Patents

Literature

560results about How to "Precision injection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

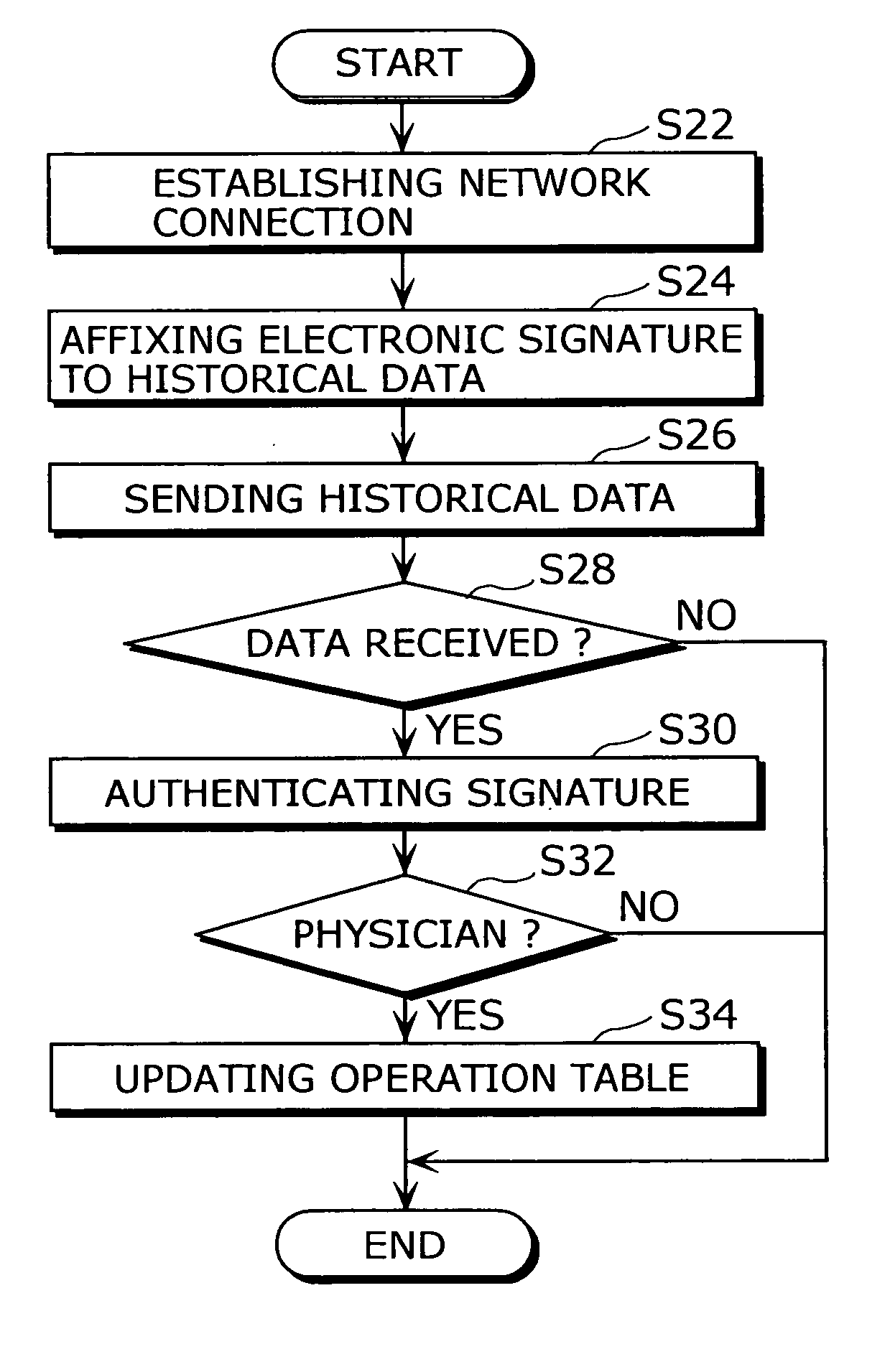

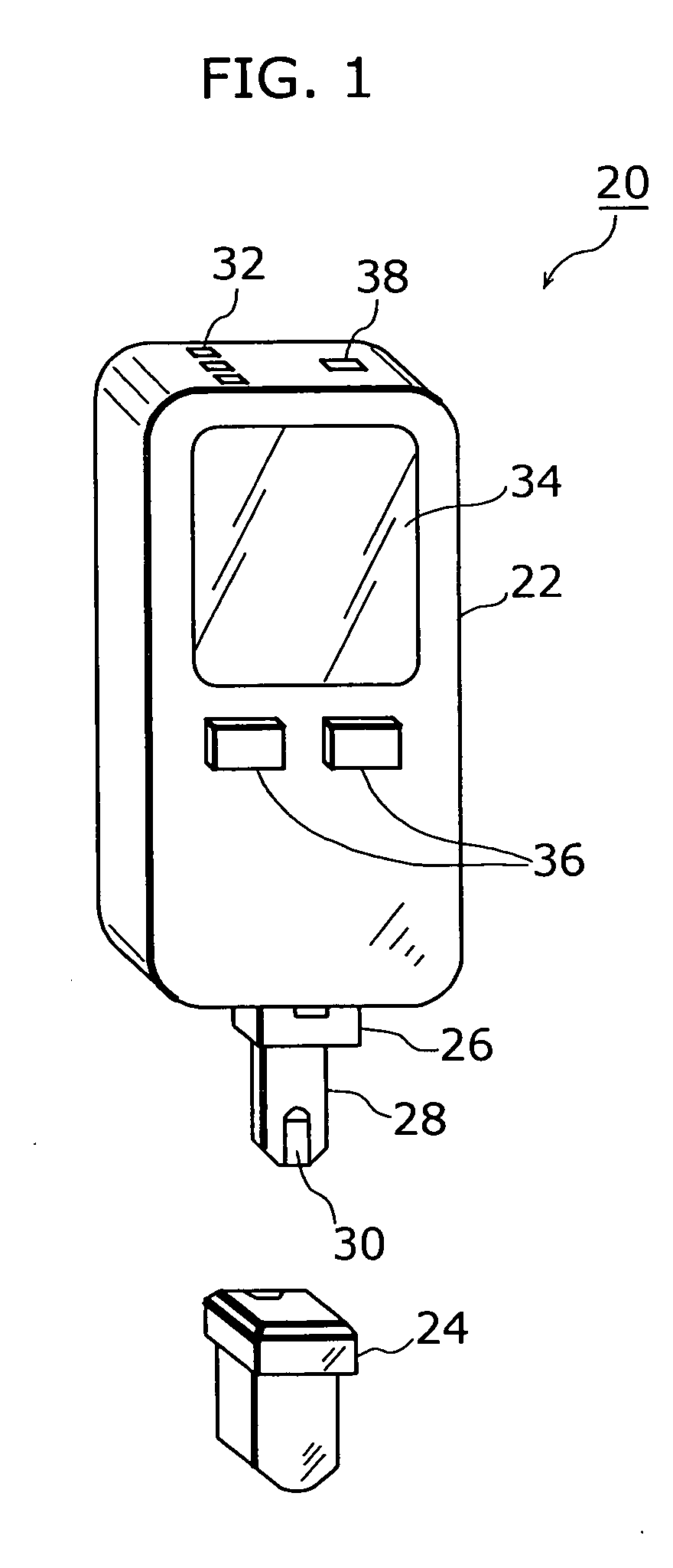

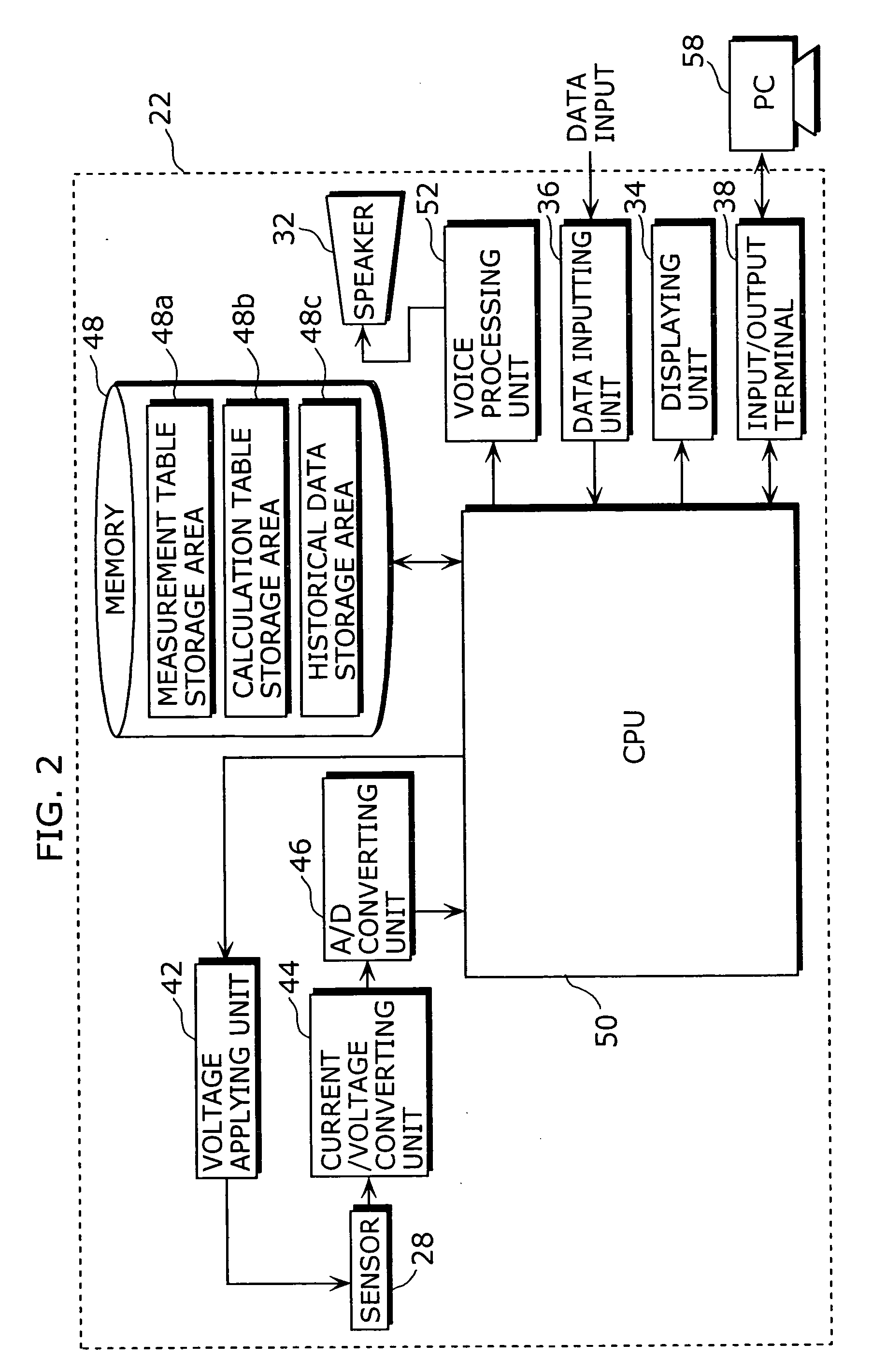

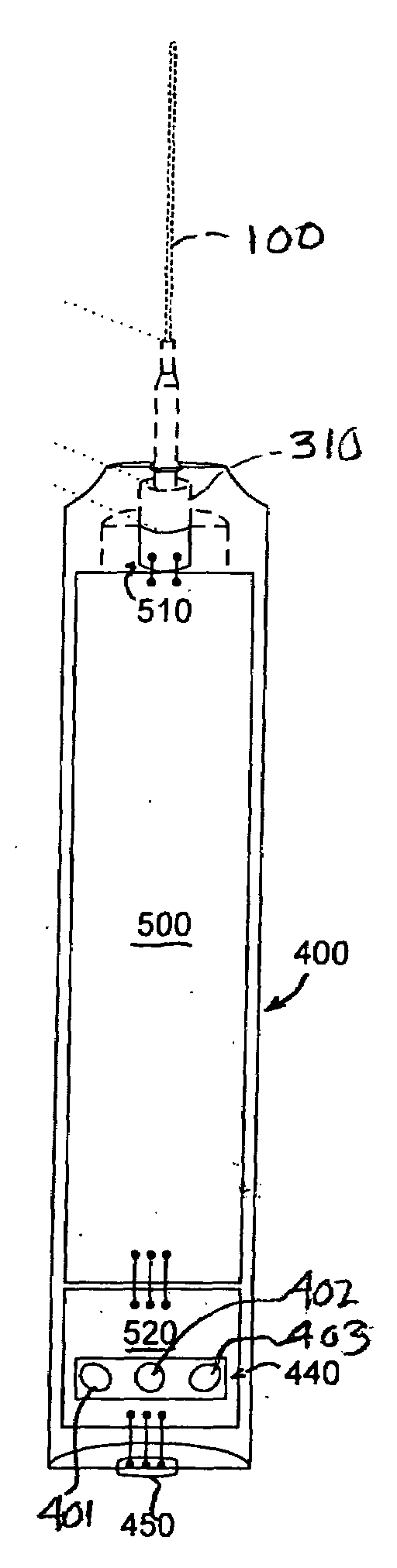

Dosage determination supporting device, injector, and health management supporting system

InactiveUS20050177398A1Improve reliabilityImprove portabilityData processing applicationsInfusion syringesSupporting systemMedicine

A dosage determination supporting apparatus, which is able to precisely determine a dosage in accordance with the health condition of a user, is provided with: a sensor (28) for measuring the blood sugar level obtained from the blood of the user; a memory (48) for storing an operation table showing a correspondence between the blood sugar level and the amount of insulin; a CPU (50) for calculating the amount of insulin corresponding to the blood sugar level, with reference to the operation table stored in the memory (48); a displaying unit (34) for displaying the amount of insulin; and a voice processing unit (52) for performing the voice processing on the amount of insulin and outputting the voice through a speaker (32).

Owner:PANASONIC CORP

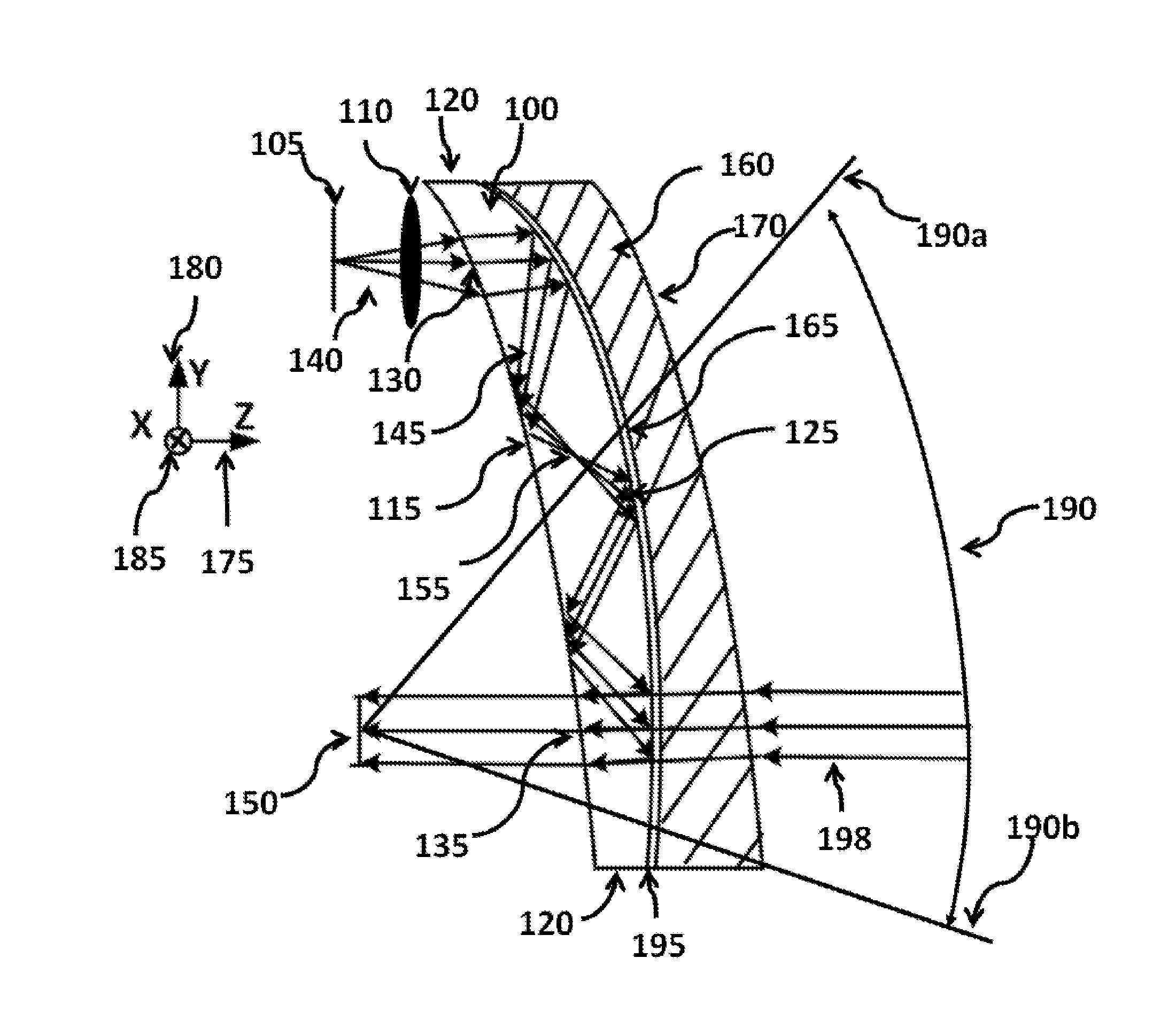

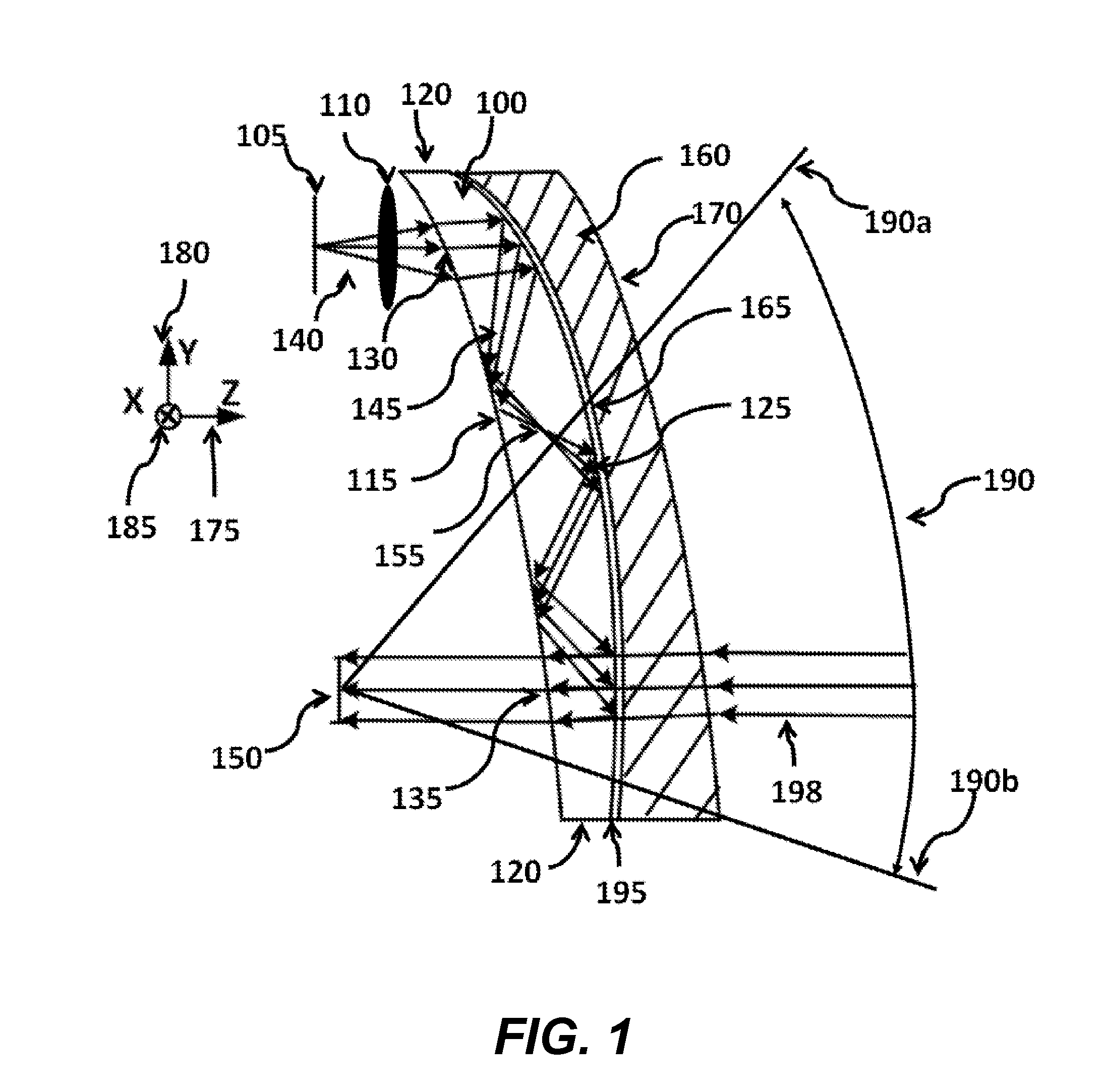

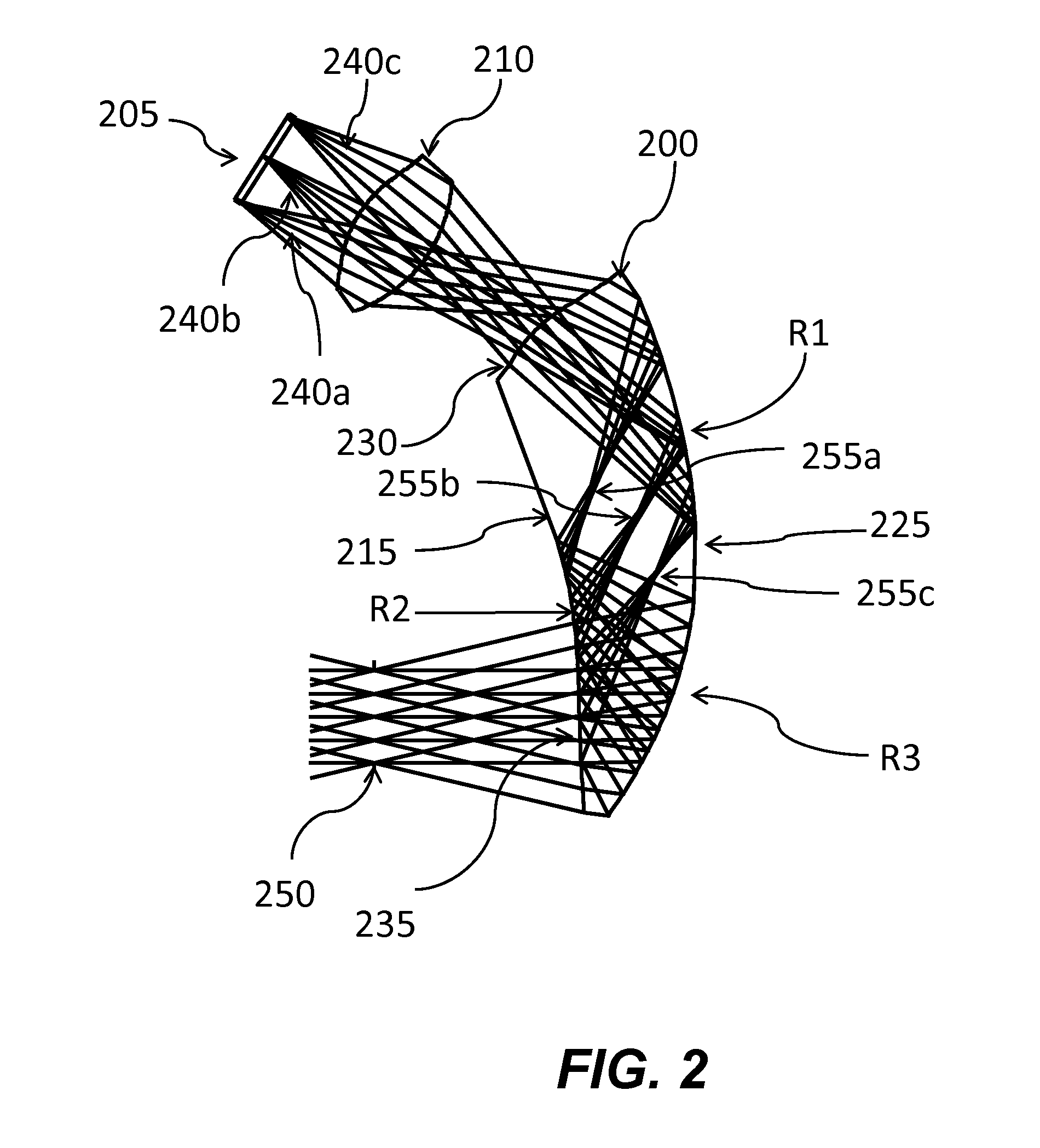

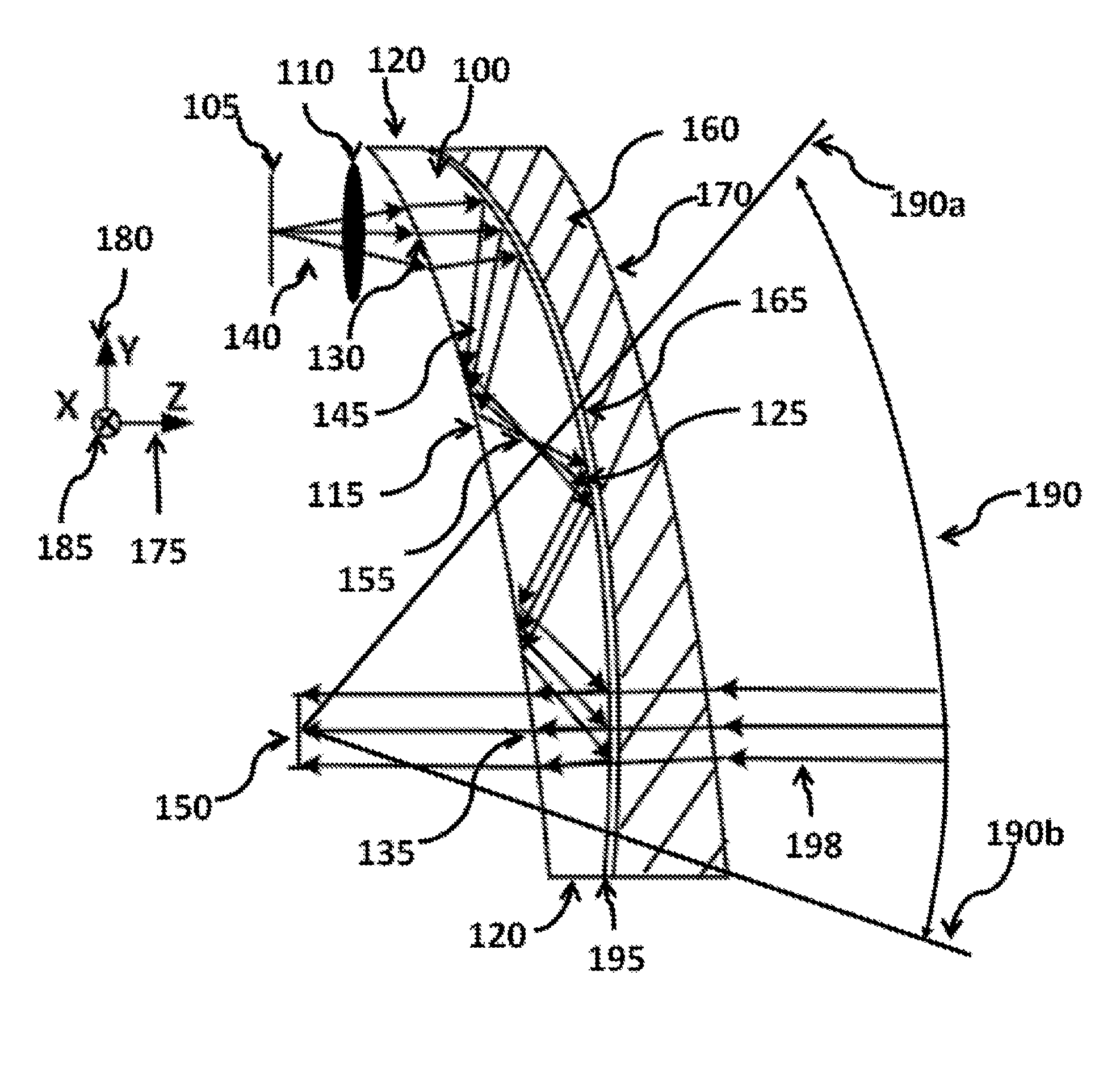

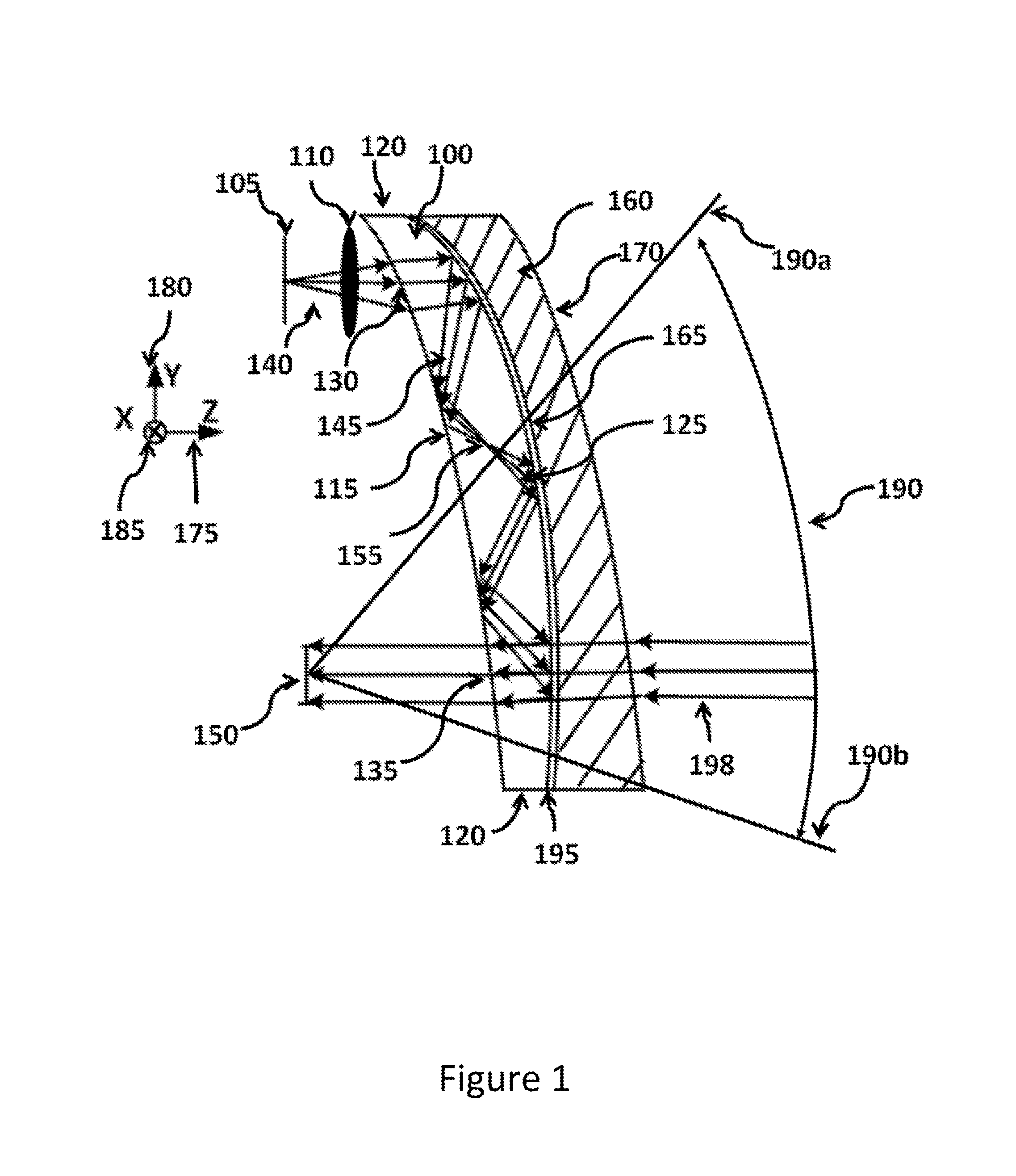

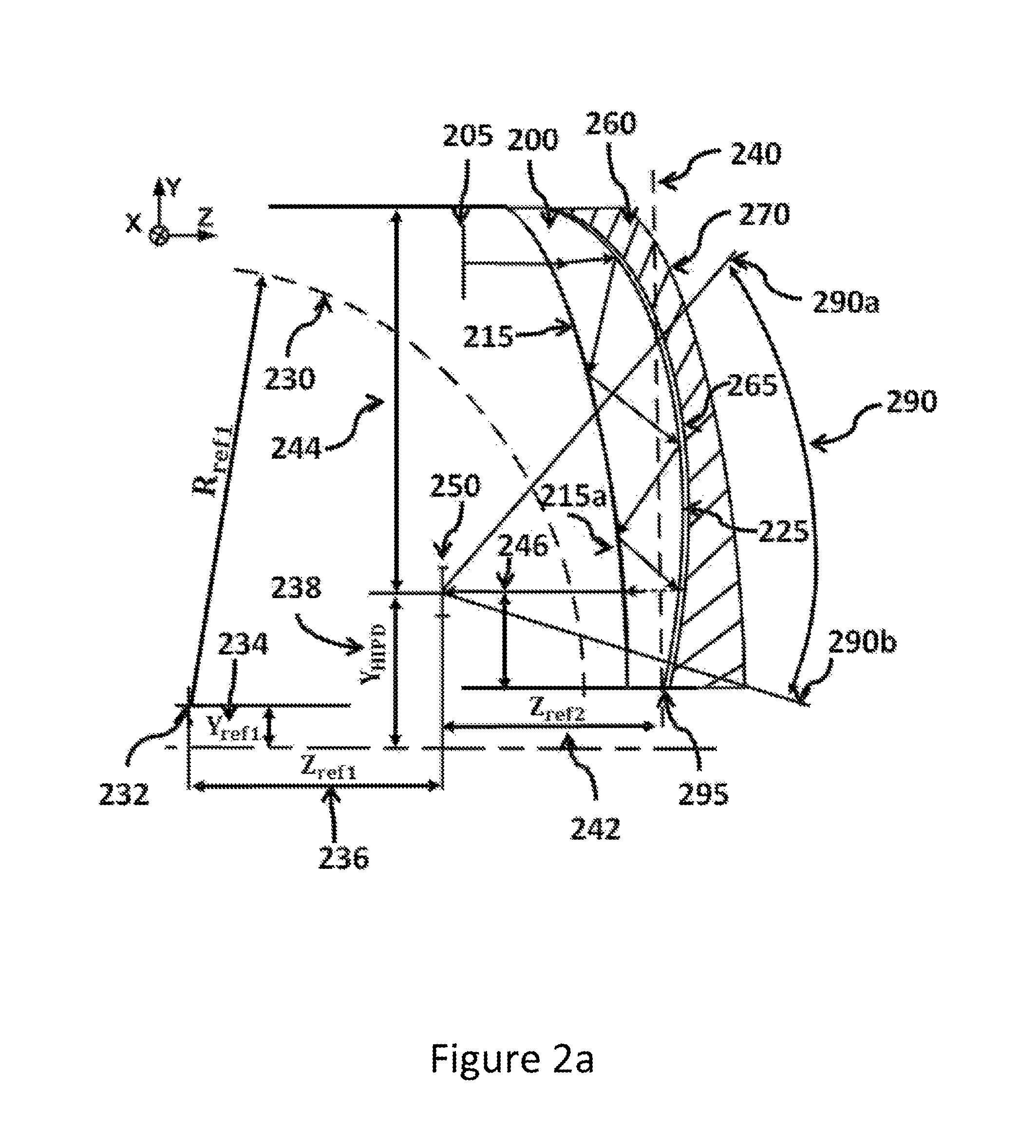

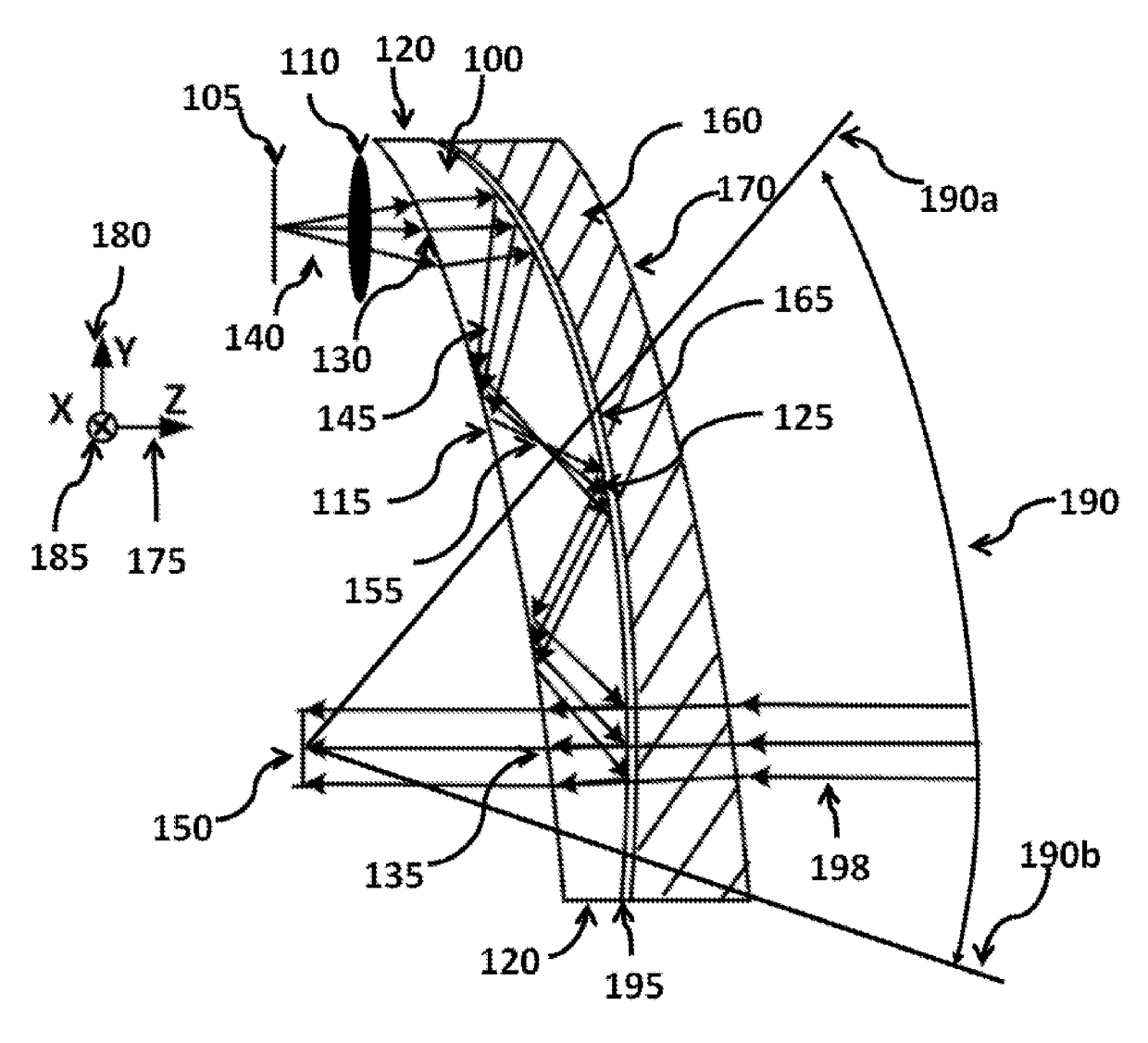

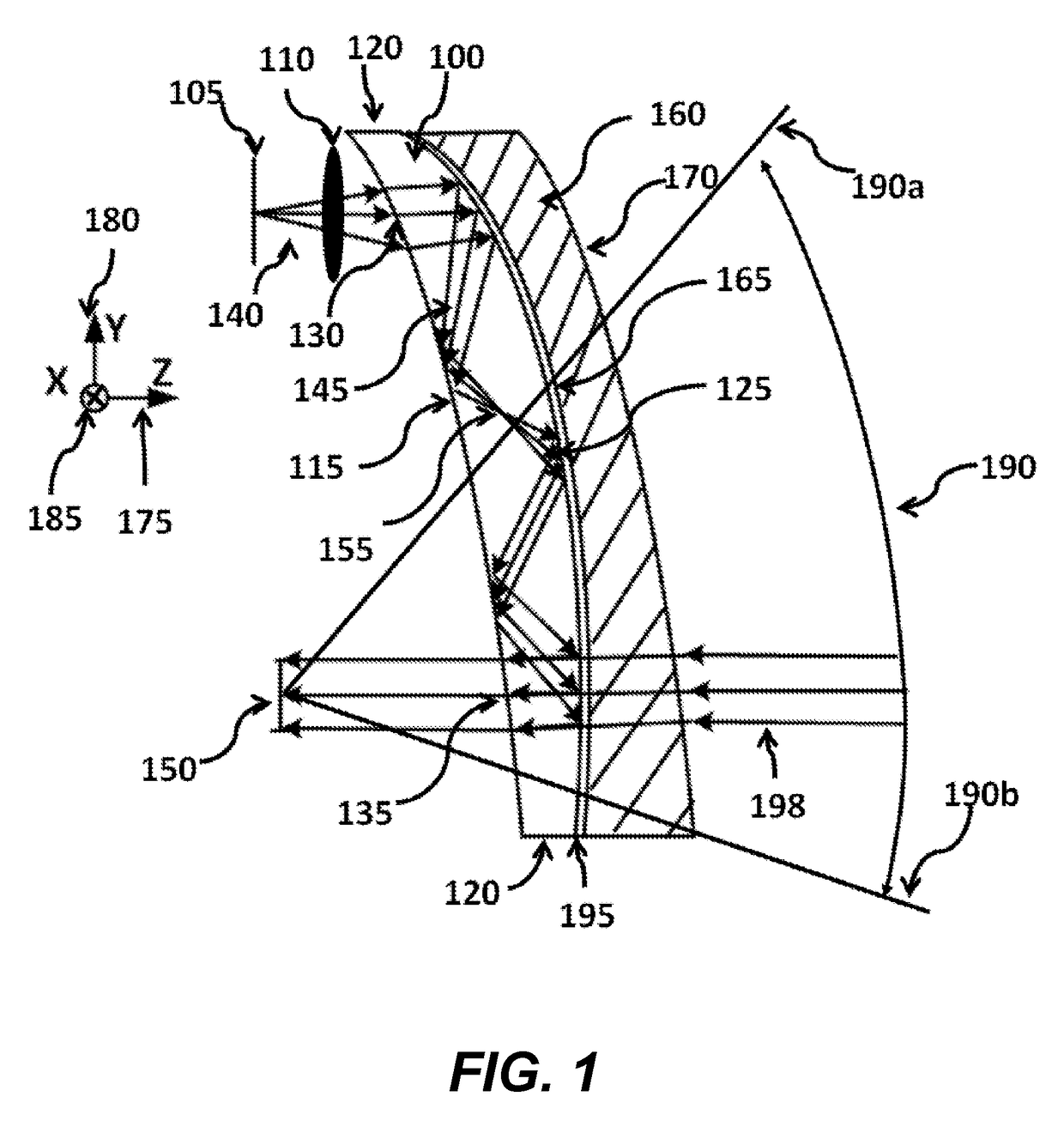

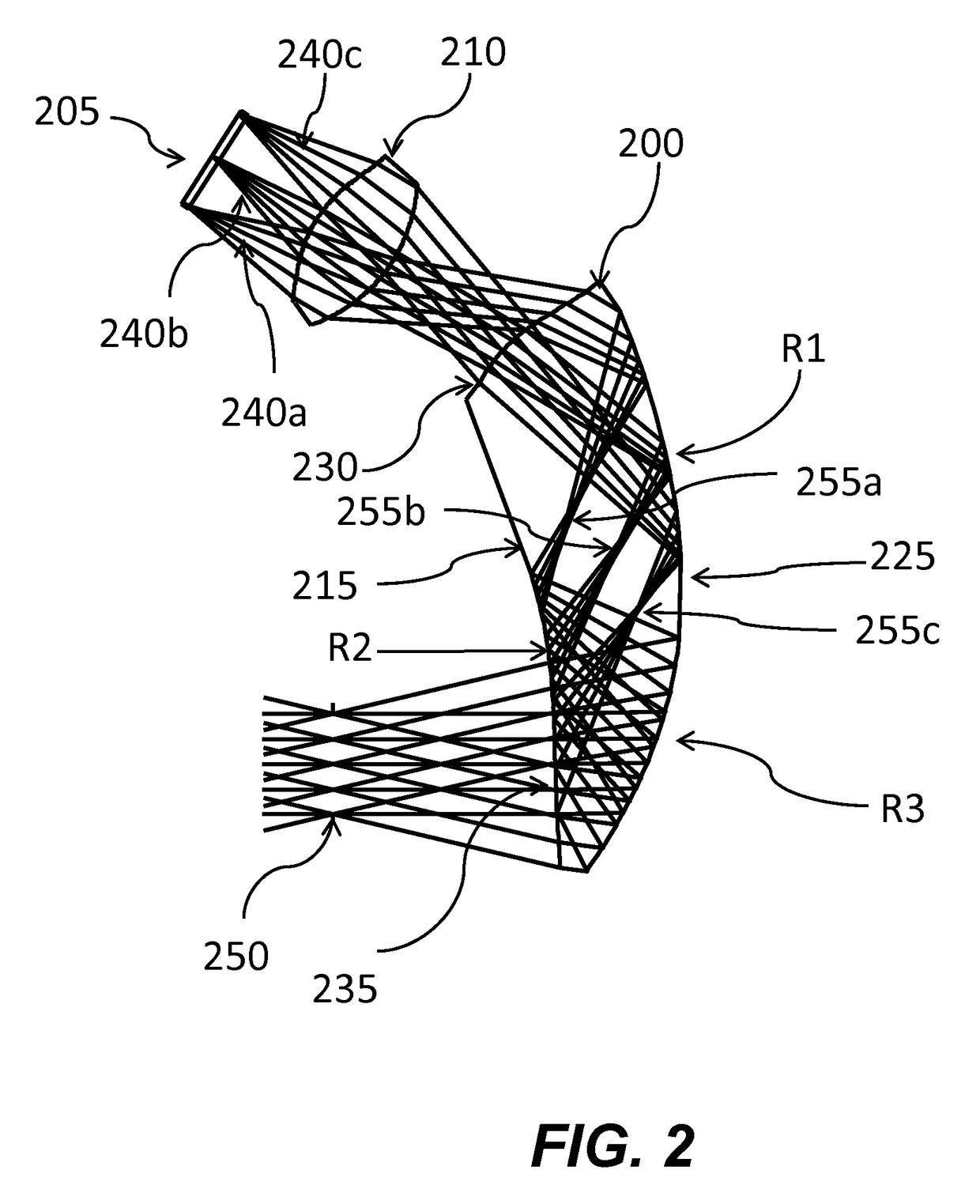

Ergonomic head mounted display device and optical system

Optical systems such as image display systems include a freeform optical waveguide prism and a freeform compensation lens spaced therefrom by a gap of air or index cement. The compensation lens corrects for aberrations which the optical waveguide prism will introduce in light or images from an ambient real-world environment. The optical waveguide prism receives actively projected images at an entry location, and emits the projected images at an exit location after internally reflecting the images along an optical path therein. The image display system may include an image source and coupling optics. The approach permits design of an optical viewing device, for example in optical see-through HMDs, achieving an eyeglass-form appearance and a wide see-through field of view (FOV).

