Electric self-propelled numerical-control plot drill seeder

A self-propelled, drill technology, applied in the directions of sowing seeders, seeder parts, etc., can solve the problems of uneven seeding amount, reduction of basic seedlings, high price, etc., and achieve high control precision, improve uniformity, control handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

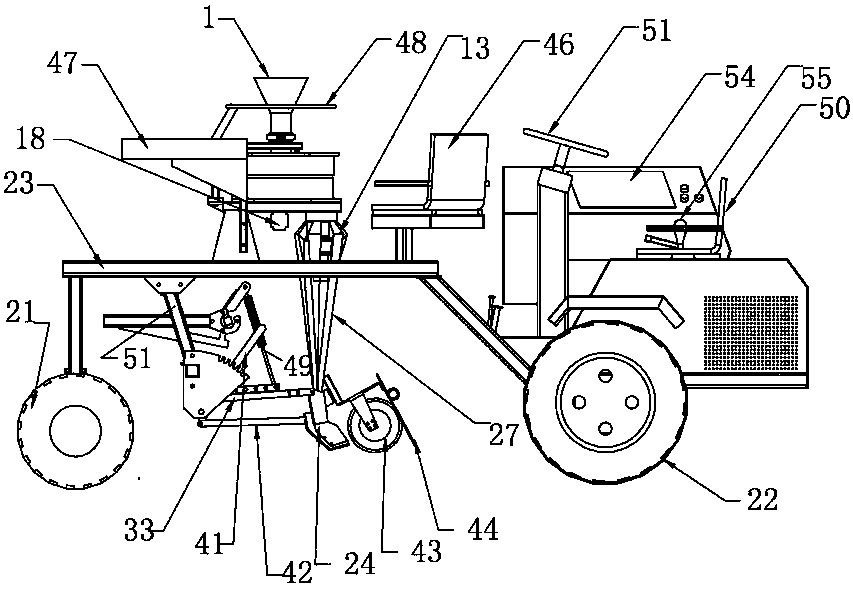

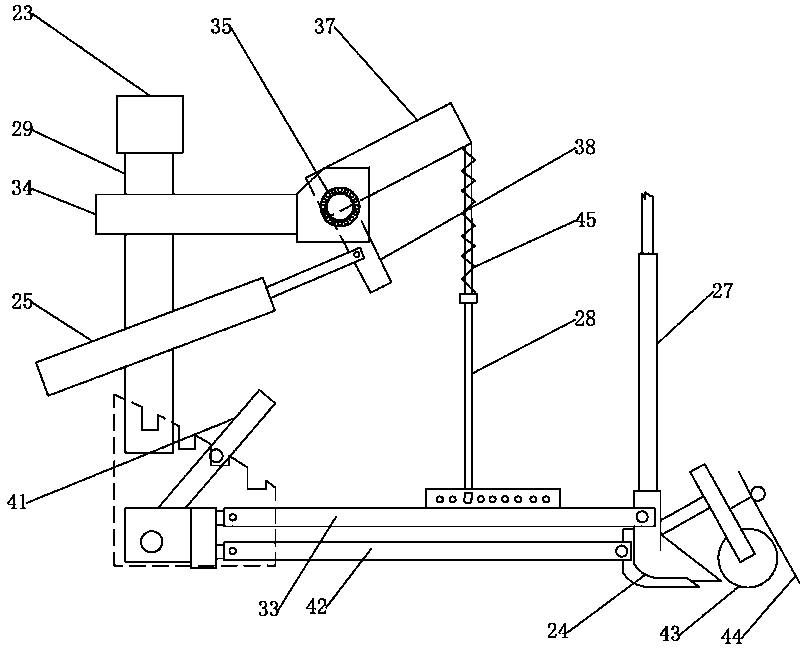

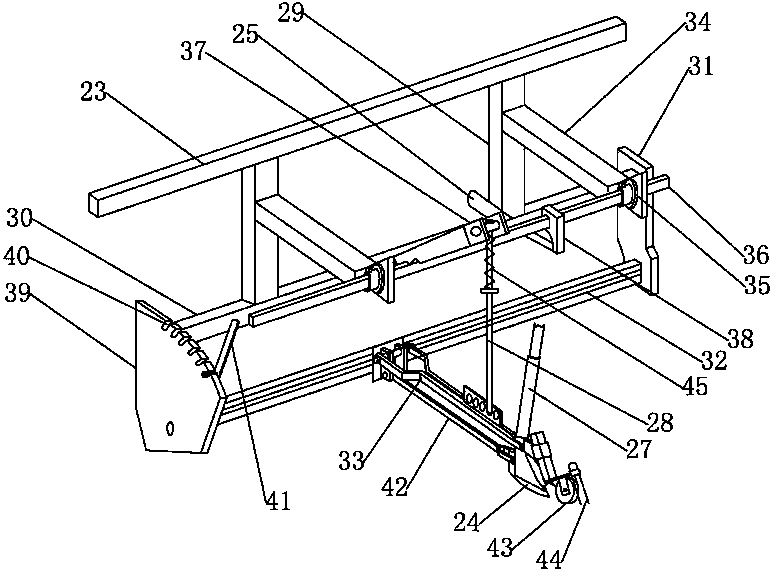

[0047] Embodiment 1: A kind of electric self-propelled numerical control plot drill machine, see Figure 1 to Figure 15 , comprising an electric traveling mechanism and a vehicle-mounted power supply, a sorting mechanism, a ditching and sowing mechanism, a lifting mechanism, and an automatic control device. The driving console 50 at the rear of the frame 23, the hydraulic steering machine 51 arranged in front of the traveling console, the steering oil cylinder 26 for controlling the steering of the two front wheels of the seed drill, the connection between the two rear wheels 22, body gearbox 56, the lifting mechanism includes a hydraulic oil pump arranged at the frame rear, a lifting cylinder 25 connected with the hydraulic oil pump for realizing the lifting action of the ditch planting mechanism; Between the front wheels 21, the hydraulic steering machine 51 is correspondingly connected with the steering oil cylinder for realizing the steering of the two front wheels; The D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com