Patents

Literature

44results about How to "Flow controllable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

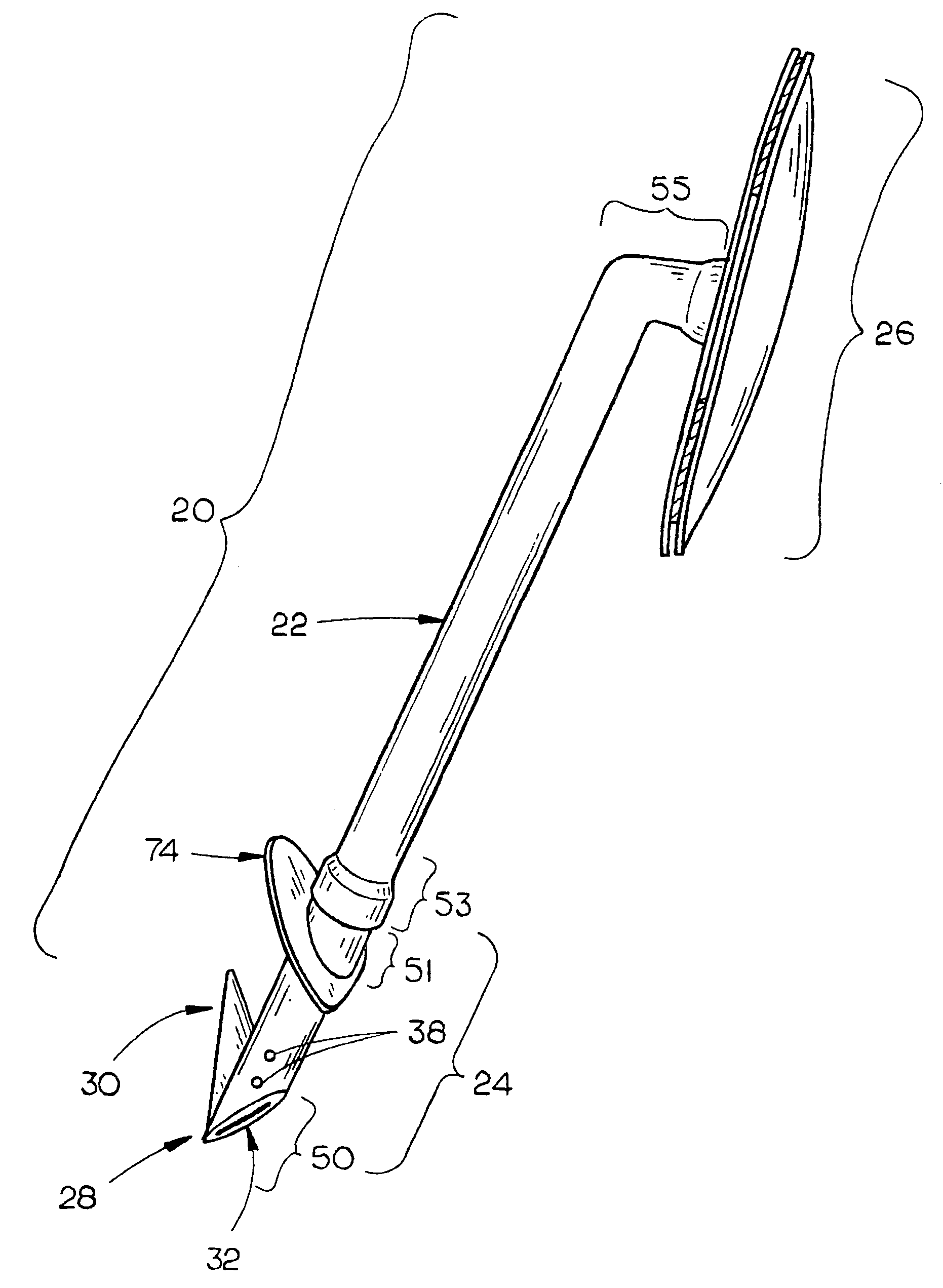

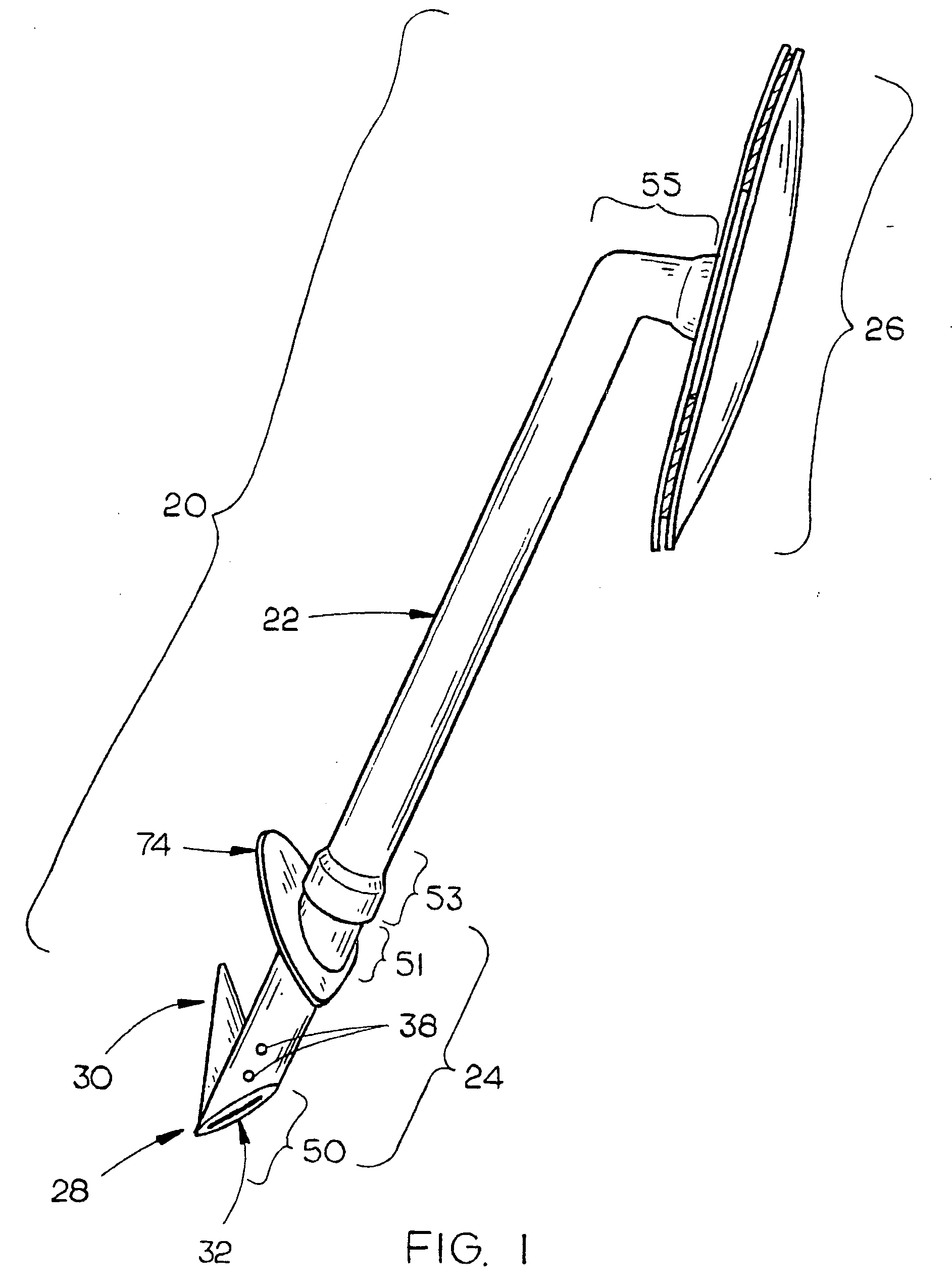

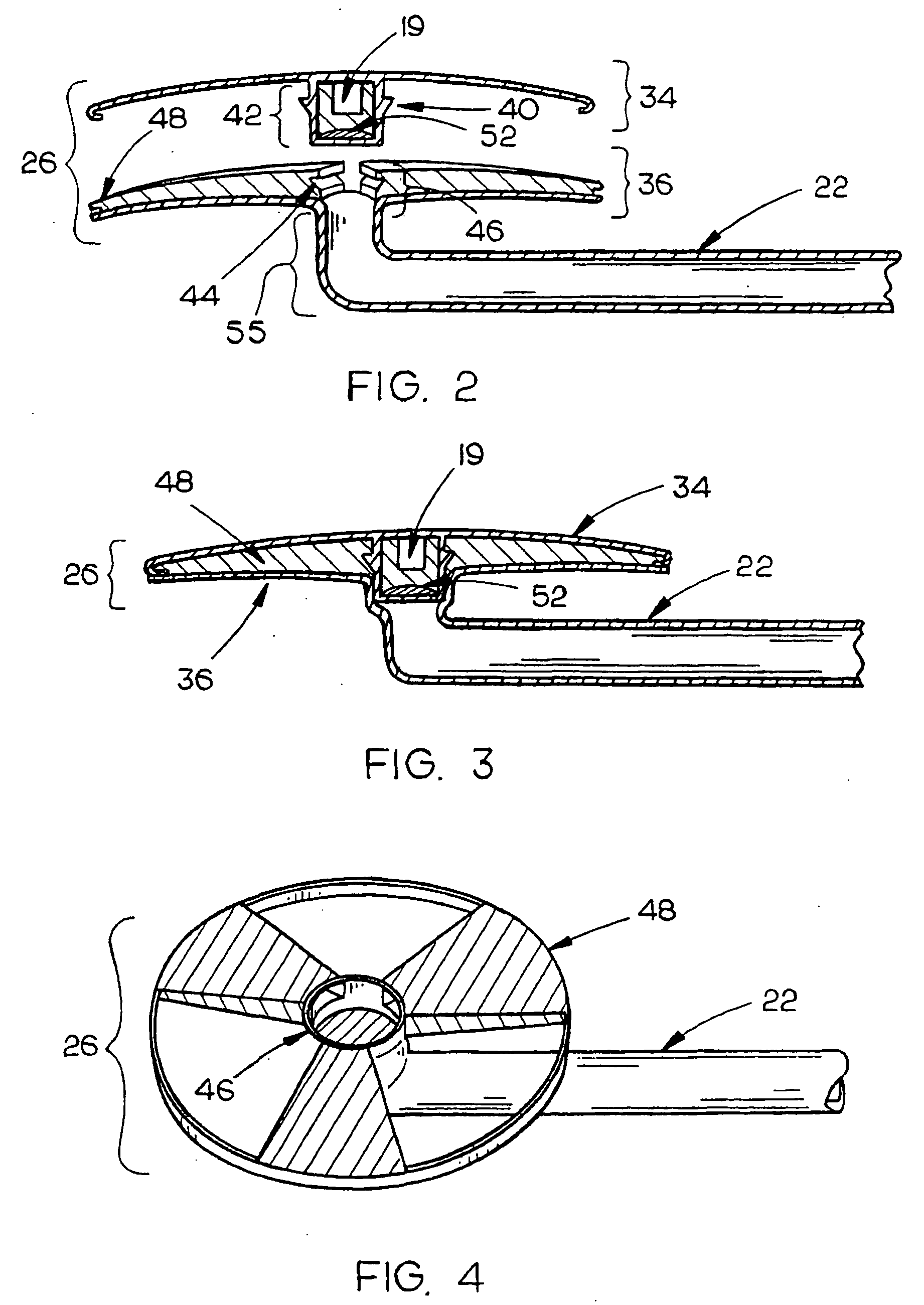

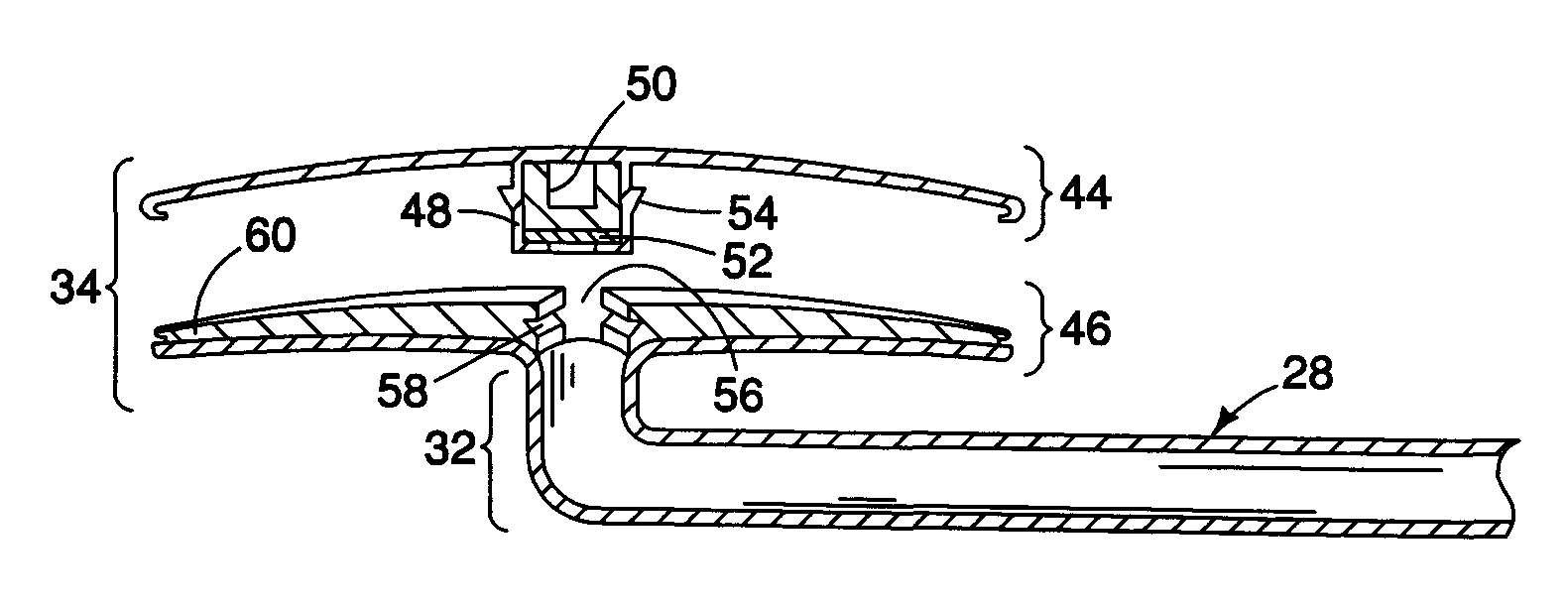

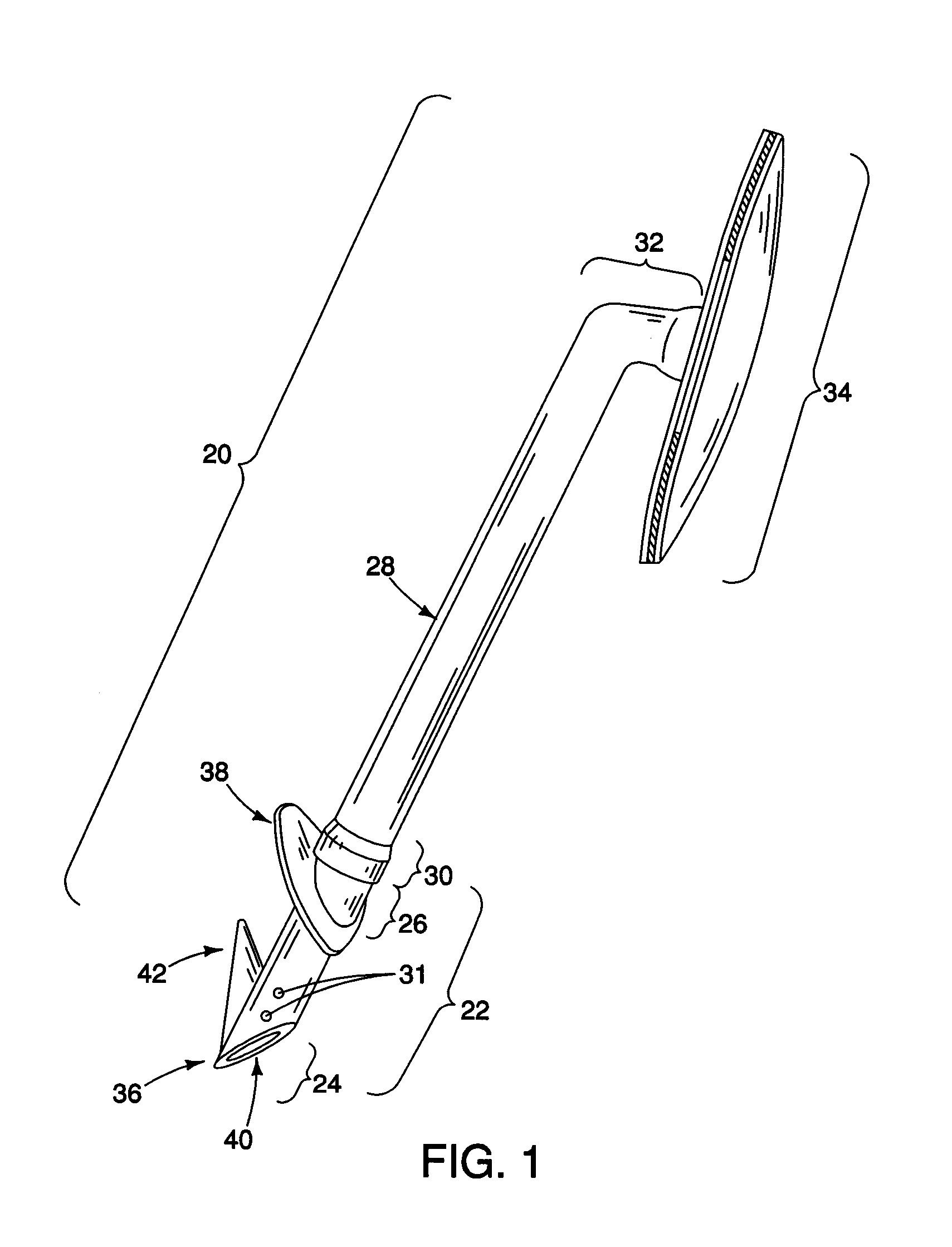

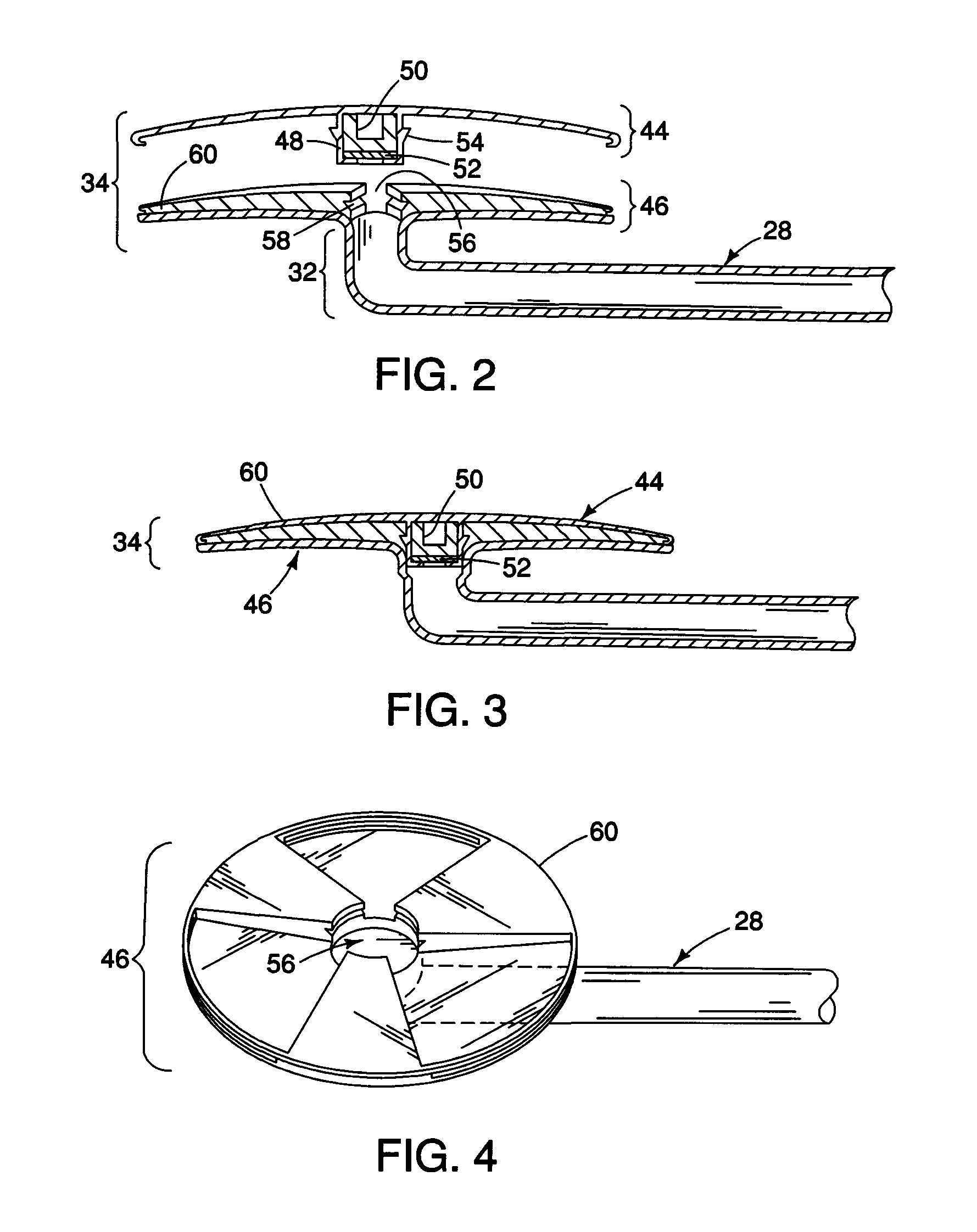

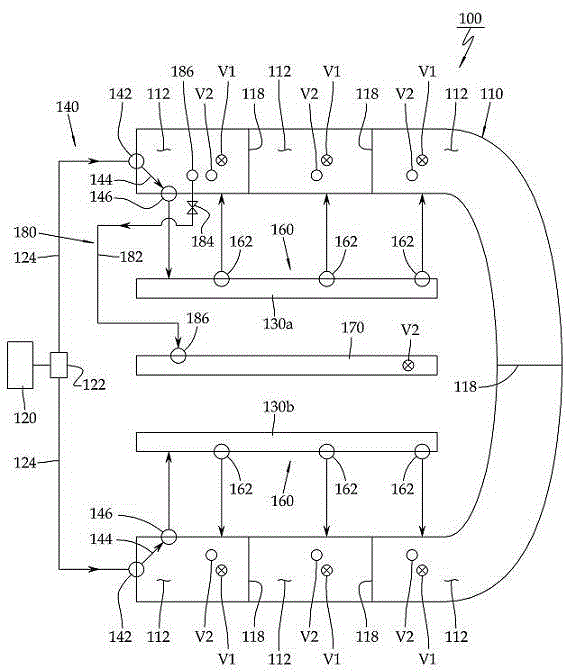

Method and apparatus for reducing intraocular pressure

An intraocular drainage apparatus for treatment of glaucoma, a device to be used in the insertion of the drainage apparatus, and a method of controllably regulating intraocular pressure in glaucoma patients through the use of the drainage apparatus is described herein. The drainage apparatus is comprised of a tube capable of conducting fluid disposed between an inlet assembly, where aqueous humor enters the apparatus, and an outlet assembly, where aqueous humor exits the apparatus. The inlet assembly is comprised of a beveled tip and preferably an anchor. The beveled tip allows the drainage apparatus to be more easily inserted into an eyeball and the anchor, when employed, functions to hold the beveled tip of the inlet assembly within the anterior chamber of the eyeball. An opening in the beveled tip of the inlet assembly allows aqueous humor from the anterior chamber of the eyeball to flow through the inlet assembly, through the tube to ultimately drain through the outlet assembly, situated on the external surface of the eyeball, so as to be drained out of the eyeball onto the exterior surface of the eyeball. The inserting apparatus is comprised of an insertion prong attached to a first handle. The insertion prong has a sharp, beveled insertion point. The insertion prong also defines an aperture wherein a second prong is slideably received. The drainage apparatus is seated in the inserting apparatus and is positioned at a proper point in the eyeball. The inserting apparatus is then manipulated so that the second prong drives the drainage apparatus into the proper position within the eyeball. The drainage apparatus also provides for the use of micropore filters and / or valves to prevent infection and / or to predictably regulate the flow of aqueous humor from the anterior chamber of the eyeball to the surface of the eyeball, thereby allowing for post-surgical adjustment of the intraocular pressure within the eyeball. An apparatus for removing and replacing these filters and / or valves is also disclosed, as are alternative embodiments of the drainage apparatus and inserting apparatus.

Owner:CAMRAS VISION +1

Method and apparatus for reducing intraocular pressure

ActiveUS7641627B2Desirable intraocular pressureFlow controllableEye surgeryCatheterAqueous humorConjunctiva

A drainage apparatus and method to reduce intraocular pressure in an eyeball that includes an anterior chamber having aqueous humor disposed therein, a cornea and a surrounding marginal limbus by which the cornea is continuous with a scleral layer and a conjunctival layer disposed on an exposed surface of the eyeball and under eyelids, the apparatus comprising an inlet assembly configured to be disposed at the anterior chamber of the eyeball, an outlet assembly configured to be disposed at the external surface of the eyeball, a tube extending between the inlet and outlet assemblies and configured to promote fluid communication between the inlet and outlet assemblies, and a control means disposed within the outlet assembly for controlling a flow of aqueous humor through the tube from the anterior chamber of the eyeball to the external surface of the eyeball, and for preventing bacterial infiltration into the anterior chamber.

