Patents

Literature

65 results about "Lubrication Problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

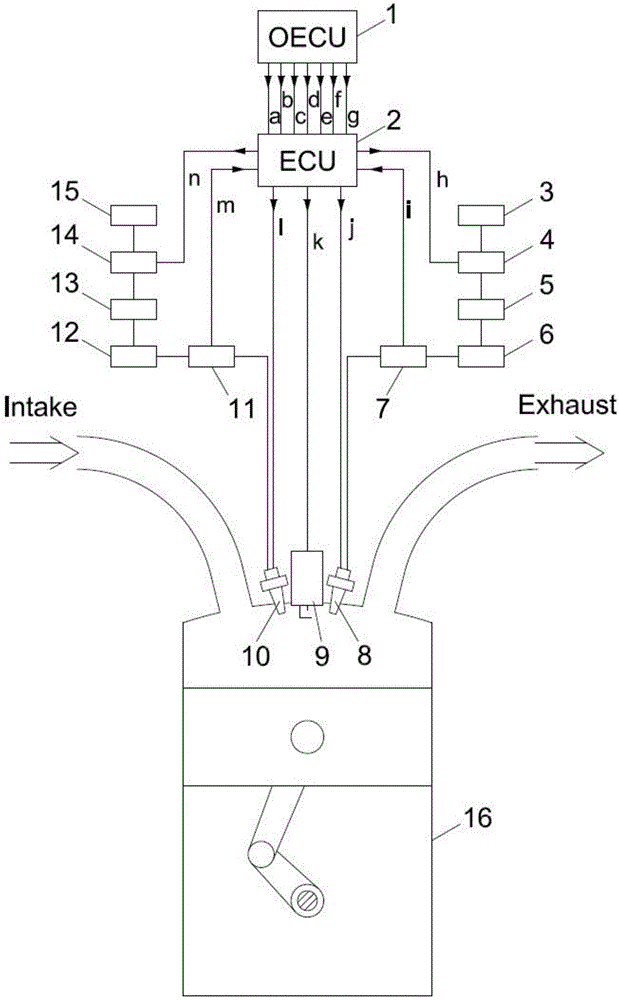

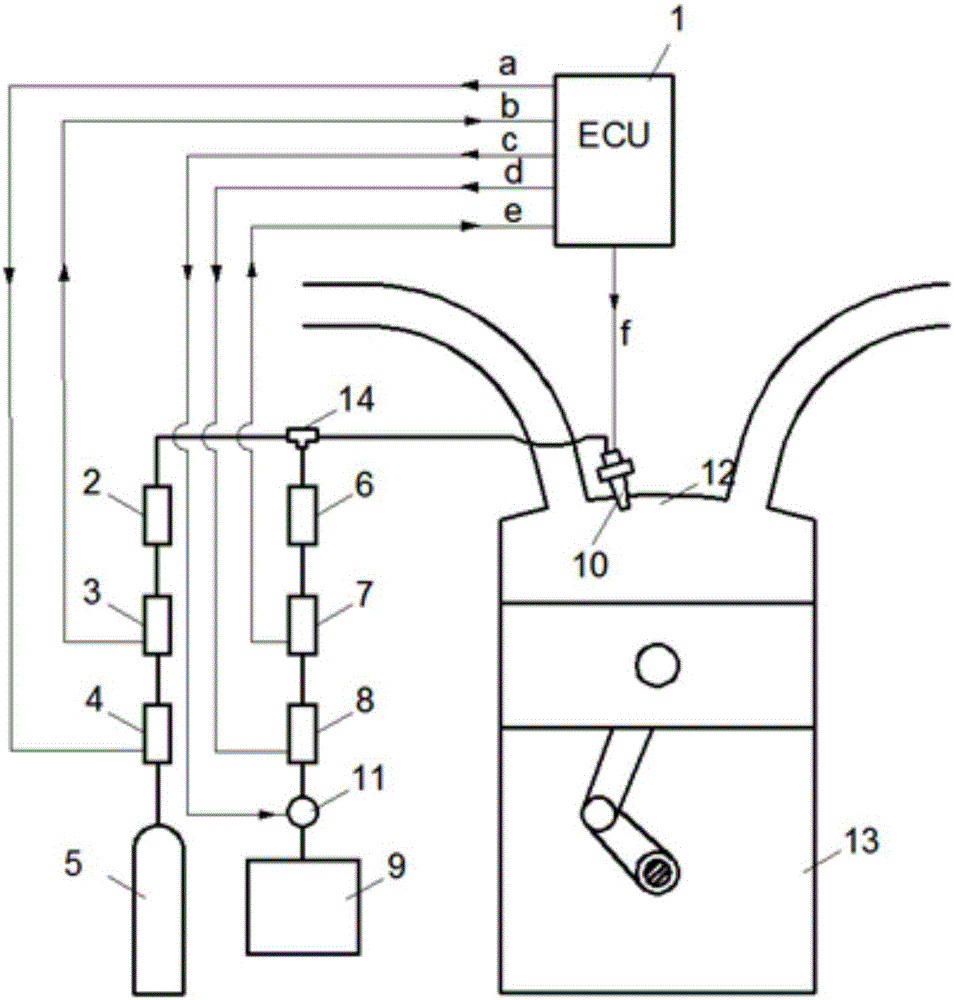

Double-nozzle gas/liquid dual-fuel in-cylinder direct injection internal combustion engine and control method

ActiveCN106499531AImprove powerImprove featuresElectrical controlInternal combustion piston enginesMass ratioLubrication Problem

The invention provides a double-nozzle gas / liquid dual-fuel in-cylinder direct injection internal combustion engine and a control method, and belongs to the field of internal combustion engine control. According to the system, on the basis of still using an ignition type internal combustion engine body, a double-nozzle gas / liquid dual-fuel ignition type internal combustion engine in-cylinder direct injection device and a fuel injection and ignition electronic control unit are additionally arranged, and the double-nozzle gas / liquid dual-fuel ignition type internal combustion engine in-cylinder direct injection device comprises a gas fuel flow sensor, a gas fuel control valve, a gas fuel pressure stabilizer, a liquid fuel flow sensor, a liquid fuel control valve and the like. The fuel injection and ignition electronic control unit adjusts injection time and injection pulse width of a gas fuel nozzle and a liquid fuel nozzle, and therefore in-cylinder injection of gas / liquid dual fuels in any ratio is achieved; the injection mass ratio of the gas / liquid dual fuels is adjusted in real time according to working conditions, and therefore the starting speed and accelerating response speed of the internal combustion engine are increased, and fuel consumption and pollutant emission are reduced; and the heat dissipation and lubrication problems caused by long-time use of the internal combustion engine are relieved by decreasing the using frequency of the gas-fuel high pressure nozzle.

Owner:BEIJING UNIV OF TECH

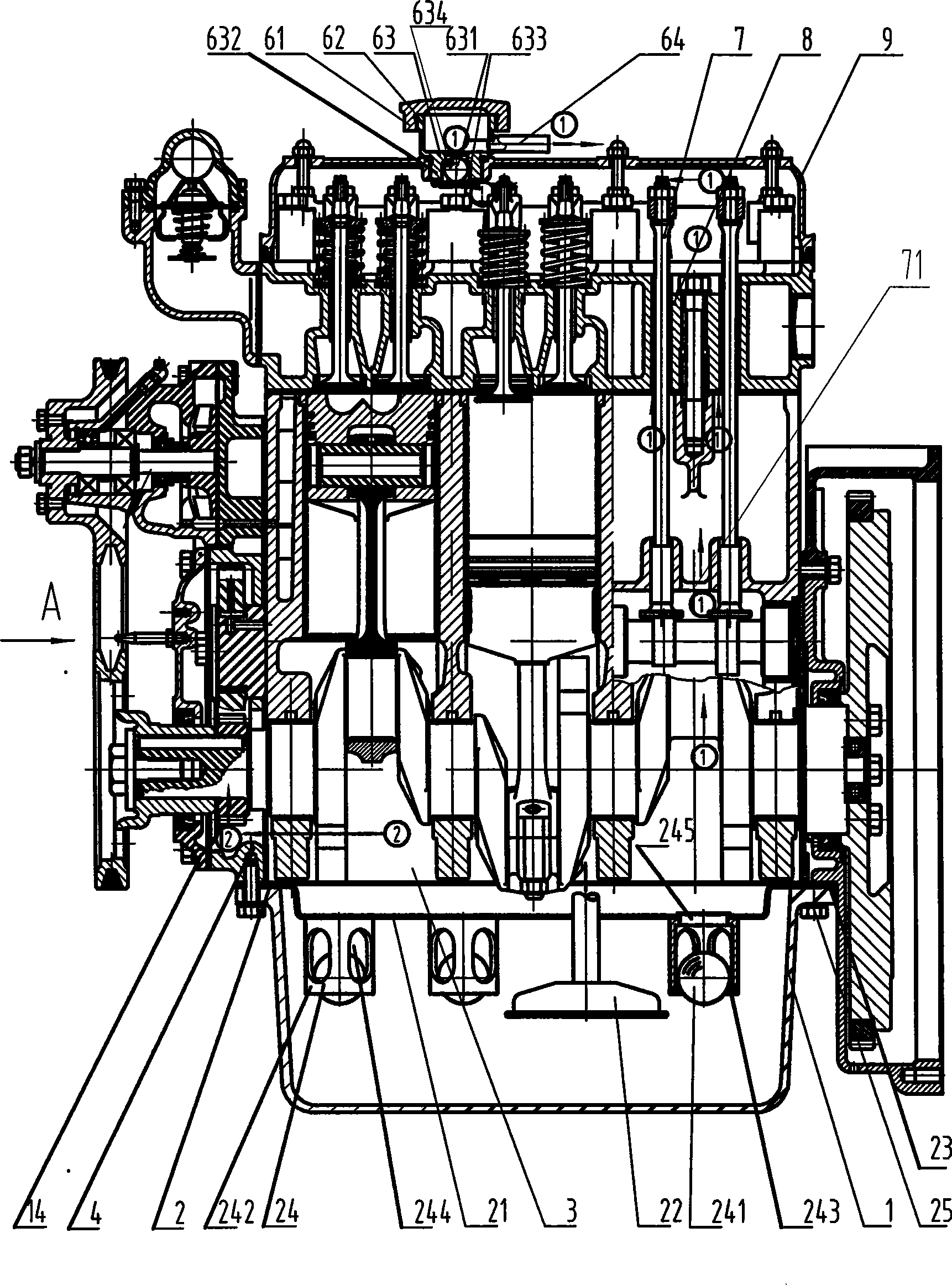

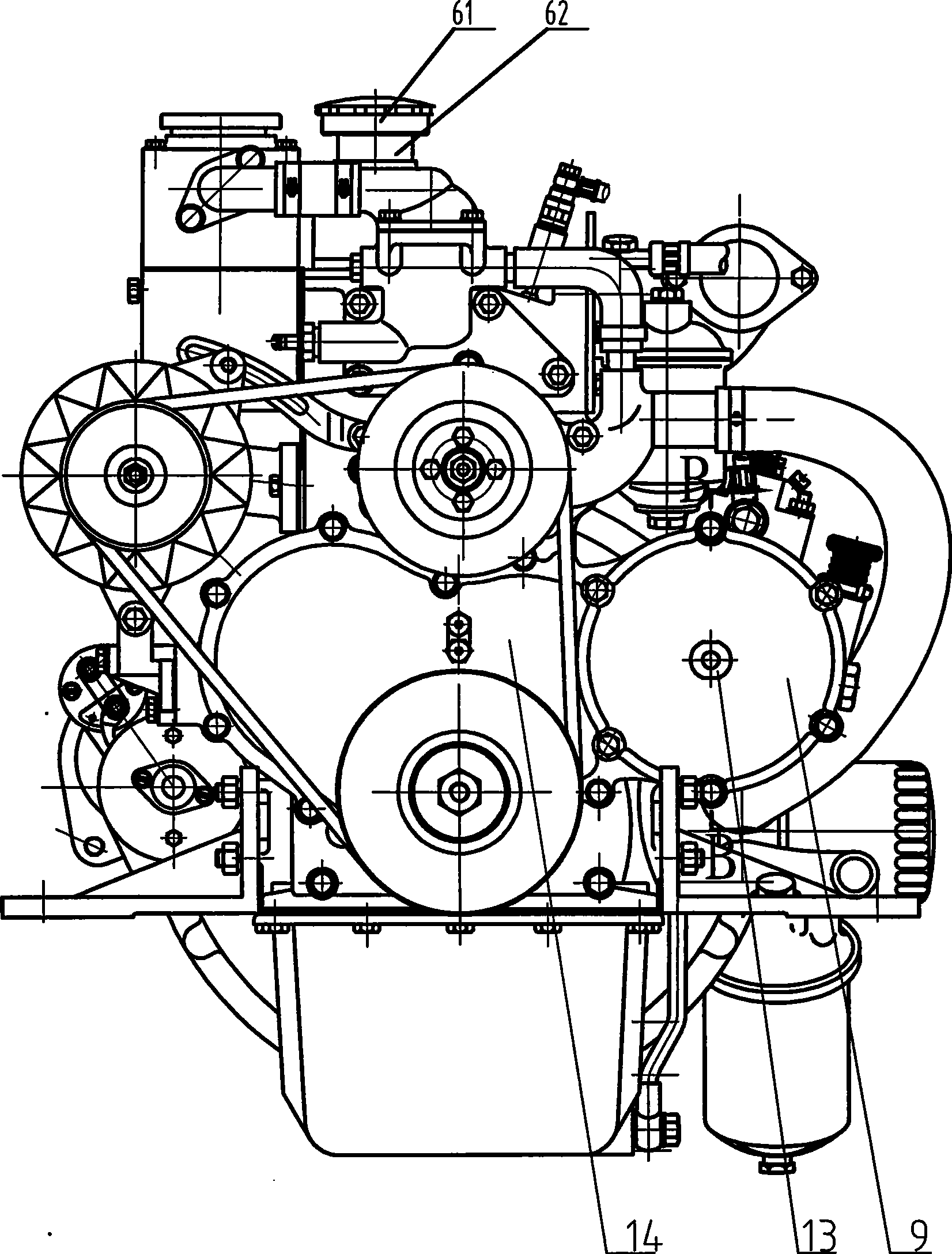

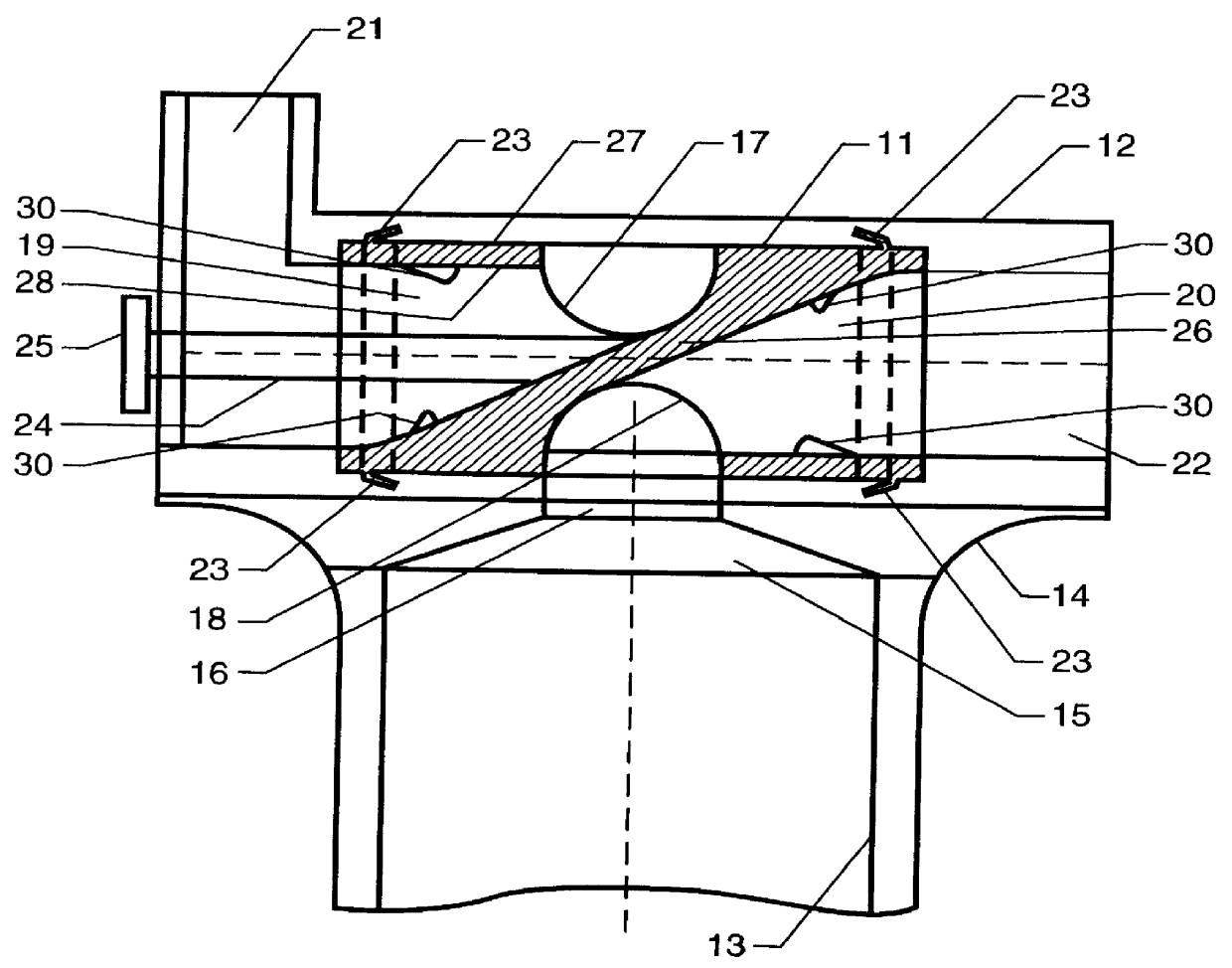

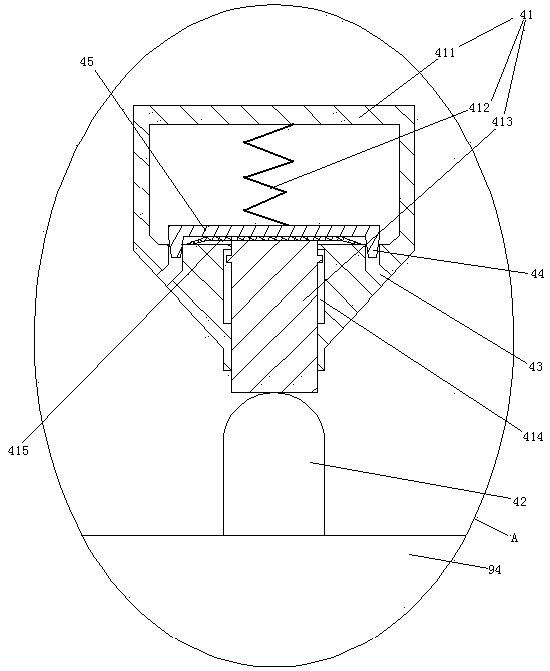

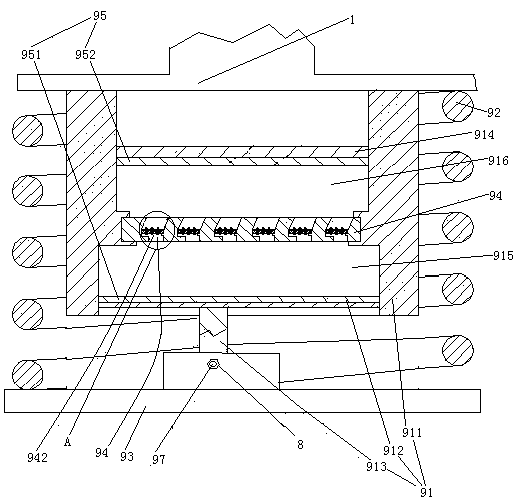

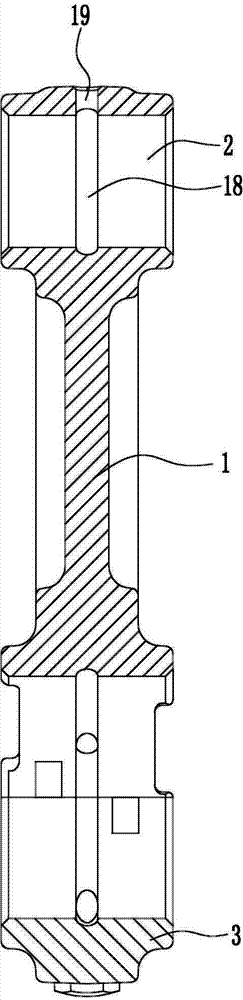

Non-stopping device for lifeboat diesel engine while inversion

InactiveCN101392670ASolve lubrication problemsSolve Exhaust ProblemsMachines/enginesPressure lubrication with lubrication pumpRespiratorLubrication Problem

The invention discloses a non-shutdown device for the inversion of a lifeboat diesel engine, which comprises a lubrication system and a respiratory system, wherein the lubrication system comprises an oil suction port of an oil pump and an oil tray arranged at the bottom of a crankcase; and the respiratory system comprises a main respirator holder arranged on a cylinder cover and a main respiration channel which passes through a machine body of the diesel engine. The top of the oil tray is provided with a unidirectional sealing mechanism, a main respirator check valve is arranged in the main respirator holder, a secondary respiration channel is arranged in the machine body of the diesel engine, and an advancer cover is provided with a secondary respirator check valve. The device has a simple structure and low cost, can meet the requirement stipulated in the SOLAS convention, and solve the lubrication problem of a diesel engine system and the air exhaust problem inside the crankcase when the lifeboat diesel engine is in an inverted state.

