Patents

Literature

171results about How to "Shorten unloading time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

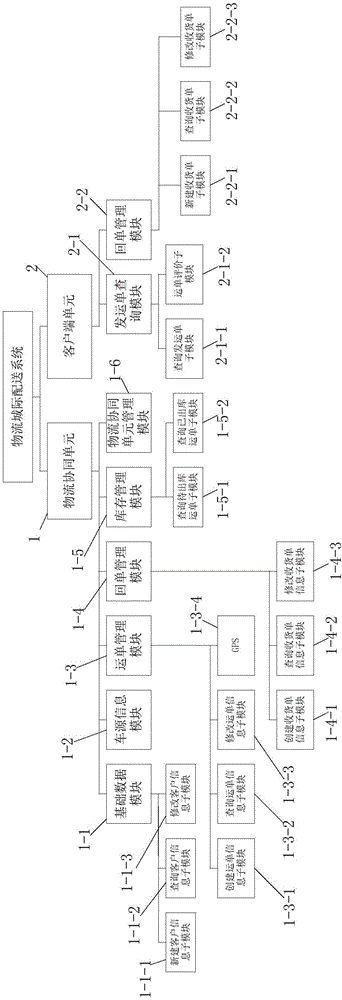

Logistics intercity distribution system

InactiveCN106779557AImprove controlImprove business operations and customer service qualityForecastingResourcesDistribution systemClient-side

Owner:贝朗科技(武汉)有限公司

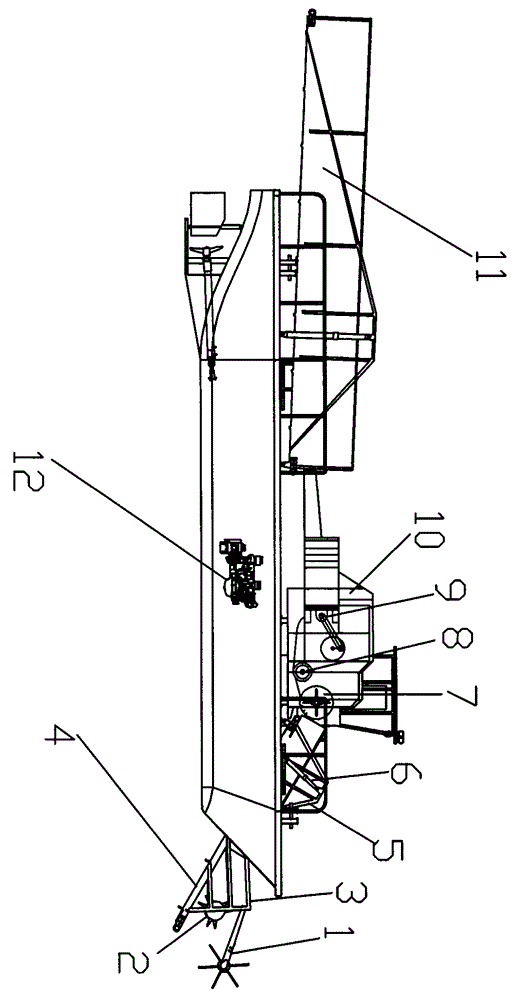

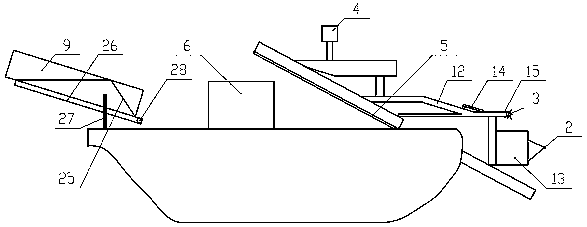

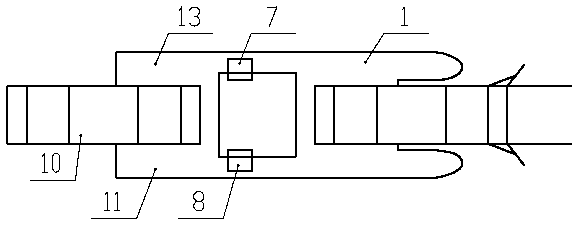

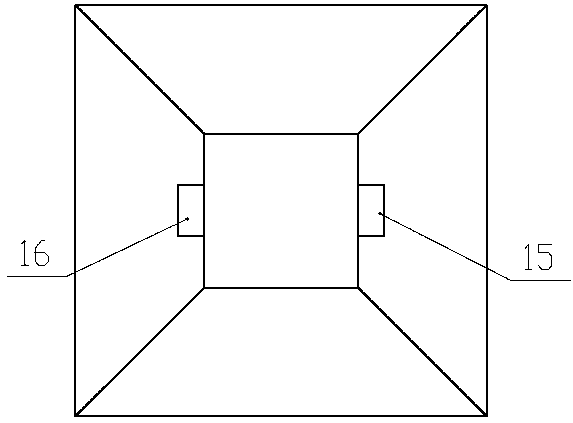

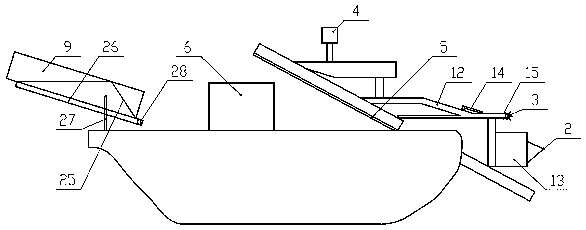

Full-automatic float-garbage clearing and packaging vessel

ActiveCN104097751AReduce volumeIncrease loading capacityWaterborne vesselsSpecial purpose vesselsMarine engineeringAquatic plant

The invention discloses a full-automatic float-garbage clearing and packaging vessel. A vessel body is of a double-head single-hull type. The vessel comprises the vessel body, a collecting device, a smashing device, a screw conveying device, a compressing and bundling device and a storing and discharging device. The collecting device, the smashing device, the screw conveying device, the compressing and bundling device and the storing and discharging device are sequentially mounted from a vessel bow to a vessel stern in the vessel body. The collecting device is arranged between two heads of the vessel bow. The vessel is adaptable to cleaning riverway rubbish and aquatic plants and capable of compressing collected and smashed rubbish and aquatic plants, thus improving load of the vessel, shortening discharging time of round trip, facilitating discharging, increasing production efficiency and saving production cost.

Owner:ZHANGJIAGANG HAIFENG WATER SURFACE ENVIRONMENTAL PROTECTION MACHINERY

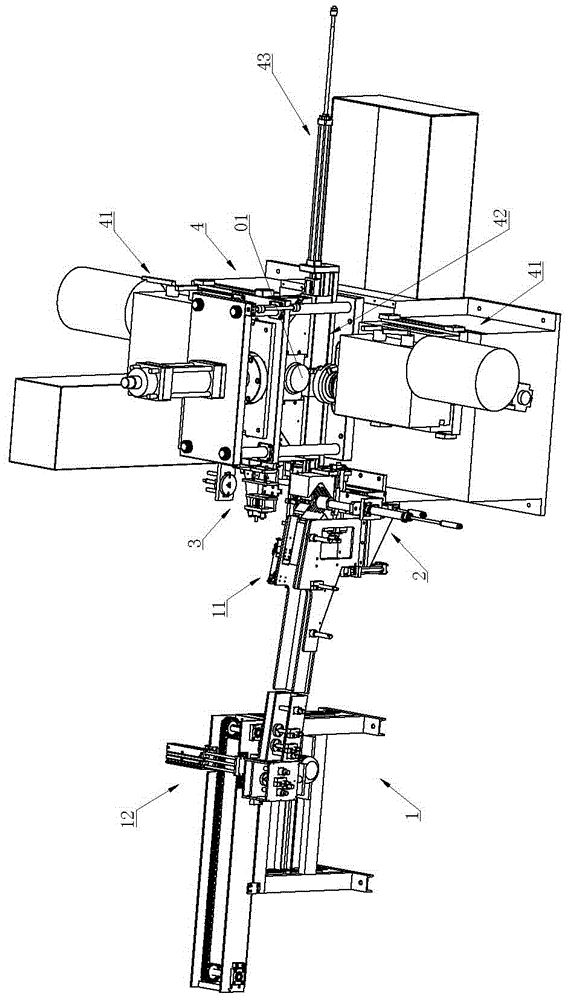

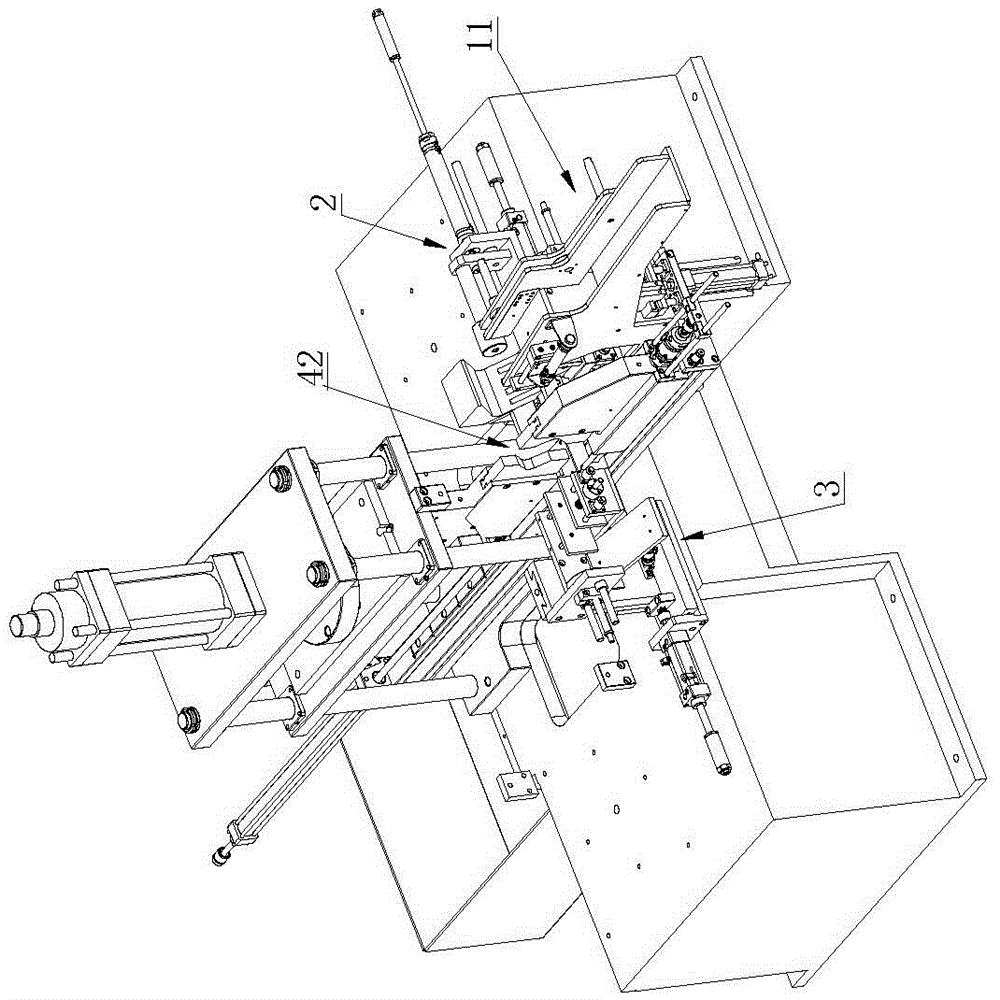

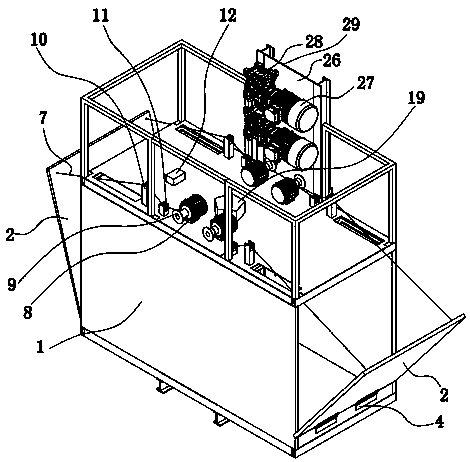

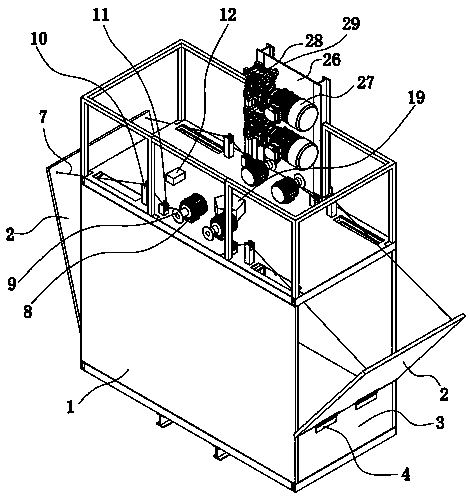

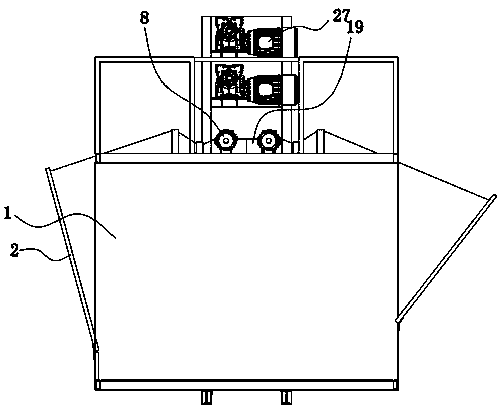

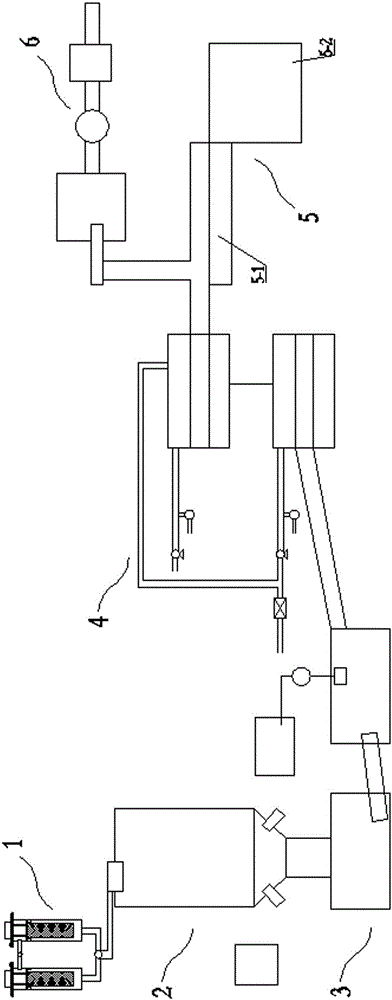

Chamfering machine

ActiveCN106002459AEasy to take outEasy to unloadWork clamping meansMetal working apparatusEngineeringPipe fitting

The invention relates to the technical field of machining equipment for materials such as cylindrical parts and pipe fittings, in particular to a chamfering machine. The chamfering machine comprises a feeding device, a pushing device arranged at a discharge port of the feeding device, a discharging device arranged on one side of the pushing device and a chamfering device for chamfering materials; the chamfering device is provided with a chamfering mechanism, a fixture mechanism for clamping the materials and a fixture moving driving mechanism for driving the fixture mechanism to move, and when the fixture mechanism takes or unloads the materials, the fixture mechanism is located between the pushing device and the discharging device. According to the chamfering machine, the structure is compact, and automated production is easy to achieve; the fixture mechanism conveniently takes or unloads the materials, the fixture mechanism is located between the pushing device and the discharging device when the fixture mechanism takes or unloads the materials, the materials are pushed by adopting the same pushing device, therefore, no other mechanism is adopted to unload the materials from the fixture mechanism, and the production cost is reduced; in addition, after unloading the materials, the fixture mechanism can take the materials immediately, the material taking or unloading time is greatly shortened, and the production efficiency is improved.

Owner:东莞市晋诚机械有限公司

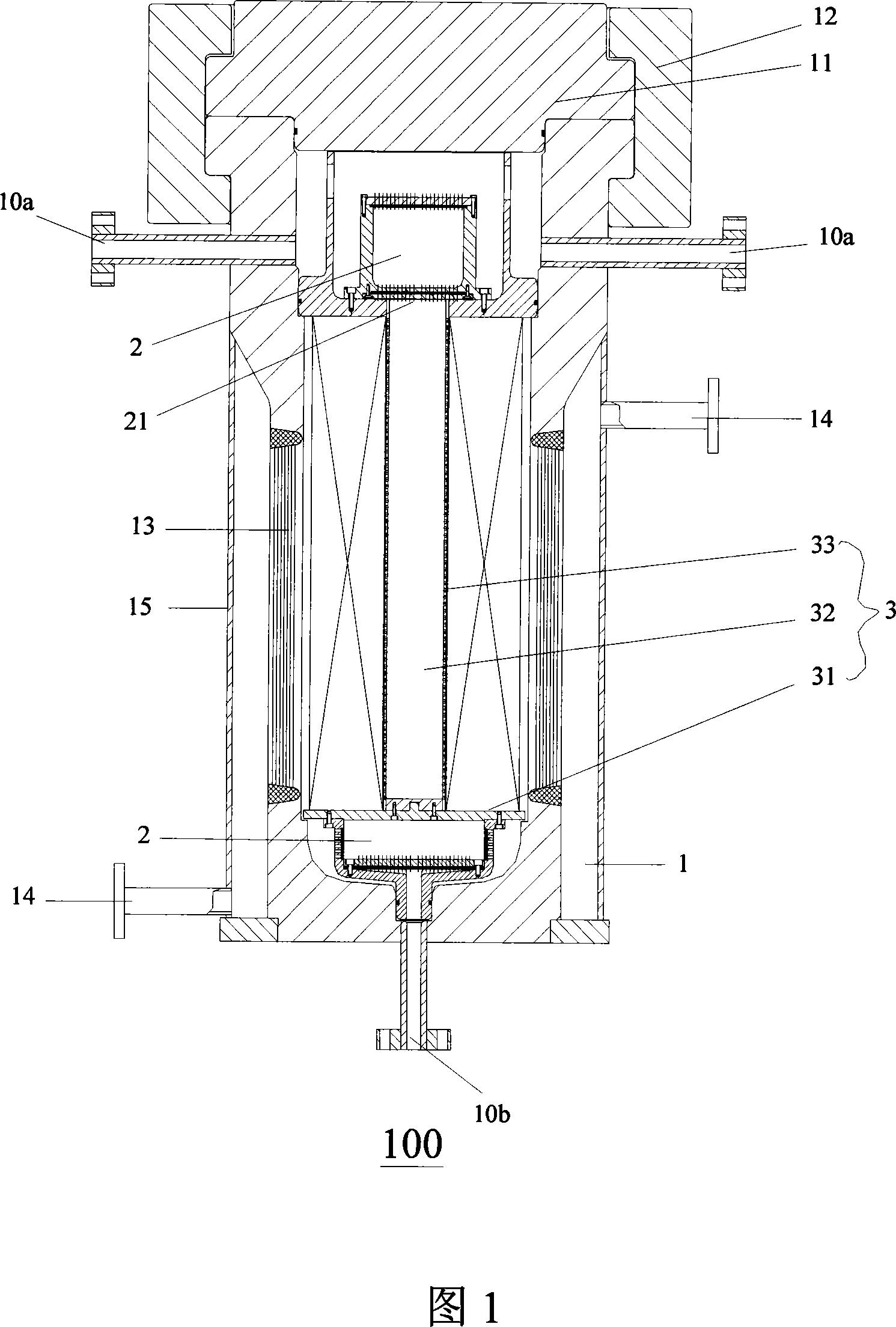

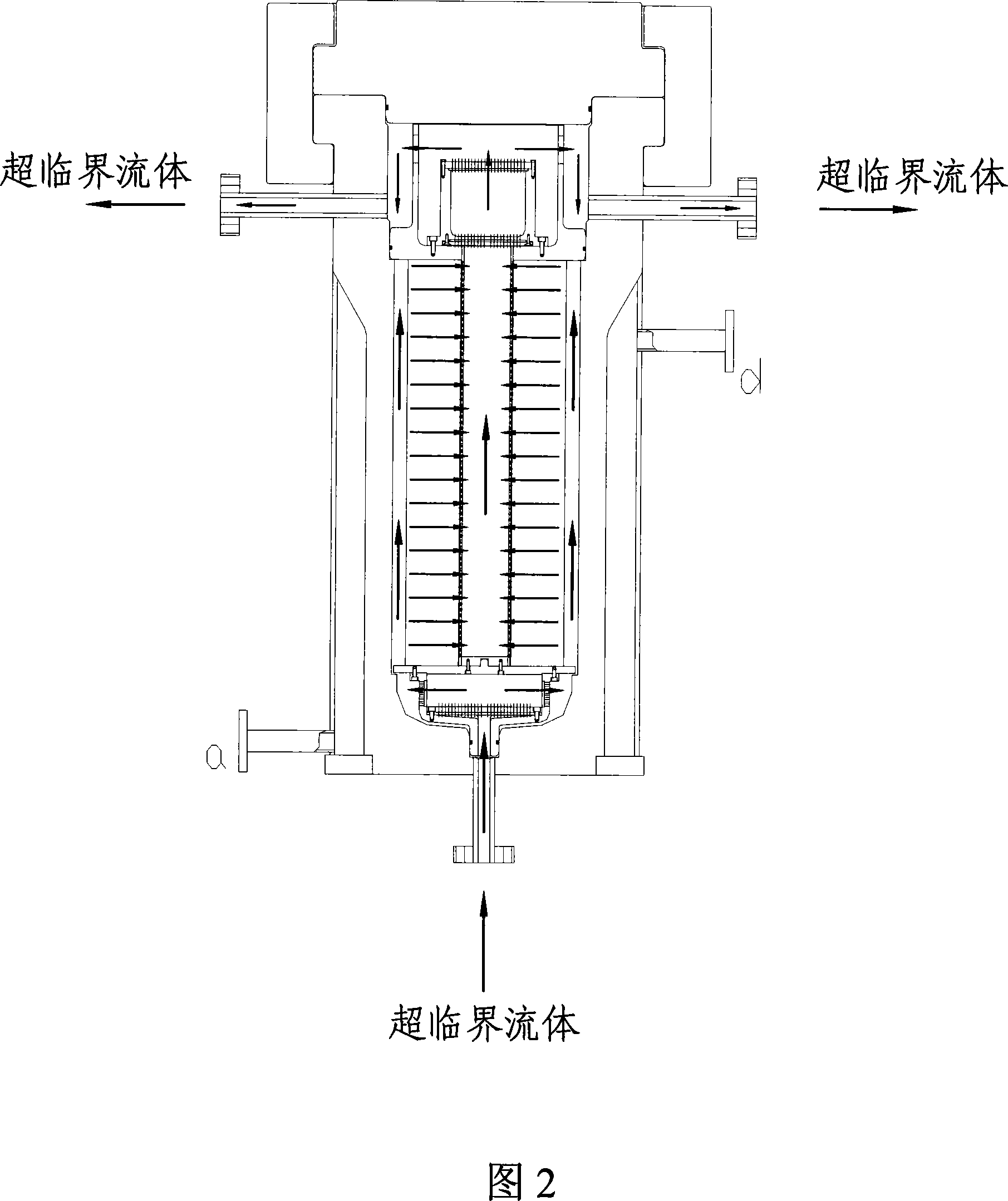

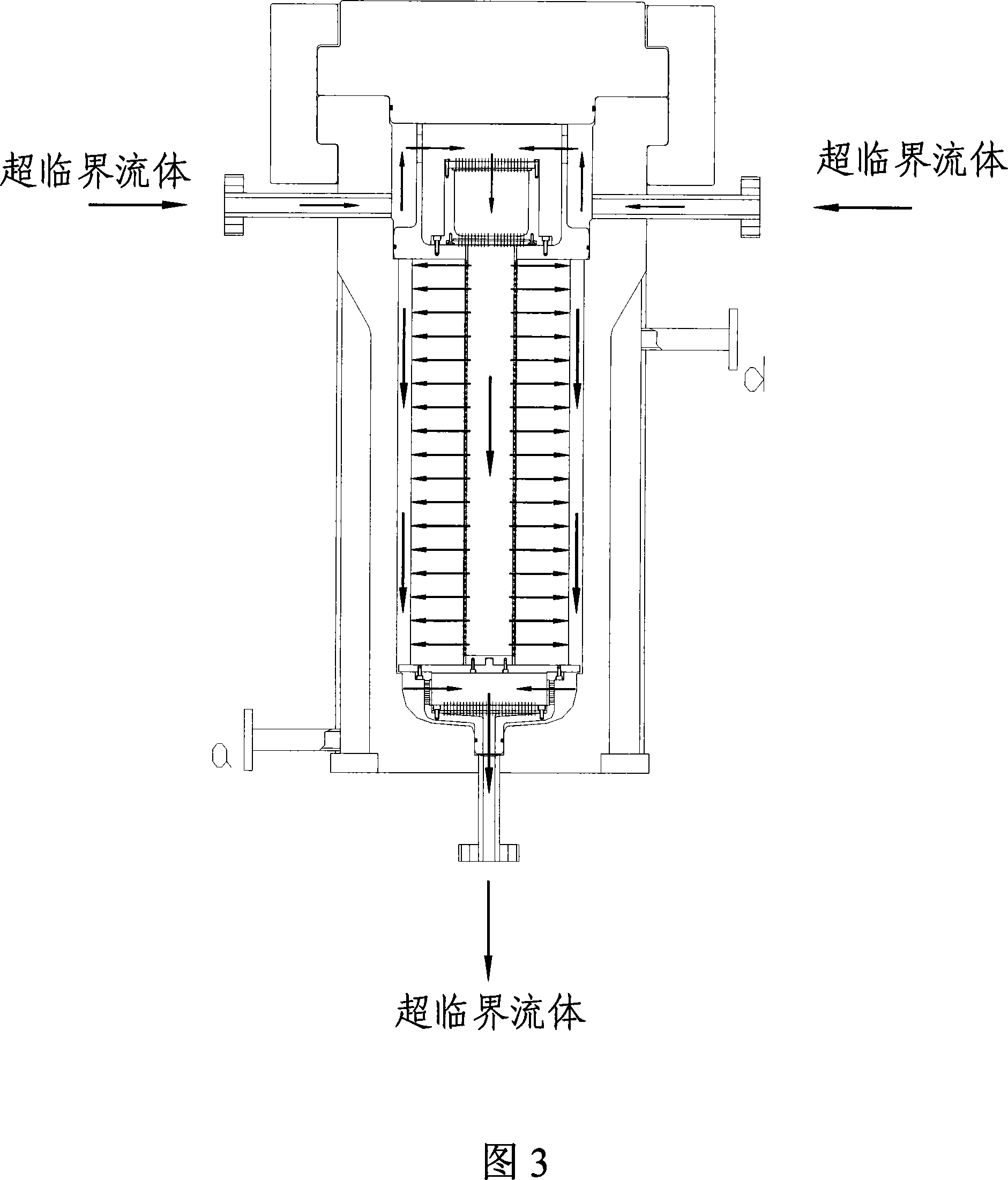

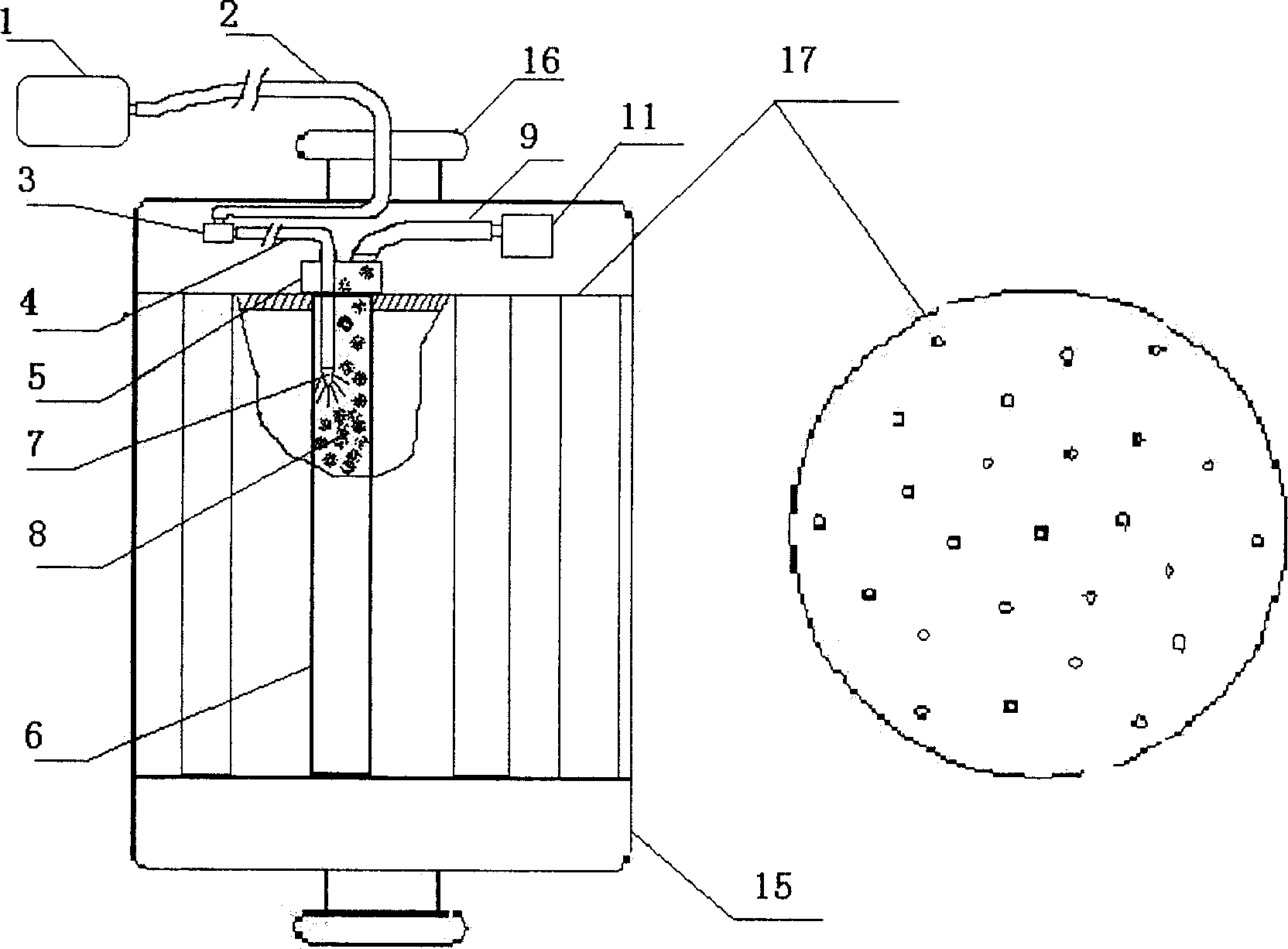

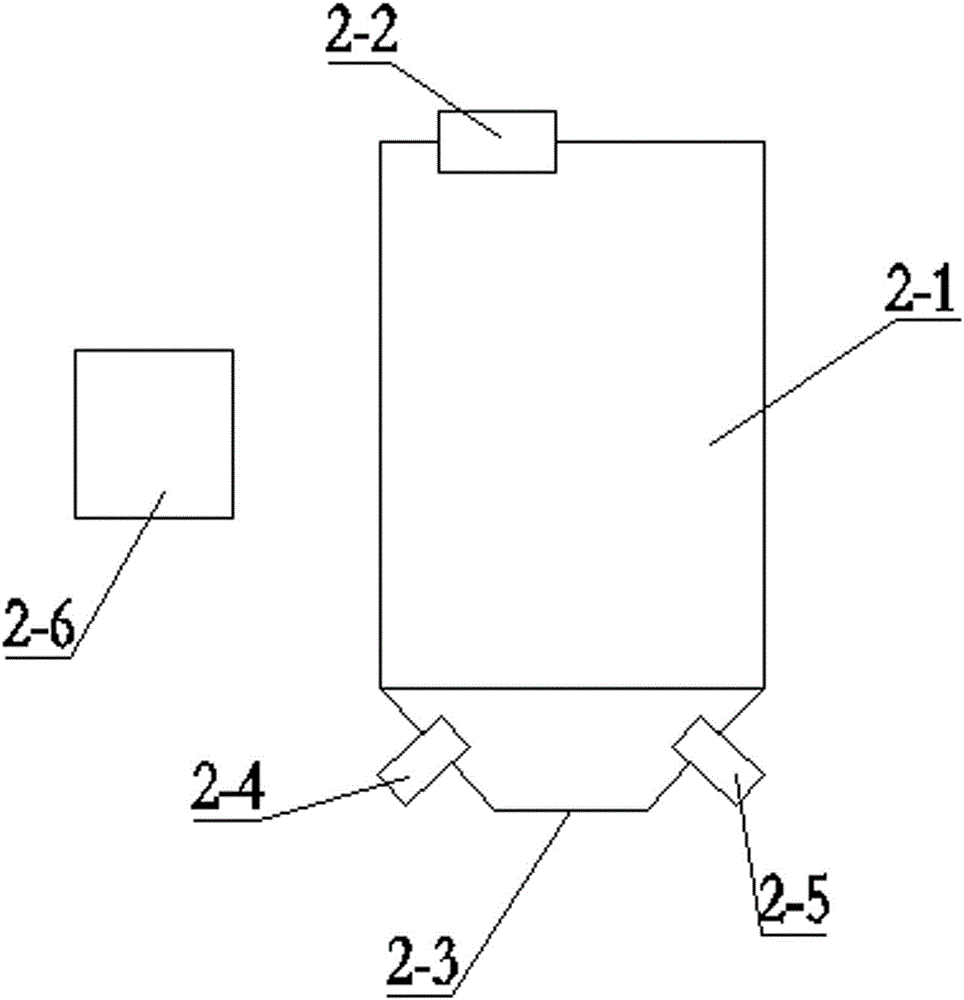

Integrated dyeing kettle

InactiveCN101021038AReduce lossReduce energy consumptionTextile treatment containersDyeing processEngineeringSupercritical fluid

