Scrap edge coiler device

An edge-rolling and reeling technology, which is applied in the field of coiling waste edges of a thick plate production line, can solve the problems of easy jamming, easy jamming of the pushing device, and difficulty in unloading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

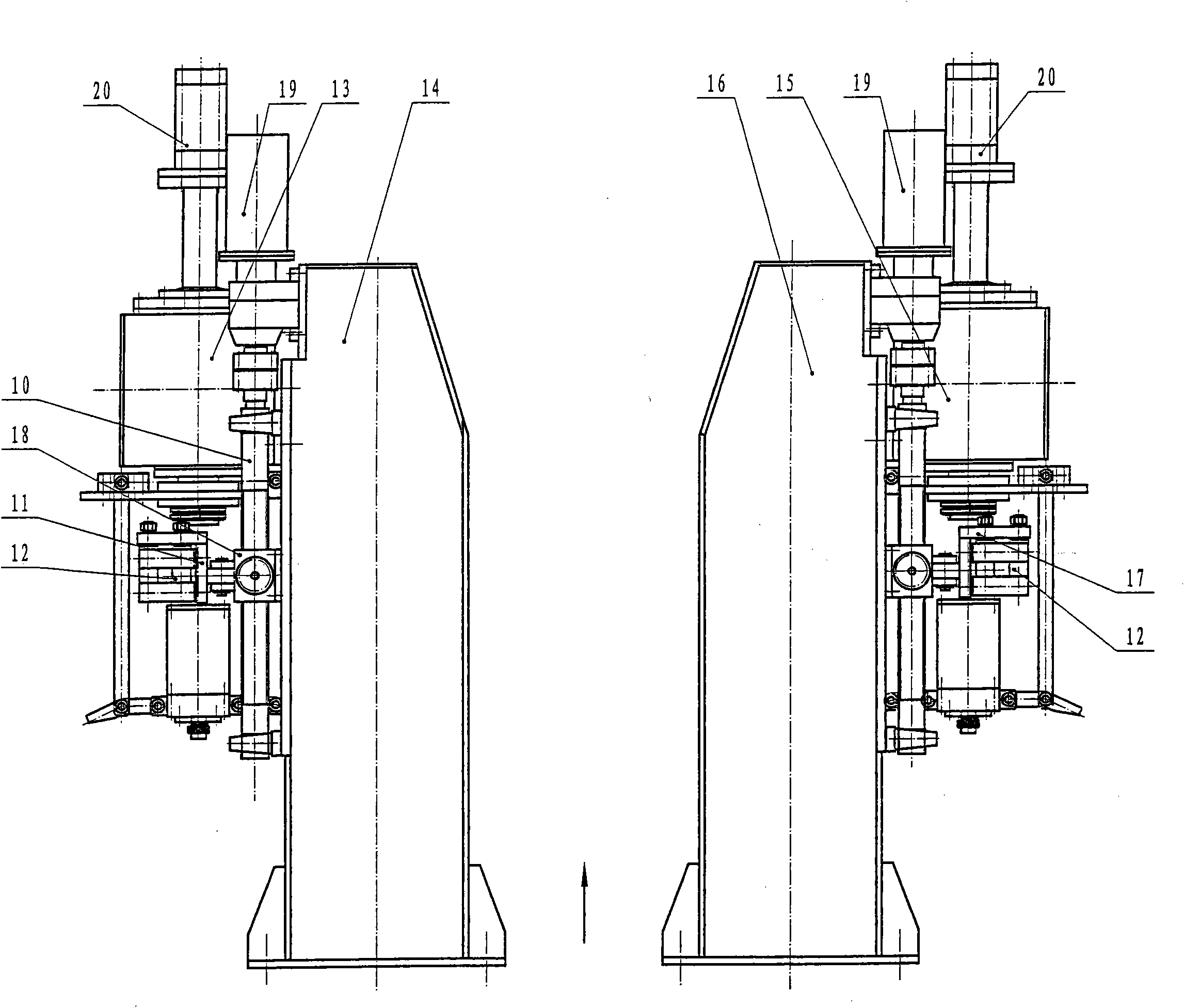

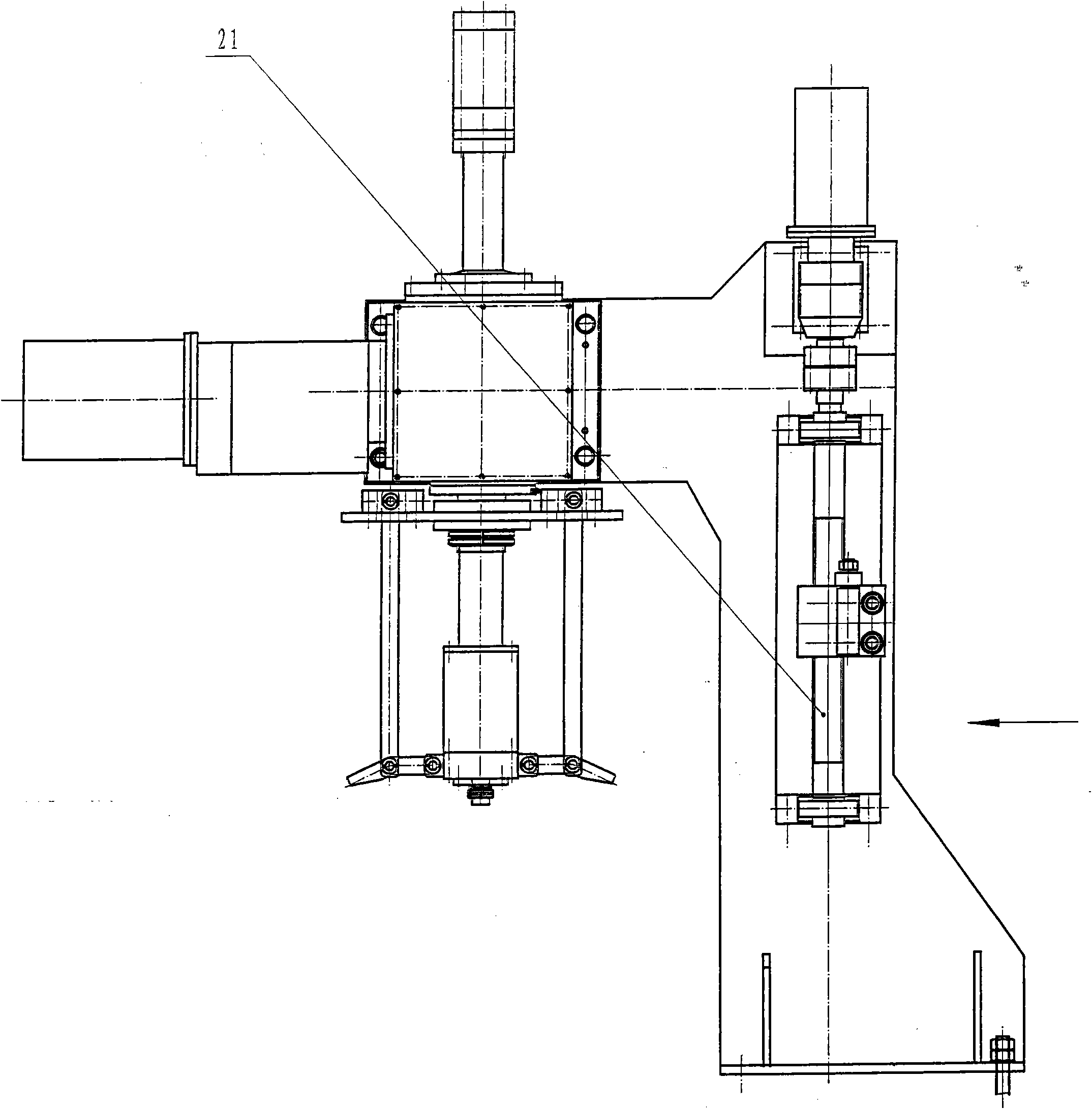

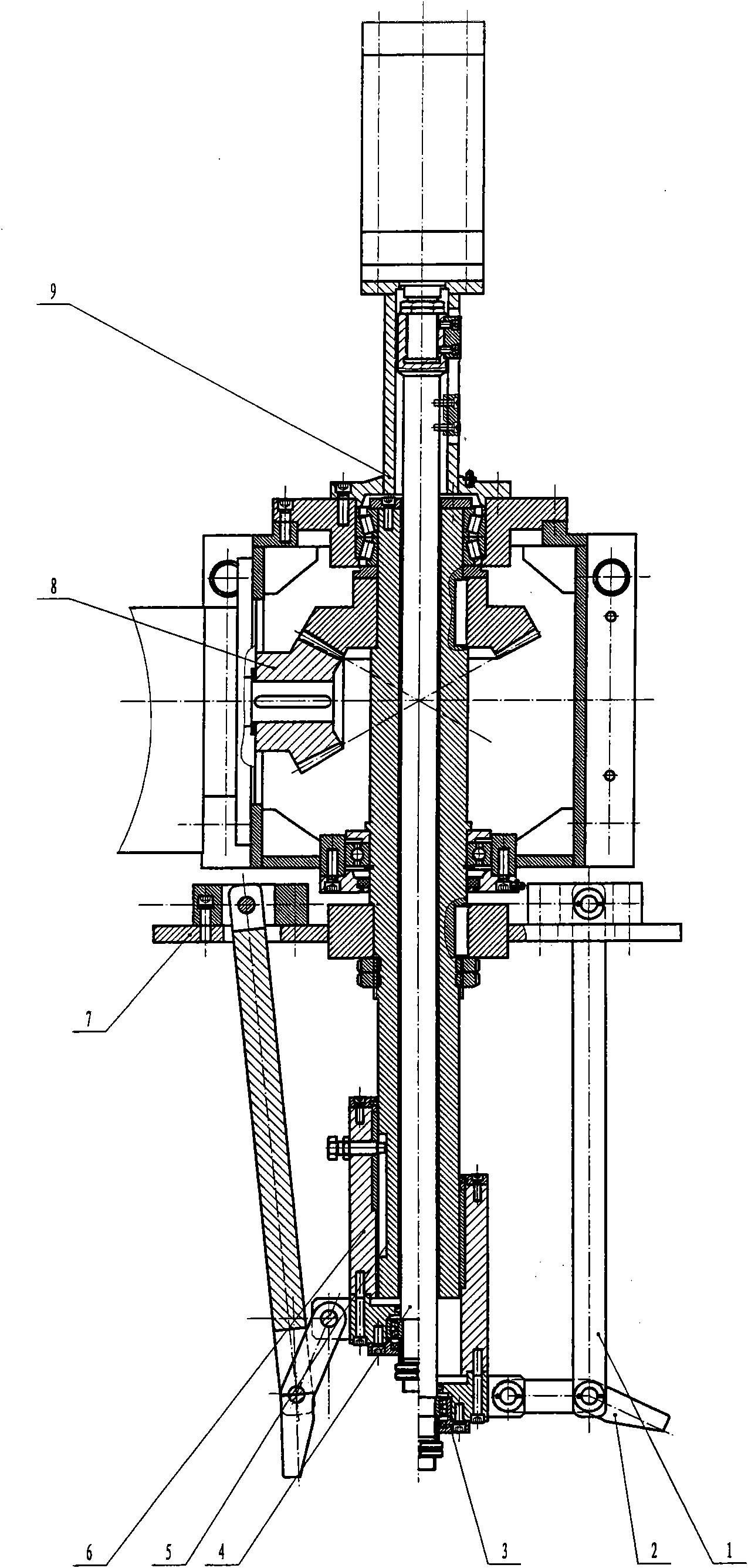

[0015] as attached Figure 1-3 As shown, on both sides of the production line, a waste edge coiler is respectively installed, and the waste edge passes through the guide wheel 12 of the guide mechanism, and is wound on the vertical pole 1 of the coiler, and the transmission mechanism 8 driven by the motor 19 drives the guide The screw mandrel 21 of the mechanism, the screw mandrel 21 rotates and drives the slider 18 worn on the top to slide along the guide bar 10, the left bracket 11, the right bracket 17 are installed on the slider 18, and the guide wheel 12 is fixed on the left and right brackets for reciprocating motion. The waste edge passes through the middle of the guide wheel, and the reciprocating motion of the slider 18 drives the guide wheel 12 on the left and right brackets to move, bringing the waste edge to reciprocate. , under the action of power, the reel rotates, and the waste edge is wound with the rotation of the reel. When it is wound into a ball of a certai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com