Patents

Literature

162results about How to "Speed up vaporization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

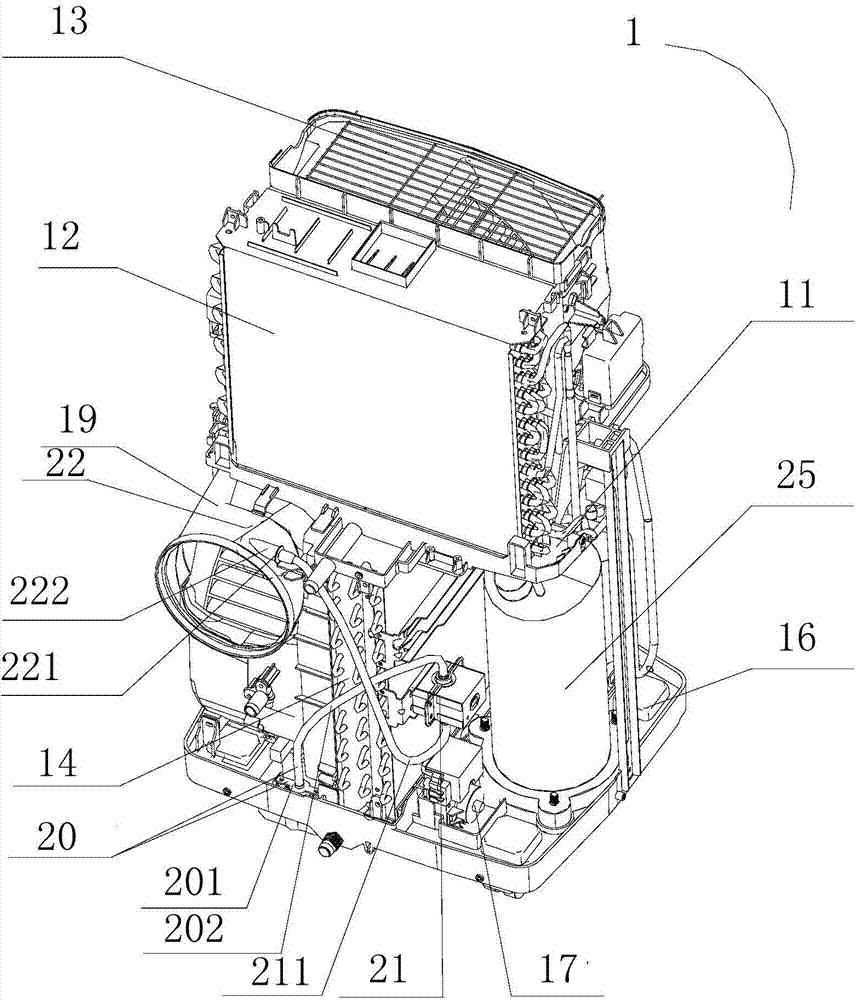

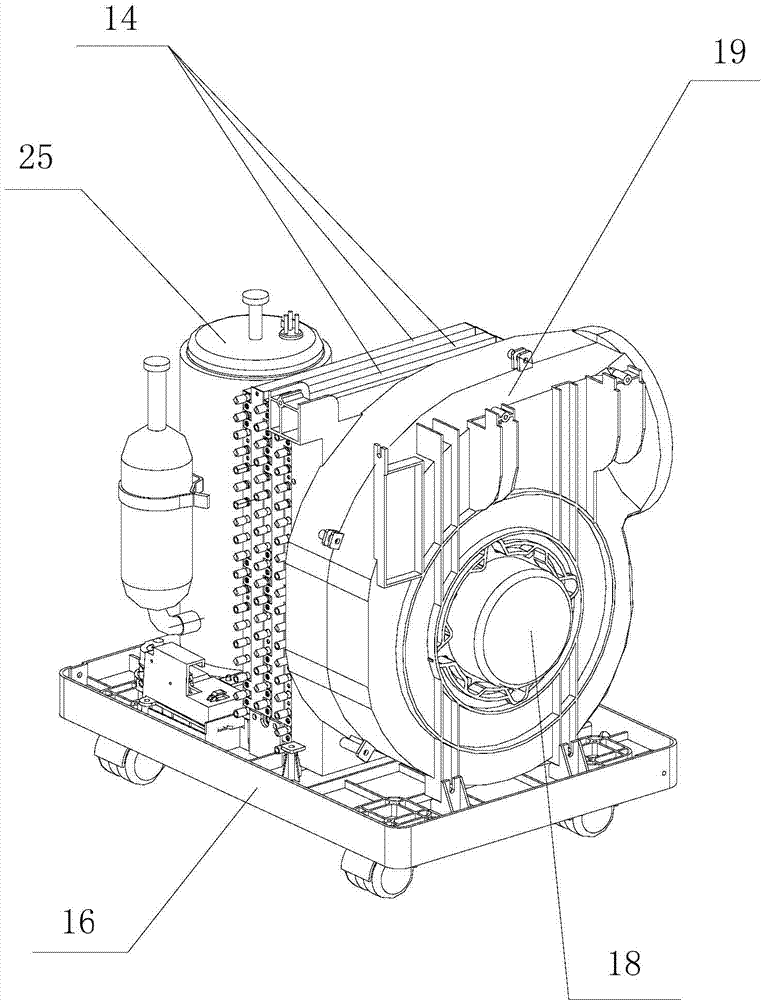

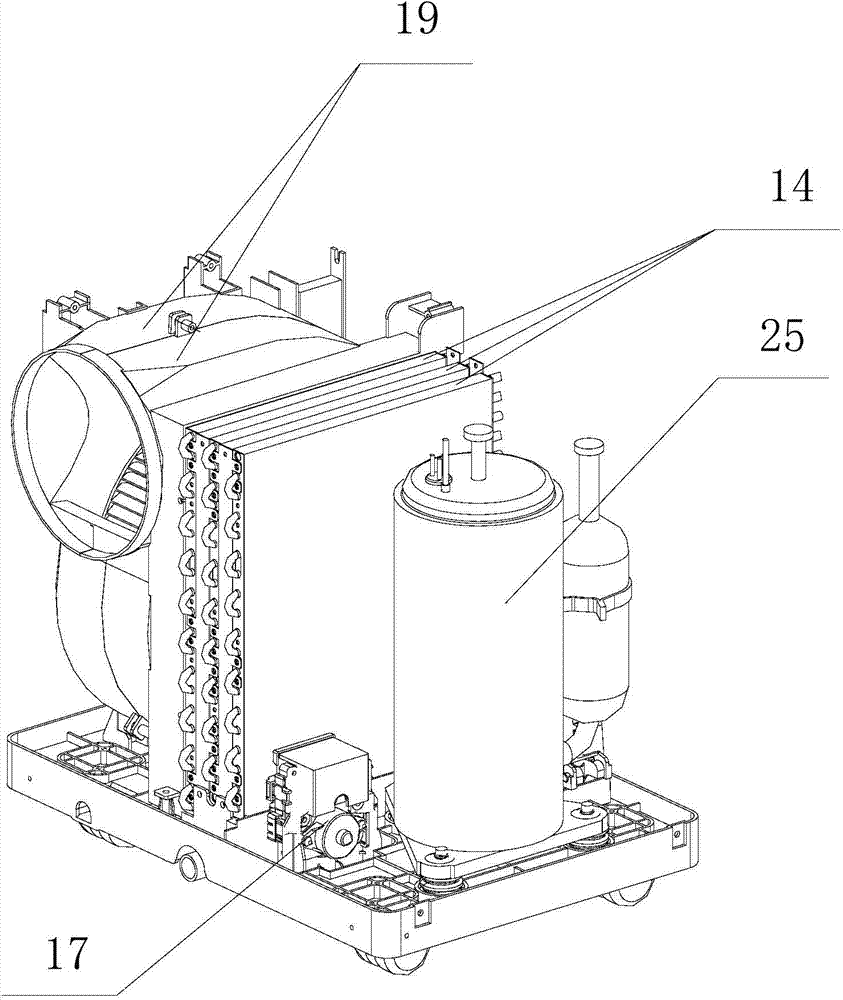

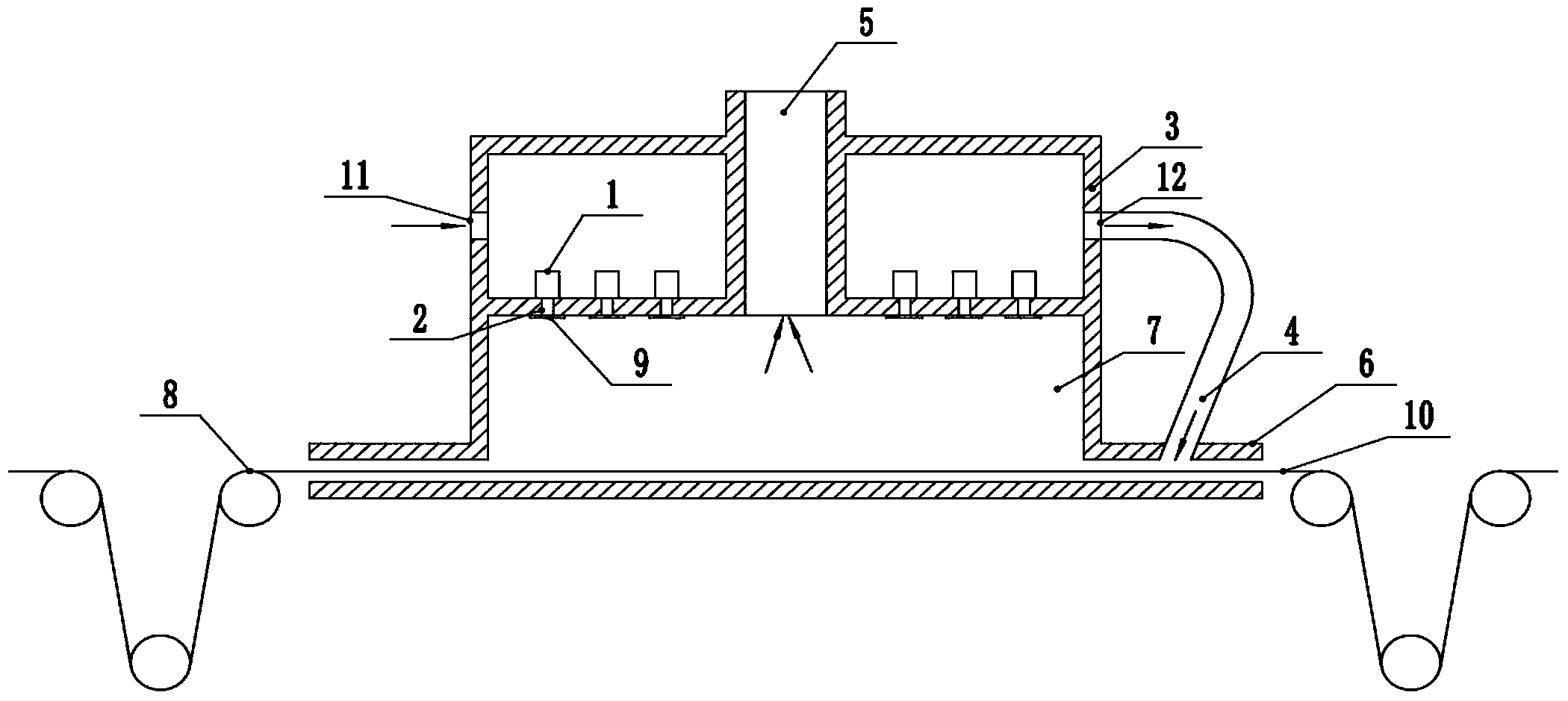

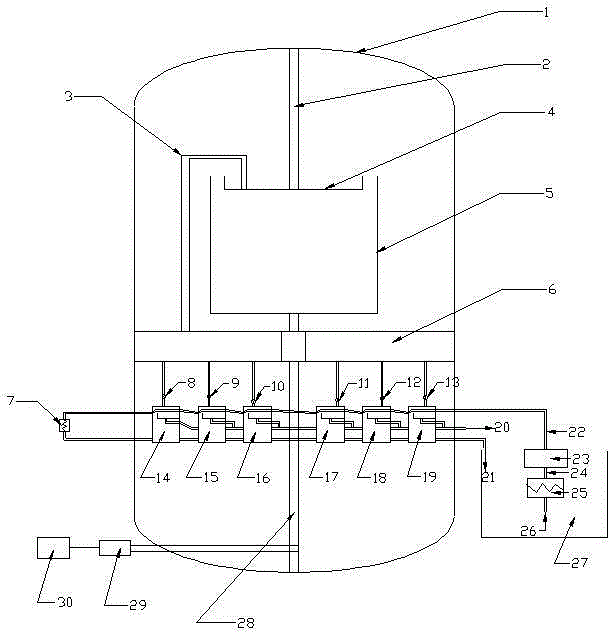

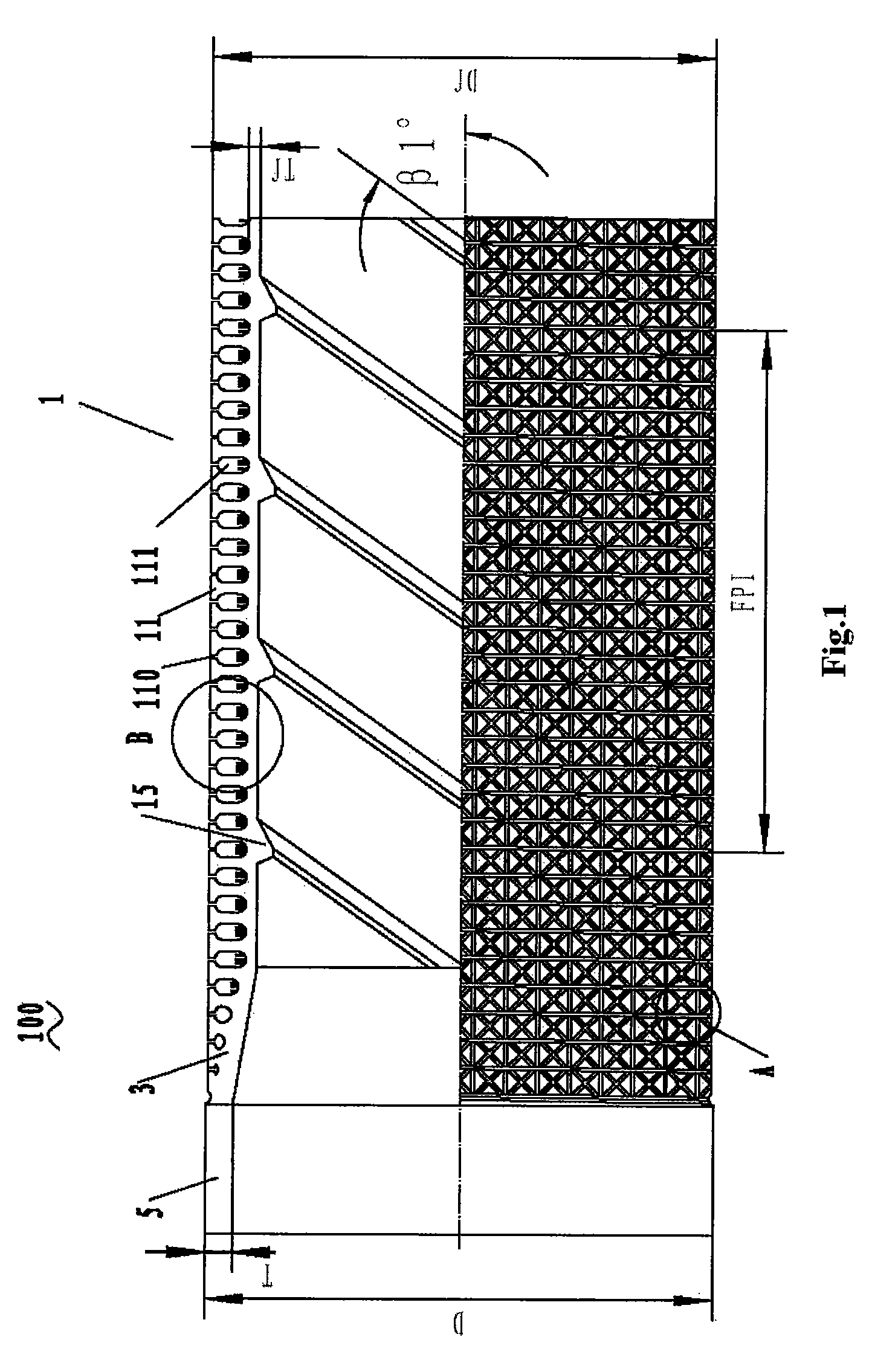

Integrated air conditioner and condensed water processing method for integrated air conditioner

ActiveCN104764095AImprove human needsFully recycleCondensate preventionLighting and heating apparatusEnvironmental engineeringWater processing

The invention discloses an integrated air conditioner and a condensed water processing method for the integrated air conditioner. The integrated air conditioner comprises an indoor water receiving plate, a drainage device connected with the indoor water receiving plate and used for leading the condensed water in the indoor water receiving plate to the outer side walls of multiple rows of condensers of the integrated air conditioner, the multiple rows of condensers used for heating condensed water on the outer side walls to at least vaporize part of the condensed water, a water tank arranged on a chassis of the integrated air conditioner and used for receiving non-vaporized condensed water on the outer side wall, and a water beating motor which comprises a plurality of water beating wheels and is used for beating the non-vaporized condensed water to the outer side walls of the condensers through the water beating wheels so as to enable the multiple rows of condensers to vaporize the non-vaporized condensed water again. By means of the technical scheme, the condensed water in the integrated air conditioner can be discharged automatically, and a user is protected from manually discharging the condensed water.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