Owner:MAGIC LEAP INC

Ergonomic head mounted display device and optical system

ActiveUS9348143B2Wide field of viewGood optical performancePolarising elementsPlanar/plate-like light guidesEyewearDisplay device

This invention concerns an ergonomic optical see-through head mounted display device with an eyeglass appearance. The see-through head-mounted display device consists of a transparent, freeform waveguide prism for viewing a displayed virtual image, a see-through compensation lens for enabling proper viewing of a real-world scene when combined together with the prism, and a miniature image display unit for supplying display content. The freeform waveguide prism, containing multiple freeform refractive and reflective surfaces, guides light originated from the miniature display unit toward a user's pupil and enables a user to view a magnified image of the displayed content. A see-through compensation lens, containing multiple freeform refractive surfaces, enables proper viewing of the surrounding environment, through the combined waveguide and lens. The waveguide prism and the see-through compensation lens are properly designed to ergonomically fit human heads enabling a wraparound design of a lightweight, compact, and see-through display system.

Owner:MAGIC LEAP INC

Ergonomic head mounted display device and optical system

ActiveUS9740006B2Good optical performancePrecision injectionCathode-ray tube indicatorsTelevision systemsFree formDisplay device

Optical systems such as image display systems include a freeform optical waveguide prism and a freeform compensation lens spaced therefrom by a gap of air or index cement. The compensation lens corrects for aberrations which the optical waveguide prism will introduce in light or images from an ambient real-world environment. The optical waveguide prism receives actively projected images at an entry location, and emits the projected images at an exit location after internally reflecting the images along an optical path therein. The image display system may include an image source and coupling optics. The approach permits design of an optical viewing device, for example in optical see-through HMDs, achieving an eyeglass-form appearance and a wide see-through field of view (FOV).

