Automatic filling machine for battery and battery filling method

A liquid injection machine and battery technology, which is applied to battery components, circuits, electrical components, etc., can solve the problems of easily damaged batteries, many manpower, and affect production efficiency, so as to achieve compact process layout, ensure performance quality, and guarantee Effect of Injection Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

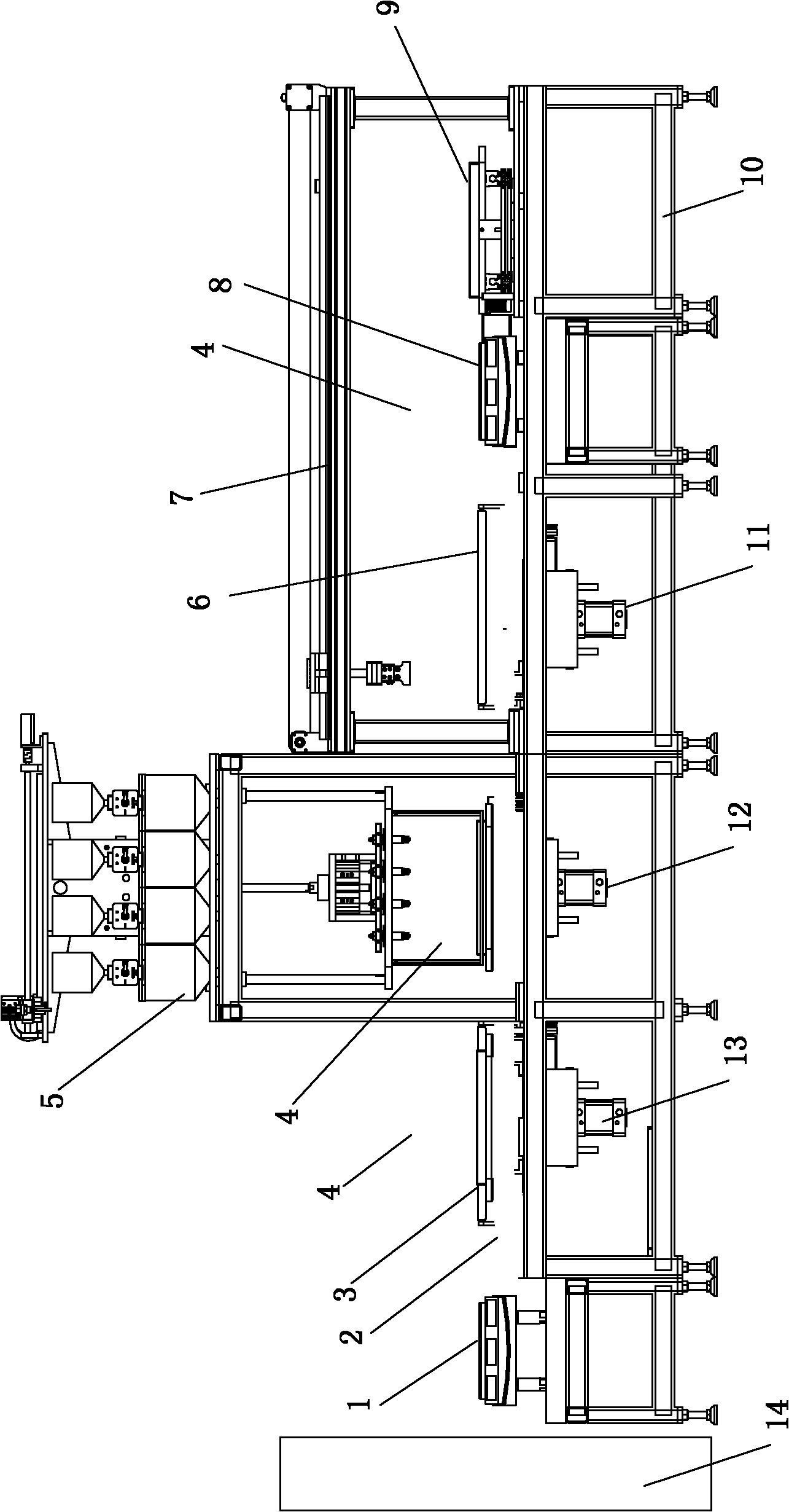

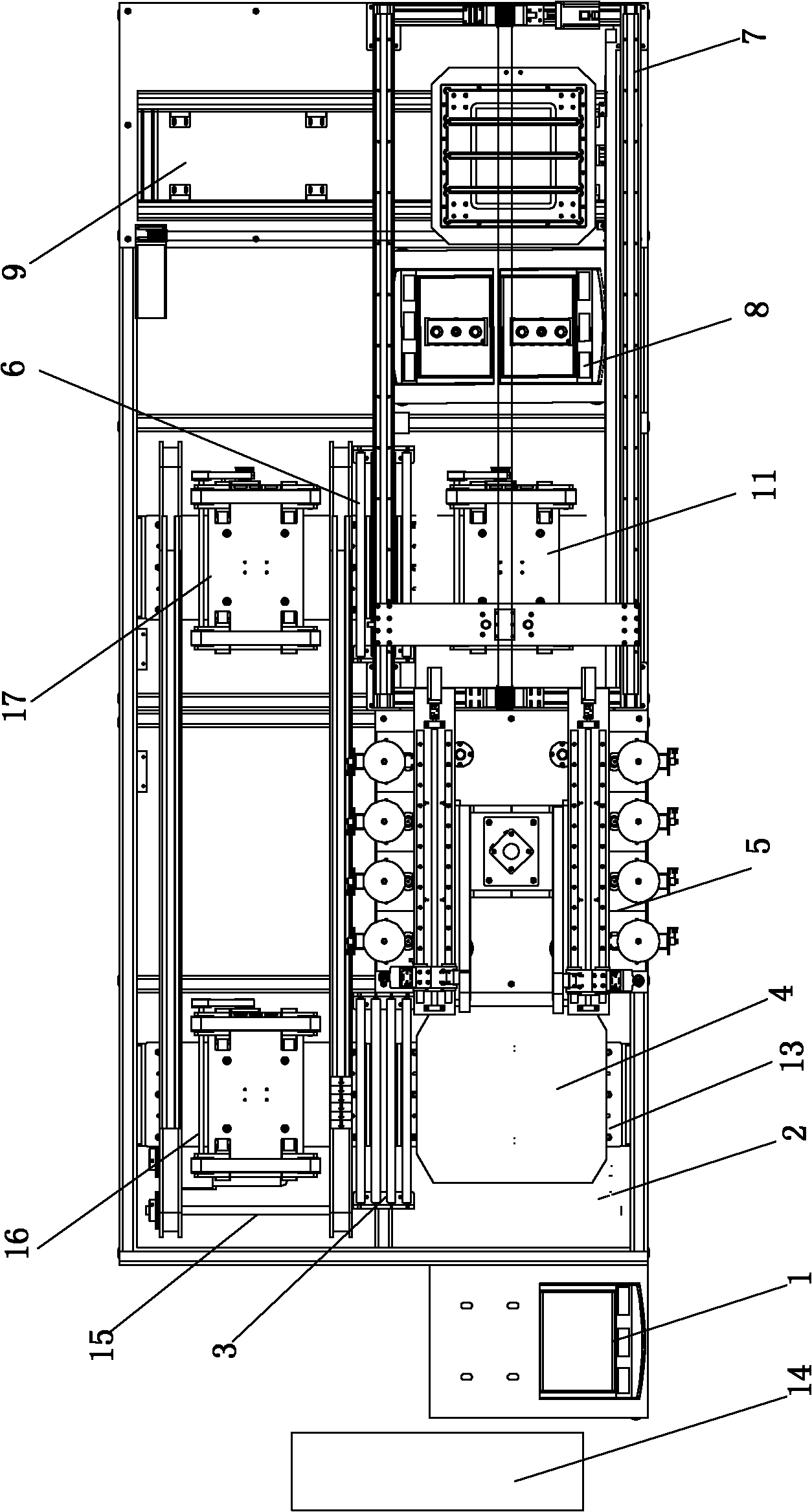

