Patents

Literature

71results about How to "Improve lubrication quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

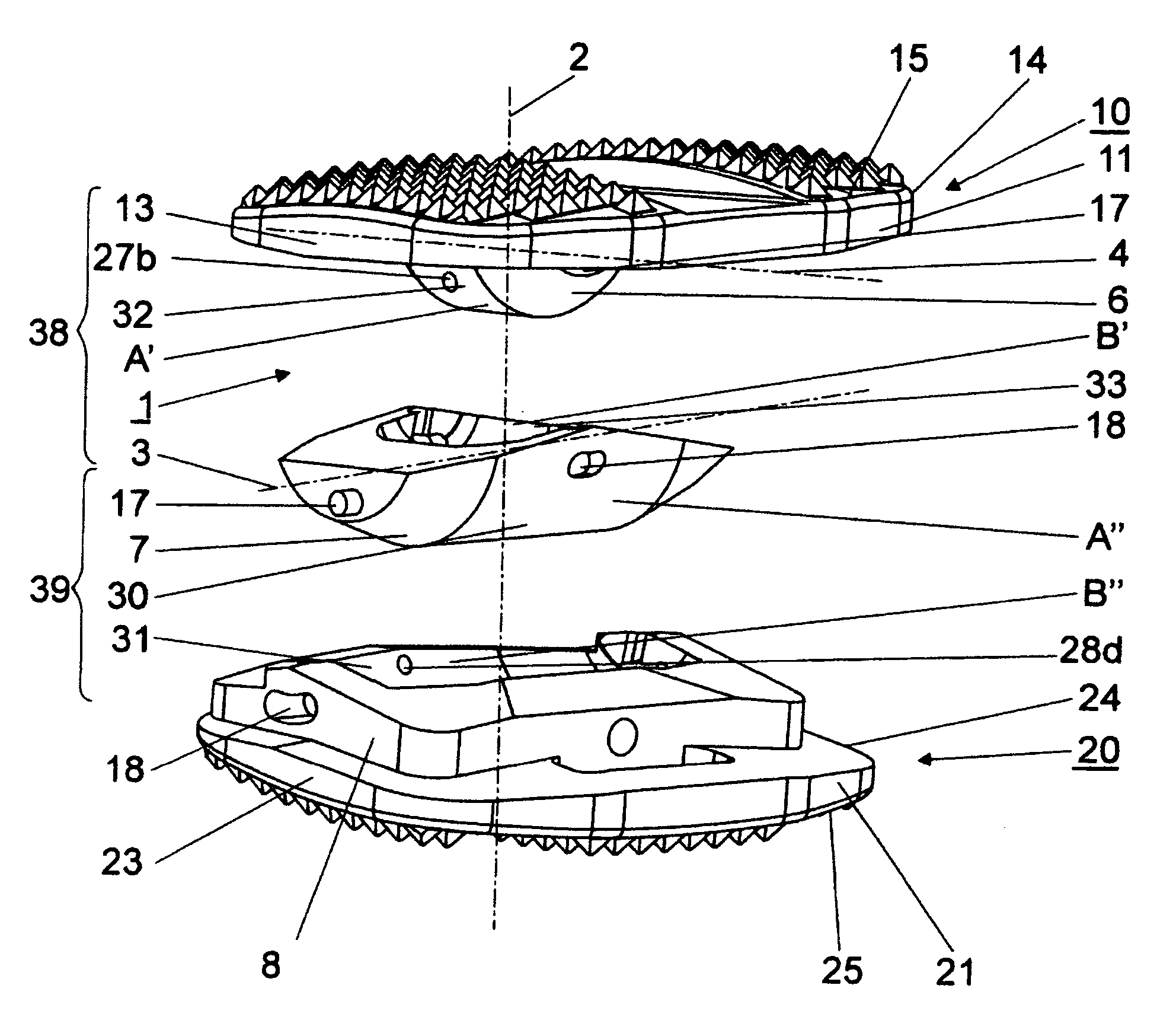

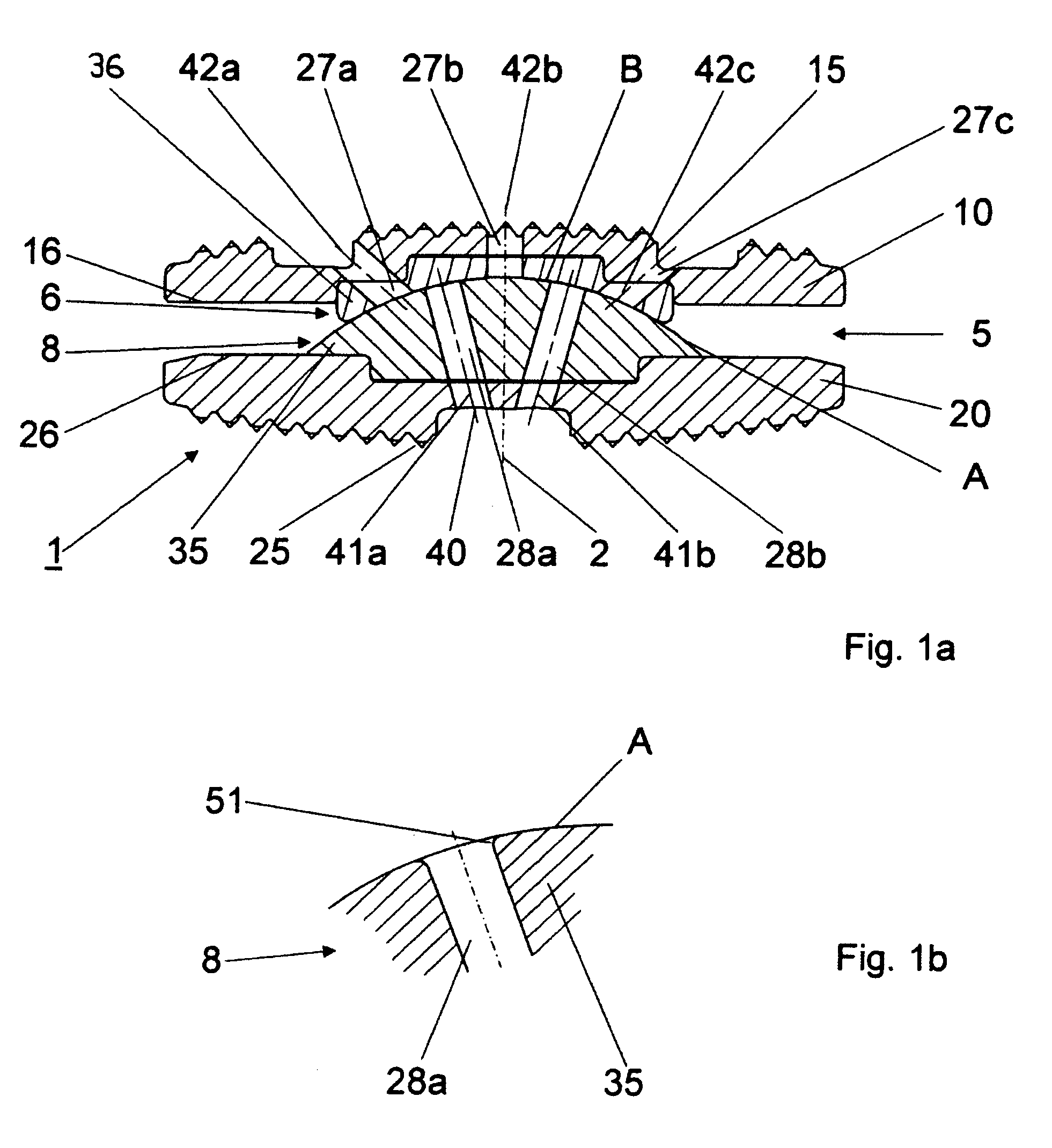

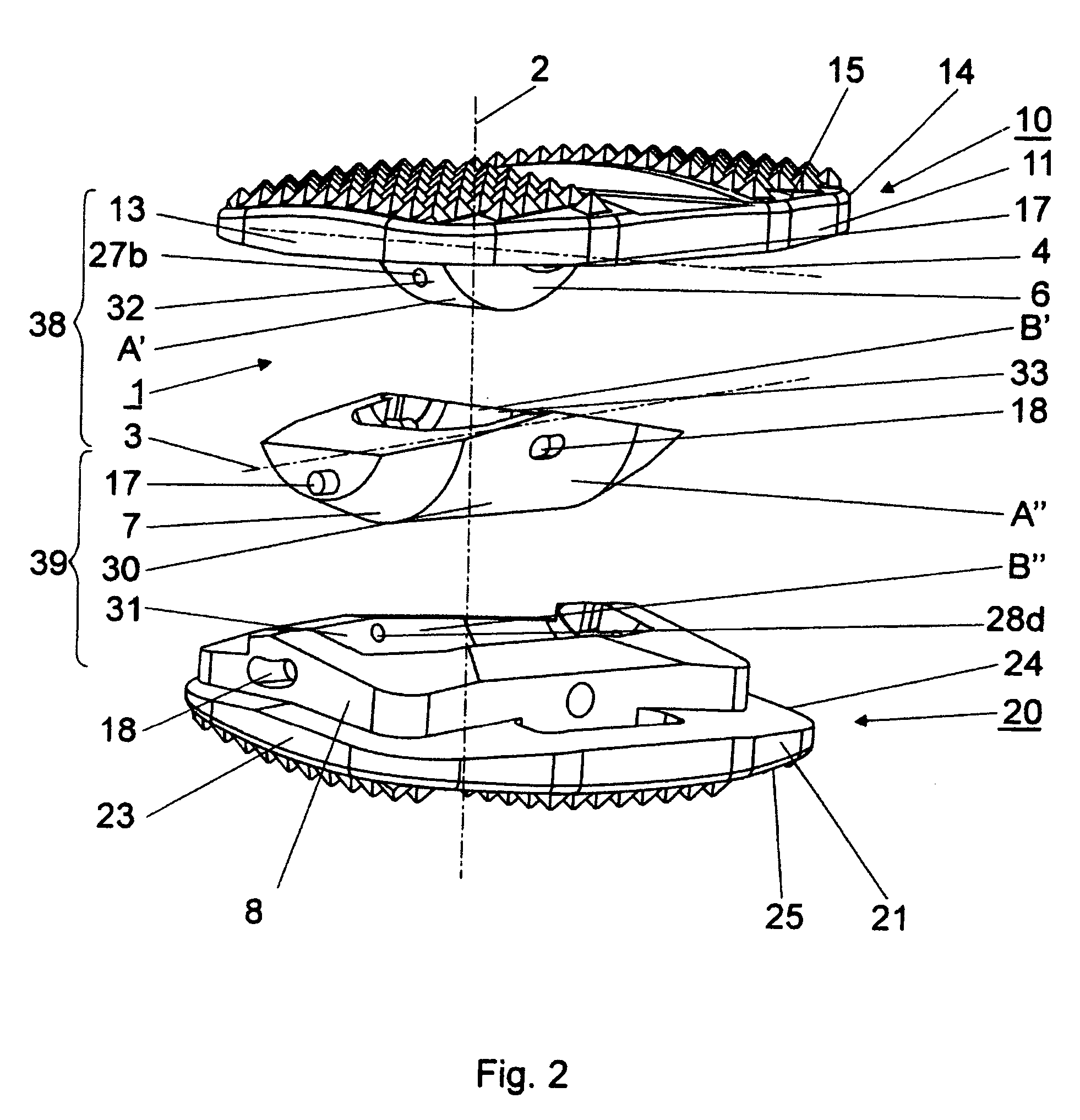

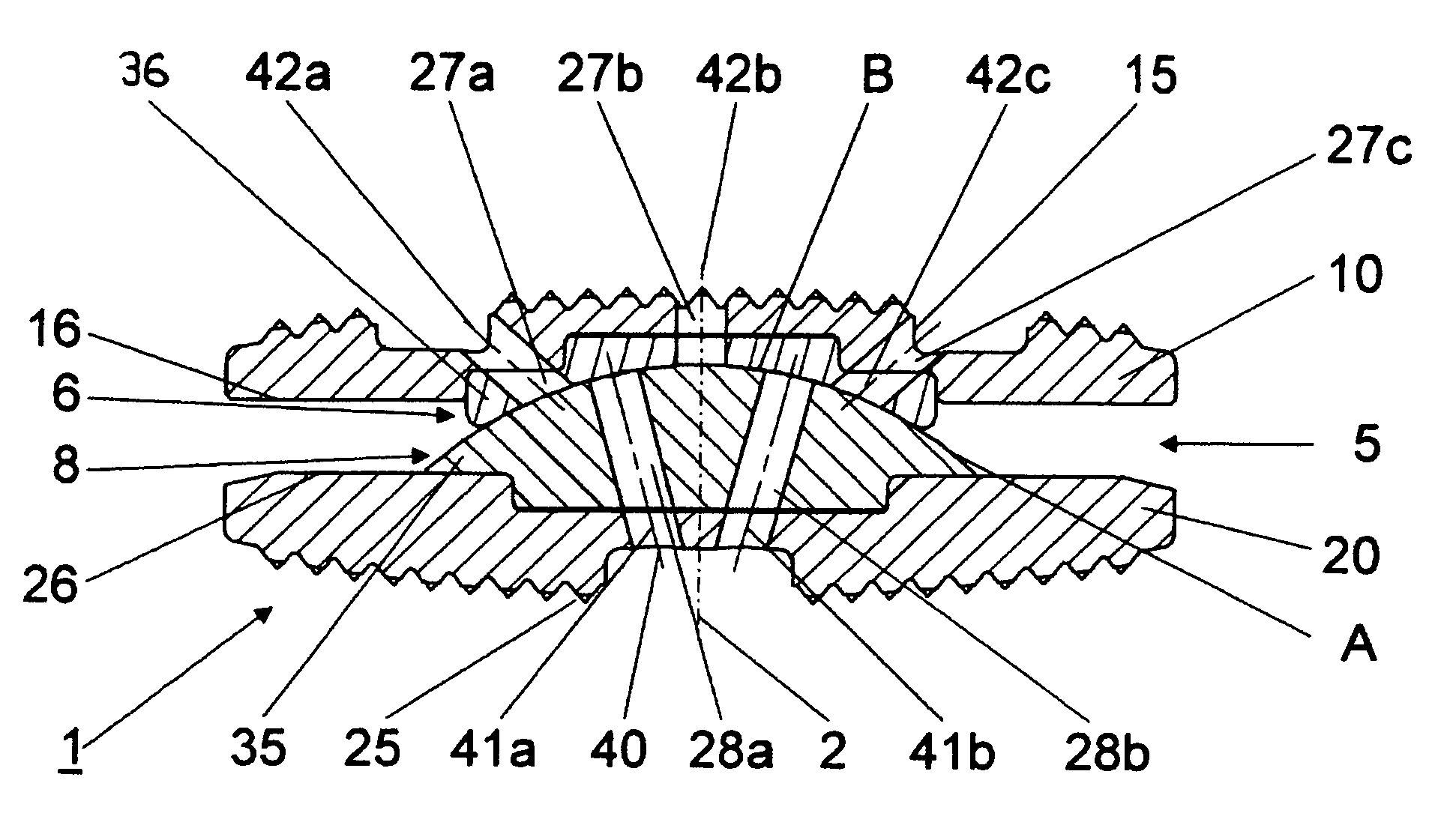

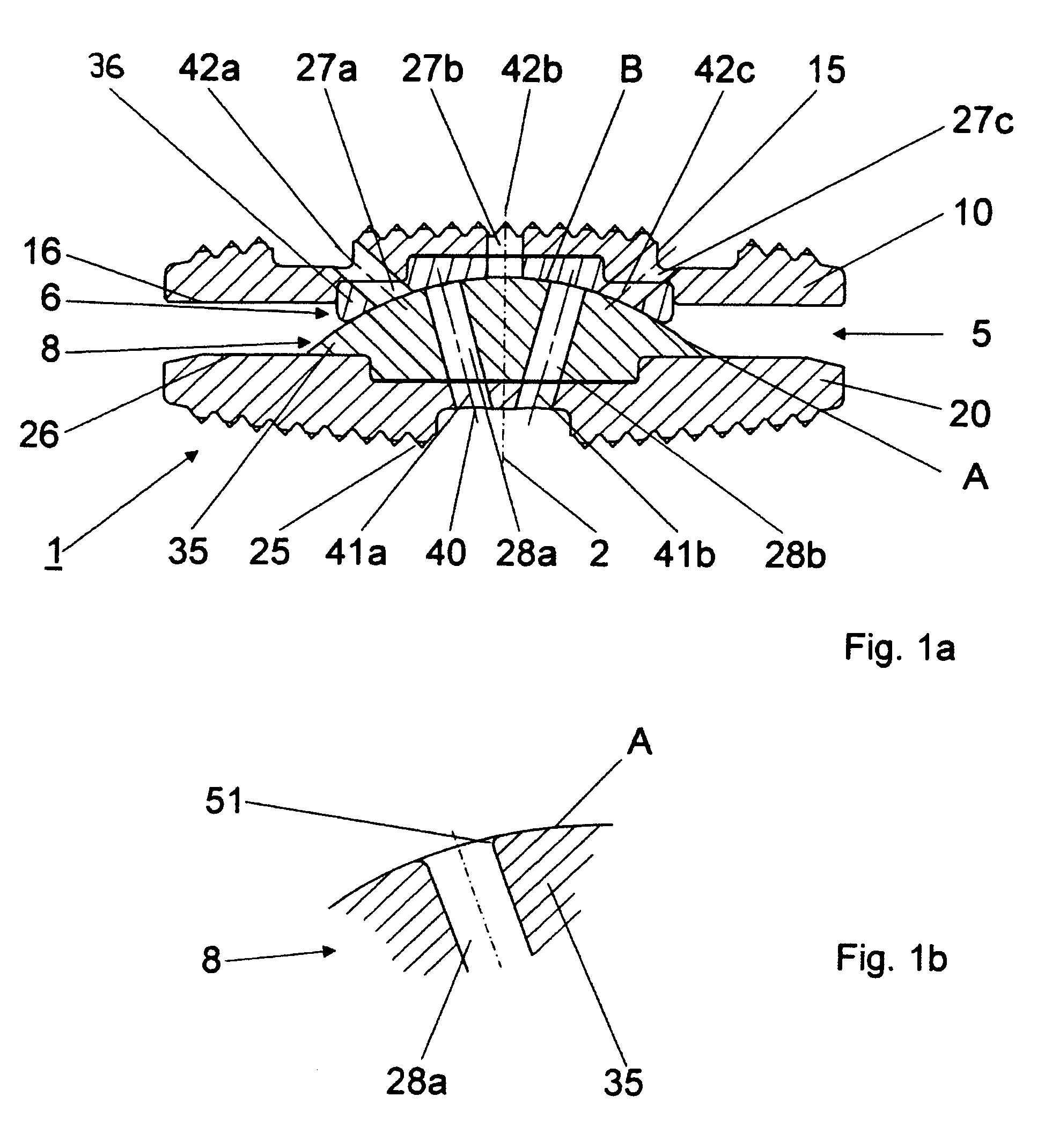

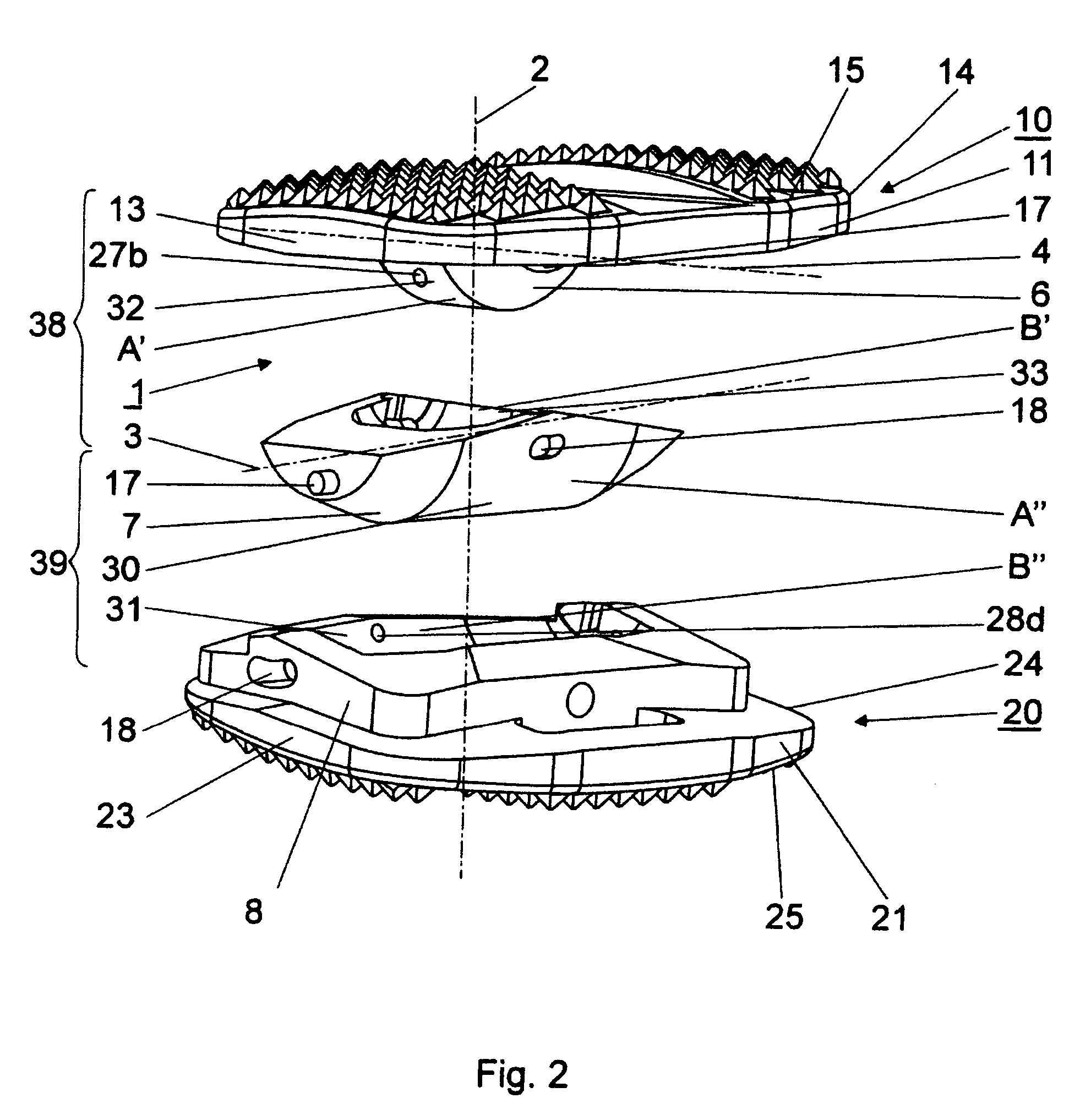

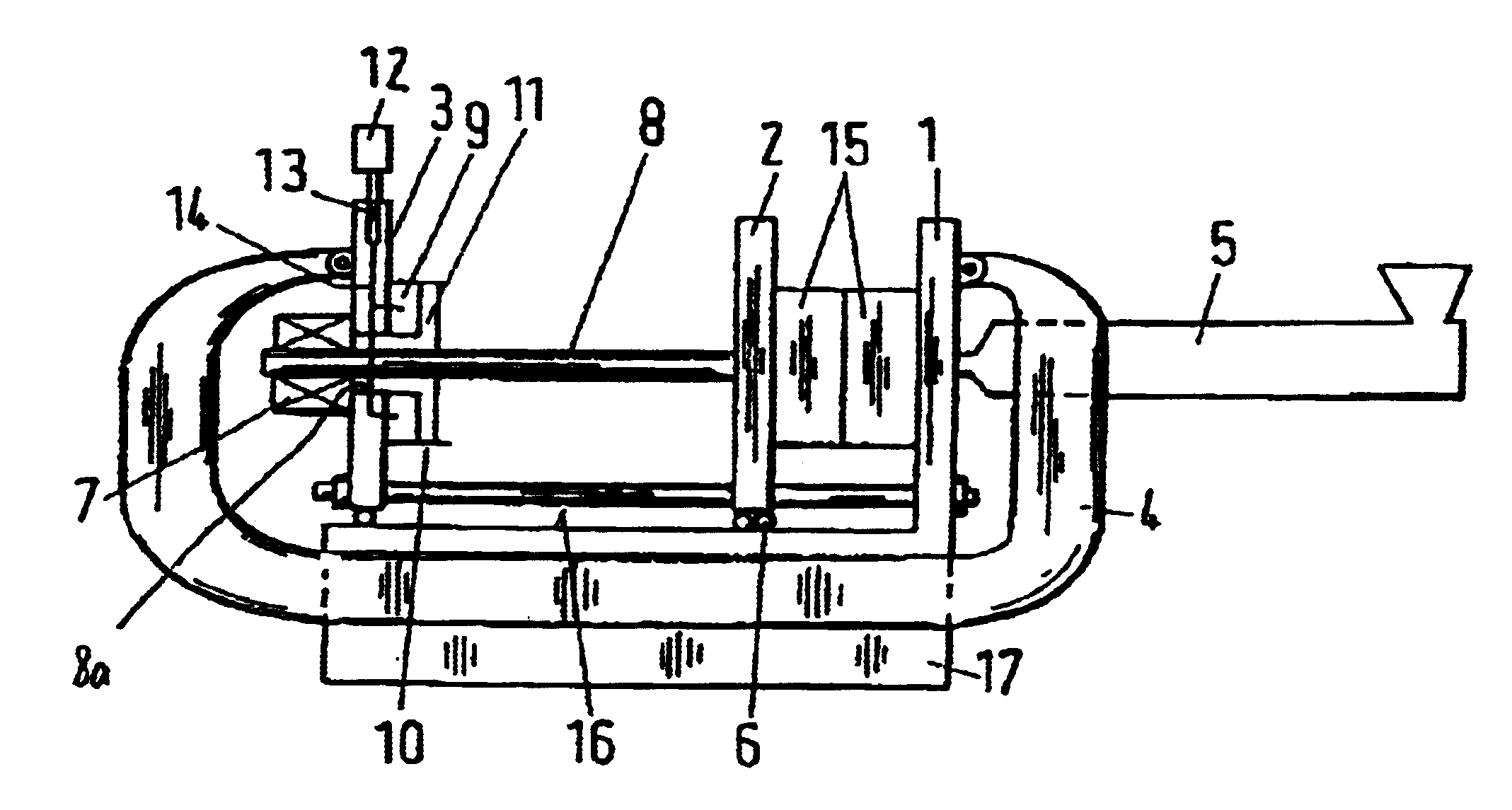

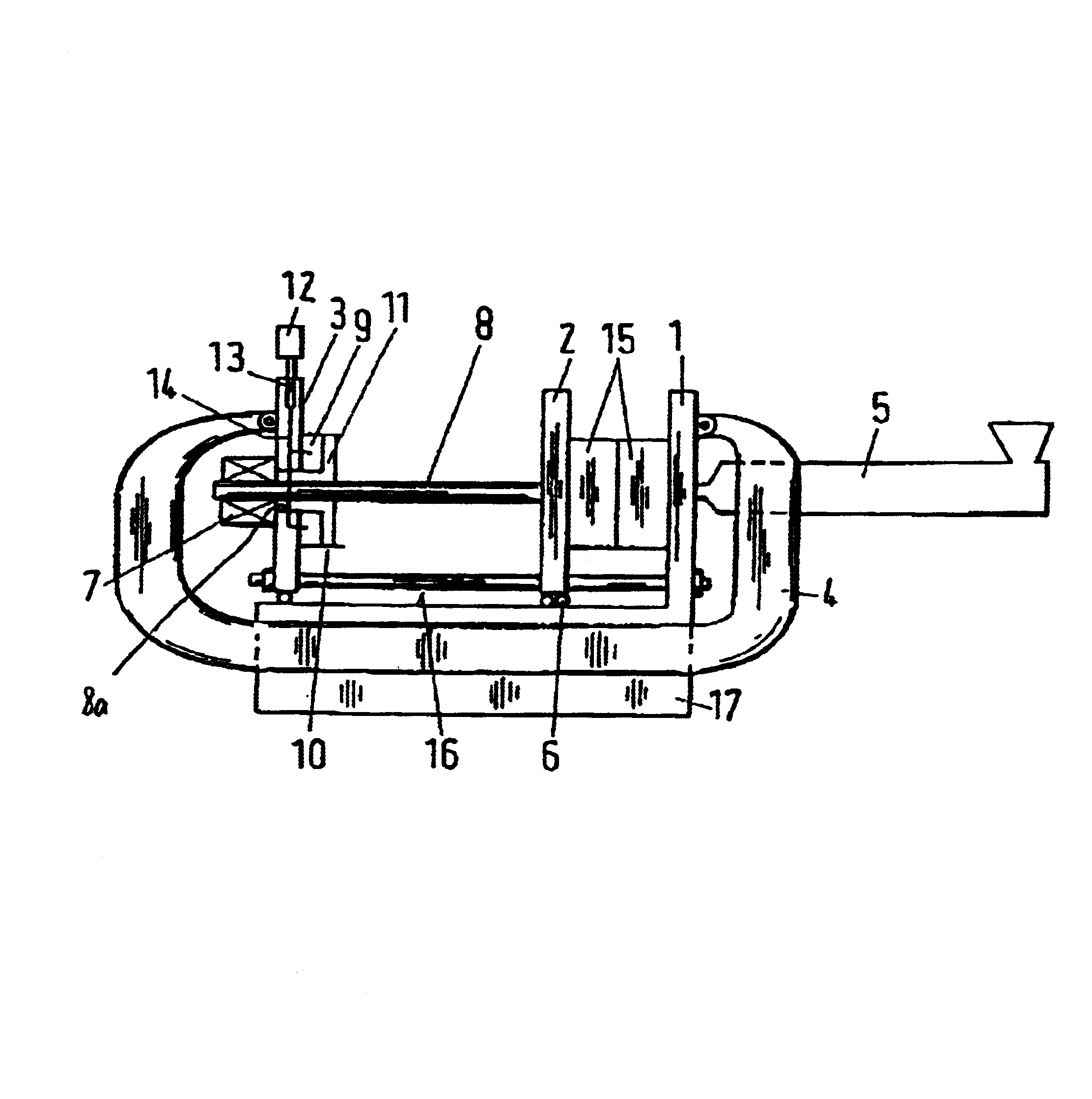

Articulated endoprosthesis

ActiveUS20060212123A1Improve lubrication qualityQuality improvementJet pumpsJoint implantsArticular surfacesArticular surface

An endoprosthesis for a joint, in particular a an intervertebral implant with a central axis, a top part, a bottom part and a joint provided between them, wherein the joint comprises at least two articular surfaces A and B that can slide on one another; the top part has a top apposed surface that intersects the central axis and lateral surfaces; the bottom part has a bottom apposed surface that intersects the central axis and lateral surfaces; and wherein the endoprosthesis comprises at least channel suitable to convey body fluid, said channel terminating in one of the two articular surfaces A and B and connecting it with the exterior of the endoprosthesis for the joint.

Owner:SYNTHES USA

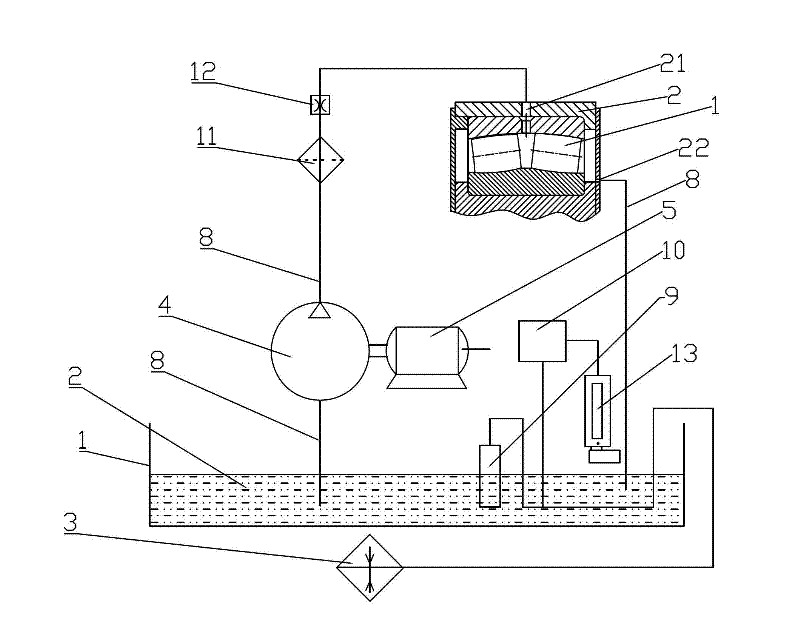

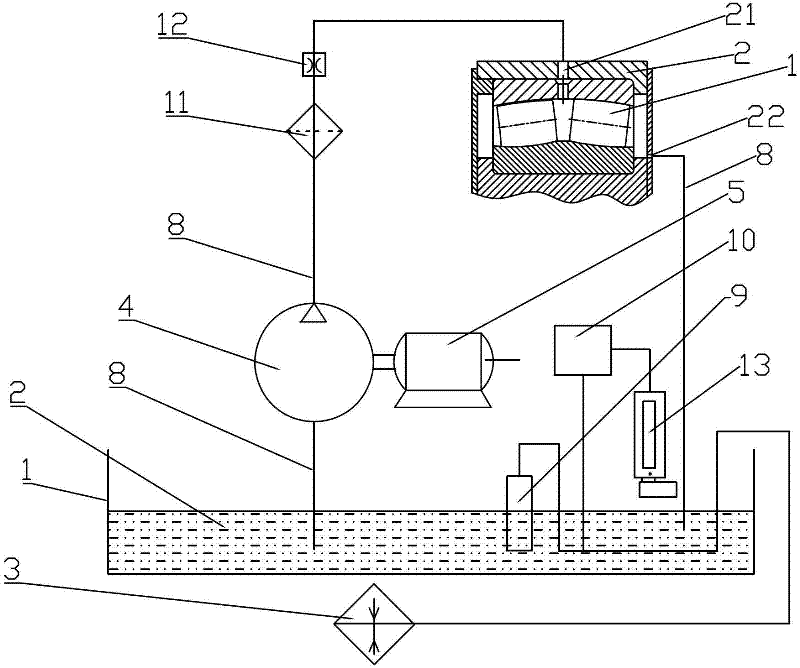

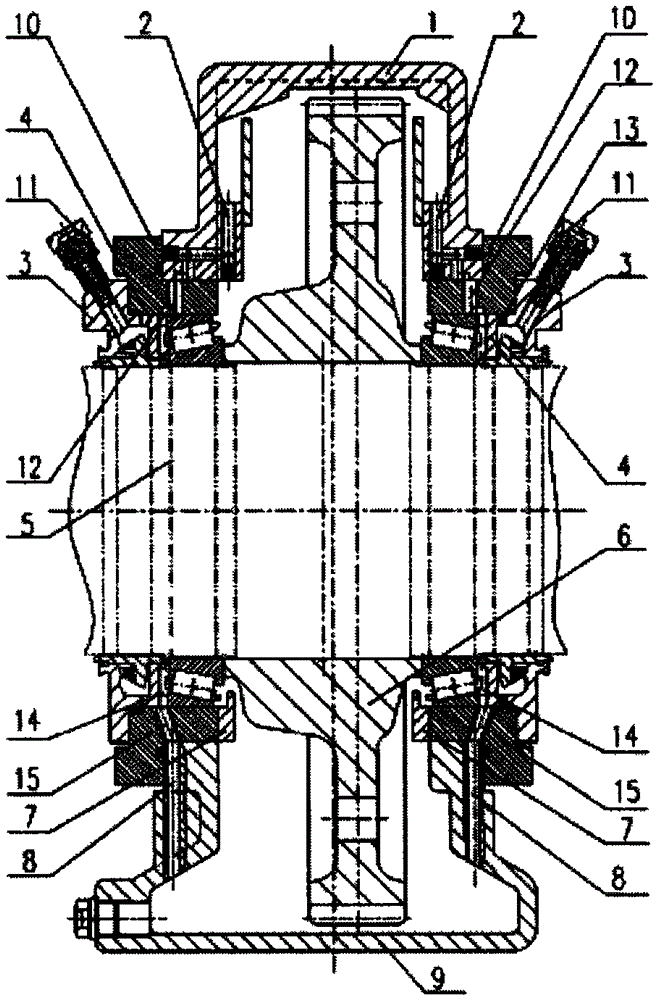

Spindle bearing lubricating system for wind driven generator

