Patents

Literature

269results about How to "Increase unloading speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

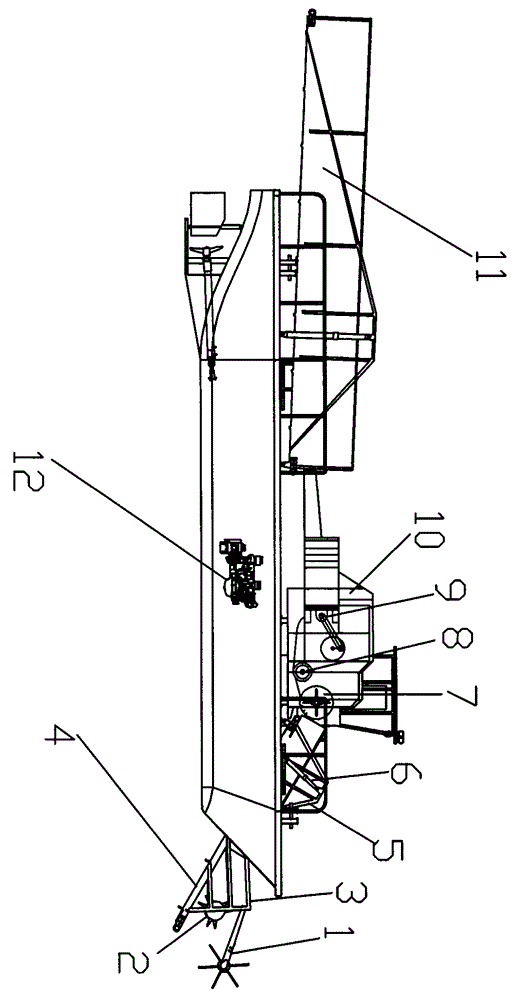

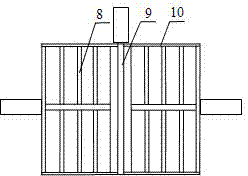

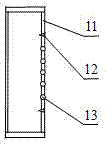

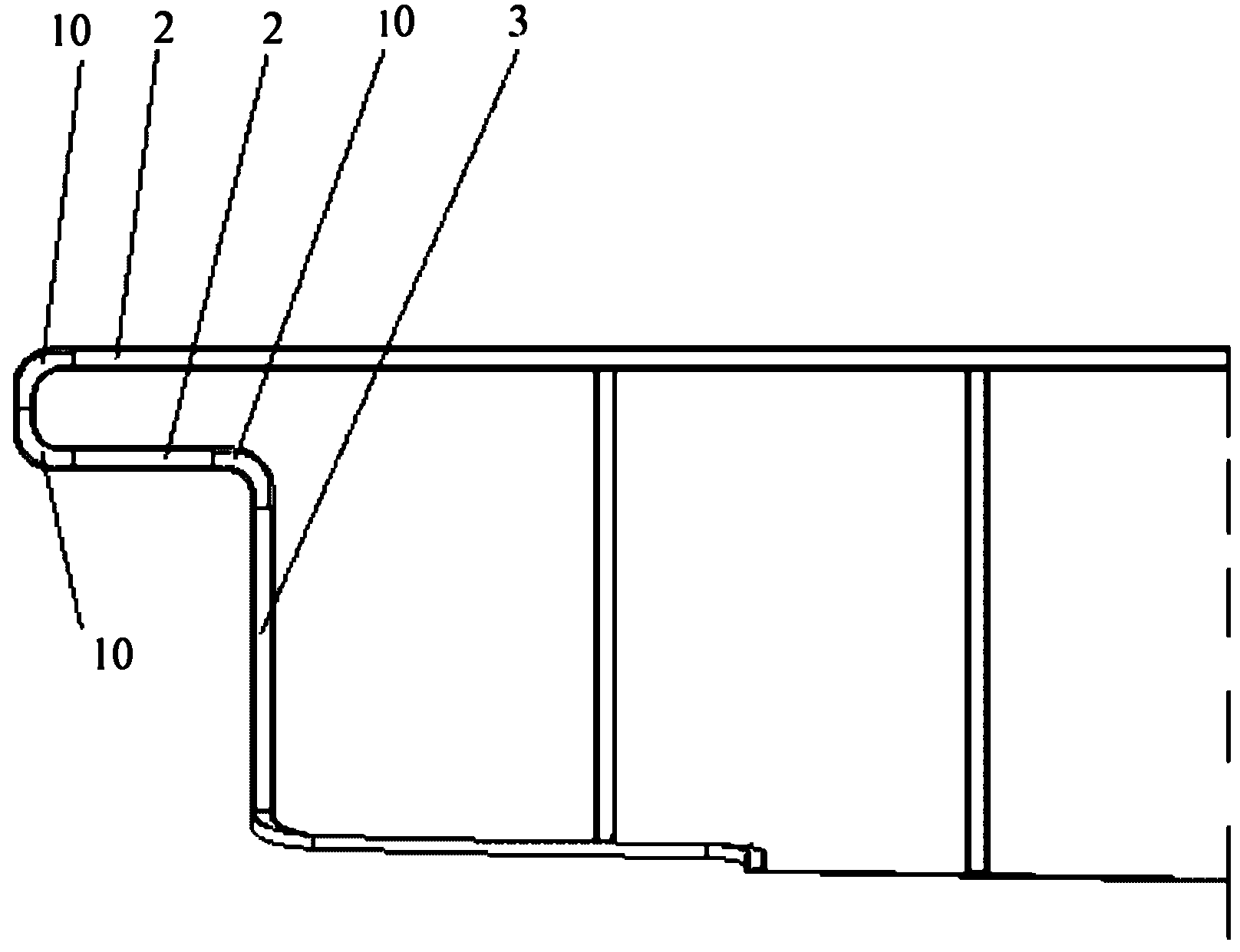

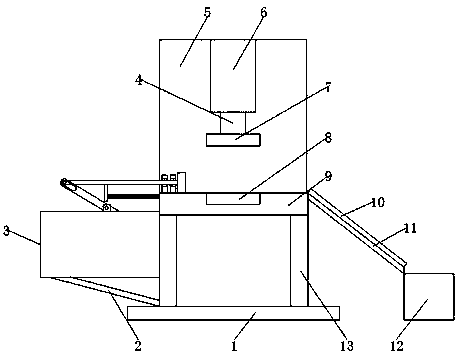

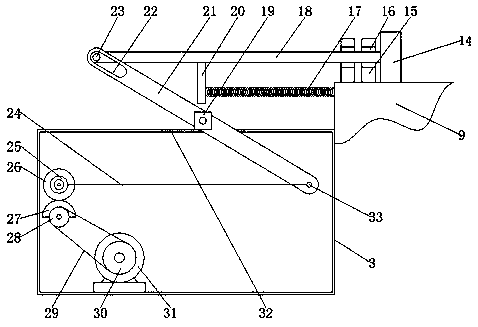

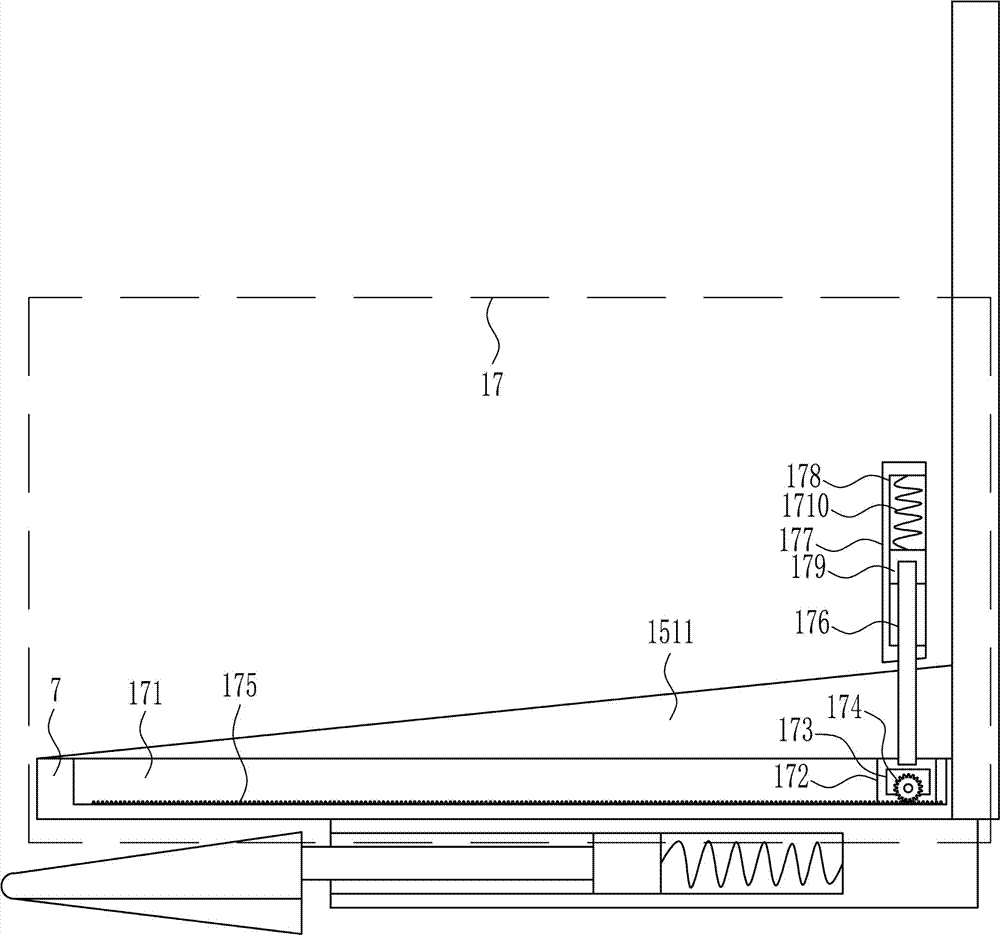

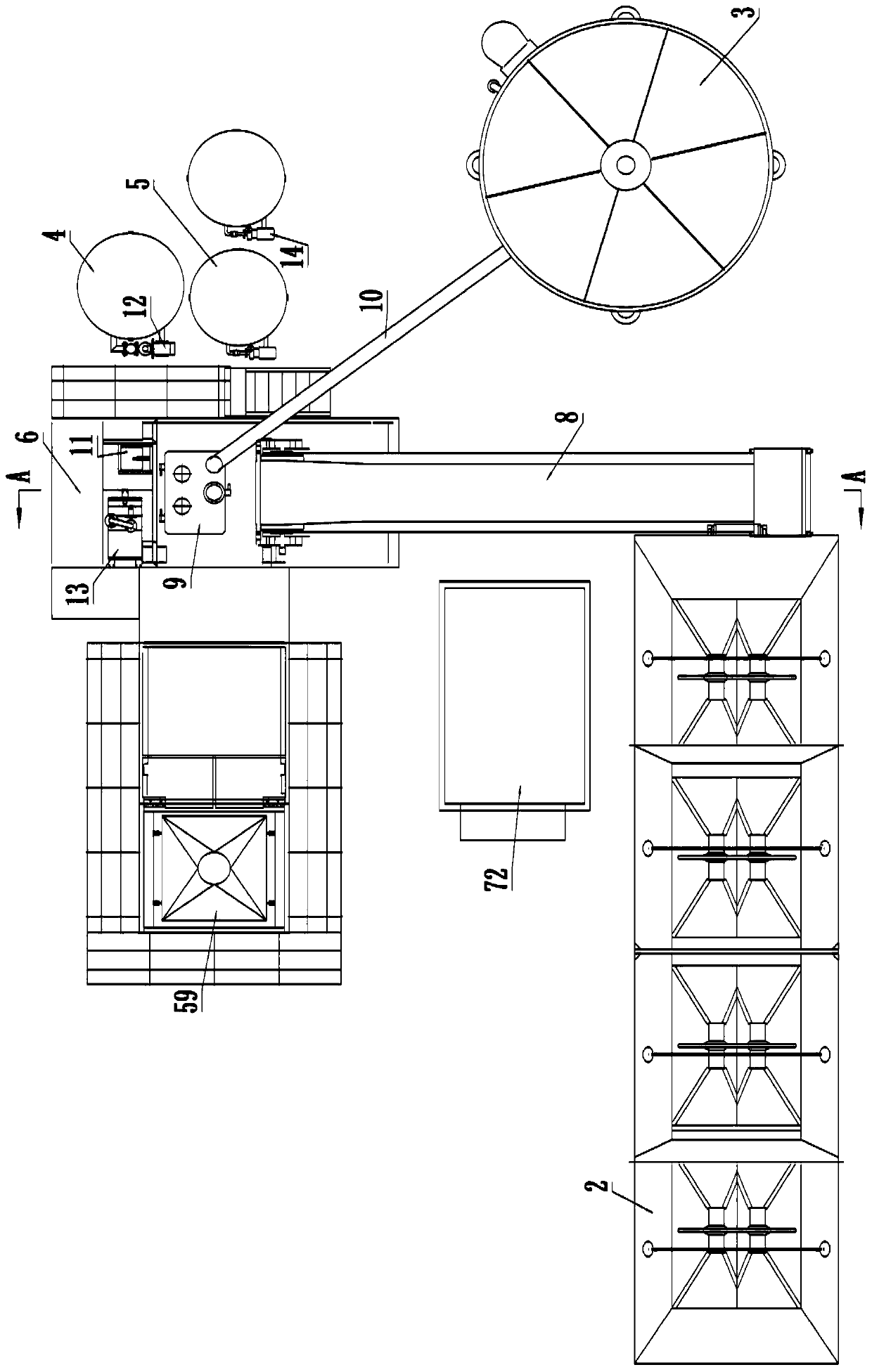

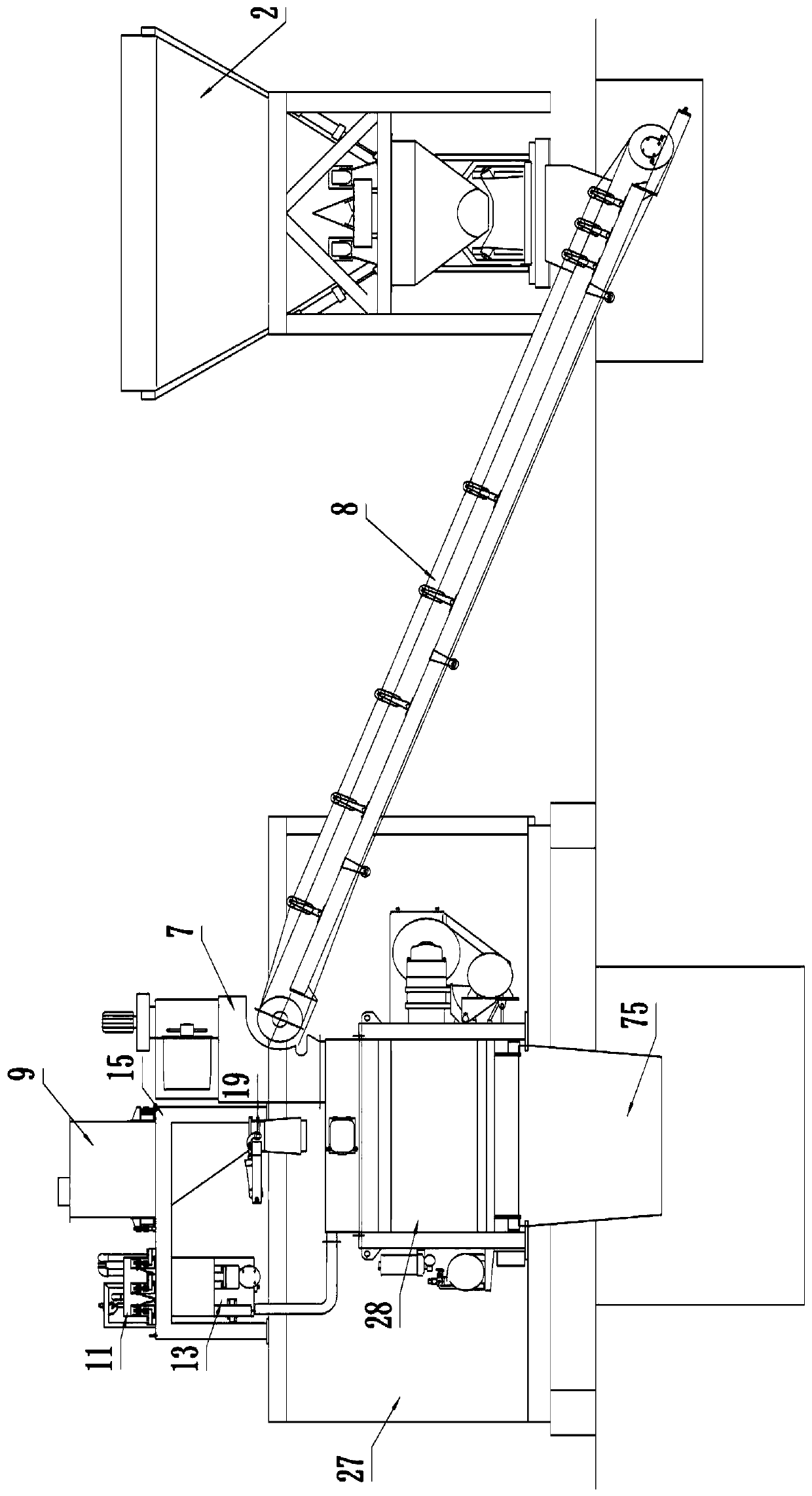

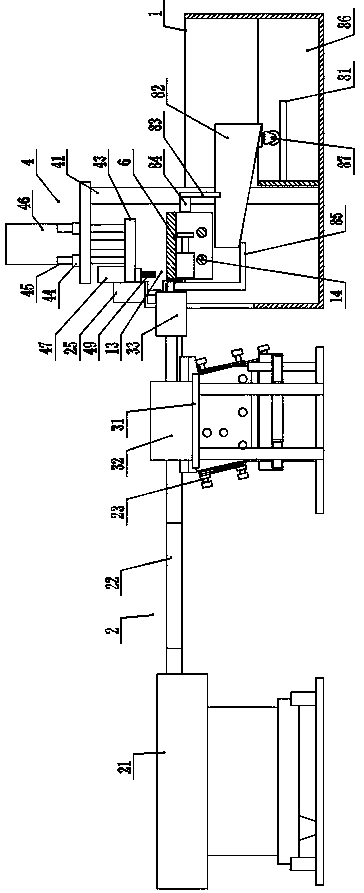

Full-automatic float-garbage clearing and packaging vessel

ActiveCN104097751AReduce volumeIncrease loading capacityWaterborne vesselsSpecial purpose vesselsMarine engineeringAquatic plant

The invention discloses a full-automatic float-garbage clearing and packaging vessel. A vessel body is of a double-head single-hull type. The vessel comprises the vessel body, a collecting device, a smashing device, a screw conveying device, a compressing and bundling device and a storing and discharging device. The collecting device, the smashing device, the screw conveying device, the compressing and bundling device and the storing and discharging device are sequentially mounted from a vessel bow to a vessel stern in the vessel body. The collecting device is arranged between two heads of the vessel bow. The vessel is adaptable to cleaning riverway rubbish and aquatic plants and capable of compressing collected and smashed rubbish and aquatic plants, thus improving load of the vessel, shortening discharging time of round trip, facilitating discharging, increasing production efficiency and saving production cost.

Owner:ZHANGJIAGANG HAIFENG WATER SURFACE ENVIRONMENTAL PROTECTION MACHINERY

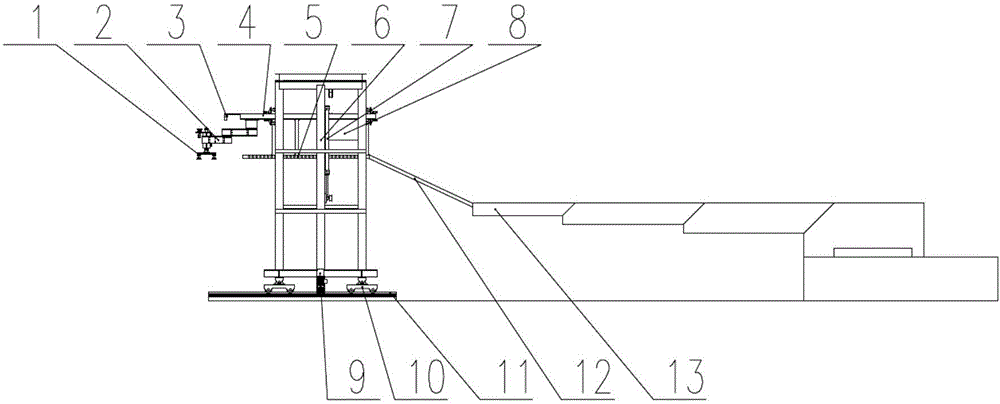

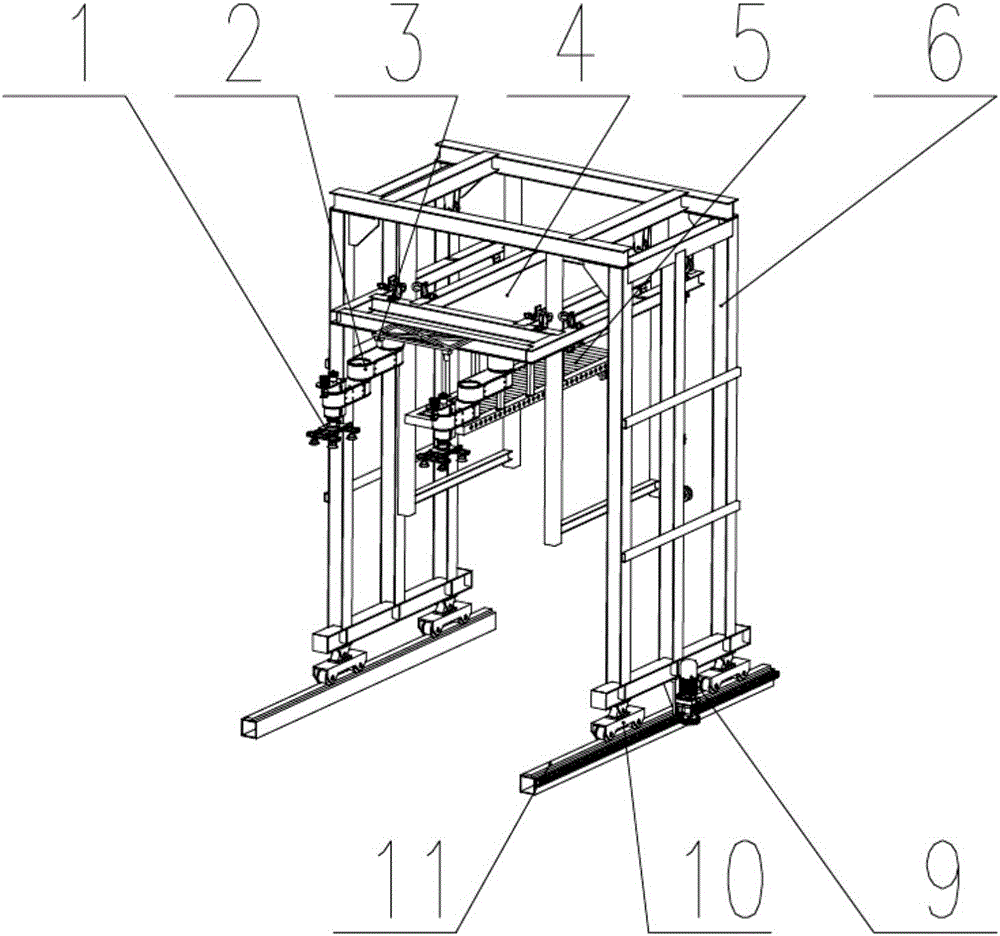

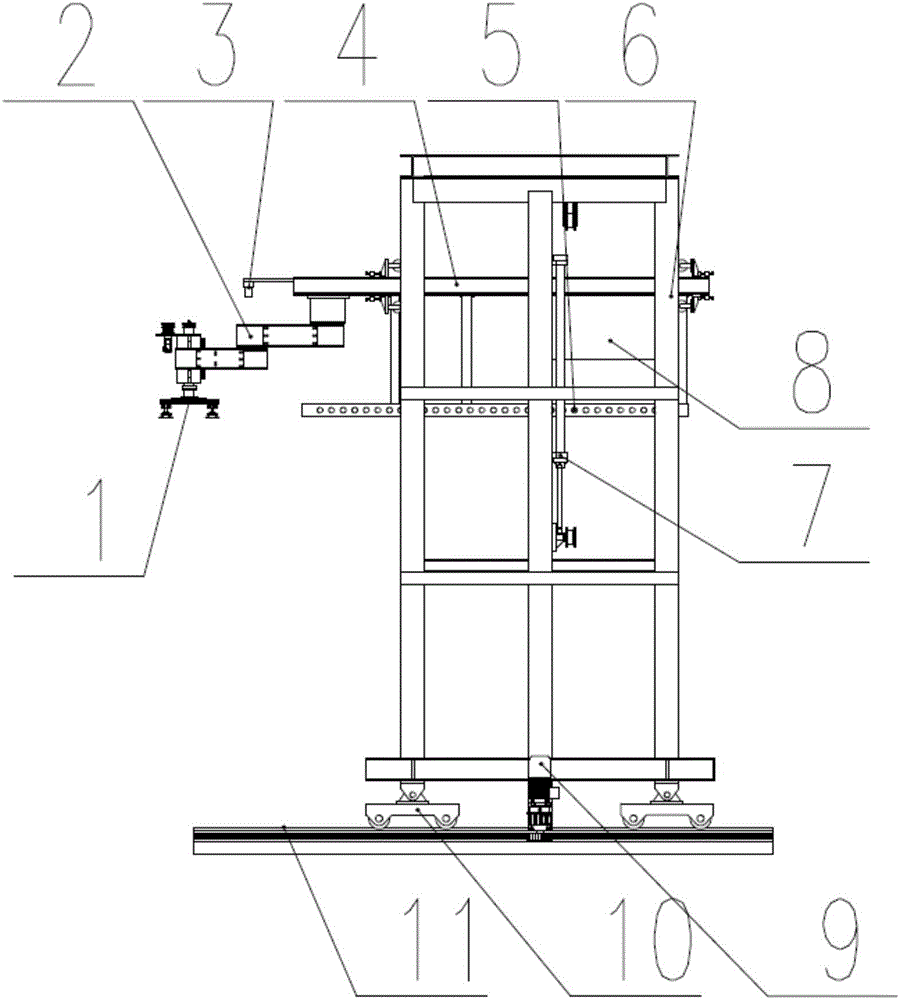

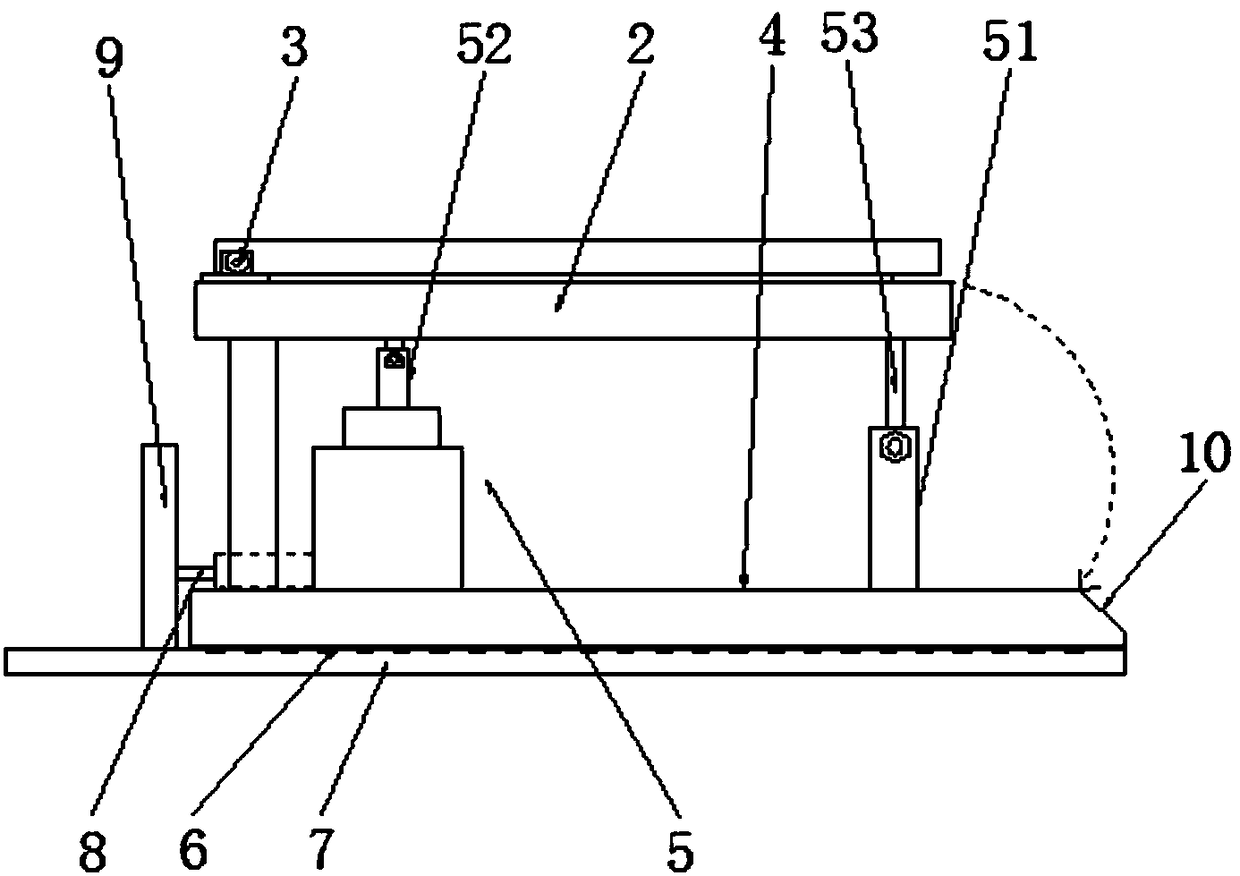

Automatic unloading robot system

The invention provides an automatic unloading robot system. The automatic unloading robot system comprises a gantry type walking vehicle, a lifting platform, a robot, a roller conveyor, a transition conveying belt, a telescopic belt conveyor, a robot visual system and a control system; the gantry type walking vehicle can cross a boxcar to longitudinally move along a freight car, so that unloading operation is convenient; the lifting platform moves and is locked in the vertical direction; the robot is installed on the lifting platform, and the height of the robot in the vertical direction is adjusted along with changes of the position of the lifting platform; the roller conveyor, the transition conveying belt and the telescopic belt conveyor cooperate with one another to work and convey unloaded freight to a specific position; the robot visual system is used for determining the freight grabbing position and cooperating with the robot to work; the control system controls the automated work of the whole automatic unloading robot system. The automatic unloading robot system can replace manual unloading and unstacking, save time and labor and improve the working efficiency.

