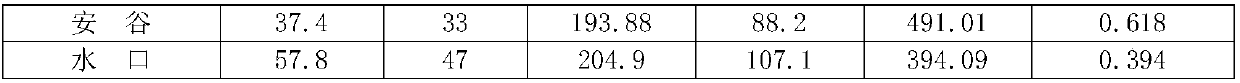

Patents

Literature

50 results about "Kaplan turbine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Kaplan turbine is a propeller-type water turbine which has adjustable blades. It was developed in 1913 by Austrian professor Viktor Kaplan, who combined automatically adjusted propeller blades with automatically adjusted wicket gates to achieve efficiency over a wide range of flow and water level.

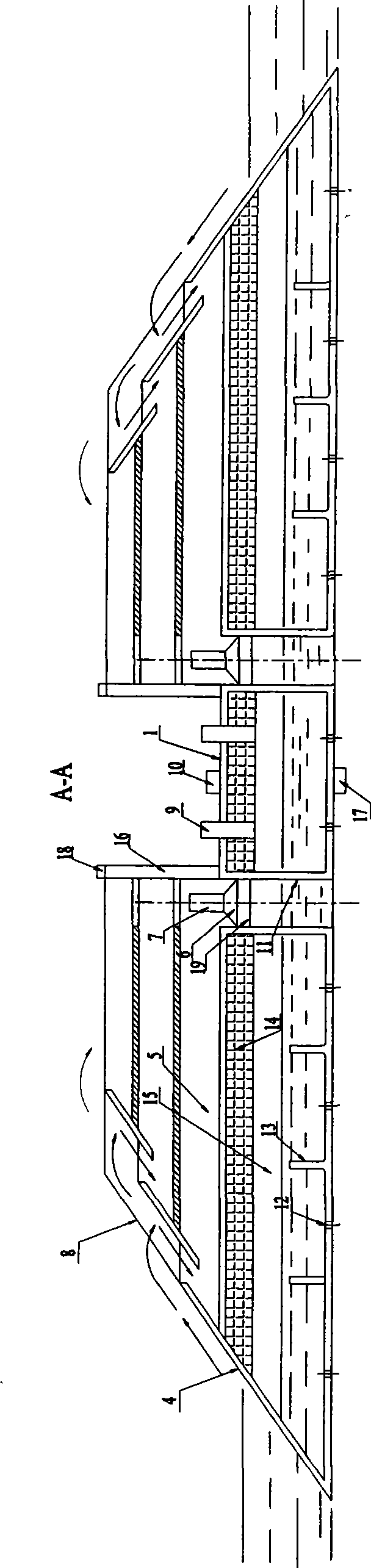

Floating cofferdam type wave generating set

InactiveCN101387260AImprove reliabilityImprove work efficiencyMachines/enginesEngine componentsTerrainWater turbine

The invention discloses a floating cofferdam type wave energy generating set, which comprises a tower convergent wave pool consisting of a platform and a multistage conic pool. The bottom of the tower convergent wave pool is divided into a plurality of ballast tanks and provided with a water level sensor, the upper cavities of the ballast tanks are filled with a buoyancy material, the platform is arranged on the buoyancy material of a groove in the middle of the convergent wave pool, and the platform is provided with a controller, a compressed air system and a baffle wall; the baffle wall is provided with a sensor, the low level of each stage of the convergent wave pool is provided with a pipeline leading to the sea level, the pipeline is internally provided with a Kaplan turbine and an asynchronous generator, the floating cofferdam type wave energy generating set is connected with anchor pipers with swivel links through anchor chains, and the anchor pipers are anchored at the bottom of the sea. According to the draught height of a wave height adjusting device, the floating cofferdam type wave energy generating set is not influenced by tide level and limited by terrain, always works towards the waves all around, can catch the wave energy as much as possible under various conditions, and has the advantage of high working efficiency; only the Kaplan turbine is the unique movable component so that the reliability of the whole set is improved.

Owner:ZHEJIANG UNIV

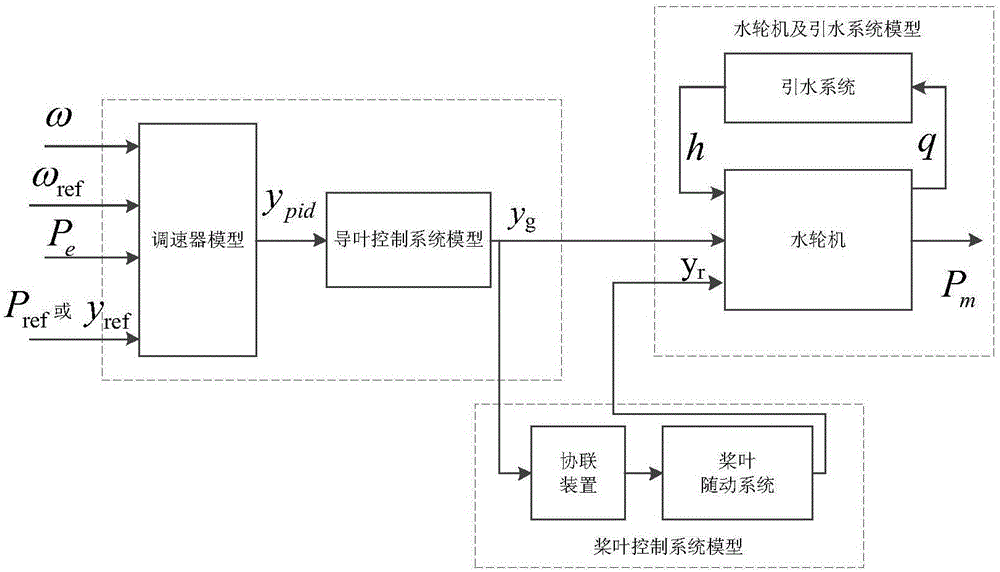

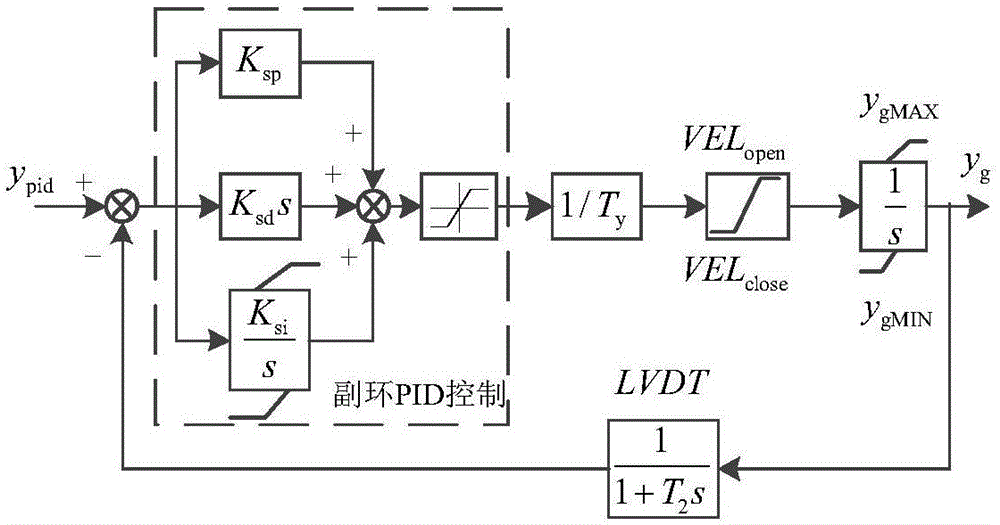

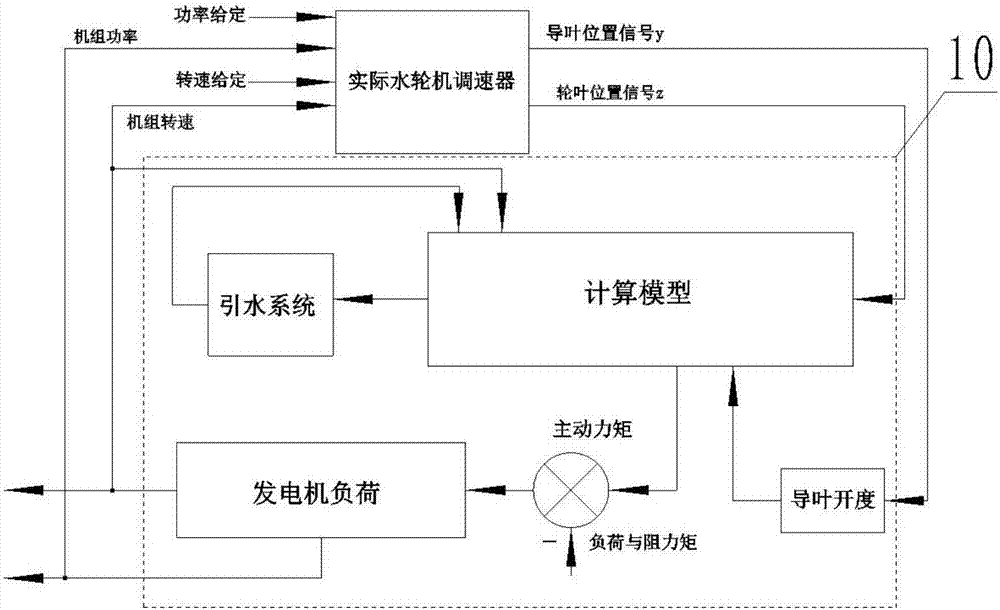

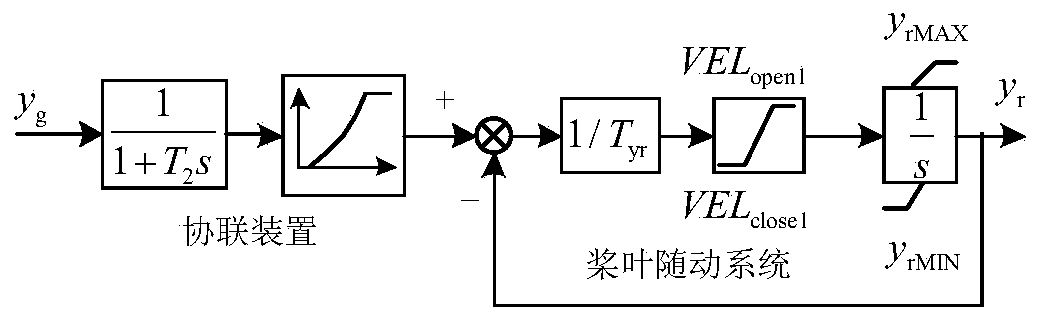

Kaplan turbine adjusting system dynamic model suitable for electric power system analysis

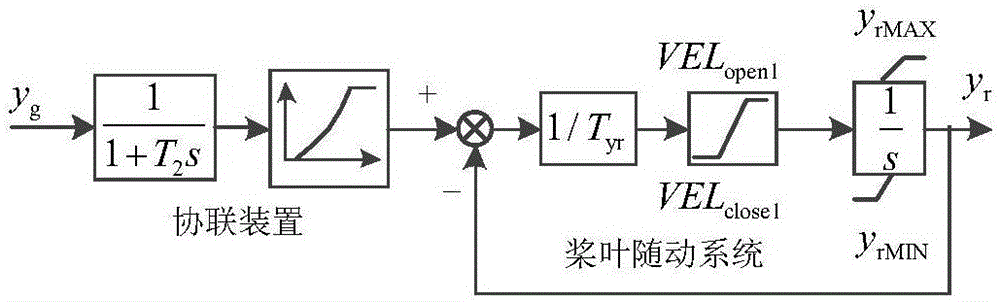

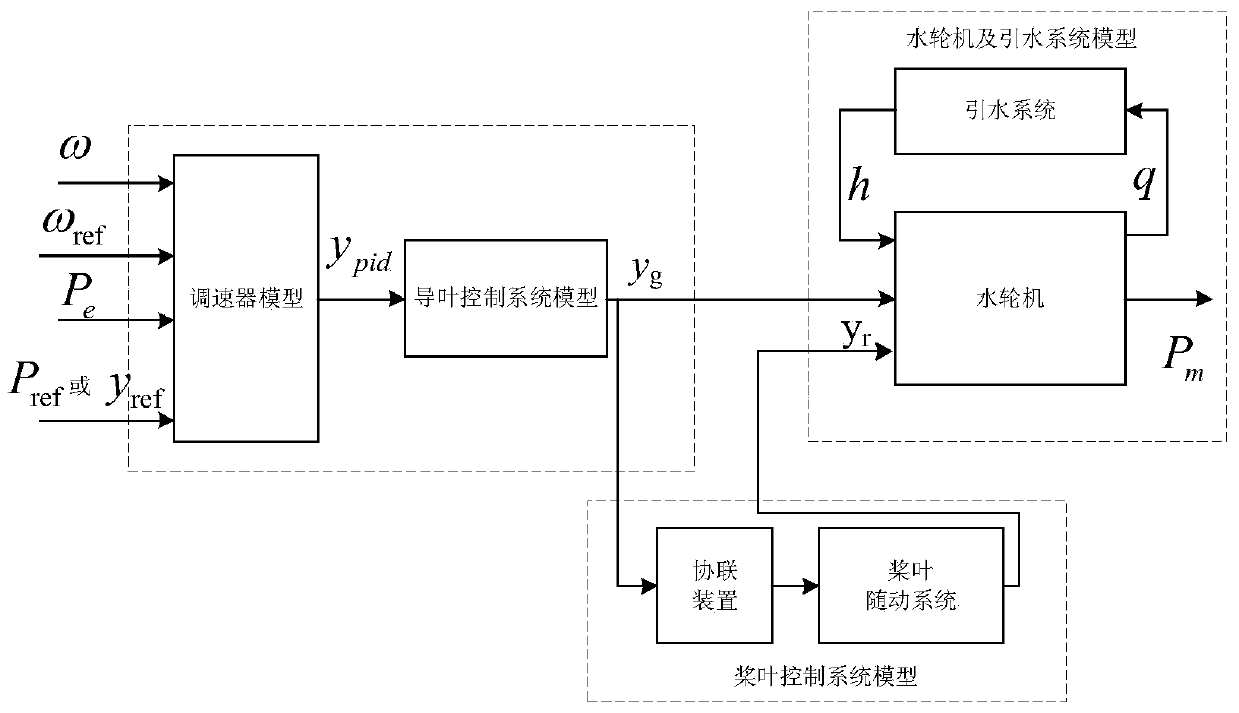

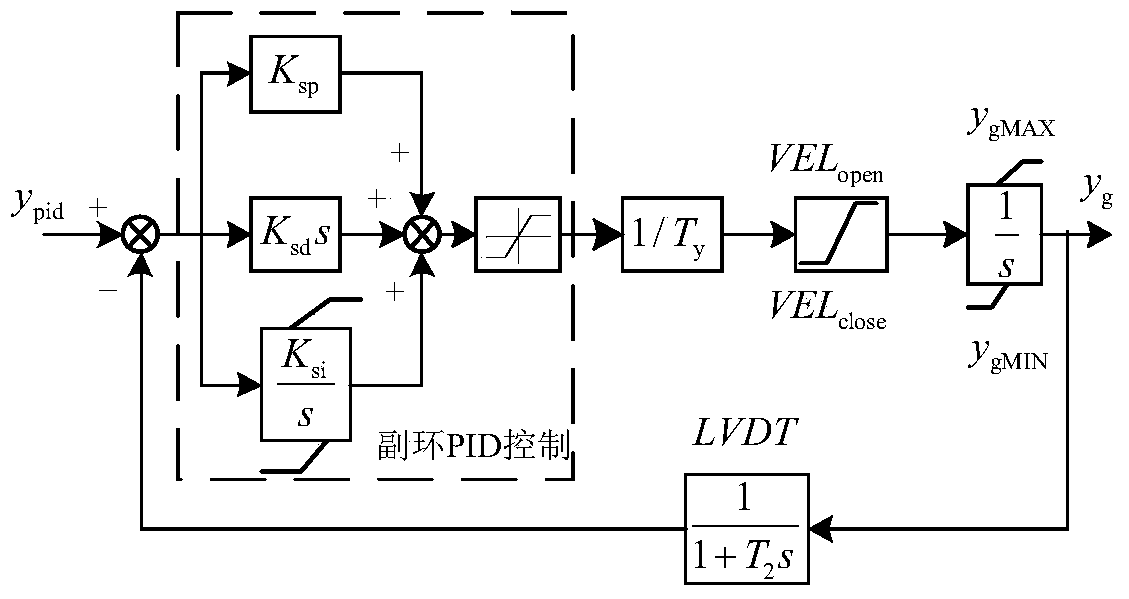

ActiveCN105068424ASimple structureClear structureAdaptive controlElectric power systemSystem dynamics model

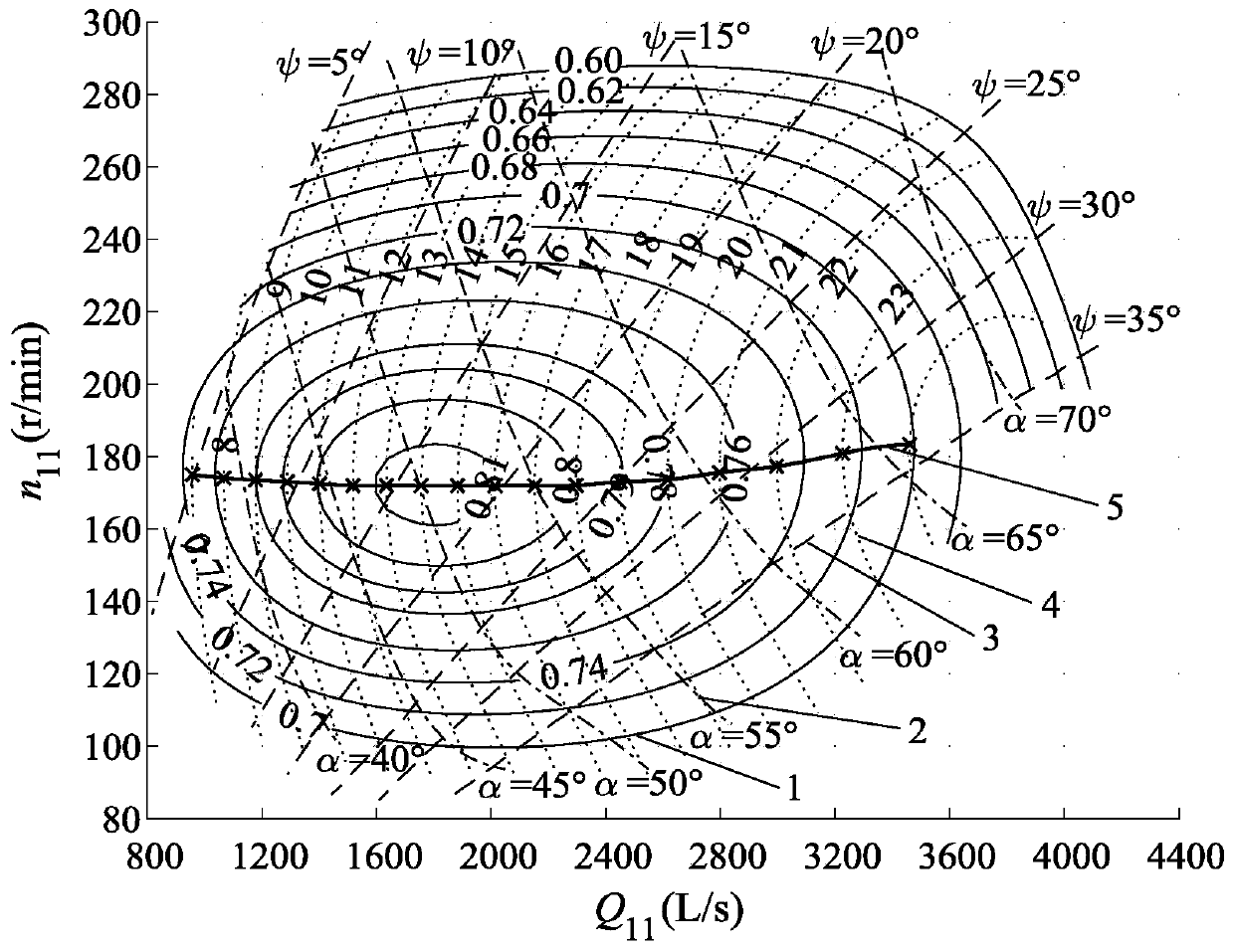

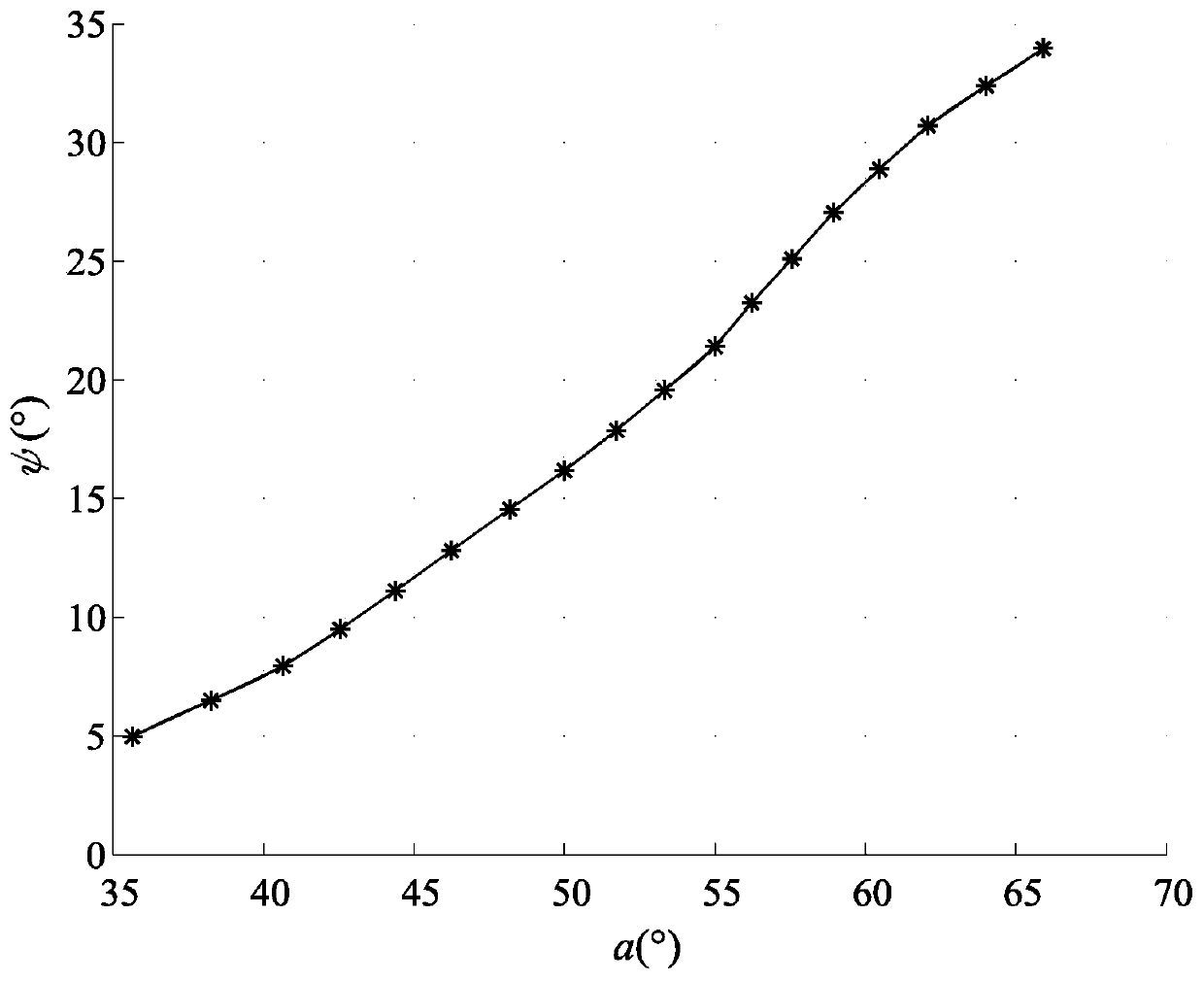

The invention discloses a Kaplan turbine adjusting system dynamic model suitable for electric power system analysis, which comprises a speed governor model, a guide vane control system model, a blade control system model, a water turbine model and a water diversion system model, wherein the guide vane control system model and the blade control system model forms a Kaplan turbine dual adjusting system, the blade control system model takes a combined relationship existing between guide vane opening degrees and blade opening degrees into account, and the combined relationship is obtained by adopting a quintic polynomial curve fitting method; and the water turbine model takes the correction function of blade angles on water turbine efficiency into account on the basis of analyzing non-linear models, the mechanical power output of the water turbine model is affected by the guide vane opening degrees and blade opening degrees together, and the nonlinearity between the guide vane opening degrees and the mechanical power is metered and is described by adopting cubic polynomial fitting. The Kaplan turbine adjusting system dynamic model is exquisite and clear in structure, has distinct and easily-obtained model parameter meanings, is fast and efficient in modeling process, and has high practicability.