Owner:JIANGSU UNIV OF SCI & TECH

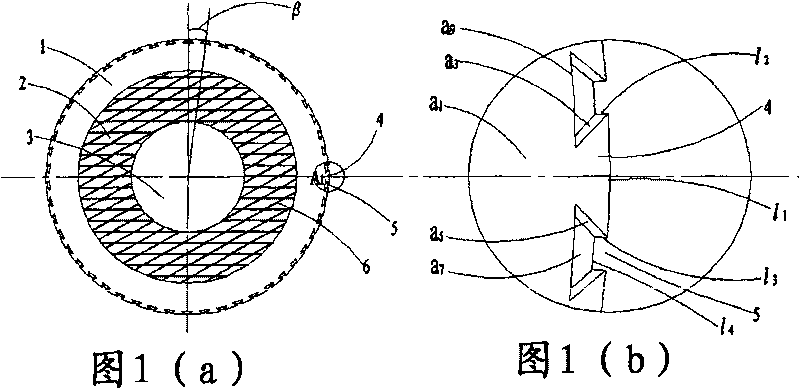

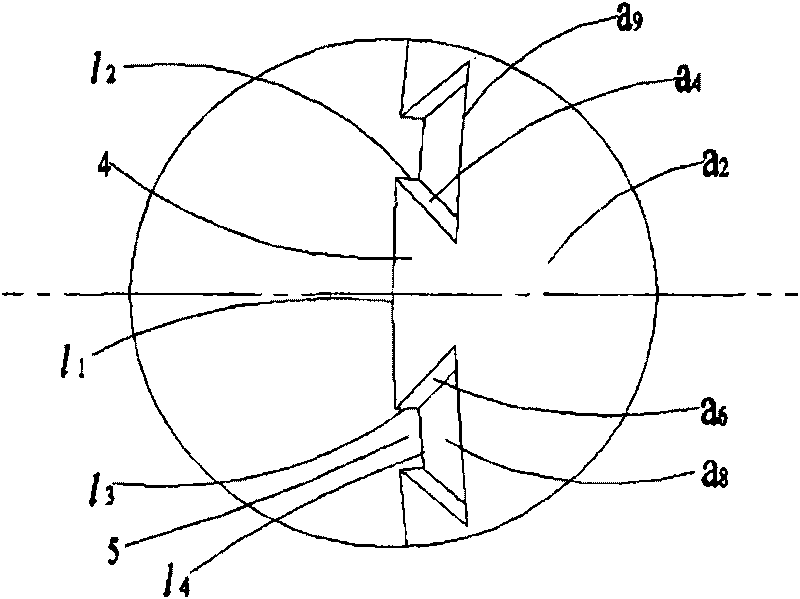

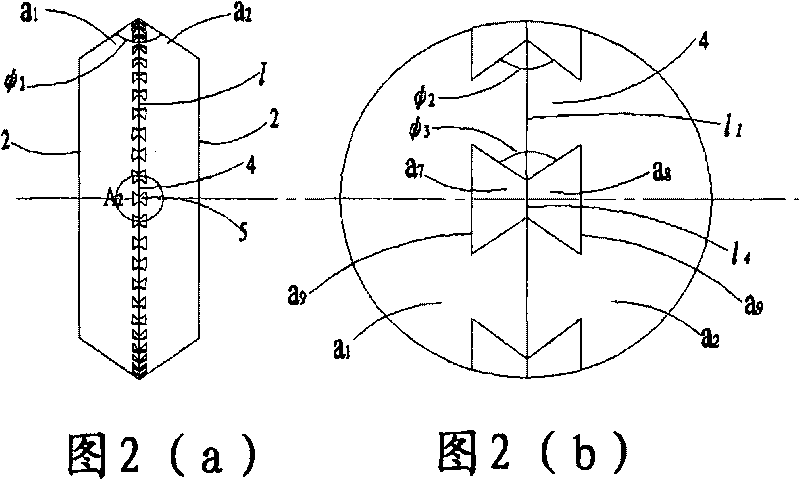

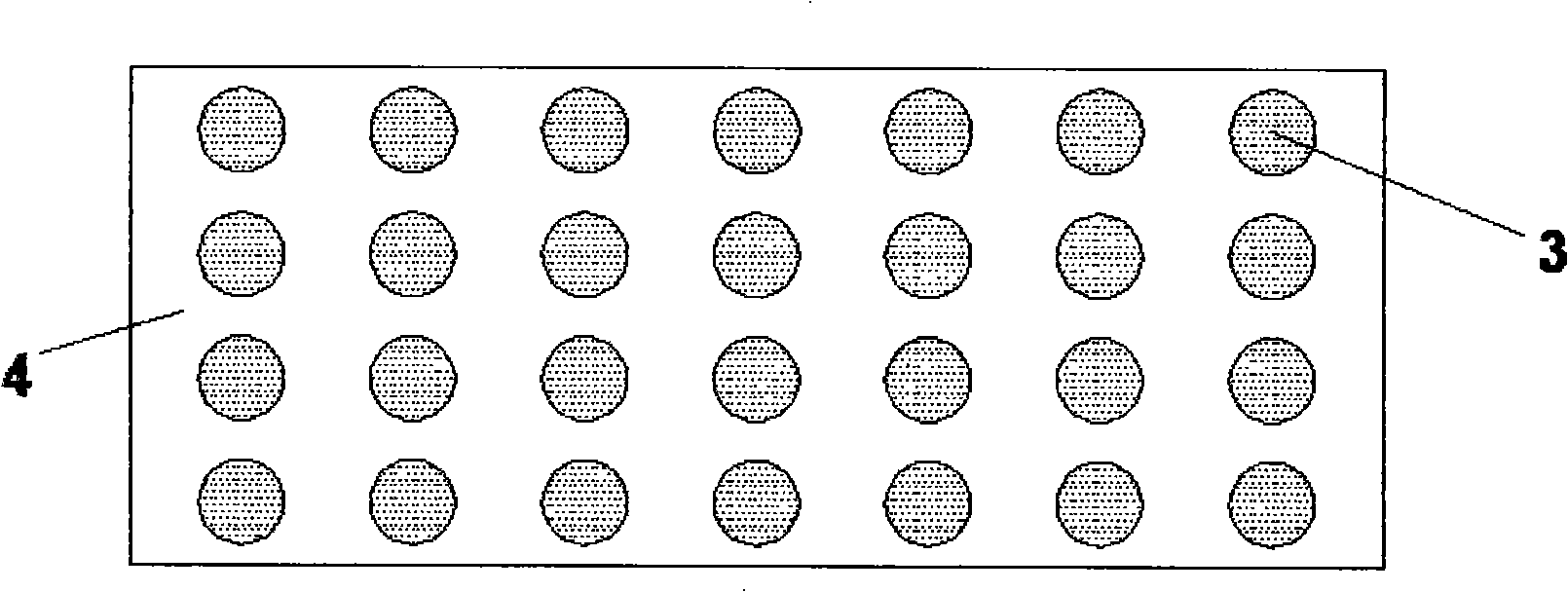

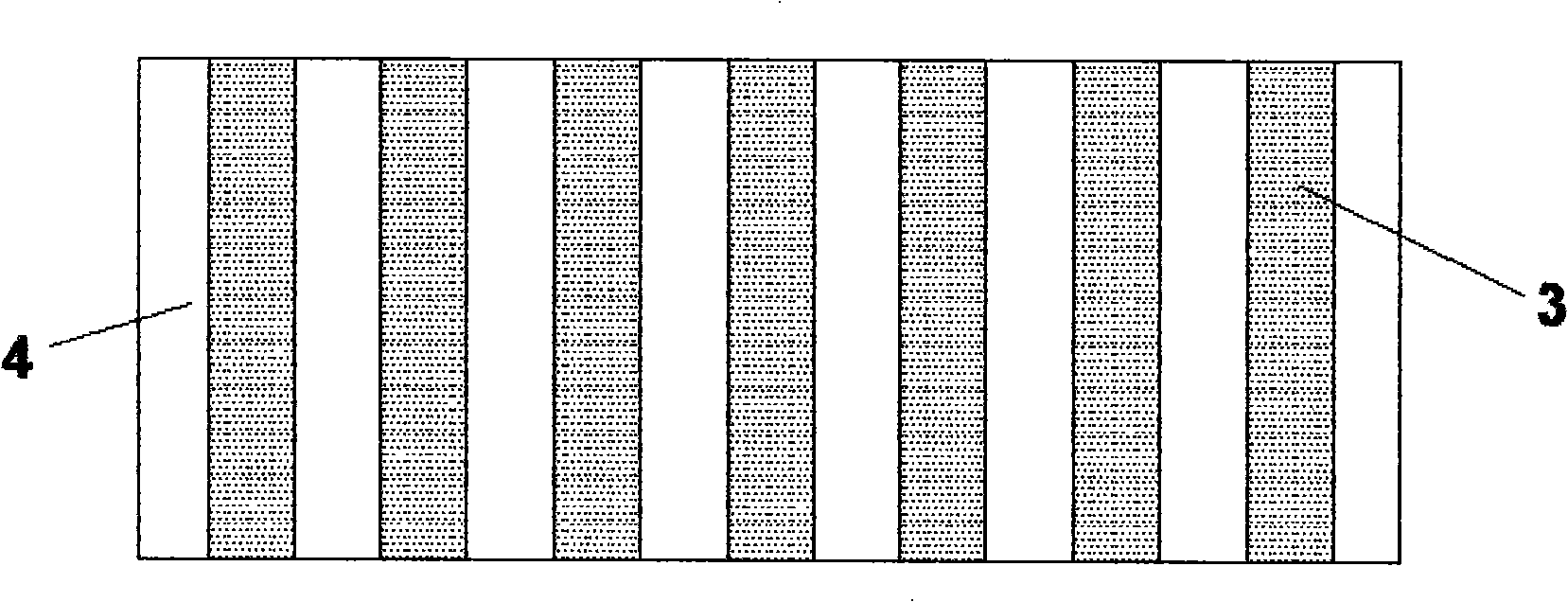

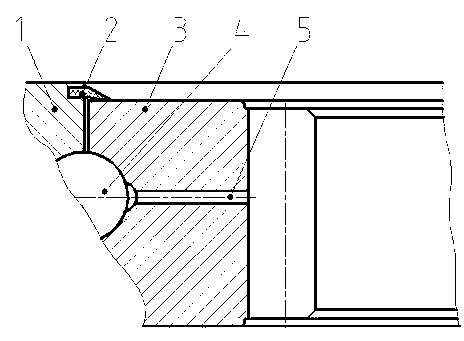

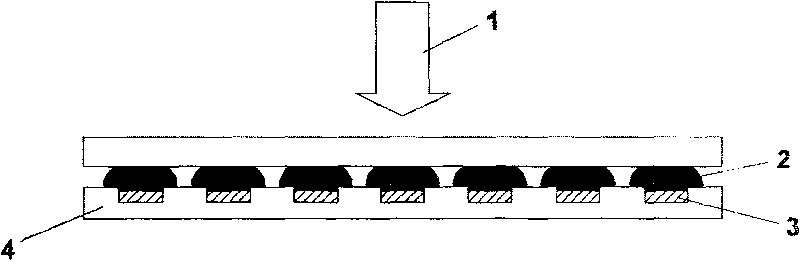

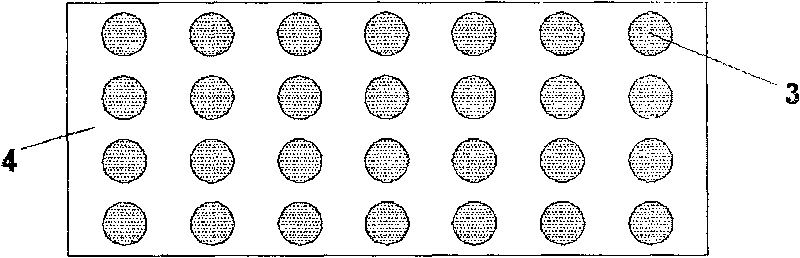

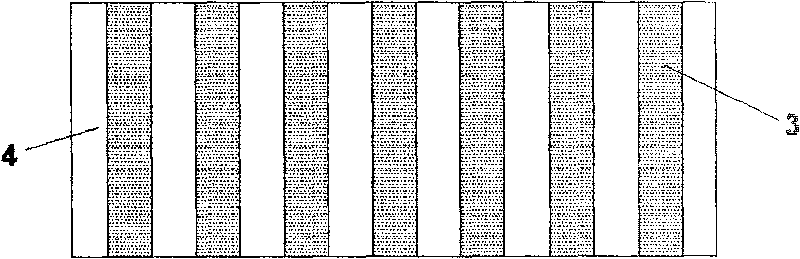

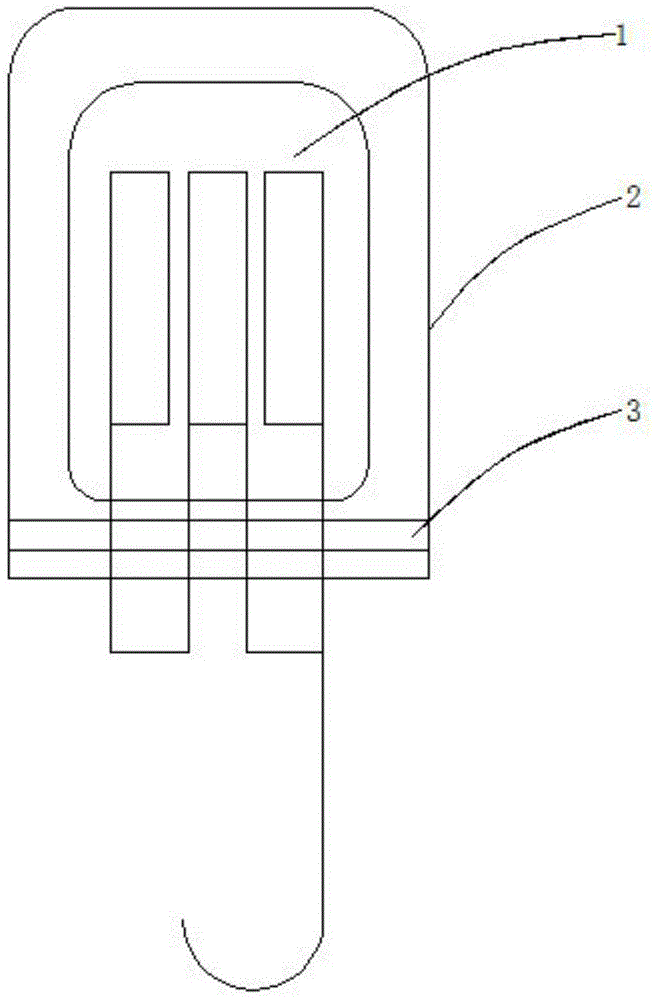

Cutter wheel for cutting brittle material and processing method thereof

InactiveCN101745990ARemoval depthExtended service lifeGlass severing apparatusMetal working apparatusLubrication ProblemLubricant

The invention discloses a cutter wheel for cutting a brittle material and a processing method thereof. The cutter wheel is provided with a V-shaped cutting blade part (1), a disc surface (2) and an axle hole (3), wherein the periphery of the chine line l at the external edge of the V-shaped cutting blade part (1) is provided with cutting blades (4) and recess structures (5), which are alternately-distributed; each cutting blade (4) comprises curved surfaces (Part a1 and Part a2), four side surfaces (a3, a4, a5 and a6) and V-shaped cutting edges (V-shaped cutting edge 1, V-shaped cutting edge 2 and V-shaped cutting edge 3)of which the included angles are respectively psi1, psi2 and psi3; and the disc surface (2) and the axle hole are provided with grid-line grooves (6), and the cutting blades (4), the recess structures (5) and the grid-line grooves (6) are obtained by the processing in a laser scanning mode. The cutter wheel with the new structure can avoid or reduce the condition that the cutter wheel is blocked when the cutter wheel with other structures cuts the material, and can prevent the material from producing radial cracks, thereby prolonging the service life of the cutter wheel and simultaneously obtaining the high-grade cutting sections. Besides, the inner walls of the grid-line grooves (6) are coated with solid lubricant, thereby well solving the lubrication problem.

Owner:孙春雨

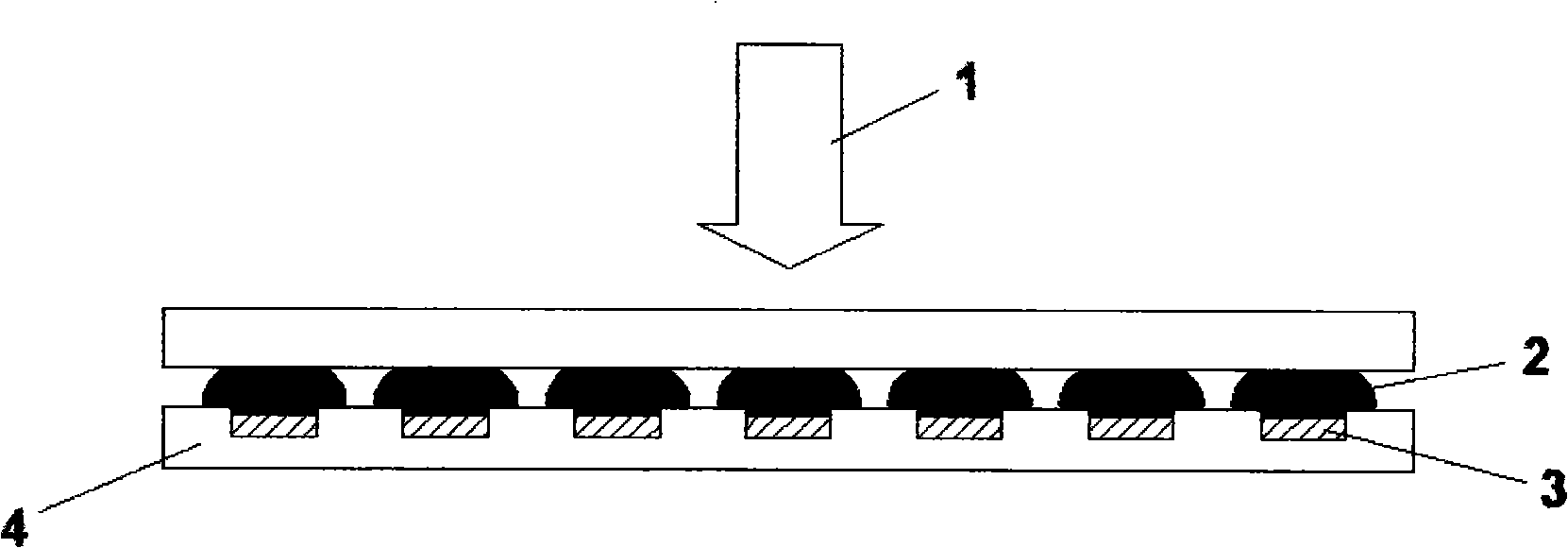

Magnetic fluid lubricating method based on tiny magnetic body array

Disclosed is a magnetic fluid lubrication method based on micro-magnet arrays, pertaining to the technical field of magnetic fluid lubrication. The method is characterized by comprising the processes as follows: (1) micro-pits or micro-grooves with a size from micron to millimeter are manufactured on friction pair surfaces; (2) permanent magnetic material is deposited on the micro-pits or the micro-grooves with a thickness of microns to millimeters to form micro-magnet arrays; (3) magnetic fluids are filled between the friction pair surfaces; under the function of the magnetic filed produced by the permanent magnetic material layer, the micro drops of the magnetic fluid are assembled to the surrounding of the magnet arrays to form supporting force. The method expands the application range and enhances the lubrication effect of the magnetic fluid lubrication, thereby providing a solution to the lubrication problems under special conditions.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

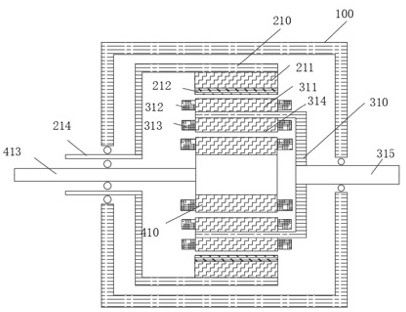

Hybrid power coupled transmission device

InactiveCN106114185AImprove recycling efficiencyUniform load distributionHybrid vehiclesGas pressure propulsion mountingMotor speedLow speed

The invention provides a hybrid power coupled transmission device. The hybrid power coupled transmission device comprises a power output system and a mechanical transmission system, wherein the power output system comprises an engine, an engine output shaft, a transmission auxiliary motor, a transmission auxiliary motor output shaft, a driving motor and a driving motor output shaft; and the mechanical transmission system comprises an engine output shaft gear, a shock absorber, an engine brake, a planet gear row, a transmission auxiliary motor speed reducing gear, a transmission auxiliary motor brake, a driving motor speed reducing gear and an output shaft. The hybrid power coupled transmission device aims at solving the problems of vibration and noise caused by low speed large torque and medium and high speed of double planet gears in the power and transmission systems, the motor cooling problem and the lubrication problem of the transmission system, the overall efficiency of the power system and the transmission system is improved, and the service life of the power system and the transmission system is prolonged.

