Patents

Literature

97results about "Magnetic layer production by plating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

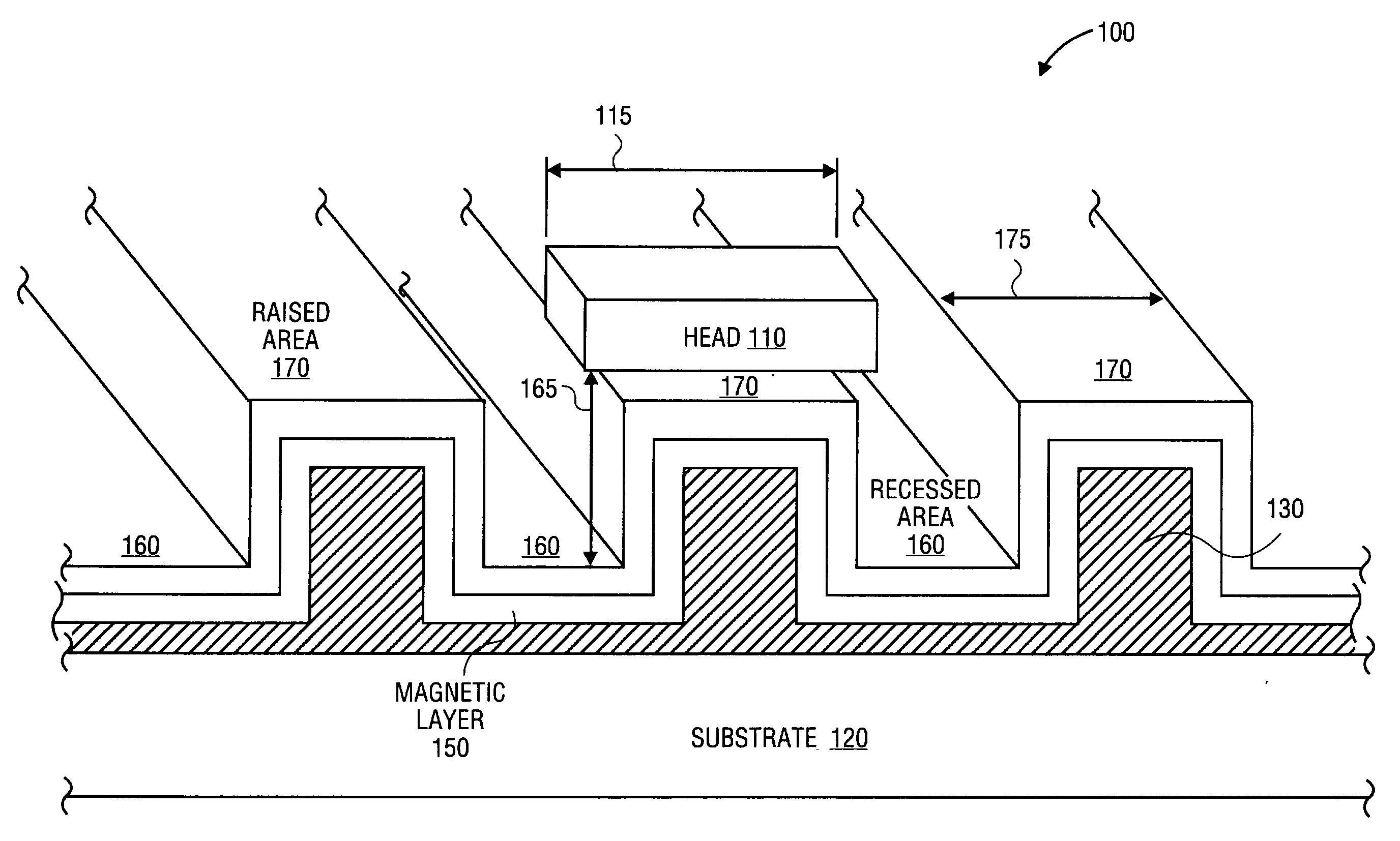

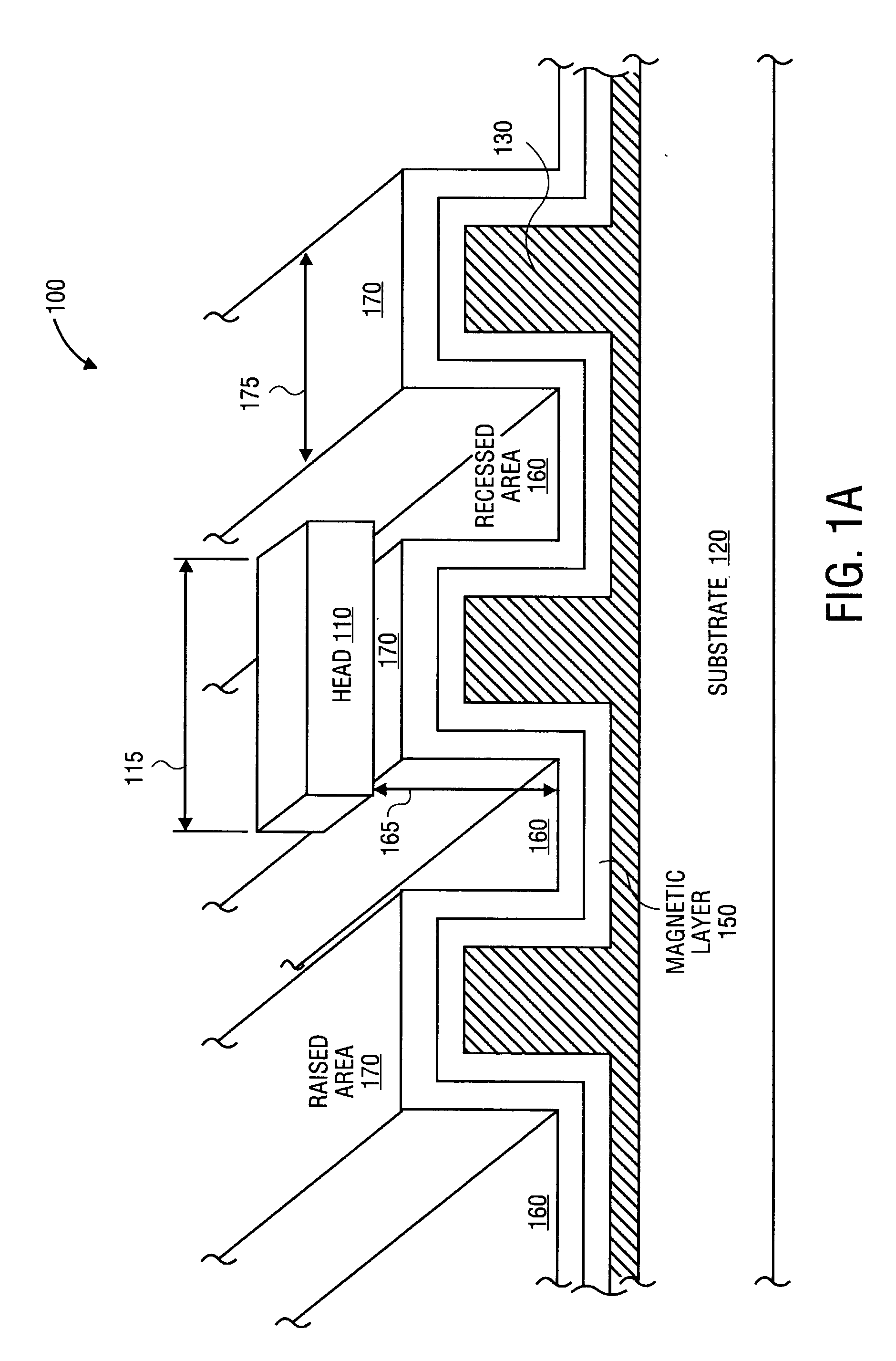

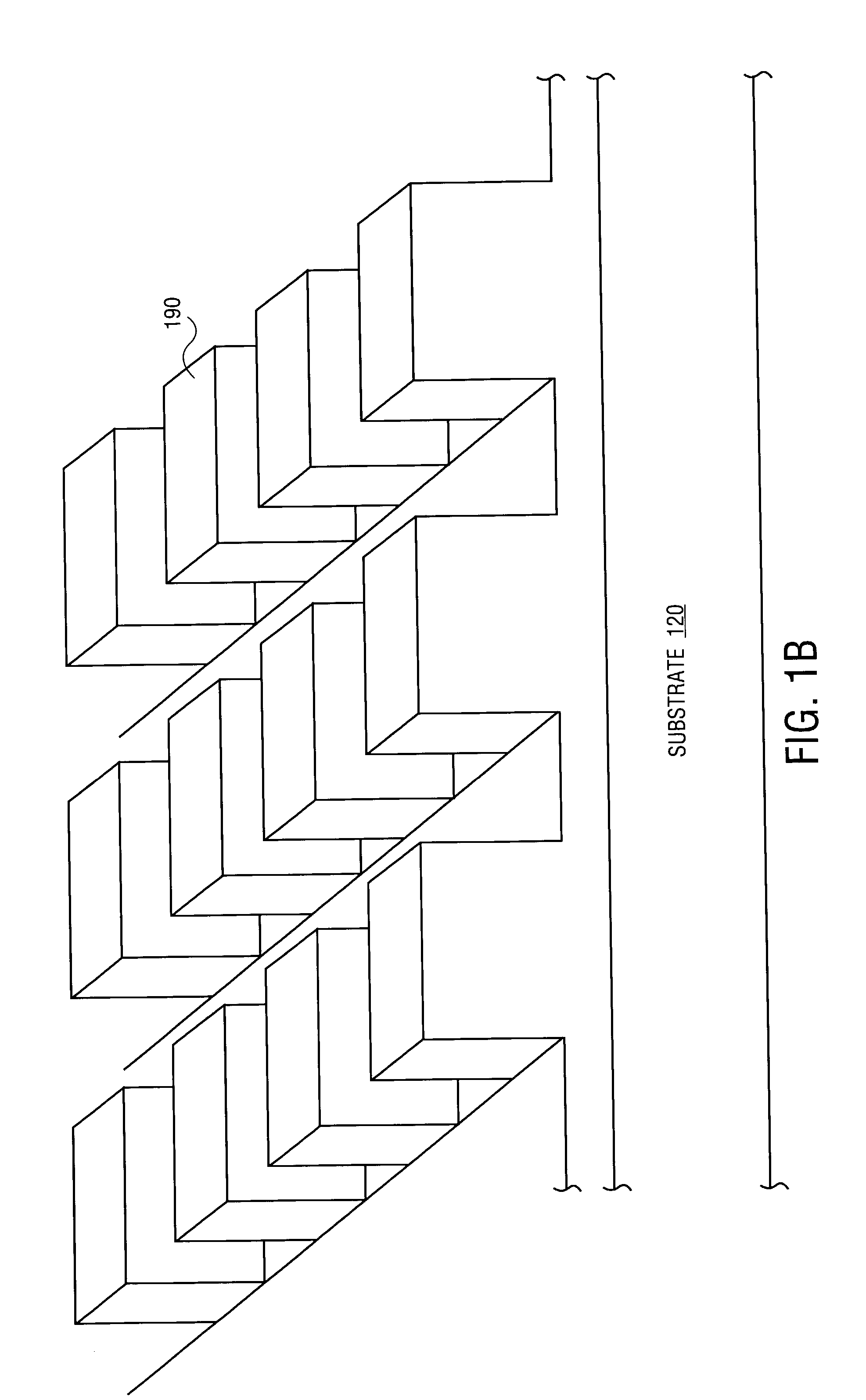

Magnetic discrete track recording disk

InactiveUS20050036223A1Protective coatings for layersBase layers for recording layersComputer science

Owner:KOMAG

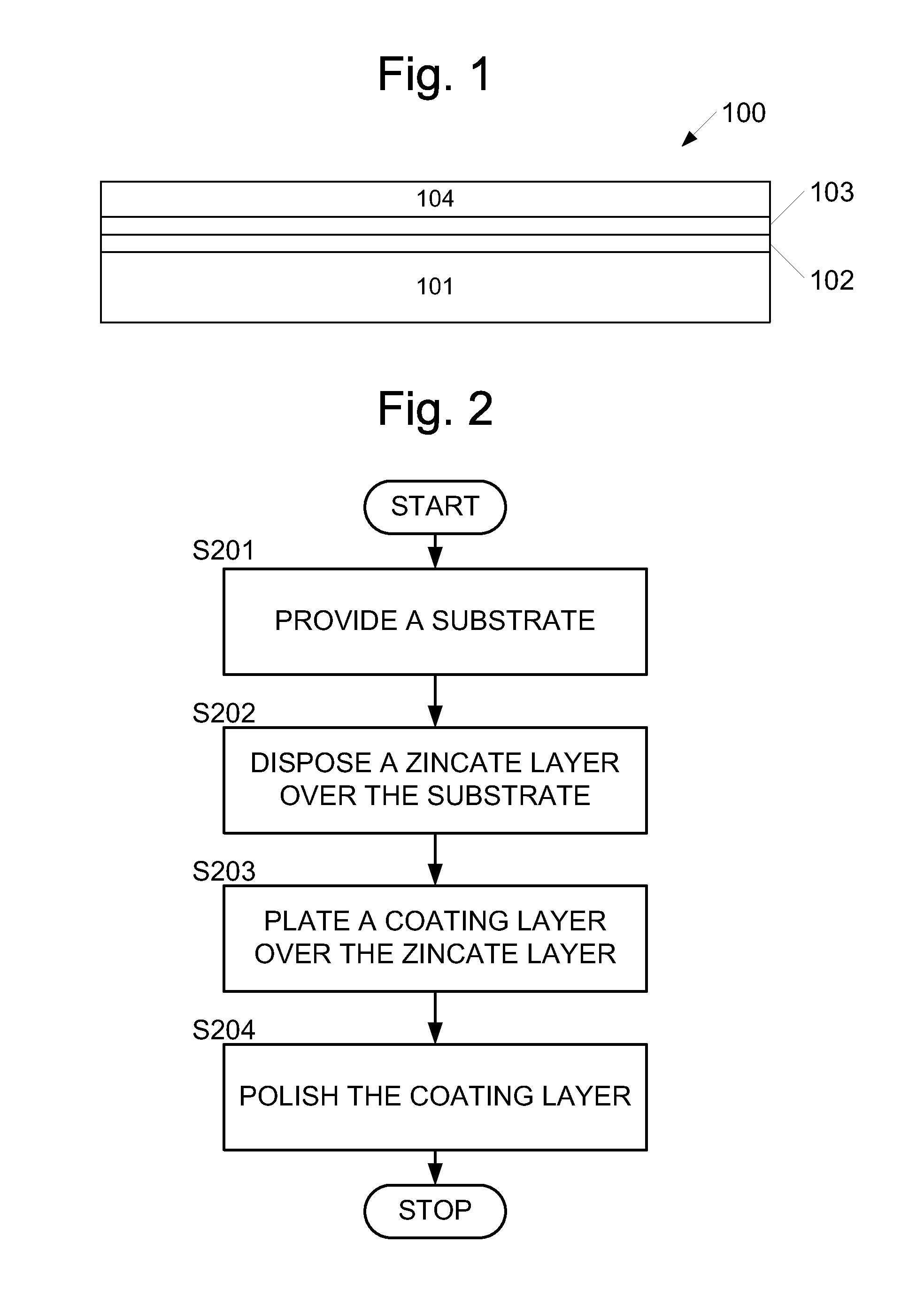

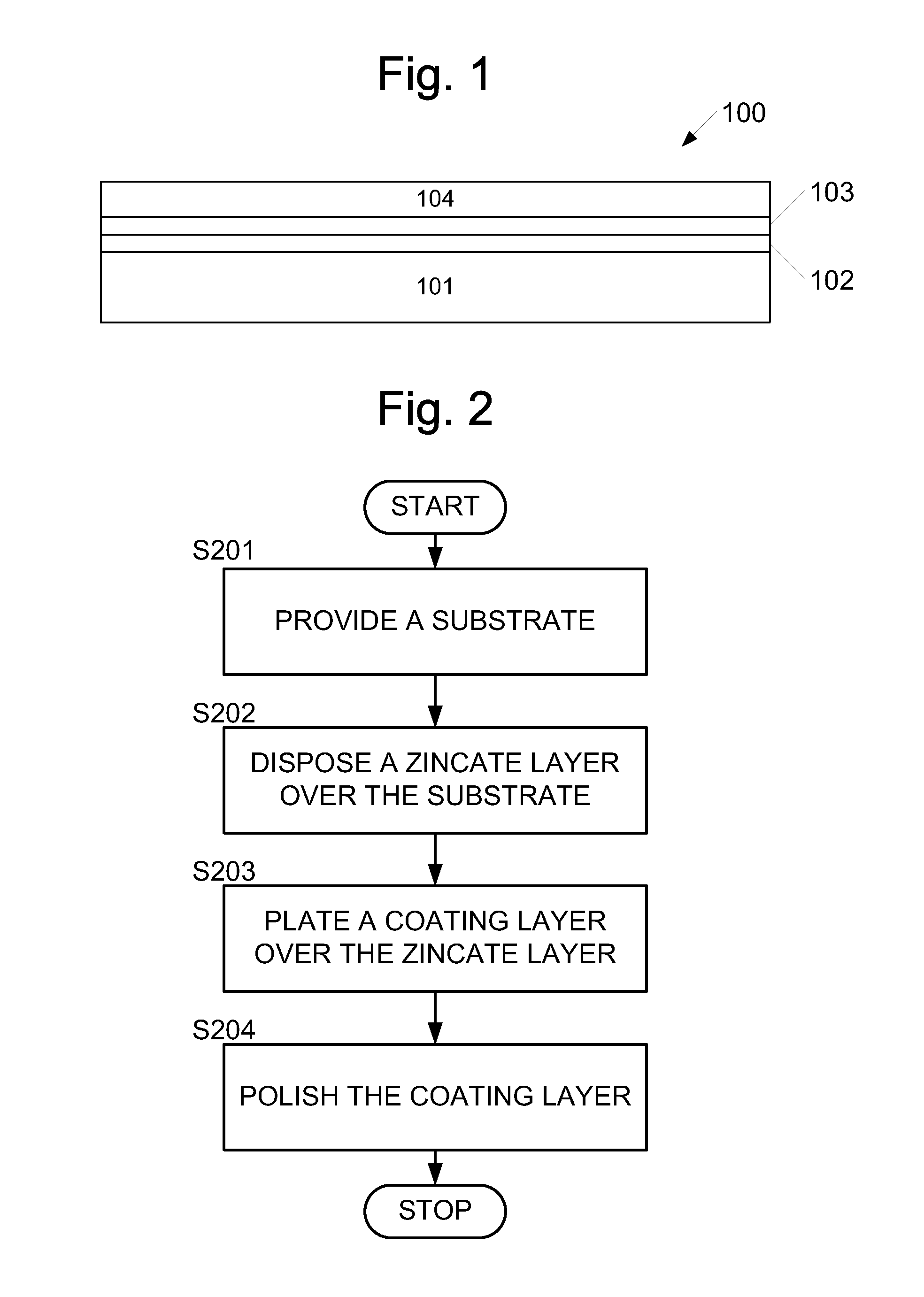

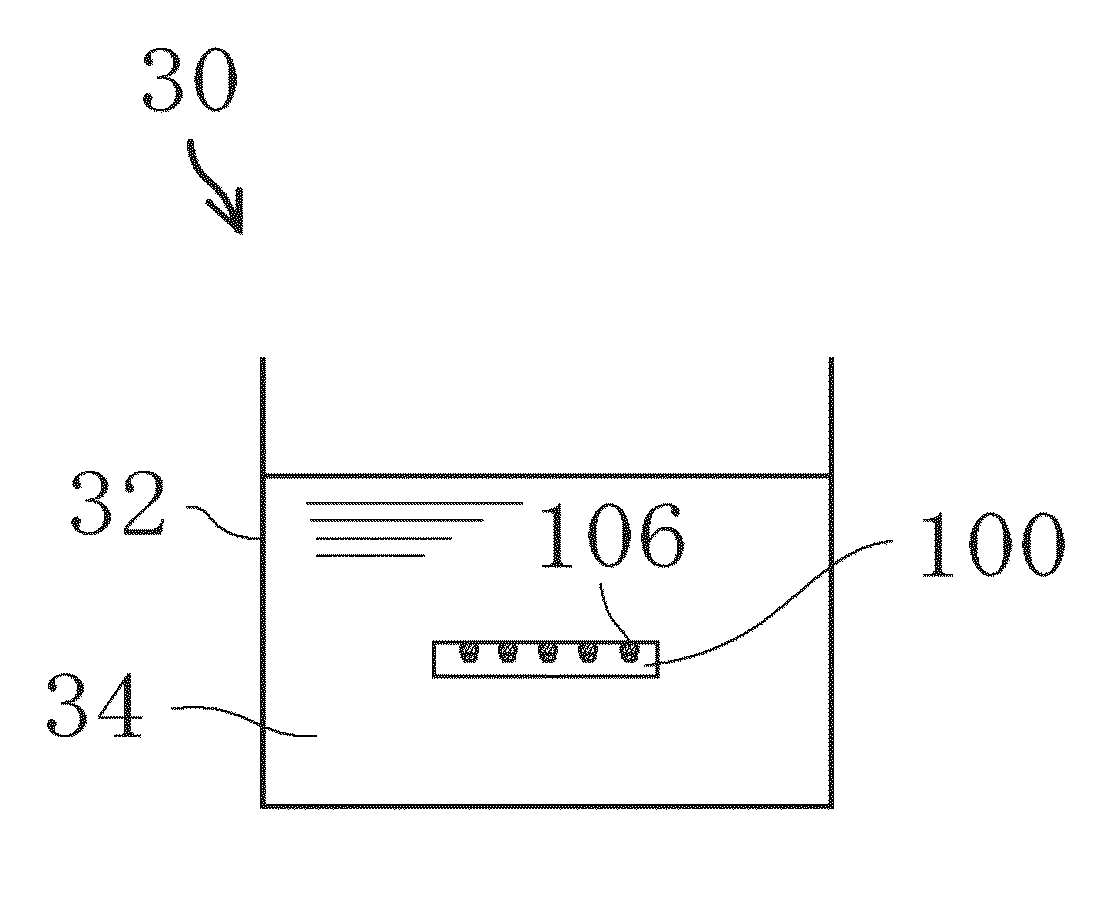

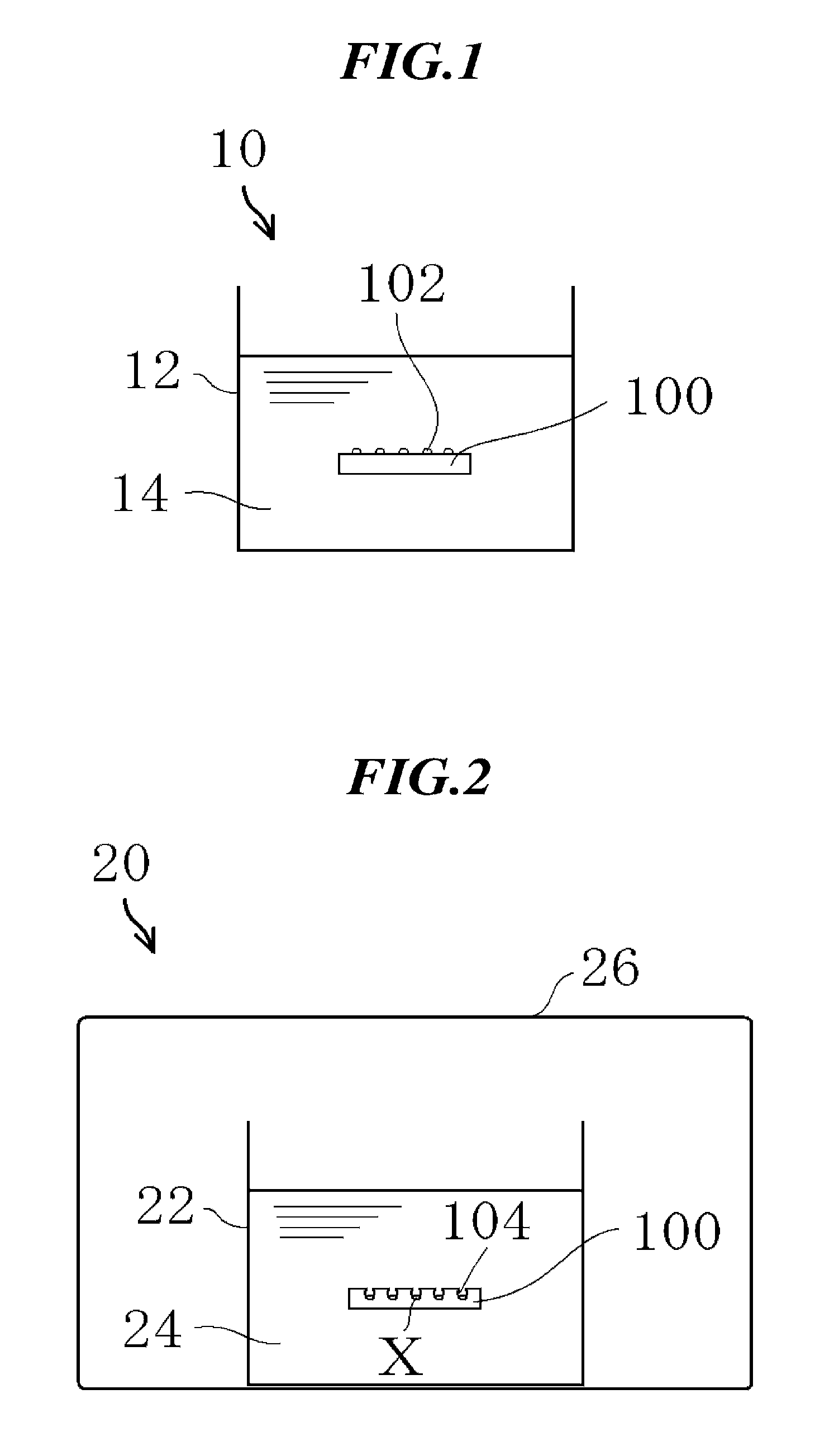

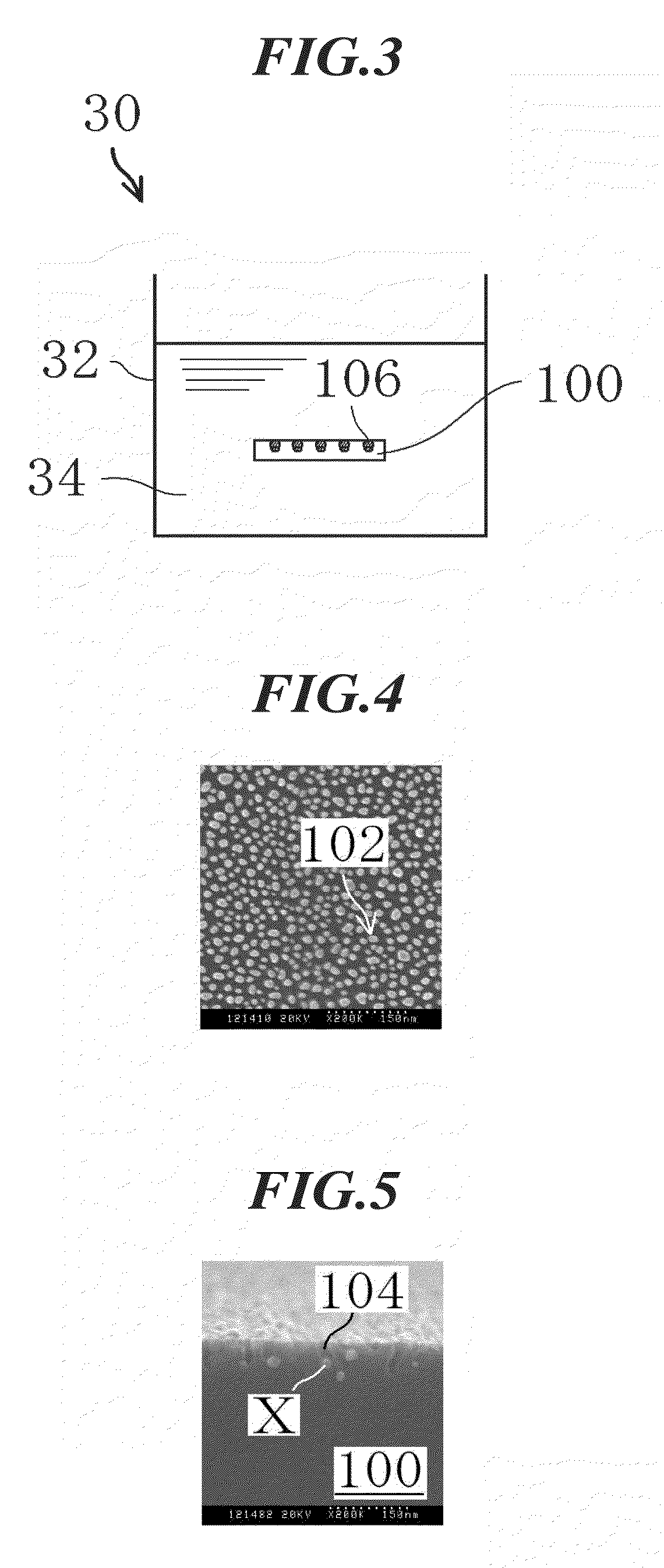

Electroless coated disks for high temperature applications and methods of making the same

ActiveUS8404369B2Improve thermal stabilityMagnetic materials for record carriersMagnetic layer production by platingHard disc driveAlloy

A disk for a hard disk drive is provided. The disk comprises a substrate comprising aluminum, and a coating layer disposed over the substrate. The coating layer comprises an alloy of Ni, X1 and X2, wherein X1 comprises one or more elements selected from the group consisting of Ag, Au, B, Cr, Cu, Ga, In, Mn, Mo, Nb, Pb, Sb, Se, Sn, Te, W, Zn and Zr, and wherein X2 comprises either B or P, and wherein X1 and X2 do not comprise the same elements.

Owner:WESTERN DIGITAL TECH INC

Fine structural body and method of producing the same

Described is a structural body including at least partially an aluminum member having on a surface an anodized film with micropores present, in which: the micropores have a coefficient of variation in pore size of 5 to 50%; and the micropores are each sealed with a metal. The structural body can generate localized plasmon resonance having a sufficiently large intensity and be produced at low cost through a simple production process, and having a large surface area.