Owner:MAGIC LEAP INC

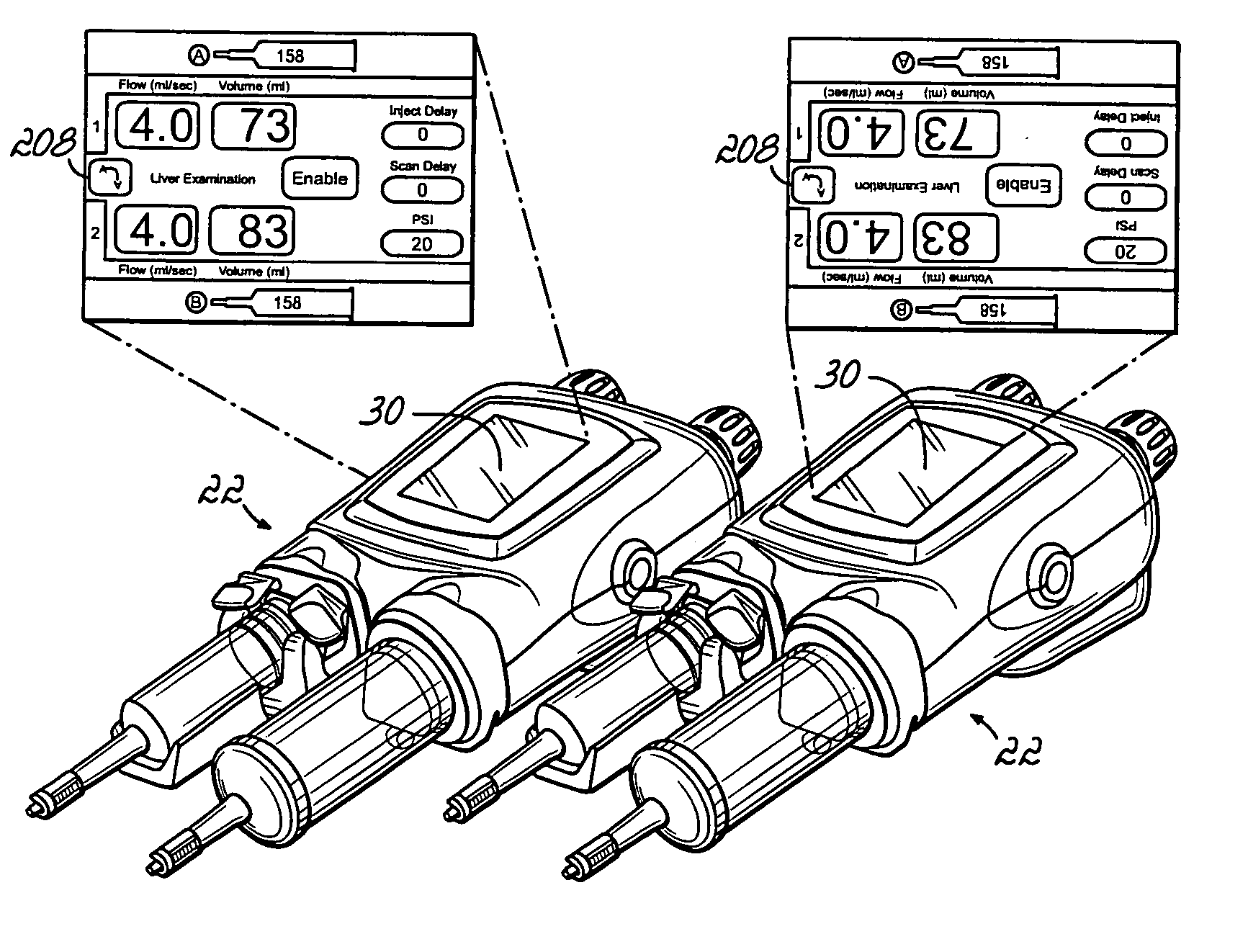

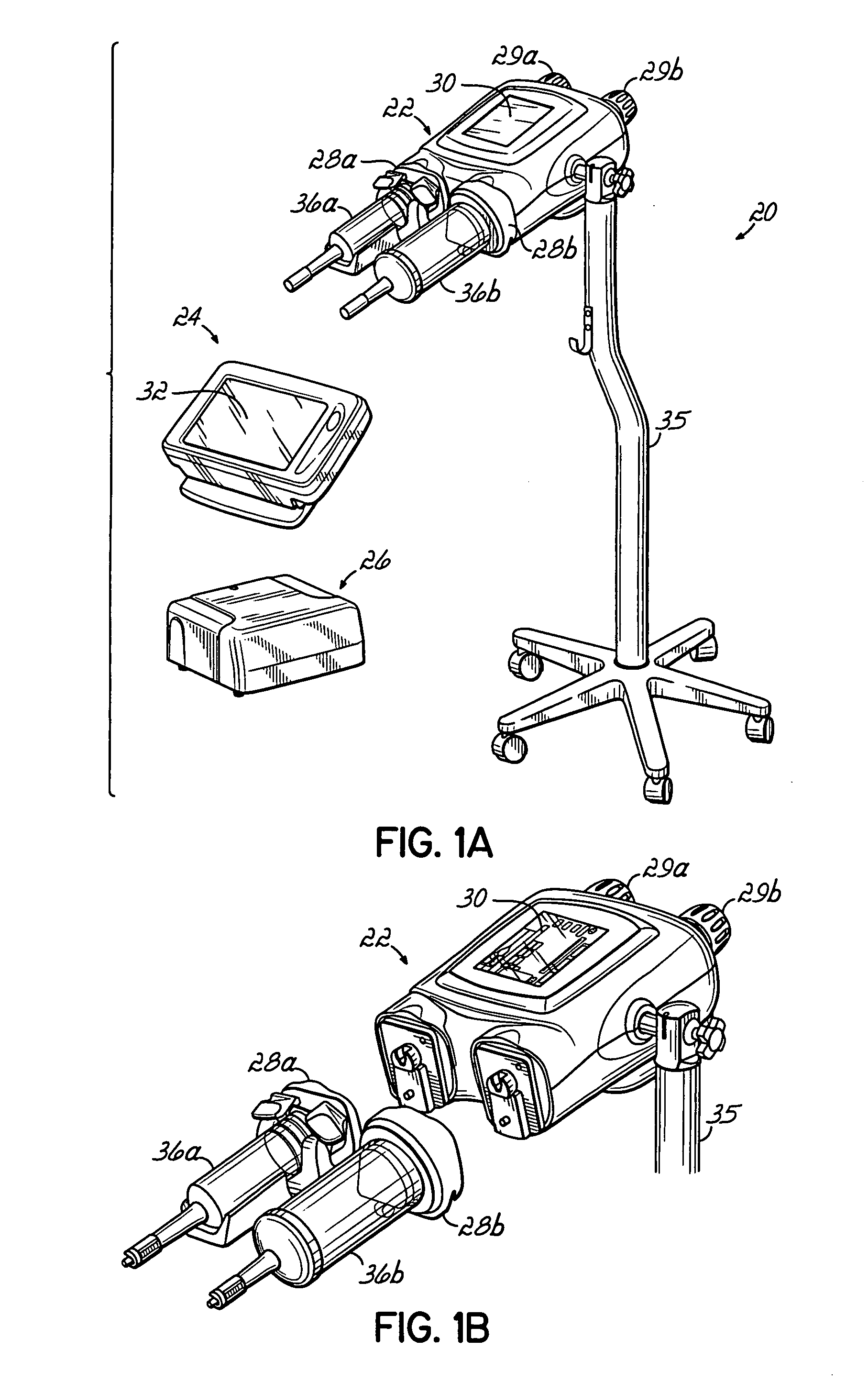

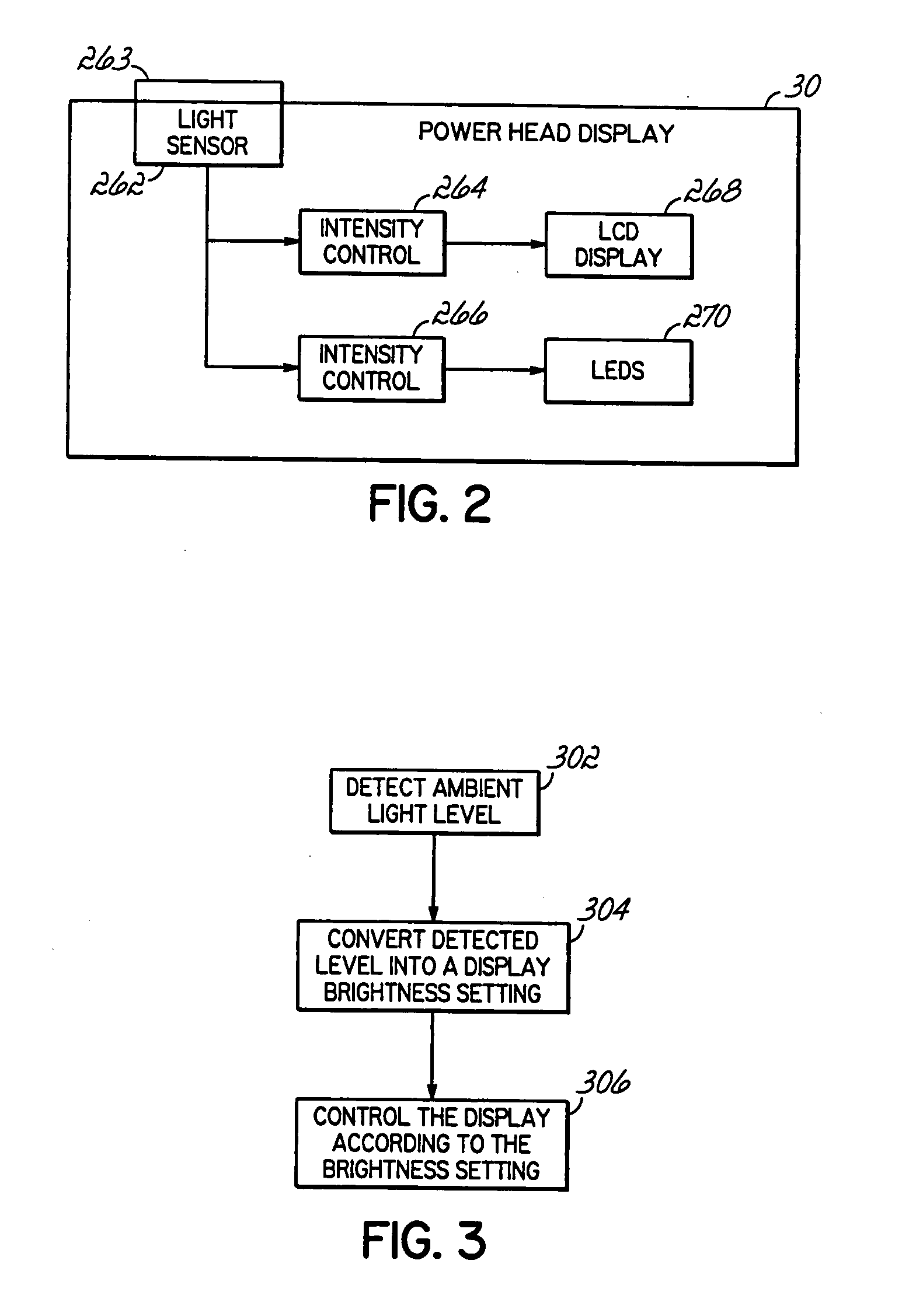

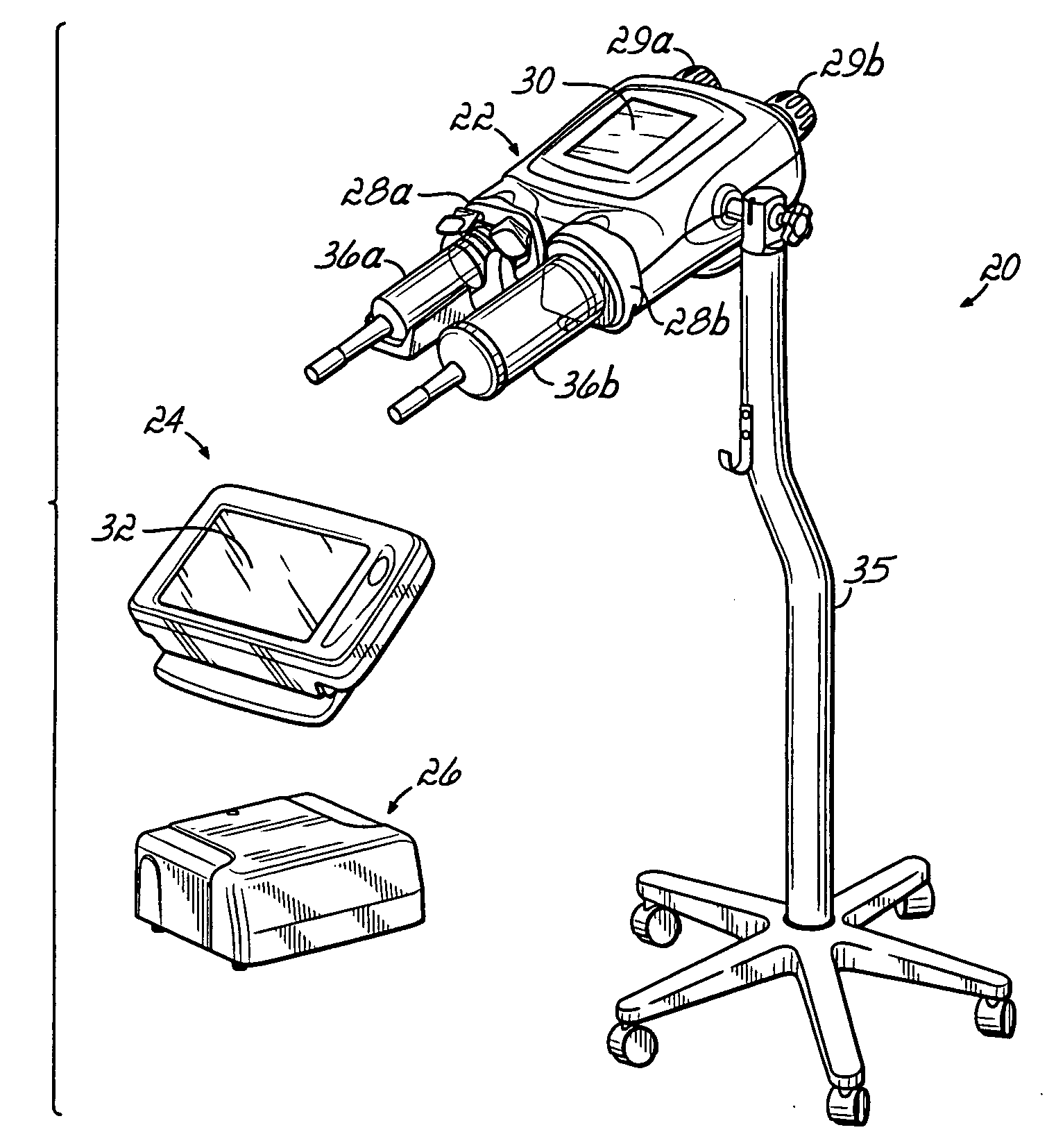

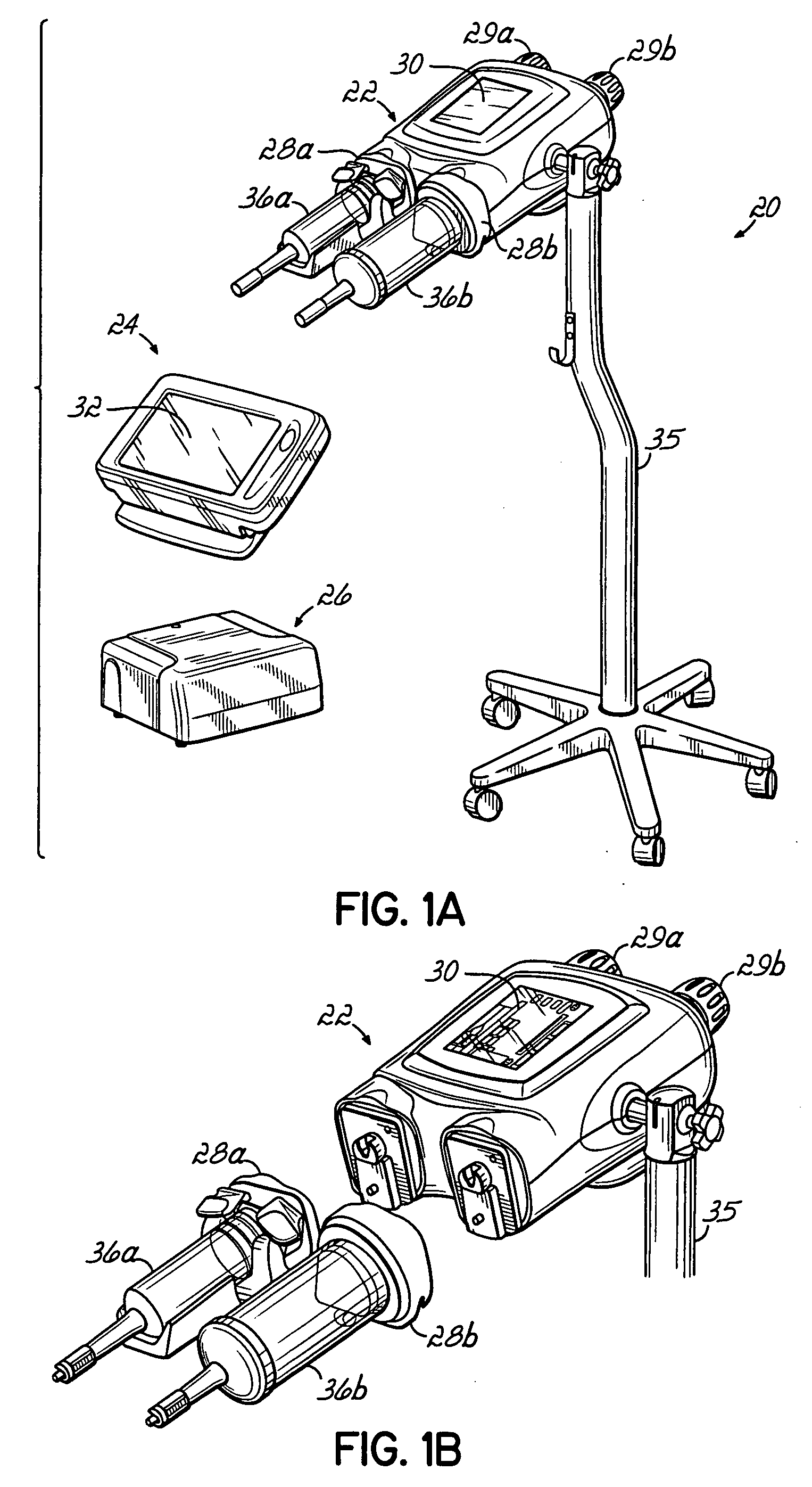

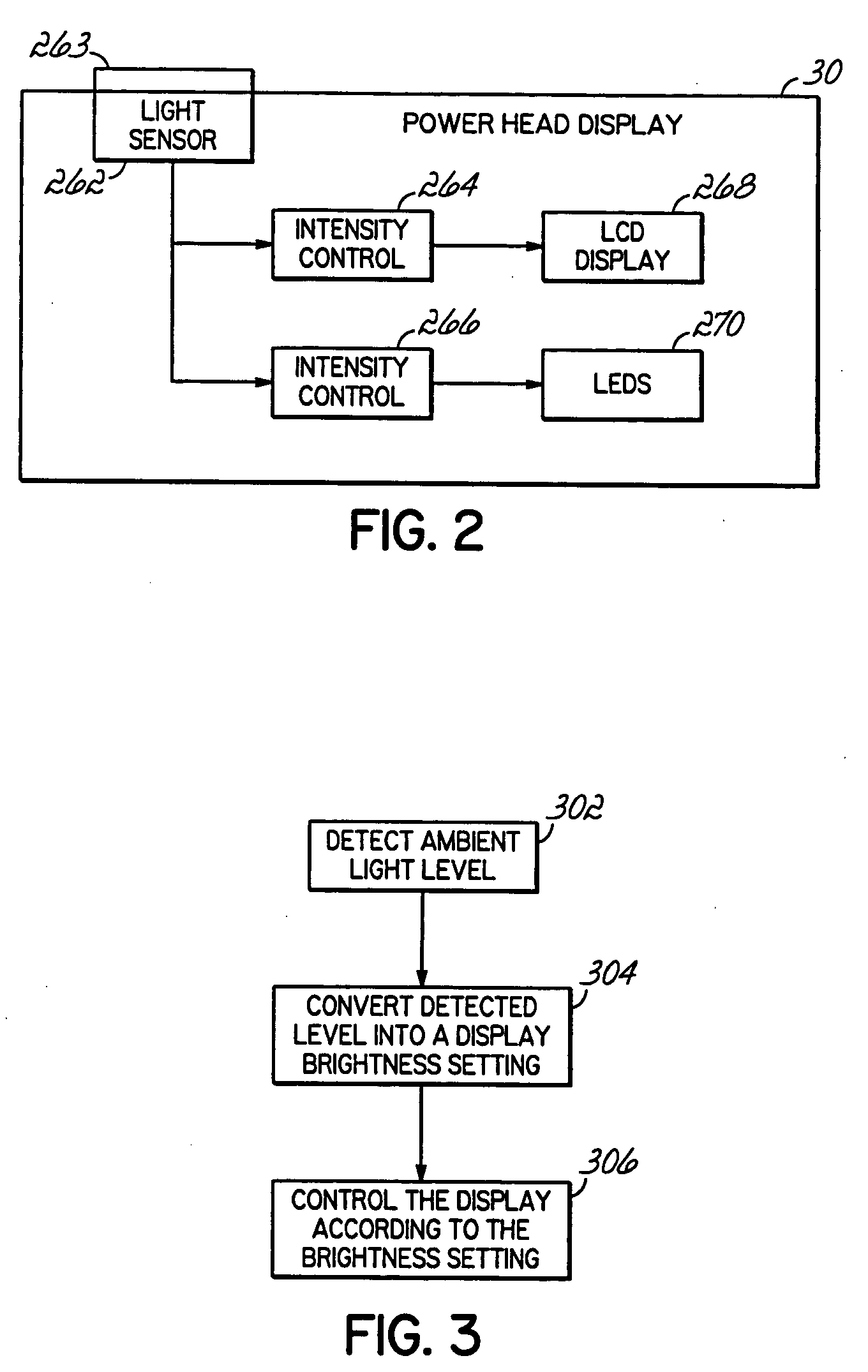

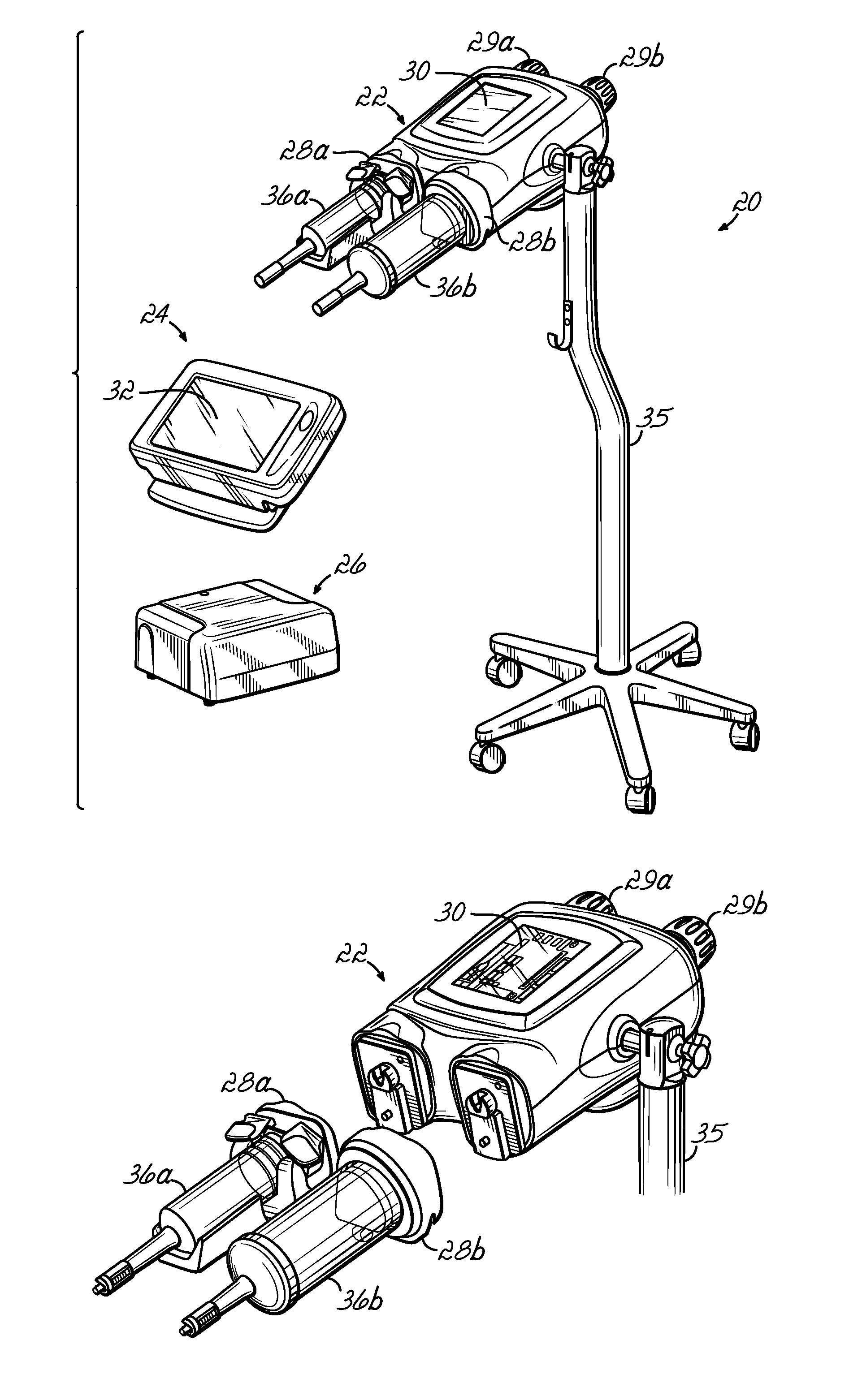

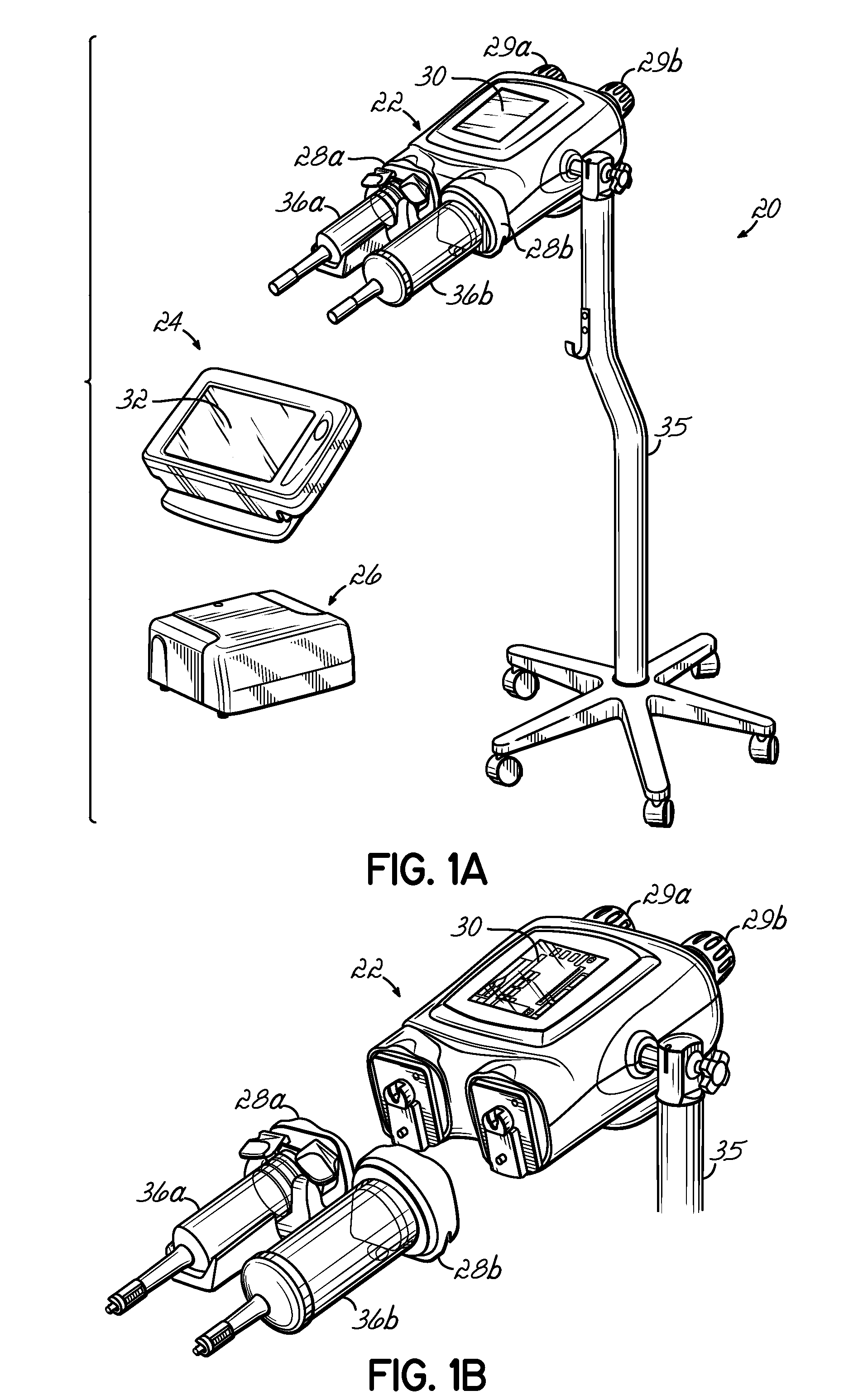

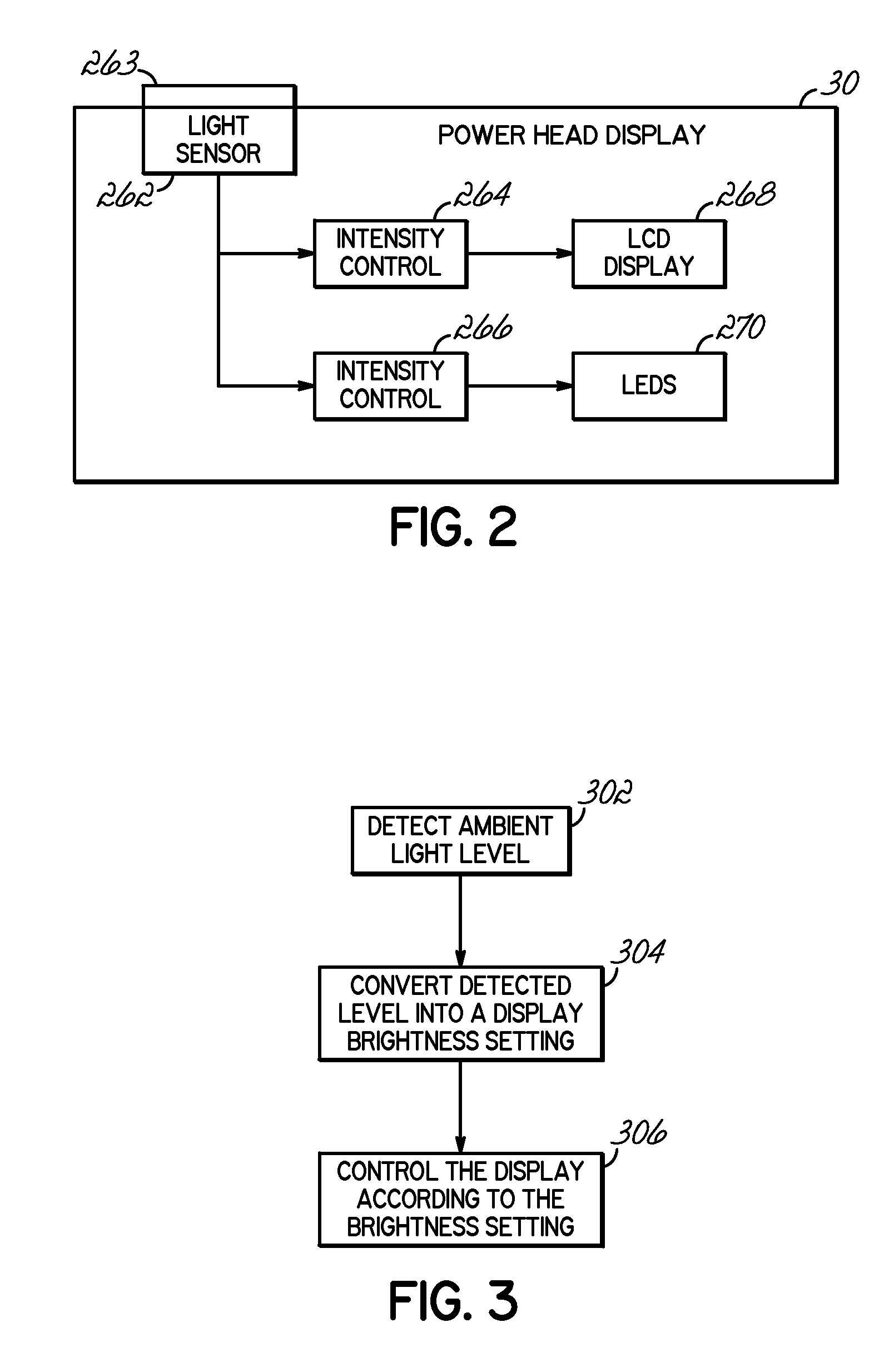

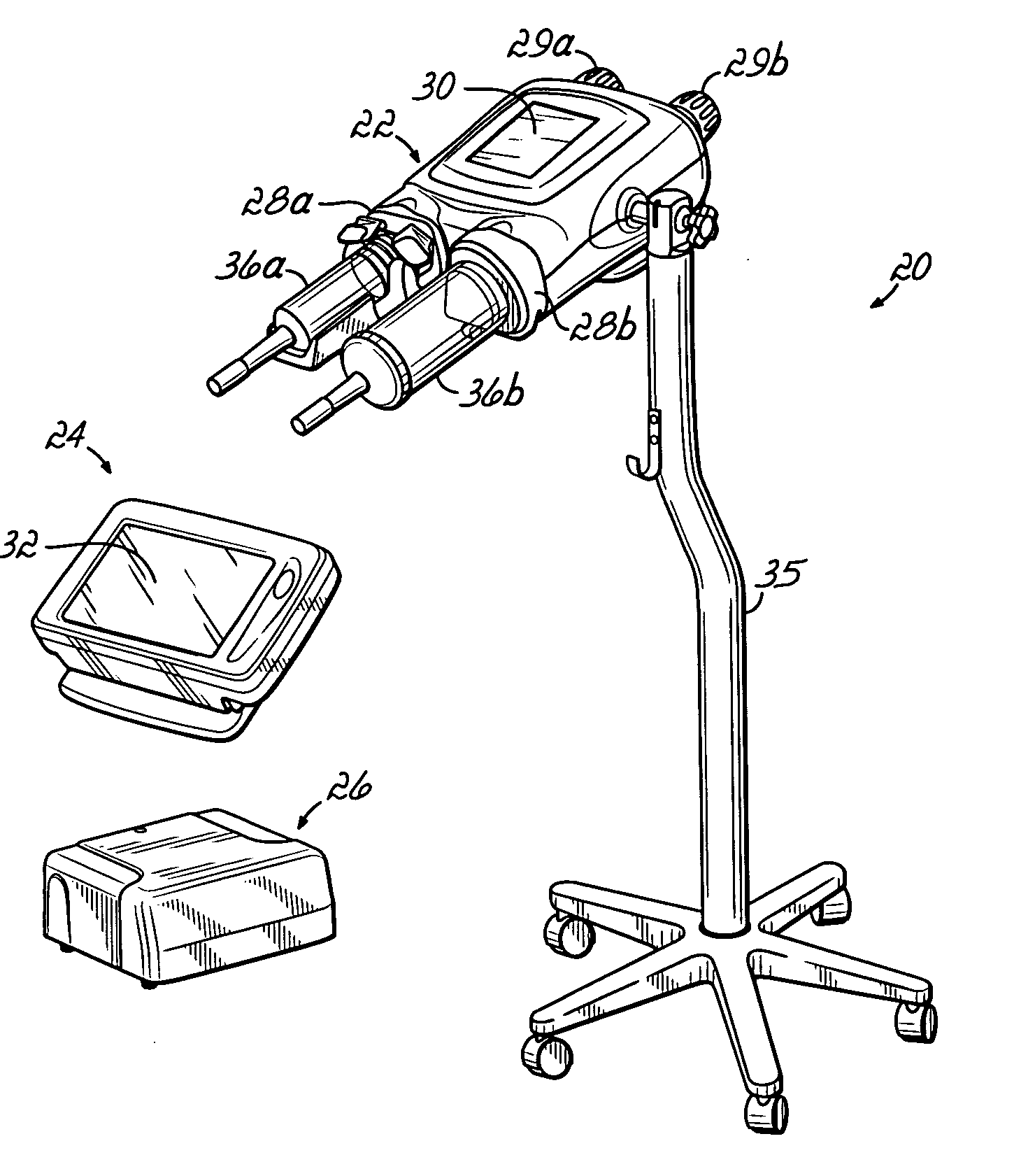

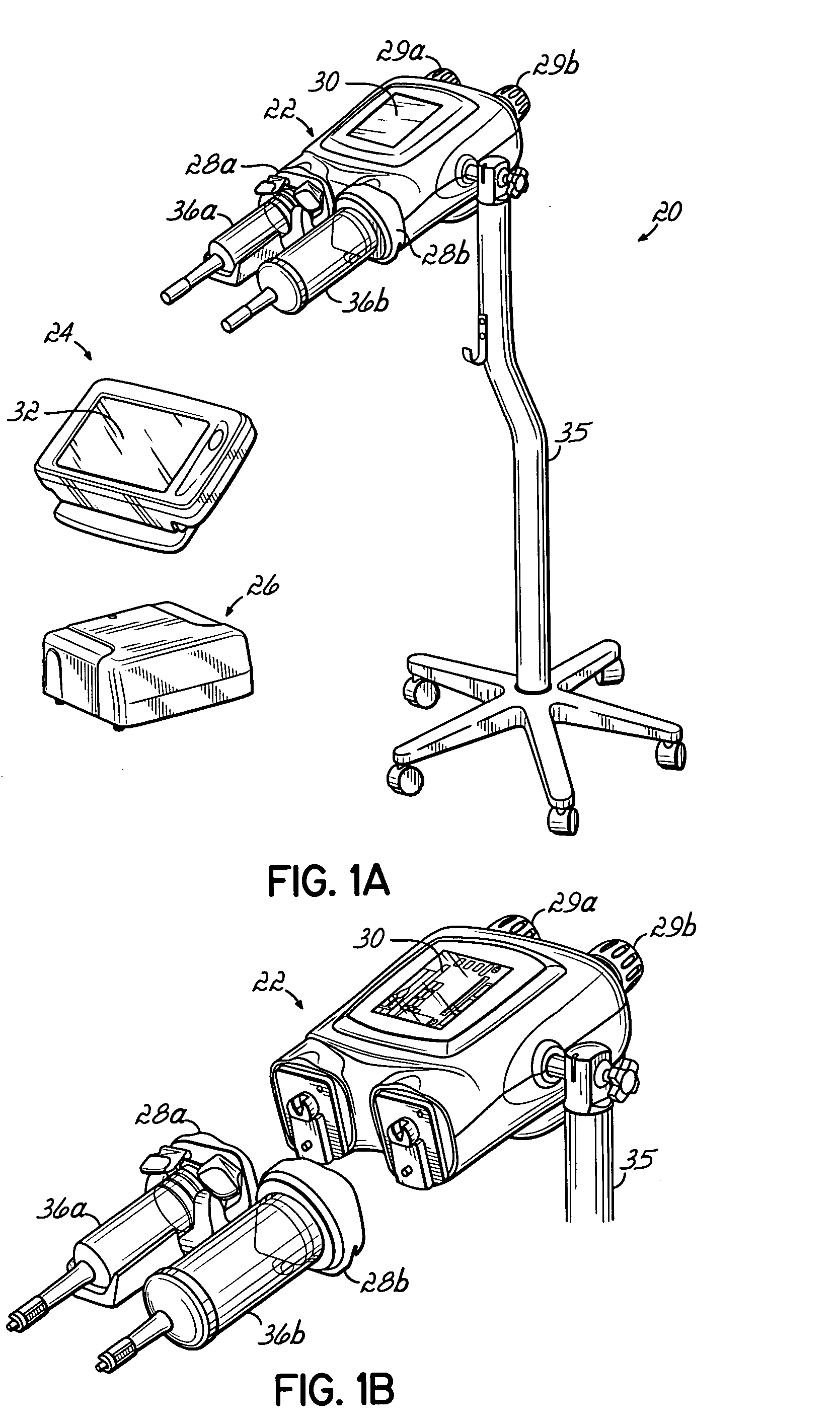

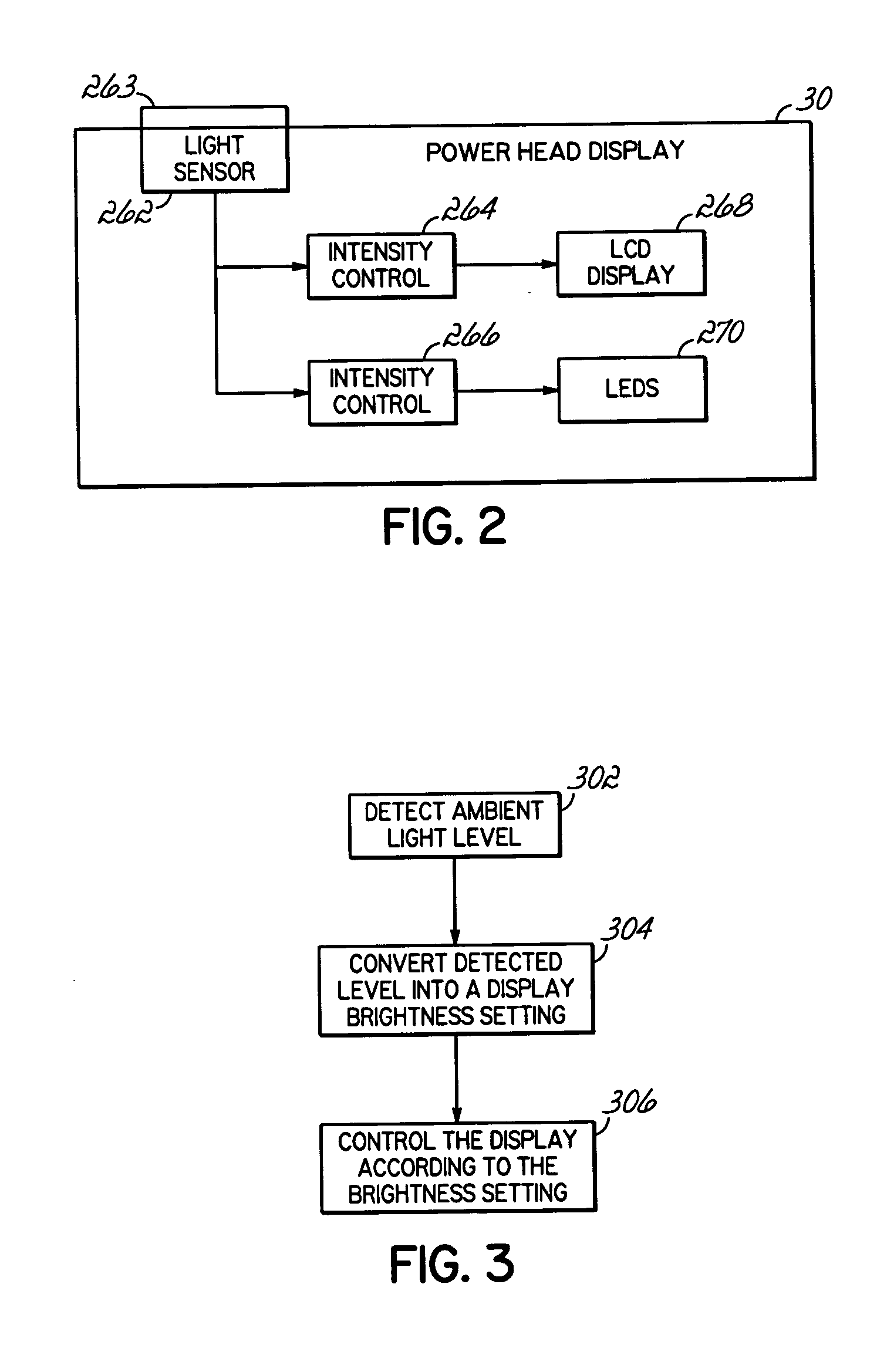

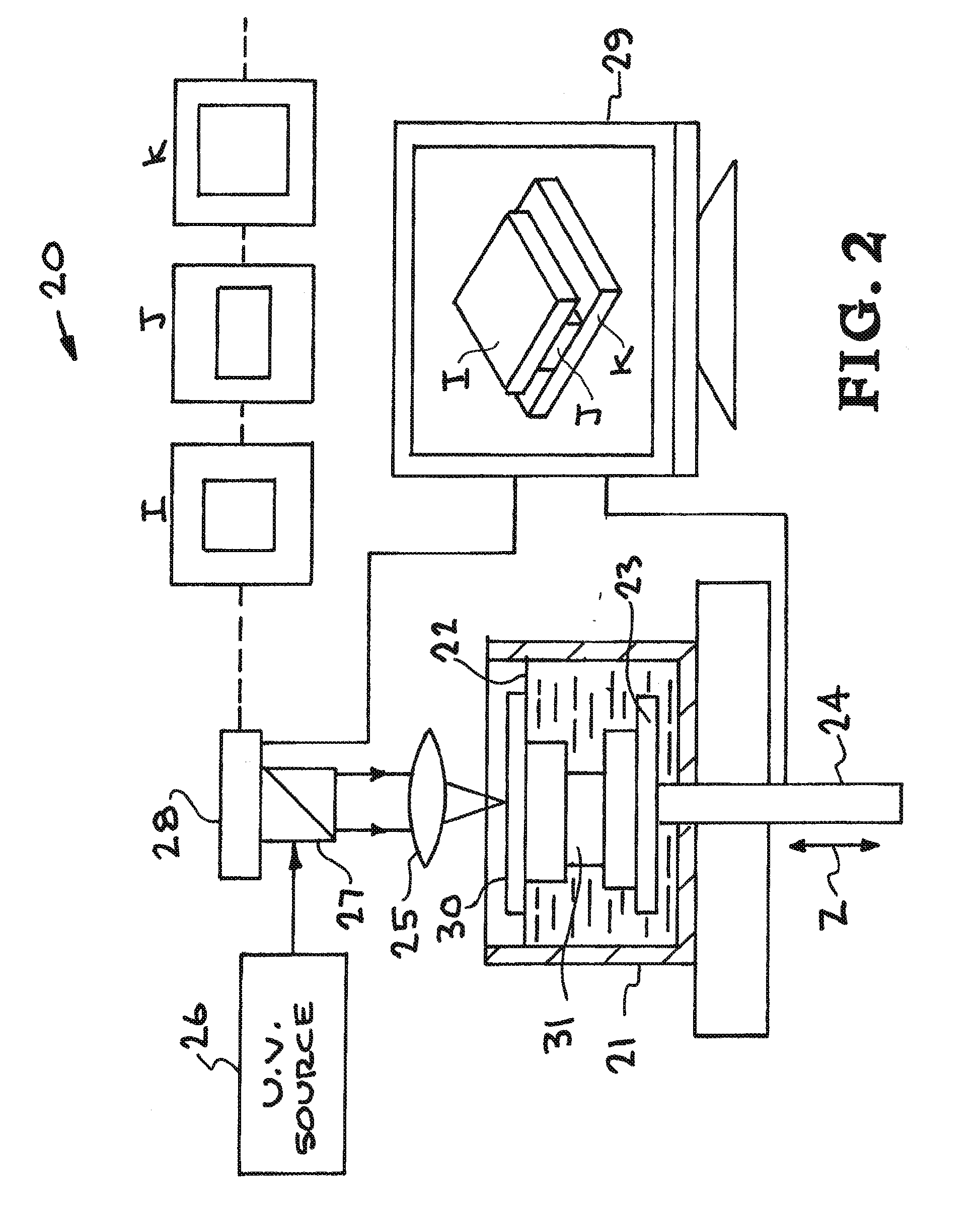

Powerhead control in a power injection system

ActiveUS20060079768A1Accurately mimicPossibility for errorMedical devicesTube connectorsDisplay deviceEngineering

A dual head contrast media injection system performs a patency check or test injection, determining flow rate and / or flow volume from the programmed protocol. The tubing that connects syringes to a patient shares only a short common section near to the patient. Appropriate injection steps are taken to compensate for tubing elasticity. A wireless remote control and a touch screen control are provided, improving functionality and information delivery. The display brightness is controlled based on the ambient light, and the display panel includes a double swivel permitting re-orientation. The orientation of the display may also be controlled based on, e.g., the current step, the tilt angle of the powerhead, or a manual control. Furthermore, the display is customizable to identify the type of fluid (contrast, saline, etc.) on either side of the injector, to provide matched color coding, and to provide a folder / tab analogy for retrieving injection protocol parameters.

Owner:LIEBEL FLARSHEIM CO

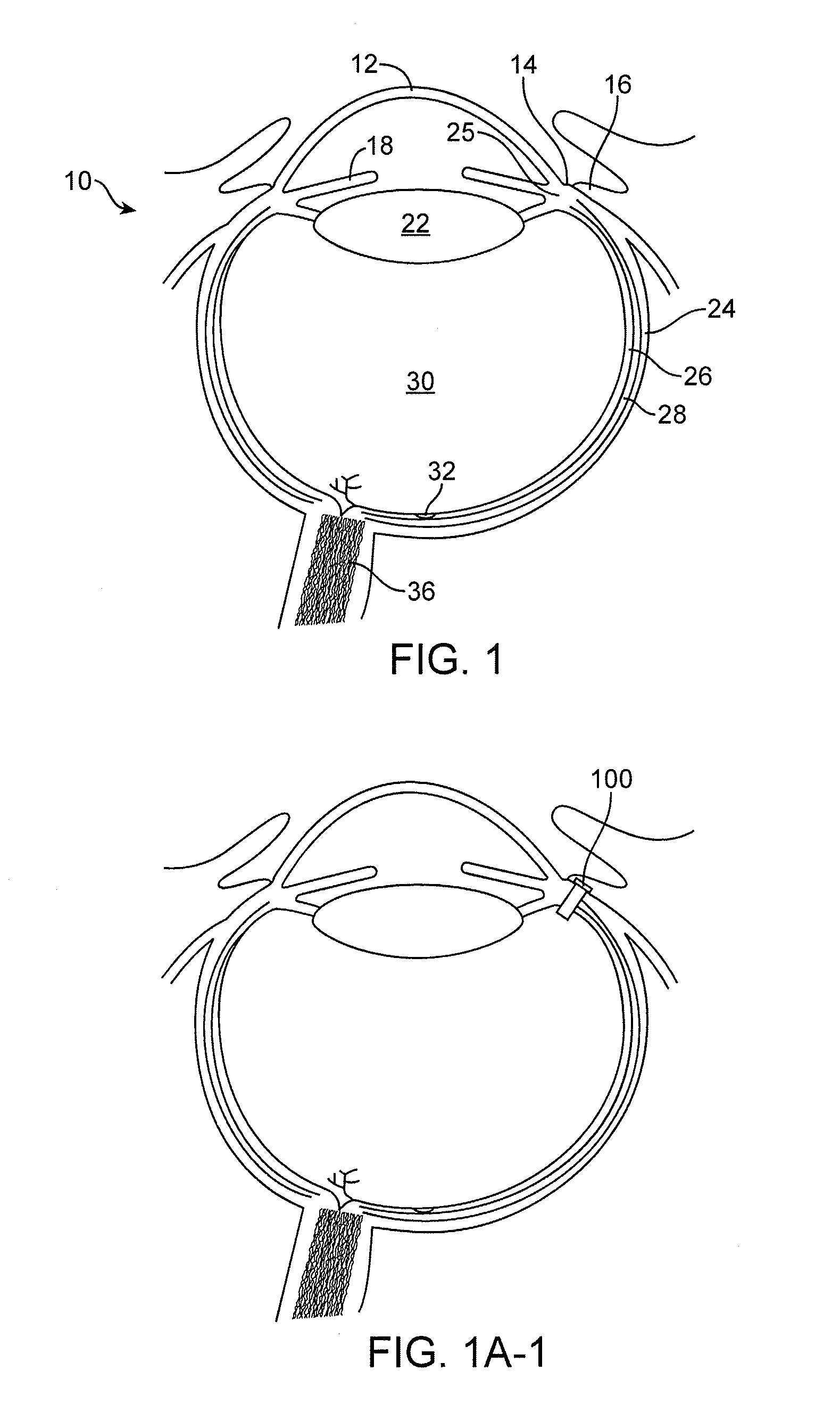

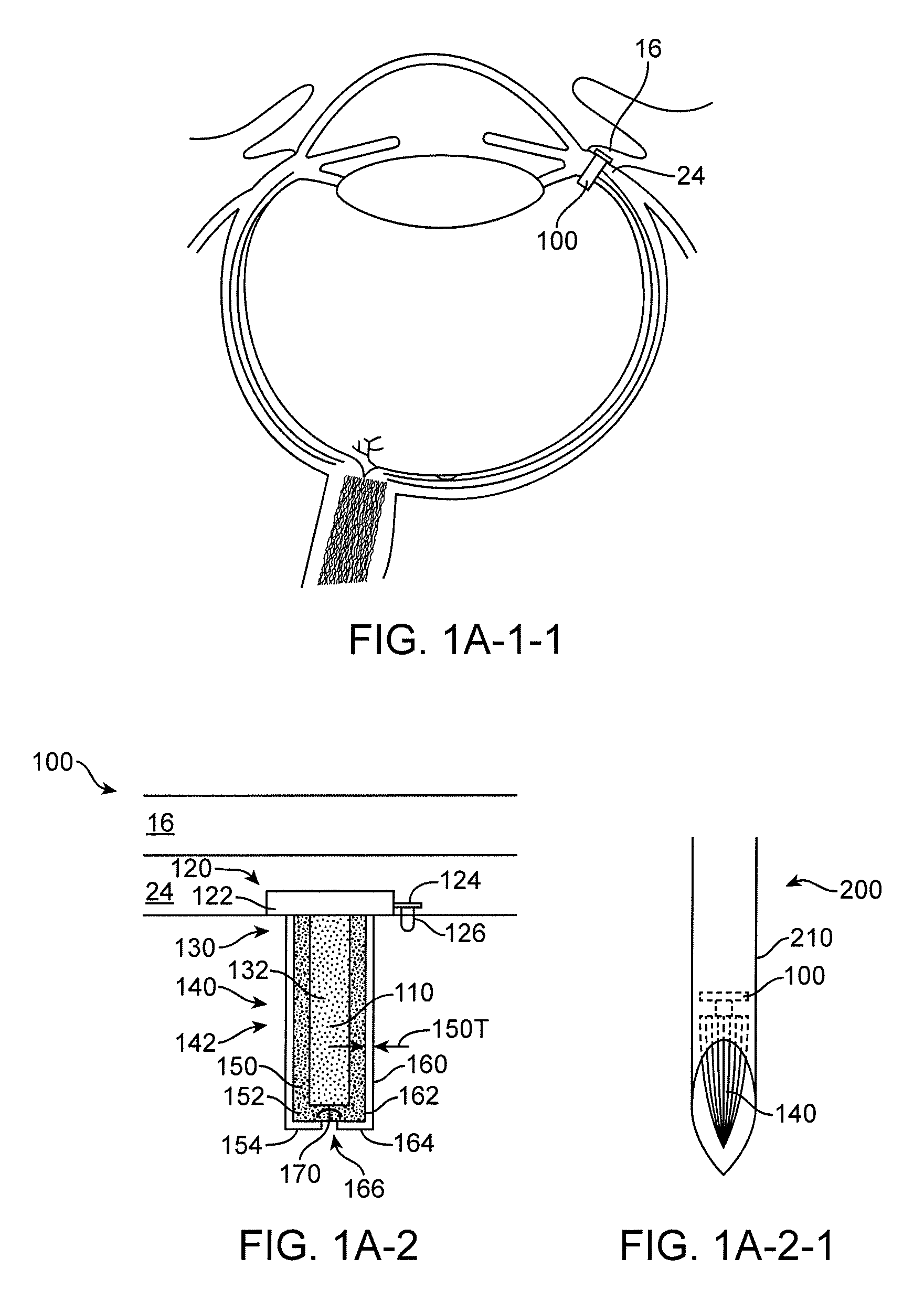

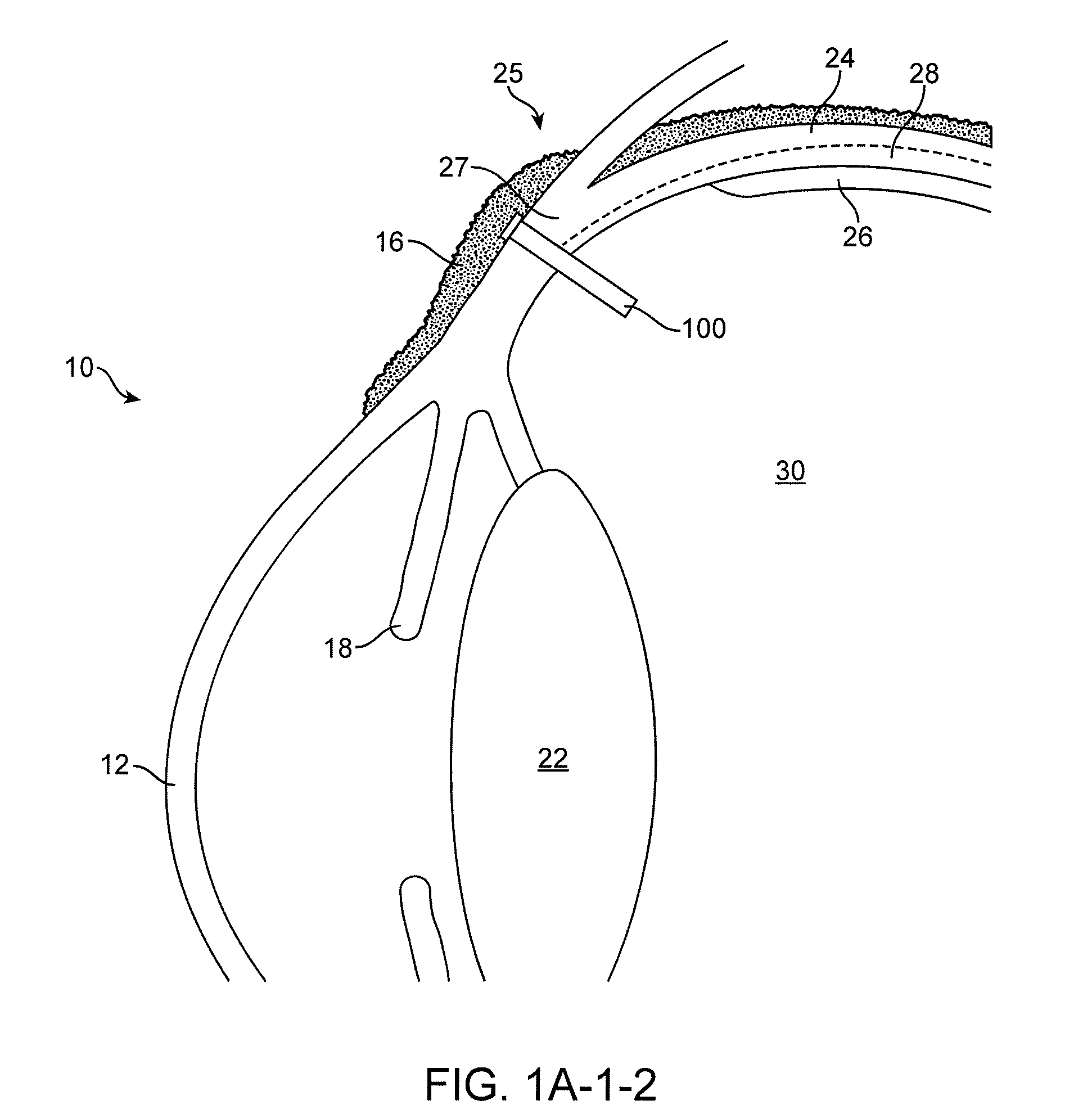

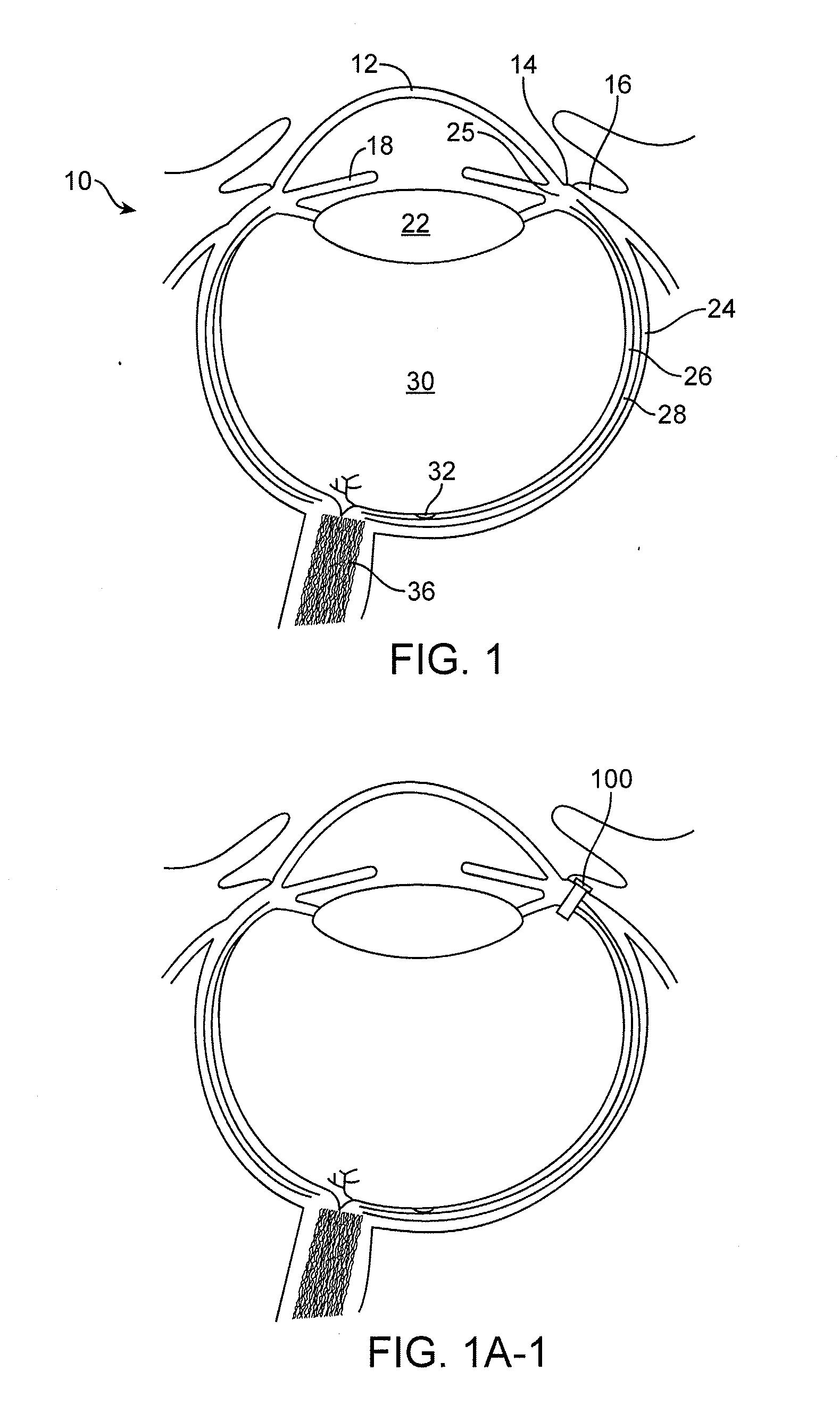

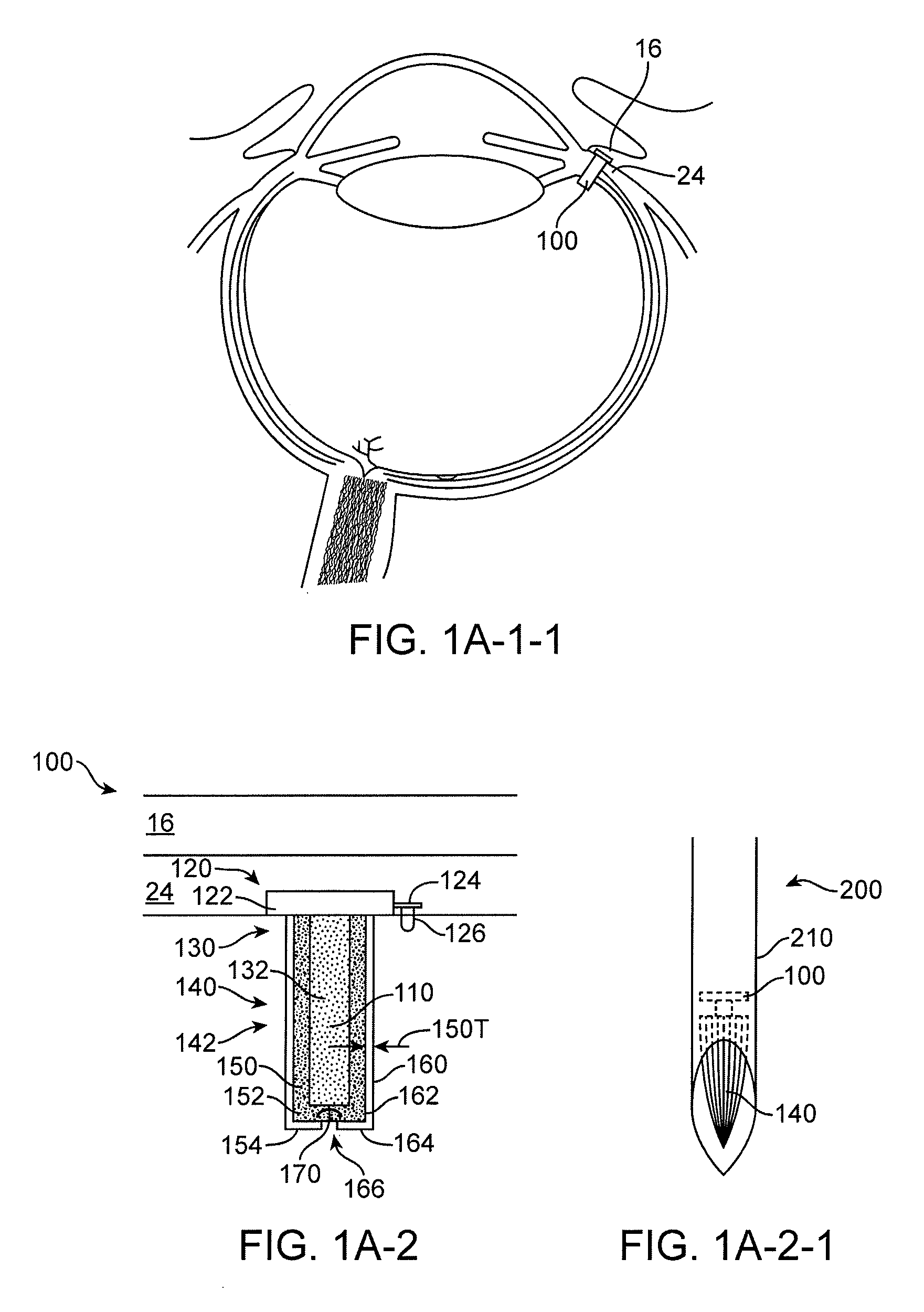

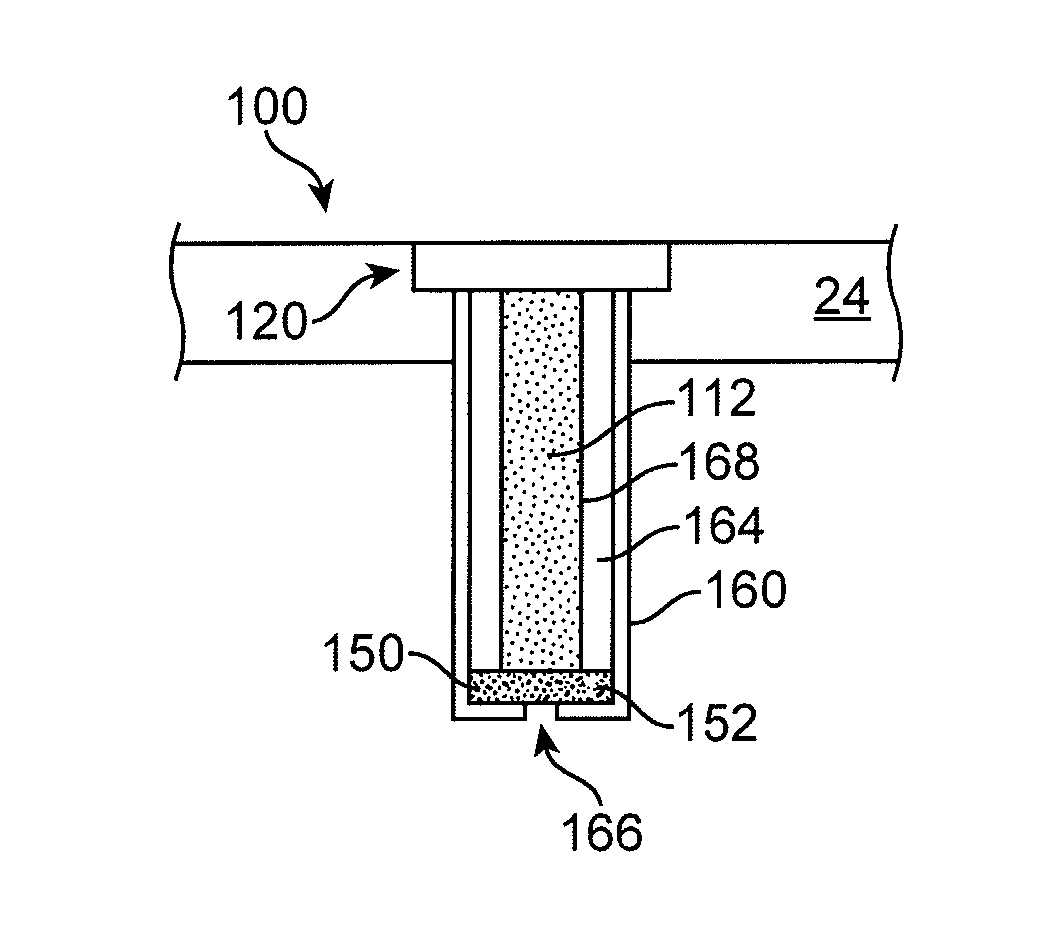

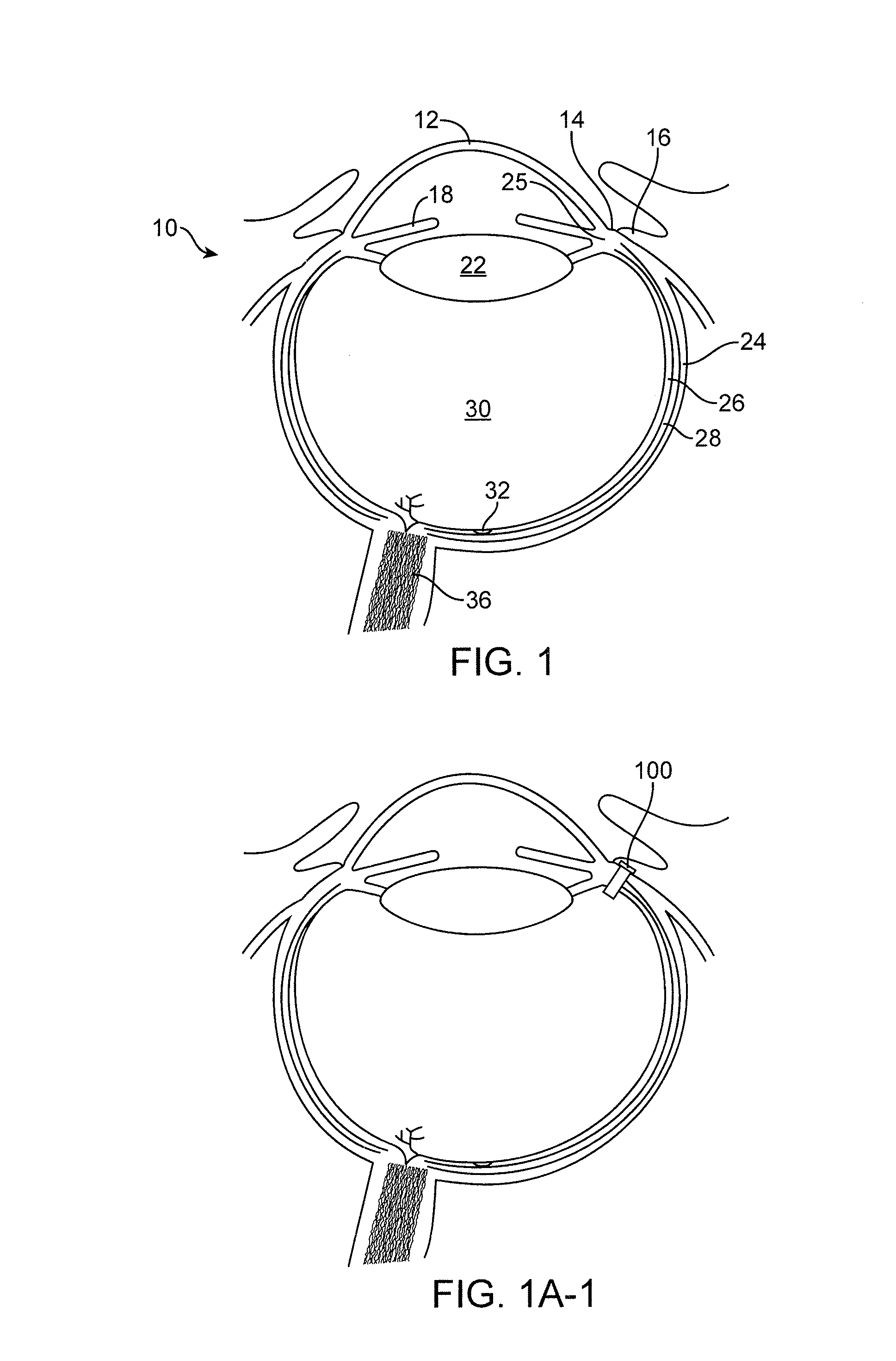

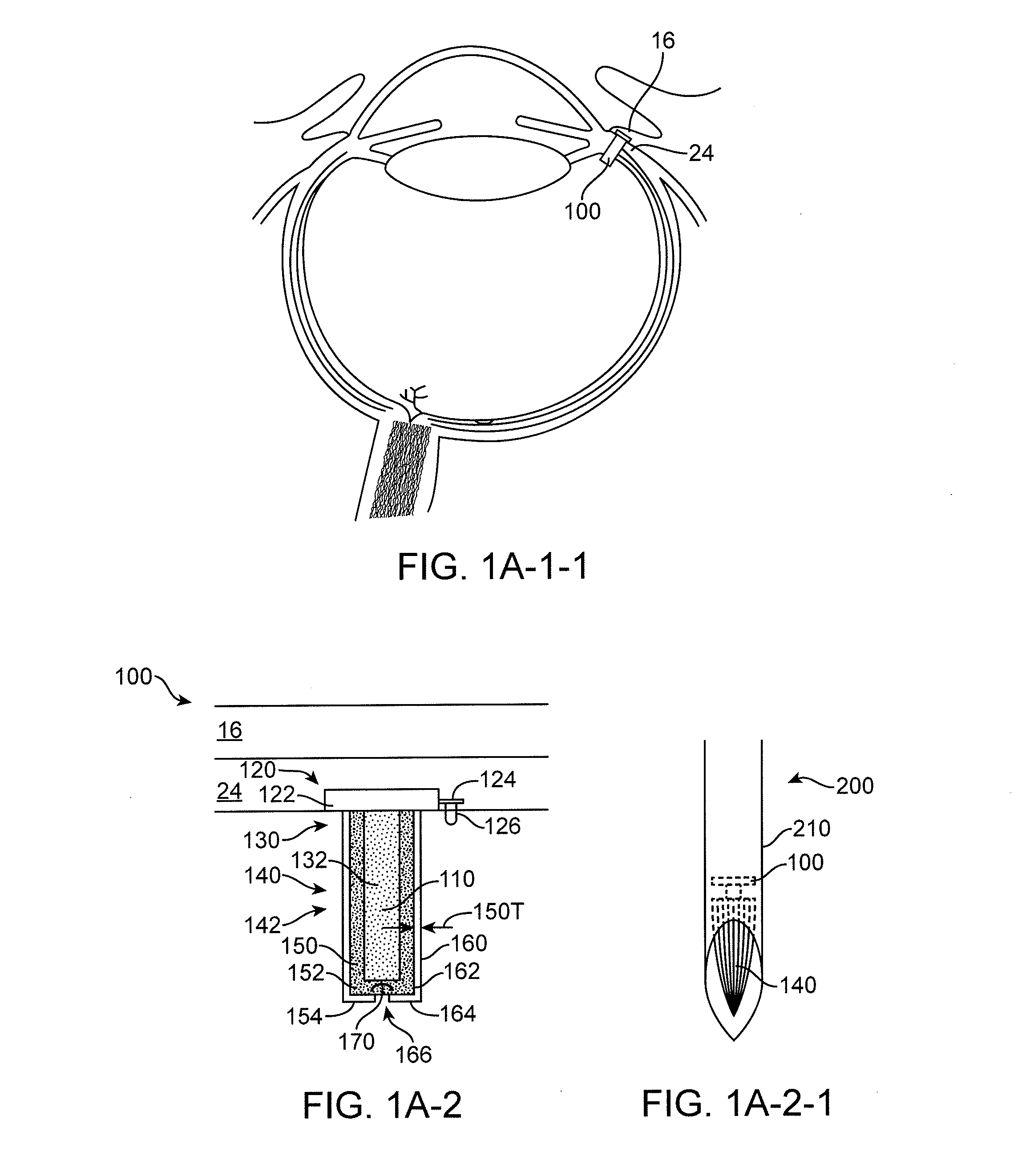

Implantable therapeutic device

ActiveUS8623395B2Reduce deliveryPrecision injectionSenses disorderPeptide/protein ingredientsTherapeutic DevicesEffective length

A therapeutic device to release a therapeutic agent comprises a porous structure coupled to a container comprising a reservoir. The reservoir comprises a volume sized to release therapeutic amounts of the therapeutic agent for an extended time when coupled to the porous structure and implanted in the patient. The porous structure may comprise a first side coupled to the reservoir and a second side to couple to the patient to release the therapeutic agent. The length of the channels extending from the first side to the second side may comprise an effective length greater than a distance across the porous structure from the first side to the second side. The therapeutic device may comprise a penetrable barrier to inject therapeutic agent into the device when implanted in the patient.

Owner:FORSIGHT VISION5 INC

Powerhead control in a power injection system

InactiveUS20060079843A1Increase powerConvenient to accommodateMedical devicesTube connectorsDisplay deviceEngineering

A dual head contrast media injection system performs a patency check or test injection, determining flow rate and / or flow volume from the programmed protocol. The tubing that connects syringes to a patient shares only a short common section near to the patient. Appropriate injection steps are taken to compensate for tubing elasticity. A wireless remote control and a touch screen control are provided, improving functionality and information delivery. The display brightness is controlled based on the ambient light, and the display panel includes a double swivel permitting re-orientation. The orientation of the display may also be controlled based on, e.g., the current step, the tilt angle of the powerhead, or a manual control. Furthermore, the display is customizable to identify the type of fluid (contrast, saline, etc.) on either side of the injector, to provide matched color coding, and to provide a folder / tab analogy for retrieving injection protocol parameters.

Owner:MALLINCKRODT INC

Powerhead Control in a Power Injection System

ActiveUS20070100282A1Accurately mimicPossibility for errorDrug and medicationsMedical devicesDisplay deviceEngineering

A dual head contrast media injection system performs a patency check or test injection, determining flow rate and / or flow volume from the programmed protocol. The tubing that connects syringes to a patient shares only a short common section near to the patient. Appropriate injection steps are taken to compensate for tubing elasticity. A wireless remote control and a touch screen control are provided, improving functionality and information delivery. The display brightness is controlled based on the ambient light, and the display panel includes a double swivel permitting re-orientation. The orientation of the display may also be controlled based on, e.g., the current step, the tilt angle of the powerhead, or a manual control. Furthermore, the display is customizable to identify the type of fluid (contrast, saline, etc.) on either side of the injector, to provide matched color coding, and to provide a folder / tab analogy for retrieving injection protocol parameters.

