Patents

Literature

61results about How to "Density is easy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vitreoretinal silicone tamponades made by supercritical fluid extraction

InactiveUS7276619B2EconomicalHighly effectiveSilicon organic compoundsSilicon compound active ingredientsSupercritical fluid extractionOligomer

A process for the purification of a silicone oil or fluid using neat supercritical carbon dioxide or a supercritical carbon dioxide mixture extraction to produce vitreoretinal silicone tamponades. The subject process is an economical, highly effective, reproducible, contaminant-free method by which unreacted relatively low molecular weight cyclic siloxanes and oligomers are removed from relatively high molecular weight silicone oil or fluid.

Owner:BARCLAYS BANK PLC AS SUCCESSOR AGENT

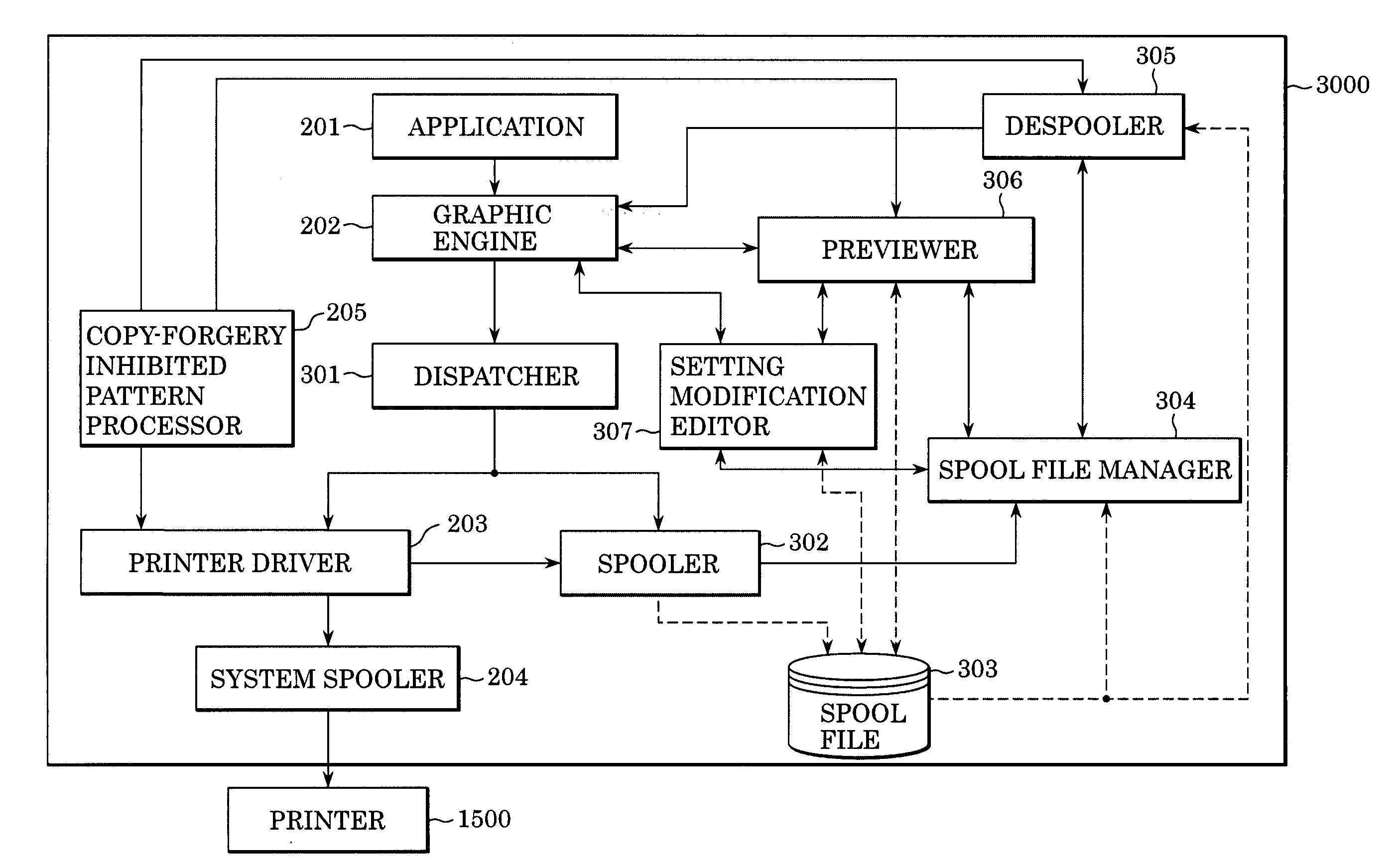

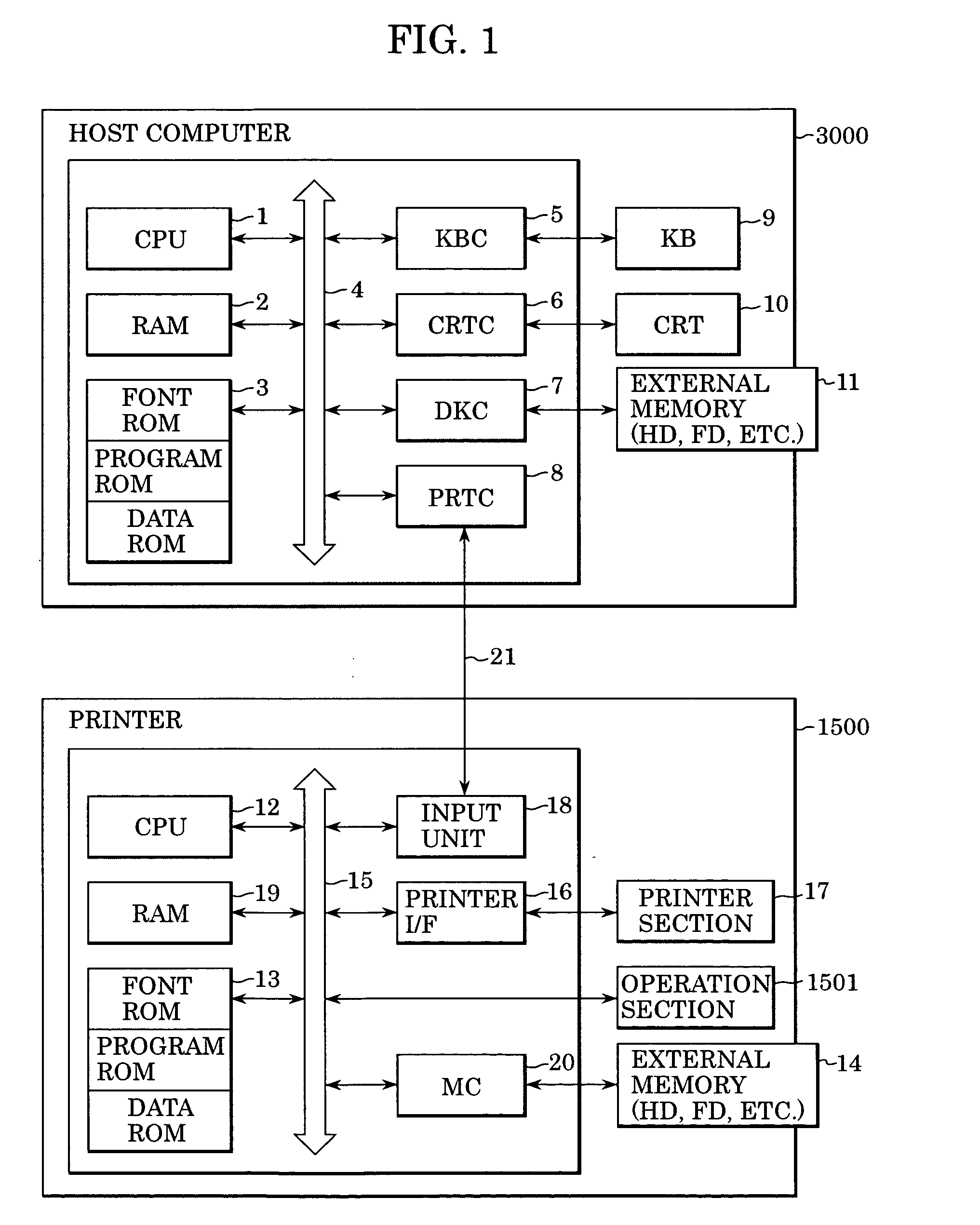

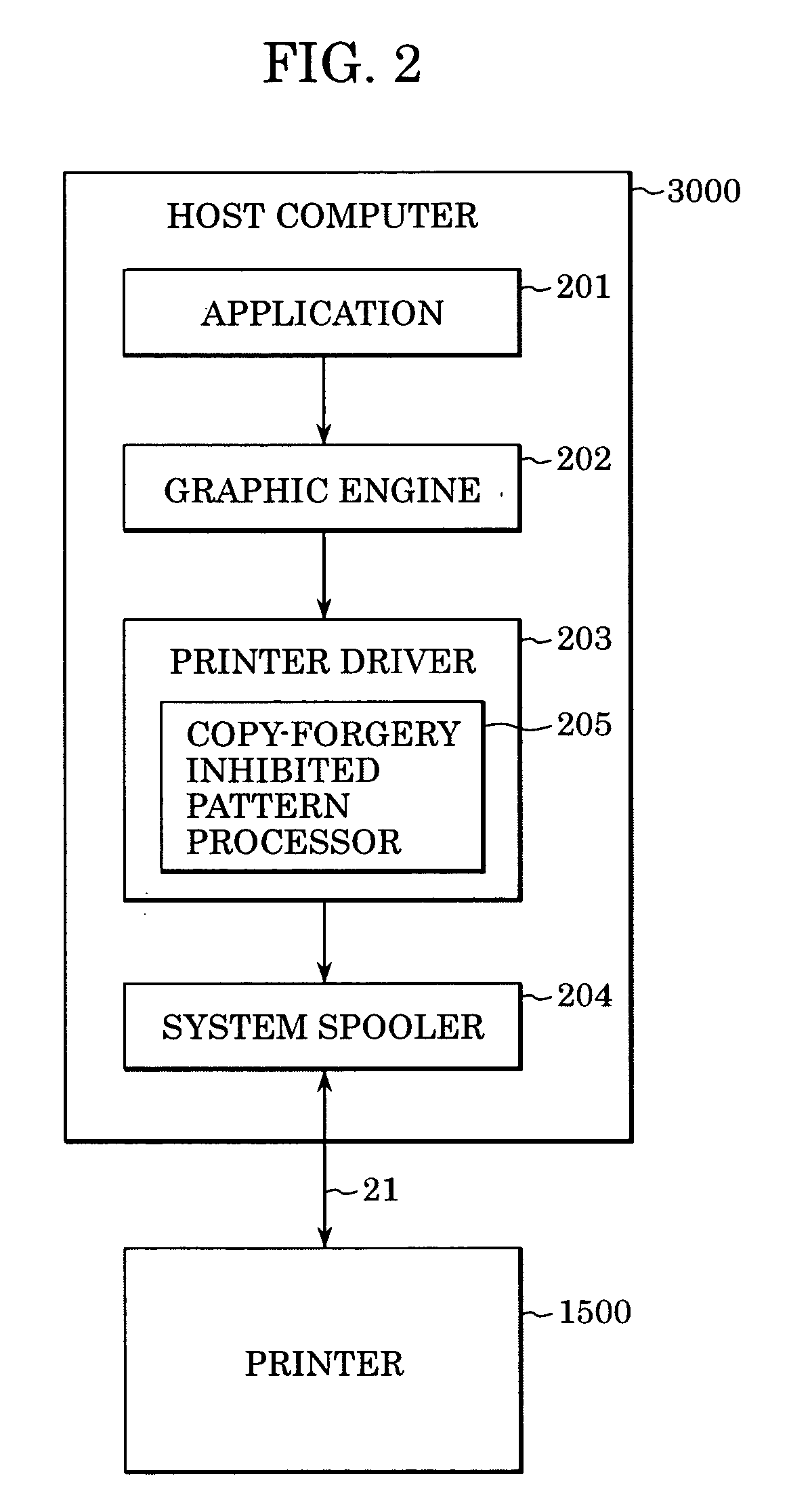

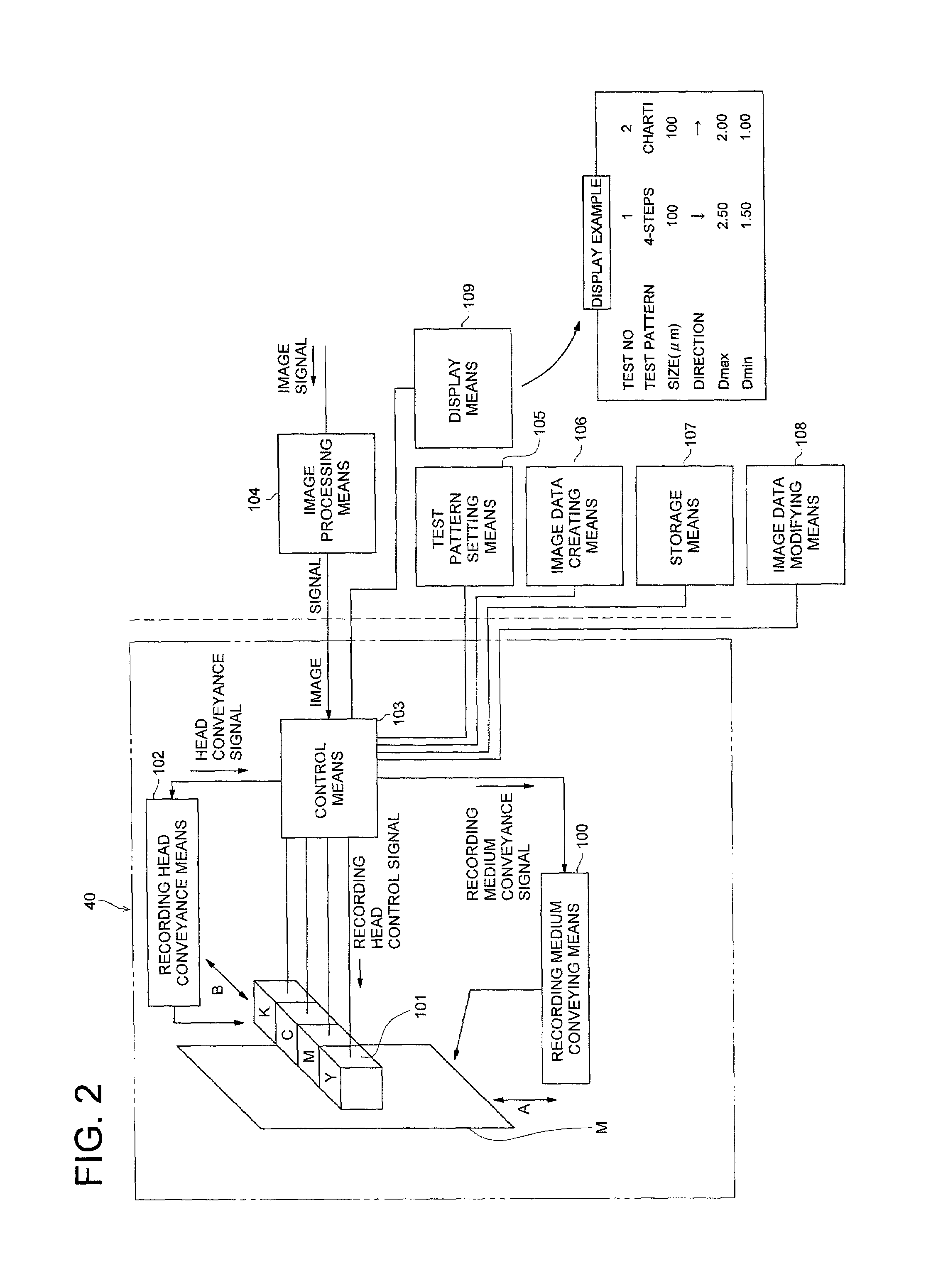

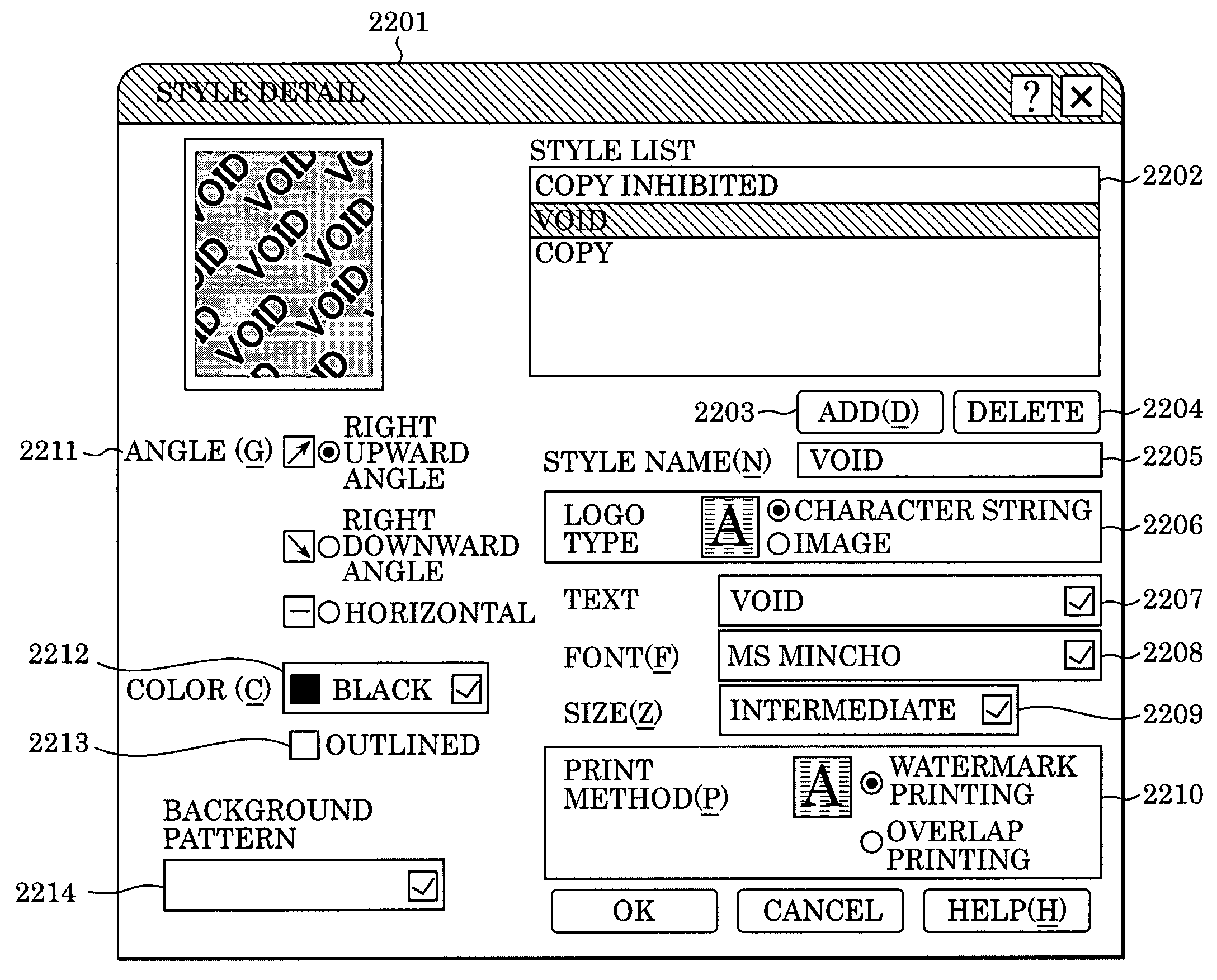

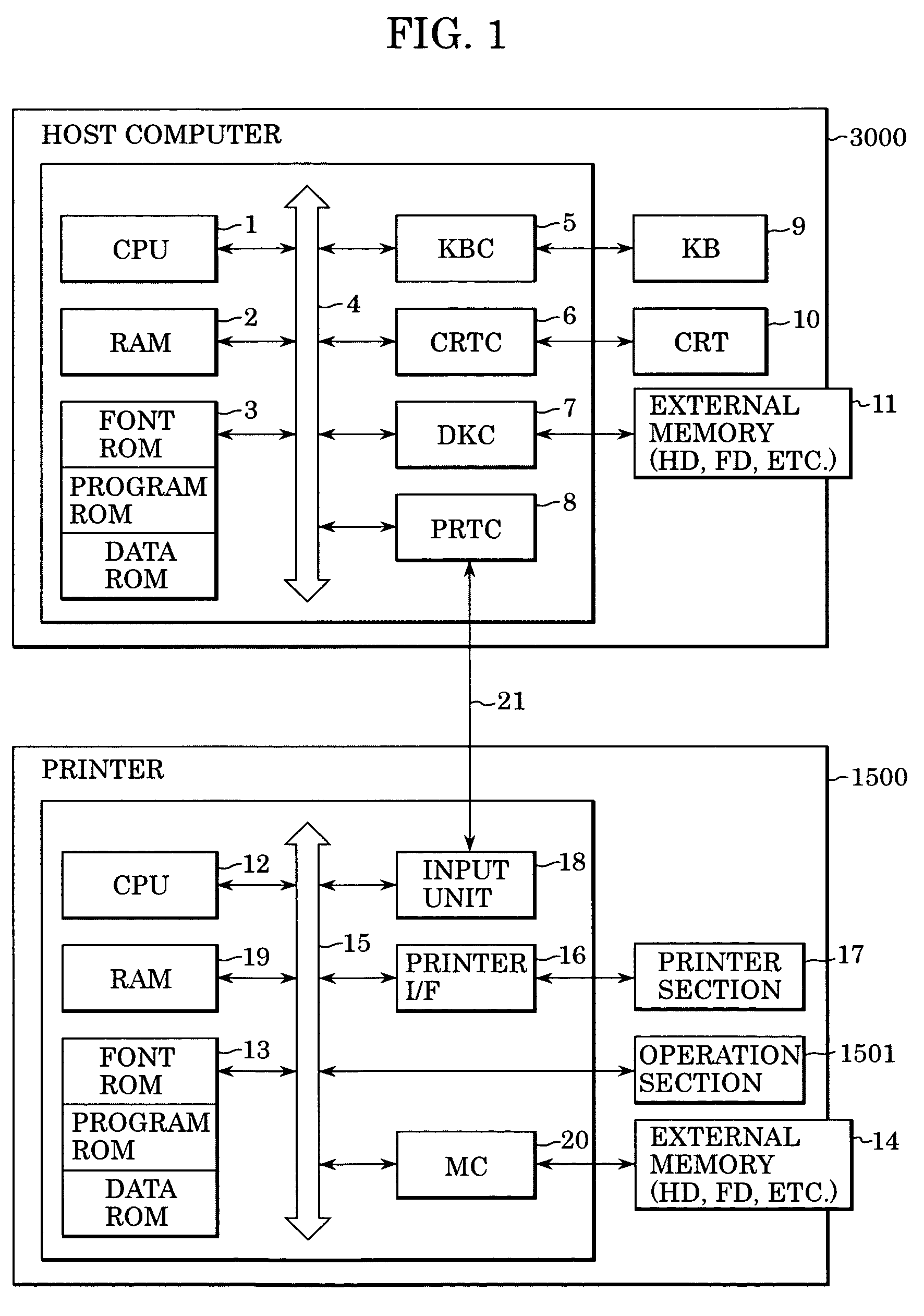

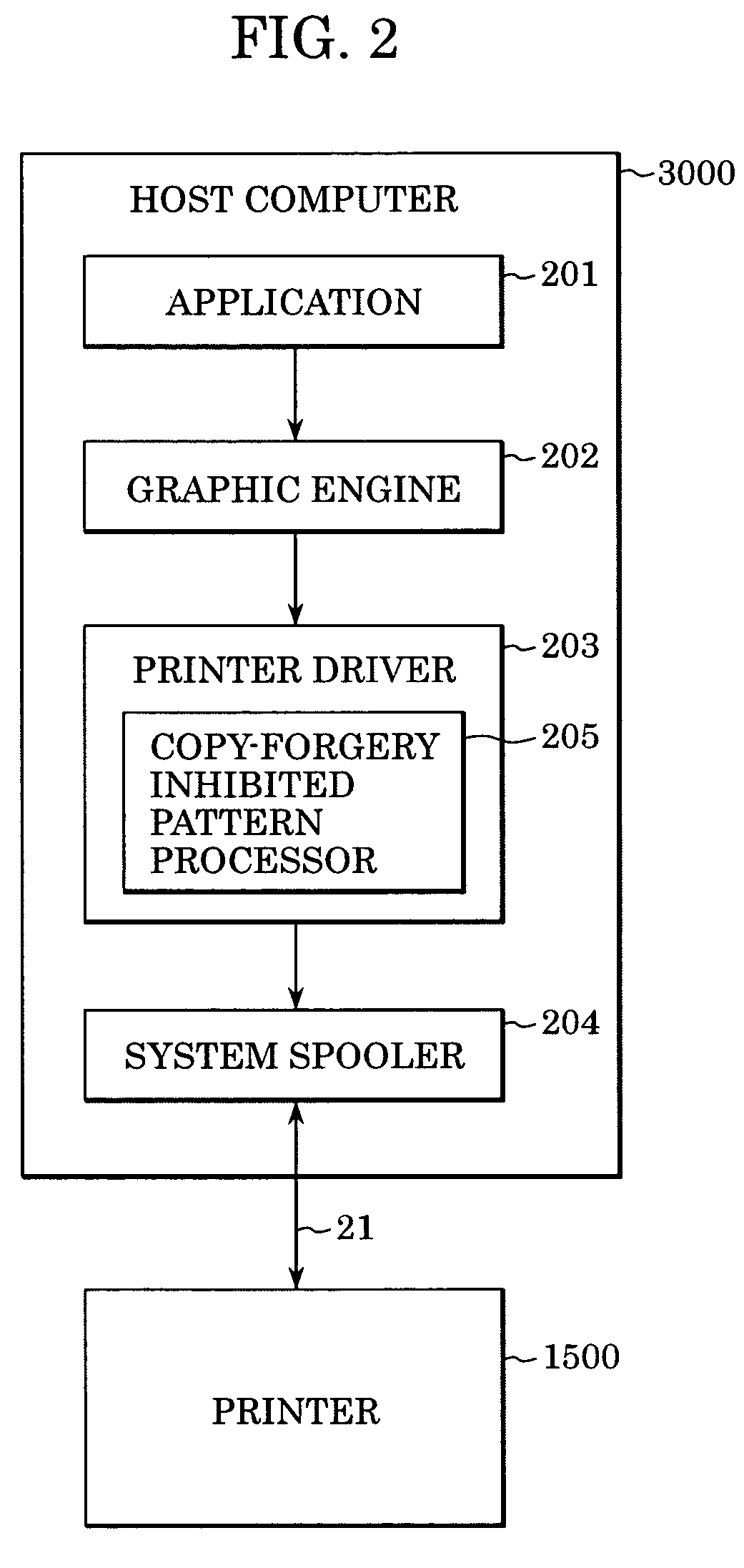

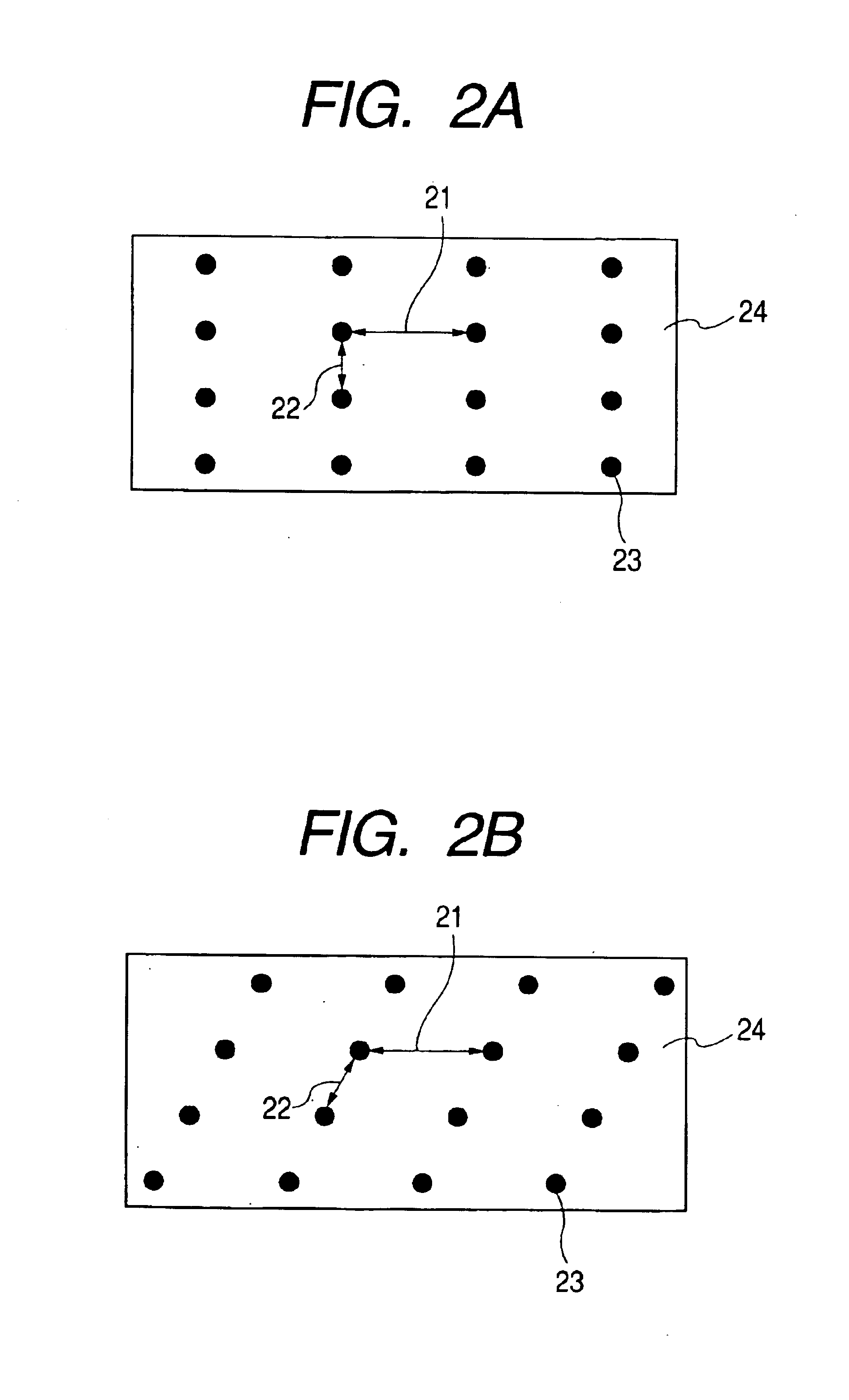

Image processing apparatus and image processing method

InactiveUS20050162682A1Easily adjust densityDensity is easyImage enhancementDigitally marking record carriersImaging processingComputer graphics (images)

An image processing apparatus performs a density adjustment process for generating an image containing a copy-forgery-inhibited pattern image for warning against the use of copy products. To help users to easily adjust the density of a latent image portion and a background portion in the copy-forgery-inhibited pattern image, the image processing apparatus determines a density relationship of the latent image portion and the background portion by performing a plurality of adjustment operations, in combination, different in the amount of adjustment relating to the range of variable density in at least one of the latent image portion and the background portion, and sets, based on the density relationship, the density data of each of the latent image portion and the background portion in the data of the copy-forgery-inhibited pattern image.

