Production line and process of steel road barrier with epoxy zinc-based polyester composite coating

A composite coating and production process technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of galvanizing manual production, waste of resources, waste of national resources, etc., to meet the uniformity of coating and reduce heat loss. , The effect of stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

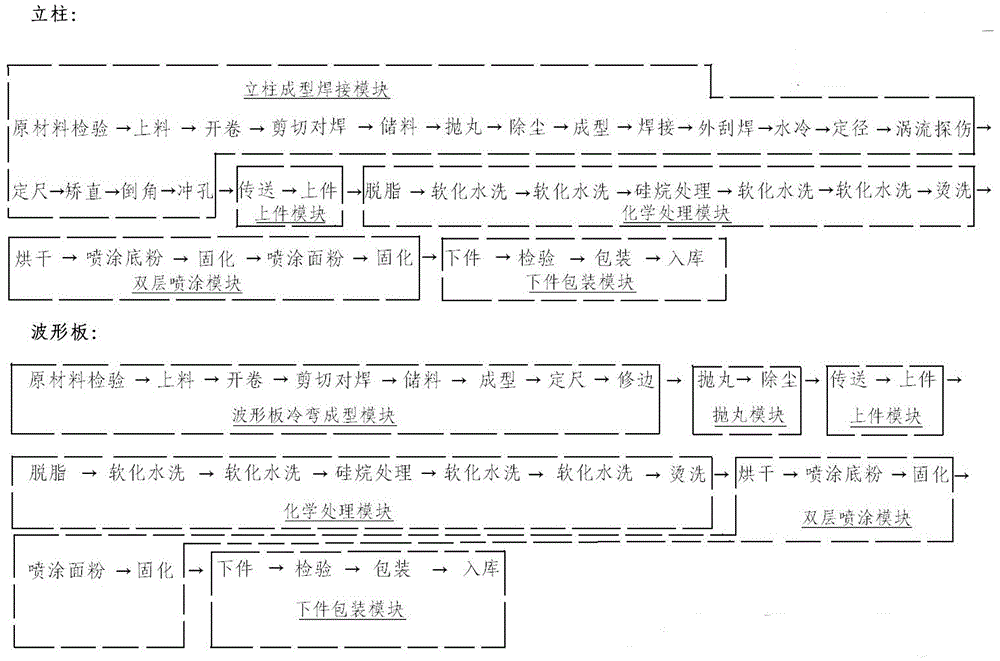

[0034] Example 1, such as figure 1 As shown, an epoxy zinc-based polyester composite coating road steel guardrail production line includes a corrugated board production equipment and a column production equipment.

[0035] The corrugated plate production equipment mainly includes the corrugated plate cold-formed module, the corrugated plate shot blasting processing module, the corrugated plate chemical processing module, the corrugated plate automatic loading module, the corrugated plate double-layer spraying module, the corrugated plate automatic loading and packaging module, each Automatic connection between modules without manual work.

