Spinning technology for phosphorus-containing flame-retardant copolyester barium sulfate nano-composite material fiber

A technology of nano-composite materials and flame-retardant copolyester, which is applied in the field of spinning technology, can solve the problems of spinning technology that have not been reported in the literature, and achieve good spinnability, flame retardancy, and good winding molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The above-mentioned spinning temperature is 250-263°C.

[0020] The above-mentioned spinning speed is 2800-3000m / min.

[0021] During the above-mentioned cooling forming process, the side air blowing temperature is between 20-30° C., and the humidity of the cooling air blowing is 68-72%.

[0022] The above cluster oiling position is 890-910mm.

[0023] Above-mentioned side blowing temperature is 26.5-27.5 ℃.

[0024] The processing parameters of the above POY bobbin are: the processing speed is 490-510m / min; the deformation temperature is 188-192°C; the draw ratio is 1.58; the surface speed of the friction disc and the speed D / Y ratio of the yarn leaving the false twister is 2.24.

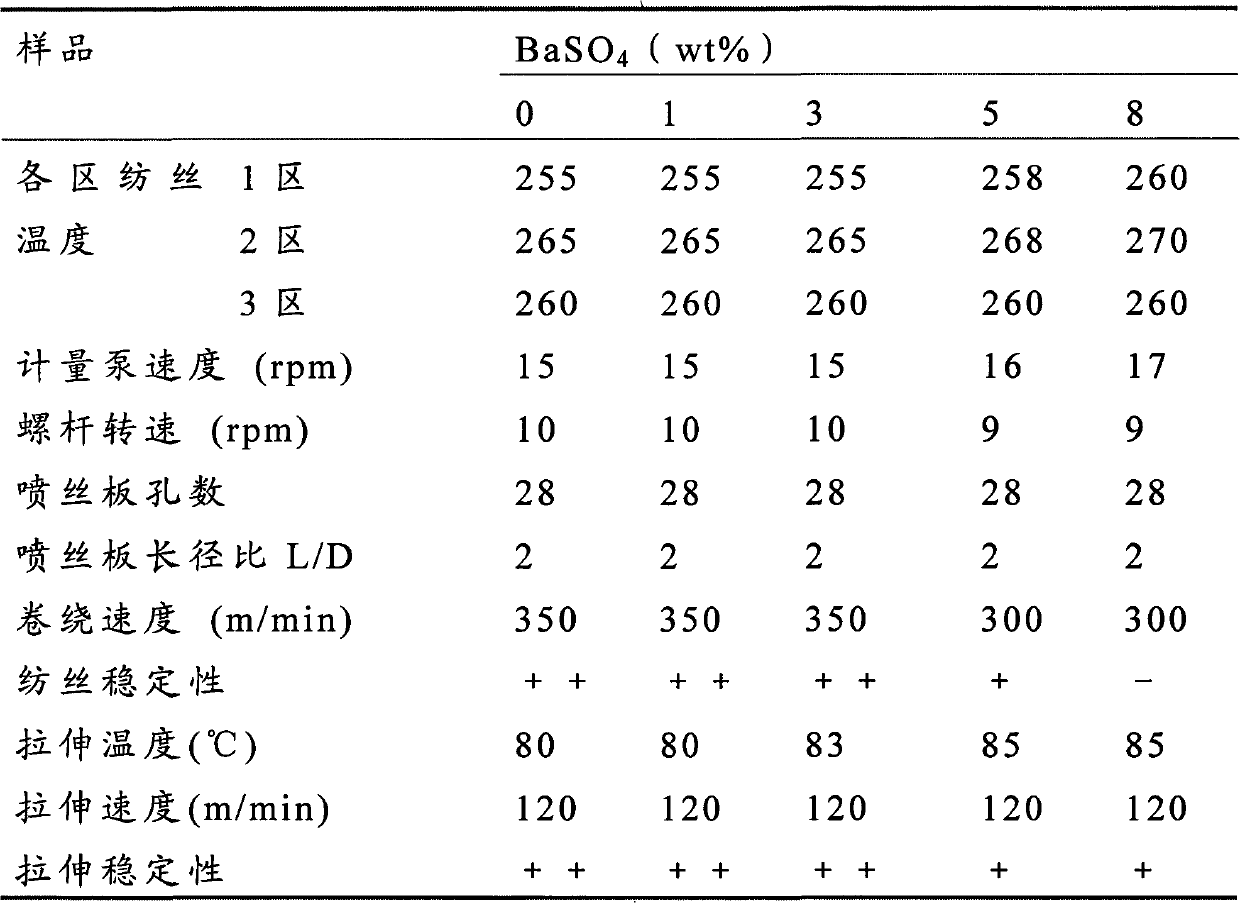

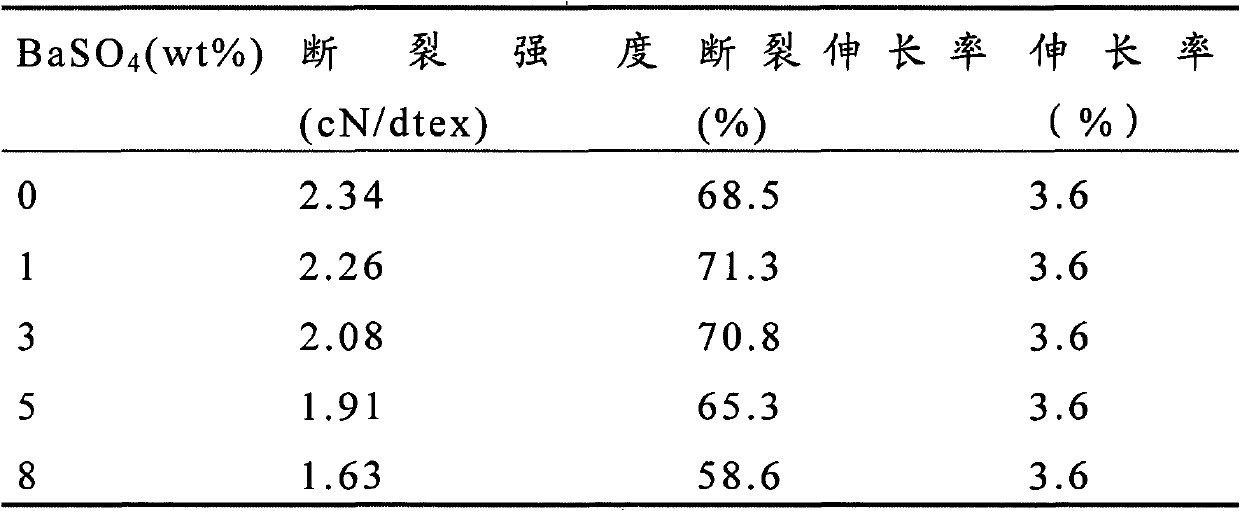

[0025] 2. Small-scale spinning raw materials and equipment:

