Patents

Literature

50results about How to "Convenient coiling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

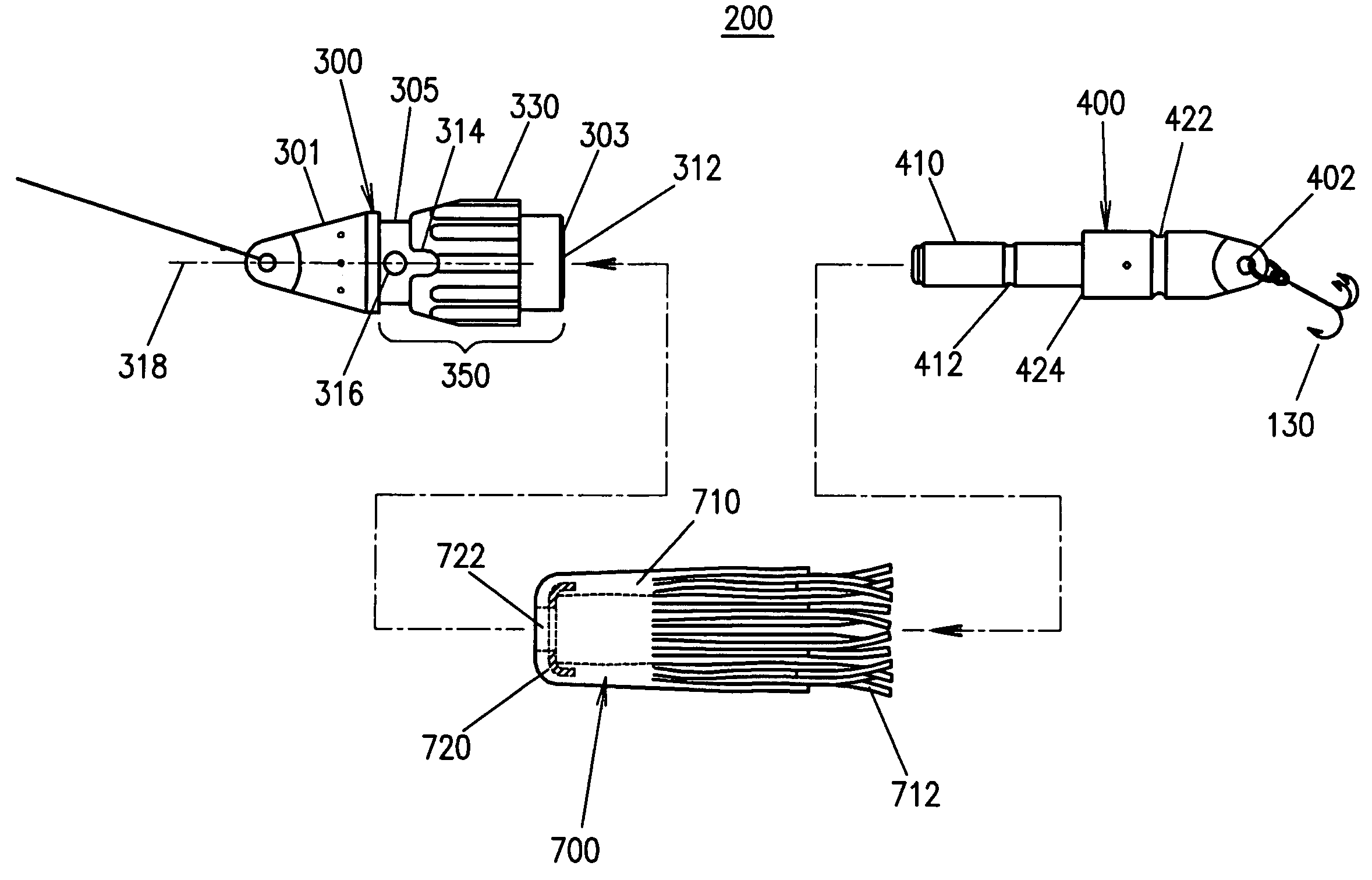

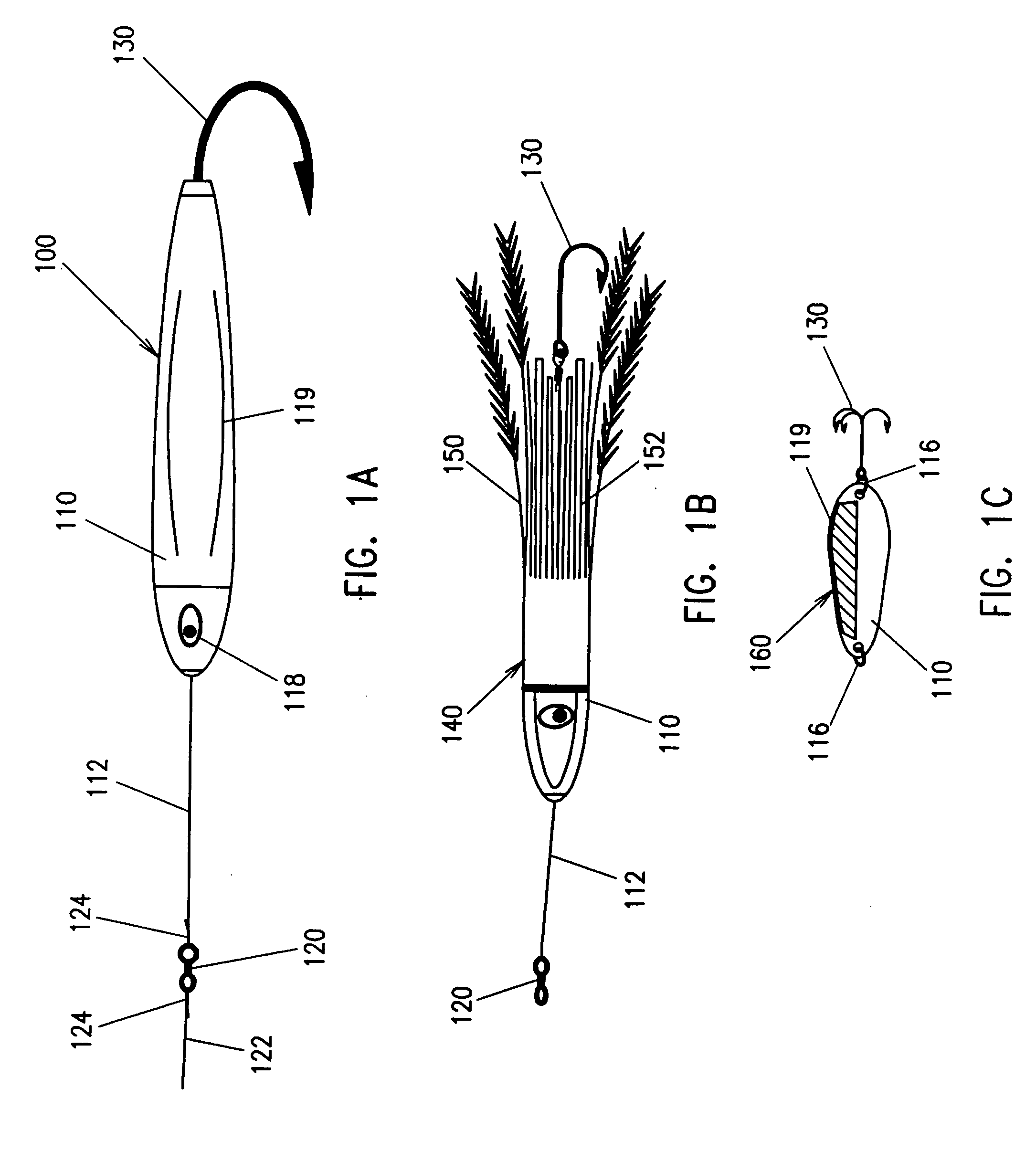

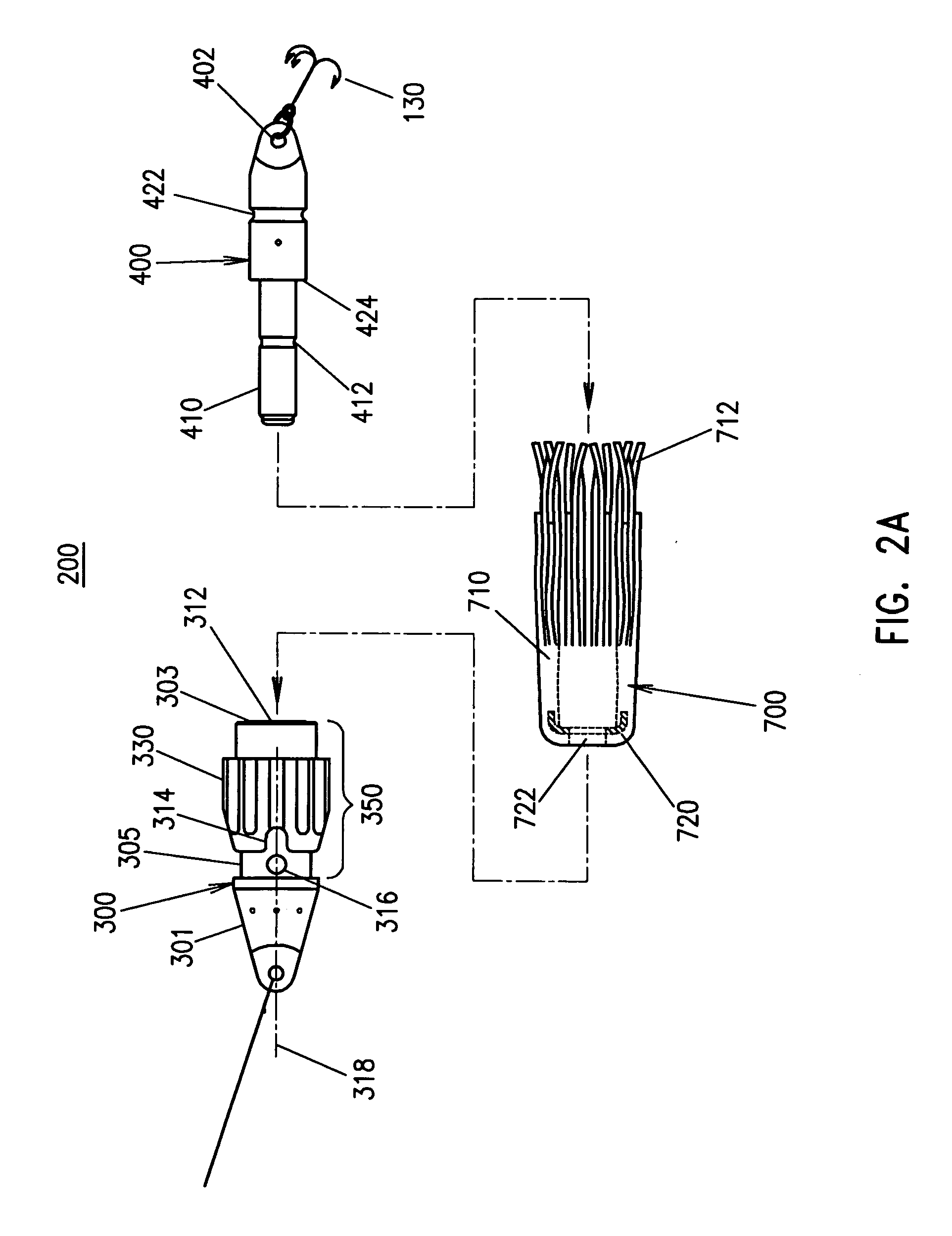

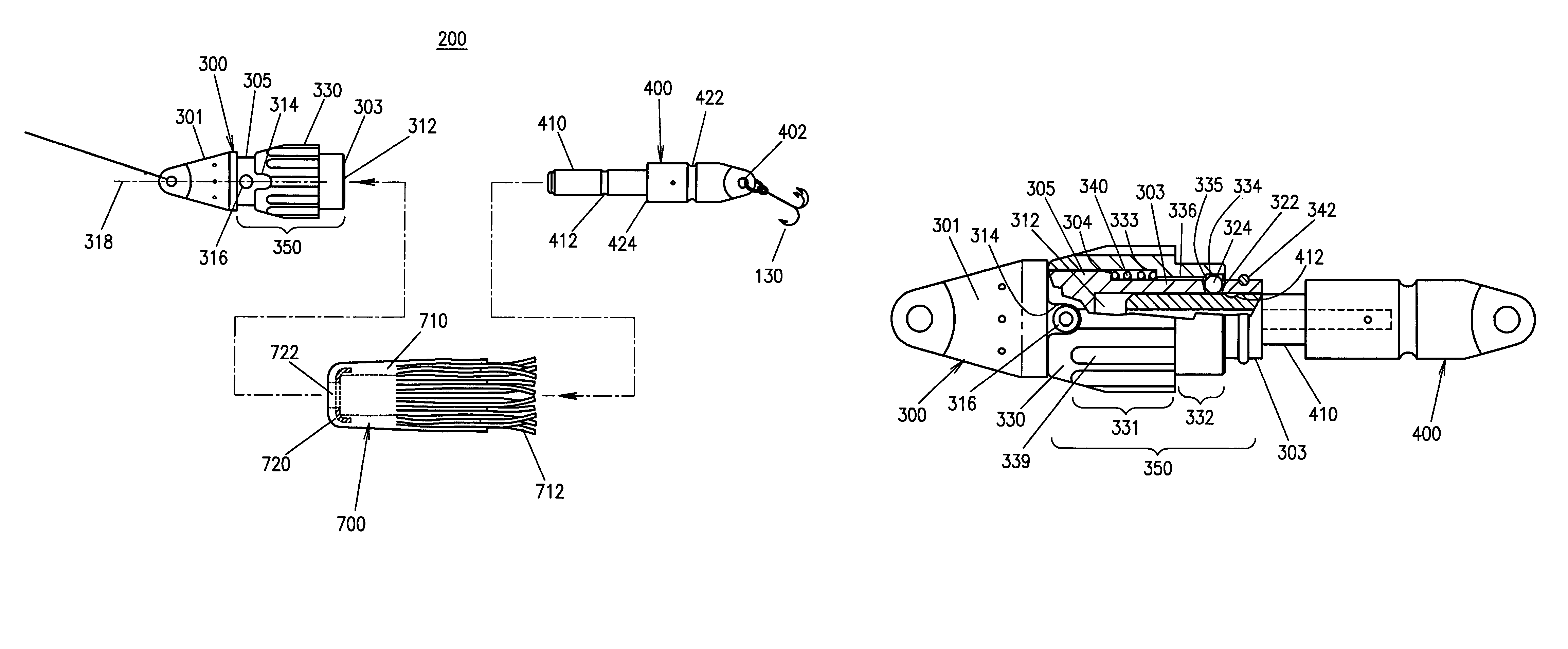

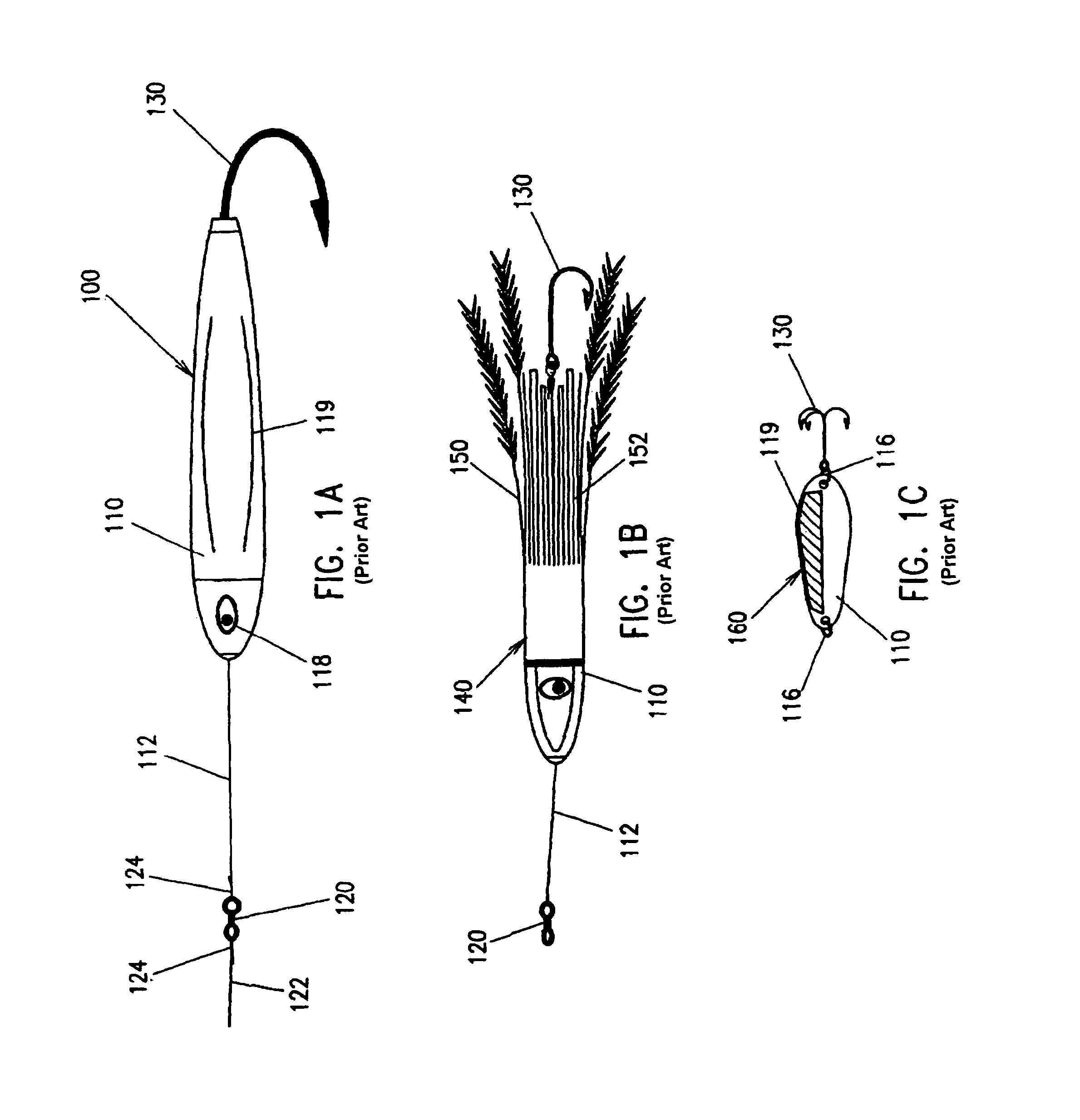

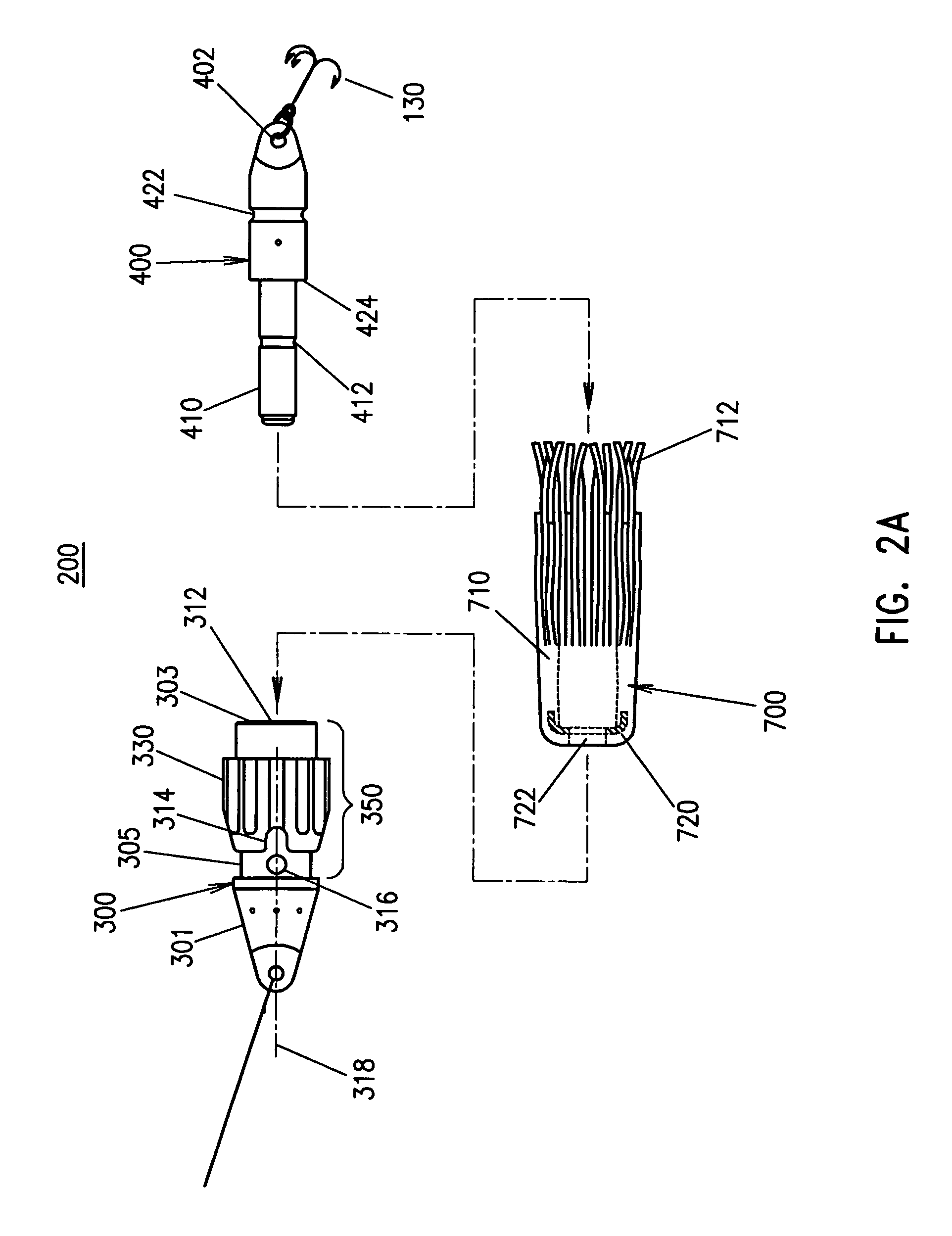

Fishing lure and kit

A fishing lure is described, having a head with a release mechanism and a removable tail. Because the tail can be released, fish caught on hooks can be released quickly, and new tails with new hooks rapidly attached to the same head. Multiple tails may be equipped with different lure skirts, for different fish and / or different conditions, and rapidly changed out in the course of fishing. A tail including a drag chute released by a fish strike, attachable to the same head, is also disclosed. A dive wing, attachable to the removable tails, is also disclosed. Tails can include bait scent chambers and release holes and water jets to attract fish. A kit with combinations of heads, tails, dive wings, and other parts and accessories is also disclosed.

