Device for producing fine denier POY (polyester pre-orientated yarn) by head spinning method

A production device and fine denier technology, applied in the field of spinning, can solve problems such as large tension fluctuations of products, restricted work, uneven denier, etc., achieve the reduction of uneven linear density deviation of denier, stabilize the tension of the tow, and improve winding Forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The specific embodiments described here are only used to explain the present invention, but not used to limit the present invention.

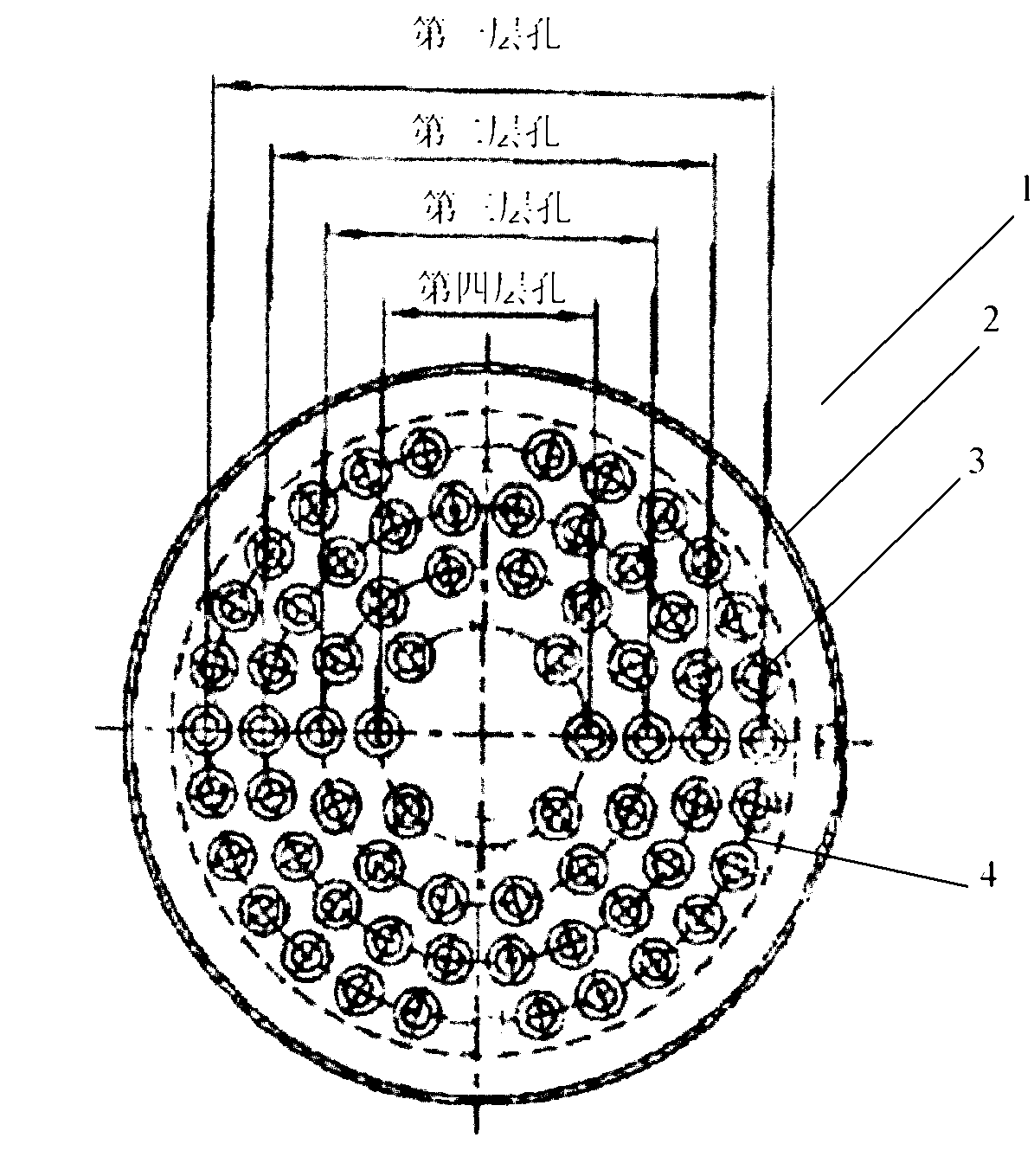

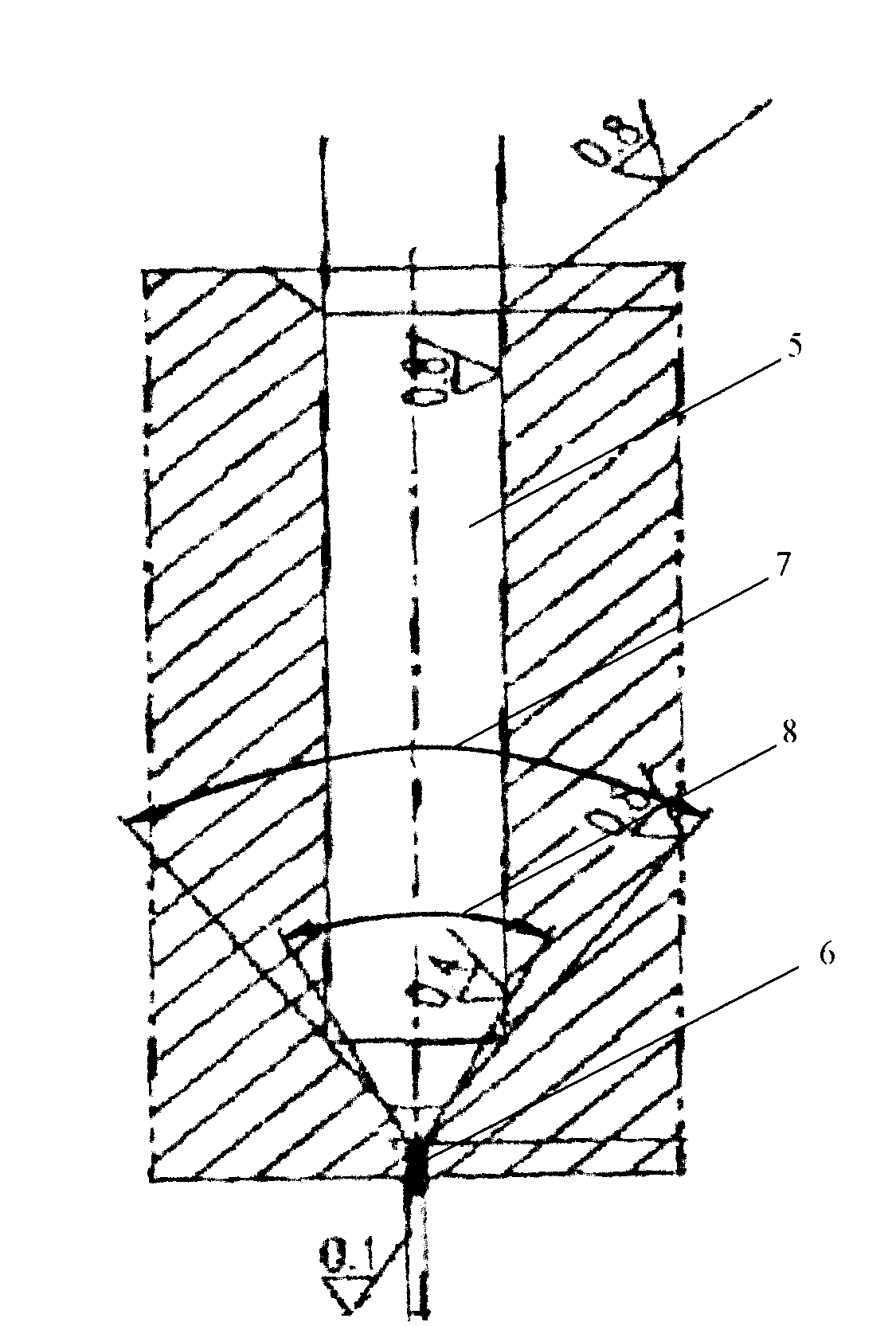

