Titan bronze for slot wedge on turbo generator rotor and its processing technology

A turbogenerator and rotor wedge technology, applied in the field of high-strength heat-resistant titanium bronze, can solve problems such as pollution, high production costs, and low pass rate of flaw detection, and achieve the effects of reducing wear and enhancing heat dissipation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

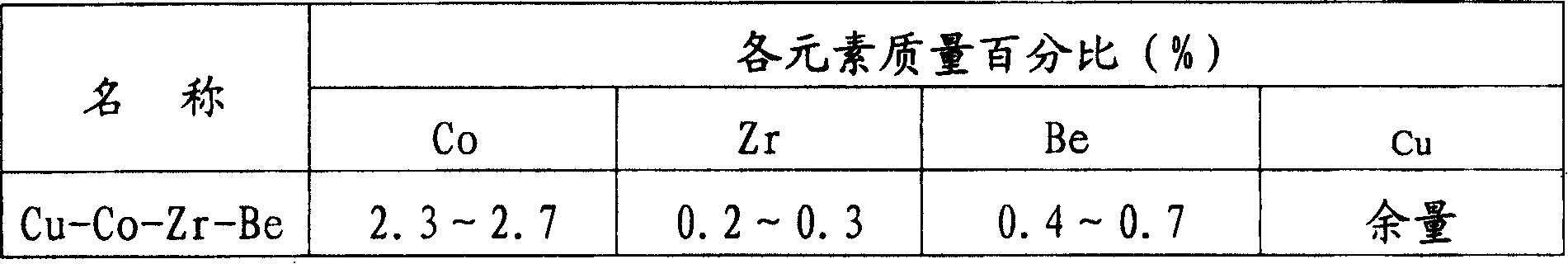

Method used

Image

Examples

Embodiment 1

[0023] When the alloy composition (percentage by weight) is: Ti0.4%, Ni2.5%, Be0.3%, when the balance is Cu, according to the following process: cryolite, salt, potassium chloride, sodium fluoride are pressed 30: Mix the refining agent in a weight ratio of 50:10:10 to remove the crystal water, weigh 0.5% of the charge weight refining agent and spread it on the bottom of the vacuum intermediate frequency induction furnace, put the above-mentioned metals into the furnace, and close the furnace shell Carry out melting and casting; after peeling the ingot, carry out temperature-controlled forging in the temperature range of 800-880°C; % polyhydroxyethylene grease; then use 20# engine oil and molybdenum disulfide phosphate grease mixed in a weight ratio of 1:0.16 for cold forming; The comprehensive mechanical performance data of the material are shown in Table 3:

[0024] Table three

[0025] Performance

Embodiment 2

[0027] When the alloy composition (percentage by weight) is: Ti0.6%, Ni1.5%, Be0.1%, when the balance is Cu, according to the following process: cryolite, salt, potassium chloride, sodium fluoride are pressed 30: Mix the refining agent in a weight ratio of 50:10:10 to remove the crystal water, weigh 0.3% of the charge weight refining agent and spread it on the bottom of the vacuum intermediate frequency induction furnace, put the above-mentioned metals into the furnace, and close the furnace shell Carry out melting and casting; after peeling the ingot, carry out temperature-controlled forging in the temperature range of 800-880°C; % polyhydroxyethylene grease; then use 20# engine oil and molybdenum disulfide phosphate ester as a lubricant mixed in a weight ratio of 1:0.15 for cold forming; after aging treatment at 480°C for 2 hours, the alloy The comprehensive mechanical performance data of the material are shown in Table 4:

[0028] Table four

[0029] Performance ...

Embodiment 3

[0031] When the alloy composition (percentage by weight) is: Ti0.5%, Ni1.8%, Be0.27%, when the balance is Cu, according to the following process: cryolite, salt, potassium chloride, sodium fluoride are pressed 30: Mix the refining agent in a weight ratio of 50:10:10 to remove the crystal water, weigh 0.4% of the weight of the furnace material and spread it on the bottom of the vacuum intermediate frequency induction furnace, put the above-mentioned metals into the furnace, and close the furnace shell Carry out melting and casting; after peeling the ingot, carry out temperature-controlled forging in the temperature range of 800-880°C; % polyhydroxyethylene grease; then use 20# engine oil and molybdenum disulfide phosphate grease mixed in a weight ratio of 1:0.2 for cold forming; The comprehensive mechanical performance data of the material are shown in Table 5:

[0032] Table five

[0033] Performance

unit

Room temperature (15~27℃)

High temperature (427°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com