Owner:ZUK ANDREW

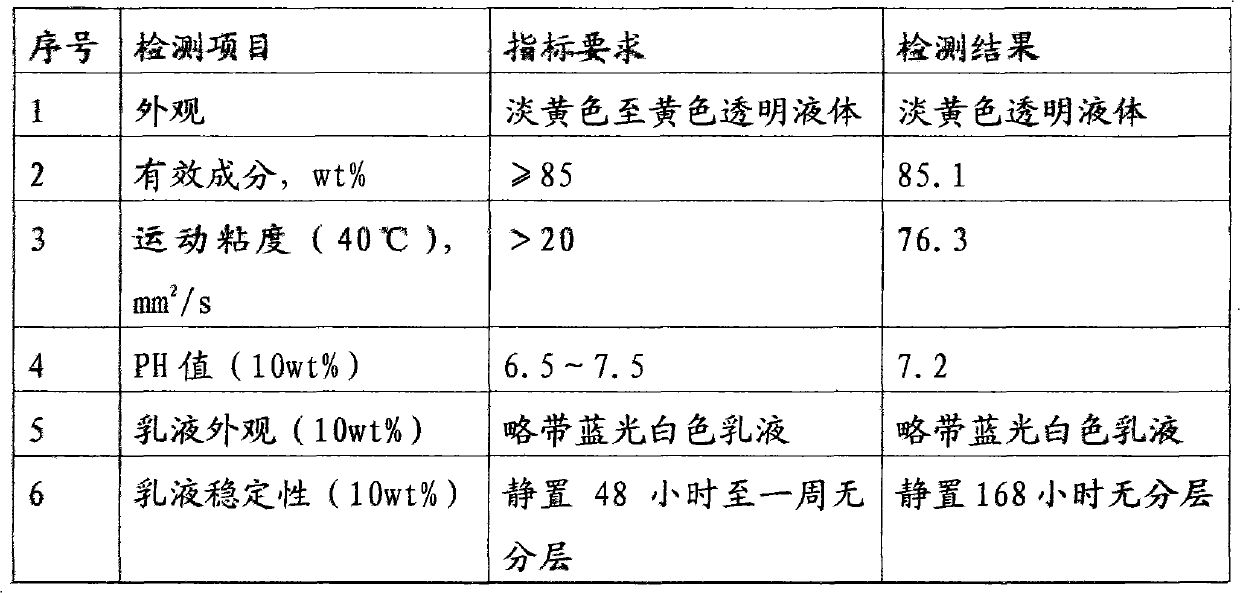

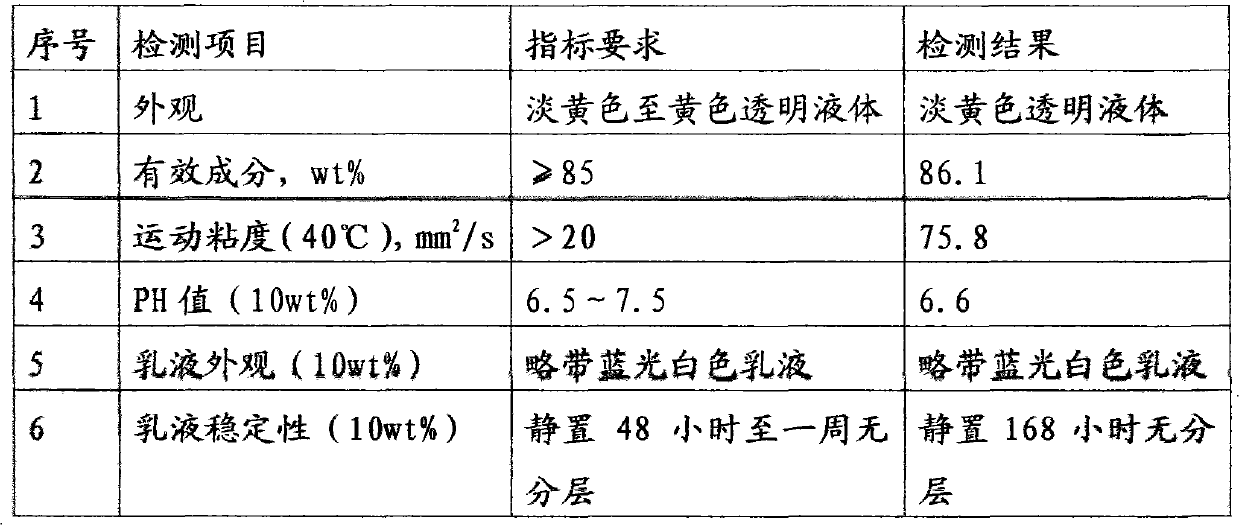

Environment-friendly polypropylene filament yarn oil agent and production method thereof

The invention discloses a preparation method of an environment-friendly polypropylene filament yarn oil agent, comprising the following steps of: weighing 40 to 60 parts by weight of fatty alcohol ether phosphate potassium salt, 2 to 8 parts by weight of polysiloxane polyether copolymer, 3 to 12 parts by weight of pentaerythritol oleate, 4 to 10 parts by weight of fatty alcohol polyoxyethylene ether, 2 to 12 parts by weight of ethylene oxide-epoxypropane block polyether, 20 to 45 parts by weight of polyethylene glycol laurate, 10 to 20 parts by weight of butter alcohol amine phosphate salt and 5 to 10 parts by weight of high-carbon heterogeneous alcohol phosphate potassium salt, heating to 40 to 80 DEG C, reacting under the stirring condition, then adding 20 to 40 parts of emulsifying agent EL-40, 1 to 5 parts of methyl-1-hydroxyethyl-2-stearyl imidazoline ammonium methosulfate, 5 to 15 parts of dimethyl silicon oil, 2 to 40 parts of deionized water and 0.001 to 0.02 part of preservative, reacting under the stirring condition at 50 to 70 DEG C, and separating to obtain the environment-friendly polypropylene filament yarn oil agent.

Owner:青岛荣达新材料研究所

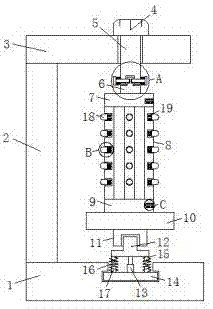

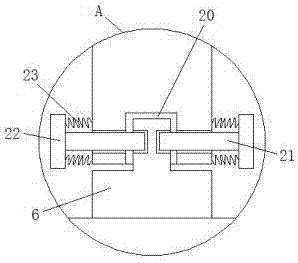

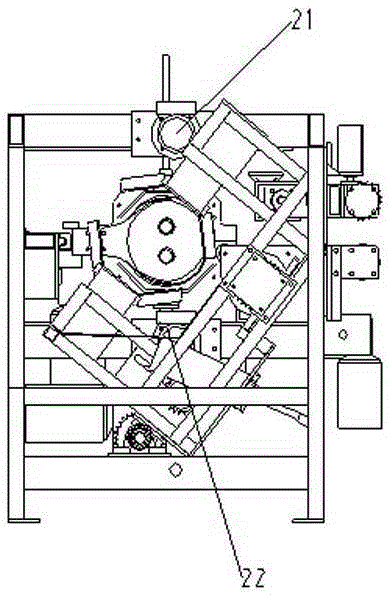

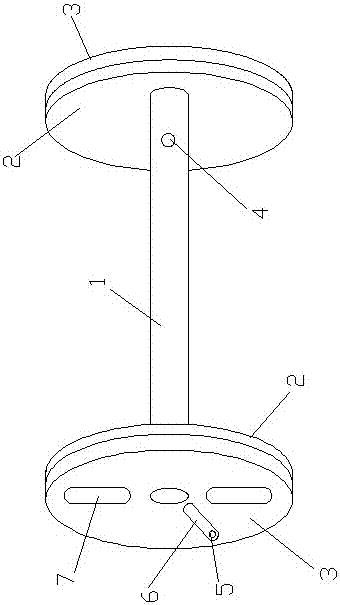

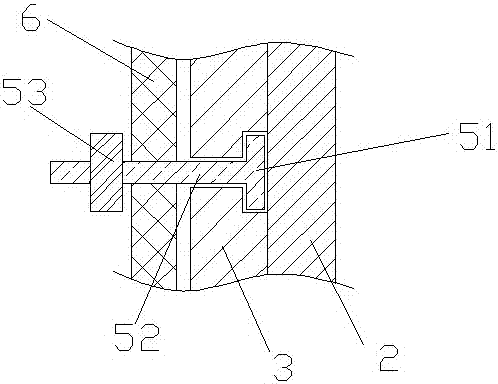

Cloth winding drum device for textile machinery

InactiveCN107472951ARealize automatic windingConvenient coilingWebs handlingAgricultural engineeringDrive motor

The invention discloses a cloth reel device for textile machinery, comprising a base, a support column is fixedly connected to one side of the upper end of the base, and a top plate is fixedly connected to the top end of the support column, and a driving motor is arranged on the upper end of the top plate. And the lower end of the driving motor is provided with a rotating shaft, and the outward extension end of the rotating shaft passing through the inner wall of the top plate is provided with a limiting groove, and a first protrusion is inserted in the limiting groove, and the lower end of the first protrusion is fixedly connected with a The first fixed plate, the bottom end of the first fixed plate is evenly surrounded by several reels, the lower end of the second fixed plate is fixedly connected with the first fixed block through the disc, the lower end of the first fixed block A second protruding block is inserted through the groove, and the second protruding block is fixedly connected with a circular clamping block through the telescopic rod. The invention has the advantages of simple structure, easy installation and disassembly, more convenient cloth coiling, no manual winding, reduced labor force, improved production efficiency, and is suitable for wide popularization.

Owner:湖州胎福工艺品有限公司

Fishing lure and kit

A fishing lure is described, having a head with a release mechanism and a removable tail. Because the tail can be released, fish caught on hooks can be released quickly, and new tails with new hooks rapidly attached to the same head. Multiple tails may be equipped with different lure skirts, for different fish and / or different conditions, and rapidly changed out in the course of fishing. A tail including a drag chute released by a fish strike, attachable to the same head, is also disclosed. A dive wing, attachable to the removable tails, is also disclosed. Tails can include bait scent chambers and release holes and water jets to attract fish. A kit with combinations of heads, tails, dive wings, and other parts and accessories is also disclosed.

Owner:ZUK ANDREW

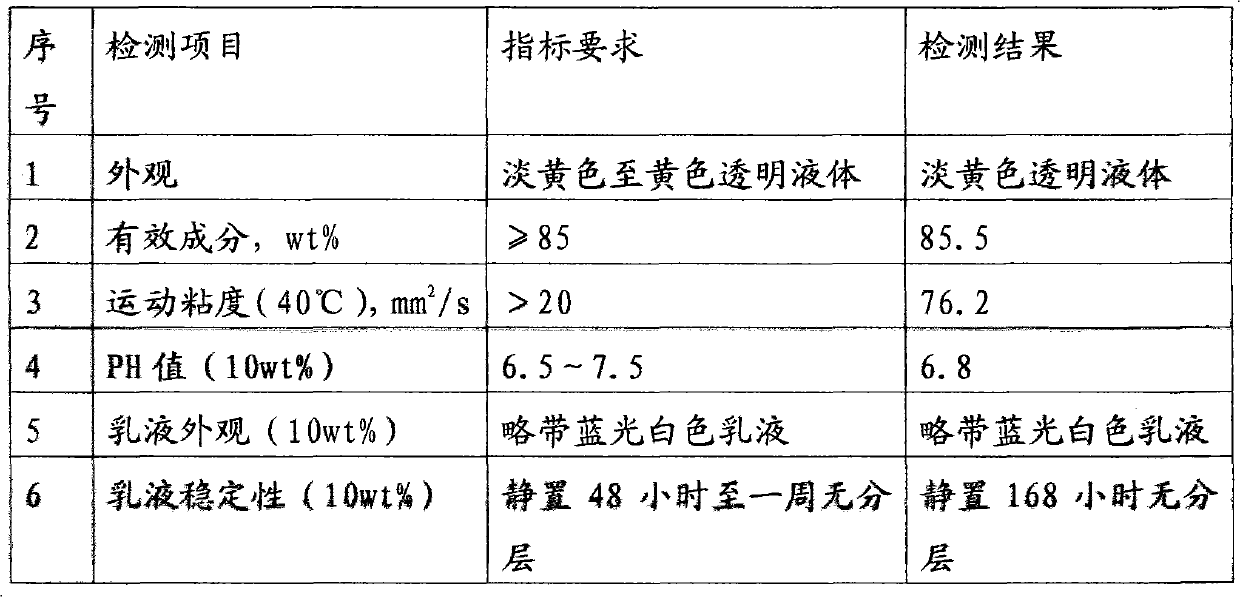

Terylene middle strength filament oil solution and production method thereof

The invention discloses a terylene moderately strong filament finish agent, mainly consisting of polyether, emulsifier, antistatic agent and additive; the invention is characterized by the part of the ingredients by weight: 75-85 parts of polyether, 6-15 parts of emulsifier, 3-8 parts of antistatic agent and 3-7 parts of additive; the preparation method thereof is as follows: according to the weight percentage of the components, exactly measured emulsifier, polyether and antistatic agent are sucked into a reaction kettle, heated to the temperature of 45-55 DEG C and evenly stirred, and then the additive is sucked into the reaction kettle and stirred for 30-50min, after even stirring, the mixture is cooled, filtered and packaged. Compared with the prior art, the finish agent has the advantages that the particles of the latex emulsion are fine, the finish agent is stable and easy to prepare and has no obvious putridity; ossified filament or broken filament is few, and abnormal broken end does not appear; the finish agent has good heat resistance and no obvious smoke; coking is little, winding formation is good, oil is evenly distributed in the fiber, the quality is steady and the elasticity is normal.

