Patents

Literature

78results about How to "Meet uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

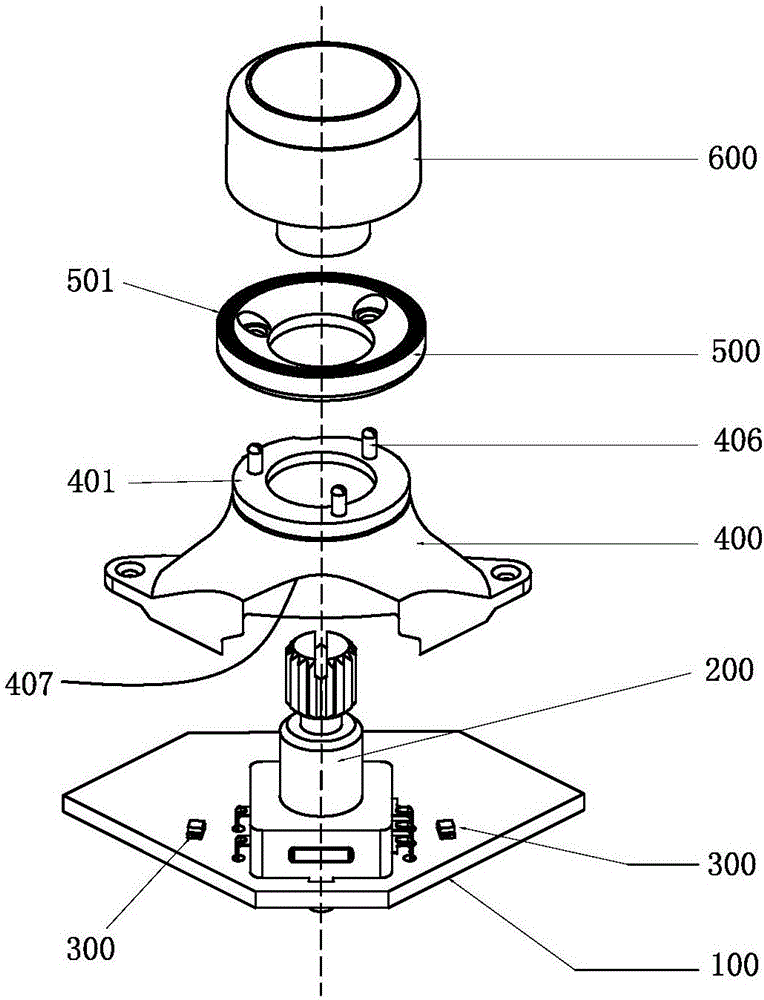

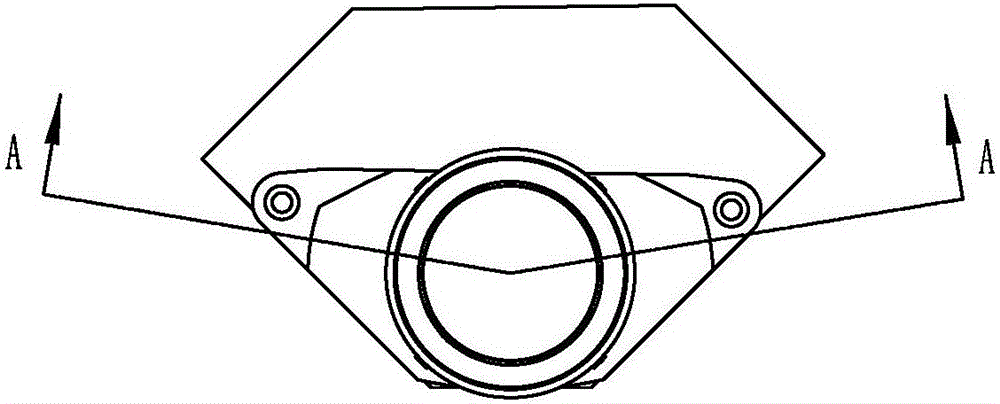

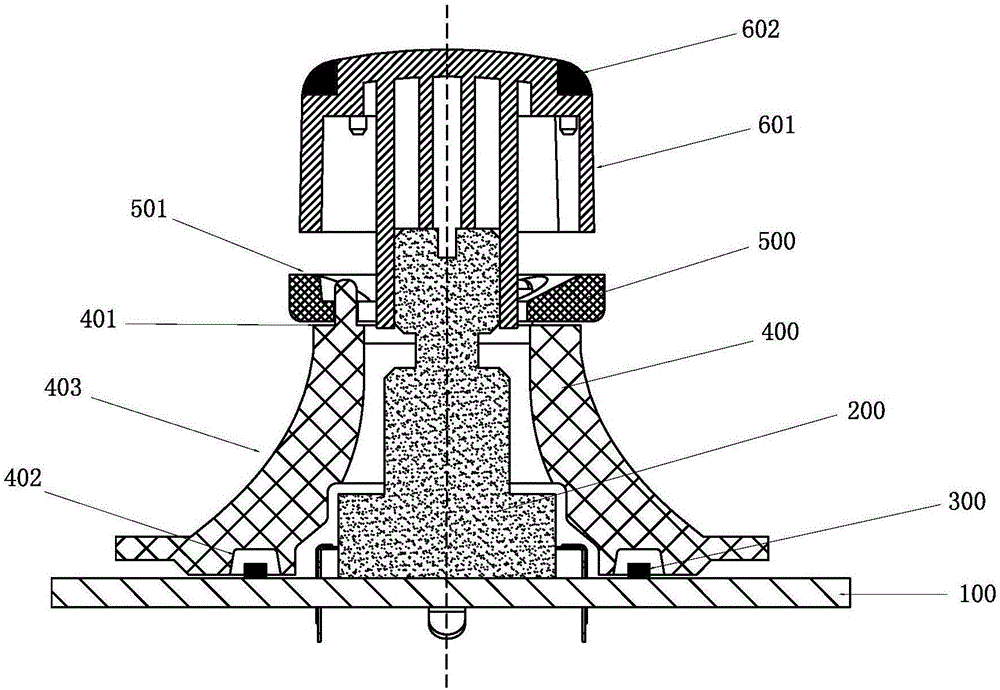

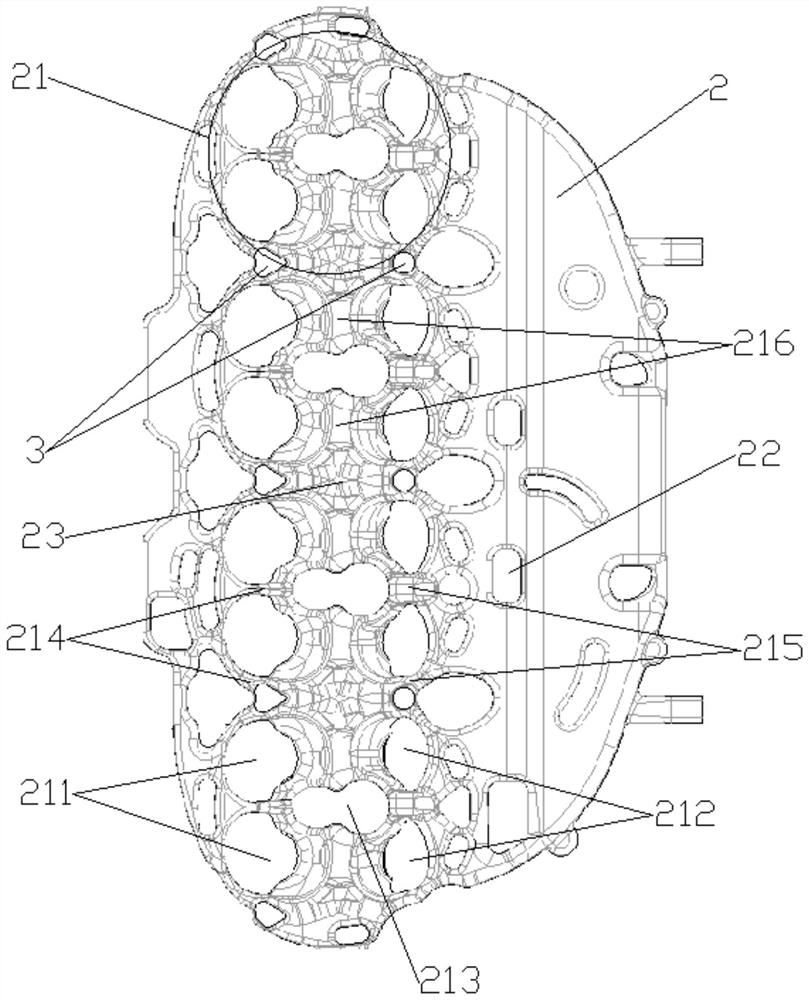

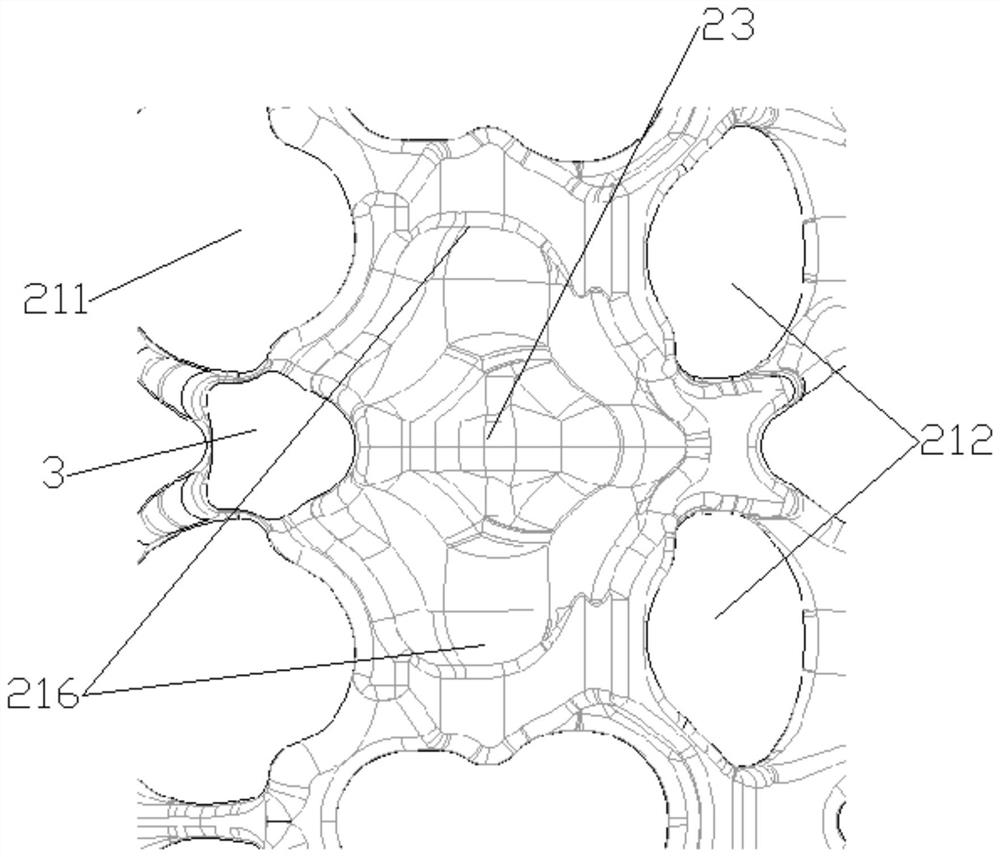

Knob light guide ring structure and light control method thereof

ActiveCN106764683ASatisfy light transmittanceMeet uniformityMechanical apparatusLight guides detailsLight guideOptoelectronics

The invention relates to a knob light guide ring structure and a light control method thereof. With a specific structure of upper and lower light guide parts, light is firstly directed to go into the lower guide part from a firstlight-entering surface, and then led out from a first light-exiting surface after undergoing multiple refraction and diffuse reflection by a structure of a first outer refraction and reflection surface and a first inner refraction and reflection surface; the light goes into the upper light guide part from a second light-entering surface, and then led out from a second light-exiting surface after undergoing multiple refraction and diffuse reflection by a structure of a second outer refraction and reflection surface and a second inner refraction and reflection surface in the upper light guide part; thus, a uniform final display effect may be achieved. The knob light guide ring structure in the invention allows uniform light guide by the outer ring gap of the knob based on a truncated cone-shapedknob light guide ring structure design with two vertical LED light sources in compact and limited structure space; thus, the number of the LED light sources may be reduced on the basis of satisfying the transmission of light and uniformity of the light guide ring, thereby saving the product costs.

Owner:FORYOU GENERAL ELECTRONICS

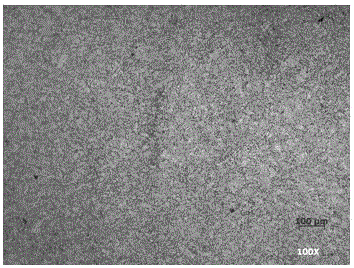

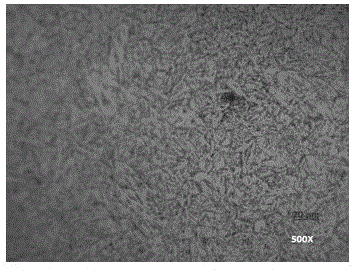

Super-thick high-strength lamellar-tearing-resistant Q500D-Z35 hydroelectric generating set steel plate and manufacturing method thereof

The invention relates to a super-thick high-strength lamellar-tearing-resistant Q500D-Z35 steel plate and meanwhile further relates to a manufacturing method of the steel plate. The steel plate meets the quality requirements of steel plates for manufacturing a large or a super-large hydropower station generator set. An appropriate amount of carbon and alloy elements are compounded; the problems of the quenching degree and hardenability of a steel plate are solved; reasonable quenching equipment and a reasonable hardening and tempering technological system are combined; the microstructure of the steel plate can achieve reasonable compounding of granular bainite, polygonal ferrite and tempered sorbite of proper morphology; and it is guaranteed that base metal of the steel plate and performance achieved after welding stress-elimination treatment can meet the using requirements. Through appropriate ingot type selection and the strict and reasonable steel-making technology, steel ingot casting technology, steel ingot forging technology and steel plate rolling technology, it is guaranteed that the required thickness and piece weight requirements for the steel plate are met; and under the conditions of high thickness and high piece weight, the excellent macrostructure is achieved, and thus the core quality and lamellar-tearing resistance of the steel plate and uniformity of the whole plate are guaranteed.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

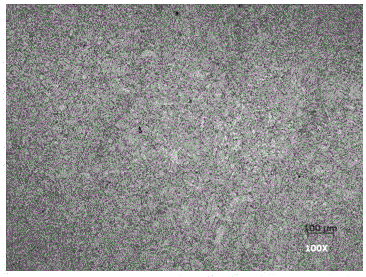

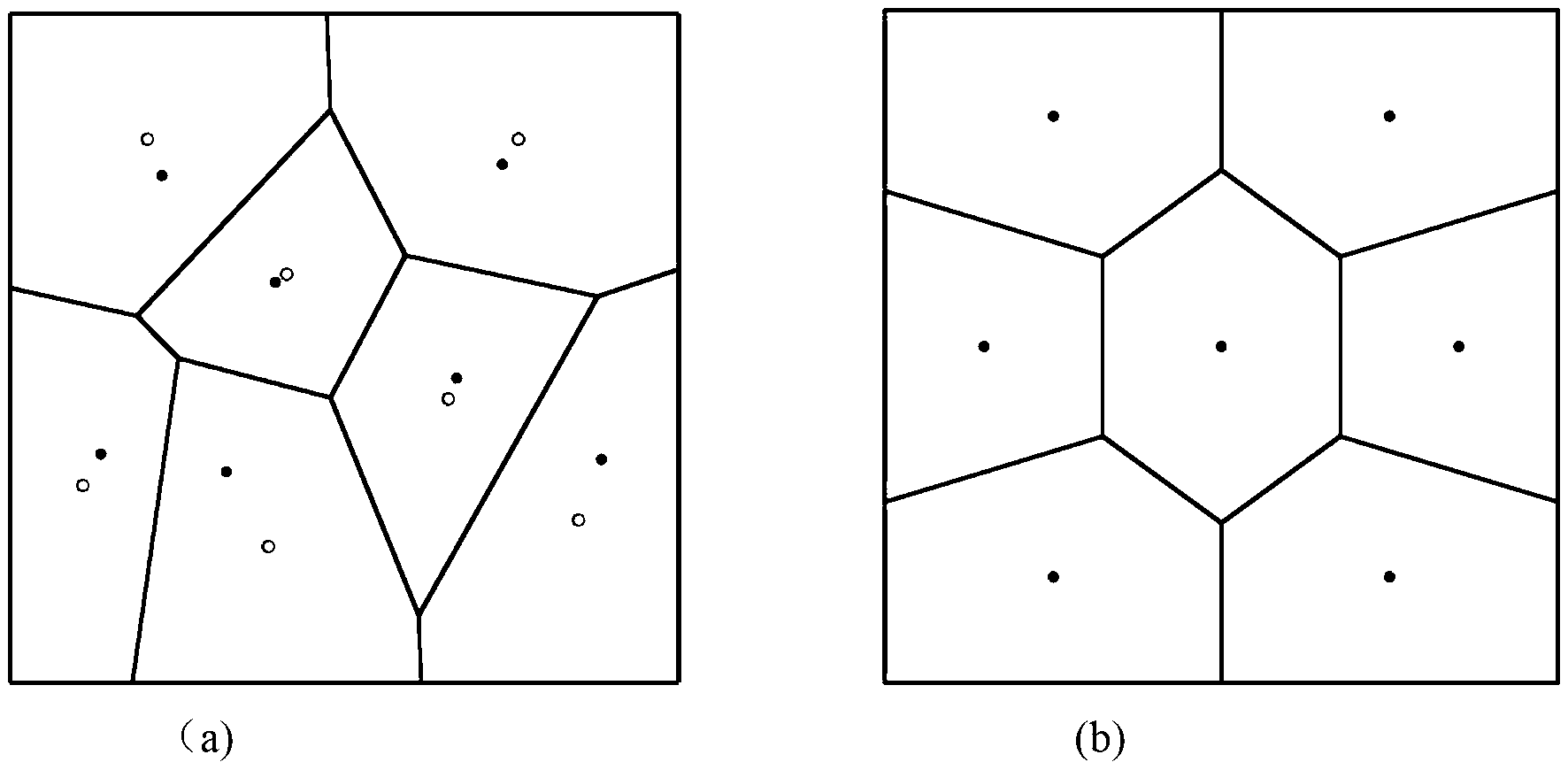

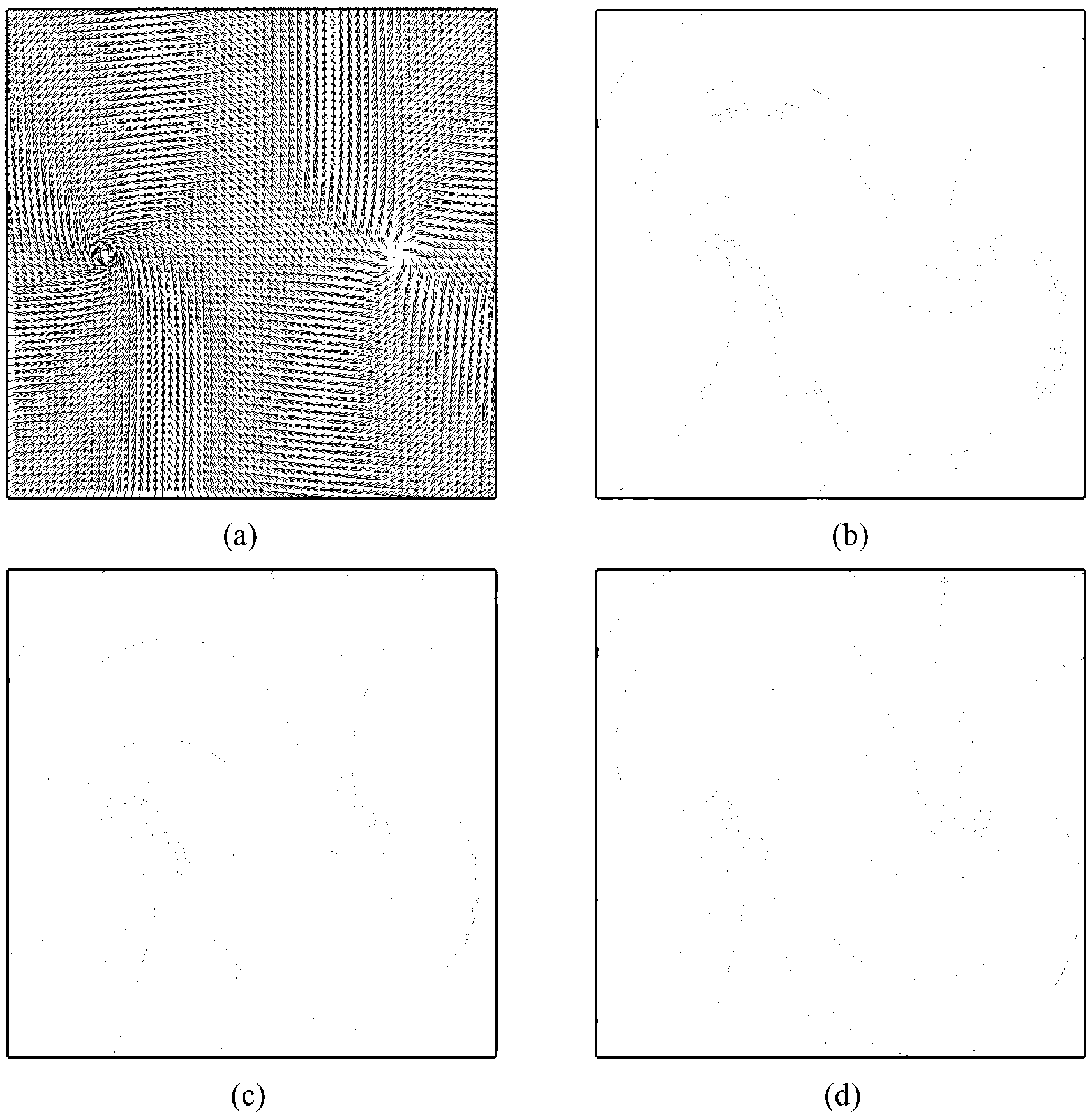

Flow field visualization method based on flow line gravity center Voronoi diagram

ActiveCN103226804AOptimize locationMeet the continuityImage data processing detailsGravity centerComputer science

The invention discloses a flow field visualization method based on a flow line gravity center Voronoi diagram. According to the method, a gravity center Voronoi diagram concept of a point is expanded to a flow line, and the effective flow field visualization method based on the flow line is provided on the basis of the flow line gravity center Voronoi diagram. The method can realize flow line layout of a better effect, compromise the coverage, uniformity and continuity of the flow line, and accomplish the flow line layout iteratively. The method comprises the steps as follows: 1) randomly generating a seed point set of the flow line, 2) tracking with a numerical integration method from seed points to obtain a long flow line, 3) calculating a Voronoi region of the long flow line, and 4) determining and minimizing an objective function of the long flow line, optimizing the objective function to obtain a new seed point set, and returning to Step 2) till the flow line is uniformly distributed in a flow field.