Owner:湖州伊立机械有限公司

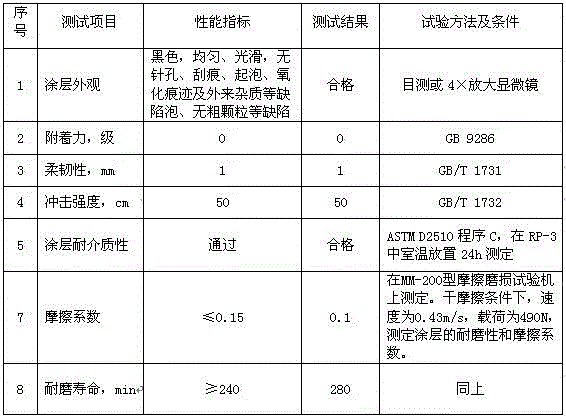

Polytetrafluoroethylene bonded solid lubricant

ActiveCN105132086ASolve lubricitySolve the wear and tear problemAdditivesLubrication ProblemPolyamide

The invention discloses a polytetrafluoroethylene bonded solid lubricant. The polytetrafluoroethylene bonded solid lubricant is prepared with polyamide-imide resin and epoxy resin as binders, polytetrafluoroethylene, melamine cyanurate and molybdenum disulfide as solid lubricants and a mixed solvent as a diluent, and contains various fillers and a modification additive. The lubricant is coated on the surfaces of mechanical components and test samples, and is heated and solidified to form polytetrafluoroethylene bonded solid lubrication coating layers. The lubricant solves the problems of lubrication and wearing of motion parts under low load and high speed conditions, such as wearing and lubrication problems between oil-free compressor rotors and between rotors and a shell, and is especially suitable for being used on screw type oil-free air compressors.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

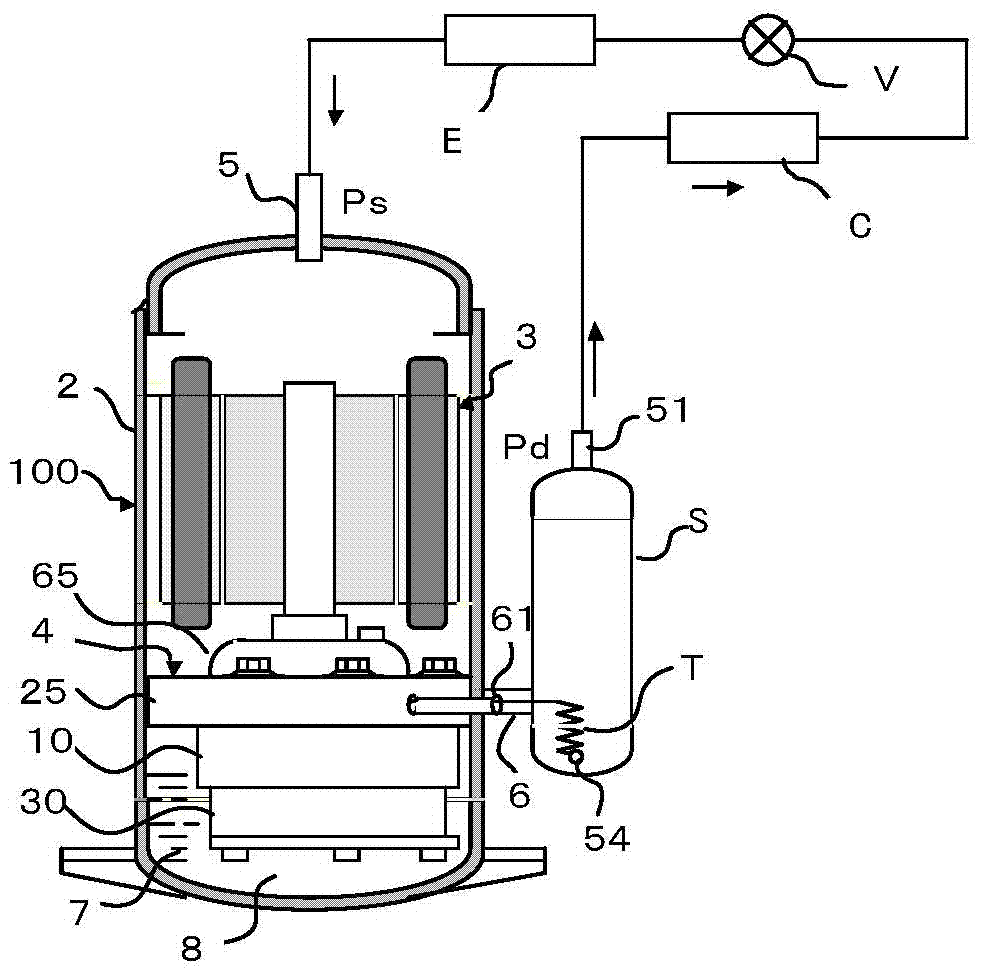

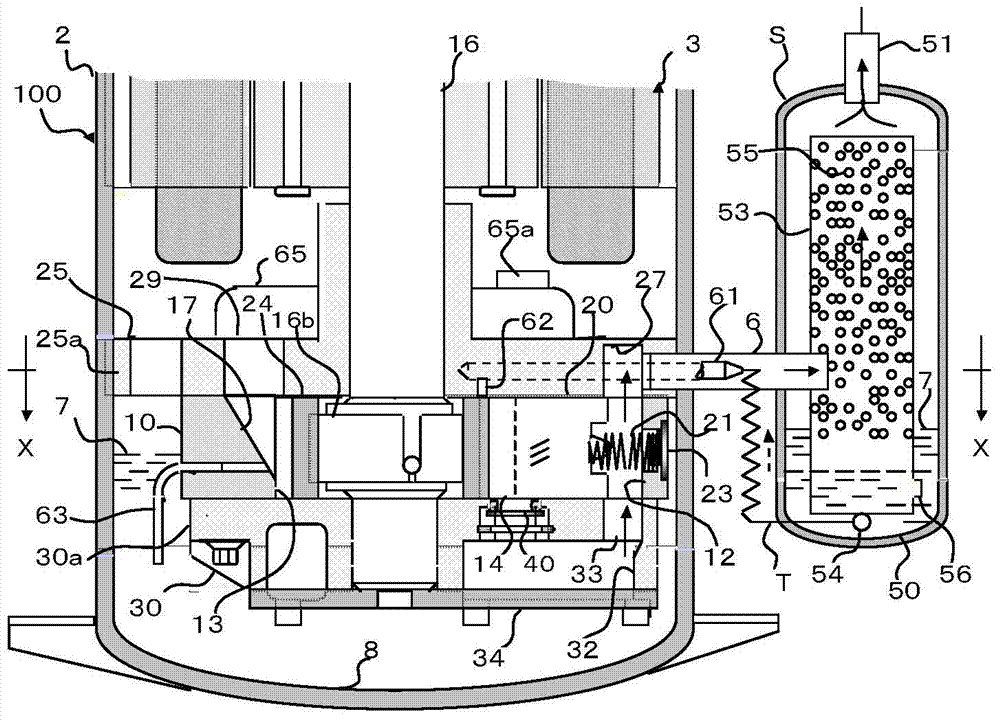

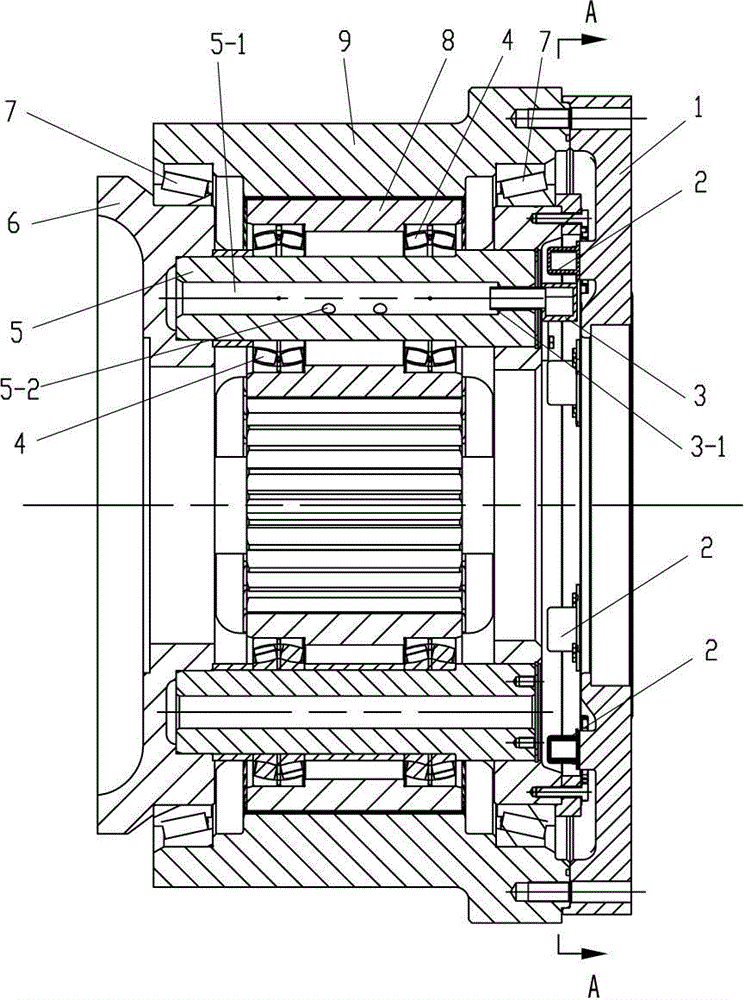

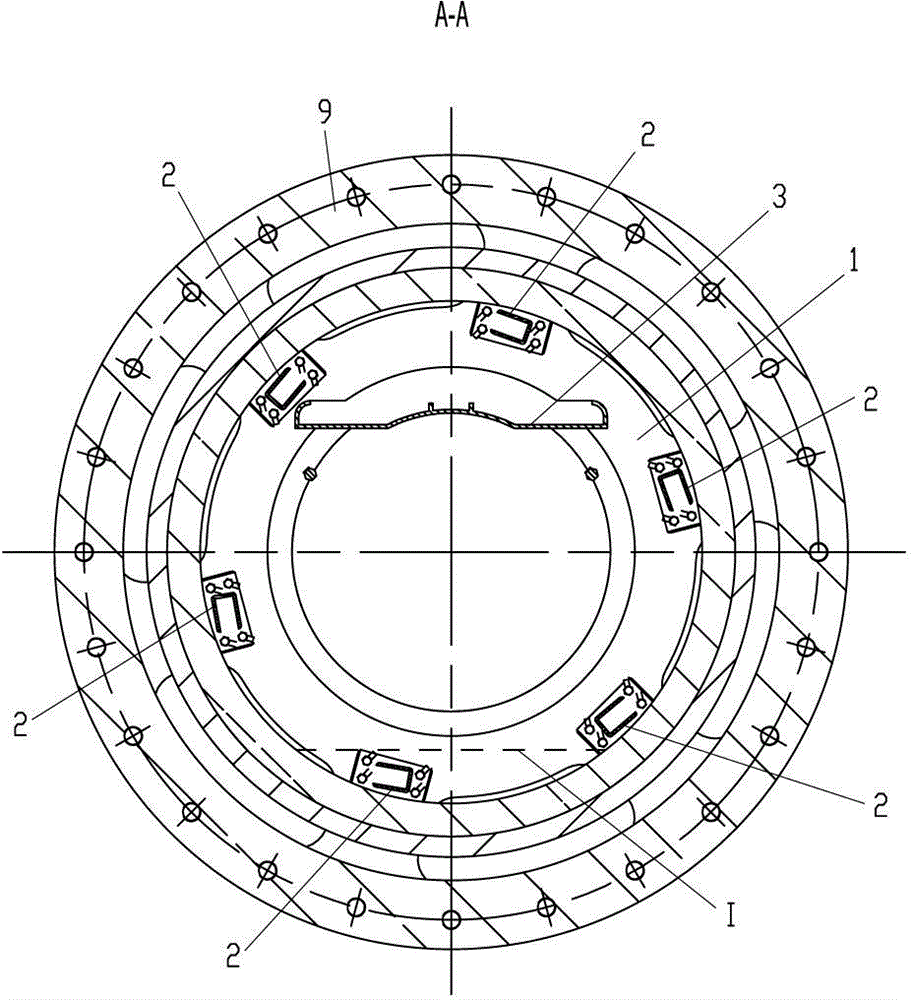

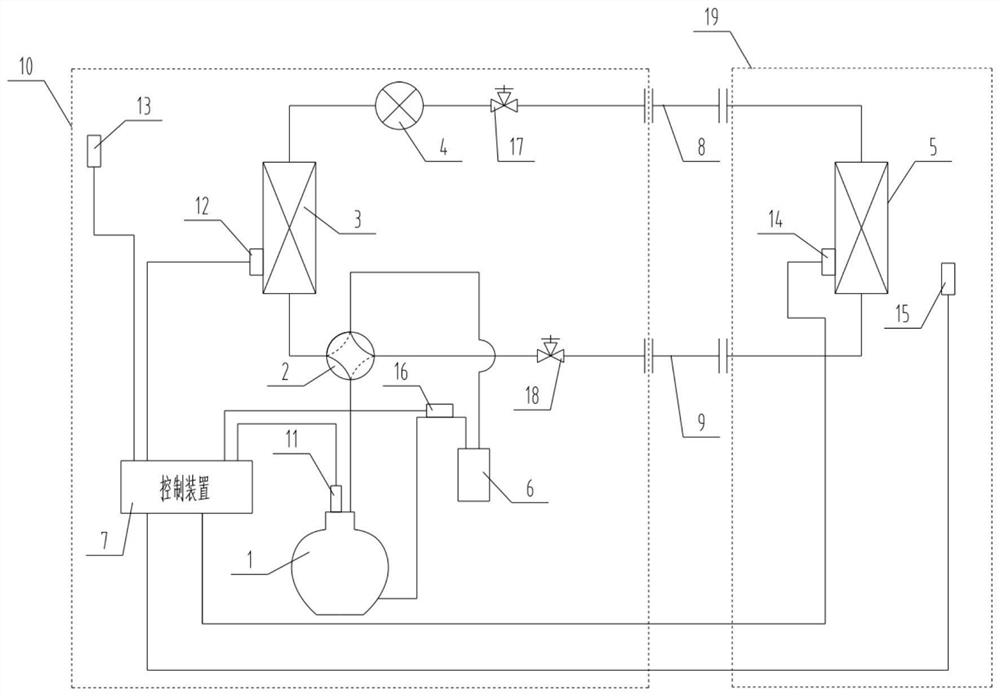

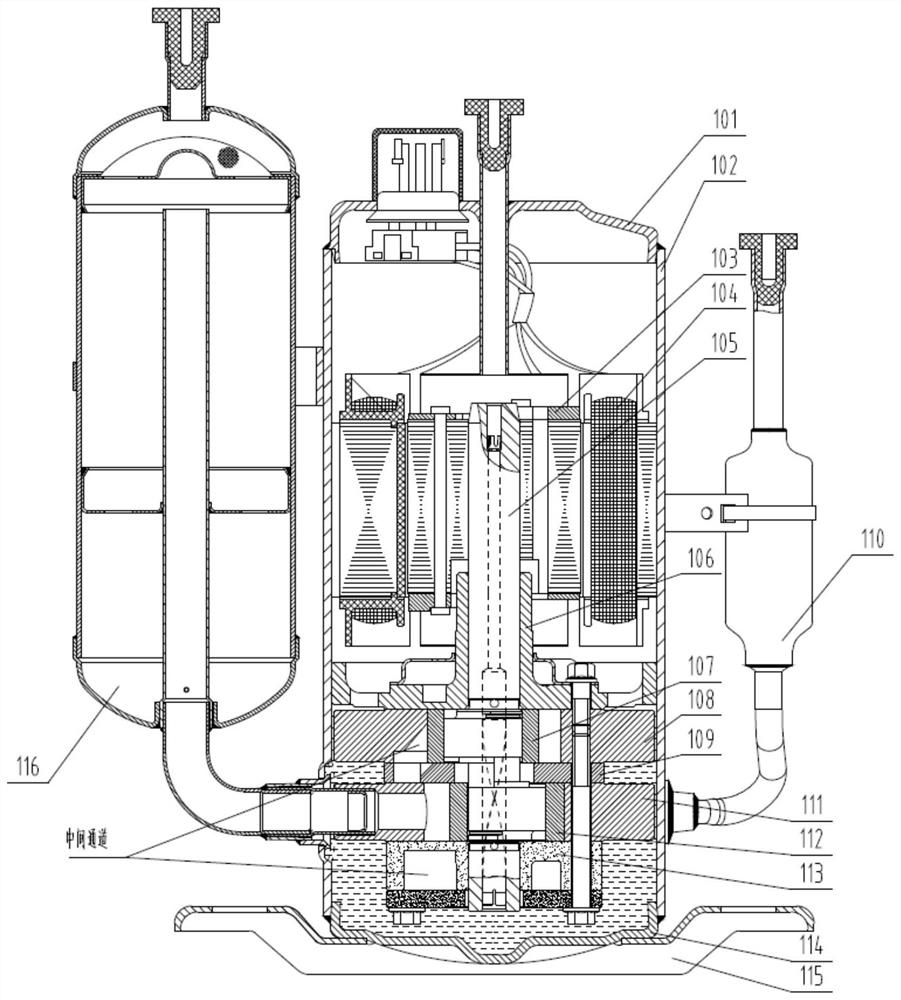

Rotating compressor and refrigeration cycle device

ActiveCN103573624ALow efficiencyEffective lubricationRotary piston pumpsRotary piston liquid enginesInternal pressureLubrication Problem

The invention discloses a rotating compressor and a refrigeration cycle device. The rotating compressor comprises lubricating oil which is sealed in a sealing shell, and an electrodynamic type motor and a rotation type compressing mechanism arranged in a shell, wherein the inner pressure of the shell and the suction pressure of the shell are same; the compressing mechanism comprises a main bearing and an auxiliary bearing and an exhaust silencer arranged on at least one of the main bearing and the auxiliary bearing, and a refrigerant of the exhaust silencer is discharged from an exhaust pipe arranged on the compressing mechanism through a sliding piece cavity. According to the rotating compressor provided by the embodiment of the invention, a sliding surface of a sliding piece is effectively lubricated, and the oil of the whole compressor is controlled, so that the reliability of the sliding piece is guaranteed, and in addition, a condition that the efficiency of the compressor is lowered because of a lubrication problem is prevented.

Owner:GUANGDONG MEIZHI COMPRESSOR

Carbon brush for starting motor of automotive engine and production method thereof

InactiveCN102447207ADetailed instructionRotary current collectorBrushes manufactureNiobiumLubrication Problem

The invention relates to a carbon brush for a starting motor of an automotive engine and a production method thereof, and the carbon brush is characterized by comprising the following components: mixed graphite powder, copper powder and niobium diselenide, wherein the mixed graphite powder comprises the following components: graphite powder, asphalt and phenolic resin. The preparation method of the carbon brush for the starting motor of the automotive engine is characterized by comprising the following steps of: firstly preparing the mixed graphite powder, adding the asphalt into the graphite powder to mix at a temperature of 220 DEG C and adding the phenolic resin after the temperature is slowly lowered below 100 DEG C; then mixing at a temperature of 90 DEG C and grinding the dried powder into the mixed graphite powder for standby; adding the copper powder and the niobium diselenide into the mixed graphite powder in a manner of dry powder, mixing in a dry mixer and pressing the carbon brush for the starting motor of the automotive engine. The invention has the advantages that as resin modified asphalt is adopted as an adhesive agent, the carbon brush has the advantages of a resin adhesive agent and an asphalt adhesive agent, so that the strength of the carbon brush is improved, and the carbon brush is not superhard; and as the niobium diselenide is used as a lubricating agent, the lubrication problem of the carbon brush is effectively solved.

Owner:温州东南碳制品有限公司

External lubrication device for transmission and method

InactiveCN106641216AMeet lubrication and cooling needsExtended service lifeGear lubrication/coolingLubrication ProblemSpray nozzle

The invention discloses an external lubrication device for a transmission and a method. An external lubrication system is added on the basis of an existing transmission lubrication system. The external lubrication device comprises an external lubrication pump and an angle switch. The external lubrication pump is used as a power source of the external lubrication system. The angle switch is used as a control element. When a vehicle reaches the set slope value in the operation process, the external lubrication pump starts by itself, and normally-engaged gears, the third-gear gear and the fourth-gear gear of the transmission are spattered and lubricated through spray nozzles. When the gradient is smaller than the set value, the angle switch is turned off, and the transmission is lubricated through an internal lubrication system of the transmission. The external lubrication device is simple in structure, convenient to operate, high in reliability, capable of effectively solving the lubrication problem under the condition that a wide-body mining vehicle climbs a slope in a heavy-loaded manner, and capable of prolonging the service life of the transmission.

Owner:SINO TRUK JINAN POWER

Carbon fiber reinforced carbon composite rotary valve for an internal combustion engine

InactiveUS6098579AHigh stiffnessHigh strengthMachines/enginesRotary slide valveFiberCarbon composites

Carbon fiber reinforced carbon composite rotary, sleeve, and disc valves for internal combustion engines and the like are disclosed. The valves are formed from knitted or braided or warp-locked carbon fiber shapes. Also disclosed are valves fabricated from woven carbon fibers and from molded carbon matrix material. The valves of the present invention with their very low coefficient of thermal expansion and excellent thermal and self-lubrication properties, do not present the sealing and lubrication problems that have prevented rotary, sleeve, and disc valves from operating efficiently and reliably in the past. Also disclosed are a sealing tang to further improve sealing capabilities and anti-oxidation treatments.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

