Patents

Literature

90results about How to "Stable oil supply" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

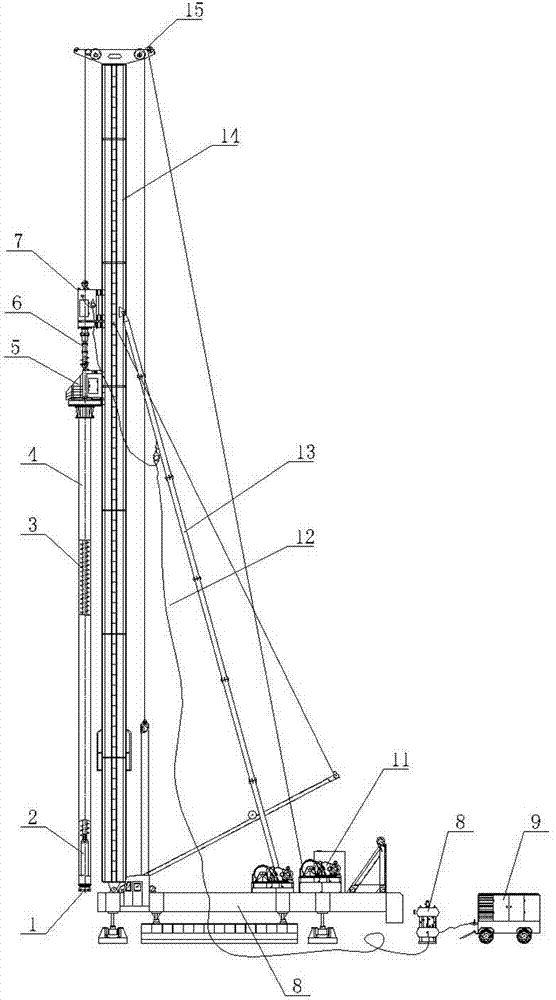

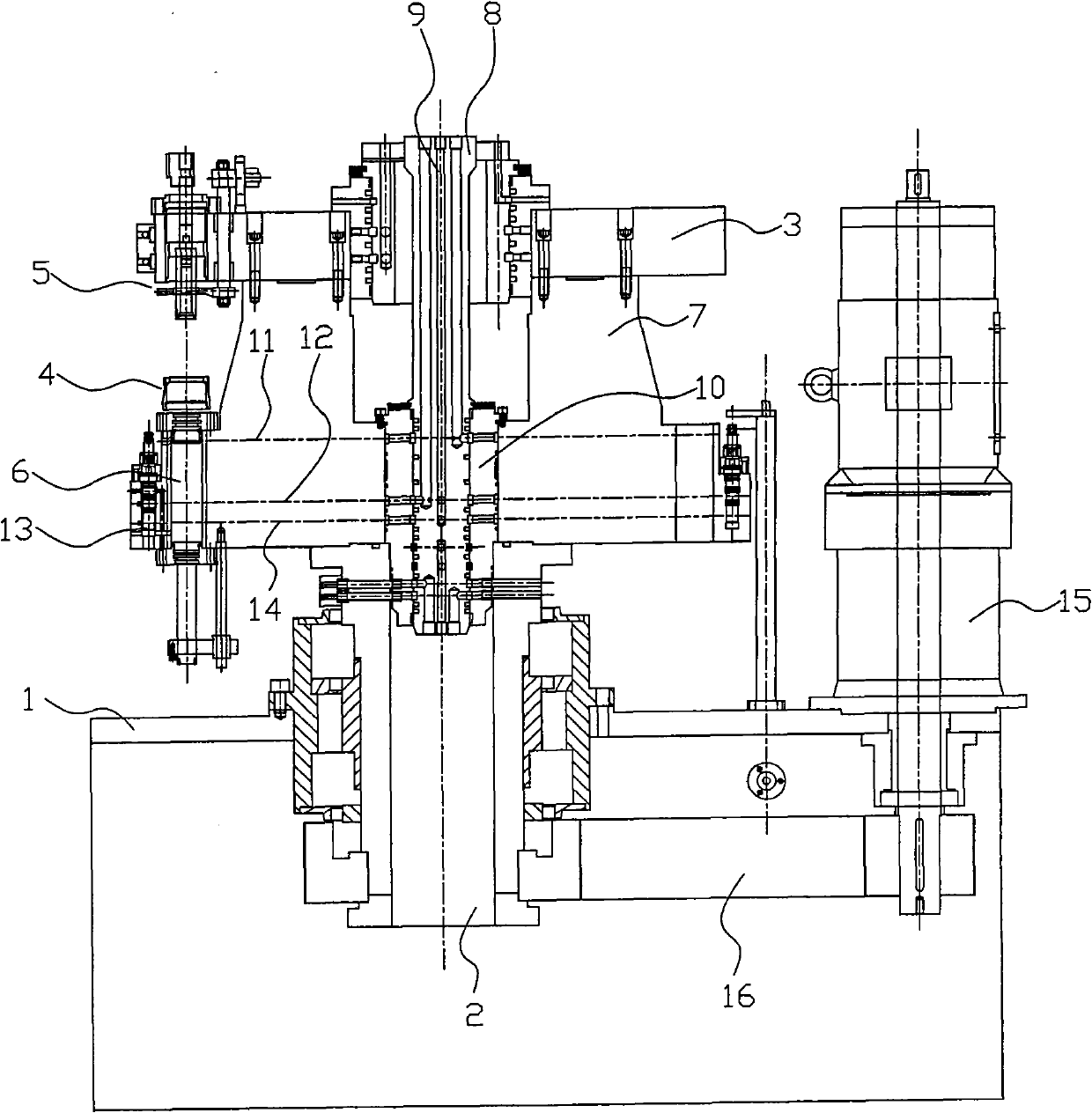

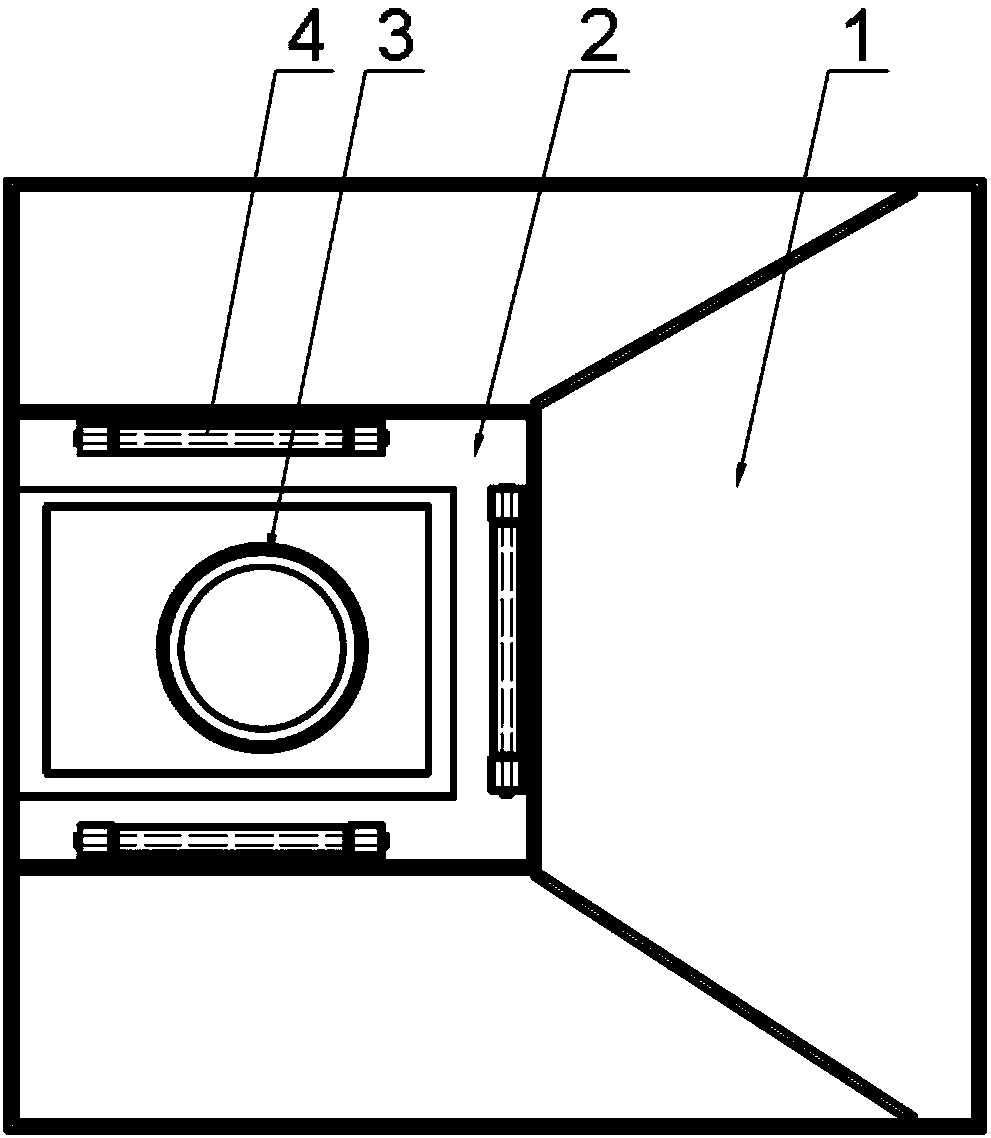

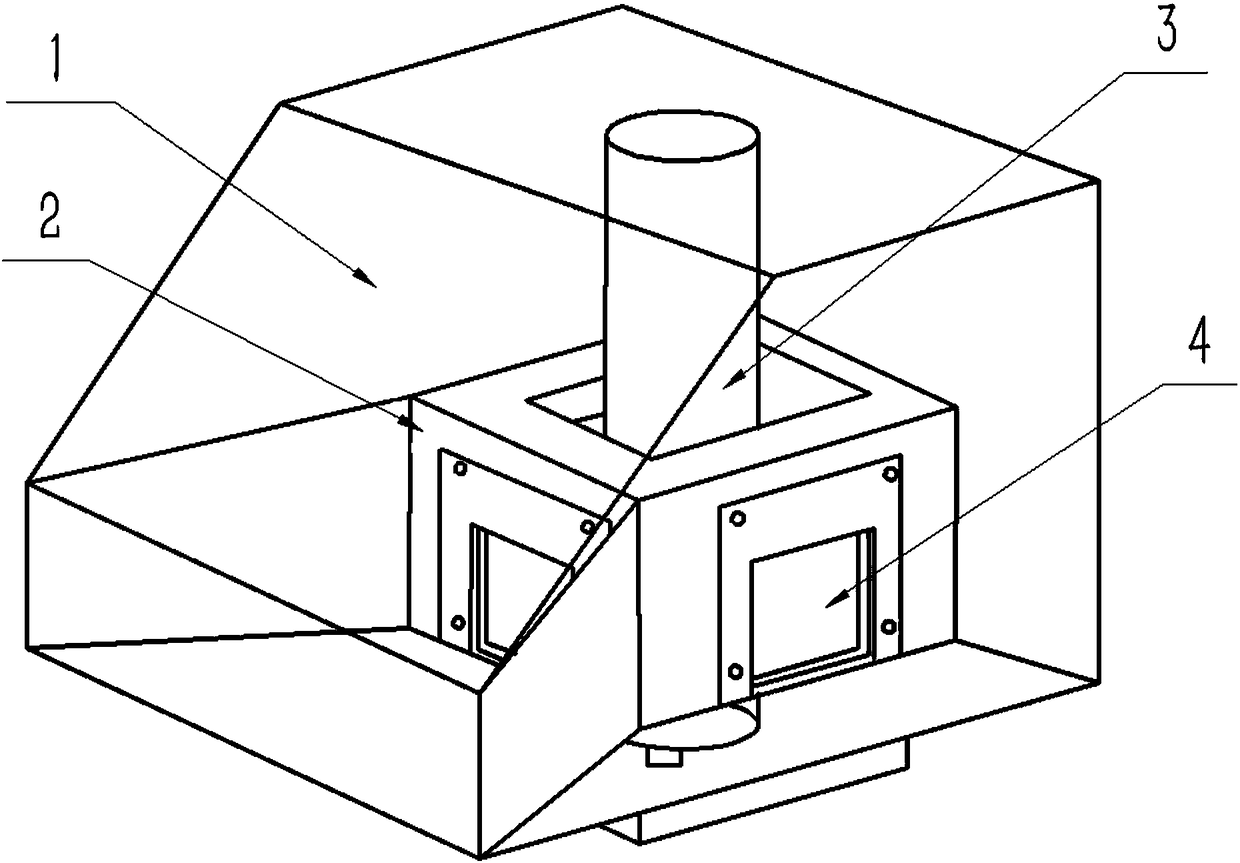

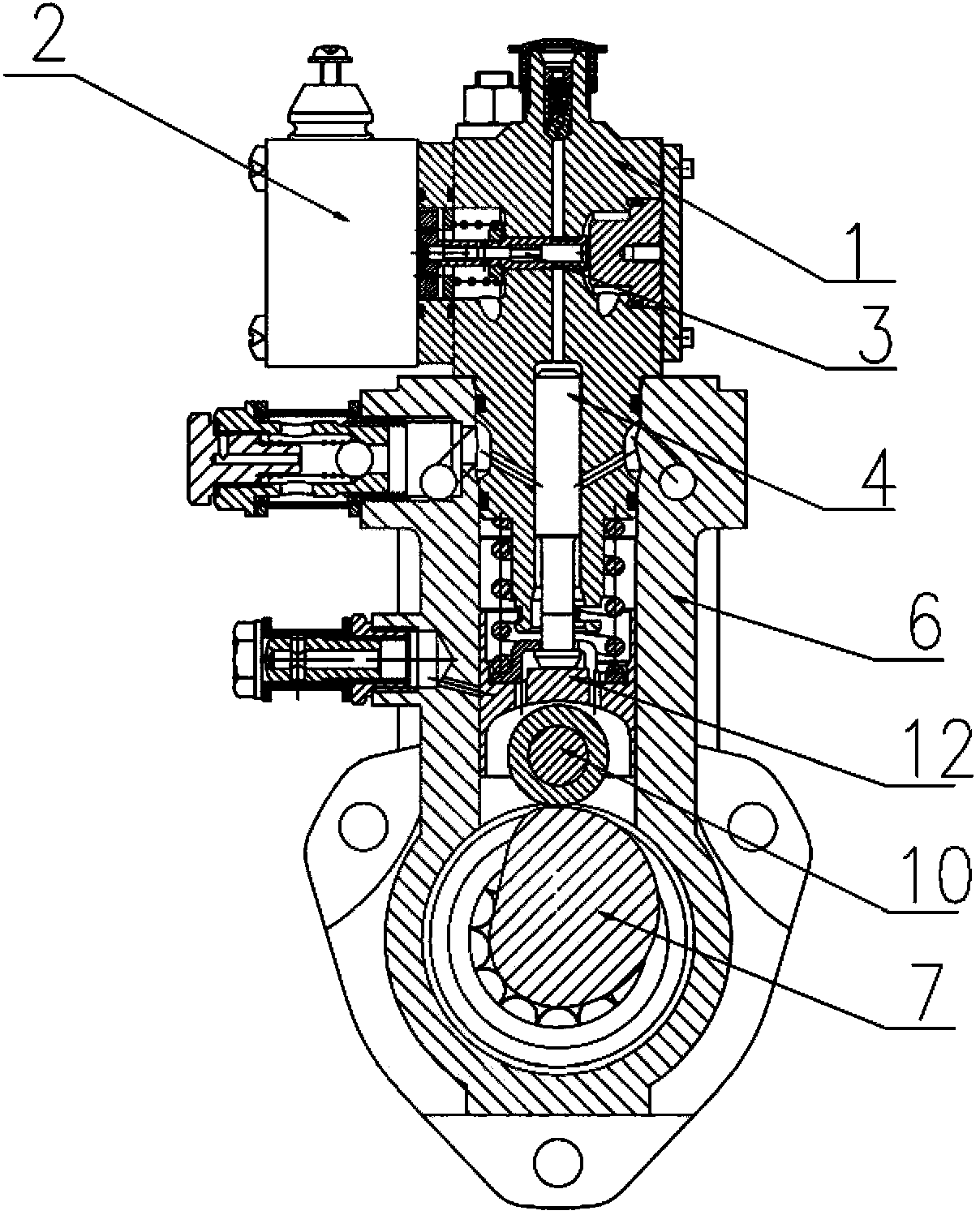

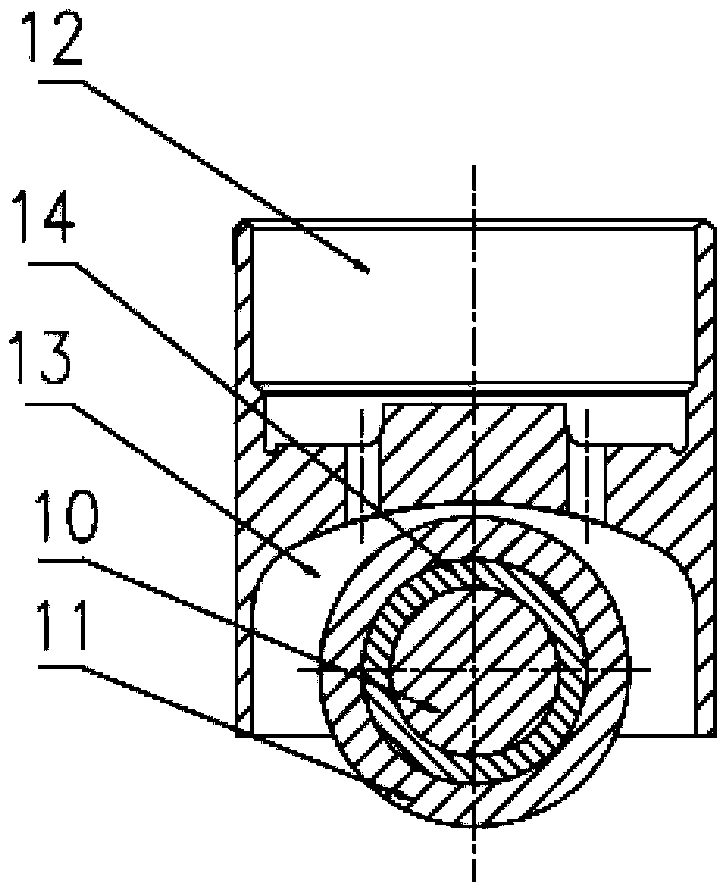

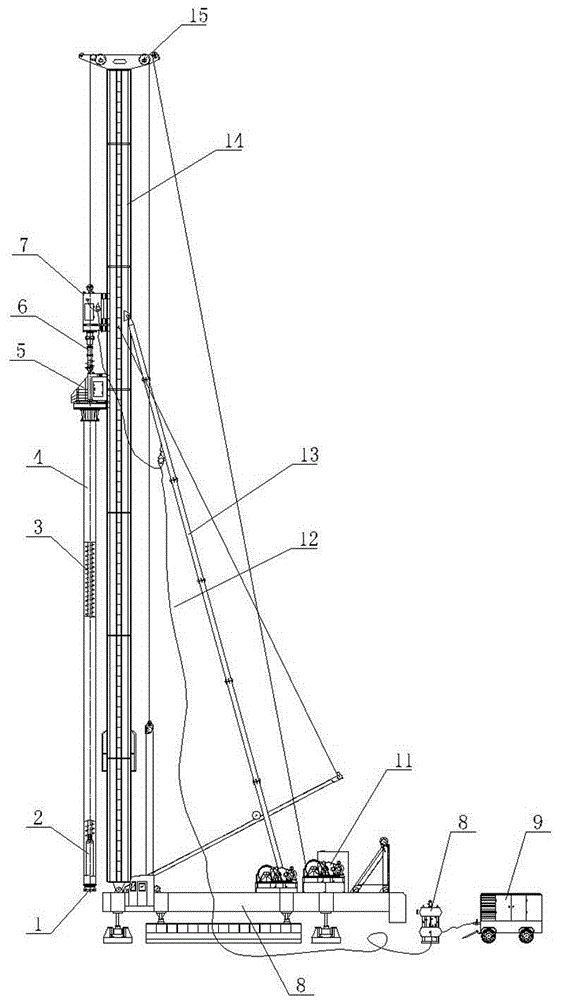

Walking dual-swing downhole drill

ActiveCN102828690AFully lubricatedOil Mist StabilizationConstructionsReciprocating drilling machinesEngineeringHigh pressure

