Semiconductor device gold beryllium alloy material and preparation method thereof

An alloy material and semiconductor technology, applied in the field of gold beryllium alloy materials for semiconductor devices and their preparation, can solve the problems of special Be chemical properties, personal injury, and reduce product purity, achieve precise control of coating uniformity, overcome brittleness, The effect of improving processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

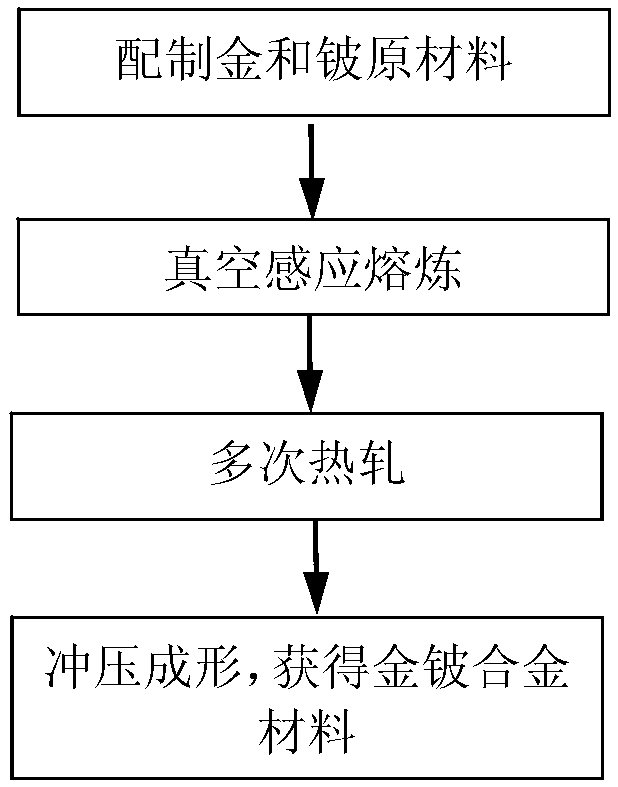

Method used

Image

Examples

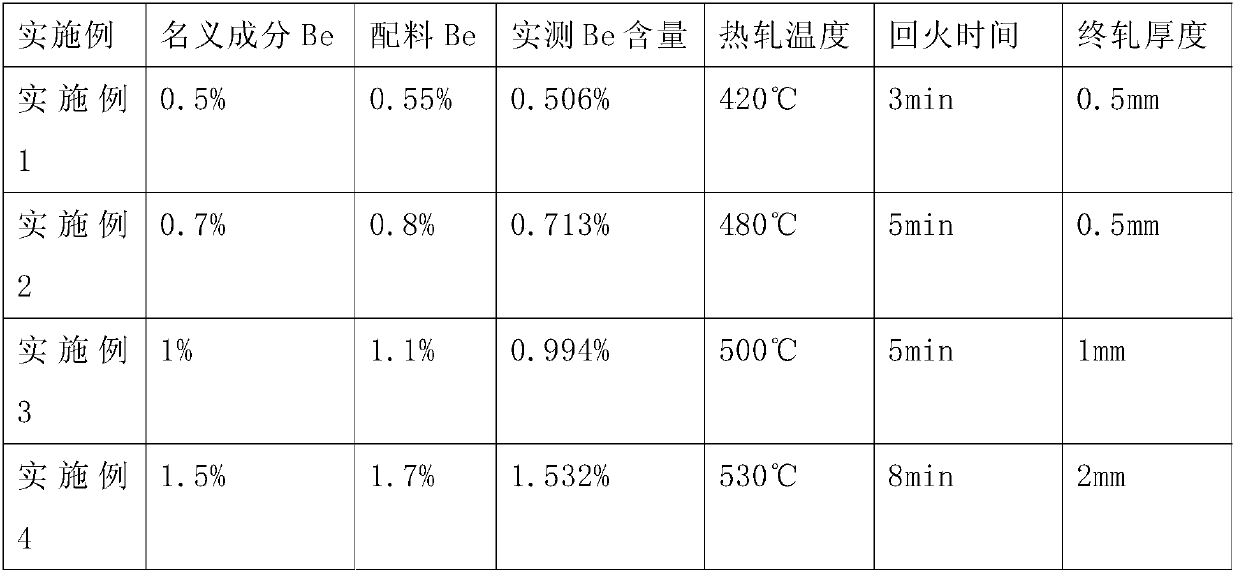

Embodiment 1

[0033] The gold-beryllium alloy material whose nominal composition is AuBe0.5 (the beryllium content is 0.5%, and the remainder is gold) is prepared in the following ways:

[0034] (1) Using gold and beryllium metal as raw materials, the purity of gold is not less than 4N, and the purity of beryllium is not less than 3N; the ingredients are formulated according to Be 0.55%, and the rest is gold. Beryllium is wrapped with gold sheets and placed in the hopper above the vacuum induction melting furnace; the remaining gold materials are placed in graphite crucibles;

[0035] (2) Vacuum until the vacuum degree reaches 5×10 -2 After Pa, open the filling valve and fill the furnace with high-purity argon to 0.05MPa;

[0036] (3) Start to transmit electricity slowly, and induction heating causes the gold in the crucible to start to melt;

[0037] (4) After the gold is completely melted, open the feeding hopper, so that the gold flakes and the beryllium material wrapped therein are ad...

Embodiment 2

[0046] The preparation composition is the gold-beryllium alloy material of AuBe0.7 (the beryllium content is 0.7%, and the remainder is gold), and its preparation method is:

[0047] (1) Using gold and beryllium metal as raw materials, the purity of gold is not less than 4N, and the purity of beryllium is not less than 3N; the ingredients are formulated according to Be 0.8%, and the rest is gold. Beryllium is wrapped with gold sheets and placed in the hopper above the vacuum induction melting furnace; the remaining gold materials are placed in graphite crucibles;

[0048] (2) vacuumize, fill with argon, smelt, refine, cast according to the method for embodiment 1, obtain gold-beryllium alloy ingot;

[0049] (3) Carry out heat treatment to the alloy ingot obtained in step (2) by using a heating furnace, the heat treatment temperature is 480°C, and the time is 35min;

[0050] (4) The gold-beryllium alloy ingot is subjected to thermoplastic processing by using plastic processing...

Embodiment 3

[0055] The preparation composition is the gold-beryllium alloy material of AuBe1 (the beryllium content is 1%, and the remainder is gold), and its preparation method is:

[0056] (1) Using gold and beryllium metal as raw materials, the purity of gold is not less than 4N, and the purity of beryllium is not less than 3N; the ingredients are formulated according to Be 1.1%, and the rest is gold. Beryllium is wrapped with gold sheets and placed in the hopper above the vacuum induction melting furnace; the remaining gold materials are placed in graphite crucibles;

[0057] (2) vacuumize, fill with argon, smelt, refine, cast according to the method for embodiment 1, obtain gold-beryllium alloy ingot;

[0058] (3) Carry out heat treatment to the alloy ingot obtained in step (2) by using a heating furnace, the heat treatment temperature is 500° C., and the time is 30 min;

[0059] (4) The gold-beryllium alloy ingot is subjected to thermoplastic processing by using plastic processing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com