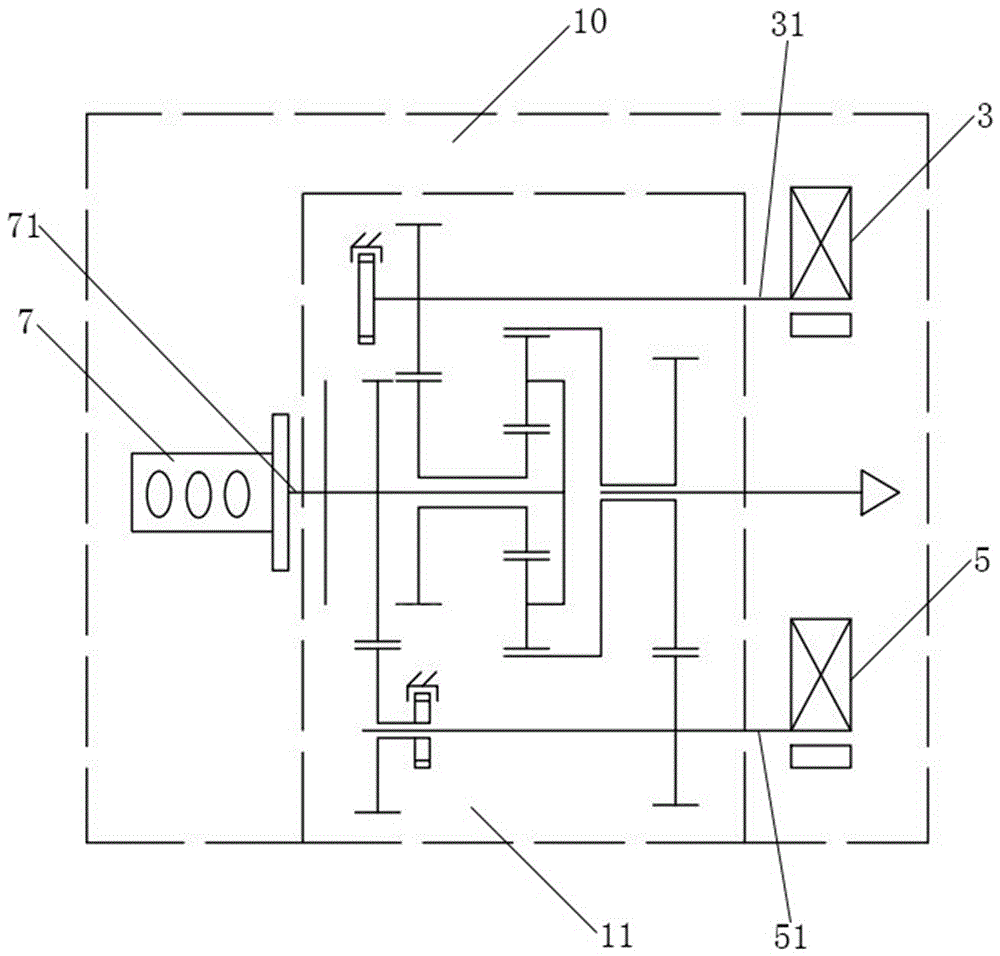

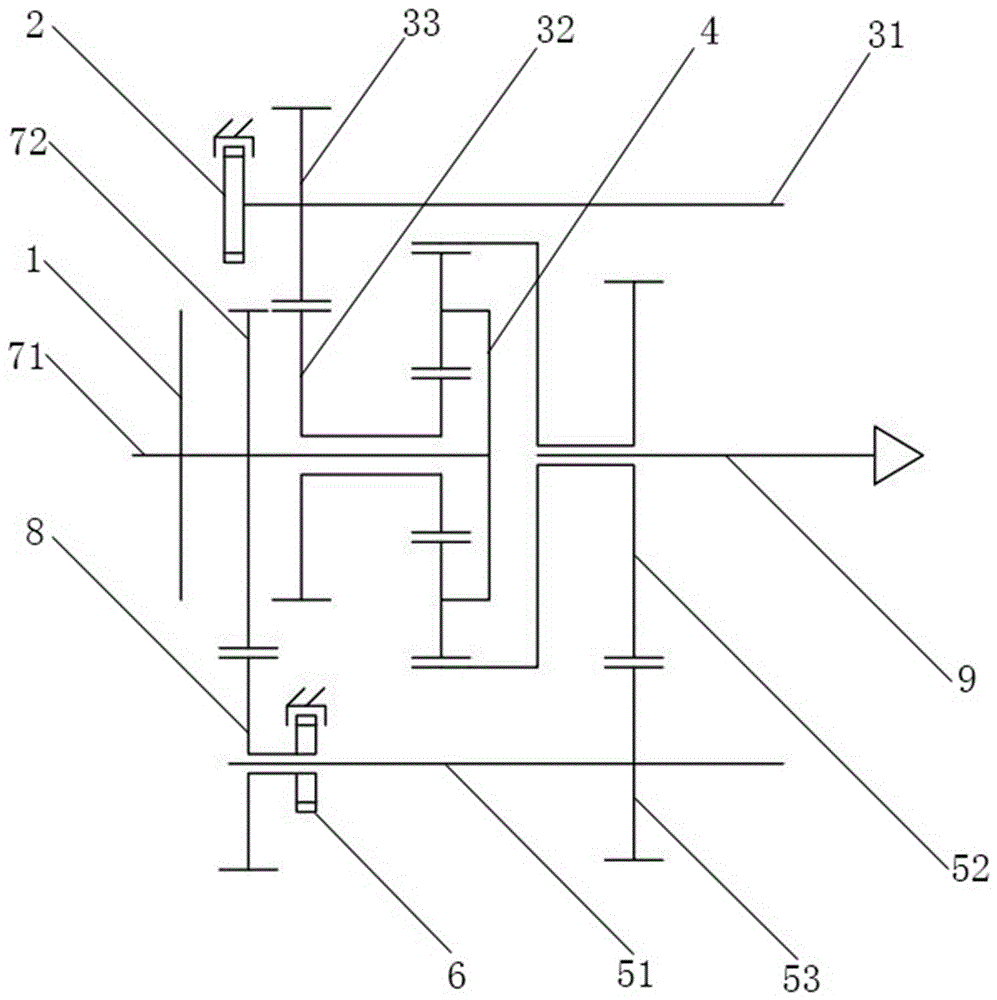

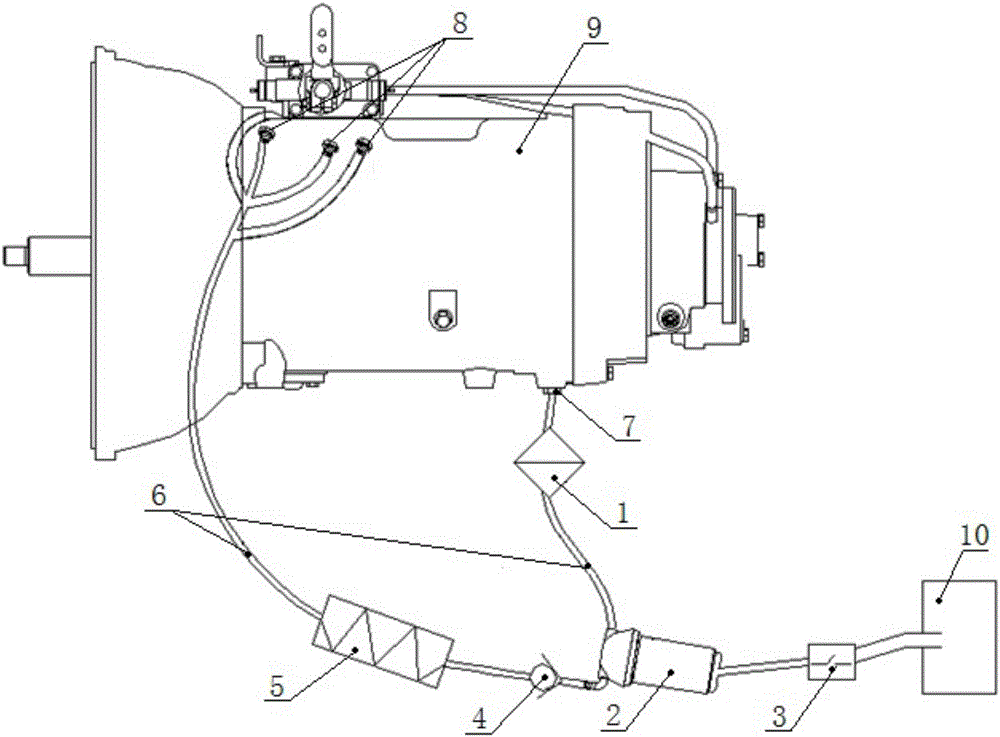

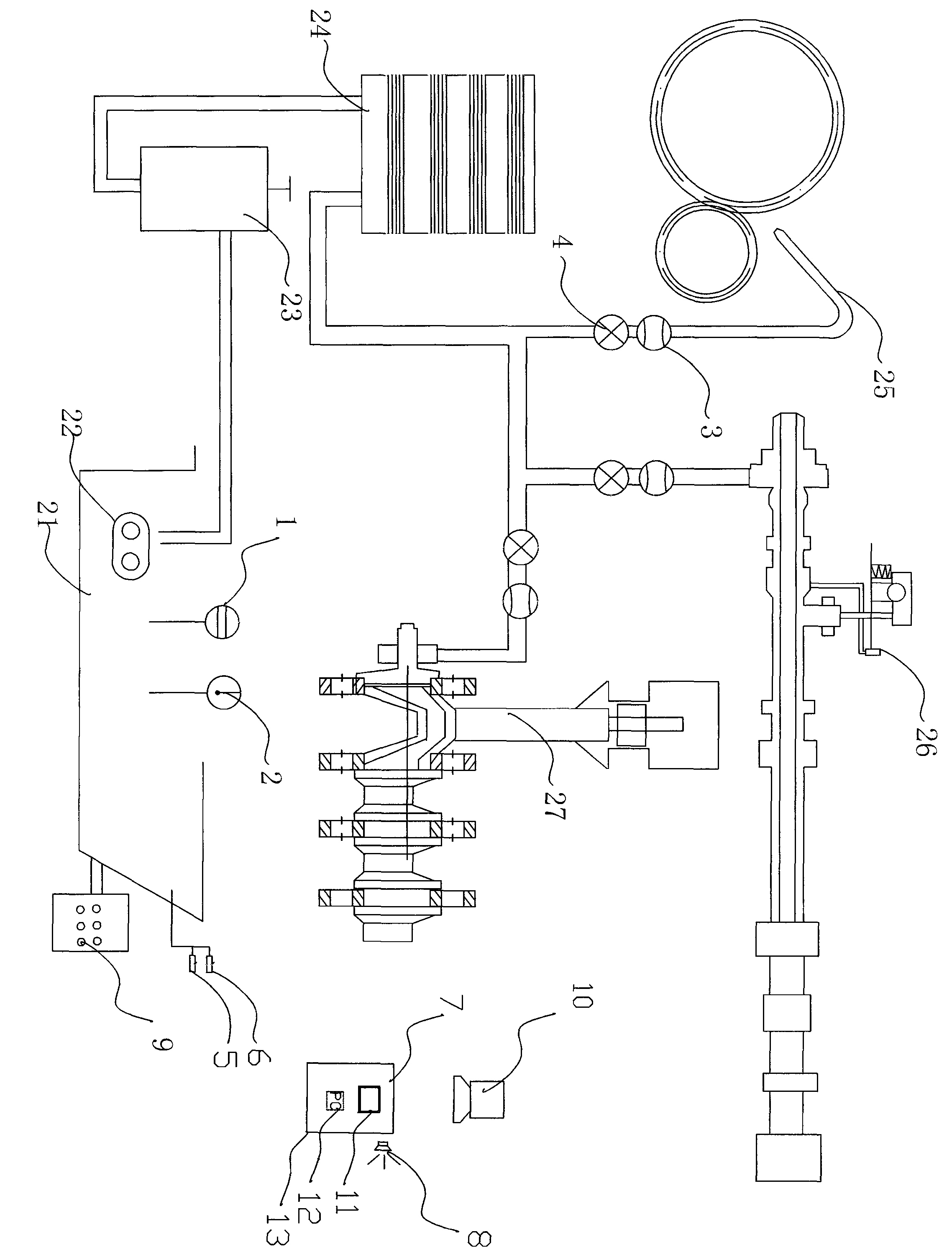

Intelligent lubricating system for marine engine

InactiveCN103670583AEnsure continuous safe operationPrevent oil pressureLubrication indication devicesSafety devices for pressure lubricationData acquisitionLubrication Problem

An intelligent lubricating system for a marine engine is composed of a temperature sensor (1), a liquid level meter (2), a flow meter (3), a pressure sensor (4), an in-oil-particle detector (5), an in-oil-moisture detector (6), a data acquisition and processing unit (7), an alertor (8), an automatic oil purifier (9) and an upper computer (10), wherein the temperature sensor (1), the liquid level meter (2), the flow meter (3), the pressure sensor (4), the in-oil-particle detector (5), the in-oil-moisture detector (6), the data acquisition and processing unit (7), the alertor (8), the automatic oil purifier (9) and the upper computer (10) are connected through wires. The temperature sensor (1) and the liquid level meter (2) are arranged in an oil tank (21), the flow meter (3) and the pressure sensor (4) are arranged on oil pipelines of lubrication points of the marine engine, the in-oil-particle detector (5) and the in-oil-moisture detector (6) are arranged outside the oil tank (21) and are connected with the oil tank (21) through pipes, and the upper computer (10) is arranged in an operation room and is communicated with the data acquisition and processing unit (7) in a wired or wireless mode. According to the intelligent lubricating system for the marine engine, the on-line detection technology and the automatic maintenance technology are applied to carry out improvement on the lubrication system on the marine engine, the lubrication problems in the marine industry can be solved to a great extent, and huge benefit can be obtained on energy saving, emission reduction and noise reduction.

Owner:宁波天扬工业新技术有限公司

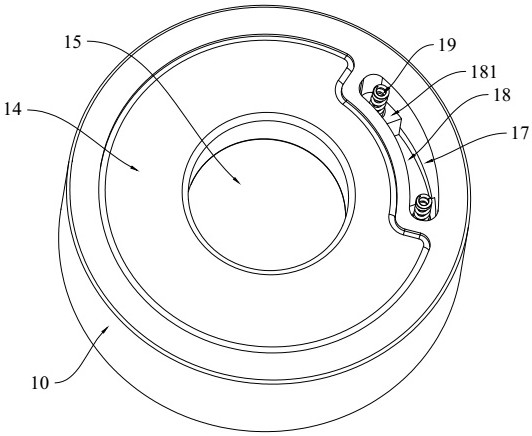

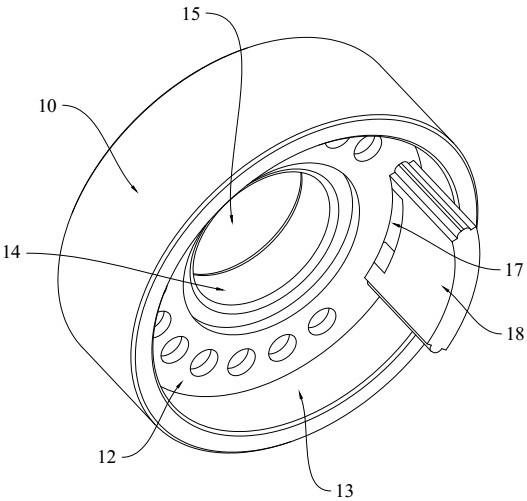

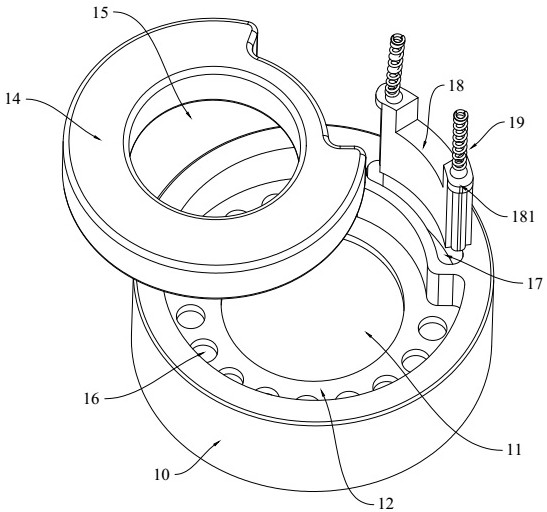

Slewing bearing with oil drainage holes

InactiveCN103291758ASolve the problem of not being able to refuelSolve the backlogBearing componentsLubrication ProblemSteel ball

The invention discloses a slewing bearing with oil drainage holes. The slewing bearing comprises an outer ring, an inner tooth ring and a sealing tape, wherein a roller path is formed between the outer ring and the inner tooth ring; a plurality of roller path steel balls for separating the outer ring from the inner tooth ring are arranged in the roller path; the sealing tape is also arranged on the slewing bearing, a plurality of oil drainage holes are uniformly formed in the inner tooth ring; an outlet of each oil drainage hole is formed in the middle of a tooth groove of each two adjacent teeth on the inner tooth ring. A certain number of oil drainage holes are additionally formed in the inner tooth ring and are uniformly distributed in the gear circumference of the inner tooth ring, redundant grease gathered in the roller path can be smoothly drained, and the drained grease enters the inner tooth ring, so that the problem of grease gathering is solved, a running gear can be additionally lubricated, and the problem that the gear cannot be lubricated in a late stage is solved. The grease is reasonably utilized, the lubrication of the gear is improved, the probability of manual handling of the lubrication problem is reduced, and the problem that the gear cannot be added with oil and fat for lubrication in the late stage is solved.

Owner:XUZHOU ROTHE ERDE SLEWING BEARING

Polyimide base high temp.-resistant and radiation-resistant lubricating paint

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

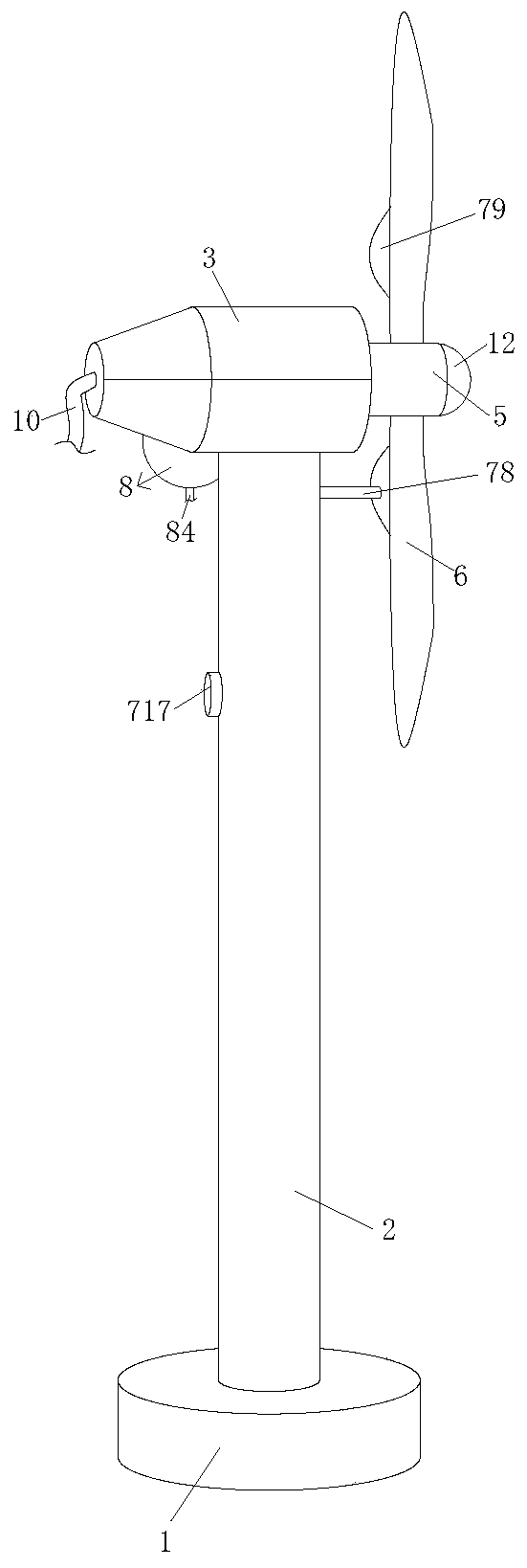

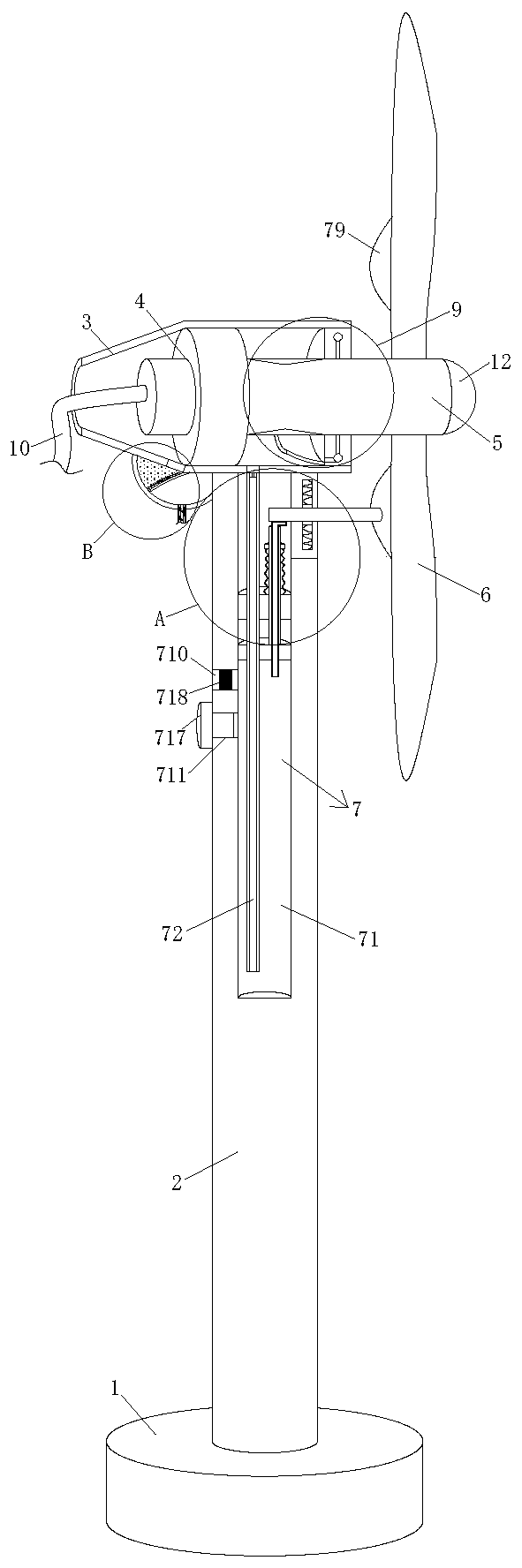

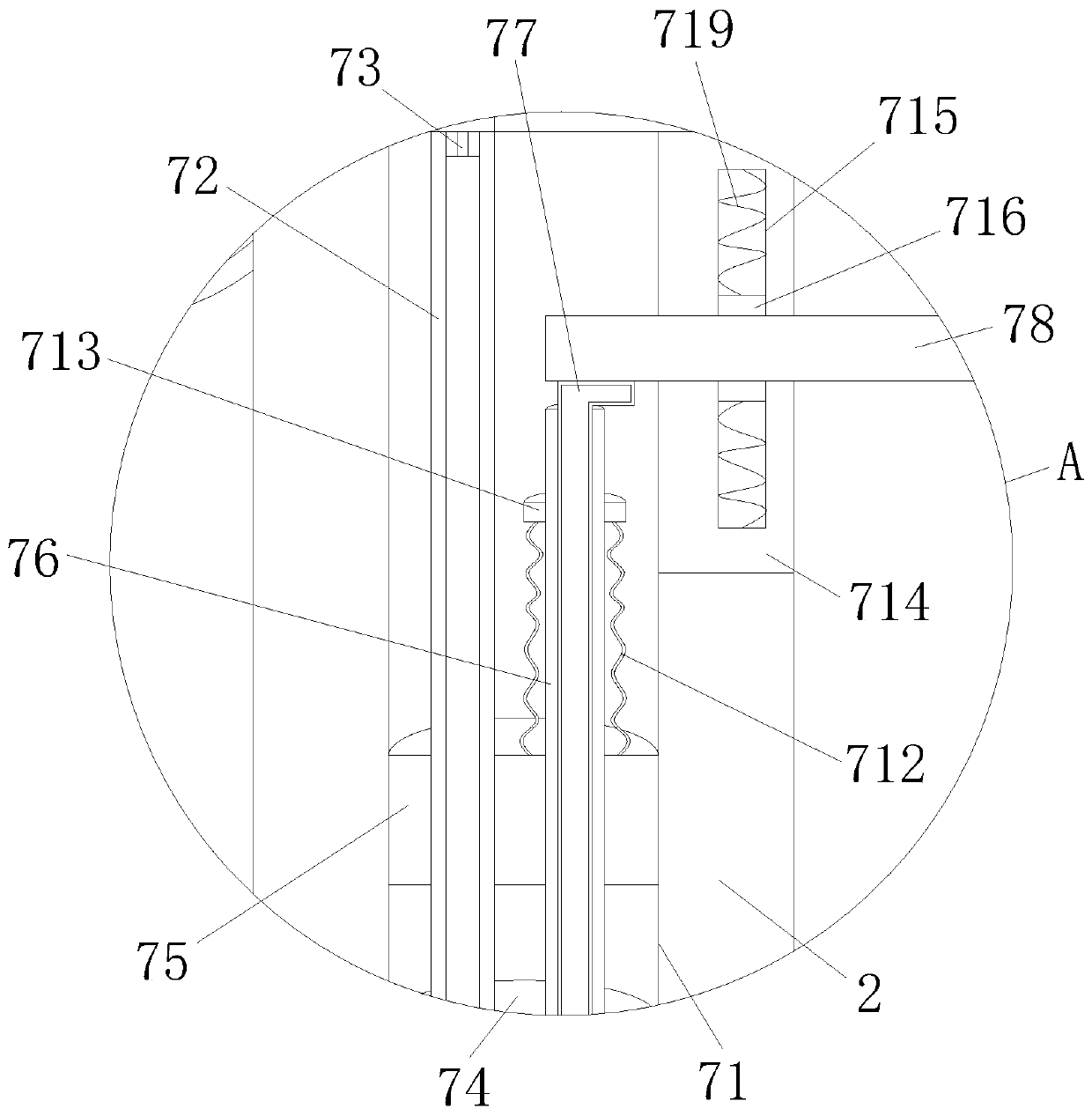

Self-lubricating wind-power wind energy generator

ActiveCN111287917AReduce wasteEasy to operateWind motor supports/mountsWind motor combinationsLubrication ProblemWaste oil

The invention provides a self-lubricating wind-power wind energy generator which comprises a base, a support rod for supporting wind power generation equipment, a case, a wind power generator, a rotary shaft, wind-power fan blades, an oil mist mechanism for storing oil and automatically discharging oil, an oil filtering mechanism for storing waste oil, and a mechanical lubricating mechanism for lubricating in a guiding way. The base is arranged on the floor; one end of the support rod is fixedly connected with the surface of the base; and the case is fixedly arranged on the top part of the support rod. The self-lubricating wind-power wind energy generator relates to the field of wind power generation. According to the self-lubricating wind-power wind energy generator, by combining with a lubricating problem existed in existing wind power generation, a special structure capable of blocking wind sand and controllably lubricating is designed for stably and effectively lubricating the equipment continuously, so that the problems that when a general wind power generation device is in use, the consumption of lubricating oil is accelerated by strong wind, the equipment needs to be frequently lubricated, an existing lubricating technology is operated frequently, the process is troublesome, and the working efficiency is affected to a certain degree are effectively solved.