Owner:SHANGHAI JIAO TONG UNIV

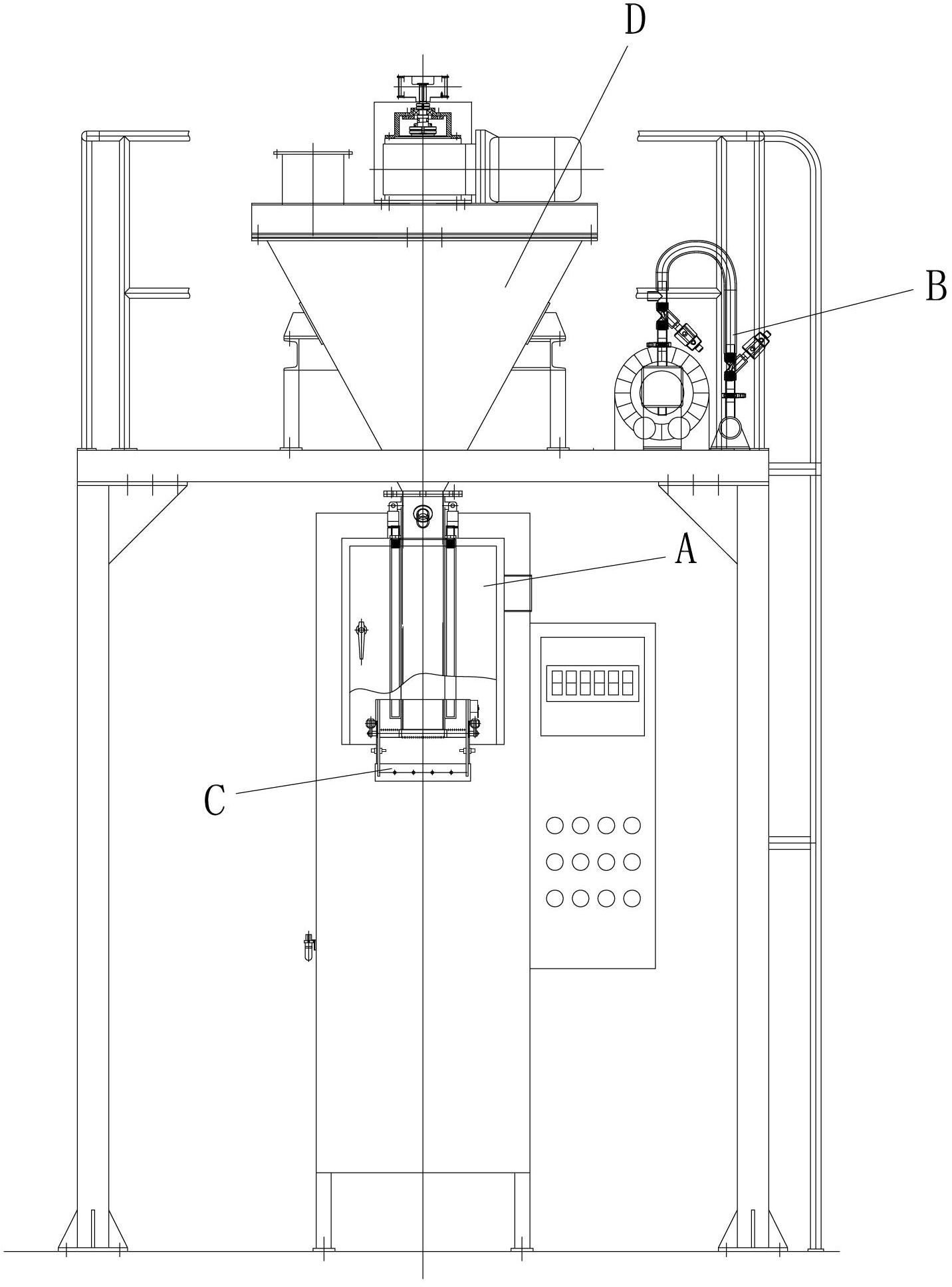

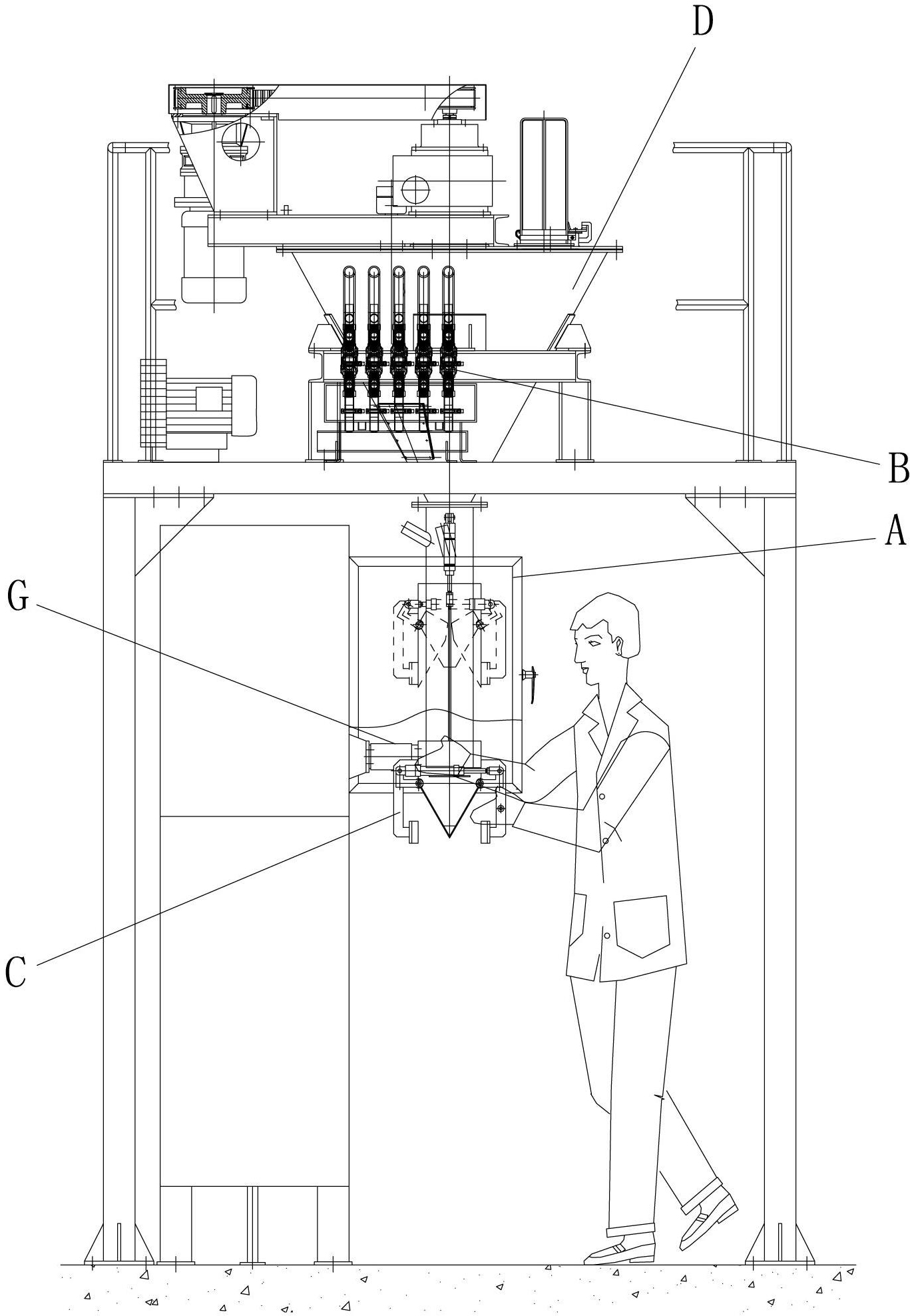

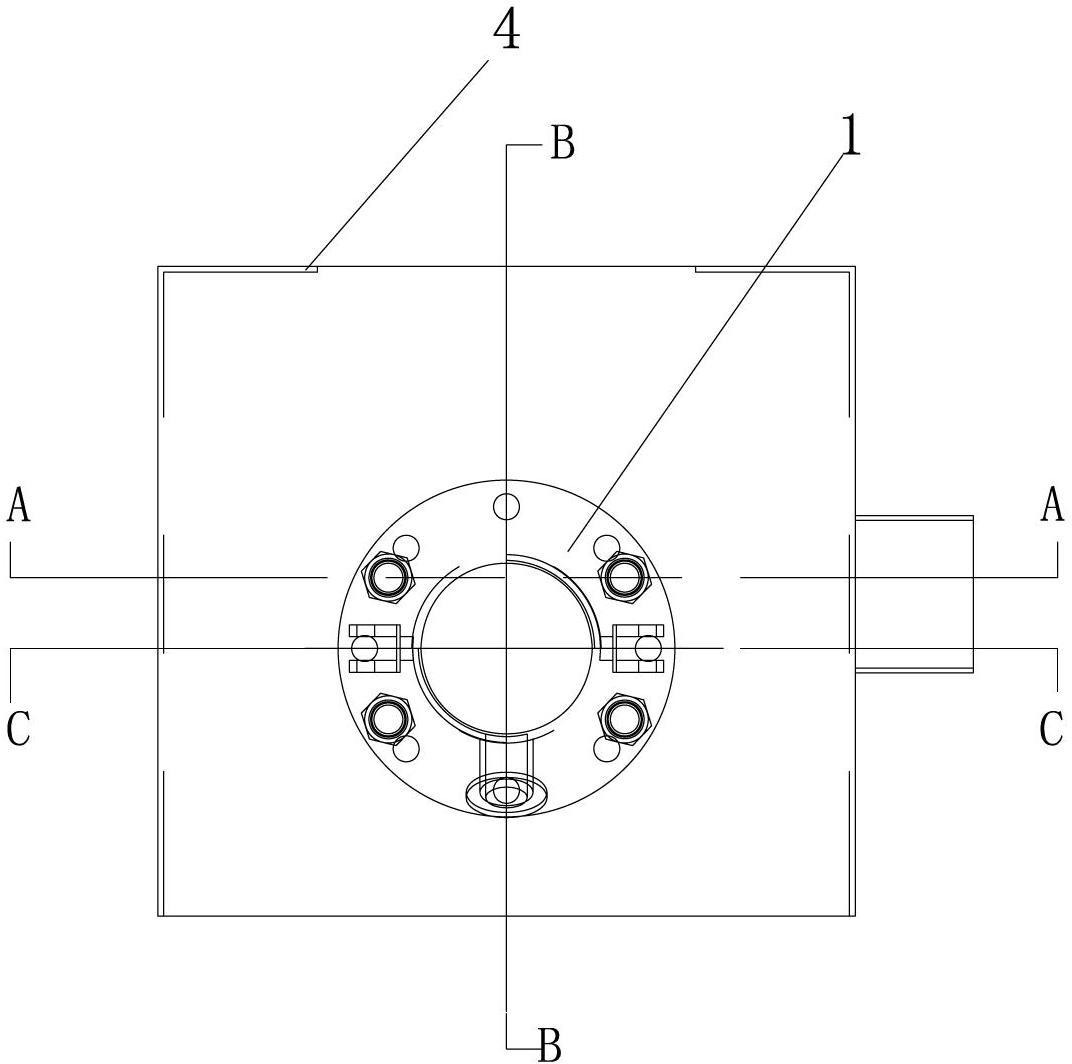

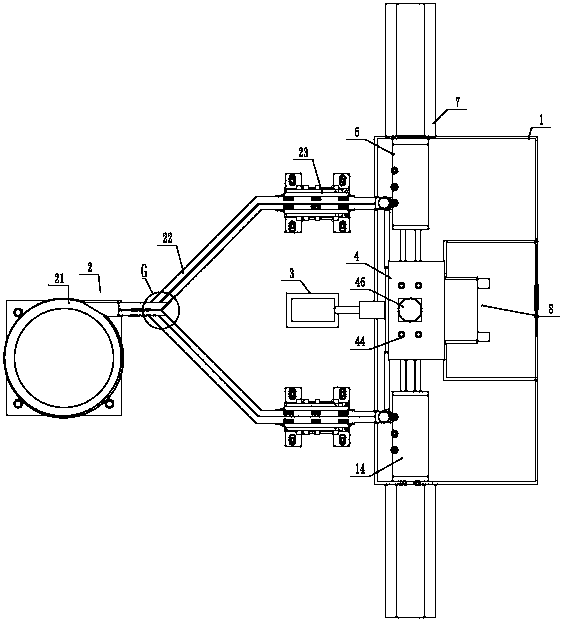

Operating method of powder material packing scale

The invention relates to an operating method of a powder material packing scale, which is suitable to solve the problems that the packaging bag is unable to be vertically placed and the rated quantity of materials are difficultly put into the bag within a normal time when powder materials with high gas contents enter a packaging bag; and the dust is easy to fly everywhere, after the packaging equipment is used, a better effect is obtained, and the efficiency is improved. The packaging scale comprises a degassing blanking device which is arranged on an outlet at the bottom of a hopper, an air suction blowing combination valve group and a vacuum pump which are used for degassing, blowing and blockage removing and are connected with the degassing blanking device, and a pneumatic bag-clamping lifting mechanism which is arranged at the bottom of the degassing blanking device; and the degassing blanking device comprises a blanking barrel, integrated microporous filter elements are arranged at both the inner wall and the outer wall of the blanking barrel, and the pore diameters of the filter elements can be set according to the sizes of material particles, and can range between 50 mum and 1mum. Ports which are communicated with a clearance between the inner wall of the blanking barrel and the inner filter elements are arranged in the outer wall of the blanking barrel; and the ports are connected with air suction blowing combination valves.

Owner:CHANGZHOU CHANGHENG DEYU POWDER INTEGRATIVE SYST

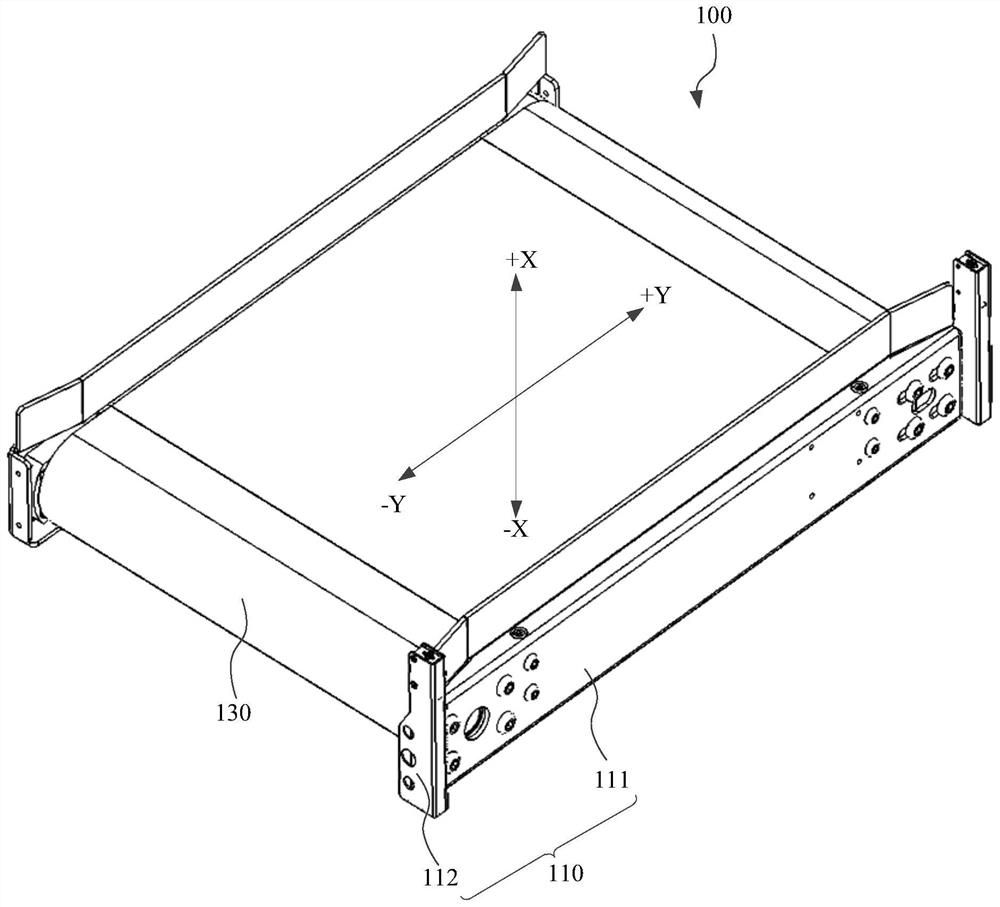

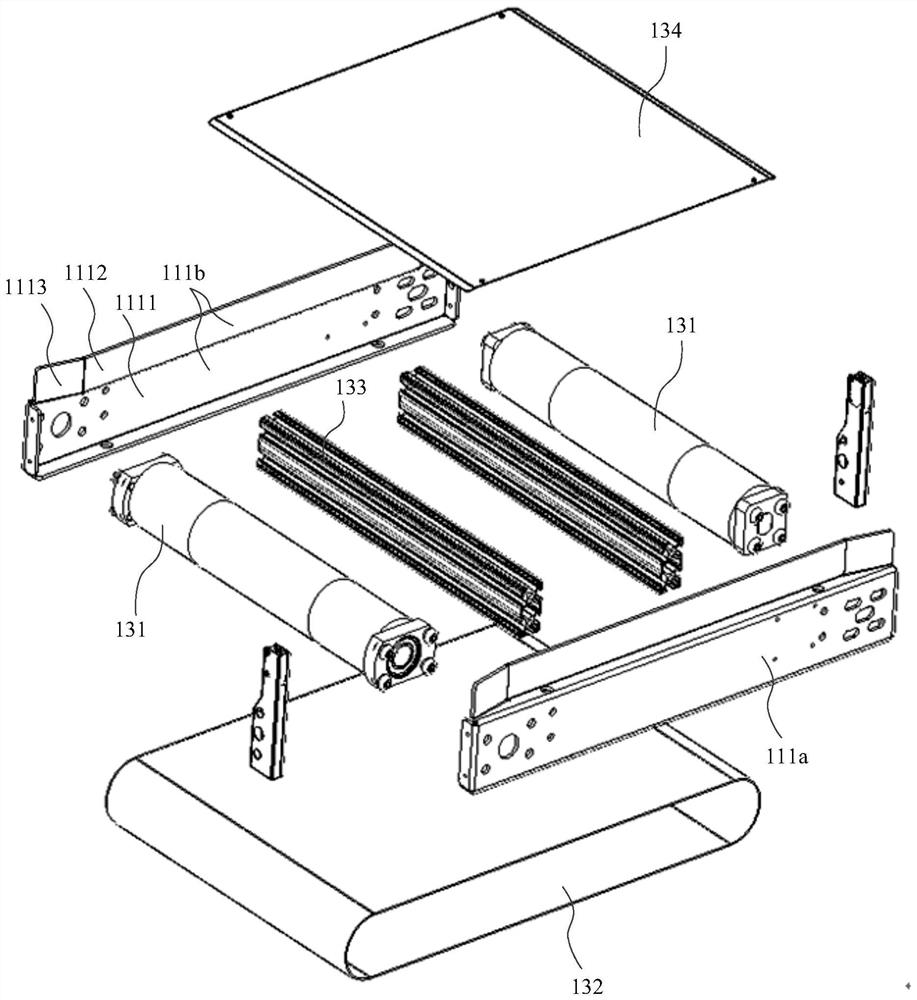

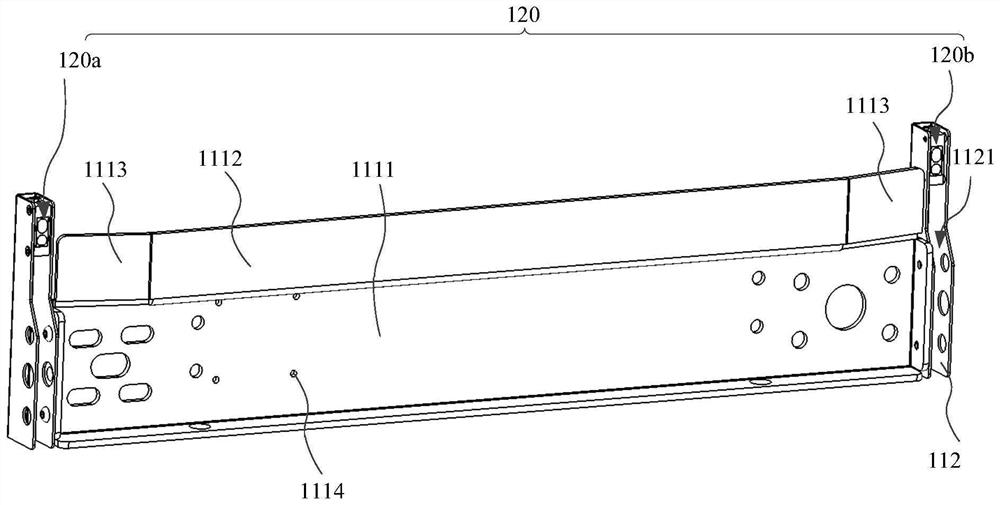

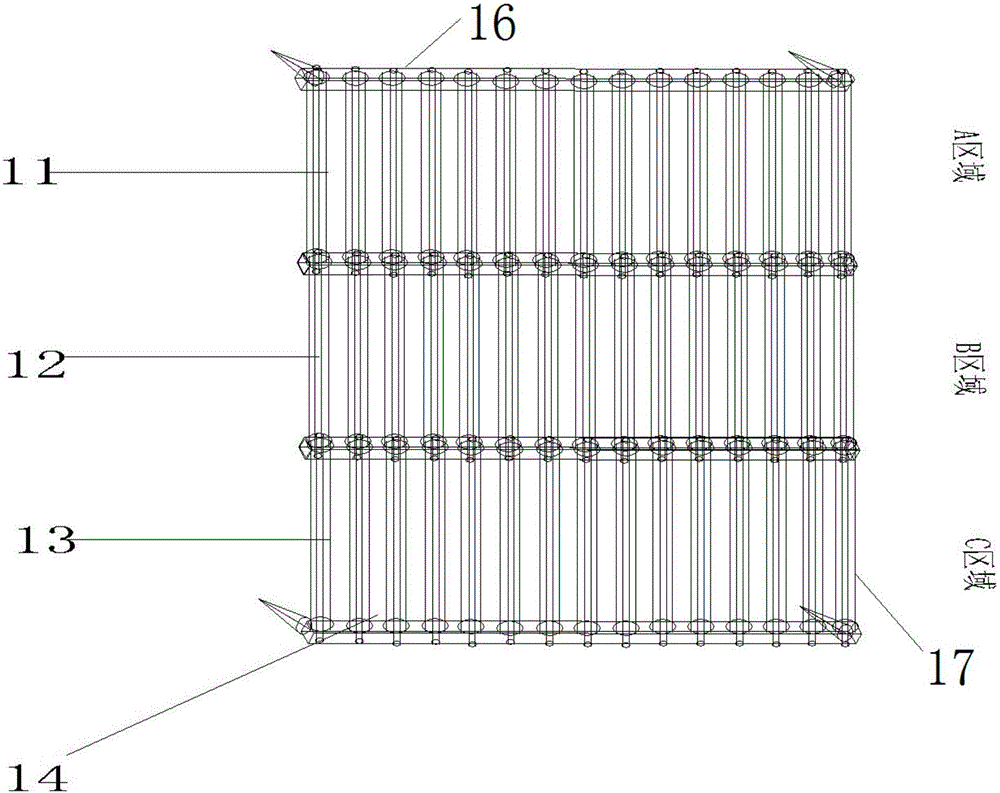

Transferring device, robot, sorting system and sorting method

PendingCN111891615AIncrease unloading speedImprove work efficiencySortingStorage devicesComputer hardwareEngineering

The invention provides a transferring device, a robot, a sorting system and a sorting method. The transferring device is applied to equipment on which multiple layers of circulating boxes can be arranged in the first direction. At least two layers of transferring devices are arranged in the first direction of the equipment. The transferring device comprises a supporting base and a first transmission assembly. The first transmission assembly is located on the supporting base. The first transmission assembly transports the circulating boxes. According to the transferring device, the working efficiency of the equipment can be improved.

Owner:HAI ROBOTICS CO LTD

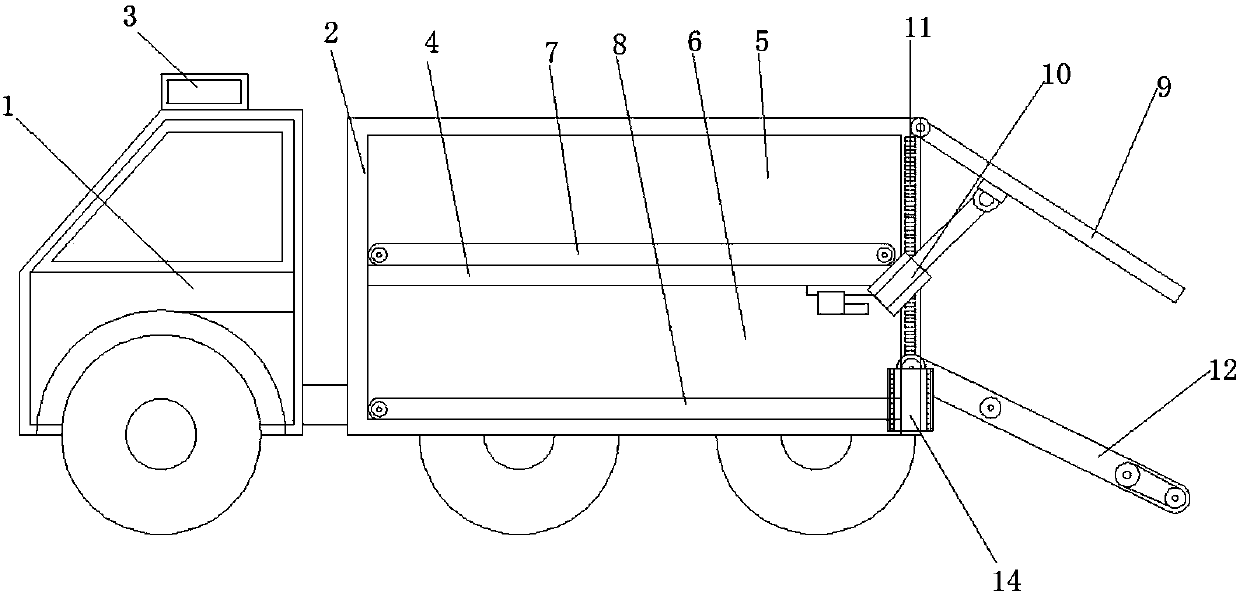

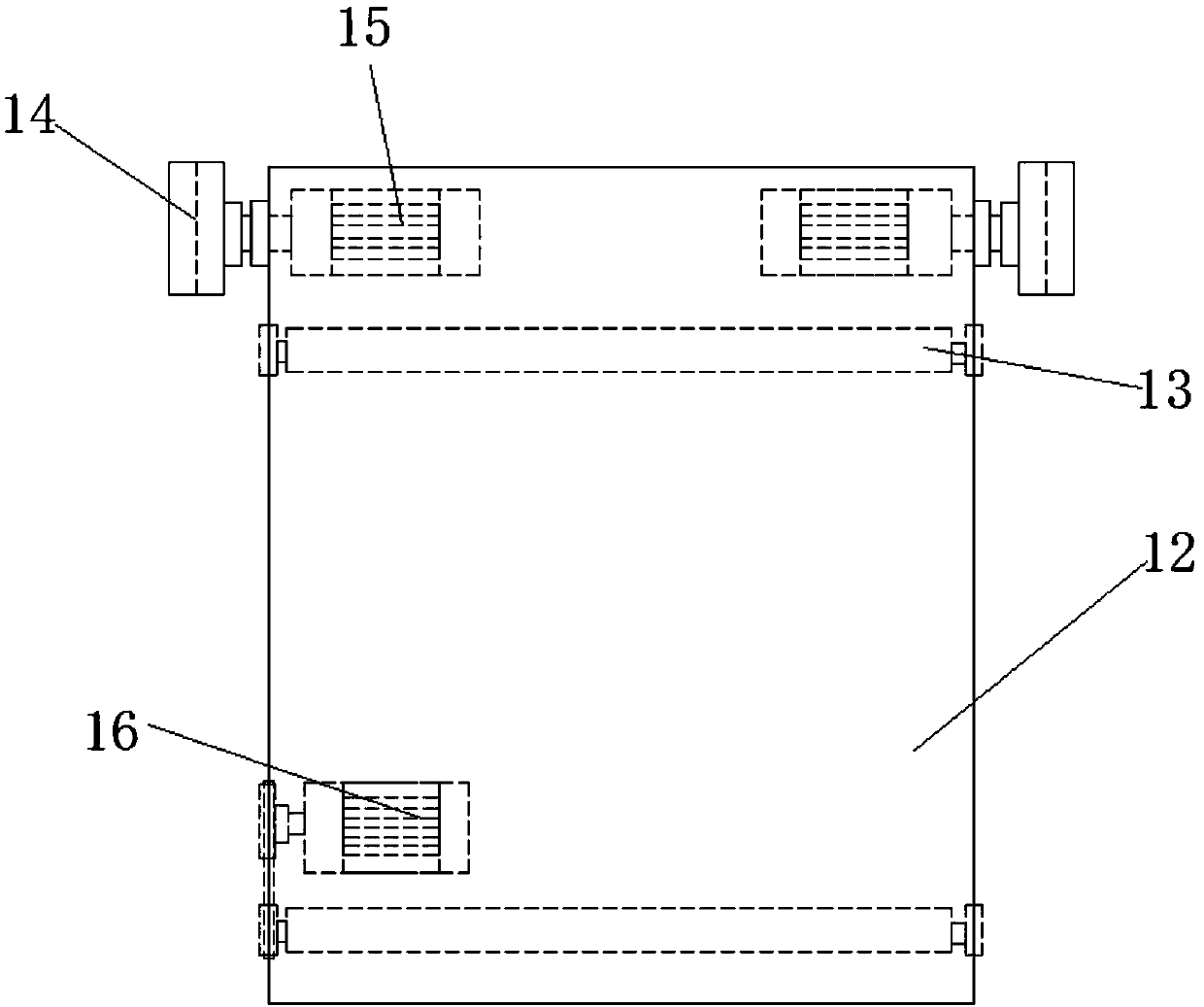

Logistics transportation vehicle based on Internet of Things technology

InactiveCN108016342AAvoid breakageReduce shipping costsVehicle with endless chains/beltsTransportation itemsLogistics managementInternet of Things

The invention discloses a logistics transportation vehicle based on an Internet of Things technology. The logistics transportation vehicle comprises a vehicle head and a vehicle compartment. The vehicle head is connected with the vehicle compartment through a connecting shaft, a wireless transceiving device is installed at the top of the vehicle head, a separation plate is arranged in the middle of the interior of the vehicle compartment, the separation plate divides the vehicle compartment into a first storage chamber and a second storage chamber, the first storage chamber is located on the upper portion of the second storage chamber, and a first conveying belt is arranged at the bottom of the first storage chamber. According to the logistics transportation vehicle, the transportation vehicle compartment is divided into the two portions of the first storage chamber and the second storage chamber, each portion is provided with one conveying belt, and a vehicle door is opened and closedby a hydraulic rod; a third conveying belt for unloading goods is arranged at the vehicle door so that the goods can be unloaded in a completely automated mode by the transportation vehicle, carryingthrough manpower is not needed, the situation that the goods are unloaded violently by an unloading person and damaged is avoided, the unloading speed of the goods is increased while the transportation cost is reduced, and the running state of the transportation vehicle can be monitored and controlled in real time by the wireless transceiving device.