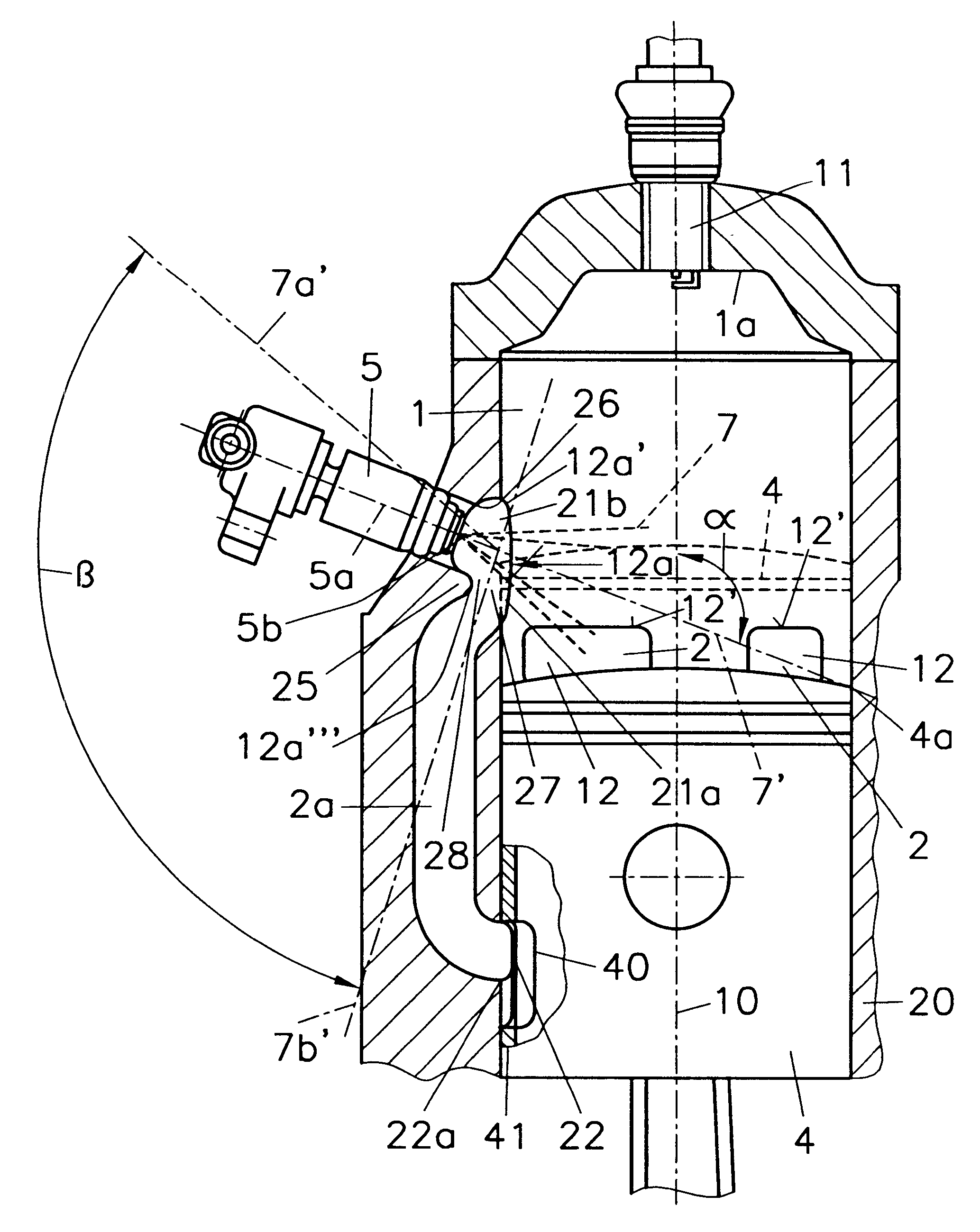

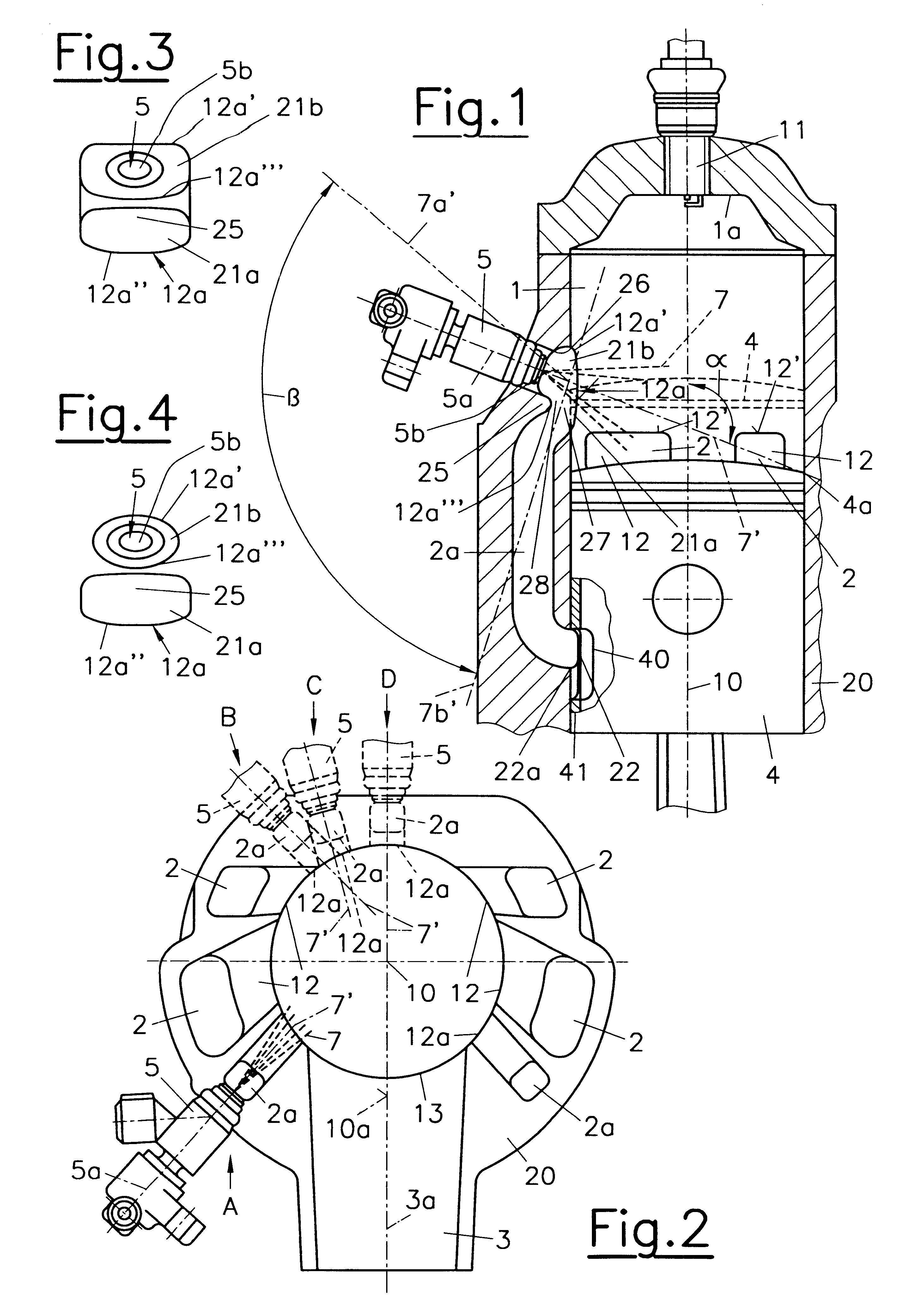

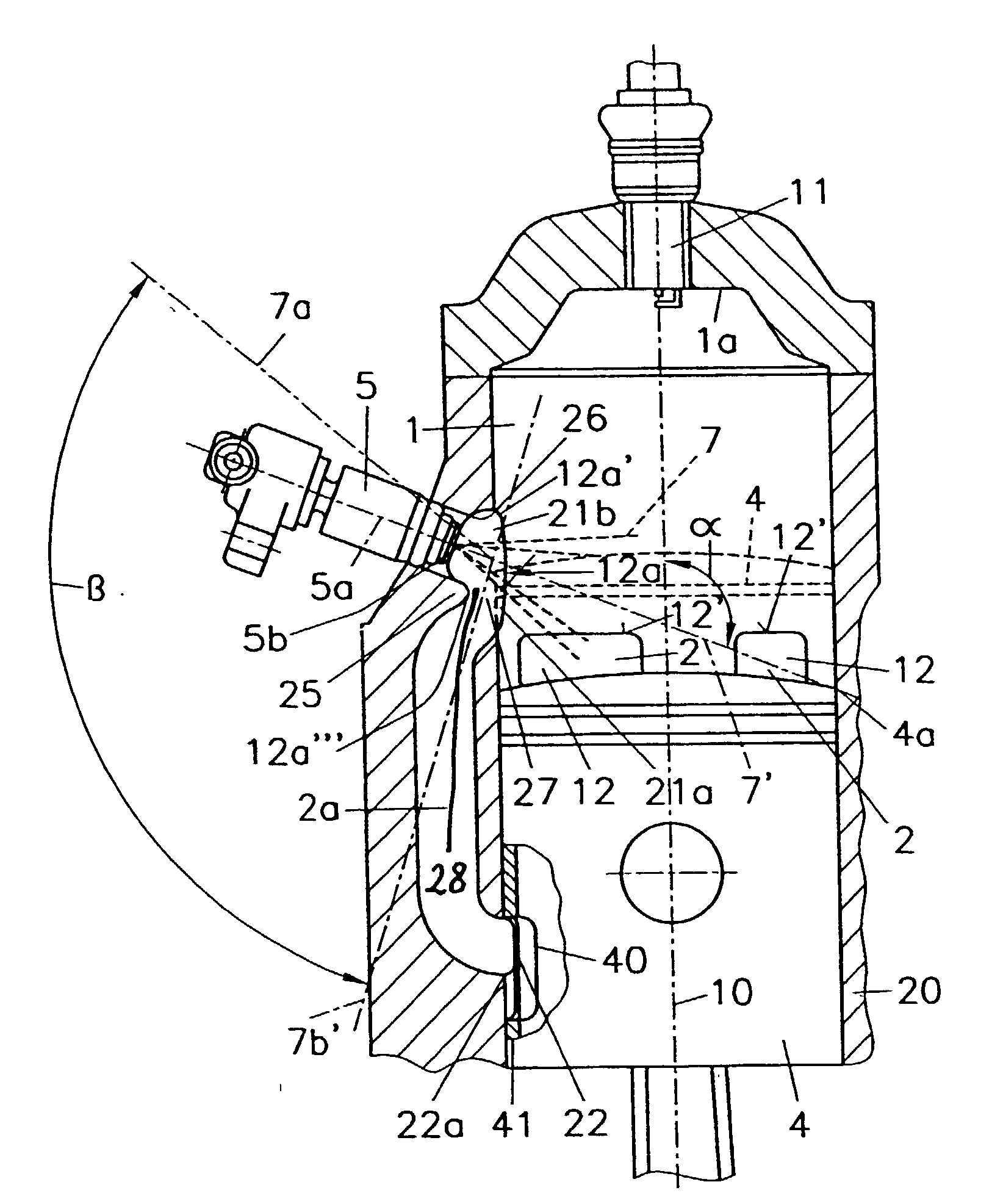

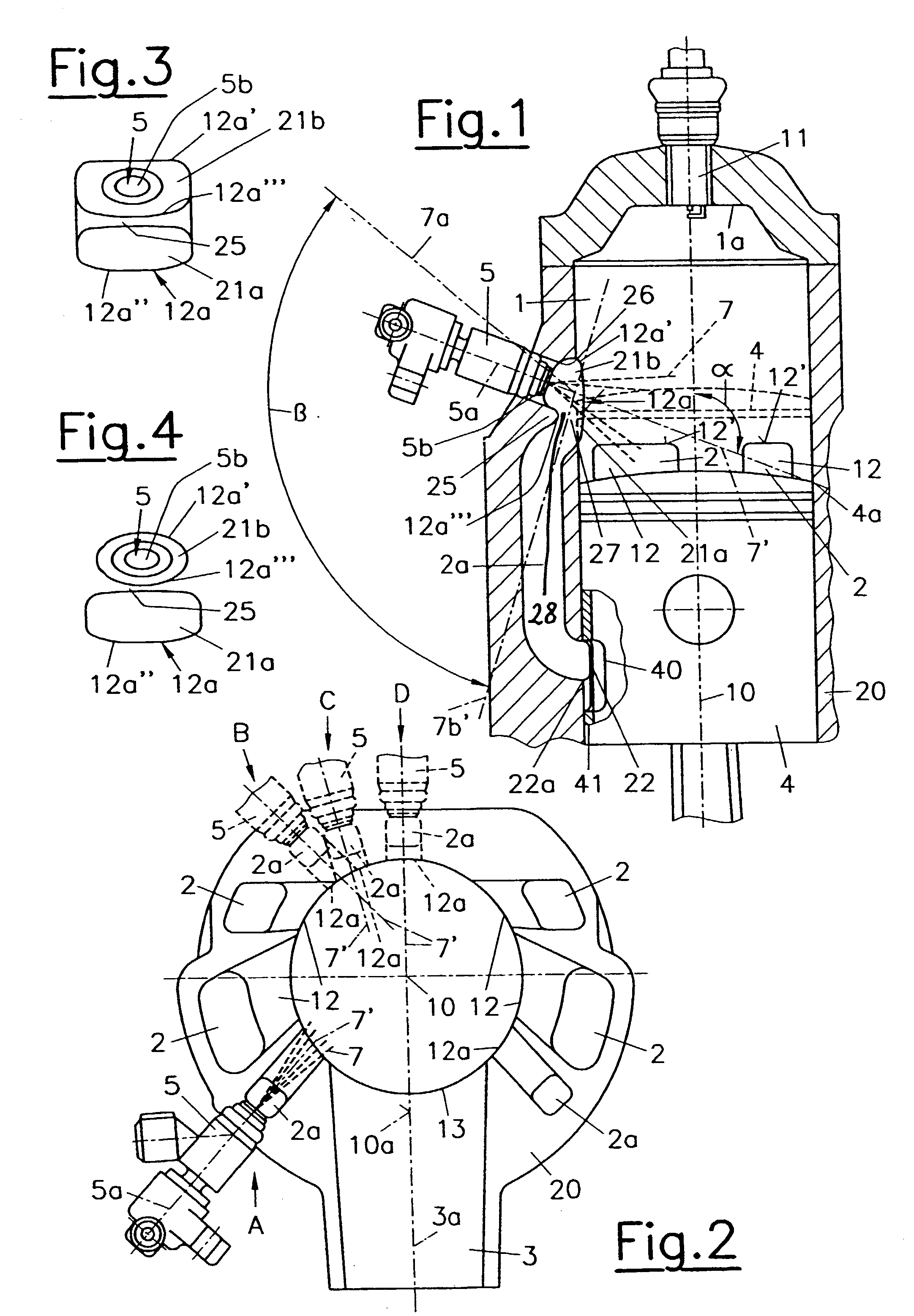

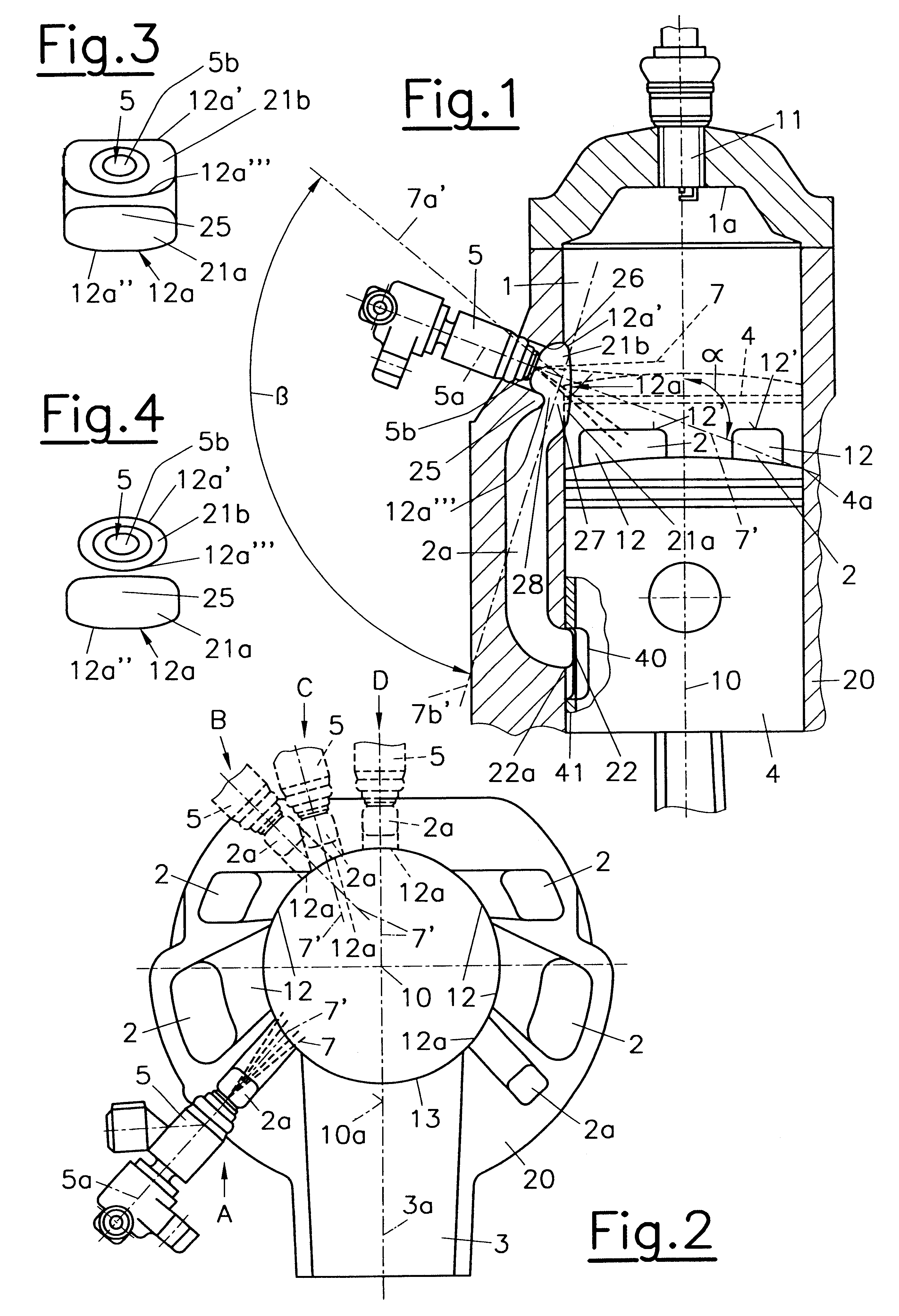

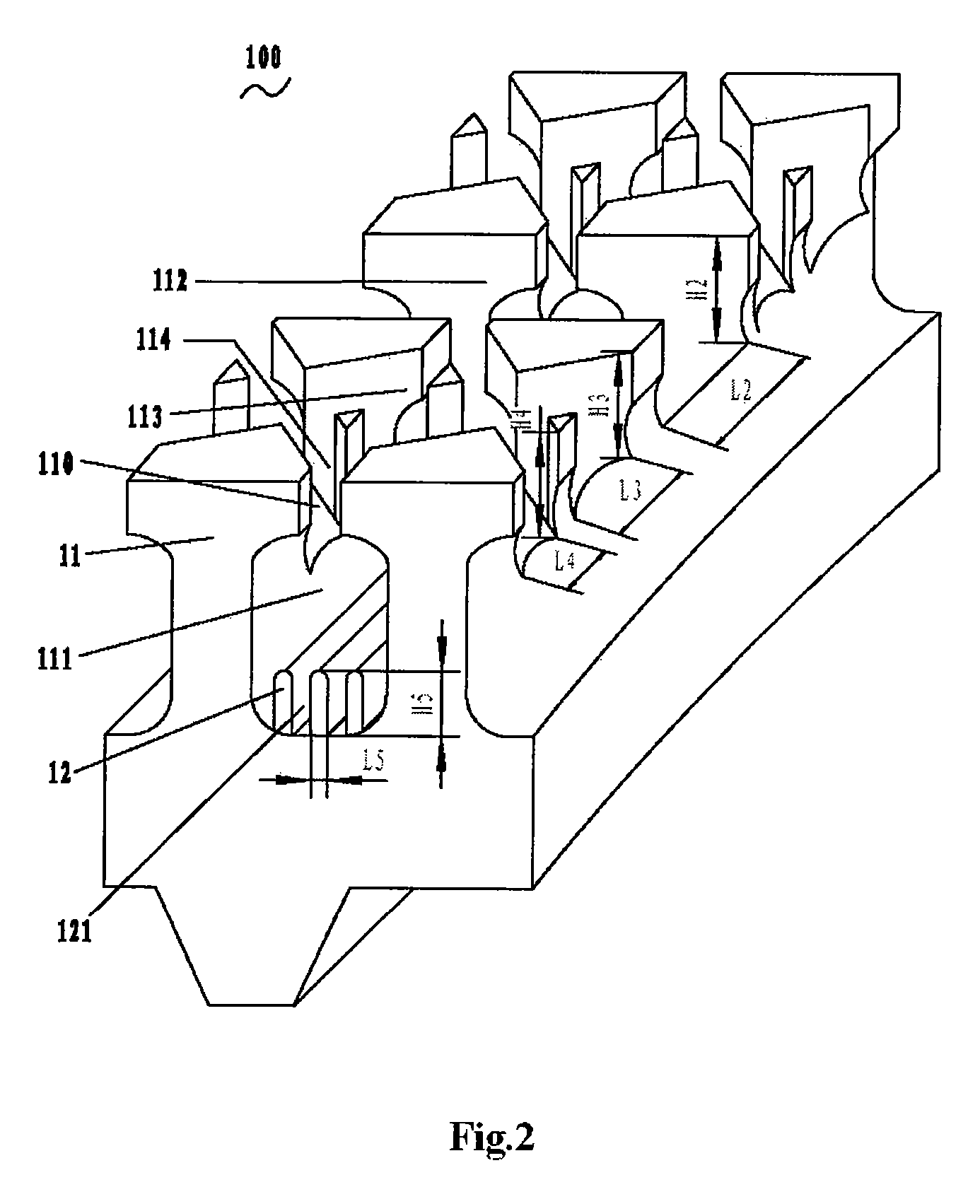

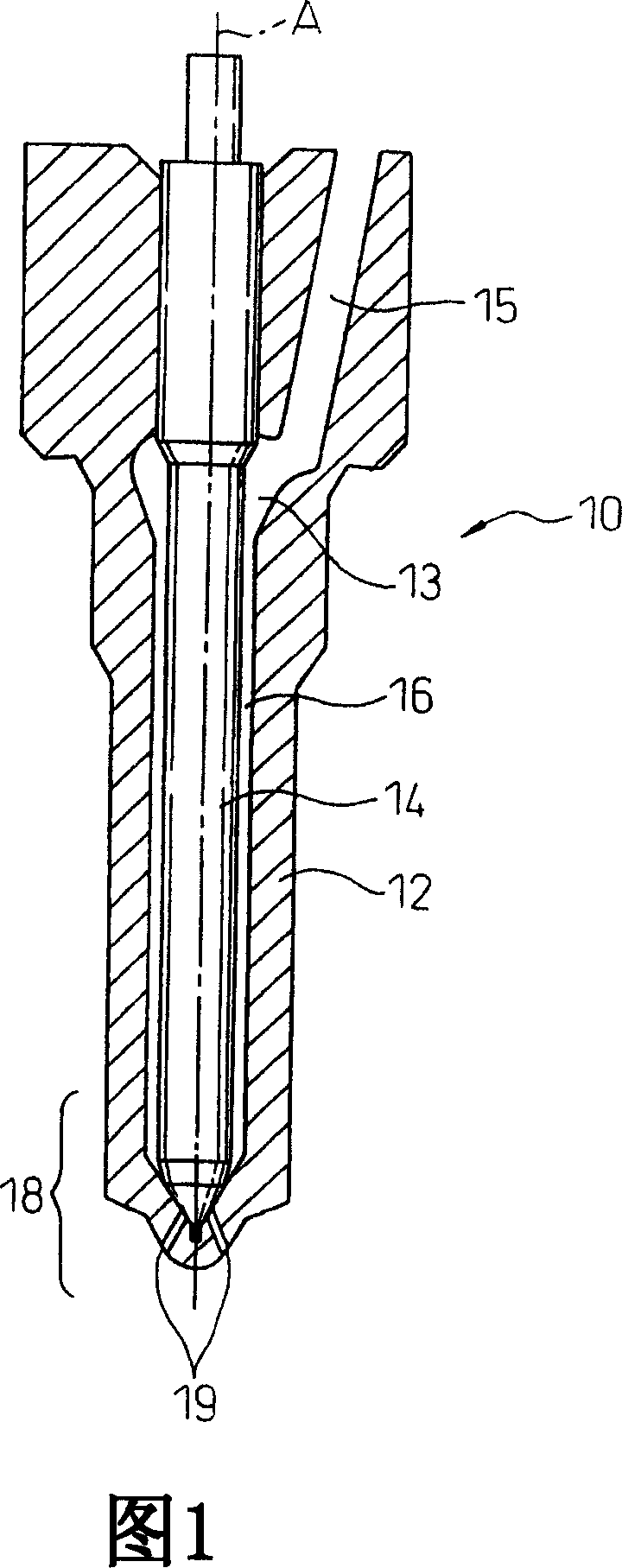

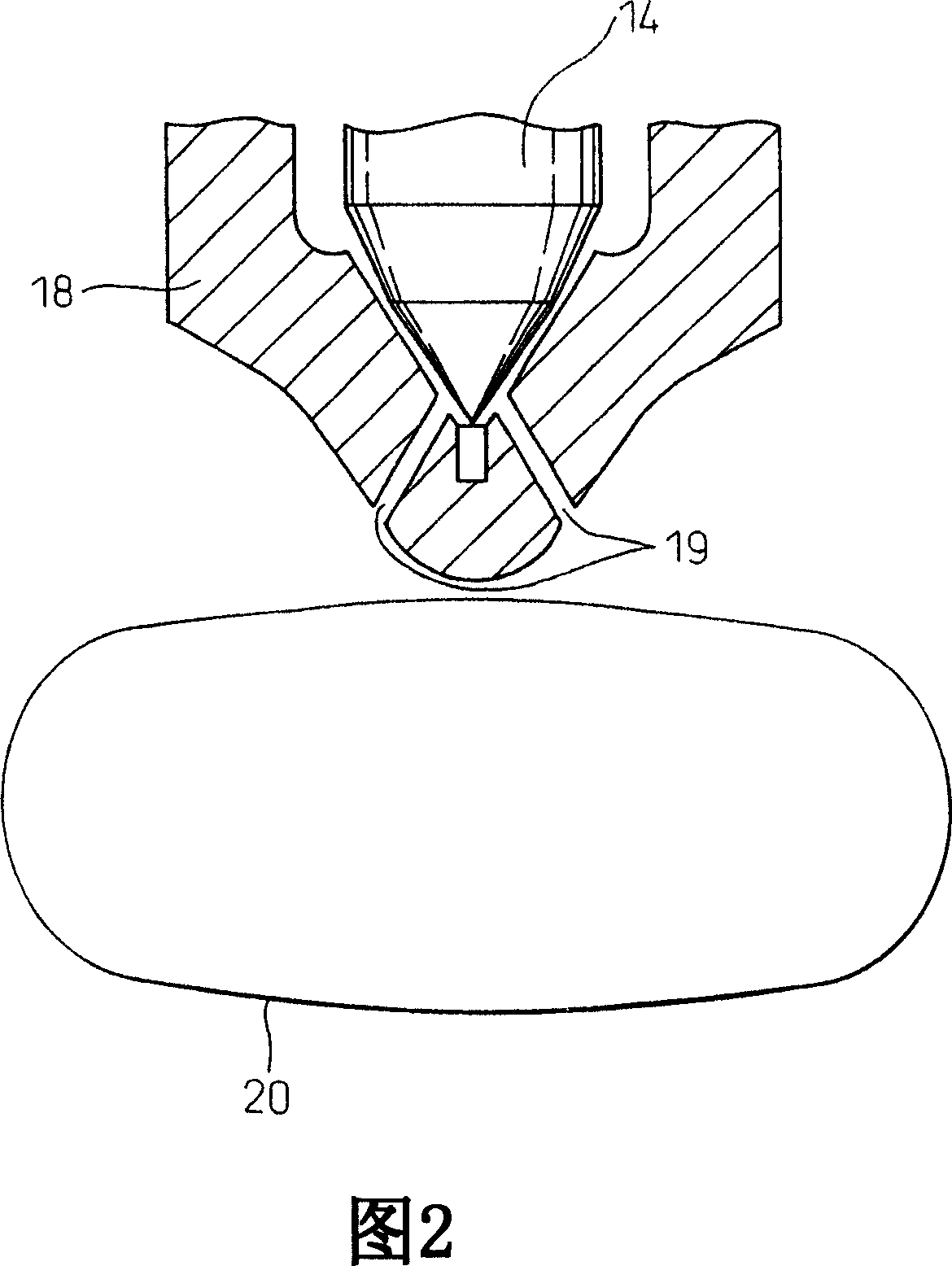

Two-stroke internal combustion engine with crankcase scavenging

InactiveUS6539900B2Extended service lifeEmission minimizationInternal combustion piston enginesCylinder headsCrankcaseEngineering

The invention relates to a two-stroke internal combustion engine with crankcase scavenging, with an exhaust passage controlled by the piston and at least two first transfer passages and at least one second transfer passage, each with a corresponding transfer window into the cylinder chamber and a window on the crankcase side for communication between the cylinder chamber and the crankcase, the transfer windows of the first transfer passages being controlled by the upper edge of the piston, and the crankcase-side window of the second transfer passage being disposed in a region of the cylinder wall that is swept by the piston skirt of the piston. The cylinder wall comprises at least one recess, which is arranged in close vicinity to the transfer window of the second transfer passage and which is in flow communication with the second transfer passage, wherein a narrow passage is arranged between the recess and the second transfer passage.

Owner:AVL LIST GMBH

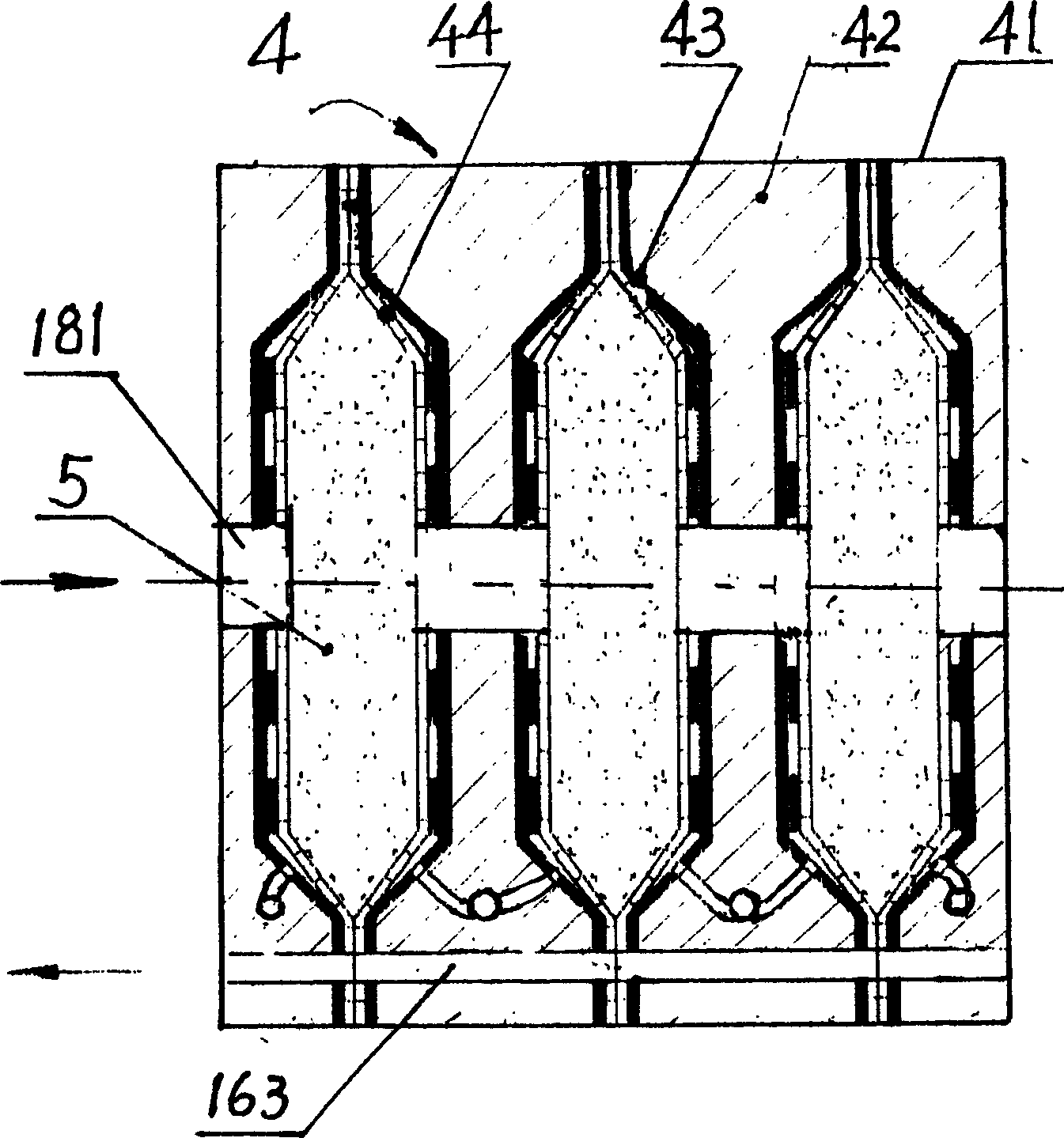

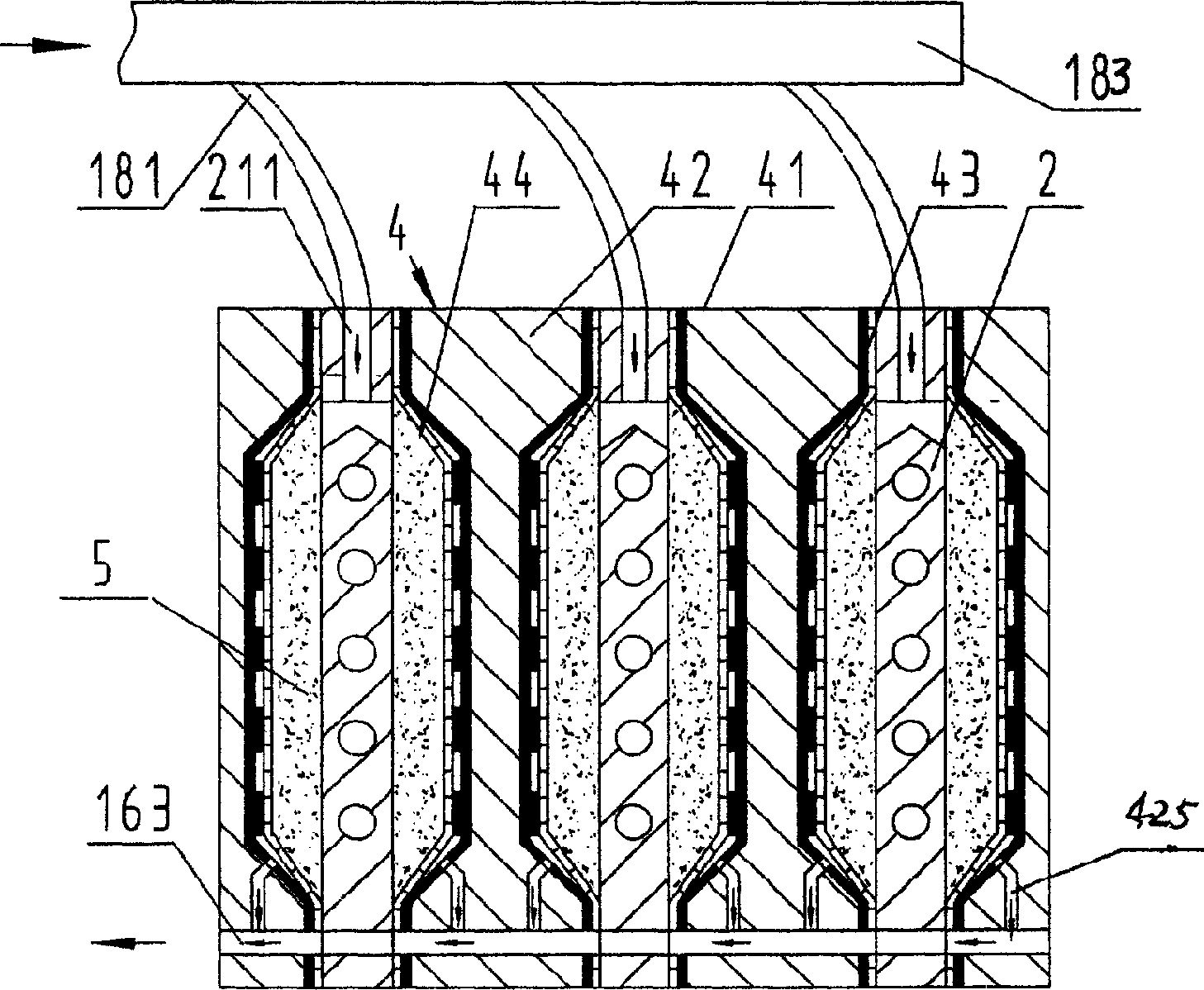

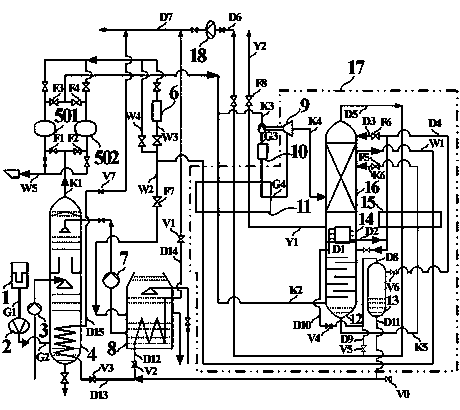

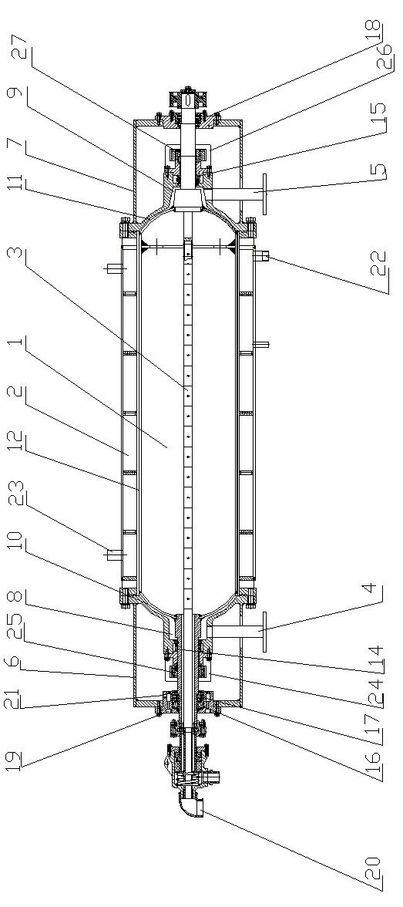

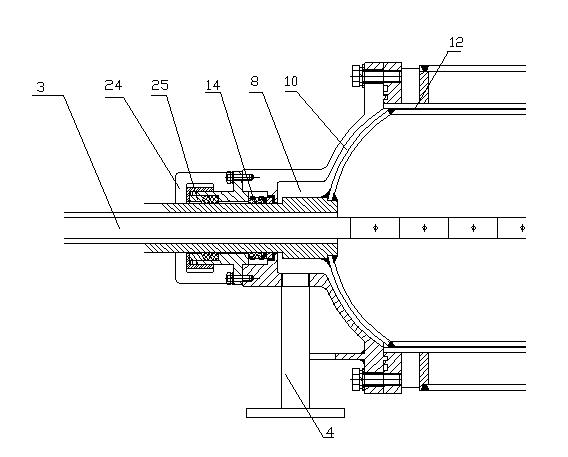

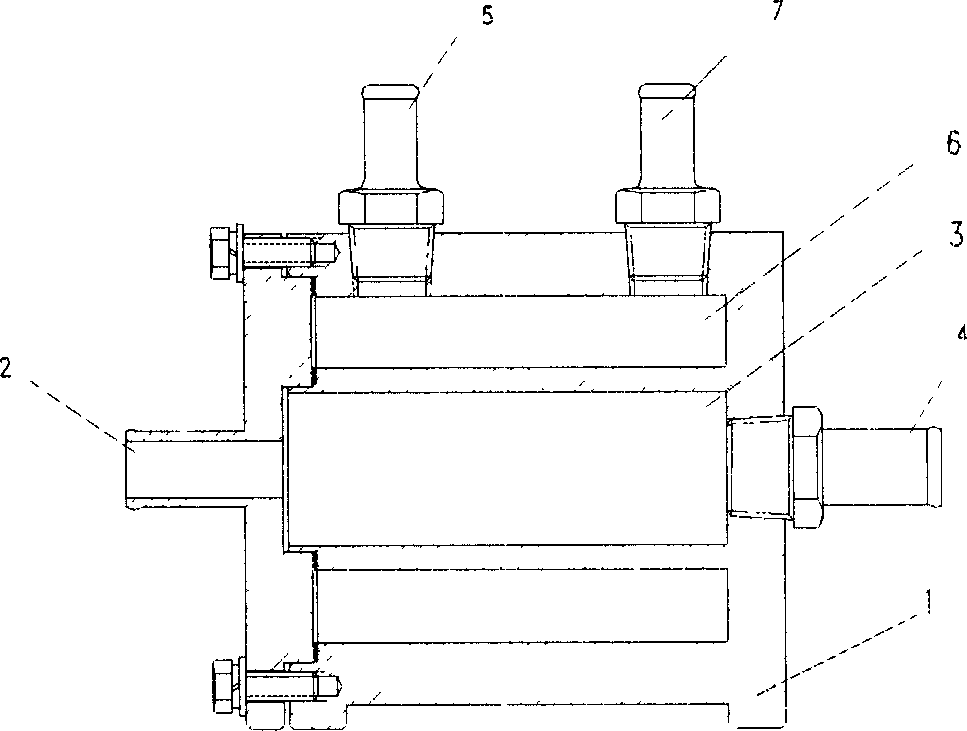

Thermal pressure filtration process for deep dehydration of fine coal suspension liquid and apparatus therefor

InactiveCN1634630ASave industrial landLess investment in infrastructureFiltration separationSeparation technologyCapillary water

The invention relates to a hot pressure filtration process and equipment for deep dehydration of fine-grained coal suspension, and relates to the technical field of solid-liquid separation of suspension. This process and equipment integrate mechanical pressure filtration and thermal drying. Mechanical pressure filtration is first performed on multiple sets of diaphragm filter plates—the drying plate unit, and a large amount of filtrate is discharged. The solid material forms a filter cake in the filter chamber, and then the drying plate Heating, pressurizing the diaphragm in the diaphragm filter plate at the same time, making the filter plate stick to the drying plate for hot pressure filtration, evaporating the capillary water into steam, and using the driving force of the steam itself to dehydrate, and at the same time to clean the drainage channel Vacuumize to speed up the dehydration. After a few minutes, the filter cake has been deeply dehydrated, then stop heating, pressurize, vacuumize, and discharge the solid materials. The membrane filter plate of this equipment - the drying plate unit, the drying plate is placed between the two membrane filter plates, so that the pressure filtration and drying are integrated into one equipment, and the equipment adopts the upper feeding or upper multi-channel feeding structure. The invention has the advantages of saving investment, occupying less land, saving energy, high production efficiency and low cost.

