A fully automatic cleaning, drifting and packing integrated ship

A fully automatic and bleaching technology, applied in the field of river cleaning operation machinery, can solve the problems of low operation efficiency, troublesome loading and unloading, small receiving capacity, etc., and achieve the effect of fast operation efficiency, fast unloading speed, and increased loading capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

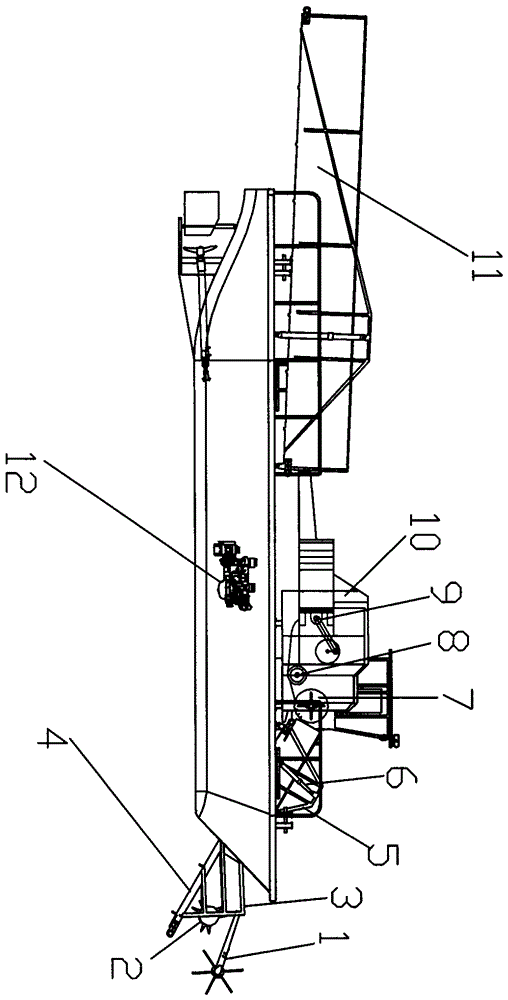

[0019] to combine figure 1 , the present invention provides a fully automatic clearing, bleaching and packaging integrated ship, the hull is a double-headed single type, including a hull, a collection device 4, a crushing device 7, a screw conveying device 8, a compression and bundling device and a storage and unloading device 11; On the hull, a collection device 4, a crushing device 7, a screw conveying device 8, a compression bundling device, and a storage and unloading device 11 are installed sequentially from the bow to the stern. When the present invention collects aquatic plants or floating garbage, it passes through the above devices in sequence, thereby Realize the collection, crushing, conveying and cutting, compressing, bundling, storage and unloading of aquatic plants and floating garbage, wherein the collection device 4 is located in the middle of the double heads of the bow.

[0020] The collection device 4 includes a conveying guide rail, a fixed frame 3, a pair ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com