Automatic assembly alignment equipment

An automatic assembly and equipment technology, applied in the direction of mechanical equipment, spraying devices, and devices for coating liquid on the surface, etc., can solve the problems of assembly and dispensing accuracy that cannot be guaranteed, affect product quality, and low efficiency, and achieve automation The effects of assembly line operation, accelerated curing speed, and improved firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

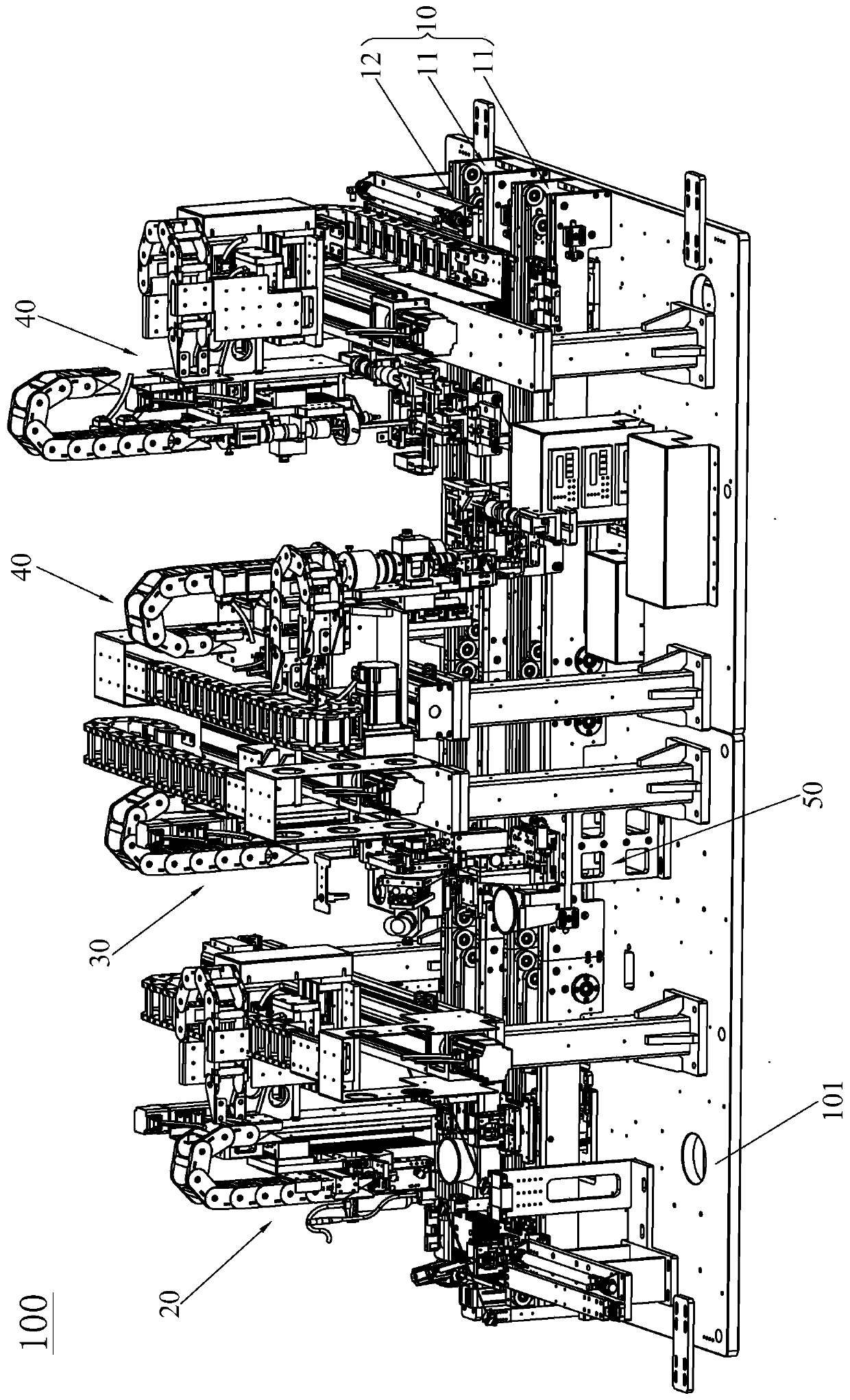

[0028] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

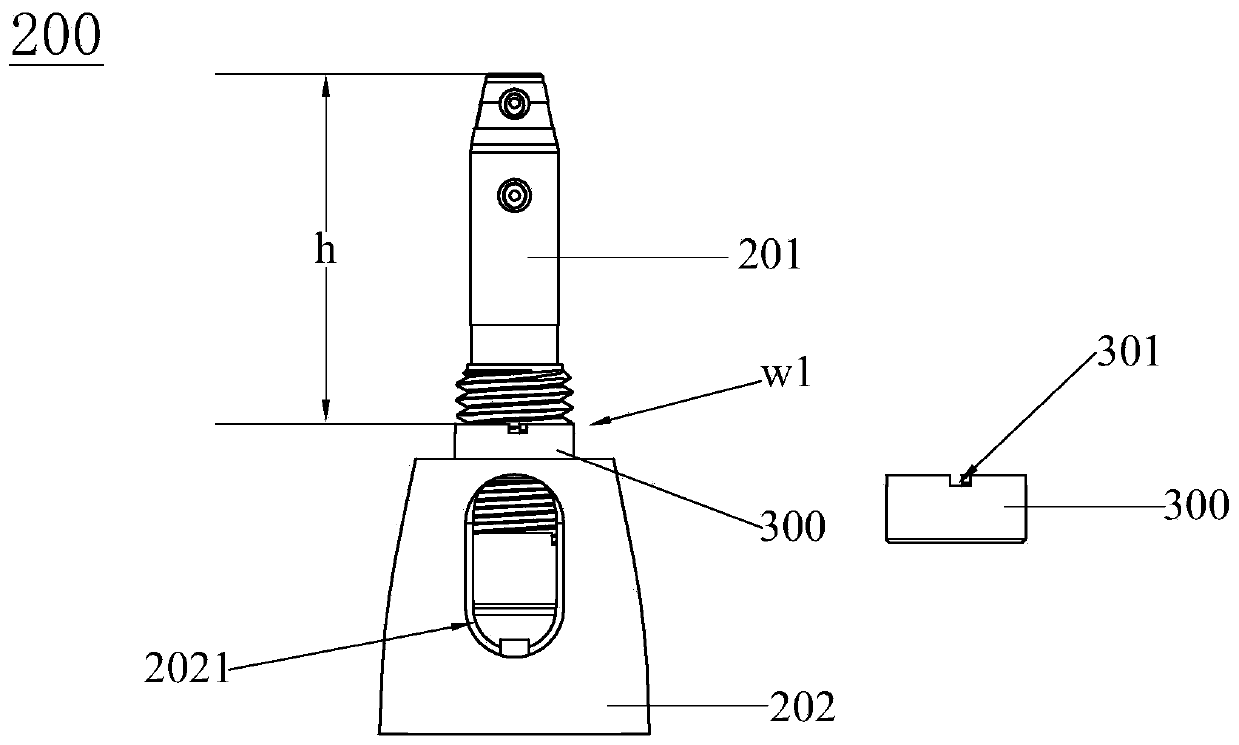

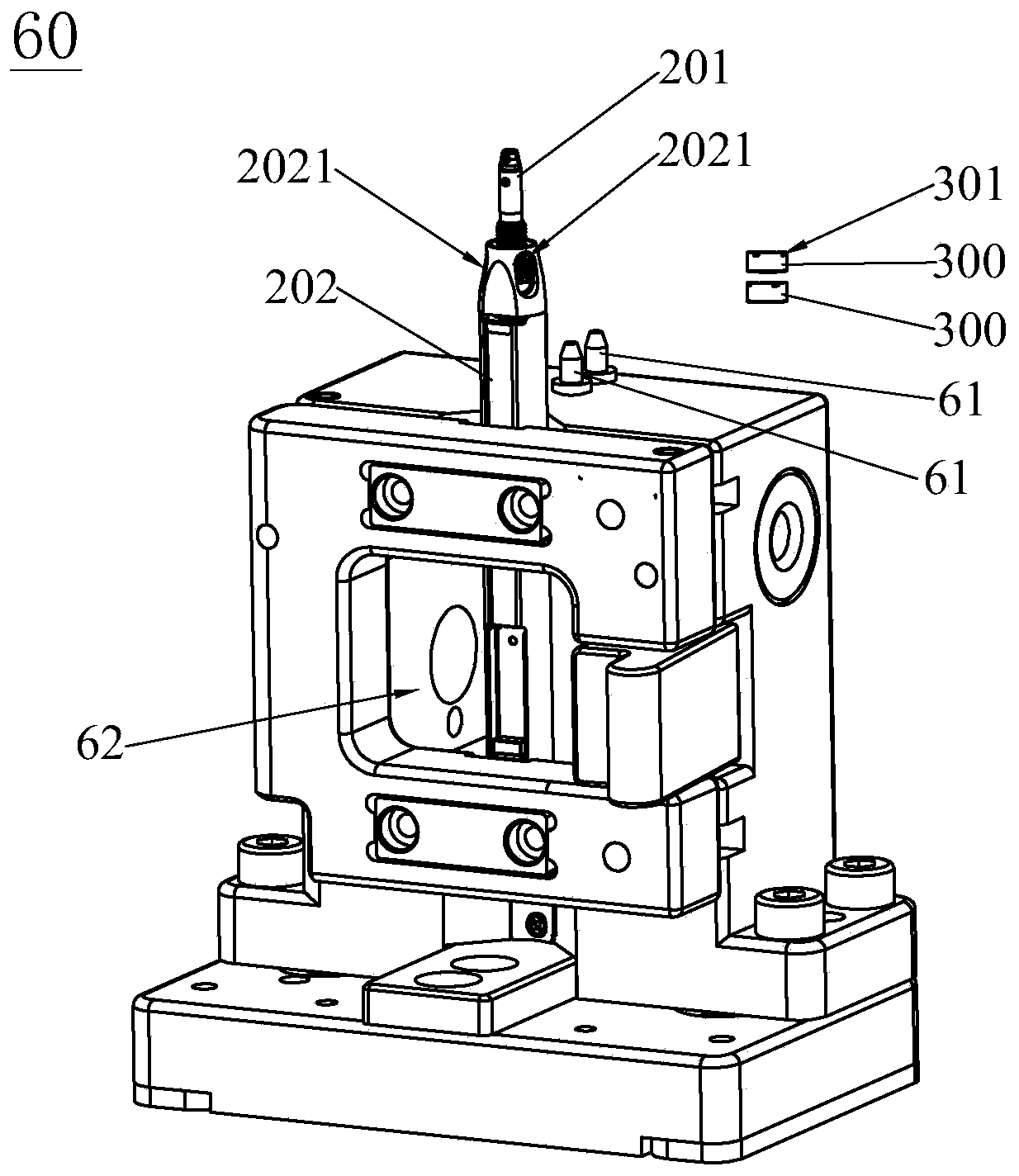

[0029] refer to figure 1 and figure 2 , the present invention relates to a stylus 200 used in electronic products such as mobile phones, tablet computers, and electronic dictionaries. To ensure the firmness of the assembly in the pen container 202 and avoid shaking, at least one fastener 300 can be assembled between the pen core 201 and the pen container 202 . Specifically, the fastener 300 includes and is not limited to a nut. The top of the fastener 300 has a plurality of grooves 301 arranged at intervals. In this embodiment, the number of the grooves 301 is four, and the grooves 301 are arranged symmetrically. . The barrel wall of the pen holder 202 is equally divided along its circumference with three slots 2021, and the three slot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com