The present invention provides one kind of integrated dyeing kettle for continuous dyeing process. The integrated dyeing kettle has one kettle body with supercritical fluid inlet and outlet, one fabric fixing device and at least one dye holding device inside the kettle body. The present invention combines the dye kettle and the dyeing kettle into one kettle and has the two technological steps of dissolving dye and dyeing fabric completed in the same kettle, so that the present invention has reduced supercritical fluid and dye loss, reduced power consumption and raised production efficiency.

Owner:MASSON GROUP

Transferring device, robot, sorting system and sorting method

PendingCN111891615AIncrease unloading speedImprove work efficiencySortingStorage devicesComputer hardwareEngineering

The invention provides a transferring device, a robot, a sorting system and a sorting method. The transferring device is applied to equipment on which multiple layers of circulating boxes can be arranged in the first direction. At least two layers of transferring devices are arranged in the first direction of the equipment. The transferring device comprises a supporting base and a first transmission assembly. The first transmission assembly is located on the supporting base. The first transmission assembly transports the circulating boxes. According to the transferring device, the working efficiency of the equipment can be improved.

Owner:HAI ROBOTICS CO LTD

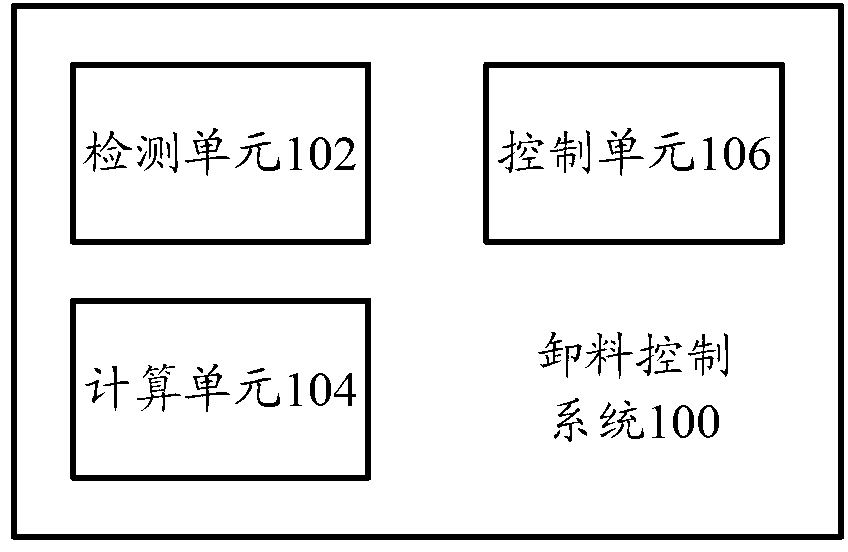

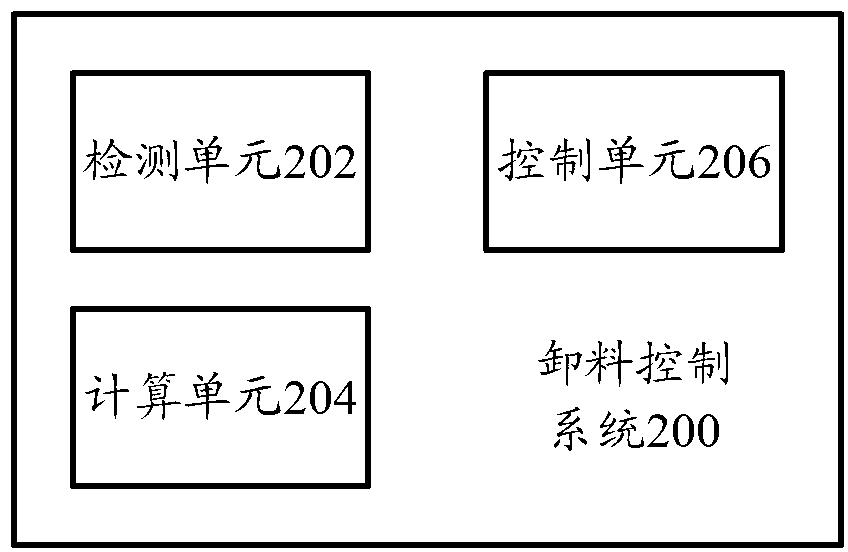

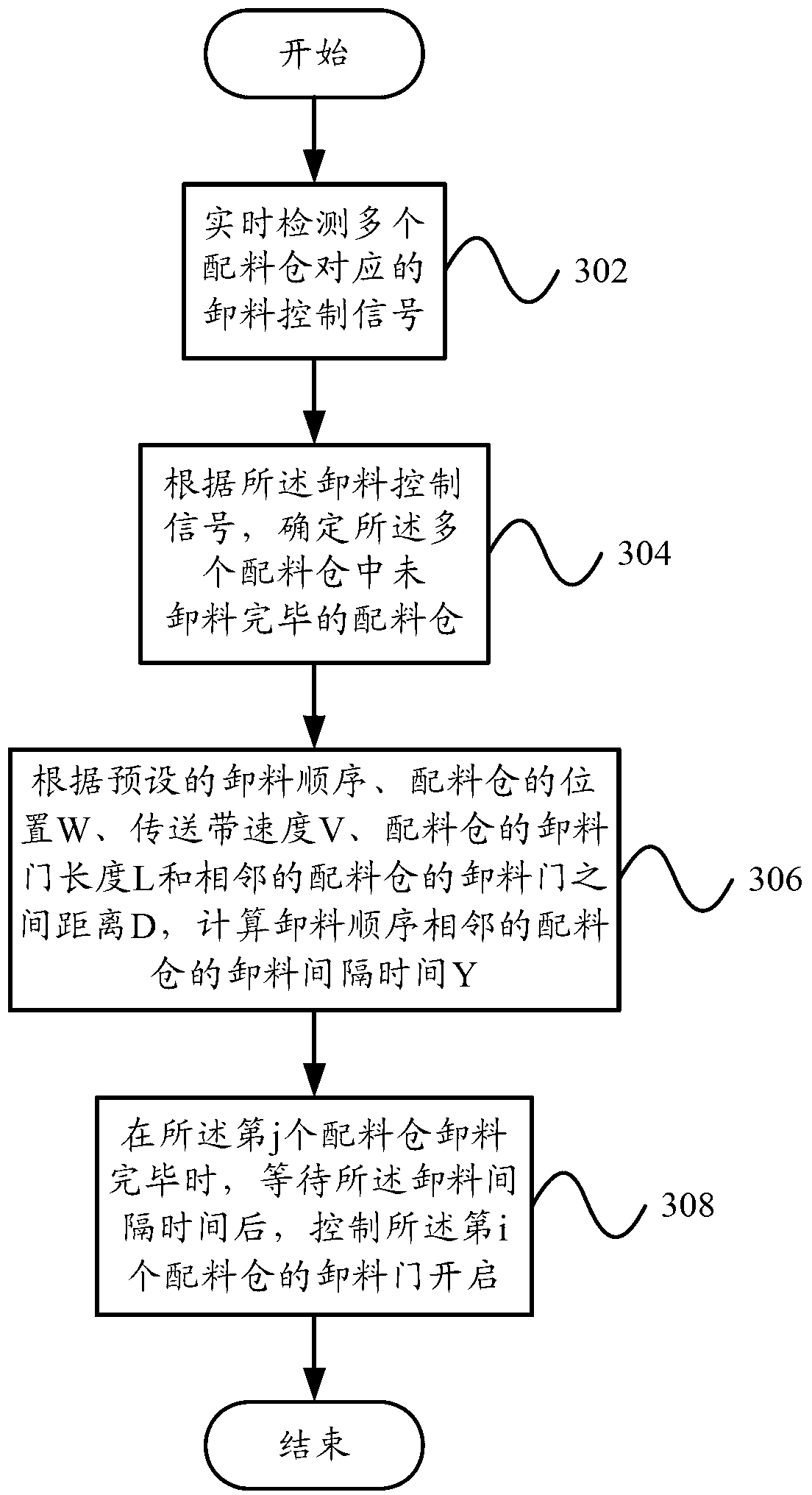

Discharging control system and discharging control method

ActiveCN103009485AAvoid scatterImprove the mixing effectDischarging apparatusProgramme control in sequence/logic controllersDischarge efficiencyControl system

The invention provides a discharging control system. The discharging control system comprises a detecting unit, a calculating unit and a control unit, wherein the detecting unit is used for determining incompletely-discharged stock bin in stock bins, the calculating unit is used for calculating the discharging interval time Y of the matched stock bins with adjacent discharging orders according to the discharging order, the positions W of the stock bins, the speed V of a conveying belt, the lengths L of discharging doors and the distance D between the adjacent discharging doors, the position Wn of the nth stock bin is equal to n which is progressively increased along the motion direction of the conveying belt, wherein Yj=(Wi-Wj+1)*X+(Wi-Wj)*J, X=L / V, J=D / V, the discharging orders of the ith stock bin and the jth stock bin are adjacent, and the ith stock bin is used for discharging after the jth stock bin is used for discharging. When the jth stock bin is used for discharging, the control unit can control the opening of the discharging doors of the ith stock bin after waiting for the waiting time Yj. The invention also provides a discharging control method. According to the technical scheme of the discharging control system, different aggregates can be prevented from being piled on the conveying belt in the discharging process so as to avoid the scattering of the aggregates. Moreover, the discharging time can be shortened, and the discharging efficiency and the aggregate mixing effect are enhanced.

Owner:SANY HEAVY IND CO LTD (CN)

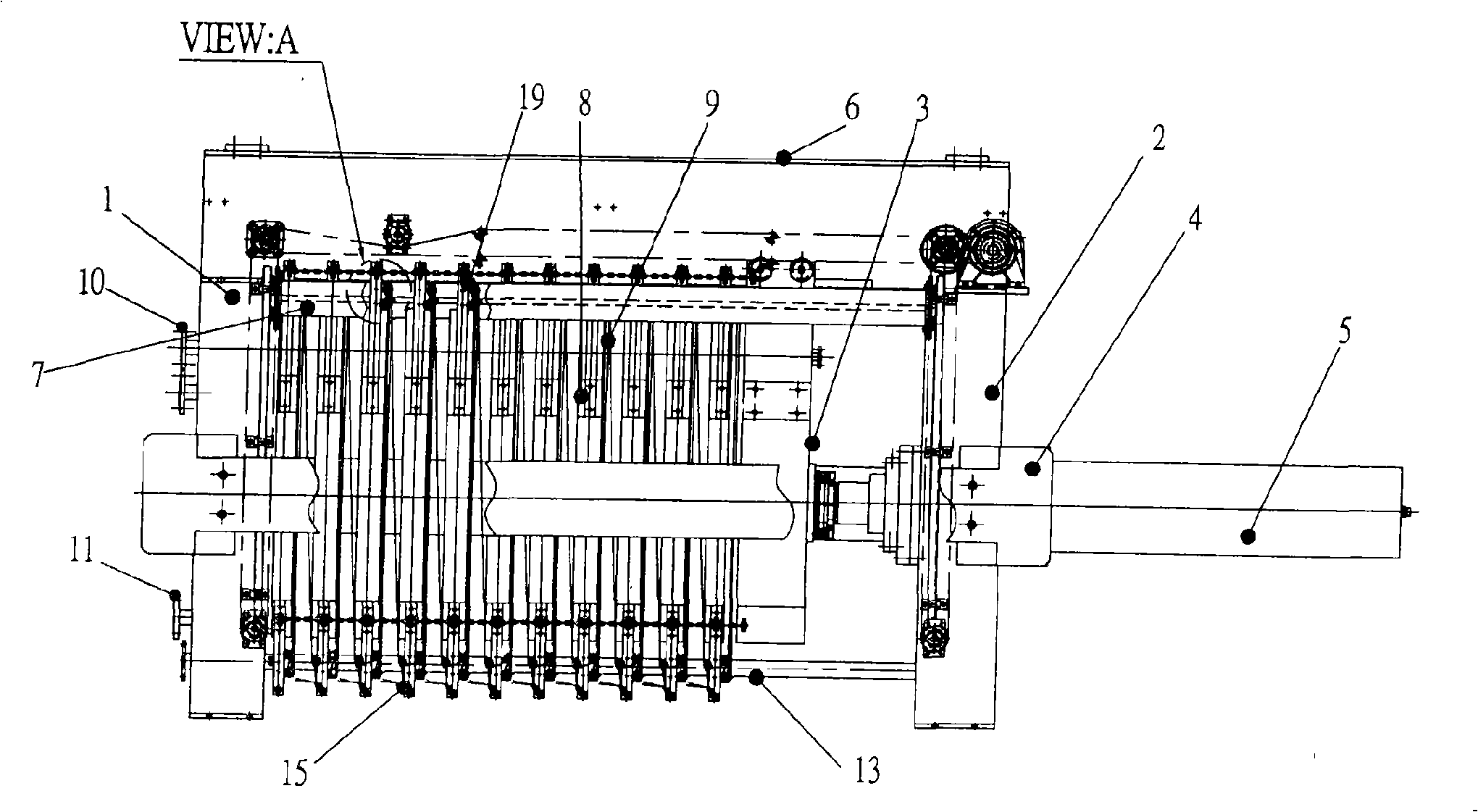

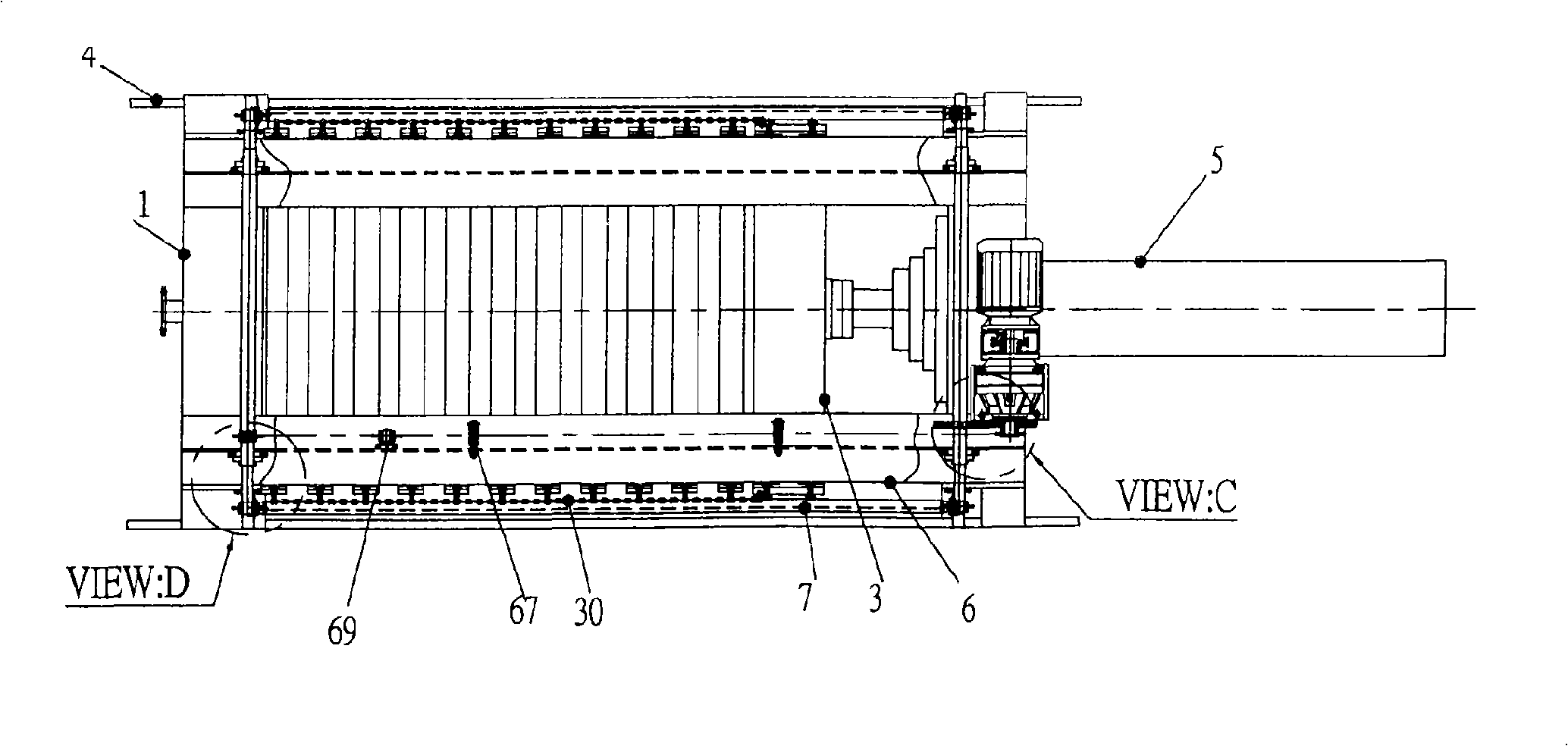

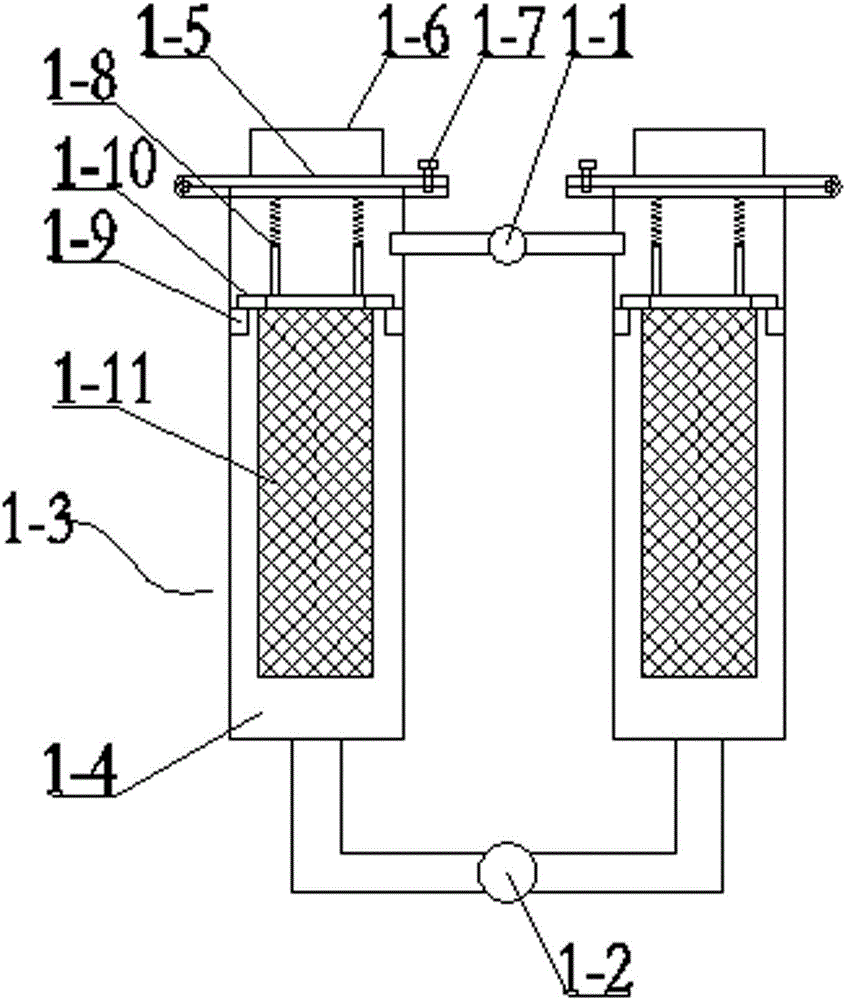

Device and method of filter press for quickly discharging material and cleaning filter cloth

InactiveCN101306269AShorten unloading timeAchieve the effect of automationFiltration separationEngineeringFilter press

The invention relates to a device and a method for rapid discharge and cleaning of a filter cloth of a press filter, and belongs to the machinery. The device comprises a filter plate group, a filter plate lower cable pulley group, a filter plate upper cable pulley group, a cloth guide cable, a filter cloth group, a clamp, a filter cloth cleaning unit, an arm guide slot group, an opening plate arm group and an opening plate arm transmission mechanism. The method for rapid discharge and cleaning of the filter cloth of the press filter comprises the step of local reflux of materials, the washing step of a material guide pipe, the cleaning step of the clamp, the discharging step of a filter cake and the washing step of the filter cloth. The device and the method have the advantages that the discharge of the filter cake is rapid and can achieve the full automation, the filter cloth is cleaned rapidly, the scope of the materials which can be filtered is wider, and the practicality is strong.