Owner:CAMRAS VISION +1

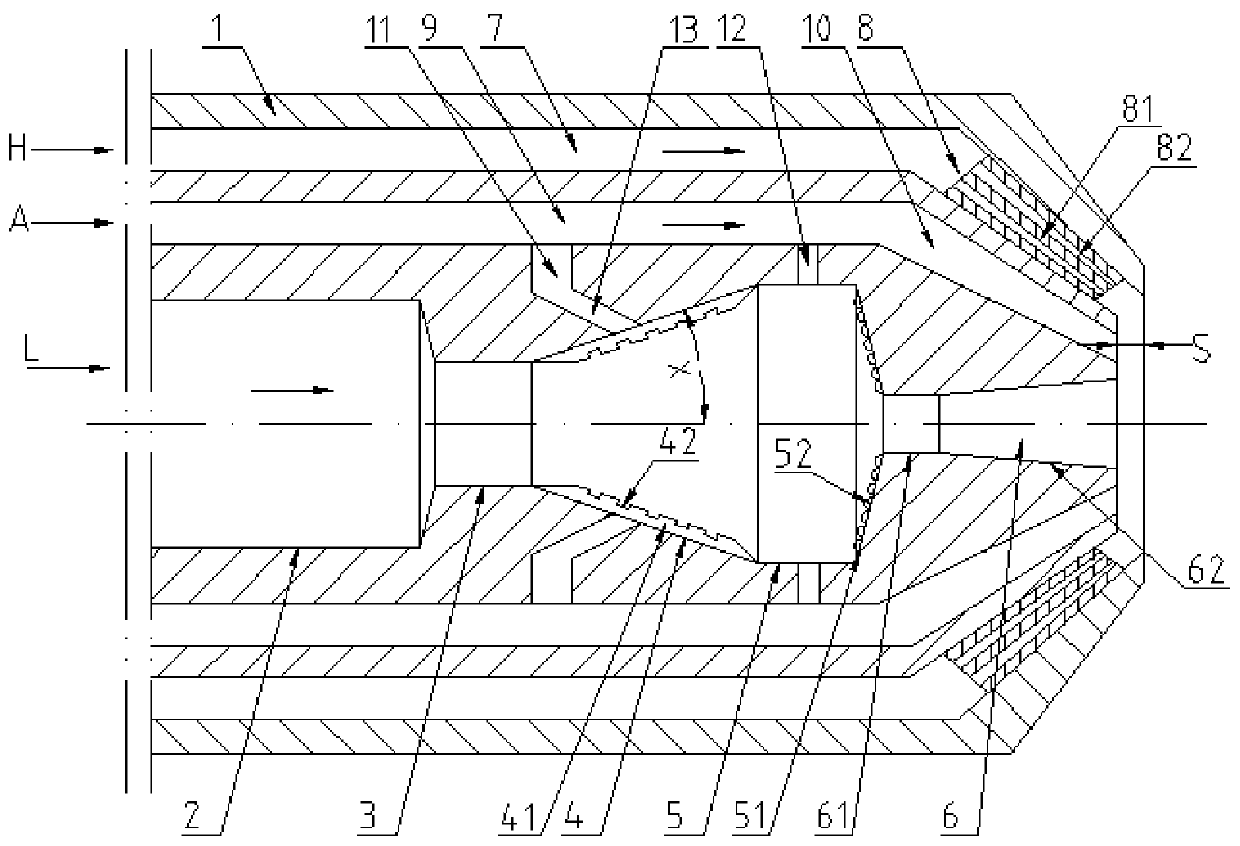

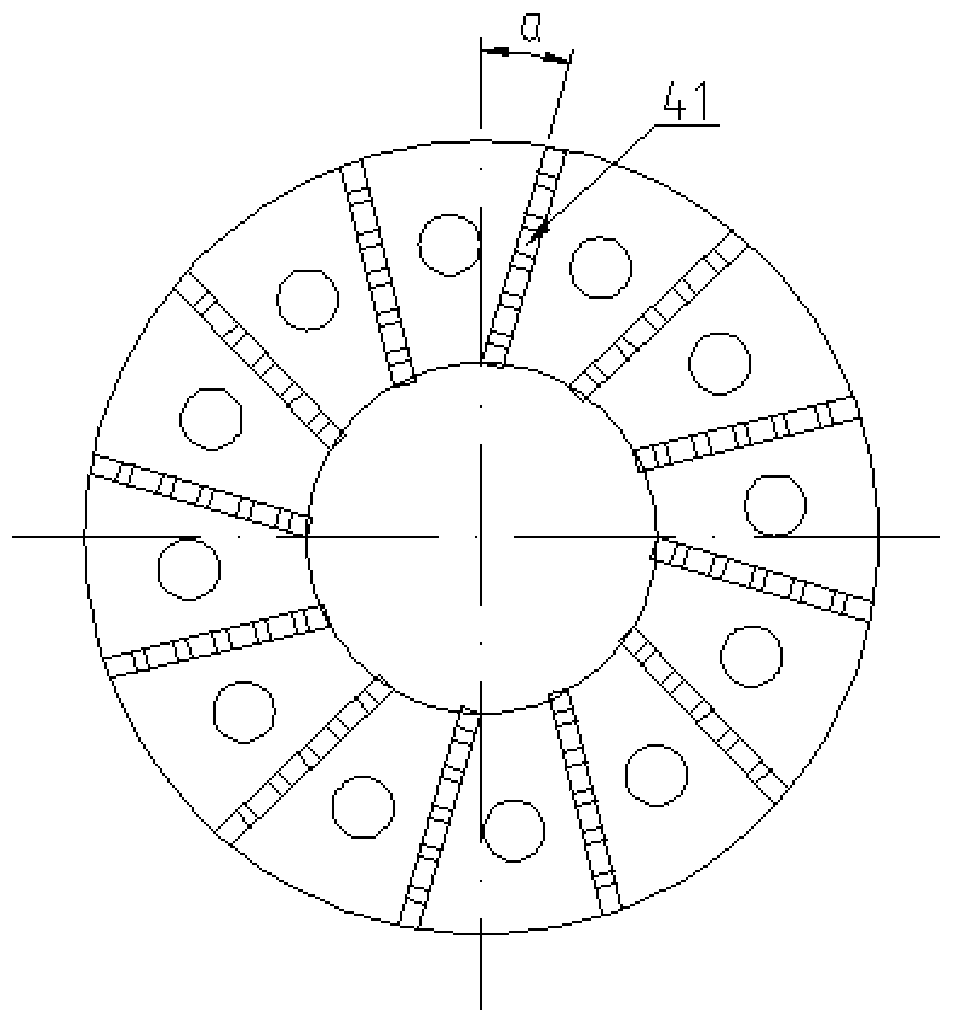

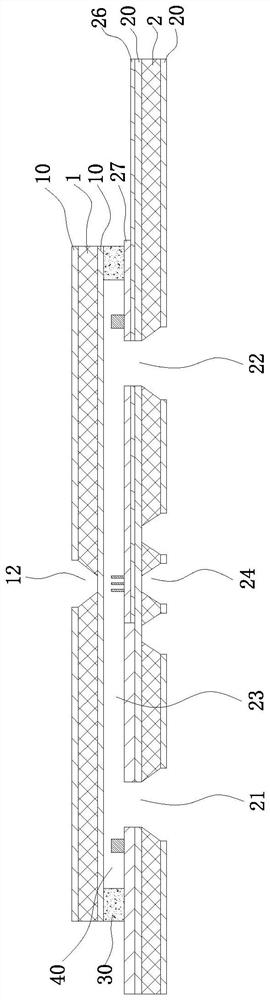

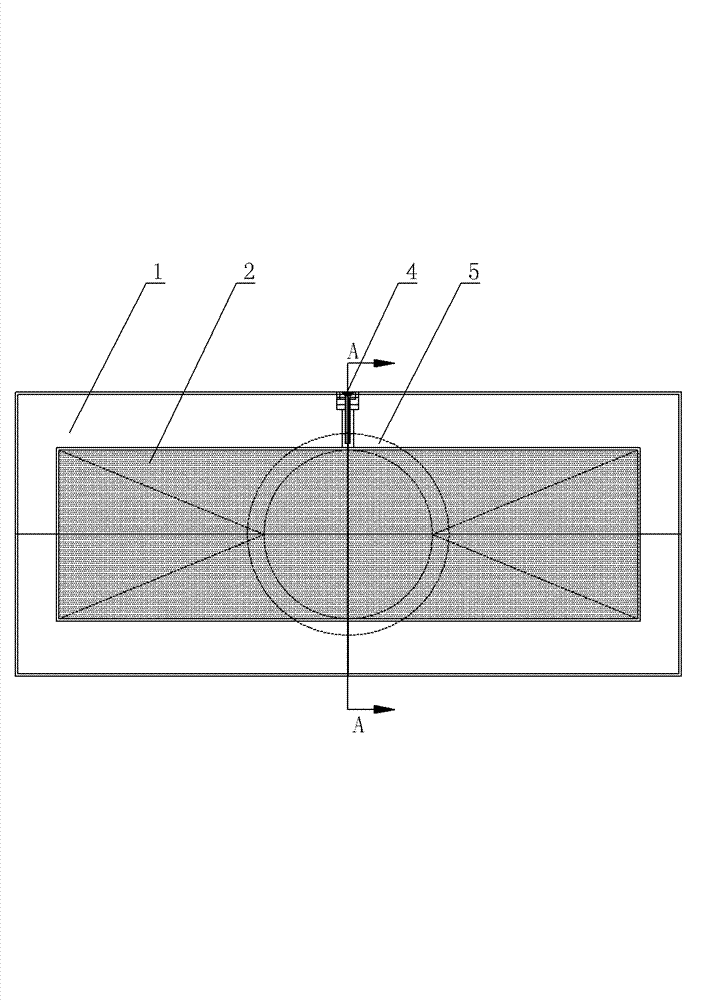

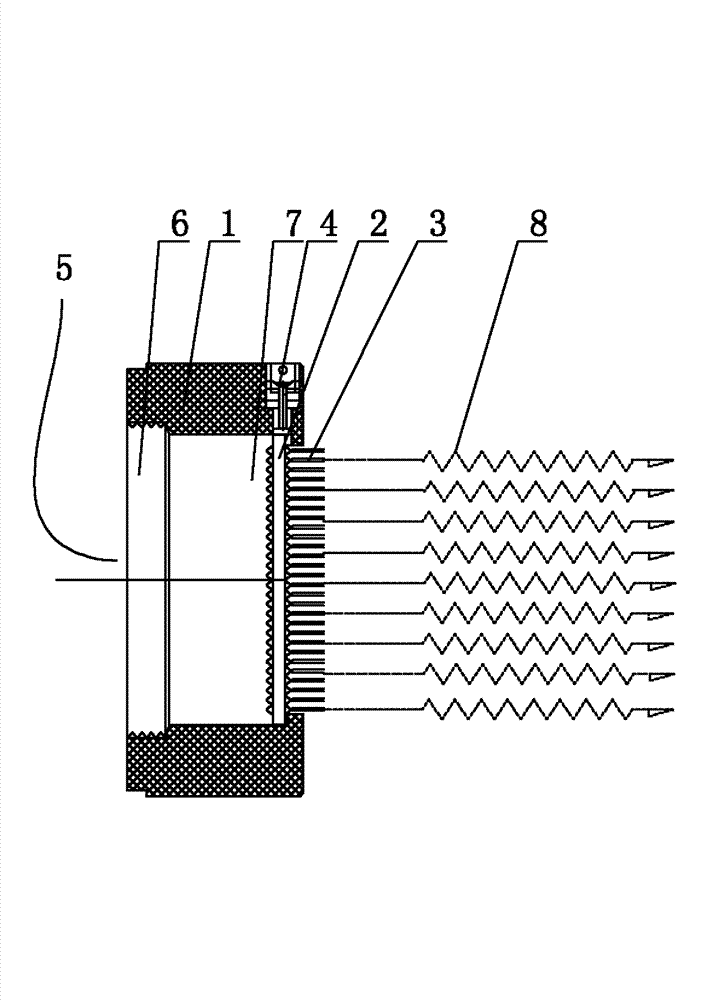

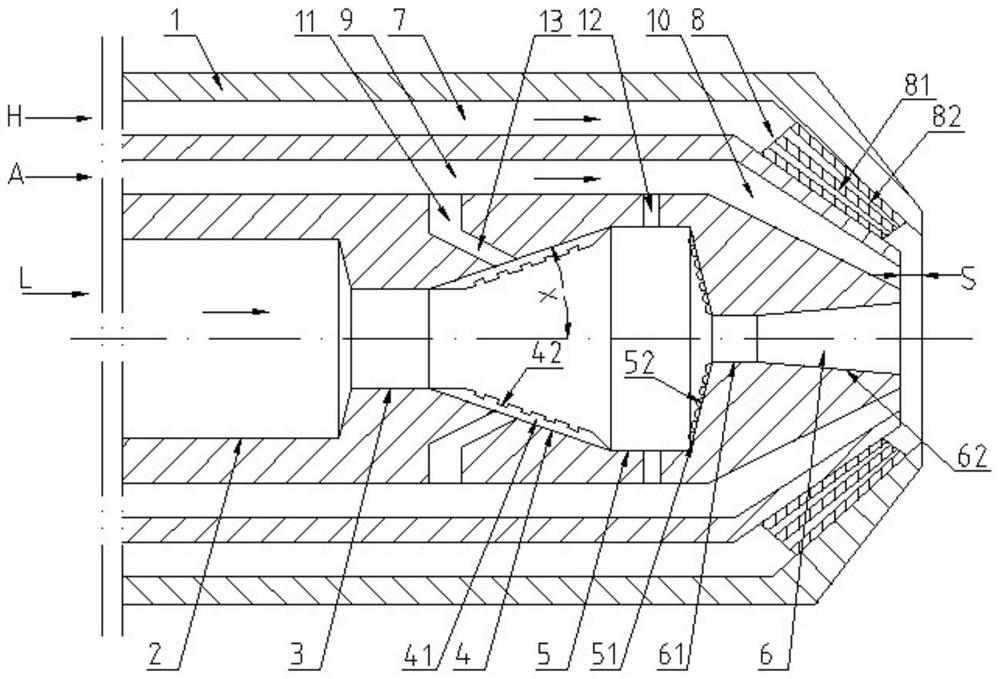

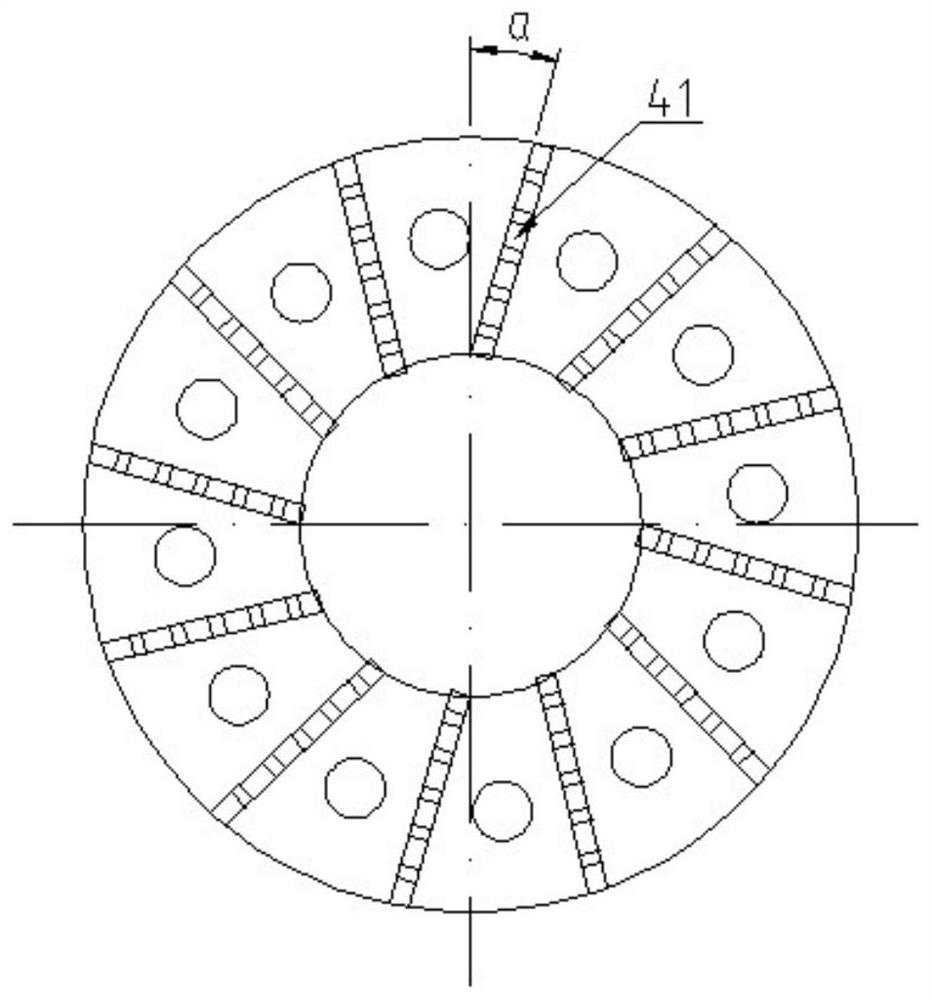

Injection device for surface treatment or coloring

InactiveCN110449282AIncrease rotational kinetic energy/tangential velocityImprove the mixing effectLiquid spraying apparatusSpray nozzleSurface finishing

The invention provides an injection device for surface treatment or coloring. The injection device comprises a nozzle body, and the nozzle body is internally provided with a liquid channel, a gas channel and a temperature regulating gas channel; the liquid channel is located at the center position of the nozzle body, and the gas channel is located on the radial outer side of the liquid channel; the temperature regulating gas channel is located on the radial outer side of the gas channel, and the liquid channel comprises a first diameter part (1), a second diameter part (2), a first tapered part (3), a diffusion cavity (5) and an outlet part (6); the injection device is characterized in that the inner peripheral surface of the first tapered part is provided with a plurality of swirl plates(41) uniformly distributed in the circumferential direction; and the radial inner edges of the swirl plates are provided with a plurality of swirl slots (42) distributed in the axial direction of theswirl plates. According to the injection device, the rotational kinetic energy / tangential speed of fluid can be increased, and the mixing effect of the fluid is improved; the injection device has theadvantages of a pressurization effect, uniform atomization of the nozzle, small size of droplets, and an excellent injection / atomization effect; the temperature regulating gas flow direction is controllable and accurate, and the flow is stable; and the subsequent drying time is shortened.

Owner:LIYANG SHENGJIE MACHINE

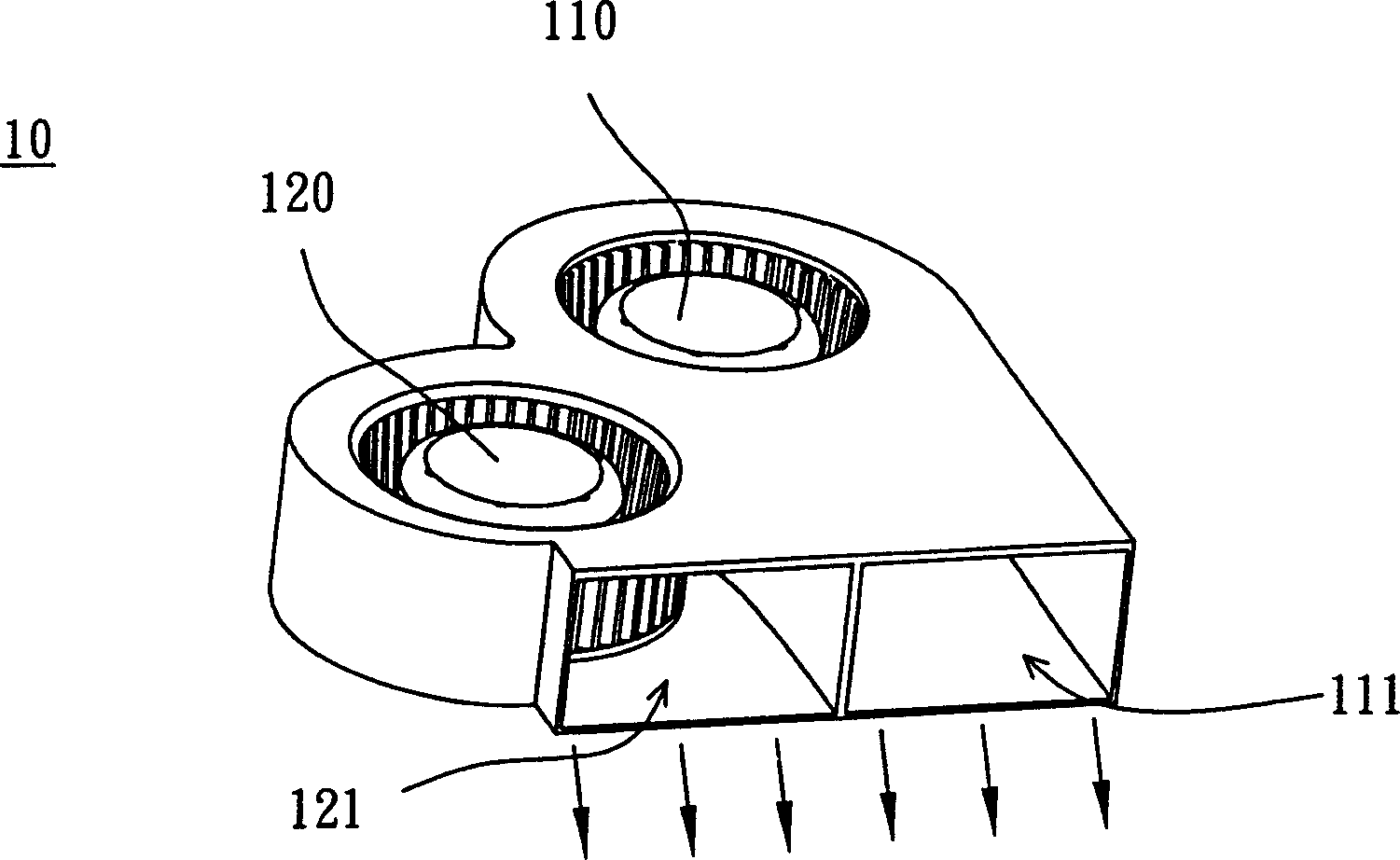

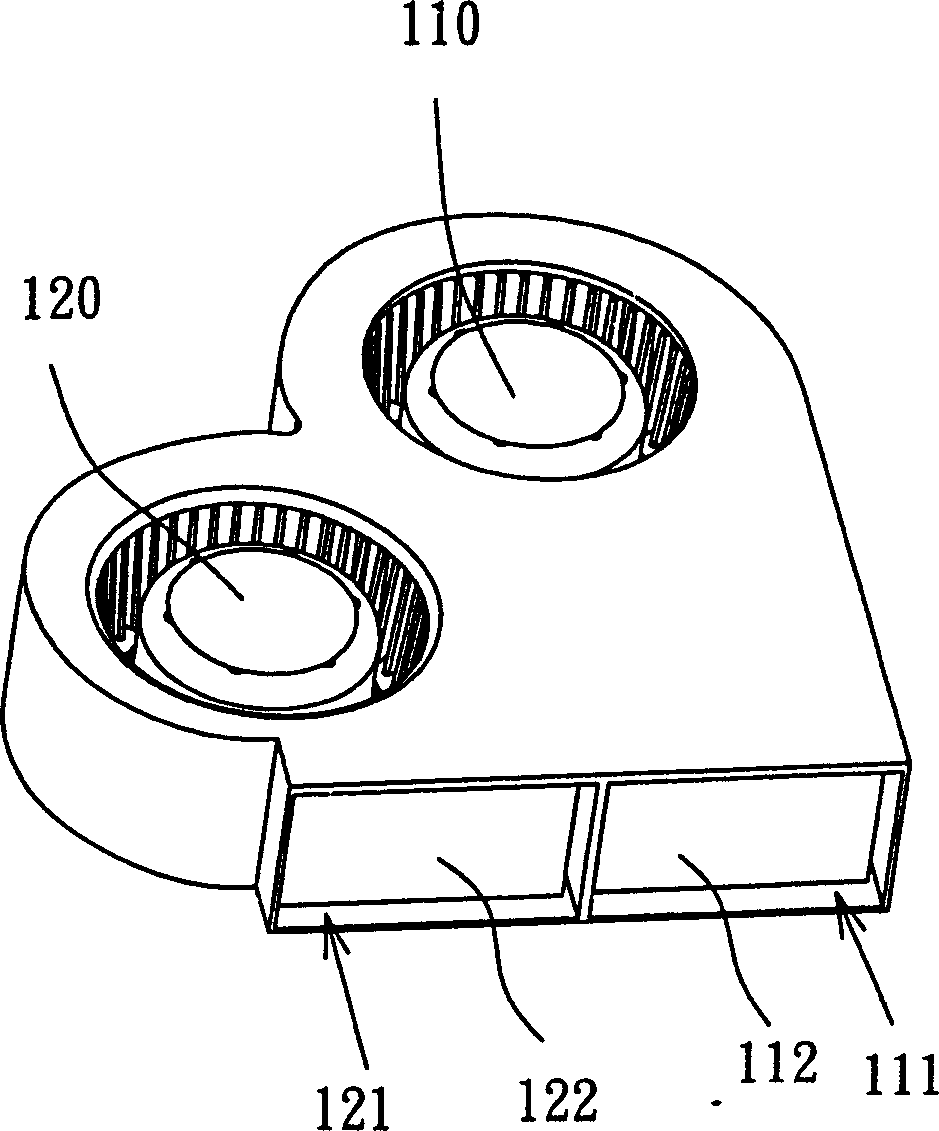

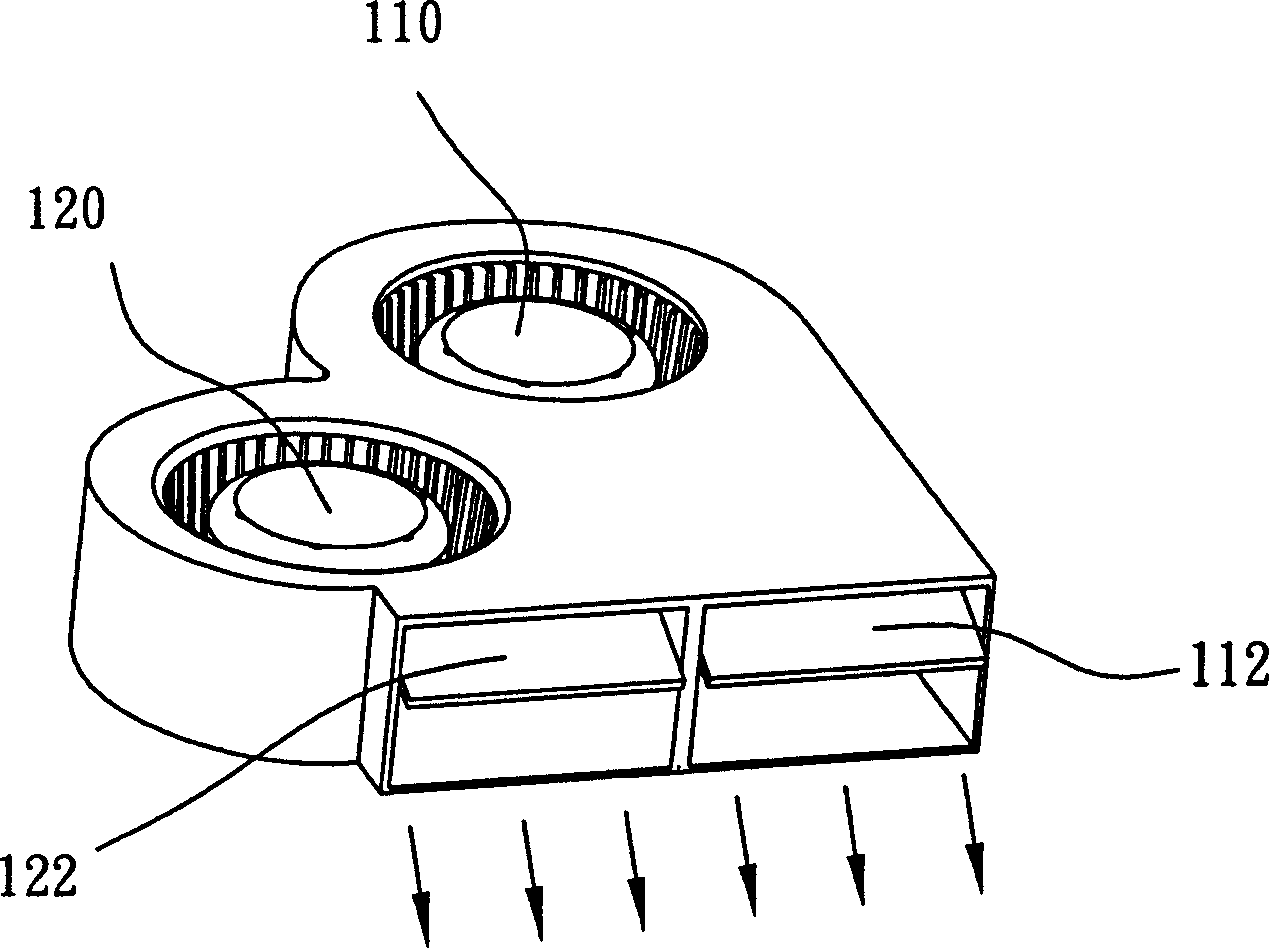

Heat radiation assembly and its flow direction control structure

InactiveCN1767182AImprove performanceFlow controllableDigital data processing detailsSemiconductor/solid-state device detailsEngineeringElectrical and Electronics engineering

Owner:DELTA ELECTRONICS INC

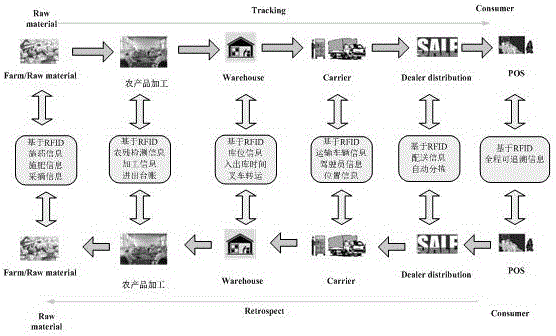

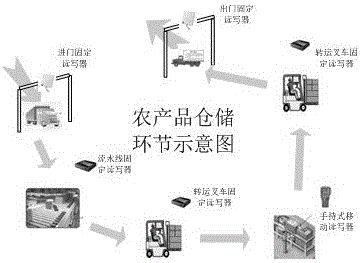

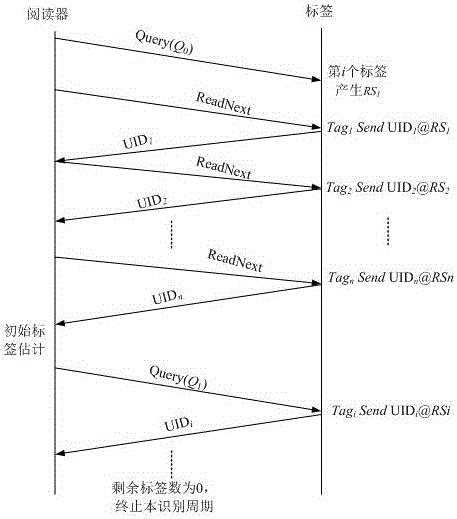

RFID-based agricultural product tracing batch tag information acquisition method

InactiveCN106599958AImprove management efficiencyShort turnaround timeCo-operative working arrangementsInformation acquisitionImproved method

The invention discloses an RFID-based agricultural product tracing batch tag information acquisition method and an RFID-based agricultural product tracing system. A whole process tracing model and a warehouse model of the tracing system are built; an EPCglobal C1 Gen2 standard-based DFSA tag anti-collision method is designed; a new frame length adjustment method is given; an initial tag number is estimated by utilizing a successful timeslot number of a first frame, an empty timeslot number and a collided timeslot number; and the timeslot global throughput performance of the frame length is adaptively adjusted to be optimal in subsequent identification. Compared with an algorithm adopted by widely applied standards such as EPCglobal C1 Gen2 standards and the like, the improved method provided by the invention has the advantage that the throughput performance is improved by 30%.

