Axial-flow Kaplan turbine runner withstand voltage operation test system

An operation test and hydraulic turbine technology, which is applied in the direction of measuring the increase and decrease rate of the fluid, using liquid/vacuum degree to measure the liquid tightness, etc., can solve the problems of the number of times of operating the blade switch, the internal leakage of the valve, and the inability to close. Serious and other problems, to achieve the effect of stable oil supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

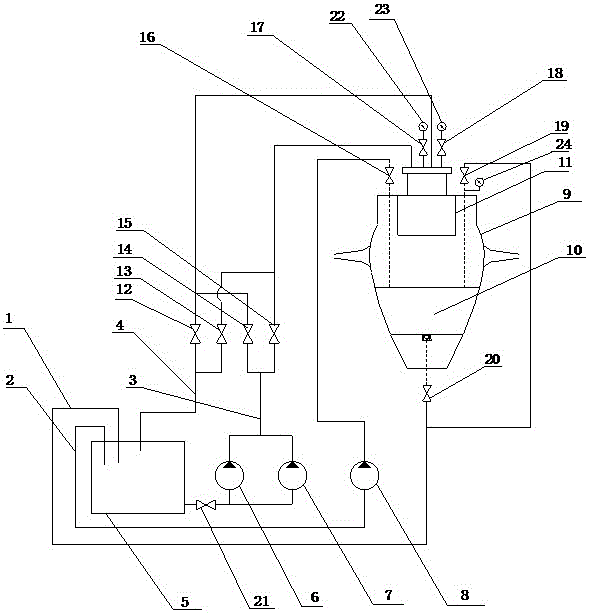

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0018] like figure 1 As shown, a pressure-resistant operation test system for an axial flow paddle turbine runner in this embodiment includes an oil storage tank 5, a first pipeline 1 and a second pipeline connecting the oil storage tank 5 and the turbine runner body 9. Pipeline 2, third pipeline 3 and fourth pipeline 4, one end of the first pipeline 1 communicates with the oil storage tank 5, and the other end connects with the water discharge cone of the runner body 9 of the water turbine through a ninth valve 20 10 is communicated with the lower port; one end of the second pipeline 2 is communicated with the oil storage tank 5, and the other end is connected with the drain cone 10 of the water turbine runner body 9 through a third oil pump 8 and a fifth valve 16 in turn. One upper port is connected; one end of the third pipeline 3 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com