Patents

Literature

122results about How to "Add spoilers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

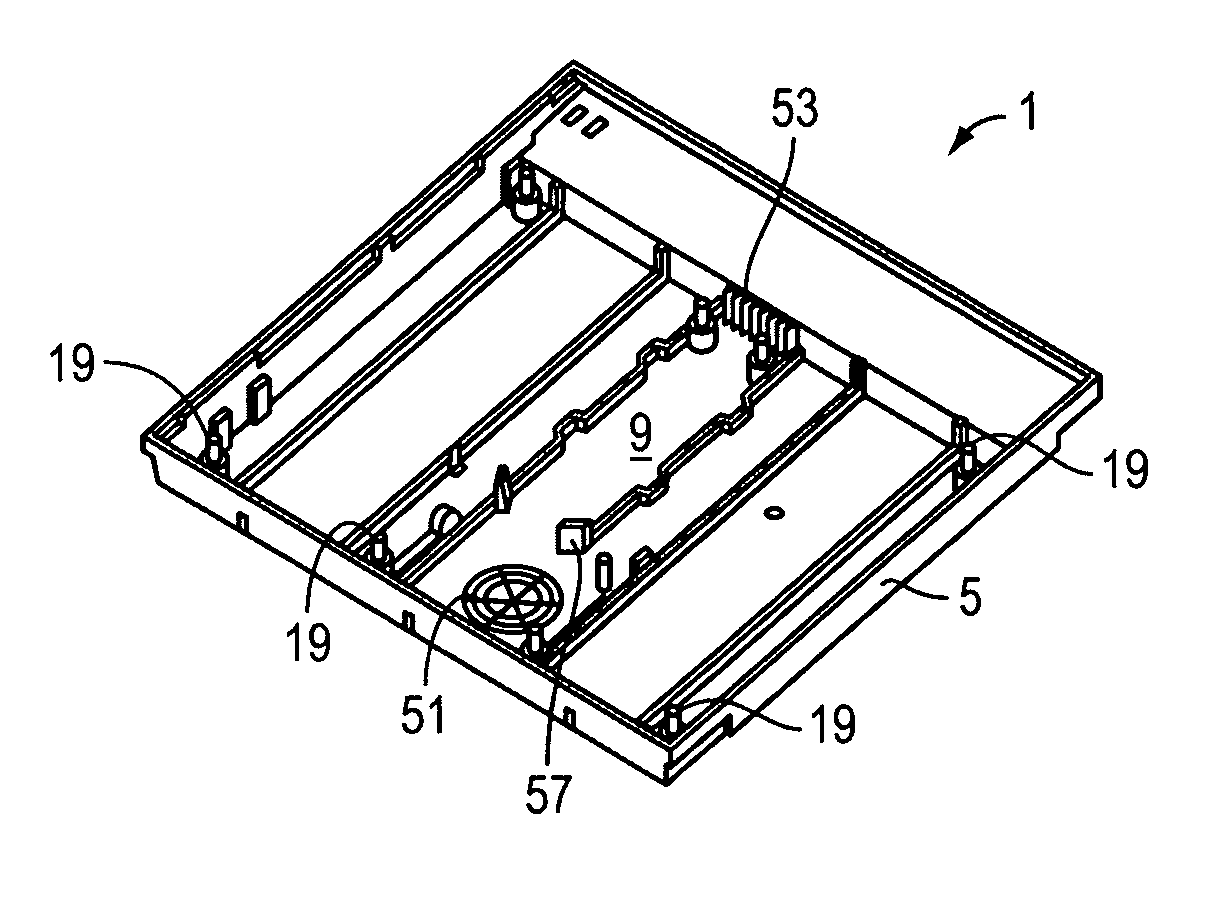

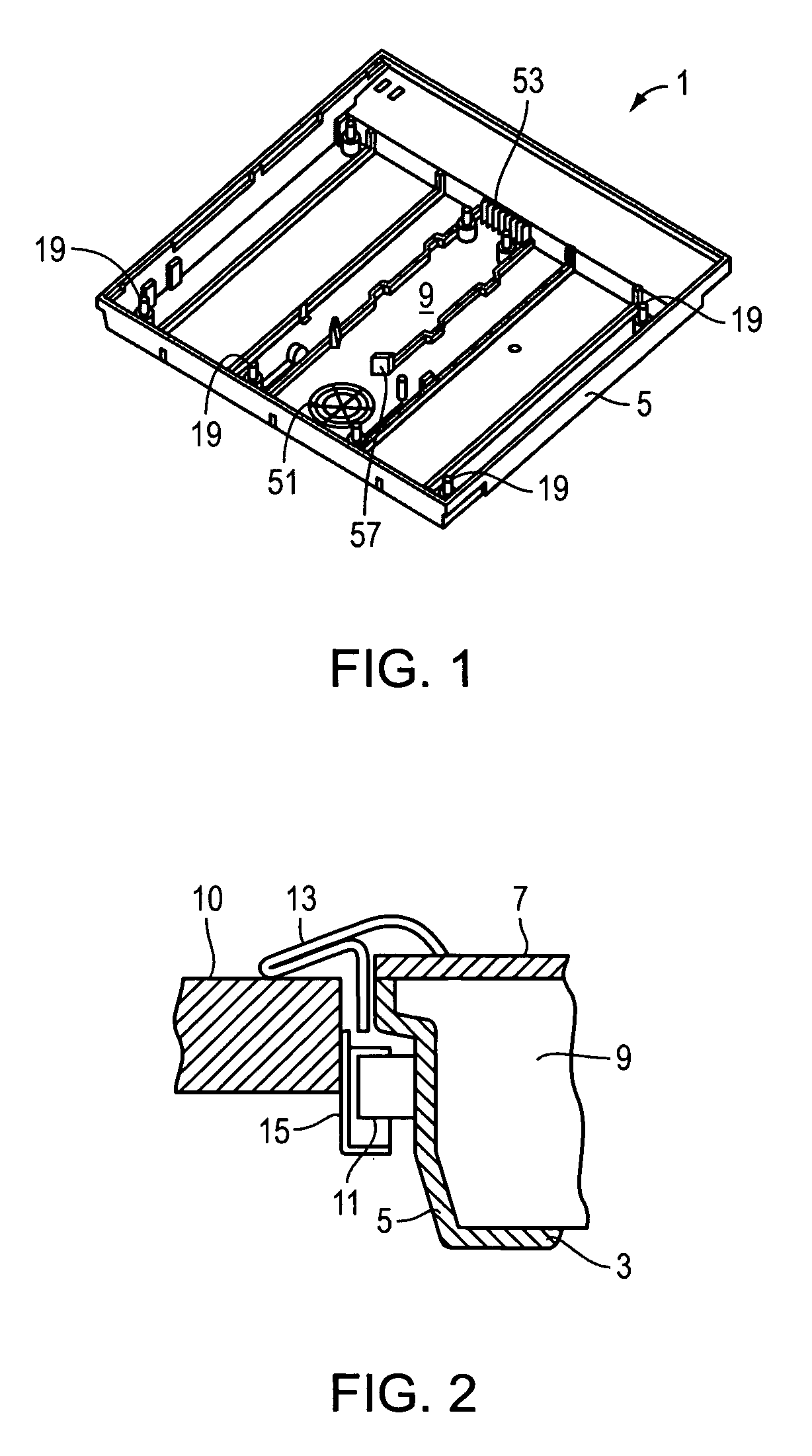

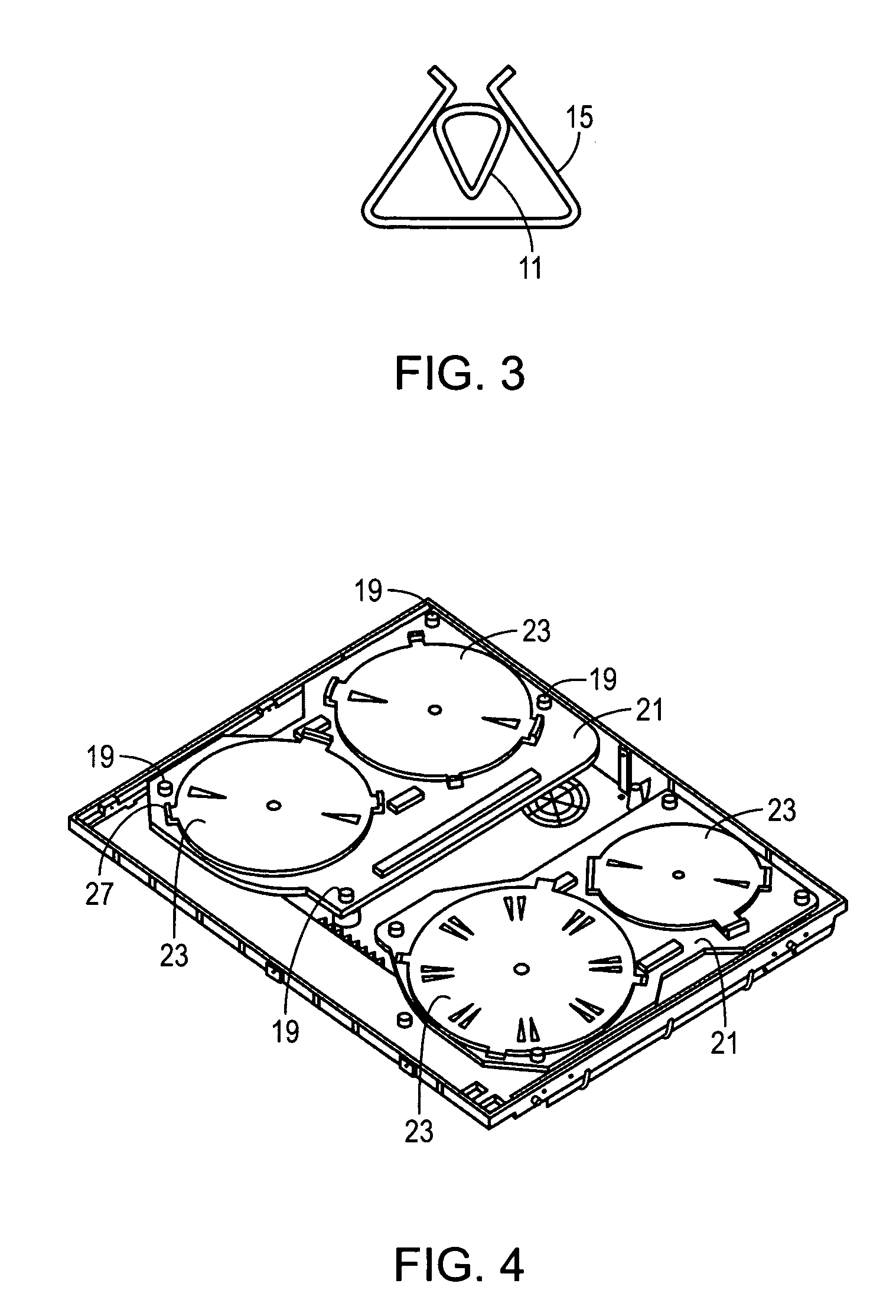

Induction hob with monobloc housing components

InactiveUS7274008B2Easy to assembleFunction increaseFurnaces without endless coreMilk preservationMechanical engineeringClassical mechanics

Owner:BOSCH SIEMENS HAUSGERATE GMBH

Gas turbine engine blade with inner meshed structure

InactiveCN103470312AImprove cooling effectIncrease contact areaBlade accessoriesMachines/enginesManufacturing technologyMachining process

The invention discloses a gas turbine engine blade with an inner meshed structure. The blade is formed by SLM or EBM material increase manufacturing technology, and the inside of the blade is provided with a meshed structure. The meshed structure is composed of sub structures arraying in a three-dimensional periodic manner, and communicated channels are formed inside the communicated meshed structure to form multiple channel structures. All or parts of the meshed structures are filled into gaps among partitioning plates of the blade. By the aid of the inner meshed structure of the blade, heat exchange effect of cooling flow can be strengthened. A blade body, tenons, inner channels and the meshed structure are formed by the material increase manufacturing technology, machining process is simple, defects that finished product rate is low by traditional casting and machining and complex inner structure cannot be manufactured are overcome, and designing and machining cost can be reduced greatly.

