A kind of preparation method of three-dimensional oxide fiber composite material

A technology of fiber composite materials and oxides, which is applied in the field of materials, can solve problems such as the difficulty in achieving uniform composite ceramic grain refinement of multi-phase materials, optimize the embedding space and three-dimensional pore structure, avoid side reactions, and have strong anti-sedimentation capabilities Effect

Active Publication Date: 2022-06-03

SHAANXI UNIV OF SCI & TECH

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the research and development of domestic oxide fibers is limited by technology, mainly based on basic research, and only technological breakthroughs have been made in the field of chopped fibers. It is technically difficult to achieve uniform compounding of multi-phase materials and The refinement of ceramic grains still has a long way to go compared with the mature fiber preparation systems in Europe, America, Japan and other countries[Effect of aluminum silicate fiber modification on crack-resistance of a ceramic mold[J].China Foundry, 2012,9(04):322-327.]

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0045] The ceramic slurry solution is deionized by mass ratio of 20% alumina, 20% silica, 10% calcium oxide and 50%

Embodiment 2

[0061] The ceramic slurry solution is deionized by mass ratio of 40% alumina, 20% silica, 10% calcium oxide and 30%

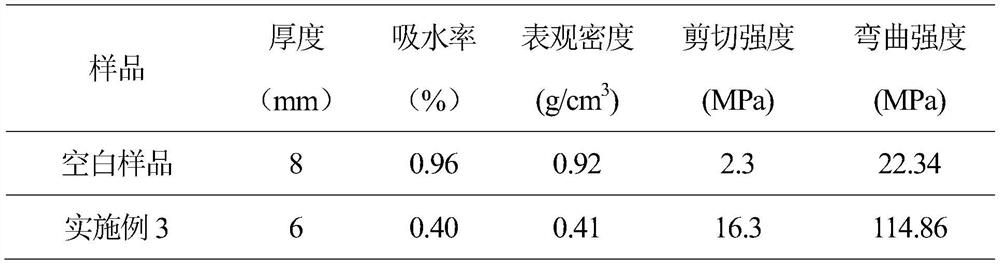

Embodiment 3

[0077] The ceramic slurry solution is deionized by mass ratio of 20% alumina, 20% silica, 30% calcium oxide and 30%