Owner:江苏万基传动科技有限公司

Magnetic fluid lubricating method based on tiny magnetic body array

InactiveCN101280803BReduce coefficient of frictionImprove the lubrication effectBearingsLubrication ProblemMagnet

Disclosed is a magnetic fluid lubrication method based on micro-magnet arrays, pertaining to the technical field of magnetic fluid lubrication. The method is characterized by comprising the processesas follows: (1) micro-pits or micro-grooves with a size from micron to millimeter are manufactured on friction pair surfaces; (2) permanent magnetic material is deposited on the micro-pits or the micro-grooves with a thickness of microns to millimeters to form micro-magnet arrays; (3) magnetic fluids are filled between the friction pair surfaces; under the function of the magnetic filed produced by the permanent magnetic material layer, the micro drops of the magnetic fluid are assembled to the surrounding of the magnet arrays to form supporting force. The method expands the application rangeand enhances the lubrication effect of the magnetic fluid lubrication, thereby providing a solution to the lubrication problems under special conditions.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

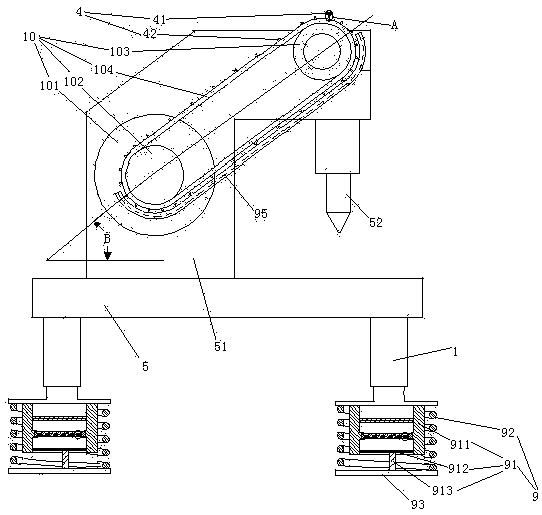

Self-lubricating vibration isolation type bench drill for vehicle remanufacturing

InactiveCN107775360AAutomatic lubricationGood shock isolationLarge fixed membersDriving apparatusIsolation effectLubrication Problem

The invention relates to tools for vehicle manufacturing, in particular to a self-lubricating vibration isolation type bench drill for vehicle remanufacturing. The self-lubricating vibration isolationtype bench drill for vehicle remanufacturing comprises a tabletop, supporting legs, a lubricating mechanism and an oil collecting groove, the tabletop is provided with a drill body and a driving mechanism, the driving mechanism comprises a chain and a motor driving the chain to rotate, the lubricating mechanism is used for automatically lubricating the chain, and the supporting legs are providedwith damping structures. The self-lubricating vibration isolation type bench drill which is for vehicle remanufacturing, can be automatically lubricated, make lubricating oil falling from the chain collected together and is good in vibration isolation effect is provided and solves the problem that an existing bench drill is poor in vibration isolation effect and needs to be manually lubricated.

Owner:杭州宏基输送机械有限公司

Transmission bearing lubrication oil-supply structure with compact structure

ActiveCN109630275AImprove the lubrication effectCompact structureTurbine/propulsion lubricationBall bearingGear wheel

The invention discloses a transmission bearing lubrication oil-supply structure with a compact structure. The transmission bearing lubrication oil-supply structure comprises an oil spraying hole formed in a spiral oil passing groove inside a power generator, the oil spraying hole directly faces a bevel gear in position, a plurality of penetrating oil passing holes are formed in the bevel gear, andlubrication oil is pumped to a to-be-lubricated ball bearing through the oil passing holes by utilizing rotating centrifugal force of the bevel gear. The transmission bearing lubrication oil-supply structure is simple in structure, an original lubrication system pipeline is fully utilized, no new part is additionally arranged, the lubrication problem of a short-life bearing is solved, and throughreal object test, the design target is achieved; and at present, the transmission bearing lubrication oil-supply structure is applied to a turbofan engine for an unmanned aerial vehicle and can be applied and popularized to the same type of engines.

Owner:BEIJING POWER MACHINERY INST

Single-nozzle internal combustion engine gas-liquid two-phase fuel injection system and method

ActiveCN106014727AReduce volumeExtend your lifeFuel injection apparatusEngine controllersWhole bodyLubrication Problem

The invention relates to a single-nozzle internal combustion engine gas-liquid two-phase fuel injection system and method, and belongs to the field of injection and two-phase fuel compound injection of internal combustion engine gas and liquid fuel in cylinders. The system is additionally provided with a gas-liquid two-phase fuel compound injection system and an electronic control unit on the basis of remaining the whole body of an original engine. The gas-liquid two-phase fuel compound injection system mainly comprises a gas fuel one-way valve, a gas fuel flow and pressure sensor, a gas fuel linear electromagnetic valve, a liquid fuel one-way valve, a liquid fuel flow and pressure sensor, a liquid fuel linear electromagnetic valve, a nozzle, a liquid fuel pump, a three-way joint and the like. The electronic control unit regulates the gas fuel linear electromagnetic valve and the liquid fuel linear electromagnetic valve so that gas fuel and liquid fuel can be injected into an air cylinder according to any mass ratio, accordingly the space needed for independently installing the gas-liquid fuel injection system is substantially reduced, and the heat dissipation and lubrication problems of the nozzle during high-pressure injection of gas fuel are solved due to injection of the liquid fuel and the gas fuel.

Owner:BEIJING UNIV OF TECH

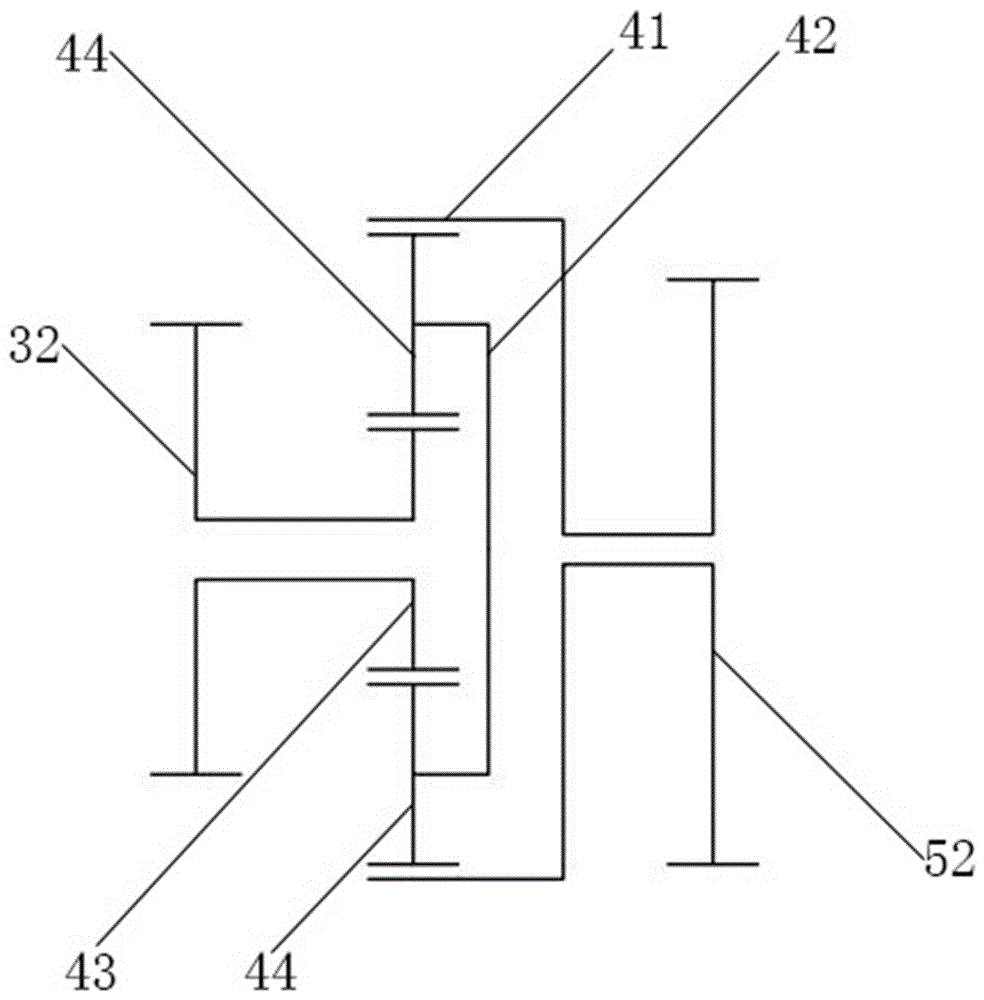

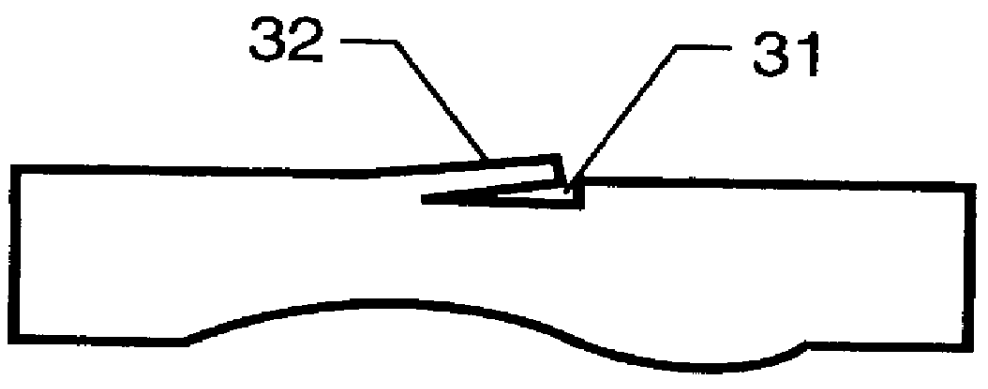

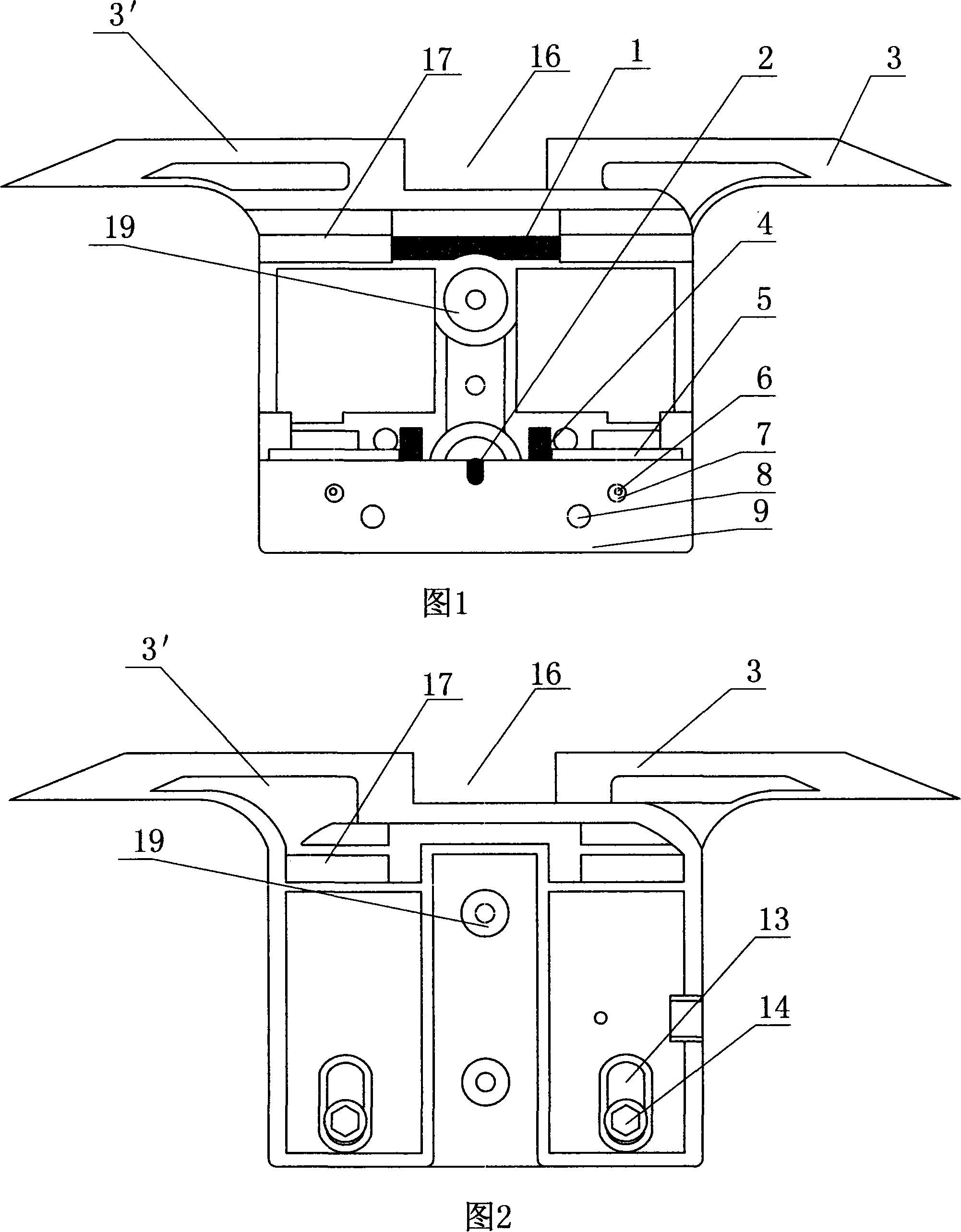

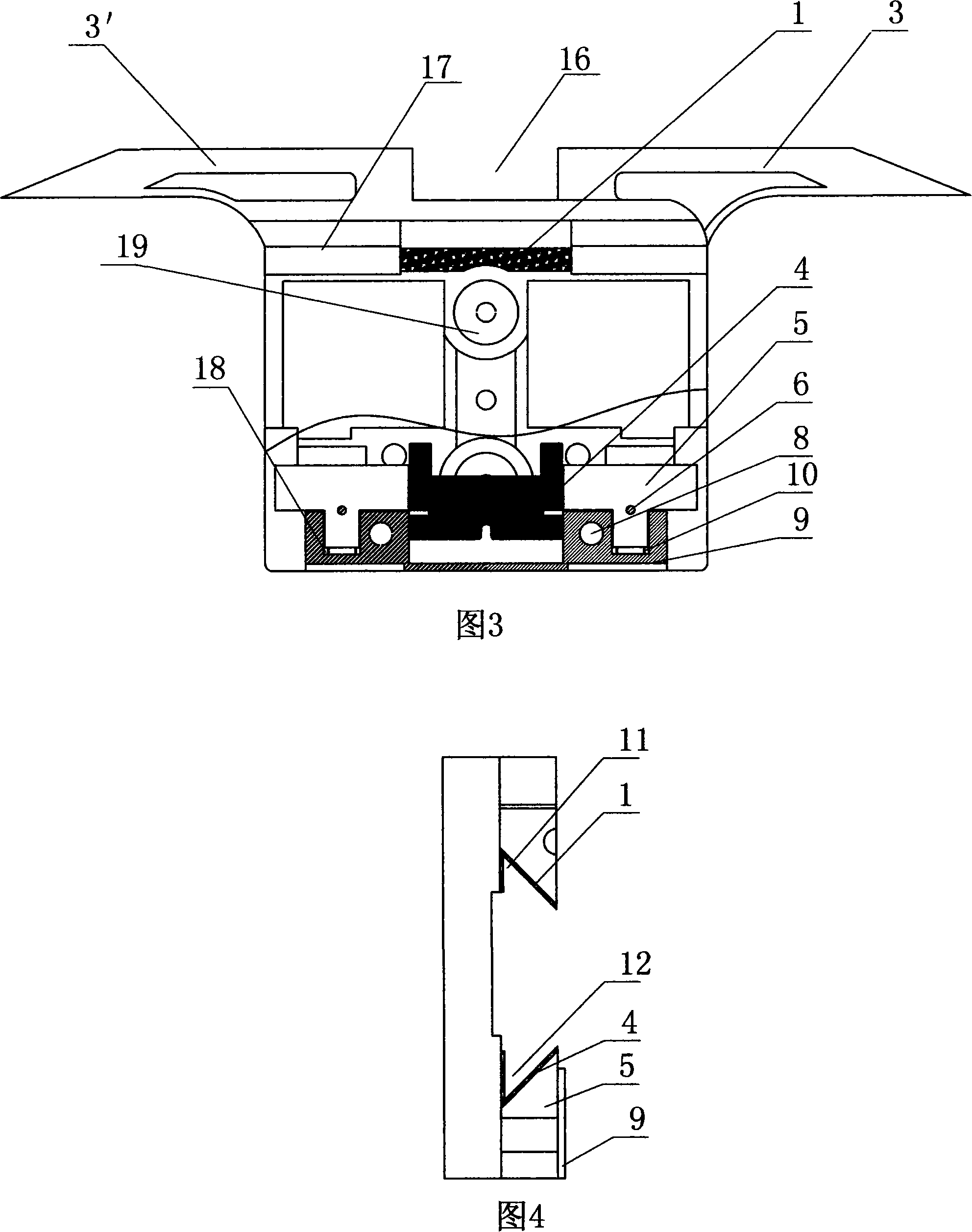

Computer flat knitting machine yarn nozzle sliding seat

InactiveCN101117754ASolve the problem of blocked movementReduce frictionWeft knittingYarnLubrication Problem

The present invention discloses a yarn carrier sliding seat for computerized flat knitting machine and belongs to a fitting for driving the yarn carrier to move on the guide of a computerized flat knitting machine. The sliding seat has a body (7) and a cover plate (9), wherein the upper part of the body is arranged with a first angular groove (11); the cover plate is arranged with a sliding block (5); one end of the sliding block has a bevel, which composes a second angular groove (12) with the body; the second angular groove and the first angular groove are in correspondence and fit with the guide of the computerized flat knitting machine; the cover plate is arranged with a spring, which connects with the slider. The present invention is characterized essentially in that the middle of the upper part of the body is arranged with a first sponge-texture body (1), which is arranged in the first angular groove; a second sponge-texture body(2) is arranged between the body and the cover plate, and the second sponge-texture body is slightly higher than the angular line of the second angular groove. The present invention solves the lubrication problem and can wipe dusts on the guide so that the yarn carrier sliding seat can normally move on the guide.