Owner:CANON KK

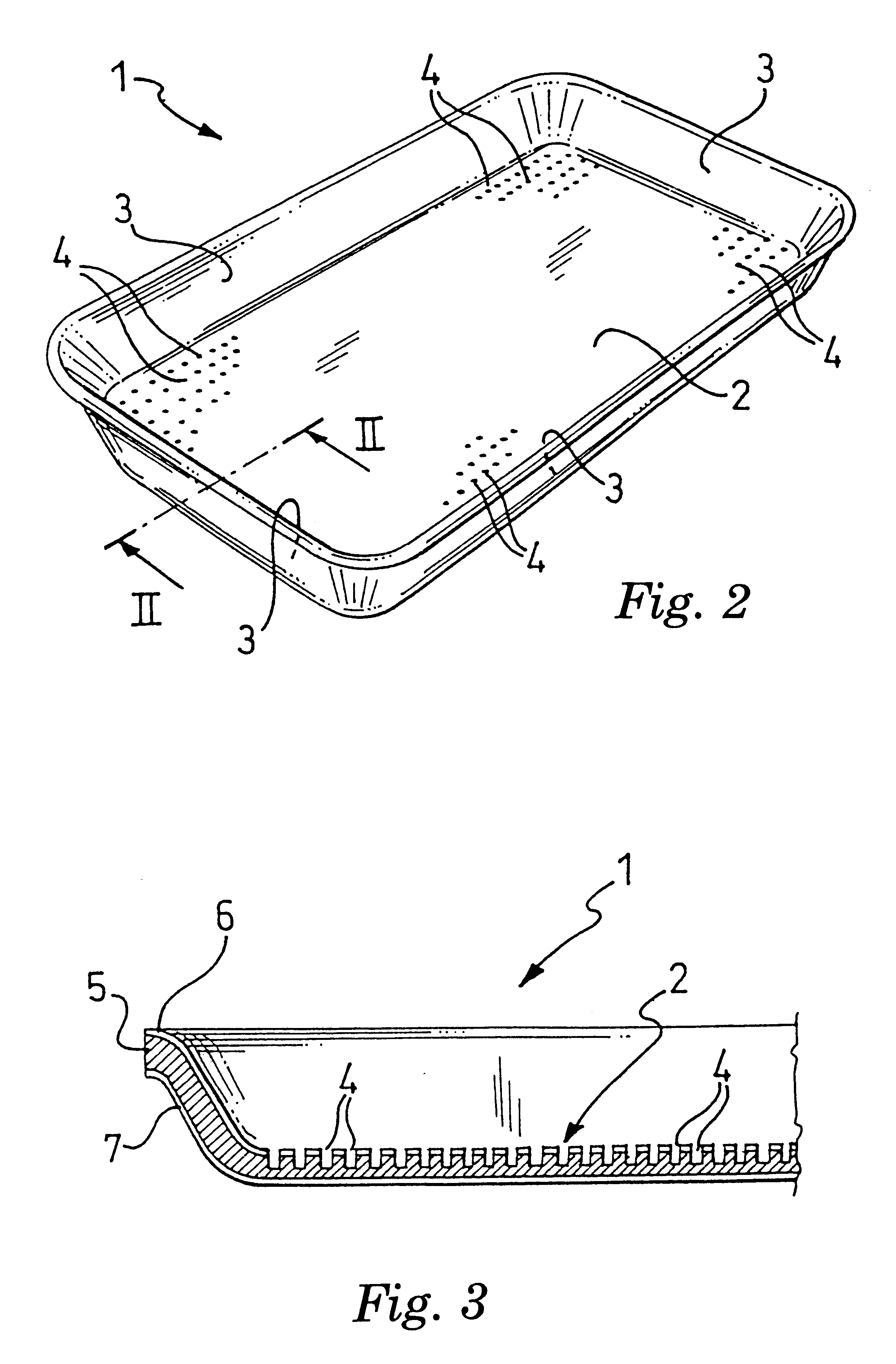

Method for the production of substantially open-cell polystyrene sheet

InactiveUSRE37780E1Low densityBig volume of liquidFoundry mouldsContainers preventing decayPolymer scienceAliphatic hydrocarbon

A method of producing a substantially open-cell, expanded polystyrene sheet, comprising the steps of:forming a mixture comprising from 30 to 95% of polystyrene incorporating an aliphatic hydrocarbon with 4-6 carbon atoms, from 0 to 65% of polystyrene, and from 0.2 to 10% of a nucleating agent,mixing the mixture obtained and melting it by heating inside an extruder,bringing the mixture to a temperature of 130-150° C. in the final portion of the extruder,extruding the mixture in a lower-pressure atmosphere to produce an expanded sheet, which has a low density and a high capacity to absorb aqueous liquids, particularly if a surfactant is added to the starting mixture, and which, when coupled with two films of plastics material gives rise to a laminate suitable for the production, by thermoforming, of trays of foods which may release aqueous liquids.

Owner:SIRAP GEMA SPA

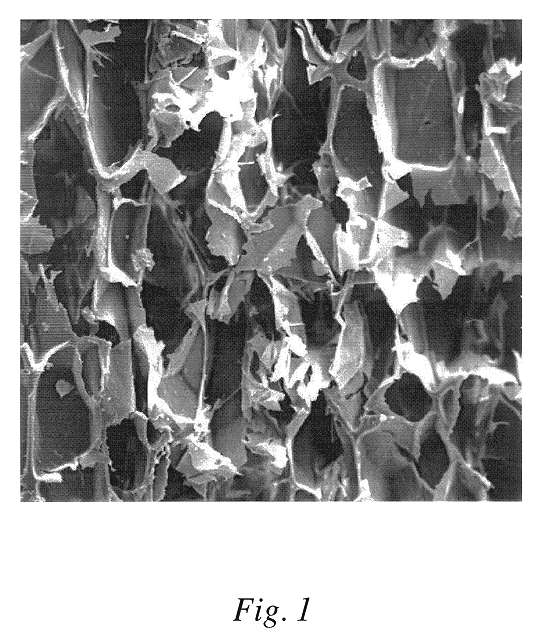

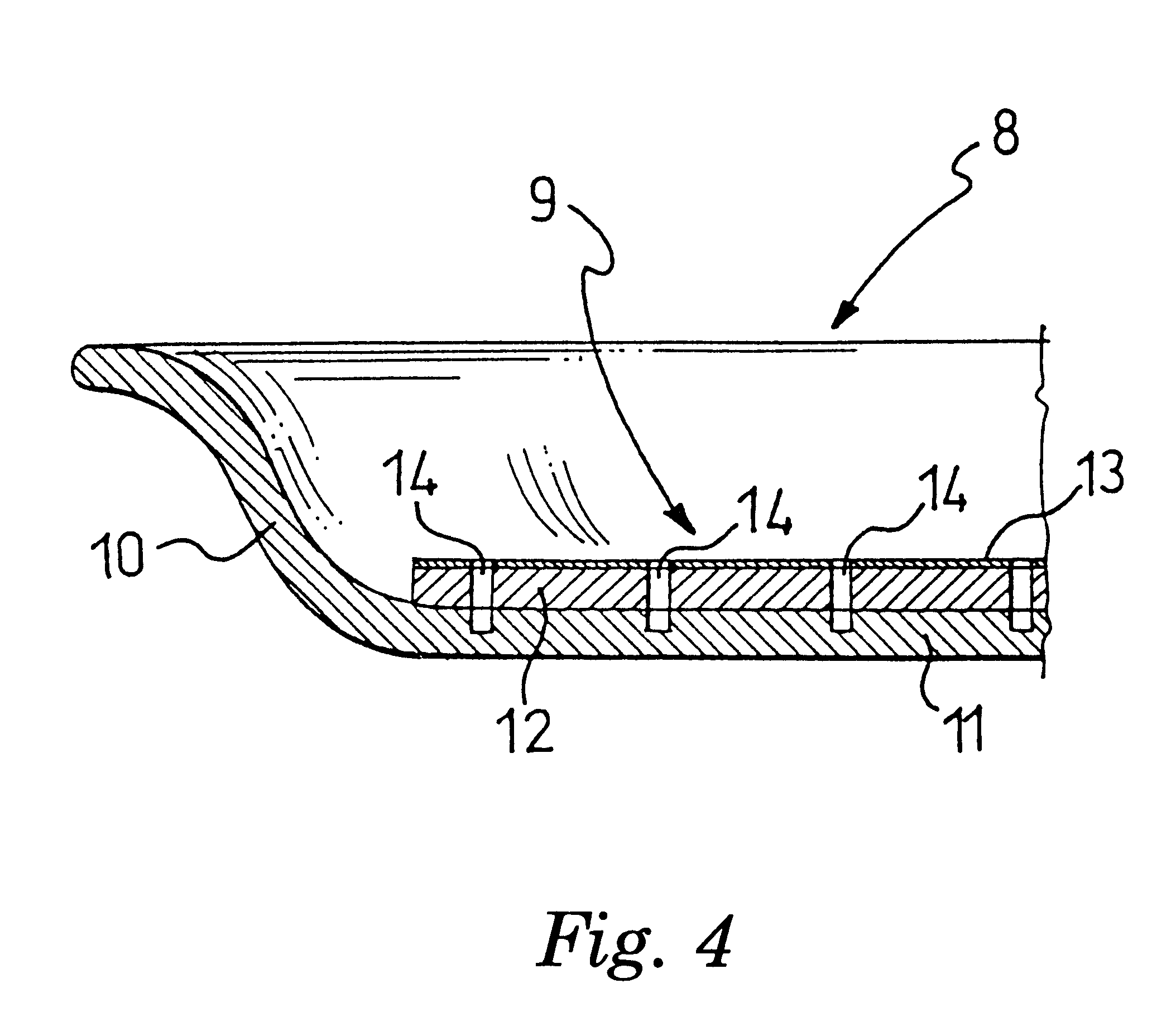

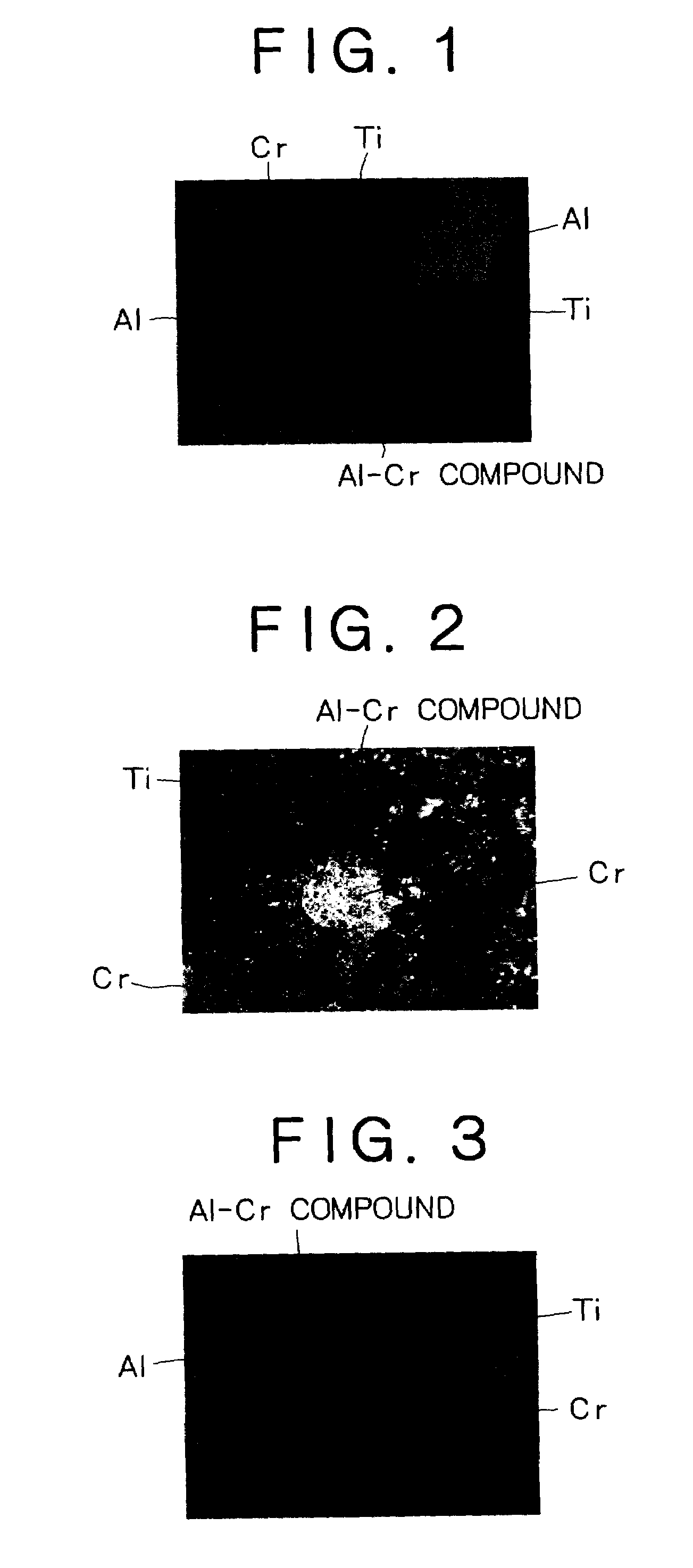

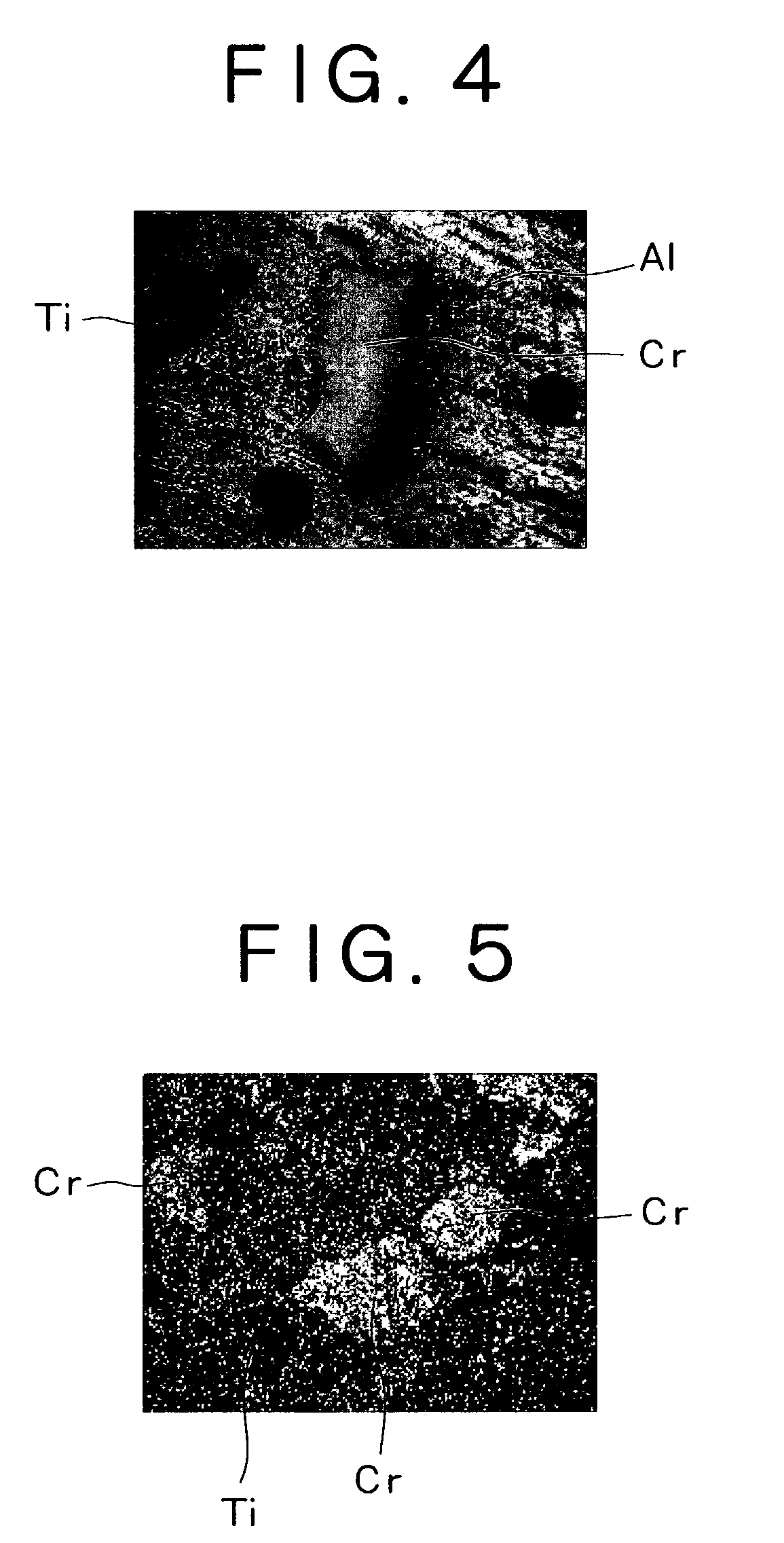

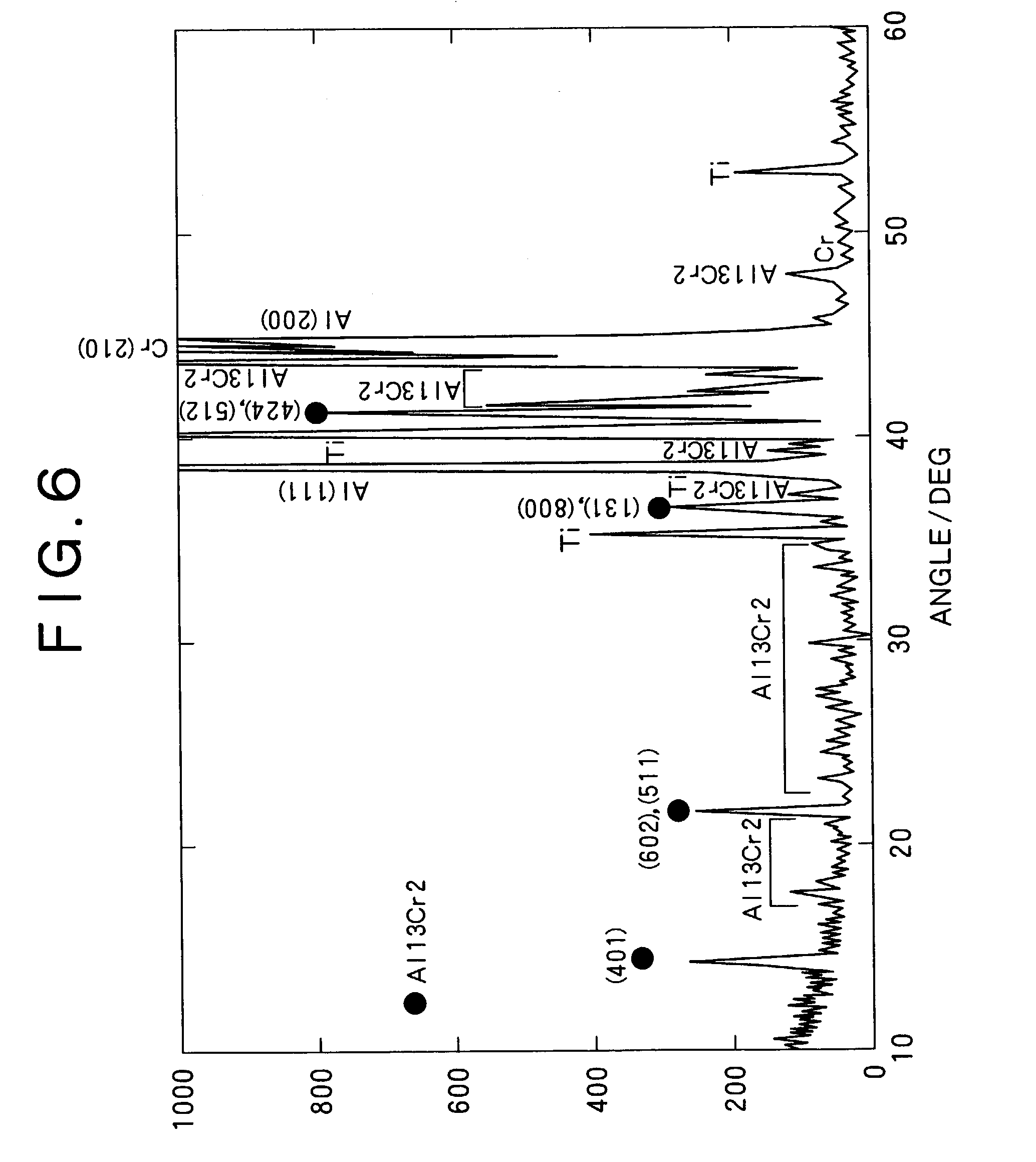

Target for cathode discharging arc ion plating and method of manufacturing the same

ActiveUS7144547B2Prevent not uniform movementInhibition formationCellsVacuum evaporation coatingX-rayPeak intensity

In a target for cathode discharging arc ion plating containing Al and Cr as an essential ingredient according to the invention, the thickness of the Al and Cr compound layer formed between Cr particles and Al contained in a target is 30 μm or less. Alternatively, the total for the peak intensities of Al—Cr compound observed between diffraction angles between 10 to 80° by X-ray diffractiometry according to θ=2θ method is 10% or less relative to the total for the peak intensities of Al, Cr and the Al—Cr compound. Further, the relative density of the target is 92% or more. The target is capable of forming hard films of high quality while preventing not uniform movement of arc spots and suppressing formation of macro particles.

