Method for preparing curcumin nanoparticles by supercritical emulsification granulation technology

A nanoparticle, curcumin technology, applied in pharmaceutical formulations, inactive medical preparations, food science and other directions, can solve the problems of inapplicability to heat-sensitive substances, poor water solubility, long time consumption, etc., to improve water solubility and bioavailability. Accurate and controllable operating conditions and improved particle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

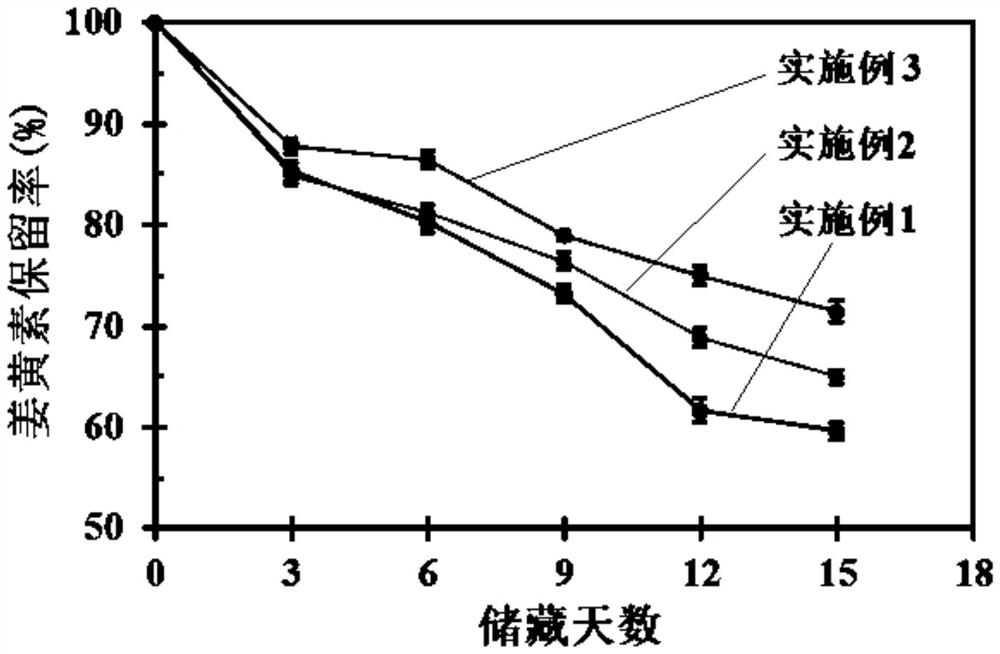

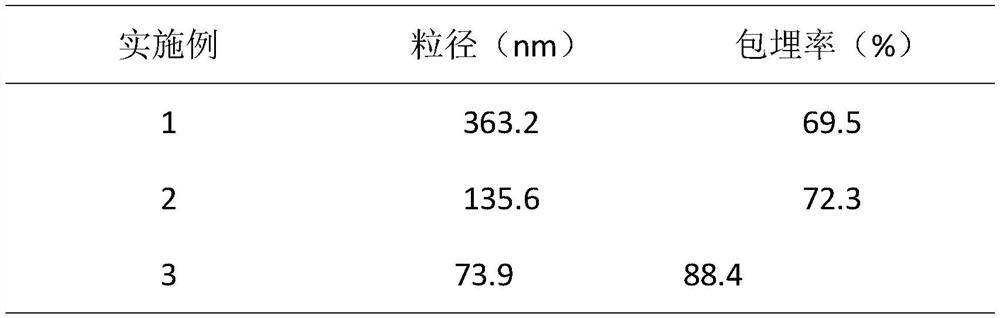

Embodiment 1

[0052] A kind of supercritical emulsification granulation technology prepares the method for curcumin nanoparticle, comprises the following steps:

[0053] Accurately measure 5L methanol, pour it into the emulsification kettle through a high-pressure pump, add 50g curcumin, 100g lecithin, turn on the magnetic stirring, the stirring power is 20KW, and the stirring time is 10min.

[0054] Dissolve 100g of hyaluronic acid and 10g of genipin in 5L of purified water, put the hyaluronic acid solution into the emulsification kettle through a high-pressure pump, continue to stir, and set the stirring power to 20KW, and the stirring time to 10min, to prepare curcumin microparticles lotion.

[0055] Supercritical CO with a high-pressure pump 2 Pass into the crystallization still with the flow velocity of 15g / mL, treat that temperature reaches 30 DEG C in the crystallization kettle, pressure reaches 10MPa, with another high-pressure pump the curcumin microemulsion is passed into the noz...

Embodiment 2

[0058] A kind of supercritical emulsification granulation technology prepares the method for curcumin nanoparticle, comprises the following steps:

[0059] Accurately measure 5L of acetone, pour it into the emulsification kettle through a high-pressure pump, add 100g of curcumin, 300g of lecithin, turn on the magnetic stirring, the stirring power is 25MPa, and the stirring time is 20min.

[0060] Dissolve 300g of hyaluronic acid and 30g of genipin in 5L of purified water, put the hyaluronic acid solution into the emulsification kettle through a high-pressure pump, continue to stir, and set the stirring power to 25MPa and the stirring time to 20min to prepare curcumin microparticles lotion.

[0061] Supercritical CO with a high-pressure pump 2 Pass into the crystallization still with the flow velocity of 15g / mL, treat that temperature reaches 40 DEG C in the crystallization kettle, pressure reaches 15MPa, with another high-pressure pump the curcumin microemulsion is passed int...

Embodiment 3

[0064] A kind of supercritical emulsification granulation technology prepares the method for curcumin nanoparticle, comprises the following steps:

[0065] Accurately measure 5L of absolute ethanol, pour it into the emulsification kettle through a high-pressure pump, add 150g of curcumin, 450g of lecithin, turn on the magnetic stirring, the stirring power is 30KW, and the stirring time is 30min.

[0066] Dissolve 450g of hyaluronic acid and 45g of genipin in 5L of purified water, put the hyaluronic acid solution into the emulsification kettle through a high-pressure pump, continue to stir, and set the stirring power to 30KW, and the stirring time to 30min, to prepare curcumin microparticles lotion.

[0067] Supercritical CO with a high-pressure pump 2 Pass into the crystallization still with the flow rate of 15g / mL, treat that temperature reaches 50 DEG C in the crystallization still, pressure reaches 30MPa, curcumin microemulsion is passed into the nozzle device of the cryst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com