InactiveCN102654238AReduce pollutionImprove the lubrication effectMachines/enginesLubrication elementsWind drivenFuel tank

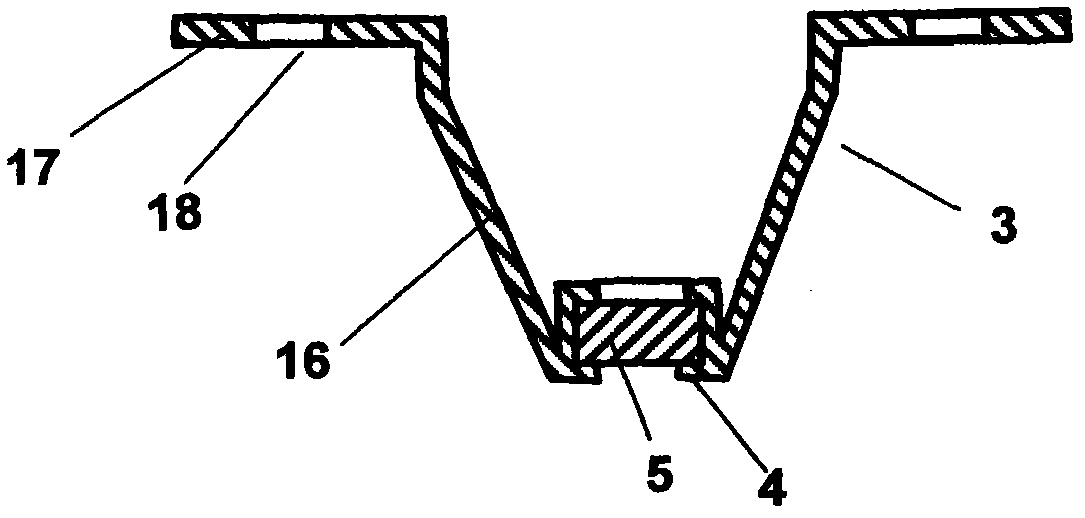

The invention relates to a spindle bearing lubricating system for a wind driven generator. The spindle bearing lubricating system comprises a spindle bearing (1) and a bearing base (2) sleeved on the spindle bearing (1), wherein an oil inlet (21) and an oil return hole (22) are arranged on the bearing base (2); the oil inlet (21) is connected with an oil pump (4) through an oil transmission pipe (31); the oil pump (4) is connected with an oil tank (5) through an oil transmission pipe (32); the oil return hole (22) is connected with one end of an oil transmission pipe (33); and the other end of the oil transmission pipe (33) extends into the oil tank (5). With the adoption of the spindle bearing lubricating system for the wind driven generator, lubrication oil can be circularly used and flows back into the oil tank after a bearing is lubricated, so as to achieve sufficient lubrication and reduce pollution to an environment. A heater is arranged in the oil tank, so that when an environment temperature is lower, the heater heats the lubrication oil to ensure that the lubricating system normally operates; and when an oil level reaches an alarming value, the spindle bearing lubricating system can automatically alarm, so that the service life of the bearing is prolonged.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

