Patents

Literature

46results about How to "Sufficient oil supply" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

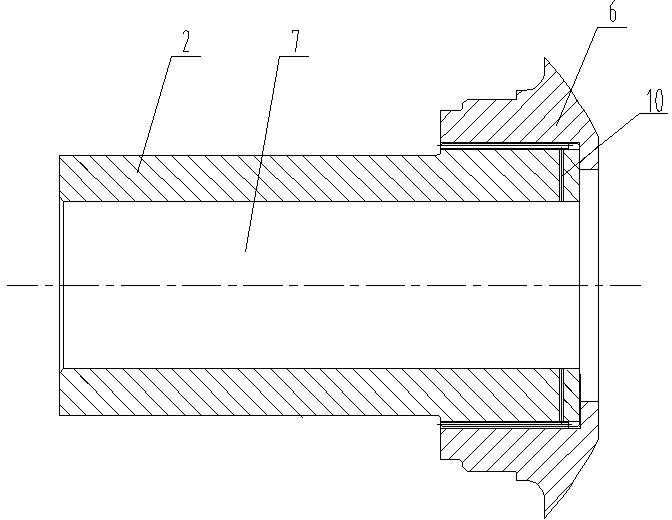

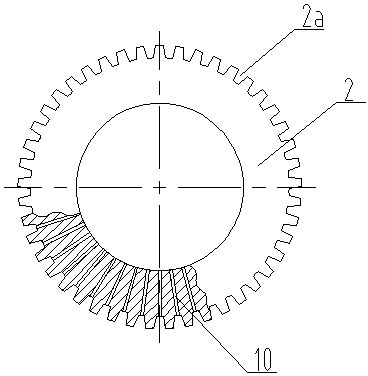

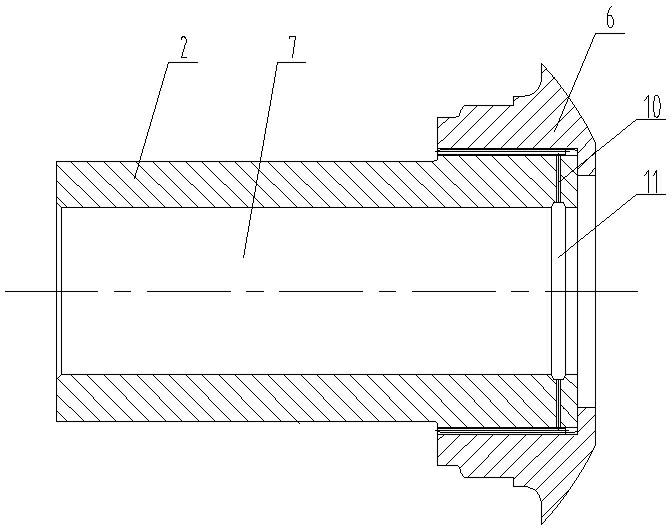

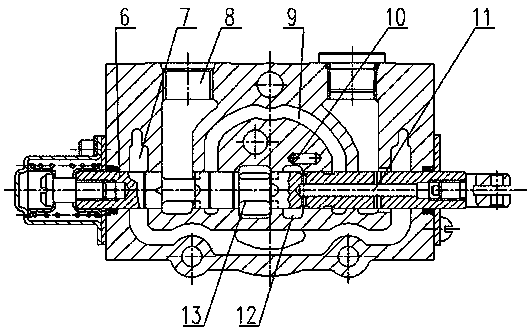

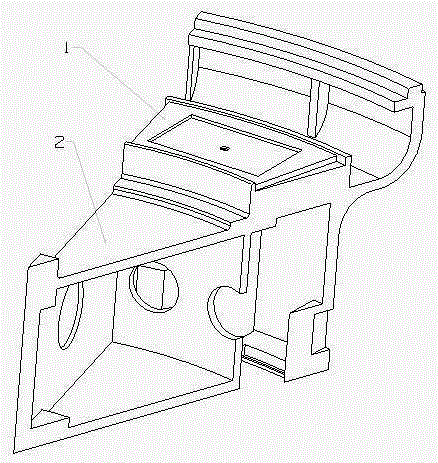

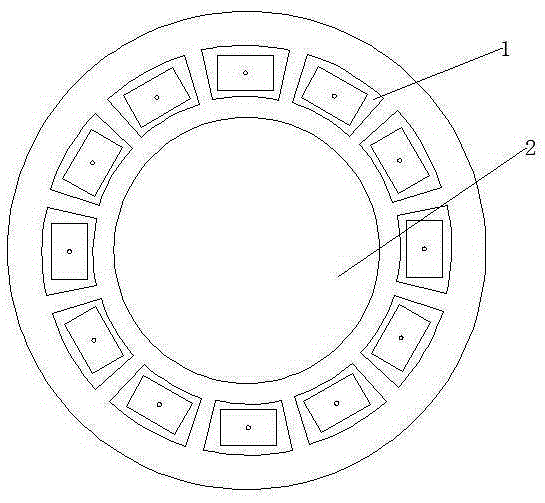

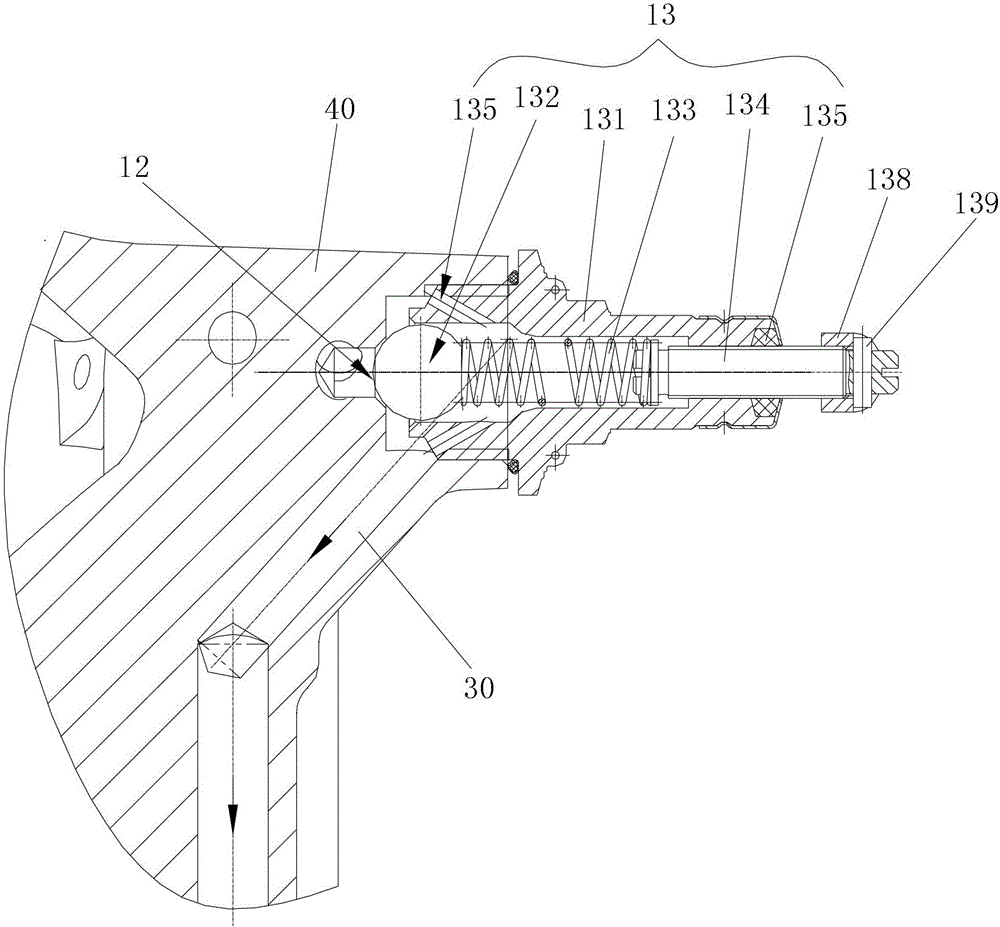

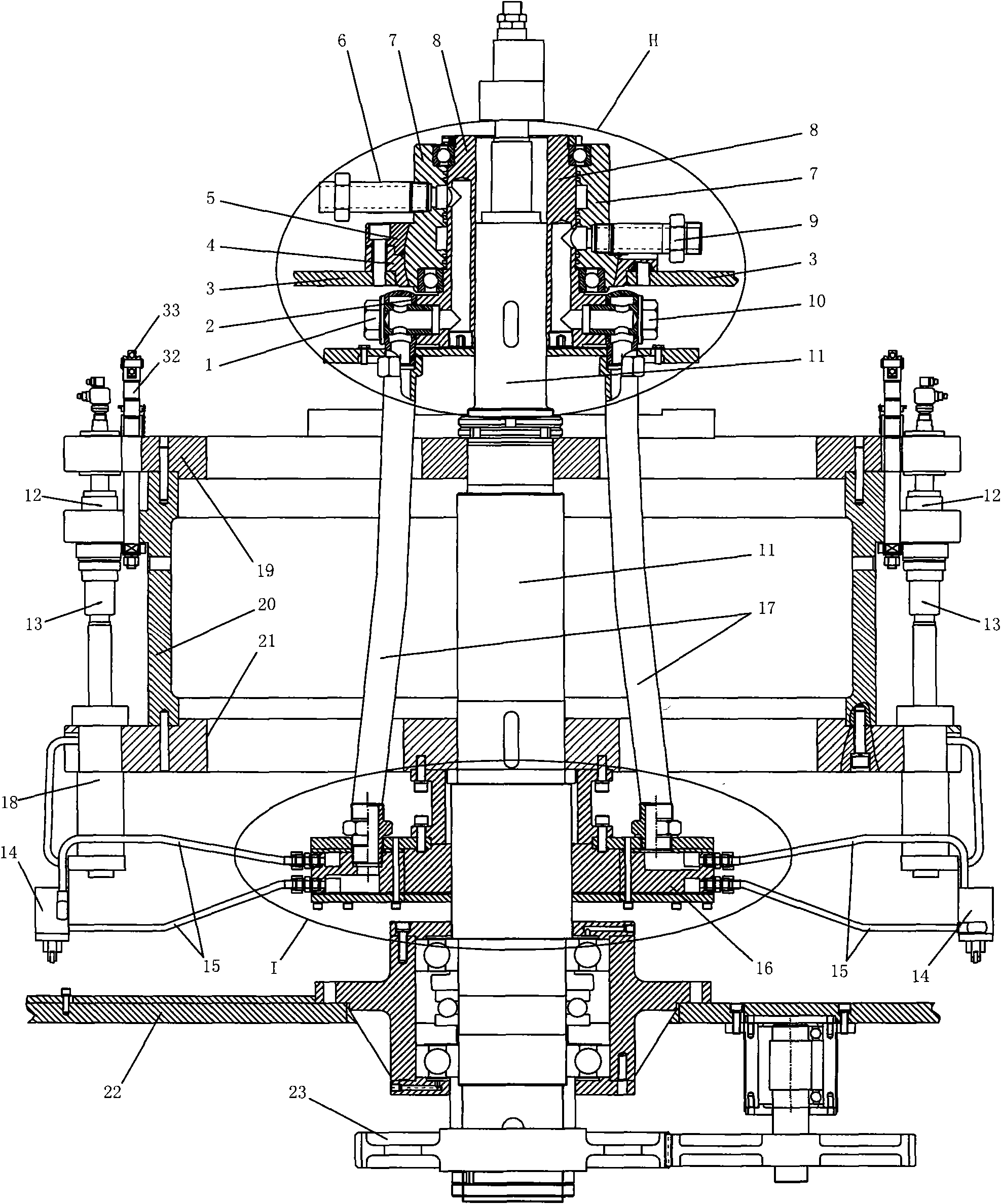

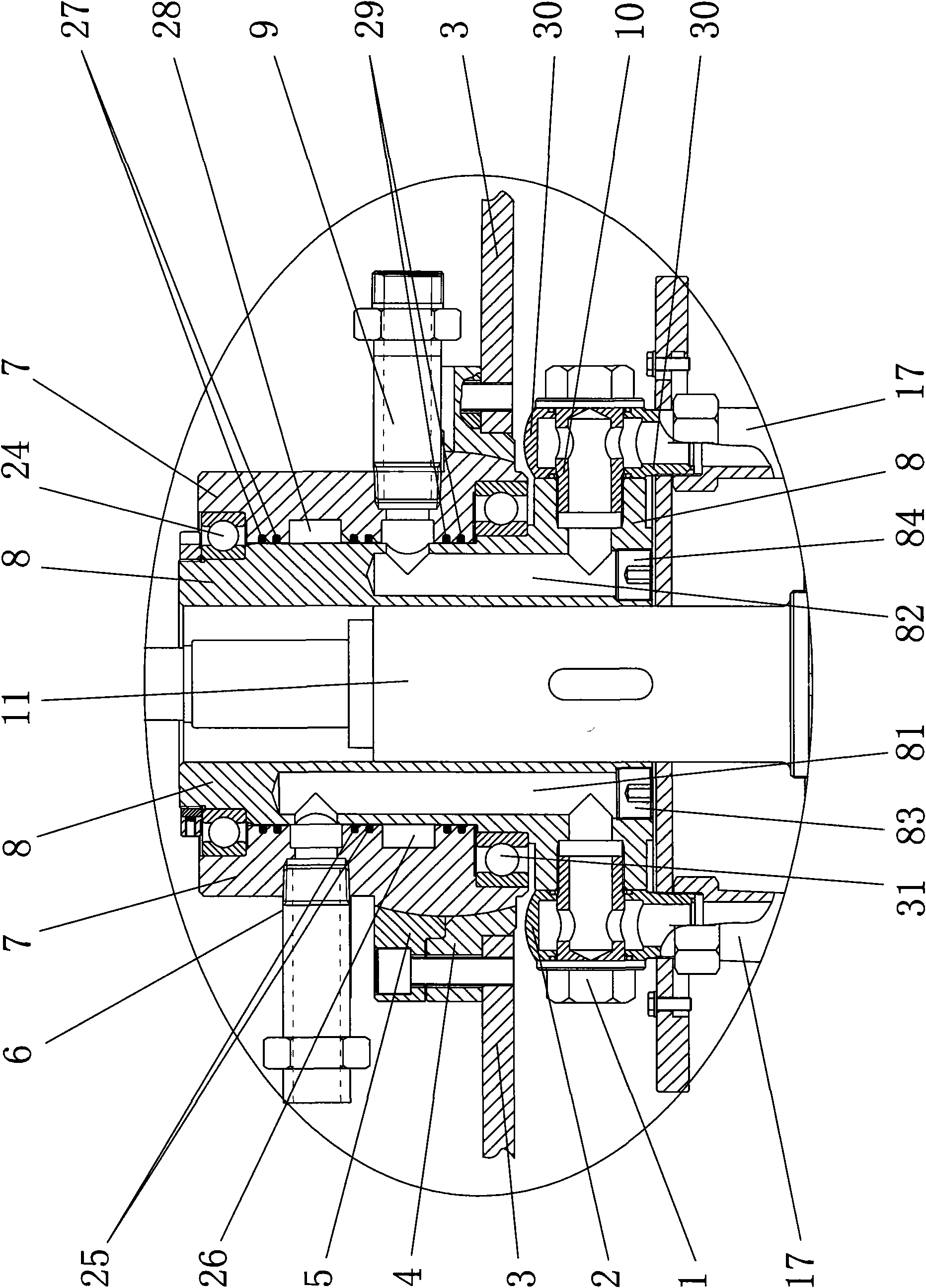

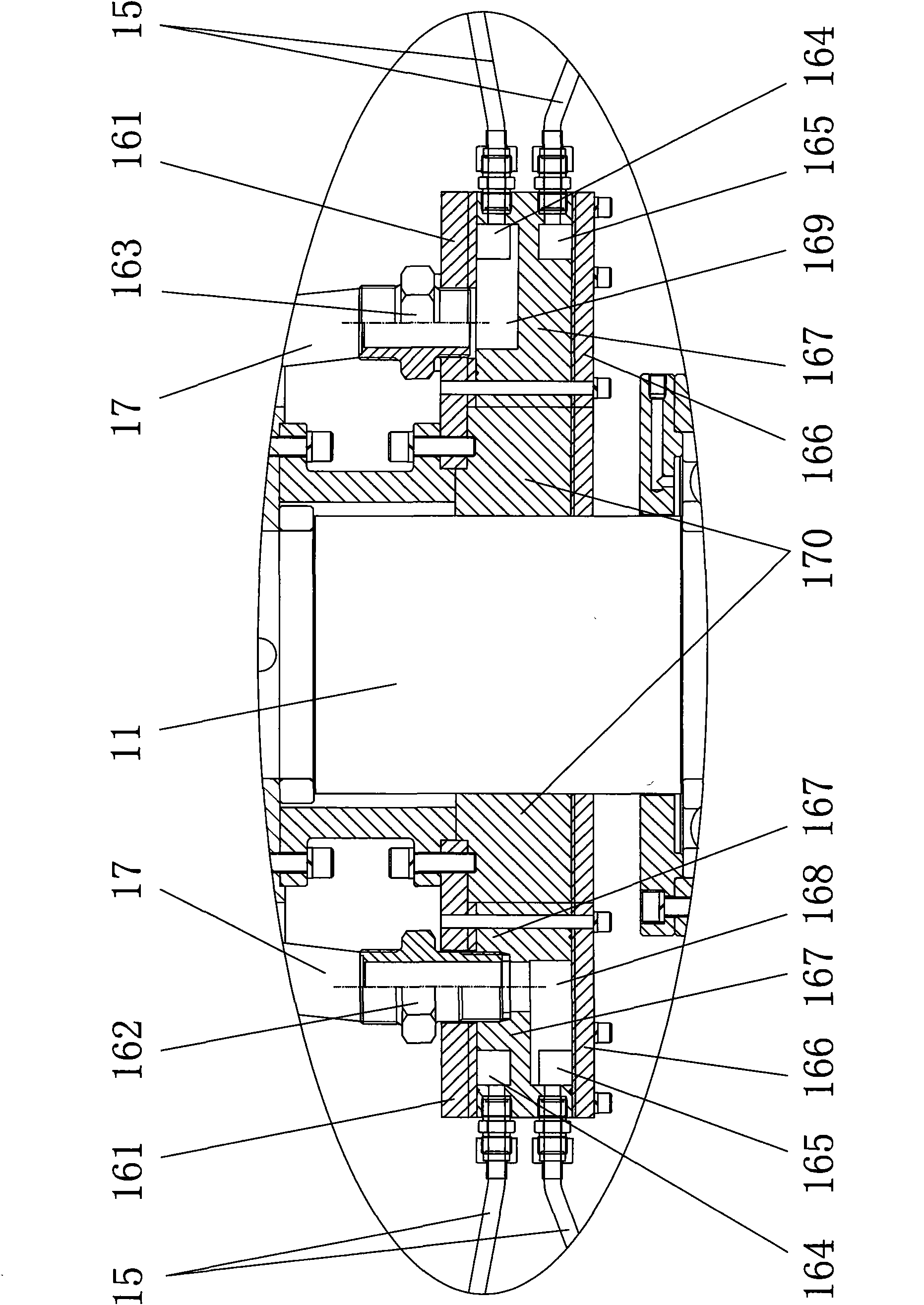

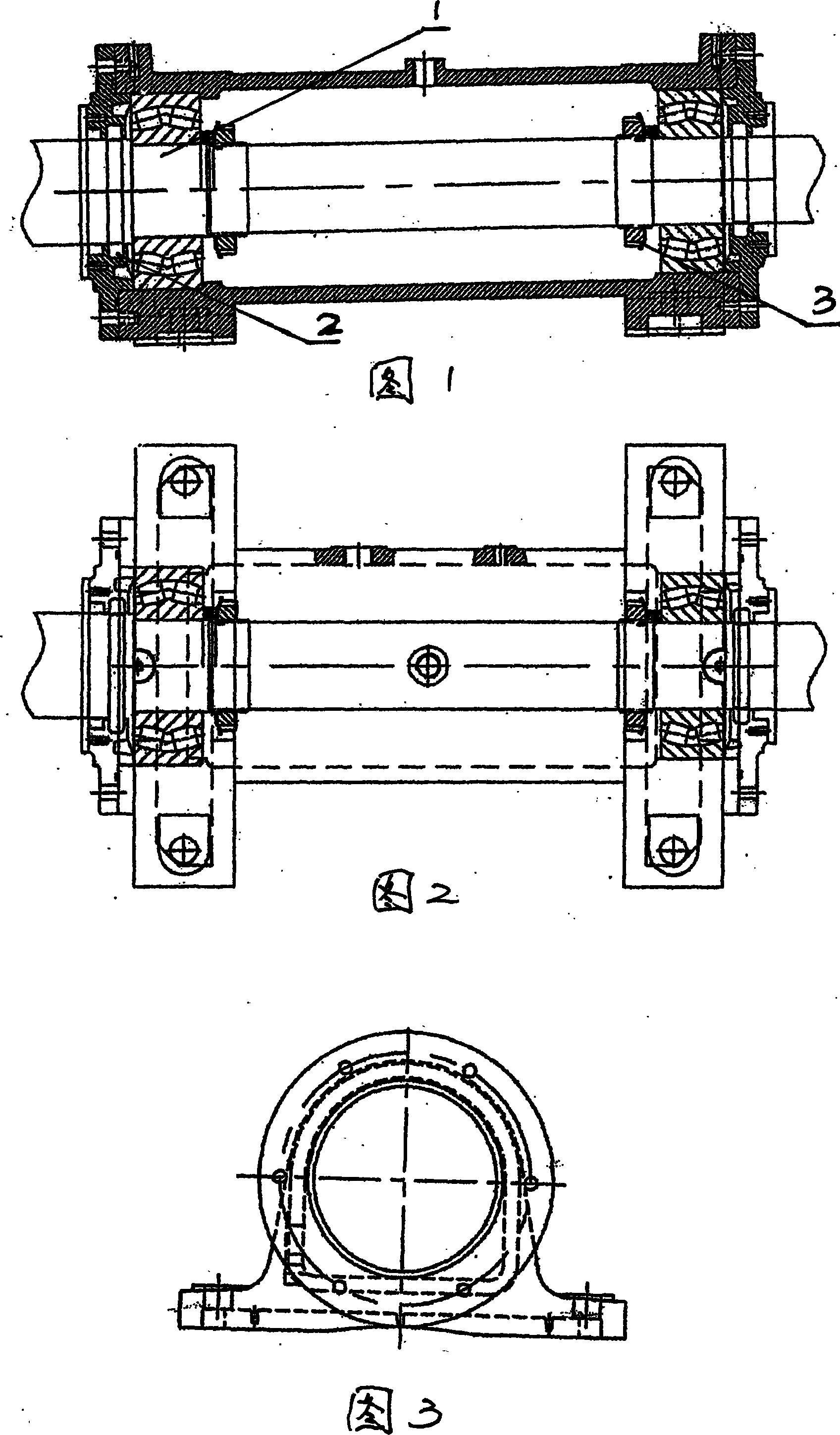

Spline lubricating structure

InactiveCN102312928ASufficient oil supplyImprove the lubrication effectClutchesCouplings for rigid shaftsEngineering