Owner:WUHAN UNIV

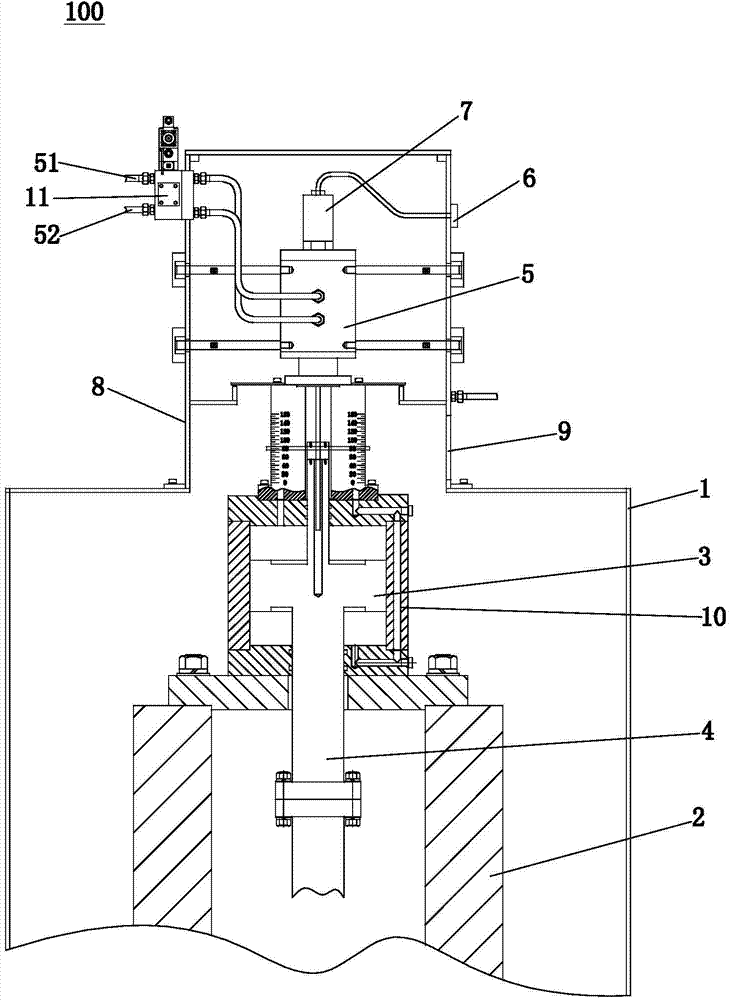

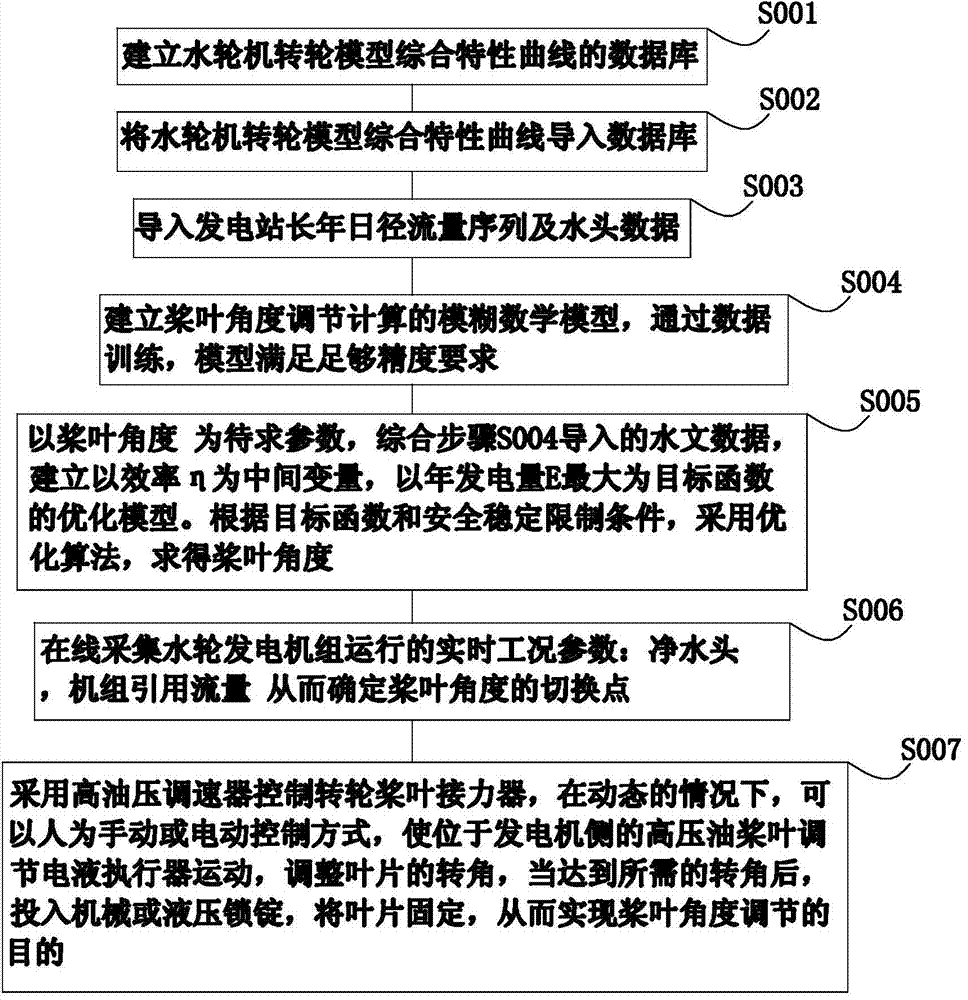

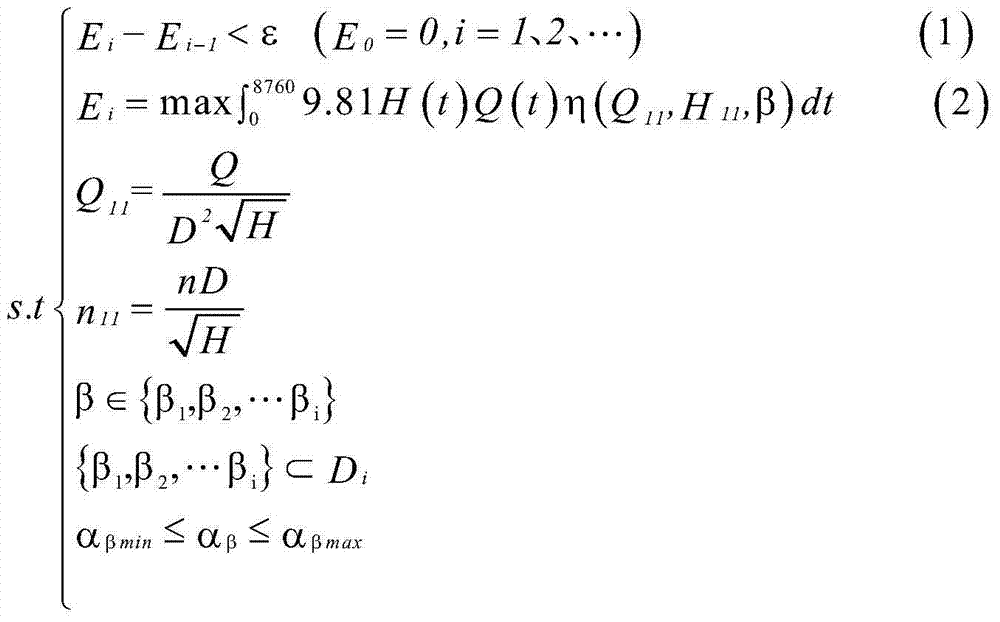

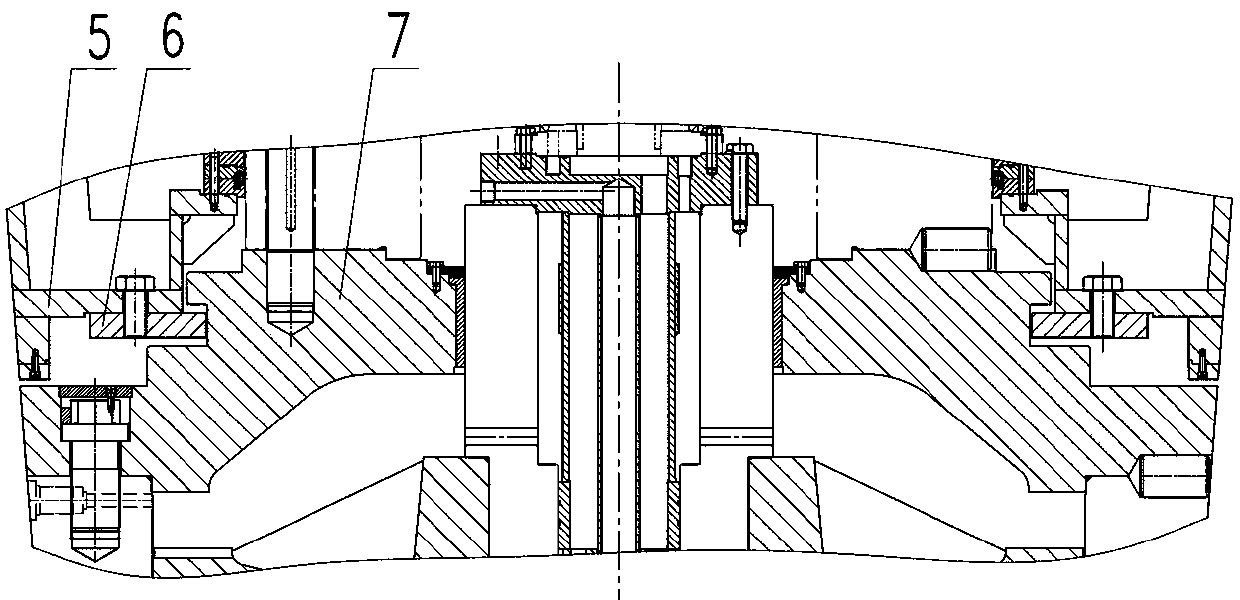

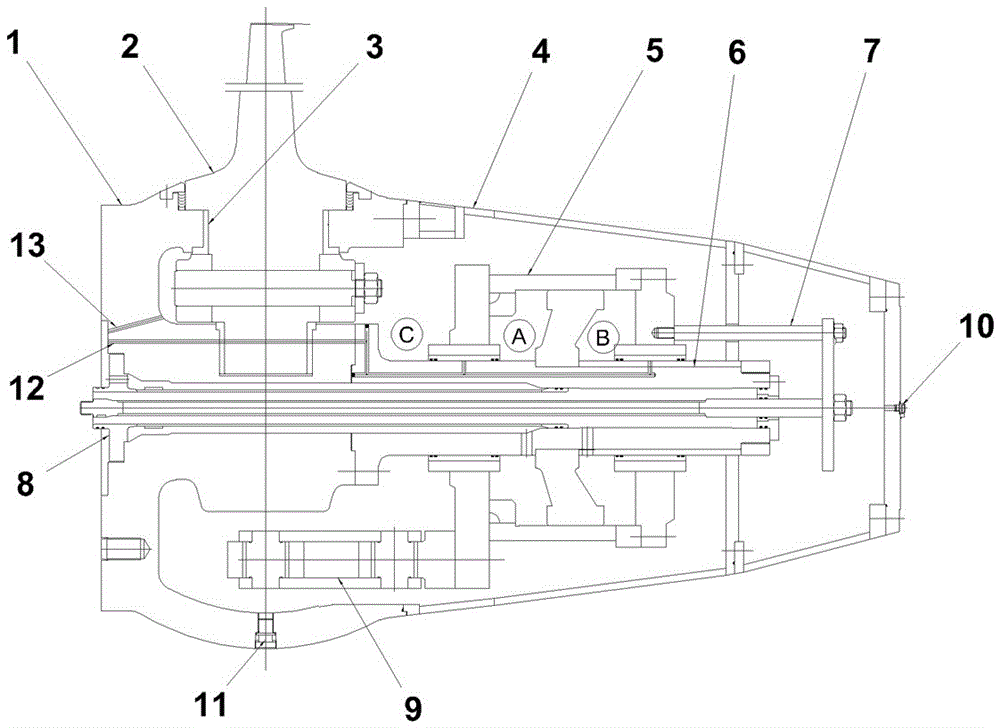

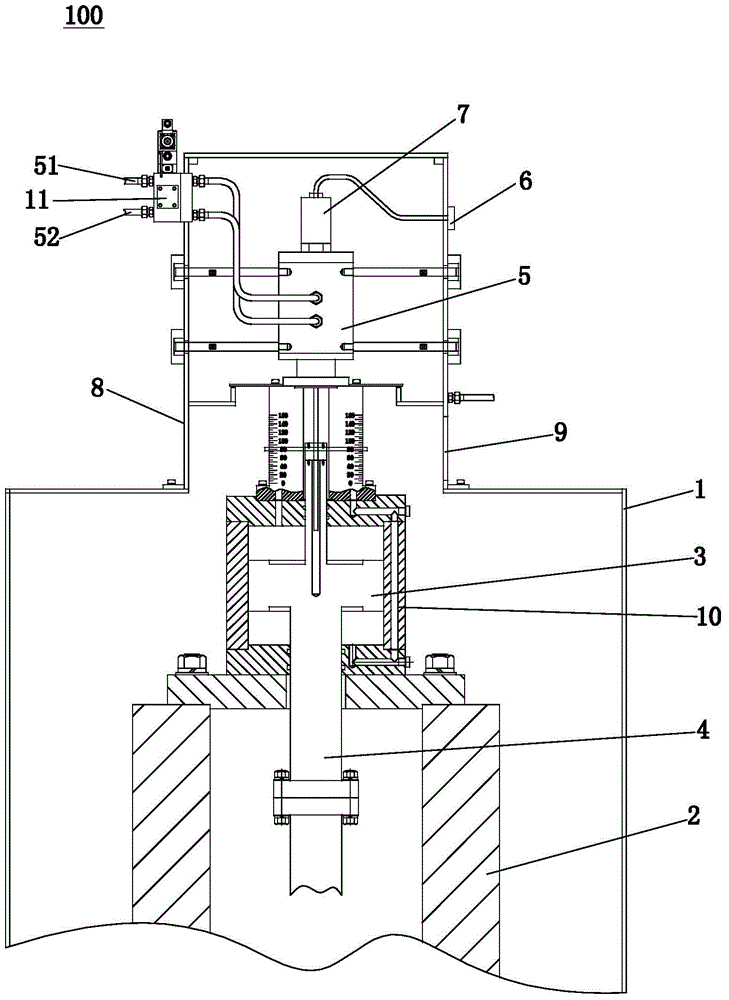

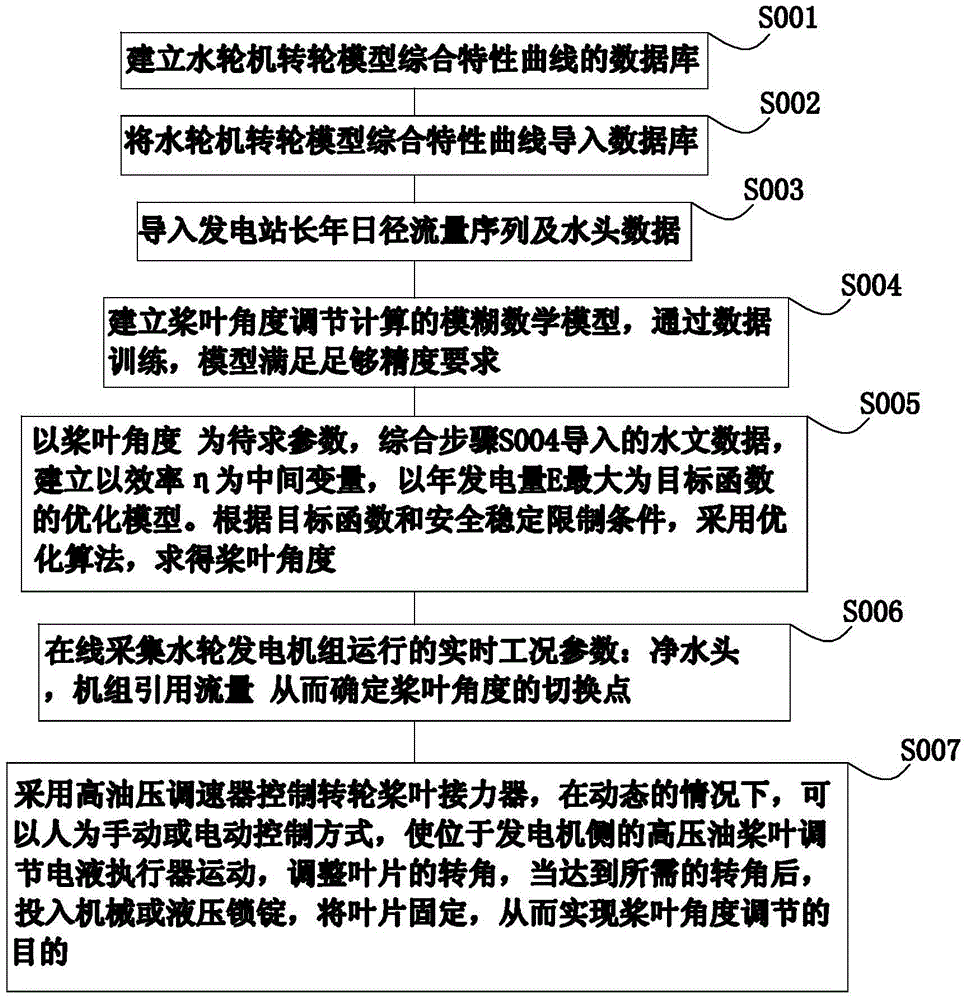

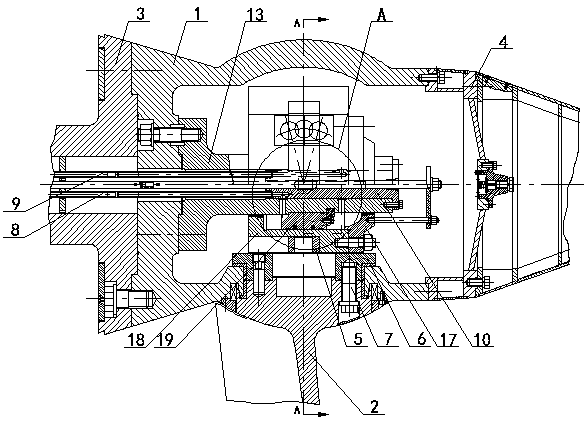

Blade electro-hydraulic adjustment method and device of high-oil-pressure control water turbine

ActiveCN103939273AWith adjustment functionTake advantage ofHydro energy generationMachines/enginesWater turbineEngineering

The invention discloses a blade electro-hydraulic adjustment method and device of a high-oil-pressure control water turbine. A fuzzy mathematic model is established for a selected blade angle calculation method according to hydropower station hydrologic data and unit parameters. Then, a high-oil-pressure control blade adjustment electro-hydraulic actuator adjusts a rotating blade to the calculated angle according to changes of the water head and flow, and therefore high hydraulic energy conversion efficiency is obtained, and the target of the maximum annual energy output of a high-oil-pressure control blade angle rapid adjustment hydroelectric generating set is achieved. According to the key technology, a high-oil-pressure control system is adopted for the turbine blade adjustment actuator, a standard ball floating seal is adopted, and therefore the problem of oil leakage of a high-oil-pressure rotating sealing device is completely solved. The blade electro-hydraulic adjustment method and device fill in technical gaps in controlling blade adjustment by a Kaplan turbine through the high-oil-pressure speed controller system, and great technical innovation is achieved for the structural design of the water turbine.