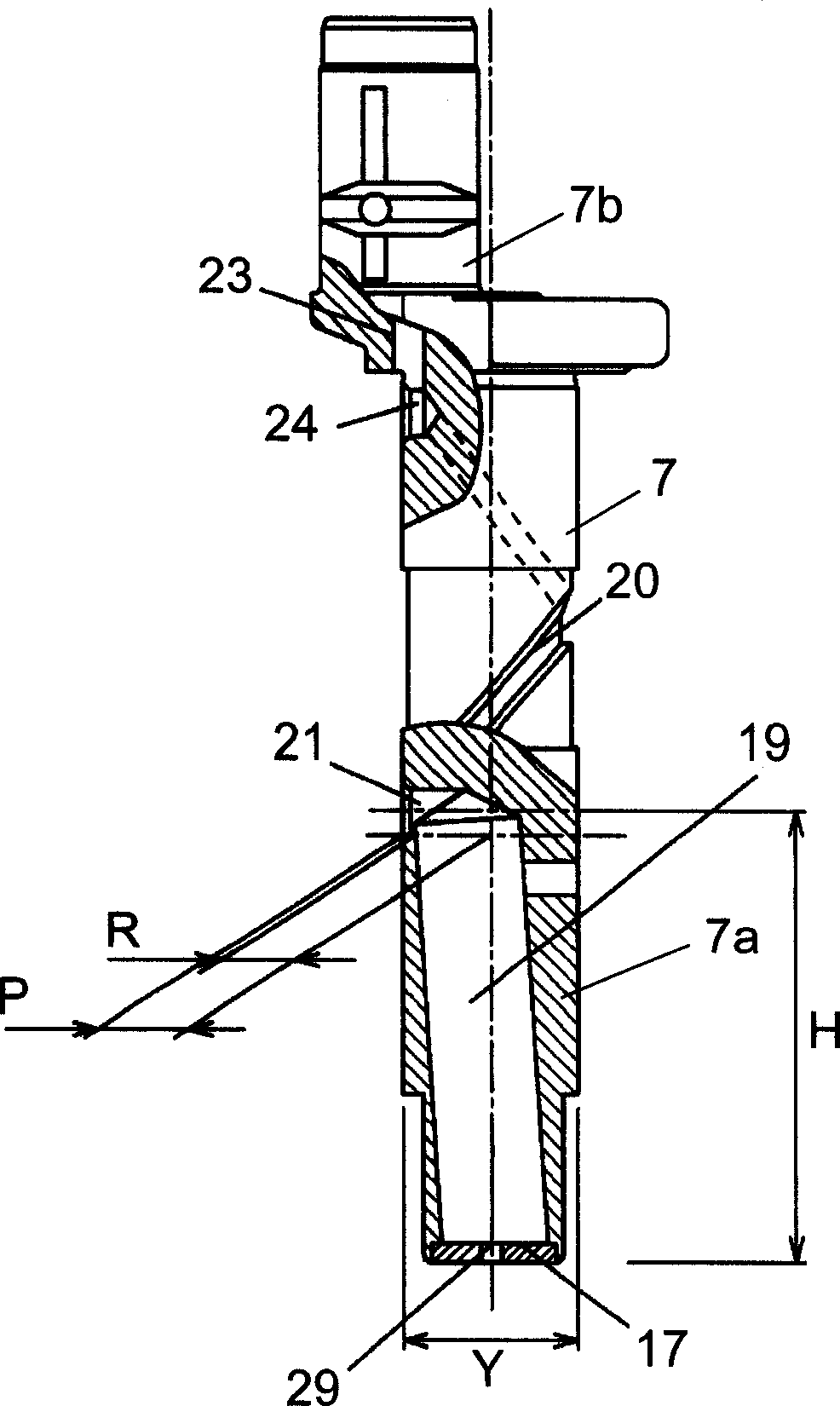

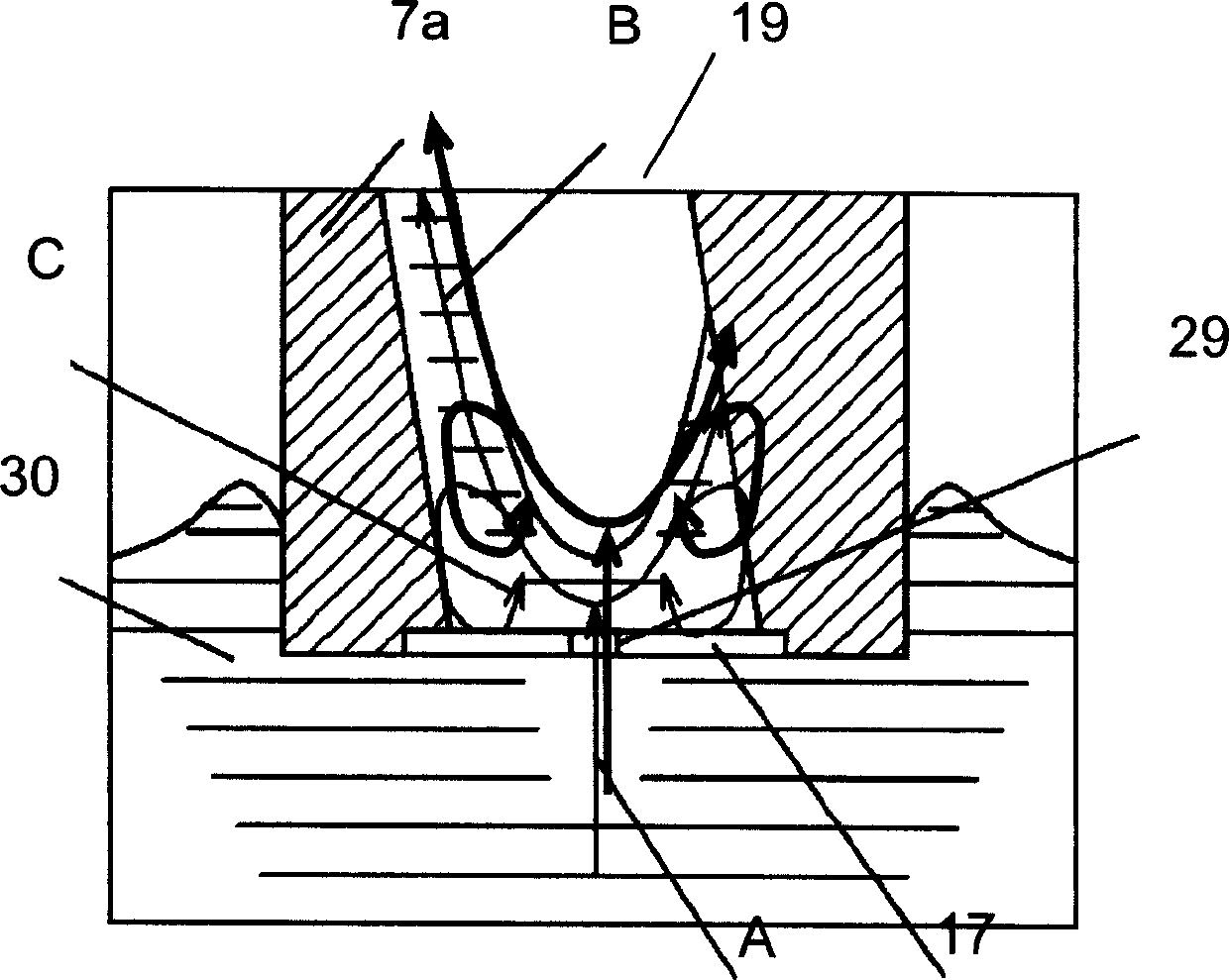

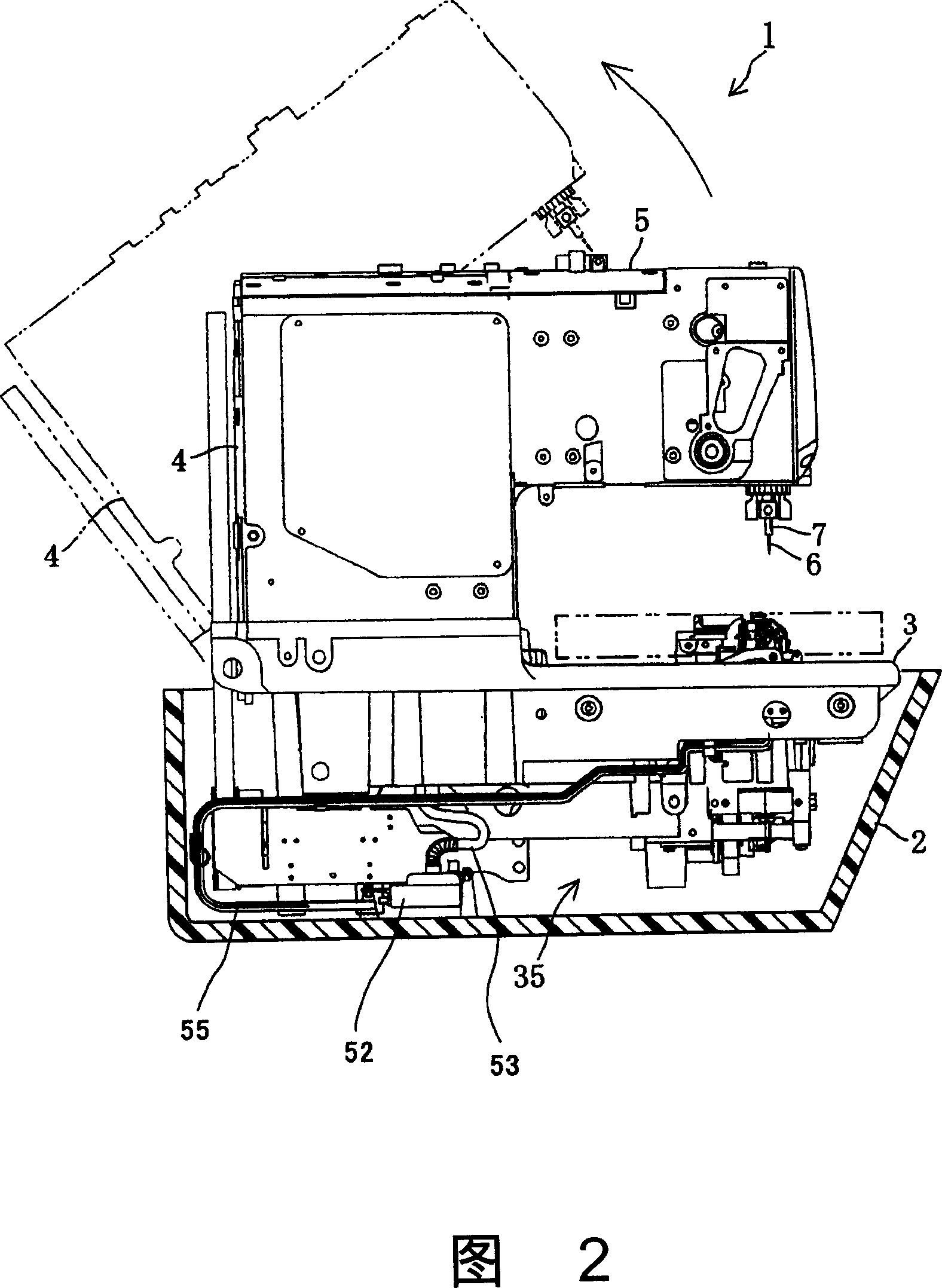

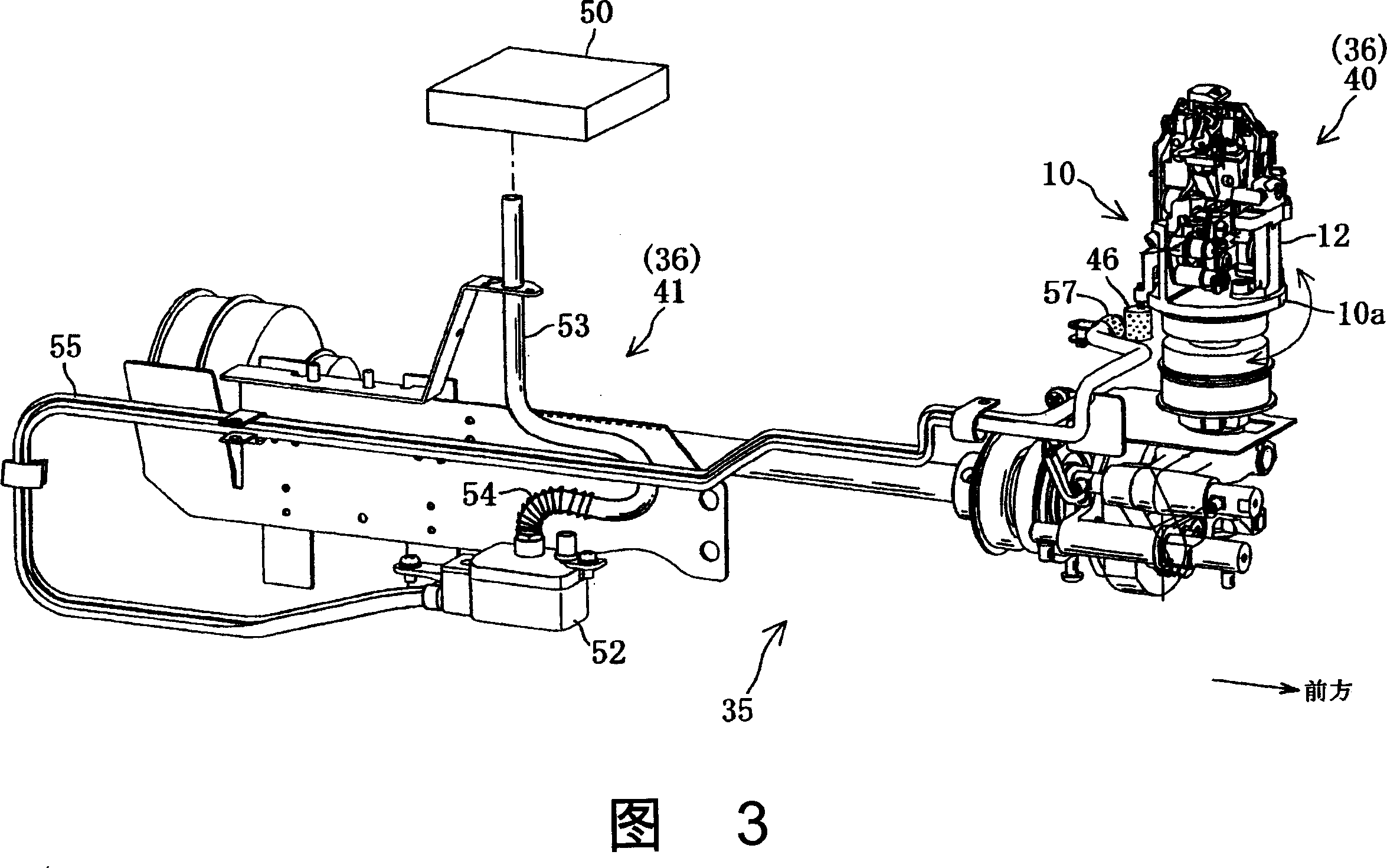

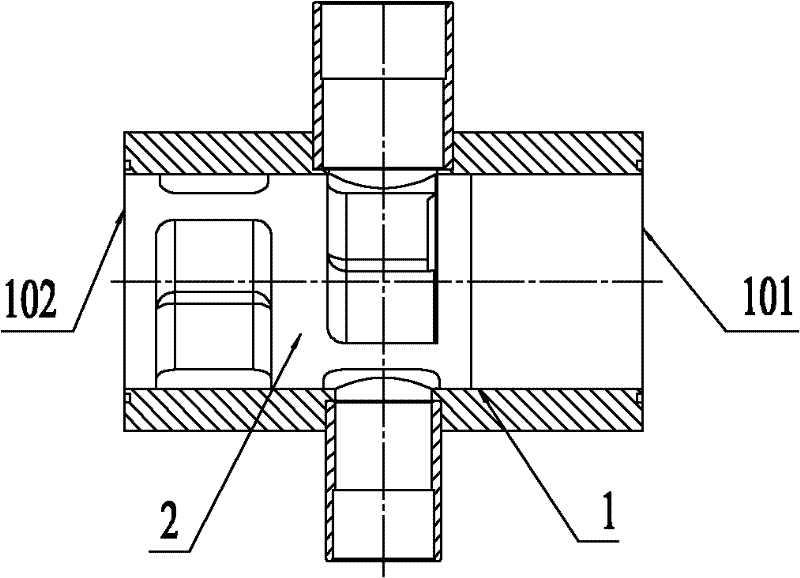

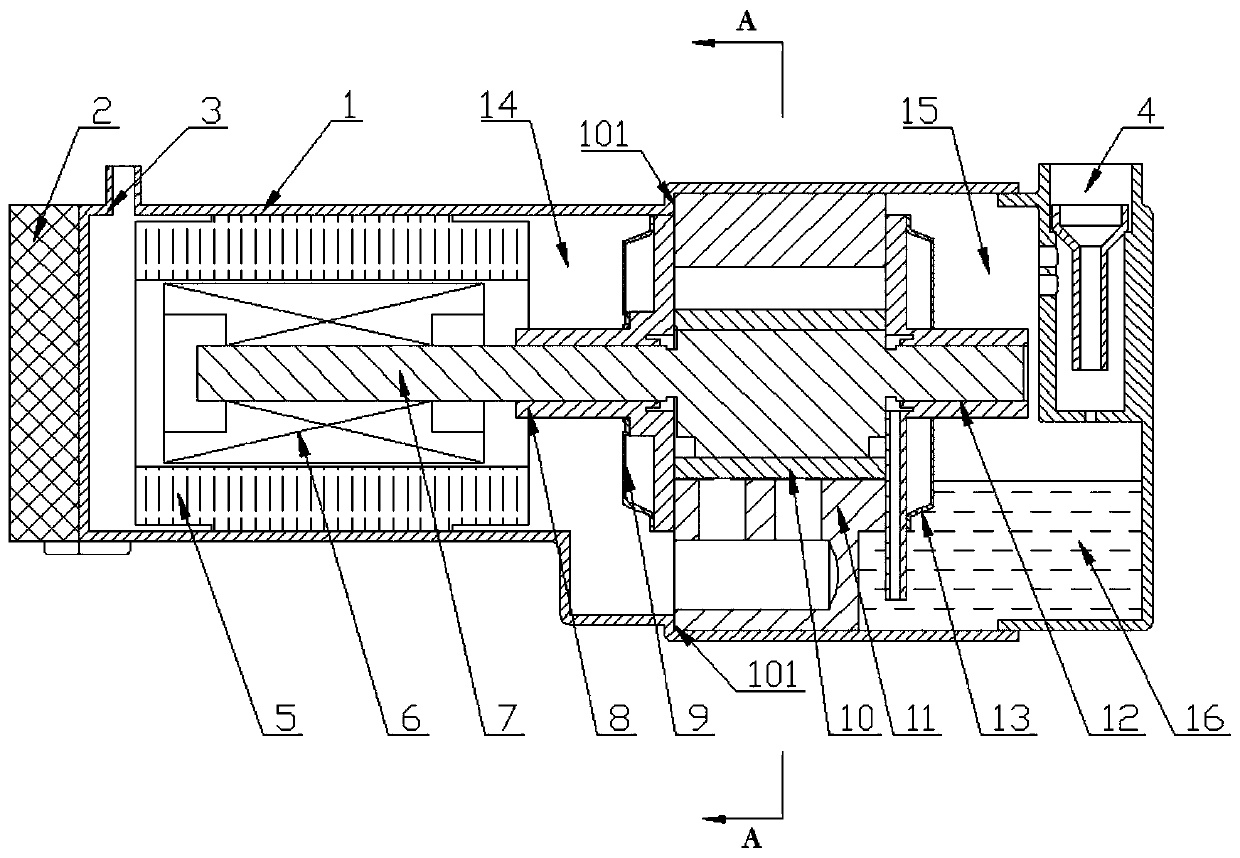

The invention discloses a walking dual-swing downhole drill, which comprises a pile frame main body and a drilling main body, wherein the drilling main body comprises an upper power head, a lower power head, an outer sleeve, a spiral drill stem and a downhole hammer; the upper power head is connected with the top end of the spiral drill stem; the bottom end of the spiral drill stem is connected with the downhole hammer; the upper power head drives the spiral drill stem and the downhole hammer to rotate clockwise when working; the lower power head is connected with the outer sleeve and drives the outer sleeve to rotate anticlockwise when working; the downhole hammer comprises an impacter and an impact hammer; the hammer head of the impact hammer is exposed out of the lower opening of the outer sleeve; a high-pressure gas channel is arranged inside the drilling main body, and the high-pressure gas passes through the upper power head, a buffer, the spiral drill stem and the impacter and is finally blown outwards from the bottom part of the impact hammer. The walking dual-swing downhole drill has main characteristics of taking soil to form a hole by a dry method without pollution, and being adapted to various geologies and stratums, such as hard lithosphere, tundra, sand bed with abundant underground water, a rubble layer and boulder, which are difficult to drill by other pile drivers.

Owner:瑞安市八达工程机械有限公司

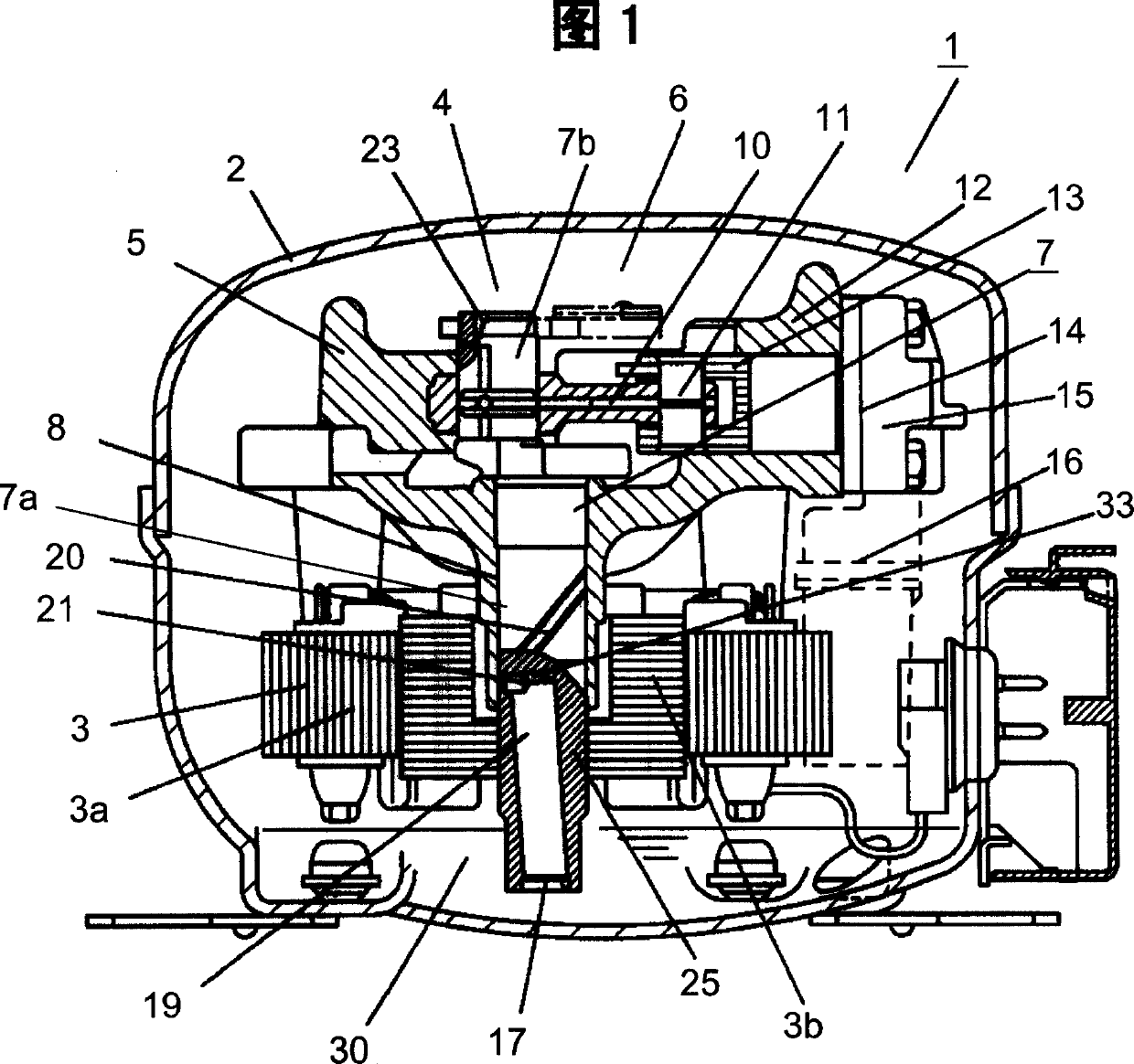

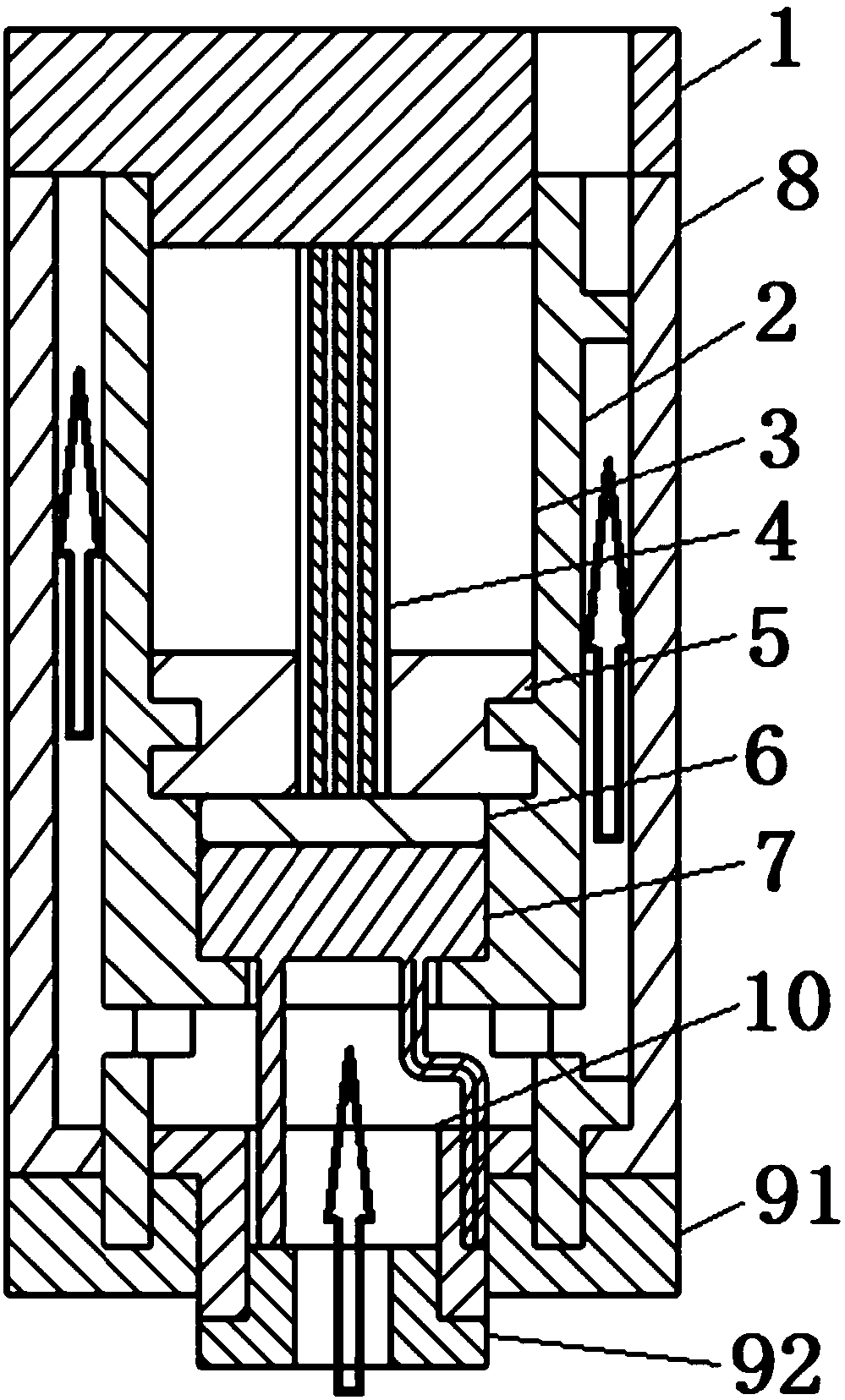

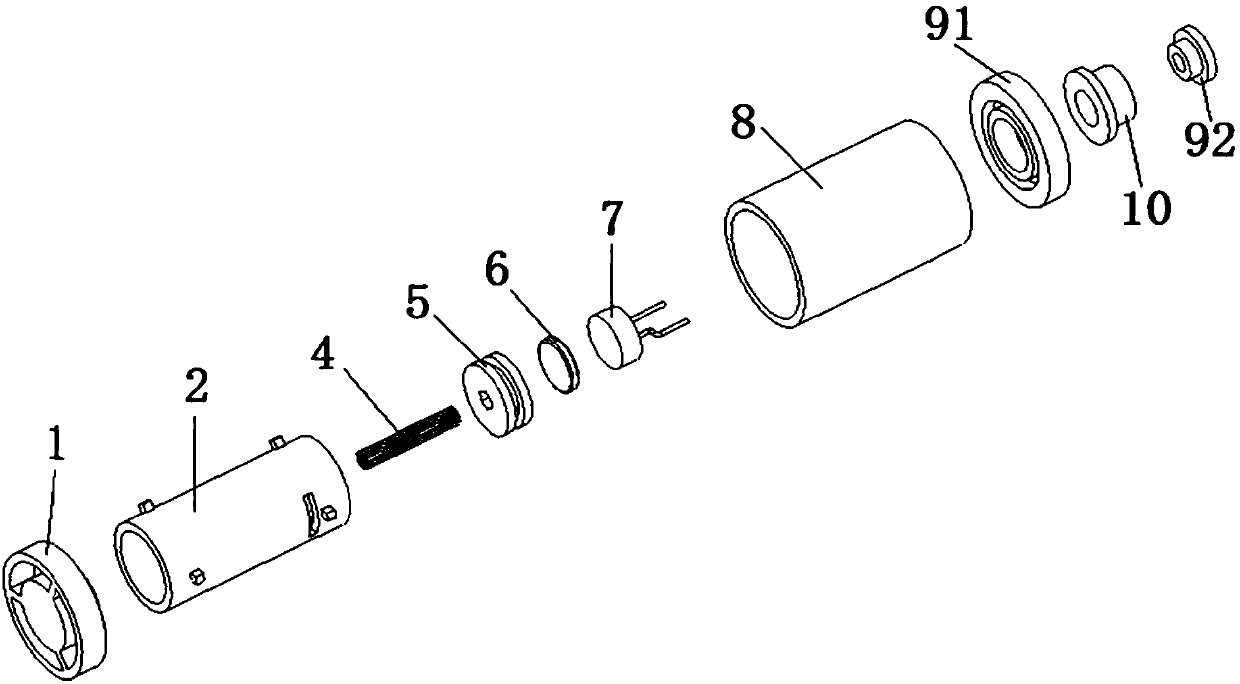

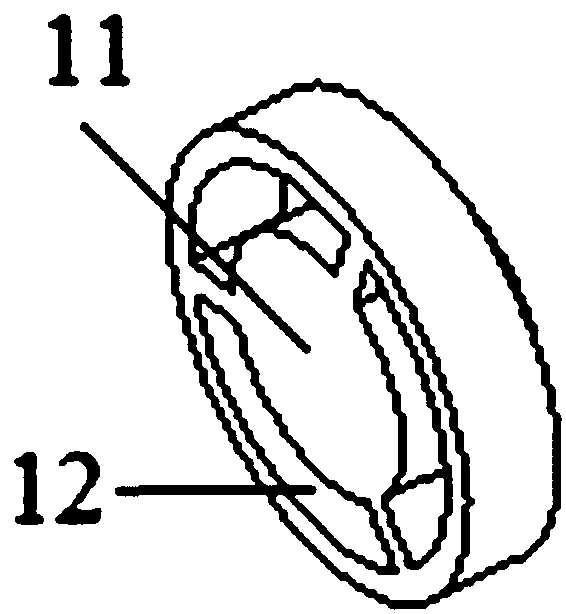

Sealed type electrically driven compressor

InactiveCN1513087ALarge oil delivery capacityLow costPositive displacement pump componentsPositive-displacement liquid enginesLow speedEngineering

A sealed type electrically driven compressor that efficiently pumps up a necessary amount of lubricating oil even during low speed rotation and achieves good assembling workability by a simple construction. It is provided with an oil pump comprising an inclined passageway formed in the lower portion of a main shaft and inclined outward from below to above, a choke having a suction hole in the center that is smaller in cross section than the inclined passageway formed in the lower end of the main shaft, and a lower communicating section establishing communication between the lower end of a spiral groove and the inclined passageway, whereby the lift for the lubricating oil can be effectively increased.