Owner:CHONGQING GEARBOX

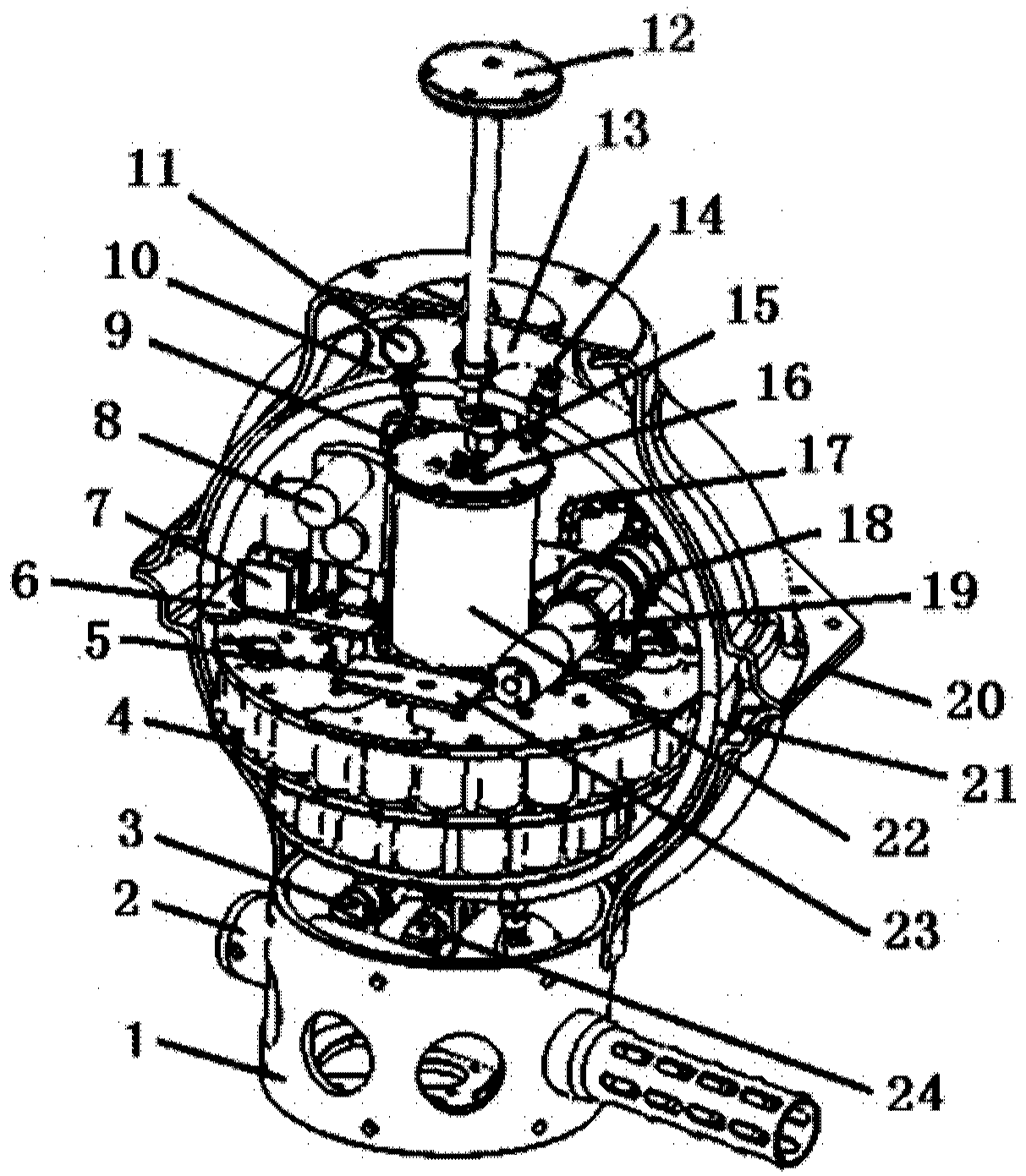

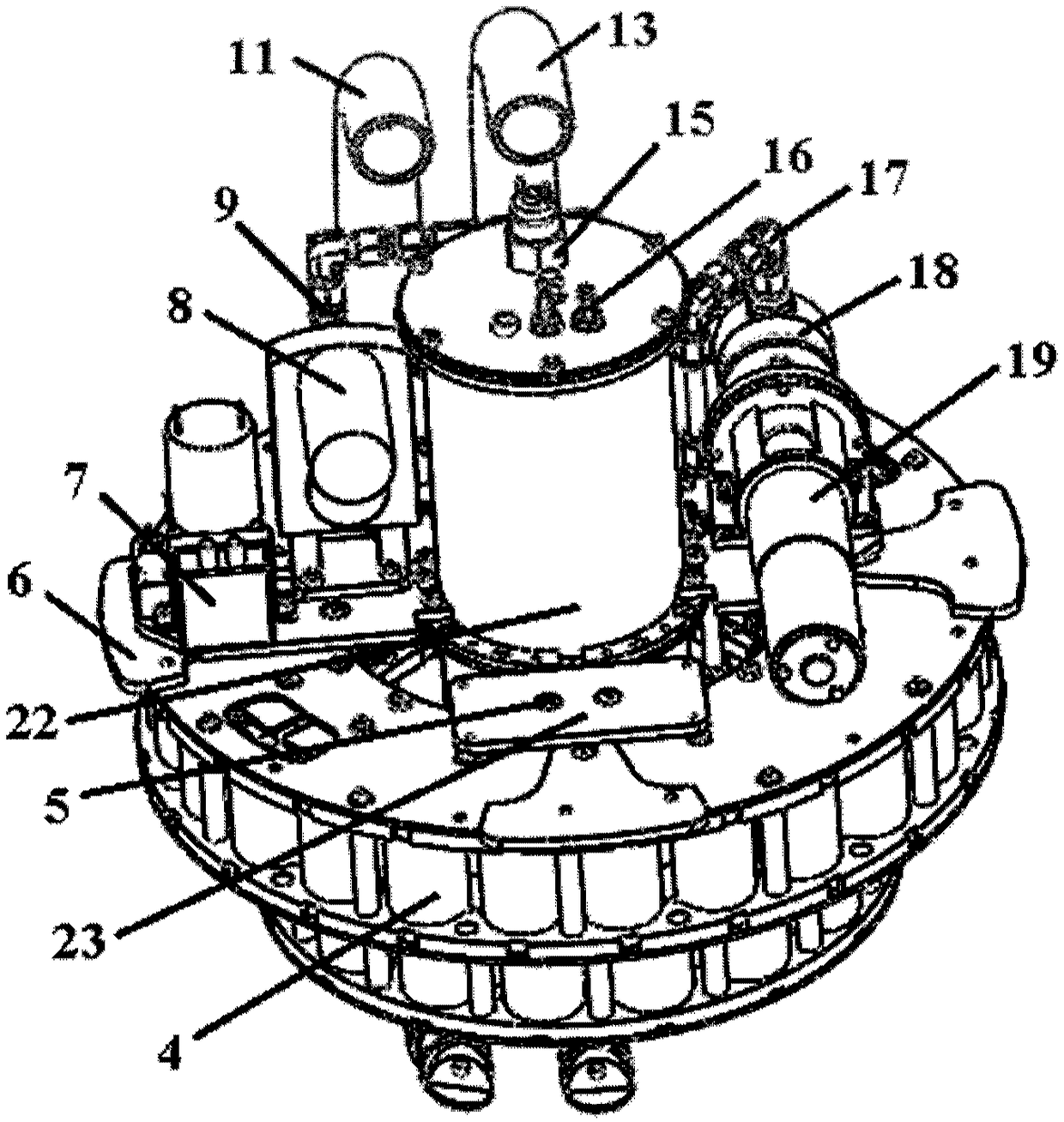

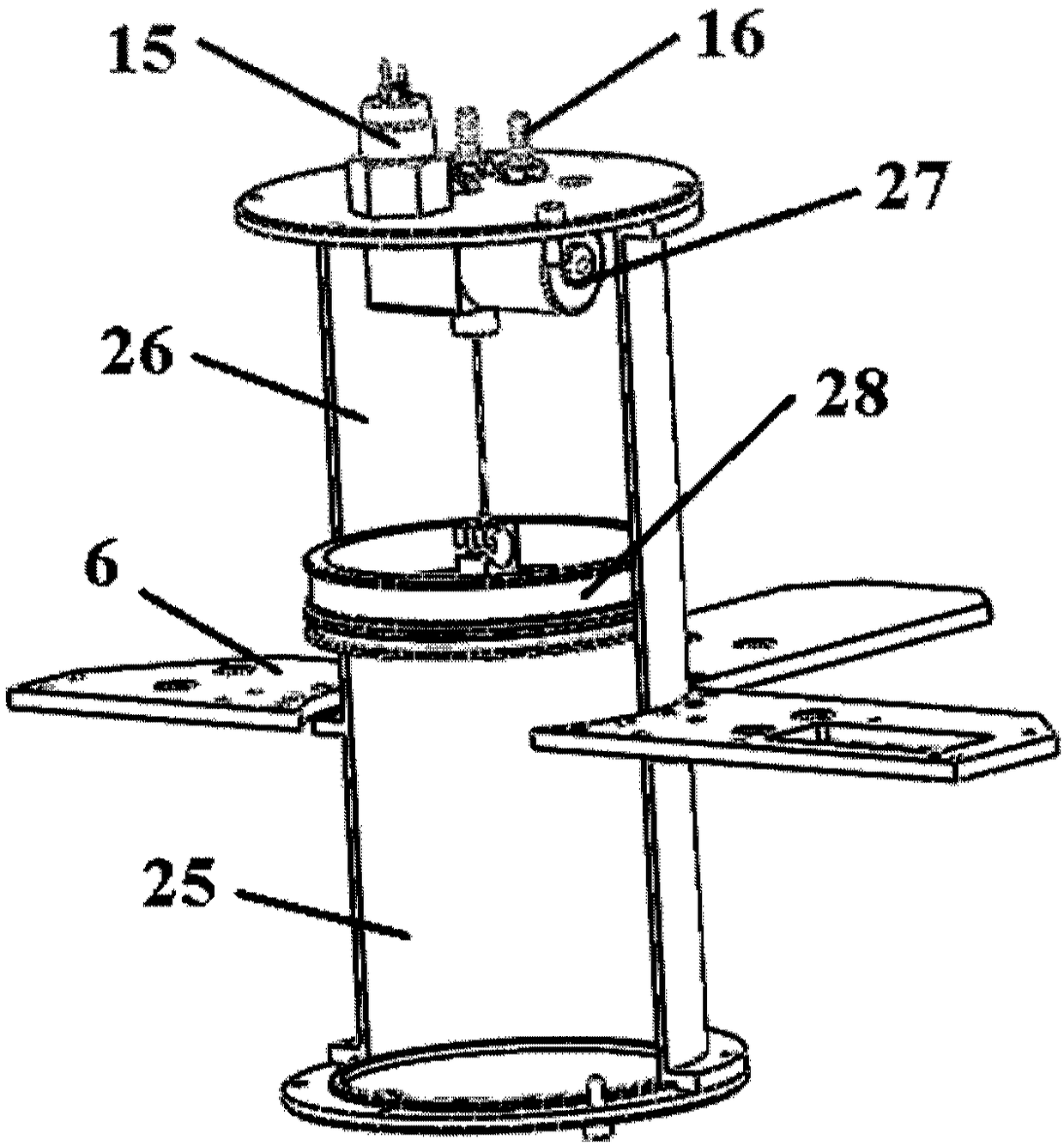

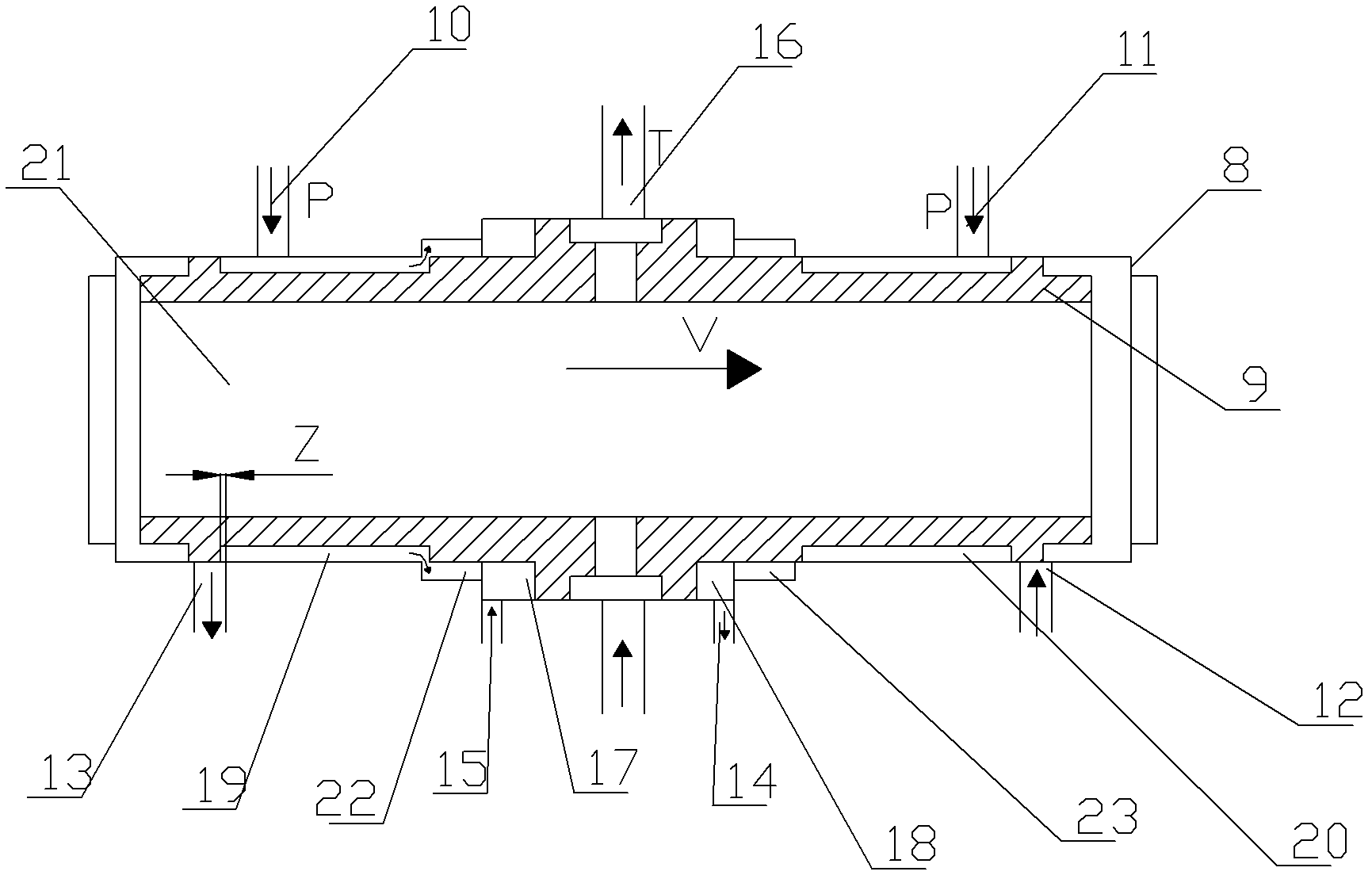

Deep-sea buoyancy adjusting system and method

PendingCN108327855ASolve the self-locking problemFor precise adjustmentWaterborne vesselsBuoysEffective densityBall valve

The invention provides a deep-sea buoyancy adjusting system and method, and aims to realize buoyancy adjustment of a deep-sea autonomous intelligent buoy along with buoyancy change of a deep sea withthe depth of 0-6000 meters. The high-pressure buoyancy adjusting system is mainly provided with a high-pressure plunger pump, the high-pressure plunger pump is driven by a direct-current motor, so that hydraulic oil in an inner oil bag is pumped into an outer oil bag, total displacement volume of the system is increased, an oil discharging stage is completed, a solenoid gas valve is started, an outer gas bag, an inner gas cavity and a glass floating ball compressive cabin are communicated, a ball valve is started, the outer oil bag is communicated with the inner oil bag, the hydraulic oil in the outer oil bag and gas in the outer air bag are pressured into the glass floating ball compressive cabin by the aid of inside and outside differential pressure of the vacuum environment in the glassfloating ball compressive cabin and outer sea water pressure, and an oil returning stage is completed. The deep-sea buoyancy adjusting system serves as a main driving unit of section movement buoyancy change of the autonomous intelligent section buoy and has high-pressure buoyancy adjusting ability, the volume of the system is changed, effective density is changed, and the buoyancy of the buoy isadjusted.

Owner:TIANJIN UNIV

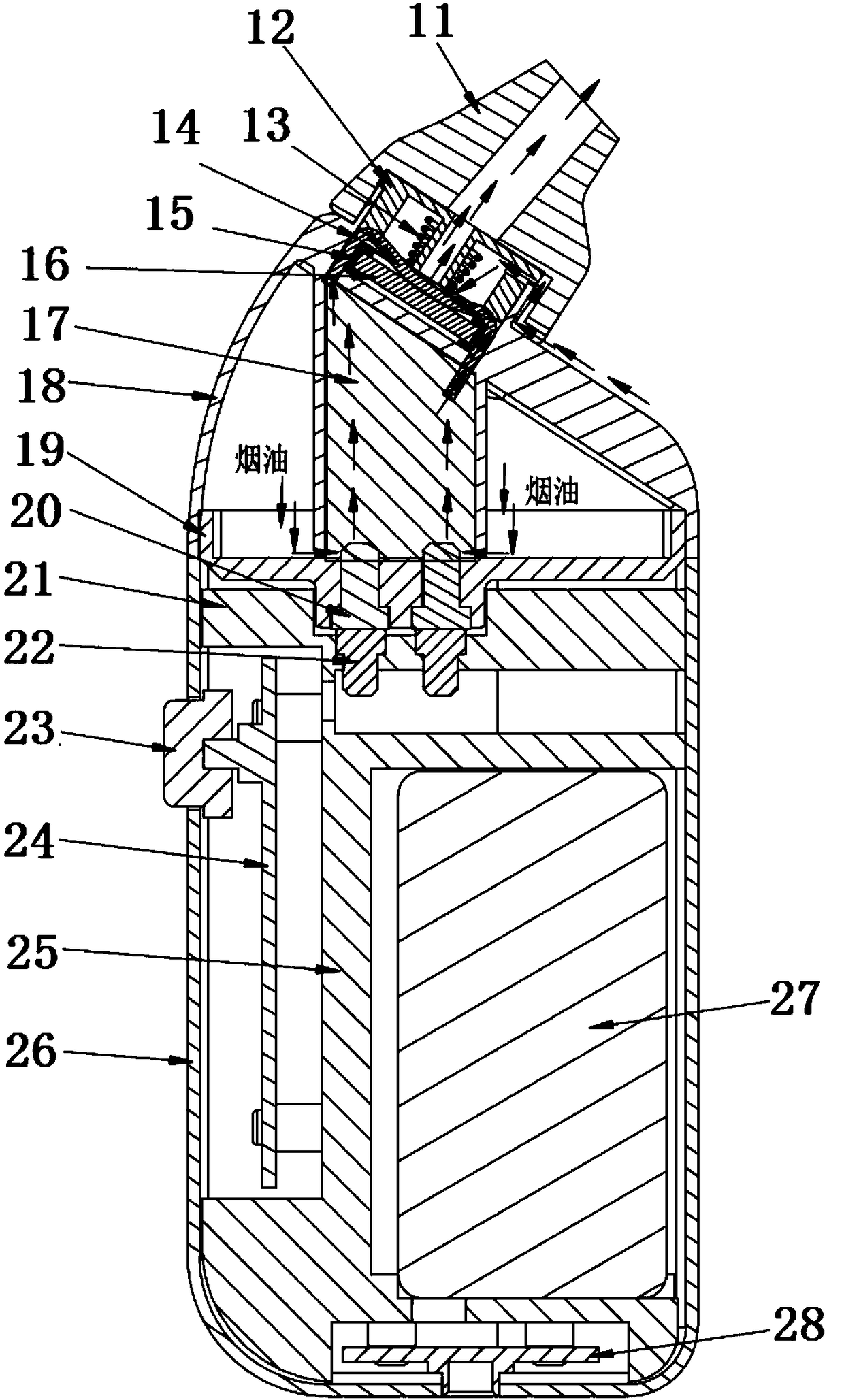

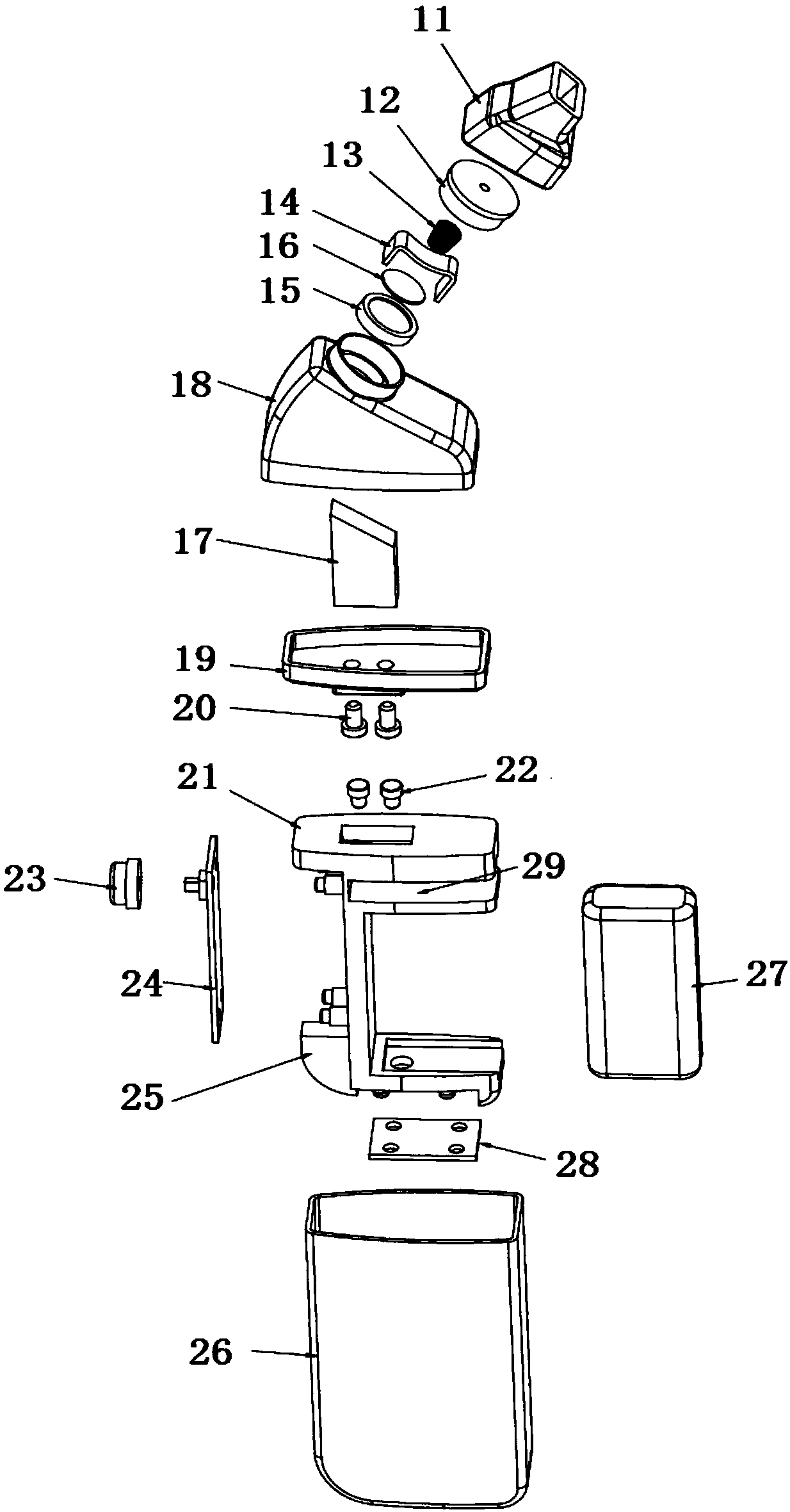

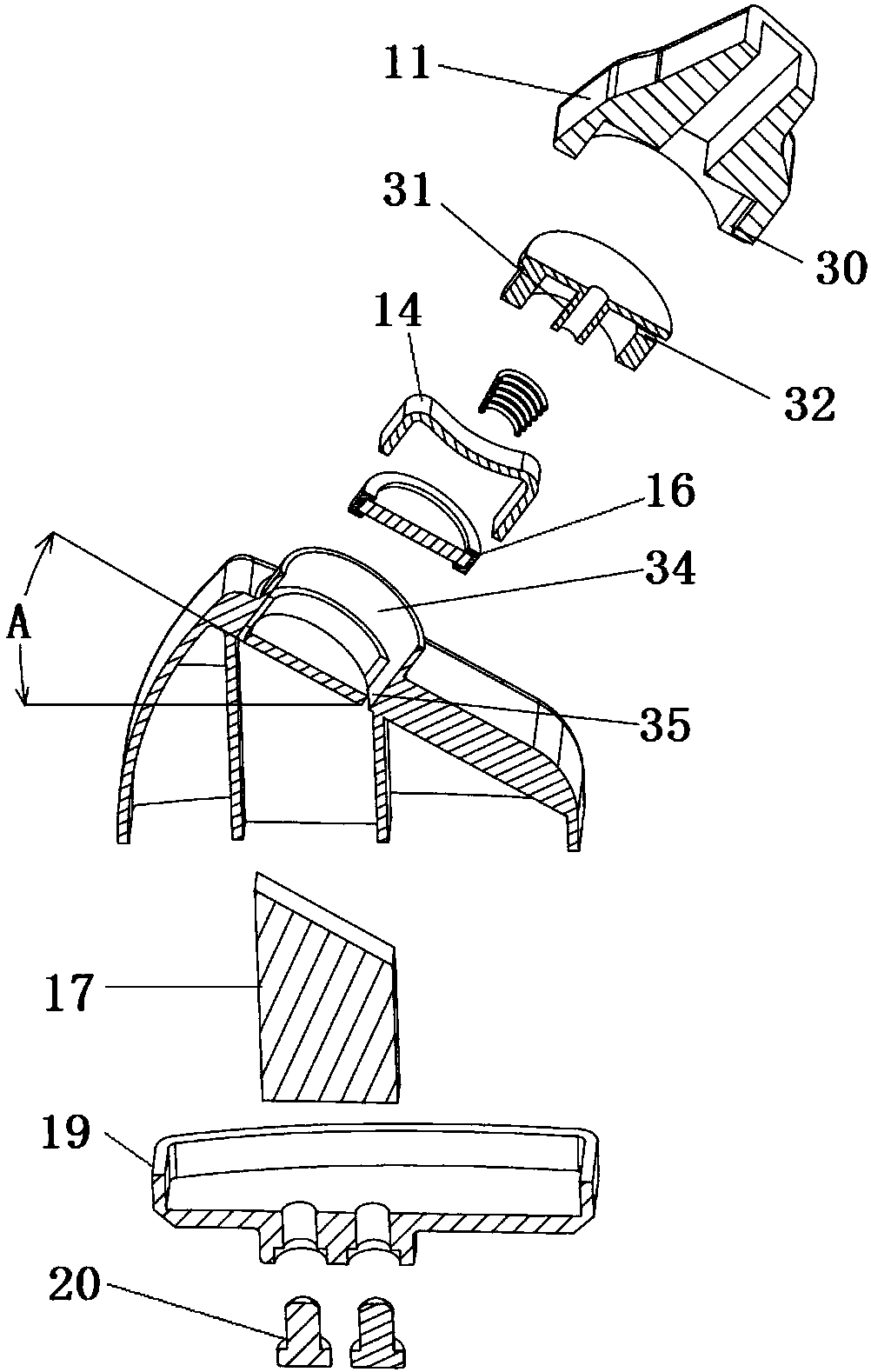

Obliquely-arranged ultrasonic atomization sheet structure, atomizer and electronic cigarette

PendingCN108078009ANo oil bubble phenomenonRealize oil guiding functionMedical devicesTobacco devicesEngineeringElectronic cigarette

The invention discloses an obliquely-arranged ultrasonic atomization sheet structure, an atomizer and an electronic cigarette. The obliquely-arranged ultrasonic atomization sheet structure comprises atomization cotton and an ultrasonic atomization sheet; the ultrasonic atomization sheet is obliquely arranged relative to the horizontal plane, and the two ends of the atomization cotton are connectedwith e-liquid in an e-liquid cavity through e-liquid guide cotton or the two ends of the atomization cotton are directly arranged in the e-liquid cavity; the lower surface of the atomization cotton is in contact with an atomization surface of the ultrasonic atomization sheet. According to the ultrasonic atomization sheet structure, the situation can be avoided that smoke cannot be atomized due tothe e-liquid foam phenomenon of the atomization sheet.

Owner:CHINA TOBACCO HUNAN INDAL CORP

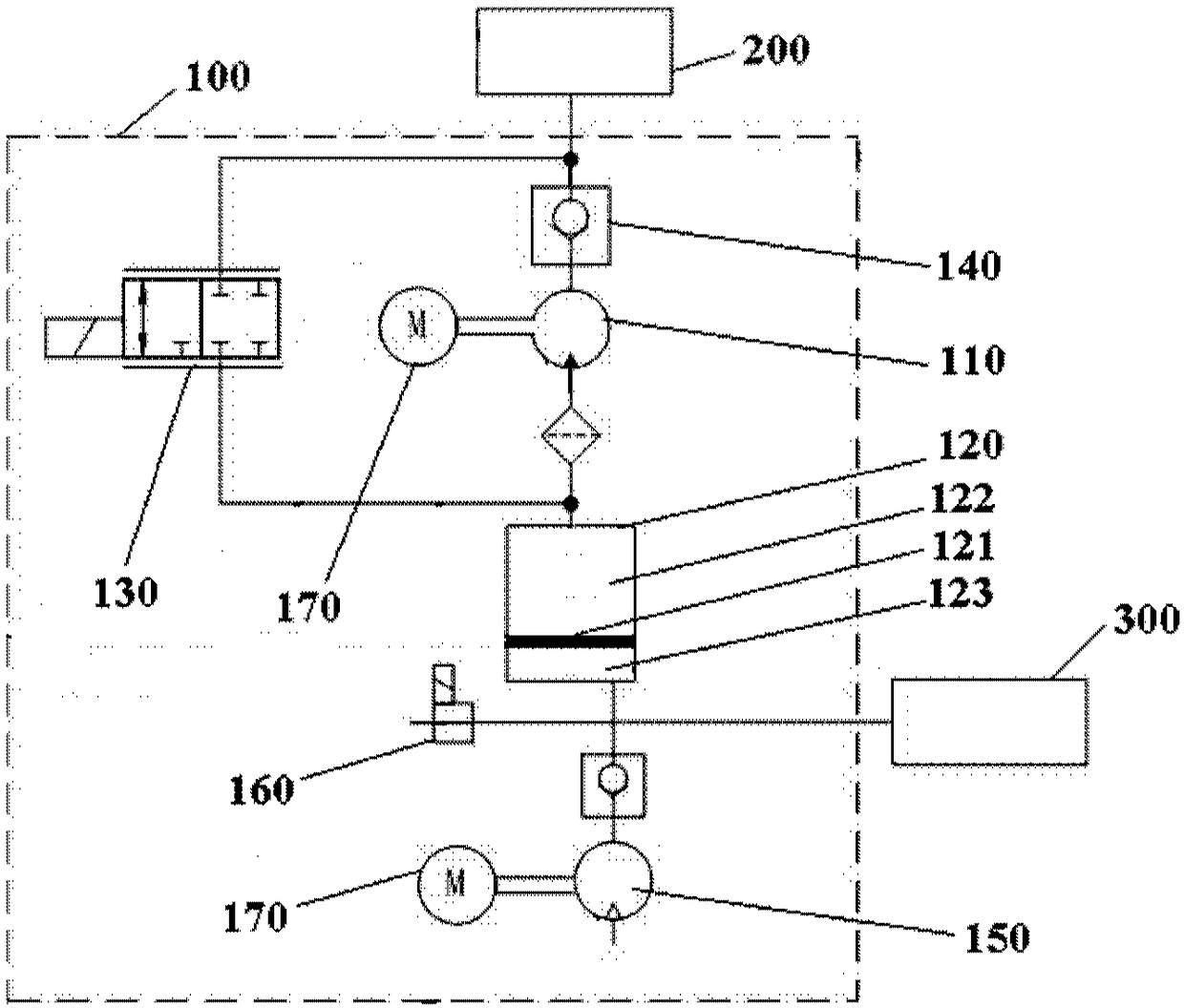

Deep-sea automatic continuous sectional intelligent buoyage system

PendingCN108248762ASufficient oil supplyAccurate measurementWaterborne vesselsBuoysBuoyHigh pressure

The invention provides a deep-sea automatic continuous sectional intelligent buoyage system. The system includes a satellite communication system, a buoy protection cover, a glass floating ball compressive cabin, a high-pressure plunger pump, an internal oil bag, a one-way valve, a ball valve, an air pump, an electromagnetic air valve, a battery pack, a circuit control system, a temperature-salinity-depth sensor and a buoy bottom base; a piston in the internal oil bag divides the internal oil bag into an internal oil cavity and an internal air cavity; the high-pressure plunger pump pumps hydraulic oil in the internal oil bag into an external oil bag to make the total drainage volume of a buoy increased and the buoy floats up; when the electromagnetic air valve is switched on, an external air bag, the internal air cavity and the glass floating ball compressive cabin are communicated, and when the ball valve is switched on, the external oil bag is communicated with the internal oil bag;an internal-external pressure difference between vacuum in the glass floating ball compressive cabin and an external sea pressure presses the hydraulic oil in the external oil bag and air in the external air bag back to the glass floating ball compressive cabin, and the buoy dives down. According to the system, by changing the self-drainage volume of the buoy, the average density is changed, it isachieved that the buoy floats up and dives down at deep-sea 0-6000 m, the cost is low, the work is reliable, and the power dissipation is very low.