Owner:XIJING UNIV

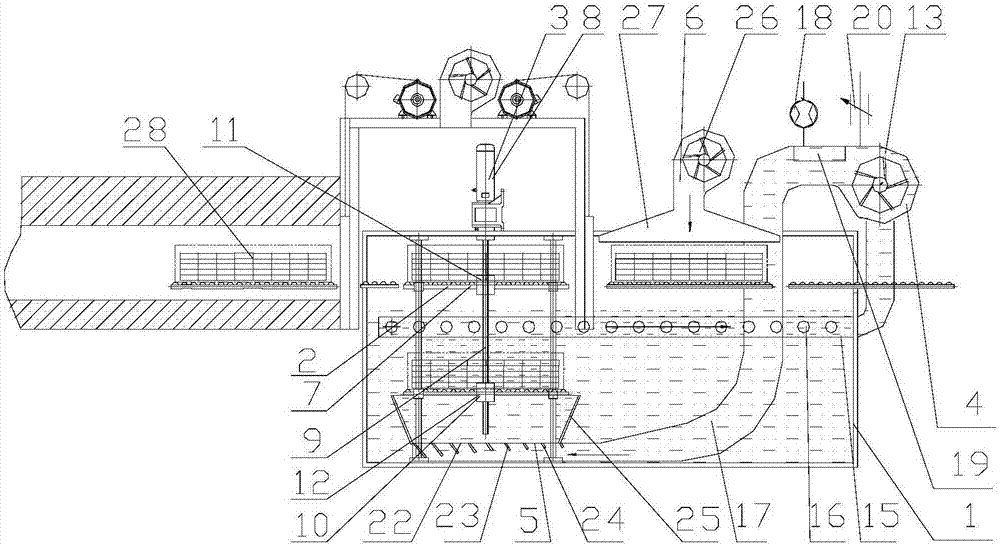

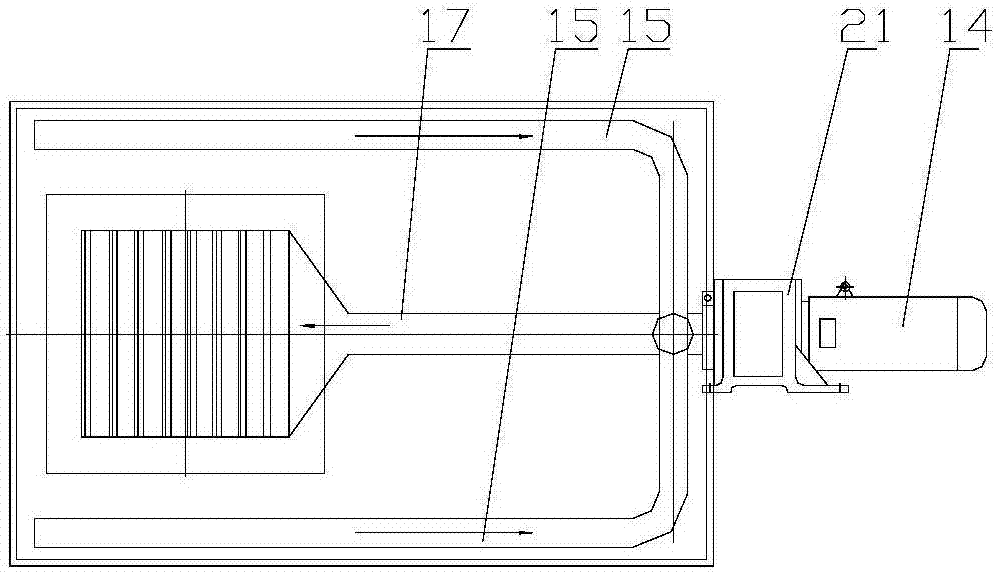

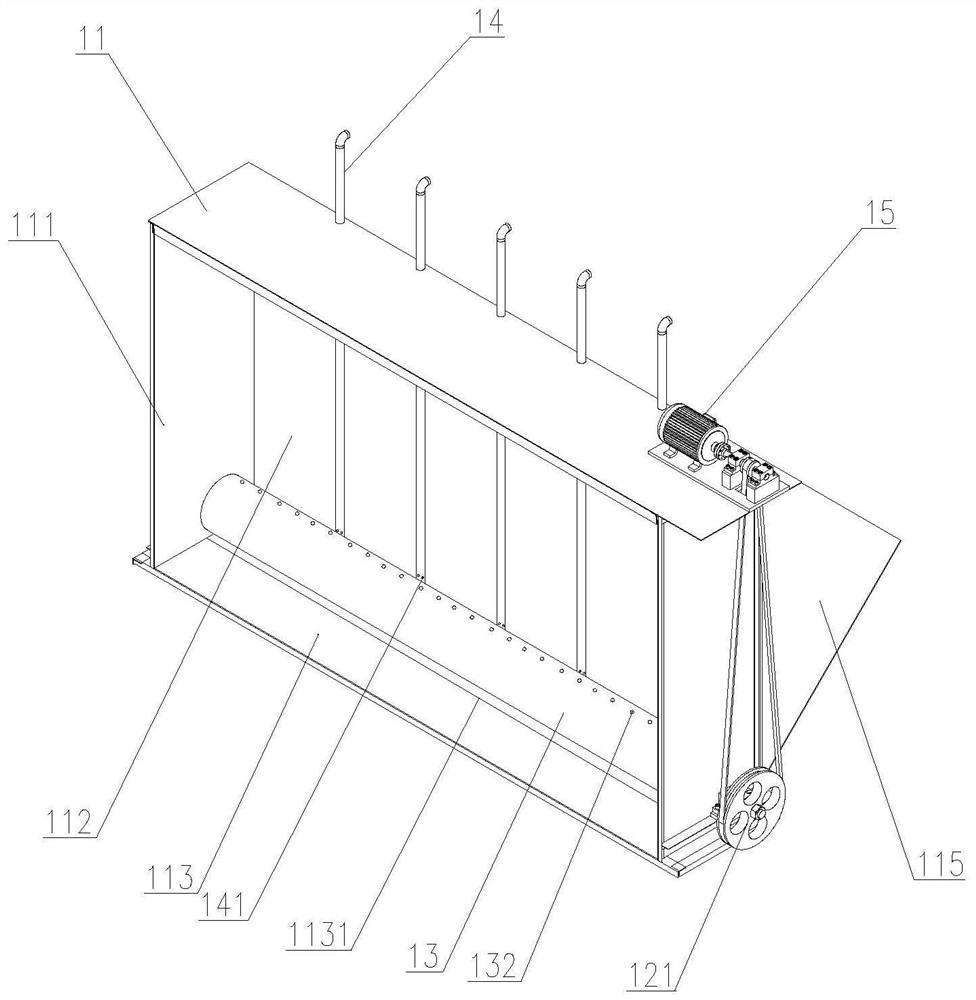

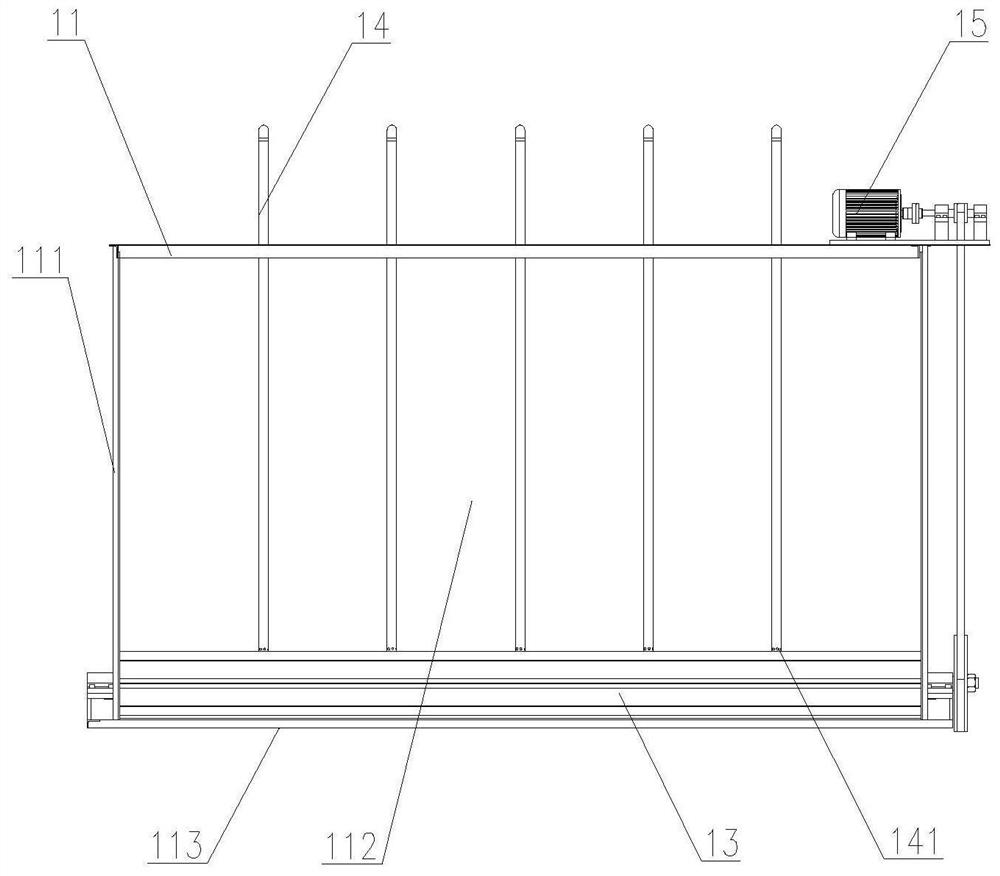

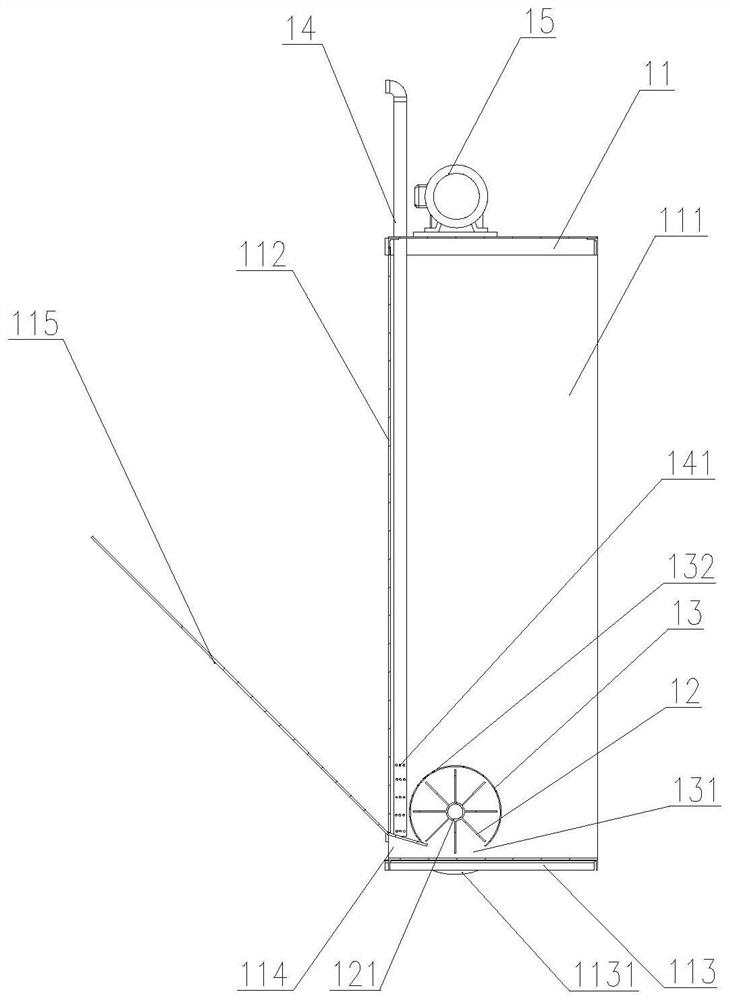

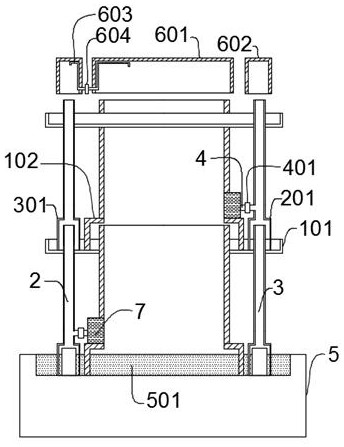

Quenching and cooling device

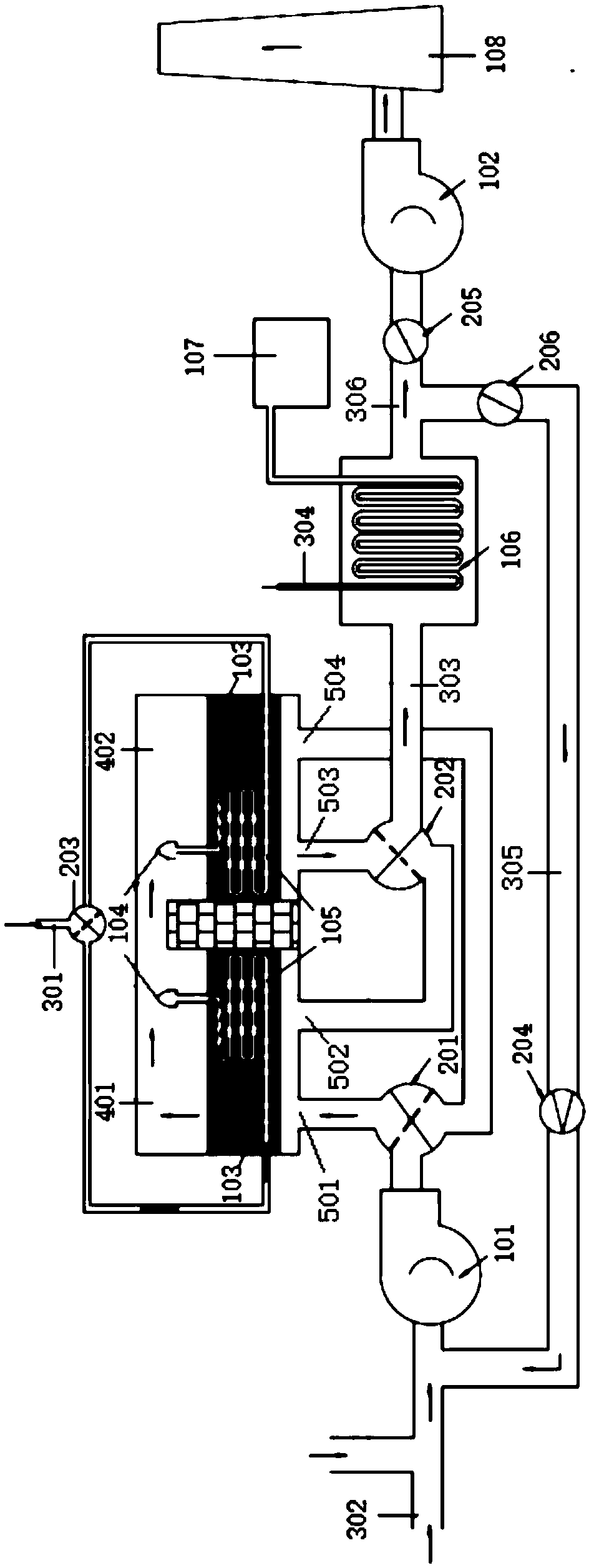

The invention belongs to the technical field of quenching and cooling, and relates to a quenching and cooling device. The quenching and cooling device includes a quenching tank, a quenching bench, a quenching bench lifting system, a medium circulating system, a medium outlet system, a medium blowdown system, a cooling zone carrier roller, a power motor, a leading screw, a nut, a guiding sleeve, a guide rail, a circulating pump, a variable frequency motor, a liquid suction pipeline, a liquid suction port, a liquid discharging pipeline, an electronic flow meter, a cooler, an electric regulating valve, a flow controller, a medium outlet, a flow guiding plate, blades, a coaming plate, a fan and a fan cover, and the quenching bench lifting system includes the power motor, the leading screw, the quenching bench, a guide sleeve and the guide rail. The quenching and cooling device has the advantages of high automation degree, fast cooling speed, controllable cooling process, controllable flow, pressure and flowing direction of a cooling medium, uniform cooling, improvement of the product heat treatment quality, reduction of the loss of the cooling medium, reduction of the cleaning workload, increase of the working efficiency, ingenious and reasonable design of the overall structure, scientific principle, convenience in operation, convenience in use, good safety and reliability, and friendliness to application environment.

Owner:QINGDAO TAIDE AUTOMOBILE BEARING

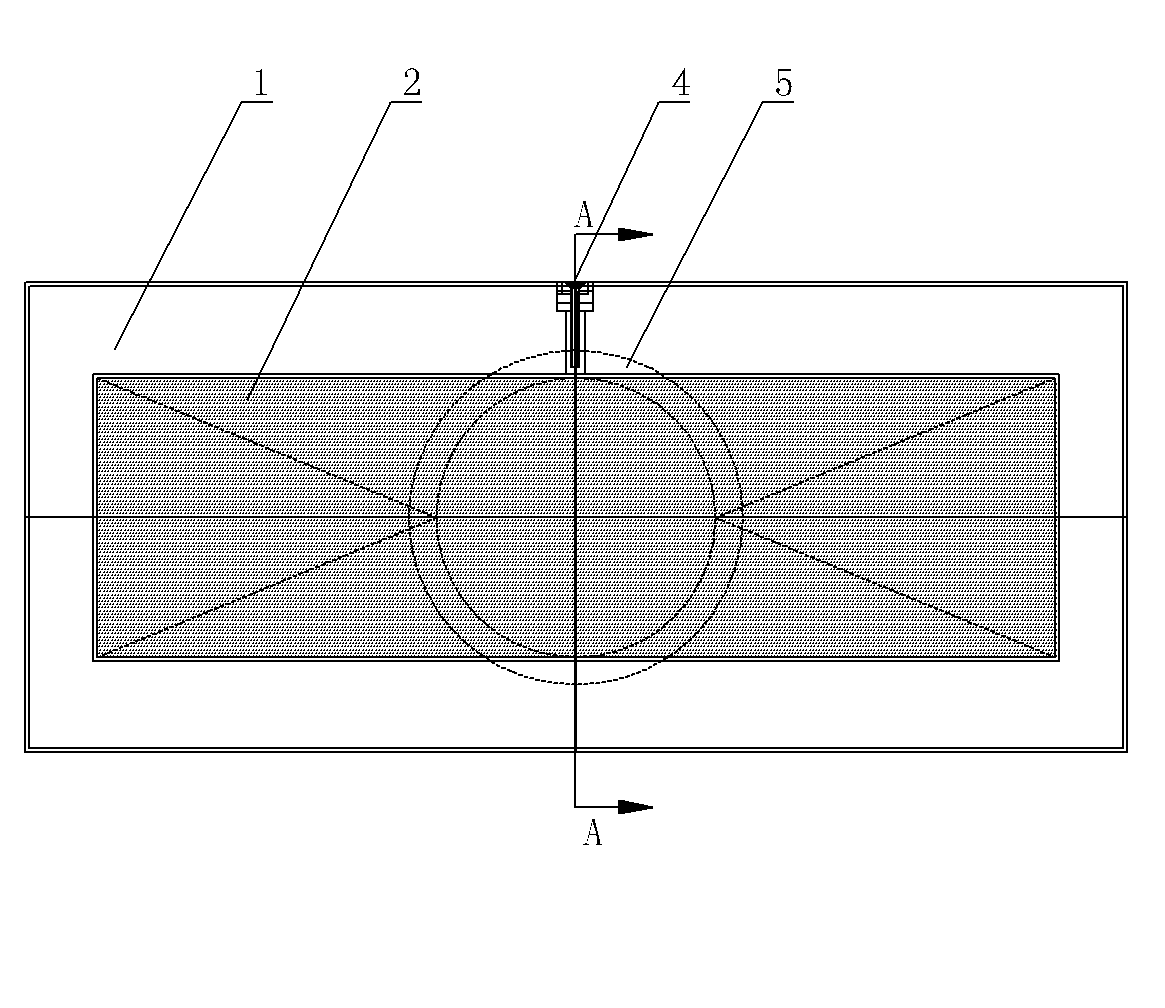

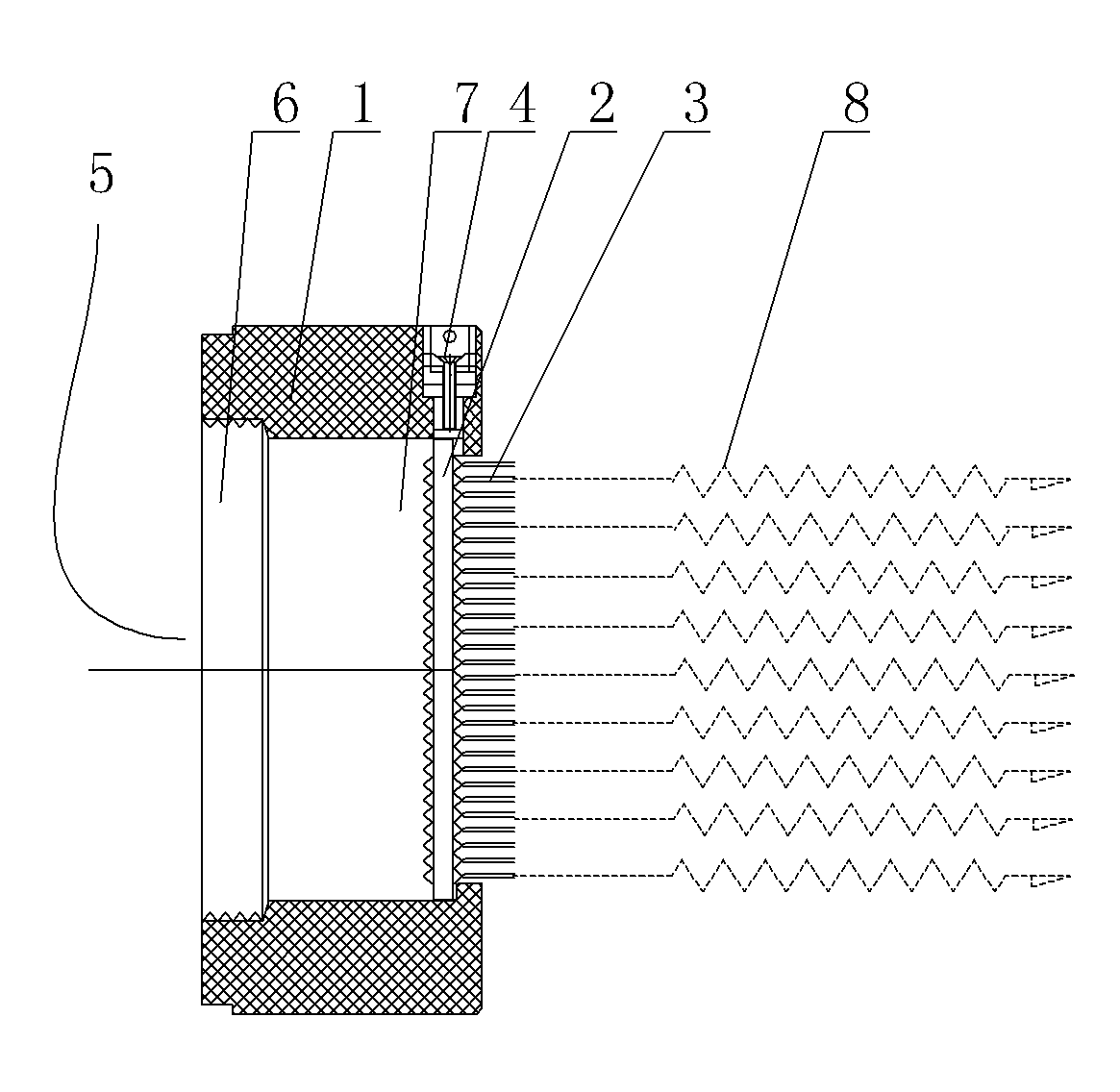

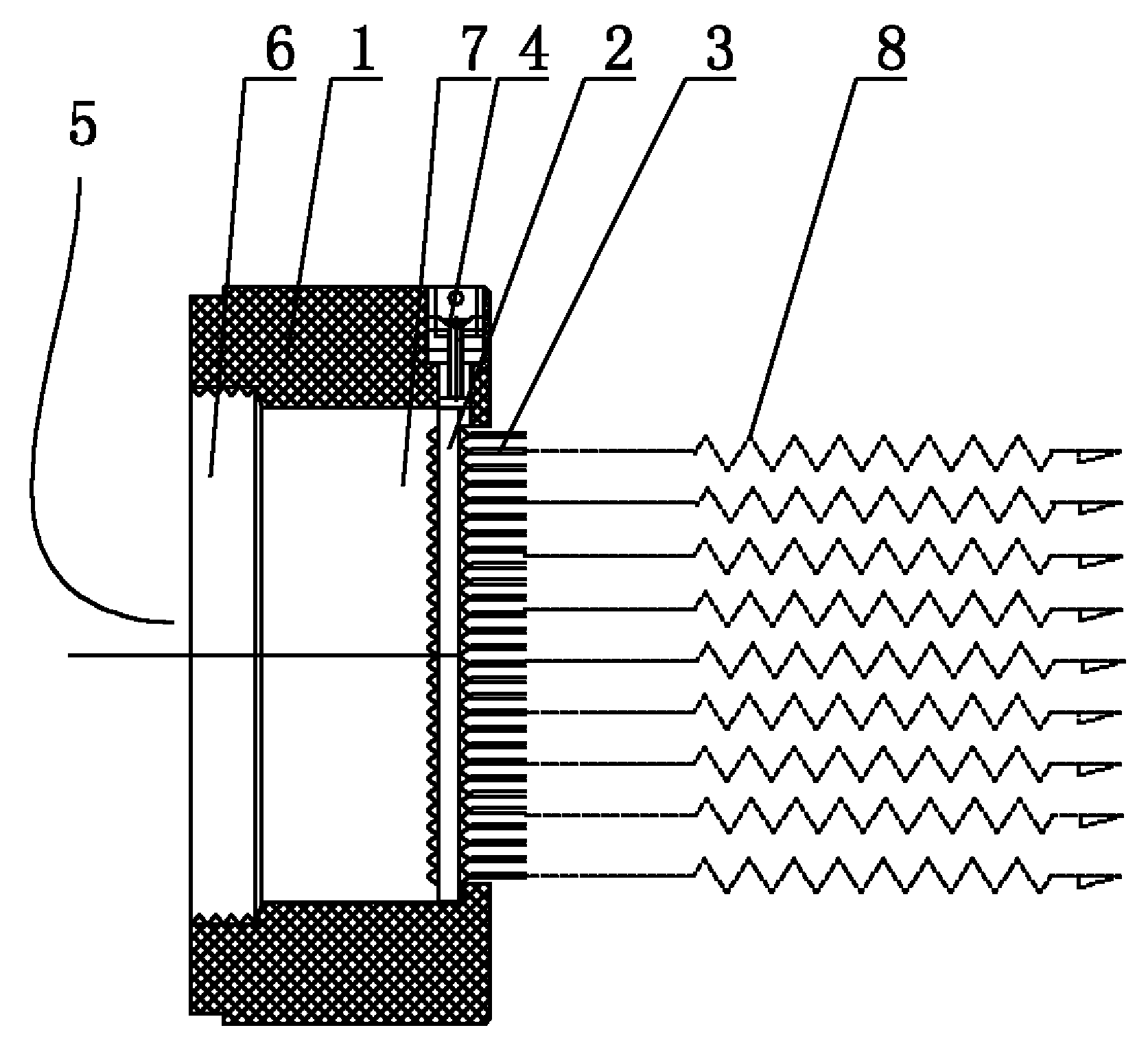

Spraying nozzle device for electrostatic spinning

ActiveCN102061529ASolve processing difficultiesReduce processing difficultySpinnerette packsFilament/thread formingElectrical conductorElectrospinning

The invention relates to a spraying nozzle device for electrostatic spinning, comprising a spinning liquid flow channel through which spinning liquid passes; the spinning liquid flow channel comprises a liquid inlet and a liquid outlet; the liquid outlet of the spinning liquid flow channel is provided with a flow dividing net in a covering manner; the side of the flow dividing net, which is far from the liquid inlet, is distributed with flow guiding filaments overhanging towards the outer side of the liquid outlet; and at least one of the flow dividing net and the flow guiding filaments is made of a conductor material. As the spraying nozzle device for electrostatic spinning adopts the flow dividing net to replace the traditional spraying head to spray spinning liquid and guides the spinning liquid to flow to form spinning liquid drop by the flow dividing filament instead of adopting the traditional spraying nozzles of spraying pipes, for the net holes compared with the spraying holesof the spraying nozzle, the processing difficulty is greatly reduced, the accuracy is easy to guarantee and the problem that the traditional spinning nozzle is difficult to process is solved; in addition, as the flow guiding filament can lead the spinning liquid flow sprayed from the net holes of the flow dividing net to further be lengthened and fined, finer flow guiding filament can be processed, and specifically, the nano level can be achieved.