Owner:SHANDONG UNIV

Method for preparing polymer electrothermal film

ActiveCN102932974ASolve the shortcomings of not being resistant to high temperature and not being flame retardantSolve uneven heating temperatureChemical industryOhmic-resistance heatingPolymer scienceHeating temperature

The invention discloses a method for preparing a polymer electrothermal film. The method comprises the following steps: according to the weight percentage of raw materials, weighing 10 to 36 percent of colloidal graphite micro powder, 8 to 33 percent of conductive carbon black micro powder, 0.1 to 15 percent of nano carbon powder, 0.1 to 18 percent of zinc oxide powder, 0.1 to 13 percent of silver powder and 0.1 to 13 percent of magnesium hydroxide powder to prepare conductive composite filling powder; then preparing conductive composite filling glue by utilizing the conductive composite filling powder; preparing a heating thin film and simultaneously preparing insulating composite filling glue; preparing an insulating film by utilizing the insulating composite filling glue; and finally, preparing the polymer electrothermal film. The invention solves the problems of nonuniform heating temperature and high heating efficiency of a conventional electrothermal film. The invention also overcomes the defects of power attenuation, short working service life and the like of the conventional electrothermal film in the using process.

Owner:苏州威泰克斯新材料科技有限公司

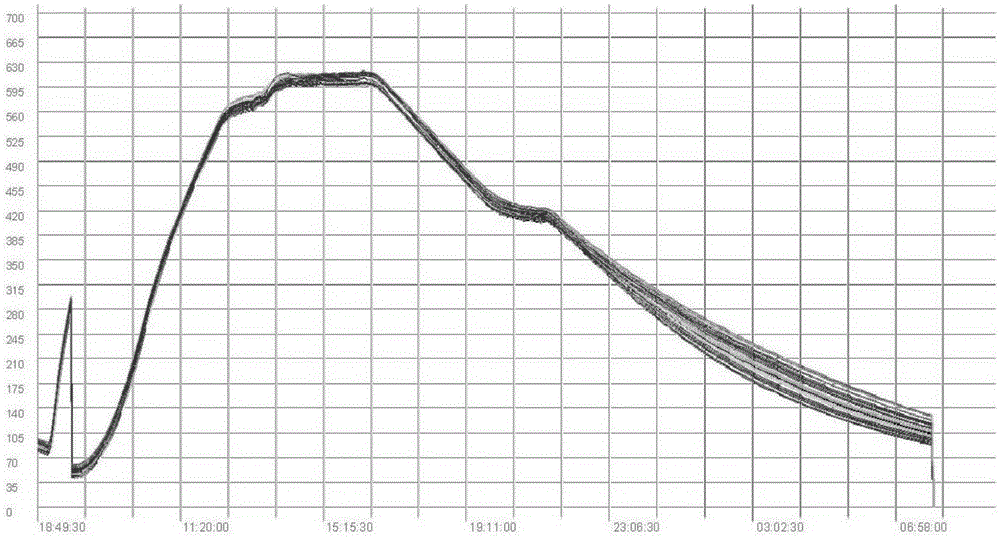

Heat treatment method after local welding of quenched and tempered material super-large container

ActiveCN105200224AAvoid the problem of heat treatment temperature overheatingImprove temperature uniformityFurnace typesHeat treatment process controlTemperature controlTemperature difference

The invention discloses a heat treatment method after local welding of a quenched and tempered material super-large container. According to the method, a temperature-controlled thermocouple is arranged on a heating sheet and is placed at a point with the highest temperature of the heating sheet, the temperature of a steel plate can reach a holding temperature required by a norm by controlling the temperature of the heating sheet and using the characteristic that a certain temperature difference exists between the temperatures of the heating sheet and the steel plate, and the temperature of the steel plate can be effectively prevented from exceeding a required upper limit value; and by performing zone control on the heating sheet, each sheet or each group of heating sheets is connected to a temperature-controlled passage or temperature-controlled device, and according to the temperature of a temperature measuring point of the steel plate, each sheet or each group of the heating sheets is subjected to temperature adjustment separately, so that the temperature uniformity of a uniform temperature zone is effectively improved. The method disclosed by the invention ensures that the temperature range of the uniform temperature zone can meet requirements of heat treatment after welding.

Owner:SHANDONG NUCLEAR POWER EQUIP MFG

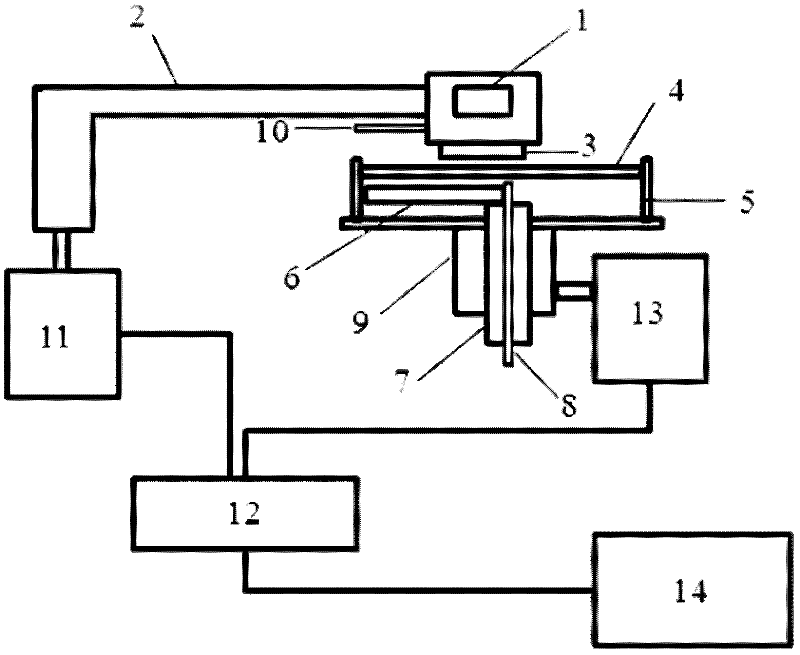

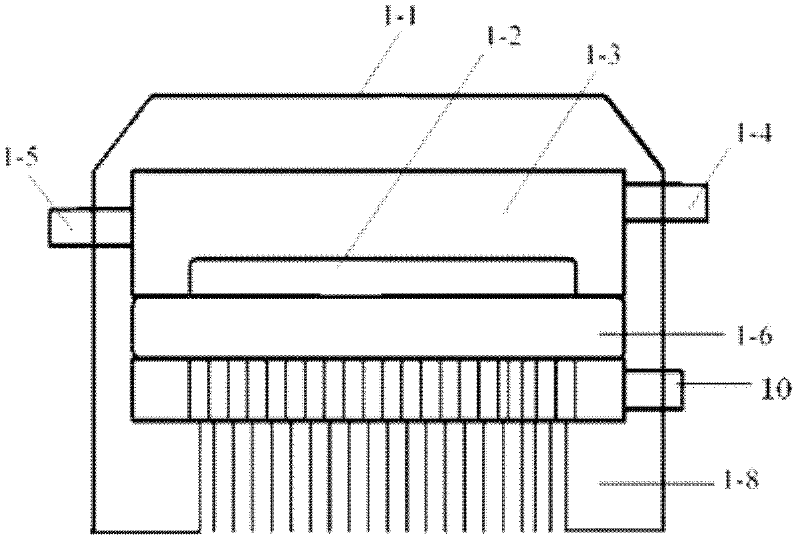

Wafer cleaning device and cleaning method

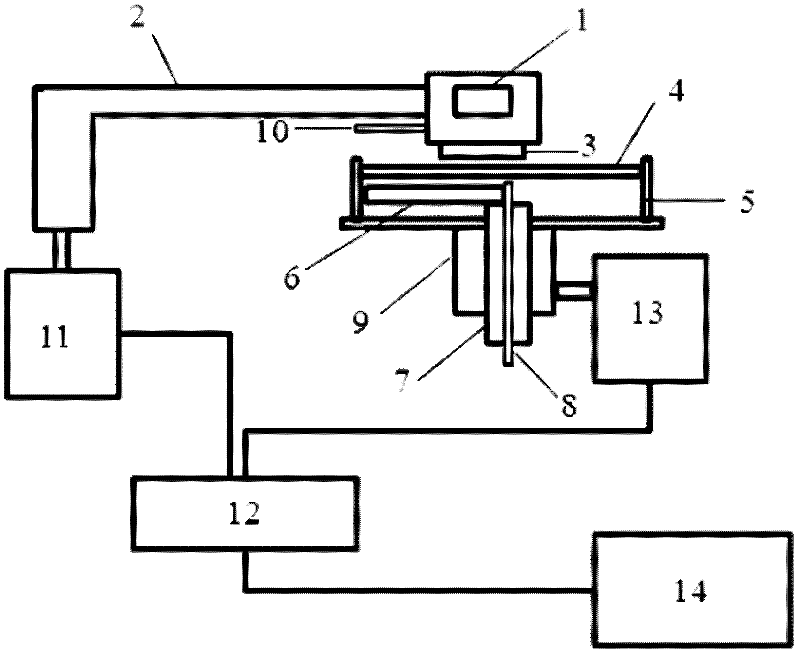

InactiveCN102641869AEasy to cleanMeet uniformitySemiconductor/solid-state device manufacturingMechanical vibrations separationCavitationPhase shifted

The invention discloses a wafer cleaning device and a cleaning method and relates to the cleaning technical field of a semiconductor integrated circuit device. The wafer cleaning device comprises a wafer bearing unit for bearing a wafer, a wafer front surface ultrasonic cleaning nozzle arranged above the wafer bearing unit, a wafer back surface ultrasonic cleaning unit arranged in the wafer bearing unit, a rotary shaft, a hollow pipe, a spraying arm, a spraying arm motor and a wafer rotating motor. According to the invention, a uniform sound field is formed in cleaning fluid of the upper surface and the lower surface of the wafer through phase shift and distortion formed by the synthesis of ultrasonic wave with a first preset frequency, generated by the wafer front surface ultrasonic cleaning nozzle and ultrasonic wave with a second preset frequency, generated by the wafer back surface ultrasonic cleaning unit, so that the wafer is cleaned, the strength uniformity of the ultrasonic wave sound field on the wafer is met, the cleaning effect on the wafer is improved, meanwhile, the damage to the feature size and structure of the wafer caused by severe cavitation generated by the ultrasonic wave is reduced and eliminated.