Owner:BEIHANG UNIV

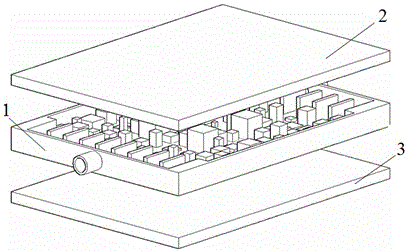

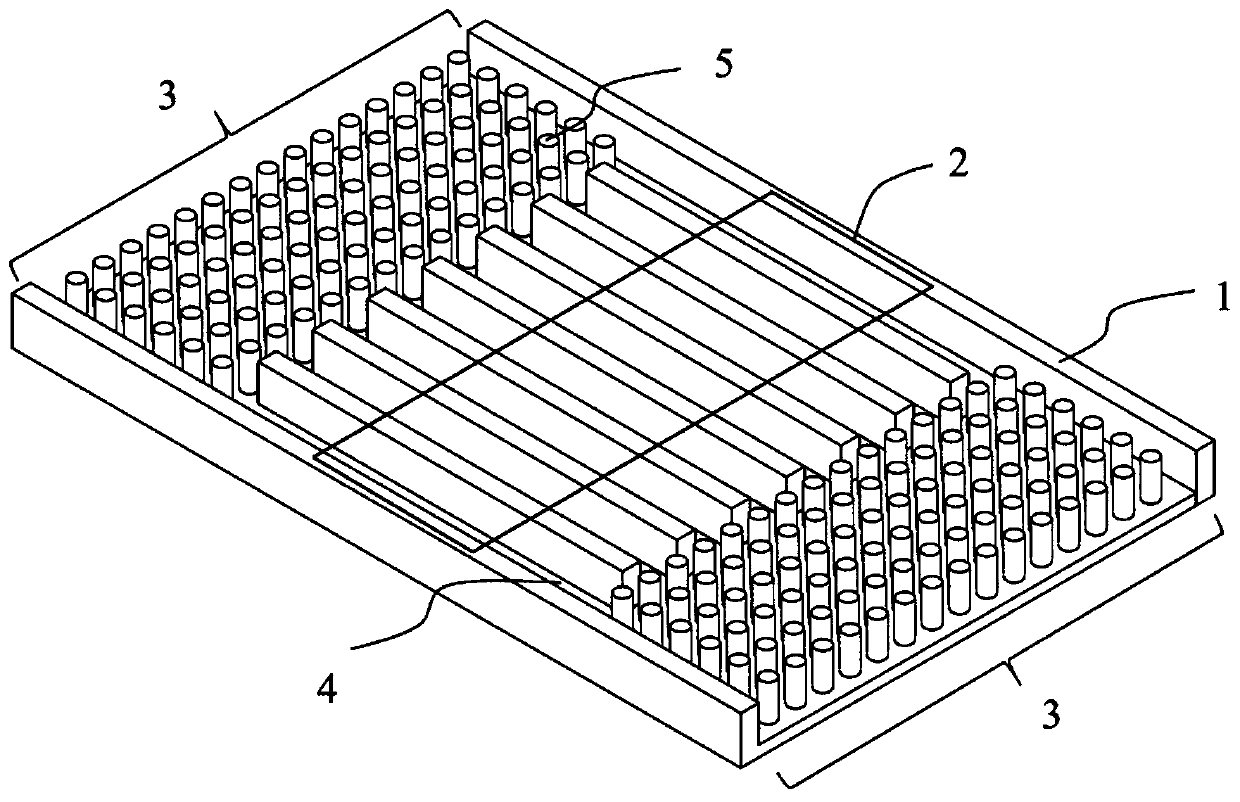

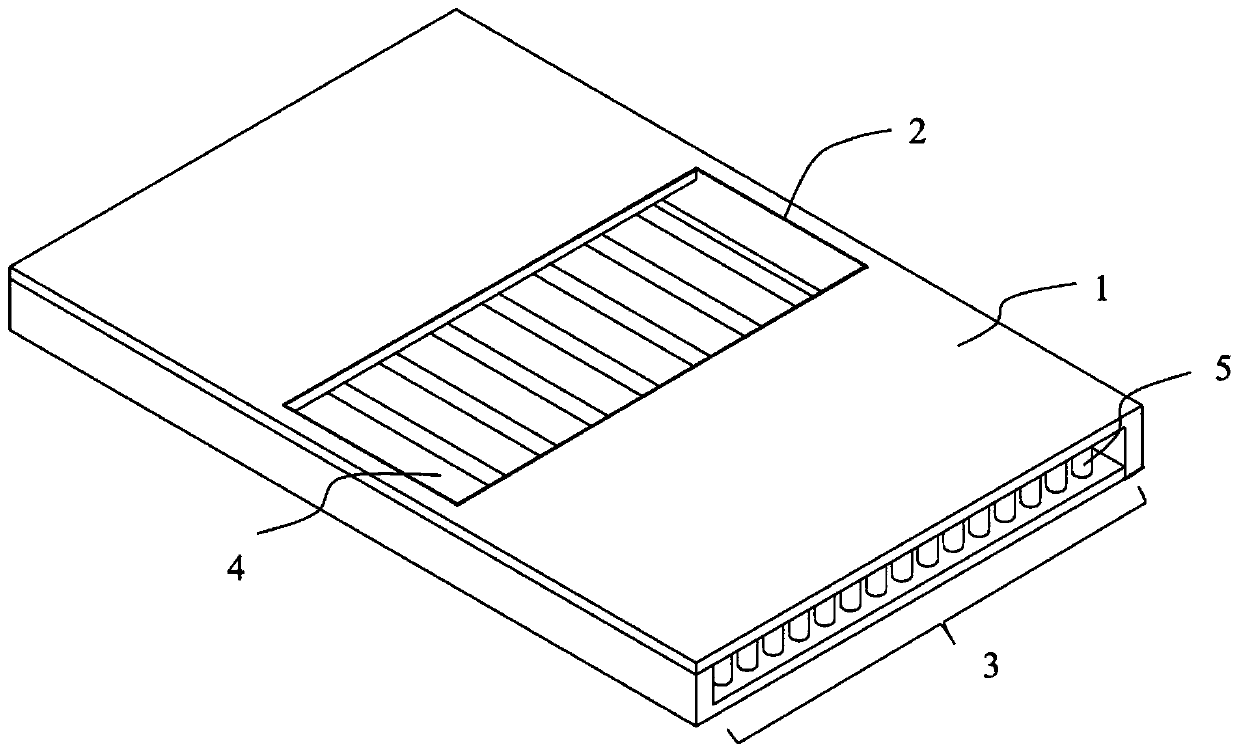

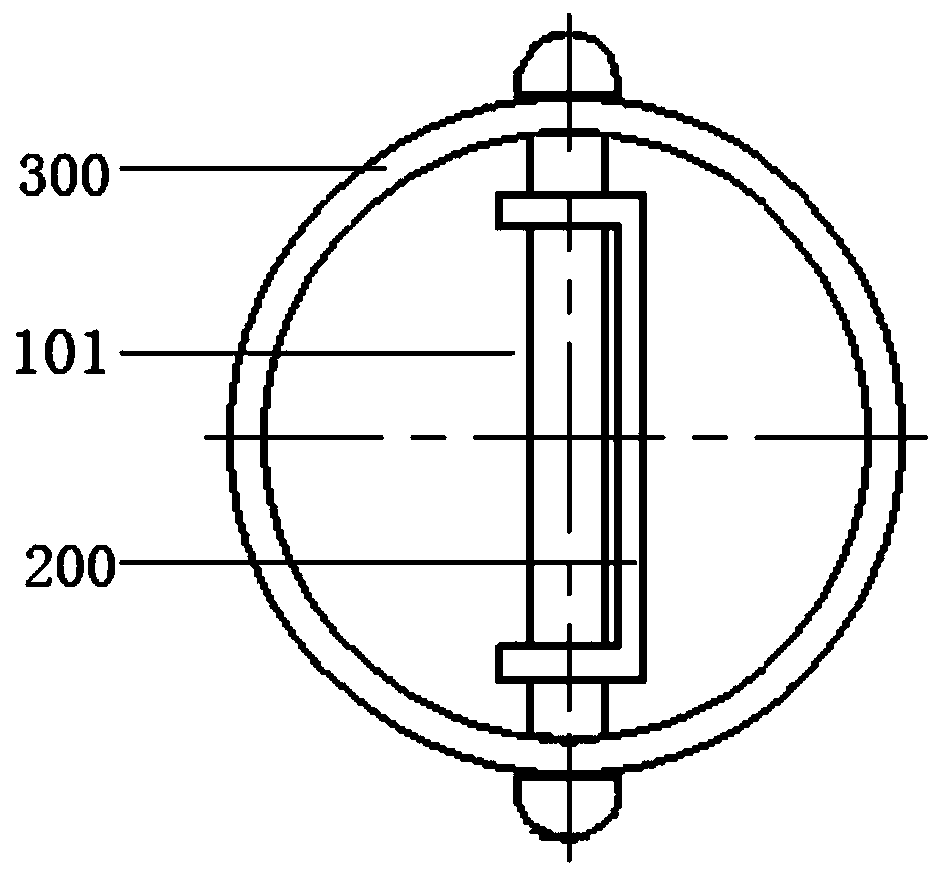

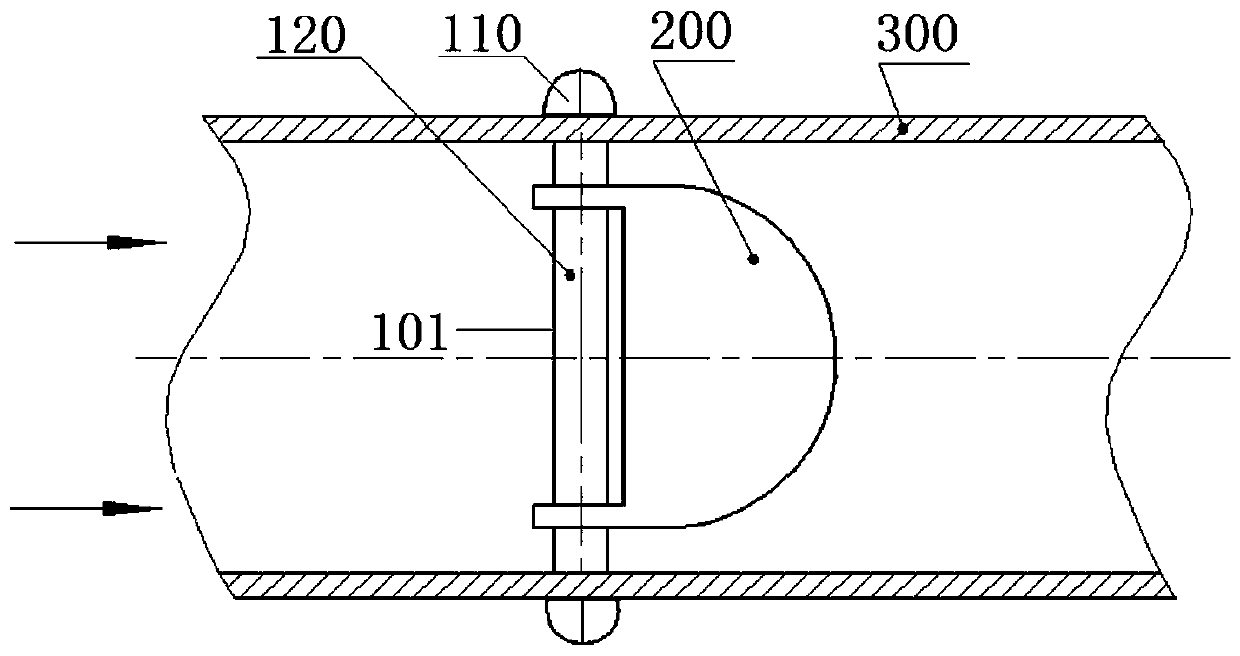

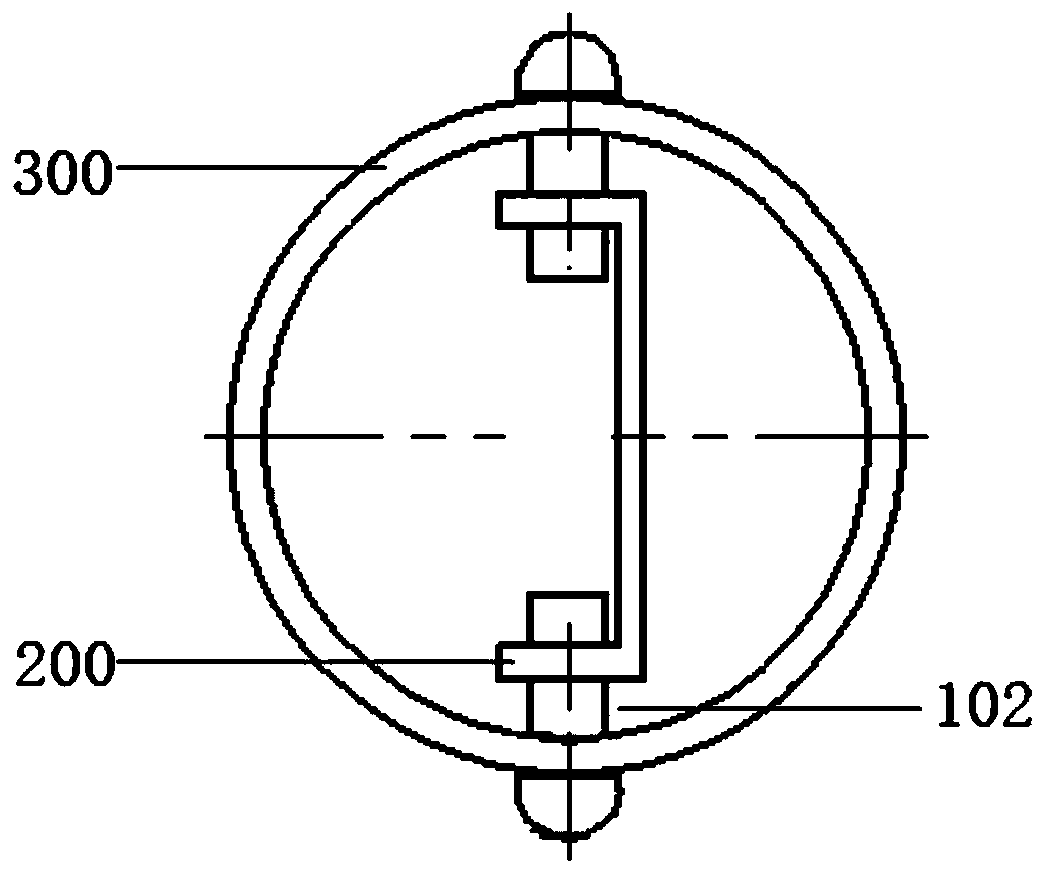

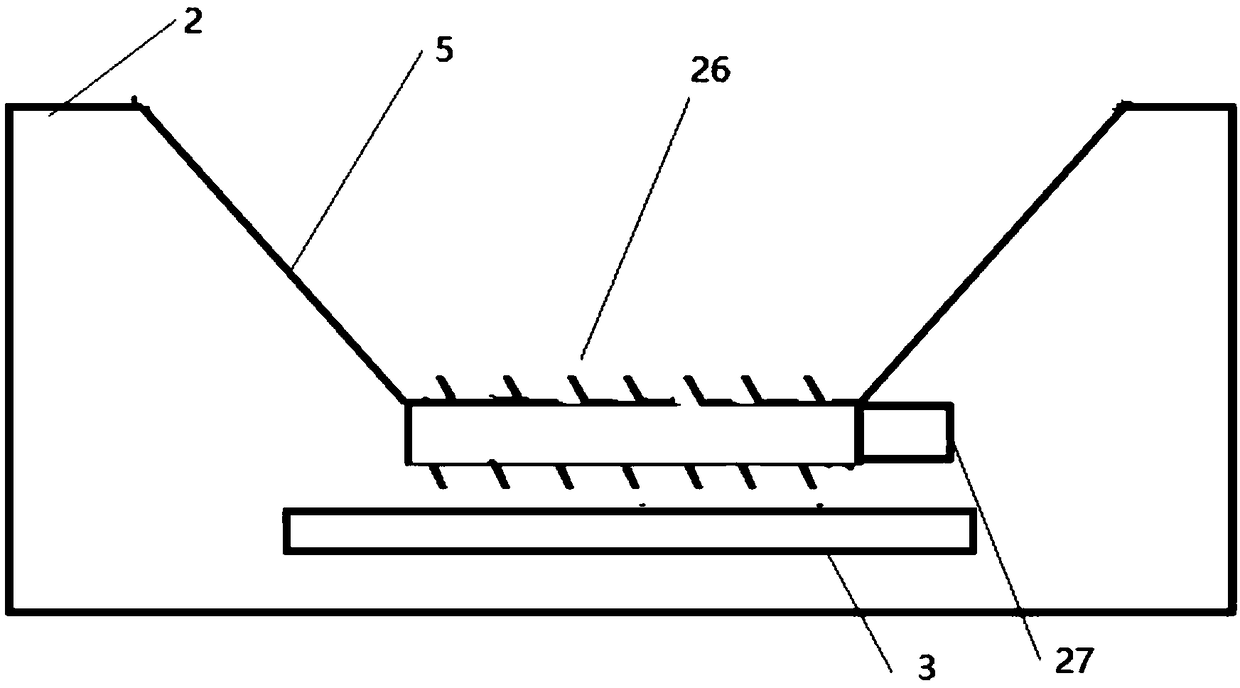

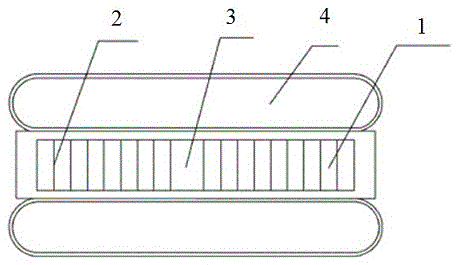

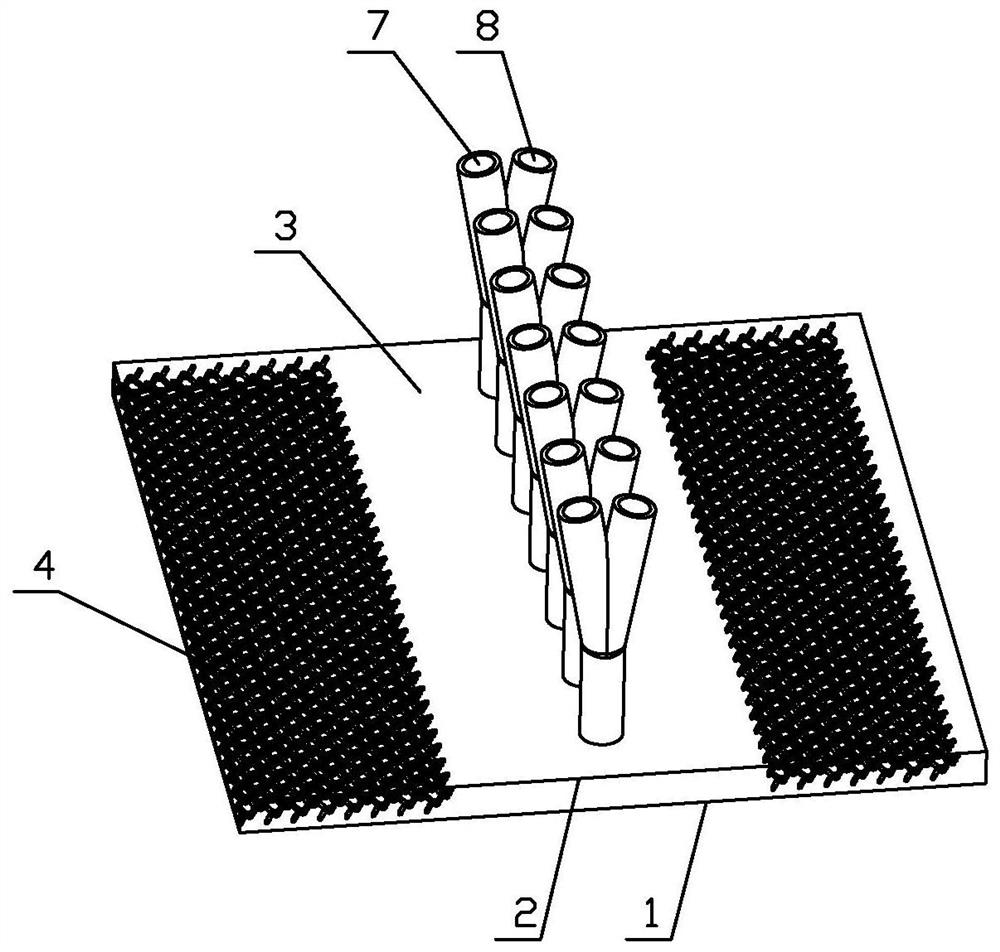

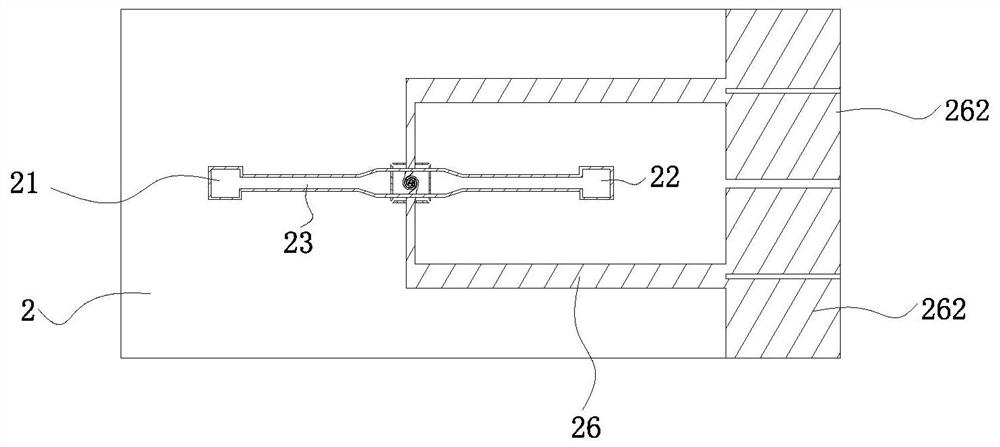

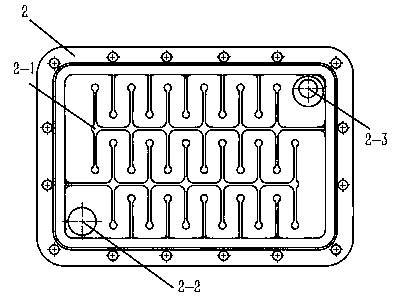

Flowing boiling micro-miniature heat exchanger

ActiveCN106061199AUniform temperatureExtend your lifeCooling/ventilation/heating modificationsEngineeringHeat transfer efficiency

The invention discloses a flowing boiling micro-miniature heat exchanger, which comprises a heat exchanger casing, a heat exchange structure passage, an inlet passage and an outlet passage, wherein the heat exchange structure passage is arranged in the heat exchanger casing; and the inlet passage and the outlet passage are arranged at the two ends of the heat exchange structure passage. The flowing boiling micro-miniature heat exchanger is characterized in that the inlet passage consists of a condensing medium input opening, a flow storage pool and an inlet flow division passage; the flow storage pool is connected between the condensing medium input opening and the inlet flow division passage; the outlet passage consists of a condensing medium output opening and an outlet flow division passage; a micro rib column group and support columns are arranged in the heat exchange structure passage; the micro rib column group consists of micro rib columns; the cross section dimension of the micro rib columns conforms to the fractal Brownian motion features; the micro rib columns are in planar distribution; the height of the micro rib columns meets the normal distribution; and the support columns are distributed in the center of the micro rib column group in an array mode. The flowing boiling micro-miniature heat exchanger has the advantages that the heat transfer efficiency is high; the flowing resistance loss is small; the surface temperature of the heat exchanger is uniform; the work is stable; and the service life is long.

Owner:SOUTHEAST UNIV

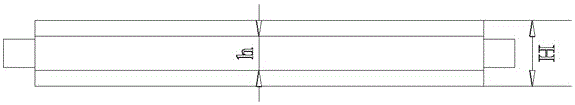

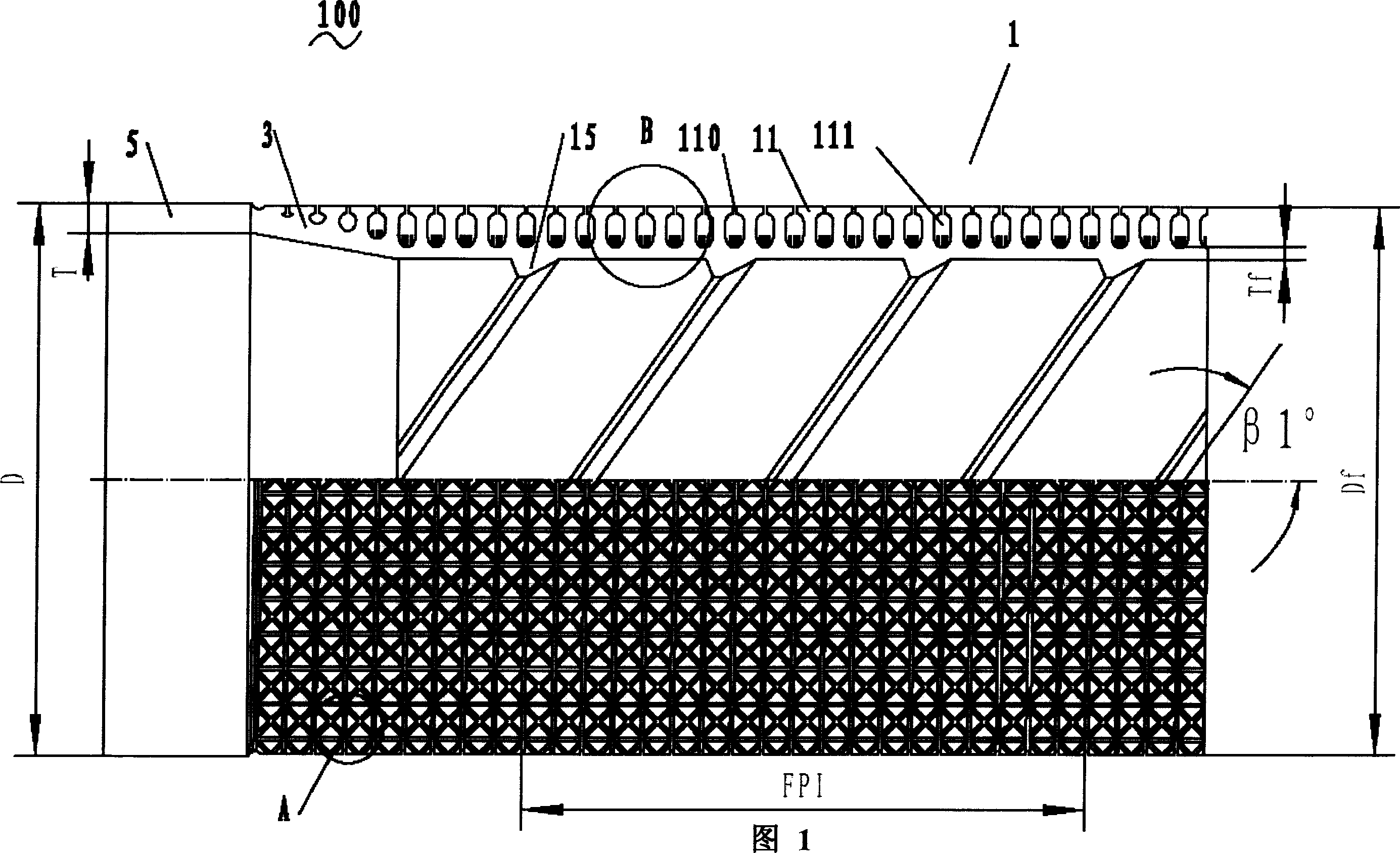

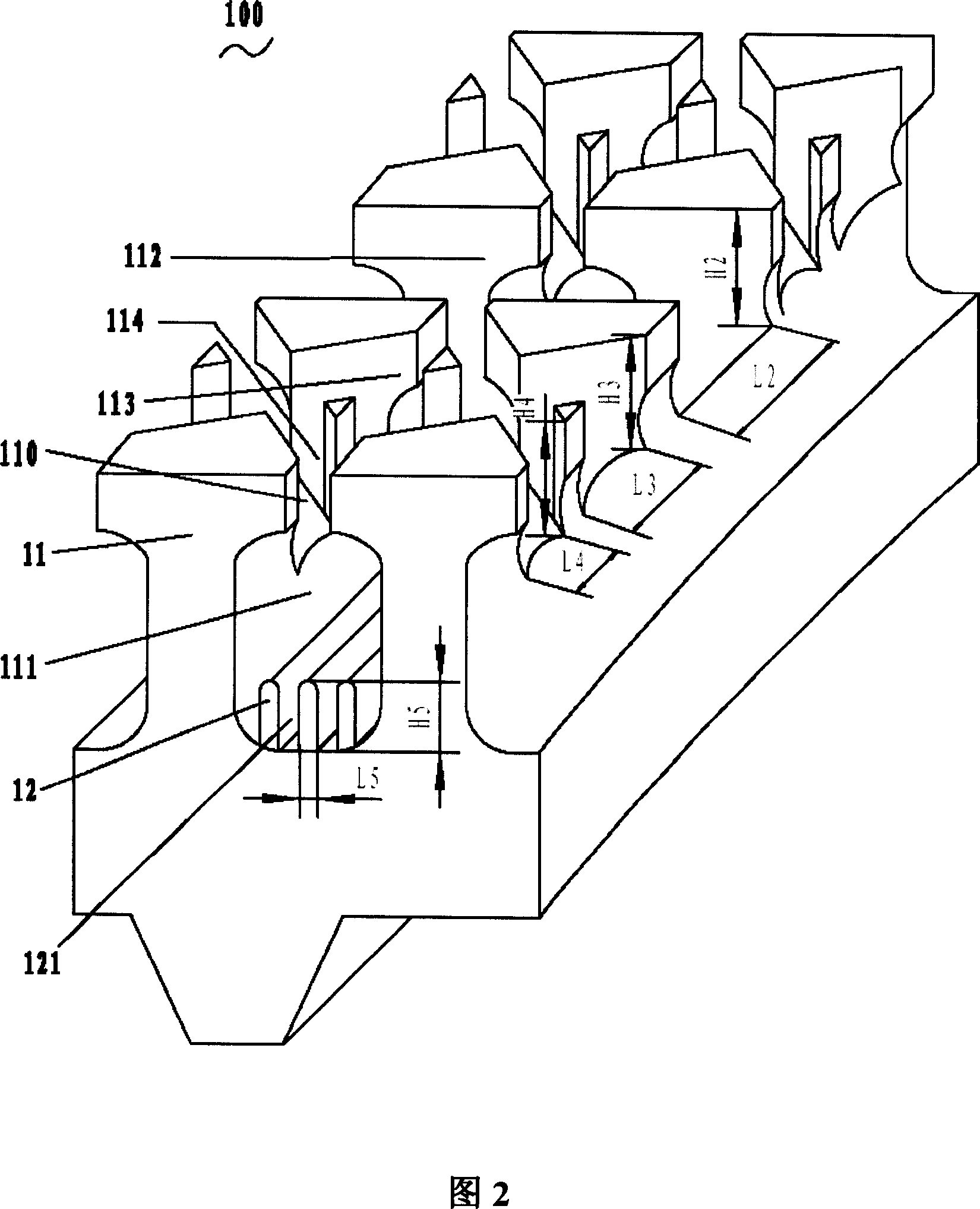

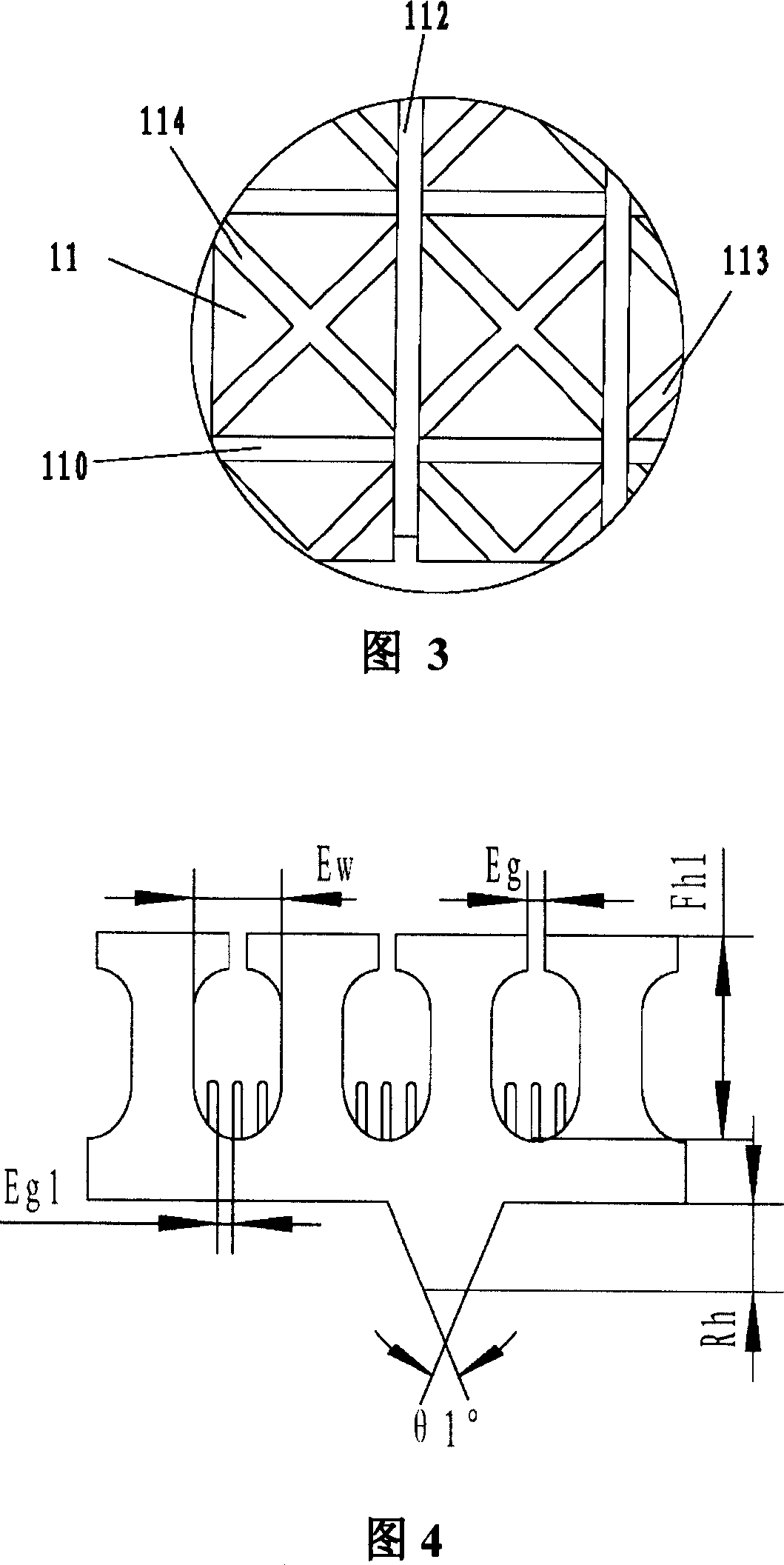

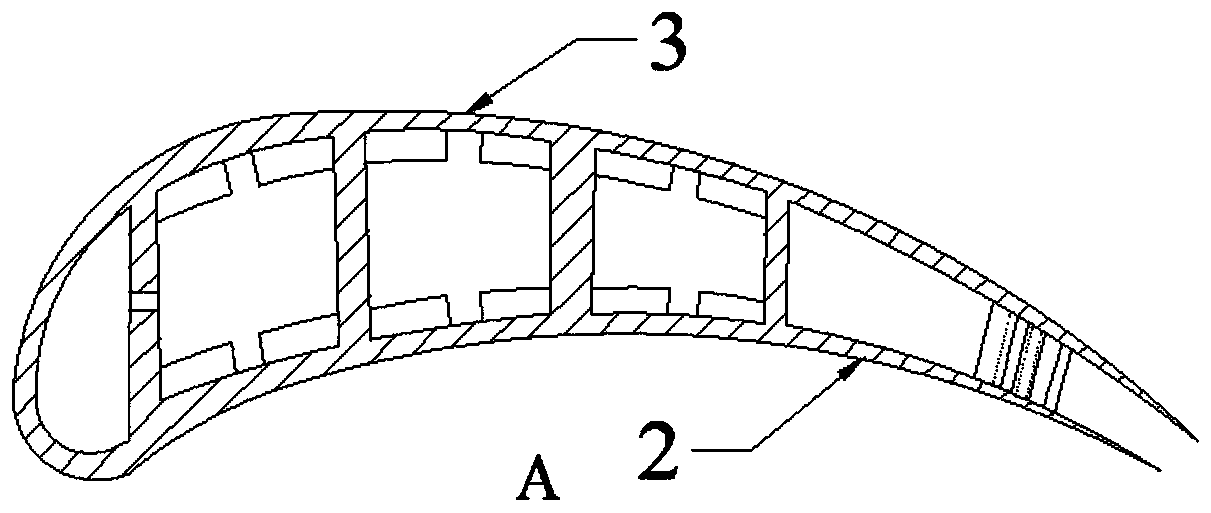

Flooded copper-evaporating heat-exchanging pipe for electric refrigerator set

ActiveCN1982827AEase of nucleation and vaporizationImprove heat transfer efficiencyHeat transfer modificationTubular elementsElectricityEvaporation

A flooded copper evaporation heat-exchange tube for electric refrigerating units comprises a polish rod pant, a fins part and a transition part for connecting the polish rod with the fins part. Between the fins is formed a single vaporization chamber and in the position extending upward from the bottom of the single vaporization chamber are disposed fins, which divide the single vaporization chamber into at least two small cavities. Between the fins of the single vaporization chamber there is an evaporation fin mouth. Because of setting several small cavities, on the base walls of the small cavities is formed the refrigerant film easily and then evaporated, and the formed bubbles escape from the evaporation fin mouth.