Owner:PANASONIC APPLIANCES REFRIGERATION DEVICES SINGAPORE

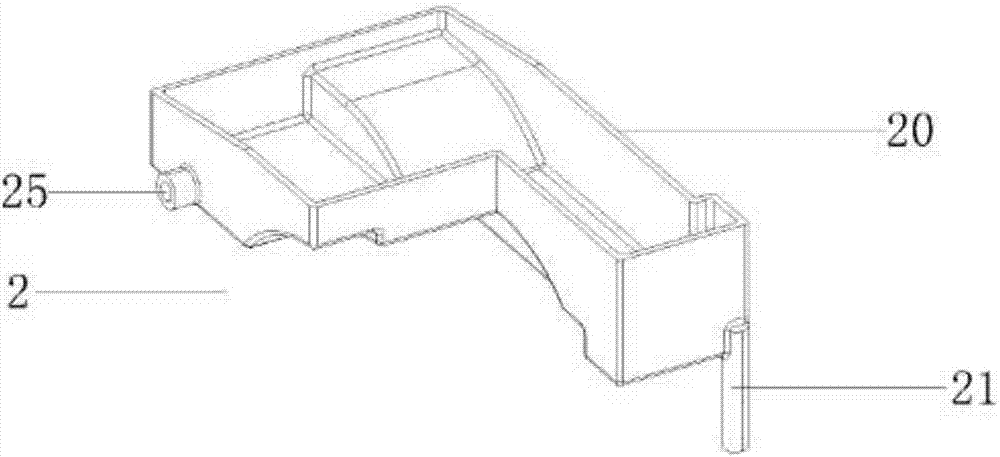

Blade electric vehicle transmission with novel lubrication structure

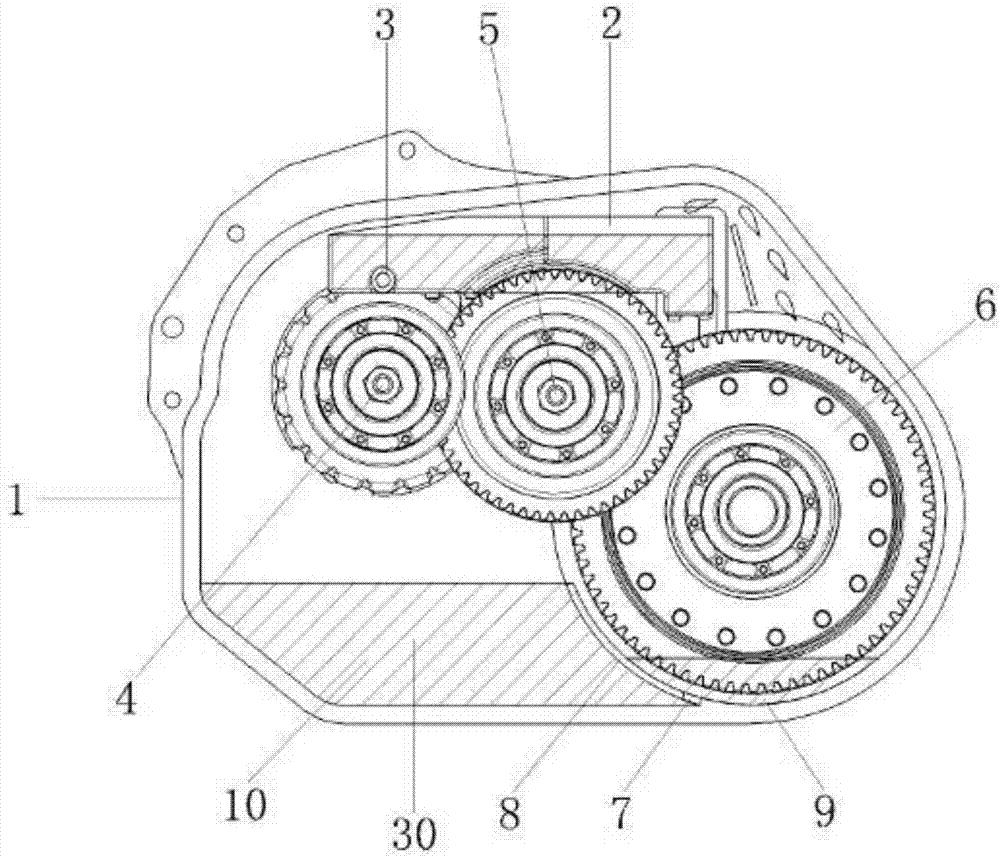

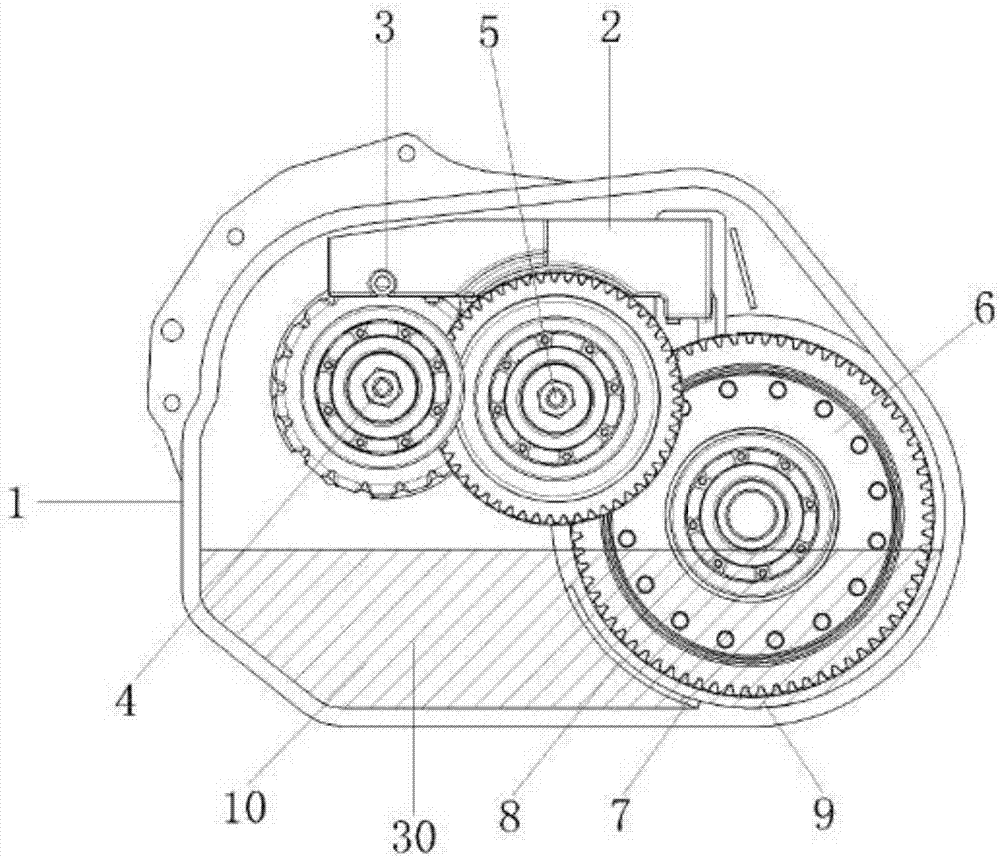

ActiveCN107314100AOutstanding and Beneficial Technical EffectsReduce dosageGear lubrication/coolingTransmission elementsCouplingGear wheel

The invention provides a blade electric vehicle transmission with a novel lubrication structure, and belongs to the technical field of transmissions. The problem that an existing structure lubrication manner is not effective enough is solved. The blade electric vehicle transmission comprises a transmission case. A temporary oil storage box is arranged on the top side in the transmission case, lubricating oil is stored on the bottom side in the transmission case, and the temporary oil storage box is provided with a plurality of lubricating oil dripping holes. A transmission input shaft and an intermediate coupling shaft which are connected through a gear are located on the lower side of the temporary oil storage box and above the lubricating oil face. An intermediate coupling shaft gear is connected with a differential mechanism gear. The lower side of the differential mechanism gear is immersed in lubricating oil. The differential mechanism gear rotates, so that the lubricating oil on the bottom side of the transmission case is splashed into the temporary oil storage box, and the lubricating oil lubricates various parts of the transmission through the lubricating oil dripping holes and then flows back to the bottom side of the transmission case to form a cycle. The blade electric vehicle transmission has the beneficial effects of being complete in lubrication, moderate in oil amount, capable of saving energy, environment-friendly and the like.

Owner:浙江鑫可传动科技有限公司

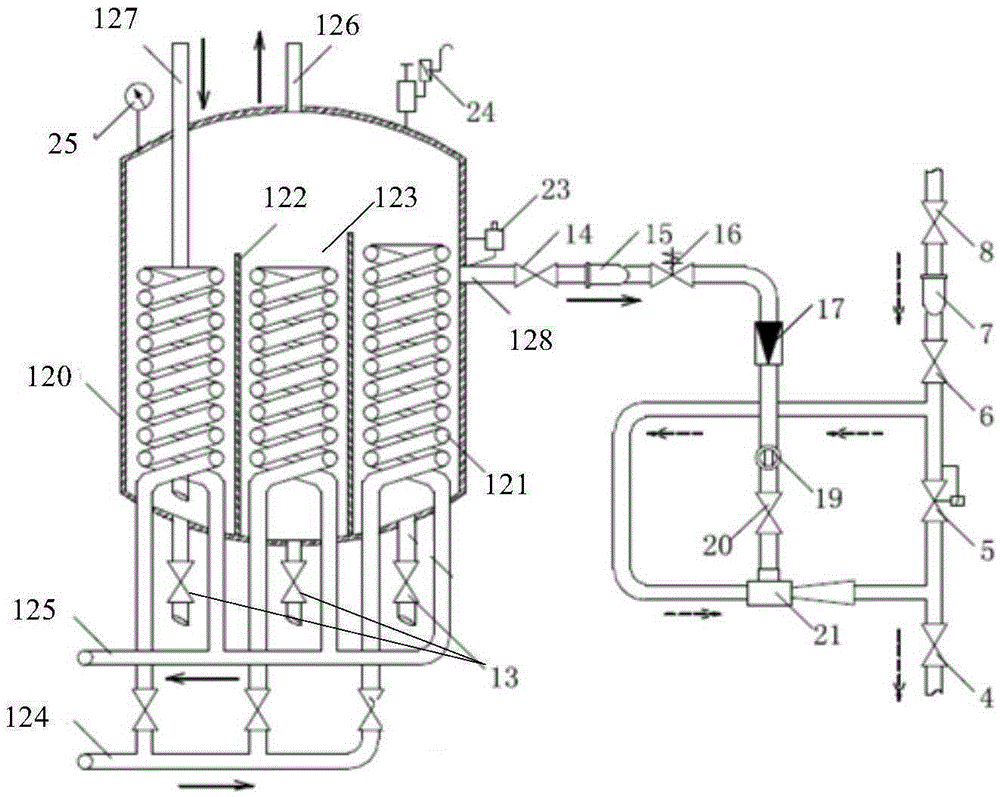

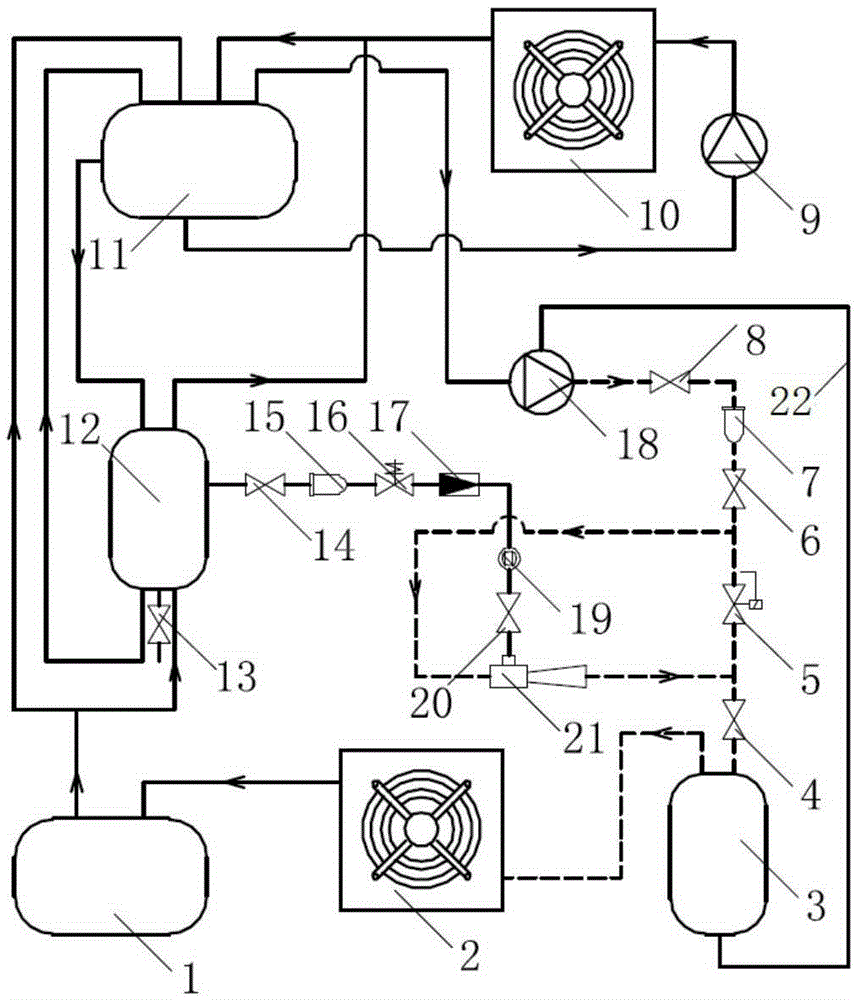

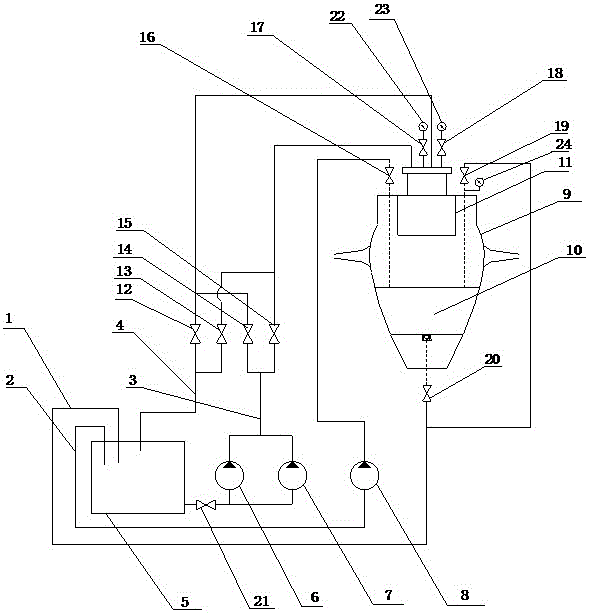

Ejecting oil return refrigerating system with oil liquid separator

ActiveCN105258373AImprove separation efficiencyReduce mixCompressorMechanical apparatusRefrigerantLiquid storage

The invention discloses an ejecting oil return refrigerating system with an oil liquid separator. The refrigerating system comprises a liquid storage device, a condenser, an oil separator, a compressor, a low-pressure circulation barrel, an evaporator and the oil liquid separator separating refrigerating oil and refrigerating fluid. The liquid storage device is connected with a liquid supply pipe of the oil liquid separator through a pipeline. A liquid outlet pipe and an air outlet pipe of the oil liquid separator are connected with the low-pressure circulation barrel through pipelines respectively. The low-pressure circulation barrel is connected with a liquid return pipe of the oil liquid separator through a pipeline. An oil outlet pipe of the oil liquid separator is connected with an oil separator pipeline through an ejector. The compressor sucks gas from the low-pressure circulation barrel and conducts compression. An exhaust pipeline of the compressor is connected with the ejector. The ejector is connected with the oil separator pipeline. Refrigerant oil in the oil outlet pipe of the oil liquid separator is ejected into the oil separator through the ejector via gas in the exhaust pipeline of the compressor, and the oil outlet of the oil separator is connected with the compressor through the oil supply pipe. The ejecting oil return refrigerating system is stable in oil return and capable of avoiding liquid shocking or oil shocking.

Owner:PANASONIC APPLIANCES REFRIGERATION SYST DALIAN CO LTD

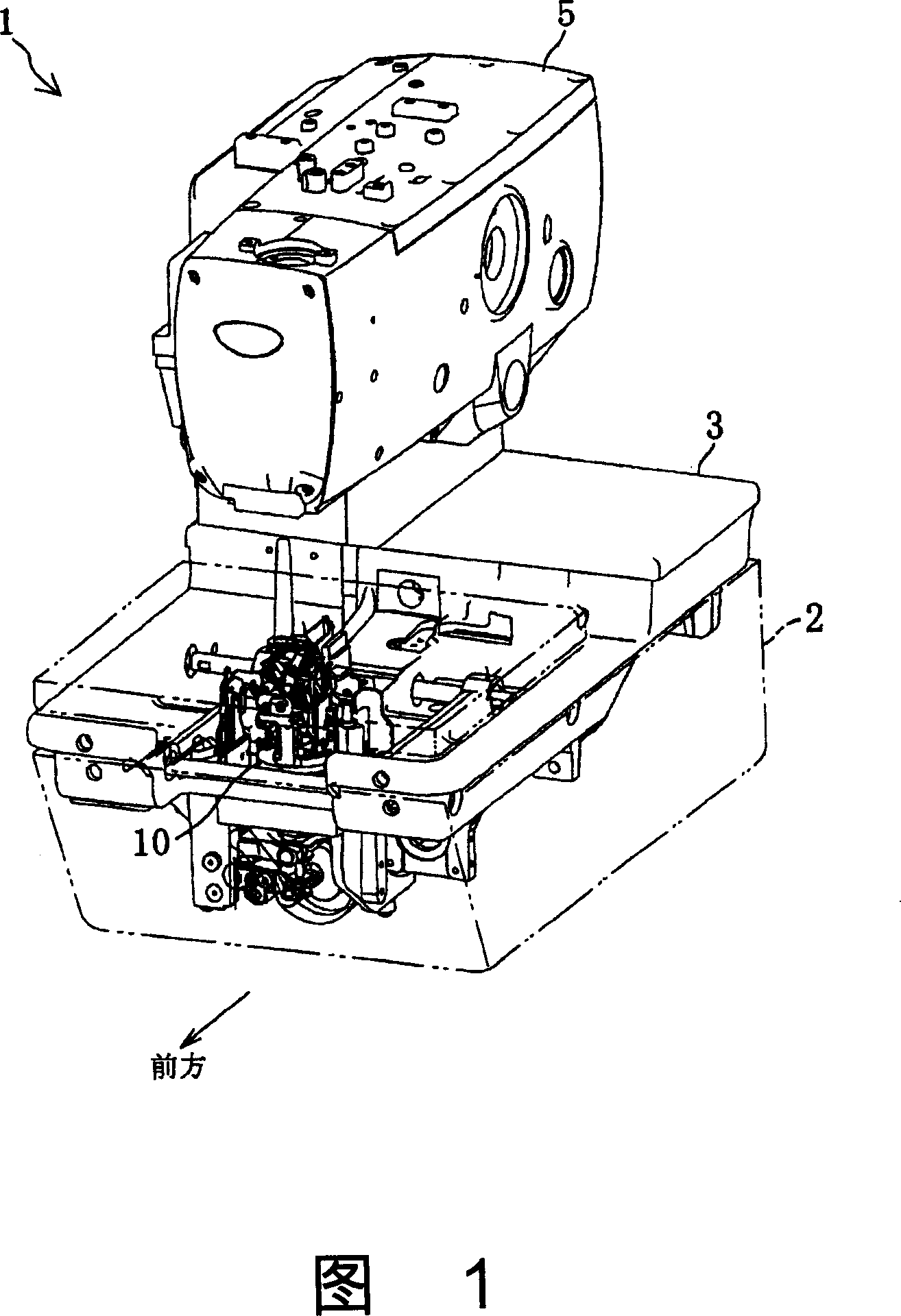

Oil supply device for curving needle holder of sartorius

An oil supply device, the deposited oil in the grease-box is filtered to the second oil line in the supplying pipe and guided to the loopier foundation, and is moved to the first oil line which contacts in the circumference and rotates on the loopier foundation, the oil supply device also supply oil to a sliding plane that slides on the support platform of a support plate actuation cam plate which contacts the front section of the first oil line, thereby, oil can be supplied to the sliding plane of the support plate actuation cam plate that swings at high speed stably, the abrasion of the sliding plane can be reduced, sinter can be avoided, the durability of a loopier foundation of the sartorial can be improved.

Owner:BROTHER KOGYO KK

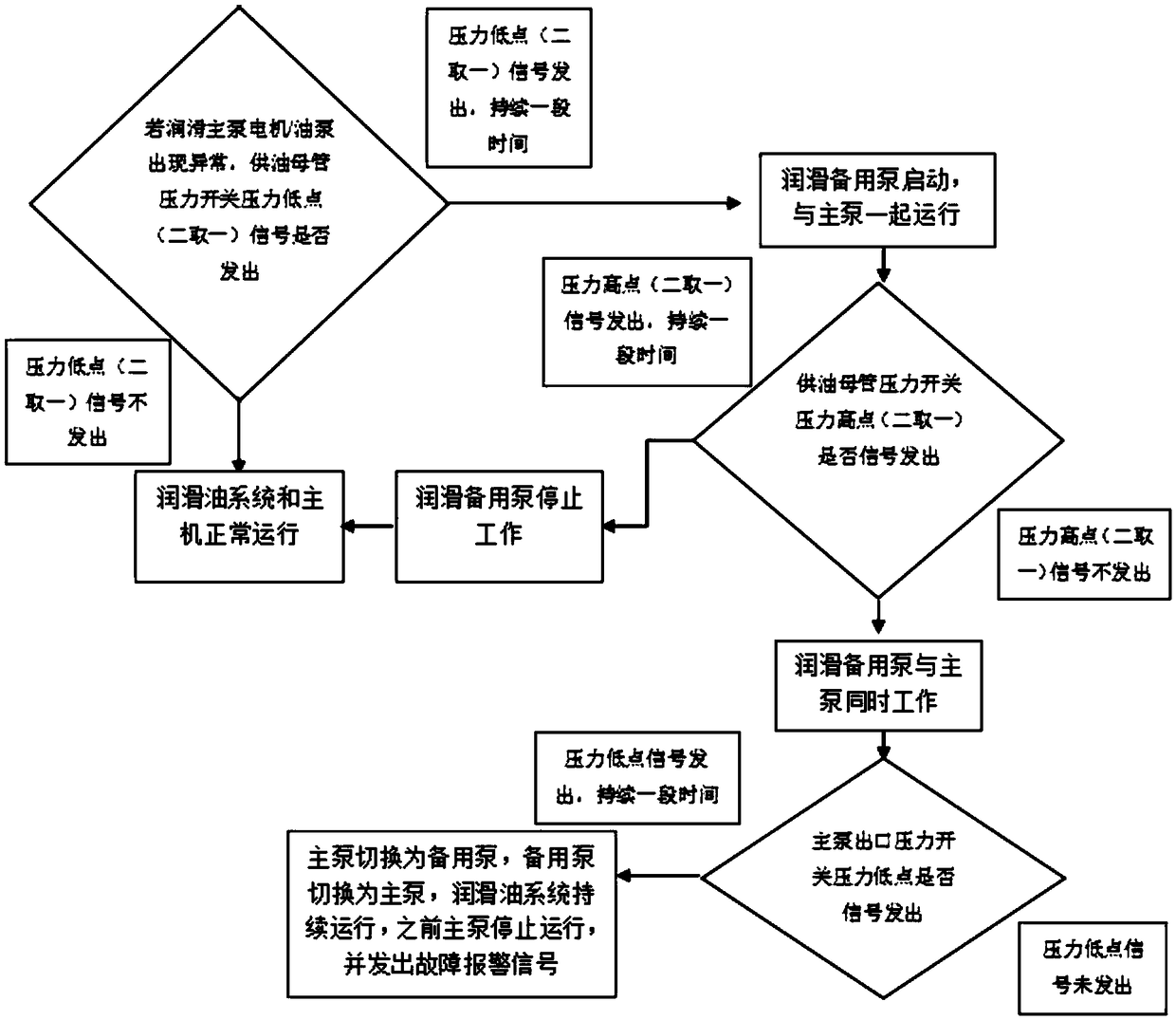

Control method for automatic judgment and switching of oil pump fault of lubricating system

InactiveCN109340549AEnsure safetyDiscovered in timeLubrication elementsSafety/regulatory devicesHigh pressureWhole systems

Owner:SICHUAN CRUN CO LTD

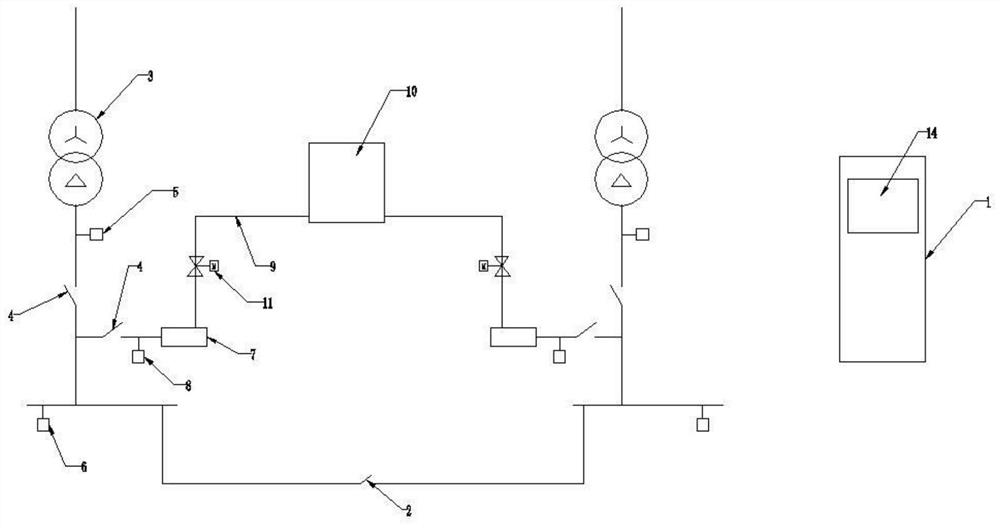

Axial-flow Kaplan turbine runner withstand voltage operation test system

The invention relates to an axial-flow Kaplan turbine runner withstand voltage operation test system comprising an oil storage tank, a group communicating the oil storage tank with a runner hub and including a first pipe, a second pipe, a third pipe and a fourth pipe. The first pipe communicates with the lower port of a runner hub runner cone via a ninth valve. The second pipe communicates with the lower port of the runner hub runner cone via a third oil pump and a fifth valve successively. The third pipeline communicates with the open chamber and the closed chamber of a runner hub piston chamber via a third valve and a fourth valve respectively. The third valve and the fourth valve communicate with the one end of the first and second branch pipelines via the third pipeline. The first and second branch pipelines communicate with a first oil pump and a second oil pump. The other ends of the first and second branch pipelines are connected to the oil storage tank through a tenth valve. A fourth pipeline communicates with the open chamber and the closed chamber of the runner hub piston chamber via the first valve and the second valve respectively The first, second and third oil pumps are electrically connected with a PLC controller. The test system is simple and reliable in pipeline connection and convenient to control.