Owner:SHENZHEN ENLAIJI ENERGY TECH CO LTD

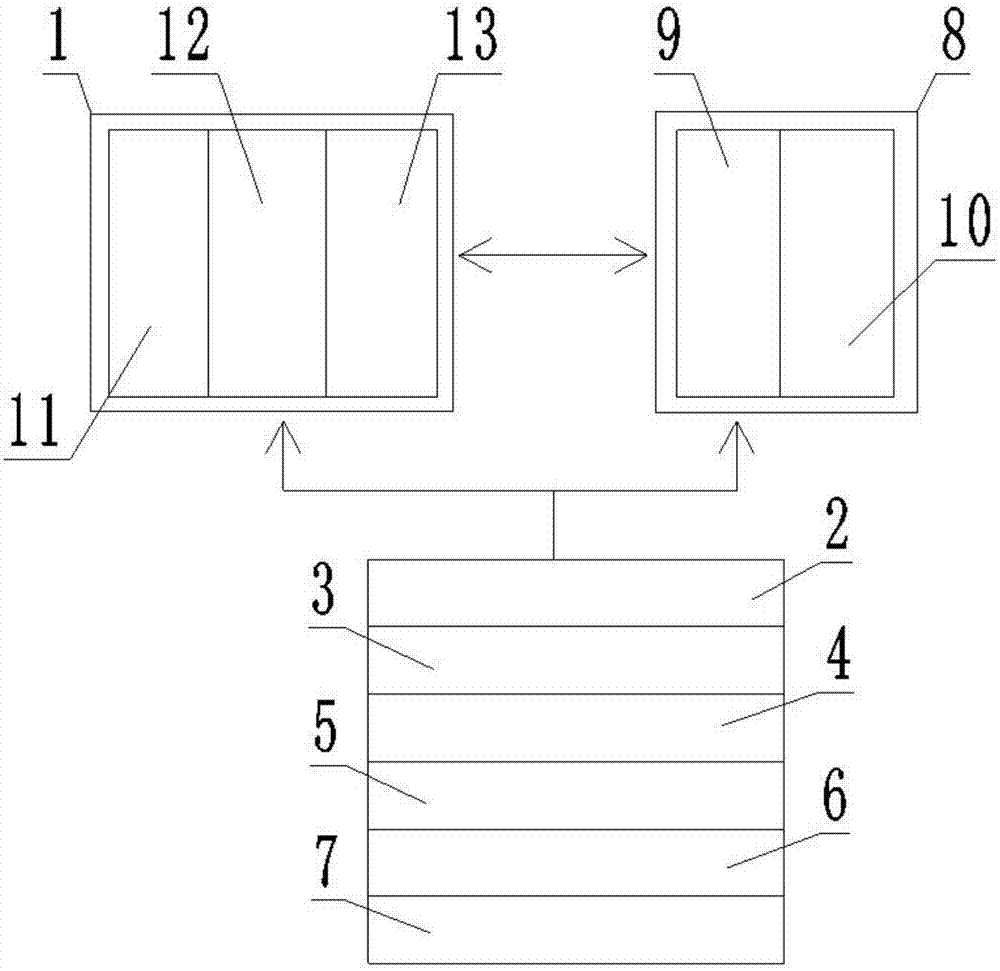

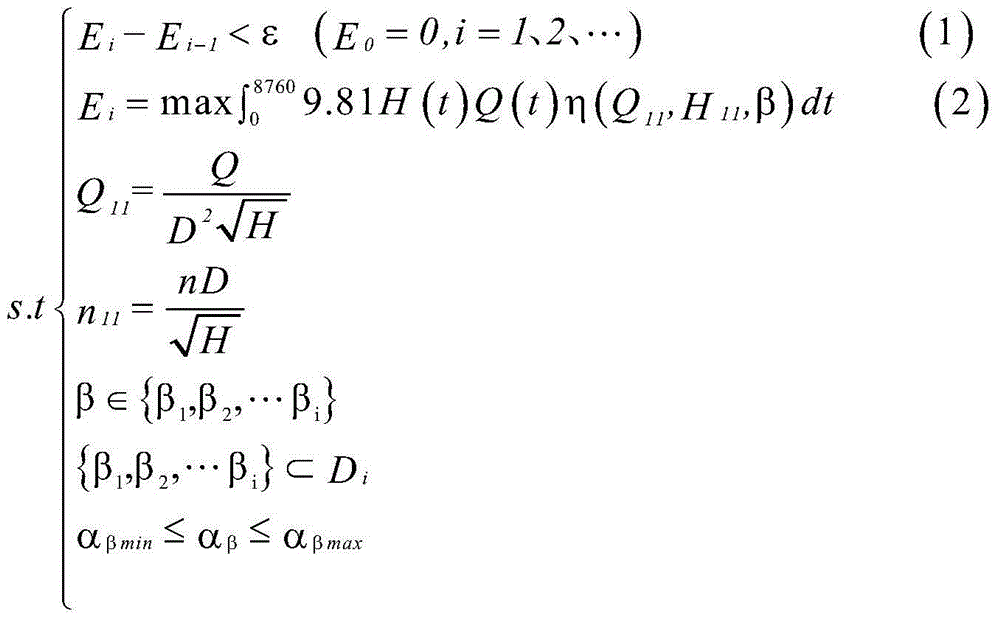

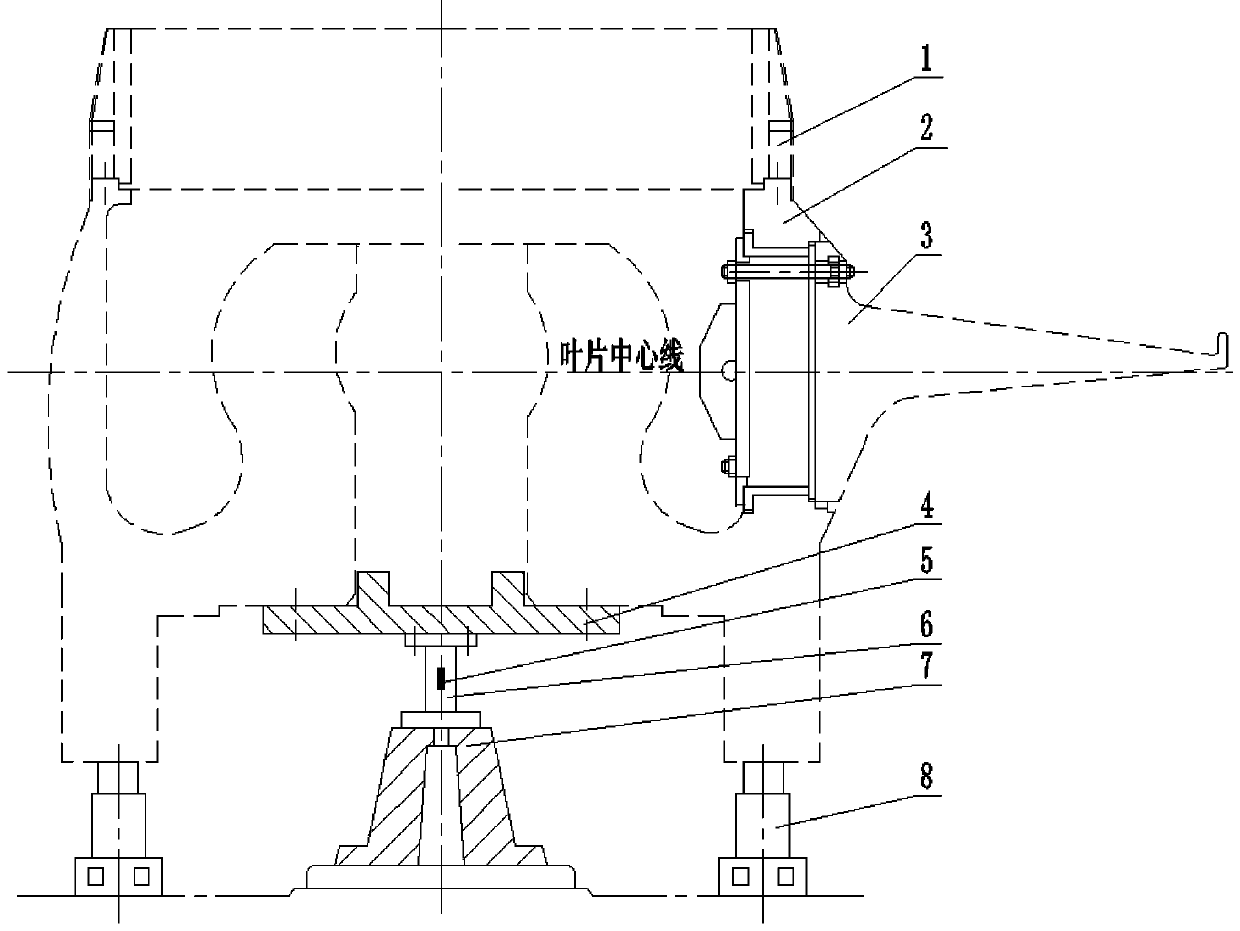

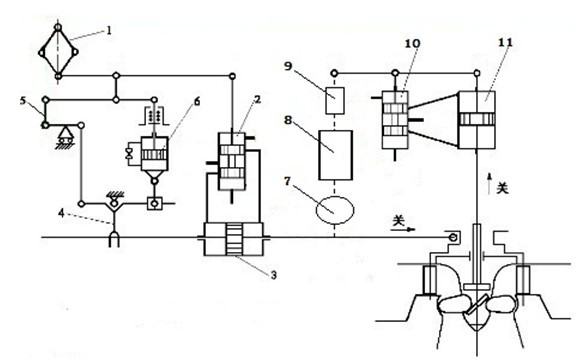

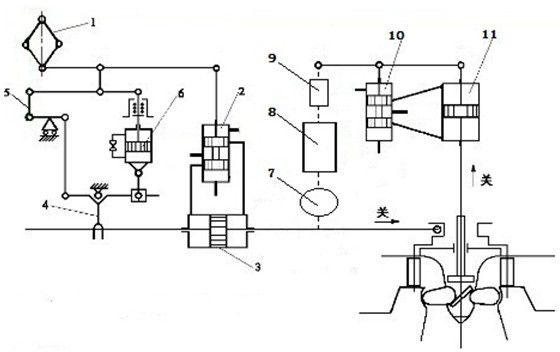

Water-saving and efficiency-improving adjusting method for Kaplan turbine and adjusting system

PendingCN107989743ARealize water saving and efficiency controlConserve waterHydro energy generationMachines/enginesPower sensorWater saving

The invention discloses a water-saving and efficiency-improving adjusting method for a Kaplan turbine and an adjusting system. The method is characterized in that a speed governor simulation system, aspeed governor control system and waterhead, flow, a guide vane opening, a blade angle, unit active power and other information of a practical unit during power generation operation acquired by various sensors are combined, so that optimum joint data is found out; iteration is continuously performed through continuous optimizing of the joint data of the practical unit, so that optimum control onthe Kaplan turbine unit is realized; the adjusting system which is built based on the method comprises a speed governor control system (1); a vibration and swing degree sensor (2), a waterhead sensor(3), a flow sensor (4), an active power sensor (5), a guide vane opening sensor (6) and a blade opening sensor (7) are connected onto the speed governor control system (1); the speed governor controlsystem (1) is connected with the speed governor simulation system (8) through data communication. The water-saving and efficiency-improving adjusting method has the advantages that efficiency can be improved, and operation safety is good.

Owner:STATE GRID CORP OF CHINA +3

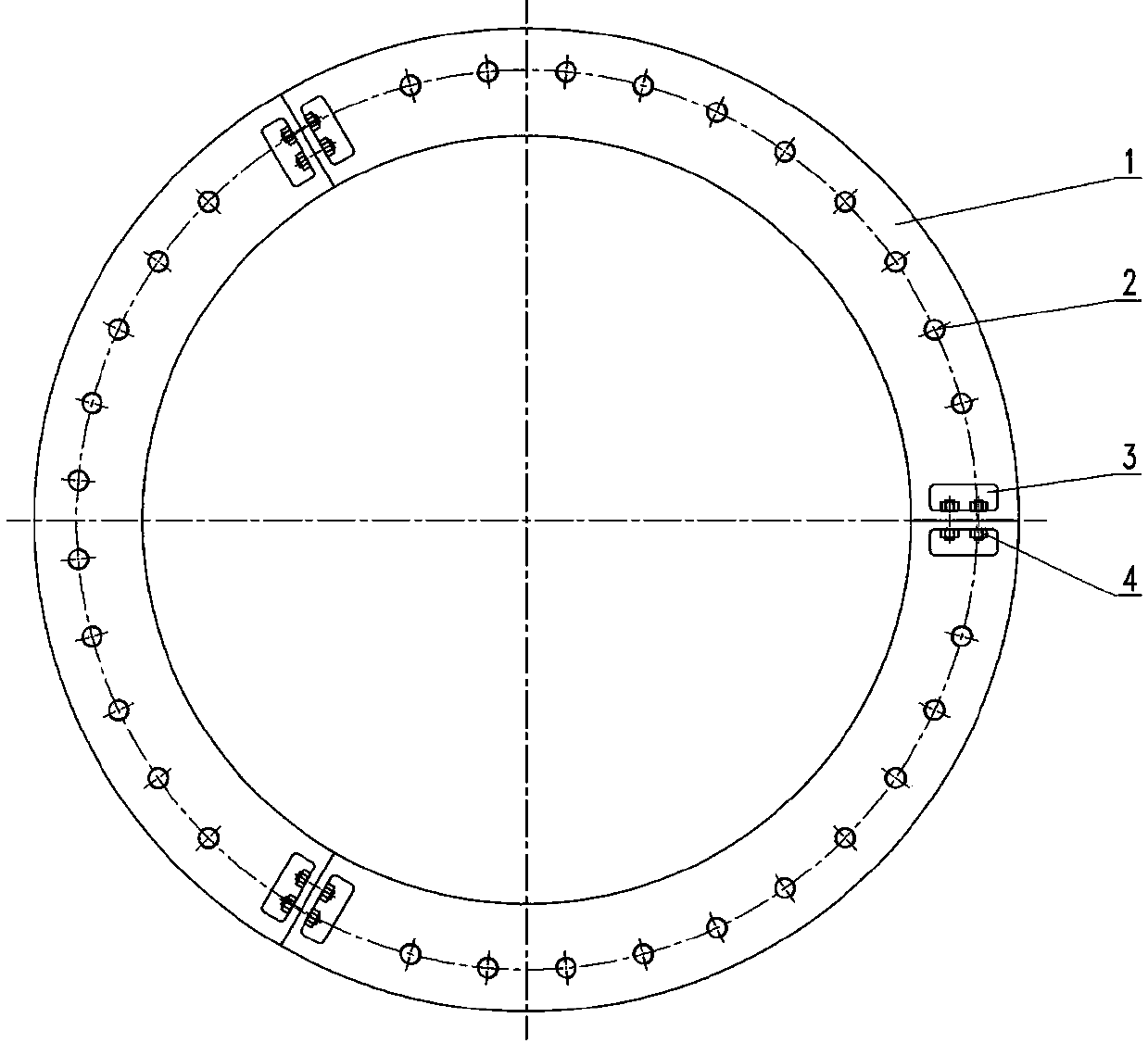

Axial-flow kaplan turbine rotating-wheel hoisting and suspension method

ActiveCN104176619AConvenience guaranteedGuaranteed accuracyLoad-engaging elementsHydraulic turbinesKaplan turbine

The invention discloses an axial-flow kaplan turbine rotating-wheel hoisting and suspension snap ring. The axial-flow kaplan turbine rotating-wheel hoisting and suspension snap ring solves the problem that the existing axial-flow kaplan turbine rotating-wheel hoisting and suspension method has complex processes and is inconvenient for operation. The axial-flow kaplan turbine rotating-wheel hoisting and suspension snap ring comprises at least two arc-shaped snap ring bodies and the snap ring bodies are uniformly provided with screw holes for combining the snap ring bodies and a kaplan turbine diversion cone. The axial-flow kaplan turbine rotating-wheel hoisting and suspension snap ring has a simple structure, is free of tooling holes of a base ring and blade main bodies, is free of a concave ring groove or a raised ring belt of a main shaft, can be simply and conveniently operated, saves many processes, and greatly improves set installation and unkeep work efficiency.

Owner:DONGFANG ELECTRIC MACHINERY

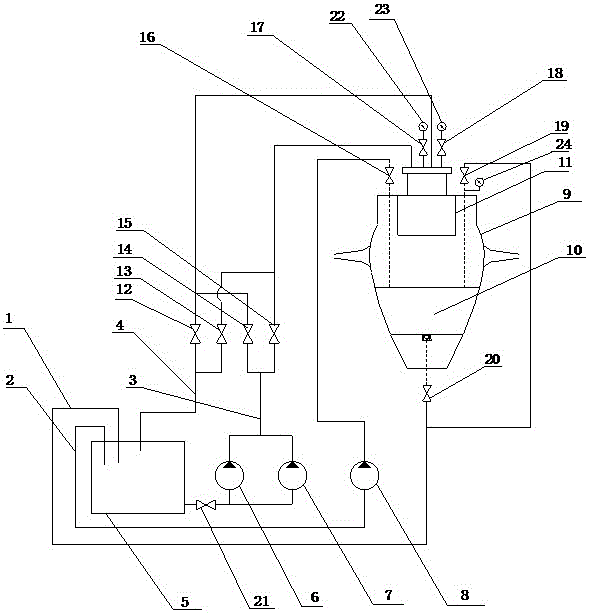

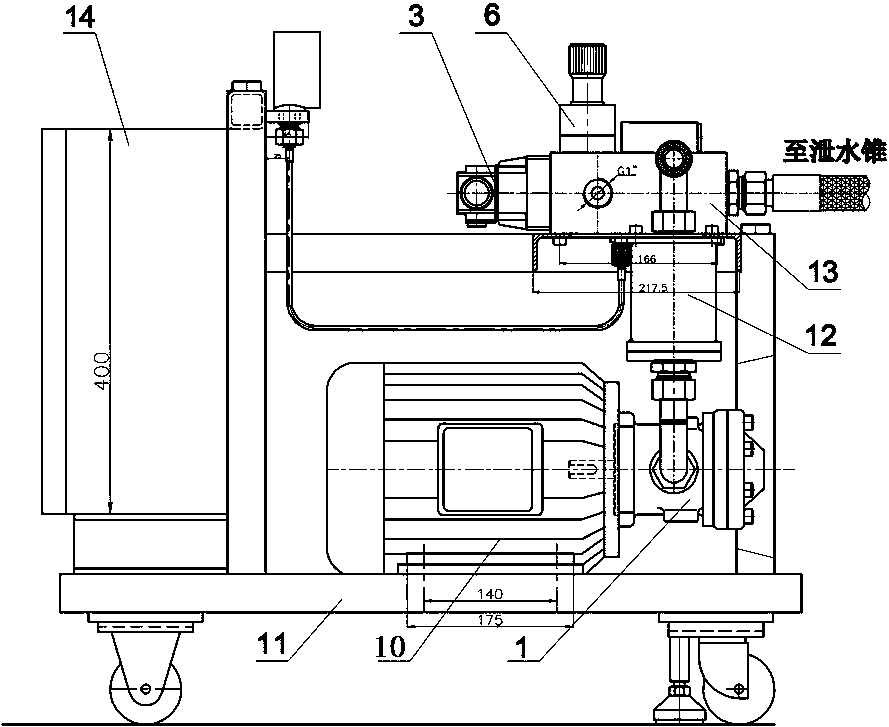

Axial-flow Kaplan turbine runner withstand voltage operation test system

The invention relates to an axial-flow Kaplan turbine runner withstand voltage operation test system comprising an oil storage tank, a group communicating the oil storage tank with a runner hub and including a first pipe, a second pipe, a third pipe and a fourth pipe. The first pipe communicates with the lower port of a runner hub runner cone via a ninth valve. The second pipe communicates with the lower port of the runner hub runner cone via a third oil pump and a fifth valve successively. The third pipeline communicates with the open chamber and the closed chamber of a runner hub piston chamber via a third valve and a fourth valve respectively. The third valve and the fourth valve communicate with the one end of the first and second branch pipelines via the third pipeline. The first and second branch pipelines communicate with a first oil pump and a second oil pump. The other ends of the first and second branch pipelines are connected to the oil storage tank through a tenth valve. A fourth pipeline communicates with the open chamber and the closed chamber of the runner hub piston chamber via the first valve and the second valve respectively The first, second and third oil pumps are electrically connected with a PLC controller. The test system is simple and reliable in pipeline connection and convenient to control.