Owner:DO FLUORIDE CHEM CO LTD

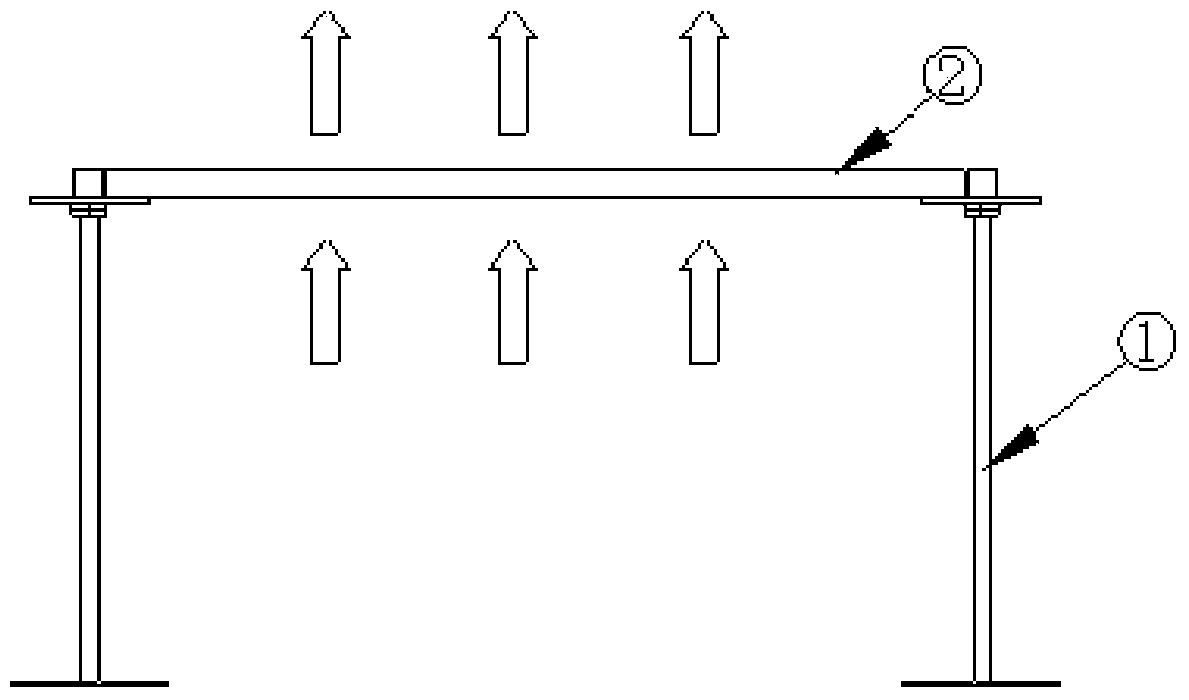

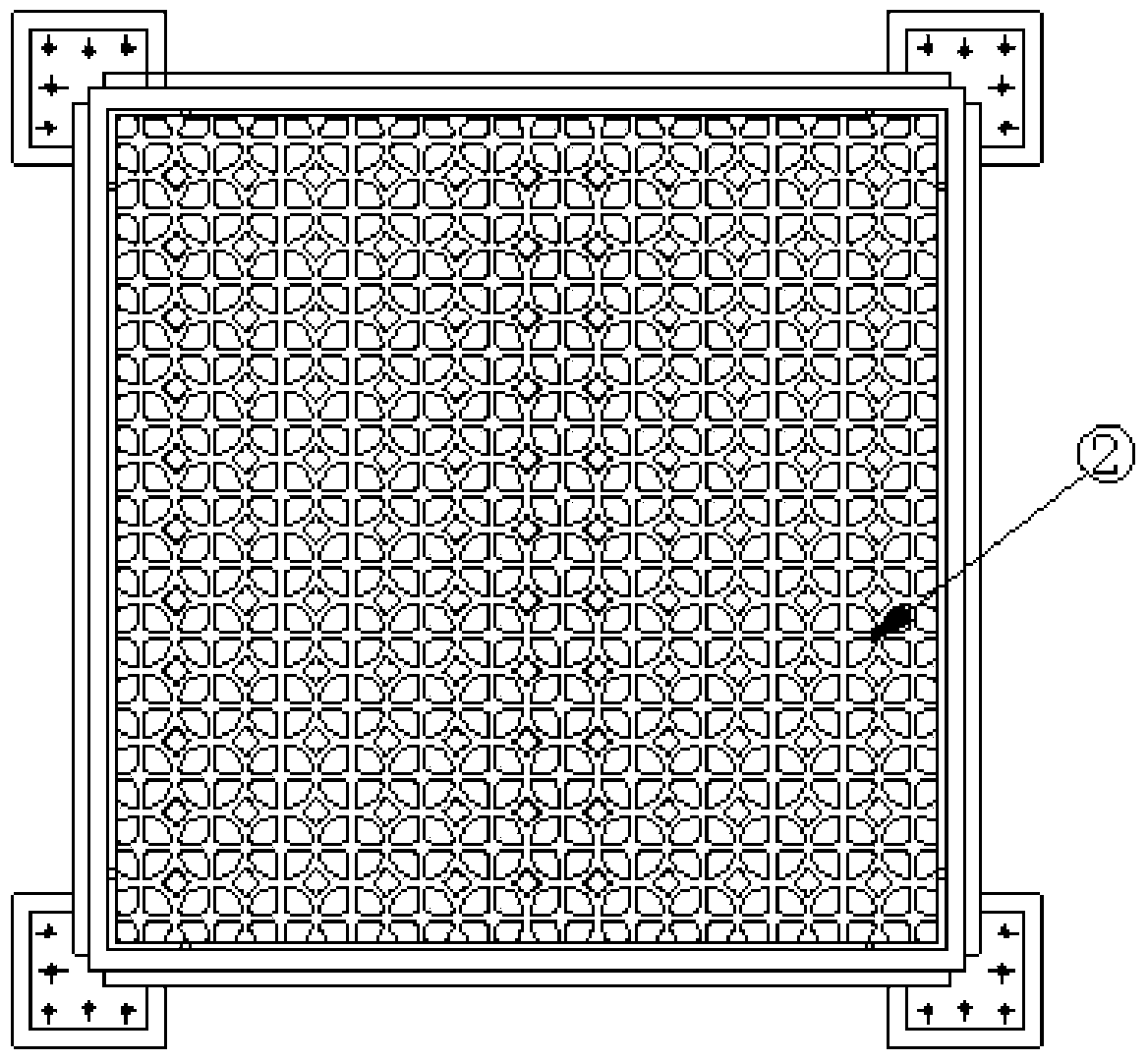

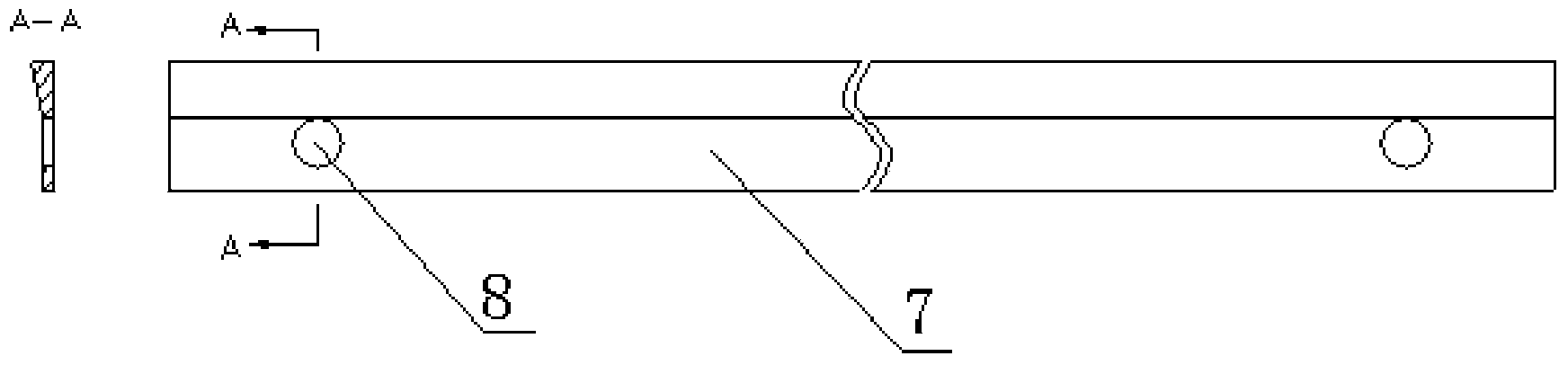

Ventilation guide plate for computer room

InactiveCN103556805AReduce lossReduce power consumptionFalse floorsAir-flow control membersPower usage effectivenessAirflow

The invention relates to the technical field of ventilation guide plates and provides a ventilation guide plate for a computer room. The plate comprises guide strips, first brackets and second brackets. The two first brackets and the two second brackets form a rectangular frame, and rectangular grooves are formed regularly in the first brackets. The upper half portion of each guide strip is a descending wedge-shaped body, and the lower half portion is a cuboid. The lower half portions of the guide strips are vertically inserted into the rectangular grooves of the first bracket to form a plurality of long thin ventilation holes. The guide plate has the advantage that the flow direction of air flow in the computer room is controllable, the air flow is blown to a server directly, air flow loss is reduced, the aims of saving energy and reducing emission are achieved, power consumption is reduced, maintenance cost is reduced, and the power usage effectiveness (PUE) of the computer room is improved.

Owner:北京世纪互联工程技术服务有限公司

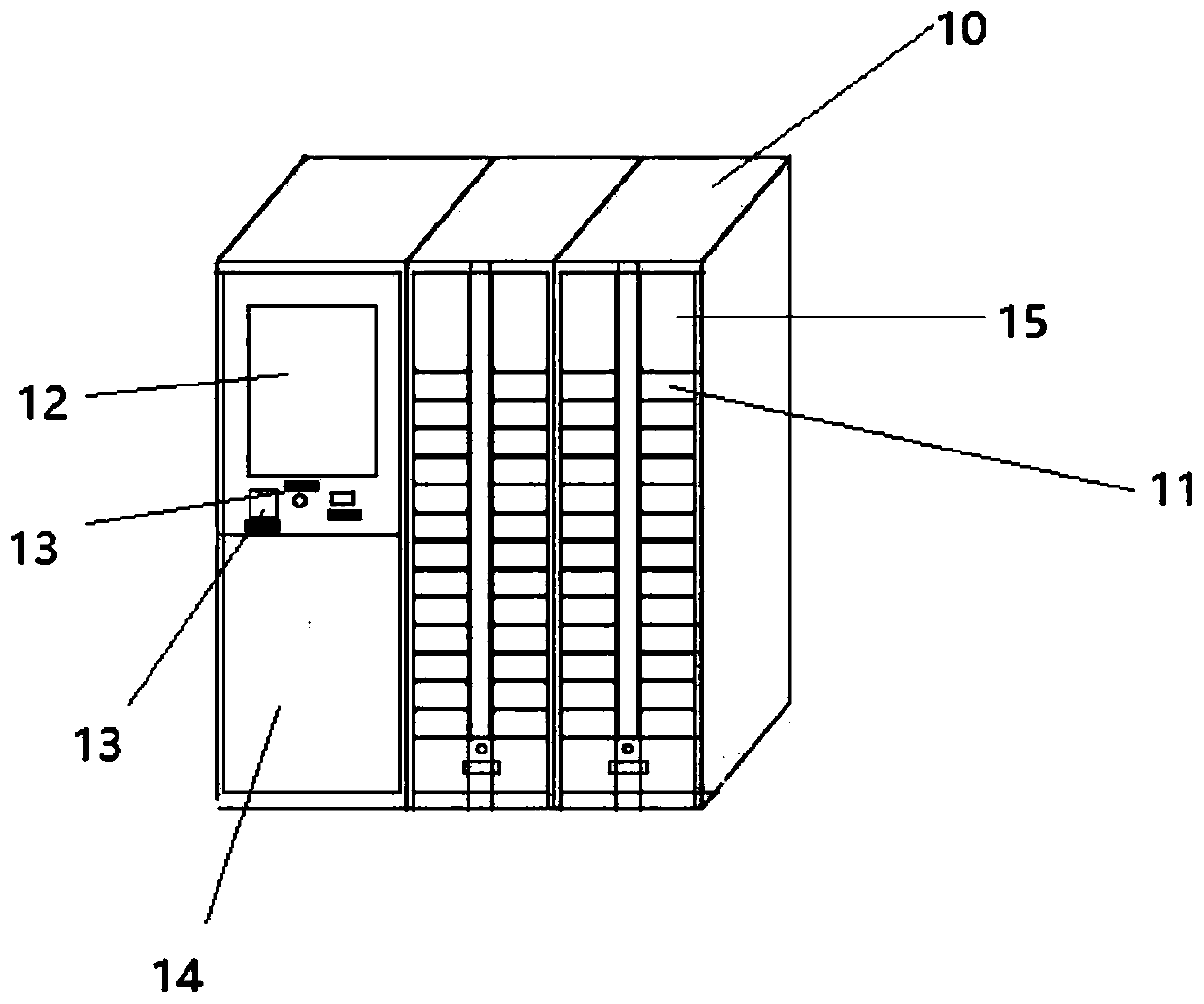

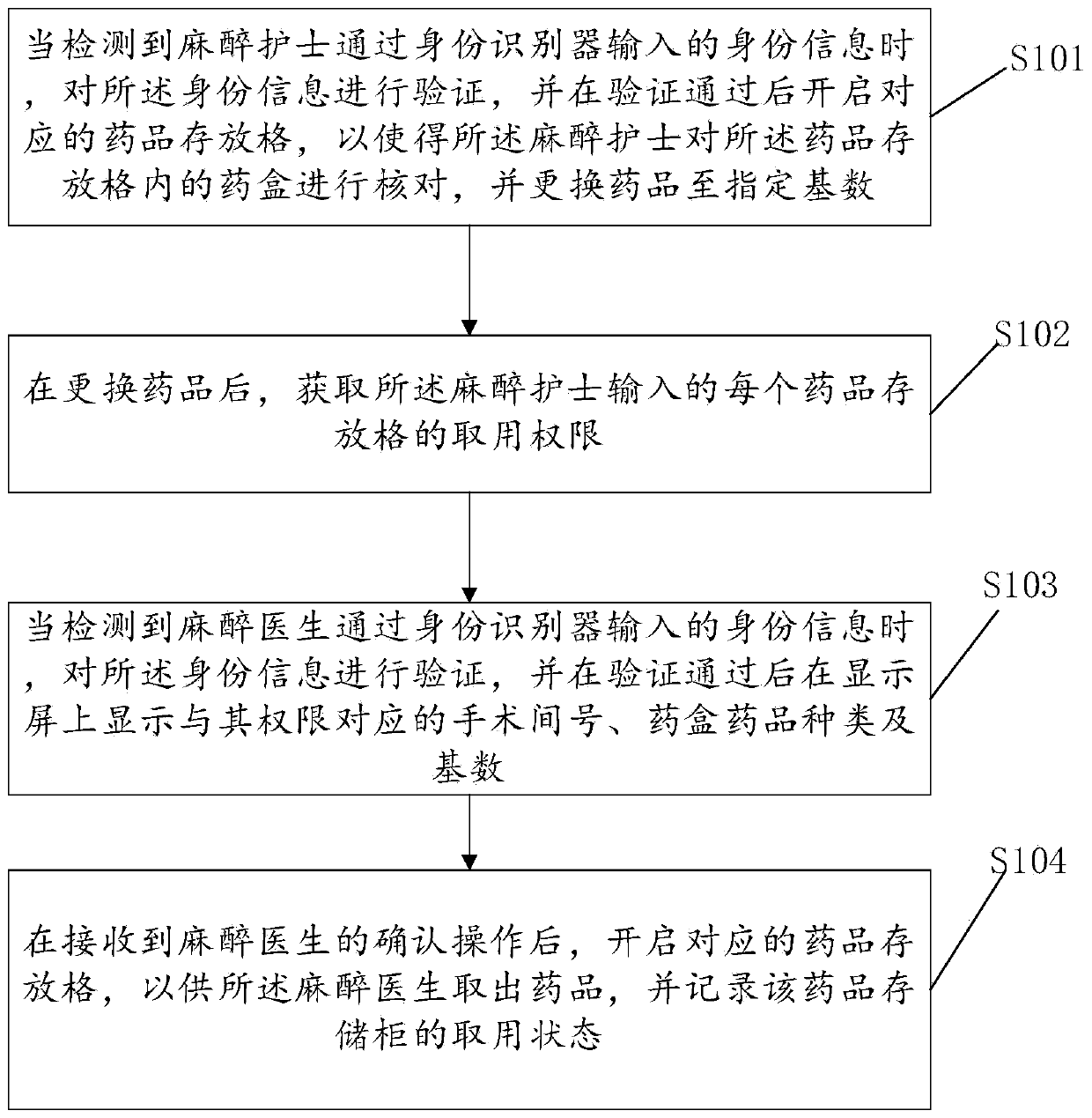

Intelligent management cabinet for poisonous and anesthetic drugs

ActiveCN111223547AReduce lossImprove efficiencyChestsDrug and medicationsIdentity recognitionIntelligent management

The invention discloses an intelligent management cabinet for poisonous and anesthetic drugs, which comprises a cabinet body, a control assembly and a plurality of drug storage cells, and is characterized in that each drug storage cell is controlled to be opened and locked through an electromagnetic lock; the control assembly comprises a touch screen computer and an identity recognizer, and the identity recognizer and the electromagnetic lock are both connected with the touch screen computer; the touch screen computer can achieve the following steps that when identity information input by an anesthesia nurse is detected, the identity information is verified, and the corresponding drug storage cells are opened after the identity information passes verification; after the drug is replaced, the taking permission of each drug storage cell input by the anesthesia nurse is obtained; when the identity information input by an anesthetist is detected, the identity information is verified, and the operation room number, the drug box and drug types and the base number corresponding to the authority of the anesthetist are displayed after the verification is passed; and after confirmation operation of the anesthetist is received, the corresponding drug storage cells are opened. The system achieves the intelligent management of toxic and numb drugs, and improves the work efficiency.

Owner:ZHUJIANG HOSPITAL SOUTHERN MEDICAL UNIV

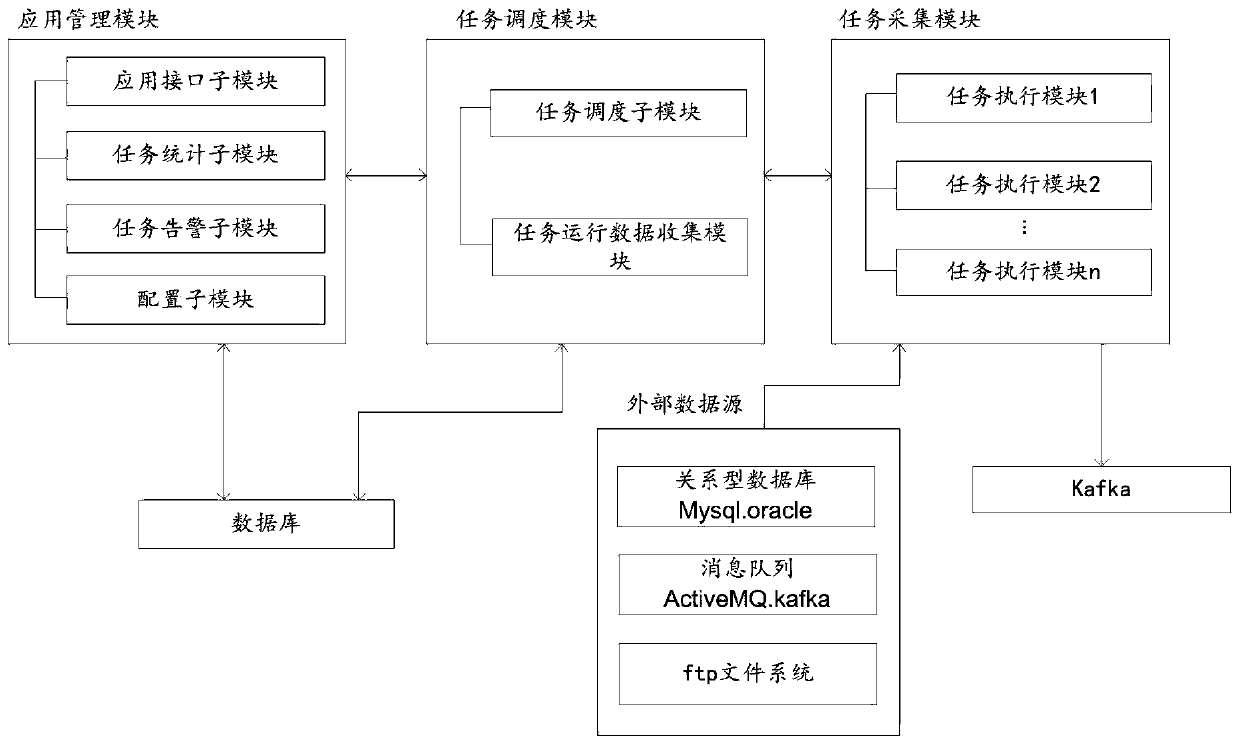

Multi-dimensional data acquisition system and method

ActiveCN110636116AFlow controllableReduce duplication of workDatabase management systemsRelational databasesExternal applicationExternal data

The invention discloses a multi-dimensional data acquisition system and method. The system comprises an application management module, a task scheduling module and a task acquisition module; the application management module is used for carrying out corresponding request data validity verification after receiving request data of a newly-built task interface of an external application, and initiating a newly-built task request to the task scheduling module after the verification is passed; the task scheduling module is used for storing corresponding request data into a database after receivinga newly-built task request, and newly building a task collection table corresponding to a task; if the task is a timed starting task, a task starting command which is required by the task acquisitionmodule and comprises a task starting parameter is generated according to the corresponding request data when the appointed time arrives, and the task starting command is sent to the task acquisition module; and the task acquisition module is used for performing data acquisition work of a corresponding external data source according to the task starting parameters after receiving the task startingcommand.

Owner:武汉众智数字技术有限公司

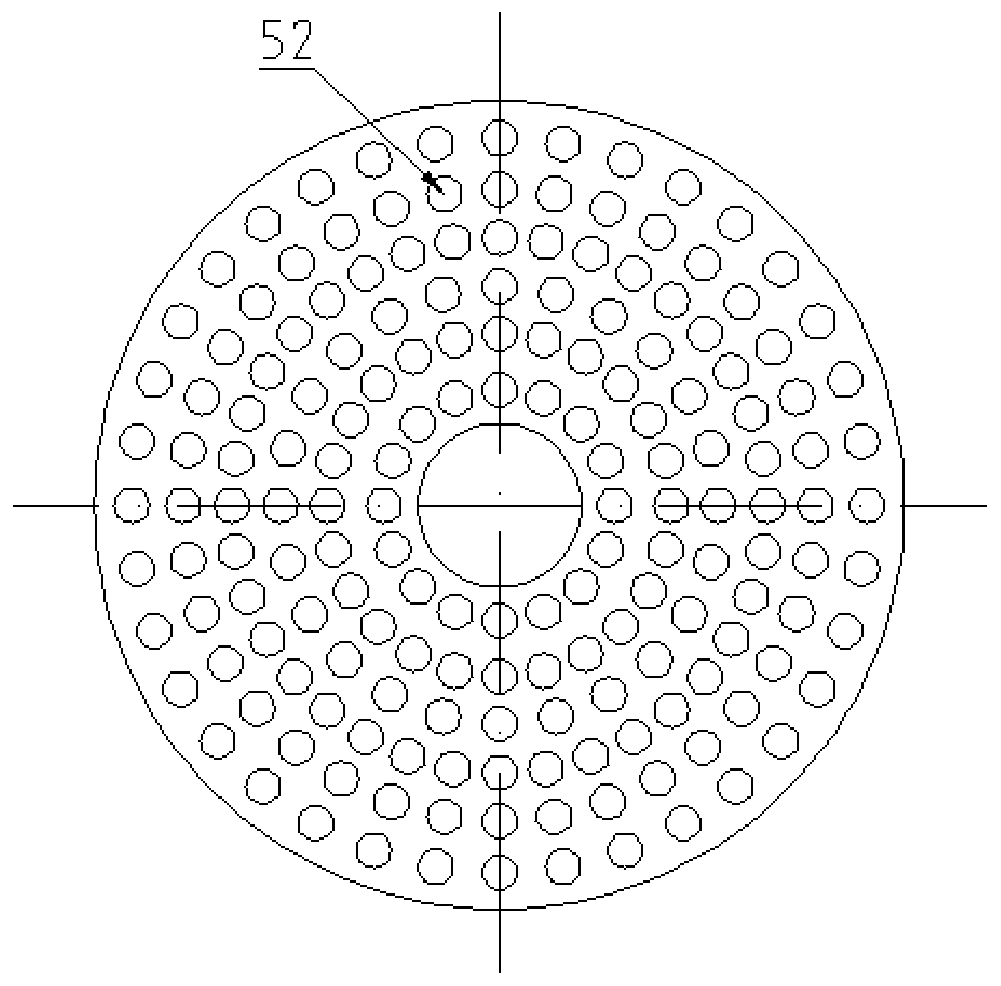

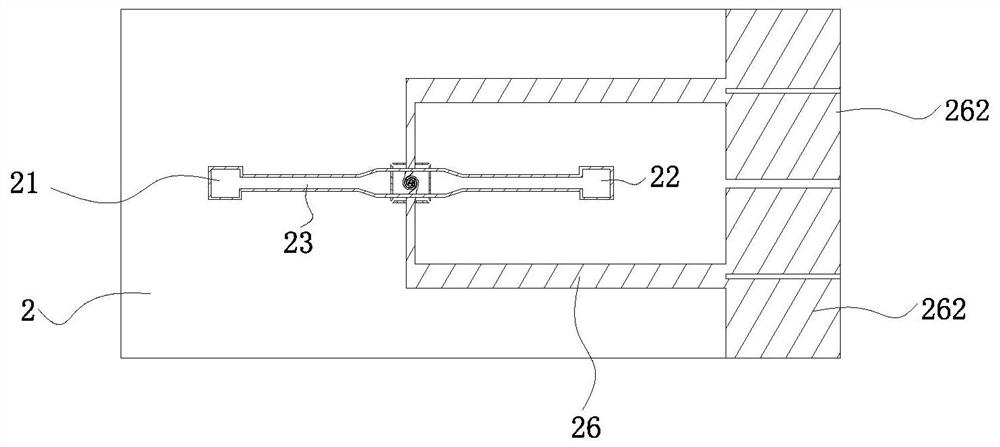

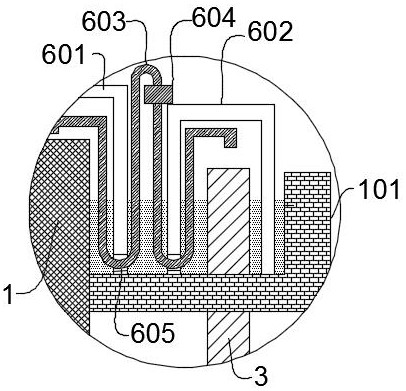

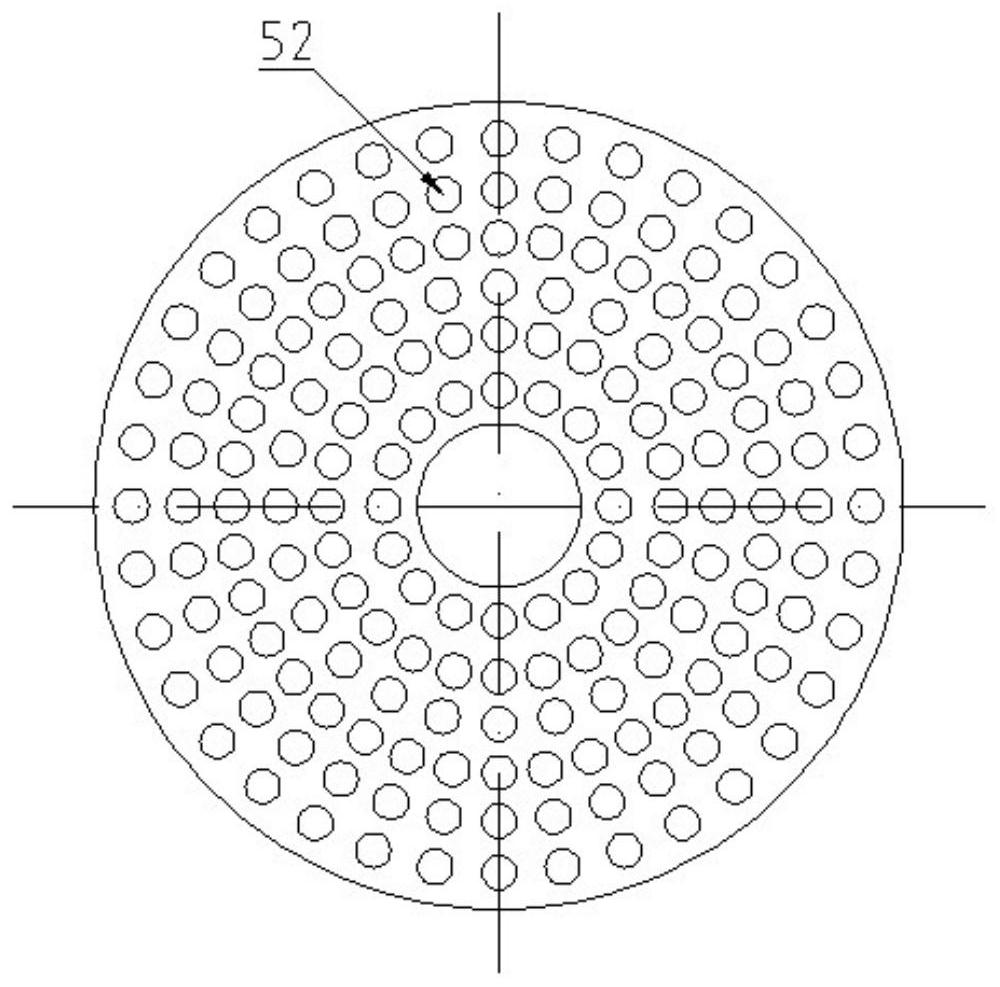

High-resolution in-situ fluid turbulence heating chip of transmission electron microscope