Owner:STATE GRID FUJIAN ELECTRIC POWER CO LTD +2

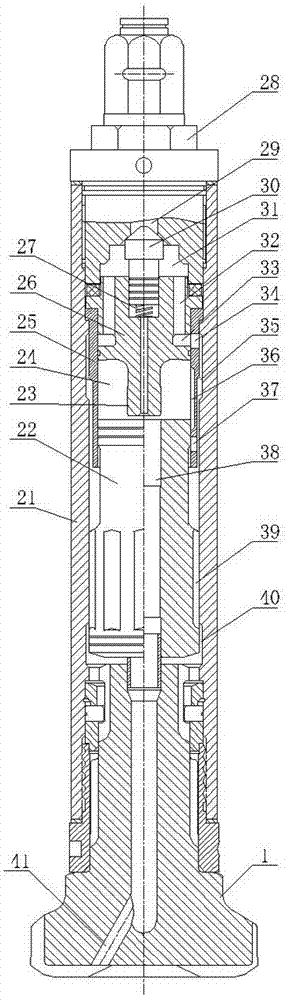

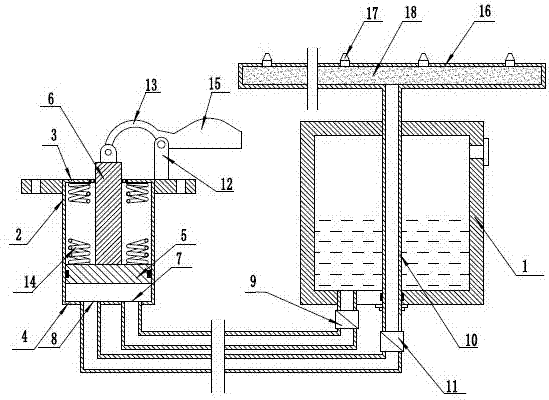

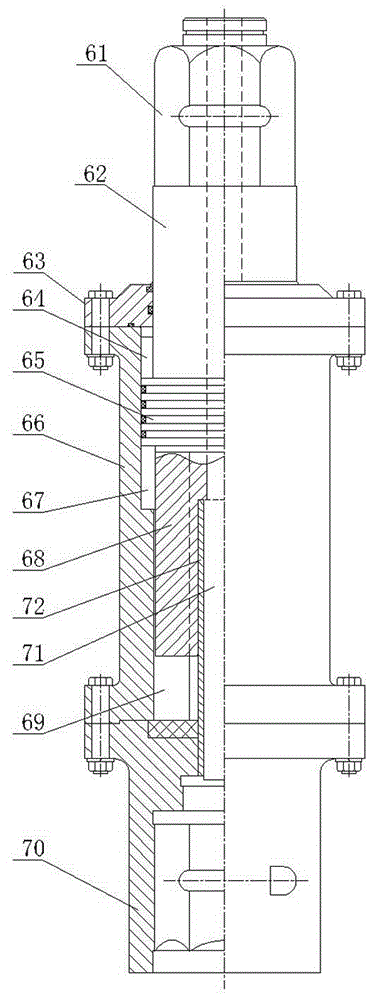

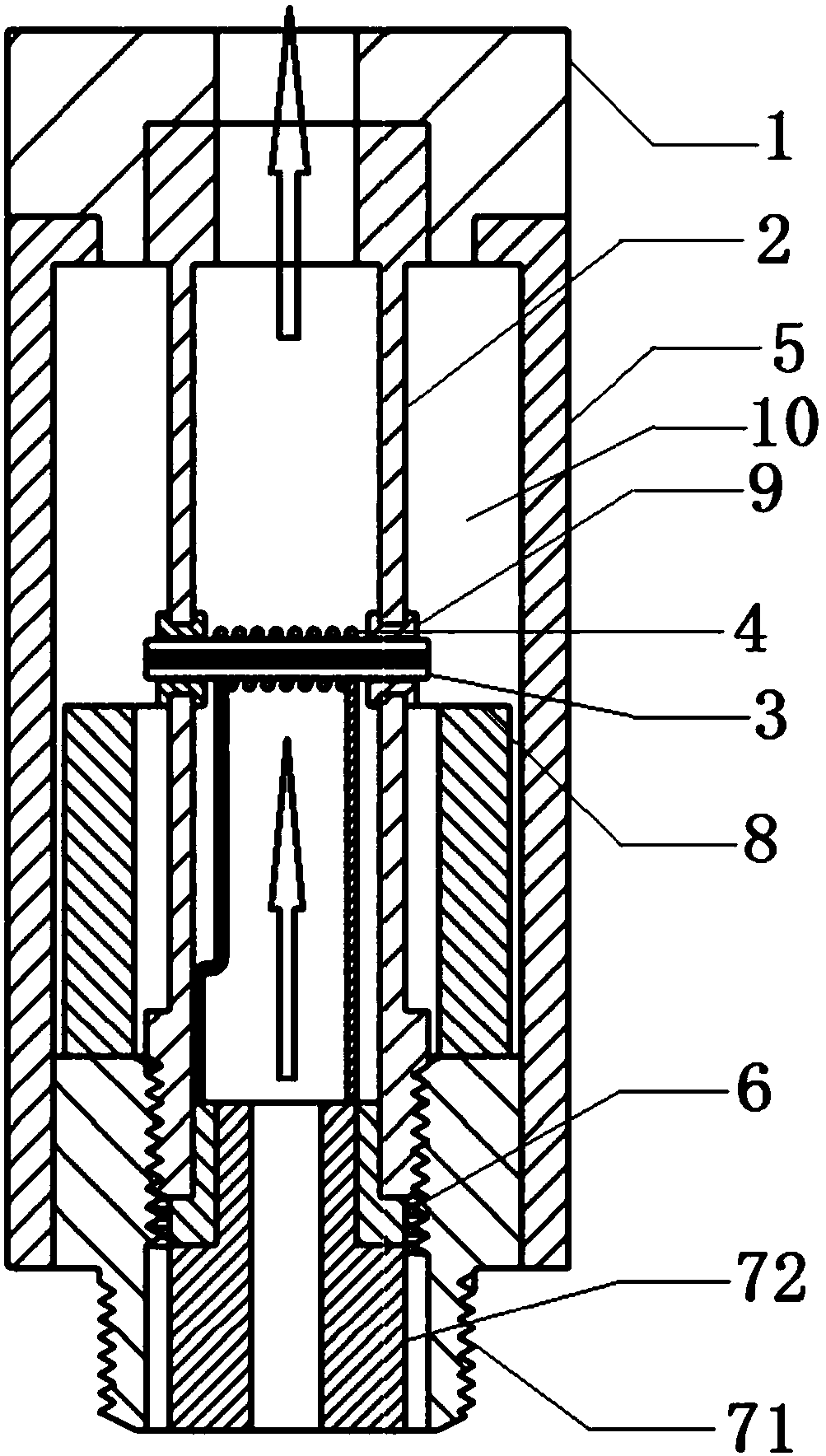

Automatic lubricating oil filling device

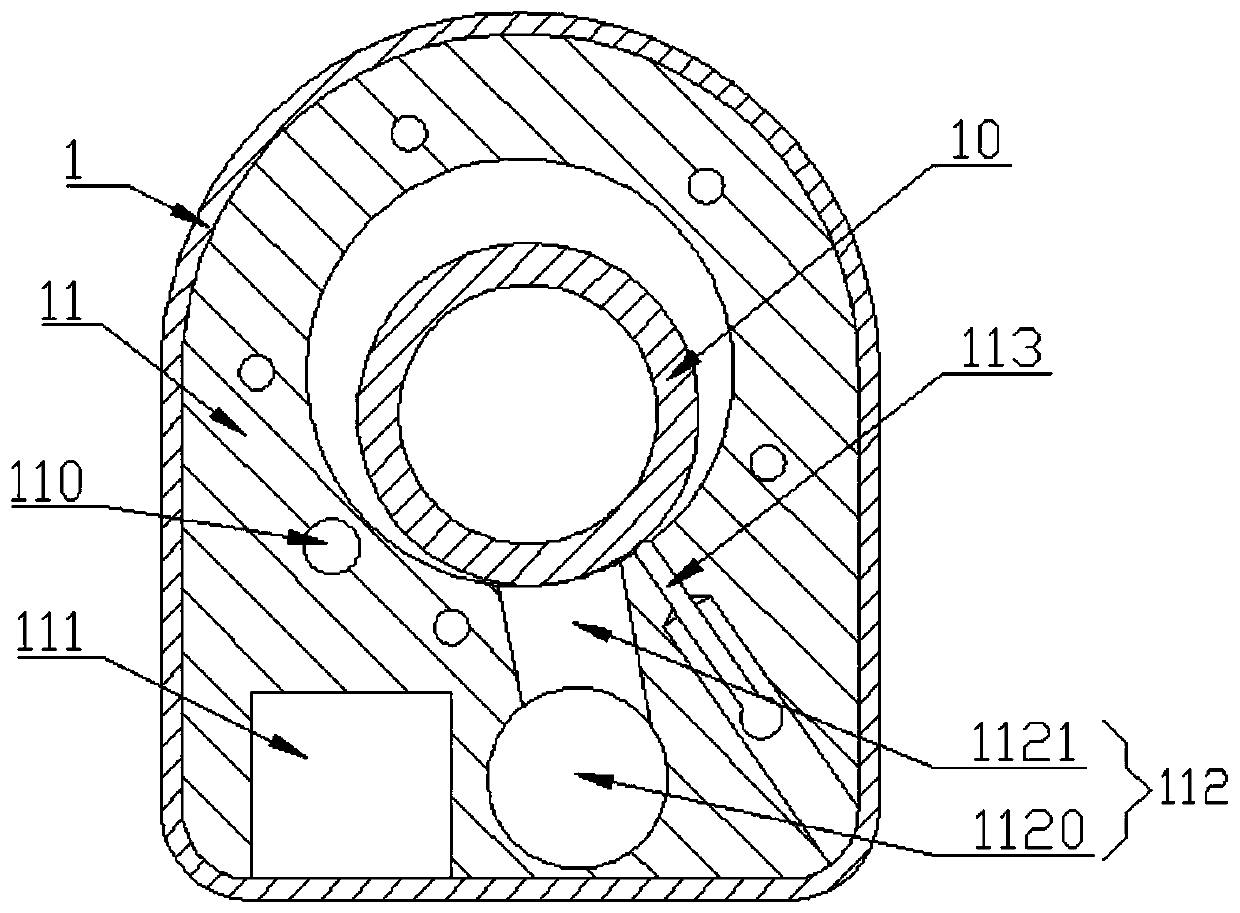

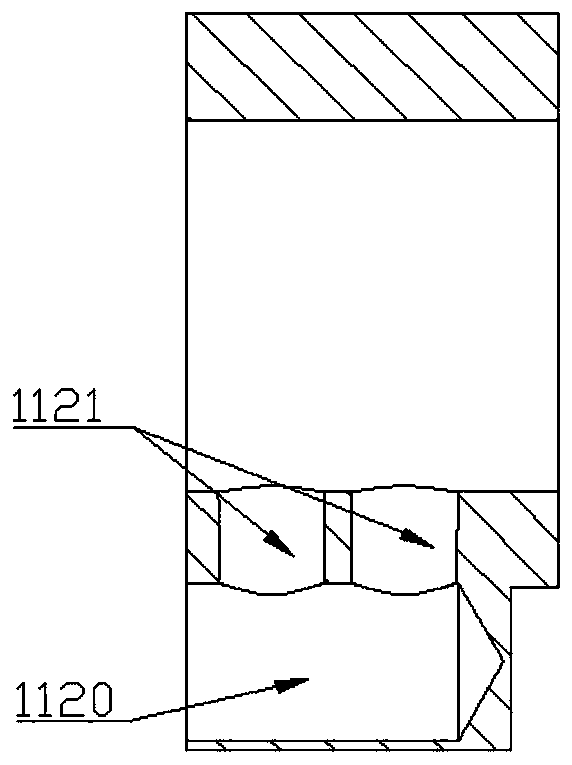

InactiveCN108006424AReasonable structureStable oil supplyEngine lubricationEngineeringPressure difference

Especially, for solving the technical problems existing in a lubricating oil filling process in a current mechanical motion process, the invention provides an automatic lubricating oil filling device.The automatic lubricating oil filling device comprises an oil storage chamber and is characterized by also comprising a suction pump; the suction pump comprises a pump body; a piston is arranged inside the pump body and is connected with a piston rod; the top of the piston rod penetrates through an upper end cover; a lower end cover of the pump body is separately provided with a sucking hole anda discharging hole; the sucking hole is connected with the oil storage chamber through a pipeline, and the connecting pipeline is provided with a first one-way valve; the discharging hole is connectedwith an oil spraying pipe through the pipeline, and the connecting pipeline is provided with a second one-way valve; the first one-way valve and the second one-way valve are characterized in that each one-way valve is opened towards a side which is relatively low in pressure when the two sides of the corresponding valve body has a pressure difference; and the top of the piston rod is connected with a driving device. The automatic lubricating oil filling device is reasonable in structure, stable in oil supply and capable of guaranteeing the real-time lubrication needs of components.

Owner:潘海军

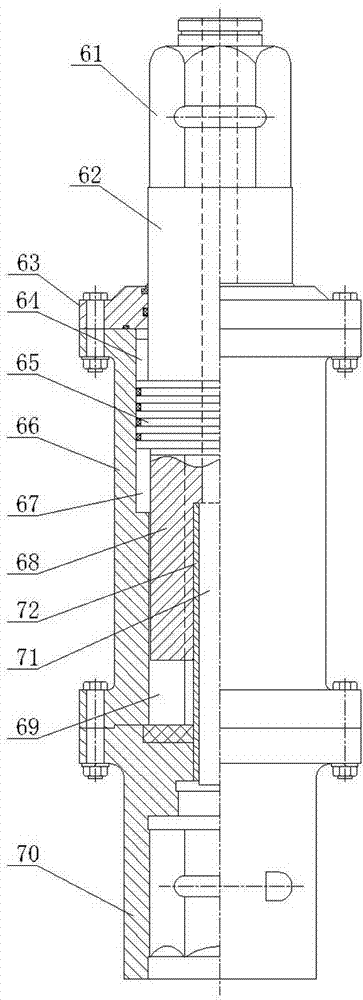

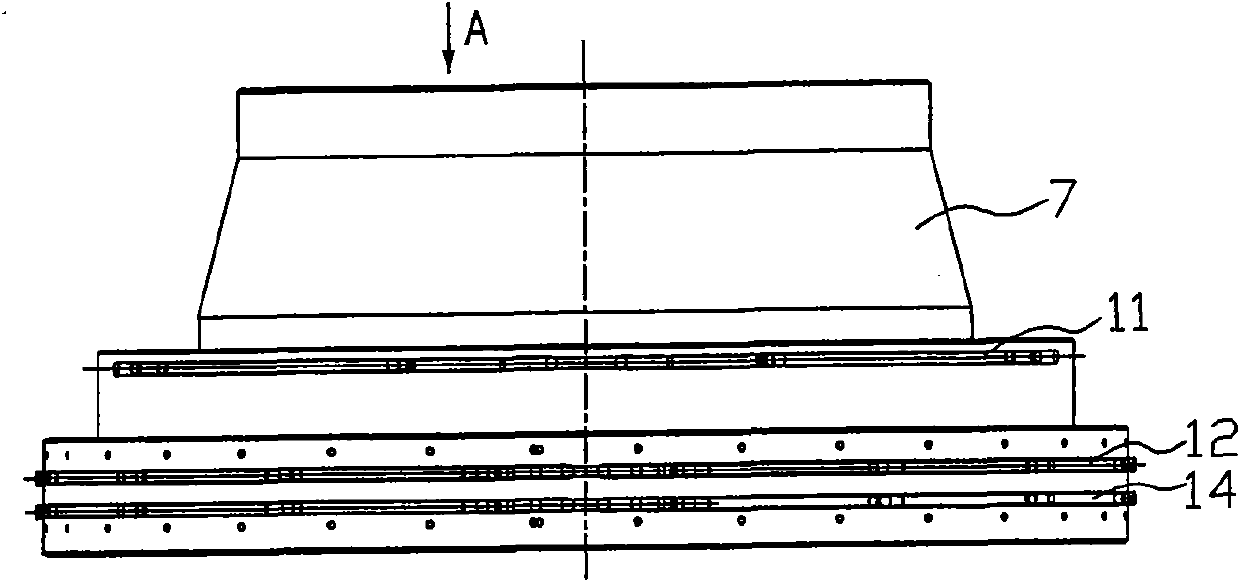

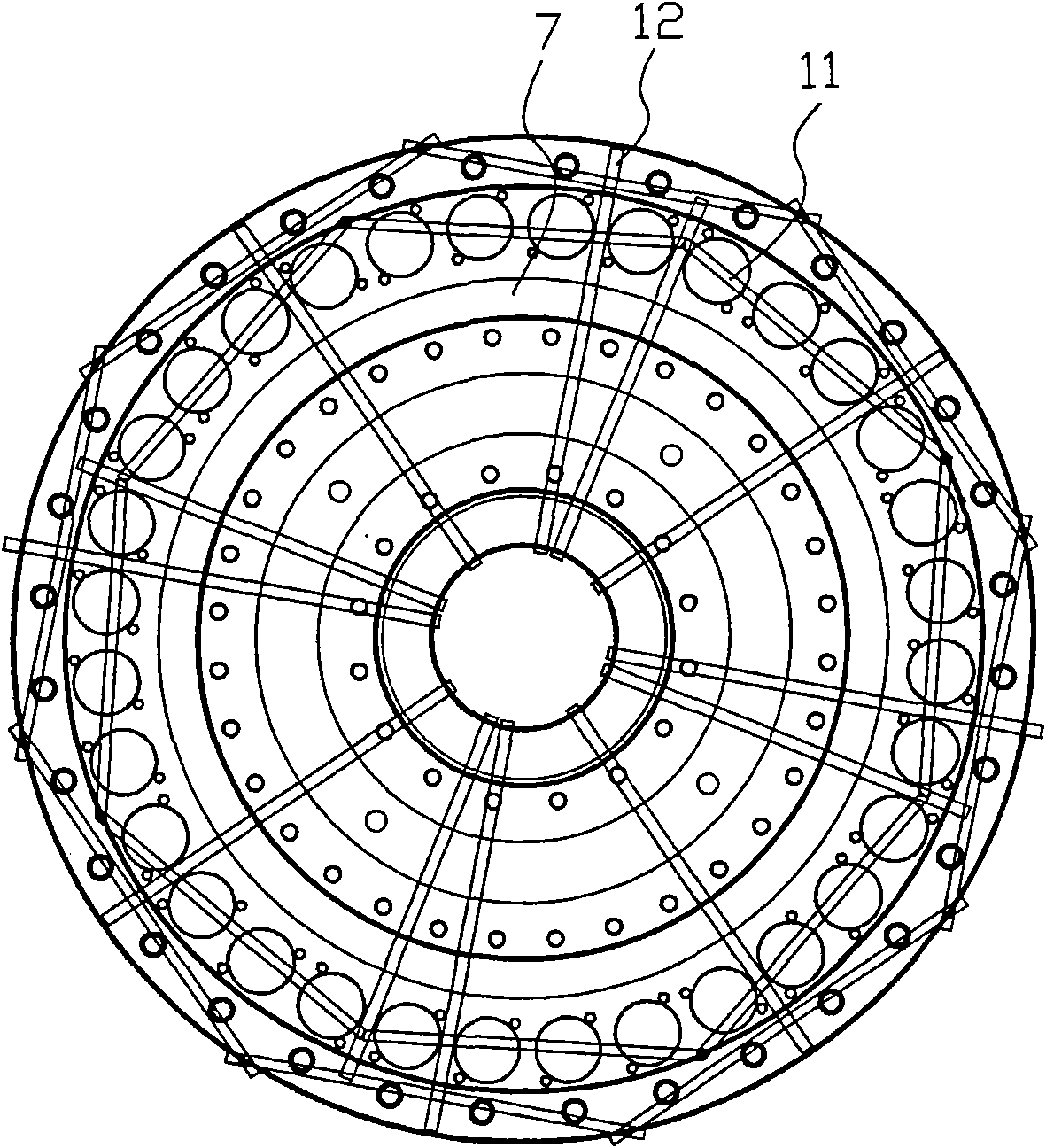

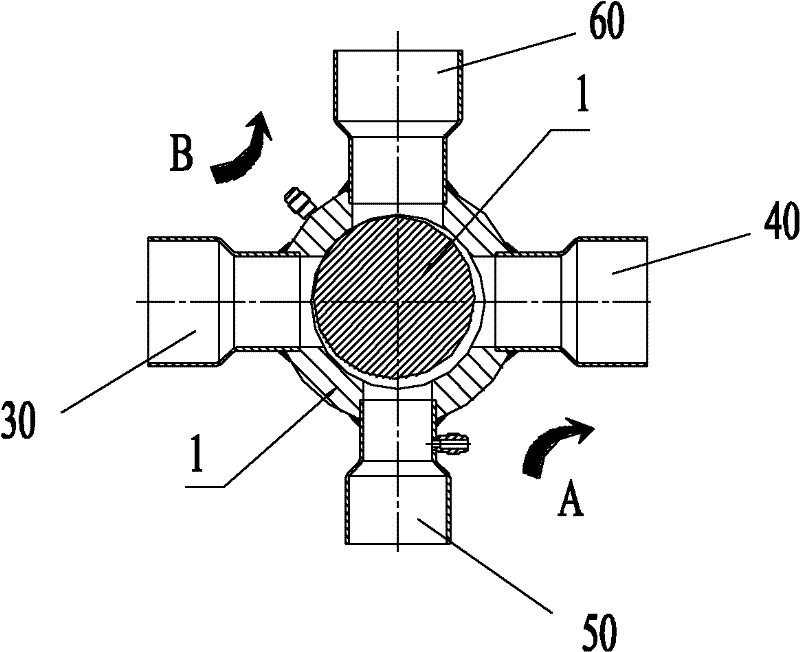

Integrated rotary tower and oil path system of bottle cap molding press

The invention discloses an integrated rotary tower and oil path system of a bottle cap molding press, which comprises a machine base, wherein a spindle is arranged on the machine base and driven by a driving force; a lower template and an upper template are arranged on the spindle; a lower mold component is arranged on the lower template and connected with an oil hydraulic cylinder; and an upper mold component is arranged on the upper template. The integrated rotary tower and oil path system of the bottle cap molding press is characterized in that: the lower template is an entire tower-shapedrotary tower; an oil inlet shaft is arranged in the rotary tower; an oil inlet is formed in the oil inlet shaft; an oil path distributor is arranged at the lower end of the oil inlet shaft; a lower seal of the oil path distributor is connected with the spindle; a low-pressure oil hole and a high-pressure oil hole are formed in the rotary tower and are communicated with the oil path distributor through the oil path distributor; the low-pressure oil hole is connected with an upper cavity of the oil hydraulic cylinder; a dismantling valve is arranged in a lower cavity of the oil hydraulic cylinder; and the high-pressure oil hole is connected with the dismantling valve. In the scheme, the lower template is used as the rotary tower platform, so the structure is simplified, the processing is labor-saving, the assembly is avoided, and the installation is convenient; particularly, the oil paths are formed in the rotary tower, oil path overall arrangement is saved, and oil is directly delivered by the oil paths, so oil supply is sufficient and oil pressure is stable.

Owner:李加庆

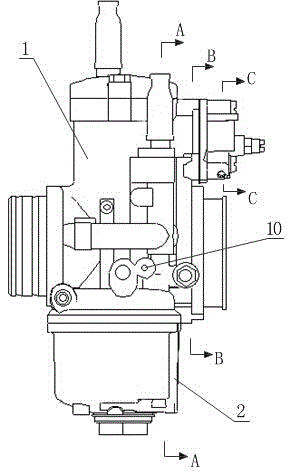

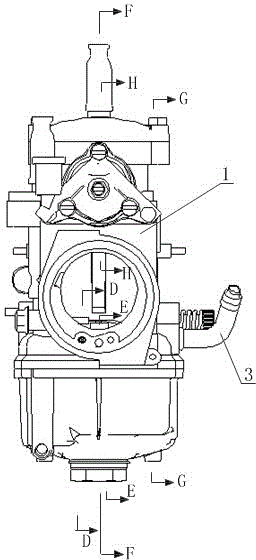

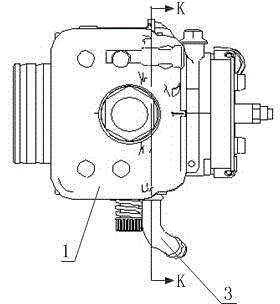

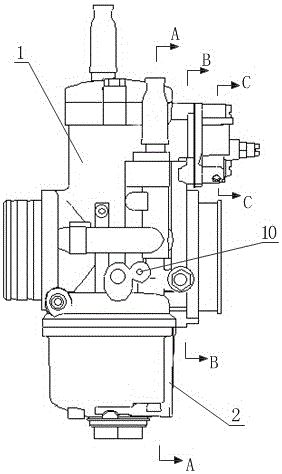

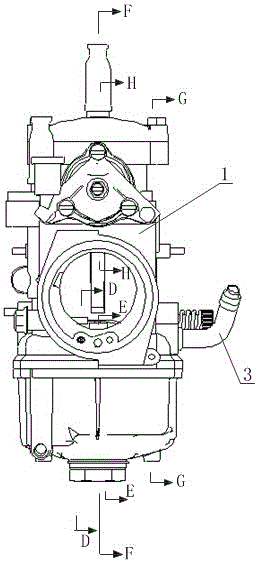

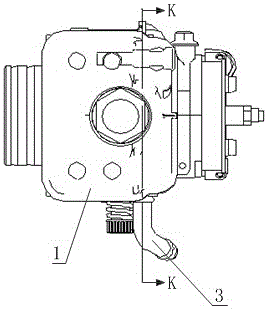

Horizontal draught type plunger piston type carburetor for large-emission competitive scrambling motorcycle

ActiveCN104481736AResponsive and timelyImprove responsivenessIdling devicesMachines/enginesOvertakingEngineering

The invention discloses a horizontal draught type plunger piston type carburetor for a large-emission competitive scrambling motorcycle. The carburetor comprises a carburetor body assembly (1), and a floater chamber assembly (2) which is mounted on the lower surface of the carburetor body assembly (1); an oil feeding system, a starting system, an idling system, a main oil system and an acceleration system are arranged in the carburetor body assembly (1). The carburetor has the beneficial effects that the structure is compact, the scrambling motorcycle can be started and run at a constant speed in an environment under a low temperature less than -40 DEG C; an accelerator can be timely responded, the acceleration for overtaking can be timely responded, the oil returning during acceleration can be effectively avoided, and the safety and reliability can be ensured.