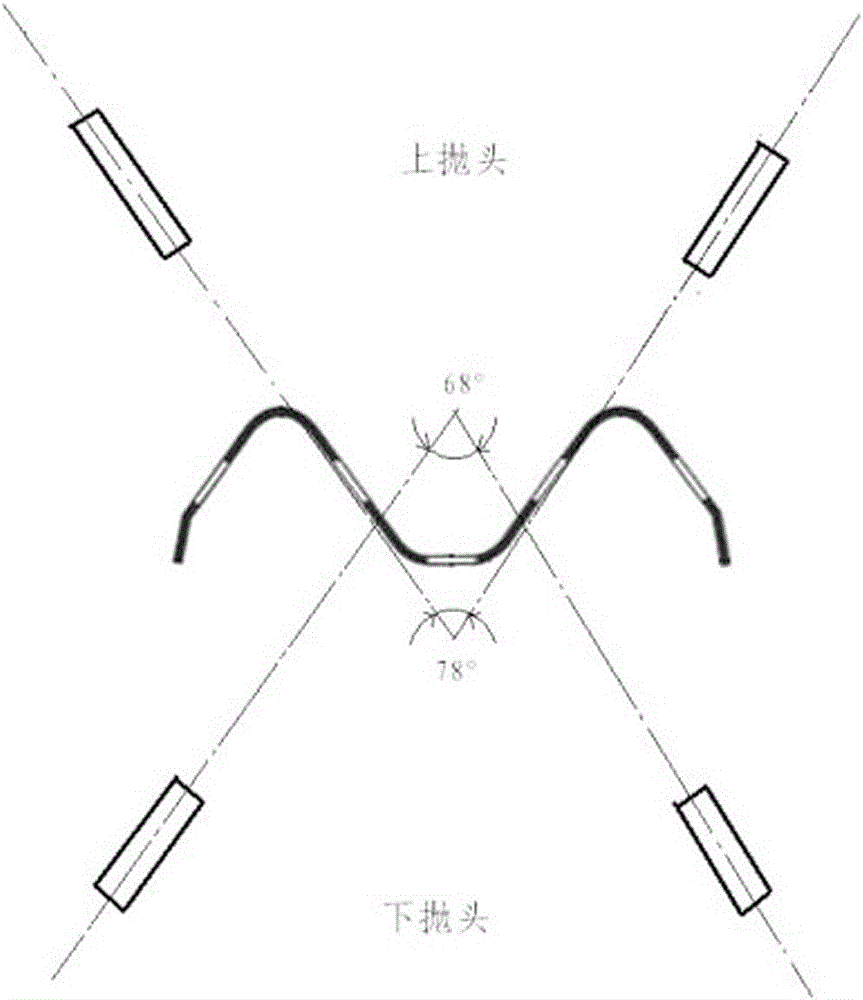

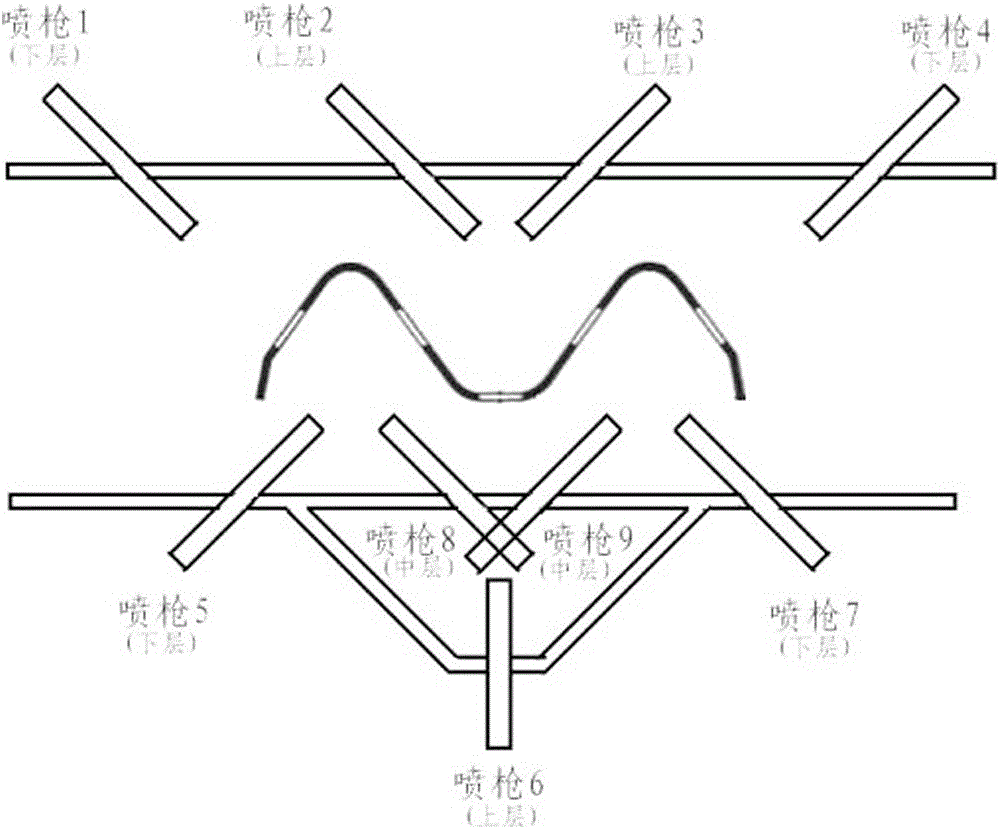

[0036] Such as figure 2 As shown, the corrugated plate is difficult to shot blasting due to its complex shape. The corrugated plate shot blasting processing module adopts a specific blasting head arrangement. There are two groups of blasting heads, one set for the upper and lower blasting heads. Perform shot blasting on the front of the corruga...

Embodiment 2

[0040] Embodiment 2 is the production process of the epoxy zinc-based polyester composite coating road steel guardrail. The production process includes the preparation process of the corrugated board and the preparation process of the column.

[0041] The preparation process of the corrugated board includes: strip steel feeding → cold bending forming → shot blasting treatment → dust removal → automatic loading → chemical pretreatment → drying → spraying primer → curing → spraying flour → curing → automatic loading → Automatic inspection → automatic packaging.

[0042] The preparation process of the column includes: strip steel feeding → shot blasting → dust removal → forming welding → automatic loading → chemical pretreatment → spraying base powder → curing → spraying flour → curing → automatic loading → automatic inspection → automatic packaging.

[0043] In the preparation process of the column, the process of forming and welding steps is anti-rust. In this embodiment, the environm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com