Owner:LIEBEL FLARSHEIM CO

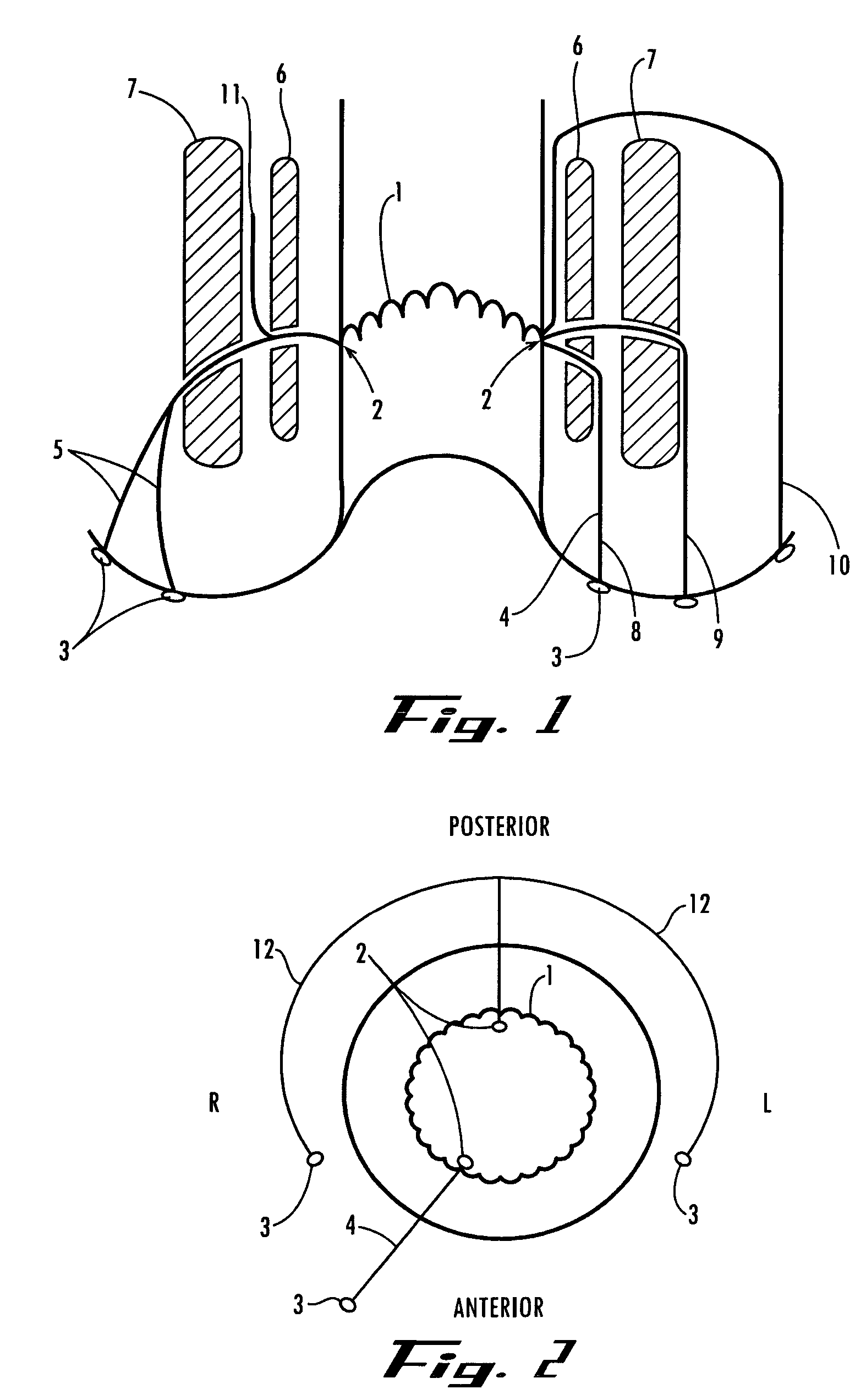

Instrument and method for endoscopic visualization and treatment of anorectal fistula

ActiveUS7645229B2Convenient treatmentAccurately identify the course of an anorectal fistula tractDilatorsEndoscopesAv fistulasAnorectal Fistula

A fiber-optic endoscopic instrument (Fistuloscope) is used to visualize anorectal fistula, and to accurately identify the course through the fistula. The instrument can be used to flush the fistula, to close the fistula tract by means of injecting sealants or placing grafts in the tract of the fistula or to pass setons, micro-instruments or other means to treat and seal the tract.

Owner:ARMSTRONG DAVID N

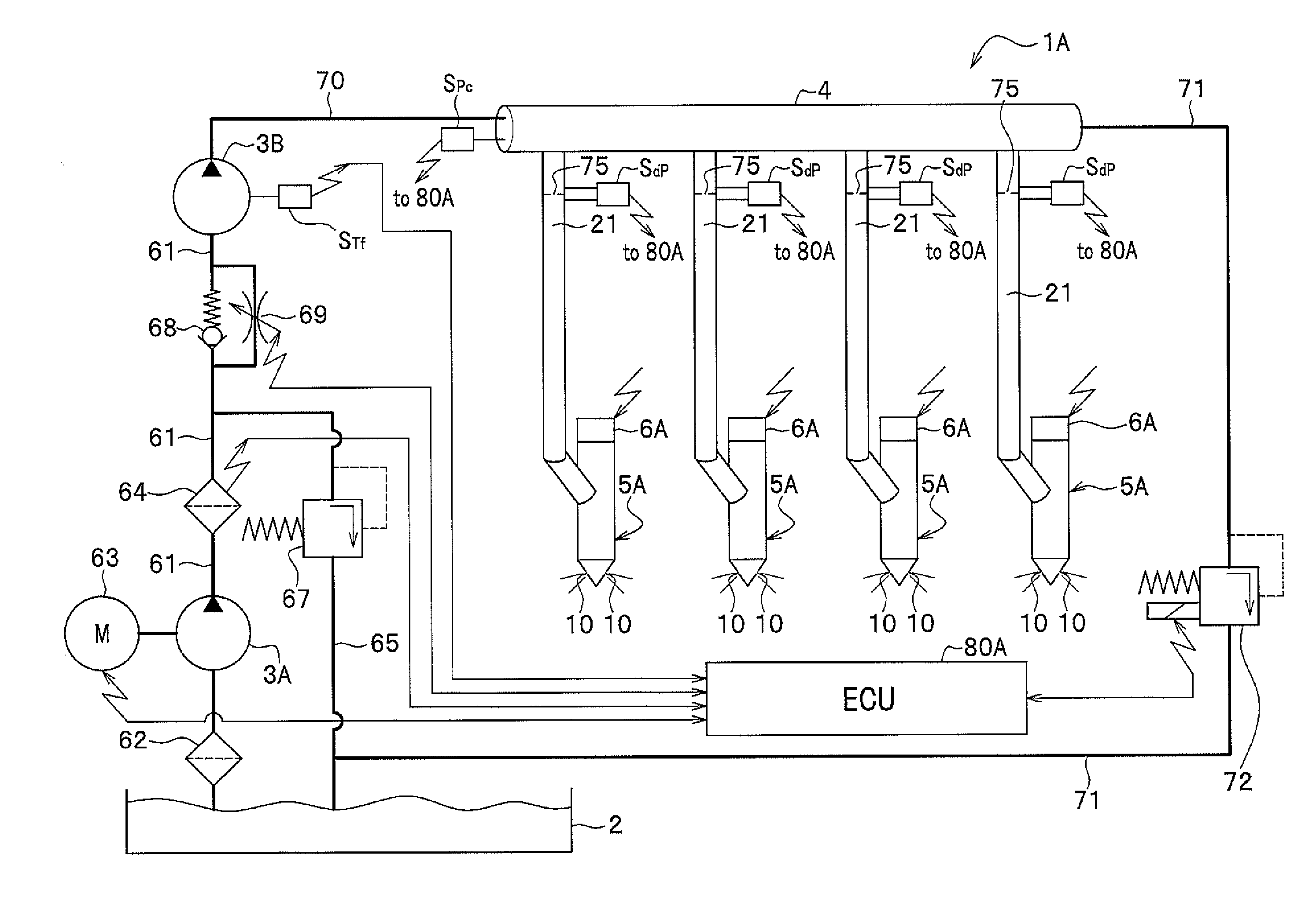

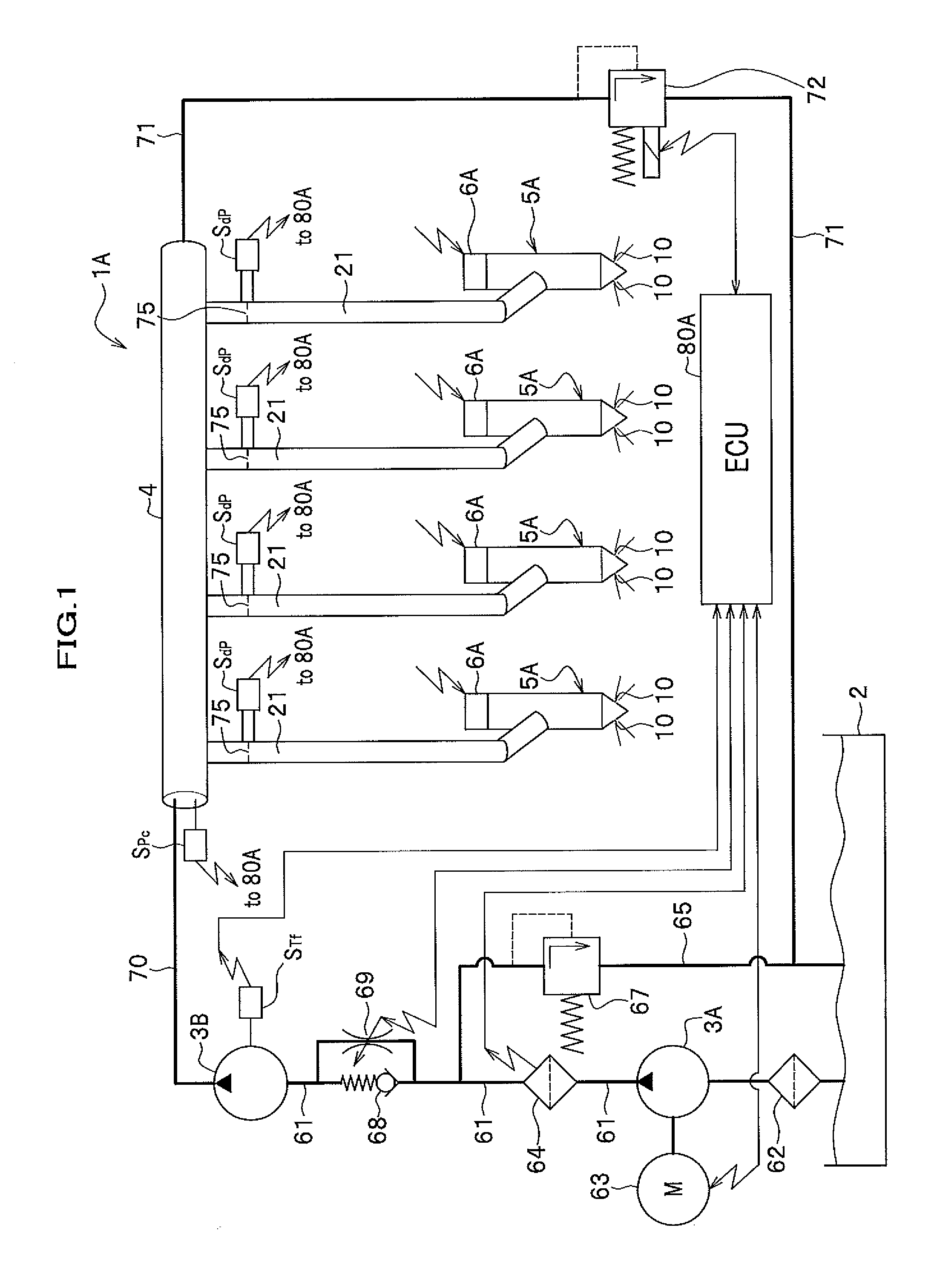

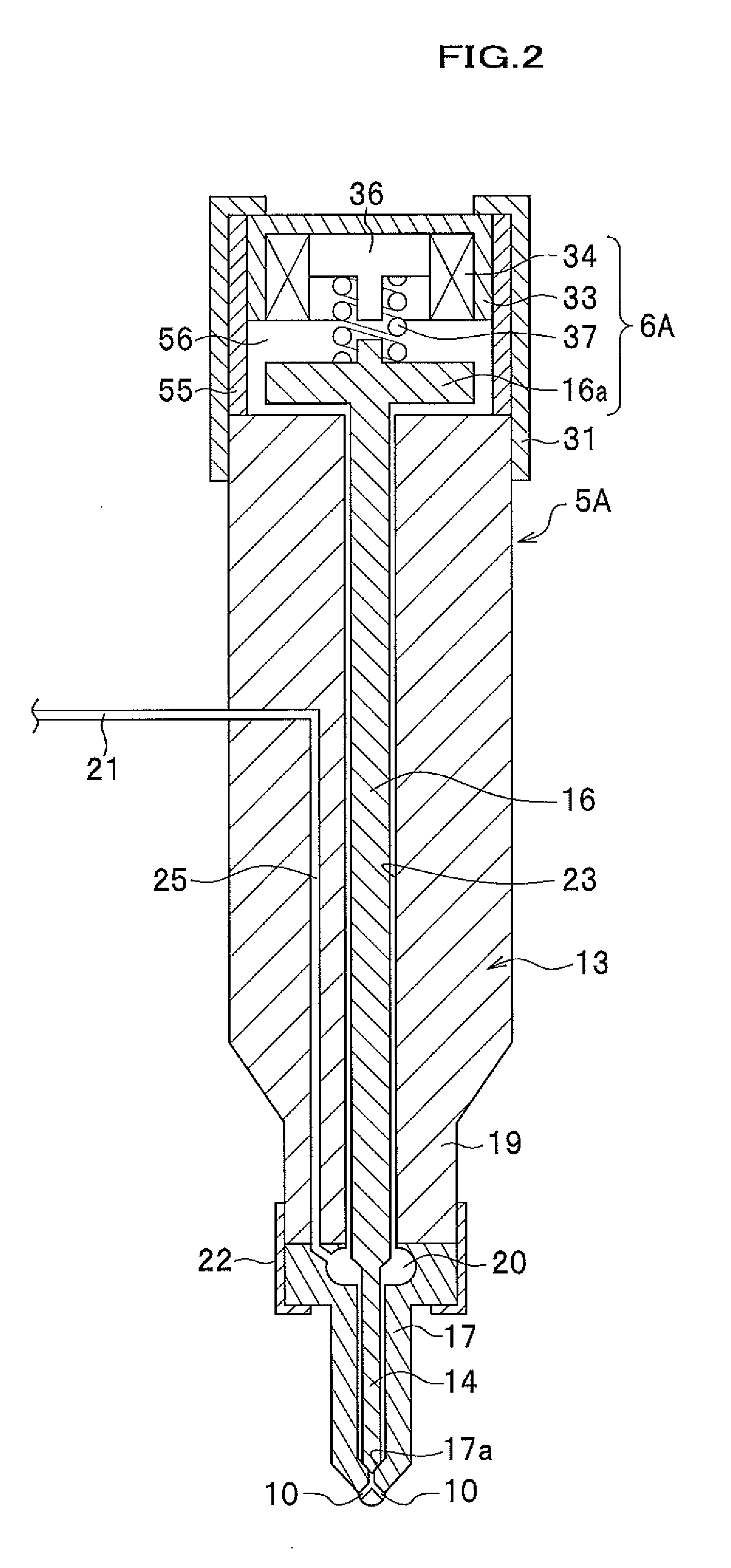

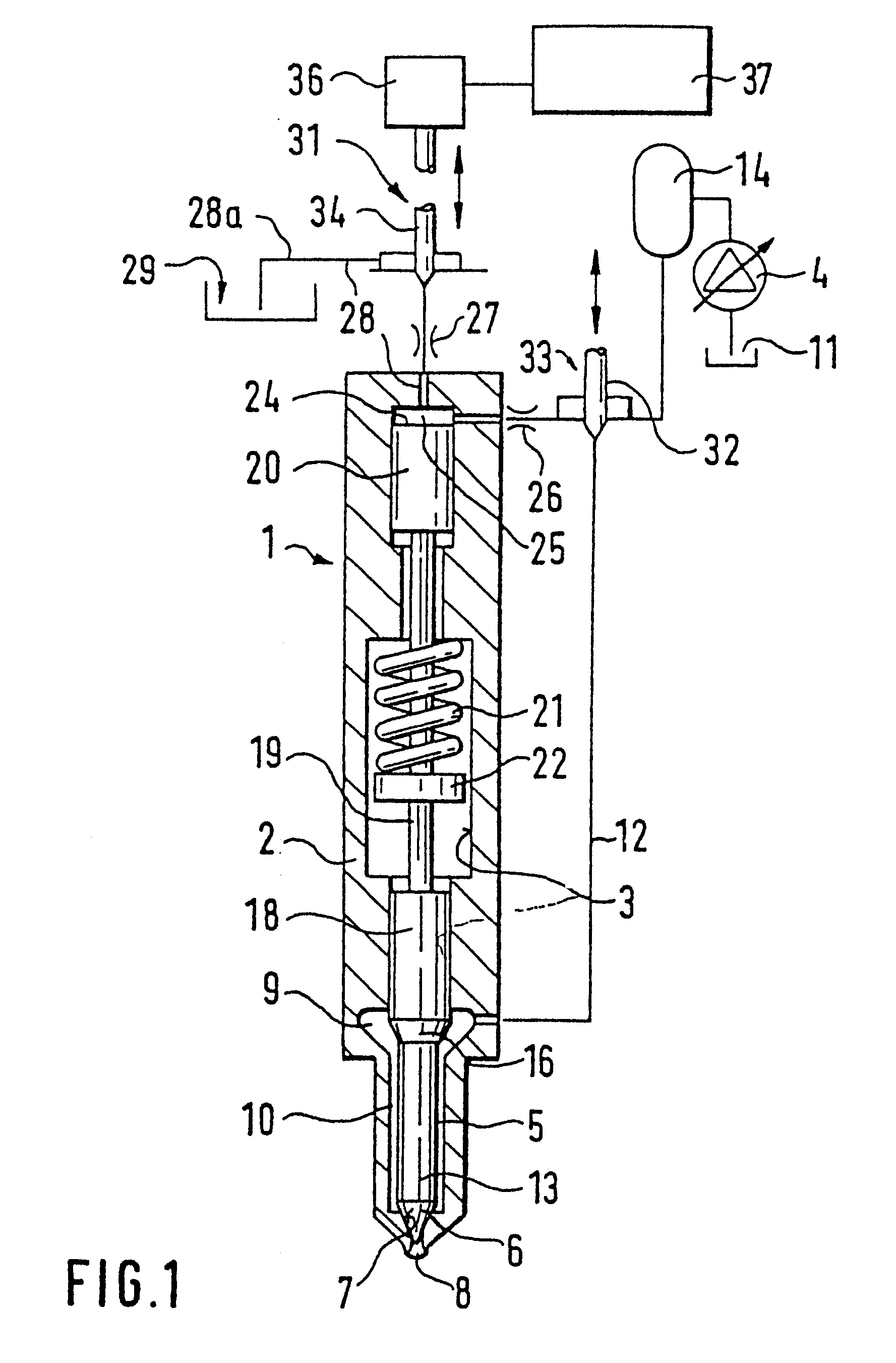

Fuel injection device

InactiveUS20090326788A1Accurate calculationPrecision injectionElectrical controlDigital data processing detailsDifferential pressureCommon rail

A fuel injection device 1A which includes a common rail 4 for accumulating fuel delivered by a high pressure pump 3B in a pressure-accumulated state, an injector for injecting in a cylinder of the diesel engine fuel supplied through a high pressure fuel supply passage 21 branched from the common rail 4, and an ECU 80A for outputting an injection command signal for injecting the fuel from the injector 5A. The fuel injection device 1A further includes an orifice 75 in the high pressure fuel supply passage 21 on the side of the common rail 4, and a differential pressure sensor SdP for detecting the pressure difference of the pressures on the upstream and downstream sides of the orifice 75. The ECU 80A calculates an actual fuel supply amount that passes the orifice 75 based on a signal from the differential pressure sensor SdP.

Owner:HONDA MOTOR CO LTD

Powerhead control in a power injection system

InactiveUS20060079842A1Accurately mimicPossibility for errorMedical devicesTube connectorsDisplay deviceEngineering

A dual head contrast media injection system performs a patency check or test injection, determining flow rate and / or flow volume from the programmed protocol. The tubing that connects syringes to a patient shares only a short common section near to the patient. Appropriate injection steps are taken to compensate for tubing elasticity. A wireless remote control and a touch screen control are provided, improving functionality and information delivery. The display brightness is controlled based on the ambient light, and the display panel includes a double swivel permitting re-orientation. The orientation of the display may also be controlled based on, e.g., the current step, the tilt angle of the powerhead, or a manual control. Furthermore, the display is customizable to identify the type of fluid (contrast, saline, etc.) on either side of the injector, to provide matched color coding, and to provide a folder / tab analogy for retrieving injection protocol parameters.

Owner:MALLINCKRODT INC

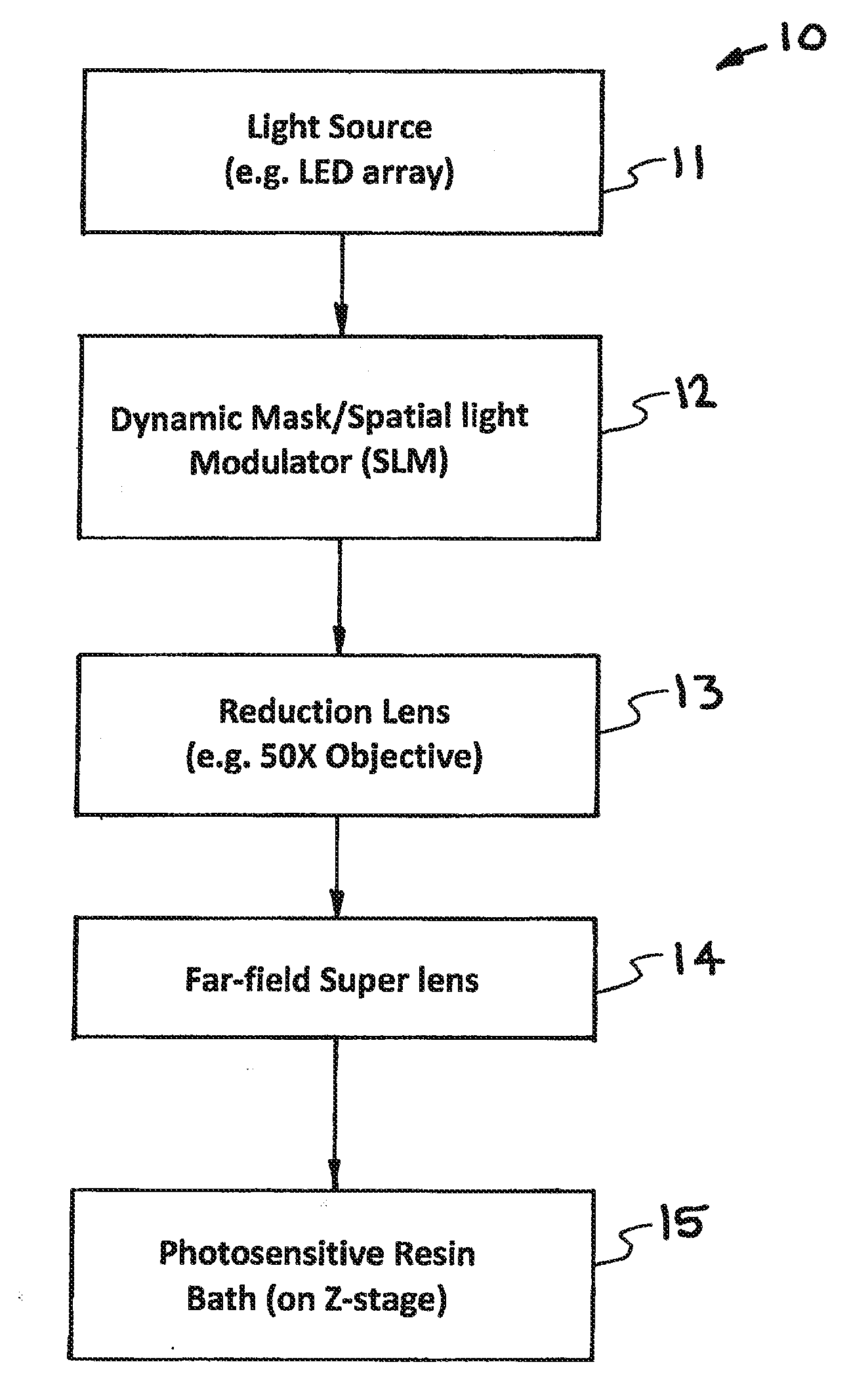

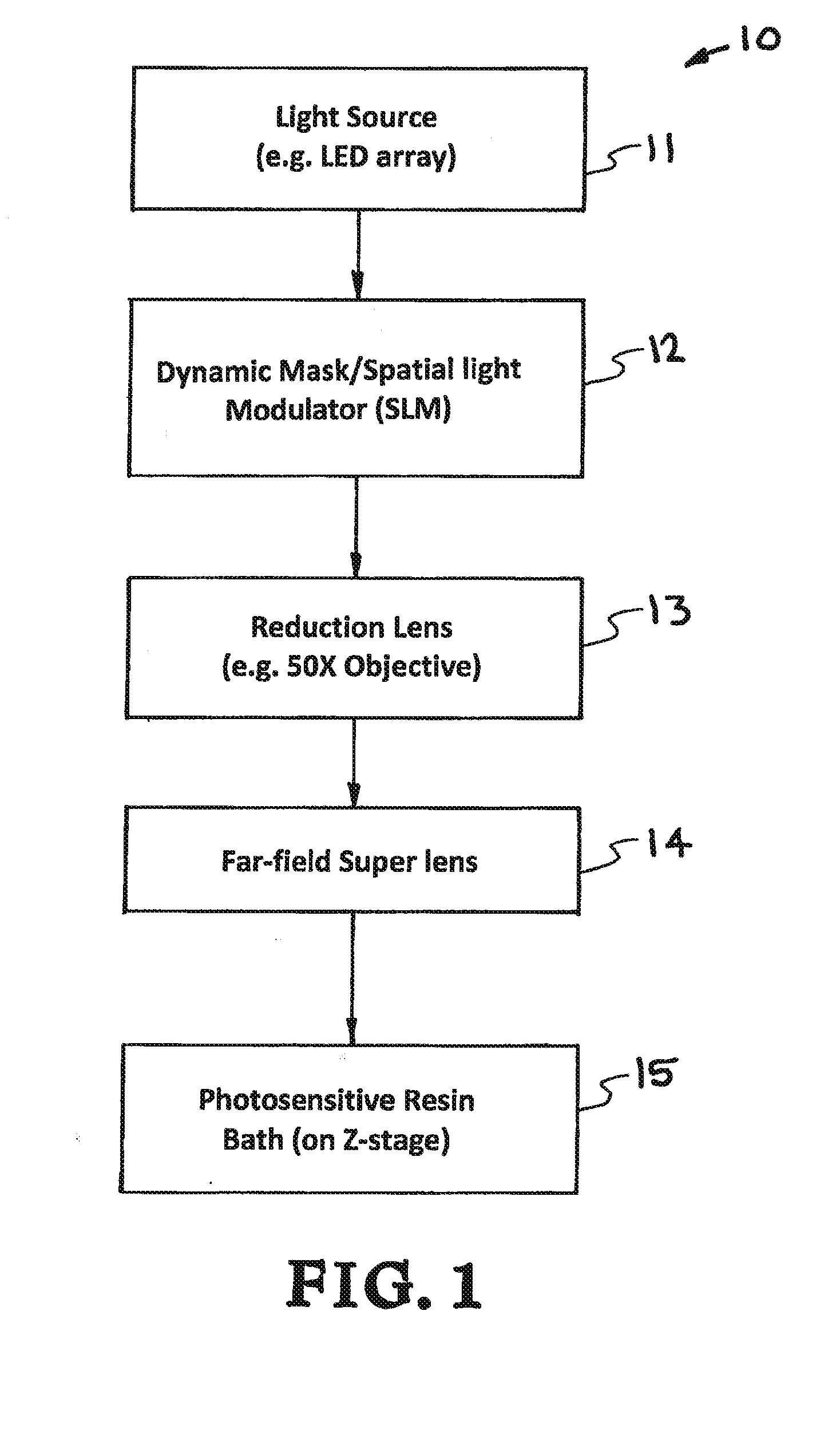

High Resolution Projection Micro Stereolithography System And Method

ActiveUS20150309473A1Increase amplitudeNegative index of refractionAdditive manufacturing apparatusPhotomechanical apparatusSpatial light modulatorCombined use

A high-resolution PμSL system and method incorporating one or more of the following features with a standard PμSL system using a SLM projected digital image to form components in a stereolithographic bath: a far-field superlens for producing sub-diffraction-limited features, multiple spatial light modulators (SLM) to generate spatially-controlled three-dimensional interference holograms with nanoscale features, and the integration of microfluidic components into the resin bath of a PμSL system to fabricate microstructures of different materials.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