Owner:周明远 +1

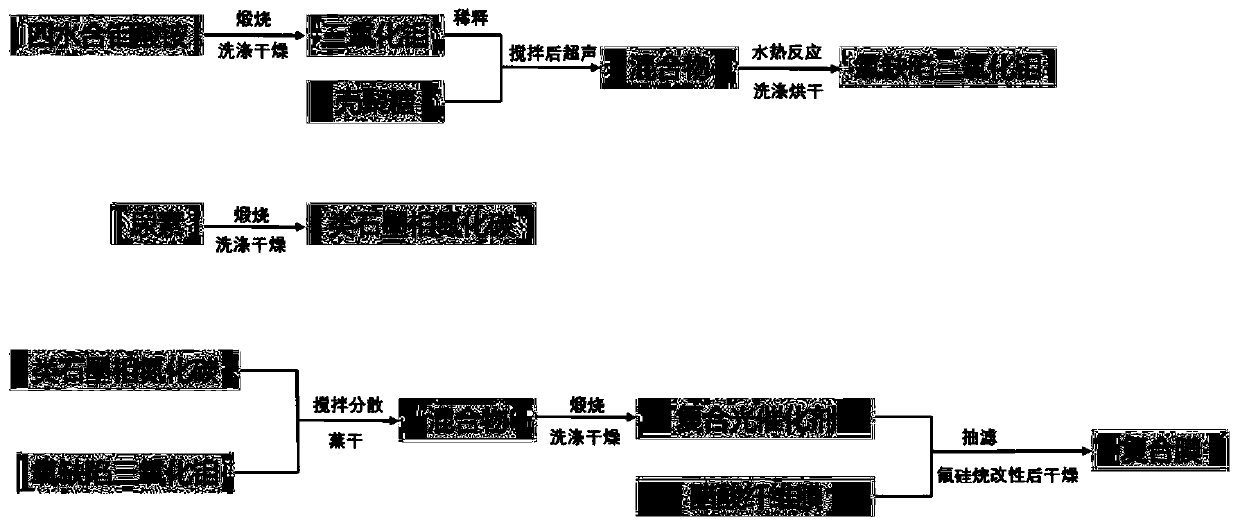

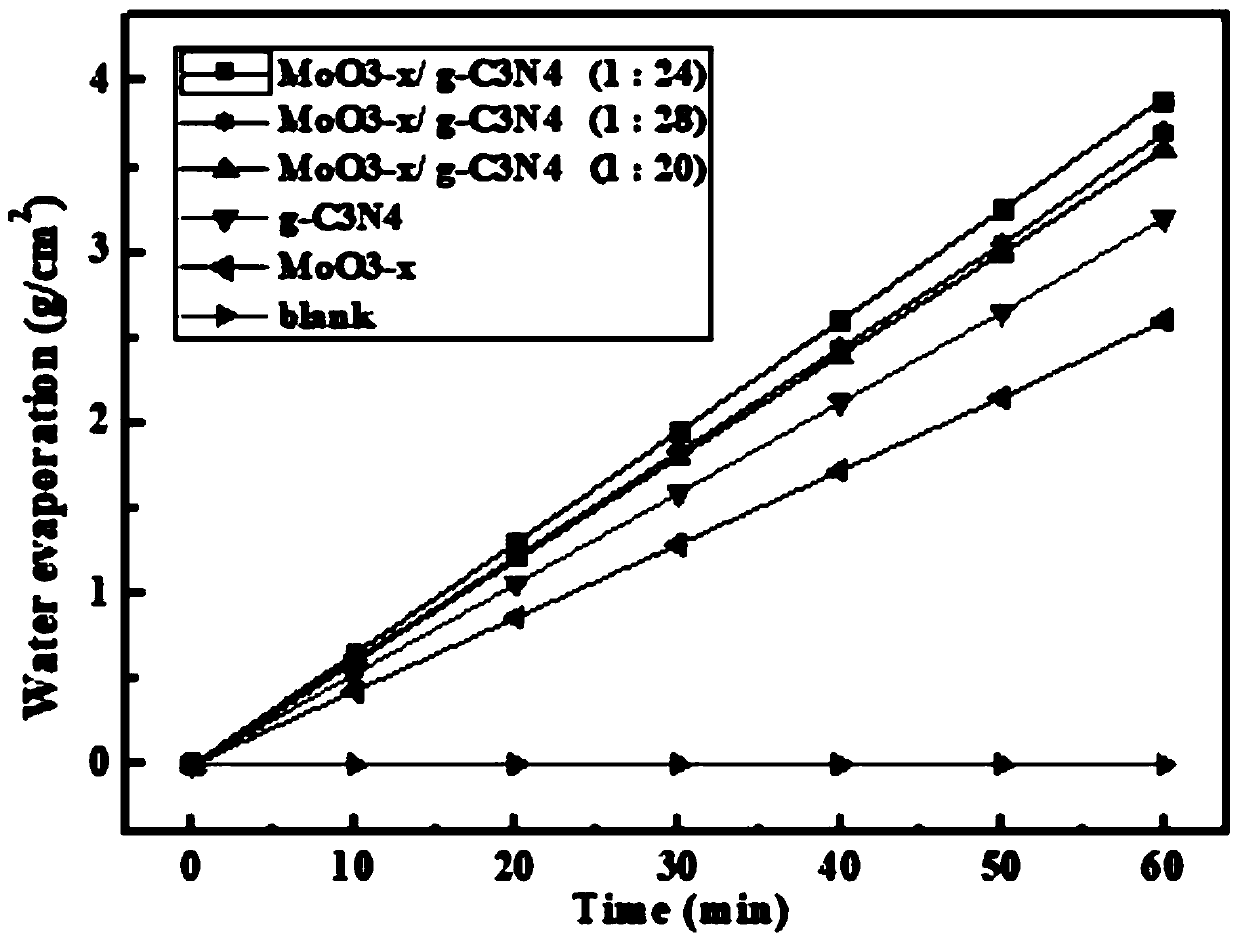

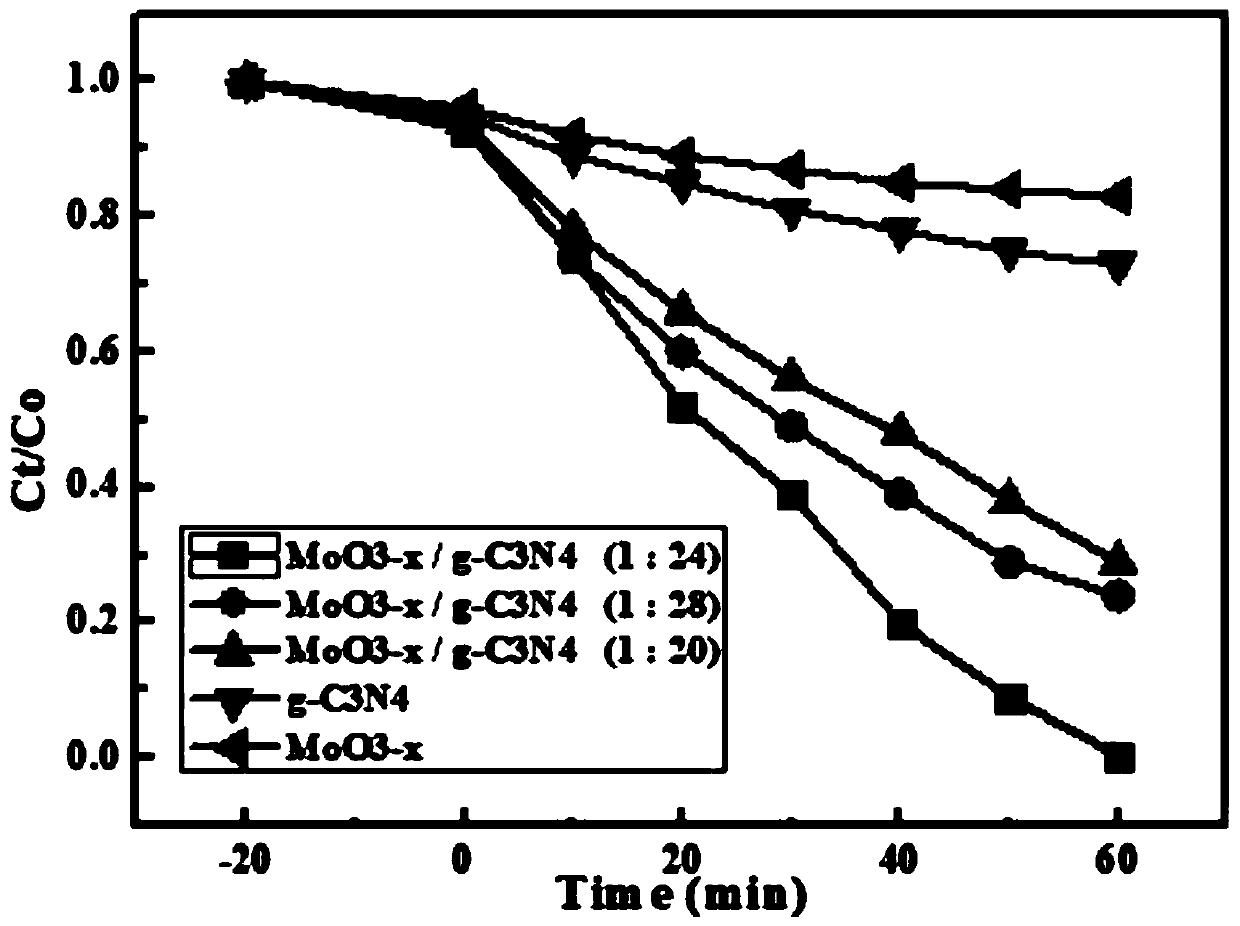

MoO<3-x>/g-C<3>N<4> composite photocatalytic material, and preparation method and application thereof

InactiveCN110227554AHigh photothermal conversion efficiencySpeed up vaporizationWater/sewage treatment by irradiationWater treatment compoundsHeterojunctionQuantum efficiency

The invention discloses a MoO<3-x> / g-C<3>N<4> composite photocatalytic material. The composite photocatalytic material is composed of a hydrophobically modified cellulose acetate membrane and a MoO<3-x> / g-C<3>N<4> compound supported on the cellulose acetate membrane, wherein the MoO<3-x> / g-C<3>N<4> compound is formed by connecting MoO<3-x> with g-C<3>N<4> via a Z-type heterojunction. The inventionalso discloses a preparation method for the above MoO<3-x> / g-C<3>N<4> composite photocatalytic material and the application of the composite photocatalytic material to degrading of VOCs in water bodies. The MoO<3-x> / g-C<3>N<4> composite photocatalytic material of the invention has high photothermal conversion efficiency and high quantum efficiency, and can improve the vaporization speed of waterand realize high-efficiency degradation of VOCs; and high-quality and high-efficiency production of clean water is successfully achieved through the synergistic effect of vaporization and degradation.

Owner:HOHAI UNIV

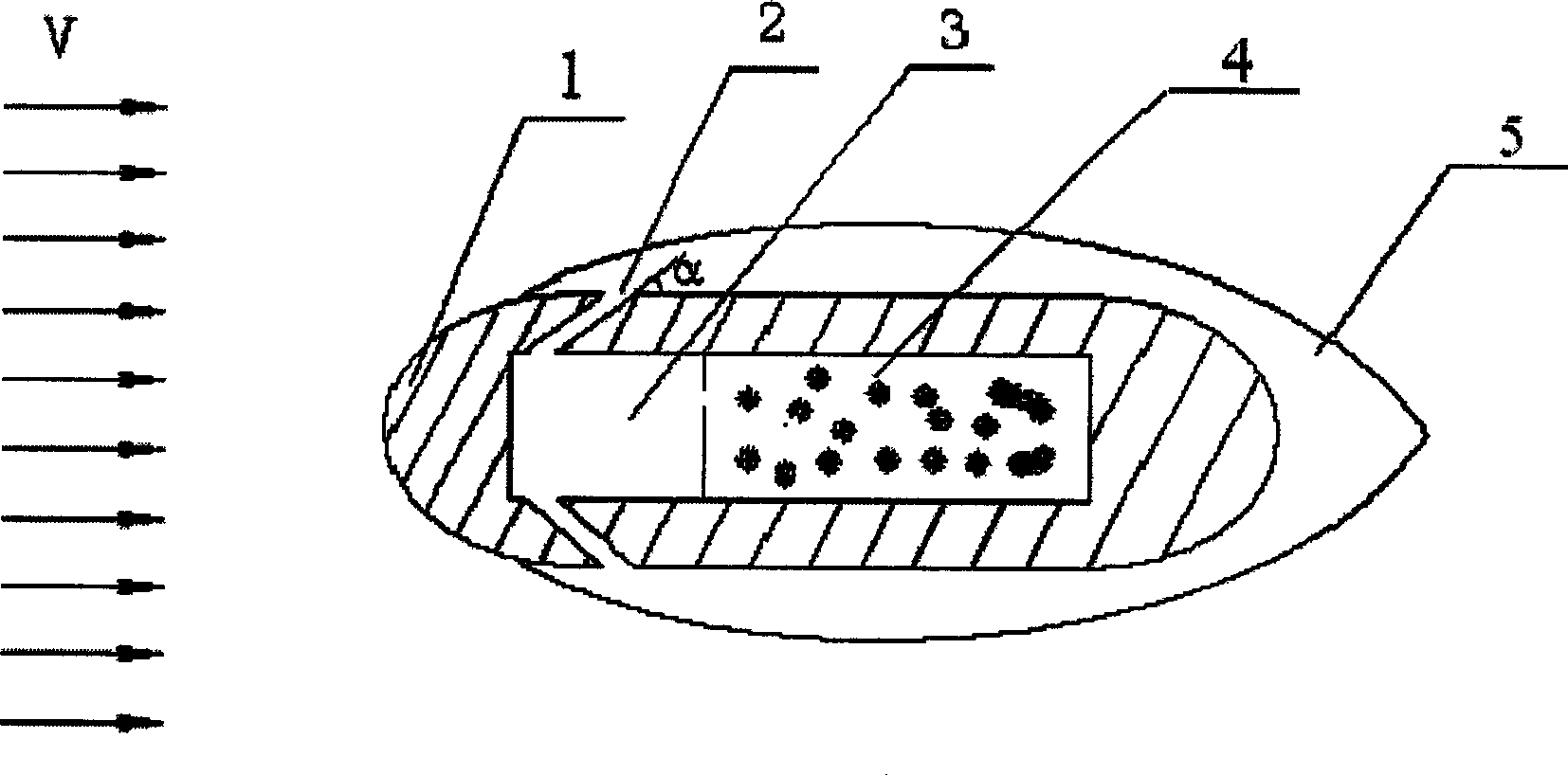

Super cavitation method and device with introduced hot steam for underwater high speed navigating equipment

InactiveCN1847084AHigh speedSpeed up vaporizationWatercraft hull designHydrodynamic/hydrostatic featuresCavitationMarine engineering

The present invention relates to super cavitation method and device with introduced overheat steam for high speed underwater navigating equipment. Overheat steam produced through heating water with fuel gas or other fuel is guided into natural bubbles so as to form stable bubbles around the navigating equipment. The bubbles are refreshed constantly, and the underwater navigating equipment progresses at high speed inside bubbles without direct contact with water. The present invention has greatly reduced navigation resistance and raised navigation speed.

Owner:SHANGHAI UNIV

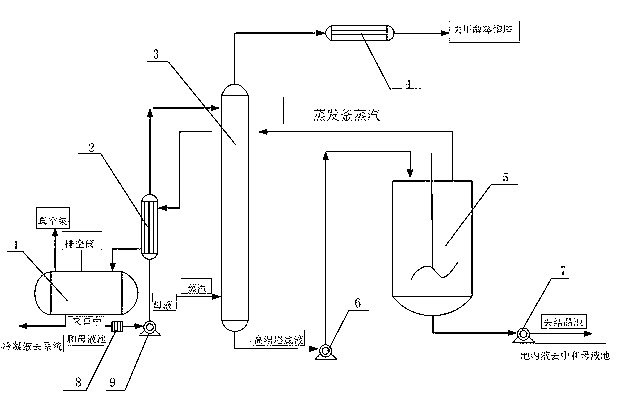

Device and production technology for treating ternary-monomer wastewater and extracting sodium sulfate

ActiveCN103253819AReduce maintenance workloadExtend the life cycleMultistage water/sewage treatmentAlkali metal sulfites/sulfatesThermodynamicsDistillation

The invention discloses a device and a production technology for treating ternary-monomer wastewater and extracting sodium sulfate. The device comprises a plate-and-frame filter press, a mother liquid heat exchanger, a stripping tower and a condenser which are sequentially communicated through a pipeline, wherein the condenser is communicated with a methane distillation tower through the pipeline. The production technology comprises the following steps of: (1) pumping neutralized mother liquid into the plate-and-frame filter press, preheating the mother liquid through the mother liquid heat exchanger, and then pumping the mother liquid into the stripping tower from the top of the stripping tower; (2) pumping steam into the stripping tower from the bottom of the stripping tower, after methane in the mother liquid is brought out by the steam, condensing the steam through the condenser, then entering the methane distillation tower, and separating to obtain methane; (3) pumping liquid at the bottom of a high-temperature tower into an evaporation and concentration kettle to be concentrated, steaming out moisture, and using the steam generated by the evaporation and concentration kettle for heating the mother liquid heat exchanger; and (4) after concentrating a material in the evaporation and concentration kettle, placing the concentrated material in a crystallizing pond, and feeding the mother liquid, Na2SO4.10H2O in which is separated out in the crystallizing pond, into a mother liquid neutralization pond to be reused.

Owner:WEIFANG WORLD CHEM

Graphite powder purification method and high-purity graphite powder prepared by method thereof

The invention provides a graphite powder purification method. The method comprises the following steps: graphite powder to be purified is placed into a high-temperature sealed kiln and undergoes vacuum calcination in the atmosphere of protective gas; when the calcination temperature reaches 2,000-3,000 DEG C, multiple pneumatic control variation steps are carried out to control periodic pulsative oscillation change of air pressure in the high-temperature sealed kiln. Each pneumatic control variation step contains a gas withdrawal step and a gas injection step. For 1-3 h of each pneumatic control variation step, range of pressure change in the high-temperature sealed kiln is controlled to 1-10 kPa. According to the invention, the graphite powder with high carbon content can be obtained under the condition of low calcination temperature. The preparation process is simple, and the requirement on equipment is low.

Owner:陕西六元碳晶科技有限公司

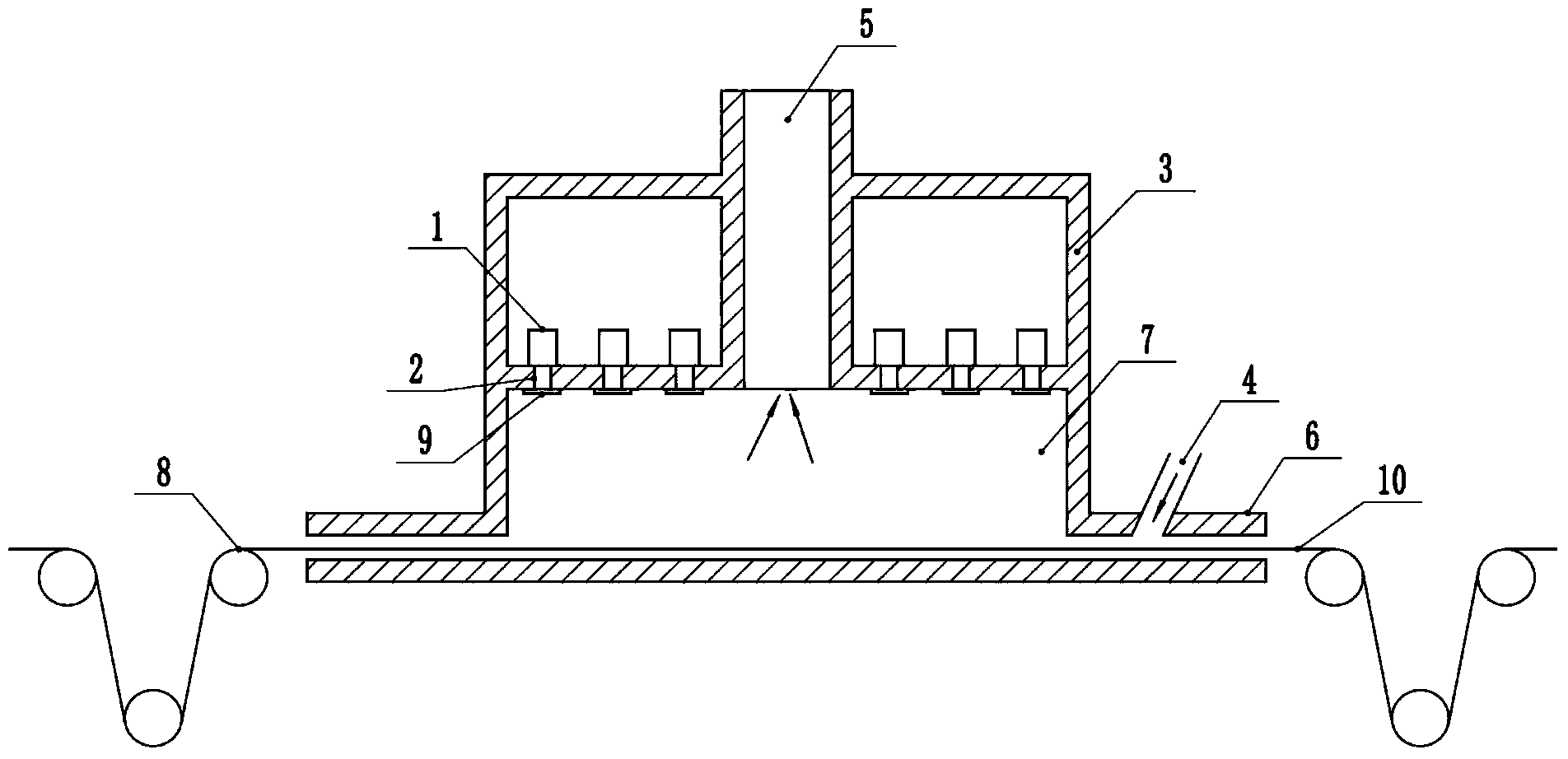

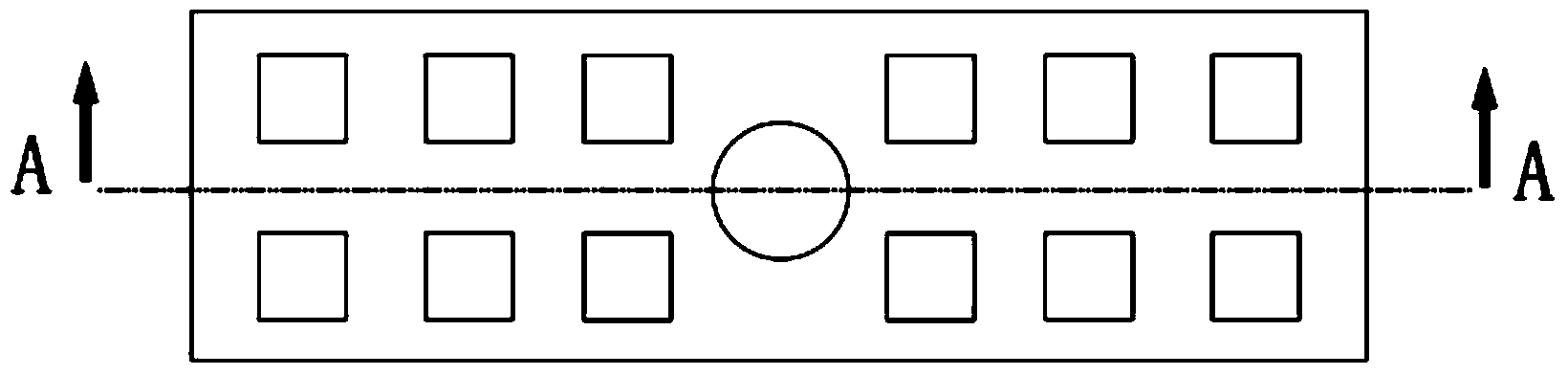

Continuous microwave drying method and device of nanometer fiber membrane

ActiveCN104075552AImprove working environmentGuaranteed flatnessDrying gas arrangementsDrying machines with progressive movementsFiberOrganic solvent

The invention provides a continuous microwave drying method of a nanometer fiber membrane. The continuous microwave drying method of the nanometer fiber membrane includes: guiding the nanometer fiber membrane which comprises, based on weight rate, less than 50% of moisture and less than 10% of organic solvent into a microwave drying device through multilevel guide rollers, and using microwave radiation to keep drying temperature in the microwave drying device at 100-120 degree centigrade for 1-5 minutes; using both a blower nozzle and an air outlet to discharge volatile components generated in the microwave drying device, and using the blower nozzle to dry residual trace moisture in the nanometer fiber membrane. The invention further provides the microwave drying device. According to the continuous microwave drying method and the microwave drying device of the nanometer fiber membrane, microwave drying technology and blast technology are combined, the nanometer fiber membrane can be continuously dried, and drying speed is high, energy consumption is low, and damage to the nanometer fiber membrane is small.