Owner:TONGKUN GRP

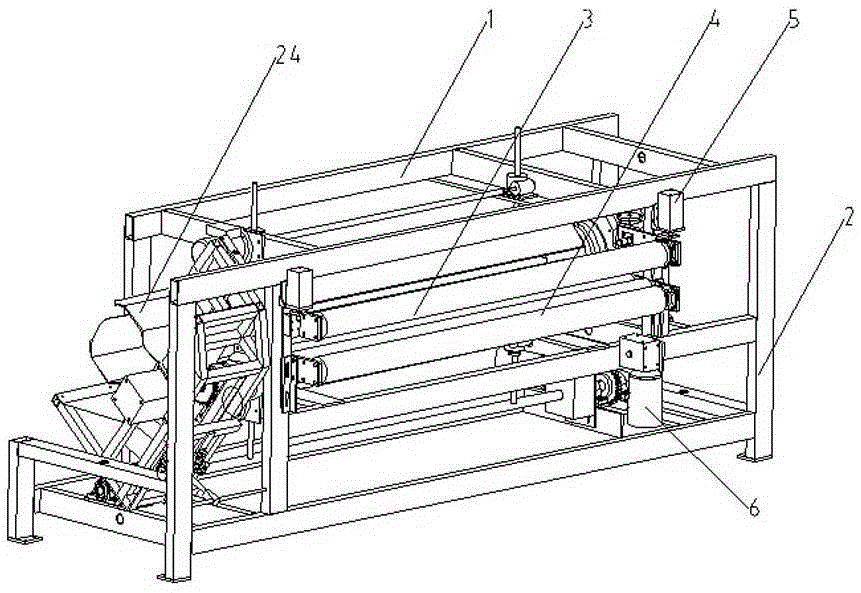

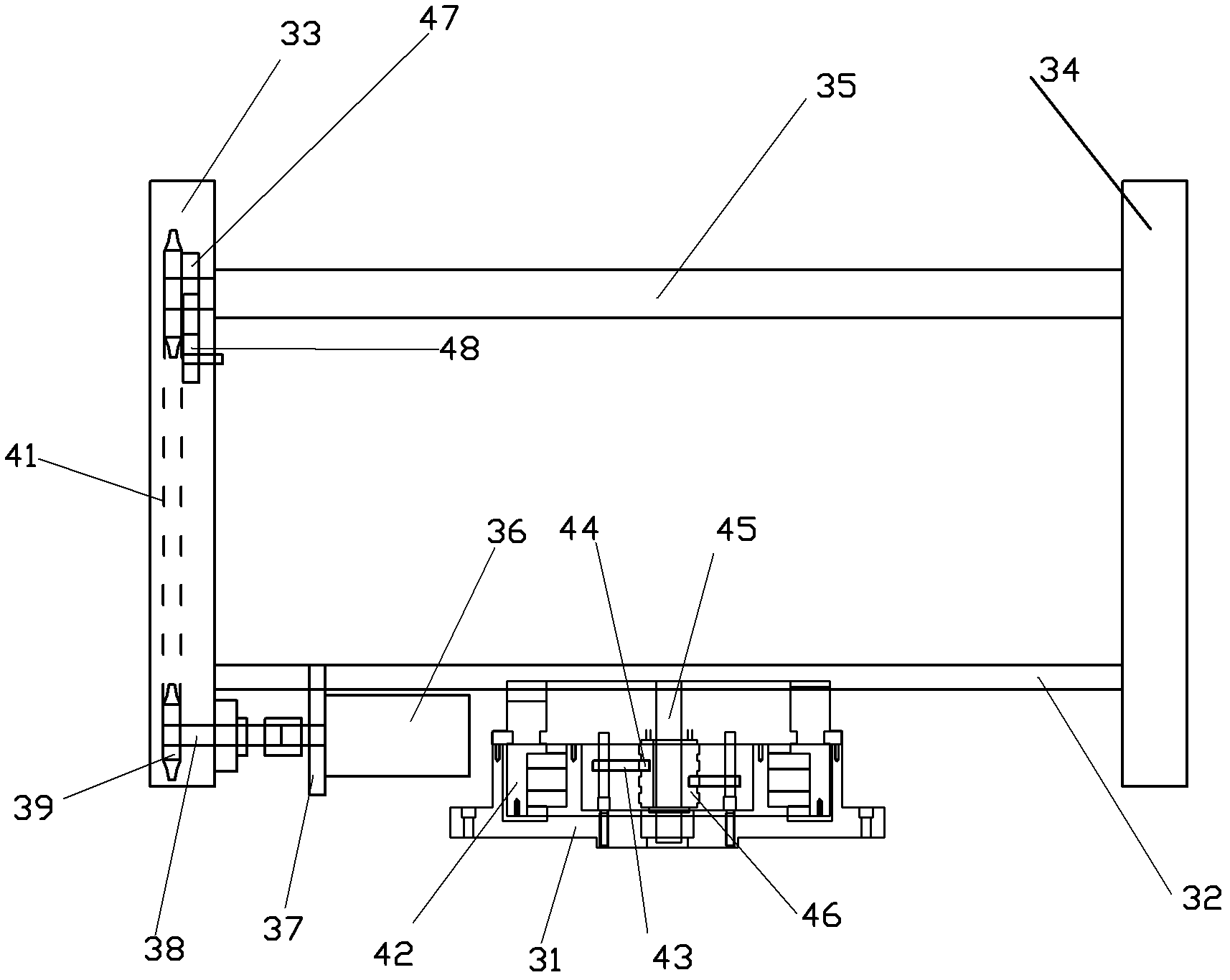

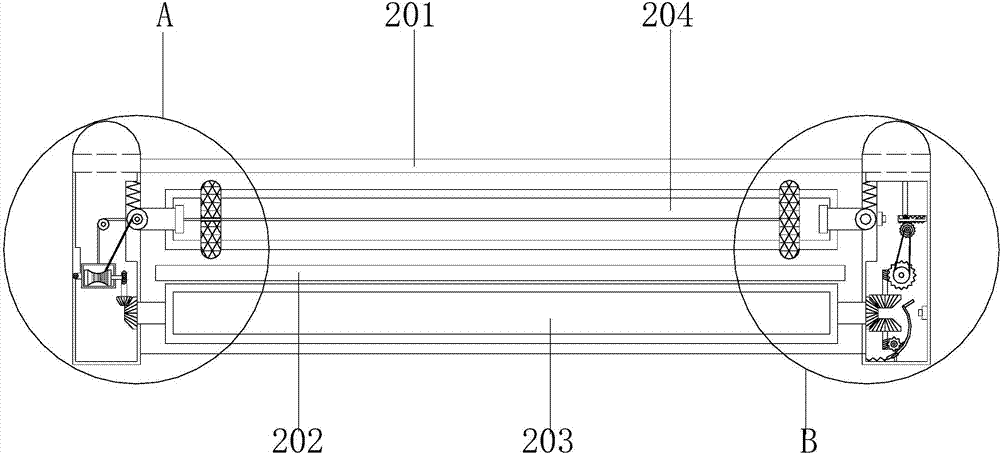

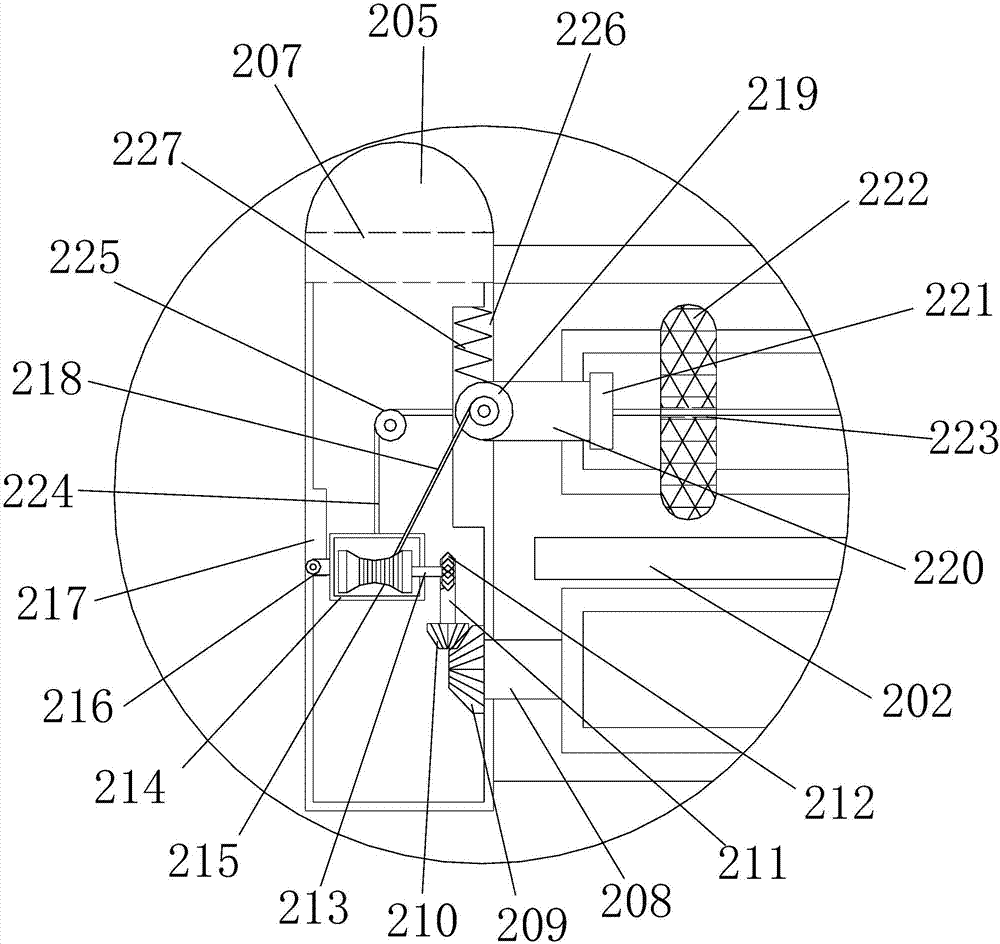

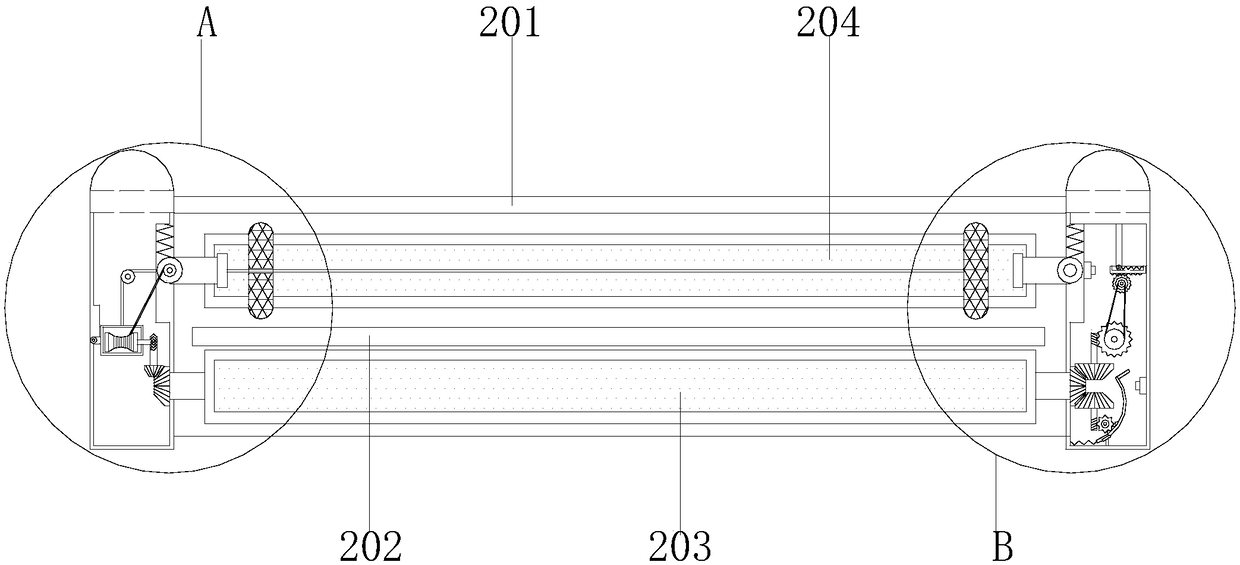

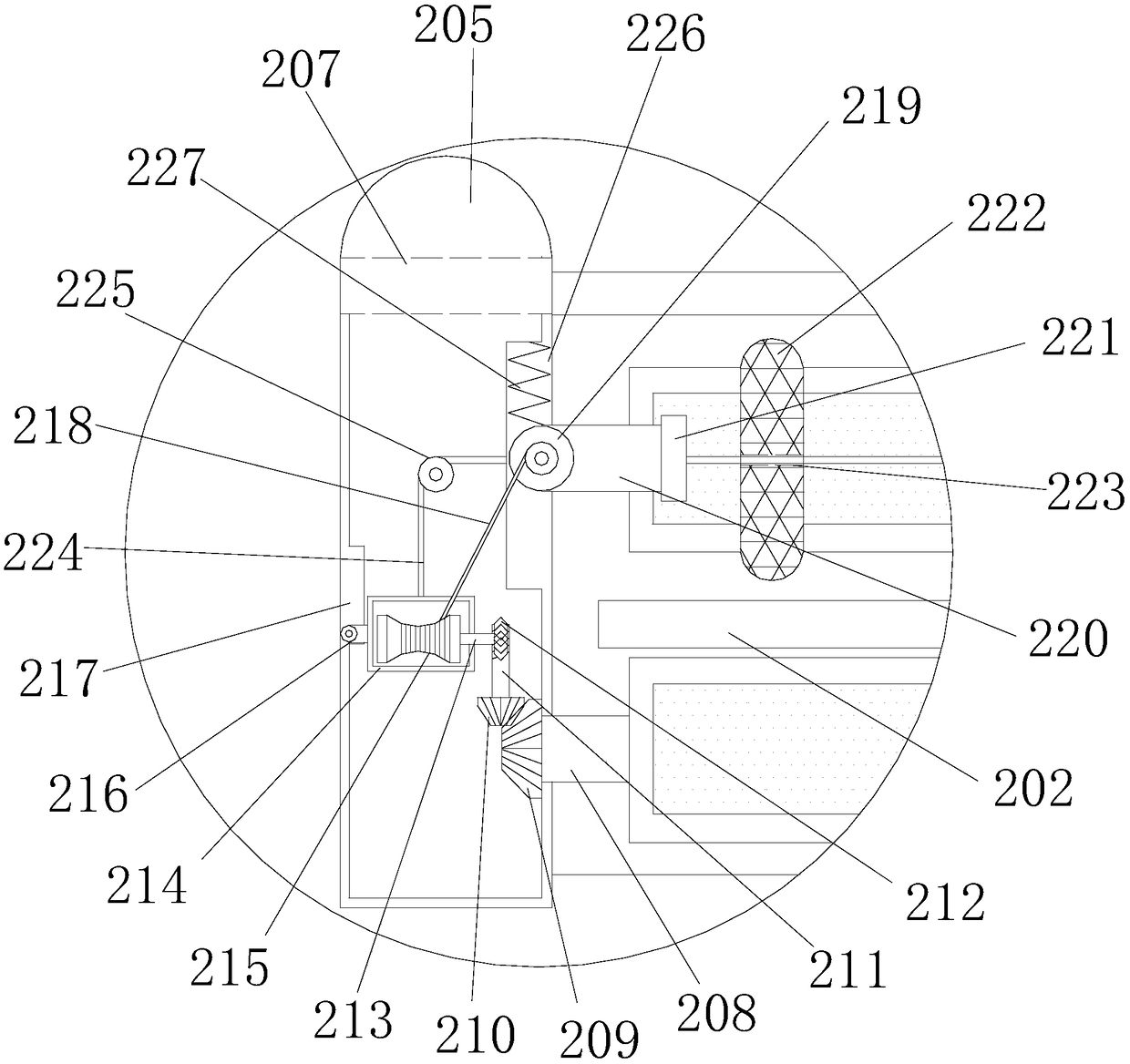

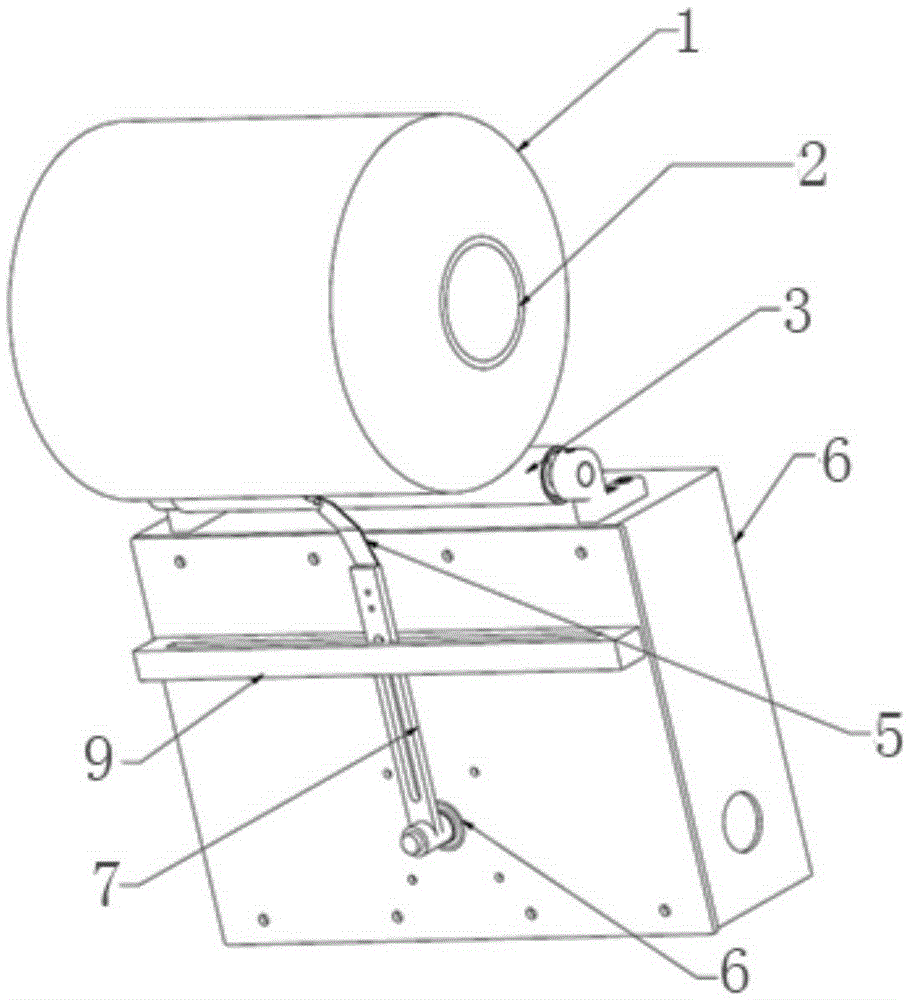

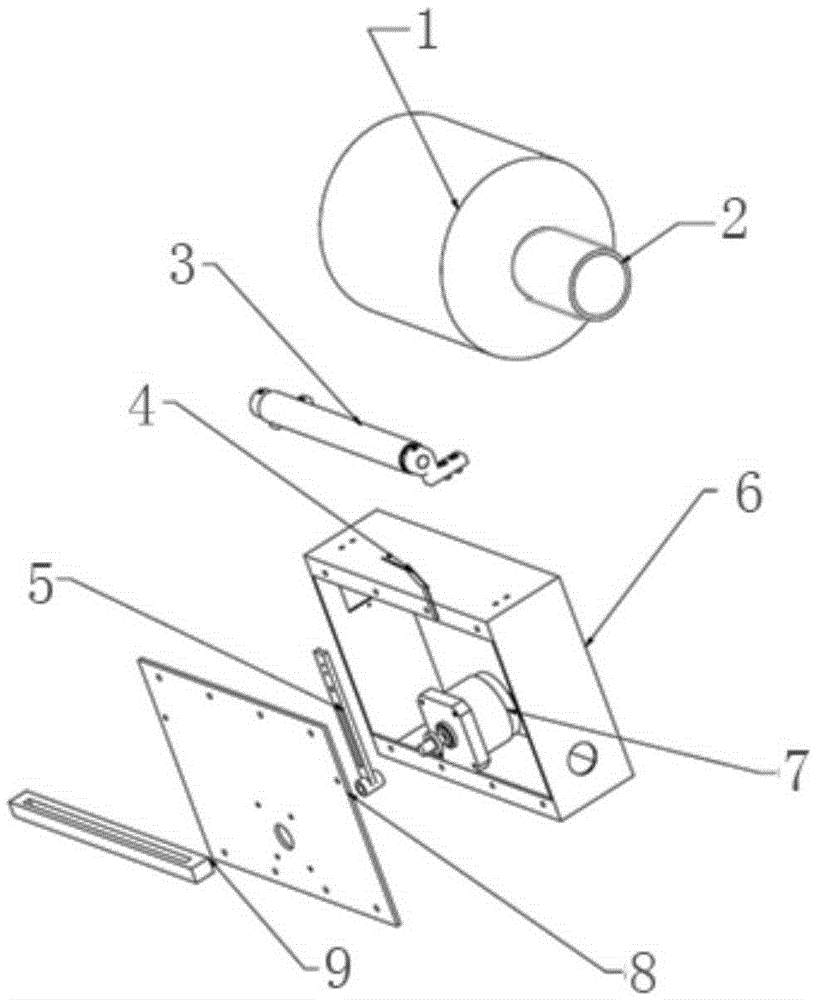

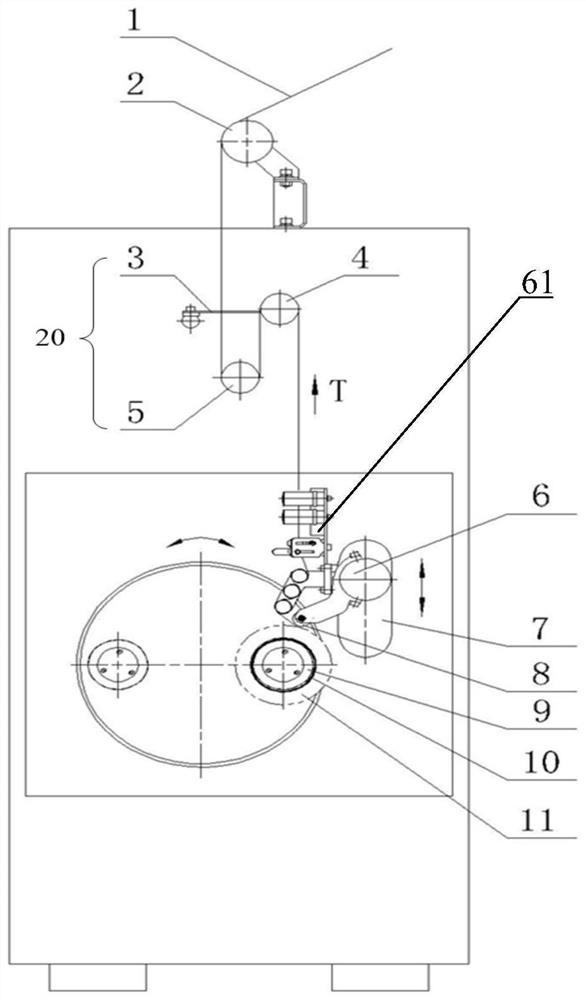

Sponge mattress winding type packaging system

ActiveCN105416730AReduce manual labor intensityImprove work efficiencyPackagingEngineeringConductor Coil

The invention relates to a sponge mattress winding type packaging system. The sponge mattress winding type packaging system comprises a winding support, a feeding mechanism, a winding mechanism and a discharging mechanism. The feeding mechanism is arranged on the side, in the long shaft direction, of the winding support and comprises a pair of movable conveying rollers vertically arranged at the side ends of the winding support and a pair of fixed conveying rollers vertically arranged at the side ends of the winding support. The winding mechanism is located in the winding support and comprises an upper housing and a lower housing which are vertically and symmetrically arranged. A pair of winding rods is arranged between the two housings. The discharging mechanism comprises a sponge push plate arranged on the winding rods in a sleeving manner, and a discharging chain extending in the long shaft direction of the winding rods. The sponge mattress winding type packaging system has the beneficial effects that by means of the packaging system, extruded sponge can be automatically processed through the feeding mechanism, the winding mechanism and the discharging mechanism to be wound into a circle roll to be discharged, the next packaging procedure is facilitated, the labor intensity of workers is effectively relieved, the work efficiency is improved, and the scale can be conveniently expanded.

