Automatic lubricating device of enameled wire

An automatic lubrication and enameled wire technology, which is applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve the problems of low operating efficiency and poor enameled wire smearing and coverage, and achieve easy implementation, improved work efficiency and lubrication quality, and adaptation to transformation strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

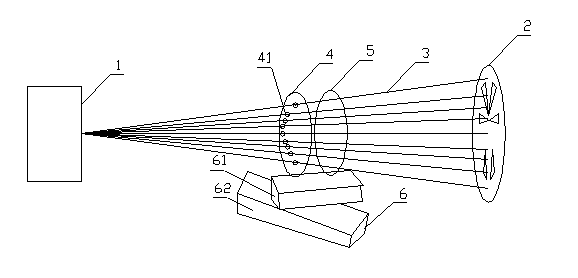

[0010] The enameled wire automatic lubricating device connects the transposition head 1 and the twist cage 2 arranged on the frame (not shown) through several enameled wires. The lubricating device includes a wire distribution plate 4, an oiling ring 5 and an oil groove unit 6. The middle part of the wire distribution plate 4 is provided with a number of wire holes 41, and a lubricating part (not shown in the figure) is provided in the wire hole, and a number of enameled wires are respectively threaded through Through the corresponding wire passing holes, the oiling ring is sleeved on the outside of the enameled wires, the oil tank unit is placed under the oiling ring, and the lower end of the oiling ring is in contact with the oil tank unit, and lubricating oil is stored in the oil tank unit. Lubricants are sponge blocks that absorb and store ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com