Owner:天津釜力科技有限公司

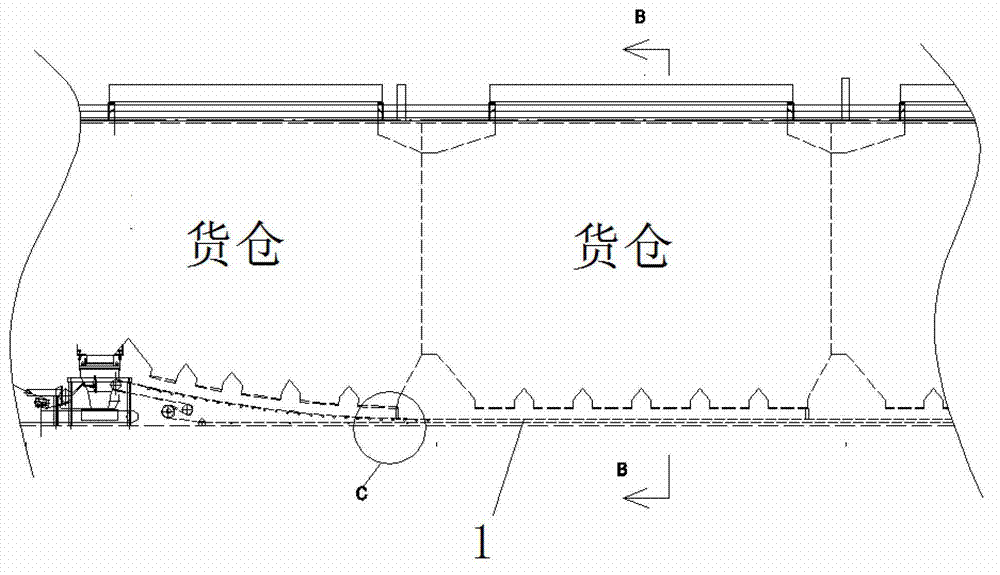

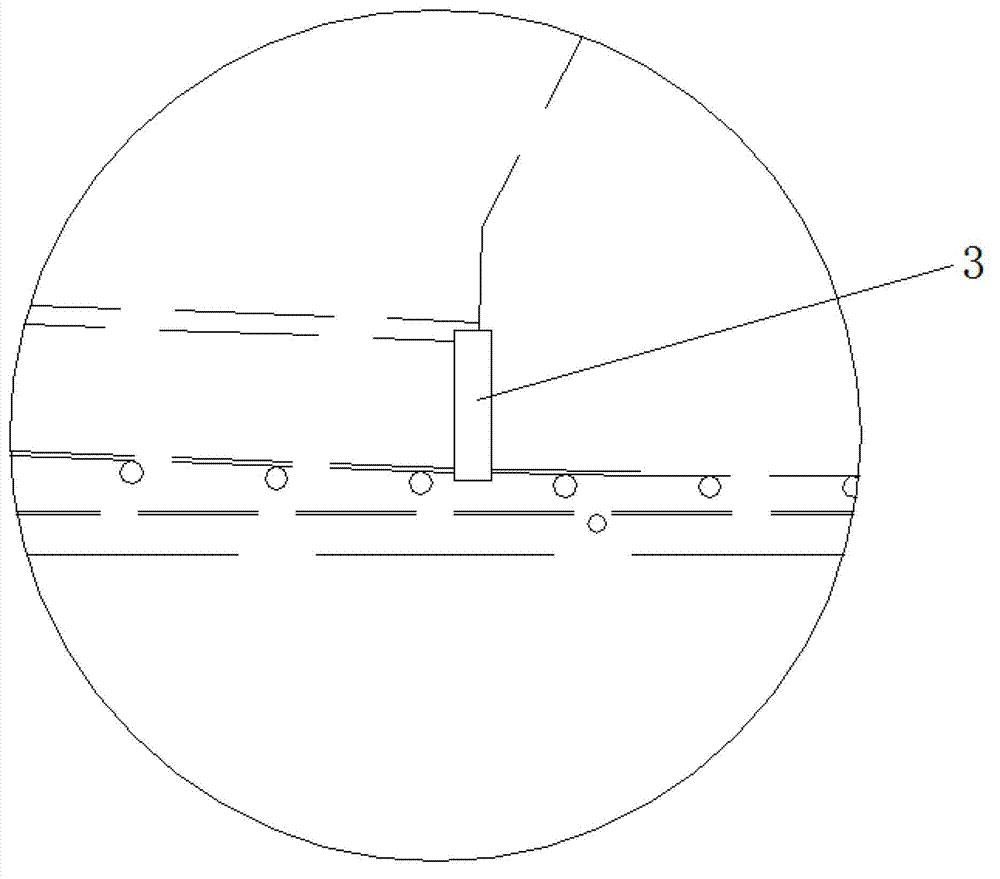

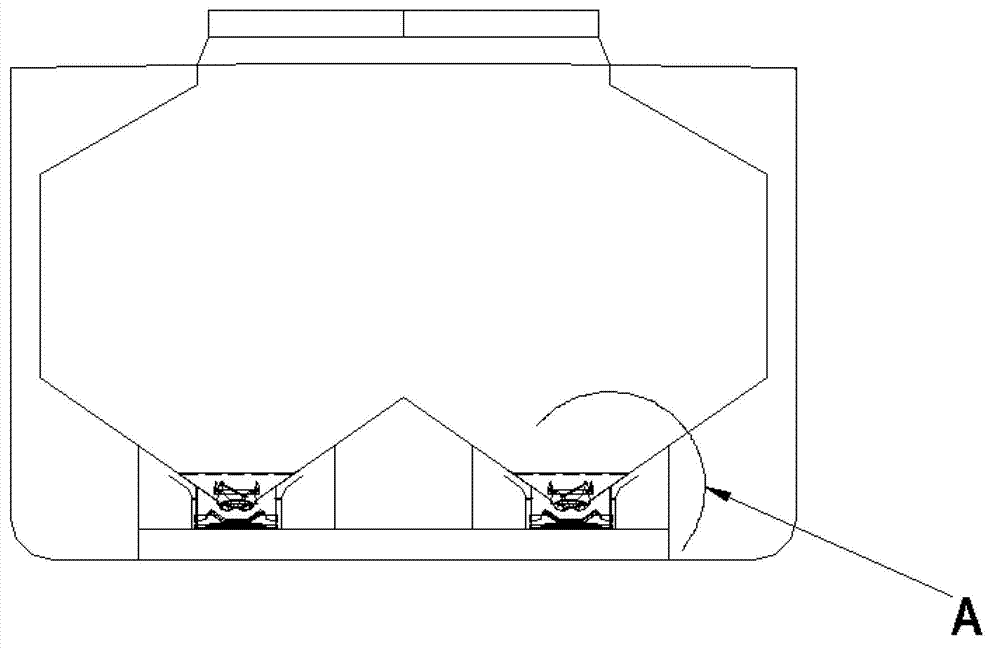

Self-unloading bulk cargo transport ship and unloading method thereof

InactiveCN103204227ASimple structureEasy to operateCargo handling apparatusPassenger handling apparatusBulk cargoConveyor belt

The invention relates to a self-unloading bulk cargo transport ship. The self-unloading bulk cargo transport ship comprises a plurality of marine cranes which are arranged above a deck, and a cargo hold grab bucket is arranged at the end of each of the marine cranes; deck hoppers which are in one-to-one correspondence to the marine cranes are arranged on the deck of a ship body and positioned on a starboard, and a longitudinal conveyor belt is arranged below the deck hoppers along the longitudinal direction of the ship body and positioned above cargo holds; a first discharge outlet is arranged on the tail portion of the longitudinal conveyor belt and corresponds to a horizontal conveyor belt, and the horizontal conveyor belt is arranged along the horizontal direction of the ship body and communicates the deck starboard and a deck larboard; a second discharge outlet is arranged on the tail portion of the horizontal conveyor belt and corresponds to an inclined conveyor belt, and the inclined conveyor belt is upwards inclined along a deck of the larboard; and a third discharge outlet is arranged at the tail end of the inclined conveyor belt and corresponds to an unloading arm of a gantry crane, the unloading arm can telescope, slew and luff, and a fourth discharge outlet is arranged at the tail end of the unloading arm.

Owner:SHANGHAI MERCHANT SHIP DESIGN & RES INST

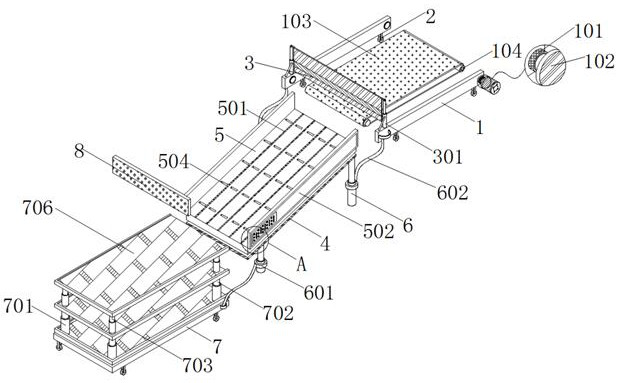

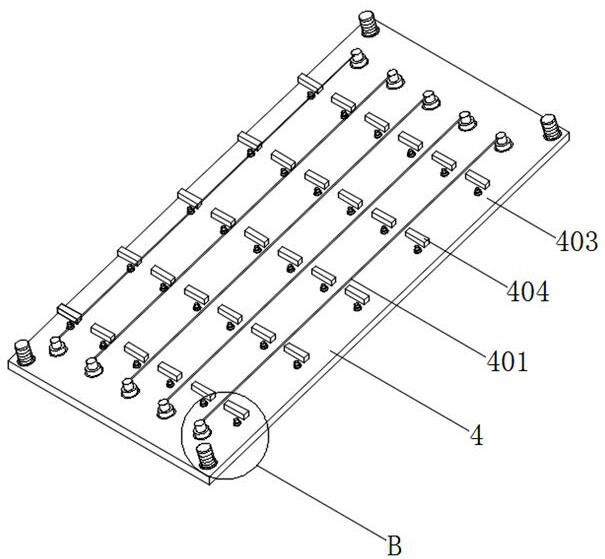

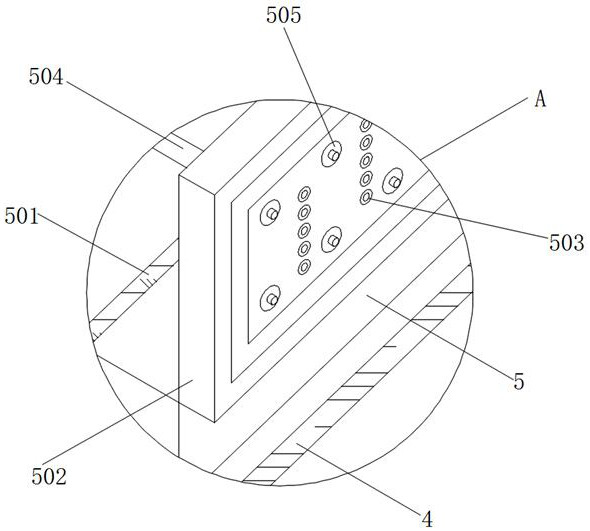

Novel unloading platform

Owner:深圳市升蓝物流有限公司

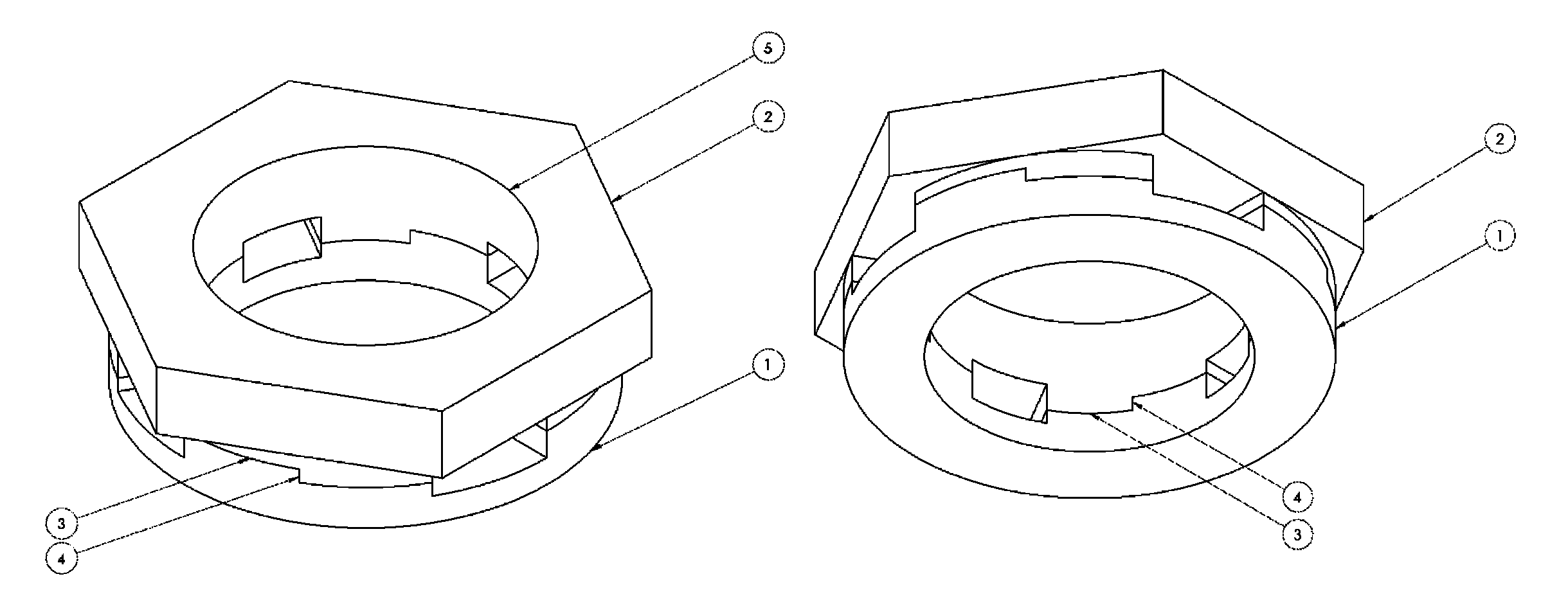

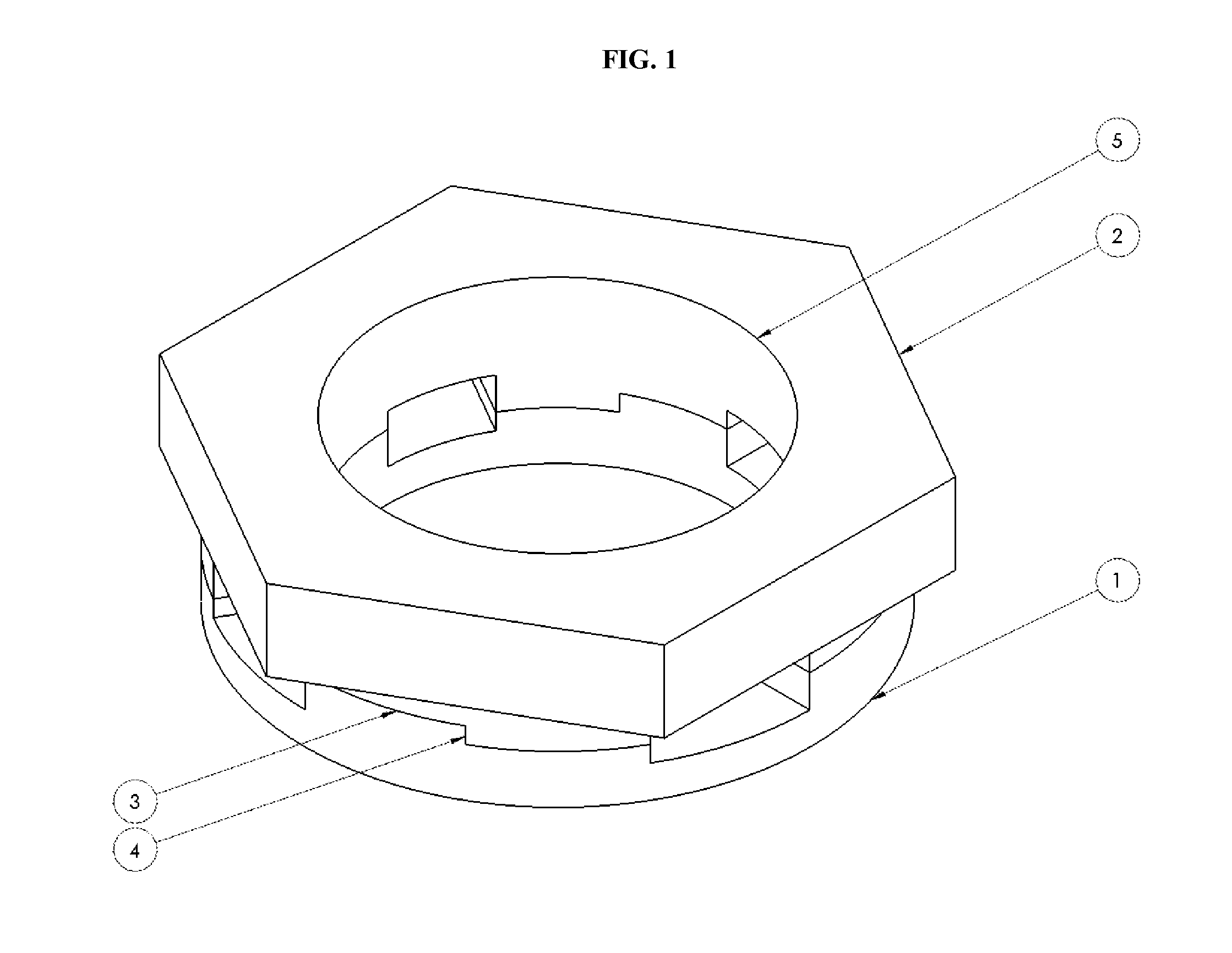

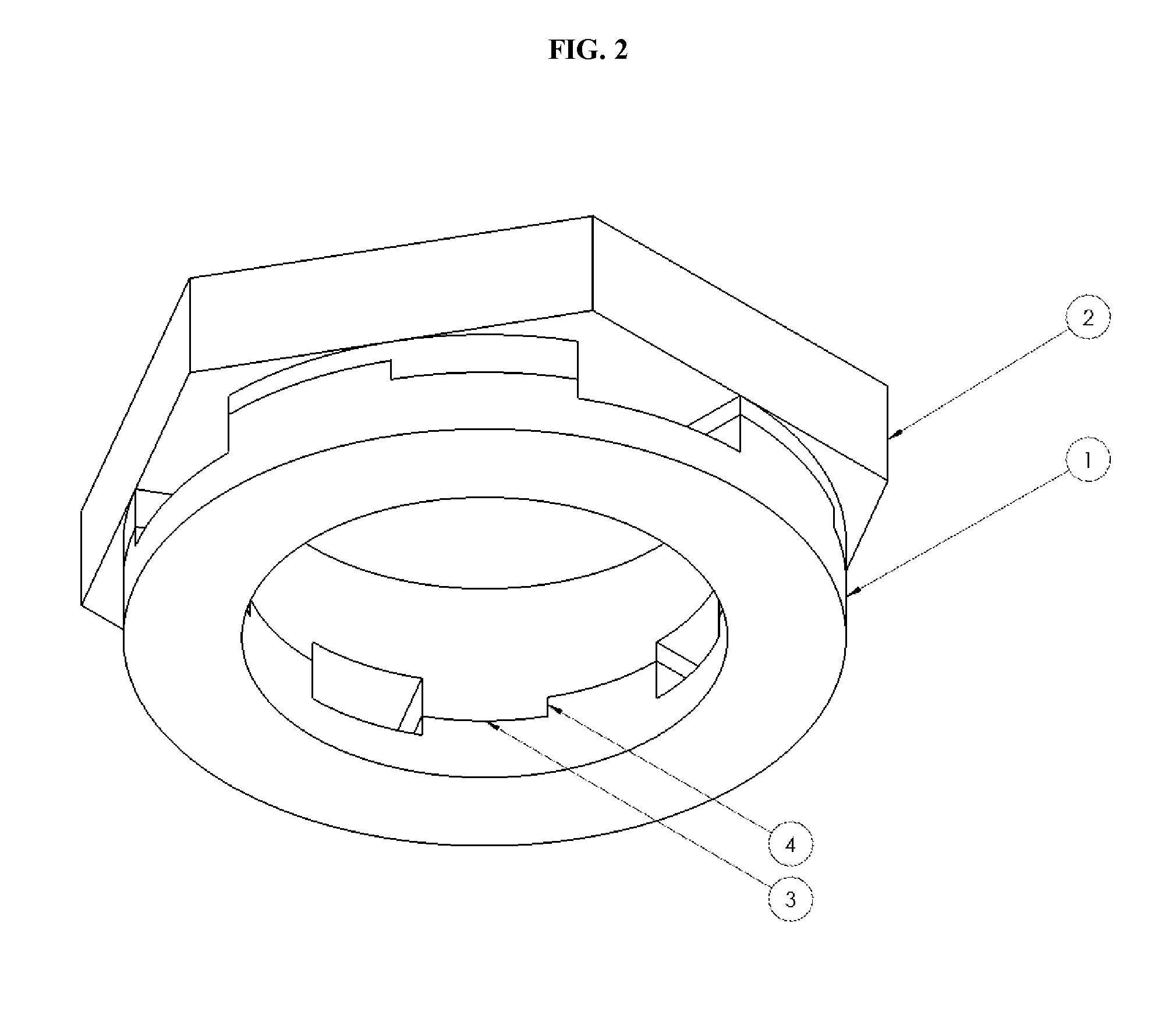

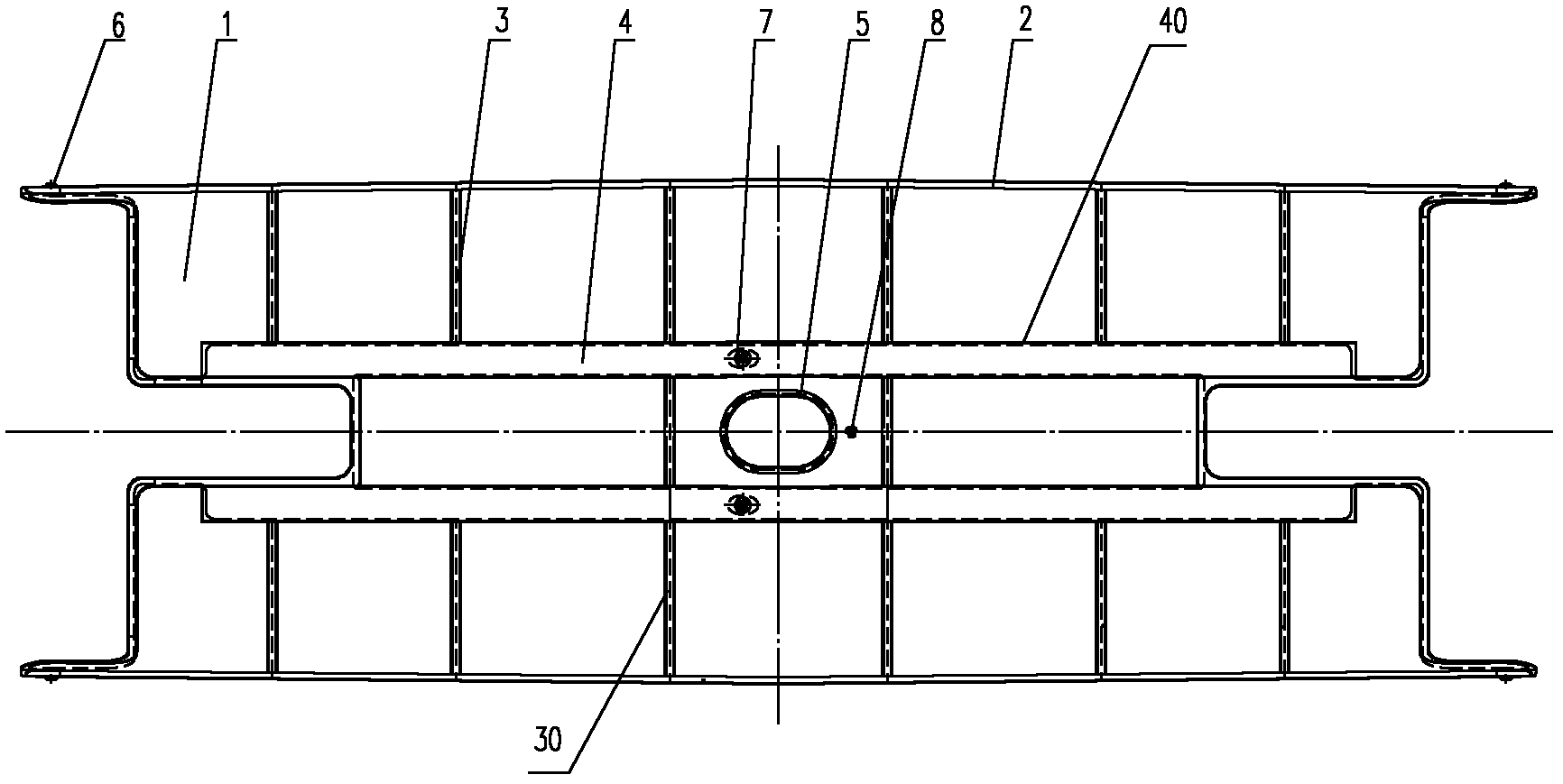

Load-relief washer assembly for threaded fasteners

ActiveUS8579572B1Reduce loadPrevention of galling featureWashersLoad modified fastenersThreaded fastenerEngineering

A load relief washer assembly for threaded fasteners comprises a lower washer piece, an upper washer piece, a plurality of complementary stepped features which further comprise the mating surfaces of the lower washer and the upper washer, such that sufficient rotation of the upper body relative to the lower body aligns the complementary stepped features allowing the upper body and the lower body to move toward each other, thereby reducing the overall height of the load relief washer assembly.