Owner:上海展恒环保科技有限公司

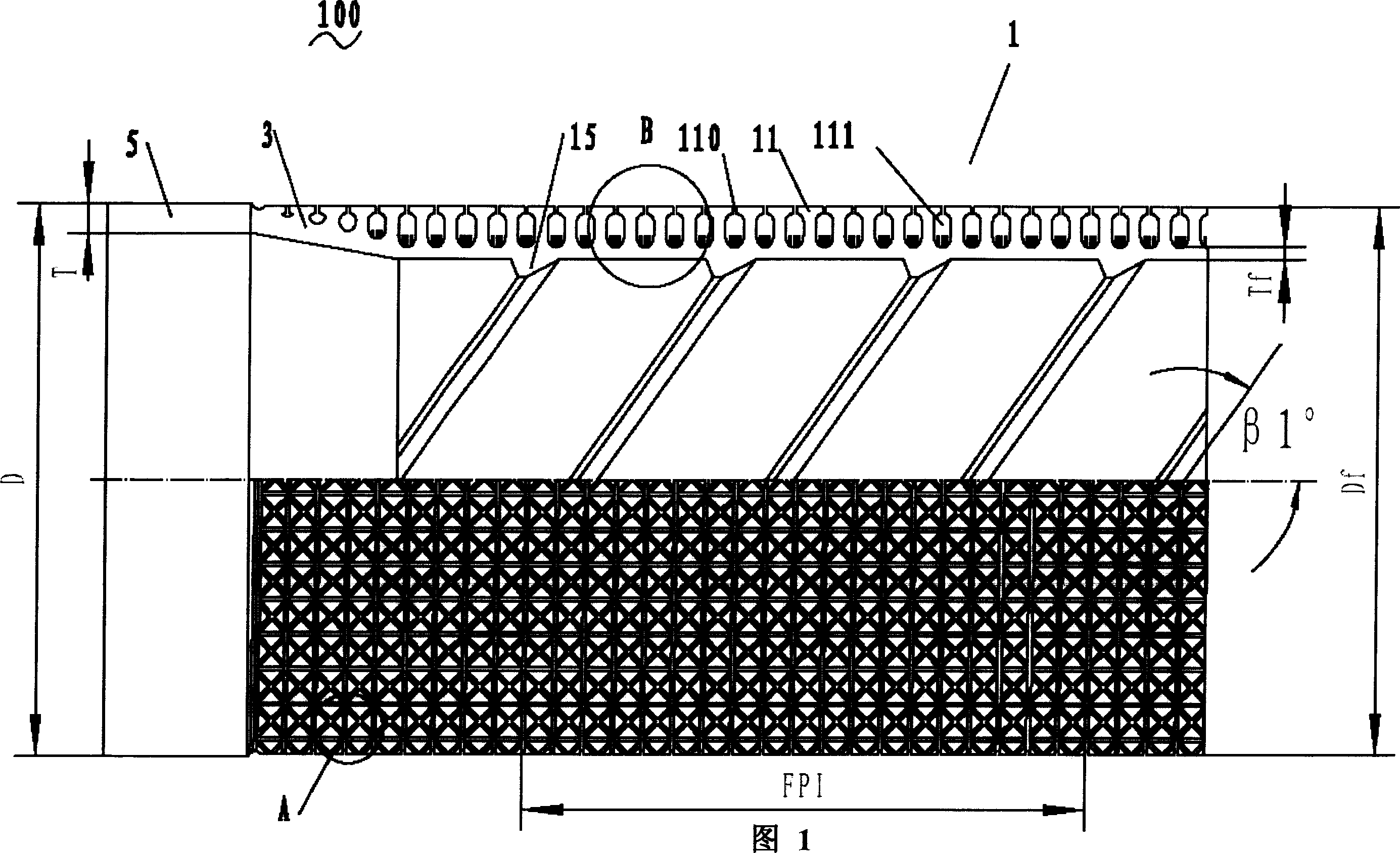

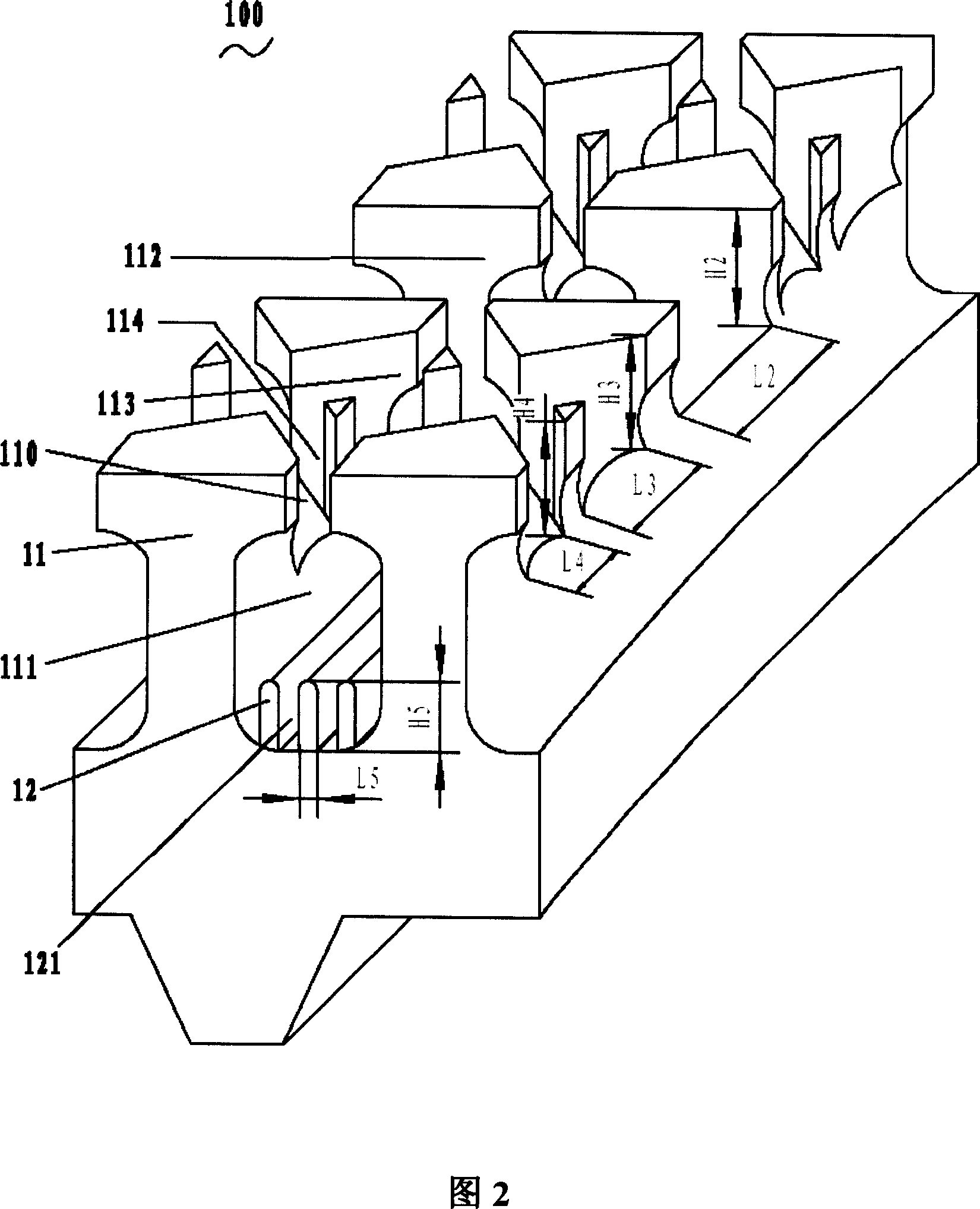

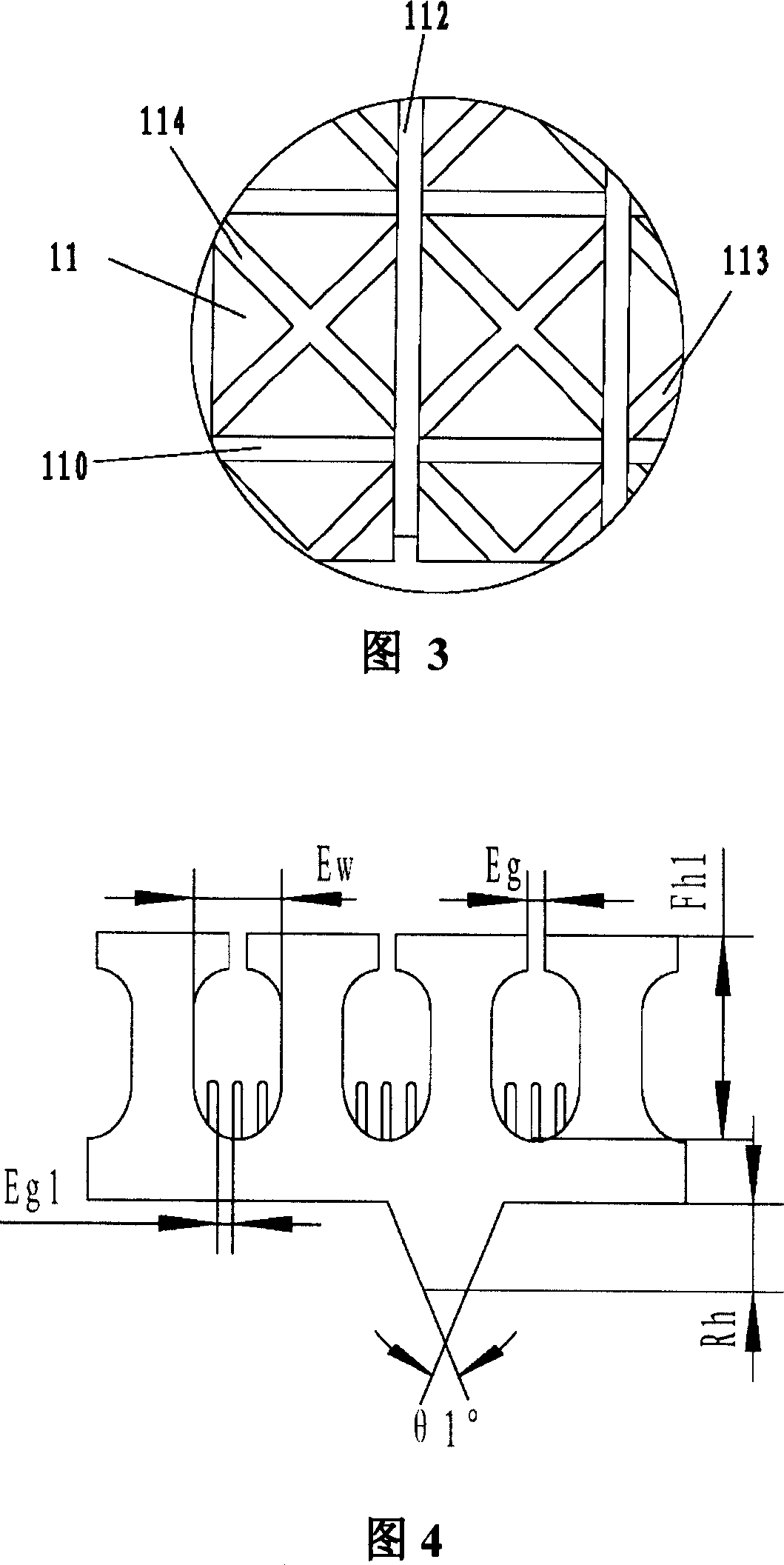

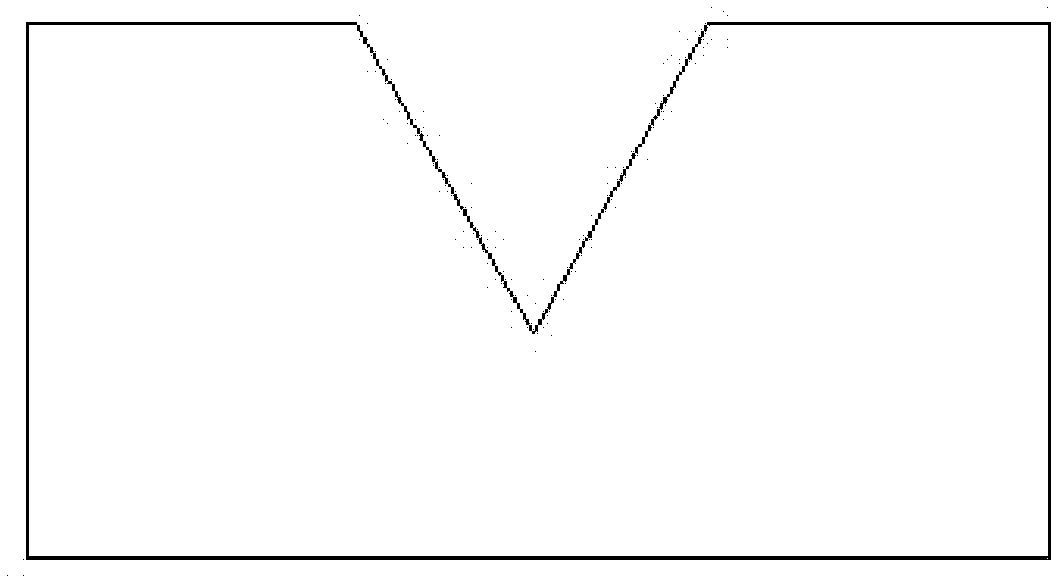

Flooded copper-evaporating heat-exchanging pipe for electric refrigerator set

ActiveCN1982827AEase of nucleation and vaporizationImprove heat transfer efficiencyHeat transfer modificationTubular elementsElectricityEvaporation

A flooded copper evaporation heat-exchange tube for electric refrigerating units comprises a polish rod pant, a fins part and a transition part for connecting the polish rod with the fins part. Between the fins is formed a single vaporization chamber and in the position extending upward from the bottom of the single vaporization chamber are disposed fins, which divide the single vaporization chamber into at least two small cavities. Between the fins of the single vaporization chamber there is an evaporation fin mouth. Because of setting several small cavities, on the base walls of the small cavities is formed the refrigerant film easily and then evaporated, and the formed bubbles escape from the evaporation fin mouth.

Owner:GOLDEN DRAGON PRECISE COPPER TUBE GROUP

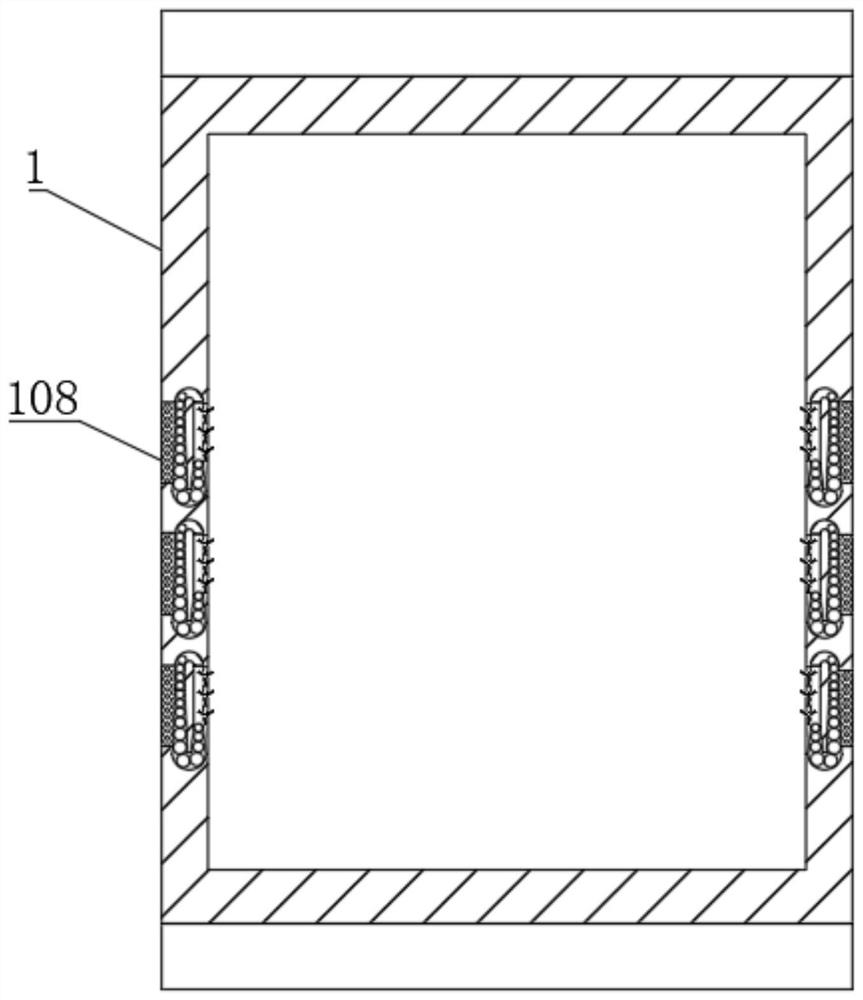

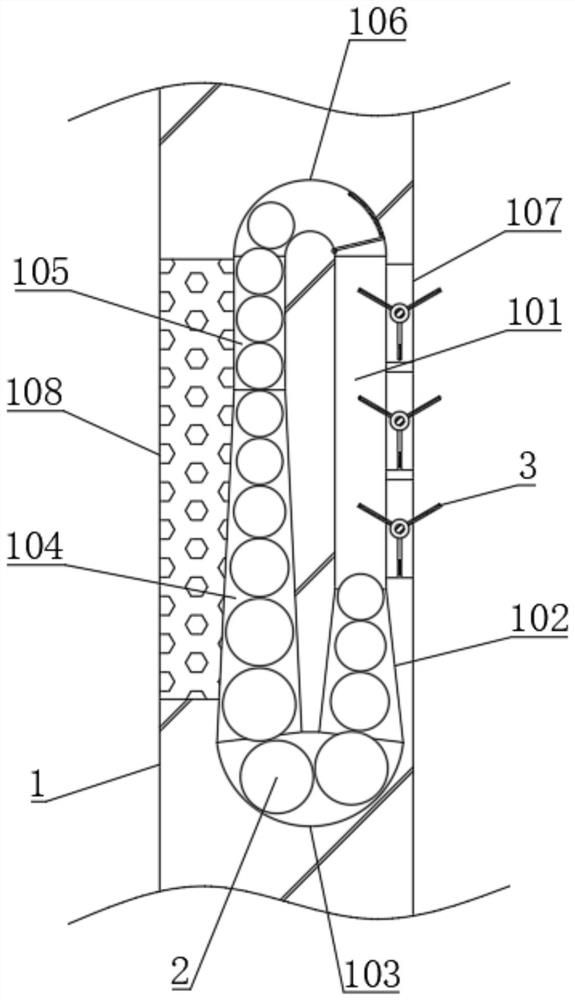

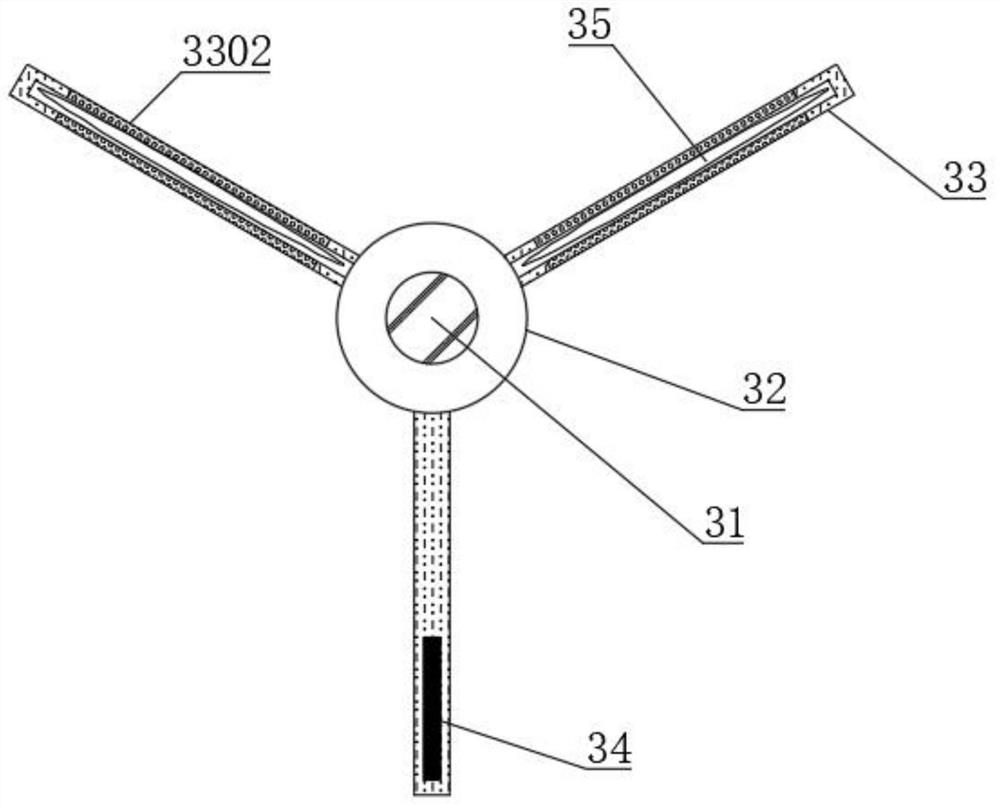

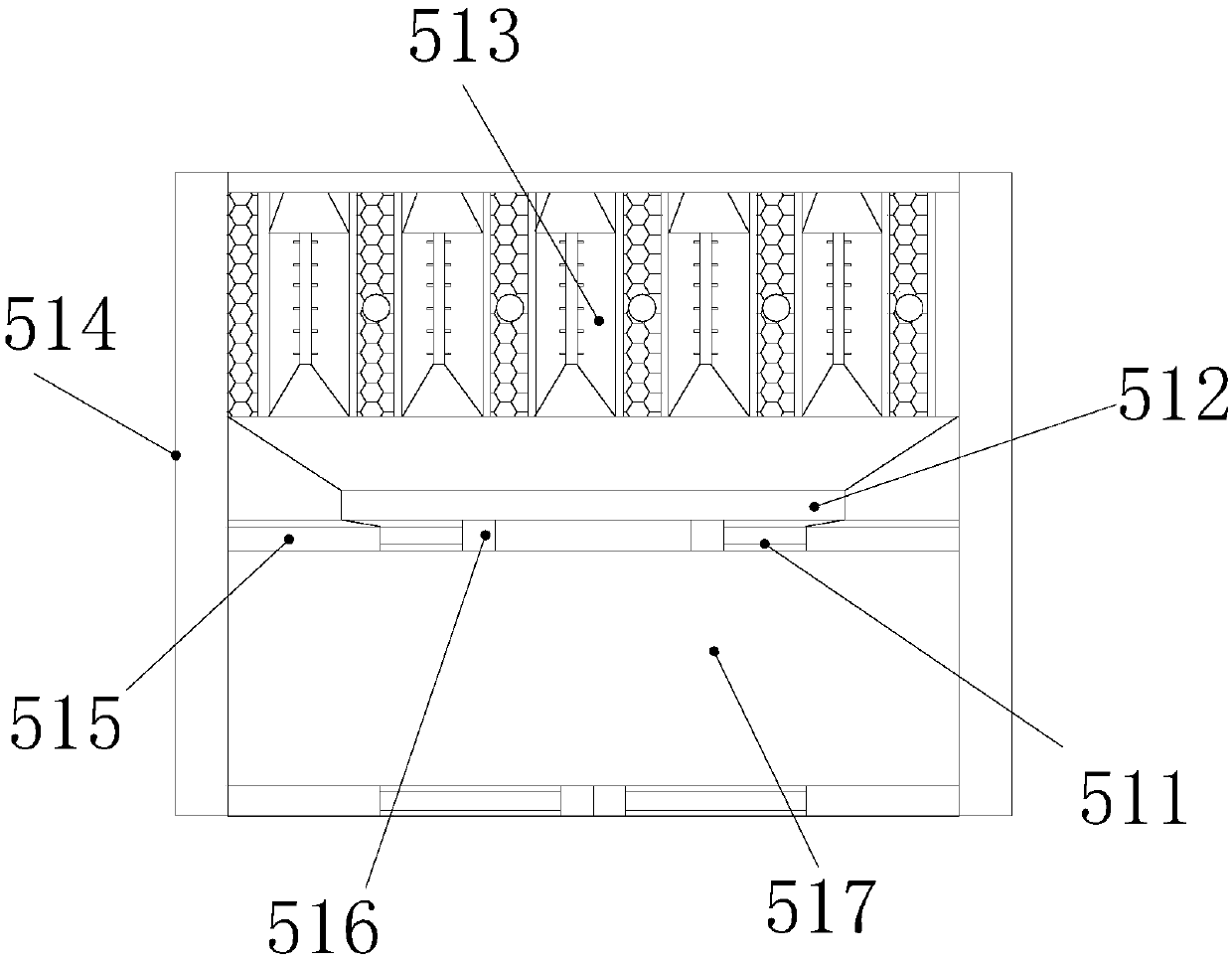

Internal heat circulation type dehumidification and heat dissipation type power distribution cabinet

InactiveCN112165012AAchieving low tide treatmentReduce the impactGas treatmentSubstation/switching arrangement cooling/ventilationHeat flowWater vapor

The invention discloses an internal heat circulation type dehumidification and heat dissipation type power distribution cabinet, belongs to the field of power distribution cabinets. The cabinet realizes the circulation flow of a heat dissipation settlement ball in a closed airflow channel through the heat absorption and heat release processes of the heat dissipation settlement ball, performs continuous heat dissipation on the interior of a cabinet body, and in the circulation flow process of the heat dissipation settlement ball, a rotary moisture reducing device is pushed to rotate through thevertical falling process of the heat dissipation settlement ball, so that the flowing of air flow in the cabinet body is accelerated, the heat dissipation efficiency can be improved, the heat in thecabinet body can be uniformly distributed, local moisture in the cabinet body is heated, the vaporization of the moisture is promoted, Water vapor can be discharged to the outside along with heat flow. In addition, the rotary moisture reduction device also has an absorption effect on vaporized moisture, the influence of the moisture on electrical equipment is reduced, and the absorbed water vaporcan be quickly diffused to the outside along with the air flow along with the rotary movement of the rotary moisture reduction device, so that the moisture reduction treatment on the interior of the cabinet body is realized.

Owner:劳业鸿

Preparation method for carbon bisulfide

ActiveCN1919731AOvercome or greatly reduce easy cokingOvercome or greatly reduce the problem of easy cloggingStatic mixerHeating furnace

The invention discloses a preparing method of carbon disulphide, which is characterized by the following: controlling the temperature of natural gas and sulphur at 550-800 deg.c at 0.3-1.0Mpa; reacting to produce carbon disulphide; blending natural gas and liquid sulphur in the heating segment of reacting furnace pipe through static blender.

Owner:SHANGHAI BAIJIN CHEM GROUP

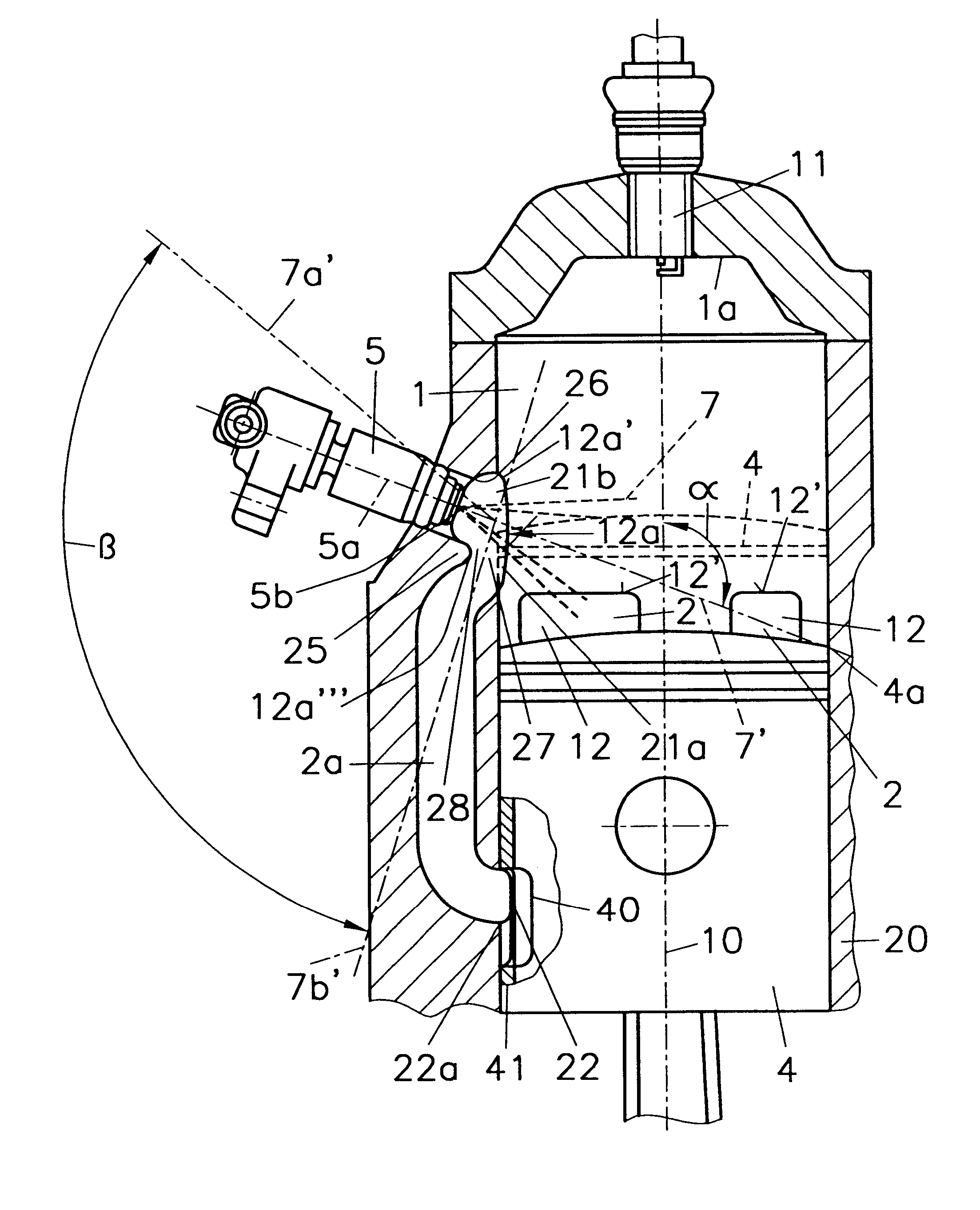

Two-stroke internal combustion engine with crankcase scavenging

InactiveUS20020179026A1Reduce carbon depositionSpeed up vaporizationInternal combustion piston enginesCylinder headsCrankcaseEngineering

The invention relates to a two-stroke internal combustion engine with crankcase scavenging, with an exhaust passage controlled by the piston and at least two first transfer passages and at least one second transfer passage, each with a corresponding transfer window into the cylinder chamber and a window on the crankcase side for communication between the cylinder chamber and the crankcase, the transfer windows of the first transfer passages being controlled by the upper edge of the piston, and the crankcase-side window of the second transfer passage being disposed in a region of the cylinder wall that is swept by the piston skirt of the piston. The cylinder wall comprises at least one recess, which is arranged in close vicinity to the transfer window of the second transfer passage and which is in flow communication with the second transfer passage, wherein a narrow passage is arranged between the recess and the second transfer passage.

Owner:AVL LIST GMBH

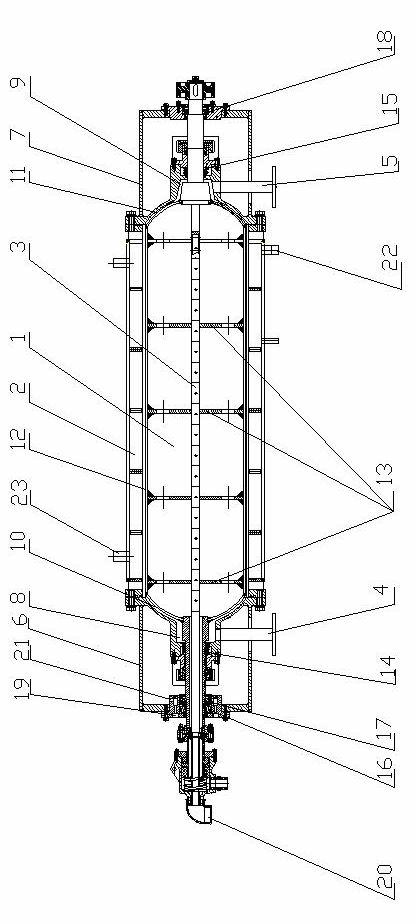

Single-vacuum-chamber super-gravity normal-temperature multi-stage flashing seawater desalination system

ActiveCN105236504AIncrease in fresh waterAvoid increasing the number of devicesGeneral water supply conservationSeawater treatmentSeawaterSaline water

The invention discloses a single-vacuum-chamber super-gravity normal-temperature multi-stage flashing seawater desalination system. The interior of a super-gravity machine is provided with a vacuum chamber, an air exchanging chamber and multiple flash chambers which are horizontally arranged from left to right; the top end of a super-gravity machine rotation shaft is fixedly connected with the center of the bottom of the vacuum chamber, the vacuum chamber is communicated with the air exchanging chamber, the top of each flash chamber is connected with the bottom of the air exchanging chamber through a corresponding pipeline with a valve, condensing areas in the upper portions of the flash chambers are communicated through a condensing pipe from right to left, evaporating areas in the lower portions of the flash chambers are sequentially connected step by step and communicated from left to right, a solar heater is connected between the leftmost end of the condensing pipe and the lower portion of the leftmost-side flash chamber, and seawater enters the system from the rightmost end of the condensing pipe. According to the single-vacuum-chamber super-gravity normal-temperature multi-stage flashing seawater desalination system, the pressure of the flash chambers is improved with the vacuum chamber, the pressure in the flash chambers is completely same, and on the condition that it is guaranteed that the pressure in the last-stage flash chamber is smaller than the saline water saturated vapor pressure, the pressure difference of the front flash chambers is increased, and then the formed fresh water quantity is increased.

