Inductively coupled plasma reactor with multiple magnetic cores

A plasma and inductive coupling technology, which is applied in the fields of plasma, semiconductor/solid-state device manufacturing, circuits, etc., and can solve the problem of increasing the volume of the processing cavity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] Hereinafter, preferred embodiments of the present invention will be described with reference to the accompanying drawings, so that the plasma reactor with multiple discharge chambers of the present invention will be described in detail.

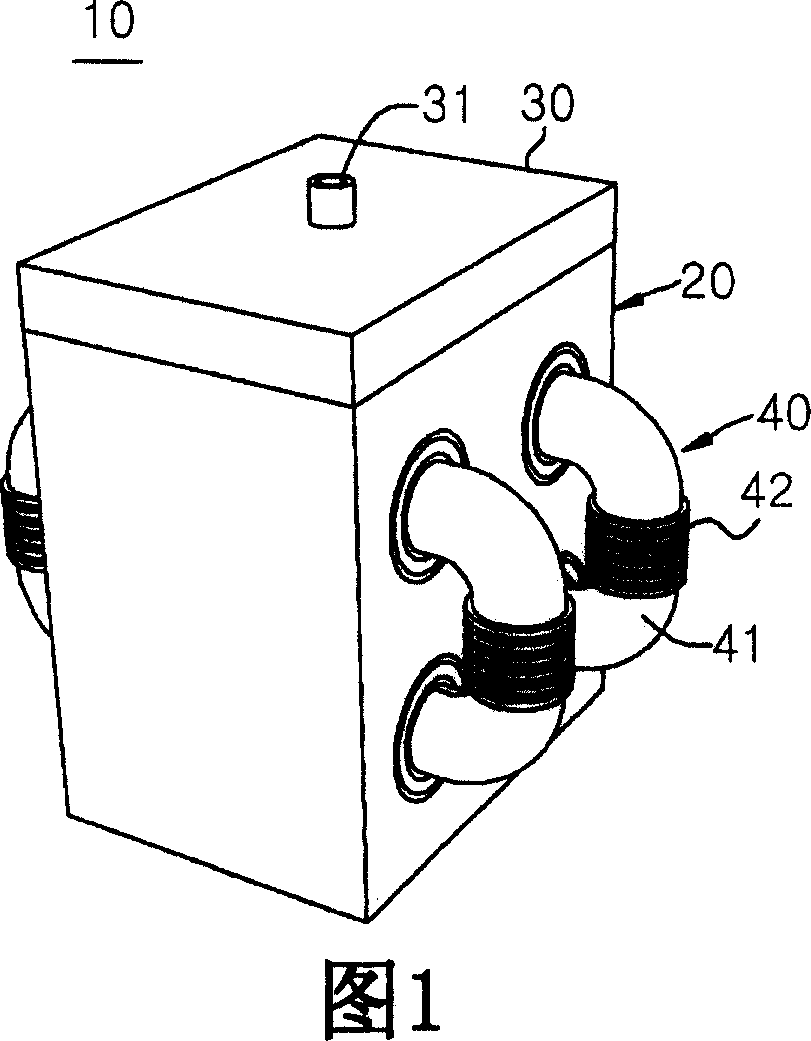

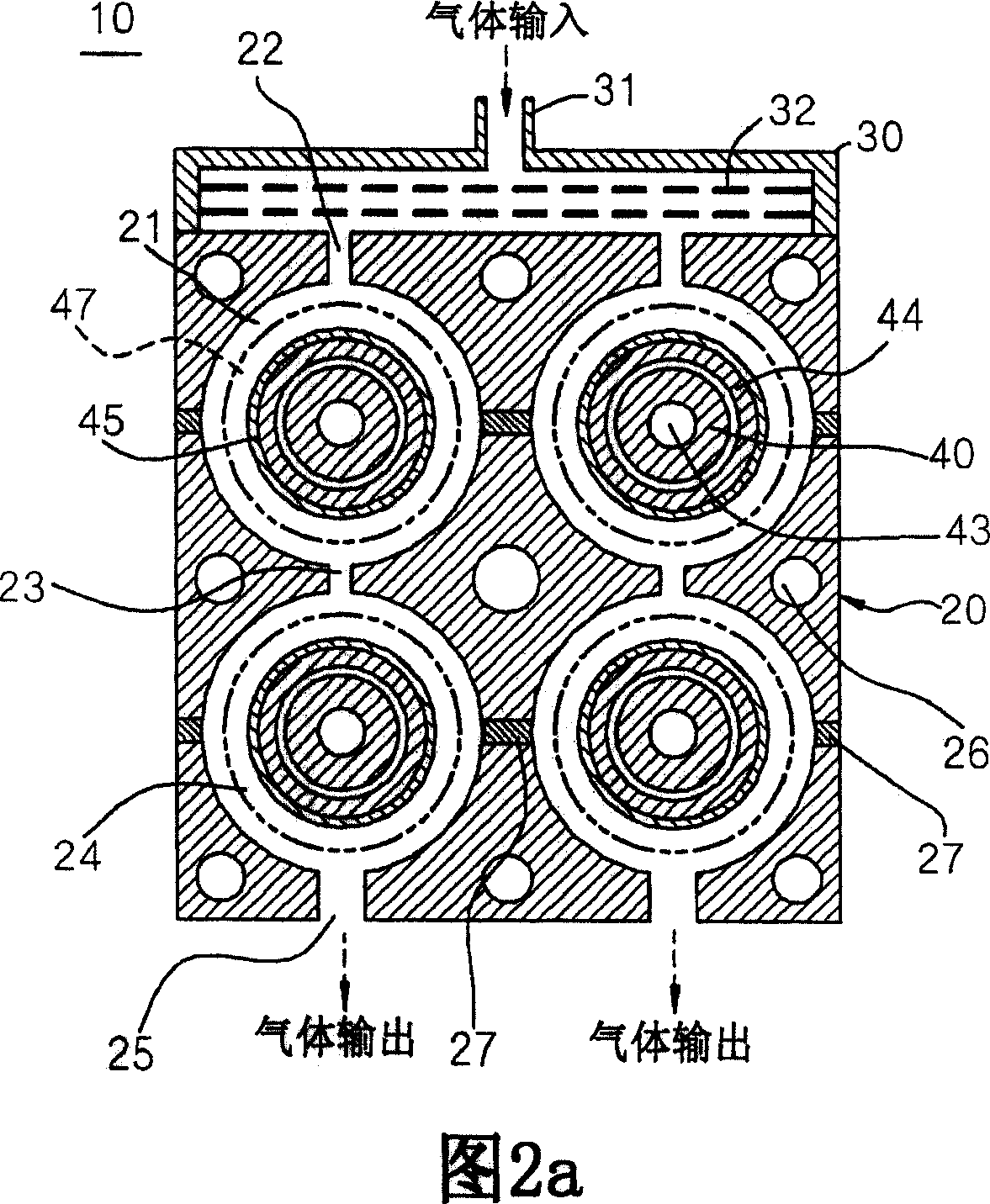

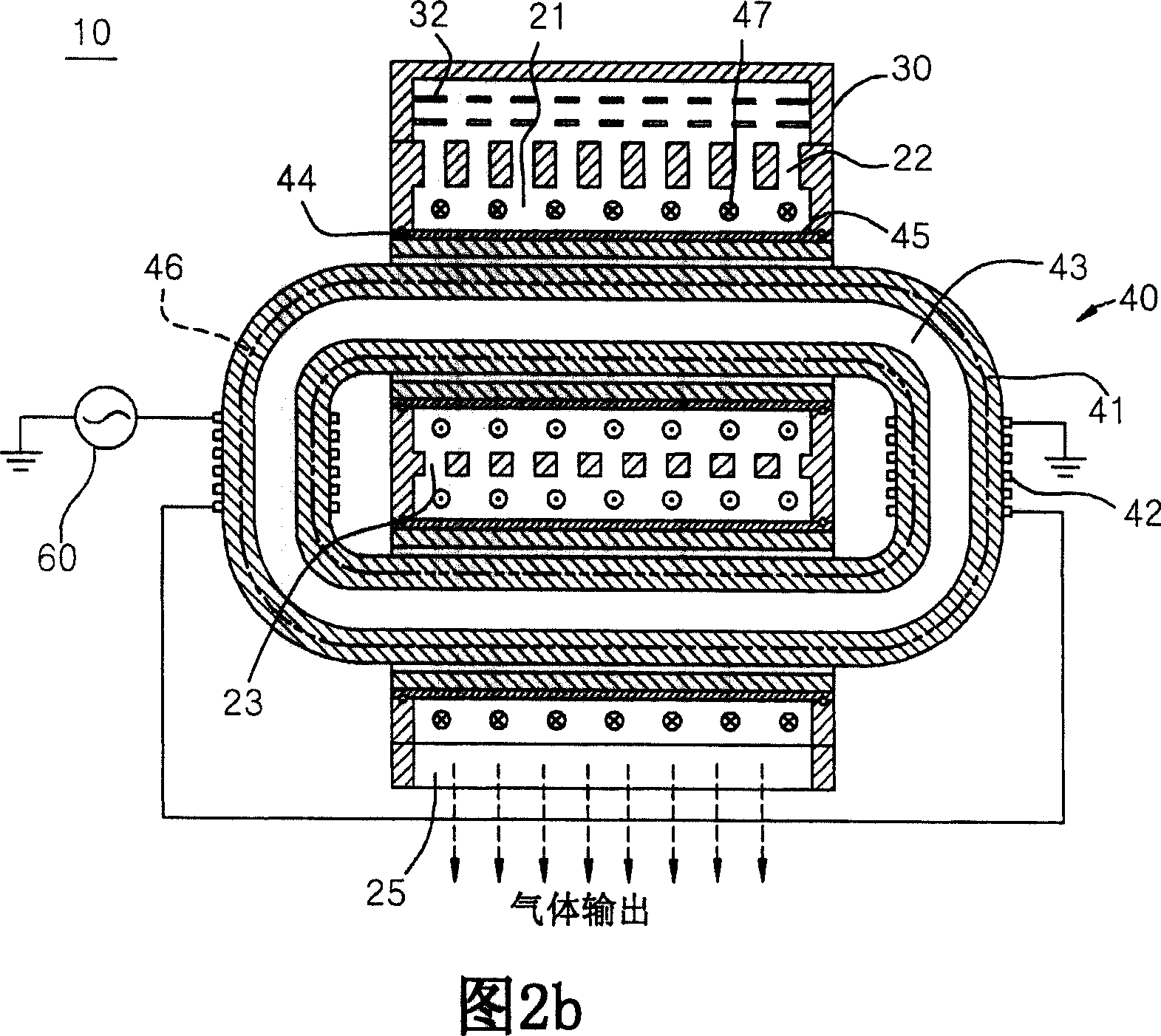

[0101] Fig. 1 is a perspective view of a plasma reactor according to a first embodiment of the present invention, and Fig. 2a and Fig. 2b are a front sectional view and a side sectional view of the plasma reactor in Fig. 1 .