Owner:INTEGRA SERVICES TECH

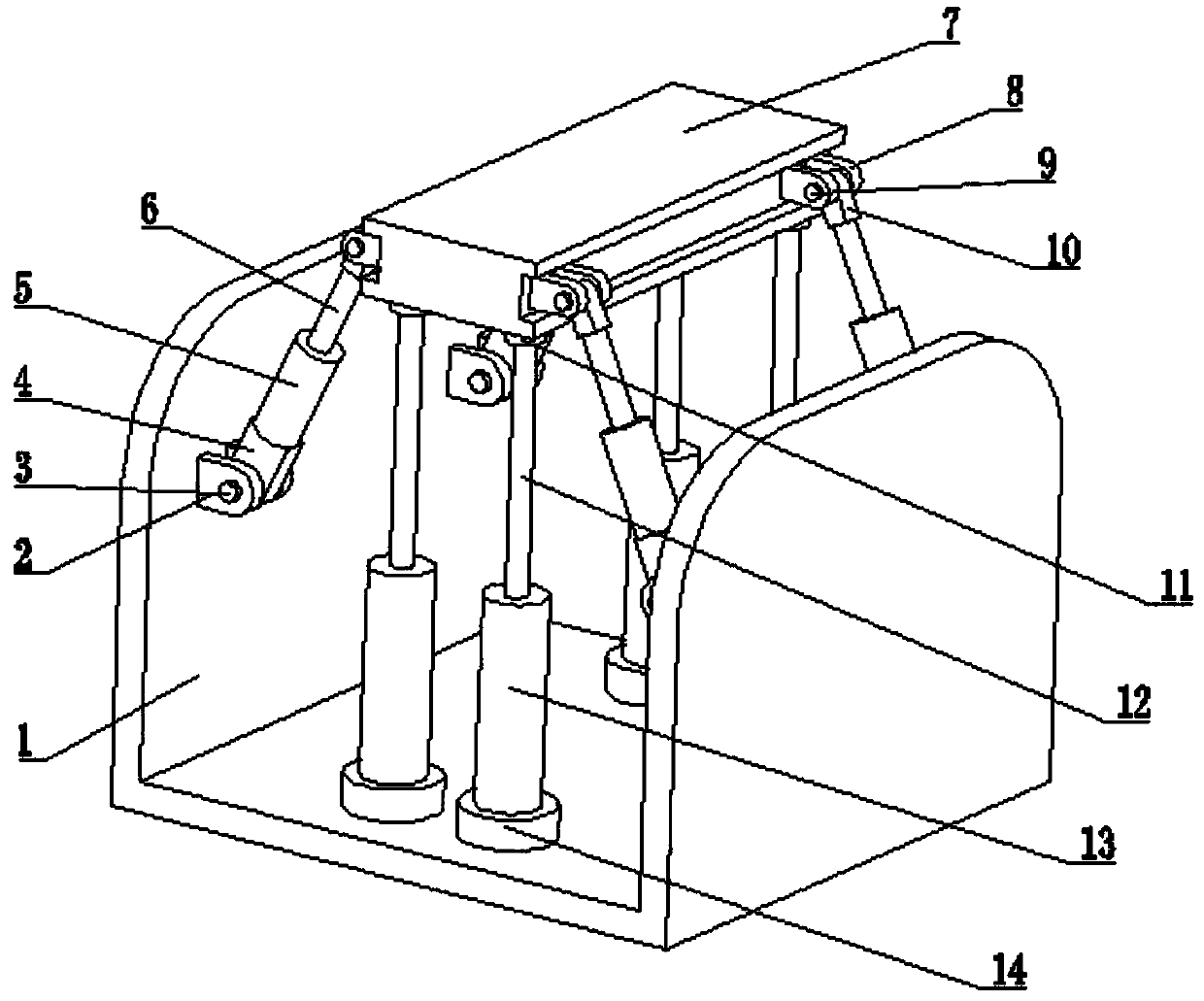

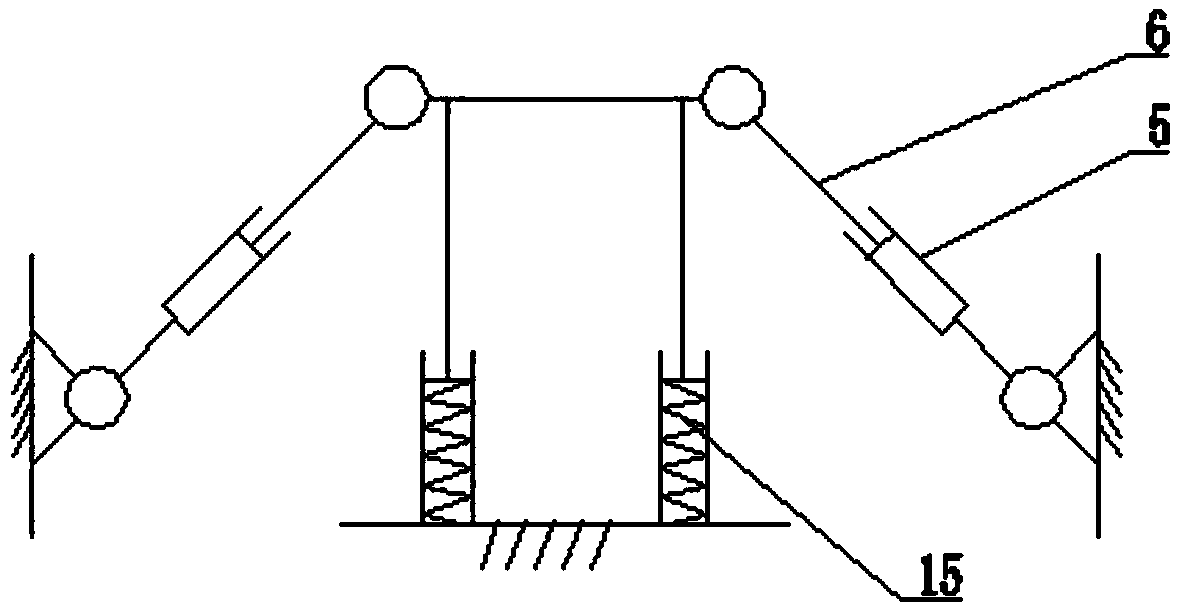

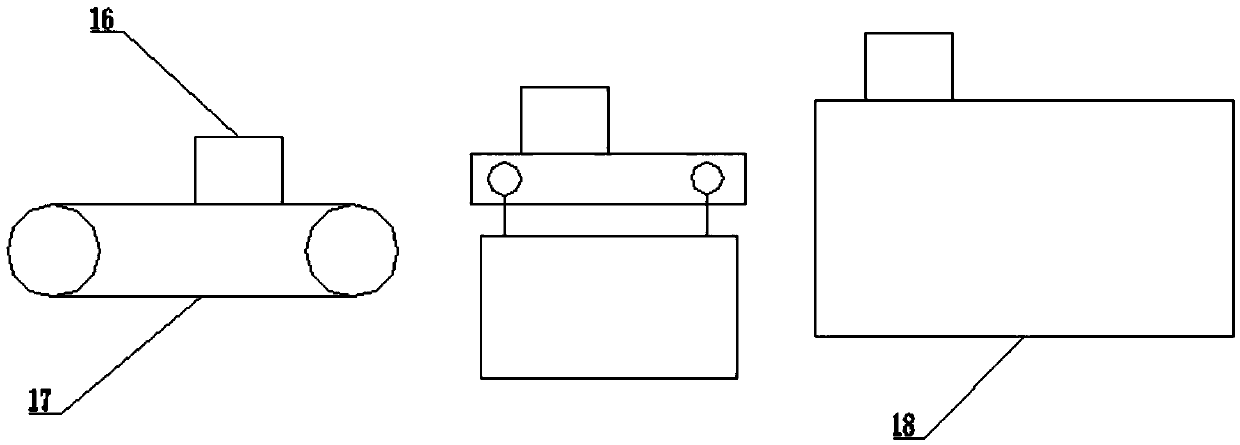

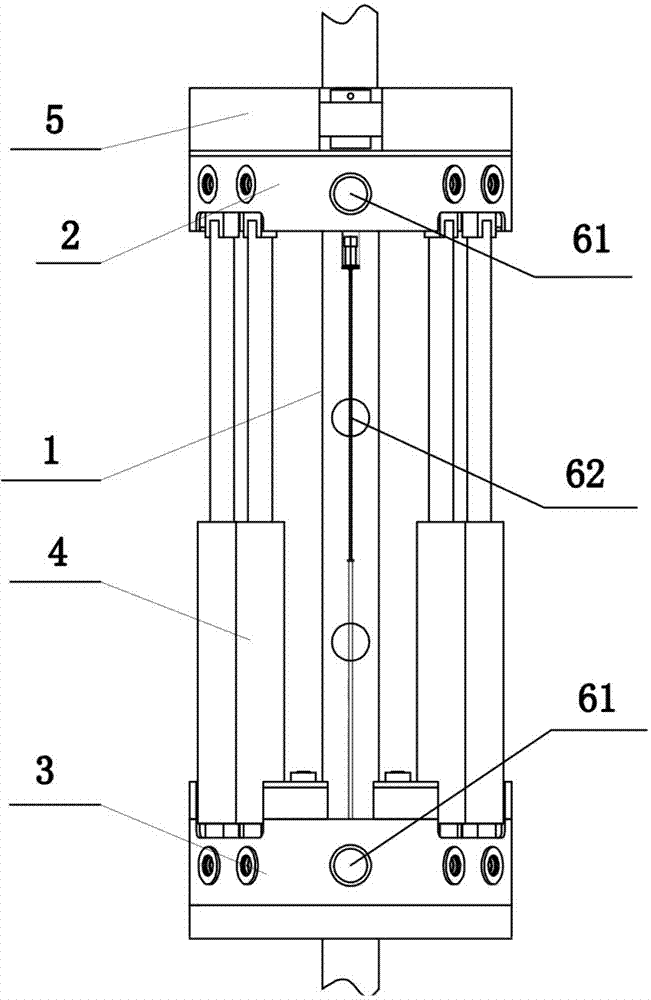

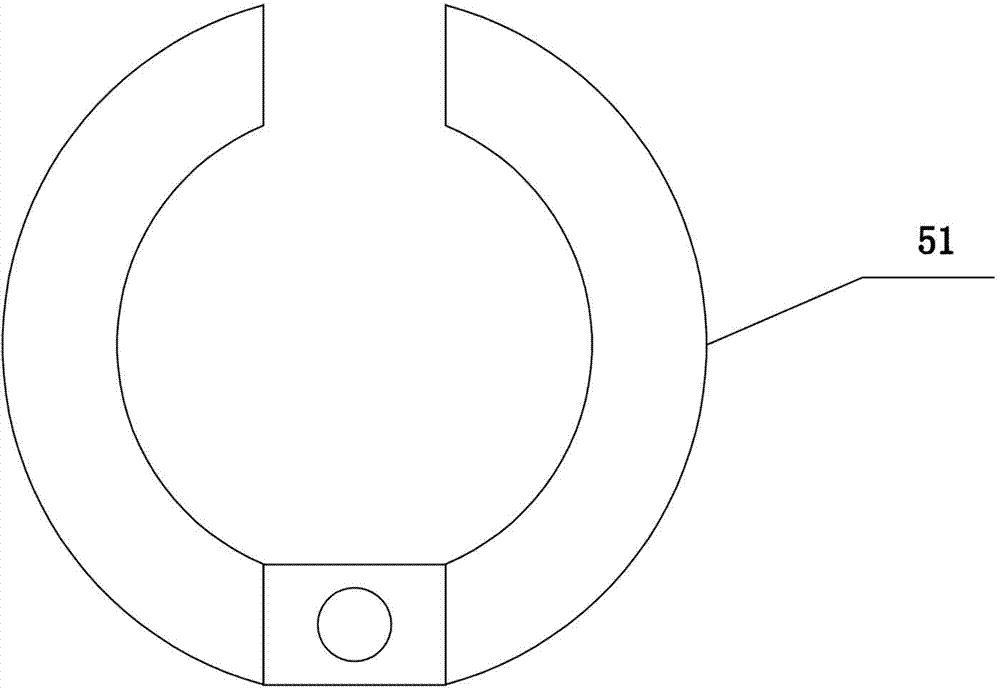

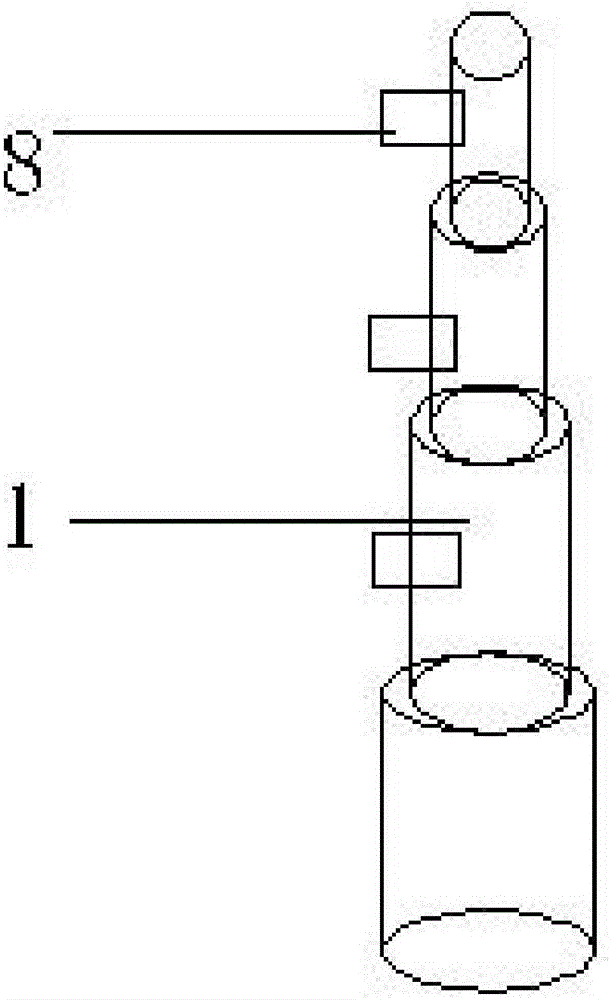

Hydraulic lifting device capable of automatically dropping and automatic pile dropping method thereof

InactiveCN104727287AFast unloading speedIncrease unloading speedArtificial islandsUnderwater structuresPetroleum engineering

The invention discloses a hydraulic lifting device capable of automatically dropping and an automatic pile dropping method thereof. The hydraulic lifting device capable of automatically dropping comprises a gauge pile, an upper ring beam, a lower ring beam and lifting oil cylinders; the upper ring beam or the lower ring beam is fixedly connected with a hull, the lifting oil cylinders are longitudinally connected with the upper ring beam and the lower ring beam, and the relative lifting and dropping between the upper ring beam and the lower ring beam are achieved through being driven by the lifting oil cylinders; the gauge pile vertically penetrates through the upper ring beam and the lower ring beam and is connected with the upper ring beam and the lower ring beam in a sliding mode, the gauge pile fixes the relative position with the upper ring beam and the lower ring beam through a pin mechanism, and the hydraulic lifting device capable of automatically dropping further comprises a clamp holder used for clamping and fixing the gauge pile.

Owner:KEEN OFFSHORE ENG CO LTD

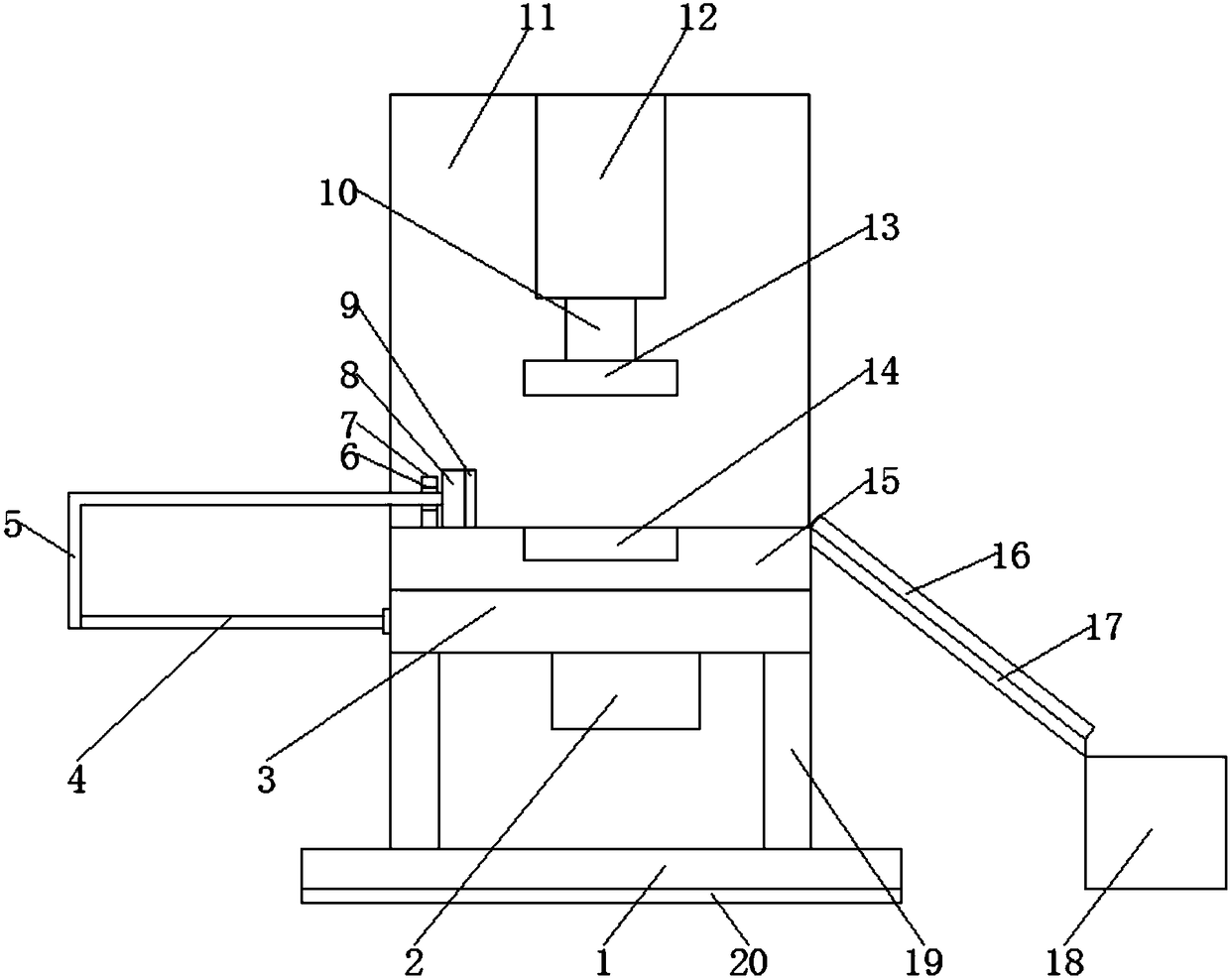

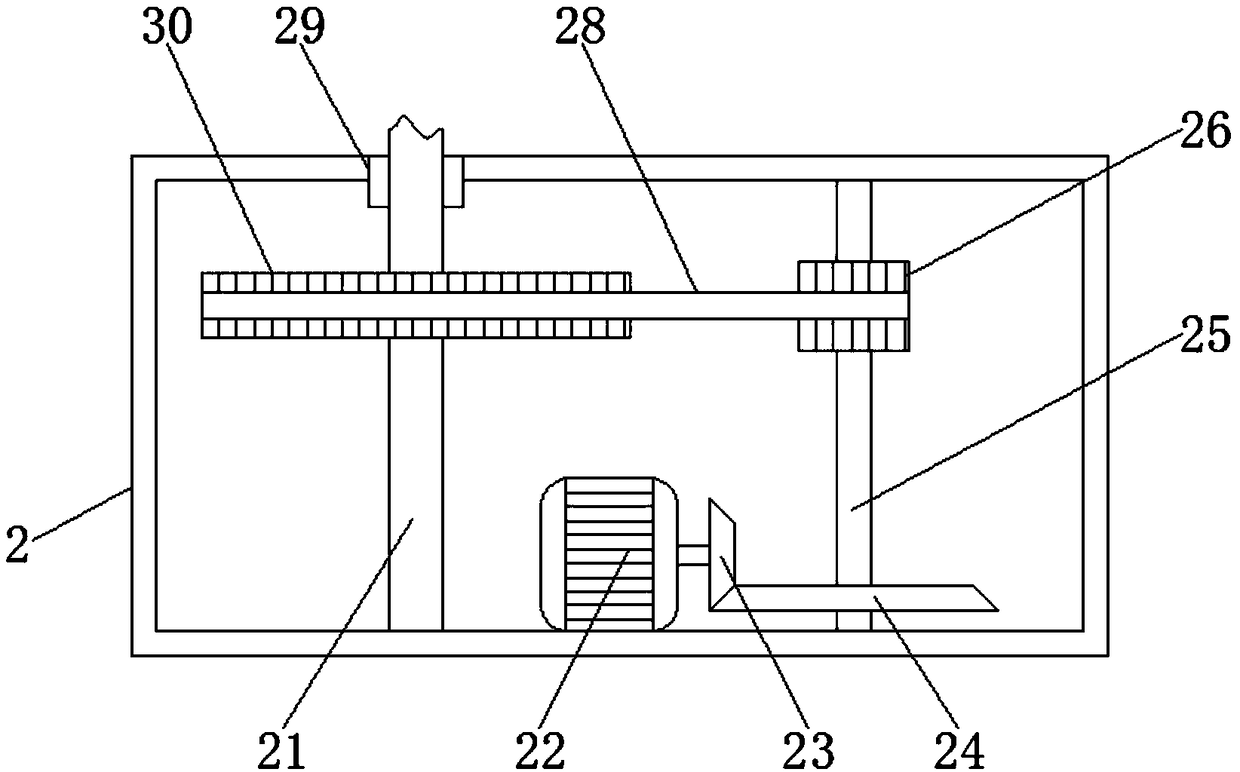

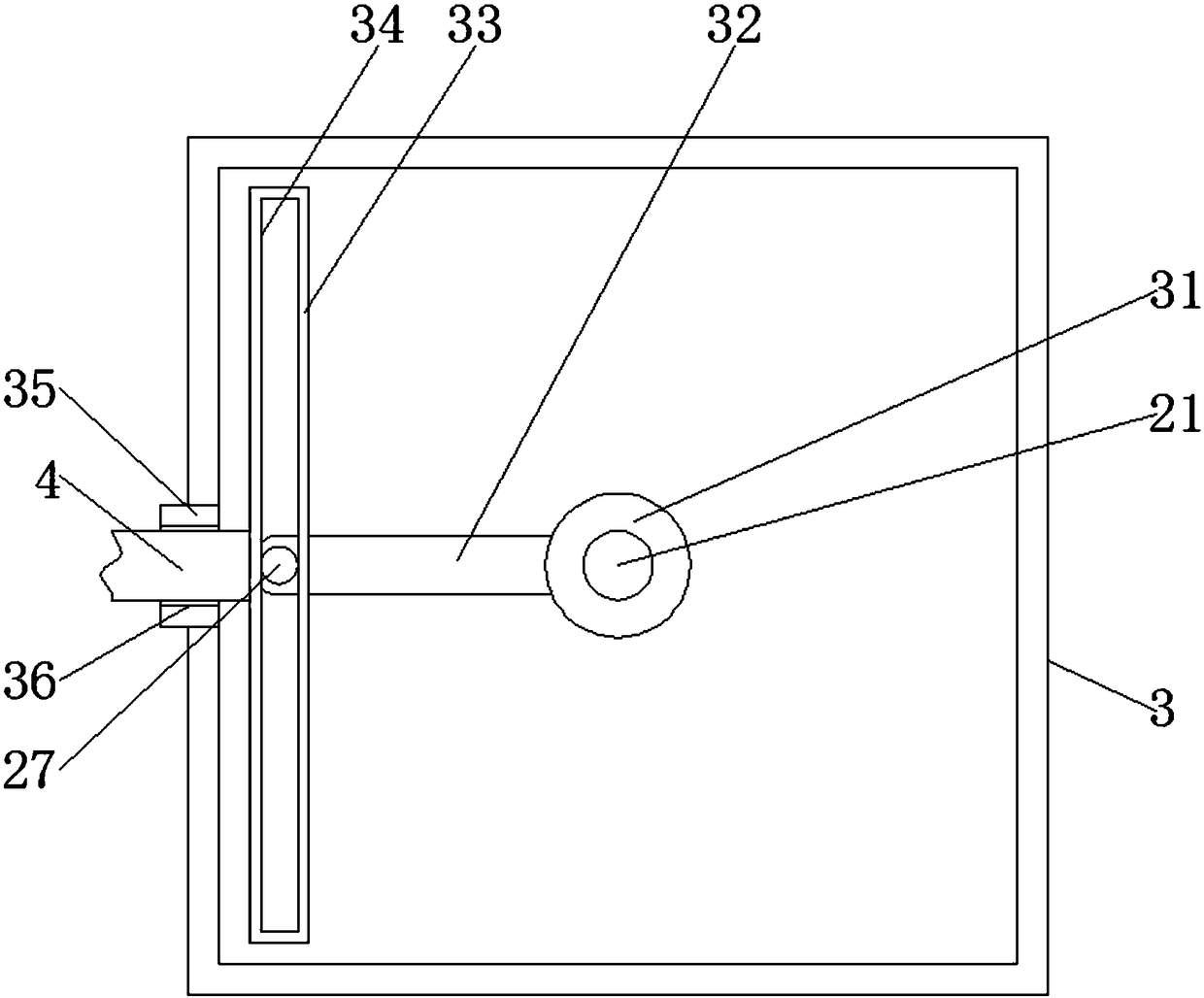

Automatic discharge punch for hardware machining

InactiveCN108421923AEasy to collectEasy to unloadStripping-off devicesDischarge efficiencyPunch press

The invention provides an automatic discharge punch for hardware machining and relates to the field of mechanical equipment. The punch comprises a base, wherein an antiskid mat is fixedly connected with the bottom of the base; antiskid stripes are arranged at the bottom of the antiskid mat; support legs are fixedly connected with the two sides of the top of the base; a discharge device is fixedlyconnected with the tops of the support legs; and the bottom of the discharge device is fixedly connected with a driving device. According to the automatic discharge punch for the hardware machining, abaffle at the top of a slide plate can allow a spare part not to deviate when the spare part moves on the slide plate; direct entry of the spare part into a collecting box is effectively guaranteed;the discharge efficiency is improved; a guide block at the top of an operating table and a guide hole in the guide block can limit a connecting rod; the connecting rod does not deviate; a moving trackof the connecting rod is defined; the discharge is more precise and stable; and with the adoption of the antiskid mat, the punch is more stable.

Owner:新昌县盛南建材有限公司

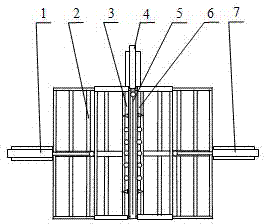

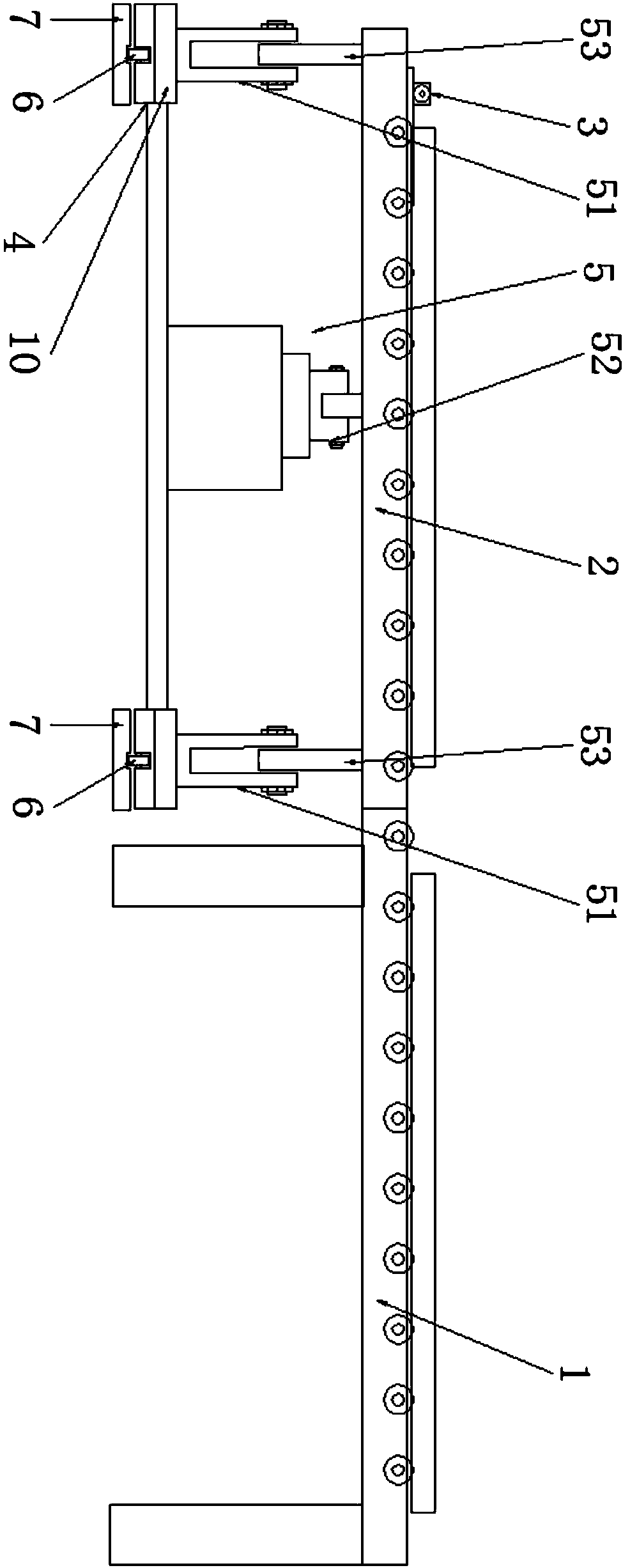

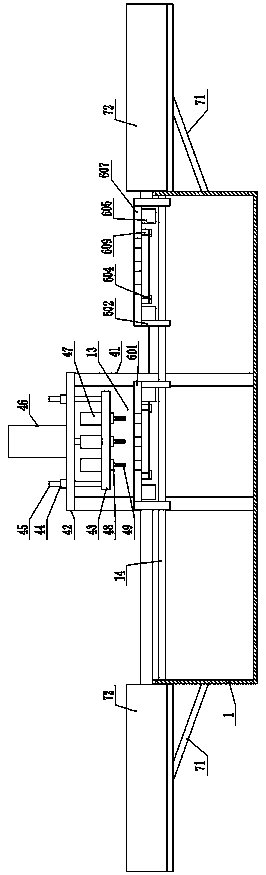

Automatic bag breaking discharge device

InactiveCN104760735ASimple structureReduce labor intensityLoading/unloadingConveyor partsEngineeringCylinder block

The invention relates to an automatic bag breaking discharge device. According to the technical scheme, a bag cutting tool (5) is installed on the middle position of the upper plane of a bag breaking tool rack (2) in the front-back direction, a left bag breaking tool (3) and a right bag breaking tool (6) are correspondingly installed on the left side and the right side of the bag cutting tool (5), and the left bag breaking tool (3) and the right bag breaking tool (6) are symmetrically arranged on the upper plane of the bag breaking tool rack (2); the working end of a piston rod of a bag cutting tool air cylinder (4) is hinged to the bag cutting tool (5), the working end of a piston rod of a left bag breaking air cylinder (1) is hinged to the left bag breaking tool (3), and the working end of a piston rod of a right bag breaking air cylinder (7) is hinged to the right bag breaking tool (6); a cylinder body of the bag cutting tool air cylinder (4), a cylinder body of the left bag breaking air cylinder (1) and a cylinder body of the right bag breaking air cylinder (7) are fixed onto a middle support, a left support and a right support correspondingly. The automatic bag breaking discharge device has the advantages that the volume is small, the dust production volume is small, the efficiency is high, the labor intensity is small, the degree of automation is high, and the requirement of conducting continuous bag breaking and material discharging of powdery materials can be met.