Owner:林良金

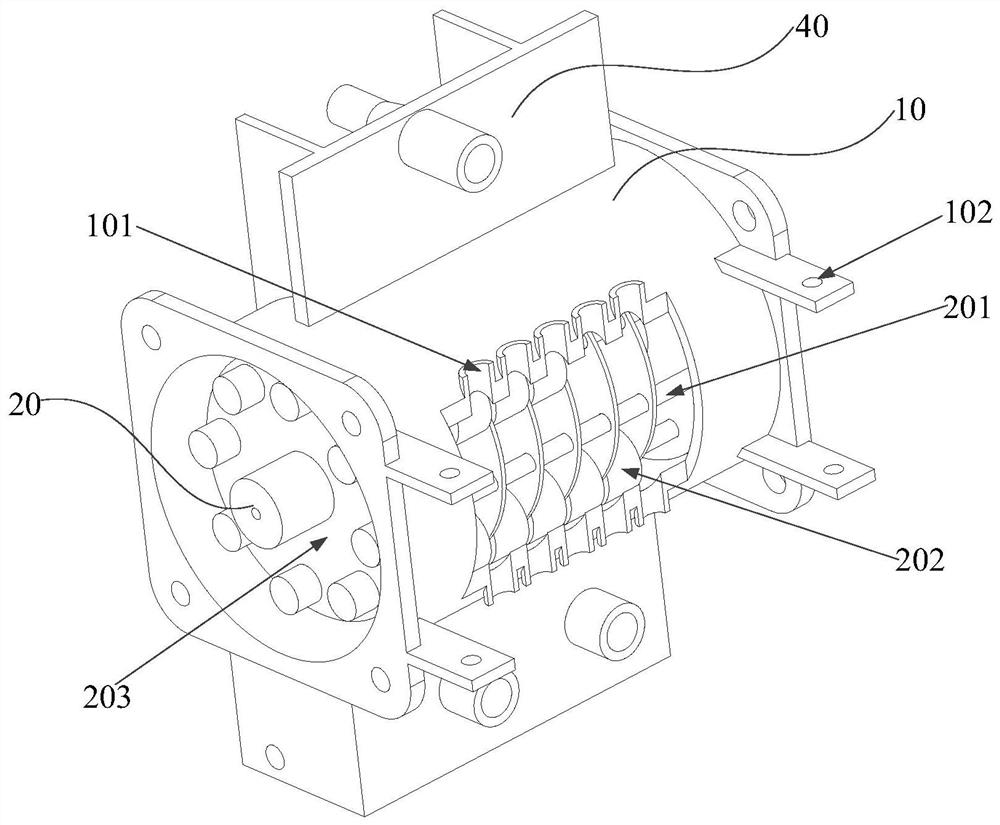

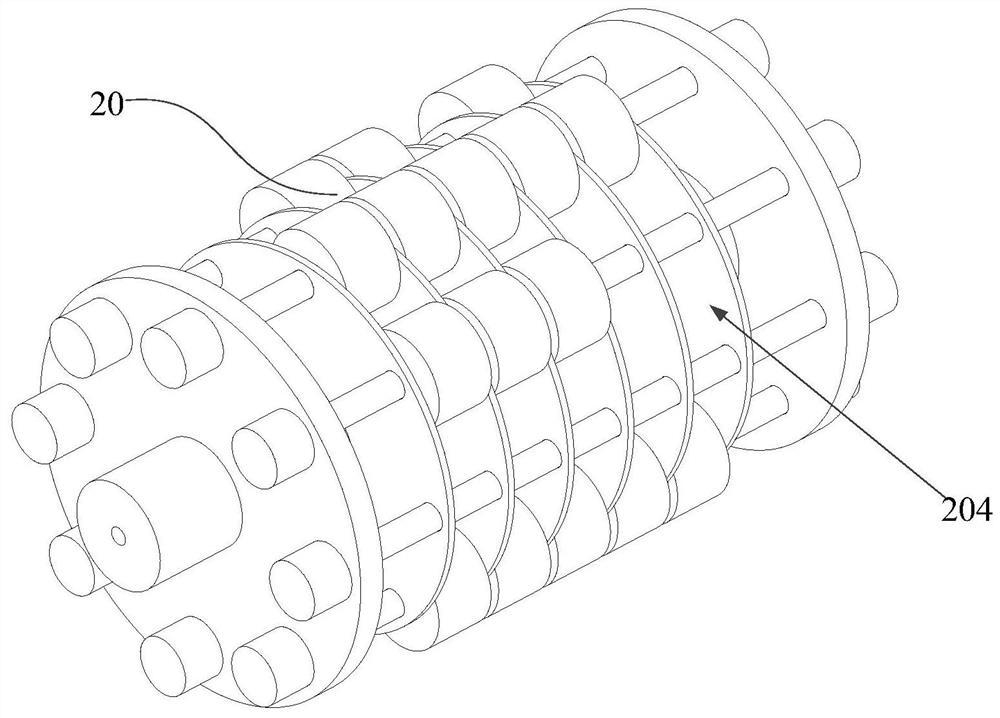

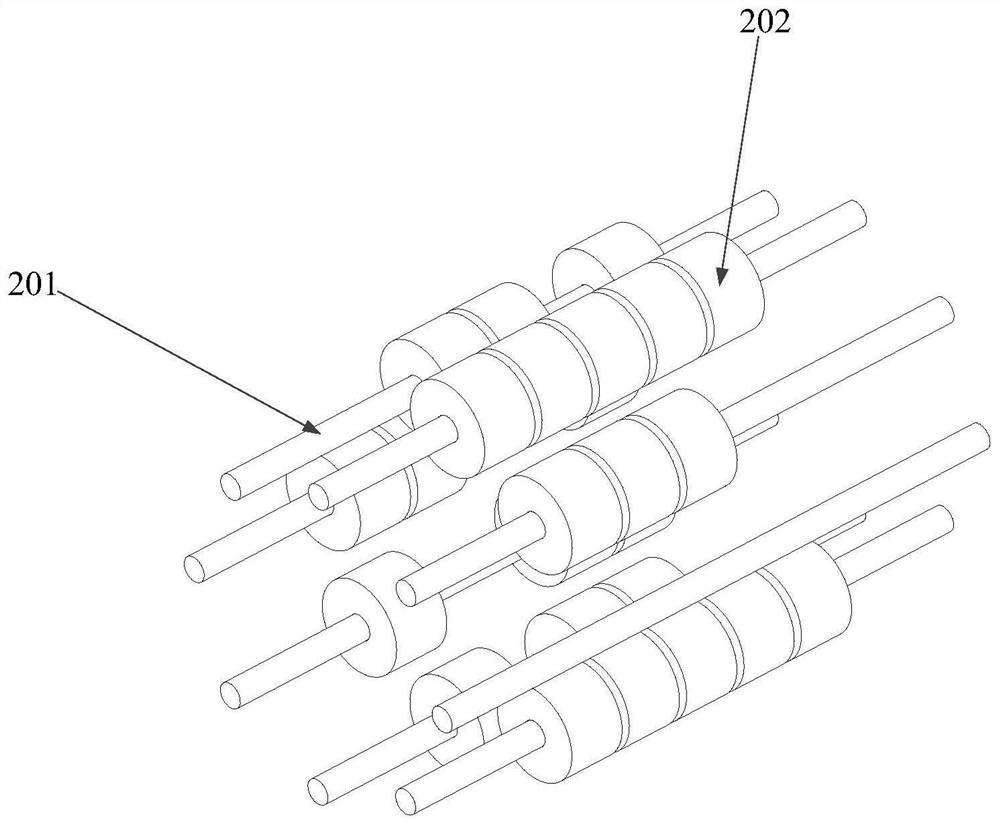

Multi-parallel control valve mechanism and medical equipment

ActiveCN112303281ASimple structureEasy to processDiaphragm valvesOperating means/releasing devices for valvesMedical equipmentElectric machinery

The invention is suitable for the technical field of medical instruments, and relates to a multi-parallel control valve mechanism. The multi-parallel control valve mechanism comprises a valve shell and a valve core; the valve core is arranged in the valve shell, and the portion, on one side of the valve core in the extending direction, of the upper part of the valve shell is hollow; the valve corecomprises a plurality of roller pins, a plurality of rollers and two fixing plates, the two ends of the roller pins are each fixed by one fixing plate, and the roller pins are sleeved with the rollers; and a plurality of hoses are placed on the valve shell, a motor drives the rollers in the valve core to rotate, and the hoses are controlled to be opened or closed according to the condition that whether the rollers extrude the hoses or not. The valve core is composed of the rollers and the roller pins, the structure is simple, and machining is convenient; and the rollers and the hoses are in direct contact and are in rolling friction, so that a push rod and a springback device are not needed, abrasion and lubrication in the movement process do not need to be considered, time and labor aresaved, and high efficiency and reliability are achieved.

Owner:HUNAN MICOME ZHONGJIN MEDICAL SCI & TECH DEV CO LTD

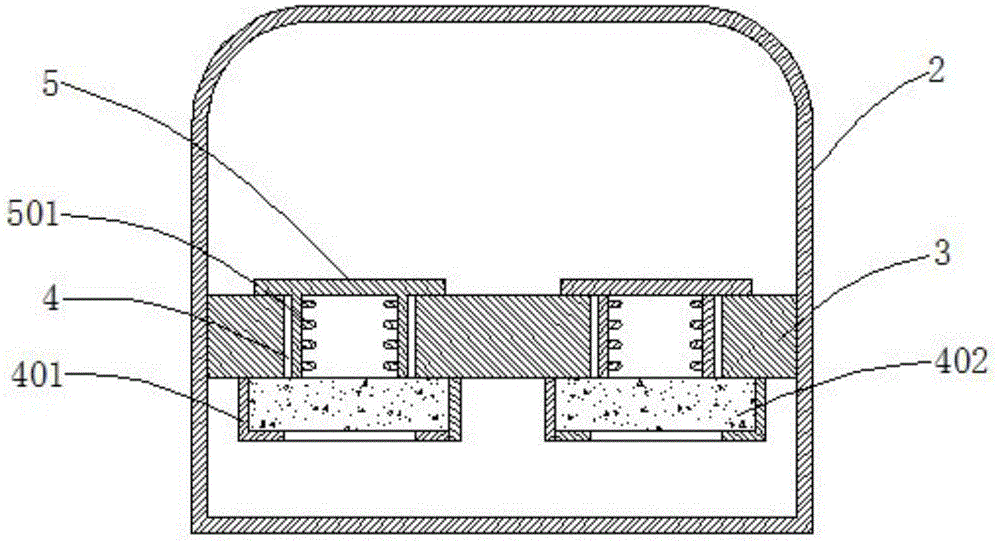

Chain block with seal lubricating device

InactiveCN105042307AImprove the smoothness of liftingFully lubricatedEngine lubricationLubrication ProblemEngineering

The invention discloses a chain block with a seal lubricating device, and comprises a chain block, a seal shield, an isolation plate, folding and unfolding holes, and a seal pad; the seal shield is arranged outside the chain block, and welded with the chain block; the isolation plate is arranged on the bottom of the seal shield, and welded with the shield; the folding and unfolding holes are arranged on the bottom of the isolation plate, and being a plurality of round through holes; the seal pad is arranged in the center of the folding and unfolding holes, is in a cylinder shape, and glued with the folding and unfolding holes. Firstly, an outer wall of the chain block is welded with the seal shield, and an inner side is filled with lubricating oil so as to fully lubricate all parts, thus thoroughly solving the poor lubrication problems in the prior art, greatly improving hoist smoothness of the chain block, and preventing deadlocking phenomenon.

Owner:安徽三雕起重机械有限公司

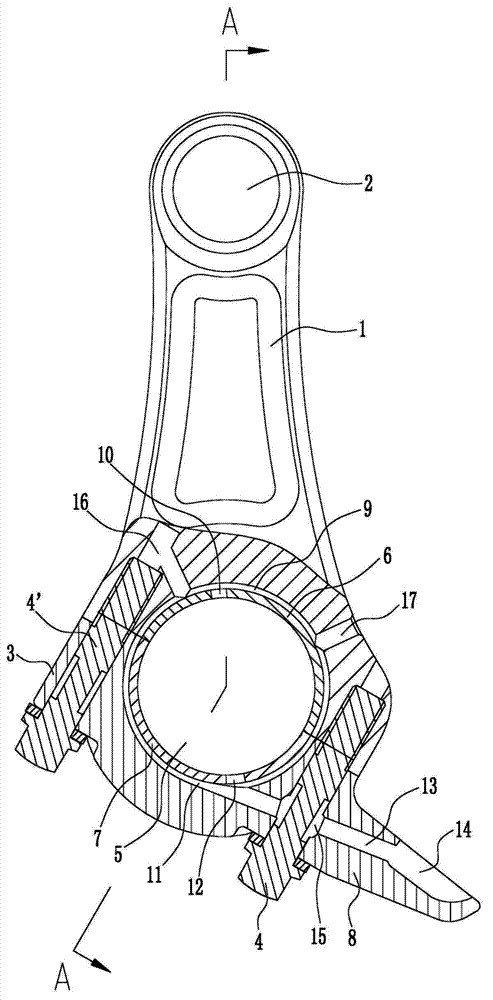

Connecting rod assembly for high rotation speed petrol engine

InactiveCN102927118ASolve lubrication problemsSufficient oil supplyConnecting rod bearingsConnecting rodsLubrication ProblemLarge head

The invention discloses a connecting rod assembly for a high rotation speed petrol engine. An upper oil collection groove (9) is arranged in the inner wall of a first arc-shaped groove of a large head of a connecting rod (1), and a first oil inlet (10) is arranged in an upper beating metal (6) and penetrates through the inner surface and the outer surface of the upper beating metal (6). A lower oil collection groove (11) is arranged in the inner wall of a second arc-shaped groove of a connecting rod cover (3), and a second oil inlet (12) is arranged in a lower beating metal (7) and penetrates through the inner surface and the outer surface of the lower beating metal (7). The lower oil collection groove (11) is communicated with an oil inlet groove (14) arranged on the top face of an oil shed block (8) through an oil duct (13). Under the condition that performance and lubricating methods of a petrol engine are not changed, a one-way lubrication oil-taking method is changed into a two-way oil-taking method, and therefore a connecting rod assembly lubrication problem of the high rotation speed petrol engine is solved thoroughly, and quantized design demands of engines are met at the same time.

