Foam adhesive tape

A tape and foam technology, applied in the direction of adhesives, film/sheet adhesives, coatings, etc., can solve the problems of affecting service life, complicated production process, and affecting the use of adhesive layers, so as to prevent falling off and degumming , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

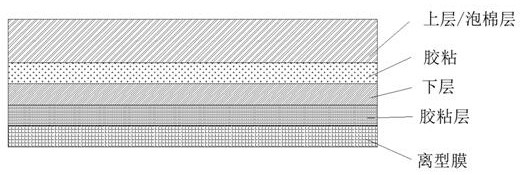

[0020] As shown in the attached figure: a kind of foam tape, including upper and lower base materials, the base materials are connected by glue, the upper base material is PET film, the foam layer is formed by coating polyethylene emulsion on the upper surface, and the lower layer The bottom of the substrate is connected with a release film through an adhesive layer.

[0021] During the use of this scheme, the connection effect between the adhesive layer and the lower layer can be improved, the bonding ability between the adhesive layer and the lower layer can be improved, and the connection between the adhesive layer and the foam layer can be avoided, which will affect its connection strength. The combination between the adhesive layers facilitates the expulsion of the air bubbles between the release film and the adhesive layer, facilitates the winding effect of the tape, and prevents the air bubbles from affecting the stacking of the tape.

[0022] In an embodiment, the lowe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com