Owner:JIANGSU UNIV OF SCI & TECH

Automobile gasoline composite modifying agent

ActiveCN103194284ANot poisonedNo carbon depositionLiquid carbonaceous fuelsFuel additivesAntioxidantSolvent

The invention relates to an automobile gasoline composite modifying agent. The raw material of the modifying agent is prepared from the following components in percentage by weight: 25-50% of an octane value promoter, 30-50% of a combustion improver and 20-25% of a latent solvent, wherein the octane value promoter comprises the following components in percentage by weight: 20-45% of sec-butyl acetate, 30-40% of diisopropyl ether, 5-10% of absolute ethyl alcohol and 20-30% of methyl tert-butyl ether; the combustion improver comprises the following components in percentage by weight: 10-20% of cyclopentane, 47-50% of mixed light arene, 30-40% of alkylate and 3-6% of 1# jet fuel; and the latent solvent comprises the following components in percentage by weight: 10-30% of acetone, 25-30% of dimethoxy ethane, 20-25% of industrial isobutyl alcohol, 22.5-28% of industrial isopropyl alcohol, 1-4% of trinitromethane, 1-2% of glycol ethylene ether, 0.1-0.2% of a clearing agent polyisobutene succinimide, 0.2-0.4% of a metal deactivator T1201 and 0.2-0.4% of an antioxidant. By adopting the automobile gasoline composite modifying agent, a three-way catalyst of an organic ashless exhaust system cannot be poisoned, a fuel spray nozzle and a cylinder exhaust valve cannot be abraded, and carbon deposition and abrasive particles cannot be generated in a machine body.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE +2

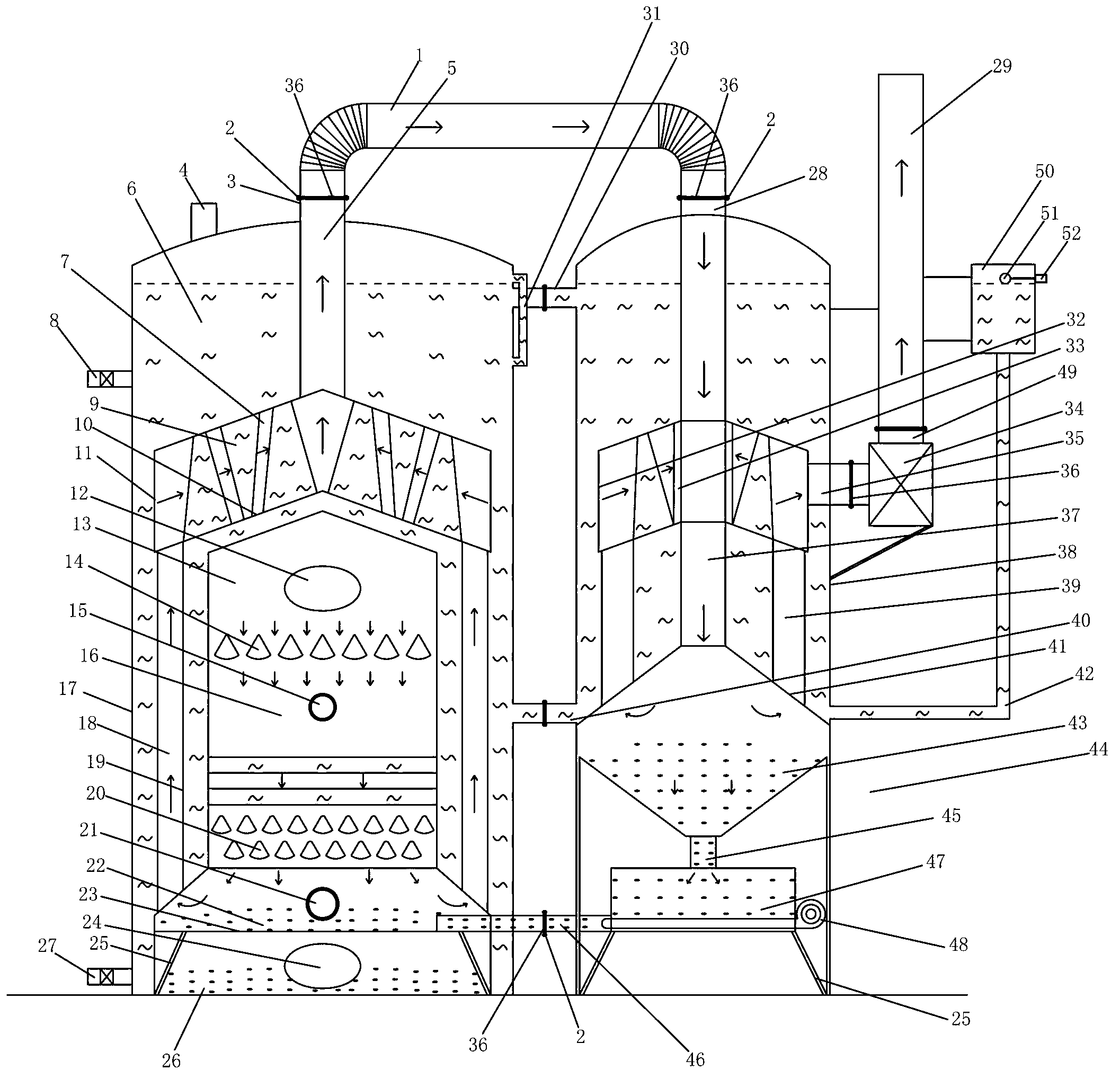

Vertical low-carbon and energy-saving counter burning furnace

InactiveCN102705800ASimple structureImprove performanceSteam generation heating methodsSolid fuel combustionCombustionEngineering

The invention discloses a vertical low-carbon and energy-saving counter burning furnace, which comprises a vertical counter burning furnace pipe and a large horizontal furnace pipe. The vertical counter burning furnace pipe is arranged on the middle lower part in a counter burning furnace body, the vertical section of the vertical counter burning furnace pipe is inverted-'T'-shaped, the large horizontal furnace pipe is arranged on the middle upper part in the counter burning furnace body, the two furnace pipes are communicated with each other by a plurality of straight fire tubes surrounding the upper part of the vertical counter burning furnace pipe, a flue is arranged on the top of the horizontal furnace pipe and penetrates through the top of the counter burning furnace body to form an afterheat flue outlet, a smoke back-combustion type afterheat apparatus is arranged on one side of the counter burning furnace body and consists of a body and a container, an afterheat flue inlet is formed in the top of the smoke back-combustion type afterheat apparatus and is communicated with the afterheat flue outlet via a flue connecting tube, inverted-fan-shaped water tubes are transversely placed in the vertical counter burning furnace pipe, and horn-shaped water tubes are vertically placed in the horizontal furnace pipe. The invention has the advantages that vertical low-carbon and energy-saving counter burning furnace is compact in structure, high in thermal efficiency, stable in performance and easy to popularize and use, and gasification and combustion are performed directly, the height of the furnace body is selectable, secondary pollution is avoided during dust removal, smoke discharge meets requirements on environment friendliness, and the like.

Owner:卢瑞琳

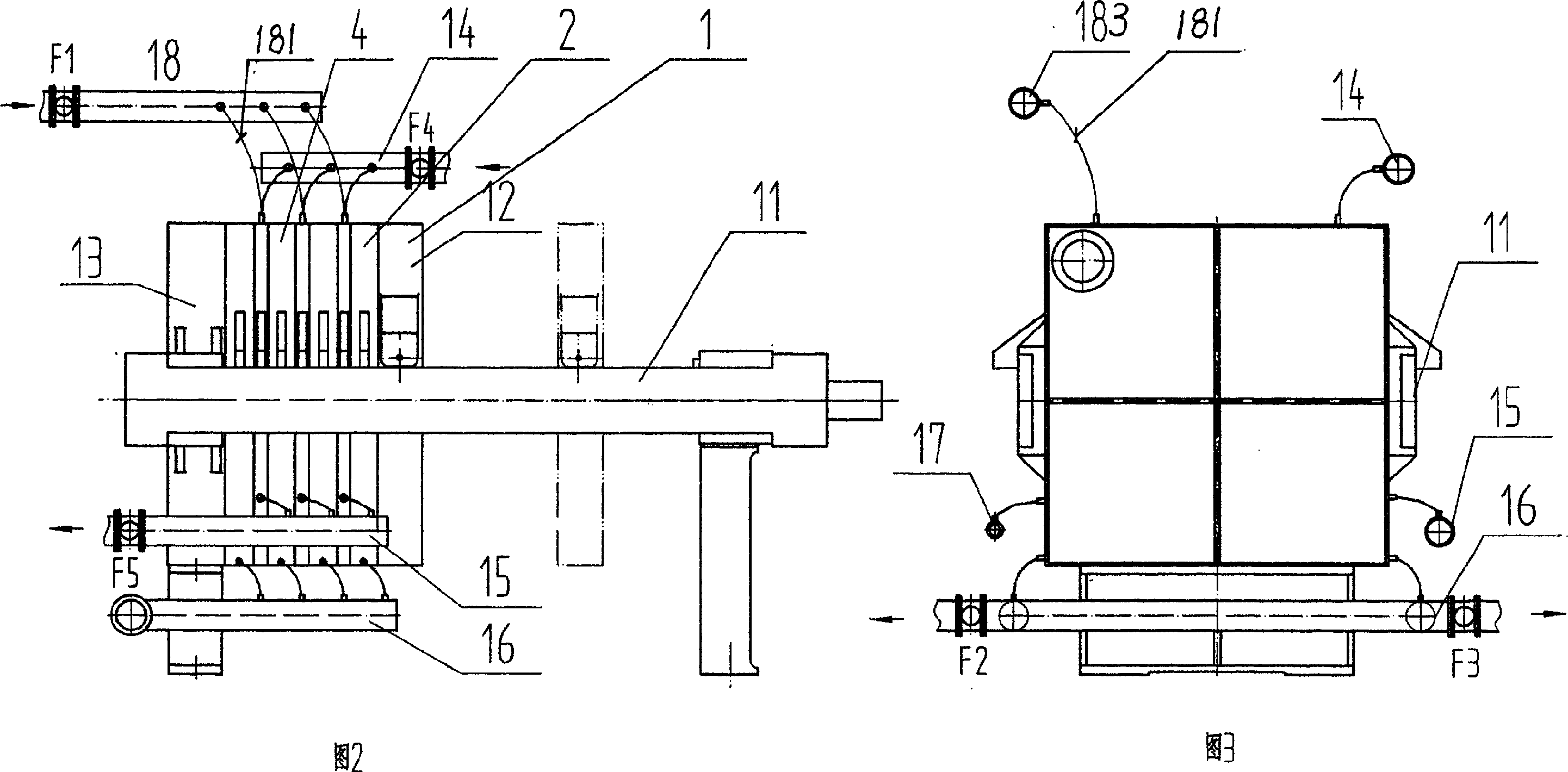

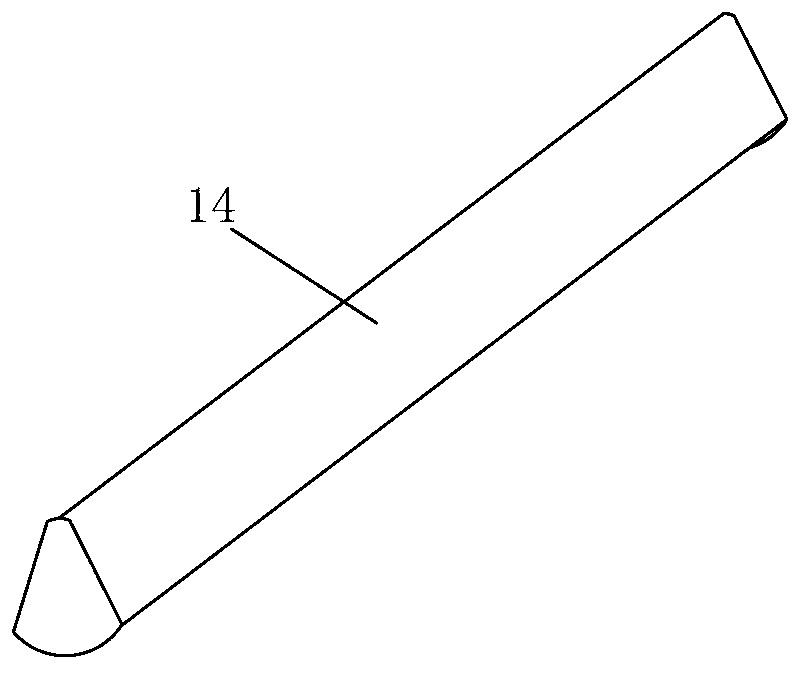

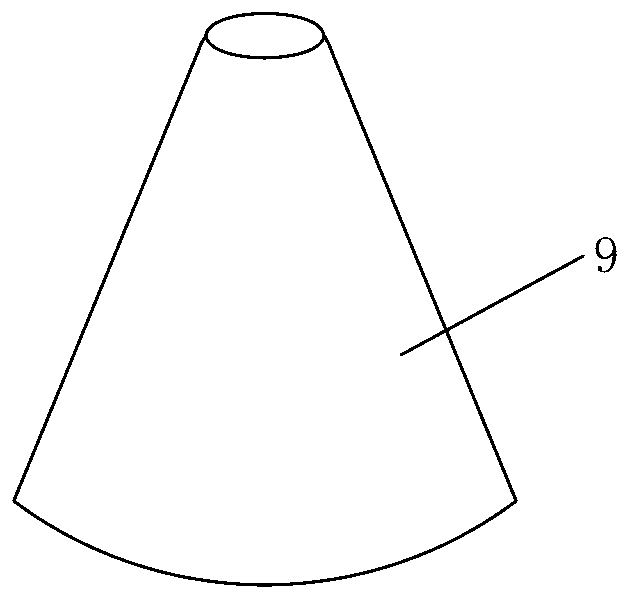

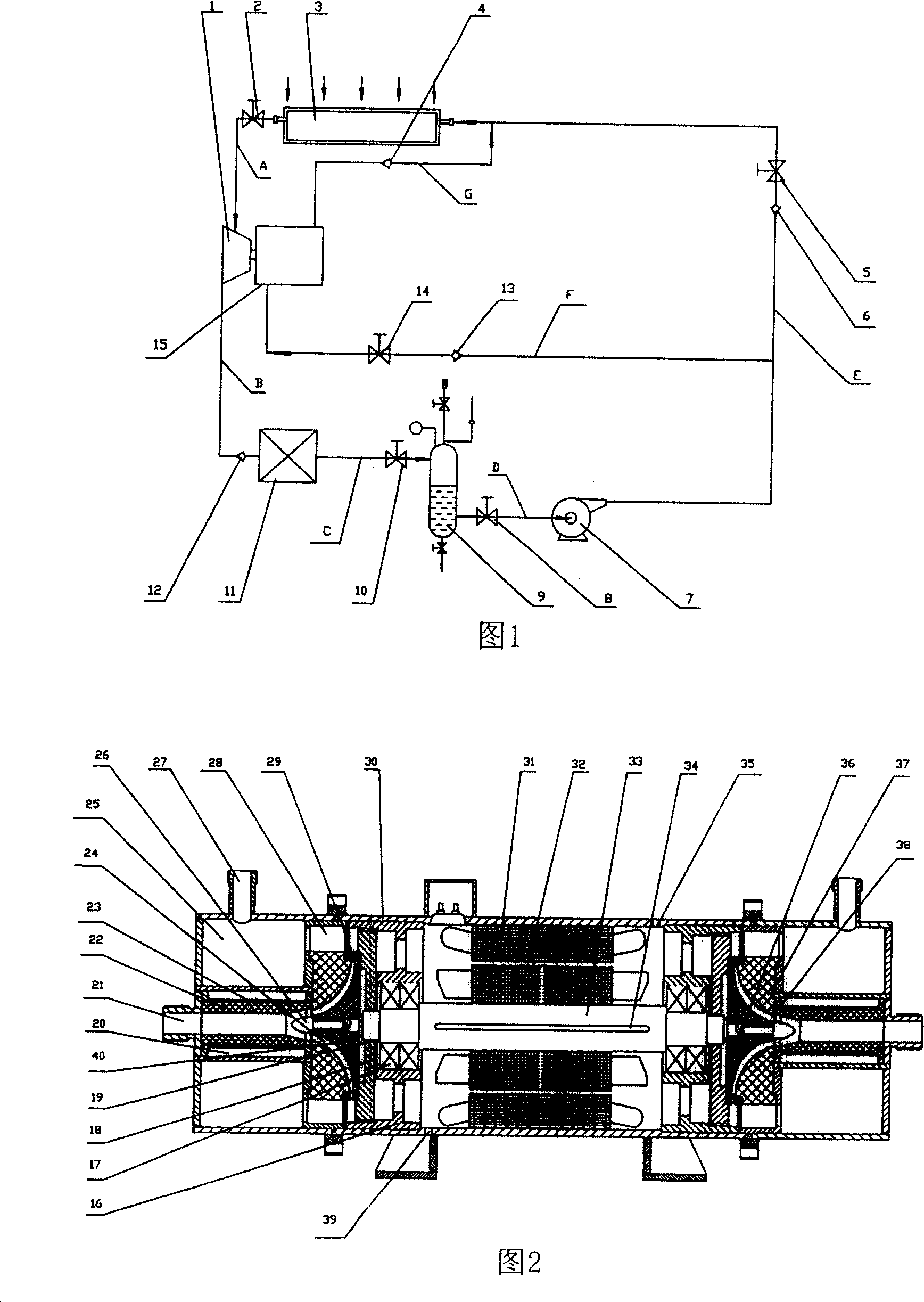

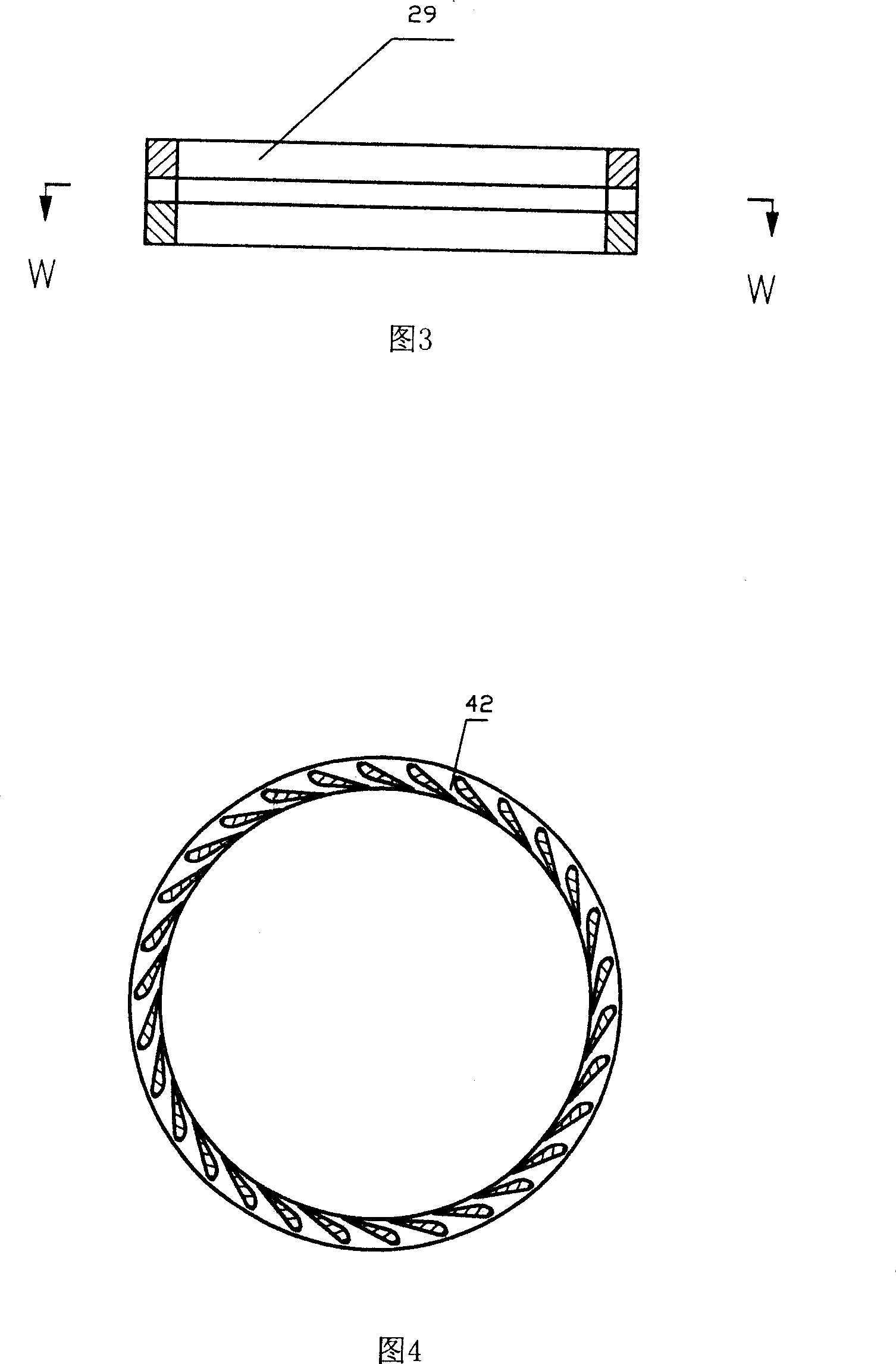

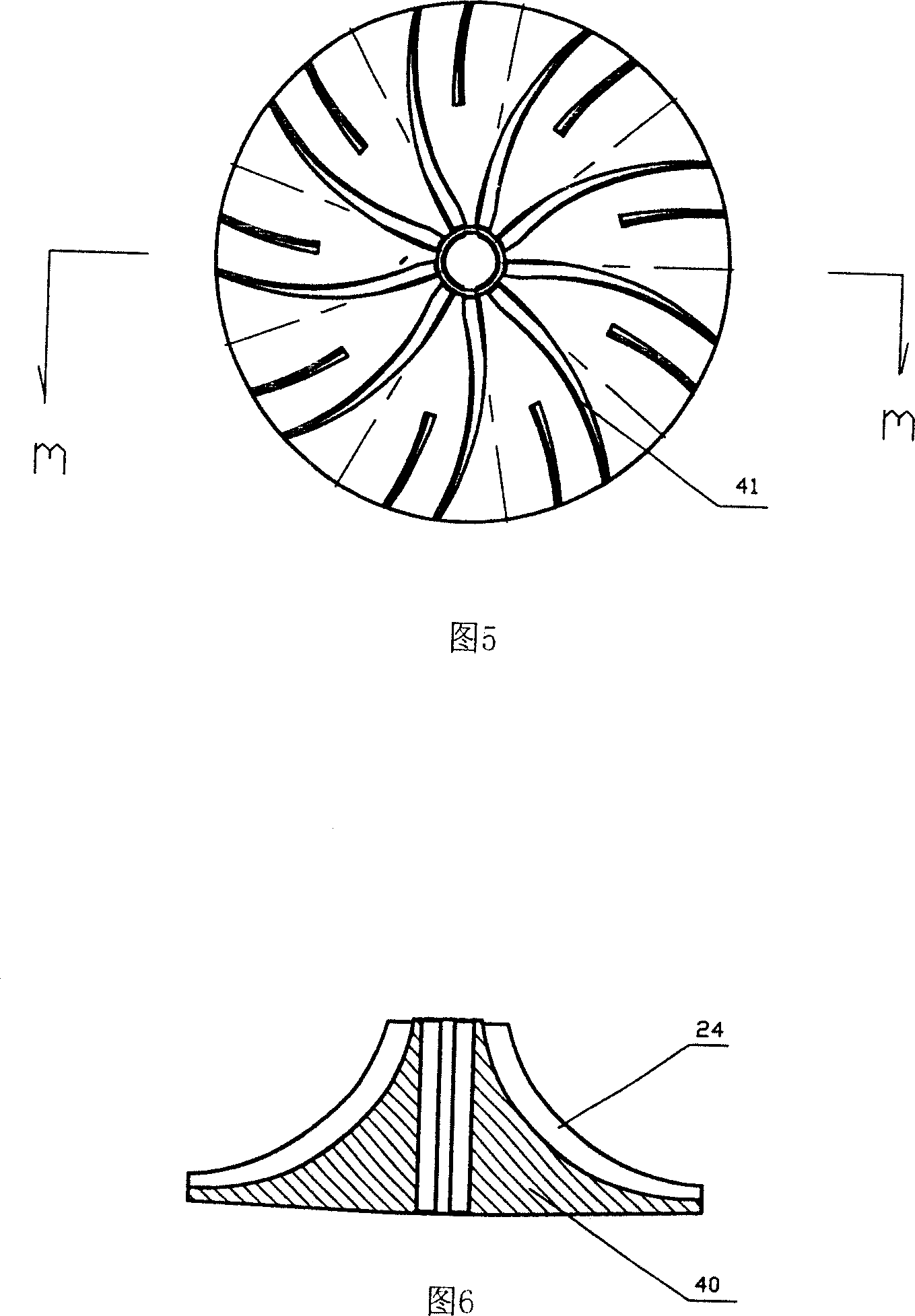

Method and device for power generating by solar energy and heat energy electricity generator

InactiveCN101113722ASpeed up vaporizationFast absorptionFrom solar energyMachines/enginesThermal energyHeat carrier

The invention discloses a dynamoelectric method, a device and a thermal energy generator thereof by using solar energy. Liquid refrigerant in a liquid storage tank is transported to a solar energy collector by a pump, making it vaporized by solar energy to drive the thermal energy generator rotor to rotate to generate. The device has a working-circuit composed of a solar energy collector (3), a thermal energy generator (1), a condenser (14), a liquid storage tank (11) and a pump (9). The refrigerant in the circuit is the working medium. The thermal energy generator used in the invention is a double-expansion impeller generator. The refrigerant in the invention is taken as a heat carrier and has less heat released and enthalpy when condensing. The method has the advantages of solar energy utilization rate up to 40-60 percent, simple generating method, less equipment used, high generator efficiency, strong practicability and broad prospect of application.