Owner:GOLDEN DRAGON PRECISE COPPER TUBE GROUP

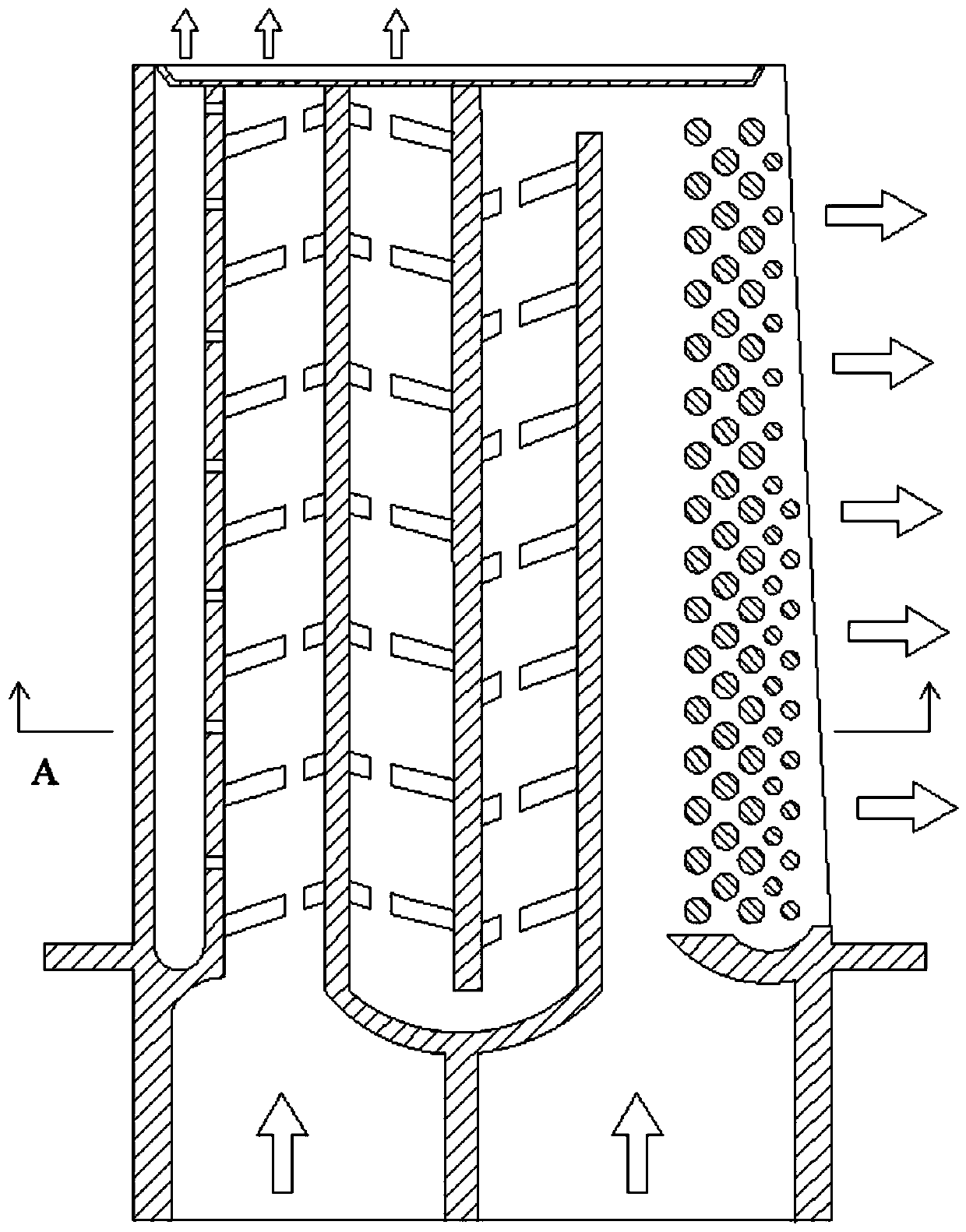

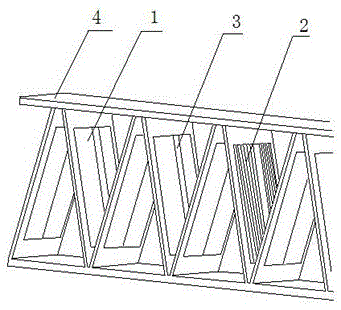

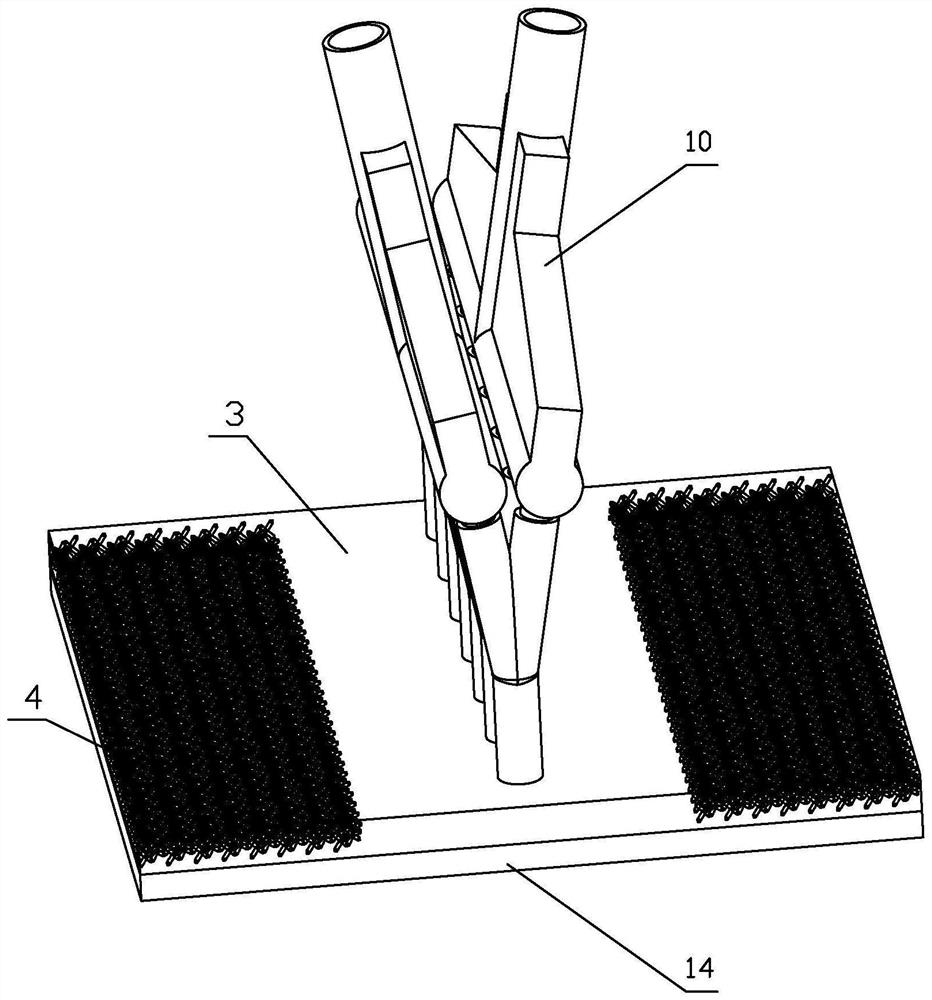

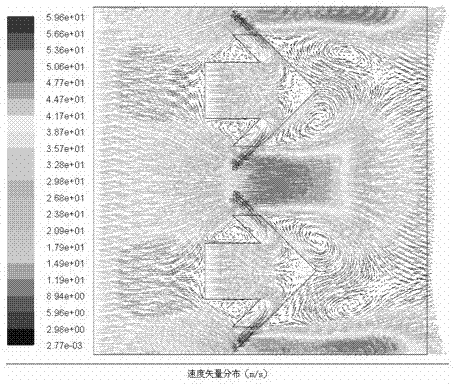

Intermittent rib inner cooling structure used for gas turbine blade

InactiveCN110043327AAdd spoilersIncreased turbulenceEngine fuctionsBlade accessoriesLeading edgeEngineering

The invention aims at providing an intermittent rib inner cooling structure used for a gas turbine blade. The structure comprises an upper wall and a lower wall. A blade main body structure is definedby the upper wall and the lower wall. A left side wall and a right side wall are arranged in the blade main body structure. The left side wall is located on one side of the front edge of the blade main body structure. The left side wall and the blade main body structure form a blade front edge impact cooling channel. The right side wall is located in the middle of the blade main body structure. Left side wall air holes are formed in the left side wall. A U-shaped fork wall is arranged in the blade main body structure. The lower end portion of the U-shaped fork wall partitions the blade root into a left air inlet portion and a right air inlet portion. The right side wall is located in the middle of the U-shaped fork wall. Air outlets are formed in the tail edge portion of the blade main body structure. Intermittent ribs are arranged on the inner side of the upper wall and the inner side of the lower wall correspondingly. Fractures of the ribs have strong turbulence on airflow, the extent of separating produced by flowing of gas is increased, accordingly, the boundary layer damage extent is increased, the fluid turbulence degree is greatly increased, and heat exchanging is greatly improved.