Owner:南通恒康数控机械股份有限公司

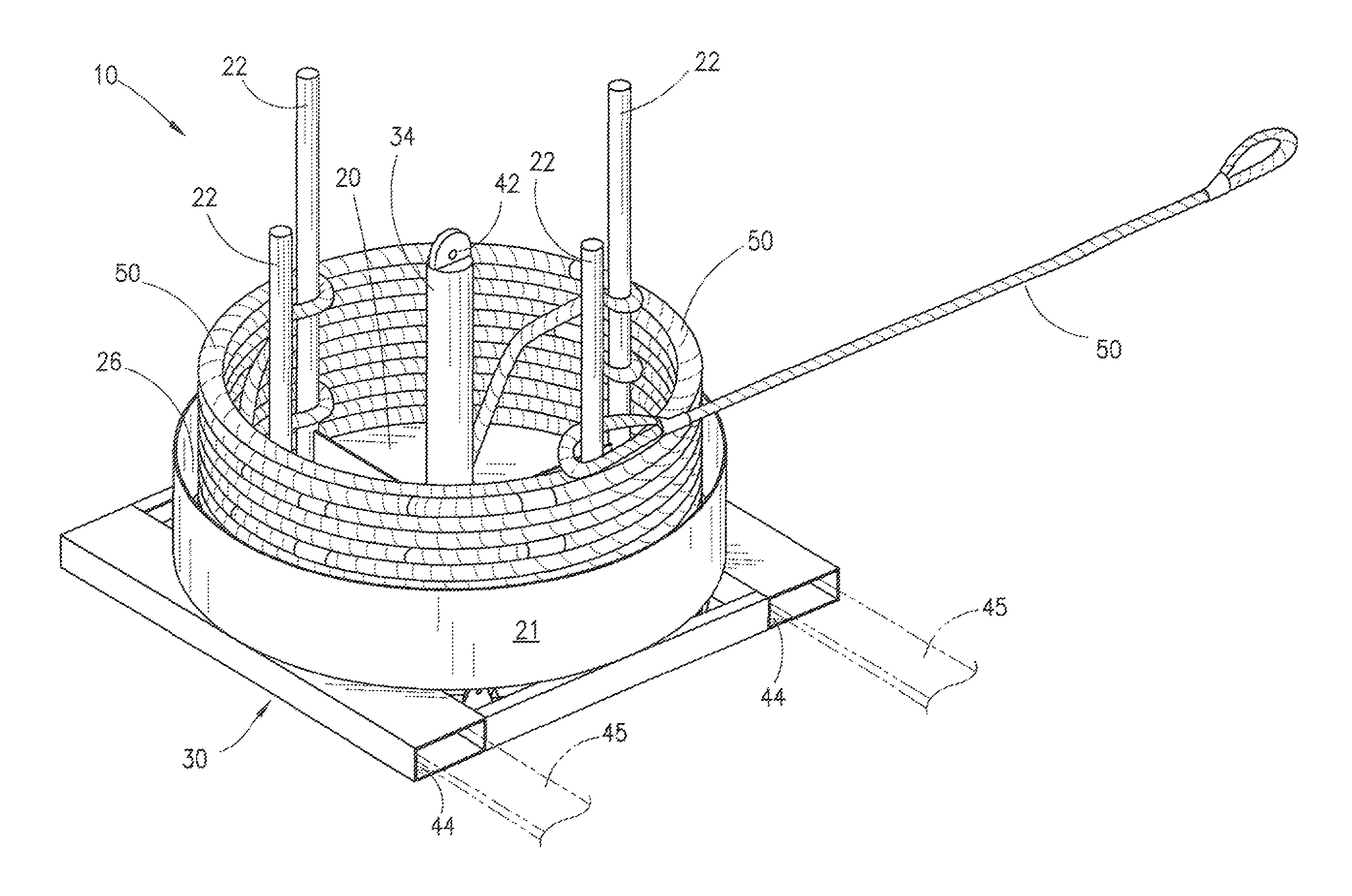

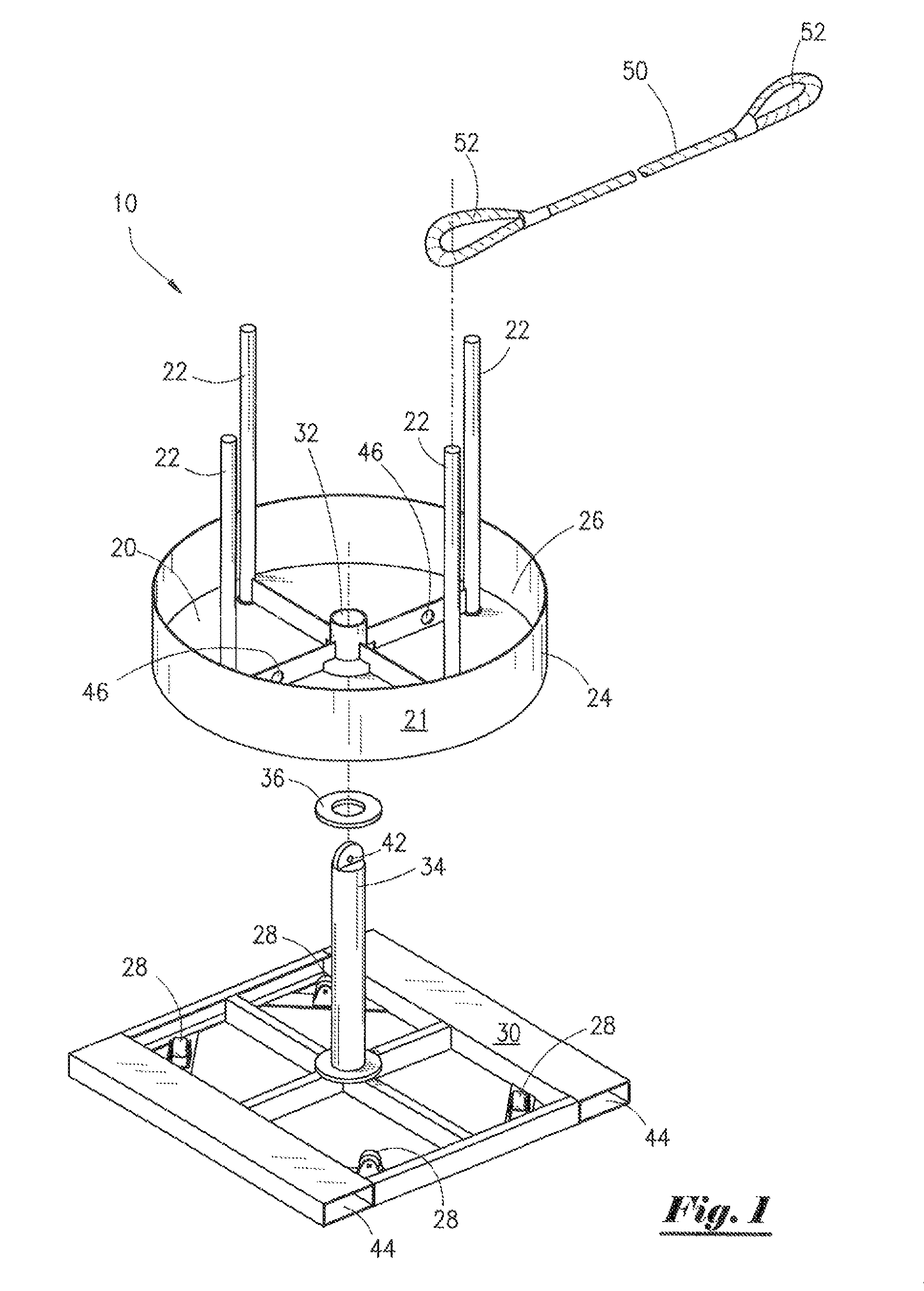

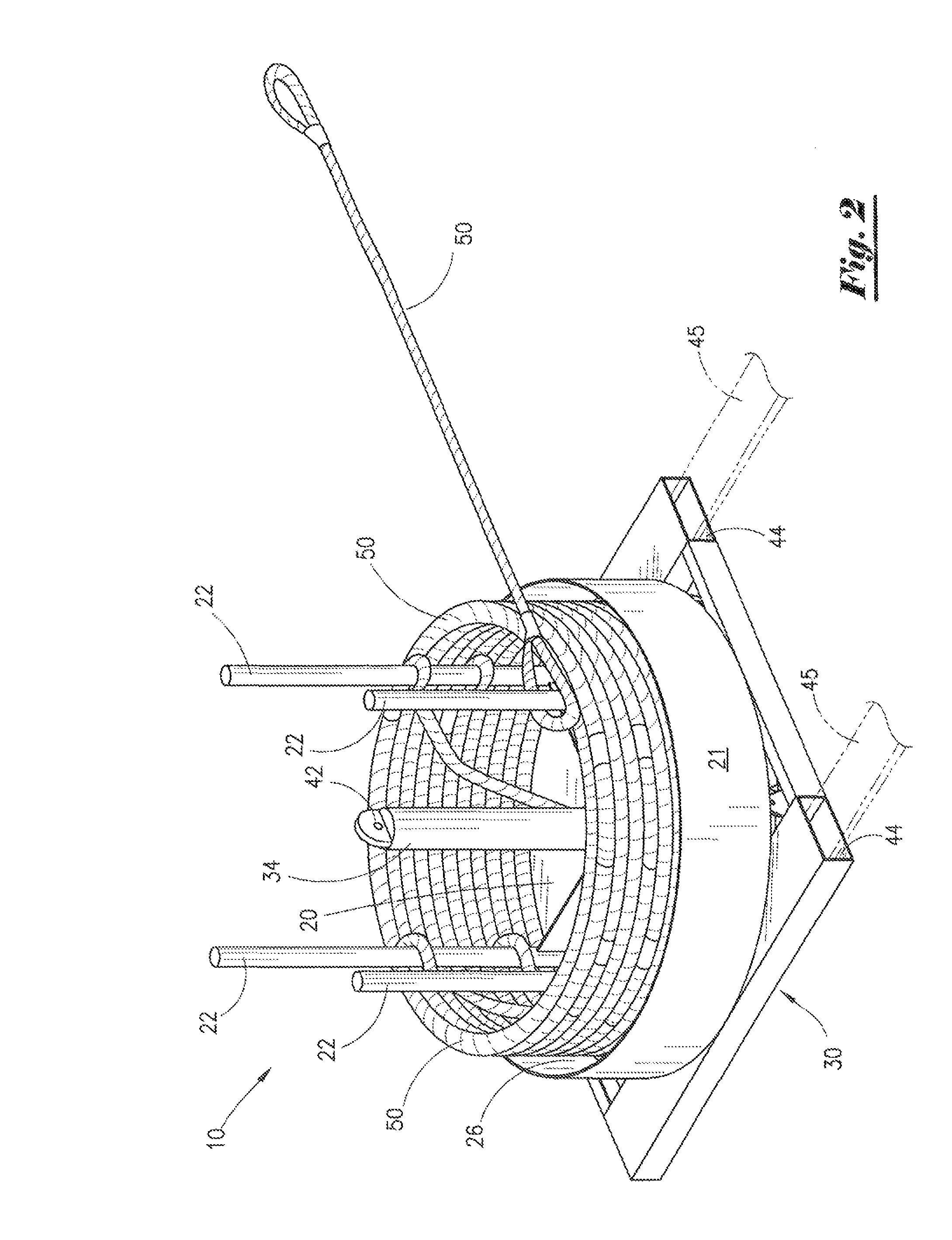

Method and apparatus for managing wire rope slings

InactiveUS7918414B1Easy to liftEasy to operateContainers for annular articlesFilament handlingWire ropeChassis

An apparatus for the storing and management of a plurality of wire rope slings is presented, such slings being those typically comprised of a length of wire rope having at least one end loop. The apparatus has a base frame upon which is rotatably mounted a sling storage bin. The storage bin has a plurality of arm members that extend from the storage bin for engaging and holding an end loop of a selected wire rope sling. Rotation of the storage bin causes the selected wire rope sling to be coiled around said projecting arms within the storage bin. The apparatus may be provided with pad eyes and forklift tine guides to facilitate its transportation.

Owner:PAWS PUMPS

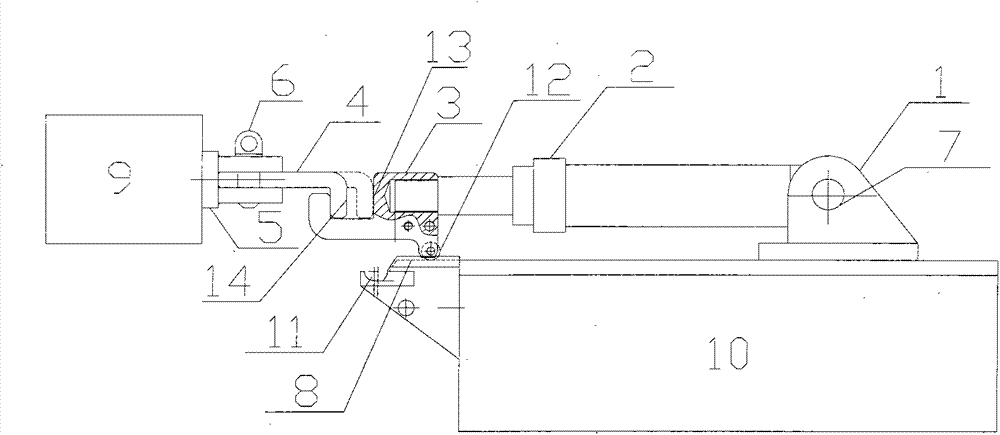

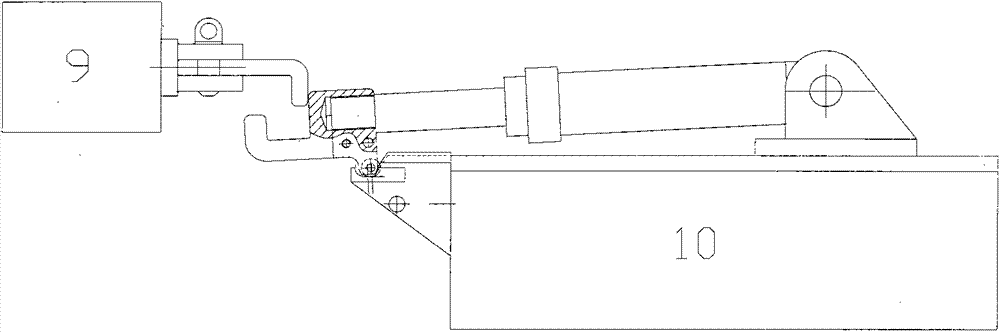

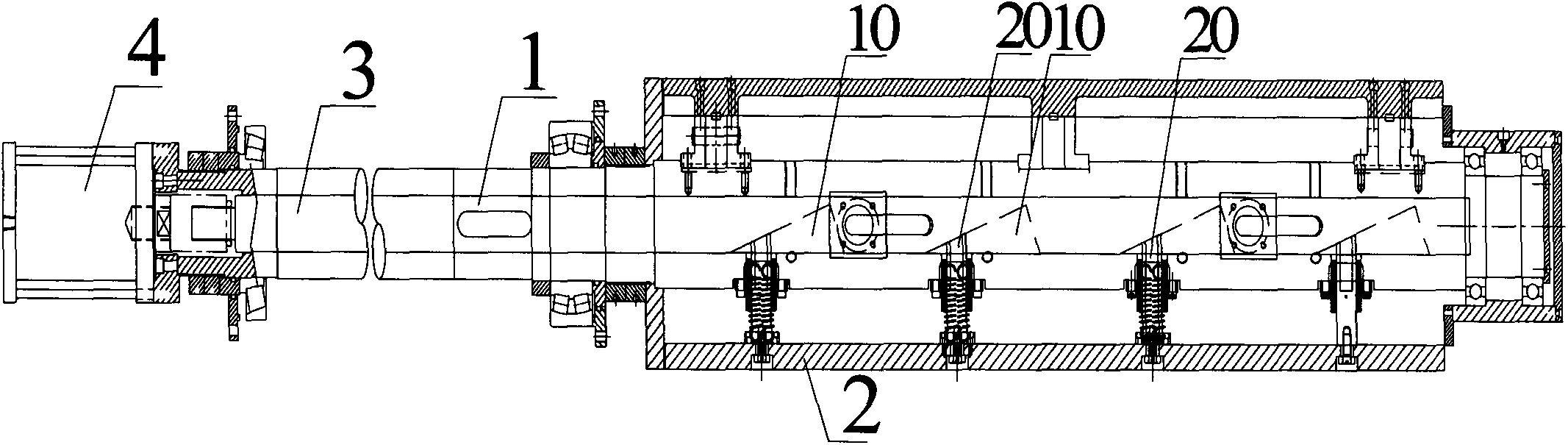

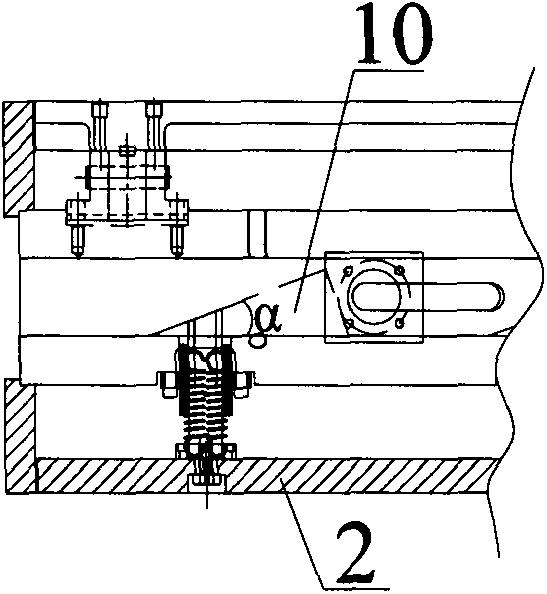

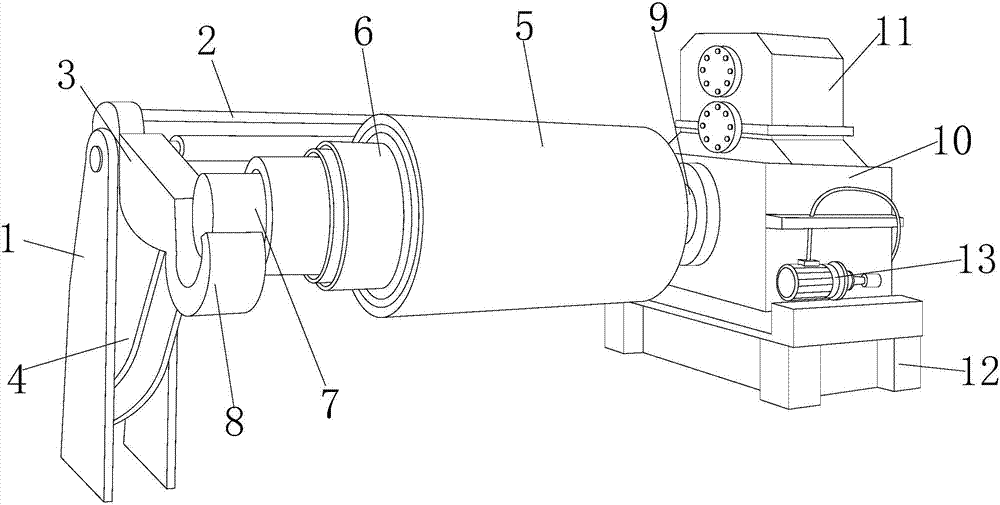

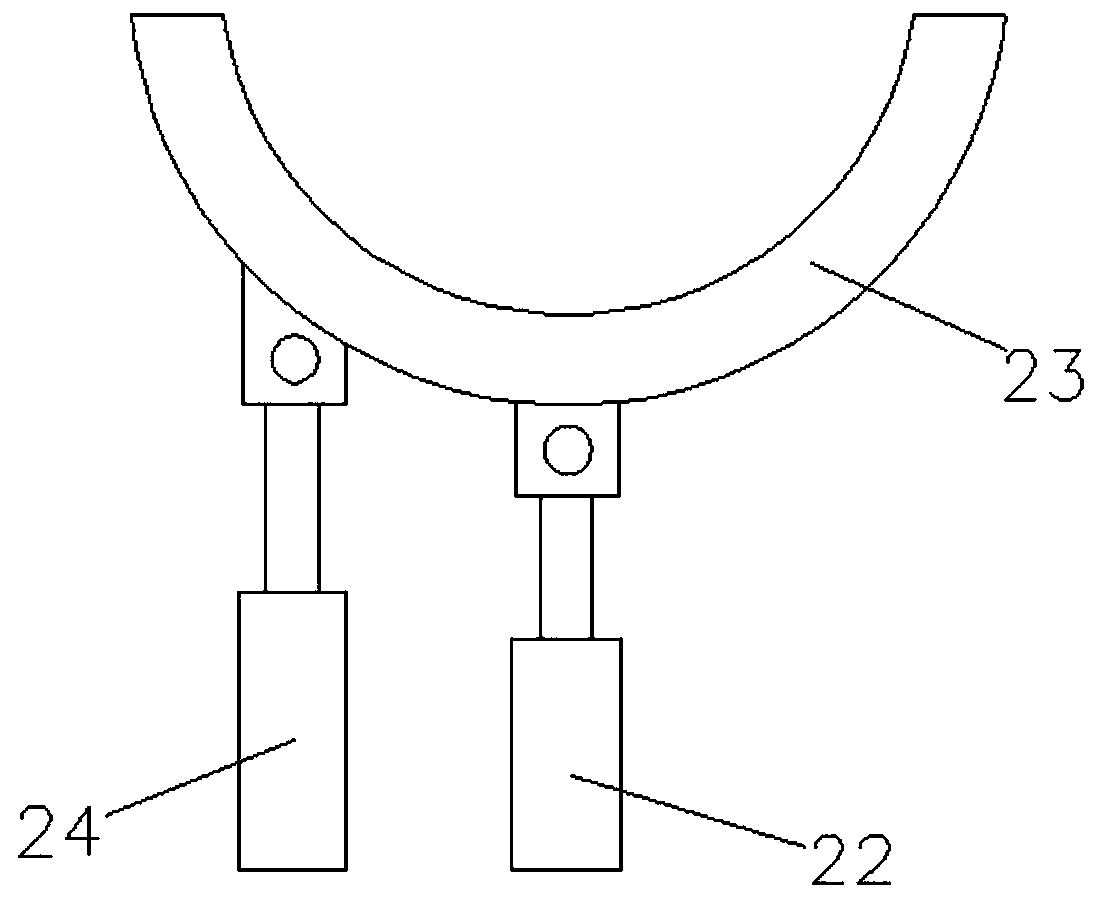

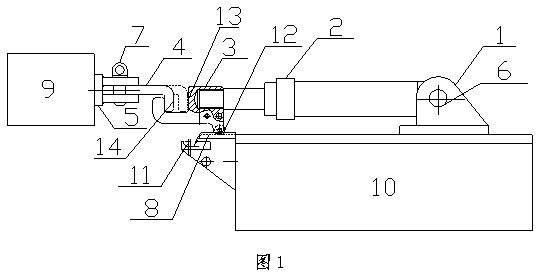

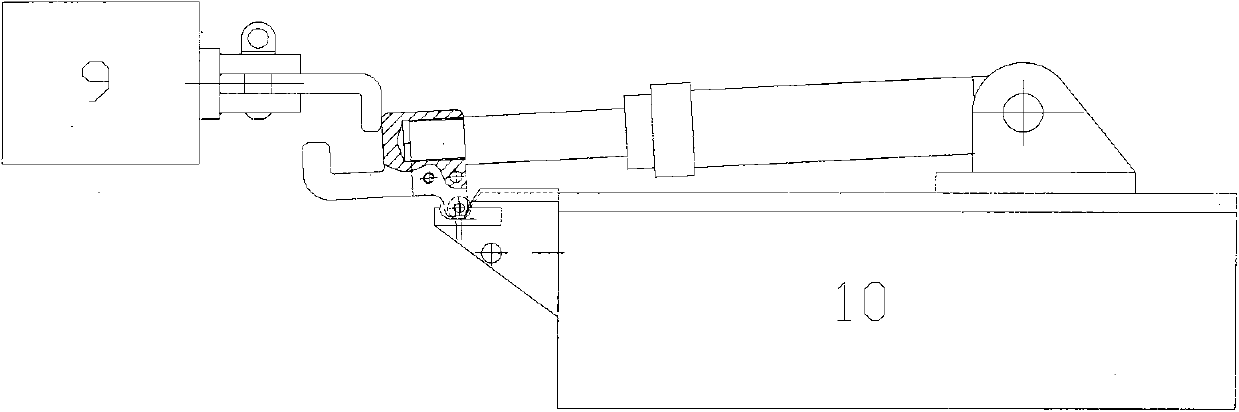

Working roll replacement auxiliary device of rough mill and roll replacement method of working roll replacement auxiliary device

ActiveCN104324942AMeet needsEasy and fast coilingMetal rolling stand detailsMetal rolling arrangementsHydraulic cylinderWork roll

The invention discloses a working roll replacement auxiliary device of a rough mill. The working roll replacement auxiliary device comprises a machine frame, a hydraulic cylinder, a first hook body and a second hook body, wherein one end of the hydraulic cylinder is hinged to the machine frame, the other end of the hydraulic cylinder is provided with an ejection rod, the first hook body is connected with the top end of the ejection rod, and is provided with a first push surface and a first hook, a movement piece is arranged under the first hook body, the machine frame is provided with a rail corresponding to the movement piece, one end, away from the hydraulic cylinder, of the rail is provided with a groove, the second hook body is connected onto a working roll, and is provided with a second push surface and a second hook, the second push surface corresponds to the first push surface, and the second hook is buckled together with the first hook. When the movement piece is moved into the groove, the first hook is separated from the second hook. The invention also discloses a working roll replacement method. The working roll replacement auxiliary device has the beneficial effects that the coiling is convenient and rapid, the replacement procedure is simple, the operation is easy, the requirements of customers are met, and the like.