Owner:王海

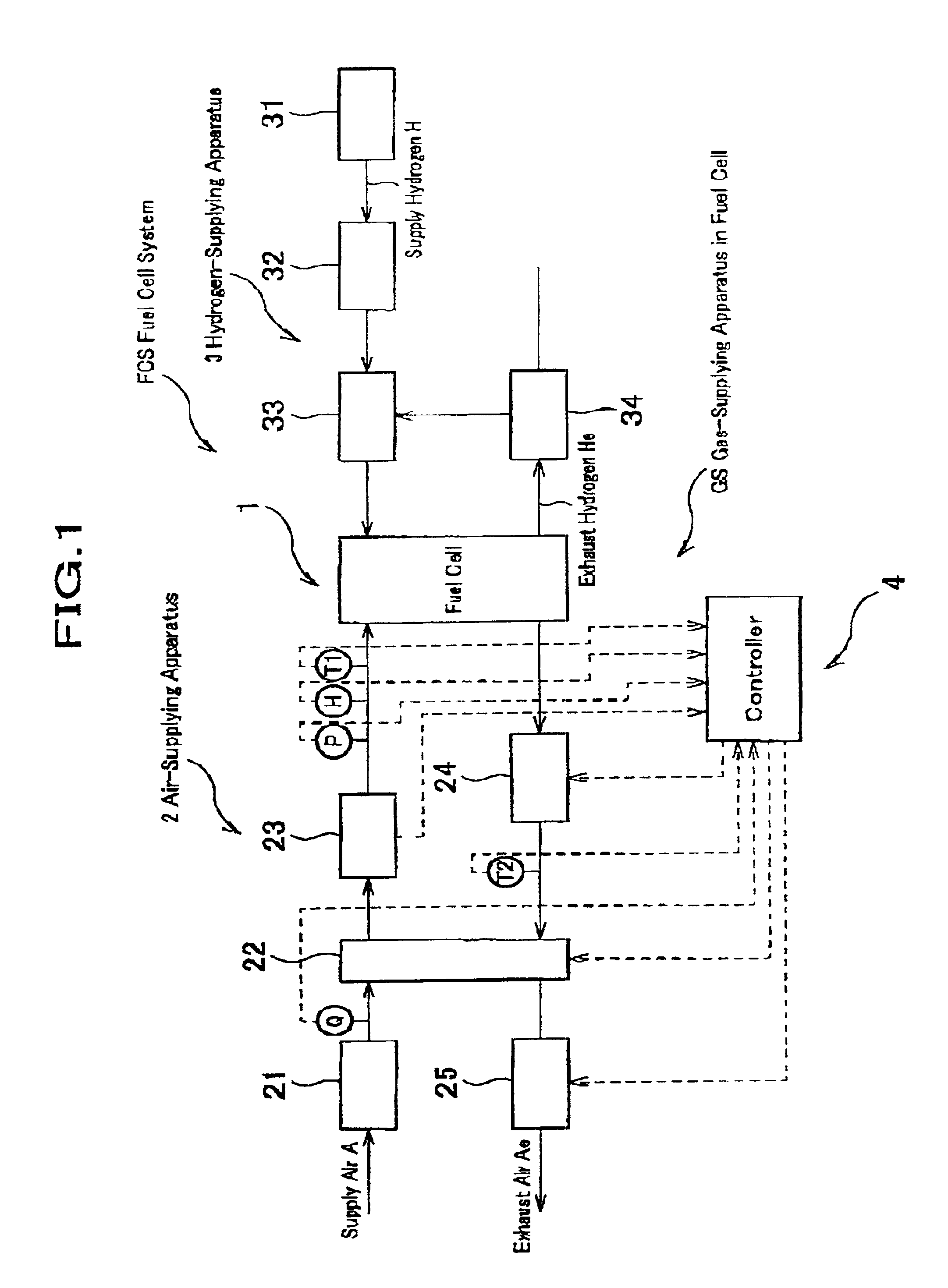

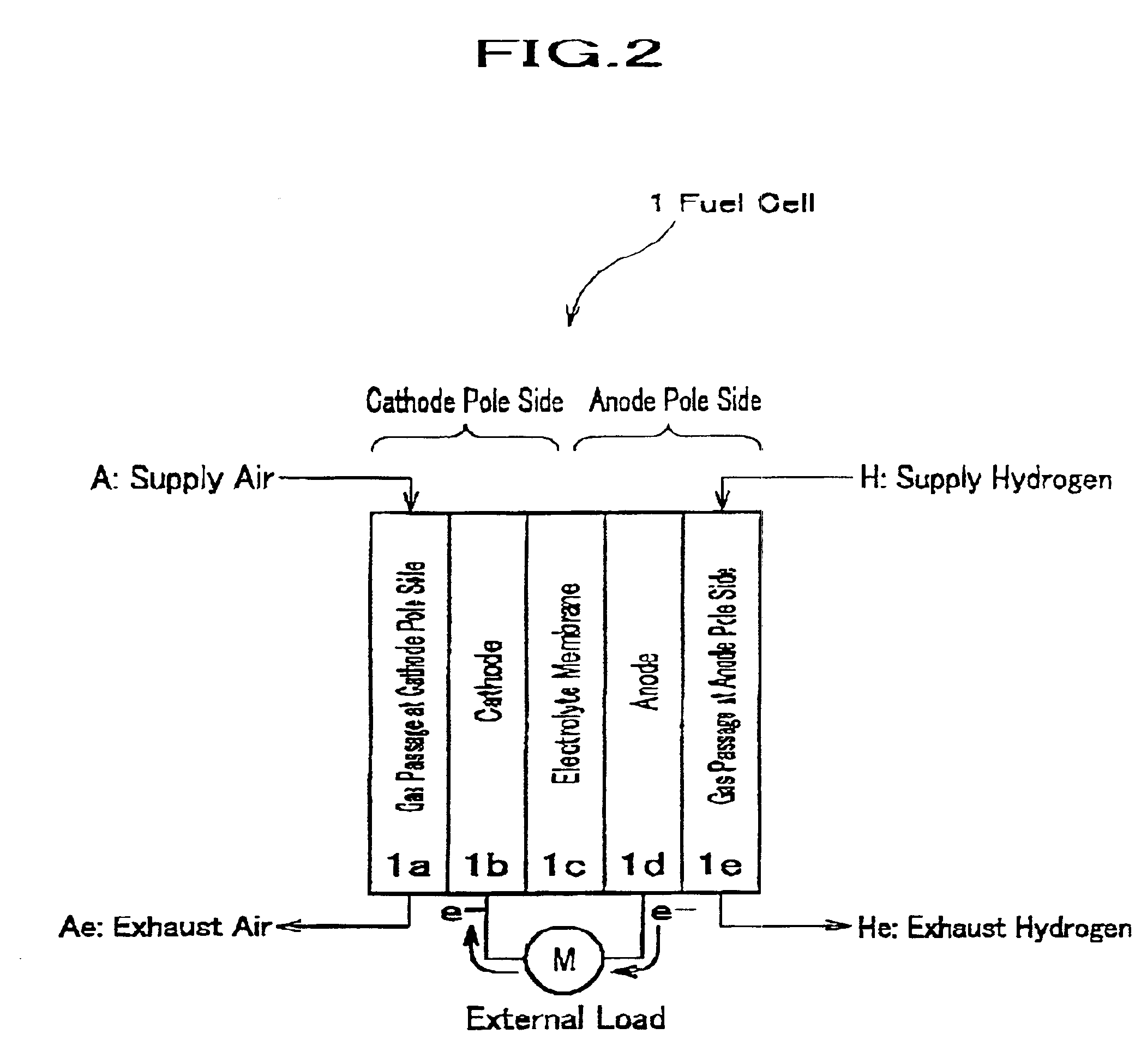

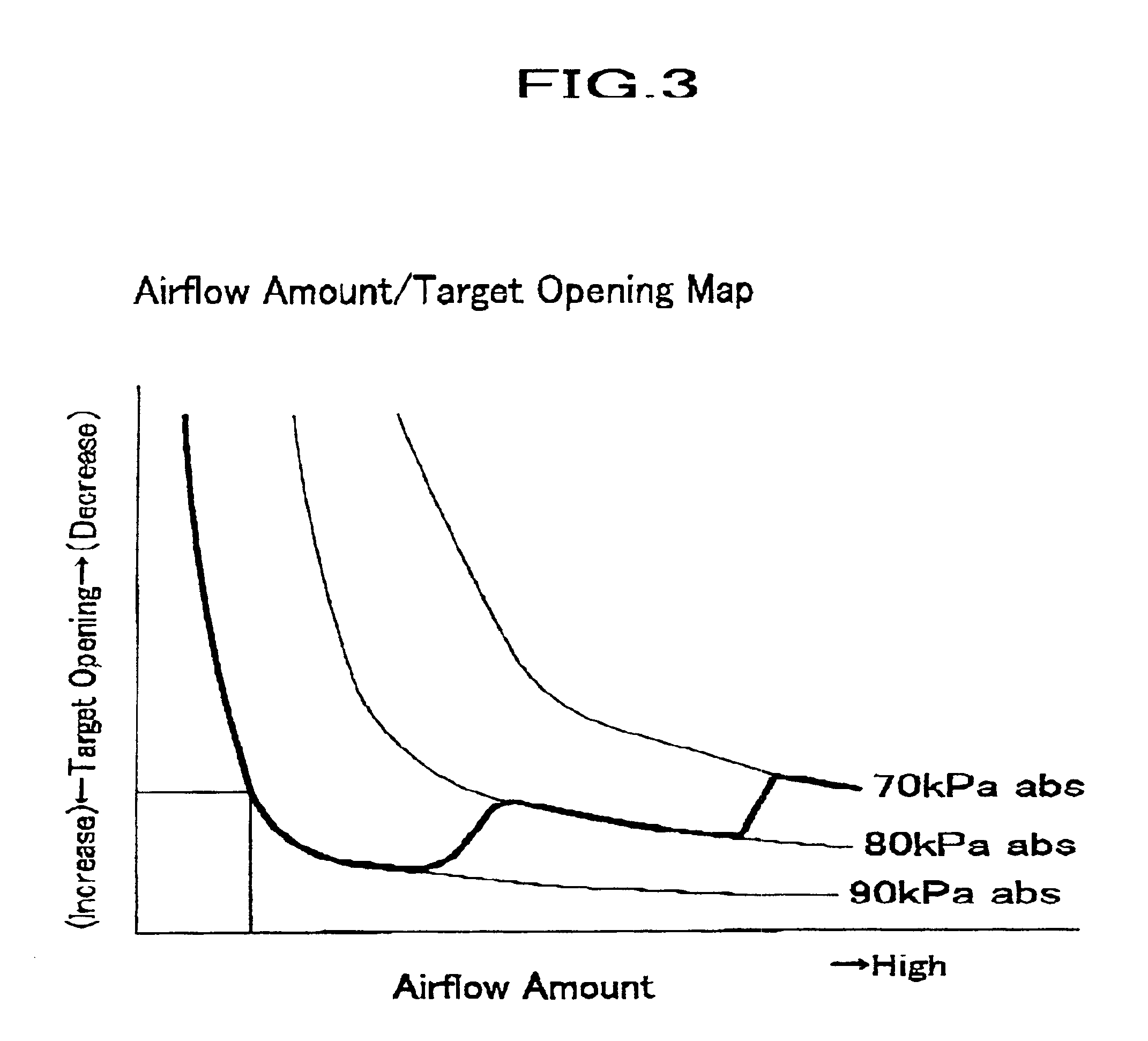

Gas-supplying apparatus for fuel cell

InactiveUS6844094B2Easy dischargeSmall electric power consumptionFuel cell auxillariesPump controlElectrochemical responseHydrogen

A gas-supplying apparatus for a fuel cell, which generates electric power due to an electrochemical reaction between oxygen and hydrogen, during which water is produced, and which has respective gas passages within the duel cell according to the present invention comprises a gas-sucking means which supplies supply gas of the fuel cell provided on the downstream of the gas passage in a gas-flowing direction; and a pressure controller which controls the pressure of the supply gas within the fuel cell, provided on the upstream of the gas passage, whereby the water produced during the course of said electrochemical reaction is discharged. When the cell voltage is decreased, the apparatus of the present invention recovers the cell voltage by making the negative pressure large to accelerate the discharge of the produced water with minimized power consumption.

Owner:HONDA MOTOR CO LTD

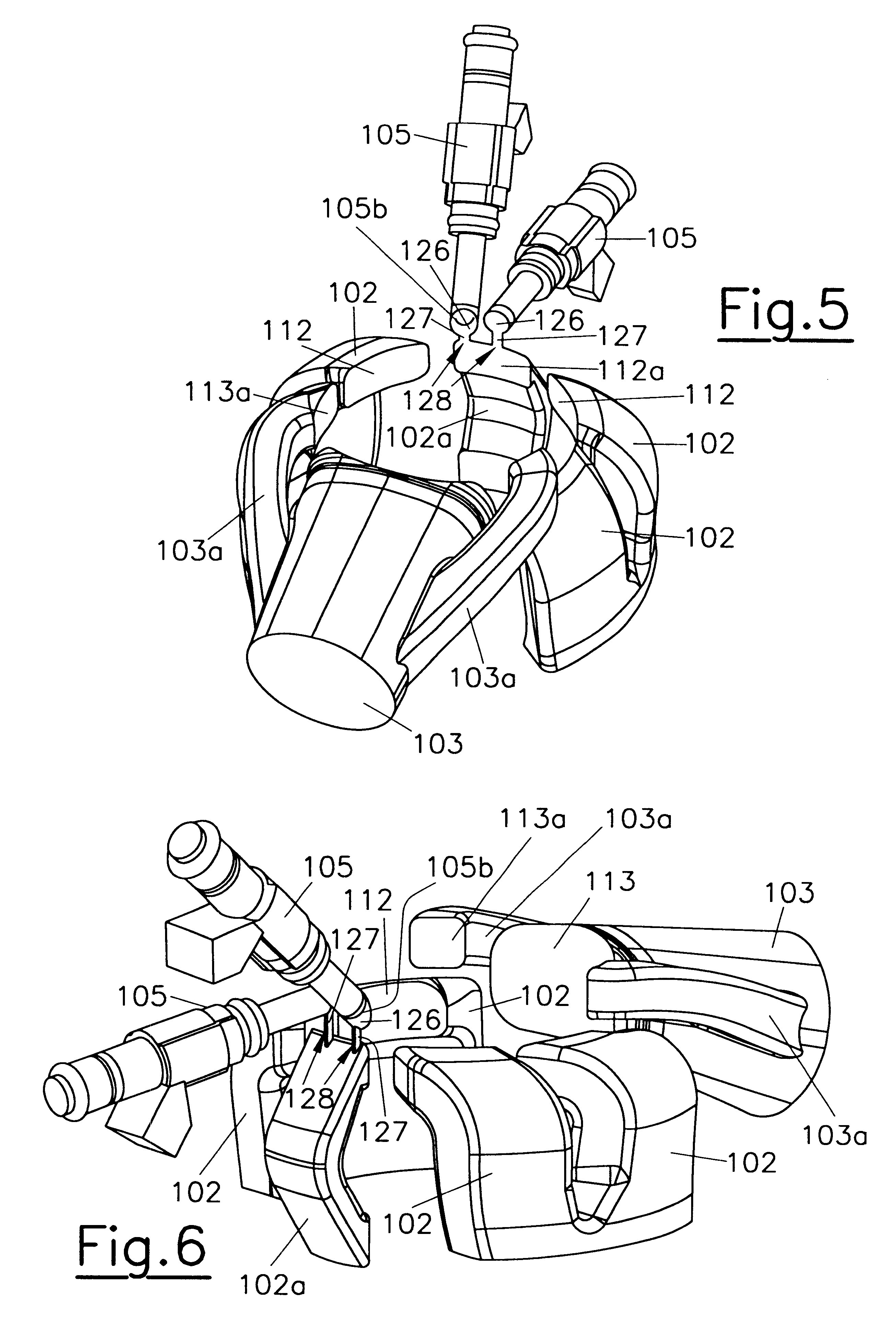

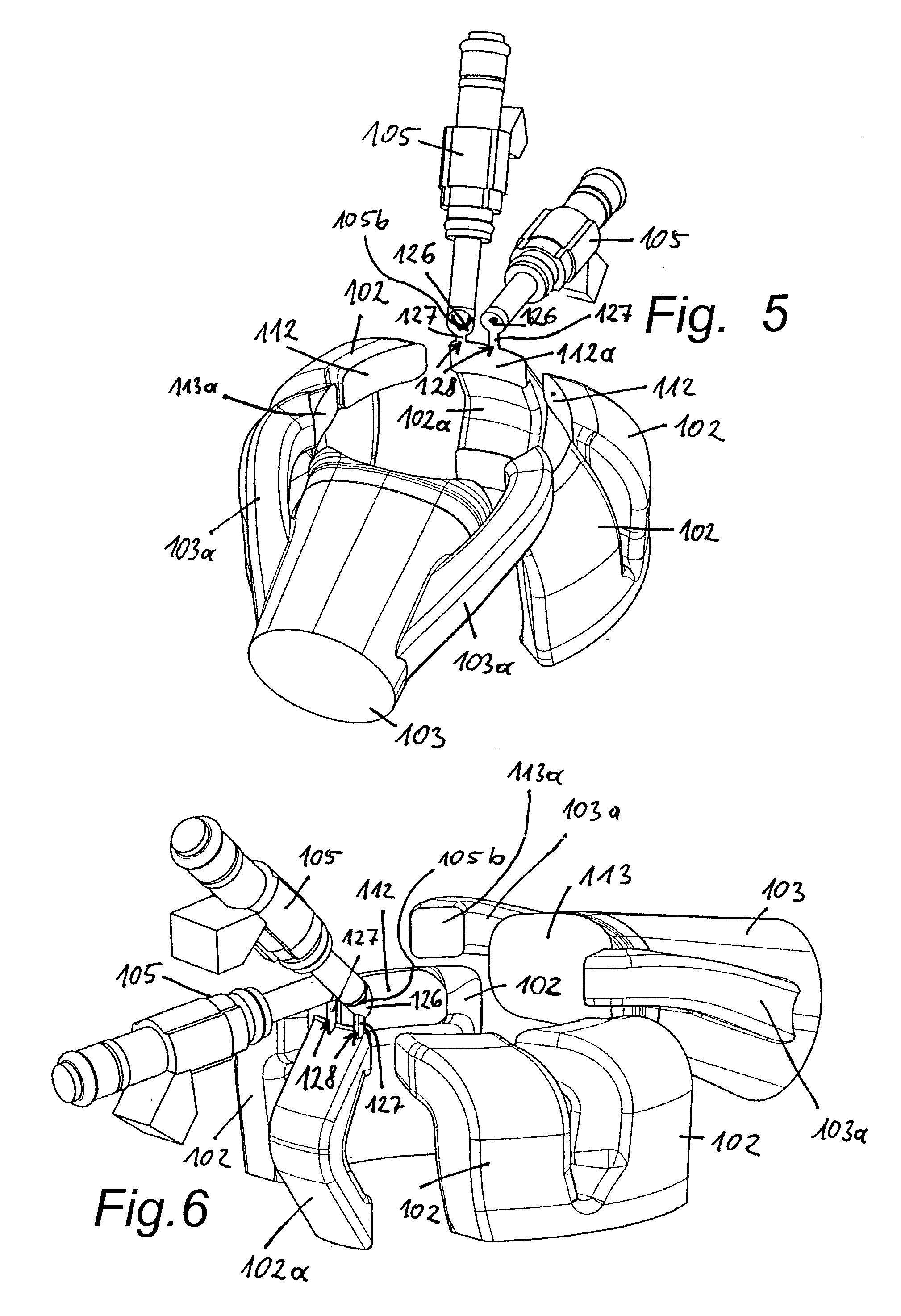

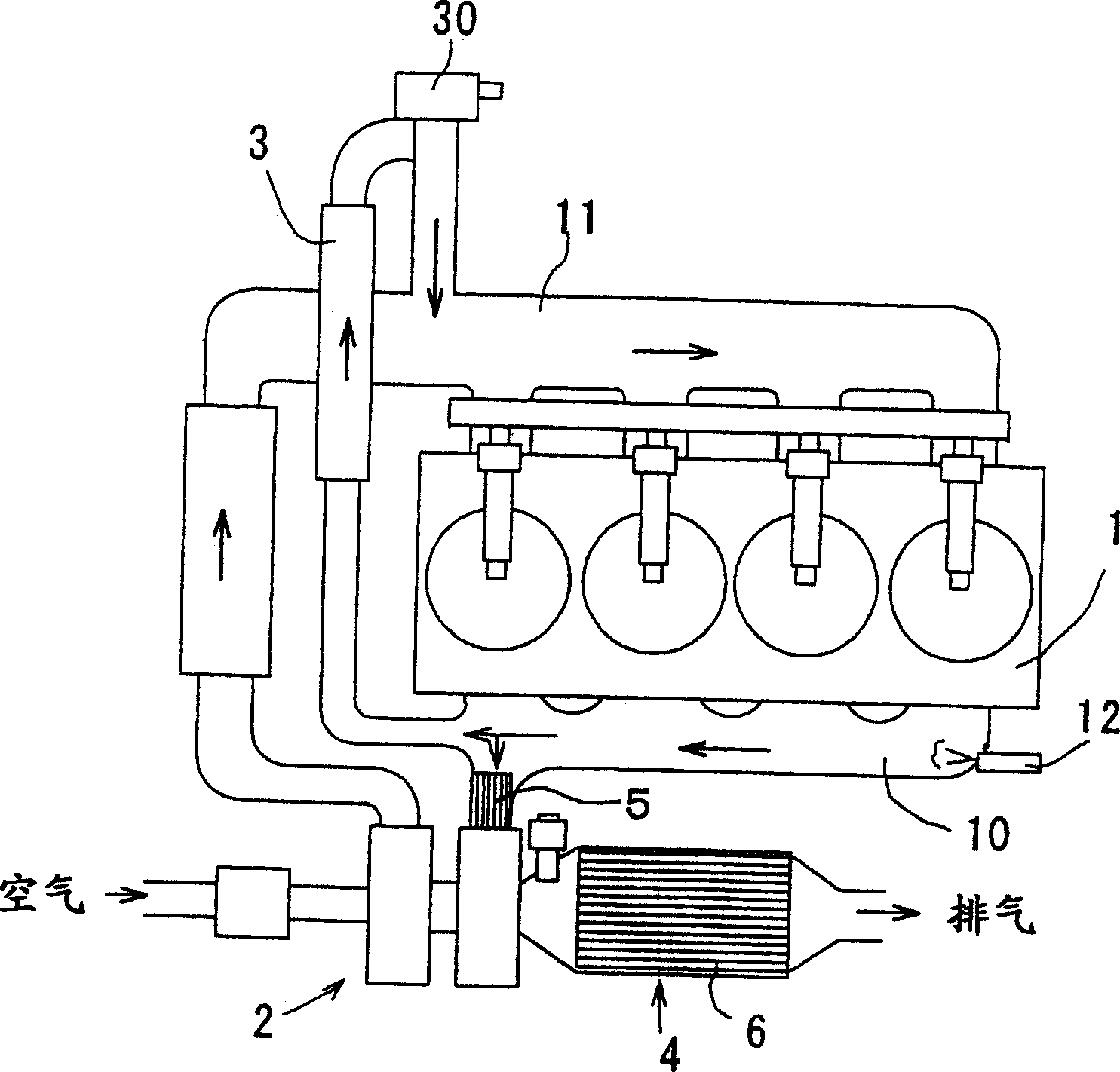

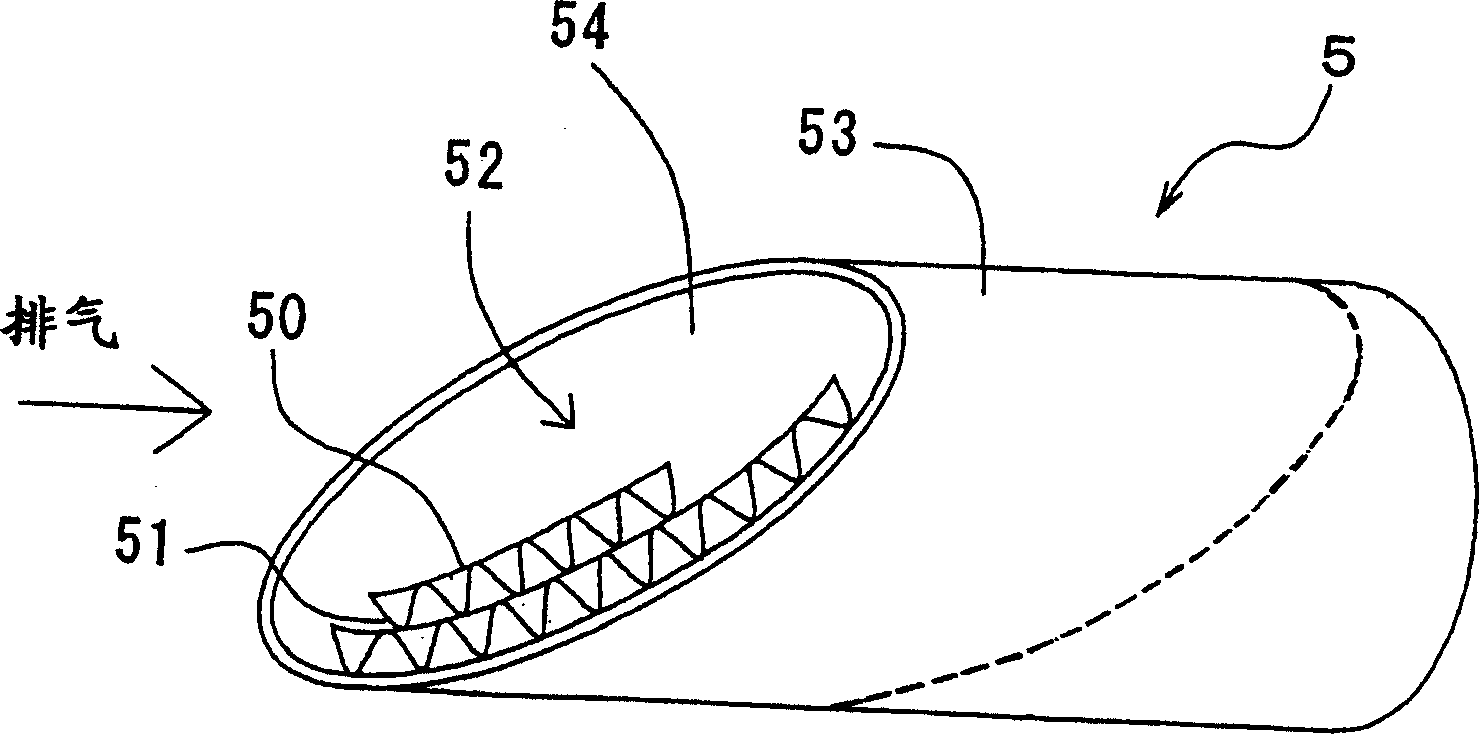

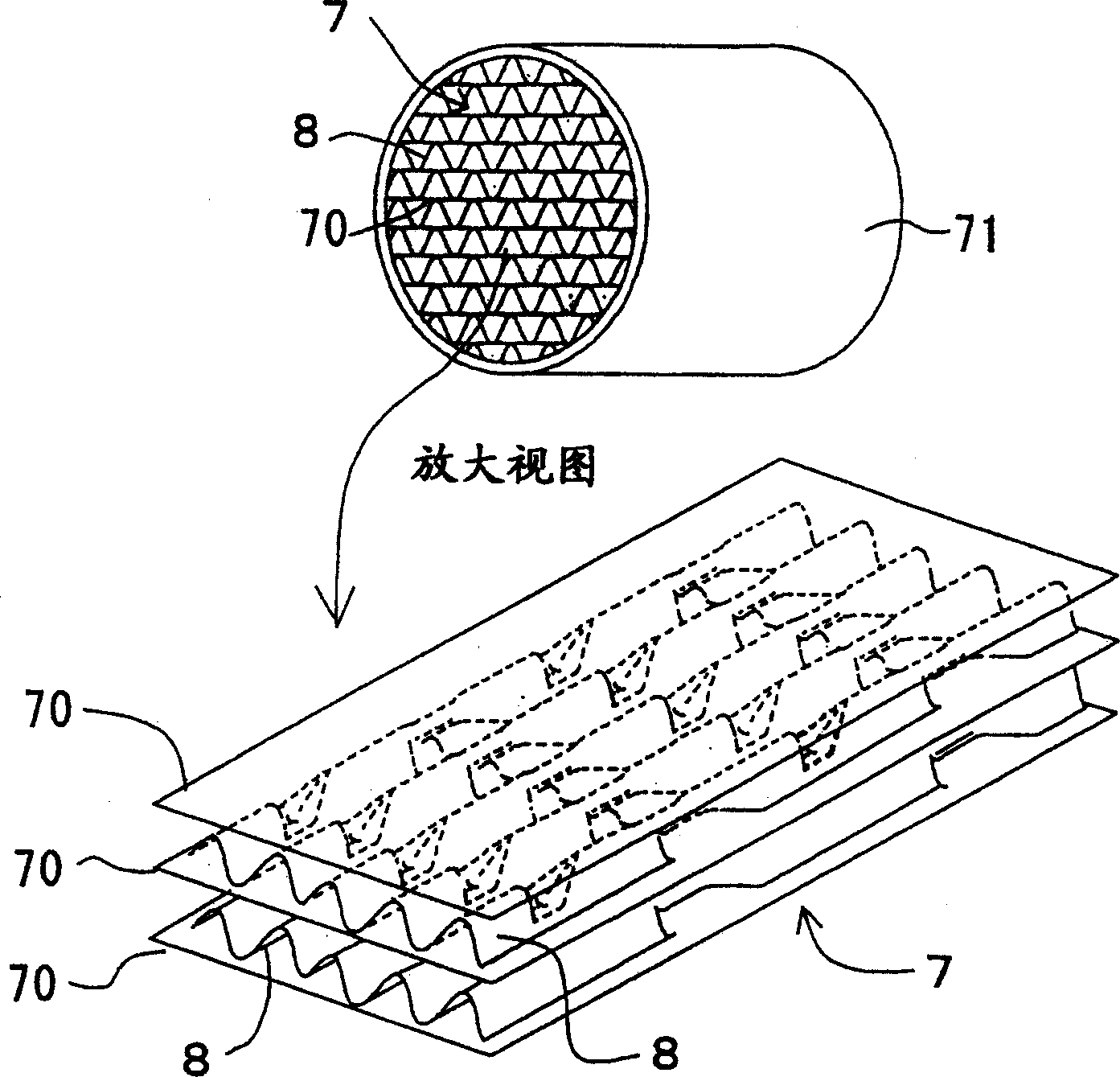

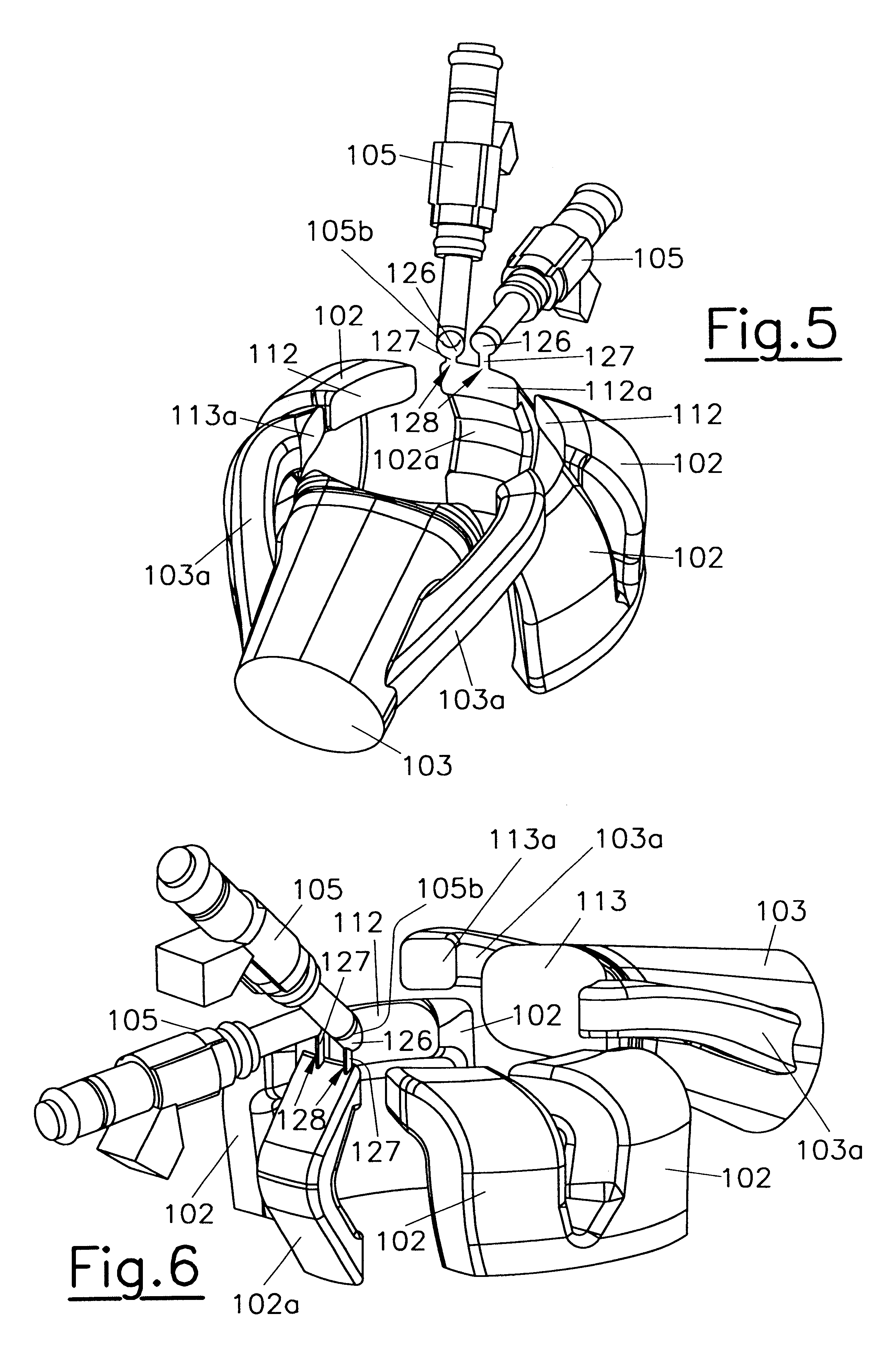

Apparatus for purifying exhaust gas

InactiveCN1756897ASpeed up vaporizationPrevent adhesionNon-fuel substance addition to fuelInternal combustion piston enginesTurbochargerVaporization

An apparatus is for purifying an exhaust gas flowing from an internal combustion engine equipped with a turbocharger (2), and includes an injector (12), a vaporization enhancer (5), and an NOx sorbing-and-reducing catalyst (4). The injector (12) injects a liquid reducing agent into the exhaust gas, and is disposed on an upstream side of the turbocharger (2). The vaporization enhancer (5) is disposed between the injector (12) and the turbocharger (2). The NOx sorbing-and-reducing catalyst (4) is disposed on a downstream side of the turbocharger (2). The vaporization enhancer (5) enhances a vaporization of the liquid reducing agent. Accordingly, the liquid reducing agent hardly adheres onto the inlet-end of the NOx sorbing-and-reducing catalyst (4). Consequently, PMs scarcely adhere onto the liquid reducing catalyst. Therefore, the exhaust pressure loss is inhibited from increasing, and the NOx purifying performance upgrades.