Owner:张凯茵

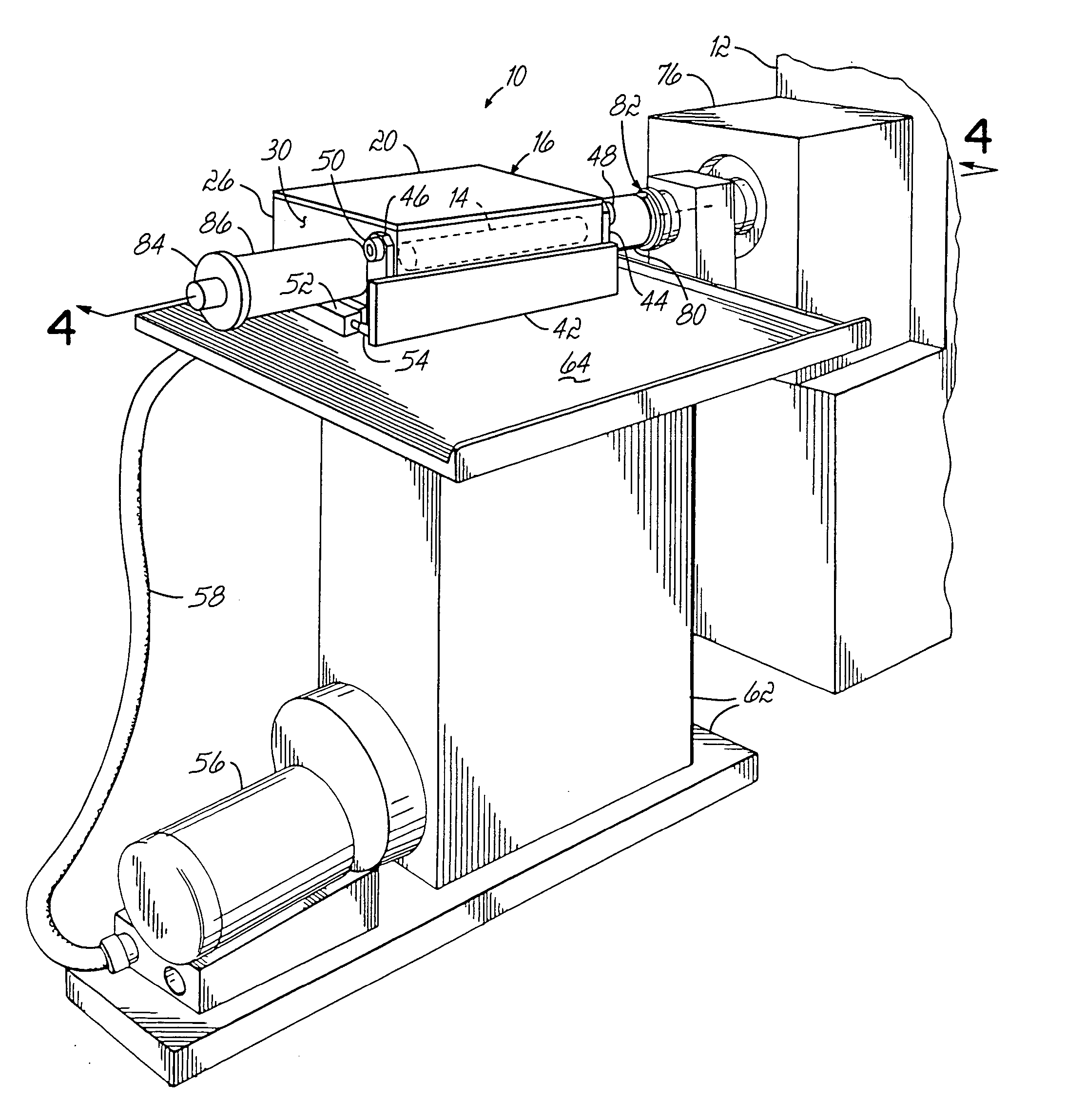

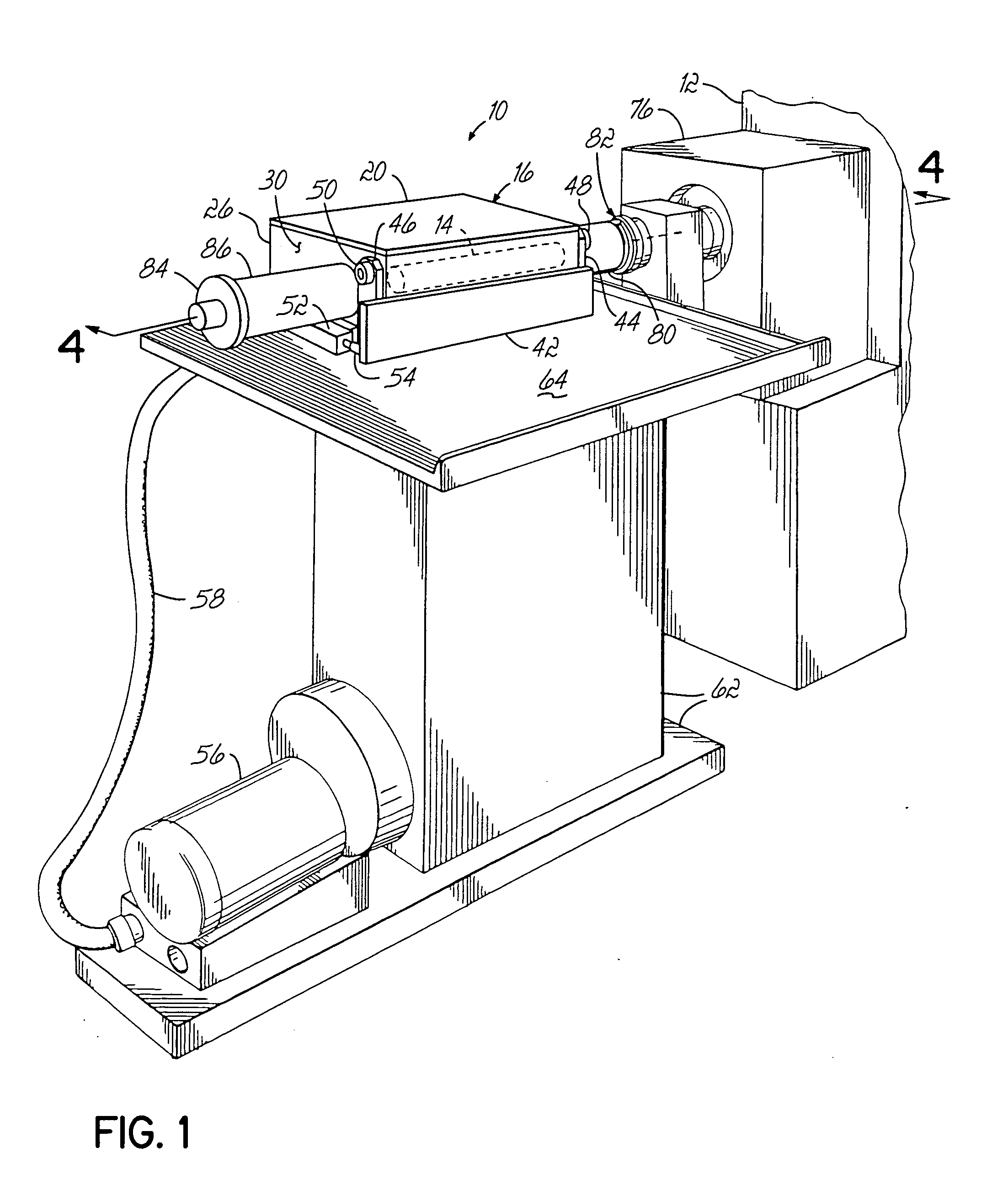

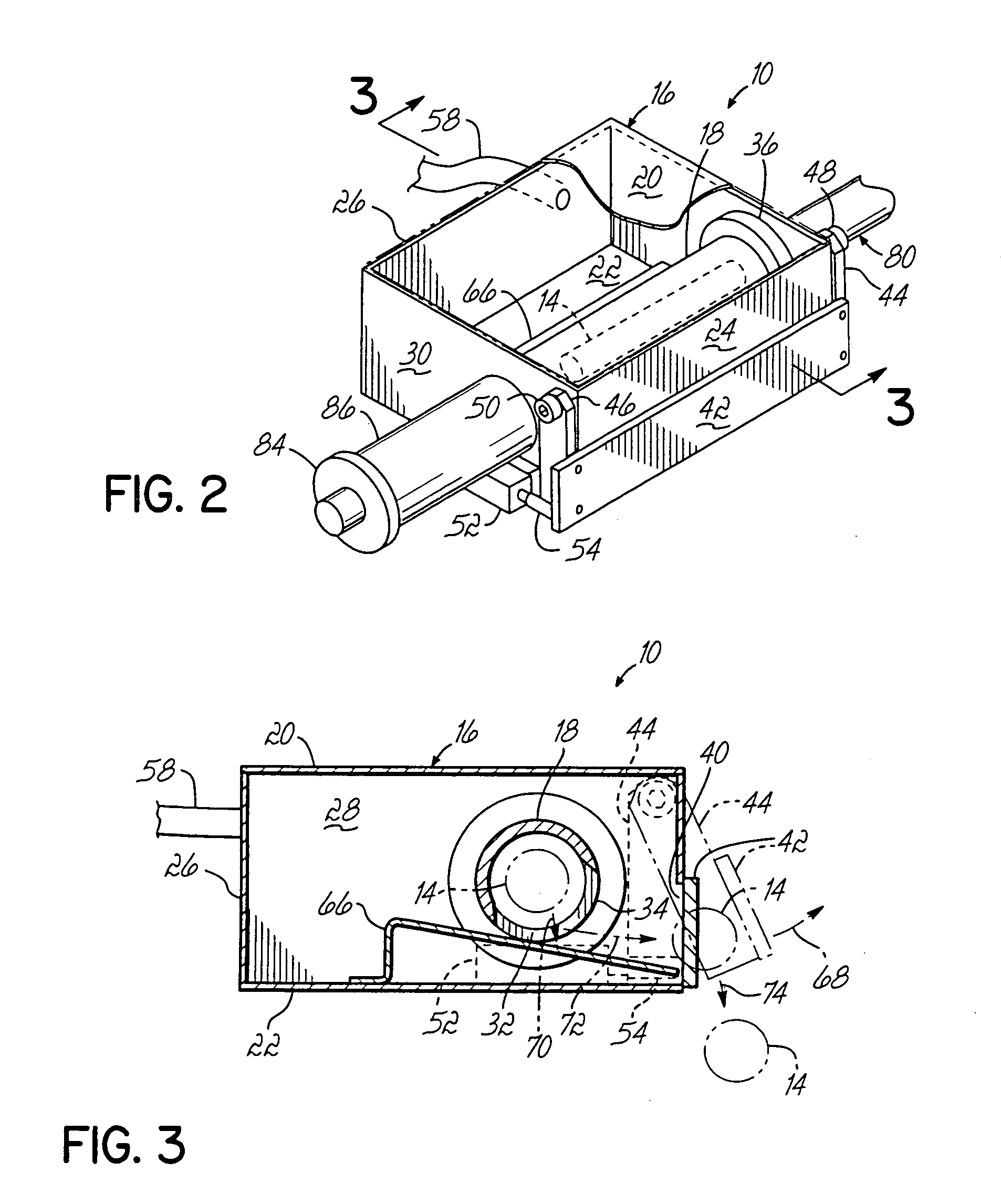

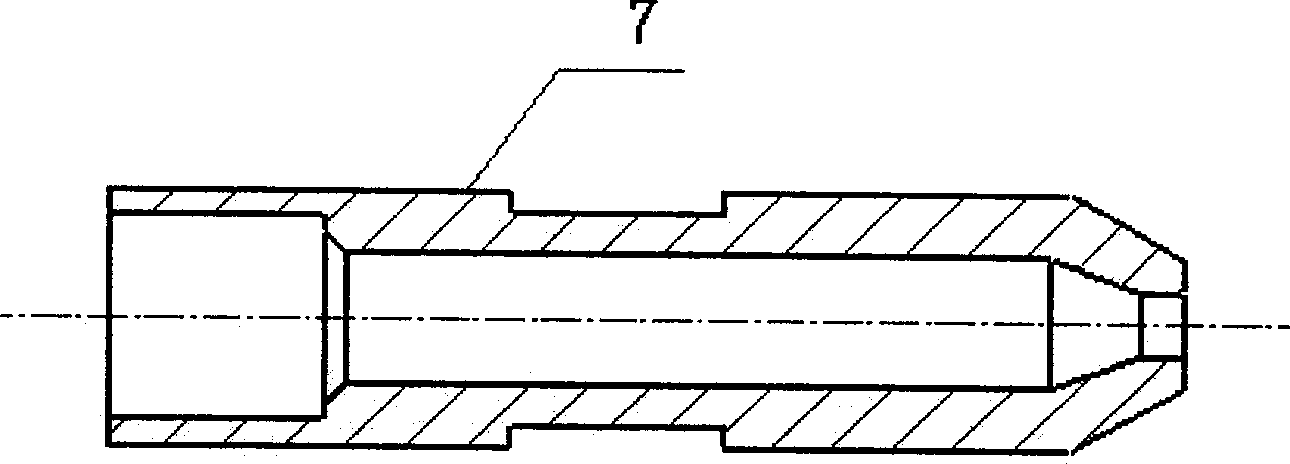

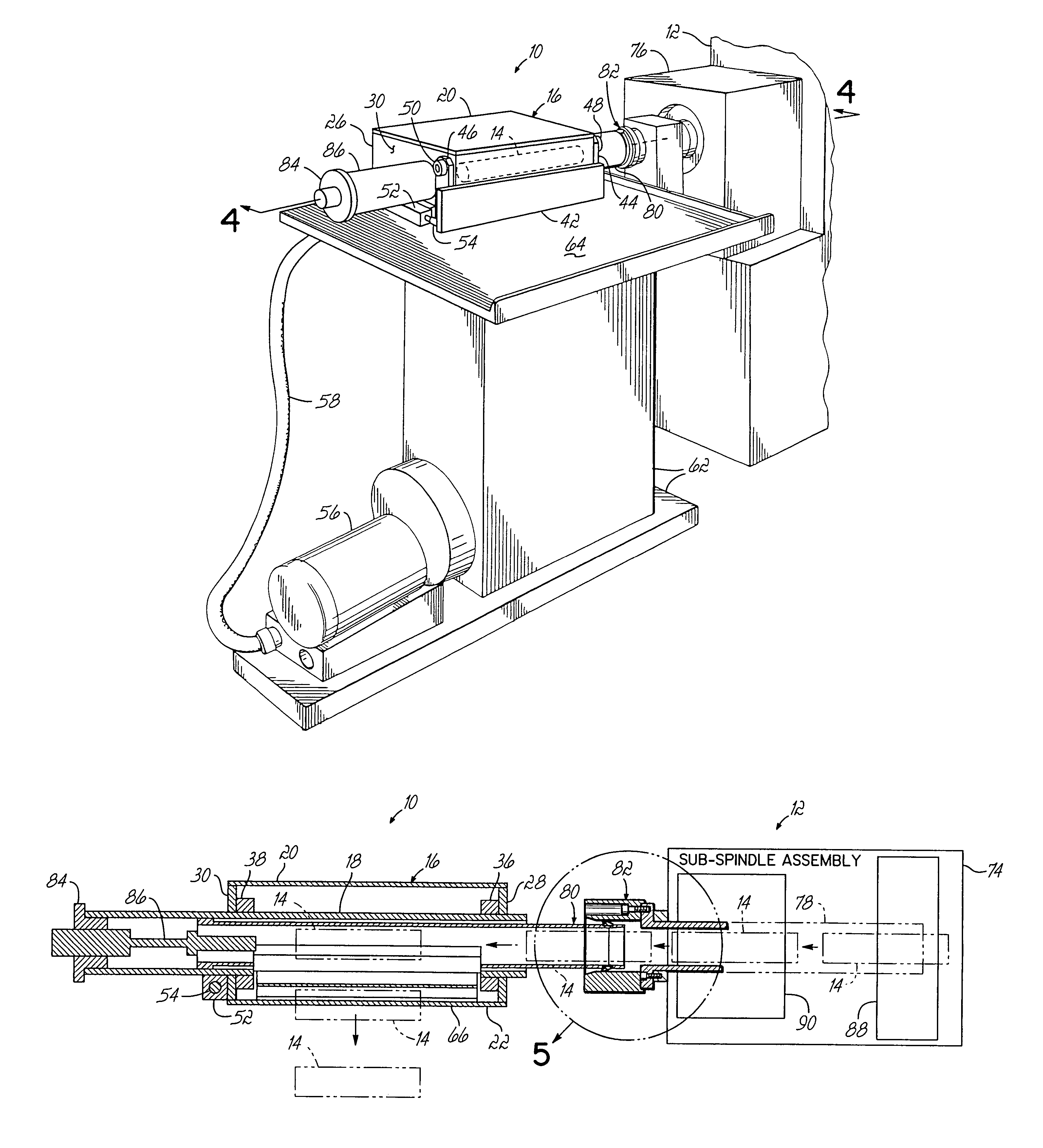

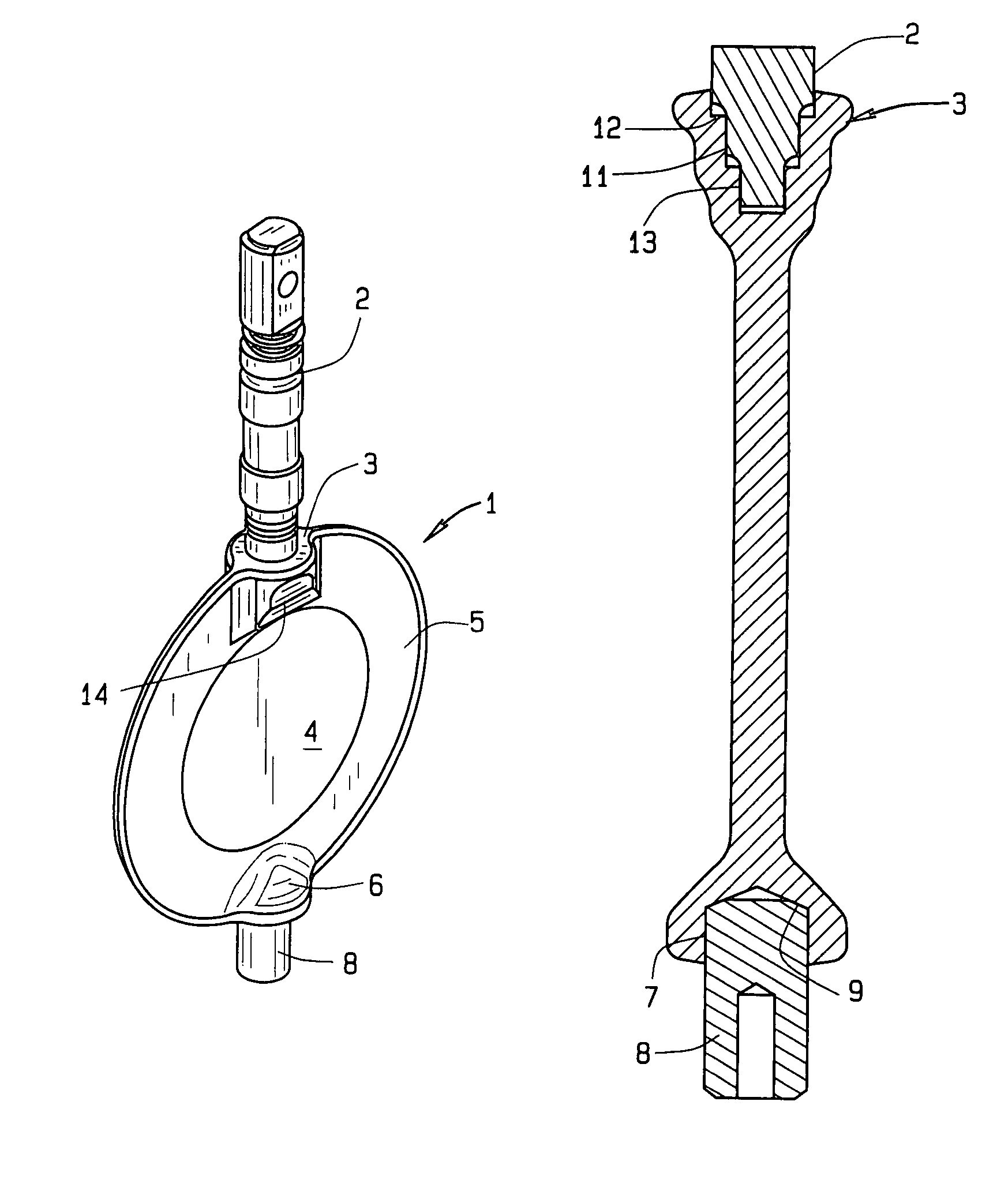

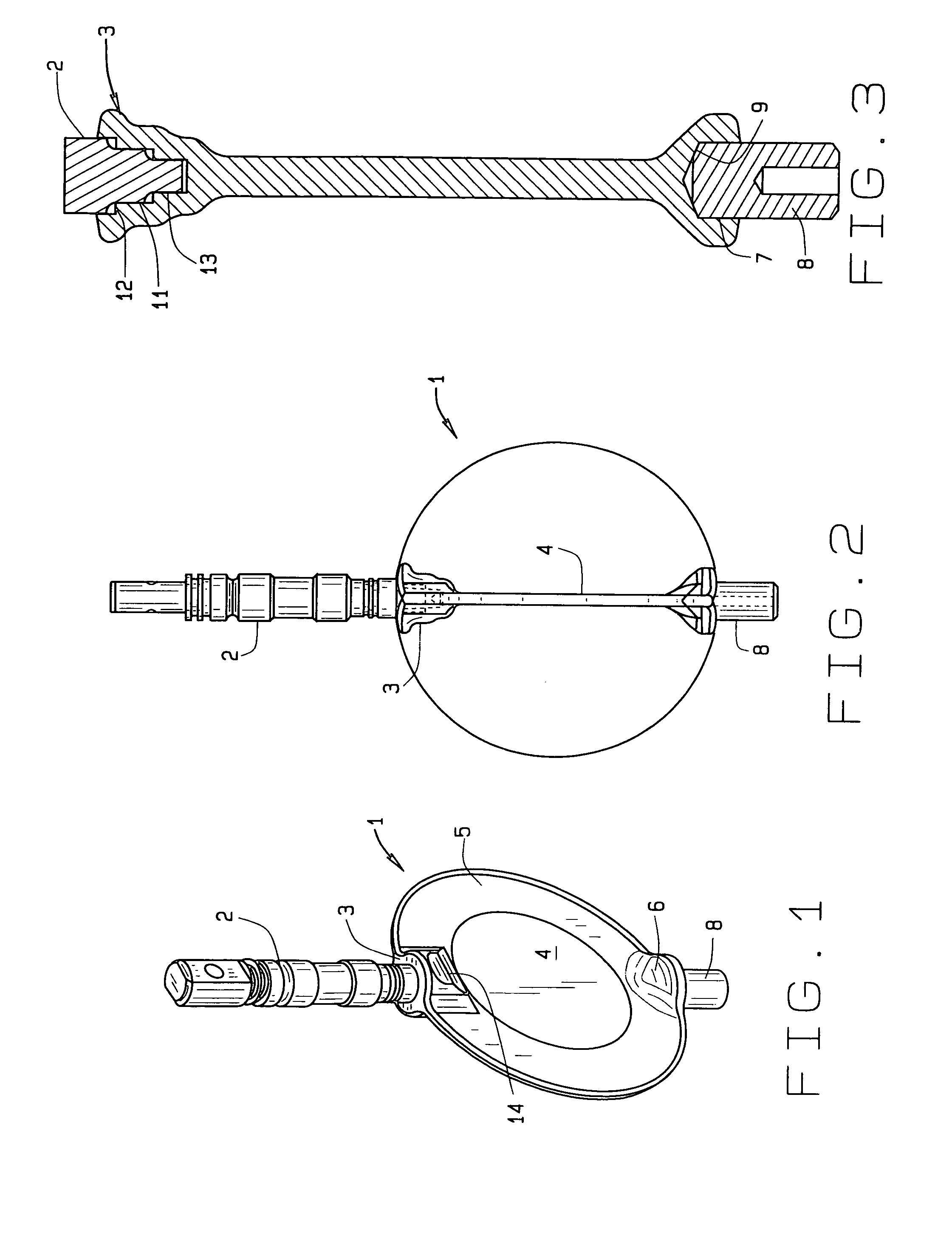

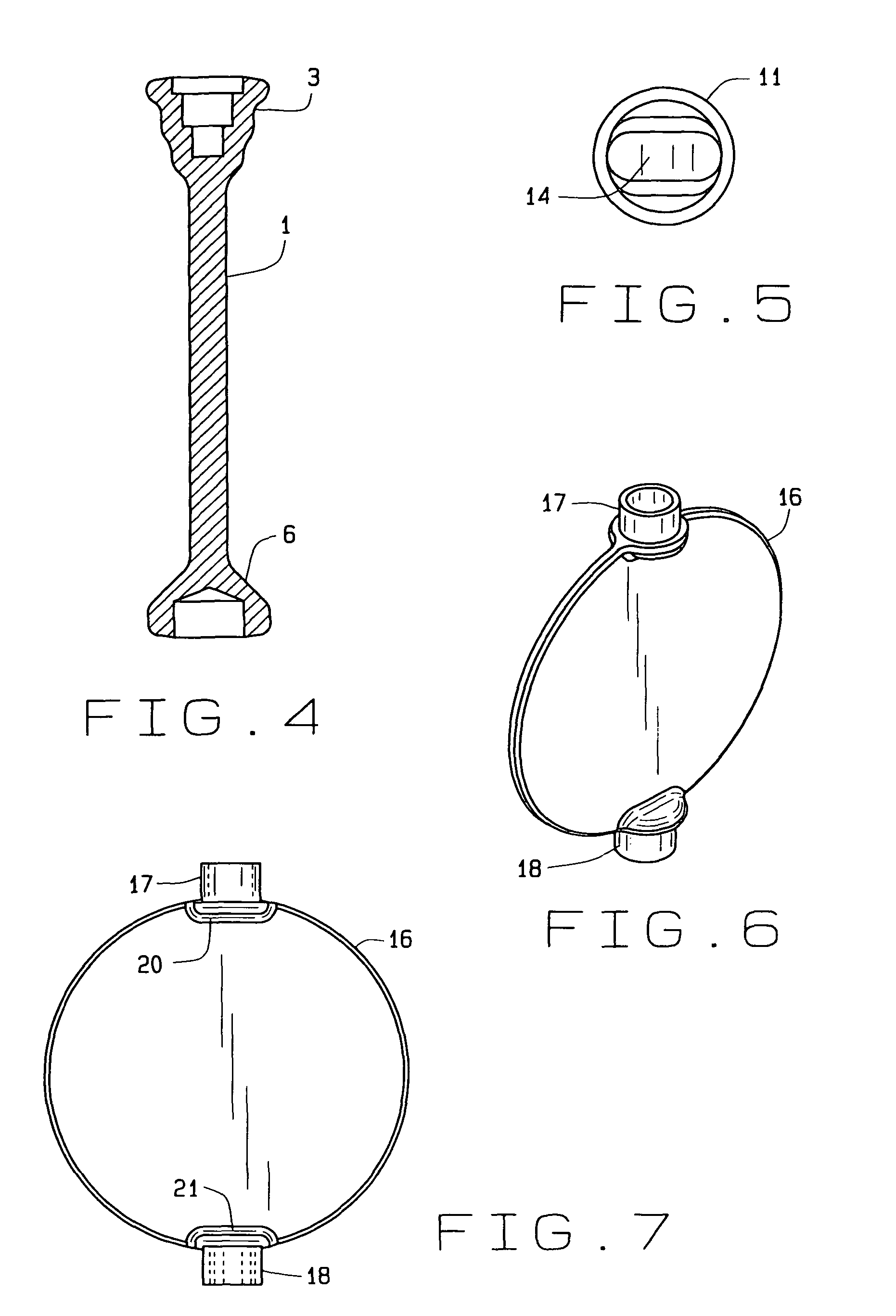

Air operated unloading device

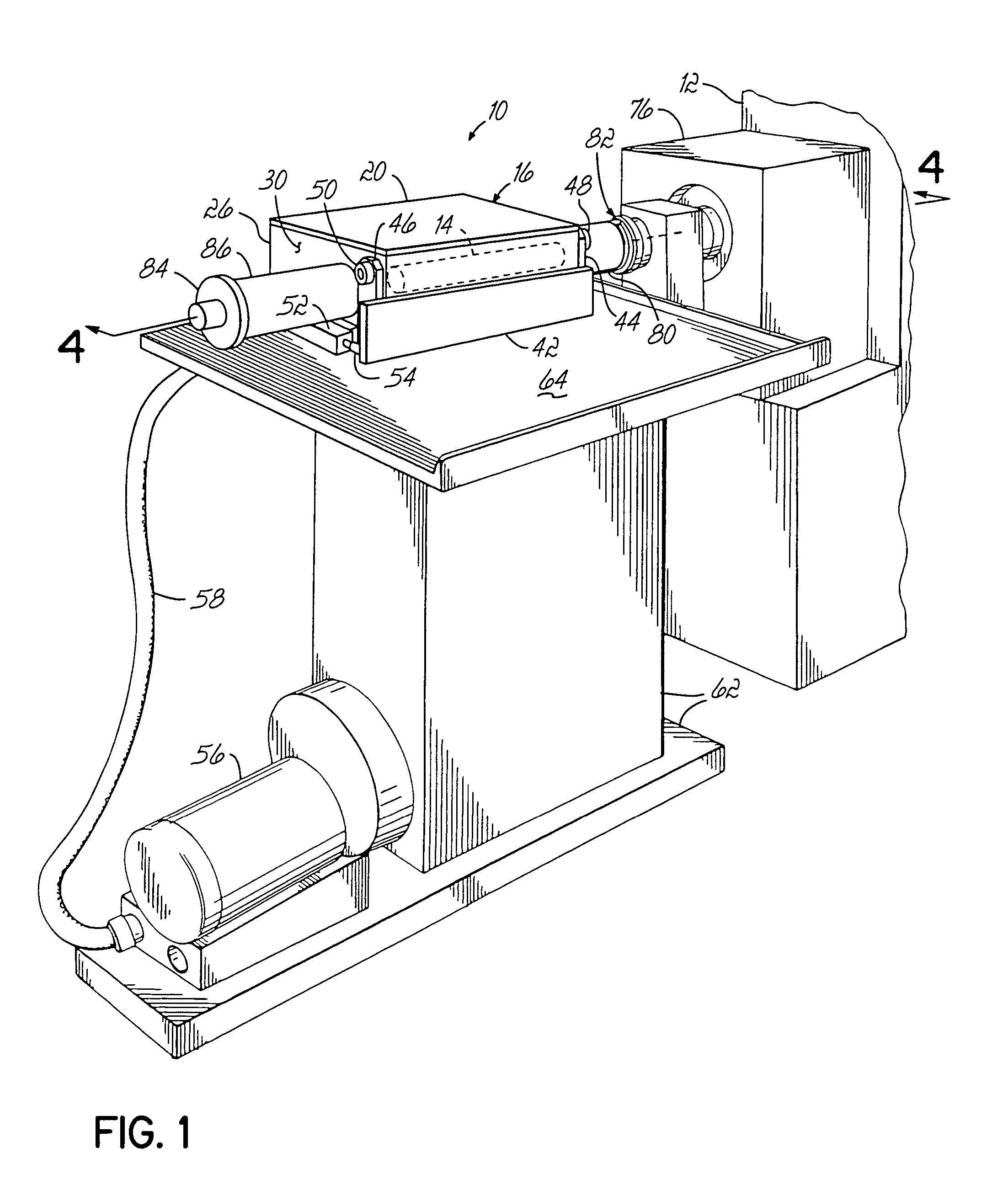

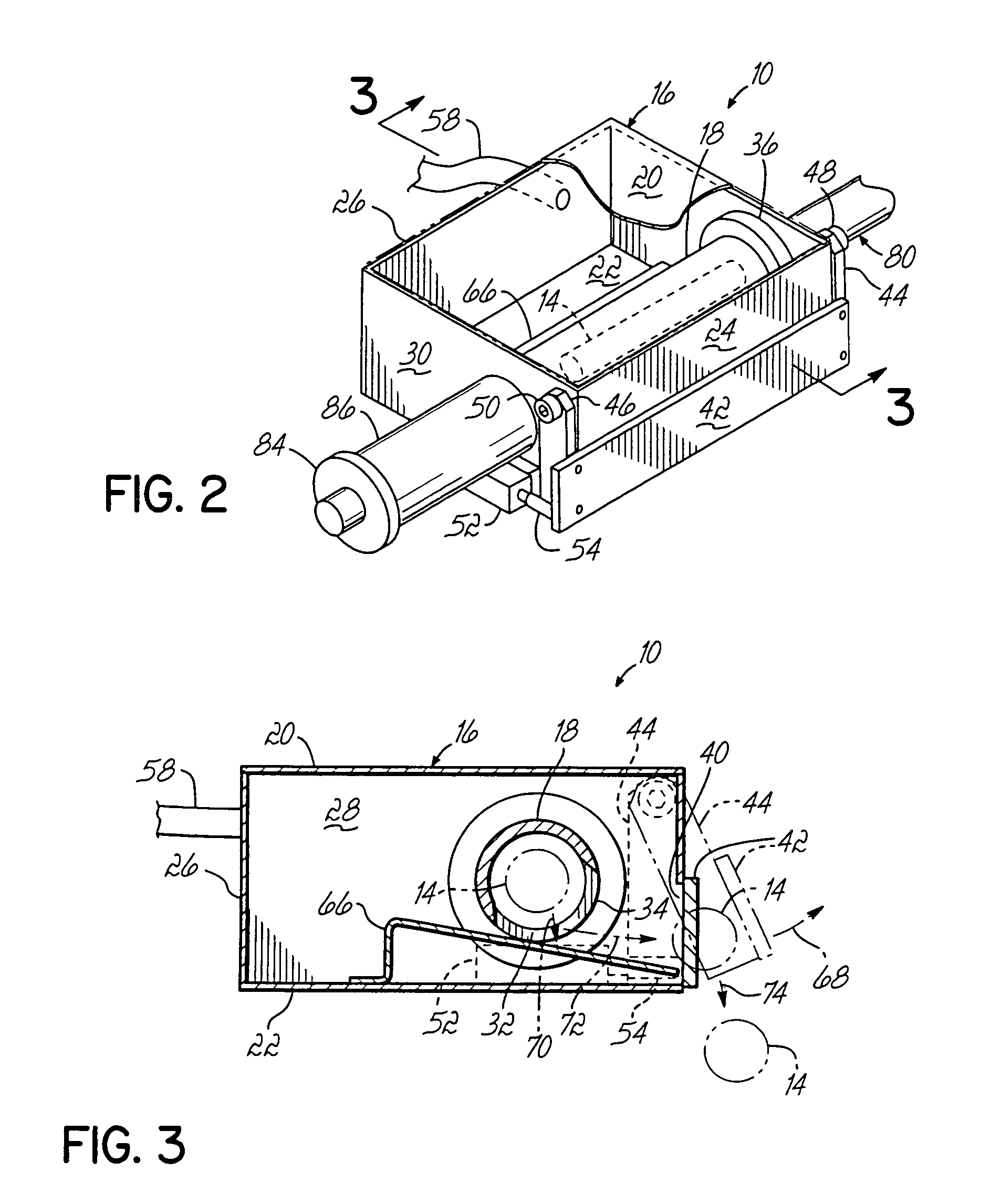

ActiveUS20050111957A1Easy dischargeSimplifies and eliminatesLathesAutomatic conveying/guiding stockCouplingEngineering

A device for effecting an unloading operation of a workpiece with respect to a machine tool. The device includes a non-rotating dump tube having one end adapted for communication with a machine tool and a sidewall defining an opening for discharging a workpiece, a vacuum chamber enclosing the opening in the sidewall and including a workpiece outlet, the chamber configured to receive a workpiece from the dump tube, a door selectively sealingly engaged with the workpiece outlet, and configured to allow the unloading of a workpiece, and a source of vacuum coupled to the vacuum chamber and configured to draw a workpiece through the dump tube and into the vacuum chamber for unloading. A coupling may be disposed between an unloading device and a machine tool to allow the machine tool to operate at increased rates during an unloading operation.