Owner:KOBE STEEL LTD

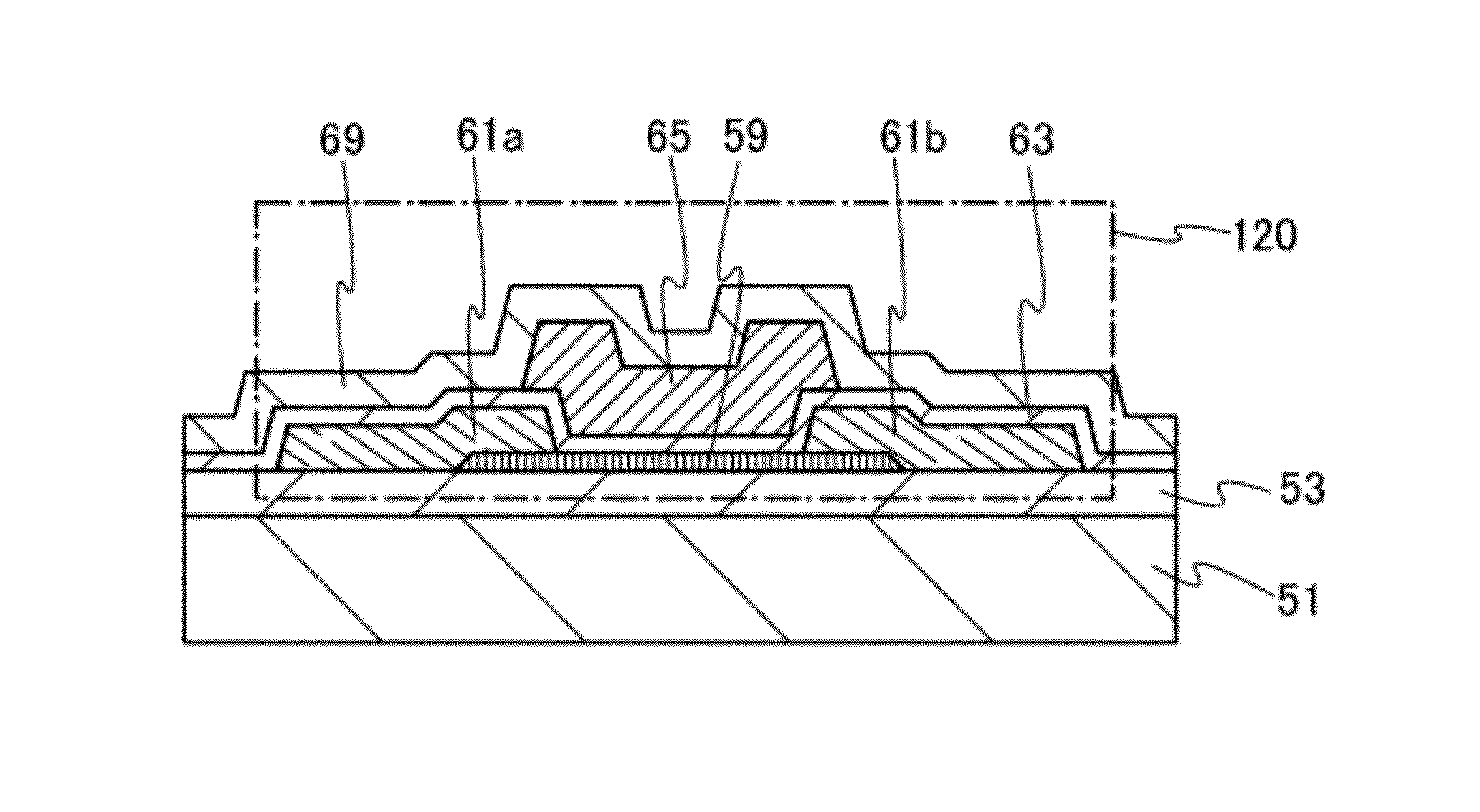

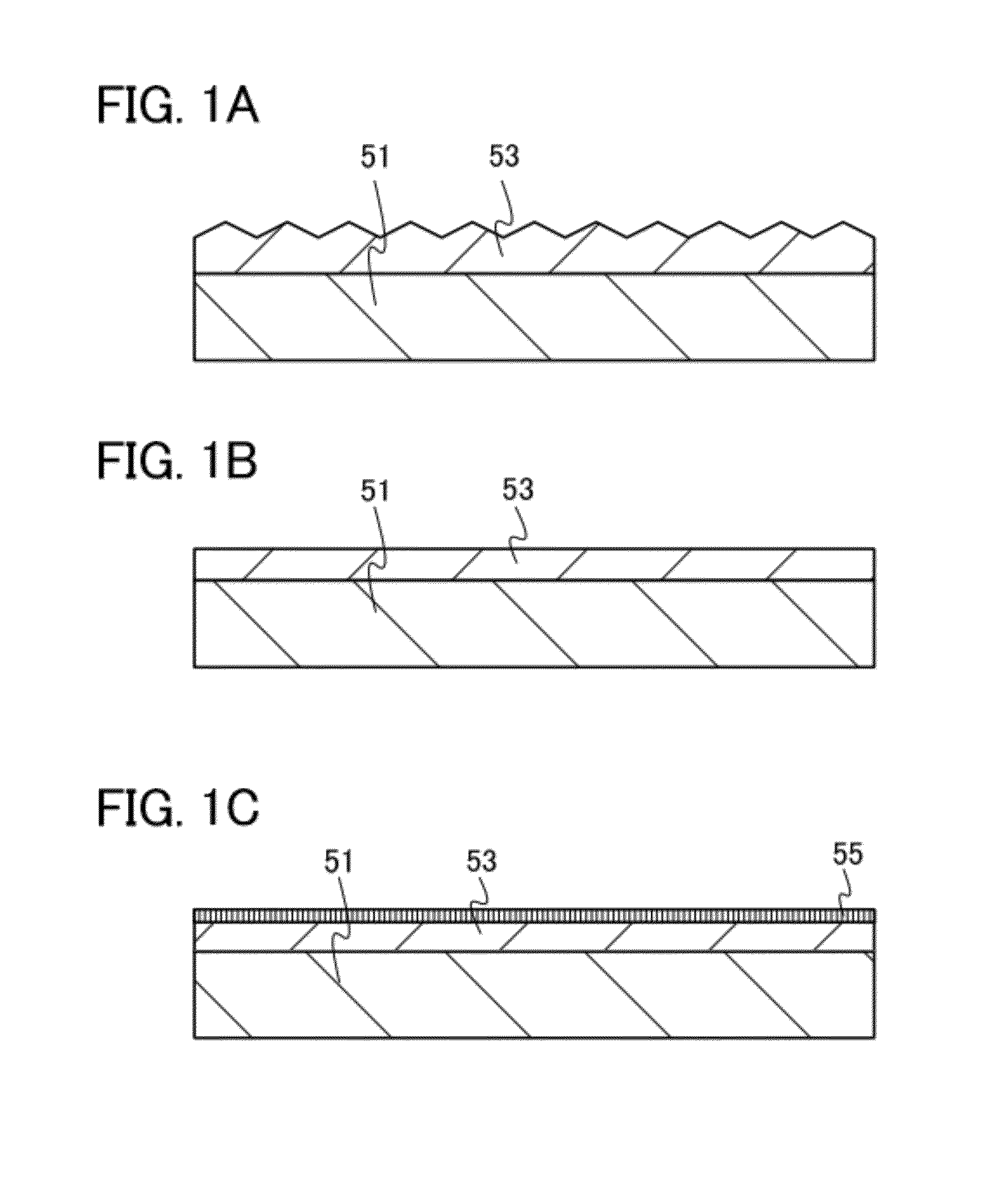

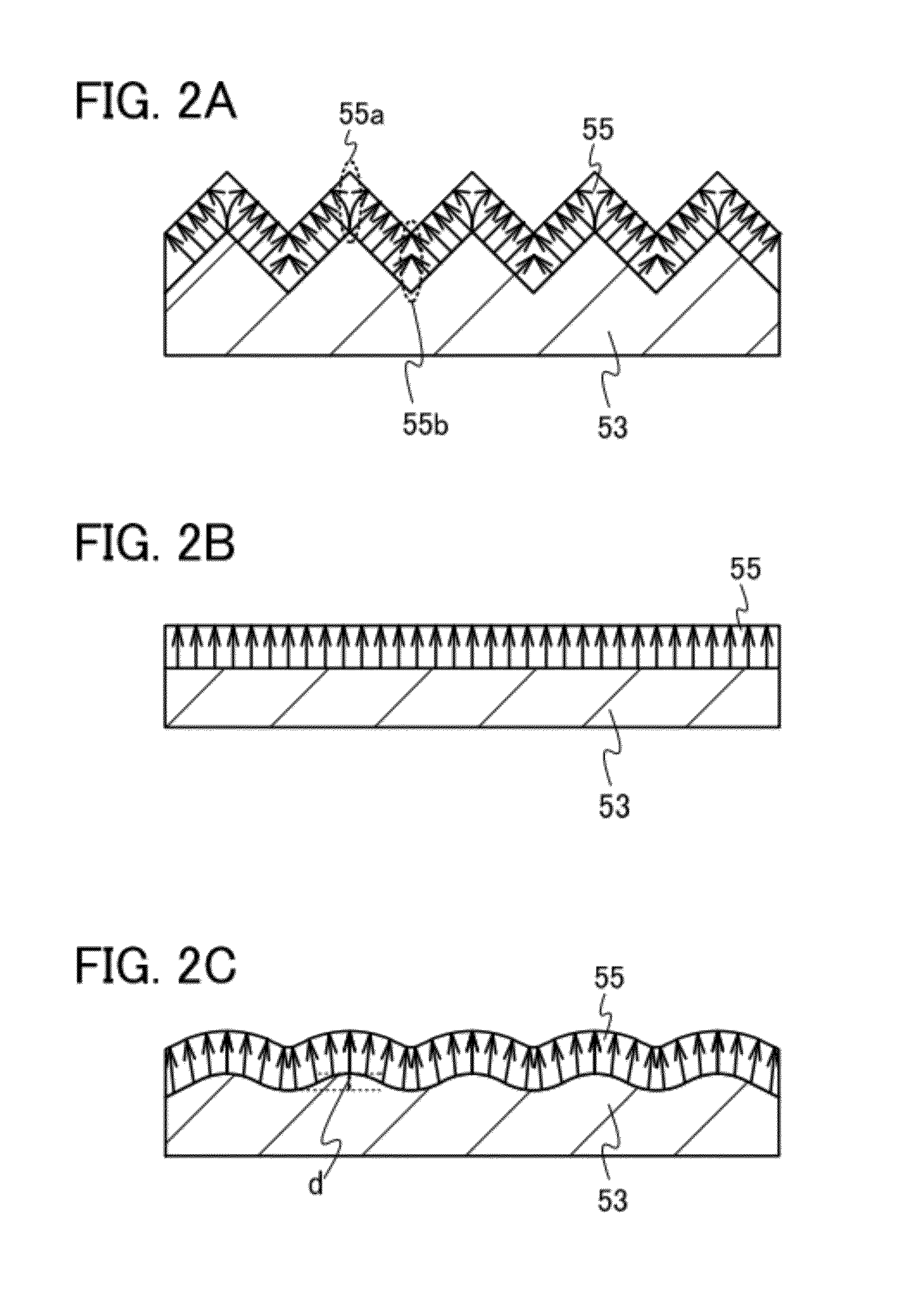

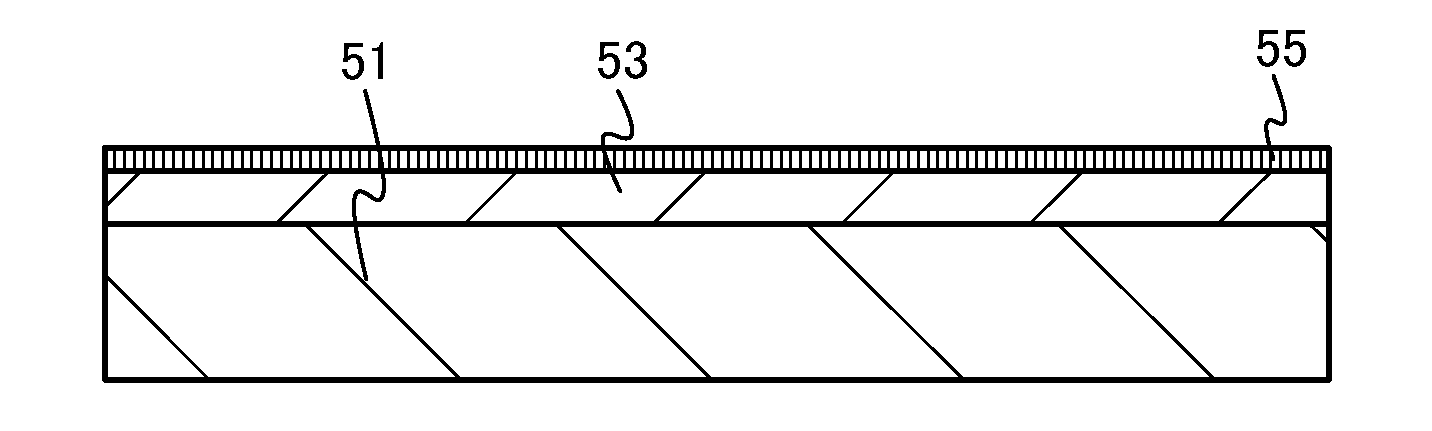

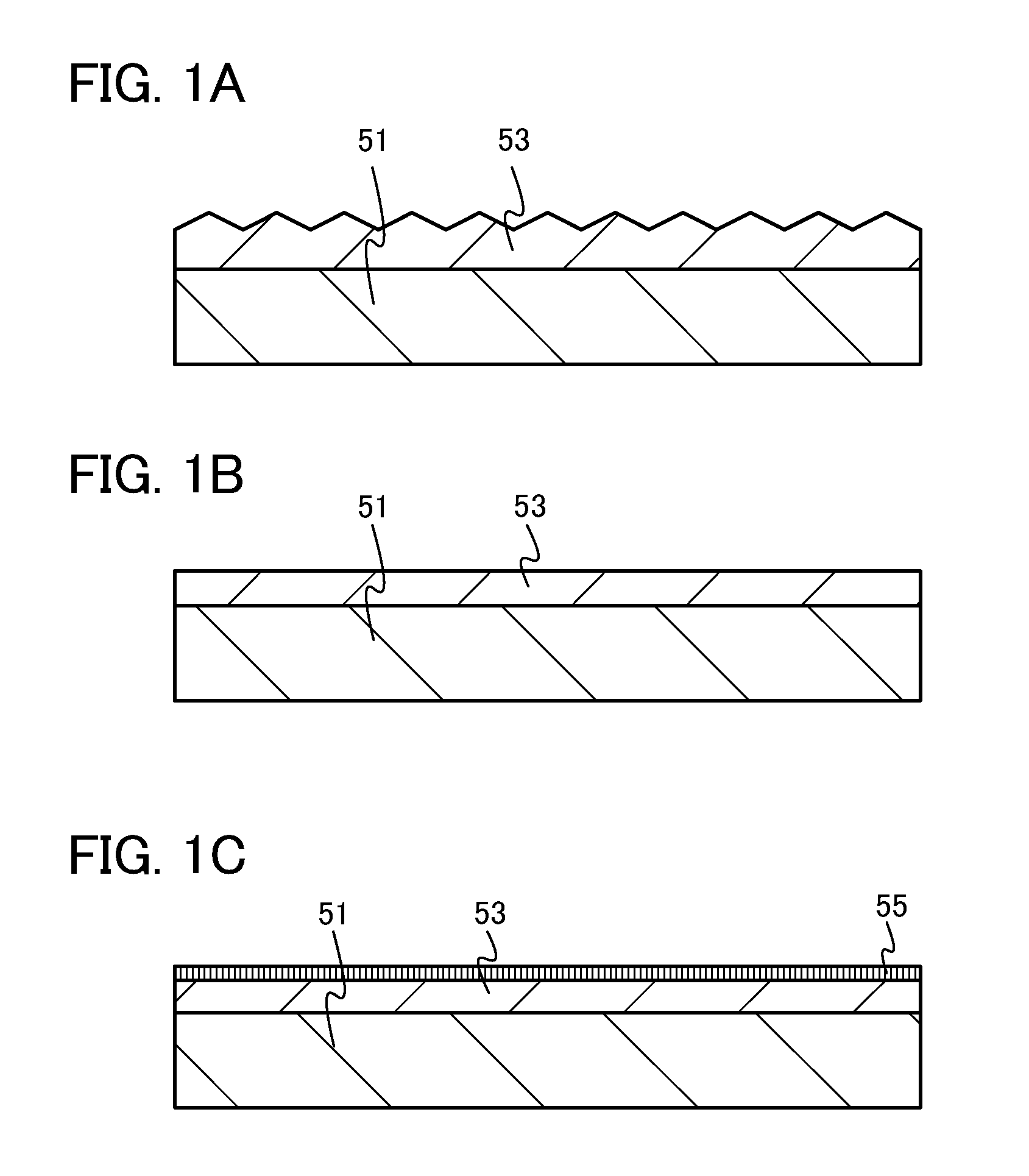

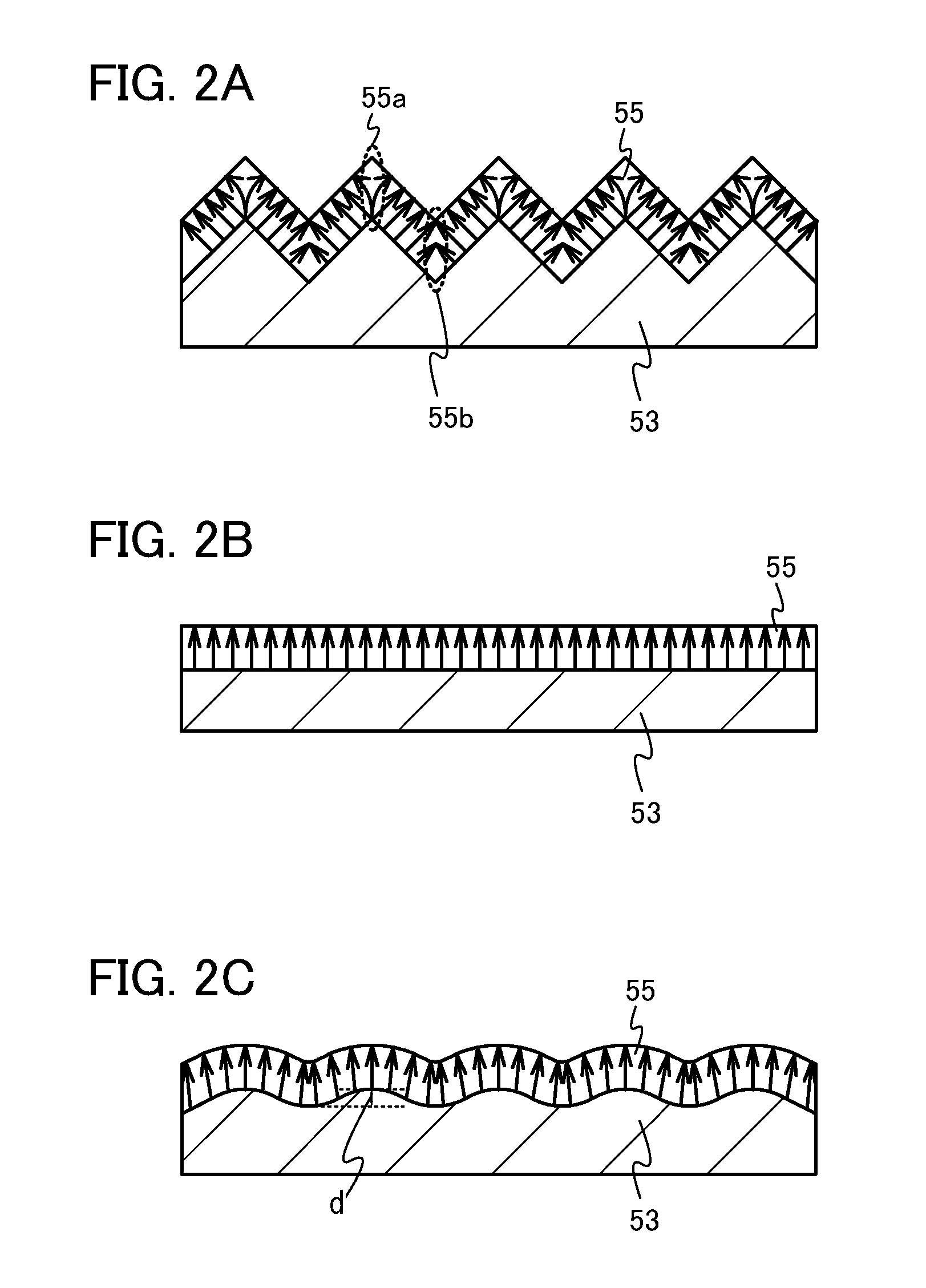

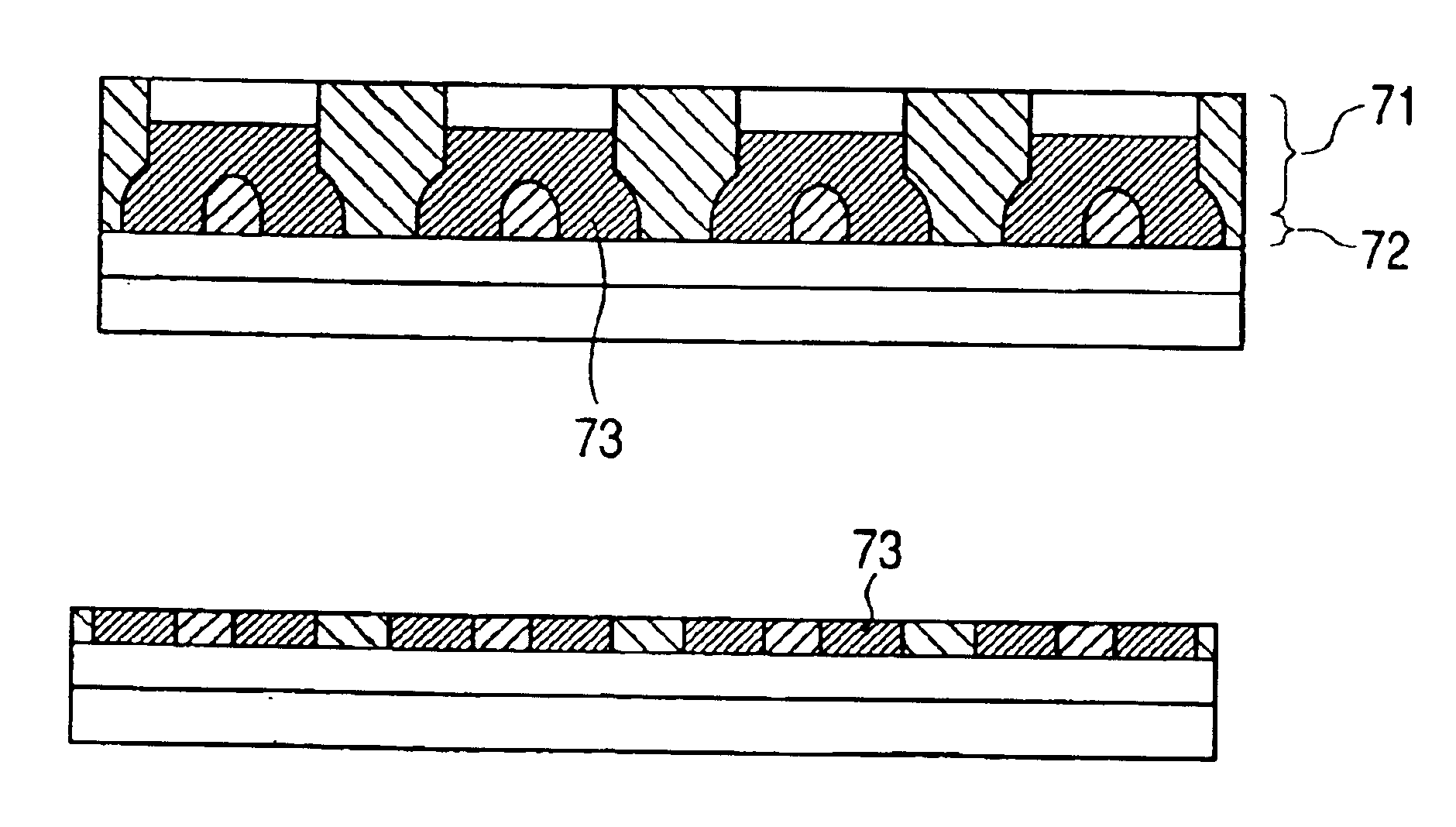

Semiconductor device and method of manufacturing semiconductor device

ActiveUS8987728B2Conductivity easilyDensity is easyTransistorSolid-state devicesCrystalline oxidePower semiconductor device

An object is to provide a highly reliable semiconductor device having stable electric characteristics by using an oxide semiconductor film having stable electric characteristics. Another object is to provide a semiconductor device having higher mobility by using an oxide semiconductor film having high crystallinity. A crystalline oxide semiconductor film is formed over and in contact with an insulating film whose surface roughness is reduced, whereby the oxide semiconductor film can have stable electric characteristics. Accordingly, the highly reliable semiconductor device having stable electric characteristics can be provided. Further, the semiconductor device having higher mobility can be provided.

Owner:SEMICON ENERGY LAB CO LTD

Semiconductor device and method of manufacturing semiconductor device

ActiveUS20120241734A1Reduce defect densityStable electrical characteristicsTransistorSolid-state devicesCrystalline oxidePower semiconductor device

An object is to provide a highly reliable semiconductor device having stable electric characteristics by using an oxide semiconductor film having stable electric characteristics. Another object is to provide a semiconductor device having higher mobility by using an oxide semiconductor film having high crystallinity. A crystalline oxide semiconductor film is formed over and in contact with an insulating film whose surface roughness is reduced, whereby the oxide semiconductor film can have stable electric characteristics. Accordingly, the highly reliable semiconductor device having stable electric characteristics can be provided. Further, the semiconductor device having higher mobility can be provided.

Owner:SEMICON ENERGY LAB CO LTD

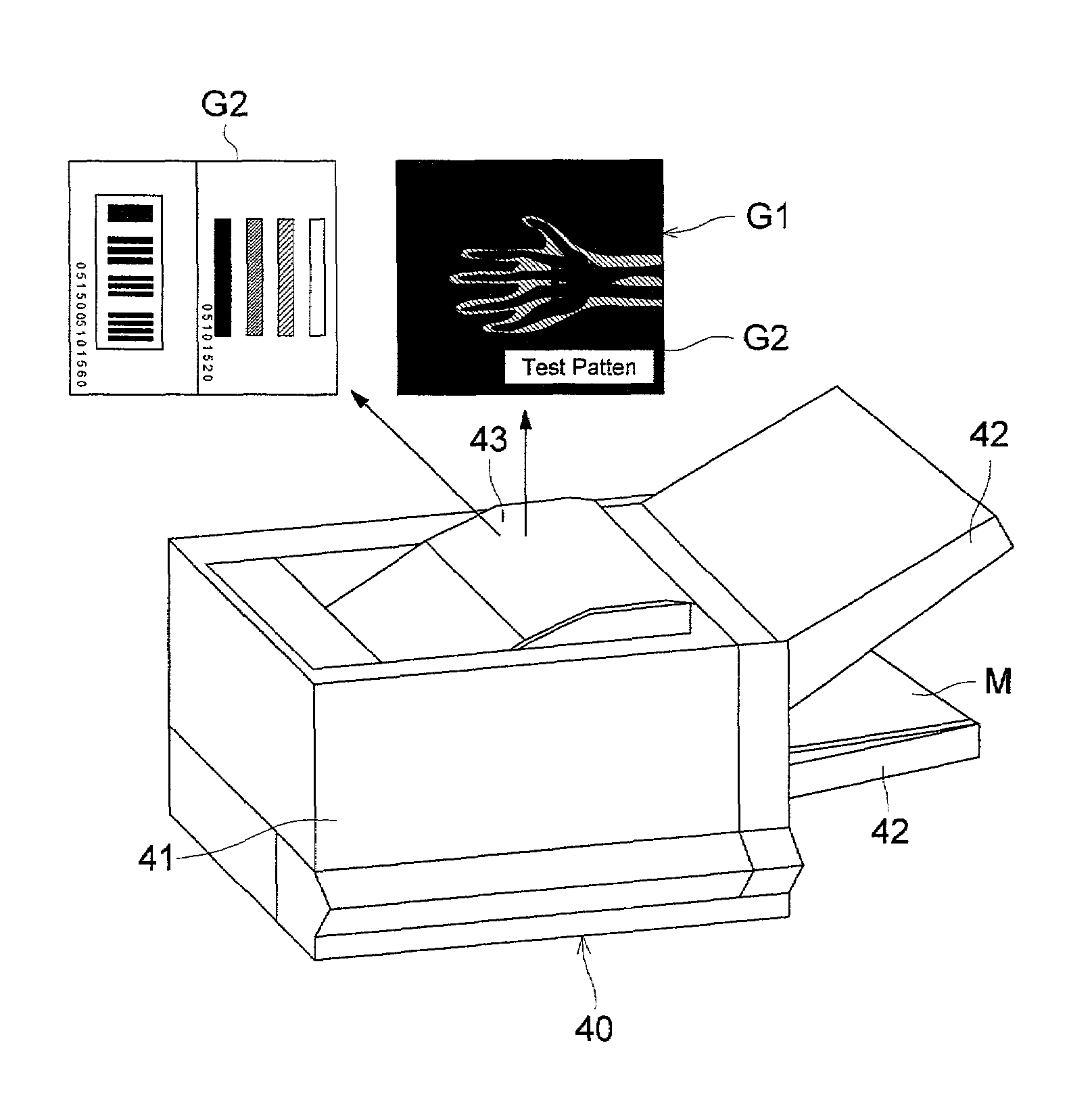

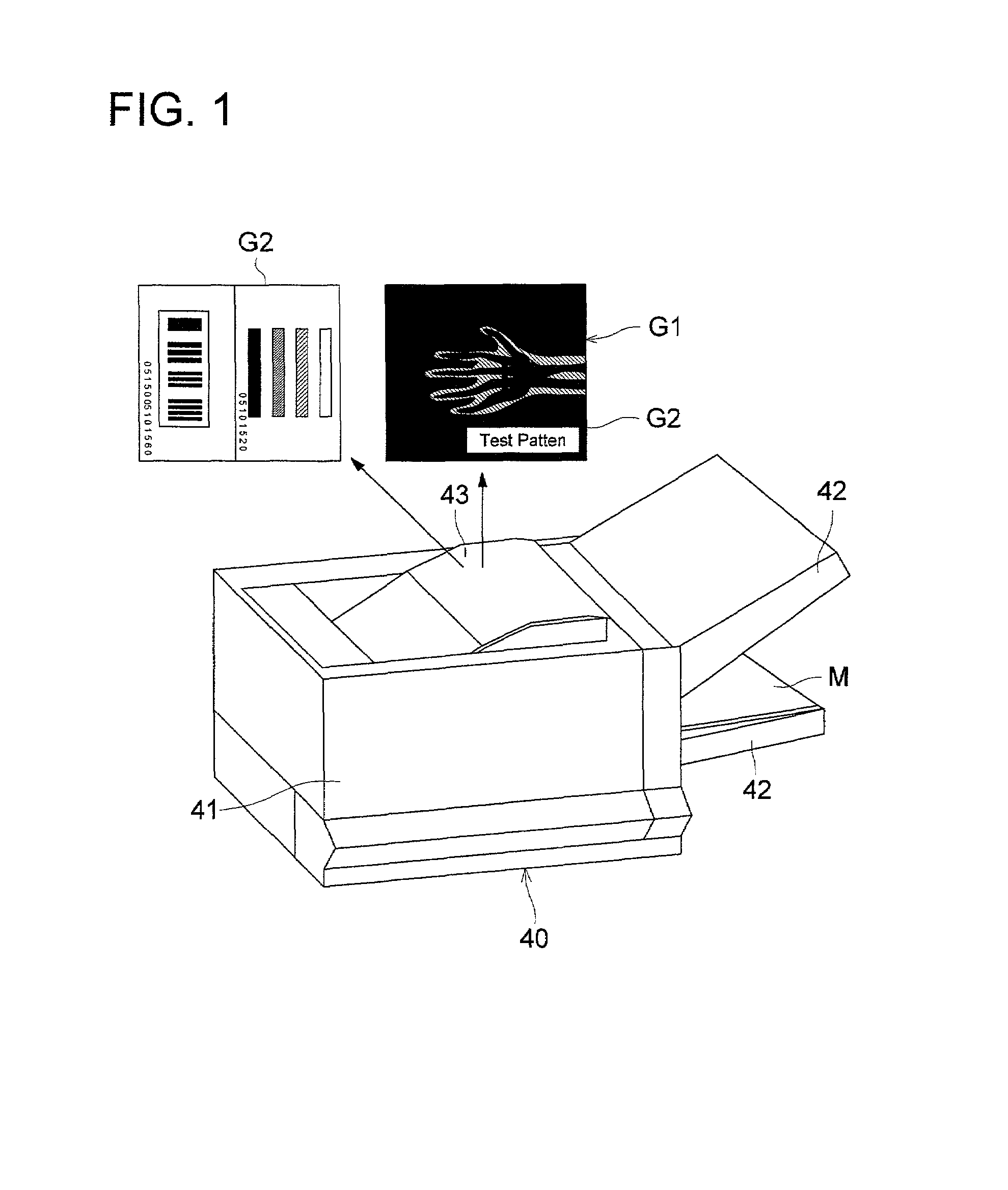

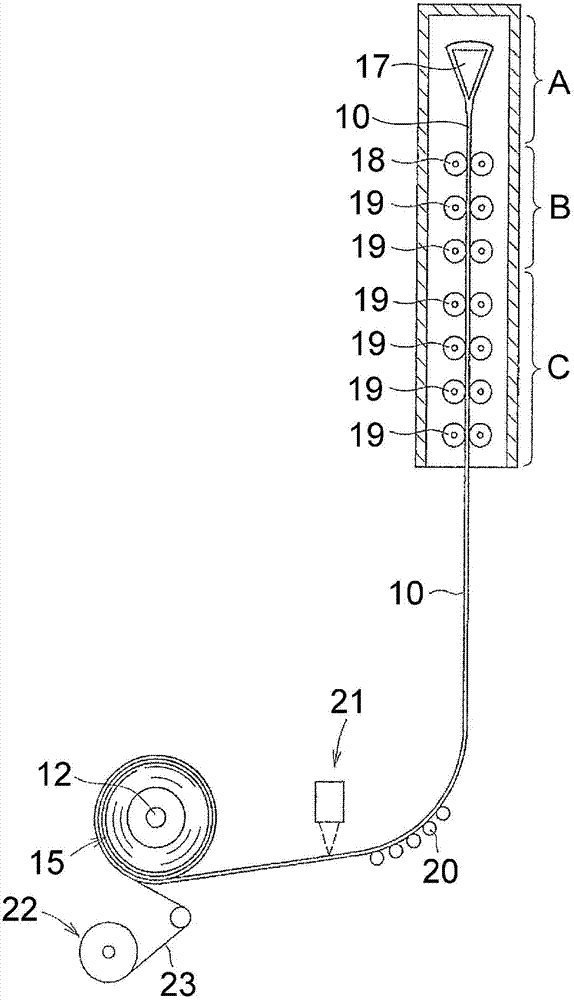

Image recording apparatus and test pattern for evaluating recorded image

InactiveUS7221464B2Density measurement can be easyEvaluate image qualityDigitally marking record carriersMechanical recordingGranularityImage recording

The invention concerns an image recording apparatus suitable for forming a medical image that is used for a medical diagnosis, and a test pattern for evaluating a quality of the medical image. The image recording apparatus includes a printing section to either the medical image or the test pattern on the recording medium, based on image date; a printing-condition setting section to set a printing condition for printing the test pattern; and a printing-condition displaying section to display the printing condition set by the printing-condition setting section. The printing section prints at least one of a sharpness-evaluating pattern and a granularity-evaluating pattern.

Owner:KONICA CORP

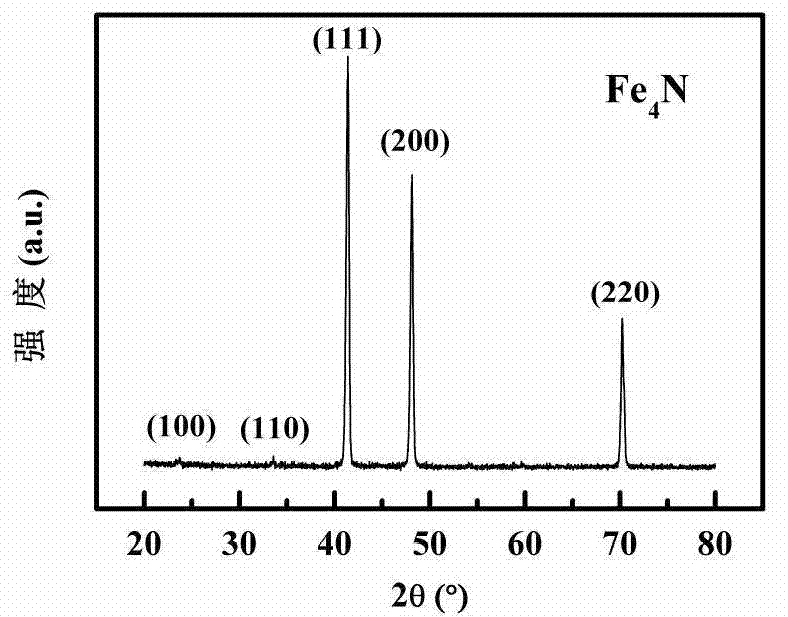

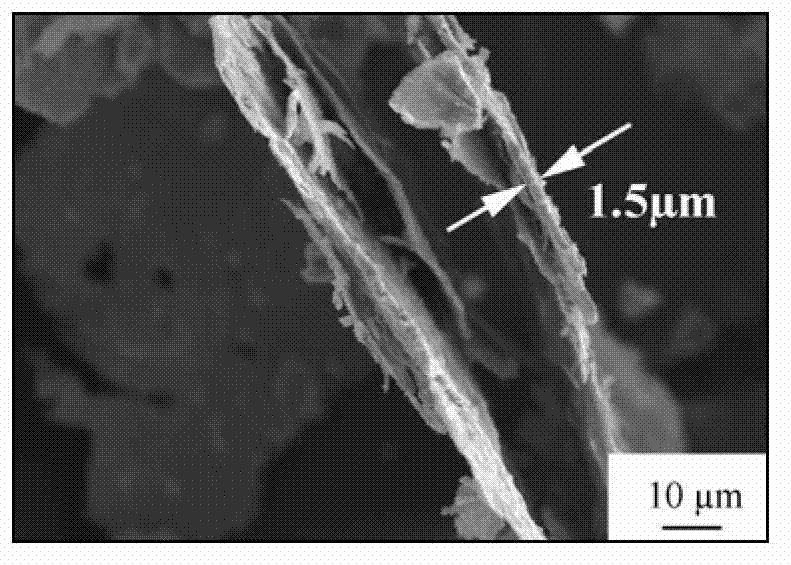

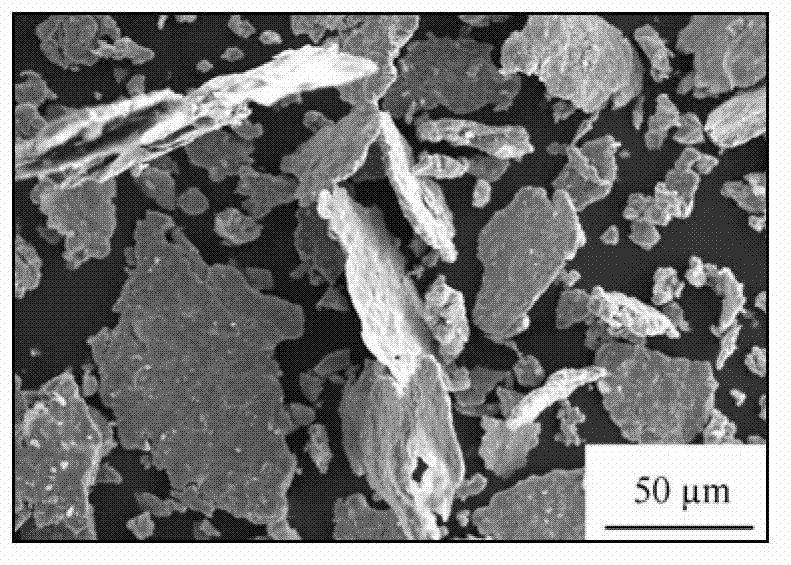

Flat magnetic powder and preparation method thereof

The invention belongs to the technical field of magnetic powder and relates to flat magnetic powder and a preparation method thereof. The main phase of the magnetic powder is gamma'-Fe4N, the thickness of the powder is 0.1-9 micrometers, and the radium-thickness ratio is 10-200. The method includes: taking pure iron powder lower in hardness as a raw material, adopting the ball-milling method for flattening treatment, nitriding in a gas mixture of ammonia / hydrogen, and controlling technical parameters such as the thickness and the flatness of the powder by adjusting process conditions such as grain size and ball-milling time of the powder to realize control on electromagnetic performances such as cutoff frequency of the powder. The flat magnetic powder effectively reduces skin effect of a Fe4N material and is in favor of high-frequency application of the Fe4N material, and the preparation method is simple, flattening time is substantially lowered, production efficiency is improved, and control on micro-topography and the electromagnetic performances of the powder can be realized.