Owner:BEIJING SEVENSTAR ELECTRONICS CO LTD

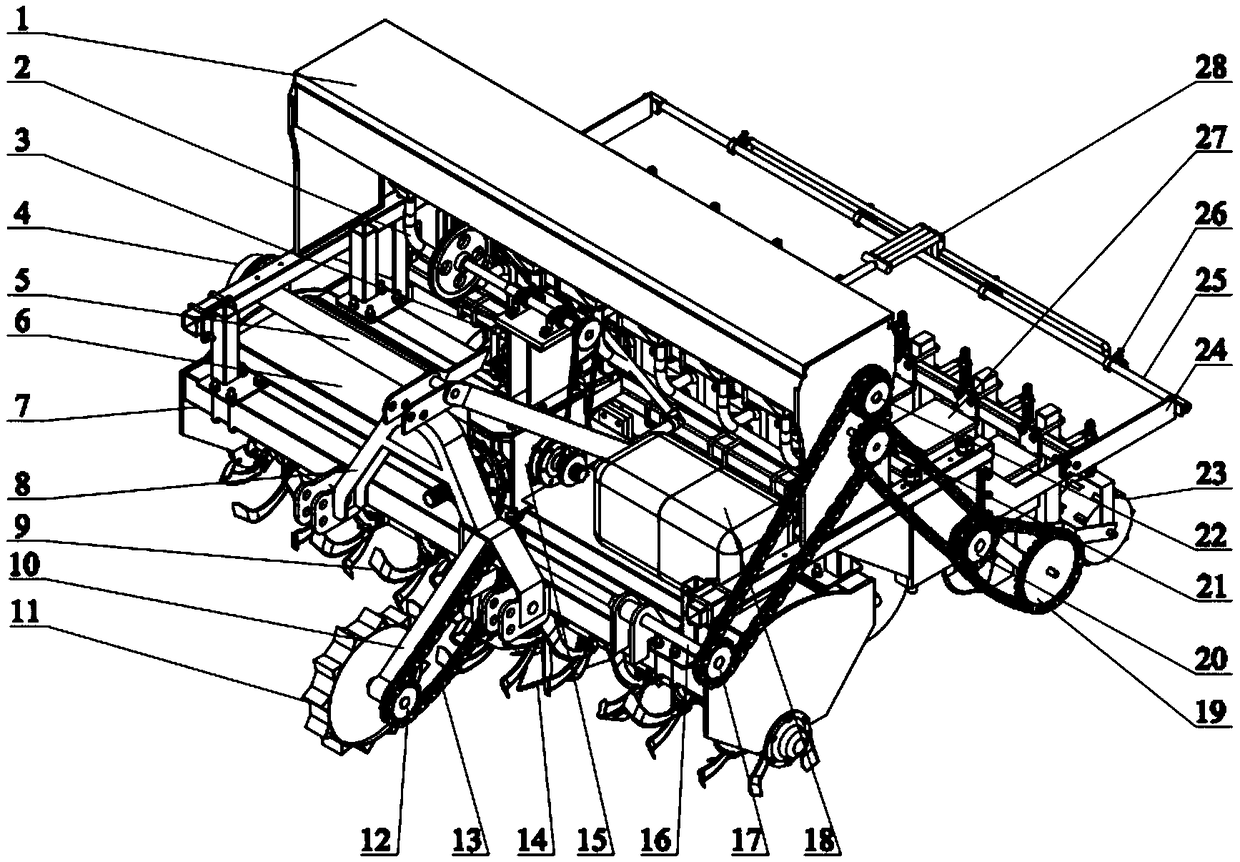

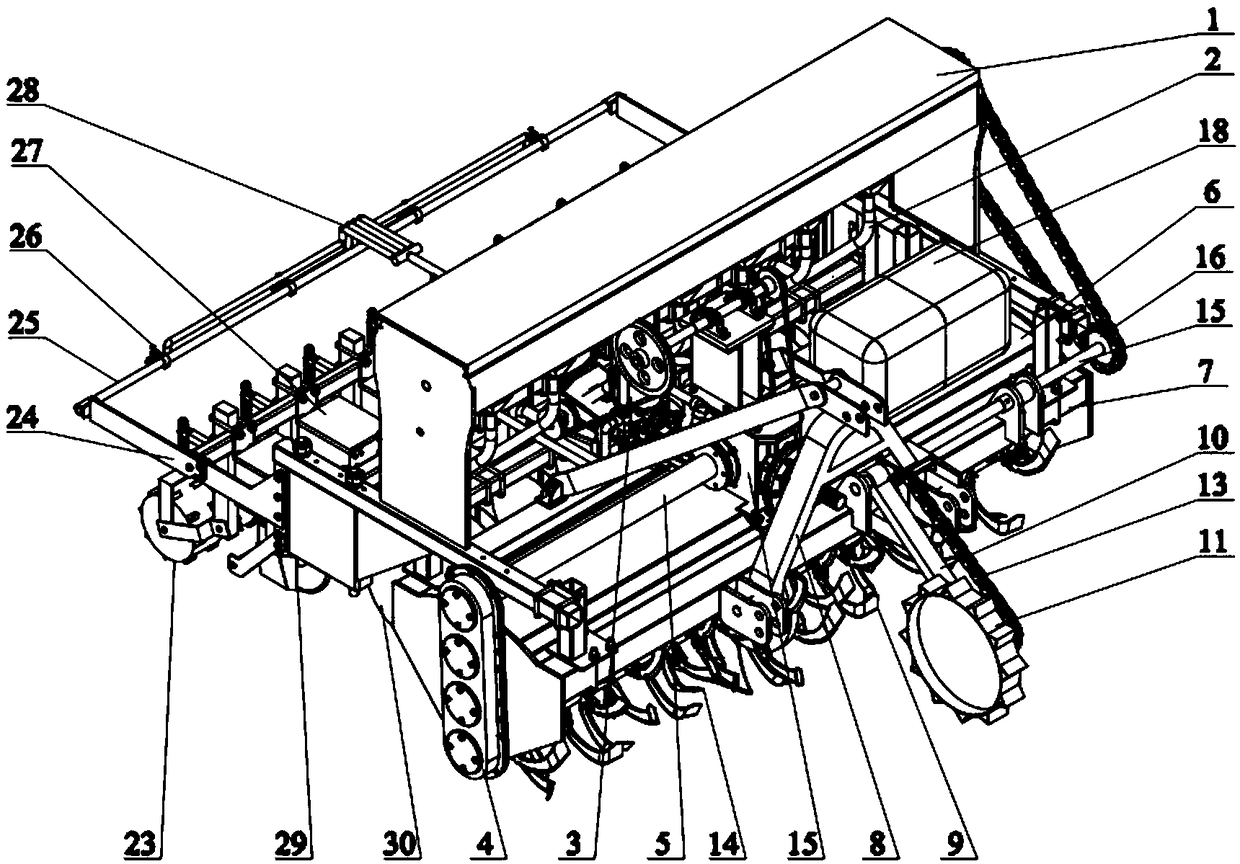

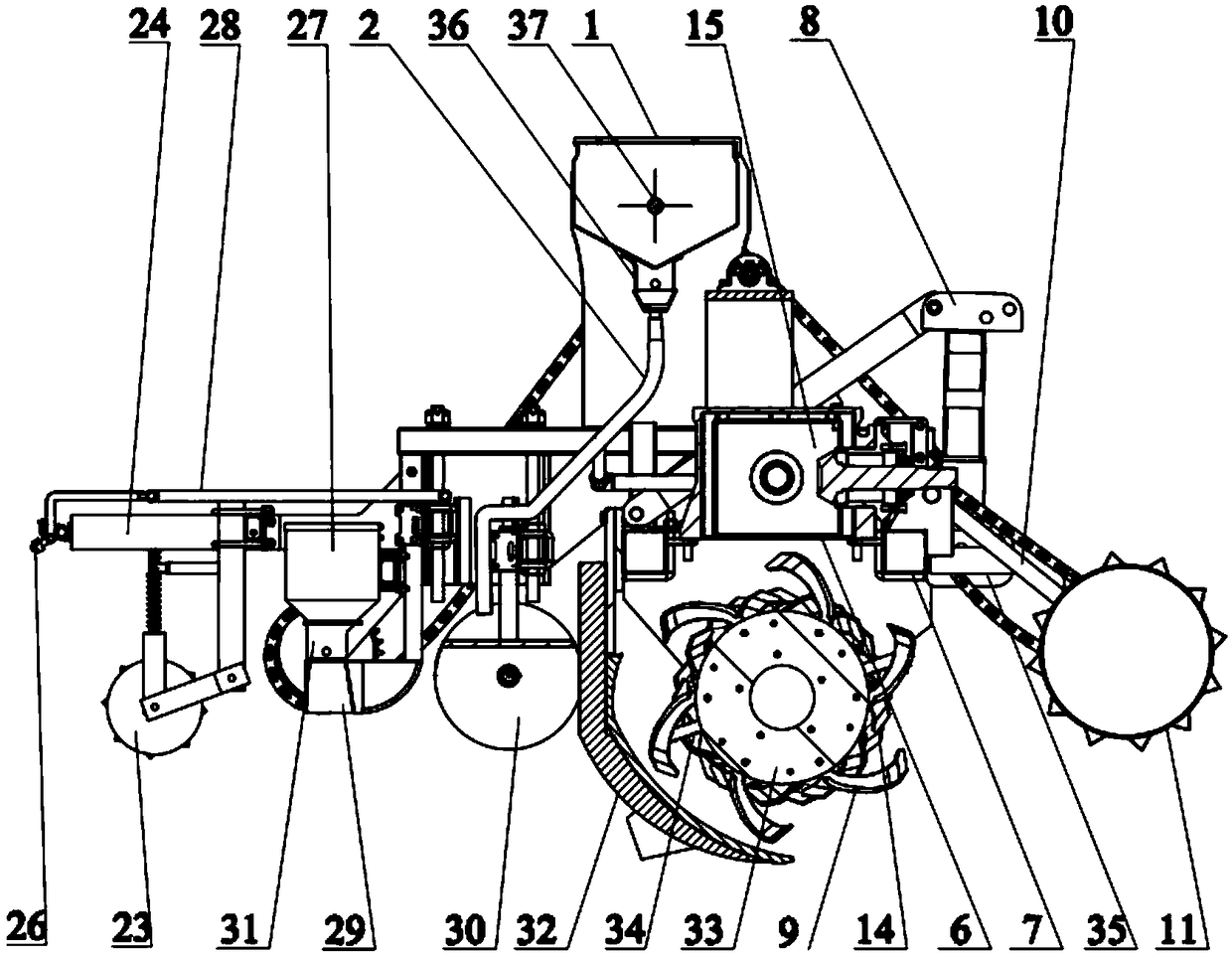

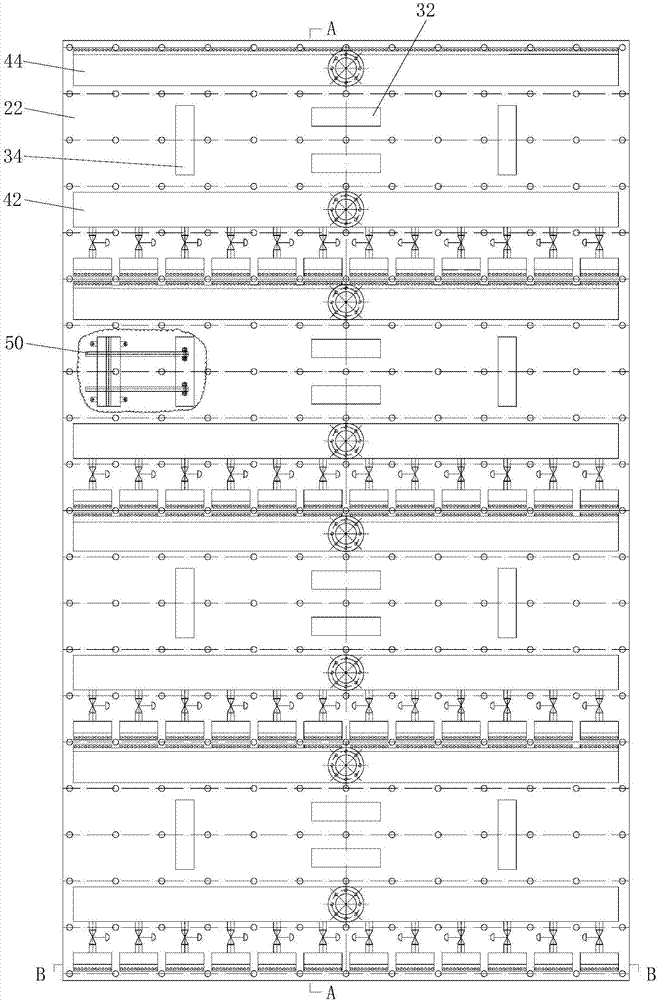

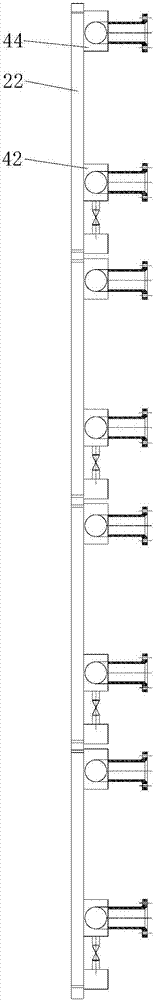

Electric self-propelled numerical-control plot drill seeder

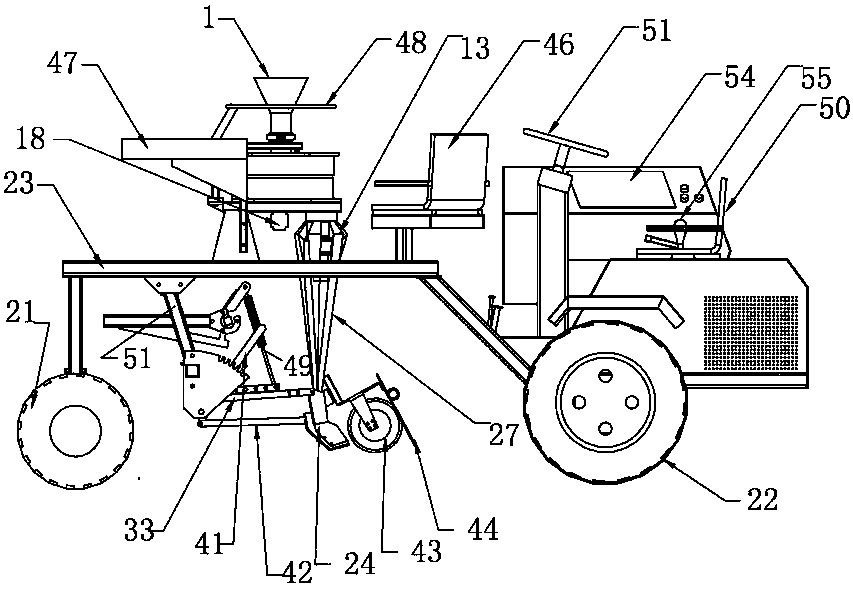

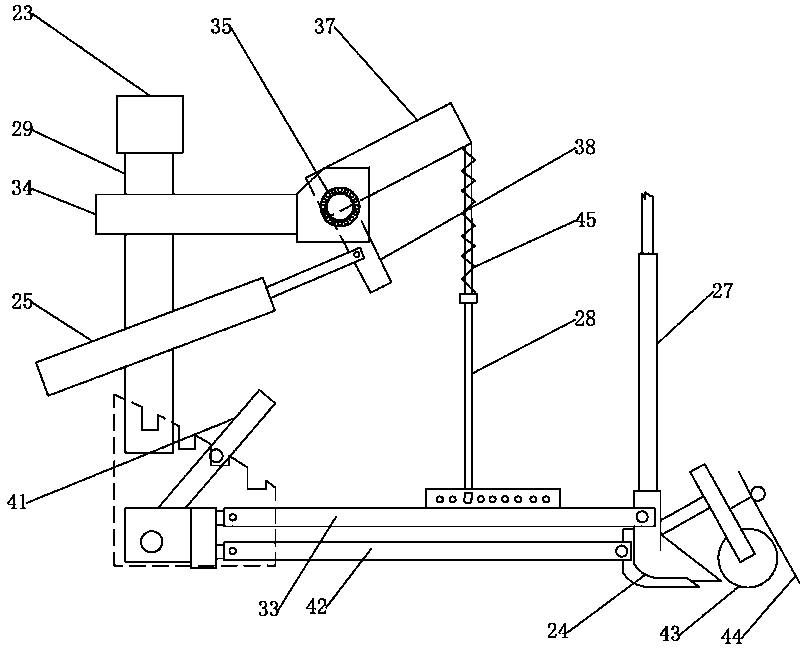

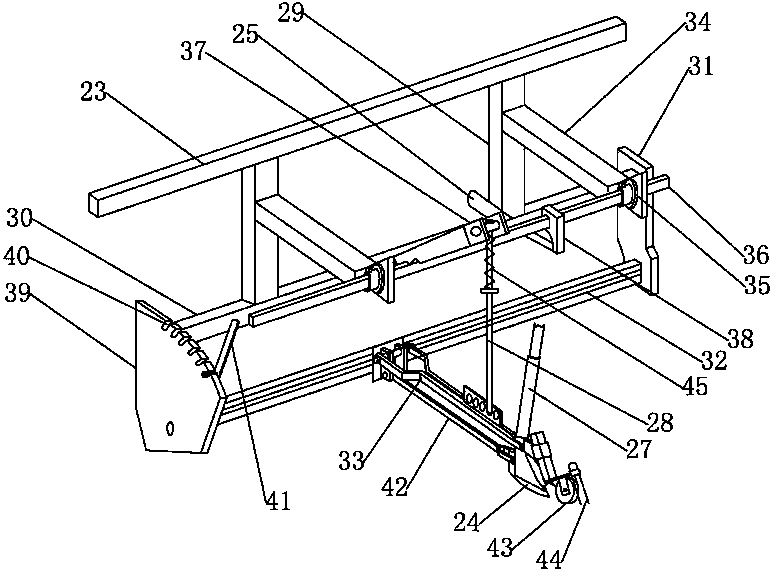

ActiveCN104012222APrecise Control of UniformityEasy to operateSeed depositing seeder partsBroadcast seedersNumerical controlSeeder

The invention relates to an electric self-propelled numerical-control plot drill seeder aiming to solve the technical problems that plot seeders in the prior art are nonuniform in seeding and not precise enough in row length control. The electric self-propelled numerical-control plot drill seeder comprises a walking mechanism, an automatic control device, a seed separation mechanism, a furrowing and seeding mechanism and a lifting mechanism, and the seed separation mechanism, the furrowing and seeding mechanism and the lifting mechanism are correspondingly arranged on the walking mechanism; the seed separation mechanism comprises a seed separation unit and a seed storage unit, the seed separation unit is arranged above the furrowing and seeding mechanism, and the seed storage unit is arranged above the seed separation unit; the walking mechanism is an electric walking mechanism; the seed separation unit comprises a seed separation disc, a seed separation servo motor or a seed separation stepping motor, and the seed separation servo motor or the seed separation stepping motor is arranged below the seed separation disc, and drives the seed separation disc to rotate; the electric self-propelled numerical-control plot drill seeder has the advantages of uniform between-row and in-row seeding, high degree of automation, stepless row length setting (arbitrary row length setting), high row length control accuracy, simple operation, high sowing efficiency and the like.

Owner:李延民

A method of preparing a reactive-sintered silicon carbide ceramic product

A method of preparing a reactive-sintered silicon carbide ceramic product is disclosed. The method includes (1) a step of preparing slurry, namely a step of adding slurry materials into a material mixing slurry preparing device, and fully stirring the slurry materials to prepare grouting slurry; (2) a step of injecting the slurry to a porous resin mold, and molding to obtain a green body; (3) a step of putting the green body into a drying oven to obtain a dried green body; and (4) a step of subjecting the dried green body to siliconizing reactive sintering in a high-temperature vacuum sintering furnace, performing siliconizing under vacuum conditions with the highest temperature being 1350-1750 DEG C, maintaining the temperature for 0.5-5 h, and cooling a product to obtain a finished product. According to the method, the occupied space of devices in the method is low, the production efficiency is high, automatic production can be achieved, the molded product has advantages of high density, good uniformity, and the like, raw materials are nontoxic, the drying efficiency is high, the production cycle is short, a cost is greatly reduced, product uniformity is better, produced products are more diversified, and the method can achieve production of large-size special-shape complex products.

Owner:NINGBO VULCAN TECH CO LTD

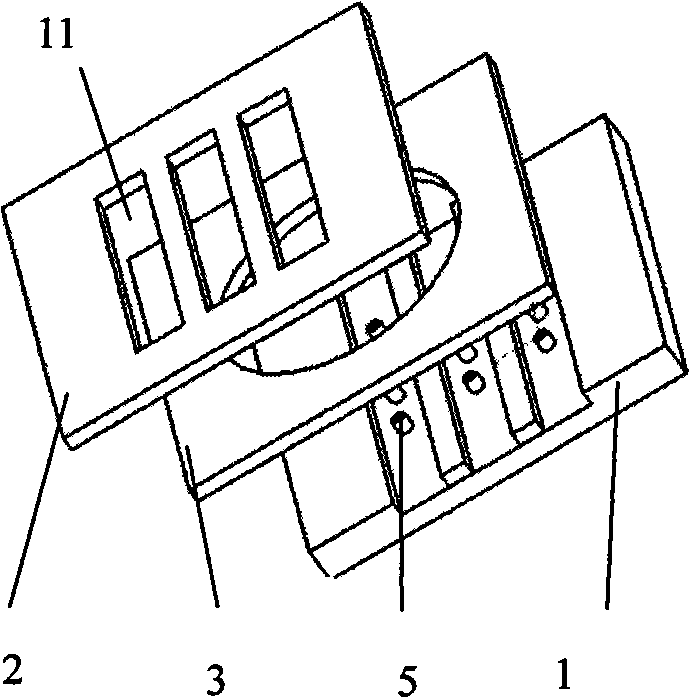

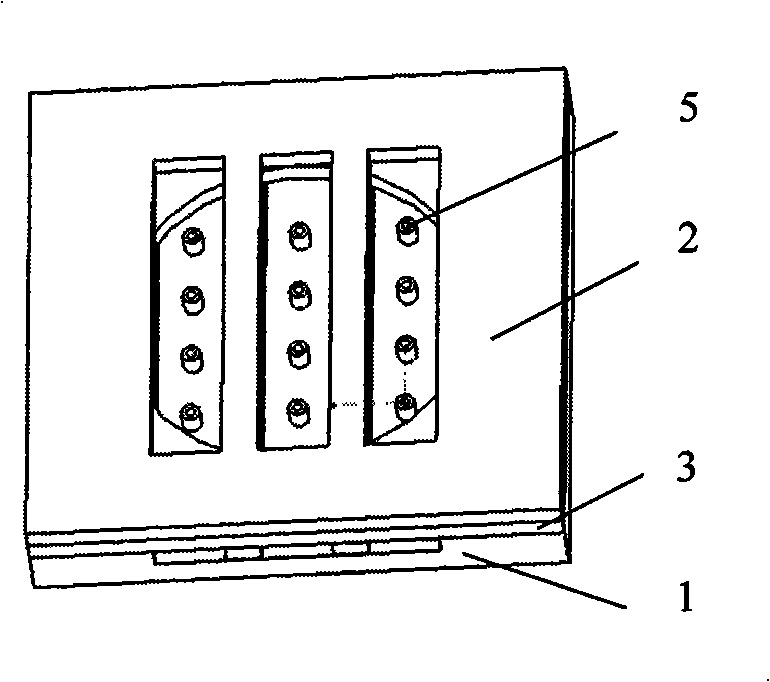

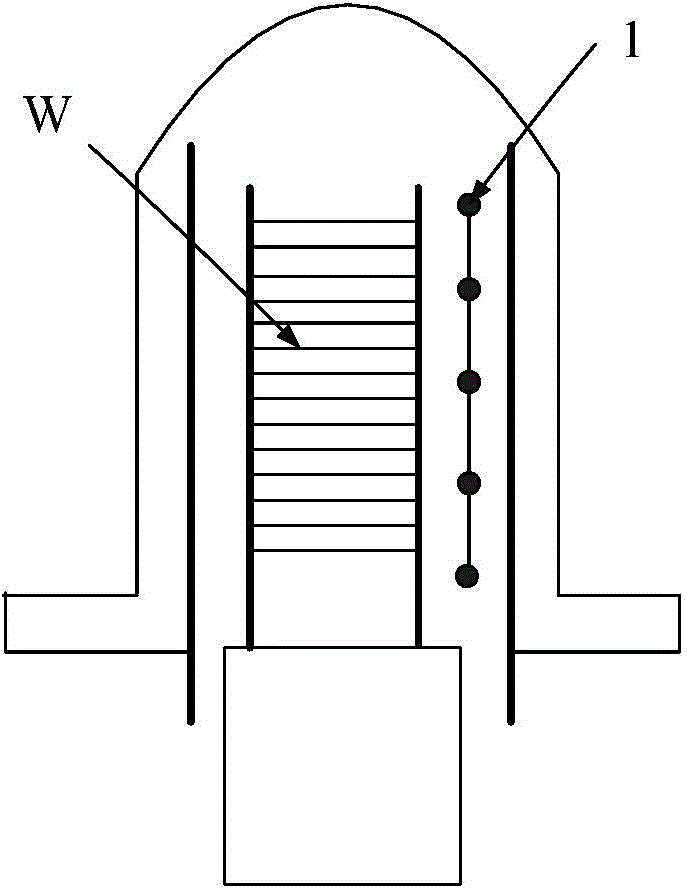

Micro array type colloid propeller

InactiveCN101539127APrevent outflowWon't overflowMachines/enginesReactive propulsion thrust deviceSputteringPropeller

The invention relates to a micro colloid propeller, in particular to a micro array type colloid propeller. The micro array type colloid propeller realizes micromation and microthrust, solves the problems of difficult control of liquid supply and jetting of a nozzle of a jetting pole and the like and comprises the jetting pole, a drawing pole and a glass supporting frame body; a base plate of the jetting pole is etched with a plurality of tubular nozzles which are arranged in row, and is also etched with a plurality of strip etching grooves which are parallel; each strip etching groove is internally provided with a row of tubular nozzles; the bottom of each etching groove and the top part of the tubular nozzle are sputtered with an aluminium layer; one end of each etching groove respectively provided with a terminal communicated with the aluminium layer at the bottom of the groove; the inside of a liquid delivery channel of the tubular nozzle is processed into a porous silicon structure by adopting HF etching technique; the drawing pole is paliform, and strip grid seams thereof face the etching grooves of the jetting pole. The micro array type colloid propeller has the advantages of stable performance, high aligning precision, convenient processing and easy control for liquid supply and jetting and the like and can realize the purpose of controlling jetting of the nozzle by batches.

Owner:ZHONGBEI UNIV

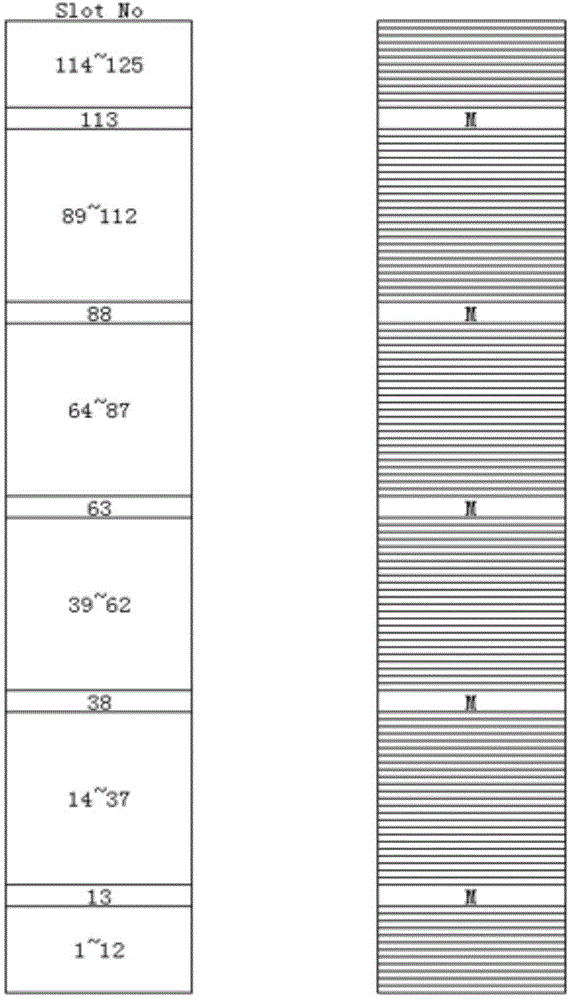

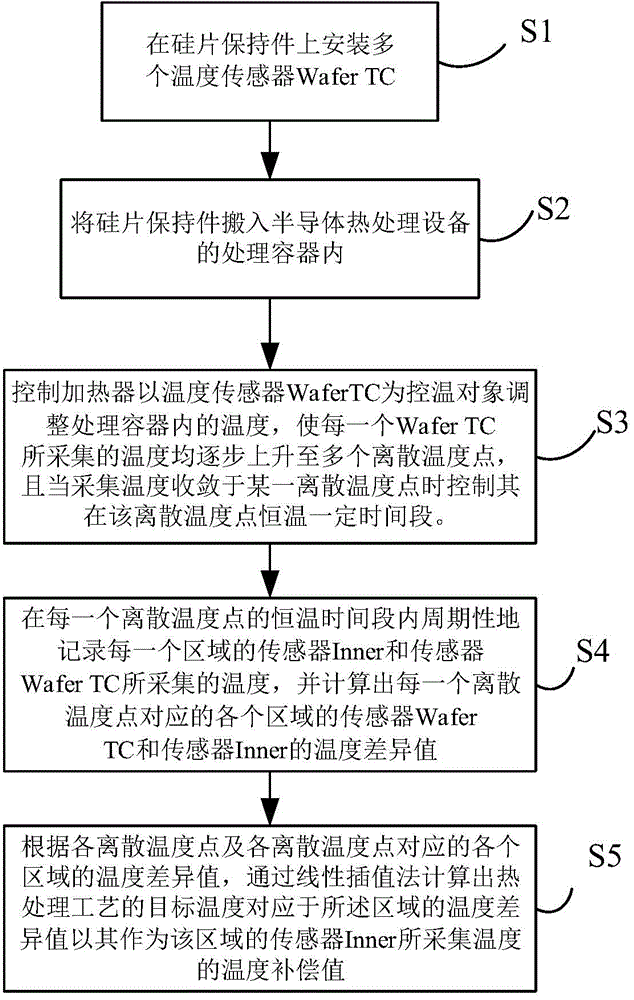

Temperature compensation method and temperature control method and system for heat treatment equipment

ActiveCN104090604AAccurately reflect the real temperatureAdjustable film thicknessAuxillary controllers with auxillary heating devicesTemperature controlEngineering

The invention discloses a temperature compensation method. The method comprises the steps that a plurality of second temperature sensors are installed on a silicon wafer keeping piece; the silicon wafer keeping piece is placed into a treatment container, and the second temperature sensors correspond to a plurality of first temperature sensors in the treatment container in a one-to-one mode; a heater is controlled to take the second temperature sensors as a temperature control object to adjust the temperature inside the treatment container, temperature collected by the second sensors rises to reach a plurality of discrete temperature points, and the collected temperature is controlled to be kept constant for a certain time period at discrete temperature points when converged at the discrete temperature points; the temperature collected by the first temperature sensors and the temperature collected by the second temperature sensors are periodically recorded within the constant temperature time period of each discrete temperature point, and a temperature difference value is calculated; in the actual heat treatment technology, according to the discrete temperature points and the corresponding temperature difference value, the temperature difference value corresponding to target temperature is calculated through a linear interpolation method and used as a temperature compensation value of the temperature collected by the first temperature sensors. The temperature compensation method can truly reflect the silicon wafer temperature.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

