Flooded copper-evaporating heat-exchanging pipe for electric refrigerator set

A heat exchange tube and flooded technology, which is applied in the field of flooded copper evaporation heat exchange tubes, can solve problems such as unfavorable condensation performance and space reservation, and achieve easy nucleation and vaporization, improved heat dissipation efficiency, and accelerated vaporization process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

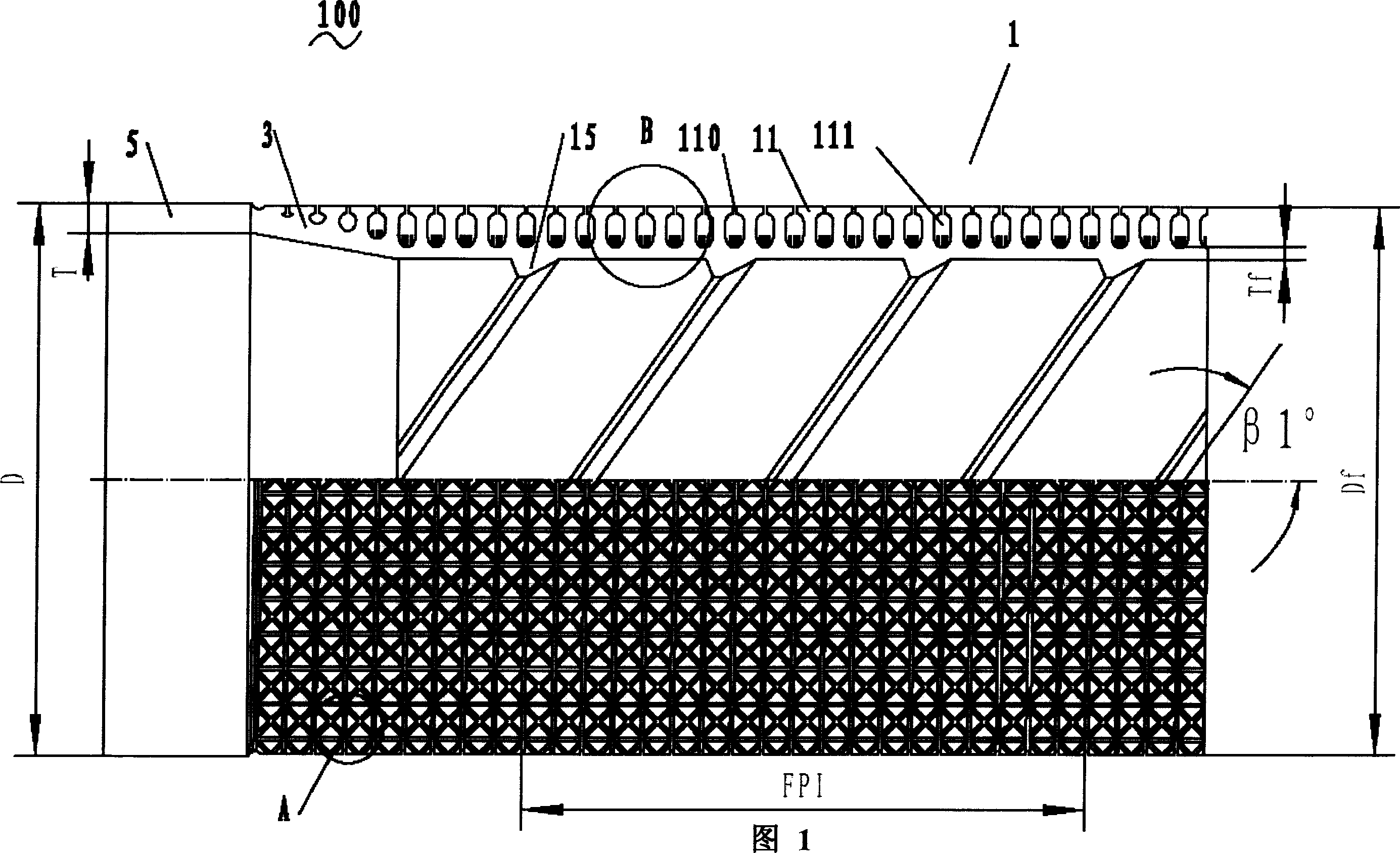