Owner:STATE GRID FUJIAN ELECTRIC POWER CO LTD +2

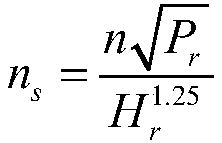

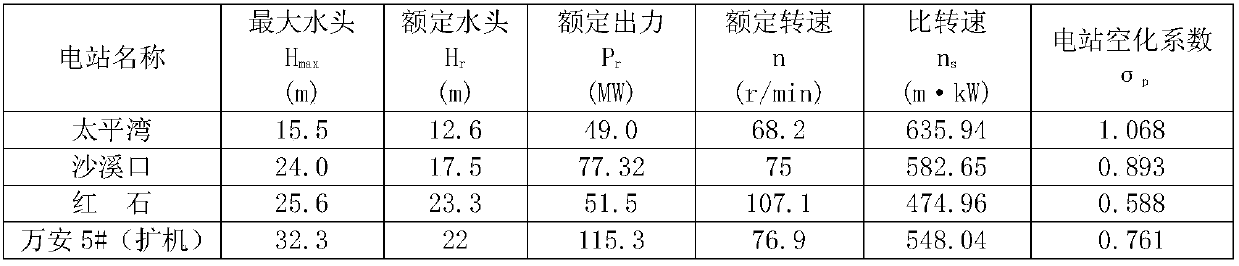

Vertical axis axial-flow kaplan turbine power station cavitation coefficient calculating method

ActiveCN108416527AThe calculation method is reasonableMeet the requirements of hydropower engineeringResourcesCavitationPower station

The invention relates to a hydropower station water turbine, and discloses a vertical axis axial-flow kaplan turbine power station cavitation coefficient calculating method. The vertical axis axial-flow kaplan turbine power station cavitation coefficient calculating method can calculate the vertical axis axial-flow kaplan turbine power station cavitation coefficient more reasonably, so as to satisfy the new water-power engineering requirement. The vertical axis axial-flow kaplan turbine power station cavitation coefficient calculating method includes the steps: determining the specific speed of an axial-flow kaplan turbine, wherein the specific speed is recorded as ns; determining the maximum application water head of the axial-flow kaplan turbine, wherein the maximum application water head is recorded as Hmax, and determining the range to which the Hmax belongs; according to the power station cavitation coefficient calculating formula of the Hmax corresponding range, calculating the power station cavitation coefficient, wherein the power station cavitation coefficient is recorded as Sigma and the power station cavitation coefficient calculating formula of the range is that: when Hmax <=30m, Sigma= 6*10(-6)*n<s><1.8698> and when Hmax>30m, Sigma= 9*10(-6)*n<s><1.8026>. The vertical axis axial-flow kaplan turbine power station cavitation coefficient calculating method issuitable for calculation of the vertical axis axial-flow kaplan turbine power station cavitation coefficient, and can preferably satisfy the new water-power engineering requirement.

Owner:POWERCHINA CHENGDU ENG

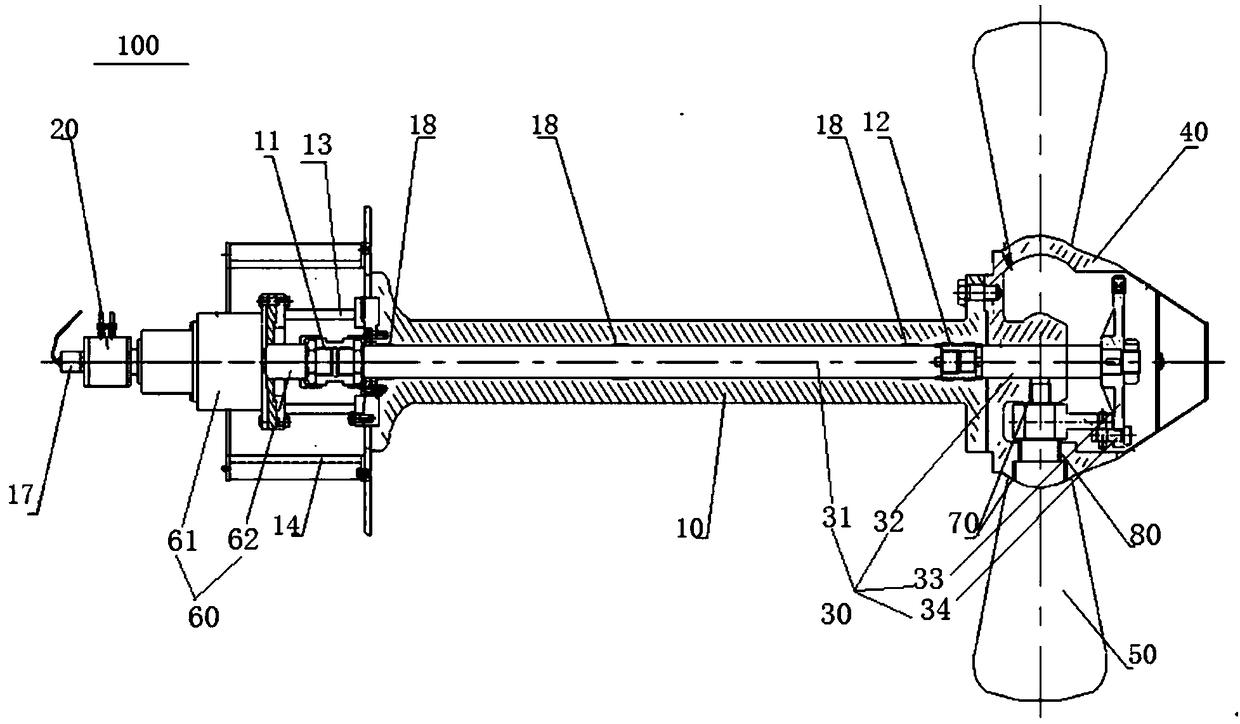

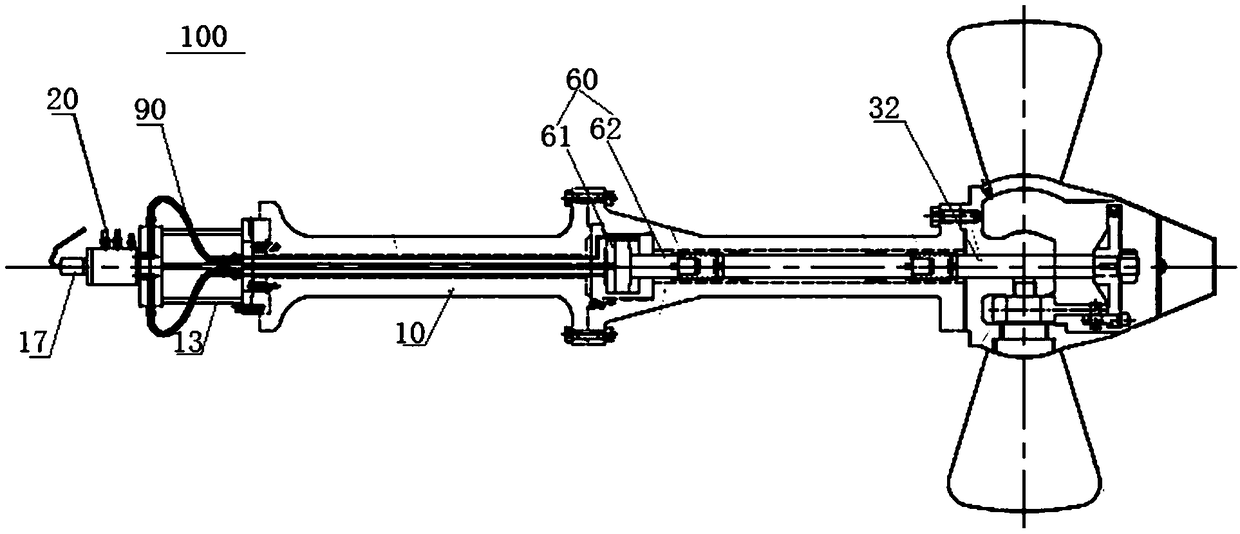

Hydraulically operated Kaplan turbine structure with oilless hub

InactiveCN109236539AAvoid pollutionSimple structureHydro energy generationReaction enginesAxial displacementServomotor

The invention provides a hydraulically operated Kaplan turbine structure with an oilless hub. According to the hydraulically operated Kaplan turbine structure, a first mounting cavity is defined in the hub; paddles are arranged on the hub, and the paddles are evenly arranged in the circumferential direction of the hub at intervals; a second mounting cavity extending in the axial direction of a spindle and penetrating through the spindle is defined in the spindle, the hub is mounted at the first end of the spindle, and the first mounting cavity is communicated with the second mounting cavity; the first end of an operation rod assembly is connected with the paddles; a servomotor assembly is connected with the second end of the operation rod assembly; an oil head is arranged at the second endof the spindle, an oil receiving hole is formed in the oil head, the oil head and the servomotor assembly are communicated through an oil path so that operation oil received from the oil receiving hole can be distributed to the servomotor assembly, the servomotor assembly can push the operation rod assembly to do axial displacement under the action of the operation oil, therefore, the paddles aredriven to rotate, and the hub, the spindle, the operation rod assembly and the paddles are further driven to synchronously rotate. According to the hydraulically operated Kaplan turbine structure with the oilless hub, oilless operation in the hub can be achieved, and oil pollution to rivers can be completely eradicated.

Owner:SHENZHEN ENLAIJI ENERGY TECH CO LTD

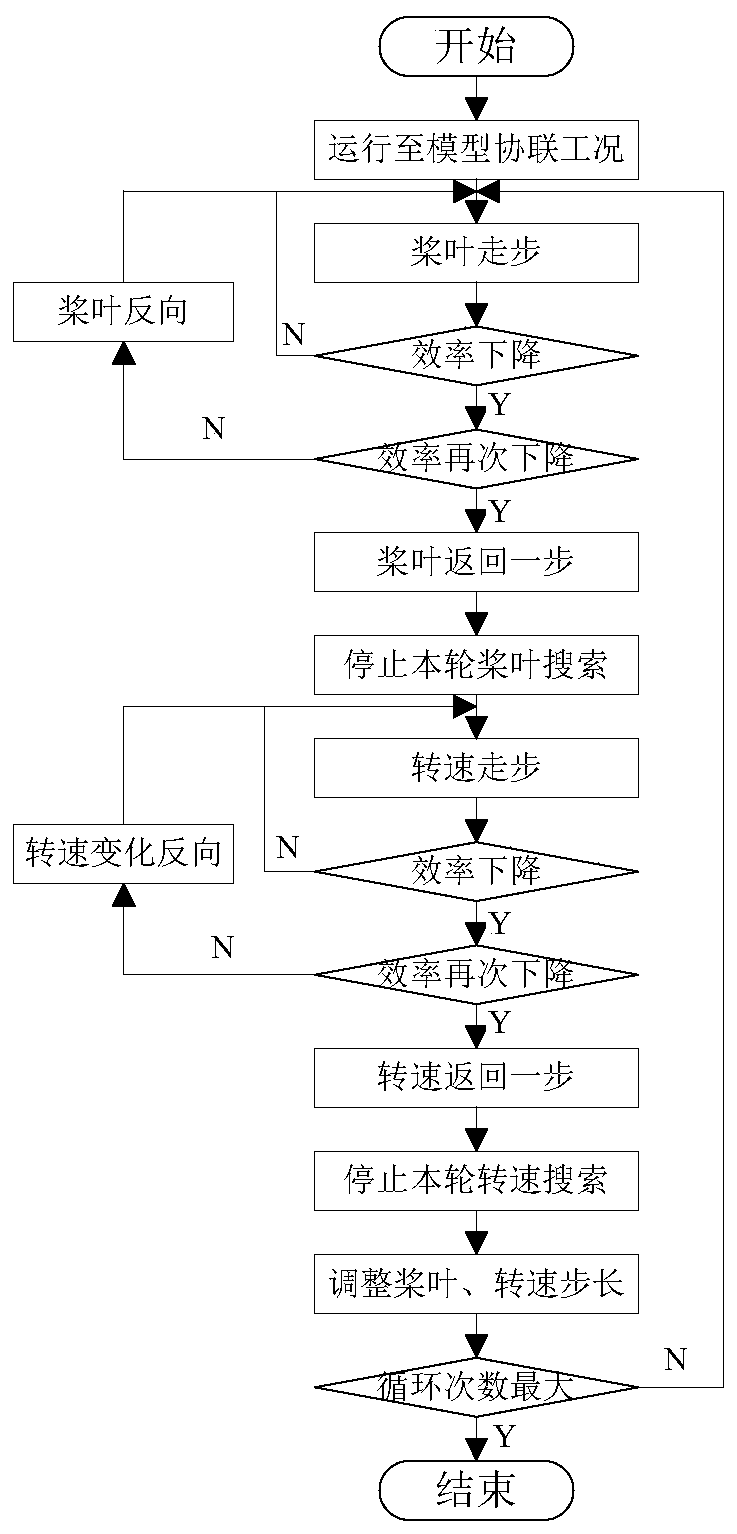

Propeller associating method for variable-rotating-speed operation of Kaplan turbine

ActiveCN110821746AReduce measurementEasy to operateHydro energy generationMachines/enginesWater turbinePropeller

Owner:XIAN UNIV OF TECH

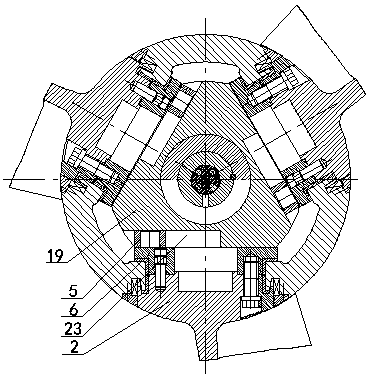

A fish-breeding axial-flow paddle turbine

InactiveCN102278260AIncrease wrap angleSufficient lengthHydro energy generationReaction enginesBroodstockWater turbine

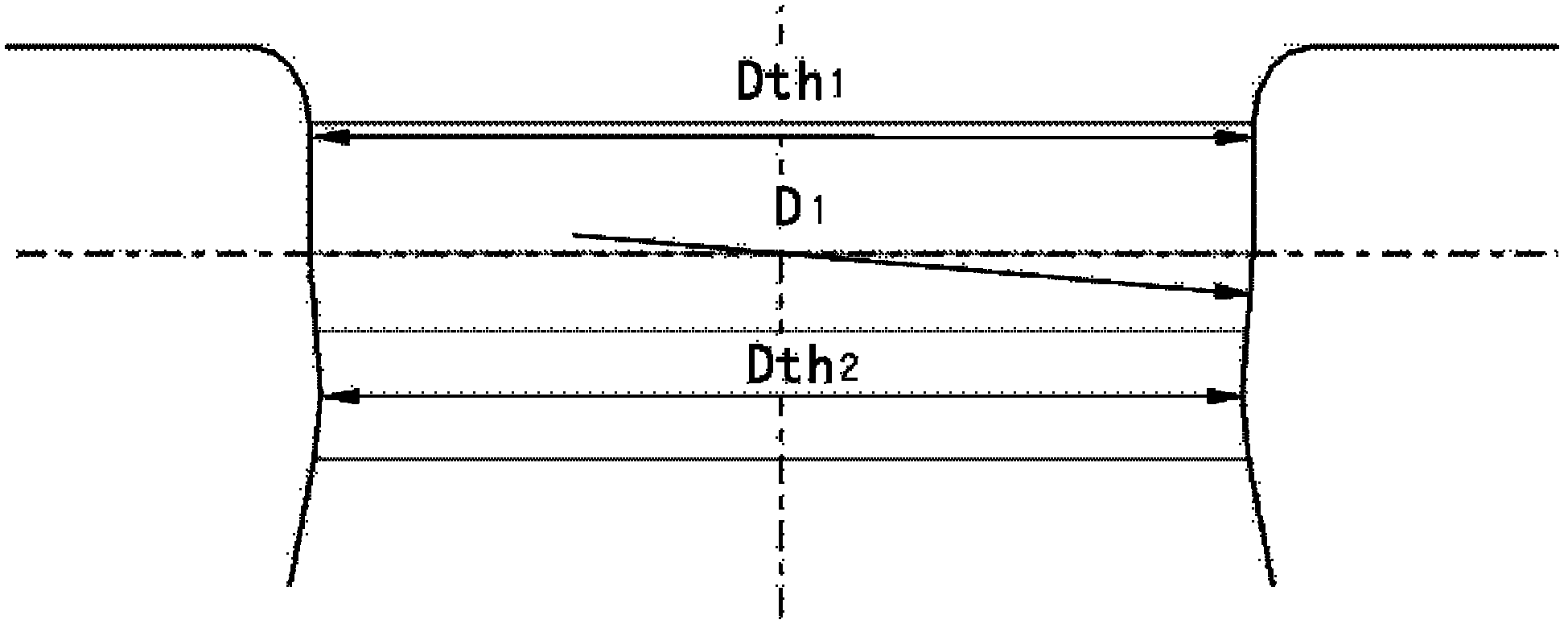

The invention relates to a parent-fish-type movable propeller turbine which comprises a runner chamber, a runner hub arranged in the runner chamber, blades connected with the periphery of the implemental runner hub and a guide vane connected with the top of the implemental runner chamber, wherein the runner hub comprises an upper cylindrical section, a spherical section, a lower cylindrical section and two frustum sections which are successively arranged; and the inner wall of the runner chamber successively comprises an cylindrical section, a middle spherical section and a lower throat section. The turbine is characterized in that the spherical section of the runner hub is composed of a plurality of projecting eccentric spherical crowns, and the quantity of the eccentric spherical crownsare same as that of the blades; each blade is respectively fixedly connected to the corresponding eccentric spherical crown on the runner hub, and the diameter of the cylindrical section of the runner chamber is lower than 0.98 times that of the spherical section; and the diameter of the throat section of the runner chamber is lower than 0.96 times that of the spherical section, the excircle arc semidiameter of the throat section is 0.02D1-0.1D1, the D1 represents the diameter of the runner chamber, and the spherical section of the runner chamber is a global section. The turbine provided by the invention can be widely used in hydroelectric installations.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES +1

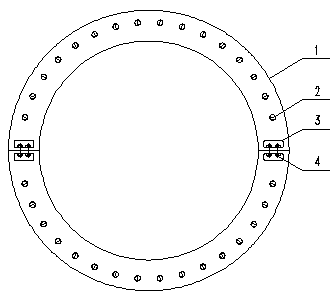

Oil-free lubrication Kaplan turbine runner

ActiveCN105545567AMonitor seal operationGuaranteed uptimeEngine fuctionsHydro energy generationOil freeEngineering

The invention discloses an oil-free lubrication Kaplan turbine runner. The oil-free lubrication Kaplan turbine runner comprises a hub body, a blade and a blade servomotor; a water injecting hole is formed in one side of the hub body for injecting clear water or other environment-friendly liquid in a hub before an unit is operated; a drain hole is formed in the bottom of the hub body for draining water in maintenance; the blade servomotor includes a cylinder body, a cylinder cover, a cavity and a piston rod; the cylinder body or the piston rod is connected with the blade through a blade connecting rod mechanism; a blade inner and outer shaft sleeve is arranged between the blade and the hub body; and shaft sleeves on the blade inner and outer shaft sleeve, the blade servomotor and the blade connecting rod mechanism are all self-lubricating bearings. The oil-free lubrication Kaplan turbine runner can adopt the water to replace lubricating oil in a conventional runner hub body, adopts the self-lubricating bearings suitable for the runner operation environment as bearings of a runner motion pair and a friction pair to enable the runner to smoothly operate without polluting rivers, adopts an anti-leaking measure to reduce the risk of the runner leaking oil to the rivers, and can be widely applied to axial flow type and cross flow type Kaplan turbines.

Owner:浙江富春江水电设备有限公司

Electro-hydraulic paddle adjusting method and electro-hydraulic paddle adjusting device of high-oil-pressure control water turbine

ActiveCN104879270AWith adjustment functionTake advantage ofHydro energy generationMachines/enginesWater turbineActuator

The invention discloses a blade electro-hydraulic adjustment method and device of a high-oil-pressure control water turbine. A fuzzy mathematic model is established for a selected blade angle calculation method according to hydropower station hydrologic data and unit parameters. Then, a high-oil-pressure control blade adjustment electro-hydraulic actuator adjusts a rotating blade to the calculated angle according to changes of the water head and flow, and therefore high hydraulic energy conversion efficiency is obtained, and the target of the maximum annual energy output of a high-oil-pressure control blade angle rapid adjustment hydroelectric generating set is achieved. According to the key technology, a high-oil-pressure control system is adopted for the turbine blade adjustment actuator, a standard ball floating seal is adopted, and therefore the problem of oil leakage of a high-oil-pressure rotating sealing device is completely solved. The blade electro-hydraulic adjustment method and device fill in technical gaps in controlling blade adjustment by a Kaplan turbine through the high-oil-pressure speed controller system, and great technical innovation is achieved for the structural design of the water turbine.