Owner:BEIJING UNIV OF TECH

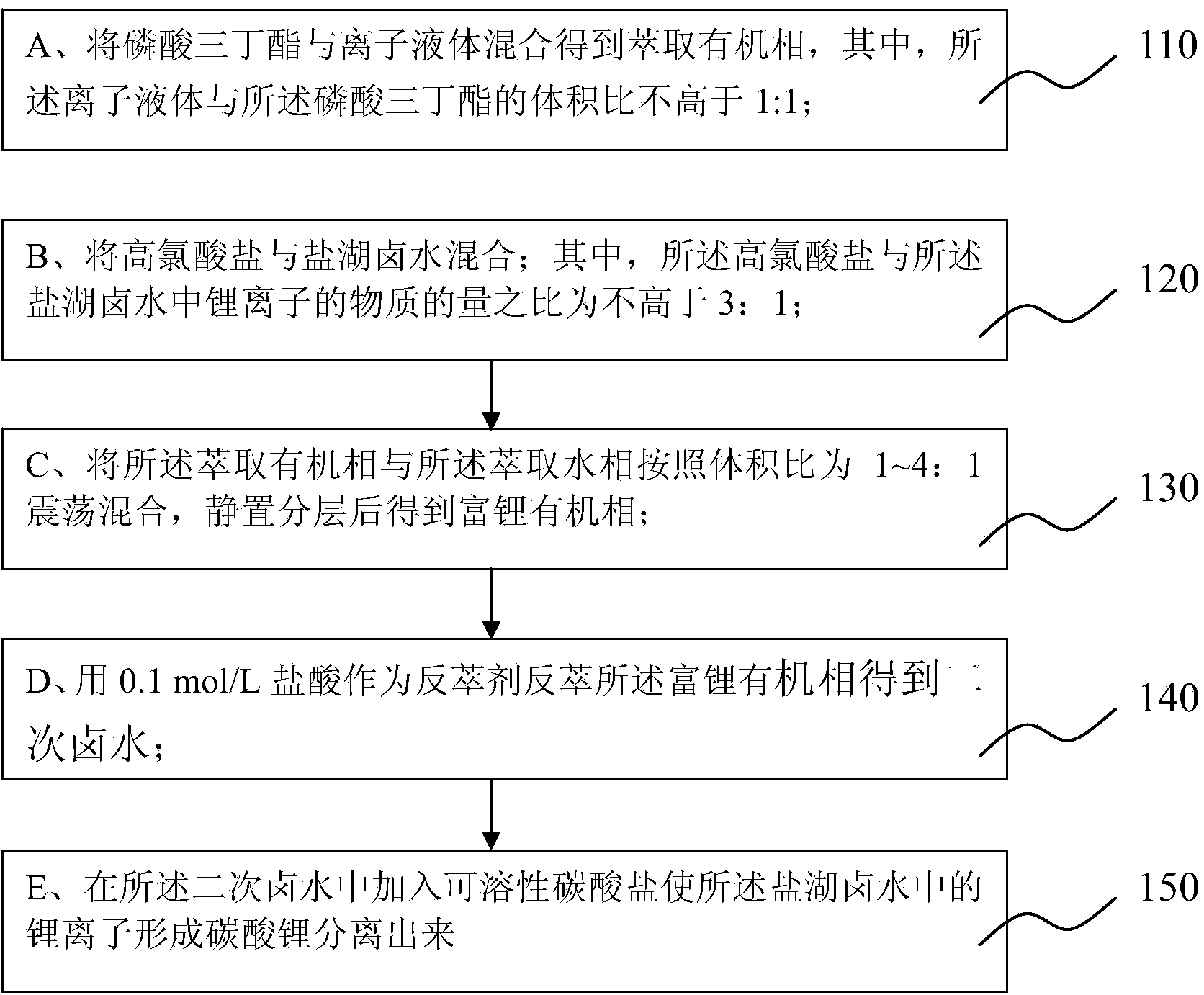

Method for separating lithium from salt lake brine

InactiveCN104232896ANo pollution in the processAvoid pollutionProcess efficiency improvementPhase splittingSalt lake

The invention discloses a method for separating lithium from salt lake brine. The method comprises the steps as follows: tributyl phosphate and an ionic liquid are mixed to obtain an extracted organic phase, wherein the volume ratio of the ionic liquid to tributyl phosphate is not higher than 1:1; perchlorate and the salt lake brine are mixed, wherein the ratio of lithium ions in the perchlorate to those in the salt lake brine is (0.5-3):1, and the extracted organic phase and an aqueous phase are oscillated and mixed for 8-12 min at room temperature at the volume ratio of (1-4):1 and is left to stand for 20 min to obtain a lithium-rich organic phase. According to the method for separating lithium from the salt lake brine, lithium is separated from the salt lake brine with high ratio of magnesium to lithium, the separating efficiency is high, and the problems of pollution caused by solvent volatilization and phase-splitting difficulty due to system emulsification are solved.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

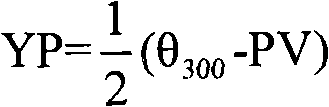

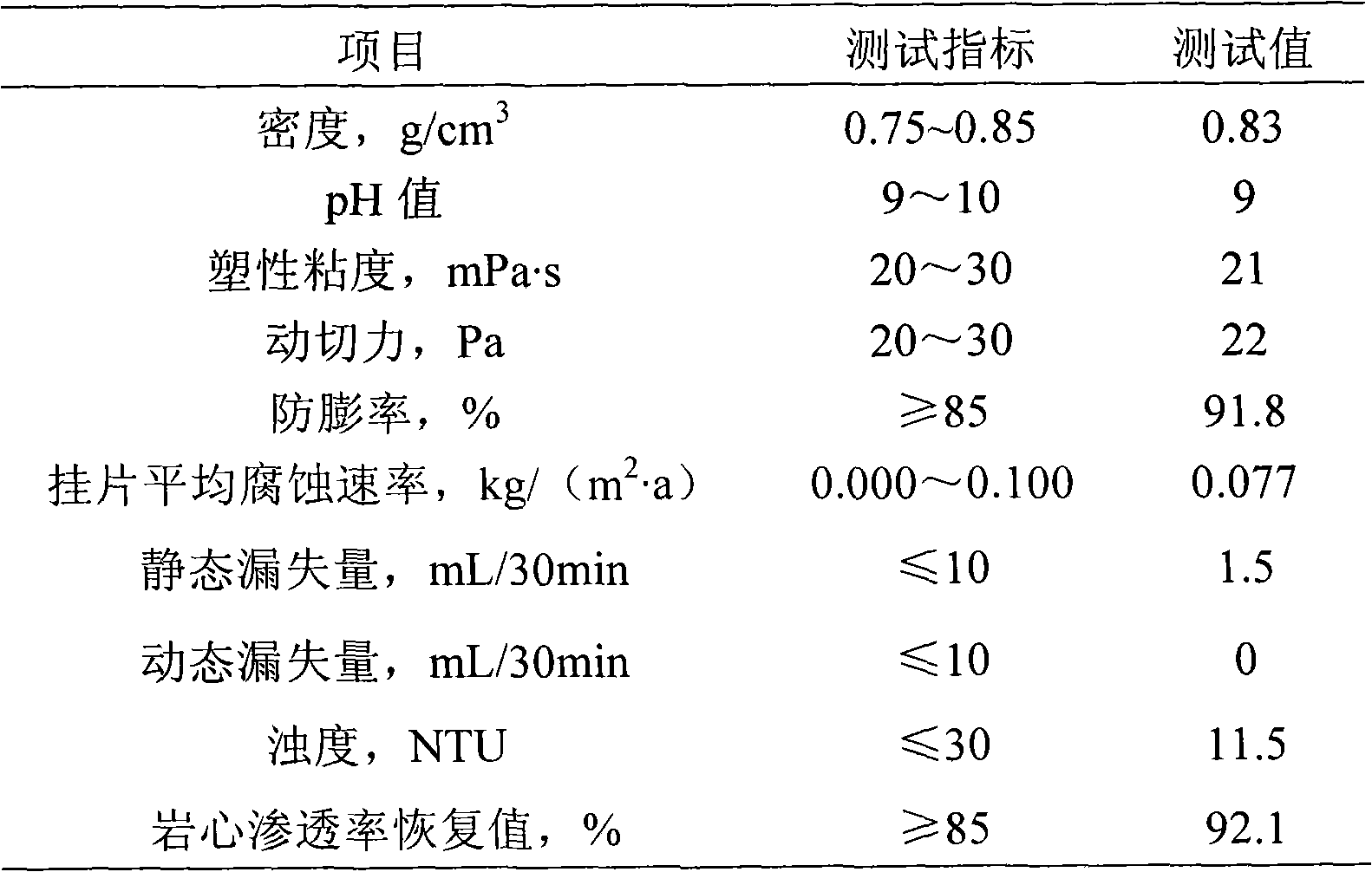

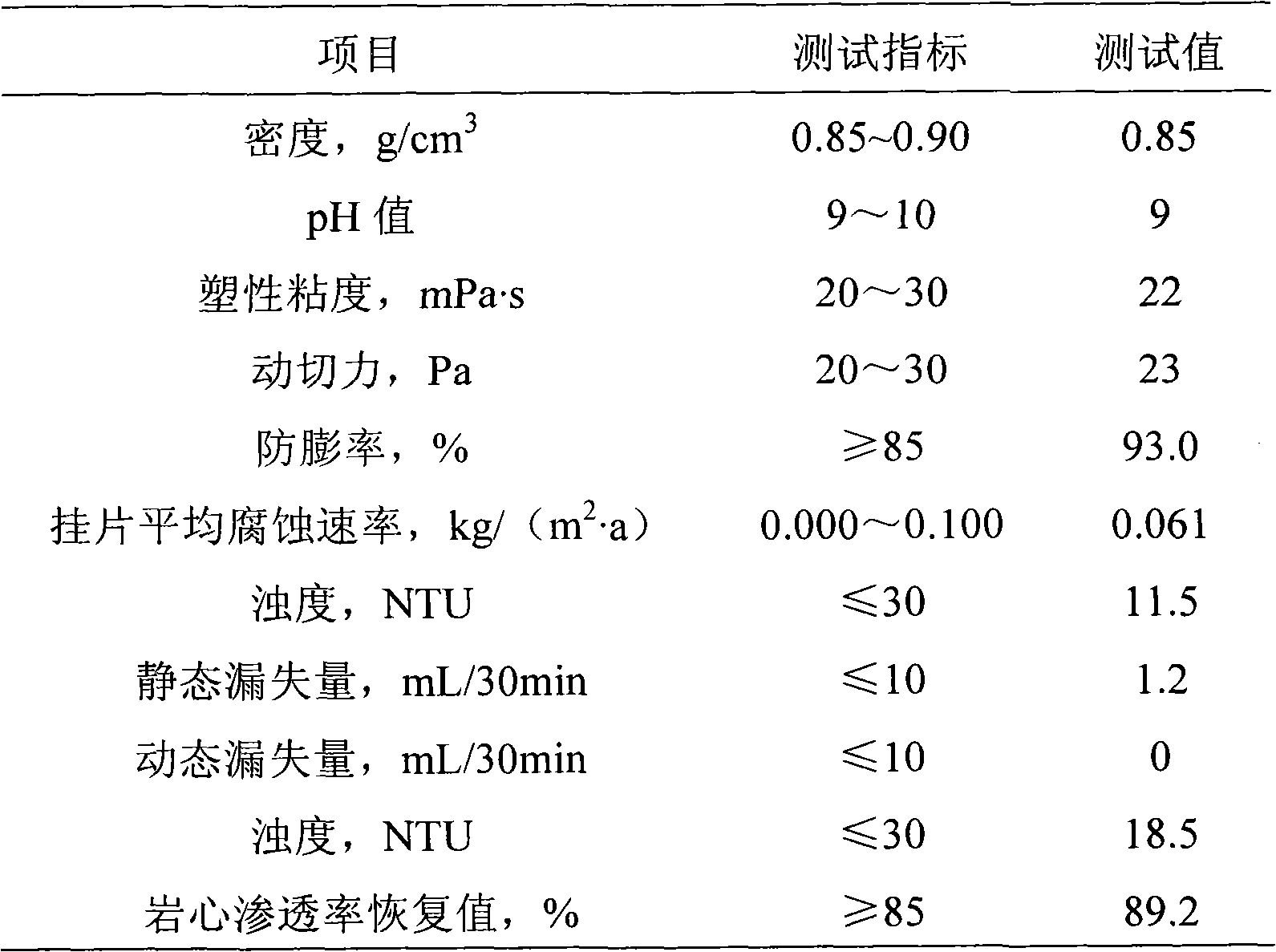

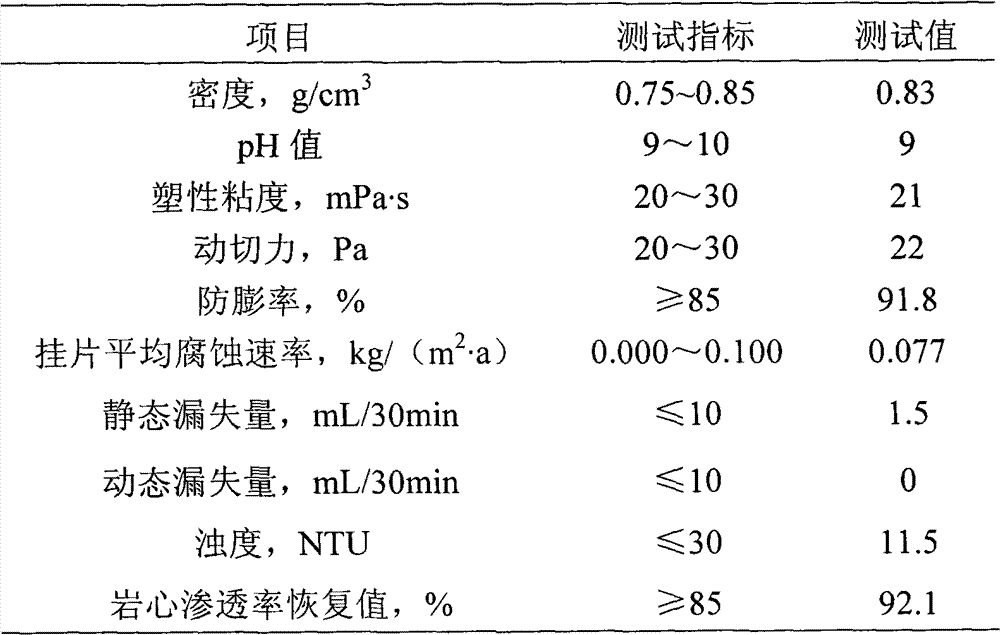

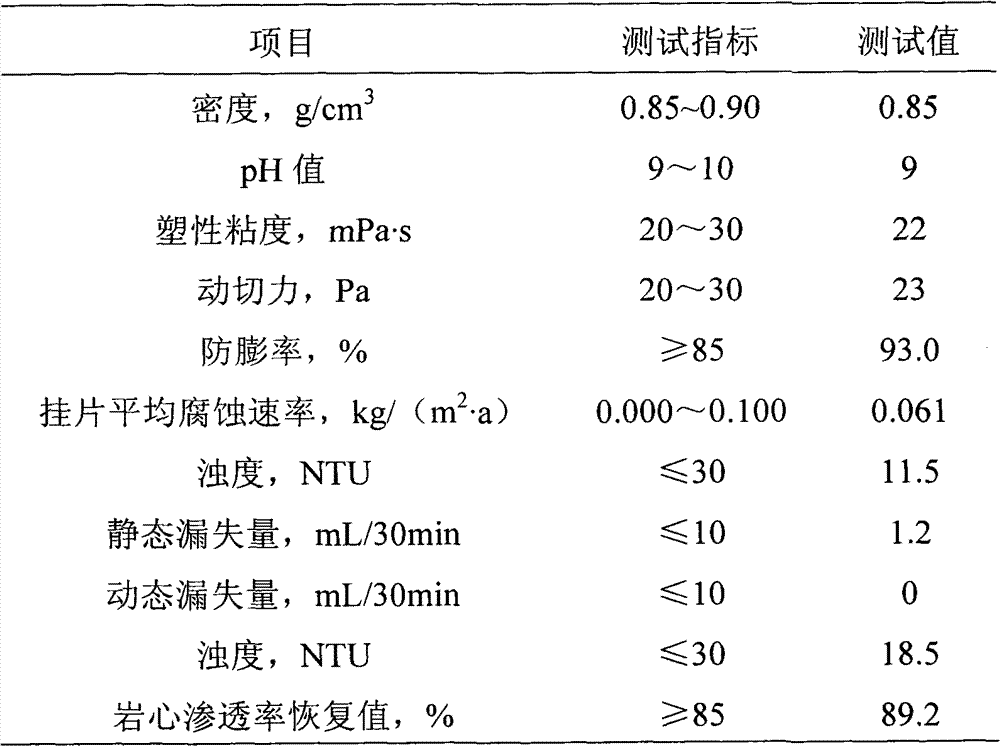

Perforating fluid for well completion

ActiveCN101974315AOvercome the disadvantage of difficult density controlInhibition of hydration swelling capacityDrilling compositionFoaming agentNitrogen

The invention discloses a low-temperature microfoam perforating fluid for an offshore oil well completion, comprising the following materials: water, sodium carbonate, flow pattern regulators, foaming agents and stabilizers, wherein the ratio of the water, the sodium carbonate, the flow pattern regulators, the foaming agents to the stabilizers is 100:(0.1-0.3):(0.3-0.4):(0.1-0.2):(0.2-0.4) in parts by weight. The low-temperature microfoam perforating fluid also comprises clay stabilizers, inhibiters and waterproof locking agents. The low-temperature microfoam perforating fluid for the offshore oil well completion is a novel perforating fluid, not only has the advantages of the traditional common perforating fluid, but also newly increases the advantages of leakage prevention and leakage stoppage on performance, solves the problem of leakage loss in the completion process and also has adjustable density. The invention overcomes the defects of numerous and jumbled nitrogen foam configuration equipment and difficult control of circular foam density on use and has simple and easy configuration equipment and convenient and easy density adjustment.

Owner:CHINA NAT OFFSHORE OIL CORP +1

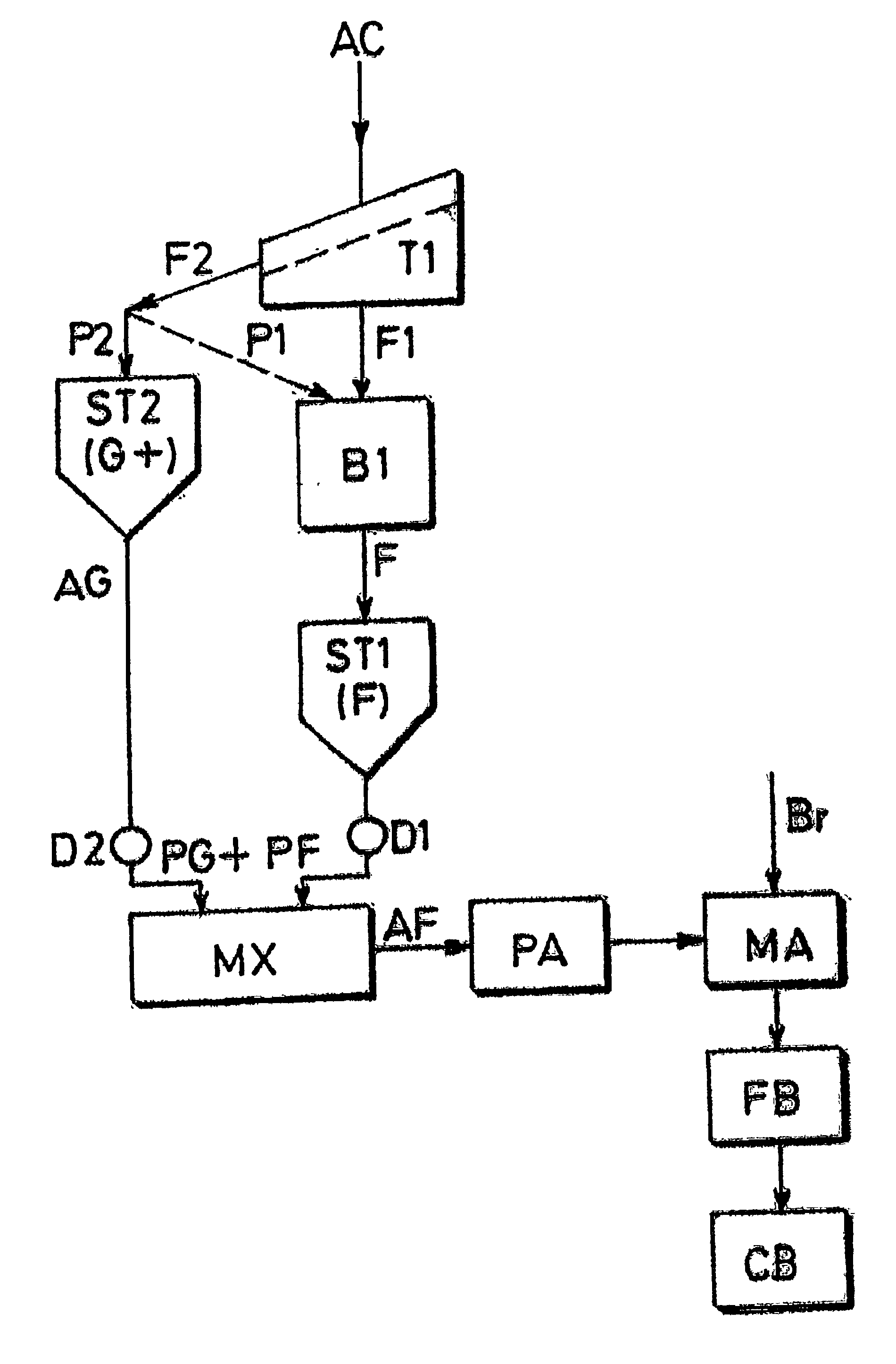

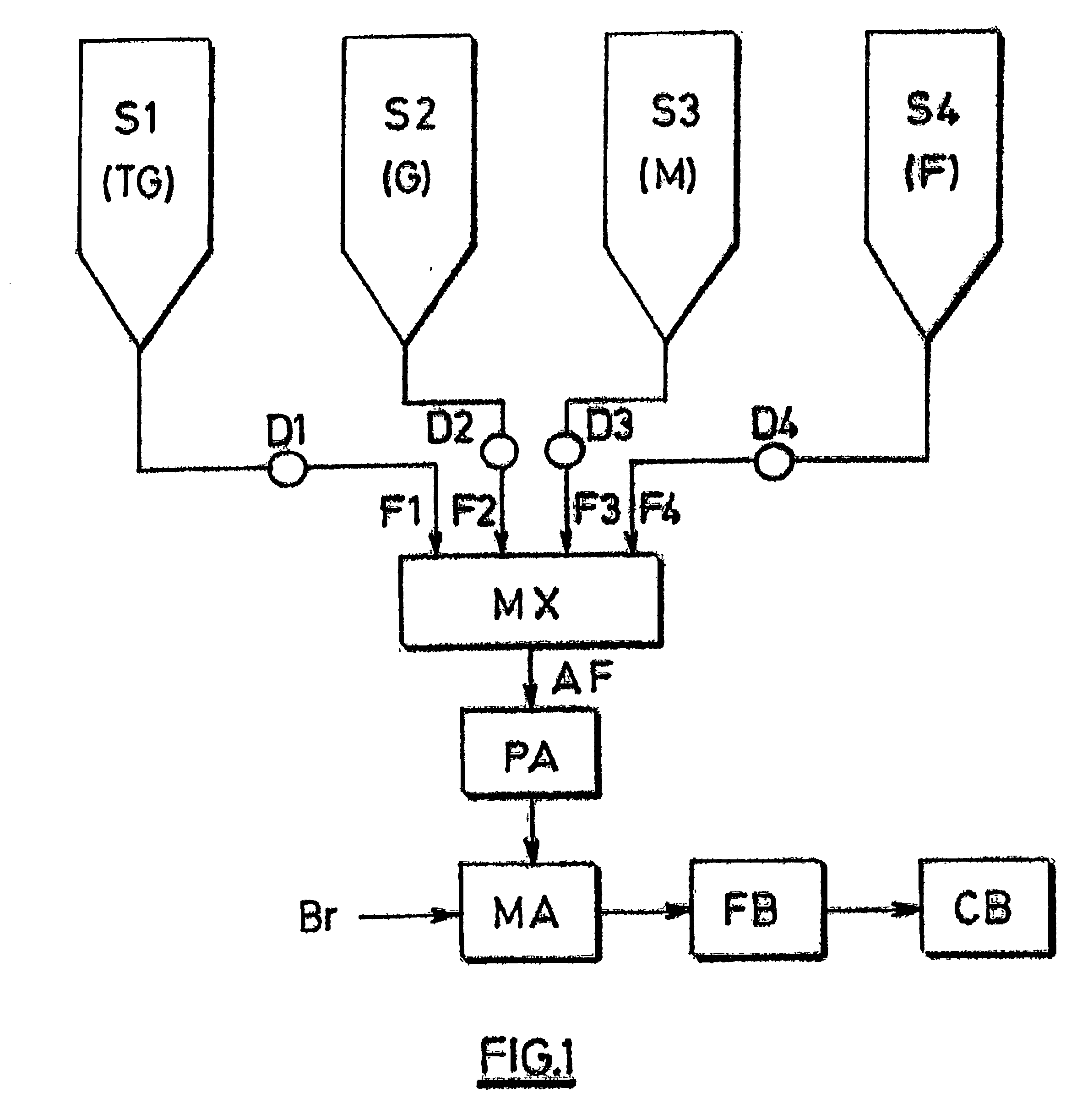

Method for making carbon blocks highly resistant to thermal shock

InactiveUS6838024B1Increase densitySufficient resistanceArtificial filament recoveryCeramic shaping apparatusCrystalliteUltra fine

The invention relates to a simplified production process with which it is possible to obtain carbon blocks, in particular anodes intended for aluminium production using the Hall-Héroult electrolysis process, which have high thermal shock resistance. This process comprises a grain size distribution adjustment operation of a carbon aggregate which includes:[0002]a) separating an initial ungraded carbon aggregate AC into a first fraction F1 made up of grains whose sizes are smaller than X, and into a second fraction F2 made up of grains whose sizes are X or greater, X lying between 0.2 and 2 mm;[0003]b) crushing B1 the first fraction F1 and part P1 of the second fraction F2 such as to obtain a powder F comprising a controlled proportion of ultra-fine grains;[0004]c) mixing the remaining part P2 of fraction F2 and said powder F in proportions with which it is possible to obtain crude carbon blocks whose so-called “Gr / S” ratio between the proportion PGr of grains larger than 0.3 mm and the proportion PS of grains between 30 μm and 0.3 mm in size is at least equal to 4 and baked carbon blocks of high density.

Owner:ALUMINUM PECHINEY +1

Image processing apparatus and image processing method

InactiveUS7847980B2Density is easyImage enhancementDigitally marking record carriersImaging processingLatent image

An image processing apparatus performs a density adjustment process for generating an image containing a copy-forgery-inhibited pattern image for warning against the use of copy products. To help users to easily adjust the density of a latent image portion and a background portion in the copy-forgery-inhibited pattern image, the image processing apparatus determines a density relationship of the latent image portion and the background portion by performing a plurality of adjustment operations, in combination, different in the amount of adjustment relating to the range of variable density in at least one of the latent image portion and the background portion, and sets, based on the density relationship, the density data of each of the latent image portion and the background portion in the data of the copy-forgery-inhibited pattern image.