Owner:HARBIN ENG UNIV

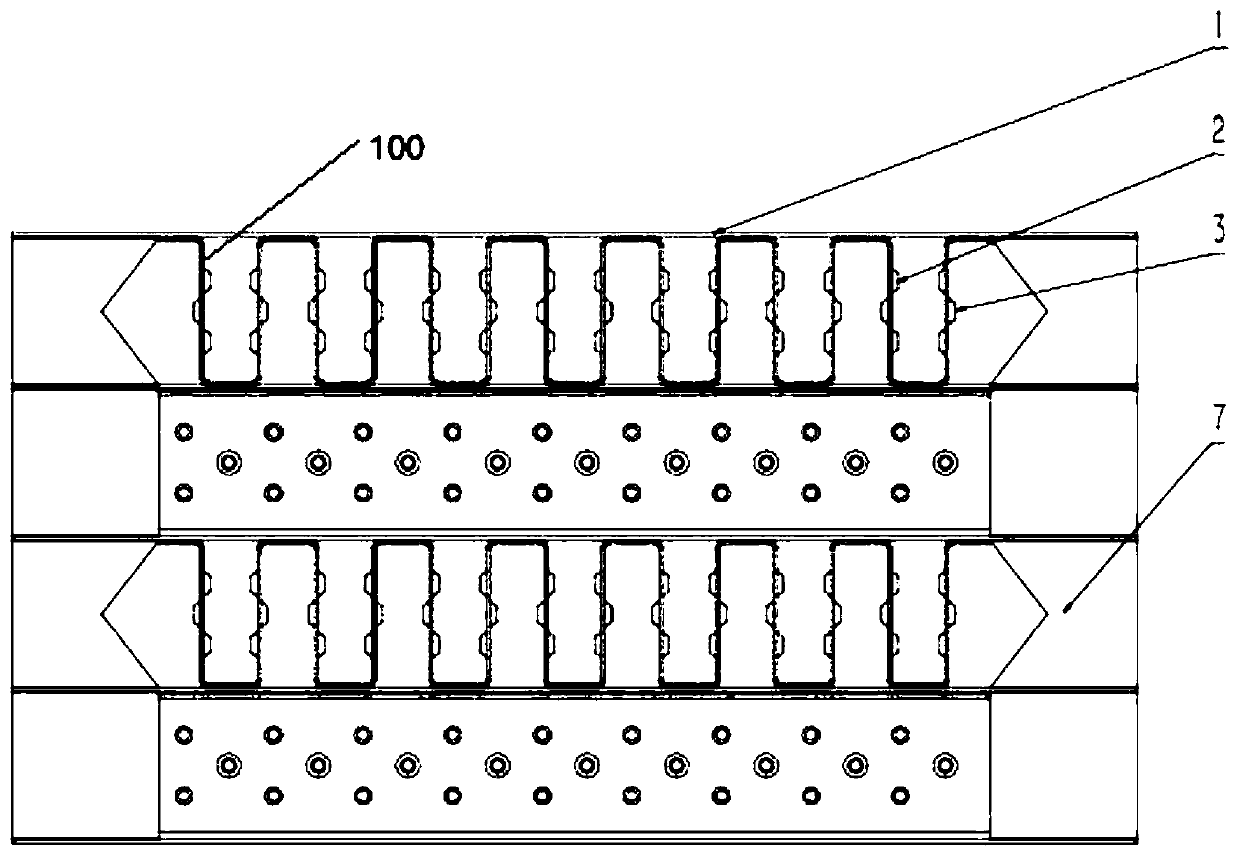

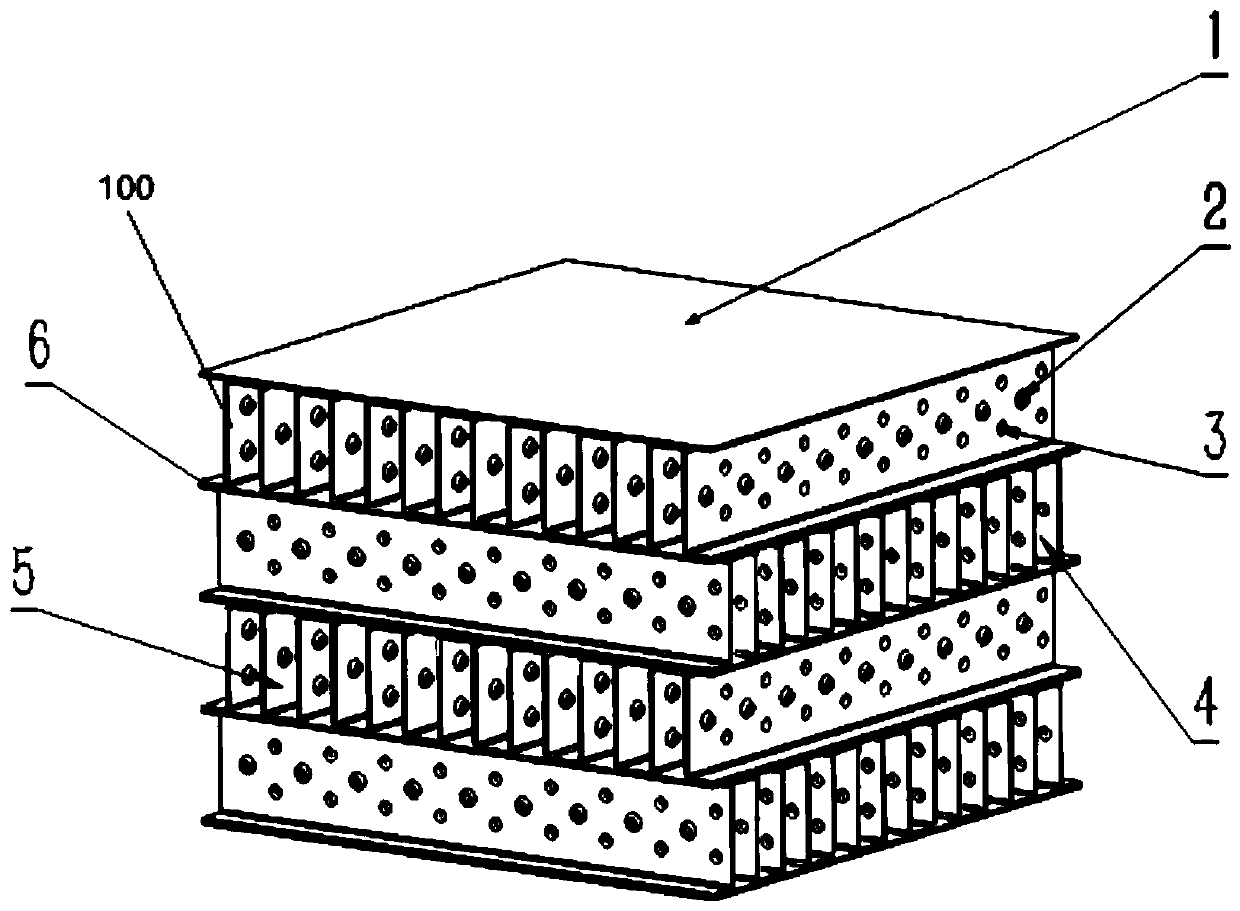

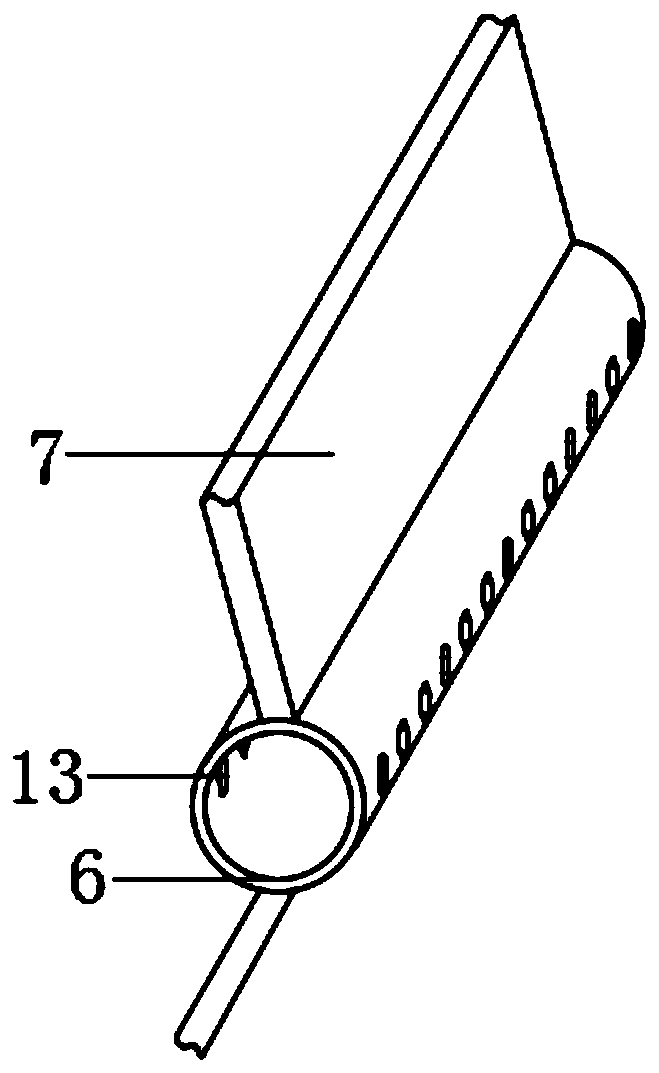

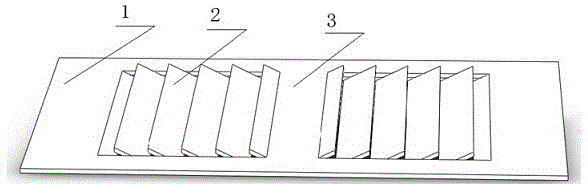

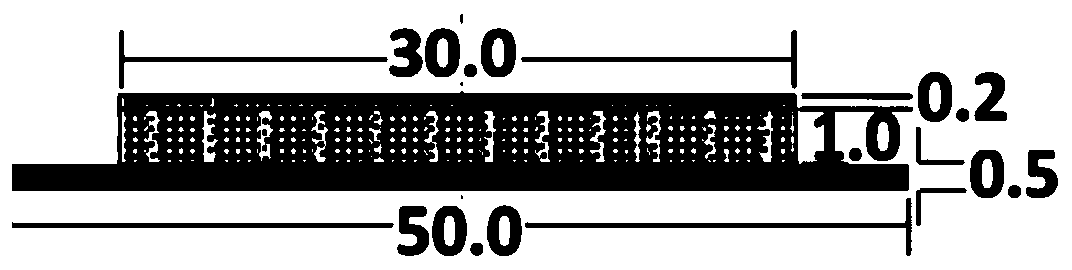

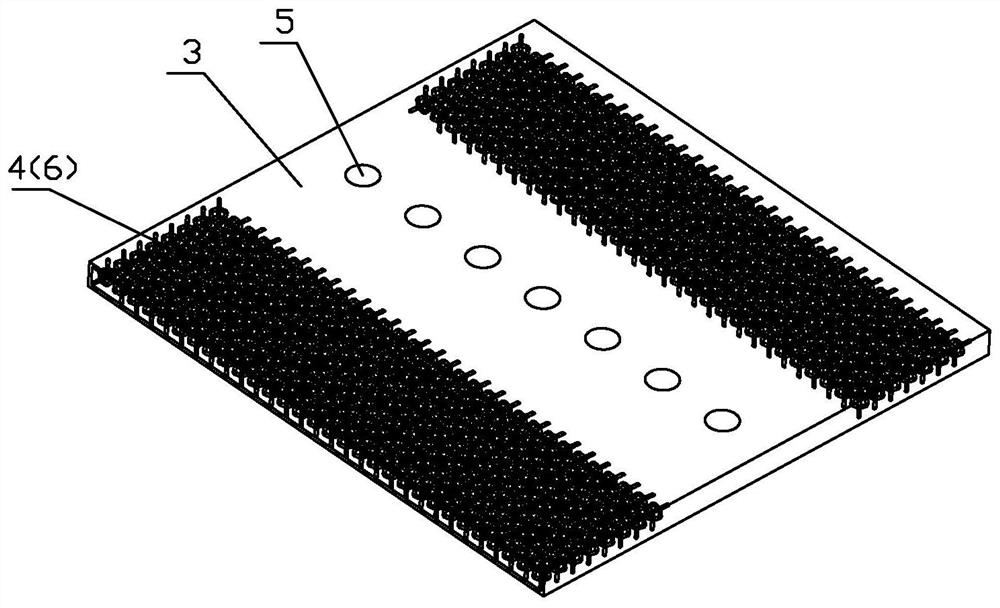

Plate-fin type heat exchanger core and fin structure thereof

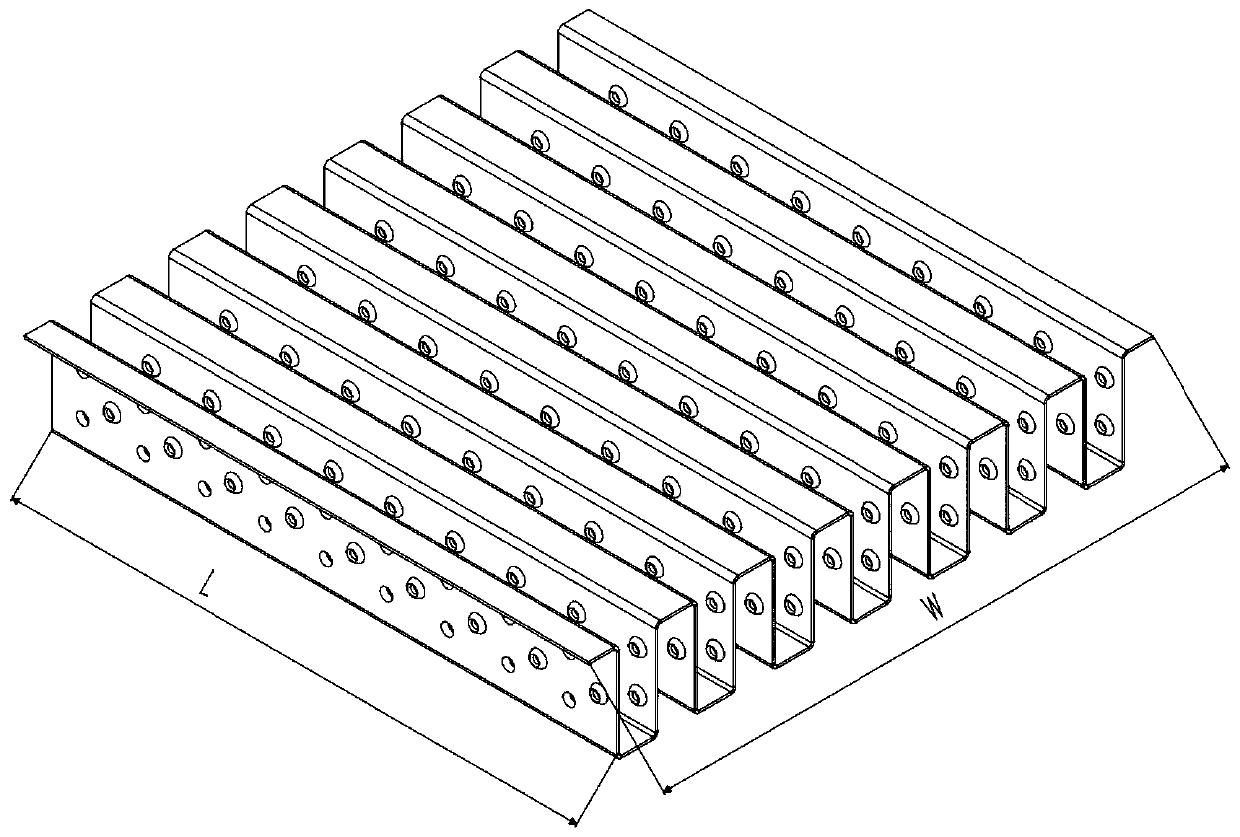

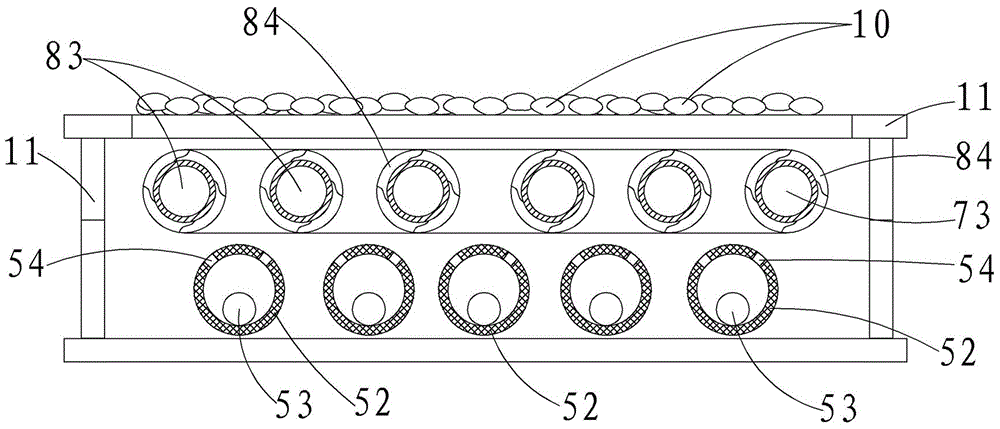

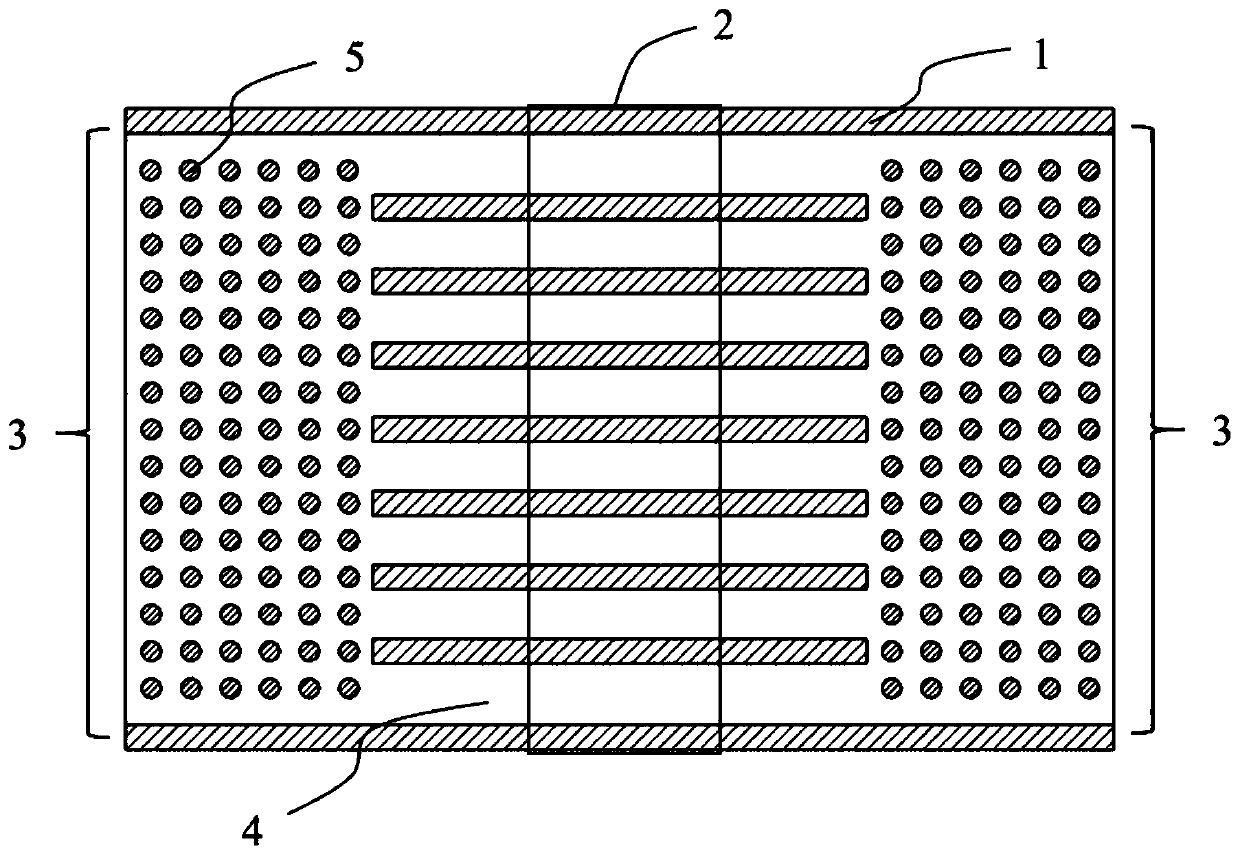

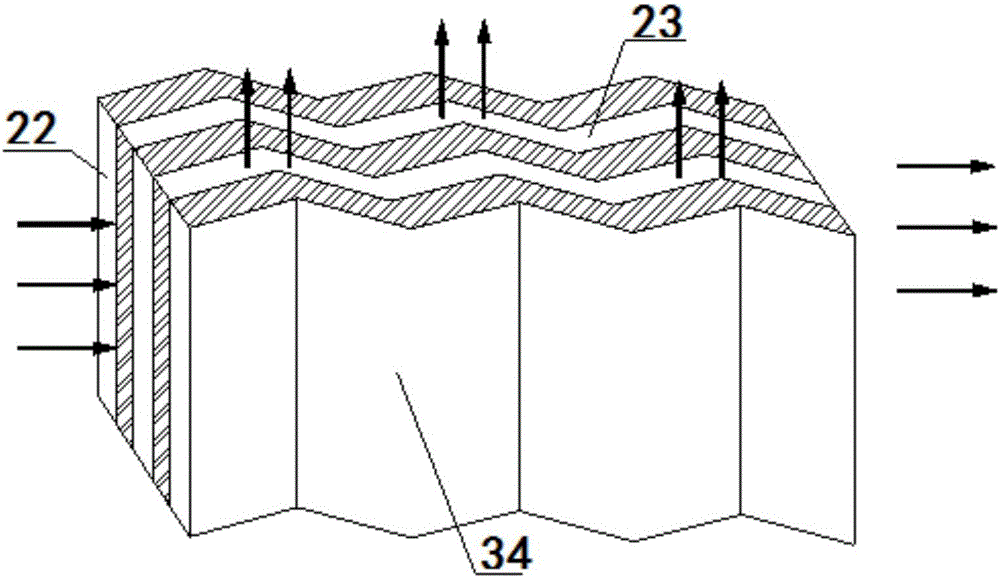

PendingCN109883238AIncrease the heat exchange areaIncreased turbulenceHeat exhanger finsLaminated elementsJet flowEngineering

The invention discloses a plate-fin type heat exchanger core and a fin structure thereof. The plate-fin type heat exchanger core comprises a plurality of partition plates and fins; each fin is supported and fixed between the two adjacent partition plates; the part between the adjacent partition plates is sealed to form a flow channel unit; the flow channel unit forms a plurality of medium flowingheat exchange channels between the adjacent partition plates; a plurality of ball convex parts / ball concave parts are arranged on the fins; and the ball convex parts / ball concave parts are provided with punched holes to form punched ball convex parts / punched ball concave parts. The core combines various advantages of the ball convex / ball concave structures and the punched structures; the fins increase the heat exchange area; the ball convex / ball concave structures improve the loading capacity of the plate-fin structure and enhance fluid turbulence, so that a flow boundary layer and a hot boundary layer are thinned; and the punched structure forms local jet flow, so that fluid mixing convection in the fin adjacent flow channels is promoted, the vortex dead zone of the ball convex / ball concave structure is reduced, and the effects of enhancing heat transfer and reducing flowing resistance are achieved.

Owner:XI AN JIAOTONG UNIV

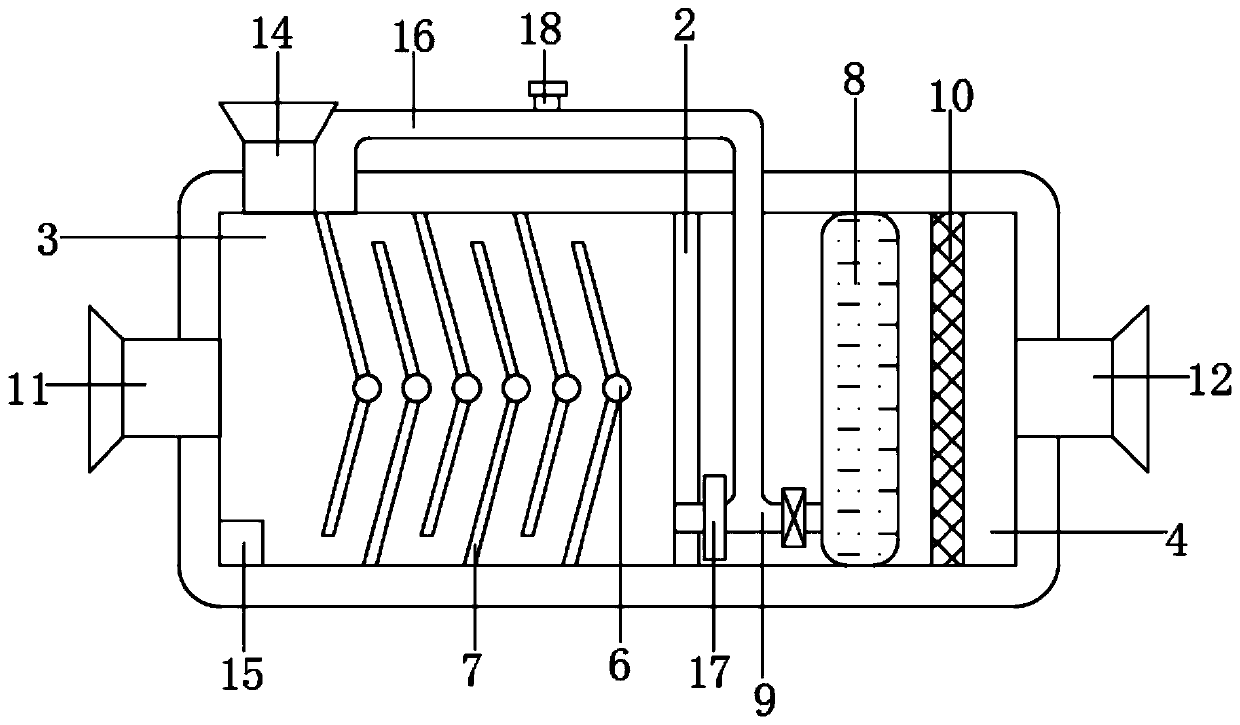

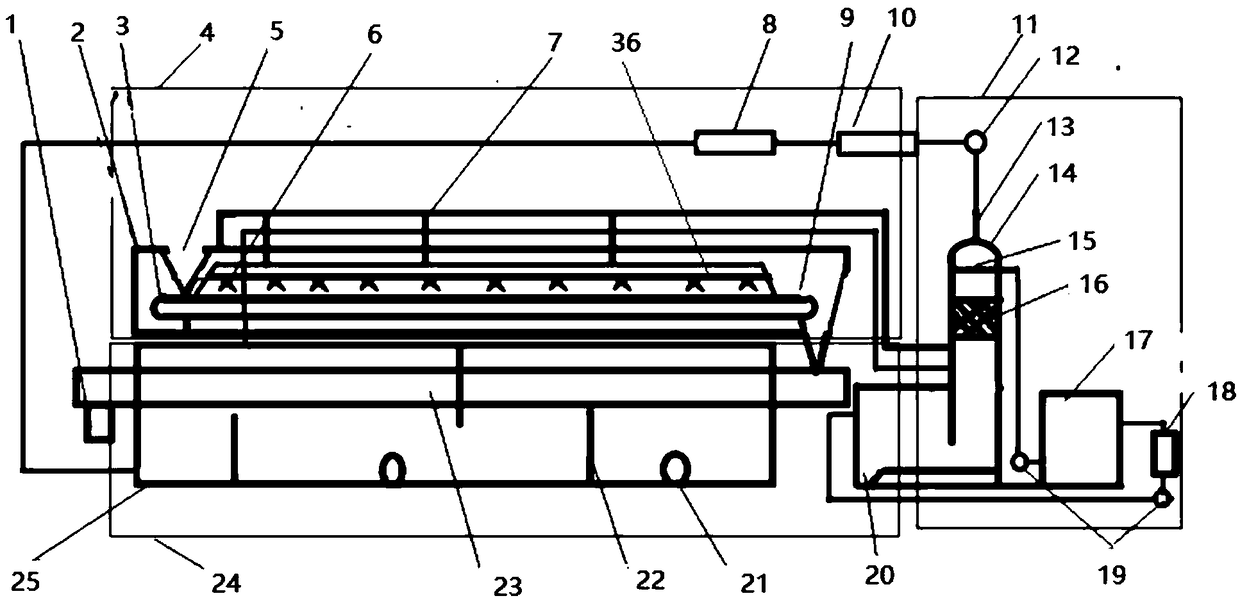

Rapid briquette coal drying system and briquette coal drying furnace

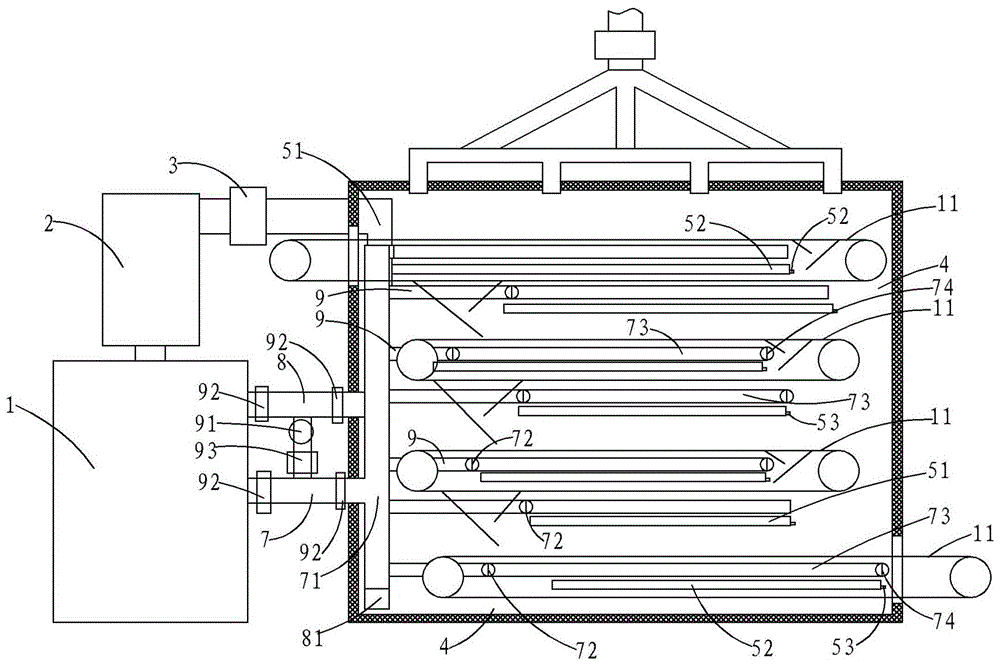

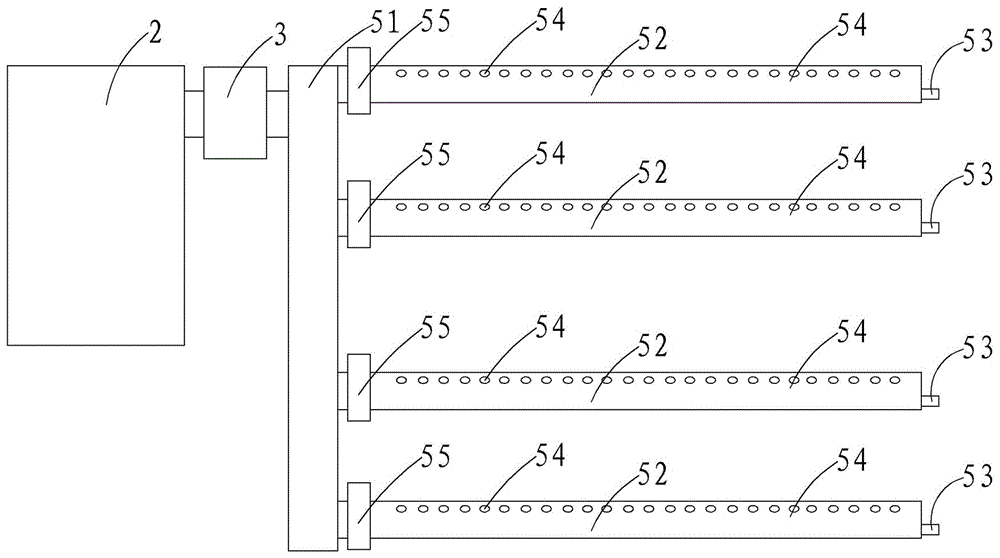

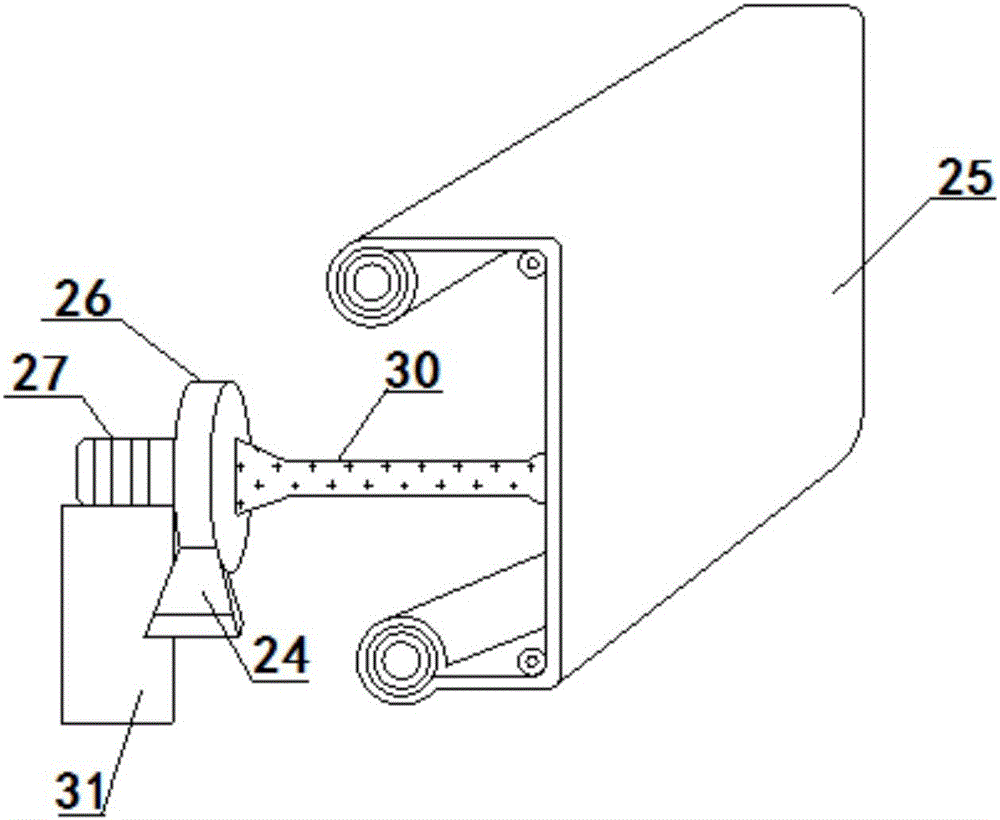

InactiveCN105758148AAdd liquid spoilerAvoid dirt depositsDrying gas arrangementsDrying machines with progressive movementsBriquetteAirflow

The invention relates to a rapid briquette coal drying system and a briquette coal drying furnace.The drying system and a hot oil system are included.The hot oil system comprises an oil inflow pipe, an oil return pipe and a heat dissipation system located in a drying cavity.The heat dissipation system comprises an oil distributing pipe communicated with the oil inflow pipe, and an oil collecting pipe communicated with the oil return pipe.The oil distributing pipe and the oil collecting pipe are communicated with multiple sets of heat dissipation coil pipes through oil guide pipes respectively.The heat dissipation coil pipes are arranged on the lower portions of briquette coal chain plate conveying device grid plates and located on the upper portions of branch air pipes.A hot air source directly conveys hot air to the bottom of briquette coal through an air distributing device via pipelines, dry air is fully utilized, it is guaranteed that the briquette coal directly makes contact with the dry hot air flow, briquettes enter the drying cavity to make contact with the dry high-temperature airflow all the time, the drying speed is increased, drying efficiency is improved, and the hot air from an air outlet of an induced draft fan is guided by the air distributing pipe, conveyed by the branch air pipes layer by layer and dispersed to the position below each briquette coal layer of the drying furnace.

Owner:石家庄市矿区丰旺机械有限公司

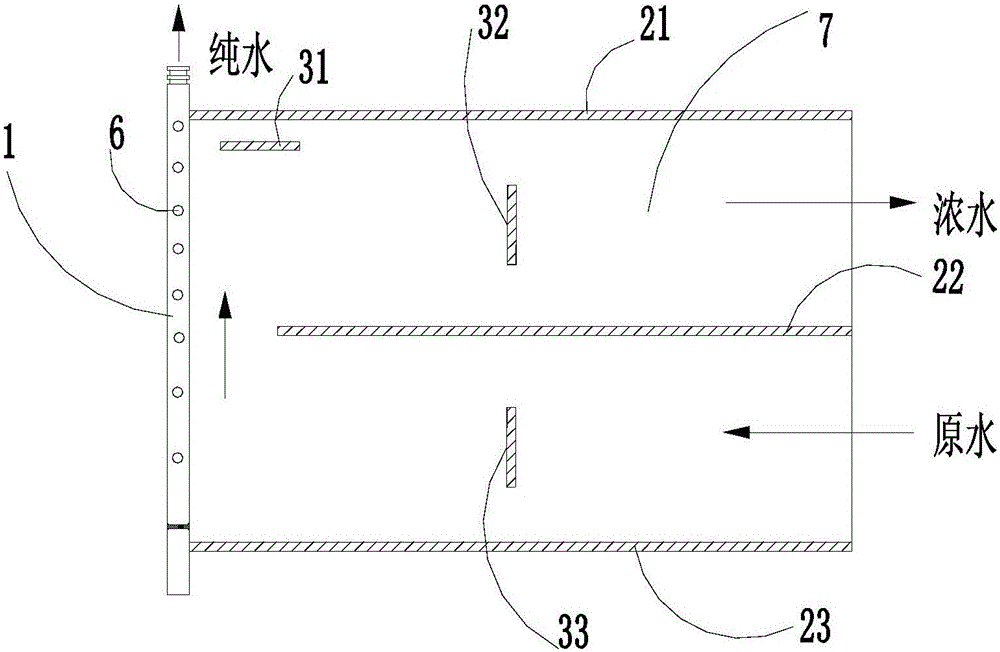

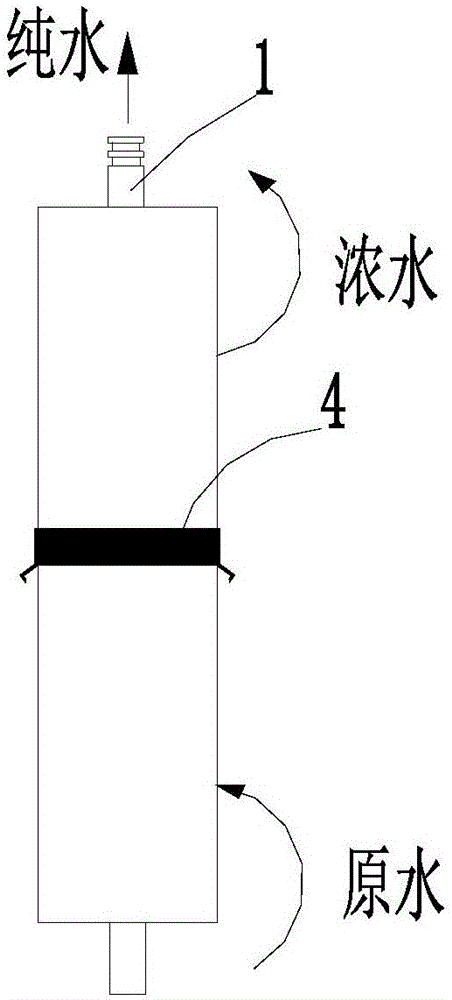

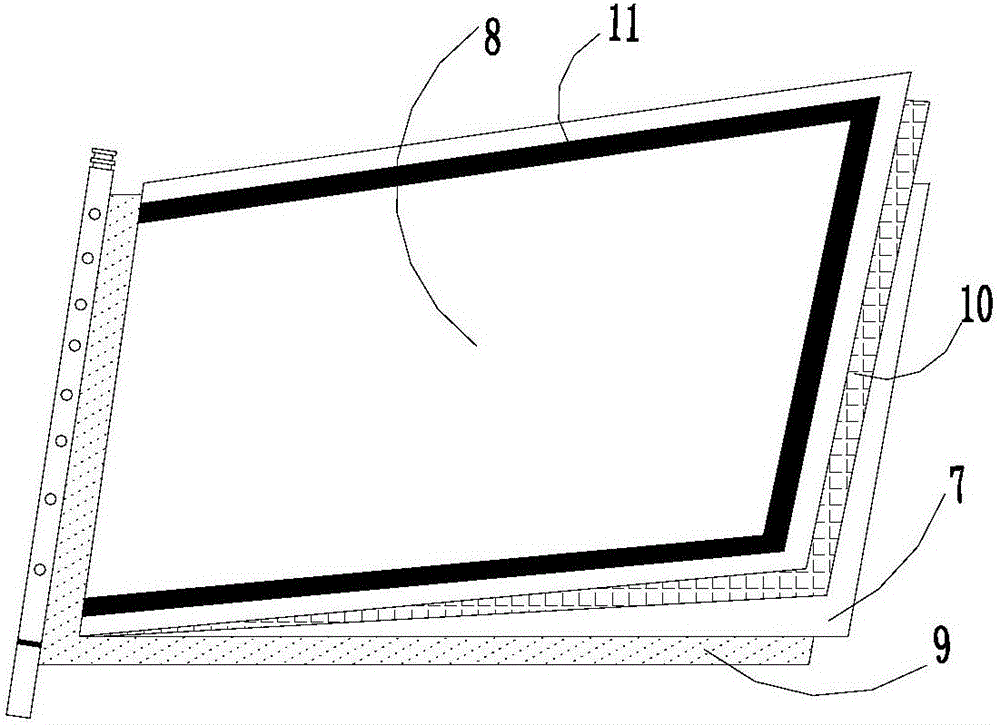

Reverse osmosis membrane element and water purification equipment

PendingCN106745524AHigh recovery rateExtended stayWater/sewage treatment bu osmosis/dialysisWater/sewage treatment apparatusRetention timeWater flow

The invention discloses a reverse osmosis membrane element and water purification equipment. The reverse osmosis membrane element comprises a central pipe of which the pipe body is provided with water inlet holes and a reverse osmosis membrane group which winds the central pipe; the reverse osmosis membrane group comprises a reverse osmosis membrane of which the front surface is folded; the front surface interlayer of the reverse osmosis membrane forms a water inlet flow channel; the back surface interlayer of the reverse osmosis membrane forms a water production flow channel which is communicated with the central pipe; the reverse osmosis membrane element also comprises a partition structure for dividing the water inlet flow channel into a raw water side water inlet flow channel and a concentrated water side water inlet flow channel which are communicated with each other in the axial direction of the central pipe along a water flowing direction; raw water flows into the raw water side water inlet flow channel from the side surface of the reverse osmosis membrane element; concentrated water flows out from the concentrated water side water inlet flow channel from the side surface of the reverse osmosis membrane element. According to the reverse osmosis membrane element, the retention time of the raw water in the reverse osmosis membrane is prolonged; the conversion rate of converting the raw water into pure water can be improved.