Owner:WUHAN UNIV OF SCI & TECH

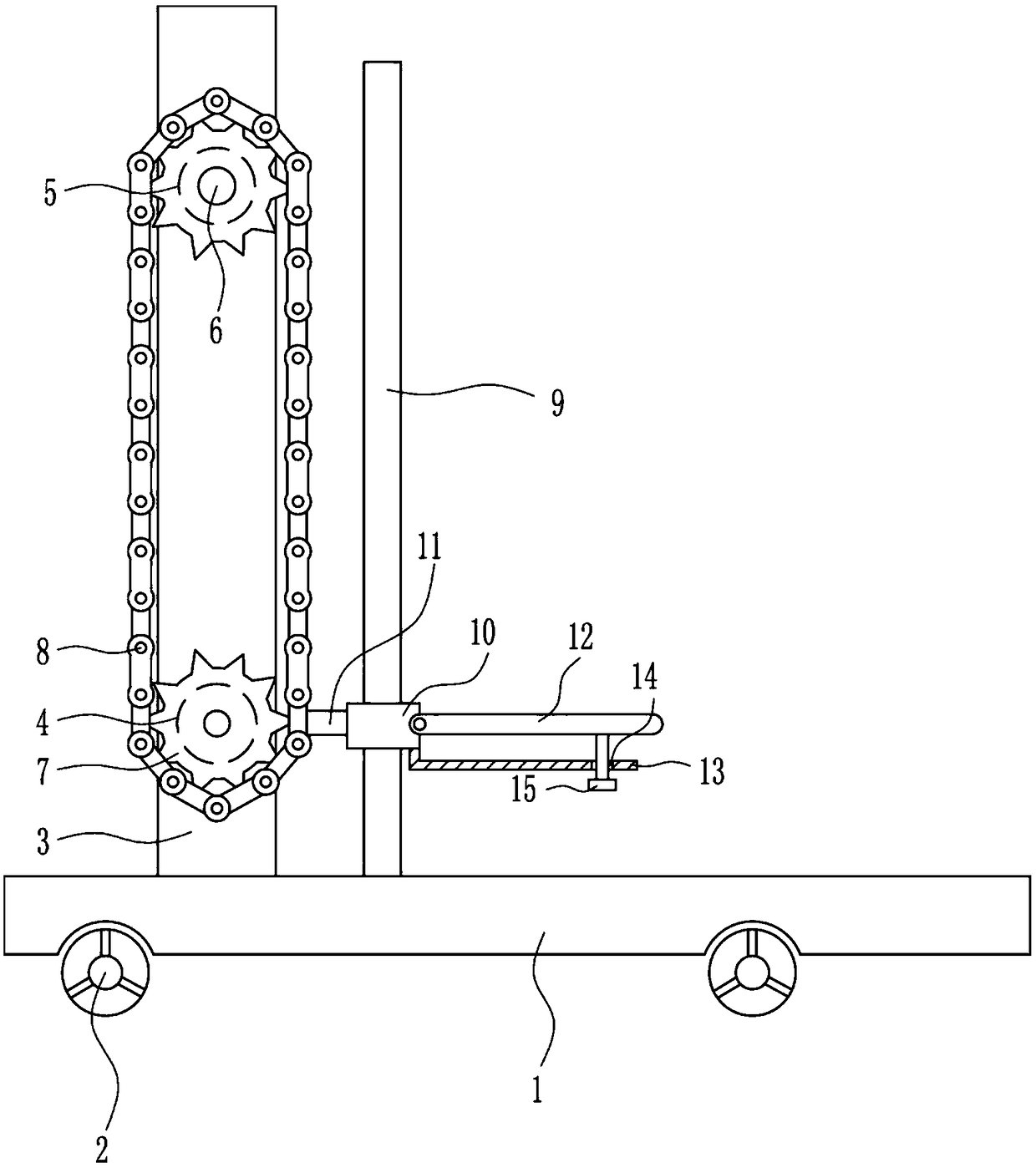

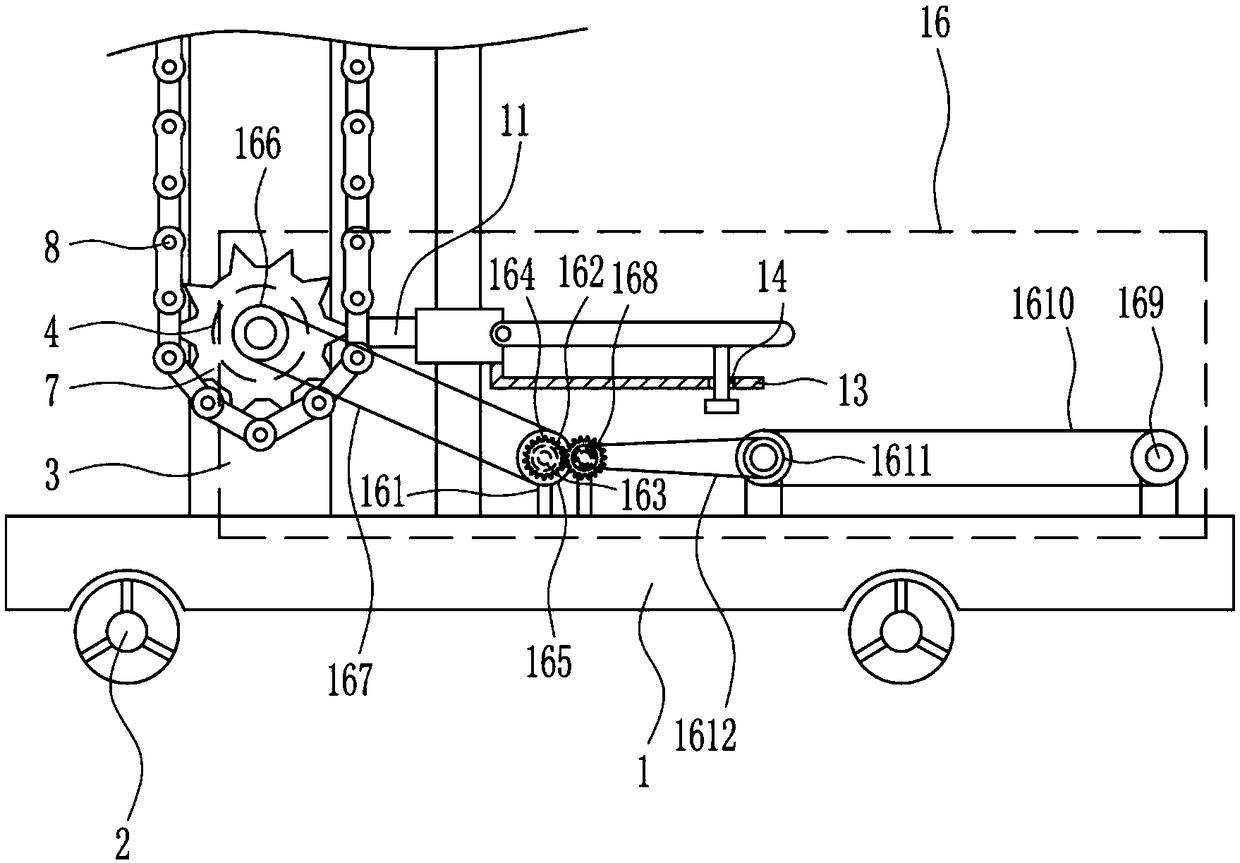

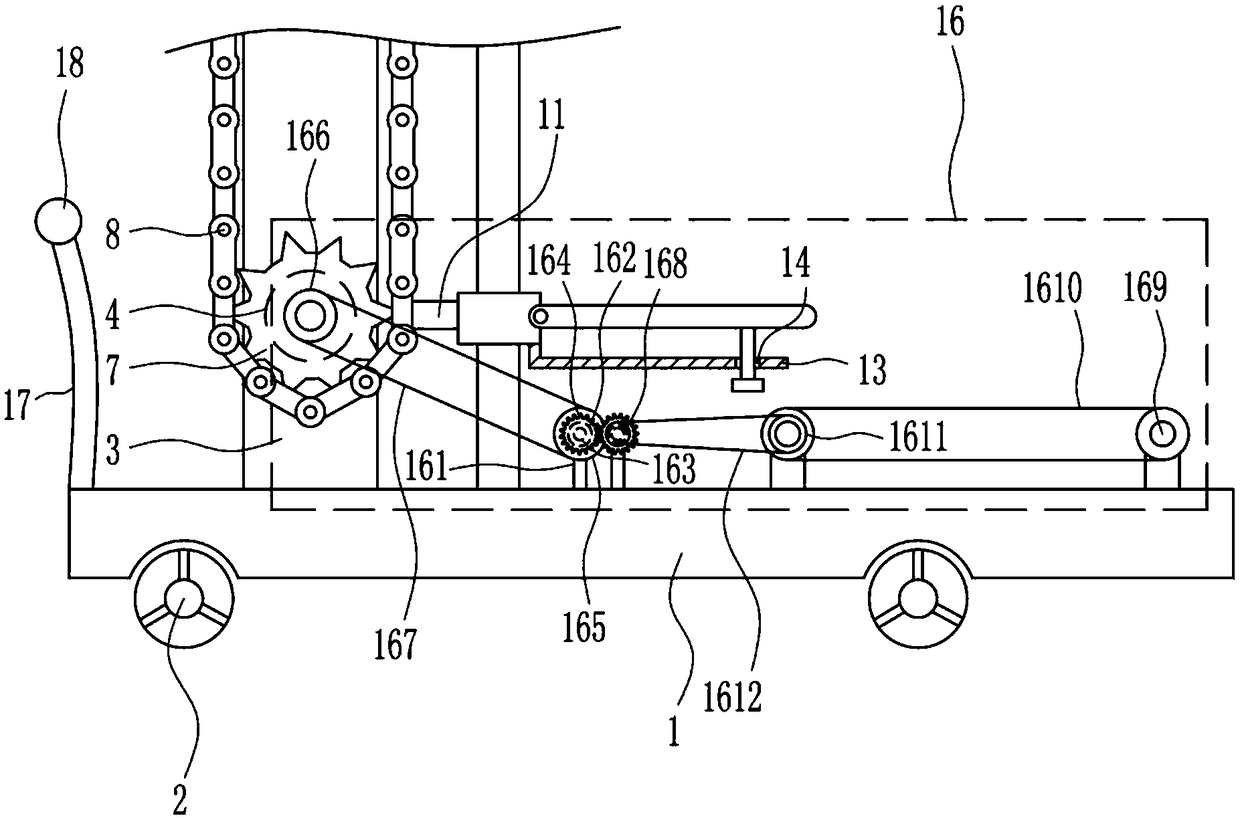

Mechanical truck-unloading device

The invention relates to a truck unloading device, in particular to a mechanical truck-unloading device. The object of the invention is to provide a mechanical truck-unloading device which can improvethe truck unloading speed and ensure the unloading safety. The invention adopts the following technical scheme: a mechanical truck-unloading device comprises a base plate, wheels, a mounting plate, amotor, a first bearing seat, a first rotating shaft, first gears, a chain, a guide rod, a guide sleeve, a connecting rod, etc., wherein the wheels are mounted at the bottom of the base plate; the mounting plate is arranged on the left side of the top of the base plate; the motor is arranged at the lower part of the front side of the mounting plate; the first bearing seat is arranged at the upperpart of the front side of the mounting plate; the first rotating shaft is arranged in the first bearing seat; and the front end of the first rotating shaft and an output shaft on the front side of themotor are both connected with the first gears. The mechanical truck-unloading device provided by the invention achieves the effects of improving the truck unloading speed and ensuring the unloading safety. Through ascending and descending of a placement plate, the mechanical truck-unloading device can conveniently and quickly unload goods from a truck; and a conveying device can convey goods on aconveying belt to the right side of the base plate, so that a user can unload the goods more conveniently.

Owner:JINYIMENG GRP CO LTD

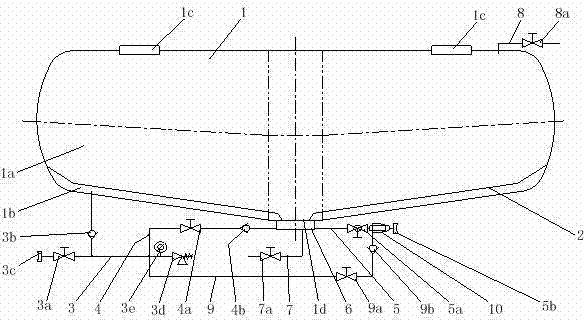

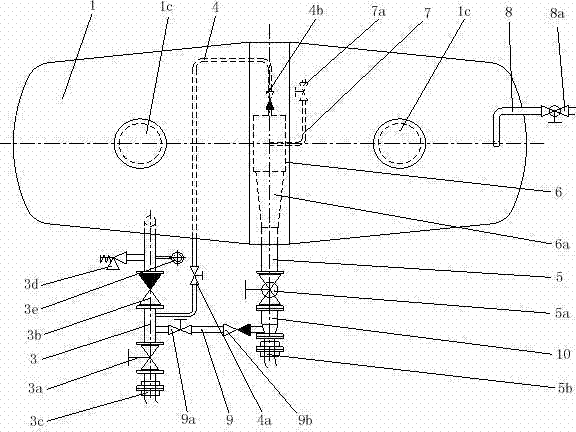

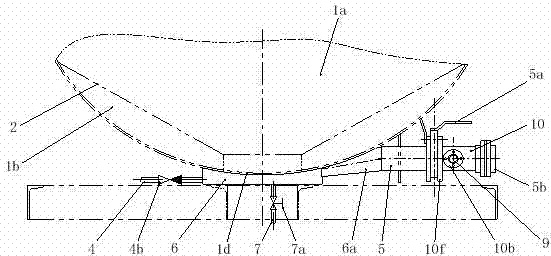

Unloading system of horizontal pneumatic powder transport vehicle

ActiveCN104843359AEliminate negative differential pressureEradicate leaksLarge containersHigh concentrationFluidized bed

The invention discloses an unloading system of a horizontal pneumatic powder transport vehicle. The unloading system comprises a tank, a fluidized bed device, a main air supply pipeline system, an unloading air inlet dredging pipeline system and an unloading pipeline system. The fluidized bed device is arranged inside the tank and is fixedly connected with the tank, a material loading compartment which is used for loading materials is formed on the upper portions of the tank and the fluidized bed device, a tank partition compartment is formed on the lower portions of the tank and the fluidized bed device, loading holes which are communicated with the material loading compartment are formed in the upper portion of the tank, a discharge groove which is communicated with the material loading compartment is formed in the bottom of the tank, the tail end of the main air supply pipeline system penetrates the bottom of the tank and is communicated with the tank partition compartment, one end of the unloading air inlet dredging pipeline system is connected with the main air supply pipeline system, the other end of the unloading air inlet dredging pipeline system is connected with one end of the discharge groove, and the other end of the discharge groove is connected with the unloading pipeline system. The unloading system has the advantages that the materials can be pneumatically transported under high-concentration and dense-phase conditions, accordingly, purposes of increasing the unloading speeds and reducing powder remain ratios can be achieved, and the unloading system has a great potential economic benefit.

Owner:CRRC MEISHAN

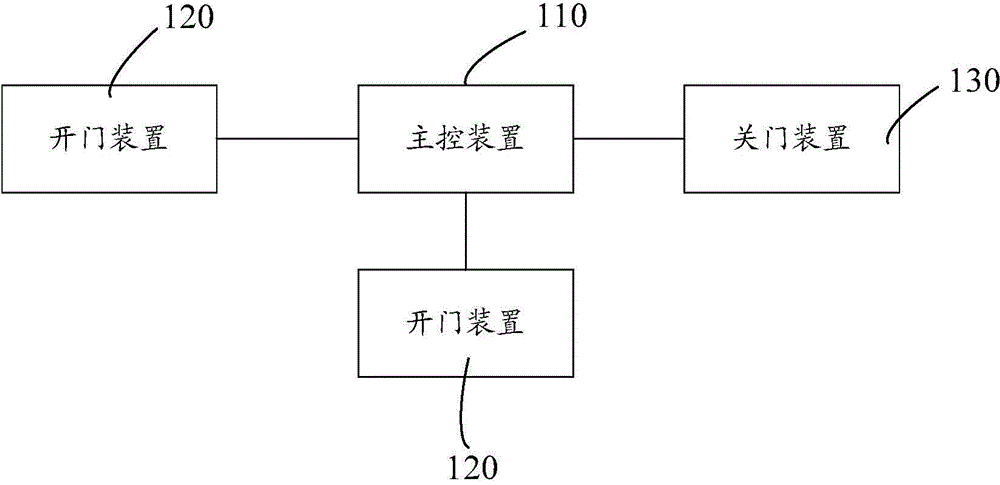

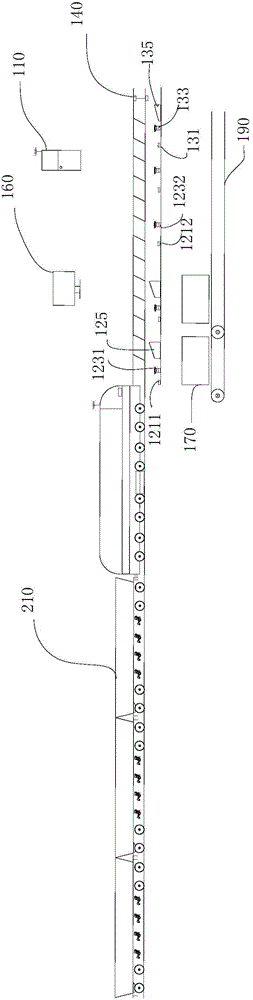

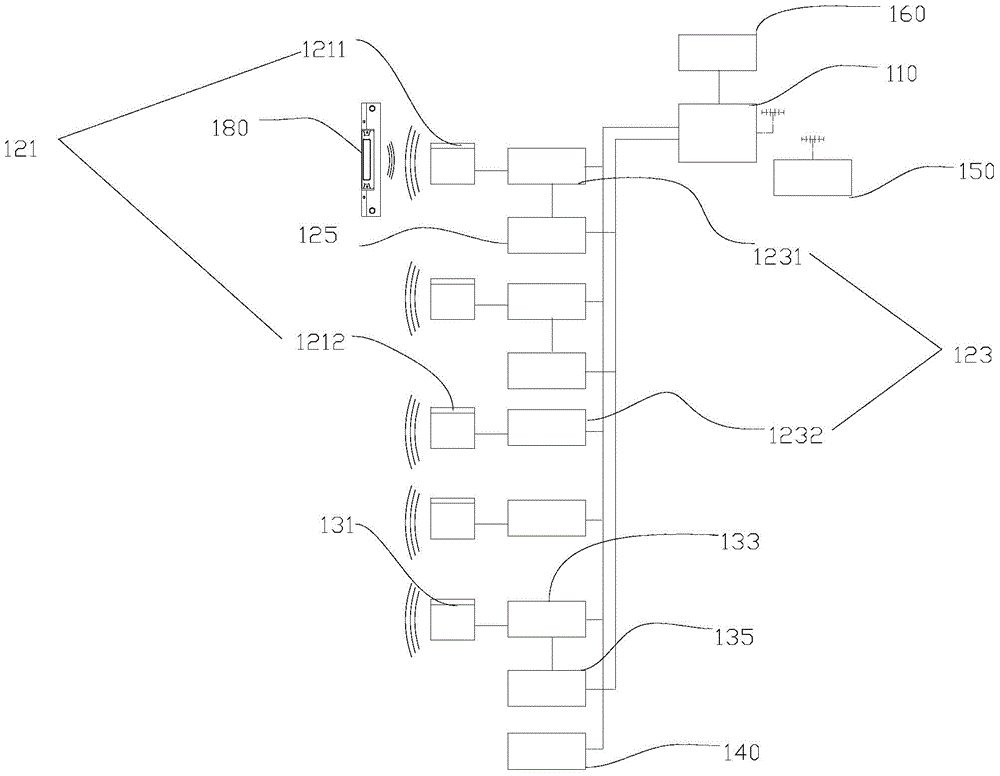

Automatic unloading control system of hopper car and control method thereof

ActiveCN104442854ARealization of automatic unloadingIncrease unloading speedHopper carsAutomatic train controlEngineering

The invention discloses an automatic unloading control system of a hopper car and a control method thereof. The automatic unloading control system of the hopper car comprises a main control device, a door closing device and at least two sets of door opening devices. The main control device is connected with the door closing device and the door opening devices, and the door opening devices and the door closing device are arranged on the side of a hopper car operation rail in the heading direction of the hopper car. The door opening devices and the door closing device acquire vehicle information and send the vehicle information to the main control device, and the main control device receives the vehicle information and then correspondingly sends a door opening drive instruction to the door opening devices to open a bottom door of the hopper car or sends a door closing drive instruction to the door closing device to close the bottom door of the hopper car. Through the door opening devices, the opening and closing control over the bottom door of the hopper car is achieved so that automatic loading can be achieved, stop unloading is of no need, the speed of unloading is increased, and therefore the unloading efficiency is improved.

Owner:湖南广思科技有限公司

Tank truck heating device

The invention provides a tank truck heating device, which is arranged on an outer surface of a lower part of a tank body of a tank truck, and comprises a heating plate, longitudinal support irons arranged on two ends of the heating plate and longitudinally arranged along the tank body, annular support irons arranged between the longitudinal support irons and arranged along the peripheral direction of the tank body and a diversion trench, and the diversion trench, wherein the shape of the heating plate is a circular arc adapted to the shape of the tank body; a plurality of annular support irons are arranged; steaming holes are arranged on the middle annular support irons; and the diversion trench is longitudinally arranged along the longitudinal support irons and is connected with the annular support irons. The tank truck heating device is an outer steam jacket type heating device with the diversion trench, and the diversion trench is arranged in the outer heating device and is used for guiding heating steam flow direction and flux, so that the heating efficiency of the outer heating device is improved, and the time for unloading is shortened.

Owner:XI AN RAILWAY TRANSPORTATION EQUIP

Automatic unloading punch for hardware processing

InactiveCN109013965AEasy to unloadIncrease unloading speedStripping-off devicesPunch pressEngineering

The invention provides an automatic unloading punch for hardware processing, and relates to the field of hardware processing equipment. The automatic unloading punch comprises a base, wherein supportlegs are fixedly connected to four corners of the top of the base respectively, an operating platform is fixedly connected to the tops of the support legs, a lower die is fixedly connected to the topof the operating platform, a punch body is fixedly connected to the top of the operating platform and is located on the back surface of the lower die, an air cylinder is fixedly connected to the top of the front surface of the punch body, a punching rod is arranged at the bottom of the air cylinder, and an upper die is fixedly connected to the bottom of the punching rod. According to the automaticunloading punch for hardware processing, a part cannot deflect when moving on a sliding plate by virtue of a baffle on the top of the sliding plate, so that the part directly enters a collecting box,and the unloading efficiency is improved; a push rod can be limited by virtue of a limiting bracket on the top of the operating platform, so that the push rod cannot deflect, and the moving track ofthe push rod is limited; and a rotary rod can rotate at a certain degree by virtue of a movable groove in the top of an unloading device, and the rotary rod cannot excessively rotate.