Owner:FUJIFILM CORP +1

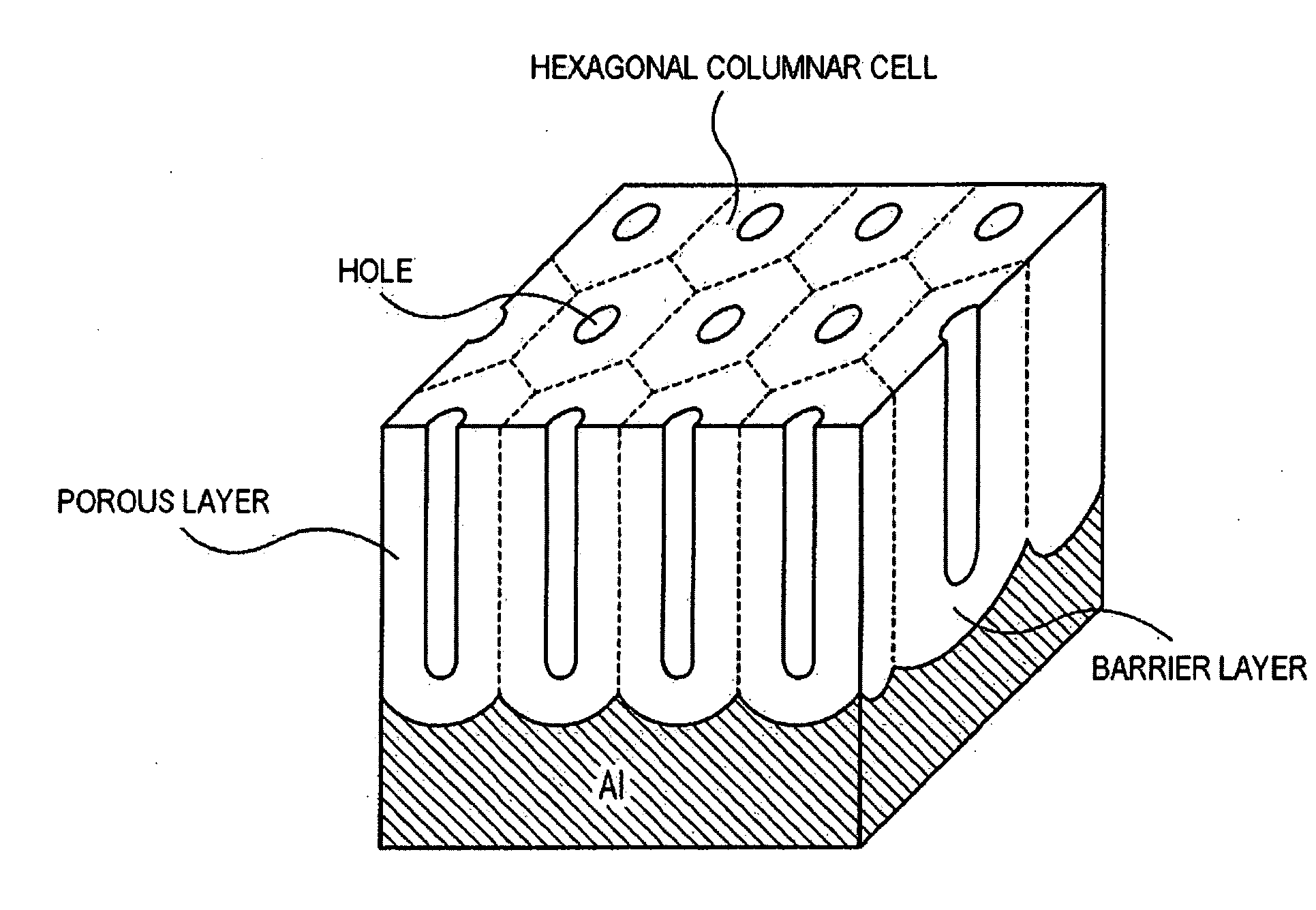

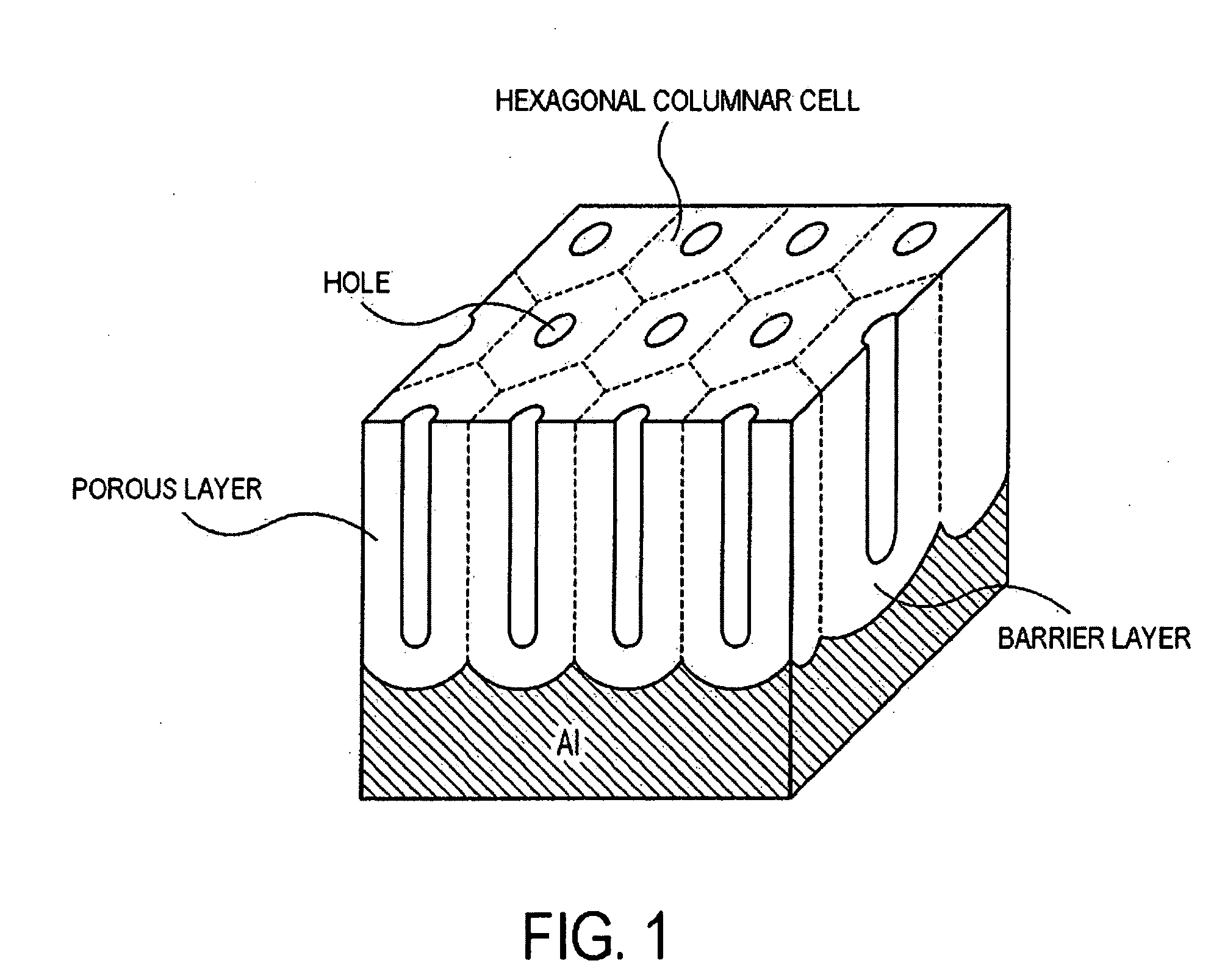

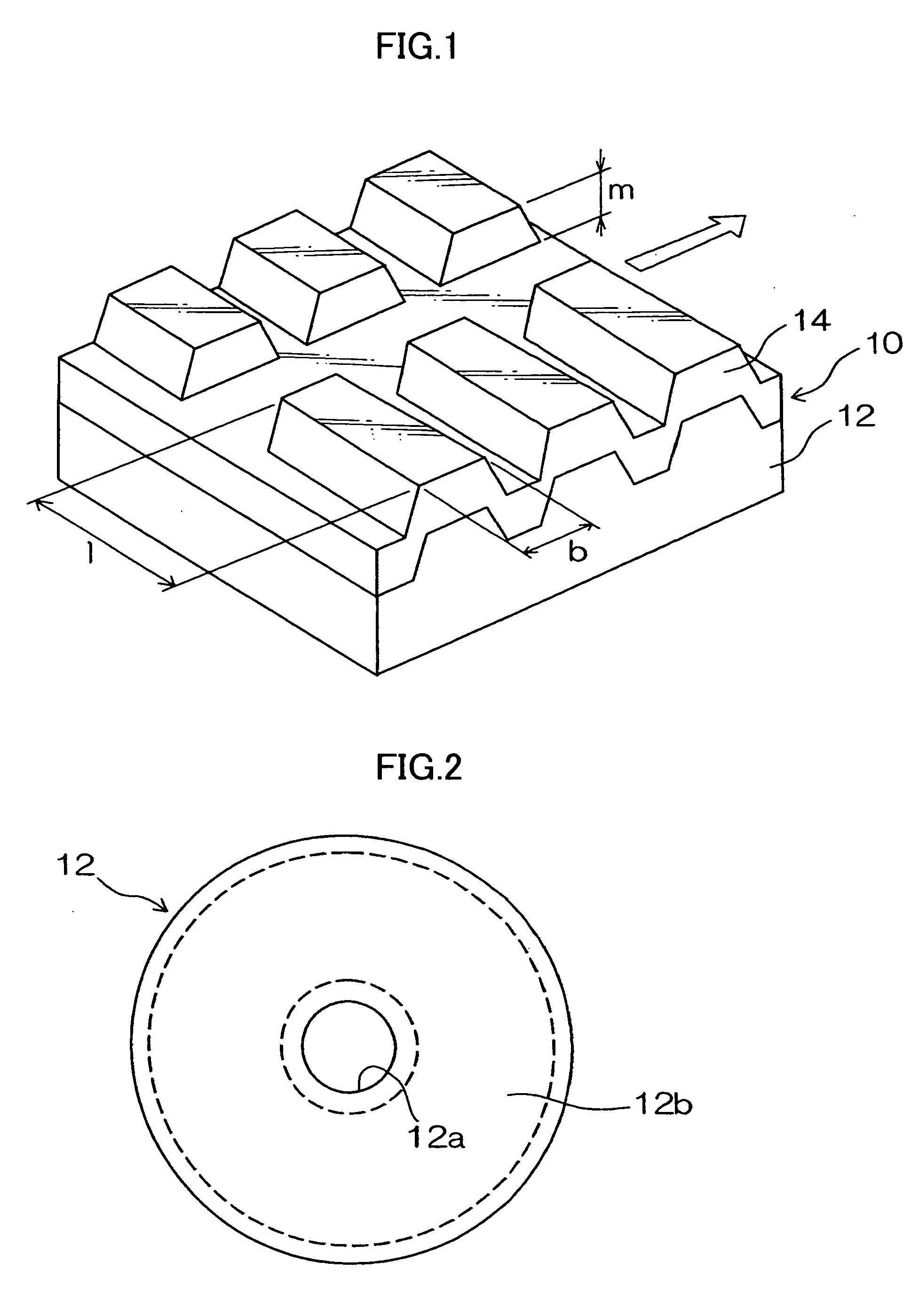

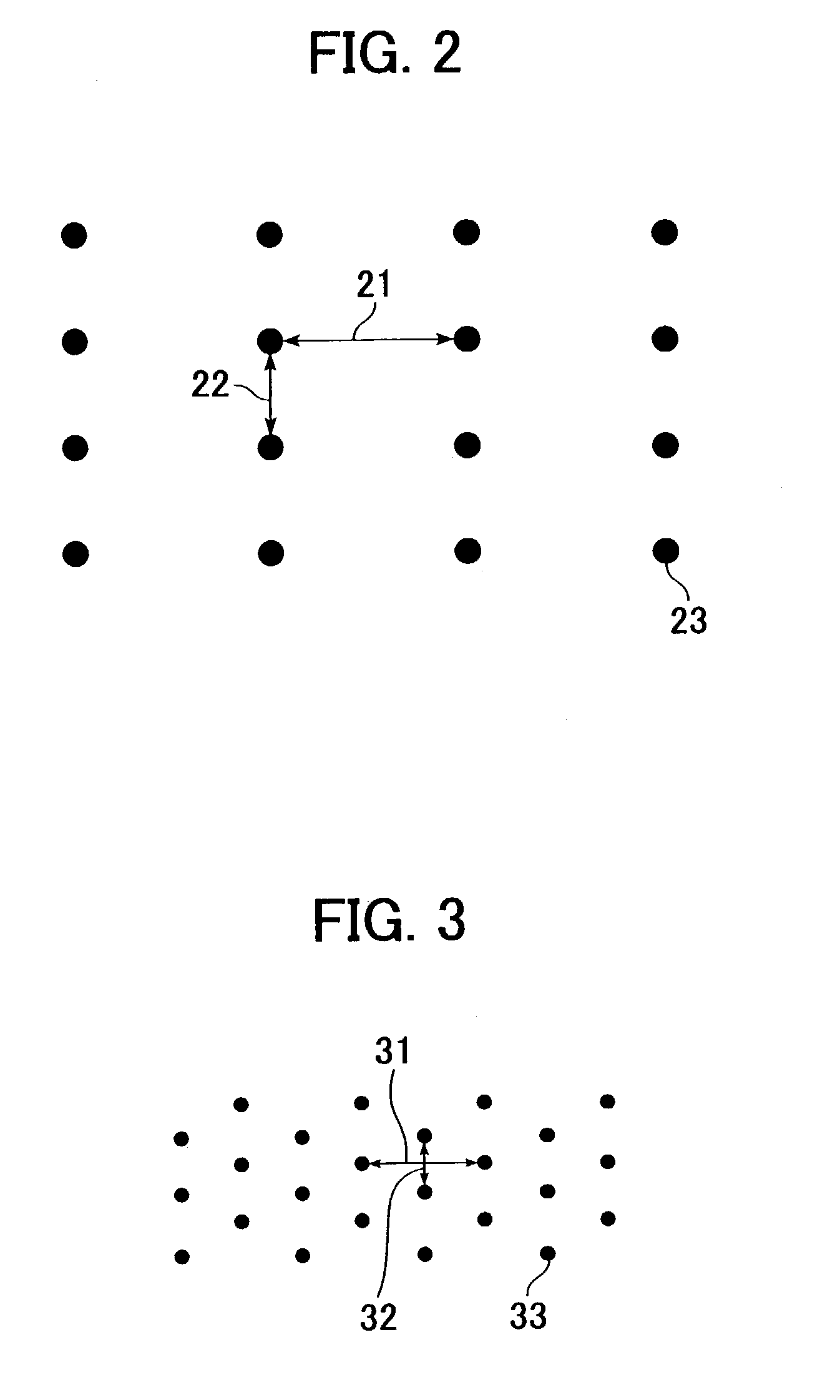

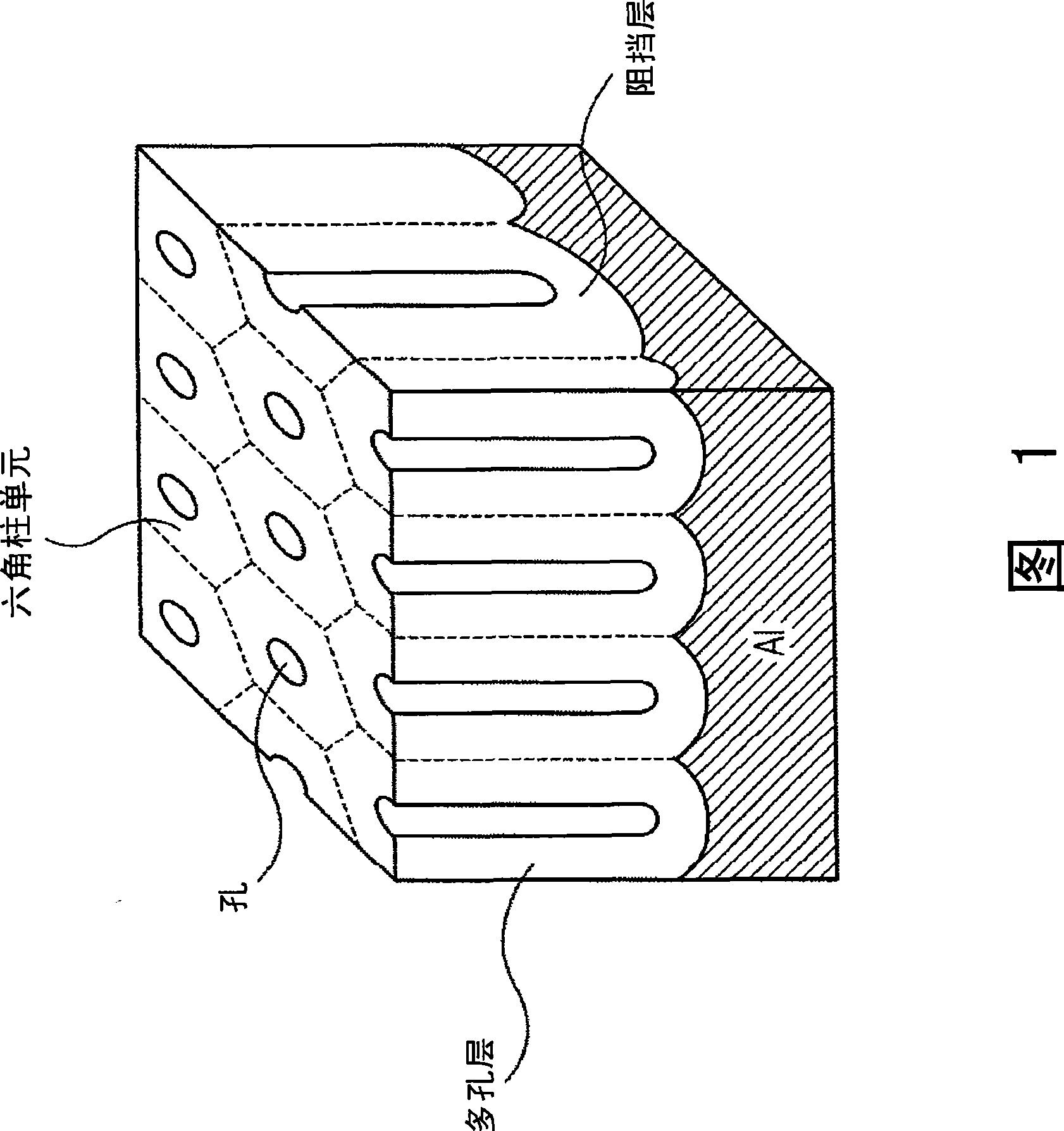

Nanoholes and production thereof, stamper and production thereof, magnetic recording media and production thereof, and, magnetic recording apparatus and method

InactiveUS20050249980A1Efficient preparationLow costMaterial nanotechnologyMagnetic materials for record carriersPorous layerEngineering

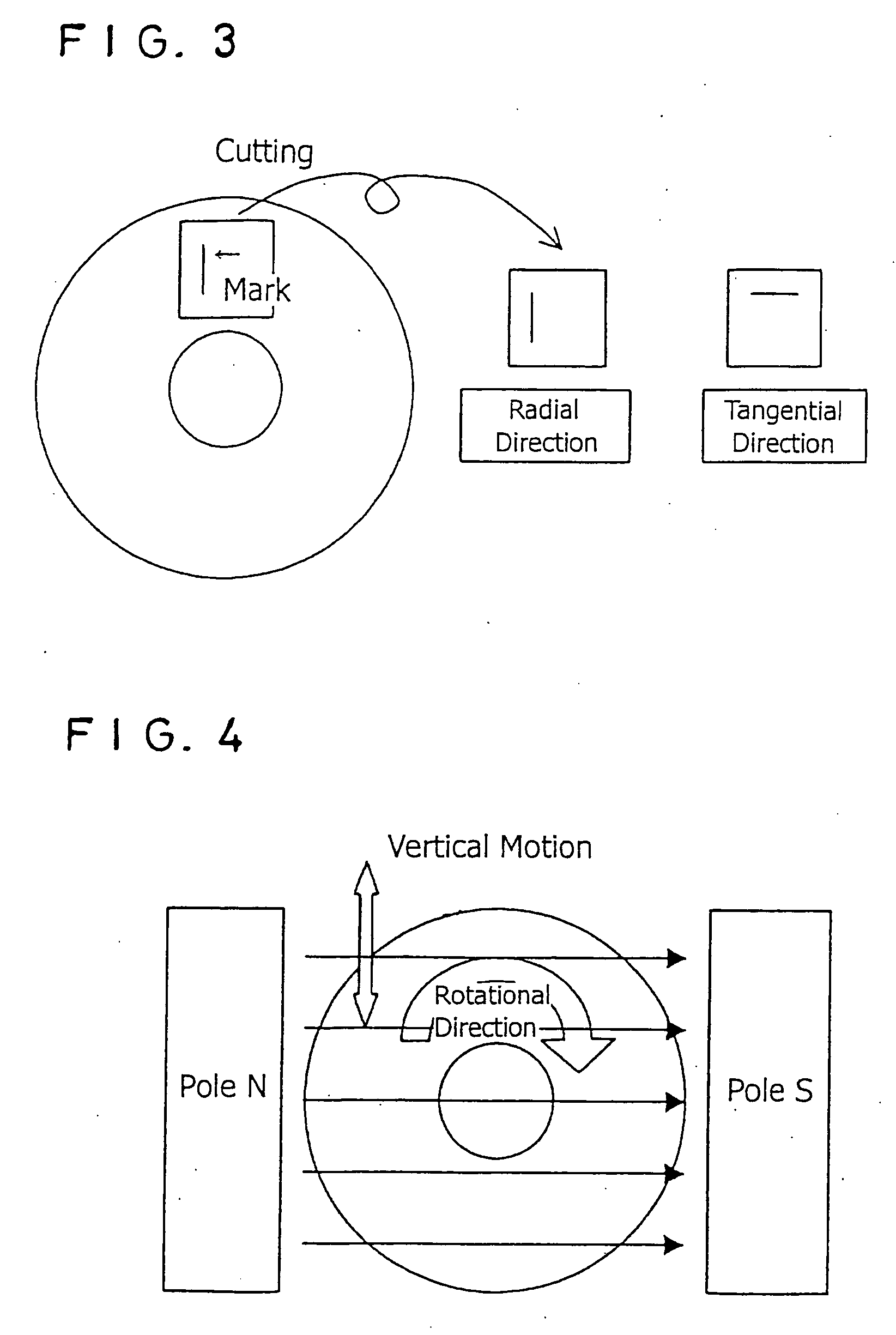

A nanohole structure includes a metallic matrix and nanoholes arrayed regularly in the metallic matrix, in which the nanoholes are spaced in rows at specific intervals to constitute rows of nanoholes. The rows of nanoholes are preferably arranged concentrically or helically. The nanoholes in adjacent rows of nanoholes are preferably arranged in a radial direction. The width of each row of nanoholes preferably varies at specific intervals in its longitudinal direction. A magnetic recording medium includes a substrate, and a porous layer on or above the substrate. The porous layer contains nanoholes each extending in a direction substantially perpendicular to a substrate plane, containing at least one magnetic material therein, and is the above-mentioned nanohole structure.

Owner:FUJITSU LTD +1

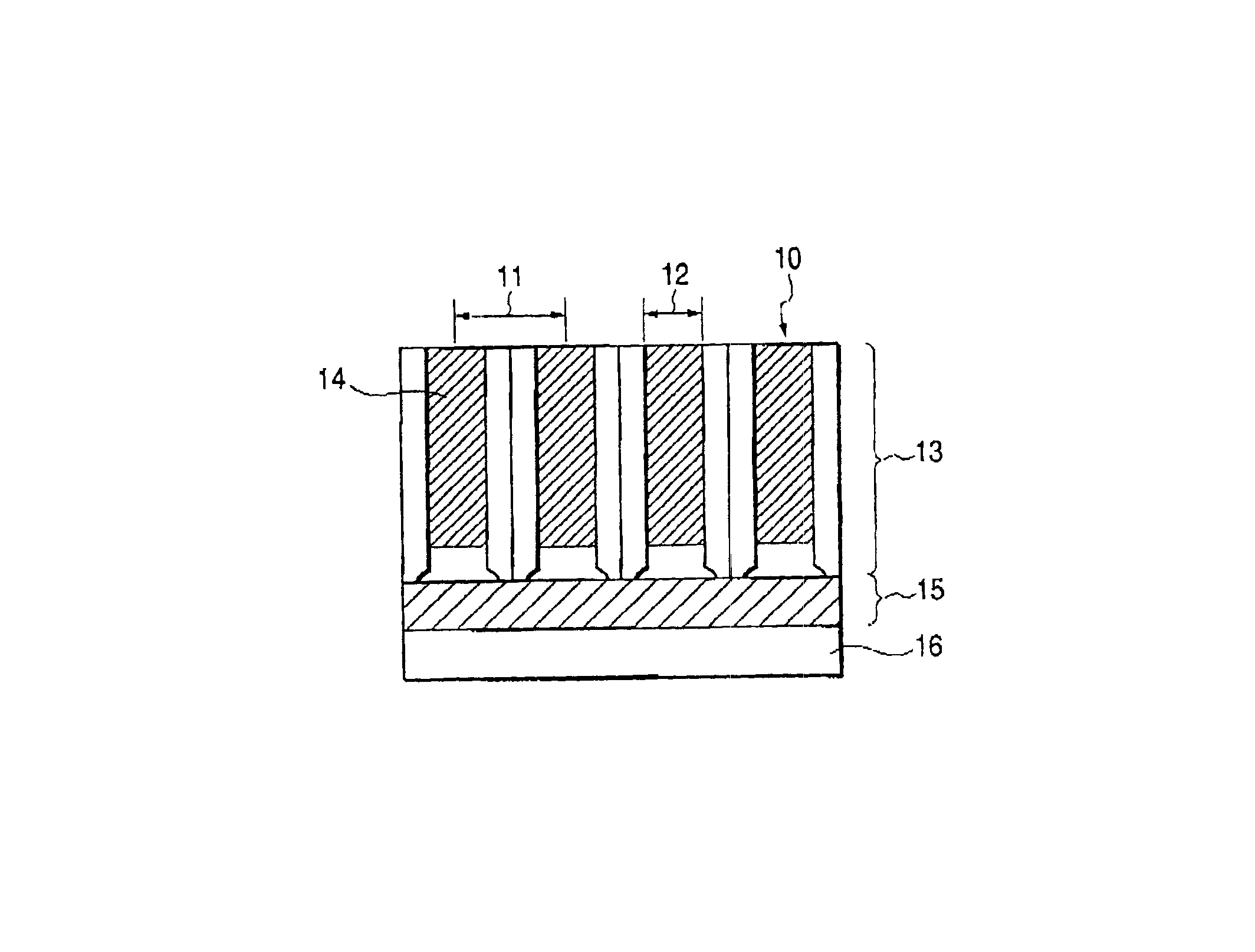

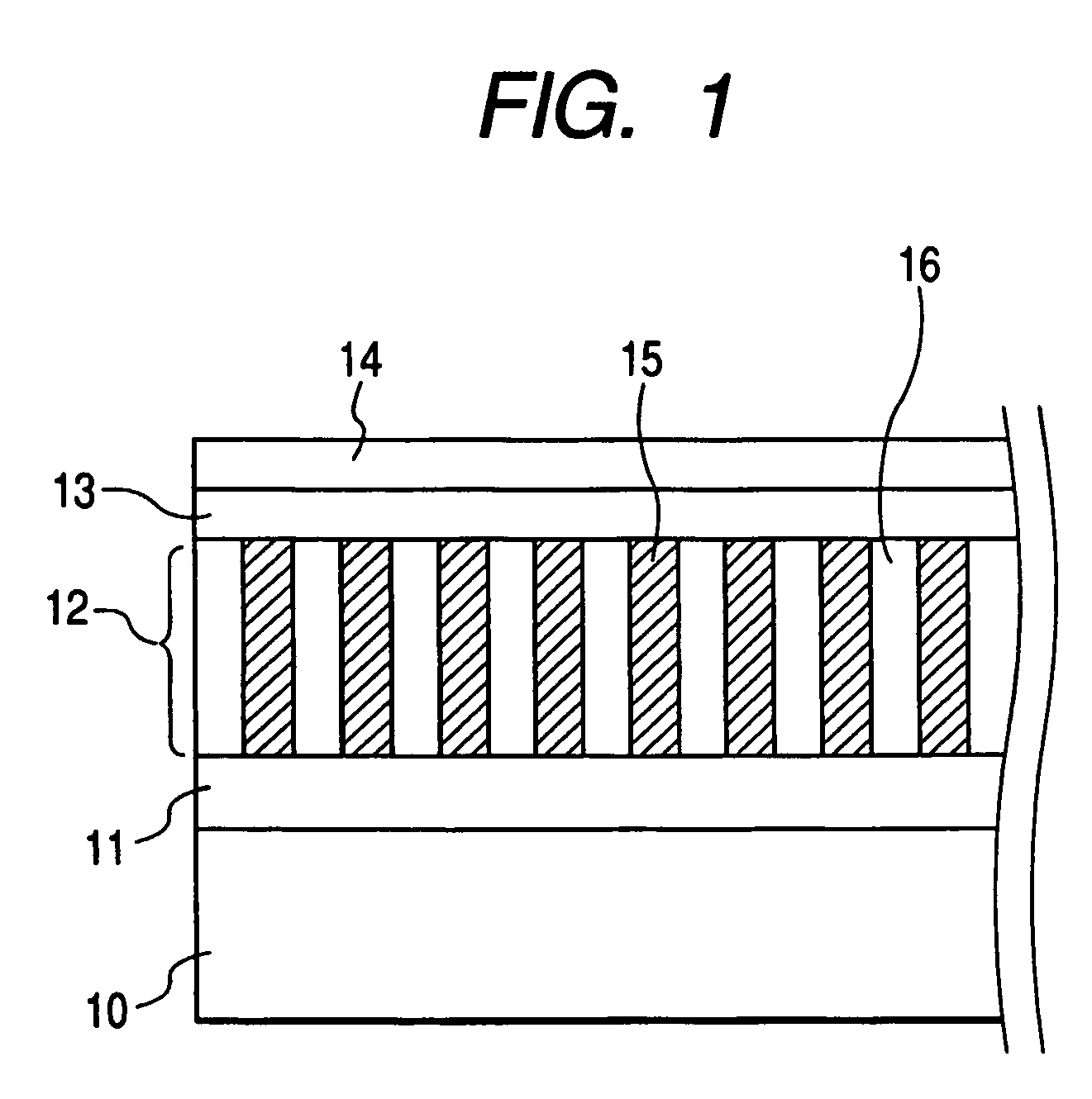

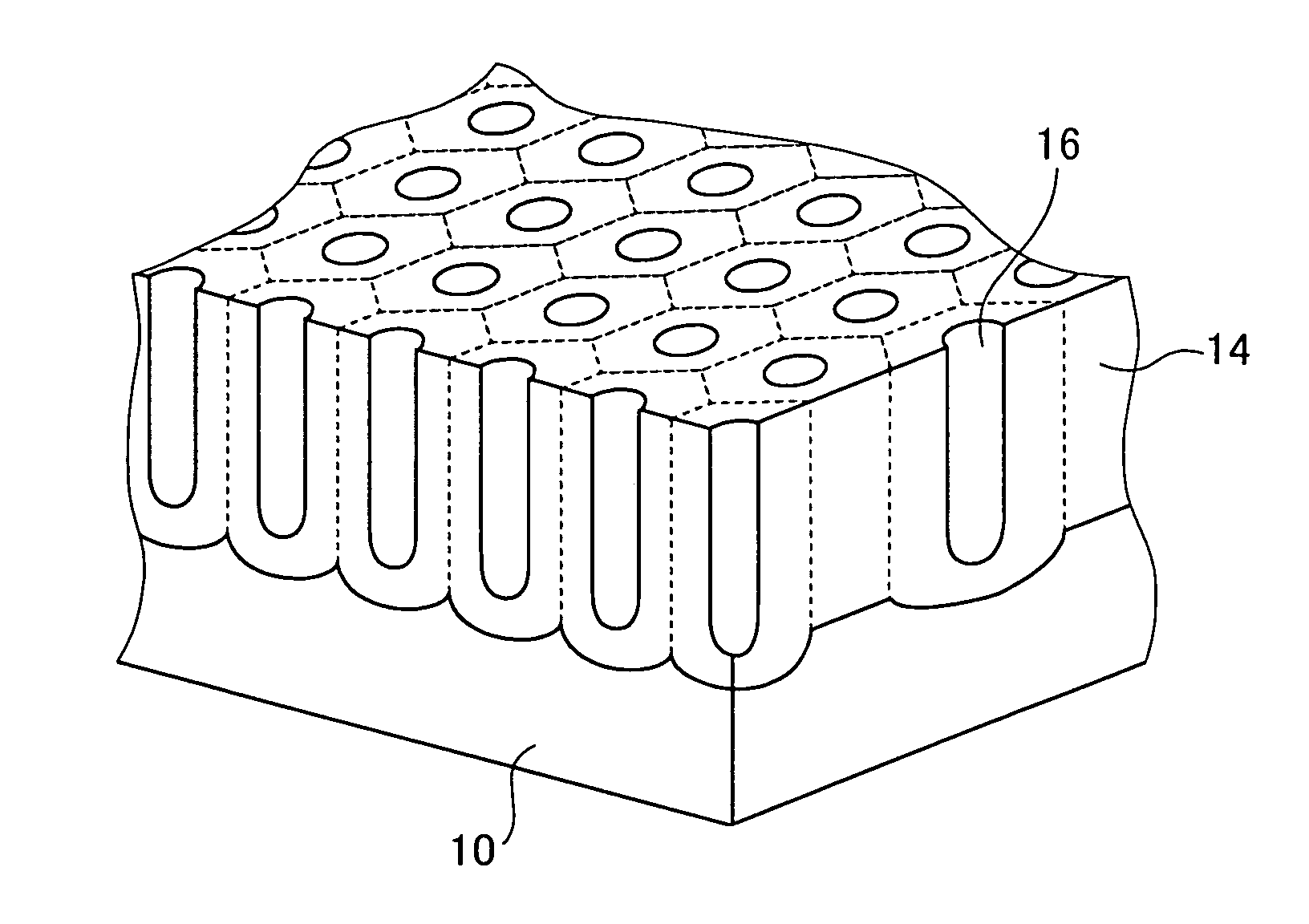

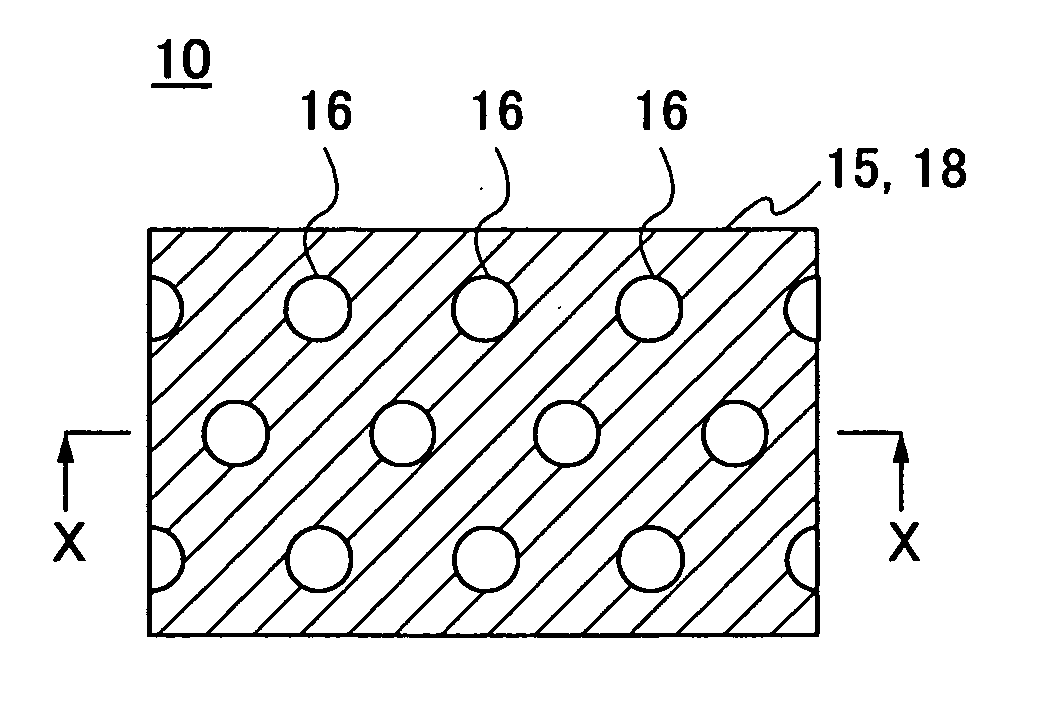

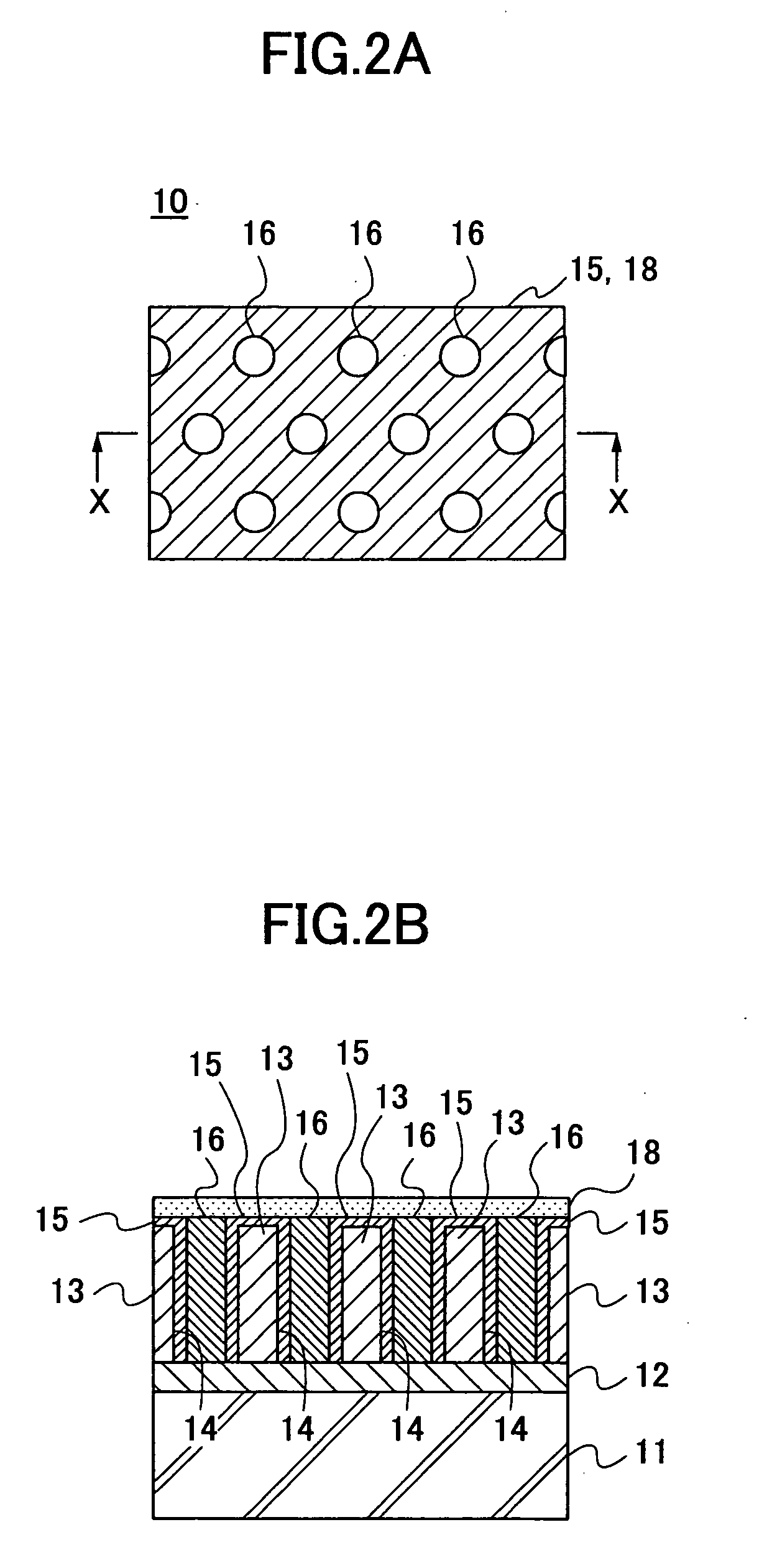

Magnetic recording medium including aluminum layer having holes and production method thereof

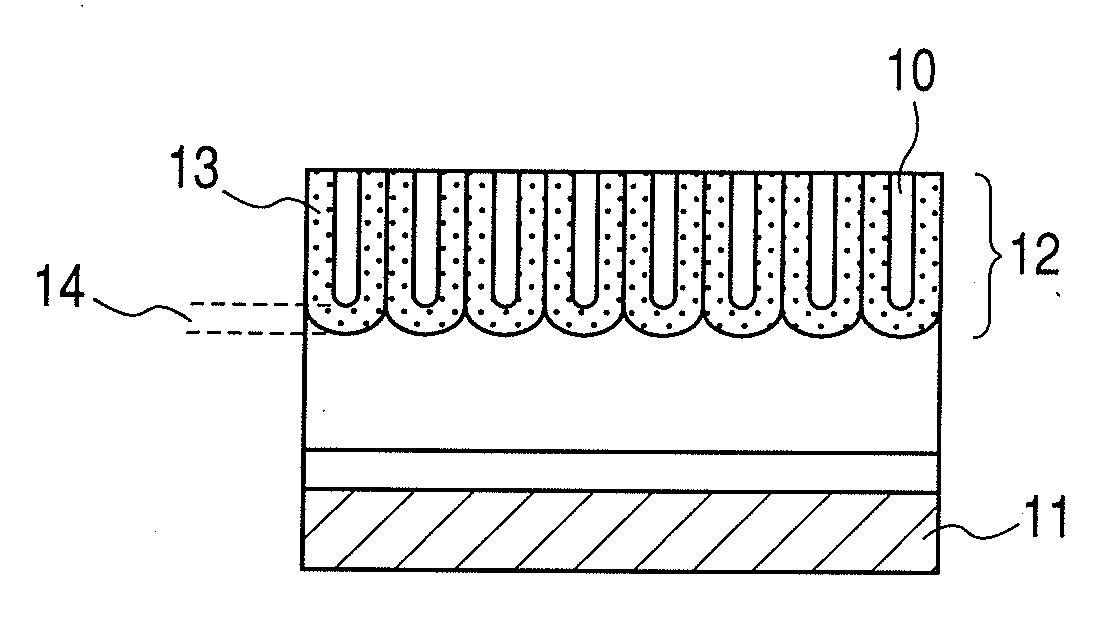

InactiveUS6858319B2Magnetic materials for record carriersMagnetic layer production by platingNanoholeOptoelectronics

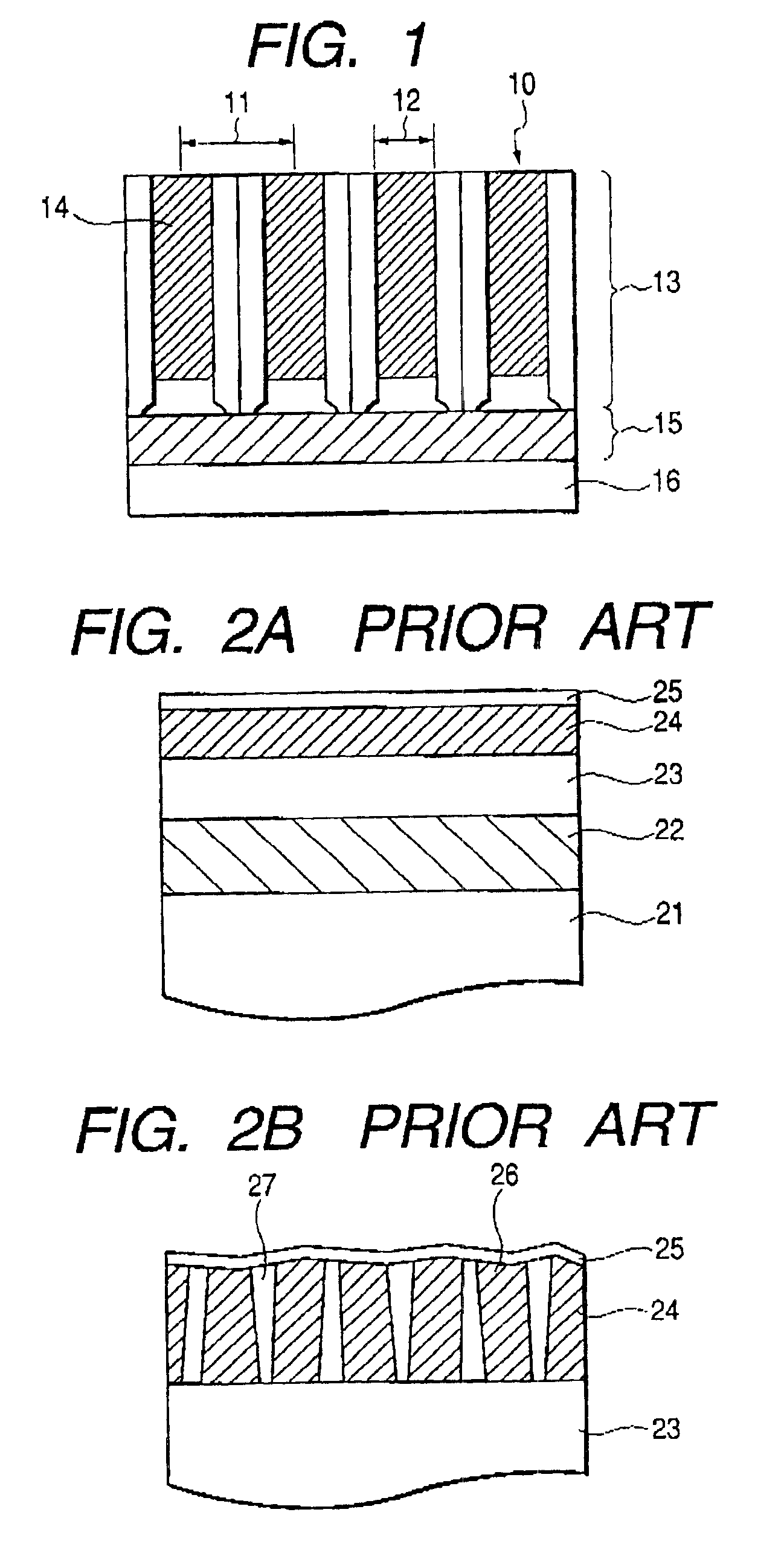

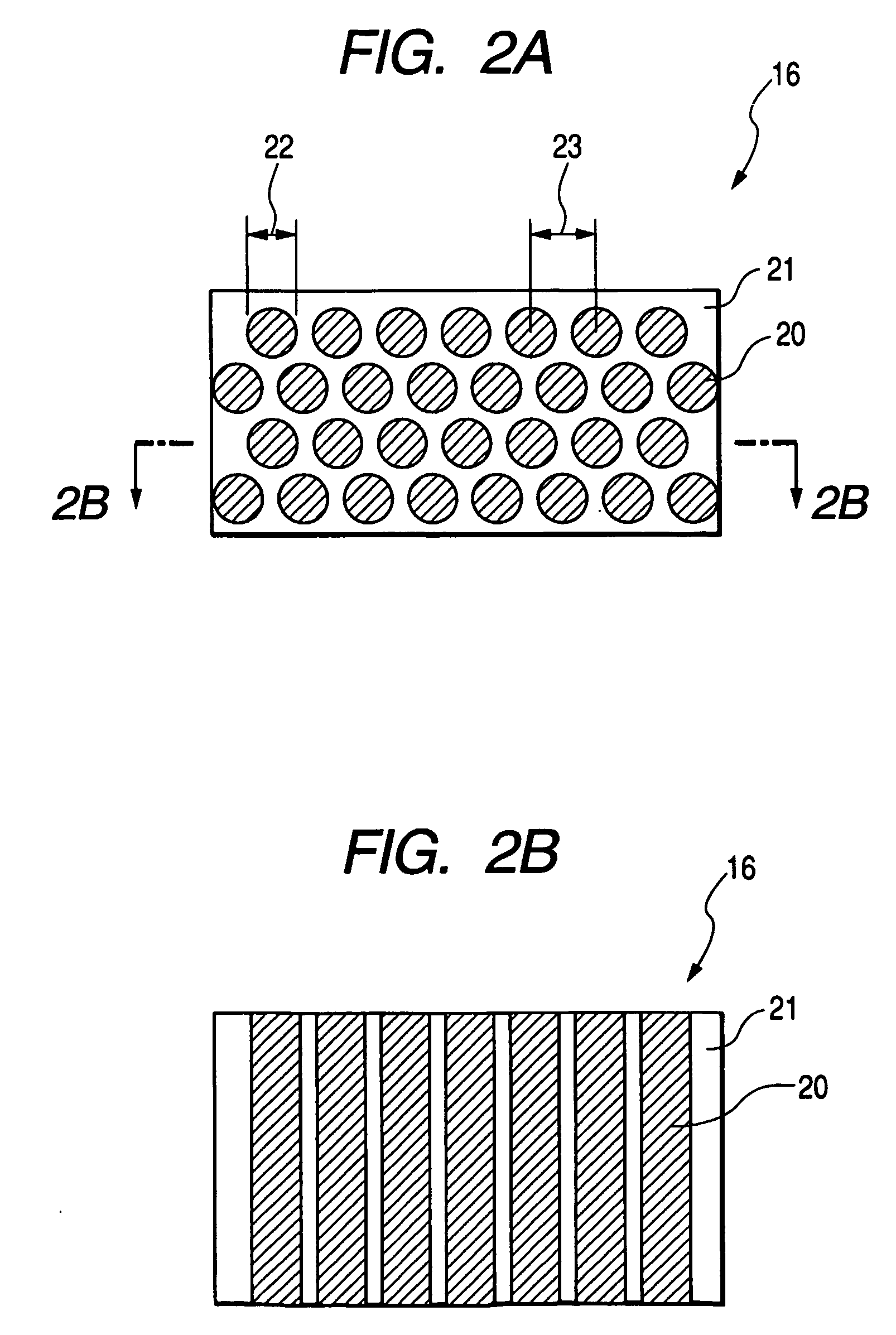

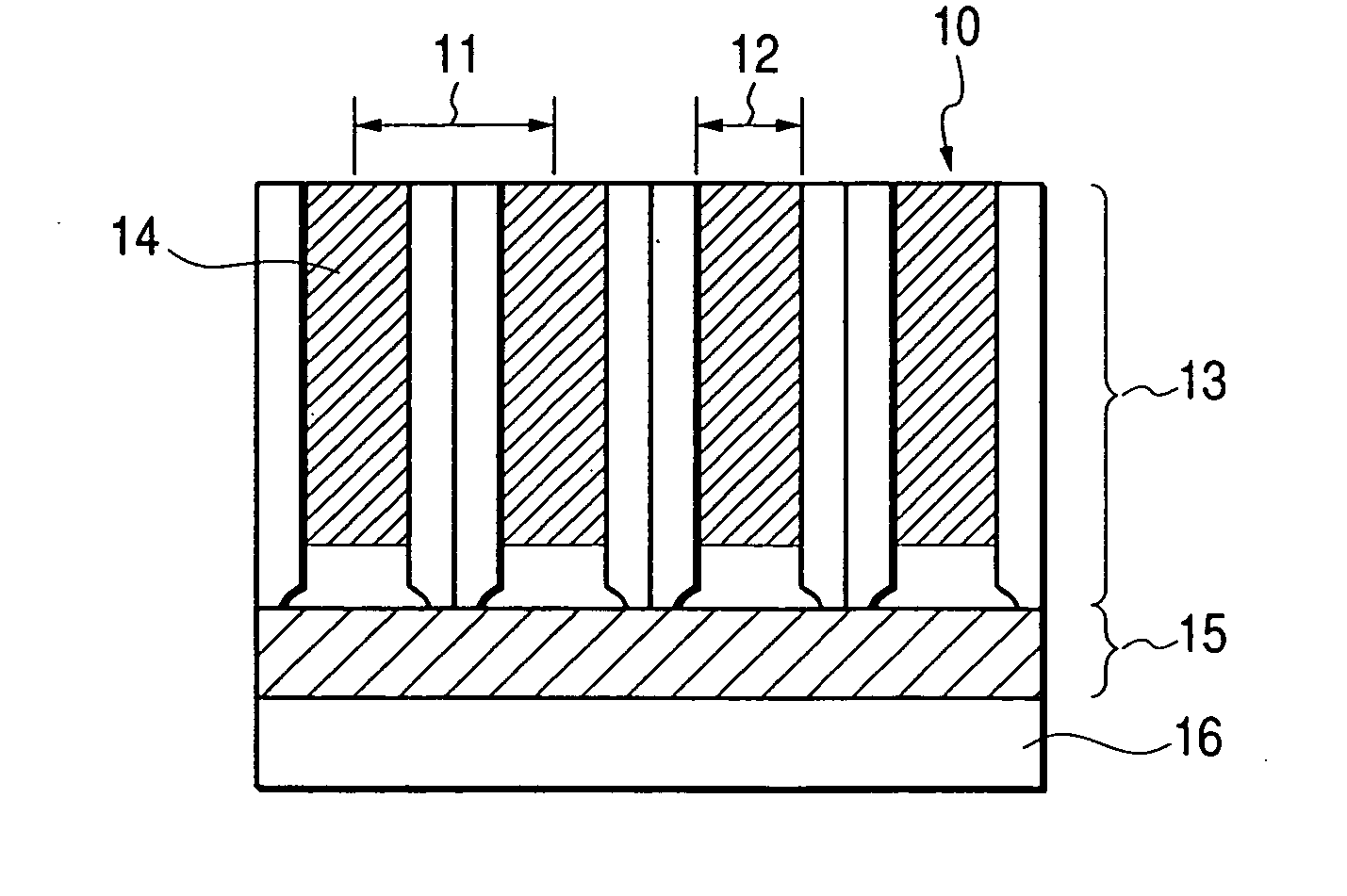

To provide a magnetic recording medium with good record and reproduction characteristics. In the magnetic recording medium having an anodic oxidized alumina nanohole film filled with a magnetic substance, the anodic oxidized alumina nanohole film 13 is formed on a substrate 16 with at least one base electrode layer 15 sandwiched therebetween, the base electrode layer 15 is a film that has fcc structure and whose (111) face is oriented in the direction perpendicularly to a substrate, and the fillers 14 in the alumina nanoholes 10 have hcp structure and include hard magnetic substance whose principal component is Co and whose c-axis is perpendicular to the substrate.