Owner:CNMC ALBETTER ALBRONZE

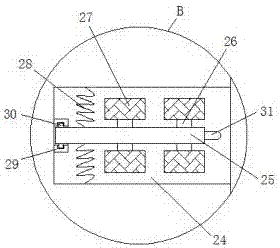

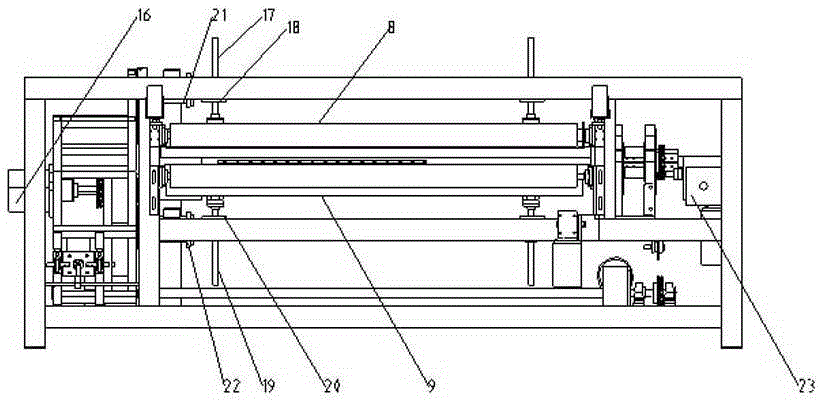

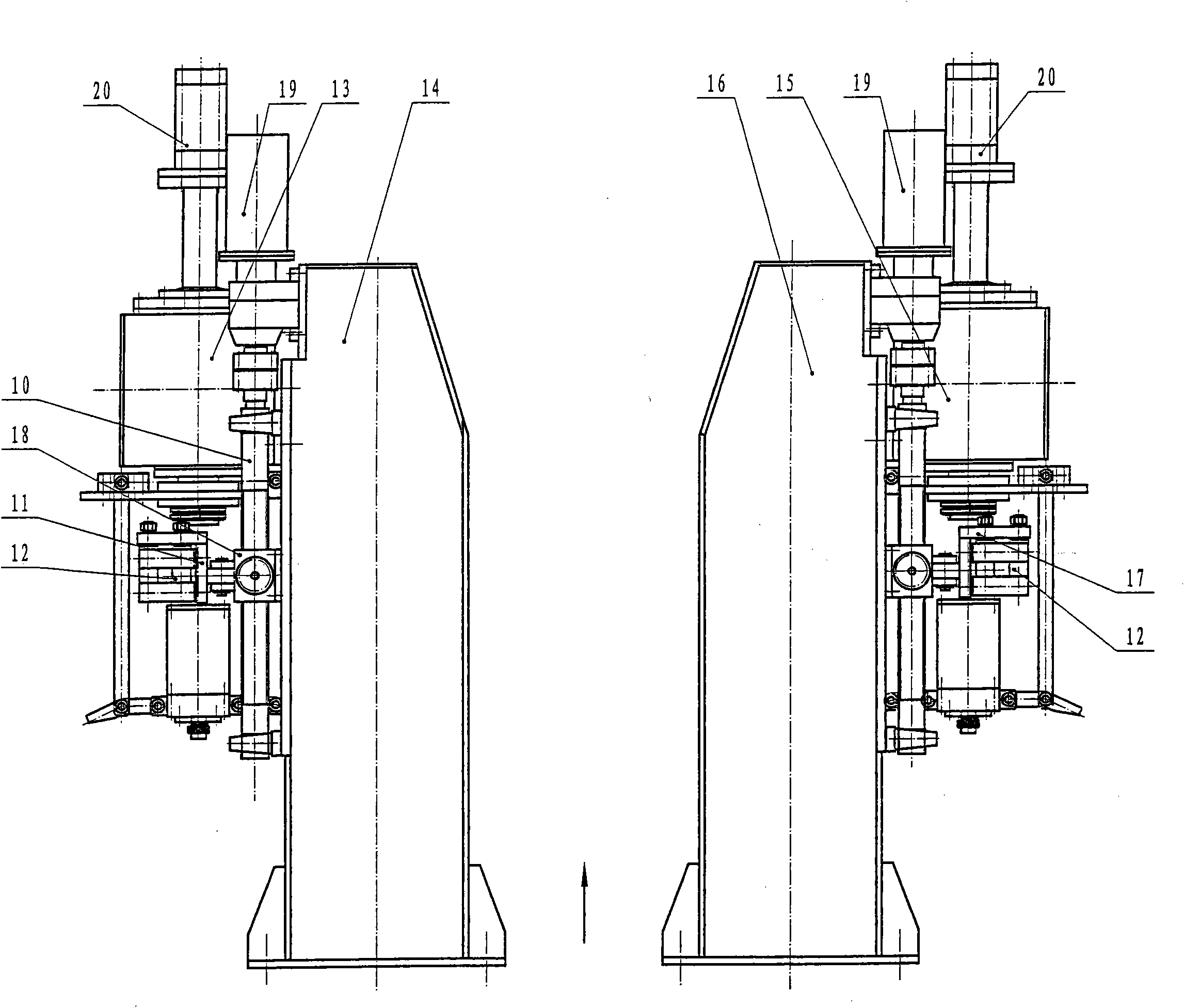

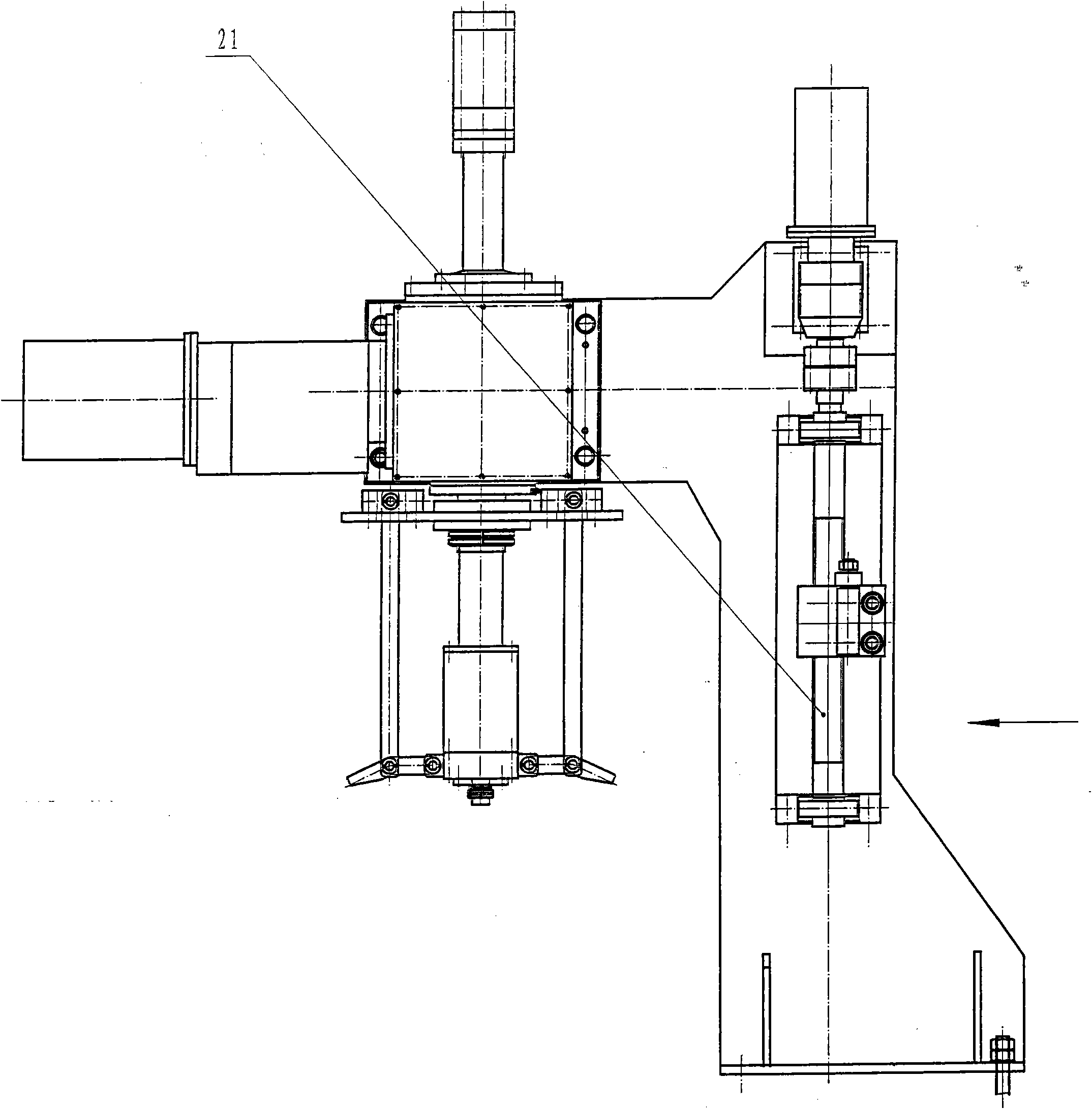

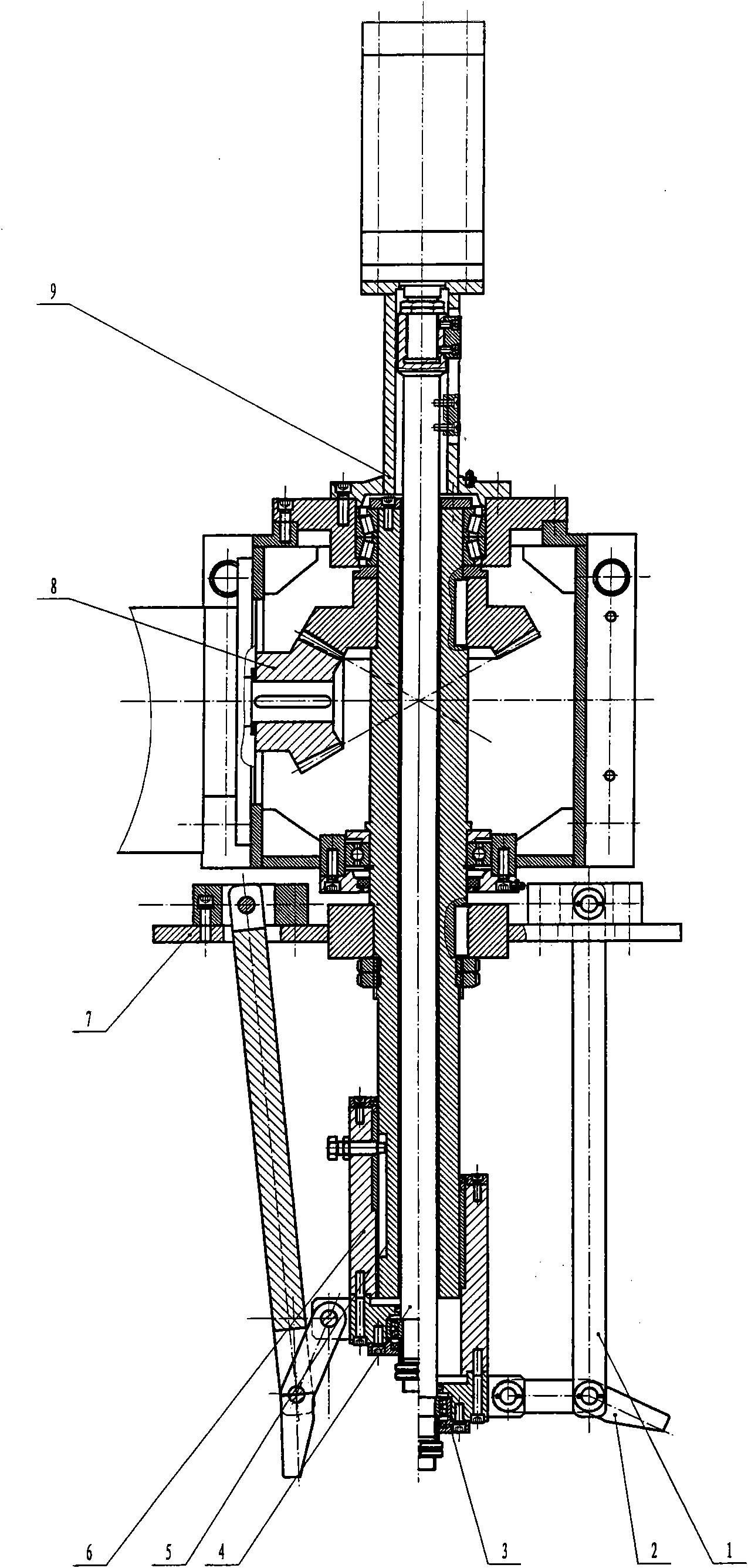

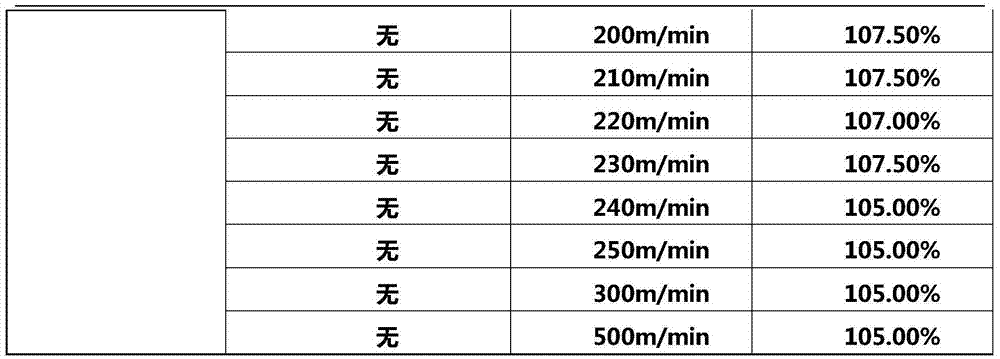

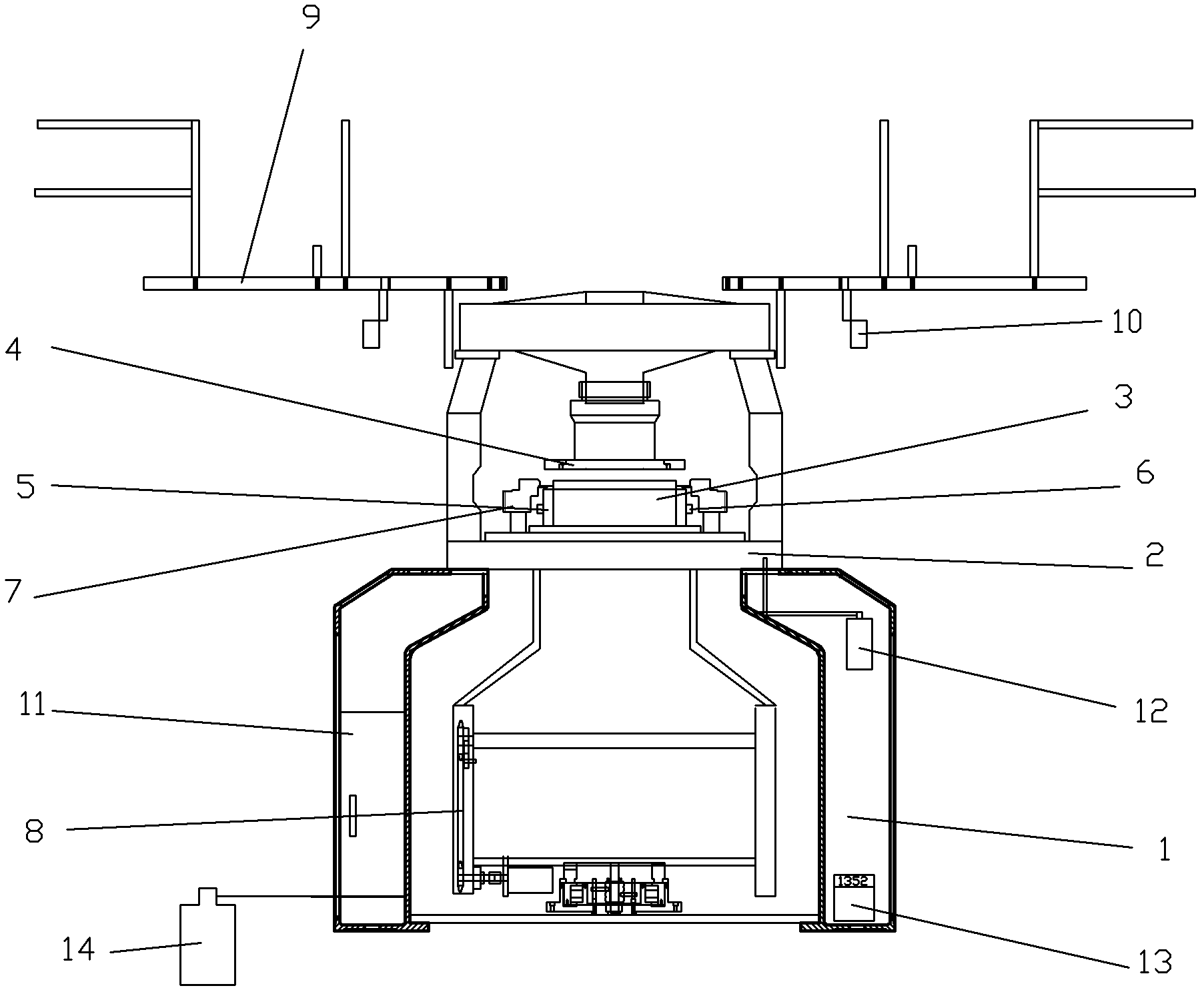

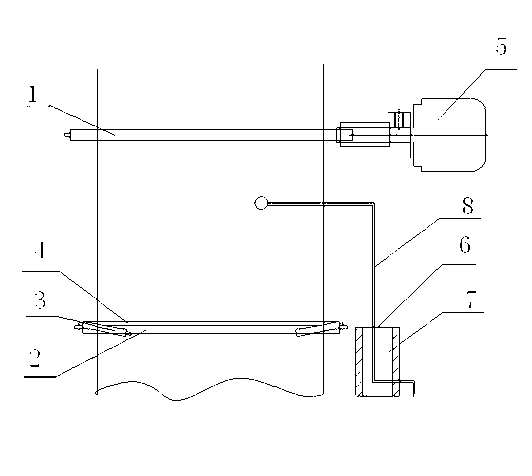

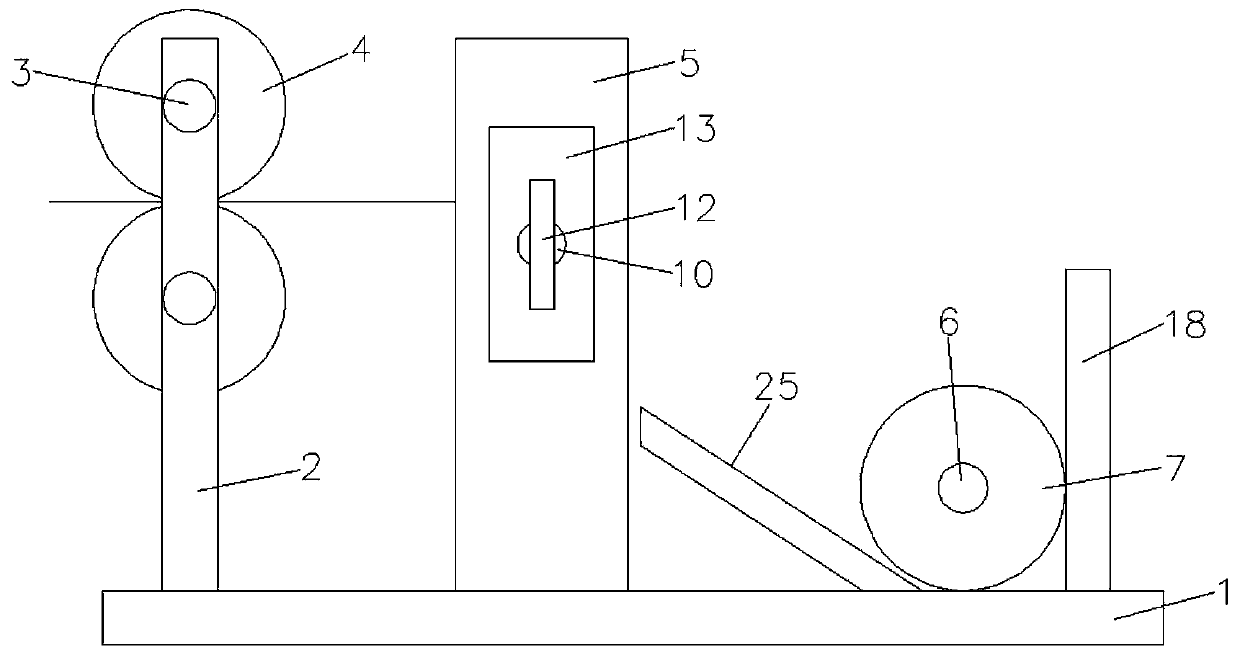

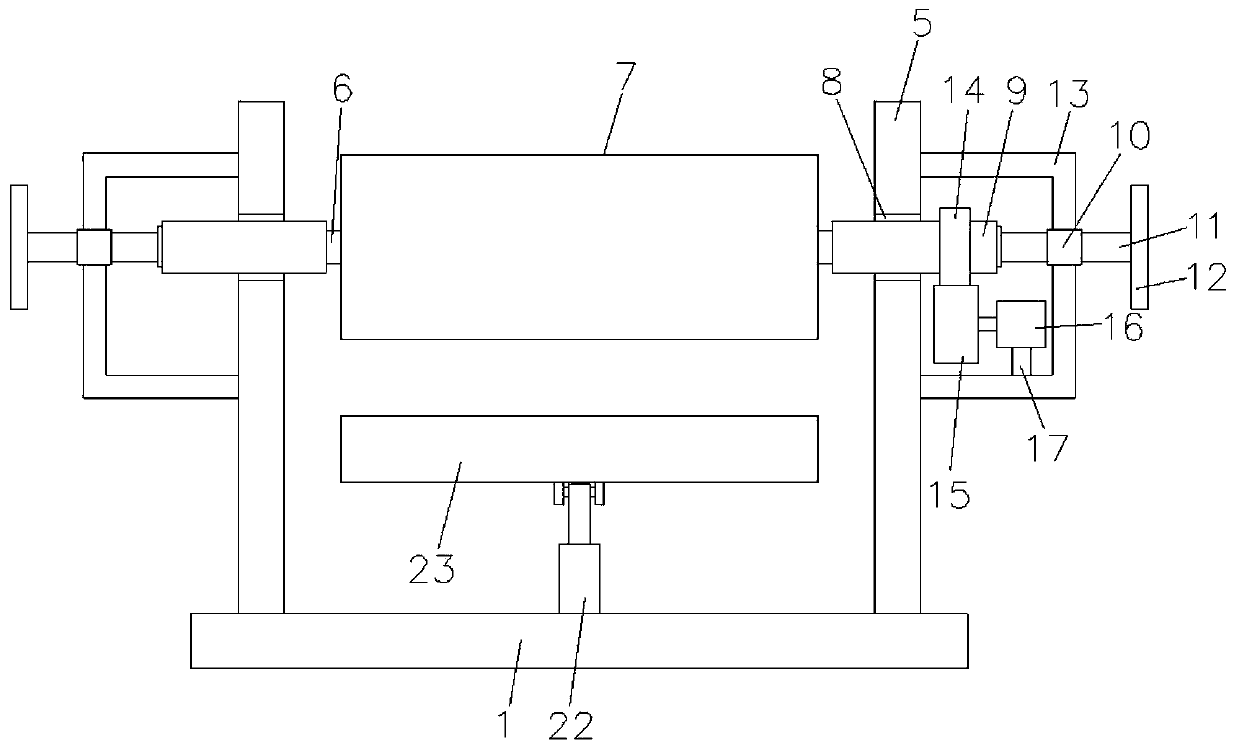

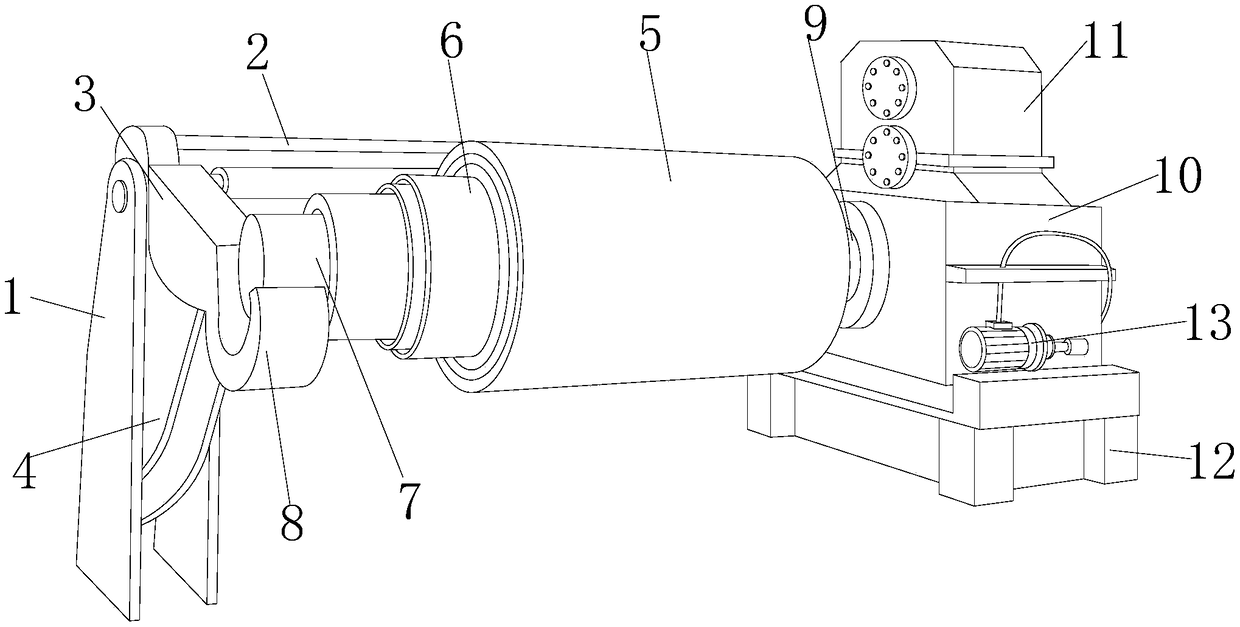

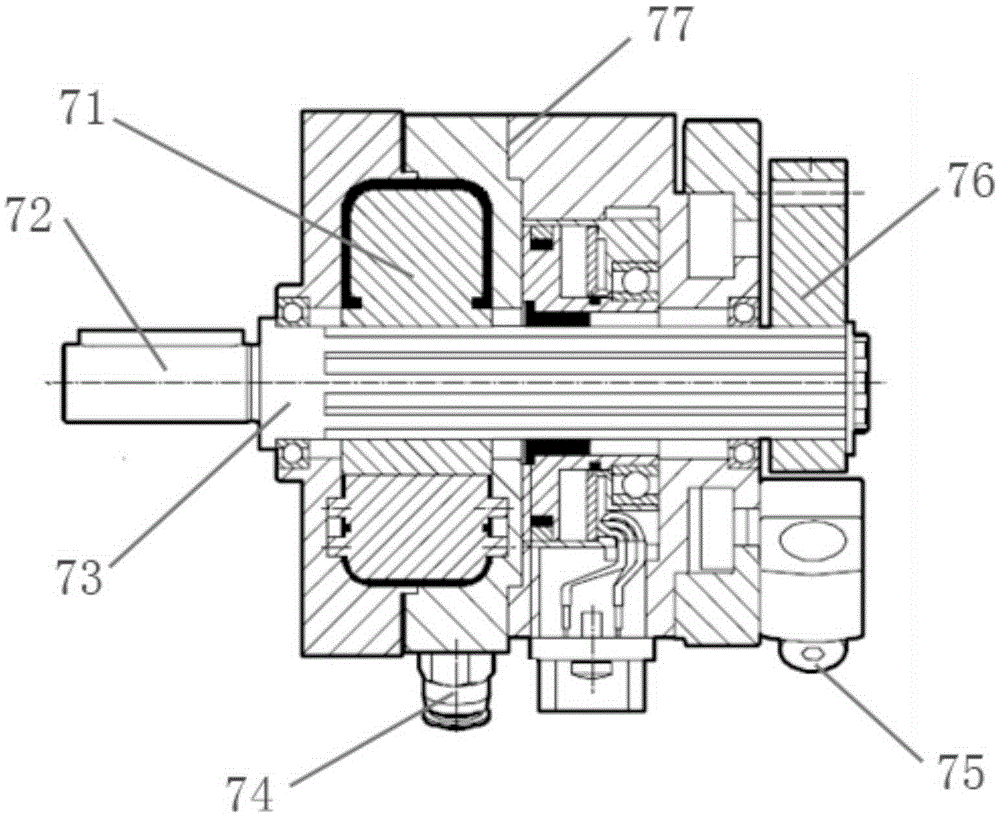

Scrap edge coiler device

The invention provides a scrap edge coiler device. One scrap edge coiler is arranged on each of two sides of the rear side of a circle shear on a production line. The device comprises the two scrap edge coilers which are symmetrically arranged on the left and right sides of the production line; each scrap edge coiler consists of a left frame (14), a right frame (16), a left gear box (13), a right gear box (15), a motor (18), a transmission mechanism (8) and a drum; the left gear box (13) is fixed on the left frame (14); the right gear box (15) is fixed on the right frame (16); the motor (18) drives the transmission mechanism (8) to rotate the drum; the drum is vertical; the expansion and shrinking of the drum is realized in the mode that an oil cylinder (19) drives a pull rod (4) to slide in a hollow shaft (5); the lower end of the pull rod (4) is fixed with a sliding sleeve (6); and the sliding sleeve (6) is connected with a rotating claw to expand and shrink. By using the scrap edge coiler device, materials can be conveniently unloaded, labor time is saved, production efficiency is improved, and the production line can operate easily and smoothly.

Owner:BEIJING STAR RIVER INTEGRATED EQUIP TECH

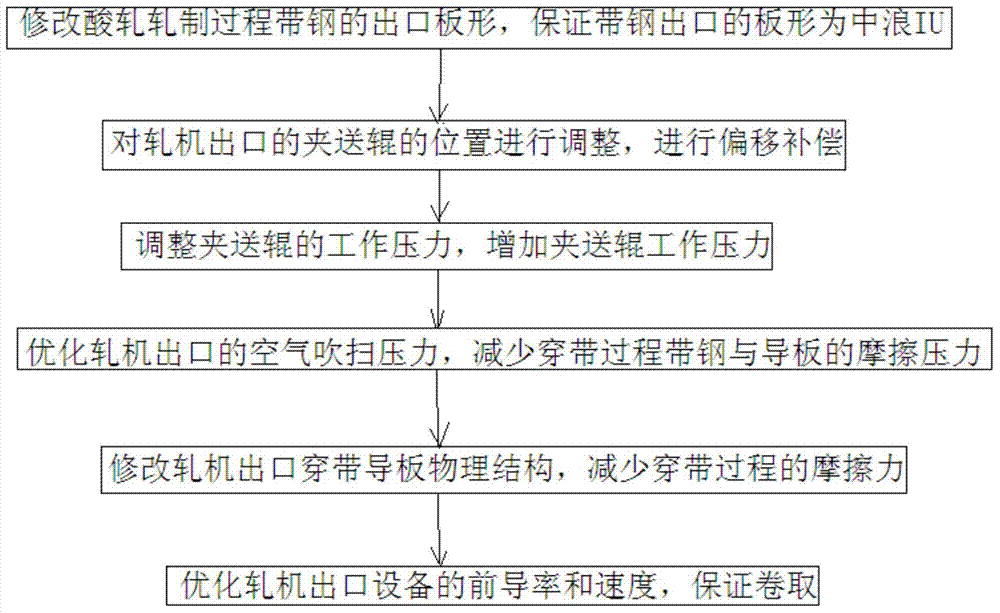

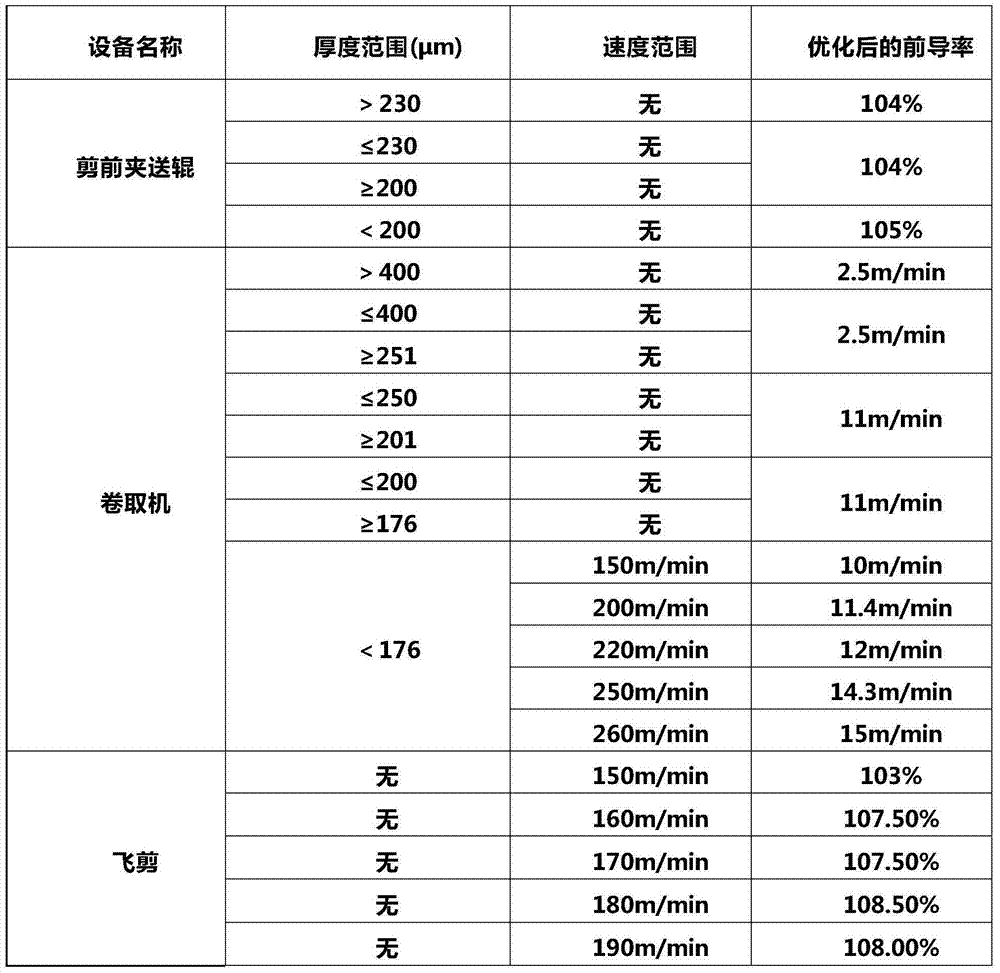

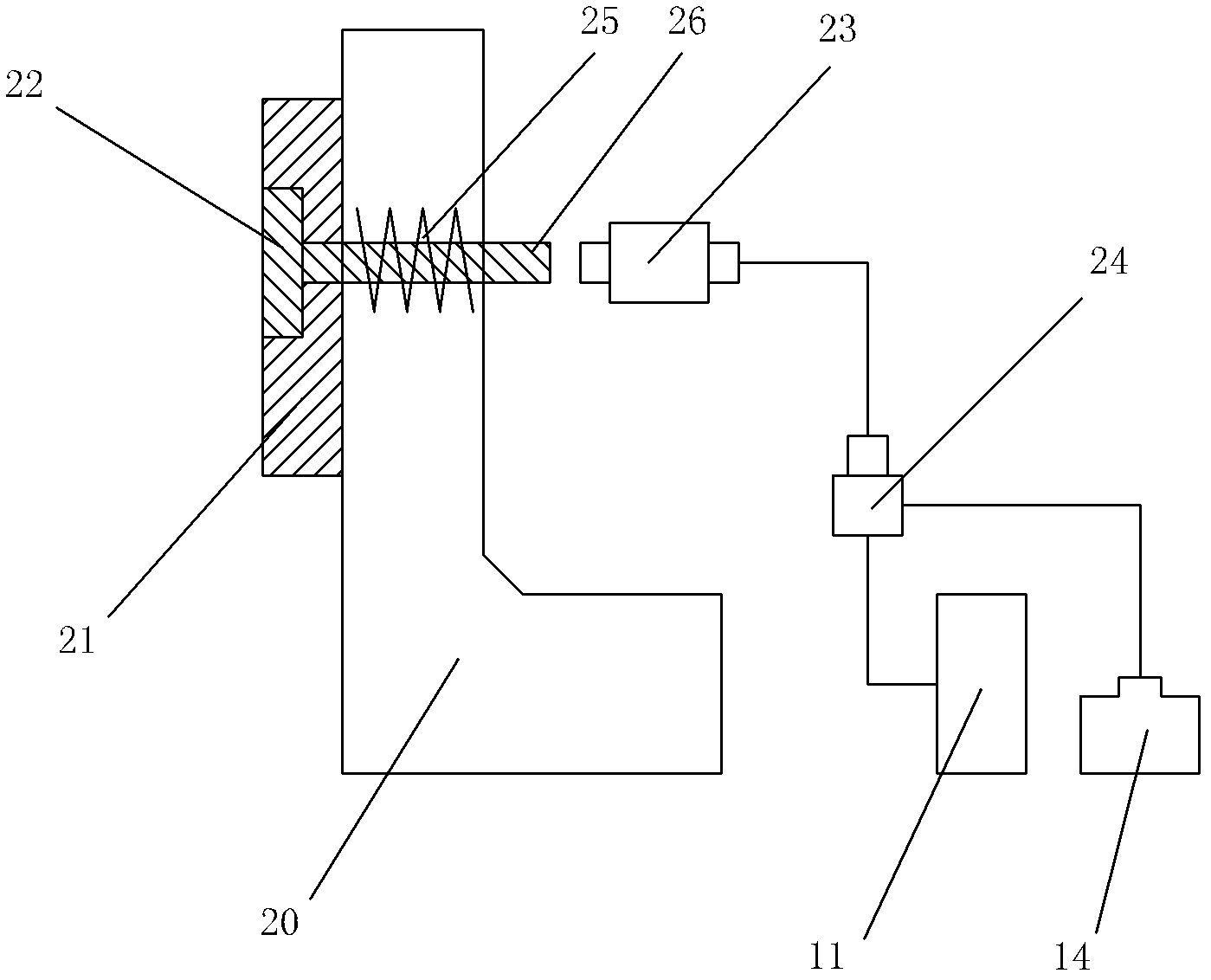

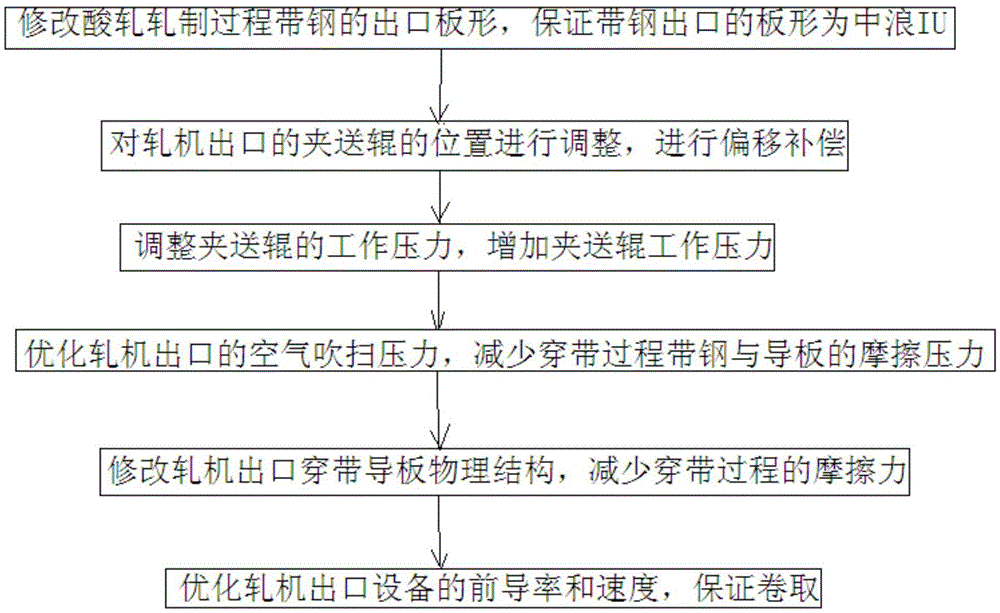

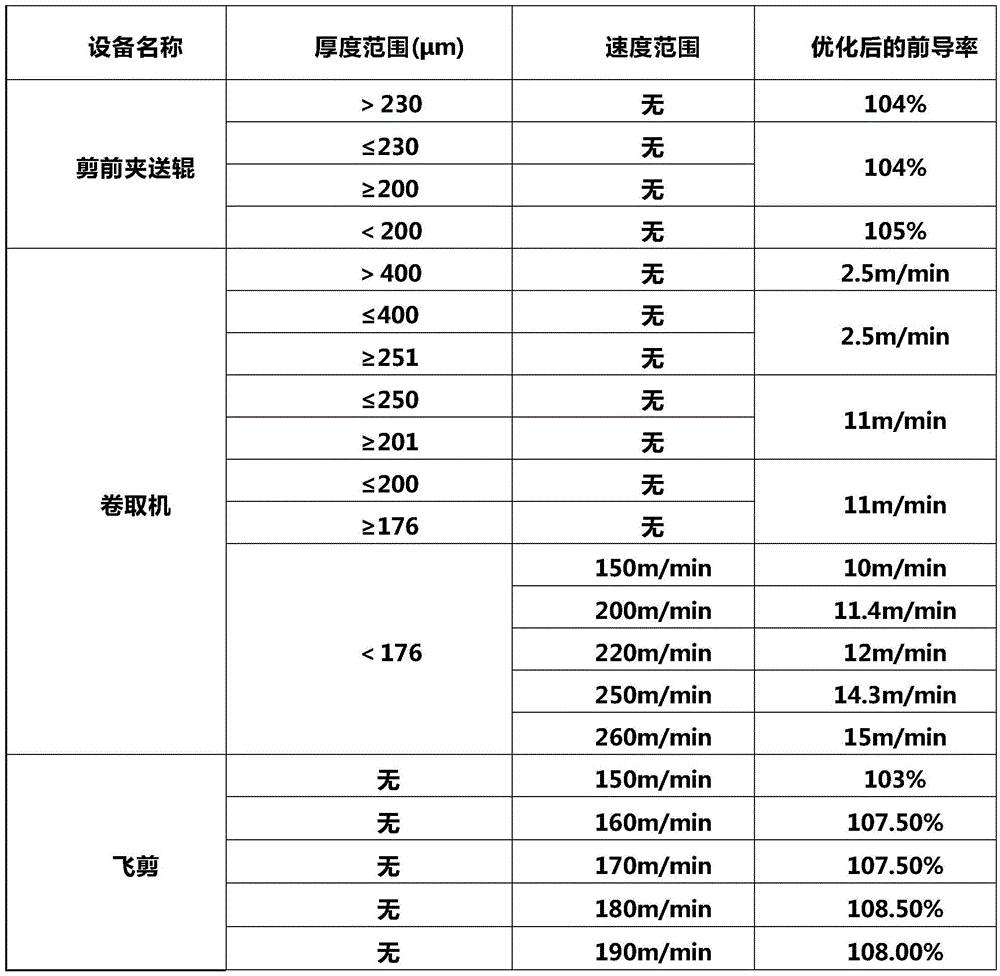

Process optimization method improving rolling and threading of ultrathin strip steel

ActiveCN104259204AImprove coiling and threading stabilityPrevent slippingGuiding/positioning/aligning arrangementsMetal rolling arrangementsProcess optimizationStrip steel