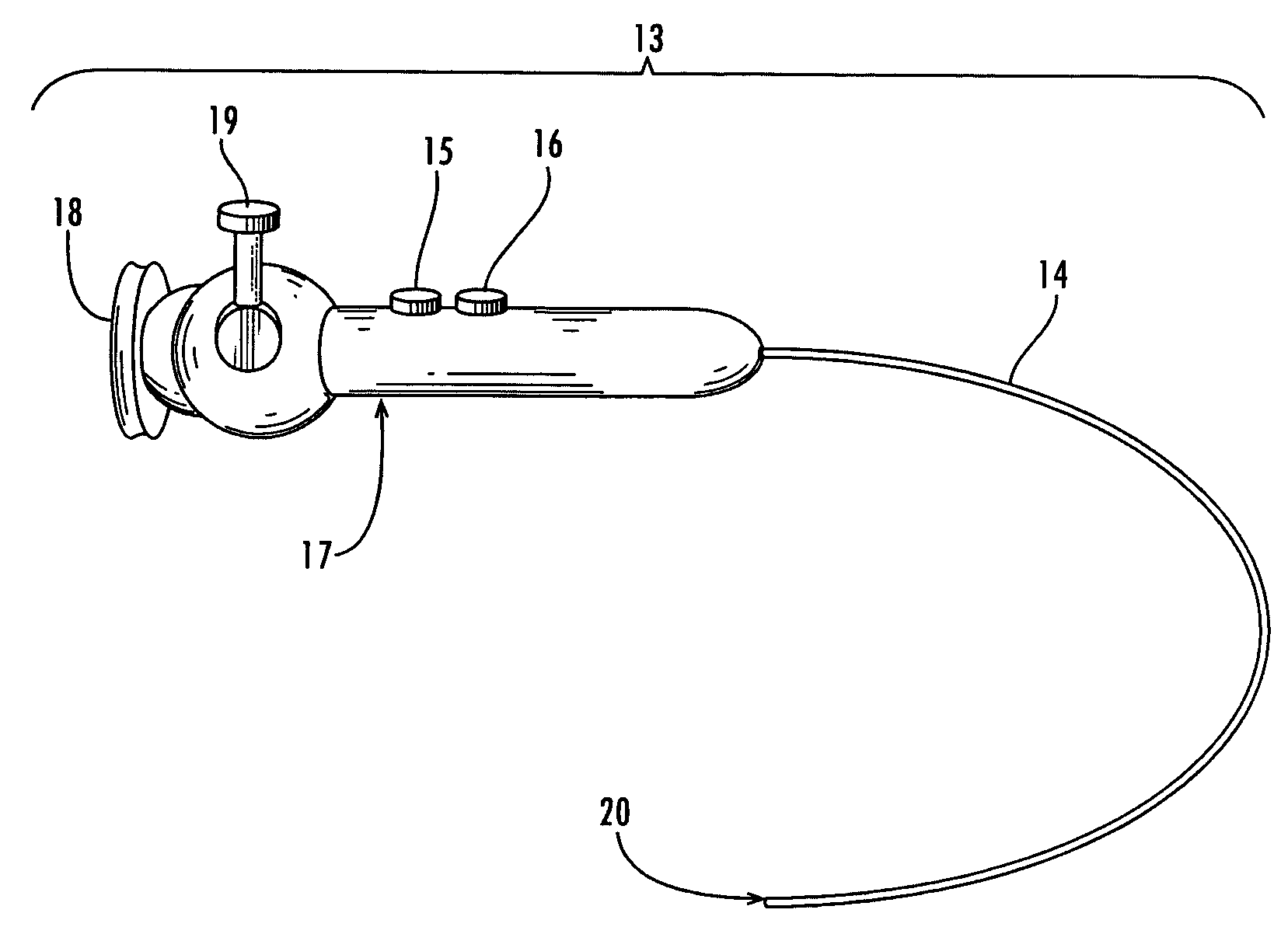

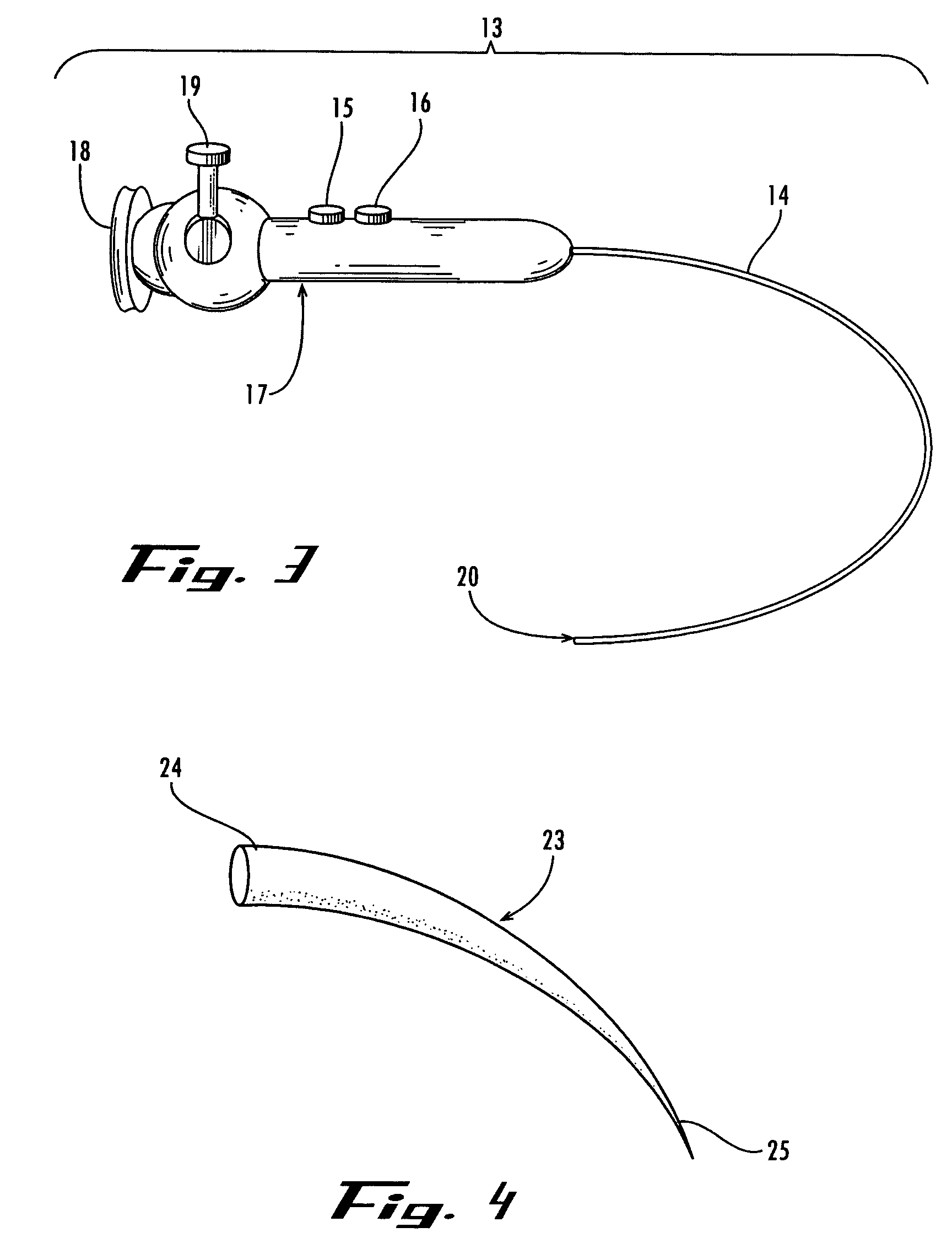

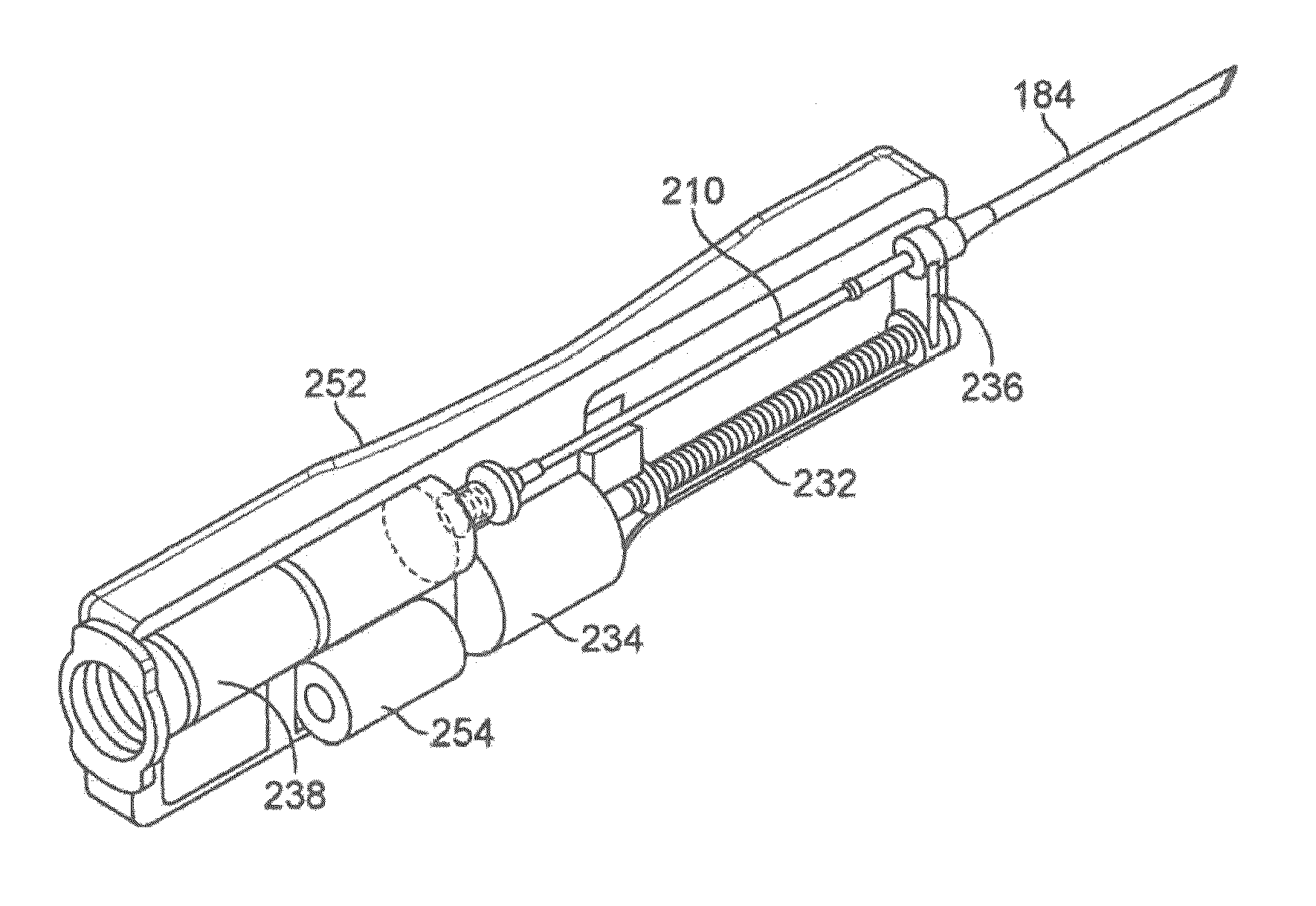

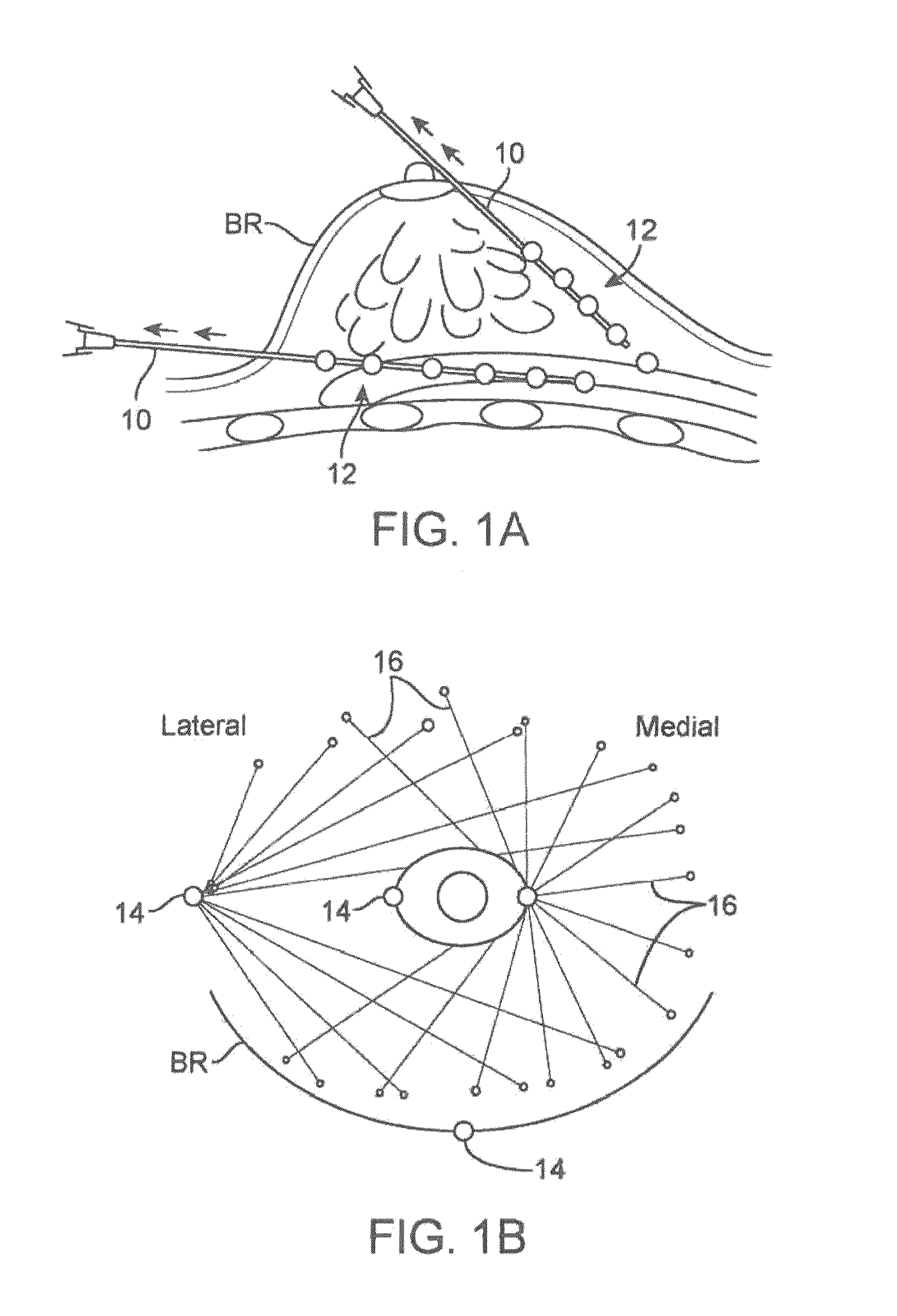

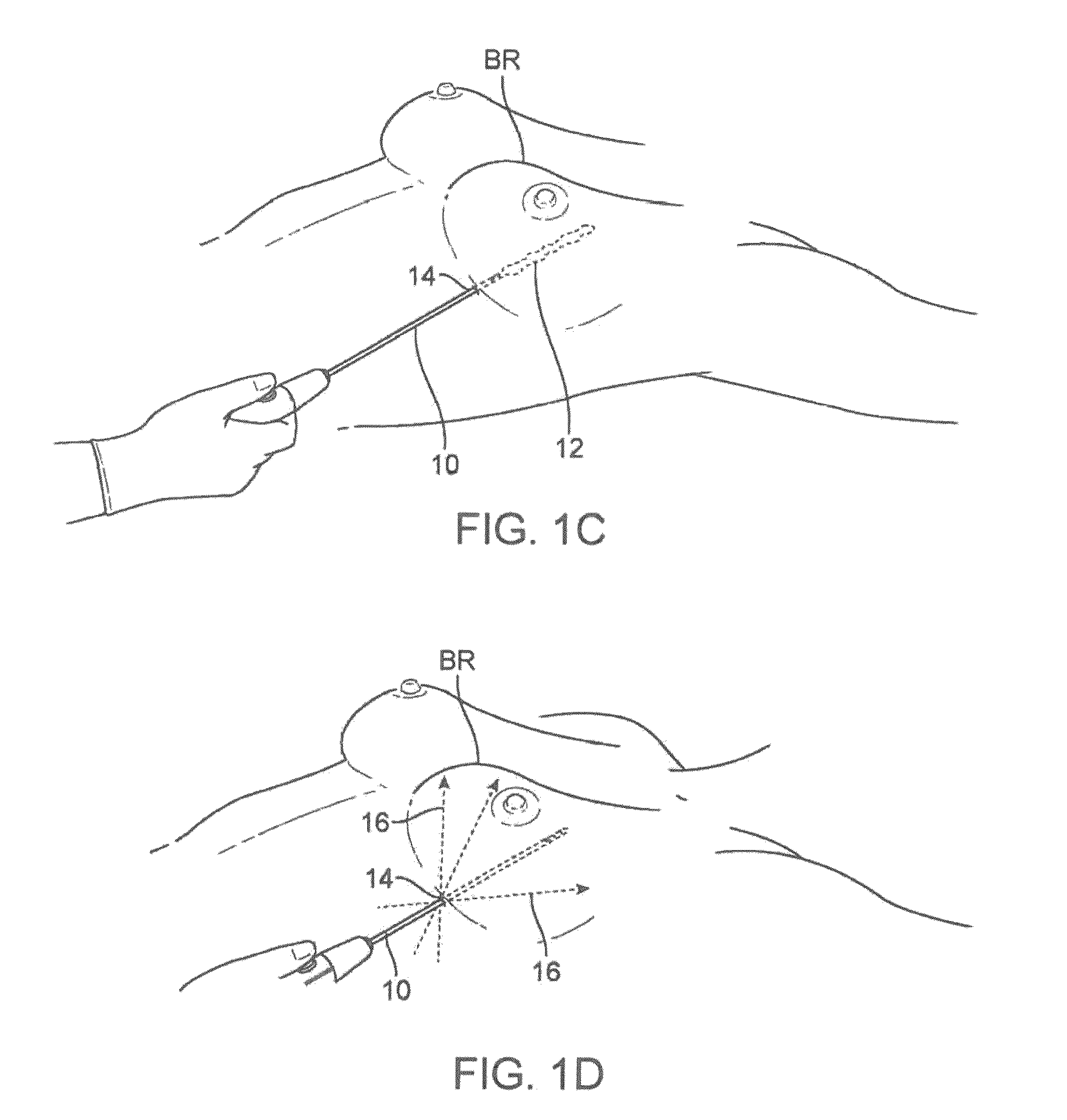

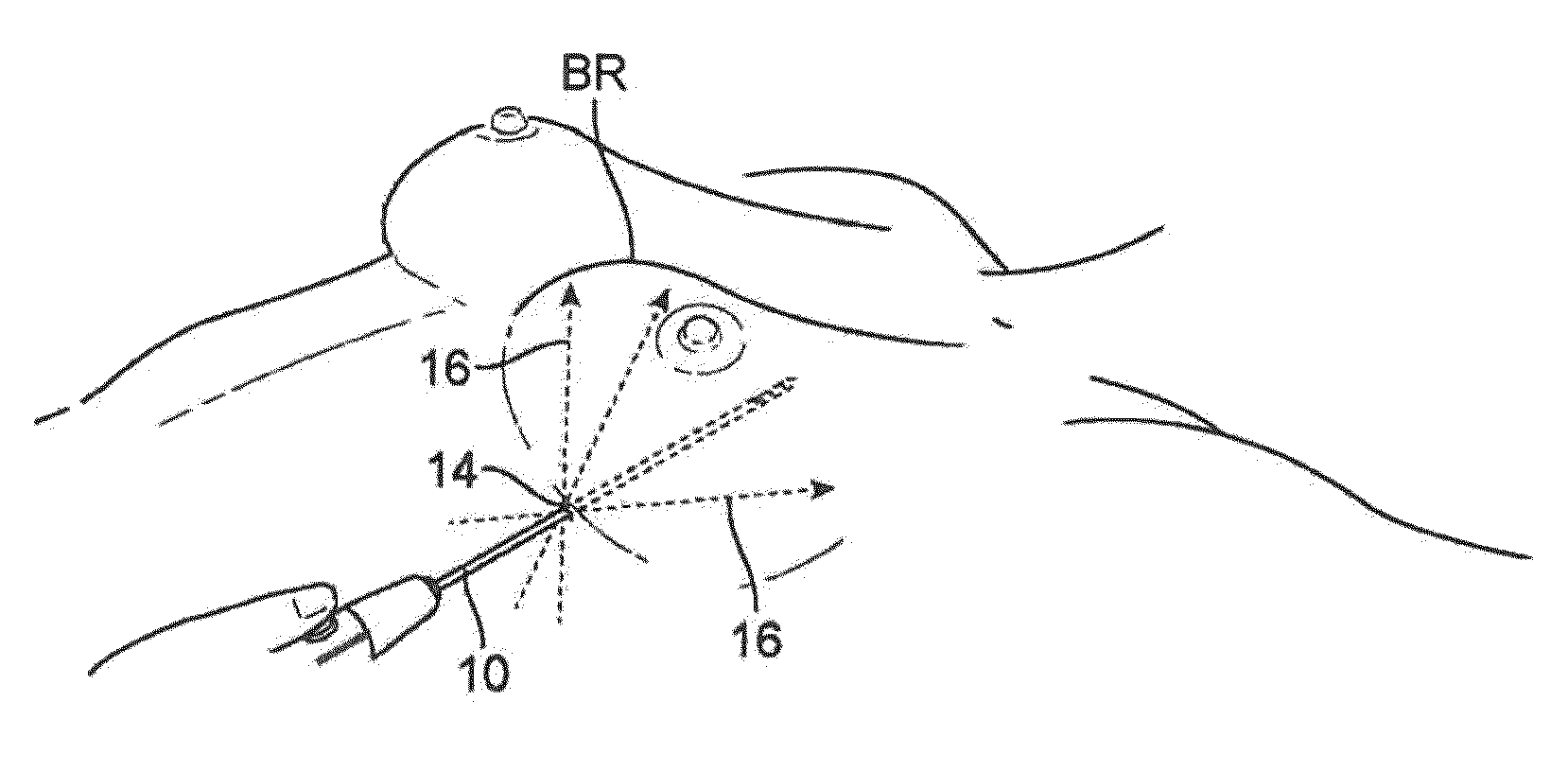

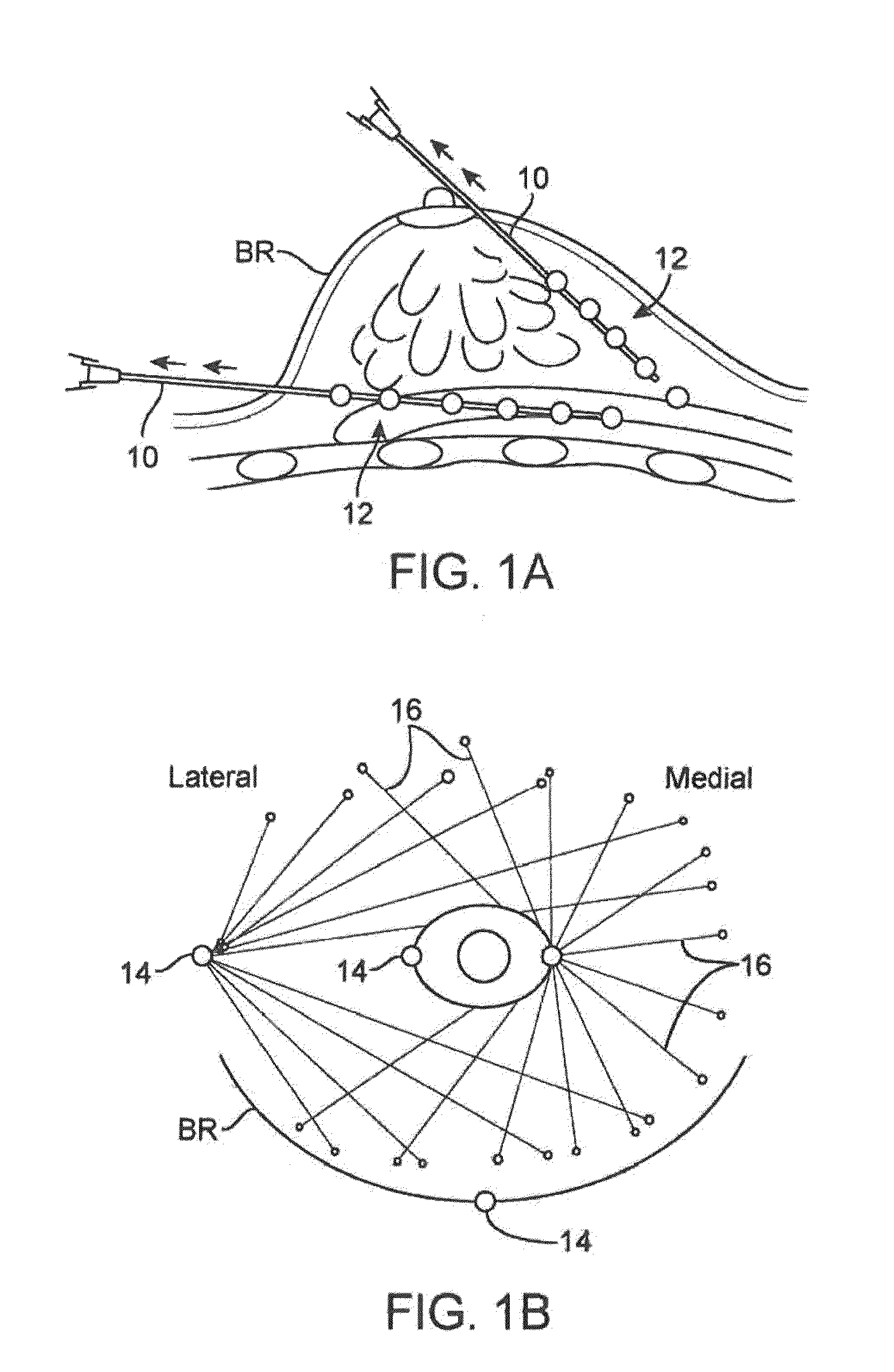

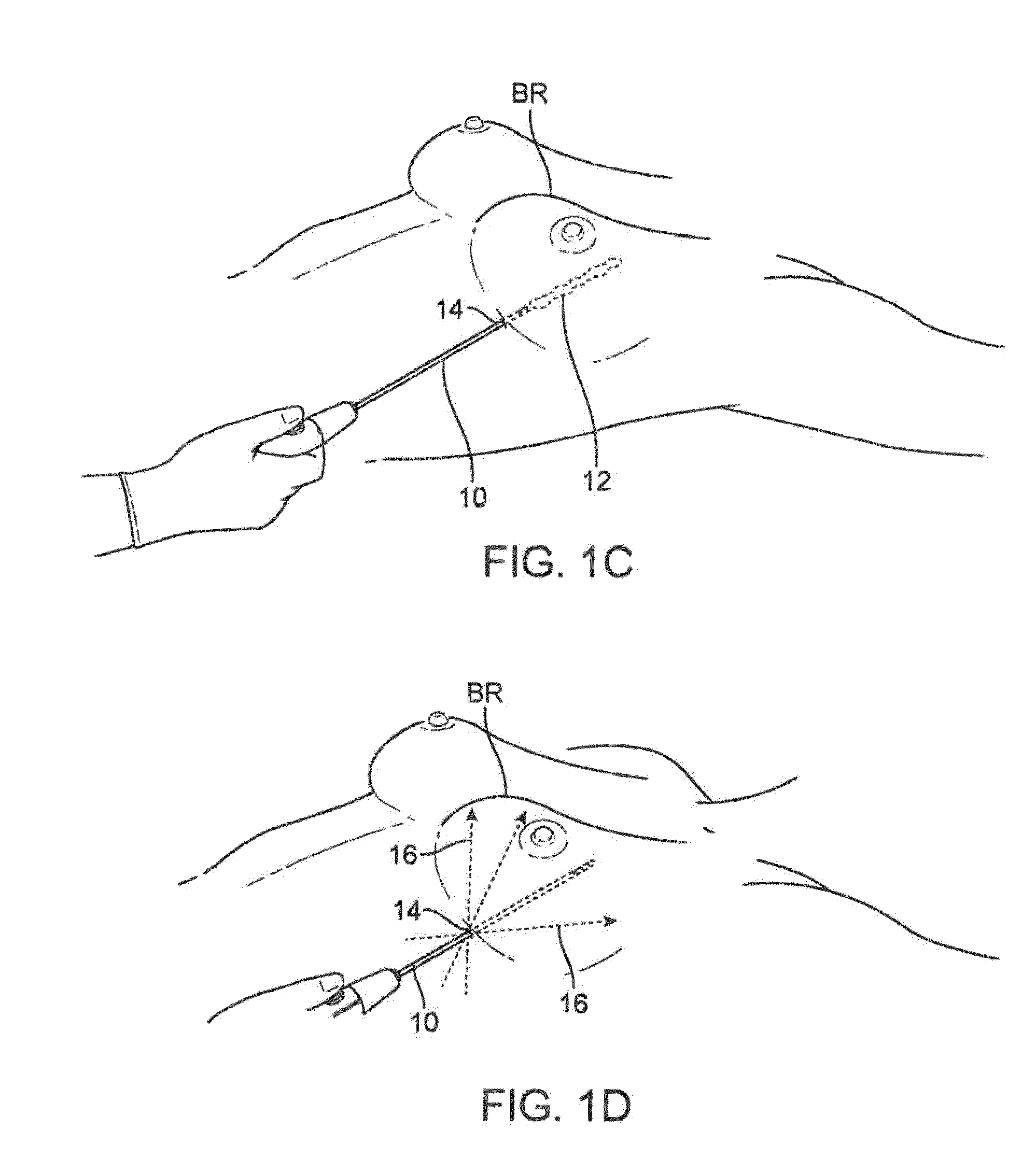

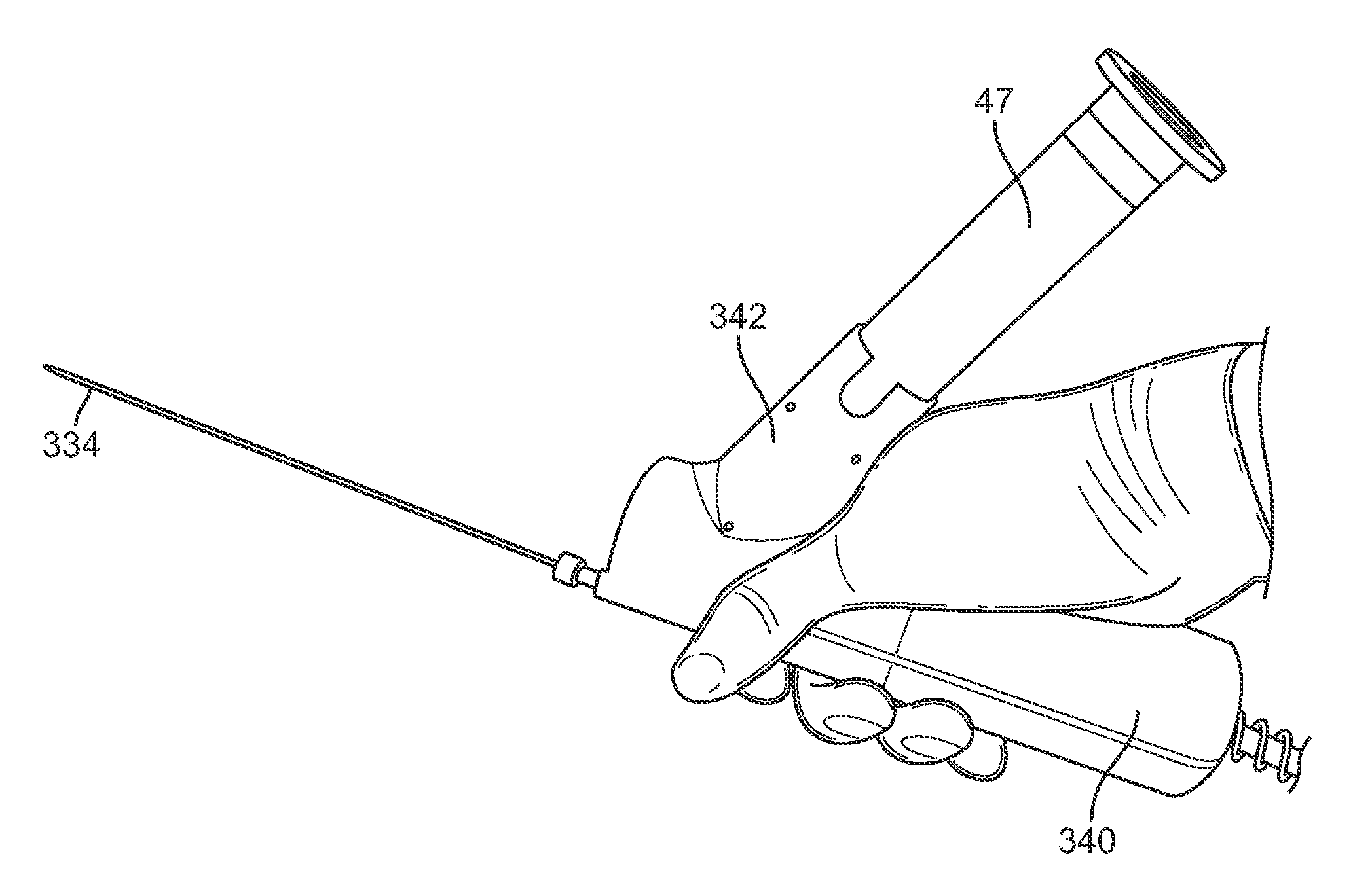

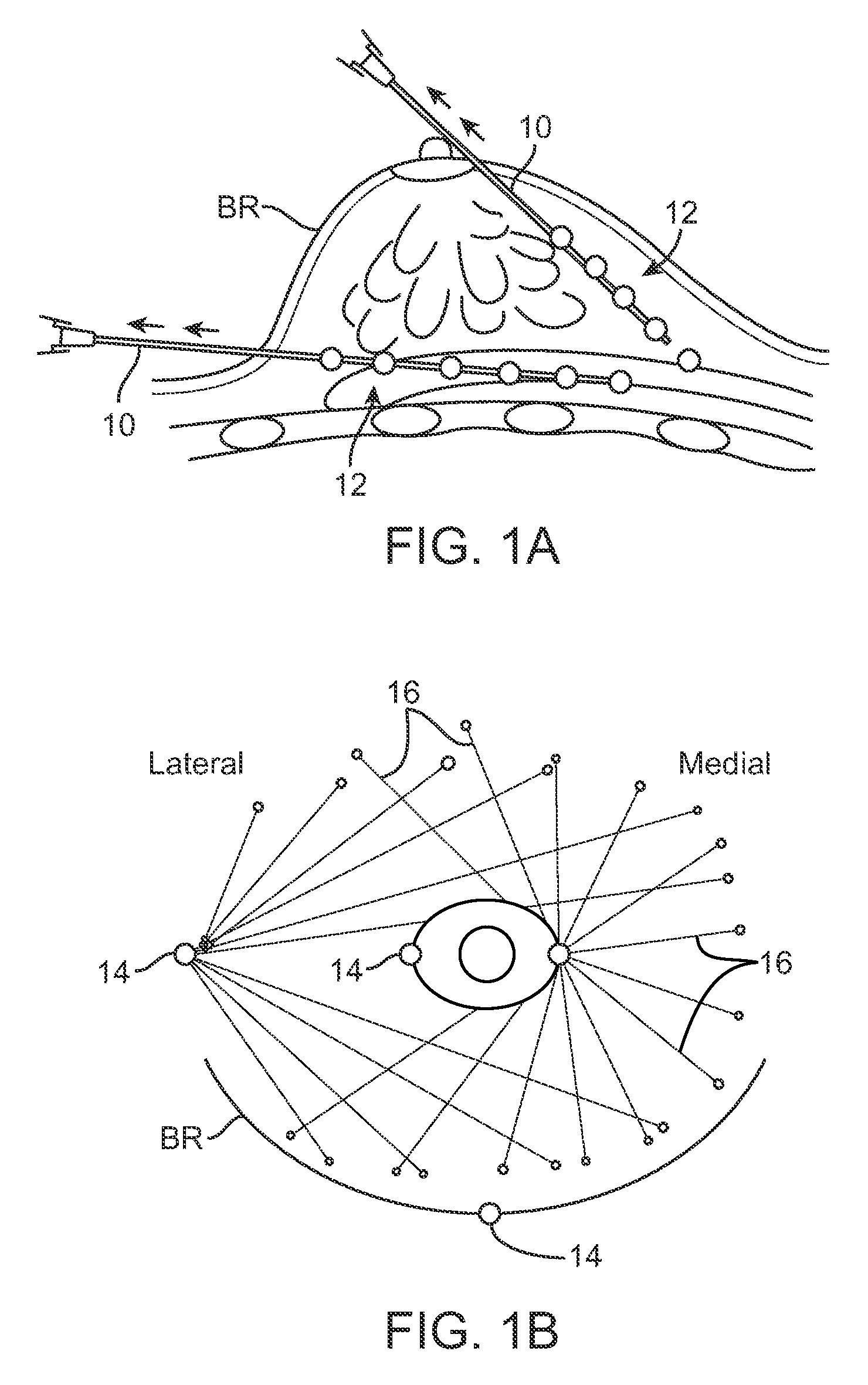

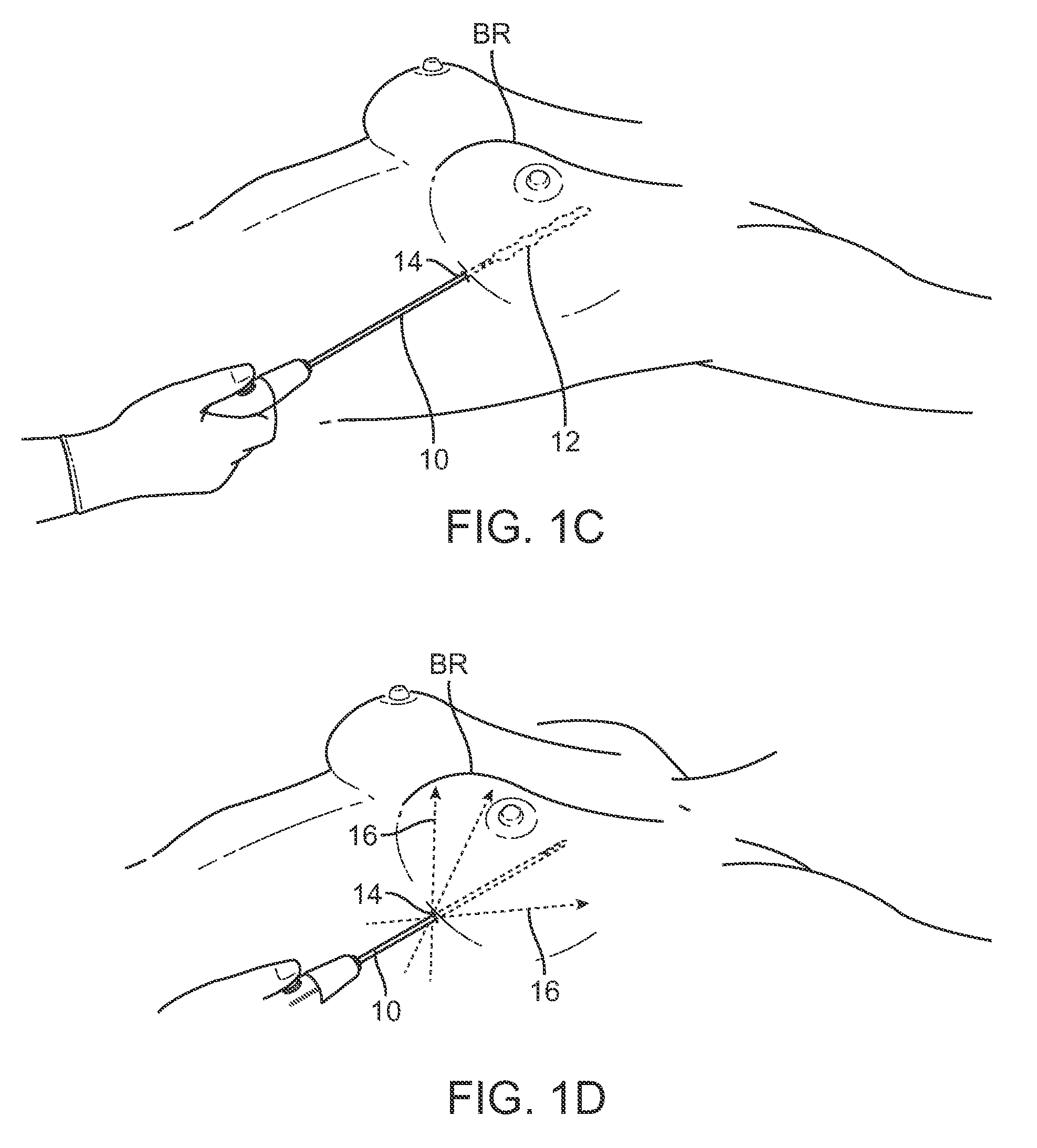

Tissue transfer systems

ActiveUS8632498B2Precision injectionEasy to controlMedical devicesFlow monitorsGuidance systemTransfer system

Devices and methods for tissue transfer are described where a cannula may be inserted into the breast of a subject at one of several points of entry. Insertion of the cannula into the breast may be accomplished by using a guidance system to distinguish between tissue types. Once desirably positioned, the cannula may be withdrawn from the breast while automatically (or manually) injecting the fat in multiple deposits of adipose tissue or fat such that the deposited fat remains within the tract formed by the withdrawn cannula. Multiple tracts of the deposited fat may be injected within the breast until the breast has been desirably remodeled and / or augmented.

Owner:LIFECELL

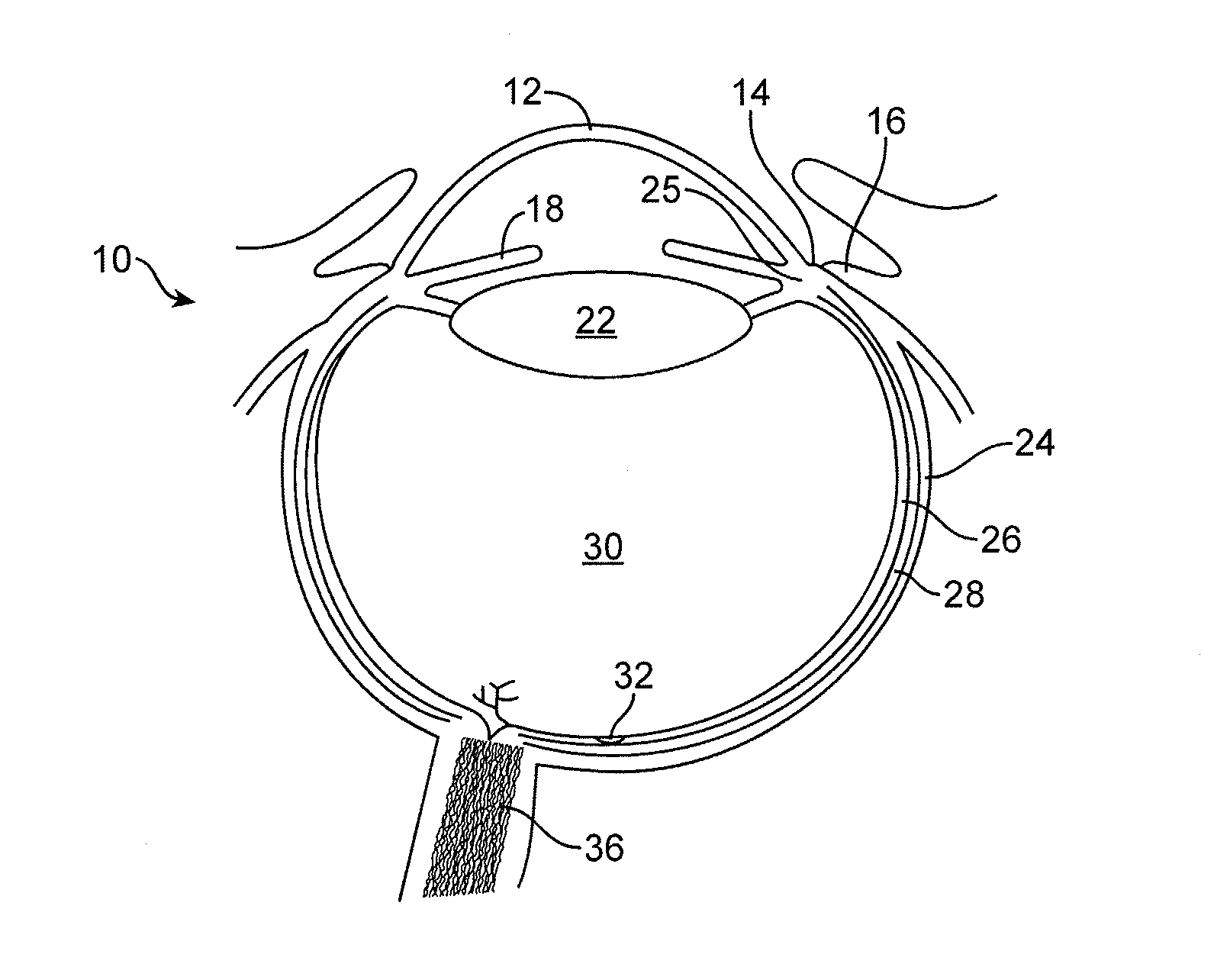

Implantable therapeutic device

ActiveUS20120095439A1Reduce deliveryPrecision injectionSenses disorderPeptide/protein ingredientsTherapeutic DevicesEffective length

A therapeutic device to release a therapeutic agent comprises a porous structure coupled to a container comprising a reservoir. The reservoir comprises a volume sized to release therapeutic amounts of the therapeutic agent for an extended time when coupled to the porous structure and implanted in the patient. The porous structure may comprise a first side coupled to the reservoir and a second side to couple to the patient to release the therapeutic agent. The length of the channels extending from the first side to the second side may comprise an effective length greater than a distance across the porous structure from the first side to the second side. The therapeutic device may comprise a penetrable barrier to inject therapeutic agent into the device when implanted in the patient.

Owner:FORSIGHT VISION5 INC

Implantable therapeutic device

ActiveUS20130324942A1Reduce deliveryPrecision injectionSenses disorderPharmaceutical delivery mechanismTherapeutic DevicesEffective length

A therapeutic device to release a therapeutic agent comprises a porous structure coupled to a container comprising a reservoir. The reservoir comprises a volume sized to release therapeutic amounts of the therapeutic agent for an extended time when coupled to the porous structure and implanted in the patient. The porous structure may comprise a first side coupled to the reservoir and a second side to couple to the patient to release the therapeutic agent. The length of the channels extending from the first side to the second side may comprise an effective length greater than a distance across the porous structure from the first side to the 188 second side. The therapeutic device may comprise a penetrable barrier to inject therapeutic agent into the device when implanted in the patient.

Owner:FORSIGHT VISION5 INC

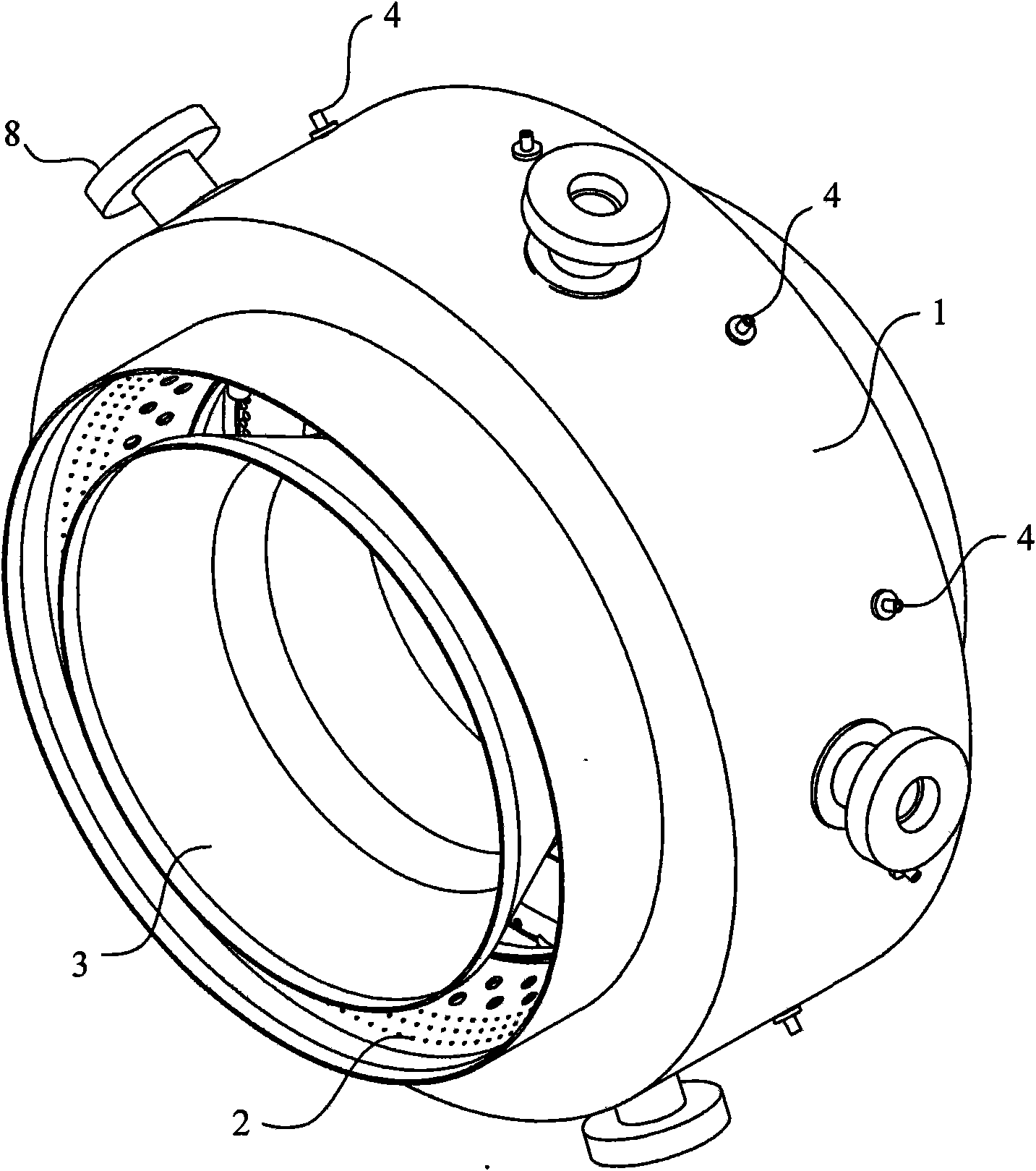

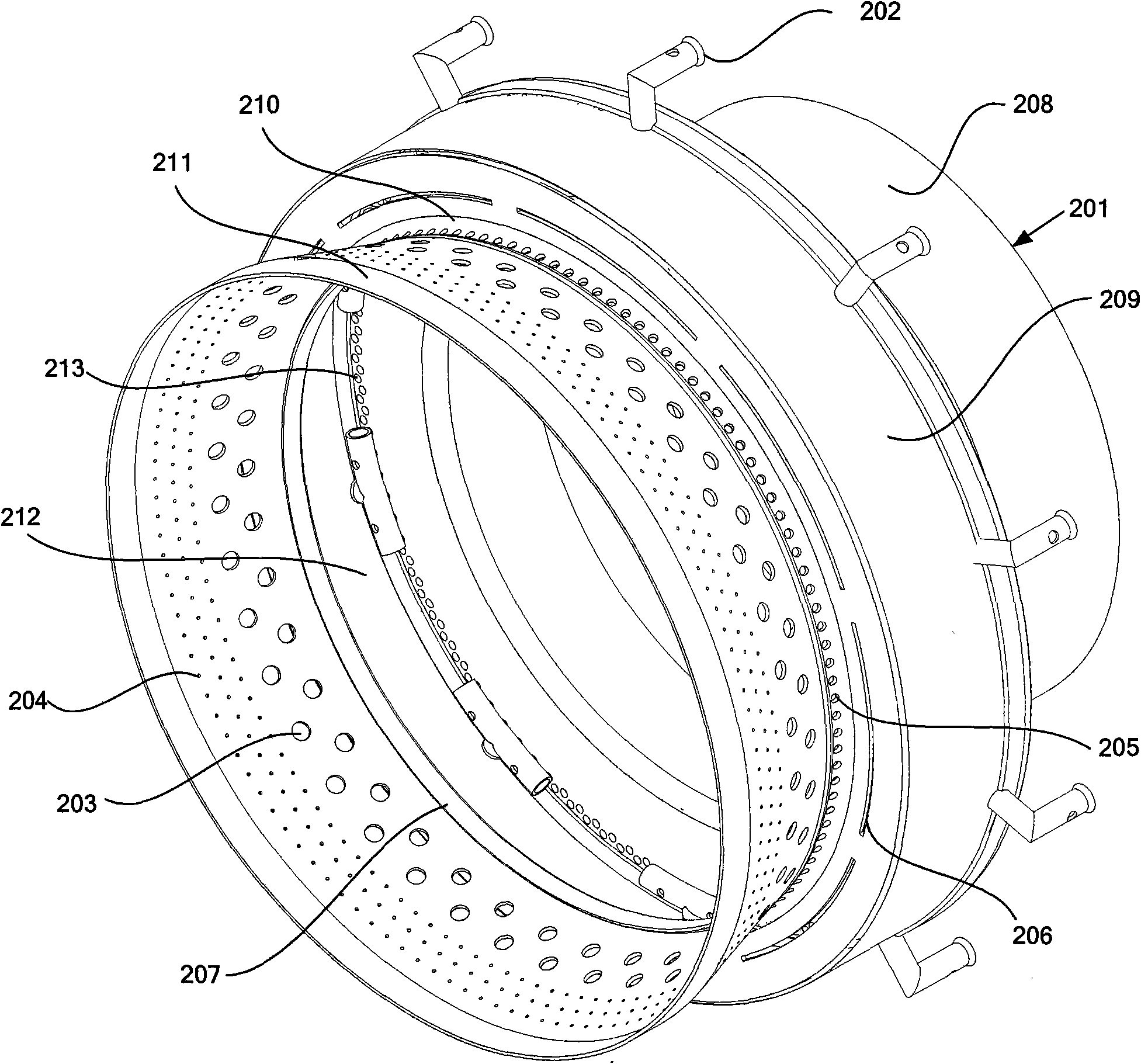

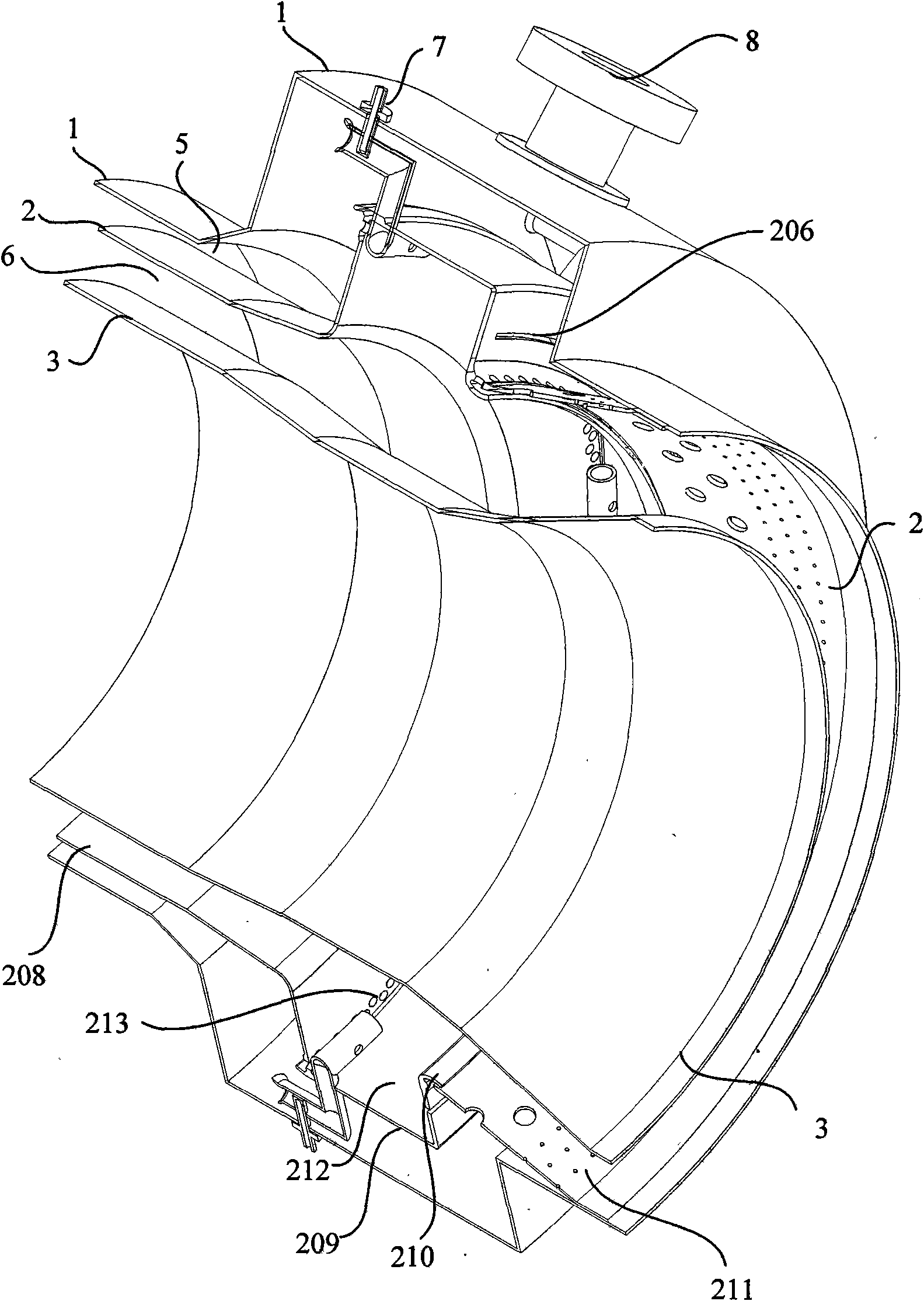

Double-vortex combustion chamber

InactiveCN101566353AReduce weightImprove combustion efficiencyContinuous combustion chamberCombustion chamberEngineering

The invention discloses a double-vortex combustion chamber which adopts a full ring shaped flame tube structure and comprises a shell, an inner flame tube and an outer flame tube. The outer wall of the outer flame tube and the inner wall of the shell form a cooling cavity channel; the inner wall of the outer flame tube and the outer wall of the inner flame tube form a combustion channel; oil injection pipes and an igniting seat are arranged on the periphery of the shell; the outer flame tube is an integral forming part, the first section thereof is a diffusion section which adopts a constant pressure gradient design, and the second section thereof is provided with two rows of advancing air holes at the edge of the front wall of a recessed cavity, an evaporating pipe extends into the recessed cavity along the periphery direction of the recessed cavity and close to the inner side of the front wall of the recessed cavity, and the back wall of the recessed cavity is provided with a back air inlet duct at the half height; the third section is provided with an air film cooling air inlet port and an air film cooling air inlet baffle; and the fourth section is provided with a blending hole and a diffusion cooling hole. The double-vortex structure formed in the recessed cavity of the double-vortex combustion chamber improves the distribution of a fuel concentration field, realizes fractional combustion, increases the residence time of fuel combustion, reduces the pollutant discharge and ensures the outlet temperature to be more uniform.