Owner:CANON KK

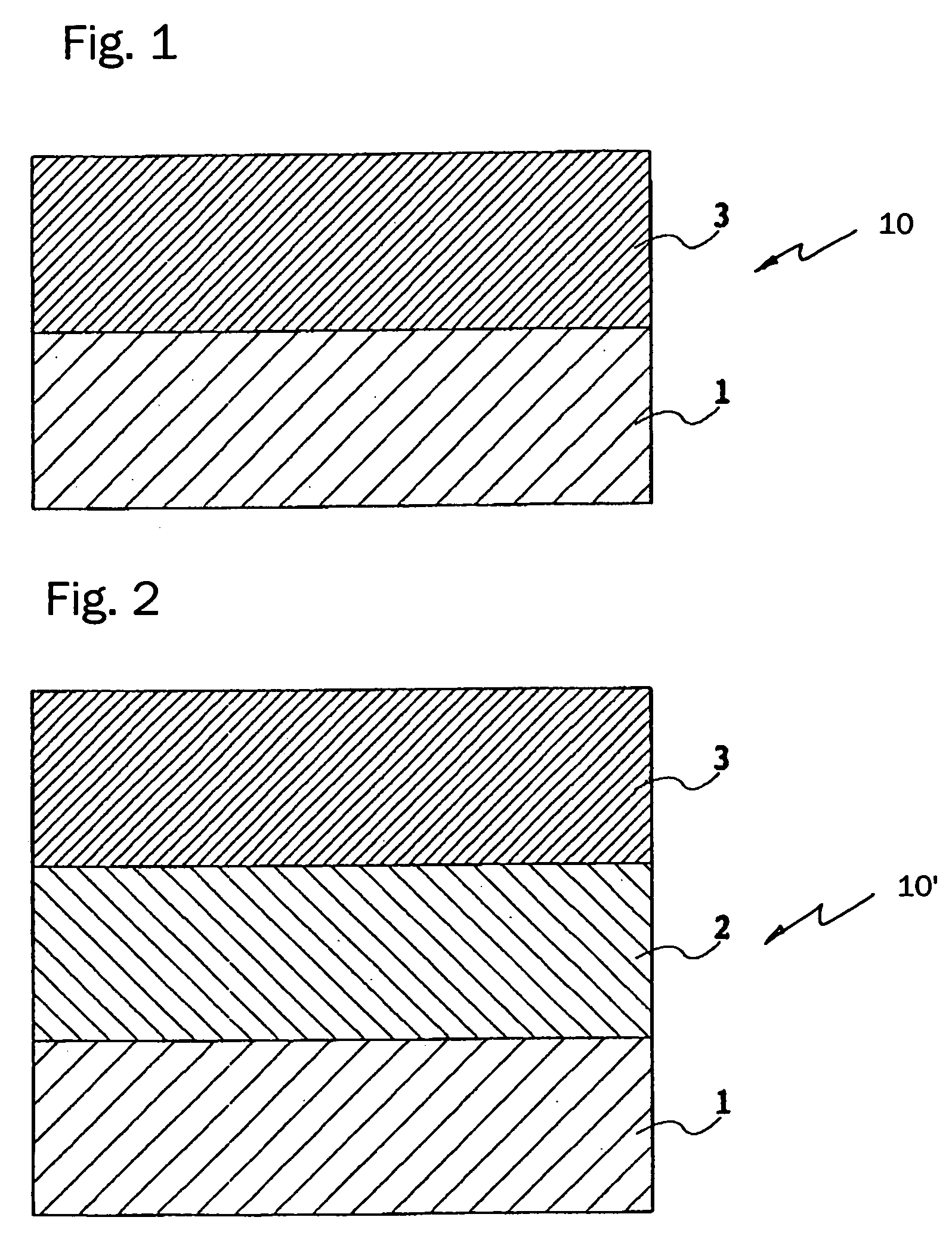

Magnetic recording media including magnetically soft composite layer and method of making same

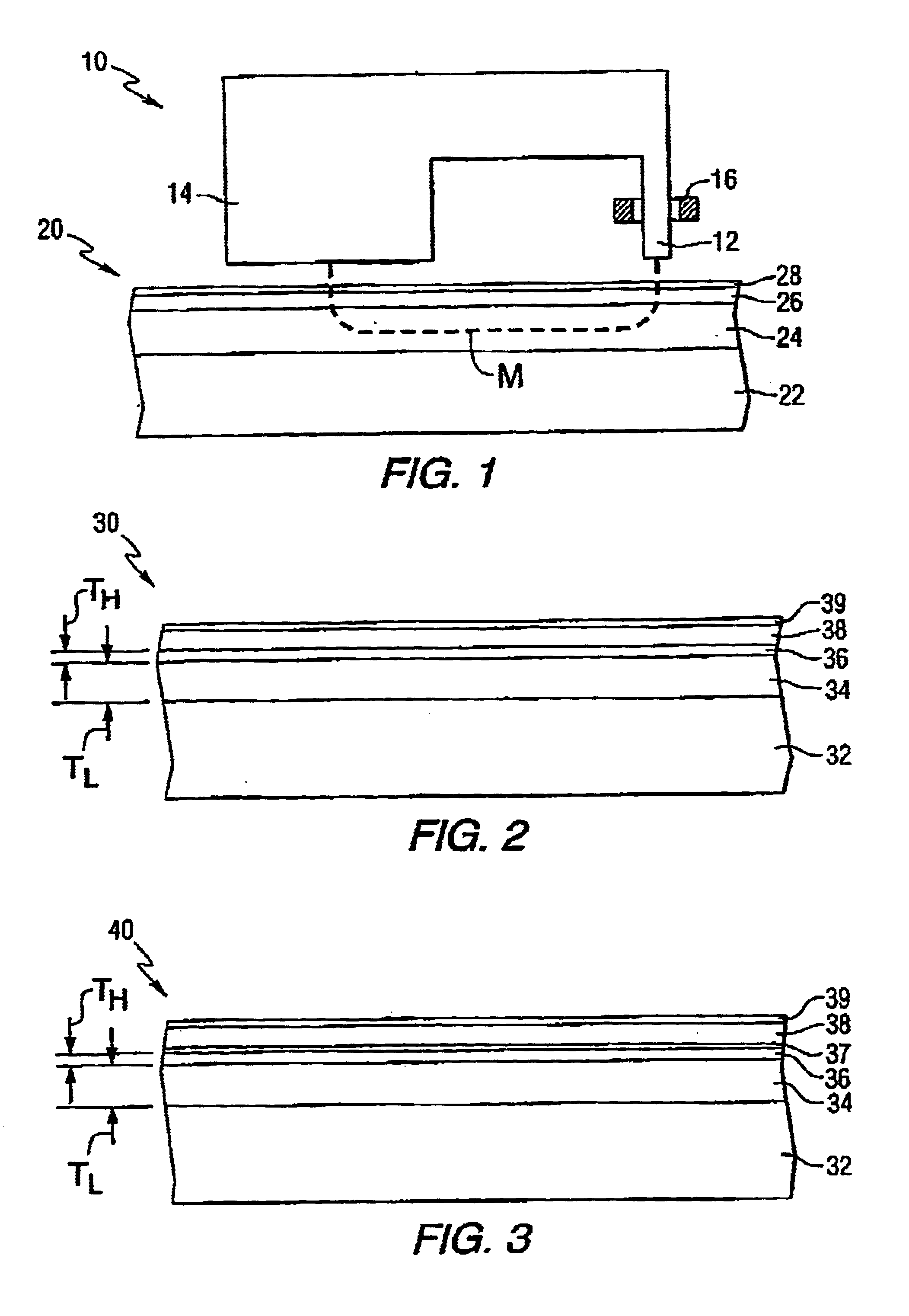

Magnetic recording disks having a composite soft magnetic layer are provided. The soft magnetic layer includes a relatively thick layer of low saturation moment soft magnetic material and a relatively thin layer of high saturation moment soft magnetic material. In a preferred embodiment, the thin layer of soft magnetic material is deposited over the thick layer, followed by deposition of a magnetically hard perpendicular recording layer.

Owner:SEAGATE TECH LLC

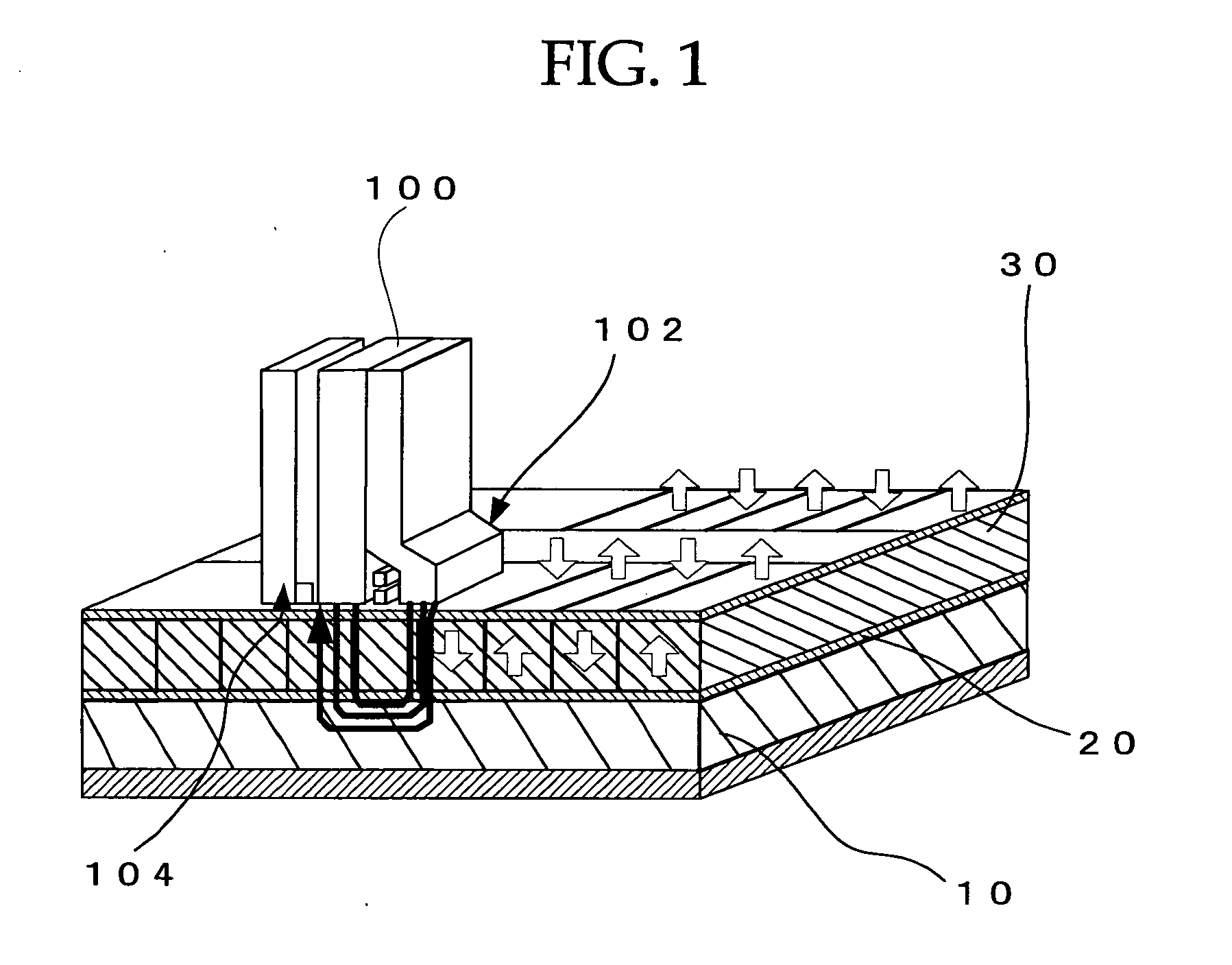

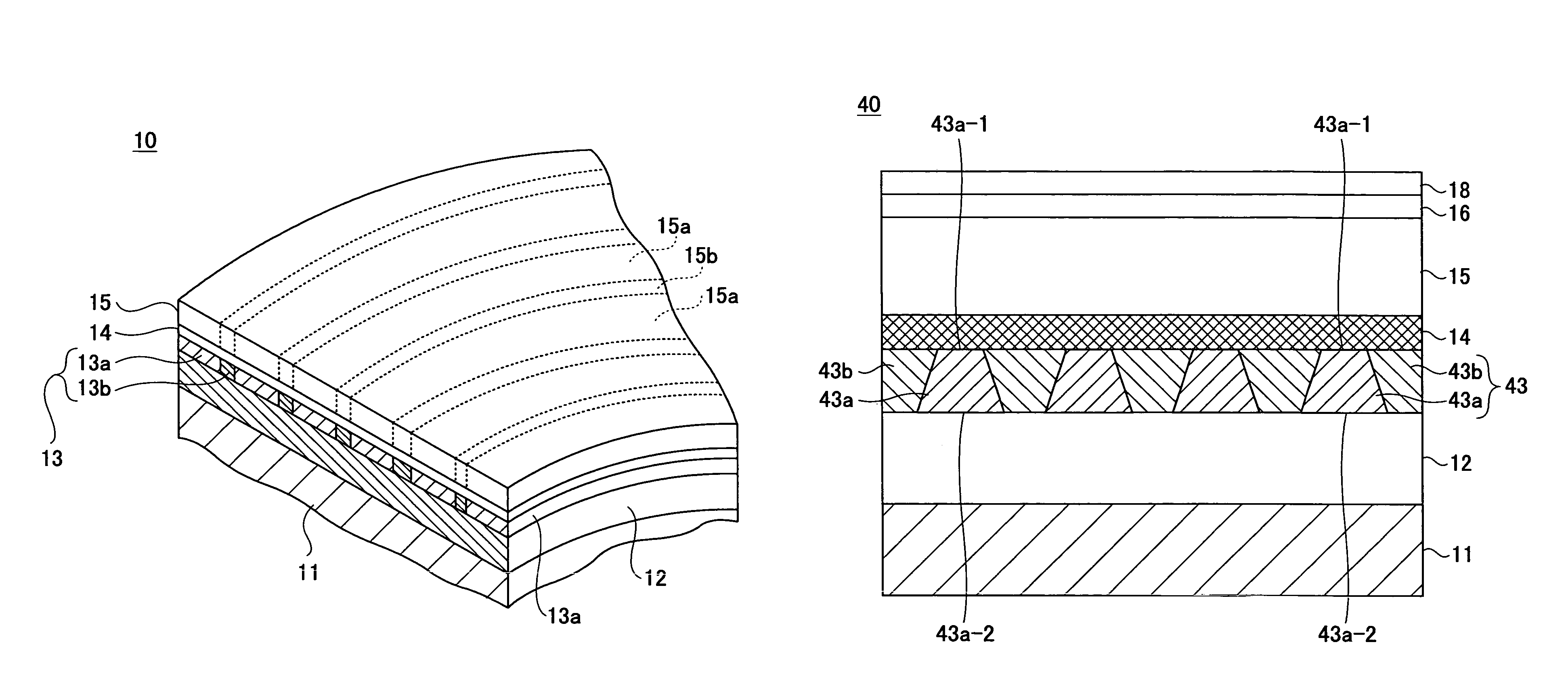

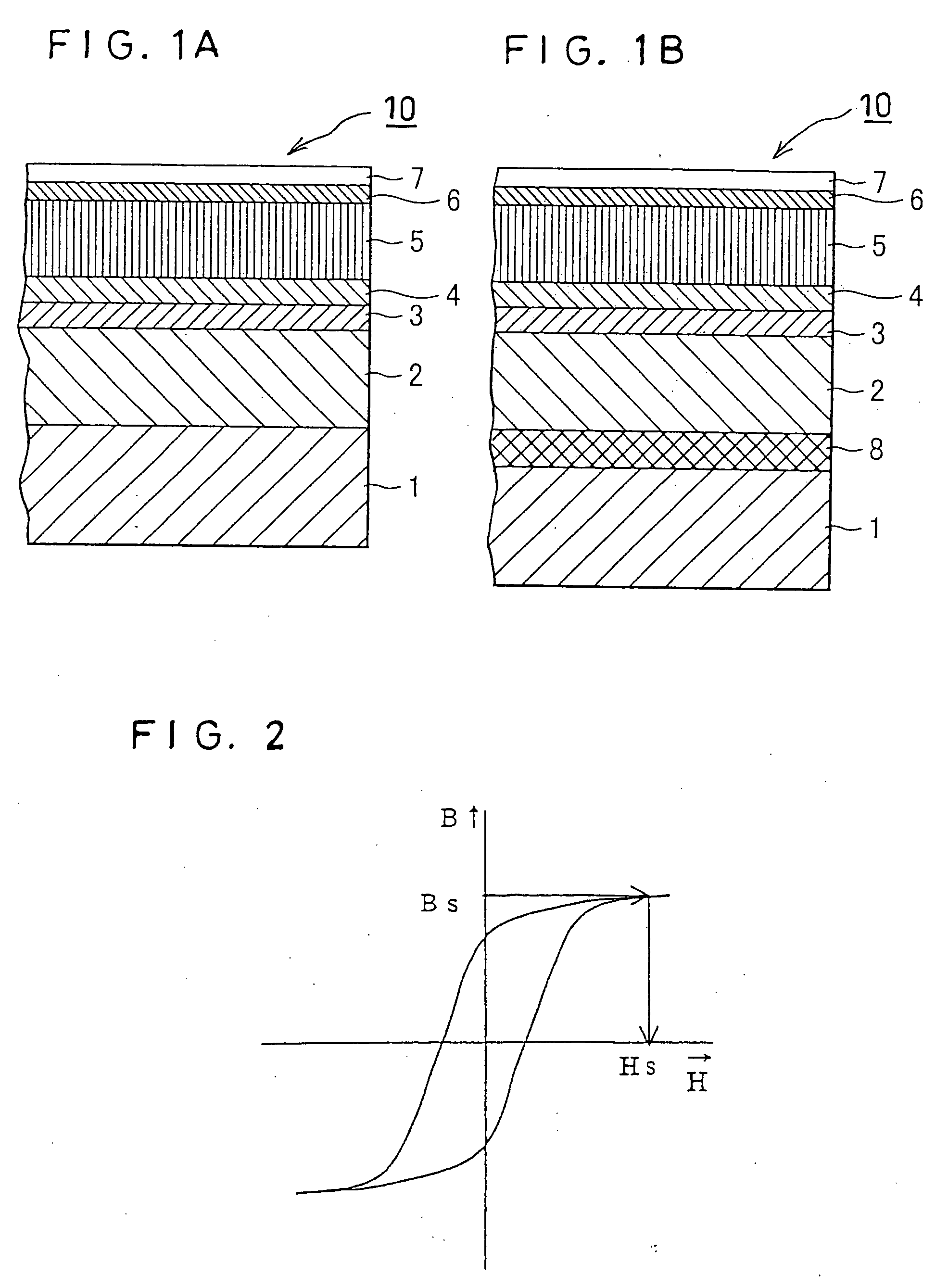

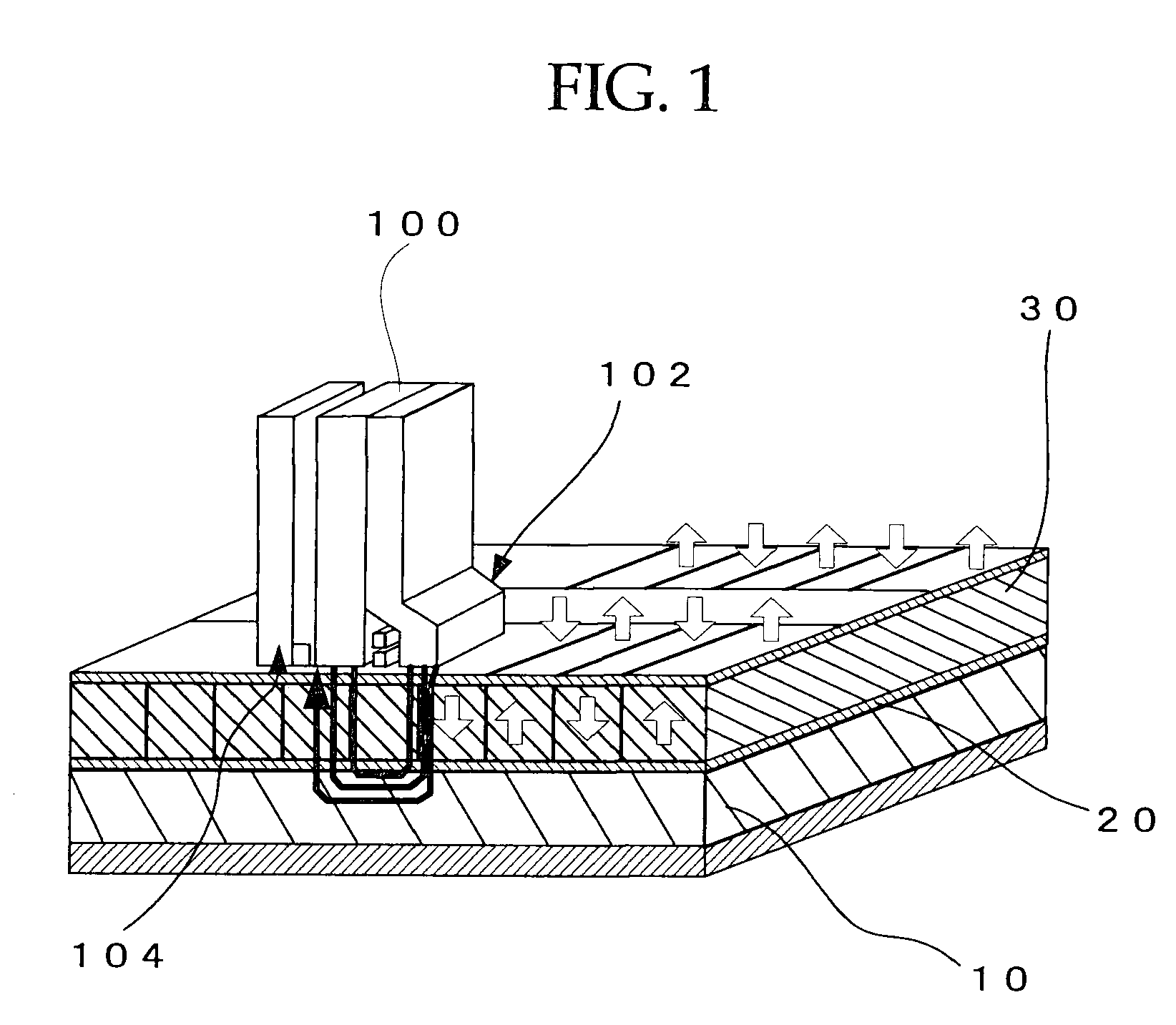

Vertical magnetic recording medium, magnetic recording apparatus and manufacturing method of a vertical magnetic recording medium

InactiveUS7422808B2Improve recording densityImprove signal-to-noise ratioDifferent record carrier formsBase layers for recording layersInter layerMagnetization

A vertical magnetic recording medium includes a substrate, a soft magnetic backing layer formed on the substrate, a magnetic flux confinement layer formed on the soft magnetic backing layer, an intermediate layer formed on the magnetic flux confinement layer, and a recording layer of a vertical magnetization film formed on the intermediate layer. The magnetic flux confinement layer has a plurality of soft magnetic parts each formed along a track region of plural track regions and a non-magnetic parts formed between adjacent track regions. The intermediate layer is formed of a non-magnetic material and is formed so as to cover a surface of the soft magnetic part and the non-magnetic parts.

Owner:RESONAC HOLDINGS CORPORATION

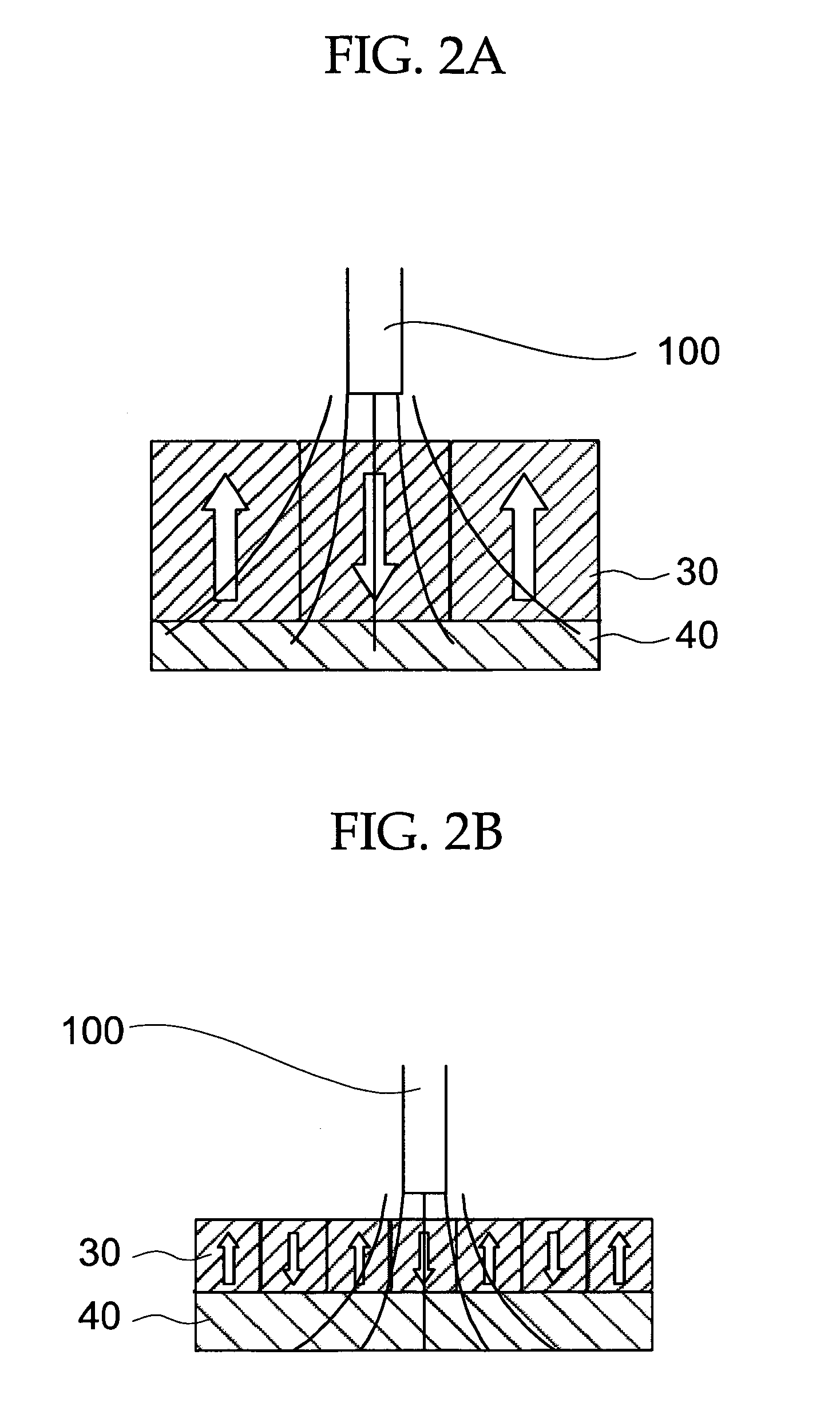

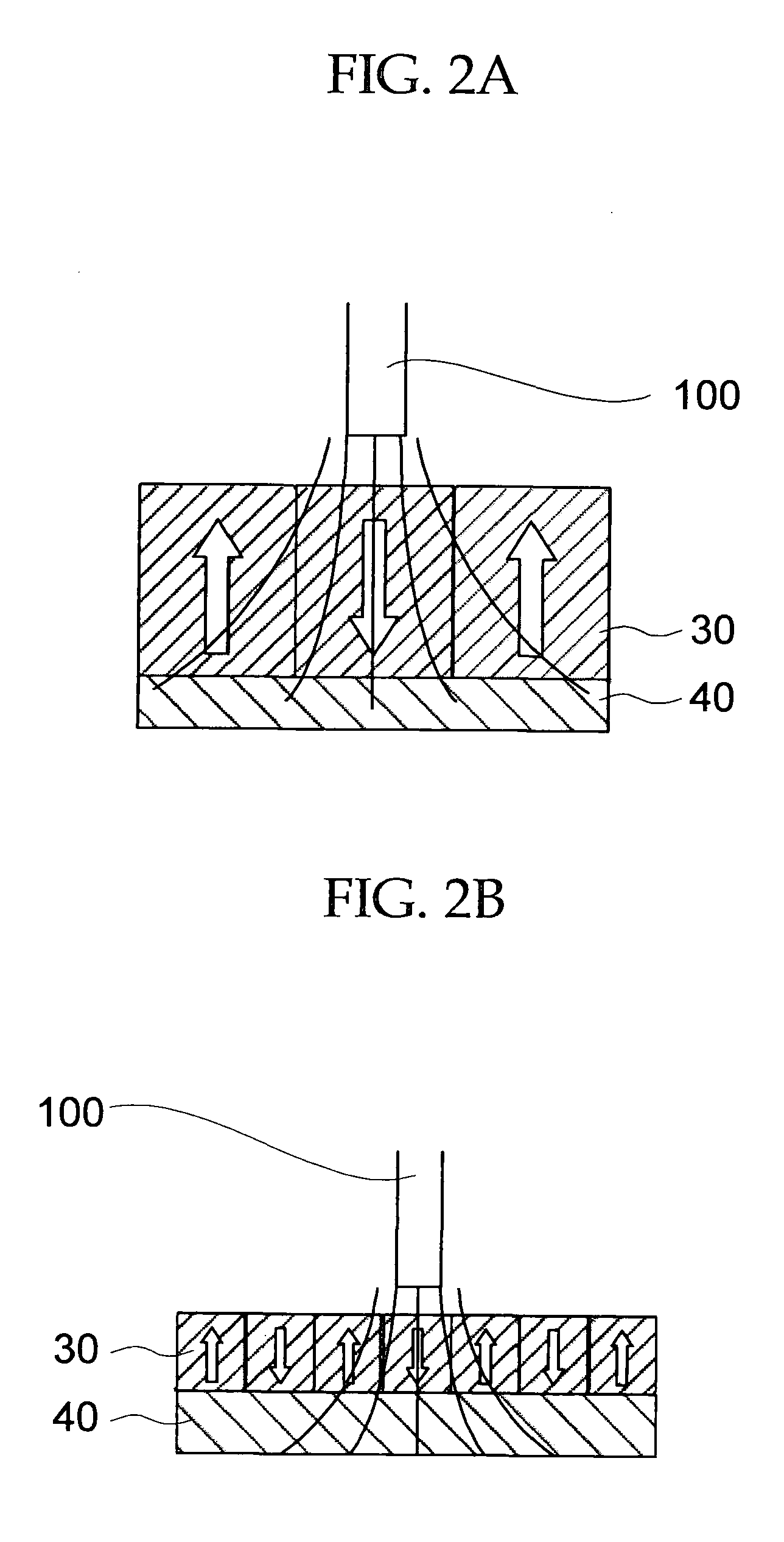

Perpendicular magnetic recording medium, production process thereof, and perpendicular magnetic recording and reproducing apparatus

InactiveUS20050249984A1Improve thermal stabilityImprove noise characteristicsConstruction of head windingsMagnetic materials for record carriersHigh densityNon magnetic

A perpendicular magnetic recording medium includes a non-magnetic substrate, and at least a soft magnetic under layer formed of a soft magnetic material, an alignment-regulating layer for regulating the crystal alignment of a layer provided directly thereon, a perpendicular magnetic layer in which easy-magnetization axes are oriented generally perpendicular to the substrate, and a protective layer, the layers and the layer being provided atop the substrate, wherein the soft magnetic under layer exhibits magnetic isotropy or has easy-magnetization axes oriented perpendicular to the substrate. According to the present invention, an undercoat layer having no magnetic domain walls can be formed. When the undercoat layer is employed, there can be provided a perpendicular magnetic recording medium and a perpendicular magnetic recording and reproducing apparatus which exhibit high thermal stability and excellent noise characteristics, and which attain high-density recording.