Owner:成都恒高机械电子有限公司

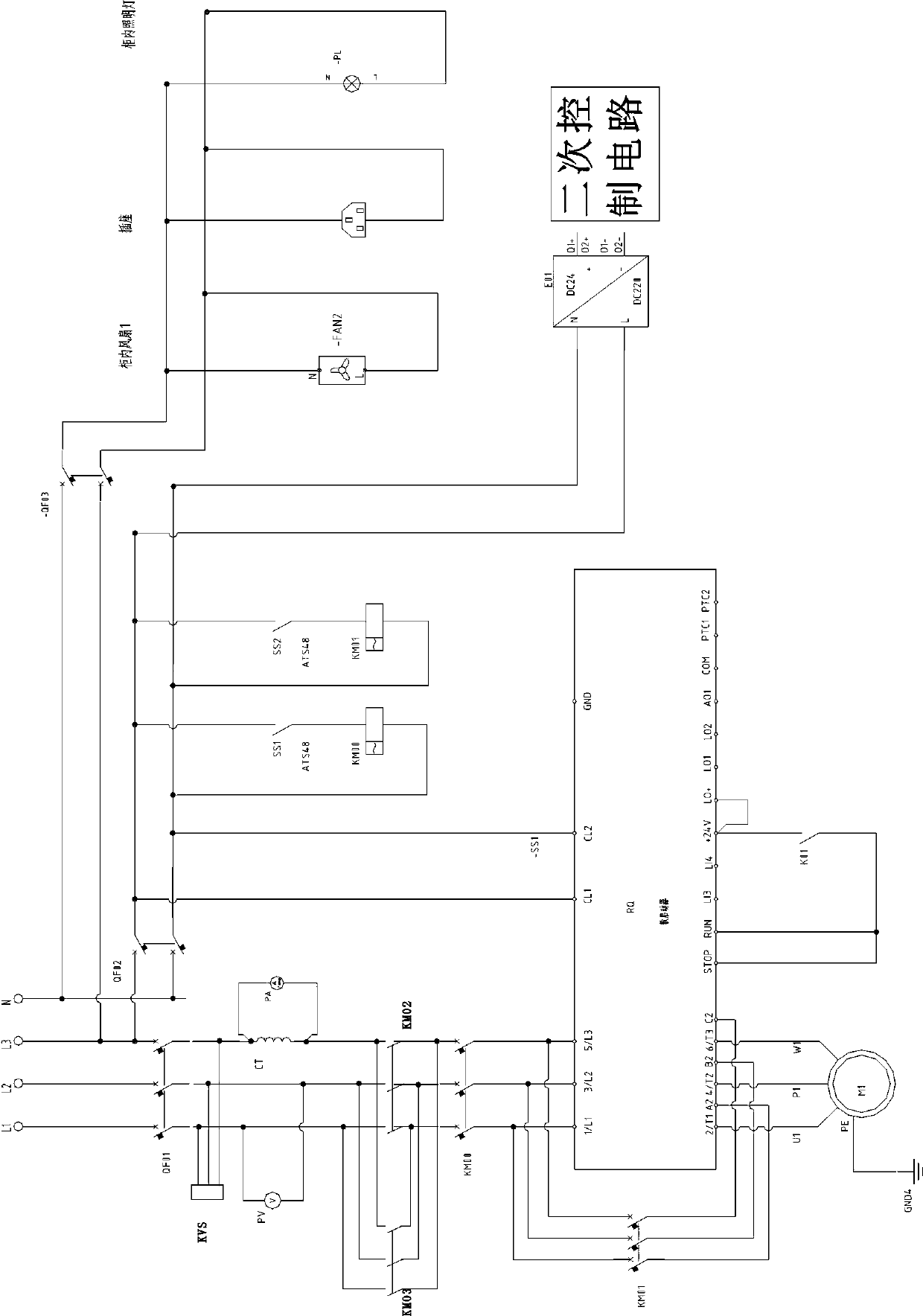

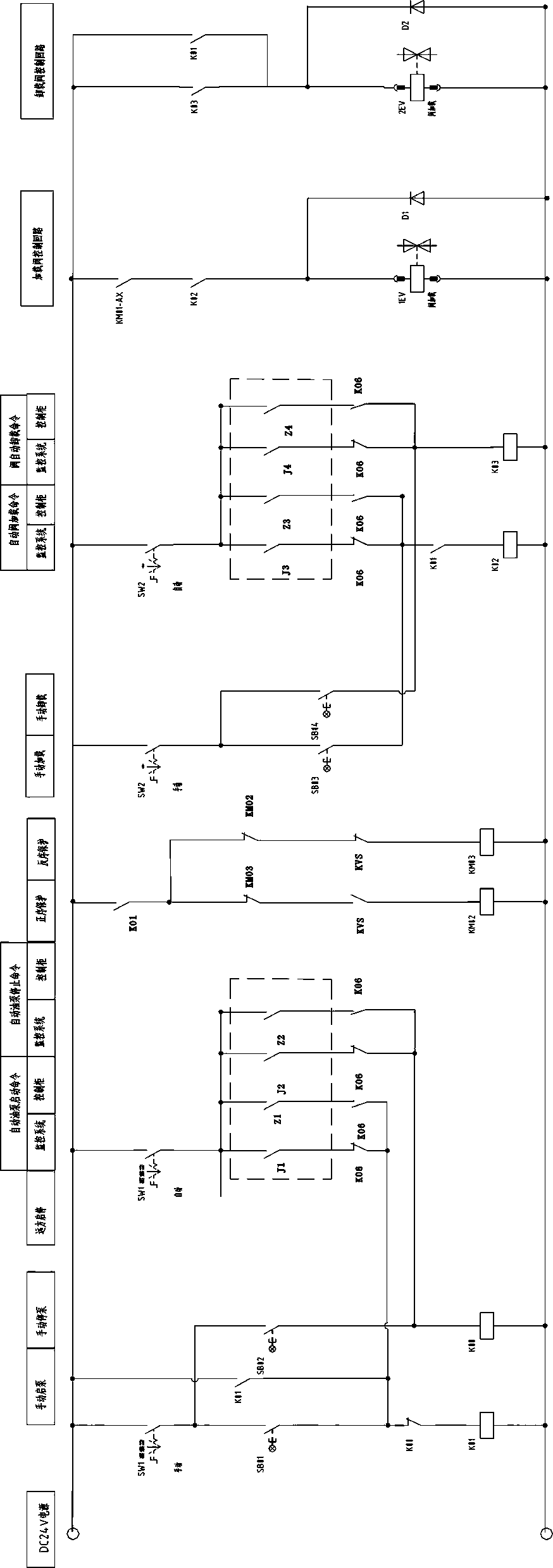

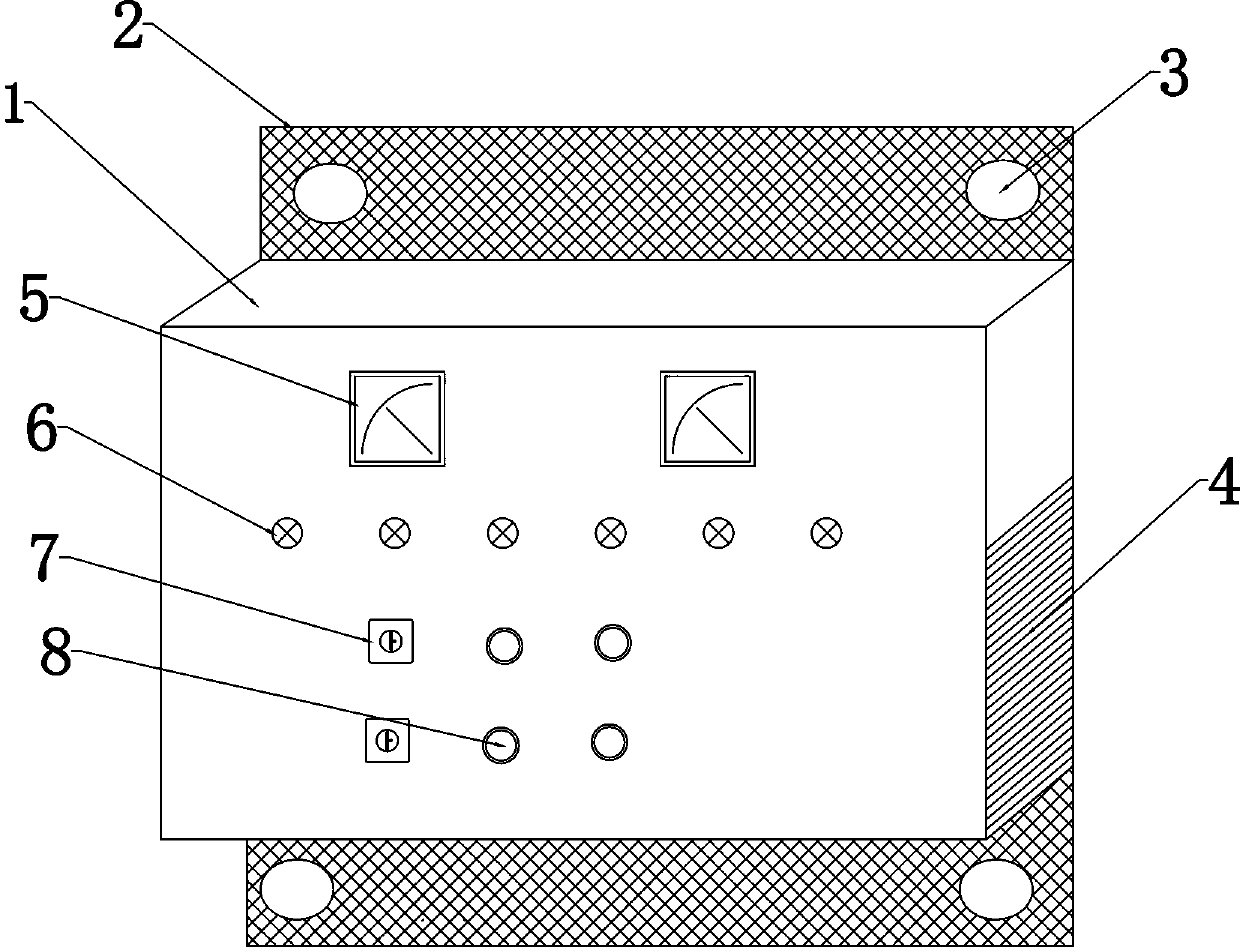

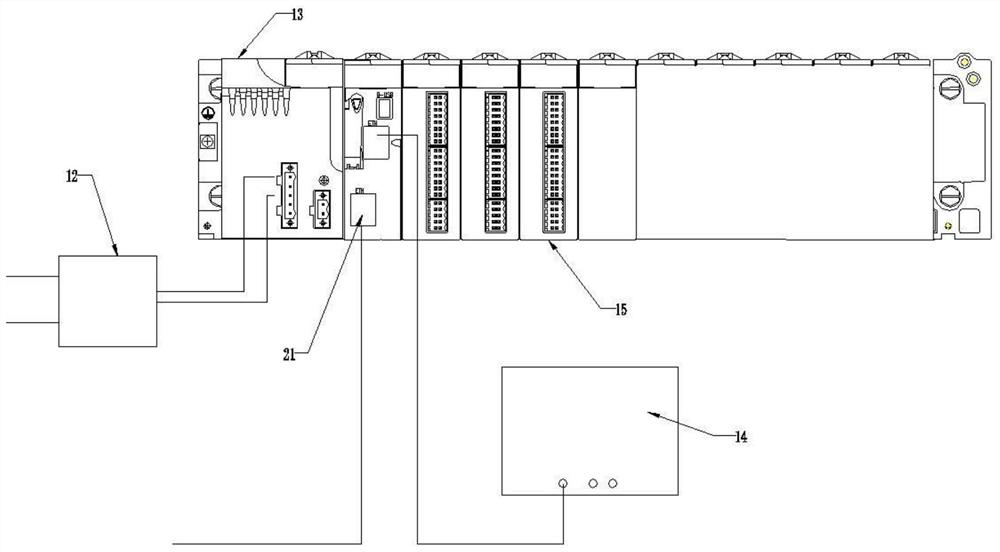

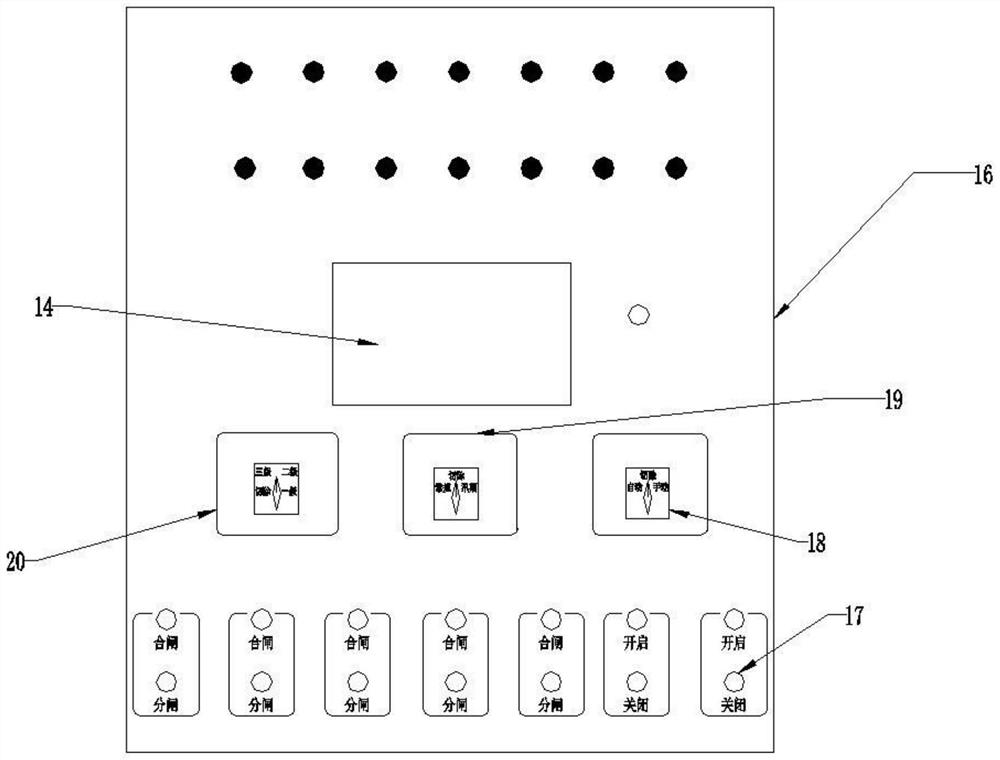

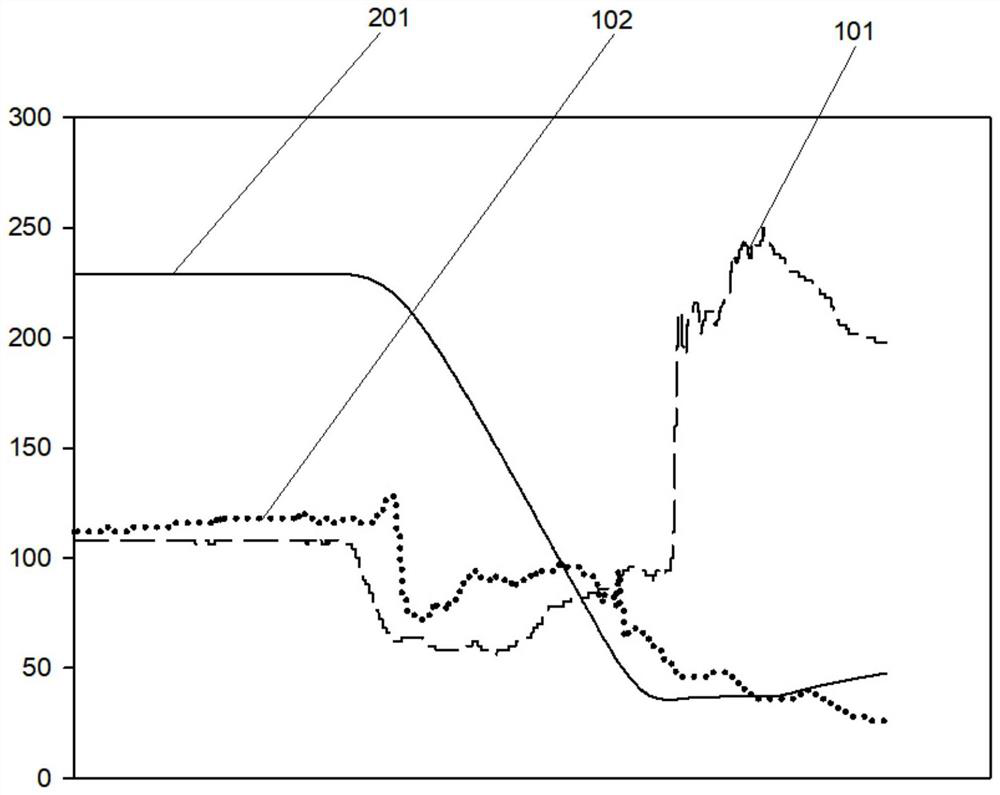

Electrical control device and method for pressure oil pump

PendingCN109751231AReduce shockReduce noisePump controlPositive-displacement liquid enginesControl mannerCircuit breaker

The invention relates to an electrical control device and method for a pressure oil pump. The electrical control device comprises a primary loop and a secondary loop. The primary loop comprises a circuit breaker QF01, a phase sequence protection device KVS, a positive sequence contactor KM02, a reverse sequence contactor KM03, a main contactor KM00, a bypass contactor KM01 and a soft starter RQ; and the secondary loop comprises a start button SB01, a stop button SB02, a loading button SB03, an unloading button SB04, a pump-starting relay K01, a pump-stopping relay K00, a loading relay K02, anunloading relay K03, a positive sequence contactor KM02, a reverse sequence contactor KM03, a loading valve 1EV, an unloading valve 2EV, a start-stop switching handle SW1, a loading-unloading switching handle SW2 and a control cabinet fault point relay K06. According to the electrical control device and method for the pressure oil pump, the control mode for the pressure oil pump of a speed regulator oil pressure device is technically optimized and studied so as to improve the operation reliability of the pressure oil pump.