Owner:BEIHANG UNIV

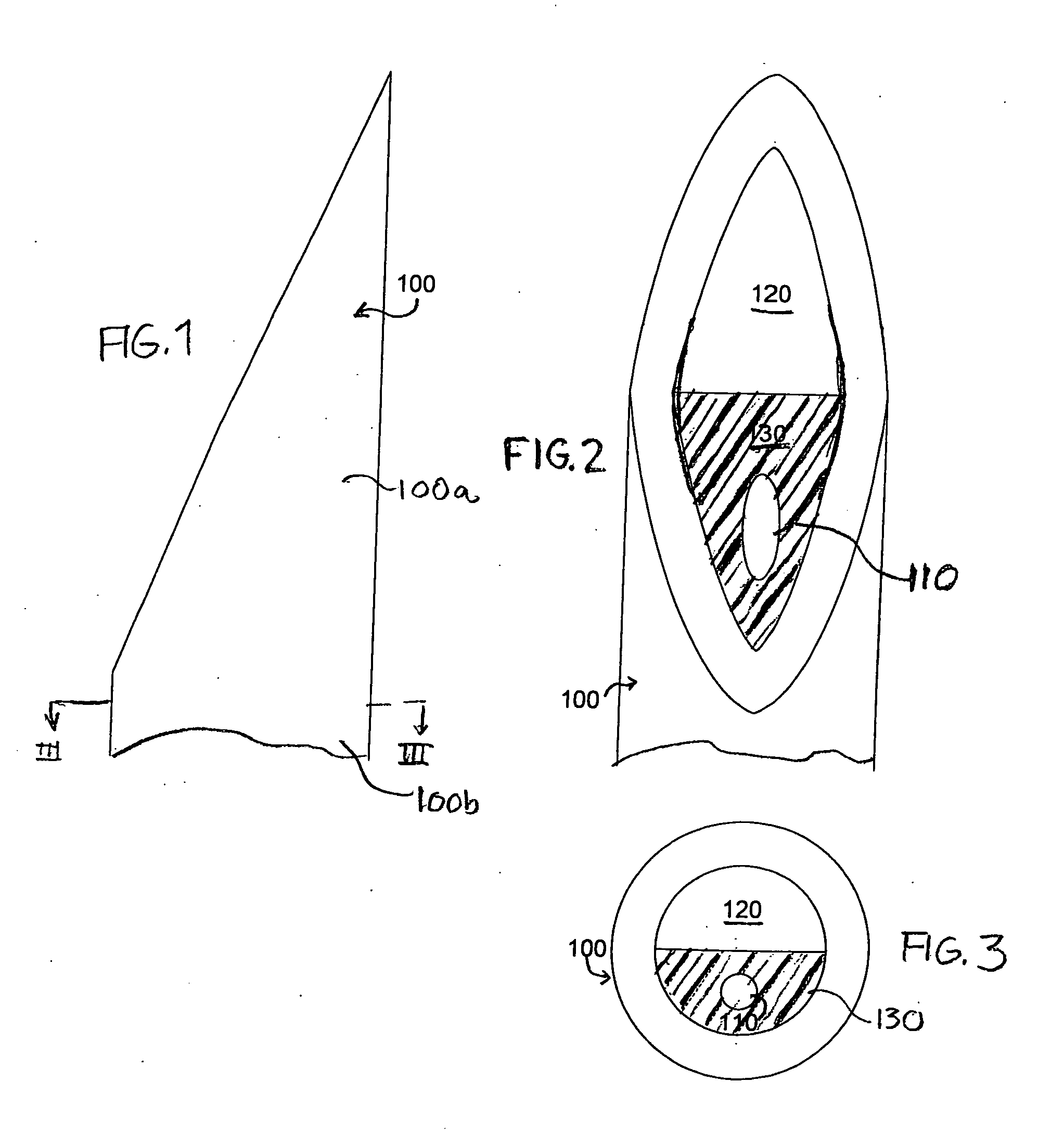

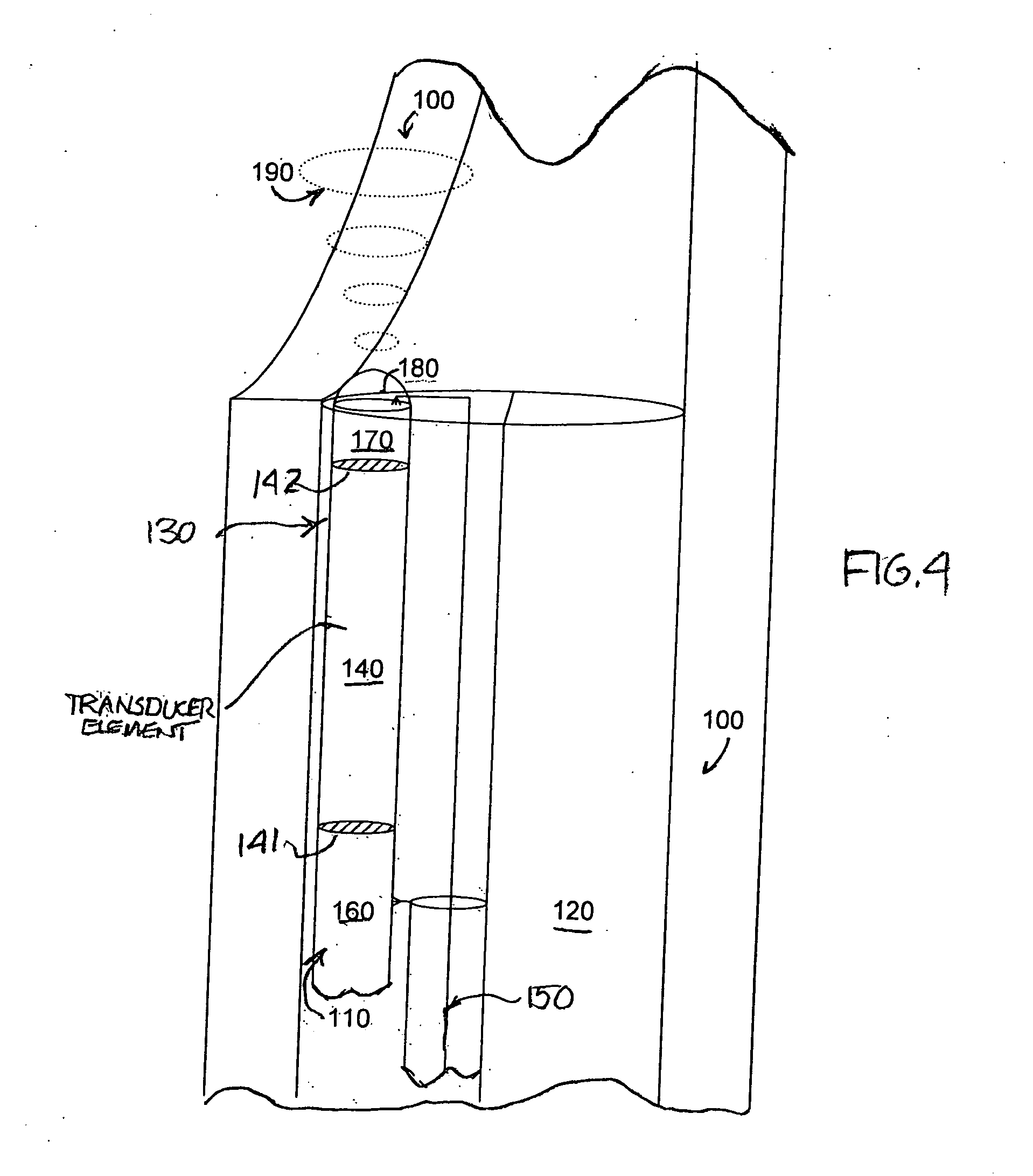

Acoustic device for needle placement into a joint

InactiveUS20080114309A1Precision injectionSurgical needlesHeart defibrillatorsTransducerSacroiliac joint

An acoustic device is provided which assists in accurate placement of a needle into a human or animal diarthrodial joint. The device includes a handpiece which mounts a needle assembly including an acoustic transducer assembly. The transducer assembly, which is incorporated into the lumen of the needle, transmits ultrasound pulses from the needle tip into the joint area and receives the ultrasound pulses that are returned. The handpiece is manipulated by the user to guide the needle during placement. The returned ultrasound pulses are processed to determine whether the needle is placed in the joint itself rather than in a location adjacent to the joint and a corresponding output is produced to aid the user in effecting proper needle placement.

Owner:ZUCKERMAN STEPHEN D

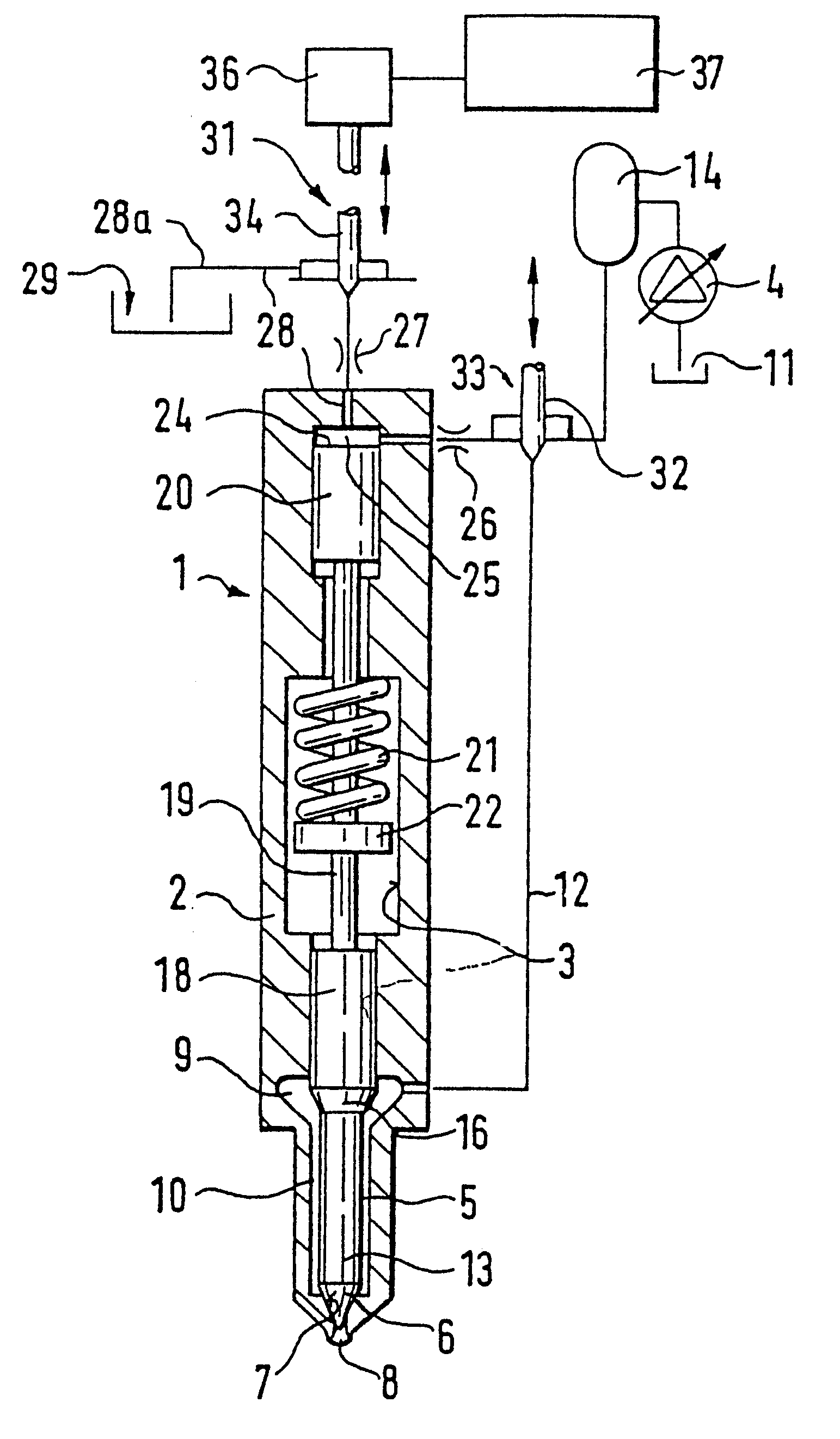

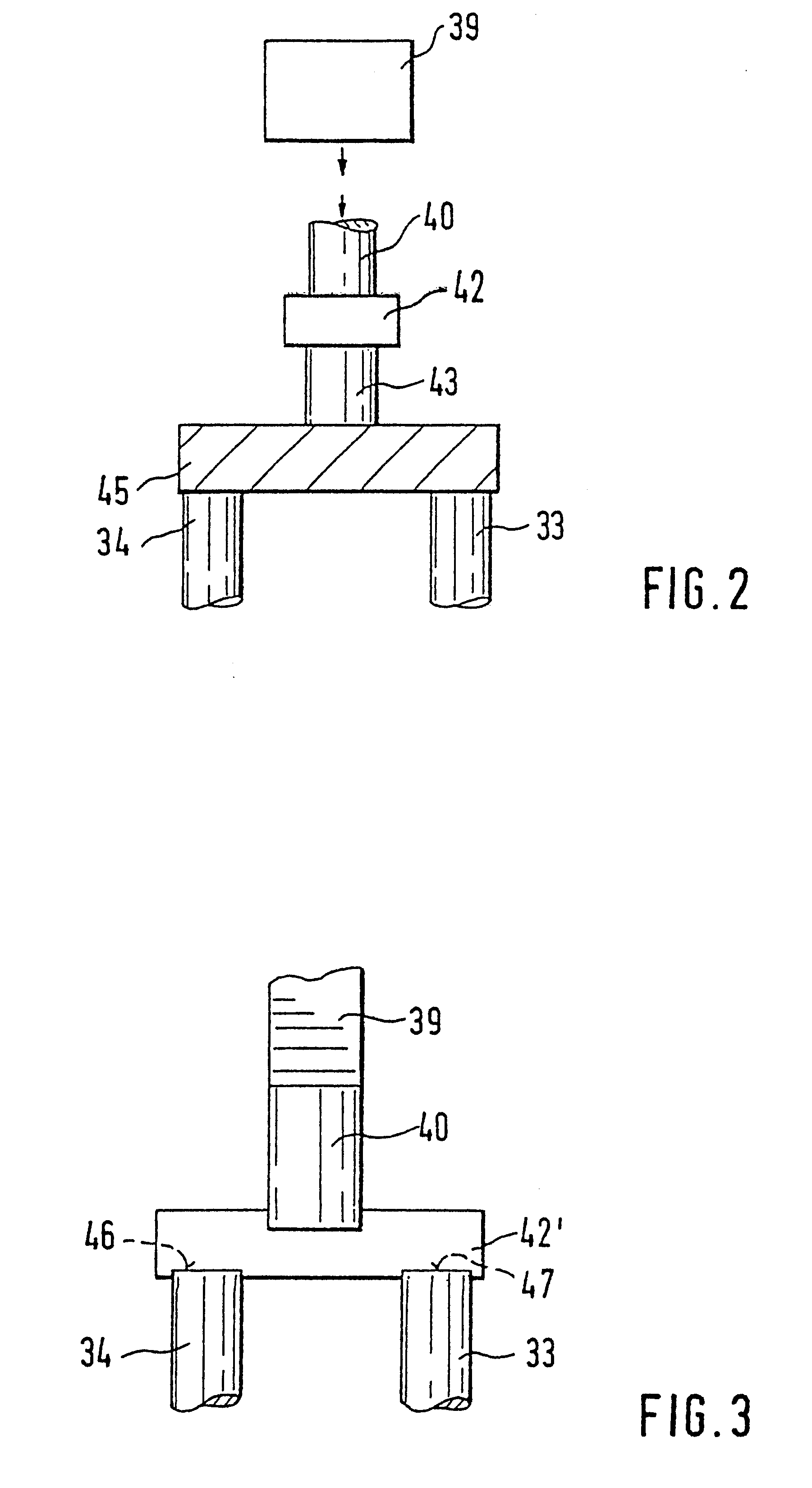

Fuel injection valve

InactiveUS6328017B1Limited durationLow structural costEngine controllersMachines/enginesCombustionEngineering

A fuel injection valve for an internal combustion engines is proposed, in which the control of the fuel injection valve member is controlled through the control of the pressure of a control chamber (25). This chamber is either relieved by means of a control valve (31) or is subjected to a high pressure, which brings the fuel injection valve member into the closed position. At the same time as the relief of the control chamber, a valve member (33) of a safety valve (32) that controls the fuel supply to the fuel injection valve is opened so that upon opening of the fuel injection valve, high-pressure fuel simultaneously also can travel by way of a pressure line (12) from a high-pressure fuel reservoir (14) to the injection openings (8) of the fuel injection valve (1). After the end of the injection, the valve member (33) is closed again, together with the closing of the fuel injection valve member (5). Consequently, in the event of a malfunction, unwanted fuel is prevented from reaching injection for a long period of time and consequently possibly destroying the associated engine due to overdosing.

Owner:ROBERT BOSCH GMBH

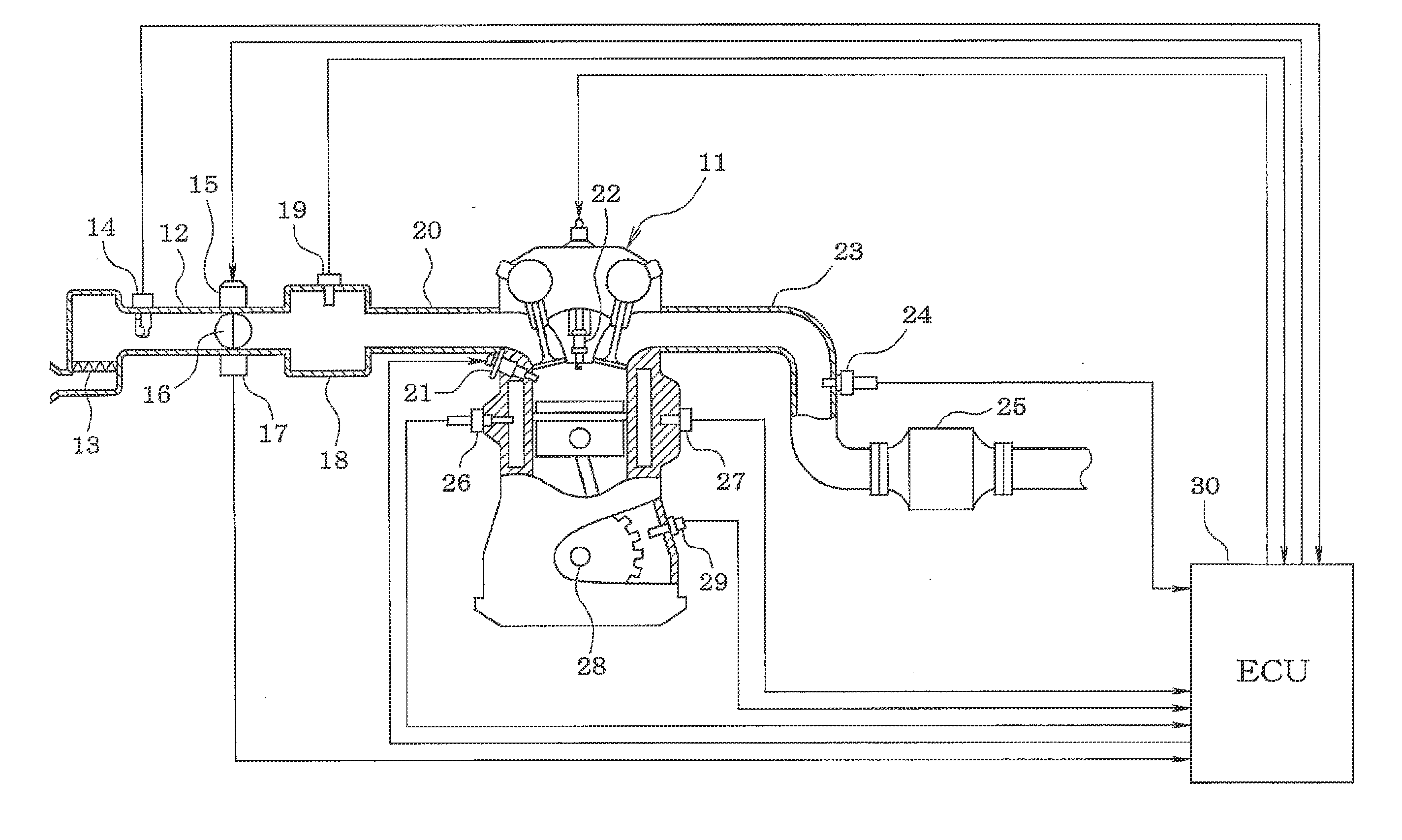

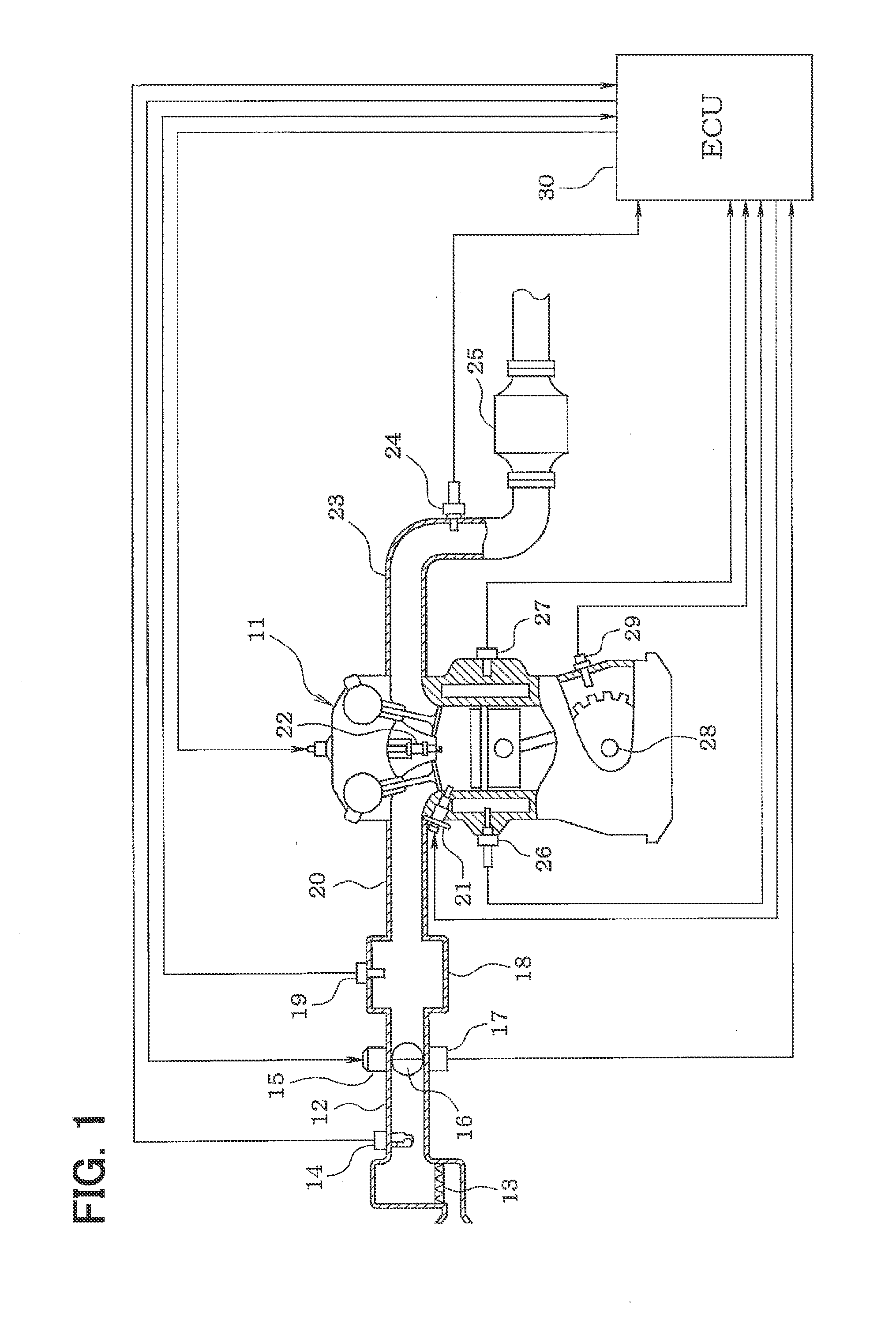

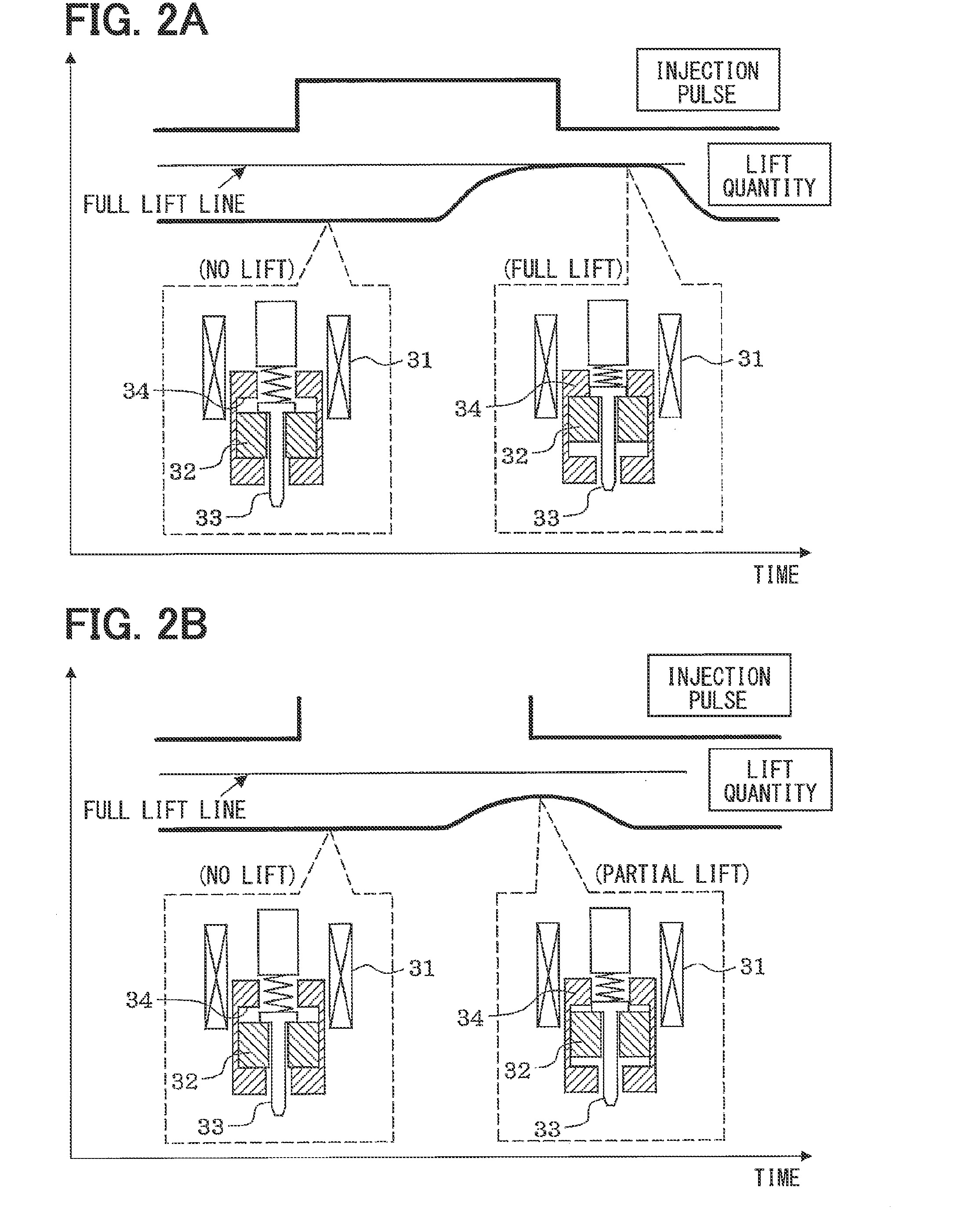

Fuel injection control device for internal combustion engine

ActiveUS20140311459A1Prevent drivabilityAvoid exhaust emissionsElectrical controlFuel injection apparatusDriving currentInternal combustion engine

When a given learning performance condition is met, a partial lift injection for opening a fuel injector is performed by an injection pulse which brings about a partial lift state in which a lift quantity of a valve body of the fuel injector does not reach a full lift position, and an integrated value of a drive current is calculated which flows through a drive coil of the fuel injector after an injection pulse of the partial lift injection is turned off. An inductance of the drive coil is calculated in consideration of a direct current superposition characteristic of the drive coil on the basis of the integrated value of the drive current, whereby the inductance of the drive coil is calculated with high accuracy. Then, the lift quantity of the valve body is estimated on the basis of the inductance, whereby the lift quantity of the valve body is estimated with high accuracy. The injection pulse of the partial lift injection is corrected on the basis of the lift quantity, whereby the injection pulse of the partial lift injection is corrected with high accuracy.

Owner:DENSO CORP

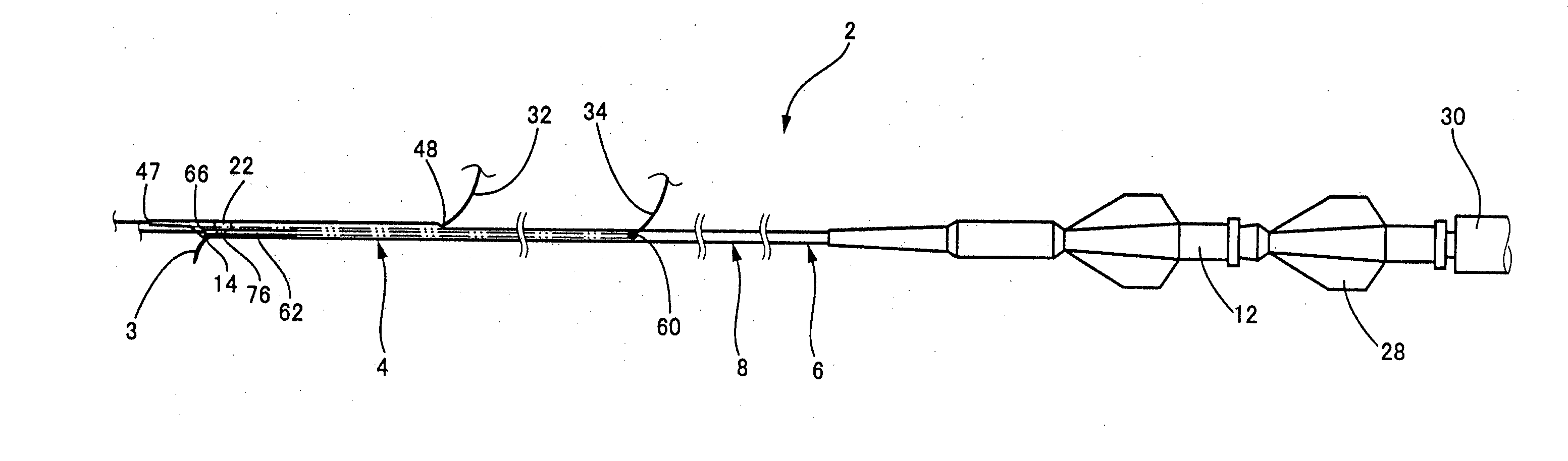

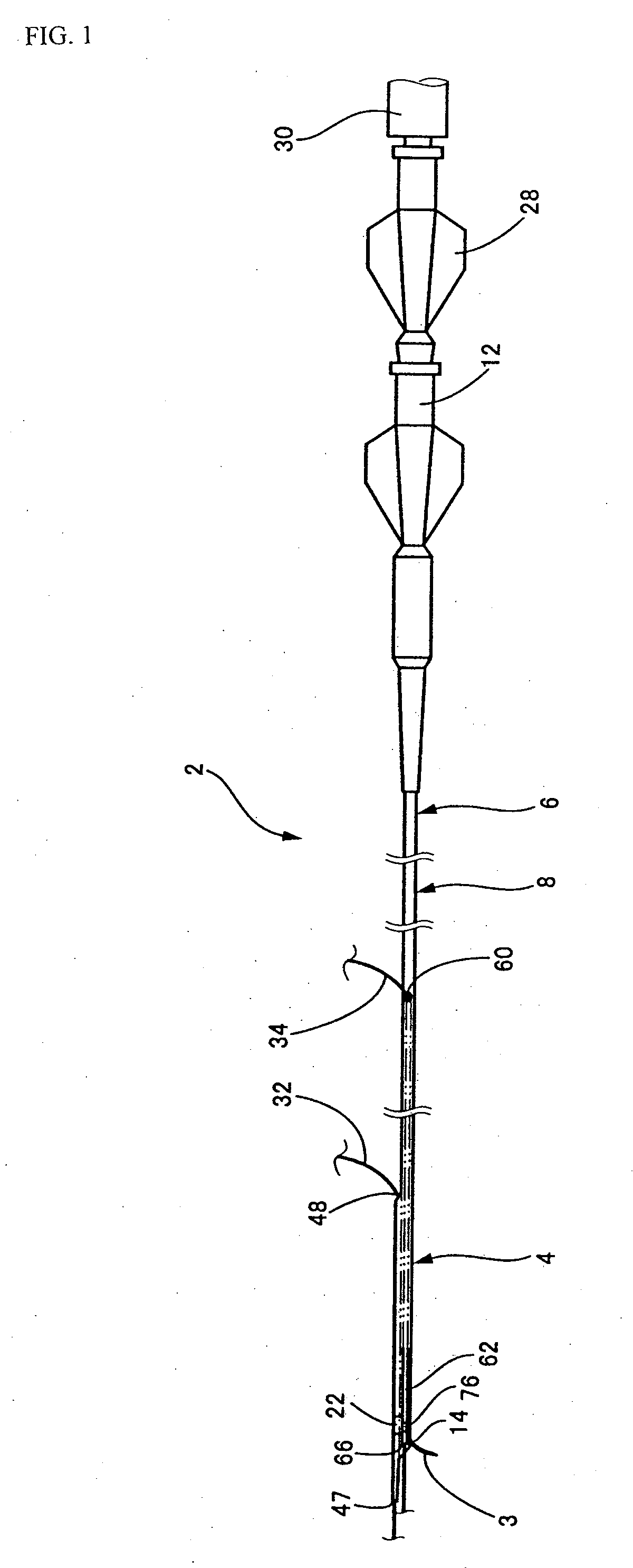

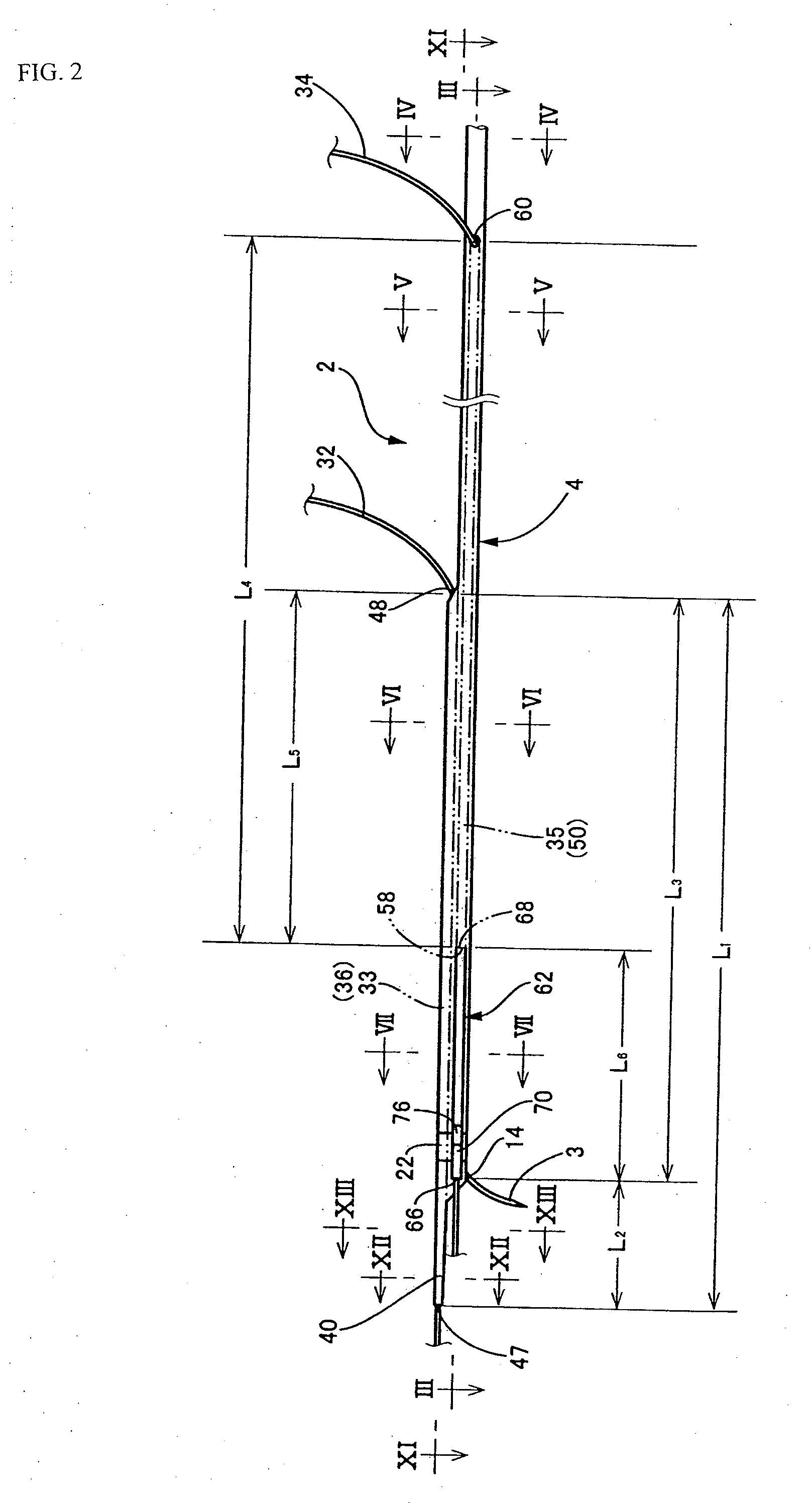

Reagent injection apparatus and method of producing the same

ActiveUS20070129706A1Reliable and smooth puncturingReduce the overall diameterInfusion syringesGuide wiresEngineeringGuide wires

A structure includes a main tube 2 that contains a needlelike tubular body lumen 10 through which a needlelike tubular body 3 is inserted, with a distal section 4 of the main tube 2 having a first guide wire insertion section 33 and second guide wire insertion section 35, respectively containing a first guide wire lumen 38 and second guide wire lumen 52 through which a first guide wire 32 and second guide wire 34 are inserted. This structure further has a support tube 62 whose tip remains a free end, wherein this support tube 62 accepts a part of the second guide wire 34 extending out of the second guide wire lumen 52 and thereby supports the second guide wire insertion section 35.