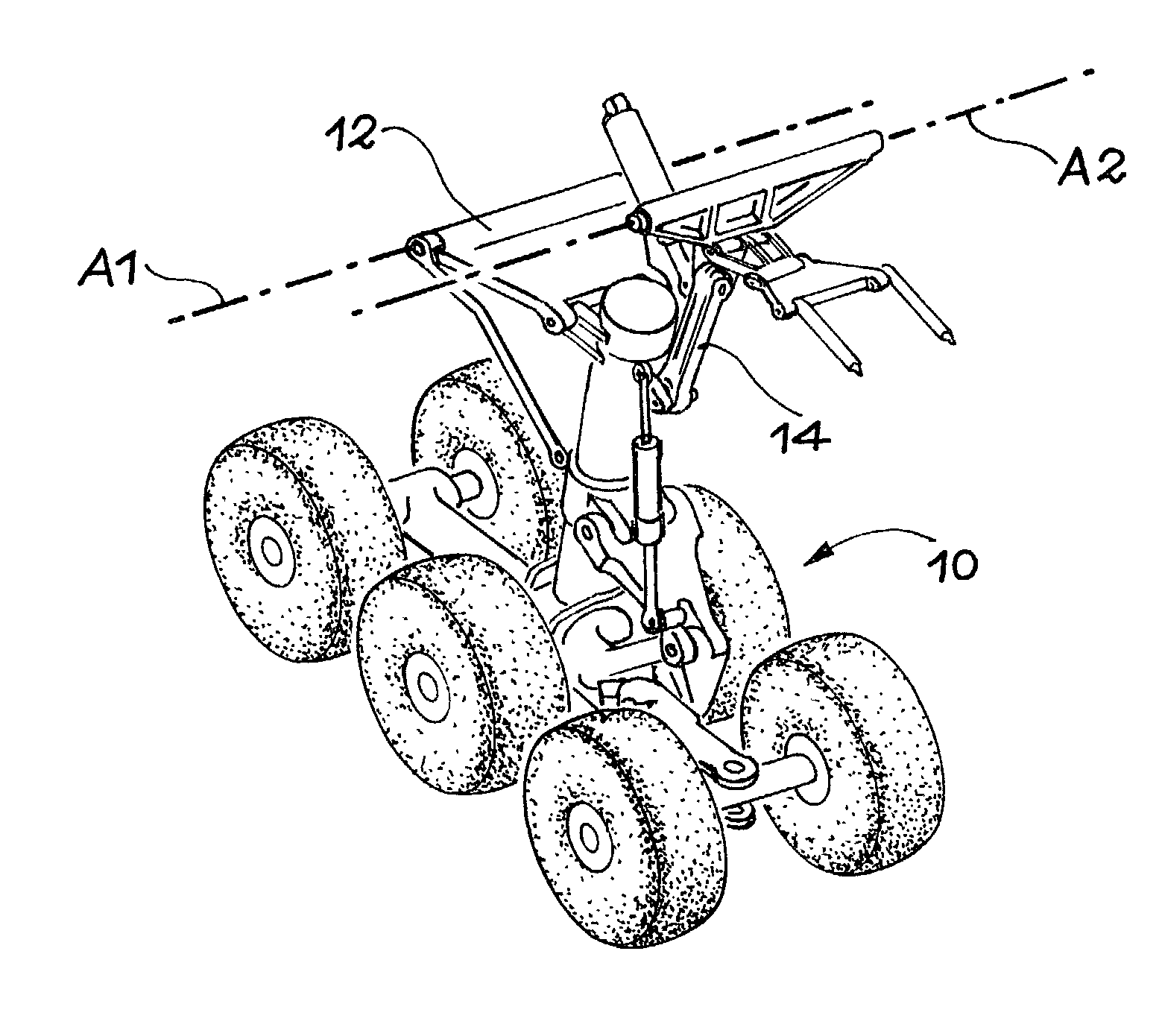

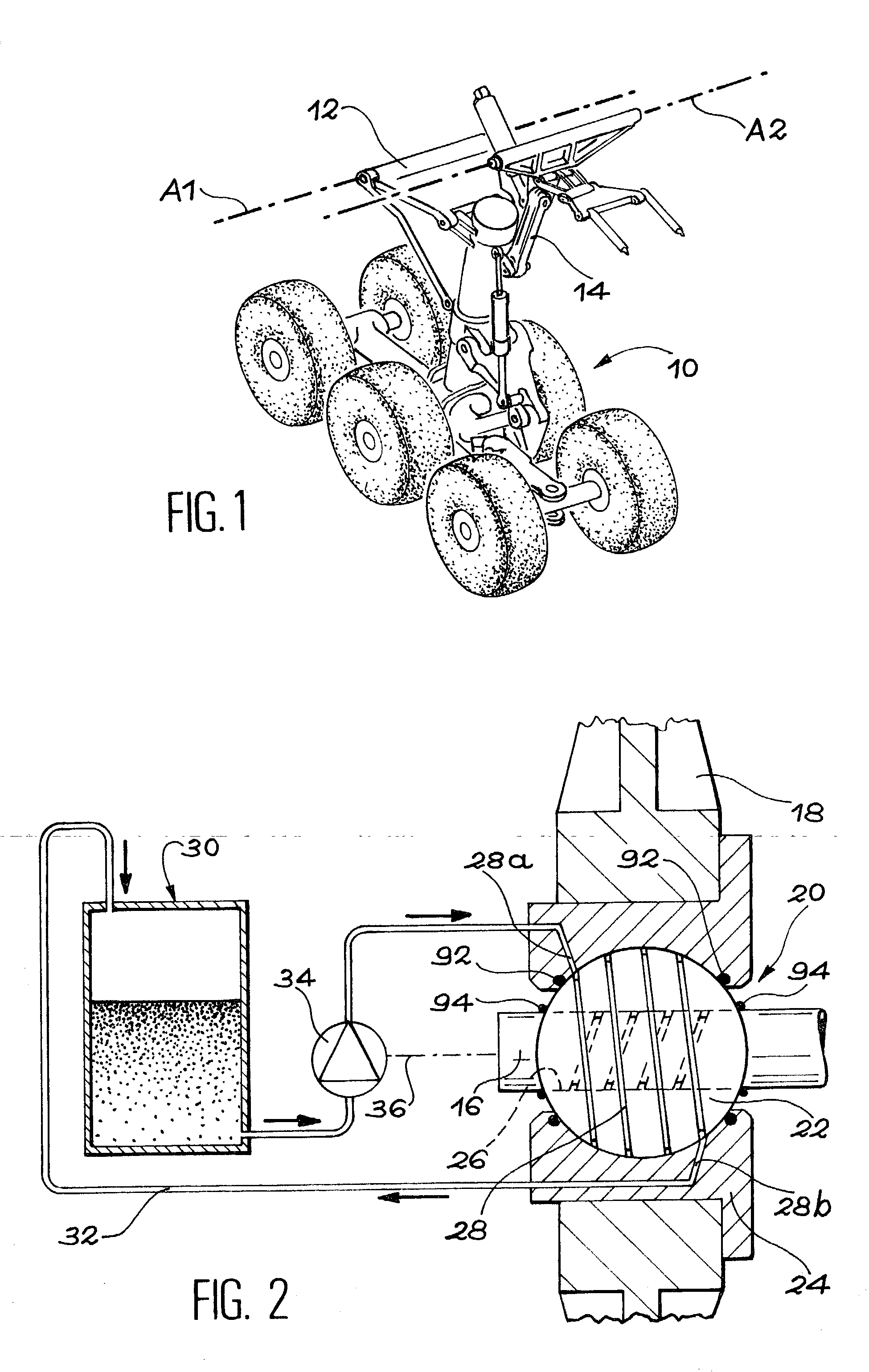

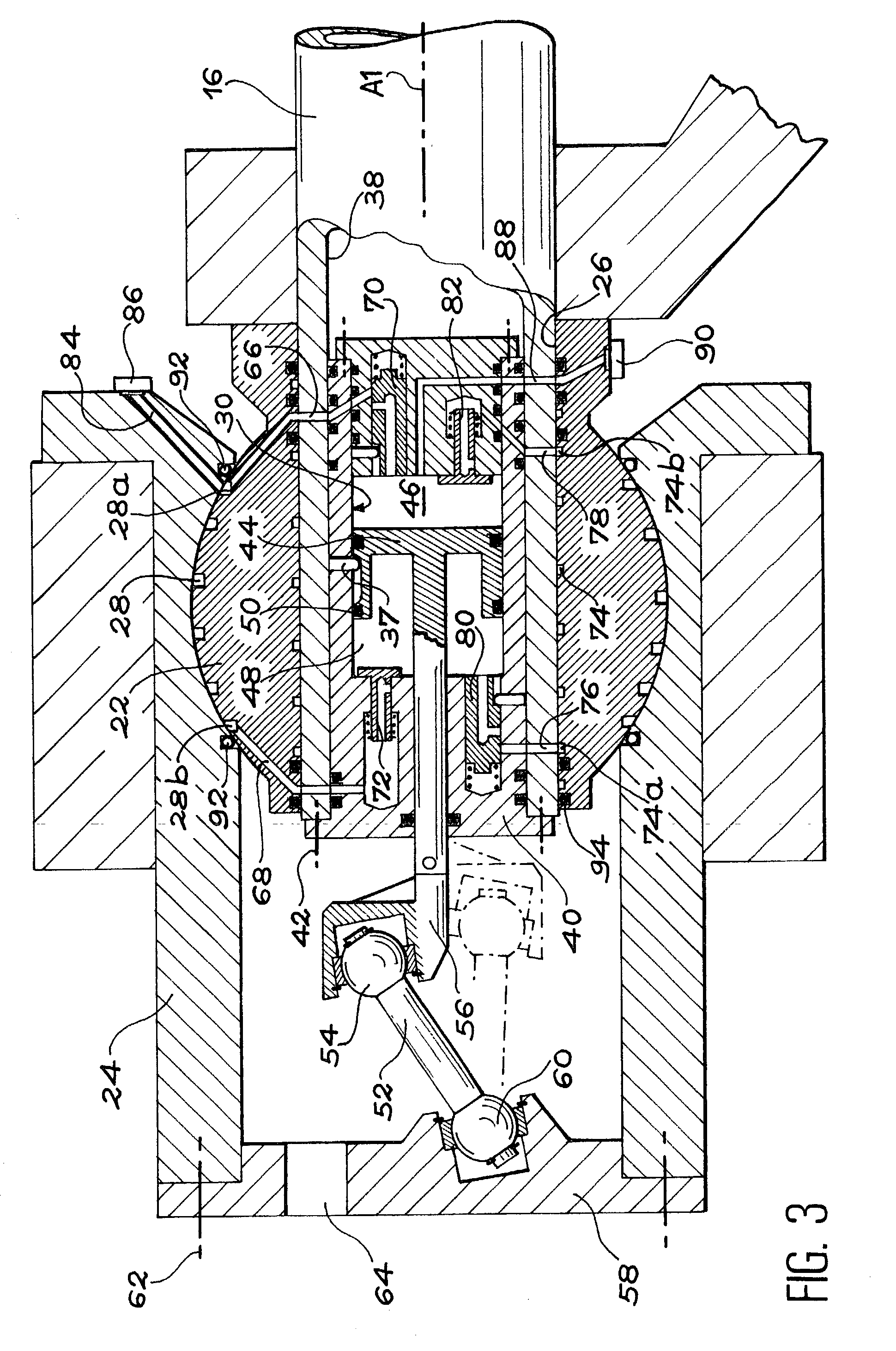

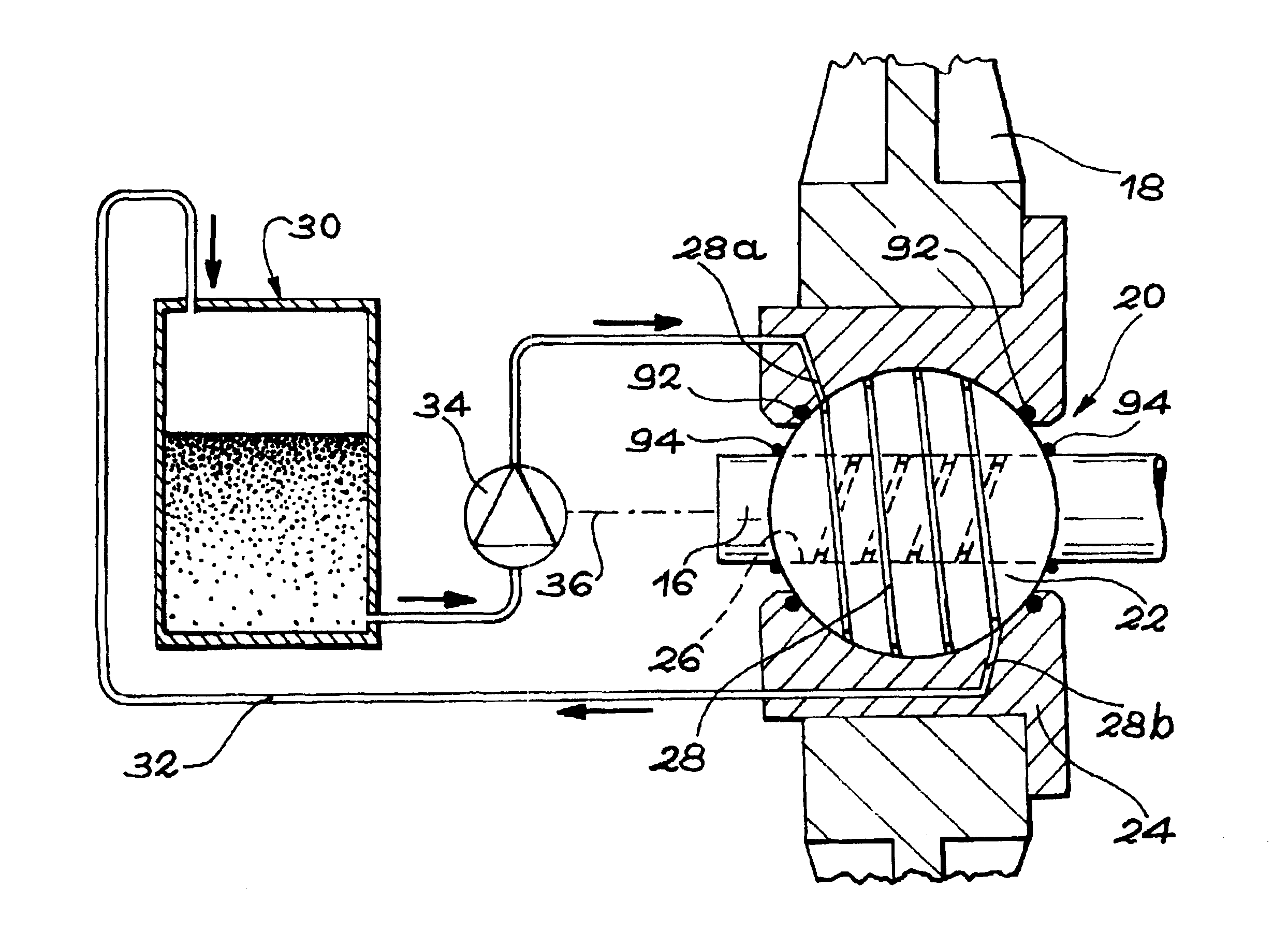

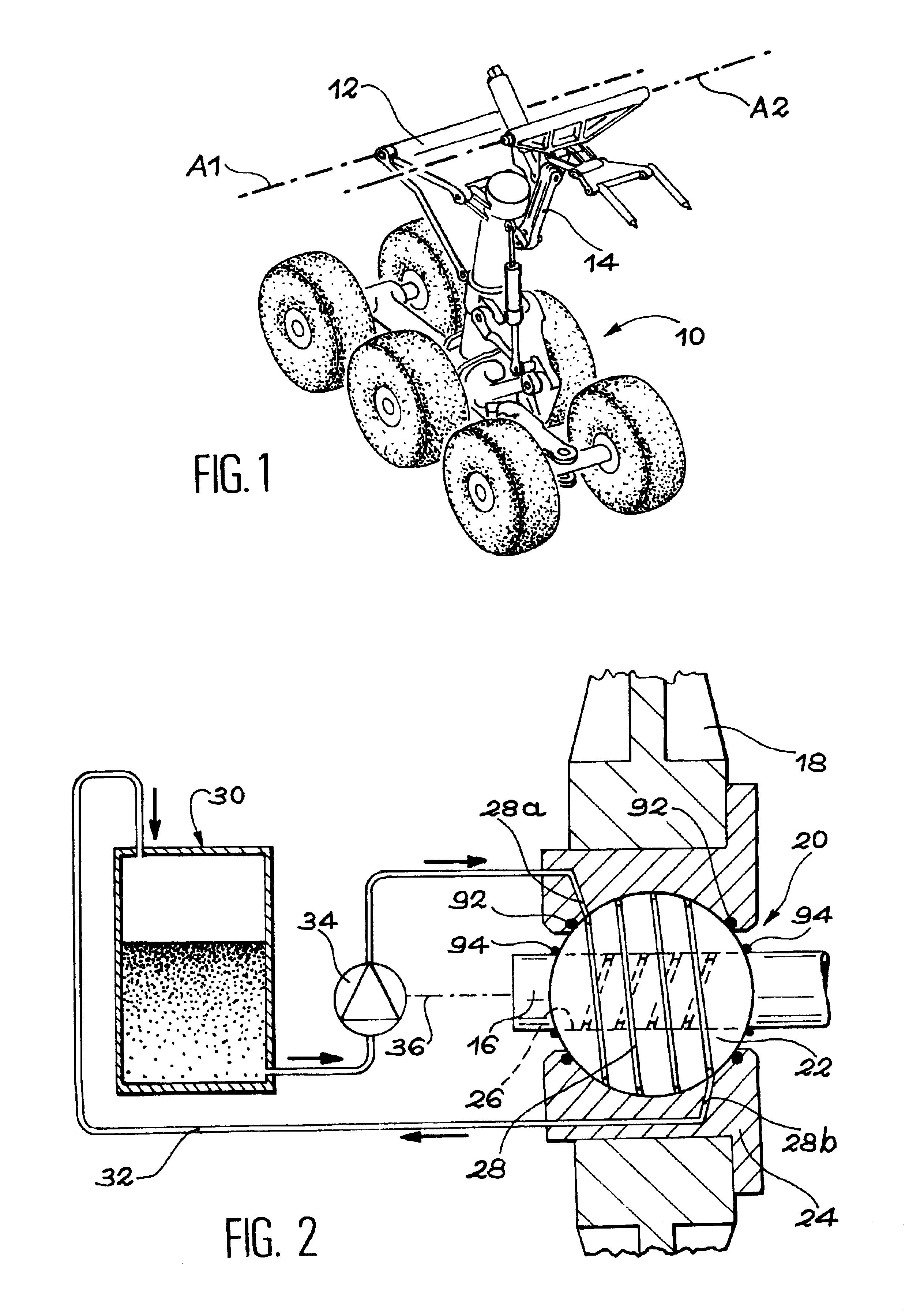

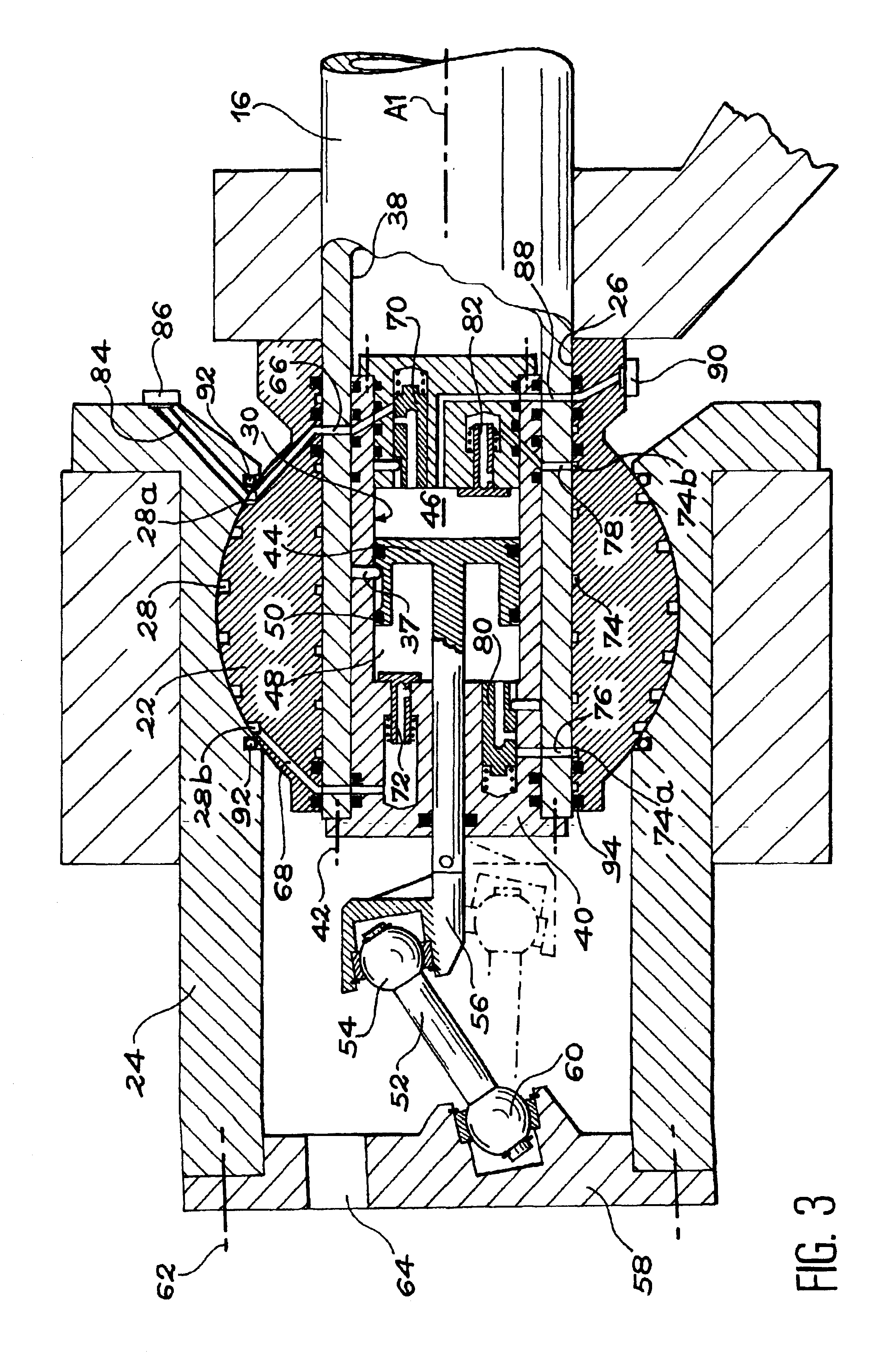

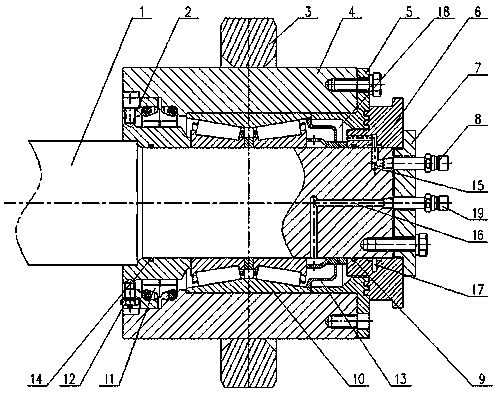

Ball joint bearing block lubrication device

InactiveUS20030085321A1Improve lubrication qualityImprove the lubrication effectRotary bearingsBearing componentsAircraft landingBall joint

Lubrication device for a ball joint bearing block. The device comprises at least one reservoir grease (30), a pump (34) capable of circulating grease between the reservoir and at least one bearing block lubrication groove (28), and a system (36) designed to actuate the pump (34) at every rotation movement of a hinge pin (16) of the bearing block. Preferably, there is a first groove (28) between the cage (24) and the ball (22) of the ball joint, and a second groove between the ball (22) and the hinge pin (16). Each rotation of the hinge pin (16) thus alternately controls injection of grease into one of the two grooves. One preferred application is lubrication of the hinge pins of aircraft landing gear.

Owner:AIRBUS OPERATIONS (SAS)

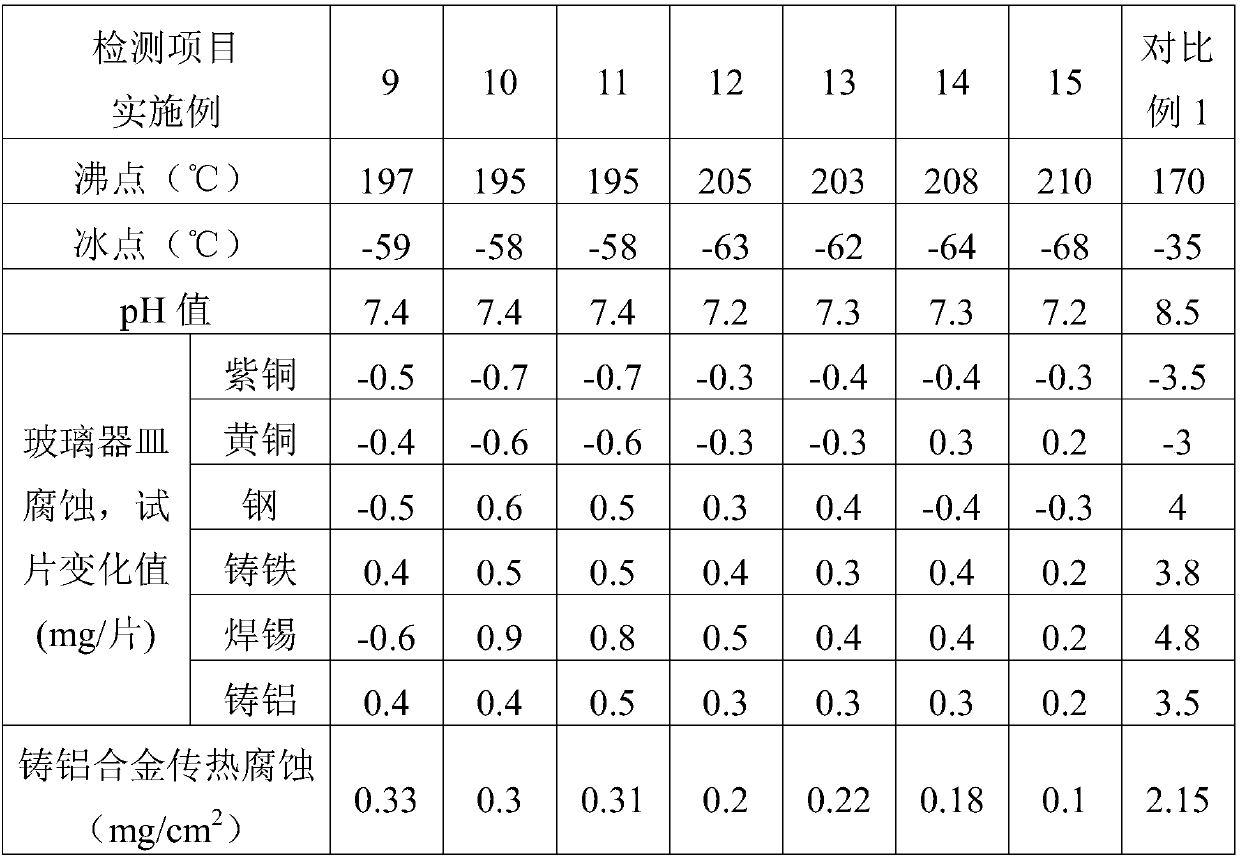

Engine anhydrous cooling liquid and preparation method thereof

ActiveCN107629765AGood conditionPowerfulHeat-exchange elementsBulk chemical productionNausea sicknessCavitation

The invention discloses an engine anhydrous cooling liquid and a preparation method thereof, wherein the engine anhydrous cooling liquid comprises the following raw materials by the weight percentage:60-70% of propylene glycol, 25-30% of ethylene glycol, 3-4% of 1,2-aminoazophenylene, 1-2% of sodium nitrate, 2-3% of glycerol, 1-2% of triethanolamine, 0.5-1.5% of sodium hydroxide, and 0.1-1% of apigment. The anhydrous cooling liquid has the freezing point lower than -52 DEG C and the boiling point more than 190 DEG C and has a large thermal safe space, so with the use of the product, the anhydrous cooling liquid can maintain a good state for operation, adequate power is maintained, noise is reduced, a water tank does not produce 'boiling', and cylinder score is not generated. With use ofthe anhydrous cooling liquid, zero corrosion can be achieved, no water rust is generated, cleaning and repair are not needed forever, and boiling, cylinder score, water tank blocking, water rust, water scale, corrosion and cavitation corrosion, engine fatigue, nausea, explosive vibration, precombustion, large noise, unstable idle speed, cylinder pressure reduction, insufficient power, oil consumption increase and large exhaust gas emission smoke and other phenomena are thoroughly eliminated.

Owner:四川路恒达机械科技有限公司

Ball joint bearing block lubrication device

InactiveUS6739786B2Improve lubrication qualityImprove the lubrication effectRotary bearingsYielding couplingEngineeringAircraft landing

Owner:AIRBUS OPERATIONS (SAS)

Articulated endoprosthesis

ActiveUS7637956B2Improve lubrication qualityQuality improvementJet pumpsJoint implantsArticular surfacesArticular surface

An endoprosthesis for a joint, in particular a an intervertebral implant with a central axis, a top part, a bottom part and a joint provided between them, wherein the joint comprises at least two articular surfaces A and B that can slide on one another; the top part has a top apposed surface that intersects the central axis and lateral surfaces; the bottom part has a bottom apposed surface that intersects the central axis and lateral surfaces; and wherein the endoprosthesis comprises at least one channel suitable to convey body fluid, said channel terminating in one of the two articular surfaces A and B and connecting it with the exterior of the endoprosthesis for the joint.

Owner:SYNTHES USA

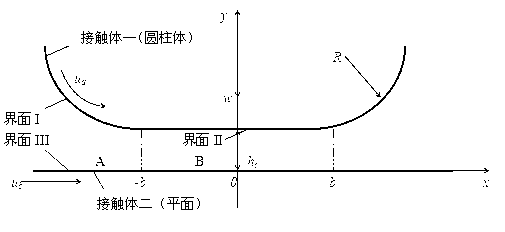

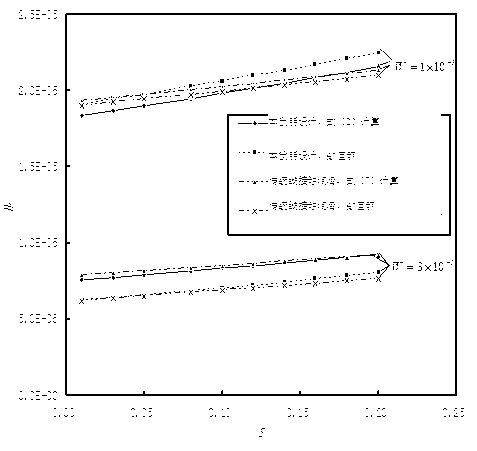

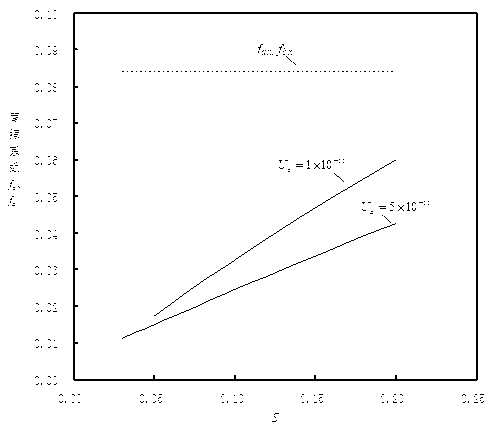

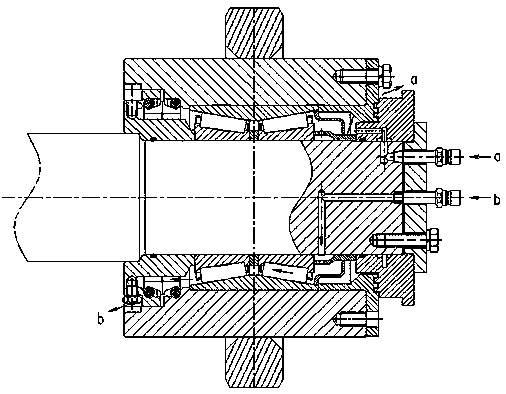

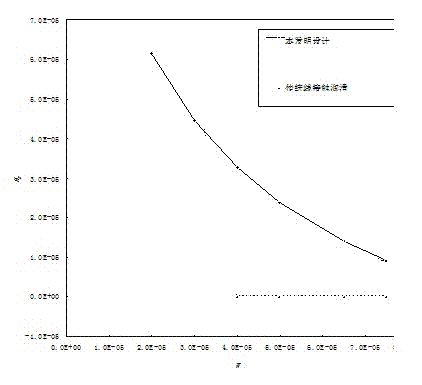

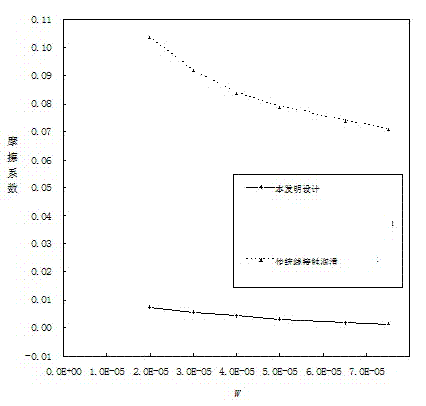

Method for improving line contact hydrodynamic lubrication under small slide-roll ratio

ActiveCN102705372AImprove lubrication qualityImprove carrying capacityBearing componentsContact pressureEngineering

The invention provides a method for improving a line contact hydrodynamic lubrication under a small slide-roll ratio, comprising the following steps of: setting two solids in reverse contact to be a contact body I and a contact body II respectively, controlling the linear speeds of the surfaces of the contact body I and the contact body II which are actually paired, a slide-roll ratio value and a non-dimensional roll speed; coating an oleophylic coating on the surface of the contact body II; and fully filling lubricant oil in a gap between the contact body I and the contact body II, controlling a load (w) applied to the line contact area of the contact body I and the contact body II so that the generated maximum Hertz contact pressure is not greater than 0.5 GPa, thus forming the designed line contact hydrodynamic lubrication. The method can greatly decrease the friction coefficient of the contact area, thereby effectively decreasing the friction coefficients, the friction energy consumptions, and the friction temperature rises of the line contact hydrodynamic lubrications of roller bearings and the like under a small slide-roll ratio, and effectively improving the qualities and the bearing capacities of the hydrodynamic lubrications.