Owner:SHENZHEN ENLAIJI ENERGY TECH CO LTD

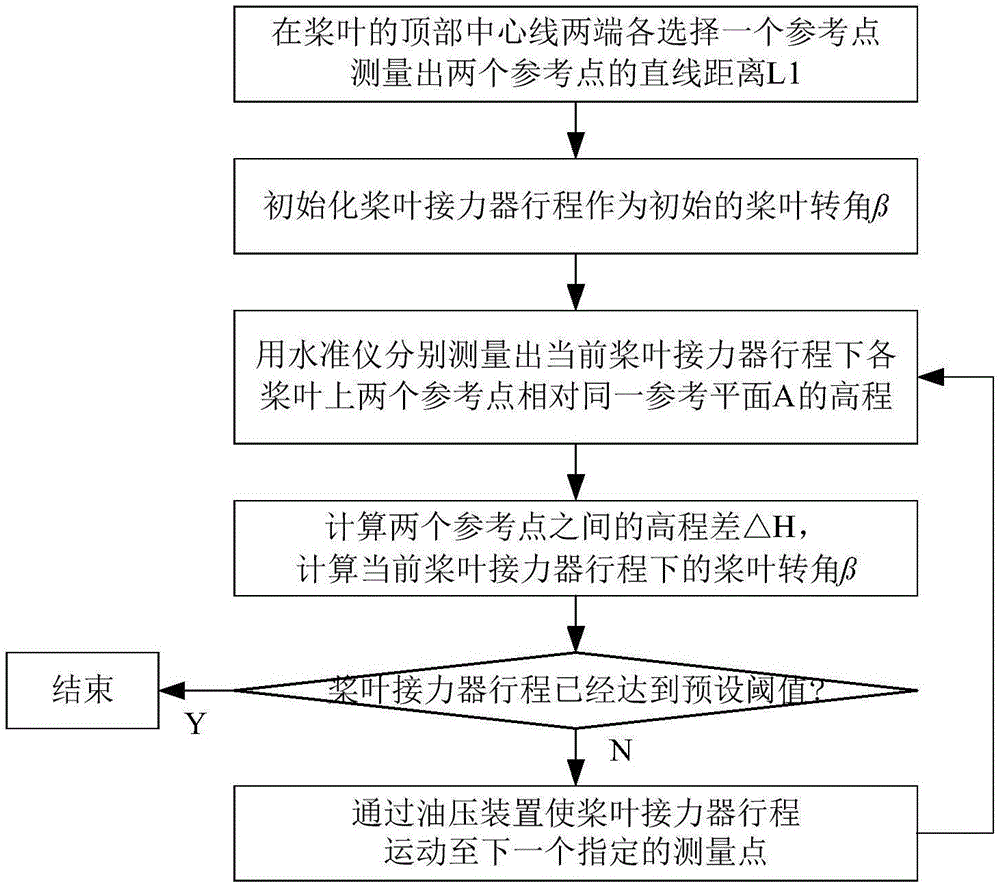

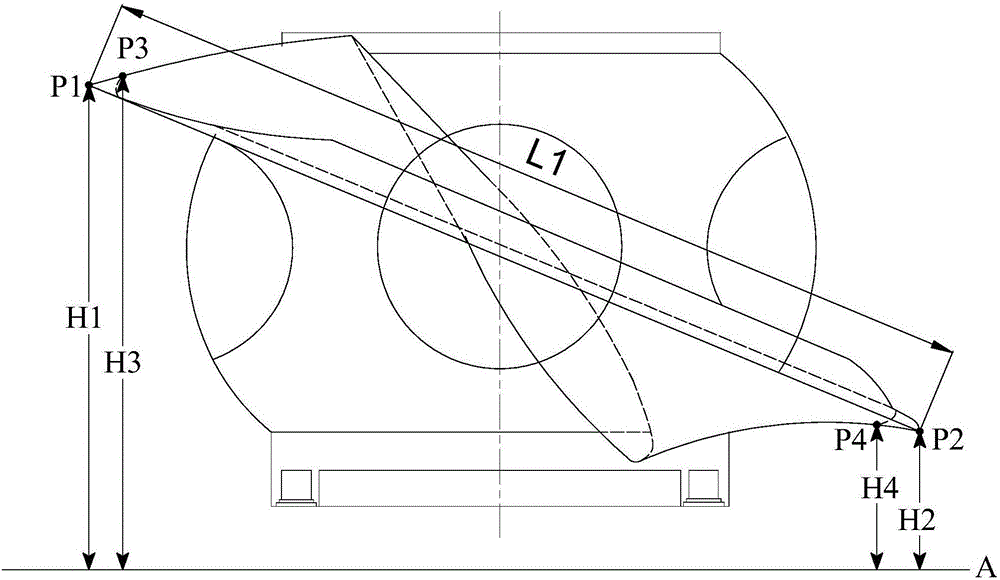

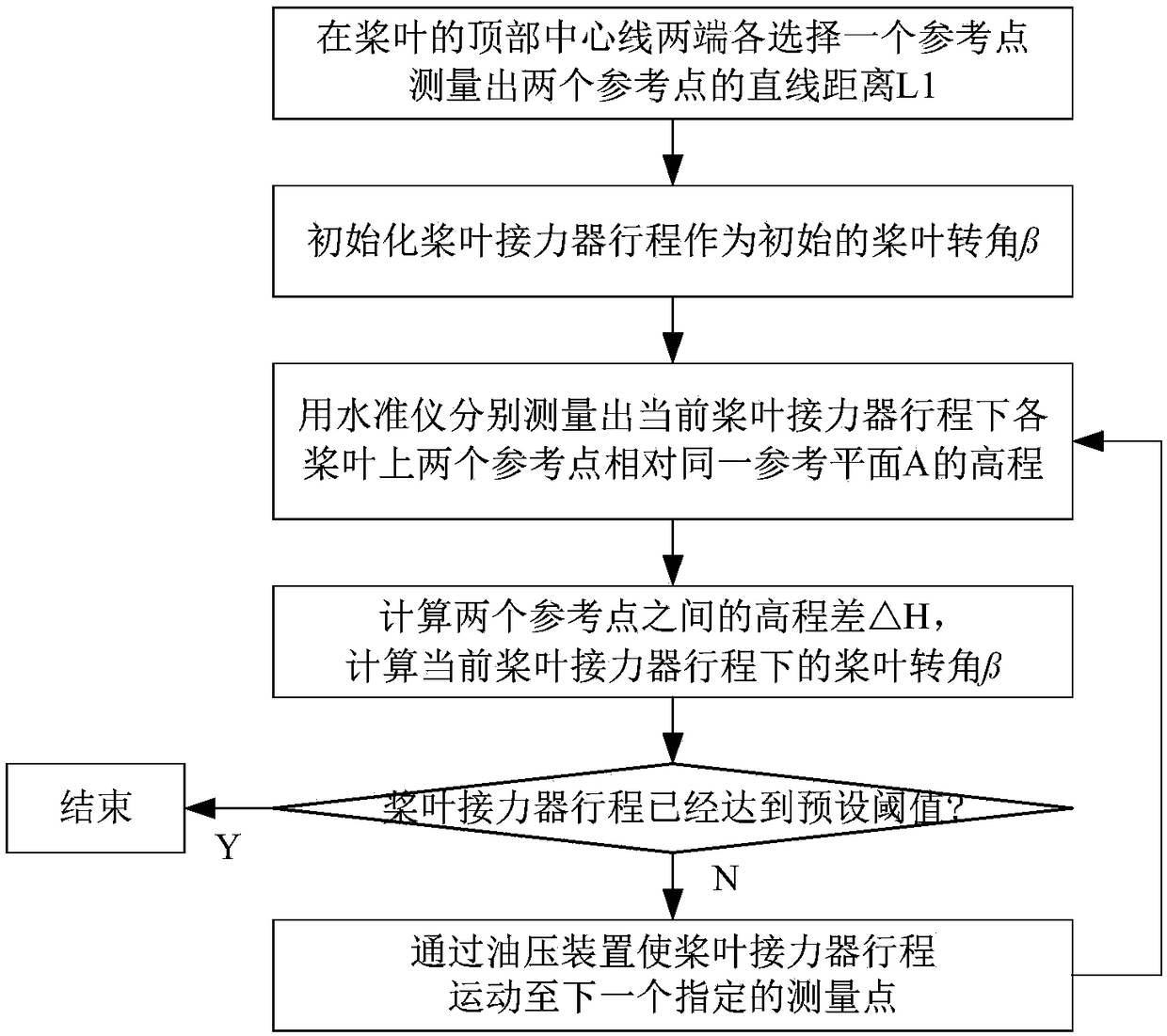

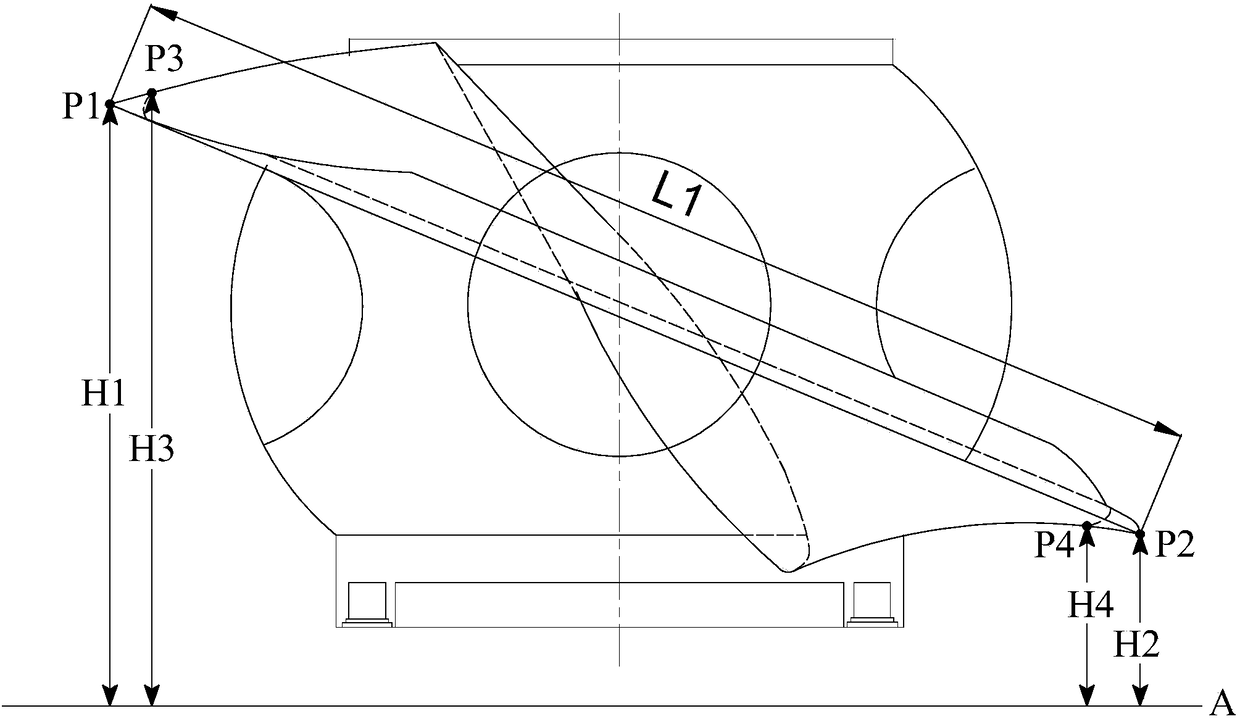

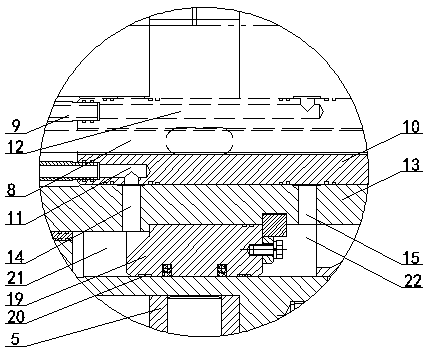

Level gauge-based water turbine blade rotation angle measurement method

The invention discloses a level gauge-based water turbine blade rotation angle measurement method. The method comprises selecting two reference points at two ends of a top center line of a blade, measuring a linear distance L1 of the two reference points, initializing a blade servomotor stroke to obtain an initial blade rotation angle beta, adjusting the blade servomotor stroke through an oil pressure unit, respectively measuring altitudes of the two reference points of each one of the blades relative to the same reference plane A in each current blade servomotor stroke through a level gauge, calculating the altitude difference delta H of the two reference points and calculating a blade rotation angle beta in each current blade servomotor stroke according to a function of beta=arcsin(delta H / L1). The method can detect internal transmission part replacement-caused blade initial angle and blade total rotation angle deviation before and after Kaplan turbine disintegration overhaul, ensure blade initial angle consistency and blade rotation angle uniformity after Kaplan turbine overhaul, is conducive to water turbine stable operation and has the advantages of simple processes and measurement accuracy.

Owner:HONGJIANG HYDROELECTRIC POWER PLANT HUAIHUA YUANJIANG ELECTRIC POWER DEV

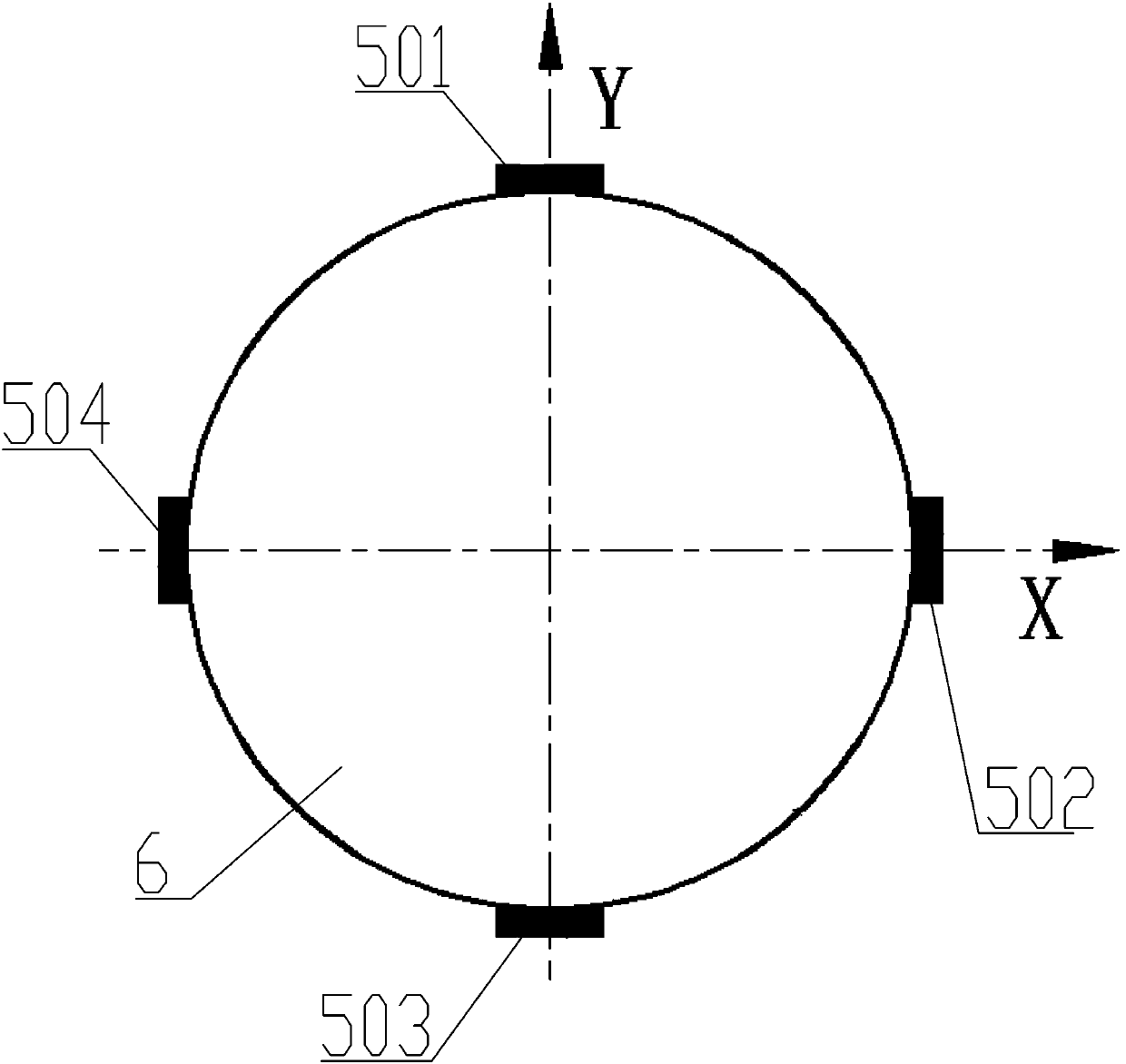

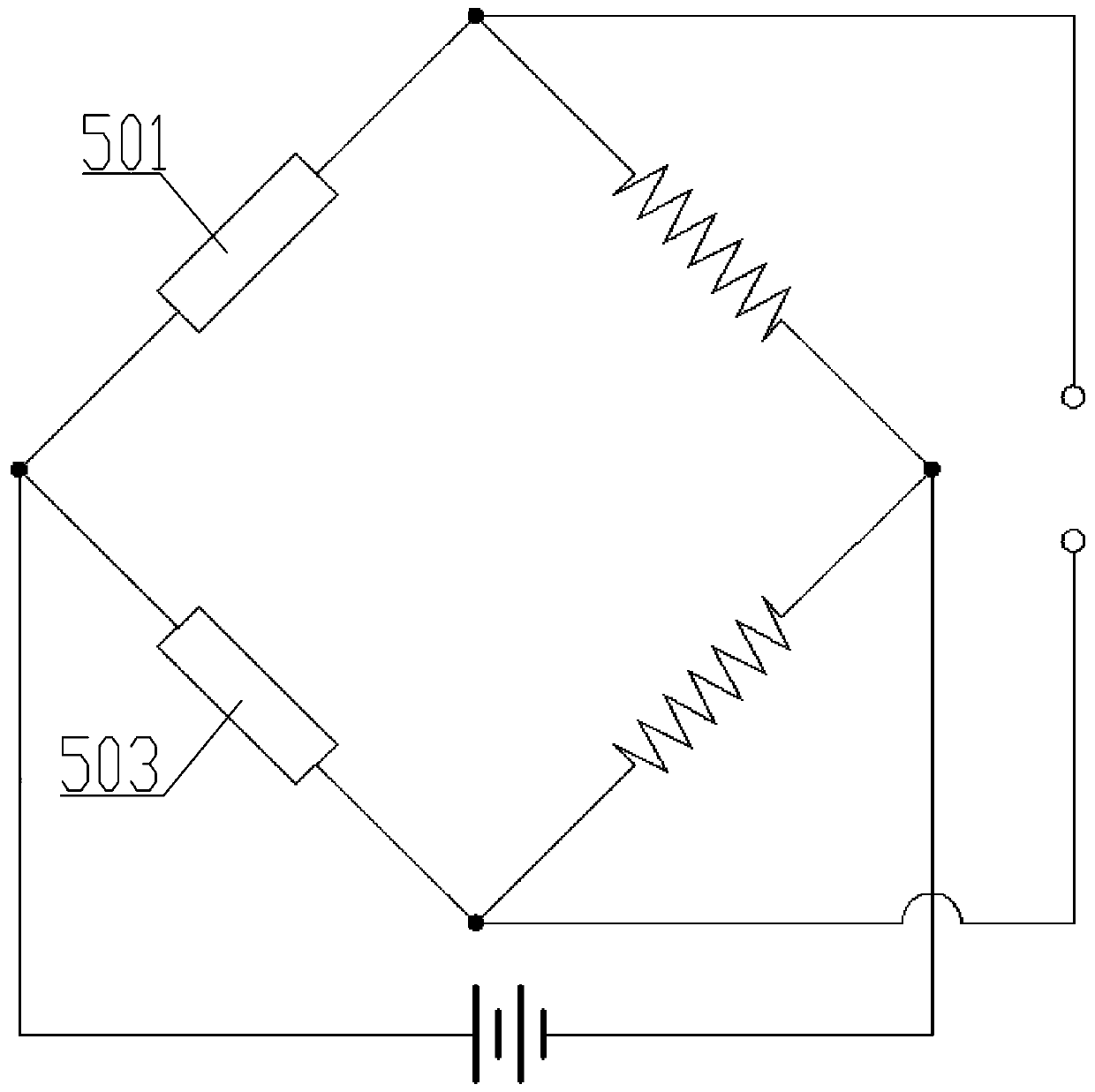

Kaplan turbine runner static balancing test device based on stress bar method, and method

PendingCN109540389AImprove securityHigh precisionStatic/dynamic balance measurementTest efficiencyEngineering

The invention discloses a Kaplan turbine runner static balancing test device based on a stress bar method, and a method. The test device comprises a balance support plate for supporting a runner body,wherein a bottom of the balance support plate is provided with a stress bar, the stress bar is supported at the top of a balance base, and a strain gauge group is adhered on the stress bar; and blades are mounted at the outside of the runner body. The device and the method provided by the invention substitute the conventional steel ball and runner plate method, are used for Kaplan turbine runnerstatic balancing, and consequently improve test efficiency and accuracy, reduce test safety risk, solidify the test device, reduce test device cost and provide guarantee for a runner static balancingtest of a power plant set.

Owner:CHINA YANGTZE POWER

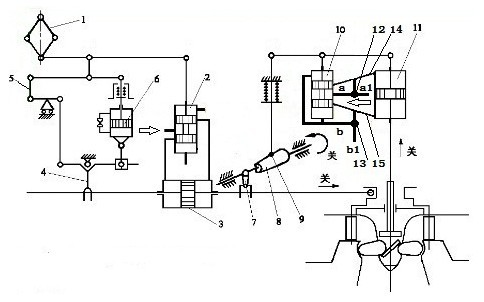

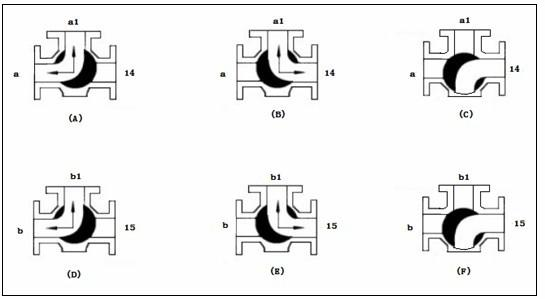

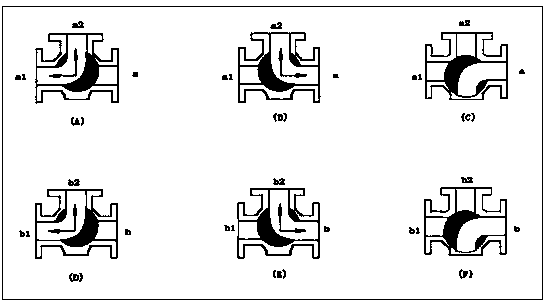

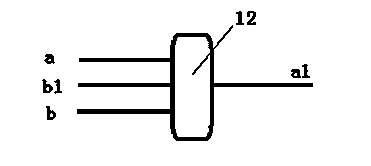

Low-head Kaplan turbine regulating method

ActiveCN102644544AConvenient downtimeReduce axial back thrustHydro energy generationMachines/enginesWater turbineProcess engineering

The invention relates to a low-head Kaplan turbine regulating method, which is characterized by, under the normally-on and operating condition of a turbine, enabling the communication between an oil supply pipe a and an oil supply path a1 via a first three-way valve (12) while disabling the communication between a first oil pipe (14) and the oil supply pipe a and the oil supply path a1; and enabling the communication between an oil return pipe b and an oil return path b1 via a second three-way valve (13) while disabling the communication between a second oil pipe (15) and the oil return pipe b and the oil return path b1. The first three-way valve (12) is connected on the oil supply path a1, and the second three-way valve (13) is connected on the oil return path b1. According to the inventive method, a turbine can obtain stable performance under shutdown condition or in the process of transiting from a power generation working condition to a phase regulation working condition, to reduce shutdown and transition time.

