Multi-functional three-dimensional energy-saving and environmentally-friendly lubricating device

A lubricating device, three-dimensional technology, applied in transportation and packaging, textiles and papermaking, and conveying filamentous materials, etc., can solve the problem of not being able to achieve the smooth weaving effect of the yarn, destroying the fiber structure of the yarn surface, and having no flying flower recovery technology To improve the level of independent innovation, reduce hairiness and fly, and improve the technical content of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

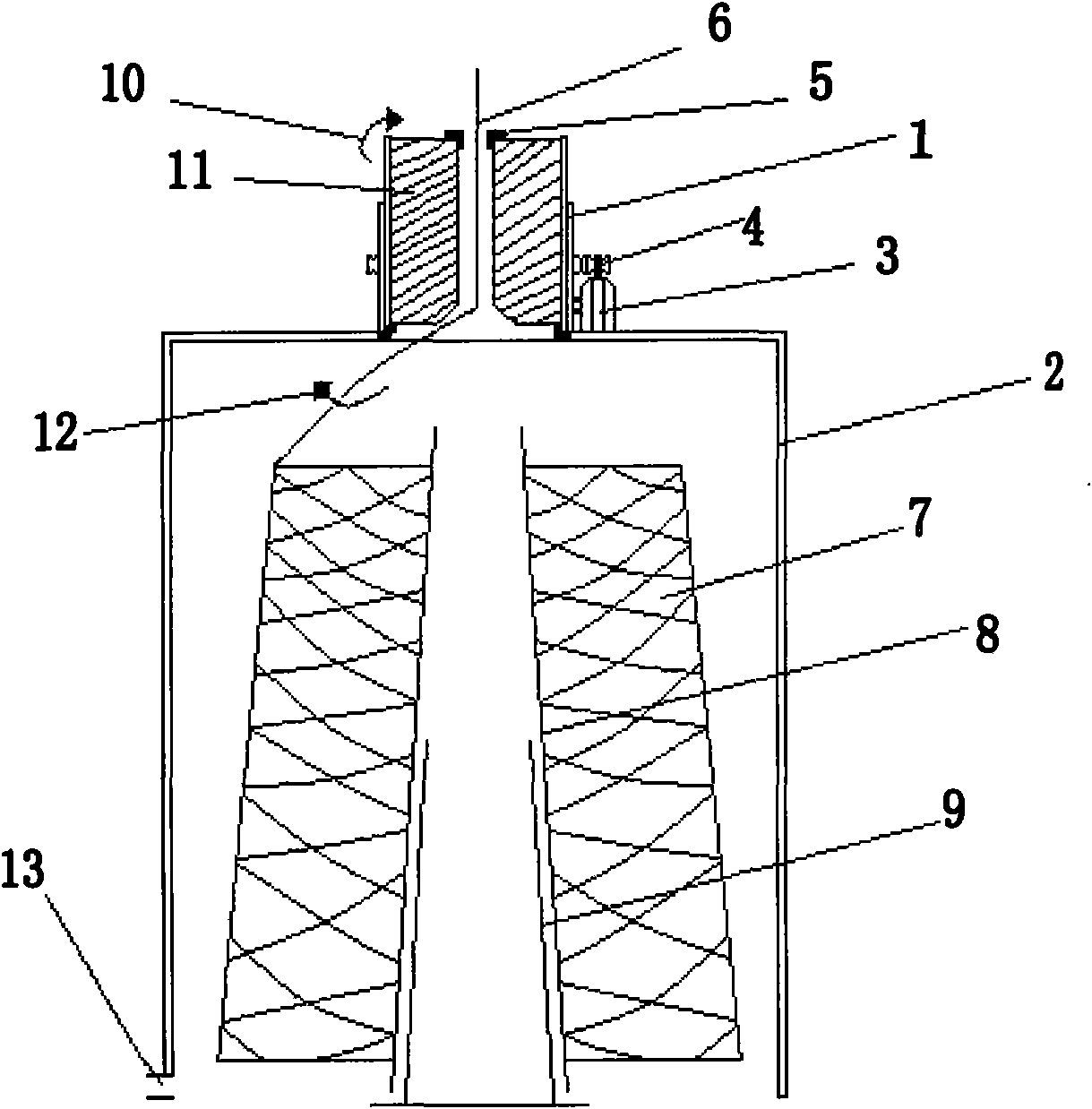

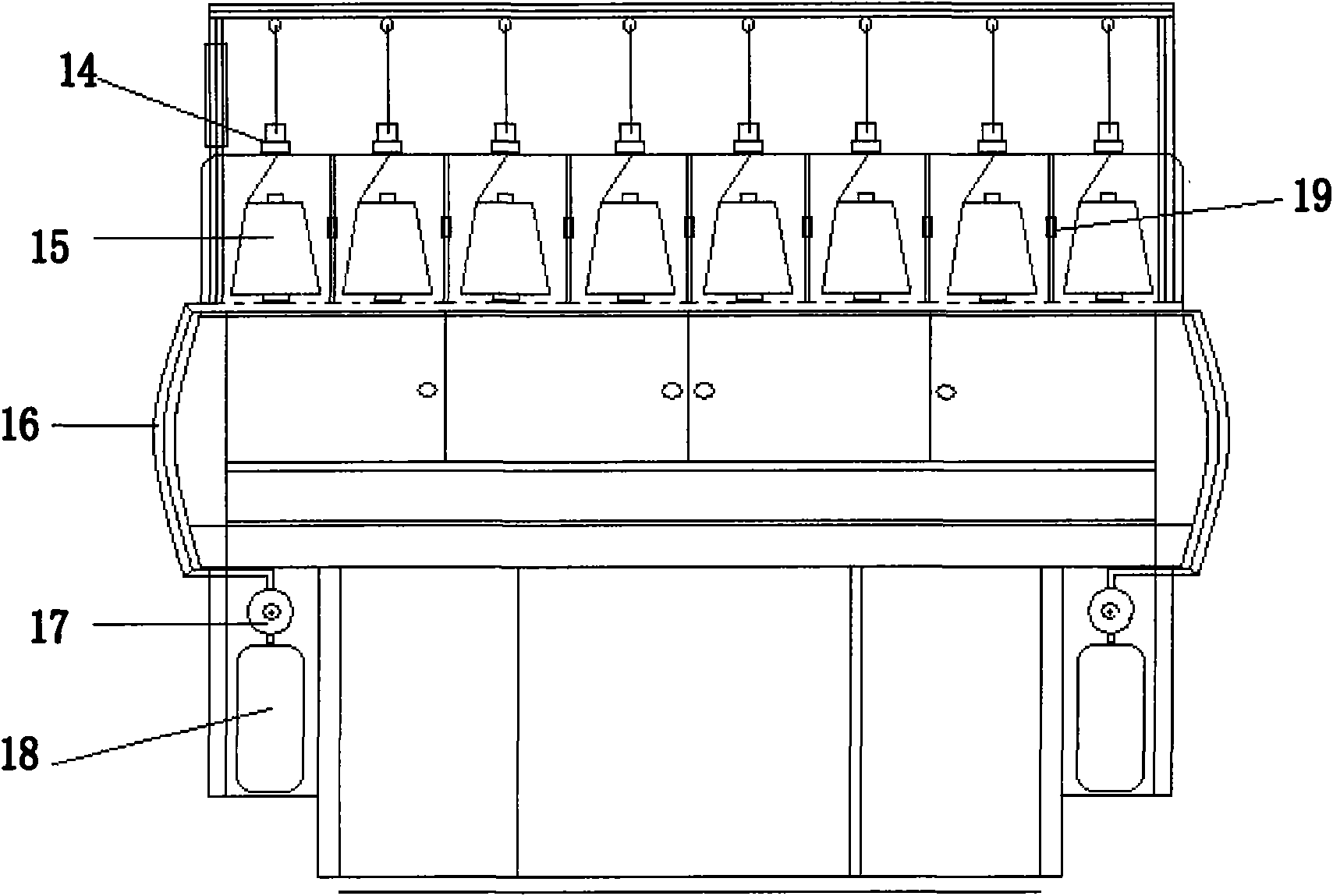

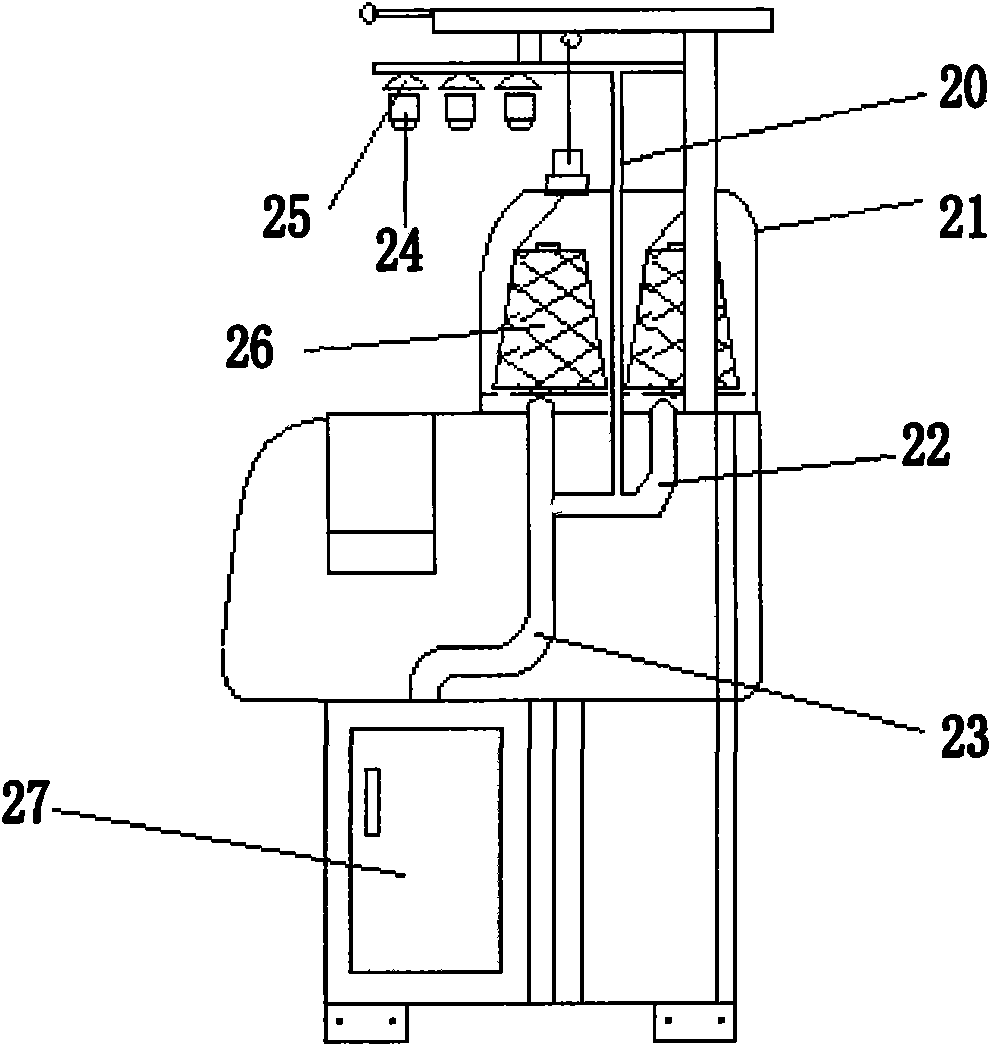

[0015] Referring to the accompanying drawings is an embodiment of the present invention, the purpose of the present invention is achieved by the following measures, the energy-saving and environment-friendly multifunctional three-dimensional lubrication device shell (1) is connected to the gear (4), and the gear (4) is connected to the frequency modulation micro-motor (3) , the motor (3) is connected to the device body (2), the lubricating device (1) is equipped with a lubricant (11), the center hole at the upper end of the lubricant is inserted into the locator (5), the lubricating device (10) rotates horizontally clockwise, and the yarn The thread (6) is drawn upward from the center hole of the lubricant, the yarn (12) rotates clockwise, the central bobbin (8) of the yarn cluster (7) is plugged into the central fixed tube (9), and the dust suction port (13 ) is connected to the suction pipe (16), the yarn clusters (15) are arranged as required (8-16 pieces), each yarn cluster...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com