Owner:徐州筑之邦工程机械有限公司

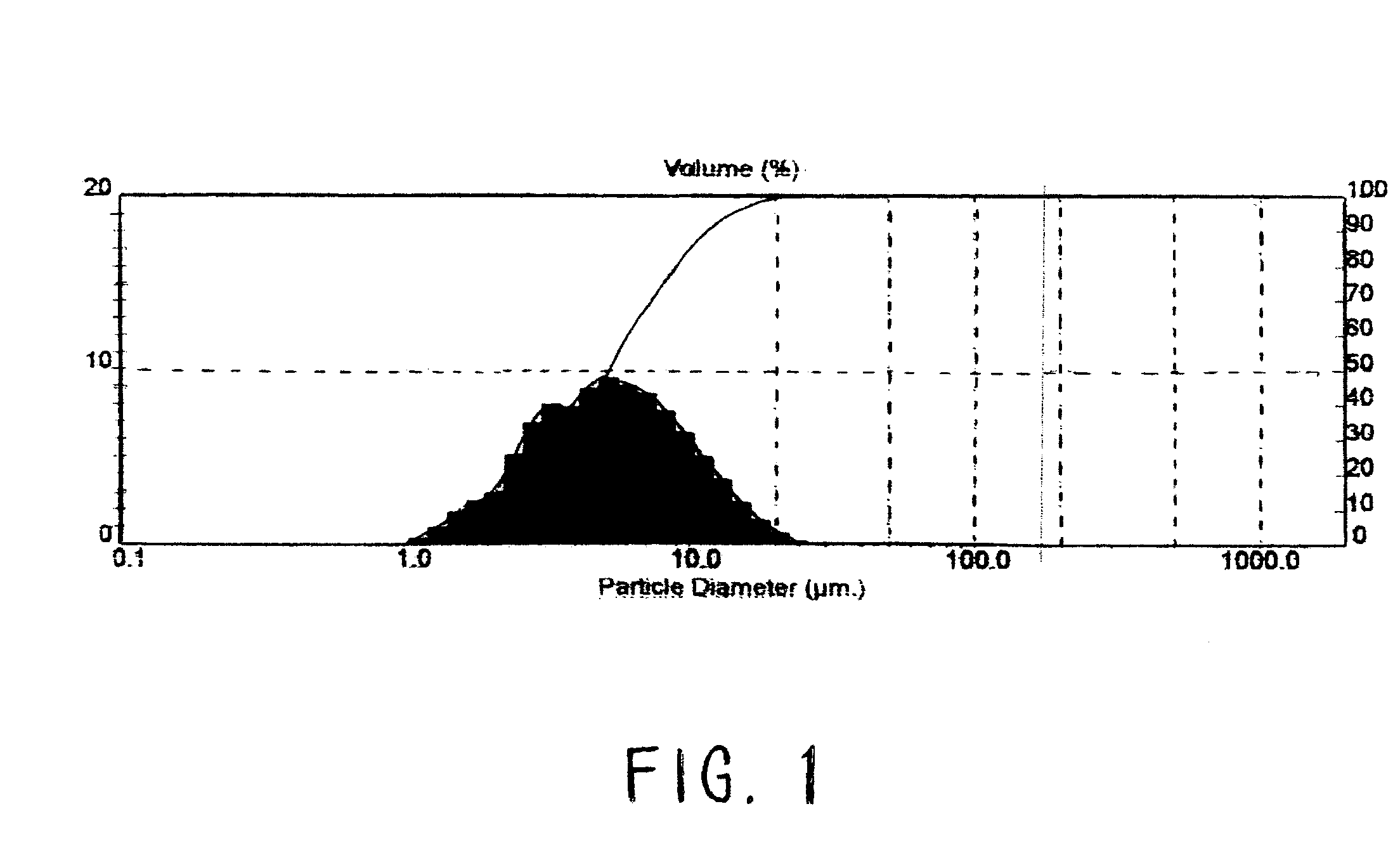

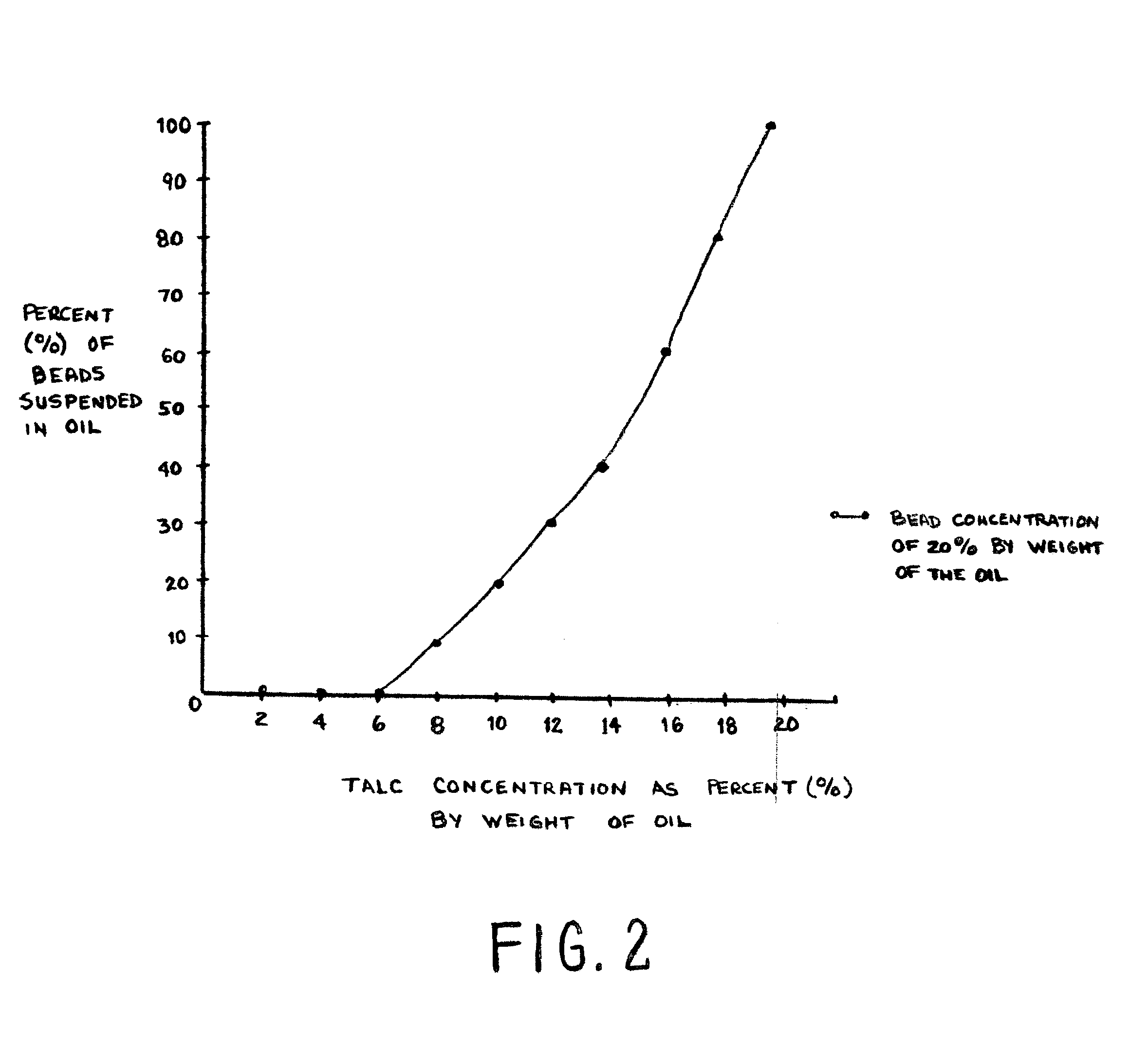

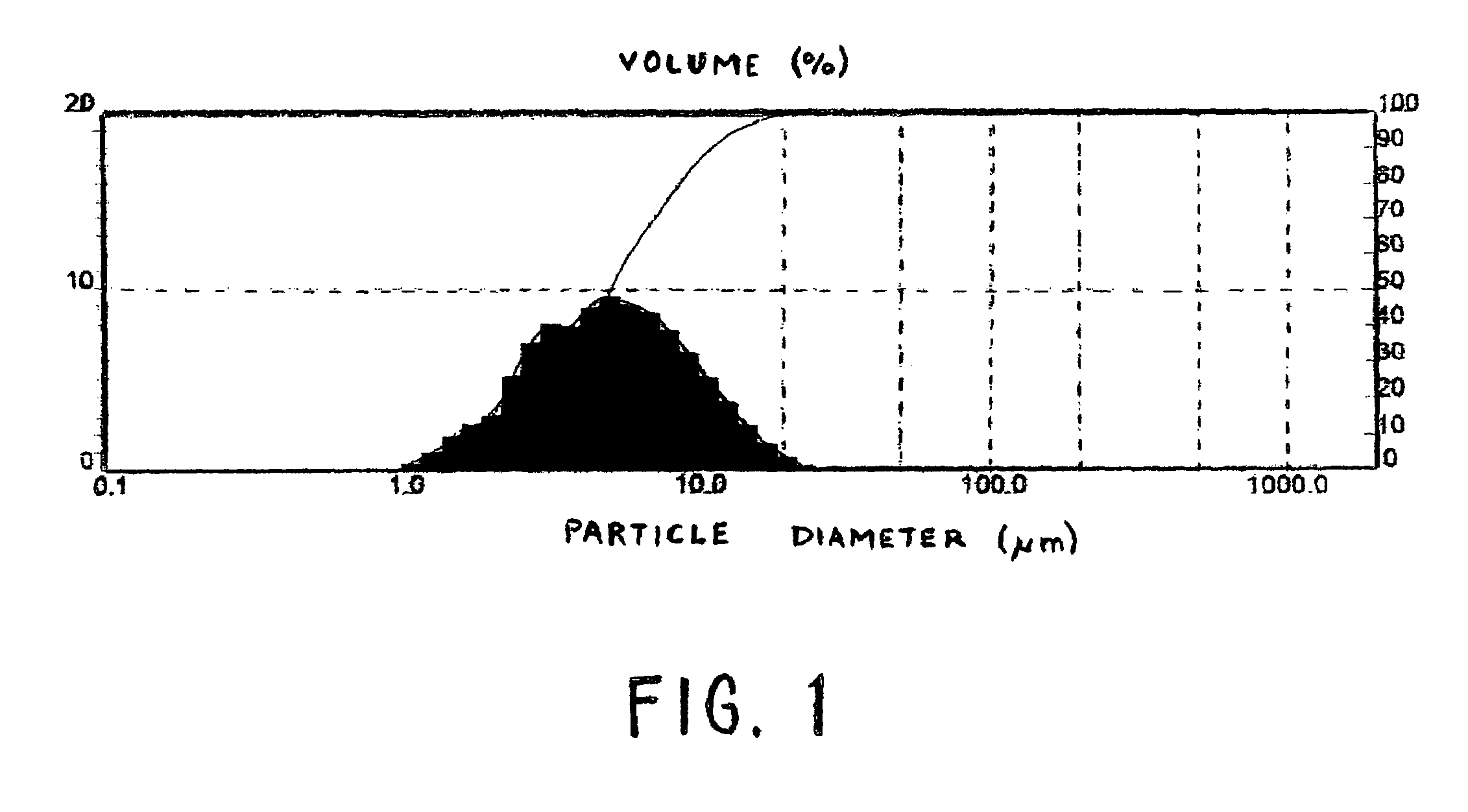

Drilling fluid additive system containing graphite and carrier

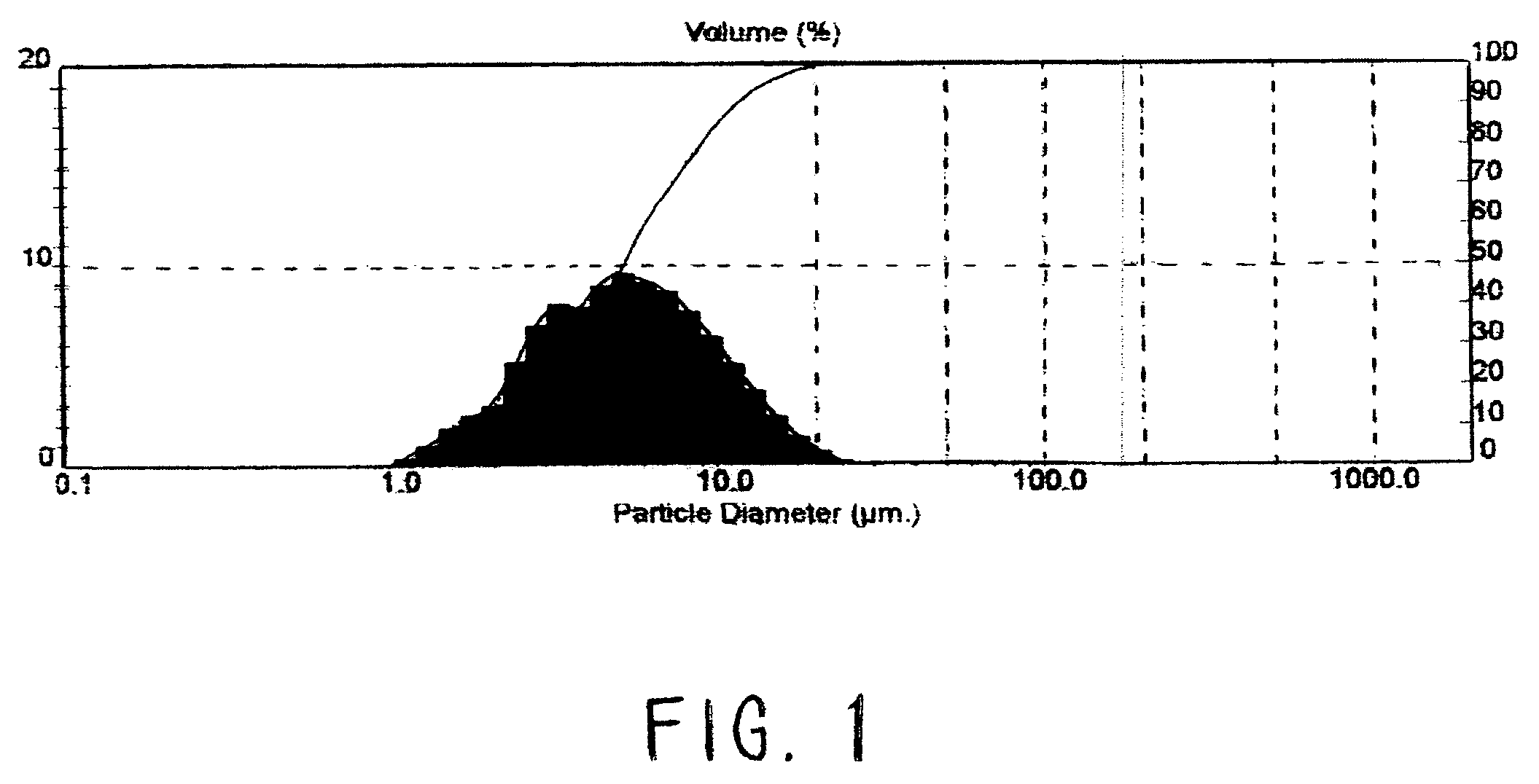

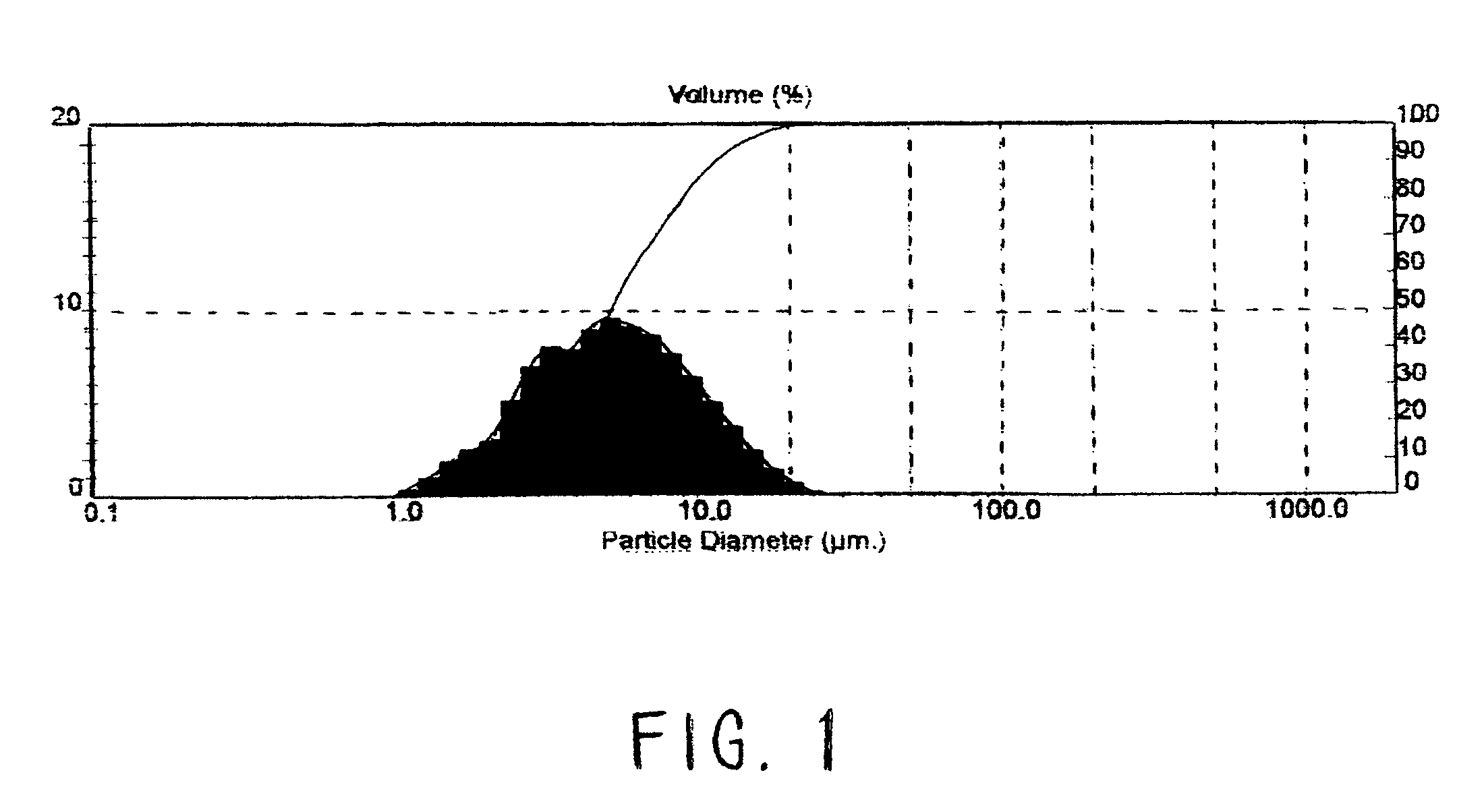

InactiveUS20040138067A1Superior pore throat sealerLowers HTHP/dynamic filtrateFlushingDrilling compositionPolypropylene glycolGraphite

A drilling fluid additive system is provided wherein the system is manufactured by a method comprised of admixing graphite with at least one carrier such as a polypropylene glycol or oil to create a suspended mixture, and allowing the surface of the graphite to be pre-wet with the carrier prior to adding the mixture to a drilling fluid; and then further admixing hydrophilic clay, a pH controller, a fluid loss controller, and at least one dispersant to said drilling fluid additive system.

Owner:MI

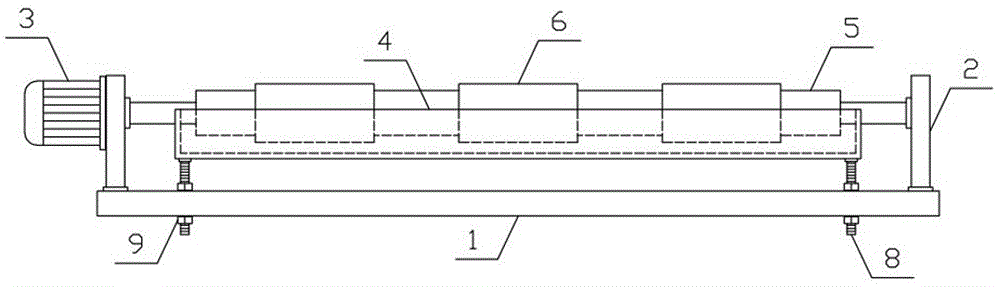

Yarn conveying lubrication device

The invention discloses a yarn conveying lubrication device and belongs to the field of textile processing machinery and equipment. The device comprises a fixing bracket, lubrication brackets, lubrication motors and an oil storage tank, wherein the lubrication brackets are vertically and symmetrically arranged on the two sides of the upper part of the fixing bracket; each lubrication motor is horizontally arranged on one side of each lubrication bracket; a lubrication roller is horizontally and rotationally connected to the lubrication bracket; a plurality of lubrication rubber sleeves are uniformly arranged on the outer side of the lubrication roller in sequence; the oil storage tank is horizontally arranged on the lower side of the lubrication roller; clamping grooves matched with the lubrication rollers are formed in the two sides of the oil storage tank respectively; two adjustment screw rods are vertically and uniformly arranged on the two sides of the lower part of the oil storage tank respectively and penetrate through the fixing bracket vertically and downwards; adjustment nuts are in threaded connection with the adjustment screw rods on the upper and lower sides of the fixing bracket; and a plurality of yarn guide wheels corresponding to the lubrication rubber sleeves are vertically and rotationally connected to one side of the oil storage tank. The device is simple in structure and can quickly and efficiently lubricate yarns in a conveying process to meet the needs of production and use.

Owner:JIAXING TUHUANG CASHMERE CO LTD

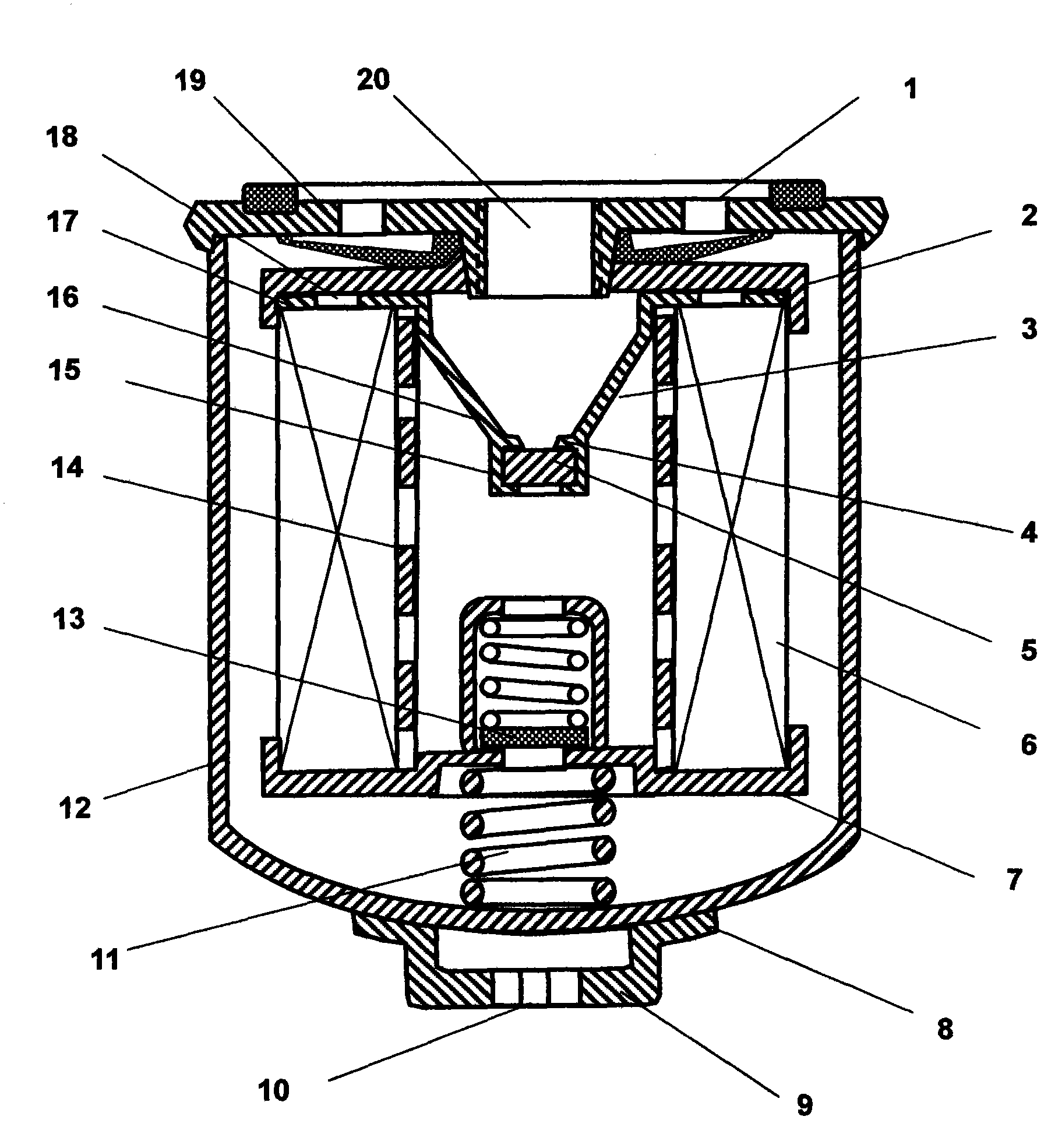

Fluid high-intensity magnetic integrated filter

A fluid high-intensity magnetic integrated filter relates to the field of fluid filters, comprises all fluid filters that filter ferromagnetic substances, and is characterized in that: a screwed covering plate is sealedly disposed on a housing of the filter; a fluid inlet and a fluid outlet are disposed on the screwed covering plate; a filter core is disposed inside the housing; the filter core comprises a filter central tube, a filter core upper end cover and a filter core lower end cover; a V-shaped magnet fixing device is fixedly disposed between a filter core end surface and the filter core upper end cover; a magnet fixing pit is disposed in the middle of the V-shaped magnet fixing device; a magnet is disposed in the magnet fixing pit; a support spring is disposed between the filter core bottom and the filter housing; with the spring, the filter core is sealedly connected with the screwed covering plate; and the main body of the filter core separates the fluid inlet from the fluid outlet. The fluid filter designed with the above scheme effectively filters ferromagnetic substances in fluid, prevents equipment wearing, prolongs service life of the equipment, enables fluid magnetization, and improves fluid use value.

