Edge sealing strip spray printing machine

A jet printer and edge banding technology, applied in printing, typewriters, printing devices, etc., can solve the problems of easy falling off of the decorative interior, affecting the decorative effect of furniture, and different flexibility, so as to achieve good curing effect and increase surface adhesion. Focus on the effect of low labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

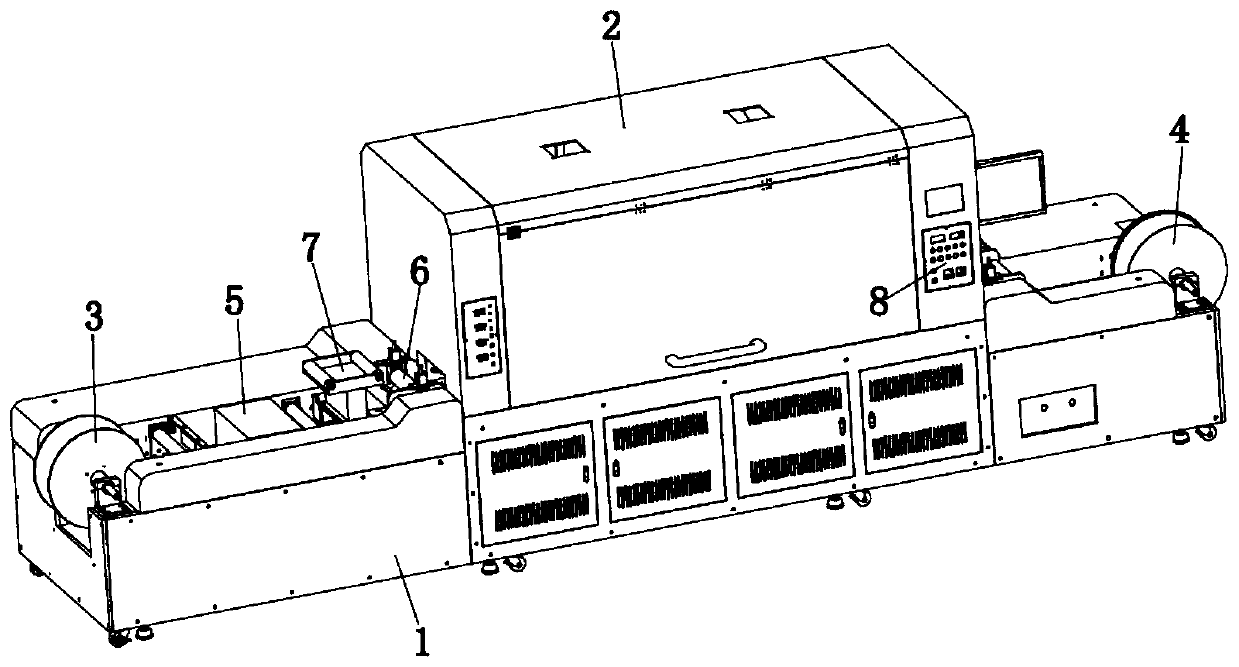

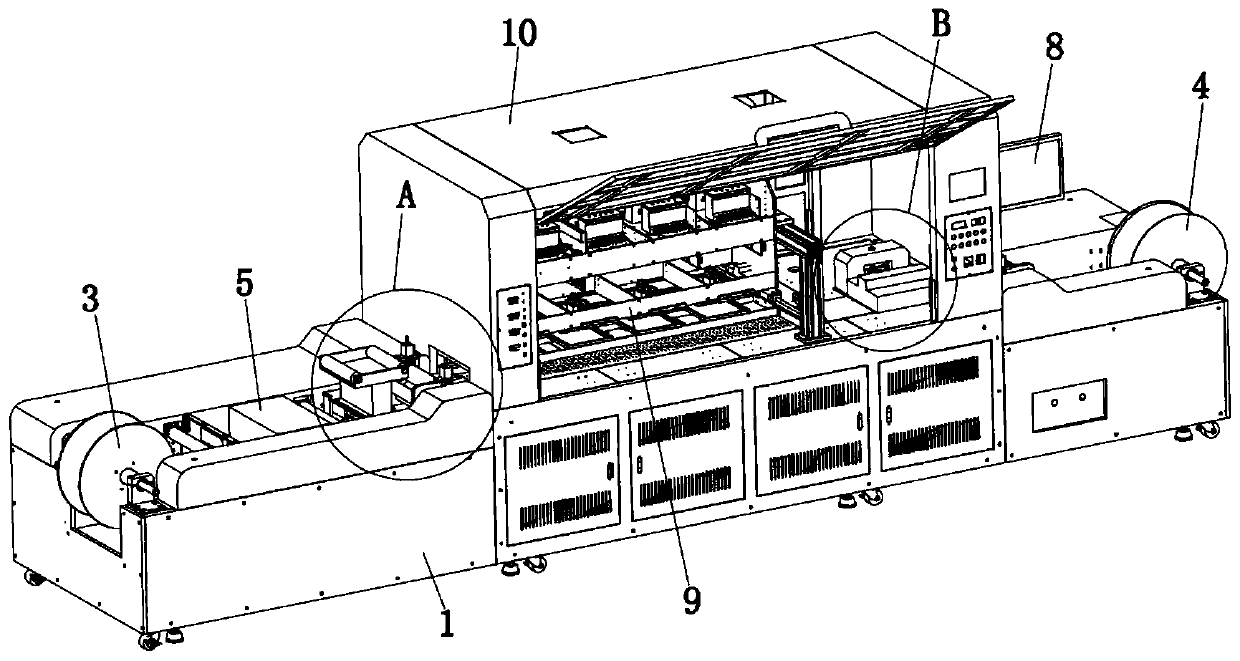

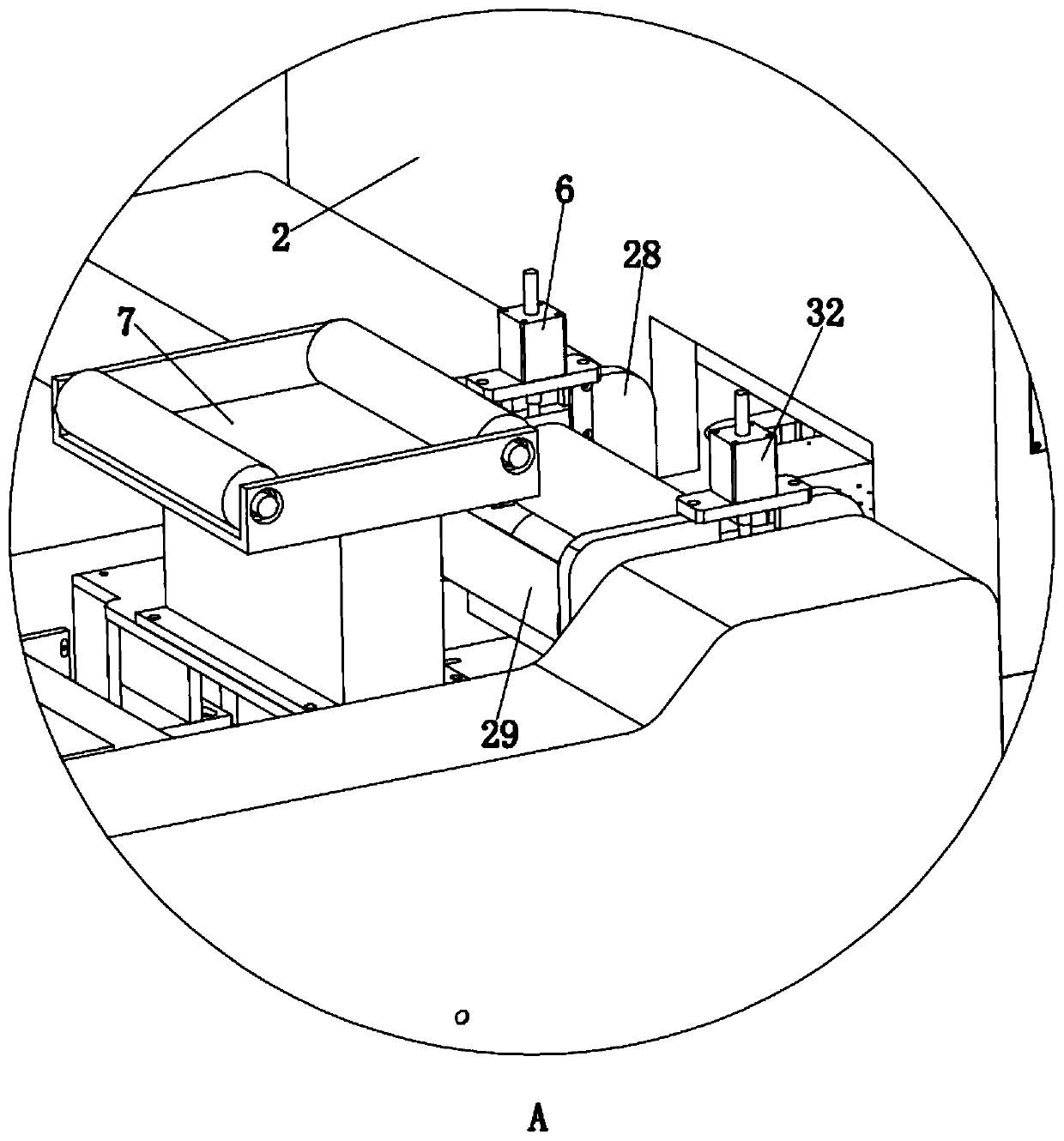

[0036] This embodiment relates to a kind of edge banding jet printing machine, such as Figure 1-12 As shown, it includes: a frame 1, an automatic inkjet printing center 2, an automatic feeding mechanism 3, an automatic receiving mechanism 4, a corona treatment device, a material coiling device, an automatic deviation correction device 7 and a control panel 8.

[0037] Such as figure 1 , 2 As shown, the automatic inkjet printing center 2 is arranged on the frame 1 and is positioned on the inkjet printing station. The automatic inkjet printing center 2 is used for jet printing operation on passing materials. Automatic feeding mechanism 3 is detachably installed on the frame 1, and is positioned on the feeding station of jet printing machine. The automatic feeding mechanism 3 is used to supply materials to the automatic inkjet printing center 2 . The automatic material receiving mechanism 4 is detachably installed on the frame 1 and located on the material receiving station ...

Embodiment 2

[0056] The difference between this embodiment and embodiment 1 mainly lies in, as Figure 11 , 12 As shown, in this embodiment, the inner wall of the fixing groove 182 is provided with a card slot 225 , the inner wall of the installation hole 211 is provided with a third sliding slot 227 , and the locking member 22 includes: a locking column 221 , a torsion spring 222 and a spring 223 .

[0057] A clamping block 224 is disposed on the side of the locking column 221 close to the clamping slot 225 , and the clamping block 224 is clamped and assembled with the clamping slot 225 . The movable end of the fixed block 21 is locked or unlocked with the fixed seat 18 through the cooperation of the locking block 224 and the locking groove 225. The torsion spring 222 is sleeved on the locking column 221, and one end of the torsion spring 222 is fixedly assembled with the locking column 221 and the other end is slidably assembled with the inner wall of the mounting hole 211. The spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com