Owner:SHOWA DENKO KK +1

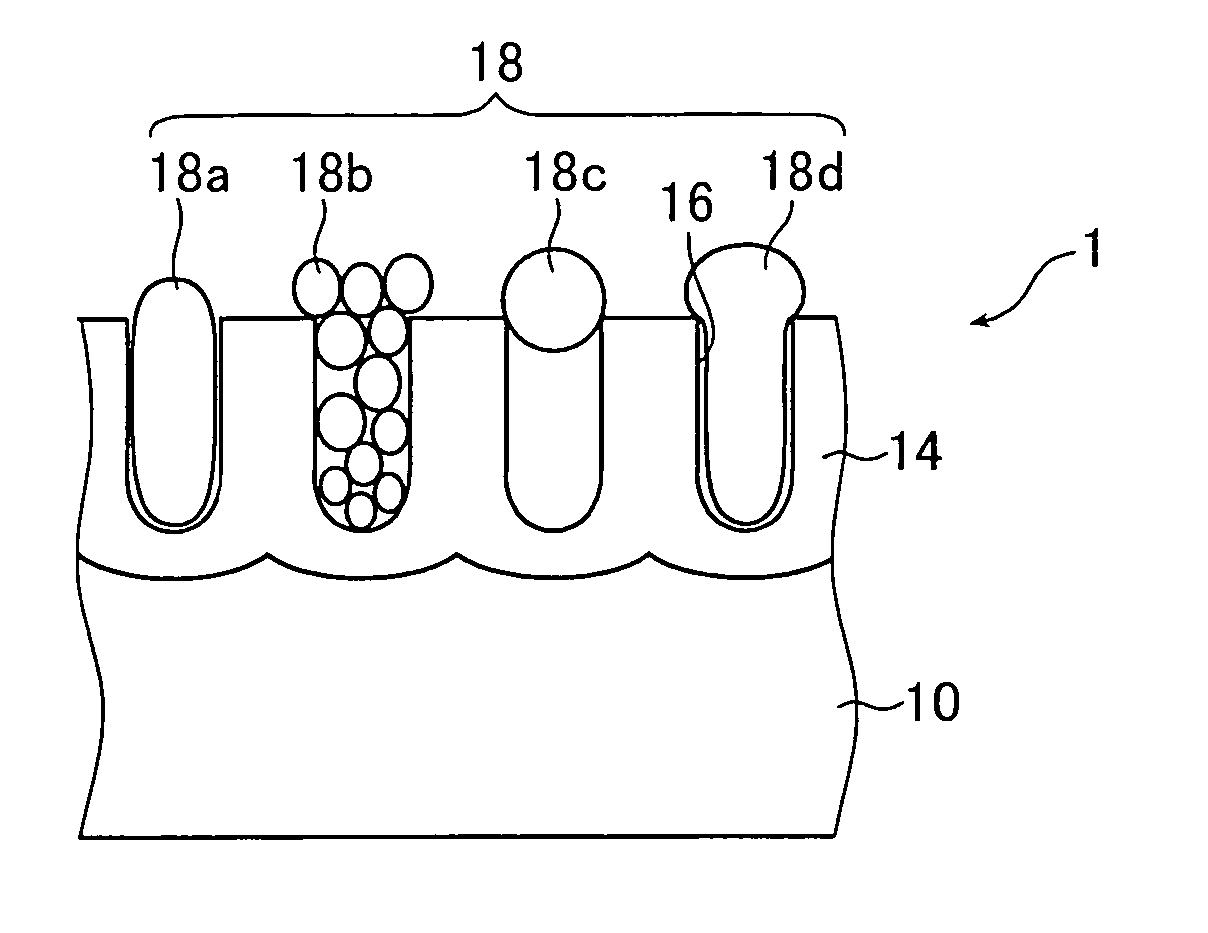

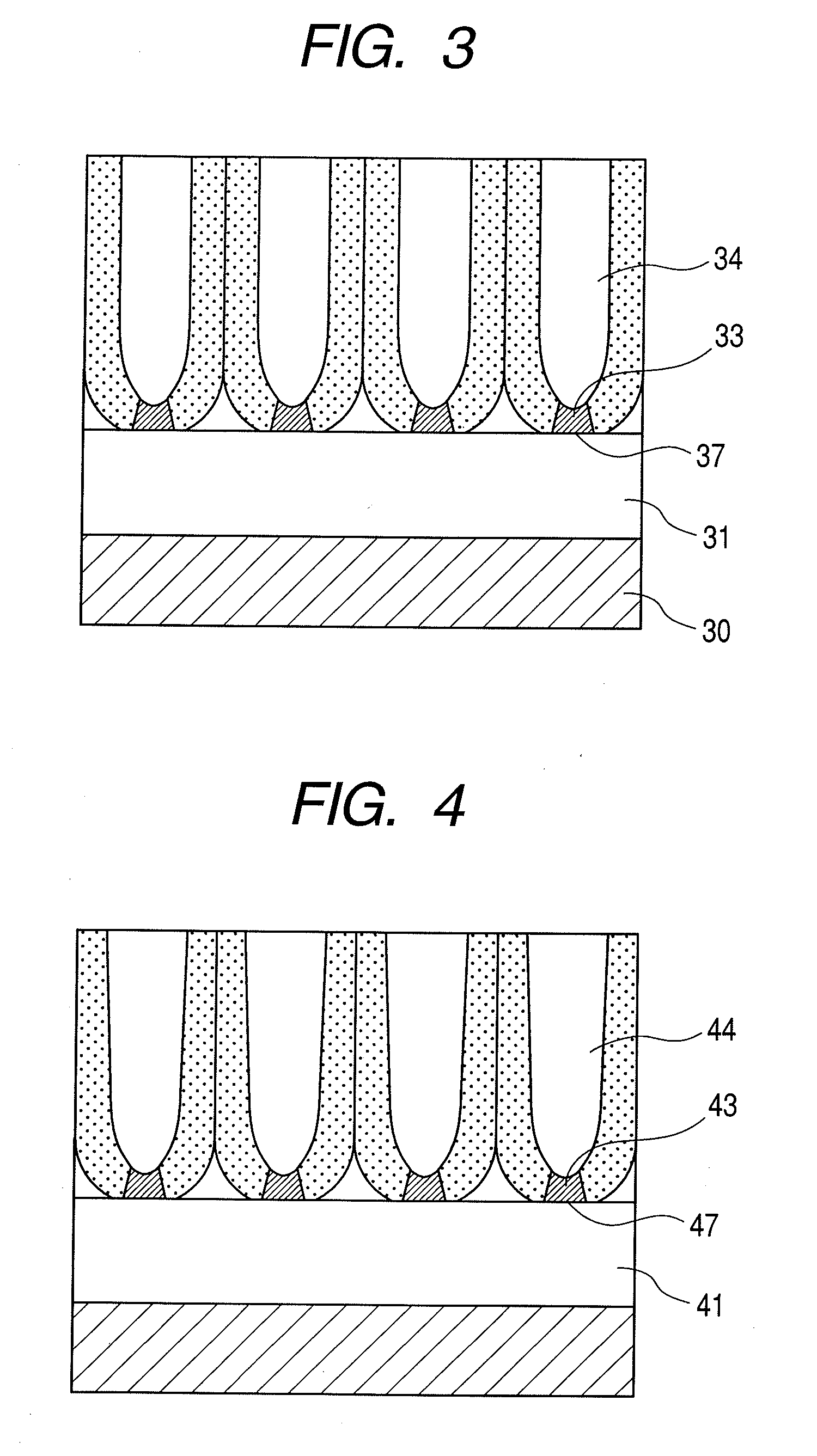

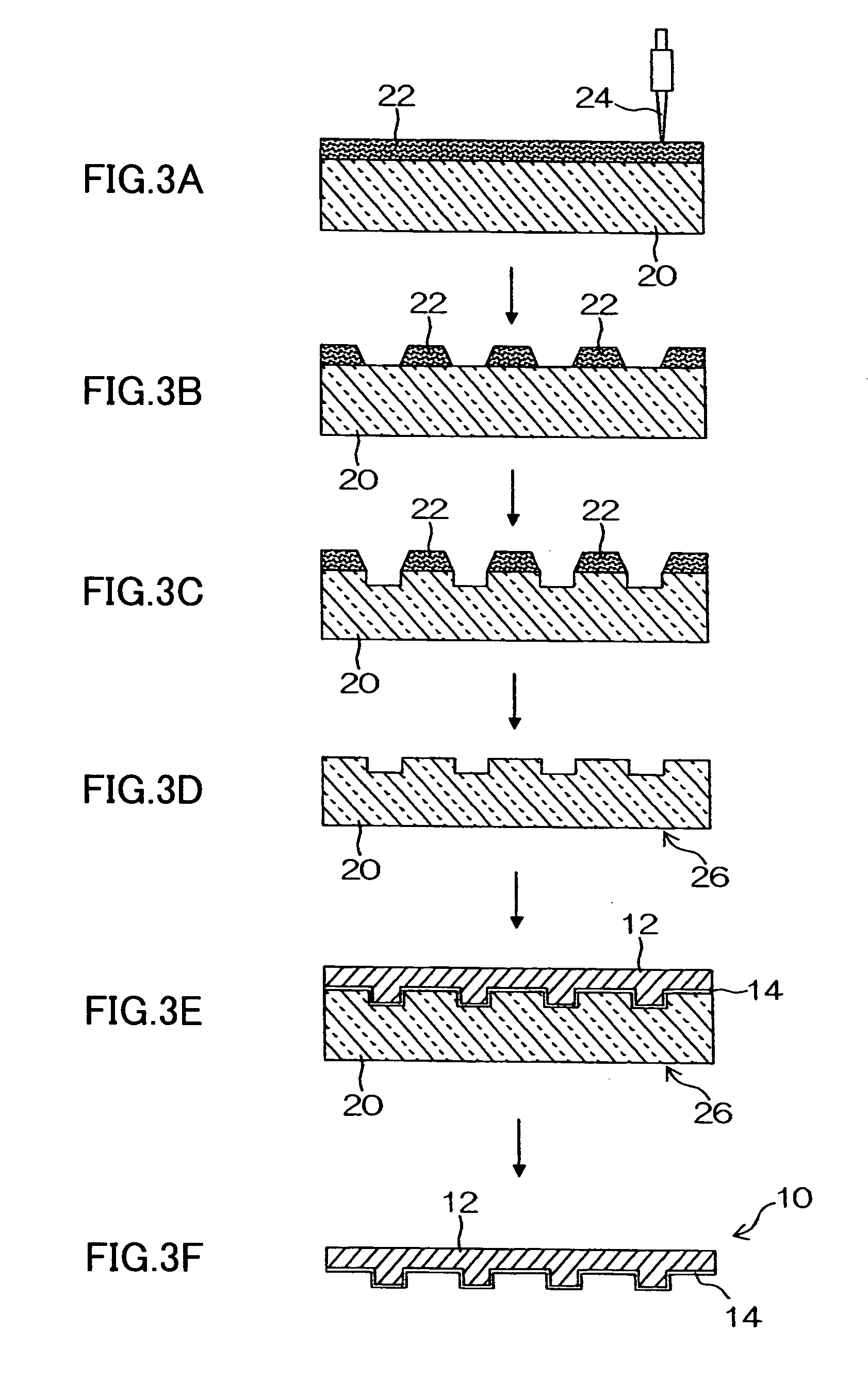

Structure and process for production thereof

InactiveUS20090034122A1High recording sensitivityMagnetic materials for record carriersMagnetic layer production by platingMetalMaterials science

A structure has projecting structural members perpendicular to a substrate, the projecting structural members having respectively a curved top-end face covered continuously with a magnetic material. A process for producing a structure comprises the steps of placing an underlying metal layer and an anode-oxidization layer successively on a substrate, anodizing the anode-oxidization layer to form a porous film having pores perpendicular to the substrate, growing an oxide of a metal of the underlying metal layer from the bottoms of the pores of the porous film to outside of the porous film to form projecting structural members through the pores, each constituted of a columnar structural portion and a curve-faced top-end portion, removing a part or the entire of the porous film, and placing a magnetic material on the top-end portions of the projecting structural members.

Owner:CANON KK

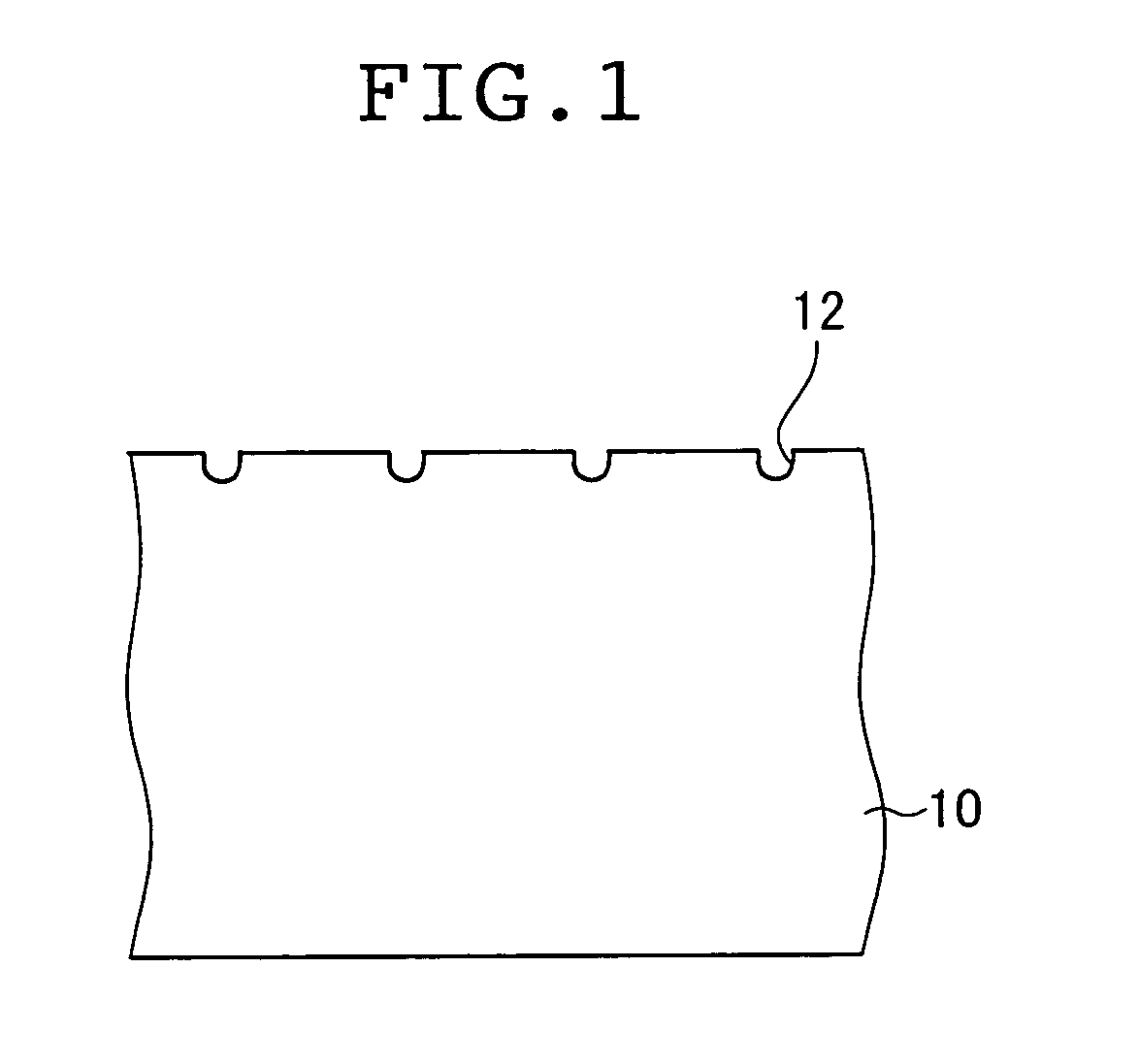

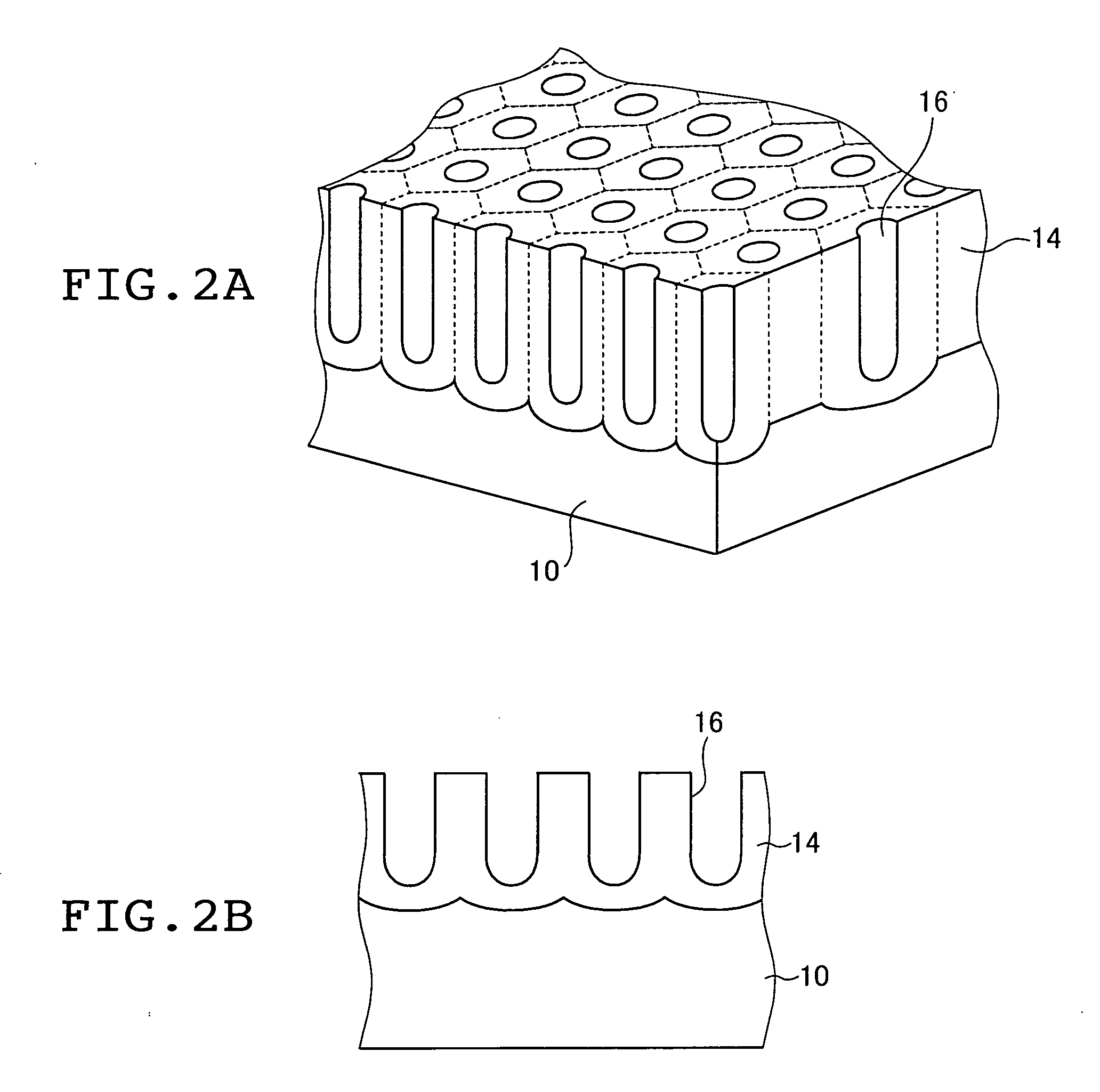

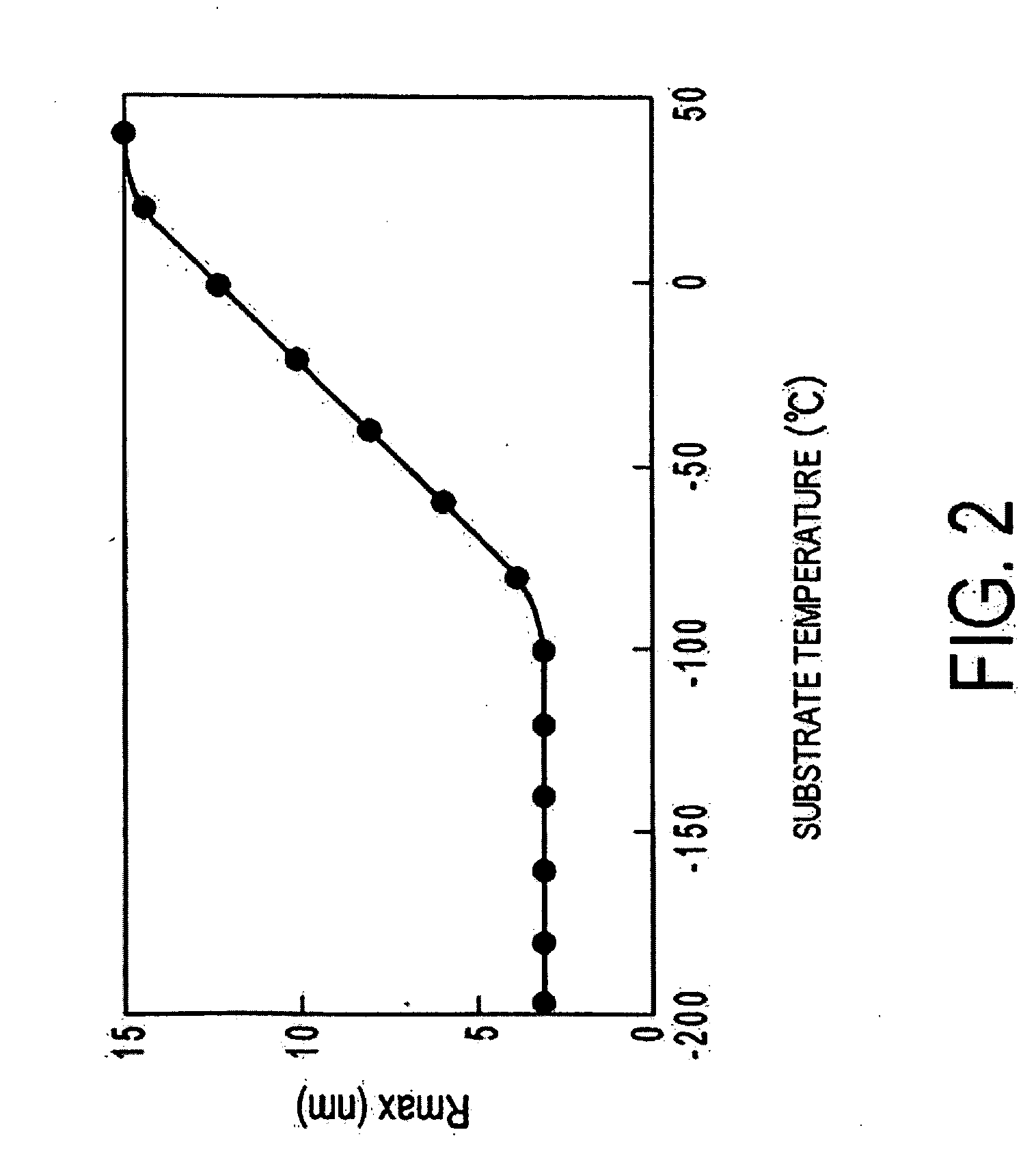

Method of fabricating an alumina nanohole array, and method of manufacturing a magnetic recording medium

InactiveUS20090145769A1Improve surface smoothnessReduce usageMagnetic layer production by platingPatterned record carriersGrain growthPatterned media

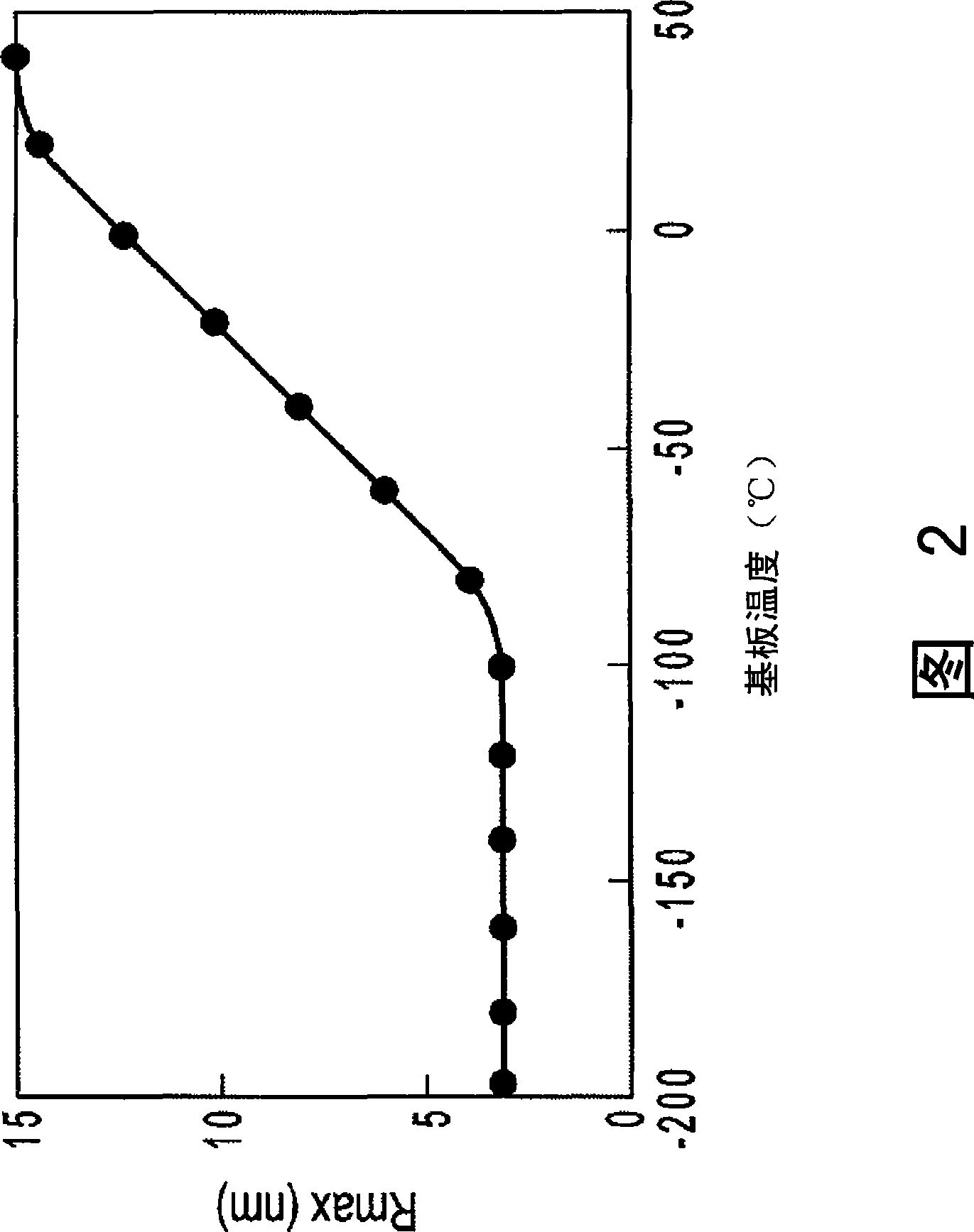

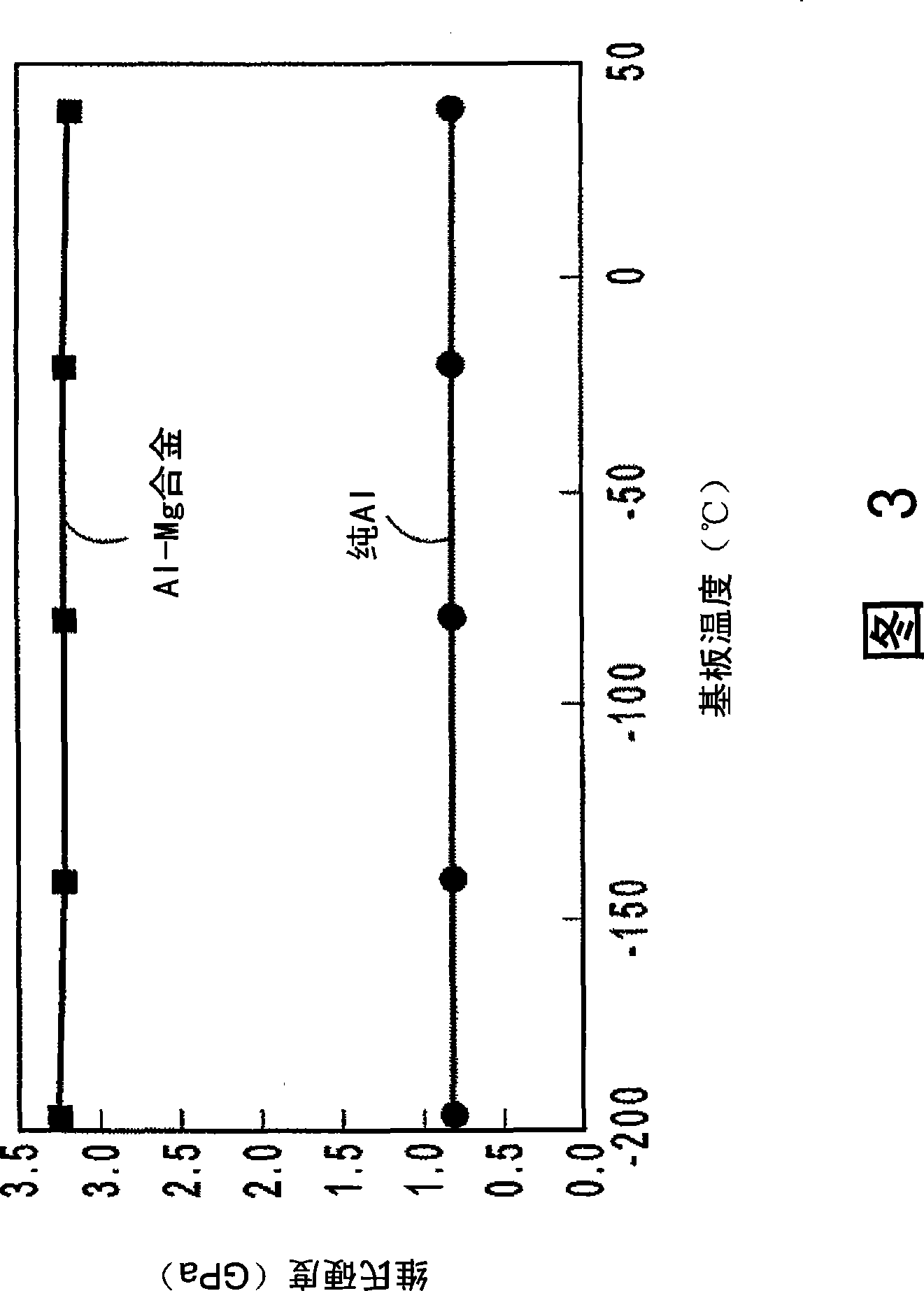

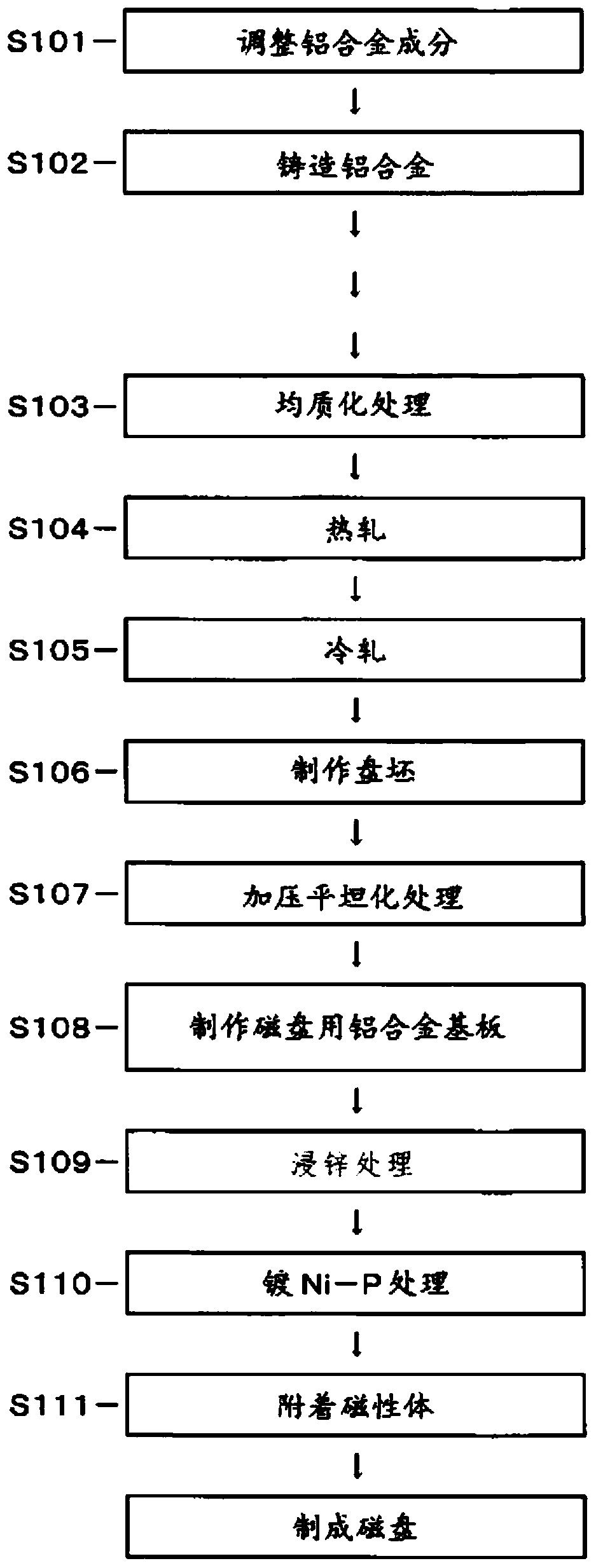

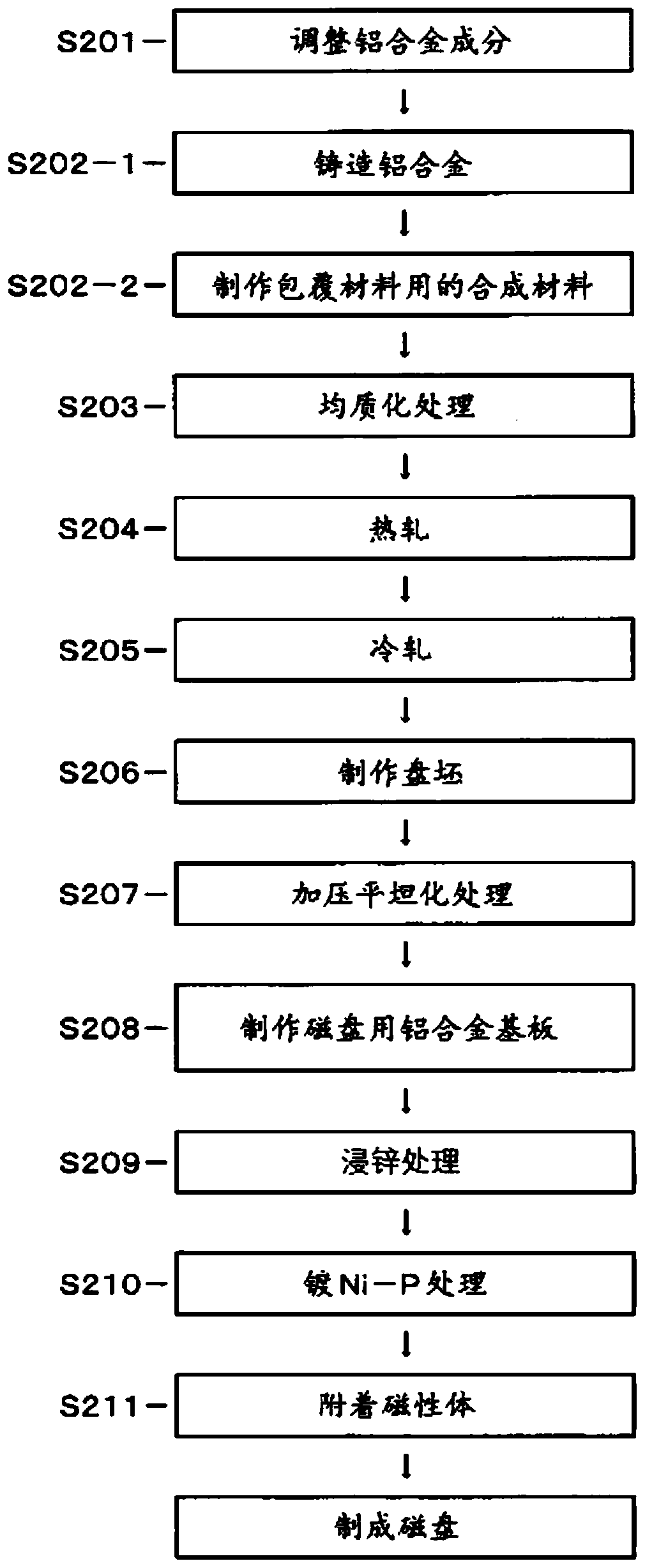

An alumina nanohole array and a method of fabricating the same includes the steps of forming an aluminum thin-film on a substrate at a substrate temperature of −80° C. or below so that crystal grain growth is suppressed, even when a high-purity aluminum material is used, thus providing improved surface smoothness; and anodizing the aluminum thin-film. Preferably, the method additionally includes texturing by pressing a mold having an orderly array of projections against the aluminum thin-film to form pits on the aluminum thin-film which enables a larger array area to be formed. When the mold and the aluminum thin-film are held at a temperature of 150 to 200° C., the pressure used for pit formation is reduced. A magnetic recording medium manufactured by a method therefore includes forming a magnetic layer within the nanoholes so that the medium is suitable as a bit patterned media for a perpendicular recording system.

Owner:FUJI ELECTRIC CO LTD

Thin-layer metal film

InactiveUS20050019502A1Less impuritiesImprove productivityMagnetic layer production by platingPretreated surfacesHigh densityThin layer

A thin-layer metal film that is high in productivity, can be prepared in a simple step, has a high density, and is superior in durability. The thin-layer metal film is obtained by reducing a metal salt on a surface of a substrate where a metal salt-containing hydrophilic graft polymer chain is present. The thin-layer metal film is obtained by reducing a metal ion adsorbed on a hydrophilic functional group of the hydrophilic graft polymer chain with a reducing agent to deposit a metal.