Owner:TIANJIN UNIV

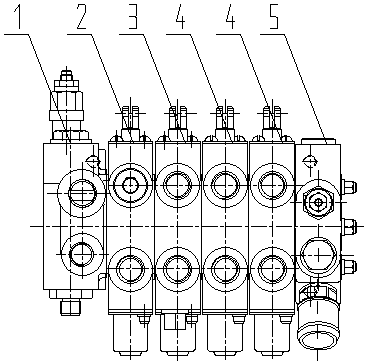

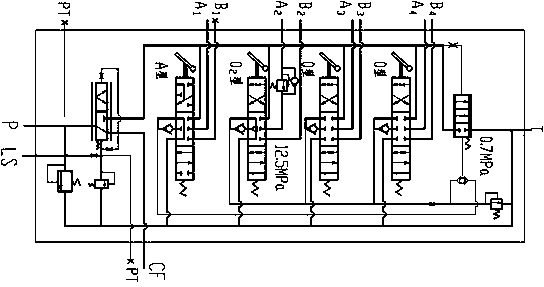

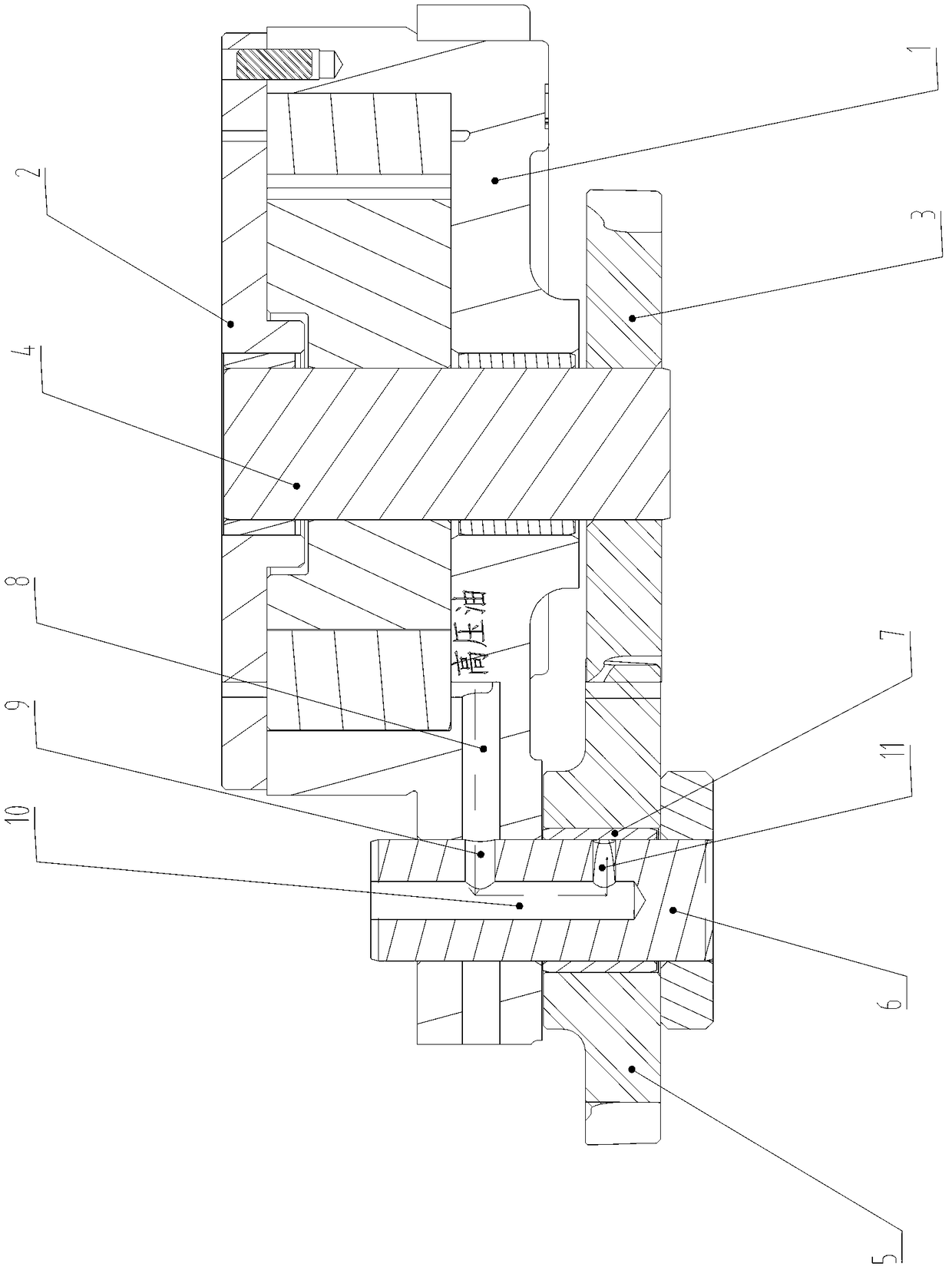

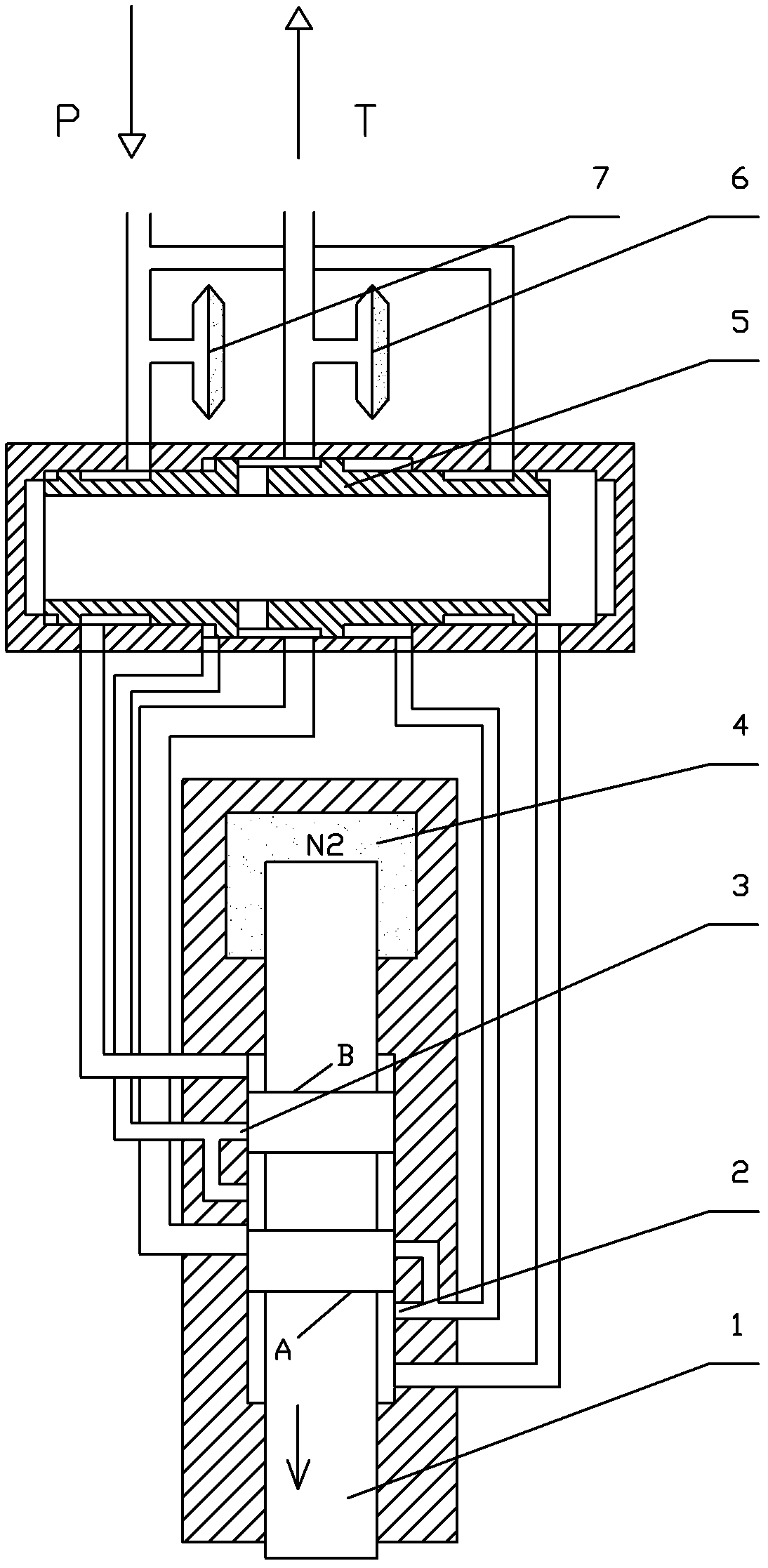

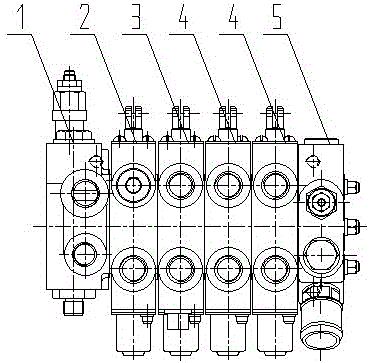

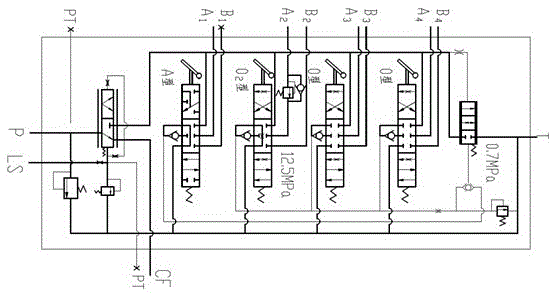

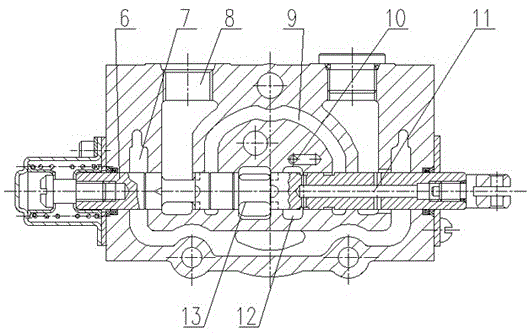

Load sensitive forklift multi-way valve

ActiveCN104141650AIncrease pressureReduce loadServomotor componentsLifting devicesInlet valveEngineering

The invention provides a load sensitive forklift multi-way valve, and belongs to the technical field of engineering machinery hydraulic components. The load sensitive forklift multi-way valve comprises an oil inlet valve piece, a lifting valve piece, an inclined valve piece, a fitting valve piece and an oil return valve piece. All the valve pieces are provided with flow control valve rods and oil inlet one-way valves respectively, the inclined valve piece is provided with a load maintaining valve, and the oil return valve piece is provided with an unloading valve core, a reset spring, a shuttle valve and a secondary overflow valve. The load sensitive forklift multi-way valve has good flow control performance, so that the speed of an executing mechanism is unrelated to the load pressure and is only associated with the stroke of the valve rods, and the pressure of a system is unrelated to flow change of oil feeding. Meanwhile, the inclined valve piece is provided with the load maintaining valve, so that the forwards leaning pressure keeps stable all the time, load on an oil cylinder is lowered, when the system flow is larger than the required flow, oil return is conducted on the redundant flow through the unloading valve core, energy consumption can be effectively reduced, and the load sensitive forklift multi-way valve is high in efficiency and less in power loss, so that fuel is saved and a hydraulic system is lower in heating quantity.

Owner:ZHEJIANG HAIHONG HYDRAULIC TECH

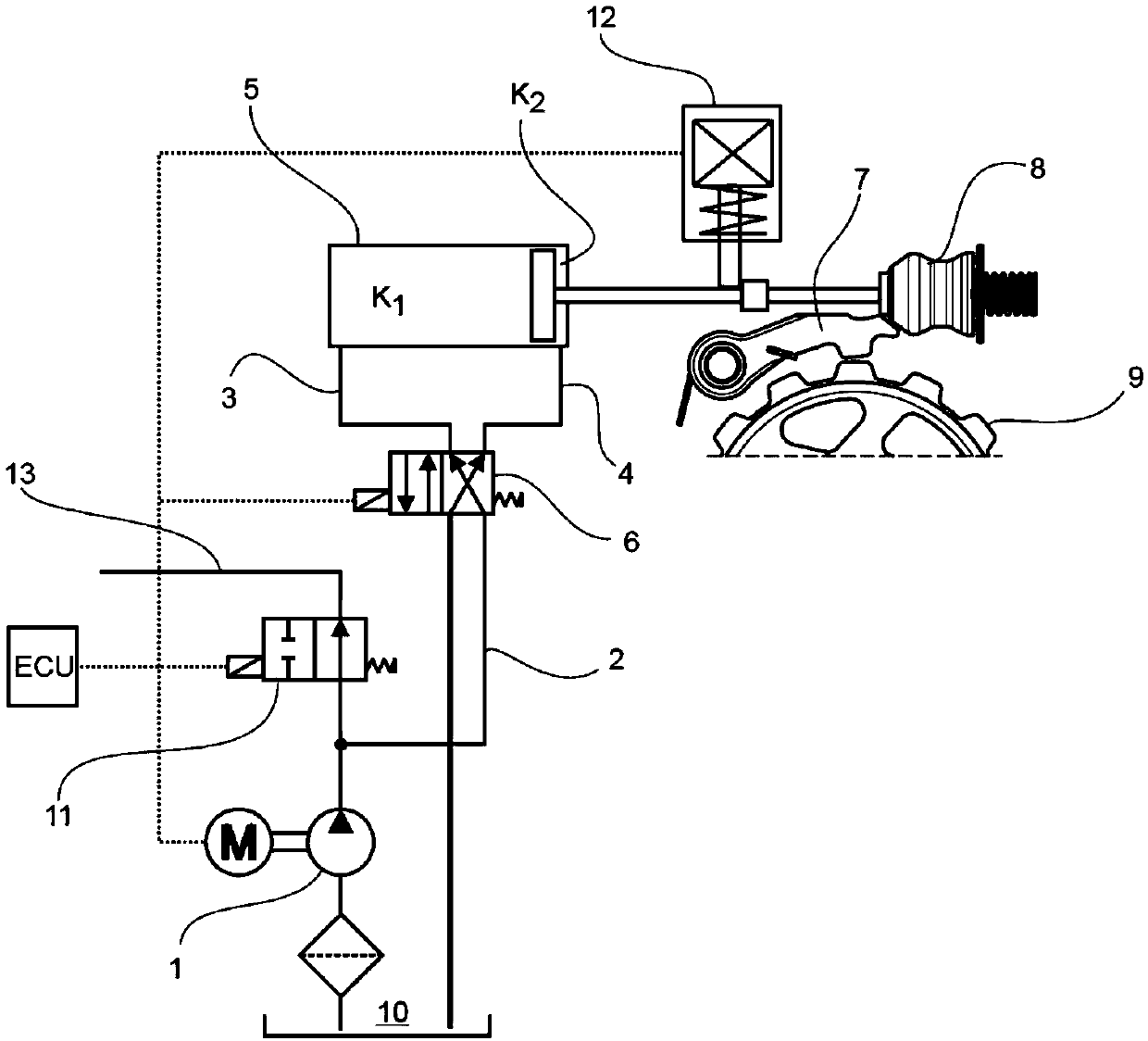

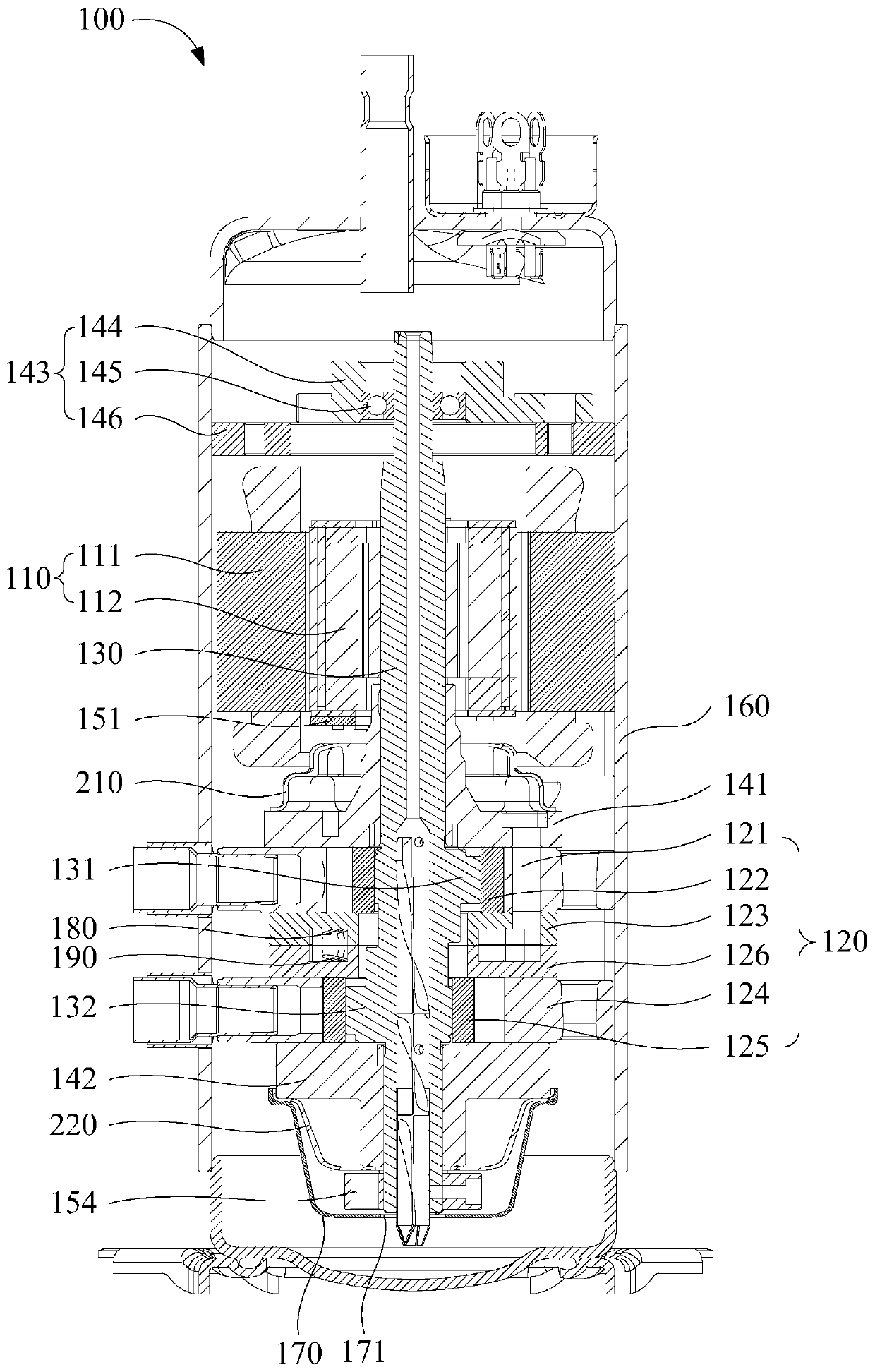

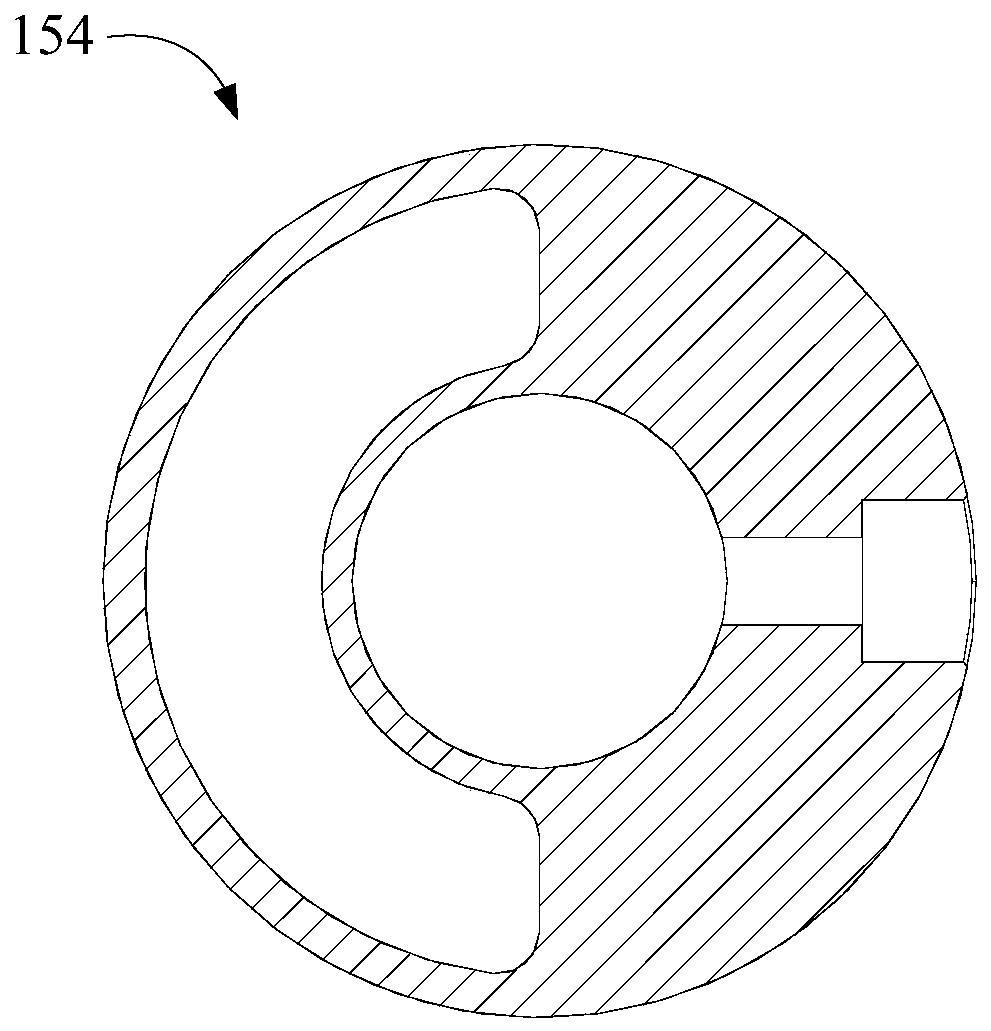

System for hydraulically actuating parking lock

ActiveCN107781412ASufficient oil supplyBraking element arrangementsServomotor componentsMobile vehicleHydraulic circuit

Owner:GKN AUTOMOTIVE LTD BIRMINGHAM

Hydrostatic pressure supporting device with rectangular cavity

InactiveCN105351362AImprove deformationReduce temperature riseLiquid cushion bearingsLarge fixed membersNumerical controlThrust bearing

The invention discloses a hydrostatic pressure supporting device with a rectangular cavity. When large vertical numerical-control machining equipment is under a high-speed, heavy-load and micro-gap extreme working condition, the shear force of an oil film is increased, the oil film deforms seriously, boundary lubrication or dry friction is formed locally, hydrostatic pressure losses are severe, and thus the situations that the supporting rigidity is reduced, the bearing capacity is insufficient, and the machining precision is low are caused. In order to solve the problems, a hydrostatic pressure supporting oil cavity is designed to be rectangular, the oil pressures of all portions of the bottom surface of the oil cavity are made equal by increasing the area of the oil cavity, so that the bearing capacity is improved, and accordingly deformation of the oil film in the operation process is effectively reduced, the supporting rigidity is improved, and a hydrostatic pressure thrust bearing can operate efficiently.