Owner:GREE ELECTRIC APPLIANCES INC

Array turbulent flow column jet cooling device

InactiveCN110662403AAchieve technical effectImprove heat transfer effectCooling/ventilation/heating modificationsEngineeringPressure difference

The invention discloses an array turbulent flow column jet cooling device, and belongs to the technical field of radiators. The cooling device is provided with a housing, a cooling working medium inlet, a cooling working medium outlet and a turbulent flow column array. The front half section of the cooling device is multiple columns of rectangular channels at equal intervals, and the rear half section of the cooling device is a turbulent flow column array which is symmetrically arranged along the center. Through the jet impingement cooling technology, gas or liquid is directly jetted to a cooled or heated surface through a rectangular nozzle (inlet) under the action of pressure difference, so that the flow path is short and a flow boundary layer on the impacted surface is thin, and an areadirectly impacted generates a very strong heat exchange effect; and the turbulent flow column array is arranged on the rear half section of the cooling device, so that the heat exchange area of the device and fluid is increased, the flow boundary layer formed in the flow channels is damaged, disturbance in flowing is increased, and furthermore, the heat exchange enhancing effect is further achieved, and the temperature equalizing effect of the cooling device is greatly improved.

Owner:BEIJING JIAOTONG UNIV

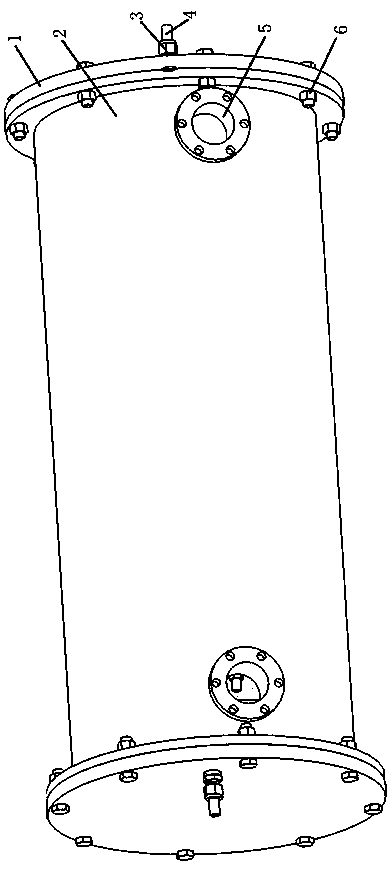

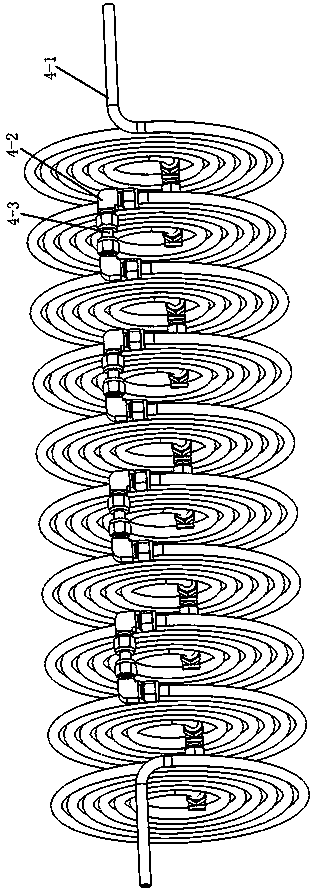

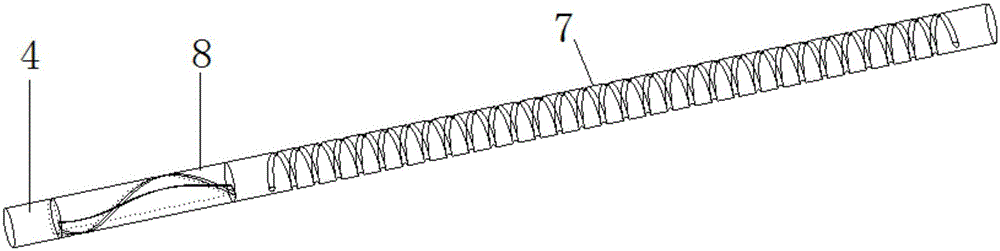

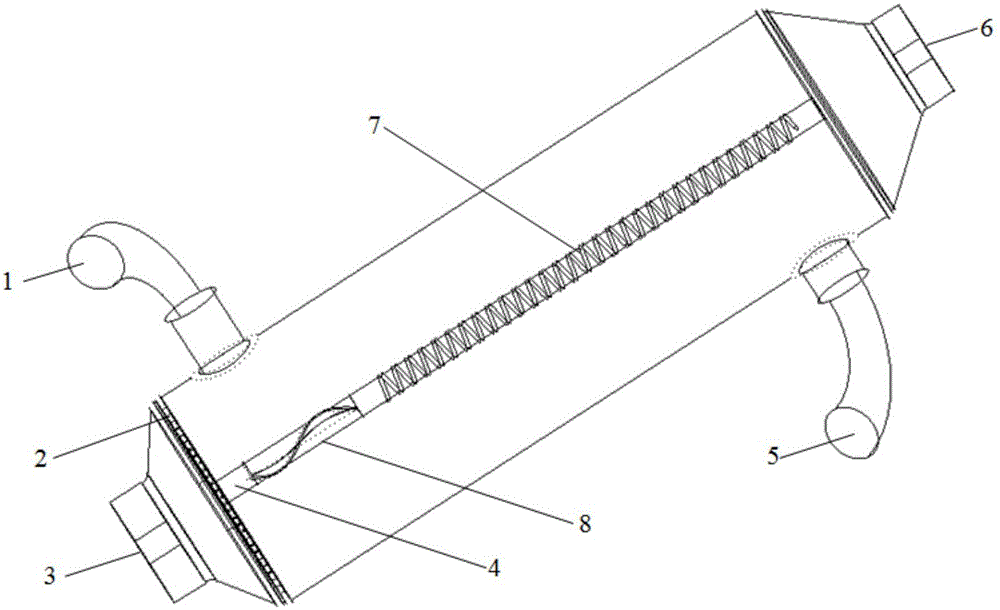

Sheet-like series shell-and-tube type heat exchanger

PendingCN110260687AHigh radial space utilizationIncrease profitHeat exchanger casingsStationary tubular conduit assembliesHigh pressure hydrogenEngineering

The invention discloses a sheet-like series shell-and-tube type heat exchanger. A shell is provided with a shell pass liquid inlet and outlet flange, an end cover of the shell is provided with a shell penetrating adapter, the shell is internally provided with a tube pass component and a baffle plate assembly, the tube pass component is formed in the manner that a plurality of parallel sheet-like concentric circular coils are connected with an adapter tube in series through welding or high-pressure special cutting ferrule elbows, and the baffle plate assembly is composed of a plurality of parallel pin rib spoilers, positioning rods for fixing the multiple pin rib spoilers, short and long positioning rod sleeves arranged on the positioning rods in a sleeving manner and used for limiting the pin rib spoilers and locking nuts installed at the two ends of each positioning rod and used for positioning and locking the short and long positioning rod sleeves. The sheet-like series shell-and-tube type heat exchanger can make the heat exchanger structure more flexible and compact, the heat exchange performance is more efficient, and the maintenance is more convenient on the premise of effectively achieving the pressure resistance of a high-pressure hydrogen pipe pass; and through spoiler design of the baffle plate assembly, a fluid boundary layer is broken to strengthen the heat transfer effect.

Owner:河南豫氢装备有限公司

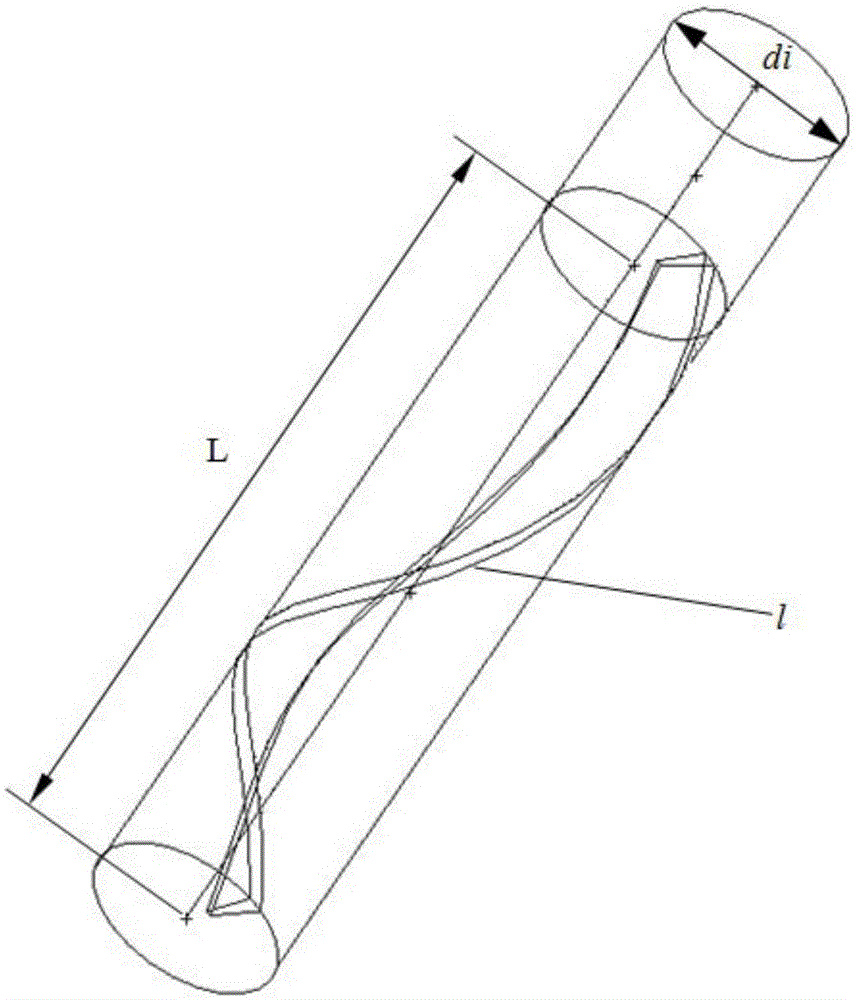

Intensified heat exchange tube provided with spiral grooved tube with spiral fin inserted inside

The invention discloses an intensified heat exchange tube provided with a spiral grooved tube with a spiral fin inserted inside. The intensified heat exchange tube comprises a reserved unthreaded tube, a spiral finned tube and the spiral grooved tube which are connected sequentially. The spiral finned tube is composed of the unthreaded tube and the spiral fin welded into the unthreaded tube, the width of the fin is 0.3-0.4 times the inner diameter of the unthreaded tube, and the total length of the fin is equal to the screw pitch length of 1-2 fin spiral lines. The spiral fin enables turbulent flow of the spiral groove tube section to be greatly enhanced, and reduces flowing resistance. When the spiral fin is matched with the spiral grooved tube, the heat exchange coefficient is higher than that of the spiral grooved tube by 3% to 10%, and the flowing resistance is reduced by 16% to 30%. The tube section with the fin inserted inside of the heat exchange tube with the spiral fin inserted inside is independently machined, small in length, convenient to wash and small in material consumption, saves space, can be matched with various tube sections of different types and has quite important engineering application value to further development of the intensified heat exchange tube.

Owner:ZHEJIANG UNIV

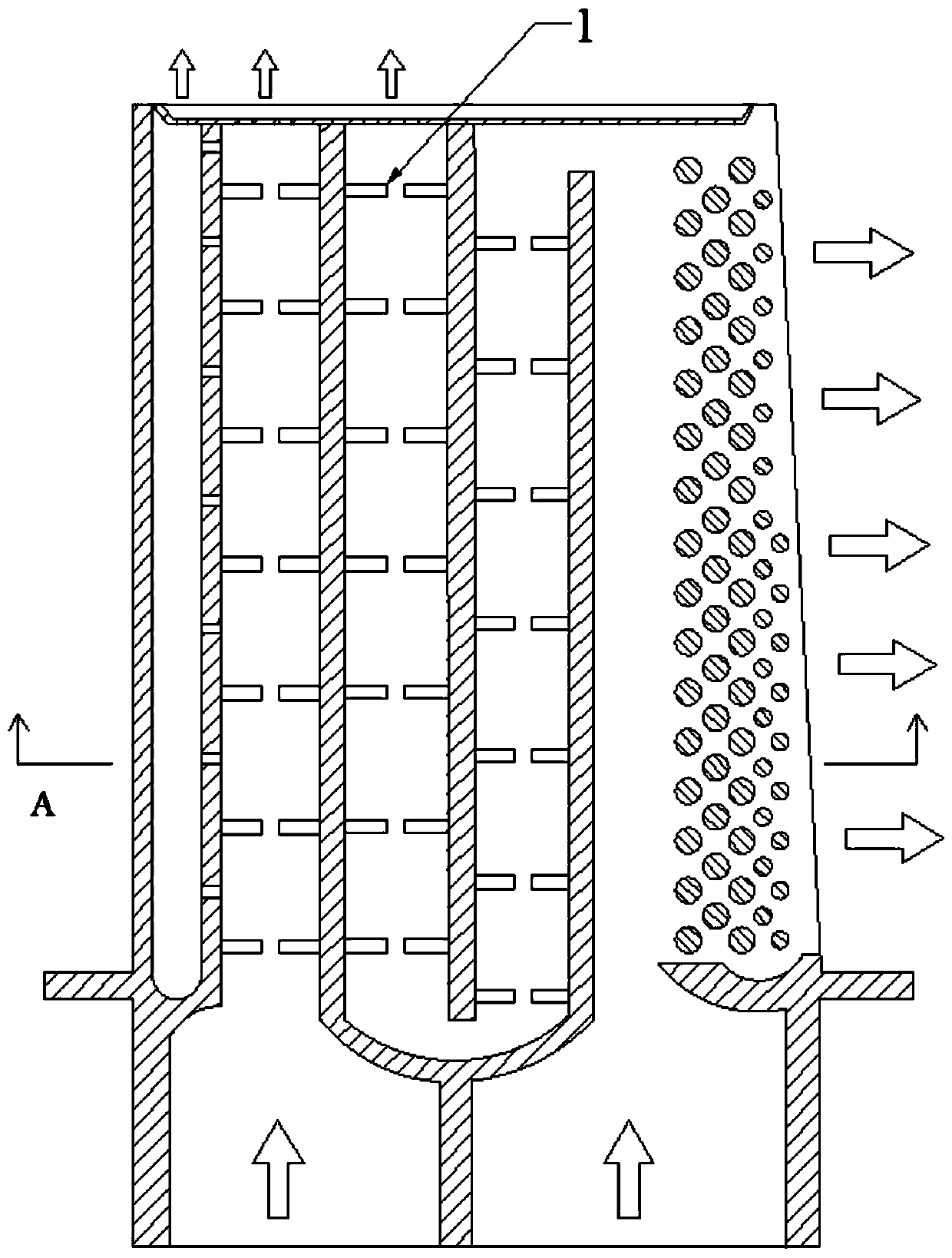

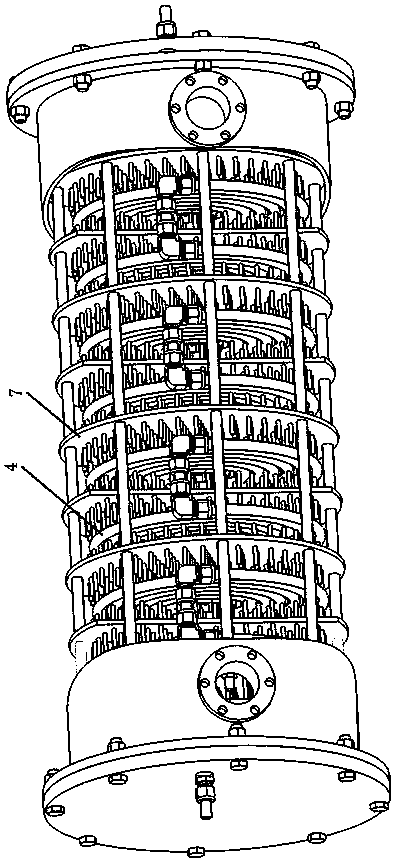

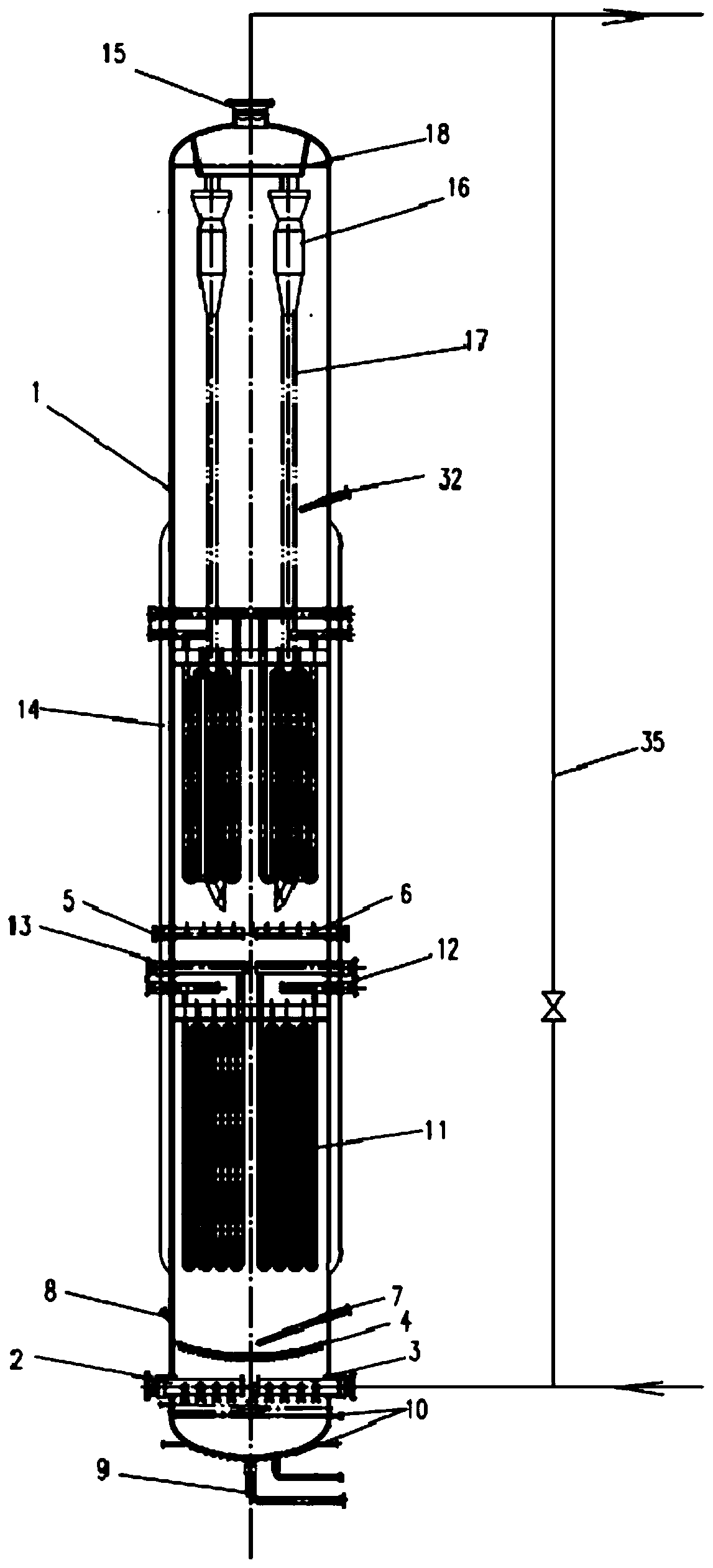

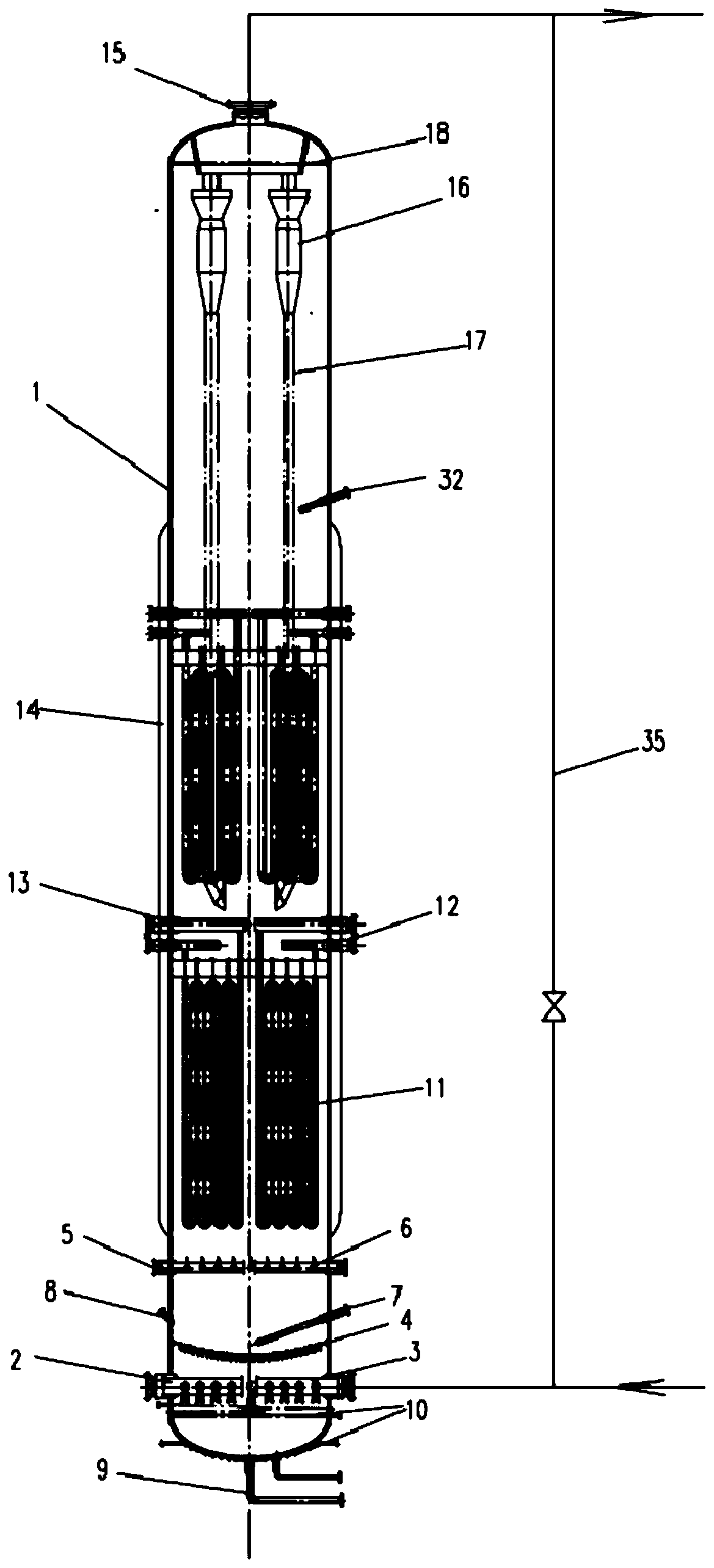

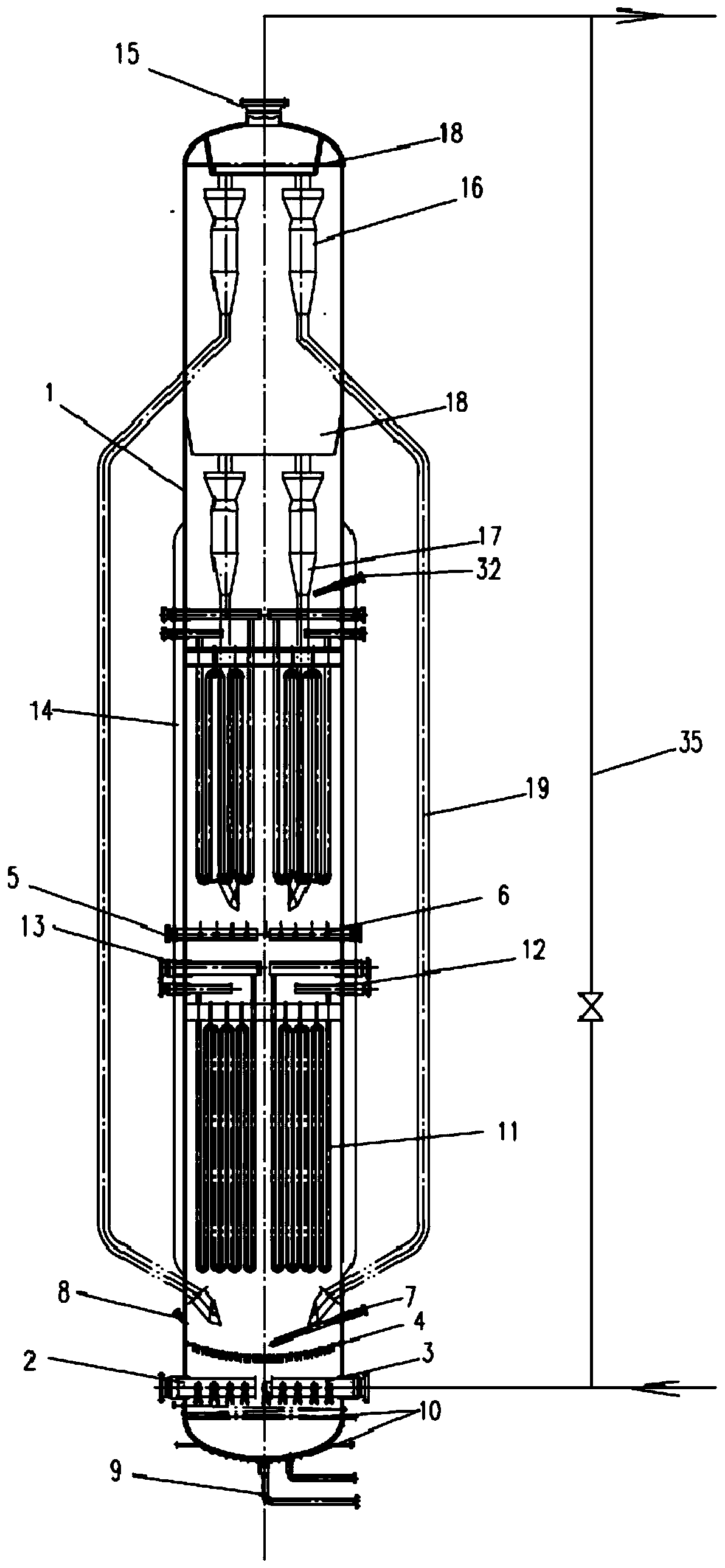

Fischer-Tropsch synthesis fluidized bed reactor

ActiveCN111286355AIncrease disturbancePlay a chilling roleLiquid hydrocarbon mixture productionChemical/physical processesPtru catalystFluidized bed

The invention relates to a Fischer-Tropsch synthesis fluidized bed reactor, wherein the fluidized bed reactor comprises a reactor cylinder and an internal component arranged in the reactor cylinder, and the internal component comprises a gas distribution mechanism, a heat exchange mechanism, a solid catalyst separation and circulation mechanism and a catalyst online feeding and discharging mechanism; the gas distribution mechanism comprises a first-stage gas distributor, a second-stage gas distributor and a third-stage gas distributor which is arranged in a main reaction dense-phase region ofthe fluidized bed reactor; the first-stage gas distributor and the second-stage gas distributor are arranged at the bottom of the reactor cylinder; a gas nozzle of the third-stage gas distributor transversely sprays gas to transversely cut longitudinally rising gas flow. Compared with the prior art, the reactor is reasonable in design structure and layout; the fluidized bed reactor is good in gas-solid contact in the reactor, uniform in fluid distribution, high in system heat transfer efficiency, uniform in temperature distribution, good in gas-solid separation effect, high in system operationflexibility and particularly suitable for design and operation of the large-scale Fischer-Tropsch synthesis fluidized bed reactor, and cavities in the fluidized bed reactor are avoided.