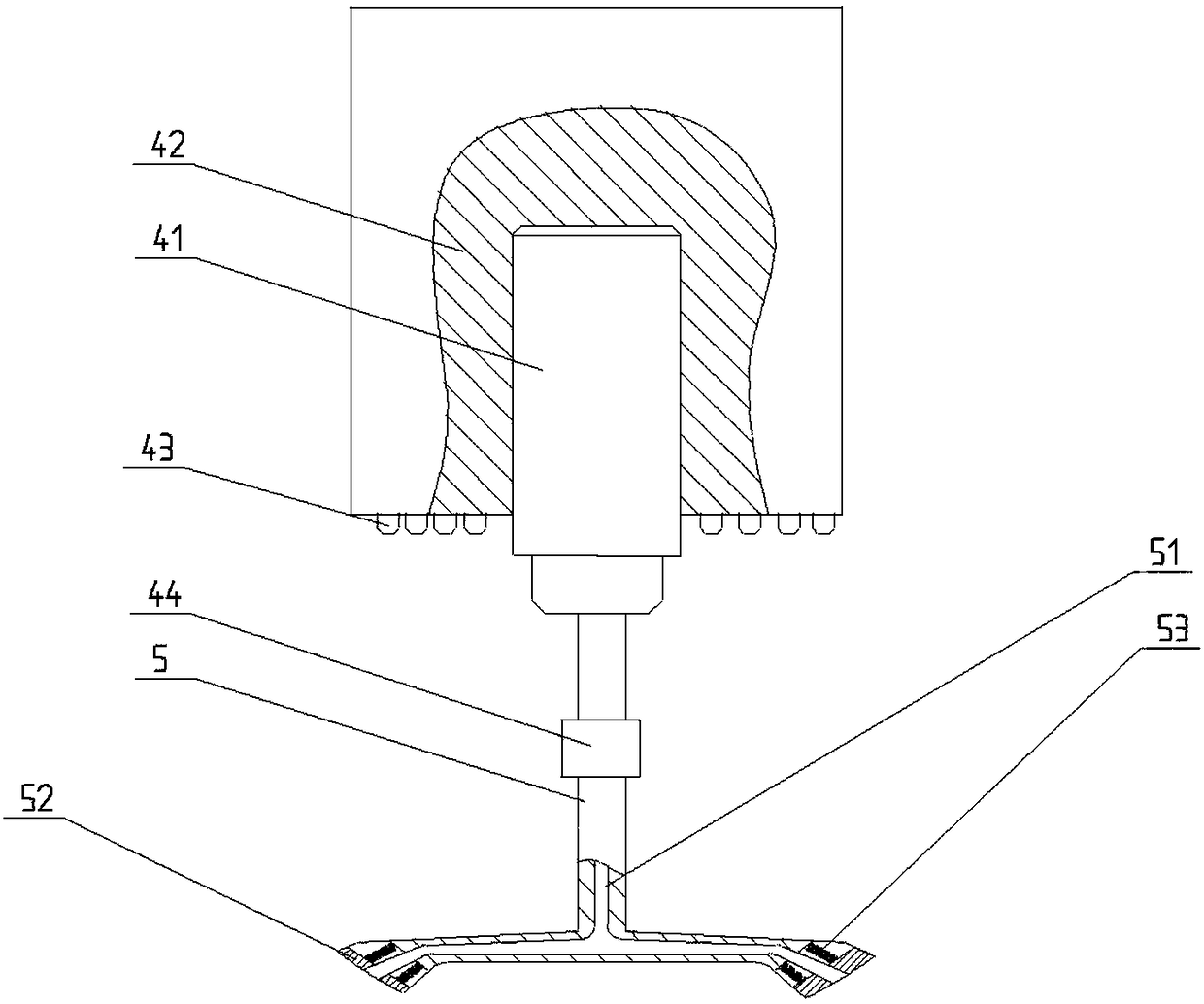

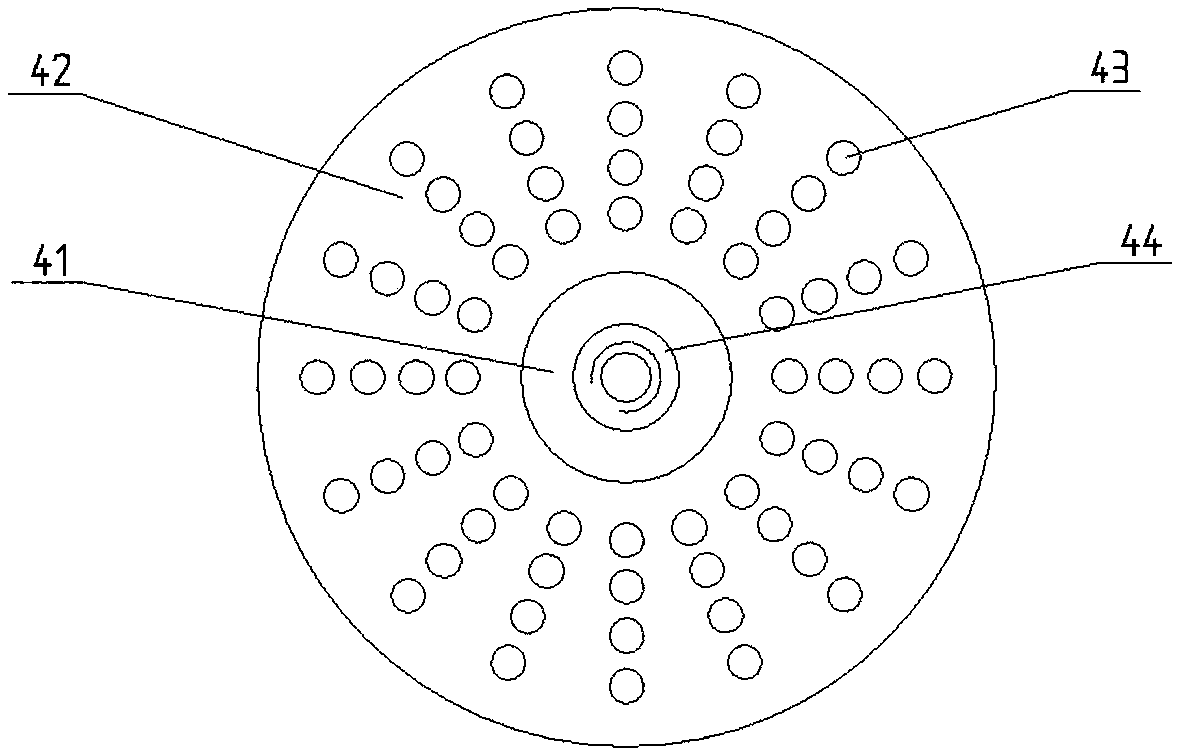

PendingCN111879797AAdd spoilersFlow controllableScanning probe techniquesMaterial analysis by transmitting radiationPhysicsMetallic bonding

The invention relates to a high-resolution in-situ fluid turbulence heating chip of a transmission electron microscope, which is structurally characterized in that an upper sheet and a lower sheet arecombined through a metal bonding layer and are self-sealed to form an ultrathin chamber; the upper piece is provided with two sample injection ports and an upper central window; the lower sheet is provided with a fluid inlet, a fluid outlet, a fluid flow channel, a lower central window, a micro-turbulence column array, a heating layer and an insulating layer; the heating layer is provided with four contact electrodes and a spiral annular heating wire; the lower central window serves as the center and is located in the central area of the spiral annular heating wire; the fluid inlet and the fluid outlet are symmetrically arranged relative to the central window, and the lower central window is located in the center of the heating layer; a micro-turbulence column array is arranged on the lower central window; the chip has the advantages of being rapid in heating and cooling, high in resolution ratio, accurate in temperature control, controllable in fluid flow direction and low in sampledrift rate.

Owner:XIAMEN UNIV

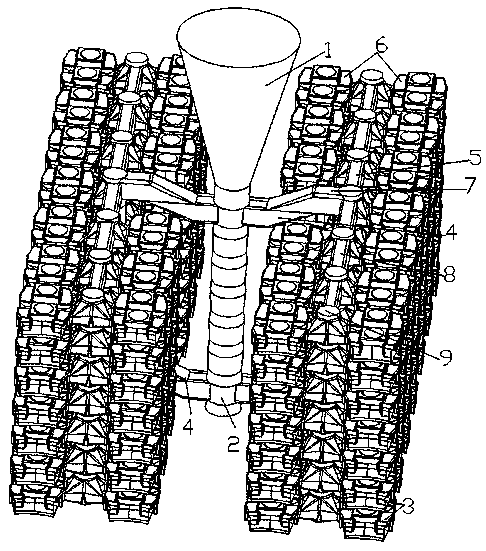

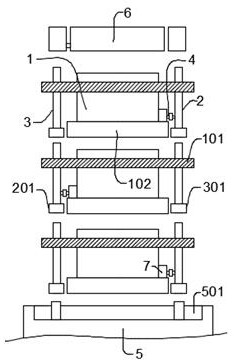

Casting device and method for precoated sand stacking type product

ActiveCN110340299AAvoid cold barrier defectsImprove production efficiencyFoundry mouldsFoundry coresCasting

The invention discloses a casting device and method for a precoated sand stacking type product. The casting device comprises a casting frame; the casting frame comprises a sprue cup, a straight pouring gate and a plurality of parallel casting layers; the sprue cup is arranged on the top of the casting frame; the straight pouring gate communicates with the sprue cup; at least a flow dividing transverse pouring gate located on the bottommost layer is included, and the flow dividing transverse pouring gate forms a flow guiding segment; during casting, the flow guiding segment is used for guidingcasting liquid at the bottommost layer to flow to an upper casting layer; the two sides of the flow guiding segment are correspondingly connected with the straight pouring gate and the transverse pouring gate; the transverse pouring gate forms the plurality of casting layers; each casting layer is provided with a plurality of inner sprues, and each inner sprue is connected with a to-be-cast casting; and the height of the casting frame is 800-1000 mm. The casting device makes casting start from the bottommost layer, the casting efficiency is improved, meanwhile, due to the casting manner, the flowing direction of molten iron is controllable, and cold insulating defects are reduced.

Owner:西安合力汽车配件有限公司

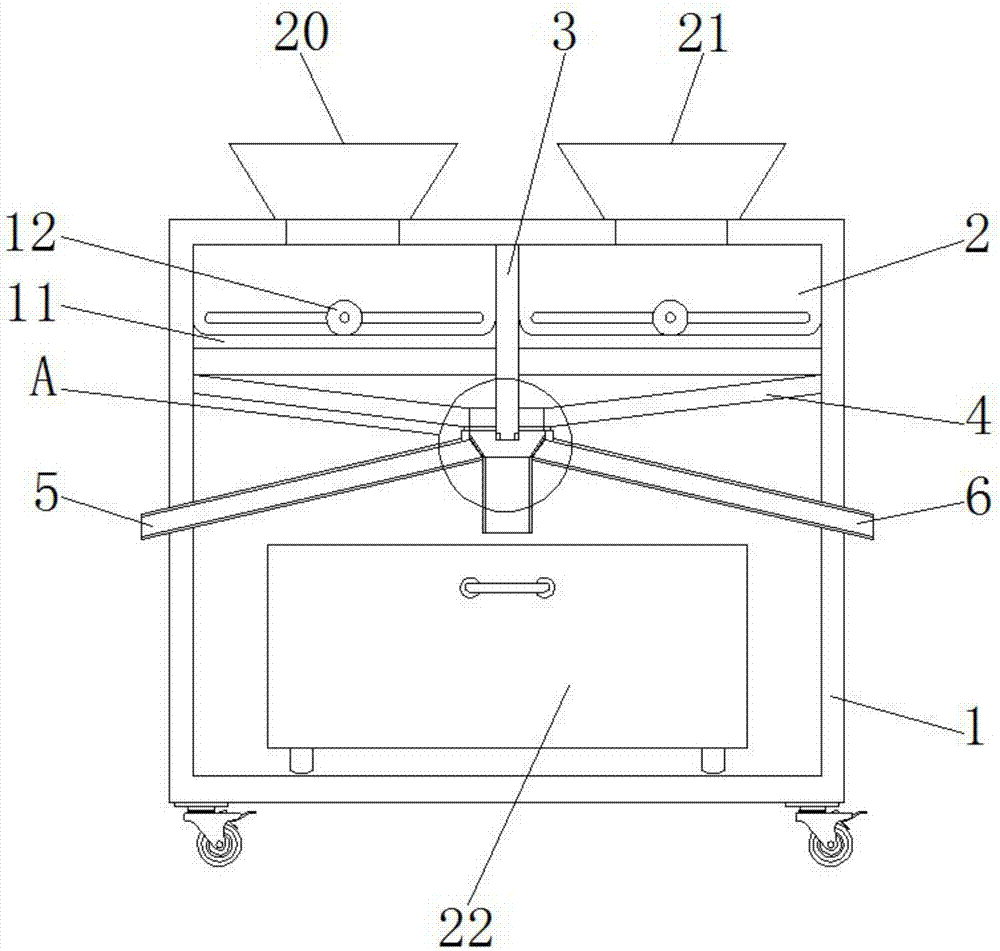

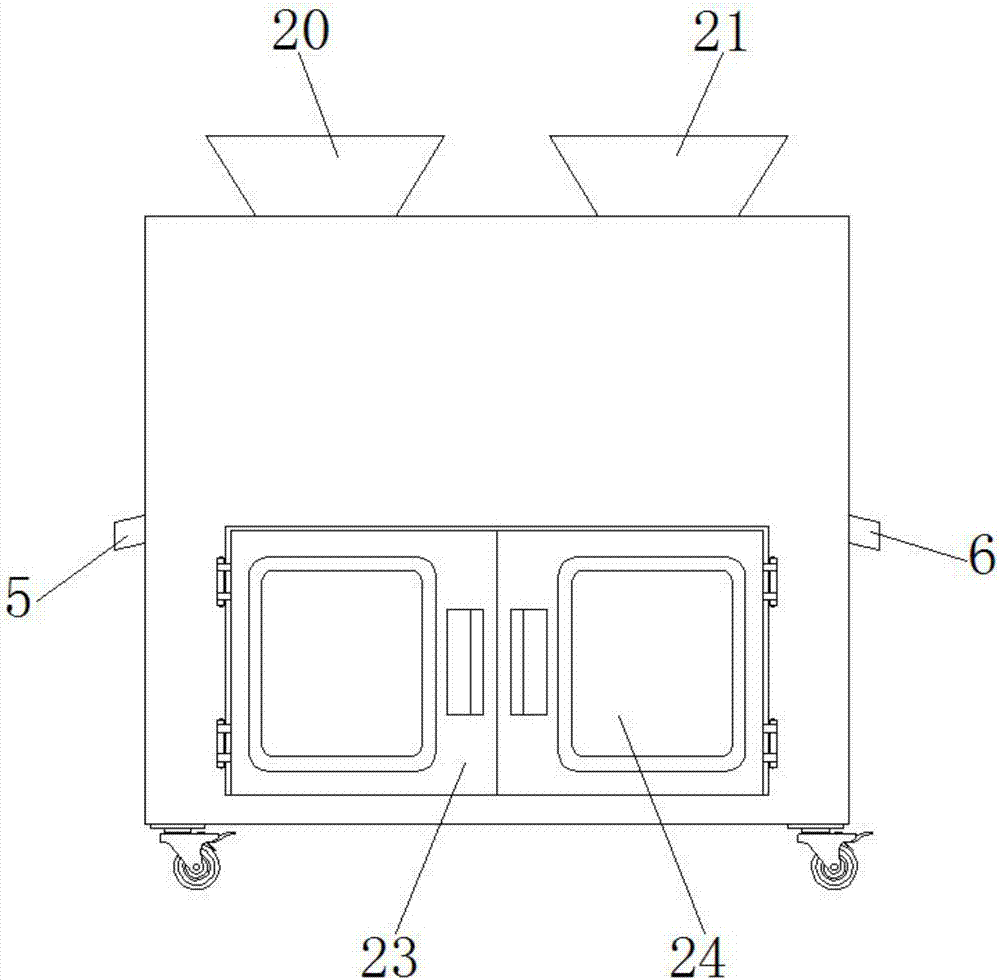

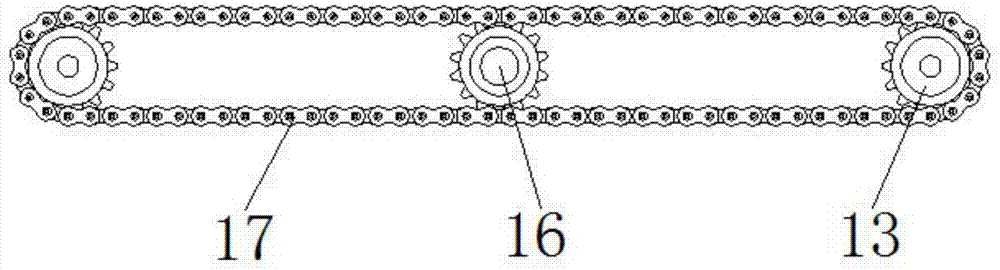

Production mixing device for animal-husbandry feed

InactiveCN107970854AEasy to produceIncrease productivityFlow mixersTransportation and packagingHybrid typeEngineering

The invention discloses a production mixing device for animal-husbandry feed. The production mixing device comprises a box body, wherein a baffle plate is fixedly mounted in the interior of the box body; a vertical plate is fixedly mounted on the front surface of the baffle plate; material collecting plates are fixedly mounted in the interior of the box body and are further located on both the left and right sides of the vertical plate. According to the production mixing device for the animal-husbandry feed, the feed fallen down from two filter plates can be discharged from two sides of the box body respectively by utilizing a first discharge pipe and a second discharge pipe; two kinds of feed are processed at the same time; the production efficiency can be improved; two materials can be mixed by utilizing a mixing pipe, and are discharged from the mixing pipe at the same time; mixed feed is conveniently produced according to a proportion, and the production mixing device has two production modes, and has higher applicability.

Owner:黄勇

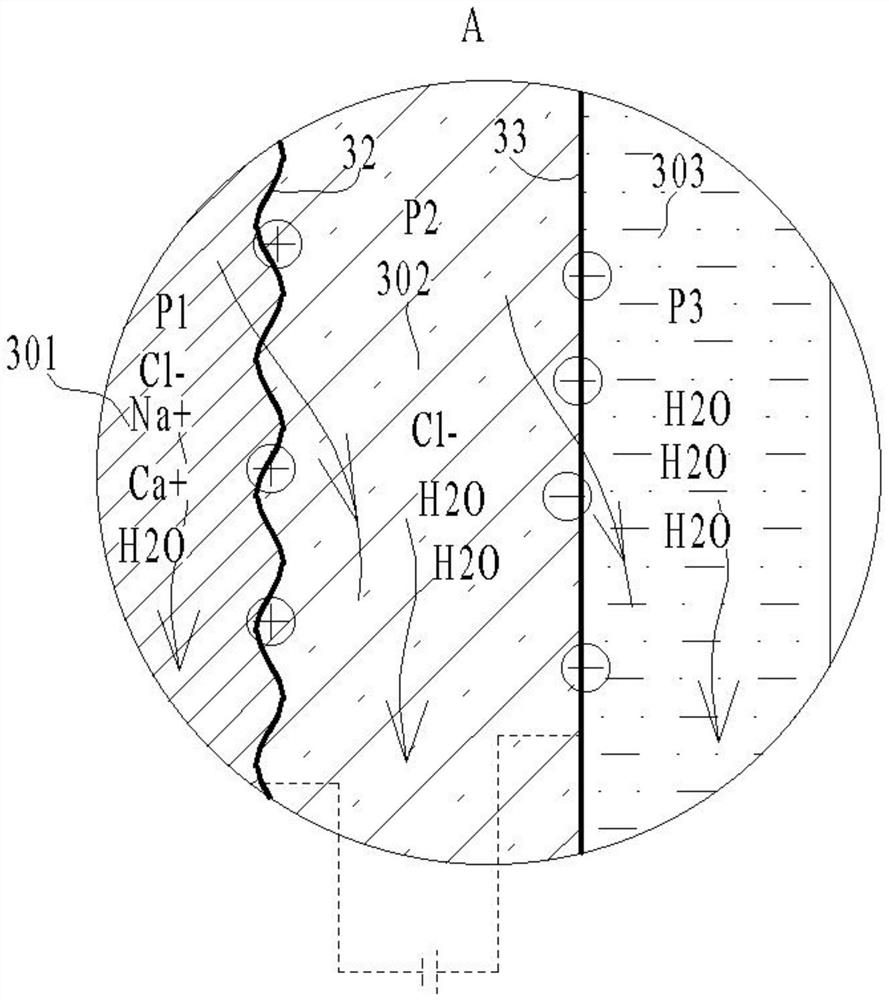

Iontophoretic device for dosaging of an active ingredient

InactiveUS20150182745A1Keep for a long timeEasy accessElectrotherapyMedical applicatorsFiberCarbon fibers