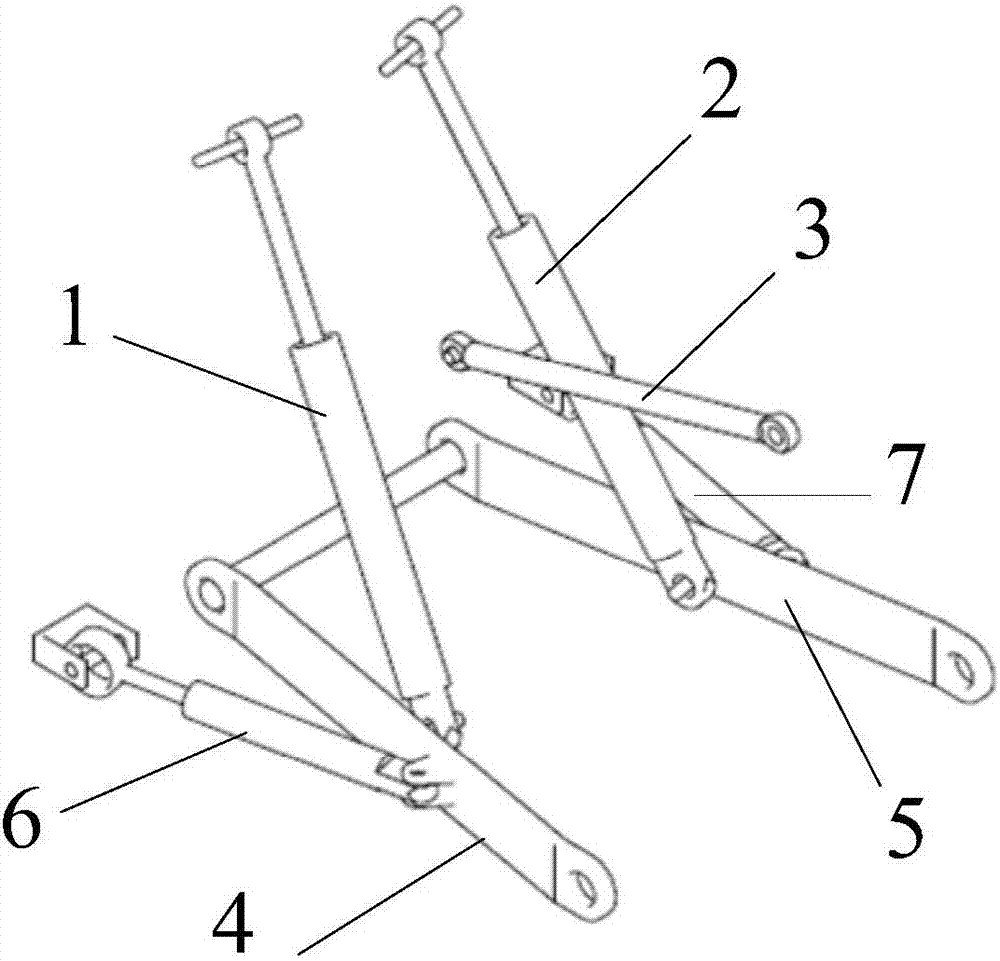

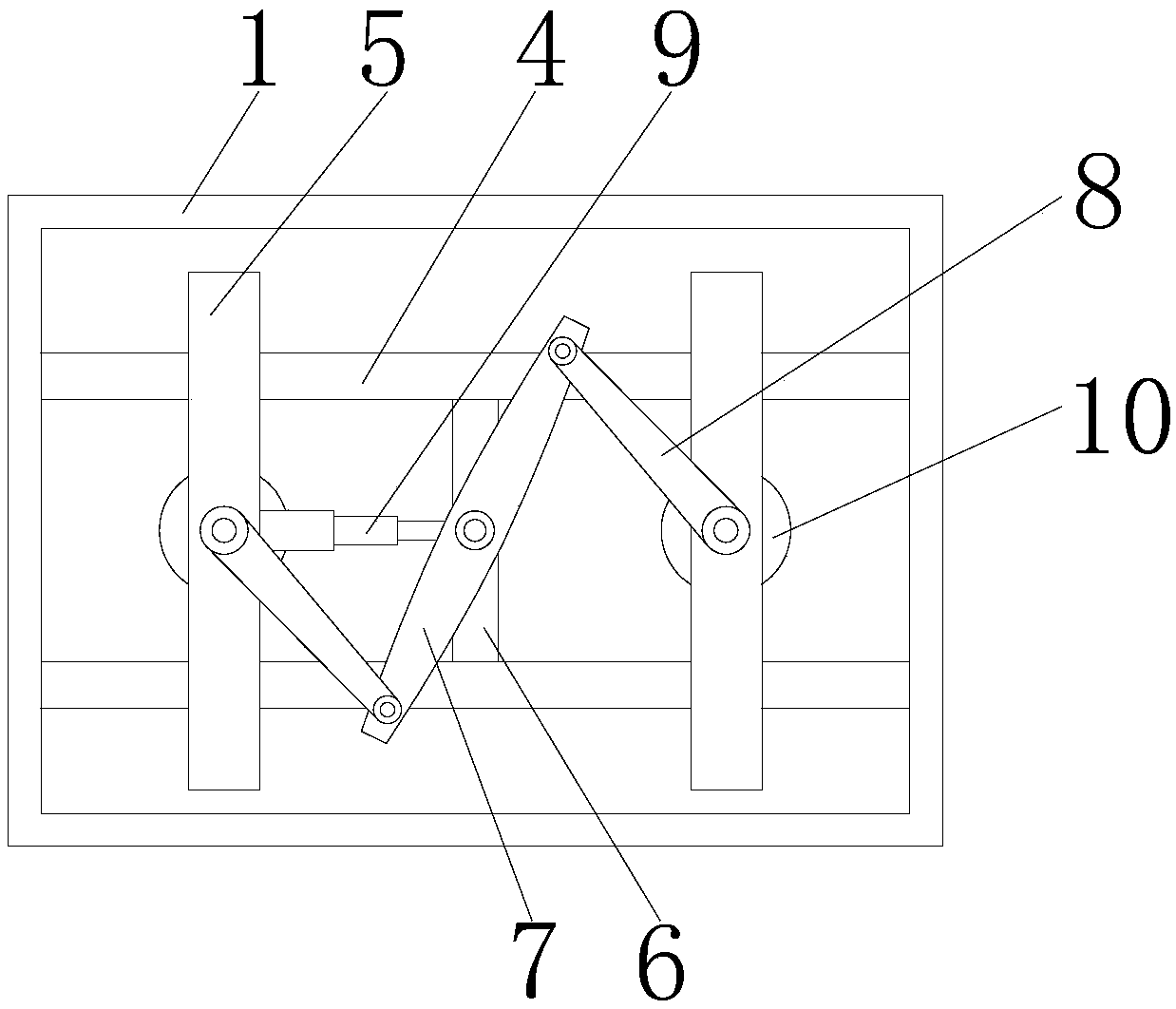

Ground contour following suspension mechanism for tractor used in hilly and mountainous areas

PendingCN107211610AWith lateral posture adjustable functionRealize the plowing operationAgricultural machinesAdjusting devicesHydraulic cylinderAutomatic control

The invention discloses a ground contour following suspension mechanism for a tractor used in hilly and mountainous areas. The ground contour following suspension mechanism comprises a left lifting hydraulic cylinder, a right lifting hydraulic cylinder, an upper pull rod, a left lower pull rod, a right lower pull rod, a limiting hydraulic cylinder and a self-regulating limiting rod. The suspension mechanism has a transverse posture adjustable function, the maximum transverse adjustable gradient of the suspension mechanism can reach 15 degrees, and the tractor can draw a farm instrument to implement ploughing operation in the hilly and mountainous areas. The suspension mechanism can adapt to large longitudinal gradient, the maximum adaptable longitudinal gradient can reach 23 degrees, and requirements of climbing and operation of the hilly and mountainous areas can be met. The suspension mechanism can be used as an executing mechanism of the ground contour following suspension mechanism, with the aid of a terrain following hydraulic control system, ground contour following can be controlled automatically, agricultural requirements of cultivated depth uniformity of operation and gradient adaptation of the hilly and mountainous areas are met further, the operation efficiency can be greatly improved, and the operation quality is improved.

Owner:CHINA AGRI UNIV

Rotary tillage, ditching, fertilizing, sowing, compacting and spraying multi-functional drought direct seeding machine

