Hermetic compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

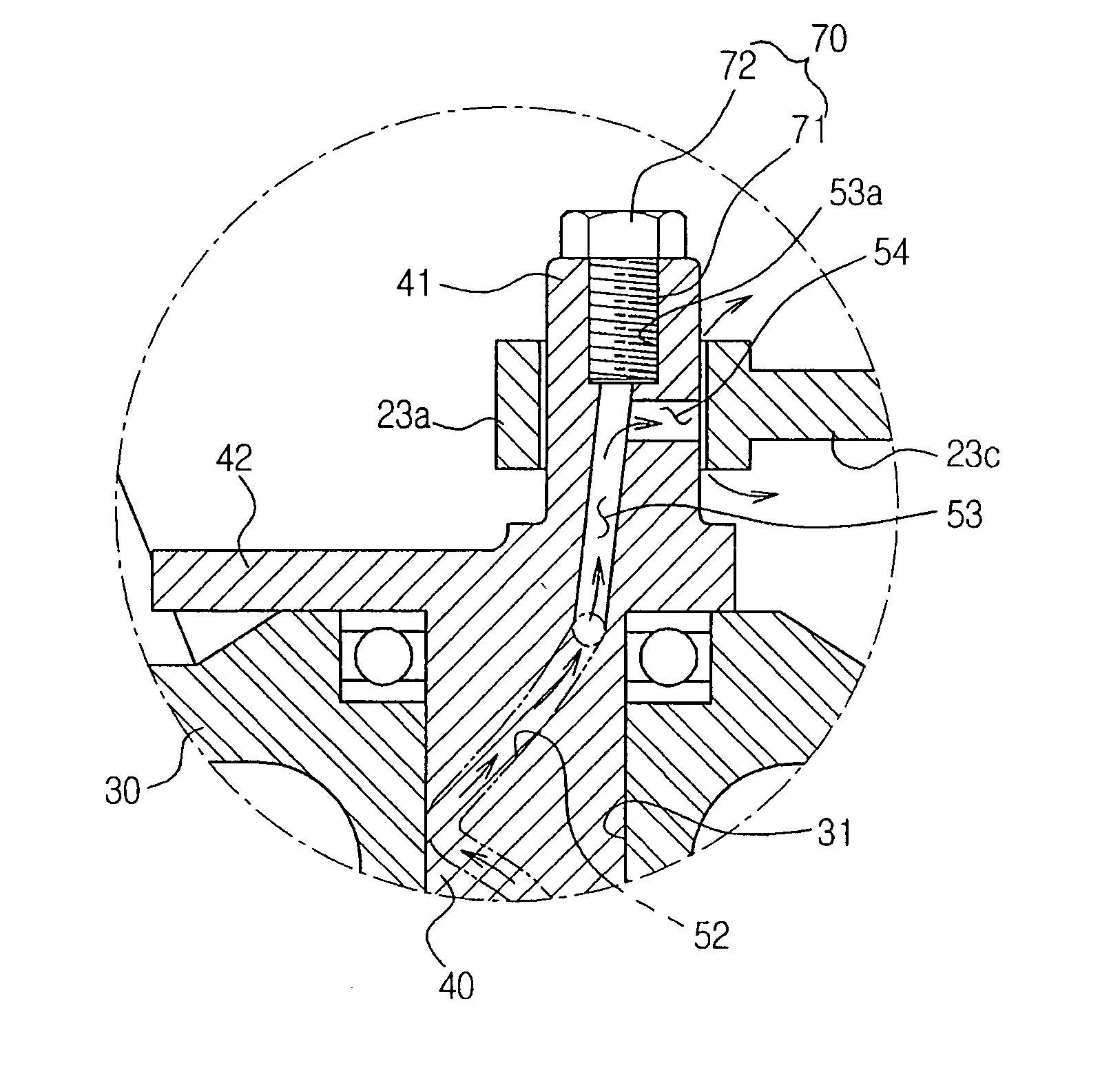

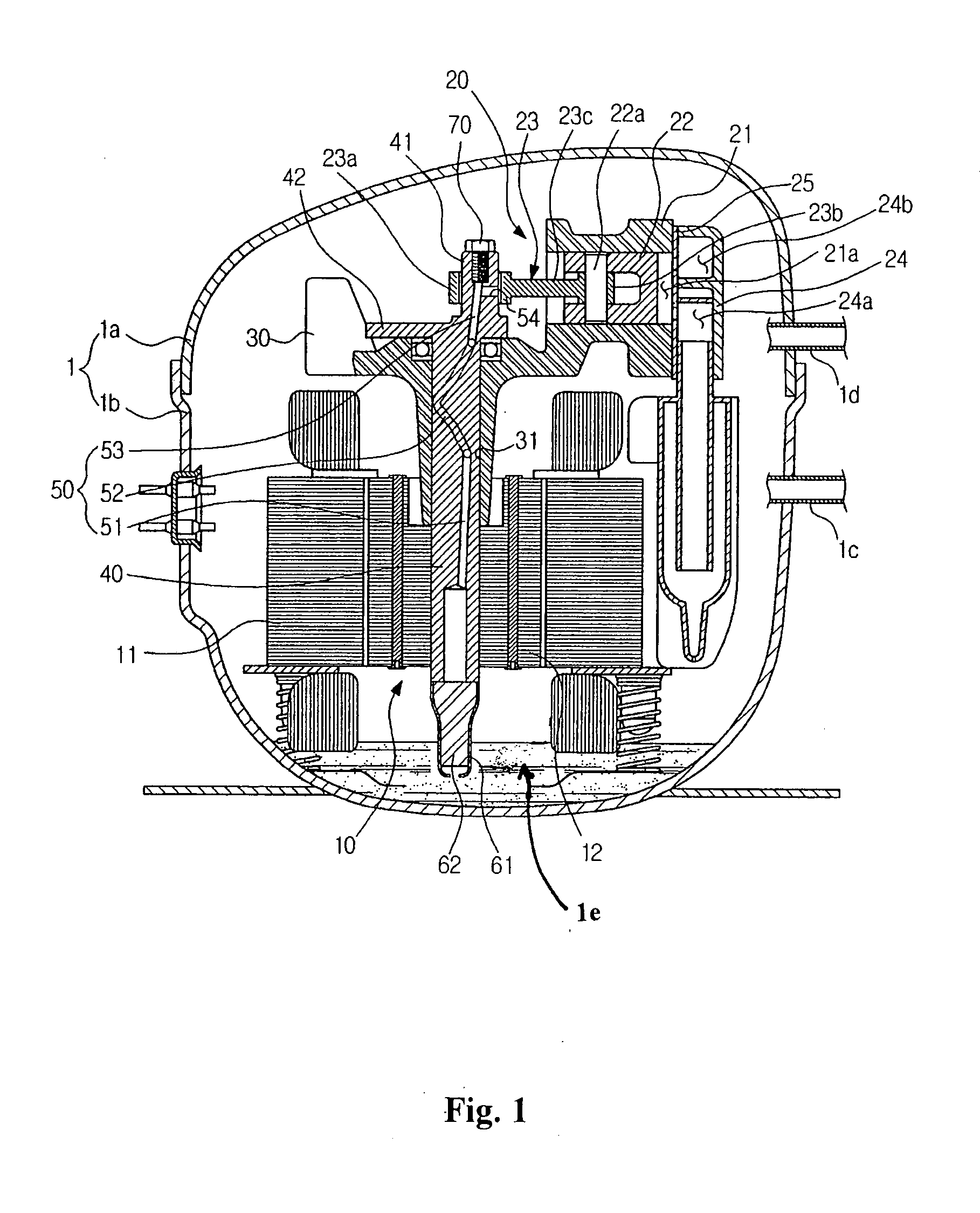

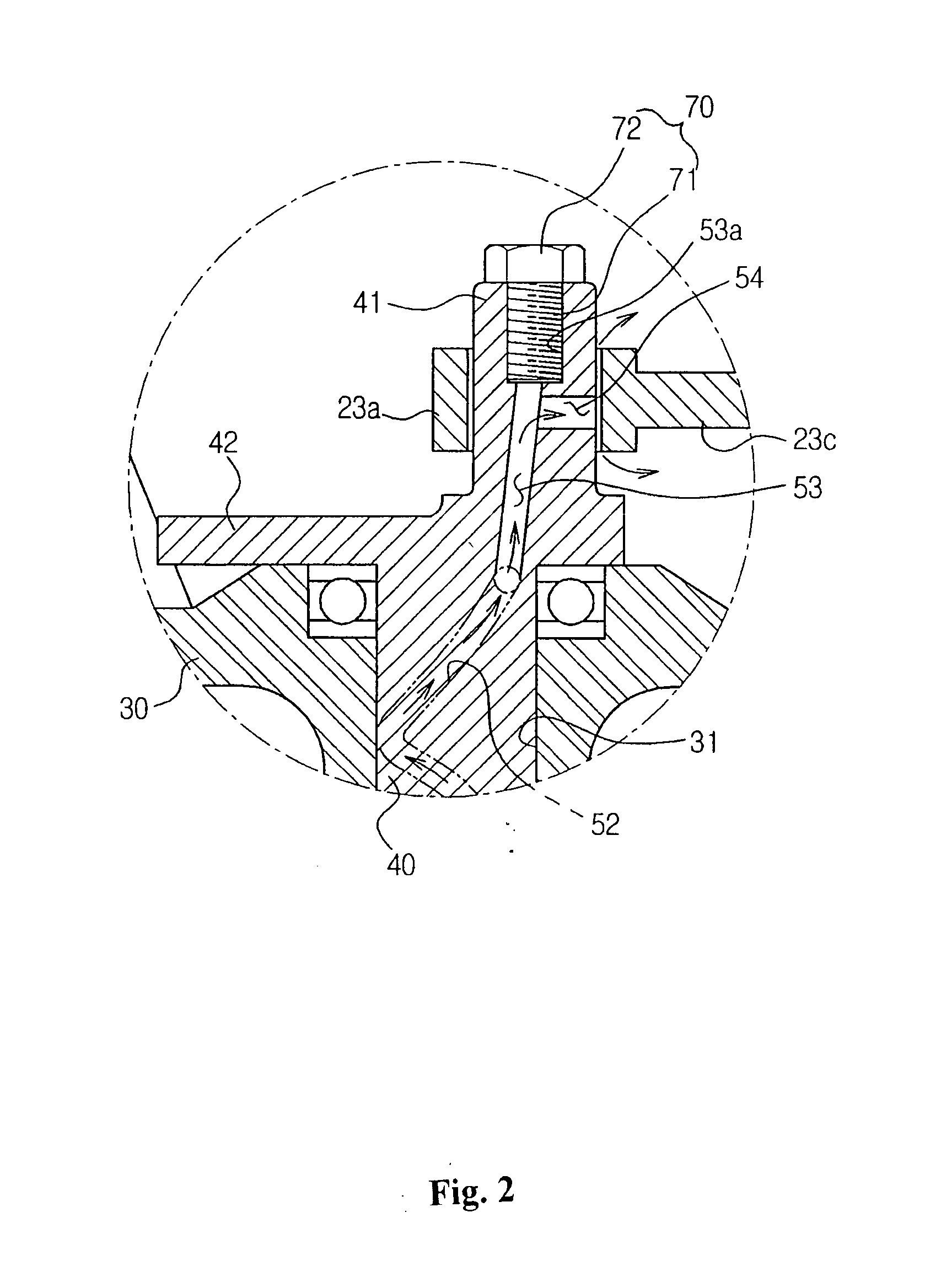

[0035]Reference will now be made in detail to an exemplary embodiment of a hermetic compressor, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to like elements throughout. The embodiment is described below by referring to the figures.

[0036]As shown in FIG. 1, the hermetic compressor includes a hermetic container 1 formed by coupling an upper container 1a and a lower container 1b to each other, the hermetic container 1 defining the outer appearance of the compressor. The hermetic container 1 is provided, at opposite sides thereof, with a suction pipe 1c to guide a refrigerant, passed through an evaporator of a refrigeration cycle, into the hermetic container 1 and with a discharge pipe 1d to guide the refrigerant, compressed within the hermetic container 1, to a condenser of the refrigeration cycle.

[0037]Provided within the hermetic container 1 are a drive unit 10 to provide power required to compress a refrigerant and a compress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com