Owner:CANON KK

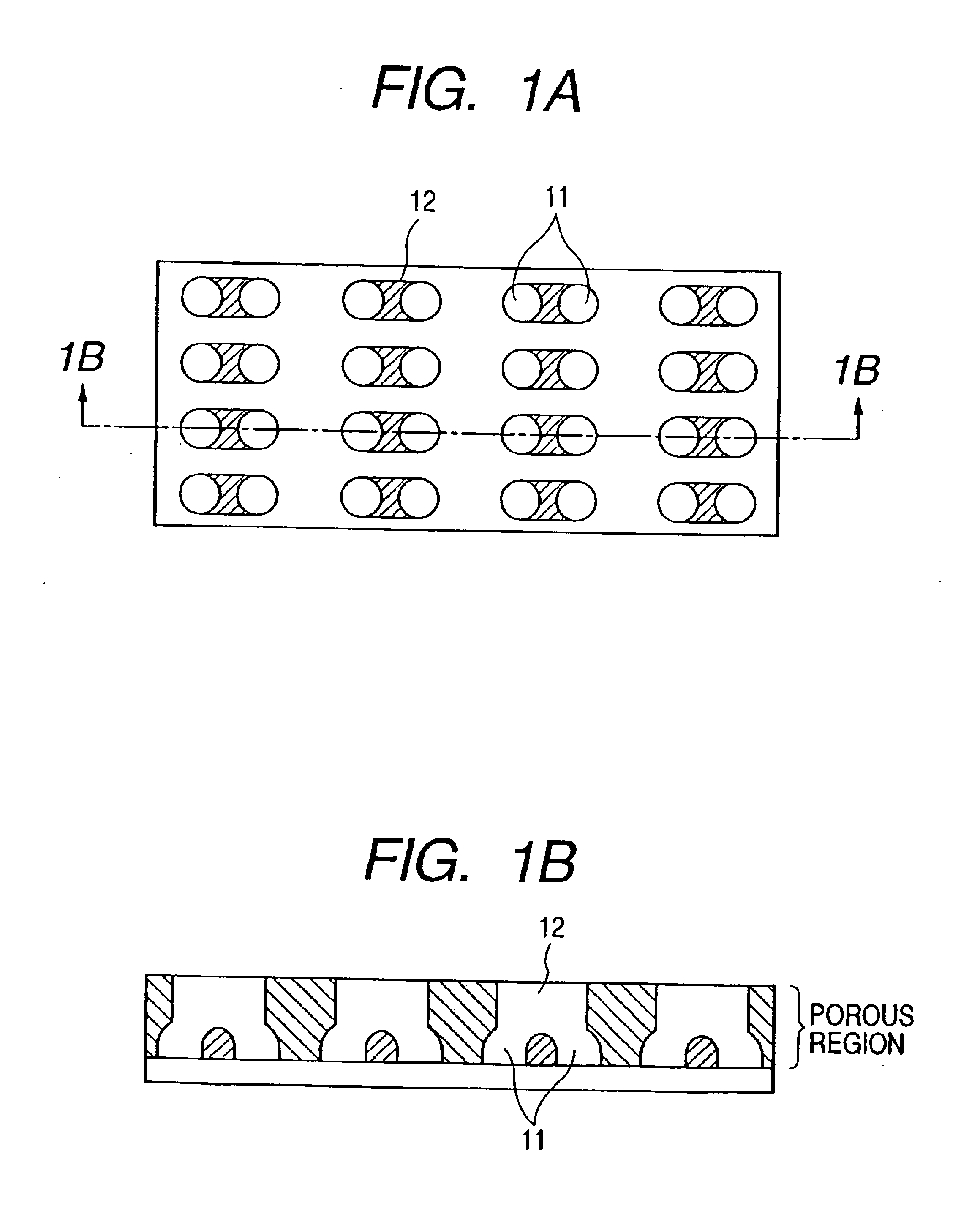

Columnar structured material and manufacturing method therefor

InactiveUS6930057B2Increase dot densityDensity is easyMagnetic layer production by platingNanoinformaticsNanoholeMagnetization

To provide a method for manufacturing a magnetic recording medium which creates anodically oxidized aluminum nanoholes so as to have a rectangular or elliptical sectional shape and gives shape anisotropy to a magnetic material filled in the nanoholes to thereby always fix a relative positional relation between magnetizations of the magnetic material and a magnetic head that detects the magnetizations. The method for manufacturing a magnetic recording medium includes: preparing a member having regularly arranged plural pits; subjecting the member to anodic oxidation treatment so that formation of holes is started with the pits as starting points, and a porous region, which has a first portion where the holes are formed without branching and a second portion where branched holes are formed, is formed; filling a magnetic material in the formed holes; and removing the non-branching portions of the holes.

Owner:CANON KK

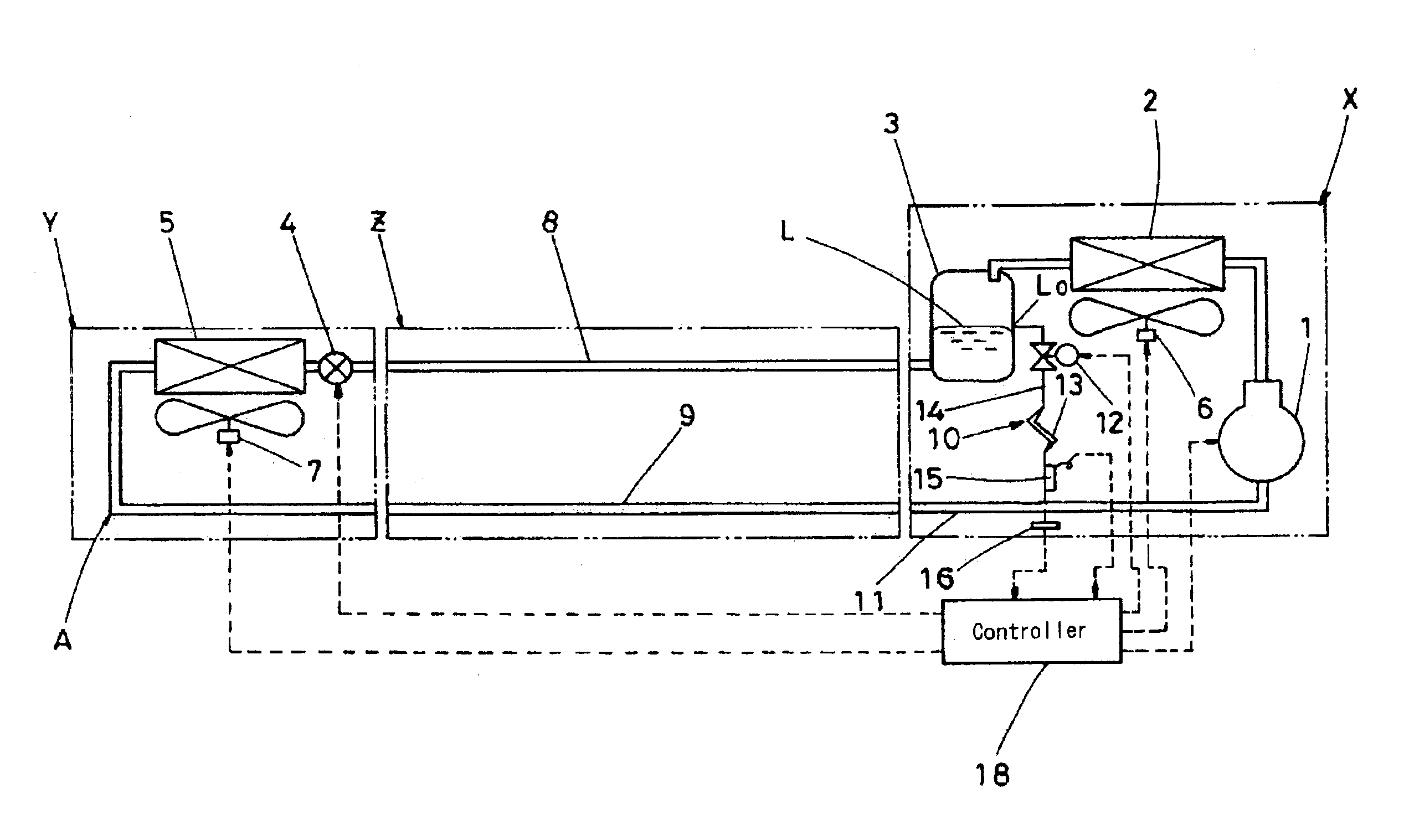

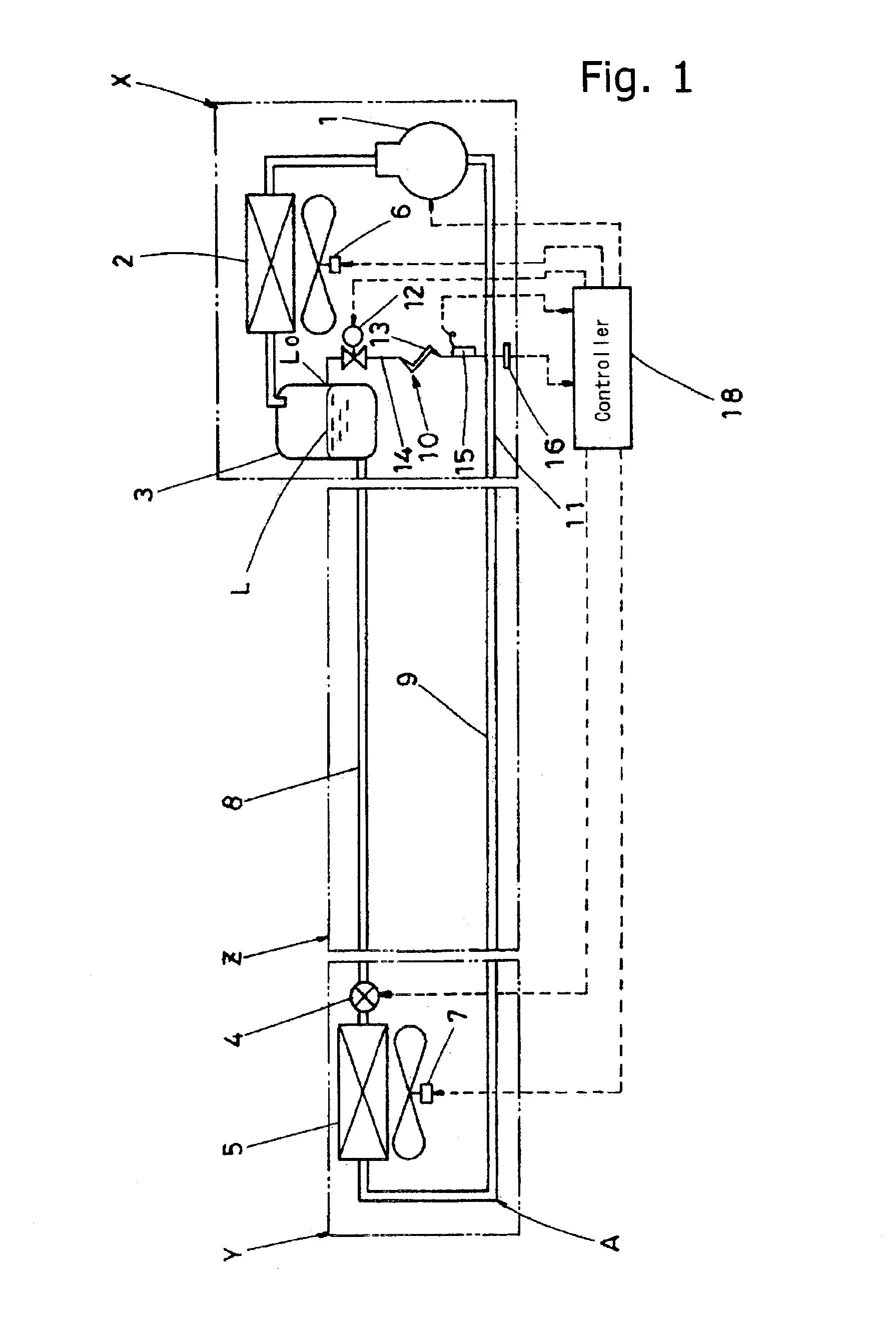

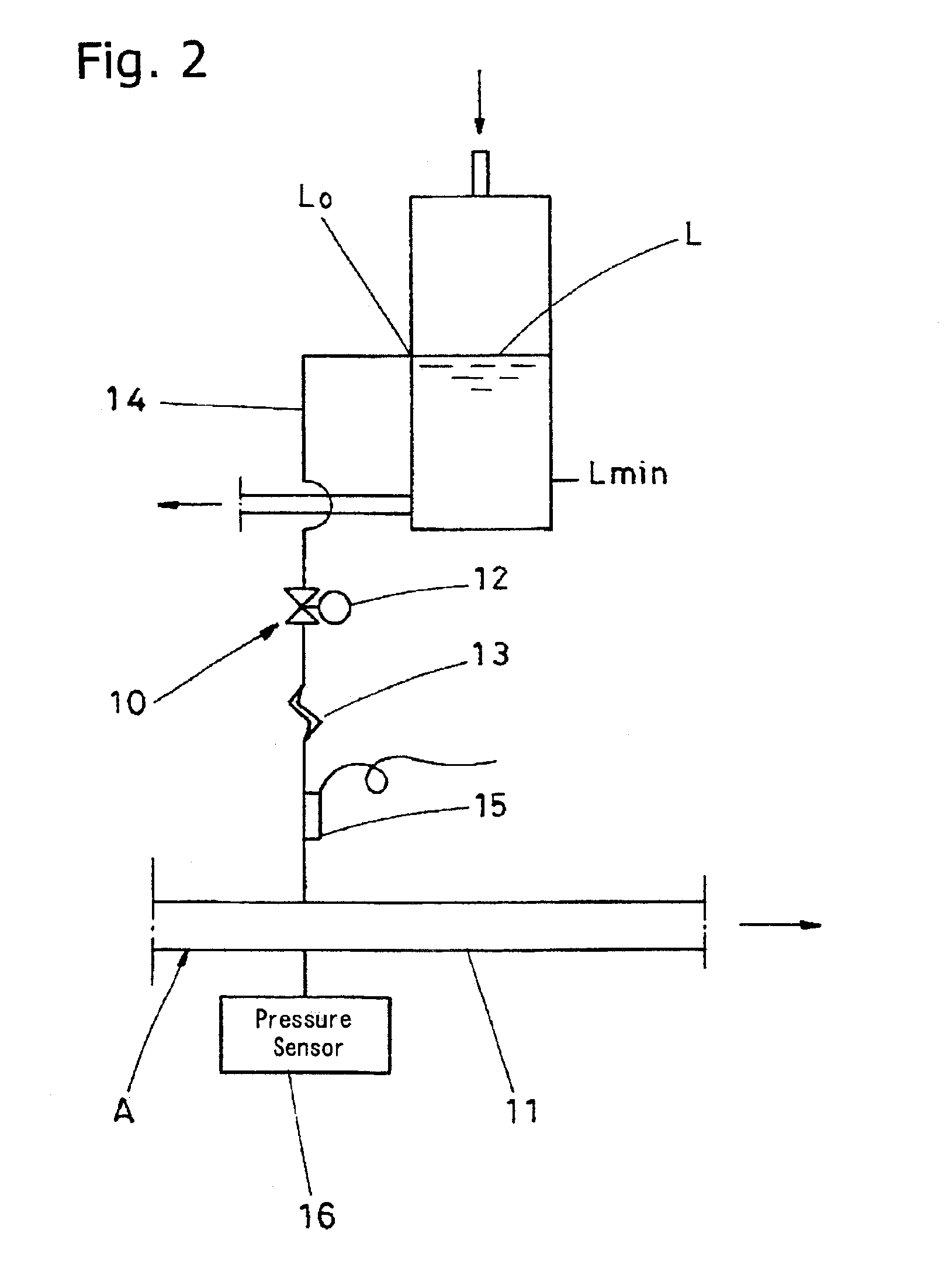

Refrigeration apparatus

InactiveUS6845626B2Easy to getReliable detectionCompression machines with non-reversible cycleEvaporators/condensersRefrigerantEvaporator

This invention makes it possible to charge a refrigeration apparatus with the amount of refrigerant that the refrigeration apparatus requires at the time of onsite installation. As a result, the optimum refrigerant charging amount can always be obtained. The refrigeration apparatus is provided with a refrigeration cycle in which an outdoor unit equipped with a compressor, a condenser, and a receiver is connected to an indoor unit equipped with an expansion valve and an evaporator via a liquid pipe and a gas pipe. The refrigeration cycle is charged with refrigerant while a refrigerant charging operation state is created in which the liquid pipe that connects the outdoor unit to the indoor unit is filled with liquid refrigerant having a prescribed density. Refrigerant charging ends when, during the refrigerant charging operation, it is detected that the level of the liquid inside the receiver has reached a prescribed level.