Owner:四平大吉强磁滤清器有限公司

Improved lubricating oil

The invention discloses an improved lubricating oil. The lubricating oil is prepared from the following raw materials in parts by weight: 7-14 parts of hydroxy benzyl aldehyde, 5-10 parts of dodecyl benzene sodium sulfonate, 5-10 parts of methyl ciTCMLIBate, 9-12 parts of dichloromethane, 4-10 parts of citric acid mono-methyl ester, 5-8 parts of potassium dihydrogen phosphate, 6-9 parts of tetrahydropalmatine, 3-5 parts of hydrochloric acid, 16-24 parts of sulfur phosphorus primary-secondary alkyl zinc salt, 9-17 parts of sodium citrate, 10-15 parts of sulfureted isobutene, 8-17 parts of sulfureted alkyl phenol calcium, 10-20 parts of methyl acrylate and 30-50 parts of lubricating base oil. The improved lubricating oil disclosed by the invention has the advantages of a better frictional property, a better abrasion-proof property, a better antirust property and stable nature, and the lubrication quality of the lubricating oil is effectively improved.

Owner:QINGDAO TONGSHENGTONG RUBBER & PLASTIC

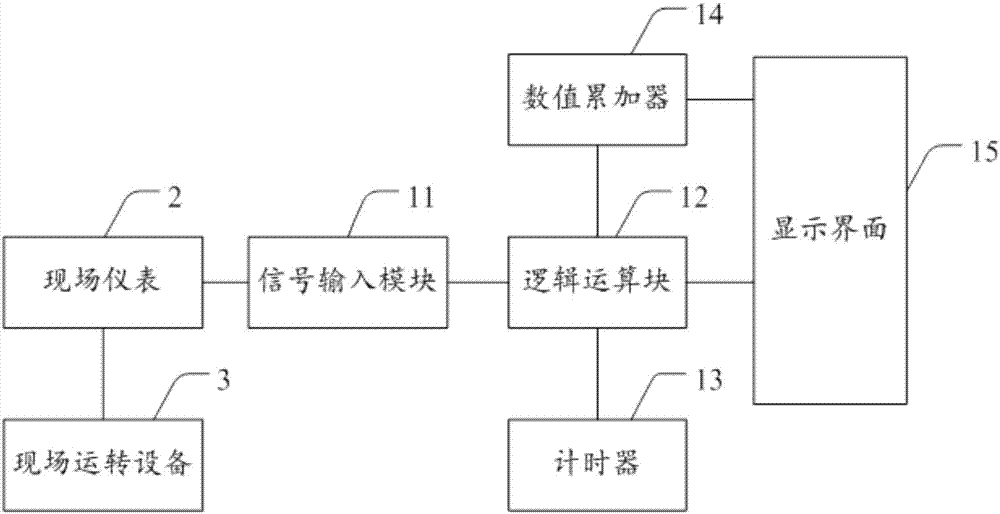

Equipment maintenance prompt system

InactiveCN107272531AAccurate measurement of actual runtimeExtended service lifeProgramme controlComputer controlComputer moduleTimer

The invention discloses an equipment maintenance prompt system, and the system comprises a signal input module, a logic operation block, a timer, and a numerical value accumulator. The signal input module is used for obtaining a state signal for representing the current state of onsite operating equipment from an onsite instrument. The logic operation block is used for recognizing whether the current state of the onsite operating equipment is an operating state or not according to the state signal and triggering the timer to carry out the timing operation when the current state of the onsite operating equipment is the operating state, is also used for triggering the timer to be zero and triggering the numerical value accumulator to operate for one time when the timer is monitored to give a breaking alarm in a timing process, and is also used for giving an equipment maintenance prompt when the operation accumulated time duration of the numerical value accumulator reaches a preset operation period. The system solves a technical problem that a conventional system for maintaining the onsite operating equipment at fixed time intervals will cause damages to the onsite operating equipment, and enables the service life of the onsite operating equipment to be longer.

Owner:BEIJING SHOUGANG CO LTD

Water-based drilling fluid additive containing graphite and carrier

InactiveUS7067461B2Superior lubricantImprove lubrication qualityFlushingDrilling compositionWater basedPolypropylene glycol

A drilling fluid additive is provided wherein the additive is manufactured by a method comprised of admixing graphite with at least one carrier such as a polypropylene glycol or oil to create a suspended mixture, and allowing the surface of the graphite to be pre-wet with the carrier prior to adding the mixture to a drilling fluid.

Owner:MI

Lubricant spraying system for gasket

Owner:镇江泛沃新能汽车技术股份有限公司

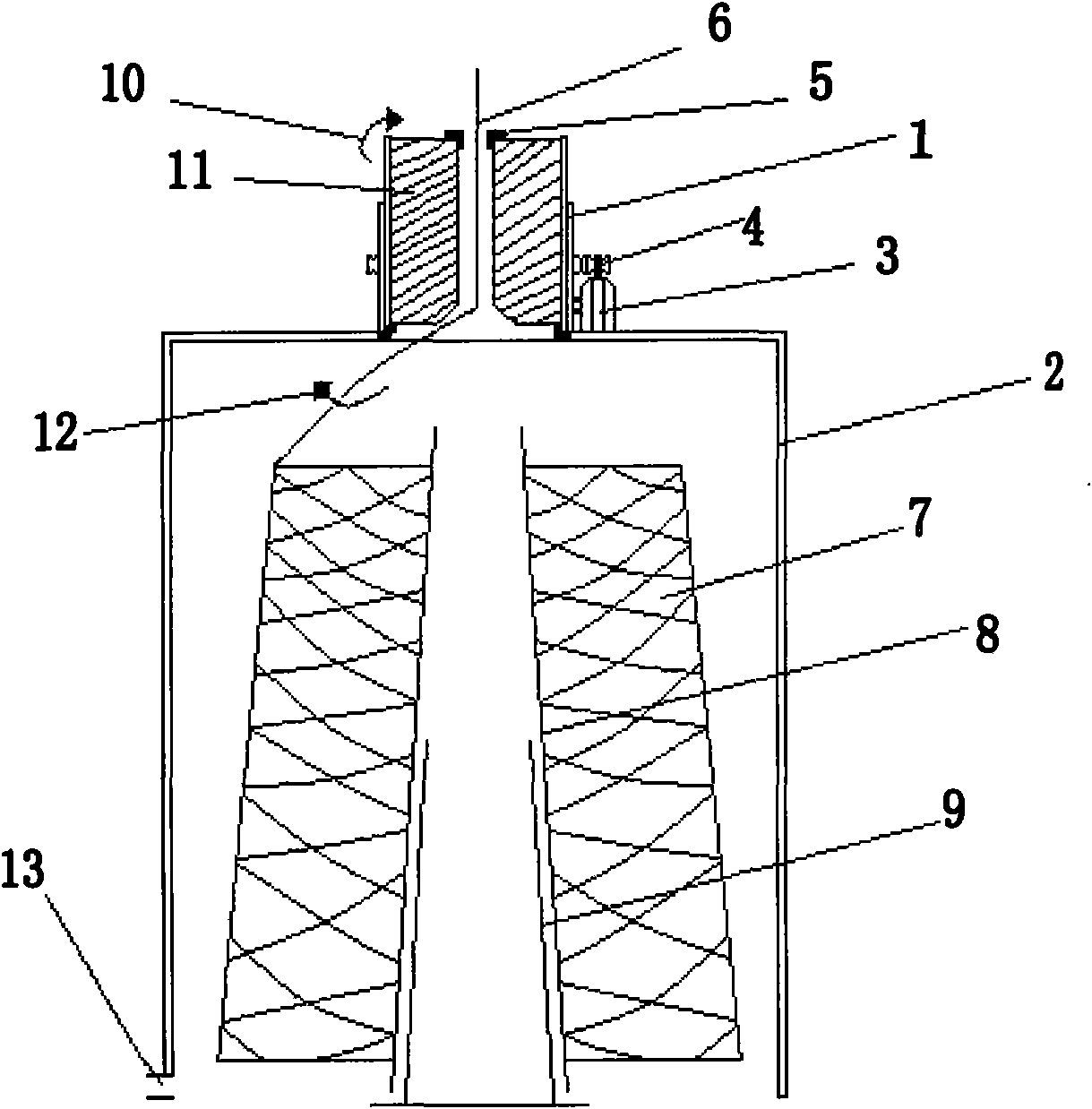

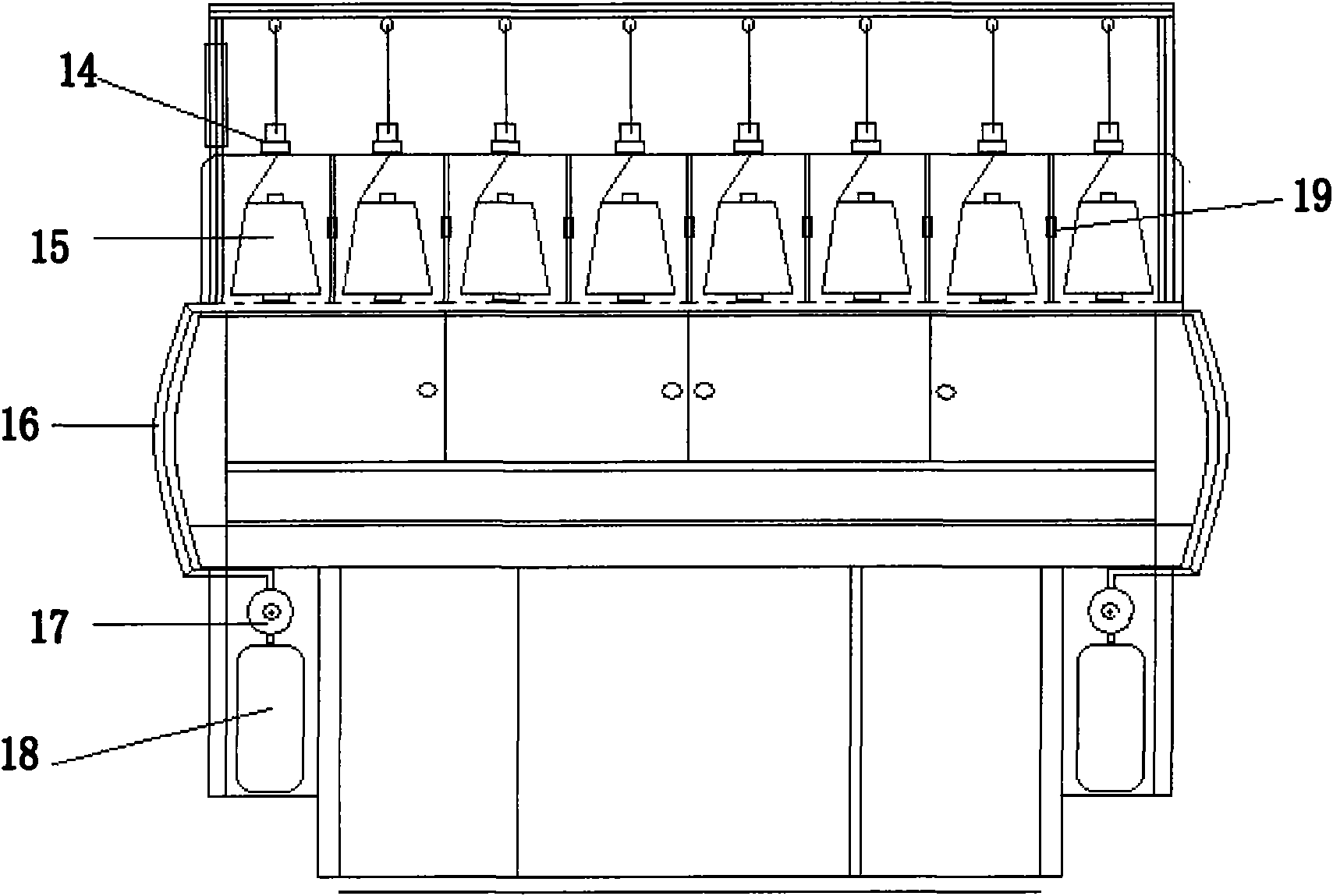

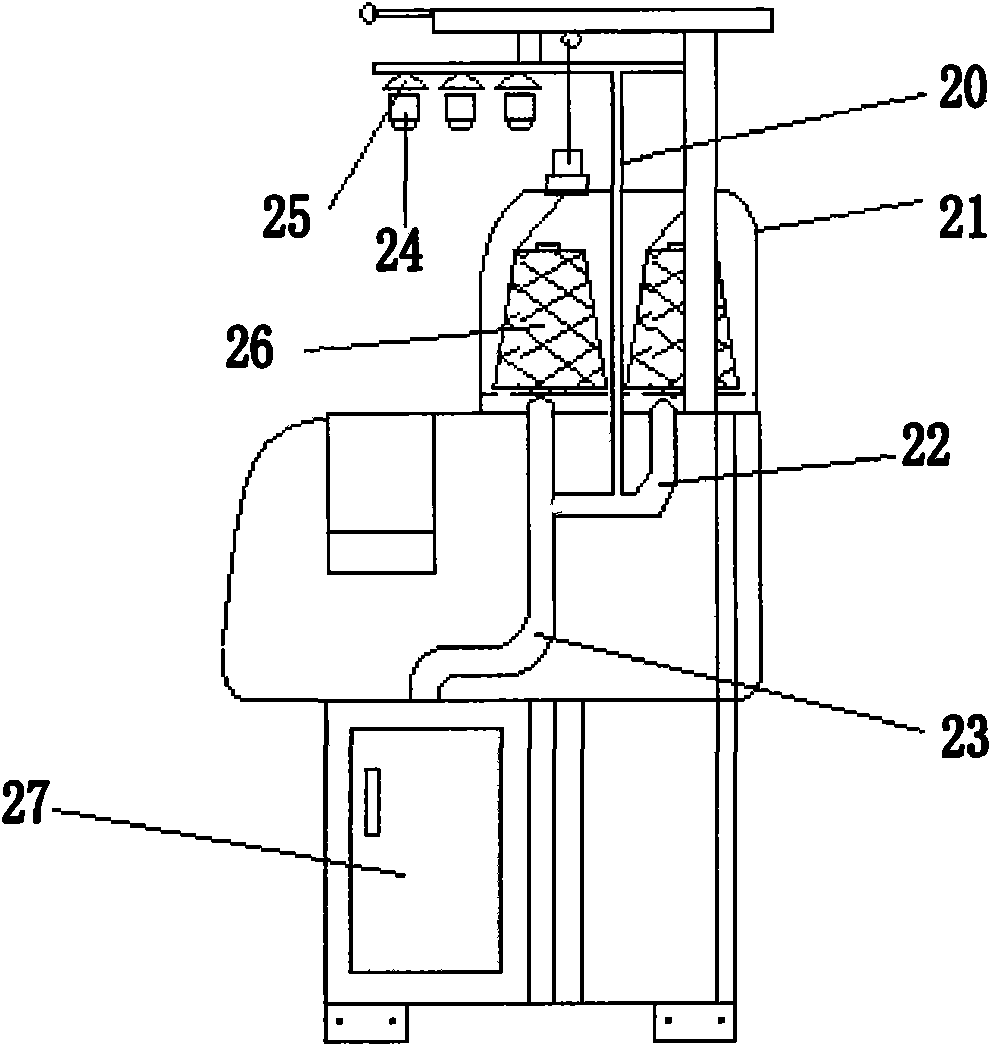

Multi-functional three-dimensional energy-saving and environmentally-friendly lubricating device

The invention relates to a multi-functional three-dimensional energy-saving and environmentally-friendly lubricating device, which belongs to the field of textile. The aim of the device is fulfilled by the following measures that: a shell of the lubricating device (1) is connected with a gear (4); the gear (4) is connected with a frequency-modulation micromotor (3); the micromotor (3) is connected with a device body (2); the lubricating device (1) is provided with lubricant (11); a positioner (5) is inserted into the central hole at the upper end of the lubricant (11); the lubricating device (10) rotates horizontally and clockwise; yarn (6) is led upward out of the central hole of the lubricant; yarn (12) rotates clockwise; a central yarn tube (8) of a yarn ball (7) is inserted in a central fixing tube (9); a dust-collecting port (13) is connected with a dust-collecting tube (16); 8 to 16 yarn balls (15) are arranged according to requirement; each yarn ball is provided with one lubricating device (14); each device door (19) is connected with another device door; a vacuum cleaner (17) is connected with a collecting bag (18); a trumpet-shaped dust-collecting mouth (25) is connected with a dust-collecting tube (20) to absorb flyings generated by a yarn feeder (24); a yarn ball (26) is connected with a transparent cover (21); and the transparent cover (21) is connected with dust-collecting tubes (22) and (23) to absorb the flyings into the collecting bag of a storage chamber (27). The device is mainly used for reducing the flyings which pollute a workshop. The technical point of the device is energy-saving and environmentally-friendly.

Owner:崔建明

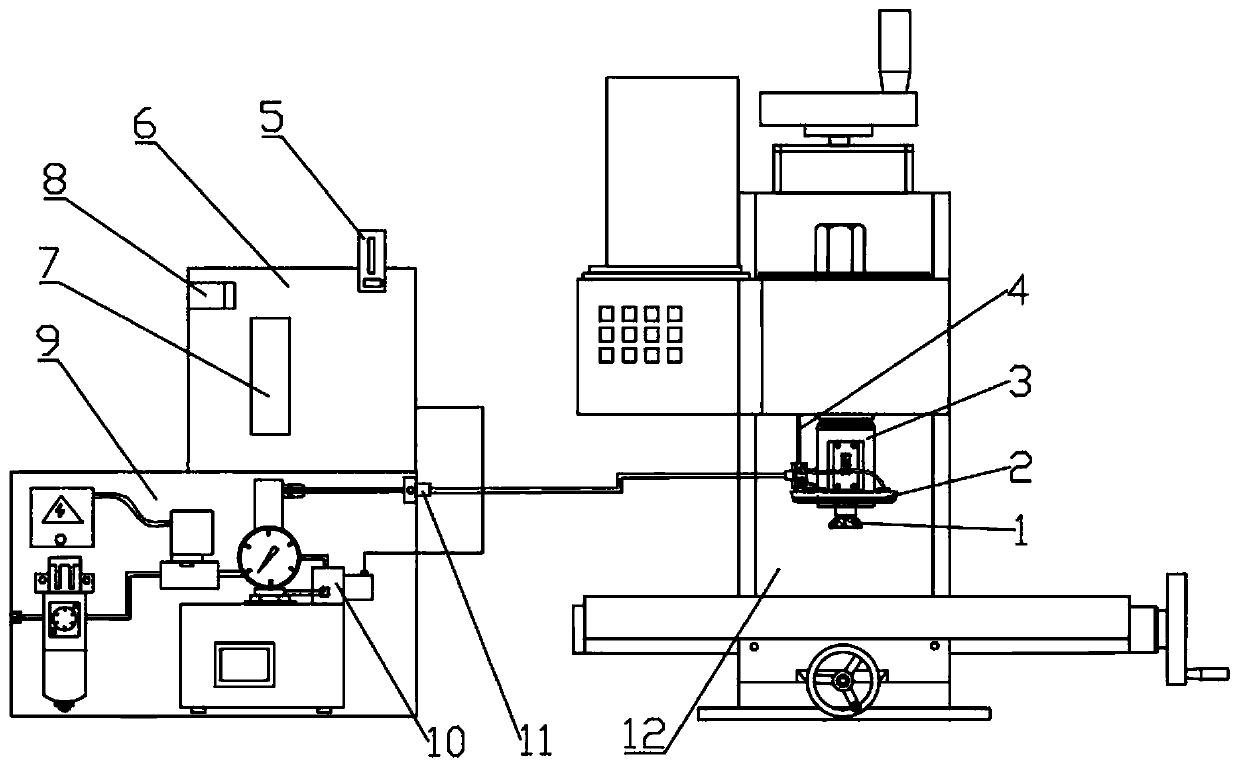

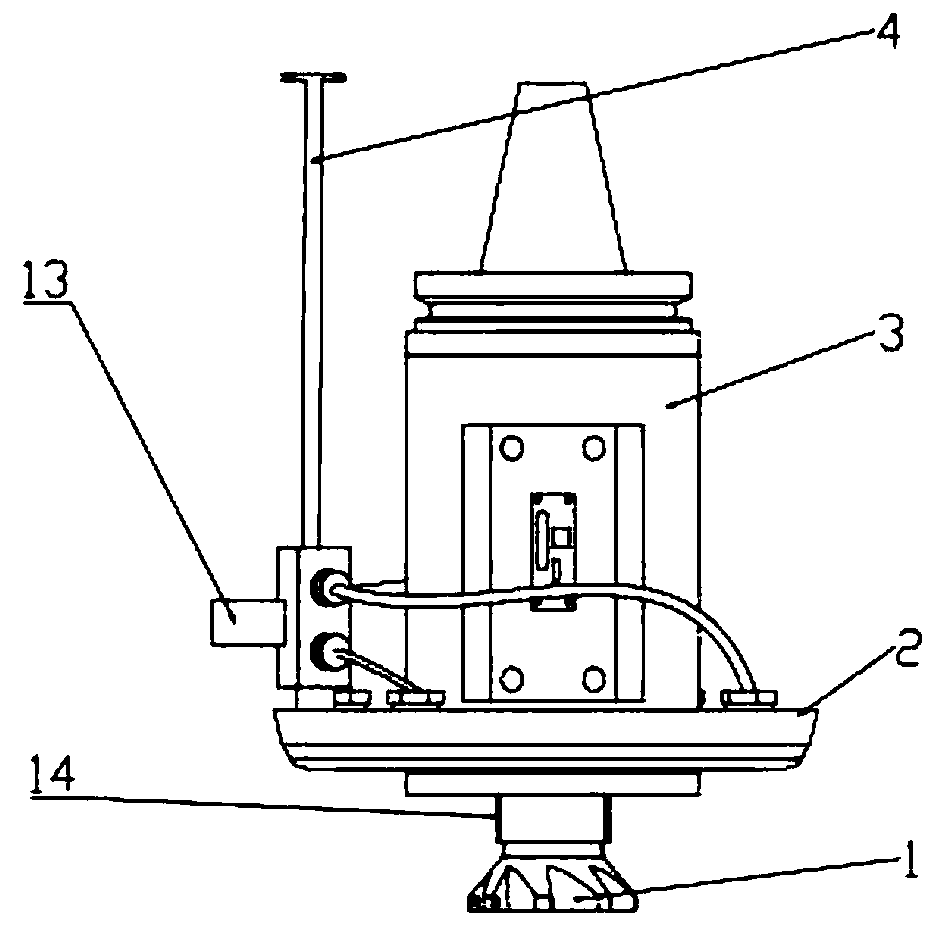

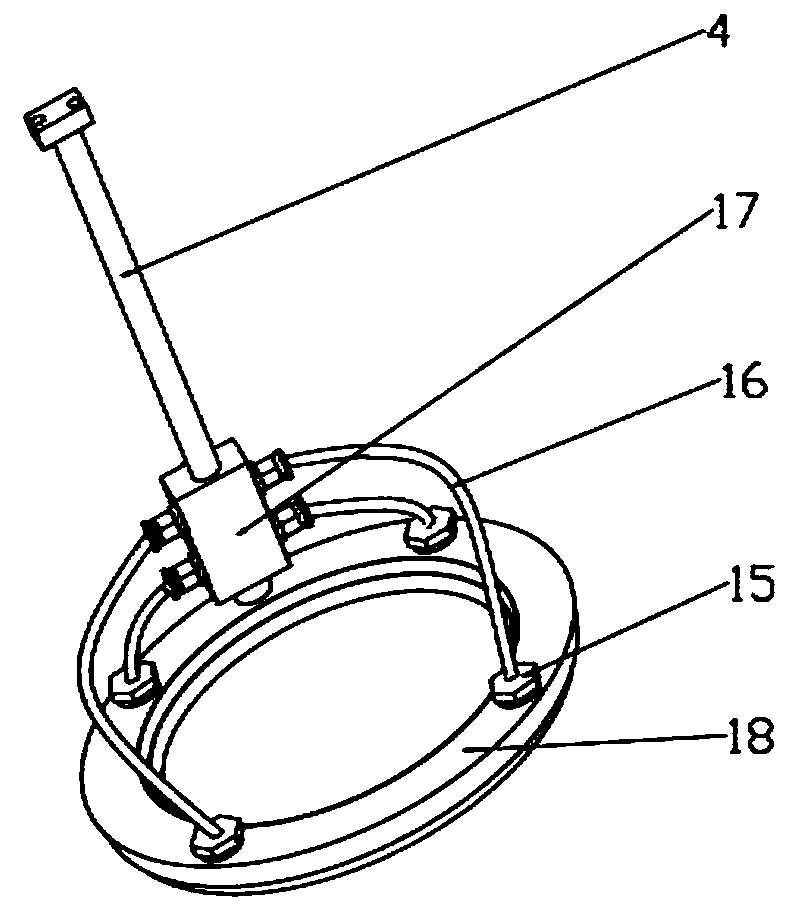

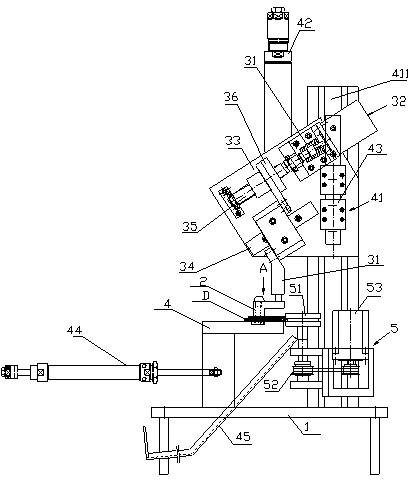

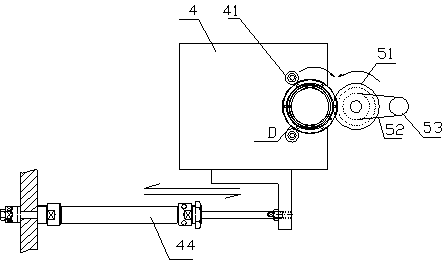

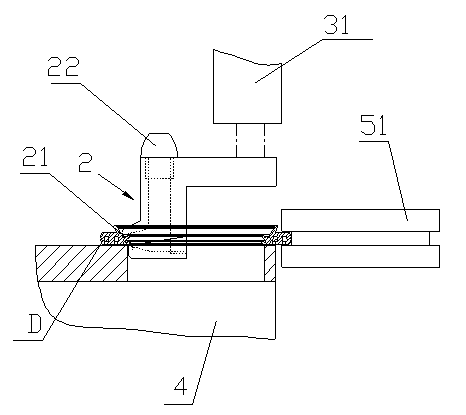

Minimal quantity lubrication system applied to facing-type cutter

InactiveCN110774050AImprove lubrication qualityWide range of applicationsMeasurement/indication equipmentsMaintainance and safety accessoriesPhysicsLubrication

The invention relates to a minimal quantity lubrication system applied to a facing-type cutter. The minimal quantity lubrication system involves a minimal quantity lubrication system, a wireless temperature measuring system and a control system, wherein the minimal quantity lubrication system comprises an annular minimal quantity lubrication nozzle, and the annular minimal quantity lubrication nozzle is arranged at the upper part of the facing-type cutter in a sleeve mode, the wireless temperature measuring system is arranged on a cutter rod of the facing-type cutter and is used for measuringthe temperature of the facing-type cutter and sending the temperature to the control system, and the control system is electrically connected with the wireless temperature measuring system and the minimal quantity lubrication system to control the lubricating flow of the annular minimal quantity lubrication nozzle according to the temperature of the facing-type cutter. According to the minimal quantity lubrication system, through cooperation of the minimal quantity lubrication system and the wireless temperature measuring system, the temperature change of a milling cutter is monitored in realtime in a milling process, the oil feeding flow of the annular minimal quantity lubrication nozzle is controlled in real time according to the temperature change range, and sufficient lubrication of the facing-type cutter is guaranteed.