Owner:CHINA YANGTZE POWER

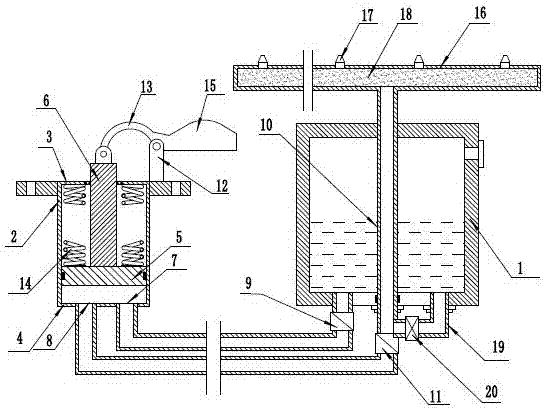

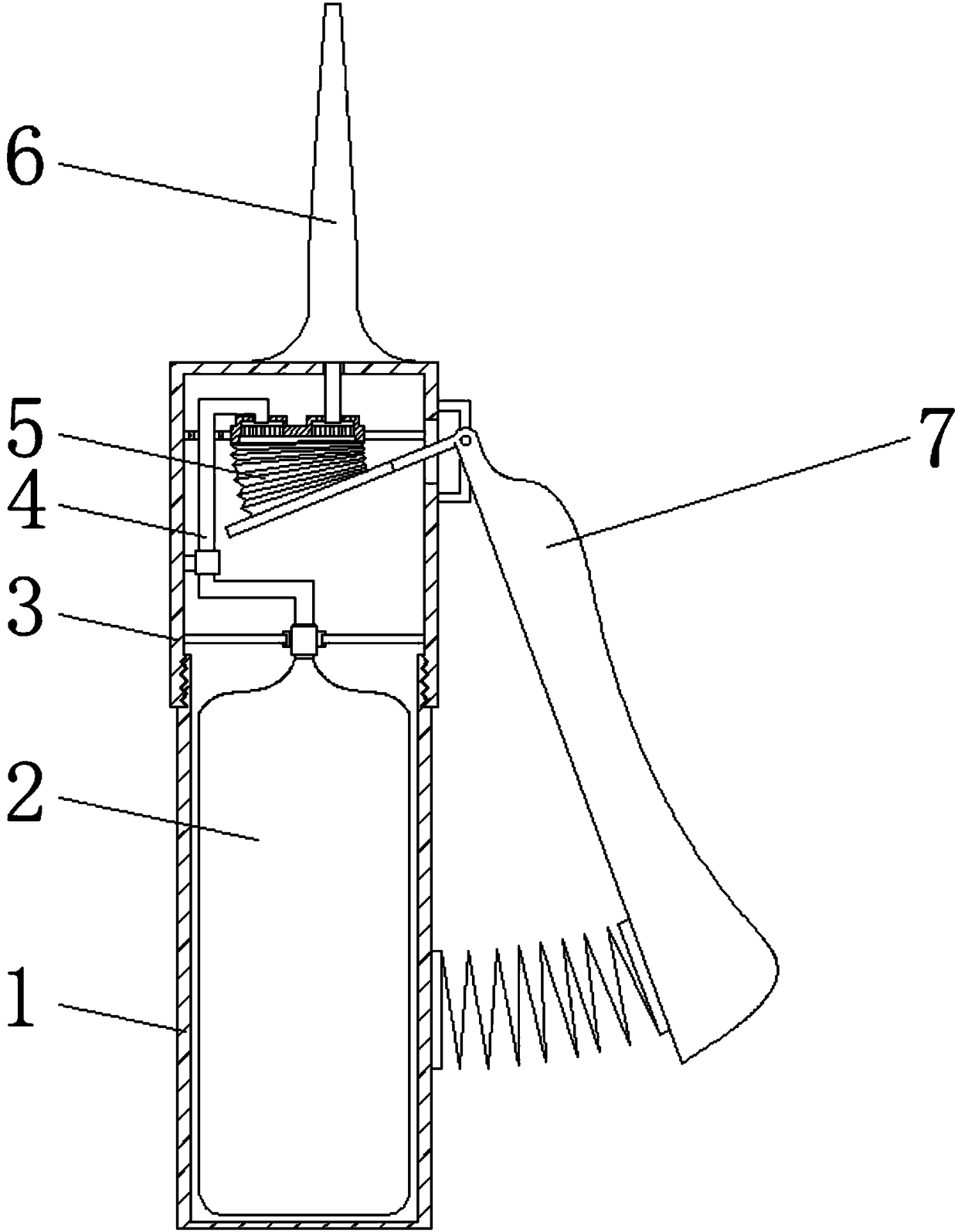

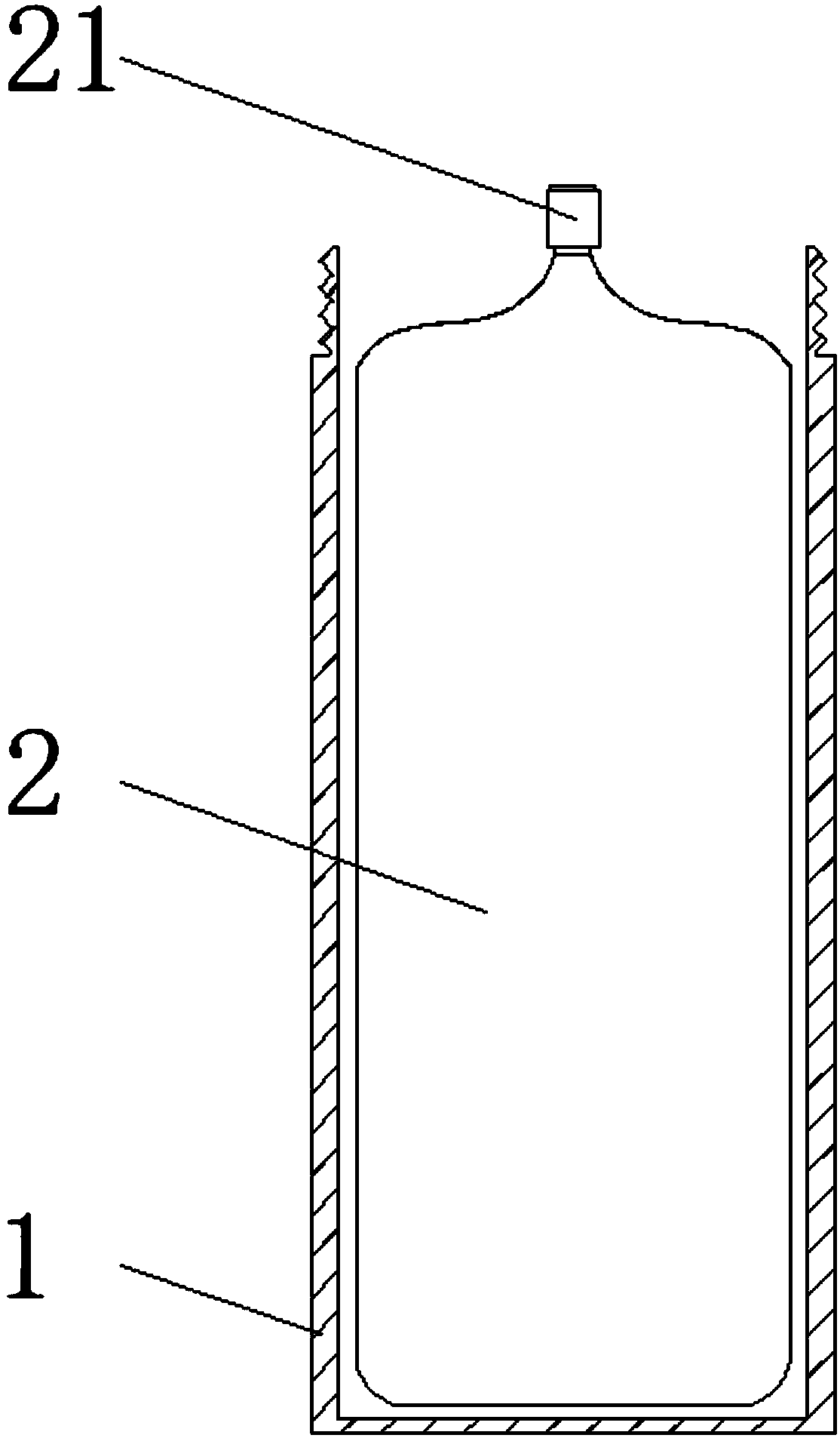

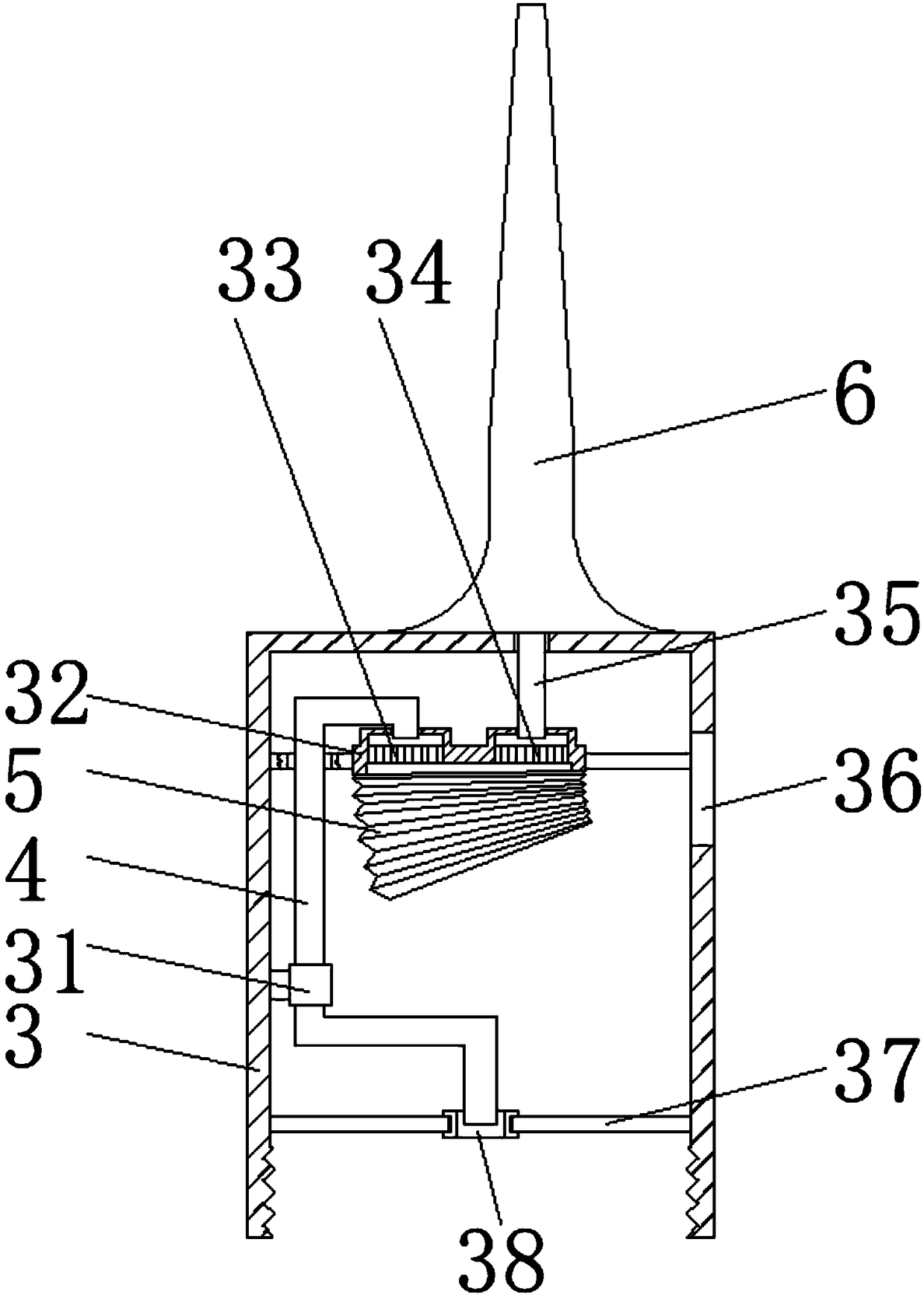

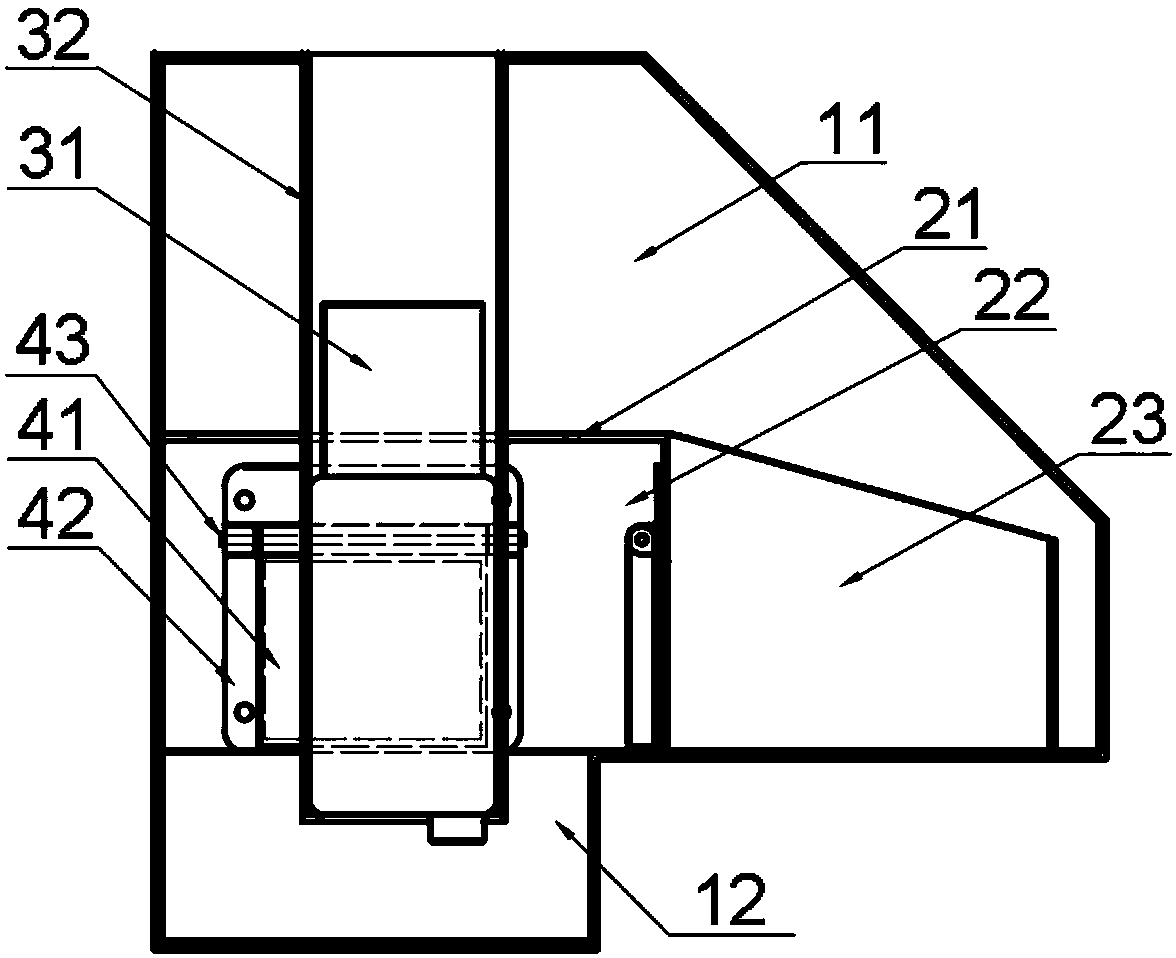

Lubricating oil adding device for sewing machine

ActiveCN108591795AStable oil supplyStable oil quantityManual lubricationLubrication check valvesCheck valveBottle cap

The invention discloses a lubricating oil adding device for a sewing machine. The lubricating oil adding device comprises a bottle body, a bottle cap, an oil conveying pipe, a handle, a connecting cover, an oil draining pipe and a spring. An oil storage bag is installed inside the bottle body. The bottom end of the bottle cap is connected with the top end of the bottle body in a threaded mode. Theoil conveying pipe is fixed into the bottle cap. The bottom end of the oil conveying pipe communicates with the oil storage bag, and the top end of the oil conveying pipe communicates with a bellows.The top end of the bellows is fixedly connected with the connecting cover. The connecting cover is fixed into the bottle cap. An oil pumping check valve and an oil draining check valve are fixed intothe connecting cover. The bellows communicates with an oil injection sharp spout. The handle is installed at one side of the bottle body. The top end of the handle is fixedly connected with a pressing plate. A rotating shaft is installed at the connecting position of the pressing plate and the handle in a rotating mode. The pressing plate penetrates through a notch and is fixedly connected with the bottom end of the bellows. The lubricating oil adding device for the sewing machine has the advantages that oil can be fed at any angle, the oil feeding amount is stable every time, the structure is simple and the oil storage bag can be replaced conveniently.

Owner:枣庄市金刚缝纫设备有限公司

FSAE racing car oil tank

The invention relates to an FSAE racing car oil tank which comprises a shell and an oil pump arranged in the shell. The shell comprises a main oil chamber and a small oil chamber. The main oil chambercommunicates with the inside of the small oil chamber. The small oil chamber is formed in the lower portion of the main oil chamber. An oil collection unit collecting oil of the main oil chamber to the small oil chamber is arranged in the position, on the upper portion of the small oil chamber, in the shell. The oil collection unit comprises multiple vertical baffles and a transverse baffle arranged on the upper portions of the vertical baffles. A cavity structure is defined by the vertical baffles and the transverse baffle. One-way oil inflow components are arranged on the vertical baffles.The oil pump is vertically arranged in the shell and penetrates through the oil collection unit. An oil suction point at the bottom of the oil pump is located in the small oil chamber. Compared with the prior art, the FSAE racing car oil tank has the beneficial effects that oil can be continuously and stably sucked, the fuel oil use rate is high, and a system is small in weight.

Owner:TONGJI UNIV

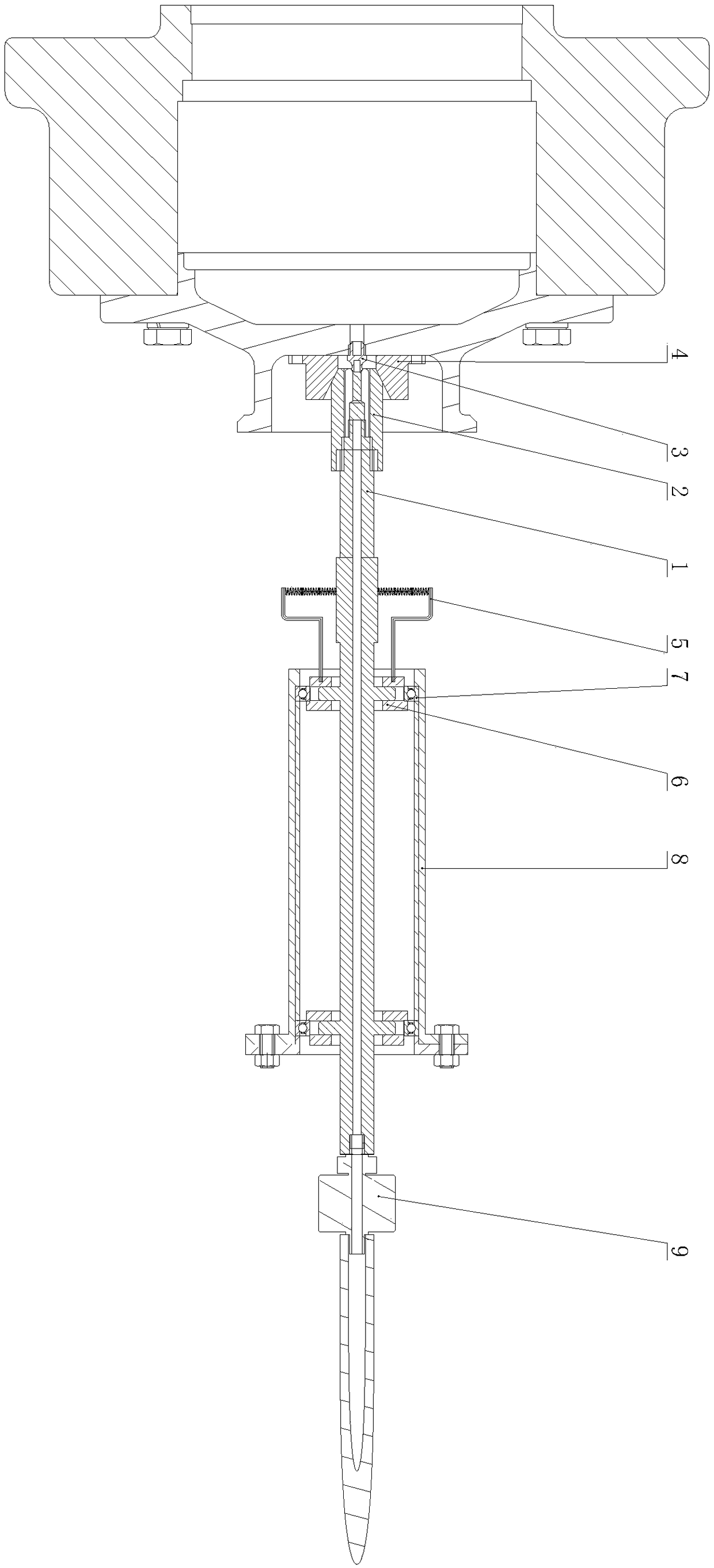

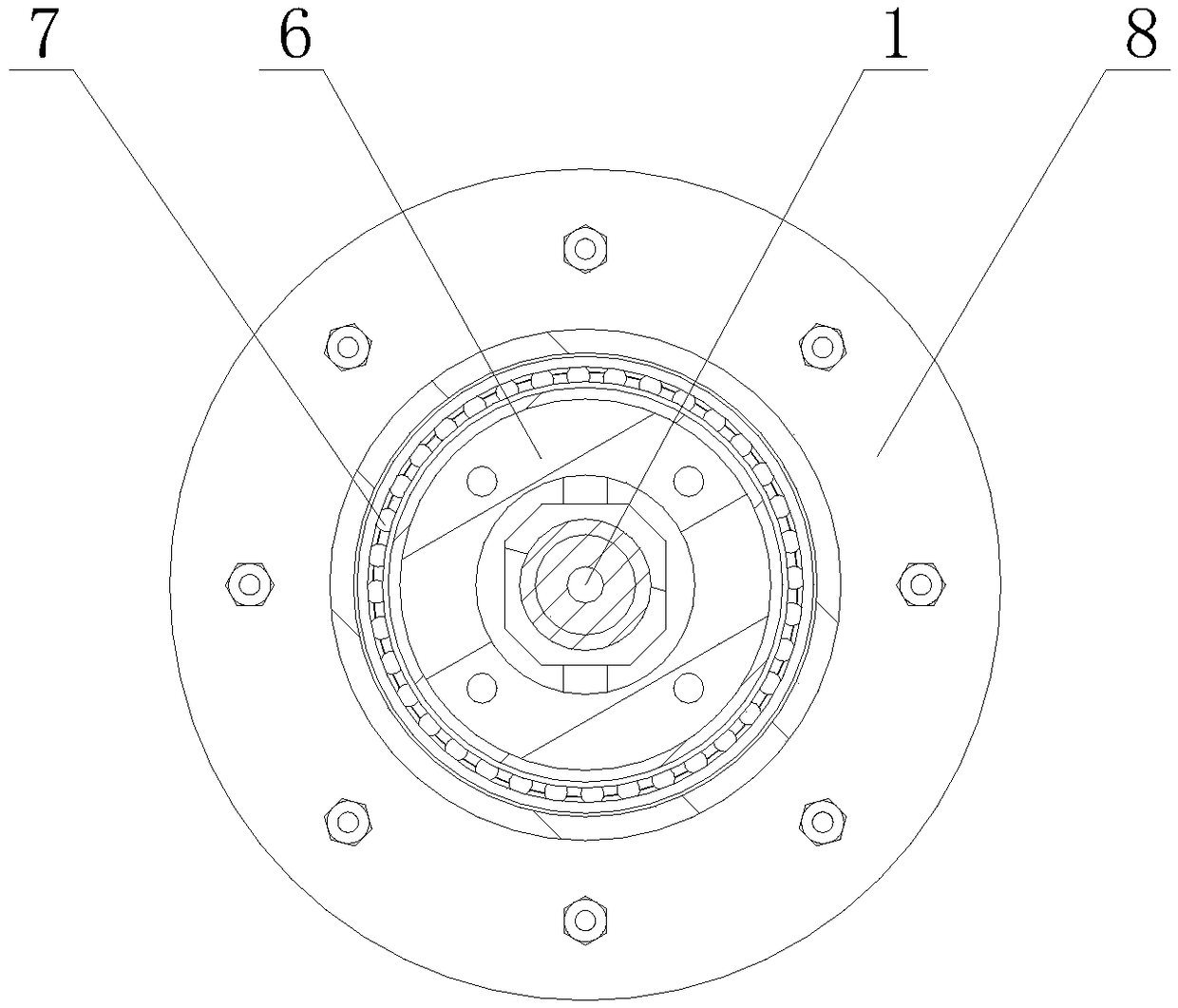

In-process sintering machine trolley wheel automatic centering device

The invention discloses an in-process sintering machine trolley wheel automatic centering device, and belongs to the technical field of sintering engineering. The in-process sintering machine trolleywheel automatic centering device comprises a rotating shaft. A shaft end connector body is arranged at one end of the rotating shaft. A rotating connector is arranged on the other end of the rotatingshaft. A rotating shaft hanger is arranged outside the rotating shaft. A rotating sleeve is arranged at the outer ring of the rotating shaft in a sleeving mode. A bearing is arranged at the outer ringof the rotating shaft. Through guiding carried out by a on-wheel positioning block, sealing fit between the shaft end connector body at the front end of the rotating shaft and an on-wheel connector body located at a wheel, and superposition displacement by relative rotation between the rotating sleeve and a shell and relative slippage between a rotating shaft cantilever and the rotating sleeve, the freedom degree of the shaft end connector body at the front end of the rotating shaft can be guaranteed to adapt to direction deviation of the wheel, lubricating grease can be guaranteed to be filled in the wheel under pressure, and therefore the oil supply process is stable, source utilization rate is effectively improved, and good economic benefits can be produced.