Owner:YANKUANG ENERGY R&D CO LTD

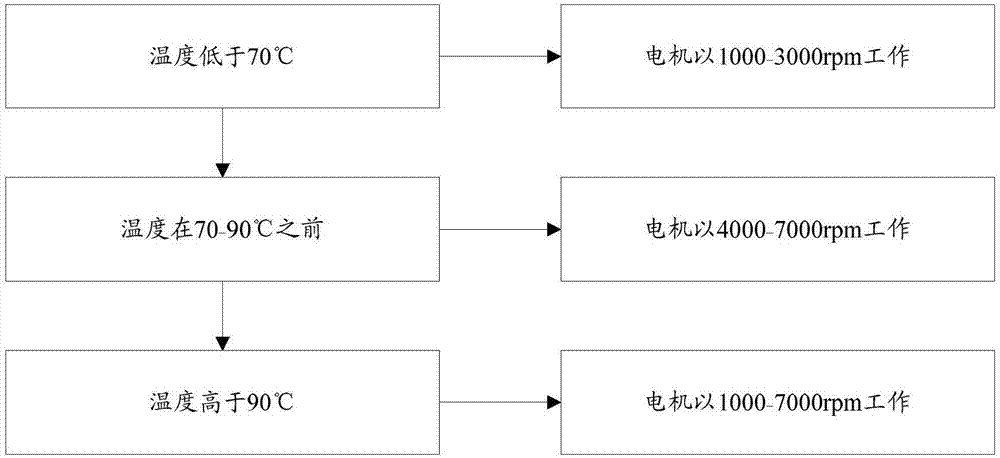

Control method of soybean milk machine

The embodiment of the invention discloses a control method of a soybean milk machine. The control method comprises the following step that during the heating process of the soybean milk machine, a motor is controlled for stirring soybean milk liquid, wherein the rotation speed of the motor changes along with the change of the temperature of the soybean milk liquid. Due to the technical scheme of the embodiment, soybean milk liquid is stirred at low rotation speed during the heating process of the soybean milk machine, the pre-grinding effect is achieved, the whole pulping period is saved, meanwhile, the temperature of the soybean milk liquid is enabled to be relatively uniform, and the overflow phenomenon caused by thermal inertia is reduced.

Owner:JOYOUNG CO LTD

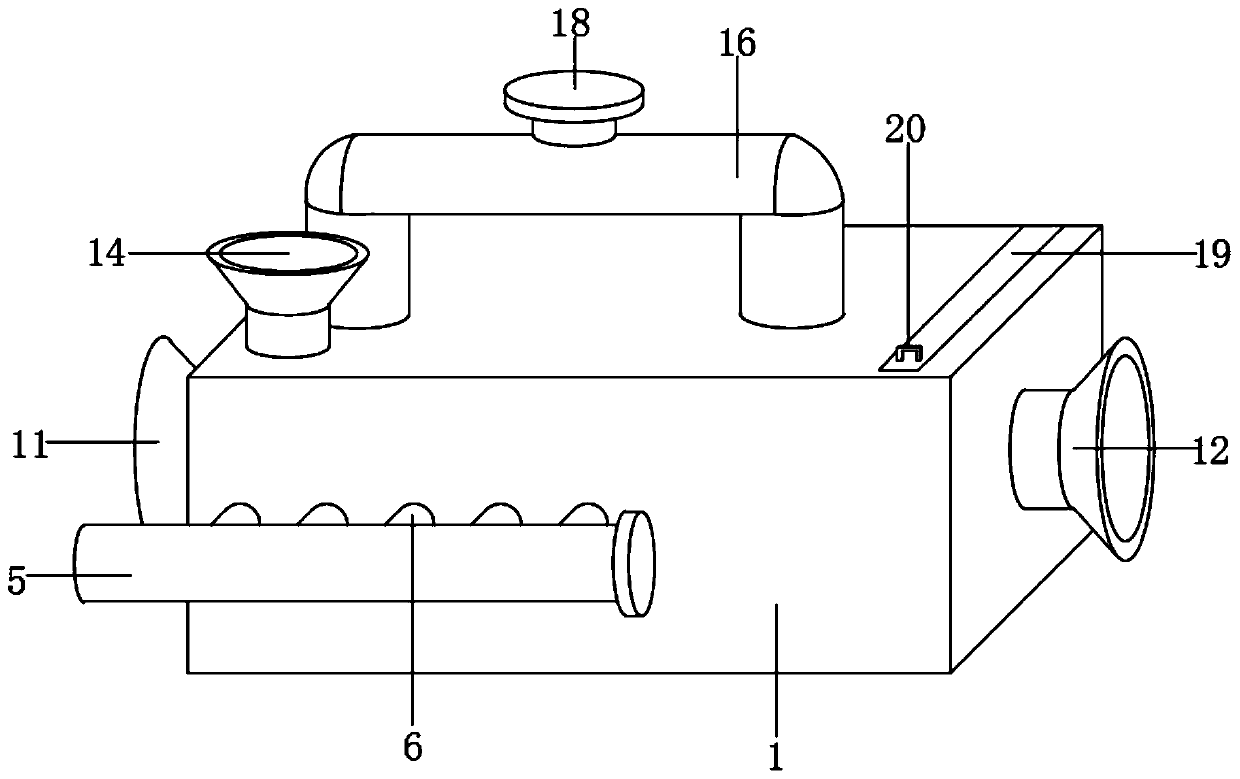

Low-consumption carbon-based catalytic desulfurization and denitrification device for flue gas purification

InactiveCN110614030AAdd spoilersExtended stayGas treatmentDispersed particle filtrationFlue gasResidence time

The invention discloses a low-consumption carbon-based catalytic desulfurization and denitrification device for flue gas purification and belongs to the technical field of flue gas purification. The device includes a treatment box, wherein a baffle is fixedly connected to the inner side of the treatment box; the treatment box is provided with a desulfurization and denitrification chamber and a purification chamber on two sides of the baffle; a carbon-based catalyst and ammonia gas are introduced into the desulfurization and denitrification chamber at the same time, so that flue gas is synchronously desulfurized and denitrified; meanwhile, the turbulent flow of the flue gas is remarkably improved through spoilers; the residence time of the flue gas in a room is prolonged; ammonia gas and flue gas are fully and uniformly mixed; the desulfurized and denitrified flue gas enters a flue gas filter through a flue gas inlet pipeline to be filtered; and after the filtering is finished, the fluegas is discharged after being filtered by a filter plate, thus completing the desulfurization and denitrification and gas purification thoroughly; further, a flue gas detector can detect whether theflue gas reaches the standard or not, if the flue gas does not reach the standard, the flue gas can enter the desulfurization and denitrification chamber again through the guide pipe to react, the desulfurization and denitrification work and the purification work are completed in the same device, energy consumption is reduced, and meanwhile the purification cost is saved.

Owner:ANHUI GUONENG YISHENG ENVIRONMENTAL PROTECTION SCI & TECH

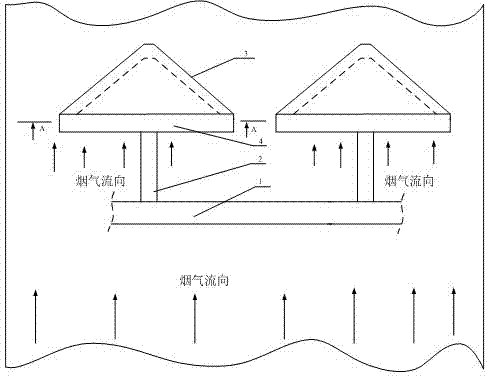

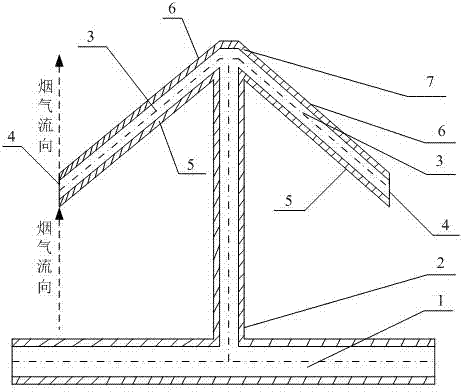

Micro-eccentric swinging type flue gas spoiler device and method for enhancing flue gas heat exchange

Owner:苏州博墨热能产品有限公司

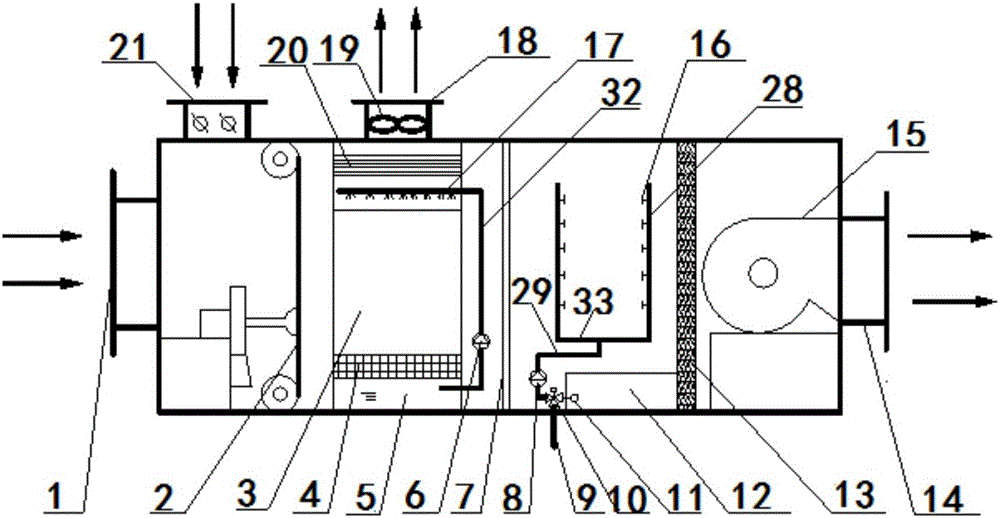

Corrugated-plate-indirect-and-hydrodynamic-force-water-spraying-chamber combined type evaporative cooling air conditioning unit

InactiveCN105042735AImprove the cooling effectReduce running timeMechanical apparatusLighting and heating apparatusFiberTextile mill

The invention discloses a corrugated-plate-indirect-and-hydrodynamic-force-water-spraying-chamber combined type evaporative cooling air conditioning unit. The air conditioning unit comprises a unit shell. An air inlet and an air outlet are formed in the two opposite side walls of the unit shell respectively. A fresh-air-and-returning-air mixing-filtering chamber, a corrugated-plate indirect evaporative cooler, a flow equalizing plate, a hydrodynamic force water spraying device, a water stop plate a and an air feeder are sequentially arranged in the unit shell in the flowing direction of entering air. An air returning opening is formed in the portion, corresponding to the fresh-air-and-returning-air mixing-filtering chamber, of the top wall of the unit shell. A secondary air exhausting opening is formed in the portion, corresponding to the portion above the corrugated-plate indirect evaporative cooler, of the top wall of the unit shell. According to the corrugated-plate-indirect-and-hydrodynamic-force-water-spraying-chamber combined type evaporative cooling air conditioning unit, a self-cleaning winding type filter is adopted, dust and cotton fibers in returning air can be effectively filtered out accordingly, and therefore the returning air can be effectively used; and indirect evaporative cooling and hydrodynamic-force water spraying cooling are combined, and therefore the temperature in workshops of a textile mill can be effectively reduced.

Owner:XI'AN POLYTECHNIC UNIVERSITY

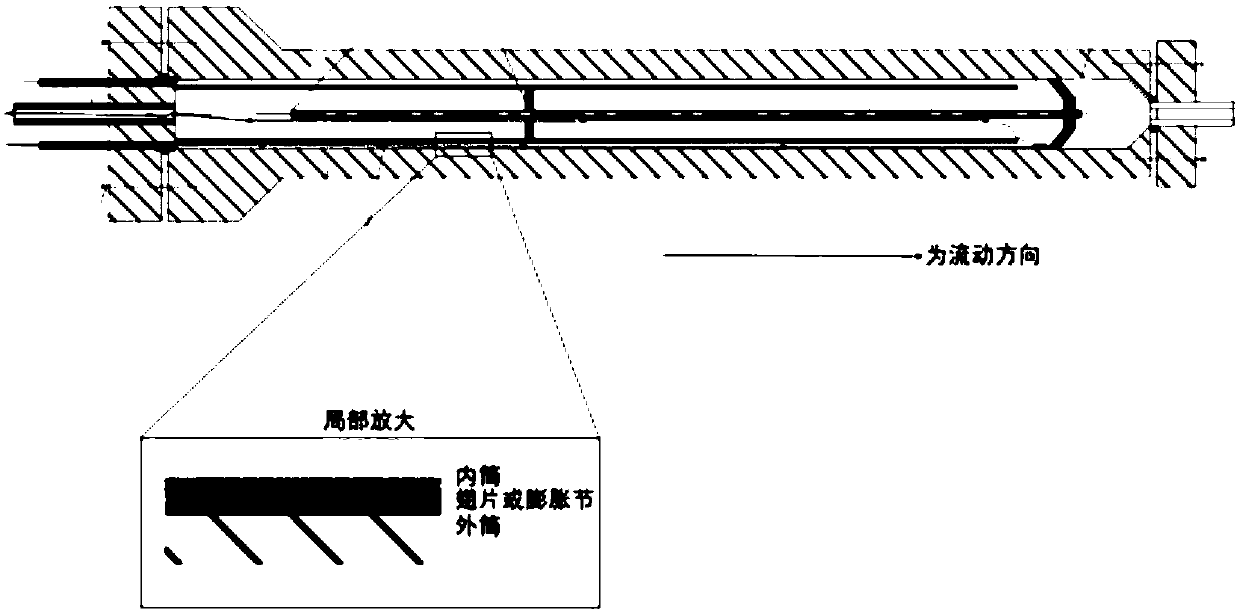

Pipe type supercritical water oxidization reactor and supercritical water oxidization system and method

ActiveCN109592774AIncrease flow itinerarySimple processWater/sewage treatment apparatusWater/sewage treatment by oxidationEngineeringExpansion joint

The invention provides a pipe type supercritical water oxidization reactor and a supercritical water oxidization system and method. The pipe type supercritical water oxidization reactor comprises an inner barrel and an outer barrel; the outer barrel sleeves the outer part of the inner barrel; a material inlet is arranged between the inner barrel and the outer barrel; a material outlet is formed inthe top of the inner barrel and a working medium flows in from the gap between the inner barrel and the outer barrel and flows out from the top of the inner barrel; and a fin or an expansion joint isadditionally arranged in the gap between the inner barrel and the outer barrel, so that the turbulent flow is increased, a flow path is lengthened and the heat exchange is reinforced.

Owner:SHANDONG UNIV

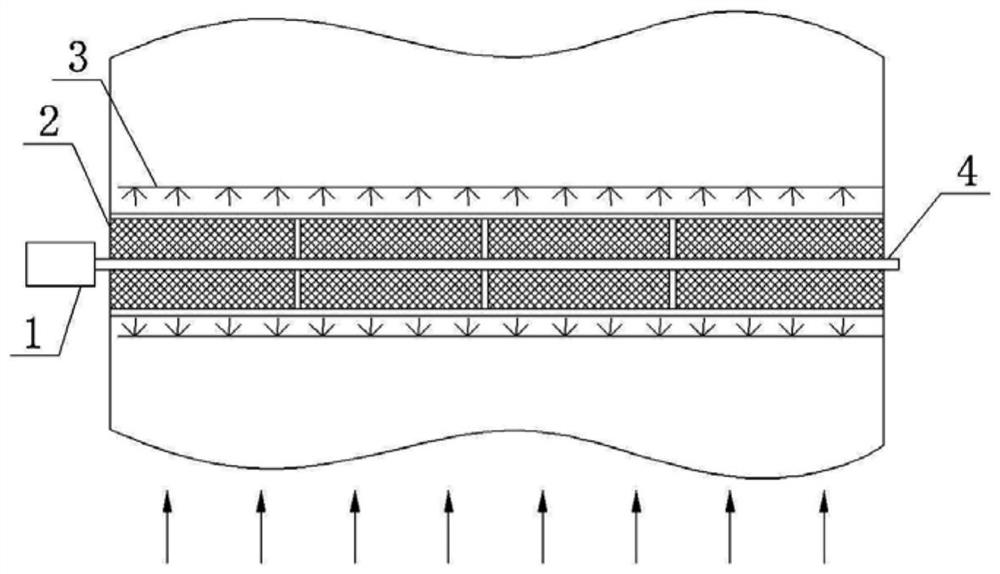

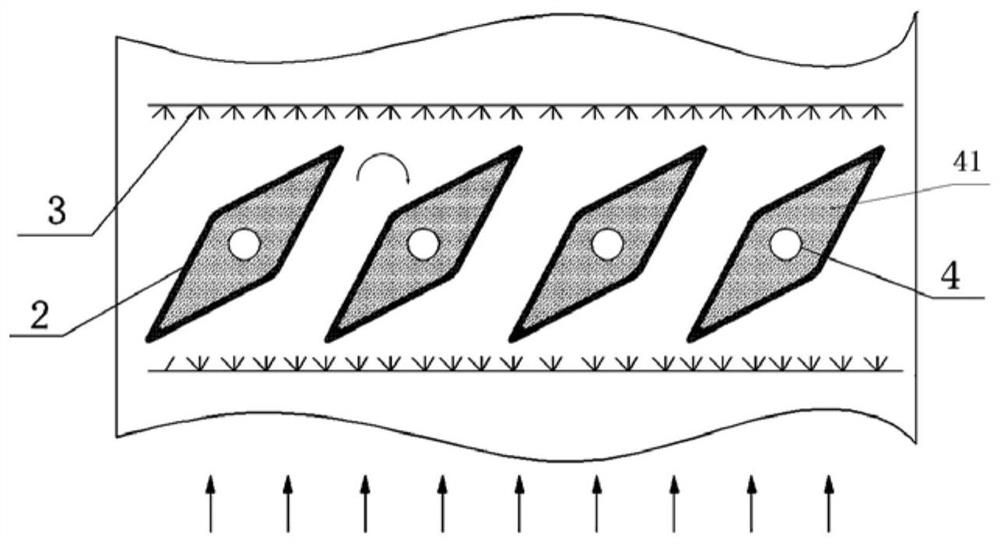

Rotary rhombic wire mesh demisting method and device

PendingCN112717615AImprove the ability of dust removal and fog removalAdd spoilersCombination devicesAuxillary pretreatmentPhysicsDemister

The invention discloses a rotary rhombic wire mesh demisting method and a rotary rhombic wire mesh demisting device. The rotary rhombic wire mesh demisting device comprises a rhombic wire mesh demisting system arranged at the top of a desulfurizing tower and an automatic rotary control system. When flue gas flows into the lower layer of the rhombus-shaped wire mesh demister, droplets and other fine particles carried in the flue gas are intercepted by a wire mesh in the rhombus-shaped wire mesh demister, the droplets and the large particles are subjected to inertial separation, the small particles are subjected to coagulation, sedimentation and separation, and the flue gas subjected to preliminary demisting of the lower layer of wire mesh enters the upper layer of wire mesh again and then is demisted and dedusted. According to the device, the wire mesh demister is rotationally combined with the connecting rod, so that the device has the characteristics of efficient demisting and dedusting, uniform flue gas distribution, energy conservation, adaptability to different working condition changes and the like, can effectively solve the problems of poor working condition applicability, large resistance, easiness in scaling and easiness in blockage of the traditional demister, and can effectively reduce the formation of gypsum rain and the secondary carrying of flue gas.

Owner:SOUTH CHINA UNIV OF TECH +1

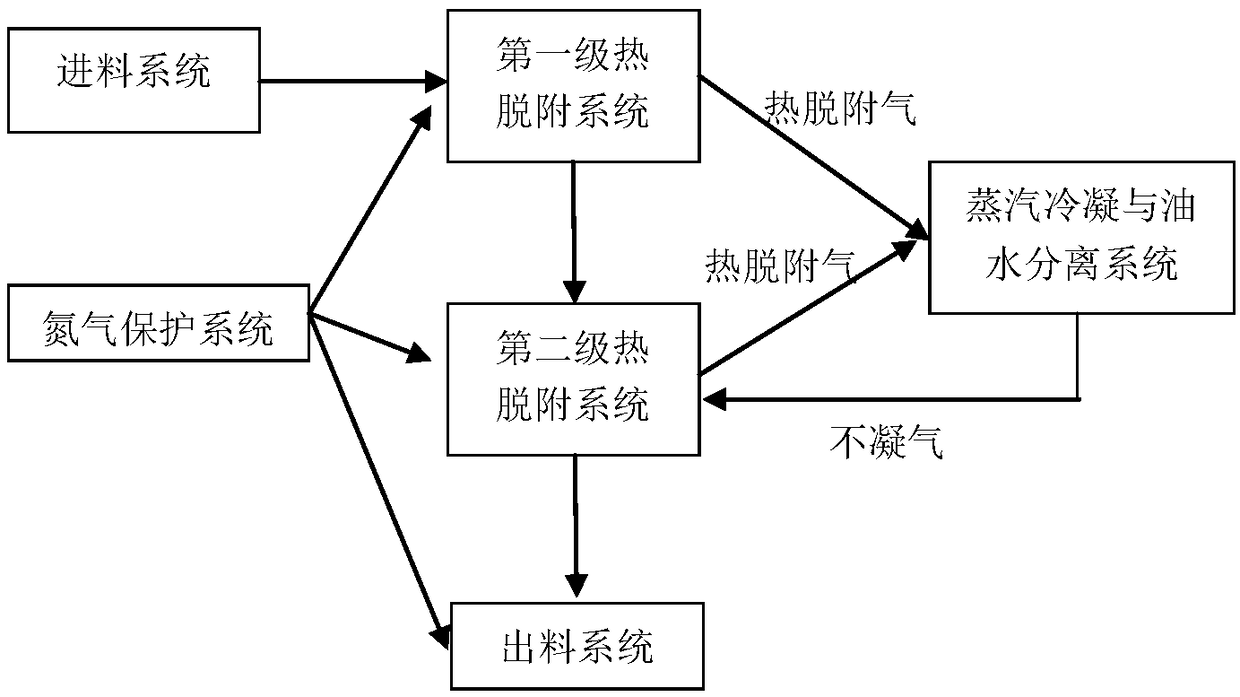

Oil mud two-stage thermal desorption system with high water content and integrated skid-mounted equipment

ActiveCN109354375AReduce energy consumptionIncrease heat absorptionSludge treatmentDispersed particle separationSteam condensationSludge

The invention discloses an oil mud two-stage thermal desorption system with a high water content and integrated skid-mounted equipment, and belongs to the technical field of oil mud treatment devices.The system includes a feeding system, a first-stage thermal desorption system, a second-stage thermal desorption system, a discharge system, a steam condensation and oil-water separation system and anitrogen protection system, which are integrated in the integrated skid-mounted equipment. The system aims at deficiencies of high energy consumption and limited treatment capacity in the oil mud thermal desorption method treatment process, reduces the water content of the oil mud through microwave thermal desorption pretreatment of first-stage thermal radiation, uses the indirect thermal desorption of second-stage heat conduction to separate oil from the soil, and improves the thermal efficiency and the processing capacity of the equipment by a first-stage thermal desorption distributor, a second-stage thermal desorption flame retardant plate and a fire blocking wall to increase the flue gas residence time. The system solves the problem that a microwave belt discharge belt adheres to theoil sludge, a steam releases on the discharge port and the sealing and the safety concern people, the structure is reasonable and compact, and the system is convenient to relocate and install, and has good application prospects.

