Variable air inlet manifold for gasoline engine

A gasoline engine, intake manifold technology, applied in engine components, engine control, machine/engine and other directions, can solve the problems of complex design, not very clear, can not meet the intake volume and other problems, to improve performance, intake uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings. However, as long as there is no special description, the size, material, shape, relative position and the like of the components described in the embodiments are not intended to limit the scope of the present invention, but are only for illustration and example.

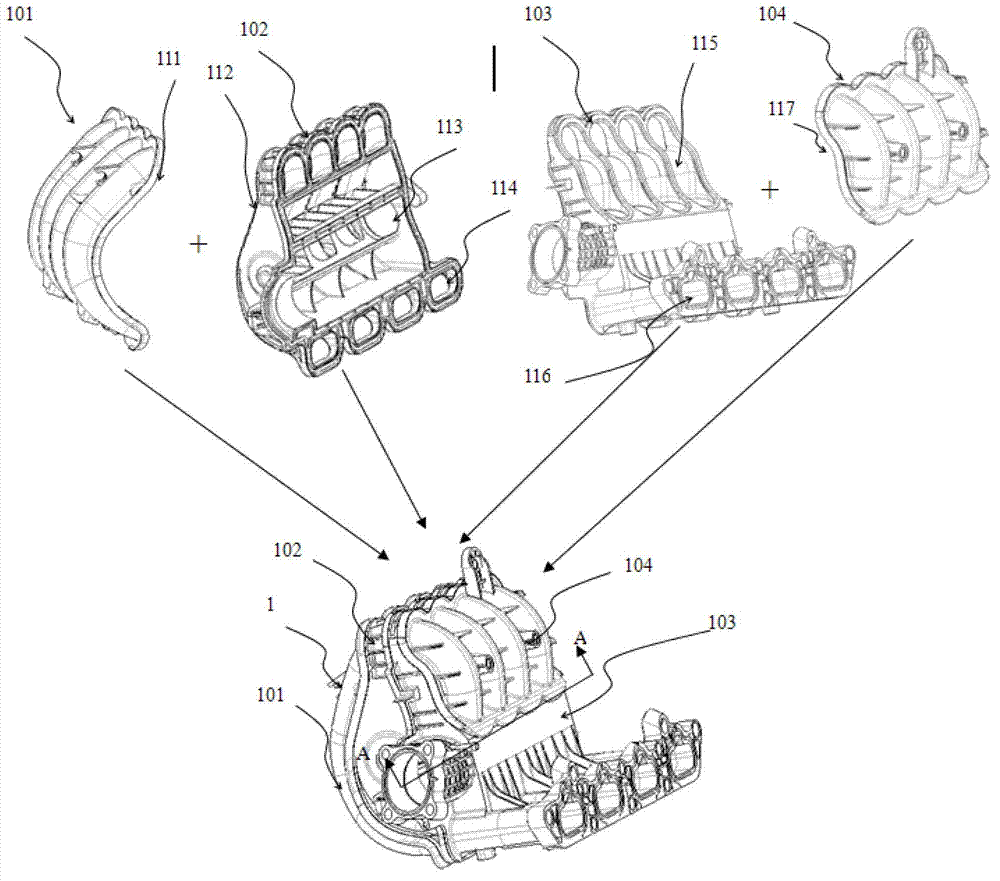

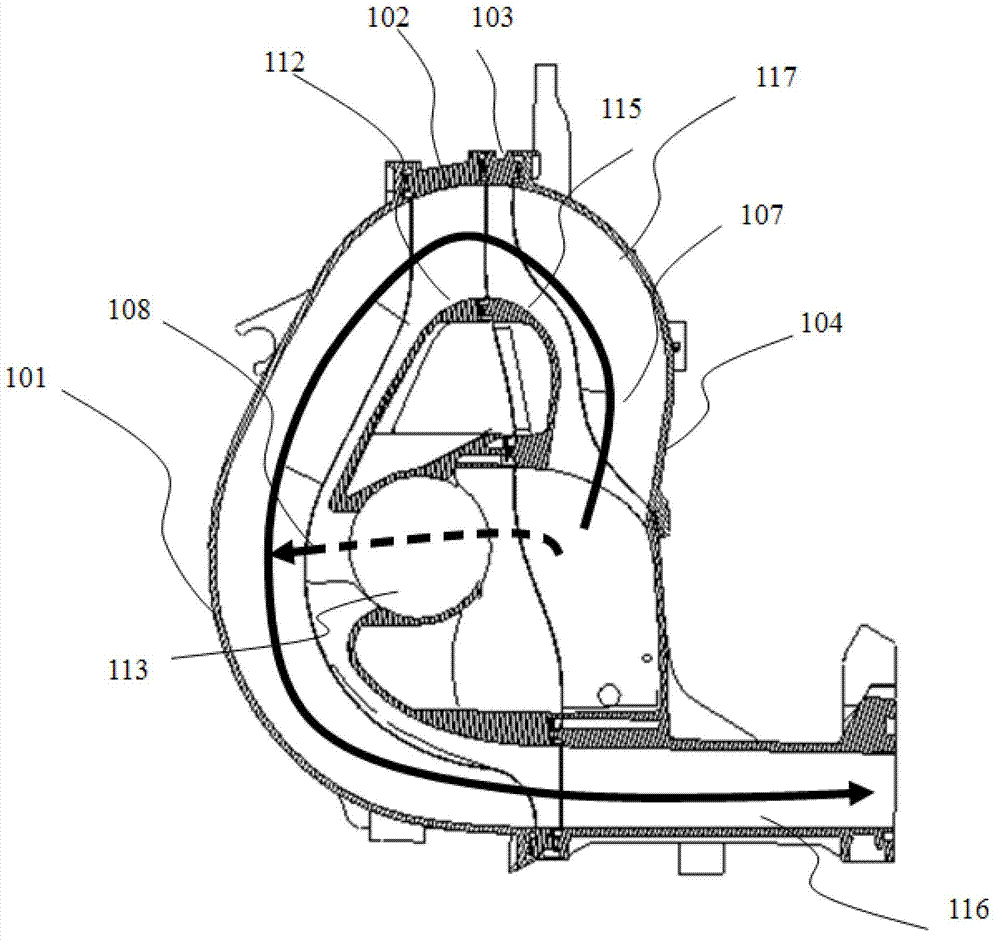