Owner:POWERCHINA XIBEI ENG

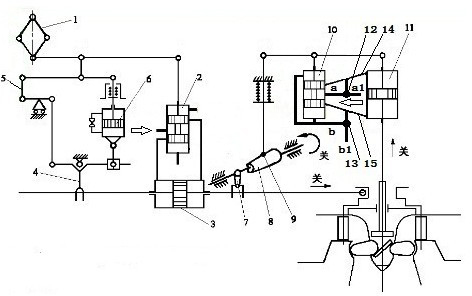

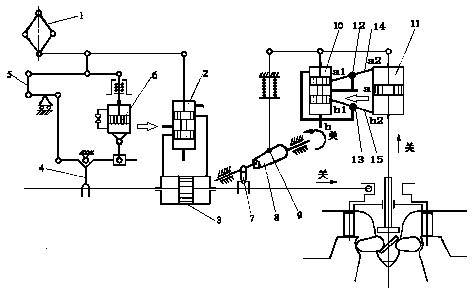

Double-regulating electric combined device and method of Kaplan turbine

ActiveCN102635492AConvenient downtimeReduce axial back thrustHydro energy generationMachines/enginesElectricityServomotor

The invention relates to a double-regulating electric combined device and method of a Kaplan turbine. The double-regulating electric combined device of the Kaplan turbine is characterized in that the turbine is connected with a centrifugal pendulum through a synchronizing mechanism; the centrifugal pendulum is connected with a guide vane pressure distributing valve through a lever mechanism; the guide vane pressure distributing valve is connected with an oil path of a guide vane servomotor; the opening or the closing or the stopping of the guide vane servomotor is manipulated through the oil path; a feedback unit is connected between the guide vane servomotor and the synchronizing mechanism; meanwhile, the guide vane servomotor is electrically connected with an electric combined and blade pressure distributing valve which is formed by sequentially connecting a displacement sensor, a processing unit and a hydraulic conversion mechanism; the vane pressure distributing valve is connected with the oil path of the guide vane servomotor; and the vane servomotor is with the turbine. The double-regulating electric combined device of the Kaplan turbine has the advantages that the stability of a set is improved, the stopping of the set is facilitated and a brake moment is increased, and the structure is simple, safe and reliable.

Owner:POWERCHINA XIBEI ENG

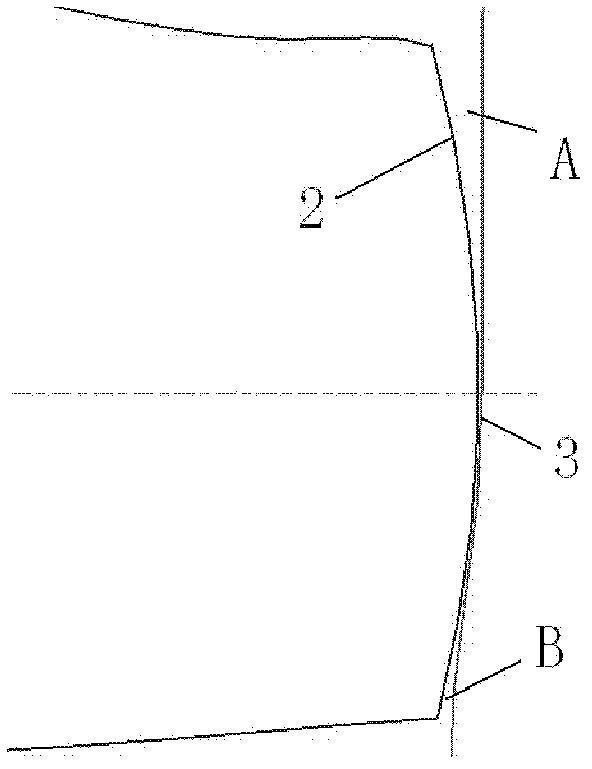

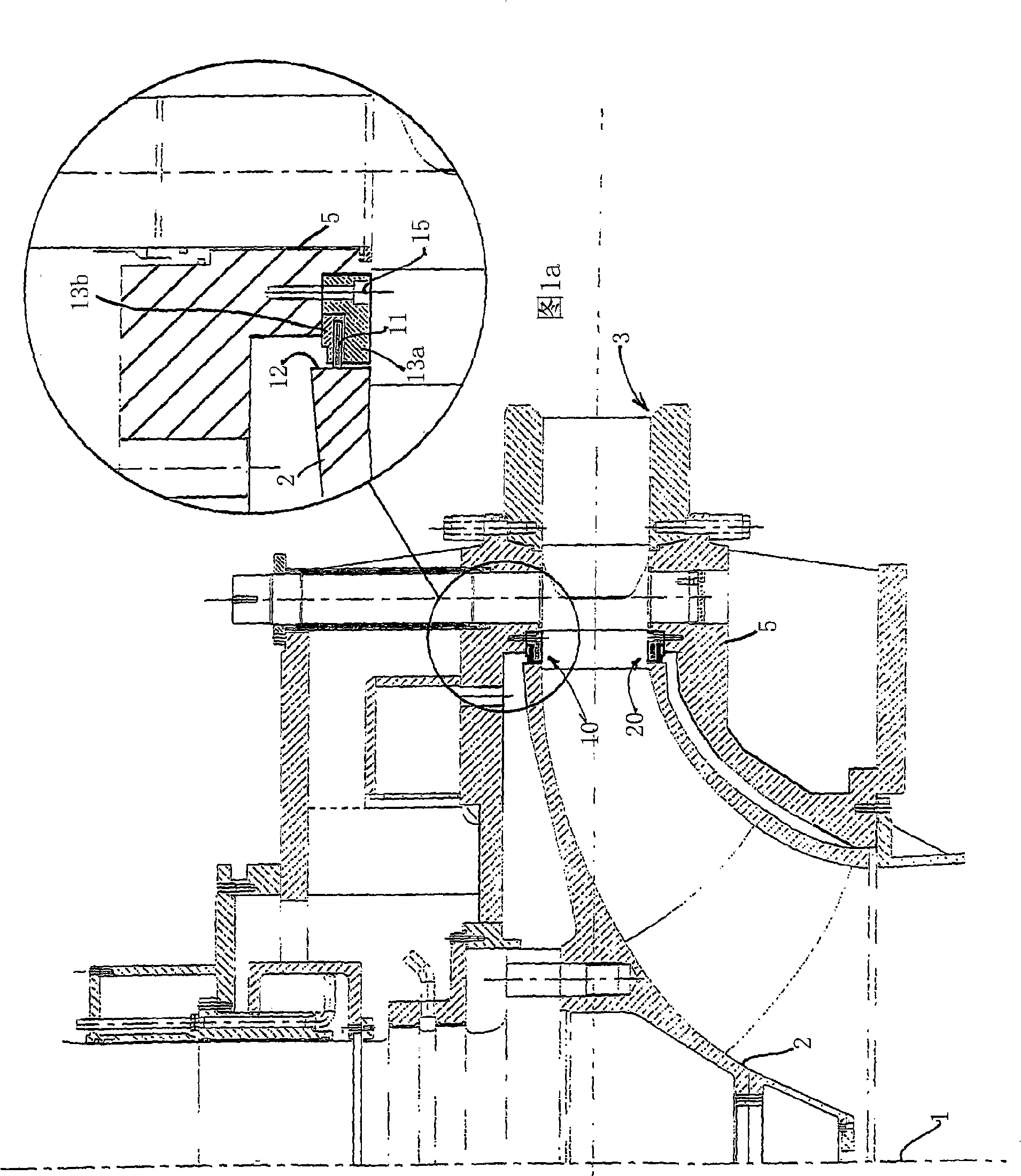

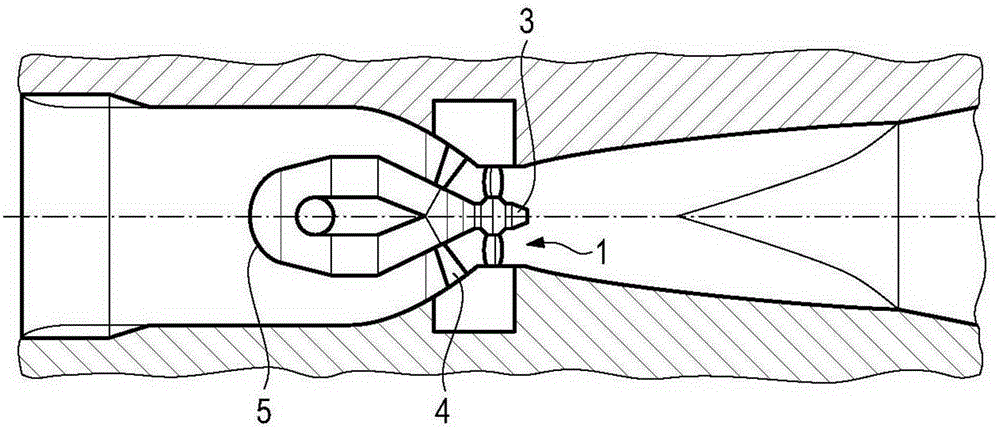

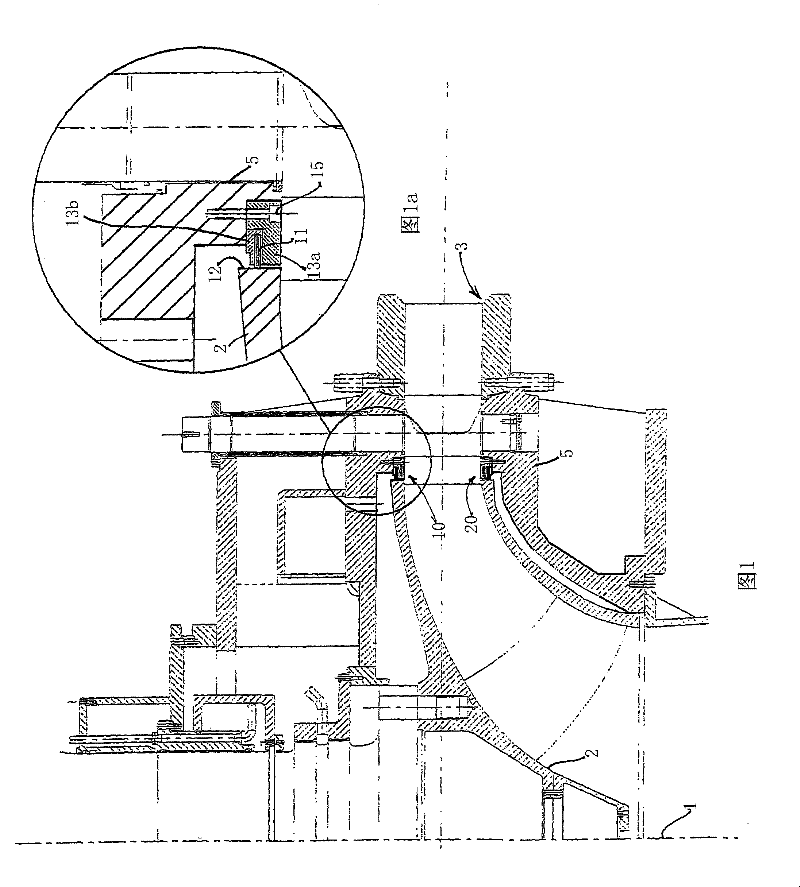

Sealing means between rotor and housing in a water turbine

InactiveCN101548096AImprove efficiencyReduce gapEngine sealsBlade accessoriesWater turbineEngineering

The present invention discloses a water turbine of the reaction type, such as a Francis or Kaplan turbine, comprising a rotor (2) and a surrounding housing (5), with sealing means (10,20) between the rotor and the housing. The sealing means comprises brush seals (11,12,13a,b) located at a radial distance from the rotor axis (1) being a major proportion of the maximum radial dimension of the rotor (2).

Owner:ANDRITZ TECH & ASSET MANAGEMENT

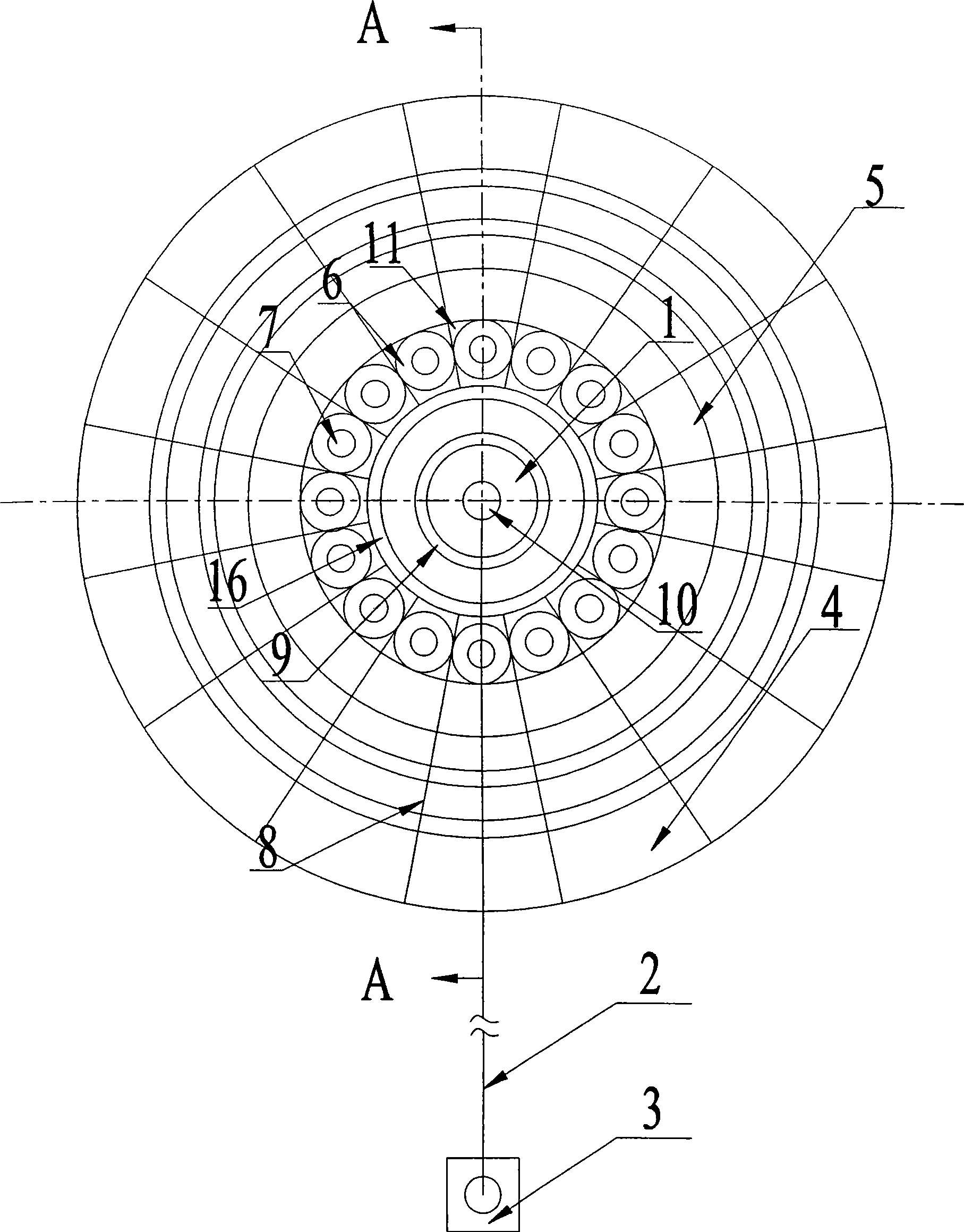

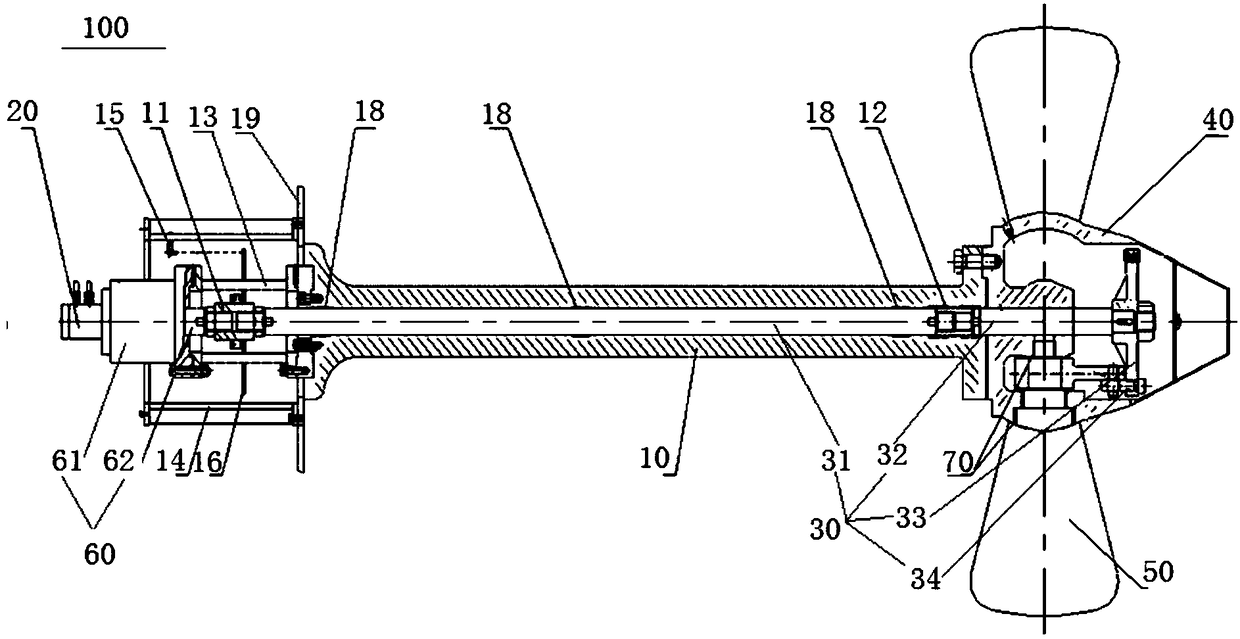

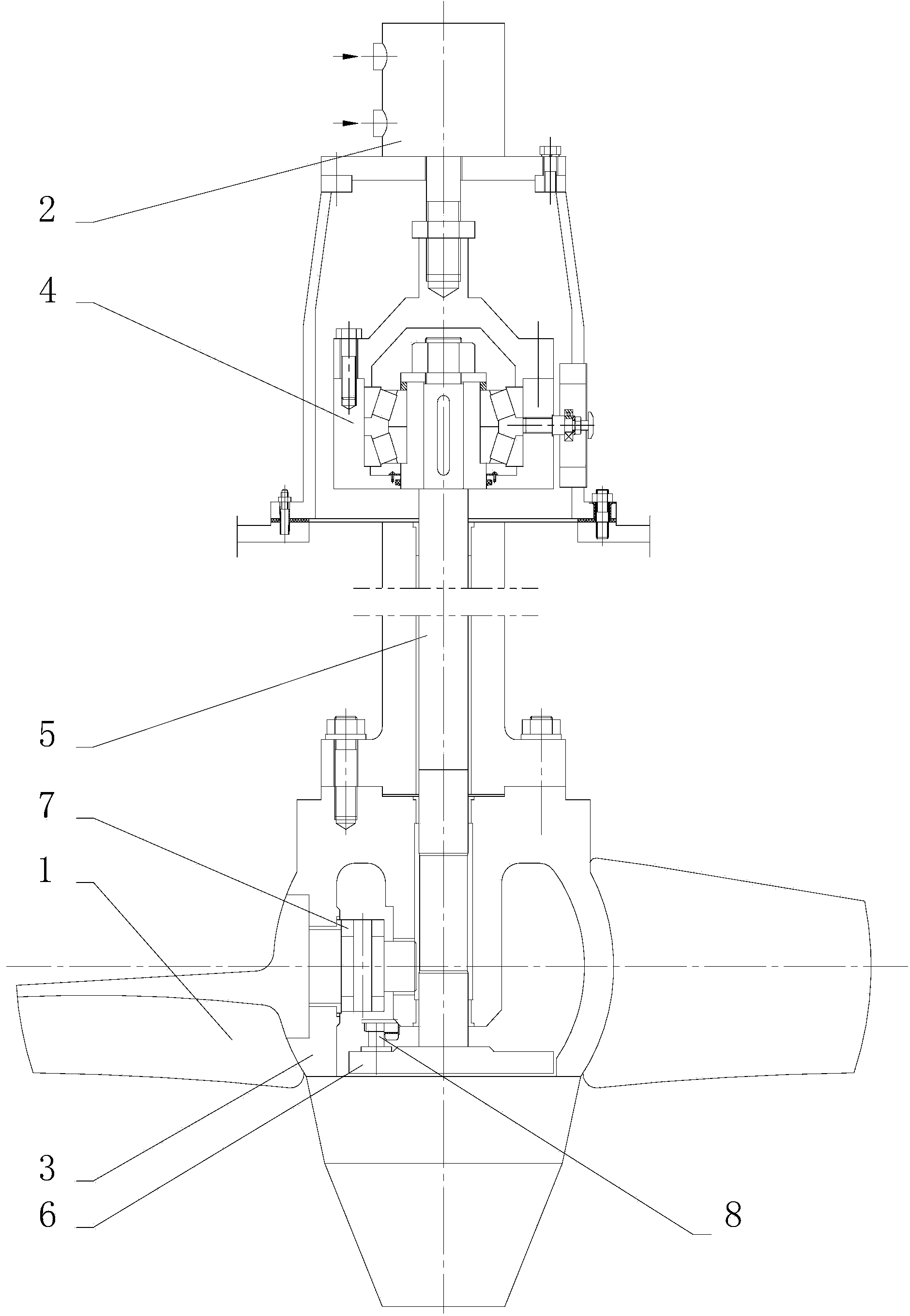

Kaplan turbine

InactiveCN103470429ARealize automatic adjustmentEfficient use ofHydro energy generationReaction enginesAuto regulationWater flow

The invention discloses a Kaplan turbine. The Kaplan turbine comprises a paddle and a rack, wherein the paddle is arranged on the rack through a paddle adjusting mechanism; the paddle adjusting mechanism comprises a hydraulic servomotor, a runner hub, a bearing group, an adjusting rod, a handling frame, a rotating arm and a connecting rod; the runner hub and the rack are fixedly connected, the hydraulic servomotor is arranged on the rack, the paddle is movably arranged on the runner hub, the rotating arm is fixedly arranged at one end, which is located at the inner part of the runner hub, of the paddle, the rotating arm is movably connected with the handling frame through the connecting rod, the handling frame and the adjusting rod are both located at the inner part of the runner hub, one end of the adjusting rod is fixedly connected with the handling frame, and the other end of the adjusting rod is fixedly connected with the hydraulic servomotor through the bearing group. The Kaplan turbine disclosed by the invention is provided with an automated paddle adjusting mechanism, the function of automatically adjusting the angle of the paddle according to water flow and a water head can be realized by the automated paddle adjusting mechanism under a controlled situation, and a paddle adjusting process can be carried out during a running process of the Kaplan turbine.