Owner:力帆科技(集团)股份有限公司

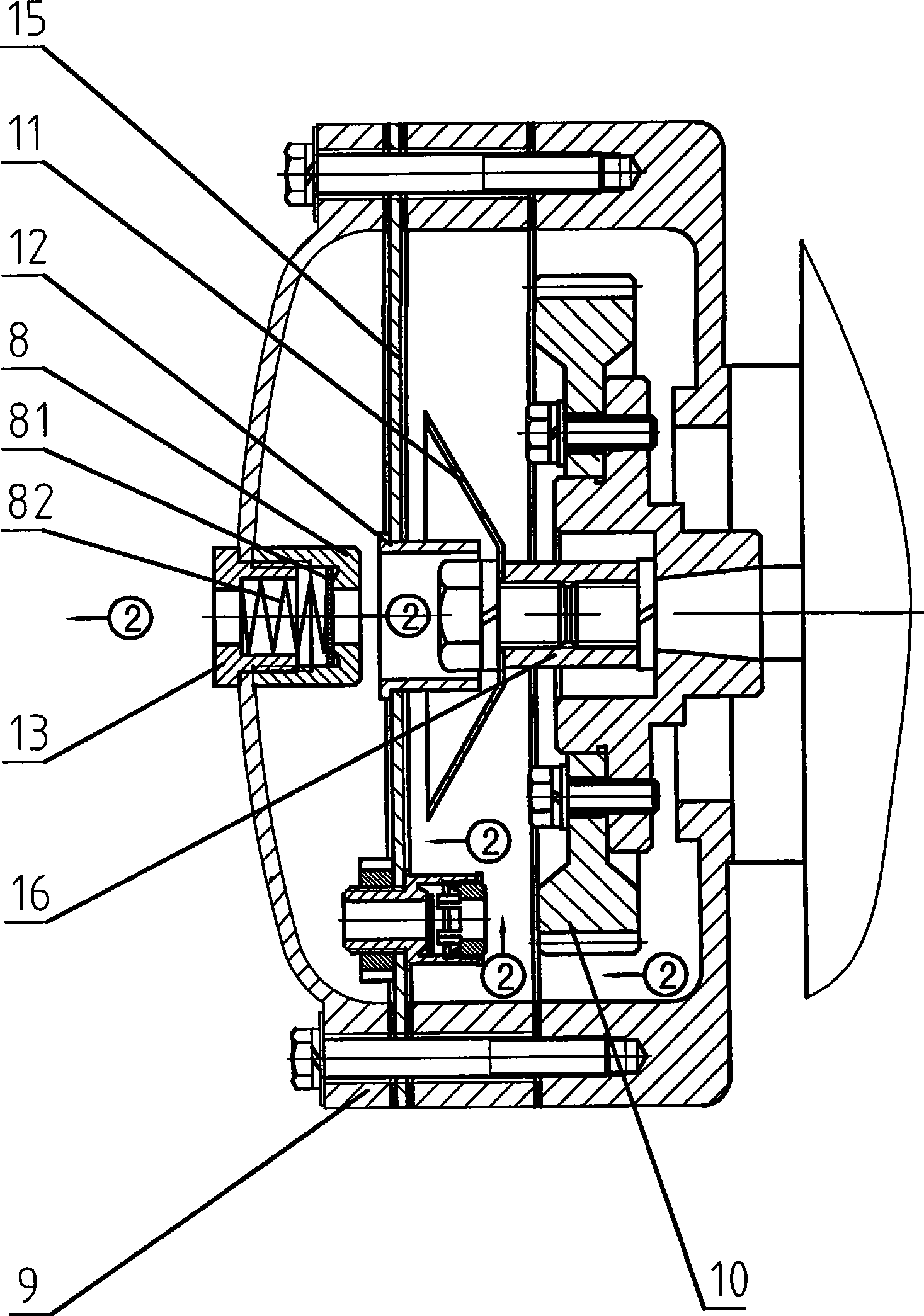

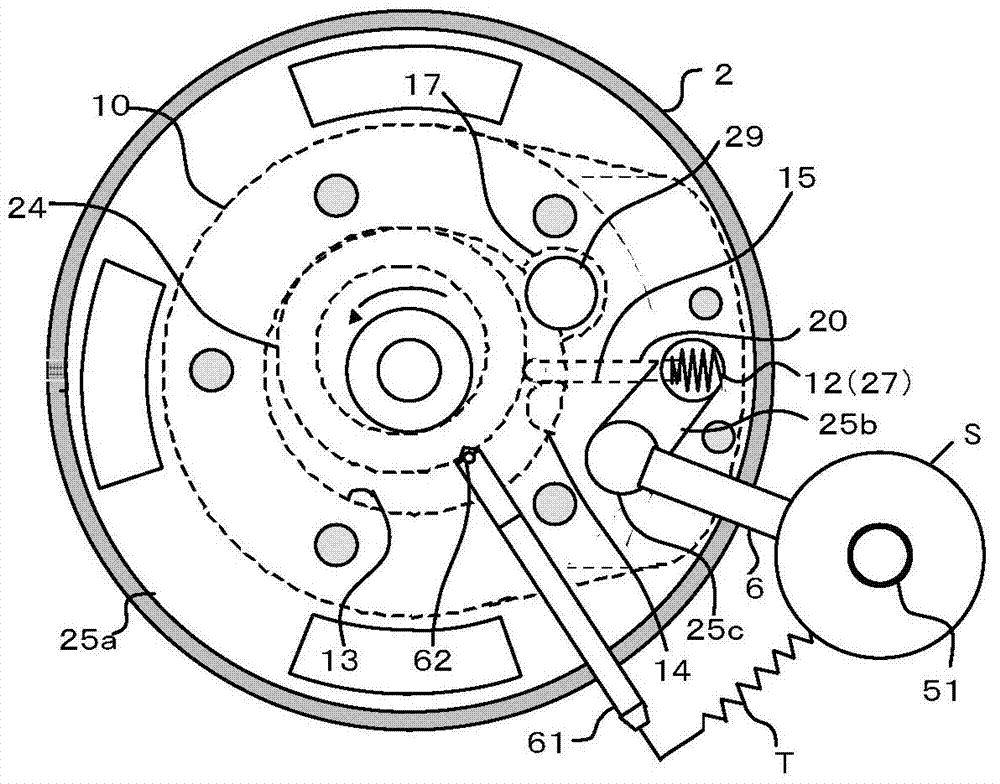

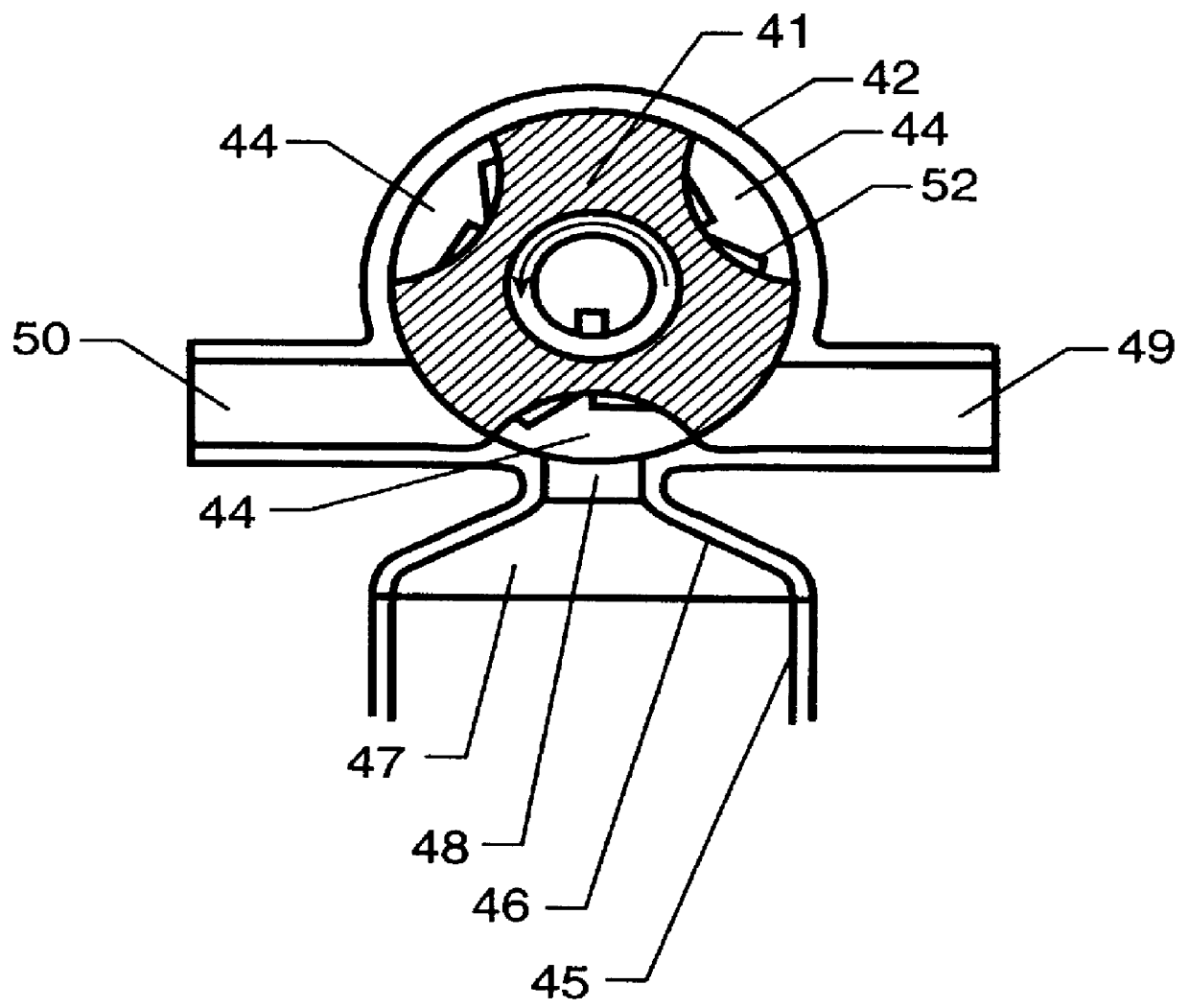

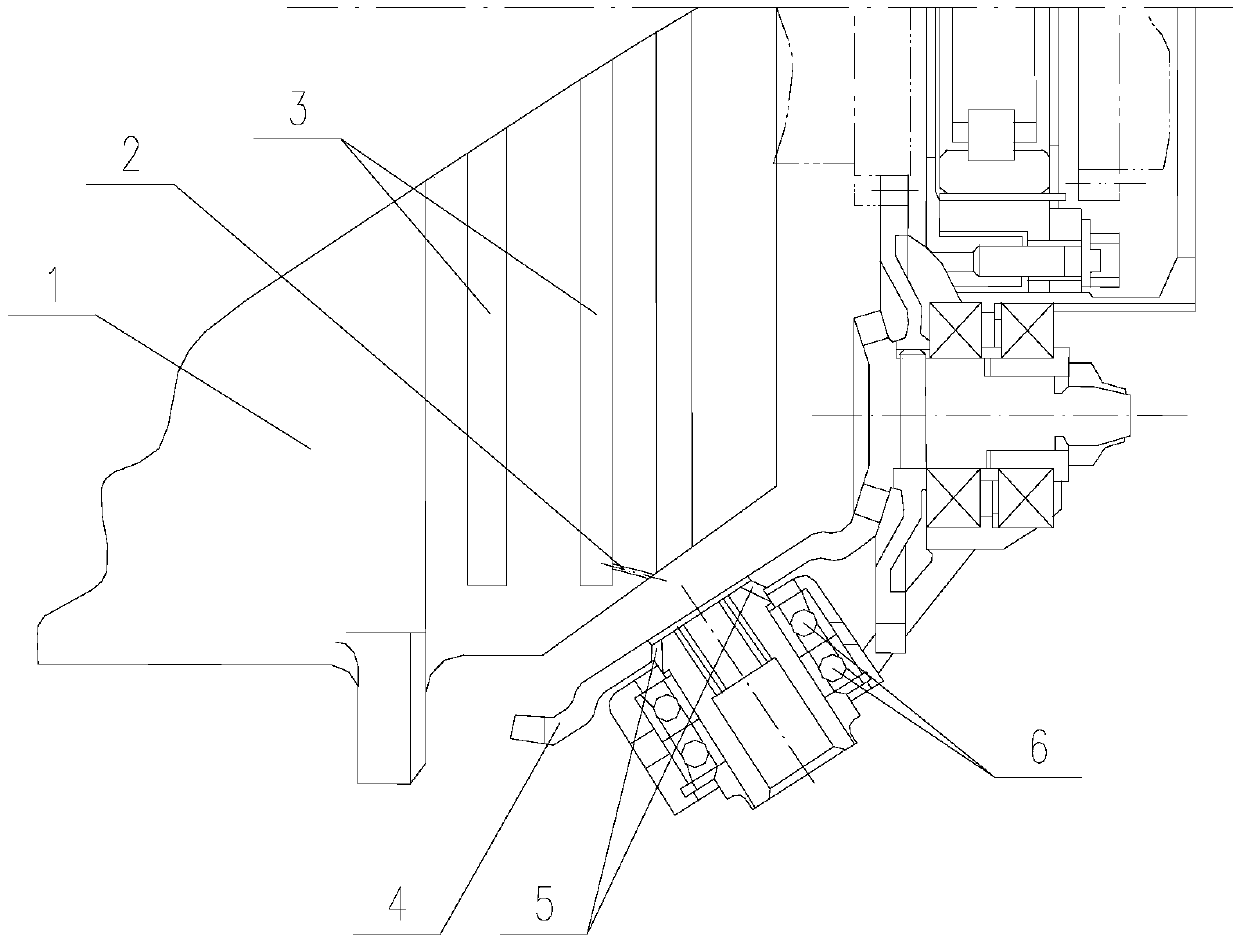

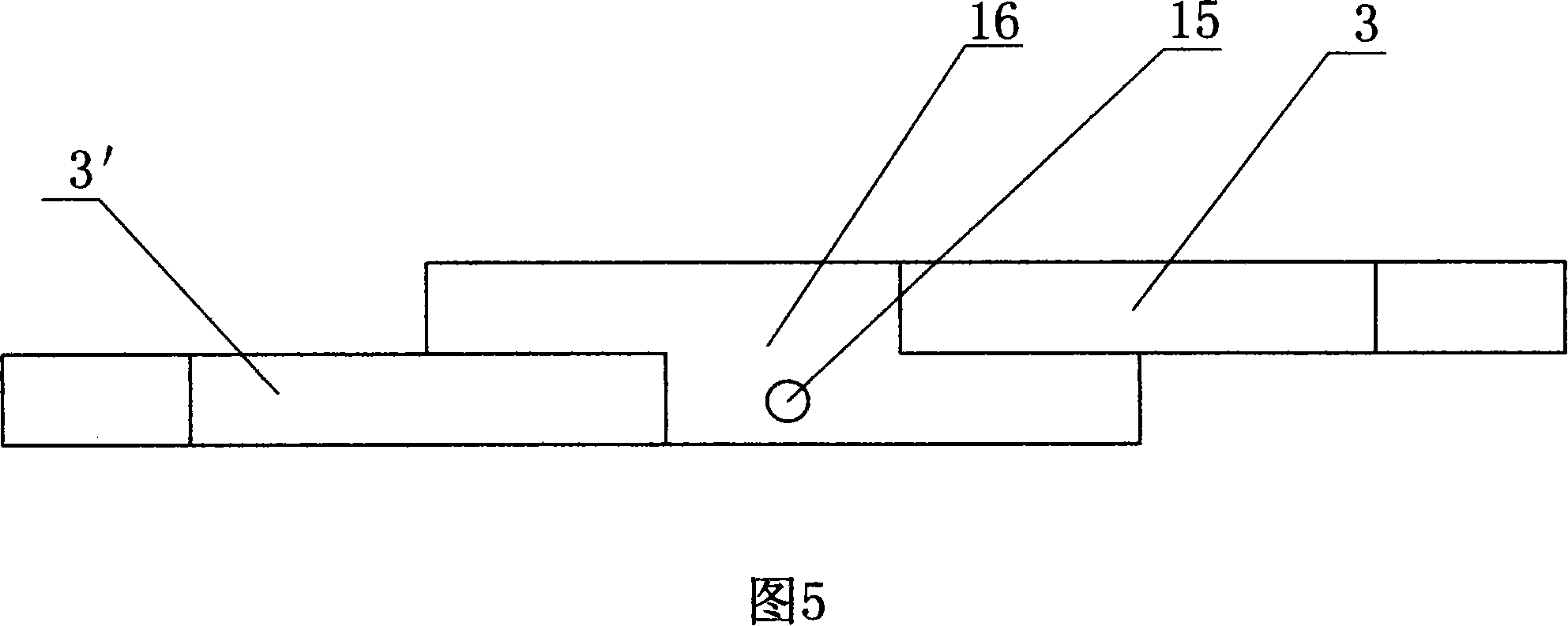

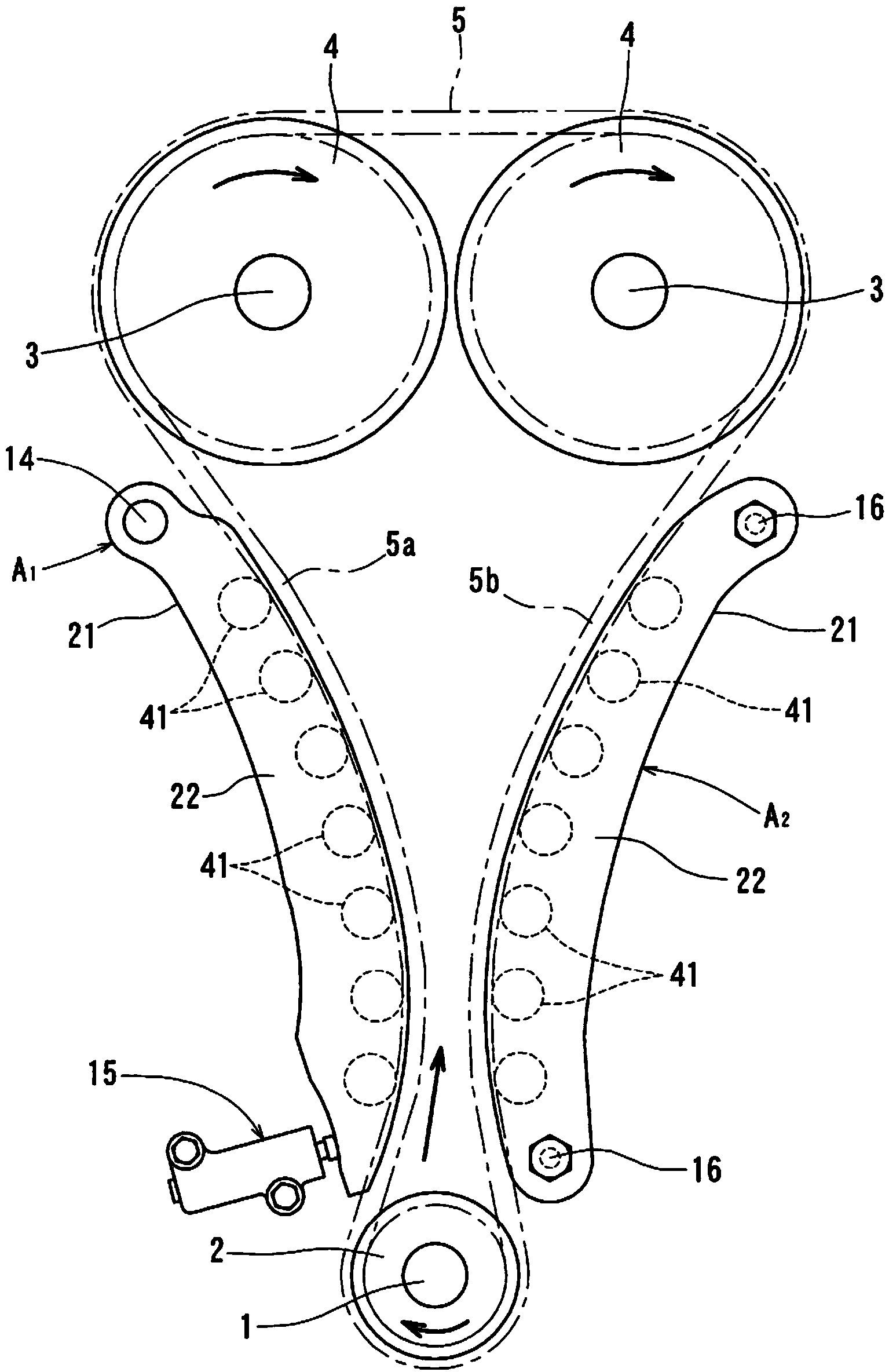

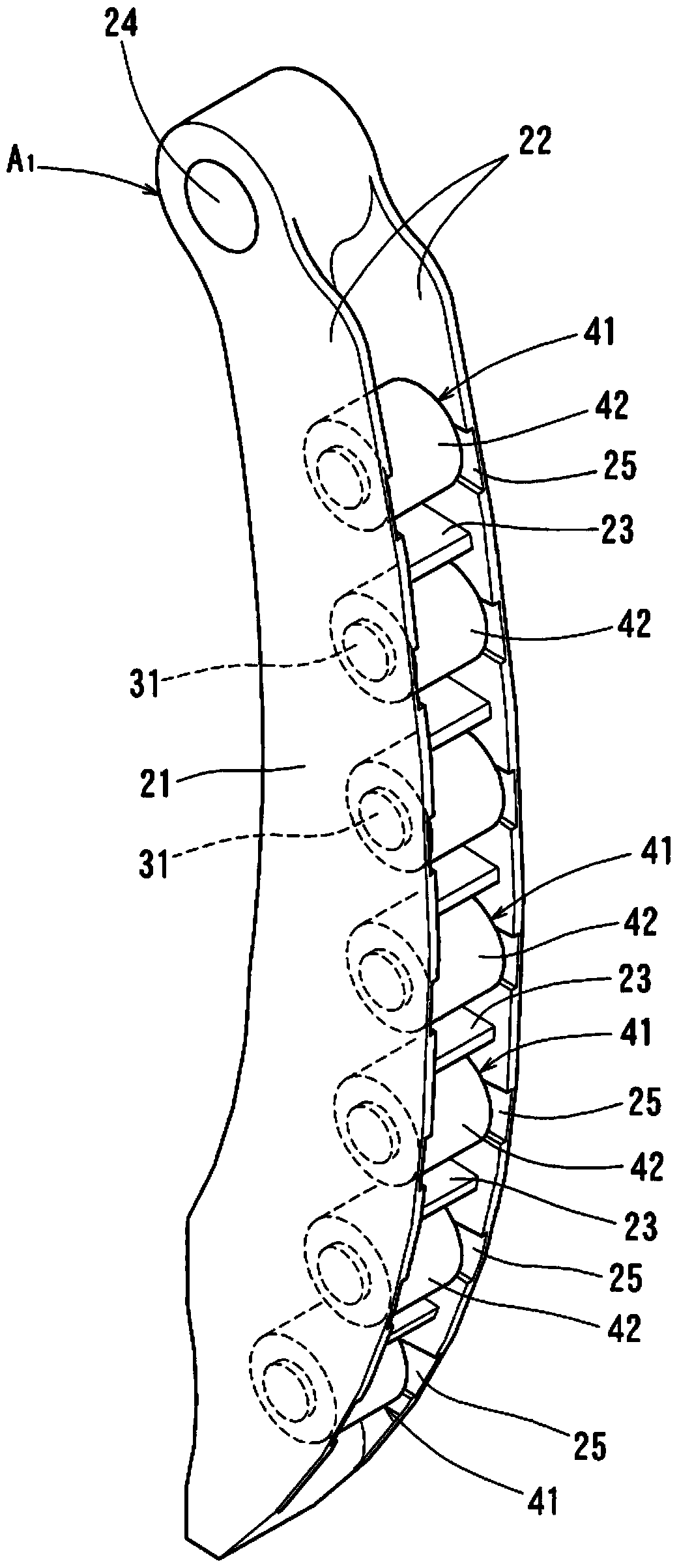

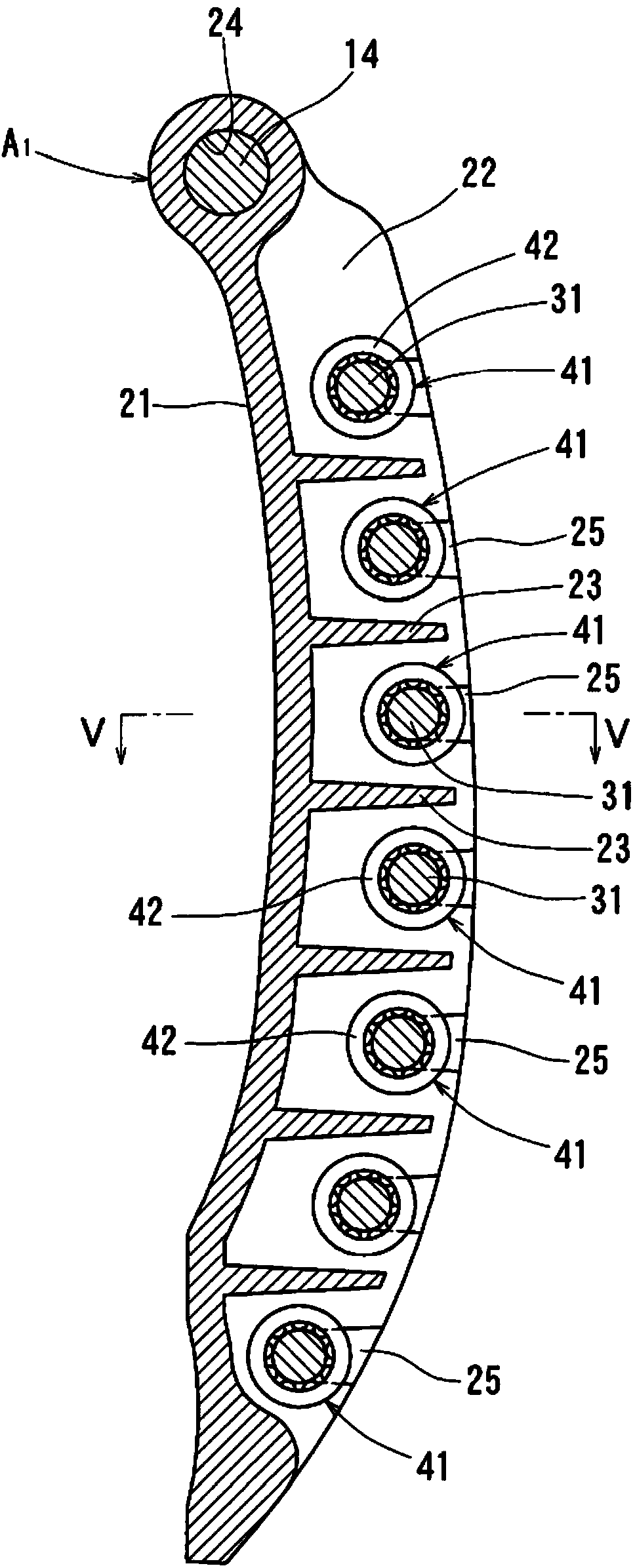

Chain drive device for camshaft drive

InactiveCN103748383AReduce resistance to movementSmooth rotationGearingMachines/enginesLubrication ProblemSprocket

In a chain drive device for a camshaft drive, a timing chain (5) is run between a drive sprocket (2) attached to a crankshaft (1) and a driven sprocket (4) attached to a camshaft (3), and a chain guide (A1) that has a plurality of rotatable rollers (41) that guide the movement of the timing chain (5) is pivotably provided on one side of the slack side of the timing chain (5). An accommodating force from a chain tensioner is applied to the pivoting end of the chain guide, pushing the rollers (41) up against the timing chain (5). The ratio (D1:D2) between the pitch circle diameter (D1) of the drive sprocket (2) and the outer diameter (D2) of the rollers (41) is between 5:3 and 5:1, preventing the chain-guiding rollers (41) from suffering lubrication problems and simplifying the engine layout.

Owner:NTN CORP

Gearbox bearing lubrication device

InactiveCN103912671AImprove working conditionsExtended service lifeGear lubrication/coolingLubrication ProblemPetroleum engineering

The invention discloses a gearbox bearing lubrication device comprising a box, a mounting block, a planet gear and an inner toothed ring. The mounting block is provided with a fixed shaft. The planet gear is rotatably supported on the fixed shaft through a planet bearing. The planet gear meshes with the inner toothed ring. The inner toothed ring is fixedly connected with the box. The inner toothed ring is rotatably supported on the mounting block through a rotary support shaft. The fixed shaft is provided with an axial oil hole and a radial oil hole communicated with each other. An inlet of the axial oil hole is arranged at one end of the fixed shaft. An outlet of the radial oil hole leads to the planet bearing. The fixed shaft is provided with an oil collector; an inner cavity of the oil collector leads to the inlet of the axial oil hole. The box is provided with a plurality of oil cups; when rotating with the box, the oil cups can arrive above the oil collector. The gearbox bearing lubrication device has the advantages that the lubrication problem of the gearbox inner bearing can be solved, the cost is low and the structure is simple.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

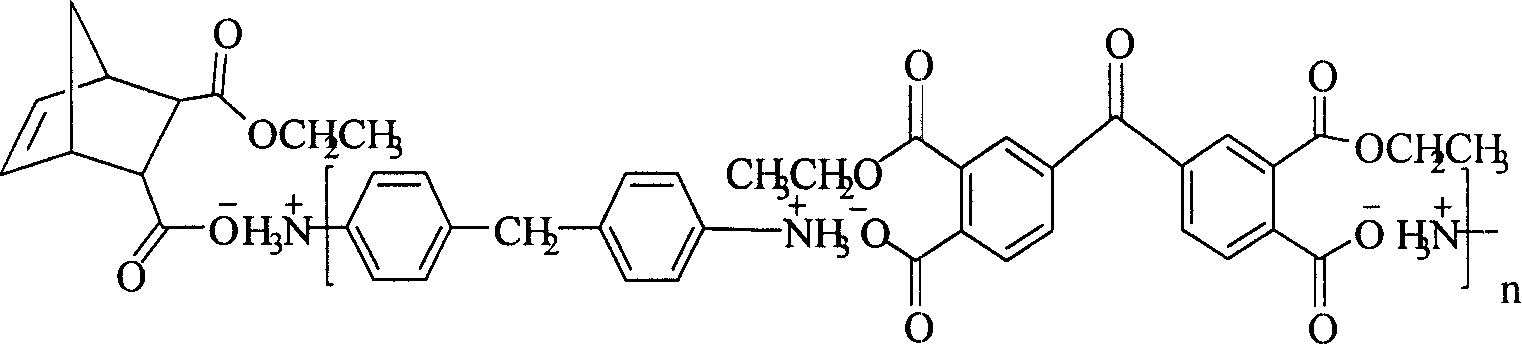

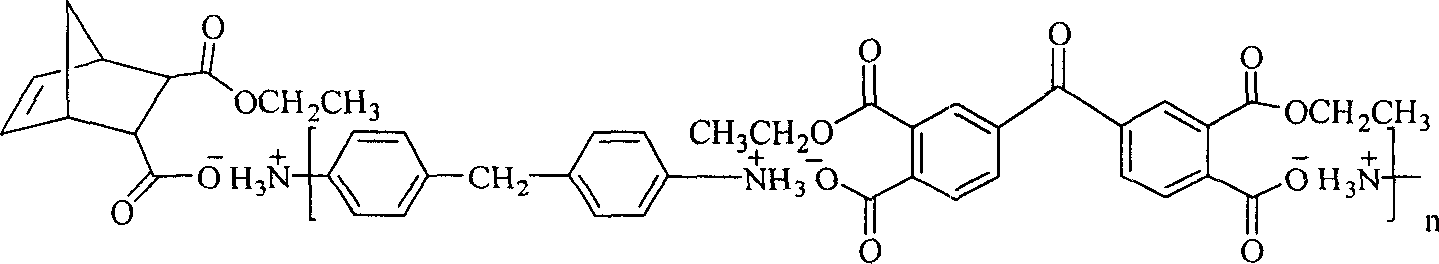

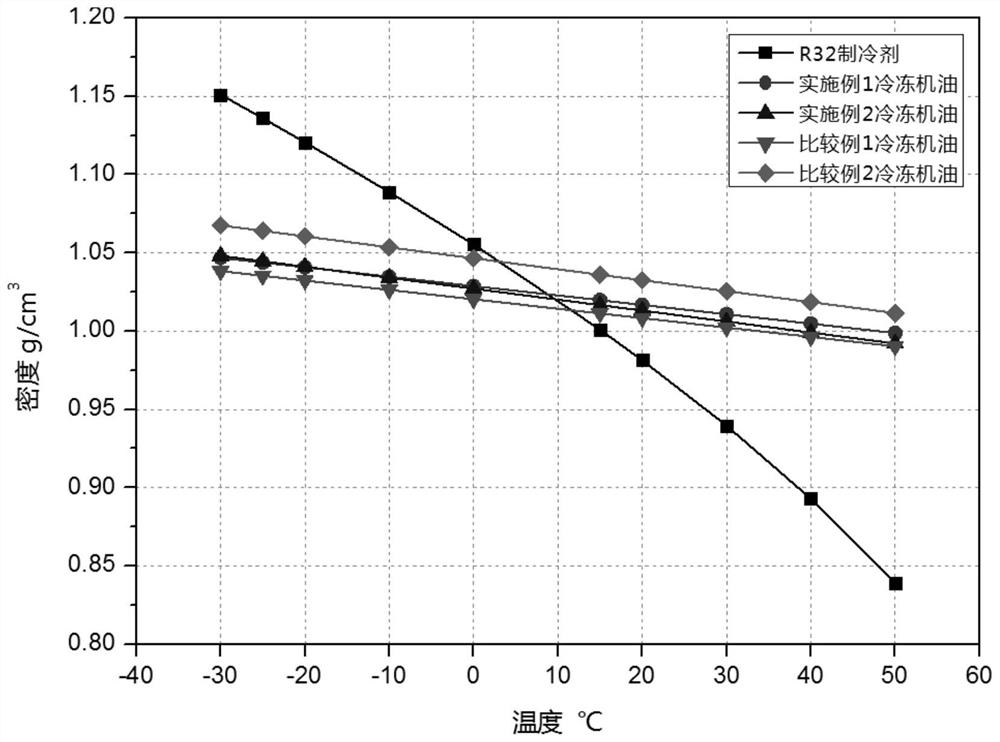

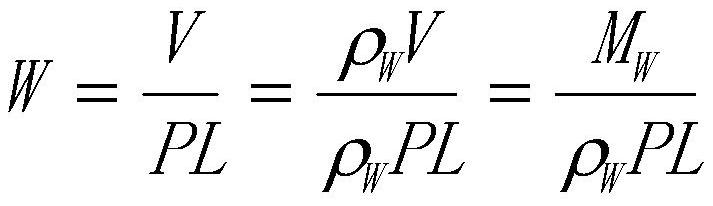

Refrigerating machine oil, working fluid composition and refrigeration cycle device

