Integrated rotary tower and oil path system of bottle cap molding press

An oil circuit system and molding machine technology, which is applied to household components, household appliances, other household appliances, etc., can solve the problems of complex, unreasonable, unstable oil pressure, etc., and achieve reliable transmission, low noise, and overcome assembly errors. and the effect of installation trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

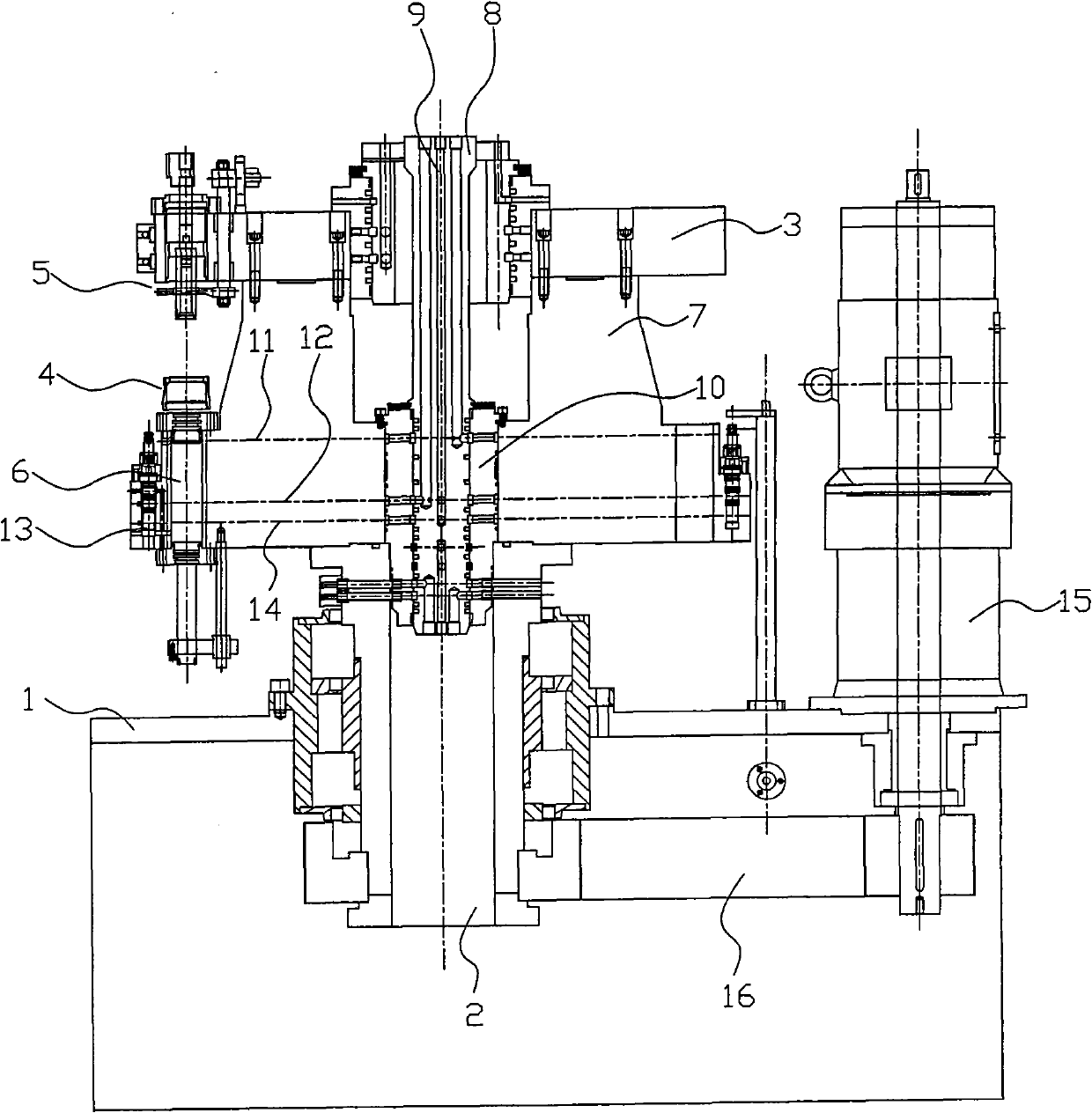

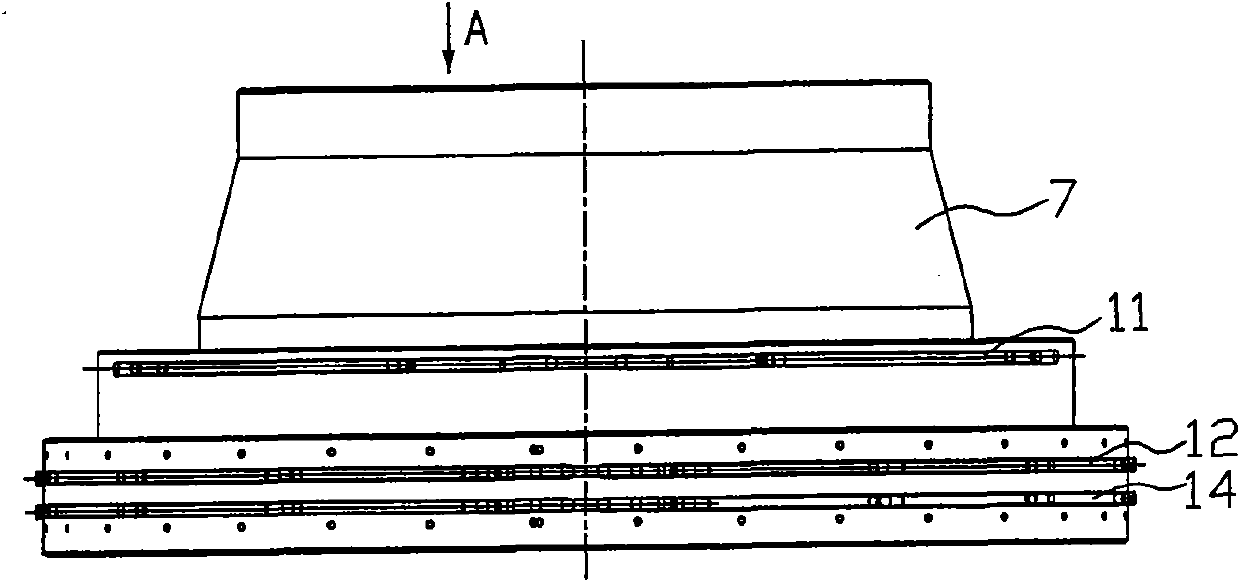

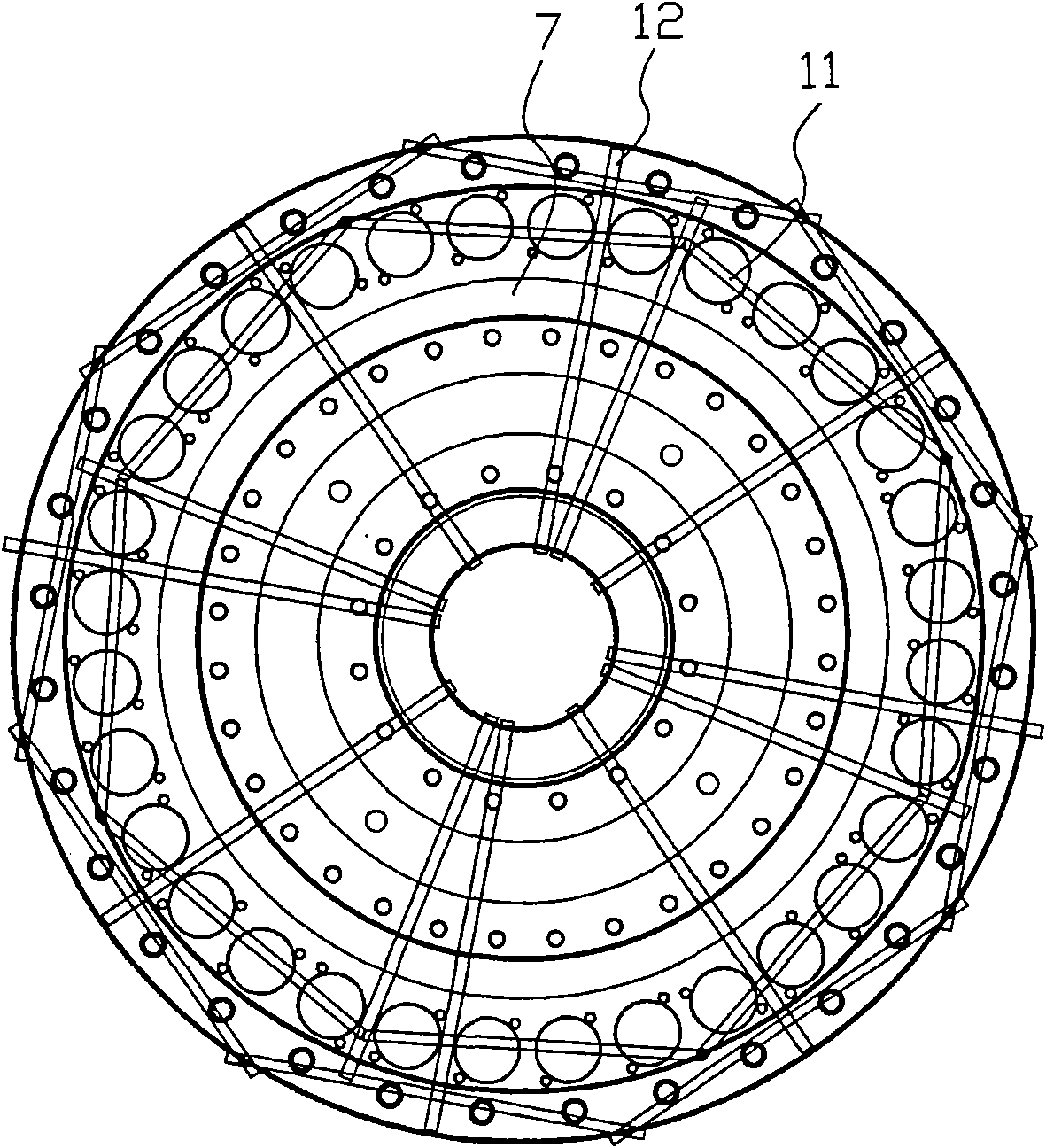

[0010] The invention relates to an integral turret and an oil circuit system of a bottle cap molding machine, such as Figure 1-Figure 3 As shown, it includes machine base 1, main shaft 2 is installed on the machine base, the main shaft is driven by power, lower template and upper template 3 are installed on the main shaft, lower mold assembly 4 is installed on the lower template, and hydraulic cylinder 6 is connected under the lower mold assembly. The upper mold assembly 5 is installed on the template, and it is characterized in that the lower template is an integral turret type turret 7, an oil inlet shaft 8 is installed in the turret, an oil inlet hole 9 is formed in the oil inlet shaft, and the lower end of the oil inlet shaft is installed Oil circuit distributor 10, the lower part of the oil circuit distributor is sealed and connected to the main shaft 2, and a low-pressure oil hole 11 and a high-pressure oil hole 12 are formed in the turret 7, and the low-pressure oil hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com