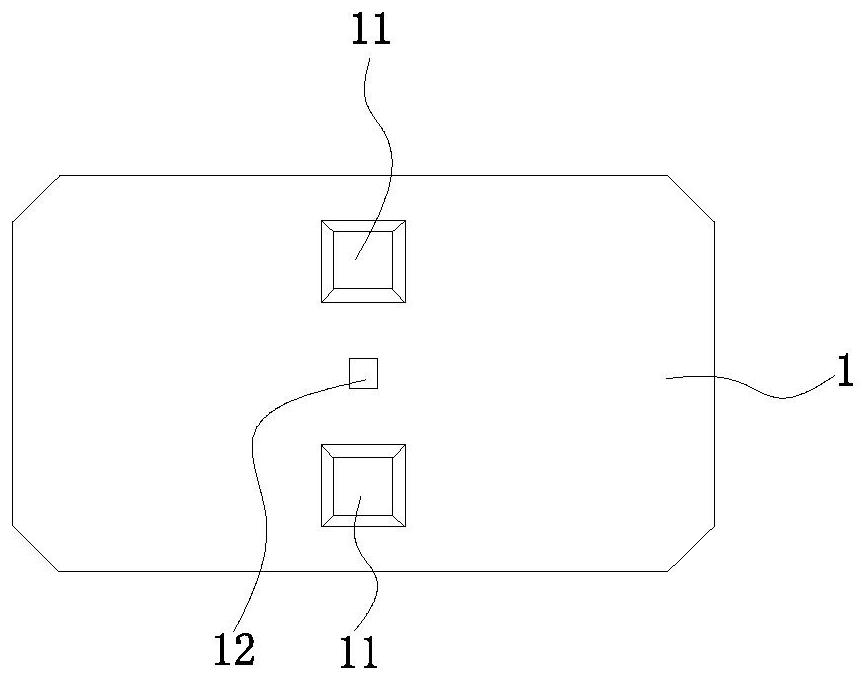

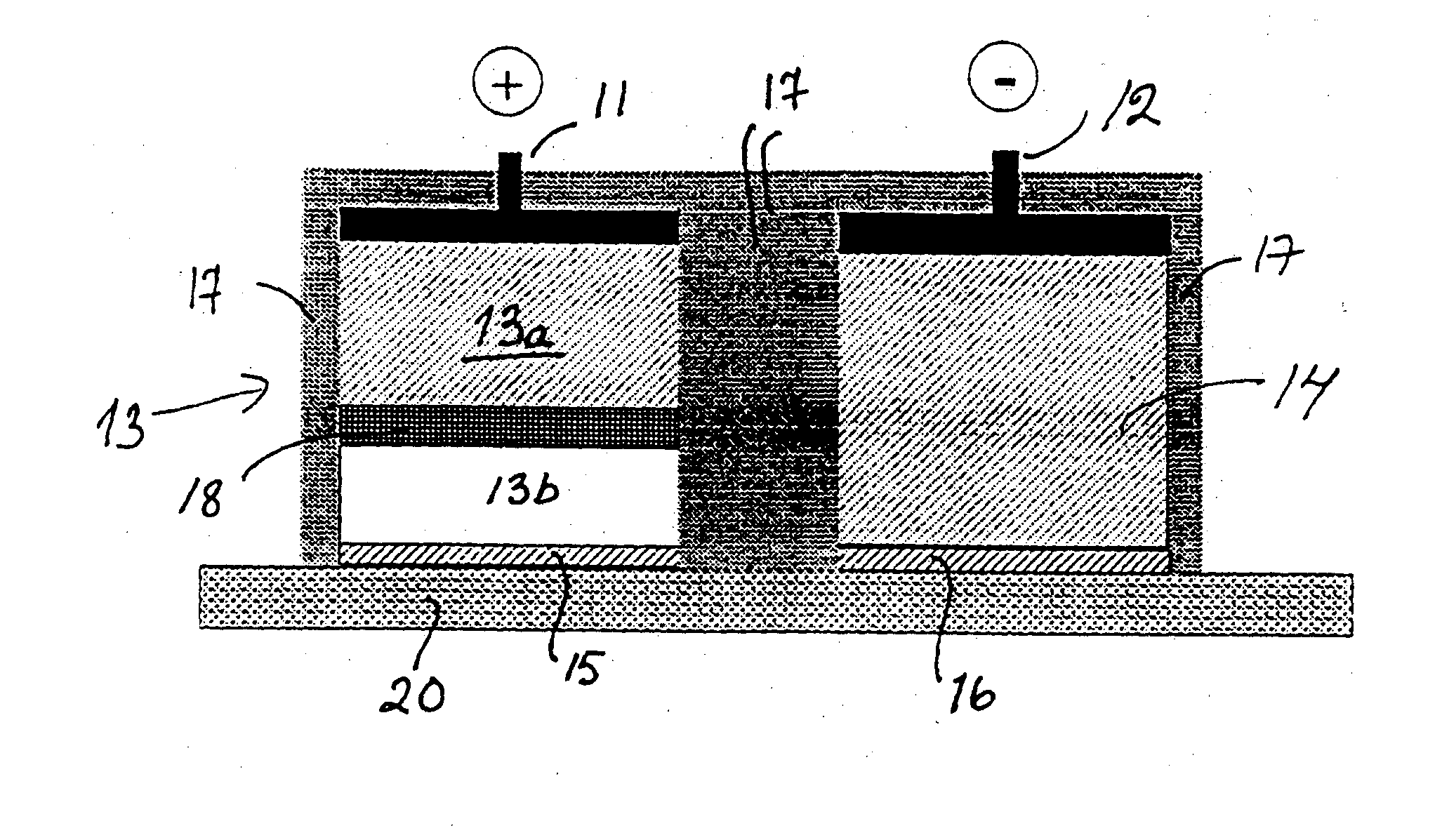

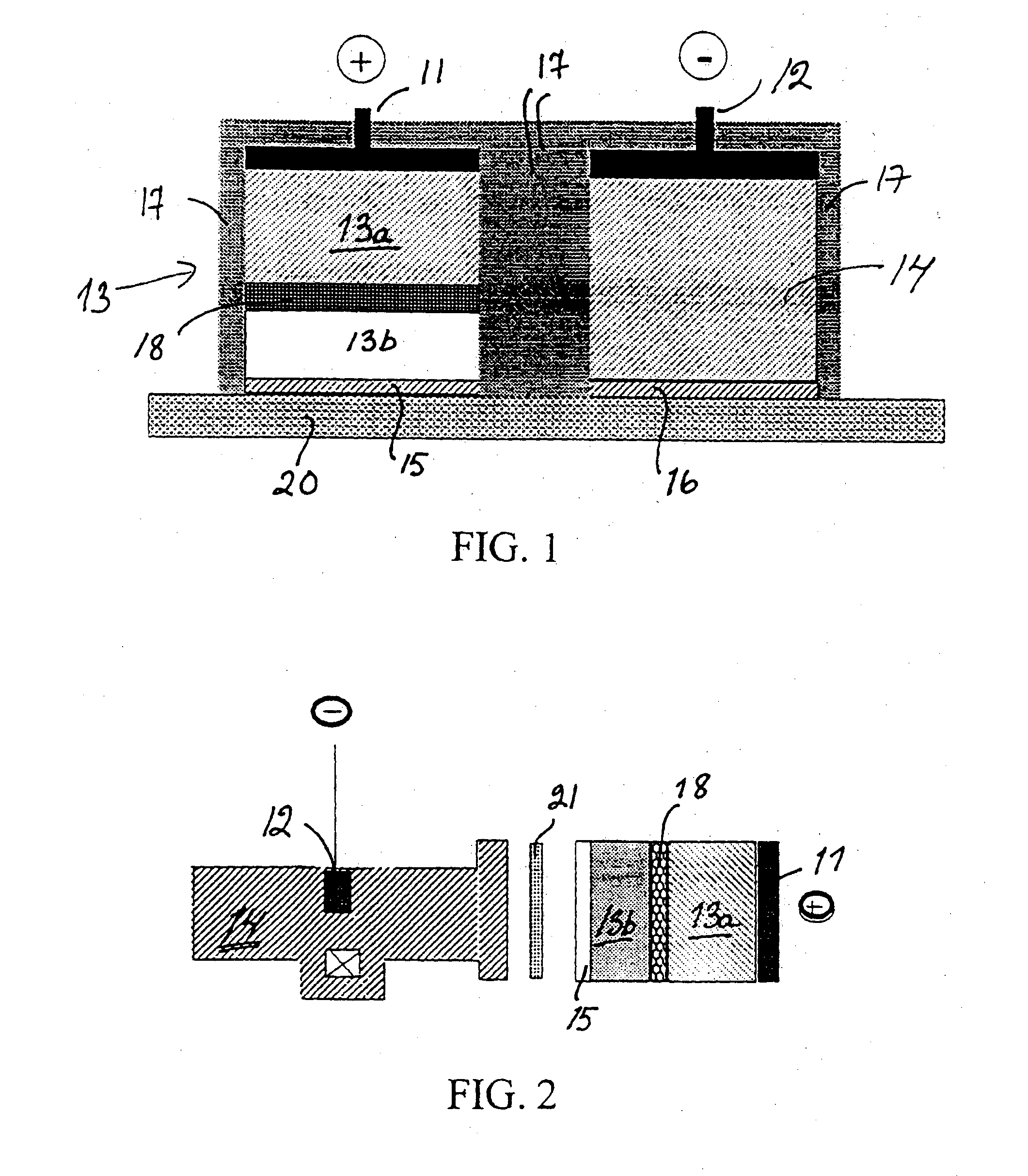

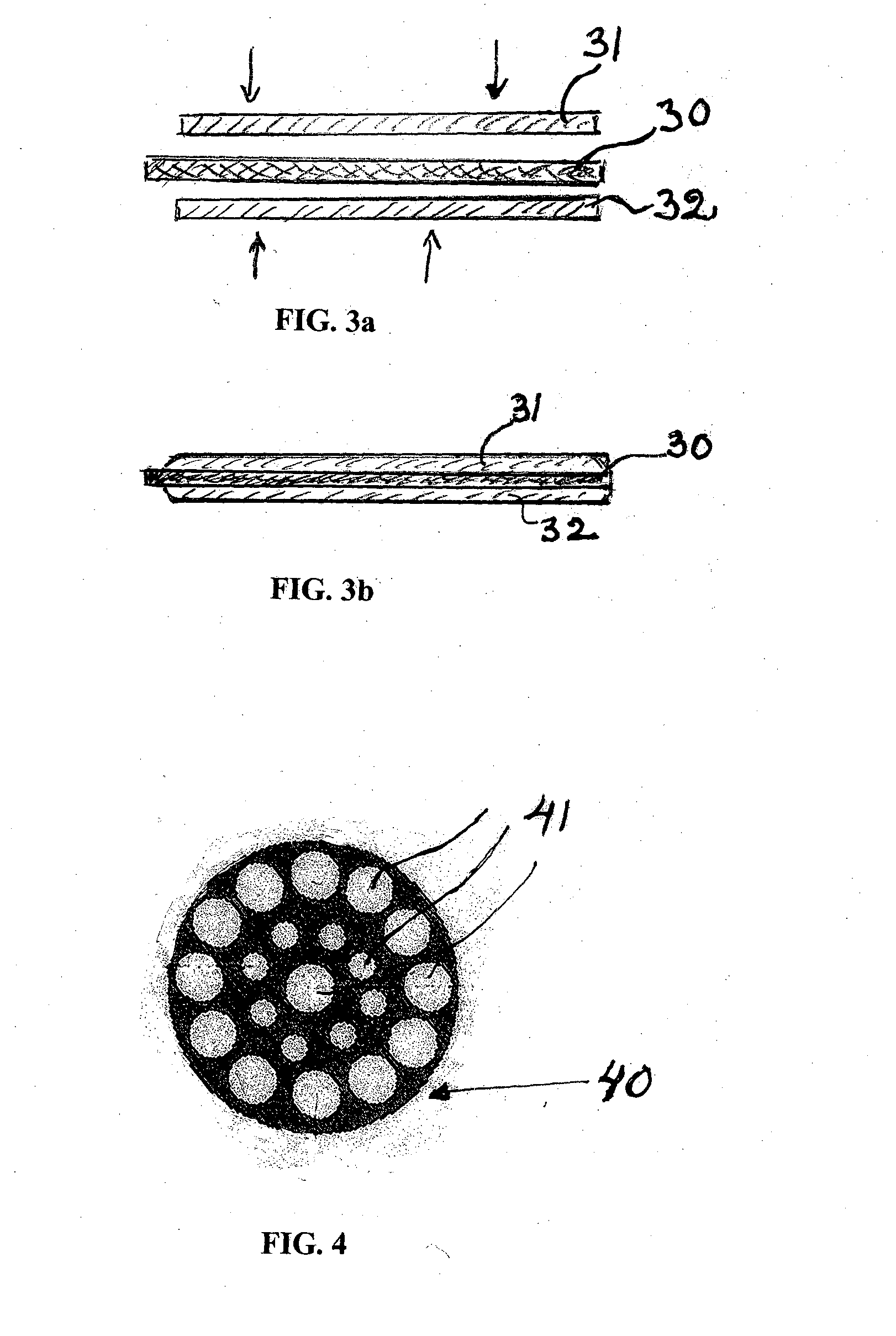

A device based on iontophoresis and intended for transdermal dosing of an active agent, said device comprisinga pair of electrodes (11,12), which can be connected to a direct-current source, andtwo chambers (13, 14), separated from each other, the first chamber (13) containing the active agent, each chamber having a porous membrane (15, 16) on the side facing the individual's skin, andthe first chamber (13) being divided in two sections (13a, 13b) in such a manner that the first chamber section (13a) is in contact with the electrode (11) and the second chamber section (13b) is in contact with the membrane (15) coming into contact with an individual's skin, wherein between the chamber sections (13a and 13b) is a membrane (18) selectively permeable either to cations or to anions,the first chamber section (13a) containing an electrolyte and the second chamber section (13b) containing the ionic active agent, bound to a ion exchanger therein, which in turn preferably comprises fibres and ion exchanging groups bound thereto.The invention is characterized in thatthe electrodes (11,12) comprise a porous carbon fibre textile (30) which is mixed with a hydrophobic agent or onto which is fitted a hydrophobic porous, preferably micro-porous membrane (31), andinto the chamber section (13a) comprising the analyte is added a fibre grafted with buffering ion exchanging groups.

Owner:NOVAGENT

Novel method of grouting under plate

The invention provides a new process for concrete pouring under plate, comprising the following steps of: pouring top plate, boring with boring machine, installing pouring pipe, and single-pore pouring. The new process has the advantages that the main novelty of the new process for concrete pouring under plate is blocking and dredging; the blocking means that the outlet passage for lost slurry is blocked and the dredging means the flowing direction of the slurry along the concrete plate; the slurry loss and waste are avoided, the construction investment is saved; the concrete pouring is carried out under the top plate, the flowing direction of the slurry is easy to be controlled, the reinforced soil is more uniform and compacter and has high quality; the concrete pouring effect is more obvious; the practices in places such as Wugang, Baogang, Debao city of Guangxi, etc. show that about 20-50% of the slurry loss can be saved relatively. The strength of soil in-situ after the concrete pouring can be directly gained by methods such as standard penetration test or light sounding test, etc. 28 days after the completion of the concrete pouring and the mechanical property is greatly improved compared with that of the soil in-situ before the concrete pouring.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

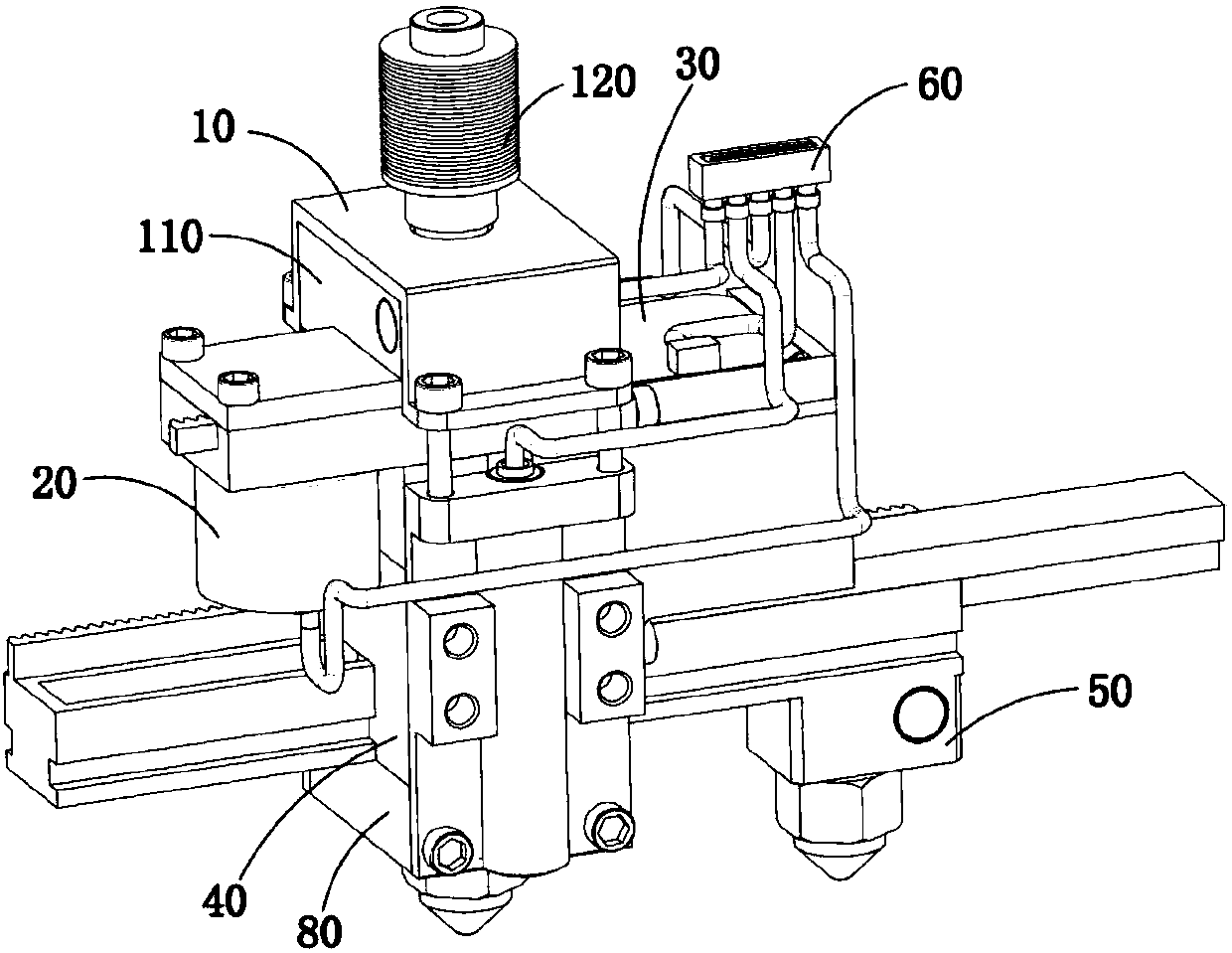

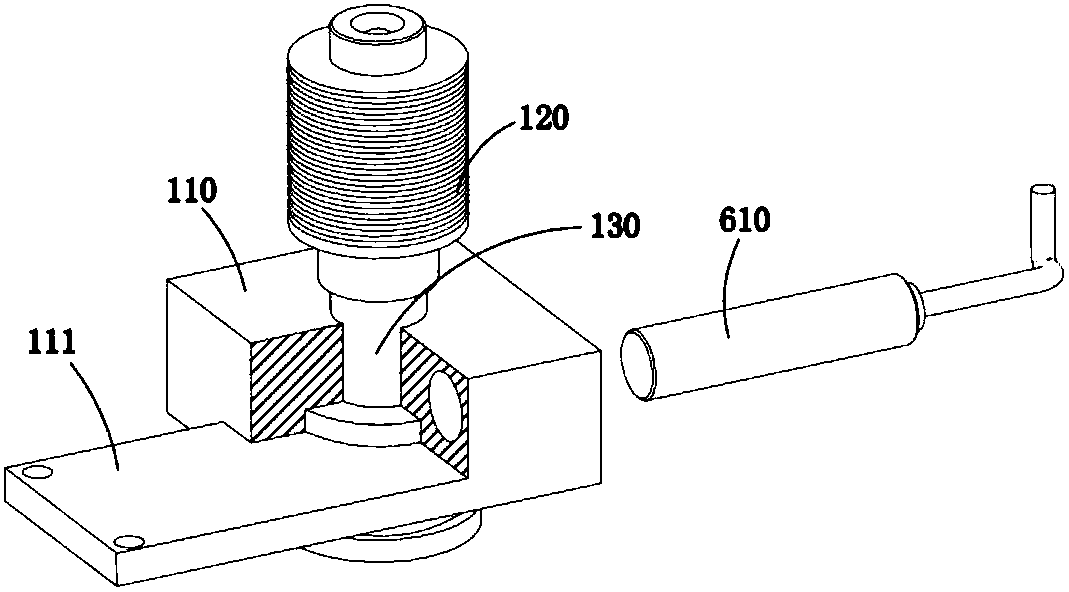

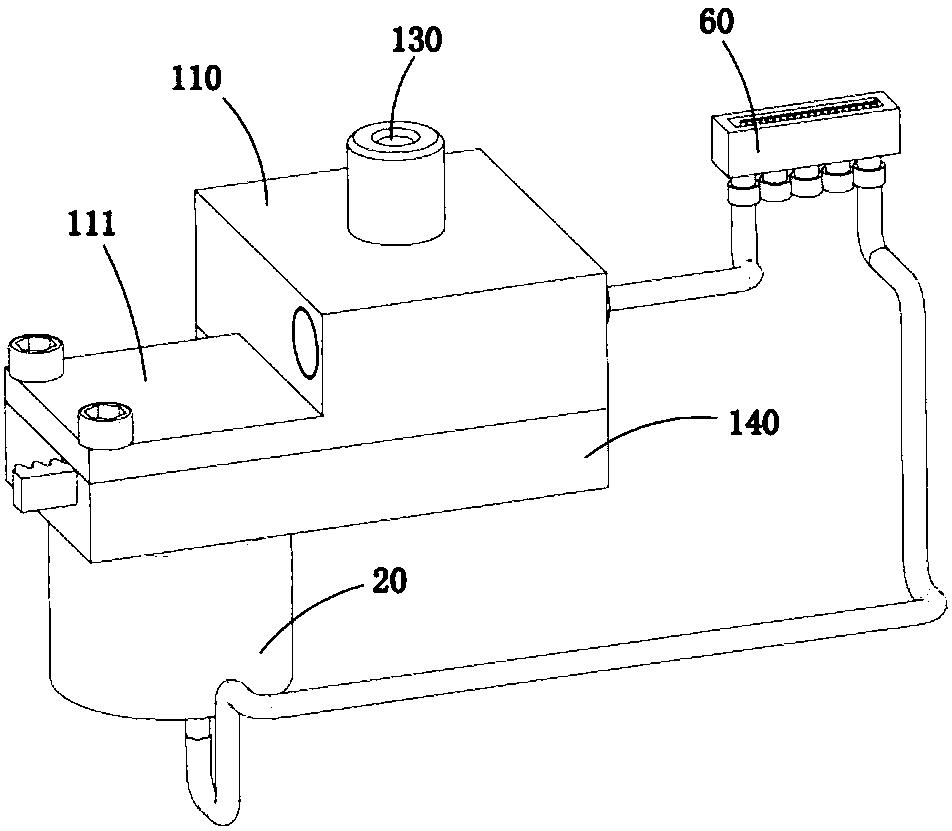

Method of single-sprinkler printing or multi-sprinkler synchronous printing of multi-shaft 3D printer

InactiveCN107584754ARealize span adjustmentFlow controllableAdditive manufacturing apparatusAdditive manufacturing with liquidsEngineering3d printer

The invention discloses a method of single-sprinkler printing or multi-sprinkler synchronous printing of a multi-shaft 3D printer. The method comprises that: S1, a reversing pipe receives or generatesa melted raw material, and an angle, at which the reversing pipe rotates about an axial of the reversing pipe itself, is controlled, and a material distributing tank communicates with a first shunting hole and a second shunting hole in sequence, wherein the first shunting hole and the second shunting hole communicate with each other through the material distributing tank; S2, when the material distributing tank communicates with the first shunting hole, and the bottom end board of the reversing pipe blocks the second shunting hole, the melted raw material flows to a first extruding head through a first communication hole and a first runner, and undergoes extrusion molding through a first extrusion head; and S3, when the material distributing tank communicates with the second shunting holeand the bottom end board of the reversing pipe blocks the first shunting hole, the melted raw material flows to a second extruding head through a second communication hole, a material pushing grooveand a second runner, and undergoes extrusion molding through a second extrusion head.

Owner:张玲玲

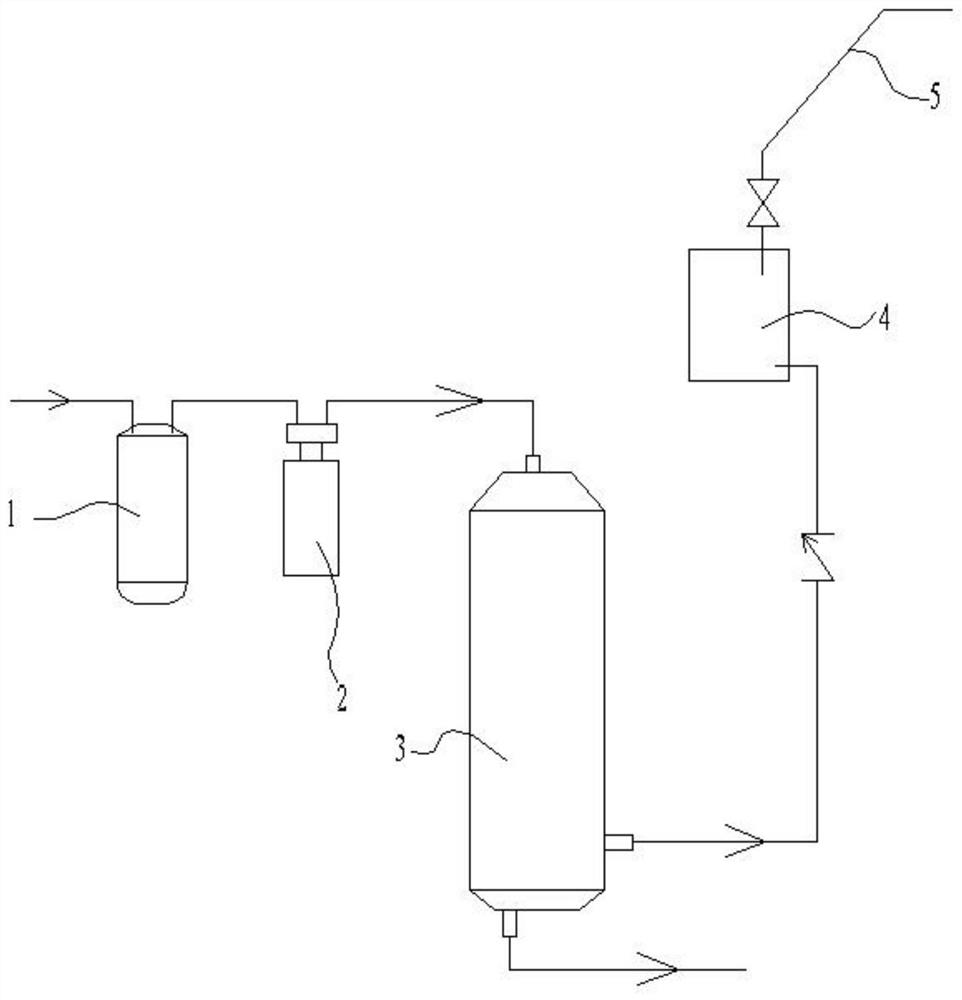

Washing device and process of PET (polyethylene terephthalate) liquid-phase tackifying kettle

The invention relates to a washing device of a PET (polyethylene terephthalate) liquid-phase tackifying kettle and a washing process using the washing device for washing the tackifying kettle, and belongs to the technical field of polyester fiber production. The washing device comprises a segmented heater, a solvent injection pipe, a circulation pipe, a buffer tank, a condenser and a liquid seal tank, wherein the segmented heater is arranged in an outer wall jacket of the tackifying kettle; the solvent injection pipe is arranged at the top of the tackifying kettle; one end of the buffer tank is connected with the tackifying kettle through the circulation pipe, and the other end of the buffer tank is connected to the top of the condenser through a steam pipe; a circulative pipe is arranged at the bottom of the condenser and divided into two branch pipes, one branch pipe is connected to the bottom of the buffer tank, and the other branch pipe is connected to the bottom of the liquid seal tank; and the upper part of the liquid seal tank is connected to the top of the condenser, and control valves are arranged on two branch pipes of the circulative pipe respectively and used for controlling connection and disconnection of corresponding pipelines. The washing device has the advantages of high washing efficiency, low cost and the like.

Owner:ZHEJIANG GUXIANDAO POLYESTER DOPE DYED YARN CO LTD

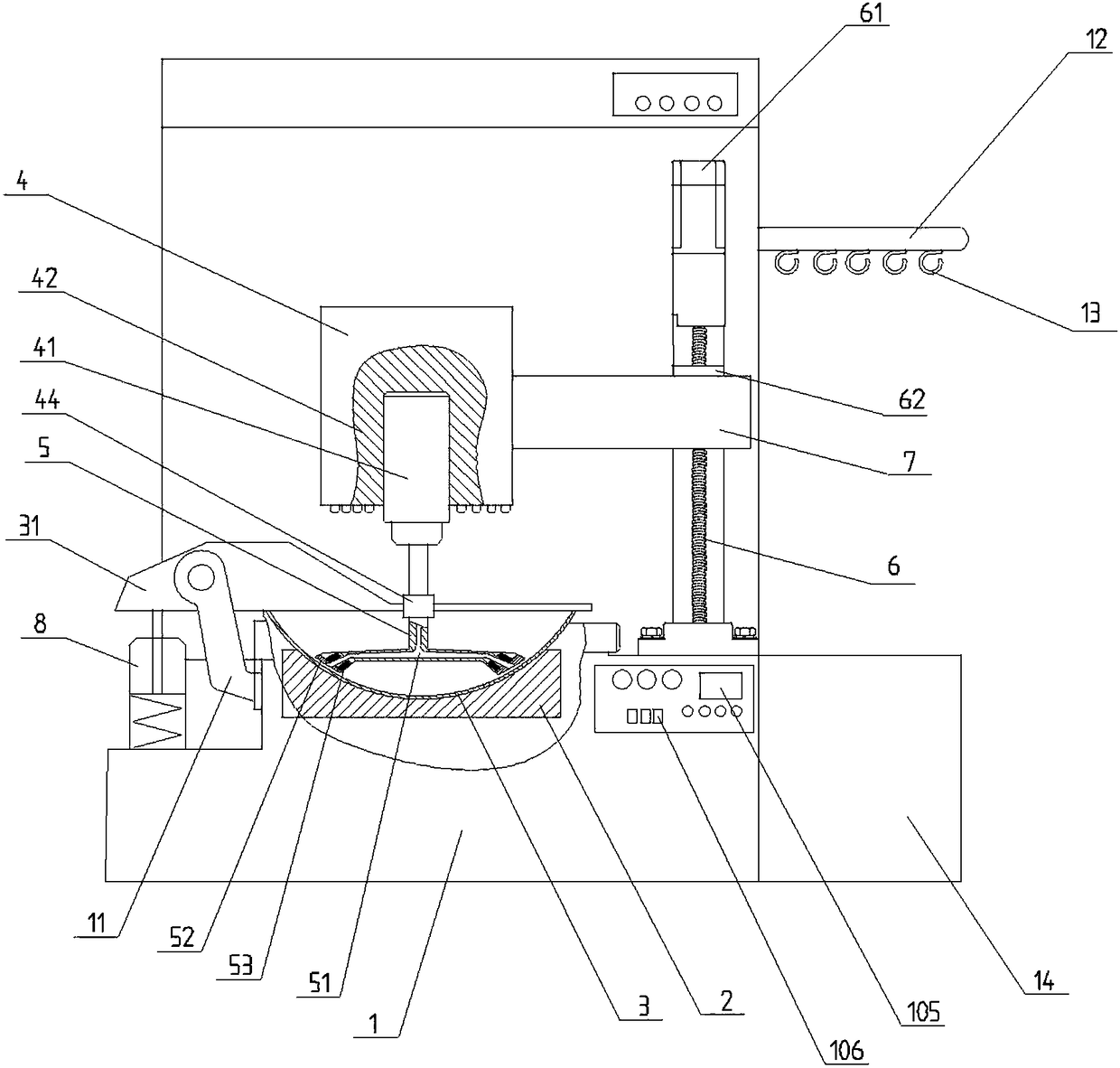

Air-blowing detachable slice for intelligent frying machine

InactiveCN108056681ASpeed up cookingEasy to manufactureCooking vessel constructionsEngineeringAir blower

The invention relates to an air-blowing detachable slice for an intelligent frying machine. The air-blowing detachable slice comprises a stirring spatula and a rotating motor capable of controlling the stirring spatula to rotate, the rotating motor is sleeved with an air blower capable of blowing air to the surface of a wok, the air blower is in a circular-ring shape, and the air blower and the rotating motor are coaxially arranged; two or above air outlets are formed in the bottom face of the air blower, and are distributed in a circumference array mode; a water through hole capable of spraying to the surface of the wok is formed in the stirring spatula; the stirring spatula is in a reverse-T shape; spatula blocks are arranged at the two ends of the bottom of the stirring spatula and connected with the stirring spatula through springs, and the water through hole is in a reverse-T shape and penetrates through the spatula blocks; the stirring spatula is detachably connected with the rotating motor through a connecting piece. According to the air-blowing detachable slice for the intelligent frying machine, the rotating motor is detachably connected with the stirring spatula through the connecting piece, the air blower is additionally arranged, and the wok can be rapidly dried.