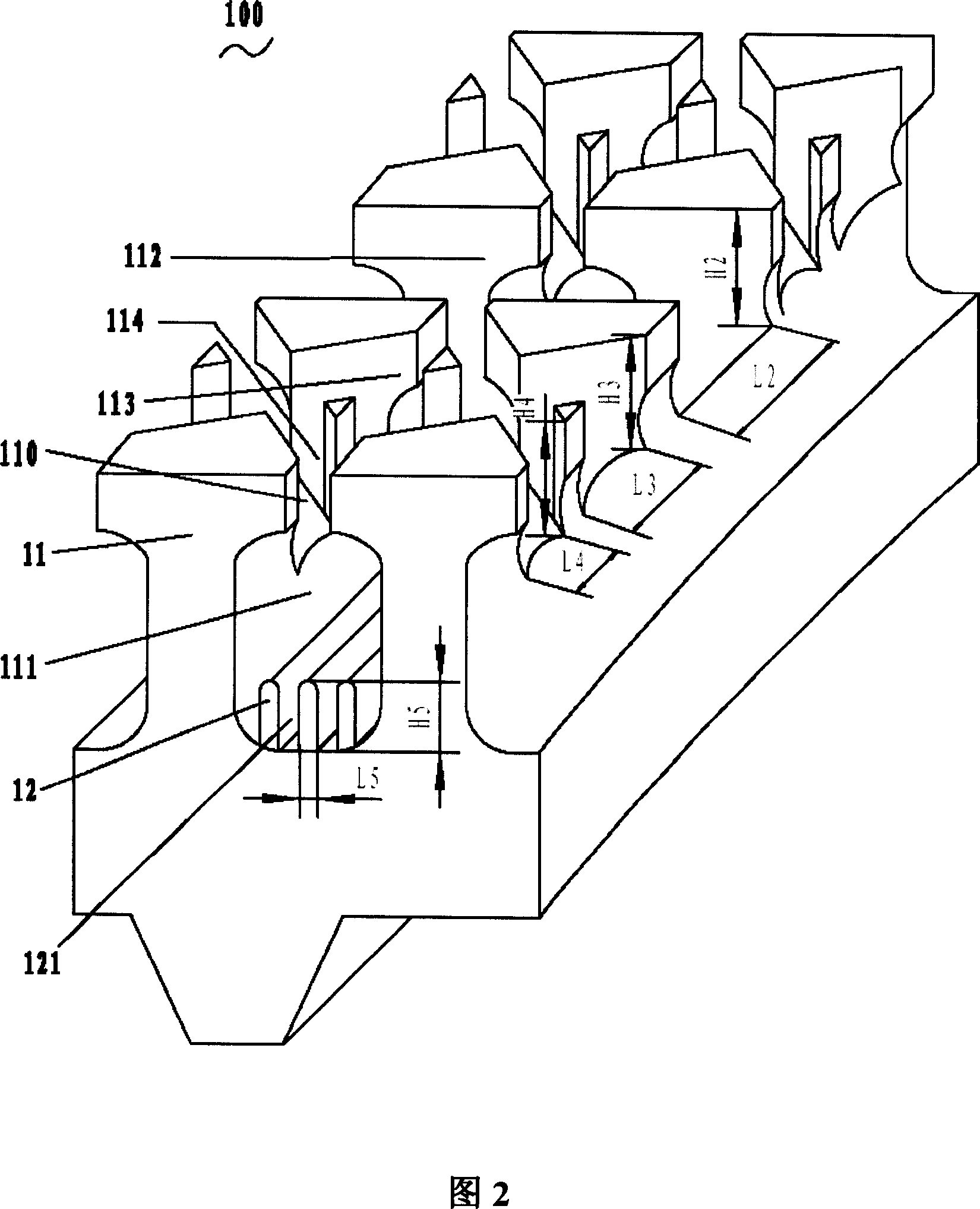

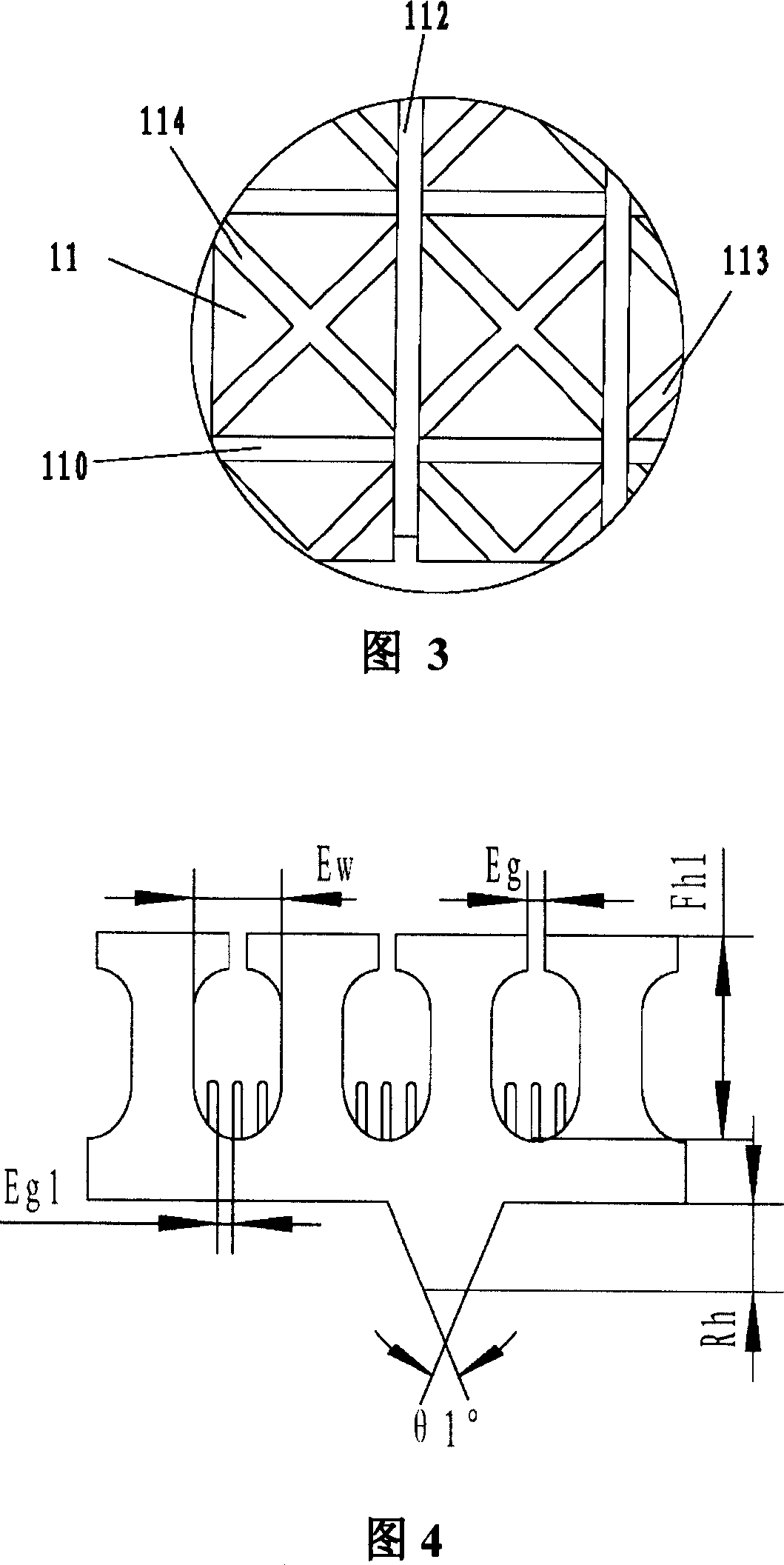

[0032] Please refer to FIG. 1, the evaporative heat exchange tube 100 of the present invention includes a fin part 1, a polished rod part 5 (only one end is shown in the figure) located at both ends of the evaporative heat transfer tube 100, and a polished rod part 5 and a finned part 1. The transition portion 3 between them is the internal teeth 15 provided on the inner surface of the evaporating heat exchange tube 100 . The diameter D of the polished rod portion 5 ranges from 12-26 mm, and the wall thickness T ranges from 0.5-0.9 mm. Preferably, the evaporation heat exchange tube 100 of the present invention is made of copper material. The present invention manufactures a flooded evaporative heat exchange tube 100 with a diameter D in the range of 12-26 mm through research on the heat exchange mechanism, forming tooling and forming proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com