Owner:ANHUI AGRICULTURAL UNIVERSITY

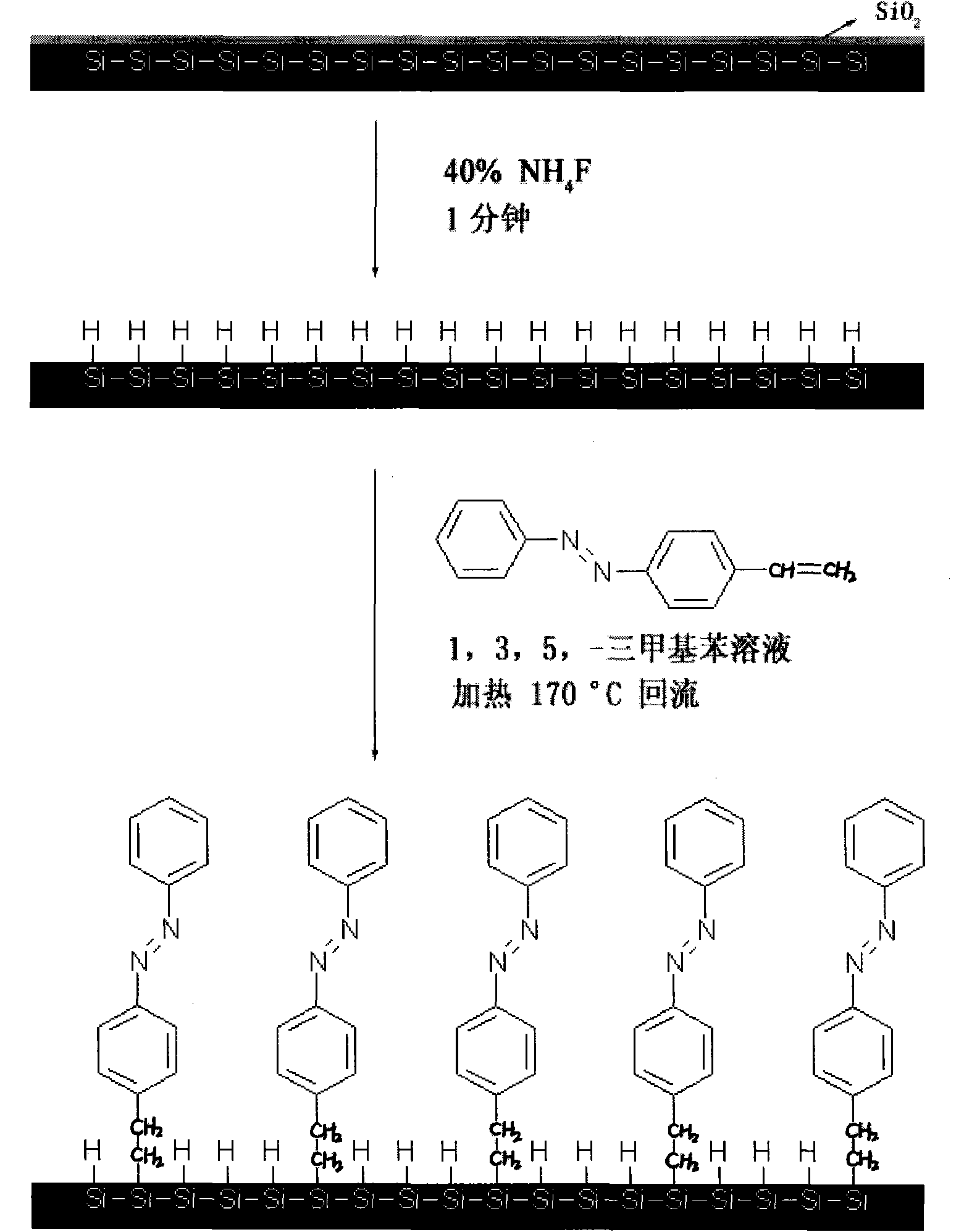

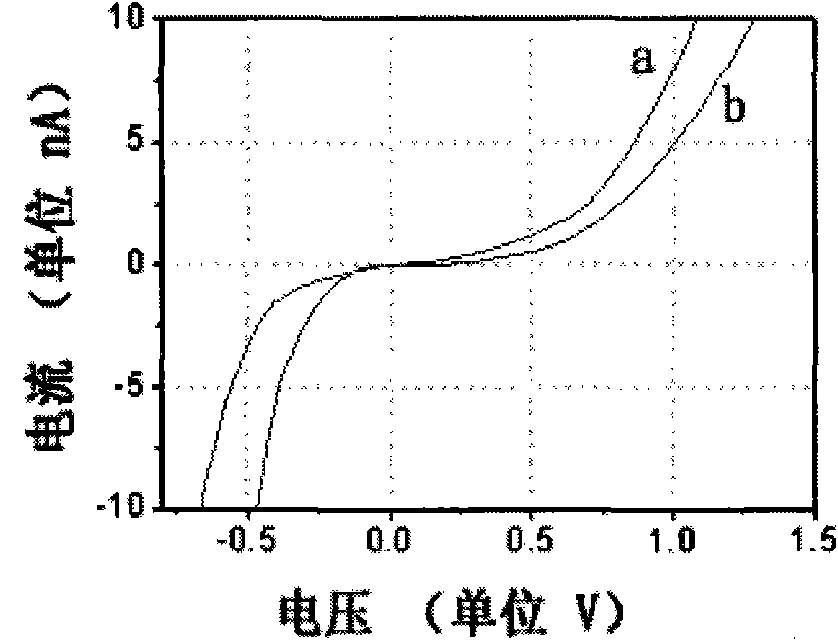

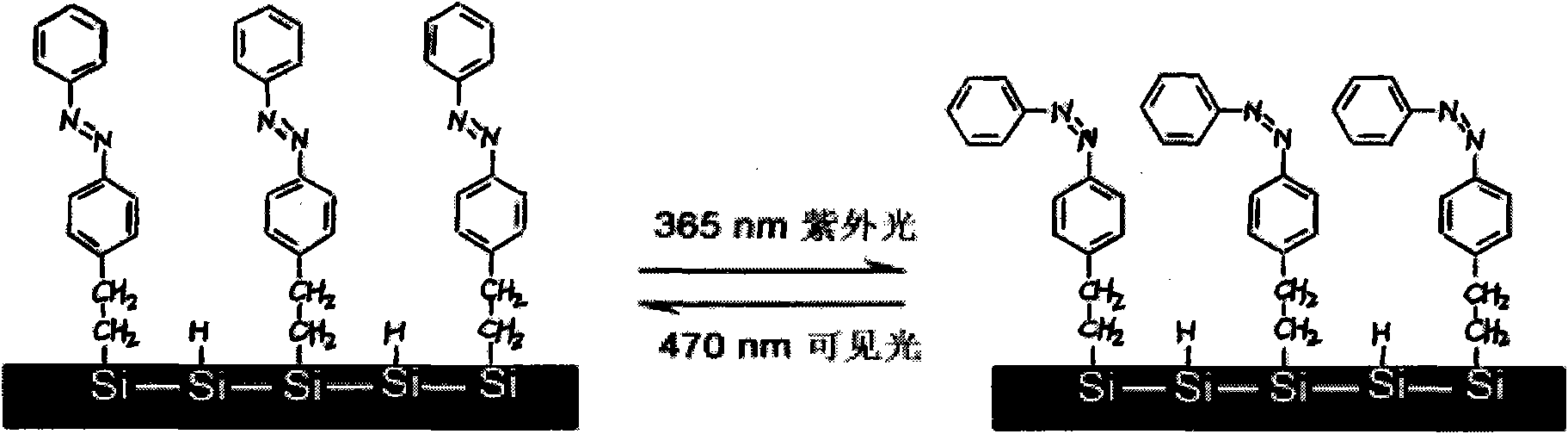

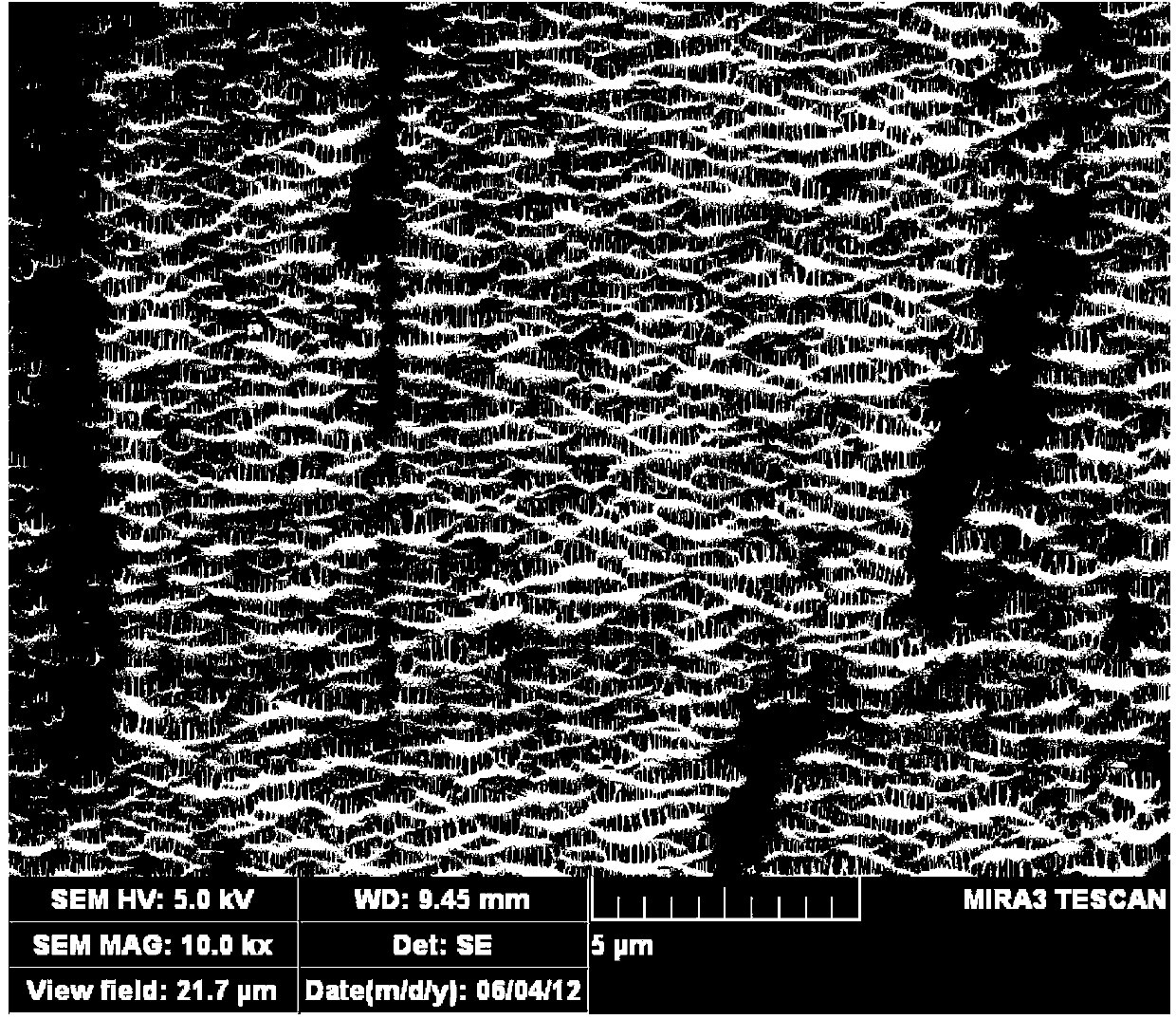

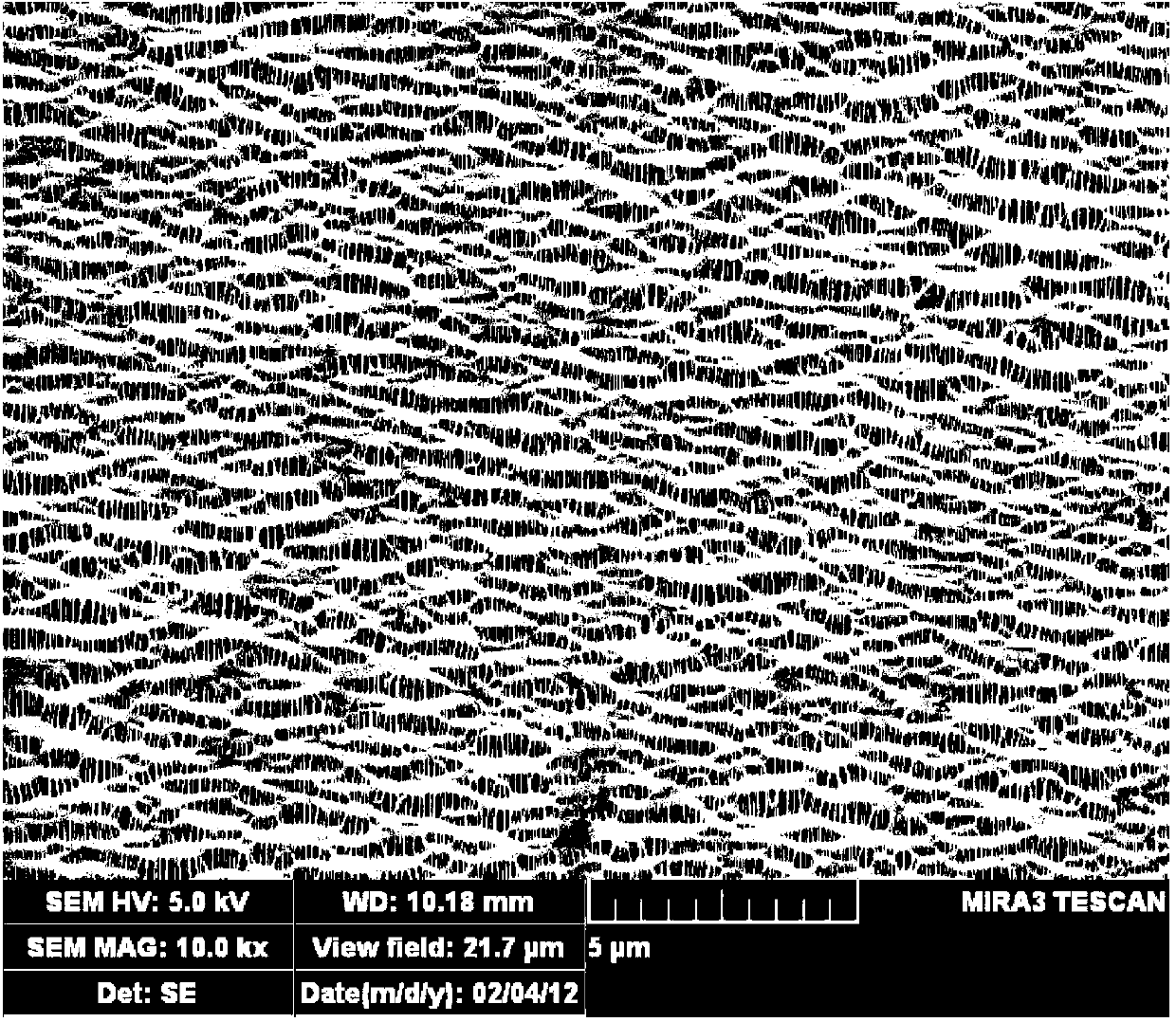

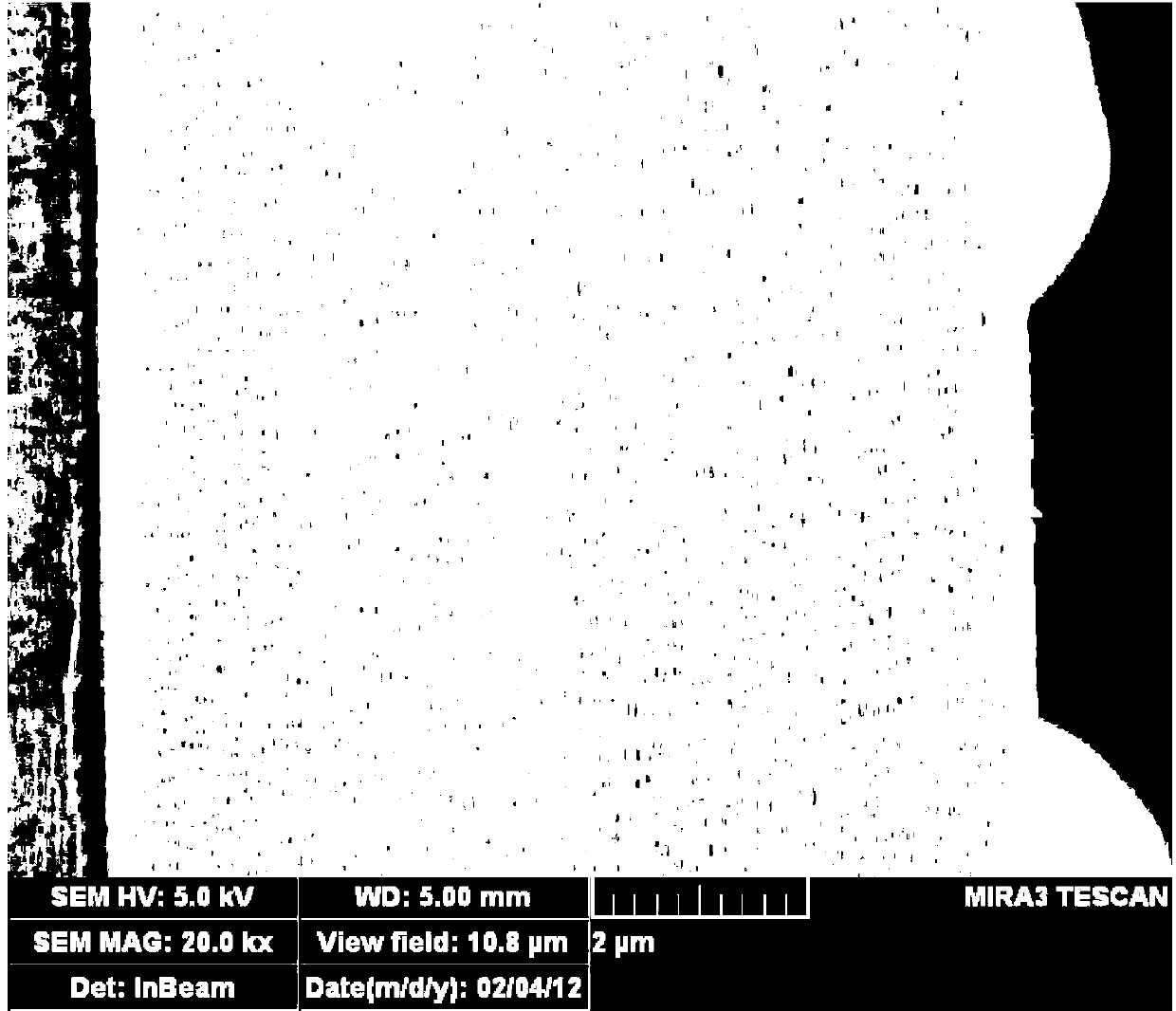

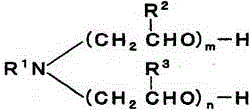

Electric conductivity adjustable organic molecular film and semiconductor hybrid material and preparation method thereof

InactiveCN101894912AImprove stabilityEnhanced electronic couplingOrganic chemistrySolid-state devicesSolventOxygen

The invention relates to electric conductivity adjustable organic molecular film and semiconductor hybrid material and a preparation method thereof. The preparation method comprises the following steps of: placing a cleaned monocrystalline silicon semiconductor substrate of which an oxidation layer is removed into 1,3,5-trimethylbenzene solvent in which organic molecules are dissolved in a closed quartz container; removing oxygen of the 1,3,5-trimethylbenzene solvent in which the organic molecules are dissolved by using high-purity argon gas or nitrogen gas; and modifying the organic molecules into a polishing surface of the monocrystalline silicon semiconductor substrate by illuminating the closed container or refluxing the 1,3,5-trimethylbenzene solvent in which the organic molecules are dissolved to obtain the electric conductivity adjustable organic molecular film and semiconductor hybrid material. The electric conductivity adjustable organic molecular film and semiconductor hybrid material is characterized in that a monomolecular film of organic molecule with light switch function is modified on the polished surface of the monocrystalline silicon semiconductor substrate. The doping uniformity of the organic molecules in the integral and nanometer range can be met, and the adjustment of the electric conductivity adjustable organic molecular film and semiconductor hybrid material by light with specific wavelength can be realized.

Owner:INST OF CHEM CHINESE ACAD OF SCI

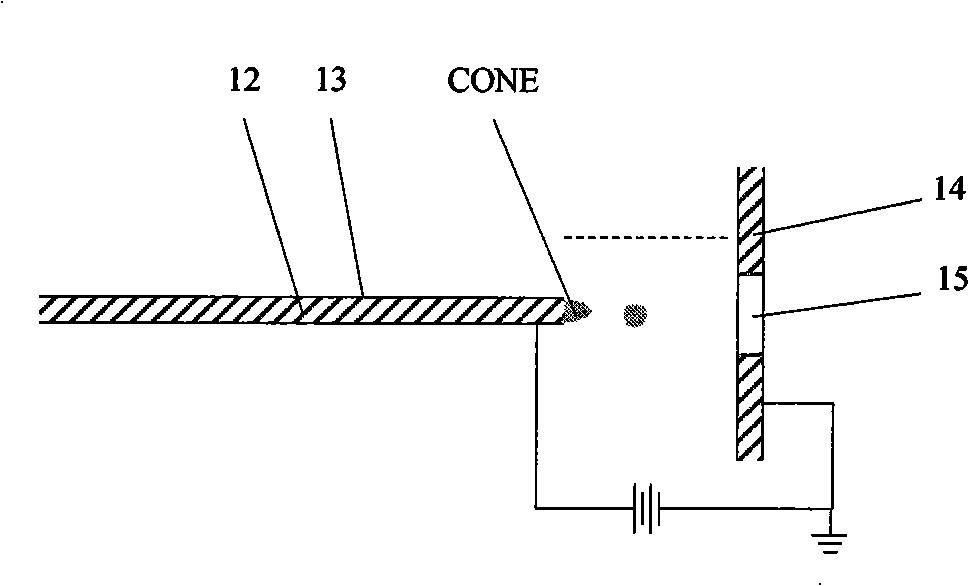

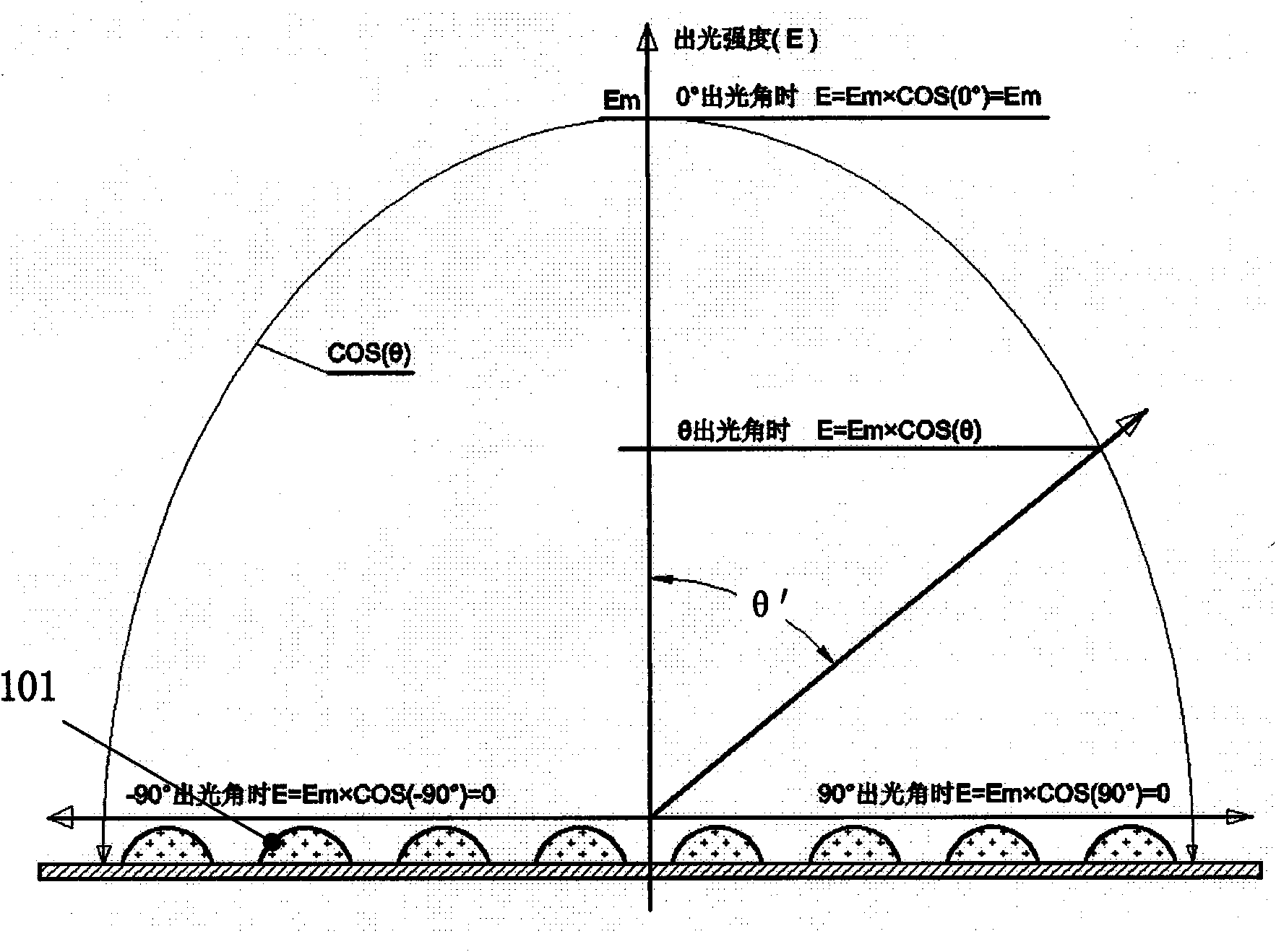

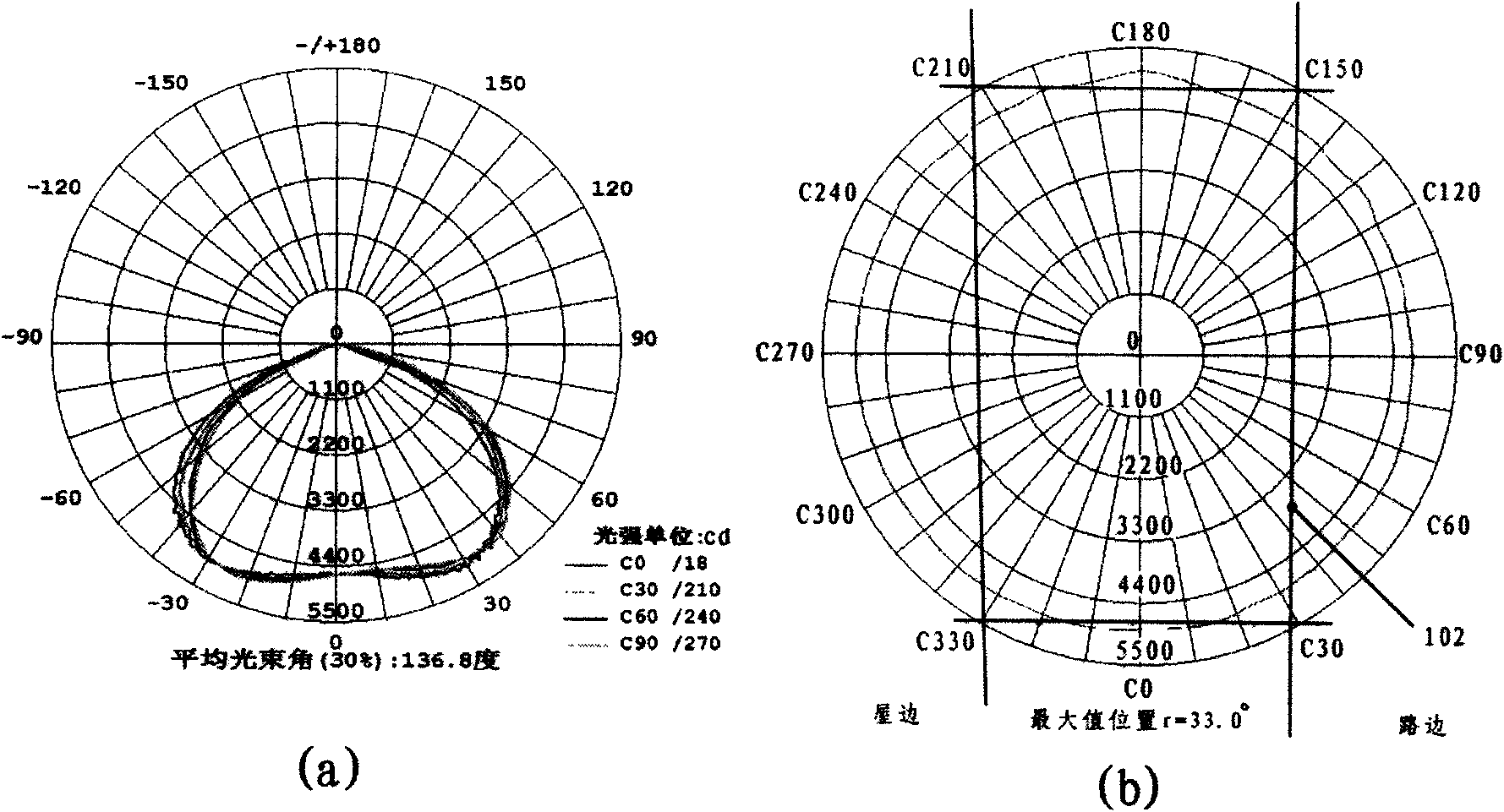

Non-imaging optical directional light distribution lens of LED light source

InactiveCN101684918ATake advantage ofHigh light efficiencyMechanical apparatusPoint-like light sourceOptoelectronicsEnergy conservation

The invention provides a non-imaging optical directional light distribution lens of an LED light source. The lens comprises a lens body, wherein the lens body is provided with an incident face and anemergent face; the incident face is an LED light incident face, and is arranged into a tooth shape; and an included angle theta between the incident face and the emergent face is between 0 and 90 degrees. By the lens, the technical problems of poor evenness of light distribution and low light efficiency due to the fact that the prior art cannot improve the Lambert character of the LED light sourceradically and cannot realize directional light distribution are solved. The lens can directionally control the light distribution of the LED light source, realizes precise light distribution, and hashigh reliability, energy conservation and environmental protection.

Owner:XIAN ZHIHAI POWER TECH

Preparation method for ultrathin polyolefin microporous membrane, and polyolefin microporous membrane prepared by same

ActiveCN103273654AUniform hole formationSolve for uniformityFlat articlesCoatingsPolymer sciencePolyolefin

The invention discloses a preparation method for an ultrathin polyolefin microporous membrane, and a polyolefin microporous membrane prepared by the same. The preparation method comprises the steps of tape casting a polyolefin melt into a substrate, annealing the substrate, stretching at a drawing ratio of 1.0-2.5, and performing thermosetting treatment to prepare the polyolefin microporous membrane. The stretching step includes cold stretching and stepwise hot stretching, wherein the conditions for the stepwise hot drawing stretching are as follows: a number of stretching points is 10-30; a stretching rate per stretching point is smaller than or equal to 200% / min; and a stretching temperature at each stretching point is from Tm-90 DEG C to Tm-15 DEGC, wherein Tm represents a melting point of the polyolefin. The method is characterized in that the prepared polyolefin microporous membrane has the characteristic of very uniform pore structure by stepwise hot stretching at relatively low stretching rate through a plurality of stretching points. Besides, the method is very suitable for making the ultrathin polyolefin microporous membrane with the thickness of 6-14 [mu]m. The polyolefin microporous membrane can meet applications having relatively high requirements for pore-forming homogeneity of the microporous membrane and the thickness of the membrane, and is particularly suitable for the fields of battery diaphragms.

Owner:SHENZHEN ZHONGXING NEW MATERIAL TECH CO LTD

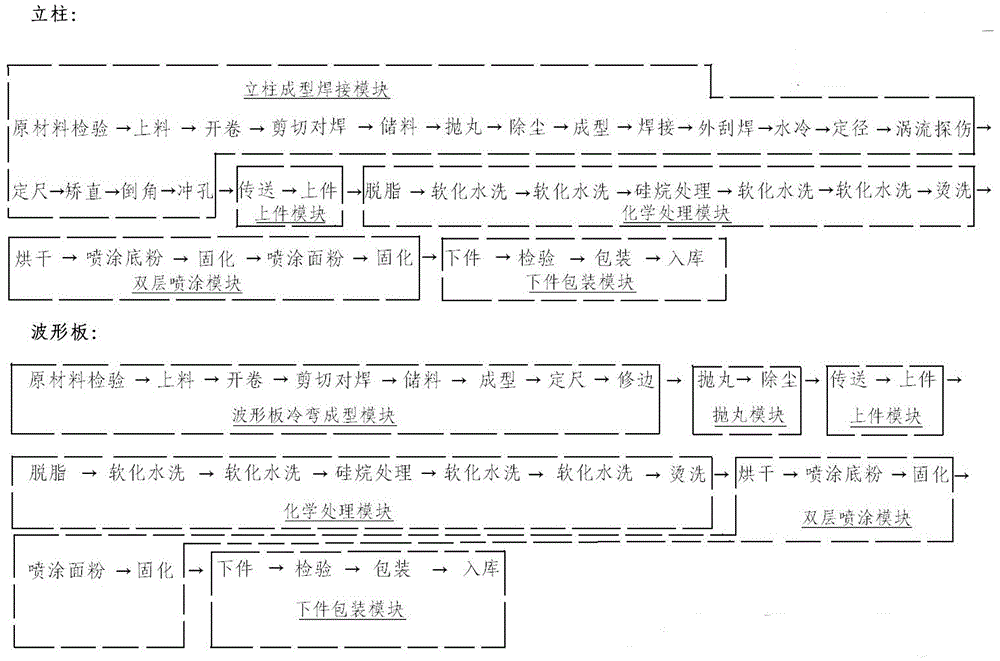

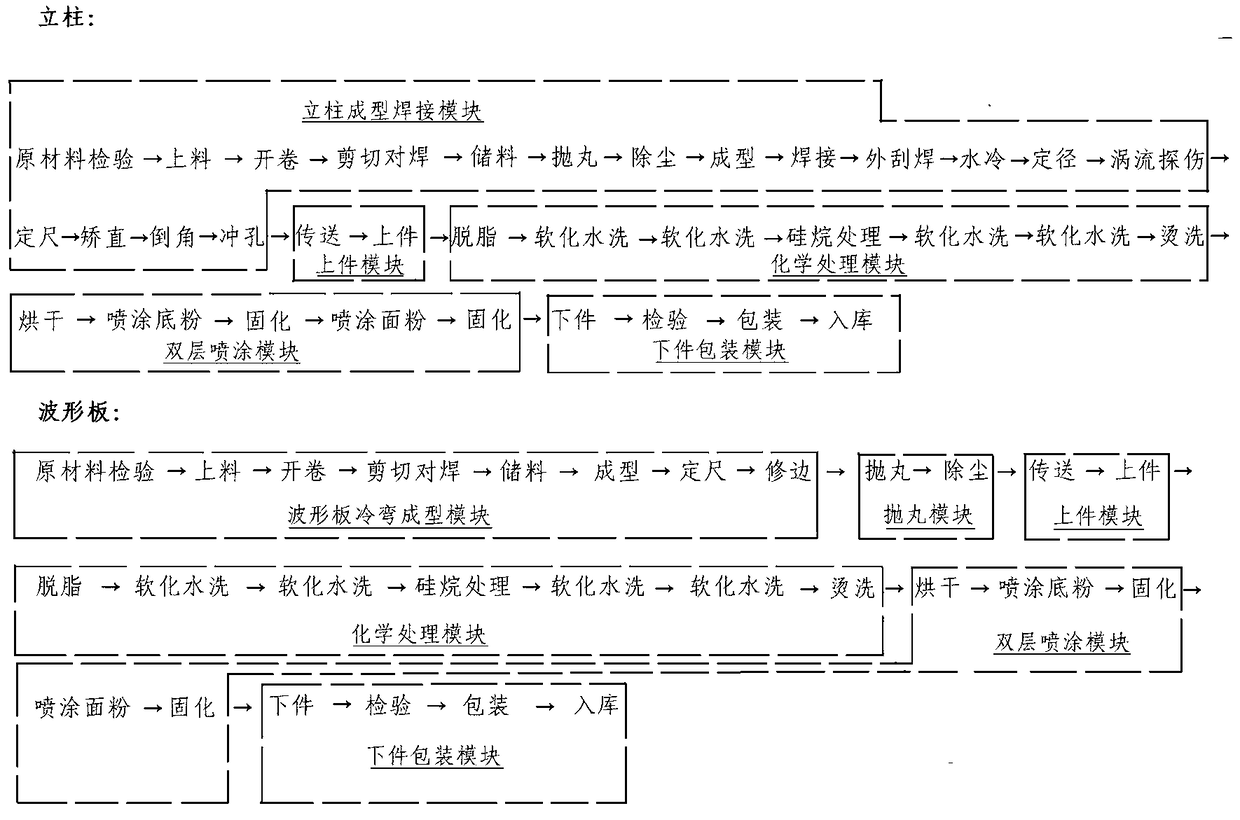

Production line and process of steel road barrier with epoxy zinc-based polyester composite coating

ActiveCN105666147AProduct quality is stableReduce laborOther manufacturing equipments/toolsZincFully automatic

The invention relates to a production line and process of a steel road barrier with an epoxy zinc-based polyester composite coating. The production line of the road barrier is a fully-automatic production line, the production line has the advantages of stable product quality, small labor amount and high efficiency in the process from strip steel loading to one-step finishing of product molding; the produced steel road barrier adopts a double-layer anticorrosive structure including a zinc-based epoxy coating and a polyester coating to replace the traditional hot galvanizing, hot galvanizing and polyester hot-dipping as well as hot galvanizing and polyethylene hot-dipping technologies, so that a product is stable in quality, good in anticorrosion, long in service life and capable of meeting the requirements for coating uniformity and range as well as coating anticorrosion, the coating range does not exceed 40mu m, and the service life of the coating is also prolonged by more than 20% than that of a conventional product; in addition, the production process of the steel road barrier is environment-friendly and pollution-free, and the curing temperature of the coating is only 200 DEG C, while the hot galvanizing temperature is 450 DEG C, so that energy is saved, and the loss of the produced heat energy is reduced by more than 60%.