[0026] Small-scale spinning raw materials: polyethylene terephthalate (PET), PET / 10% DDP, PET / 10% DDP / 1% BaSO 4 , PET / 10%DDP / 3%BaSO 4 , PET / 10%DDP / 5%BaSO 4 , PET / 10%DDP / 8%BaSO 4

[0027] Small-scale drying equipment: us...

Embodiment 2

[0044]1. Refer to Embodiment 1 for the technical process.

[0045] 2. Pilot spinning raw materials and equipment:

[0046] Raw material for pilot spinning: PET / 10%DDP / 5%BaSO 4

[0047] Drying equipment: domestic drum dryer plus a filled drying tower with humid and hot air circulation, dry the slices in the drum dryer at the glass transition temperature for 2 hours, and pre-crystallize for 2 hours near the crystallization temperature, which is about 10°C higher than the crystallization temperature Keep warm for 4 hours.

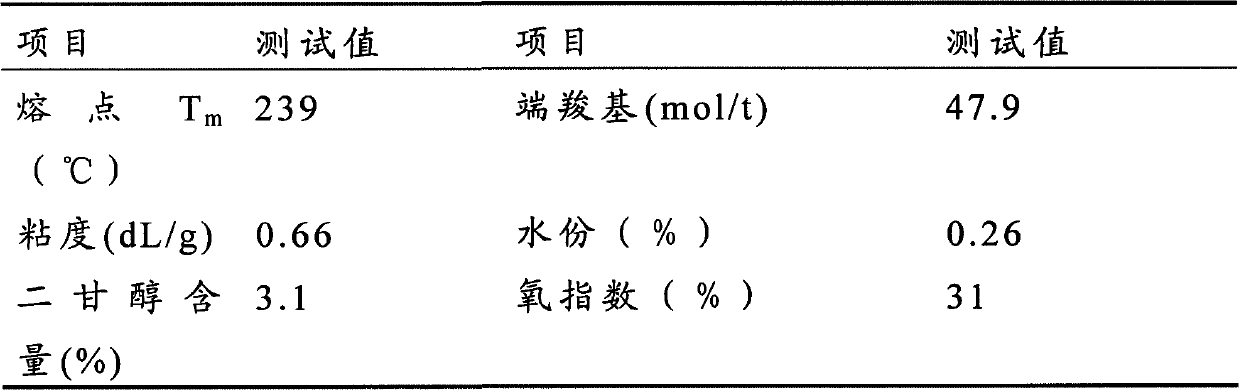

[0048] Spinning equipment: use the JHNX-2586-12 one-position twin-screw compound spinning machine produced by the US Hills Company to test the pilot product PET / 10%DDP / 5%BaSO 4 (Slice quality indicators are shown in Table 3) High-speed spinning test was carried out to obtain polyester pre-oriented yarn (POY), and FK6M-700 stretch texturing machine trial-produced stretch textured yarn (DTY).

[0049] Table 3 PET / 10%DDP / 5%BaSO 4 Physical and chemical proper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| deformation temperature | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com