Owner:HUATIAN ENG & TECH CORP MCC

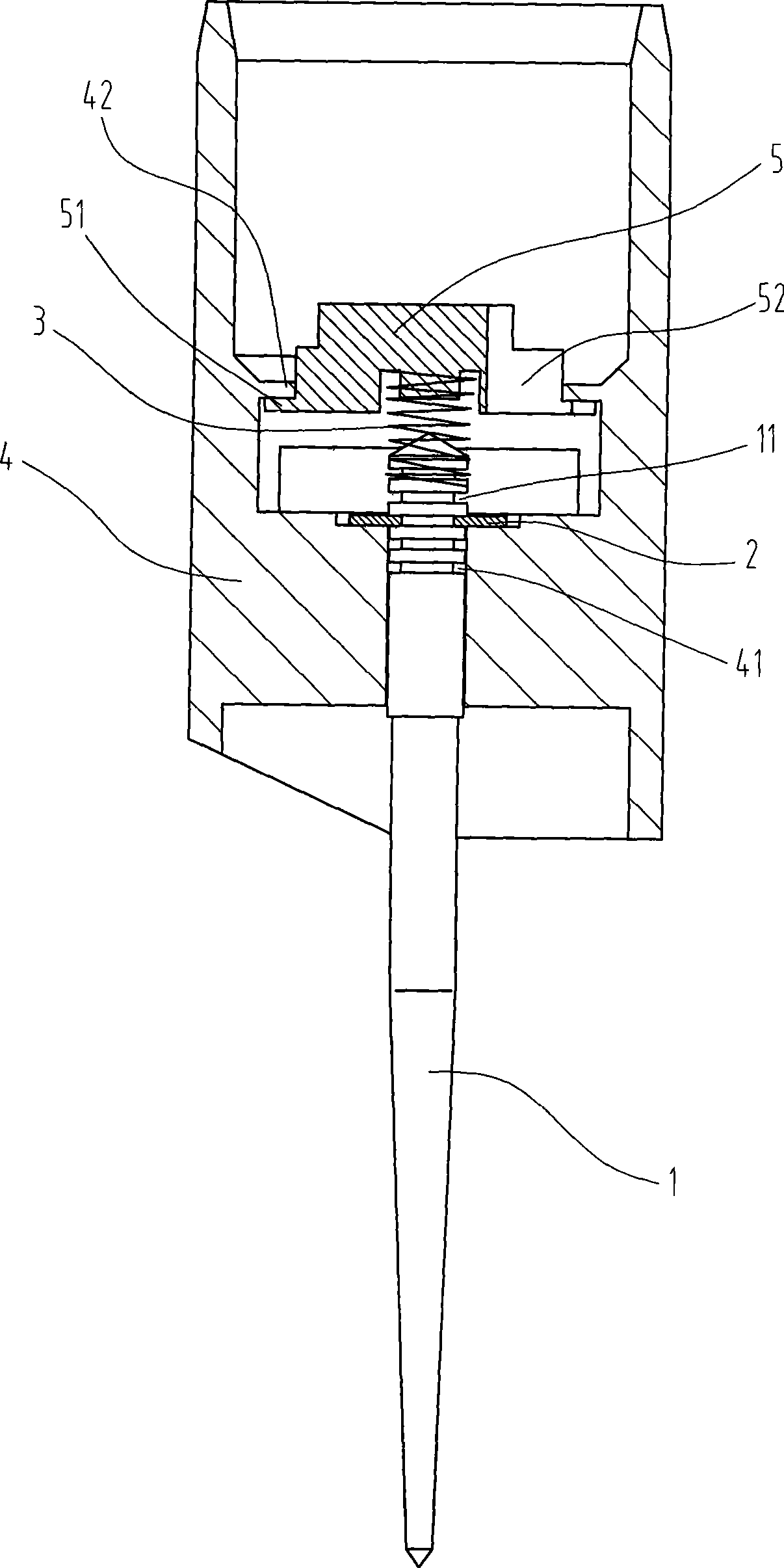

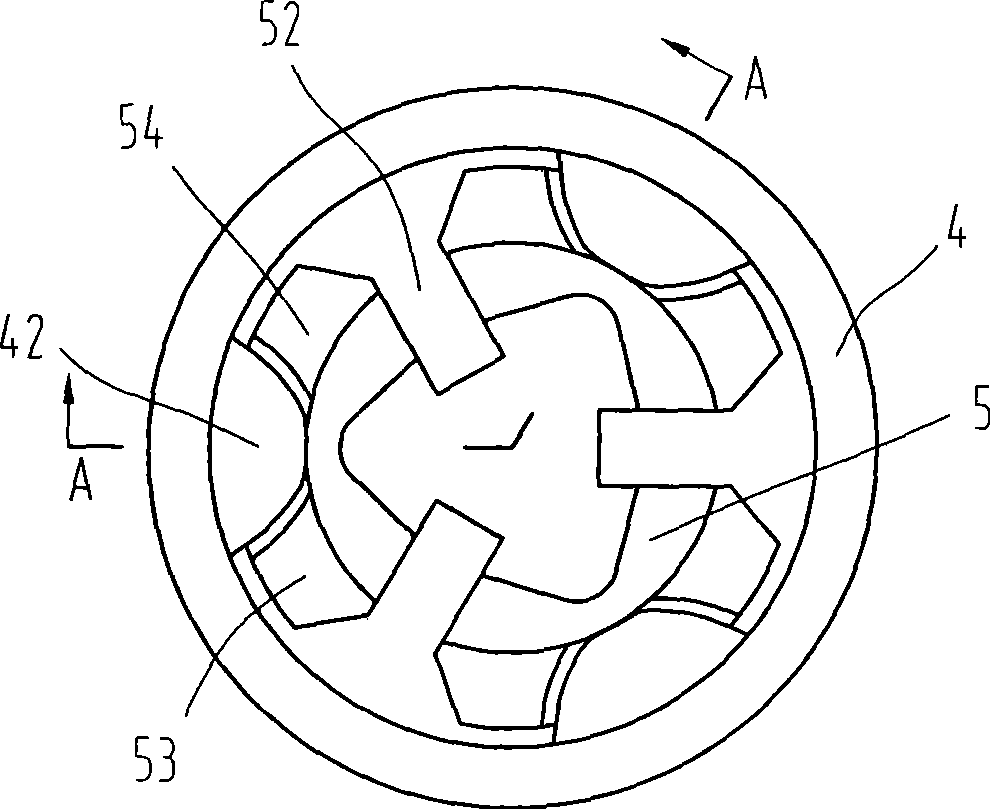

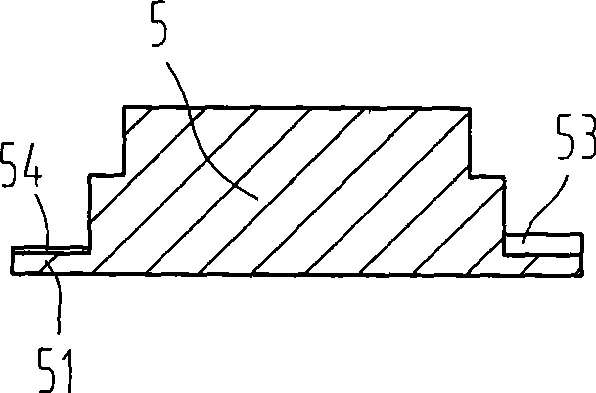

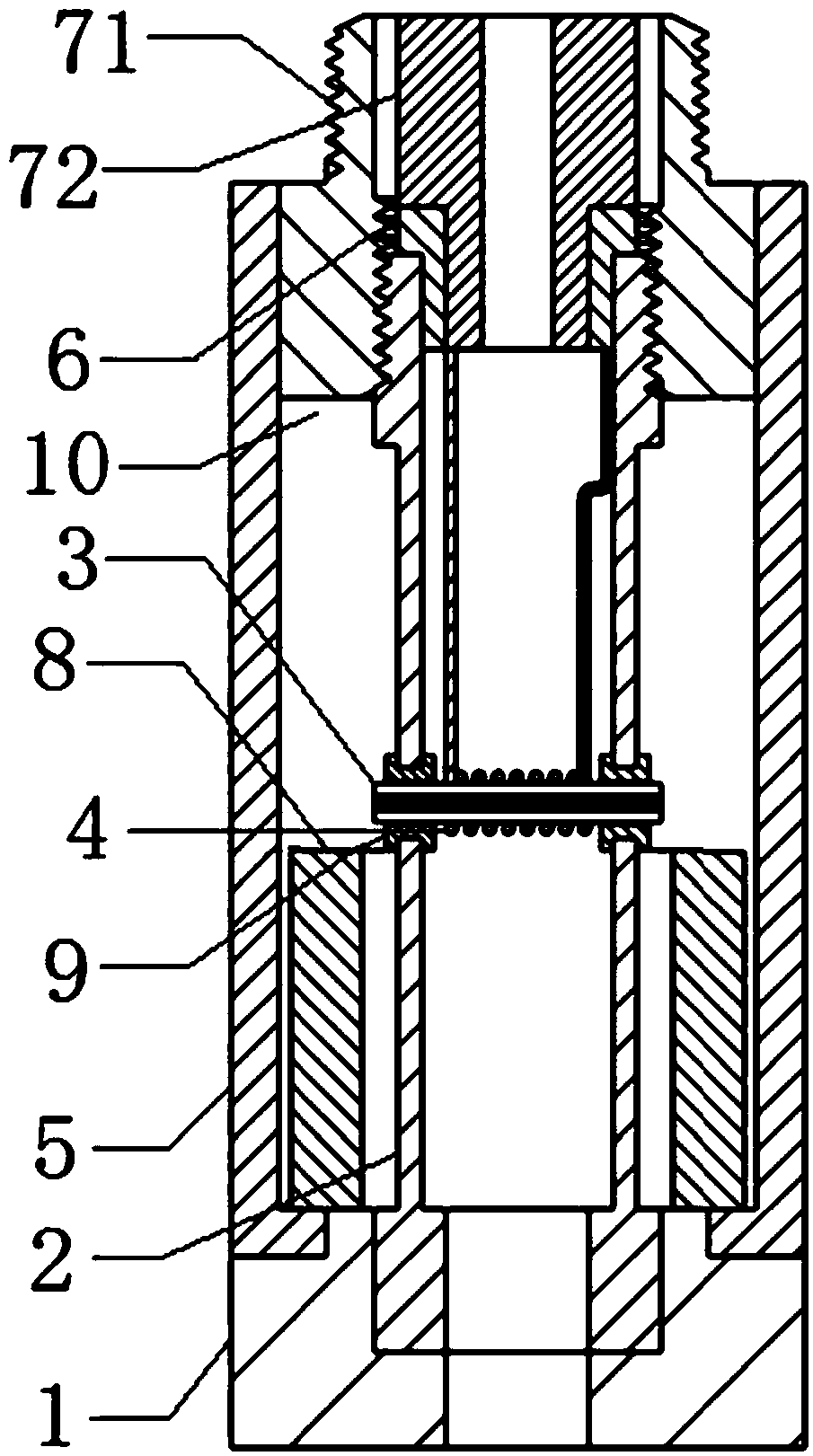

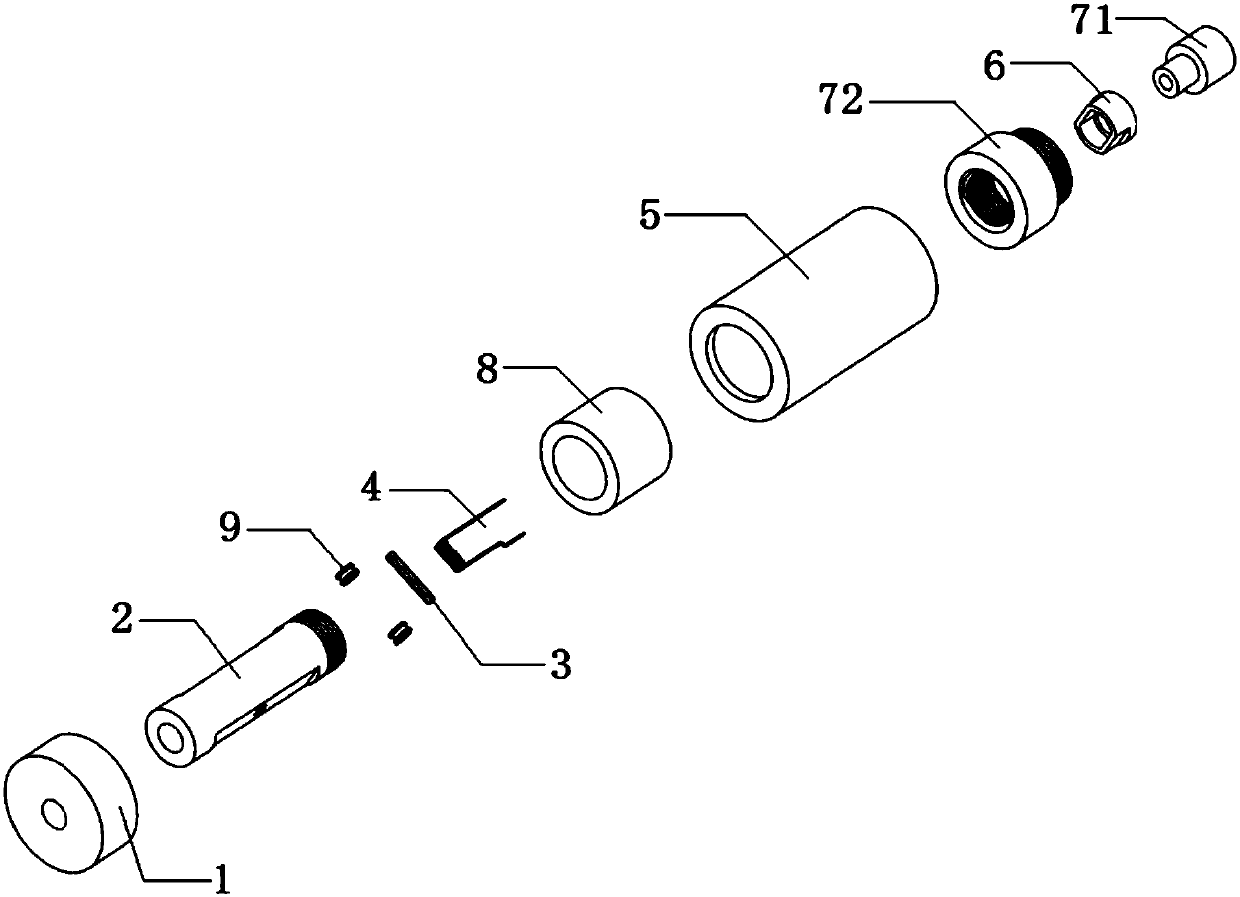

Mounting structure for carburetor needle valve

InactiveCN101382098AStable oil supplyReduce fuel consumptionMachines/enginesCarburettorsNeedle valveFixed frame

The invention relates to a structure for mounting an oil needle of a carburetor, which comprises a plunger and the oil needle. One end of the oil needle is provided with a groove while the other end of the oil needle is conical, a lathedog is arranged in the groove, the end of the oil needle provided with the groove is sleeved with a spring, the oil needle passes through an oil needle hole at the bottom of the plunger and is limited by the lathedog, one end of the spring is abutted against a fixed frame, and the fixed frame is limited by a lug boss positioned in the inner wall of the plunger. With adoption of the invention, the oil needle is more stably and reliably connected with the plunger so as to effectively avoid up-down movement of the oil needle in use, thereby allowing the carburetor to stably supply the oil, allowing an engine to stably operate and contributing to reduction of oil consumption of the engine.

Owner:CHONGQING LONCIN MOTOR

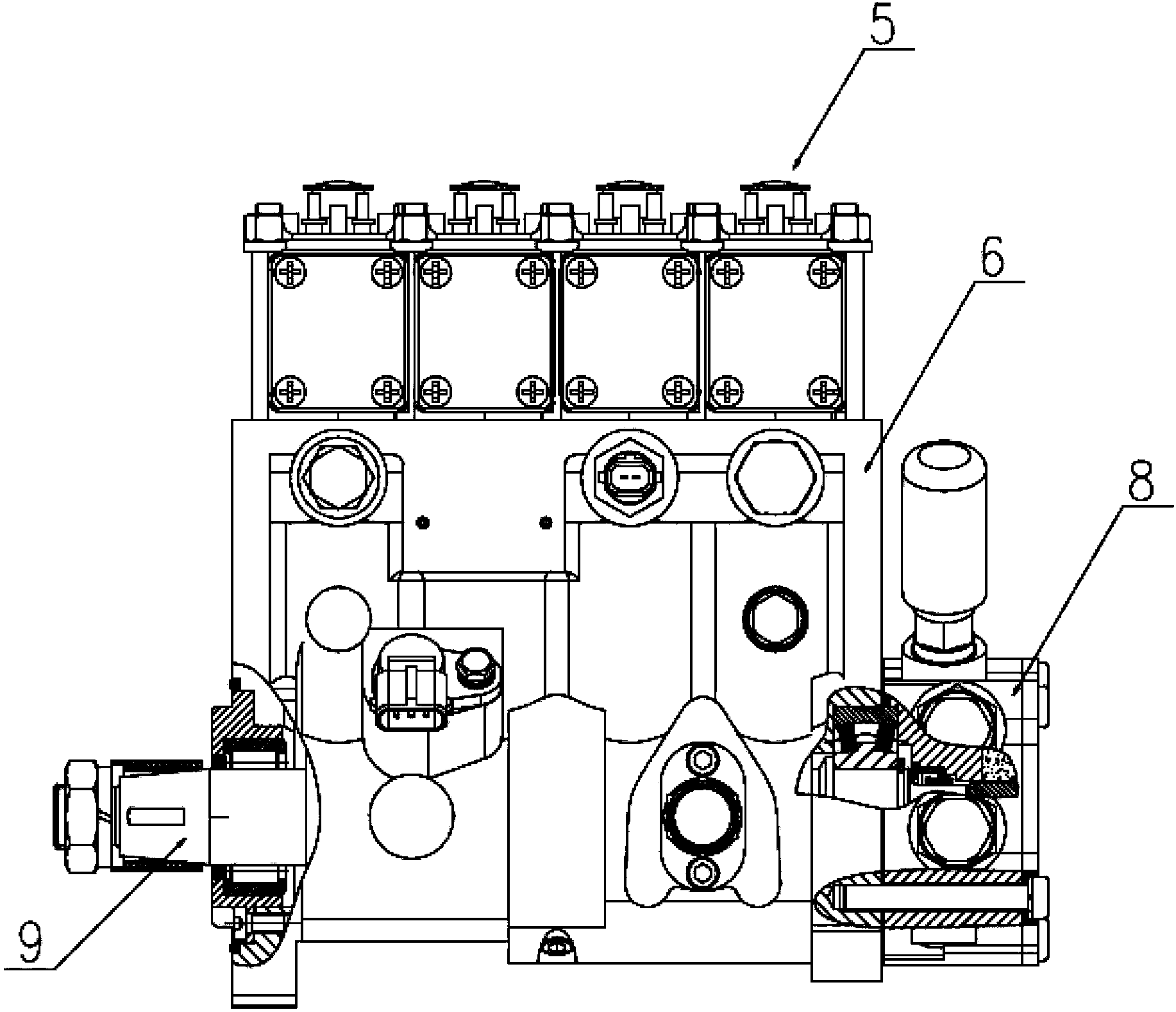

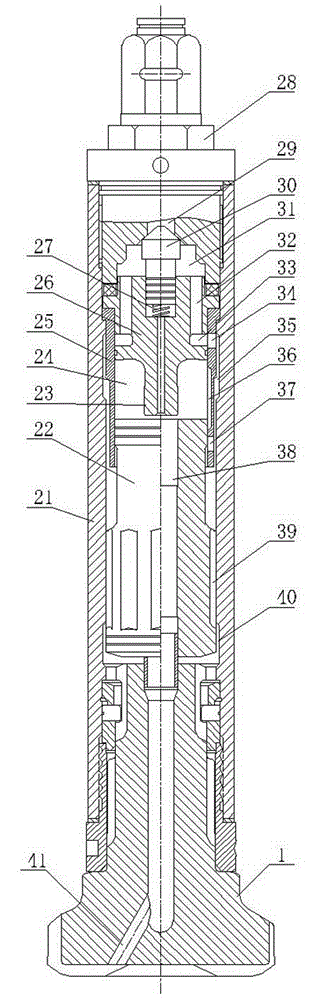

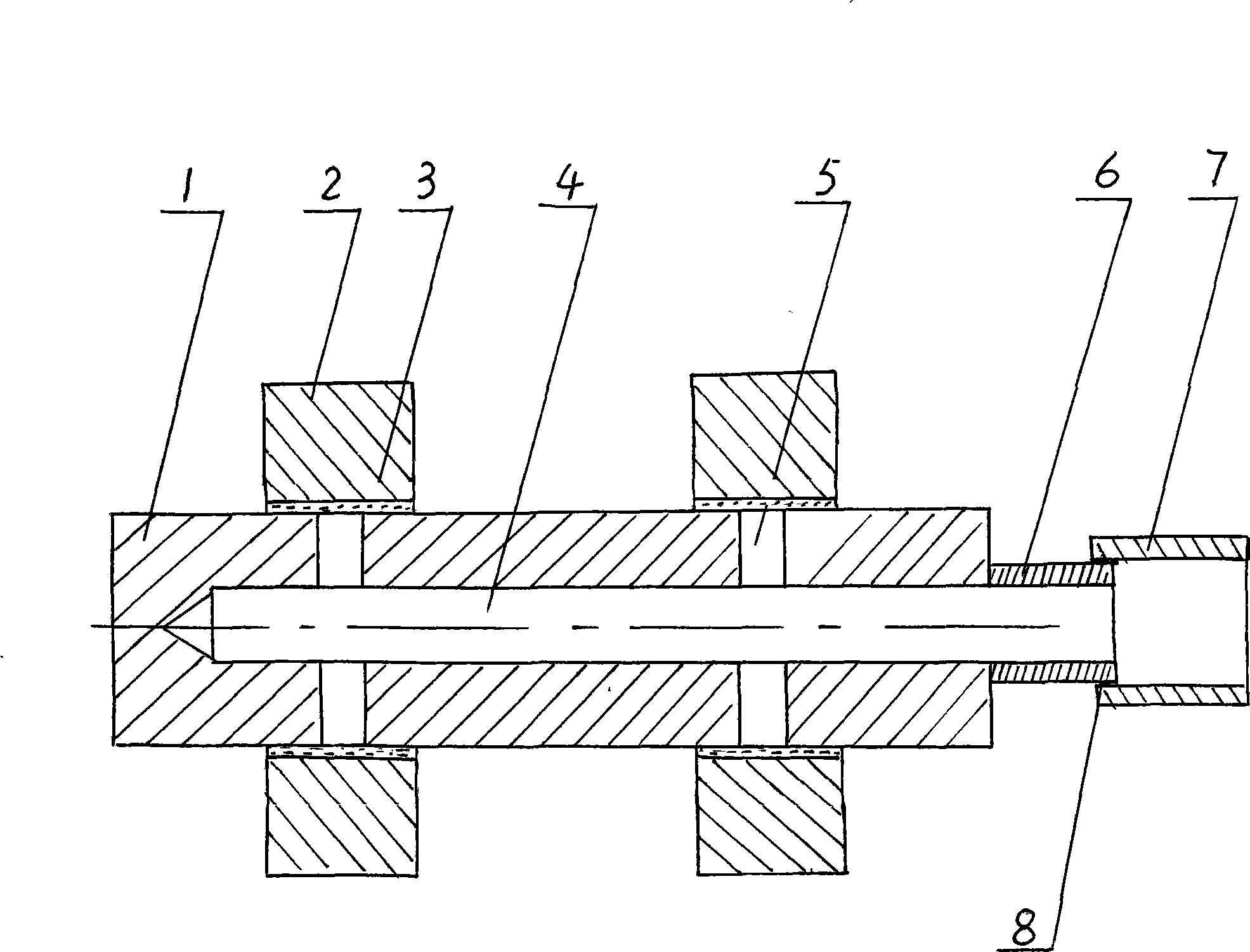

Electronic unit composite pump for light-vehicle diesels

ActiveCN103410643AGuaranteed working lengthReduce weightFuel injection apparatusMachines/enginesCamEngineering

The invention relates to the technical field of vehicle engine manufacturing, in particular to an electronic unit composite pump for light-vehicle diesels. The electronic unit composite pump for light-vehicle diesels comprises a composite pump body, an oil conveying pump, a camshaft, a plurality of electronic unit pumps, tappet body assemblies corresponding to the electronic unit pumps and a cam, and is characterized in that the electronic unit pumps are installed on the composite pump body and comprise unit pump bodies, a plunger, control valve elements and electromagnets installed on one sides of the unit pump bodies, the oil conveying pump is installed on one side of the composite pump body, the tappet body assemblies are arranged between the cam and the plunger and comprise tappets, rolling wheels and rolling wheel pins, and U-shaped cavities are formed in the ends where the tappets make contact with the rolling wheels, wherein the plunger and the control valve elements are arranged in the unit pump bodies. The electronic unit composite pump for light-vehicle diesels has the advantages of being more compact in structure and capable of acquiring higher working speed so as to be matched with the high-speed diesels.

Owner:龙口龙泵柴油喷射高科有限公司

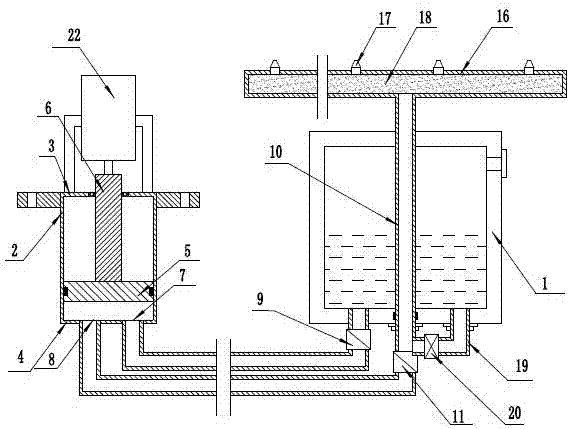

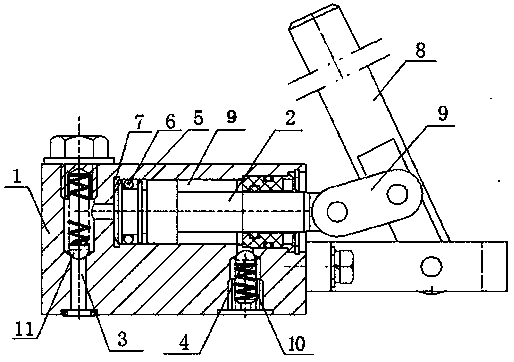

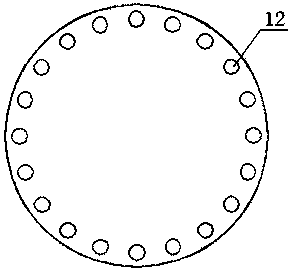

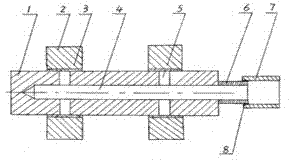

Hydraulic manual pump

InactiveCN103382928AStable oil supplySimple structurePiston pumpsPositive-displacement liquid enginesHydraulic pumpEngineering

The invention discloses a hydraulic manual pump, which comprises a pump body, a piston rod, an oil inlet pipeline, an oil outlet pipeline and a handle component, wherein a cylinder-shaped space is arranged in the pump body to serve as a piston cylinder; the oil inlet pipeline is communicated with the closed end of the piston cylinder; the oil outlet pipeline is arranged on the side wall of a tail end of the piston cylinder; the piston rod is arranged in and matched with the piston cylinder, and can move in the piston cylinder; the handle component is connected with the tail end of the piston rod; a ring-shaped groove is formed in the front end of the piston rod, and a sealing ring is arranged in the groove; a plurality of through holes are formed in the ring surface of a front flange of the groove. The hydraulic manual pump is simple in structure, can realize automatic open / close of hydraulic oil by manually operating a handle, and is smooth in oil supply for an oil cylinder.

Owner:刘建

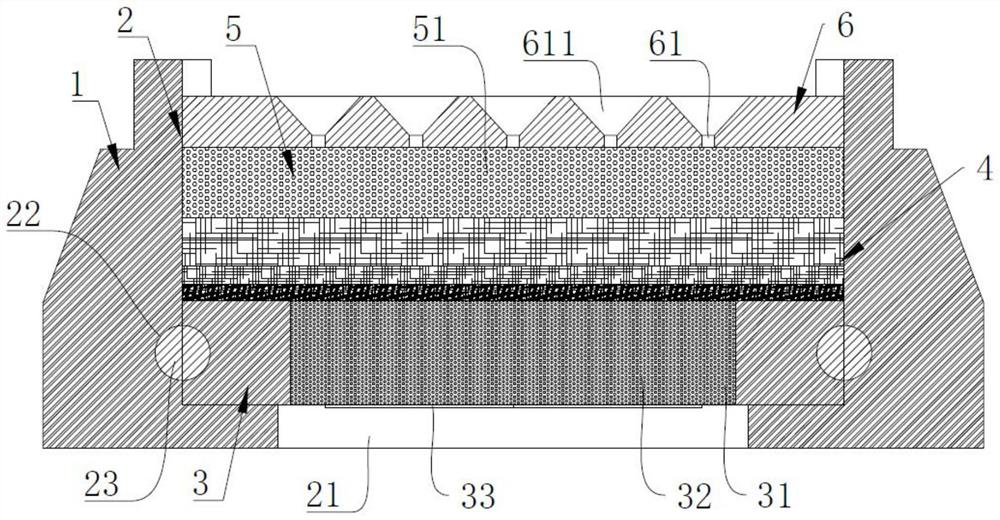

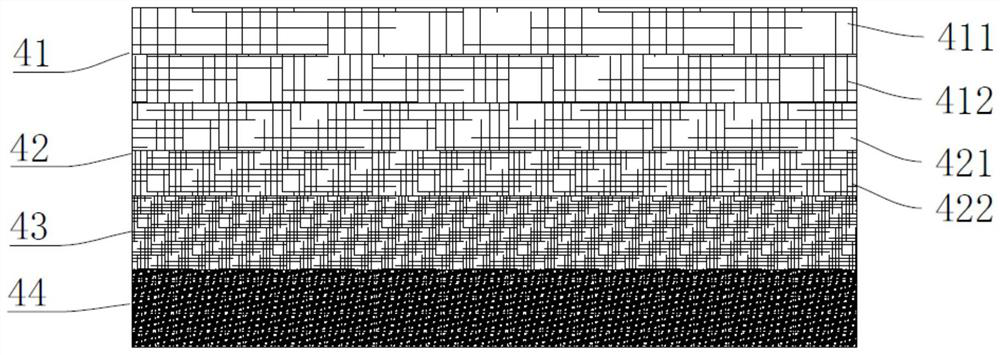

Porous silicon heating structure with oil storage packaging structure and electronic cigarette comprising porous silicon heating structure

The invention relates to the technical field of electronic cigarettes, in particular to a porous silicon heating structure with an oil storage packaging structure and an electronic cigarette comprising the porous silicon heating structure, and the porous silicon heating structure comprises a fixed seat, an atomization cavity formed in the fixed seat, and a heating sheet body, oil storage cotton, an oil conveying sheet and an oil guide sheet which are sequentially arranged in the atomization cavity from bottom to top, and the heating sheet body is provided with a permeation area; micropores are uniformly distributed in the permeation area, the micropores are connected with the oil storage cotton, oil conveying holes are uniformly distributed in the oil conveying sheet, the oil conveying holes are communicated with the oil storage cotton, a heating circuit is arranged on the heating sheet body, oil guide holes are formed in the oil guide sheet, and the oil guide holes are communicated with the oil conveying holes; the heating circuit is arranged in the permeation area and deviates from one surface of the oil storage cotton; through the cooperation of the oil conveying sheet and the oil storage cotton, the electronic cigarette can be used for storing tobacco tar, sufficient tobacco tar can be conveniently provided when the electronic cigarette is used every time, the heating and atomizing effects on the tobacco tar are good, and the taste is improved.

Owner:SHENZHEN KELAI PENG TECH CO LTD

Hydropower station dam intelligent standby power supply system

PendingCN112311086AStable power supplyContinuous power supplyPower network operation systems integrationInformation technology support systemTransformerEngineering

The invention discloses a hydropower station dam intelligent standby power supply system, and the system comprises two sets of standby power supply devices which are communicated with each other, wherein the standby power supply devices are connected through an interconnection circuit breaker, each standby power supply comprises a transformer, and a power supply of a mains supply network is converted into electric energy required by a dam power utilization system through the transformers. A control switch is arranged at the output end of the transformer, voltage measuring sensors are arrangedon the two sides of the control switch respectively, the output end of the transformer is further connected with a diesel generator in parallel, and the output end of the diesel generator is providedwith the voltage measuring sensors and the control switch. Dual backup of the standby power supply is realized through the two groups of standby power supplies and the diesel generator, so that the stability of the standby power supply is greatly improved; meanwhile, the control circuit comprises the voltage measurement sensor and the circuit control switch, so the circuit structure of the whole system is greatly simplified, the reliability and stability of operation are improved, and the fault of the power grid can be ensured.

Owner:SICHUAN HUANENG BAOXINGHE HYDROPOWER CO LTD

Walking dual-swing downhole drill

ActiveCN102828690BFully lubricatedOil Mist StabilizationReciprocating drilling machinesConstructionsEngineeringHigh pressure

The invention discloses a walking dual-swing downhole drill, which comprises a pile frame main body and a drilling main body, wherein the drilling main body comprises an upper power head, a lower power head, an outer sleeve, a spiral drill stem and a downhole hammer; the upper power head is connected with the top end of the spiral drill stem; the bottom end of the spiral drill stem is connected with the downhole hammer; the upper power head drives the spiral drill stem and the downhole hammer to rotate clockwise when working; the lower power head is connected with the outer sleeve and drives the outer sleeve to rotate anticlockwise when working; the downhole hammer comprises an impacter and an impact hammer; the hammer head of the impact hammer is exposed out of the lower opening of the outer sleeve; a high-pressure gas channel is arranged inside the drilling main body, and the high-pressure gas passes through the upper power head, a buffer, the spiral drill stem and the impacter and is finally blown outwards from the bottom part of the impact hammer. The walking dual-swing downhole drill has main characteristics of taking soil to form a hole by a dry method without pollution, and being adapted to various geologies and stratums, such as hard lithosphere, tundra, sand bed with abundant underground water, a rubble layer and boulder, which are difficult to drill by other pile drivers.

