Method of plating on a glass base plate, a disk substrate, method for manufacturing the same and a perpendicular magnetic recording medium

A technology of perpendicular magnetic recording and glass substrate, which is applied in magnetic recording, data recording, recording information storage, etc., and can solve problems such as unsatisfactory adhesion, uniformity and smoothness, cost increase, and unoptimization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

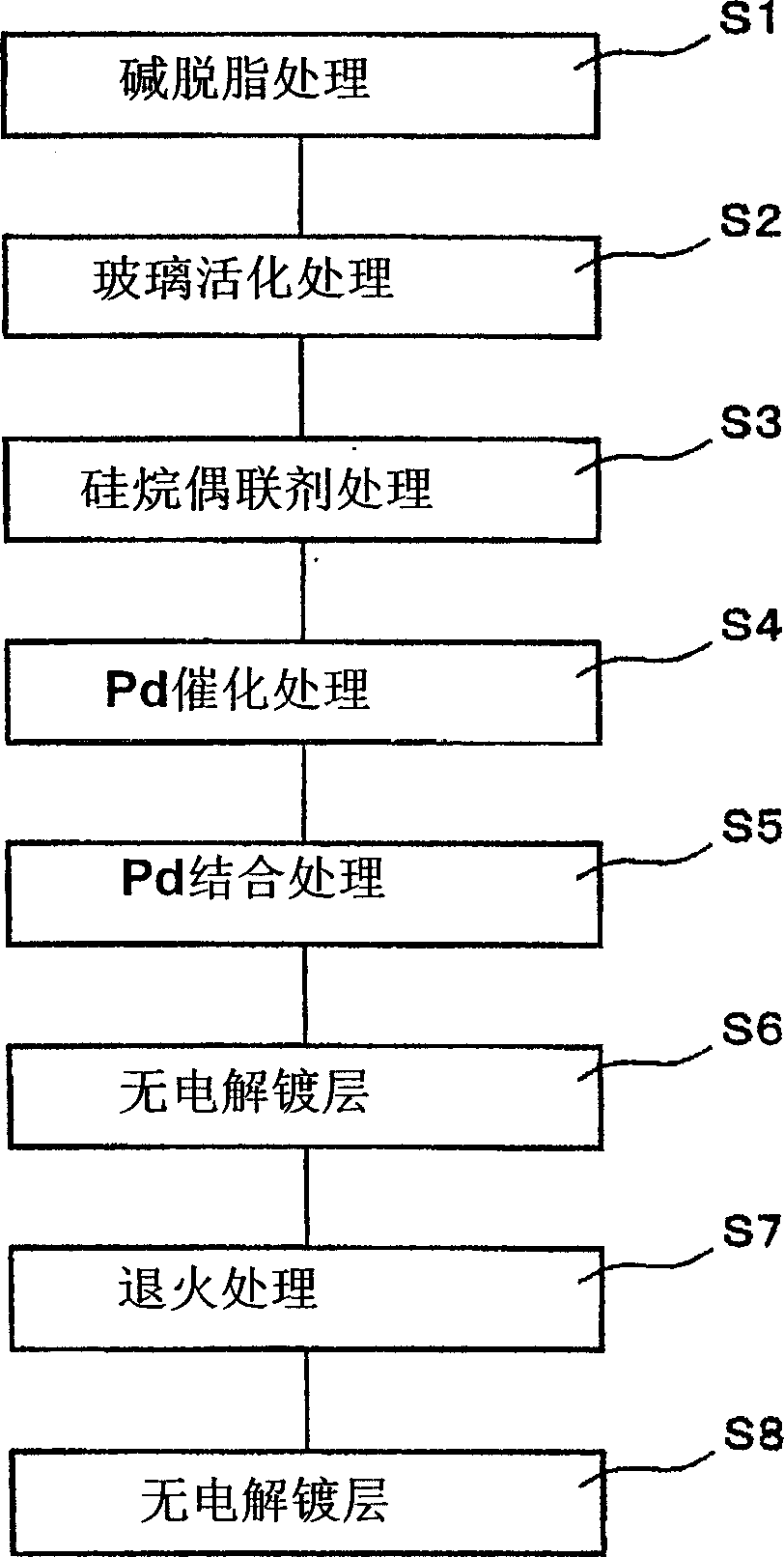

[0153] Using a tempered glass substrate (manufactured by HOVA: trade name N5) as a glass substrate 1, the following steps (1) to (8) were sequentially performed.

[0154] (1) As step S1, immerse for 3 minutes in an aqueous solution of an alkaline detergent having a temperature of 50° C. and a concentration of 1.5% by mass. In addition, it was immersed in an aqueous KOH solution having a temperature of 50° C. and a concentration of 7.5% by mass for 3 minutes to perform an alkali degreasing treatment.

[0155] (2) As step S2, at a temperature of 20°C and a concentration of 1.0% by mass of H 2 SO 4Immerse in the aqueous solution for 3 minutes. Next, glass activation treatment was performed by immersing for 3 minutes in an HF aqueous solution having a temperature of 20° C. and a concentration of 1.0% by mass.

[0156] (3) As step S3, immerse in an aqueous solution of 3-aminopropyltriethoxysilane (compound of formula (III)) at a temperature of 20° C. and a concentration of 1.0% ...

Embodiment 2

[0166] It carried out similarly to Example 1 except having changed the film thickness of the buffer layer 4 to 0.2 micrometer, and changed the annealing temperature to 200 degreeC.

Embodiment 3

[0168] It carried out similarly to Example 1 except having changed the film thickness of the buffer layer 4 to 0.2 micrometer, and changed the annealing temperature to 280 degreeC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com