[0081]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

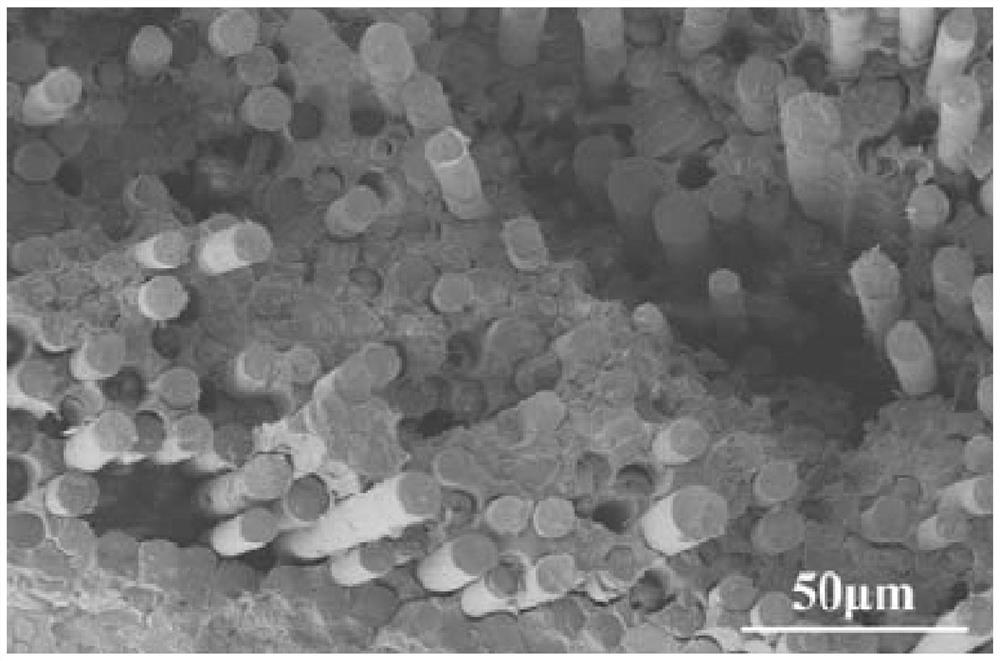

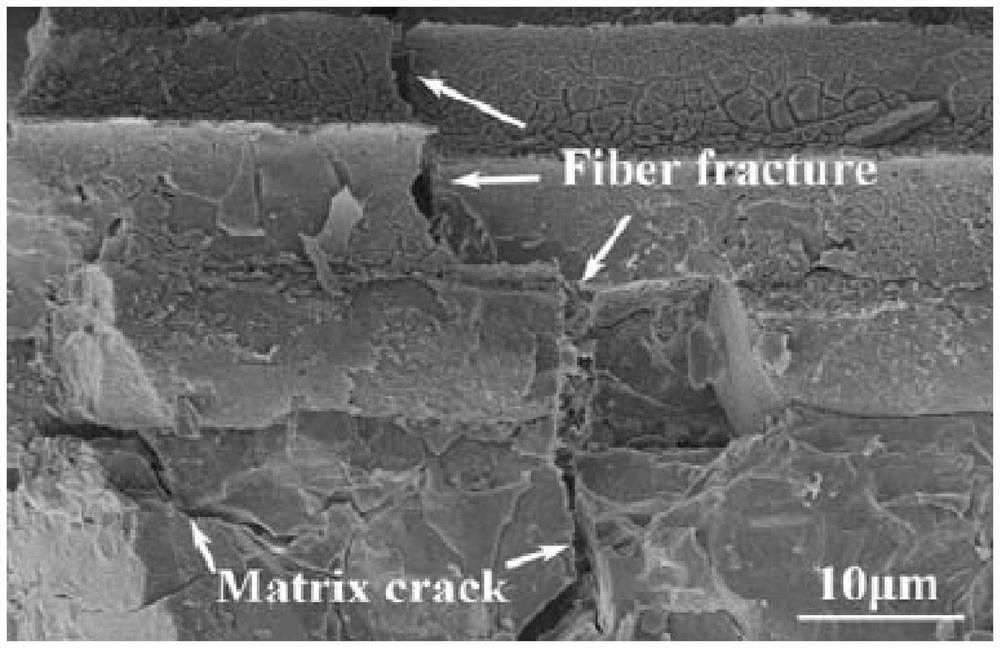

A method for preparing a three-dimensional oxide fiber composite material, using low-cost ceramic powder waste as a matrix material and supplemented with a dual-phase fiber body as a reinforcement, which is environmentally friendly and meets the requirements of green industrialization, and indirectly alleviates environmental governance pressure. According to the difference in the properties of different fibers, the present invention creates a composite method of "double mutual complementarity". By introducing low-cost reagents such as oxalic acid and isobutanolamine to modify and etch the surface of the fiber and precursor solution, the different fibers are improved. The interfacial bonding force and dispersion performance between the two materials have realized the laminated composite of aluminum silicate fiber cloth with high melting point and poor thermal shock resistance and alumina fiber cloth with low melting point and good thermal shock resistance, effectively avoiding the single The mechanical defects of phase fiber cloth and construct a three-dimensional fiber composite system of "dual-phase fiber-filler-cheap matrix" with excellent mechanical properties.

Description

A kind of preparation method of three-dimensional oxide fiber composite material technical field The invention belongs to material field, be specifically related to a kind of preparation method of three-dimensional oxide fiber composite material. Background technique [0002] The high temperature oxide / oxide ceramic matrix composite is a combination of a ceramic matrix and a better compatible reinforcement. product, since the 1980s, this type of material has gradually been used in the industry due to its excellent high temperature oxidation resistance, high hardness and stress elasticity Commercial fields such as aircraft turbines and automobile friction plates have achieved large-scale industrial production and application. In 2019, the domestic market The share has reached more than 100 billion yuan [Zhao Hong.Fiber Composites Growth[J].China Textile, 2019 (07):8‑10.]. [0003] Most of the high temperature oxide / oxide ceramic matrix composites use polycrystalline oxi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): D06M11/72D06M13/192D06M11/82D06M13/165D06M13/148D06M15/333D06M13/262D06M13/368C25D13/16C25D13/02

CPCD06M11/72D06M13/192D06M11/82D06M13/165D06M13/148D06M15/333D06M13/262D06M13/368C25D13/16C25D13/02

Inventor 曹丽云钟辛子黄剑锋欧阳海波张文渊李哲源李晓艺姚依林

Owner SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com