Owner:JIANGYIN CHANGJING CAR & SHIP ACCESSORY

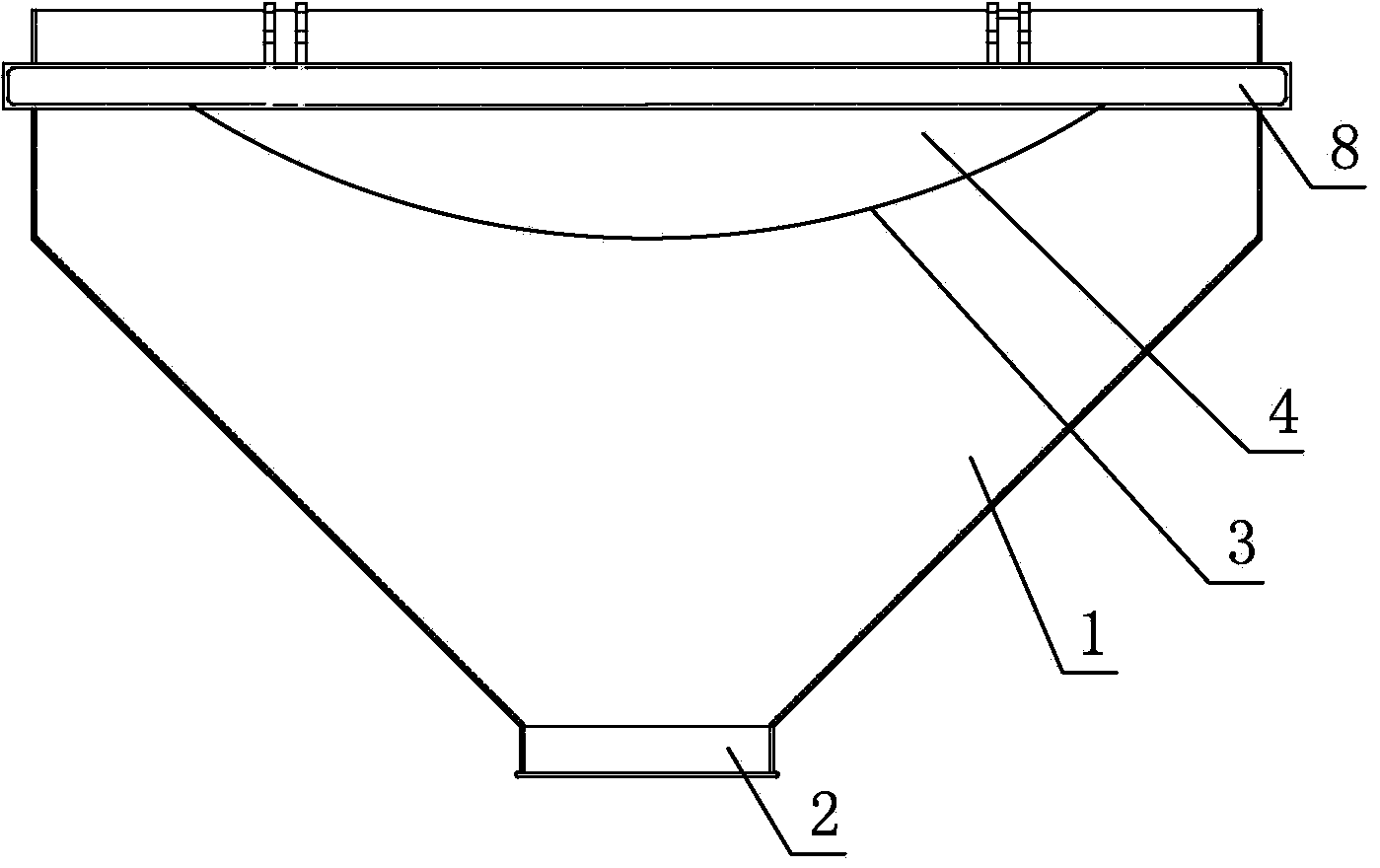

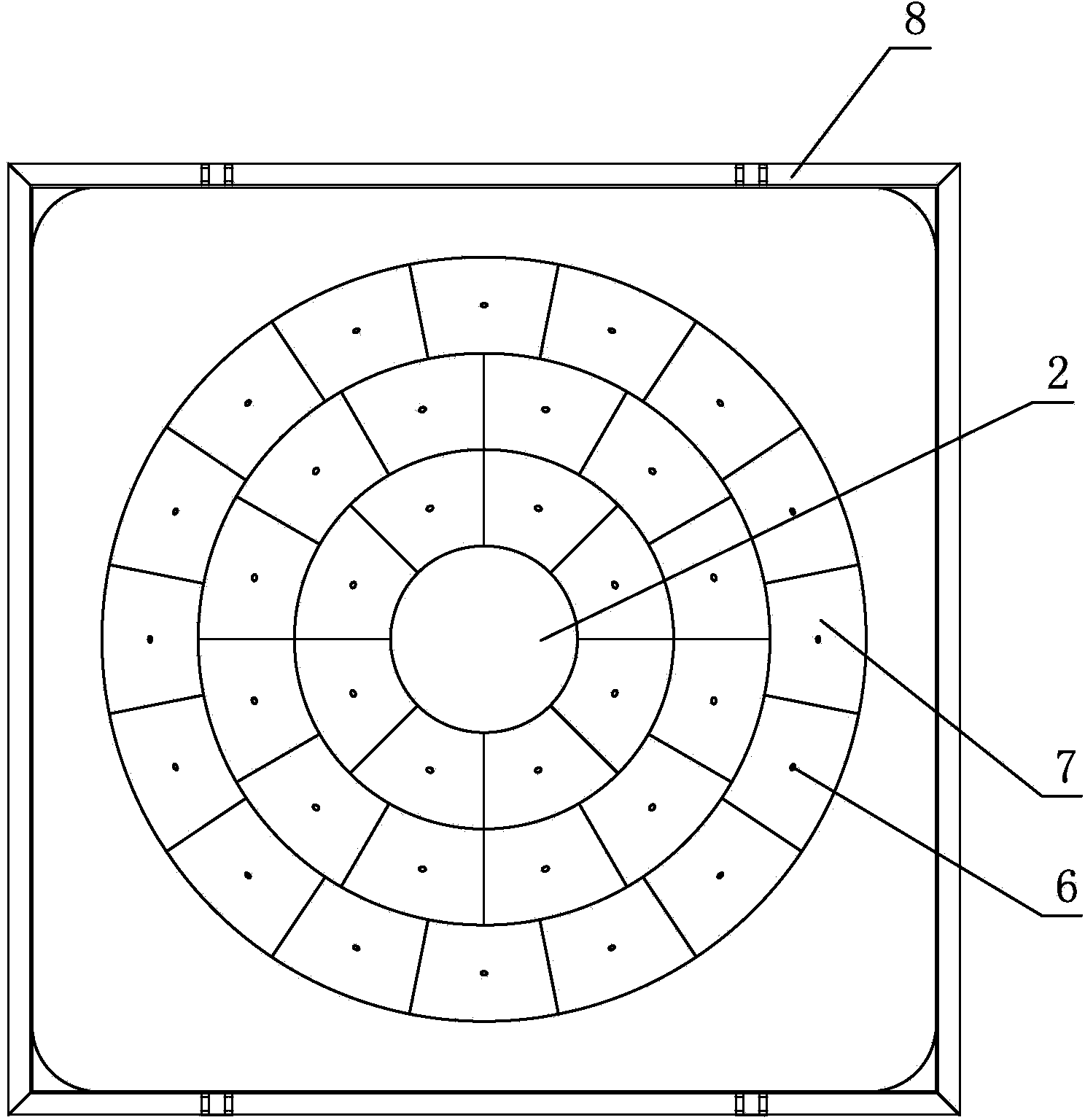

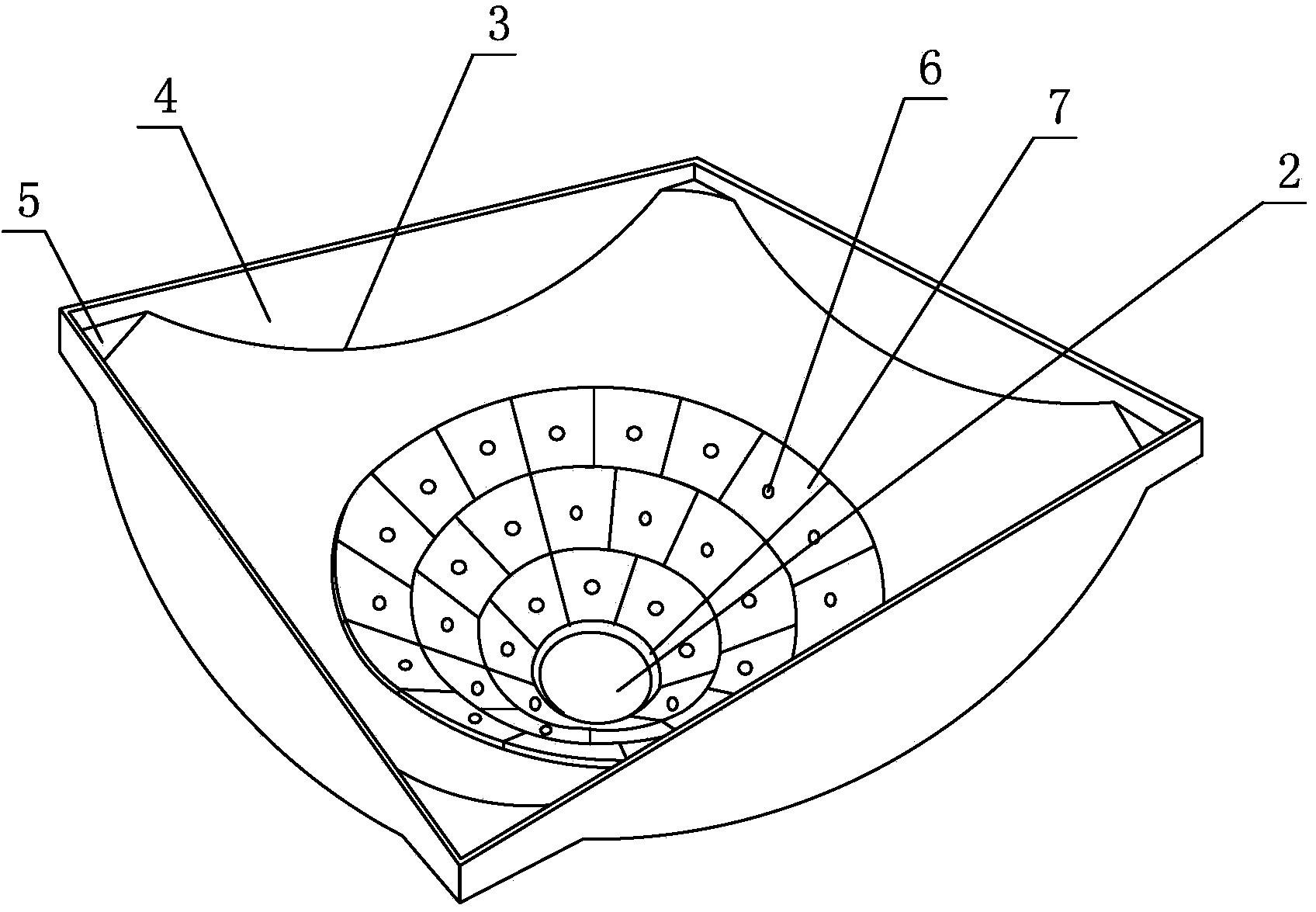

Gathering hopper of stirring station

The invention discloses a gathering hopper of a stirring station. The gathering hopper comprises a conical material barrel, wherein a material blanking port is formed in the bottom of the conical material barrel; four arc-shaped notches with the same size are uniformly formed in the circumference of the top end of the conical material barrel; a material blocking plate is vertically arranged at each arc-shaped notch; the ends of each two adjacent material blocking plates are vertically welded; the four material blocking plates define a square feed port which is matched with the square installation port on the platform of the stirring station; a seal plate is arranged at the clearance which is between the top end of the conical material barrel between each two arc-shaped notches and the welded materials plates arranged at the two arc-shaped notches. The structure of the gathering hopper is reasonable in design; the conical material barrel is adopted and the inner surface is arc-shaped, so that discharge dead angle does not exist, concrete is avoided from adhering to the material barrel and the normal material blanking of the conical material barrel is guaranteed; besides, a replaceable arc-shaped lining plate is additionally arranged at the lower part of the inner side of the conical material barrel, so that the service life of the gathering hopper is greatly prolonged.

Owner:SHANDONG MIX MACHINERY EQUIP

Container vehicle hopper used for mine-use electric locomotive and capable of quickly and thoroughly unloading

ActiveCN107139957ARaise the oreAvoid cloggingRailway device loading/unloadingMine carsEngineeringBolt connection

The invention relates to a mine-use electric locomotive, in particular to a container vehicle hopper used for the mine-use electric locomotive and capable of quickly and thoroughly unloading. The technical purpose is to provide the container vehicle hopper used for the mine-use electric locomotive and capable of quickly and thoroughly unloading, the unloading speed is high, the unloading efficiency is high, unloading is complete and no residues are left; the container vehicle hopper used for the mine-use electric locomotive and capable of quickly and thoroughly unloading includes a container vehicle hopper body, a first sliding rail, a first slider, a handle, a push plate, a placement plate, a support base, a first rotating shaft, a cover plate, a first nut and the like; the inside of the right side wall of the container vehicle hopper is provided with the first sliding rail in a bolted connection mode, and the inside of the first sliding rail is connected with the first slider in a sliding mode. The container vehicle hopper achieves the effects that the unloading speed is high, the unloading efficiency is high, unloading is complete and no residues are left, and a brushing board is adopted to brush ore on a first inclined plate down.

Owner:FUJIAN MAKENG MINING CO LTD

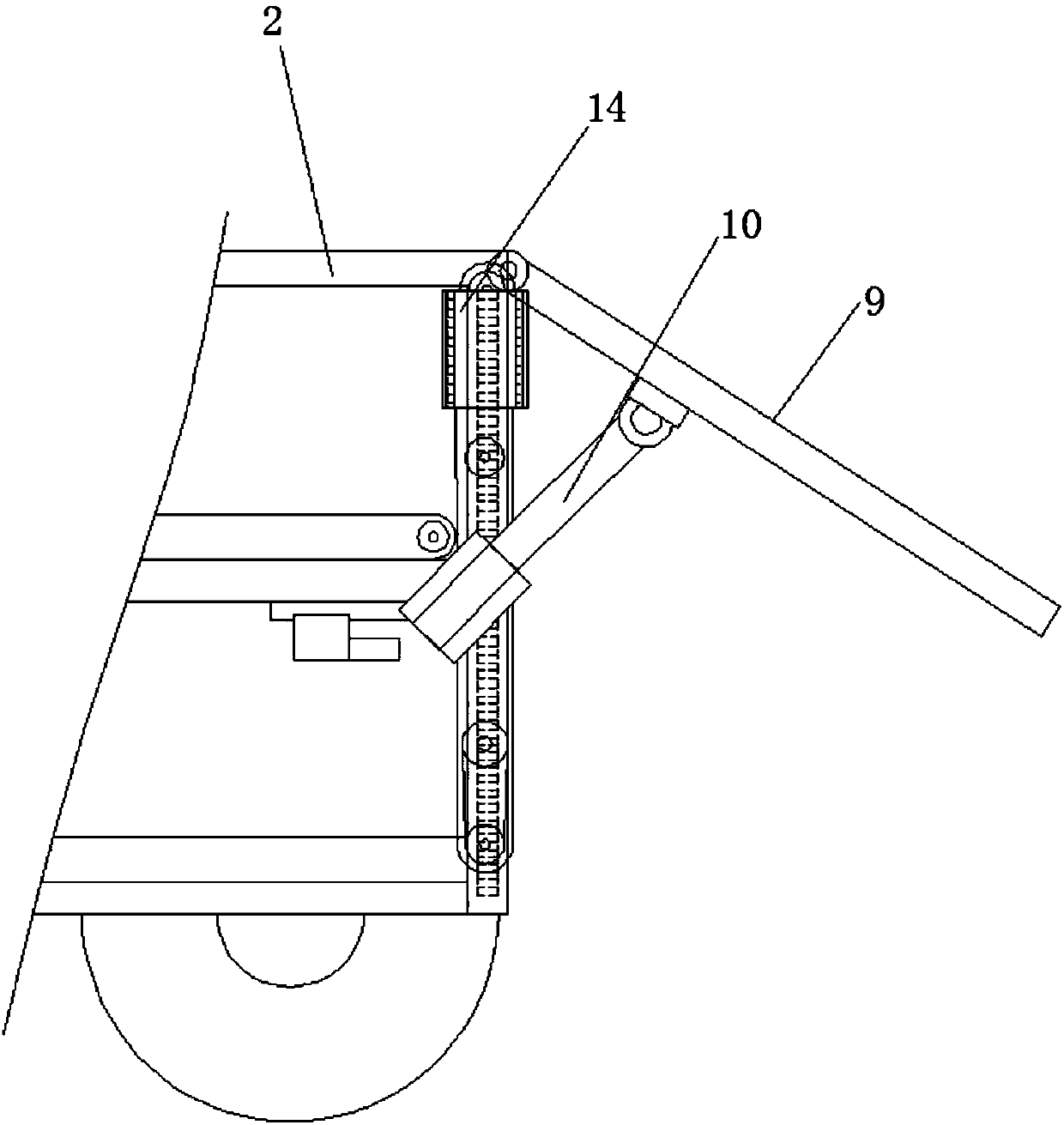

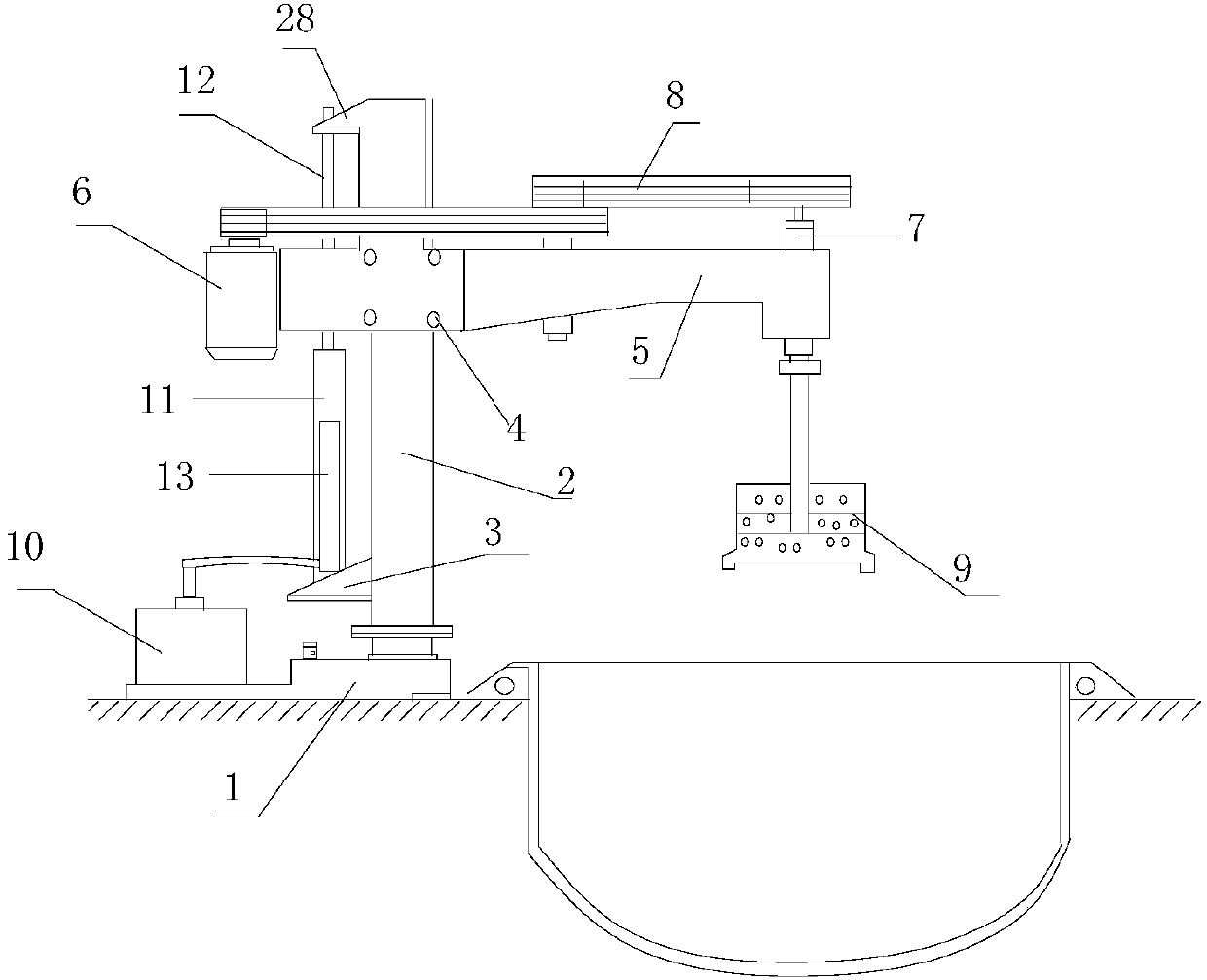

Slag-salvaging stirring machine

PendingCN107931595AReduce lossesEven by forceCasting cleaning apparatusSlagAssistive device/technology

The invention belongs to the technical field of metal smelting auxiliary equipment. A slag-salvaging stirring machine comprises a base, a lifting mechanism and a working cantilever. The lifting mechanism comprises a main body guiding column and a hydraulic pushing rod, the main body guiding column is connected with the base, a hydraulic rod base is arranged on the main body guiding column, the hydraulic pushing rod is arranged on a hydraulic pushing rod base, and the lifting mechanism is used for rising and falling of the working cantilever; the working cantilever comprises a guiding wheel device, a cantilever body, a transmission motor, a rotating shaft, a transmission belt and a slag-salvaging hopper; the guiding wheel device is slidably connected with the main body guiding column, the cantilever body is fixedly connected with the guiding wheel device, the transmission motor is arranged at one end of the cantilever body, and the other end of the cantilever body is provided with the rotating shaft; and an output shaft of the transmission motor and one end of the rotating shaft are connected through the transmission belt, and the slag-salvaging hopper is mounted at the other end ofthe rotating shaft. According to the slag-salvaging stirring machine, in the slag-salvaging process, metal loss is less, and the slag-salvaging working efficiency is high.

Owner:南丹县南方有色金属有限责任公司

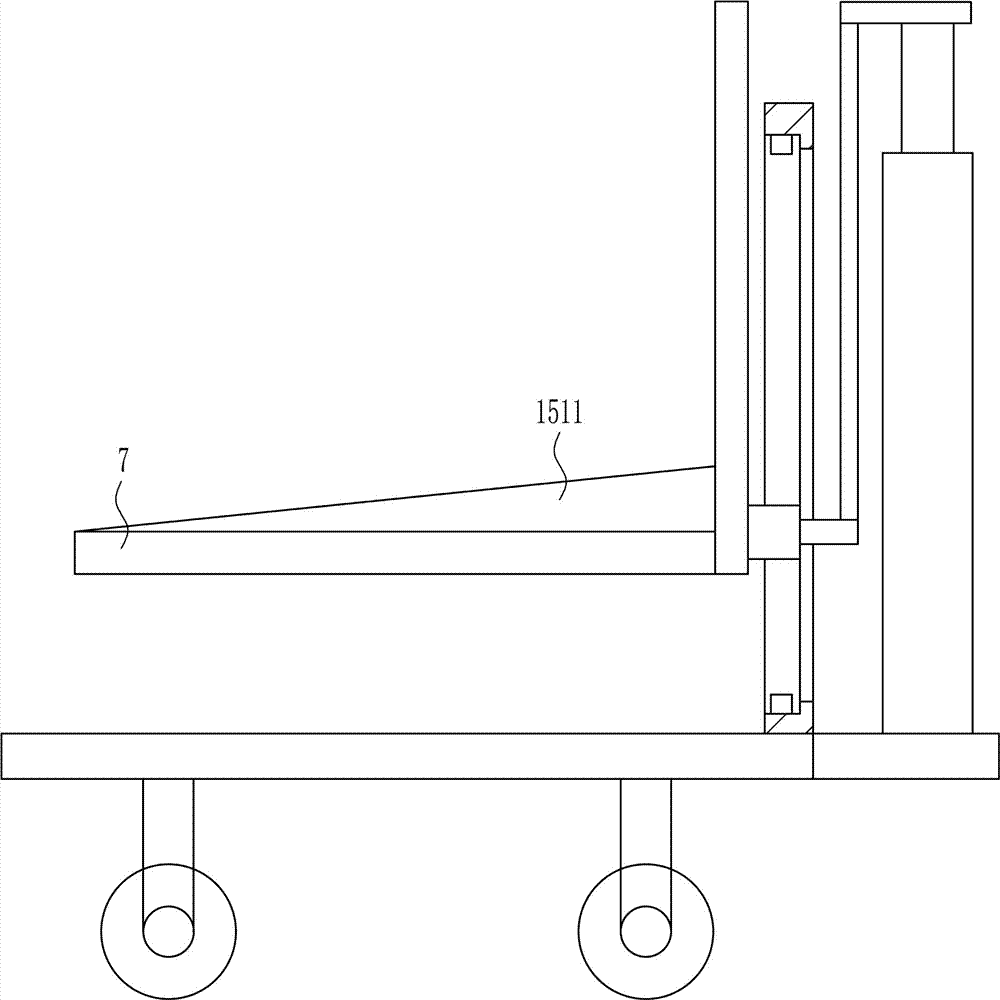

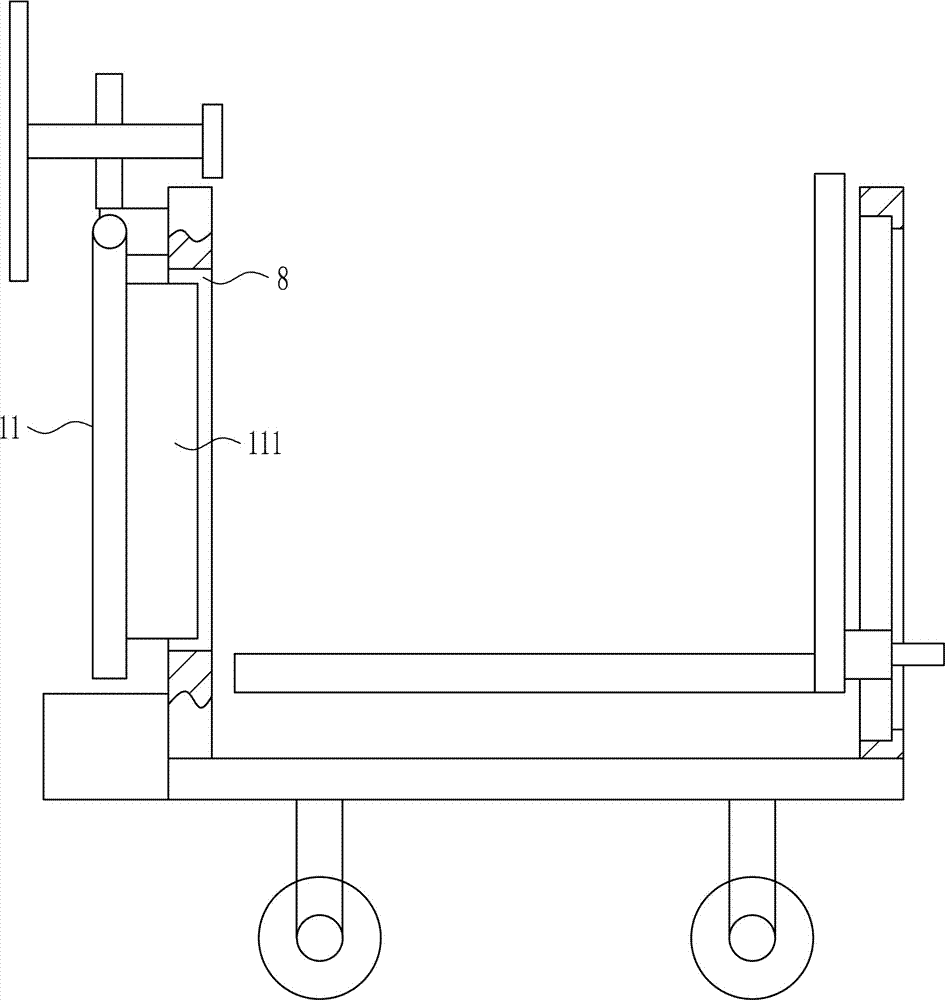

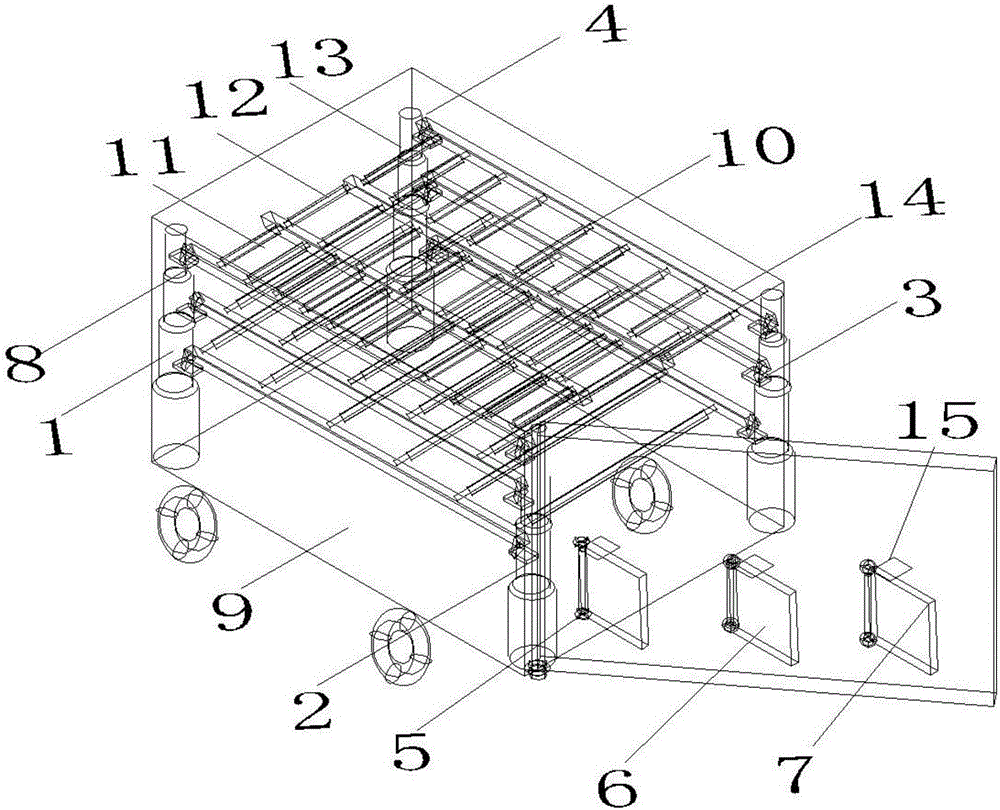

Mechanical automatic unloading device

ActiveCN113353535AReduce downtimeAvoid interruptionConveyorsStacking articlesStructural engineeringMechanical engineering

The invention discloses a mechanical automatic unloading device. The mechanical automatic unloading device comprises a bottom plate and telescopic supporting columns. The telescopic supporting columns are mounted at the four corners of the bottom plate through shaft pieces. The top of the bottom plate is connected with a multifunctional unloading plate through a threaded column. The surfaces of the telescopic supporting columns are sleeved with lantern rings. The surfaces of the lantern rings are connected with traction ropes. The tail ends of the two traction ropes are connected with a vertical plate. A transfer intercepting structure is mounted at the top of the vertical plate. The tail ends of the other two traction ropes are connected with an auxiliary unloading plate. Moving pieces are mounted at the bottoms of the vertical plate and the auxiliary unloading plate. Protection plates are mounted on the two sides of the top of the multifunctional unloading plate. An embedding groove is formed in the front face of one protection plate. The front faces of the protection plates are in sliding connection with a blocking plate through the embedding groove. According to the mechanical automatic unloading device, through arrangement of the auxiliary unloading plate, the single-time unloading bearing capacity of the device can be improved, accordingly, the unloading frequency is reduced, and the unloading efficiency of the device is improved.