Owner:TOYOTA JIDOSHA KK

Two-stroke internal combustion engine with crankcase scavenging

InactiveUS6729275B2Extended service lifeEmission minimizationInternal combustion piston enginesCylinder headsEngineeringCrankcase

A two-stroke internal combustion engine with crankcase scavenging includes an exhaust passage controlled by the piston and at least two first transfer passages and at least one second transfer passage, each with a corresponding transfer window into the cylinder chamber and a window on the crankcase side for communication between the cylinder chamber and the crankcase, the transfer windows of the first transfer passages being controlled by the upper edge of the piston, and the crankcase-side window of the second transfer passage being disposed in a region of the cylinder wall that is swept by the piston skirt of the piston. The cylinder wall includes at least one recess which is arranged in close vicinity to the transfer window of the second transfer passage and which is in flow communication with the second transfer passage, wherein a narrow passage is arranged between the recess and the second transfer passage.

Owner:AVL LIST GMBH

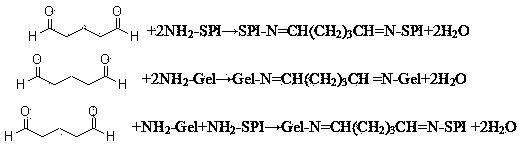

Edible composite membrane with stable mechanical properties and preparation method thereof

ActiveCN103740117AStable mechanical propertiesImprove mechanical propertiesFlexible coversWrappersCarrageenanPlasticizer

The invention discloses an edible composite membrane with stable mechanical properties and a preparation method thereof. Soybean protein isolate and gelatin are subjected to steam cross-linking processing under the participation and assistance of kappa-carrageenan and under unique reaction conditions, so that the internal structure of soybean protein isolate and gelatin protein is reconstructed; and also by further choosing specific usage amount of various compositions and specific plasticizer compositions and ratio, protein forms a relatively compact uniform three-dimension stereo net structure, so that the stability of the membrane material is effectively improved, the variation amplitude of mechanical properties is relatively small within the storage period of 3 months, the tensile strength is reduced only by 5-12%, the composition membrane is increased in water permeability only by 5-8%, increased in oxygen permeability only by 3-5.5% and increased in carbon dioxide permeability only by 2-4.5%, the color and the transparency are not influenced, and the shelf life of food is prolonged. According to the composite membrane, the operation is simple, the product quality is stable and reliable, and the composite membrane is suitable for industrial production.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

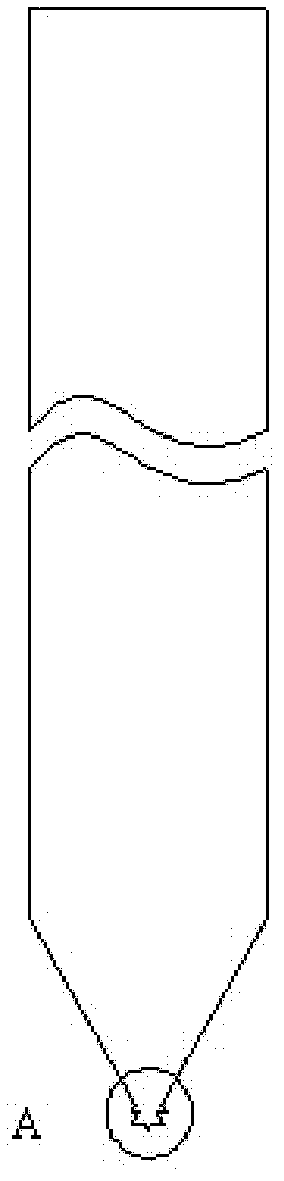

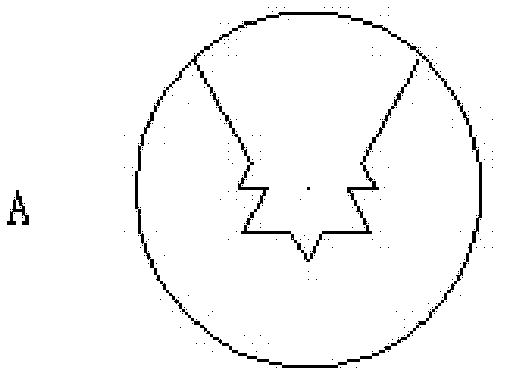

Microchannel heat exchange plate with V-shaped fractal structures and preparation method of microchannel heat exchange plate

ActiveCN102519292AIncrease the number of vaporization coresEnhanced vaporization processLaminated elementsBoiling processPlough

The invention discloses a microchannel heat exchange plate with V-shaped fractal structures and a preparation method of the microchannel heat exchange plate. A microchannel is processed on a single surface of a heat exchange plate, three stages of V-shaped fractal structures are arranged on the microchannel, and two second-stage V-shaped microchannels are respectively uniformly distributed on two side walls of a first-stage V-shaped microchannel. Two third-stage V-shaped microchannels are respectively uniformly distributed on two side walls of each second-stage V-shaped microchannel. A plate to be processed is flattened by a planer tool, and then is subject to plough cutting by the aid of a multistage composite fractal plough cutter, by the aid of movement of a planer worktable and a toolrest, and the pitches and the depths of the fractal microchannels are controlled, so that the microchannel with the V-shaped fractal structures is formed. The heat exchange plate has large specific surface area, nucleus of boiling can be greatly increased, vaporization in an evaporation boiling process is realized advantageously, so that the heat exchange plate has excellent boiling strengthening heat exchange ability, processing efficiency is greatly enhanced, processing technology is simple, and cost is low.

Owner:SOUTH CHINA UNIV OF TECH

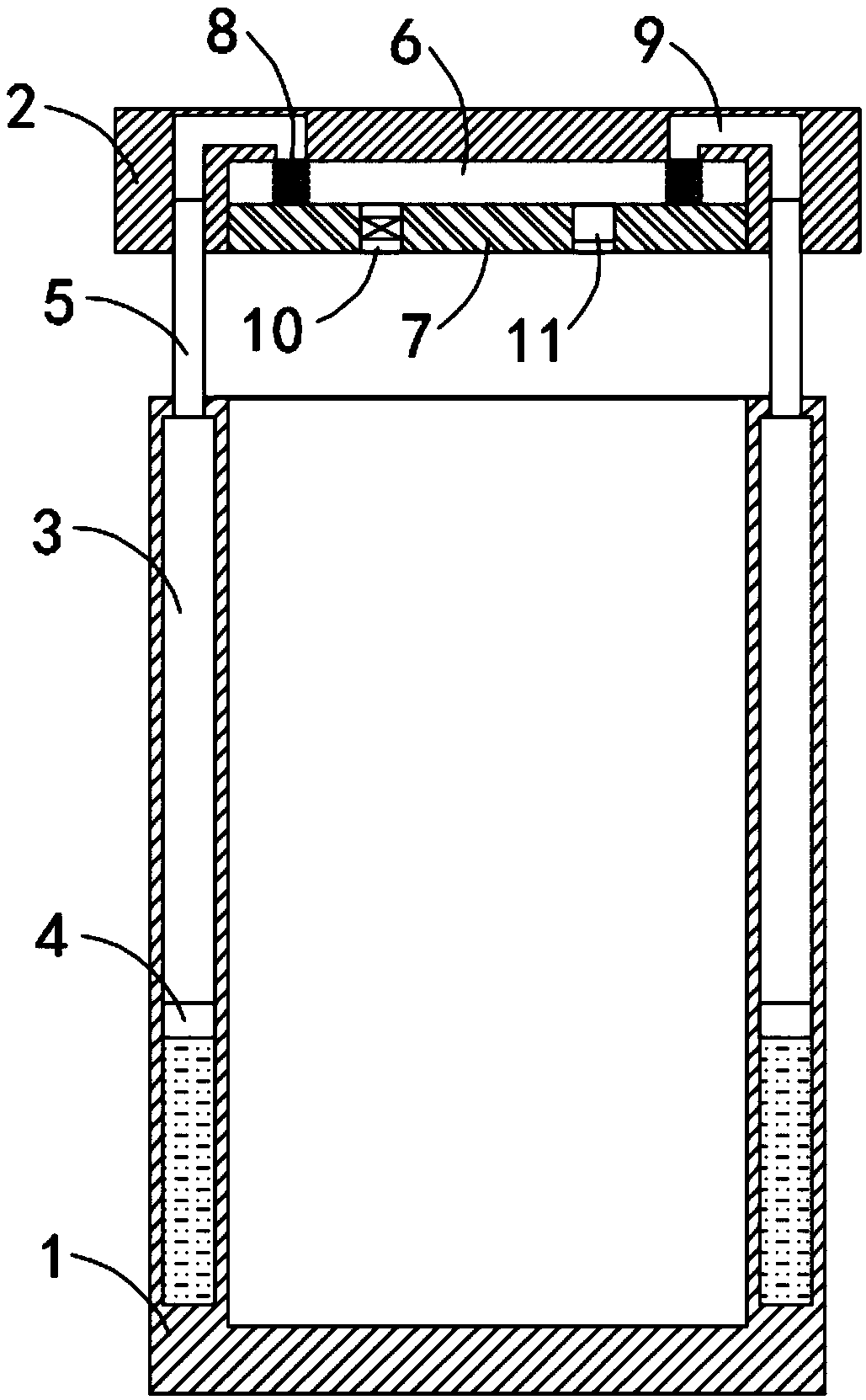

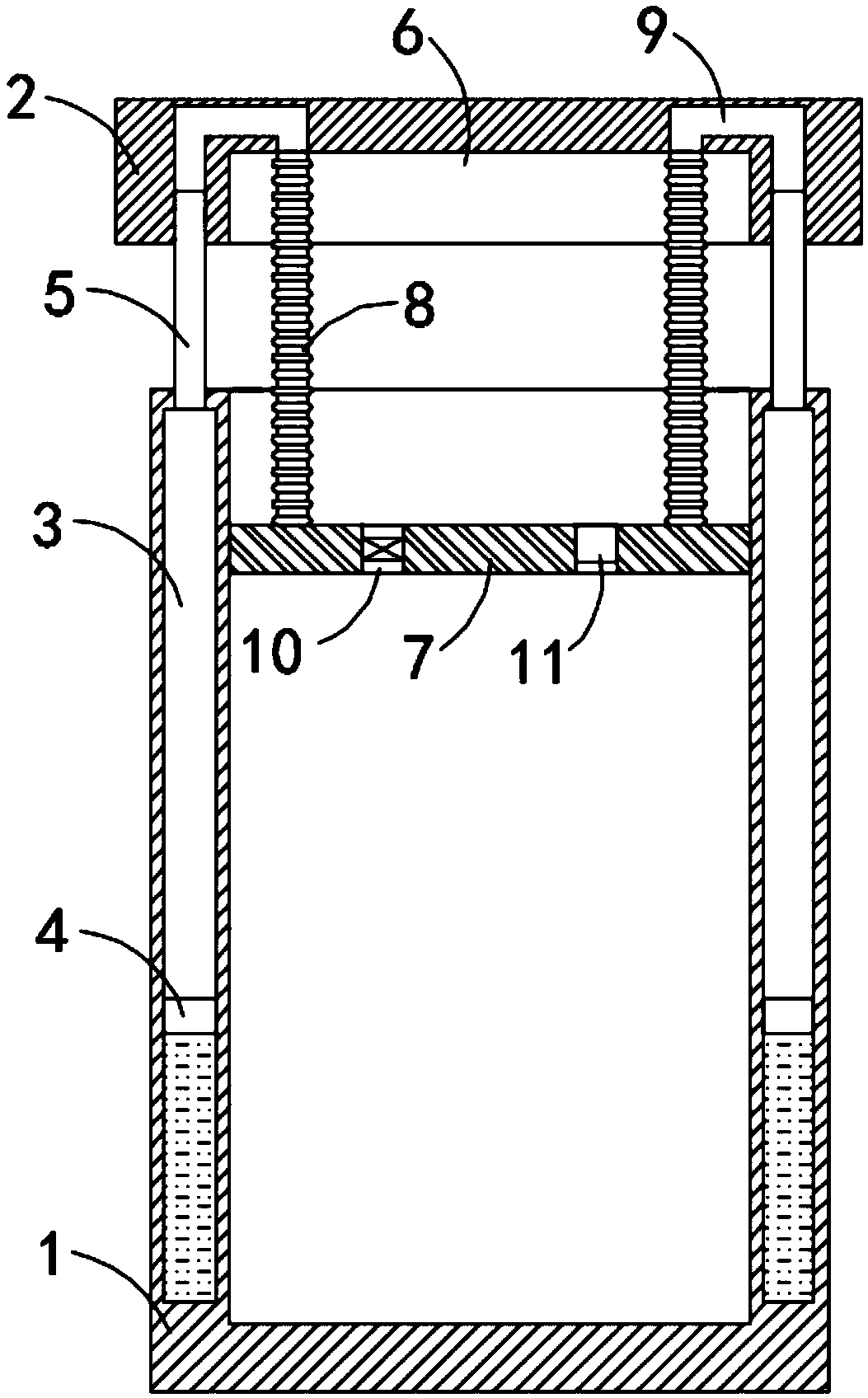

Safe flame-retardant garbage can

The invention belongs to the field of garbage cans, and particularly relates to a safe flame-retardant garbage can. The safe flame-retardant garbage can comprises a can body and a cover body, an annular cavity is formed in the side wall of the can body, a piston ring is slidably connected in the annular cavity in a sealing mode, an evaporation liquor fills a sealing space formed by the piston ringand the lower portion of the annular cavity, connecting pipes are fixedly connected to the four corners of the lower end of the cover body, the lower ends of the connecting pipes are fixedly connected with the upper end of the can body, the lower ends of the connecting pipes communicate with the annular cavity, a containing groove is formed in the lower surface of the cover body, a sealing movable plate matched with the can body is arranged in the containing groove, corrugated stretchable pipes are fixedly connected to the four corners of the upper end of the sealing movable plate, the four corrugated stretchable pipes are in one-to-one correspondence with the four connecting pipes correspondingly, channels for allowing the corrugated stretchable pipes and the connecting pipes to communicate are arranged in the cover body, two openings are formed in the sealing movable plate, and a one-way valve and a manual valve are installed in the two openings correspondingly. According to the safe flame-retardant garbage can, when the garbage can is combusted, an outlet can be automatically blocked for fire extinguishing.

Owner:南京金升华包装材料有限公司

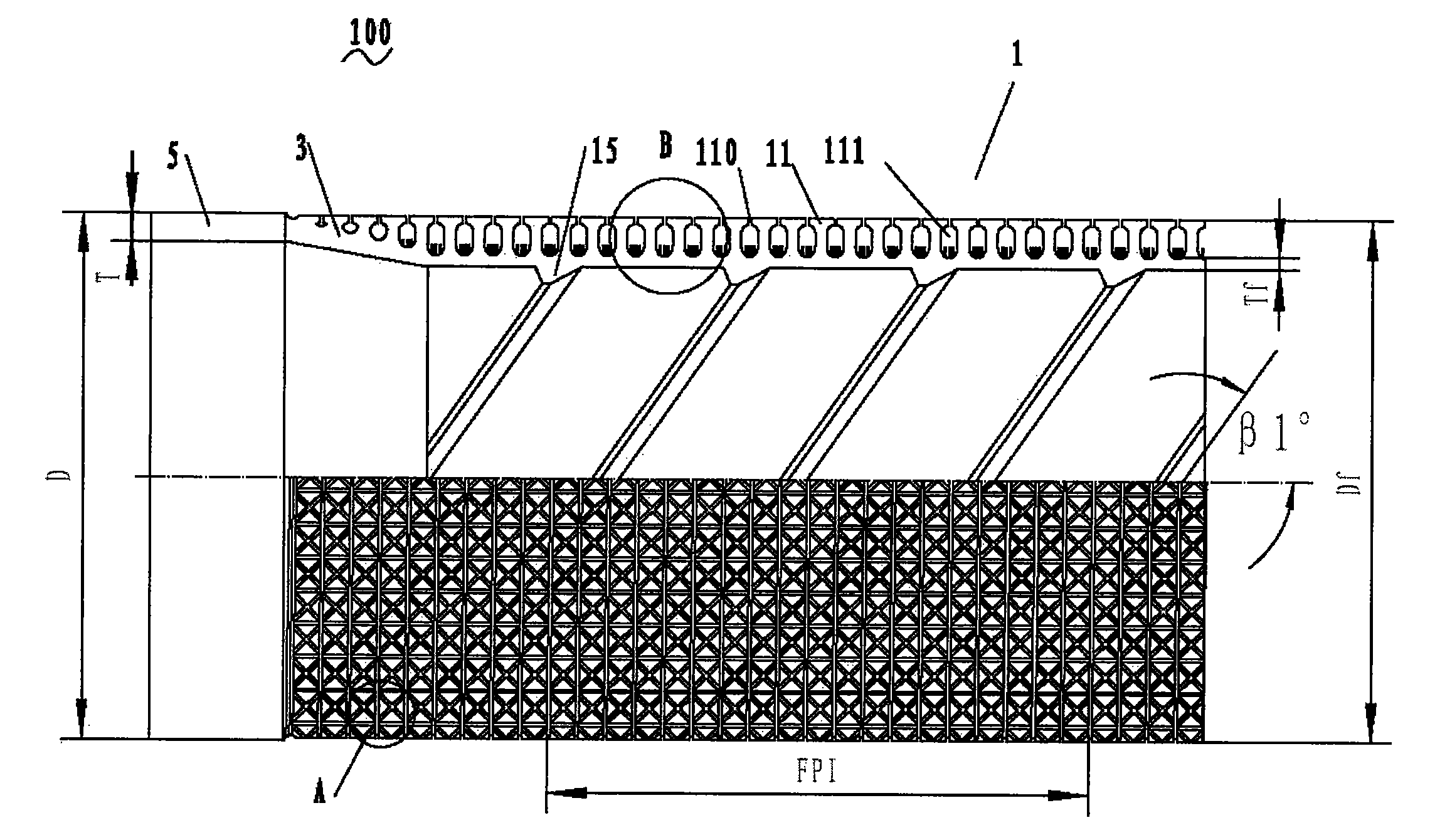

Flooded type evaporating heat-exchange copper tube for an electrical refrigeration unit

ActiveUS7841391B2Improve efficiencyNucleation is easyCorrosion preventionCoatingsElectricityEvaporation

The present invention discloses a flooded type evaporating heat-exchange copper tube for an electrical refrigeration unit. The evaporating heat-exchange tube comprises a smooth surface portion, a finned portion provided with plurality of fins and a transitional portion connecting the smooth surface portion to the finned portion, with primary evaporating chambers defined between the fins. Fifth fins extending upwardly are provided on a bottom wall of the primary evaporating chamber, which divide the primary evaporating chamber into at least two minor cavities, and an evaporating opening is defined between adjacent fins of the primary evaporating chamber. Due to plurality of minor cavities arranged in the evaporating heat-exchange tube, refrigerant film is easy to form on bottom walls of the minor cavities, and nucleus boiling is easily to be developed. Thereafter, the refrigerant gets boiled and evaporated to form bubbles to escape via evaporating openings. Surrounding refrigerant refills the empty minor cavities via the evaporating opening. This process of boiling, evaporation and refilling continues to go on. Thus, the number of vaporization nucleus is dramatically increased, and the refrigerant is much easier to form nucleus and get vaporized, thus improving the heat transfer property of the evaporating heat-exchange tube.

Owner:GOLDEN DRAGON PRECISE COPPER TUBE GROUP

Device and method for oxygen and nitrogen separation through air and rapid increase of pressure nitrogen loads

ActiveCN103575064AReduce production redundancyReduce energy consumptionSolidificationLiquefactionCooling towerAir separation

The invention provides a device and a method for oxygen and nitrogen separation through air and rapid increase of pressure nitrogen loads. According to the device and the method for oxygen and nitrogen separation through air and rapid increase of the pressure nitrogen loads, on the basis of a full low pressure external compression air separation process, according to a condition of peripheral requirement for pressure nitrogen, a liquid nitrogen bare tank with an appropriate volume is arranged in an ice box of an air separation device to be used for storing redundant liquid nitrogen of the air separation device during a normal production period; the liquid nitrogen bare tank and a liquid nitrogen vaporizer valve and pipelines which are arranged at bottoms of a water cooling tower and an air cooling tower are in organic connection with the air separation device to enable the liquid nitrogen inside the liquid nitrogen bare tank to be rapidly vaporized when external supplied nitrogen is increased suddenly and generate small disturbance to production working conditions of an original air separation device. The device and the method for oxygen and nitrogen separation through air and rapid increase of the pressure nitrogen loads have the advantages of enabling pressure nitrogen outside delivered loads to be increased by 100 % in few minutes to enable accidents of a production device to be coped with, solving the problem of increase of sudden pressure nitrogen loads, reducing nitrogen yield redundancy when a novel air separation device is designed and enabling energy consumption of the air separation device during the normal operation period to be reduced.

Owner:CHINA PETROLEUM & CHEM CORP

Rotary-type sugar crop vaporizing device

ActiveCN102688604AReduce spacingShort residence timeConfectionerySweetmeatsAgricultural engineeringSugar

The invention discloses a rotary-type sugar crop vaporizing device, and belongs to a device for concentrating liquid sugar crops in the industry of industrial or food processing. The rotary-type sugar crop vaporizing device mainly comprises an inner cylinder and an outer cylinder; sugar crops are heated by utilizing the clearance between the inner cylinder and the outer cylinder, thus the sugar crops in the clearance are heated and vaporized rapidly so as to achieve the aims of dehydration. The rotary-type sugar crop vaporizing device provided by the invention has the advantages that the vaporizing effect is obvious, the sugar crops are heated uniformly, and the sugar crops can not be leaked.

Owner:DUJIANGYAN TIANWANG FOOD IND

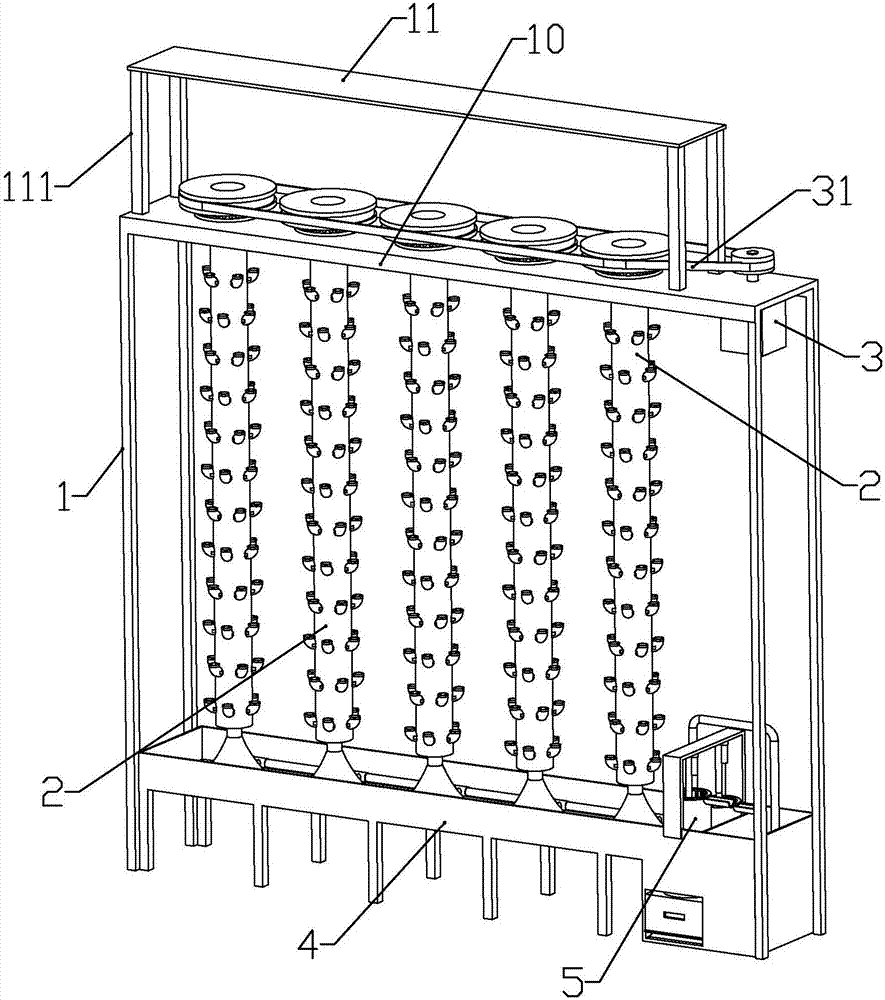

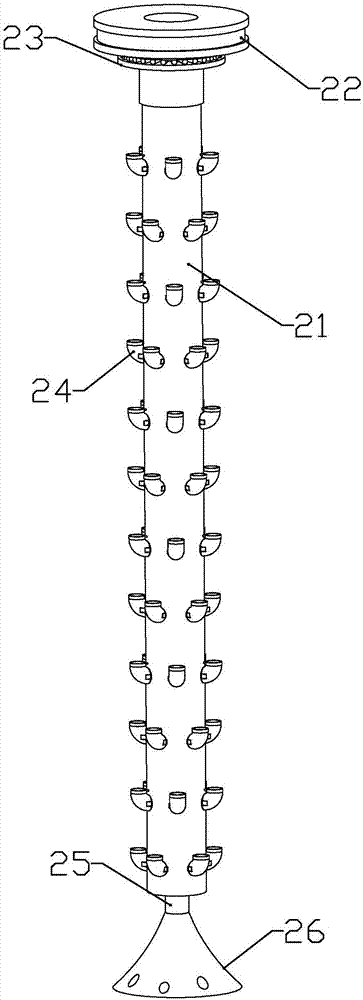

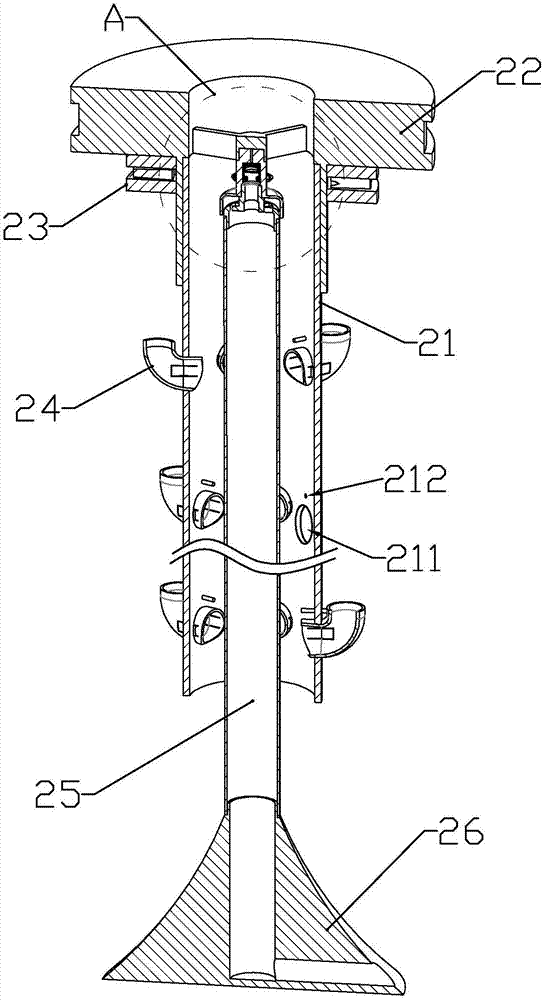

Multifunctional plant aerosol cultivation equipment

ActiveCN106962170APromote growthPurifySelf-acting watering devicesAgriculture gas emission reductionElectricityAgricultural engineering

The invention discloses multifunctional plant aerosol cultivation equipment. The equipment is characterized by comprising a support, a plurality of planting assemblies which are rotatably mounted at the lower end of the support and arranged vertically and water tanks arranged under all the planting assemblies; the upper end of the support is fixedly connected with a horizontal mounting plate, the planting assemblies comprise belt pulleys located on the top of the mounting plate and arranged horizontally, a bearing connected between the mounting plate and the belt pulleys, planting pipes coaxially connected to the lower ends of the belt pulleys, a plurality of planting elbows mounted on the outer walls of the planting pipes and communicated inside the planting pipes, a water inlet pipe coaxially arranged in each planting pipe and a fixed base fixedly connected to the lower end of the water inlet pipe and fixedly mounted at the bottom of the water tank; a drive motor is mounted on the mounting plate, and the belt wheel on each planting assembly is connected with the drive motor in a transmission mode through a driving belt; the drive motor and a solar panel are electrically connected with a controller. According to the multifunctional plant aerosol cultivation equipment, not only can the growth of plants be promoted, but also air can be purified at the same time.