Owner:杭州知意达科技有限公司

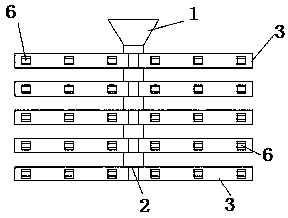

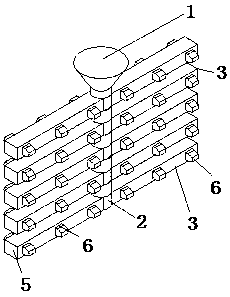

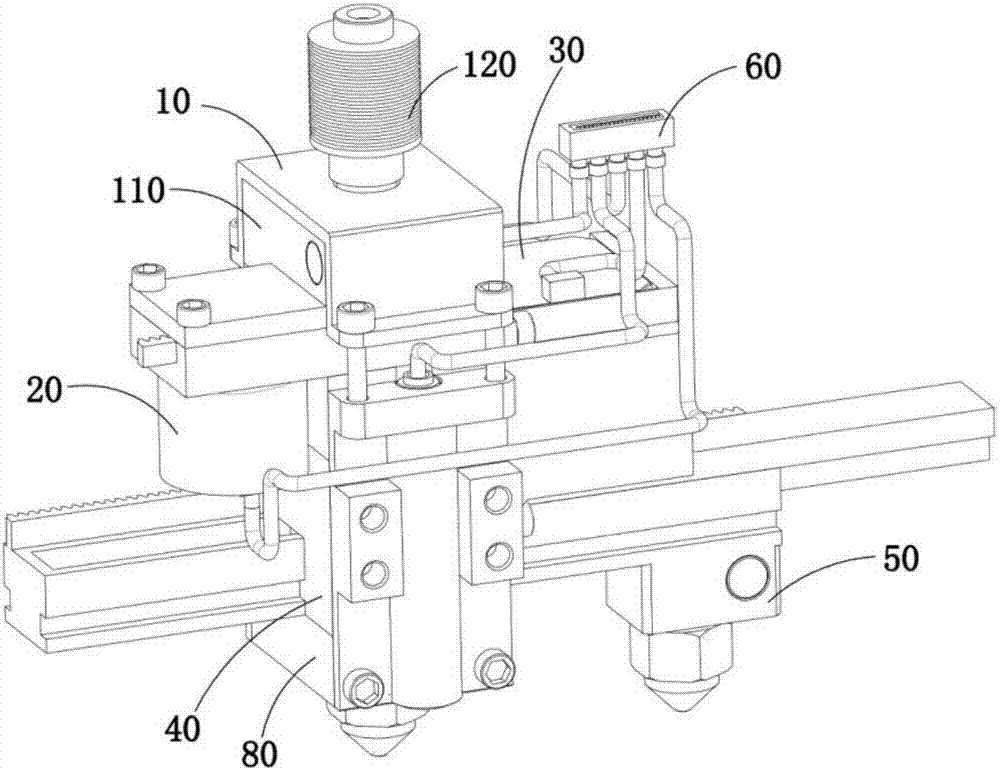

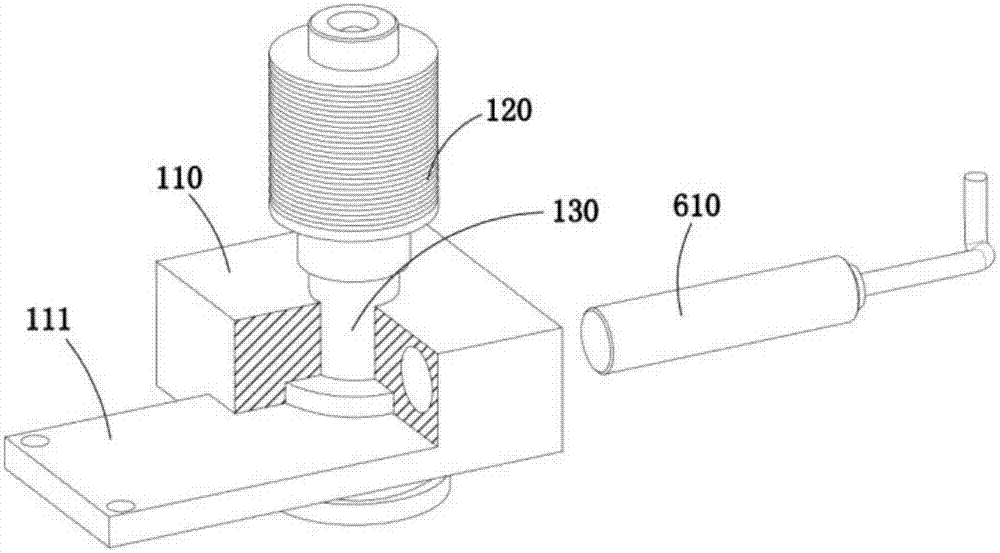

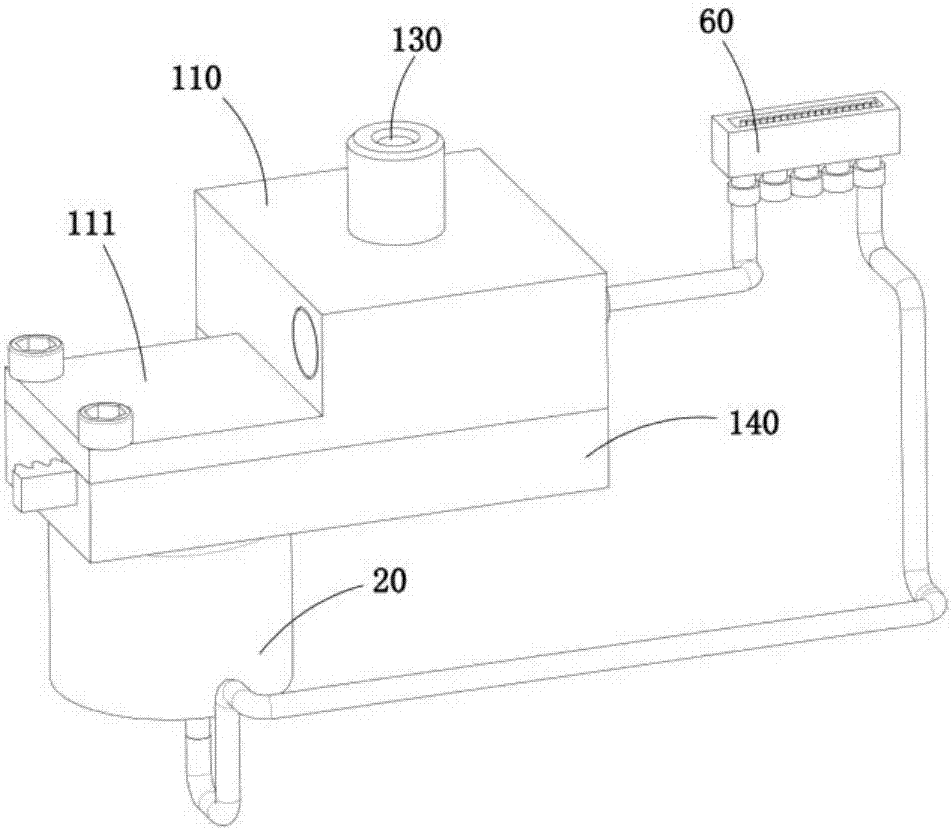

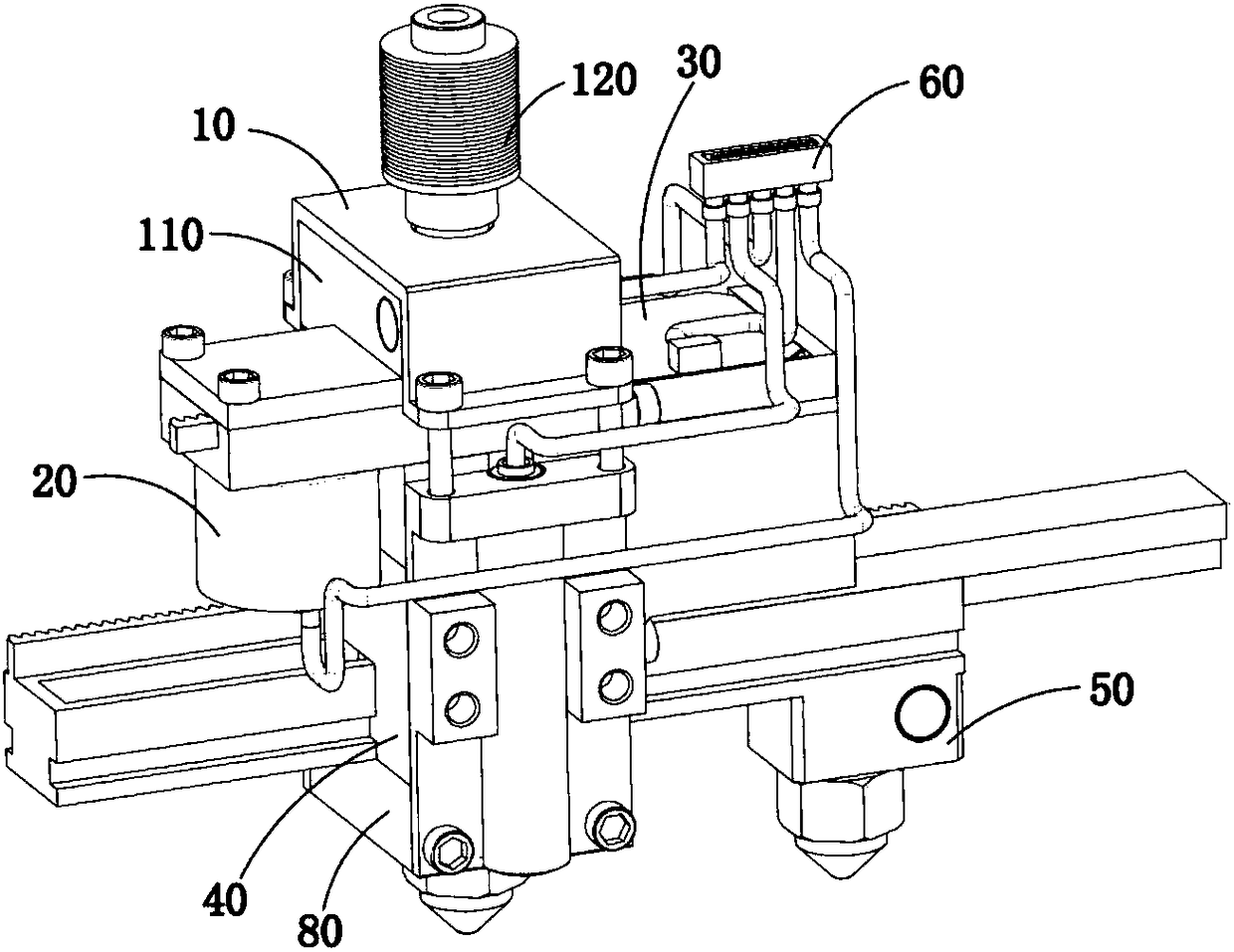

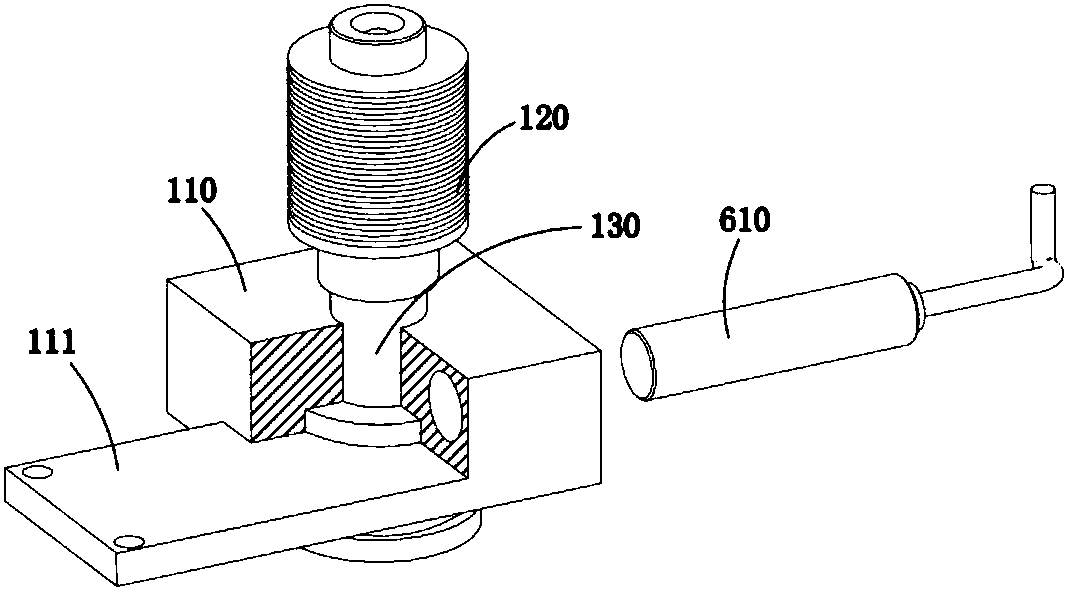

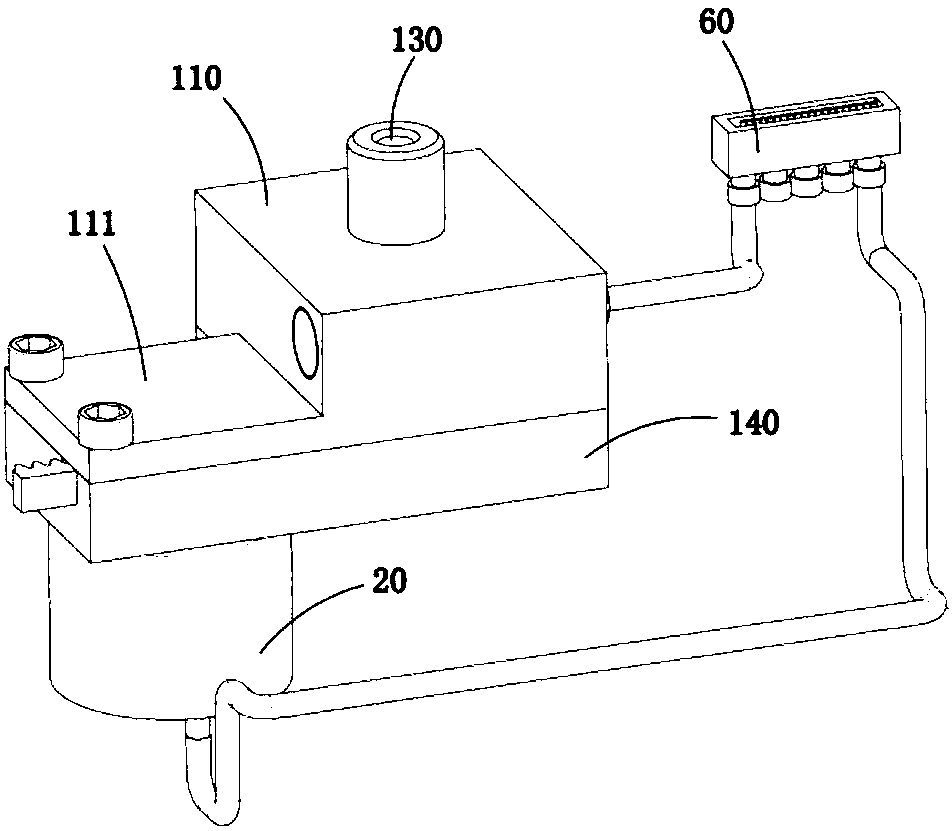

High-precision multi-axis 3D printer

ActiveCN107351391AFlow controllableAchieve integrationAdditive manufacturing apparatusMulti axisExtrusion

The invention discloses a high-precision multi-axis 3D printer comprising a reversing pipe capable of generating or receiving a molten raw material and a splitter plate connected with the discharging end of the bottom of the reversing pipe; the bottom of the splitter plate is also provided with a guide mechanism capable of receiving the molten raw material discharged from the splitter plate; the guide mechanism comprises a guide supporting body and a guide rail fixedly connected with the guide supporting body and arranged in a way of extending along a horizontal direction; a first extrusion mechanism capable of receiving the molten raw material flowing out of a first communicating hole is connected below the guide supporting body; and the guide supporting body is also slidably connected with a second extrusion mechanism capable of moving along the guide direction of the guide rail and receiving the molten raw material flowing out of a second communicating hole.

Owner:安徽硕创电气科技发展有限公司

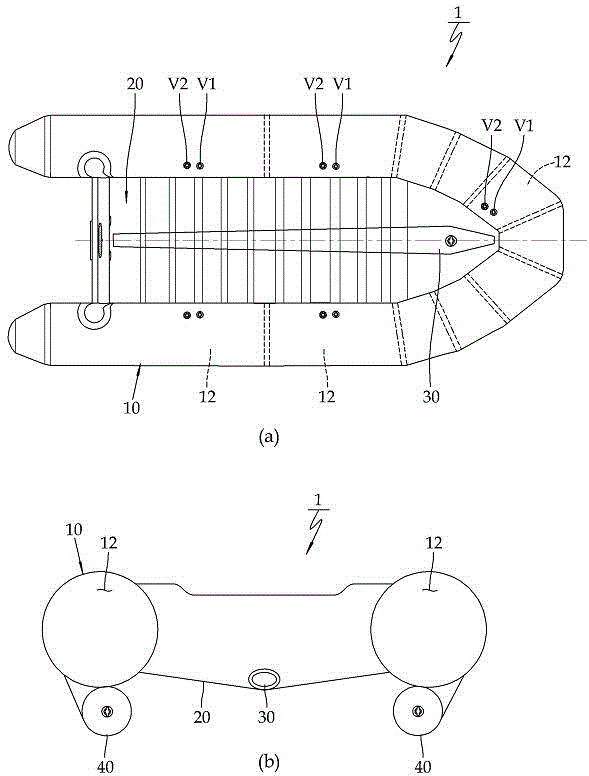

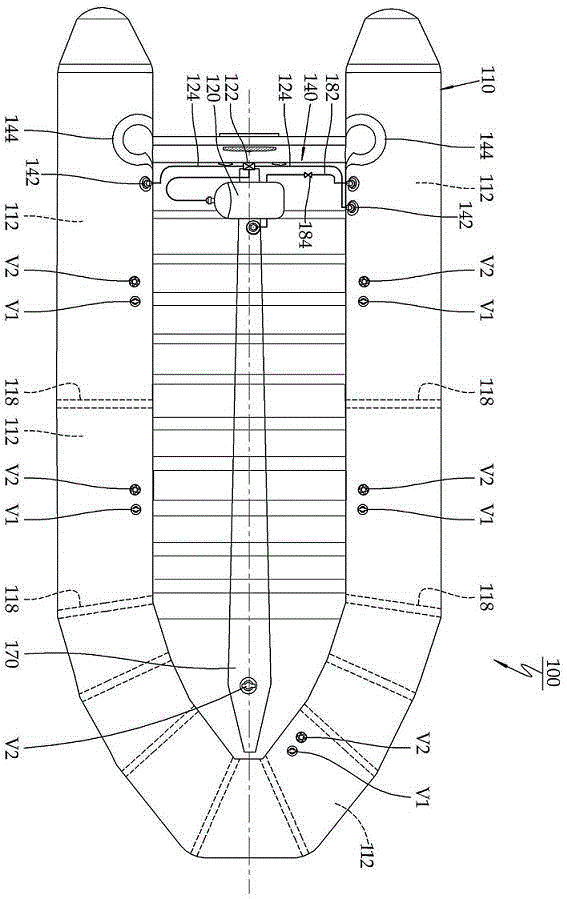

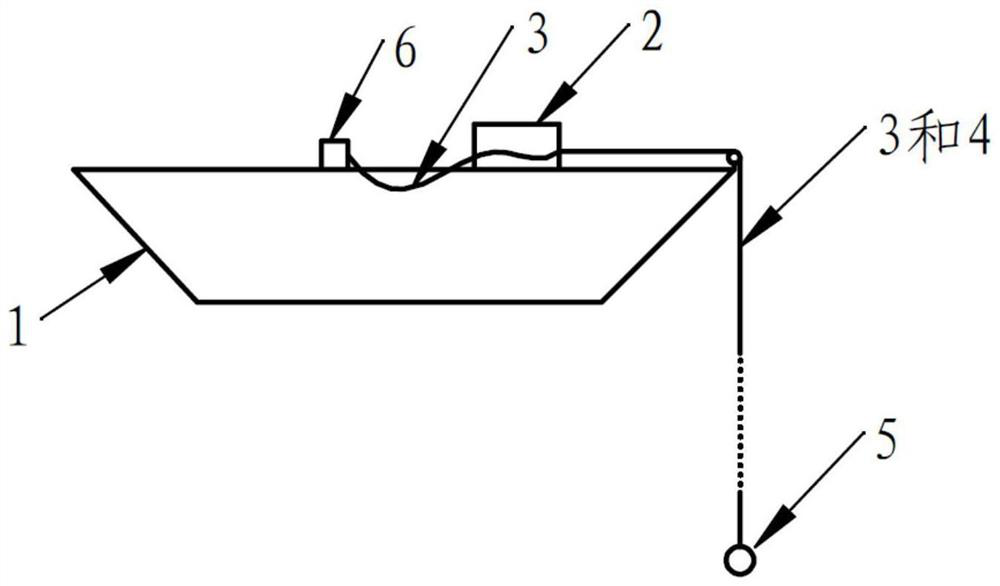

self inflatable boat

InactiveCN102267540BFlow controllableDesign pressure holdVessel salvagingFoldable/inflatable hullsInflatable boatKeel

The invention discloses an automatic inflatable boat. It includes: a tubular hull part with a plurality of air chambers inside; a velocity tube or an air delivery pipe installed on the tubular hull part; a compressed air supply source is fixed behind the tubular hull part, thereby The compressed air supply part that generates compressed air and provides compressed air to the velocity tube; the air distribution part that supplies compressed air to each air chamber of the hull part at the design pressure through the above velocity tube; the above hull part supplies the keel with the design pressure Air connection section for air. In the present invention, through the high-pressure intake valves at 1-2 places, the air of the required pressure is quickly input to each air chamber at the same time, so it can be quickly put into use in an emergency. It is especially suitable for the evacuation and transfer of rescue ships or military ships with emergency needs, ensuring that any air chamber in the hull part is damaged without affecting the remaining air chambers, ensuring safety.

Owner:따리엔조양워터크래프트컴퍼니리미티드

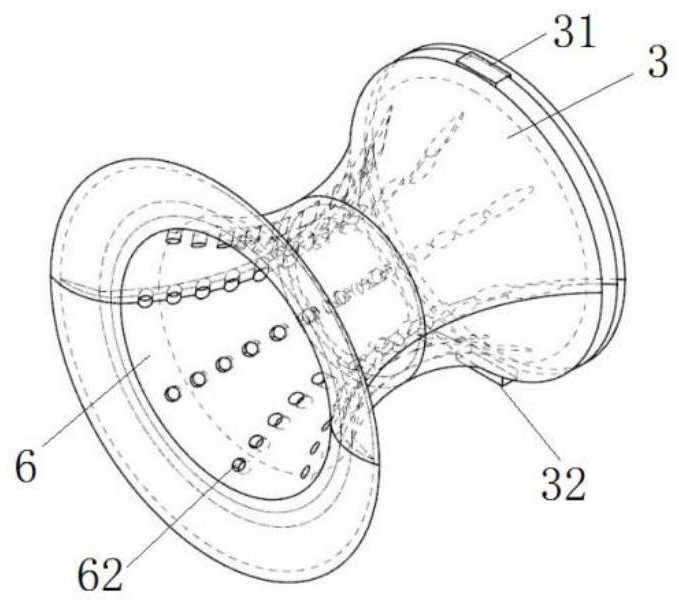

Water pushing oxygenation device and breeding tank thereof

ActiveCN113575501ASimple structureEasy to assembleClimate change adaptationPisciculture and aquariaUnderwaterOxygen enhanced

The invention provides a water pushing oxygenation device and a breeding tank thereof. The water pushing oxygenation device comprises a support, an impeller, an impeller cover, an air guide pipe and a driving motor, wherein the impeller is installed between two side plates of the support and is completely immersed underwater, the impeller cover is installed on the impeller in a sleeving mode, one end of the air guide pipe extends out of the water surface, the other end of the air guide pipe is installed close to the impeller cover, and the driving motor is installed on the support and used for driving the impeller to rotate; and the impeller cover is provided with an opening for water to enter and exit. The breeding tank comprises the water pushing oxygenation device, a U-shaped tank and a sewage discharging device; the water pushing oxygenation device is installed at the water inlet end of the U-shaped groove, and the sewage discharging device is installed at the water outlet end of the U-shaped groove; and an aeration device for increasing the oxygen content of a water body is arranged at the bottom in the U-shaped groove. The water pushing oxygenation device realizes unpowered automatic oxygen dissolving of water for the breeding tank; the tank body adopts a self-floating assembly type design, and spare parts are pre-assembled in a factory and assembled on site; and the structure is simple, the production cost is reduced, and the water area adaptability is good.