Owner:HANGZHOU SANHUI HYDROELECTRIC EQUIP

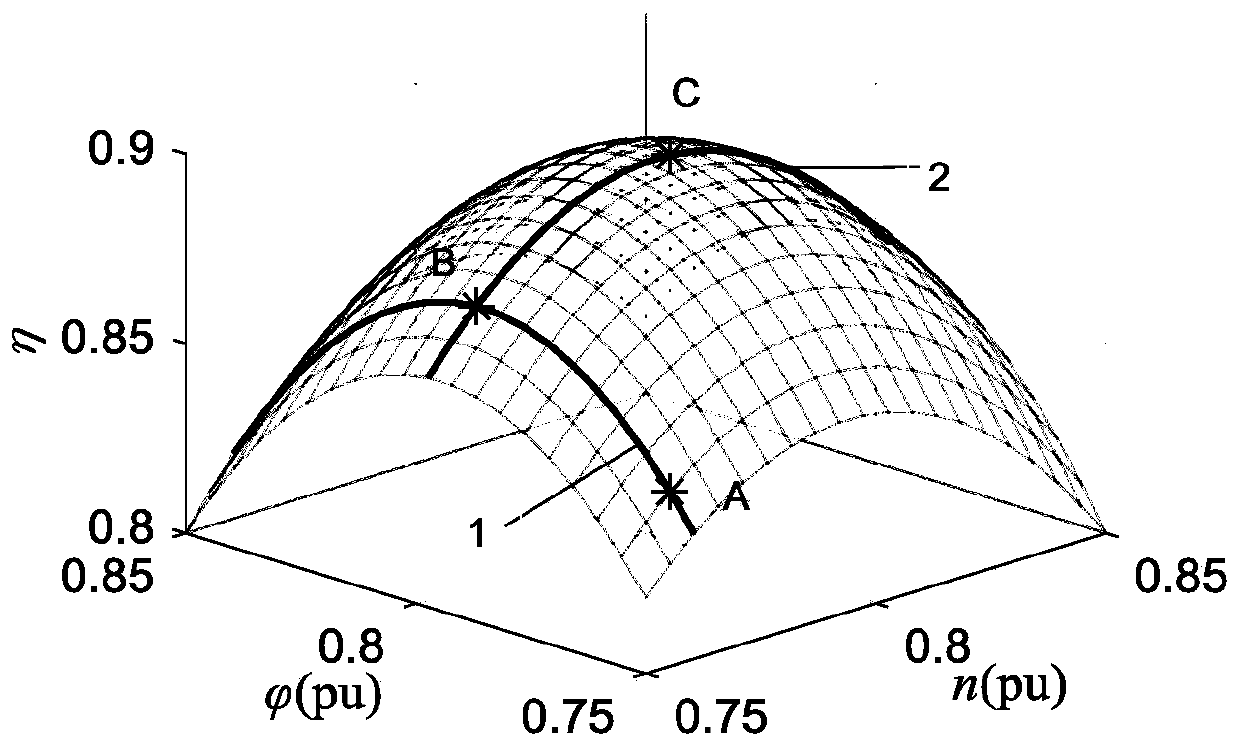

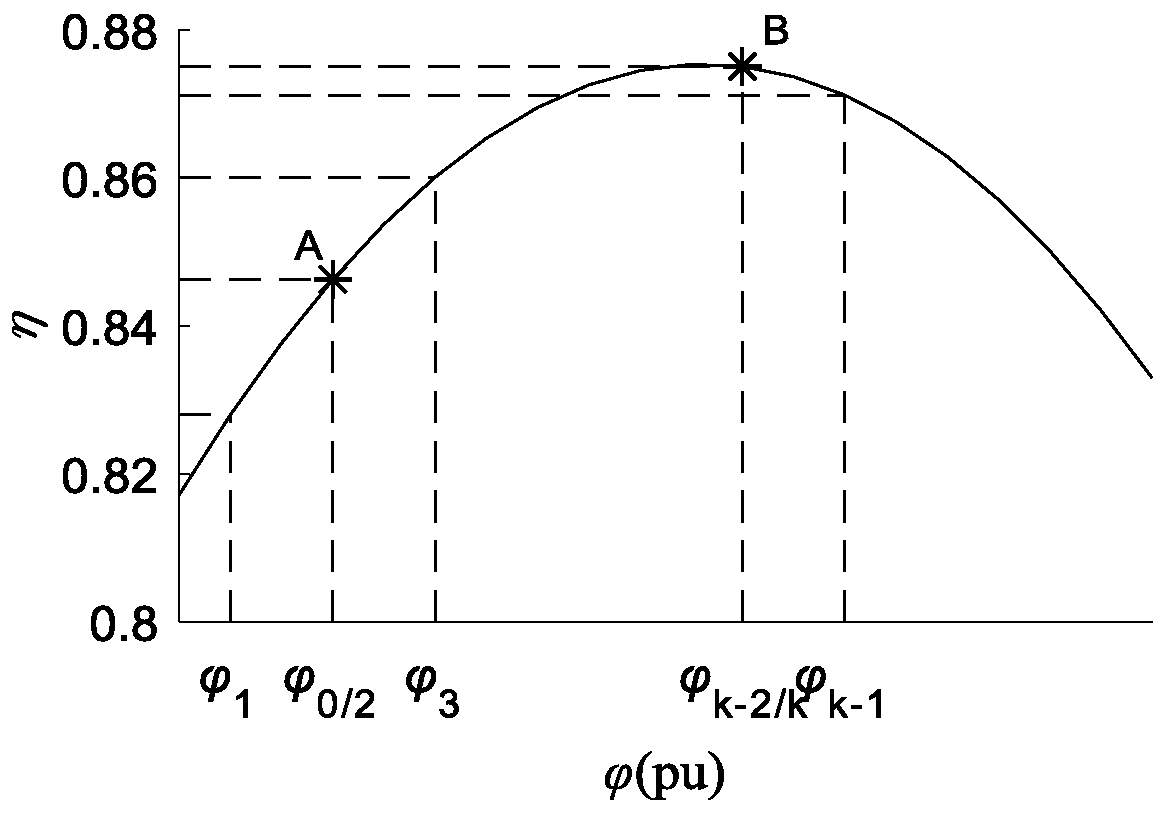

Method for optimizing the efficiency of Kaplan turbine by taking rotating speed and blade opening degree as variables

ActiveCN110889223ASolve the problem that cannot be coordinated to the optimal efficiencyImprove economyGeometric CADDesign optimisation/simulationWater turbineControl theory

The invention discloses a method for optimizing the efficiency of a Kaplan turbine by taking a rotating speed and a blade opening degree as variables. The method includes: obtaining the initial rotating speed and the initial blade opening degree of a real machine according to the water turbine model association relationship, and on the basis, respectively changing the rotating speed and the bladeopening degree of the unit and judging the efficiency change condition of the water turbine, so as to obtain the optimal rotating speed or the optimal blade opening degree. The method solves the problem that the variable-speed operation of the Kaplan turbine cannot be coordinated to the optimal efficiency, the variable-speed operation efficiency of the Kaplan turbine is improved, and the operationstability of a unit is improved.

Owner:XIAN UNIV OF TECH

Method for measuring uniformity and synchronism of blade opening

PendingCN114876697AReduce slippageReduce riskHydro energy generationReaction enginesWater turbineStructural engineering

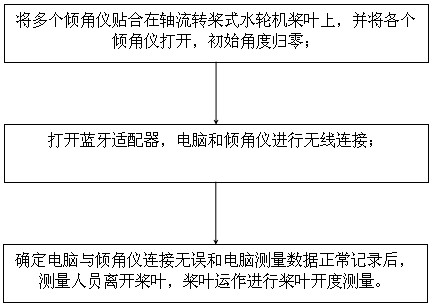

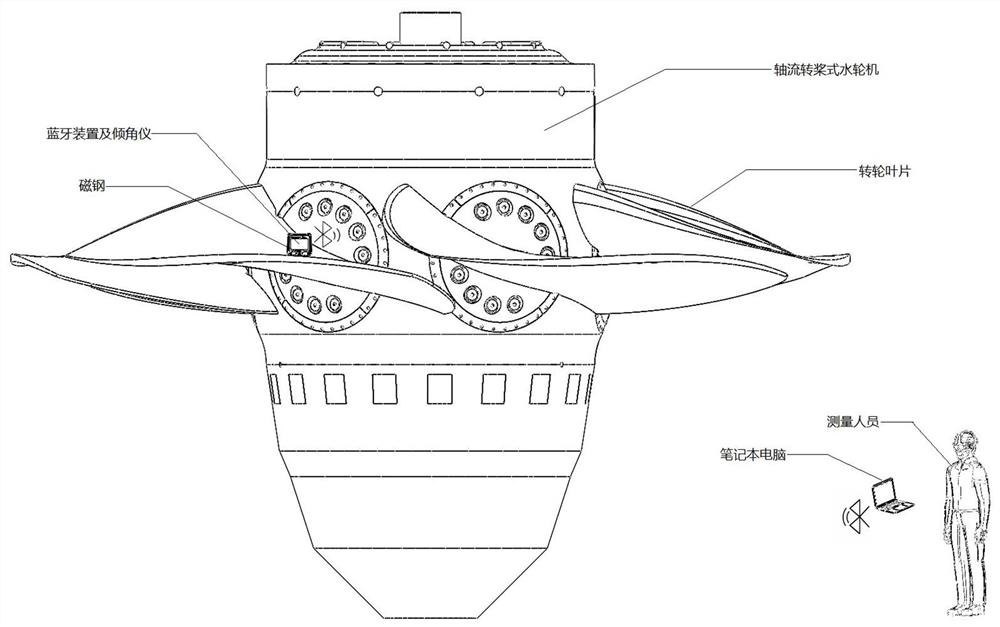

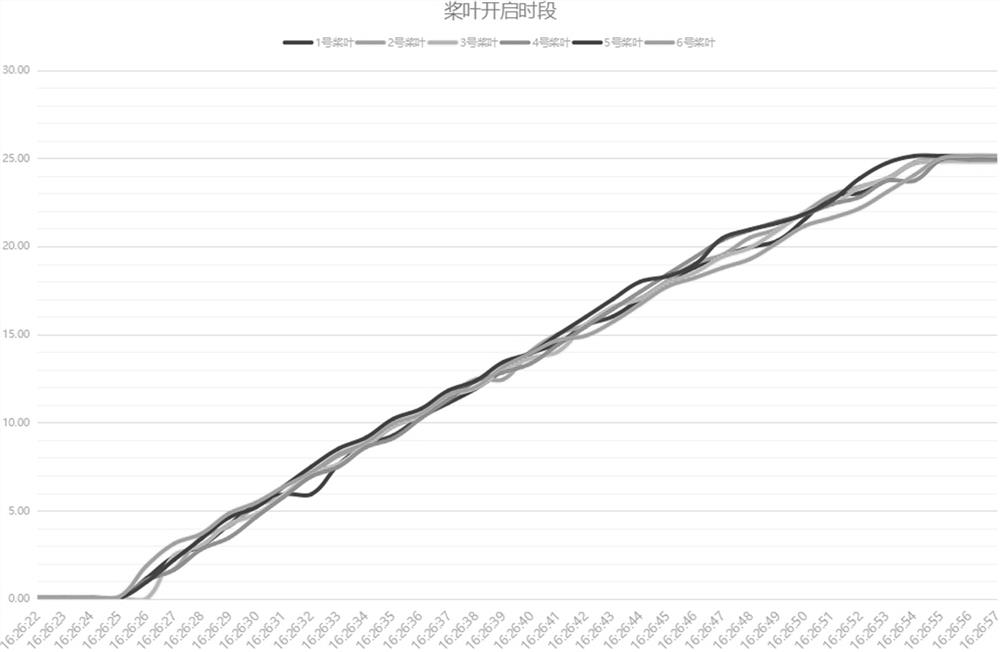

The invention discloses a blade opening uniformity and synchronism measuring method, which comprises the following specific steps of: 1, fitting a plurality of inclinometers on a blade of an axial-flow Kaplan turbine, opening each inclinometer, and returning an initial angle to zero; 2, opening the Bluetooth adapter, and wirelessly connecting the computer and the inclinometer; and 3, after determining that the computer and the inclinometer are connected correctly and computer measurement data are normally recorded, the measurer leaves the blade, and the blade operates to measure the opening degree of the blade. Compared with the conventional measurement method, the implementation process is simplified, the operation risks of slipping, mechanical injury, even high-altitude falling and the like of measurement personnel in the blade opening measurement process are greatly reduced, and the safety of the measurement personnel is effectively ensured.

Owner:CHONGQING DATANG INT WULONG HYDROPOWER DEV

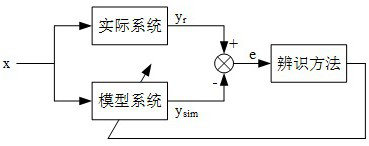

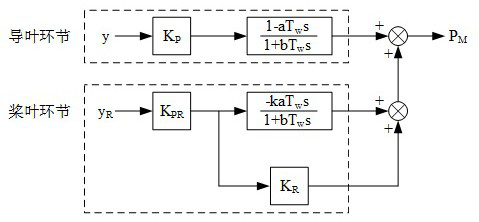

Parameter identification method for prime mover model of axial-flow Kaplan turbine

PendingCN114756987AImprove efficiencyImprove accuracyGeometric CADData processing applicationsPrime moverWater turbine

The invention relates to an axial-flow Kaplan turbine prime mover model parameter identification method. The method is suitable for parameter identification of the axial-flow Kaplan turbine described by adopting a rigid water hammer model and a water diversion system of the axial-flow Kaplan turbine. Due to the fact that when the axial flow movable propeller turbine operates, guide vanes and paddles act in a combined mode, the guide vane opening degree and the action of the paddle opening degree on mechanical power are mutually coupled, and therefore seven to-be-identified model parameters are difficult to accurately identify through a conventional identification method. According to the method, the prime mover model is divided into the guide vane link and the paddle link, and the guide vane link and paddle link parameters are sequentially identified in combination with a de-association field test mode, so that the identification efficiency and accuracy are improved.

Owner:STATE GRID FUJIAN ELECTRIC POWER RES INST +2

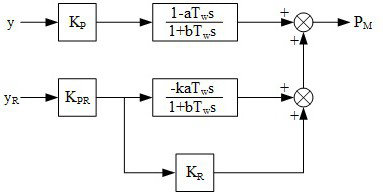

A dynamic model of paddle turbine regulating system suitable for power system analysis

The invention discloses a Kaplan turbine adjusting system dynamic model suitable for electric power system analysis, which comprises a speed governor model, a guide vane control system model, a blade control system model, a water turbine model and a water diversion system model, wherein the guide vane control system model and the blade control system model forms a Kaplan turbine dual adjusting system, the blade control system model takes a combined relationship existing between guide vane opening degrees and blade opening degrees into account, and the combined relationship is obtained by adopting a quintic polynomial curve fitting method; and the water turbine model takes the correction function of blade angles on water turbine efficiency into account on the basis of analyzing non-linear models, the mechanical power output of the water turbine model is affected by the guide vane opening degrees and blade opening degrees together, and the nonlinearity between the guide vane opening degrees and the mechanical power is metered and is described by adopting cubic polynomial fitting. The Kaplan turbine adjusting system dynamic model is exquisite and clear in structure, has distinct and easily-obtained model parameter meanings, is fast and efficient in modeling process, and has high practicability.

Owner:WUHAN UNIV

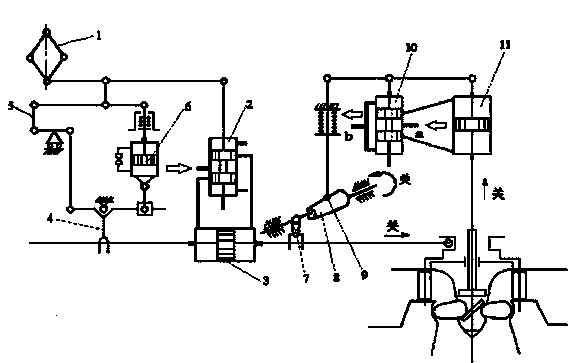

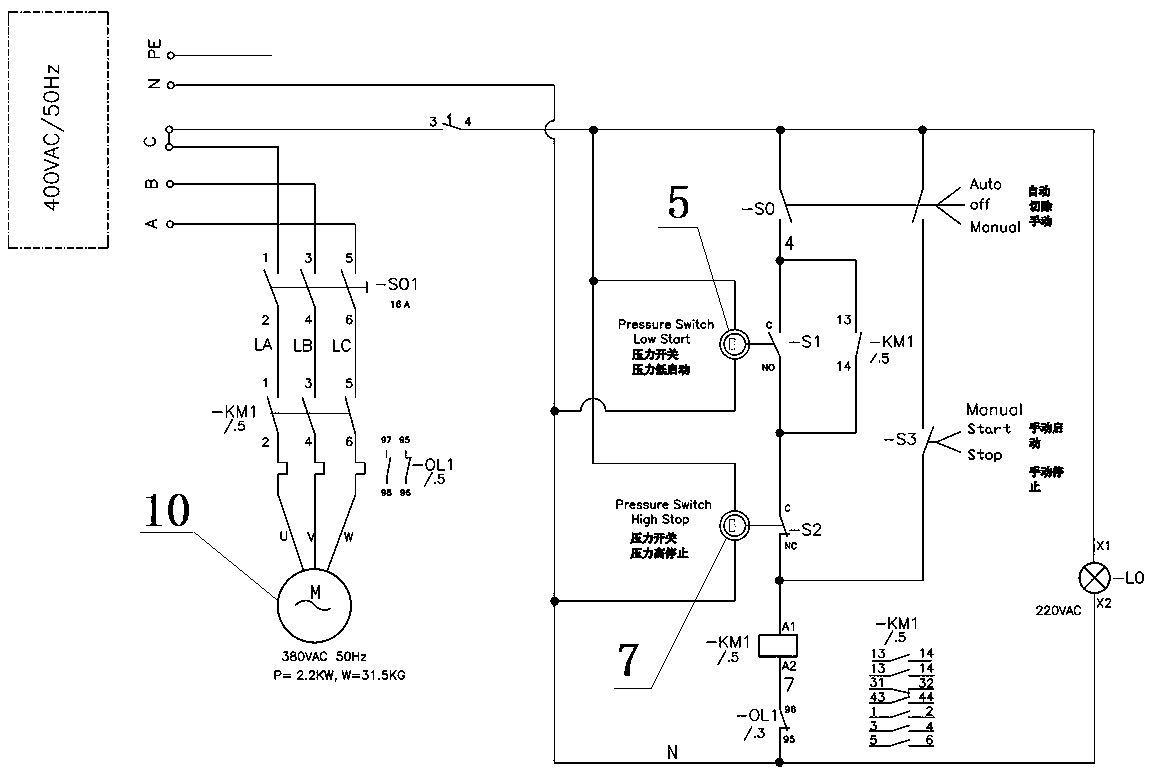

Double-control device and method for low waterhead Kaplan turbine

ActiveCN102650257BConvenient downtimeReduce axial back thrustHydro energy generationMachines/enginesBrake torqueStable state

The invention belongs to hydraulic mechanical engineering, and particularly relates to a double-control device and method for a low waterhead Kaplan turbine. The device is characterized in that a first three-way valve (12) is connected onto a first oil pipe (14) between a blade distributing valve (10) and a blade servomotor (11), and a second three-way valve (13) is connected onto a second oil pipe (15) between the blade distributing valve (10) and the blade servomotor (11). The device has the advantages that: 1, a stand water-wheel power generation set can be prevented from raising during the processes of shutting down or converting from a power generation working condition to a phase modulation working condition, reduce the axial backward thrust of a horizontal water-wheel power generation set to a flow pair unit during the two processes, so the stability of the unit is improved; 2, the device is beneficial to shutting down the unit, and the braking torque is increased; the device is beneficial to shortening the time for the process of converting from the power generation working condition to the phase modulation working condition, so the unit is quickly shifted to a stable state; and 3, the device has a simple structure, is safe and reliable.