ActiveCN112410109AIncrease choiceMeet long-term durabilityCompression machines with non-reversible cycleChemical industryPolyolesterWorking fluid

The invention relates to the technical field of refrigerating machine oil products and refrigeration devices, in particular to refrigerating machine oil, a working fluid composition and a refrigeration cycle device. The refrigerating machine oil takes polyol ester synthesized by esterification of polyol and fatty acid as base oil, the viscosity of the refrigerating machine oil at 40 DEG C is 60-100cst, the density of the refrigerating machine oil at 20 DEG C is greater than 1g / cm < 3 >, and the refrigerating machine oil and an R32 refrigerant are subjected to two-layer separation in a workingtemperature range of a refrigeration system to form a lean oil layer and an oil-rich layer. The working fluid composition formed by mixing the refrigerating machine oil and the R32 refrigerant can meet the test requirements of long-term durability, ultralow-temperature startability and oil return performance of a compressor, can be widely applied to the refrigeration cycle device taking R32 as therefrigerant, under the condition that the compressor and the refrigeration cycle device are not transformed, the problems of oil return and lubrication of refrigerating machine oil which is difficultto dissolve in a refrigerant or is dissolved in an intermediate phase in the R32 refrigeration cycle device are solved, and the selection range of the refrigerating machine oil of the R32 refrigeration cycle device is widened.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

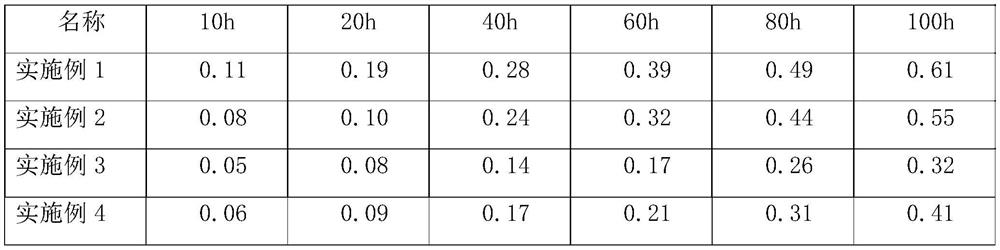

Self-lubricating composite material and preparation method thereof

InactiveCN113462922AImprove wear resistanceImprove antioxidant capacityLubricant compositionLubrication ProblemOxidation resistant

The invention provides a self-lubricating composite material and a preparation method thereof, and mainly relates to the field of self-lubricating materials. The self-lubricating composite material can solve the problems of self-lubrication and narrow use temperature range of materials. The self-lubricating composite material mainly comprises a base material, a solid lubricant, graphene and a coupling agent, wherein the base material comprises the following components in percentage by mass: 48% of titanium, 46% of aluminum, 2% of chromium, 2% of niobium, 1% of boron and 1% of magnesium; the mass of the solid lubricant is 5-10% of the mass of the base material; the mass of the graphene is 50-80% of the mass of the solid lubricant; and the mass of the coupling agent is 80-120% of the mass of the graphene. The self-lubricating composite material has the advantages of wider effective lubricating temperature range, higher wear resistance, higher oxidation resistance and higher corrosion resistance; and the dust falling in the wear process of the fitting prepared from the self-lubricating composite material is the composite solid lubricant, thereby achieving the self-lubricating effect.

Owner:山东朝阳轴承有限公司

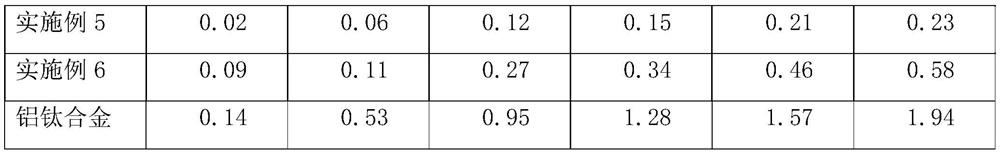

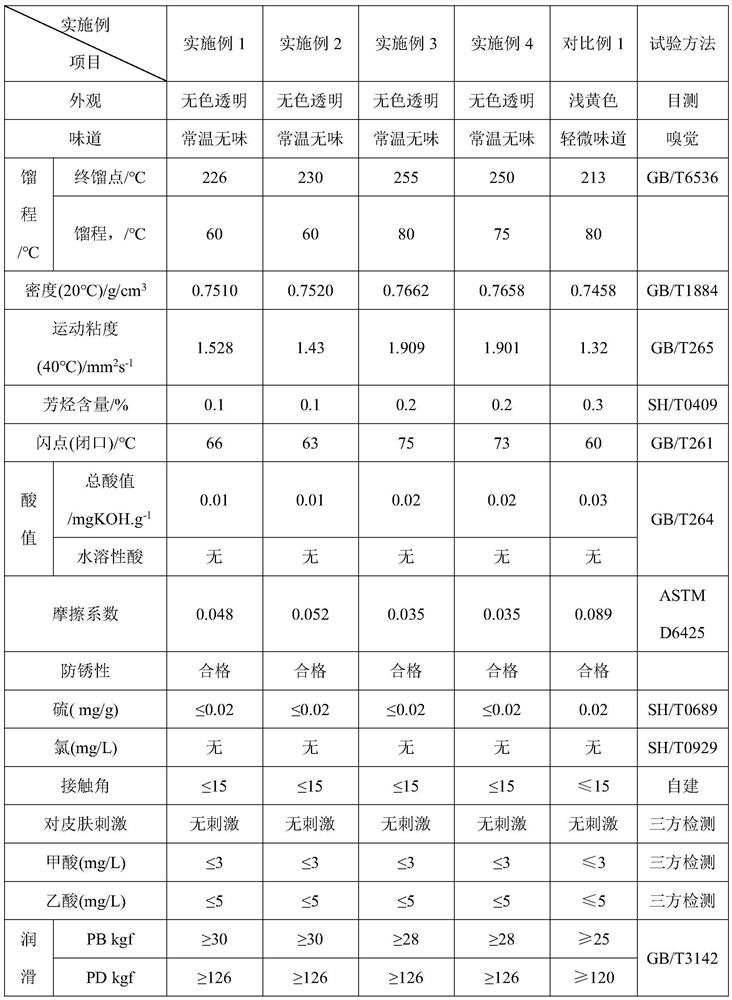

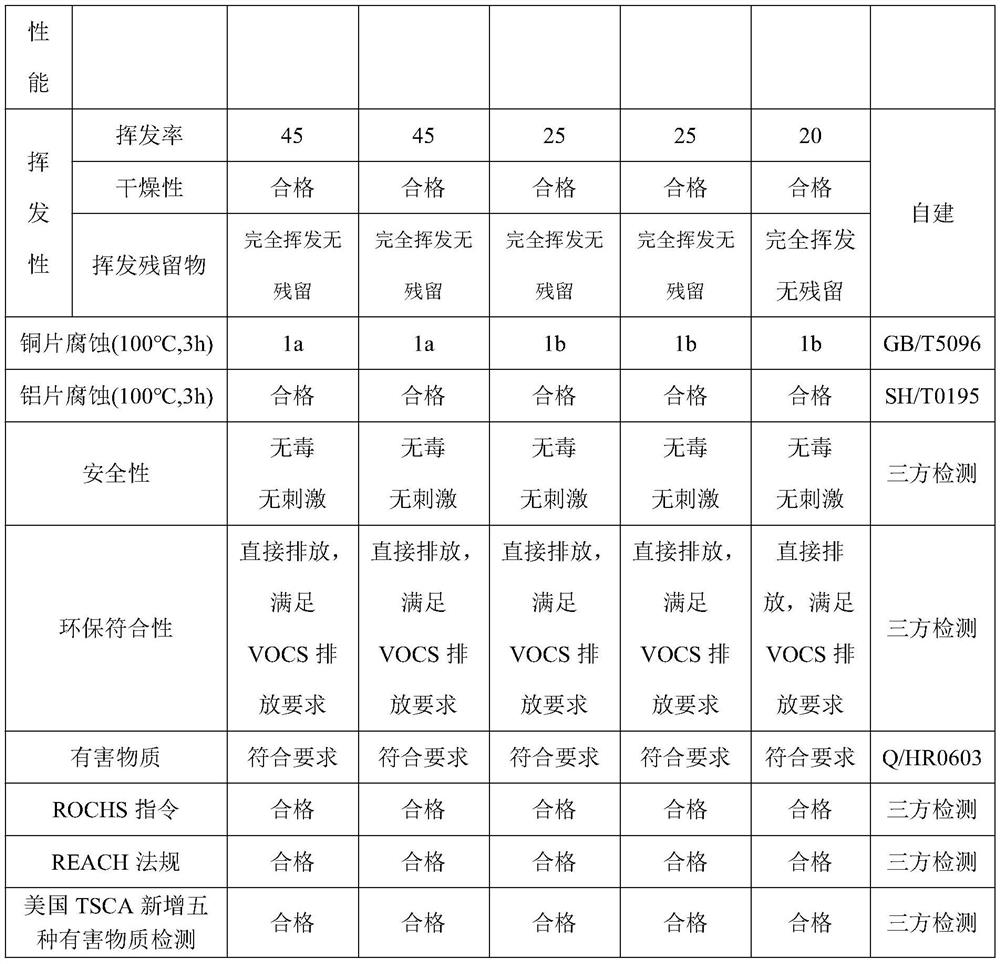

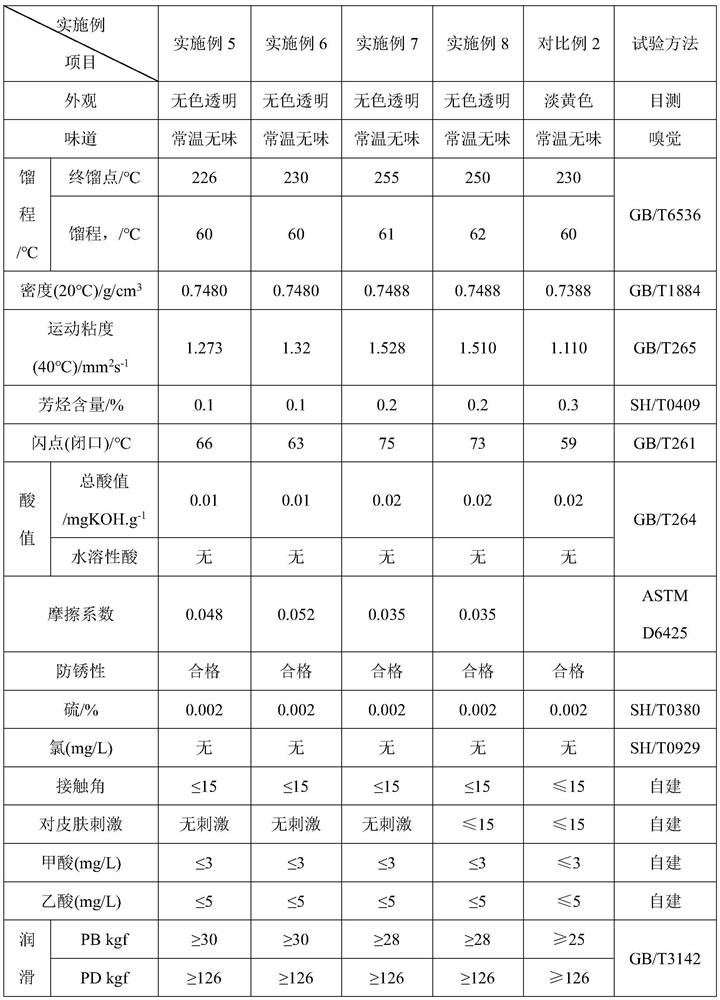

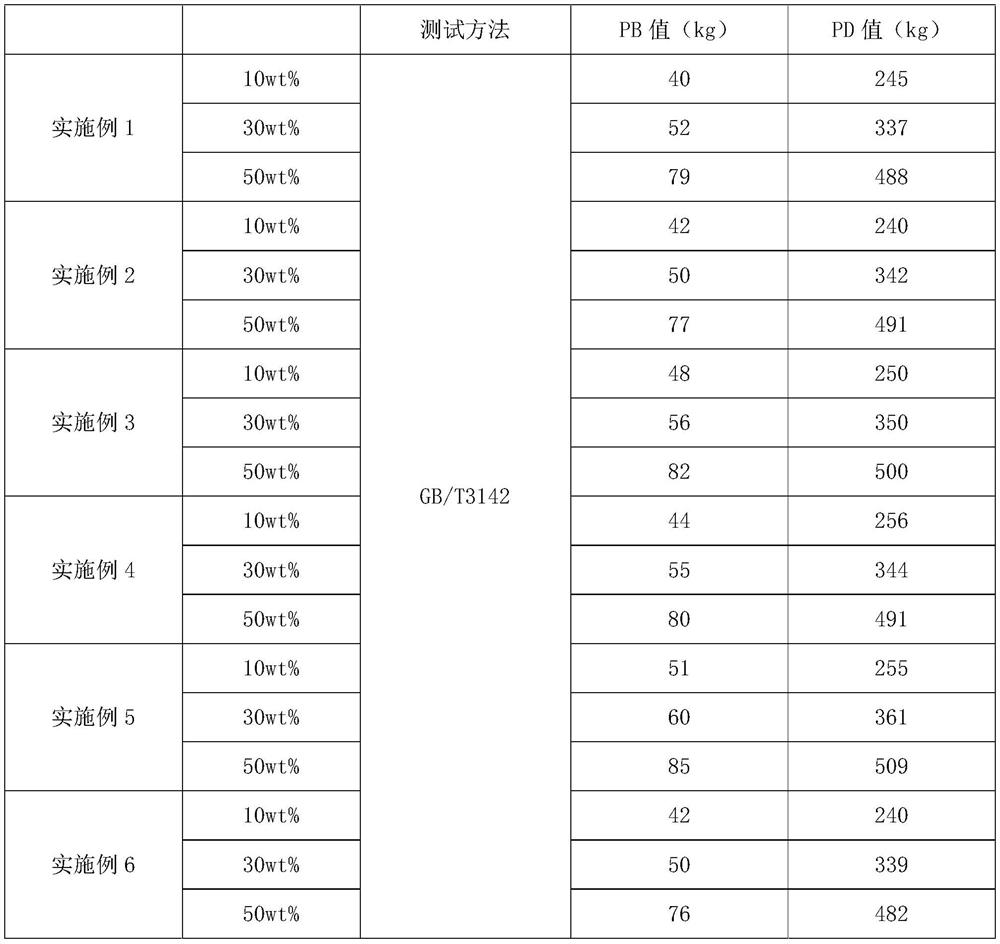

Volatile stamping oil

ActiveCN113278461ANot corrosiveReduce breakage rateLubricant compositionPhysical chemistryLubrication Problem

The invention discloses volatile stamping oil, which belongs to the field of stamping oil, and is characterized in that the stamping oil comprises the following components in percentage by mass: 98-99% of base oil, 0.1-0.5% of an extreme pressure additive, 0.2-0.4% of a hydrophilic additive, 0.3-0.7% of a friction coefficient improver and 0.1-0.5% of a nano additive. The stamping oil has excellent lubricating performance, breaks through the lubricating performance of current common products, forms a compact protective film on the metal surface, solves the lubricating problem, protects and prolongs the service life of equipment, reduces the breakage rate of aluminum foil, improves the flash point, ensures the safe production of production enterprises, and is non-toxic and odorless. workers do not feel allergic during use, and the physical and psychological health of the workers is facilitated.

Owner:无锡中石油润滑脂有限责任公司

Water-based automobile plate stamping oil as well as preparation method and use method thereof

PendingCN113201391AReduce dosageShorten cleaning timeLubricant compositionElectrophoresesActive agent

The invention relates to water-based automobile plate stamping oil as well as a preparation method and a use method thereof. The water-based automobile plate stamping oil comprises the following components in parts by weight: 20-50 parts of base oil, 5-10 parts of oleic acid, 5-20 parts of synthetic ester, 5-10 parts of a surfactant, 5-10 parts of alkali, 5-10 parts of an antirust agent, 1-3 parts of a bactericide and a proper amount of water. The water-based automobile plate stamping oil can be used in a stock solution or mixed with water, the use amount is greatly reduced, the use cost is reduced, the stamping oil is very easy to clean subsequently, the lubrication problem is solved, meanwhile, the stamping and cleaning cost is reduced, and the electrophoresis yield is increased.

Owner:AMER TECH CO LTD

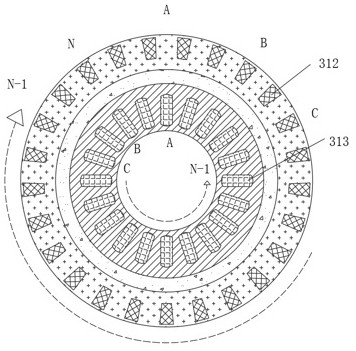

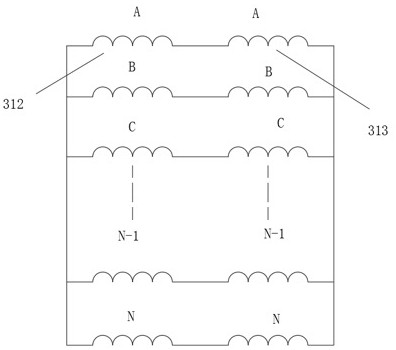

Electromagnetic planetary gear

The invention relates to the technical field of mechanical and electromagnetic transmission, in particular to an electromagnetic planetary gear which comprises a fixing frame, and a gear ring component, a planetary component and a sun gear component are arranged in the fixing frame. Non-contact gear transmission is achieved through the electromagnetic induction principle, the electromagnetic planetary gear concept is put forward for the first time, a theoretical basis is laid for subsequent research, original theoretical value is achieved, and the engineering significance is that non-contact transmission fundamentally solves the problems of tooth surface abrasion, vibration, noise and lubrication during operation of a mechanical gearbox; the maintenance-free electromagnetic planetary gear has the natural overload protection capability, when the load exceeds the limit torque, only out-of-step oscillation can be caused, the gear cannot be damaged, the locking and tooth breaking phenomena of a mechanical gear are eliminated, and the electromagnetic planetary gear is dual with the mechanical planetary gear in topology and principle and consistent with the mechanical planetary gear in external characteristics. Seamless butt joint with a mechanical planetary gear can be achieved, and the gear box has the potential of replacing a mechanical gear box in part of application occasions.

Owner:明扬动力设备(昆山)有限公司

Lubricating device for hydraulic cylinder and hydraulic cylinder with lubricating device

PendingCN114109965ASolve lubrication problemsSmall running resistanceFluid-pressure actuatorsEngine lubricationHydraulic cylinderThermodynamics

The lubricating device for the water pressure cylinder comprises a cylinder body, a separation ring is arranged in the middle of the cylinder body to divide the cylinder body into an upper oil storage cavity and a lower oil storage cavity, and the upper oil storage cavity is filled with an oil coating part capable of adsorbing lubricating oil; the oiling part is provided with a center hole for a piston rod of the water pressure cylinder to penetrate through and makes contact with the periphery of the piston rod through the inner wall of the center hole to be used for oiling and lubricating the piston rod, and the lower oil storage cavity is used for temporarily storing lubricating oil so as to oil and lubricate the piston of the water pressure cylinder. The lubricating device is used in the water pressure cylinder in a matched mode and can effectively lubricate the piston and the piston rod of the water pressure cylinder, the lubricating problem of the water pressure cylinder due to tap water media is solved, the running resistance of the piston and the piston rod can be effectively reduced, and abrasion of a sealing piece is relieved. The invention further provides the water pressure cylinder which is provided with the lubricating device, the running resistance of the piston and the piston rod can be effectively reduced, and abrasion of a sealing piece is relieved.

Owner:GUANGXI COLLEGE OF WATER RESOURCES & ELECTRIC POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com