Owner:FUJIFILM CORP

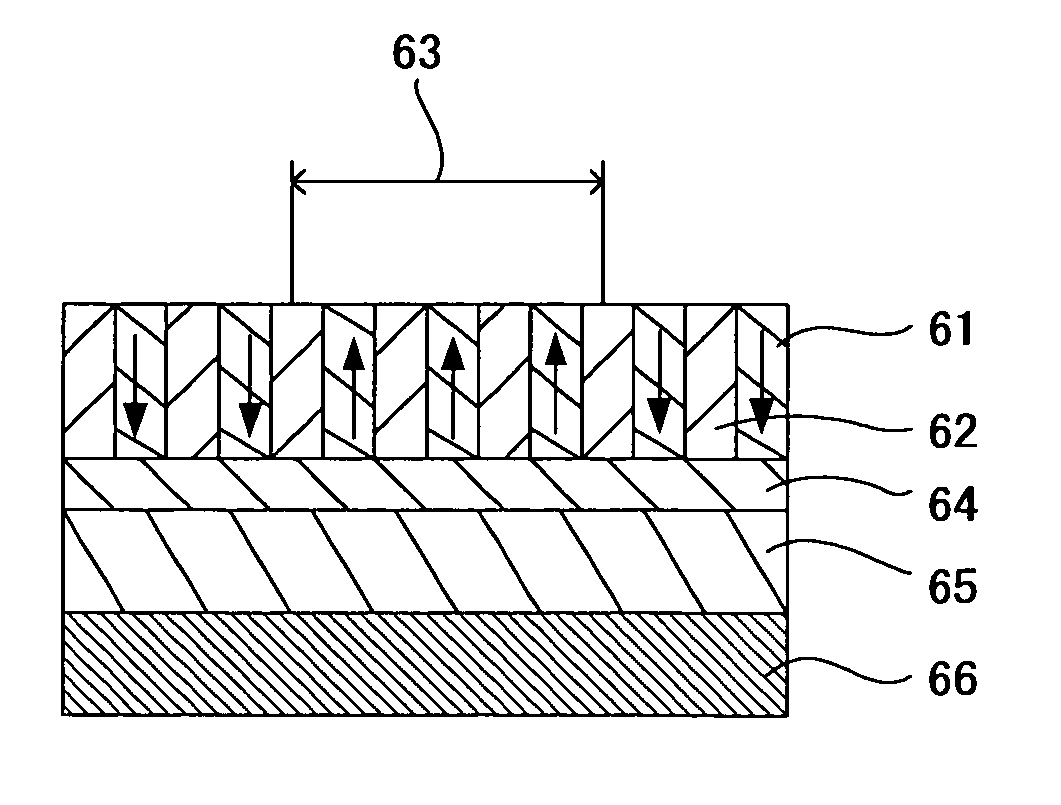

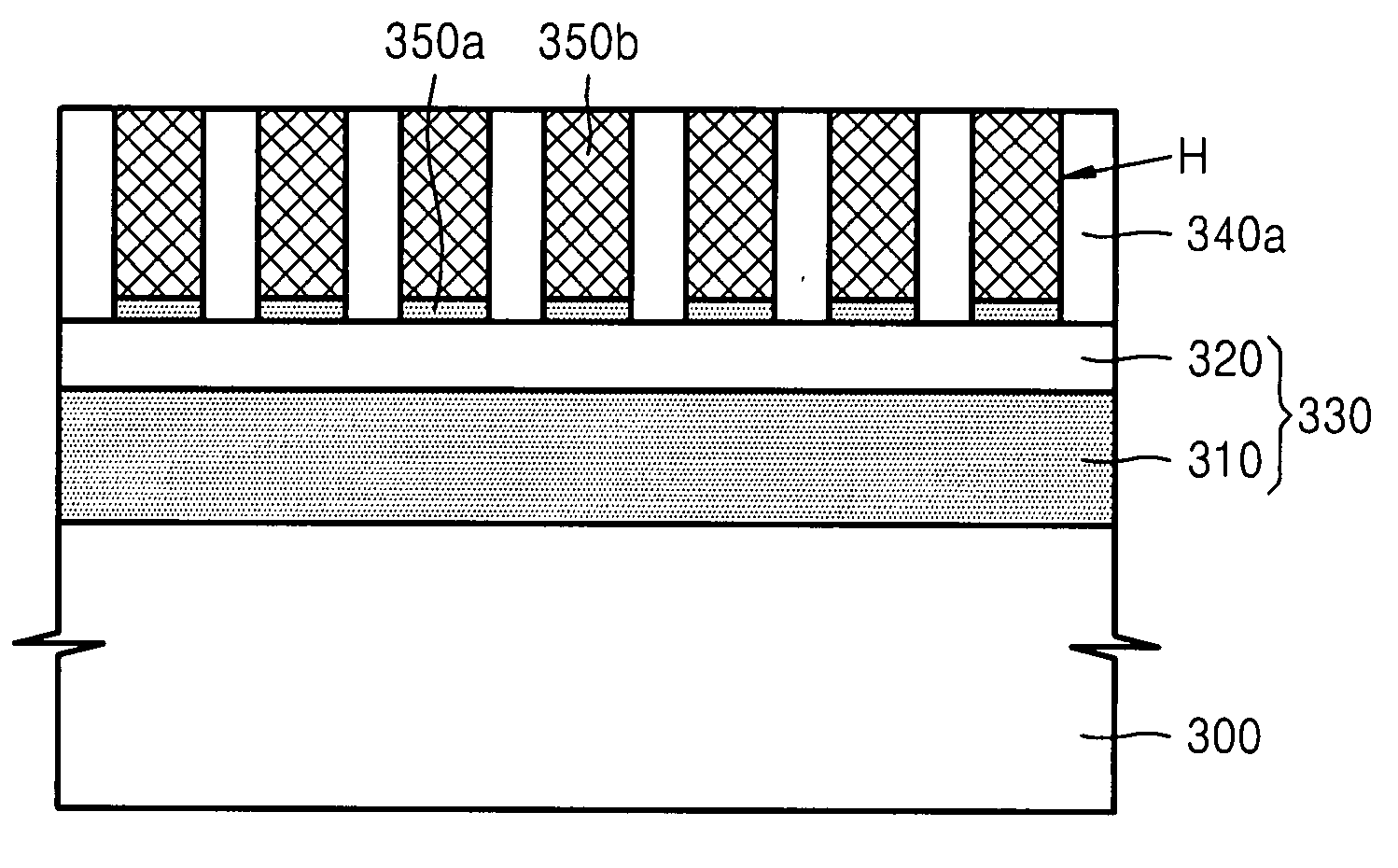

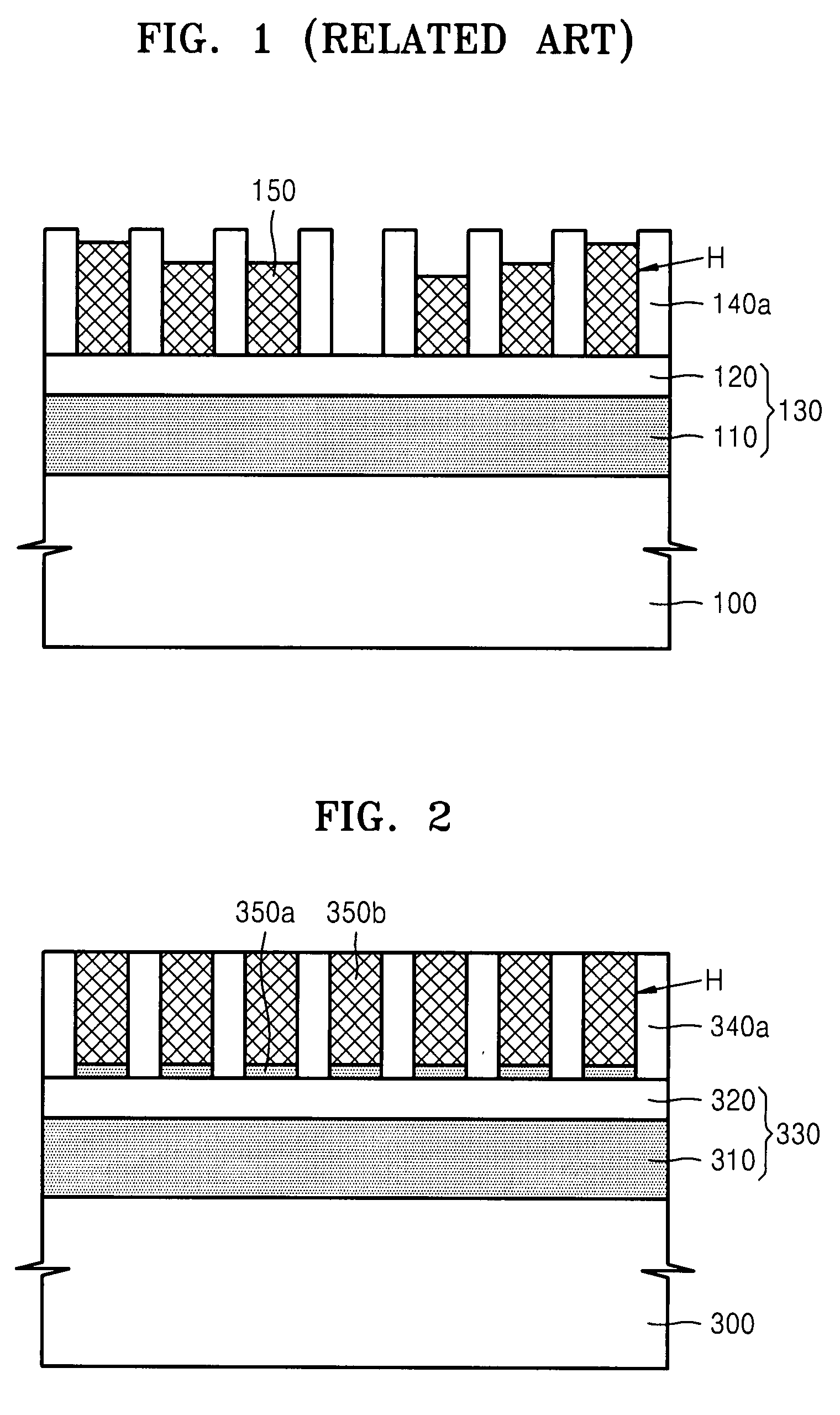

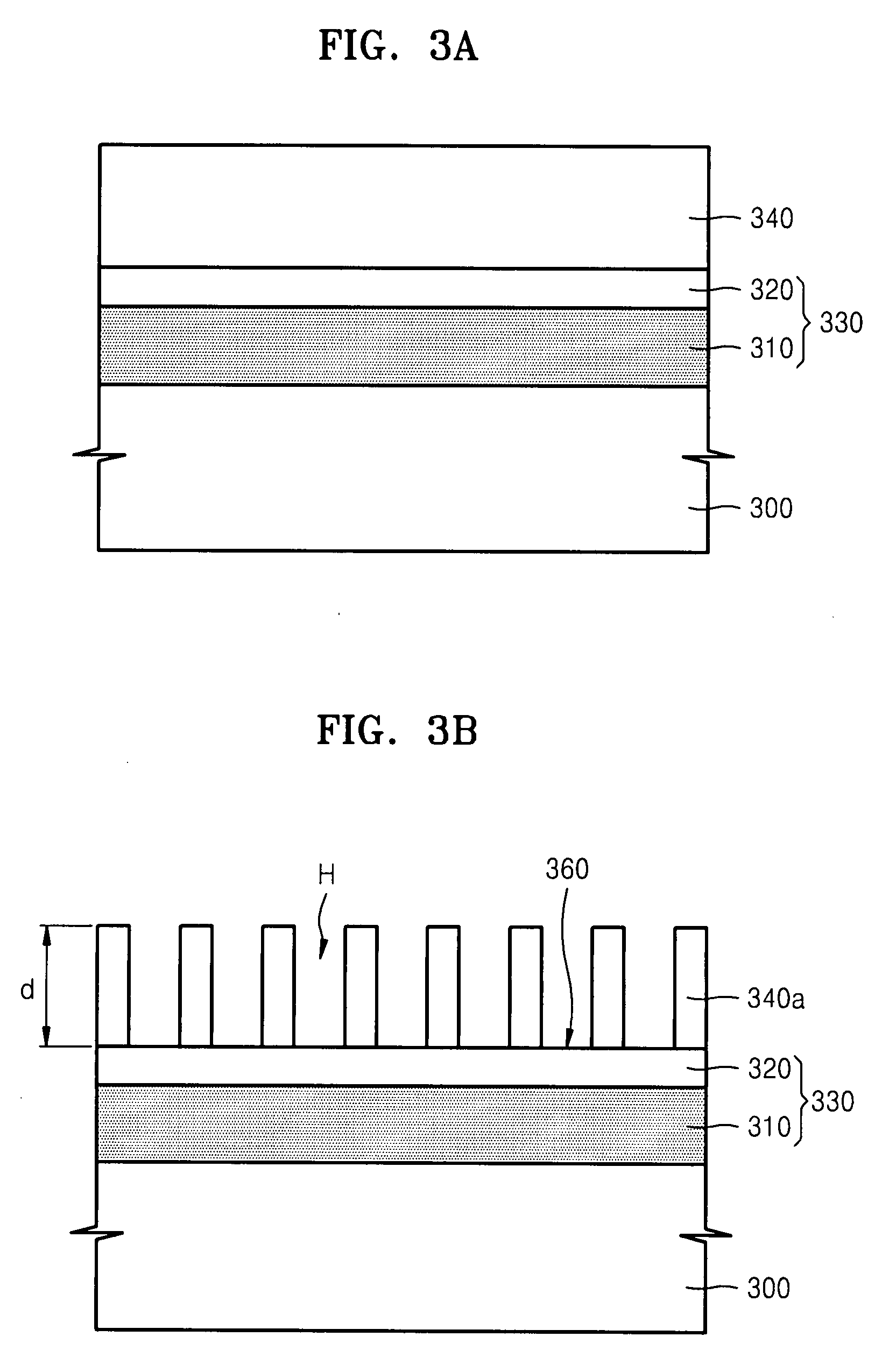

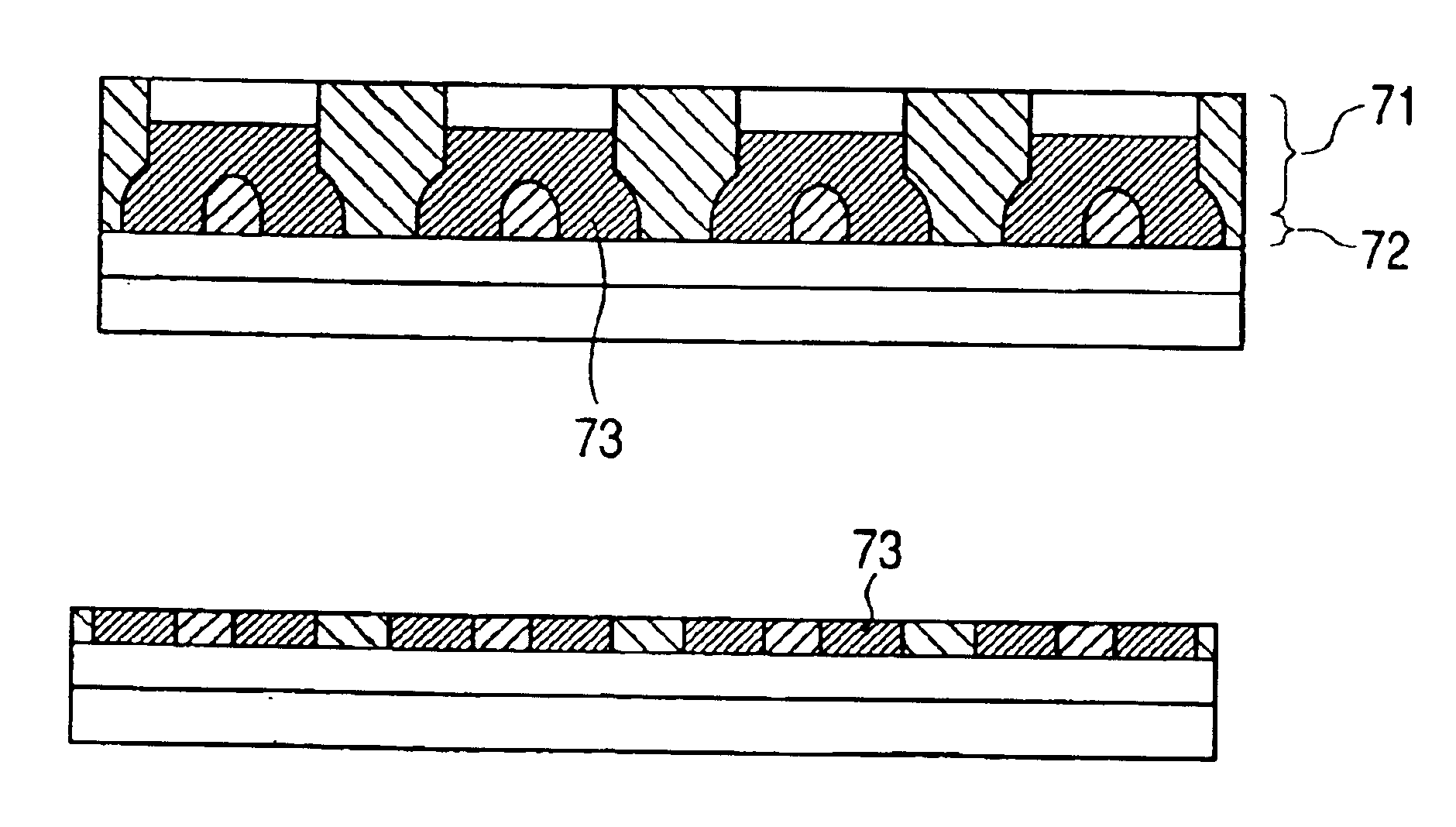

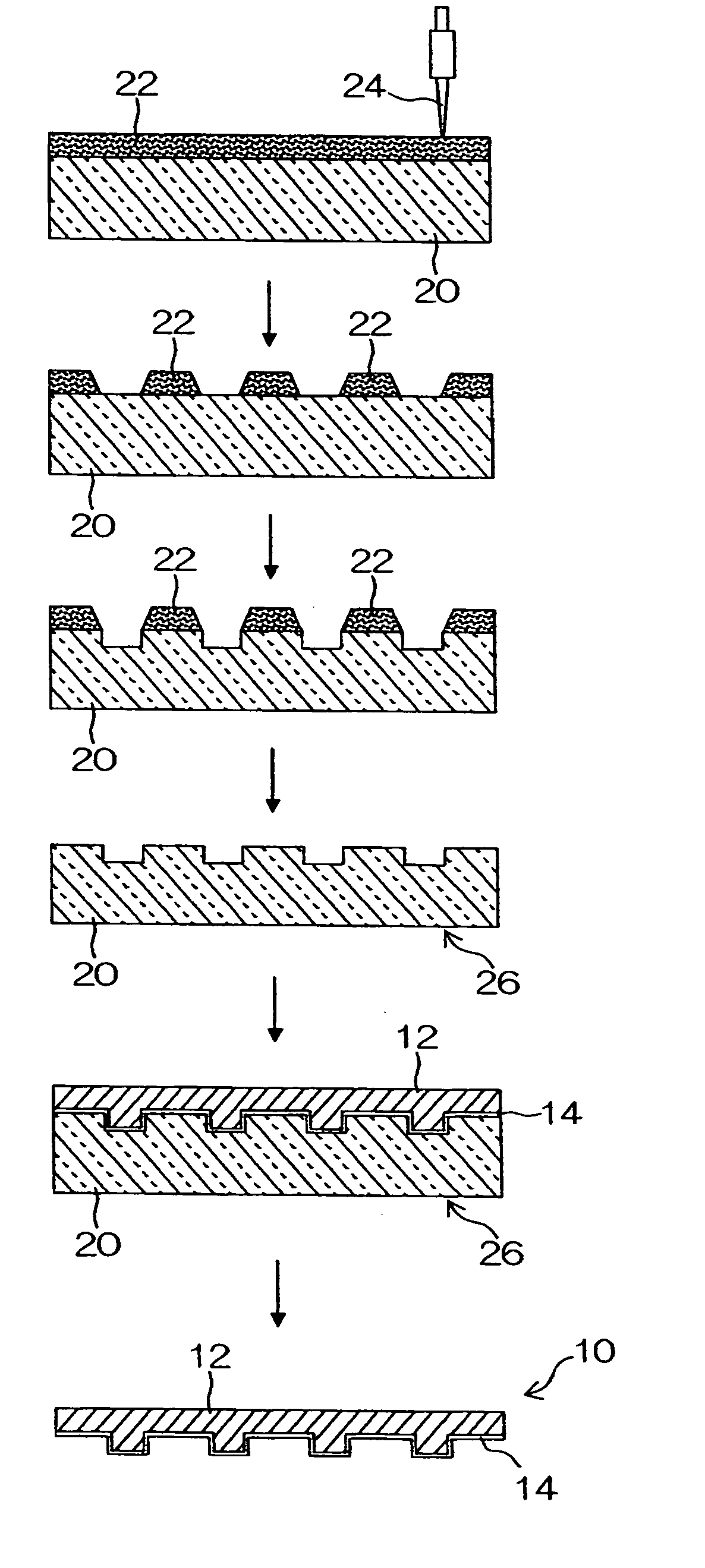

Method of manufacturing magnetic layer, patterned magnetic recording media including magnetic layer formed using the method, and method of manufacturing the same

InactiveUS20080050616A1Uniform thicknessMagnetic materials for record carriersMagnetic layer production by platingEngineeringMagnetic layer

Provided are a method of manufacturing a magnetic layer, a patterned magnetic recording medium including magnetic layers formed using the method, and a method of manufacturing the patterned magnetic recording medium. The method of manufacturing the magnetic layers includes: forming a template provided with an opening; forming a seed layer on a bottom of the opening; and inserting a magnetic material onto the seed layer to form a magnetic layer. The patterned magnetic recording medium includes a lower layer formed on a substrate; a template formed on the lower layer and including a plurality of holes exposing the lower layer; seed layers covering the lower layer exposed through the holes; and magnetic layers formed on the seed layers to fill the holes.

Owner:SAMSUNG ELECTRONICS CO LTD

Cobalt-platinum or iron-plantinum magnetic material containing 1% to 40% Cu, Ni or B

InactiveUS7286324B2Reduce the temperatureLiquid applicationMagnetic layer production by platingMagnetic anisotropyElectroplating

A CoPt- or FePt-alloy magnetic material in which a temperature to transform into an L10-ordered alloy is reduced and magnetic anisotropy energy is controlled, and a method for manufacturing the magnetic material are provided. In a CoPt- or FePt-alloy magnetic material obtained according to plating, at least one element of Cu, Ni and B is contained with an atomic percent equal to or more than 1% and equal to or less than 40%. A method for manufacturing a magnetic material includes a step of depositing a magnetic material in which at least one element of Cu, Ni and B is contained in a CoPt- or FePt-alloy magnetic material with an atomic percent equal to or more than 1% and equal to or less than 40%, from a plating solution, and a step of transforming the deposited magnetic material into an L10-ordered alloy according to annealing at a temperature equal to or lower than 500° C.

Owner:CANON KK

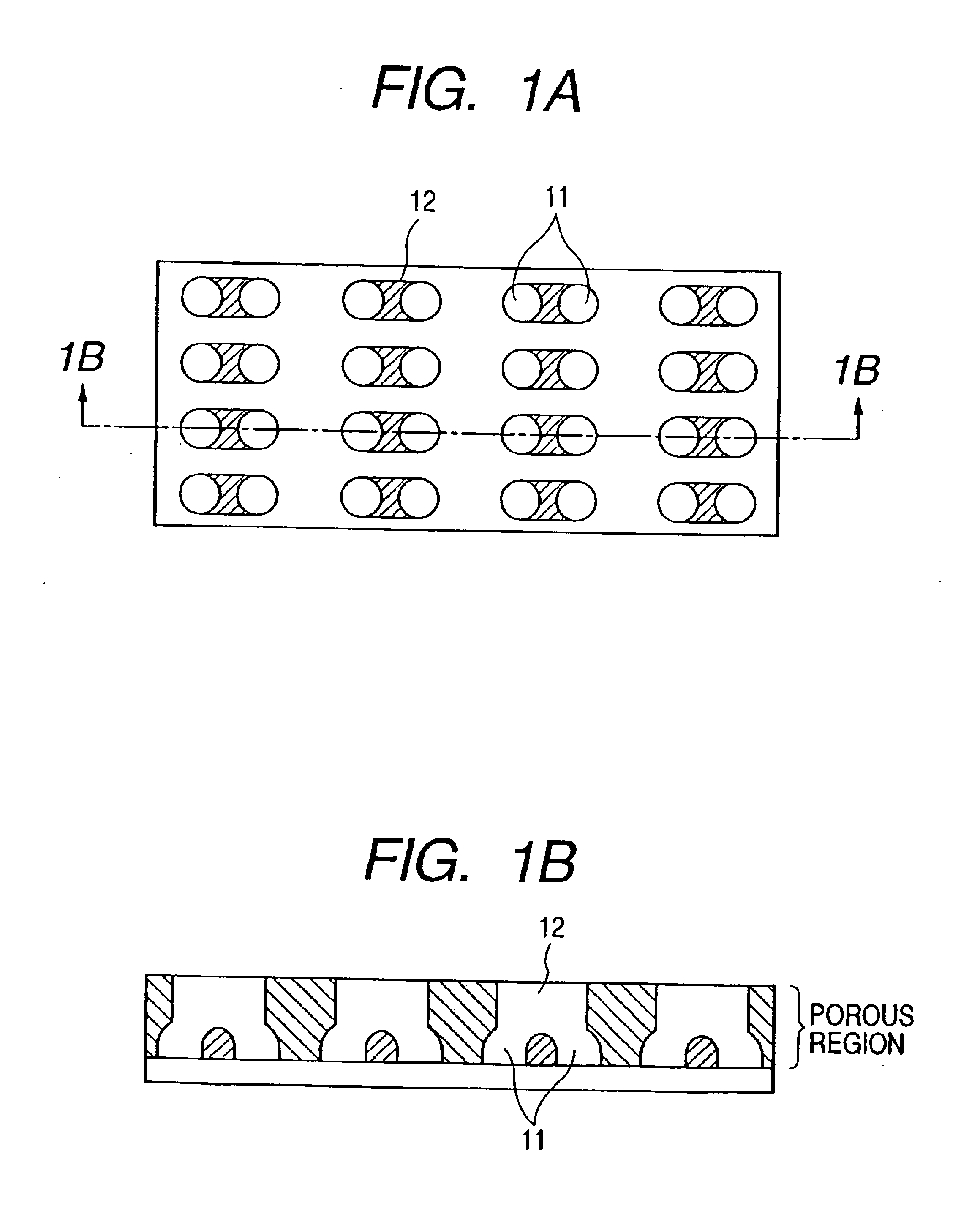

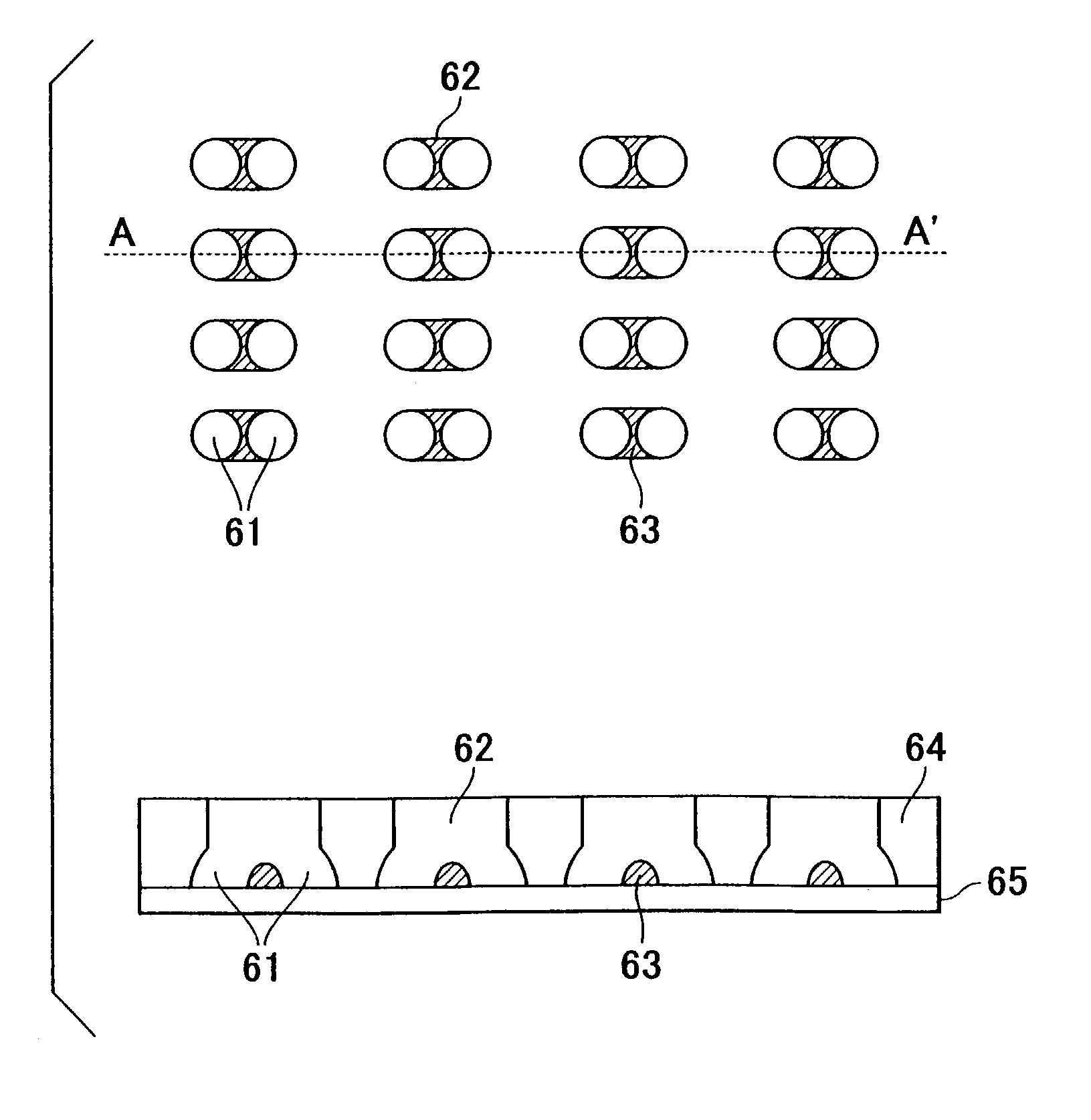

Columnar structured material and manufacturing method therefor

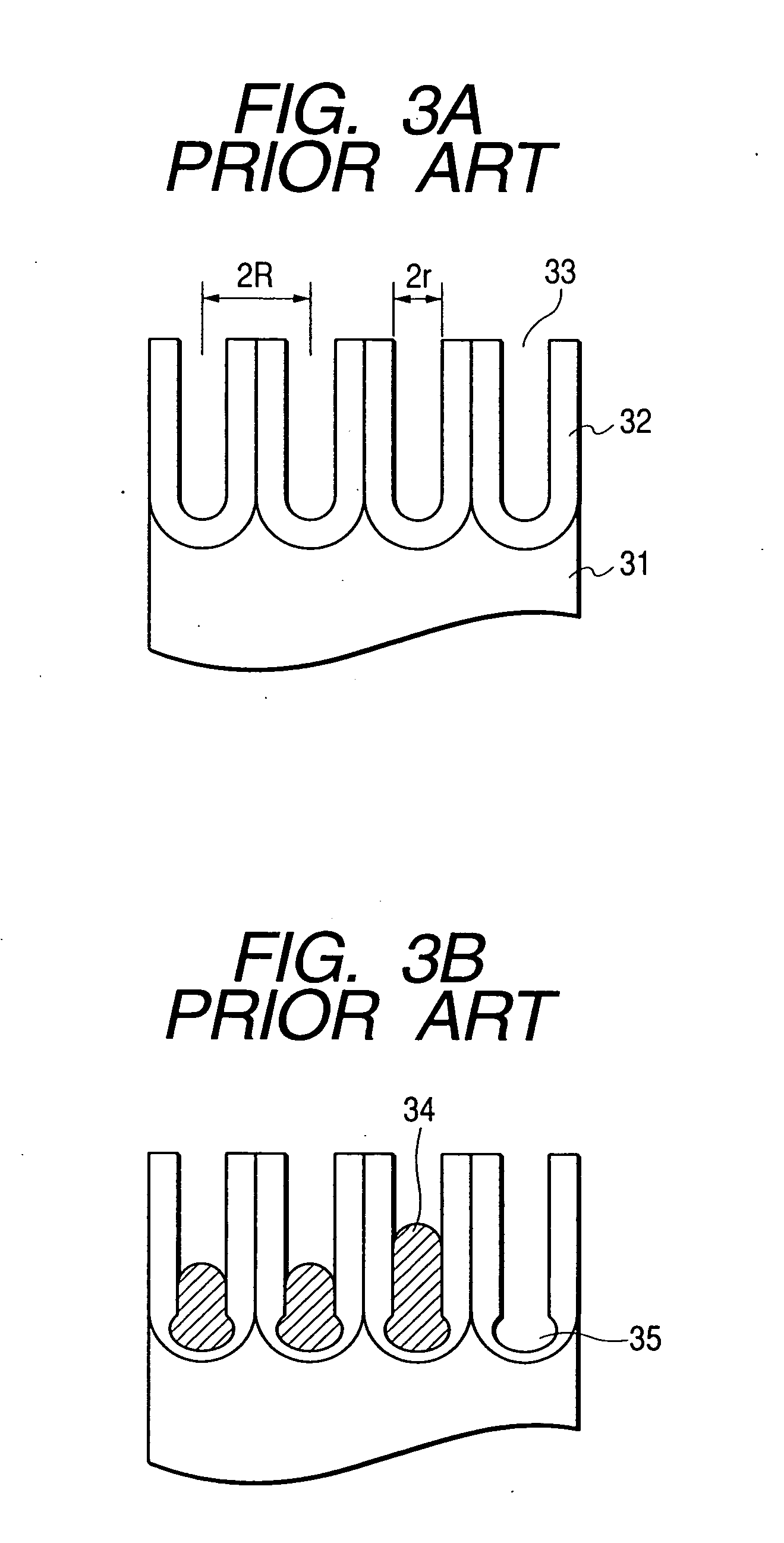

InactiveUS6930057B2Increase dot densityDensity is easyMagnetic layer production by platingNanoinformaticsNanoholeMagnetization

To provide a method for manufacturing a magnetic recording medium which creates anodically oxidized aluminum nanoholes so as to have a rectangular or elliptical sectional shape and gives shape anisotropy to a magnetic material filled in the nanoholes to thereby always fix a relative positional relation between magnetizations of the magnetic material and a magnetic head that detects the magnetizations. The method for manufacturing a magnetic recording medium includes: preparing a member having regularly arranged plural pits; subjecting the member to anodic oxidation treatment so that formation of holes is started with the pits as starting points, and a porous region, which has a first portion where the holes are formed without branching and a second portion where branched holes are formed, is formed; filling a magnetic material in the formed holes; and removing the non-branching portions of the holes.

Owner:CANON KK

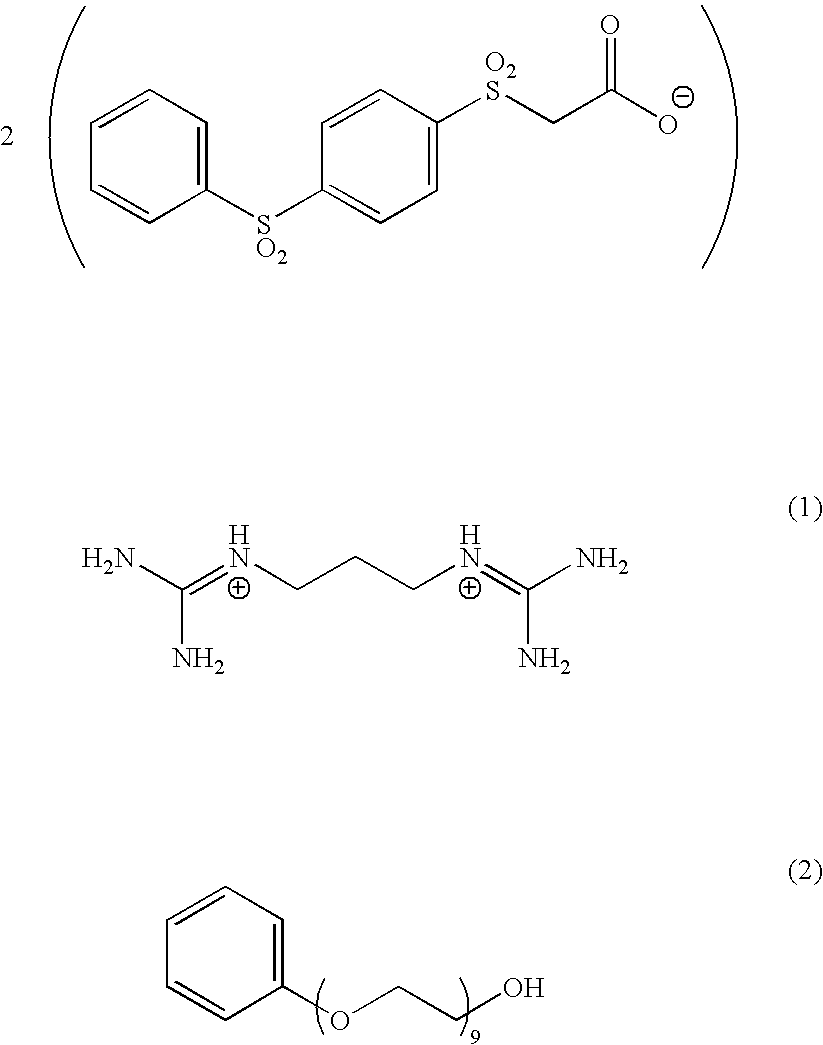

Plating solution, process for producing a structure with the plating solution, and apparatus employing the plating solution

A stable FePt plating solution is provided. Further a process for electroplating is provided for producing an FePt magnetic material having especially strong coercive force and excellent properties by use of the plating solution. The plating solution contains ionic Fe, ionic Pt, and a complex agent, at a molar ratio (Fe / Pt) of the ionic Fe to the ionic Pt ranging from 0.75 to 3.

Owner:CANON KK

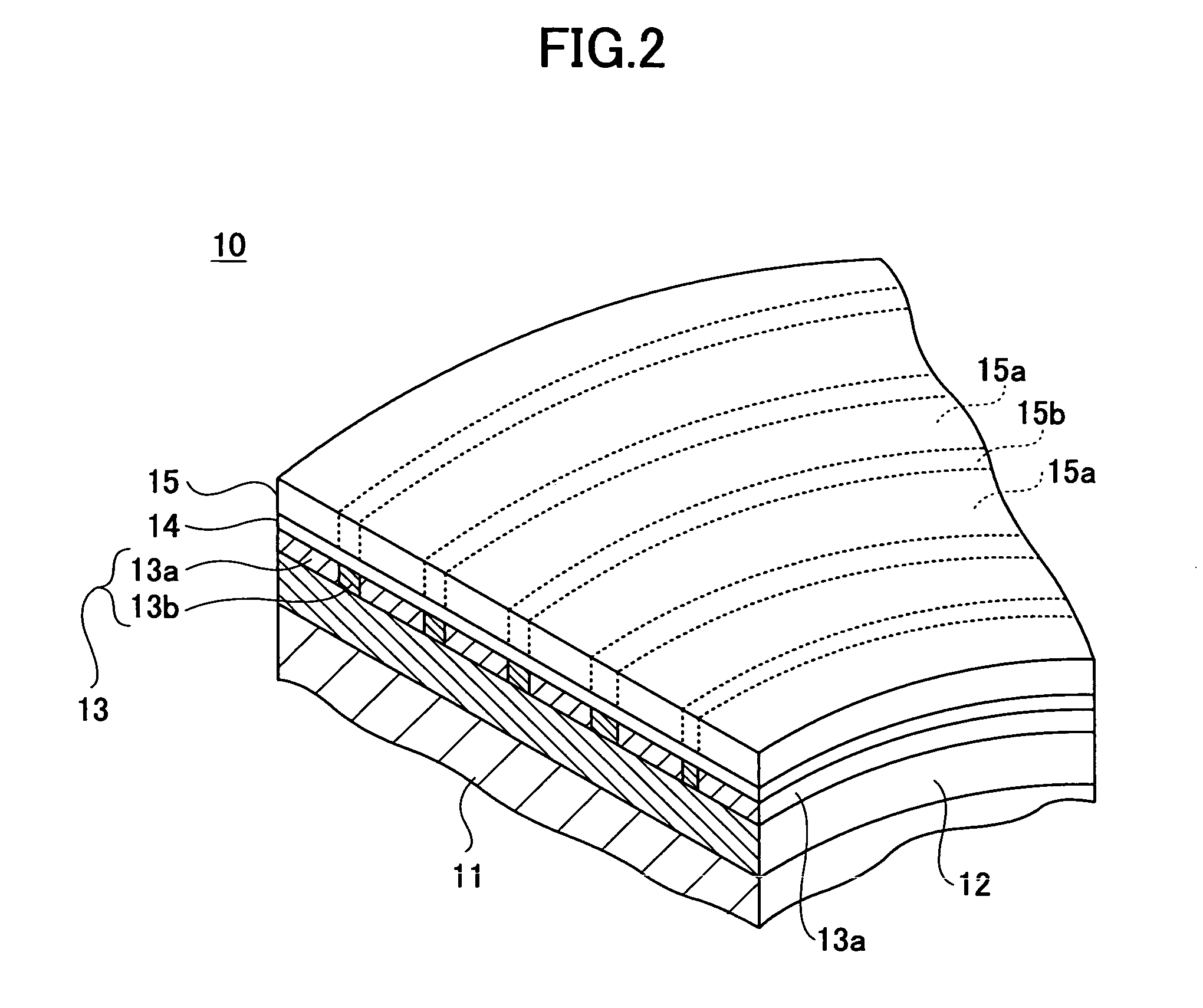

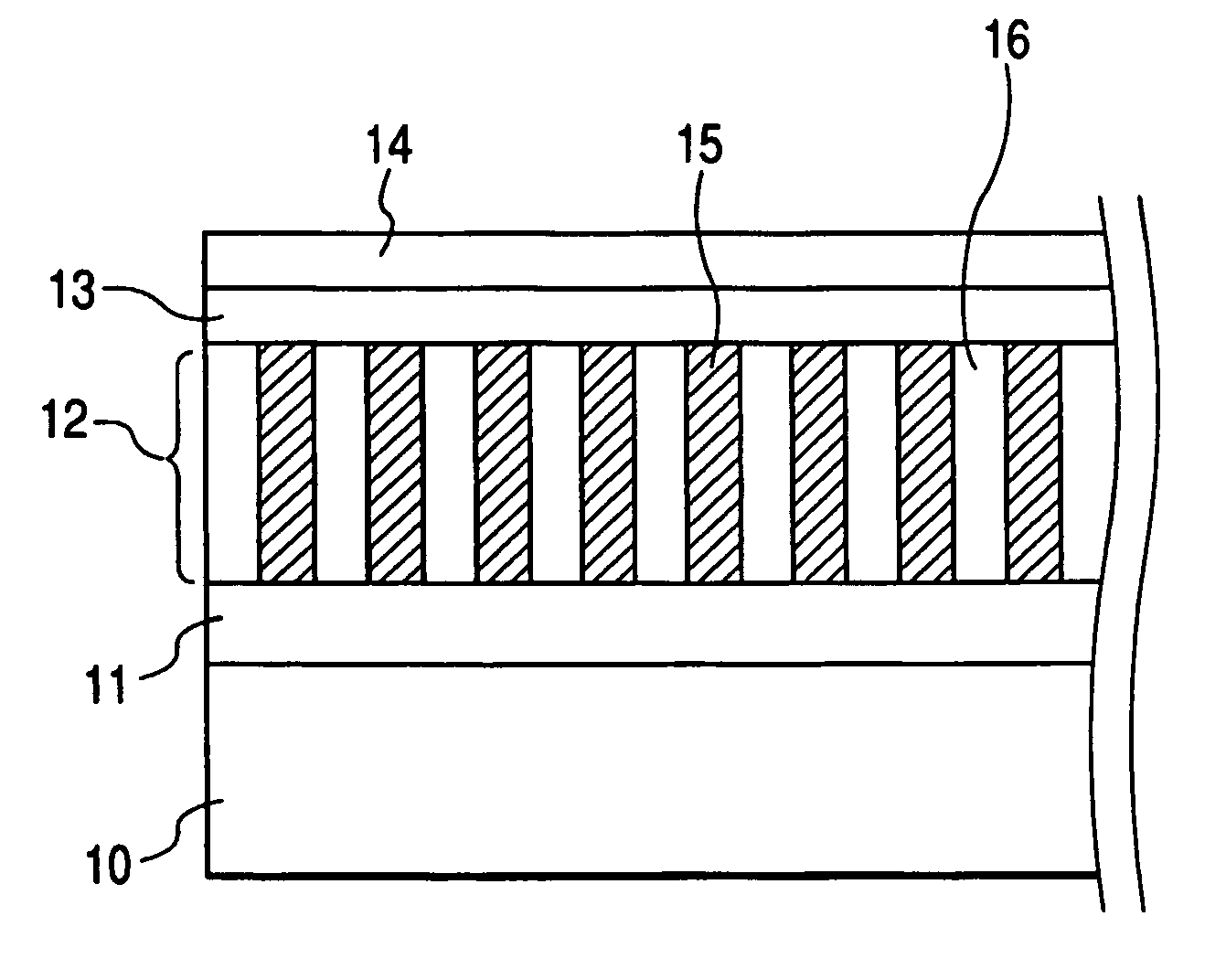

Magnetic recording medium and producing method thereof

InactiveUS20050031905A1Magnetic layer production by platingRecord information storageNanoholeOptoelectronics

To provide a magnetic recording medium with good record and reproduction characteristics. In the magnetic recording medium having an anodic oxidized alumina nanohole film filled with a magnetic substance, the anodic oxidized alumina nanohole film 13 is formed on a substrate 16 with at least one base electrode layer 15 sandwiched therebetween, the base electrode layer 15 is a film that has fcc structure and whose (111) face is oriented in the direction perpendicularly to a substrate, and the fillers 14 in the alumina nanoholes 10 have hcp structure and include hard magnetic substance whose principal component is Co and whose c-axis is perpendicular to the substrate.