Owner:潍坊东方钢管有限公司

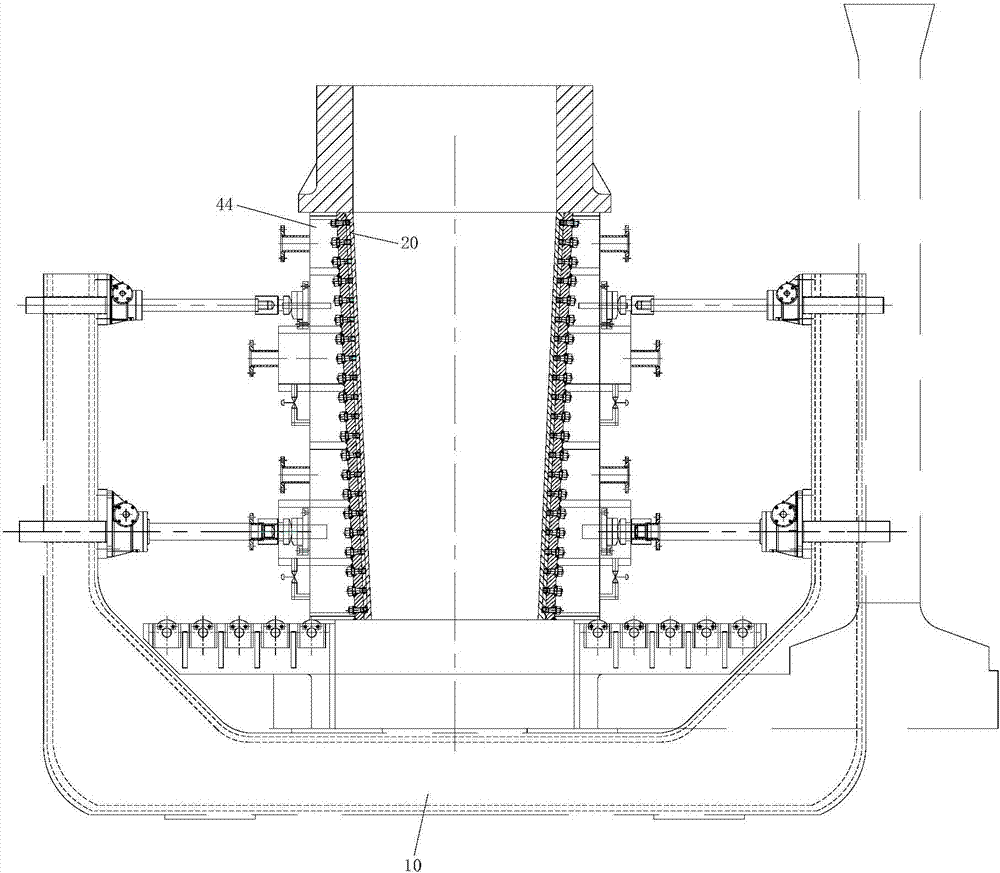

Multi-zone electromagnetic stirring device and method for continuous casting machine crystallizer

The invention discloses a multi-zone electromagnetic stirring device and a multi-zone electromagnetic stirring method for a continuous casting machine crystallizer, and belongs to the technical field of continuous casting equipment and the continuous casting method, and the device and the method are used for improving the electromagnetic stirring effect of the whole crystallizer area. According to the technical scheme, the invention adopts a combined structure of an upper electromagnetic stirring coil and a lower electromagnetic stirring coil, and a stirring method, so that the stirring effect of molten steel at the meniscus of the crystallizer is guaranteed, and the stirring zone of the molten steel is prolonged. The upper electromagnetic stirring coil can be started for steel types with high surface quality requirements, the lower electromagnetic stirring coil can be started for steel types with strict subcutaneous and segregation requirements, and the two groups of electromagnetic stirring coils are simultaneously started to work for the steel types with casting blank surface quality requirements and internal quality requirements. The structure of the conventional electromagnetic stirring device and the stirring method are broken through, the electromagnetic stirring metallurgical requirements of different zones of the crystallizer can be improved in a targeted mode, requirements of different steel types on equipment performances can be met, the quality of the casting blank can be effectively improved, and the economic benefits are remarkable.

Owner:SHIJIAZHUANG IRON & STEEL

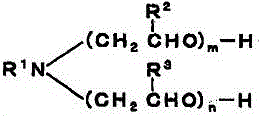

Polyester synthetic fiber textile treatment agent, polyester synthetic fiber treatment method and polyester-based synthetic fiber

The present invention provides a polyester synthetic fiber textile treatment agent, a polyester synthetic fiber treatment method employing the treatment agent and polyester synthetic fiber which is obtained via the treatment method. The polyester synthetic fiber textile treatment agent can satisfy requirement for fiber web uniformity in high-speed combing processes, winding roller resistance, scum accumulation resistance and yarn formation performance in high speed ring spindle drawing processes, scum accumulation resistance in high speed ring spinning processes and scum accumulation resistance in high speed rotor free end spinning processes. The polyester synthetic fiber textile treatment agent comprises 10 to 90% by mass of a specific alkyl phosphate salt containing an alkyl group having 12 to 22 carbon atoms in its molecule, and a specific alkylphosphate amine salt containing 5 to 80 % by mass of a specific surface active agent and 0.1 to 45% by mass of a C 12-22 alkyl group in the molecule; the total of the components is 100% by mass.

Owner:TAKEMOTO YUSHI KK

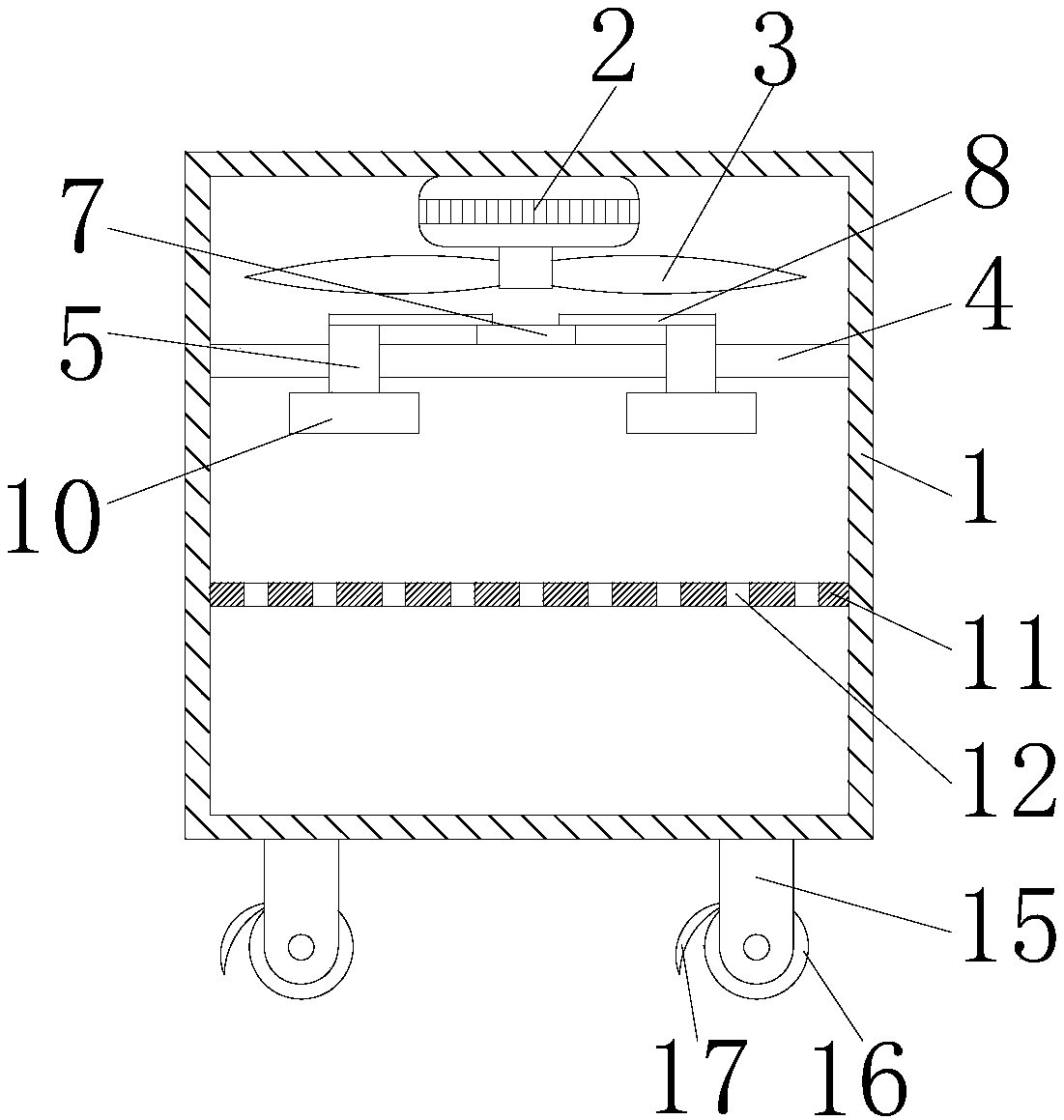

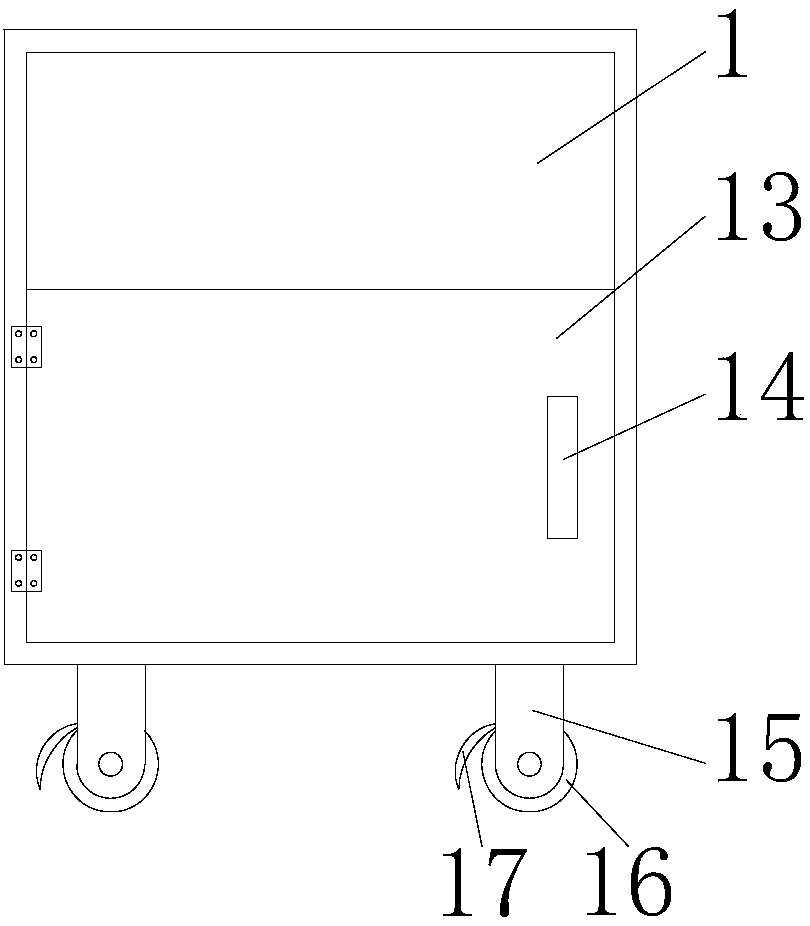

Medical cabinet with good refrigeration effect

InactiveCN107917568AImprove refrigeration effectEven and thorough coolingLighting and heating apparatusDomestic refrigeratorsEngineeringRefrigeration

The invention discloses a medical cabinet with good refrigerating effect, which comprises a cabinet body. A motor is fixedly connected to the top of the inner cavity of the cabinet, and a fan is fixedly connected to the output shaft of the motor. Both ends and below the fan are fixedly connected with support rods, and both sides of the surfaces of the two support rods are sleeved with slide rods. The medical cabinet with good refrigeration effect, through the setting of support rods, sliding rods, horizontal rods, spindle rods, connecting rods, electric telescopic rods and refrigerators, jointly constructs a left and right reciprocating device that can expand the cooling range. The settings of the above structures together build a downward blowing device, which can blow the cold air through the through holes to the bottom of the cabinet, which can make the cooling more uniform and thorough. The combination of the above structures meets the requirements of uniform cooling and long-term storage. The purpose is to solve the problem that it cannot be cooled evenly and stored for a long time.

Owner:付淑珍

Highway Steel Guardrail Production Line and Production Technology of Epoxy Zinc-based Polyester Composite Coating

ActiveCN105666147BMeet uniformityImprove product qualityOther manufacturing equipments/toolsEpoxyProduction line

The invention relates to a production line and process of a steel road barrier with an epoxy zinc-based polyester composite coating. The production line of the road barrier is a fully-automatic production line, the production line has the advantages of stable product quality, small labor amount and high efficiency in the process from strip steel loading to one-step finishing of product molding; the produced steel road barrier adopts a double-layer anticorrosive structure including a zinc-based epoxy coating and a polyester coating to replace the traditional hot galvanizing, hot galvanizing and polyester hot-dipping as well as hot galvanizing and polyethylene hot-dipping technologies, so that a product is stable in quality, good in anticorrosion, long in service life and capable of meeting the requirements for coating uniformity and range as well as coating anticorrosion, the coating range does not exceed 40mu m, and the service life of the coating is also prolonged by more than 20% than that of a conventional product; in addition, the production process of the steel road barrier is environment-friendly and pollution-free, and the curing temperature of the coating is only 200 DEG C, while the hot galvanizing temperature is 450 DEG C, so that energy is saved, and the loss of the produced heat energy is reduced by more than 60%.

Owner:潍坊东方钢管有限公司

Preparation method of metal ceramic coating

The invention discloses a preparation method of a metal ceramic coating. The method comprises the following steps: polishing the surface of a matrix, cleaning the ceramic matrix, removing oil, airing,and preparing a middle layer slurry; spraying the surface of the ceramic matrix wit the middle layer coating material, and sintering the ceramic matrix surface coated with a transition layer in a central control furnace to obtain a uniform and compact transition layer; preparing a surface layer coating; coating the surface of the ceramic with the surface layer slurry, and sintering the ceramic matrix surface coated with the transition layer in a vacuum furnace to obtain a uniform and compact metal ceramic outer layer. According to the invention, the ceramic matrix is pretreated to improve theadsorption effect of the middle layer slurry on the ceramic and ensure the coating uniformity of the middle layer coating material, and the ceramic sprayed with the middle layer coating material andthe surface layer coating material is sintered by adopting a vacuum sintering method so as to improve the uniformity of the coating, reduce the defects of cavities and cracks on the surface of the ceramic and improve the thermal shock resistance and the high-temperature oxidation resistance of the coating on the surface of the ceramic.

Owner:界首市伟盛古窑彩陶制作发展有限公司

Manufacturing method of polytetrafluoroethylene sealing sheet or sealing strip for aircraft hatch cover

The invention discloses a manufacturing method of a polytetrafluoroethylene sealing sheet or sealing strip for an aircraft hatch cover. Polytetrafluoroethylene dispersion resin with the molecular weight of 30000 or above is selected as a raw material, aviation kerosene is added and mixed, the mixture is put into a thermostat for heat preservation, a blank is made in a knocking mode, the blank is put into the thermostat for heat preservation, extrusion molding is carried out to form a blank, the blank is extruded into a strip-shaped flat blank, degreasing and unidirectional stretching are carried out, the flat blank is put into the thermostat, a film material is formed after bidirectional stretching, the film material is moved into a setting furnace for setting and rolled, and multiple layers of the film materials are overlapped, put into a bulking furnace for bulking, and compounded to form an integrated wide sheet material, the wide sheet material is cut into needed flaky or strip-shaped product specifications, and packaging and warehousing are carried out after quality inspection. The whole processing technology is beneficial to continuous and batch work of a production line, production efficiency is high, the quality is guaranteed, the main performance indexes are superior to those of existing similar products, and high-quality sealing materials are provided for aircraft andother aviation and aerospace equipment.