Owner:POWERCHINA XIBEI ENG

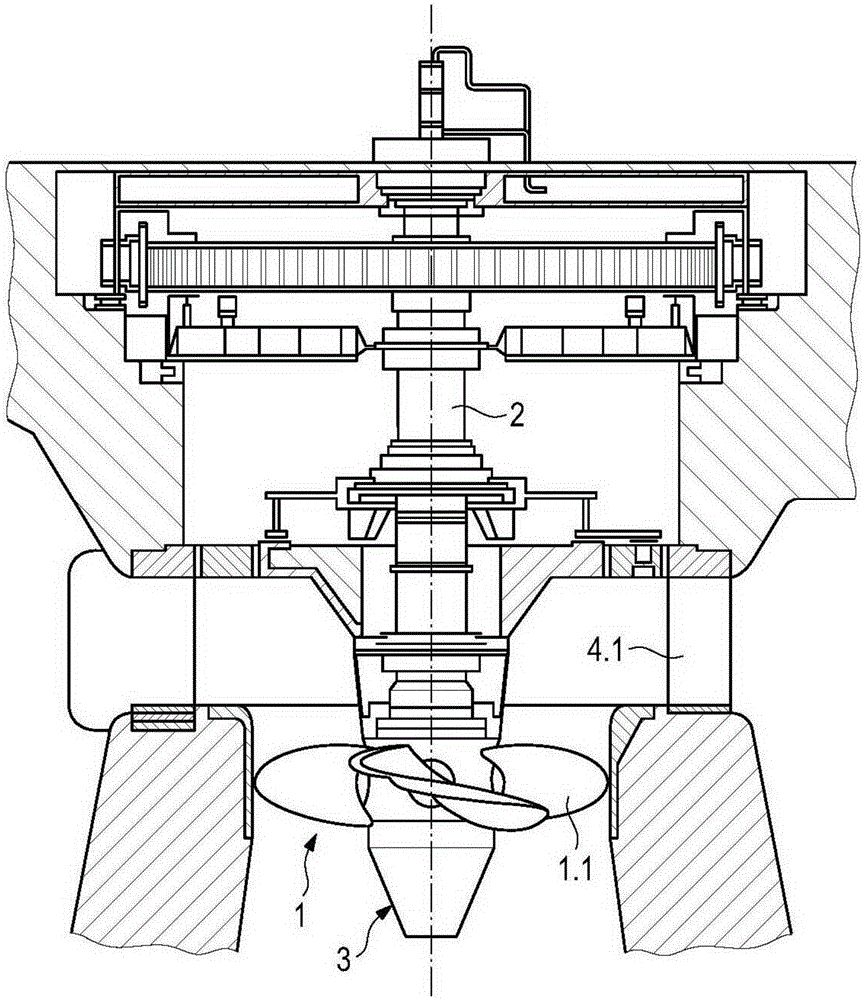

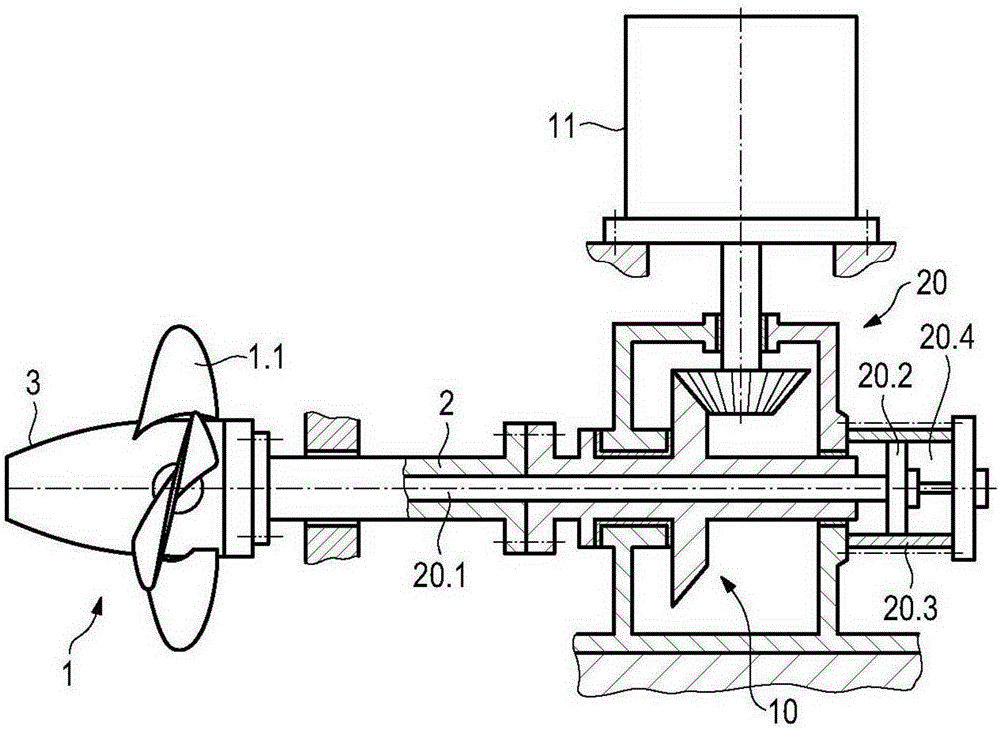

Impeller for a Kaplan turbine

InactiveCN105209745APrevent penetrationEasy to modifyEngine fuctionsHydro energy generationImpellerEngineering

The invention relates to an impeller for a Kaplan turbine, comprising the following features or components: a shaft, a plurality of blades; a hollow hub which is located on the free end of the shaft and which carries the blades; an adjustment device for rotating the blades around axes of rotation perpendicular to the axis of rotation of the shaft. The invention is characterized by the following features: the interior of the hub is connected to a source of compressed air; branch lines are provided inside the hub to supply the compressed air to bearings or other lubrication points for the adjustment device.

Owner:VOITH PATENT GMBH

Joint control device and method for low waterhead Kaplan turbine

ActiveCN102650259BReduce downtimeShort transition timeHydro energy generationMachines/enginesFour-way valveEngineering

The invention belongs to hydraulic mechanical engineering, and particularly relates to a joint control device and method for a low waterhead Kaplan turbine. The device at least comprises a blade distributing valve (10) which is connected with a joint mechanism, wherein two ways of a four-way valve (12) are connected between an oil supply pipe of the blade distributing valve (10) and an oil supply line, and the other two ways of the four-way valve (12) are connected between an oil return pipe of the blade distributing valve (10) and an oil return line. The device and the method provided by the invention can let the turbine to obtain stable performance during the process of shutting down or shifting from a power generation working condition to a phase modulation working condition, and is beneficial to reducing the time for shutting down and transition.

Owner:POWERCHINA XIBEI ENG

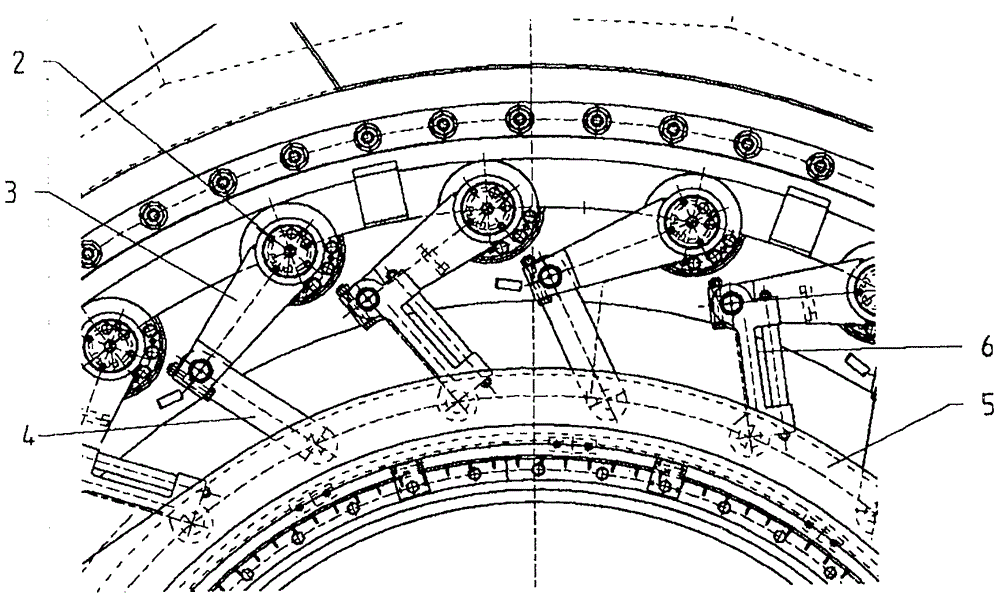

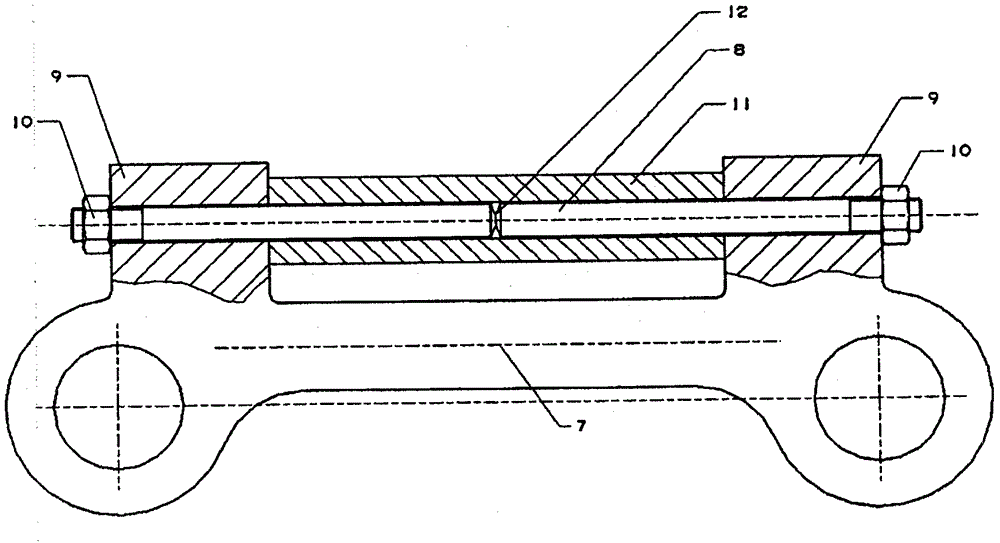

Guide vane assembly for continuous flow machines

The invention relates to a flow guide device for turbomachinery, in particular for Francis or Kaplan turbines or for pumps or pump turbines, having a plurality of guide vanes ( 3 ) which ( 3) Actuated in each case by a link (4) on the common adjustment element (5). Here, each guide vane or each second guide vane is equipped with a safety element. Its principle is characterized in that an anti-bending link (6), which can have a threaded connection and a bending body (7), is provided as a safety element. The threaded connection is prestressed and configured with a predetermined rupture section (12). Thus, the triggering force on the bending breaking link (6) and the holding force after breaking of the safety element can be selected independently of each other. In this guide device, the guide vanes are protected from being damaged by foreign objects.

Owner:ANDRITZ HYDRO GMBH

Measurement method of turbine blade rotation angle based on level gauge

Owner:HONGJIANG HYDROELECTRIC POWER PLANT HUAIHUA YUANJIANG ELECTRIC POWER DEV

Sealing means between rotor and housing in a water turbine

The present invention discloses a water turbine of the reaction type, such as a Francis or Kaplan turbine, comprising a rotor (2) and a surrounding housing (5), with sealing means (10,20) between the rotor and the housing. The sealing means comprises brush seals (11,12,13a,b) located at a radial distance from the vertical rotor axis (1) being a major proportion of the maximum radial dimension of the rotor(2).

Owner:ANDRITZ TECH & ASSET MANAGEMENT

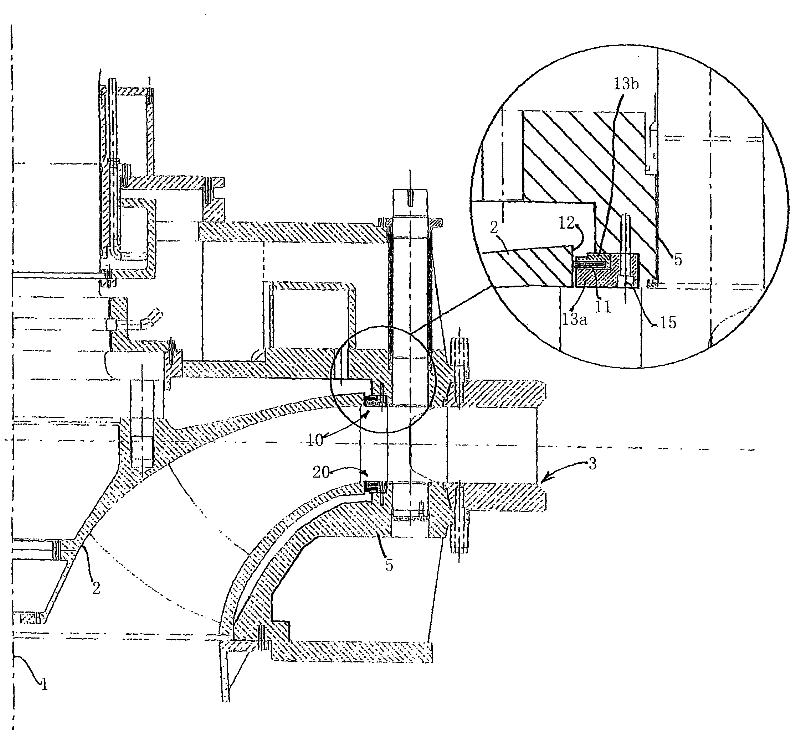

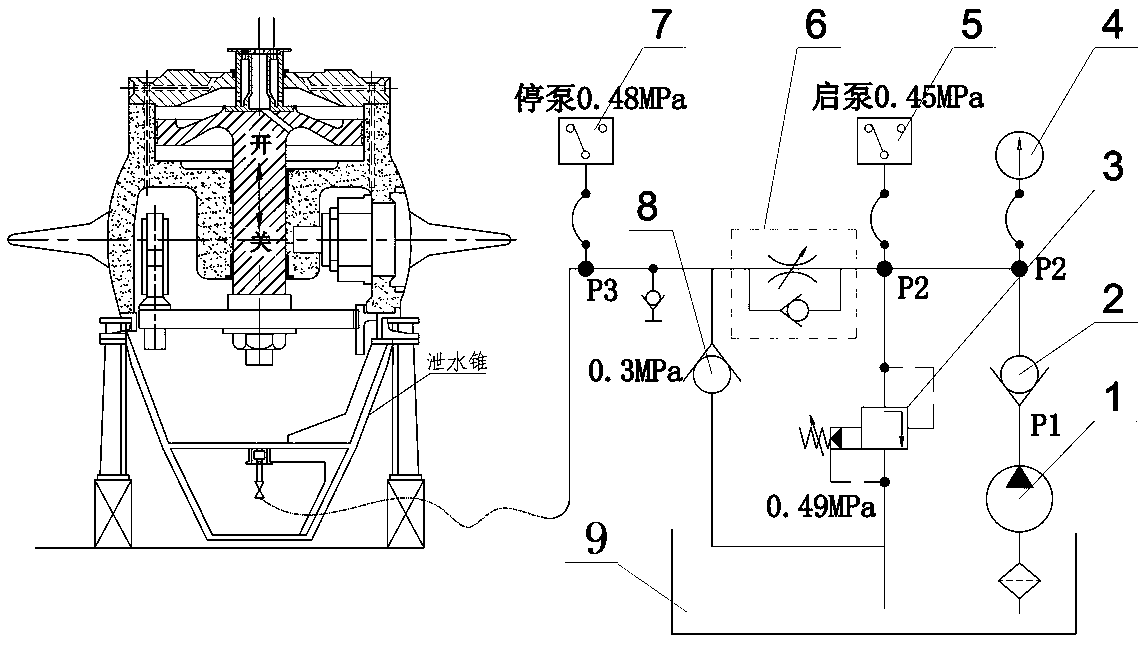

Runner cone pressure resistance test device of axial-flow Kaplan turbine and control method

ActiveCN110907097AGuaranteed pressure stabilityEasy to useFluid-tightness measurement using fluid/vacuumPressure stabilizationWater turbine

The invention provides a runner cone pressure resistance test device of an axial-flow Kaplan turbine and a control method. The runner cone pressure resistance test device is characterized in that a hydraulic system pipeline connected with a turbine runner hub runner cone is provided with an overflow valve, a first intelligent pressure switch and a second intelligent pressure switch; the overflow valve is used for controlling the highest working pressure of a system; the first intelligent pressure switch is used for starting an oil pump when the system pressure is lower than a preset low pressure value; and the second intelligent pressure switch is used for closing the oil pump when the system pressure is higher than the preset high pressure value. The runner cone pressure resistance test device can guarantee the pressure stability of the runner cone in the pressure-resistant test process effectively, is convenient to use, is high in automation degree, and enables the efficiency to be greatly improved.

Owner:FUJIAN SHUIKOU POWER GENERATION GROUP +1

Kaplan turbine blade operating mechanism

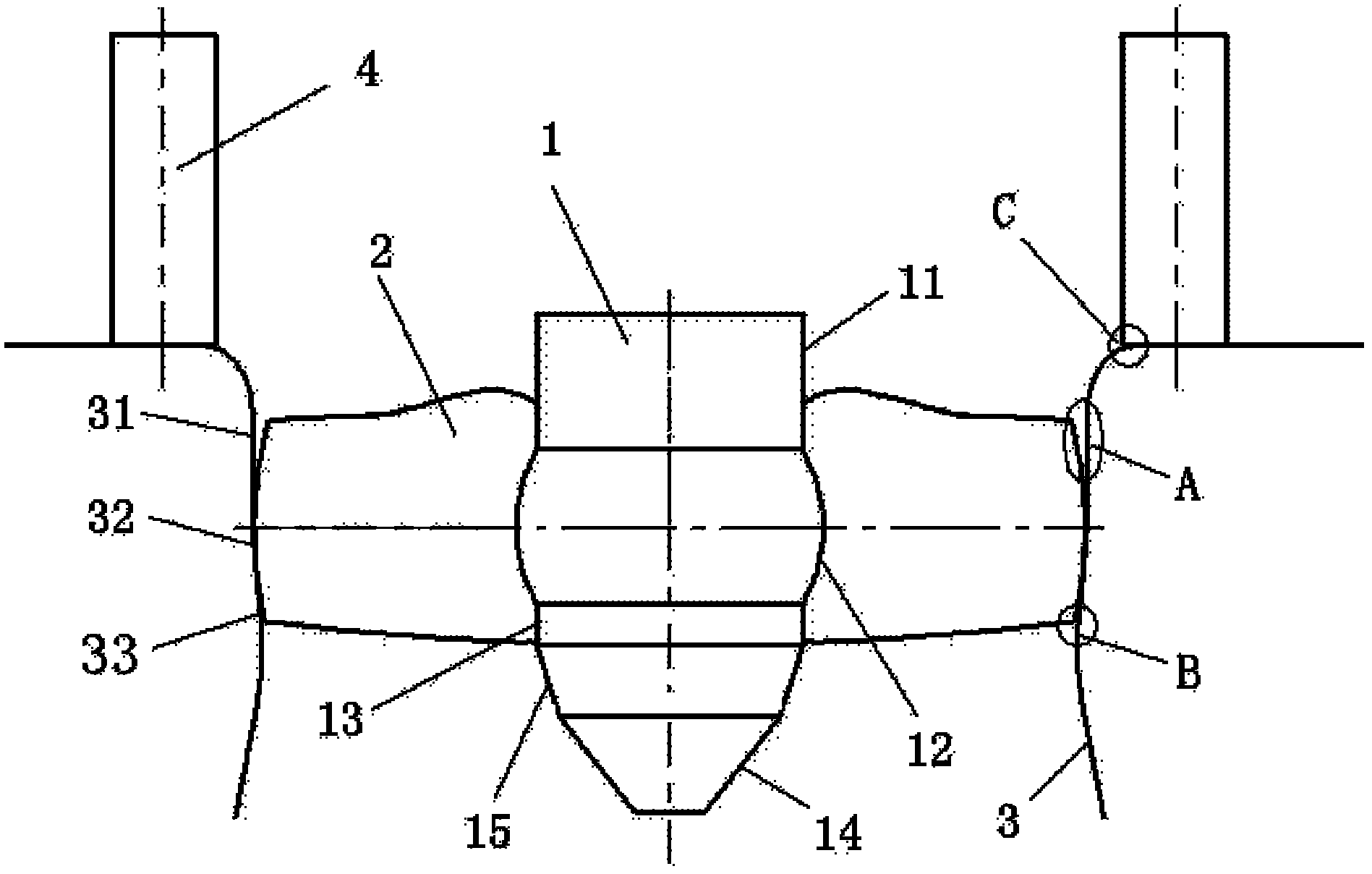

PendingCN111207031AReduce in quantitySimple structureFinal product manufactureHydro energy generationWater turbineRocker arm

The invention discloses a Kaplan turbine blade operating mechanism. The blade operating mechanism comprises a runner body (1), wherein at least three blades (2) are arranged on the runner body (1), awater turbine main shaft (3) and a runner cone (4) are arranged at the two ends of the runner body (1) correspondingly, an operating oil pipe is arranged in the runner body (1), one end of the operating oil pipe penetrates through the water turbine main shaft (3) and penetrates into the runner body (1), an oil inlet and outlet mechanism is arranged at the penetrating-in end of the operating oil pipe, a super relay mechanism communicating with the oil inlet and outlet mechanism is arranged on the oil inlet and outlet mechanism, and the super relay mechanism is connected with a blade (2) throughsliding blocks (5) and rocker arms (6). The blade operating mechanism has the advantages of being simple in structure, ingenious in design, reliable in use and low in cost, the number of parts can bereduced, the space is saved, the manufacturing difficulty is lowered, the design and manufacturing period is shortened, and the cost is saved.

Owner:CHONGQING WATER TURBINE WORKS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com