Owner:KATOH OSAMU +1

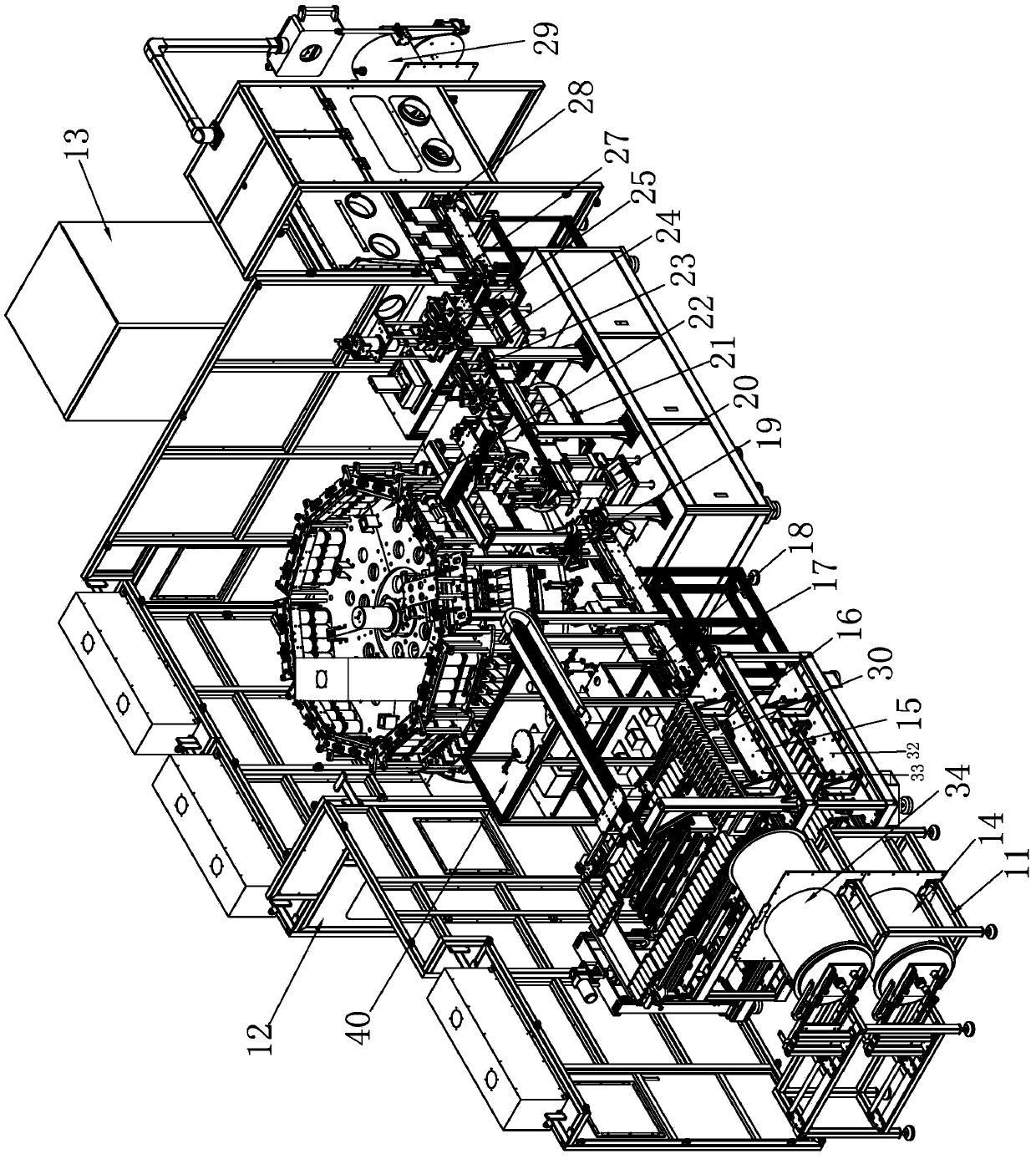

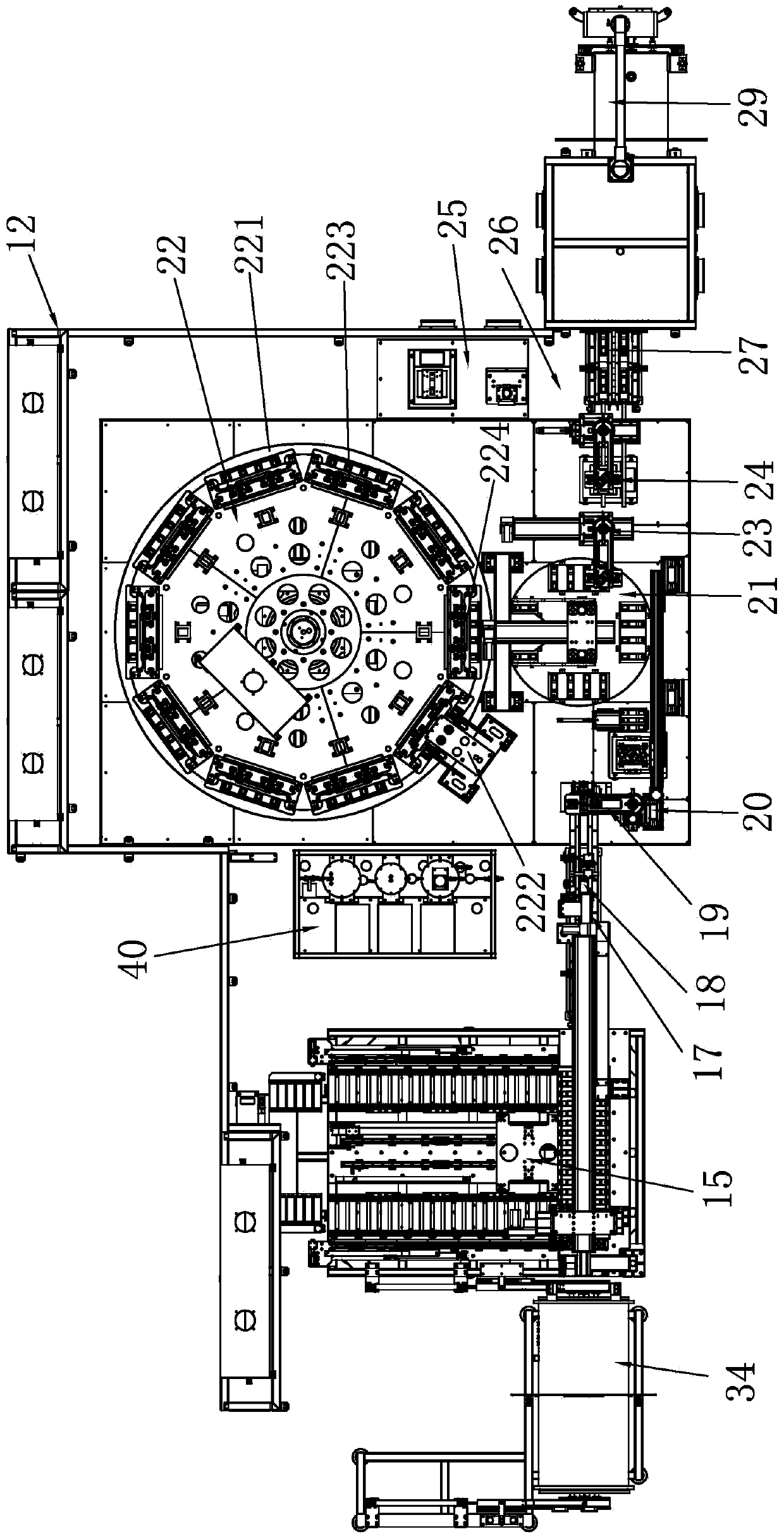

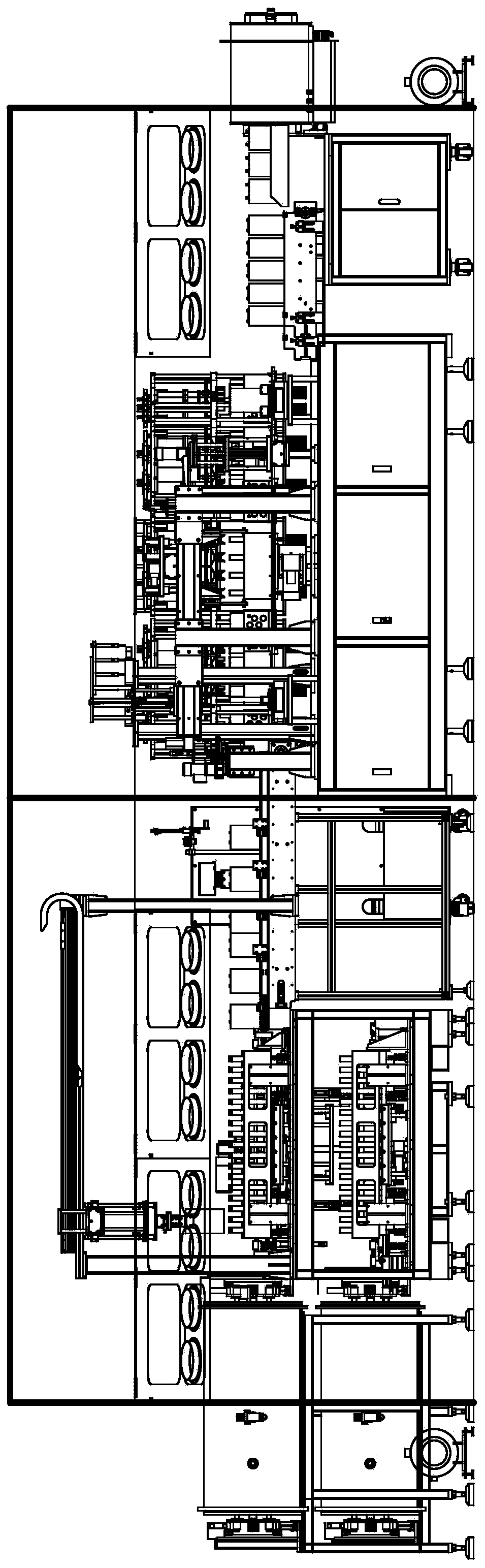

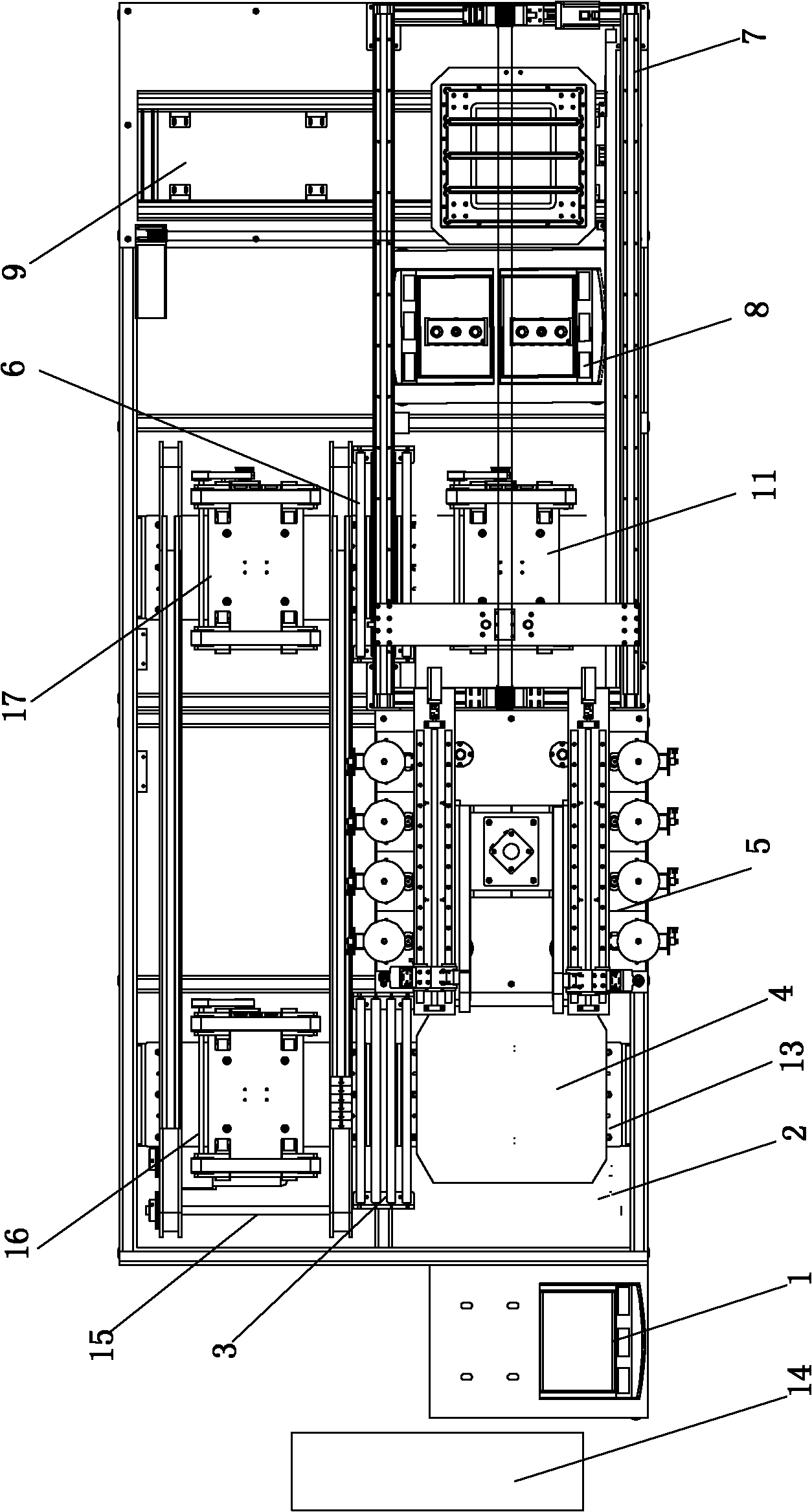

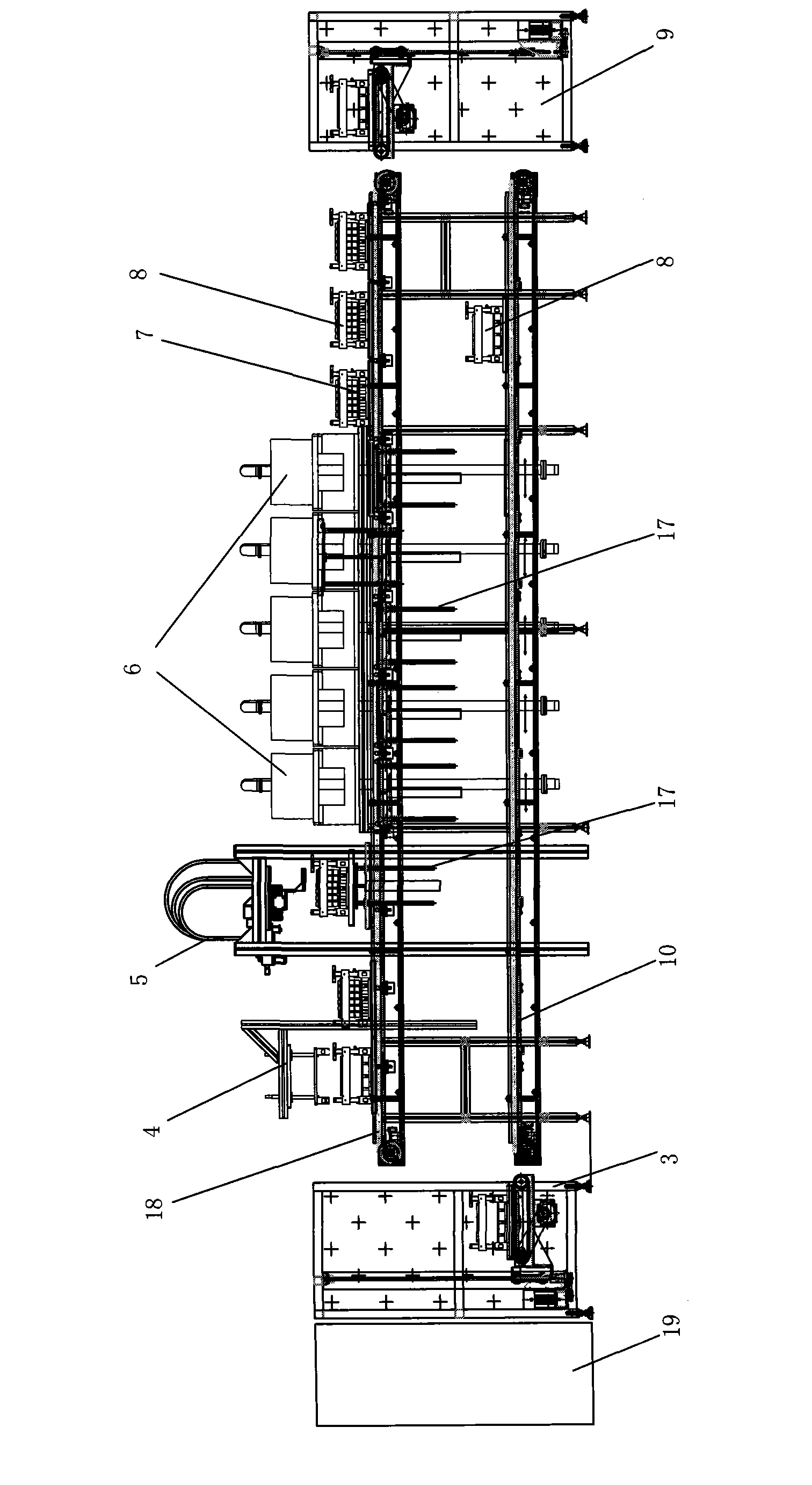

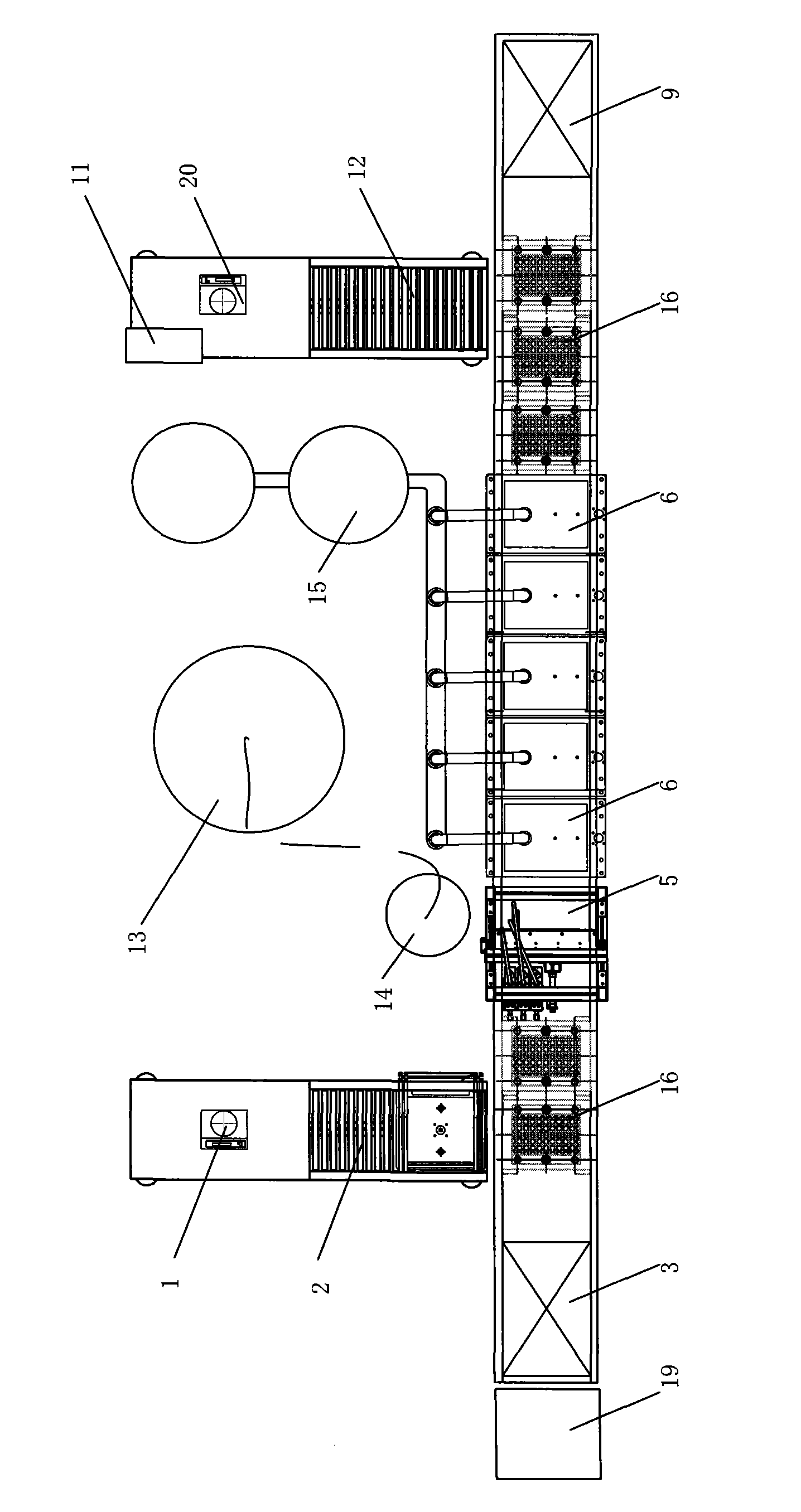

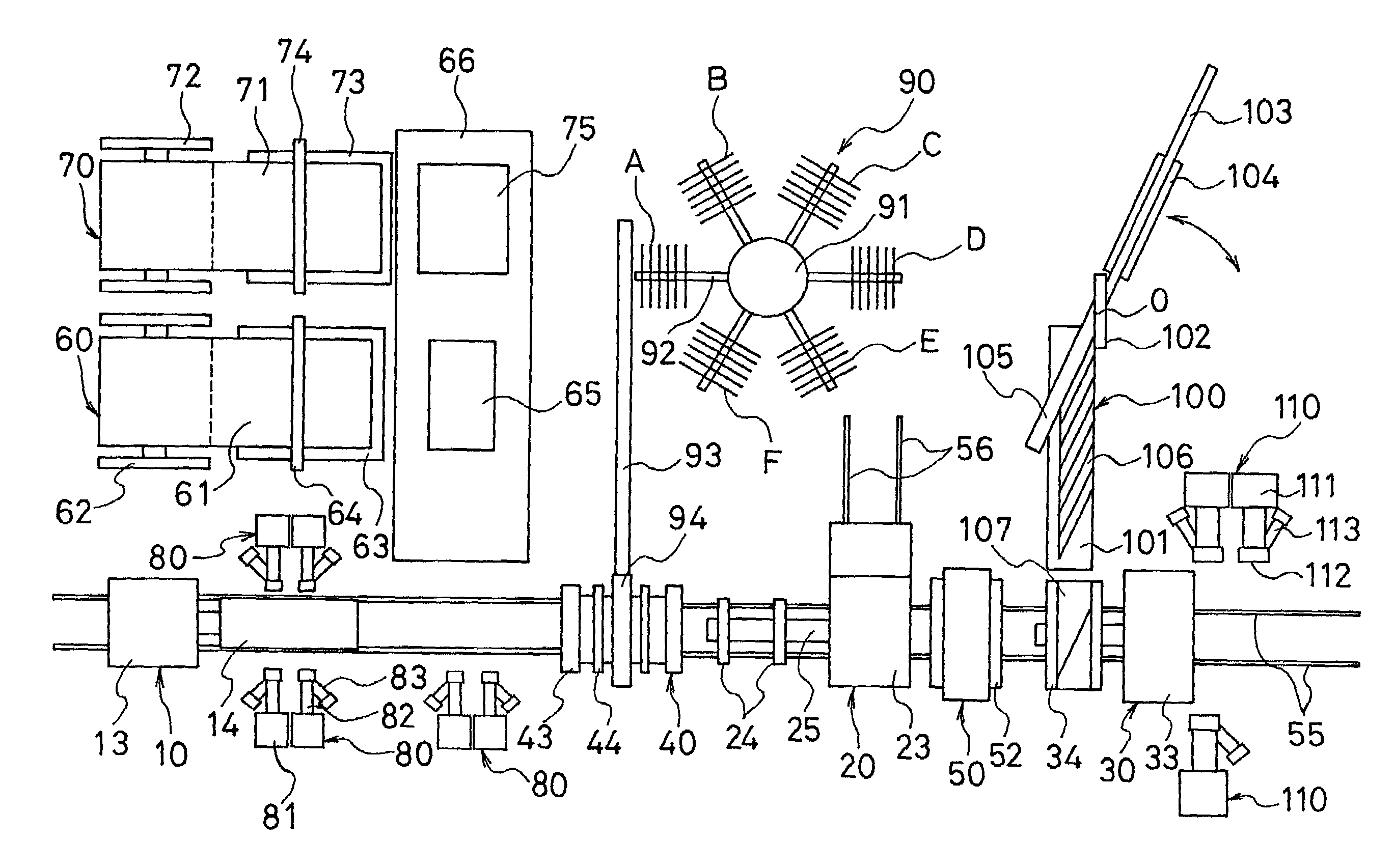

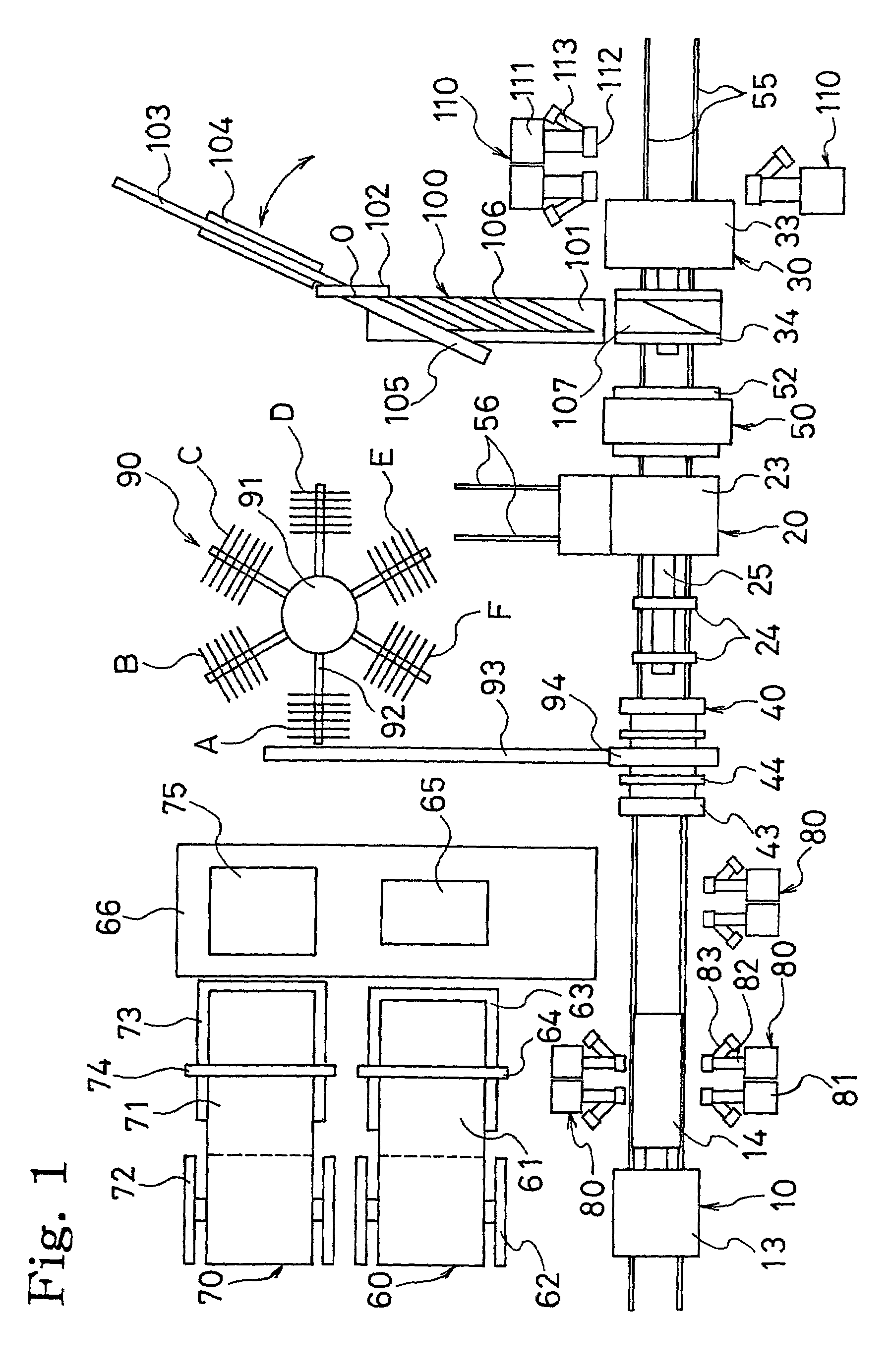

Automatic electrolyte injection equipment for batteries

ActiveCN104241592AQuality improvementExtended service lifeCell component detailsInjection equipmentEngineering

The invention discloses automatic electrolyte injection equipment for batteries. The automatic electrolyte injection equipment comprises a stander, a closed box body covering the stander, an electric cabinet independently arranged outside the closed box body, as well as a loading vacuum transition cabin, a drying and cooling mechanism, a loading manipulator, a loading conveyer belt, an insulation resistance test mechanism, a loading code-scanning and weighing manipulator, a pre-injection weighing mechanism, a turntable loading mechanism, an injection electrolyte circulation standing turntable mechanism, an unloading code-scanning and weighing manipulator, a post-injection weighing mechanism, an electrolyte supplement station, a rubber plug insertion station, an unloading conveyor belt, an unloading transfer tray and an unloading vacuum transition cabin which are sequentially arranged on the stander along the battery conveying direction, and the automatic electrolyte injection equipment further comprises a drying tray used for bearing a battery. Therefore, through the cooperation of each part, the whole automation degree of the equipment is improved, and the production efficiency is greatly improved; meanwhile, the equipment ensures that no bubble exists in the injected electrolyte, realizes stable and reliable electrolyte injection, improves the battery quality and prolongs the service life of the battery.

Owner:DONGGUAN HONBRO LI BATTERY EQUIP TECH

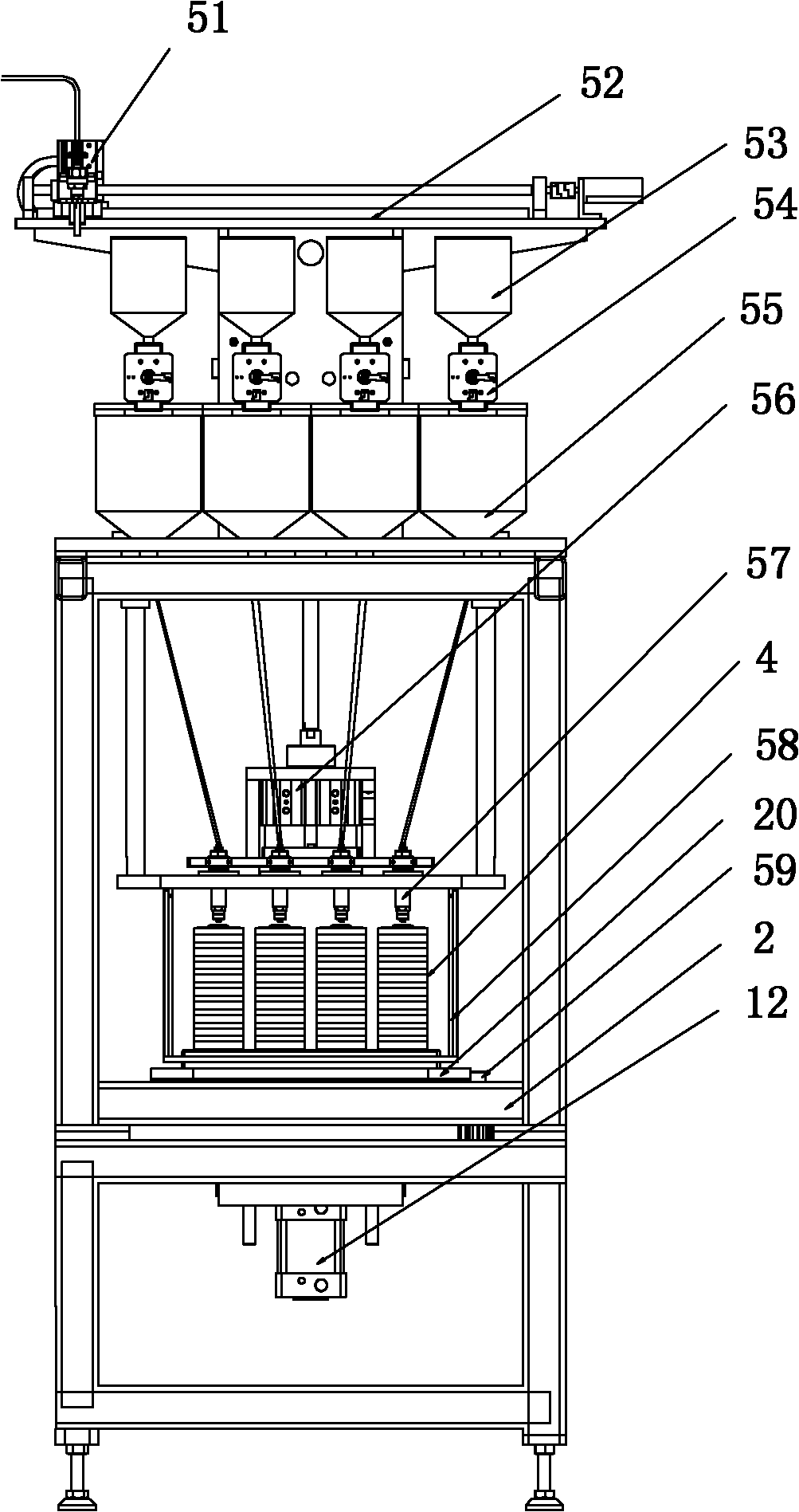

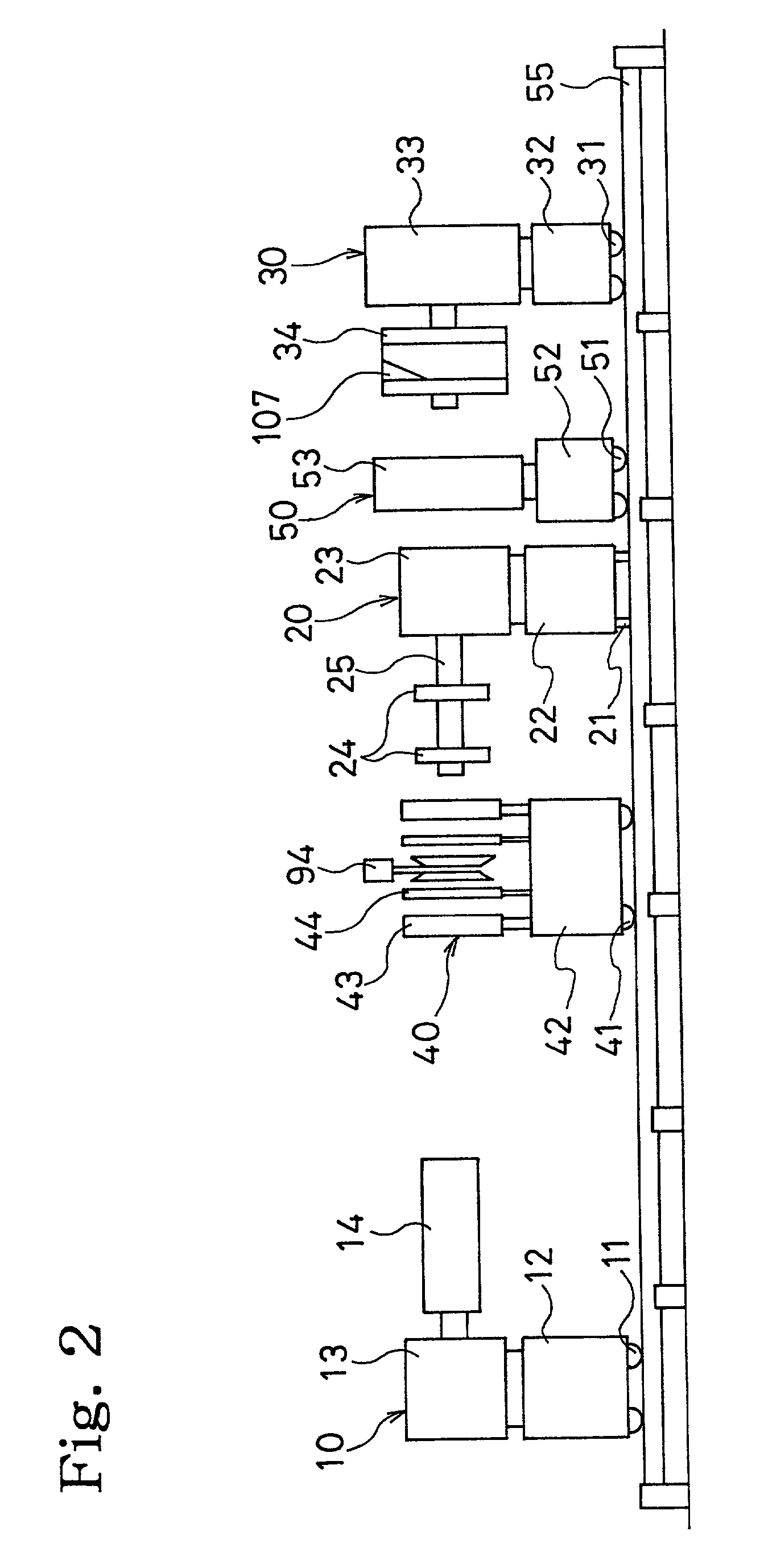

Automatic filling machine for battery and battery filling method

InactiveCN102148349ARealize automatic flow operationCompact machine designCell component detailsBuffer tankEngineering

The invention discloses an automatic filling machine for a battery and a battery filling method. The filling machine comprises a rack, a front weighing device arranged on the rack, a filling conveying line, an evacuation filling device, a discharging device, a rear weighing device and a control module. The filling machine also comprises a carrier backflow mechanism which comprises a carrier conveying line parallel to the filling conveying line and carrier transfer devices arranged at two ends of the filling conveying line and the carrier conveying line; and the evacuation filling device comprises a filling nozzle, a driving part for driving the filling nozzle to move, a filling cup communicated with the filling nozzle, a filling buffer tank communicated with the filling cup and a sealing cylinder for sealing the filling nozzle and the battery in the sealing cylinder. In the invention, automatic operations of battery conveying, filling, evacuation and discharging are ensured, the machine design and process layout are compact, the vacuum and high-pressure circulating alternate filling method is adopted, and the full absorption and filling precision of electrolyte of the battery are ensured.

Owner:GEESUN AUTOMATION TECH

Tissue transfer systems

ActiveUS20130131635A1Easy to controlPrecision injectionDiagnosticsPharmaceutical delivery mechanismGuidance systemTransfer system

Devices and methods for tissue transfer are described where a cannula may be inserted into the breast of a subject at one of several points of entry. Insertion of the cannula into the breast may be accomplished by using a guidance system to distinguish between tissue types. Once desirably positioned, the cannula may be withdrawn from the breast while automatically (or manually) injecting the fat in multiple deposits of adipose tissue or fat such that the deposited fat remains within the tract formed by the withdrawn cannula. Multiple tracts of the deposited fat may be injected within the breast until the breast has been desirably remodeled and / or augmented.

Owner:LIFECELL

Devices and methods for tissue transfer

ActiveUS9314568B2Precision injectionEasy to controlMedical devicesVaccination/ovulation diagnosticsAnatomyCannula insertion

Devices and methods for tissue transfer are described where a cannula may be inserted into the breast of a subject at one of several points of entry. Insertion of the cannula into the breast may be accomplished by using a guidance system to distinguish between tissue types. Once desirably positioned, the cannula may be withdrawn from the breast while automatically (or manually) injecting the fat in multiple deposits of adipose tissue or fat such that the deposited fat remains within the tract formed by the withdrawn cannula. Multiple tracts of the deposited fat may be injected within the breast until the breast has been desirably remodeled and / or augmented.

Owner:LIFECELL

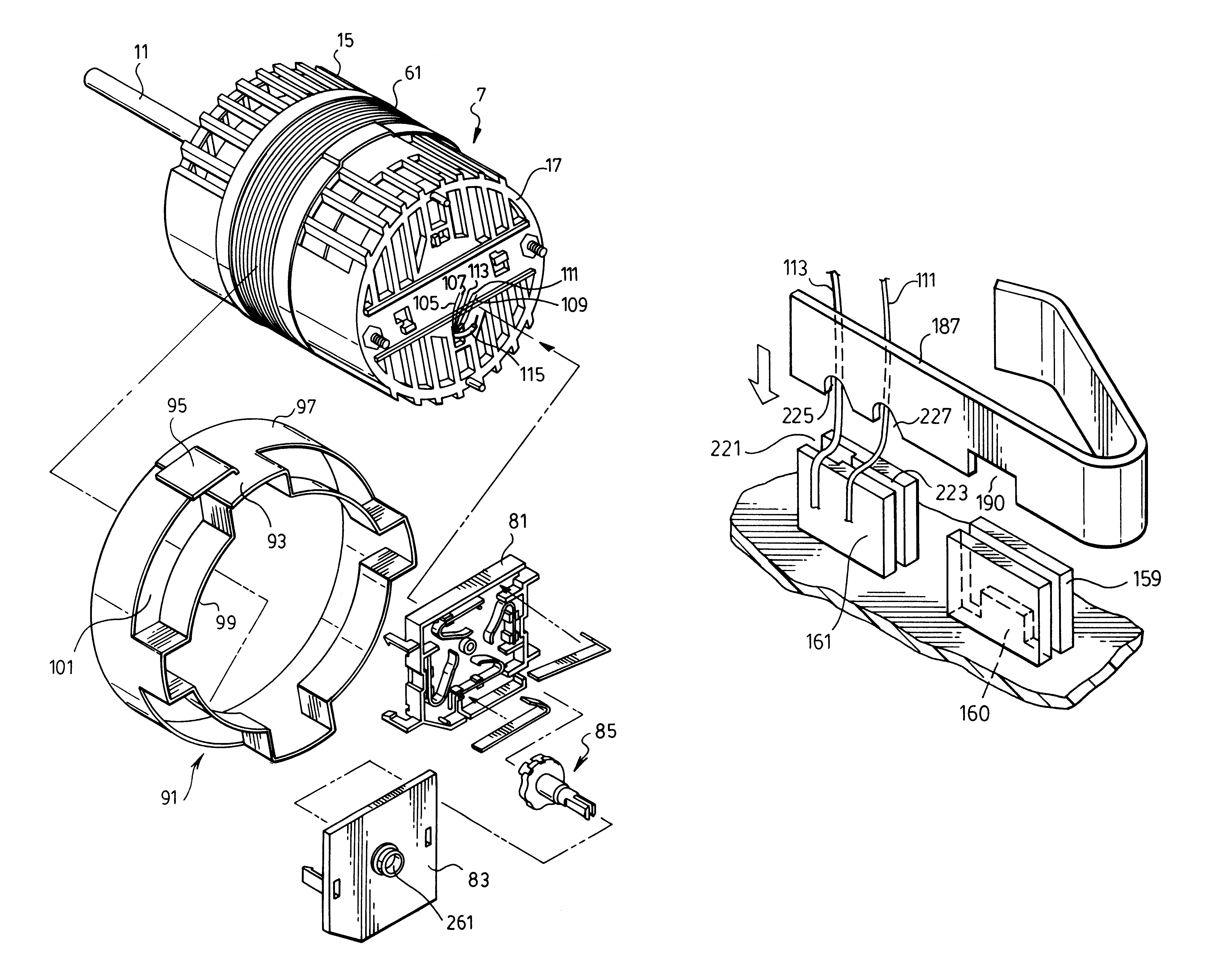

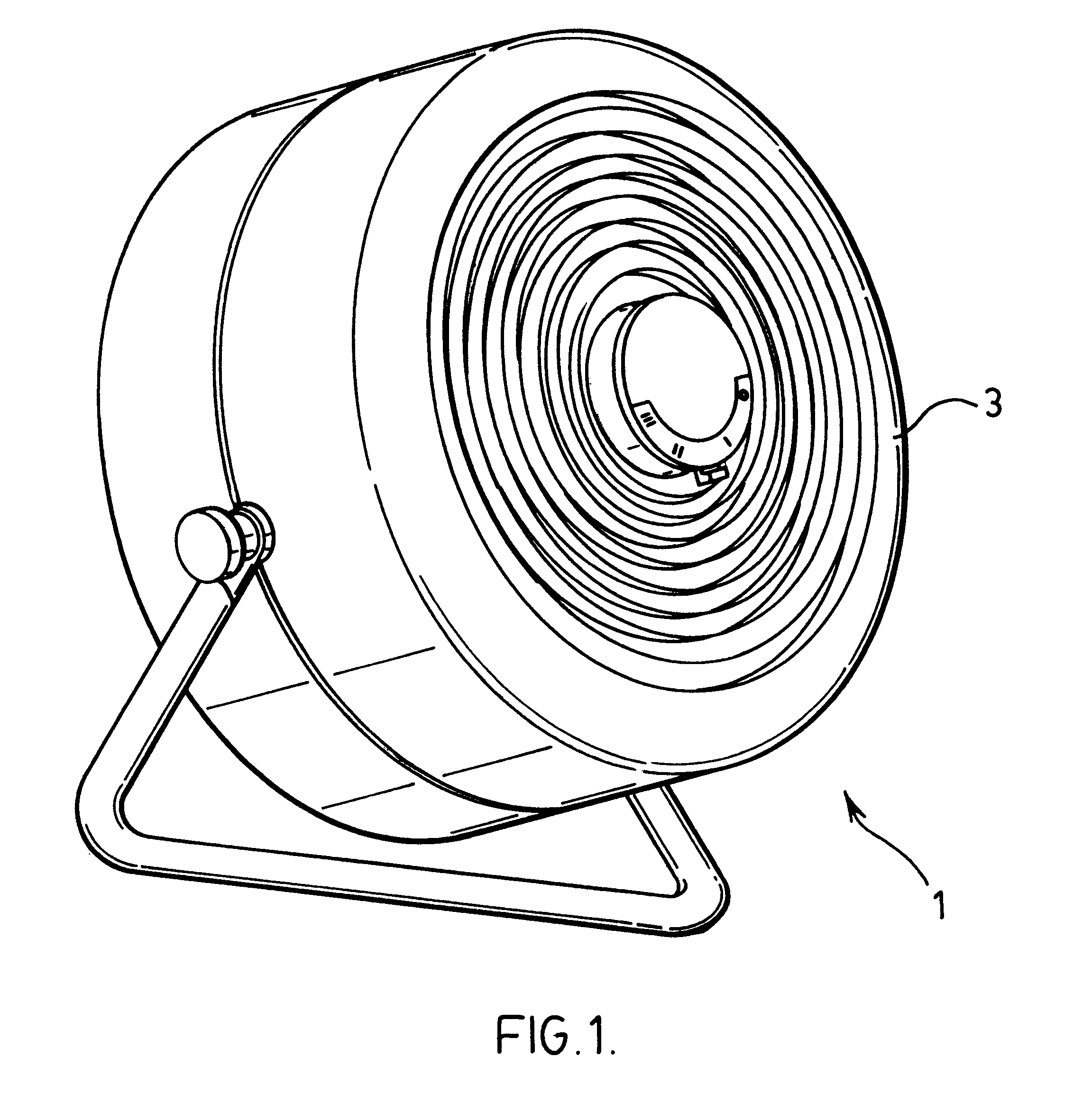

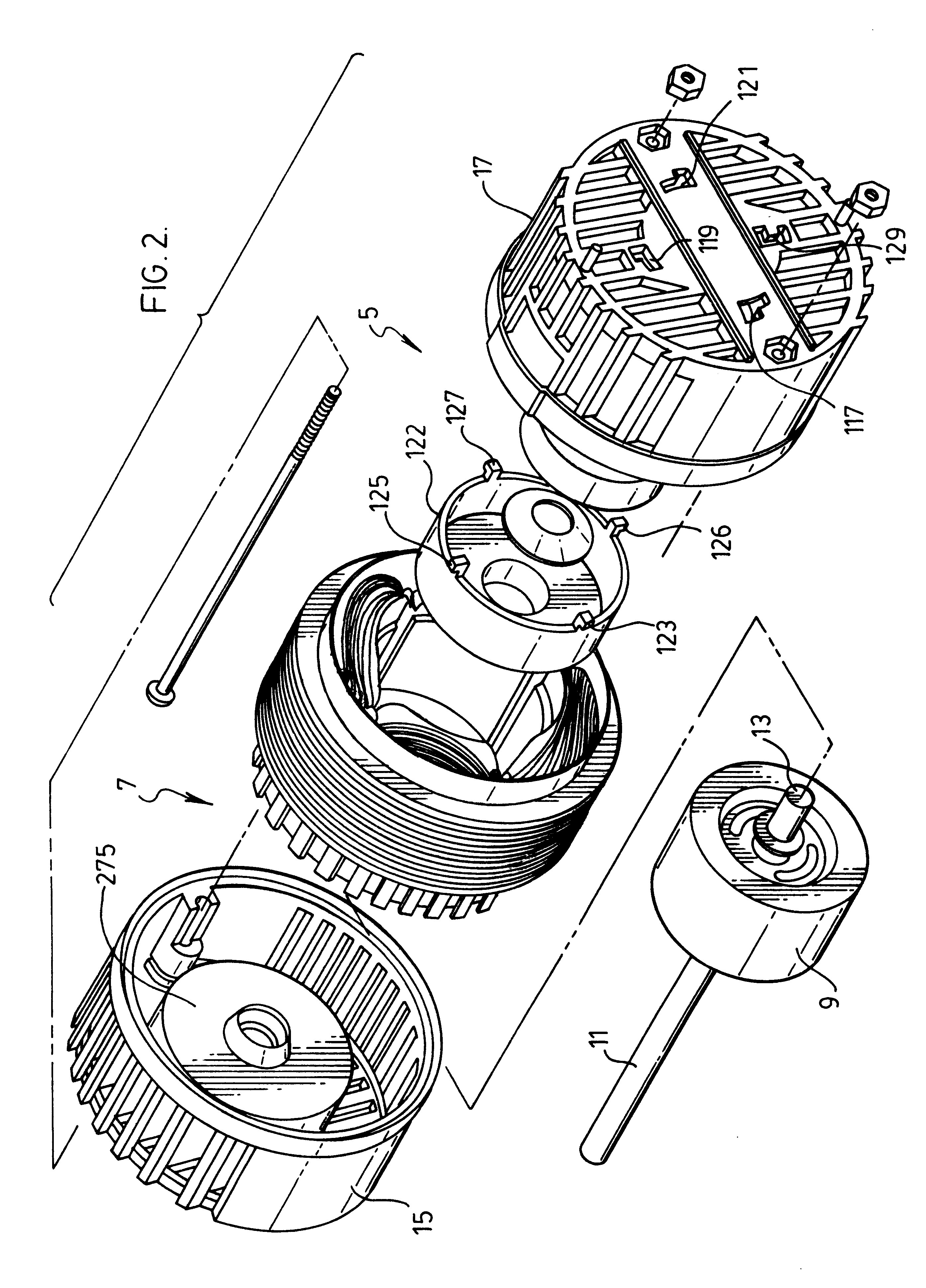

Motor mounted switch

InactiveUS6376947B1Avoid shortingPrecision injectionCoupling device connectionsWindingsMagnetic fluxElectric wire

An electrical appliance which operates at multiple speeds includes a motor construction having a stator and a rotor which rotates within the stator. The stator includes a plurality of magnetic flux inducing wires coiled on different poles of the stator. The stator and the rotor are contained within a motor housing with the appliance further including a switch housing mounted directly to the motor housing. The flux inducing wires have wire ends which extend out of the motor housing and into the switch housing which includes receptors to receive the ends of the flux inducing wires and which also receive electrical contact members which secure and electrically connect with the ends of the flux inducing wires within the receptors of the switch housing.