Owner:李小玲 +2

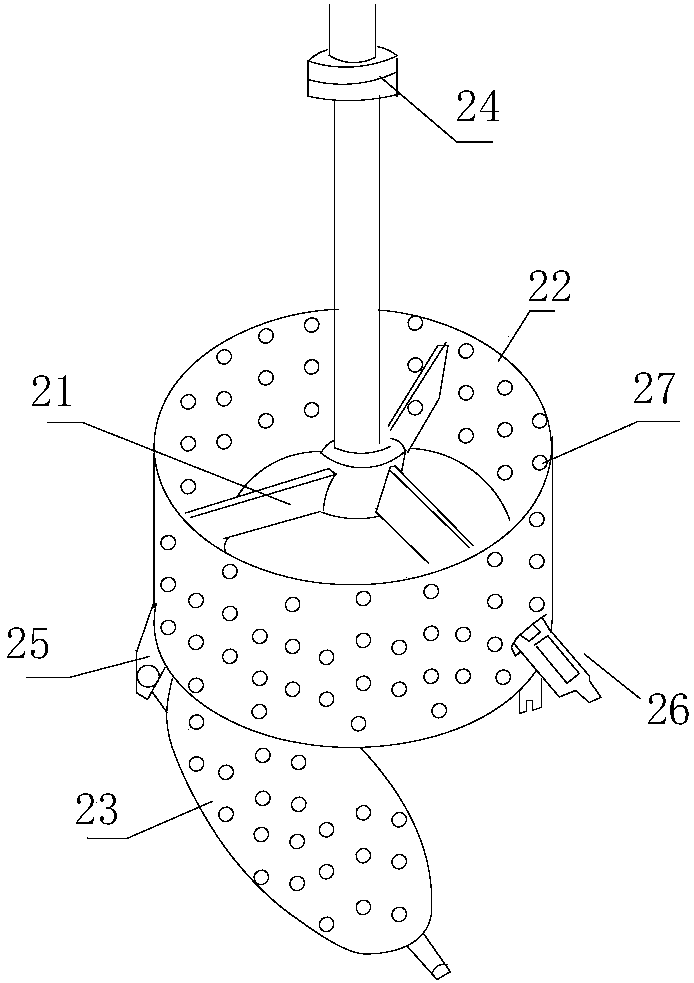

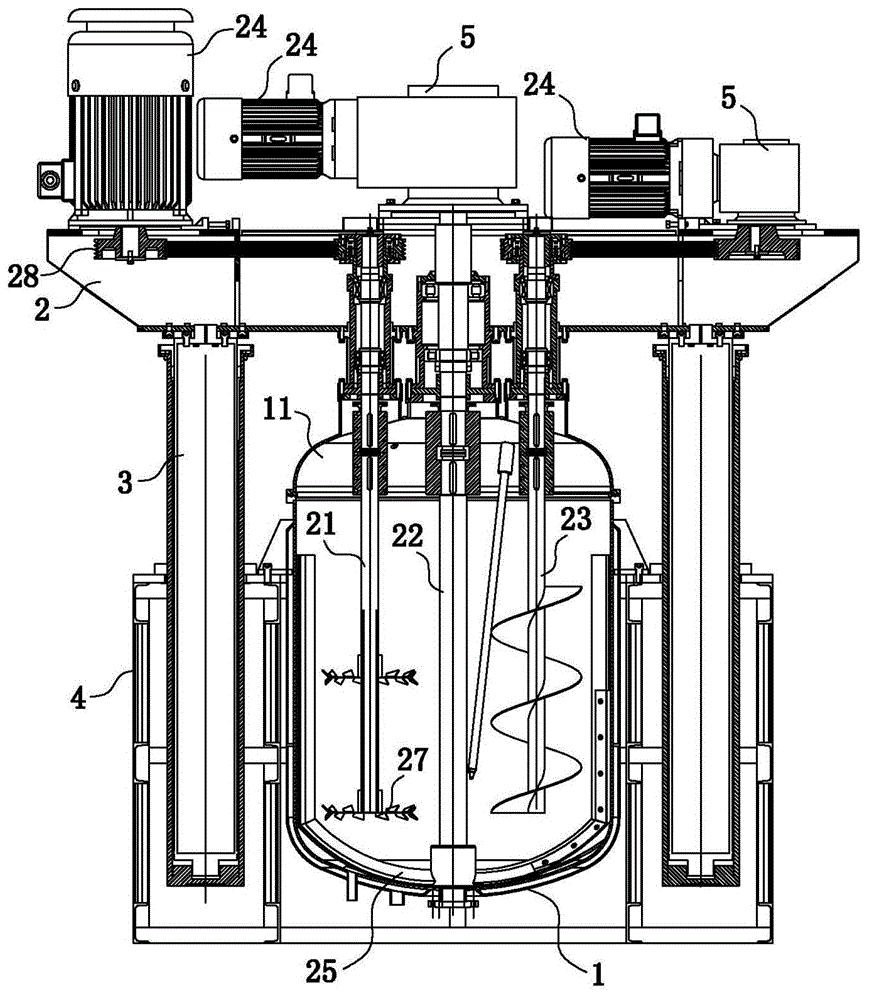

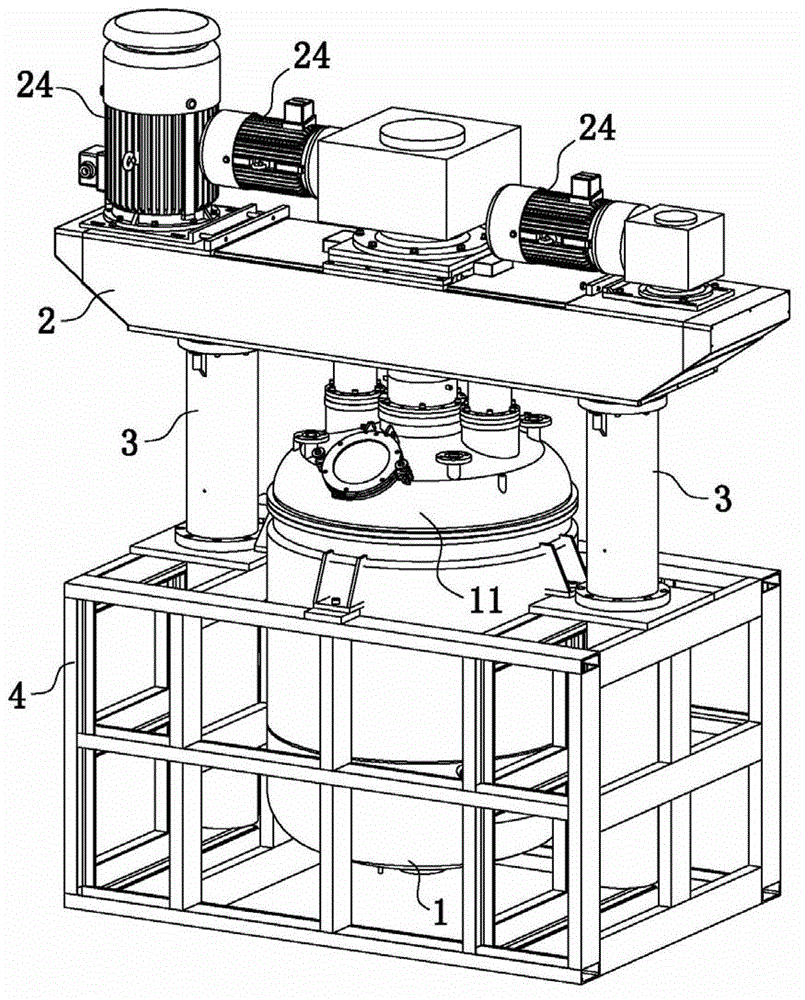

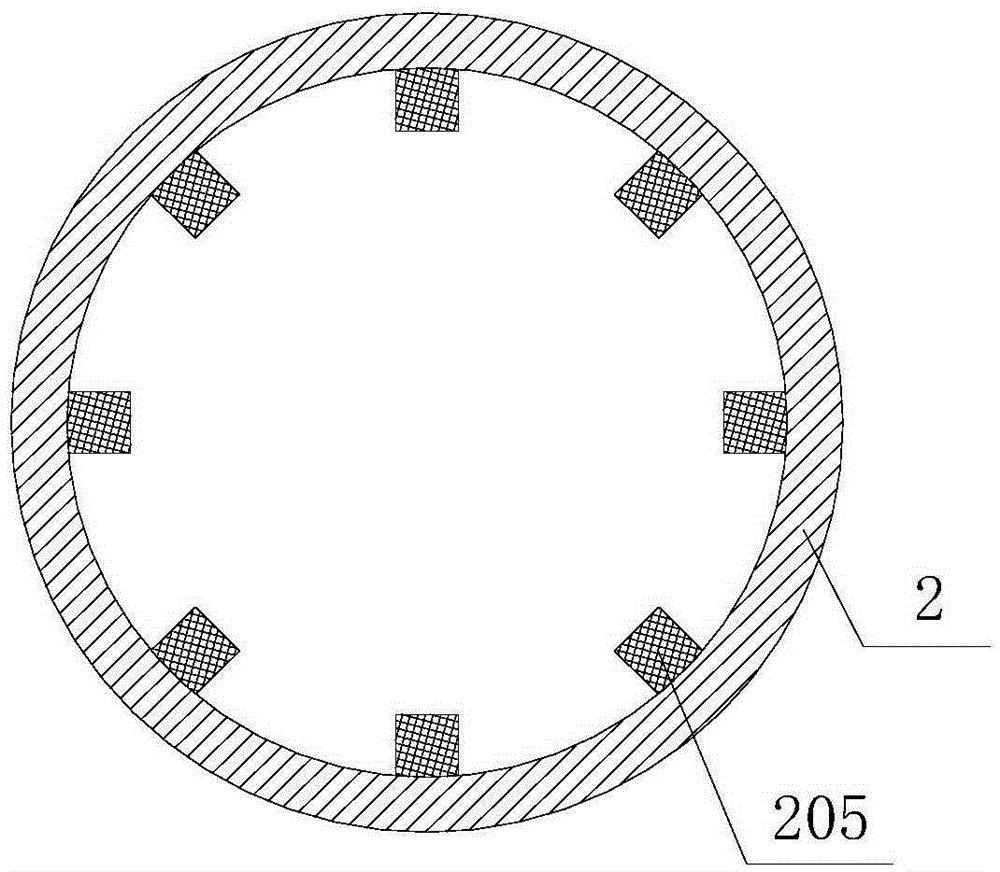

Wall-scrapping type high-speed disperse mixer

ActiveCN102974242AImprove uniformitySimple structureRotary stirring mixersMixer accessoriesLow speedEngineering

The invention discloses a wall-scrapping type high-speed disperse mixer, belonging to a material stirrer. The wall-scrapping type high-speed disperse mixer comprises a kettle body and a stirring device arranged above the kettle body, wherein the stirring device internally comprises a high-speed shaft, an intermediate-speed shaft, a low-speed shaft and a motor, wherein the top ends of the high-speed shaft, the intermediate-speed shaft and the low-speed shaft are respectively in power connection with an output shaft of the motor, and the high-speed shaft, the intermediate-speed shaft and the low-speed shaft extend into a cavity in the kettle body through a kettle cover; and at least one tooth-shaped dispersing disc is arranged on the high-speed shaft, and the lower end of the low-speed shaft is provided with a frame type stirrer. The kettle body is internally provided with the high-speed shaft, the intermediate-speed shaft and the low-speed shaft, which are rectilinearly arranged with one another, the material is writhed up and down in the kettle body to have a complex motion under the action of the stirring devices on different shafts, and the solid-phase material can be quickly dispersed. The wall-scrapping type high-speed disperse mixer provided by the invention is simple in structure, suitable for the dispersing and stirring of various sticky materials, and suitable for the technical preparation of pastes such as sealant, cosmetics, ink, chocolate and ointment, thereby being wide in application range.

Owner:CHENGDU GUIBAO SCI & TECH

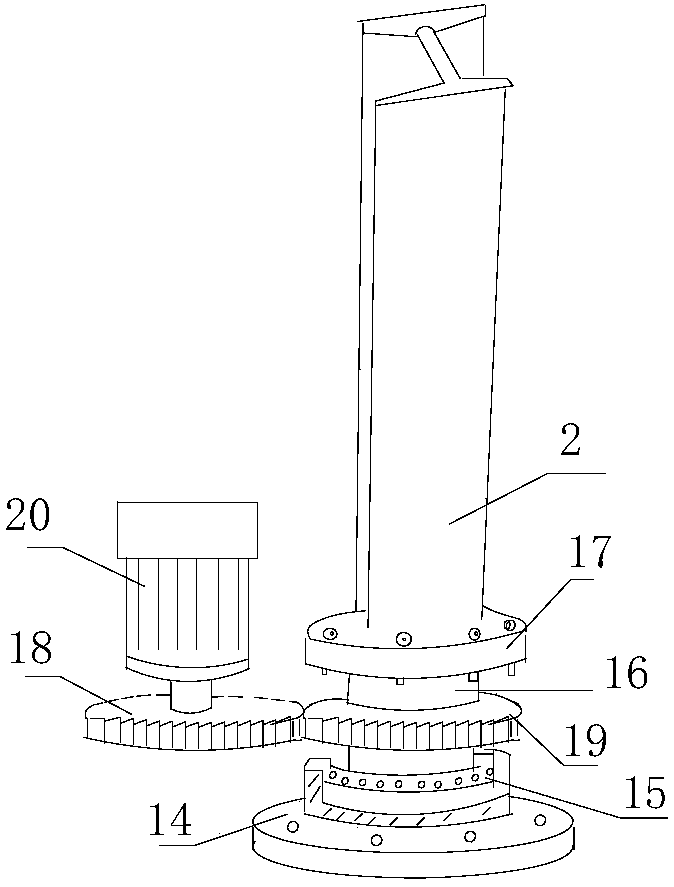

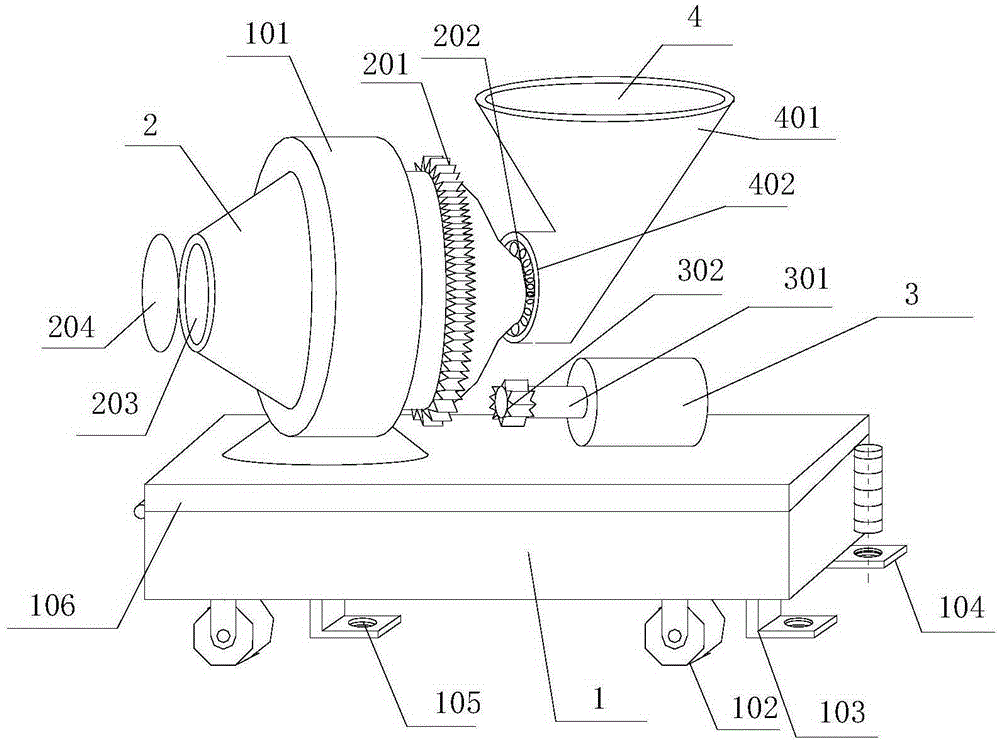

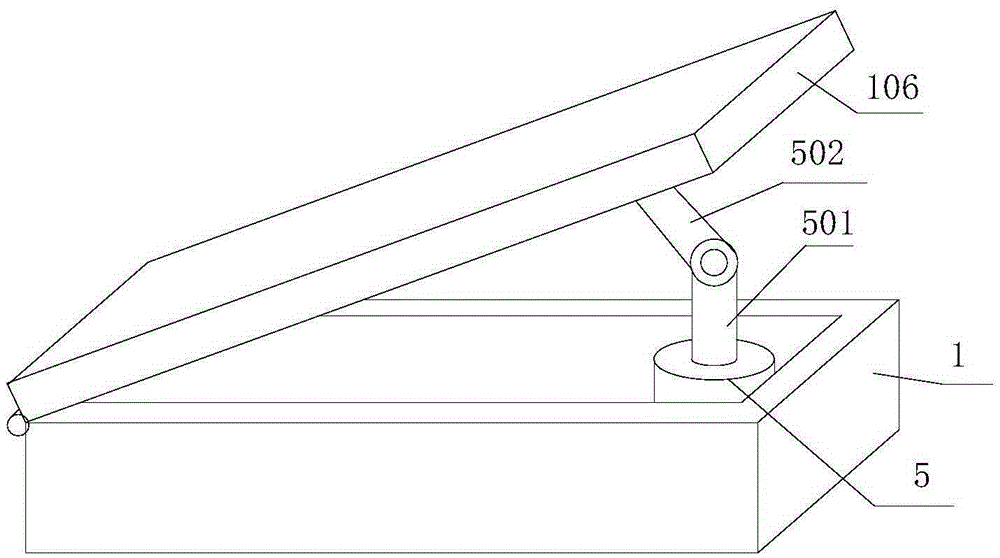

Easy-to-unload type concrete stirring device

InactiveCN106671289AEasy flipAvoid dead-end situationsDischarging apparatusCement mixing apparatusPulp and paper industryBarrel Shape

The invention discloses an easy-to-load type concrete stirring device. The concrete stirring device comprises a machine frame, a stirring tank and a motor, wherein the stirring tank adopts a barrel shape; a tooth ring which winds a barrel body by one round is arranged on the stirring tank; a gear which is matched with the tooth ring is arranged at the tip of a shaft of the motor; a feed opening is formed in one end of the stirring tank; a discharge opening is formed in the other end of the stirring tank; a feed device is arranged at the discharge opening of the stirring tank; the stirring tank and the motor are both mounted on an overturning plate on the machine frame; one end of the overturning plate is hinged to the machine frame, and the other end of the overturning plate is connected to an air cylinder; the air cylinder is arranged at the inner part of the machine frame; and a cylinder rod of the air cylinder is hinged to a connecting rod on the overturning plate. The concrete stirring device disclosed by the invention has the beneficial effects that the stirring tank of the device is arranged on the overturning plate which can overturn, so that the stirring tank can be overturned to dump materials, and the material unloading speed is raised; and besides, the overturning plate is pushed to overturn by the air cylinder, so that time and labor are saved.

Owner:重庆特安建筑消防工程质量检测有限公司

Slate conveying device

PendingCN108557436AEasy flipFast unloading speedConveyorsControl devices for conveyorsAutomatic controlEngineering

The invention discloses a slate conveying device. The slate conveying device comprises a roller conveying frame, the tail end of the roller conveying frame is provided with an overturning conveying frame, the tail end of the overturning conveying frame is provided with a sensing device, and a sliding supporting base which supports the overturning conveying frame and can slide to one side is arranged below the overturning conveying frame; a jacking mechanism for jacking the overturning conveying frame and enabling the overturning conveying frame to overturn to one side is arranged on the sliding supporting base, and the sliding supporting base is provided with a walking mechanism which drives the sliding supporting base to slide to one side. According to the slate conveying device, the overturning conveying frame is automatically controlled to overturn, so that slates on the overturning conveying frame slide down at a discharging position, overturning is convenient, the discharging speed is high, and manual operation is not needed; when the slates different in size are conveyed, a sensor can be adjusted in position for sensing the slates different in size, and the adaptability is good; damage to the slates in the conveying process is little.

Owner:广西钟山县天顺石材有限公司

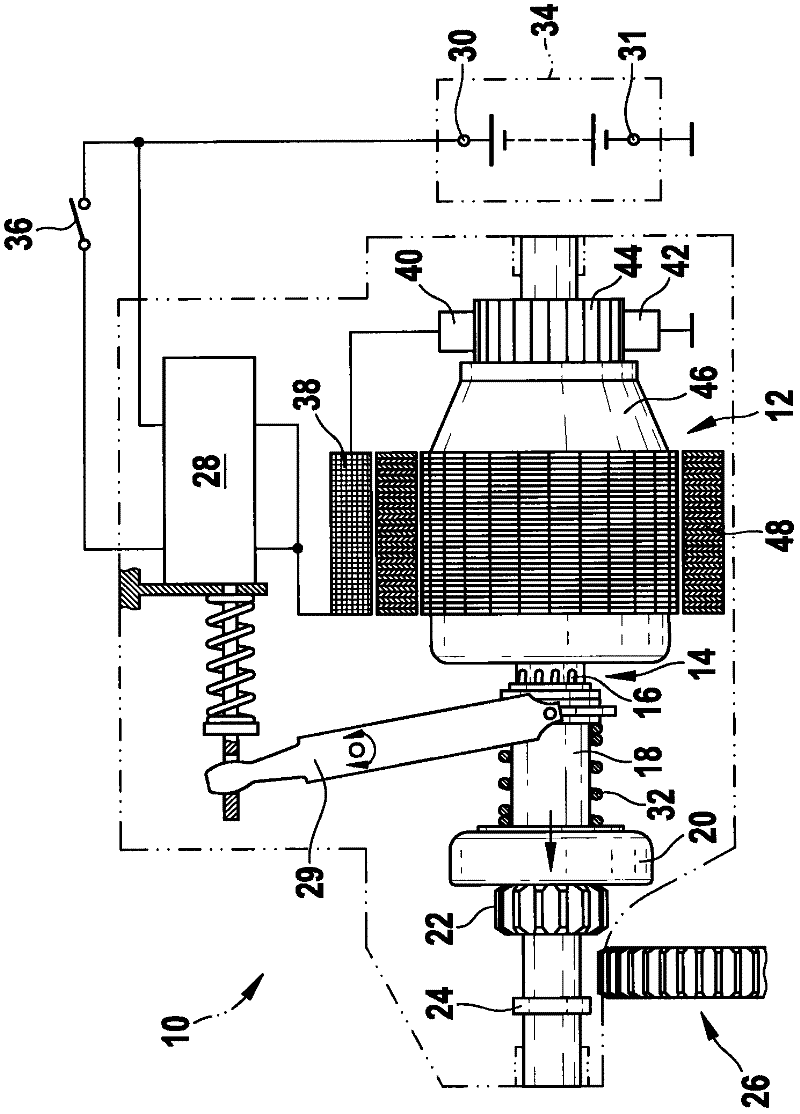

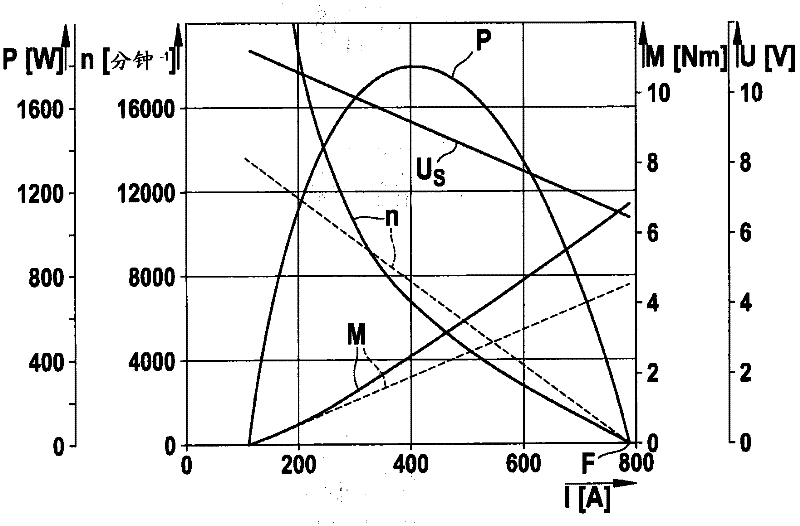

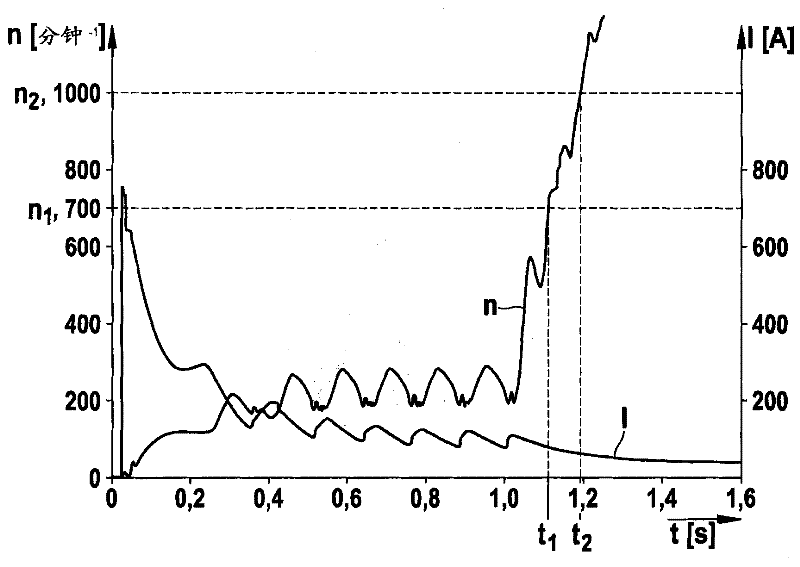

Method for operating a D.C. generator

InactiveCN102598500AIncrease unloading speedIncrease speedPower operated startersBatteries circuit arrangementsEngineeringInternal combustion engine

The invention relates to a method for operating a d.c. generator, especially a starter (10) for an internal combustion engine, the armature (46) of the machine being fed by brushes (42) and a commutator (44) from a constant voltage source (30, 31). The patination of the commutation system is monitored by the machine-specific startup current (I) and corrected by changing the operating parameters of the machine. The monitoring of the startup current (I) of the machine is carried out preferably on the basis of the power fade [delta]U during the startup in the main current circuit of the machine.

Owner:SEG AUTOMOTIVE GERMANY GMBH

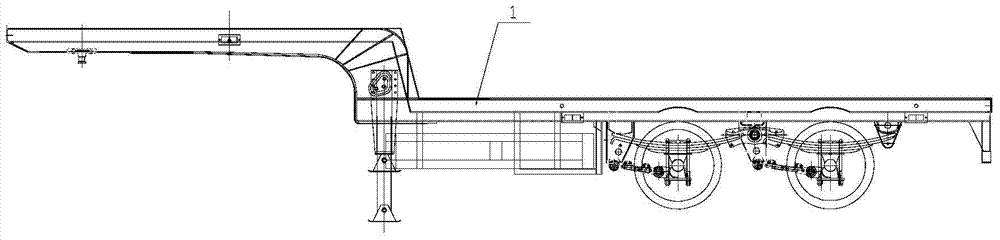

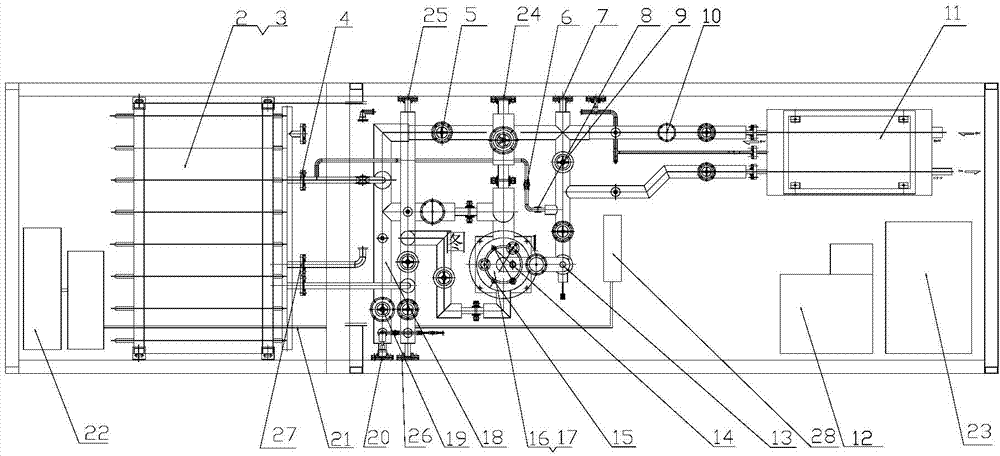

Small-chassis-removable LNG loading pry

ActiveCN104295888ALower installation heightImprove efficiencyContainer discharging methodsContainer filling under pressureEngineeringAir compressor

The invention relates to a small-chassis-removable LNG loading pry. A loading machine, an explosion-proof electrical cabinet, a supercharger, an EAG heater, an explosion-proof air compressor, a pump sump, an immersed pump, a vacuum pipeline system, a compressed air pipeline system, a loading machine electric system and a pneumatic electromagnetic valve are fixed to a small chassis. The loading machine electric system and the loading machine form a loading system. A liquid inlet of the supercharger is sealingly communicated with a liquid phase opening of a tank car, a liquid phase opening of a storage tank and a liquid outlet of the immersed pump respectively, and a liquid outlet of the supercharger is sealingly communicated with a gaseous phase opening of the storage tank and a gaseous phase opening of the tank car respectively, so as to form a supercharging system. An inlet of the EAG heater is connected with relief openings of all safety valves, so as to form a relief heating system. The explosion-proof air compressor is sealingly communicated with a compressed air main-pipeline of a pry body, so as to form the compressed air pipeline system. The immersed pump is put into the pump sump, so as to form a power system of the loading pry. First and second low-temperature quick action emergency valves, a low-temperature stop valve, a low-temperature check valve and a vacuum line form the vacuum pipeline system of the pry body.