Owner:广安铭鸿环保科技有限责任公司

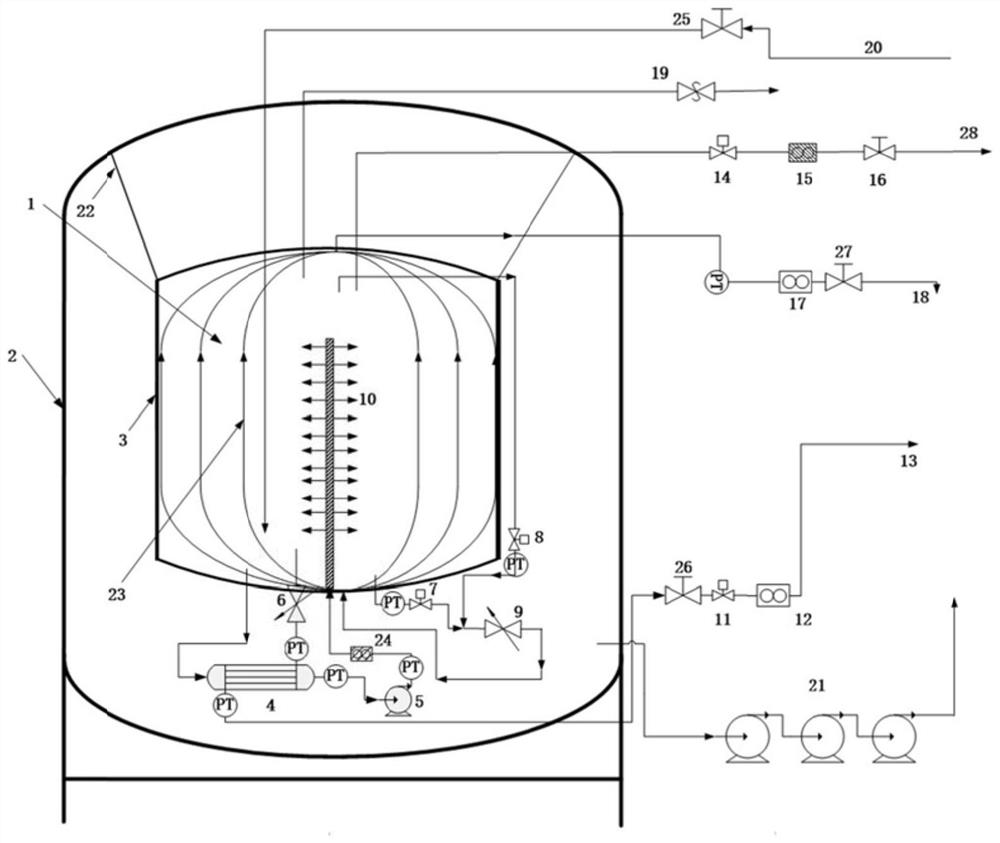

Ground integration test device and method for cryogenic propellant thermodynamic exhaust system

ActiveCN112550779AImprove stabilitySimple structureCosmonautic condition simulationsEngineeringPumping vacuum

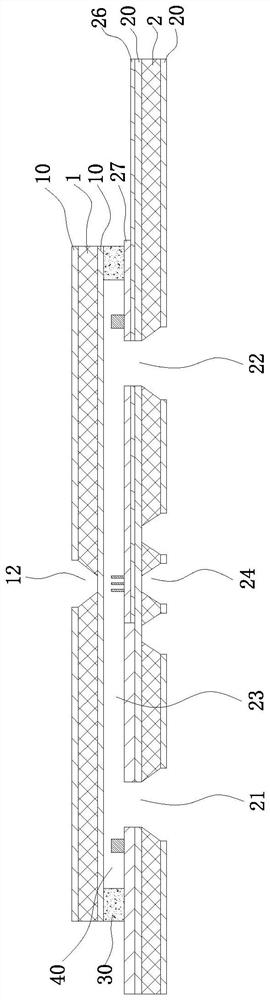

The invention provides a cryogenic propellant thermodynamic exhaust system ground integration test device and method, the cryogenic propellant thermodynamic exhaust system ground integration test device comprises a storage tank (1), a vacuum container (2), an active thermodynamic exhaust system and a passive thermodynamic exhaust system, the storage tank (1) is located in the vacuum container (2)and is fixedly connected with the inner wall of the vacuum container (2); an interlayer between the storage tank (1) and the vacuum container (2) is vacuumized through a vacuum unit (21) to simulate the outer space environment. According to the ground integration test device and method, various exhaust schemes and combinations thereof can be tested, most test structural parts in each scheme are arranged outside the storage tank, maintenance is convenient, and the design reliability is improved; structural parts such as a jet mixing device arranged in the storage tank are simple in structure and high in stability.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

Gas turbine engine blade with inner meshed structure

InactiveCN103470312BImprove cooling effectIncrease contact areaBlade accessoriesMachines/enginesManufacturing technologyMachining process

The invention discloses a gas turbine engine blade with an inner meshed structure. The blade is formed by SLM or EBM material increase manufacturing technology, and the inside of the blade is provided with a meshed structure. The meshed structure is composed of sub structures arraying in a three-dimensional periodic manner, and communicated channels are formed inside the communicated meshed structure to form multiple channel structures. All or parts of the meshed structures are filled into gaps among partitioning plates of the blade. By the aid of the inner meshed structure of the blade, heat exchange effect of cooling flow can be strengthened. A blade body, tenons, inner channels and the meshed structure are formed by the material increase manufacturing technology, machining process is simple, defects that finished product rate is low by traditional casting and machining and complex inner structure cannot be manufactured are overcome, and designing and machining cost can be reduced greatly.

Owner:BEIHANG UNIV

Sectional type oil nozzle and optimization design method thereof

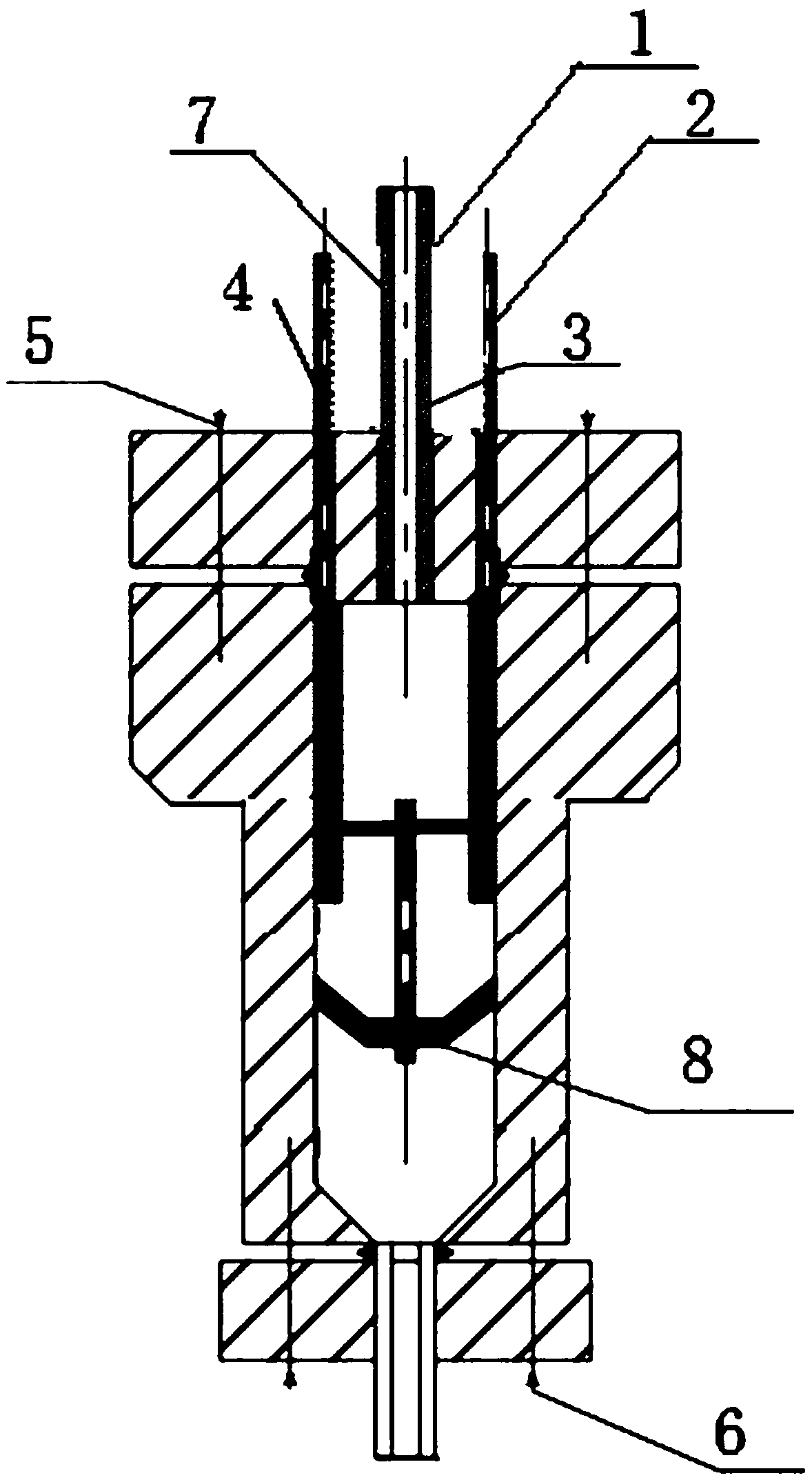

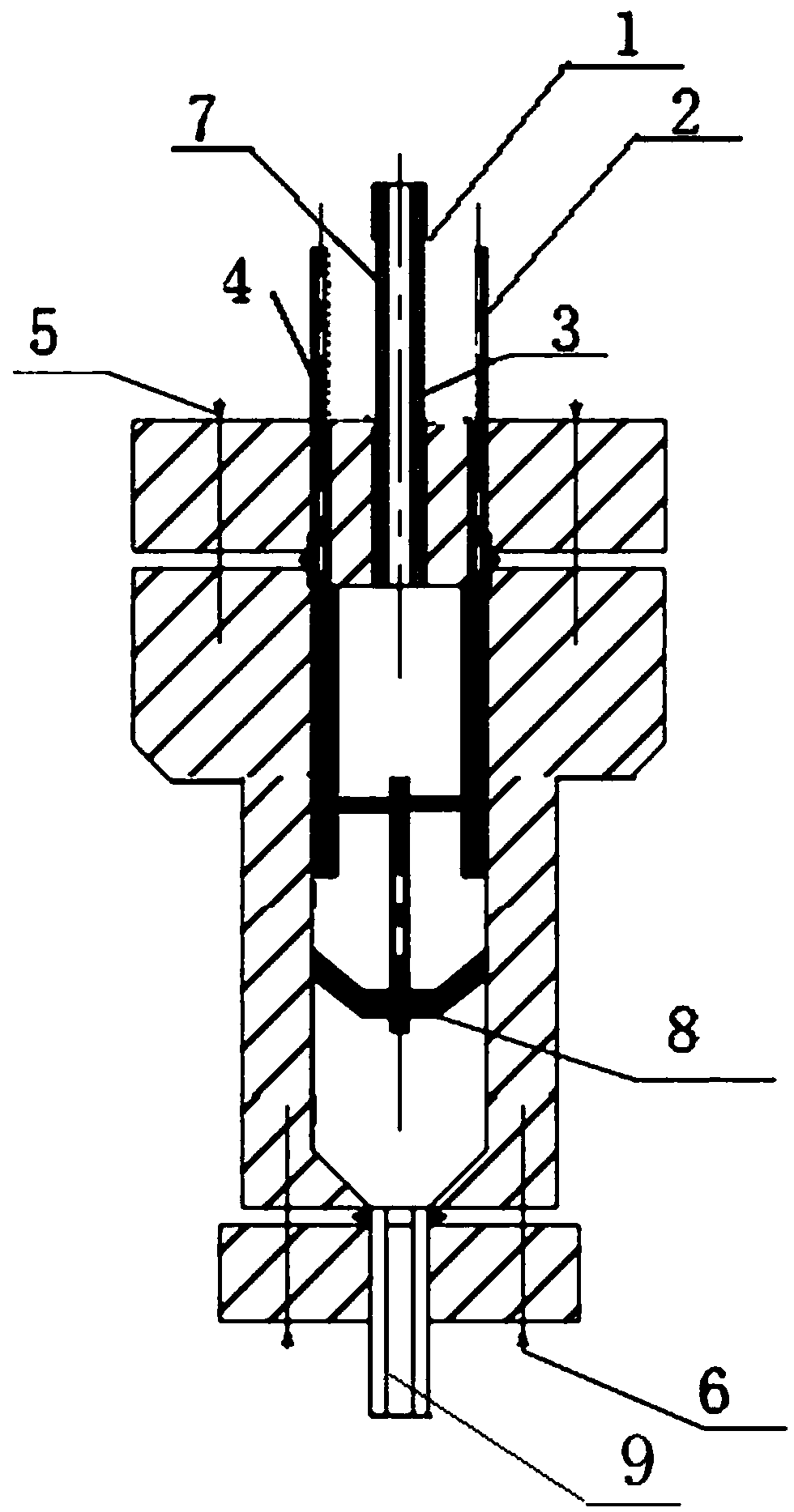

PendingCN114060192AReduce energy lossGeometric cavitation suppressionFuel injection apparatusMachines/enginesOptimal designNeedle valve

The invention discloses a sectional type oil nozzle and an optimization design method thereof. The oil nozzle comprises a needle valve, a needle valve body and a turbulent flow ring sleeve, wherein the needle valve and the needle valve body are coaxially matched, and the needle valve is located in the needle valve body; oil injection holes which are evenly distributed in the circumferential direction are formed in the needle valve body, turbulent flow concave cavities and flare openings are formed in the turbulent flow ring sleeve, and the turbulent flow concave cavities, the flare openings and the oil injection holes are coaxially distributed and are the same in number; and the turbulent flow ring sleeve is in threaded connection with the needle valve body, adjacent boundaries are consistent in shape and are in close fit, and the structure can enhance the circulation performance and the atomization performance of the oil nozzle at the same time. Based on the sectional type oil nozzle, a transparent oil nozzle internal flow and spray visualization experiment table is established; factors, levels and indexes of sectional nozzle structure design are extracted, an experiment is carried out based on orthogonal experiment design, and sensitivity analysis is carried out on data; and a BP neural network model is established and trained based on MATLAB, an optimal solution combination and a multi-index weight coefficient are solved by using the model, the correctness of results is verified through carrying out a visual experiment, and the optimization of the oil nozzle design is completed.

Owner:JIANGSU UNIV

Novel fin heat exchanger of louver

InactiveCN105547042AReduce thicknessSmall pressure dropHeat exhanger finsHeat transfer modificationEngineeringPlate fin heat exchanger

The invention belongs to the field of heat exchangers and provides a novel fin heat exchanger of louver. The fin heat exchanger of the louver comprises oblique base plates, louver fins, transition base plates and multi-hole flattened tubes. The louver fins are installed on the oblique base plates in a grouped mode. Every two adjacent louver fins are connected through the transition base plates, and every two adjacent oblique base plates are installed between the upper multi-hole flattened tube and the lower multi-hole flattened tube in an inverted-V-shaped mode. According to the novel fin heat exchanger, when air enters a fin area along the oblique base plates, the flow direction of air is changed through the louver fins, and meanwhile air is prevented from continuing to form a thermal boundary area layer on the oblique base plates; due to the fact that the louver fins have a flow disturbing function, the thickness of the thermal boundary area layer on the louver fins is greatly decreased, and therefore the effect of reinforcing heat conduction is achieved; in addition, the pressure drop on the air side is greatly reduced through the oblique base plates while turbulent flow is increased, so that the heat exchange effect is improved, and meanwhile the resistance loss on the air side is reduced.

Owner:ZHENGZHOU UNIV

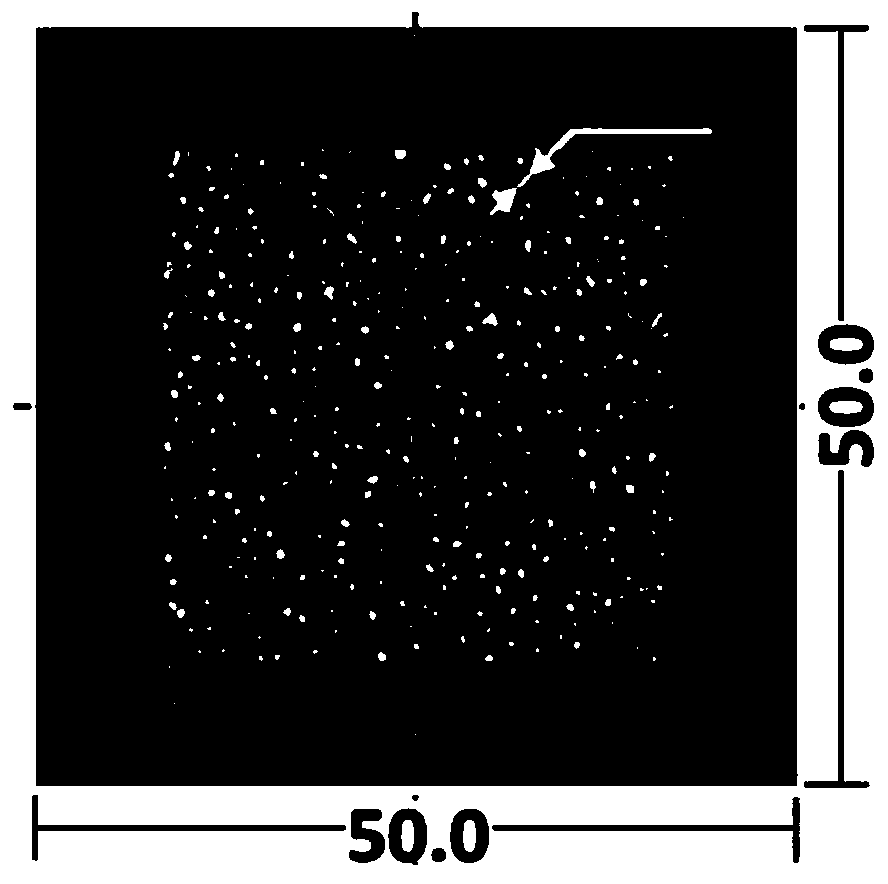

Free particle/porous medium composite enhanced boiling structure and preparation method thereof

ActiveCN110842202AAdd spoilersFast heat conductionHeat transfer modificationThermodynamicsPorous medium

The invention discloses a free particle / porous medium composite enhanced boiling structure. The structure comprises a substrate and a porous matrix structure formed on the surface of the substrate, aplurality of pore cavities are formed in the porous matrix structure, and free particles capable of moving in the pore cavity are dispersed in the pore cavity. When the free particle / porous medium composite enhanced boiling structure is prepared, metal particles are sintered to prepare a porous material matrix, the porous material matrix is drilled to form the pore cavity, and then the pore cavityis filled with free particles and sealed. The structure is based on the enhancing characteristics of nucleation activation in the boiling heat transfer process and liquid supply of a liquid absorbingcore to a nucleation site, bubbles are prevented from being mixed and the liquid backflow resistance is reduced by means of bubble nucleation and liquid supply partition. Meanwhile, the free particles collide with one another in the boiling process, so that heat transfer, microlayer evaporation and convective heat transfer in working fluid are enhanced, bubble nucleation is easy, the growth speedis high, the separation frequency is high, and therefore the enhanced boiling heat transfer is realized.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

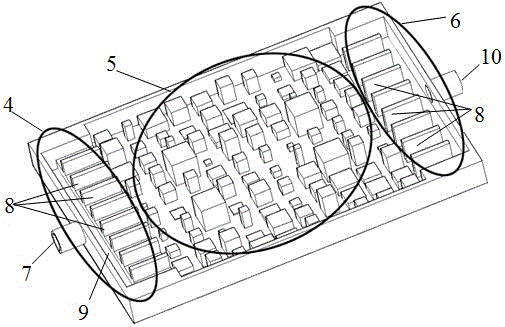

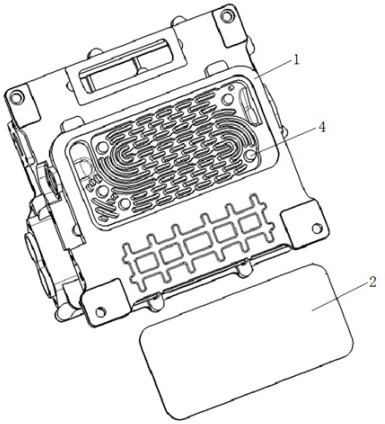

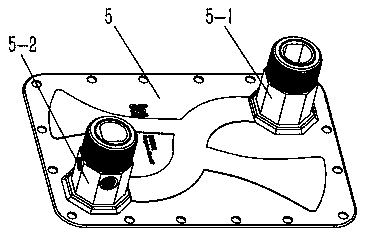

Heat dissipation water channel of new energy motor controller

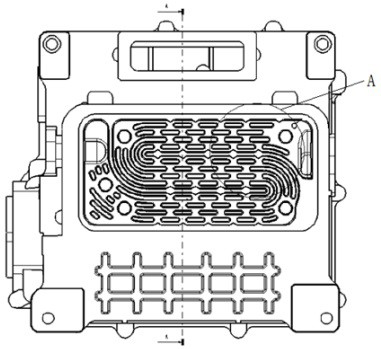

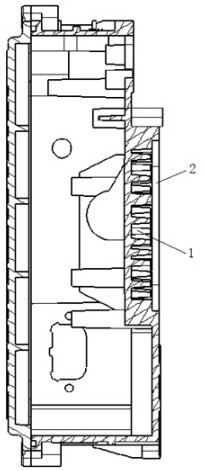

InactiveCN112040742AStable jobImprove cooling effectCooling/ventilation/heating modificationsThermodynamicsElectric machine

The invention discloses a heat dissipation water channel of a new energy motor controller, relates to the technical field of electric vehicle driving motor assemblies, and aims to solve the problems that a cooling liquid in an existing heat dissipassion device cannot fully absorb heat of the heat dissipassion device, the inlet and outlet temperature difference is large, the heat dissipation effectis poor, the temperature of an IGBT module is too high, and long-time stable work of the motor controller is not facilitated. According to the scheme, the heat dissipation water channel comprises a heat dissipassion device body, wherein a heat dissipation water channel main body is arranged in the heat dissipassion device body; two sets of flow guide blocks are arranged in the heat dissipation water channel main body; BOSS bosses are arranged on the two sides of each flow guide block; a plurality of heat dissipation ribs are arranged on the sides, close to each other, of the two sets of flowguide blocks; four water channel partition plates are arranged among the plurality of radiating ribs; and a plurality of second inner wall spoiler blocks are arranged on the water channel partition plates. According to the heat dissipation water channel of the new energy motor controller, the heat dissipation effect is improved, heat dissipation is more balanced, and the motor controller can stably work for a long time at a comfortable temperature.