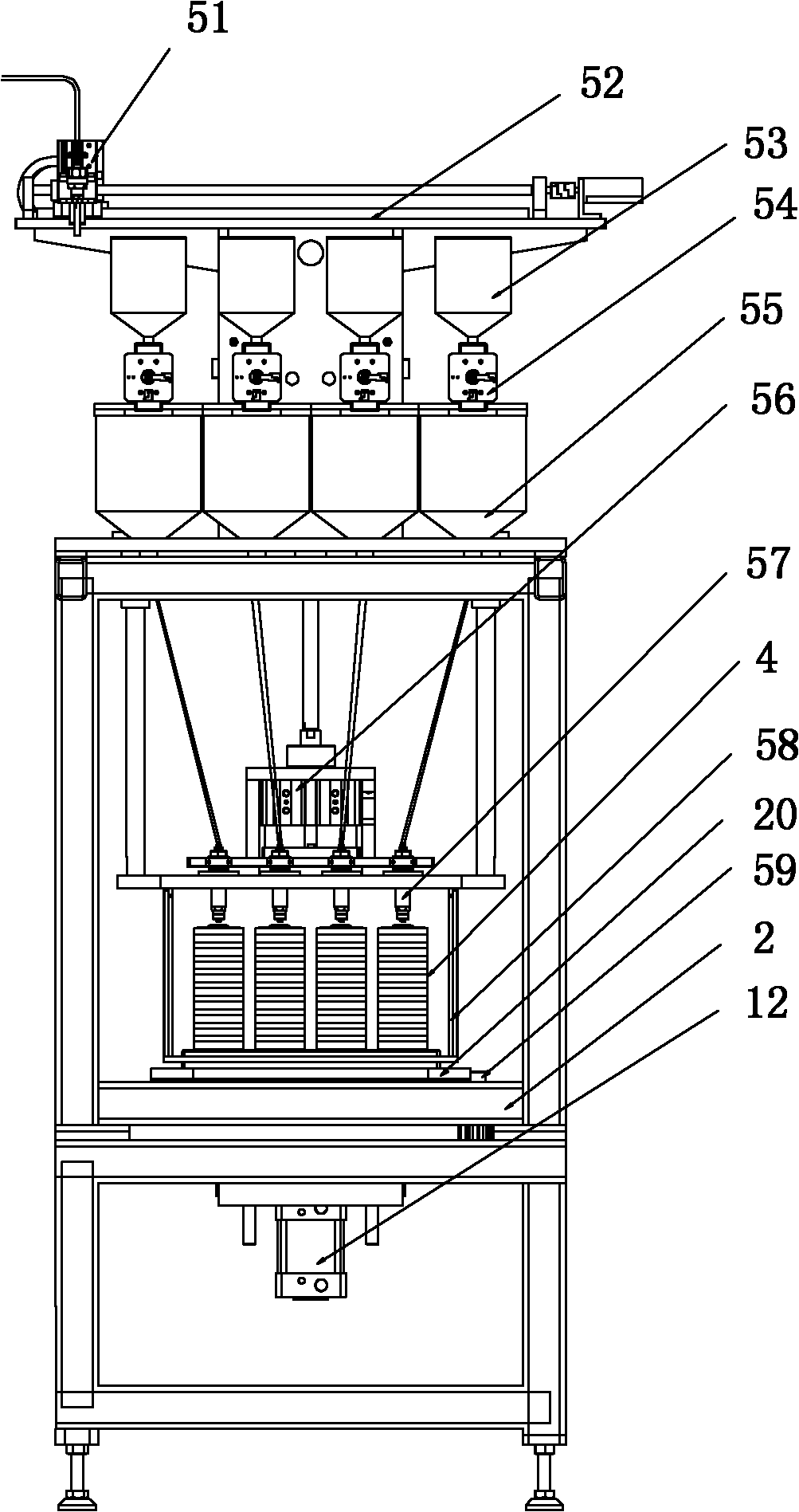

[0024] Such as figure 1 and figure 2 A battery automatic liquid filling machine shown includes a frame 10, a front weighing device 1 installed on the frame 10, a liquid injection conveying line 2, a vacuum liquid injection device 5, a carrier positioning lifting device, a discharge Device 7, rear weighing device 8, control box 14, unloading conveying line 9, carrier return mechanism.

[0025] in,

[0026] The carrier return mechanism includes a carrier transfer line 15 arranged in parallel with the liquid injection transfer line and moving in reverse, and a carrier transfer device arranged at both ends of the liquid injection transfer line and the carrier transfer line. The first lifter 13 and the second lifter 11 at the front end and the rear end of the liquid conveying line, the third lifter 17 and the fourth lifter 16 at the front end and the rear end of the carrier conveying line, the first lifter and the fourth lifter The front transition roller device 3 between the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com