Owner:HARBIN UNIV OF SCI & TECH

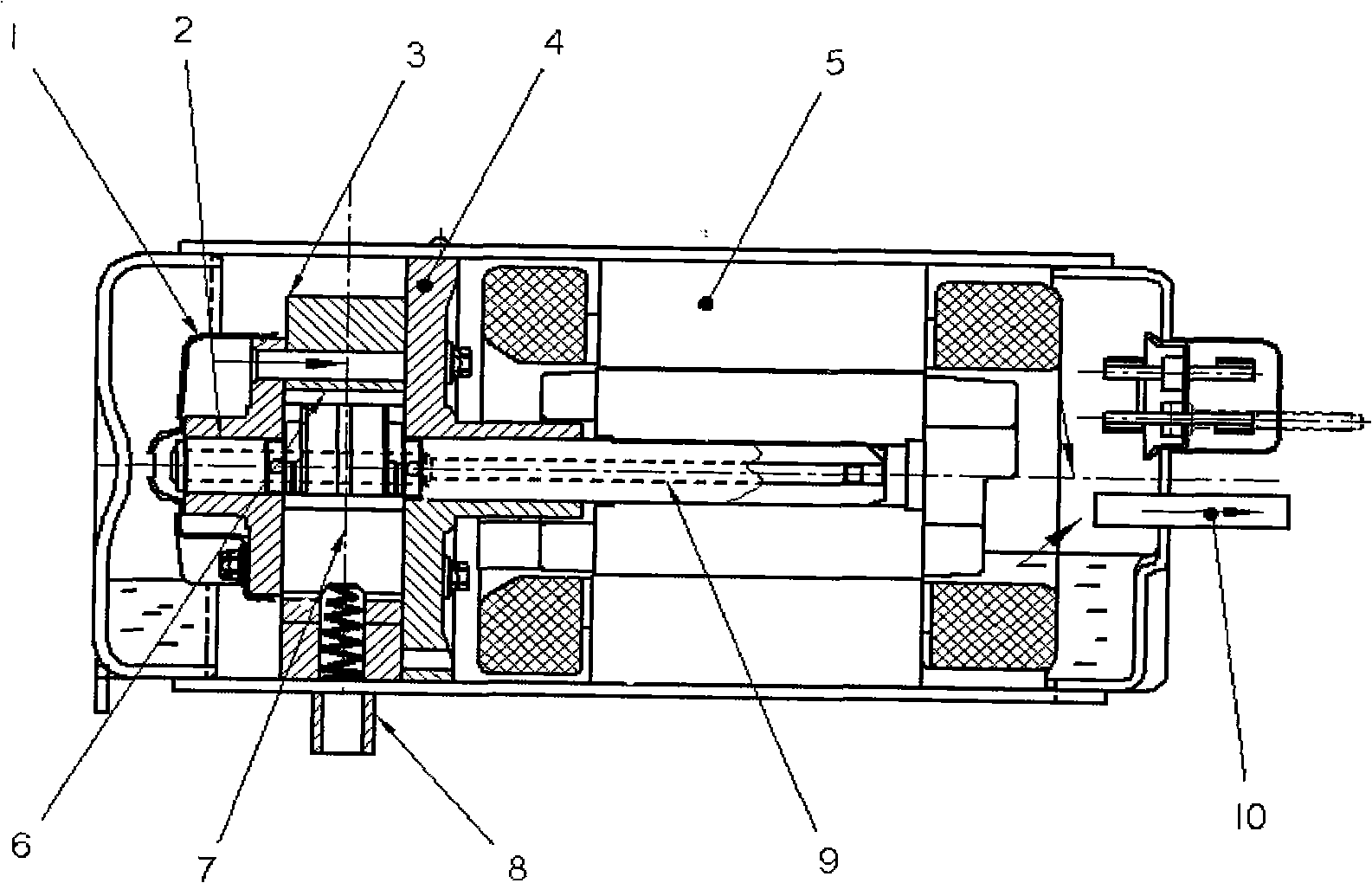

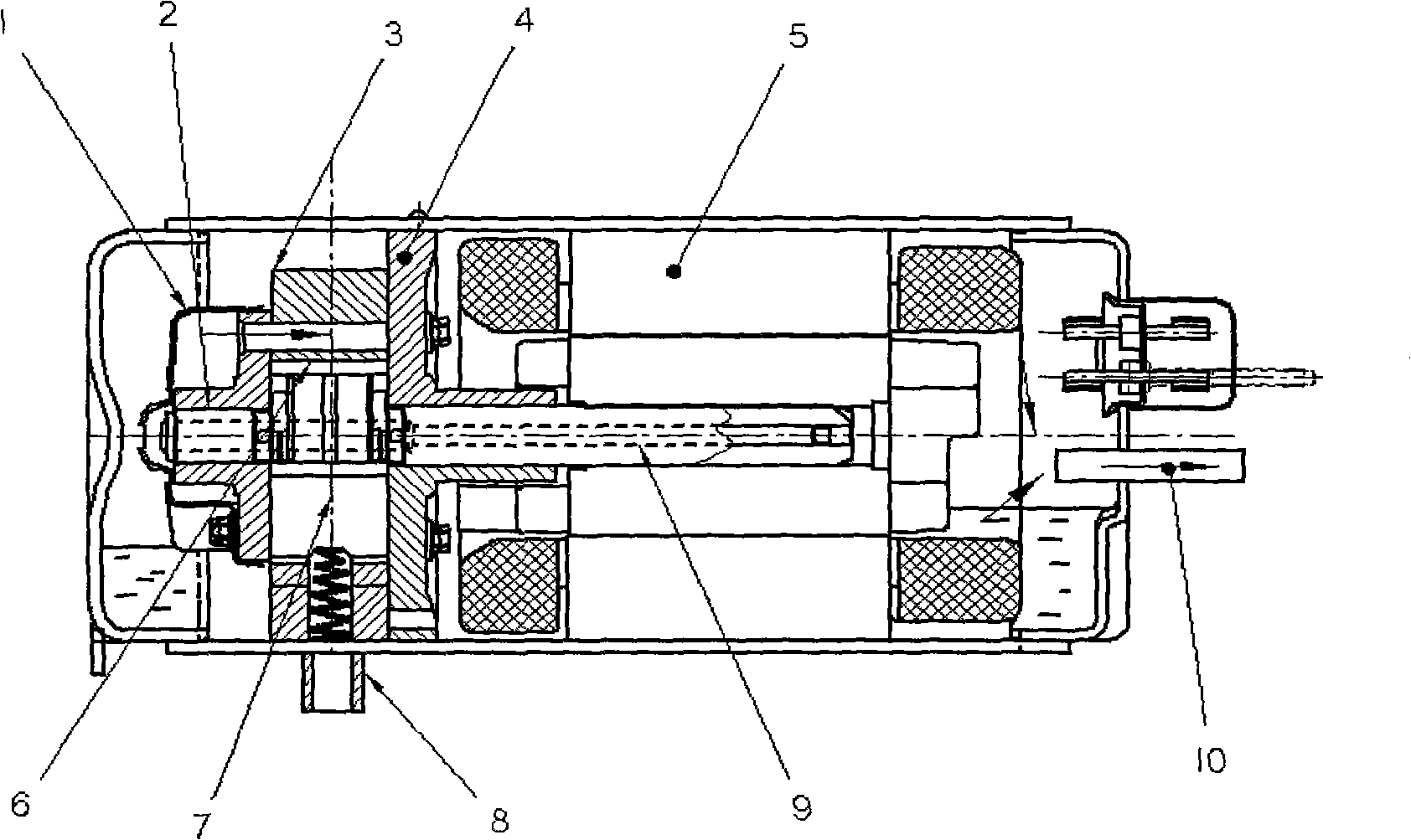

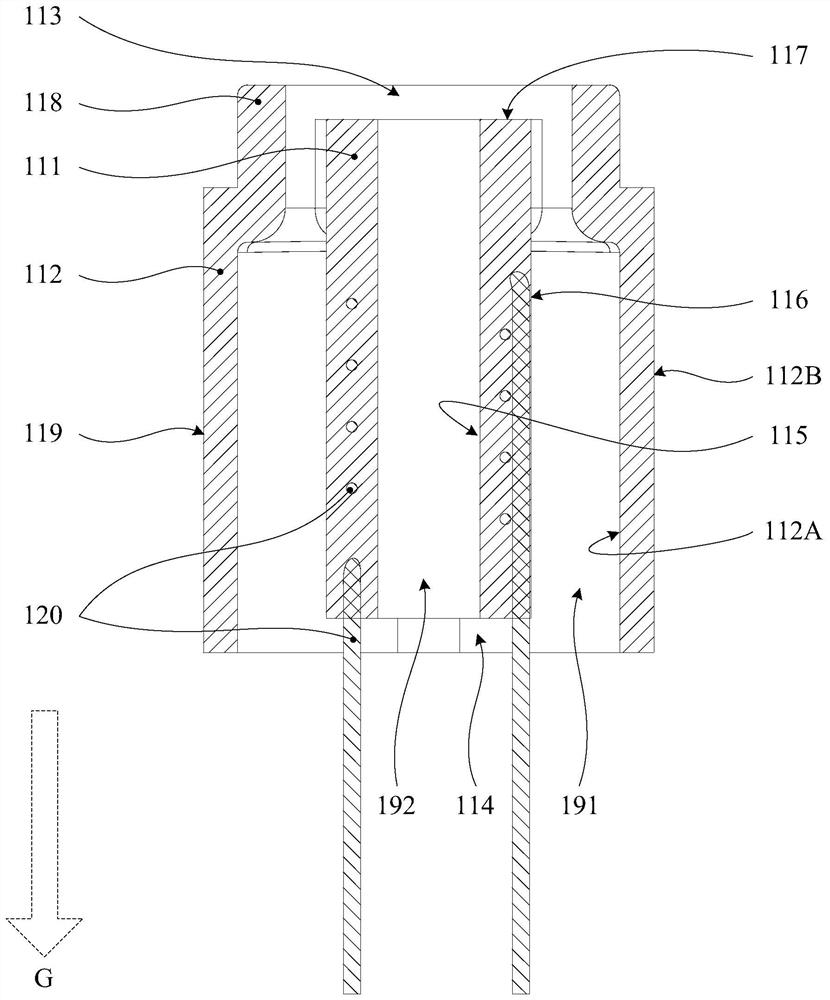

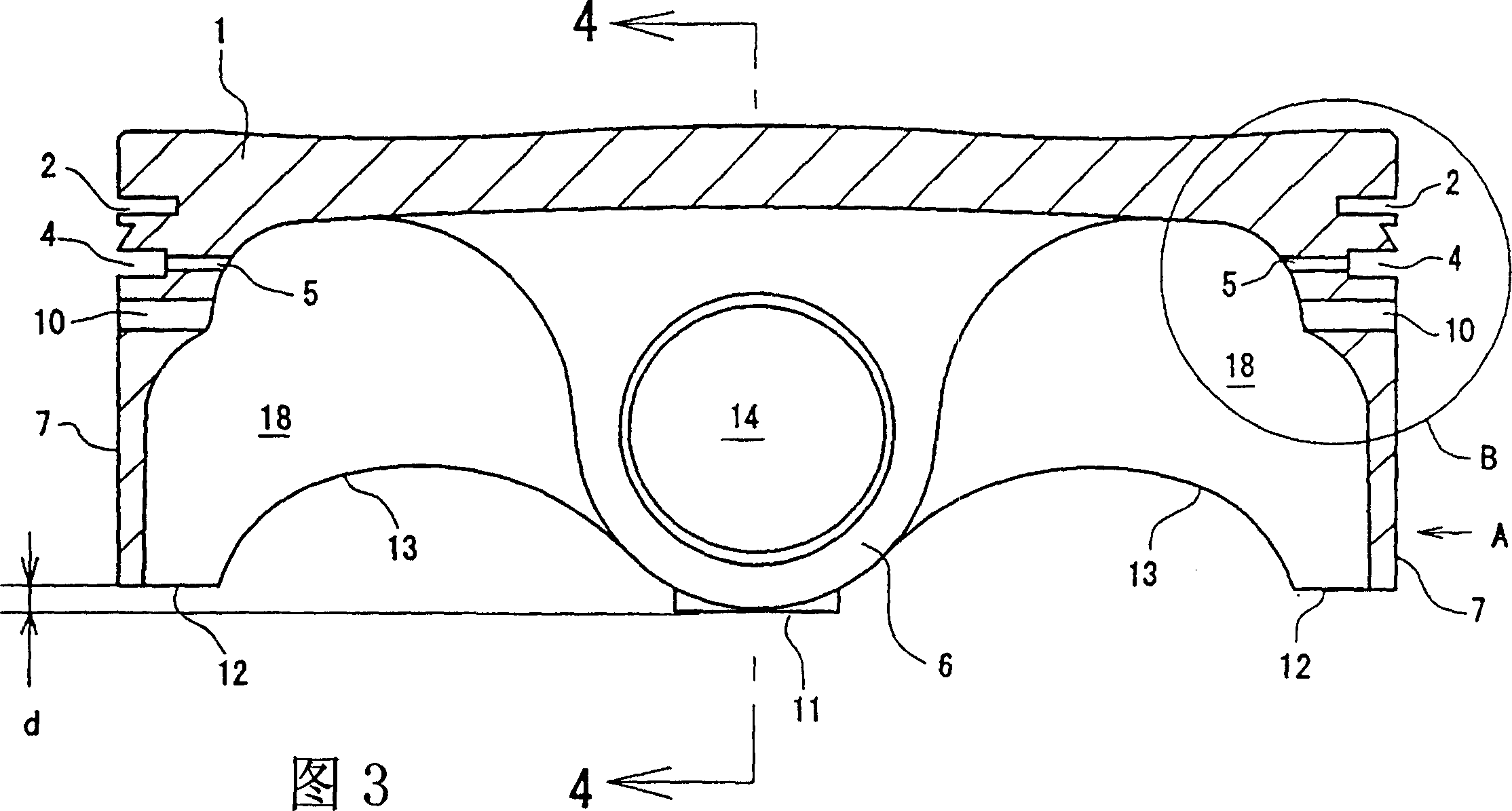

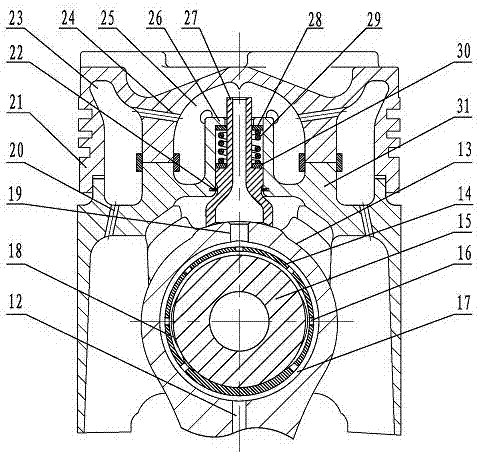

Horizontal type rolling rotor compressor return air cooling structure

InactiveCN101338750ARaise the oil levelImprove motor efficiencyRotary piston pumpsRotary piston liquid enginesPistonCrankshaft

The present invention relates to a return air cooling structure of a horizontal rolling rotor compressor, which comprises an upper cylinder cover, an air cylinder, a lower cylinder cover, an electric motor, a piston, blades, an air inlet pipe, a crankshaft, an exhaust pipe, a muffle as well as a return air pipe; wherein, the return air pipe, which can guide exhausted air to cool the electric motor and increase the level of the pump body side oil surface, is arranged on the end of the electric motor which is far from a pump body; the exhaust pipe is arranged on the pump body side; the exhausted air is exhausted into the cavity of the electric motor through a channel on the air cylinder and the upper cylinder cover, then flows back to a compressing cavity through the return air pipe and is finally exhausted through the exhaust pipe; therefore the exhausted air can directly cool the electric motor. Compared with the prior art, the return air cooling structure can reduce the temperature of the electric motor and increase the level of the oil surface of the compressing cavity, thus increasing the efficiency of the electric motor and greatly improving the reliability of the compressor.

Owner:SHANGHAI HITACHI ELECTRICAL APPLIANCES CO LTD

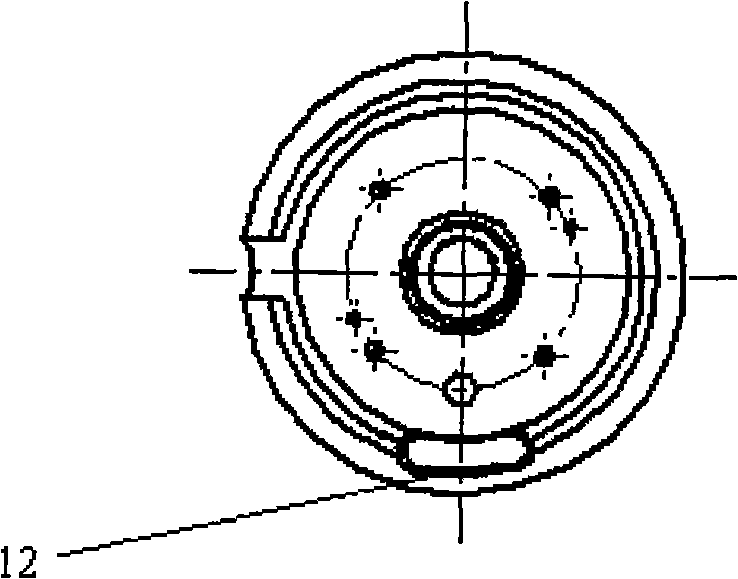

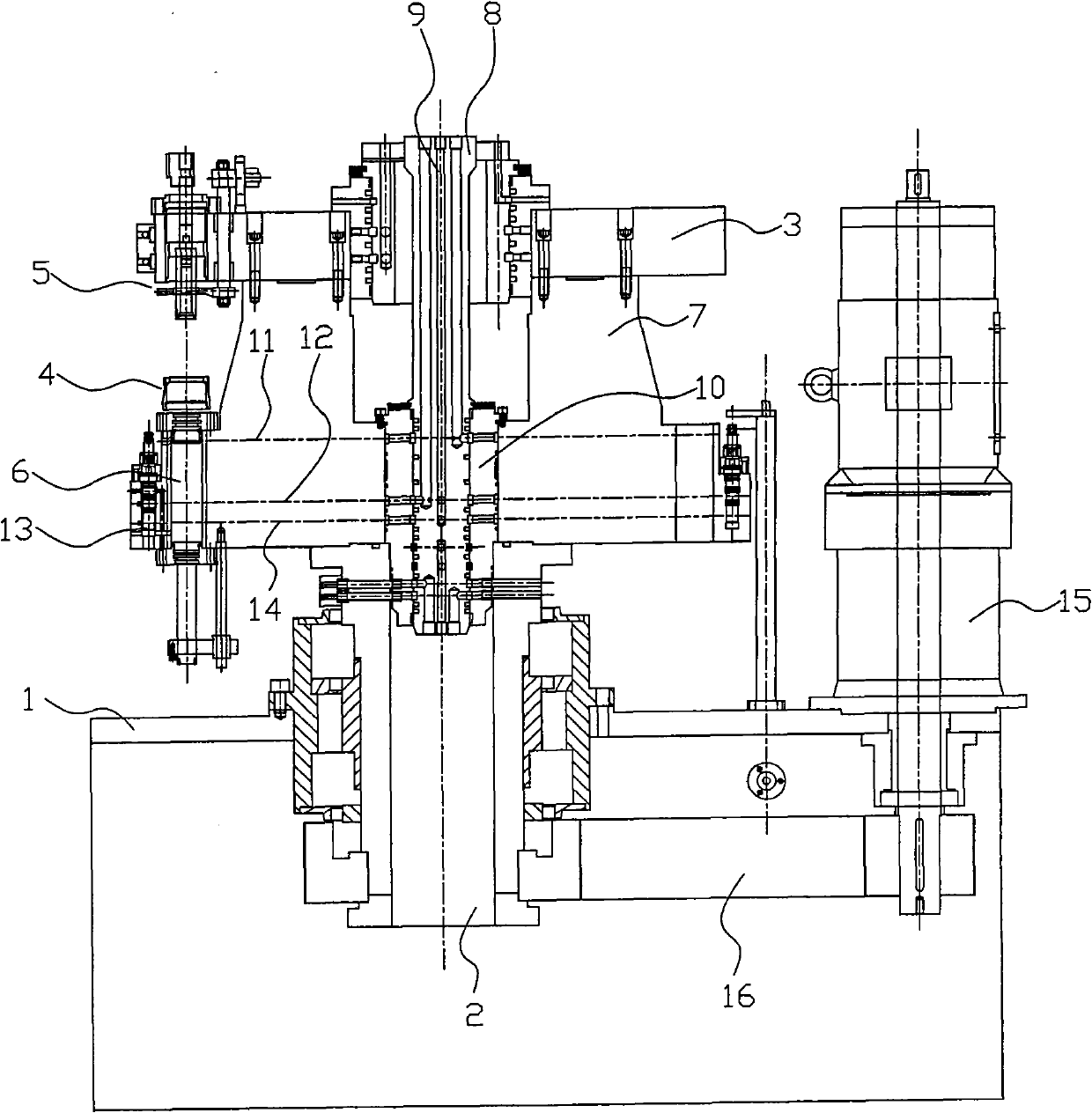

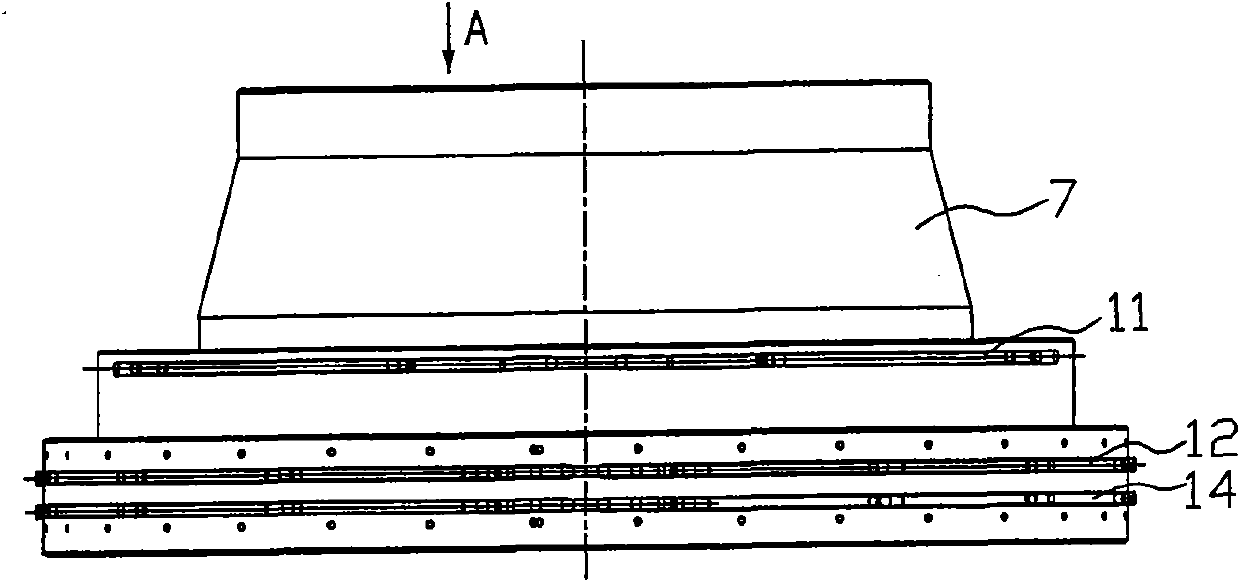

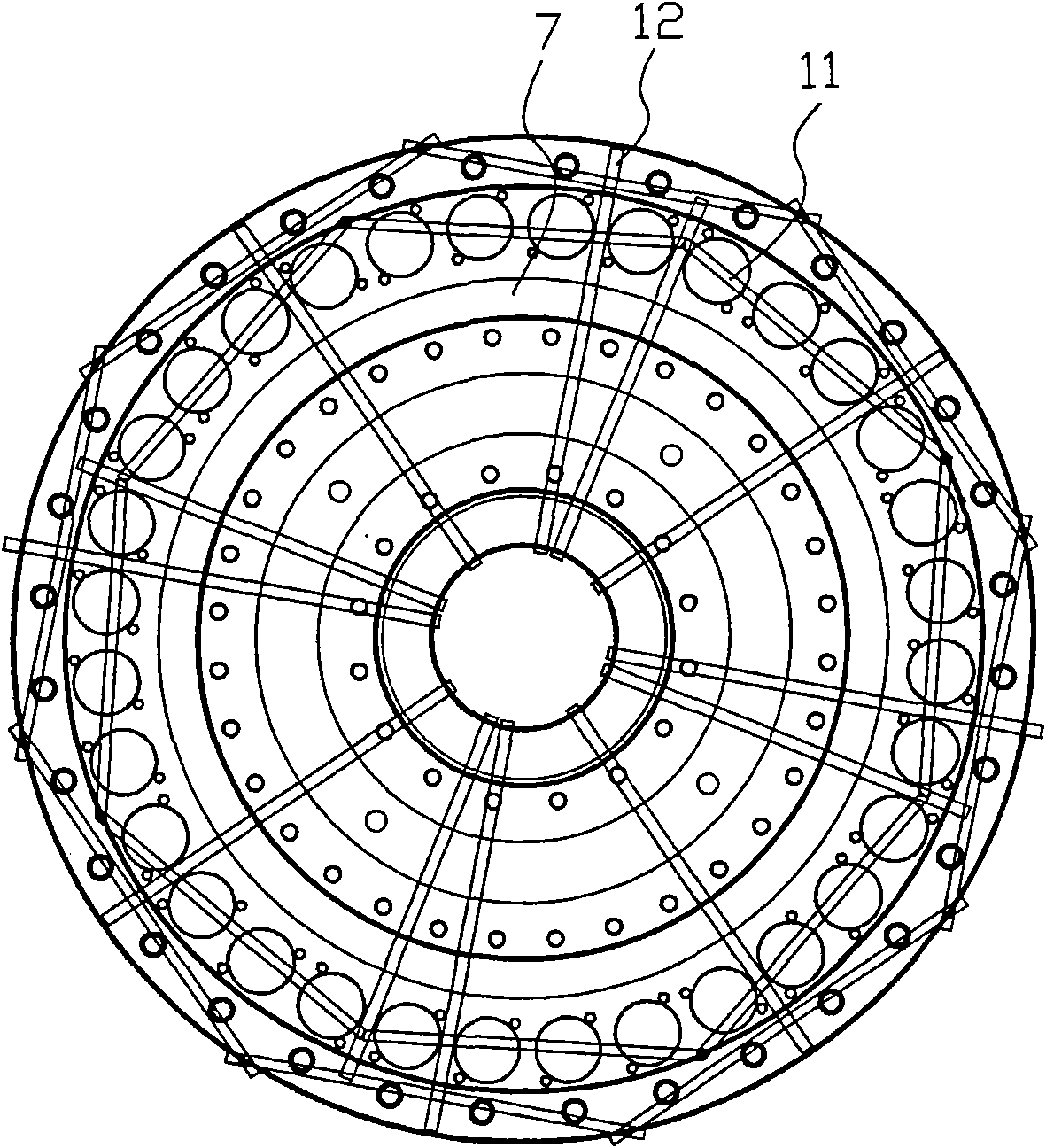

Integrated rotary tower and oil path system of bottle cap molding press

The invention discloses an integrated rotary tower and oil path system of a bottle cap molding press, which comprises a machine base, wherein a spindle is arranged on the machine base and driven by a driving force; a lower template and an upper template are arranged on the spindle; a lower mold component is arranged on the lower template and connected with an oil hydraulic cylinder; and an upper mold component is arranged on the upper template. The integrated rotary tower and oil path system of the bottle cap molding press is characterized in that: the lower template is an entire tower-shapedrotary tower; an oil inlet shaft is arranged in the rotary tower; an oil inlet is formed in the oil inlet shaft; an oil path distributor is arranged at the lower end of the oil inlet shaft; a lower seal of the oil path distributor is connected with the spindle; a low-pressure oil hole and a high-pressure oil hole are formed in the rotary tower and are communicated with the oil path distributor through the oil path distributor; the low-pressure oil hole is connected with an upper cavity of the oil hydraulic cylinder; a dismantling valve is arranged in a lower cavity of the oil hydraulic cylinder; and the high-pressure oil hole is connected with the dismantling valve. In the scheme, the lower template is used as the rotary tower platform, so the structure is simplified, the processing is labor-saving, the assembly is avoided, and the installation is convenient; particularly, the oil paths are formed in the rotary tower, oil path overall arrangement is saved, and oil is directly delivered by the oil paths, so oil supply is sufficient and oil pressure is stable.

