Tank truck heating device

A technology of heating device and tank car, applied in the direction of tank car, transport passenger car, railway car body parts, etc., can solve the problems of unsatisfactory heating unloading effect, inconvenient tank washing, environmental pollution, etc., so as to shorten the medium unloading time and improve the utilization rate. , the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

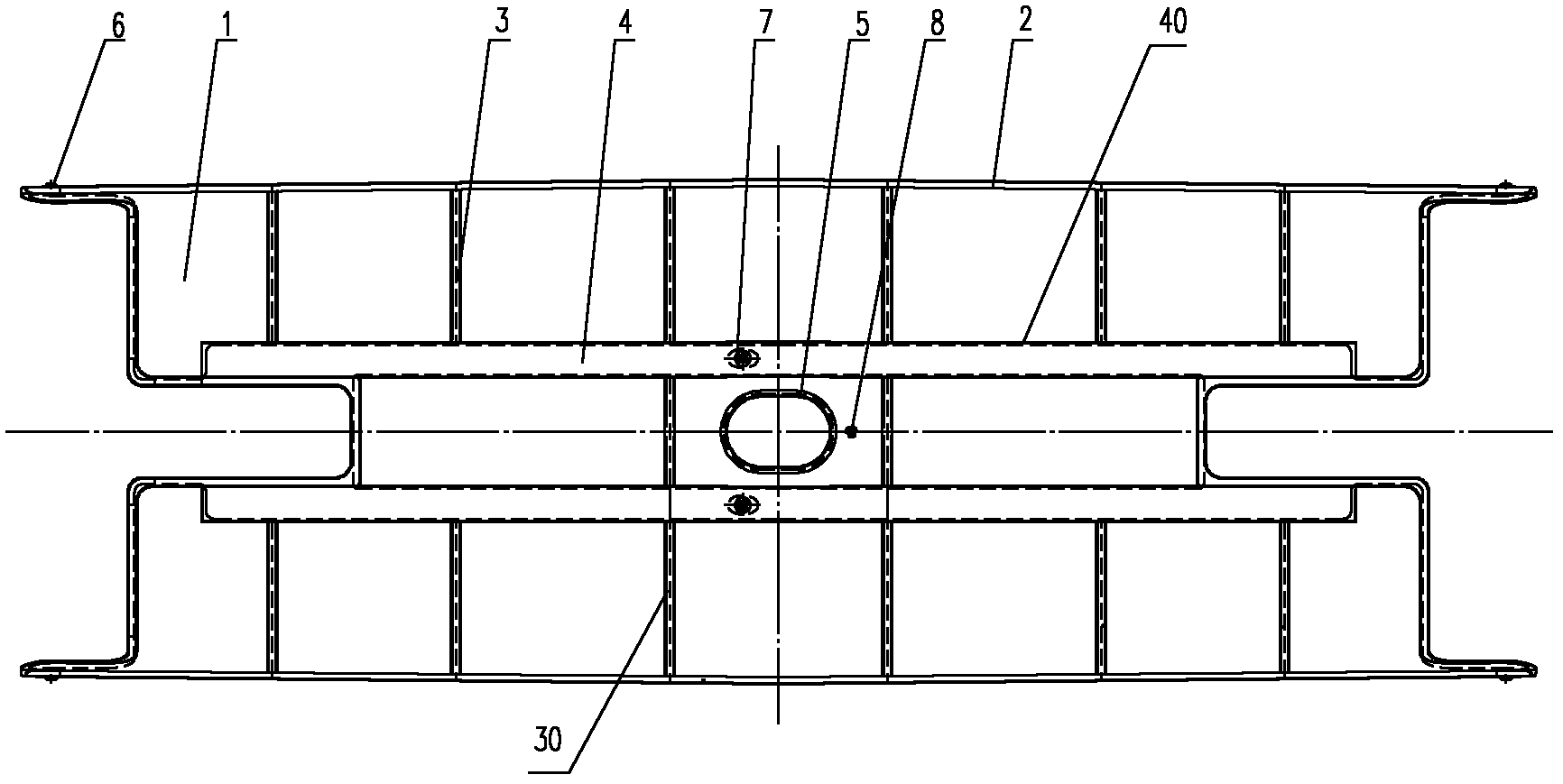

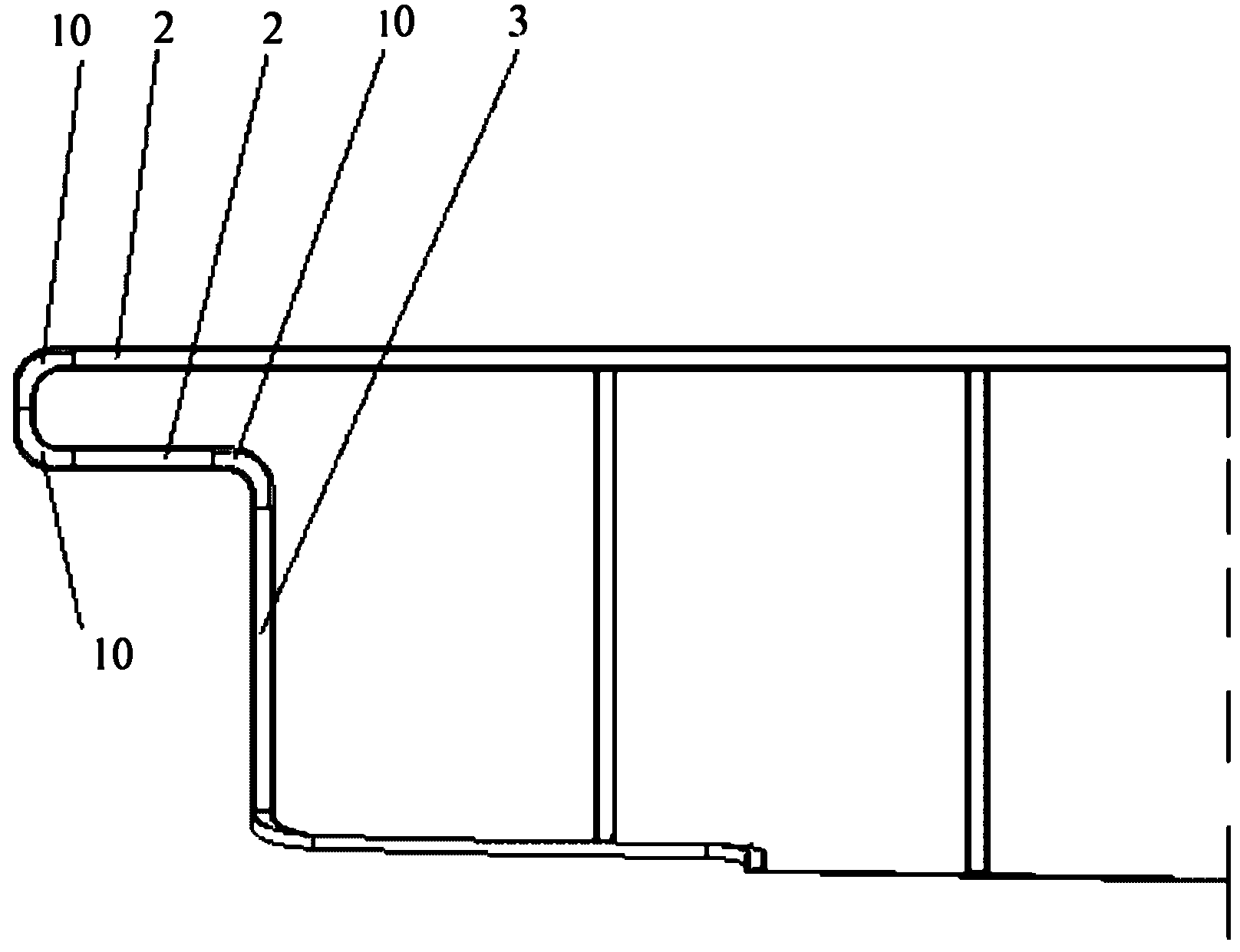

[0027] see figure 1 , the tank car heating device of the present invention includes a heating plate 1, a longitudinal support iron 2, a circumferential support iron 3, a diversion groove 4, a valve seat support iron 5, a steam exhaust port 6, a steam inlet port 7 and a water discharge port 8; The whole heating device is arranged on the outer surface of the lower part of the tank body, and is assembled and welded with the tank body. The shape of the heating device matches the shape of the tank body, that is, it is in the shape of an arc. The valve seat support iron 5 is welded on the bottom of the tank body, and the circumferential support iron 3 is arranged along the circumferential direction of the tank body. Arranged along the longitudinal direction of the tank body, each circumferential support iron 3 communicates with the diversion groove 4, allowing steam to enter the circumferential support iron 3; the central circumferential support iron 3 is provided with a U-shaped o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com