Owner:嘉善东方氟塑有限公司

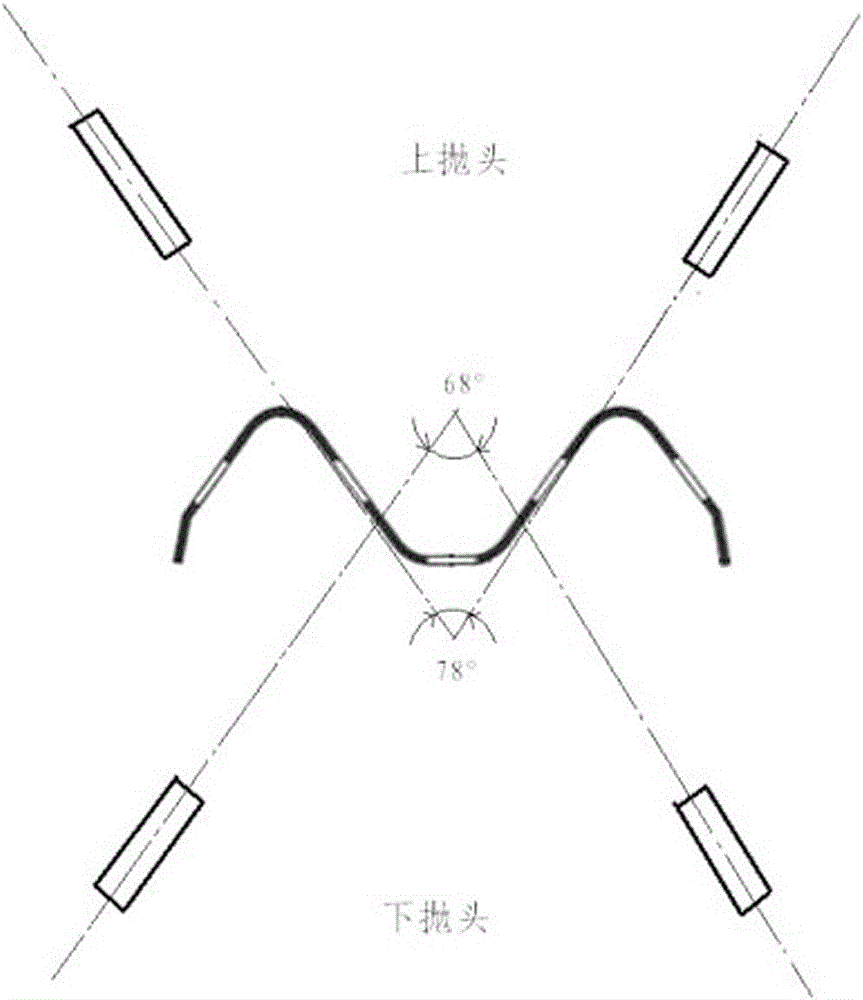

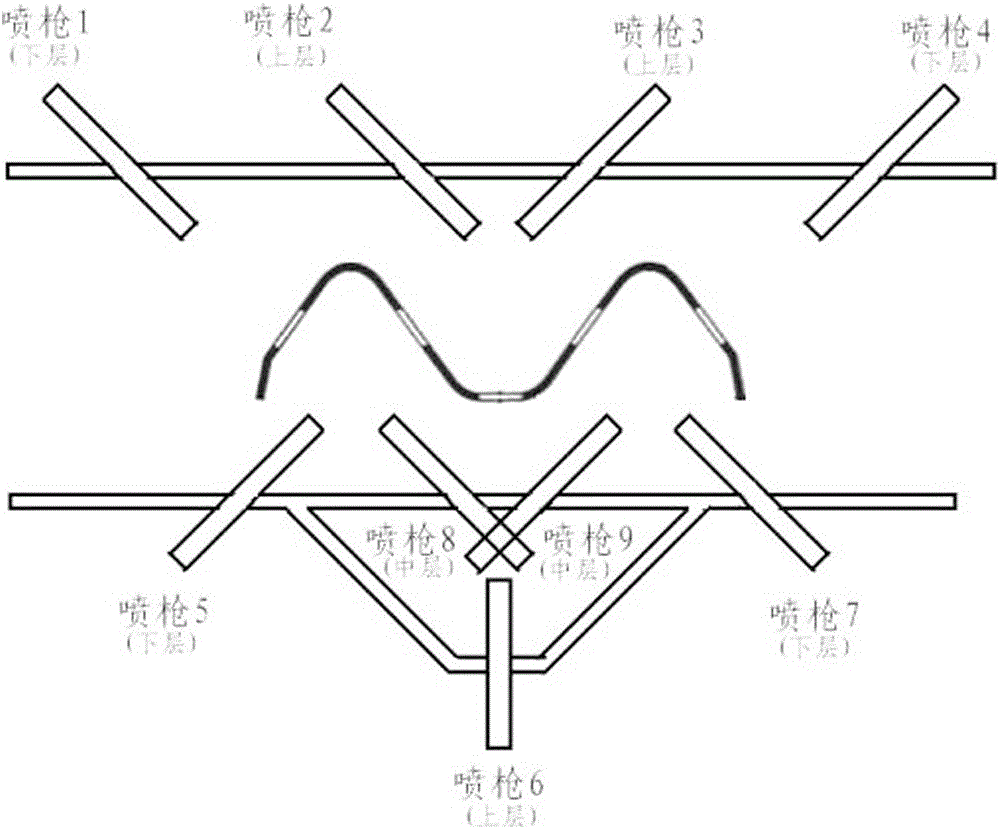

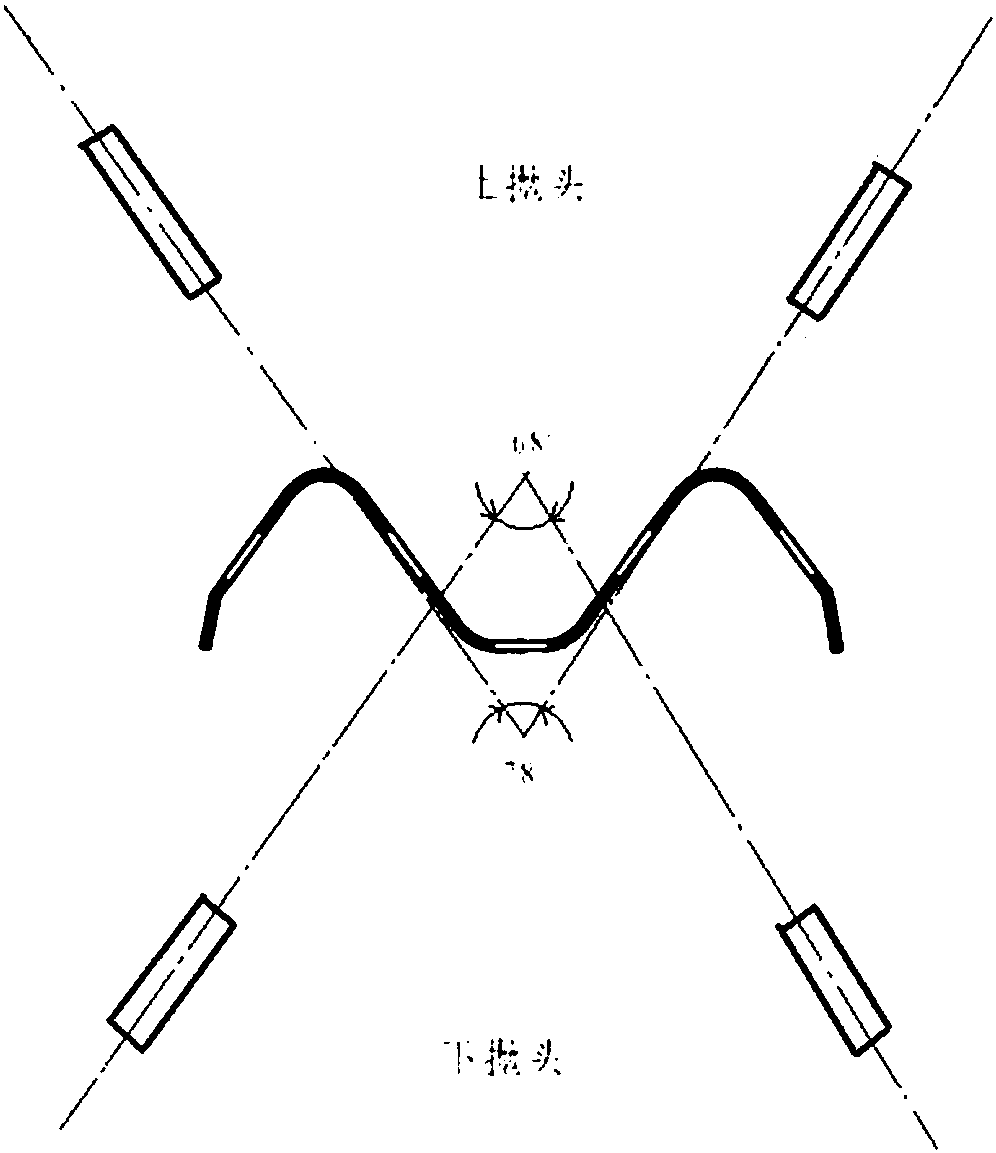

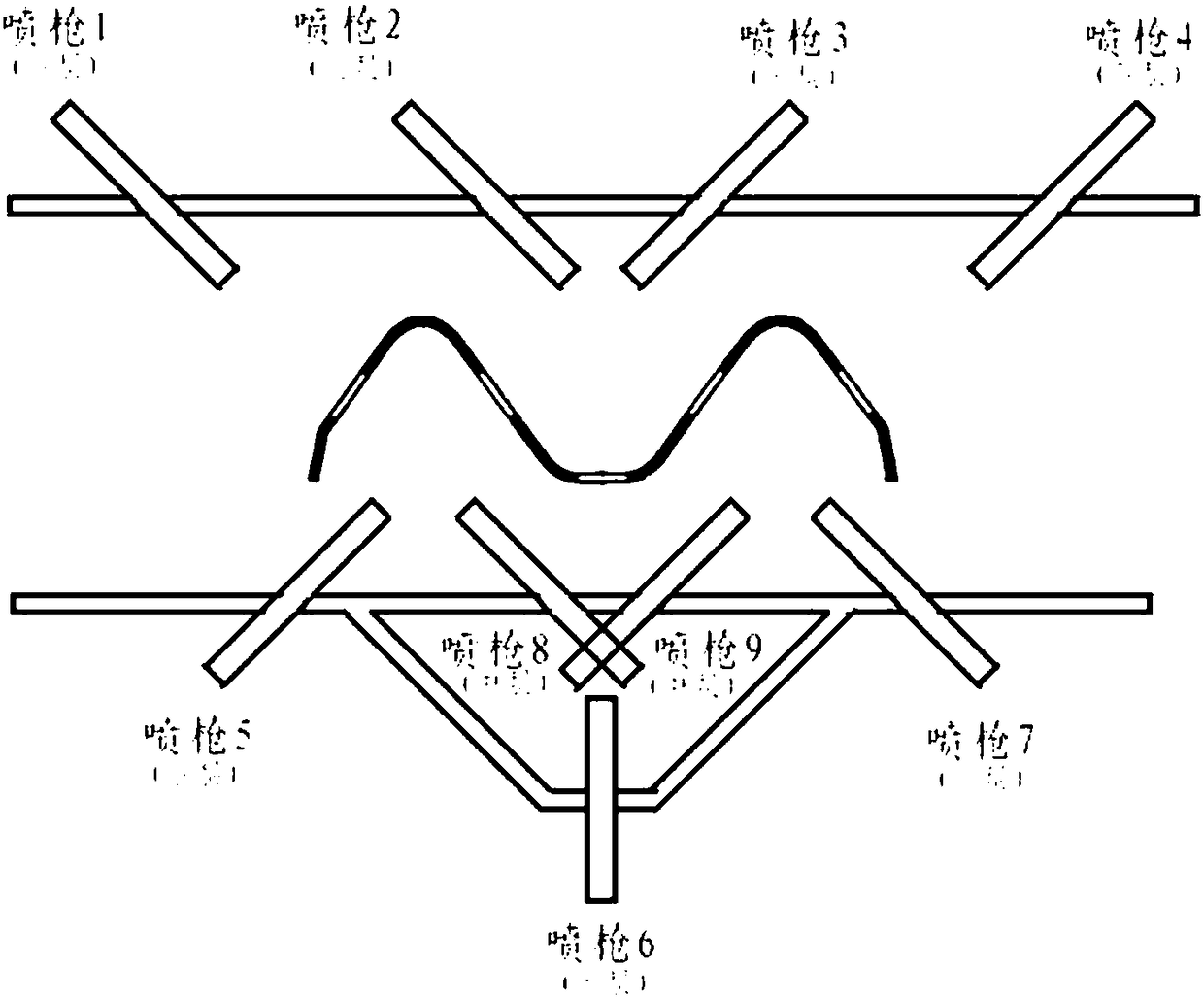

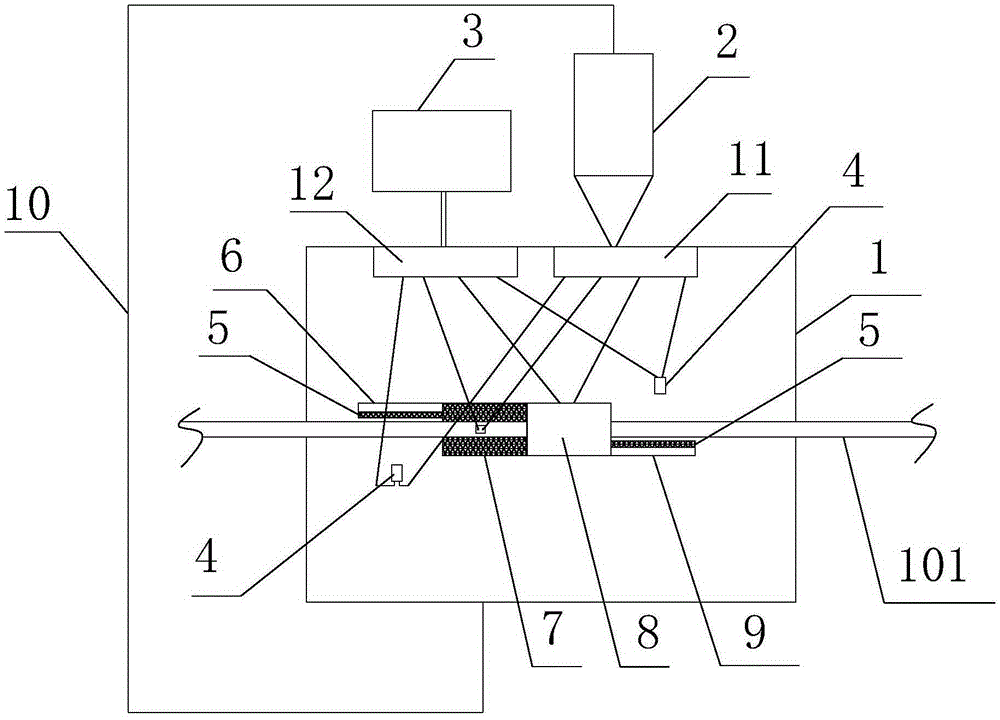

Machining device for matt cable

ActiveCN105382705AEffect of mechanical strengthAffect conductivityAbrasive machine appurtenancesAbrasive blasting machinesSand blastingEngineering

The invention discloses a machining device for a matt cable. The machining device comprises a sand blasting box, a centrifugal chamber and a high-pressure gas source. A sand guide pipe and a high-pressure gas pipe are arranged in the sand blasting box. The centrifugal chamber is arranged above the sand blasting box and communicated with the sand guide pipe. The high-pressure gas source is communicated with the high-pressure gas pipe. A cable inlet and a cable outlet are formed in the two sides of the sand blasting box respectively. Multiple baffles are arranged at the portion, between the cable inlet and the cable outlet, in the sand blasting box and distributed criss-cross in the cable conveying direction. One side of each baffle is provided with at least one spray gun, spray openings of the spray guns face the baffle faces, close to the conveyed cable, of the baffles, gaps allowing the cable to pass are reserved between the spray guns and the baffle faces of the baffles, each spray gun is provided with two inlets, one inlet of each spray gun is connected with the sand guide pipe, and the other inlet of each spray gun is connected with the high-pressure gas pipe. By the adoption of the machining device, the baffles are arranged criss-cross in the cable conveying direction, so that the situation that the cable swings and shakes due to blasting force in the sand blasting process, the sand blasting face is uneven, and conveyance is unstable is avoided.

Owner:蚌埠格识知识产权运营有限公司

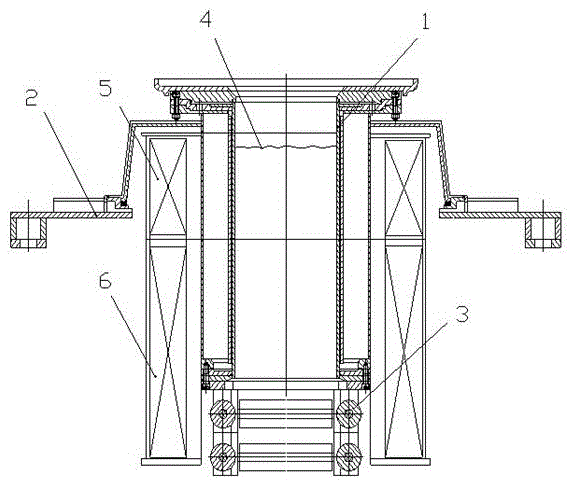

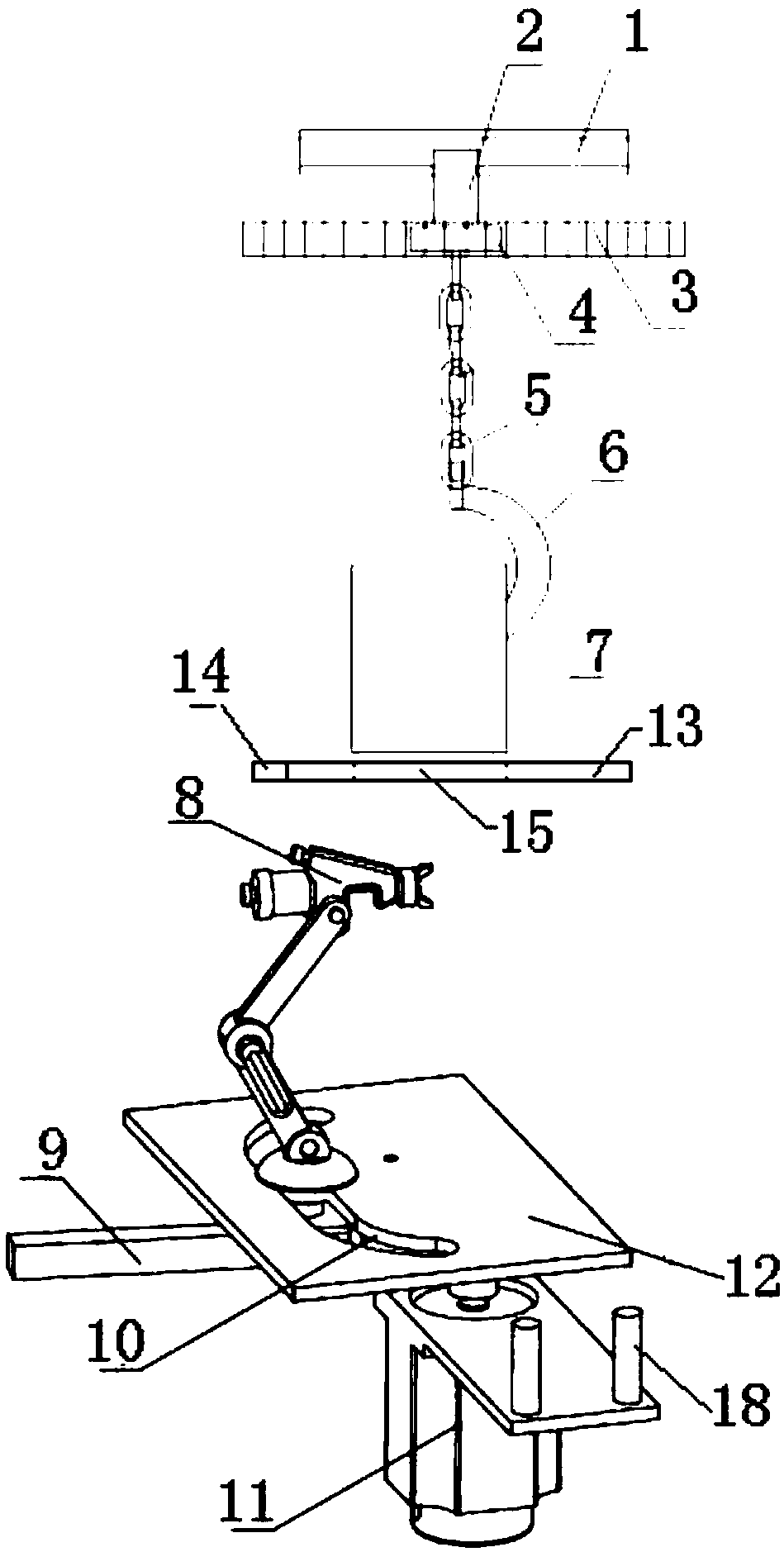

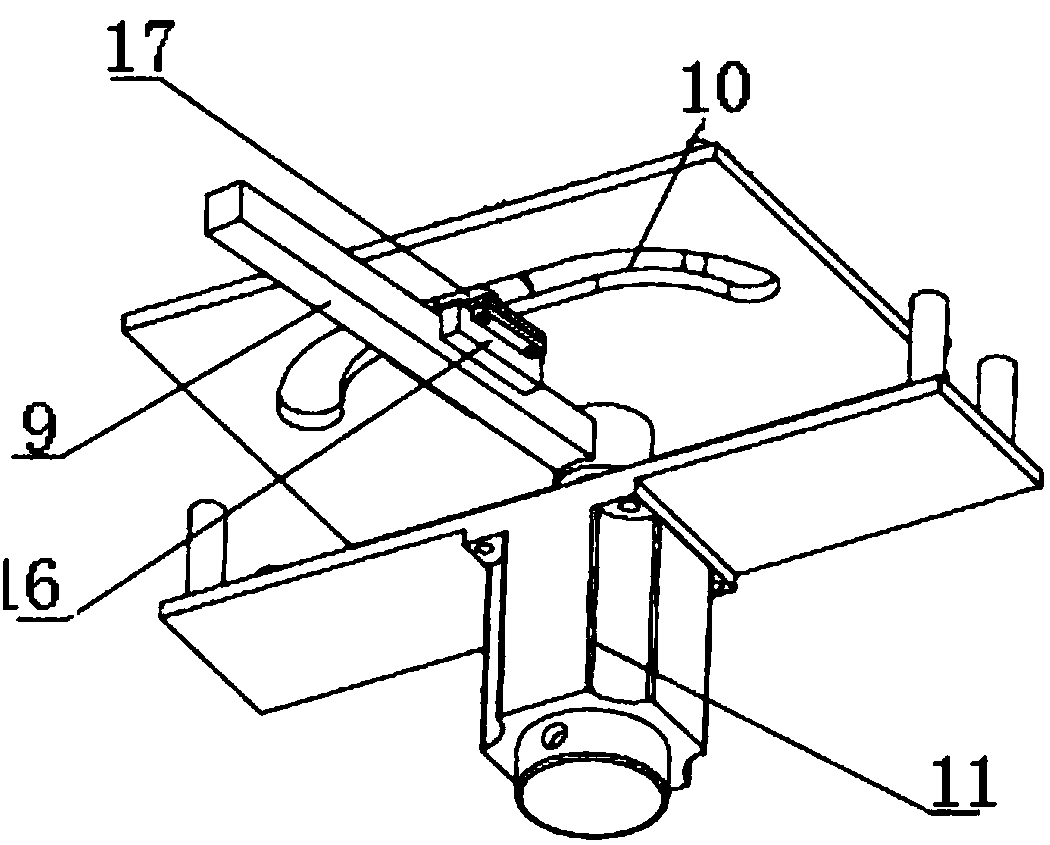

Weather-resistant protective device for casting

InactiveCN108372043AMeet uniformityImprove product qualitySpraying apparatusAutomatic controlMechanical engineering

A weather-resistant protective device for a casting comprises a casting transporting device and a spraying device. The casting transporting device is arranged above the spraying device and comprises amovable chain; a connecting block is arranged on the movable chain; a gear is arranged below the connecting block and engaged with a rack; and the bottom of the gear is provided with a hanging chain,and the bottom of the hanging chain is provided with a hook for hooking the casting. The spraying device comprises an automatic spraying head; a crank arm connecting rod which can adjust the height and the angle is hinged to the bottom of the automatic spraying head; a stopping block is arranged at the bottom of the crank arm connecting rod; a sliding piece is arranged at the bottom of the stopping block; a moving piece is arranged at the bottom of the sliding piece; the sliding piece is arranged in an arc-shaped guiding rail groove in the middle of a guiding plate; the moving piece is arranged in a linear guiding rail at the bottom of the moving piece; and the end, close to the crank arm connecting rod, of the linear guiding rail is connected with a motor. The product quality is improved, the adaptability is improved, meanwhile, automatic control is achieved, operation is convenient, manpower is saved, and the efficiency is improved.