Owner:CANON KK

Fine structural body and method of producing the same

ActiveUS7435488B2Large intensityLow costMaterial nanotechnologyAnodisationManufacturing technologyResonance

Owner:FUJIFILM CORP +1

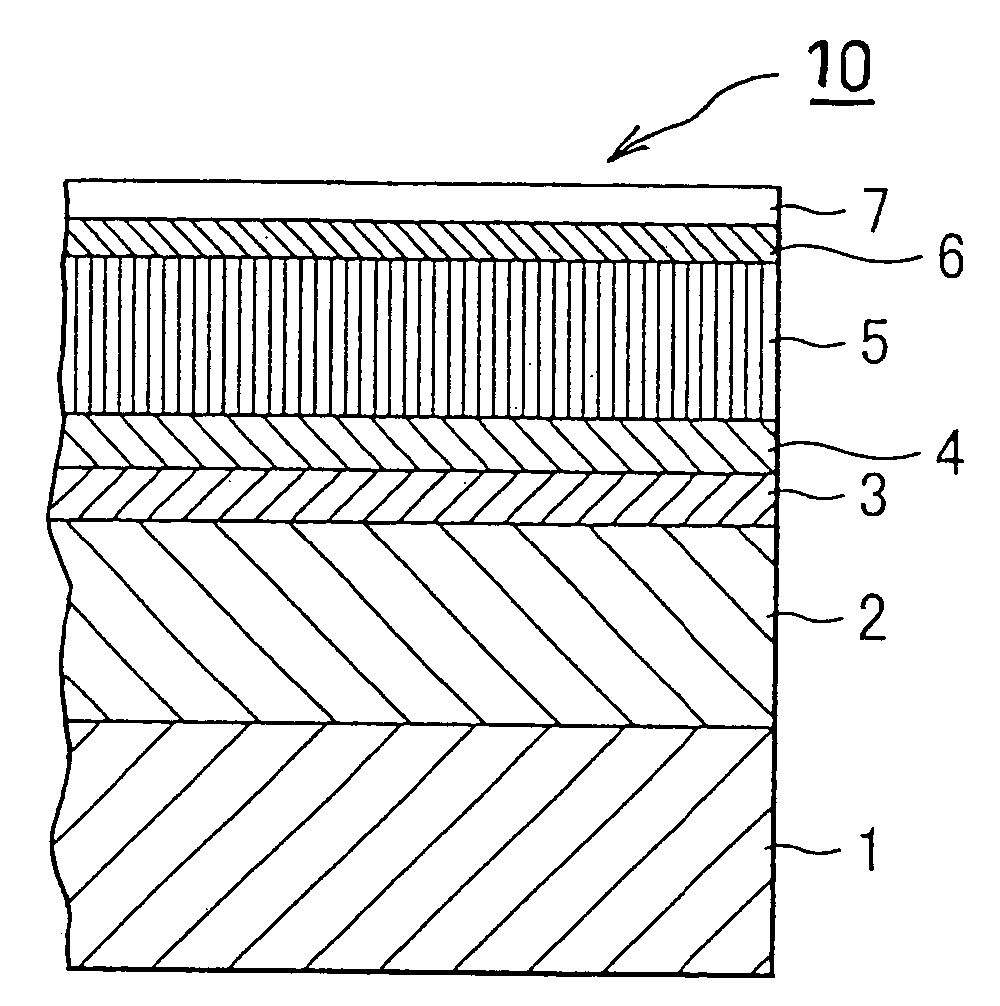

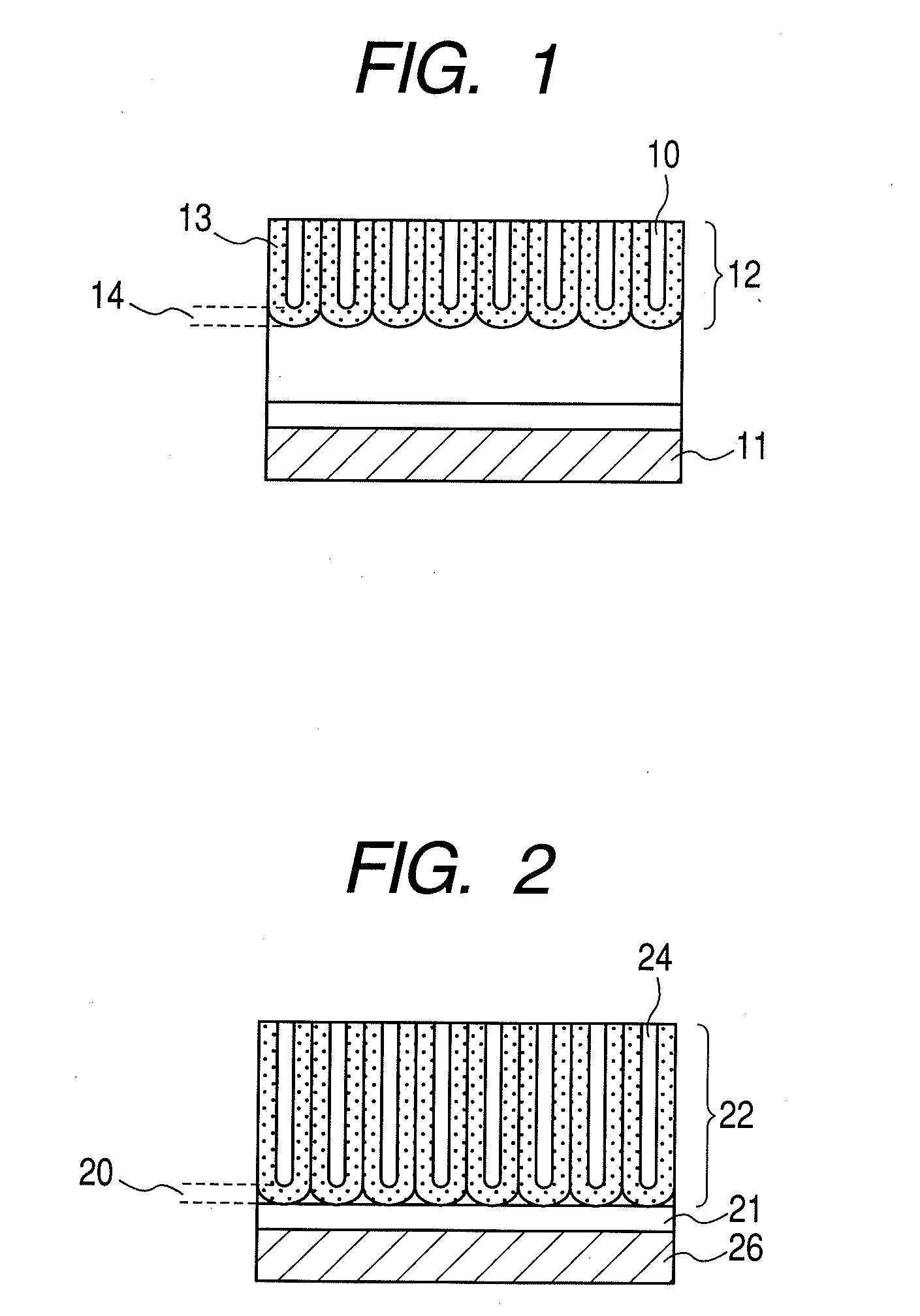

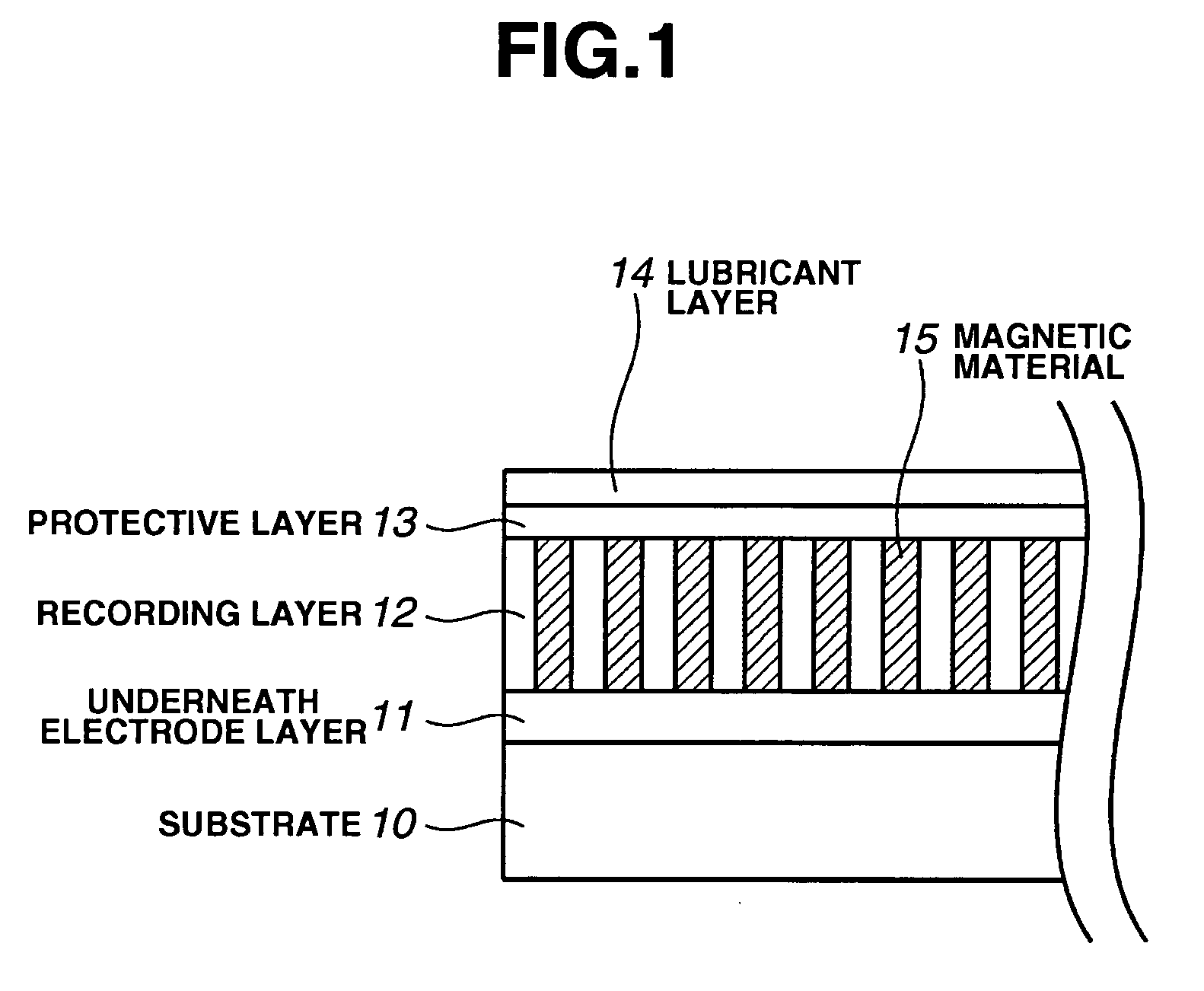

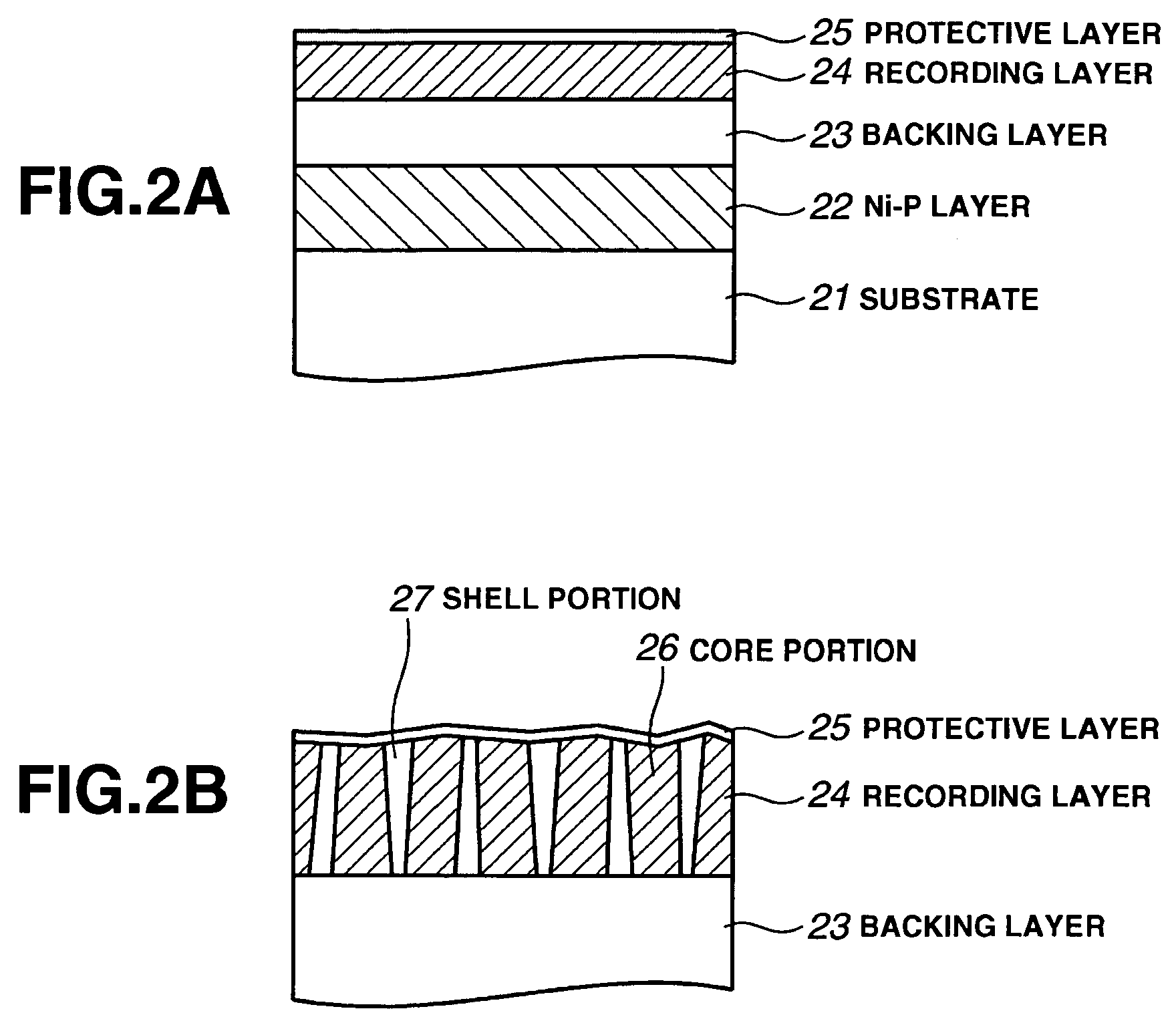

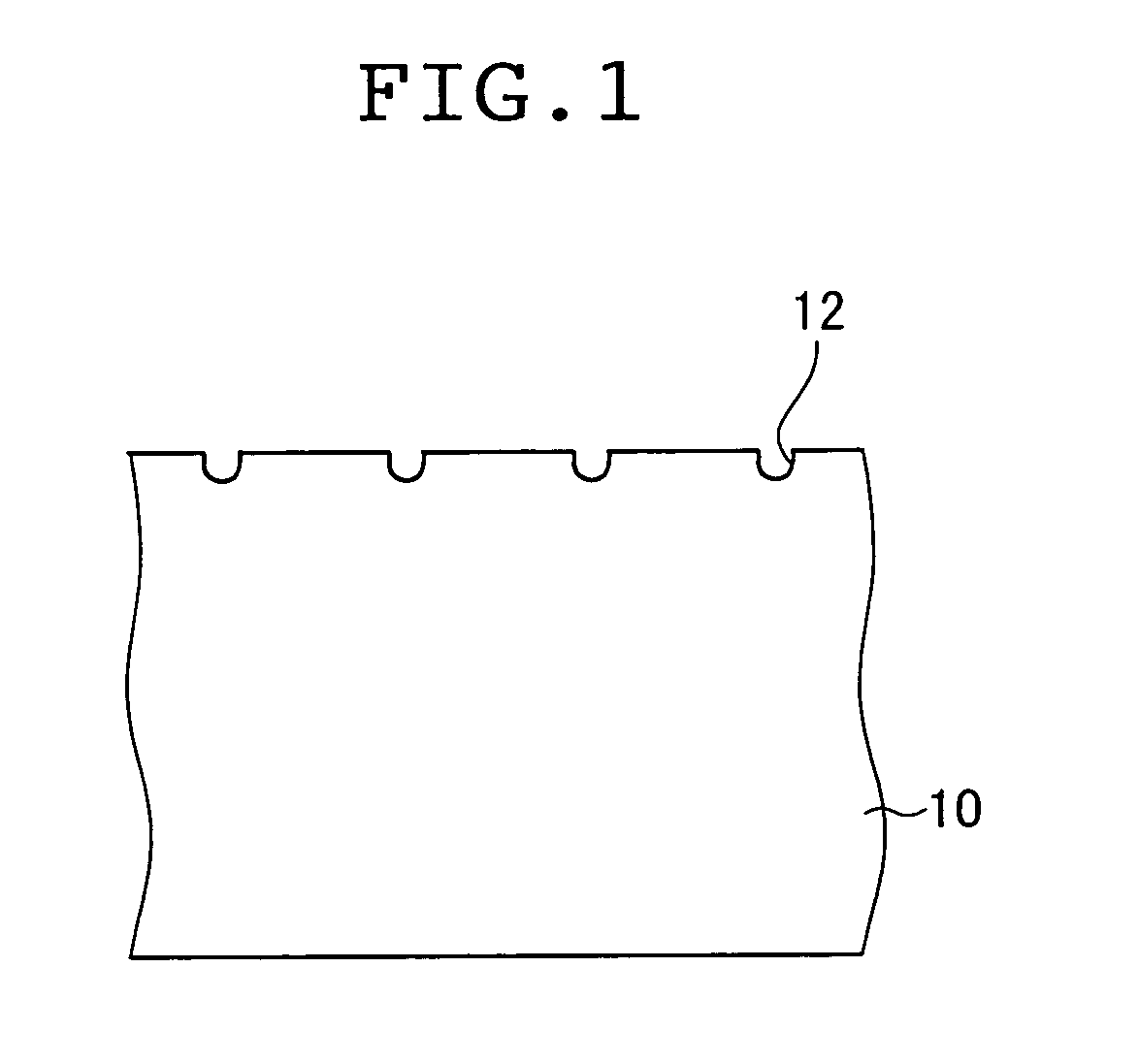

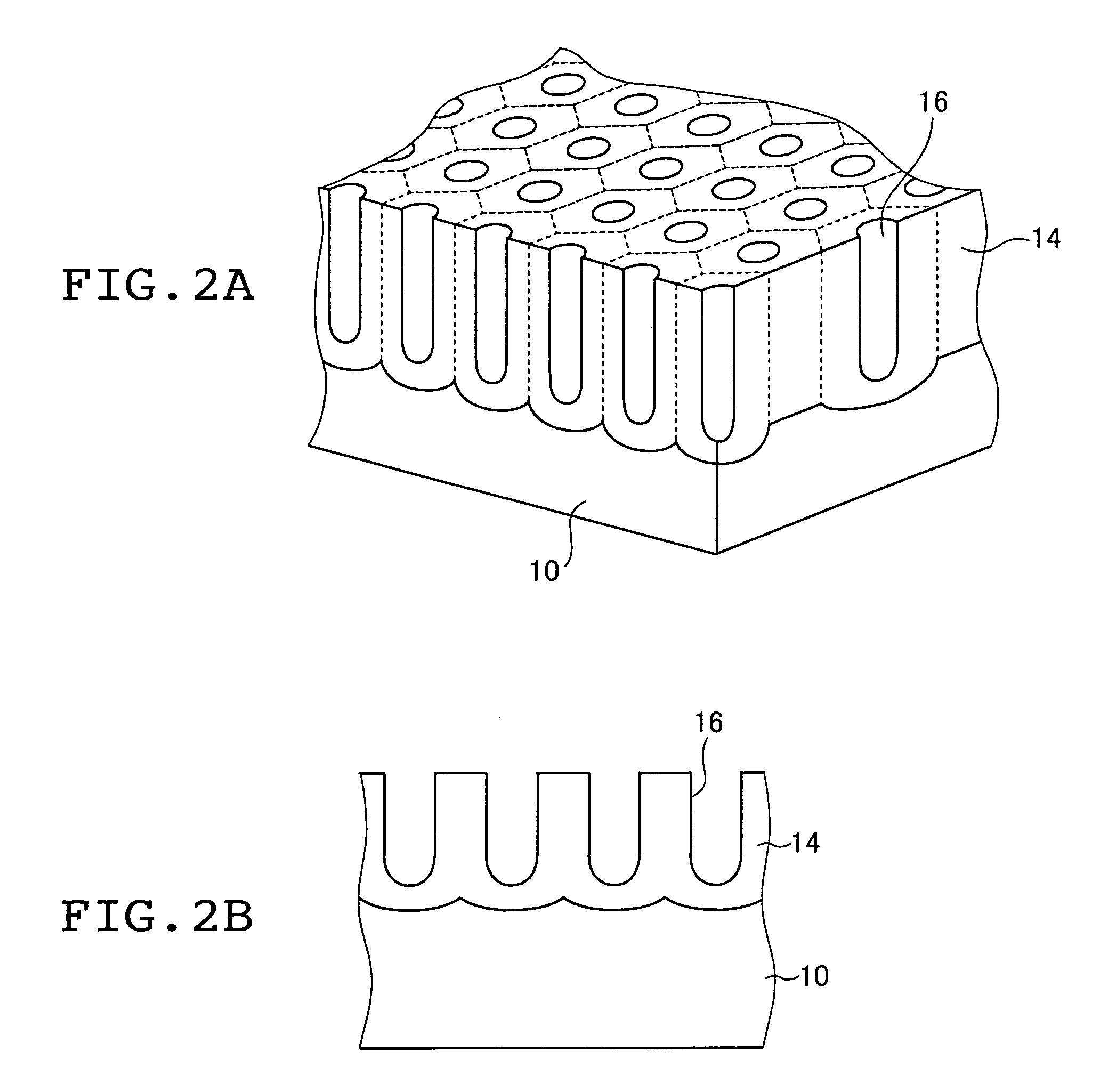

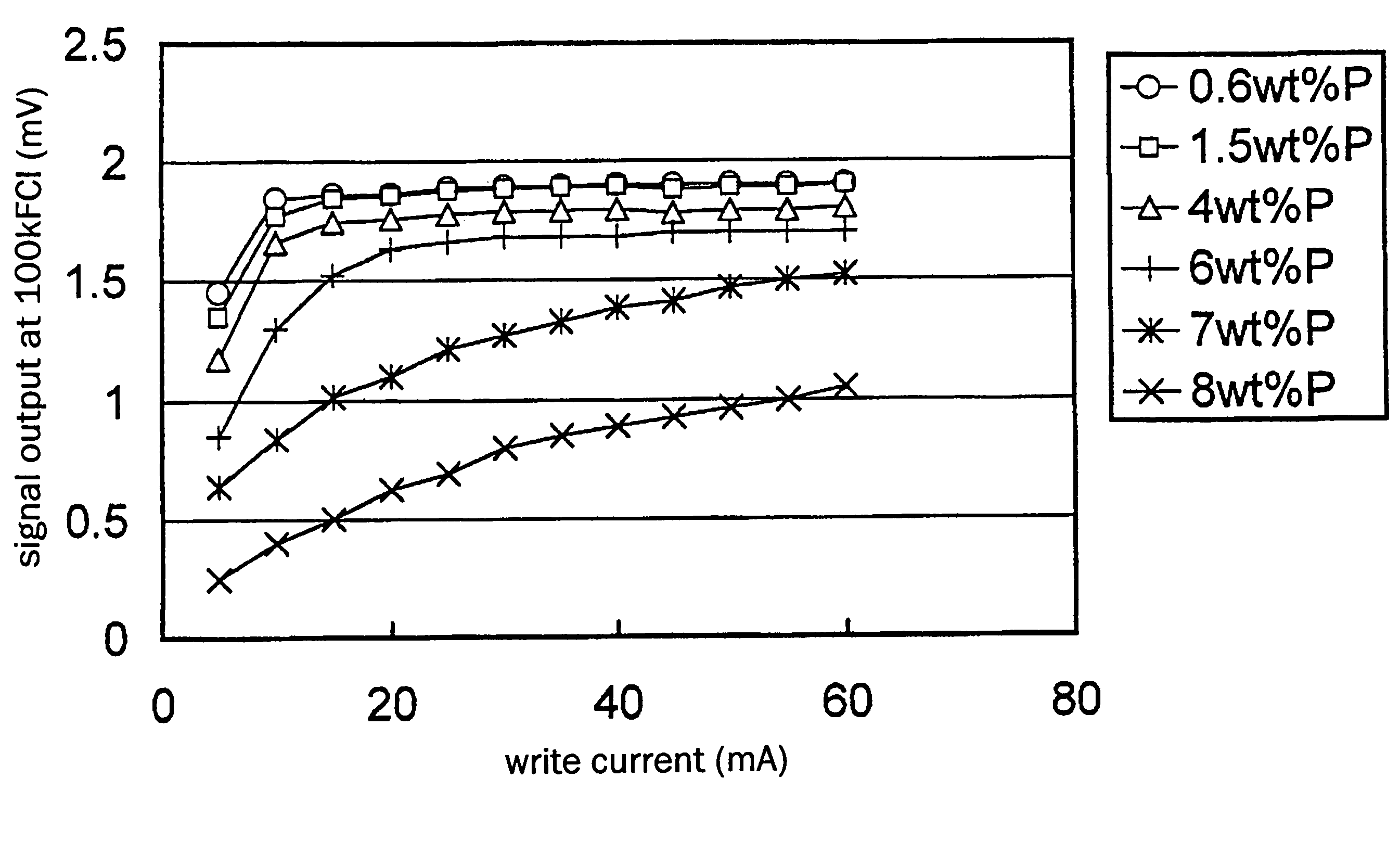

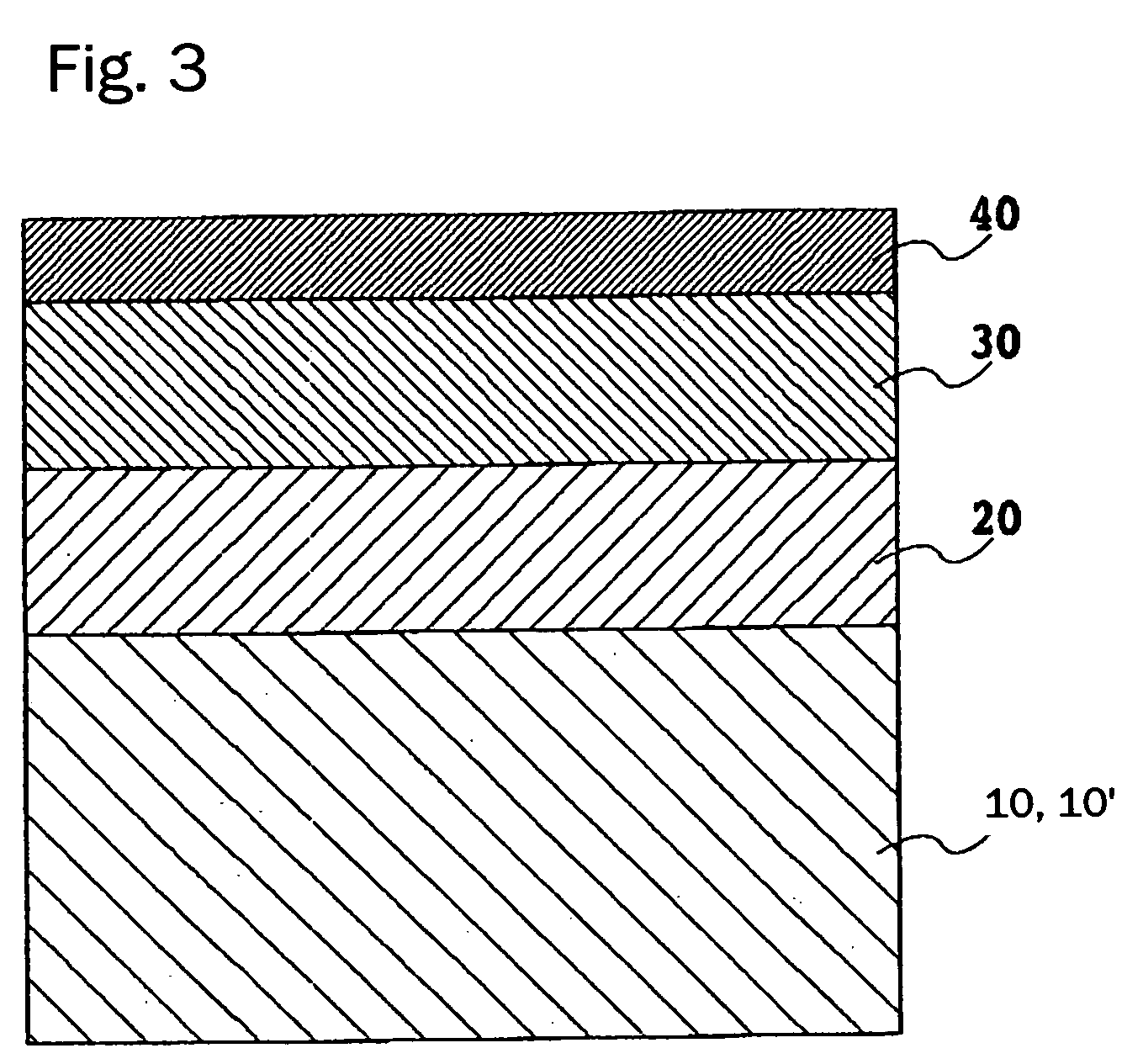

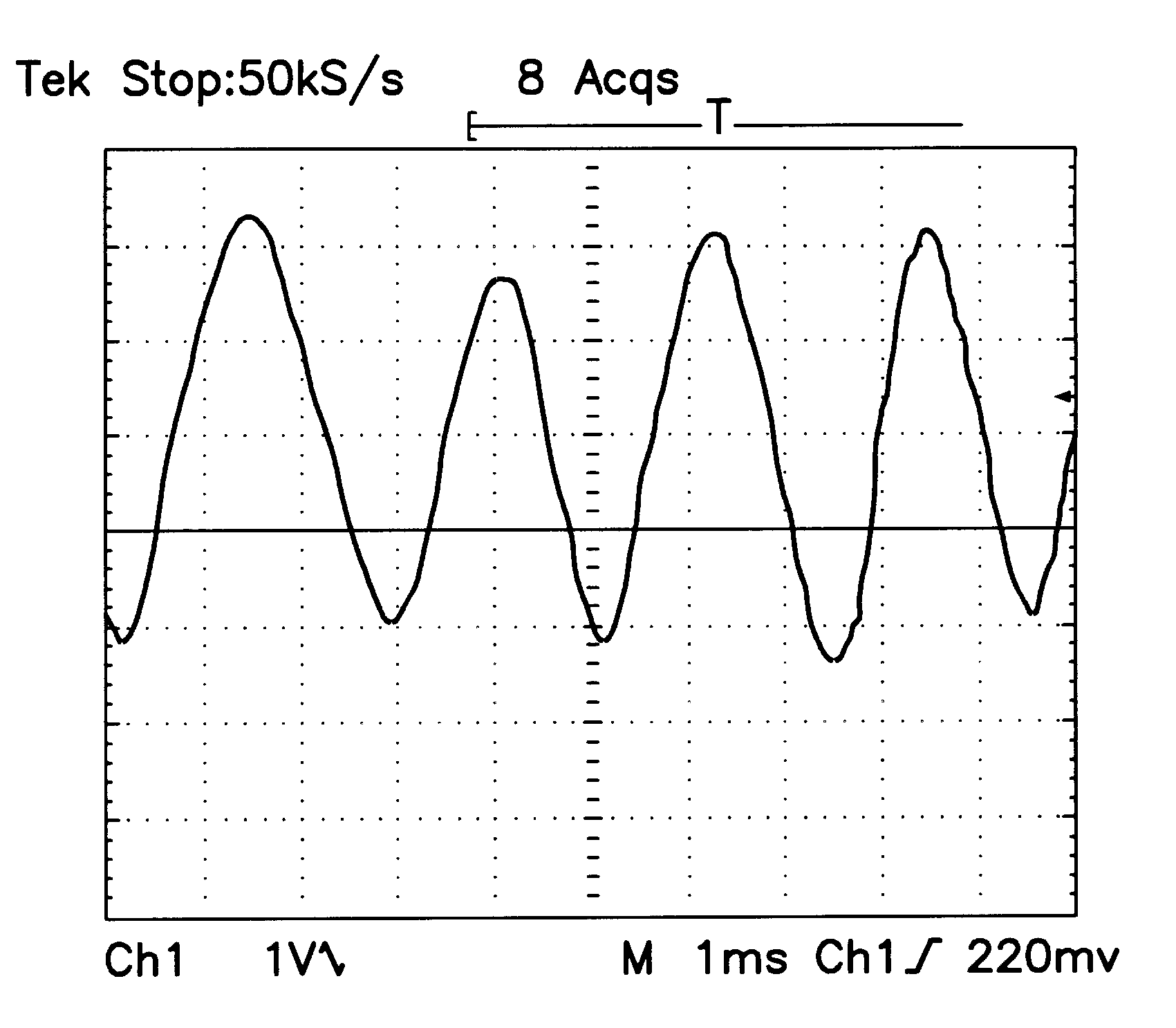

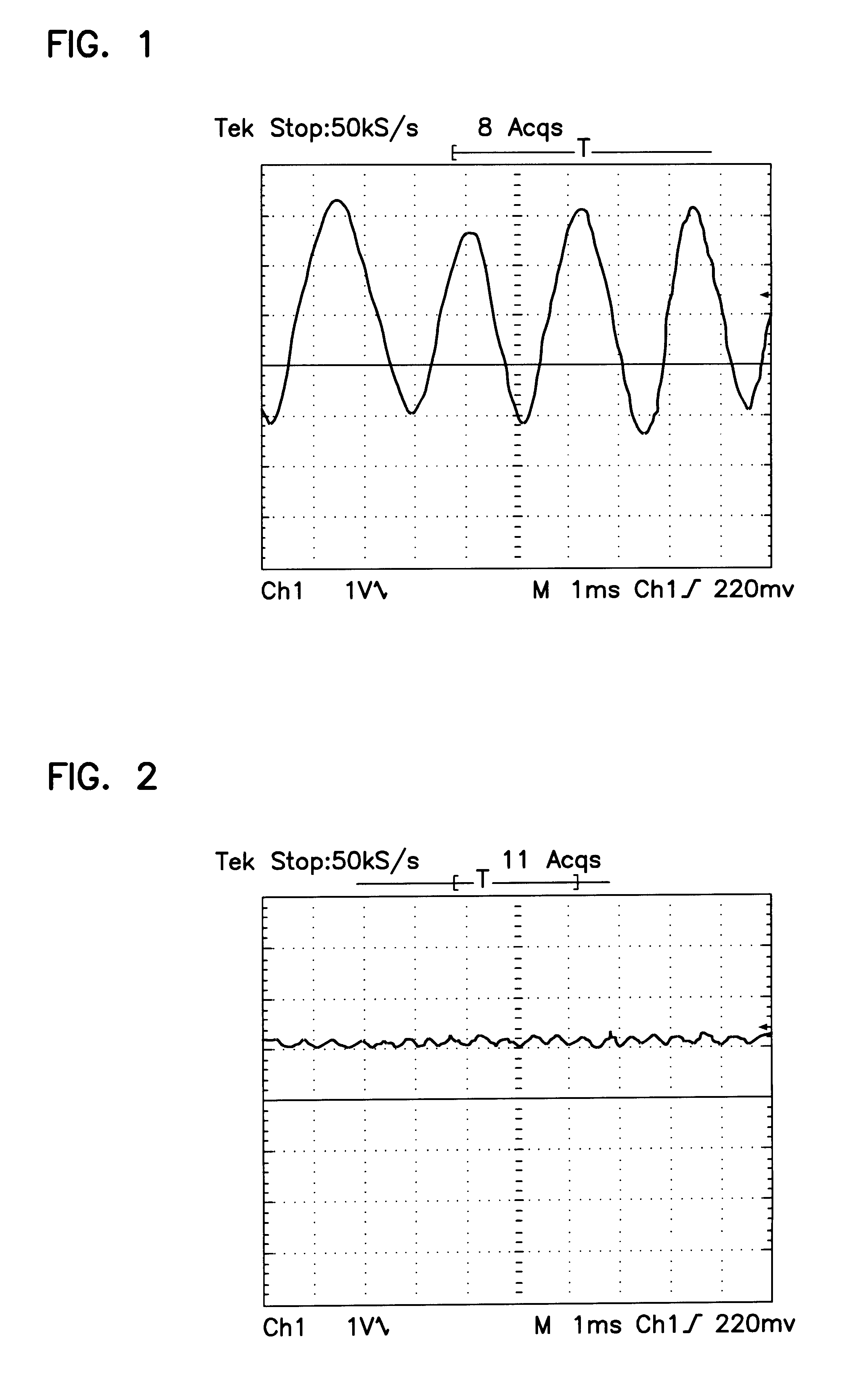

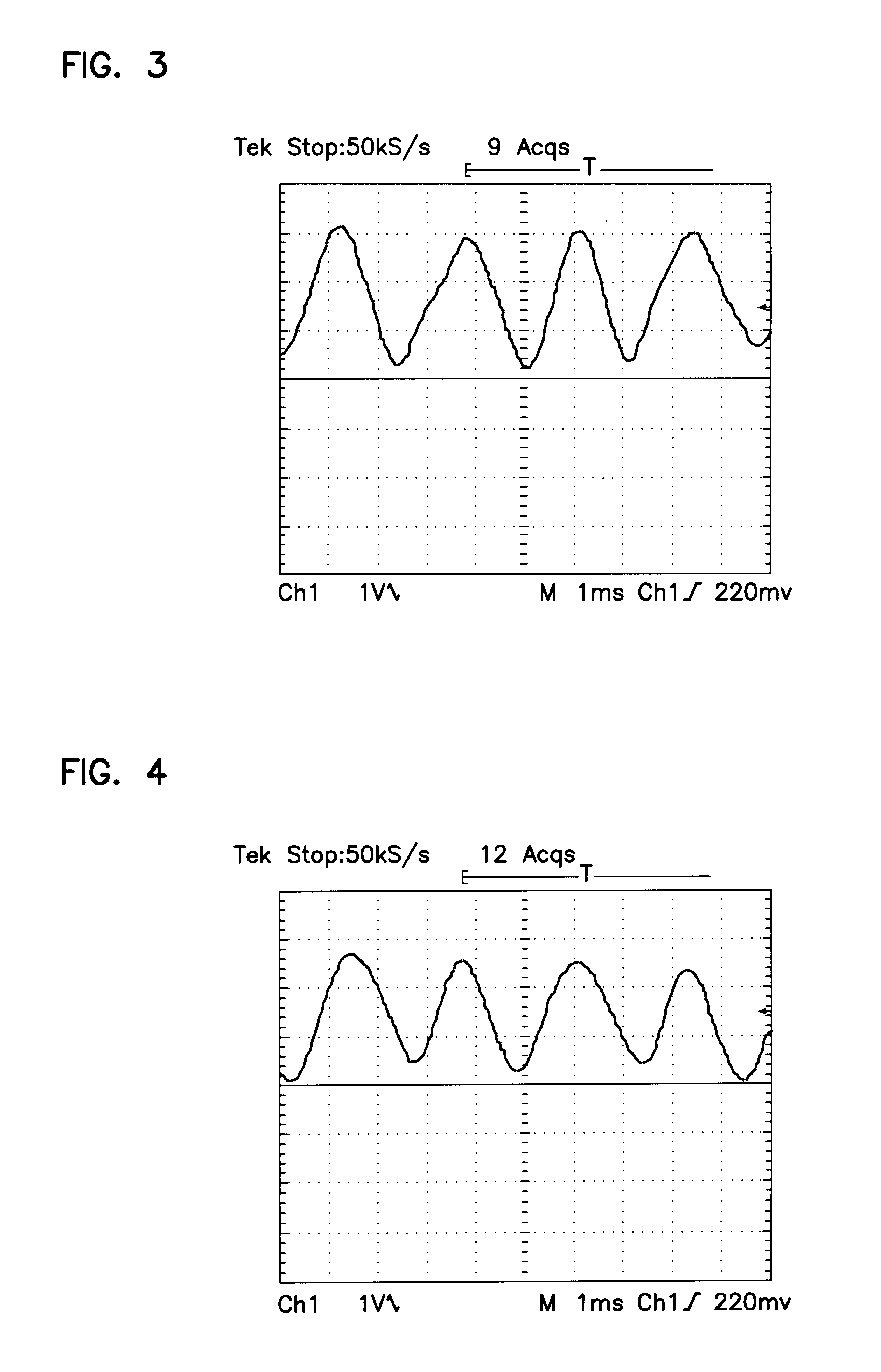

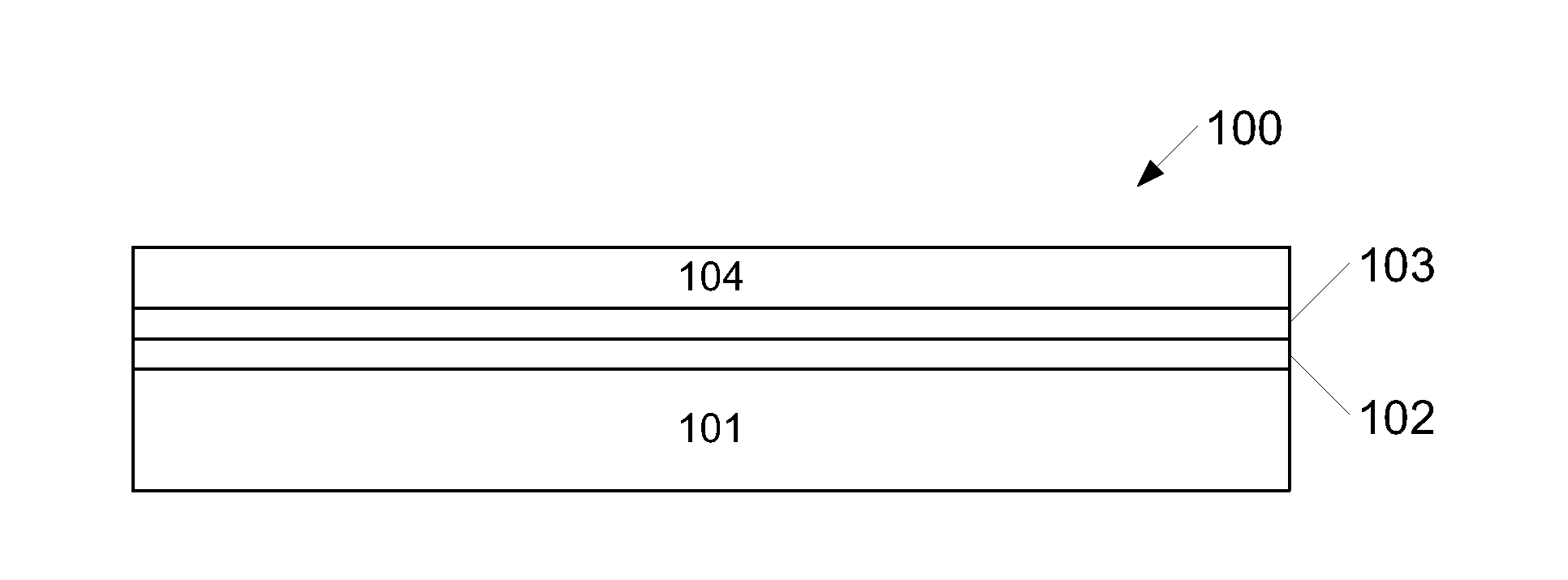

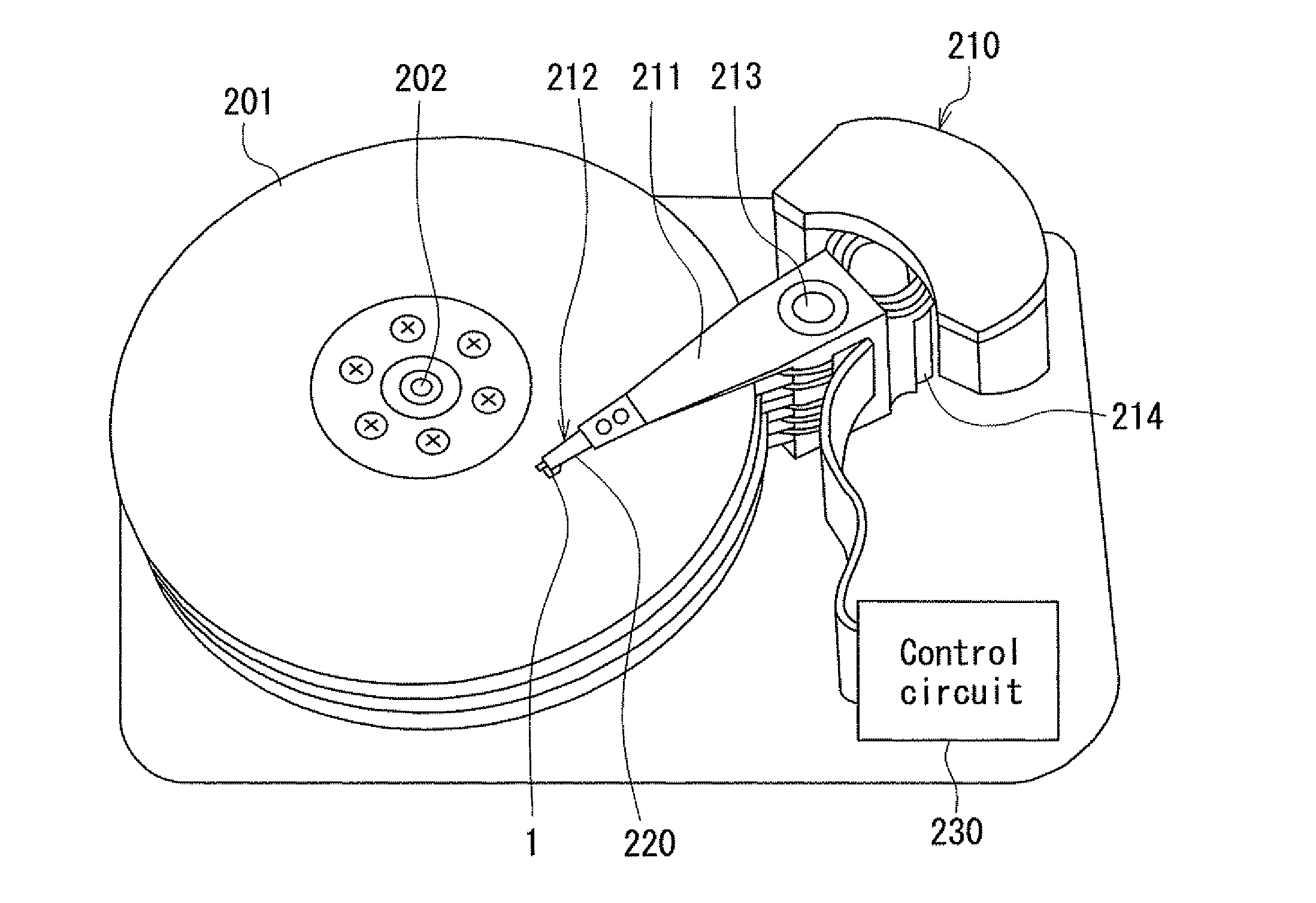

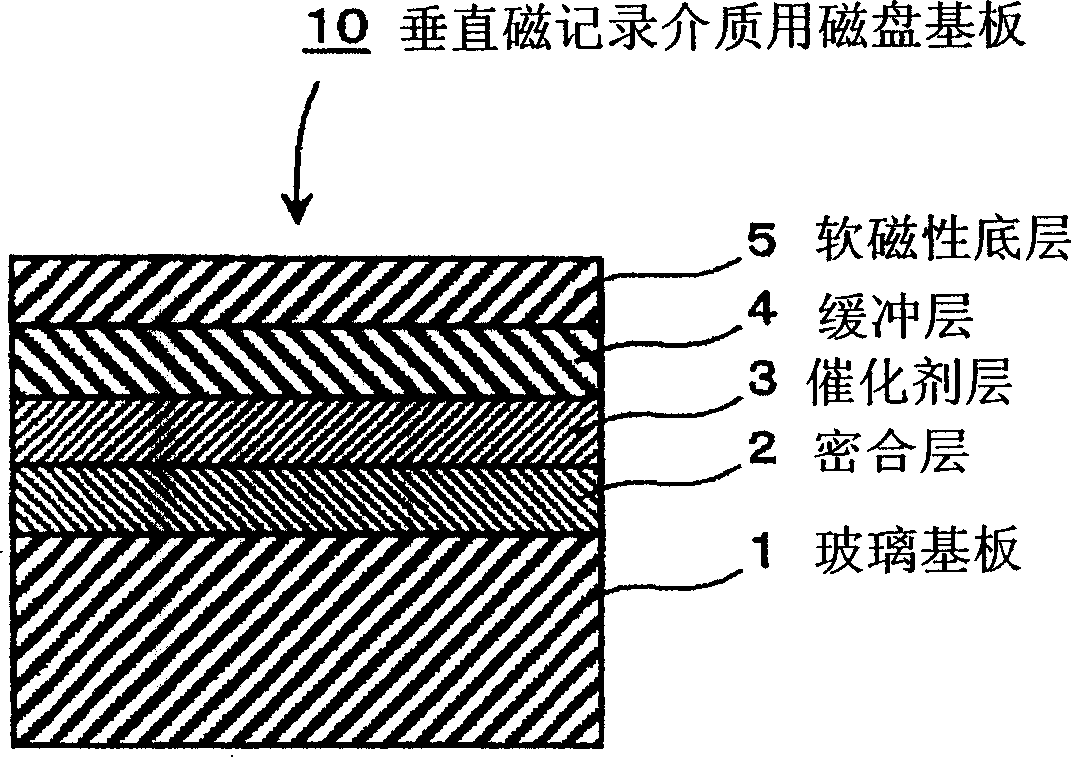

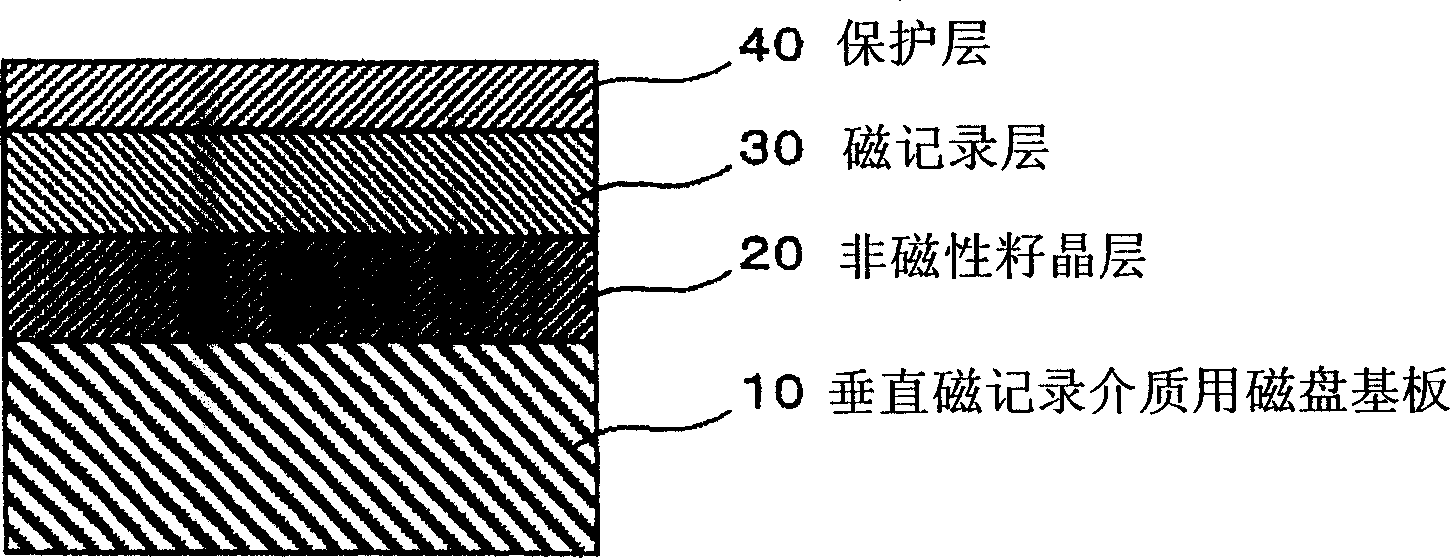

Substrate for a perpendicular magnetic recording medium, perpendicular magnetic recording medium, and manufacturing methods thereof

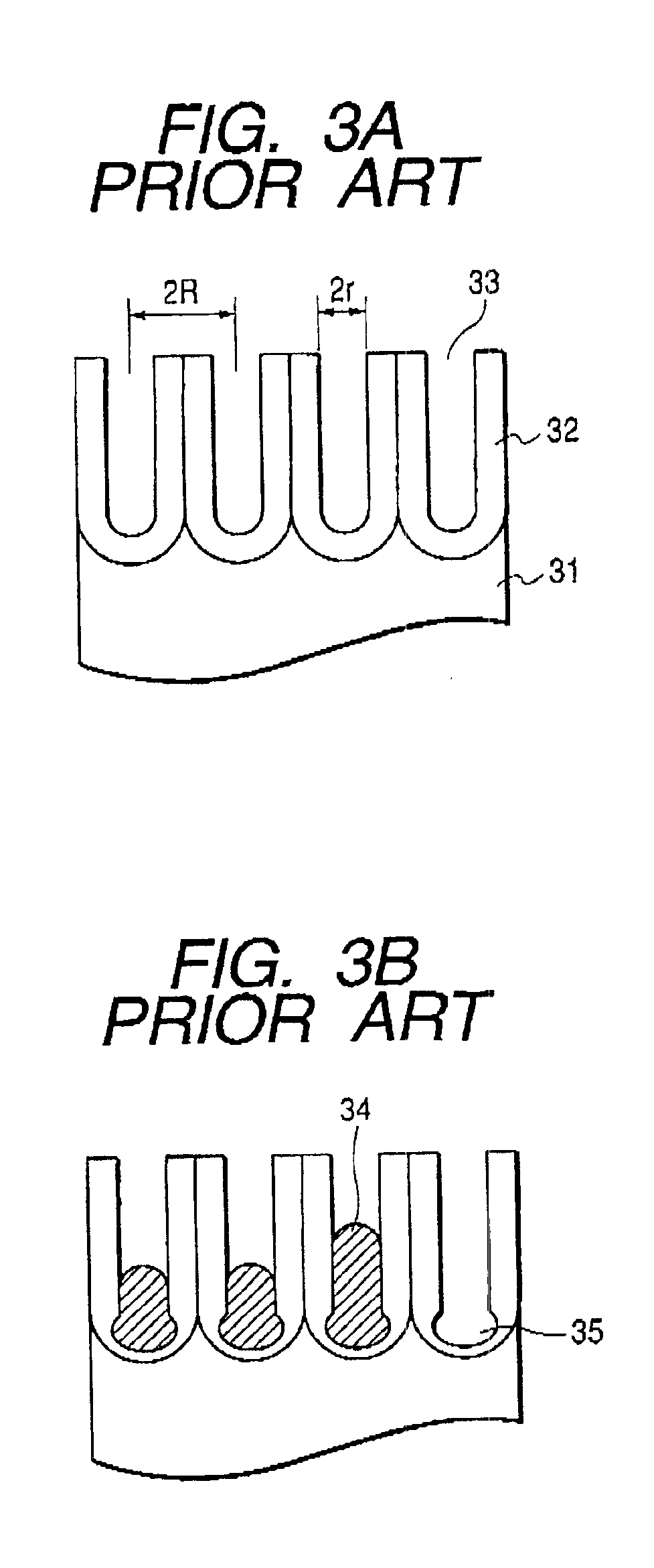

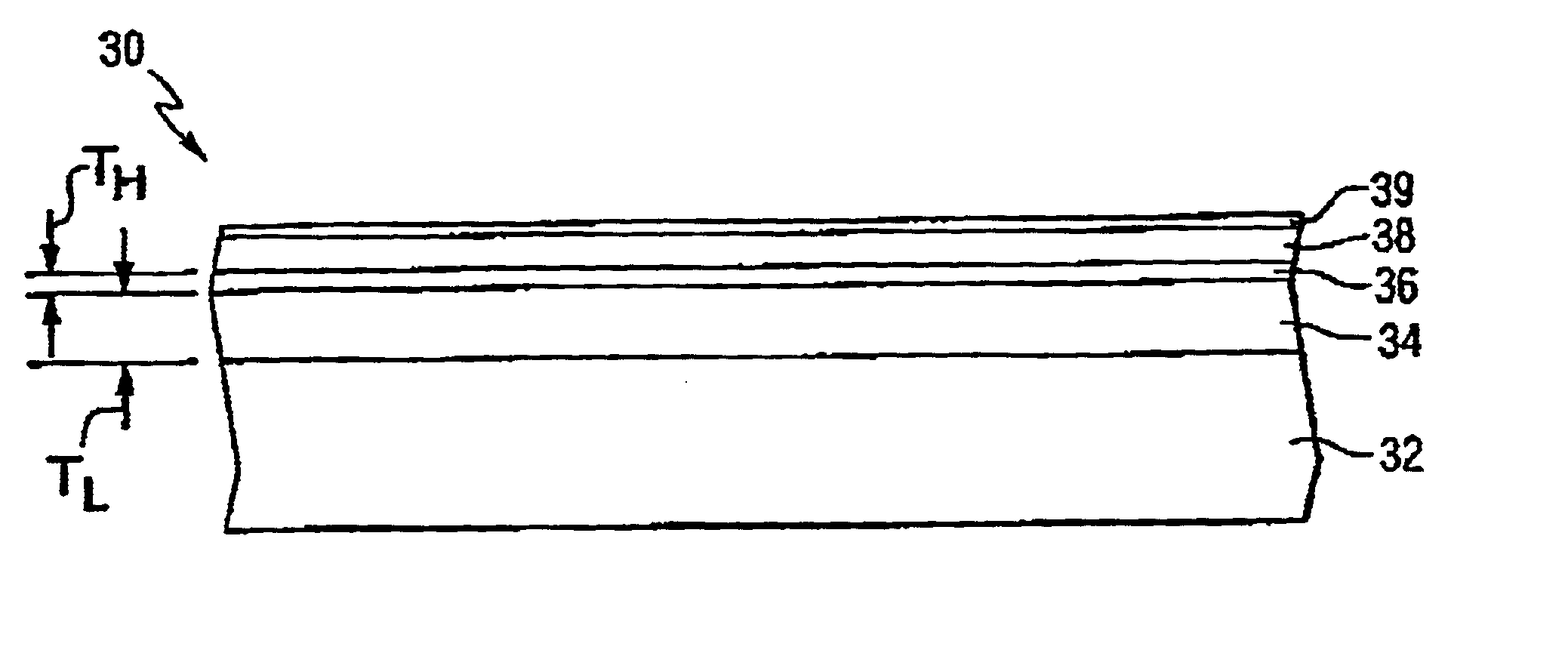

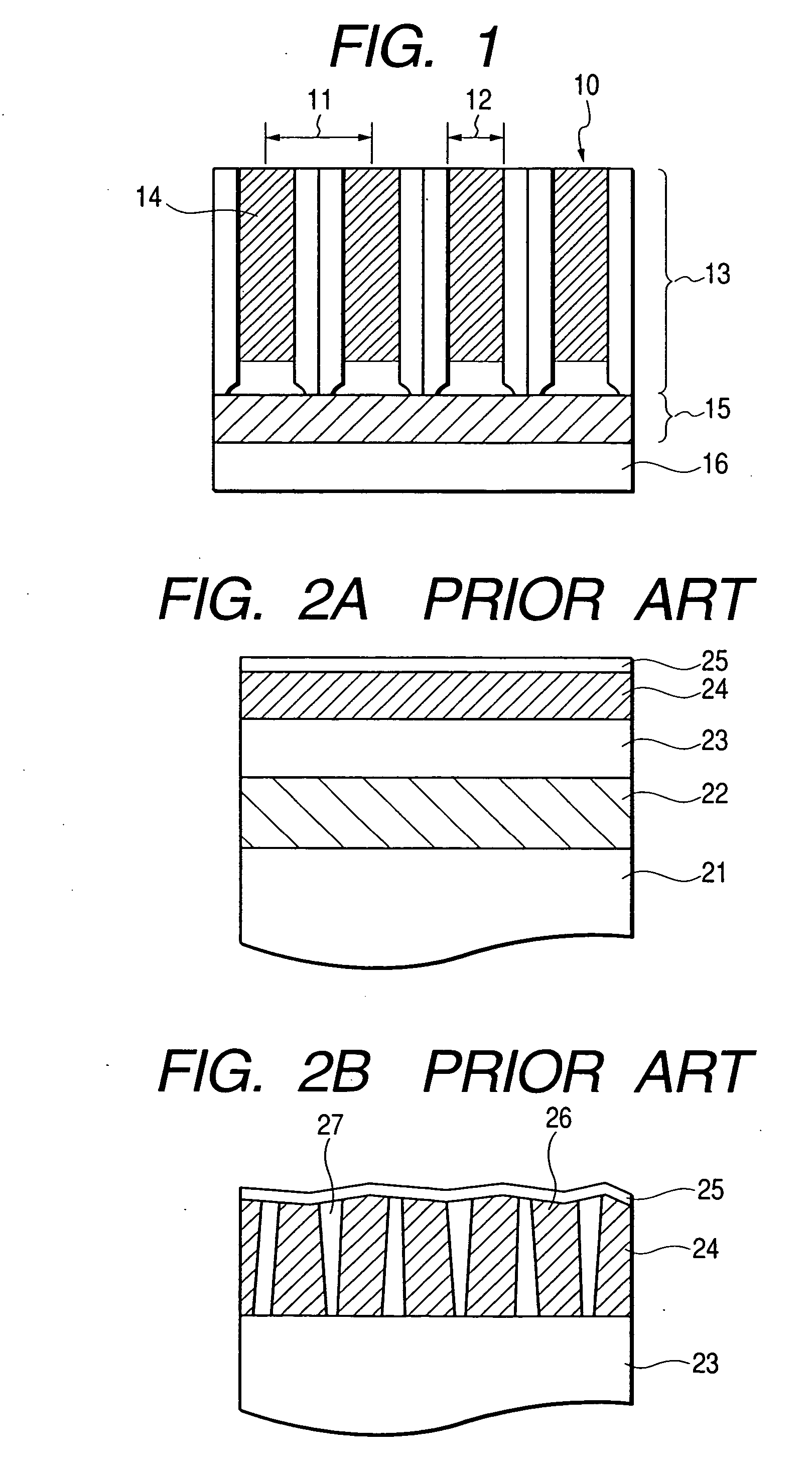

A substrate for a perpendicular magnetic recording medium has a soft magnetic underlayer that functions as a soft magnetic backing layer of a perpendicular magnetic recording medium. The substrate for a perpendicular magnetic recording medium has a nonmagnetic base made of Al—Mg alloy or the like. The soft magnetic underlayer is formed of a Ni—P alloy containing phosphorus in a range of 0.5 wt % to 6 wt % formed by electroless plating on the nonmagnetic base. The substrate can also include a nonmagnetic underlayer formed by electroless plating on the base before electroless plating the soft magnetic underlayer. To form the perpendicular magnetic recording medium, the surface of the soft magnetic is textured using free abrasive grains. Thereafter, a nonmagnetic seed layer, a magnetic recording layer, and a protective layer can be formed by sputtering. A soft magnetic supplemental layer also can be formed on the soft magnetic underlayer before forming the seed layer.

Owner:FUJI ELECTRIC CO LTD

Method of manufacturing master disk for magnetic transfer

InactiveUS20060177569A1Improve transmission characteristicsEasy to shapeMagnetic layer production by platingRecord information storageMaterials scienceMagnetic layer

The present invention provides a method of manufacturing a master disk for magnetic transfer, comprising steps of: forming a magnetic layer on the surface of a substrate on which concavo-convex patterns are formed; forming a reverse plate made of a metal plate having a prescribed thickness by electrodepositing a metal on the surface of the substrate on which the magnetic layer is formed; and exfoliating the reverse plate from the substrate and obtaining a master disk for magnetic transfer which has, on the surface thereof, patters reverse to the concavo-convex patterns and is the reverse plate in which the magnetic layer is formed on a surface of the reverse patterns.

Owner:FUJIFILM HLDG CORP +1

Electrodeposition process of a cobalt-chromium film on aluminum alloys for magnetic recording

InactiveUS6187461B1Enhanced magnetizationClear signalBase layers for recording layersMagnetic layer production by platingPhosphateMagnetization

