Sealed bearing seat suitable for severe working environment

A technology for sealing bearings and working environments, which is applied in the direction of bearing components, shafts and bearings, rigid supports of bearing components, etc. It can solve the problems of poor sealing of bearing seats, dust, sand, and inconvenient maintenance, etc., and achieves convenient maintenance , Improve lubrication quality and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

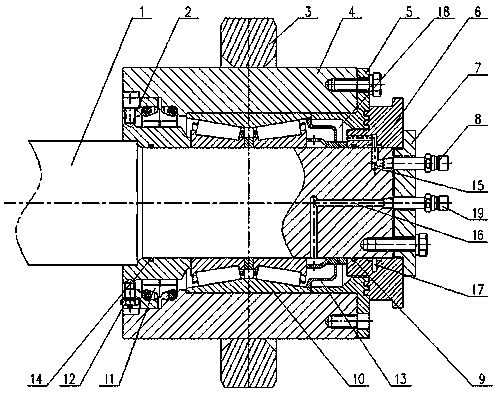

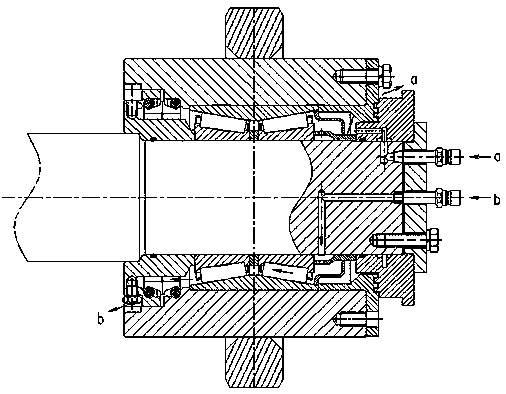

[0029] like Figure 1-2 As shown, the present invention provides a sealed bearing housing adapted to harsh working environments, including a seat body 4 and an end cover 7, and is characterized in that it also includes a shaft 1, a support ring 2, a bearing fixing ring 5, a sealing ring 6, a sealing Bearing 10, floating oil seal 11 and pressure relief nozzle 12.

[0030] The base body 4 is provided with an oil discharge groove, an oil seal groove and a bearing cavity in sequence from left to right, and the support ring 2, the sealed bearing 10 and the seal ring 6 are connected with the shaft 1 by interference fit in sequence from left to right, and the A first O-ring seal 14 is provided between the support ring 2 and the shaft 1 , and a second O-ring 9 is provided between the seal ring 6 and the shaft 1 .

[0031] The left end surface of the support ring 2 is flush with the left end surface of the seat body 4, and the support ring 2 is provided with an oil retaining flange, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com