Owner:J F BERNS

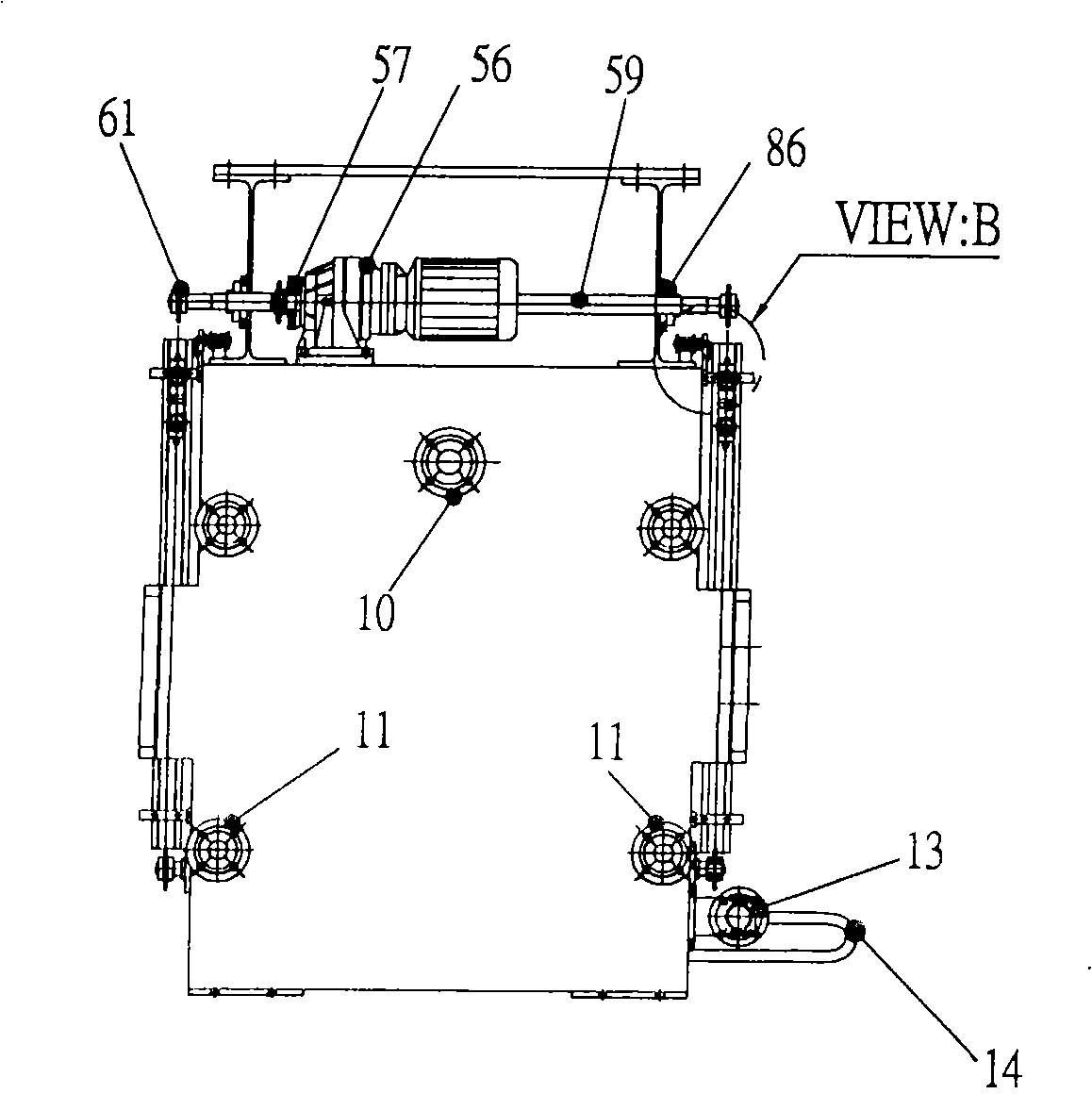

Salvage ship used for salvaging water surface floating objects in classified mode

PendingCN108773464AIncrease loading capacityImprove collection efficiencyWater cleaningWaterborne vesselsMarine engineeringCompression method

Owner:SHANDONG JIAOTONG UNIV

A fishing method for classifying and salvaging surface floats

InactiveCN109080780AIncrease loading capacityImprove collection efficiencyWater cleaningWaterborne vesselsEngineeringCompression method

The invention relates to a fishing method for classifying and salvaging surface floats, A surface float is searched by a surface search device, Afterwards, the salvage objects are broken and salvagedby the crushing device, and the salvage objects on the conveying device are judged by the water surface float property judging device, the classification of the water surface floating objects is completed, and the salvage storage is completed by adopting different compression methods according to the properties of the classified floating objects. The salvaging method can greatly improve the collection efficiency, enhance the collection capacity of the salvage ship, increase the loading capacity of the ship, and reduce the round-trip unloading time.

Owner:SHANDONG JIAOTONG UNIV

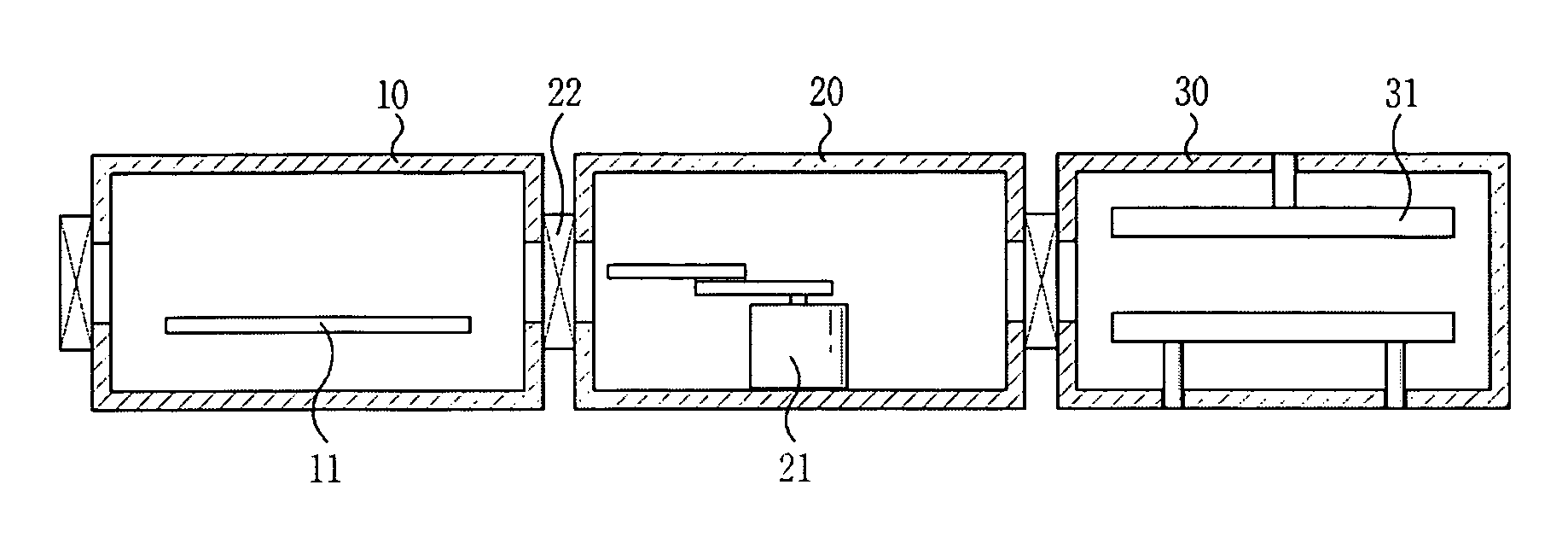

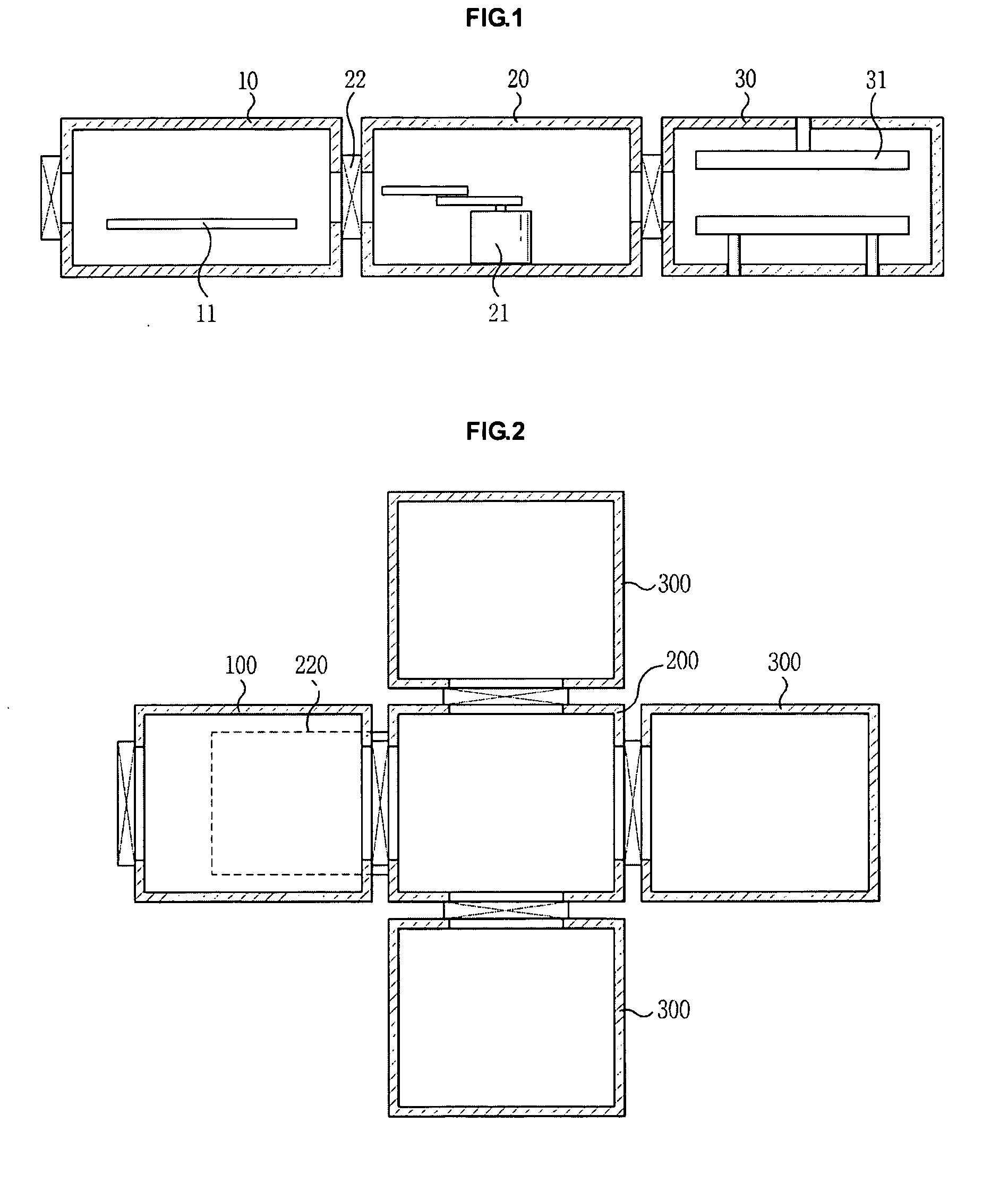

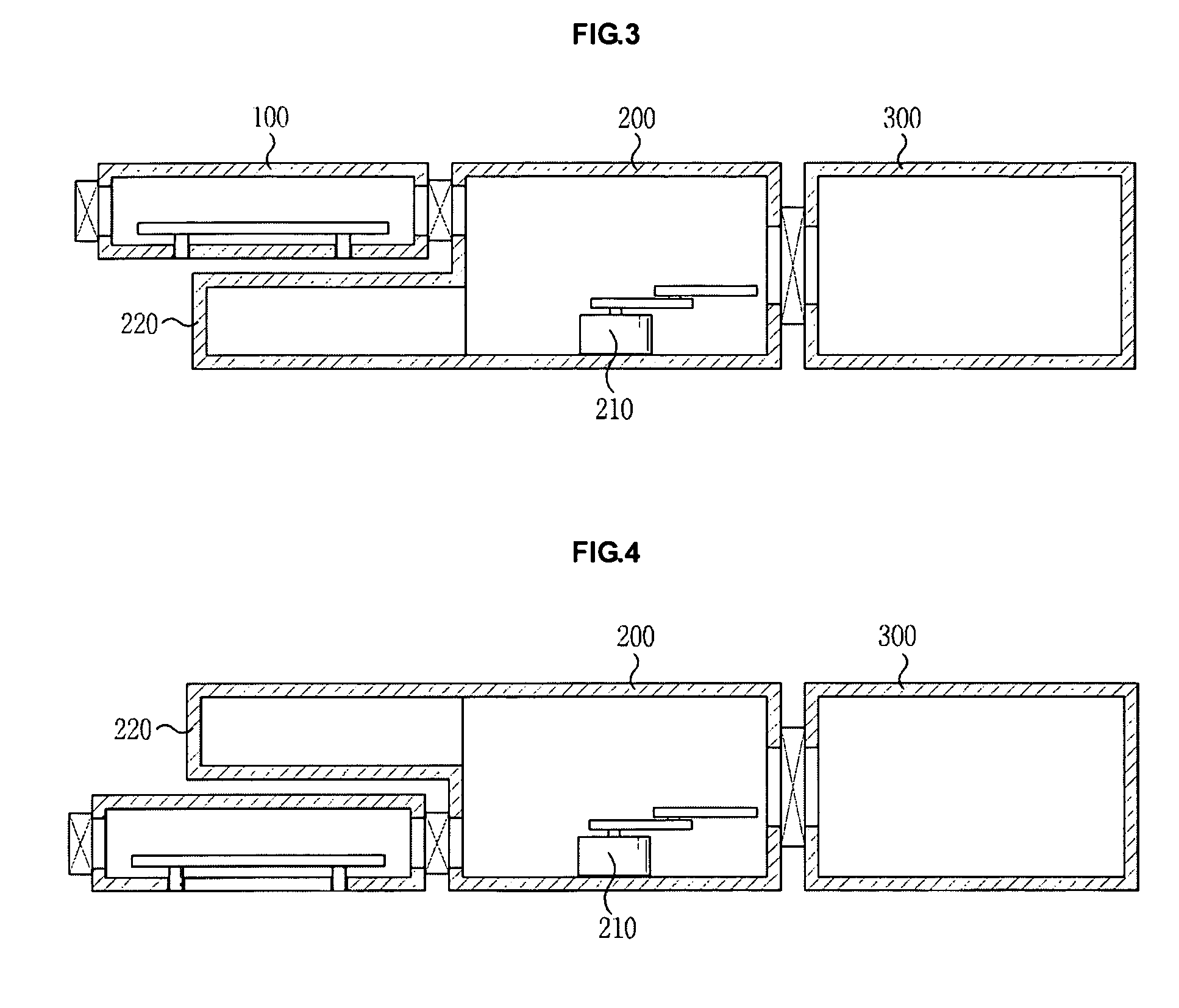

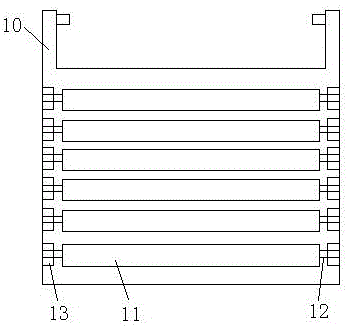

Apparatus for manufacturing flat-panel display

InactiveUS20050183665A1Reduce substrate loadingShorten unloading timeCosmonautic condition simulationsSemiconductor/solid-state device manufacturingElectricityDisplay device

A flat-panel display (FPD) manufacturing apparatus is disclosed which not only includes a load lock chamber, a feeding chamber, and a processing chamber, at least one of which has a vertically-stacked chamber structure to achieve an enhancement in substrate processing efficiency, but also includes a temporary substrate storing space for temporarily storing substrates in the feeding chamber to reduce the time taken to feed substrates. Another FPD manufacturing apparatus is disclosed which includes a load lock chamber, a feeding chamber connected to the load lock chamber, a temporary substrate storing space arranged at a predetermined portion of the feeding chamber, and at least one processing chamber connected to the feeding chamber.

Owner:ADVANCED DISPLAY PROCESS ENG

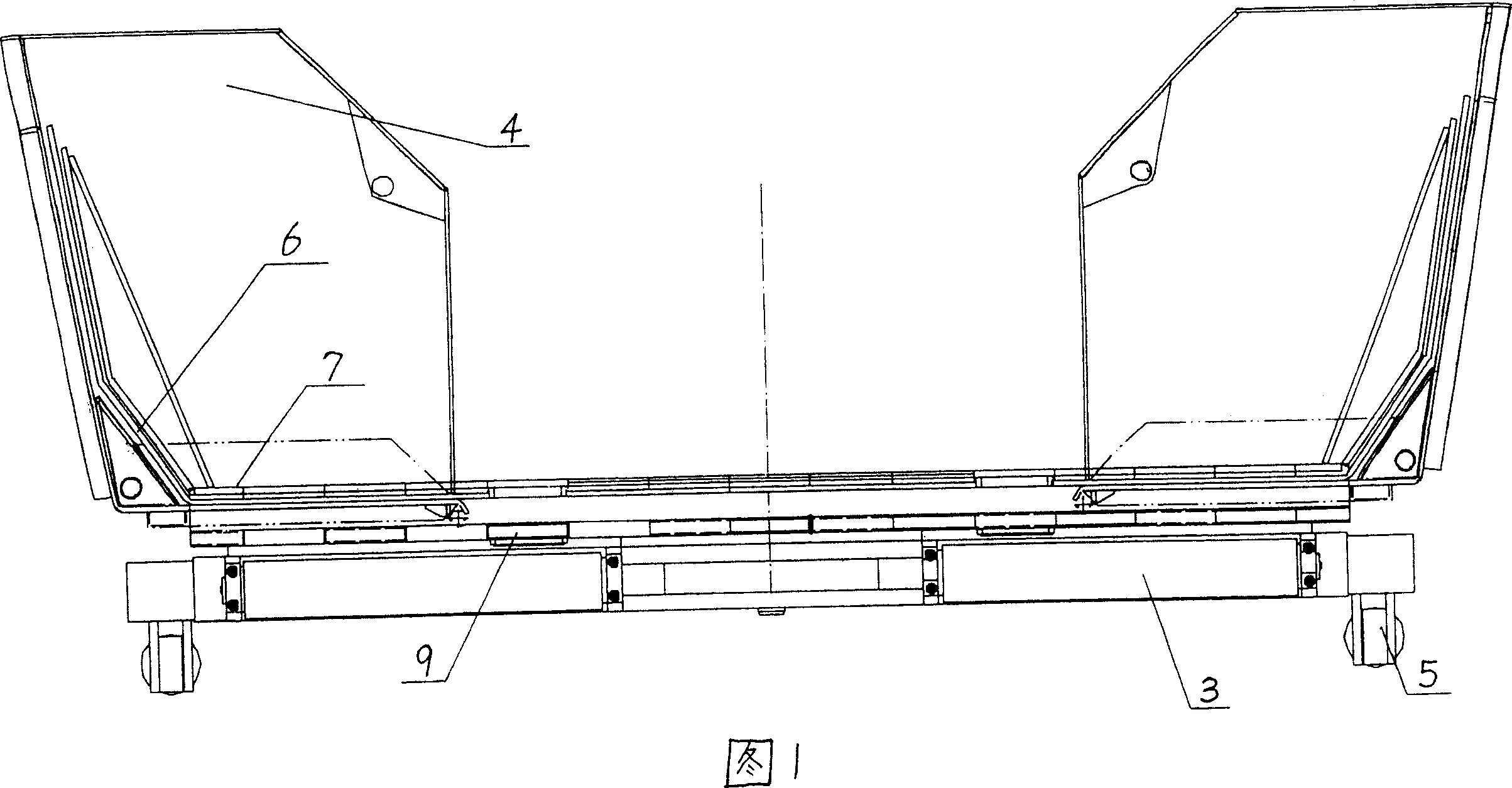

Flex overturning type auxiliary movable hopper for spreading machine

This invention discloses one spreader contract tilting assistant active bunker, which comprises guide channel set on both sides of spreader with one end of slide axis into guide channel and with other end connected to pull assemble fixed with fix bunker and tilt bunker, wherein, the contract cylinder one end is hinged on guide channel and other end hinged onto pull assembly; the active bunker contracts front and back under contract cylinder; the tilt cylinder one end is hinged onto fix bunker and other end connected with tilt with tilt cylinder fixed on middle or both sides of active bunker to realize tilt under tilt cylinder.

Owner:SHAANXI JOINTARK MASCH GRP CO LTD

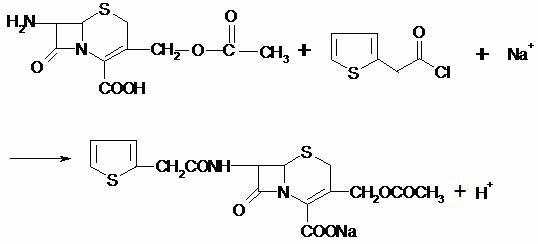

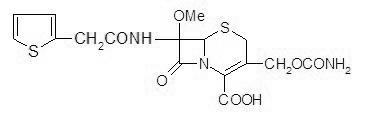

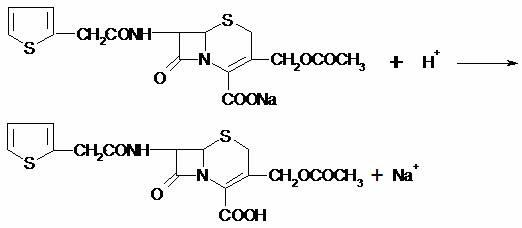

Method for producing cephalothin acid by water phase method

InactiveCN102040614AReduce consumptionLower skill requirementsOrganic chemistryOrganic solventAklanonic acid

The invention discloses a method for synthesizing cephalothin acid by using 7-aminocephalosporanic acid (7-ACA) as a raw material, which is characterized in that: the 7-ACA and a 2-thiophene acetylation reagent are subjected to condensation reaction in a water phase solvent, and the production process sequentially comprises the following steps of: performing condensation reaction on the 7-ACA in a water phase; performing centrifugal filtration on a reaction product; refining and decolorizing; and performing crystallization separation, centrifugal filtration and vacuum drying to obtain a cephalothin acid product. The production process is simplified, the requirement on equipment is reduced, the amount of an organic solvent can be saved by over 70 percent, potential safety hazard and environmental pollution due to high consumption of the inflammable, explosive and volatile organic solvent are eliminated, the safety requirement level of the production field is reduced, production cost is greatly reduced, and the method is easy to operate and suitable for mass production and has high technical and economic feasibility.

Owner:湖南永利化工股份有限公司

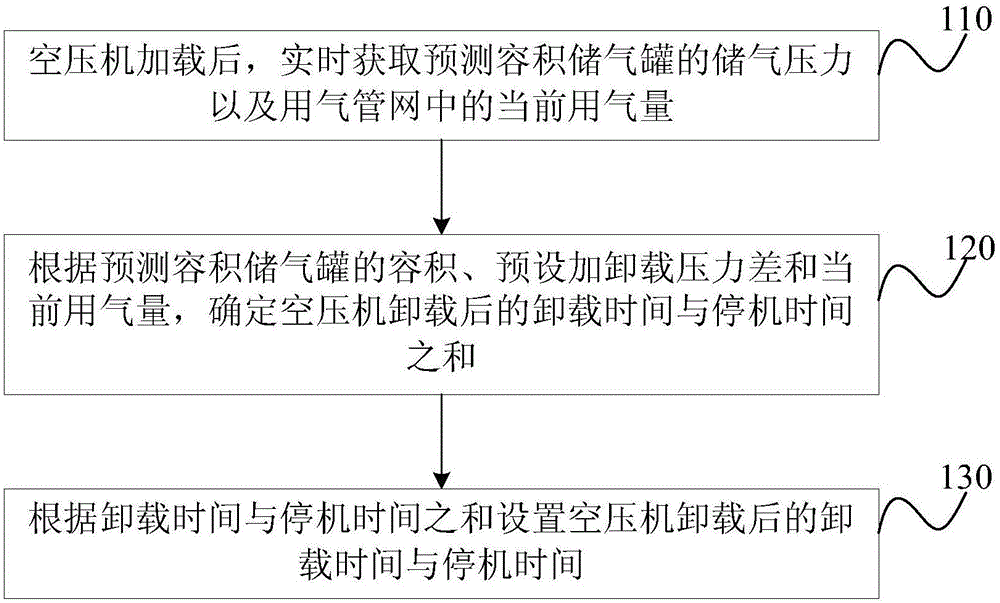

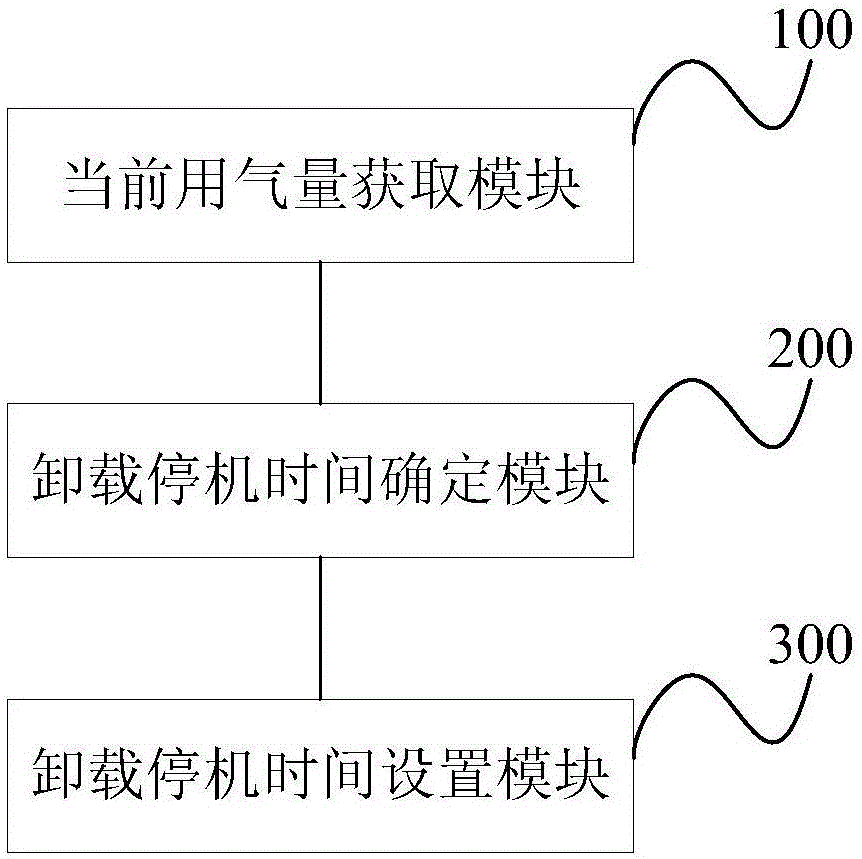

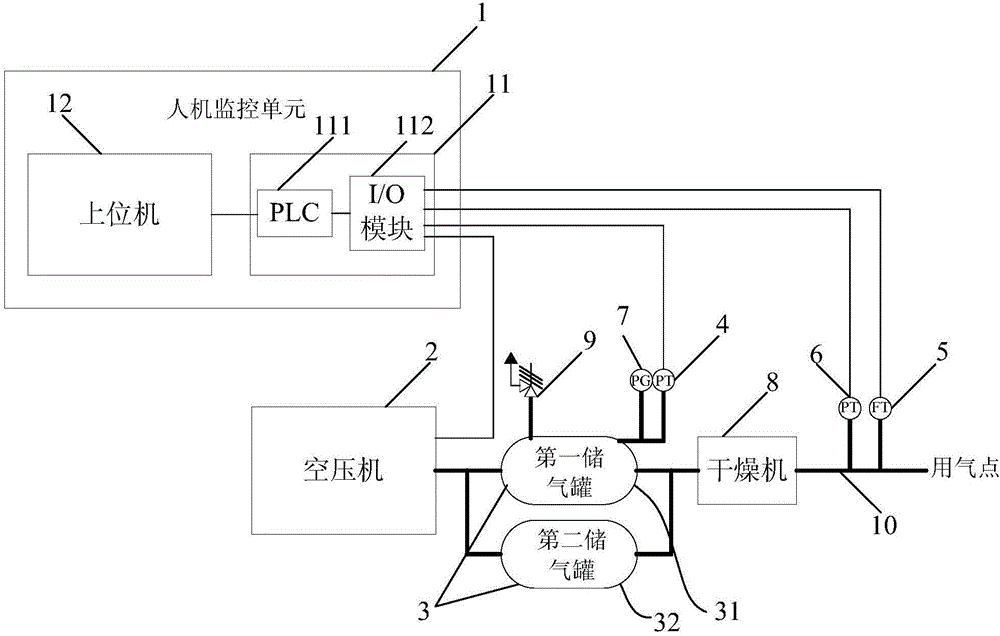

Air compressor energy saving control method, device and system

ActiveCN106499617AIncrease the start-stop cycleShorten unloading timePump controlPump installationsStop timeEngineering

The invention discloses an air compressor energy saving control method, device and system. The method comprises the steps that after an air compressor loads, air storage pressure of a forecast volume air storage tank and current air consumption of an air pipe network are acquired in real time, wherein an air inlet of the forecast volume air storage tank is connected with an air output port of the air compressor, and an air outlet of the forecast volume air storage tank is connected to an air using place through the air pipe network; the sum of the unloading time and the stop time which are needed after the air compressor unloads is determined according to the volume of the forecast volume air storage tank, a preset loading and unloading pressure difference and the current air consumption, wherein the preset loading and unloading pressure difference is a difference between preset unloading pressure and preset loading pressure; the unloading time and the stop time which are needed after the air compressor unloads are set according to the sum of the unloading time and the stop time, wherein the stop time is longer than 0. Accordingly, the energy saving effect of the fixed-frequency air compressor is improved at low cost.