The invention discloses a process optimization method improving rolling and threading of ultrathin strip steel and belongs to the technical field of steel rolling. The method comprises correcting the outlet strip shape of the strip steel during an acid rolling process; guaranteeing that a strip steel outlet is in the strip shape of intermediate wave IU (i-unit); adjusting the position of the pinch rolls of a rolling mill outlet for deviation compensation; adjusting the working pressure of the pinch rolls to increase the working pressure of the pinch rolls; optimizing the air blowing pressure of the rolling mill outlet and reducing the friction pressure between the stripe steel and a guide plate during a threading process; correcting the physical structure of the threading guide plate of the rolling mill outlet to reduce the friction force during the threading process; optimizing the leading rate and the speed of rolling mill outlet equipment to guarantee rolling. The process optimization method improving rolling and threading of the ultrathin strip steel effectively reduces the possibility and accidents of rolling and threading stacking of the ultrathin strip steel at the acid rolling outlet, and effectively improves the rolling and threading stability of the ultrathin strip steel at the acid rolling outlet.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD +1

Full-computerized double-side seamless casting-on circular weft knitting machine

InactiveCN102425028AIncrease diversityIncrease color varietiesCircular knitting machinesYarnComputer control system

The invention belongs to the field of knitting machinery, and discloses a full-computerized double-side seamless casting-on circular weft knitting machine. The circular weft knitting machine comprises a frame, a transmission mechanism, a knitting mechanism, a fabric rolling-up device, a bank, a computer control system, a driving force motor and the like, wherein the knitting mechanism comprises a needle cylinder, a needle cover, a triangular component and a yarn mouth. The circular weft knitting machine is characterized in that the triangular component comprises a triangular seat, a triangle, a moving triangle, a cylinder and a pressure spring, the cylinder is controlled by the computer control system, and the moving triangle carries out in and out movement inside the triangle under the interaction of the pressure spring and the cylinder. According to the circular weft knitting machine disclosed by the invention, under the condition that an electronic needle selecting device is not used for needle selection, by virtue of the movement of the moving triangle and a variable needle lifting rule, the knitting of rib stitch casting-on is realized and the fabric is tailored. The design structure has the advantages that the machine runs more stably and reliably, the manufacturing cost is low and the like.