Owner:重庆毅尚生态农业发展有限公司

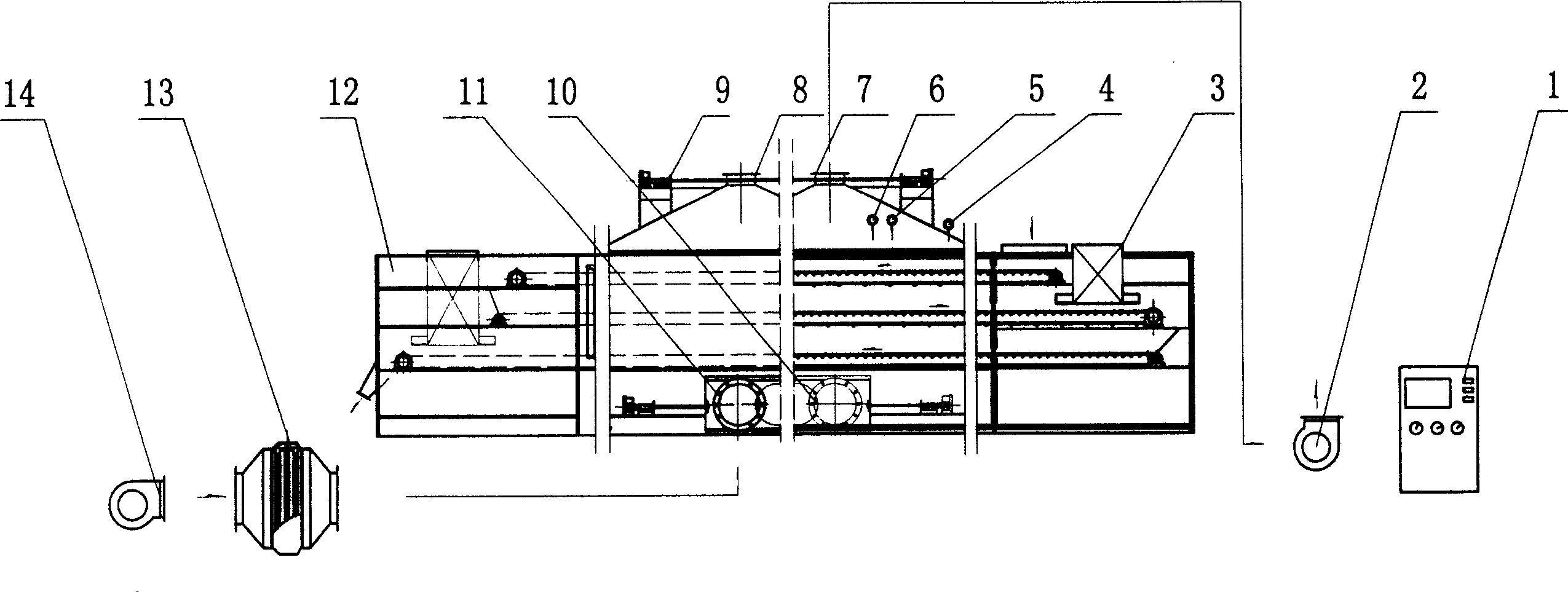

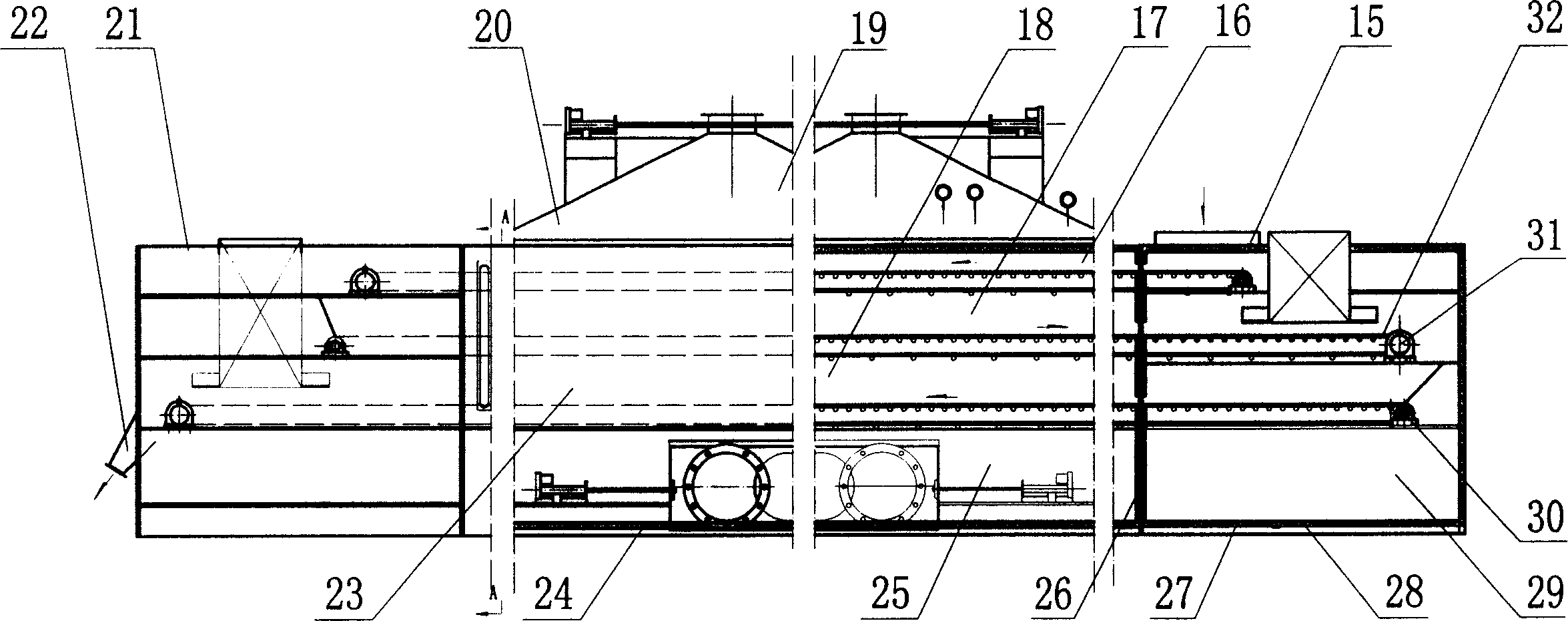

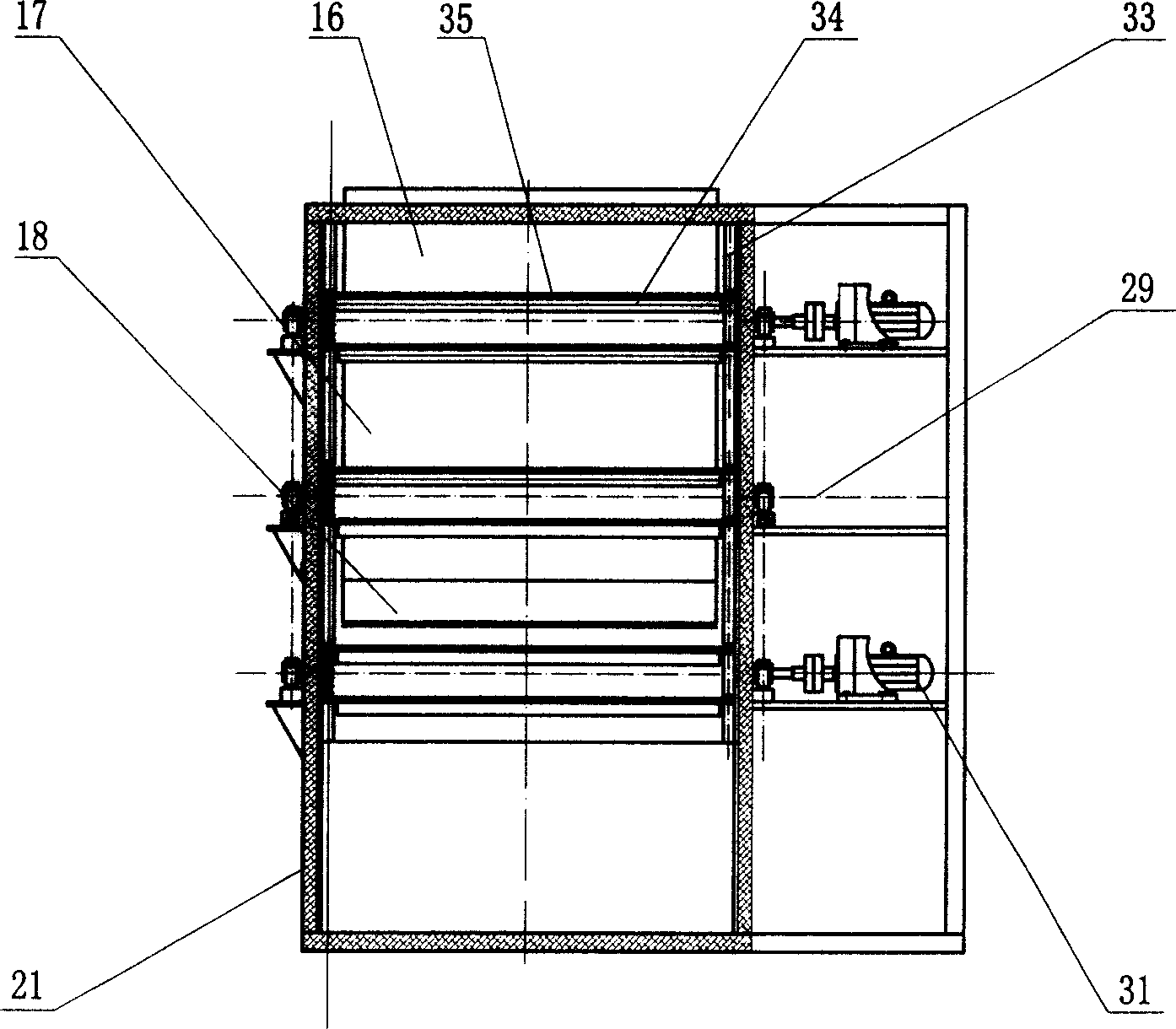

Fresh keeping device by utilizing multiple energy to dry

InactiveCN1731058AOvercoming the use of multiple devicesAccelerate outward transfer speedDrying machines with progressive movementsCentrifugal pumpProcess engineering

The intact preservation apparatus utilizing comprehensive energy includes machine frame, drier and controller inside the machine frame. Technologically, the present invention features the machine frame comprising head box, drying box and tail box connected together; the drier comprising three-layer folded material conveyer, closed slowly drying part, at least one water molecule stimulating energy generator, moist eliminating part, centrifugal pump, air distributor, blower, drying box with preheating part, evaporating part and drying part. The present invention has comprehensive utilization of several kinds of energy, short drying period, obviously raised heat efficiency, low power consumption, low running cost, use safety and high quality of dried material.

Owner:辽宁中田干燥设备制造有限公司

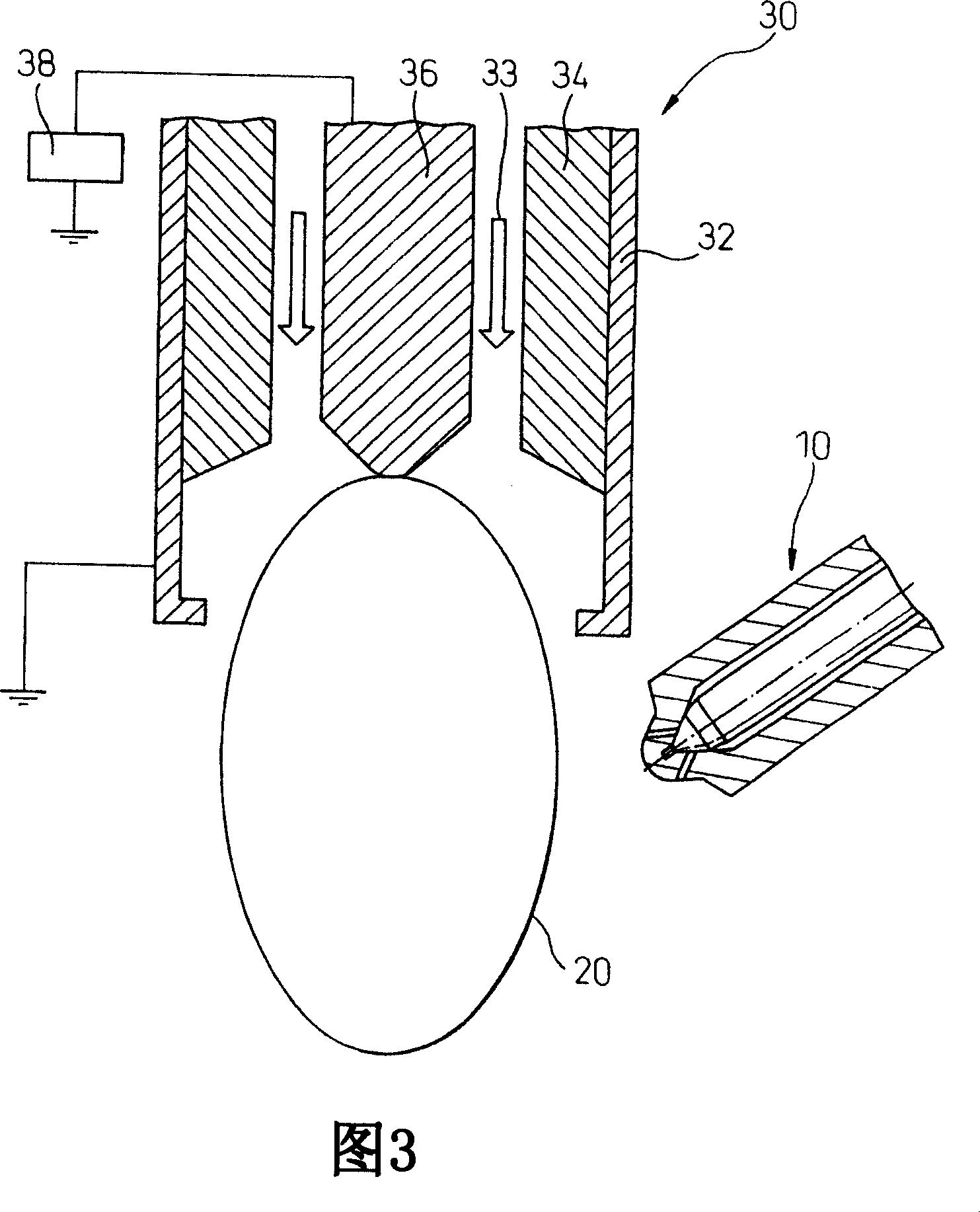

Device and method for supplying fuel or reducing agent, and plasma torch

InactiveCN101094975ASpeed up vaporizationImprove responseInternal combustion piston enginesNon-fuel substance addition to fuelEngineeringProduct gas

The present invention provides an device and a method for supplying a fuel or a reducing agent, where a fuel or reducing agent supplied by injection can be vaporized and / or a fuel or reducing agent having high reactivity can be provided, and provides a plasma torch (30) usable therefor. The device for supplying a fuel or a reducing agent comprises a plasma torch (30) for converting a gas (23, 33) into a plasma and blowing out the plasma, and an injector (18) for injecting a fuel or a reducing agent to a region (20) where the plasma is supplied. The method comprises converting a gas (23 33) into a plasma, blowing out the plasma, and injecting a fuel or a reducing agent to the plasma region (20).

Owner:TOYOTA JIDOSHA KK

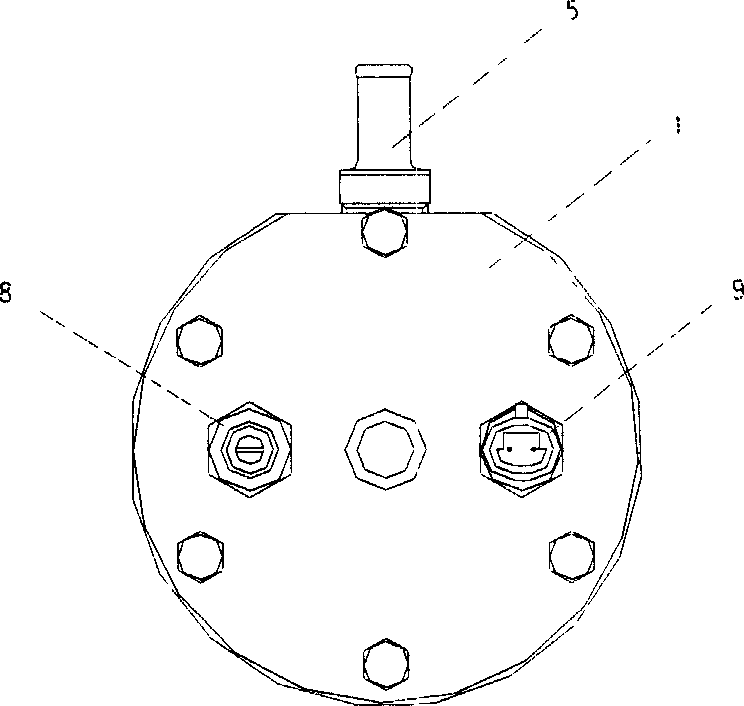

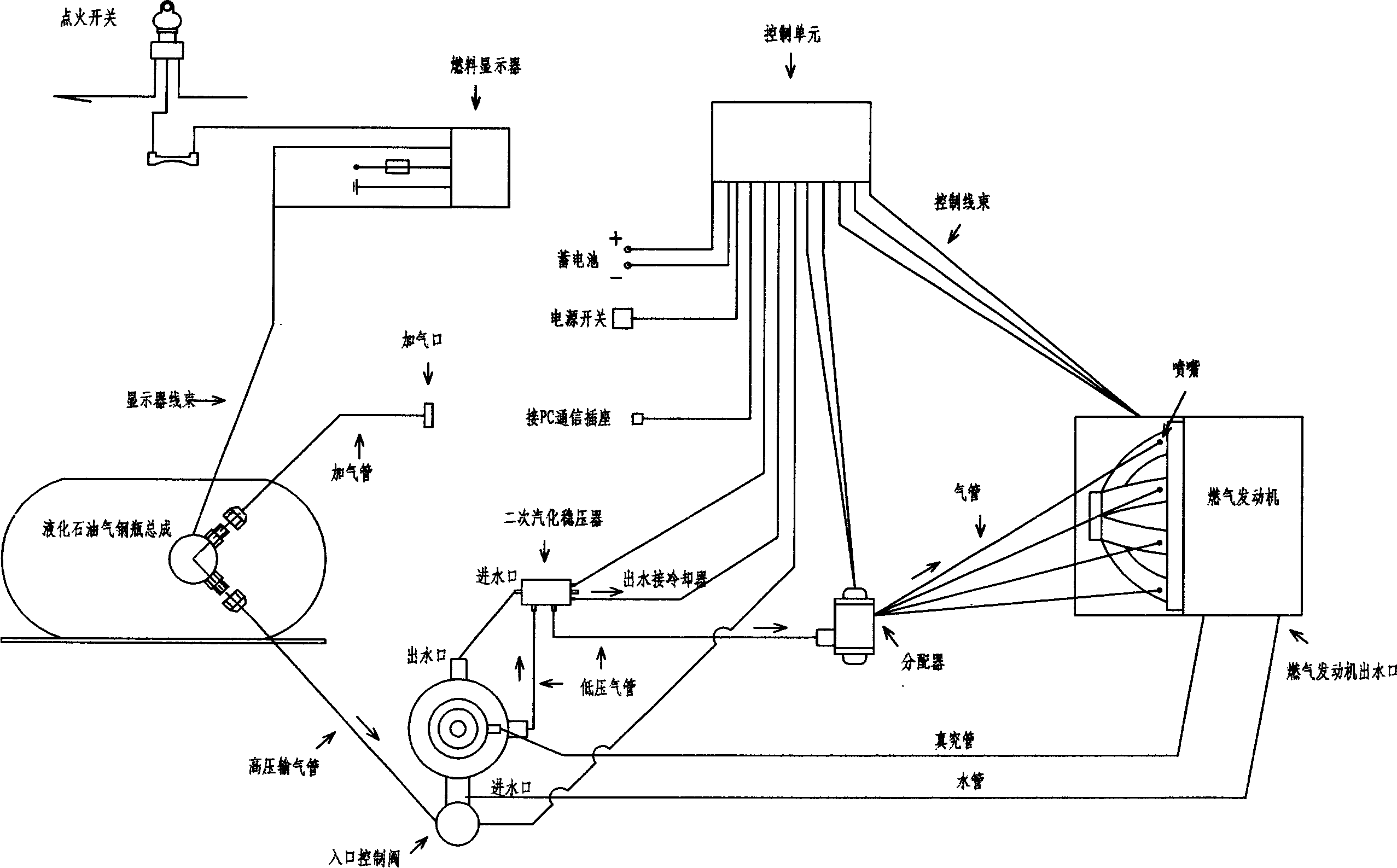

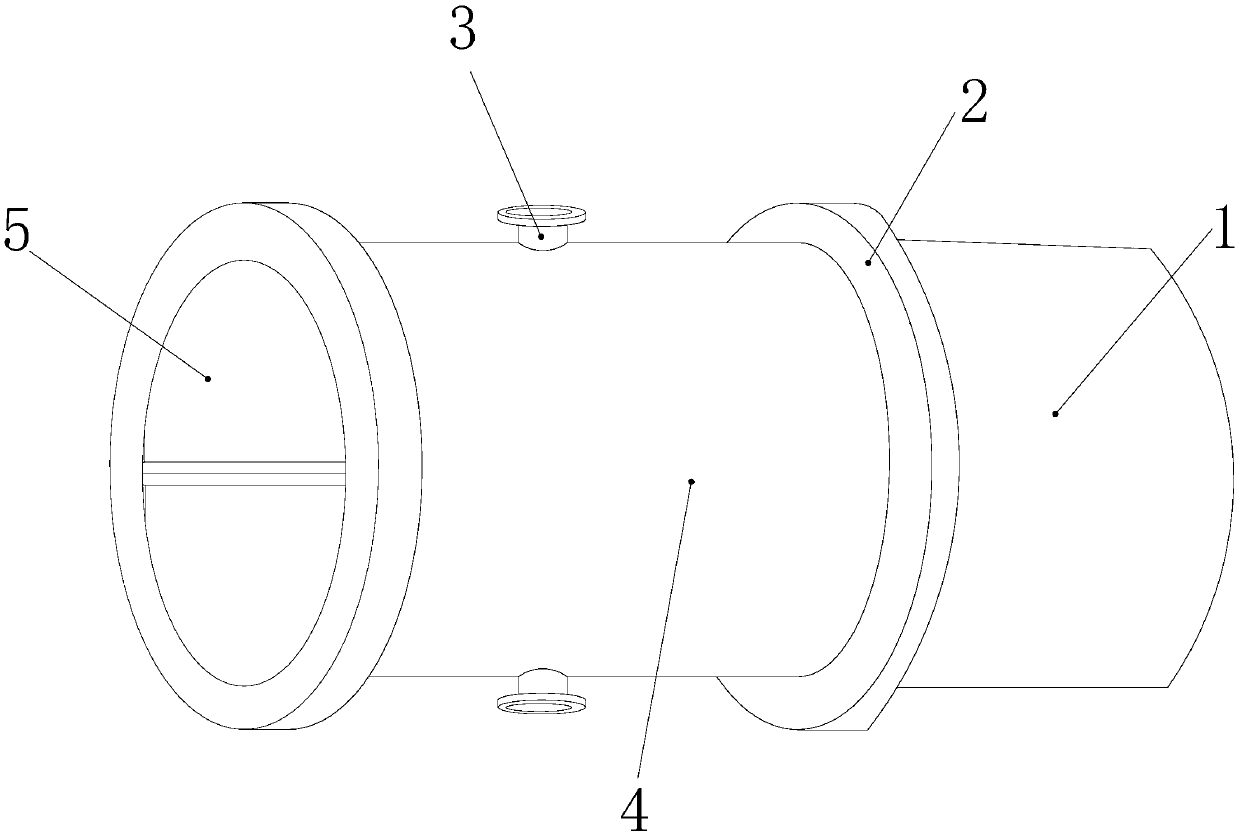

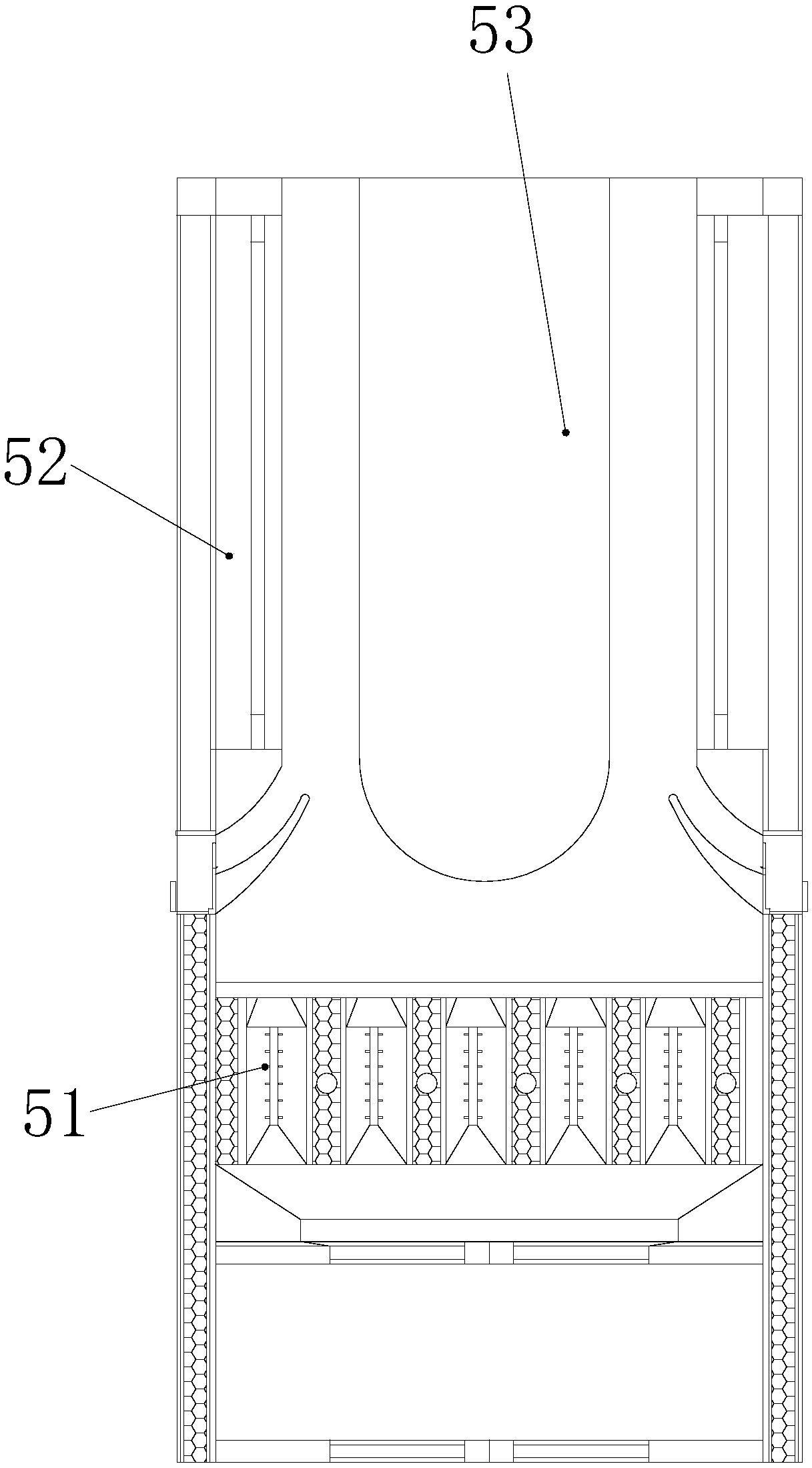

Gas engine

InactiveCN1746476AUniform air intakeSpeed up vaporizationInternal combustion piston enginesFuel supply apparatusReducerProcess engineering

A gas engine using LPG or natural gas as fuel supply has a secondary vaporizer in between the reducer and distributor. The secondary vaporizer is comprised by a sealed water pipe and a sealed gas pipe which are connected side by side. On the secondary vaporizer may install a heating system and temperature sensor. The engine of this kind of structure is characterized of balanced gas distribution in each cylinder and stable running.

Owner:吕国怀 +2

Environmental-friendly chimney device for removing stains of inner wall in manner of heating and circulating water vapor by waste gas afterheat

InactiveCN109595577AReduce wasteIncrease temperatureElectrostatic separationDispersed particle separationActivated carbonWater vapor

The invention discloses an environmental-friendly chimney device for removing stains of an inner wall in a manner of heating and circulating water vapor by waste gas afterheat. The environmental-friendly chimney device structurally comprises a joint pipe, a movable base, a water inlet pipe, a device shell and a movable smoke discharging device, wherein the movable smoke discharging device is positioned in the device shell and is also fixedly connected with the device shell, and water flow formed on a heating rack is heated through afterheat of waste gas, and thus, the produced water vapor is adsorbed on an electrified rack along with the dust, the dust is carried and discharged after condensation is carried out, dust stacked in the device can be prevented, and air flow is separated by using an adsorption rack, and therefore, the inner airflow can be adsorbed by activated carbon preferably, and cleaner gas can be exhausted; through combination of a plurality of equal-size adsorption layers, inner airflow is subjected to subdivision directional output through small hole tubes, and adsorption treatment on a small part of airflow is carried out by using a single adsorption layer; and moreover, the inner activated carbon can be conveniently taken out and replaced in a pushing-embedding mounting way, and the waste of the activated carbon can be reduced.

Owner:黄佩媛

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com