Owner:瑞安市八达工程机械有限公司

Atomization device and electronic cigarette using same

PendingCN109953379AStable aerosol qualityIncrease contact areaTobacco devicesEngineeringElectronic Cigarette Use

The invention provides an atomization device and an electronic cigarette using the same. The atomization device comprises a liquid guide component, a heating component, a liquid storage cavity, an upper cover and a support frame tube, wherein the liquid storage cavity is arranged in the support frame tube; the upper cover is arranged at one end of the liquid storage cavity; the liquid guide component is arranged in the liquid storage cavity; the liquid storage component consists of a plurality of tightly arranged fine pipes; one end of the liquid guide component is abutted against the upper cover; the other end of the liquid guide component is abutted against the heating component. A cache component is also arranged between the liquid guide component and the heating component in the atomization device and is used for caching liquid guided in from the liquid guide component; the problem of seepage of the liquid that is guided out is avoided; the liquid guide effect is improved; the liquid is stably supplied.

Owner:SHANGHAI NEW TOBACCO PRODUCTS RESEARCH INSTITUTE CO LTD

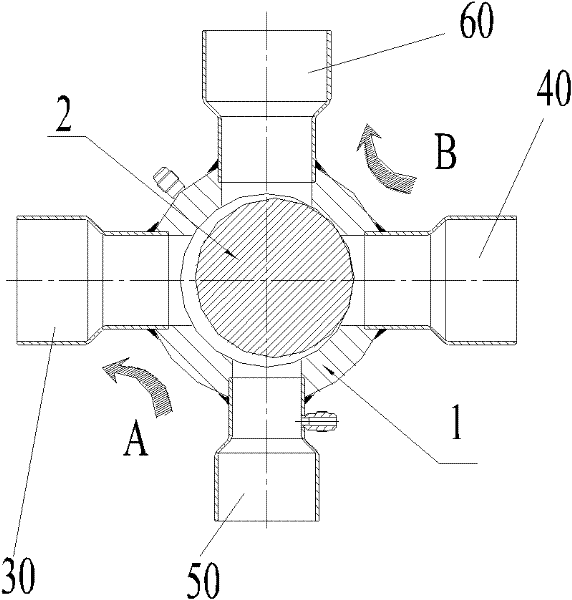

High-capacity four-way reversing valve

InactiveCN101968128BGuaranteed normal commutationStable oil supplyMultiple way valvesLow voltageEvaporation

The invention provides a high-capacity four-way reversing valve, comprising a main valve and a pilot valve. The main valve comprises a valve body and a piston arranged in the valve body; the valve body comprises a low-voltage exhaust pipe, a high-pressure intake pipe, a condensation pipe and an evaporation pipe which are arranged on the valve body; an oil inlet and an oil outlet are arranged on the valve body; the piston comprises a lubricant passage arranged on the piston and a pressure balance groove; the oil inlet and the oil outlet are communicated with the lubricant passage; the lubricant passage comprises a first lubricant groove, a second lubricant groove and a connection groove, wherein the first lubricant groove is arranged on a first outer side surface of the piston, the second lubricant groove is arranged on a third outer side surface of the piston, and the connection groove is arranged on the outer side surface of a connection part between the upper and the lower runners of the piston and connected with the first and the second lubricant grooves. The invention can effectively solve the problem of blocking between the piston and the valve body to ensure that the force bearing point between the piston and the valve body (namely, the cylinder body) has sufficient refrigeration oil to form an oil film; furthermore, the force at the force bearing point between the piston and the cylinder body is decreased to ensure that the piston can reverse normally in the cylinder body.

Owner:ZHEJIANG DUNAN MASCH CO LTD

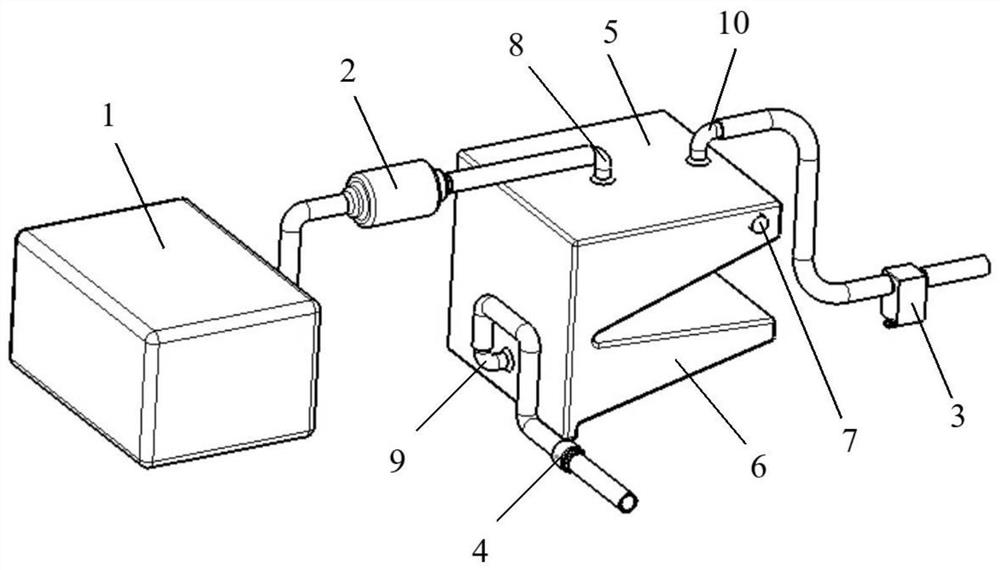

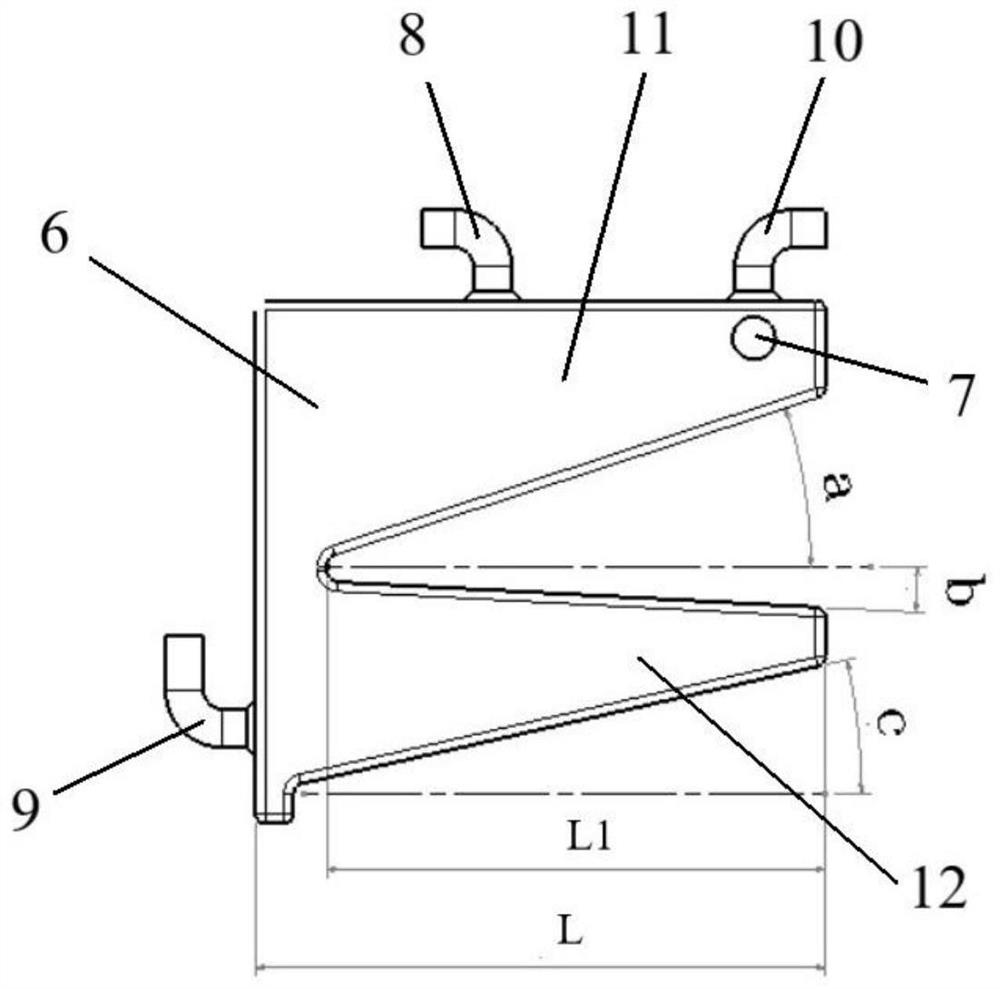

Double-cavity fuel system suitable for diving flight of unmanned aerial vehicle and design method thereof

ActiveCN112340037AUninterrupted supplyAvoid the impact of oil supply reliabilityPower plant fuel tanksWeight reductionMarine engineeringFuel tank

The invention provides a double-cavity fuel oil system suitable for diving flight of an unmanned aerial vehicle and a design method thereof. An outlet of a soft oil tank in the double-cavity fuel oilsystem communicates with an oil inlet in the upper end of an oil-gas separator through an oil pump, and an oil outlet in the lower end of the oil-gas separator is externally connected with an engine oil inlet through a one-way valve. An oil inlet and an exhaust port are formed in an upper end cover of the oil-gas separator; an oil outlet is formed in the lower part of the side wall of the oil-gasseparator; and a liquid level sensor is mounted on a side wall plate of the upper cavity. The oil-gas separator is divided into an upper cavity and a lower cavity. Reliable oil supply during normal flight of the unmanned aerial vehicle can be met, the fuel oil system can stably and reliably supply pure fuel oil to the engine when the unmanned aerial vehicle flies in a large maneuvering flight attitude, especially in dive flight and pull-up re-flight, normal work of the engine is guaranteed, and the influence on the oil supply reliability at the oil outlet due to violent shaking of the fuel oilliquid level caused by adverse factors such as yawing, overload and wind gushing of the unmanned aerial vehicle during flight can be effectively avoided.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

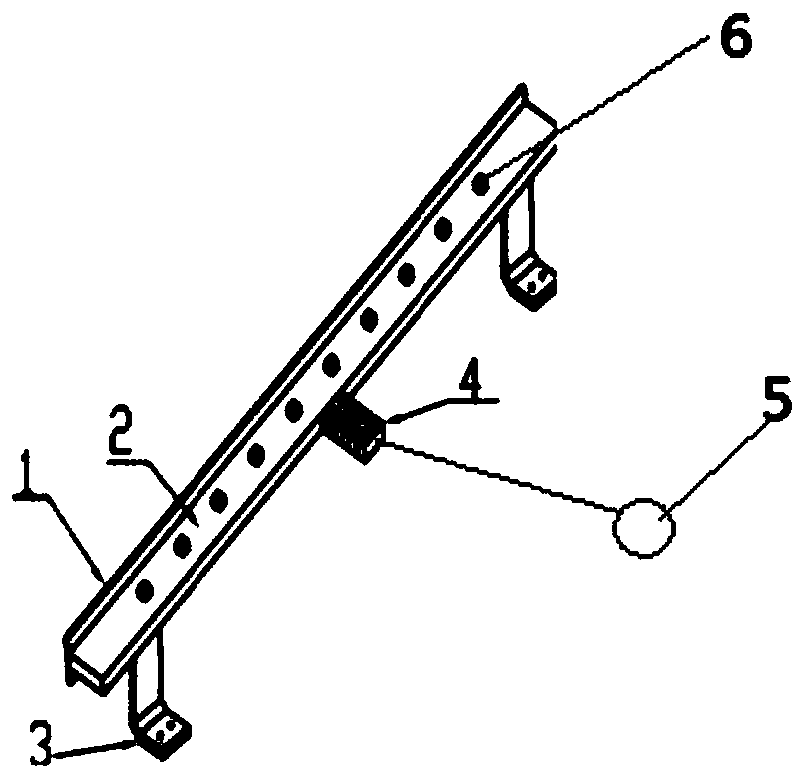

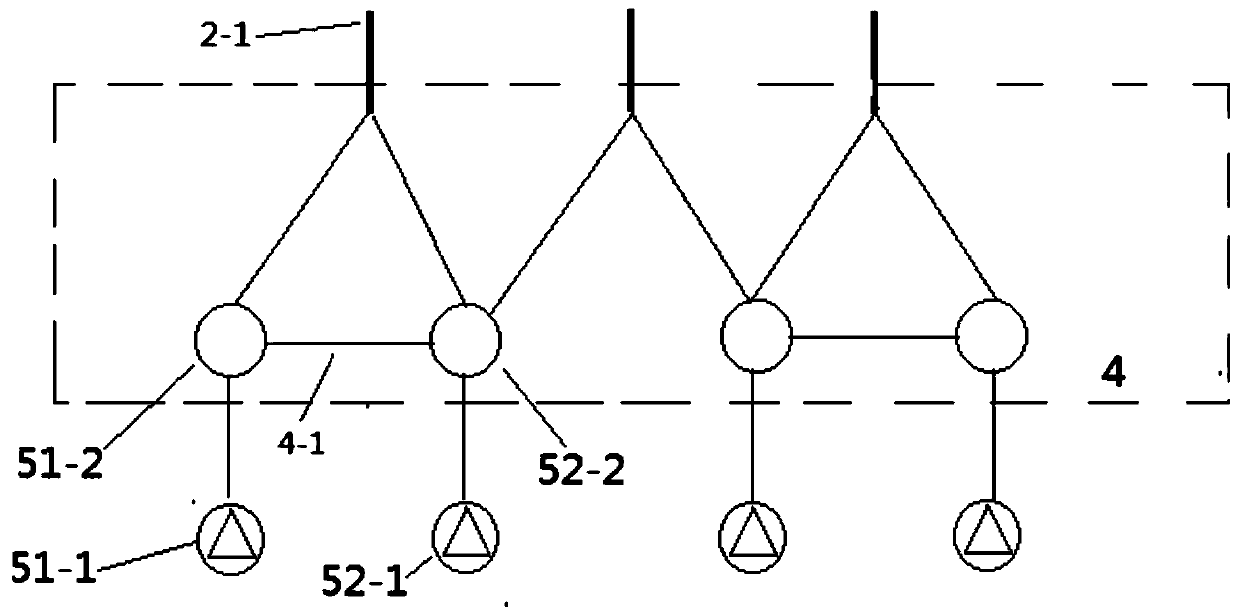

Track lubrication spraying device

InactiveCN109882727AImprove stabilityImprove the lubrication effectProportioning devicesConduits/junctionsEngineeringLubrication

The invention discloses a track lubrication spraying device. The track lubrication spraying device is designed according to the shape of a train track and installed on the side face of a rail, an oilpumping device with a plurality of oil outlets and a plurality of pump cores is arranged, every two oil outlets are connected in series through an injection assembly, and each oil passage in a main plate of a coating plate is connected with at least two oil outlets; the stability of oil supply is improved through structure arrangement of the injection assemblies, when the oil outlet of the oil pumping device is blocked, other oil outlets can supply oil to the corresponding oil passage connected with the blocked oil outlet, the oil pump capacity is stable and the spraying quantity is even, andthe lubrication effect is significantly improved; and soft oil grooves are formed, lubricants transported by the oil passages are temporarily stored in the soft oil grooves, when a train squeezes thesoft oil grooves through wheels, the lubricants such as anti-wear agents are evenly attached to the wheels and taken away, and oil coating is even.

Owner:SHANDONG NORMAL UNIV

Atomization device and electronic cigarette using same

The invention provides an atomization device and an electronic cigarette using the same. The atomization device comprises a liquid guide component, a liquid storage cavity and a support frame tube, wherein the liquid storage cavity is arranged outside the support frame tube; the liquid guide component is arranged in the support frame tube; at least one end of the liquid guide component is communicated with the liquid storage cavity; a slide block is arranged in the liquid storage cavity, and can slide in the liquid storage cavity. The atomization device has the advantages that the liquid utilization rate is obviously improved; the liquid can also be stably provided under the condition of little liquid; particularly when the device is used as the atomization device of the electronic cigarette, the liquid storage cavity stores tar; the stable tar smoke quality can be provided; the smoking experience of users is further improved; the atomization device also adapts to different smoking habits of the users.

Owner:SHANGHAI NEW TOBACCO PRODUCTS RESEARCH INSTITUTE CO LTD

A flat-suction plunger carburetor for large-displacement competitive cross-country motorcycles

ActiveCN104481736BResponsive and timelyImprove responsivenessIdling devicesMachines/enginesOvertakingCarburetor

The invention discloses a horizontal draught type plunger piston type carburetor for a large-emission competitive scrambling motorcycle. The carburetor comprises a carburetor body assembly (1), and a floater chamber assembly (2) which is mounted on the lower surface of the carburetor body assembly (1); an oil feeding system, a starting system, an idling system, a main oil system and an acceleration system are arranged in the carburetor body assembly (1). The carburetor has the beneficial effects that the structure is compact, the scrambling motorcycle can be started and run at a constant speed in an environment under a low temperature less than -40 DEG C; an accelerator can be timely responded, the acceleration for overtaking can be timely responded, the oil returning during acceleration can be effectively avoided, and the safety and reliability can be ensured.

Owner:成都恒高机械电子有限公司

Kinetic pressure bearing

InactiveCN101235846AStable oil supplyStabilize the oil volume in the oil chamberBearing componentsSliding contact bearingsRotational axisCentrifugal force

The invention belongs to the field of mechanical processing, in particular to a hydrodynamic bearing, which comprises a rotating shaft and a shaft sleeve, wherein a wedge oil cavity is arranged between the rotating shaft and the shaft sleeve. The hydrodynamic bearing is characterized in that a central oil hole is arranged on the axis of the rotating shaft, a vertical oil hole which is vertical to the axis is arranged on a position where the rotating shaft corresponds to the wedge oil cavity, the vertical oil hole is communicated with the central oil, a rotating oil pipe is arranged on a position of the central oil hole which is arranged on one end of the rotating shaft, the rotating oil pipe is arranged in a fixed oil pipe, and a sealing ring is arranged on the middle portion. Pressure oil of the invention enters the central oil hole from the fixed oil pipe through the rotating oil pipe, and then enters into the oil cavity through the vertical oil hole. When the rotating shaft rotates, because the action of centrifugal force, the pressure oil is hurled to the oil cavity from the central oil hole through the vertical oil hole, thereby being capable of guaranteeing that the oil cavity steadily supplies oil in a high speed state, the oil mass of the oil cavity of the hydrodynamic bearing is steady, and the vibration of the hydrodynamic bearing is small.

Owner:潘旭华

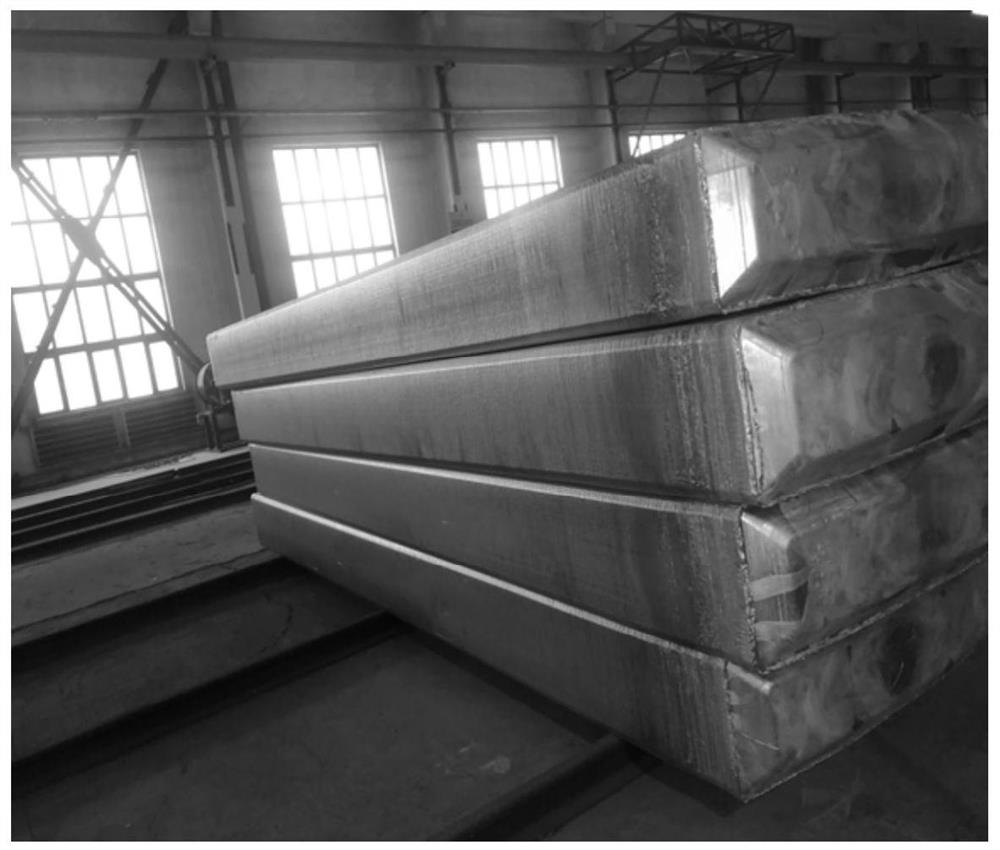

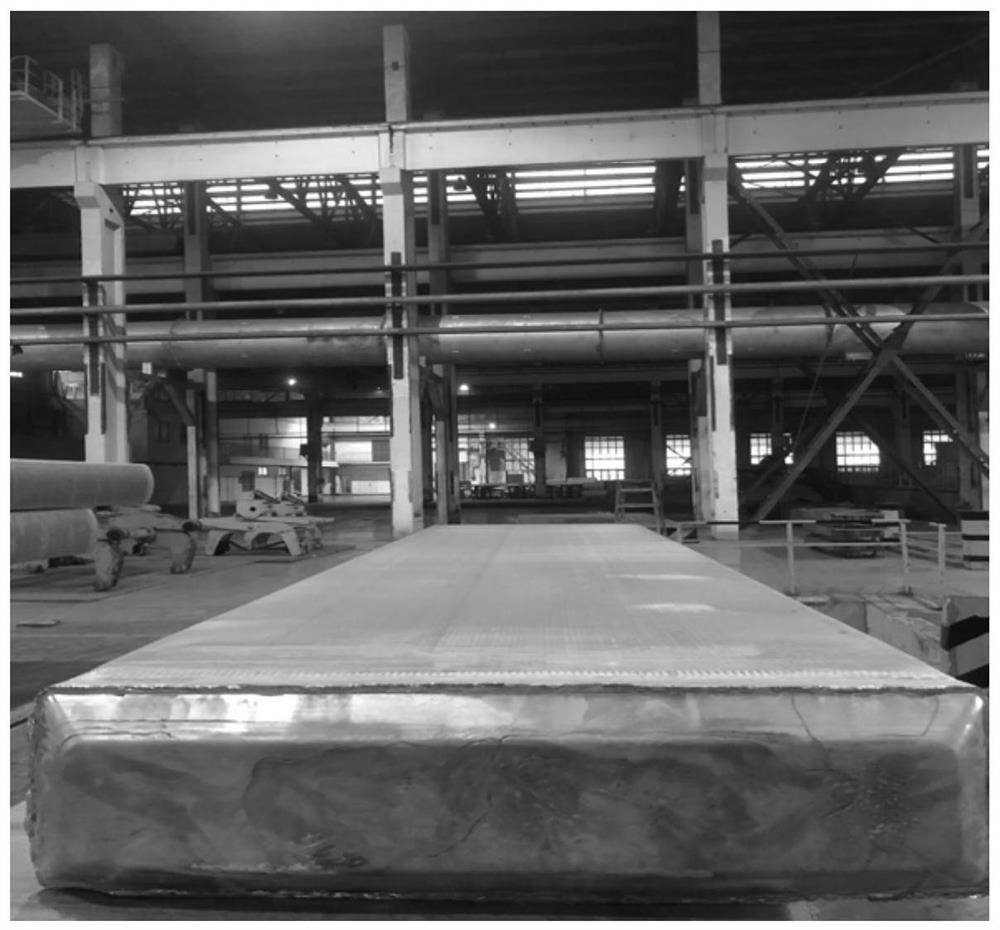

Composite core material aluminum alloy flat cast ingot and manufacturing method thereof

ActiveCN112593124AGuaranteed uniformityGuaranteed steady moldingGas emission reductionSlagCrack free

The invention discloses a composite core material aluminum alloy flat cast ingot and a manufacturing method thereof, and belongs to the field of alloy cast ingot manufacturing. The problems of high crack tendency and low casting yield in the existing method for producing a composite core material aluminum alloy with higher Ti content are solved. The materials are composed of Si, Fe, Cu, Mn, Mg, Zn, Zr, Ti and the balance aluminum. The preparation method comprises the following steps of 1, weighing the materials, 2, smelting to obtain an aluminum alloy melt, 3, preparing a casting melt, and 4,forming. According to the composite core material aluminum alloy flat cast ingot and the manufacturing method thereof, the problems that in the prior art, when the composite core material aluminum alloy with the high Ti content is produced, the crack tendency is large, and consequently casting beginning aluminum leakage and hanging defects are caused are effectively solved, and forming is guaranteed; the cast ingot is good in surface forming, free of surface defects, cracks, slag inclusion and air holes, and the rate of finished products reaches 95%; the internal metallographic structure of the cast ingot manufactured through the method is free of looseness, overall uniform and free of coarse grain defects, and the internal performance reaches the standard; and the preparation method is suitable for manufacturing the composite core material aluminum alloy flat cast ingot.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Horizontal type rotating compressor for electric car air conditioner and work method

PendingCN110617222AStable oil supplyReduce installation process and costRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsMain bearingOil supply

Owner:XI AN JIAOTONG UNIV

Dynamic-pressure bearing stable in oil supply

The invention belongs to a dynamic-pressure bearing stable in oil supply, which comprises a rotary shaft and shaft sleeves. Wedged oil cavities are formed among the rotary shaft and the shaft sleeves. The dynamic-pressure bearing is characterized in that t a center oil hole is arranged in the axial center of the rotary shaft, and perpendicular oil holes perpendicular to the axial center line of the rotary shaft are arranged on the rotary shaft, correspond to the wedged oil cavities and are communicated with the center oil hole. A rotary oil pipe is arranged at the center oil hole at one end of the rotary shaft and is mounted in a fixed oil pipe, and a sealing ring is mounted in the middle of the rotary oil pipe. Pressure oil enters the center oil hole from the fixed oil pipe through the rotary oil pipe and then flows into the oil cavities through the perpendicular oil holes. When the rotary shaft rotates, the pressure oil can be thrown to the oil cavities from the center oil hole through the perpendicular oil holes under the action of centrifugal force, accordingly, stable oil supply for the oil cavities at high speed can be guaranteed, the oil quantity of the oil cavities of the dynamic-pressure bearing is stable, and vibration of the dynamic-pressure bearing is low.

Owner:DALIAN CHUANGDA TECH TRADE MARKET

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com