Owner:浙江欣君成服饰有限公司

Improved plastic film flattening device

The invention discloses an improved plastic film flattening device. The improved plastic film flattening device comprises an upper film guide roller, a lower film guide roller, flattening guide rollers and a flattening guide roller support, wherein the upper film guide roller is connected with a stepping motor, the flattening guide roller support is installed on one side of the lower film guide roller in parallel, and the flattening guide rollers are respectively arranged on the two ends of the flattening guide roller support; and the improved plastic film flattening device is characterized in that the improved plastic film flattening device is further provided with a static electricity elimination device, wherein the static electricity elimination device comprises a base, a static electricity transfer rod is arranged on the base, the lower end of the static electricity transfer rod penetrates out of the base to be grounded, the upper end of the static electricity transfer rod extends to the surface of a plastic film, and the upper end of the static electricity transfer rod is spherical. The improved plastic film flattening device has the advantages that the improved plastic film flattening device is reasonable in structure, is convenient to roll and can effectively prevent static electricity from hurting hands.

Owner:NANTONG JUFA PLASTIC PROD

Preparation method of polyester spinning oil

InactiveCN106939512ANot easy to make fiber fuzzyIt is not easy to cause fiber breakageGrip property fibresFiberPolyester

The invention relates to a preparation method of polyester spinning oil and belongs to the technical field of textile auxiliaries. The preparation method comprises mixing white oil and pentaerythritol oleate to obtain mixed oil, mixing Arabic gum and deionized water, heating the mixture, adding maltodextrin into the mixture, carrying out stirring, adding the mixed oil into the mixture, carrying out emulsification and homogenization to obtain high temperature-resistant capisulazed mixed oil, mixing the high temperature-resistant capisulazed mixed oil, polyoxyethylene sorbitan monolaurate and lauroyl diethanolamine to obtain a composite emulsifier, mixing the composite emulsifier and the high temperature-resistant capisulazed mixed oil, carrying out ultrasonic emulsification to obtain an emulsion and mixing the emulsion and sodium benzoate. The polyester spinning oil has good heat resistance and a smoking temperature of 220 to 240 DEG C, improves the smoothness of the oil film, reduces fiber filament and breaking possibility, and can be widely used in the polyester spinning field.

Owner:CHANGZHOU OPTICAL MATERIAL

Steel plate coiling device

Owner:KUNSHAN GUOZHI PRECISION MACHINERY

Aluminum plate coiling device for automobile part production

The invention discloses an aluminum plate coiling device for automobile part production. The structure of the aluminum plate coiling device comprises a supporting frame, a double-face heating mechanism, a hook arm, an angle adjusting frame, an aluminum plate, a coiling rotating sleeve, a center roller, a fixing hook, a rotating power roller, a power crate, a coiling machine body, a machine base and a motor. The double-face heating mechanism is transversely arranged between the supporting frame and the power crate and connected with the supporting frame and the power crate in an electric welding mode. The hook arm is arranged on the front portion of the upper end of the supporting frame and connected with the upper end of the supporting frame through a hinge. The aluminum plate coiling device for automobile part production has the beneficial effects that the double-face heating mechanism is arranged, and the distance between an upper heating roller and a lower heating roller can be automatically adjusted according to the thickness of the aluminum plate, so that the heating rollers make effective contact with the aluminum plate, rapid heating of the aluminum plate is achieved, the aluminum plate is made to soft and easy to coil, the coiling rate is increased, coiling gaps are reduced, the coiling efficiency of the aluminum plate coiling device for automobile part production is effectively improved, and the coiling precision is improved.

Owner:扬州易达利机械科技有限公司

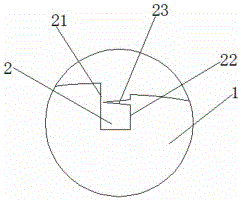

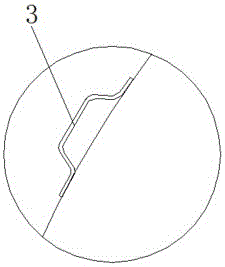

Textile winding roller

The invention relates to a textile winding roller. The textile winding roller is characterized by comprising a roller body; an opening groove is formed in the roller body, and axially penetrates through the roller body; the opening groove has a first groove wall and a second groove wall; the distance between the outer end edge of the second groove wall and the axis of the roller body is smaller than the distance between the outer end edge of the first groove wall and the axis of the roller body; a sting part is arranged on the second groove wall; and the sting part can be punctured at the winding beginning end of a textile. The opening groove is formed in the roller body of the winding roller; the winding beginning end of the textile is positioned in the opening groove; and the distance between the outer end edge of the second groove wall of the opening groove and the axis of the roller body is smaller than the distance between the outer end edge of the first groove wall and the axis of the roller body, so that the distance difference can prevent the thickness of the winding beginning part of the textile from causing indentations on the textile wound by the second lap, the third lap or more laps, and the quality of the textile is guaranteed.

Owner:XINCHANG COUNTY XINLIANXING TEXTILE CO LTD

Efficient plastic woven bag winding and storing device

InactiveCN110155783ARestore flatnessFacilitate the subsequent winding processWebs handlingGravitational potentialConductor Coil

The invention discloses an efficient plastic woven bag winding and storing device. A base is included. The upper end of the base is sequentially provided with an extrusion flattening mechanism, a fixing winding mechanism and a jacking mechanism from left to right. The extrusion flattening mechanism comprises two first vertical plates fixedly connected to the upper end of the base, the ends, closeto each other, of the two first vertical plates are jointly rotationally connected with two roller shafts, and the outer walls of the roller shafts are fixedly in cup joint with extrusion rollers. Thefixing winding mechanism comprises two second vertical plates fixedly connected to the upper end of the base, the sides, close to each other, of the two second vertical plates are provided with a rolling shaft, plastic woven bags are wound around the outer wall of the rolling shaft, and the ends, away from the rolling shaft, of the plastic woven bags penetrate through the position between the twoextrusion rollers. The efficient plastic woven bag winding and storing device can conduct rolling on rolling shafts different in length and plastic woven bags different in width, one machine has multiple purposes, the equipment cost is saved, and after winding is finished, a plurality of assemblies can be used for consuming the gravitational potential energy of the rolling shaft, and potential safety hazards caused by sudden falling are avoided.

Owner:徐州立峰塑料制品有限公司

An aluminum plate coiling device for the production of auto parts

Owner:扬州易达利机械科技有限公司

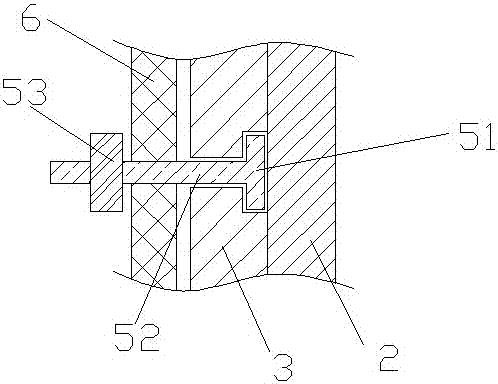

Anti-looseness metal hose winding method

The invention discloses an anti-looseness metal hose winding method. The method comprises the following operation steps: (1) manufacturing of a winding shaft: a winding shaft body and two end covers are selected; the two end covers are respectively fixed at two ends of the winding shaft body; the winding shaft body is provided with wound holes near the end covers; multiple strip holes are formed in the end covers; and rope penetrating rings are respectively arranged beside all the strip holes; and (2) winding of a metal hose: the head end of the metal hose is inserted in the round holes; the metal hose is wound on the winding shaft body; and after the metal hose is wound, the tail end of the metal hose penetrates through the adjacent strip hole to inserted in the adjacent rope penetrating ring. One end of the metal hose is fixed by the round holes; after the metal hose is wound, the tail end penetrates through the strip hole to insert in the rope penetrating ring; the tail end of the metal hose is fixed; and the metal hose can be stably fixed on the winding shaft without loosening.

Owner:WUXI YONGXING METAL HOSE

Pneumatic yarn winding and guiding device

The invention provides a pneumatic yarn winding and guiding device and belongs to the technical field of textile machines. The pneumatic yarn winding and guiding device comprises a yarn guiding seat, a swing arm, a yarn guiding device, a guide block and a swing air cylinder. The swing air cylinder is arranged in the yarn guiding seat. The guide block is fixedly arranged on the front side face of the yarn guiding seat and provided with a vertically-through transverse sliding groove. The lower end of the swing arm is connected with a swing shaft of the swing air cylinder. The upper end of the swing arm penetrates the transverse sliding groove. The yarn guiding device is arranged at the upper end of the swing arm. The swing air cylinder drives the swing shaft to swing in a reciprocating manner so as to drive the yarn guiding device at the upper end of the swing arm to conduct reciprocating motion along an arc track. The chord direction of the arc track is the same as the direction of a bobbin shaft installed on a supporting bobbin. By the adoption of the pneumatic yarn winding and guiding device, yarn guiding efficiency is improved, and the yarn bobbin forming effect is good.

Owner:ZHEJIANG RIFA TEXTILE MACHINERY TECH CO LTD

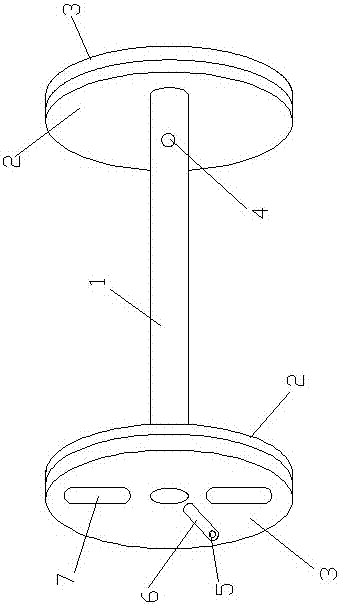

Metal hose scroll capable of preventing metal hose from loosening

The invention discloses a metal hose scroll capable of preventing a metal hose from loosening. The metal hose scroll comprises a scroll body, wherein the two ends of the scroll body are equipped with end covers perpendicular to the scroll body; each end cover is equipped with a plurality of long strip holes; in the thickness direction of each end cover, the long strip holes penetrate through the corresponding end cover; the long strip holes extend to the edge close to each end cover from the central position of the corresponding end cover; a rope penetrating ring is arranged beside each long strip hole; and a circular hole which penetrates into the scroll body is formed in a position, close to the end cover, of the scroll body. According to the metal hose scroll disclosed by the invention, one end of the metal hose is fixed through the circular hole, the tail end of the metal hose passes through the long strip holes after the metal hose is scrolled, and then passes through the rope penetrating ring, so that the tail end of the metal hose is fixed, and therefore, the metal hose can be stably fixed on a scroll shaft and is not loosened.

Owner:WUXI YONGXING METAL HOSE

Filament collecting device for carbon fiber winding forming and carbon fiber winding forming method

The invention provides a wire collecting device for carbon fiber winding forming and a carbon fiber winding forming method. The technical problem that in the prior art, the carbon fiber winding effect is not good is solved. According to the filament collecting device for winding and forming of the carbon fibers and the winding and forming method of the carbon fibers, the tension sensor is used for detecting the real-time detection tension of the filament bundle in the winding process in real time; due to the fact that the coiling diameter of the silk coil is larger and larger in the process that the tow is coiled into the silk coil, the tension of the silk coil is linearly and proportionally reduced along with the increase of the coiling diameter of the silk coil, and the silk coil can be formed excellently. Therefore, the tension of the tows can be regulated and controlled, and the tension is reduced, so that the tension of the tows is reduced in a linear proportion, and a wire coil can be formed excellently. When the winding parameters are controlled, the winding parameters are regulated and controlled from the principle, the winding parameters can be regulated and controlled in real time, in addition, different winding parameters can be matched according to different carbon fiber tows, and the winding formability of the carbon fiber tows is improved.

Owner:ZHEJIANG JINGGONG SCI & TECH

Preparation method of polyester spinning oil

The invention discloses a preparation method of a polyester spinning oil. An emulsifier in the invention can form an oil film on the surface of a chemical fiber, and a hydrophilic matrix in the oil film adsorbs moisture in air in order to form a continuous water film on the surface of the fiber, so accumulation of static charges, caused by friction, is reduced, apron winding, roller winding, cylinder winding and other undesirable phenomena are avoided, broken filaments and broken ends are reduced, and the quality of a fiber product is ensured.

Owner:南通凯大纺织有限公司

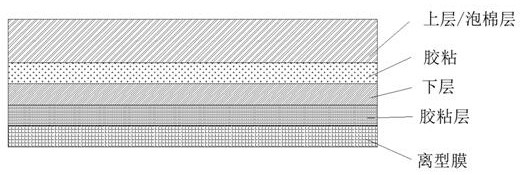

Foam adhesive tape

InactiveCN112126367AGood removal effectReduce manufacturing costFilm/foil adhesivesCoatingsPolymer scienceThin membrane

The invention provides a foam adhesive tape which comprises an upper base material layer and a lower base material layer, the base materials are connected in an adhesive mode, the upper base materiallayer is a PET film, the upper surface of the upper base material layer is coated with polyethylene emulsion to form a foam layer in a foaming mode, and the bottom of the lower base material layer isconnected with a release film through an adhesive layer. According to the scheme, the adhesive tape is simple in structure and convenient to use, the problem that the bonding strength of the adhesivelayer and the foam layer is insufficient is effectively solved by adopting the double-layer base layer material, the adhesive layer can be better and tightly bonded with the lower-layer base layer material, degumming is avoided, the service life of the adhesive tape is prolonged, meanwhile, bubbles in the adhesive layer can be removed under the action of the lower-layer base material, so that theadhesive layer and a clutch layer are further prevented from falling off, the adhesive tape is convenient to wind, and the processing and production efficiency of the adhesive tape is improved.

Owner:HENGSHAN JIACHENG NEW MATERIAL

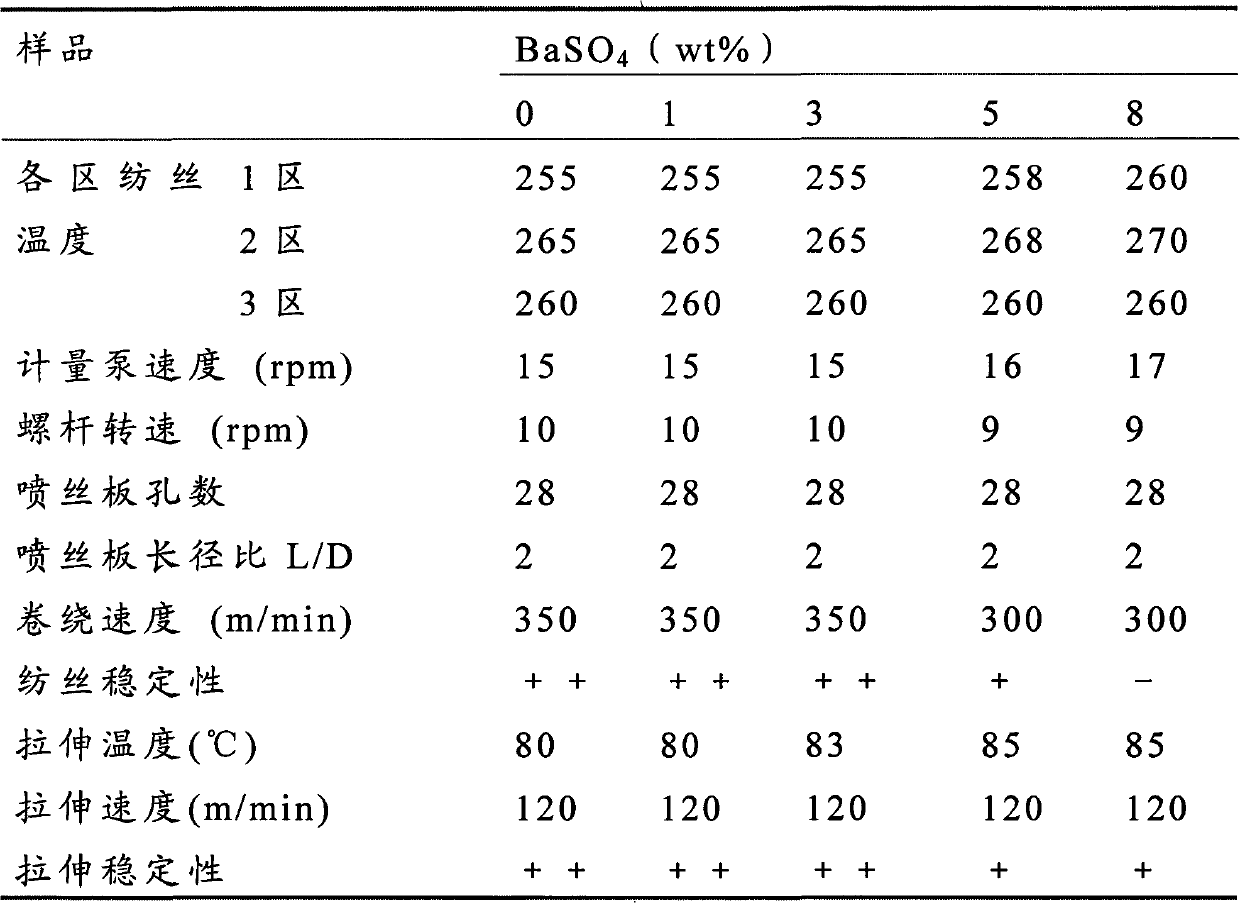

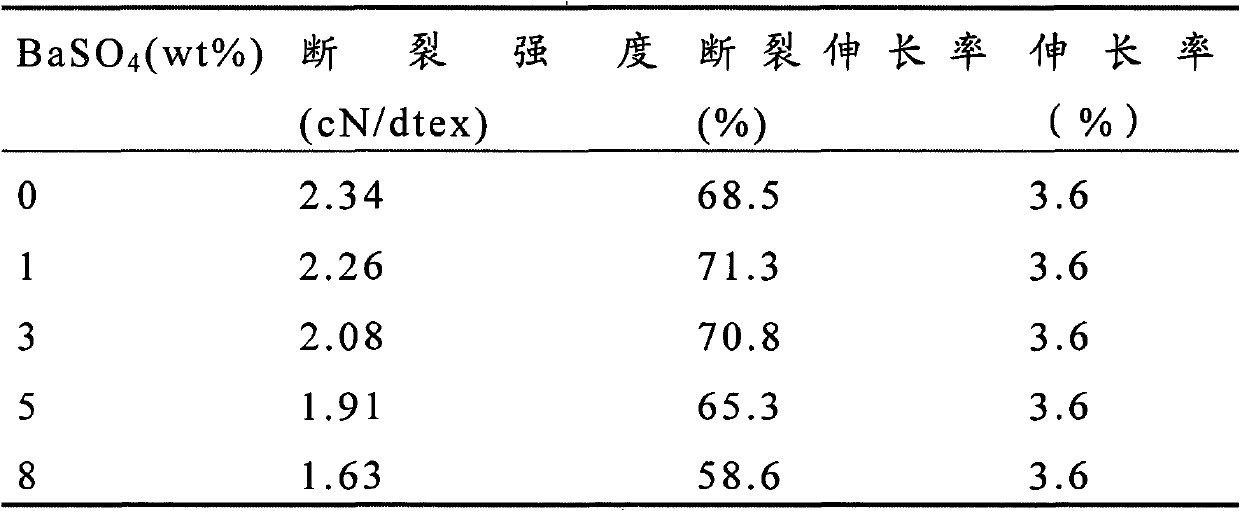

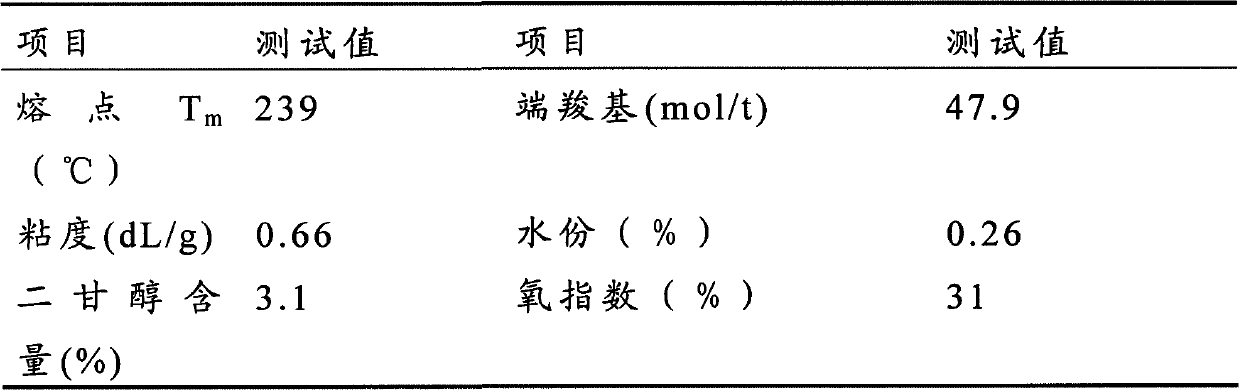

Spinning technology for phosphorus-containing flame-retardant copolyester barium sulfate nano-composite material fiber

InactiveCN102021667ASimple preparation processImprove spinnabilityMelt spinning methodsMonocomponent polyesters artificial filamentFiberSpinning

The invention relates to a spinning process technology, in particular to a spinning technology for phosphorus-containing flame-retardant copolyester barium sulfate nano-composite material (NPFRP) fiber. The process comprises the following steps: 1) slicing and drying; 2) melting and extruding; 3) filtering melts ; 4) spinning; 5) cooling and moulding; 6) oiling; 7) winding at a high speed; 8) performing POY bobbin processing; 9) balancing; 10) drawing for increasing elasticity; and 11) inspecting DTY finished products. The temperature for slicing and drying is higher than the crystallization temperature of 8 to 12 DEG C. The spinning temperature is lower than the spinning temperature of 22 to 28 DEG C for ordinary PET fiber. The application experiment of NPFRP slices in the invention indicates that under reasonable condition of spinning process, the spinnability of the slices is good, winding and moulding is good, the DTY processing effect is good, and requirements on garment purpose and home textile can be reached. After the fiber is woven into suspenders, oxygen index can reach 30.5, which satisfies the national flame-retardant standard, that is, LOI is equal to or greater than 28.

