy to processSpray nozzlesSuperconductor device manufacture/treatmentTransparent conducting filmEngineering

A special spray head for preparing large-area transparent electrically conductive film by high-speed ultrasonic deposition method features that the atomized raw material comes in its air inlet tube, is divided into three channes, and finally sprayed onto a large-area (20X20 sq.cm) glass substrate via the slits.

Owner:NANKAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com