Owner:李加庆

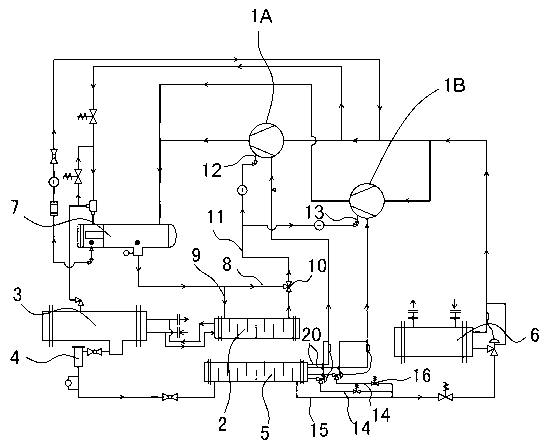

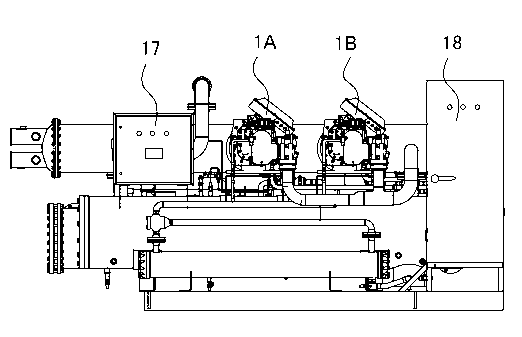

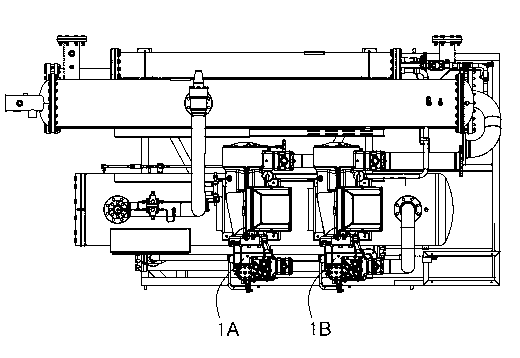

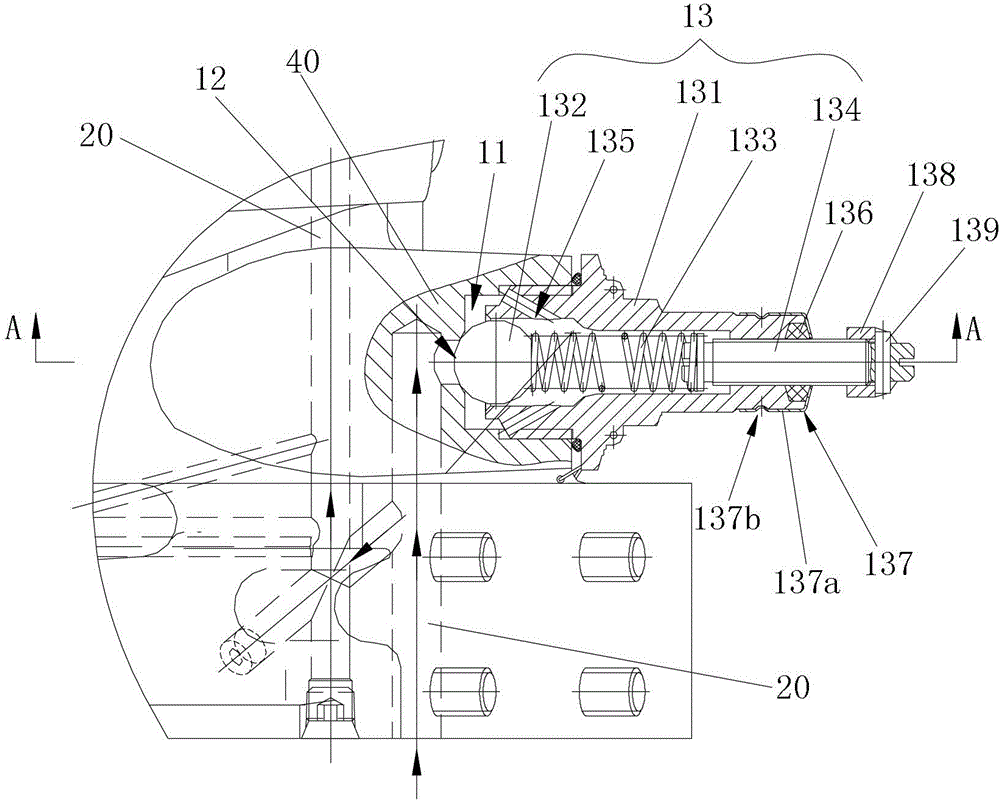

Screw brine refrigeration unit

ActiveCN102914102AControllable oil temperatureFlow is easy to controlCompressorFluid circulation arrangementOil temperatureRefrigeration

The invention discloses a screw brine refrigeration unit, which comprises compressors, an oil cooler, a condenser, a dry filter, an economizer, an evaporator and an oil separator, wherein the oil cooler, the condenser, the dry filter, the economizer, the evaporator and the oil separator are connected with the compressors; an oil outlet pipe of the oil separator comprises a first branch and a second branch; the oil of the first branch oil is not cooled by the oil cooler, and the second oil branch is connected with the first branch and the compressor after the oil of the second branch is cooled by the oil cooler. The temperature and the flow of the oil of the screw brine refrigeration unit entering each compressor are controllable; the stability of the temperature of the oil entering each compressor is ensured, and the oil supply is enough; adjustment of cold flow in a 12.5-100% of large range is achieved by parallel connection of two compressors, and the outlet water temperature range is -10 DEG C to 50 DEG C.

Owner:GREE ELECTRIC APPLIANCES INC

Automatic regulating device and automatic regulating method for lubrication oil pressure of aerial piston engine

InactiveCN102720556ASufficient oil supplyLubrication pressure controlAtmospheric pressureLubrication

The invention discloses an automatic regulating device and an automatic regulating method for lubrication oil pressure of an aerial piston engine. The automatic regulating method comprises that the oil return quantity from a main oil passage to an oil return passage is controlled through a pressure regulating valve which is arranged between the main oil passage and the oil return passage of a lubricating system, wherein the oil return quantity which is controlled by the opening degree of the pressure regulating valve decreases with the lubricating oil pressure in the main oil passage, the pressure regulating valve is turned off under the lubricating oil pressure that the lubricating system is at a critical height, the lubricating oil quantity supplied to the main oil passage by the lubricating system at the critical height exceeds the minimum lubricating oil circulation quantity required by the engine, and the critical height is a preset value which is higher than the ceiling height of an aircraft. In the device, when the lubricating oil pressure decreases, the oil return quantity from the main oil passage to the oil return passage decreases till the pressure regulating valve is turned off, so that sufficient oil supply for lubrication pairs is guaranteed, and influence of atmospheric pressure during high-altitude flight is avoided.

Owner:CHINA HANGFA SOUTH IND CO LTD

Hydraulic oil pipe system for plastic bottle cap molding press

InactiveCN101570043BSufficient oil supplyStable oil pressureDomestic articlesOil pressurePetroleum engineering

The invention discloses a hydraulic oil pipe system for plastic bottle cap molding press, comprising a machine bracket and a spindle; the upper end of the spindle is sheathed with a rotary internal connector and a connector sleeve; the rotary internal connector is fixed with the circumference of the spindle; the connector sleeve is connected with the machine bracket; the lower end of the spindle is provided with an oil separating disc; an oil inlet and an oil outlet are arranged on the connector sleeve; a plurality of annular oil grooves are arranged between the connector sleeve and the rotaryinternal connector; the upper and the lower ends of the ring oil grooves are both sealed by sealing rings; a plurality of oil transporting channels which are corresponding to the annular oil groovesone by one and are communicated individually are arranged within the rotary internal connector; the oil transporting channels are in communication with the oil supplying space and the oil reflowing space by independent oil transporting pipelines; the oil supplying space and the oil reflowing space in the oil separating disc are both sealed and separated from each other without communication; and the oil supplying space and the oil reflowing space are connected with the reversing valve of each molding press unit by independent oil pipes. This technical scheme has the characteristics of sufficient oil supply, stable oil pressure, rational structure, convenient maintenance, etc.

Owner:SHAOXING HUANGGUAN MACHINERY

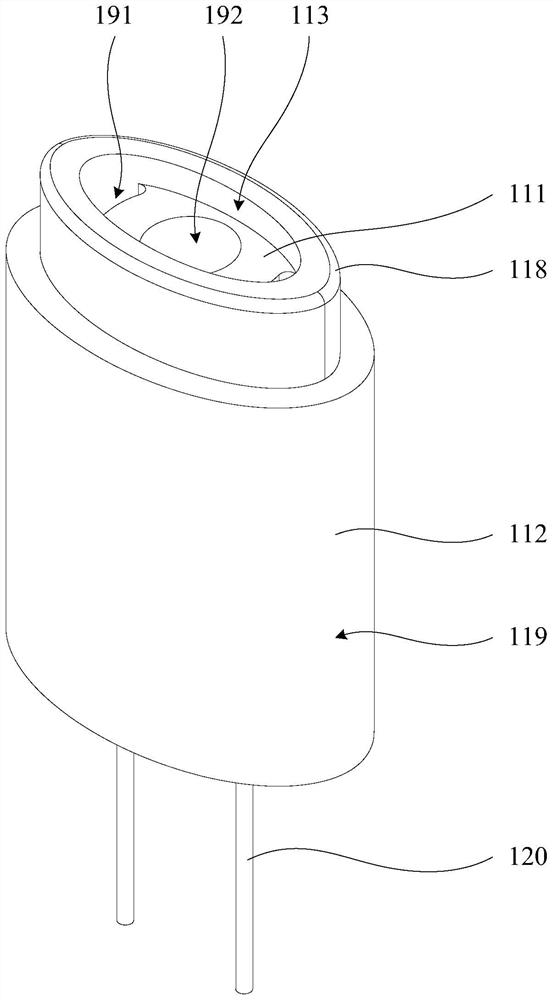

Atomization assembly, atomizer and aerosol generating device

The invention relates to an atomization assembly, an atomizer and an aerosol generating device, a heating body is at least partially embedded in an atomization part, and the atomization part is fixed in a guide part; the guide part is in contact with the atomizing medium and transmits the atomizing medium to the atomizing part; the inner wall of the atomizing part forms a first atomizing surface and a first air channel, and the outer wall forms a second atomizing surface and a second air channel. On one hand, a physical interval is formed between the atomizing surface and the liquid absorbing surface, and the heating body indirectly contacts with the atomizing medium in the liquid storage cavity through the guide part, so that a long distance exists between the heating body and the atomizing medium in the liquid storage cavity, heat transfer is effectively isolated, and the atomizing medium in the liquid storage cavity can be prevented from deteriorating due to high temperature; due to heat concentration, the heating efficiency of the whole atomization assembly is high; on the other hand, the atomization part and the oil guide part are connected, the guide part obtains the atomization medium through the liquid suction face, the oil guide area is large, oil is guided in all directions, and sufficient oil supply can be effectively guaranteed.

Owner:深圳市大迈发展有限公司

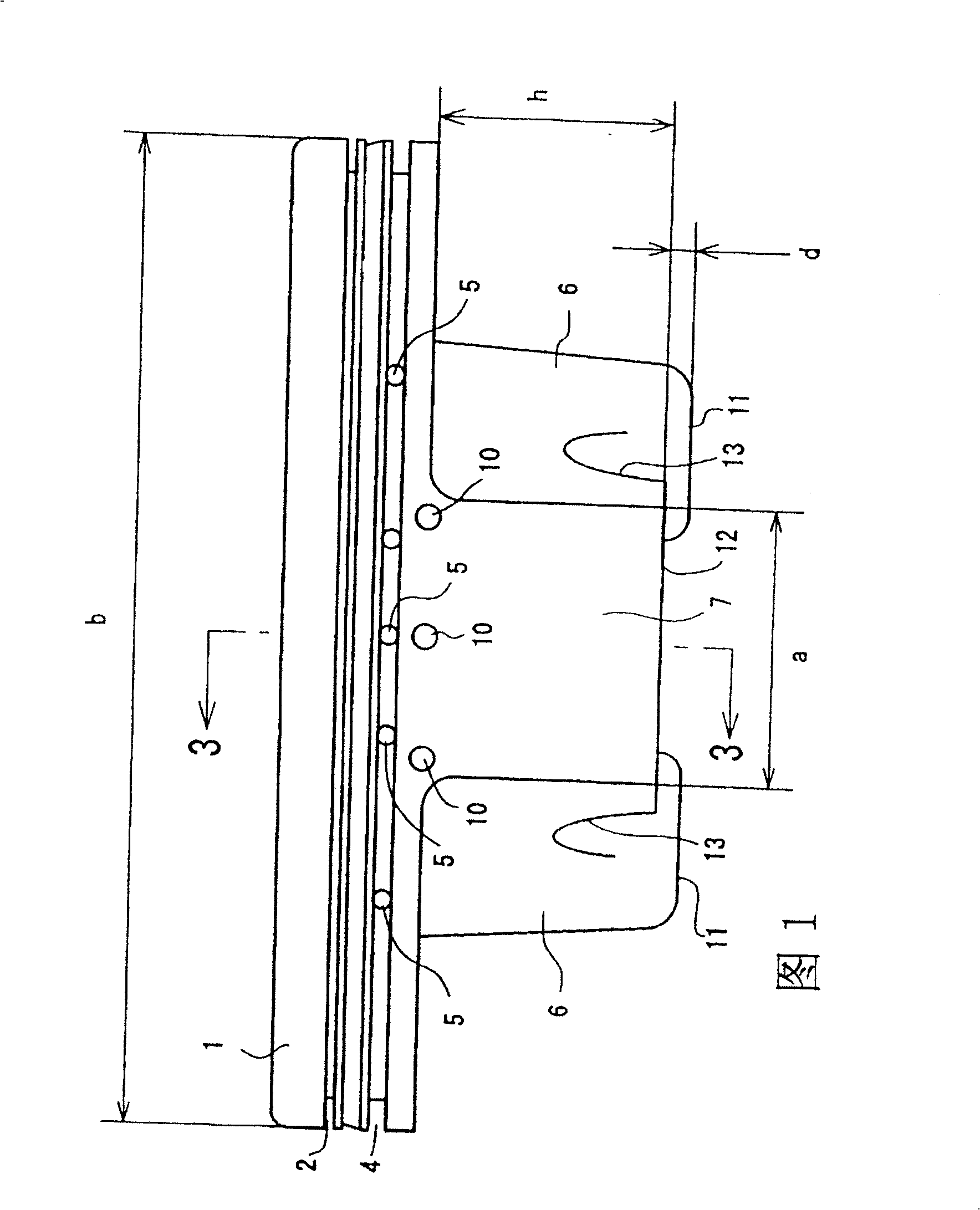

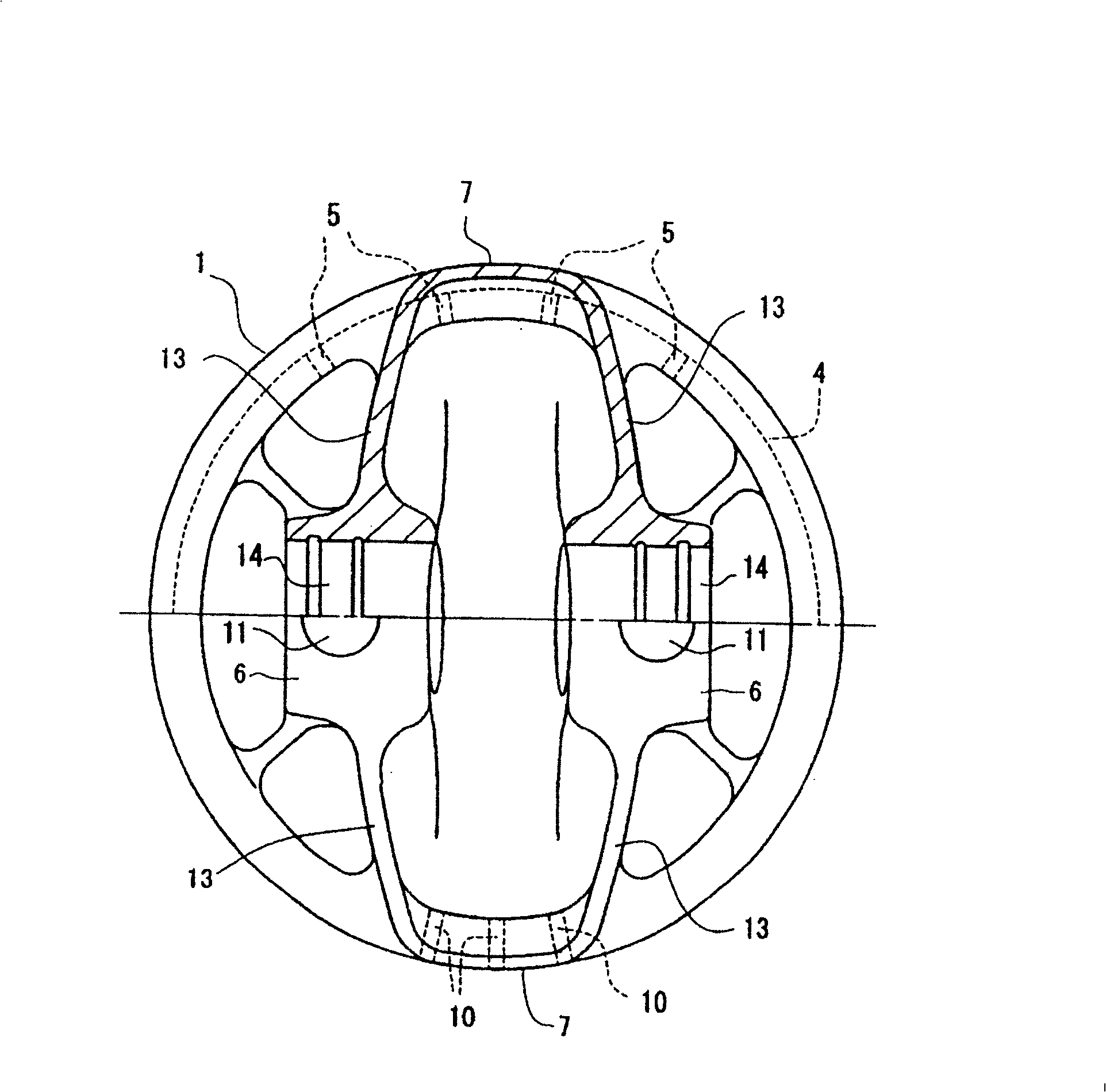

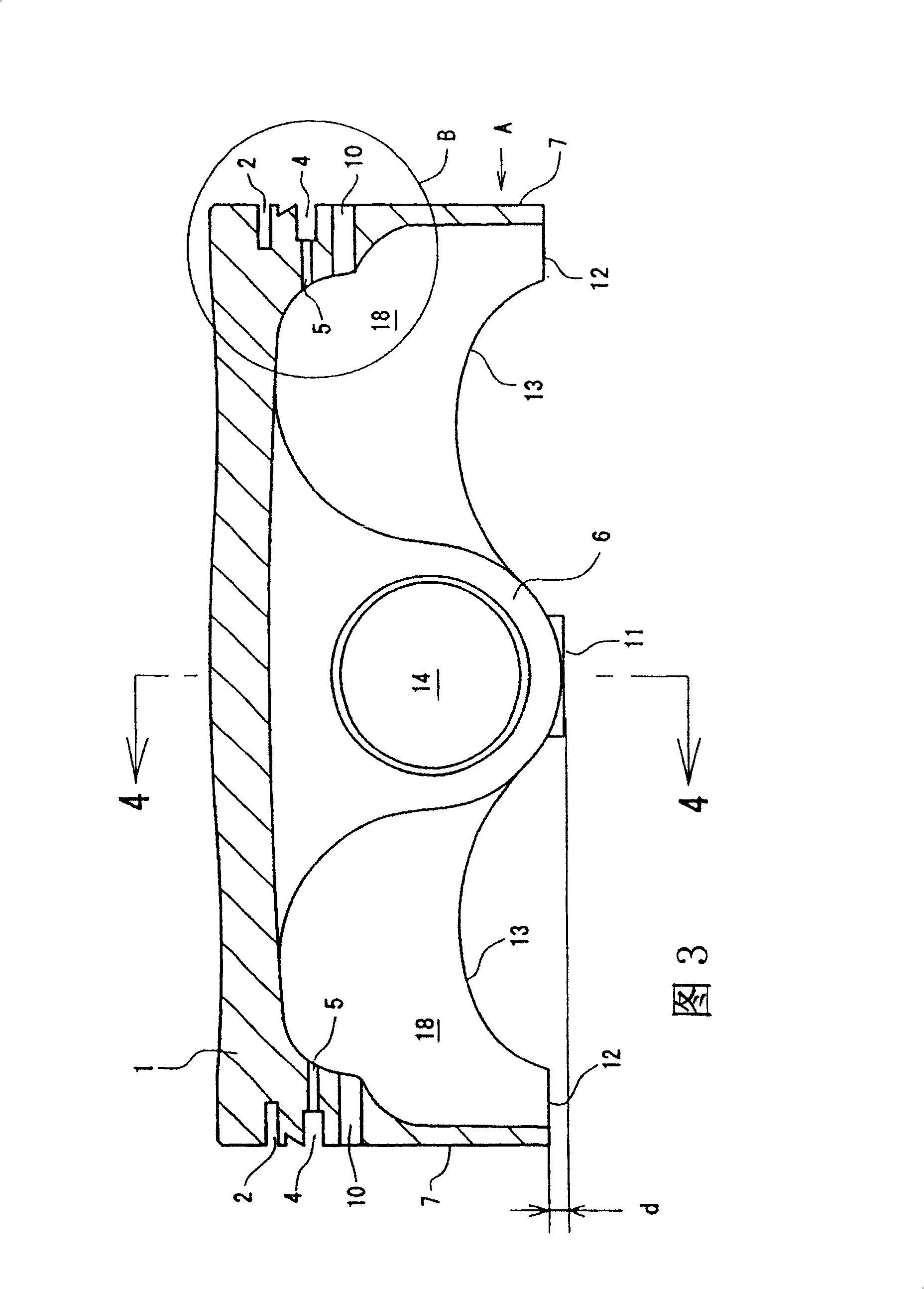

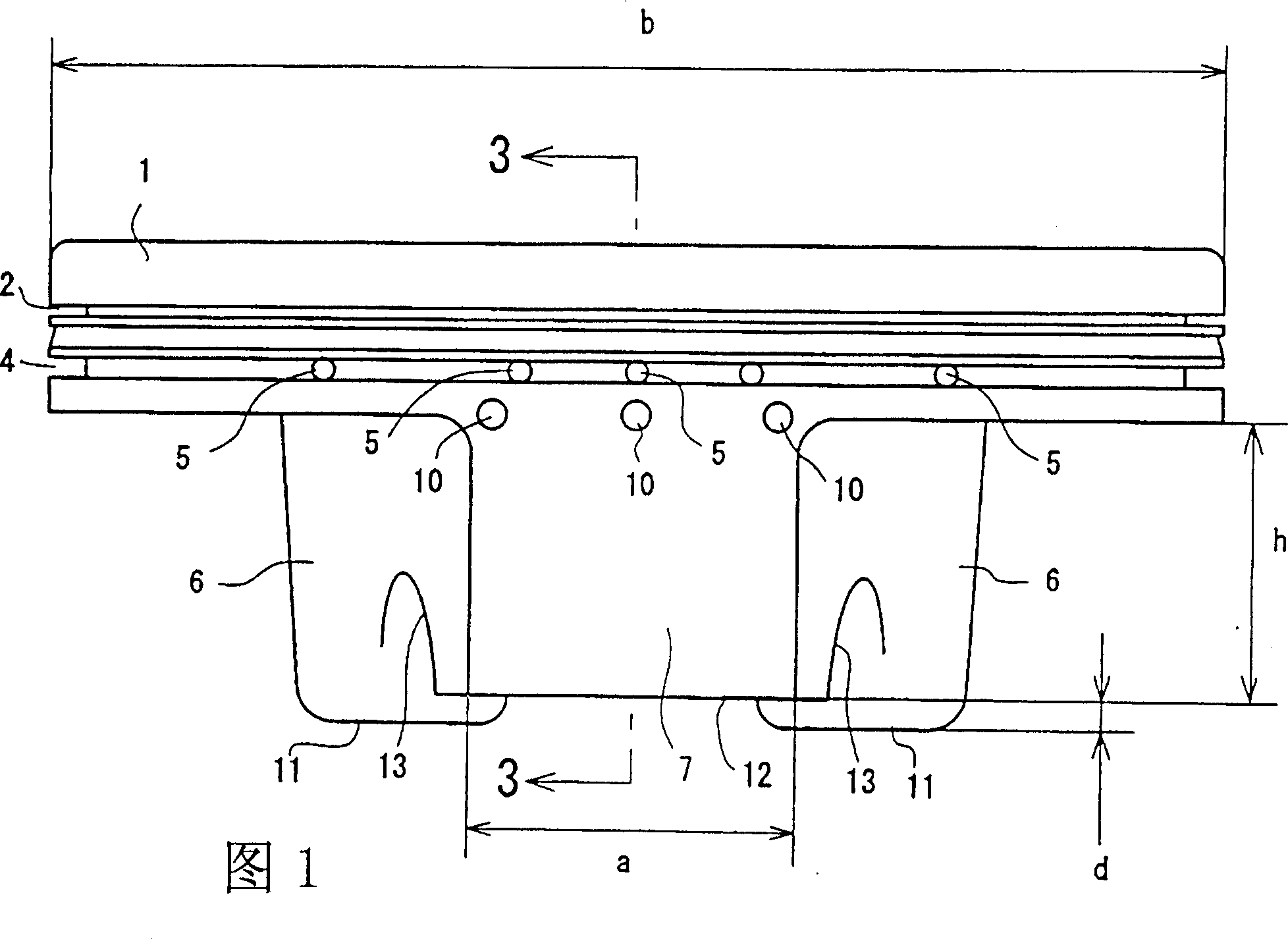

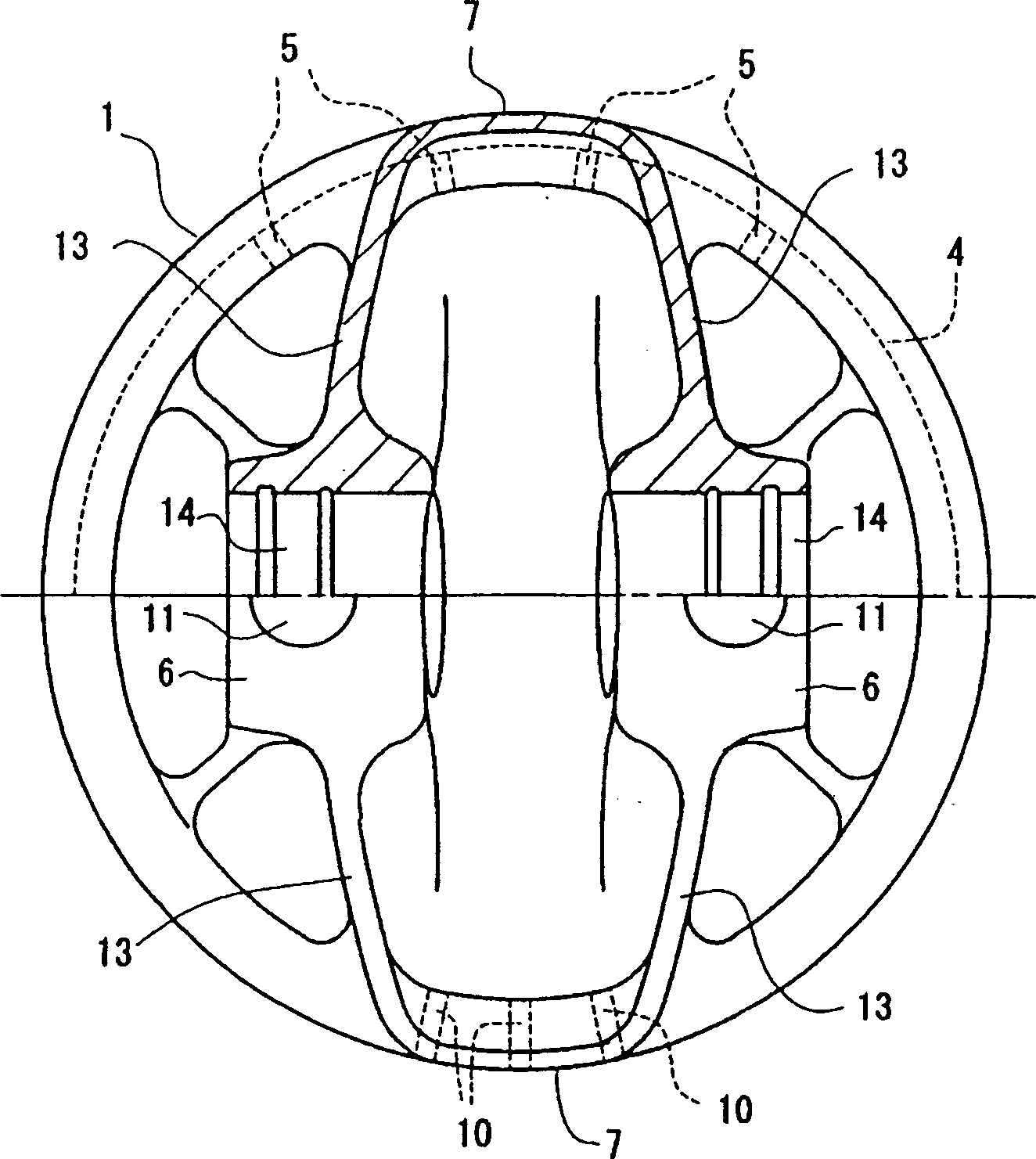

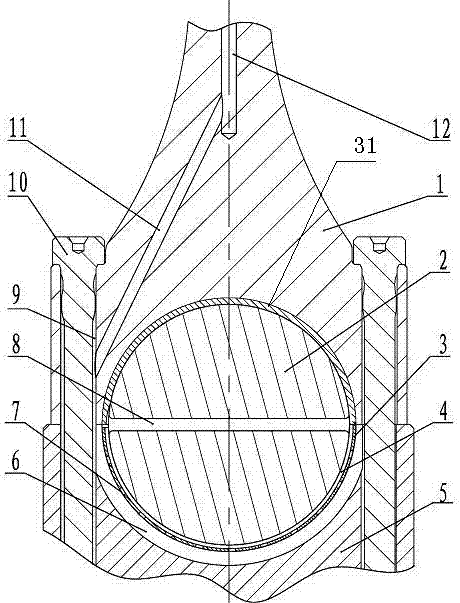

Piston for internal combustion engine

InactiveCN100476185CAvoid weight gainAchieve high rotationPlungersLubricant conduit arrangementsInternal combustion enginePiston