Owner:DAIKIN IND LTD

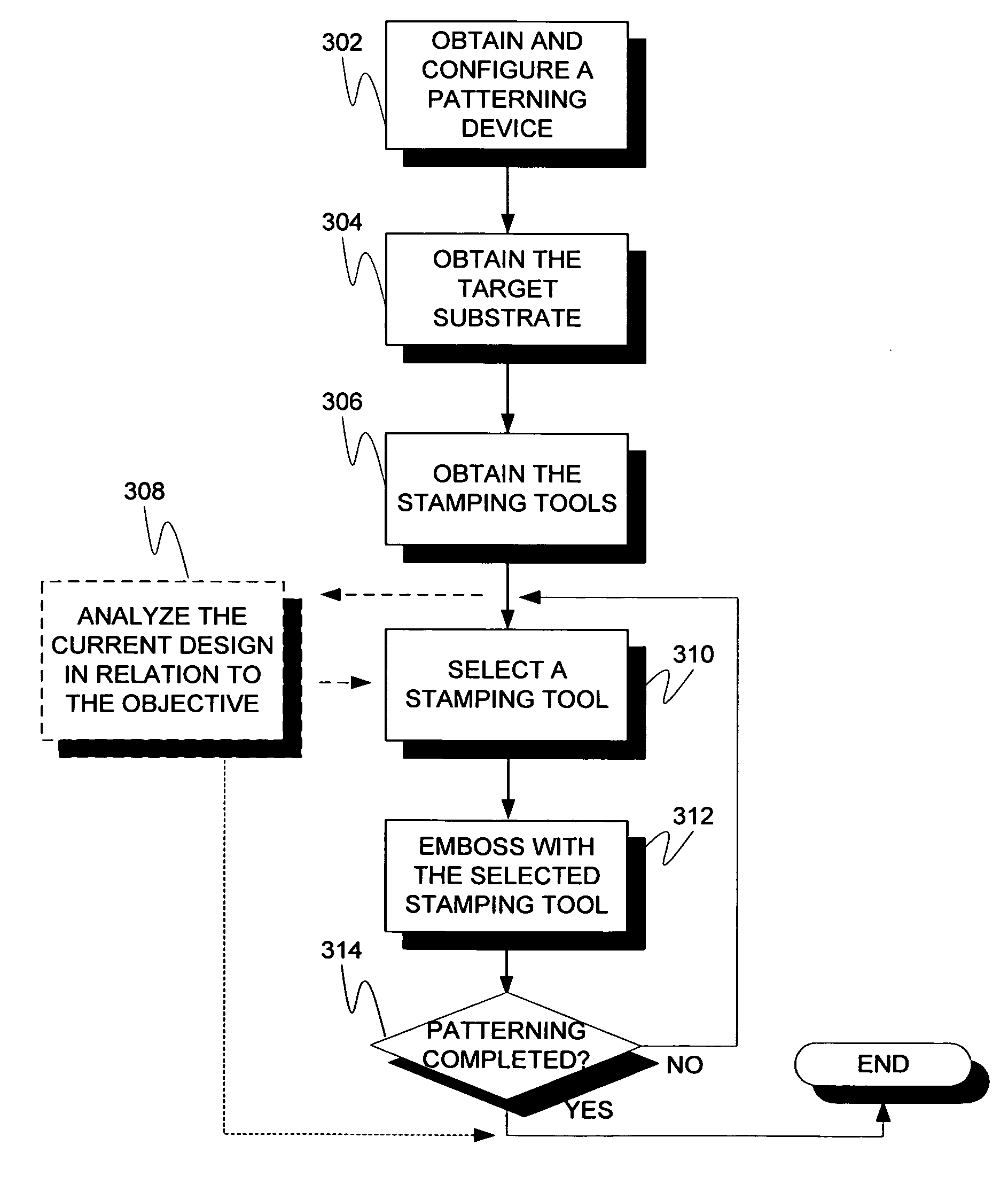

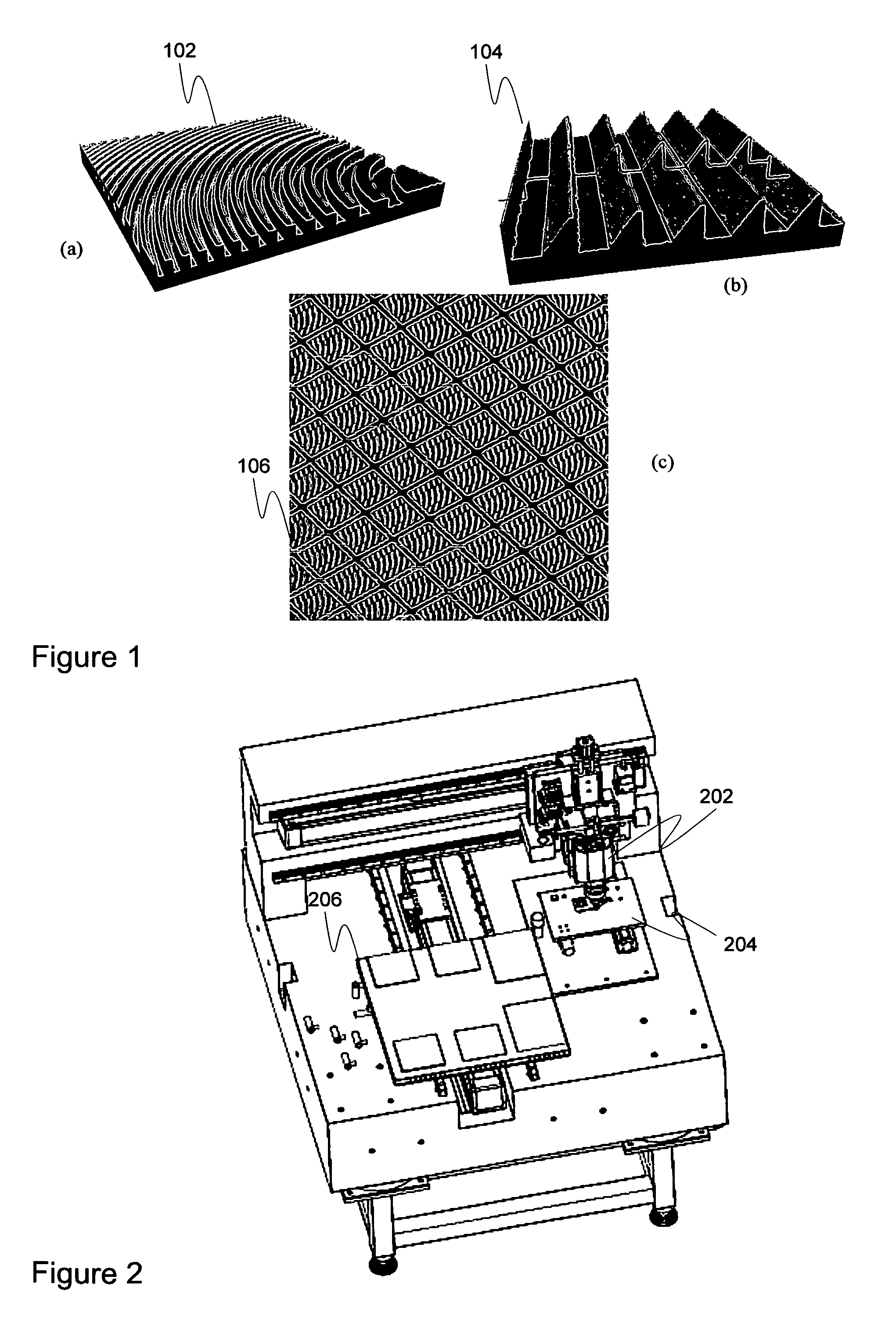

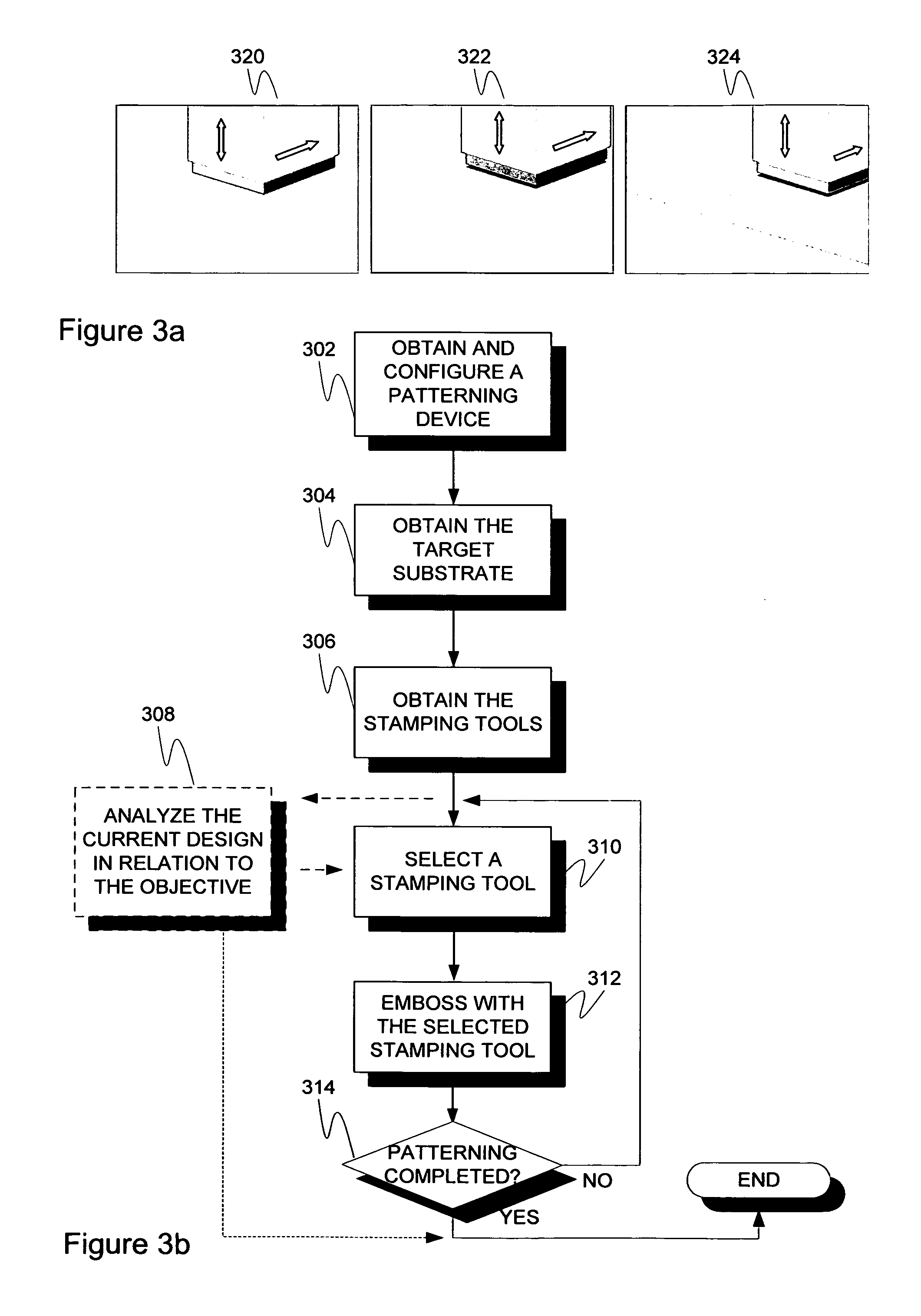

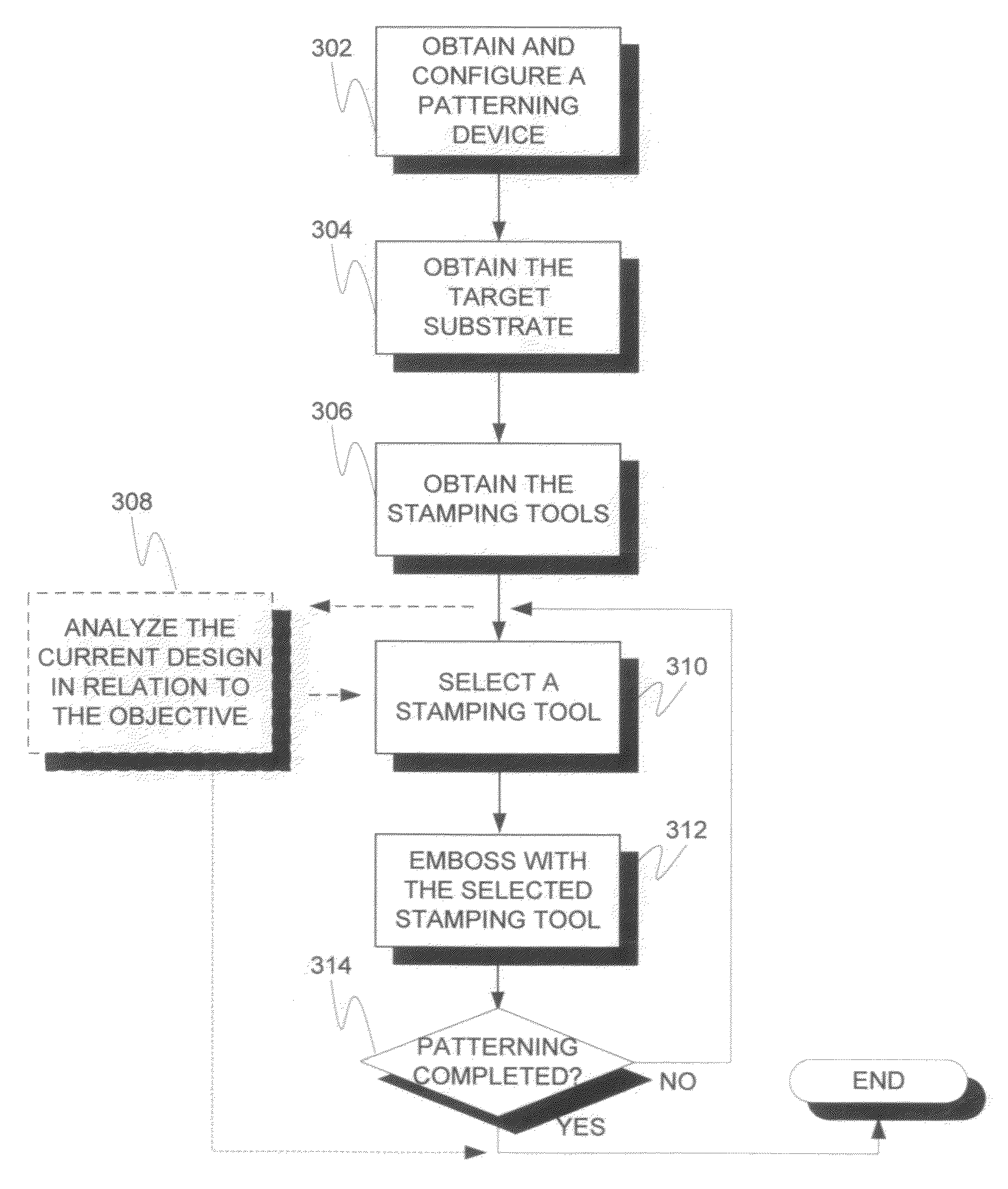

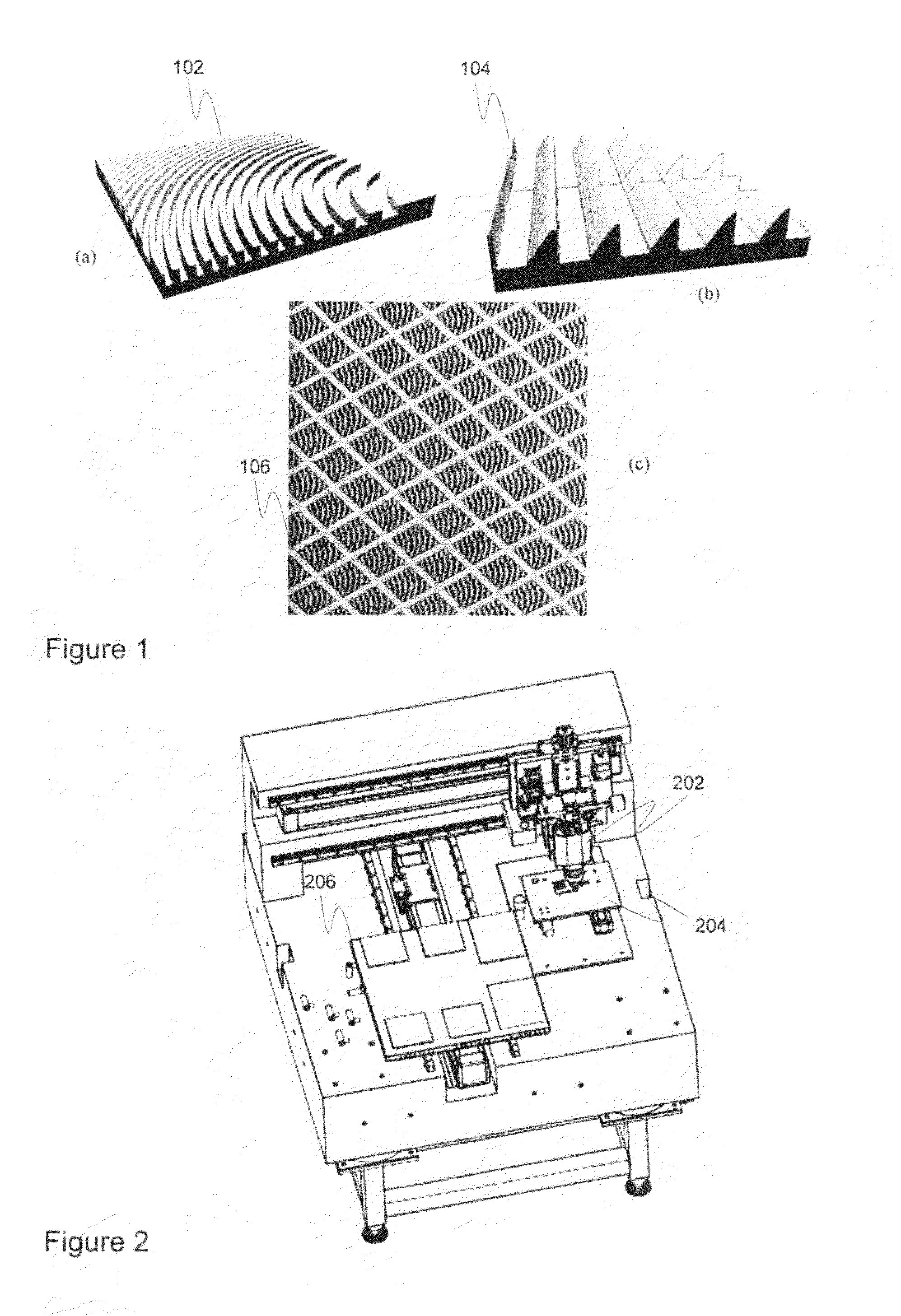

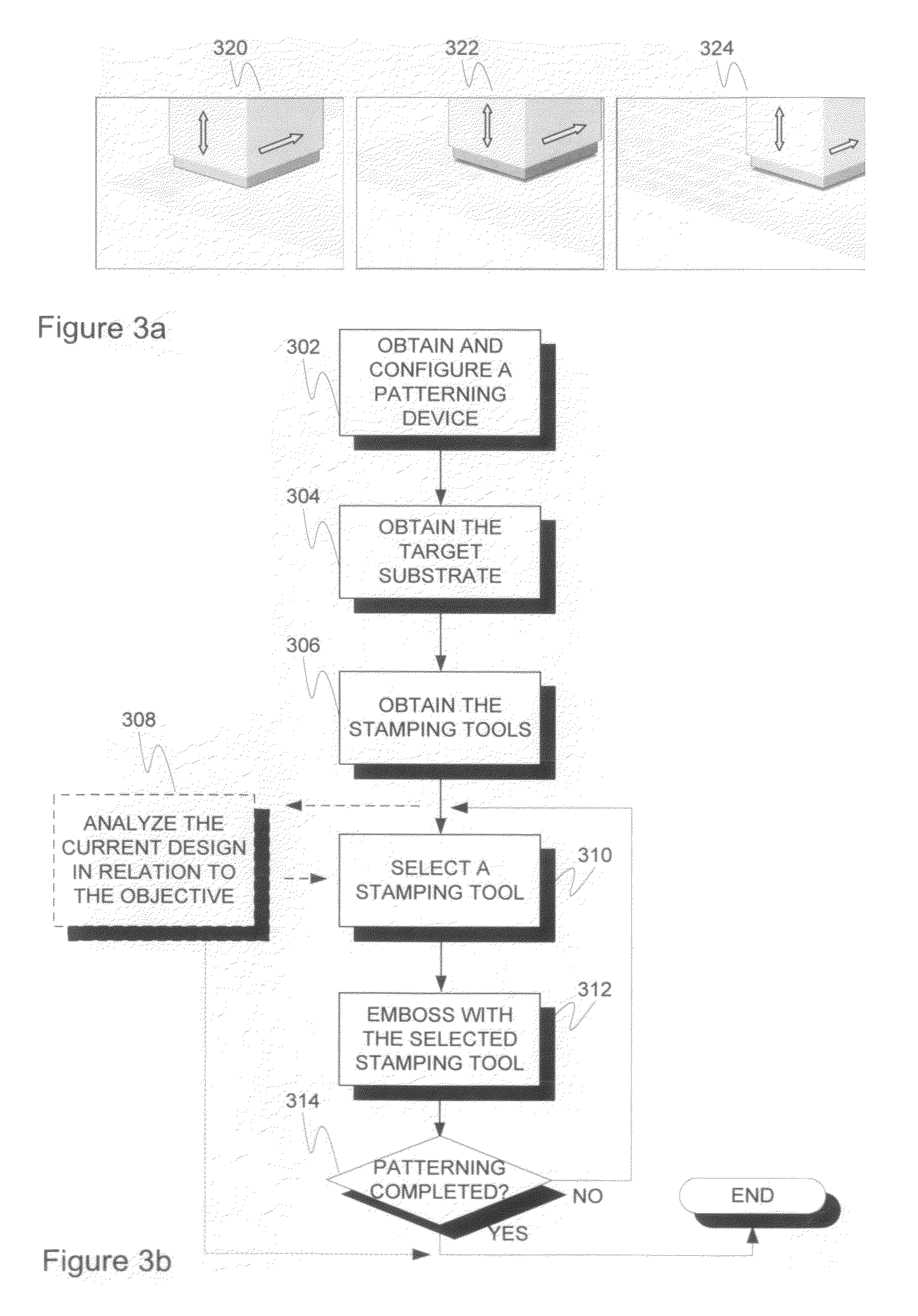

Method and arrangement for manufacturing optical products with complex three-dimensional forms

InactiveUS20080196607A1Density of pattern can be easilyEasy to manageMechanical working/deformationDecorative surface effectsUltraviolet lightsEngineering

A method, an arrangement and computer program product for manufacturing micro-optic surface design with complex, variable three-dimensional forms. A step embossing, step imprinting, a chip bonding or a corresponding device capable of patterning the surface of a target substrate is obtained. The target substrate whereto the micro-optic structures shall be patterned is obtained. A plurality of different stamping tools operable with the device is obtained. Each stamping tool includes one or more surface relief forms defining one or more micro-optic structures. A stamping tool is selected from the plurality of stamping tools by the device. The target substrate is embossed with the selected stamping tool as controlled by the device. The selected stamping tool is optionally heated or assisted by at least one ultraviolet light so as to cure the target substrate during or after the embossing. The selecting and embossing steps are repeated until the micro-optic surface design has been completed on the substrate.

Owner:MODILIS HLDG LLC

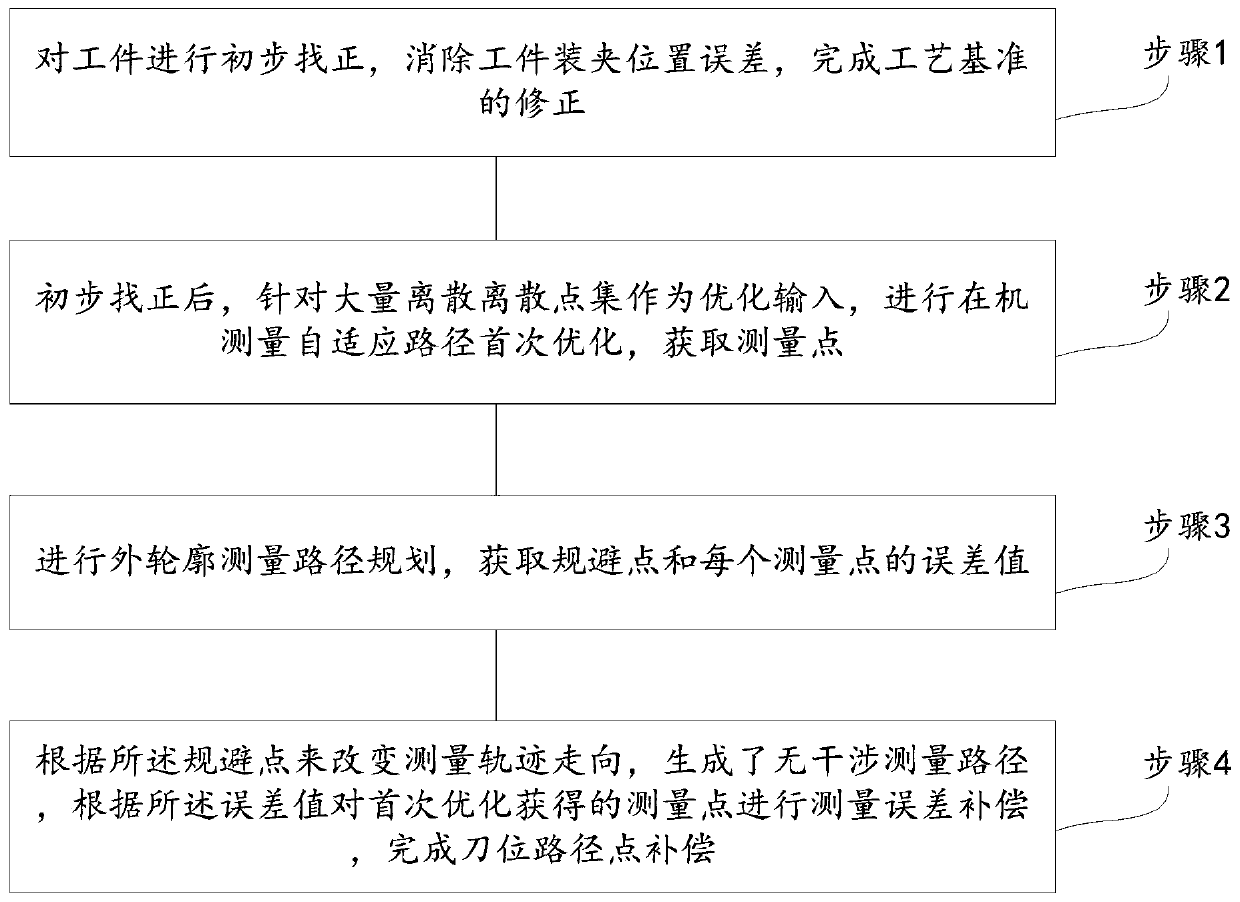

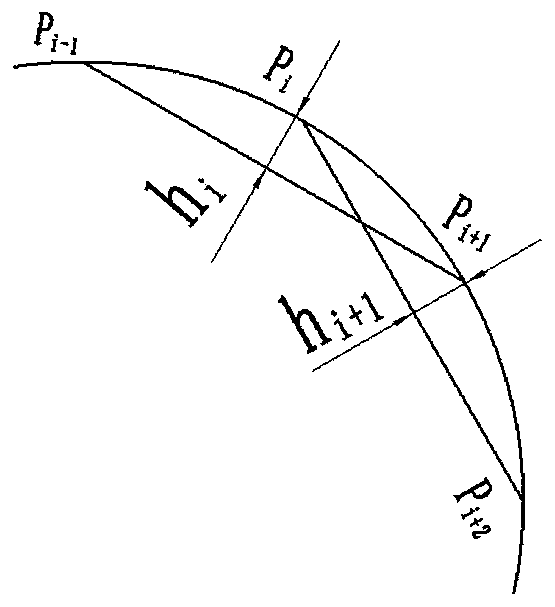

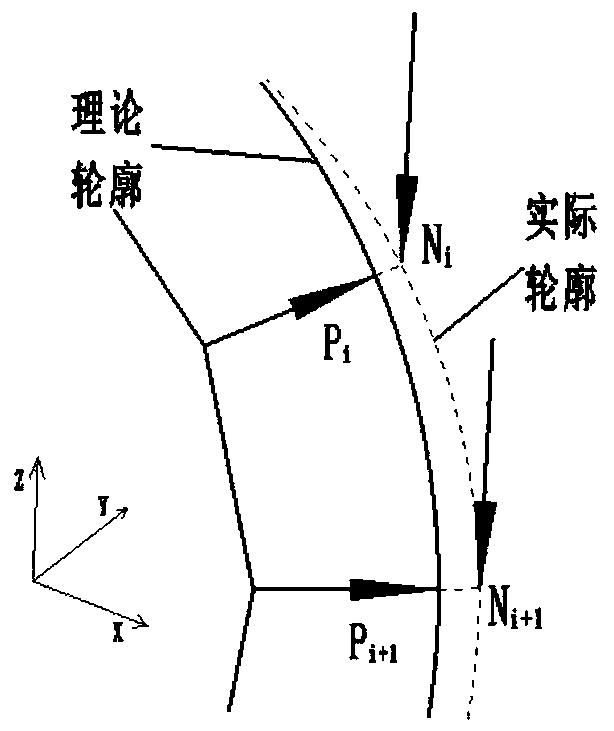

3C product shell transition area machining path self-adaptive planning method

InactiveCN109782692ADensity is easyImprove measurement efficiencyProgramme controlComputer controlObservational errorCutter location

The invention relates to a 3C product shell transition area machining path self-adaptive planning method which comprises the steps that a workpiece is preliminarily aligned, a workpiece clamping position error is eliminated, and correction of a technological reference is completed. After preliminary alignment, a large number of discrete point sets are taken as optimization input, on-machine measurement adaptive path first optimization is carried out, and measurement points are obtained; an outer contour measurement path is planned, and an error value of an avoidance point and each measurementpoint is obtained; the direction of the measurement track is changed according to the avoidance point, a non-interference measurement path is generated, and measurement error compensation is carried out on the measurement point obtained by first optimization according to an error value to complete cutter location path point compensation. According to the method, the density of the measurement points can be changed along with the change of the contour curvature, the larger the change of the contour curvature to be measured is, the denser the measurement points are, the reasonable obstacle avoidance distance given by the obstacle avoidance points is determined through the method, the measurement path cannot be placed too much, and the planning process of the collision-free measurement path is achieved under the condition that the precision and the efficiency are both considered.

Owner:WUHAN HUAZHONG NUMERICAL CONTROL +1

Ink jet recording sheet

Provided is an ink jet recording sheet suitable for outdoor use, the recording sheet giving rise to no blurring of an image, being provided with an ink receiving layer and a print portion having high water-resistance and excellent abrasive resistance in a wet condition while maintaining color developing ability and ink-fixing ability and having excellent color reproducibility and light resistance. The ink jet recording sheet comprises an ink receiving layer disposed on a substrate, said ink receiving layer being formed by preparing a layer containing a porous filler and a binder by application and drying on the substrate and thereafter allowing the layer to be impregnated with a water-soluble cationic organic material, wherein said layer containing the porous filler and the binder is formed using a coating liquid having a pH of 4 or less, the amount of the water-soluble cationic organic material contained in said layer containing the porous filler and the binder after the layer is impregnated with the water-soluble cationic organic material is 2% by weight or less in terms of solid ratio to the layer and said filler is contained in an amount of 40 to 80% by weight in the total solid of the ink receiving layer.

Owner:NISSHINBO IND INC

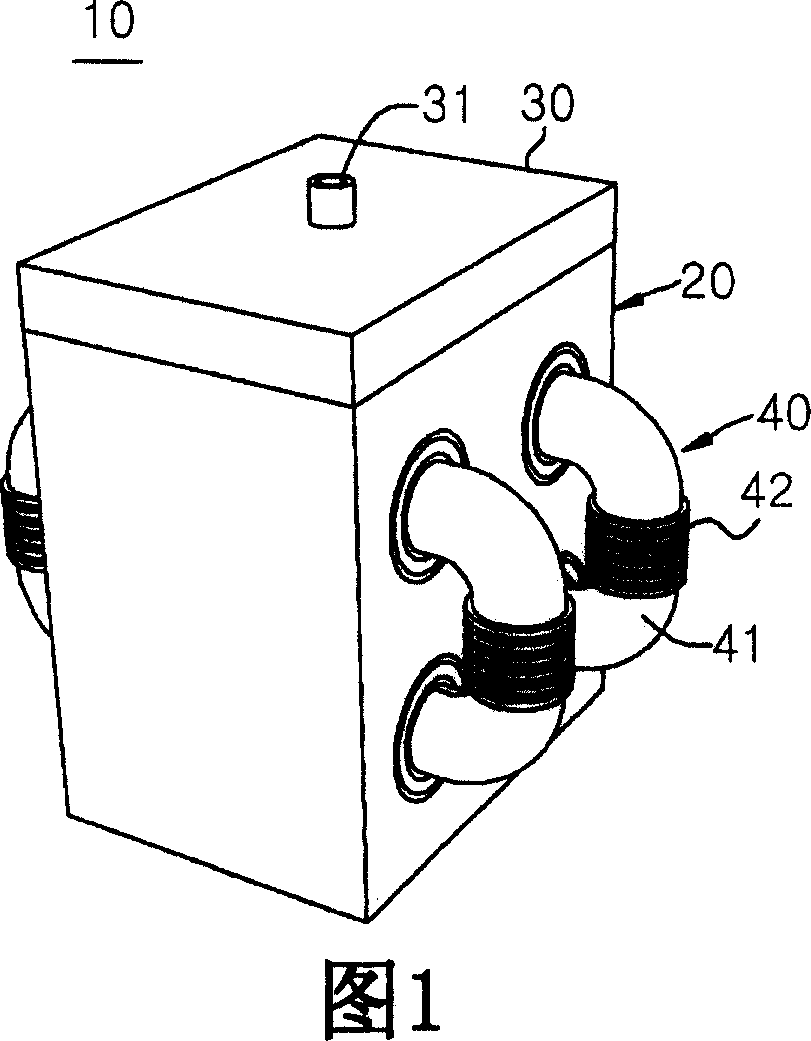

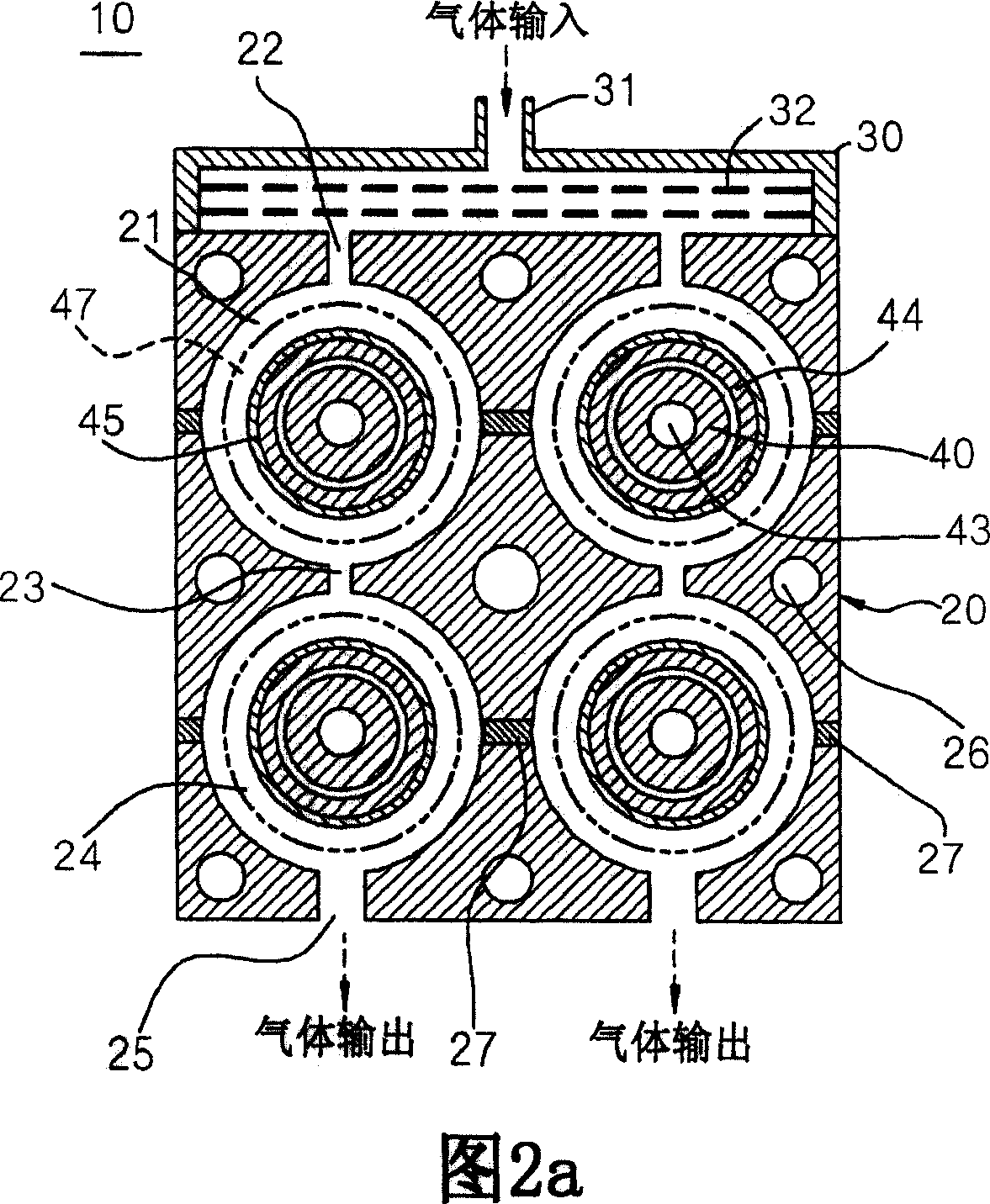

Inductively coupled plasma reactor with multiple magnetic cores

InactiveCN101064986AHigh densityDensity is easyElectric discharge tubesSemiconductor/solid-state device manufacturingPlasmonic couplingTransformer

There is provided an inductively coupled plasma reactor (10). The inductively coupled plasma reactor is connected to a transformer (60) with multiple magnetic cores (41) and a primary winding (42), to transfer an electromotive force for plasma discharge to a plasma discharge chamber (21) of a reactor body. Parts of magnetic core positioned in side the plasma discharge chamber are protected by being entirely covered by a core protecting tube (45). The primary winding is electrically connected to a power supply source providing radio frequency power. In the inductively coupled plasma reactor, since a number of magnetic core cross sectional parts are positioned inside the plasma discharge chamber, the efficiency of transferring the inductively coupled energy to be connected with plasma is very high.

Owner:NEW POWER PLASMA CO LTD

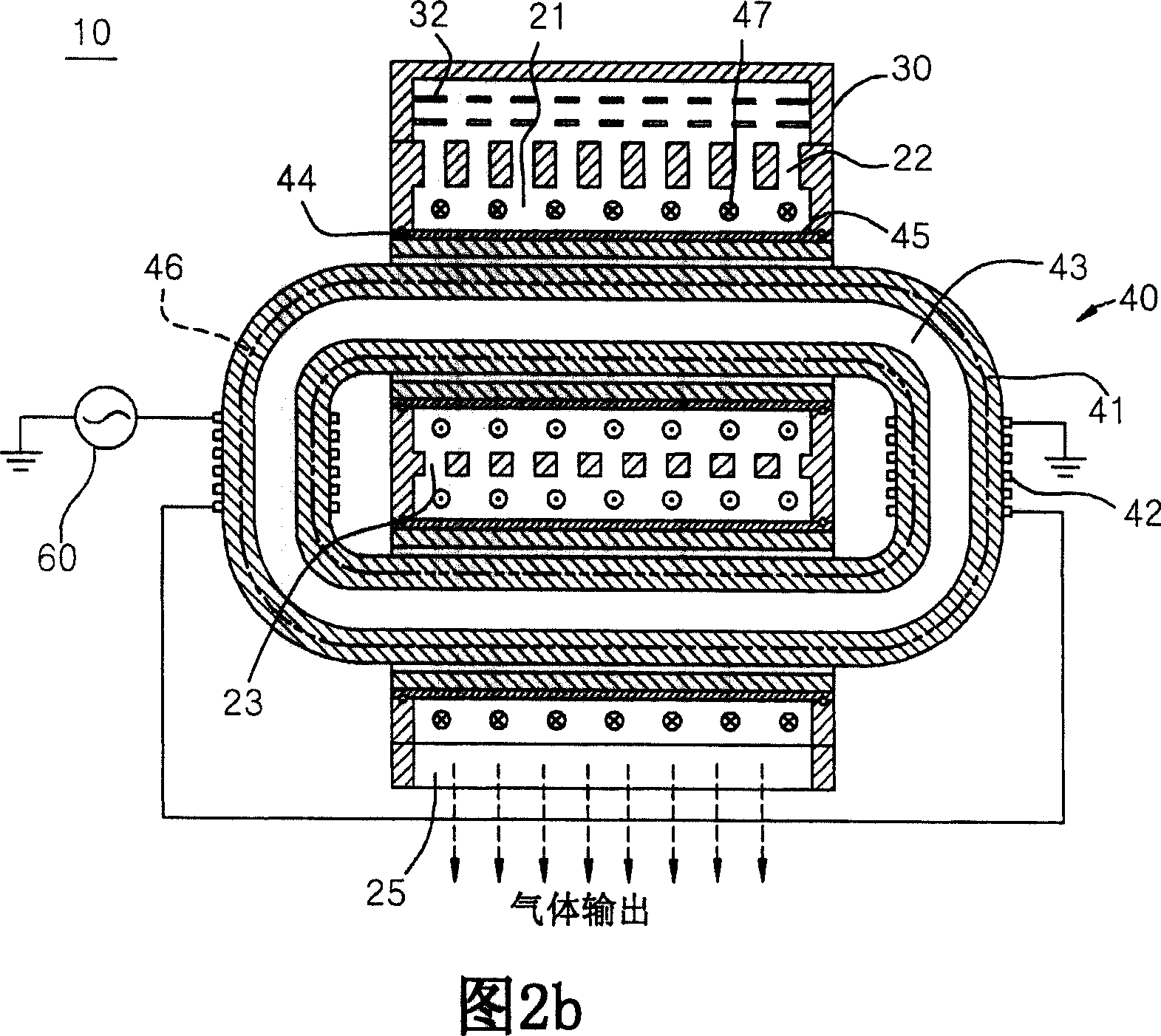

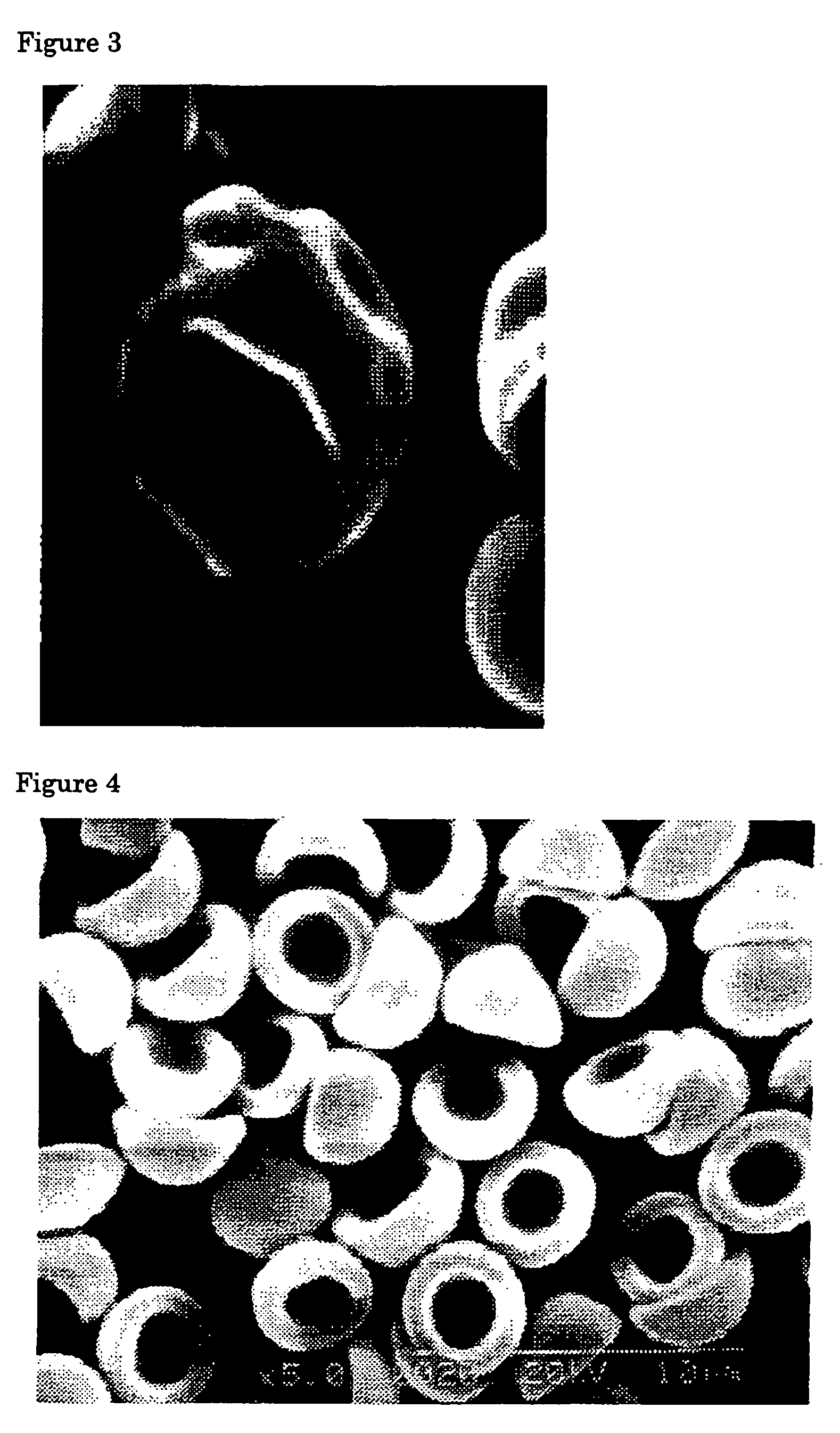

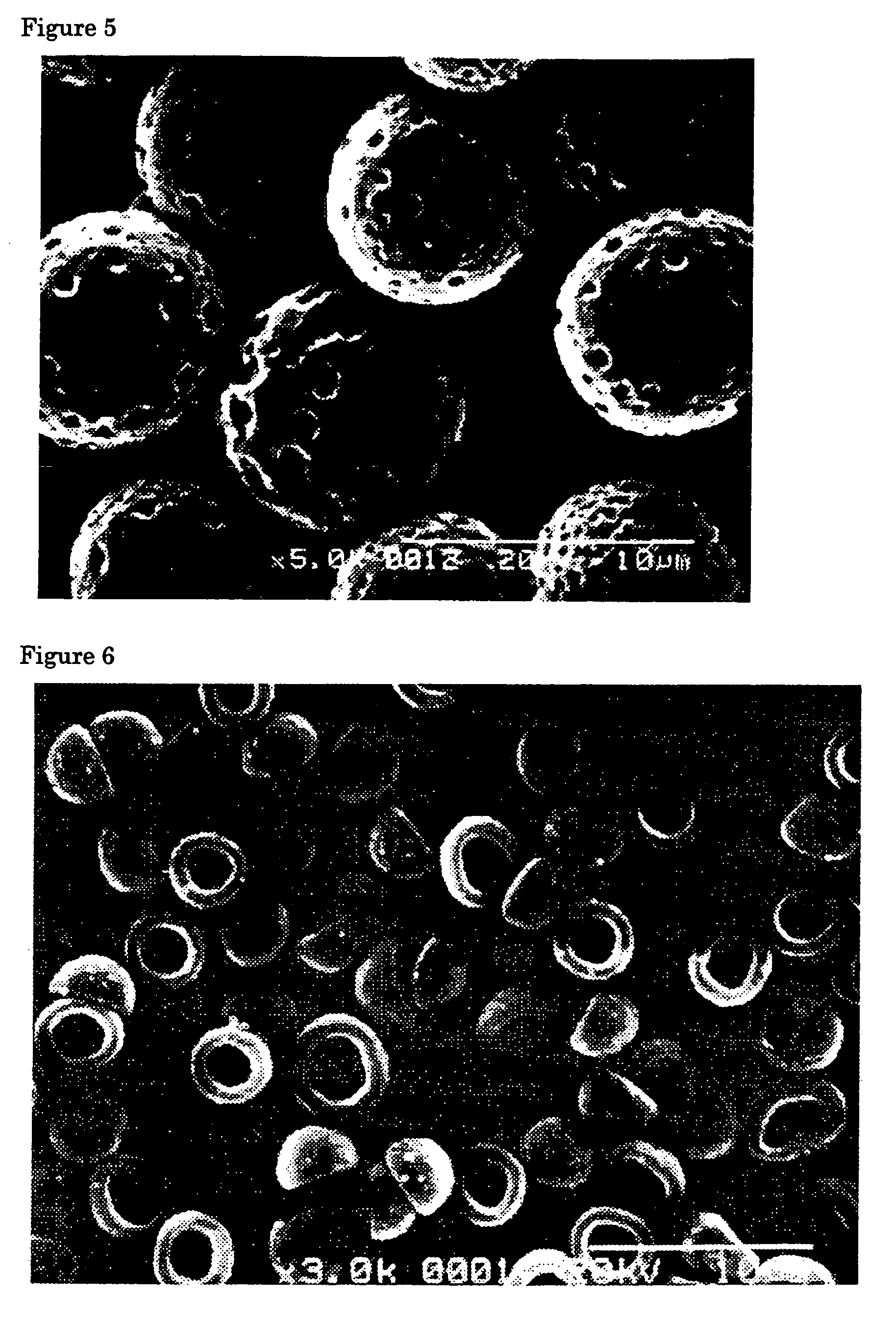

Flat particles and process for production thereof

InactiveUS7387832B2Easy to controlReaction rate can be efficientlySynthetic resin layered productsCellulosic plastic layered productsDouble bondSolvent

Flaky particles which are produced through easy conversion from mother particles by using an organic compound other than monomers having double bonds as the hardening and crosslinking agent and to which at least one mechanical or functional characteristic selected from among reactivity, close adhesion, and tackiness is imparted by the presence of part of the unreacted reactive groups of the organic compound inside and on the particles; and a process for the production of the flaky particles. More specifically, flaky particles composed of mother particles (A) having functional groups and an organic compound (B) which has groups reactive with the functional groups of the particles (A) and is soluble in a solvent, characterized in that at least part of the functional groups of the mother particles (A) and at least part of the reactive groups of the organic compound (B) react with each other to form crosslinks.