Owner:DYNAX SEMICON

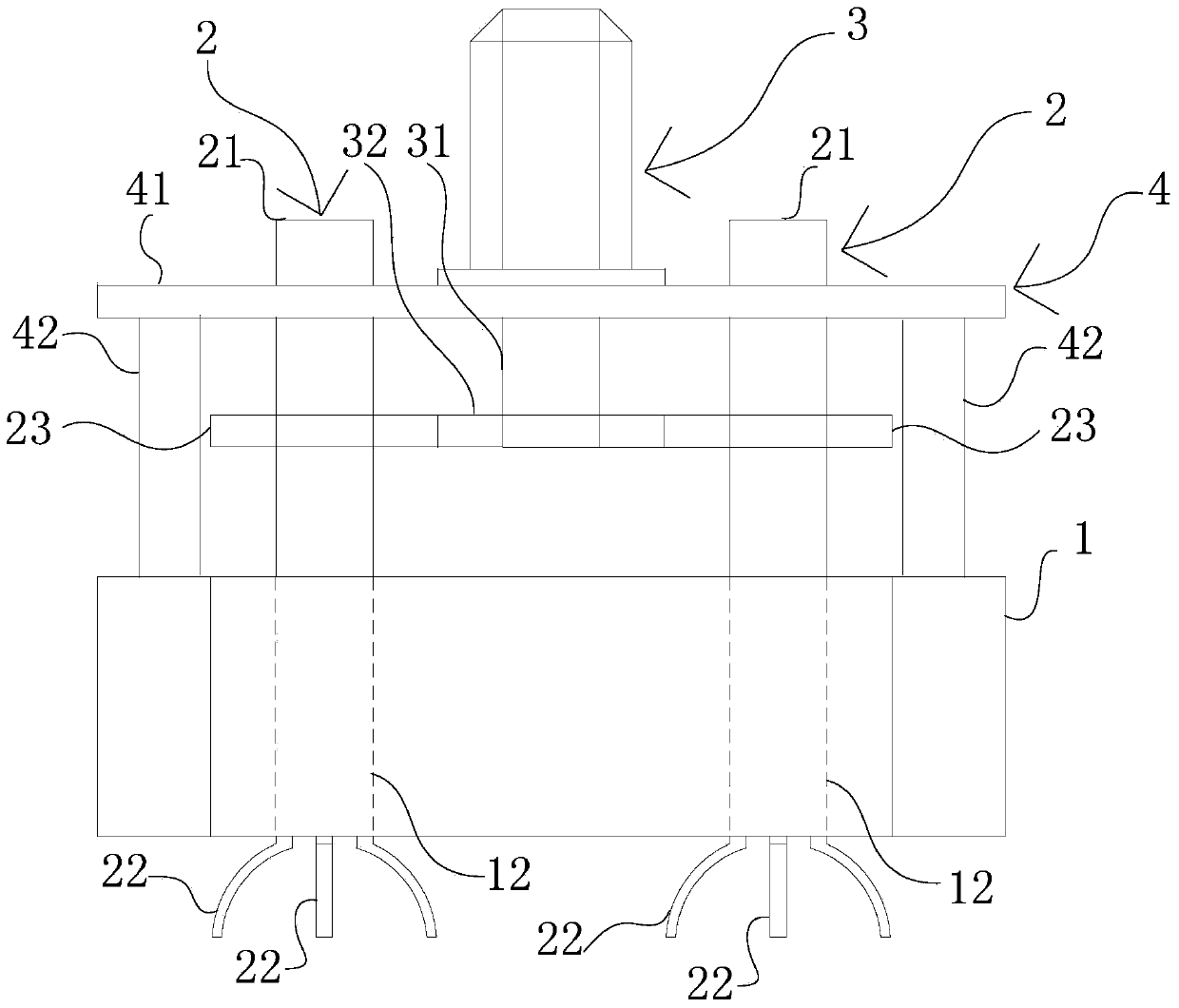

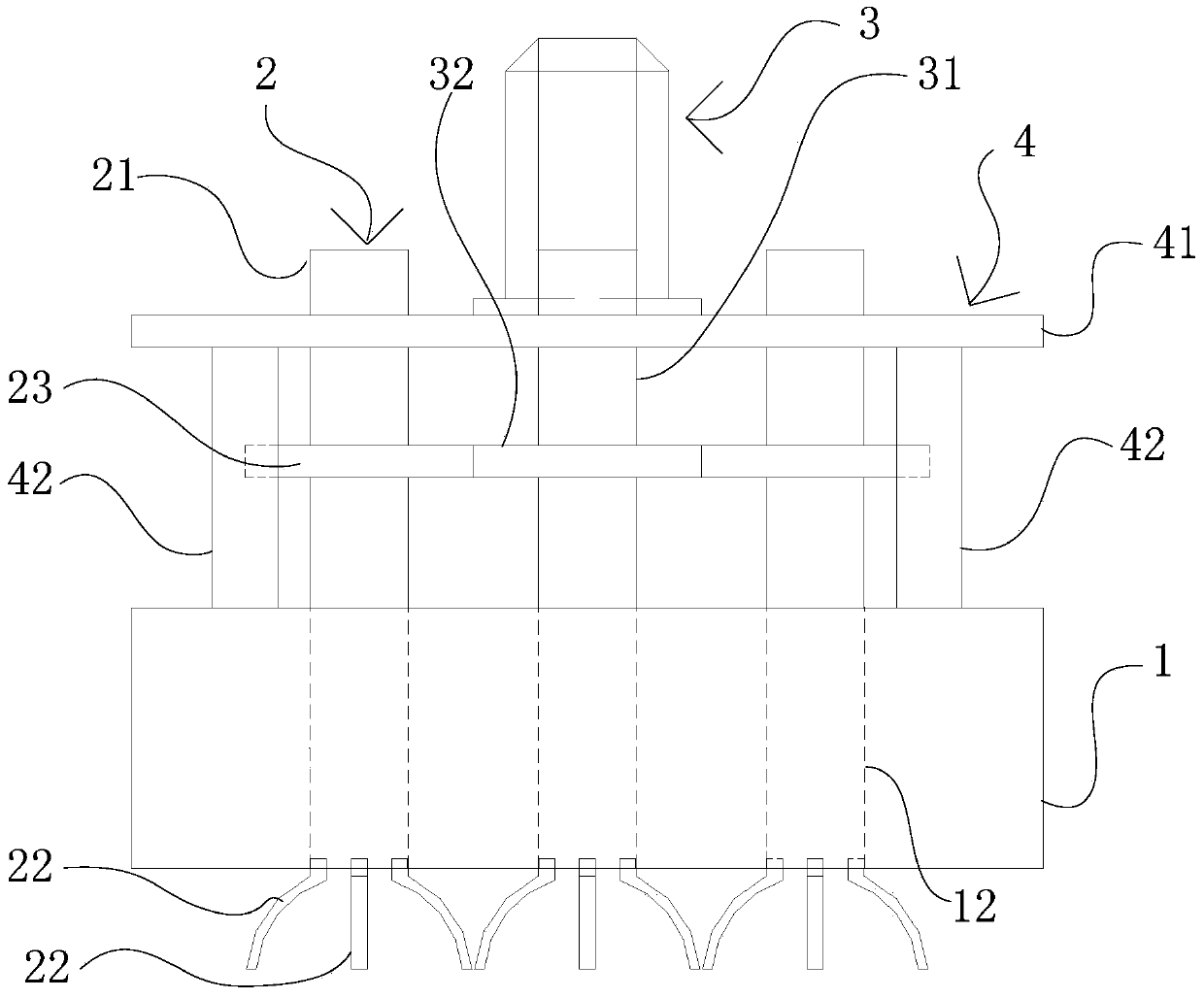

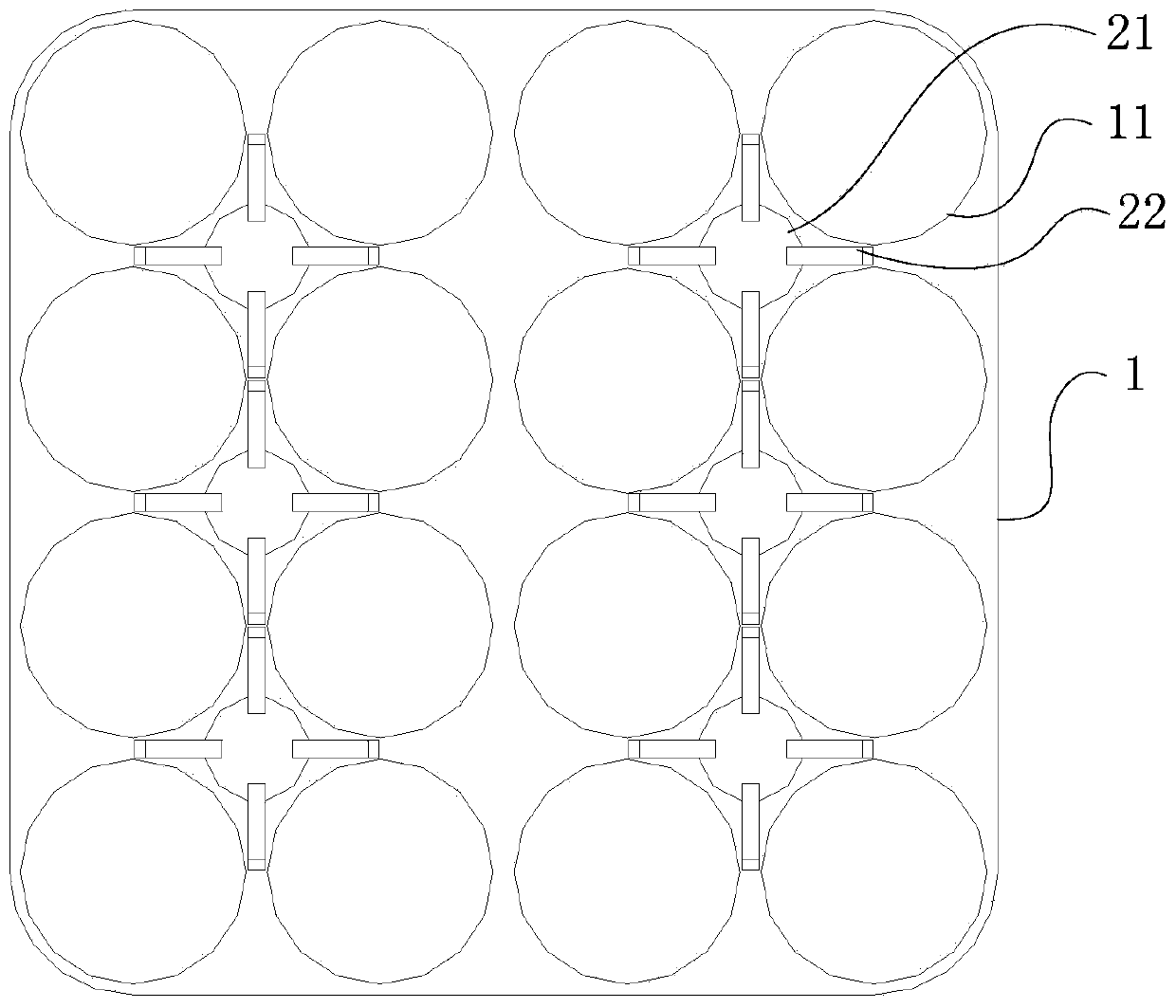

Unloading device and unloadingmethod for pebble-bed reactorfuel spheres

ActiveCN103971772ARealize batch unloadingShorten unloading timeNuclear energy generationReactor fuel elementsMechanical engineeringPebble-bed reactor

The invention discloses an unloading device and an unloading method for pebble-bed reactorfuel spheres. Theunloading device comprises an unloadingcomponent, at least one limiting device, a driving device and a fixing device, wherein theunloading component is used for accommodating a plurality of to-be-unloaded fuel spheres; each limiting device is used for limiting each corresponding to-be-unloaded fuel sphere; and the driving device is used for providing a driving force for each limiting device. Theunloading method comprises the steps as follows: S1, theunloading component is aligned to each corresponding to-be-unloaded fuel sphere; S2, each limiting device is located in a set initial position; S3, the driving device drives each limiting device to rotate to enable each corresponding to-be-unloaded fuel sphere to completely enter theunloading component; S4, each to-be-unloaded fuel sphere is unloaded to a corresponding designated position; S5, steps S1-S4 are repeated. According to the unloading device and the unloading method, unloading of the pebble-bed reactorfuel spheres arranged regularly and batch unloading of the fuel spheres can be realized.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Tank truck heating device

The invention provides a tank truck heating device, which is arranged on an outer surface of a lower part of a tank body of a tank truck, and comprises a heating plate, longitudinal support irons arranged on two ends of the heating plate and longitudinally arranged along the tank body, annular support irons arranged between the longitudinal support irons and arranged along the peripheral direction of the tank body and a diversion trench, and the diversion trench, wherein the shape of the heating plate is a circular arc adapted to the shape of the tank body; a plurality of annular support irons are arranged; steaming holes are arranged on the middle annular support irons; and the diversion trench is longitudinally arranged along the longitudinal support irons and is connected with the annular support irons. The tank truck heating device is an outer steam jacket type heating device with the diversion trench, and the diversion trench is arranged in the outer heating device and is used for guiding heating steam flow direction and flux, so that the heating efficiency of the outer heating device is improved, and the time for unloading is shortened.

Owner:XI AN RAILWAY TRANSPORTATION EQUIP

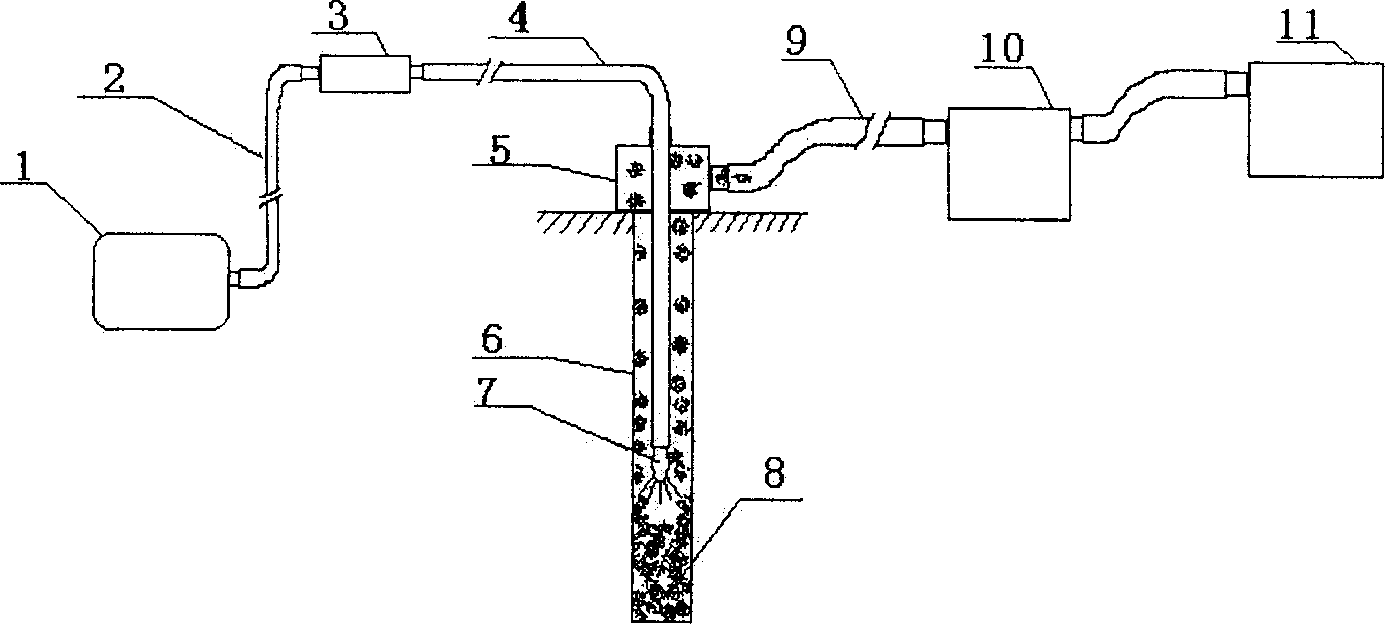

Process for unloading of silver catalyst reactor and its apparatus

InactiveCN1724137AShorten unloading timeReduce lossesChemical/physical processesPtru catalystPhysical chemistry

A material unloading method and apparatus for the silver catalyst reaction tube is disclosed. Said method features that the high-pressure gas is introduced to the catalyst reaction tube and a sucking unit is installed to the top of reaction tube to carry the silver catalyst from reaction tube to the filtering and recovering unit. Its apparatus is composed of high-pressure gas pump, high-pressure gas delivering tube, valve, high-pressure gas tube, and said sucking unit and filtering and recovering unit.

Owner:BEIJING UNIV OF TECH

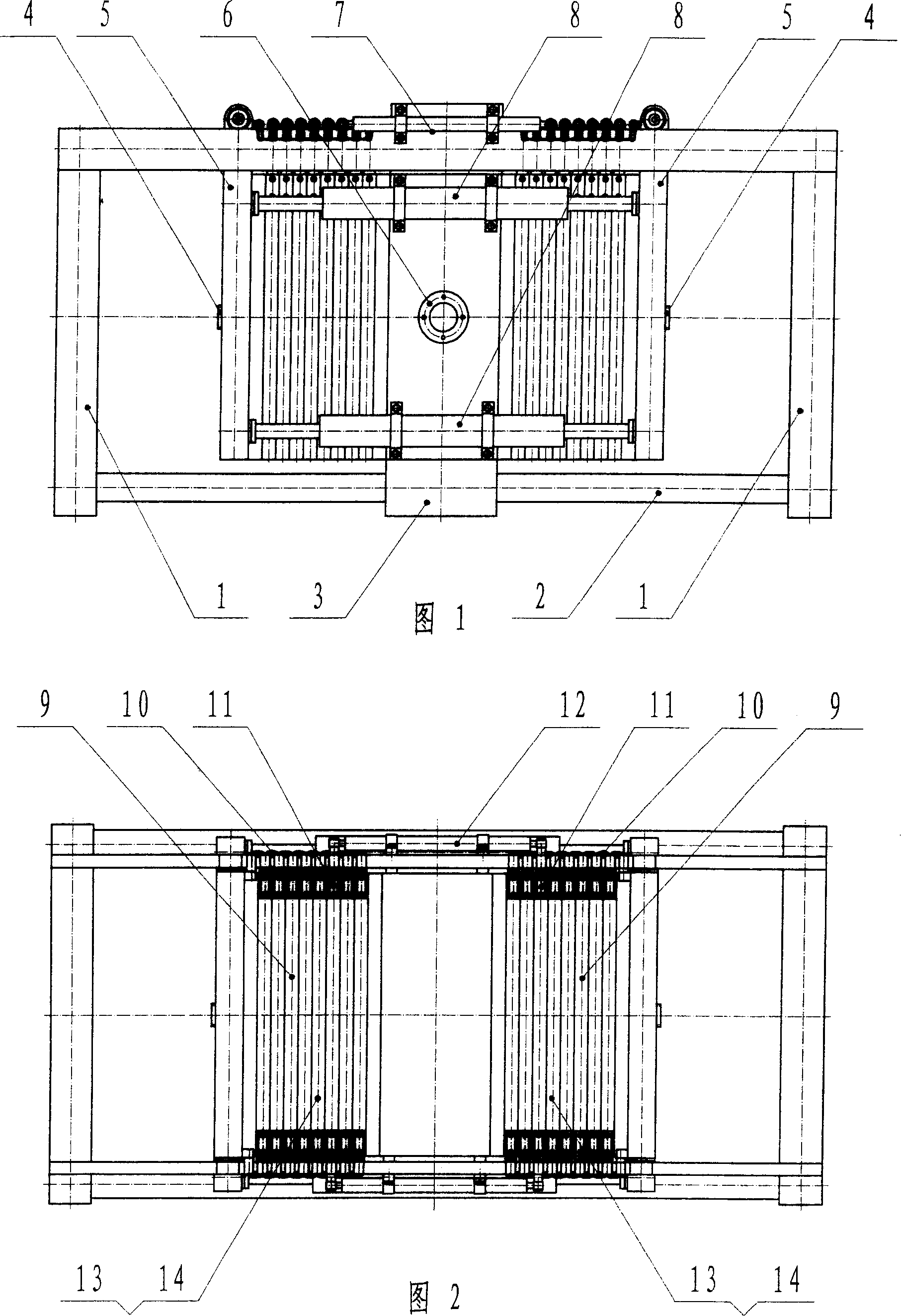

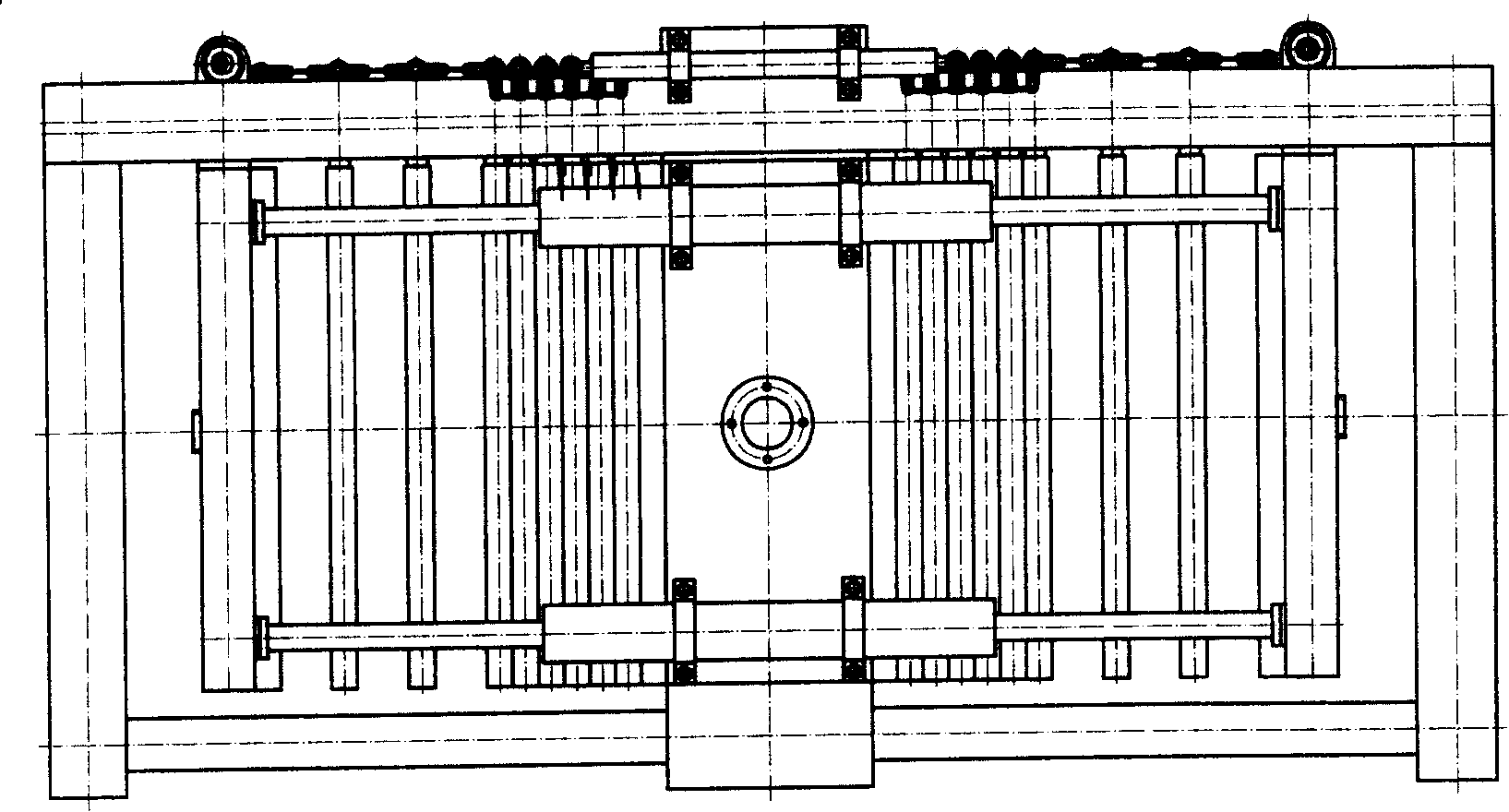

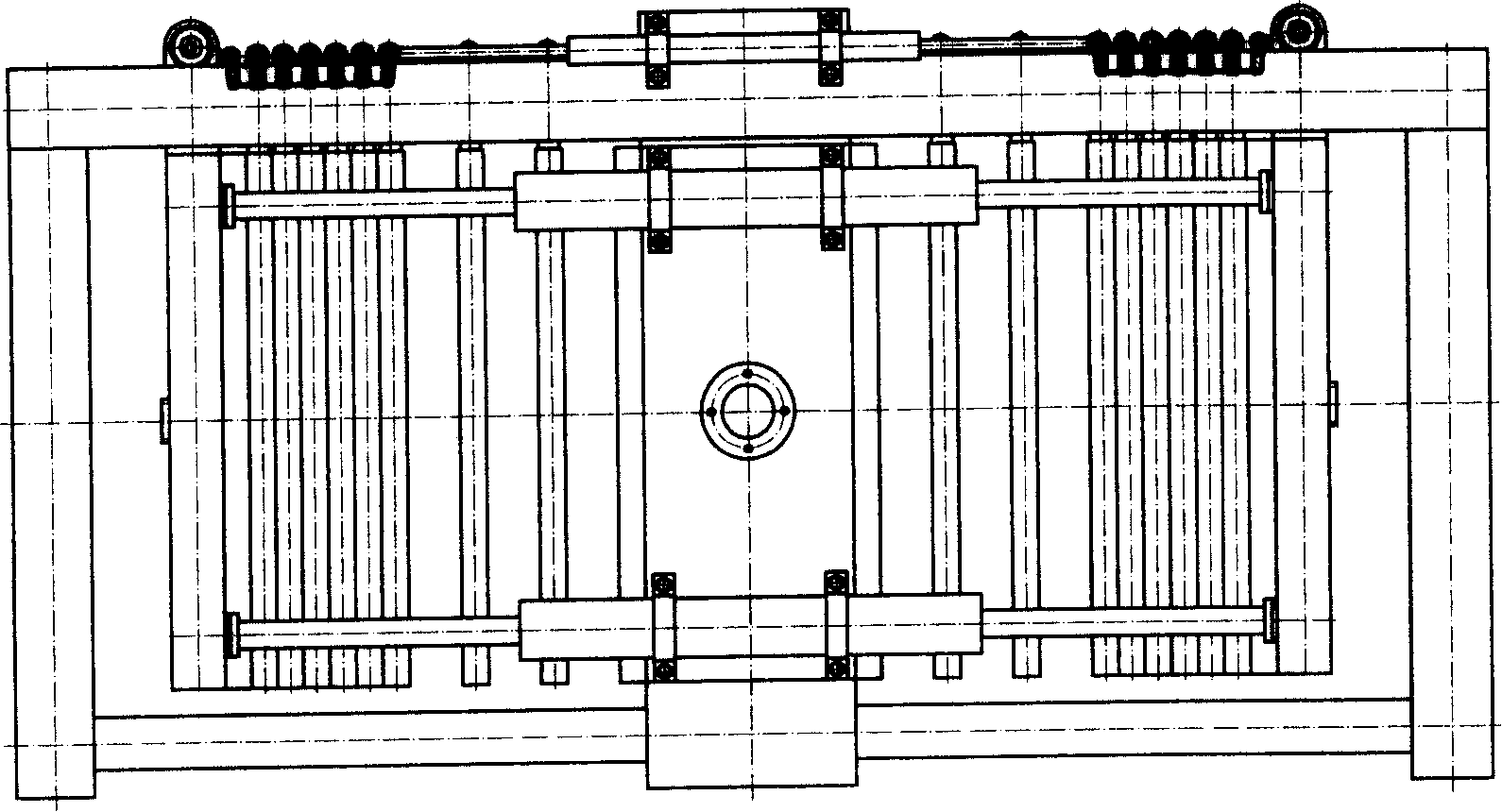

Rapid pressure filter

InactiveCN101172205AImprove stress conditionImprove reliabilityFiltration separationHydraulic cylinderEngineering

A fast filter press, which is composed of two end brackets, a middle plate, two top beams and two bottom beams connected by bolts to form a frame structure frame symmetrical to the middle plate, and the two sides of the middle plate are arranged symmetrically in sequence Filter unit and compression plate, all the filter plates in each filter unit are divided into three groups with the same number of filter plates with the connecting filter plate and the middle filter plate as the boundary, the filter plates and the filter plate and the compression plate are connected by hinges, The tensioning device and the pulling plate device composed of double-piston rod hydraulic cylinders are installed in the middle of the frame, and the piston rods at both ends of the respective hydraulic cylinders are respectively hinged with the compression plate and the connecting filter plate; the machine adopts symmetrical tension and compression The tensioning method of the plate presses the filter unit, the filter plate is divided into groups three times to unload and unload, and the two ends move and the middle is fixed. The problem of low efficiency and poor reliability caused by the inherent defects in the structural design of the machine.