Owner:HONDA MOTOR CO LTD

Fuel pump inner and outer rotor assembly and production method thereof

InactiveCN103194666AAvoid smashingGive full play to the chemical functionRotary piston pumpsRotary piston liquid enginesBench testHardness

The invention discloses a fuel pump inner and outer rotor assembly and a production method thereof. The fuel pump inner and outer rotor assembly comprises an inner and outer rotor, a shaft and a fixed stud, and is characterized in that the inner and outer rotor body is prepared by comprising the following components according to the weight ratio: Fe: C: P: sulphur: zinc stearate: lubricant is equal to (94.3-98): (1-1.5): (0.5-1.1): (0.4-1.1): (0.6-0.8): (0.01-0.03). Through tests, after being subjected to bench test and installing for use, the technological indexes of the fuel pump inner and outer rotor assembly can achieve the standards of imported components, the density is greater than 6.5MP2, the apparent hardness is HB80-130, and the warp-wise conquassation strength is greater than 410MP2. Copper with higher cost is omitted, the precious resource can be saved, and the production cost can be lowered by 20.4%; and the wear resistance property of products can be improved, the strength and hardness of the products are proper, the thermal absorption and radiation properties are good, the sufficient oil supply can be ensured, and the service life of the product can be prolonged.

Owner:SICHUAN PROVINCE NANBU JIALING POWDER METALLURGY

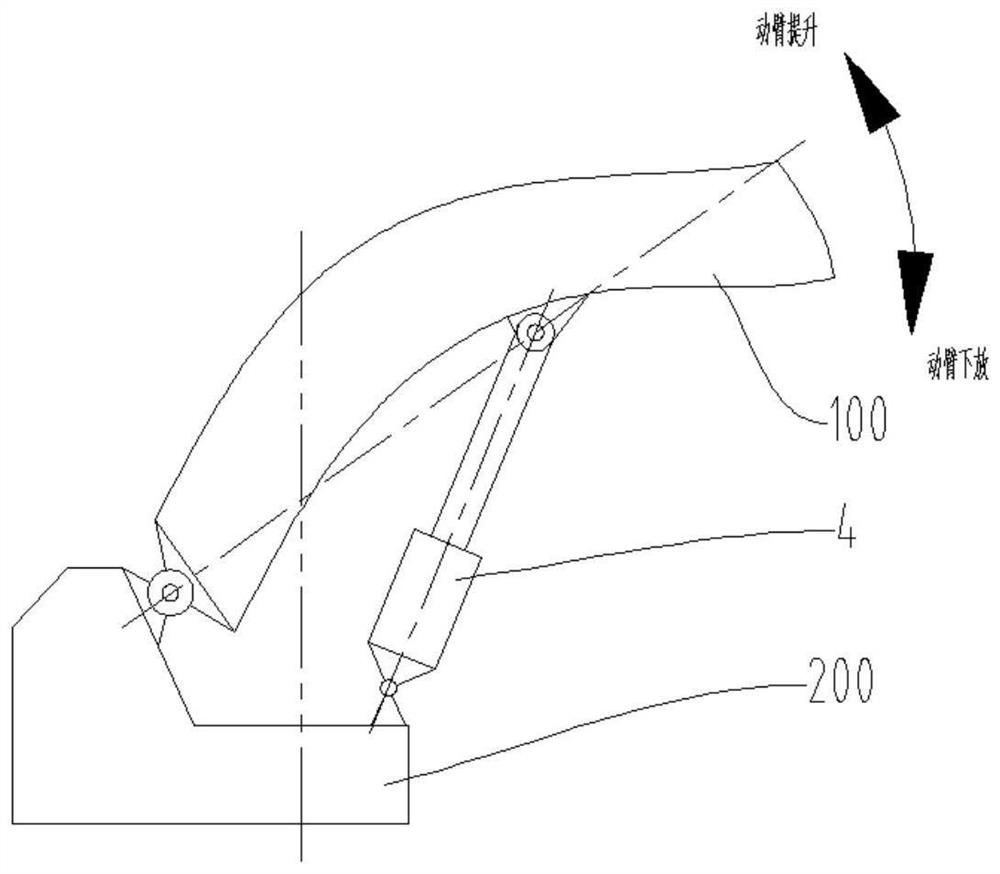

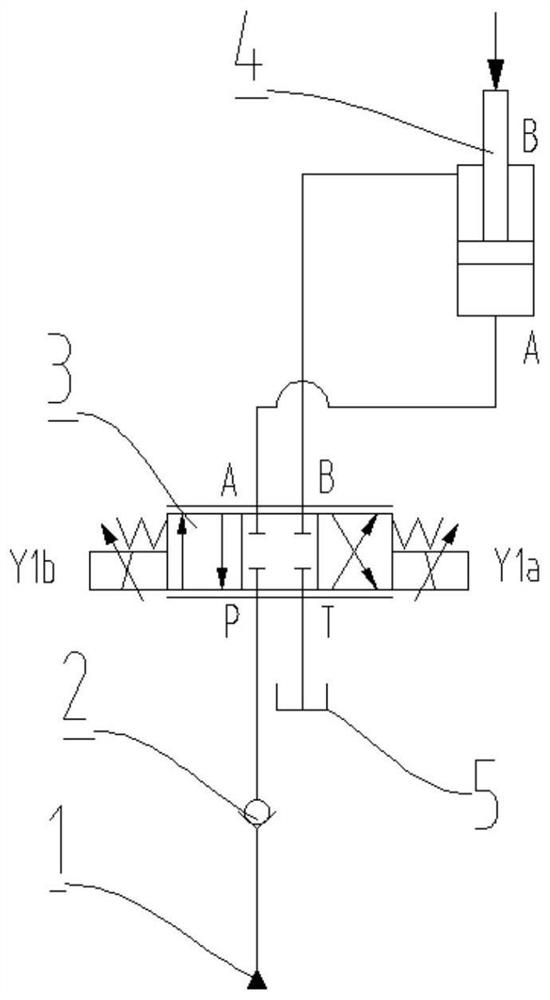

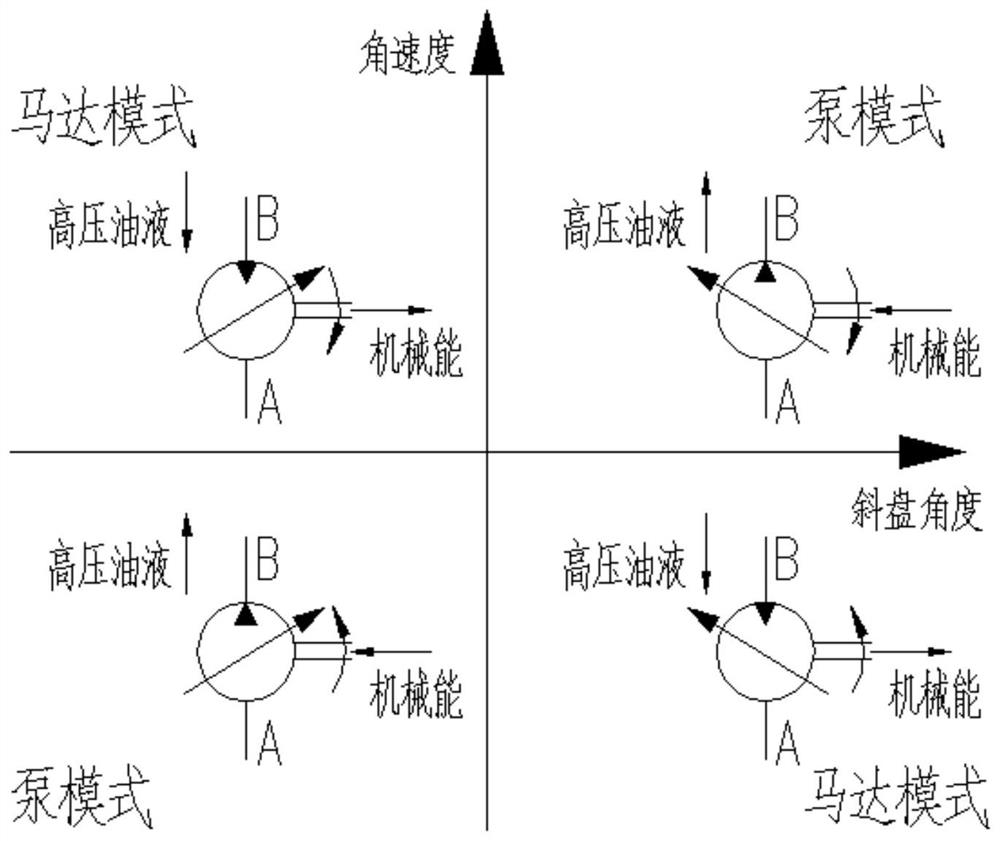

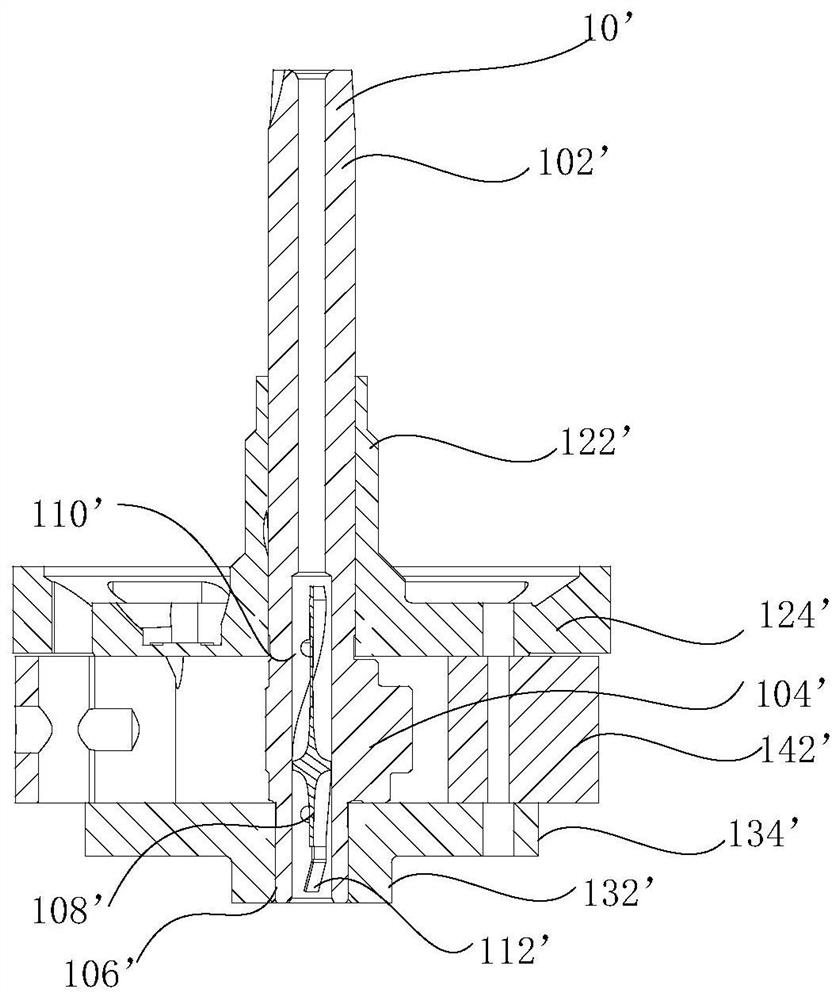

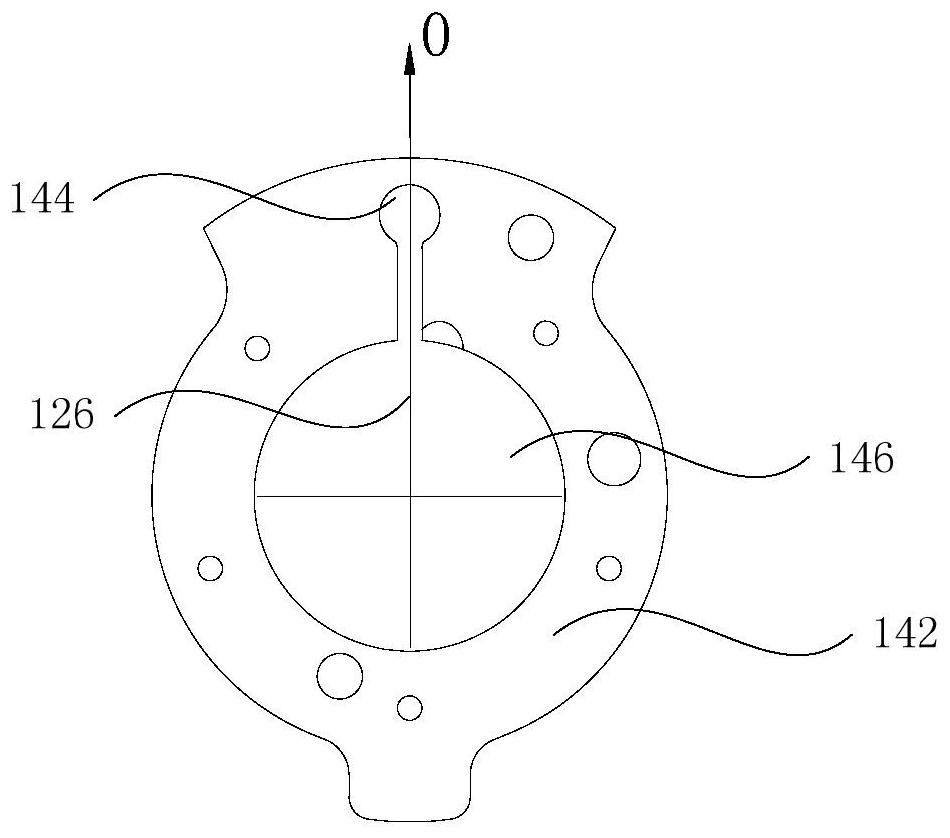

Excavator movable arm energy-saving system

ActiveCN111733906ARealize replenishmentSufficient oil supplyMechanical machines/dredgersServomotorsGear wheelFlywheel

The invention relates to an excavator movable arm energy-saving system. A port P of a hydraulic motor is connected with a rodless cavity of a movable arm hydraulic cylinder through a first reversing valve, a port A of the hydraulic motor is connected with an energy accumulator, and a transmission shaft of the hydraulic motor is connected with a flywheel through a gearbox and a clutch; a port B ofa second one-way valve and a port A of a third one-way valve are connected with a port A of the first reversing valve; a port A of the second one-way valve and a port B of the third one-way valve arecorrespondingly connected with an oil tank and a port P of the main reversing valve; a gearbox comprises a box body, a first transmission shaft unit, a second transmission shaft unit, a sliding blockassembly, a shifting fork and a linear electric push rod, and the first transmission shaft unit comprises a first transmission shaft, a first bevel gear A, a shaft sleeve A, a third gear A, a fourth gear A, a shaft sleeve B and a second bevel gear A; the second transmission shaft unit comprises a second transmission shaft, a first bevel gear B and a second bevel gear B; and the sliding block assembly comprises a sliding block body, a first transition gear ring and a second transition gear ring. The system can reduce the manufacturing cost of a recovery system.