A cobalt-chromium (Co-Cr) magnetic film electrodeposited on the surface of an aluminum alloy. A process for making an aluminum alloy electrodeposited a cobalt-chromium (Co-Cr) magnetic film comprises the steps of chemically polishing an aluminum alloy substrate, pretreating either with phosphate or with zincate and electrodepositing in a plating bath containing cobalt and chromium ions to prepare the cobalt-chromium thin film on the aluminum alloy. Chromium content in the film can be designed by adjusting the parameters of pretreatment and electroplating. The produced cobalt-chromium film can flexibly adjust the magnetic characteristics (e.g. coercive force (Hc) and ramanence magnetization (Mr)) and is suitable for use in a magnetic recorder. The chemical composition, adhesion, microhardness, magnetic properties of the deposits indicate that the Co-Cr films produced are satisfactory for magnetic recording service.

Owner:NAT SCI COUNCIL

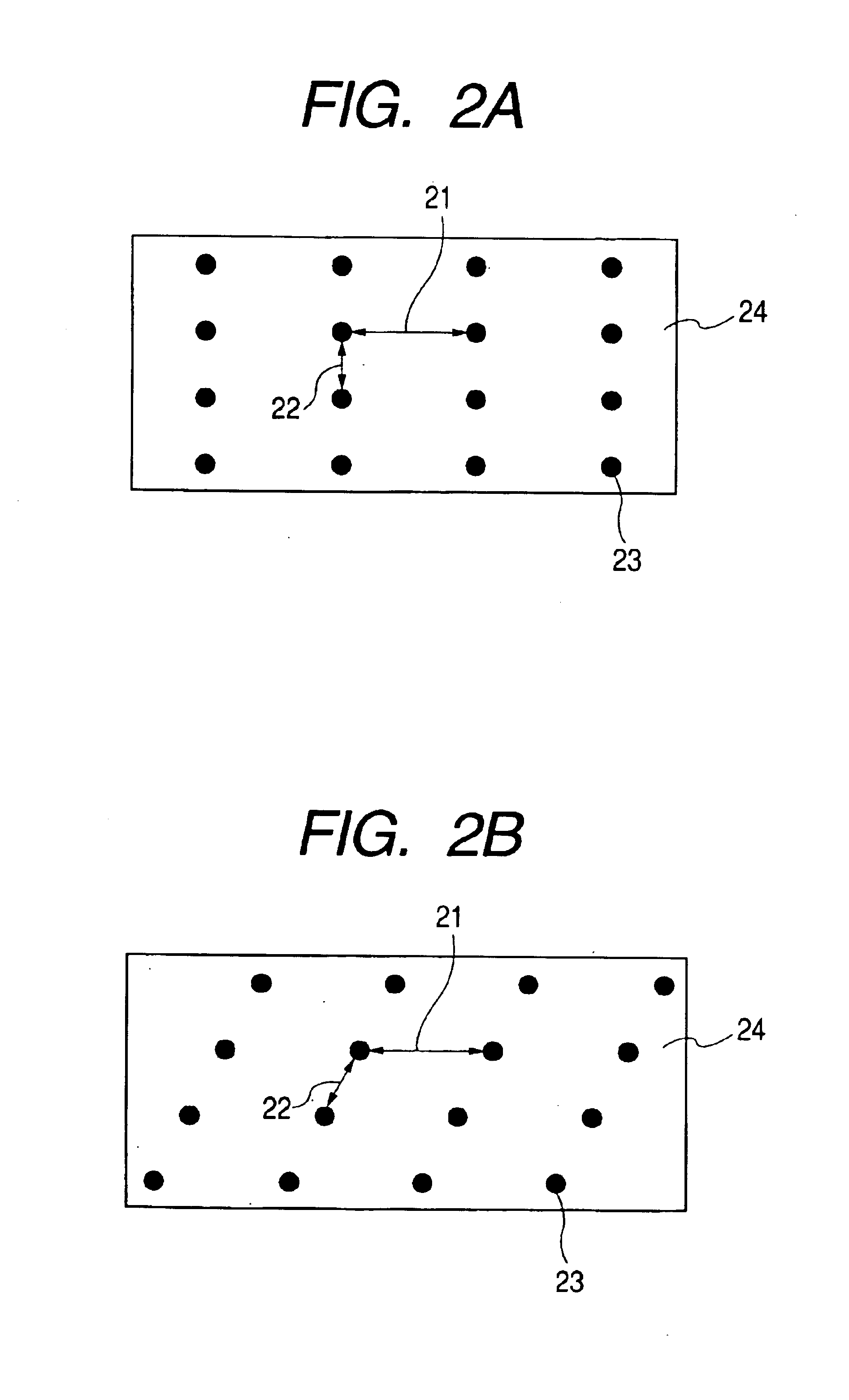

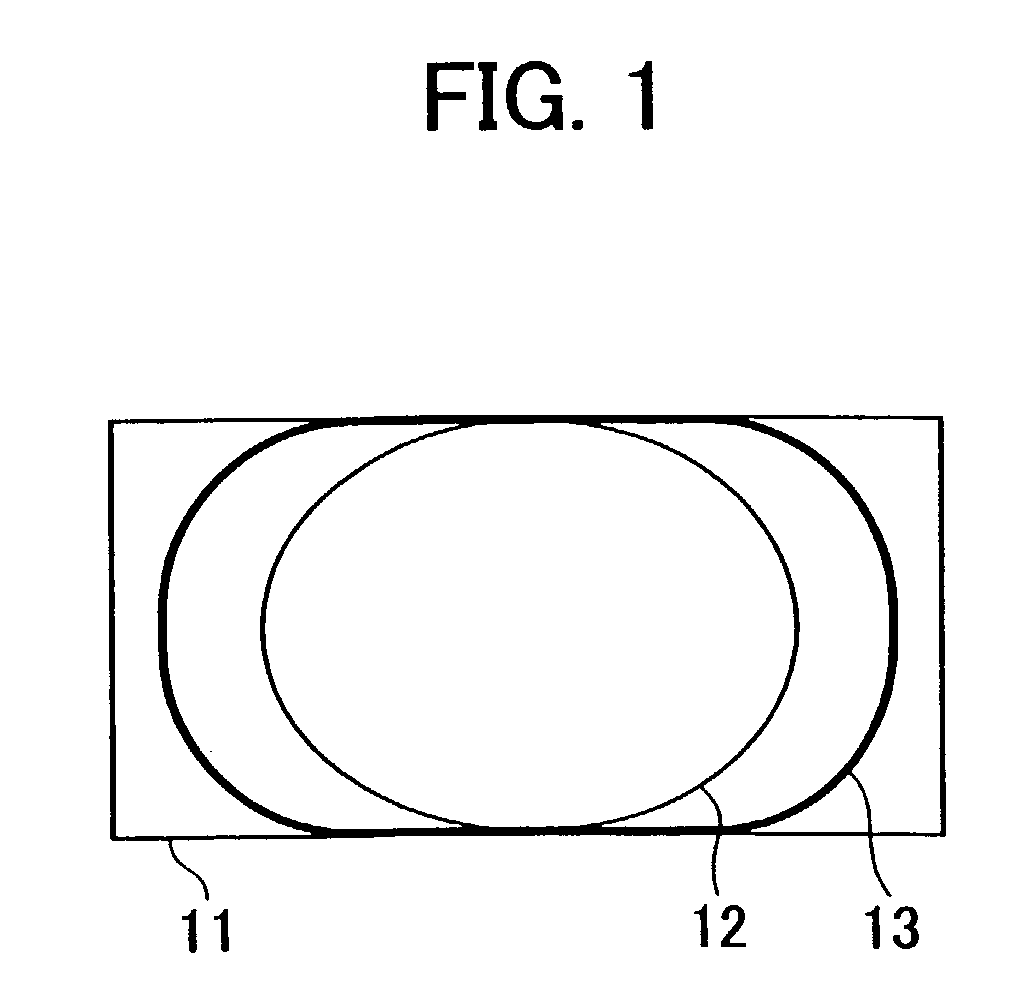

Structure having pores, magnetic recording medium, and method of manufacturing same

The invention provides a magnetic recording medium and a method of manufacturing the magnetic recording medium, in which a high density and good storage stability can be achieved by giving anisotropy in shape to a magnetic substance. A plan shape of the magnetic substance in the magnetic recording medium, which appears on the recording surface side, is an ellipse that is present within a rectangle and has a minor axis with a length equal to a short side of the rectangle. A quadrilateral defined by four intersects of two adjacent vertical rows and two adjacent horizontal rows, each of these rows comprising a plurality of pores, has a rectangular or rhombic shape.

Owner:CANON KK

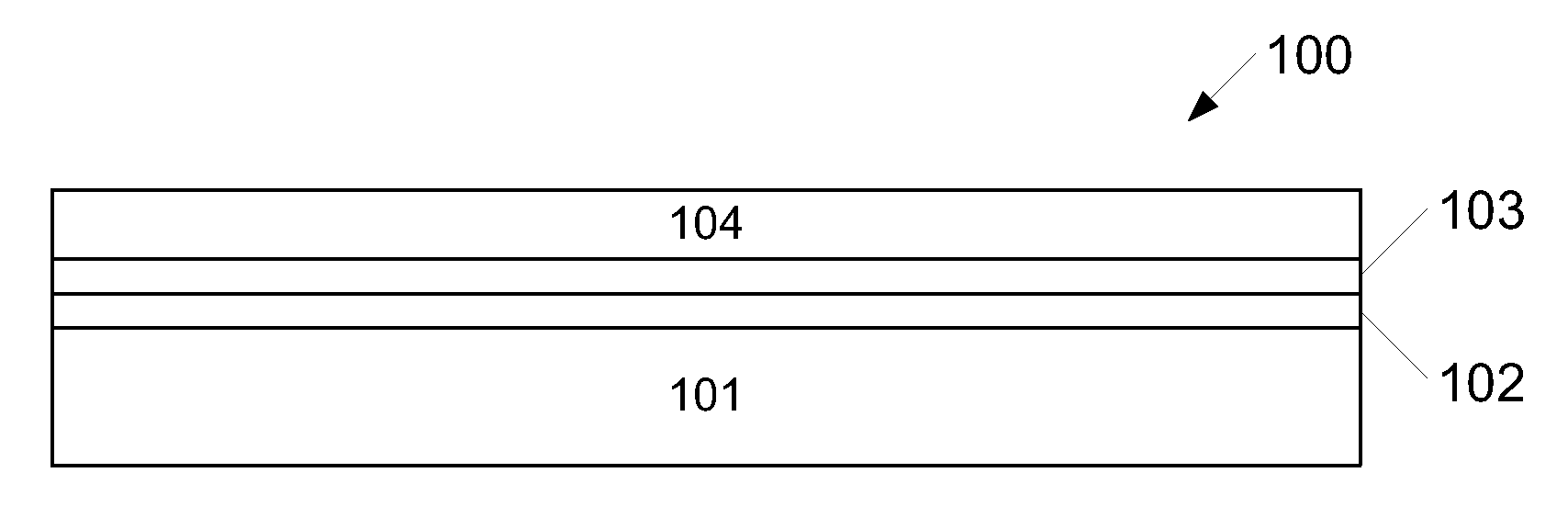

Electroless coated disks for high temperature applications and methods of making the same

ActiveUS20120034492A1Improve thermal stabilityMagnetic materials for record carriersMagnetic layer production by platingHard disc driveAlloy

A disk for a hard disk drive is provided. The disk comprises a substrate comprising aluminum, and a coating layer disposed over the substrate. The coating layer comprises an alloy of Ni, X1 and X2, wherein X1 comprises one or more elements selected from the group consisting of Ag, Au, B, Cr, Cu, Ga, In, Mn, Mo, Nb, Pb, Sb, Se, Sn, Te, W, Zn and Zr, and wherein X2 comprises either B or P, and wherein X1 and X2 do not comprise the same elements.

Owner:WESTERN DIGITAL TECH INC

Composite material comprising silicon matrix and method of producing the same

InactiveUS20120321798A1Material nanotechnologyMagnetic layer production by platingSilicon matrixSurface layer

Proposed are a composite material, wherein non-penetrating pores that are formed in a silicon surface layer are filled up with a metal or the like without leaving any voids by using the plating technique, and a method of producing the composite material. A composite material, which has been packed at a high accuracy, or in other words, in which little voids are left, can be obtained by filling up non-penetrating pores that are formed from a silicon surface (100) substantially with a second metal or an alloy of the second metal (106) with the use of the autocatalytic electroless plating technique wherein a first metal located at the bottom of the non-penetrating pores as described above serves as the starting point.