Owner:TATEISHI ART

Liquid-injecting method of battery and liquid-injecting production line thereof

InactiveCN101635343AAccurate weighingImprove work efficiencyCell component detailsWeight valueEngineering

The invention discloses a liquid-injecting method of a battery and a liquid-injecting production line thereof. The method comprises the following steps of: a) putting an electric core which is not injected with liquid on a front weighing device to weigh, and memorizing the weight value of the electric core which is not injected with the liquid in a control module; b) putting the electric core which is not injected with the liquid in a tray, and putting the tray on the liquid-injecting production line; c) injecting the liquid to the eclectic core by the liquid-injecting device at the tray which is put with the electric core, and vacuuming the electric core by a vacuuming device; and d) putting the electric core which is injected with the liquid on a back weighing device to weigh, and memorizing the obtained weight value of the electric core which is injected with the liquid in the control module; and e) comparing the weight value of the electric core which is not injected with the liquid with the weight value of the electric core which is injected with the liquid by the control module, if the different value exceeds a set value, supplying the liquid to the electric core. Each of the trays is provided with the plurality of electric cores. The invention is provide with the control module for memorizing and comparing the weight value of the electric core before and after liquid injection, has exact weighing and high automation degree, and improves the work efficiency of the production line.

Owner:GEESUN AUTOMATION TECH

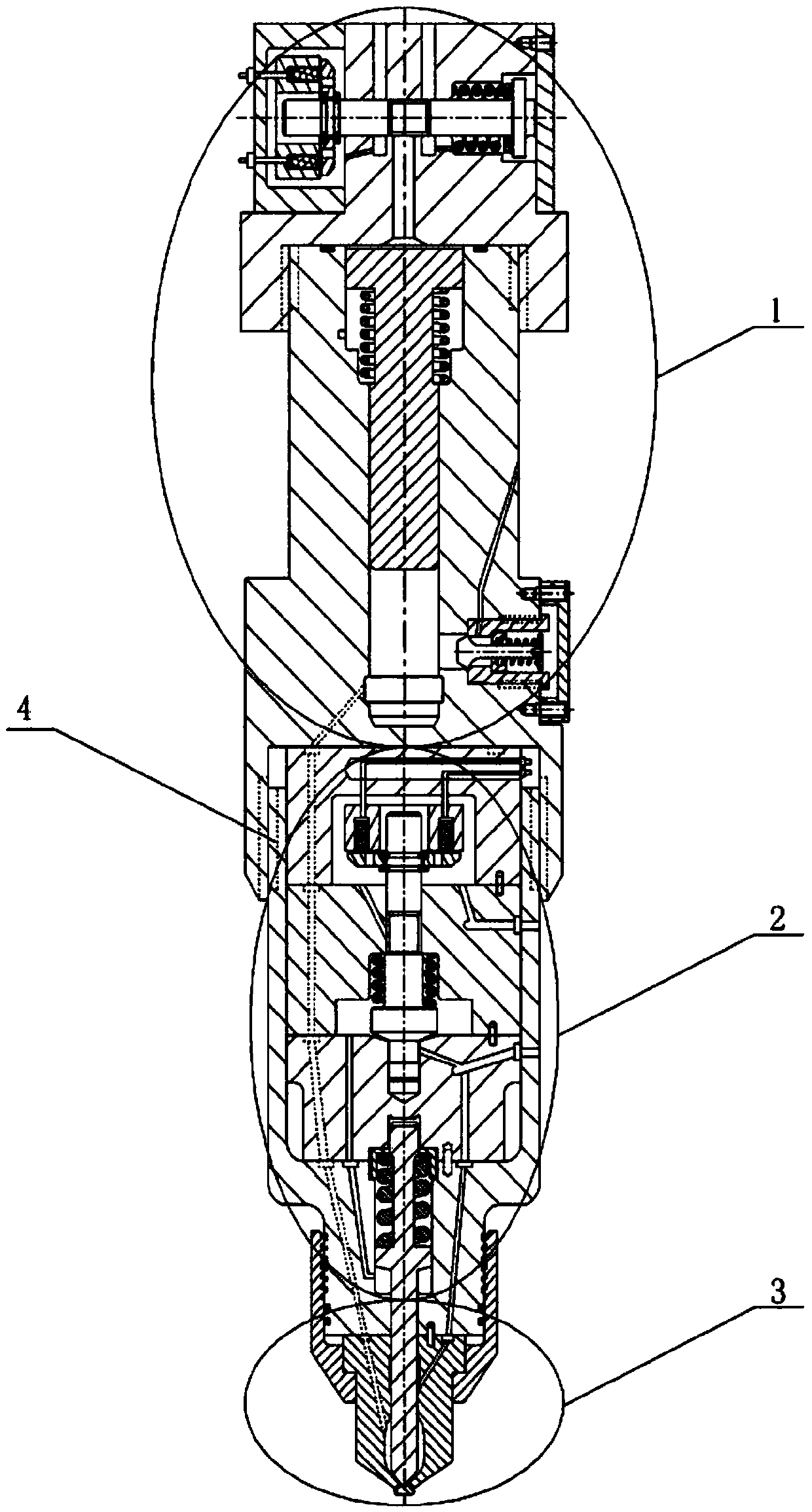

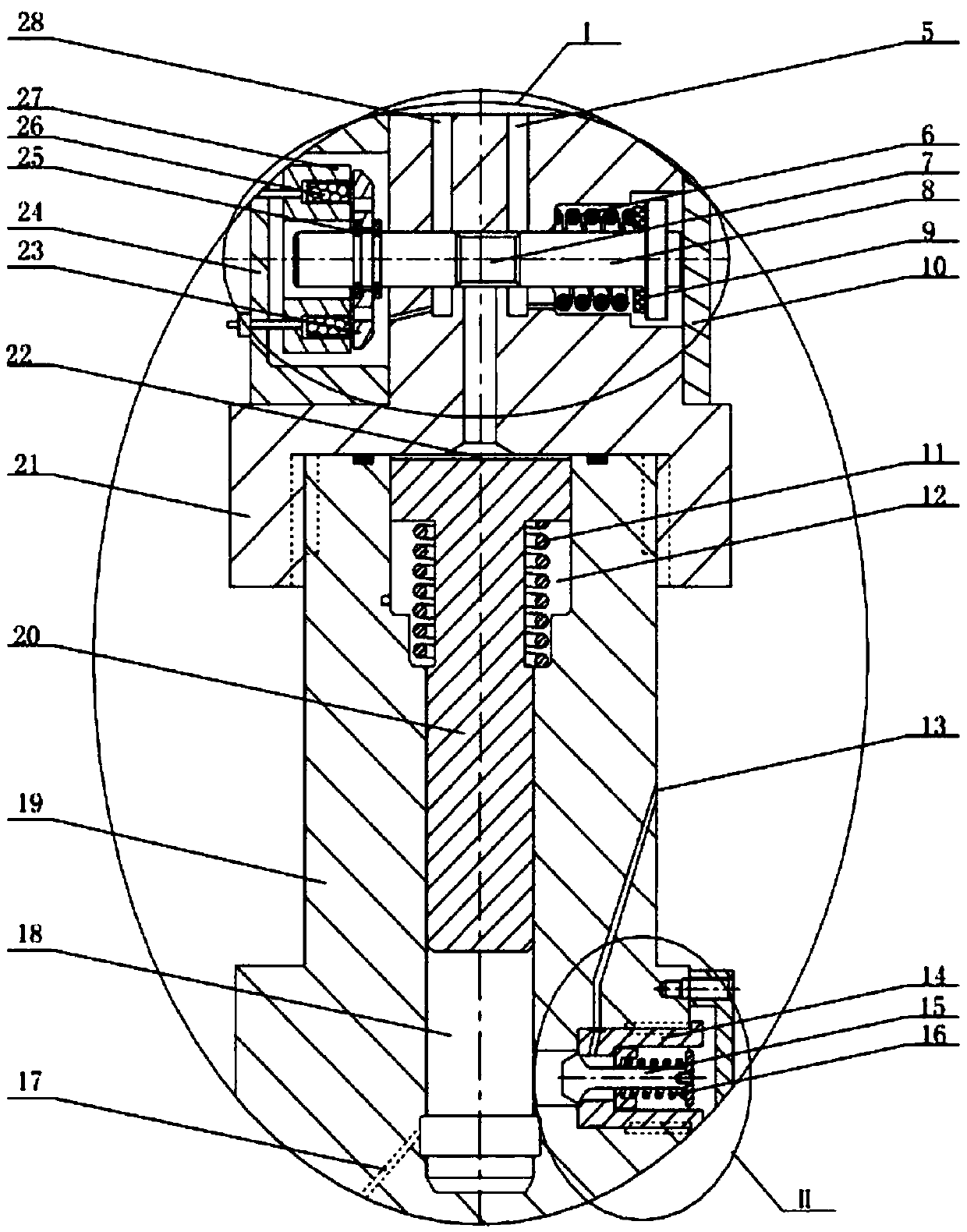

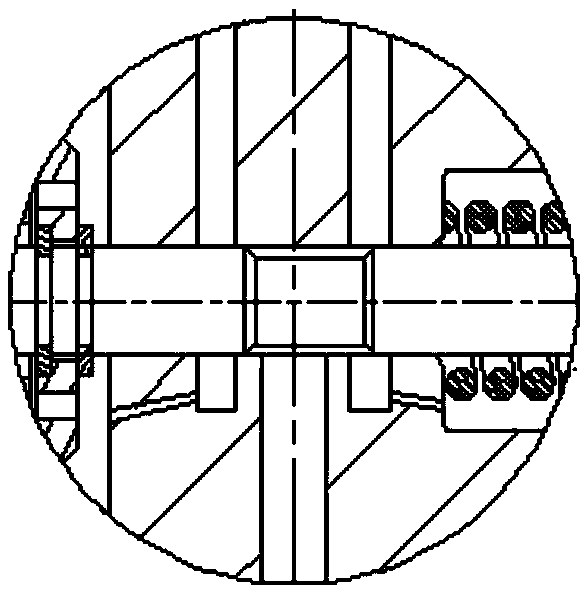

Pressurized leakage-free electromagnetically-controlled gas injection device

ActiveCN105508082APrecision injectionImprove stabilityInternal combustion piston enginesFuel supply apparatusInjection pressureCoupling

The invention aims at providing a pressurized leakage-free electromagnetically-controlled gas injection device. The pressurized leakage-free electromagnetically-controlled gas injection device comprises a pressurization part, a control part, a nozzle part and an injection device shell. A pressure is formed in a control cavity by virtue of high-pressure oil to lift a needle valve, response is rapid, and control for a gas injection amount is accurate; a control oil drainage path passes through the upper parts of electromagnetic valves to play a cooling role, thus the stability of the working of the electromagnetic valves is improved; a gas is pressurized by virtue of a pressurization piston, the processes of gas pressurization and gas injection are controlled separately by virtue of two electromagnetic valves, the gas injection process can be flexibly switched between a pressurization mode and a non-pressurization mode, and the pressurization process is slow at first and then fast, thus a variable gas injection rule can be realized, and the requirements of different working conditions of an engine on a gas injection pressure can be met; and in the pressurization part, gas leakage of a pressurization chamber is prevented by virtue of a long sealing coupling and a large oil cavity, a sealing ring belt is arranged between the needle valve and a needle valve base, and a part of control oil is introduced as sealing oil for sealing the gas, thus gas leakage in a needle valve cavity is prevented.

Owner:HARBIN ENG UNIV

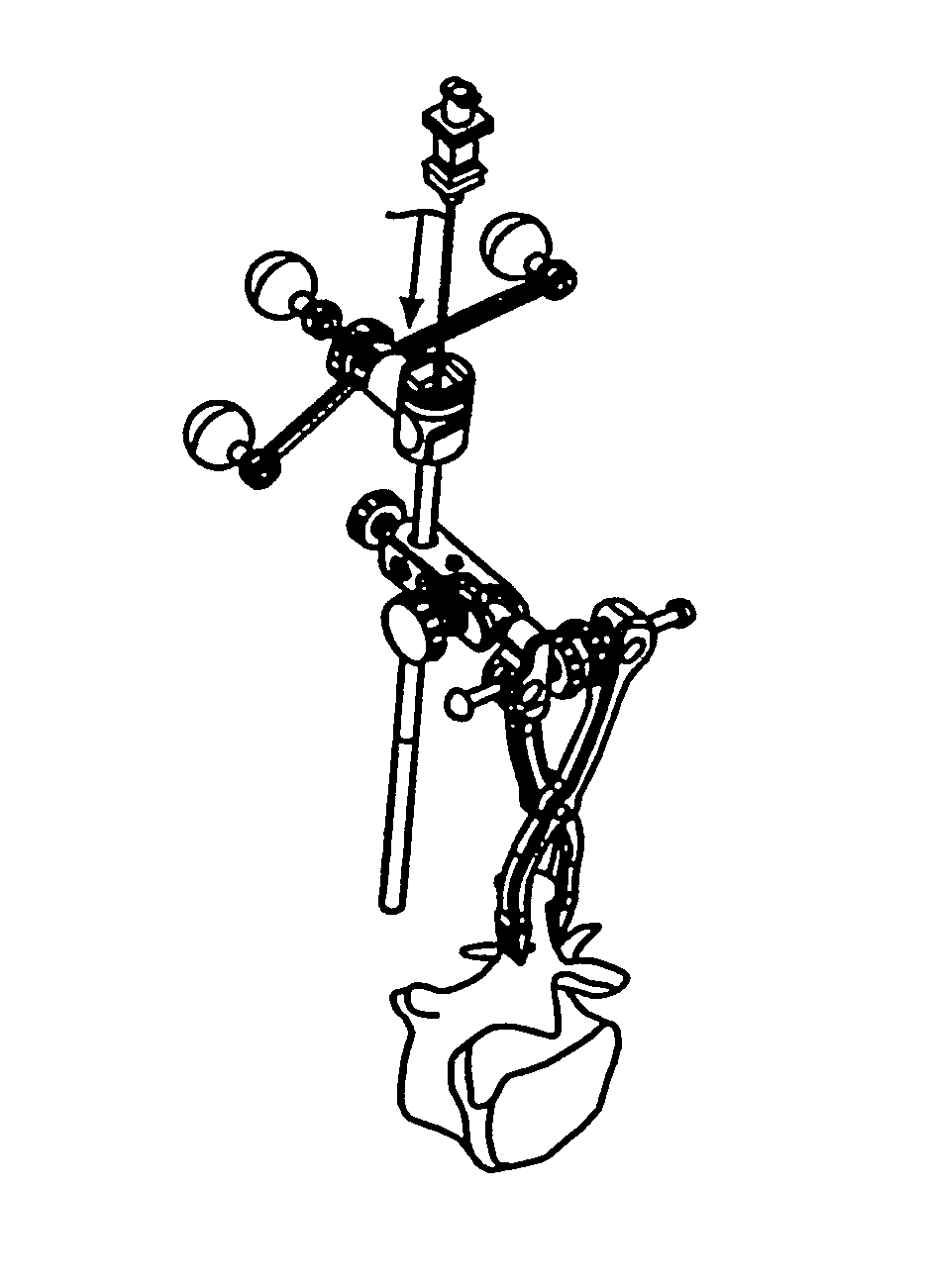

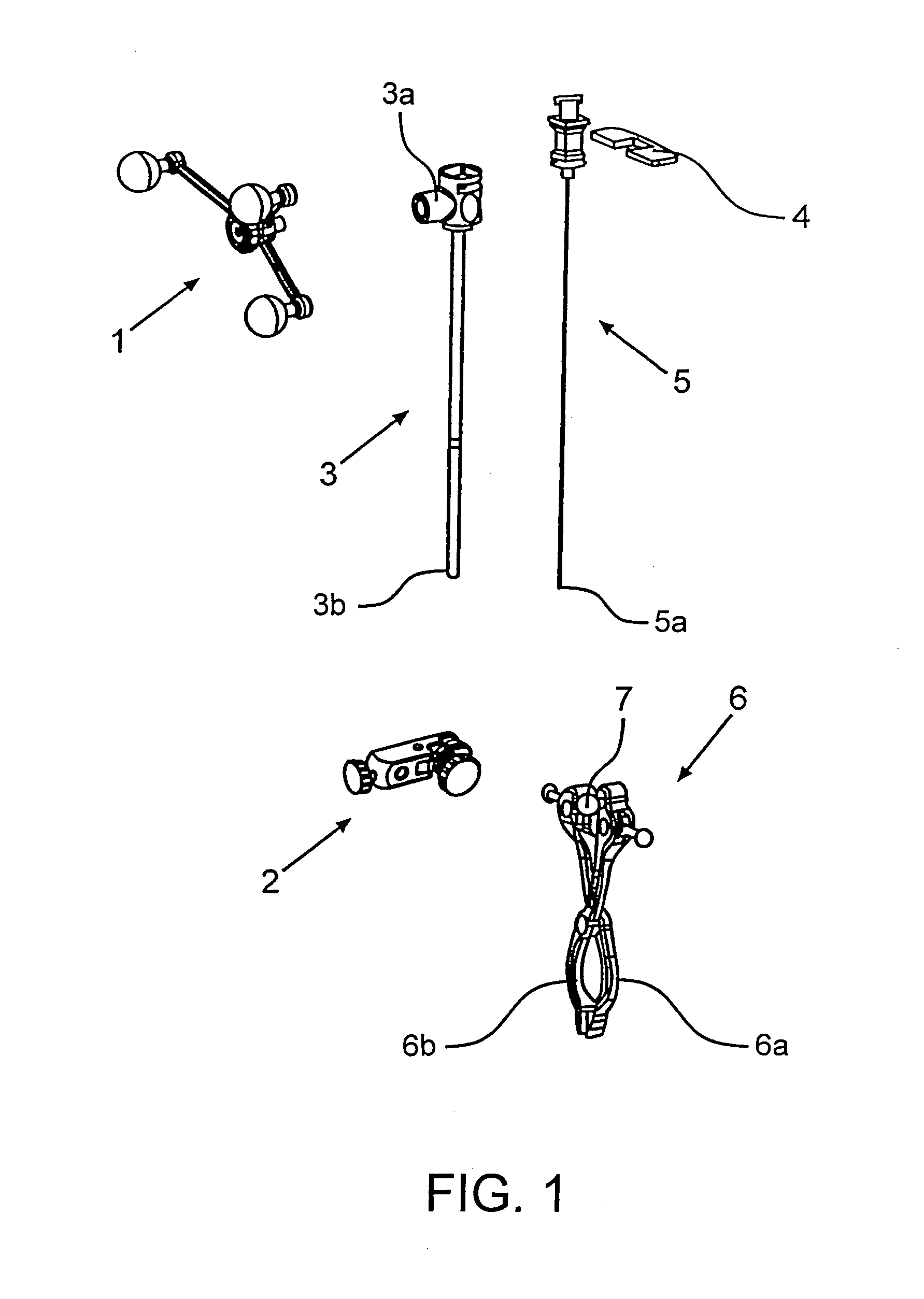

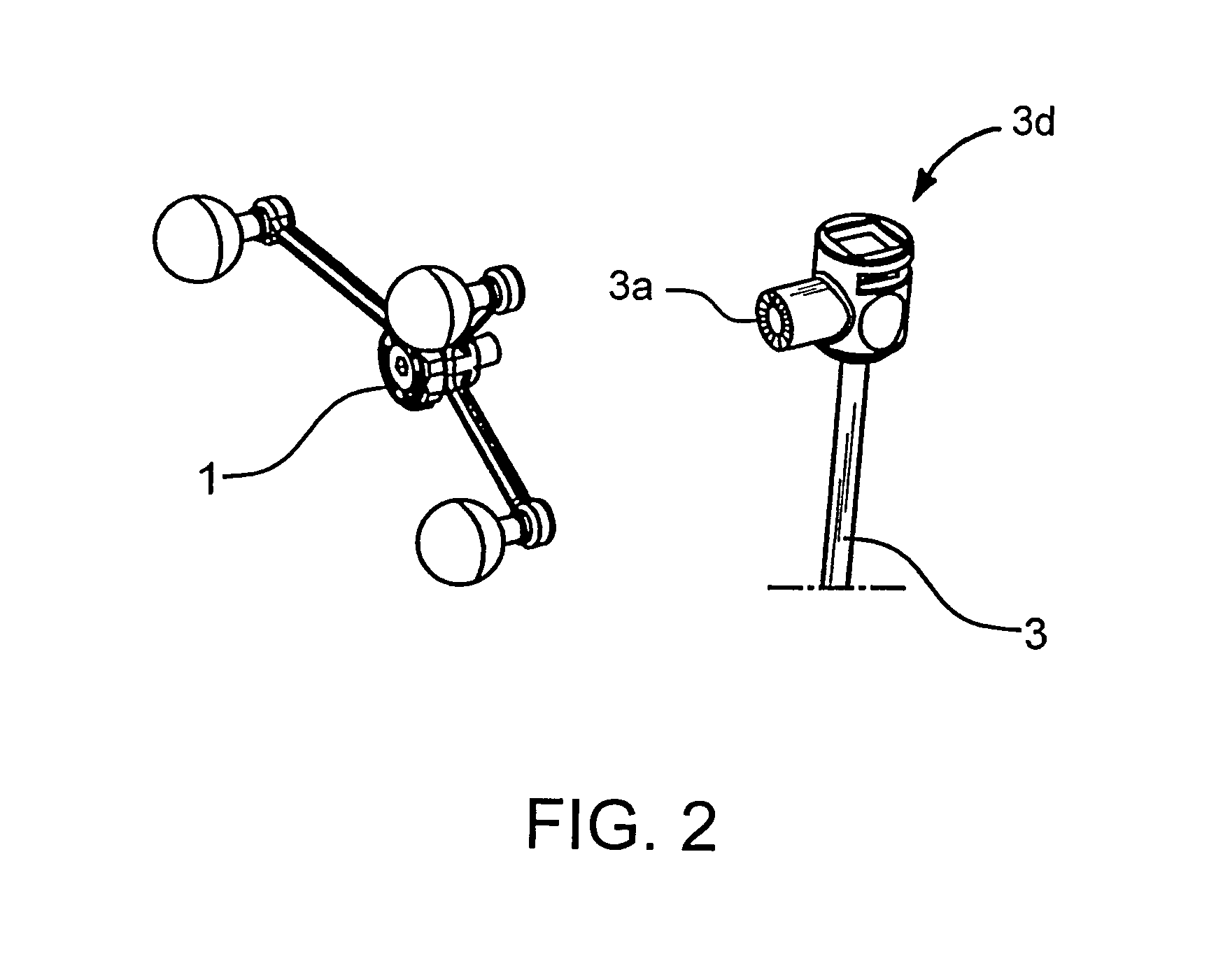

Navigated application guide for targeted spinal drug delivery

ActiveUS9005211B2Accurate and stable placement and guidanceAccurately determineSurgical needlesSurgical navigation systemsSurgeryGuide tube

An apparatus and method for positioning a guide tube fixation device at a spinal structure of a patient are provided. The method includes attaching an attachment element to the spinal structure, attaching a guide tube to the attachment element, wherein said guide tube is calibrated prior to attachment, and navigating a part of the guide tube to a predetermined location relative to a target region of the patient. The apparatus includes an attachment device for attaching to the spinal structure, a joint attached to the attachment device, and a guide tube holding device attached to the joint and operable to hold and / or guide a guide tube, said guide tube configured to guide a cannula, needle and / or fluid to a desired site or location.

Owner:BRAINLAB

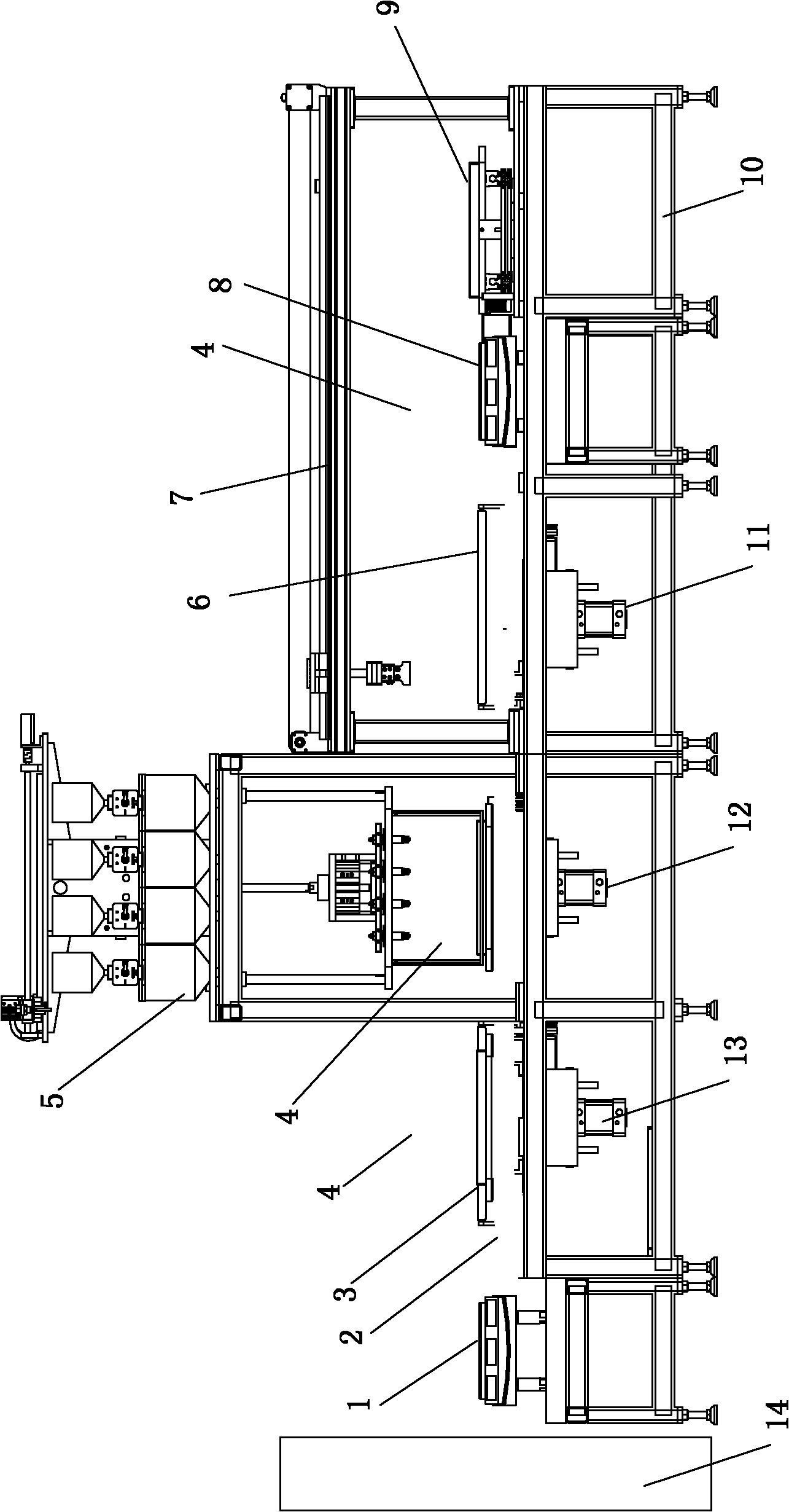

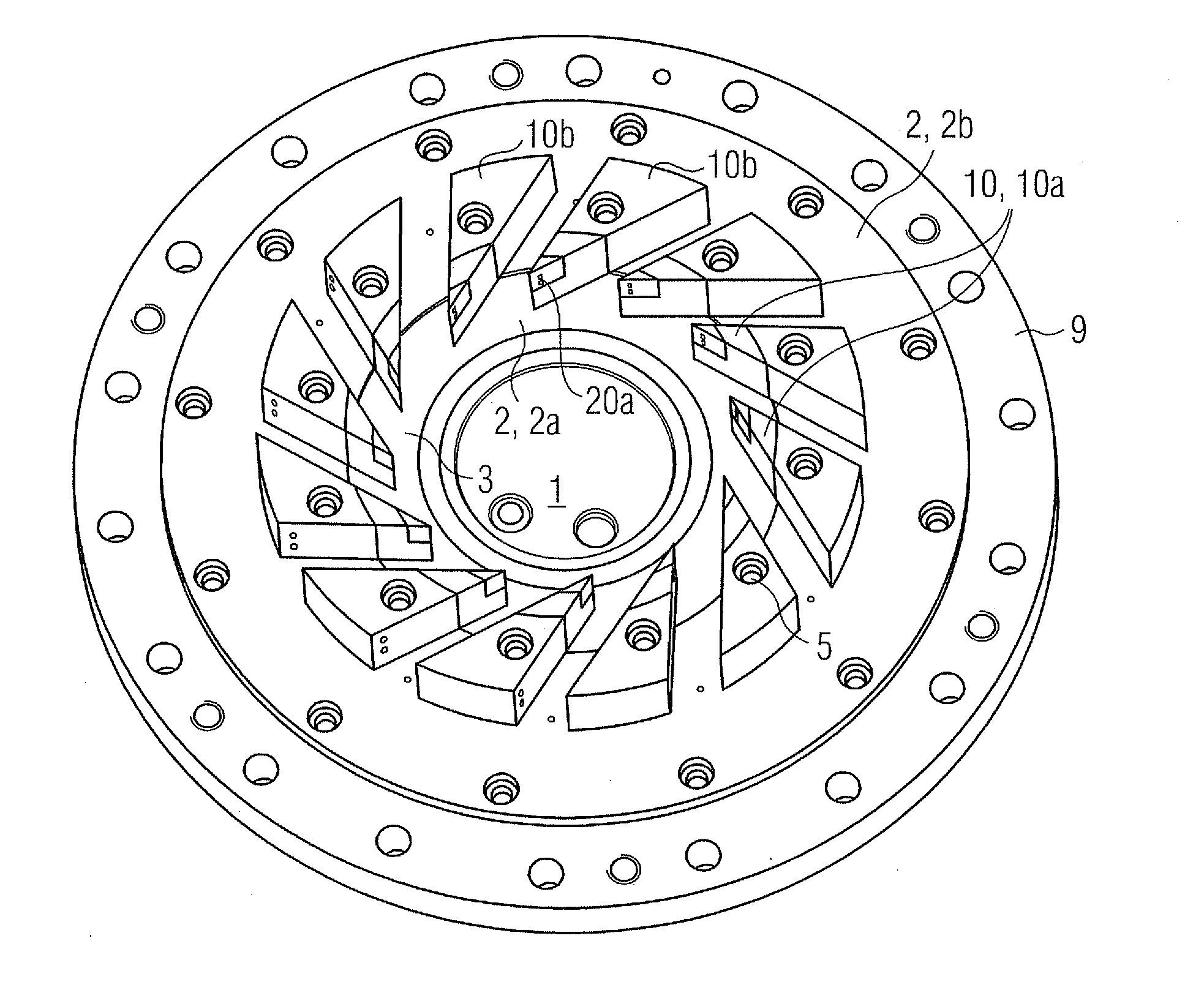

Tire forming system and tire forming method

InactiveUS6979378B2Facilitate a stage switchover of tires differentIncrease productivityTyresPneumatic tyre reinforcementsEngineeringMechanical engineering

A tire forming system includes a band forming machine, a shaping forming machine, a belt / tread forming machine, means for supplying a band member and means for supplying a belt / tread member. The means for supplying the band member include an inner liner supply means, carcass supply means, band rubber parts supply means and bead supply means. The means for supplying the belt / tread member include belt supply means and tread rubber parts supply means. The means for supplying the band member and the means for supplying the belt / tread member are operative to cooperate with one another to continuously in series form a plurality of tires having different tire sizes.

Owner:THE YOKOHAMA RUBBER CO LTD

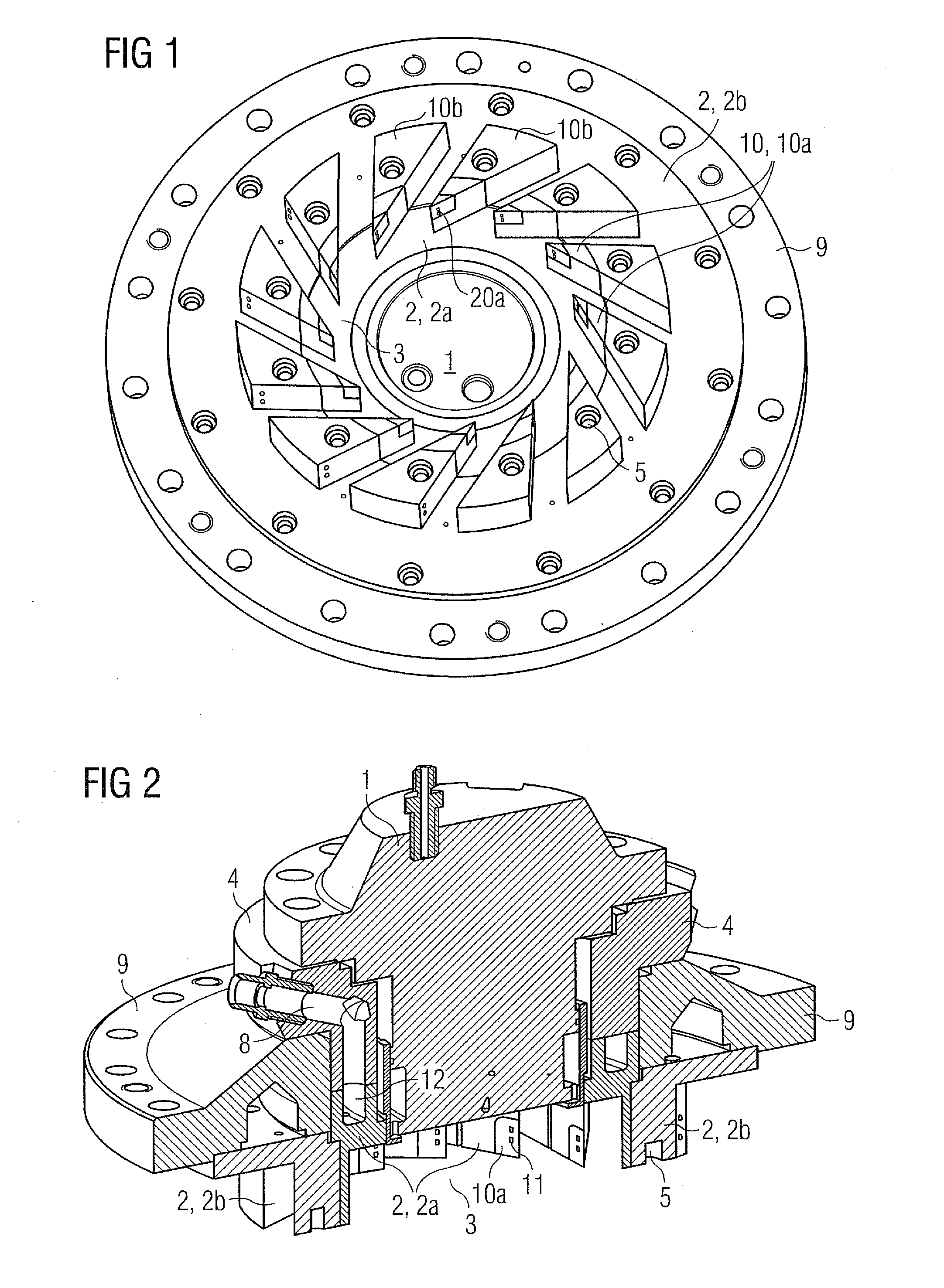

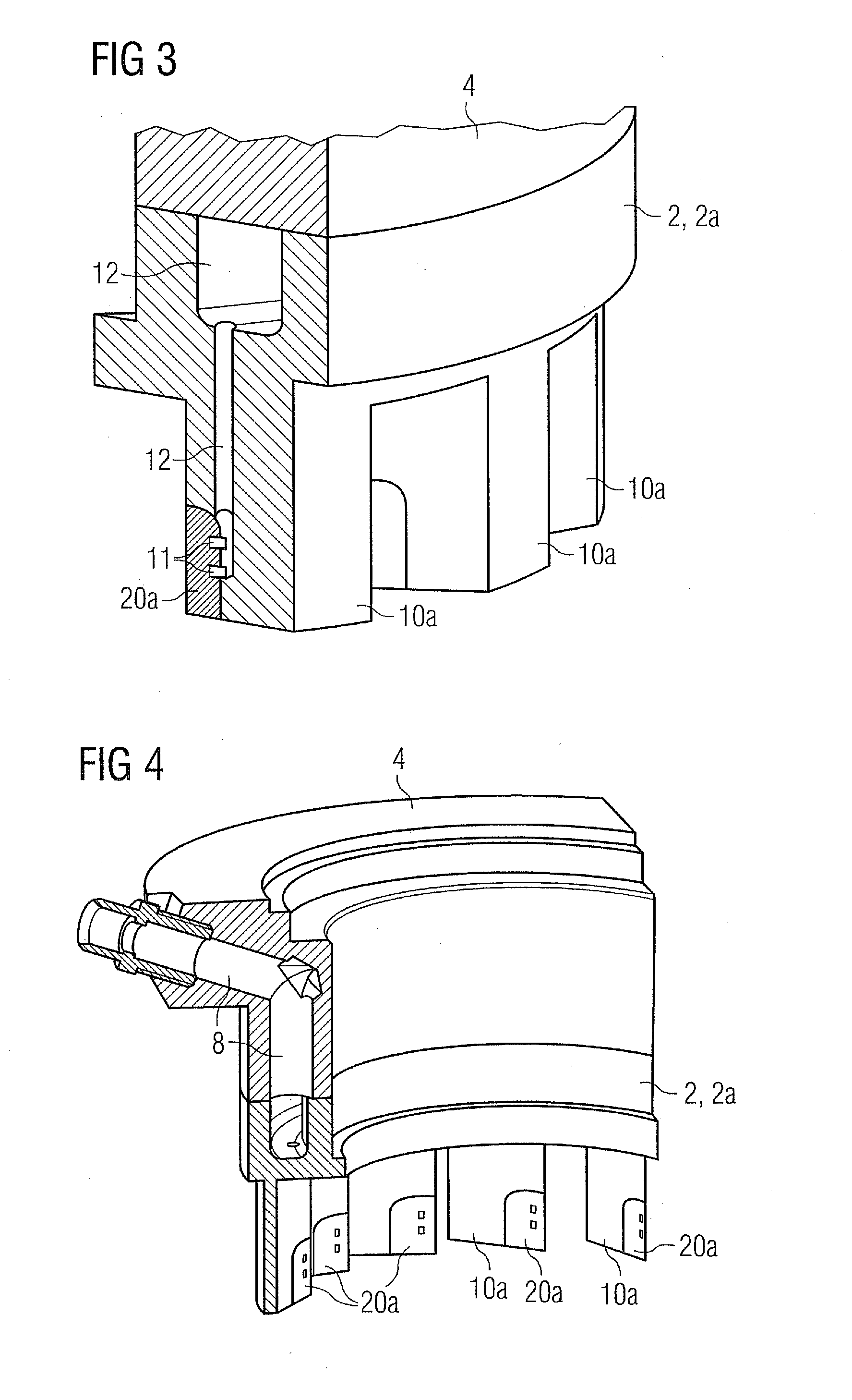

Swirler Vane, Swirler and Burner Assembly

InactiveUS20110113784A1Relaxation stressEasy to controlTurbine/propulsion fuel supply systemsContinuous combustion chamberCombustorLiquid fuel

A swirler vane for providing fuel, particularly liquid fuel, to a swirling zone of a burner assembly is provided. The swirler vane includes at least one injection hole for injecting the fuel to the swirling zone of the burner and an injection feed hole passage connecting the at least one injection hole with a main fuel feed. The swirler vane or a tip of the swirler vane, where the at least one injection hole is arranged, is manufactured by laser deposition or includes at least a surface manufactured by laser deposition. A swirler including a plurality of such swirler vanes and a burner assembly including the swirler with such swirler vanes are also provided.

Owner:SIEMENS AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com