Owner:王智民

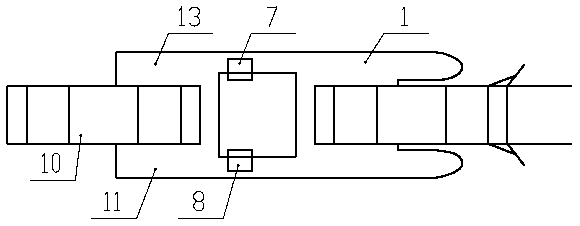

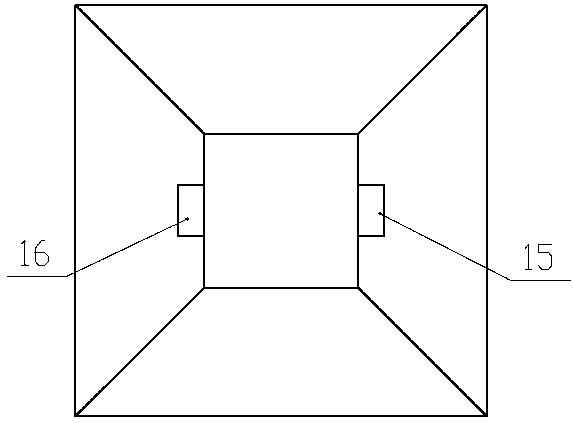

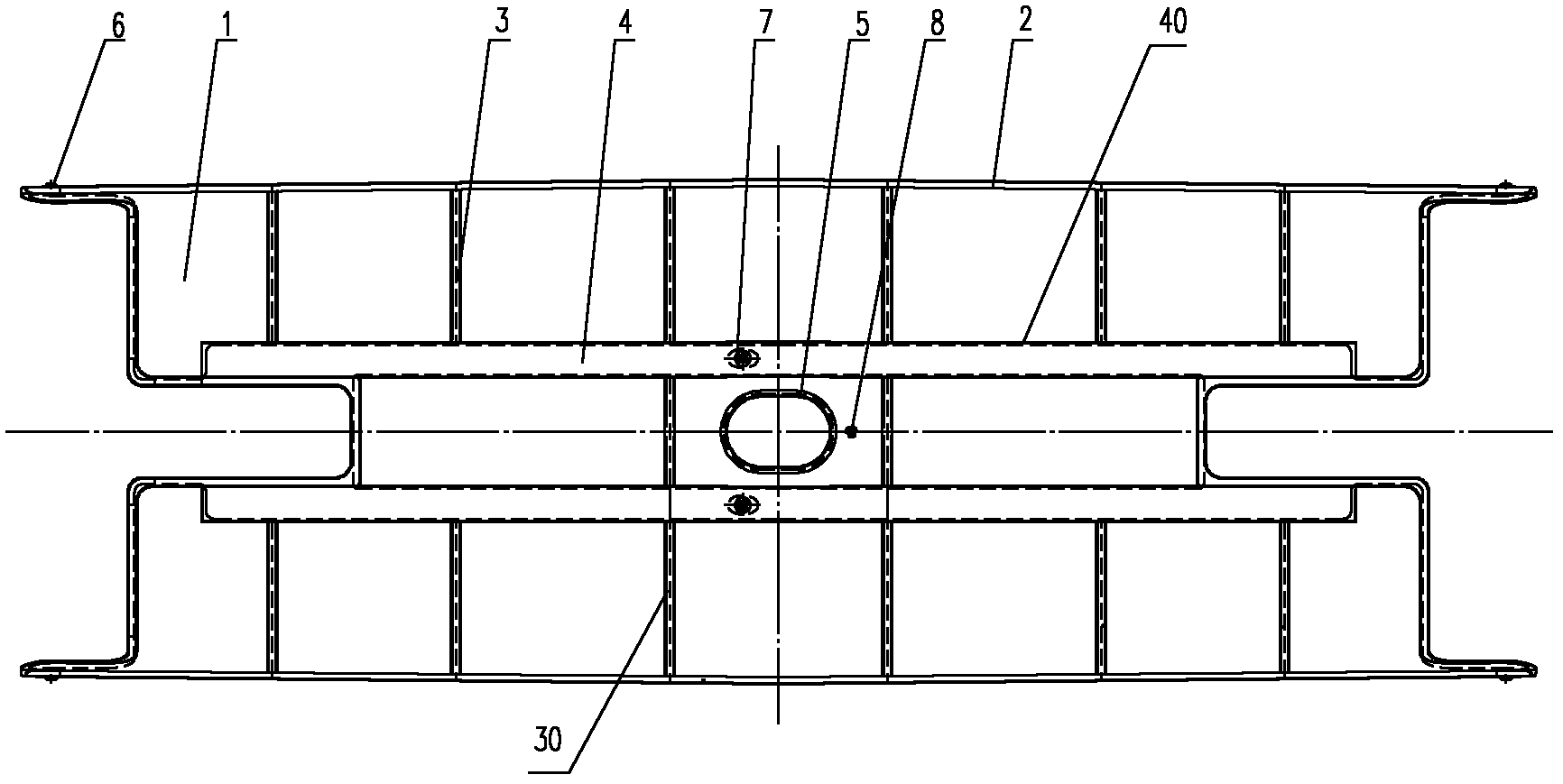

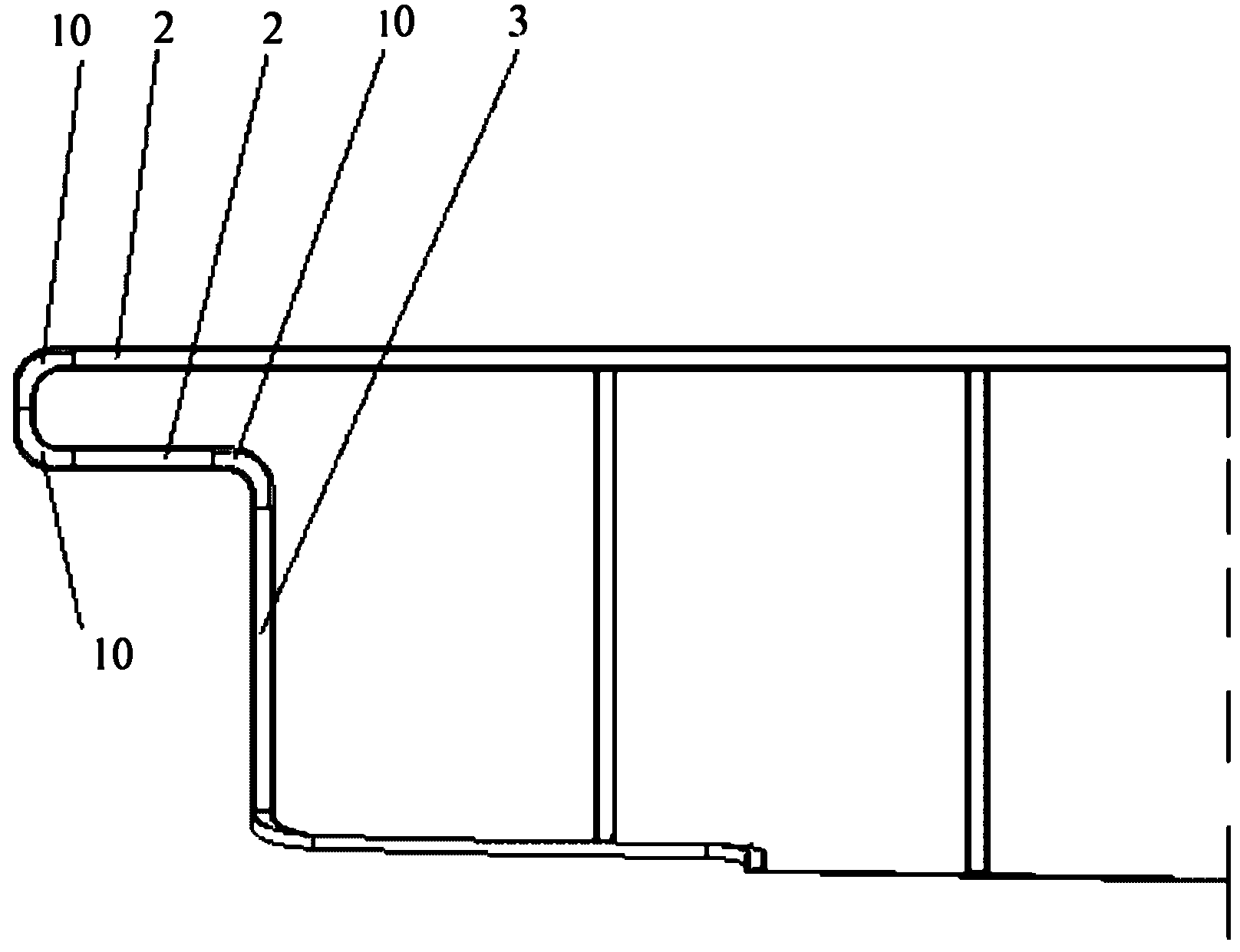

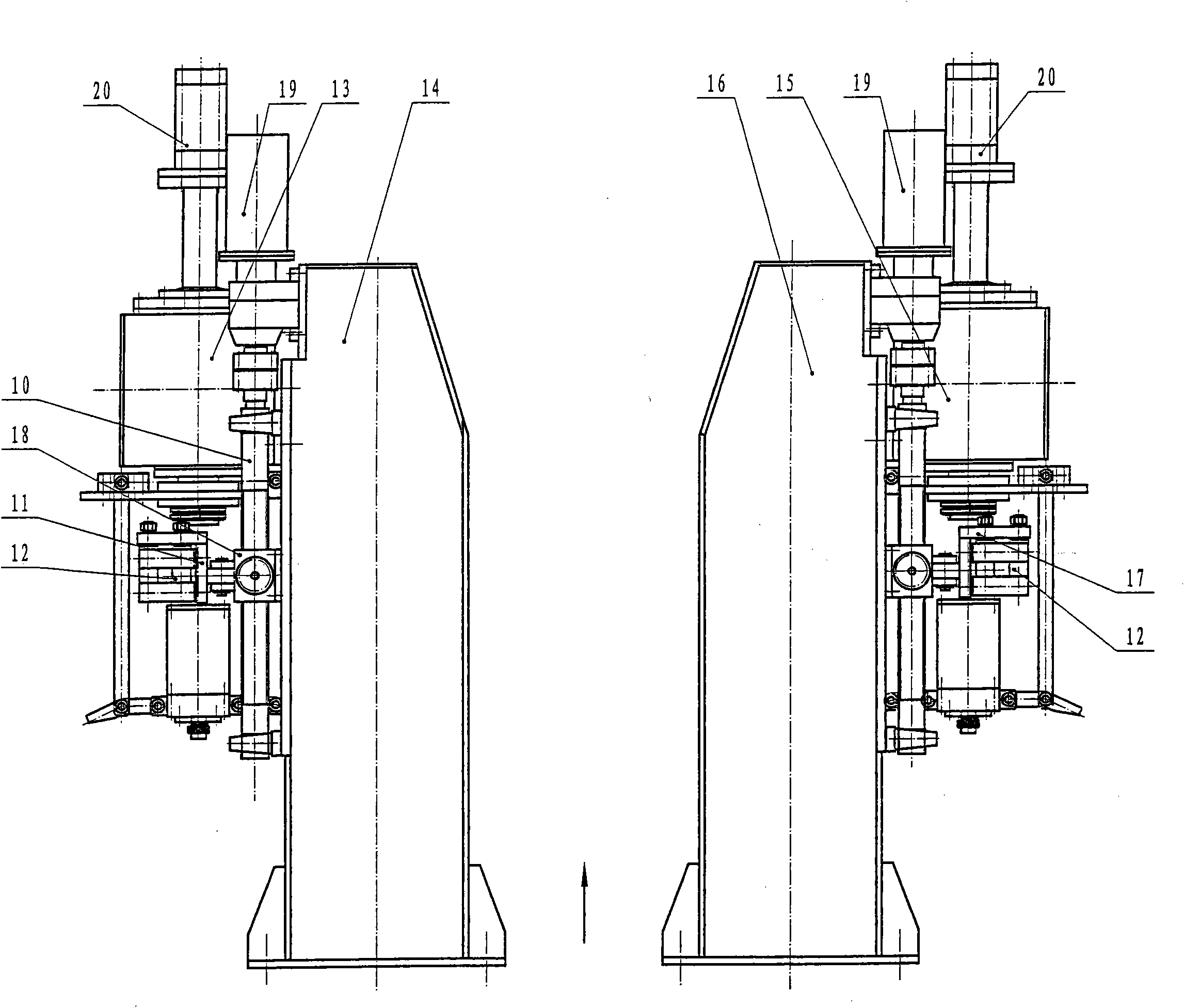

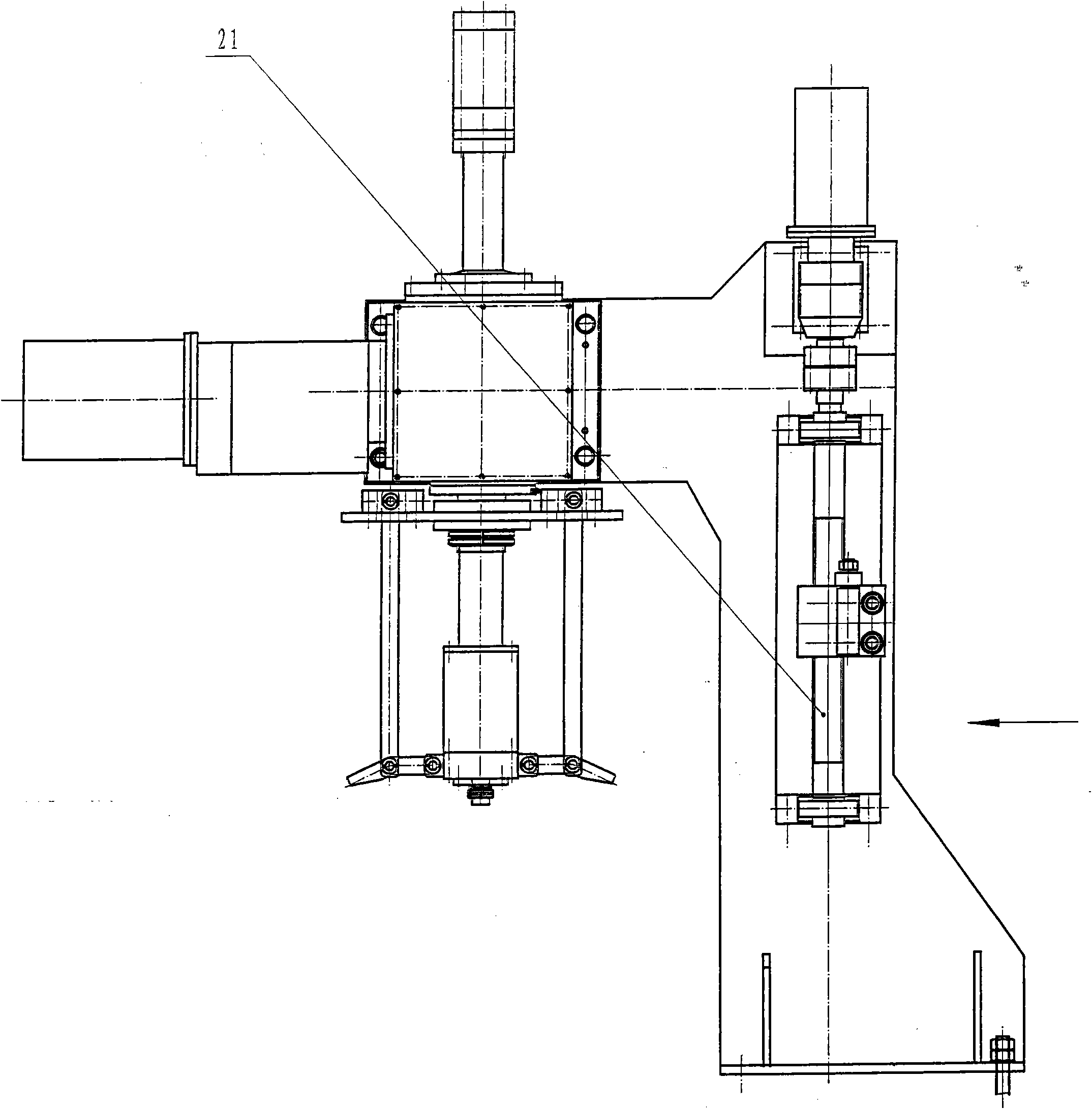

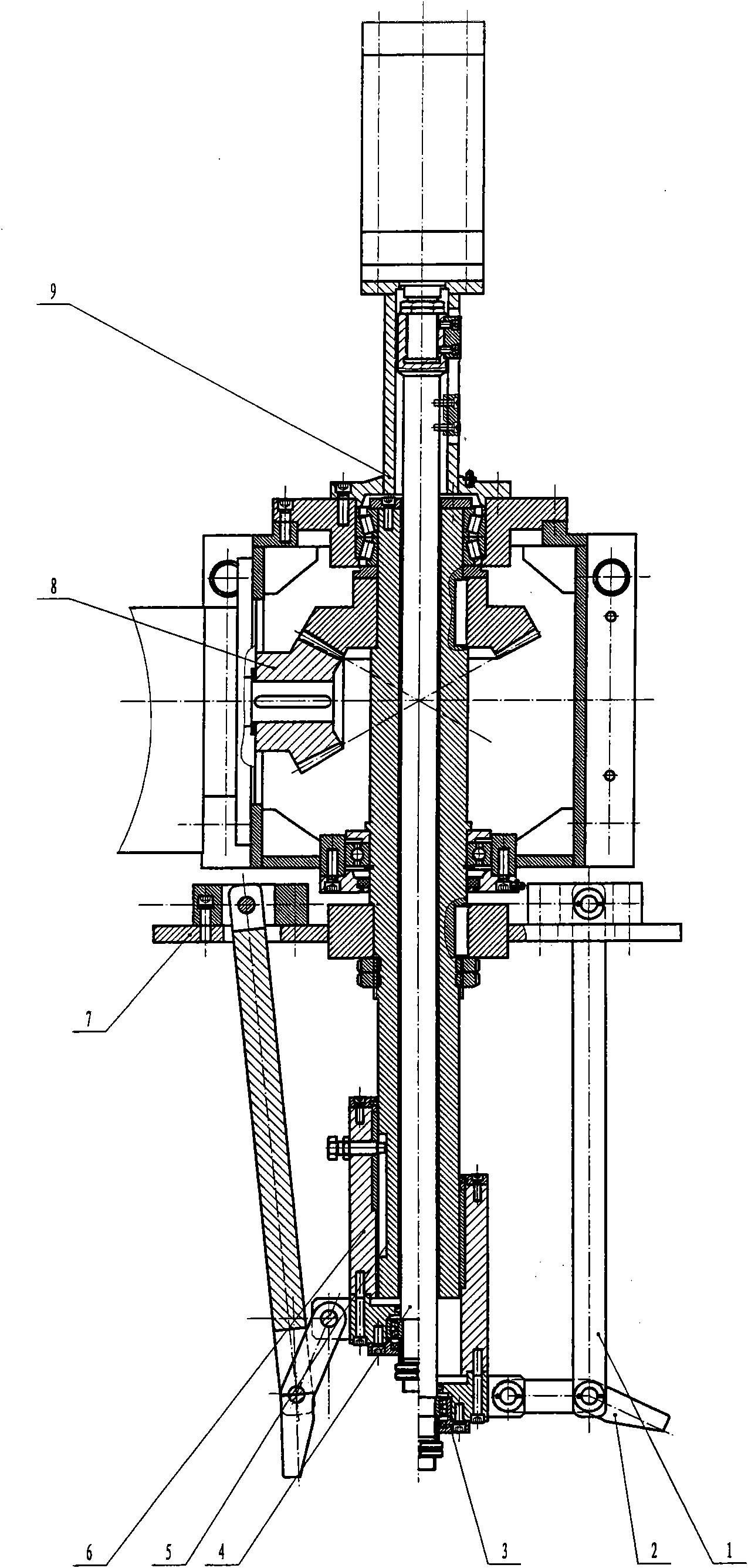

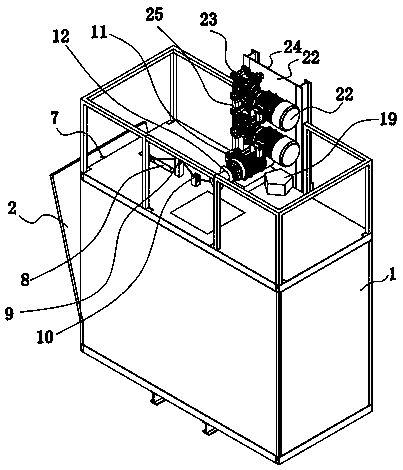

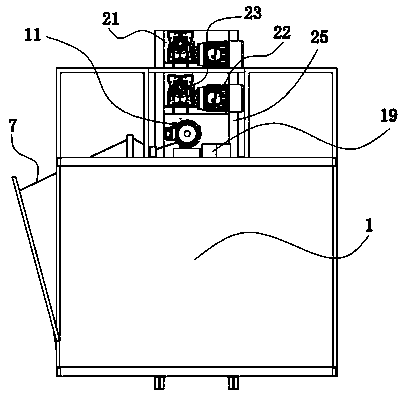

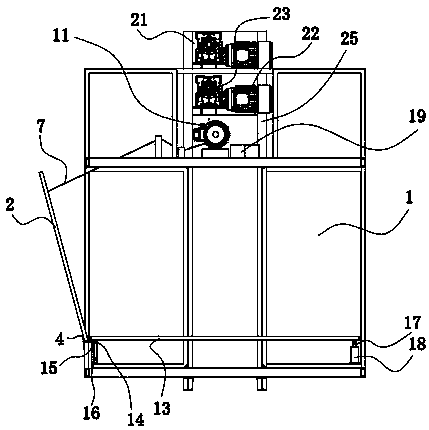

Scrap edge coiler device

The invention provides a scrap edge coiler device. One scrap edge coiler is arranged on each of two sides of the rear side of a circle shear on a production line. The device comprises the two scrap edge coilers which are symmetrically arranged on the left and right sides of the production line; each scrap edge coiler consists of a left frame (14), a right frame (16), a left gear box (13), a right gear box (15), a motor (18), a transmission mechanism (8) and a drum; the left gear box (13) is fixed on the left frame (14); the right gear box (15) is fixed on the right frame (16); the motor (18) drives the transmission mechanism (8) to rotate the drum; the drum is vertical; the expansion and shrinking of the drum is realized in the mode that an oil cylinder (19) drives a pull rod (4) to slide in a hollow shaft (5); the lower end of the pull rod (4) is fixed with a sliding sleeve (6); and the sliding sleeve (6) is connected with a rotating claw to expand and shrink. By using the scrap edge coiler device, materials can be conveniently unloaded, labor time is saved, production efficiency is improved, and the production line can operate easily and smoothly.