[0102] A plasma reactor (10) according to a first embodiment of the present invention has a reactor main body (20) having a plurality of independent plasma discharge chambers (21). A transformer (40) is incorporated on the reactor body (20) for transferring electromotive force for plasma discharge to the plasma discharge chamber (21). The transformer (40) has a magnetic core (41) and a primary coil (42) arranged across the plasma discharge chamber (21). The part of the magnetic core (41) located inside the plasm...

Embodiment 2

[0126] 9 is a perspective view of a plasma reactor according to a second embodiment of the present invention, and FIG. 10 is a perspective view showing the main structure of the plasma reactor of FIG. 9 . Also, FIG. 11 is a partially exploded perspective view showing the inside of the plasma reactor of FIG. 9 .

[0127] The plasma reactor (100) of the 2nd embodiment of the present invention has reactor main body (110), and this reactor main body (110) constitutes plasma discharge chamber (113), has gas inlet (120) and gas outlet ( 121). The transformer (130) includes: two or more core cross-sections traversing the inside of the plasma discharge chamber (113); a magnetic core (131) having a part of the core located outside the plasma discharge chamber (113); and The primary coil (132) is wound on the magnetic core (131). The primary coil (132) is electrically connected to a power supply source (133) (see FIG. 13).

[0128] The power supply source (133) is configured using an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com