Owner:XUZHOU COLLEGE OF INDAL TECH

Pump body assembly, compressor and air conditioner

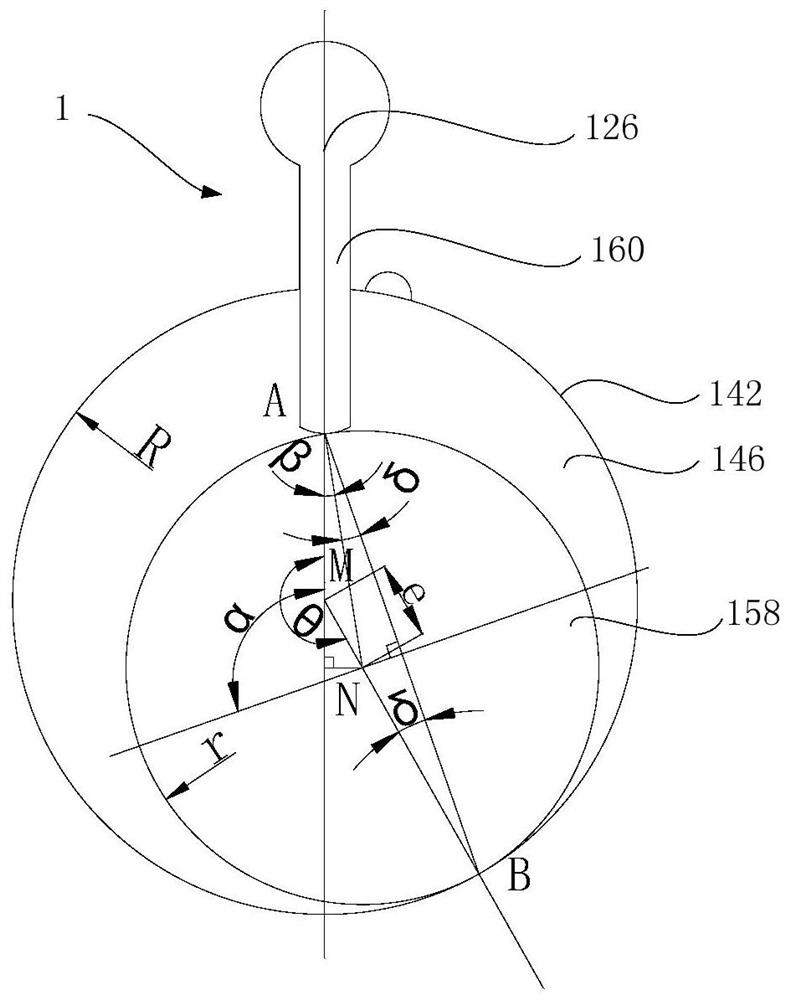

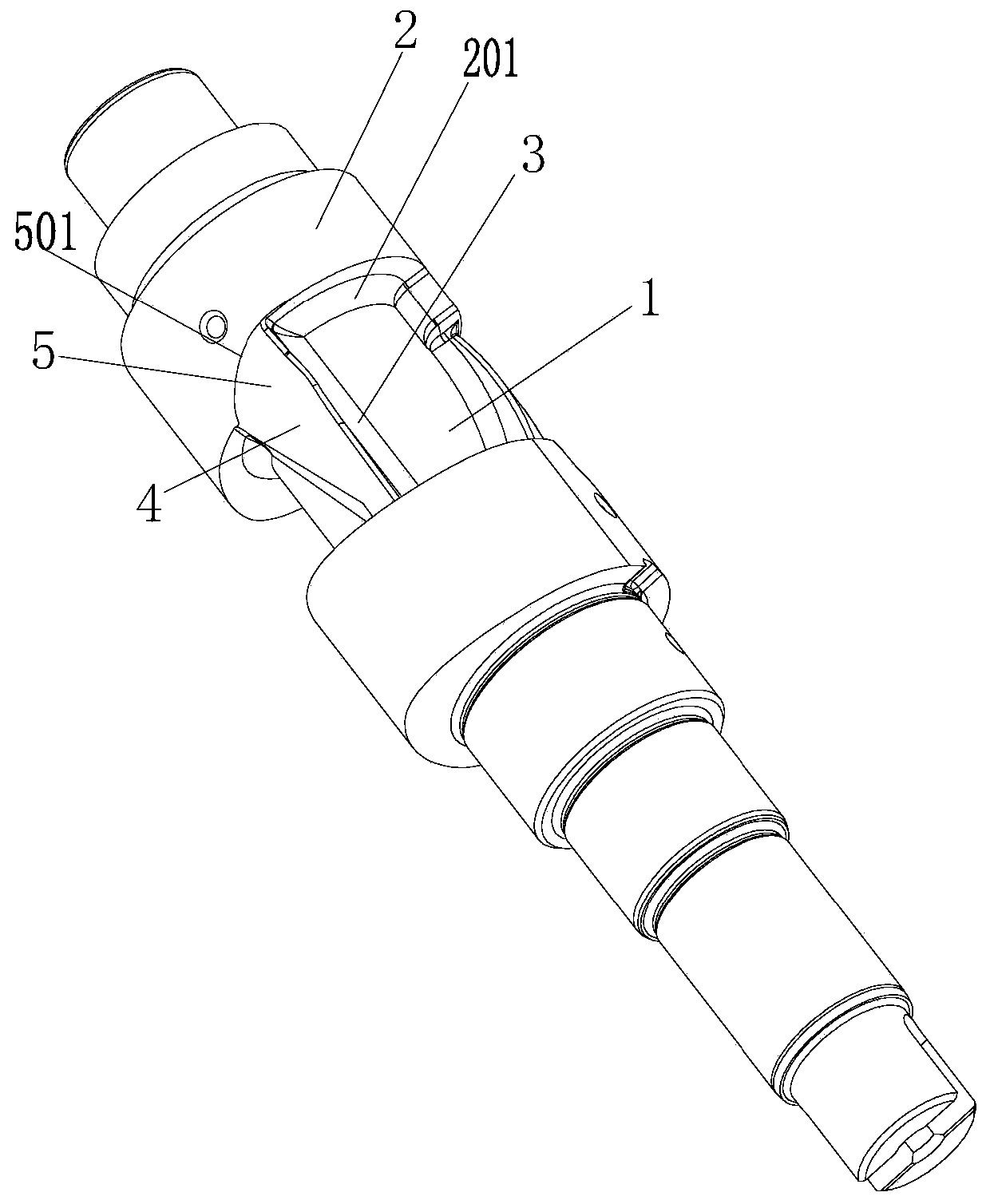

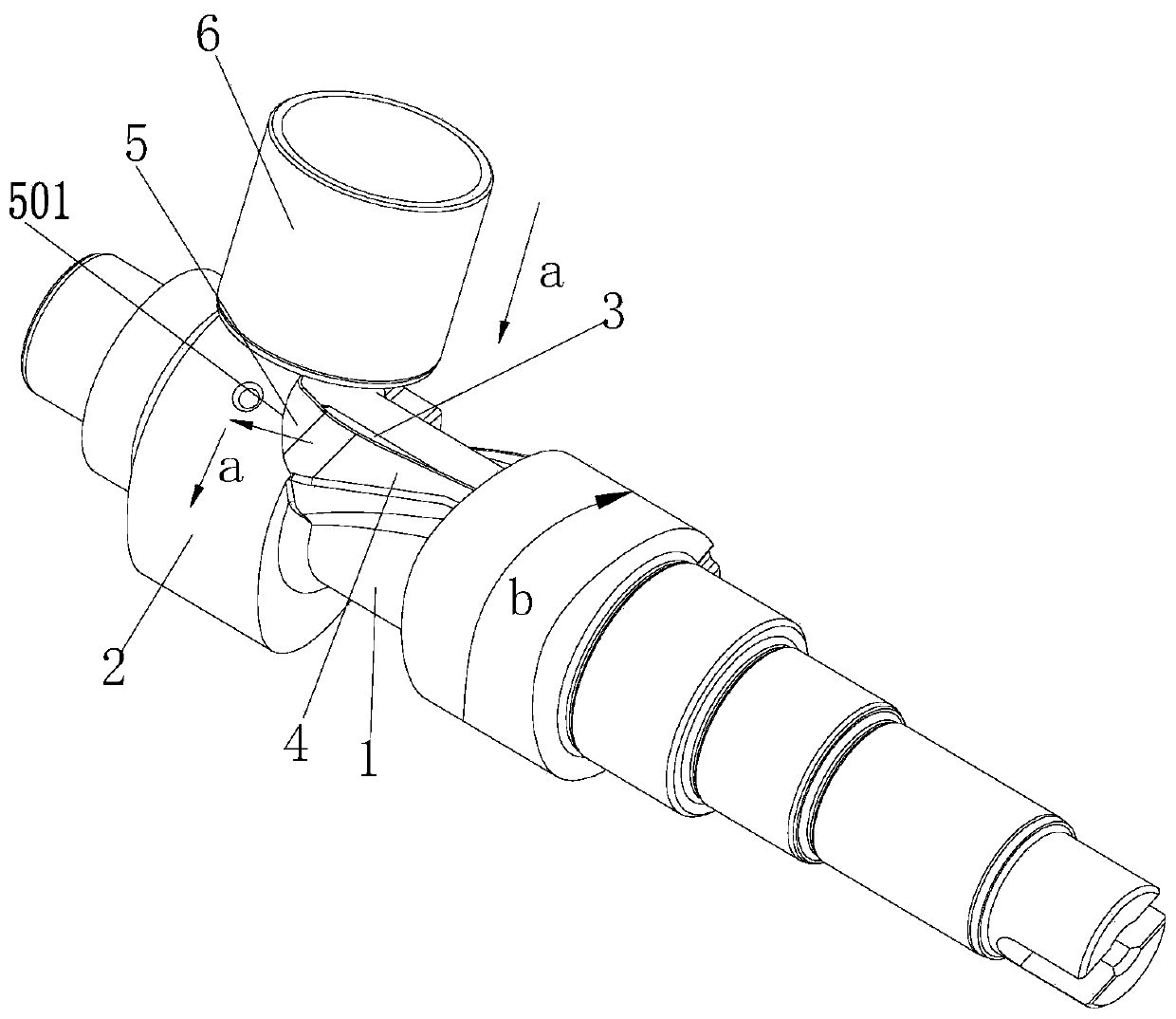

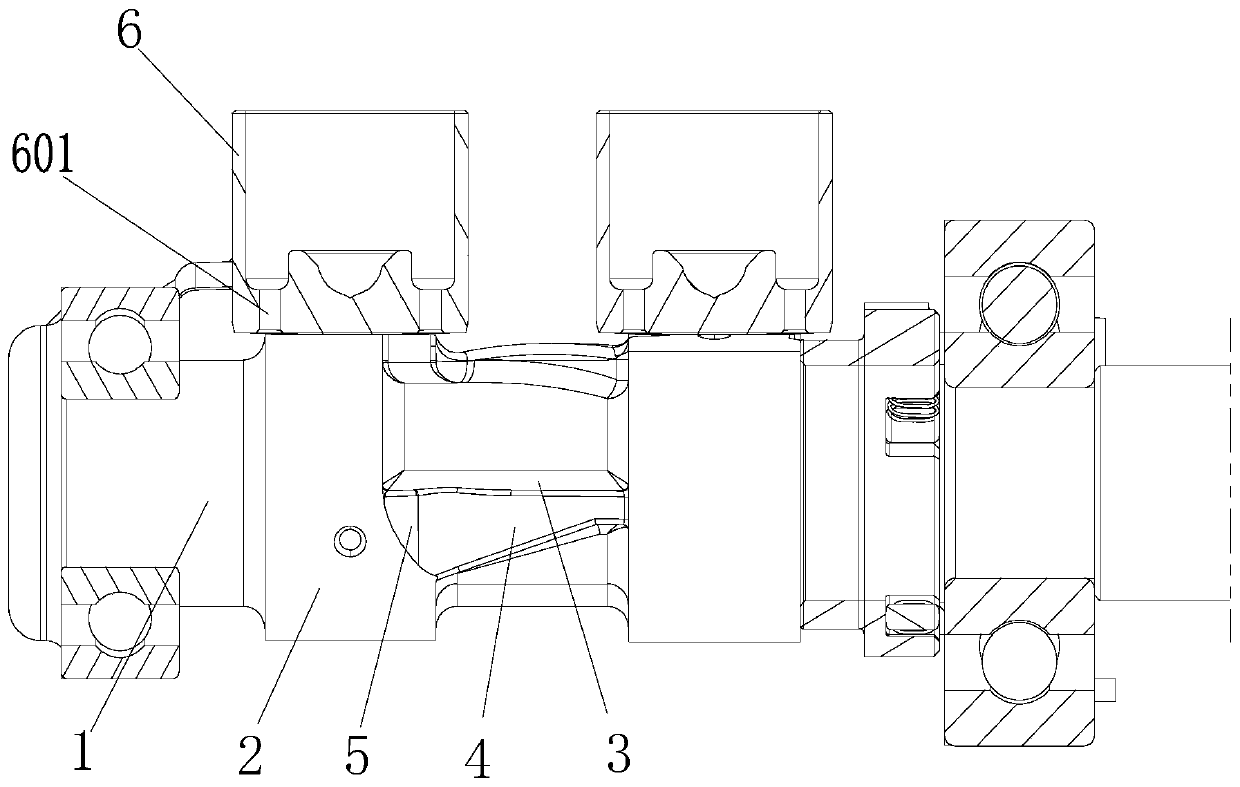

ActiveCN112145419AAvoid stickingAvoid problems such as crankshaft breakagePositive displacement pump componentsRotary piston pumpsEngineeringCylinder block

The invention provides a pump body assembly, a compressor and an air conditioner. The pump body assembly comprises a crankshaft, main bearings and cylinder bodies; the crankshaft comprises a main shaft part and an eccentric part, and the distance between the center line of the main shaft part and the center line of the eccentric part is e; the main bearings comprise hub parts, the main shaft partpenetrates through through holes of the hub parts, and first oil guide grooves are formed in the hole walls of the through holes; the cylinder bodies are provided with sliding sheet grooves and centerholes, the crankshaft is arranged in the center holes in a penetrating mode, the main bearings are located on the two sides of the cylinder bodies, the radius of the center hole is R, and the difference value between R and e is r; and the value range of an included angle formed by a first connecting line between the center of the center hole and the center of the sliding sheet groove in the sameprojection plane and a second connecting line between the termination point of the first oil guide groove at the end, away from the eccentric part, of the hub part and the center of the through hole is as follows: see the specification for the symbol. According to the pump body assembly, oil films at all positions, in contact with the main bearings, of the crankshaft are uniform, the abnormal abrasion problem of the crankshaft main shaft part is effectively solved, and the service life of the compressor is prolonged.

Owner:ANHUI MEIZHI PRECISION MFG

Active lubrication valve mechanism and engine

ActiveCN110748395ASufficient oil supplyThe oil conduction process is smooth and unimpededValve arrangementsLubrication of auxillariesCamLubrication

The invention relates to an active lubrication valve mechanism and an engine. The active lubrication valve mechanism comprises a cam shaft and a tappet, wherein the cam shaft comprises a cam shaft body and at least one cam; an oil guide inclined surface is arranged on the outer circle surface of the cam shaft body; and when the cam shaft rotates, the oil guide inclined surface guides lubricating oil on the oil guide inclined surface to climb to the radial surface of the corresponding cam. The oil guide inclined surface is arranged on the cam shaft body, and when the cam shaft rotates, the oilguide inclined surface can guide the lubricating oil to flow to the cam, so that a climbing effect is achieved; and the structure improves a lubrication mechanism at the matching position of the cam shaft and the tappet, provides conditions for forming sufficient lubrication, reduces the abrasion of the cam shaft and the tappet, improves the operation precision, reduces the operation noise, facilitates energy conservation and consumption reduction, and is simple in structure and convenient to manufacture.

Owner:CHONGQING LONCIN MOTOR +1

Compressor and refrigeration device

InactiveCN110685911AReduce weightSlow downRotary/oscillating piston combinations for elastic fluidsRotary/oscillating piston pump componentsElectric machineryEngineering

The invention provides a compressor and a refrigeration device. The compressor comprises a housing, a stator, a rotor, a first air cylinder, a first piston, a second air cylinder, a second piston, a crankshaft, a bearing system, a balance system and an insulation hood, wherein the first piston is arranged in the first air cylinder; the second piston is arranged in the second air cylinder; the crankshaft is provided with a first eccentric part and a second eccentric part; the first piston is arranged on the first eccentric part in a sleeving manner; the second piston is arranged on the second eccentric part in a sleeving manner; the crankshaft penetrates through the rotor and a compression component; the bearing system comprises a first bearing, a second bearing and an auxiliary bearing; the first bearing is arranged on one side, close to a driving motor, of the first air cylinder; the second bearing is arranged on one side, far from the driving motor, of the second bearing; the auxiliary bearing is arranged on the crankshaft and positioned on one side, far from the compression component, of the driving motor; the balance system comprises a rotor balance block and a crankshaft balance block; the rotor balance block is arranged on the rotor; the crankshaft balance block is arranged on the crankshaft and positioned on one side, far from the first bearing, of the second bearing; and a part of the isolation hood surrounds the crankshaft balance block. The high-speed operation reliability of the compressor is improved.

Owner:ANHUI MEIZHI PRECISION MFG

Oil pump capable of providing lubrication for idler gear bushing

PendingCN108662422AImprove the lubrication effectSufficient oil supplyLubricating pumpsEngineeringIdler-wheel

The invention provides an oil pump capable of providing lubrication for an idler gear bushing. The oil pump comprises a pump body, a pump cover, a pump shaft, a pump driving gear, an idle gear and anidler wheel shaft, wherein a rotor cavity and an idler wheel shaft mounting hole are formed in the pump body, a bushing is arranged in a shaft hole of the idle gear, the idle gear is sleeved on the upper section of the idler wheel shaft through the bushing and can rotate around the idler wheel shaft, the lower section of the idler wheel shaft is fixedly installed in the idler wheel shaft installing hole, a first oil passage for communicating the rotor cavity and the idler shaft mounting hole is arranged between the rotor cavity and the idler wheel shaft mounting hole, an axial second oil way is arranged on the idler wheel shaft, a hole A which is in butt joint with the first oil passage is formed in one end of the second oil passage, the other end is provided with a hole B for lubricatingthe bushing, the hole A and the hole B are both radial holes, a wedge-shaped gap is formed between the idler wheel shaft and the bushing, and the hole B is aligned with the large opening part of the wedge-shaped gap. According to the structure, the optimal lubricating effect can be provided for the bushing.

Owner:HUNAN OIL PUMP

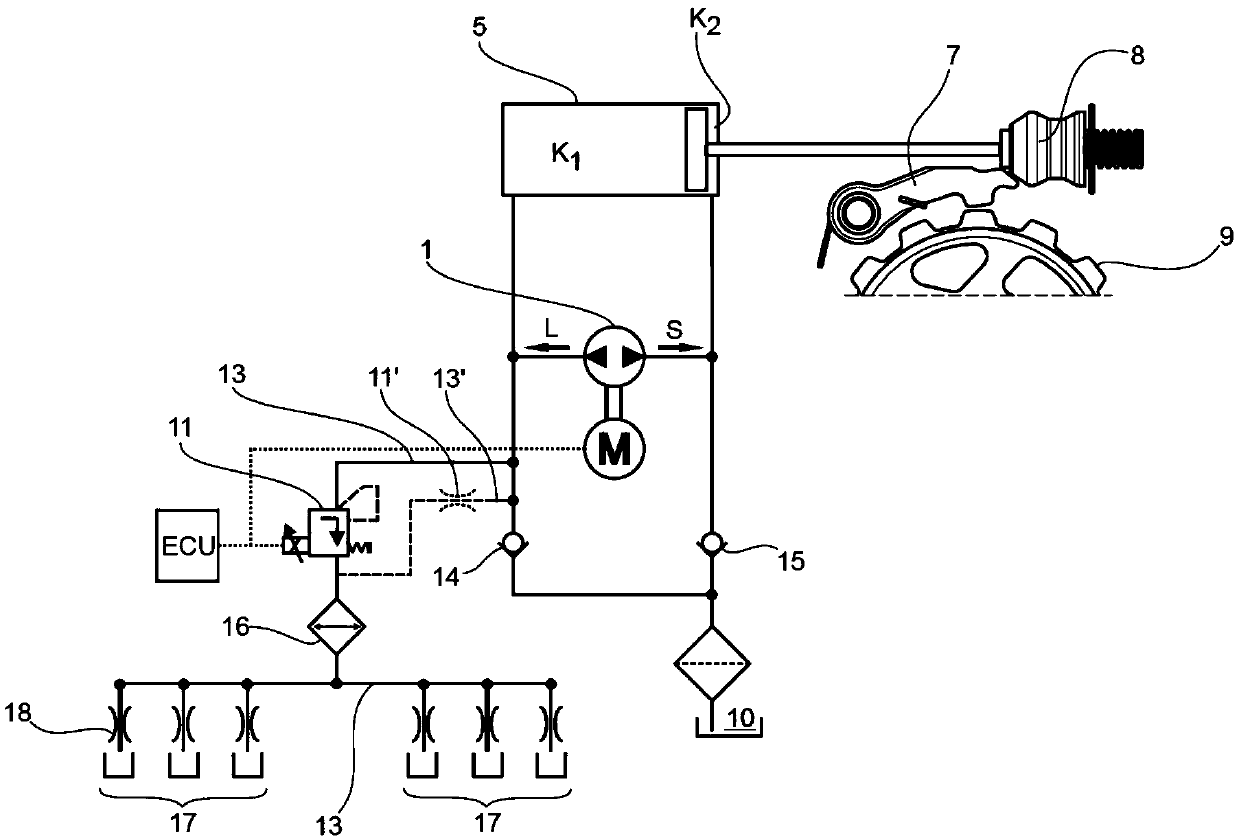

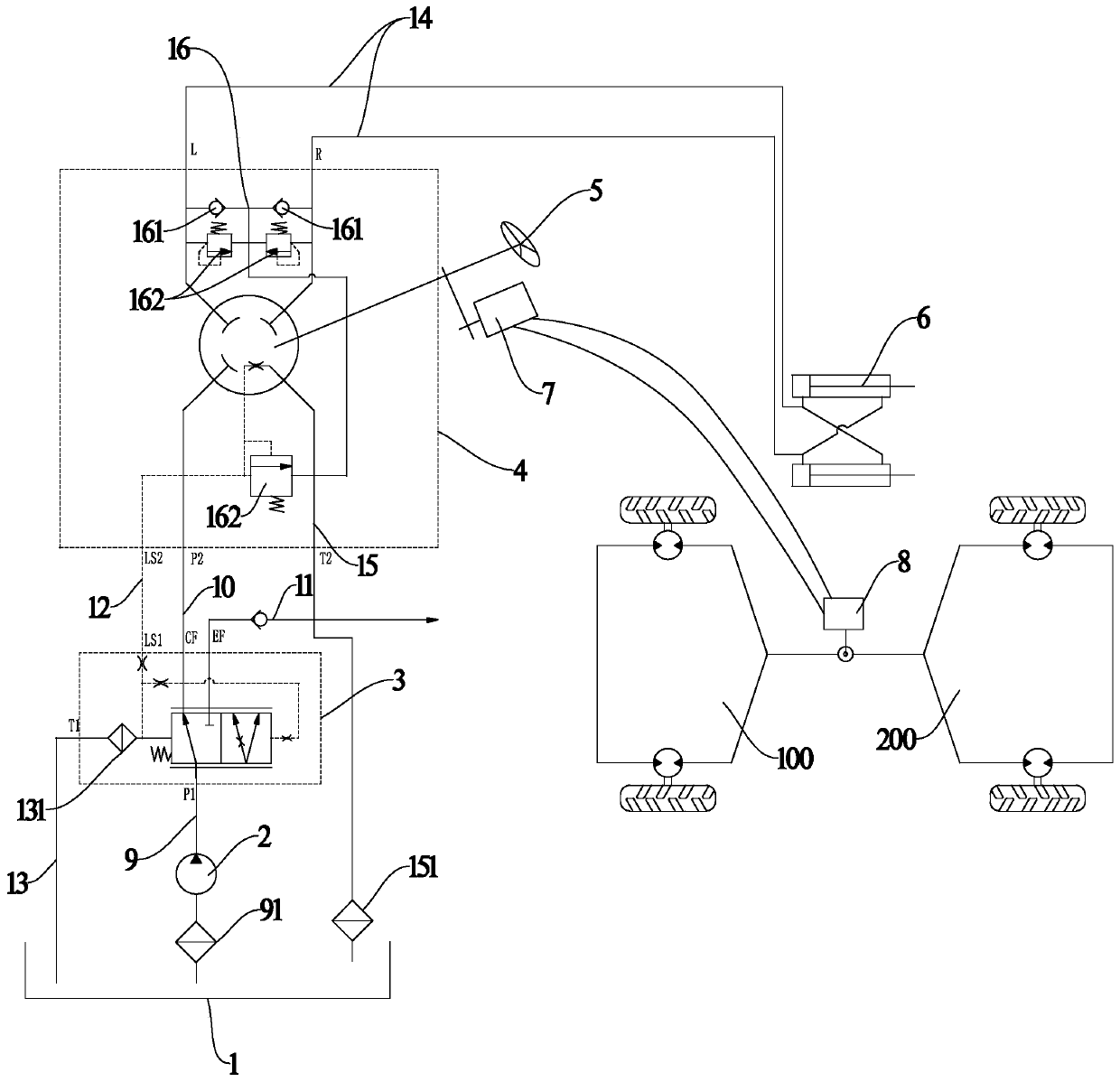

Dynamic load sensing all-hydraulic steering system of street sweeper

PendingCN110254509ASufficient oil supplySteering is smooth and reliableFluid steeringRoad cleaningSteering wheelLoad sensing

The invention discloses a dynamic load sensing all-hydraulic steering system of a street sweeper. The system comprises an oil tank, an oil pump, a pressure compensation priority valve, a pressure compensation all-hydraulic steering gear, a steering wheel and a steering cylinder, wherein the steering cylinder is arranged between a front frame and a rear frame which are hinged to each other, the front frame and the rear frame can be driven to rotate so as to perform the steering action, the pressure compensation priority valve is provided with a P1 port, a CF port, an EF port, an LS1 port and a T1 port, and the pressure compensation all-hydraulic steering gear is provided with a P2 port, an L port, an R port, an LS2 port and a T2 port. The system has the advantages of being flexible in steering performance, capable of realizing small-size installation, capable of reducing power loss, high in adaptability to cold weather, simple in operation, safe and reliable.

Owner:NINGBO EASYFAST ENVIRONMENTAL SANITATION EQUIP CO LTD

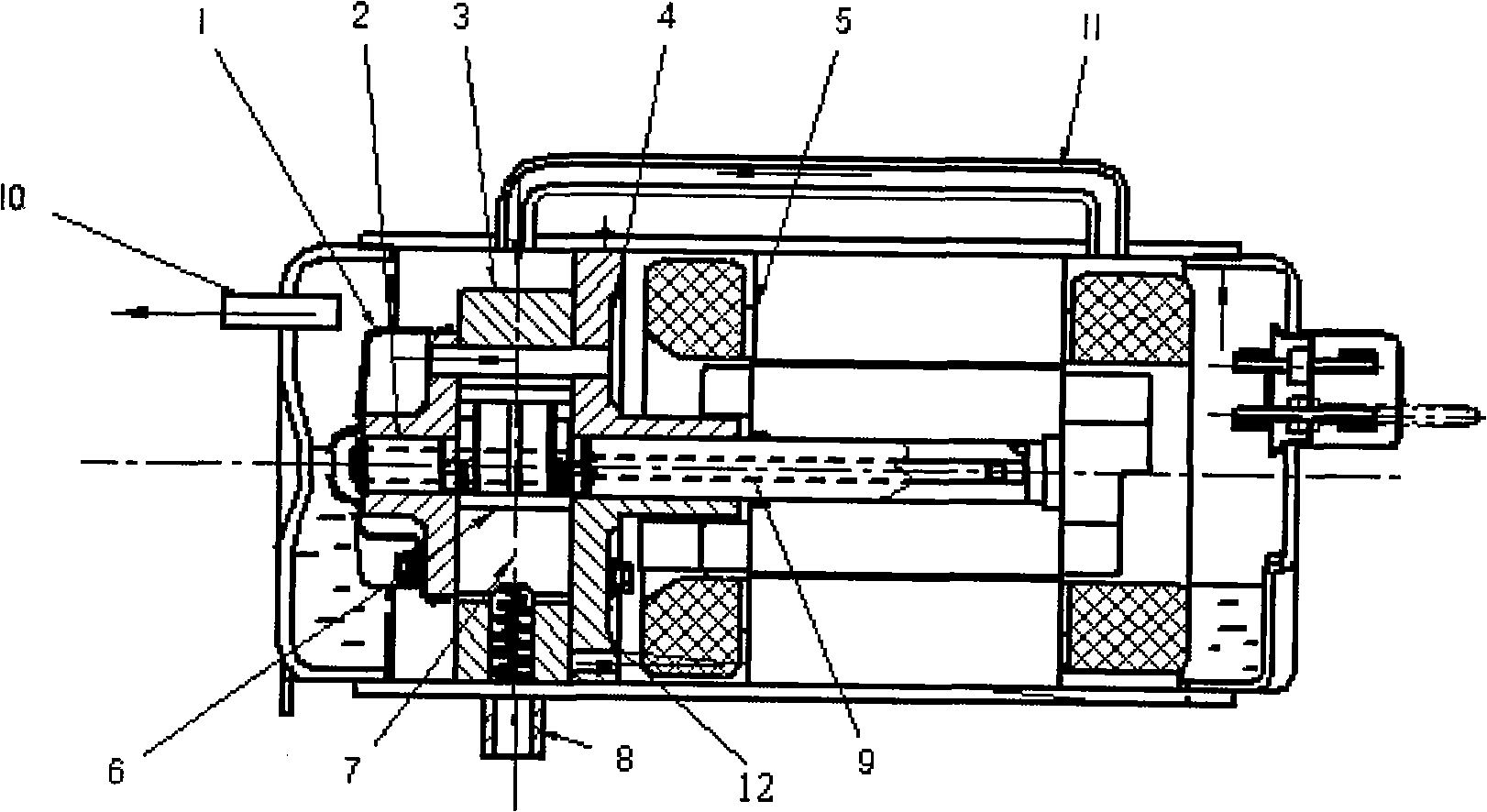

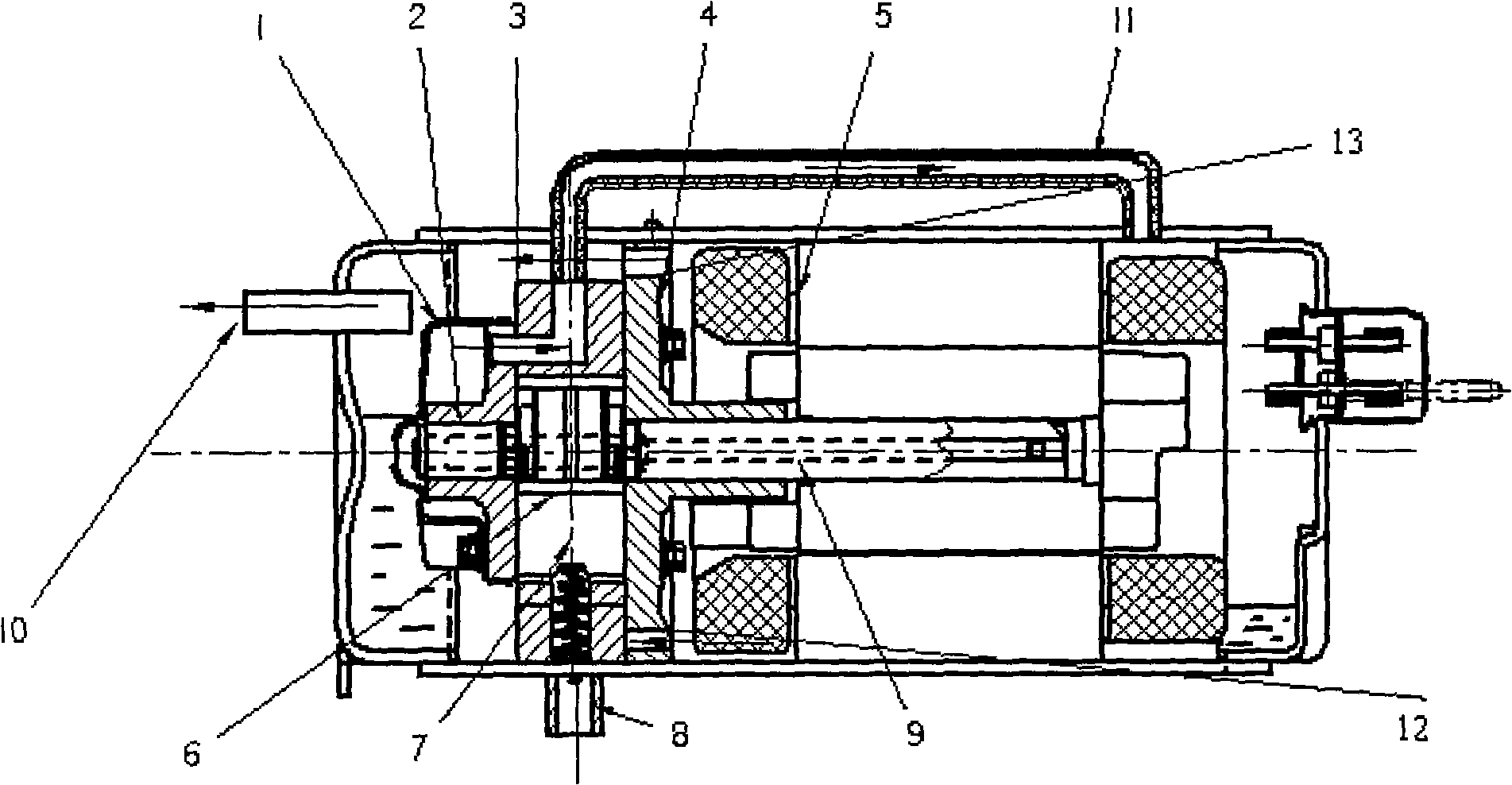

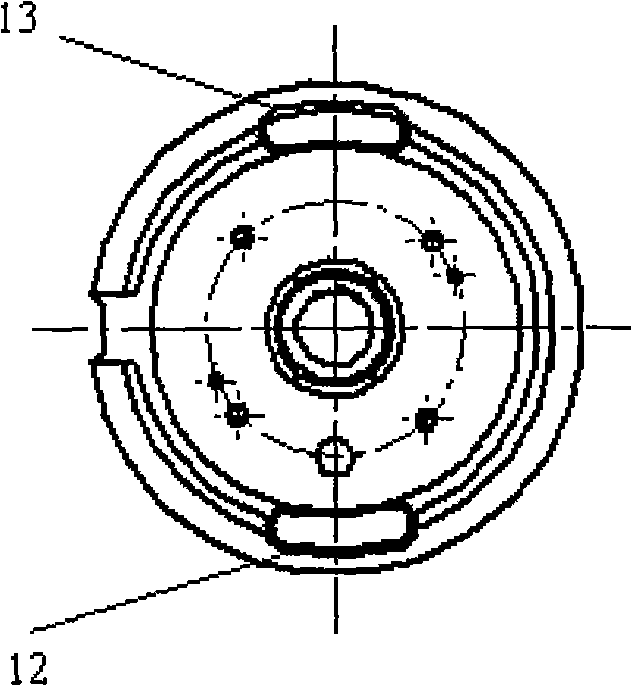

Self-cooling horizontal type rolling rotor compressor

InactiveCN101338751AImprove efficiencyRaise the oil levelRotary piston pumpsRotary piston liquid enginesEngineeringExhaust pipe

The present invention relates to a self-cooling horizontal rolling rotor compressor, which comprises an upper cylinder cover, an air cylinder, a lower cylinder cover, an electric motor, a piston, blades, an air inlet pipe, a crankshaft, an exhaust pipe, a muffle as well as a return air pipe; wherein, the upper cylinder cove is provided with a return air hole; the exhaust pipe is arranged on the pump body side; exhausted air enters into the return air pipe through a channel arranged on the pump body and is led into the end of the electric motor far from a pump body from a housing or a housing cover through the return air pipe in order to directly cool the electric motor; then the exhausted air enters into a compressing cavity through the return air hole on the upper cylinder cover and is exhausted through the exhaust pipe. Compared with the prior art, the present invention improves the operation conditions of the horizontal compressor, so that the reliability of the compressor is greatly improved.