Owner:BEIJING STAR RIVER INTEGRATED EQUIP TECH

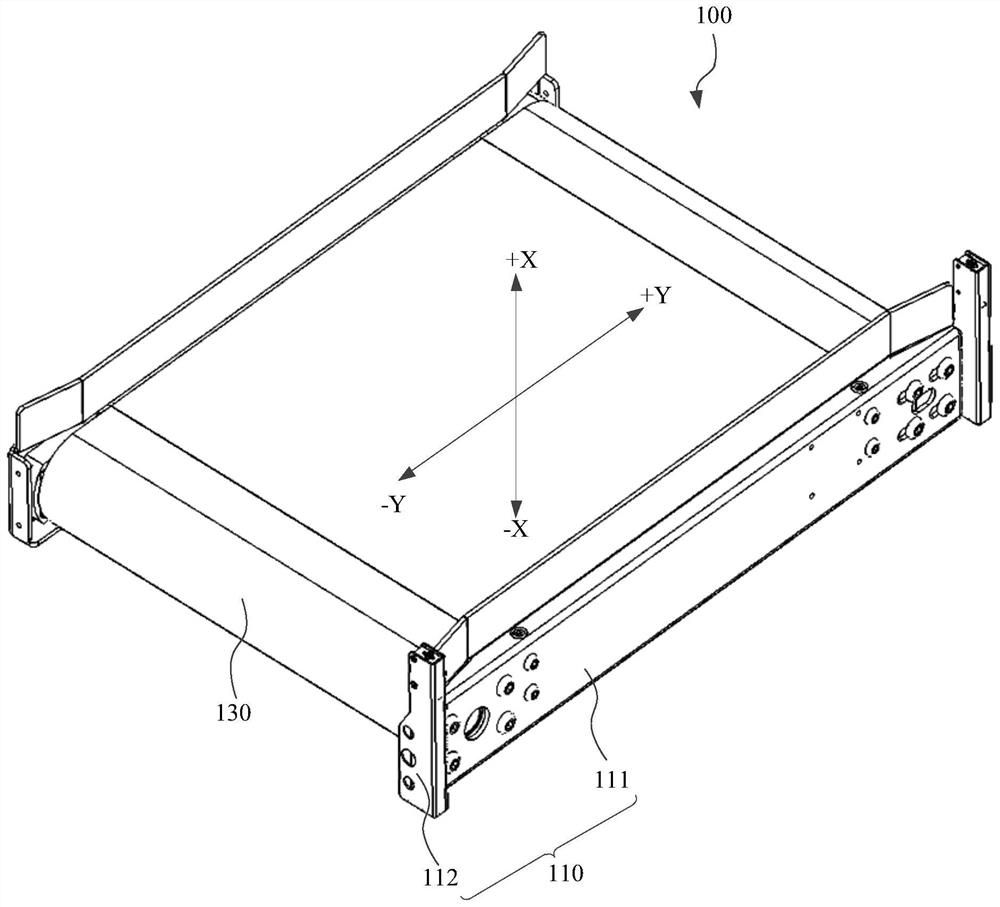

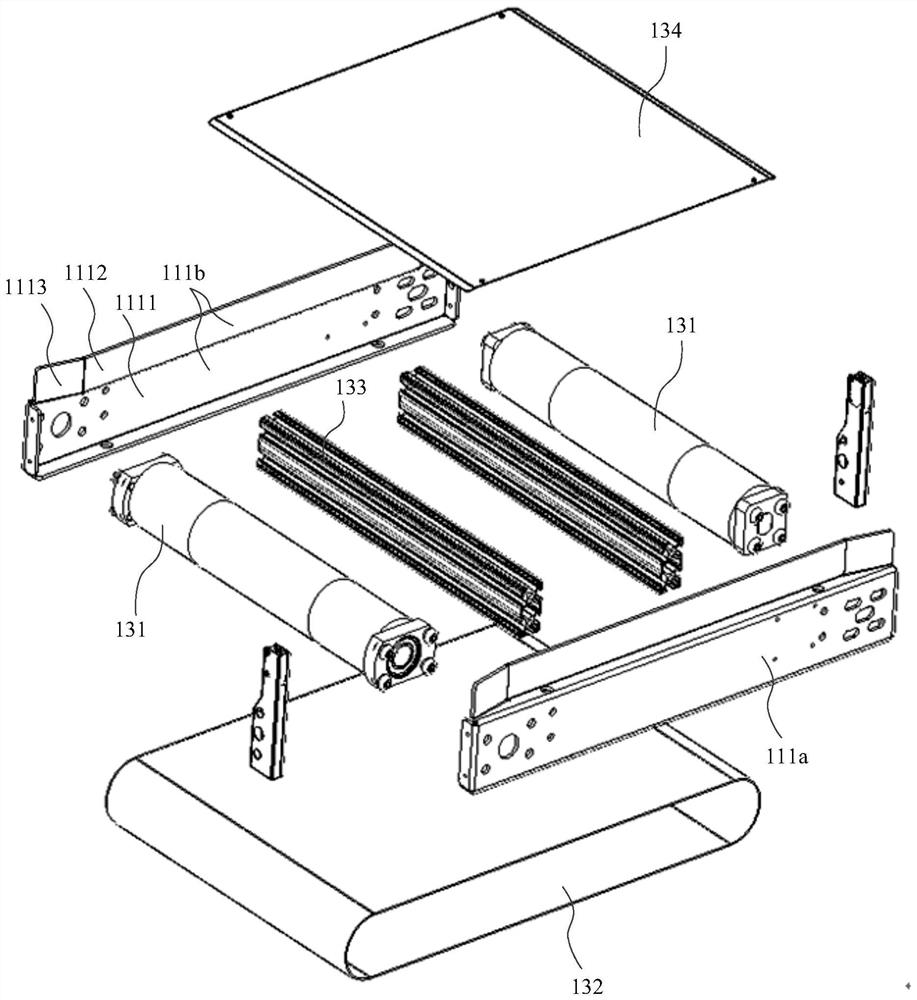

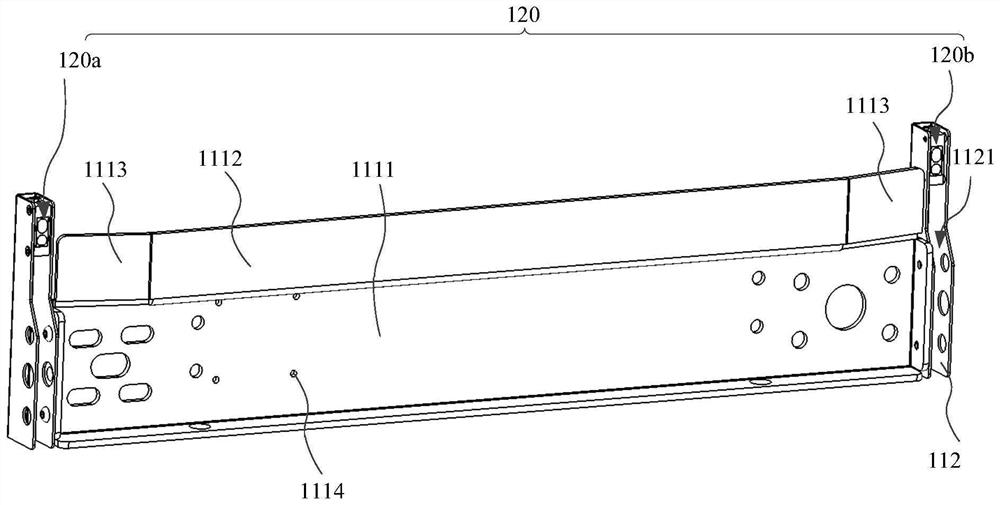

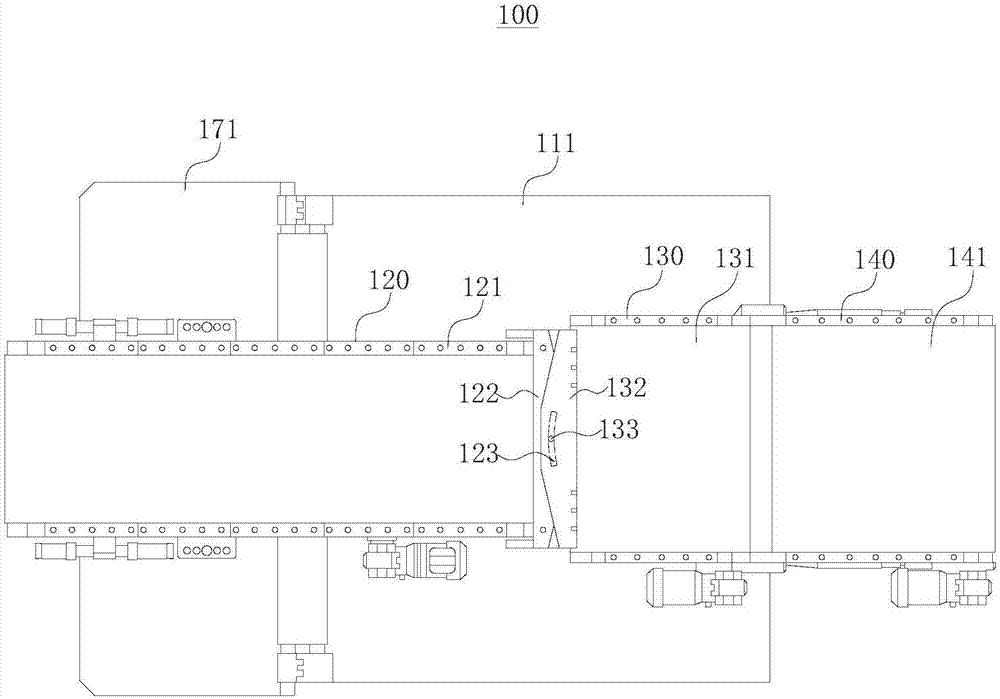

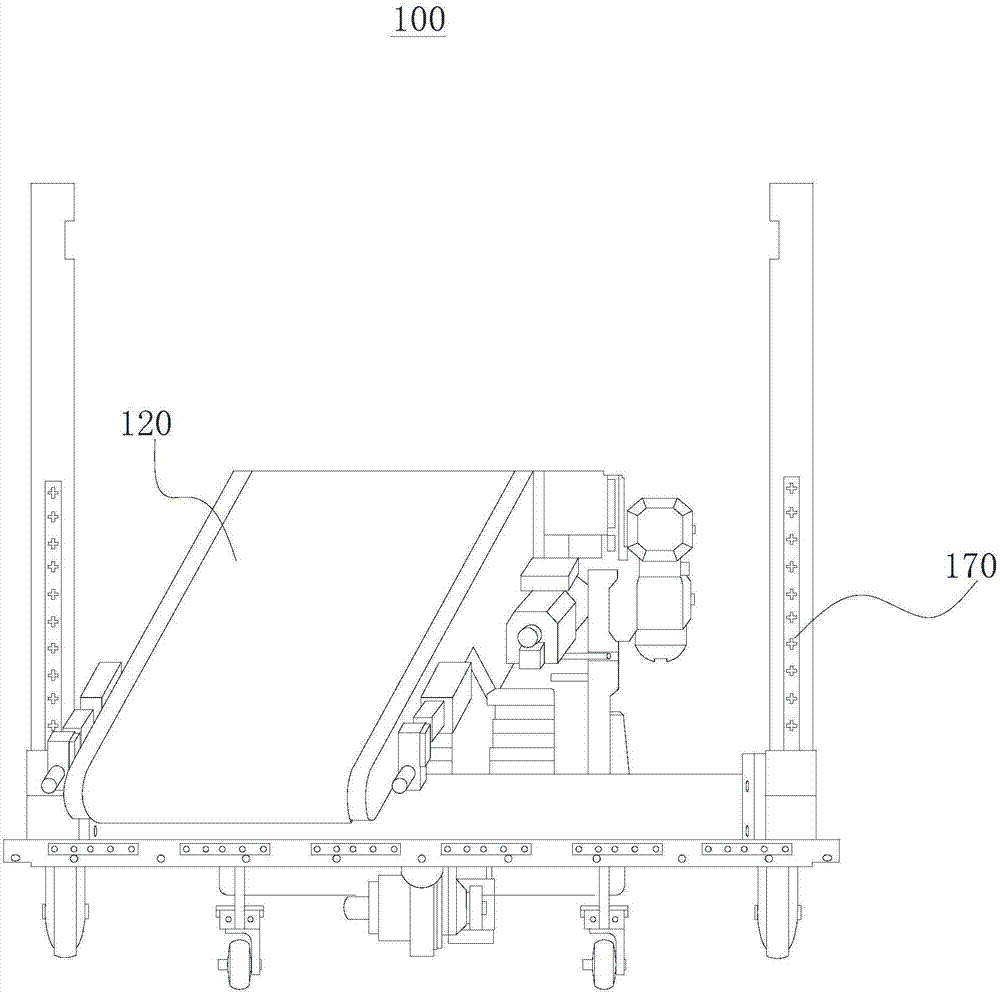

Semi-automatic unloading device and unloading equipment

ActiveCN107187899AReduce work intensityAvoid lifting up and downFinal product manufactureLoading/unloadingSemi automaticEngineering

The invention relates to the field of handling equipment and provides a semi-automatic unloading device. The semi-automatic unloading device comprises a trolley body, a first rack and a second rack, wherein the first rack and the second rack are installed on the trolley body; the first rack is provided with a first conveying belt; the second rack is provided with a second conveying belt; the second conveying belt is located at the discharging end of the first conveying belt; and the trolley body is provided with a first swing assembly used for driving the first rack to swing in the horizontal direction and a second swing assembly used for driving the first rack to swing in the vertical direction. According to the semi-automatic unloading device, the first rack is driven by the first swing assembly and the second swing assembly to move up and down, and left and right so as to be close to to-be-unloaded goods, the action that unloading personnel carry the goods up and down is avoided, and therefore the work intensity of the unloading personnel is relieved. Besides, the invention further provides unloading equipment which comprises a sorting device and the semi-automatic unloading device, goods transported on the semi-automatic unloading device enter the sorting device to be sorted, and the pipelined operation of fast unloading and sorting is achieved.

Owner:JIANGSU GUANCHAO LOGISTICS TECH CO LTD

Transportation system for unloading of goods

InactiveCN106241265ARealize deliverySmooth unloadingConveyorsSupporting framesEngineeringMechanical engineering

A transportation system for unloading of goods comprises a baseplate. A turnplate is arranged at one side of the baseplate. A housing of an oil cylinder I is fixedly connected to the baseplate. A retractable rod of the oil cylinder I is hinged to the turnplate. A housing of an oil cylinder II is hinged to the turnplate. A retractable rod of the oil cylinder II is hinged to one side of a transporting plate of a frame-type structure, and the turnplate is hinged to the other side of the transporting plate. Multiple rollers are arranged at intervals in the transporting plate of the frame-type structure and are mounted on a shaft I in a tight fit manner, and two ends of the shaft I are fixed in bearings I on the transporting plate. Two sides of the upper surface of the transporting plate are respectively provided with one baffle for preventing boxed goods from sliding down. The rear end of the transporting plate is hinged to a concave connecting plate. The transportation system for unloading of goods is simple in structure, easy to operate, and can be more steady during unloading of goods; reduction of time in unloading of goods and improvement of the unloading efficiency can be achieved.

Owner:江苏博达生物科技有限公司

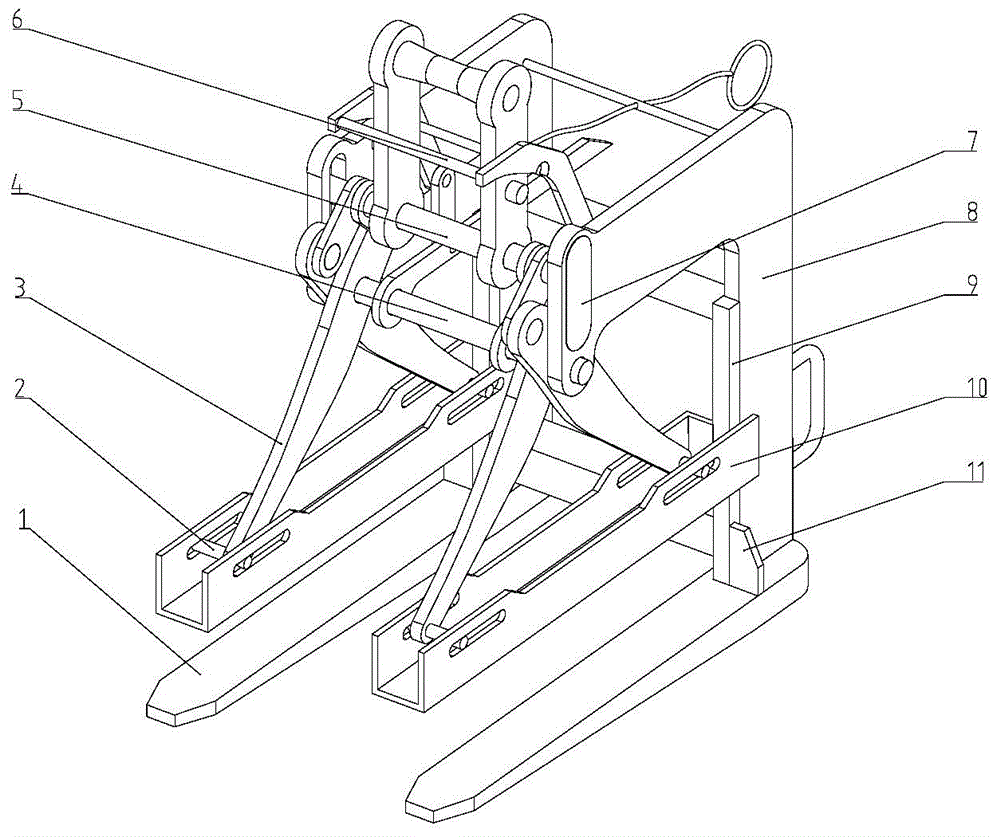

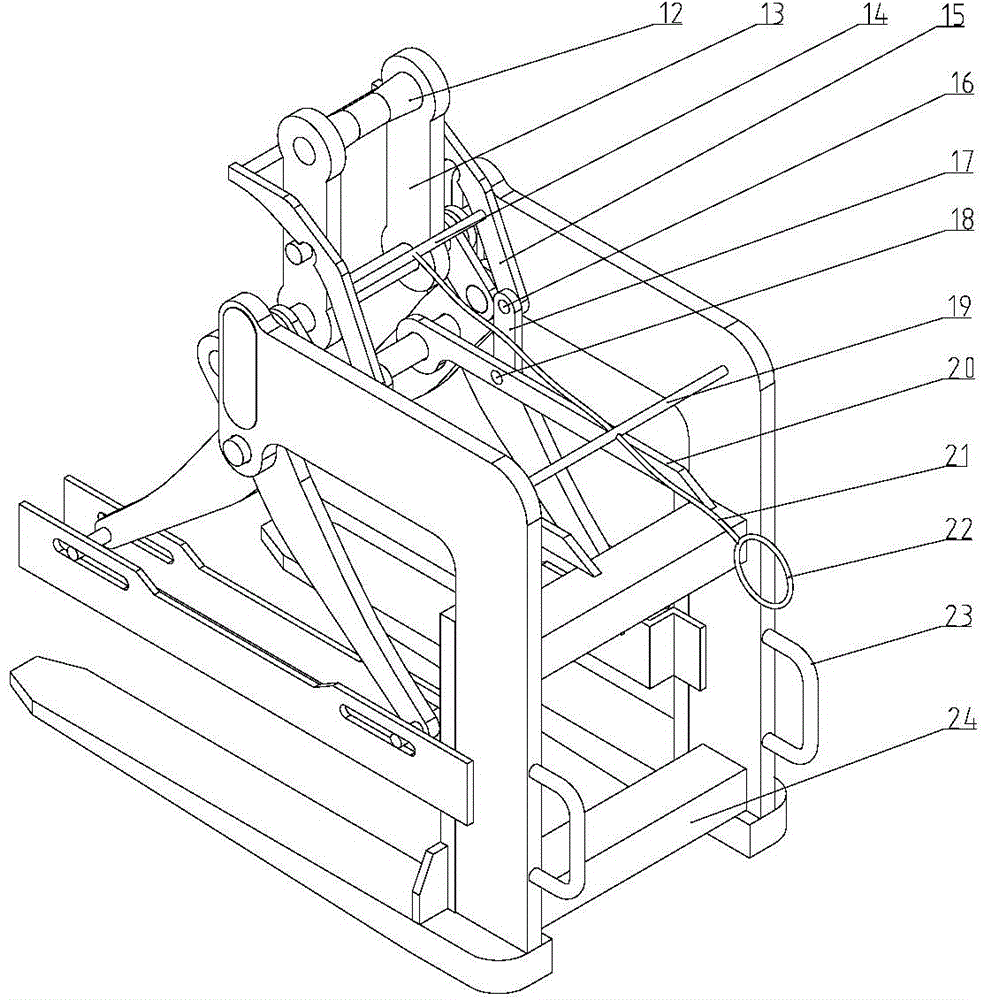

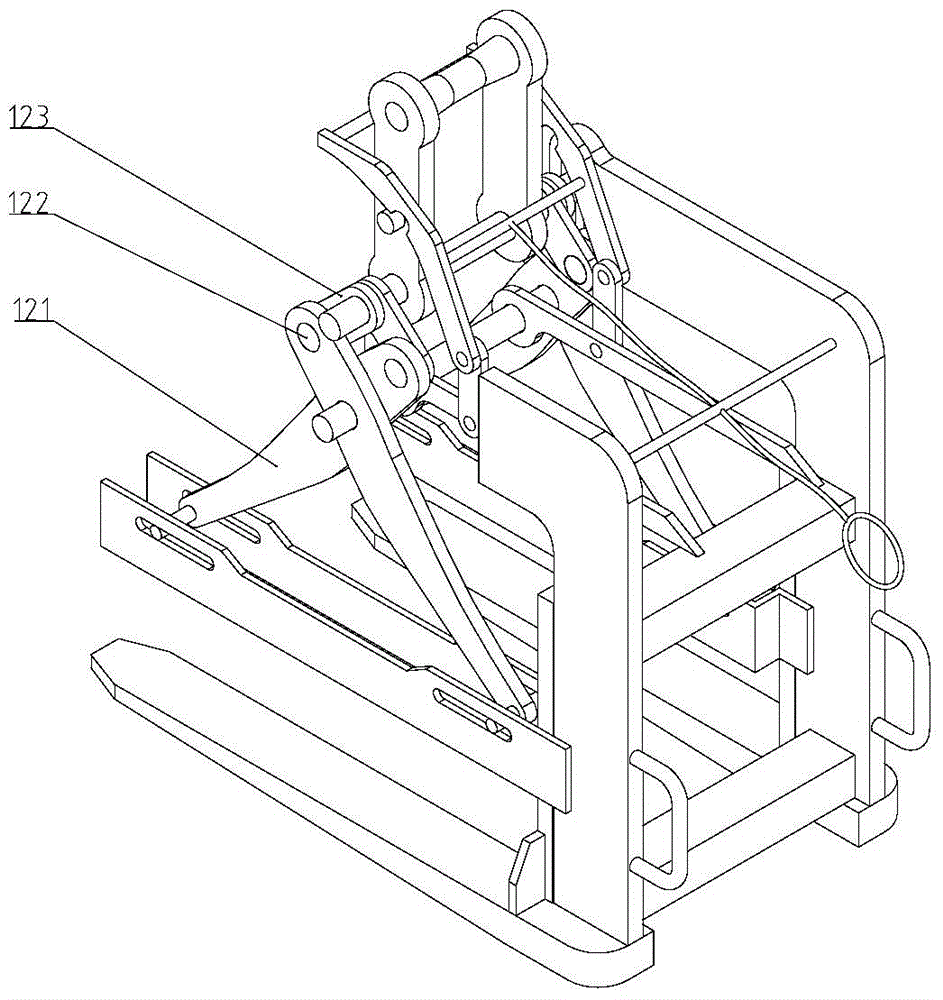

Scissor type lifting tool for plate stacking

ActiveCN104803277AImprove securityElimination of stray and strippingLoad-engaging elementsWork in processMechanical engineering

The invention relates to a scissor type lifting tool for plate stacking. The scissor type lifting tool comprises a scissor type lever mechanism, a main frame, a locking device and a lifting rod, wherein the scissor type lever mechanism comprises two bilaterally symmetrical connecting rod mechanisms, the main frame comprises a fork-shaped bottom plate, a machine body connected onto the fork-shaped bottom plate as well as machine body crosspieces and push-pull handles which are arranged on the machine body, the locking device comprises bottom locking rods, short locking connecting rods, locking rods, a steel unlocking cable and an unlocking pull ring which are connected onto the upper side of the machine body, and the lifting rod is arranged at the top of the machine body. Compared with the prior art, the scissor type lifting tool has the advantages that the lifting tool is safe and reliable, the working efficiency is improved, the quality of semi-finished products is guaranteed and the like.

Owner:SHANGHAI DAZHONG XIANGYUAN POWER SUPPLY

Fast construction method and fast unloading lift car for unloading platform for building construction

ActiveCN107814299AShorten unloading timeImprove securityBuilding liftsArchitectural engineeringBuilding construction

The invention relates to a building construction method and a goods carrying device, in particular to a fast construction method and a fast unloading lift car for an unloading platform for building construction According to the fast construction method for the unloading platform for building construction, on the basis of an existing construction loading lift, the two side walls of the lift car arearranged into overturning doors, and the overturning doors and a bottom plate of a car body of the lift car are made to integrally form the unloading platform. The fast unloading lift car for the unloading platform for building construction comprises a car body; and the front side wall and the rear side wall of the car body are each provided with an overturning door, and the two overturning doorsand the bottom plate of the car body are made to integrally form the unloading platform. Or, the two overturning doors and an unloading supporting plate are made to integrally form the horizontal unloading platform. By means of the fast construction method and the fast unloading lift car for the unloading platform for building construction, the unloading time is shortened, the safety performanceis improved, the building contracting cost is reduced, the using cost is reduced, and the environment friendliness is improved.

Owner:CHONGQING IND POLYTECHNIC COLLEGE

Polyacrylamide production line

ActiveCN105061646AFirmly connectedGuaranteed SolubilityDispersed particle filtrationGranulation by liquid drop formationProduction lineProcess engineering

The invention relates to a polyacrylamide production line. A reactor prefilter, an oil inlet lubrication polymerization reactor, an oil inlet lubrication smashing and pelleting device and a polyacrylamide colloid drying production line are connected in sequence, and the polyacrylamide colloid drying production line is respectively connected to a screening and grinding device and a pulse dust tail gas treatment device. The polyacrylamide production line is simple in structure, impurities in polyacrylamide production raw materials can be effectively filtered, the discharging time of a reactor is shortened, the amount of polymerization reactions is increased, colloid pelleting can be effectively lubricated, colloidal particles with the grain diameters of about 4 mm are obtained while the molecular weight of polyacrylamide is not reduced, required drying air quantity and energy consumption are reduced, the drying condition and standing time of materials are easily adjusted and controlled, the production capacity and product quality are improved, and the tail gas is effectively dedusted.

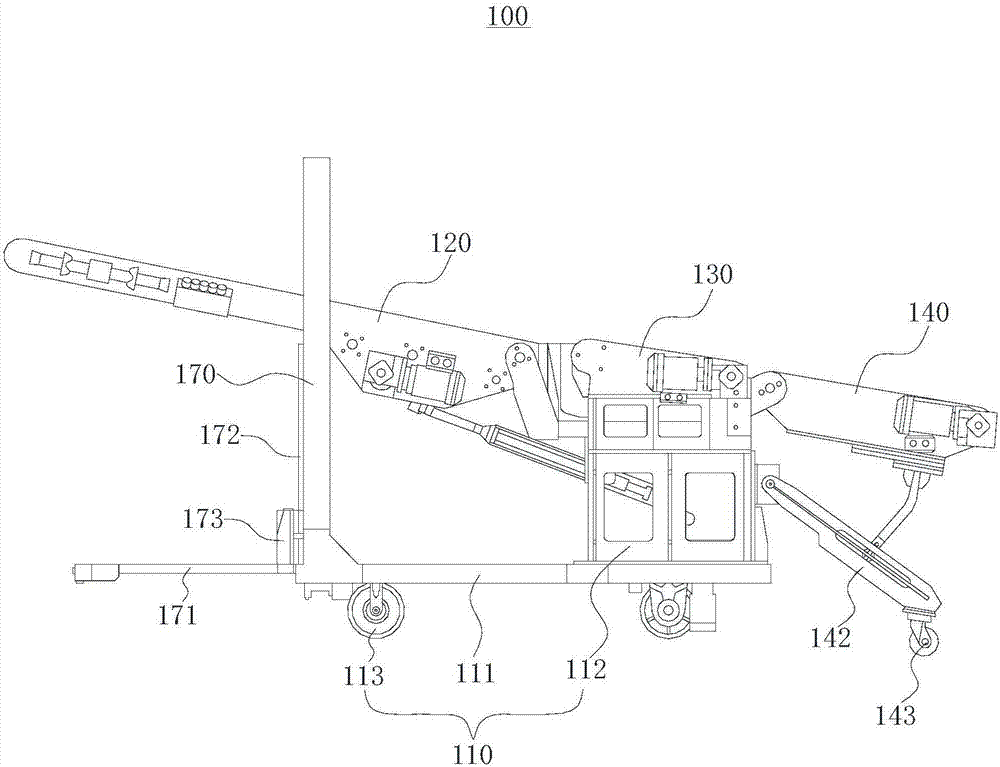

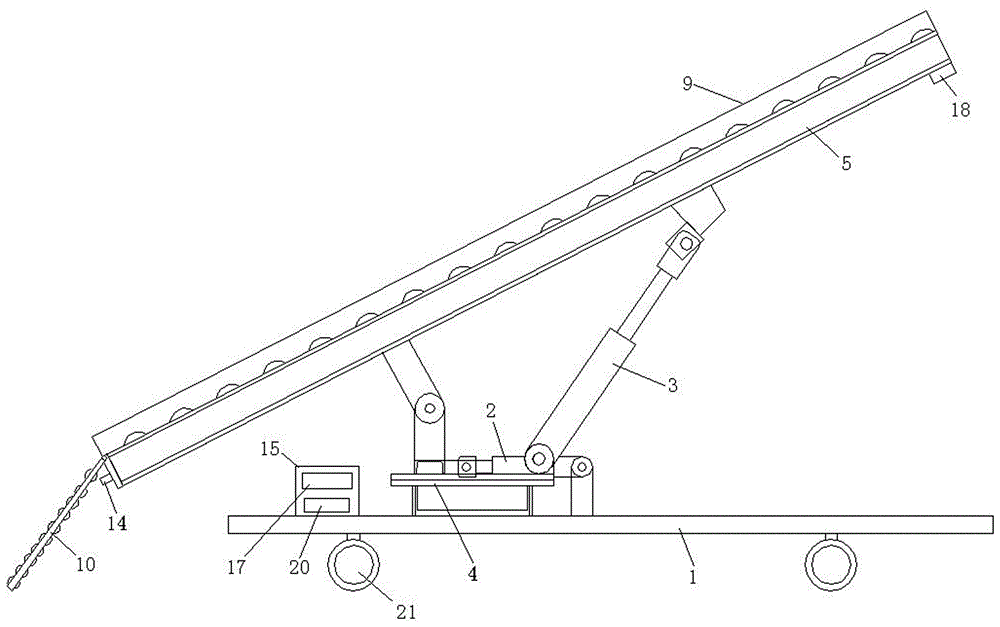

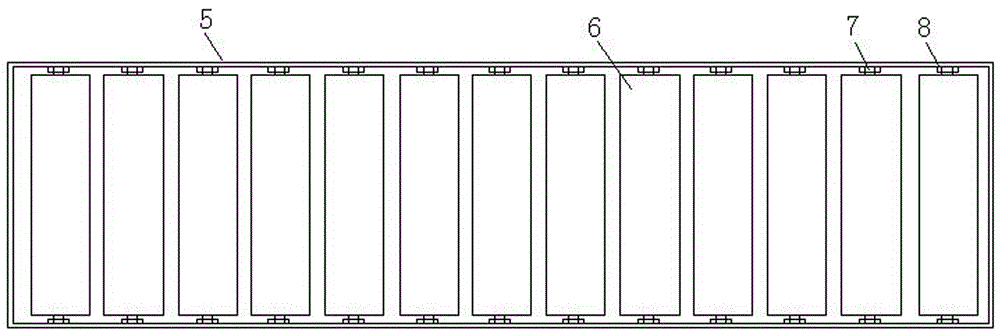

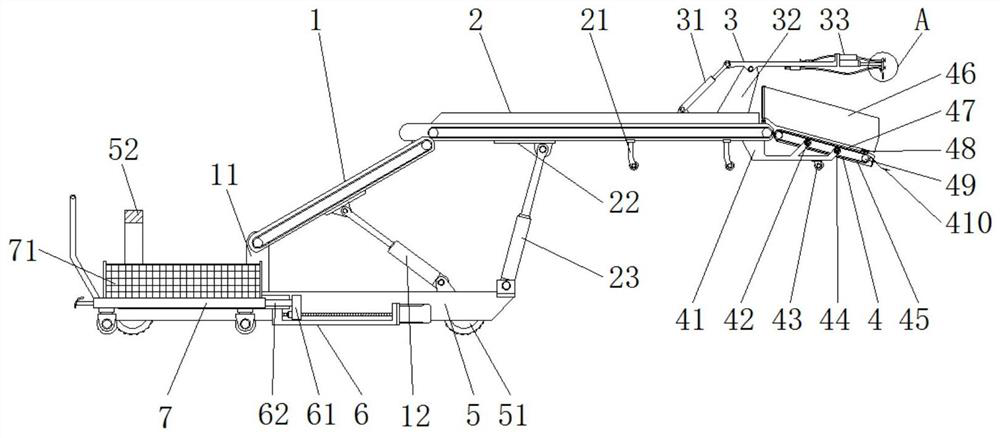

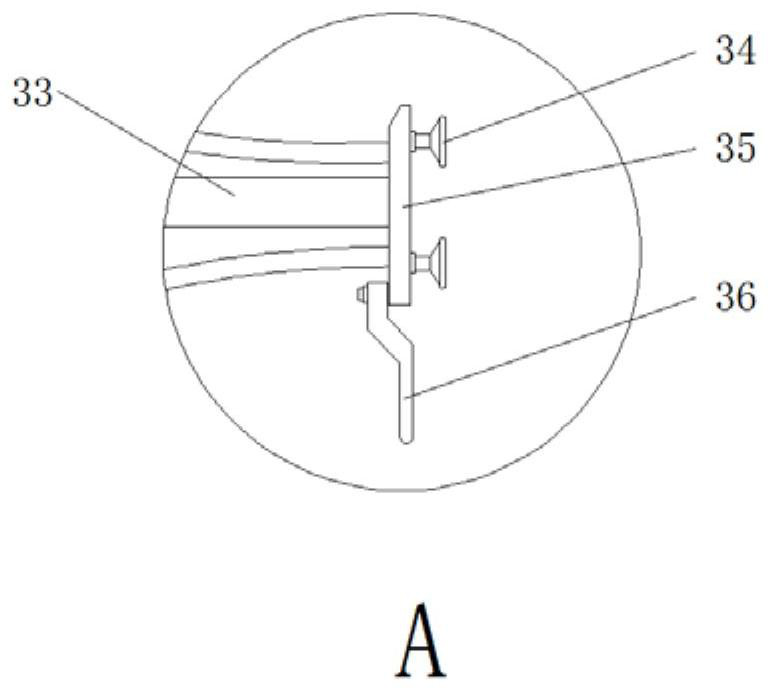

Small parcel rapid unloading machine for logistics

ActiveCN113264391AAutomation of the unloading processActive Bulk ReceiveConveyorsLoading/unloadingLogistics managementRobot hand

The invention relates to a small parcel rapid unloading machine for logistics and belongs to the technical field of logistics machinery. The machine comprises a lifting conveyor, the lower end of the lifting conveyor is rotationally connected with a moving base, a goods receiving trolley is arranged on the portion, close to the lower end of the lifting conveyor, of one side of the moving base, and the upper end of the lifting conveyor is movably connected with a horizontal conveyor. The portion, away from the lifting conveyor, of one end of the horizontal conveyor is provided with an adjustable conveying shovel, and the portion, close to one end of the adjustable conveying shovel, of the top of the horizontal conveyor is provided with a raking and sucking manipulator. According to the machine, through the cooperation of the adjustable conveying shovel and the raking and sucking manipulator, active in-batch receiving of small parcels in a carriage can be achieved, the unloading process of the small parcels is more automatic, manual burden is greatly reduced, and the goods are automatically transferred out of a vehicle through the cooperation of the horizontal conveyor and the lifting conveyor, and finally, are stacked to the goods receiving trolley. Automatic unloading and stacking are achieved, and more convenience and high efficiency are achieved.