Owner:SHANGHAI UNIV OF ENG SCI

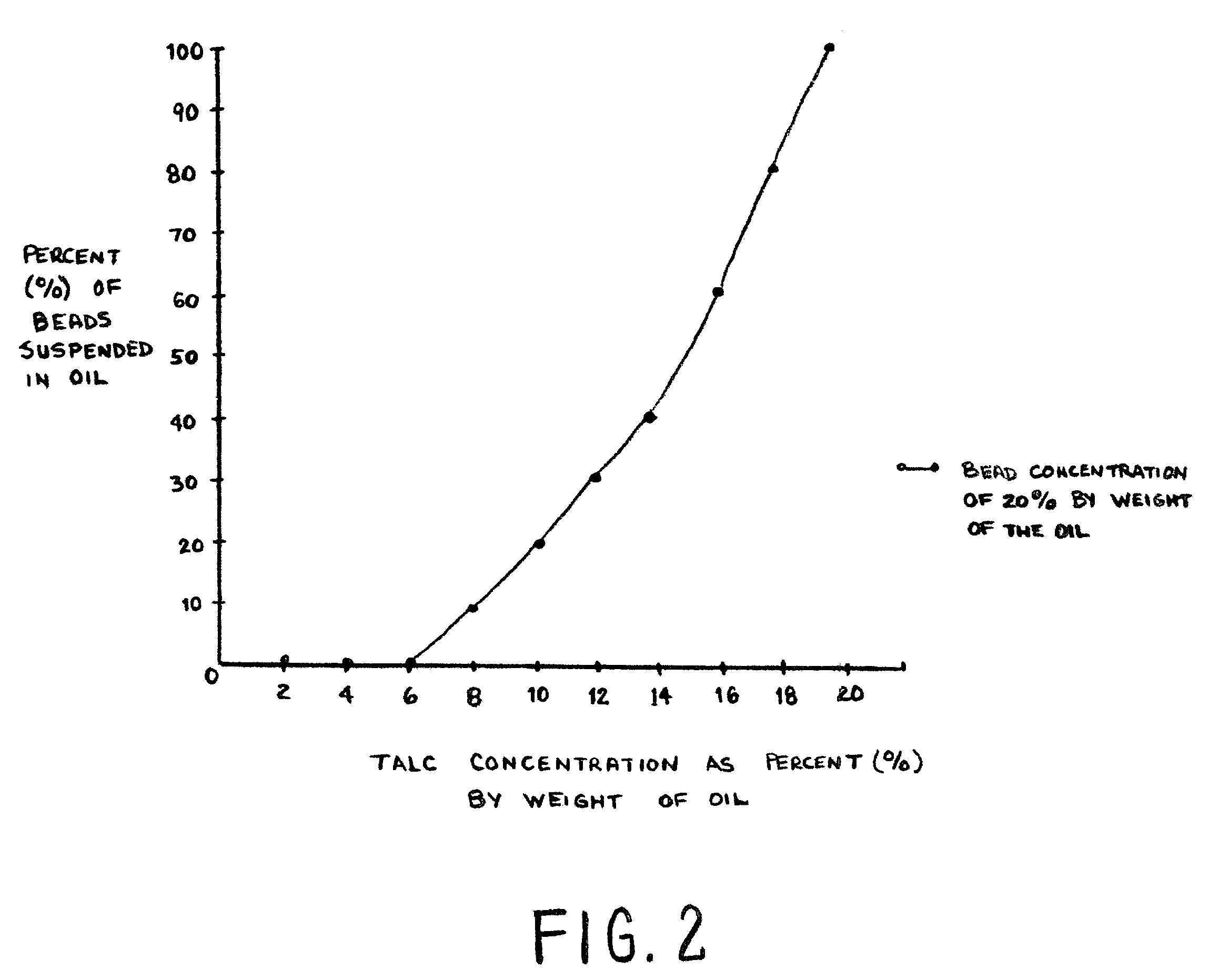

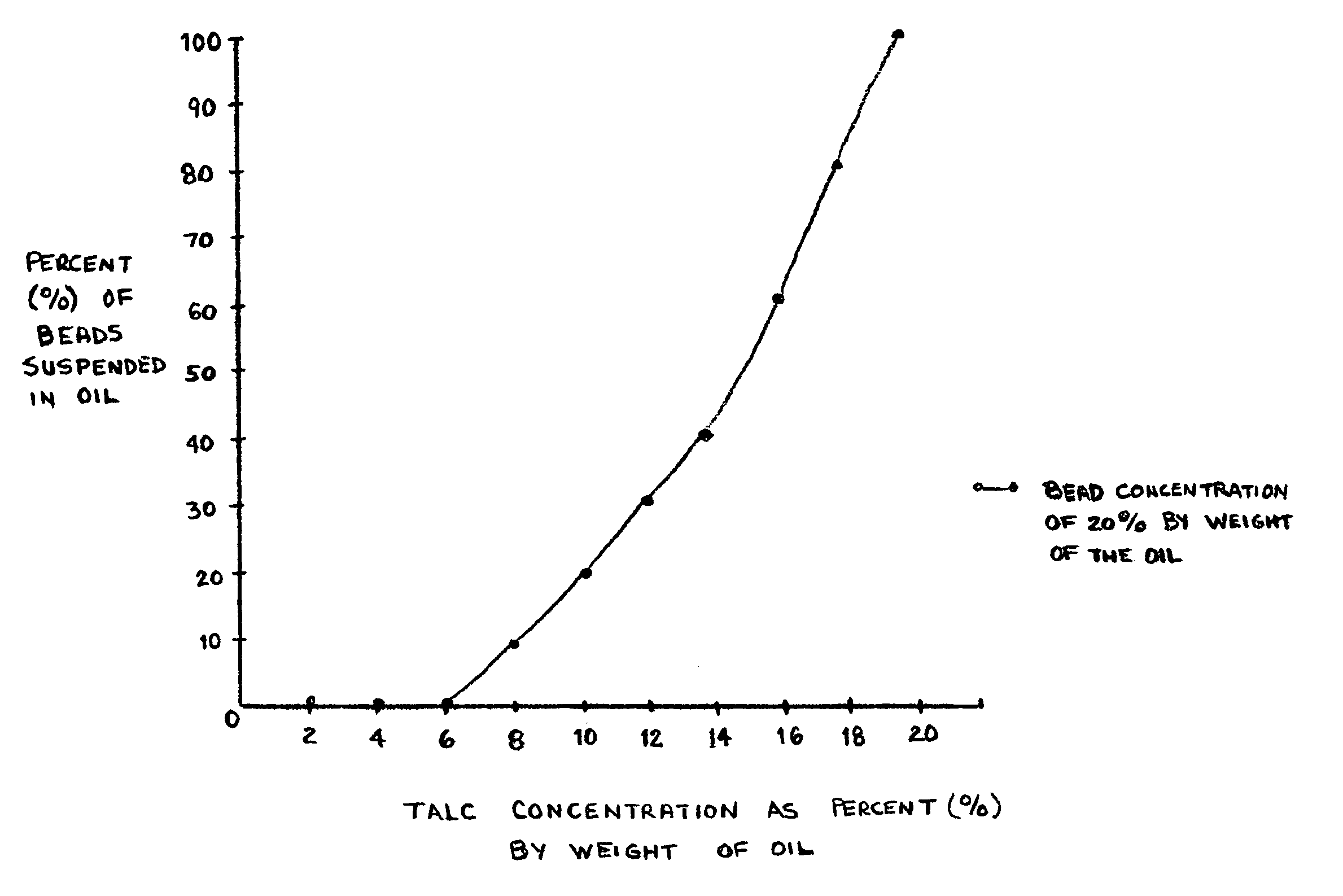

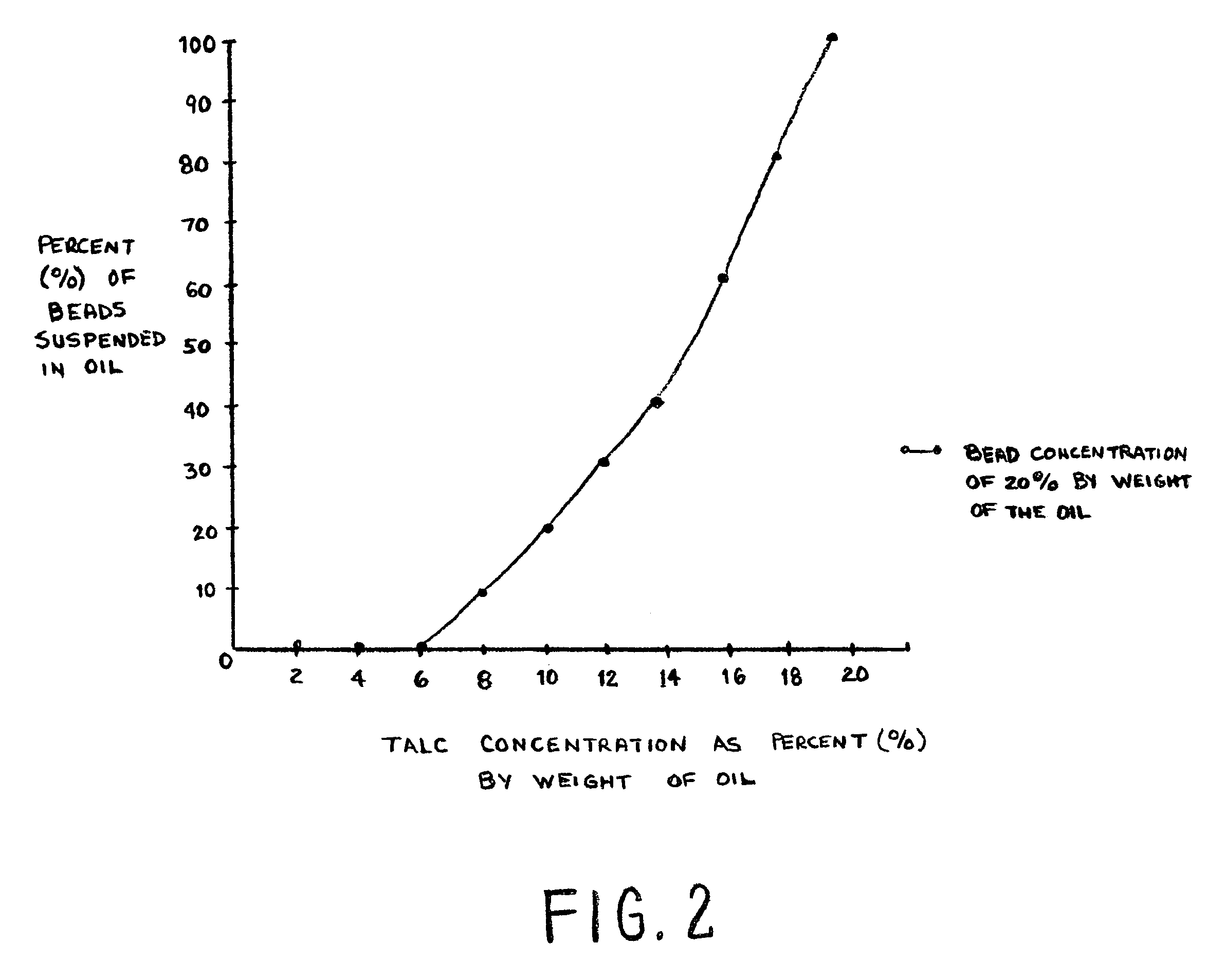

Water-based drilling fluid additive containing talc and graphite

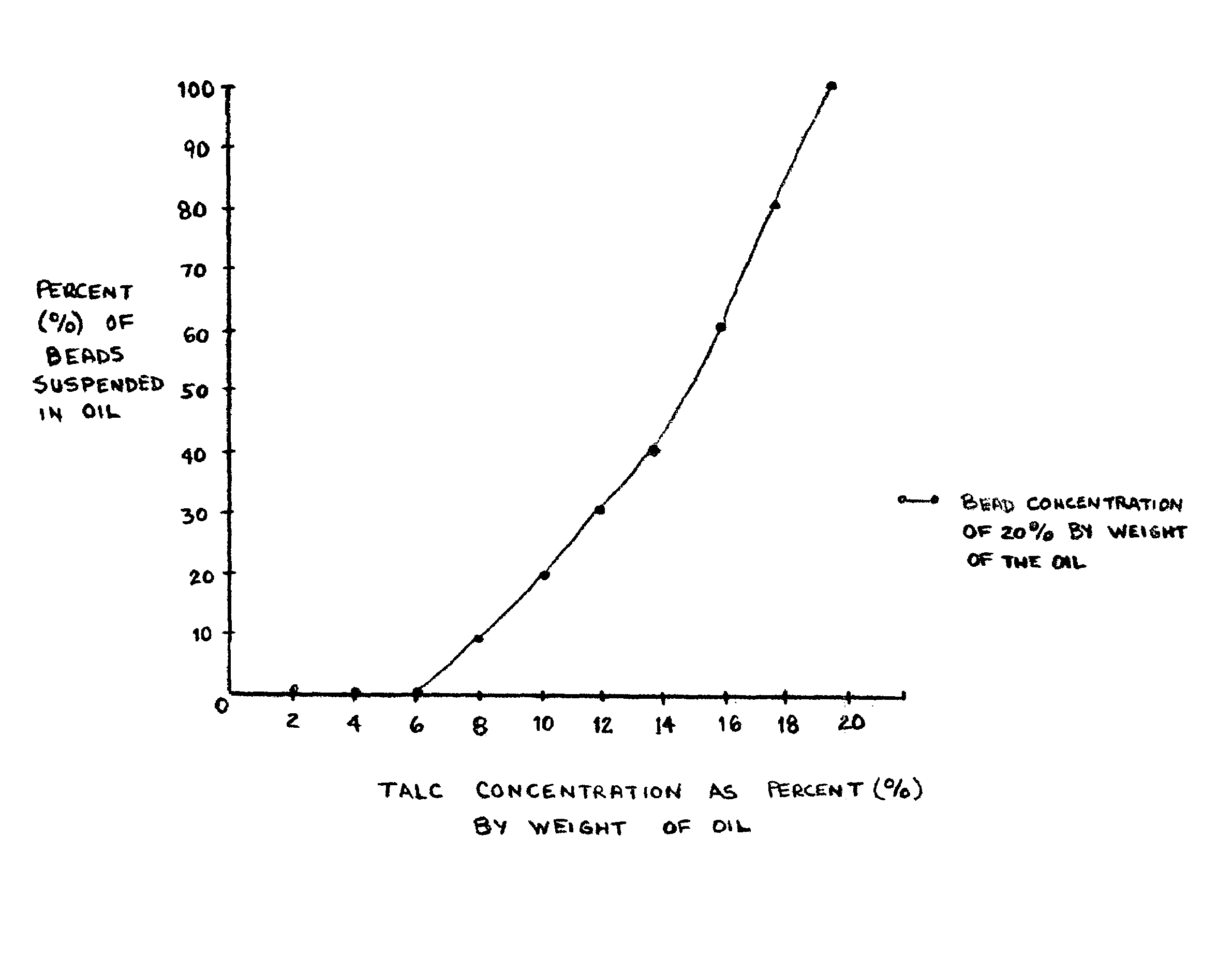

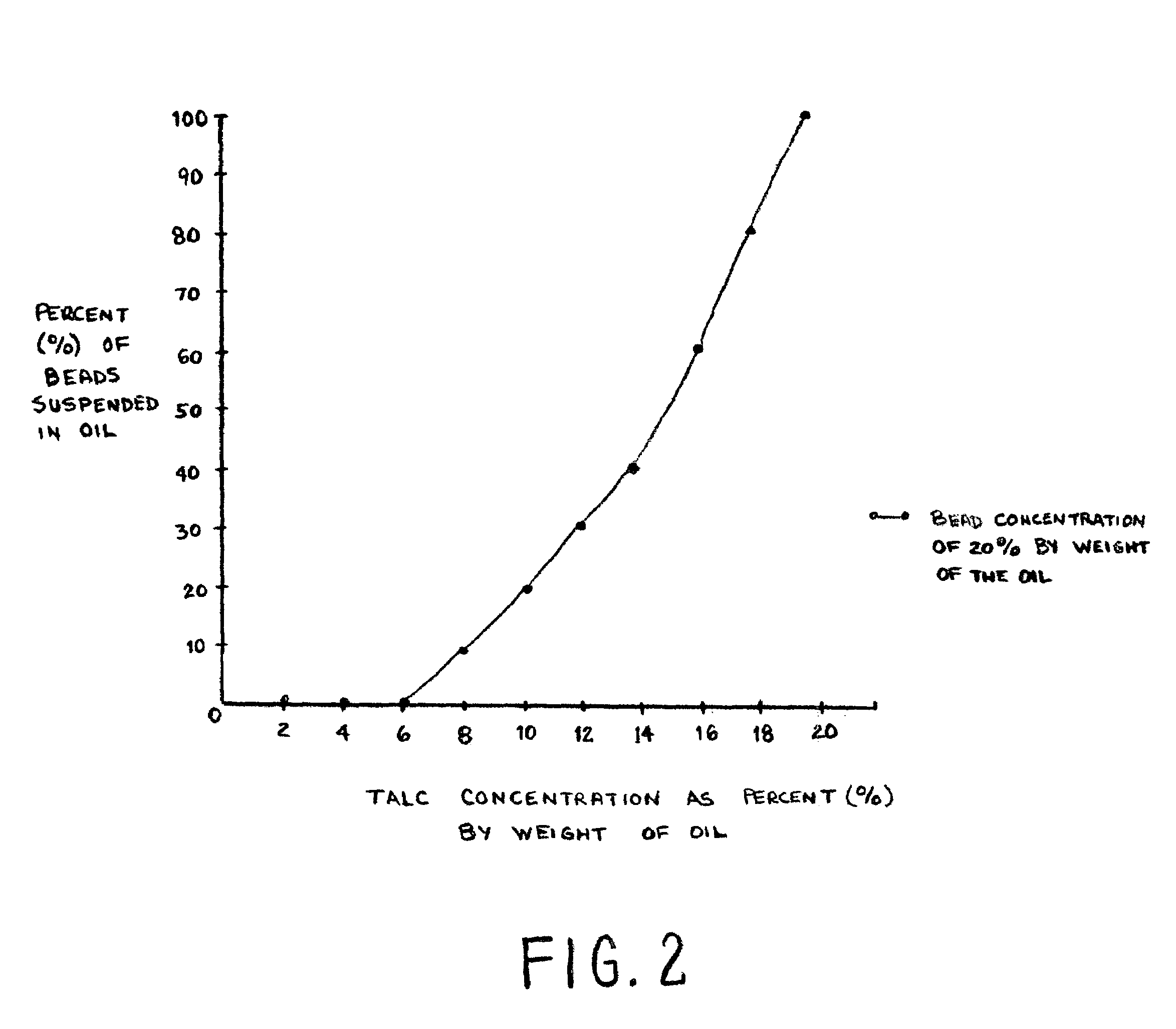

InactiveUS7001871B2Improve the lubrication effectSuperior lubricantFlushingDrilling compositionWater basedPolypropylene glycol

A drilling fluid additive is provided wherein the additive is manufactured by a method comprised of admixing at least one carrier such as a polypropylene glycol to talc and subsequently admixing graphite to the talc and carrier mixture; and then admixing an uintaite to the talc, carrier and graphite mixture.