Owner:HUNAN AGRICULTURAL UNIV

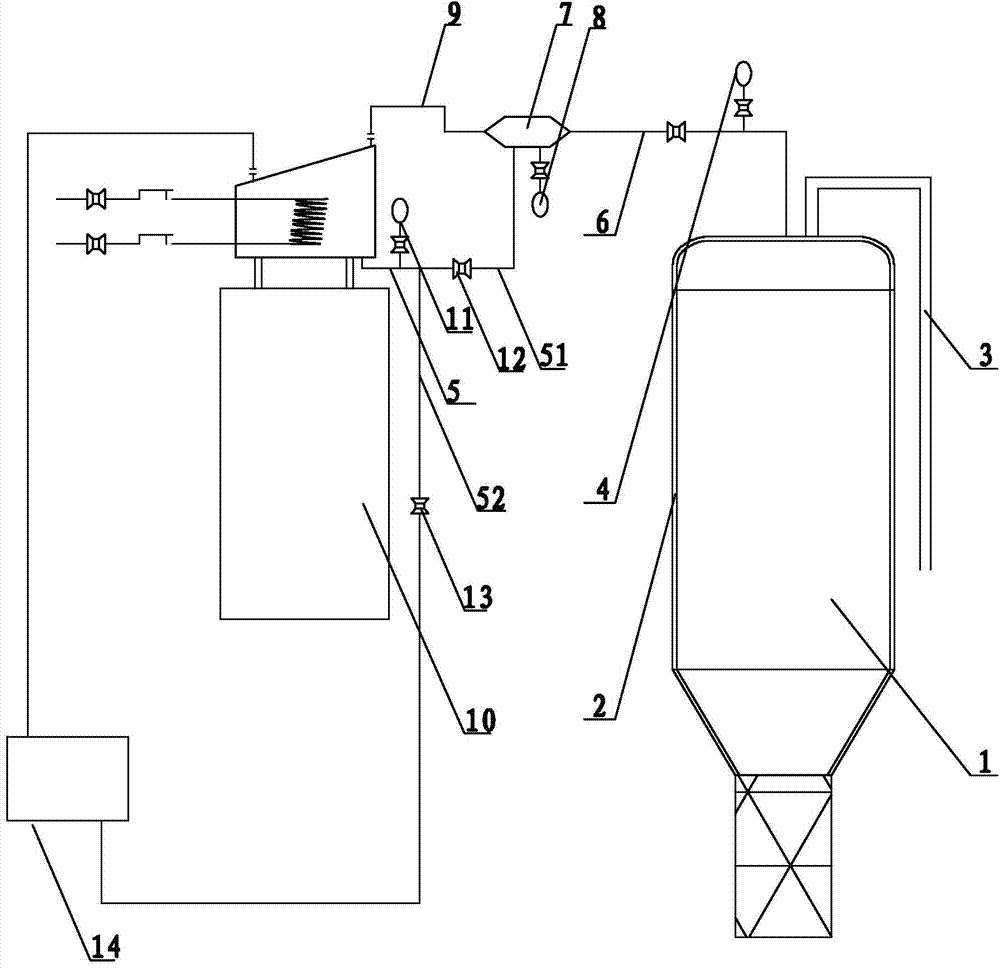

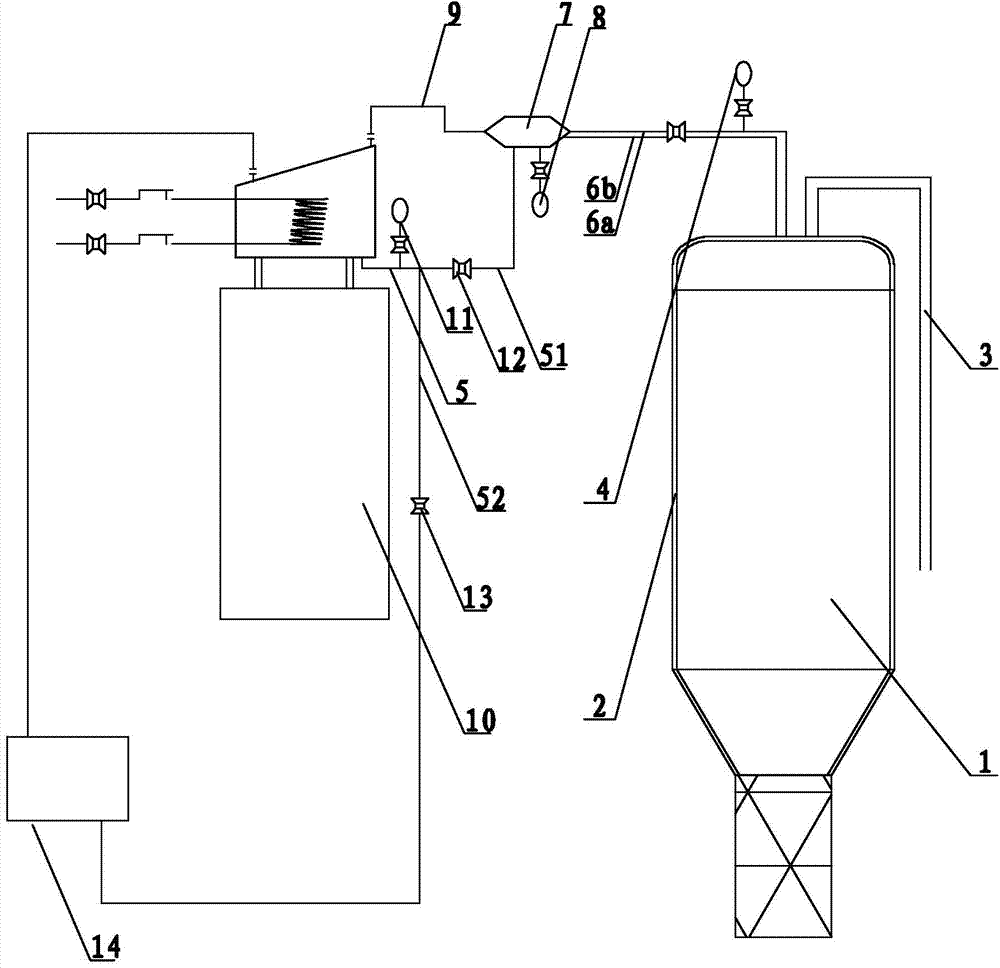

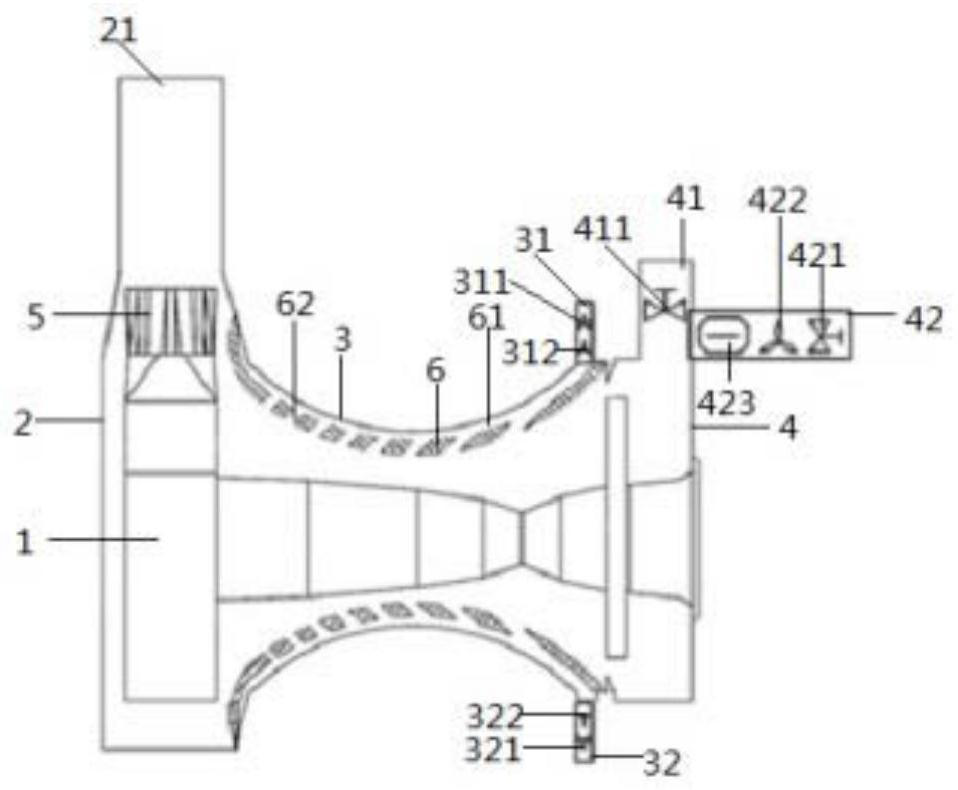

Exhaust gas combustion furnace and exhaust gas treatment equipment

InactiveCN109489052AIncrease profitReduce consumptionIncinerator apparatusCombined combustion mitigationCombustorCombustion chamber

The invention discloses an exhaust gas combustion furnace and exhaust gas treatment equipment. The exhaust gas combustion furnace comprises a combustion chamber, heat accumulators, gas preheating pipelines, combustors, an exhaust gas conveying pipeline, an exhaust pipeline and a gas conveying pipeline, wherein the combustion chamber comprises a first combustion chamber and a second combustion chamber; the upper part of the first combustion chamber communicates with the upper part of the second combustion chamber; each heat accumulator is positioned at the bottom of the combustion chamber; a gas inlet of each gas preheating pipeline is used for communicating with the external gas conveying pipeline; each heat accumulator is internally provided with the corresponding gas preheating pipeline;a gas outlet of each gas preheating pipeline extends out of the combustion chamber; and the air outlet of each gas preheating pipeline is provided with the corresponding combustor. By the scheme, onone hand, the exhaust gas combustion furnace increases the utilization rate of gas, on the other hand, the exhaust gas combustion furnace quickens decomposition of harmful gases in the exhaust gas, reduces consumption of the gas, improves the incineration efficiency and effect of the exhaust gas and achieves good economical benefits and environmental protection benefits.

Owner:SHANGHAI BAOSTEEL ENERGY TECH

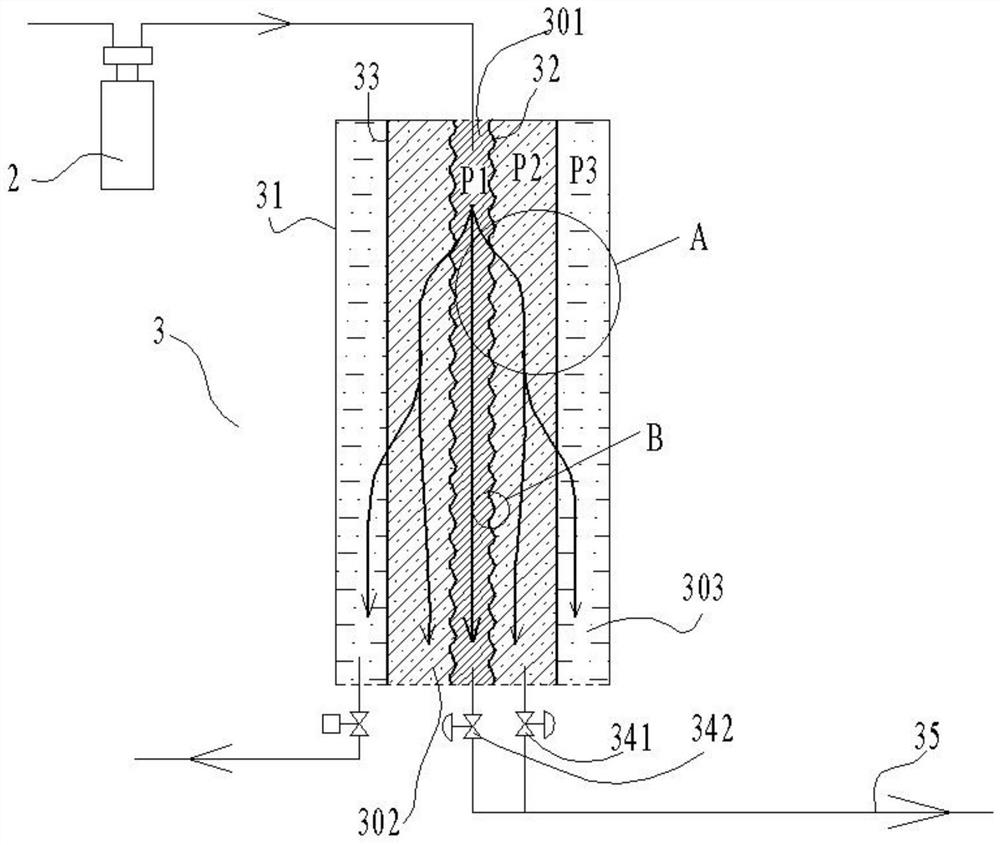

Water purifying equipment with directional selective reverse osmosis filtering structure

ActiveCN113087080AEven contactIncrease the area of the first-stage semipermeable membraneSpecific water treatment objectivesWater/sewage treatment bu osmosis/dialysisWater pipeMechanical engineering

The invention discloses water purification equipment with a directional selective reverse osmosis filter structure, which comprises an inlet filter element, a booster pump and a reverse osmosis filter element, which are sequentially connected together through water pipes; the reverse osmosis filter element comprises a shell, a first semi-permeable membrane, a second semi-permeable membrane and a discharge port, wherein the interior of the shell is divided into three flow channels by a first semi-permeable membrane and a second semi-permeable membrane in sequence, namely a first flow channel, a second flow channel and a third flow channel; one end of the first runner serves as a reverse osmosis filter element inlet, and the other end of same is connected to the discharge port; a first pressure regulating valve is arranged on a pipeline through which the first flow channel is connected to the discharge port; one end of the second flow channel is closed, one end is connected to the discharge port, a second pressure regulating valve is arranged on a pipeline for connecting the second flow channel to the discharge port, one end of the third flow channel is closed, and the other end of same is used as a purified water outlet of the reverse osmosis filter element.

Owner:上海求越实业有限公司

A high-precision multi-axis 3D printer

ActiveCN107351391BFlow controllableAchieve integrationAdditive manufacturing apparatusEngineeringMulti axis

The invention discloses a high-precision multi-axis 3D printer comprising a reversing pipe capable of generating or receiving a molten raw material and a splitter plate connected with the discharging end of the bottom of the reversing pipe; the bottom of the splitter plate is also provided with a guide mechanism capable of receiving the molten raw material discharged from the splitter plate; the guide mechanism comprises a guide supporting body and a guide rail fixedly connected with the guide supporting body and arranged in a way of extending along a horizontal direction; a first extrusion mechanism capable of receiving the molten raw material flowing out of a first communicating hole is connected below the guide supporting body; and the guide supporting body is also slidably connected with a second extrusion mechanism capable of moving along the guide direction of the guide rail and receiving the molten raw material flowing out of a second communicating hole.

Owner:安徽硕创电气科技发展有限公司

Liquid-sealed controlled-atmosphere storage tank and method based on combination of monomer structures

ActiveCN113170815BStable flowFlow controllablePackaging under vacuum/special atmosphereShock-sensitive articlesThermodynamicsProcess engineering

The invention discloses a liquid-sealed modified-atmosphere storage tank based on a combination of monomer structures and a method thereof, including a storage container, a first pipeline and a second pipeline are respectively arranged on both sides of the storage container, and the first pipeline and the second pipeline The center of the storage container is symmetrically arranged, the above-mentioned first pipeline is provided with a connecting pipe, and the above-mentioned connecting pipe is connected to the inner cavity of the storage container, and the lower ends of the above-mentioned first pipeline and the second pipeline are respectively provided with a first connecting cover and a second connecting cover. The upper end of the storage container is open, the side wall of the storage container is provided with a liquid tank, and the lower end of the storage container is provided with a main body connection cover corresponding to the opening, through liquid sealing at the bottom, construction of a combination, sealing at the top, precooling of fruits and vegetables, and air conditioning of fruits and vegetables to achieve desired To improve the large-scale use of controlled atmosphere storage boxes, the space may be limited. Fruit and vegetable precooling and controlled atmosphere storage cannot be carried out on the same equipment, and there are differences in the structure of controlled atmosphere boxes, which increases the cost of manufacturing and installation.

Owner:SICHUAN UNIV

Environment control system and control method for box-packed body of gas turbine

ActiveCN113586252AImprove cooling effectIncrease flexibilityTurbine/propulsion engine coolingGas turbine plantsControl systemEngineering

The invention discloses an environment control system and control method for a box-packed body of a gas turbine. A heat shielding cover is arranged on the inner surface of a chest drum type middle box section, the left end and the right end of the heat shielding cover are connected with two ends of the chest drum type middle box section in a closed mode to define an airflow cavity, a plurality of air film holes are formed in the inner wall face of the heat shielding cover, a third air inlet pipeline and a fourth air inlet pipeline which communicate with the airflow cavity are symmetrically arranged on the upper surface and the lower surface of the right side end of the chest drum type middle box section, and valves and fans are sequentially arranged on the third air inlet pipeline and the fourth air inlet pipeline from outside to inside; and a second air inlet pipeline is connected to the side of a first air inlet pipeline in a penetrating mode, and a valve, a fan and a heater are sequentially arranged on the second air inlet pipeline from outside to inside. According to the control system, the use mode can be adjusted according to different working conditions, and the internal temperature of the box-packed body and the surface temperature of the gas turbine are promoted to rapidly return to the optimal data environment state; and due to the design of the air film holes, backflow of an outlet of an ejector and the self-locking condition of airflow in the box-packed body can be restrained.

Owner:JIANGSU UNIV OF SCI & TECH

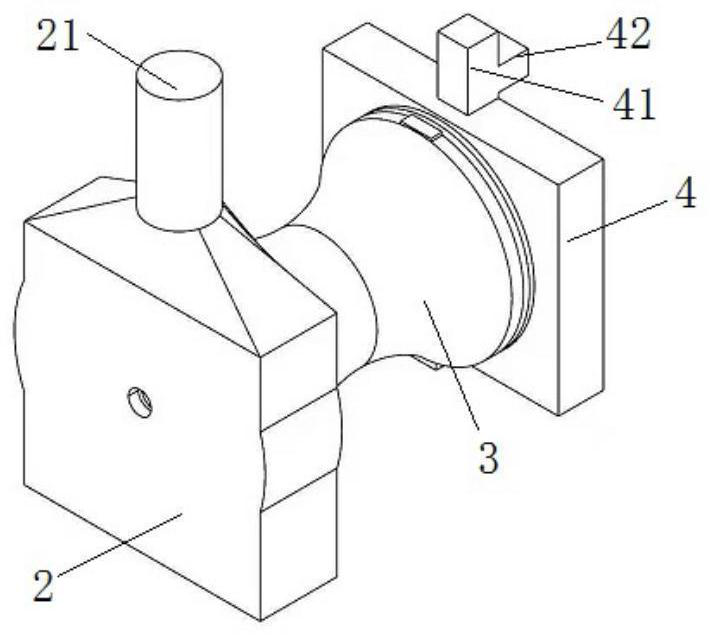

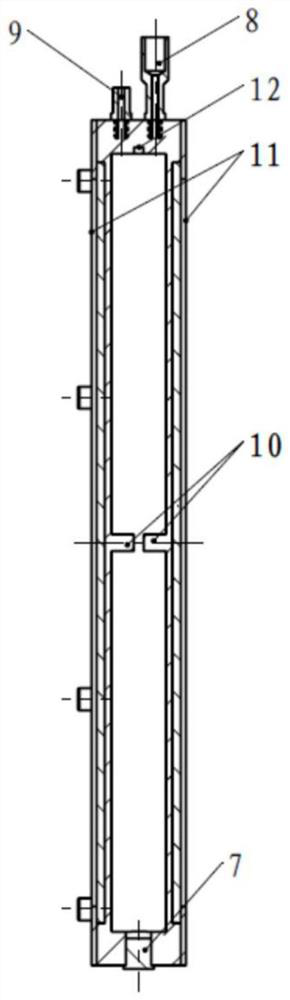

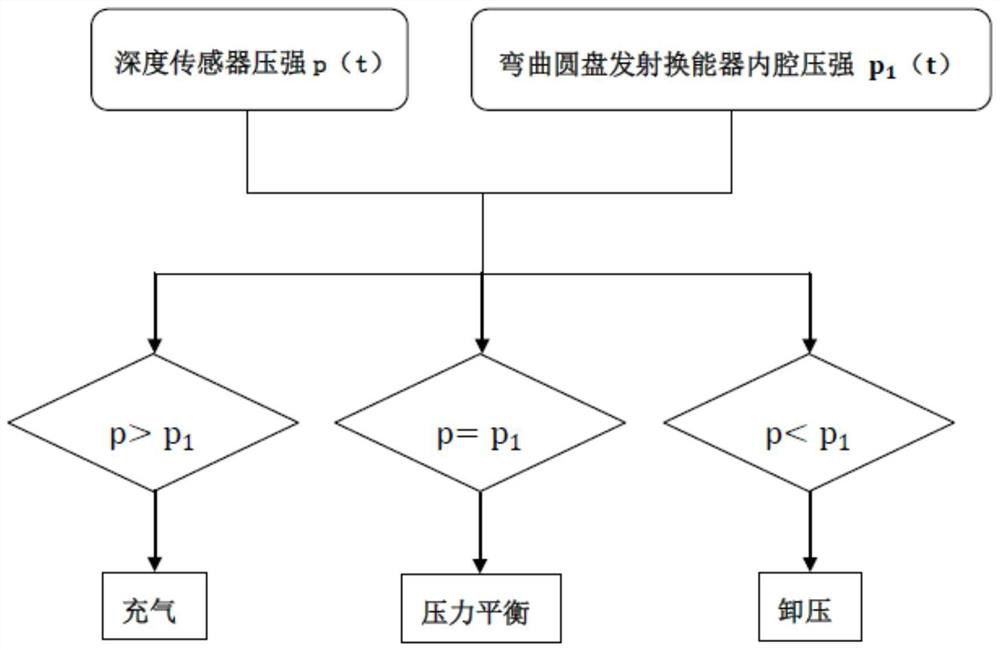

Deepwater pressure compensation type extremely-low-frequency bending transmitting transducer system

PendingCN114183324AFlow controllableFast compensationPump testingPositive displacement pump componentsEngineeringExtremely low frequency

The invention relates to the technical field of transducers, in particular to a deepwater pressure compensation type extremely-low-frequency bending type transmitting transducer system which comprises a bending type transmitting transducer, a signal source, a power amplifier, a high-pressure gas compressor, a high-pressure hose and a bearing cable, and the high-pressure gas compressor comprises a compressor, a controller, a pressure regulating valve set and an electronic pressure gauge. An external overpressure prevention structure is arranged in the bending type transmitting transducer, an internal pressure prevention structure is arranged outside the bending type transmitting transducer, a depth sensor is arranged outside the bending type transmitting transducer, and an electronic pressure gauge is arranged in the bending type transmitting transducer. The transmitting transducer is arranged in deep water, the pressure intensity of an inner cavity of the bent transducer is adjusted in real time through the dry-end high-pressure gas compressor and the high-pressure hose, the pressure intensity is kept consistent with the water pressure, and therefore the pressure compensation effect is achieved; and the limitation of the working depth of the transducer is broken.

Owner:THE 715TH RES INST OF CHINA SHIPBUILDING IND CORP +1

Spraying nozzle device for electrostatic spinning

ActiveCN102061529BSolve processing difficultiesReduce processing difficultySpinnerette packsFilament/thread formingElectrical conductorElectrospinning

The invention relates to a spraying nozzle device for electrostatic spinning, comprising a spinning liquid flow channel through which spinning liquid passes; the spinning liquid flow channel comprises a liquid inlet and a liquid outlet; the liquid outlet of the spinning liquid flow channel is provided with a flow dividing net in a covering manner; the side of the flow dividing net, which is far from the liquid inlet, is distributed with flow guiding filaments overhanging towards the outer side of the liquid outlet; and at least one of the flow dividing net and the flow guiding filaments is made of a conductor material. As the spraying nozzle device for electrostatic spinning adopts the flow dividing net to replace the traditional spraying head to spray spinning liquid and guides the spinning liquid to flow to form spinning liquid drop by the flow dividing filament instead of adopting the traditional spraying nozzles of spraying pipes, for the net holes compared with the spraying holesof the spraying nozzle, the processing difficulty is greatly reduced, the accuracy is easy to guarantee and the problem that the traditional spinning nozzle is difficult to process is solved; in addition, as the flow guiding filament can lead the spinning liquid flow sprayed from the net holes of the flow dividing net to further be lengthened and fined, finer flow guiding filament can be processed, and specifically, the nano level can be achieved.

Owner:DO FLUORIDE CHEM CO LTD

Injection device for surface treatment or coloring

ActiveCN112024148AIncrease rotational kinetic energy/tangential velocityImprove the mixing effectLiquid spraying apparatusEngineeringMixing effect

The invention provides an injection device for surface treatment or coloring. The injection device comprises a nozzle body, a liquid channel, a gas channel and a temperature adjusting gas channel arearranged in the nozzle body, the liquid channel is positioned in the center of the nozzle body, the gas channel is positioned on the radial outer side of the liquid channel, and the temperature adjusting gas channel is positioned on the radial outer side of the gas channel. The liquid channel sequentially comprises a first diameter part (2), a second diameter part (3), a first conical part (4), adiffusion cavity (5) and an outlet part (6). The injection device is characterized in that a plurality of swirl plates (41) uniformly distributed in the circumferential direction are arranged on the inner circumferential surface of the first conical part, and a plurality of swirl grooves (42) distributed in the axial direction of the swirl plates are arranged at the radial inner edges of the swirlplates. According to the injection device for the surface treatment or coloring, the rotating kinetic energy / tangential speed of fluid can be increased, the mixing effect of the fluid is improved, the pressurizing effect is achieved, atomization of a nozzle is uniform, the droplet size is small, and the injection / atomization effect is excellent; and the flow direction of the temperature adjustinggas is controllable and accurate, the flow is stable, and the subsequent drying time is shortened.

Owner:LIYANG SHENGJIE MACHINE

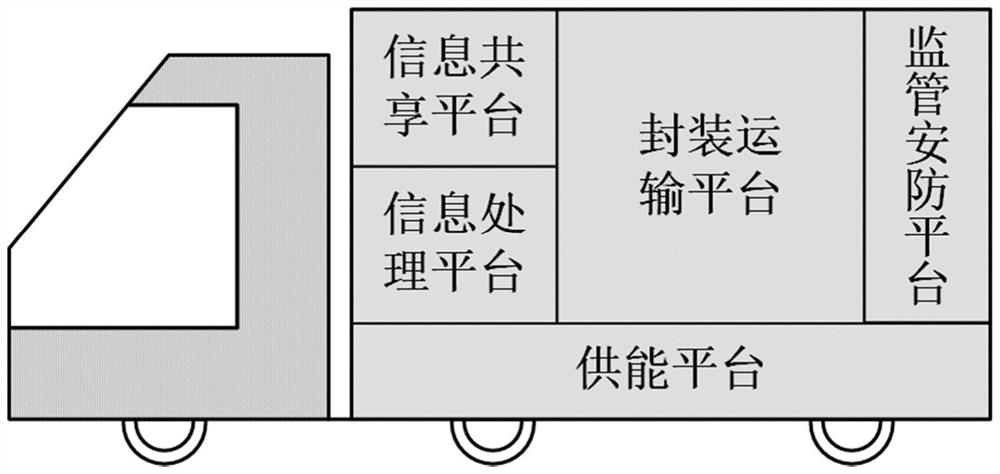

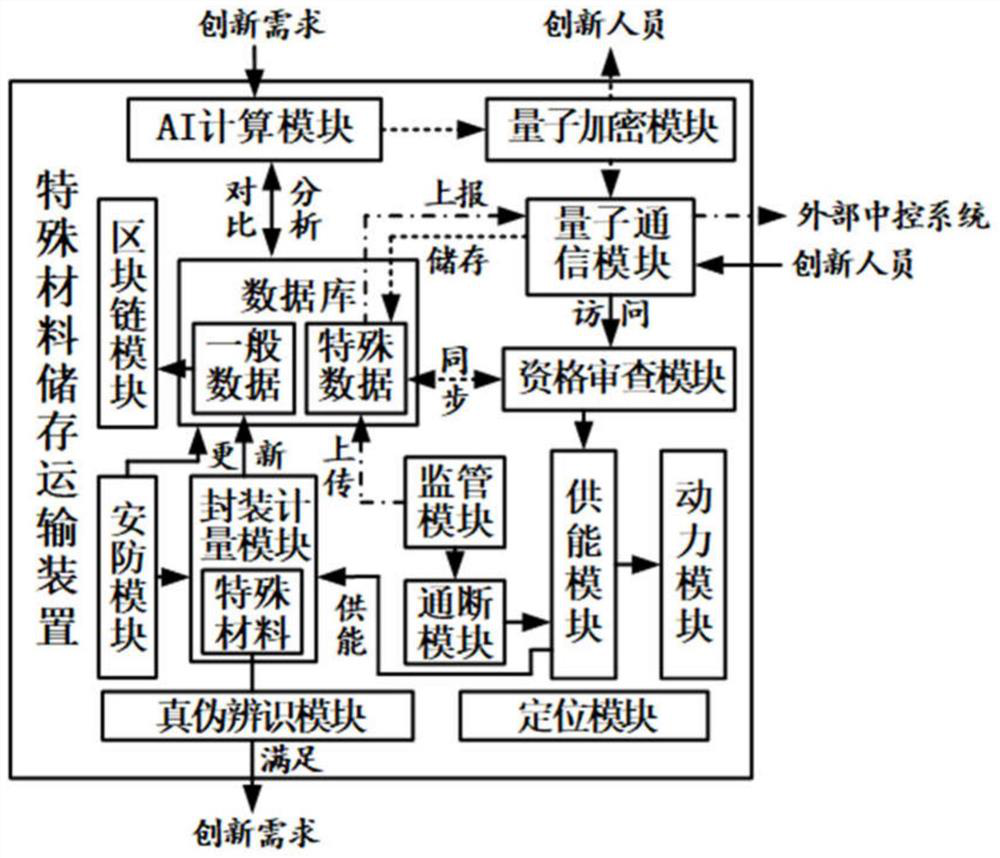

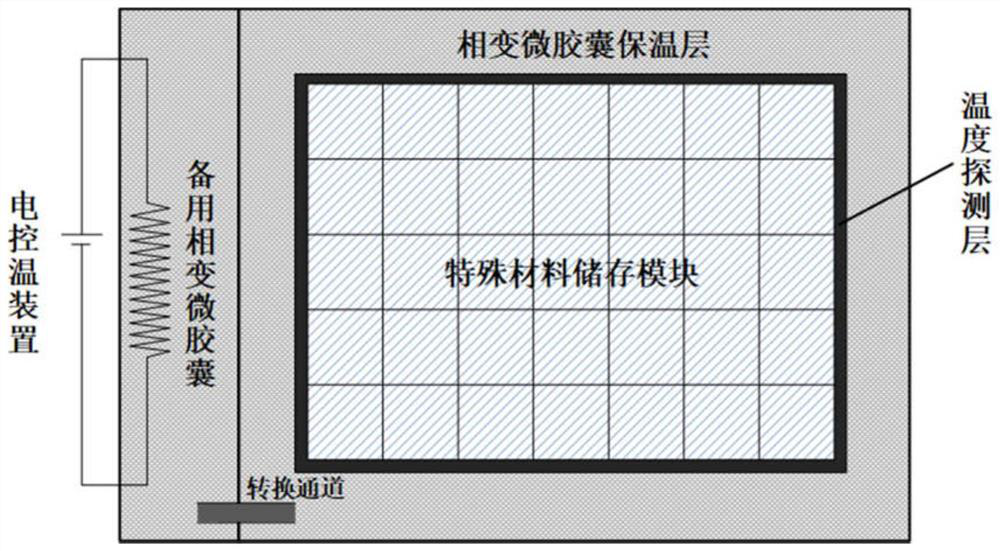

Storage and transportation device for special materials and storage and transportation method thereof

ActiveCN111746869BHigh regulatory authorityRealize direct controlWrapper twisting/gatheringSolid materialInformation processingInformation sharing

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com