Owner:JAPAN SCI & TECH CORP

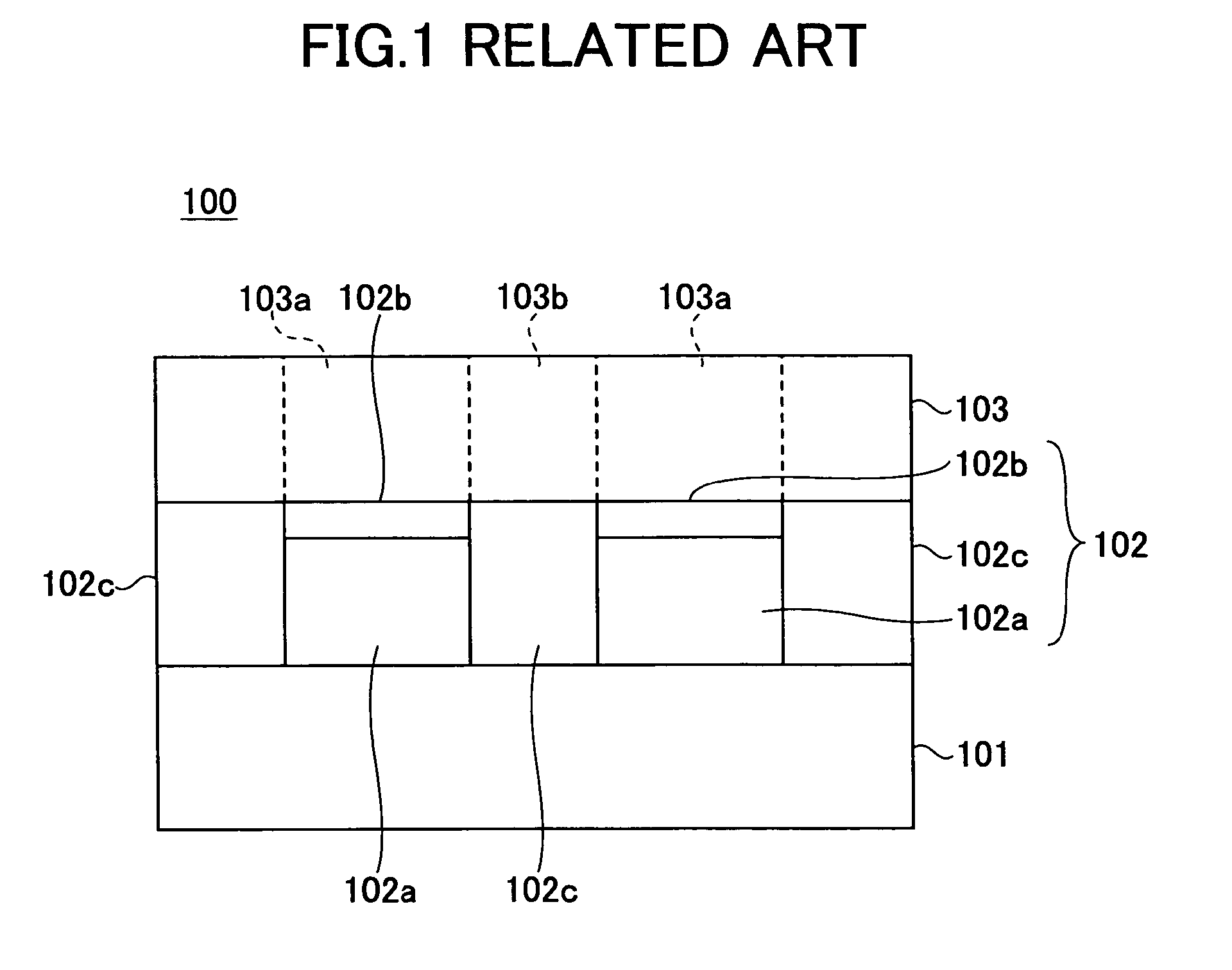

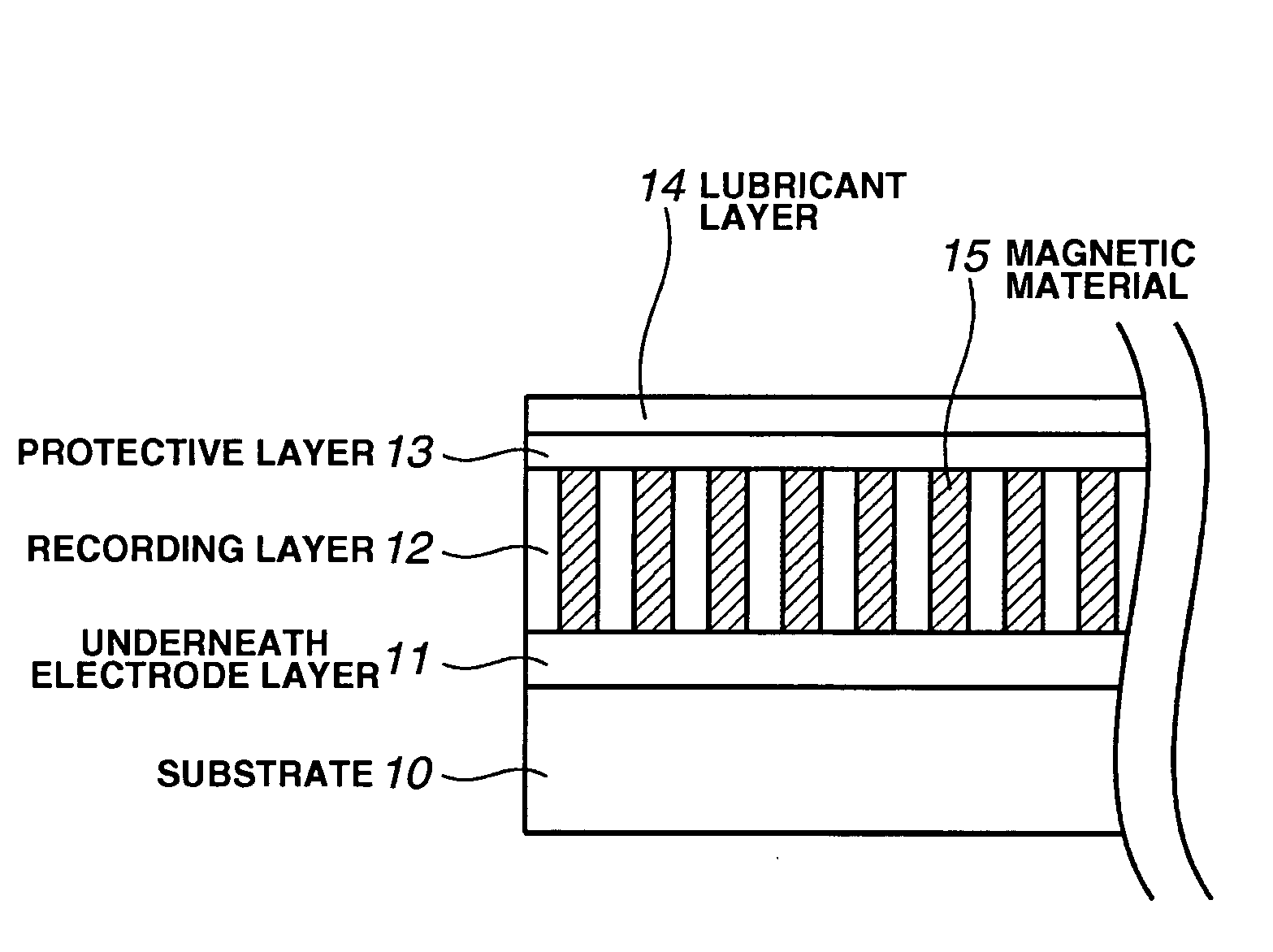

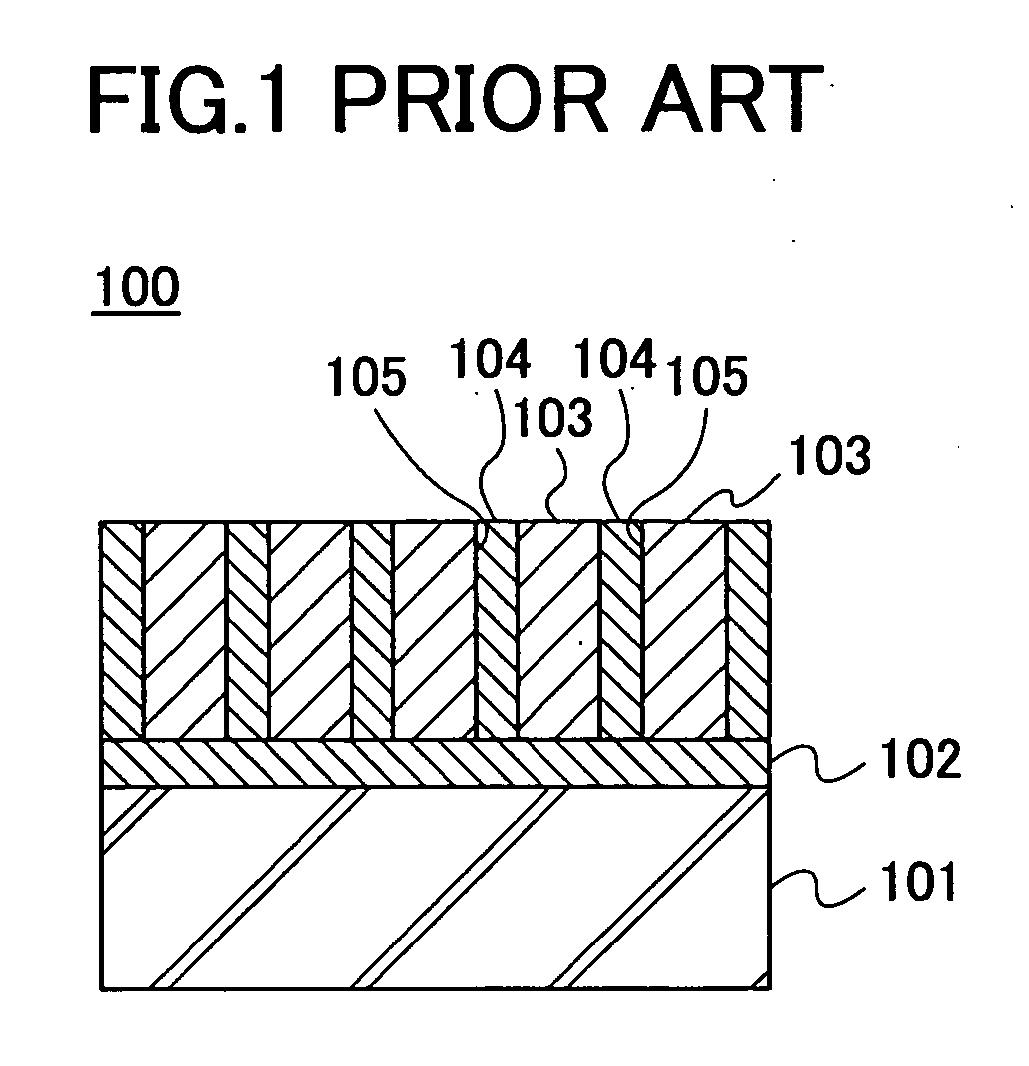

Magnetic recording medium, method of manufacturing the same, magnetic medium substrate employed in the magnetic recording medium, and magnetic storage unit

InactiveUS20050196644A1Excels in corrosion resistanceExcels in durabilityProtective coatings for layersMagnetic materials for record carriersCarbon layerMagnetic storage

A magnetic recording medium is disclosed that includes a substrate; an anodic alumina film formed on the substrate; a pore formed in the anodic alumina film; a carbon layer covering the surface of the anodic alumina film and the inner wall of the pore; a magnetic particle formed on the carbon layer inside the pore; and a lubrication layer covering the carbon layer and the magnetic particle.

Owner:FUJITSU LTD

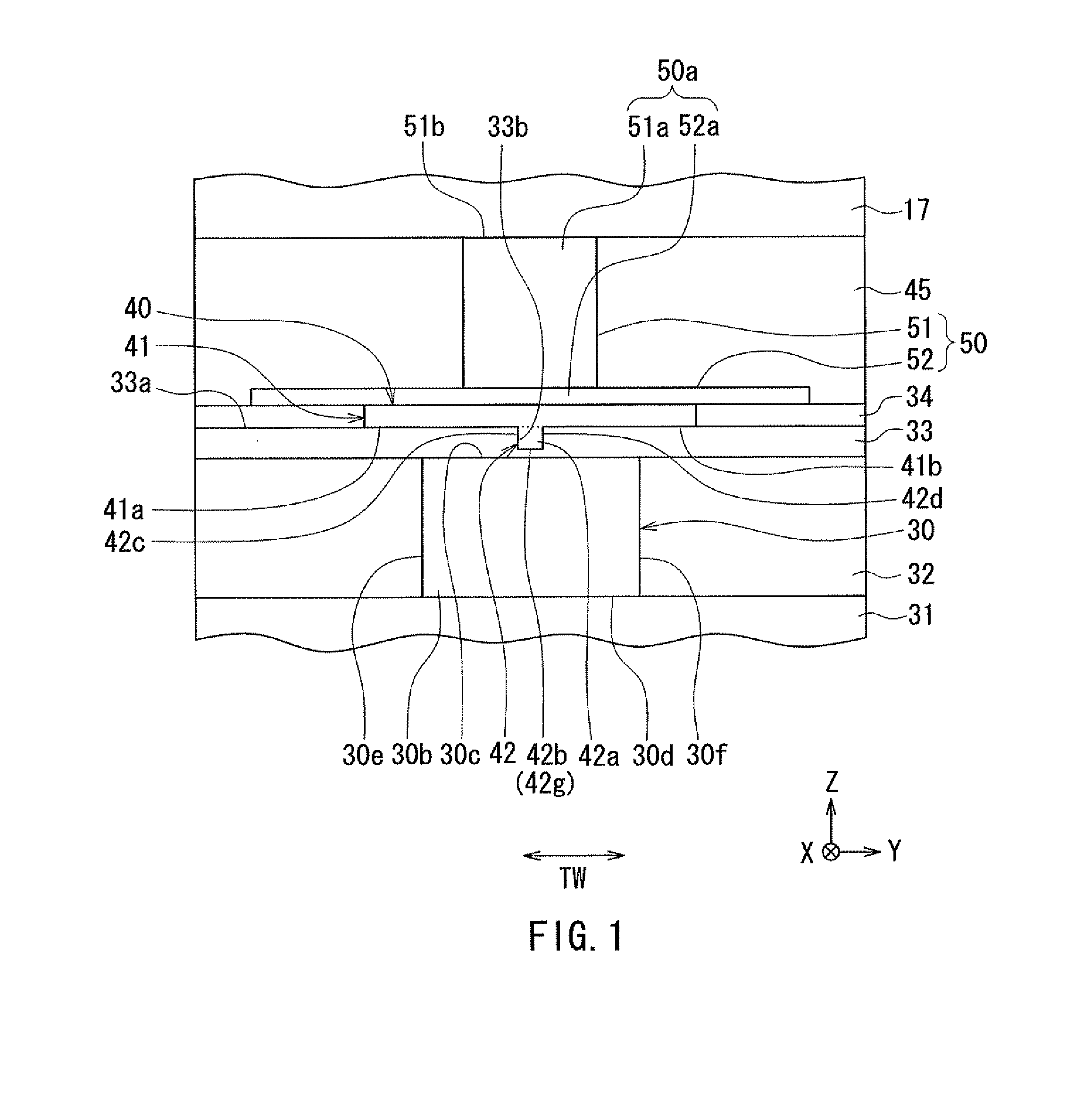

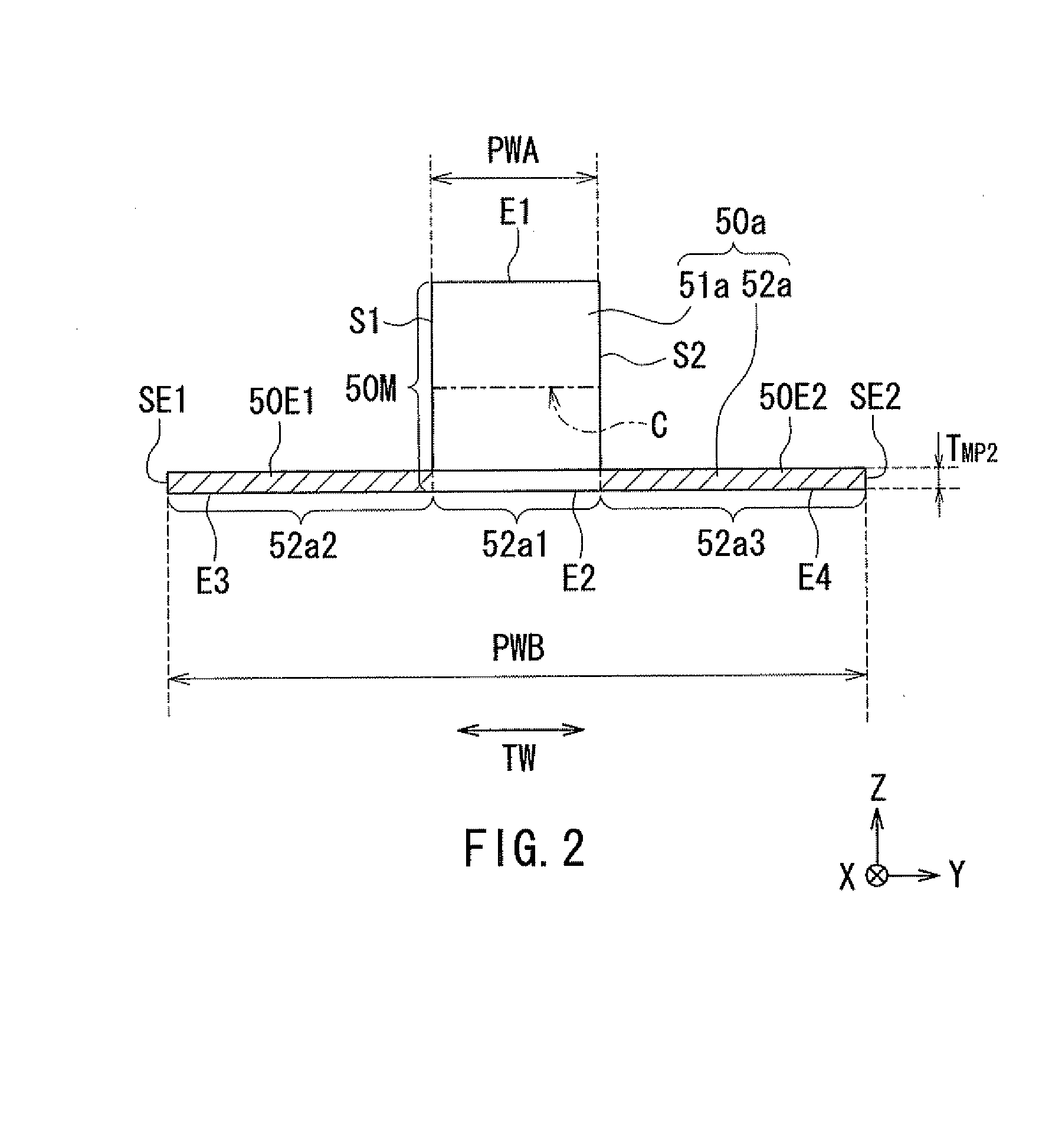

Thermally-assisted magnetic recording head including a magnetic pole and a heating element

ActiveUS20130229730A1Reduce distanceDisposition/mounting of recording headsMagnetic layer production by platingHeat-assisted magnetic recordingMagnetic poles

A thermally-assisted magnetic recording head includes a magnetic pole and a heating element. The magnetic pole has a front end face located in a medium facing surface. The magnetic pole forms on a track a distribution of write magnetic field strength that peaks at a first position on the track. The heating element forms on the track a distribution of temperature that peaks at a second position on the track. The first position is located on the trailing side relative to the second position. The front end face of the magnetic pole has a main portion and first and second extended portions. The first and second extended portions are extended in the track width direction from the main portion at positions on the leading side relative to the center of the main portion in the direction of travel of a magnetic recording medium.

Owner:TDK CORPARATION

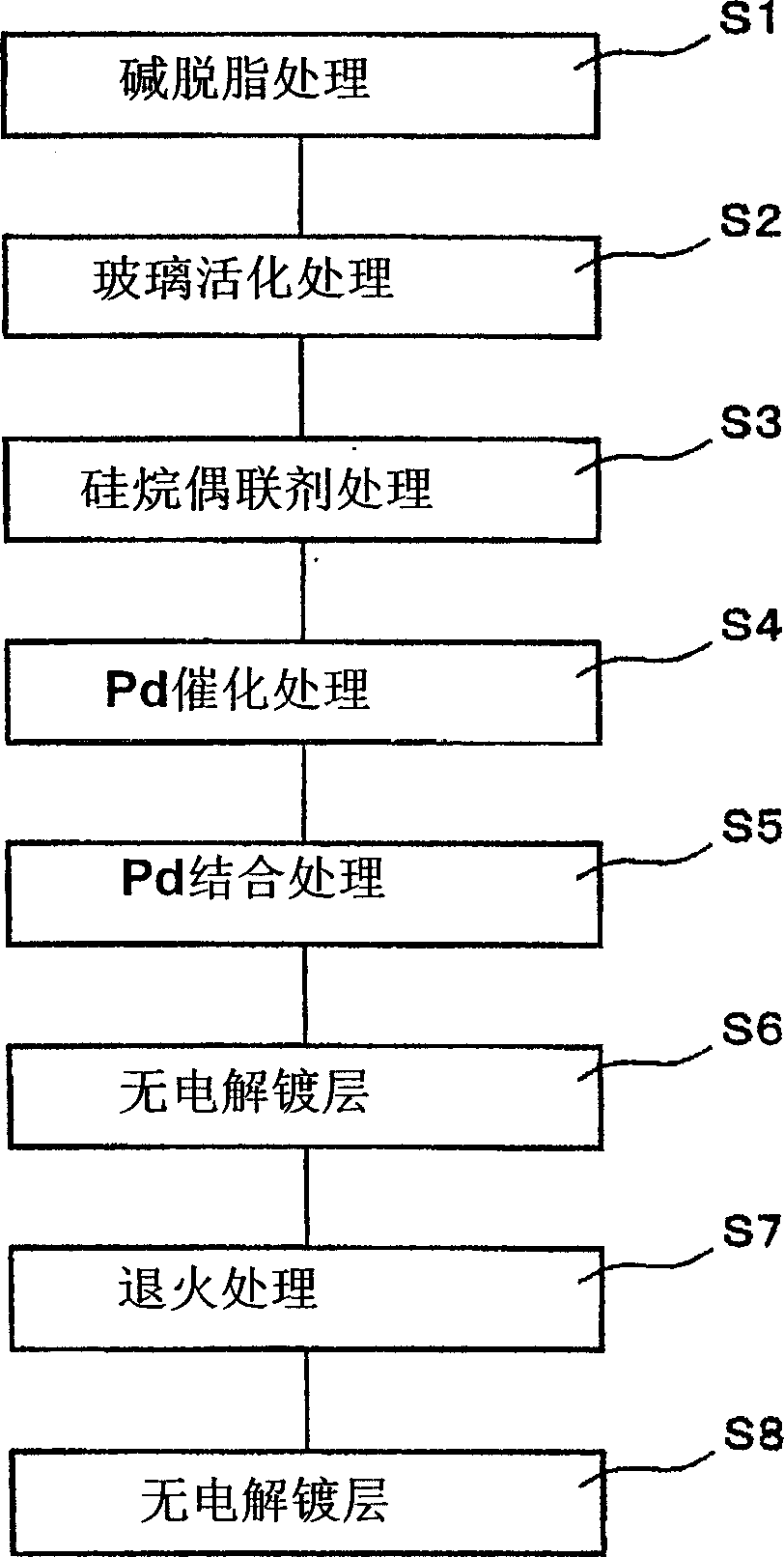

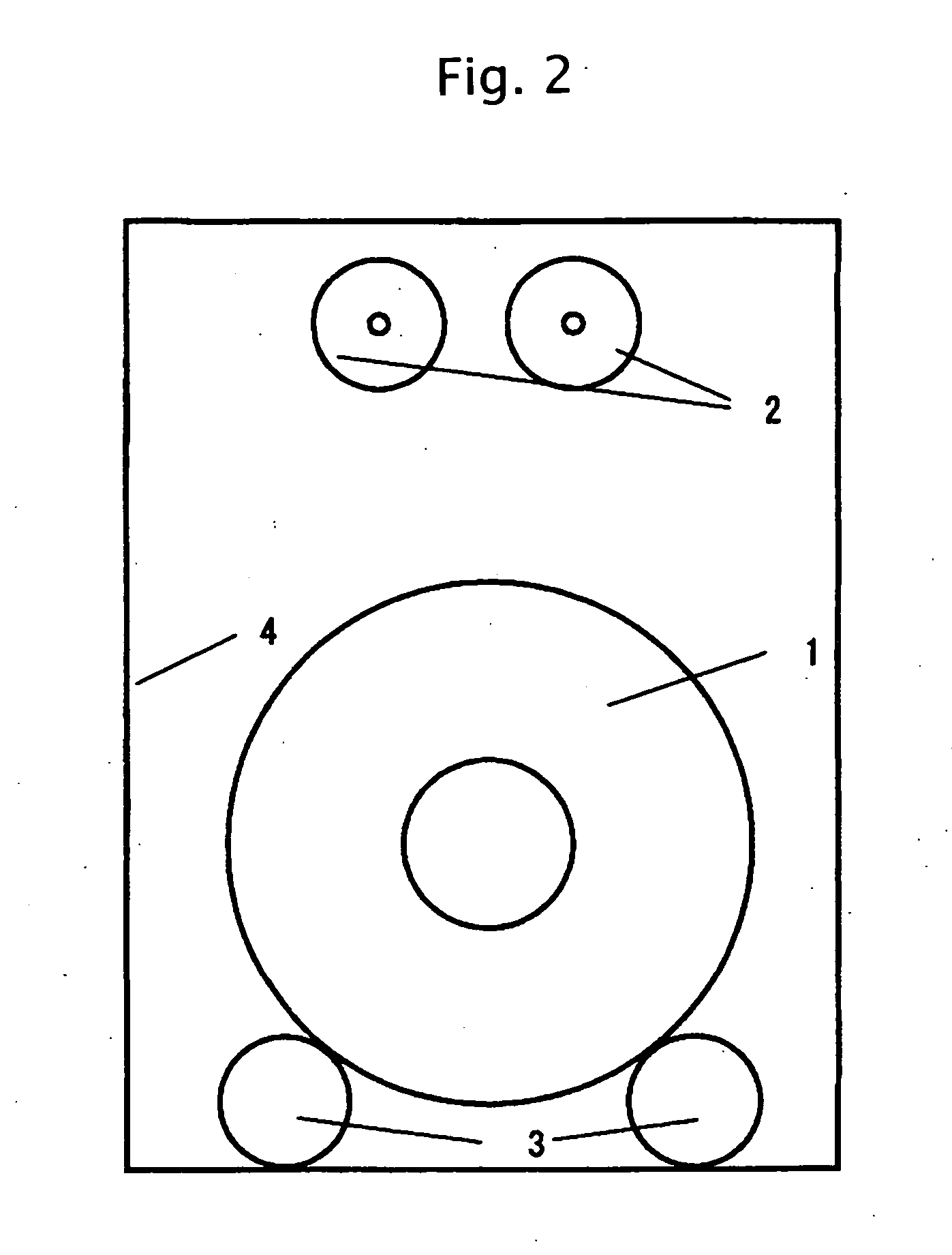

Method of plating on a glass base plate, a disk substrate, method for manufacturing the same and a perpendicular magnetic recording medium

InactiveCN1843997AExcellent adhesionMeet the magnetic propertiesMagnetic layer production by platingRecord information storageElectrolysisSilanes

A method of plating on a glass base plate is disclosed. The method allows a plating film to be formed on a base plate composed of a glass material with excellent adhesivity and homogeneity by means of an electroless plating method, even to a thickness of 1 mum or more. Before forming the plating film by electroless plating, a series of surface treatments are conducted on the surface of the base plate composed of a glass material. The surface treatments comprises at least a glass activation treatment, a silane coupling agent treatment, a palladium catalyst treatment, a palladium bonding treatment, ab electroless plating to form a preliminary plating film having a thickness in the range of 0.02 mum to 0.5 mum, and an annealing at a temperature in the range of 200 DEG C. to 350 DEG C.

Owner:FUJI ELECTRIC CO LTD

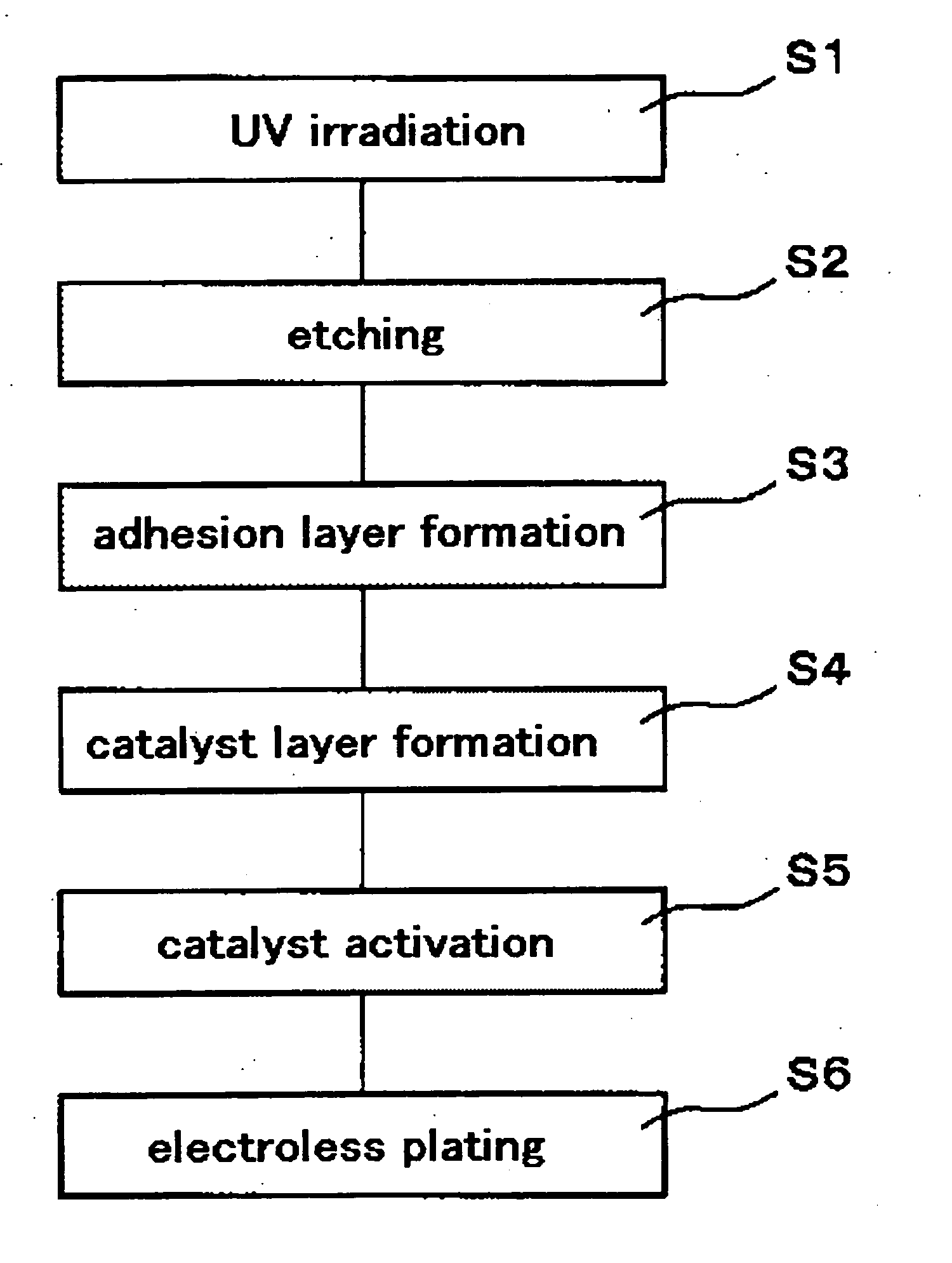

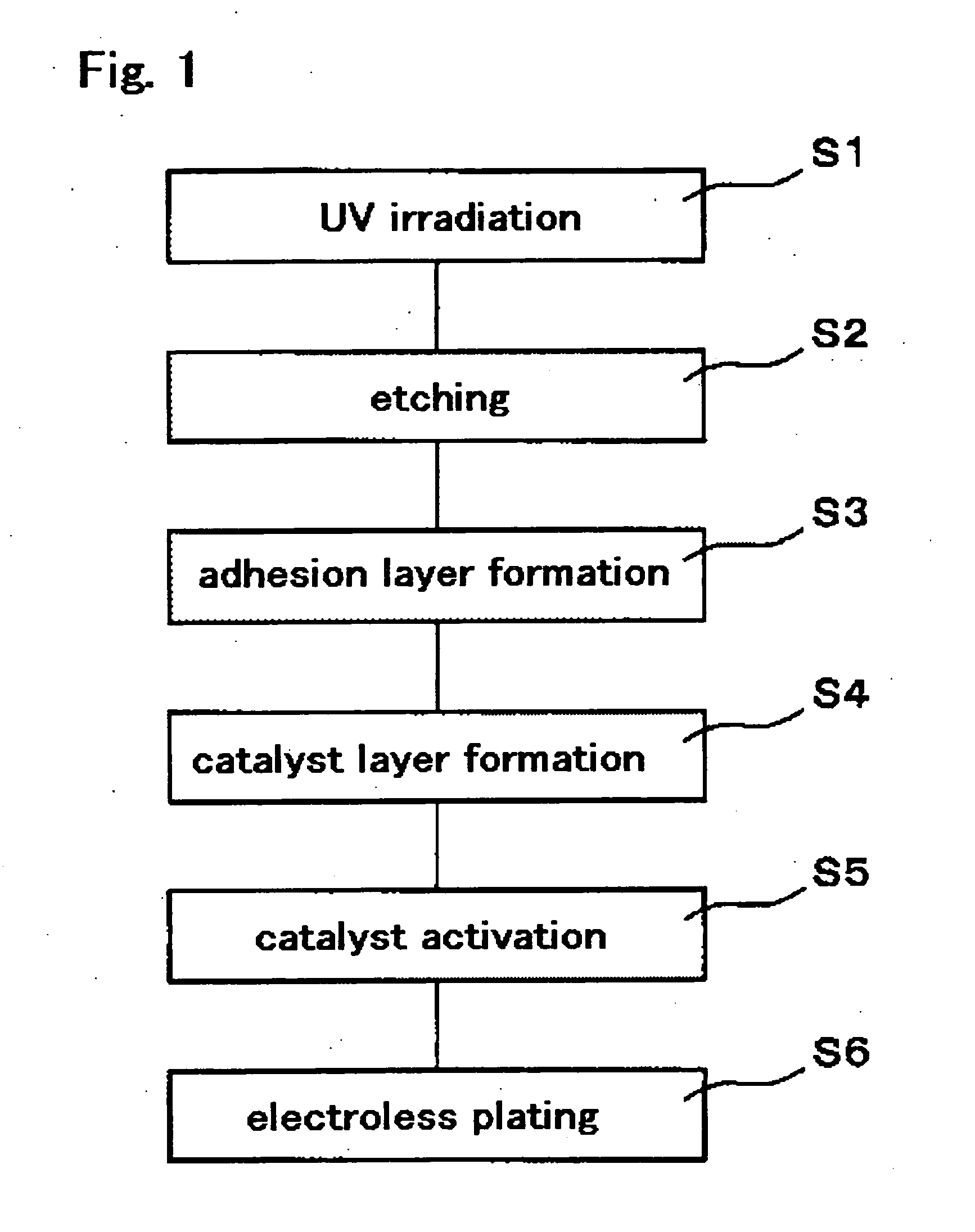

Method of plating on a glass base plate and a method of manufacturing a perpendicular magnetic recording medium

InactiveUS20060228493A1Avoid breakingImprove adhesionRadiation applicationsMagnetic layer production by platingAlkaline earth metalUltraviolet lights

A plating method on a glass base plate is disclosed. The method allows an electroless plating film to be formed on a base plate composed of a glass material with excellent adhesivity through a process that removes alkaline and alkaline earth metals on the surface of the base plate. Also disclosed is a method of manufacturing a magnetic recording medium employing the method of plating on a glass base plate. Before forming a plating film in a step of electroless plating, a series of surface treatments are conducted on the surface of the base plate composed of a glass material. The series of surface treatments comprises at least an ultraviolet light irradiation, an etching treatment, an adhesion layer formation treatment, a catalyst layer formation treatment, and a catalyst activation treatment.

Owner:FUJI ELECTRIC CO LTD

Nanoholes and production thereof, stamper and production thereof, magnetic recording media and production thereof, and, magnetic recording apparatus and method

InactiveUS20080145522A1Easy and efficient to manufactureHigh densityMaterial nanotechnologyMagnetic layer production by platingPorous layerEngineering

A nanohole structure includes a metallic matrix and nanoholes arrayed regularly in the metallic matrix, in which the nanoholes are spaced in rows at specific intervals to constitute rows of nanoholes. The rows of nanoholes are preferably arranged concentrically or helically. The nanoholes in adjacent rows of nanoholes are preferably arranged in a radial direction. The width of each row of nanoholes preferably varies at specific intervals in its longitudinal direction. A magnetic recording medium includes a substrate, and a porous layer on or above the substrate. The porous layer contains nanoholes each extending in a direction substantially perpendicular to a substrate plane, containing at least one magnetic material therein, and is the above-mentioned nanohole structure.

Owner:FUJITSU LTD +1

Method of fabricating an alumina nanohole array, and method of manufacturing a magnetic recording medium

InactiveCN101451259AVickers hardness low valueAnodisationMagnetic layer production by platingThin membraneOptoelectronics

The invention provides a method of fabricating the alumina nanohole formed by aluminum thin-film with improved surface smoothness, preferably a method of fabricating the alumina nanohole array capable of reducing pressure used for pit formation for forming alumina nanohole and a method of fabricating magnetic recording medium by using the alumina nanohole. The alumina nanohole array is fabricated by forming an aluminum thin-film on a substrate at a substrate temperature of -80 DEG C. or below, or using the mold to cause the aluminum thin-film to have structure before anodic oxidation and the mold and the aluminum thin-film are held at a temperature of 150 to 200 DEG.

Owner:FUJI ELECTRIC DEVICE TECH CO

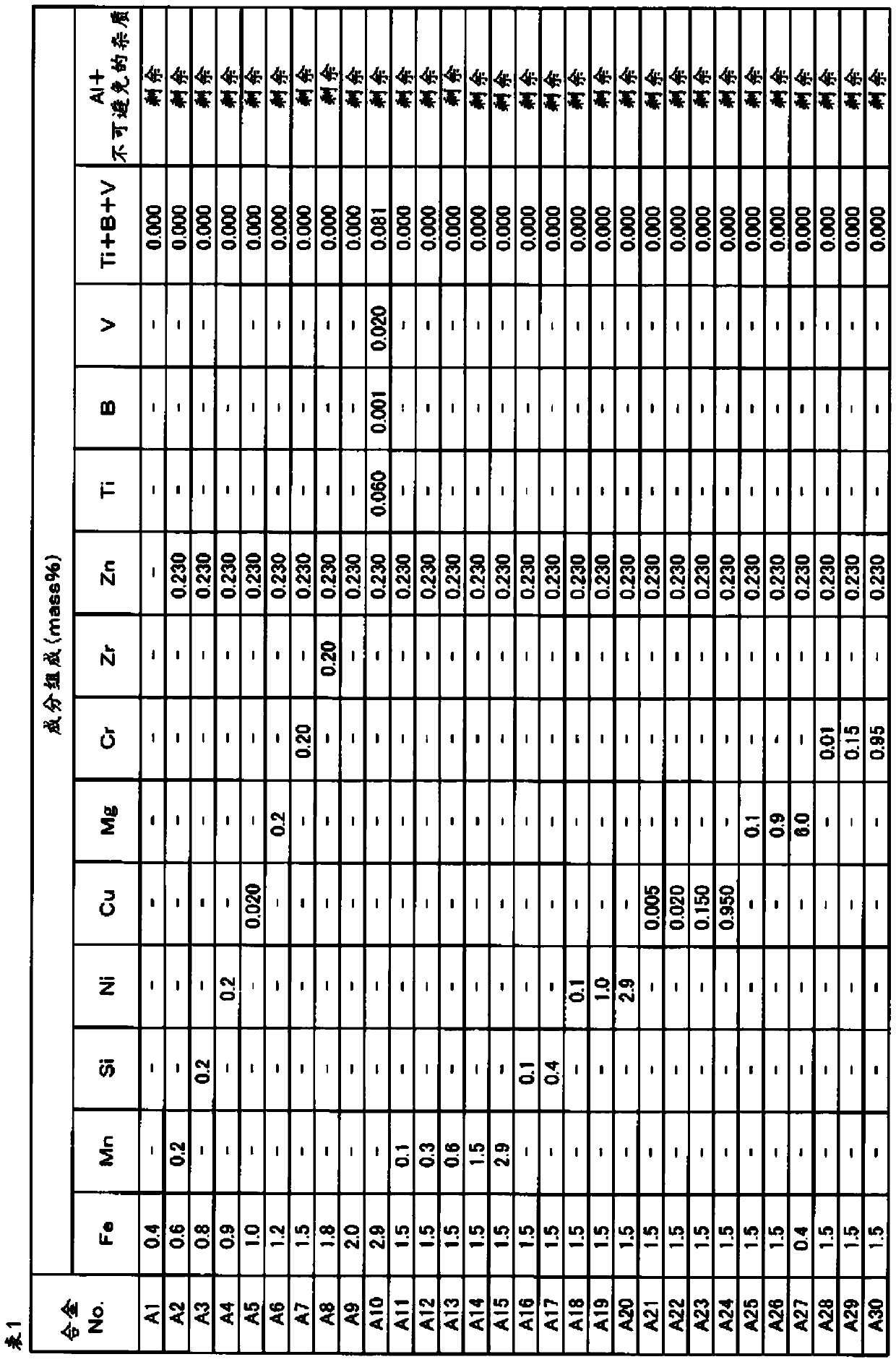

Aluminum alloy substrate for magnetic disks, method for producing same, and magnetic disk using aluminum alloy substrate for magnetic disks

ActiveCN110337692AHigh strengthExcellent chatter characteristicsBase layers for recording layersMagnetic layer production by platingAlloy substrateImpurity

Owner:FURUKAWA SKY ALUMINUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com