Owner:SHANGHAI HITACHI ELECTRICAL APPLIANCES CO LTD

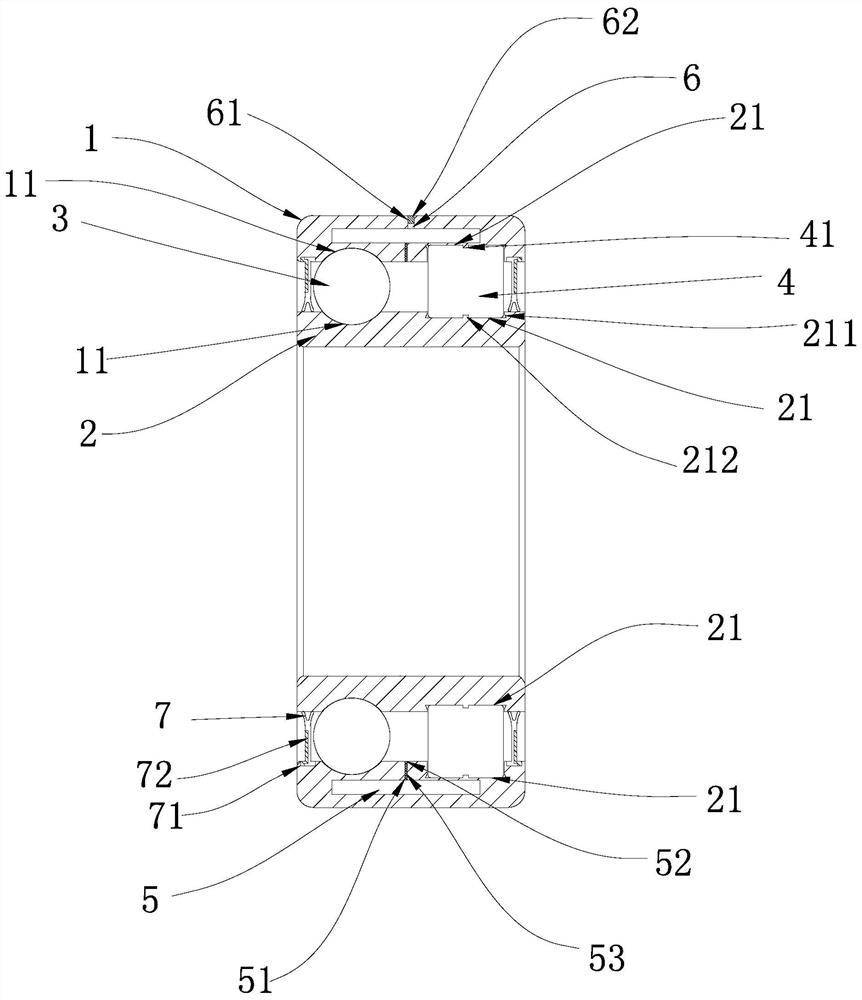

Novel combined bearing

InactiveCN112483541AImprove anti-overturn performanceGuaranteed normal operationBall and roller bearingsBearing componentsAxial loadIndustrial engineering

The invention discloses a novel combined bearing. The novel combined bearing comprises an outer ring, an inner ring, a row of balls and a row of cylindrical rollers, wherein the inner circumferentialwall of the outer ring and the outer circumferential wall of the inner ring are each annularly provided with a first roller path allowing the corresponding row of balls to roll, the inner circumferential wall of the outer ring and the outer circumferential wall of the inner ring are each annularly provided with a second roller path allowing the corresponding row of cylindrical rollers to roll, thefirst roller paths are located on one sides of the second roller paths, abutting grooves used for preventing the cylindrical rollers from bearing excessive overturning moment are formed in the innerwalls of the two sides of the two second roller paths correspondingly, limiting rings used for preventing the cylindrical rollers from bearing excessive overturning moment protrude out of the inner circumferential walls of the two second roller paths correspondingly, the outer circumferential wall of each cylindrical roller is annularly provided with a limiting groove allowing the corresponding limiting ring to be inserted therein, and the outer ring is provided with an oil supplementing piece used for supplementing oil into the bearing. The problems that in the prior art, a bearing is prone to damage under radial loads and axial loads, and oil supply in the bearing is insufficient are solved.

Owner:C&U CO LTD +1

Atomization structural member, atomizer and aerosol generating device

The invention relates to an atomizing structural member, an atomizer and an aerosol generating device. A guide part is in contact with an atomizing medium, and the atomizing medium is transferred into an atomizing part through an inner wall part and an outer wall in sequence; the outer wall forms a first atomizing surface, and a first air channel for transmitting aerosol generated by the first atomizing surface is formed between the outer wall and the inner wall part. The heating body indirectly makes contact with the atomizing medium in the liquid storage cavity through the guiding part, a long distance exists between the heating body and the atomizing medium in the liquid storage cavity, heat transfer is effectively isolated, the atomizing medium in the liquid storage cavity is prevented from deteriorating due to high temperature, and the heating efficiency of the whole atomizing structural part is high; the outer wall of the atomizing part is in direct contact with the inner wall of the guiding part, the guiding part obtains the atomizing medium through the liquid suction face, the oil guiding area is large, oil guiding is conducted in all directions, sufficient oil supply can be effectively guaranteed, it is guaranteed that the atomizing medium is smoothly conveyed to a heating body, and the problems that in traditional atomization, the atomizing effect is poor, and the smoke amount is insufficient are solved.

Owner:深圳市大迈发展有限公司

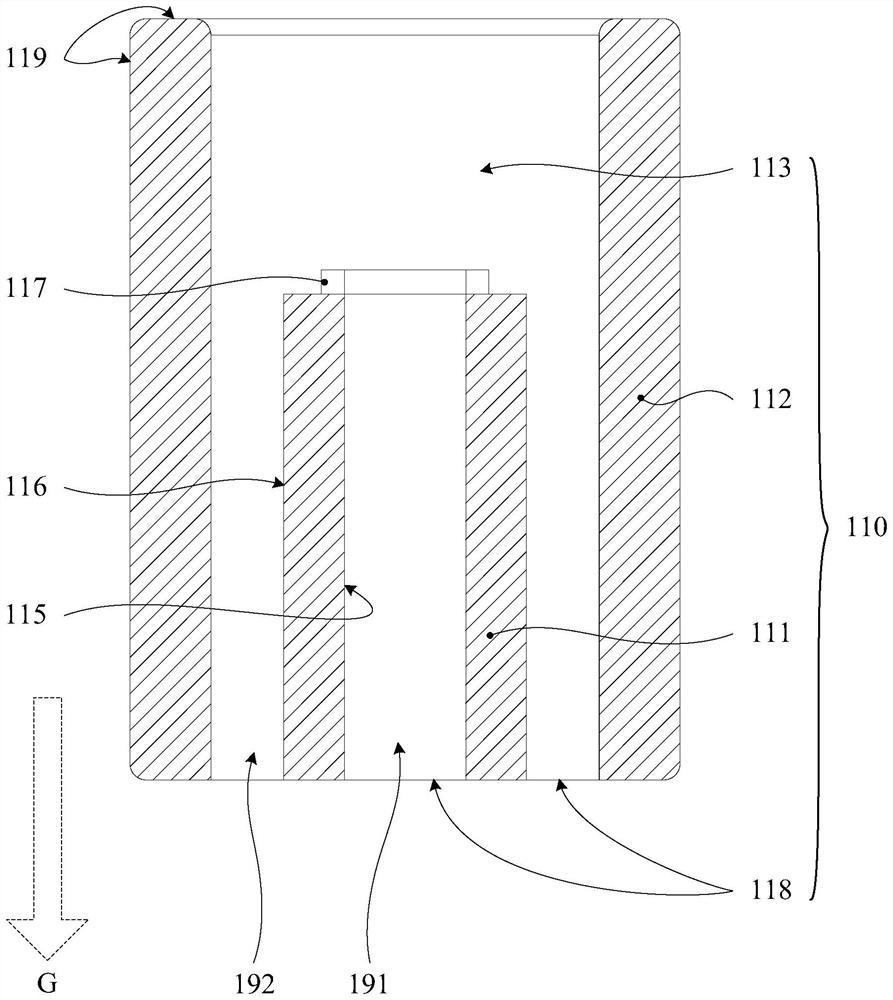

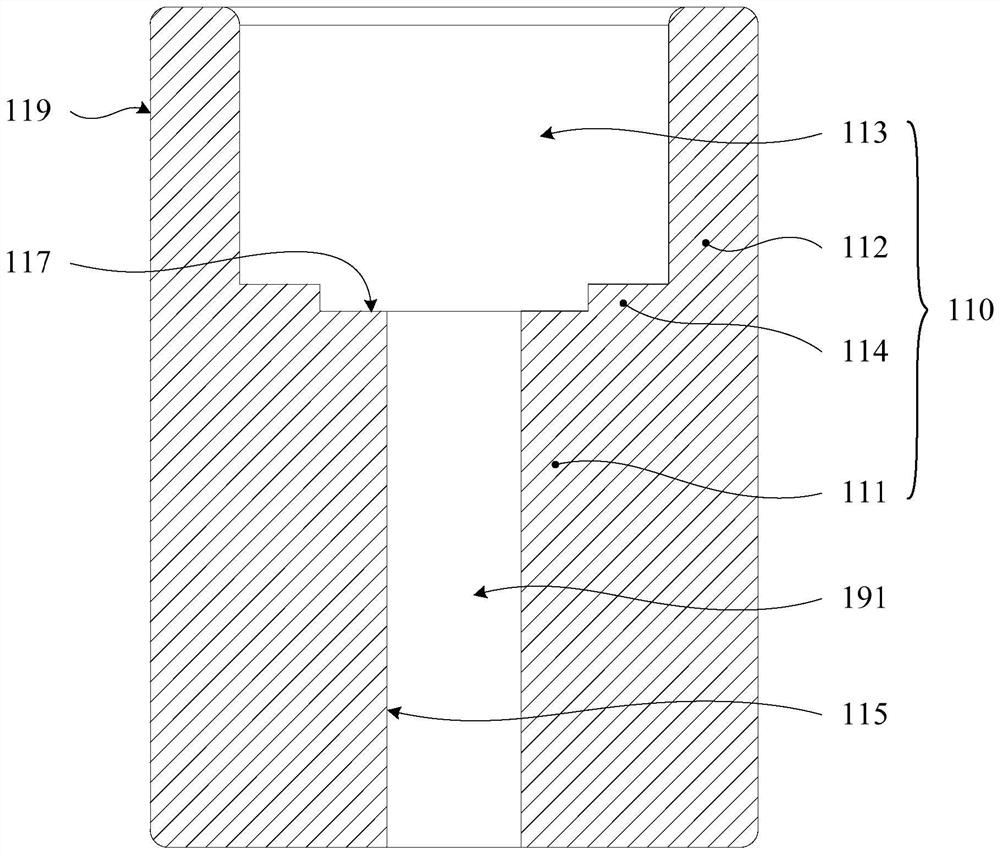

Piston for internal combustion engine

InactiveCN1384279AAvoid weight gainAchieve high rotationPlungersLubricant conduit arrangementsEngineeringInternal combustion engine

The invention discloses a piston for an internal combustion engine. The piston for high rotation is formed through lighter weight and compactness. A first air ring groove 2 and an oil ring groove 4 are formed around the crown 1, and an oil supply hole 5 is provided inside the oil ring groove 4, and a pair of air ring grooves 5 are arranged at positions opposite to the bottom of the crown 1 continuously. The piston pin seat 6 is provided with a skirt 7 staggered by 90 degrees from the piston pin seat 6, the lower end 12 of the skirt 7 is located above the lower end 11 of the piston pin 6, and on the upper part of the skirt 7, the oil An oil supply hole 10 is provided below and near the ring groove 4 .

Owner:HONDA MOTOR CO LTD

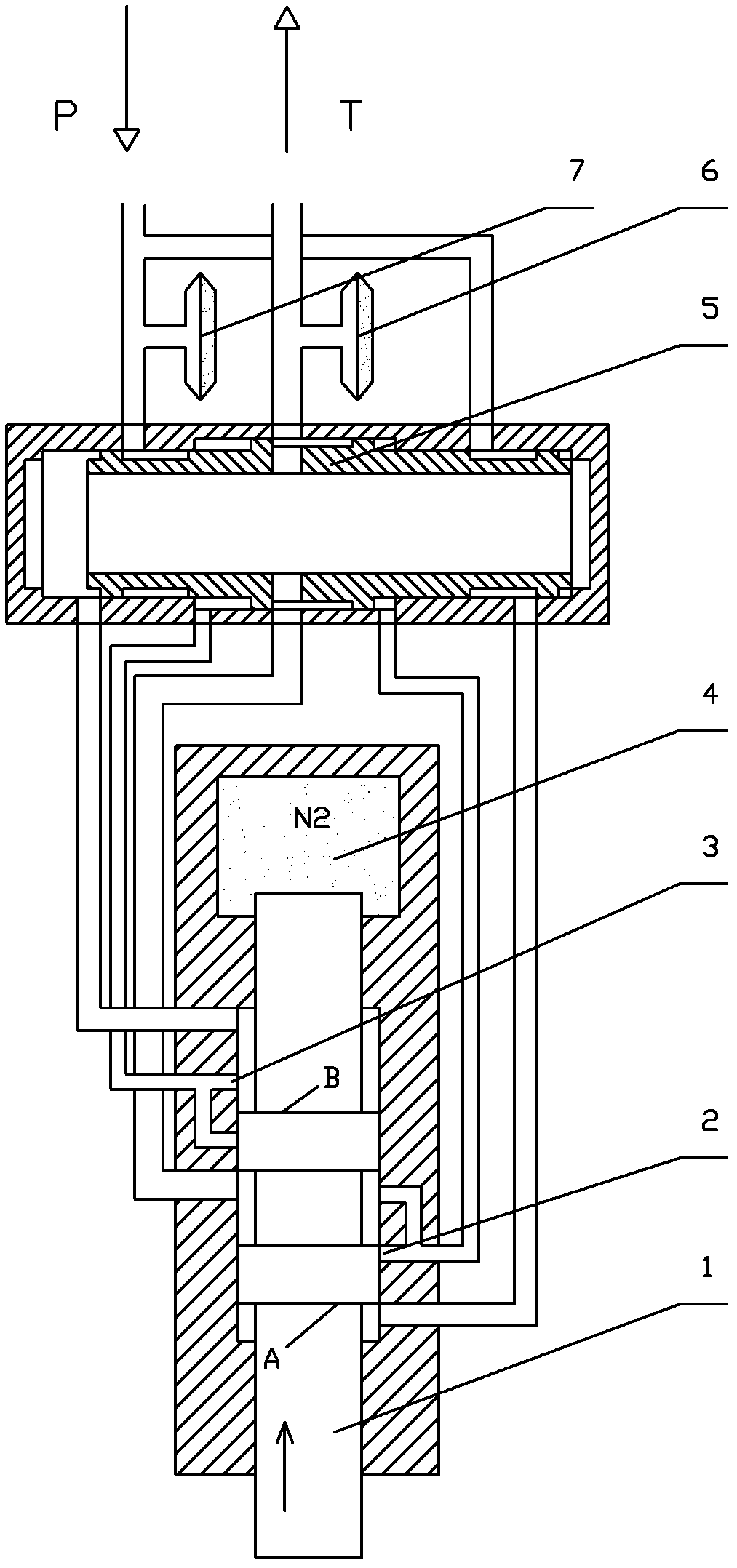

Gas-liquid combined hydraulic impacter

InactiveCN102635588AIncrease impactImprove energy utilizationPortable percussive toolsFluid-pressure actuatorsNitrogenEngineering

The invention discloses a gas-liquid combined hydraulic impacter. The gas-liquid combined hydraulic impacter disclosed by the invention comprises a valve body, a valve core and a double-sided oil feed / discharge impacter, wherein the double-sided oil feed / discharge impacter comprises a piston, a pilot operated directional control valve and an oil way; the tail end of the piston is provided with a nitrogen chamber, a joint of the nitrogen chamber and the piston is hermetically connected, and the tail end of the piston is arranged in the nitrogen chamber both in the processes of returning and stroking. The impacter disclosed by the invention is high in energy utilization ratio, so that the oil supply quantity of a valve pushing cavity is sufficient, thereby preventing the occurrence of a 'suction' phenomenon and reducing hydraulic shocks, vibration and noises, in such a way, the operations of the pilot operated directional control valve and the piston are stable, and the service lives of the pilot operated directional control valve and the piston are prolonged.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

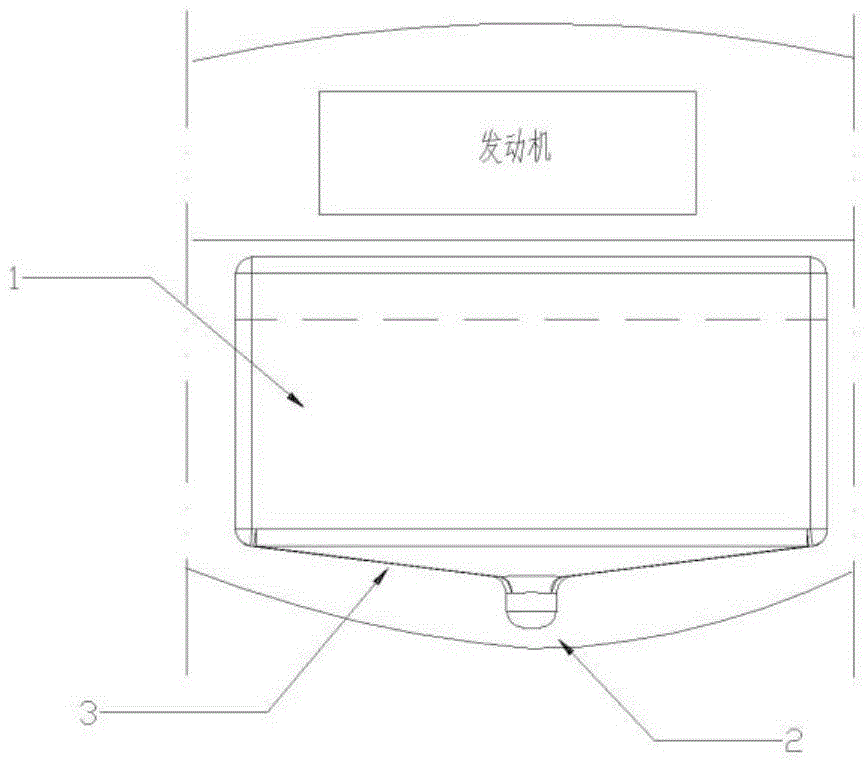

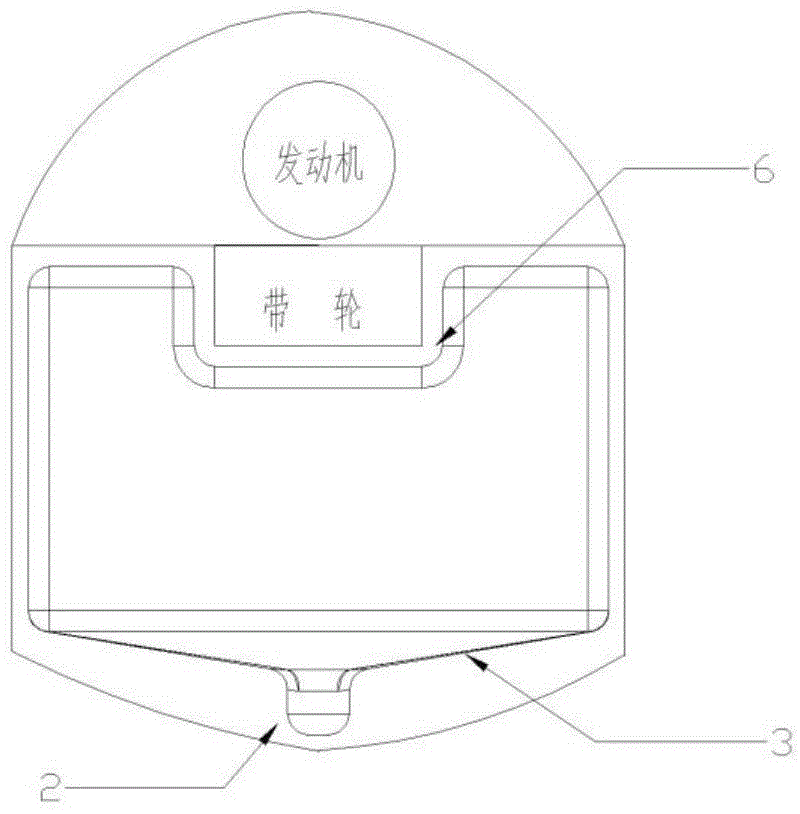

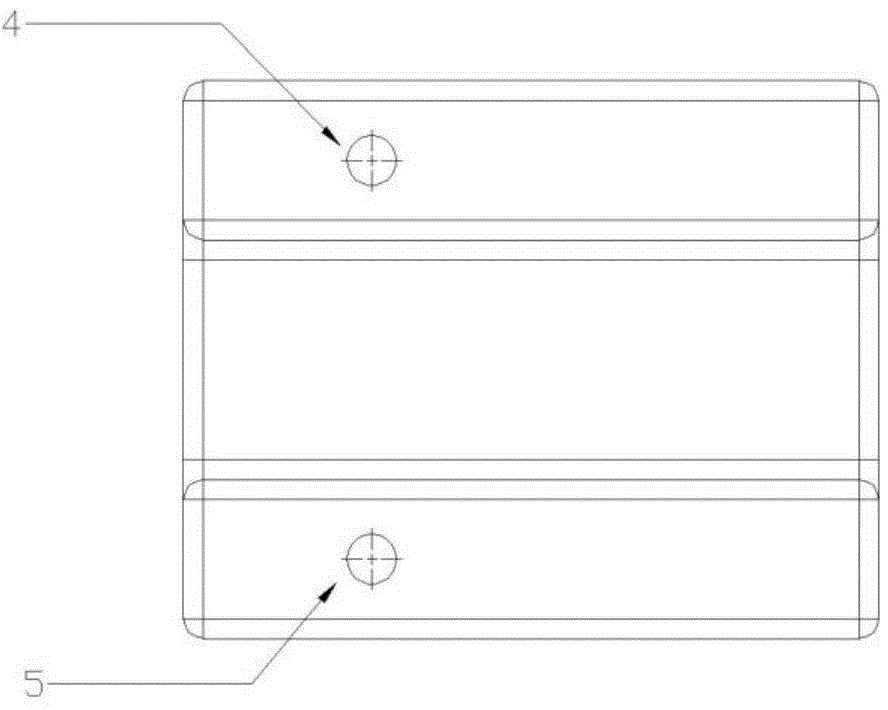

Thin-wall oil tank of unmanned helicopter

ActiveCN104925266AIncrease fuel capacityExtend working hoursPower plant fuel tanksWeight reductionAirplaneThin walled

The invention discloses a thin-wall oil tank of an unmanned helicopter. The oil tank adopts a cubic irregular profile structure, and the oil tank is formed by connecting an upper part and a lower part, wherein the upper part adopts a cubic structure with a groove; the lower part adopts a slope structure formed by splicing four triangle plates, and an oil whirling is arranged at the bottom of the slope structure; a helicopter engine and a belt wheel connected with a helicopter empennage are arranged at the middle upper part of the oil tank; the groove of the oil tank is right matched with the belt wheel, and the heights of both sides of the groove are increased. The lower part of the unmanned helicopter body is curved, and the bottom of the oil tank adopts the slope structure, so that bottom of the oil tank is right fit with the helicopter body. Through the adoption of the design of the oil tank disclosed by the invention, the oil capacity of the oil tank of the helicopter is increased farthest, and the working time of the helicopter is prolonged.

Owner:TIANXUN INNOVATION BEIJING TECH CO LTD

Special oil lubrication solid bearing seat for ventilating machine

The invention provides a bearing seat special for ventilator. Two bearings fix the blade of the ventilator. The oil supply circuit of the bearing is of labyrinth structure. One bearing is big and the other is small, the end bearing is of small diameter and the middle bearing is of large diameter. As adopting large, small two bearings, mounting can be done at one side, and the labyrinth structure of the ventilator ensures the oil supply to bearing more sufficient. Advantages: avoided over heated of machine oil, long service life and convenient mounting.

Owner:SUZHOU HUASHENG FAN PLANT

Lubricating and cooling combined structure of engine piston and connecting rod group

ActiveCN105156171BSimple designImprove reliabilityLiquid coolingMachines/enginesFree-piston engineCooling chamber

The invention belongs to the technical field of machinery and proposes a lubricating and cooling combined structure of an engine piston connecting rod group. A combined lubricating and cooling structure for an engine piston and connecting rod group proposed includes a connecting rod lubricating structure and a piston cooling structure; the connecting rod lubricating structure has a connecting rod journal oil hole (8) located on the connecting rod journal of the crankshaft; The rod journal oil hole (8) is a radial through hole located on the connecting rod journal of the crankshaft and communicates with the main oil passage of the diesel engine; the upper end of the small end of the connecting rod (13) is provided with a guide for communicating with the piston cooling structure. The oil jacket (27); the inner cooling cavity (25) of the piston cooling structure; the upper end outlet of the oil guide sleeve (27) is located in the inner cooling cavity (25); the outer cooling cavity (25) is provided with an outer cooling cavity ( twenty three). The cooling of the piston and the lubricating of the connecting rod in the invention share the same engine oil passage, the design is simpler, the reliability is higher, and the lubricating and cooling efficiency is high.

Owner:HENAN DIESEL ENGINE IND

A load-sensitive forklift multi-way valve

ActiveCN104141650BIncrease pressureReduce loadServomotor componentsLifting devicesInlet valveShuttle valve

The invention provides a load sensitive forklift multi-way valve, and belongs to the technical field of engineering machinery hydraulic components. The load sensitive forklift multi-way valve comprises an oil inlet valve piece, a lifting valve piece, an inclined valve piece, a fitting valve piece and an oil return valve piece. All the valve pieces are provided with flow control valve rods and oil inlet one-way valves respectively, the inclined valve piece is provided with a load maintaining valve, and the oil return valve piece is provided with an unloading valve core, a reset spring, a shuttle valve and a secondary overflow valve. The load sensitive forklift multi-way valve has good flow control performance, so that the speed of an executing mechanism is unrelated to the load pressure and is only associated with the stroke of the valve rods, and the pressure of a system is unrelated to flow change of oil feeding. Meanwhile, the inclined valve piece is provided with the load maintaining valve, so that the forwards leaning pressure keeps stable all the time, load on an oil cylinder is lowered, when the system flow is larger than the required flow, oil return is conducted on the redundant flow through the unloading valve core, energy consumption can be effectively reduced, and the load sensitive forklift multi-way valve is high in efficiency and less in power loss, so that fuel is saved and a hydraulic system is lower in heating quantity.

Owner:ZHEJIANG HAIHONG HYDRAULIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com