Owner:TIANJIN YUXINGDA CASTING IND CO LTD

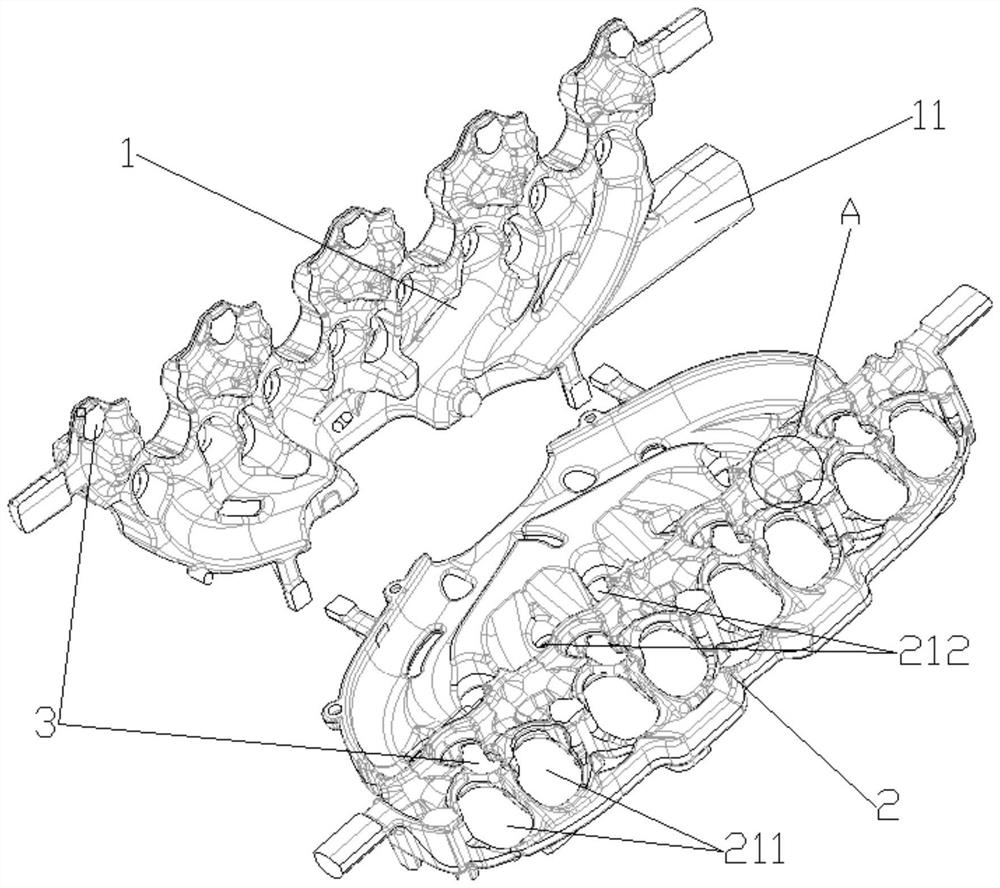

Double-layer cylinder cover water jacket, air cylinder and vehicle

ActiveCN112576401AImprove yieldMeet uniformityInternal combustion piston enginesCylinder headsCombustion chamberExhaust valve

The invention is applicable to the field of vehicles, and discloses a double-layer cylinder cover water jacket, an air cylinder and a vehicle. The double-layer cylinder cover water jacket comprises anupper water jacket and a lower water jacket, wherein the upper water jacket and the lower water jacket are stacked up and down, the upper water jacket is provided with an upper water cavity for accommodating cooling water and a water outlet for discharging the cooling water out of the upper water cavity, the lower-layer water jacket is provided with a lower water cavity used for containing the cooling water and a water inlet used for leading the cooling water into the lower water cavity, the lower water cavity is provided with a combustion chamber area corresponding to the upper portion of acylinder combustion chamber, the combustion chamber area involves an exhaust valve area, a communicating hole used for communicating the upper water cavity with the lower water cavity is formed between the upper-layer water jacket and the lower-layer water jacket, and the communicating hole is located at the position near the exhaust valve area. The invention further provides the air cylinder andthe vehicle. According to the double-layer air cylinder cover water jacket, the air cylinder and the vehicle, the cooling water can be guided to the high-heat area of the air cylinder cover, a water flow dead zone is avoided, and the cooling effect of a key high-heat part meets the requirement.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

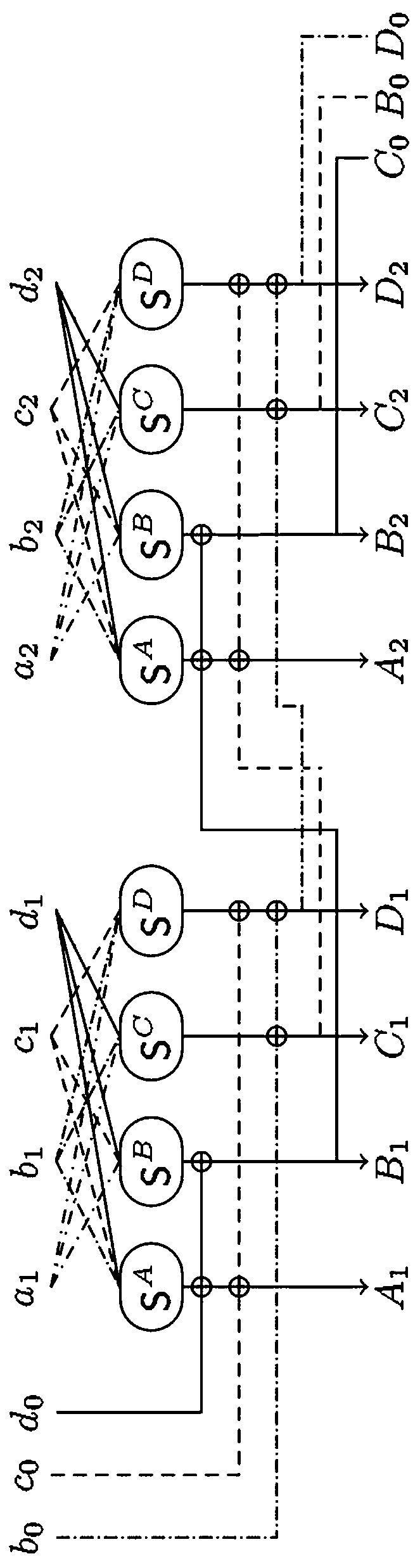

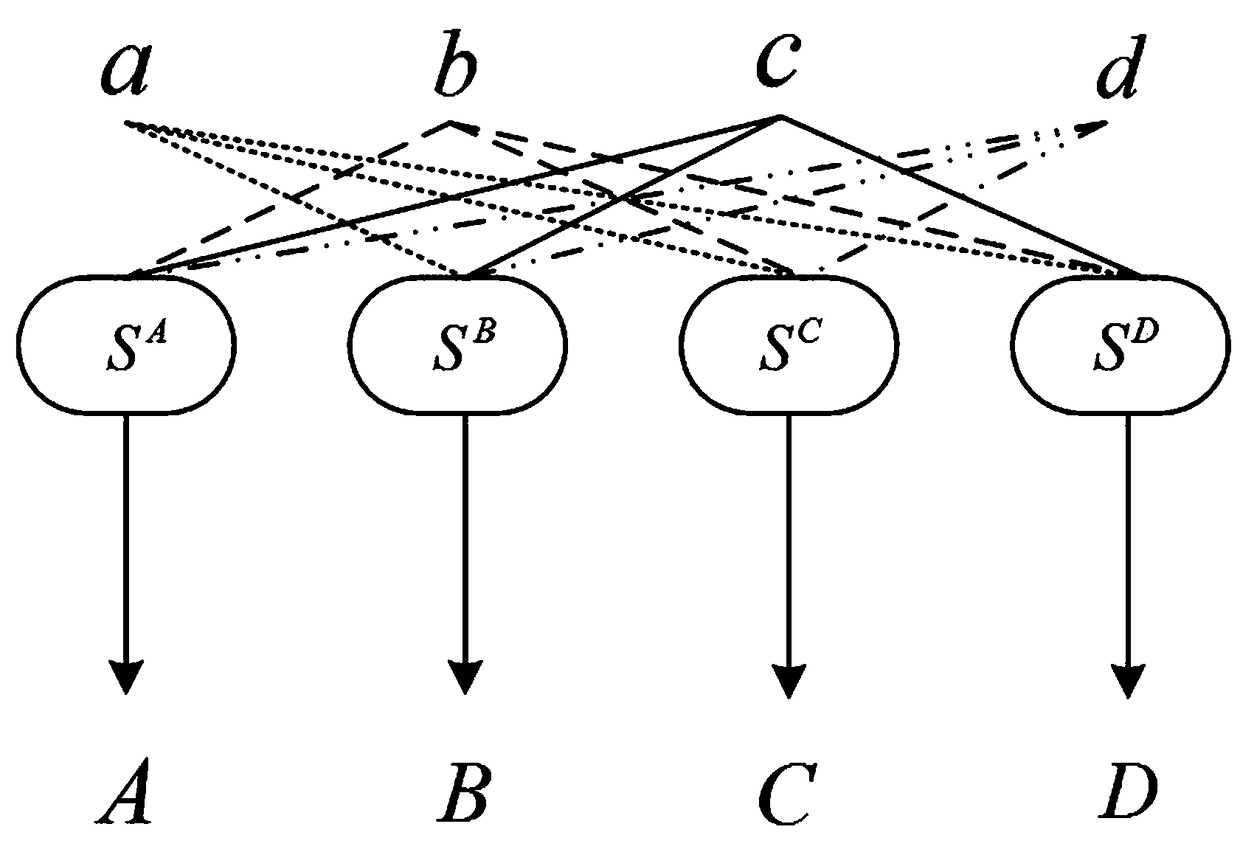

Novel method for password S box threshold implementation without random numbers

ActiveCN108718230AAchieve uniformityAvoid participationCryptographic attack countermeasuresMultiplexingS-box

The invention discloses a novel method for password S box threshold implementation without random numbers. A traditional idea of introducing the additional random numbers is abandoned, emphasis is puton an S box itself, a uniformity multiplexing technology is used for repeatedly using output sharing factors of the password S box, and the output sharing factors of the S box are used as the new random numbers for input to replace the originally required additional random numbers to ensure the uniformity of an entire nonlinear layer, so that addition of the additional random numbers is skillfully avoided. Not only is the uniformity of a threshold implementation function satisfied, but also the chip area can be saved. A new idea is provided for the lightweight design of a password S box maskscheme, and a broad application prospect is achieved.

Owner:GUILIN UNIV OF ELECTRONIC TECH

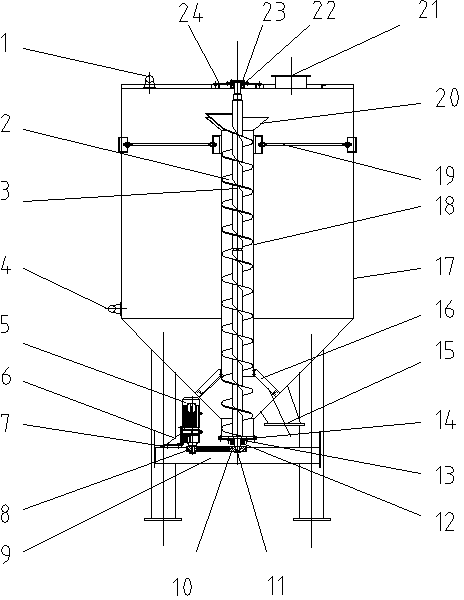

Tobacco sheet stem powder raw material pretreatment mixing and stirring device

InactiveCN103877897AMeet uniformityWell mixedRotary stirring mixersTransportation and packagingVertical mixingEngineering

The invention relates to a tobacco sheet stem powder raw material pretreatment mixing and stirring device which is a device for blending and stirring the prepared dry materials to be uniformly mixed before tobacco sheet stem powder raw materials are leached, belonging to the technical field of tobacco machinery. The device is mainly characterized by comprising a vertical mixing spiral shaft arranged in a tank body, a reducing motor outside the tank body, a feeding and discharging material level detector on the tank body, and a frame, wherein the reducing motor fixed on the frame drives a spindle in the vertical mixing spiral shaft; when the tobacco sheet stem powder raw materials are mixed, the tobacco stems and tobacco powder are vertically conveyed to the upper part of the tank through the vertical mixing spiral shaft, the materials are thrown to the periphery through the effects of spiral stirring blades which extend outwards and a throwing hopper, and the materials drop along the interior of the tank. When sliding to the bottom of the tank body, the tobacco stems and tobacco powder are lifted upwards by the vertical mixing spiral shaft again. The tobacco stems and tobacco powder are repeatedly recycled until the materials are uniformly mixed. The device is simple in structure and convenient to operate, and the batching uniformity can be met.

Owner:JIANGSU WELL ELECTRIC

Heating process for sulfuric acid leaking point corrosion resisting band steel

ActiveCN104004898AGood temperature baseReduce the temperatureFurnace typesHeat treatment process controlTemperature controlHeating furnace

The invention discloses a heating process for sulfuric acid leaking point corrosion resisting band steel. A heating furnace used in the heating process comprises a preheating section, an upper heating section, a soaking section, a lowering heating end calcining section and a lower heating side calcining section; the heating furnace is provided with six temperature detection points, including a preheating section temperature control point, a lower heating side calcining temperature detection point, an upper heating section temperature detection point, a lower heating end calcining temperature detection point I, a lower heating end calcining temperature detection point II and a soaking side calcining temperature detection point. By adopting the heating process disclosed by the invention, the rolling requirements can be met, and the problem that stainless steel for a fume extractor and fume waste heat utilization equipment or high alloy steel can be severely corroded is solved.

Owner:NANJING IRON & STEEL CO LTD

Cooling mold and method for cooling steel ingot

The invention provides a cooling mold and a method for cooling a steel ingot. The cooling mold comprises a pouring chassis and condensation walls, and each condensation wall comprises at least two cooling layers which are vertically arranged in sequence. The cooling mold further comprises at least two pairs of electromagnetic induction components which are arranged on the outer side of the condensation walls, each pair of the electromagnetic induction components are symmetrically arranged on the two sides of a casting cavity, and each cooling layer is provided with at least one pair of electromagnetic induction components; each electromagnetic induction component comprises at least two pairs of coils which can be connected to the corresponding condensation wall in a sliding manner, and the two coils in each pair of the coils are oppositely arranged in parallel; among all the electromagnetic induction components, at least one pair of the coils are vertically arranged, at least one pair of the coils are horizontally arranged, and all the horizontally arranged coils are located between center lines of all the vertically arranged coils; and the two ends of all the coils are sequentially opposite to each other or sequentially connected end to end to form a semi-closed or closed rectangle in an enclosing manner. According to the cooling mold, molten steel can be stirred in the horizontal direction and in the vertical direction separately, and the quality of steel ingots is improved.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

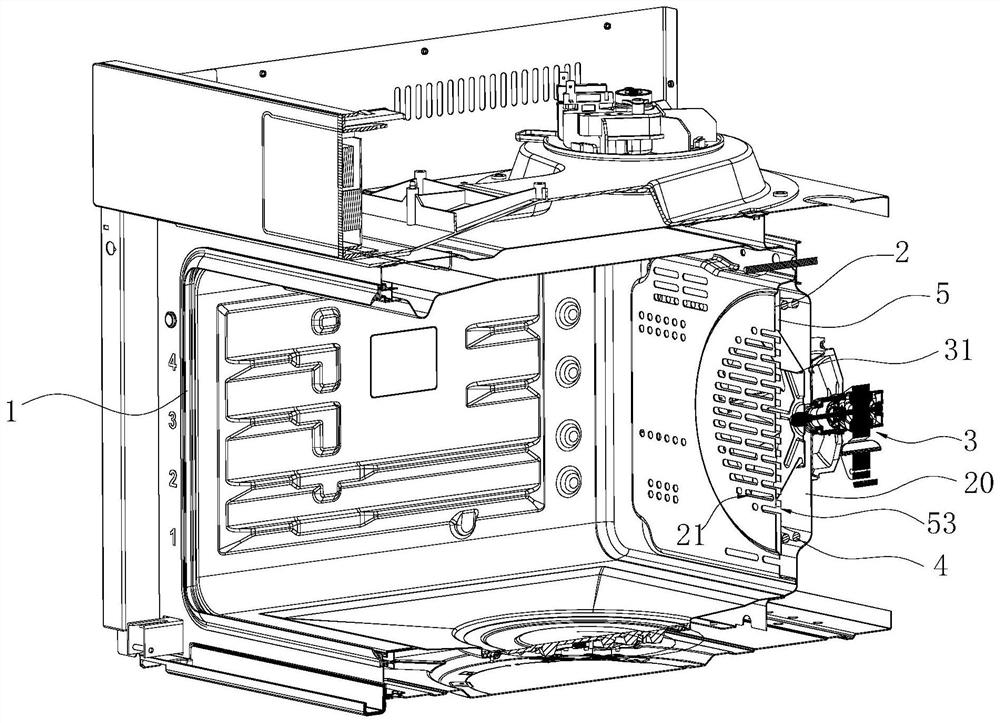

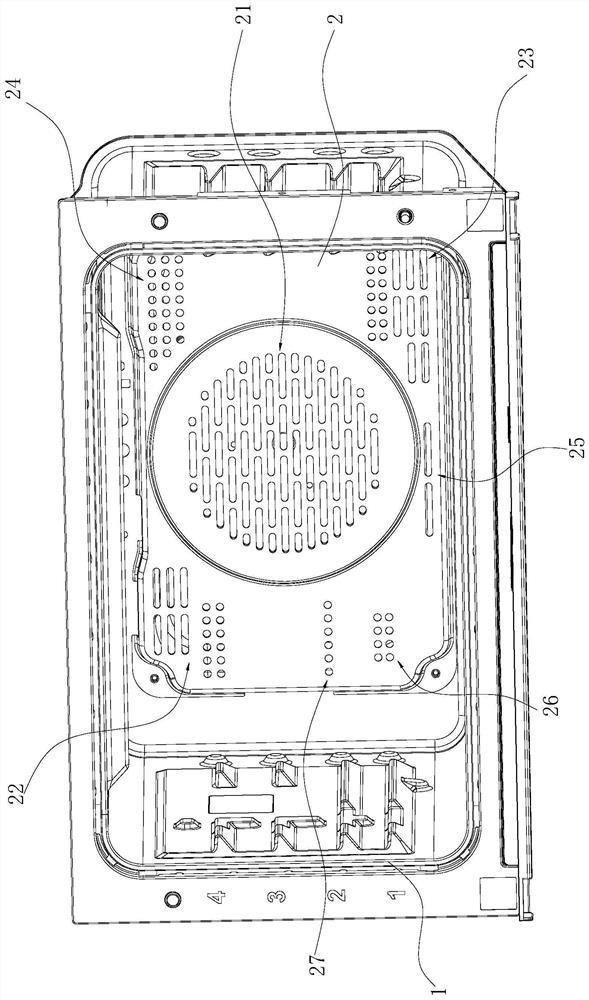

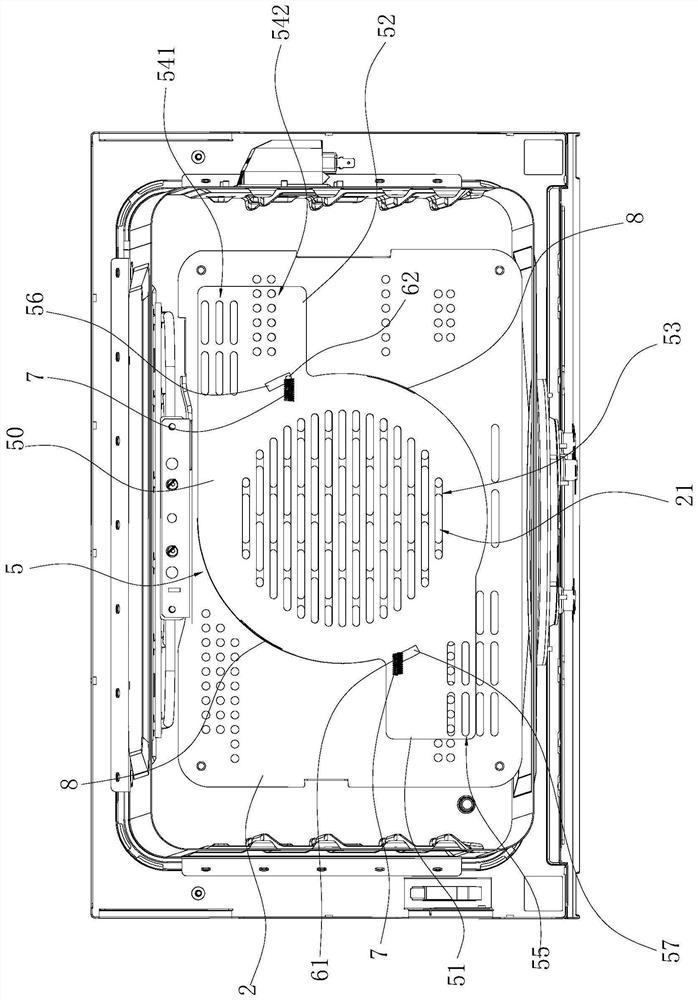

Cooking liner structure and oven with same

The invention relates to a cooking inner container structure and an oven with same. The structure comprises an inner container, a hot air baffle with an air inlet and an air outlet is arranged on the rear side of an inner cavity of the inner container, a hot air chamber is defined by the hot air baffle and a back plate of the inner container, an air heater is installed in the hot air chamber, heating pipes are arranged on the peripheries of fan blades of the air heater, the air inlet area of the air inlet is larger than the total air outlet area of the air outlet, the air outlet comprises a first air outlet located in the upper left portion of the hot air baffle and a second air outlet located in the lower right portion of the hot air baffle, the sum of the air outlet amount of the first air outlet and the air outlet amount of the second air outlet is larger than 50% of the total air outlet amount of the air outlet, and the air outlet amount of the first air outlet is larger than that of the second air outlet. The air inlet amount of the hot air chamber can be increased, then the air outlet amount needed by cooking is met, the cooking heat needed by the inner container is met on the basis that only one heating pipe is arranged, the uniformity of a temperature field in the inner container can be promoted, and then the cooking effect of the inner container is improved. In addition, the cooking efficiency and the cooking effect can be improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com