Rapid unloading method and lift car for constructional engineering goods lift

A technology of construction engineering and elevators, which is applied to elevators, transportation and packaging in buildings. It can solve the problems of high cost of building materials transshipment, slow progress of building materials in place, and influence on project progress, so as to shorten unloading time and shorten construction. Cycle, the effect of improving environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

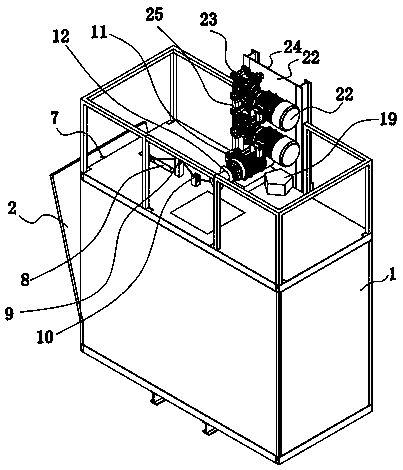

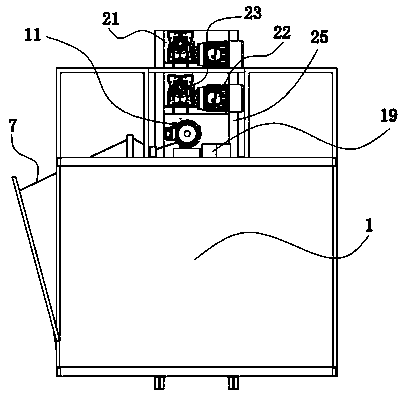

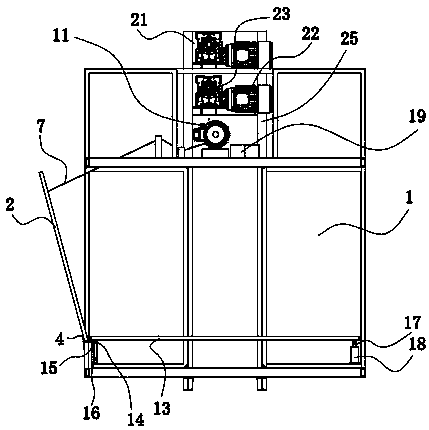

[0026] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0027] A fast unloading method for a construction freight elevator, wherein: on the basis of the existing engineering construction freight elevator, the side-opening elevator doors on the car of the existing engineering construction freight elevator are cancelled, and A reversing door is arranged on the rear side wall of the car body, and the reversing door closes the box body of the car under normal conditions. It is realized by retracting and unwinding the steel rope on the winch;

[0028] A unloading plate is arranged on the bottom plate of the inner cavity of the box body of the car, and the unloading plate is normally parallel to the bottom plate of the inner cavity of the box body;

[0029] The unloading plate is tilted up and down under the action of external force by taking the edge close to the reversing door as the fulcrum, and the up and down tilt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com