Owner:DEZHOU UNIV

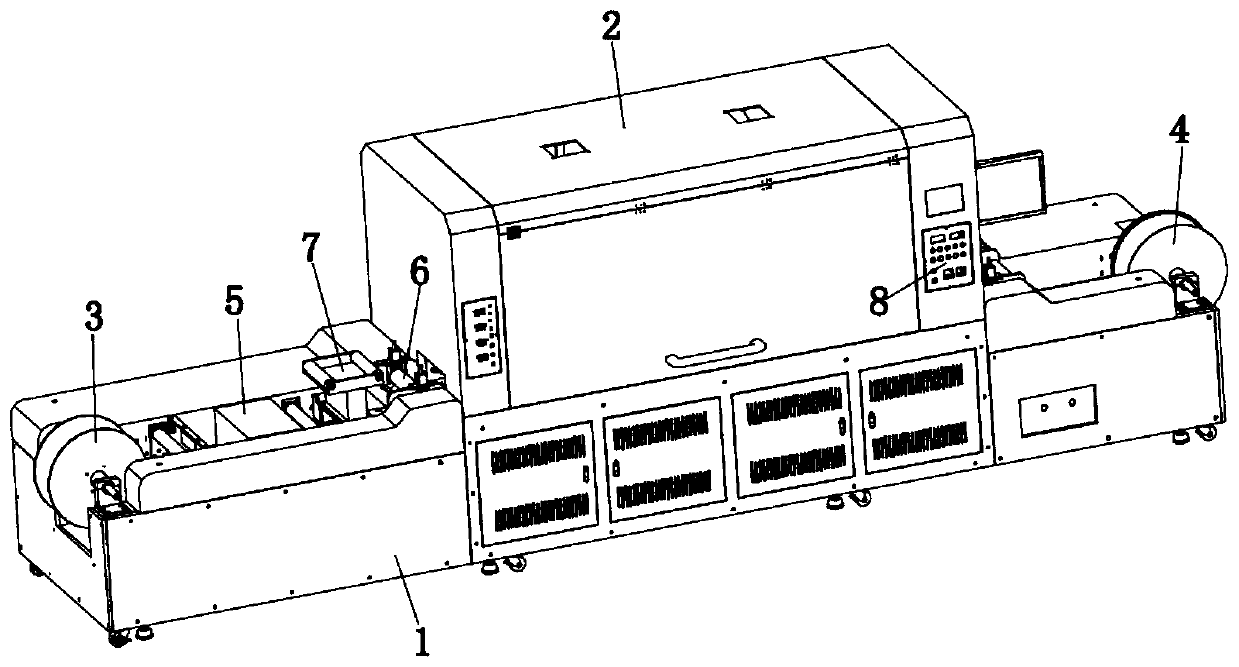

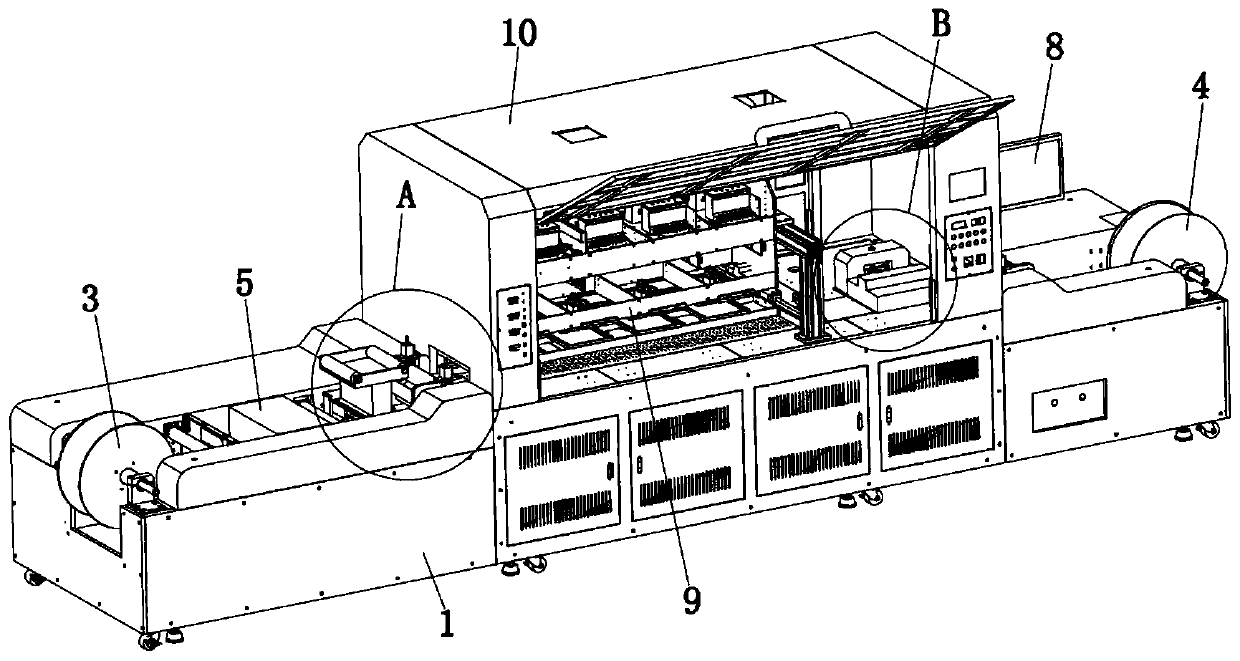

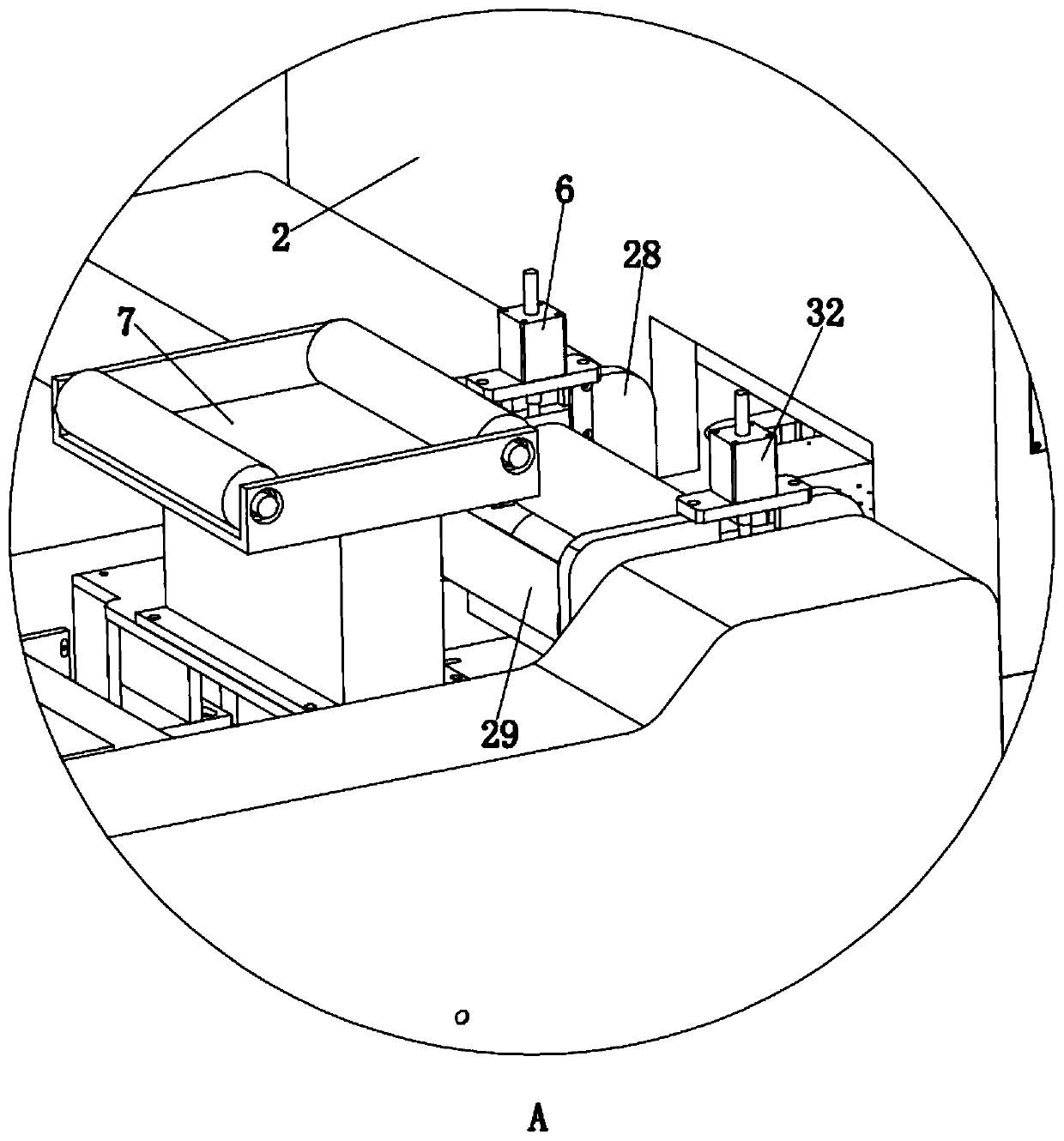

Edge sealing strip spray printing machine

PendingCN110576684AMention stabilityImprove stabilityTypewritersOther printing apparatusEngineeringAutomation

The invention provides an edge sealing strip spray printing machine, and relates to the technical field of industrial spray printing devices. The edge sealing strip spray printing machine comprises amachine frame, an automatic ink-jet printing center arranged on the machine frame and located on an ink-jet printing station, an automatic material placement mechanism detachably installed on the machine frame and located on a material placement station of the spray printing machine, an automatic material collection mechanism detachably installed on the machine frame and located on a material collection station of the spray printing machine, a corona treatment device arranged on the machine frame, located on one side of the material placement station and used for conducting corona treatment onmaterials, a material winding mechanism arranged on the machine frame and located between the corona treatment device and the automatic ink-jet printing center, an automatic deviation correction device arranged on the machine frame and located between the corona treatment device and the material winding mechanism, and a control operation plate arranged on the ink-jet printing center. The edge sealing strip spray printing machine adopting the technical scheme mentioned above has the advantages of being good in spray printing effect, high in spray printing speed, high in automation degree, goodin solidification effect after spray printing, low in labor cost and high in spray printing efficiency.

Owner:深圳市东方龙科实业有限公司

A Process Optimization Method for Improving Ultra-Thin Steel Strip Strip Strip Strip Pulling and Threading

ActiveCN104259204BImprove coiling and threading stabilityPrevent slippingGuiding/positioning/aligning arrangementsMetal rolling arrangementsProcess optimizationStrip mill

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD +1

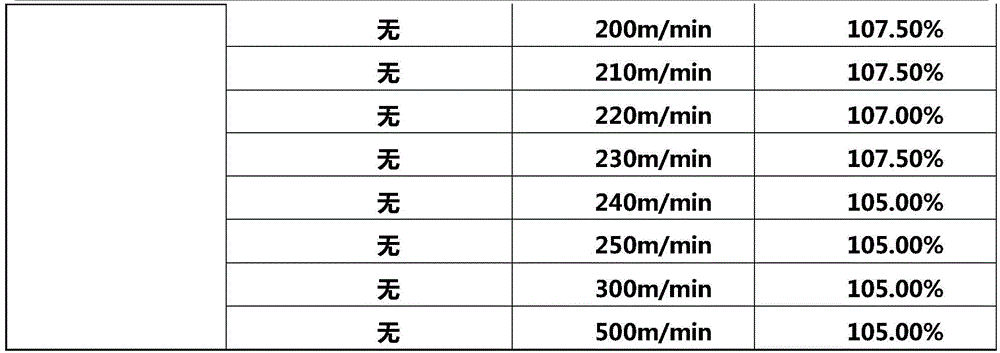

Machining method and device of strip steel X80

InactiveCN110624953AConvenient coilingIncrease temperatureRare end control deviceTemperature control deviceContact timeStrip steel

The invention discloses a machining method of strip steel X80. The method includes the steps of selecting any strip steel X80 as the target strip steel, rolling the target strip steel, controlling a layer-cooling collector to be started when the head portion with the preset length from the movement front end to the movement tail end of the target strip steel is located below the layer-cooling collector, and winding the target strip steel. The target strip steel is rolled first, the layer-cooling collector can cool the target strip steel, the layer-cooling collector has a certain length in thedistribution direction, the target strip steel can move in the distribution length direction of the layer-cooling collector, since the target strip steel is in a moving state all the time, the contacttime of the head portion of the target strip steel and a strand of cooling flow is shorter than the contact time of the body portion of the target strip steel and the strand of cooling flow, the temperature of the head portion can be controlled to be higher than the temperature of the body portion, and the target strip steel can be easily wound. The invention discloses the machining device of thestrip steel X80.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

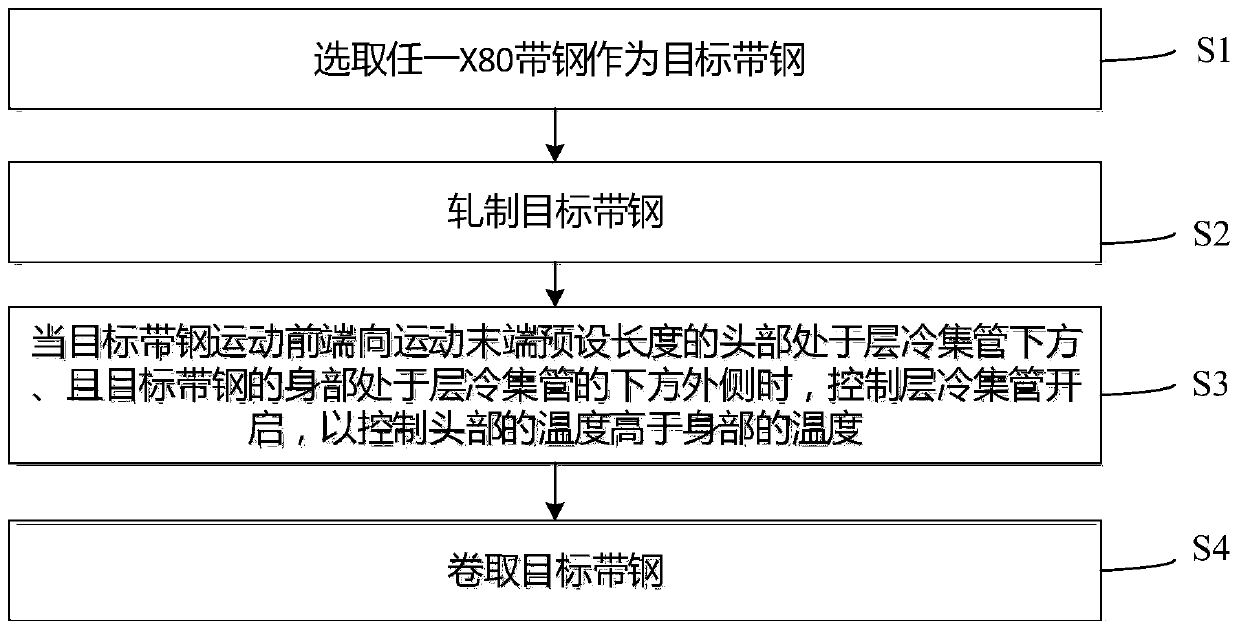

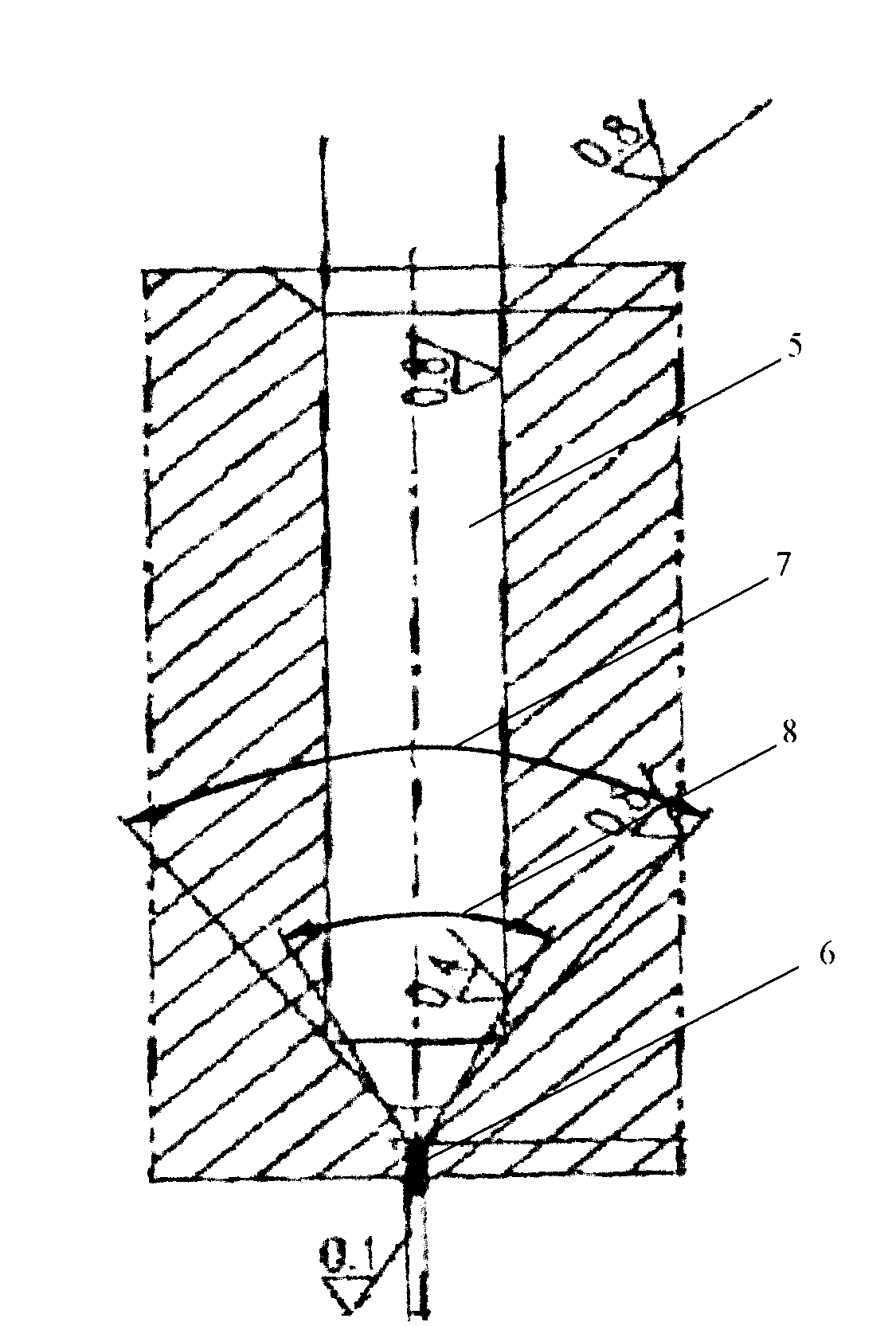

Device for producing fine denier POY (polyester pre-orientated yarn) by head spinning method

InactiveCN102418155AConvenient coilingStable tensionSpinnerette packsArtificial thread manufacturing machinesHEAD SPINNINGPolyester

The invention discloses a device for producing fine denier POY (polyester pre-orientated yarn) by a head spinning method, which comprises a winding rack and a spinneret plate with a spinneret plate distribution plate, wherein the spinneret plate distribution plate comprises a first part positioned at the left side and a second part positioned at the right side, and the first part and the second part are separated from each other; the spinneret plate comprises four rings of radially distributed spinneret holes, and the spinneret holes in each ring of spinneret holes are communicated by shallow grooves; each spinneret hole comprises a pilot hole groove and a microhole, and the pilot hole groove comprises a cavity, a first-stage cone and a second-stage cone which are sequentially arranged, so that two-stage cone angle transition is formed; and the microhole is arranged at the lower end of the second-stage cone, and a plurality of godets which are arranged in an S shape and a winding head are arranged in the winding rack. Therefore, the size unevenness linear density deviation value of products can be reduced, the tow tension can be stabilized, and the winding molding of tows can be improved.

Owner:JIANGSU SHENJIU CHEM FIBER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com