Owner:NISSHINBO IND INC

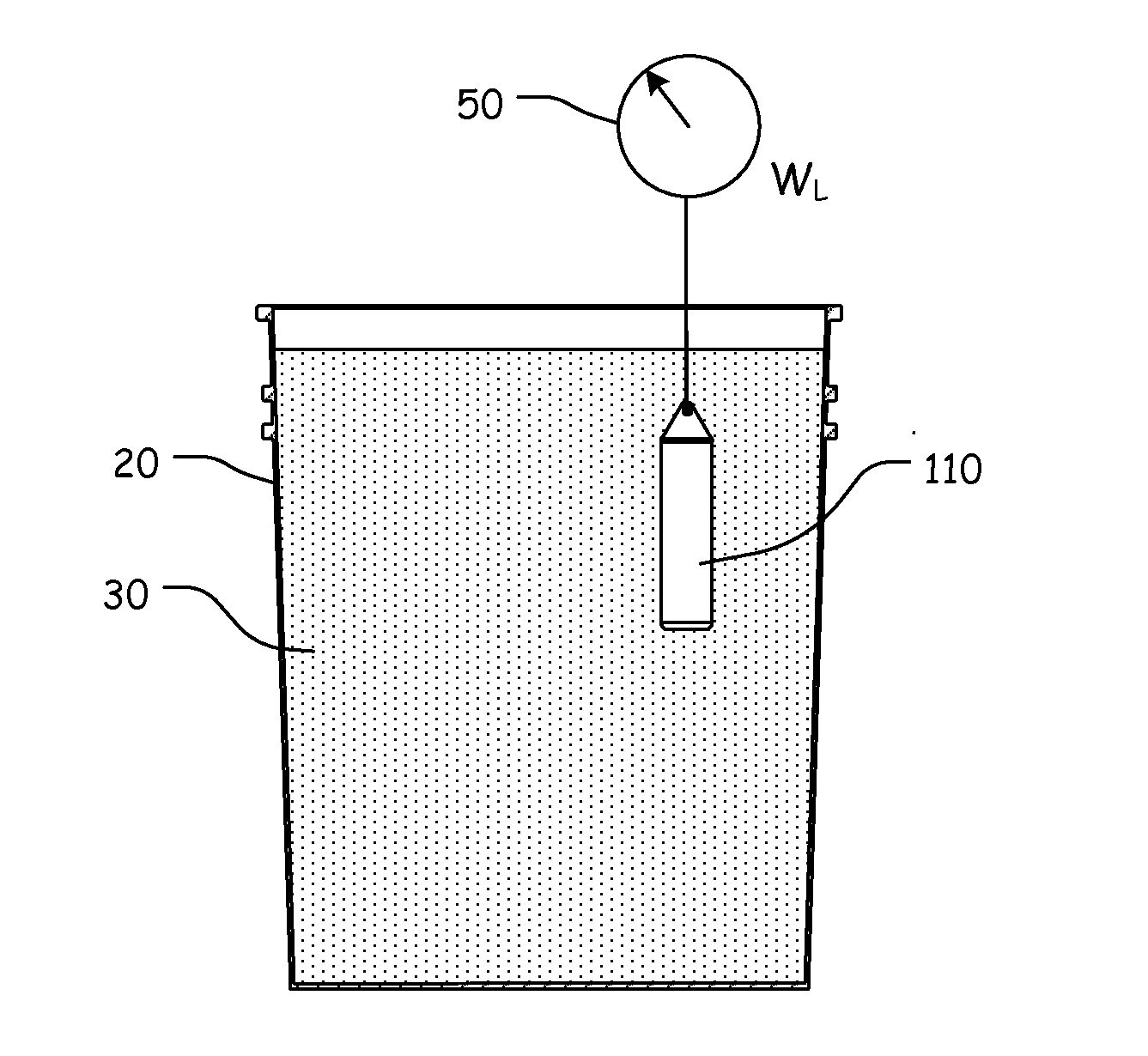

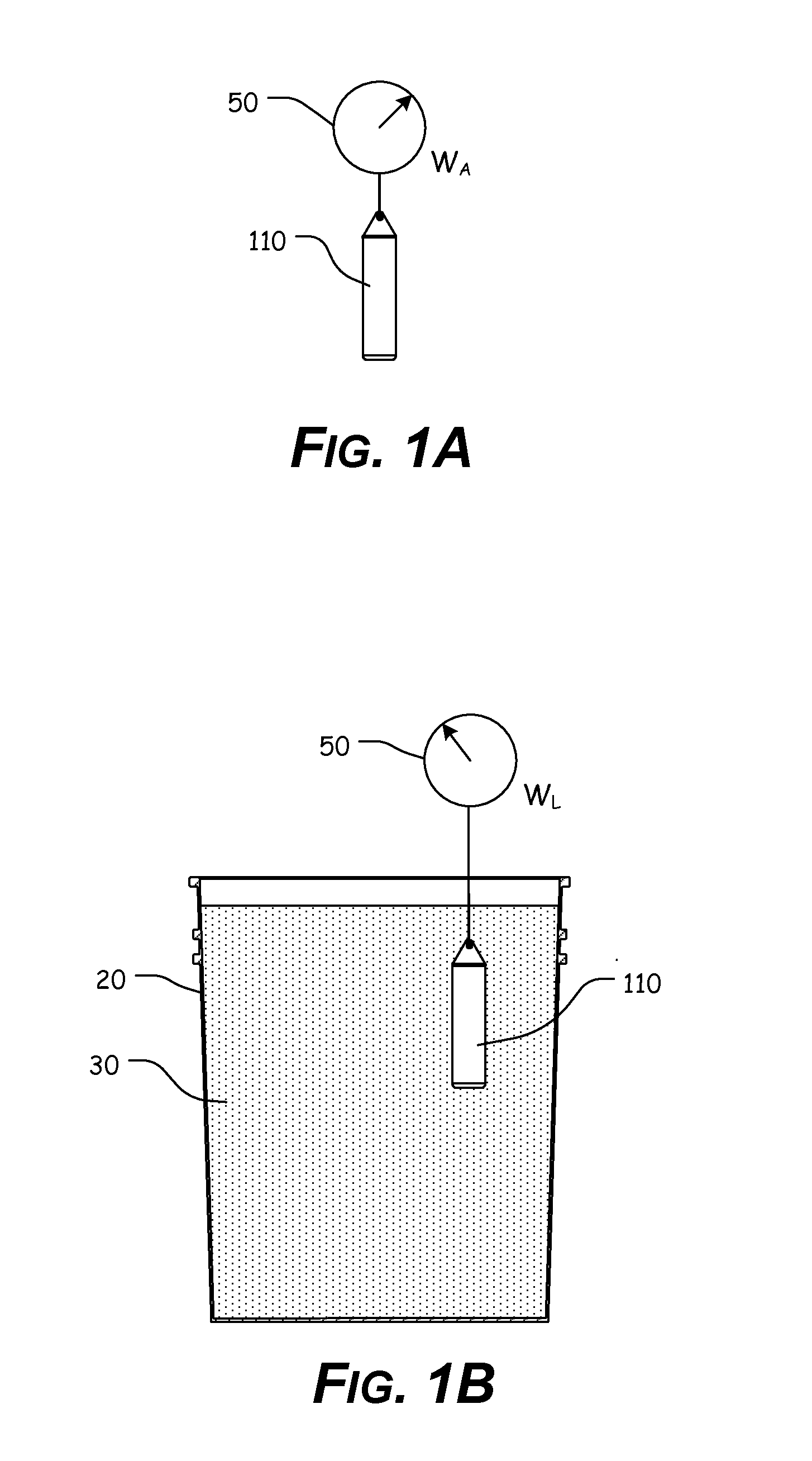

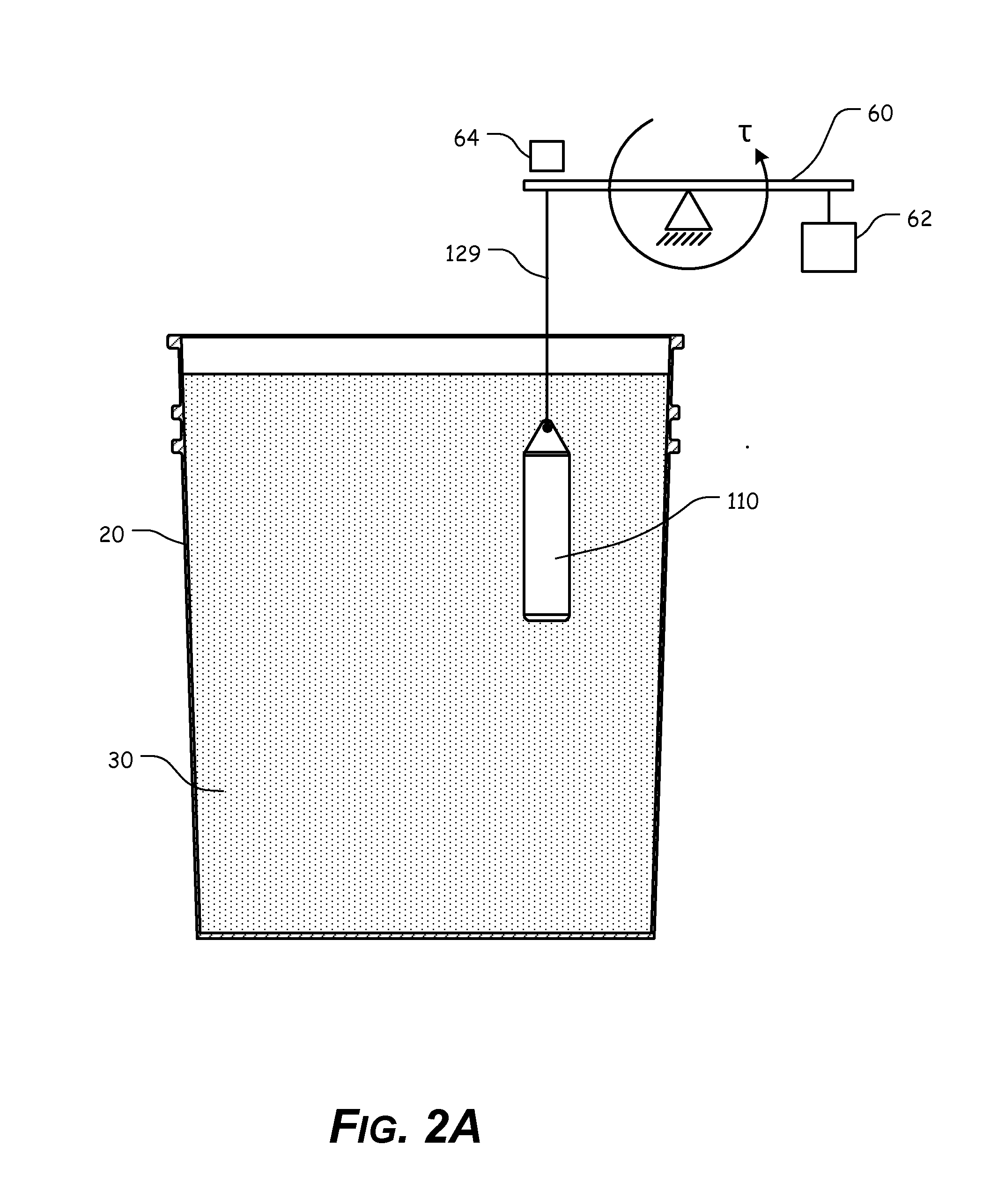

Systems, Methods, and Apparatuses for Monitoring and/or Controlling the Density of a Fluid

InactiveUS20160252440A1Precision FiltrationQuickly and easily ascertainMaterial analysis by observing immersed bodiesEngineeringMechanical engineering

Owner:PARASITX LLC

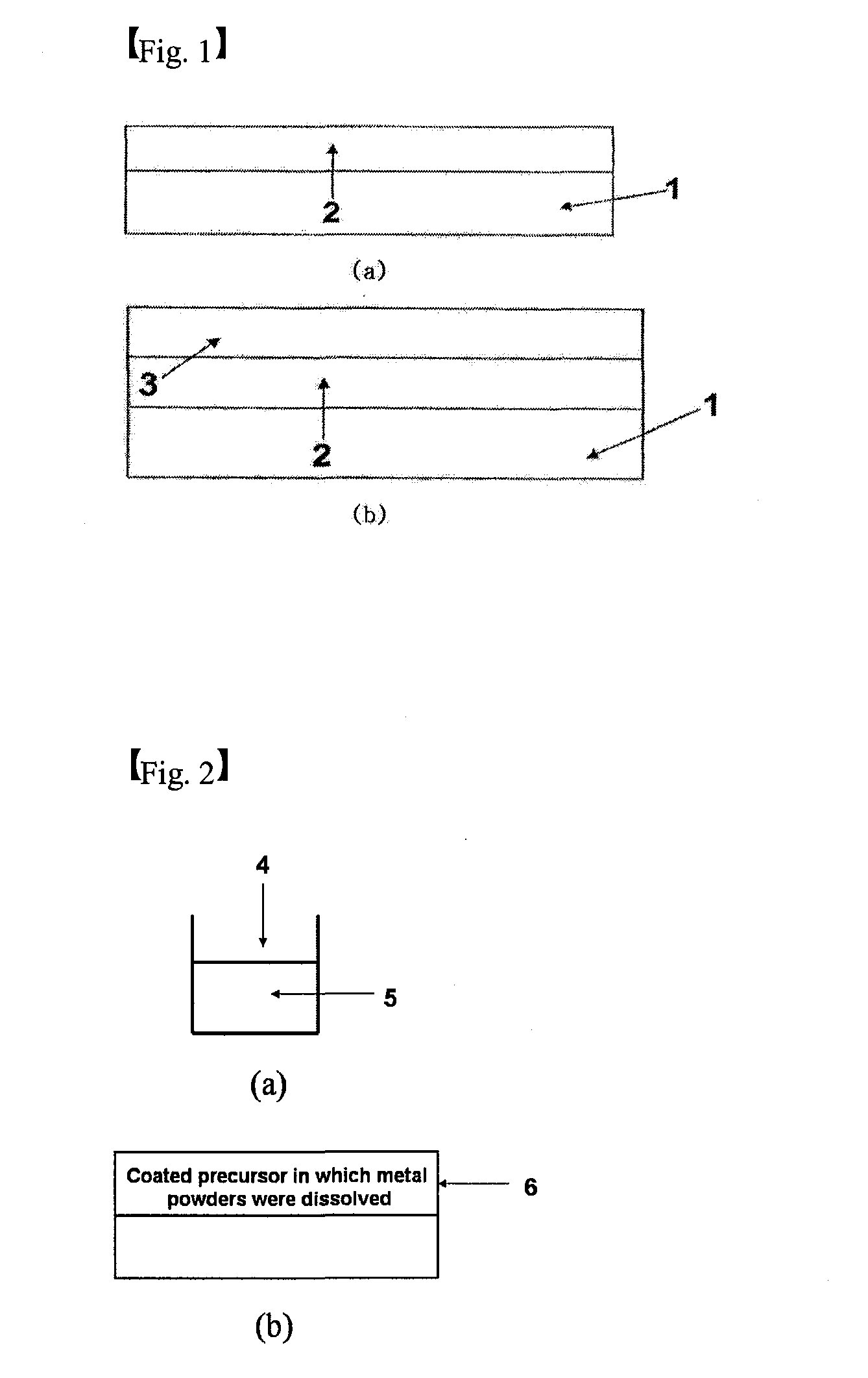

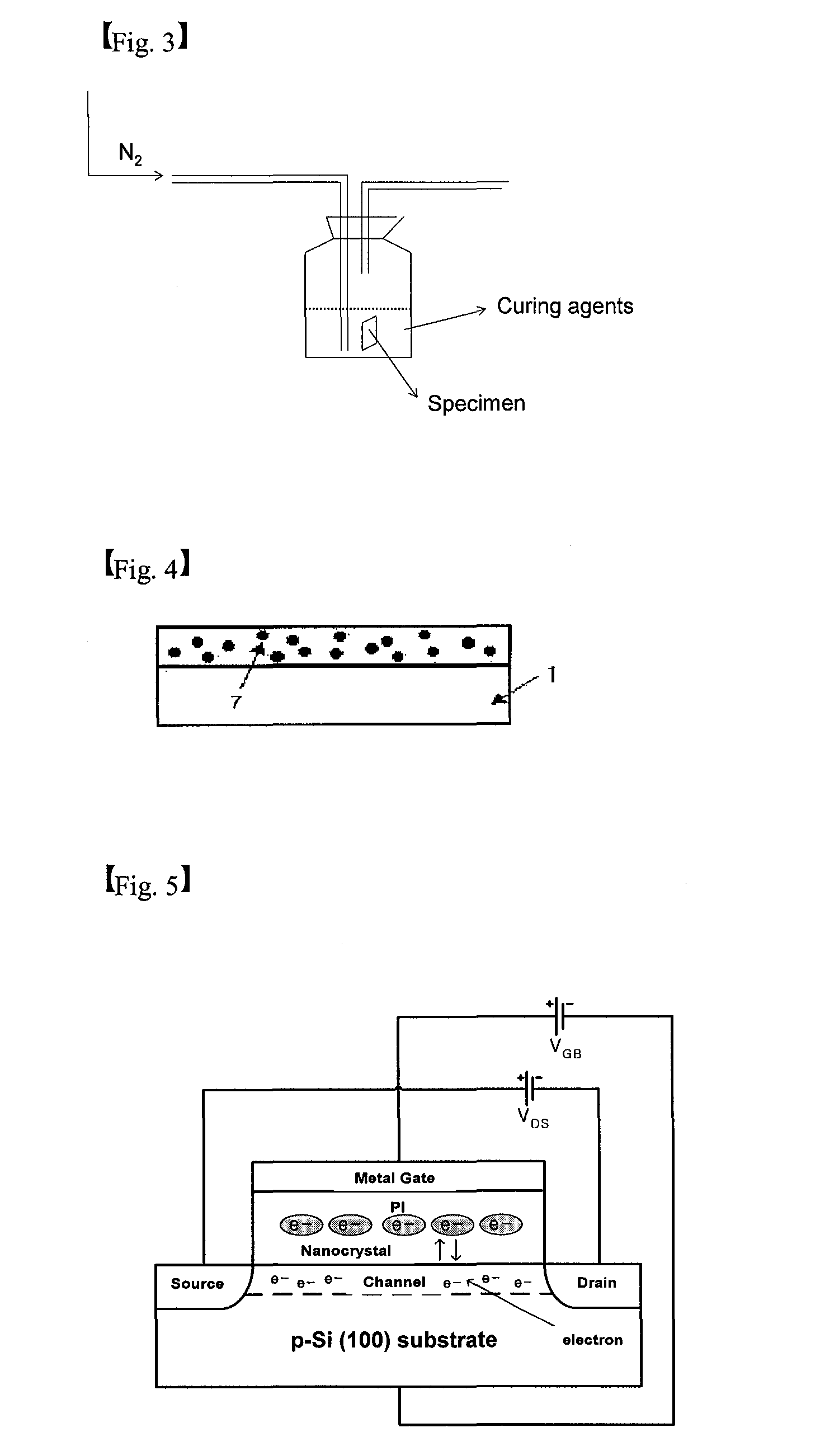

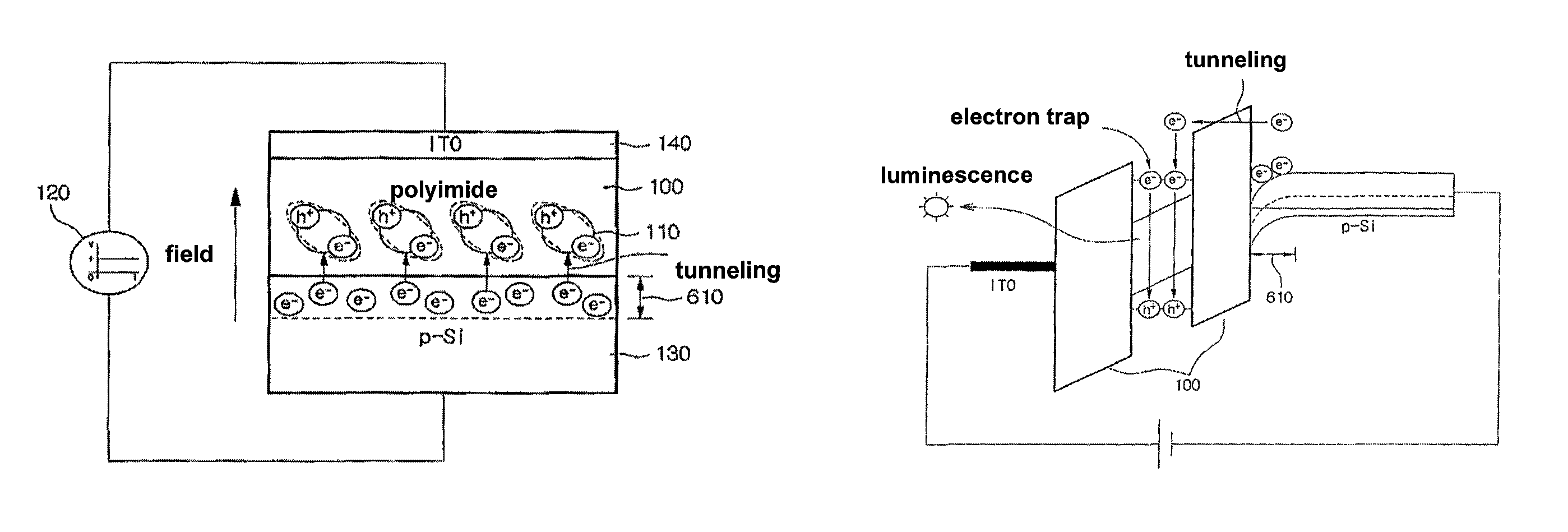

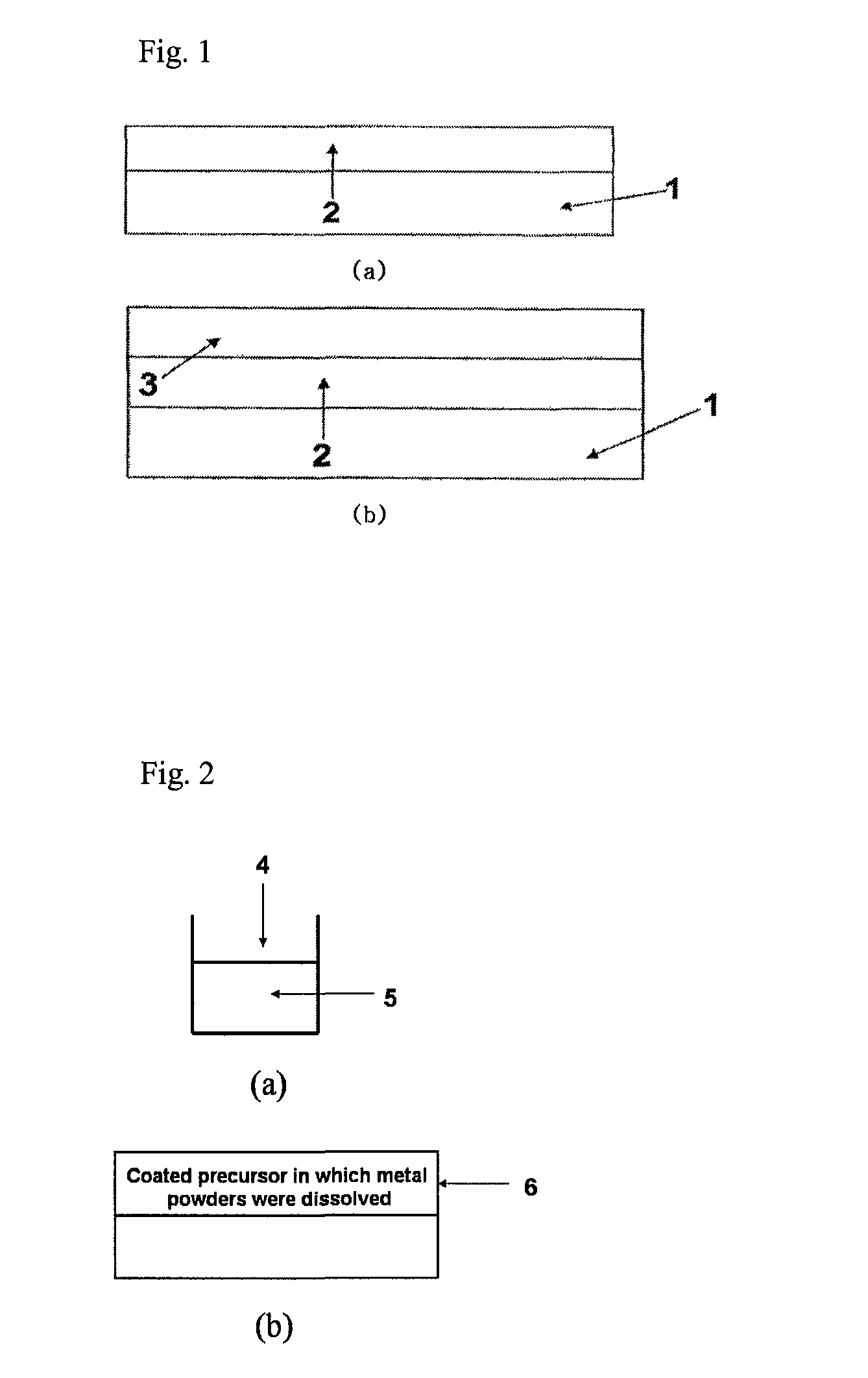

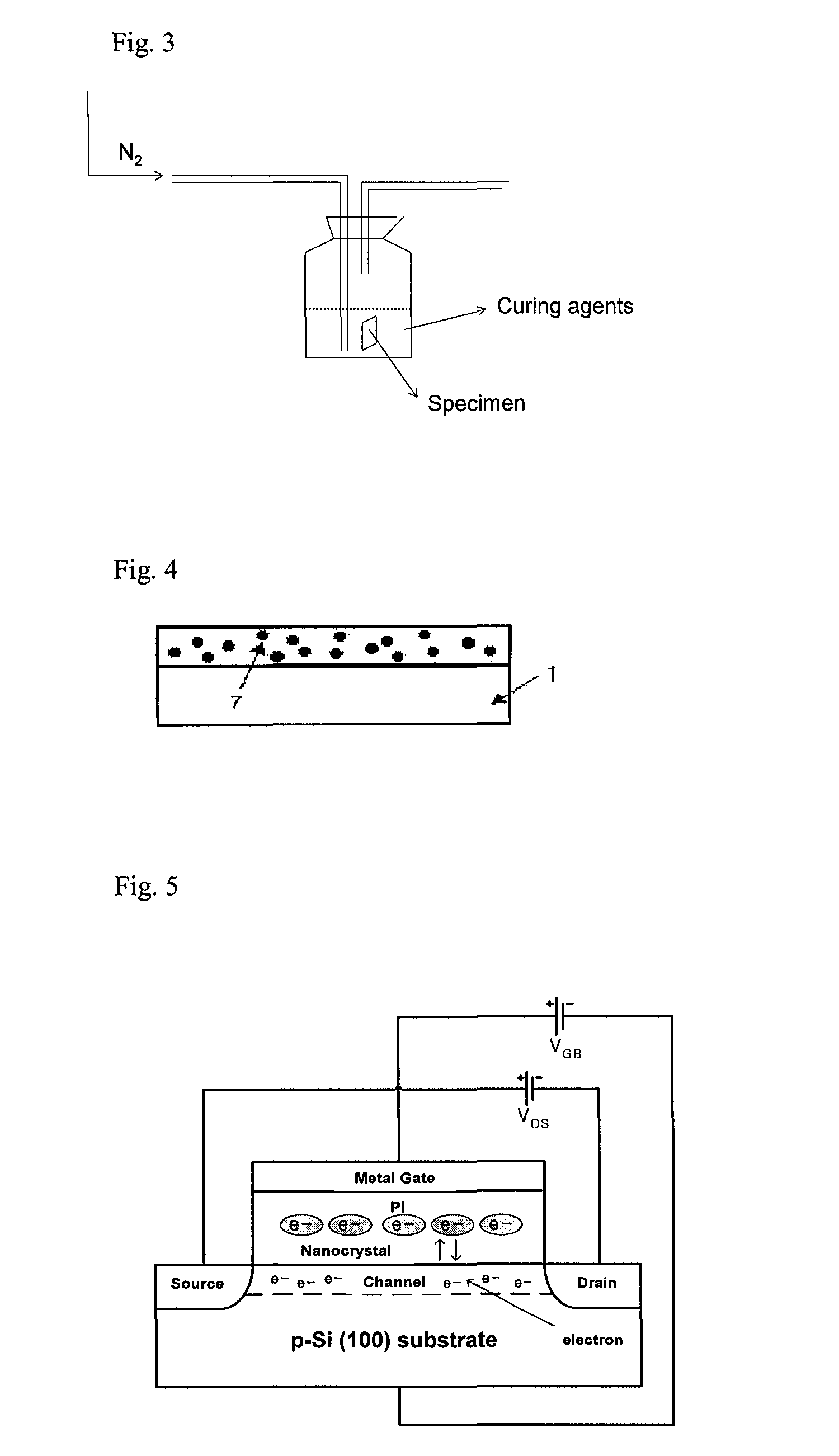

Fabrication method of nanoparticles by chemical curing

InactiveUS20090121272A1Size and density can be easilyHigh densityTransistorMaterial nanotechnologyNanometreCompound (substance)

Disclosed is a method of producing nanoparticles by using chemical curing. The method includes depositing a metal thin film on a substrate, applying an insulator precursor on a metal thin film, and adding a curing agent and a catalyst to the insulator precursor to perform the chemical curing. The method also includes mixing metal powder and an insulator precursor, applying a mixture on a substrate, and adding a curing agent and a catalyst to the mixture to perform the chemical curing. Since the chemical curing process is used in the method, it is possible to form nanoparticles by using a simple process at low cost while a high temperature process such as thermal curing is not used.