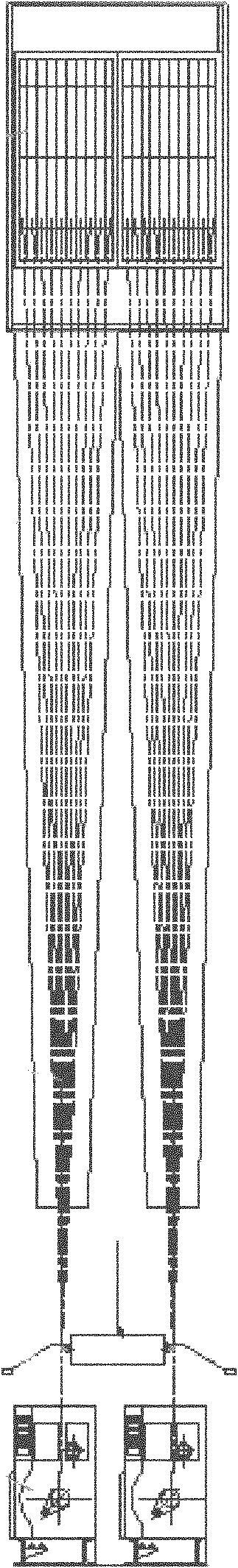

[0025] Such as figure 1 with figure 2 As shown, a production device for producing fine denier POY by sub-head spinning includes a spinneret 1 with a spinneret distribution plate 2 and spinneret holes 3, and a side blower (not shown in the figure), wherein The spinneret distribution plate 2 is divided into a first part on the left and a second part on the right. The first and second parts are separated from each other. The spinneret 1 includes four radially distributed spinneret holes 3, each spinneret hole Each spinneret hole 3 is connected by a shallow groove 4; the spinneret hole 3 includes a guide hole groove 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com