Owner:宁波市奉化锦屏绿苑配菜有限公司

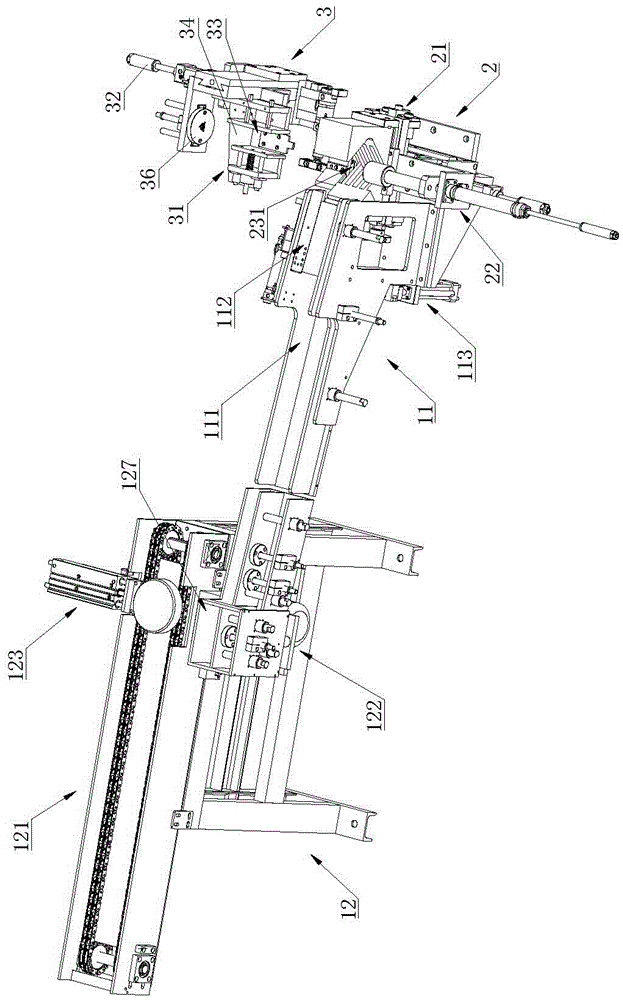

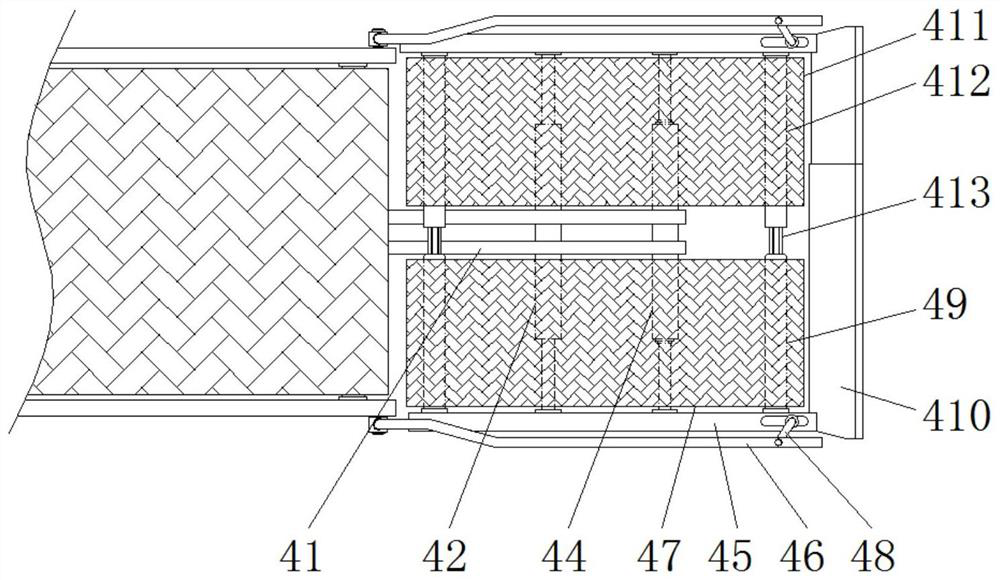

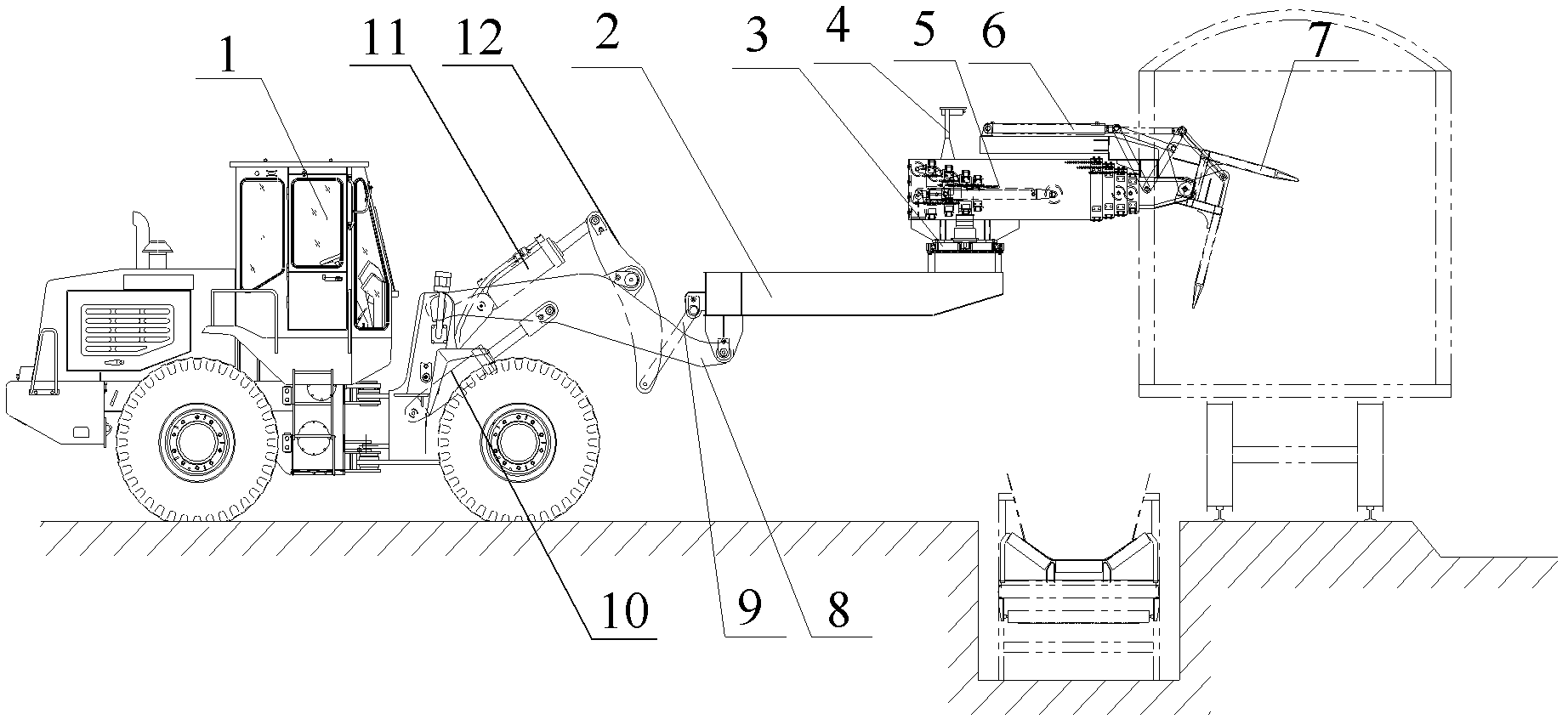

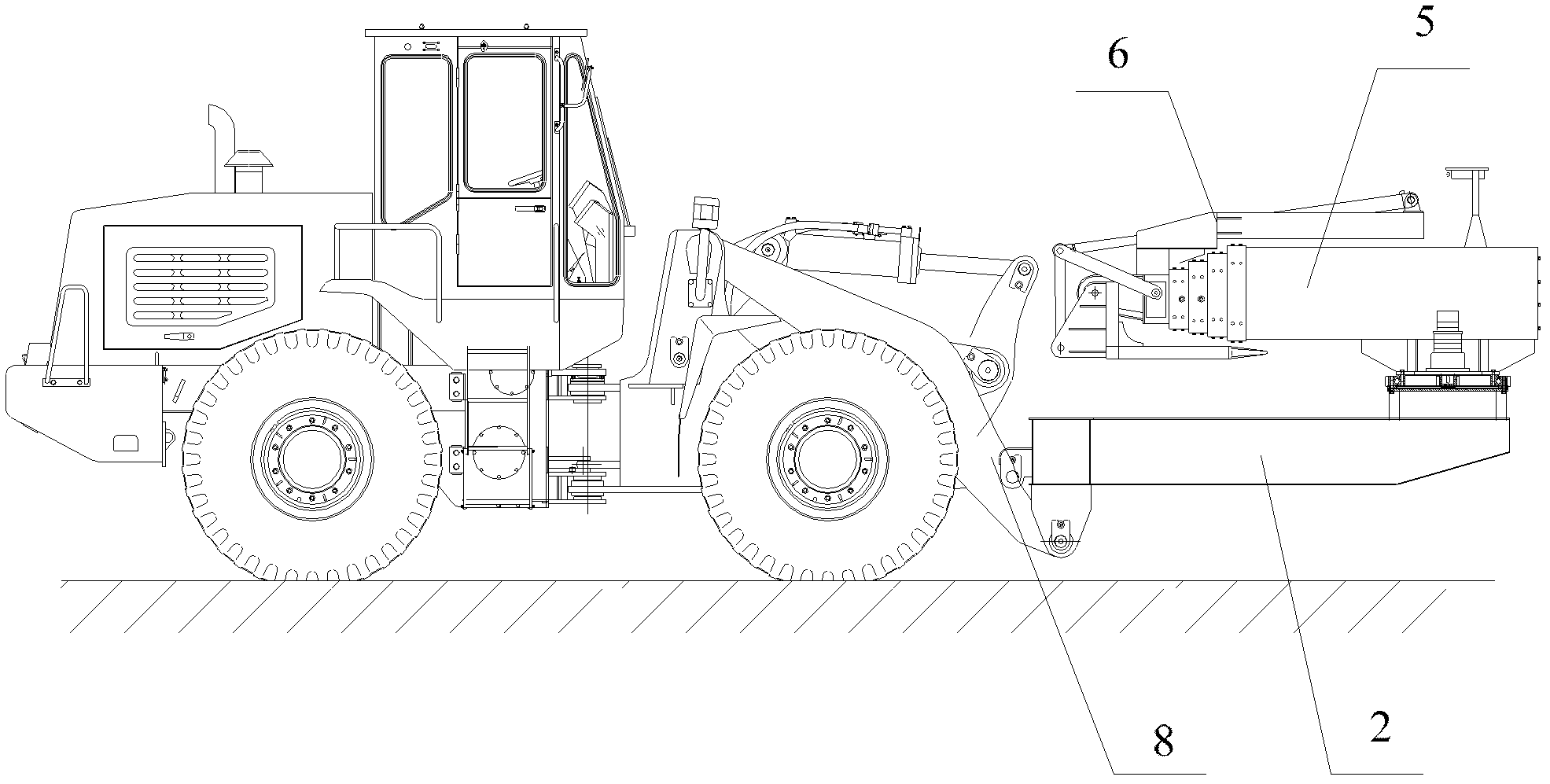

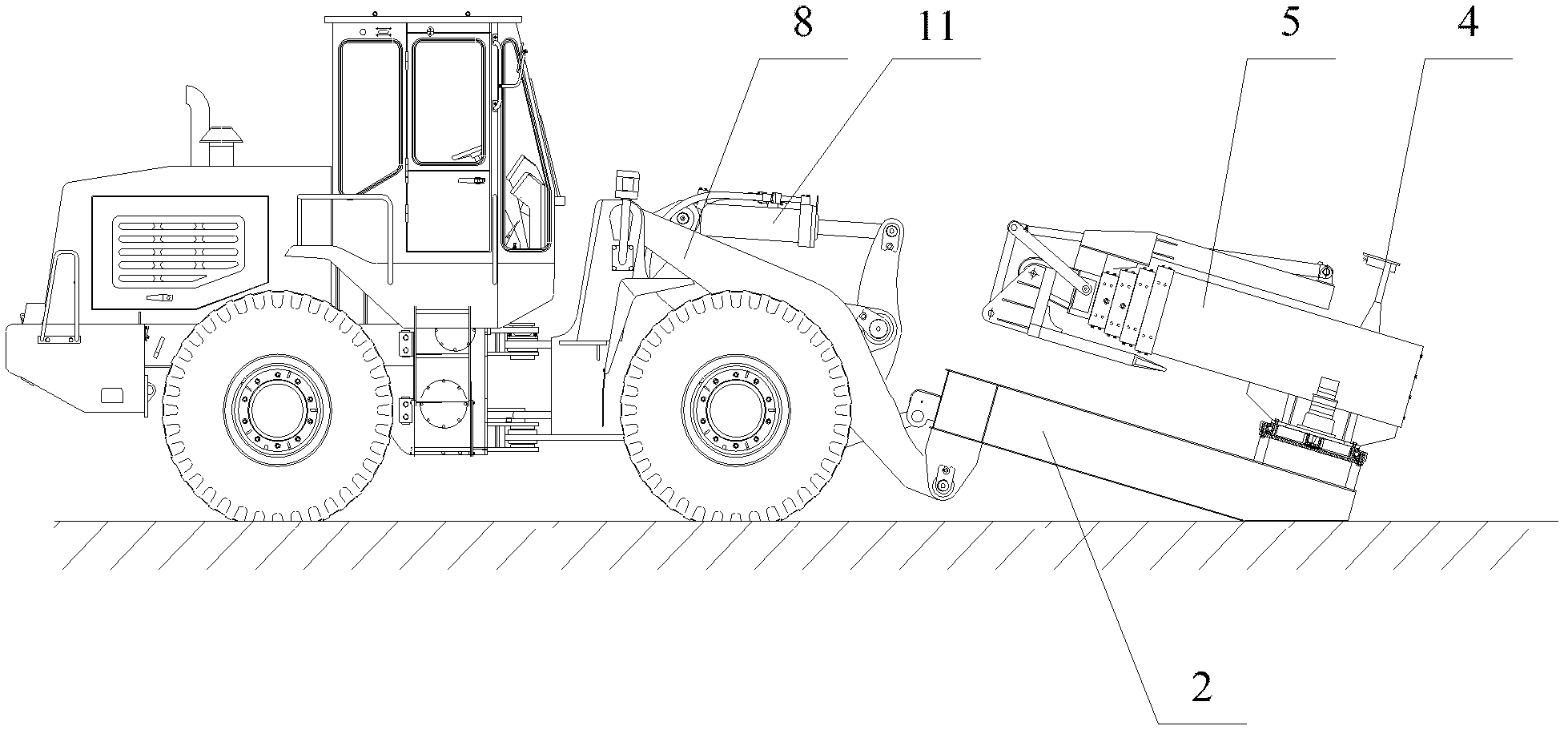

Multi-functional wheel-type telescopic arm unloading machine

The invention discloses a multi-functional wheel-type telescopic arm unloading machine which comprises a main machine of a wheel-type loader, a cantilever bearing beam, a telescopic arm, a rake claw and a first hydraulic cylinder; a lifting device is arranged on the main machine of the wheel-type loader host; one end of the cantilever bearing beam is connected with the lifting device; the telescopic arm is arranged on the cantilever bearing beam through a rotary mechanism; the rake claw is hinged at the head of the telescopic arm; the first hydraulic cylinder is arranged on the telescopic arm, and a piston rod of the first hydraulic cylinder is connected with the rake claw through a first connecting rod; and one end of the first connecting rod is hinged with the piston rod of the first hydraulic cylinder, and the other end of the first connecting rod is hinged with the rake claw. The multi-functional wheel-type telescopic arm unloading machine unloads wood chips in a shed car through the lifting of the lifting device, the horizontal swinging and the expansion of the telescopic arm in the shed car as well as the excavation of the rake claw. The unloading operation by the multi-functional wheel-type telescopic arm unloading machine can reduce the labor intensity of an operator, improve the working efficiency, shorten the unloading time, and simultaneously reduce the cost produced by the staying time of a carriage.

Owner:HUNAN WANTONG TECH

Rapid unloading method and lift car for constructional engineering goods lift

InactiveCN107720493AImprove cleanlinessShorten unloading timeBuilding liftsArchitectural engineeringWinch

The invention relates to a rapid unloading method and a loading device for building construction, in particular to a rapid unloading method and a lift car for a constructional engineering goods lift.According to the rapid unloading method for the constructional engineering goods lift, a turnover door is arranged on the rear side wall of a box body of the lift car, and a bottom plate of an inner cavity of the box body of the lift car is provided with an unloading plate. The lift car for the constructional engineering goods lift comprises the box body and the turnover door located on the box body, the turnover door is located on the rear side wall of the box body, the upper portion of an inner panel of the turnover door is fixedly provided with at least one pull rope fixing base integratedwith the inner panel of the turnover door, each pull rope fixing base is fixed to one end of a pull rope, the other end of the pull rope is connected with a winch, and the inner cavity of the box bodyis internally provided with an unloading supporting plate. By means of the rapid unloading method and the lift car, the unloading time is shortened, the transportation efficiency is improved, the construction period is shortened, the cleanliness of the ground around a building is advantageously improved, the safety is improved, the building cost is reduced, and the environmental friendliness is improved.

Owner:CHONGQING IND POLYTECHNIC COLLEGE

Air operated unloading device

ActiveUS7513181B2Easy dischargeSimplifies and eliminatesLathesAutomatic conveying/guiding stockCouplingEngineering

Owner:J F BERNS

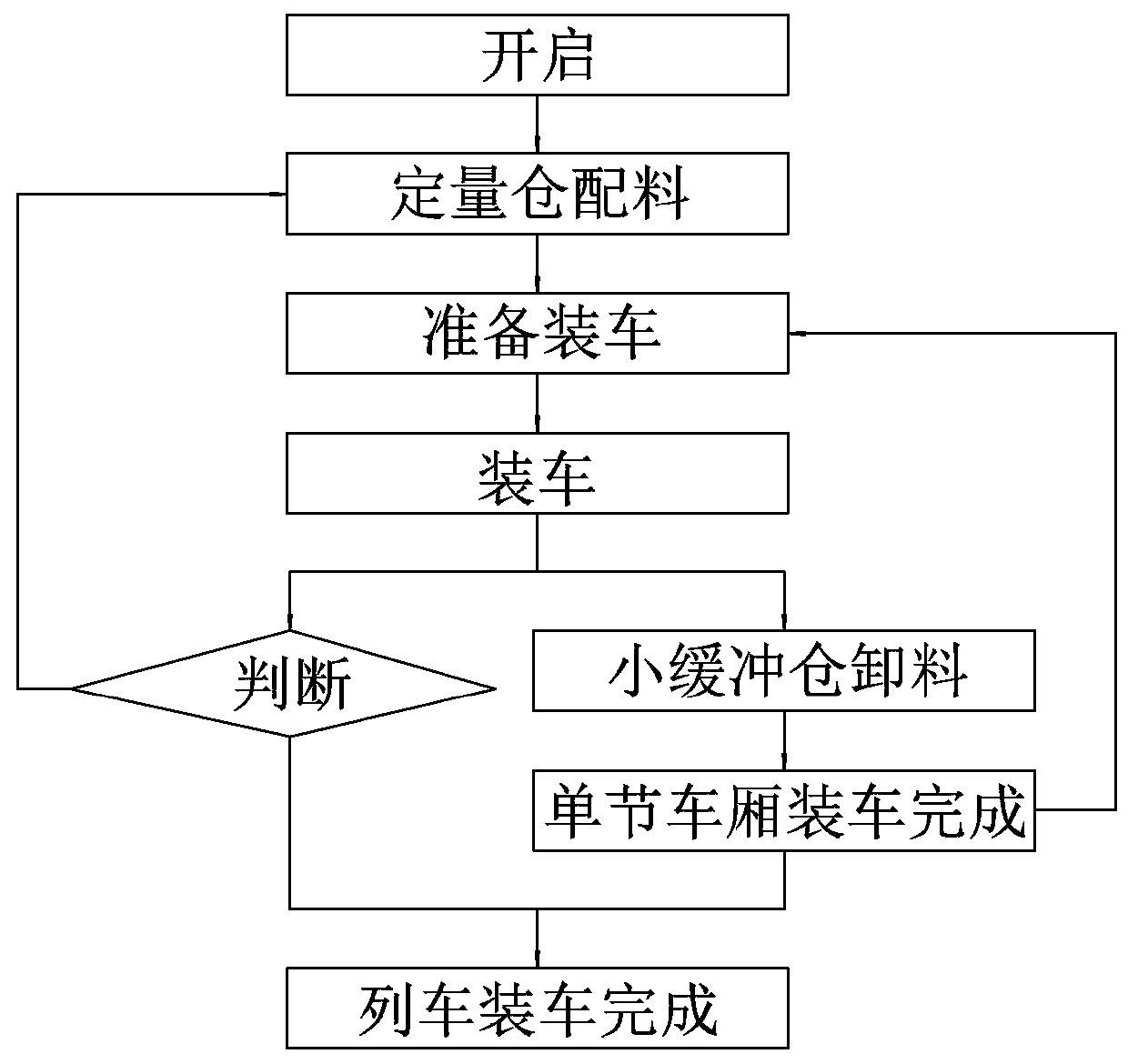

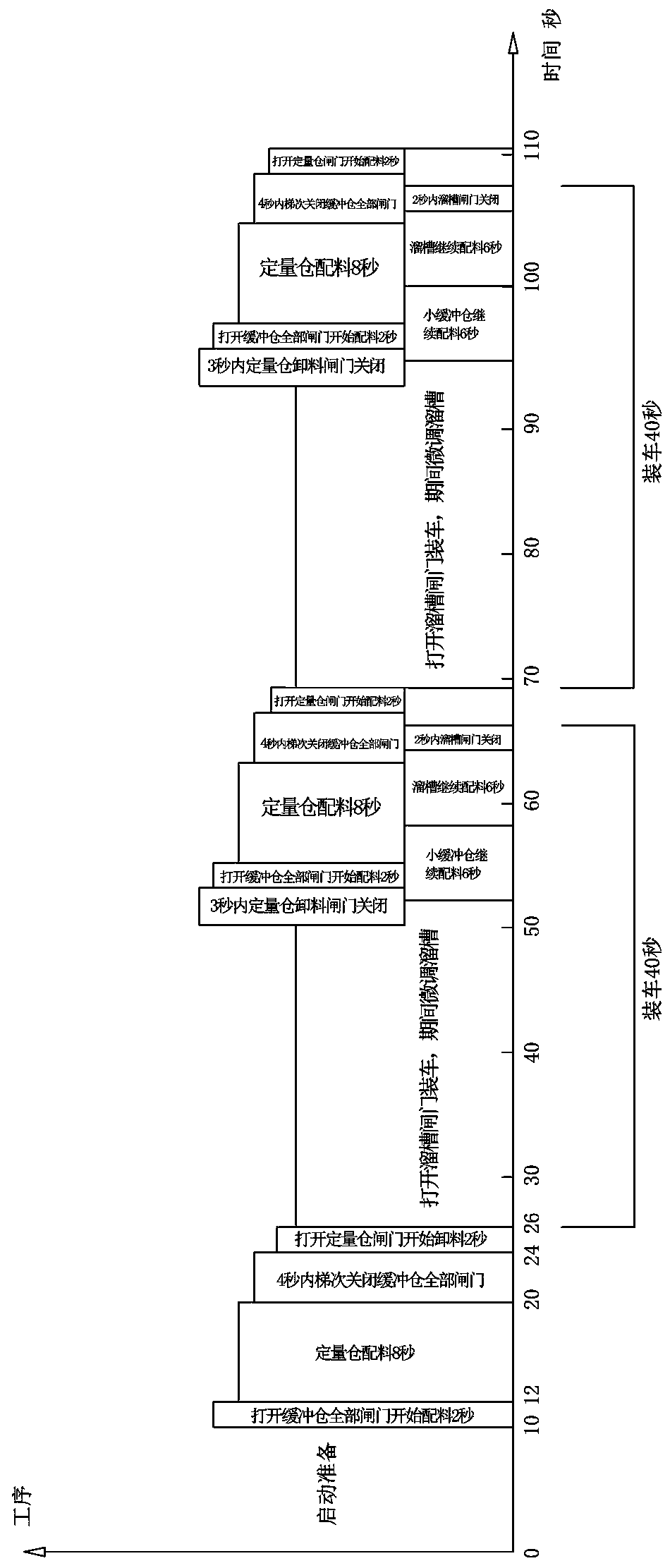

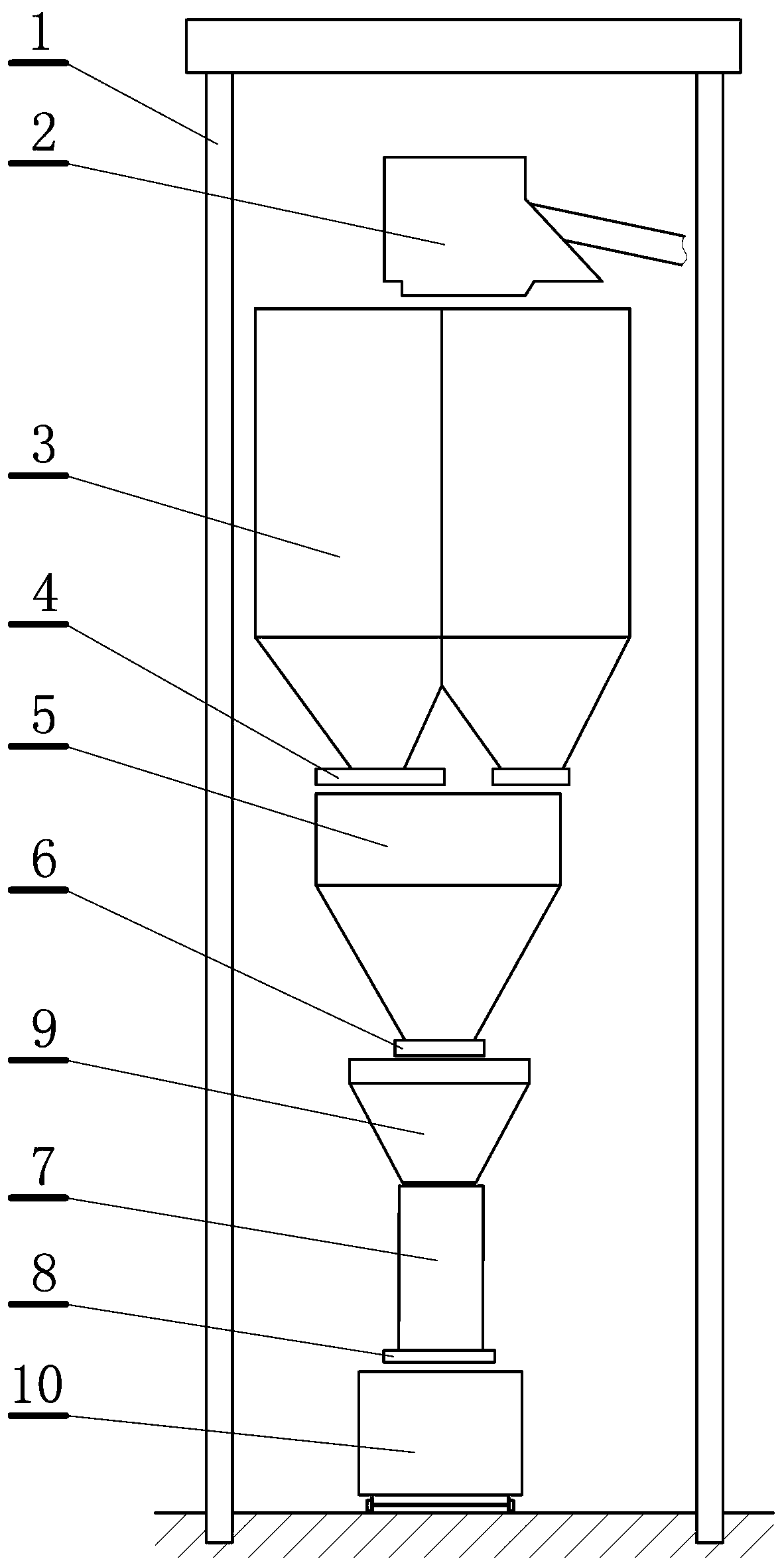

Fast quantitative loading station and method with super loading capacity

InactiveCN108891940AShorten unloading timeIncrease cache spaceConveyorsLoading/unloadingEngineeringTower

The invention relates to a fast quantitative loading station and method with super loading capacity, comprises a steel structure tower, wherein the steel structure tower is sequentially arranged fromtop to bottom: a belt machine head, a cushioning bin, a cushioning bin proportioning gate, a dosing bin, a dosing bin unloading gate, a loading chute and a chute gate, wherein a small cushioning bin is arranged between the dosing bin unloading gate and the loading chute. By overlapping the proportioning time of the ration bin and the unloading time of the small buffer bin, the loading time of eachcarriage is reduced by more than ten seconds, which greatly improves the loading efficiency. And increase small buffer silo only need very low cost, the main structure of the loading station can notmake a big change, can achieve the increase of loading capacity. Especially in some of the loading stations that have been built, the effect of increasing loading capacity can be achieved after reasonable transformation in the form of adding small buffer warehouses.

Owner:TIANDI SCI & TECH CO LTD

Butterfly valve disc to attain accelerated flow

ActiveUS9057445B2Enhance and accelerate flowReduce the amount of noiseLift valveArcuate shapeButterfly valve

An improved disc for a butterfly valve having reduced structure within the bore of the valve, so as to minimize obstruction to the flow of granular material therethrough. Accelerated flow of granular material through the valve is obtained because of the thin dimensions of the butterfly valve. The modified disc includes upper and lower sockets, most of its structure is outside the perimeter of the disc. The disc may be of arcuate shape.

Owner:BULK TANK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com