Owner:MI

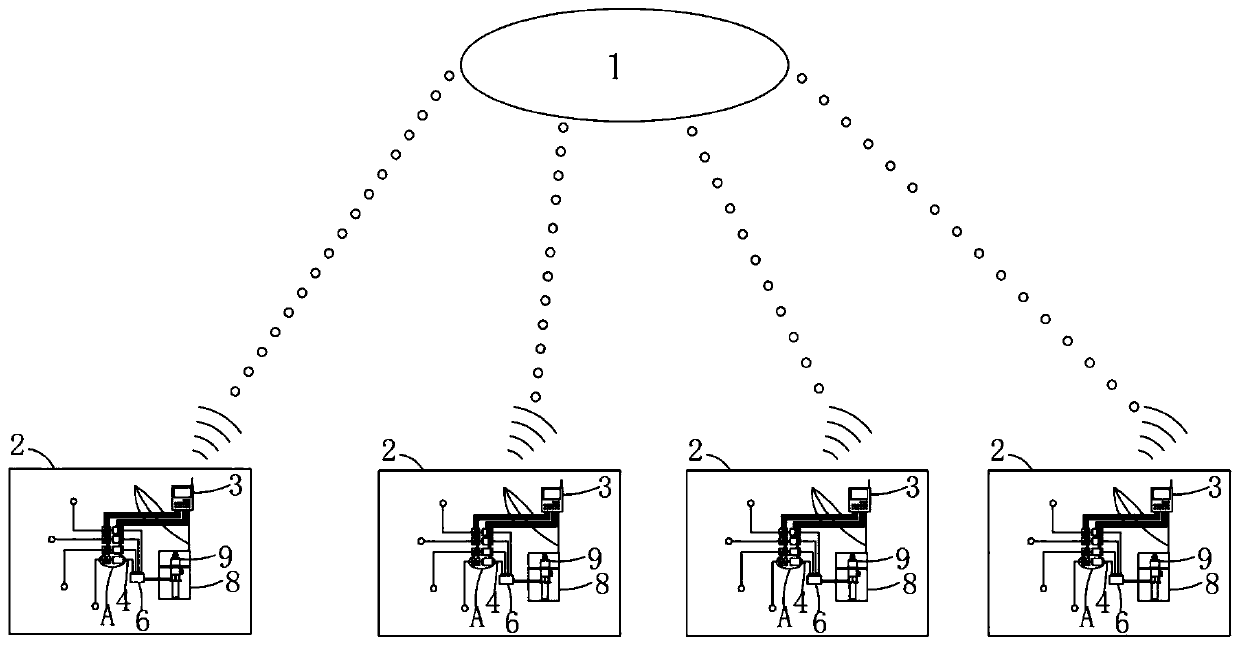

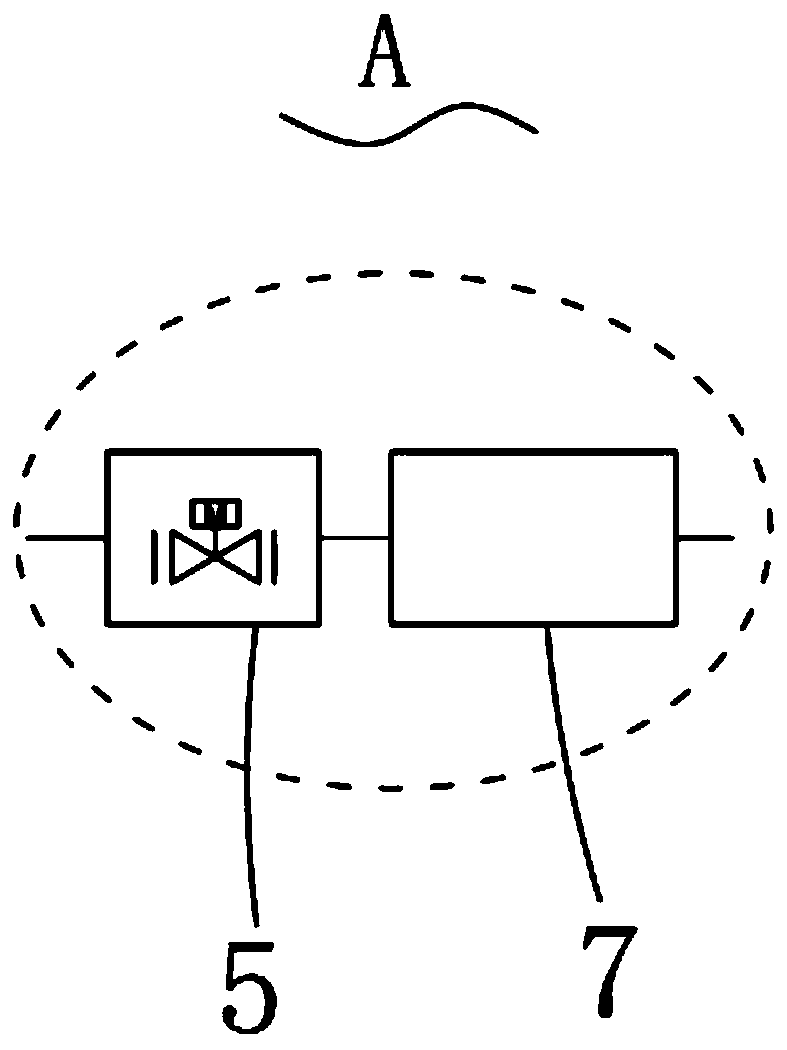

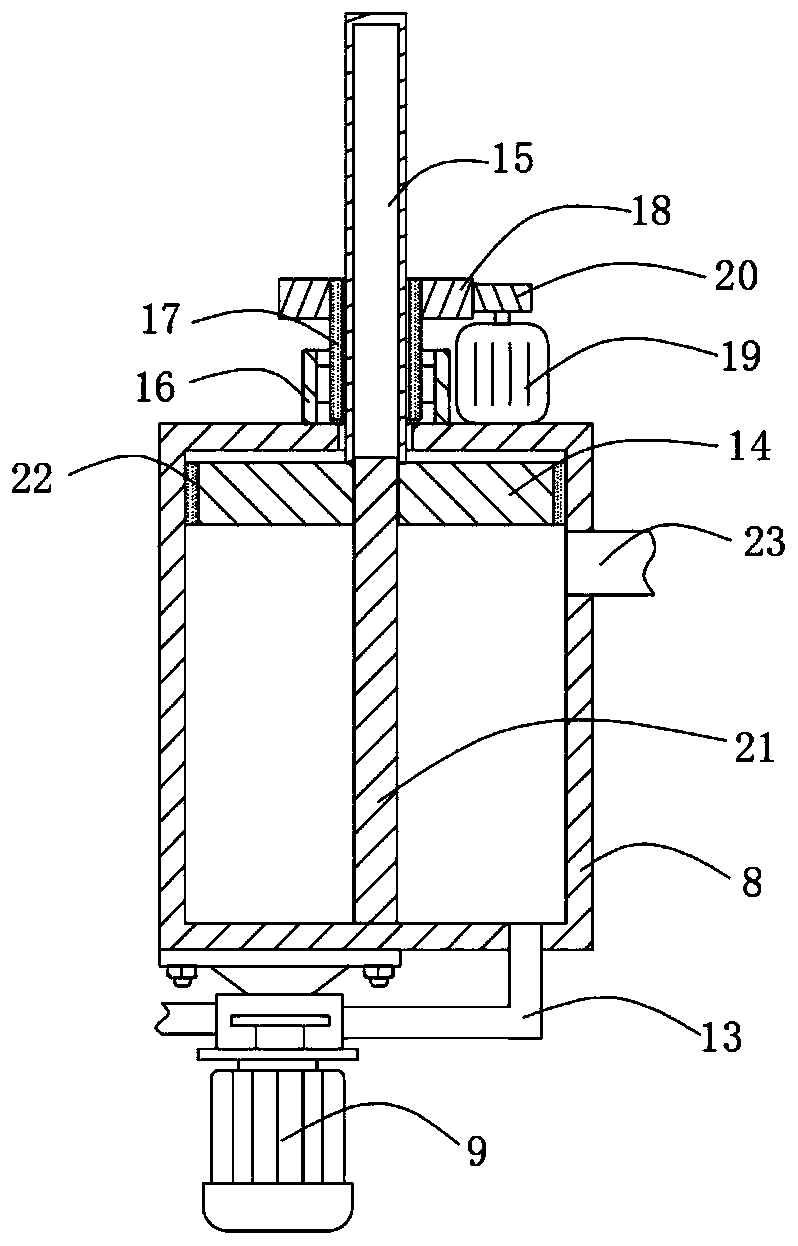

Centralized lubrication pump data intelligent transmission system

PendingCN111503501AReduce wasteRealize data visualizationSignal processingBearing componentsRemote controlControl engineering

The invention discloses a centralized lubrication pump data intelligent transmission system which comprises a distributed data transmission system consisting of a server and a lubrication terminal. The centralized lubrication pump data intelligent transmission system is characterized in that the lubrication terminal comprises a networking control module for information interaction with the serverand multiple paths of mechanical bearing lubrication point conveying channels, wherein each mechanical bearing lubricating point conveying channel is internally provided with a volume type flow moduleused for collecting flow and sending pulse signals to the networking type control module. The centralized lubrication pump data intelligent transmission system has the beneficial effects that the lubricating state of a mechanical bearing needing to be lubricated is effectively supervised through real-time data analysis, remote control is achieved, high-efficiency intellectualization, data visualization, accuracy and high efficiency are achieved, the application range is wide, and meanwhile the method is suitable for places where the environment is severe and manual work is not easy or oilingcannot be achieved; and accurate lubrication under five-point management of bearing lubrication points is achieved, the equipment working efficiency is improved, the labor intensity of workers is reduced, the safety coefficient is high, meanwhile, lubricating grease waste is reduced, and the equipment lubrication quality is improved.

Owner:深圳西通流体技术有限公司

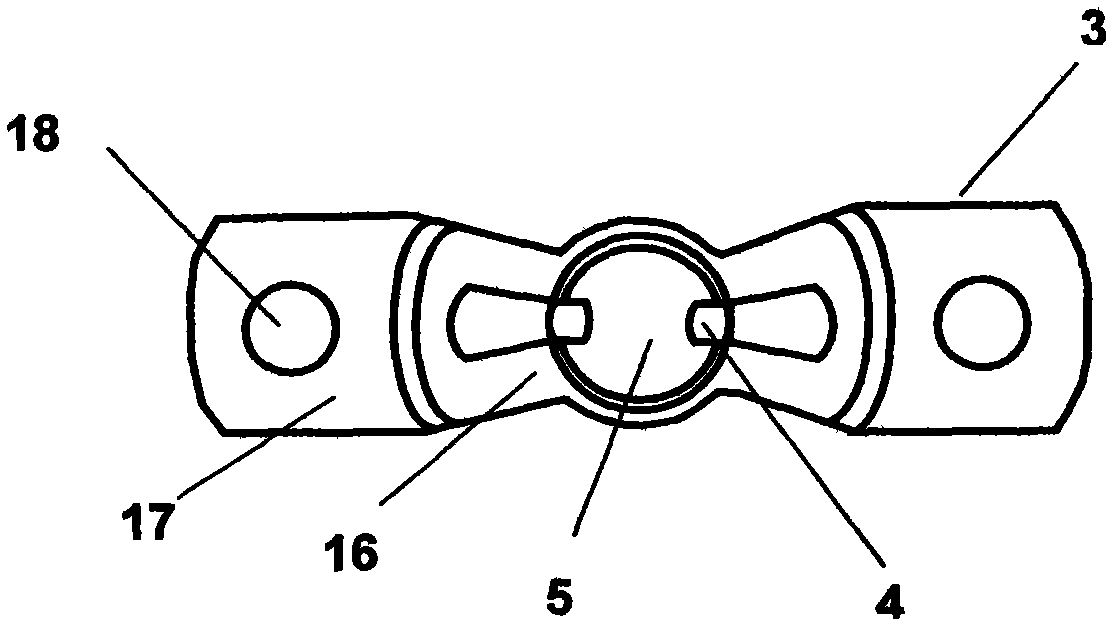

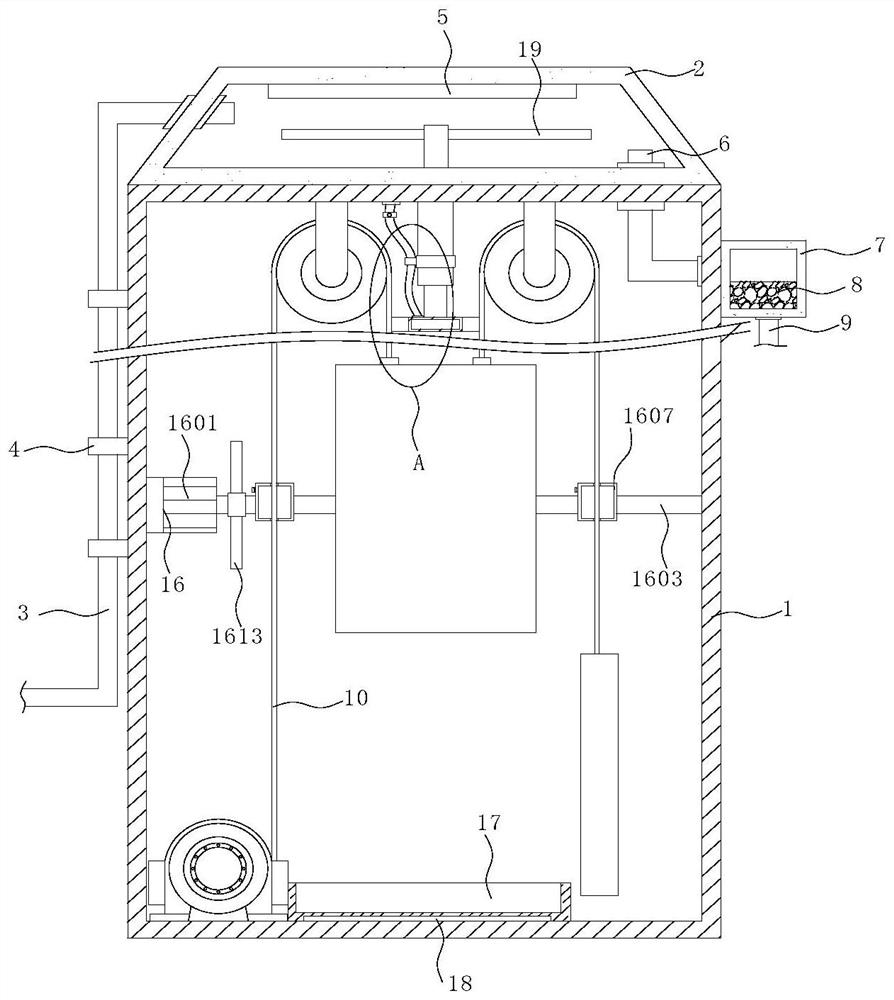

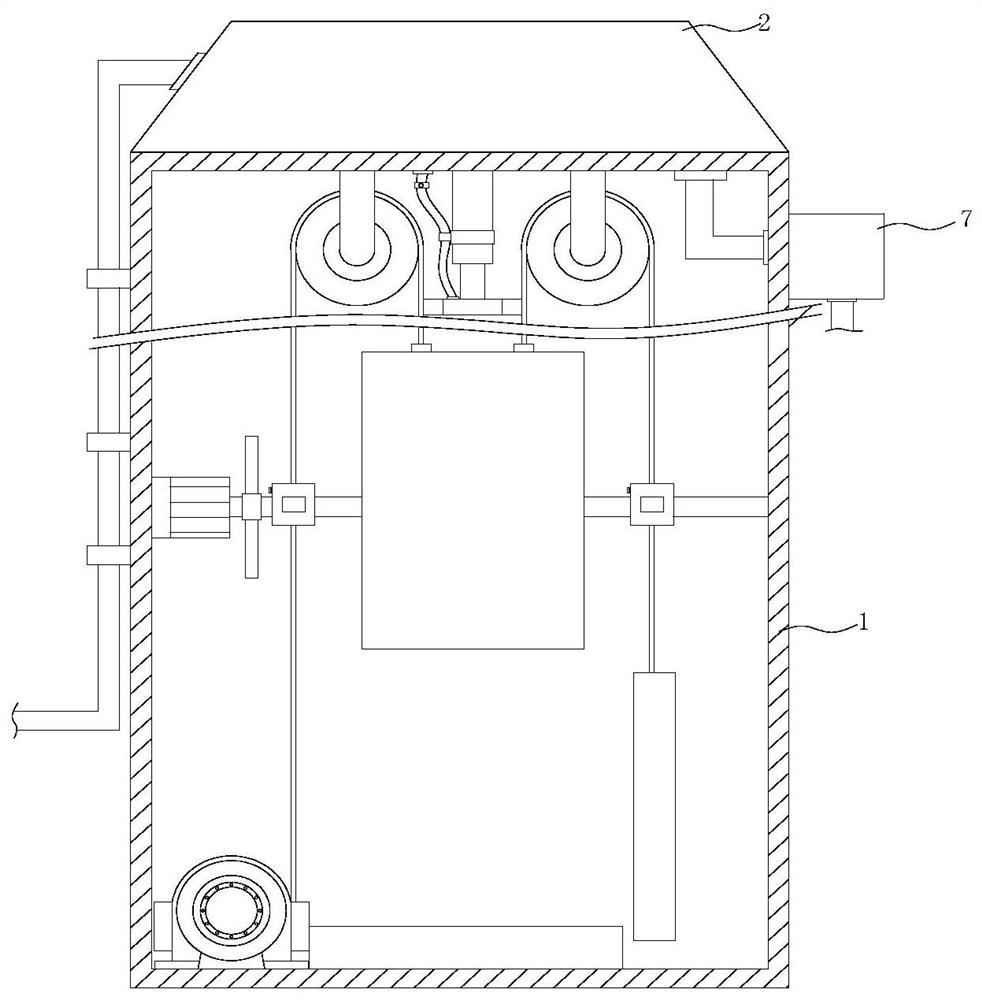

Automatic lubricating device of enameled wire

ActiveCN102800425AEffective lubricationImprove work efficiencyCable/conductor manufactureEngineeringLubrication

The invention relates to an automatic lubricating device of an enameled wire. A transposition head and a twisting cage arranged on a rack are connected through a plurality of enameled wires; the transposition head is fixedly arranged; the enameled wires are driven by the twisting cage to rotate; the automatic lubricating device of the enameled wire comprises a noseplate, an oiling ring and an oil tank unit, wherein a plurality of wiring holes are formed in the middle of the noseplate; lubricating pieces are arranged inside the wiring holes; the plurality of enameled wires penetrate through the wiring holes respectively; the oiling ring is sleeved outside the plurality of enameled wires; the oil tank unit is arranged below the oiling ring; the lower end of the oiling ring is in contact connection with the oil tank unit; and lubricating oil is stored inside the oil tank unit. According to the device, by utilizing the rotation of the twisting cage, the lubricating oil is driven inside a lubricating piece through the oiling ring, so that each enameled wire passing through the wiring hole is lubricated effectively, and the working efficiency and the lubrication quality are improved; and the existing production line equipment of transposed conductors is utilized sufficiently, and the device is strong in transformation adaptability and easy to realize.

Owner:JIANGSU ZHONGRONG ELECTRIC

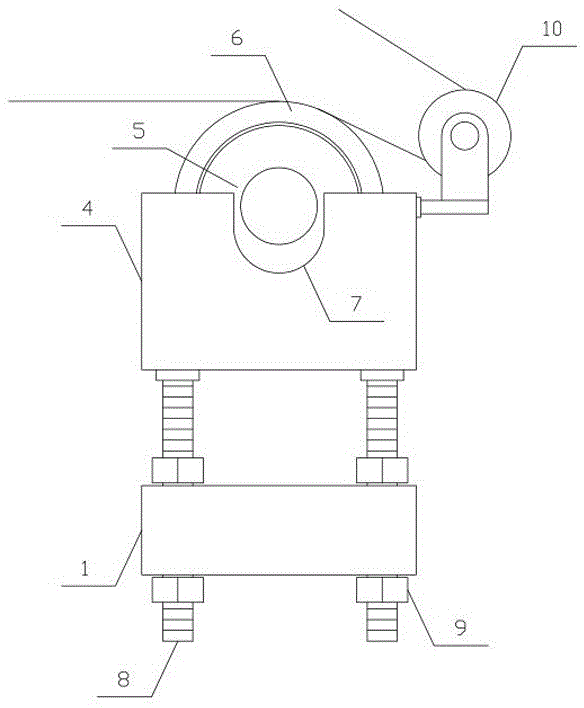

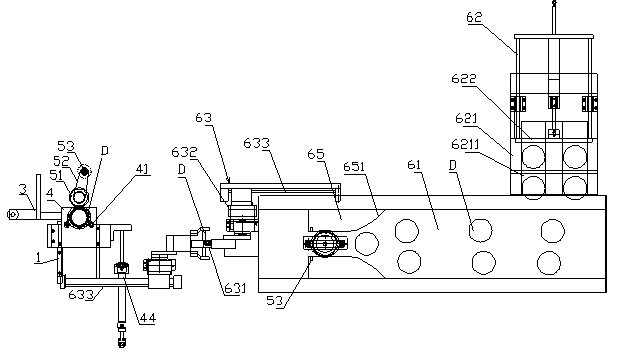

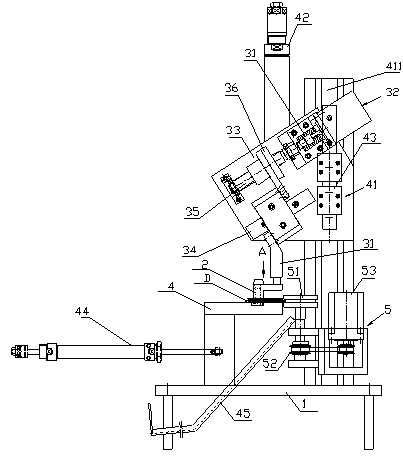

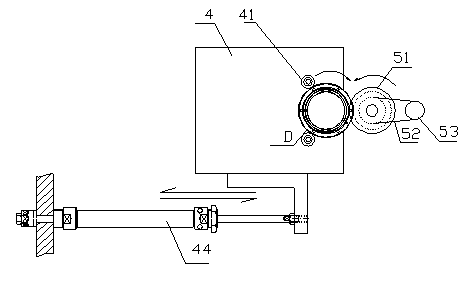

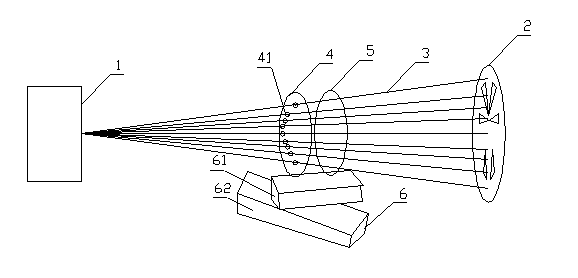

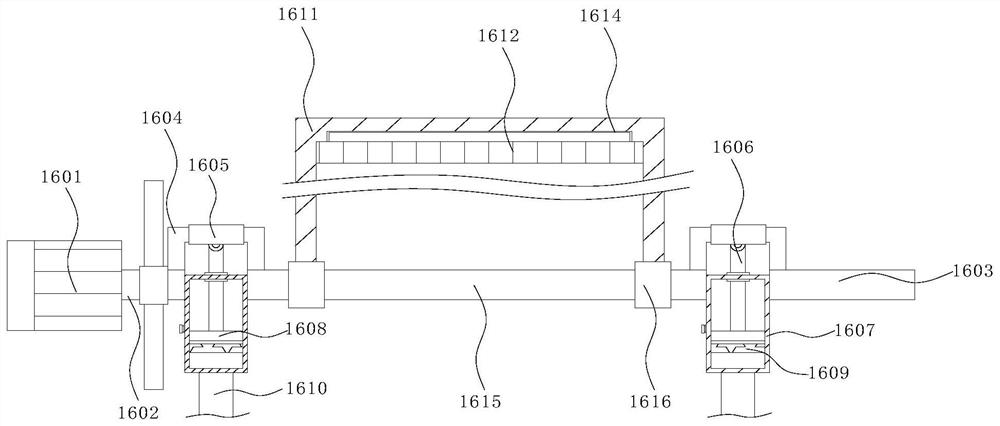

Lubricant spraying system for gasket

ActiveCN103212503AImprove lubrication qualityPrecise dose controlSpraying apparatusRolling resistanceFriction force

The invention relates to a lubricant spraying system for a gasket. The lubricant spraying system for the gasket comprises a gasket platform used for placing the gasket to be sprayed, a spraying nozzle capable of obliquely moving to the inner side of the gasket, and a friction wheel capable of being arranged at one side of the gasket platform in a rotary mode, wherein at least two rotation rollers are symmetrically arranged on the gasket platform, and the gasket is in contacting connection with the rotation rollers and the friction wheel and rotates under the driving of rolling frictional force of the friction wheel. The lubricant spraying system for the gasket is capable of automatically spraying lubricant to the inner side of the gasket, accurately controls the dosage and uniformity of the lubricant on each gasket, and improves the lubricating quality of the gasket.

Owner:镇江泛沃新能汽车技术股份有限公司

Lubricating equipment for elevator steel wire rope parts

ActiveCN112193965AEasy lubrication and oilingEasy maintenanceDirt cleaningLubrication elementsOil and greaseWire rope

The invention discloses lubricating equipment for elevator steel wire rope parts, and relates to the technical field of elevators. The lubricating equipment for the elevator steel wire rope parts comprises an elevator working box, wherein a steel wire rope and a lubricating mechanism are arranged in the elevator working box, an oil tank is welded to the top of the elevator working box, a heating plate is welded to the top of the inner side of the oil tank, and an input pipeline is arranged on one side of the elevator working box. According to the lubricating equipment, oil of the steel wire rope needing to be lubricated can be stored, the steel wire rope can be lubricated and oiled conveniently at any time, the steel wire rope can be maintained conveniently, the stability of the elevator speed is guaranteed in the operation process of the steel wire rope, the situations that due to long-time use of the steel wire rope, grease is gradually reduced, and the surface of the steel wire ropeis stained with dirt such as dust, so that the steel wire rope and a rope sheave are abraded and rusted, due to the arrangement of a bidirectional hydraulic rod and a stirring rod, oil in the oil tank can be mixed, and the situations of solidification and layering are avoided.

Owner:重庆市华创电梯部件有限公司

Cold machining manufacturing method of large-diameter thin-wall zirconium alloy pipe

ActiveCN113441568AGuaranteed stabilityGuaranteed performanceNuclear energy generationFurnace typesHot workingMachining process

The invention discloses a cold machining manufacturing method for a large-diameter thin-wall zirconium alloy pipe. The method comprises the steps that firstly, a zirconium alloy pipe raw material is subjected to head grinding treatment and then is ground, cleaned, flushed and dried, and a to-be-treated zirconium alloy pipe is obtained; secondly, after soaking, washing with deionized water and drying, a pretreated zirconium alloy pipe is obtained; thirdly, after the surface is coated with a lubricant, drawing is conducted through a fixed core head, and a drawn zirconium alloy pipe is obtained; fourthly, ultrasonic degreasing, flushing, acid pickling, flushing and drying are carried out; and fifthly, the dried drawn zirconium alloy pipe is subjected to vacuum annealing treatment, and the zirconium alloy pipe is obtained. According to the method, soaking pretreatment is combined with the fixed core head drawing to conduct cold machining on the zirconium alloy pipe to prepare the large-diameter thin-wall zirconium alloy pipe, the size precision of the pipe is strictly controlled, impurity elements are prevented from being adsorbed to the surface of the zirconium alloy pipe in the conventional hot machining process, the stability of chemical components of the zirconium alloy pipe is guaranteed, and the performance of the zirconium alloy pipe is effectively ensured.

