Method for forming car rear shaft support assembly cross beam

A bracket assembly and forming method technology, applied in the direction of forming tools, perforating tools, feeding devices, etc., can solve the problems that cannot meet the requirements of large batches, large-scale production, many steel plate materials, and low production efficiency, so as to save processing procedures , high production efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0054] Example one:

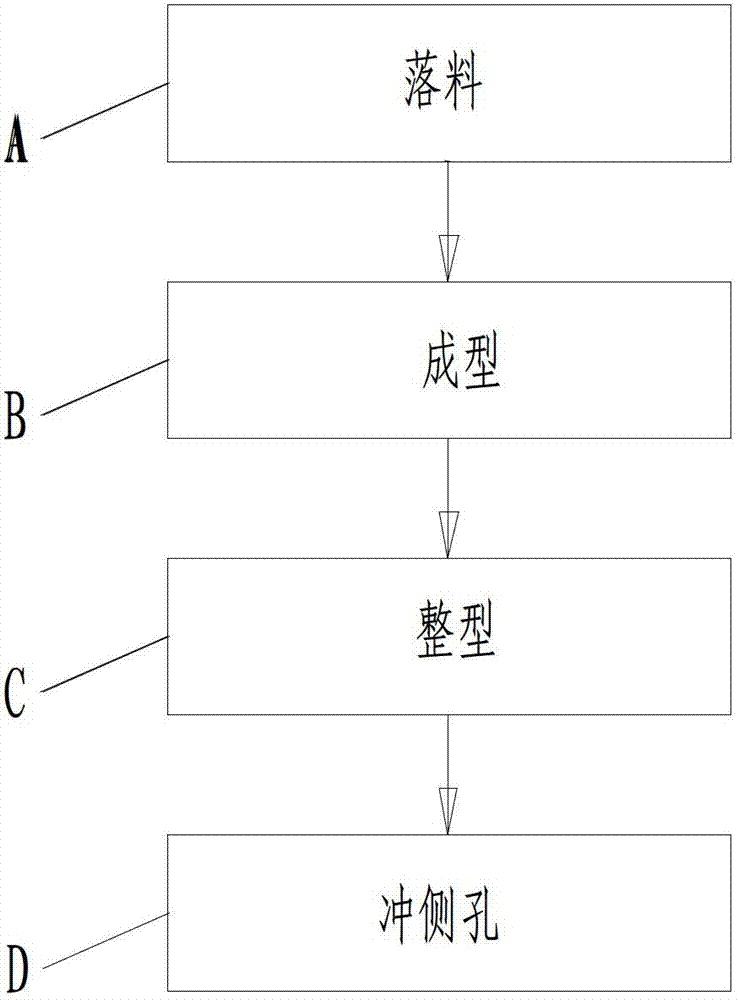

[0055] A method for forming a beam of an automobile rear axle bracket assembly, the method includes the following steps (see figure 1 Flow chart shown):

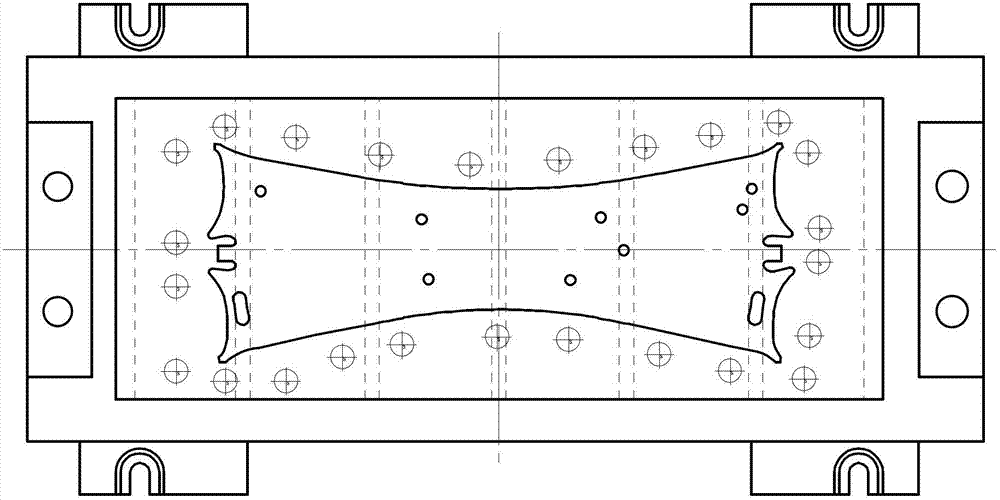

[0056] A. Blanking: The blanking die 1 is used to punch the steel plate on the punching machine to obtain a waist-drum-shaped blank plate 2 with multiple mounting holes in the middle and large at both ends;

[0057] B. Forming: Using a forming die 3 on a hydraulic press, the waist drum-shaped blank plate 2 is stamped into a preformed tank 4 composed of a deformed top surface and two waist-drum-shaped sides;

[0058] C. Shaping: 4 pairs of pre-formed tanks continue to be shaped on the hydraulic press;

[0059] D. Punching side holes: The punching die 5 is used on the punching machine to punch the side holes of the reshaped preformed trough body 4 to obtain the finished automobile rear axle bracket assembly beam 6.

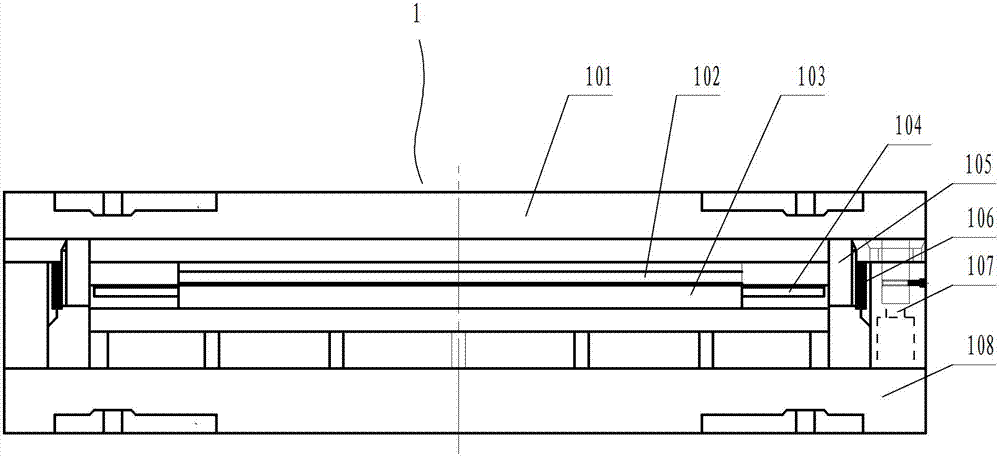

[0060] The blanking mold 1 used in the above step A includes a blanking upper mold base 101, a blank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com