Method for improving lubrication of line contact fluid under simple sliding

A technology of fluid lubrication and contact body, which is applied in the direction of gear lubrication/cooling, etc. It can solve the problems of failure of lubricating oil film in the contact area, decrease of lubricating oil viscosity, and decrease of bearing capacity in the contact area, so as to improve the anti-adhesion ability of the surface and improve the lubrication state , the effect of reducing frictional energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

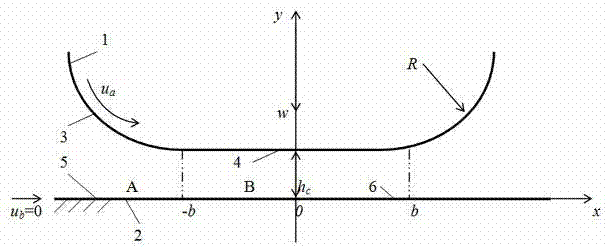

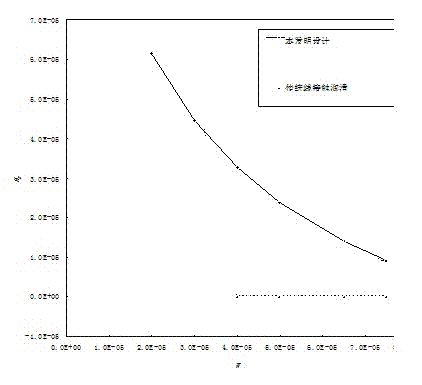

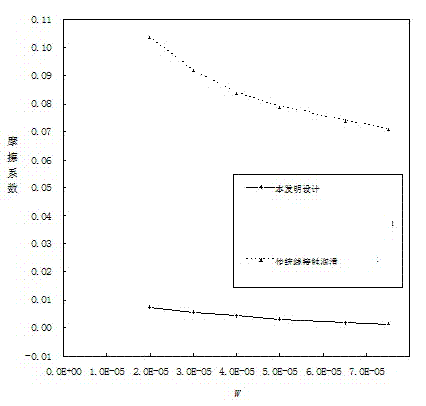

[0052] Both contact body 1 and contact body 2 are made of rigid materials, and the surface of the contact body 2 at the interface III is coated with a strong oil-repellent fluorocarbon coating, and the surface of the contact body 2 at the interface IV is coated with a strong Lipophilic titanium dioxide coating, lubricating oil is No. 50 mechanical oil, then , , , ;Pick : (1) when , When the entire surface of the contact body is coated with a mica powder coating modified by a silane coupling agent, it can be obtained , the film thickness of the line contact fluid lubrication center of the present invention is , the friction coefficient of the two contacting surfaces is = = . like figure 2 As shown, the center film thickness of the line contact fluid lubrication of the present invention is greater than that of the traditional line contact fluid lubrication center film thickness. like image 3 As shown, the friction coefficient of the line contact fluid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com