Owner:西安西部新锆科技股份有限公司

Molding machine

InactiveUS6739864B2High viscosityReduce liquidityCeramic shaping apparatusFood shapingMolding machineEngineering

Owner:MANNESMANN PLASTICS MACHINERY

Sealed bearing seat suitable for severe working environment

PendingCN110332240AExtended service lifeGuaranteed directional dischargeBearing unit rigid supportWorking environmentEngineering

The invention relates to the technical field of bearing seats, in particular to a sealed bearing seat suitable for a severe working environment. The sealed bearing seat suitable for the severe workingenvironment comprises a seat body, an end cover, a shaft, a supporting ring, a bearing fixing ring, a sealing ring, a sealed bearing, a floating oil seal and a pressure relief oil nozzle. The sealedbearing seat suitable for the severe working environment has the advantages that two independent oil paths are arranged, the oil paths in the sealed bearing seat are divided into two by the sealing ring, the uncertainty is reduced, old lubricating grease can be directionally discharged, the lubricating quality is improved, and the service life of the bearing seat is prolonged; multiple sealing protection is achieved by combining floating oil seal, a labyrinth structure and the sealed bearing, and the reliability of the bearing seat is improved; a centralized oil supply system is used for supplying oil to the sealed bearing seat, so that the bearing seat is convenient to operate; and parts of the sealed bearing seat can be detached from the end of a shaft, and are convenient to maintain.

Owner:JIAOZUO CREATION HEAVY IND CO LTD

Novel lubricating oil accelerator

InactiveCN104293421AImprove fatigue resistanceImprove lubrication qualityAdditivesPtru catalystAluminum silicate

The invention relates to a novel lubricating oil accelerator. The raw material formula of the accelerator comprises caprolactam disulfide, a catalyst, rosin, copper sulfate, ethyl acetate, turkey red oil and aluminum silicate. The accelerator substantially improves the fatigue resistance of engines, improves the integral lubricating quality of the engines, has a low cost, and is in favor of popularizing application.

Owner:QINGDAO HI TECH PATENT TECH TRANSFER PLATFORM

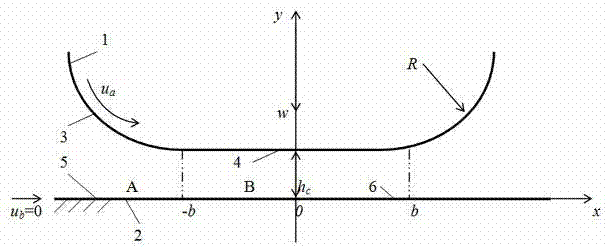

Method for improving lubrication of line contact fluid under simple sliding

ActiveCN102889373AReduce coefficient of frictionImprove carrying capacityGear lubrication/coolingEngineeringMechanical engineering

The invention discloses a method for improving lubrication of line contact fluid under simple sliding, and relates to lubrication of the line contact fluid under simple sliding. A lubrication oil and contact surface adhering interface is designed on the moving contact surface of a lubrication inlet region, so that a lubrication oil film does not slide on the contact surface; and a lubrication oil and contact surface sliding interface is designed on the moving contact surface of a hertz contact region, so that the lubrication oil film slides on the contact surface. A lubrication oil and contact surface sliding interface is designed on a static contact surface of the lubrication inlet region, so that the lubrication oil film slides on the interface; and a lubrication oil and contact surface adhering interface is designed on the static contact surface of the hertz contact region, so that the lubrication oil film does not slide on the interface. By the method, friction energy consumption and friction temperature rising of the line contact fluid during lubrication can be greatly reduced; the lubrication state of lubrication of the line contact fluid is greatly improved; the working performance of a transmission part under the lubrication condition is obviously improved; and the service life of the line contact fluid is prolonged.

Owner:南通东湖国际商务服务有限公司

Novel gearbox

InactiveCN106838273AExtend your lifeAvoid failureGear lubrication/coolingEngineeringProcess complexity

The invention discloses a novel gear box. In order to solve the problem of oil leakage and the complex adjustment process of the bearing axial clearance in the existing gear box; the gear box includes a driven gear, a box body, an outer end cover and a bearing retaining ring; It is composed of the lower box body, and the upper box body and the lower box body have corresponding oil passages; there is an outer oil chamber between the bearing retaining ring and the outer end cover, and an inner oil chamber between the bearing retaining ring and the bearing. Cavity; between the box, the bearing retaining ring and the two outer end caps, there are bearing bushes; the bearing bushes are provided with bushings that communicate with the corresponding oil passages on the upper box and the lower box. Sleeve oil passage; the bush oil passage communicates with the inner oil chamber or the outer oil chamber. The invention improves the service life and lubricating quality of the driven gear bearing, reduces the complexity of the process, and improves the assembly efficiency of the gearbox.

Owner:CHANGZHOU KAIFA GUANGMING CASTING FACTORY GENERAL PARTNERSHIP

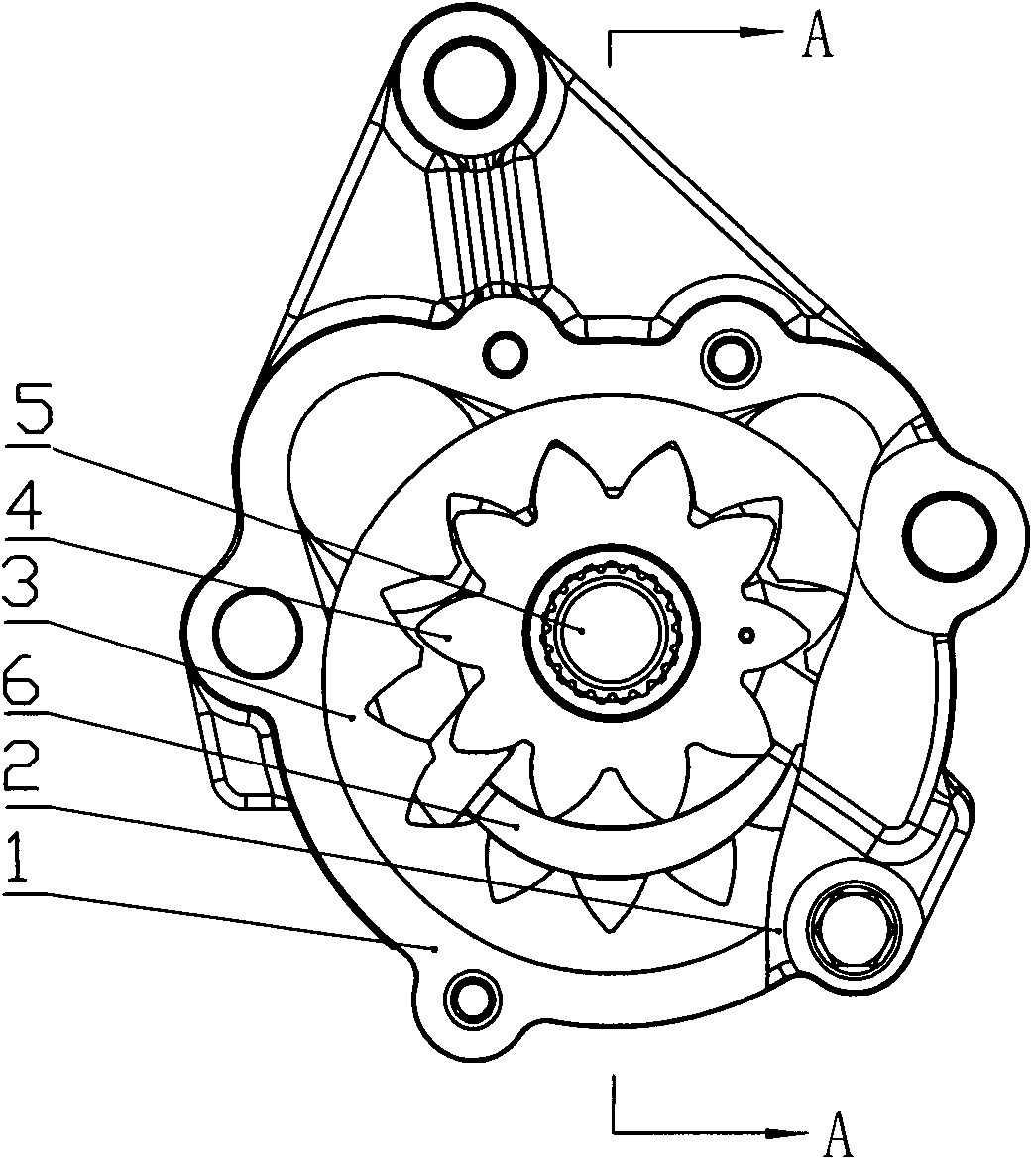

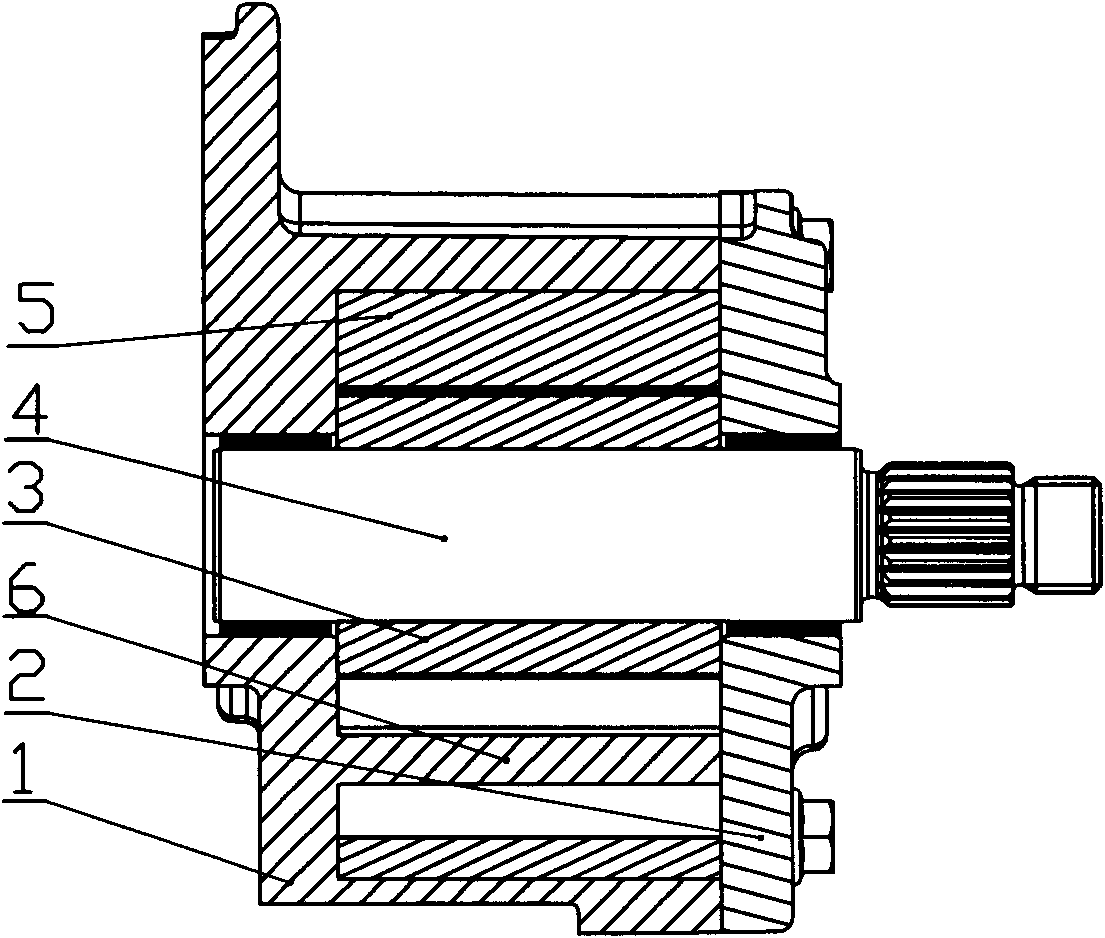

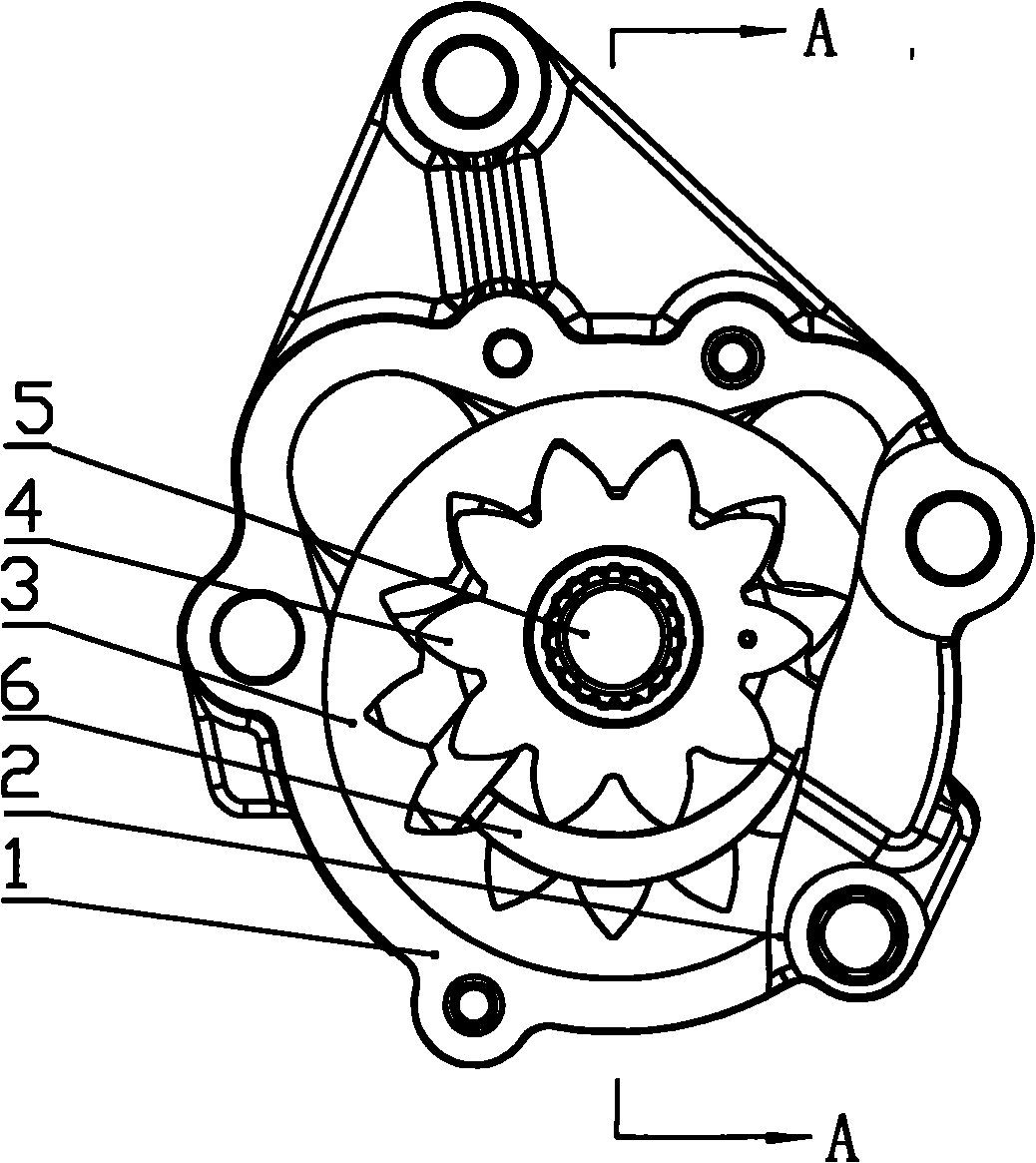

Oil pump with inside engaged gear

InactiveCN102022319ASimple structureReduce noiseRotary piston pumpsRotary piston liquid enginesEngineeringLow noise

The invention relates to an oil pump with an inside engaged gear, which comprises a pump body 1, a pump cover 2, an inside gear 3, an outside gear 4 and a transmission shaft 5. The middle of the transmission shaft 5 is in interference connection with the outside gear 4 and arranged together with the inside gear 3 in the gear hole and axleholes of the pump body 1 and the pump cover 2. A crescent spacer 6, which is not only a channel for separating and transferring lubricating oil in the gear cavities of the inside gear 3 and the outside gear 4, but also an separator for separating the oil outlet cavity from the oil inlet cavity and preventing the pressure oil from backflowing, integrally formed with the pump body 1 is arranged in an eccentricity space formed mutually by the outside and the inside gear holes in the inner cavity of the pump body 1. By adopting the above design, compared with prior art, the invention has the advantages of simple structure, low noise, stable oil transfer, strong self-absorption, high lubricating efficiency, good lubricating effect, good low-high rotating speed characteristic and improves the lubricating efficiency and quality so that the safety, reliability and service life of the oil pump are improved to a great extent.

Owner:HUNAN OIL PUMP

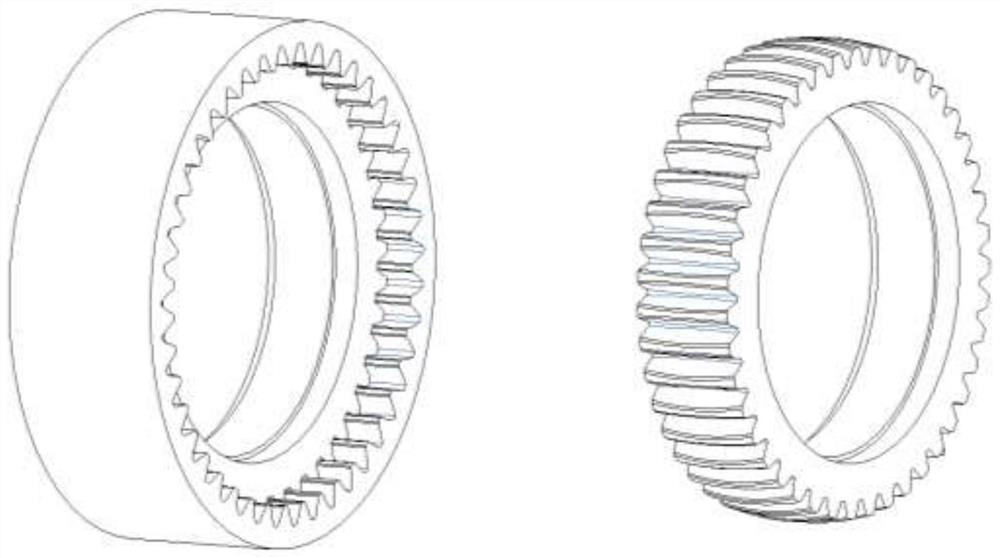

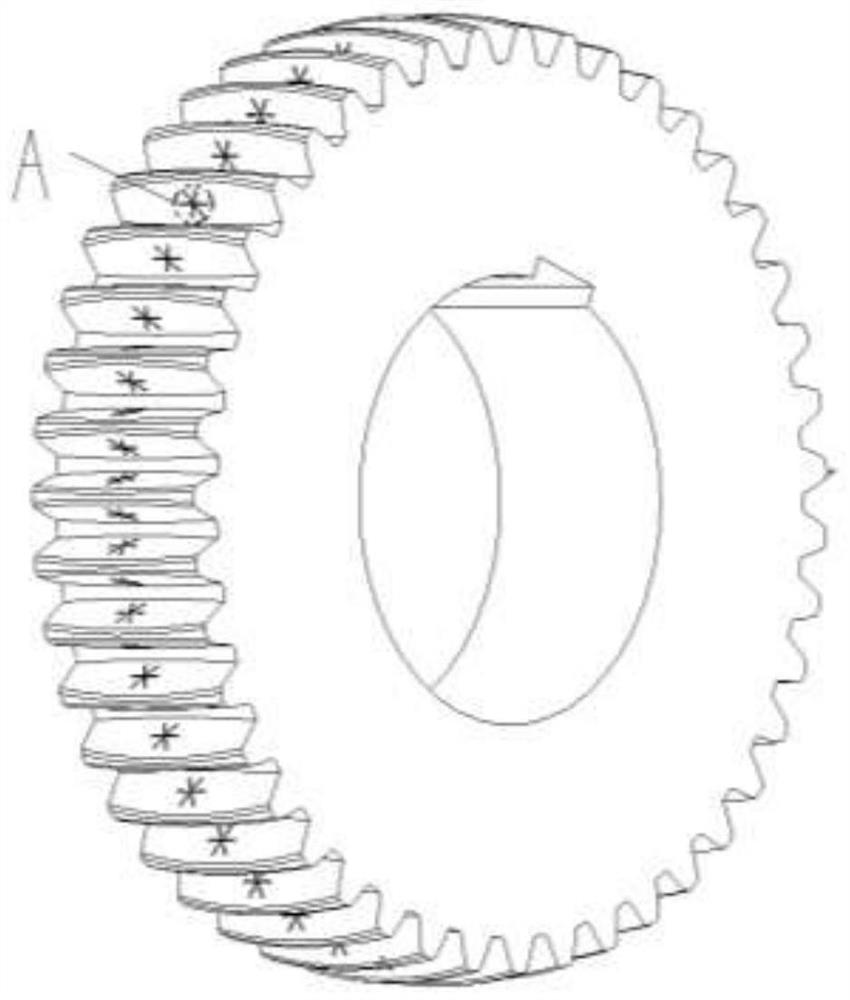

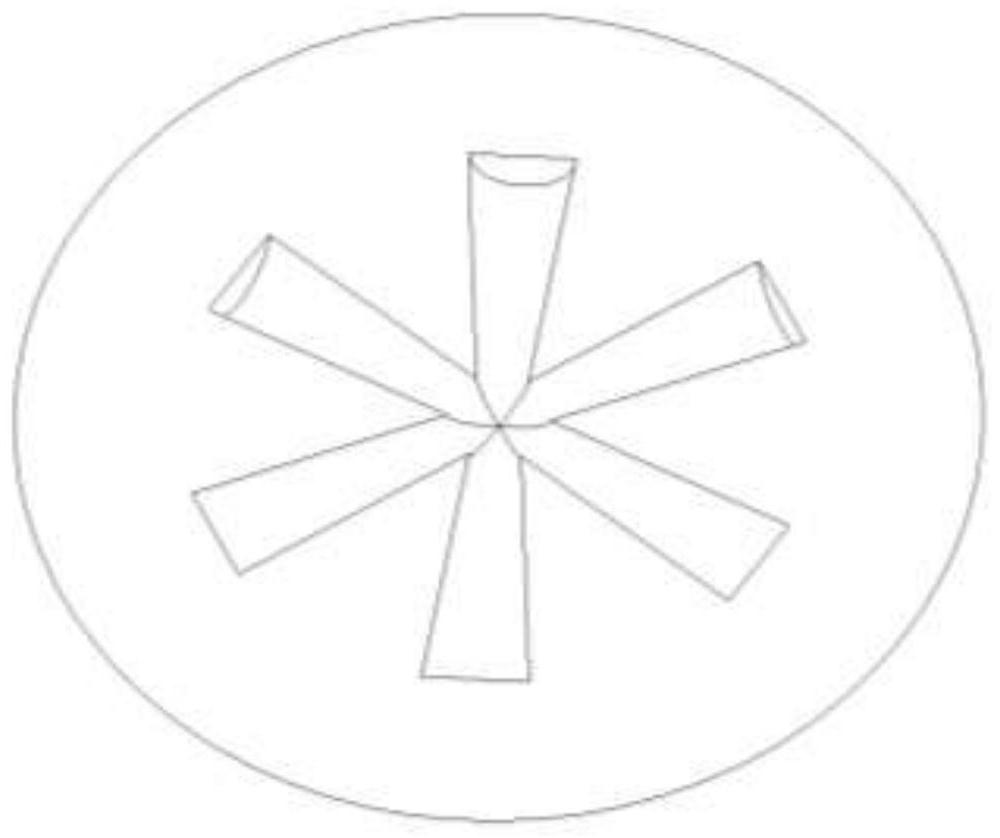

Drum-type gear with oil supply and lubrication functions

ActiveCN112879527AGuaranteed lubrication effectEnhanced dynamic pressure bearing capacityGear lubrication/coolingPortable liftingOil supplyTransmission equipment

The invention discloses a drum-type gear with oil supply and lubrication functions. The drum-type gear comprises a gear base body, drum-type teeth, micropore grooves, a shaft hole and key groove holes, wherein the drum-type teeth and the gear base body are integrated, the micropore grooves are formed in the tooth faces of the drum-type teeth, the shaft hole is formed in the center position of the gear base body, the key groove hole is formed in the inner wall of the shaft hole, the micropore grooves are evenly formed in the contact area of the front tooth face and the rear tooth face of each tooth of the drum-type teeth, the number of the micropore grooves in each tooth face is 6-12, the micropore grooves are distributed in the tooth surface contact areas in an annular array mode, and each micropore groove is in conical transition from large to small from the outer edge to the center. According to the drum-type gear, lubricating oil on the end face of a gear pair can permeate into a contact interface, circulating flow of a lubricating agent is formed between the contact interfaces, efficient lubrication of the drum-type gear is guaranteed, and the working requirement of continuous casting and rolling metallurgy transmission equipment is met.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY +1

Drilling fluid additive system containing talc and graphite

InactiveUS7060660B2Improve the lubrication effectSuperior lubricantFlushingDrilling compositionGraphiteTalc

A drilling fluid additive system is provided wherein the system comprises: a drilling fluid additive comprising talc, graphite and at least one carrier such as a glycol; and hydrophilic clay, a pH controller, a fluid loss controller, and at least one dispersant.

Owner:MI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com