Owner:安徽鸿创新能源动力有限公司

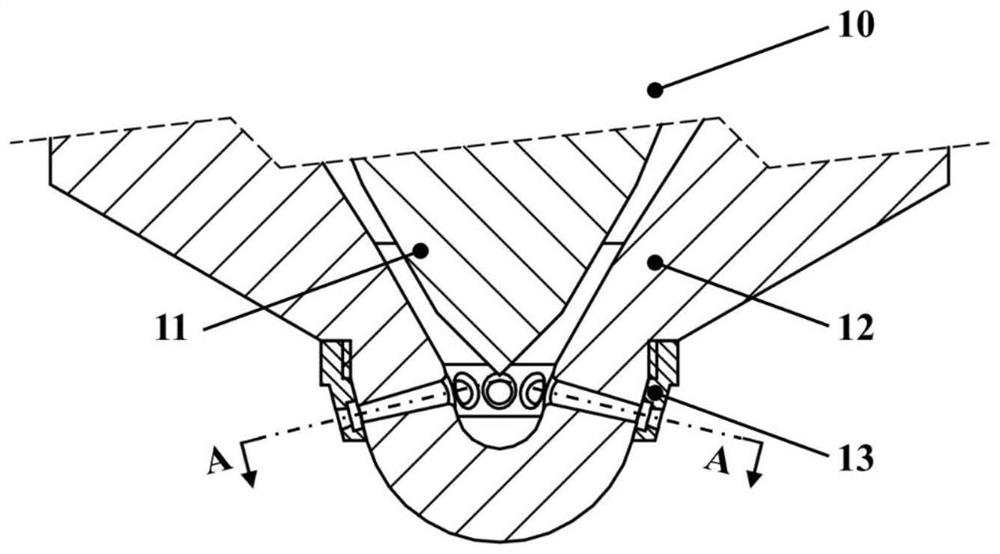

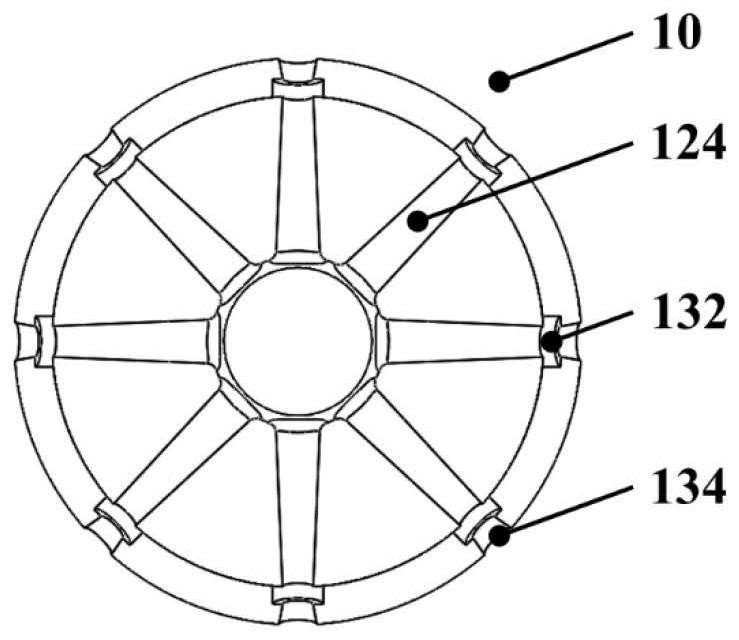

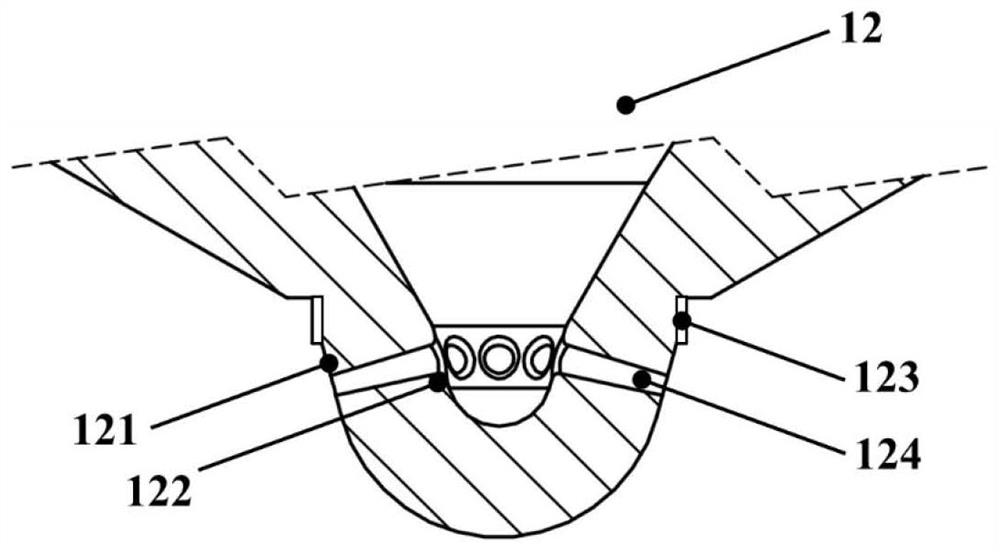

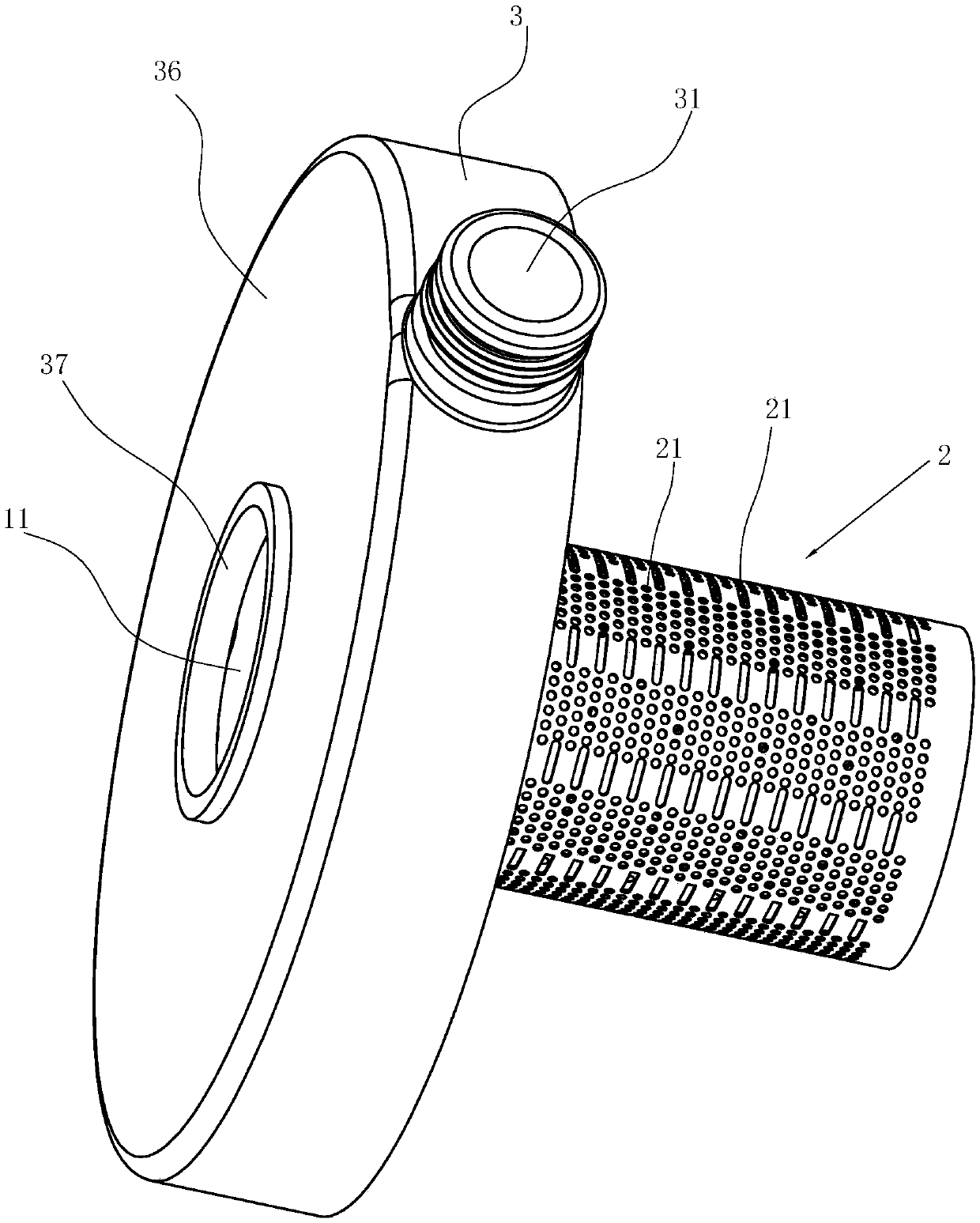

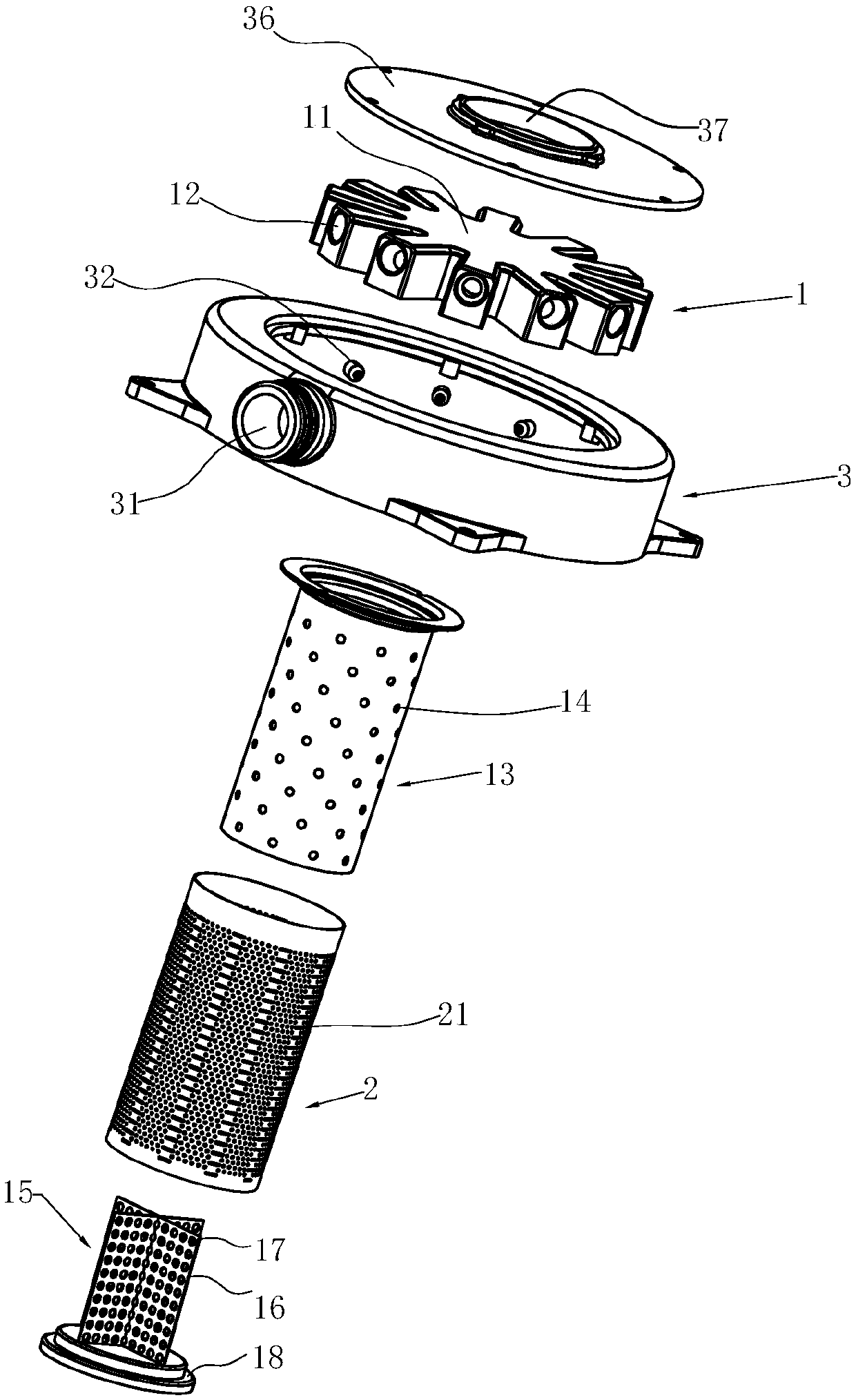

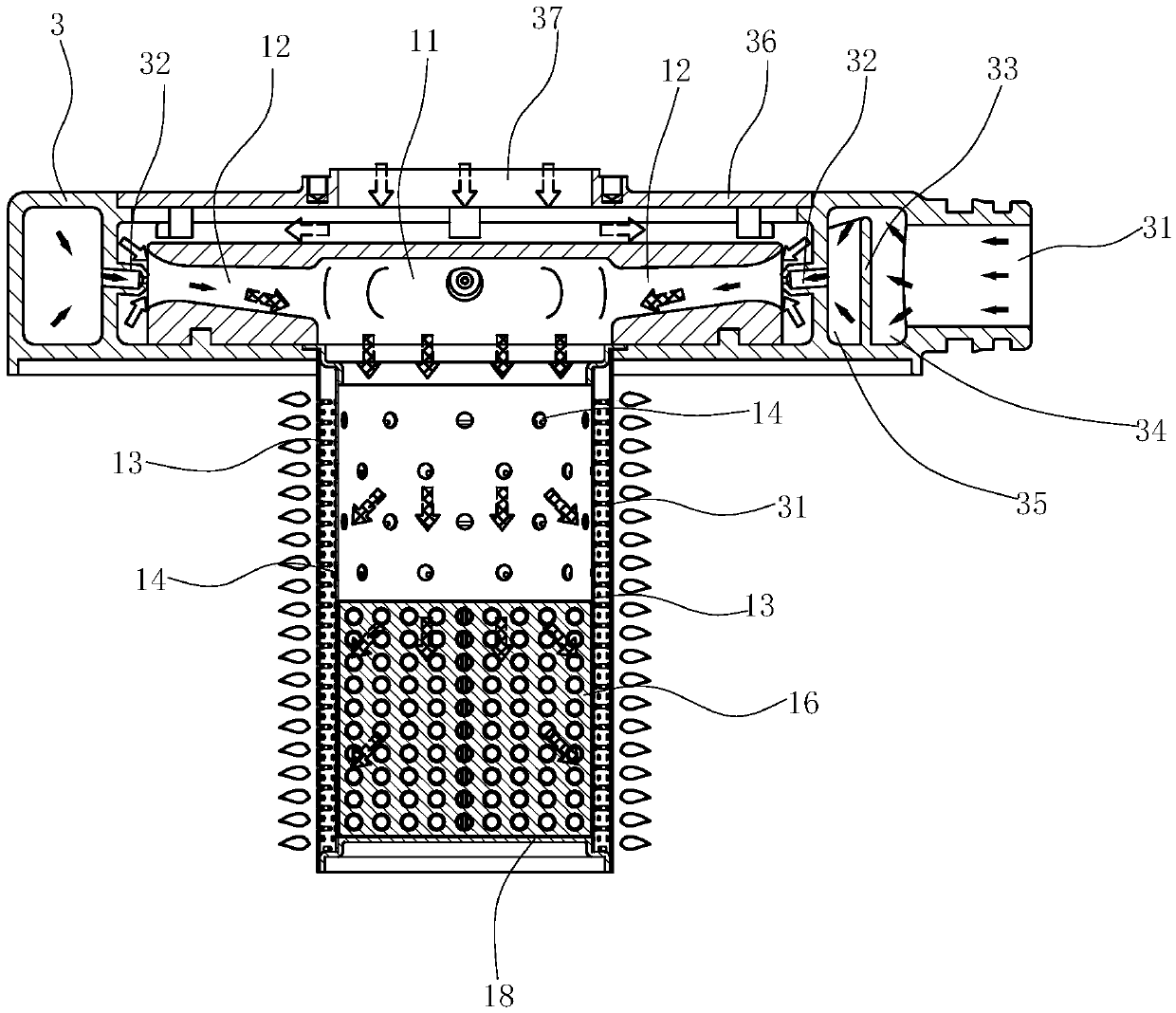

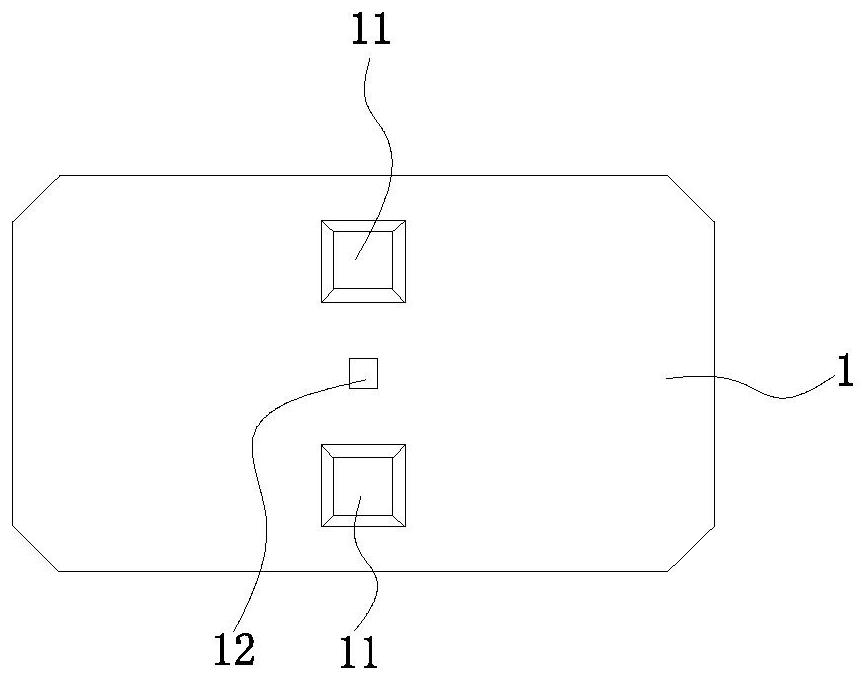

Burner

The invention relates to a burner. The burner comprises an ejector (1) and a burning head (2) and is characterized in that the ejector (1) is sleeved with an annular fuel gas distribution pipe (3), the fuel gas distribution pipe (3) is provided with a fuel gas inlet (31) communicating with an inner cavity of the fuel gas distribution pipe, and the side wall of the fuel gas distribution pipe is further provided with multiple spray nozzles (32) communicating with the inner cavity of the fuel gas distribution pipe at intervals. The ejector (1) comprises a gas mixing chamber (11) and multiple mutually-independent ejection channels (12), inlets of all the ejection channels are opposite to the corresponding spray nozzles (32) respectively and communicate with the surrounding environment, outletsof all the ejection channels communicate with the gas mixing chamber (11), and an outlet of the gas mixing chamber (11) is connected with an inlet of the burning head (2).

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Porous medium turbulent flow jet cooling device

PendingCN112788918AExtended stayIncrease the heat exchange areaCooling/ventilation/heating modificationsCold plateMechanics

The invention provides a porous medium turbulent flow jet flow cooling device which comprises a first cold plate and a second cold plate. The first cold plate is tightly attached to a heating element, a jet flow cavity is formed between the first cold plate and the second cold plate, the second cold plate is provided with jet flow holes, jet flow enters the jet flow cavity through the jet flow holes and impacts the first cold plate. The impacted surface of the first cold plate is a smooth surface; a turbulent flow cavity is further formed between the first cold plate and the second cold plate, the turbulent flow cavity is communicated with the jet flow cavity, and a porous medium is arranged in the turbulent flow cavity. The fluid passes through the jet flow inlet and impacts the inner surface of the first cold plate, the flow path is short, and a flow boundary layer on the impacted surface is thin, so that the area which is directly impacted generates a very strong heat exchange effect. And after the heat exchanger passes through the turbulent flow porous medium, the porous medium destroys a flow boundary layer formed in the flow channel and increases turbulent flow in the flow, so that the heat exchange effect is further enhanced.

Owner:CRRC DALIAN INST CO LTD

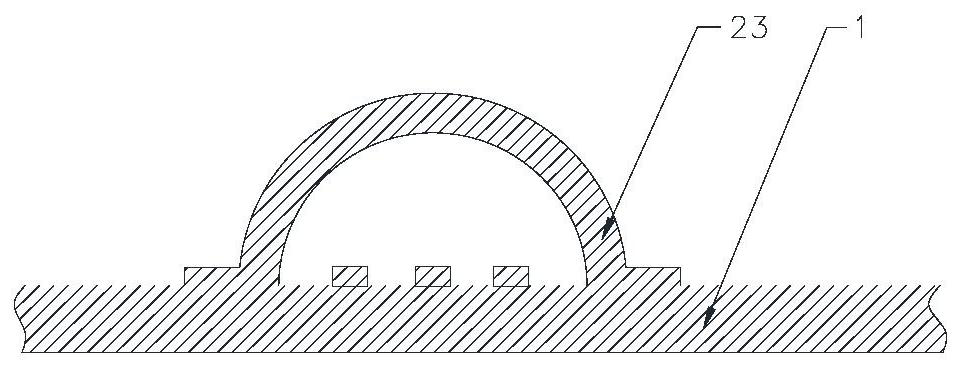

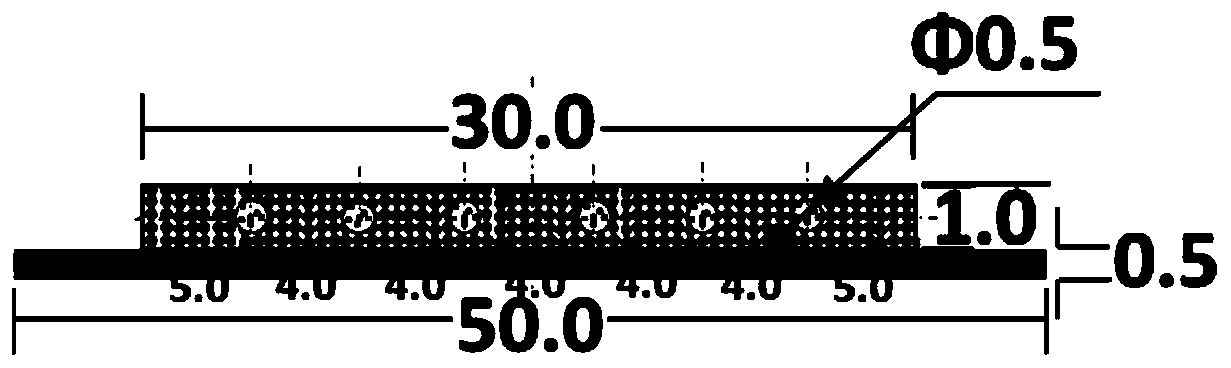

High-resolution in-situ fluid turbulence heating chip of transmission electron microscope

PendingCN111879797AAdd spoilersFlow controllableScanning probe techniquesMaterial analysis by transmitting radiationPhysicsMetallic bonding

The invention relates to a high-resolution in-situ fluid turbulence heating chip of a transmission electron microscope, which is structurally characterized in that an upper sheet and a lower sheet arecombined through a metal bonding layer and are self-sealed to form an ultrathin chamber; the upper piece is provided with two sample injection ports and an upper central window; the lower sheet is provided with a fluid inlet, a fluid outlet, a fluid flow channel, a lower central window, a micro-turbulence column array, a heating layer and an insulating layer; the heating layer is provided with four contact electrodes and a spiral annular heating wire; the lower central window serves as the center and is located in the central area of the spiral annular heating wire; the fluid inlet and the fluid outlet are symmetrically arranged relative to the central window, and the lower central window is located in the center of the heating layer; a micro-turbulence column array is arranged on the lower central window; the chip has the advantages of being rapid in heating and cooling, high in resolution ratio, accurate in temperature control, controllable in fluid flow direction and low in sampledrift rate.

Owner:XIAMEN UNIV

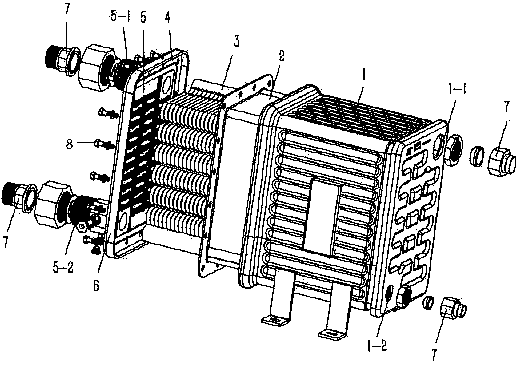

Heat exchanger with double-shell structure

ActiveCN103557722AEasy to disassembleImprove insulation effectHeat exhanger sealing arrangementHeat exchanger casingsPlate heat exchangerAnti freezing

The invention discloses a heat exchanger with a double-shell structure. The heat exchanger with the double-shell structure comprises an outer shell body, an inner shell body and a heat exchange core arranged in the inner shell body, wherein the inner shell body comprises an inner shell with an opening and an inner shell cover plate arranged at an opening end and detachably connected to the inner shell; the outer shell body comprises an outer shell with an opening and an outer shell cover plate arranged at an opening end and detachably connected to the outer shell; the inner shell is sleeved in the outer shell; the inner shell cover plate is sleeved in the outer shell cover plate. That is to say, in the invention, the inner and outer shell bodies can be detached from each other, and the inner and outer shell bodies per se also can be detached, so that the heat exchanger is convenient for cleaning and replacement of a heat exchange core mounted inside the heat exchanger, and avoids damage to the inner and outer shell bodies; meanwhile, a heat insulating material is filled between the inner shell and the outer shell, so that heat-retaining capacity of the heat exchanger per se is enhanced, heat leakage can be prevented, and anti-freezing capability of the heat exchanger is enhanced.

Owner:HANGZHOU SHENSHI ENERGY CONSERVATION TECH

Nozzle device for smoke injection system

ActiveCN103203183AAvoid cloggingShorten the mixing distanceDispersed particle separationSpray nozzlesEngineeringFlue

The invention discloses a nozzle device for a smoke injection system. The nozzle device for the smoke injection system comprises an injection body provided with an injection cavity, wherein the end face of the injection opening of the injection cavity is parallel to the main airflow direction of smoke; the opening direction of the injection opening faces to the inner wall of a flue; airflow injected from the injection opening is circular; and the direction of the airflow injected from the injection opening and the main airflow direction of the smoke form an included angle of 105-165 degrees. According to the nozzle device for the smoke injection system provided by the invention, the mixing effect of the airflow injected by a nozzle and the smoke can be improved through novel and specific nozzle structural design, so that the turbulent flow effect and the mixing effect can be enhanced, the nozzle device for the smoke injection system is beneficial to saving mixing time, and the mixing distance of the smoke and the airflow injected from the nozzle is reduced. Therefore, the investment cost of the smoke injection system is reduced, and the efficiency of the smoke injection system is improved. The nozzle device provided by the invention further can be used for preventing the nozzle from blocking, so that the operation reliability of the system is greatly improved.

Owner:浙江博众数智科技创新集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com