[0020] Such as Figure 1 to Figure 5 As shown, the variable intake manifold 1 of the gasoline engine is provided with a short air passage 108 and a long air passage 107 communicating with each other in the air passage. 108 switch section.

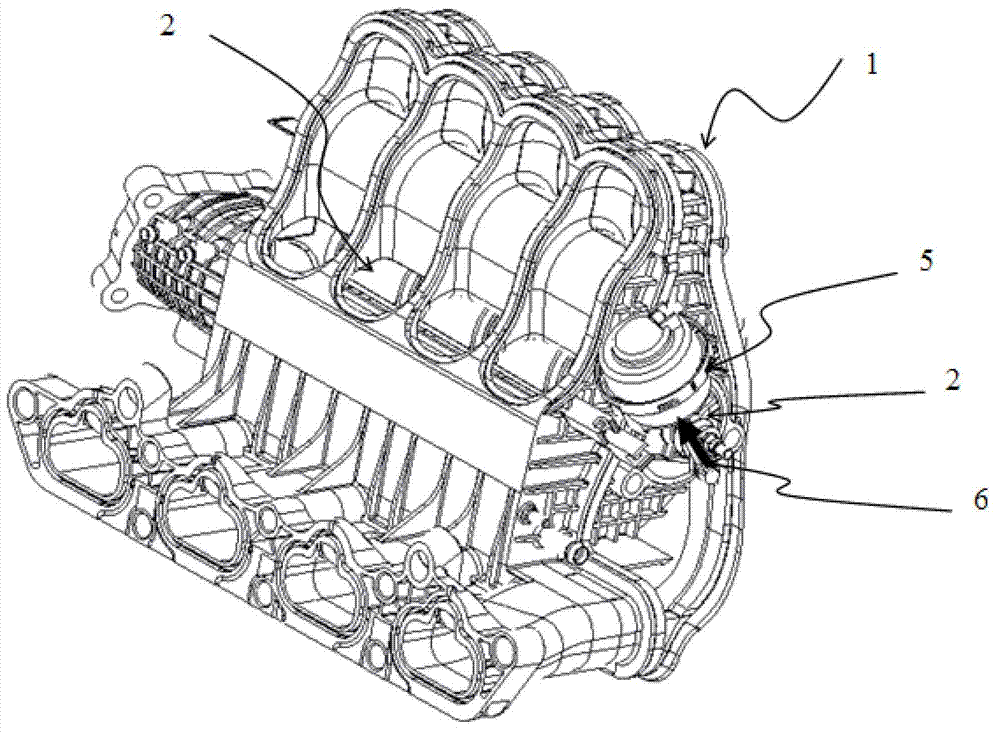

[0021] The switch part is a drum 2 that can rotate with a fixed axis. On the drum 2, there are flow holes along the direction perpendicular to the central axis of the drum; When the air inlet of the air passage 108 is open, the short air passage 108 is in an open state; when the rotating drum 2 makes the flow holes on it break away from the air inlet of the short air passa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com