Owner:XINXING ENERGY EQUIP

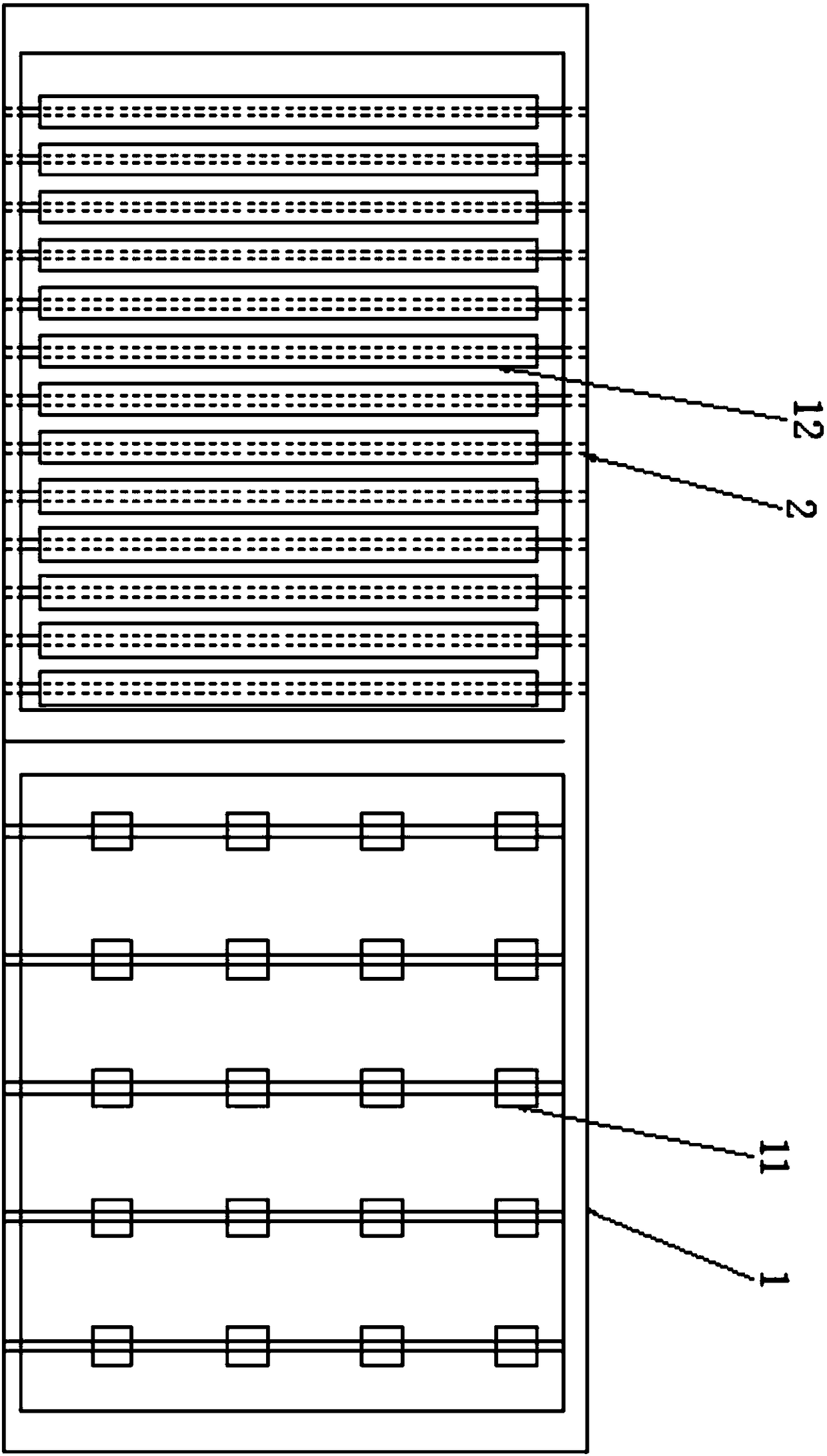

Transportation system, loading method and unloading method suitable for cold chain logistics container

InactiveCN105857151AAvoid pollutionReduce lossRefrigerated goods vehicleLoading/unloading vehicle arrangmentRefrigerator carEngineering

The invention discloses a transportation system, loading method and unloading method suitable for a cold chain logistics container. The transportation system comprises a container body. A plurality of lifting devices are arranged in the container body. Each lifting device comprises a plurality of stages of lifting mechanisms. Each stage of lifting mechanism is provided with shelf supporting brackets in a matched mode. The shelf supporting brackets of the same stage of lifting mechanism are used for supporting the same shelf. Each shelf is divided into N storage areas. N discharging ports are formed in the side wall of the container body. A discharging door is arranged at each discharging port in a matched mode. The shelves of each storage area are in one-to-one correspondence with the discharging doors. By the adoption of the transportation system, loading method and unloading method, transport workers can pull the container out of a compartment in a chain transportation mode without entering a refrigerator car; and the multiple small-sized discharging ports are designed, transferring and unloading can be conducted by multiple workers at the same time, and accordingly the discharging speed is improved by several times, time is shortened, and the transferring and unloading operation can be finished efficiently, conveniently and rapidly. Constant-temperature transferring and unloading of temperature-sensitive objects are guaranteed to the greatest extent, quality change is prevented, and energy waste is reduced.

Owner:SHANDONG JIAOTONG UNIV

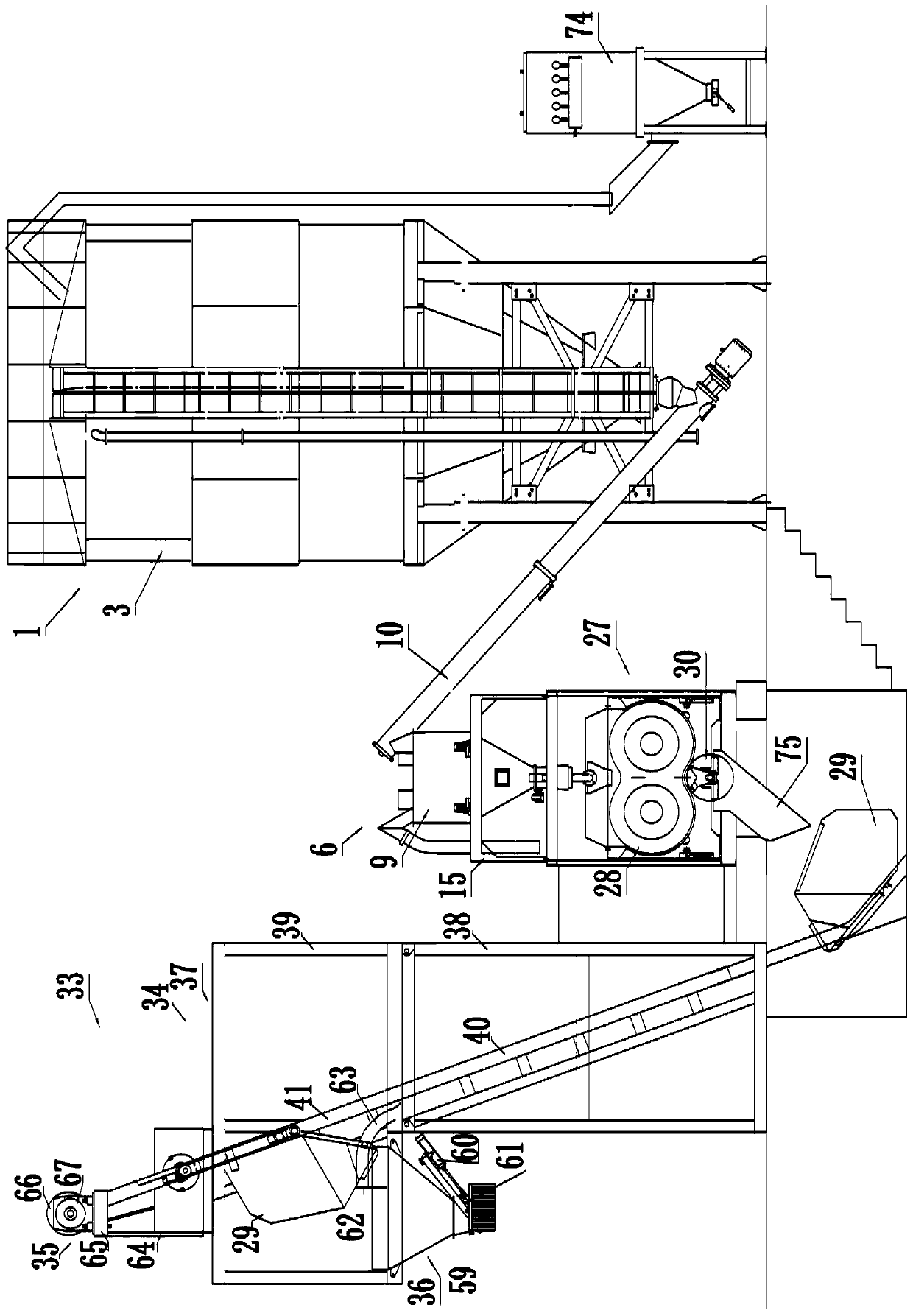

Compact modular concrete stirring equipment

InactiveCN110653945ALower the altitudeSolve environmental pollutionDischarging apparatusMixing operation control apparatusCold areaStructural engineering

The invention provides compact modular concrete stirring equipment. The compact modular concrete stirring equipment comprises a storage material module, a material weighing and batching module, a stirring main machine module and a concrete lifting and discharging device, and due to the concrete lifting and discharging device can raise the concrete to a high position, so that the stirring main machine module can be lowered to the ground for installation, so that the height of a stirring station is greatly reduced. The stirring main machine is lowered to the ground for installation through the deformation design, then the concrete is lifted and discharged through a concrete lifting discharging trolley, the height of the main body is further reduced; the structure of a powder material storagebin adopts a large-diameter vertical cylindrical bin structure, so that the height of the powder material storage bin is reduced, the height of the whole stirring station is greatly reduced, If the construction site has a factory building, the equipment can be arranged in the factory building, the factory building heating can solve the stirring of concrete in winter in the severe cold area, a dust removal device is arranged on the factory building, namely, and the dust removal device can effectively solve the problem of environmental pollution caused by flying dust.

Owner:中国人民解放军火箭军士官学校

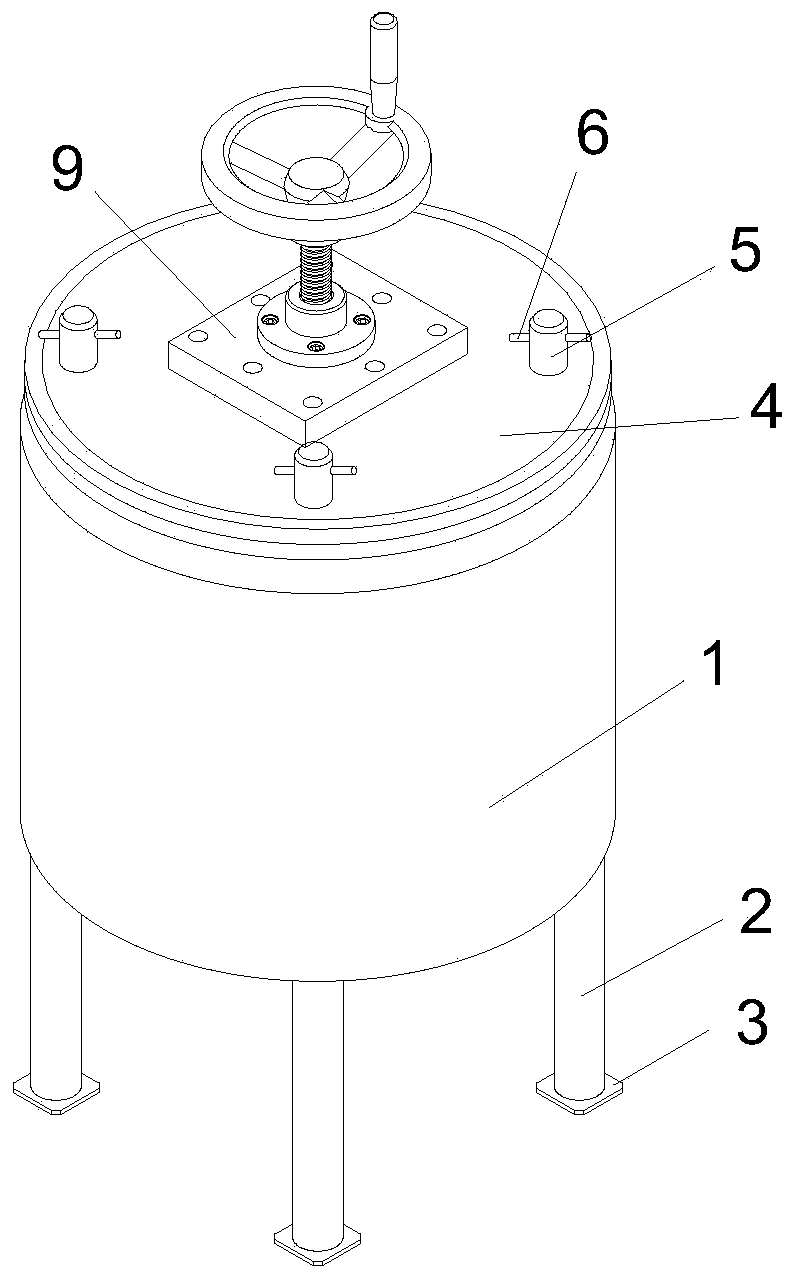

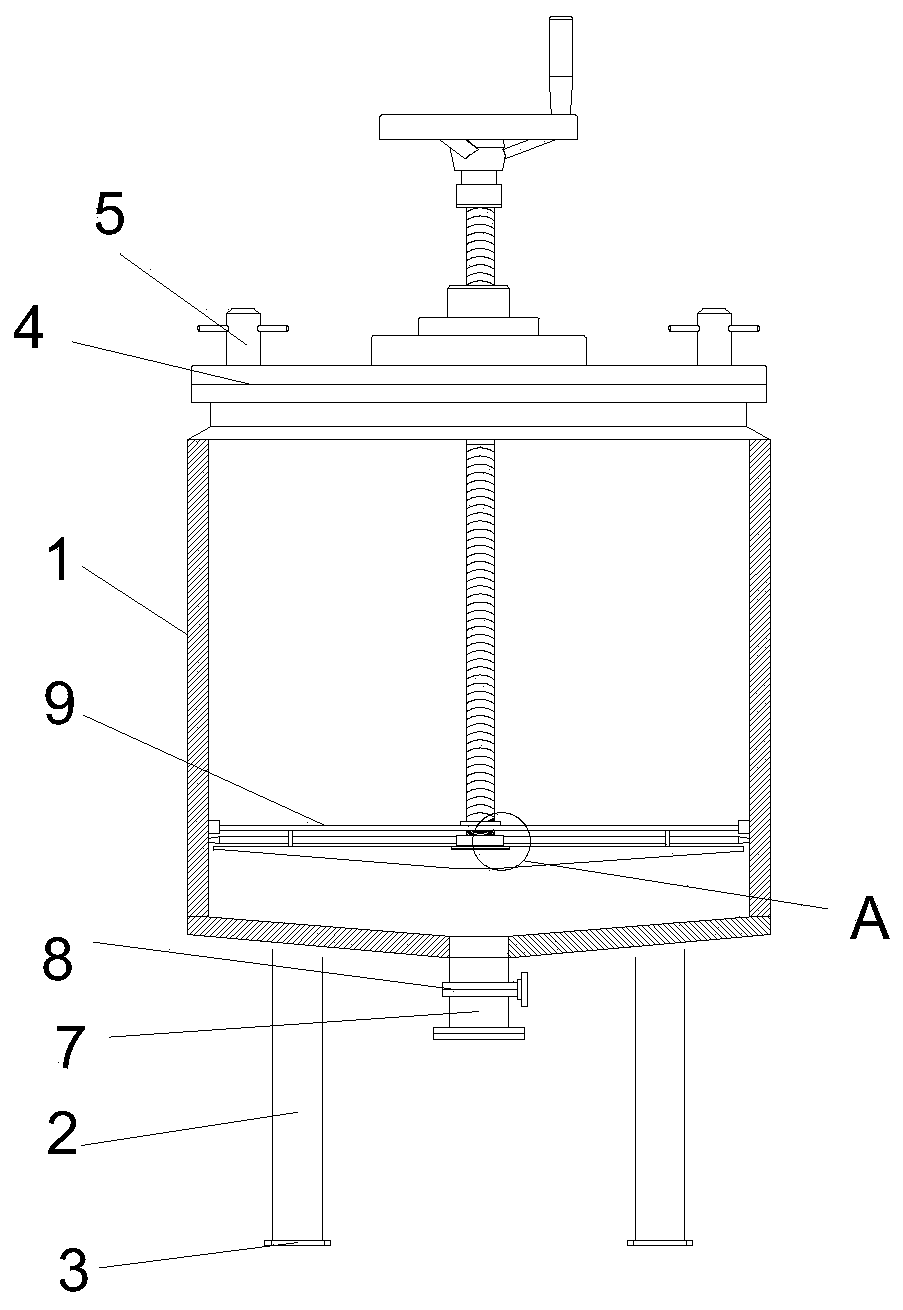

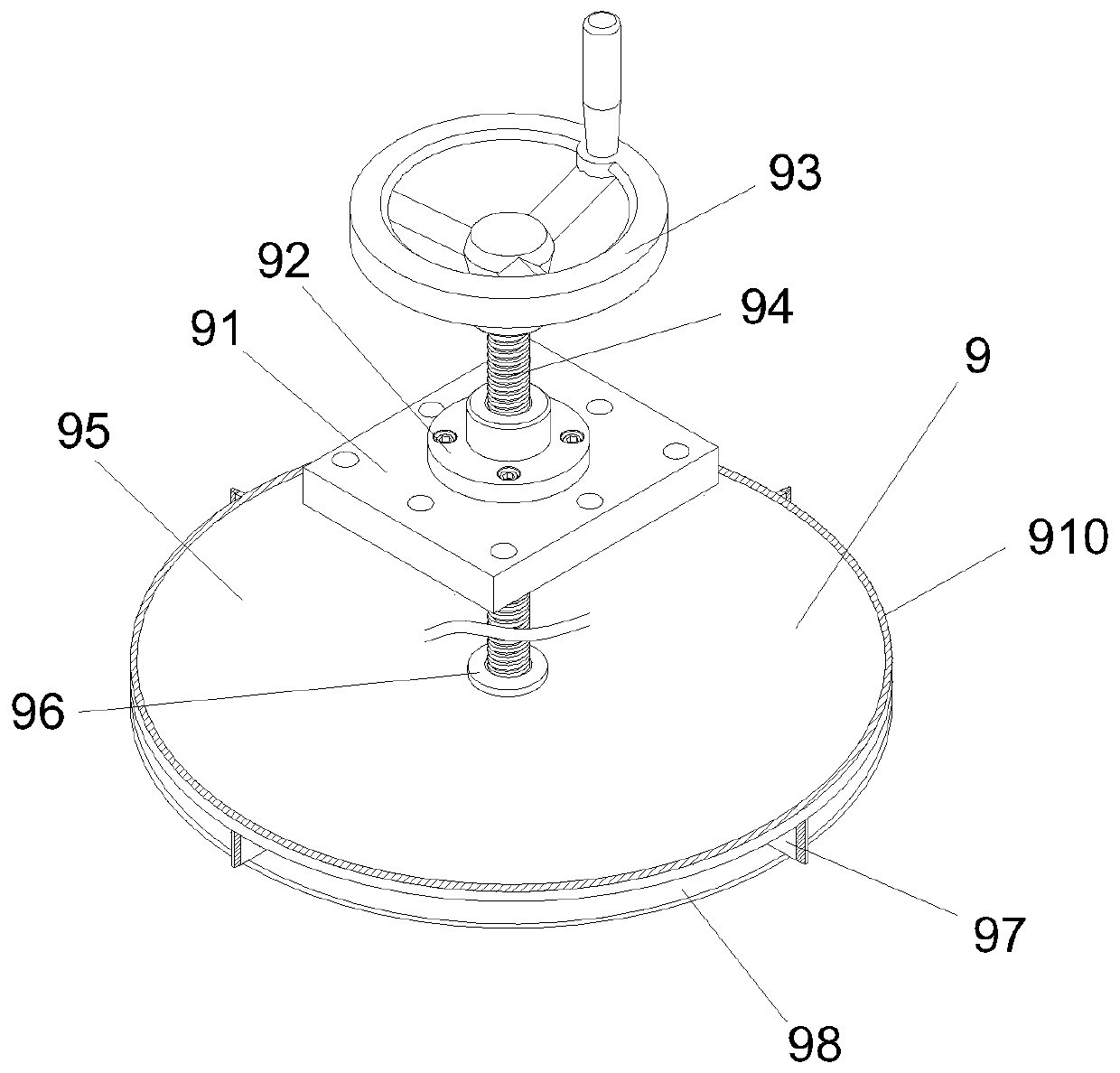

Safe transportation tank for polyurethane resin

ActiveCN110817165AIncrease unloading speedImprove cleanlinessLarge containersPolymer scienceEngineering

The invention discloses a safe transportation tank for polyurethane resin. The safe transportation tank for polyurethane resin comprises a tank body, supporting legs, foot pads, a sealing cover, a locking bolt, a knob, a discharge port, a discharge valve and an extrusion and pushing device. According to the safe transportation tank for polyurethane resin, the extrusion and pushing device is arranged in the tank body, and when discharging is carried out, a hand wheel is rotated to drive a pressing plate through a screw rod so as to extrude and push downward the internal storage polyurethane resin, so that the discharging of the polyurethane resin is accelerated; a cleaning device is arranged at the bottom of a partition top plate, and the polyurethane resin adhering to the inner wall of thetank body is scraped off through a scraping head on a scraping plate, so that the cleanliness of the inside of the tank body is improved; and meanwhile, a sealing structure is arranged on an outer ring of the partition top plate, a mounting fixing frame is tightly attached to the partition top plate, and then a center ring, a first side sealing ring and a second side sealing ring seal the partition top plate, so that the polyurethane resin is prevented from passing through the gap between the extrusion and pushing device and the inner wall of the tank body, and the discharging efficiency is improved.

Owner:东莞市嘉洋塑胶科技有限公司

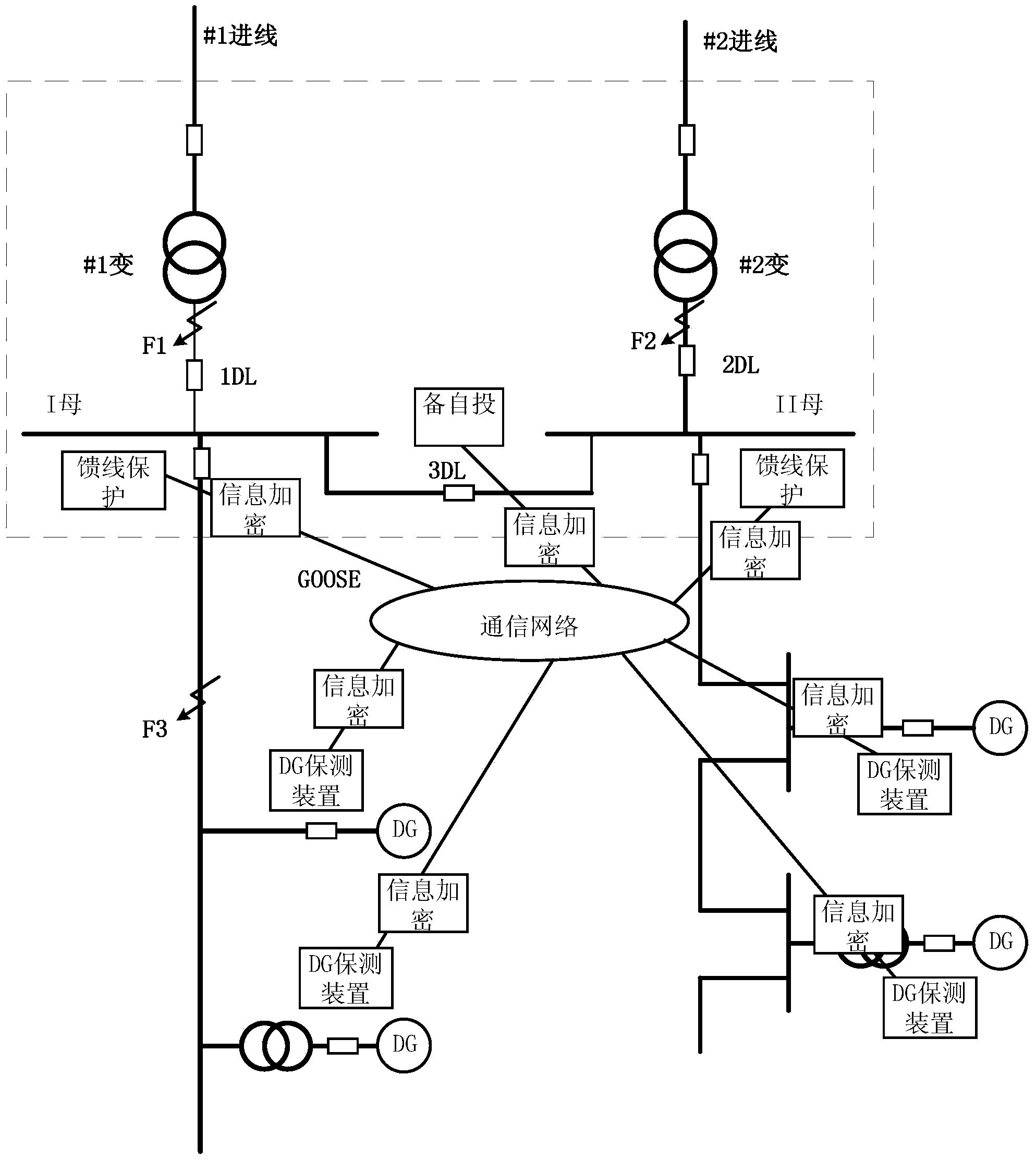

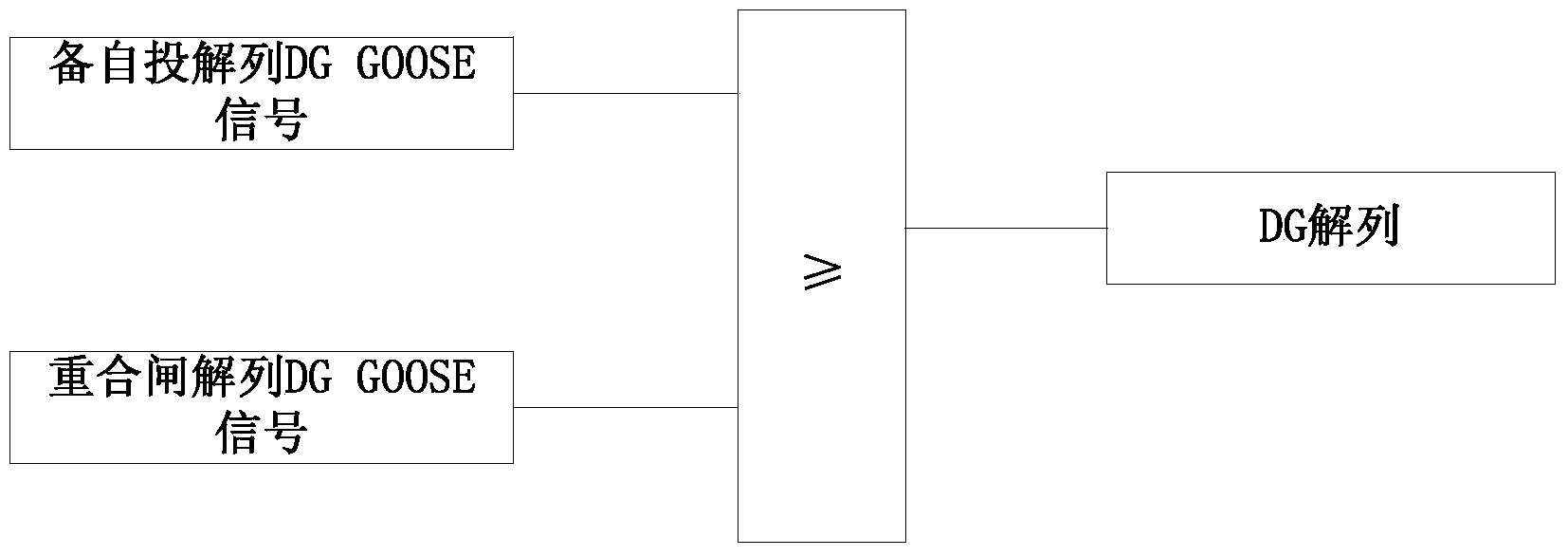

Distributed generation fast-disconnecting system and method

ActiveCN104242343AReduce riskIncrease success rateSingle network parallel feeding arrangementsSystems intergating technologiesEncryptionPower substation

The invention discloses a distributed generation fast-disconnecting system. The distributed generation fast-disconnecting system is characterized in that the system comprises a backup automatic switching device, feeder protection devices, a communication network, distributed generation (DG) measure preserving devices and information encryption devices. The backup automatic switching device, the feeder protection devices and the DG measure preserving devices are connected through the communication network; the backup automatic switching device and the feeder protection devices are located in substations; the DG measure preserving devices are located in distributed substations; the backup automatic switching device sends encrypted GOOSE disconnecting signals to all the DG measure preserving devices connected with feeders of the substations, and the feeder protection devices send the encrypted GOOSE disconnecting signals to all DGs, connected with the feeder protection devices, of the feeders; the DG measure preserving devices receive the GOOSE disconnecting signals sent by the backup automatic switching device and the feeder protection devices and judge whether to perform tripping operation for disconnection after the GOOSE disconnecting signals are decrypted.

Owner:NR ELECTRIC CO LTD +3

Continuous nut tapping device with function of bidirectional feeding

PendingCN111069719AHigh degree of automationIncrease productivityThread cutting feeding devicesThread cutting machinesControl engineeringAutomation

The invention discloses a continuous nut tapping device with a function of bidirectional feeding. The continuous nut tapping device with the function of bidirectional feeding comprises a rack, a double-track feeding mechanism, a nut pressing mechanism and a tapping mechanism, wherein two feeding stations, two processing stations and a tapping station are arranged in the rack; the output ends of the double-track feeding mechanism extend to the feeding stations; two sliding rods are fixed in the rack; two nut bearing mechanisms are slidably installed on the sliding rods; and linear driving mechanisms drive the nut bearing mechanisms on the same sides to perform feeding at the feeding stations, stop at the processing stations and stop alternately at the tapping station. The device has the highest degree of automation, and can perform feeding, clamping, processing and discharging automatically during working, and the labor cost is apparently saved; and by means of bidirectional feeding, the interval time between feeding and tapping is shortened, a plurality of nuts can be processed simultaneously, continuous tapping is achieved, feeding, clamping and discharging are fast, and production efficiency is high.

Owner:邯郸市澳嘉紧固件制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com