Owner:IUCF HYU (IND UNIV COOP FOUNDATION HANYANG UNIV)

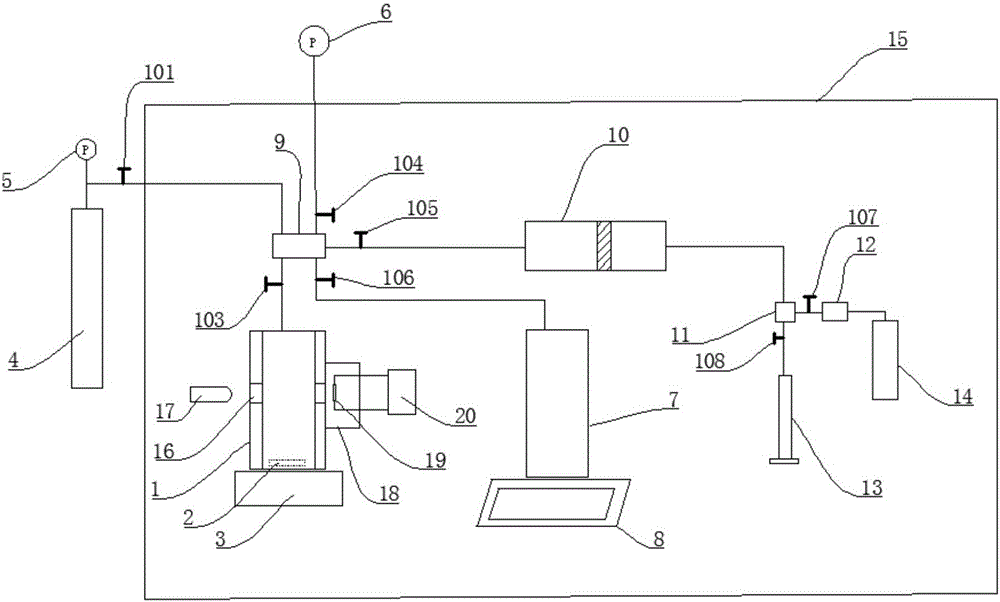

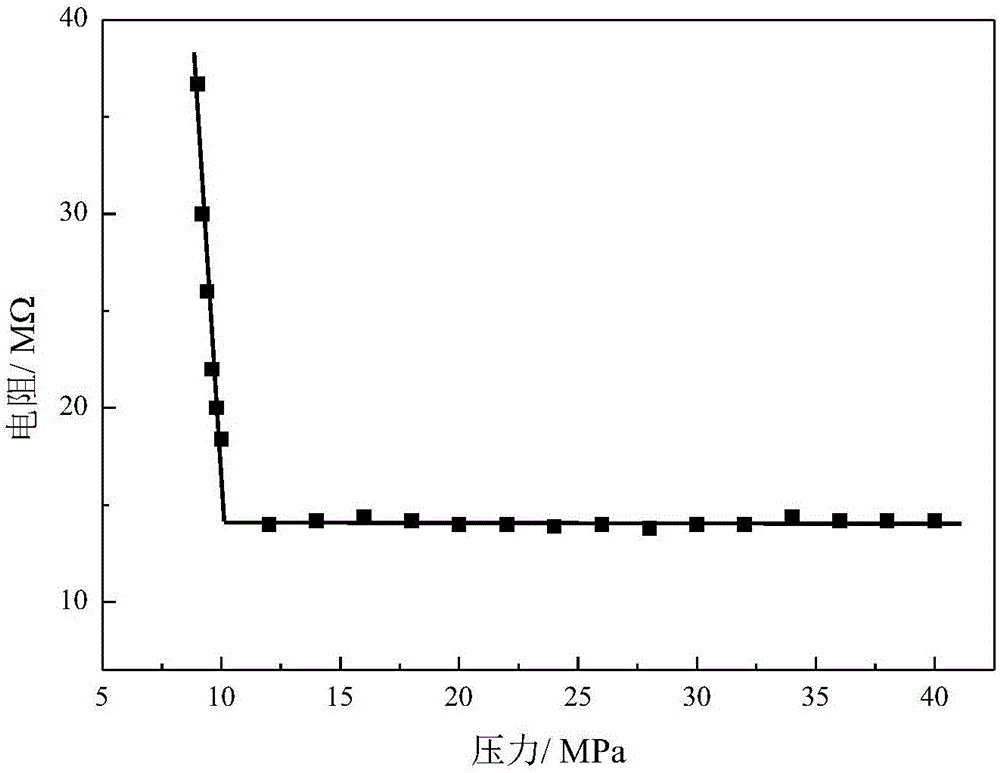

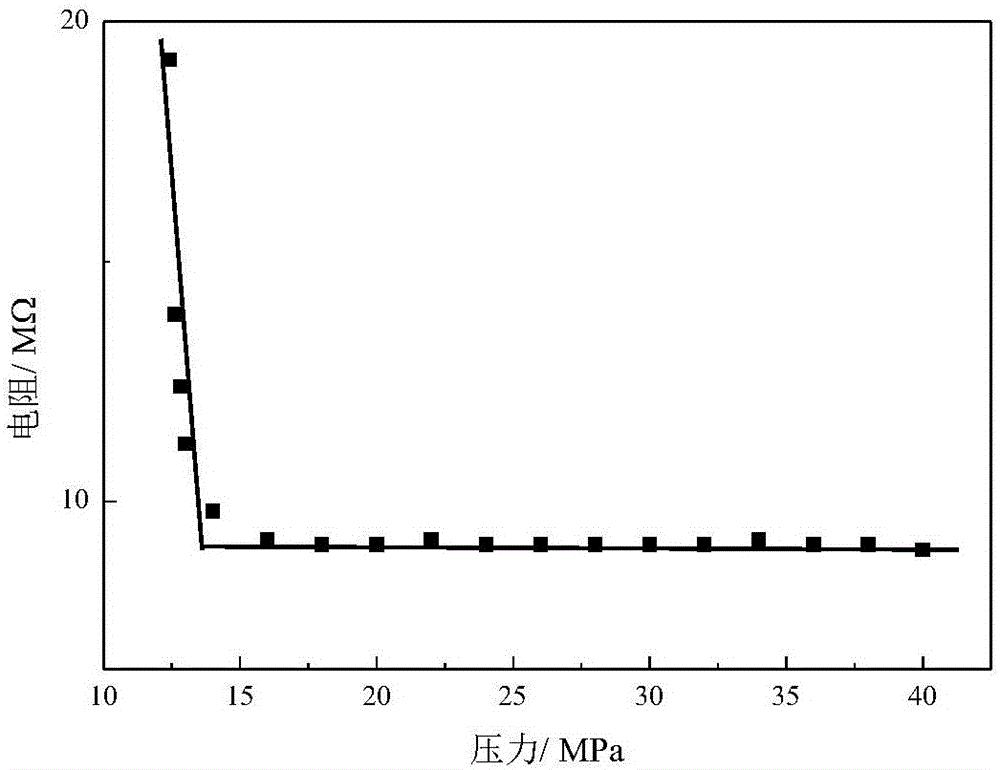

Apparatus and method for measuring cloud point pressure and density of supercritical CO2 microemulsion system

InactiveCN105890839ASimple structureImprove sealingFluid pressure measurementMaterial resistanceGas cylinderWater storage tank

The invention discloses an apparatus and method for measuring the cloud point pressure and density of a supercritical CO2 microemulsion system. A magneton is arranged in a visual container, an electronic stirrer is arranged under the visual container, and the upper portion of the visual container is connected with a five-way valve. A quartz window is arranged on each of two parallel sides on the lower portion of the visual container, a light source is arranged on the outer side of one quartz window, and an opaque chamber is arranged on the outer side of the other quartz window. A photoresistor connected with a universal meter is arranged in the opaque chamber, and a CO2 gas cylinder is connected with the five-way valve. A second pressure transducer is connected to the five-way valve, one end of an intermediate container is connected to the five-way valve, and the other end of the intermediate container is connected with a three-way valve. A gas tank is connected with the five-way valve, one end of a high-pressure plunger pump is connected to the three-way valve, and the other end of the high-pressure plunger pump is connected with a water storage tank. A liquid volume metering device is connected with the three-way valve. The cloud point pressure of a supercritical CO2 microemulsion system and the density of the supercritical CO2 microemulsion system under the cloud point pressure can be obtained under same condition, the influence of minimal difference in parallel experiment processes can be minimized, and important basic data for designing construction scheme of an oil field can be provided.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Fabrication method of nanoparticles by chemical curing

InactiveUS8422289B2Small sizeDensity is easyMaterial nanotechnologyMetal-working apparatusNanoparticleCompound (substance)

A method of producing nanoparticles by using chemical curing. The method includes depositing a metal thin film on a substrate, applying an insulator precursor on a metal thin film, and adding a curing agent and a catalyst to the insulator precursor to perform the chemical curing. The method also includes mixing metal powder and an insulator precursor, applying a mixture on a substrate, and adding a curing agent and a catalyst to the mixture to perform the chemical curing. Since the chemical curing process is used in the method, it is possible to form nanoparticles by using a simple process at low cost while a high temperature process such as thermal curing is not used.

Owner:IUCF HYU (IND UNIV COOP FOUND HANYANG UNIV)

Method and arrangement for manufacturing optical products with complex three-dimensional forms

InactiveUS8371215B2Density is easyEasy to manageMechanical working/deformationDecorative surface effectsEngineeringOptical surface

A method, an arrangement and computer program product for manufacturing micro-optic surface design with complex, variable three-dimensional forms. A step embossing, step imprinting, a chip bonding or a corresponding device capable of patterning the surface of a target substrate is obtained. The target substrate whereto the micro-optic structures shall be patterned is obtained. A plurality of different stamping tools operable with the device is obtained. Each stamping tool includes one or more surface relief forms defining one or more micro-optic structures. A stamping tool is selected from the plurality of stamping tools by the device. The target substrate is embossed with the selected stamping tool as controlled by the device. The selected stamping tool is optionally heated or assisted by at least one ultraviolet light so as to cure the target substrate during or after the embossing. The selecting and embossing steps are repeated until the micro-optic surface design has been completed on the substrate.

Owner:MODILIS HLDG LLC

Flat particles and process for production thereof

InactiveUS20060052549A1Easy to controlReaction rate can be efficientlySynthetic resin layered productsCellulosic plastic layered productsSimple Organic CompoundsPolymer science

Flaky particles which are produced through easy conversion from mother particles by using an organic compound other than monomers having double bonds as the hardening and crosslinking agent and to which at least one mechanical or functional characteristic selected from among reactivity, close adhesion, and tackiness is imparted by the presence of part of the unreacted reactive groups of the organic compound inside and on the particles; and a process for the production of the flaky particles. More specifically, flaky particles composed of mother particles (A) having functional groups and an organic compound (B) which has groups reactive with the functional groups of the particles (A) and is soluble in a solvent, characterized in that at least part of the functional groups of the mother particles (A) and at least part of the reactive groups of the organic compound (B) react with each other to form crosslinks.

Owner:NISSHINBO IND INC

Method for producing beta-1,3-glucan by utilizing non-growth coupling characteristic of bacteria

ActiveCN112646846AIncrease accumulation speedIncrease productionMicroorganism based processesFermentationGlucanFermentation broth

Owner:JINAN GUOLI BIOLOGICAL SCI & TECH +1

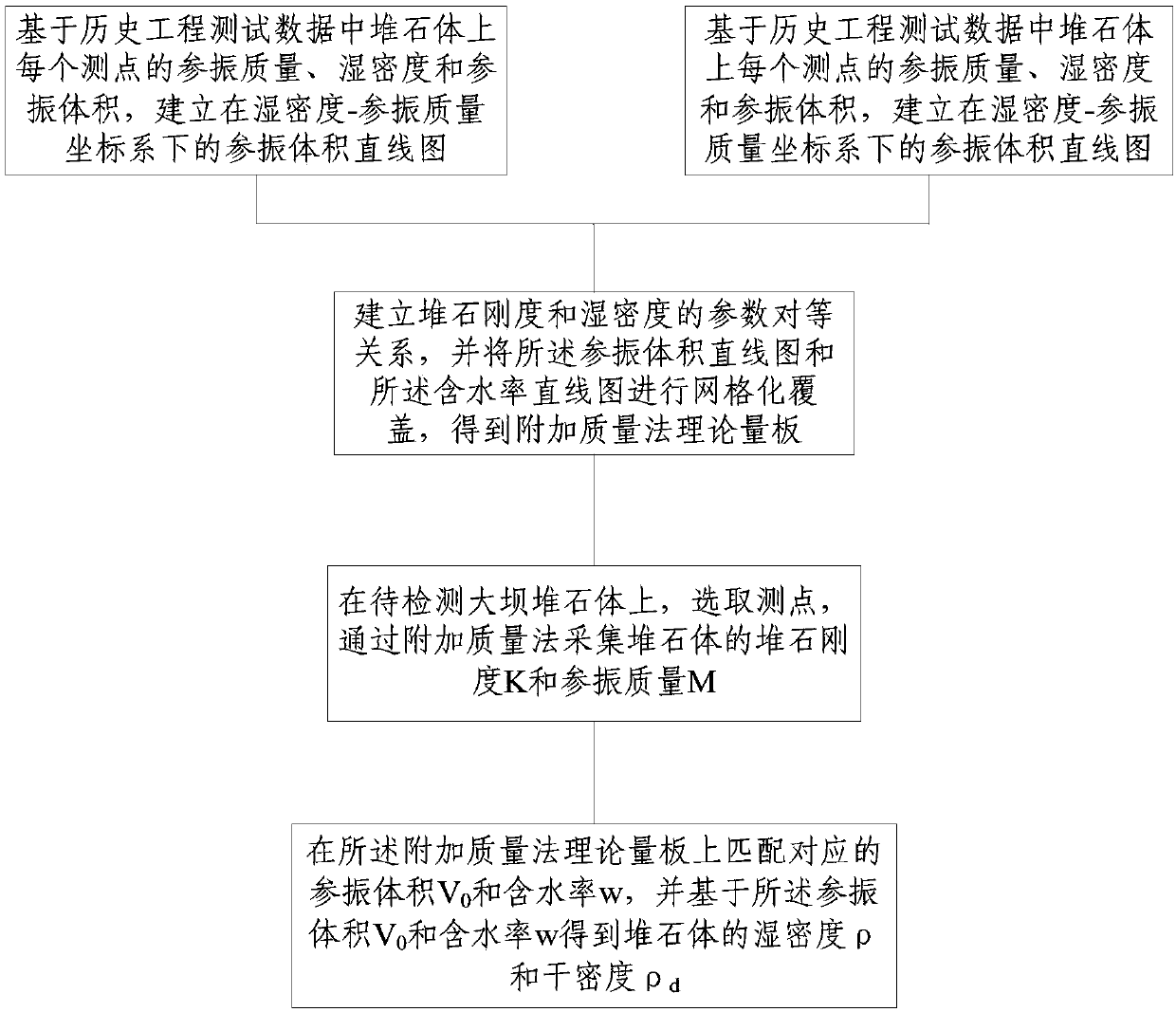

Rockfill density measuring method based on additional mass process theoretical measuring plate

ActiveCN108872008ASimple calculationParameters are peer-to-peer and flexibleSpecific gravity measurementPhysicsMoisture

The embodiment of the invention provides a rockfill density measuring method based on an additional mass process theoretical measuring plate. The rockfill density measuring method comprises the following steps: establishing a vibrating volume line graph under a wet density-vibrating mass coordinate system and a moisture content line graph based on vibrating mass, rockmill density, wet density, vibrating volume, dry density and moisture content of each measuring point on a rockmill body based on historical engineering test data; establishing a parameter peer relationship between the rockmill density and the wet density, and performing gridding coverage on the vibrating volume line graph and the moisture content line graph to obtain the additional mass process theoretical measuring plate; selecting a measuring point on a to-be-detected dam rockmill body, acquiring rockmill rigidity K and vibrating mass M of the rockmill body through the additional mass process, enabling the rockmill rigidity K and vibrating mass M to match with the corresponding vibrating volume Vo and the moisture content w on the additional mass process theoretical measuring plate, and obtaining wet density rhp anddry density rhp d of the rockmill body based on the vibrating volume V0 and the moisture content w.

Owner:CHANGJIANG GEOPHYSICAL EXPLORATION & TESTING WUHAN CO LTD

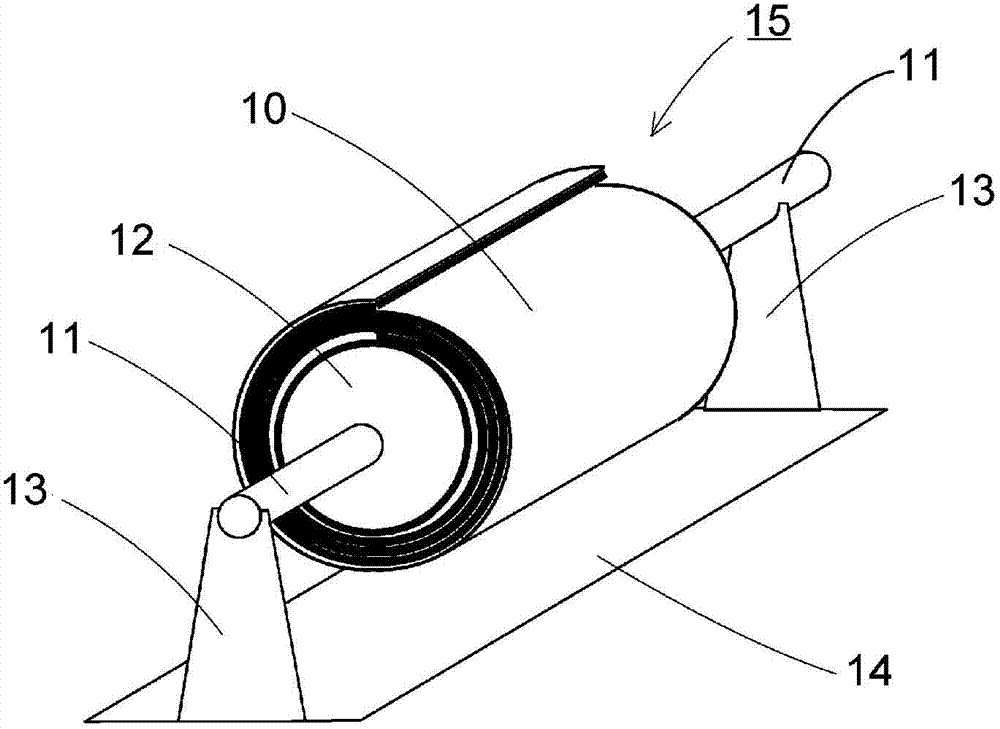

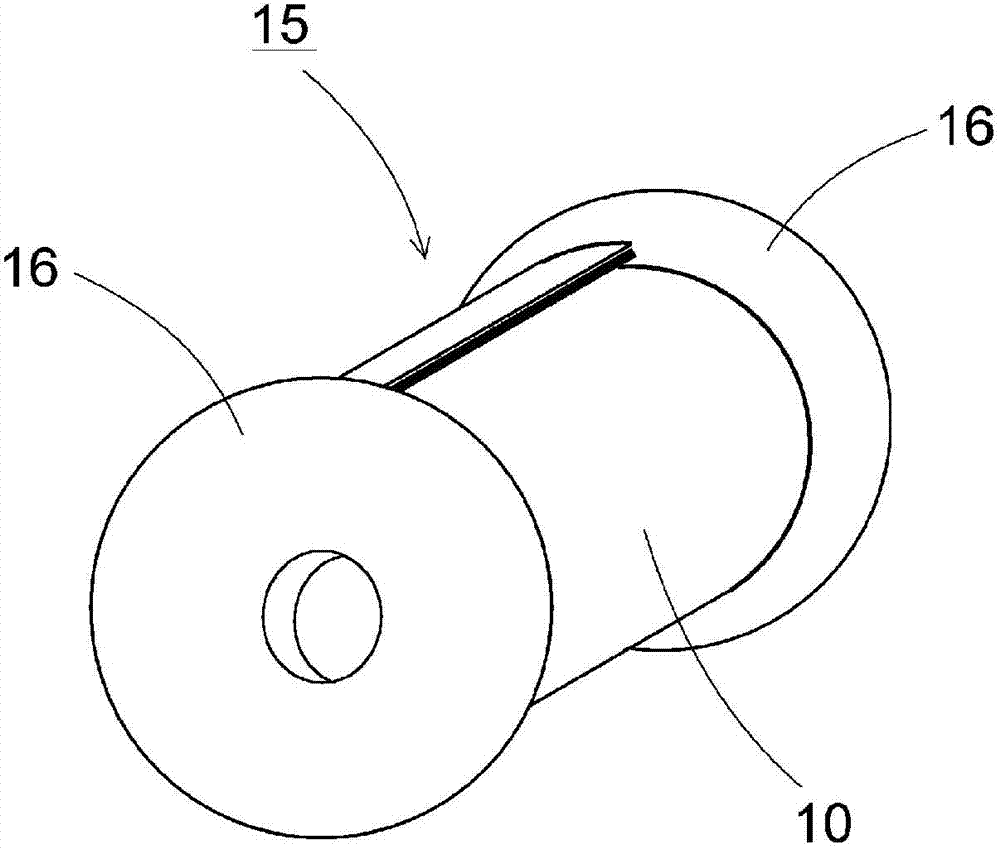

Glass roll and method for manufacturing same

ActiveCN102770381AInhibit breakageAvoid breakageGlass forming apparatusGlass/slag layered productsGlass film

Disclosed is a method for manufacturing a glass roll by taking up a long glass film having a thickness of 0.5-300 [mu]m, whereby breakage of the glass film positioned at the inner layer portion of the glass roll is suppressed. The glass roll (15) is manufactured by taking up the glass film (10) into a roll, said glass film having a thickness of 0.5-300 [mu]m, and a density less than 2.45g / cm<3>.

Owner:NIPPON ELECTRIC GLASS CO LTD

Perforating fluid for well completion

ActiveCN101974315BOvercome the disadvantage of difficult density controlInhibition of hydration swelling capacityDrilling compositionFoaming agentNitrogen

The invention discloses a low-temperature microfoam perforating fluid for an offshore oil well completion, comprising the following materials: water, sodium carbonate, flow pattern regulators, foaming agents and stabilizers, wherein the ratio of the water, the sodium carbonate, the flow pattern regulators, the foaming agents to the stabilizers is 100:(0.1-0.3):(0.3-0.4):(0.1-0.2):(0.2-0.4) in parts by weight. The low-temperature microfoam perforating fluid also comprises clay stabilizers, inhibiters and waterproof locking agents. The low-temperature microfoam perforating fluid for the offshore oil well completion is a novel perforating fluid, not only has the advantages of the traditional common perforating fluid, but also newly increases the advantages of leakage prevention and leakage stoppage on performance, solves the problem of leakage loss in the completion process and also has adjustable density. The invention overcomes the defects of numerous and jumbled nitrogen foam configuration equipment and difficult control of circular foam density on use and has simple and easy configuration equipment and convenient and easy density adjustment.

Owner:CHINA NAT OFFSHORE OIL CORP +1

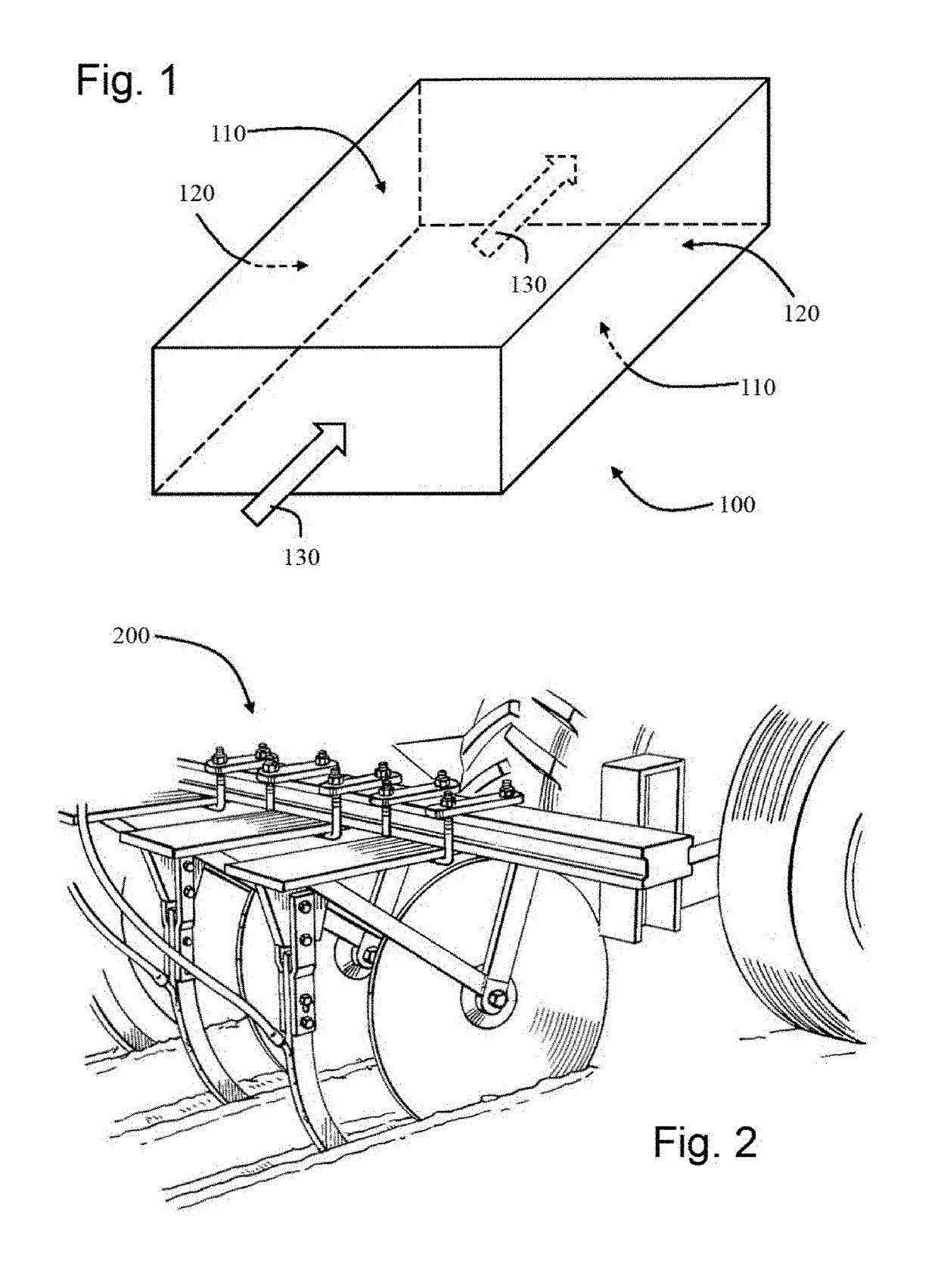

Flow sensor based on electrical capacity

ActiveUS20190285448A1Density is easyImprove uniformityCapacitance measurementsFlow propertiesElectricityCapacitance

An electric measurement method and apparatus for detecting a mass by an electric capacity (permittivity) or a material's dielectric constant, or alternatively, electric inductance (permeability). The mass may be any phase or combination of phases. The mass may be stationary or flowing. It may comprise discrete particles such as grain, or manufactured products such as ball bearings or threaded fasteners, etc. The mass may be a flow element in a rotameter or similar flow measurement device. The sensor comprises a volume which may be completely full or only partially full of the material. The material may be discrete components or a continuum. Sensor signals may be received by existing planter monitoring systems. In some embodiments the flow sensors are positioned external to the application port. In some embodiments sensors may be utilized which are responsive to the refractive index variation of specific chemicals.

Owner:AMERICAN CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com