Patents

Literature

143results about How to "Increase wrap angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

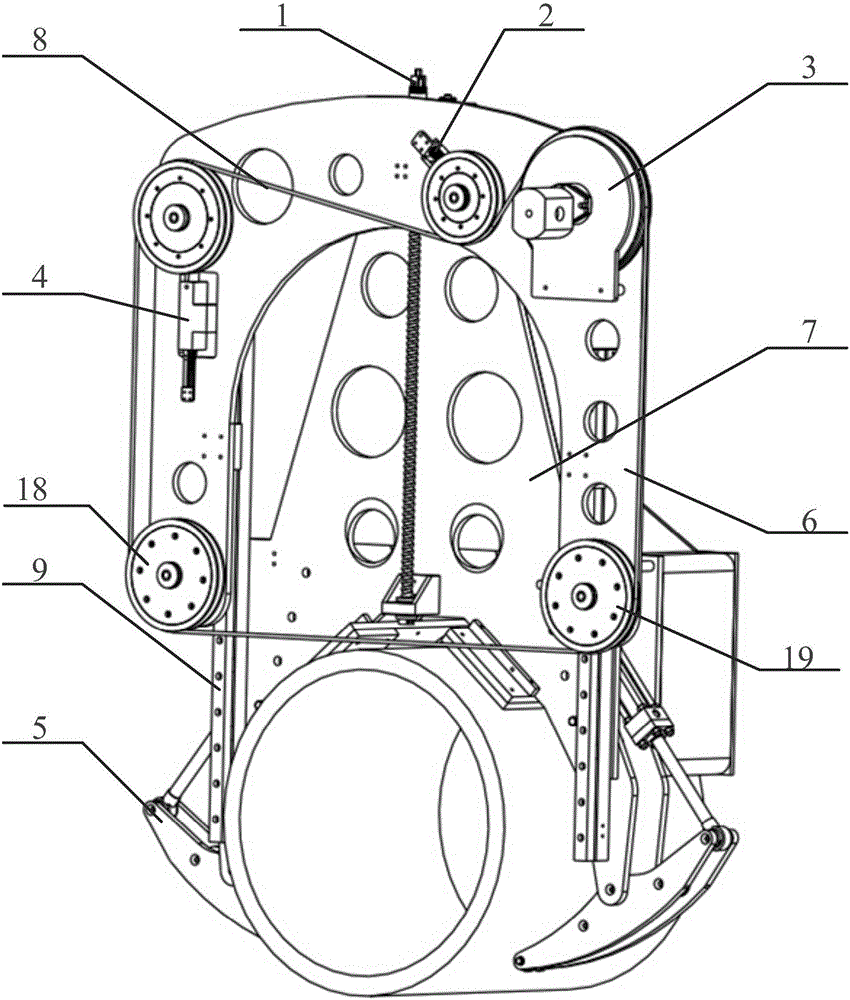

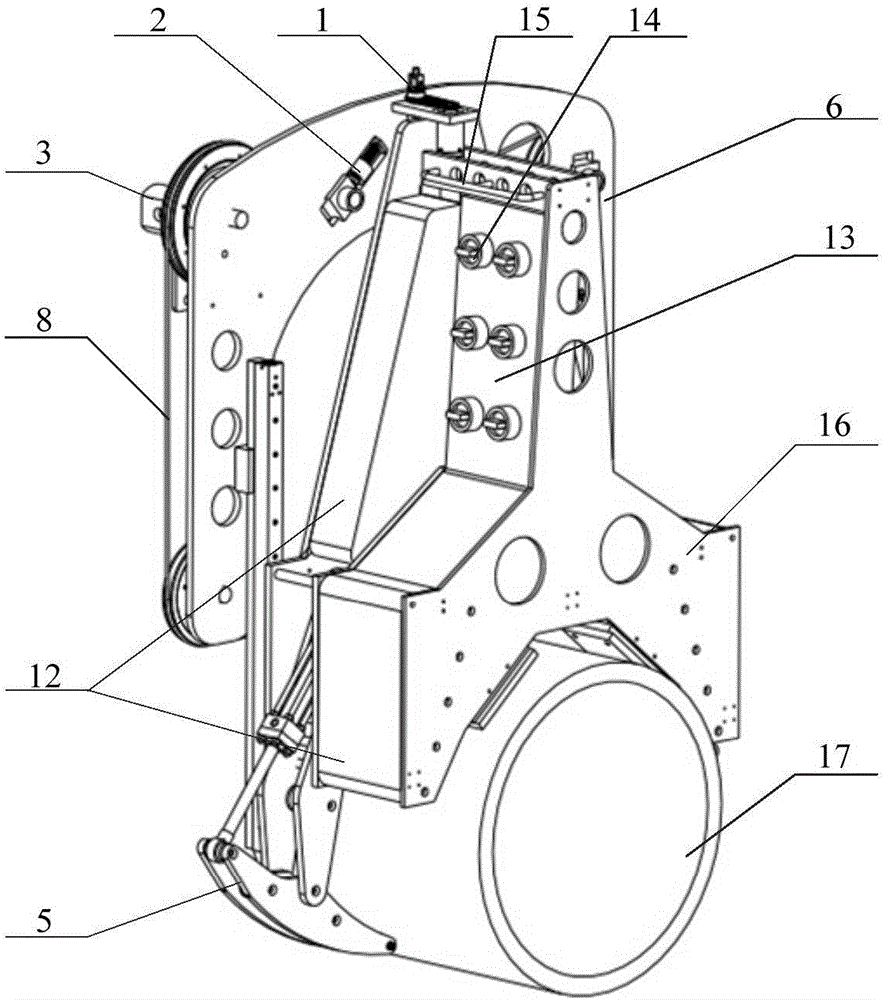

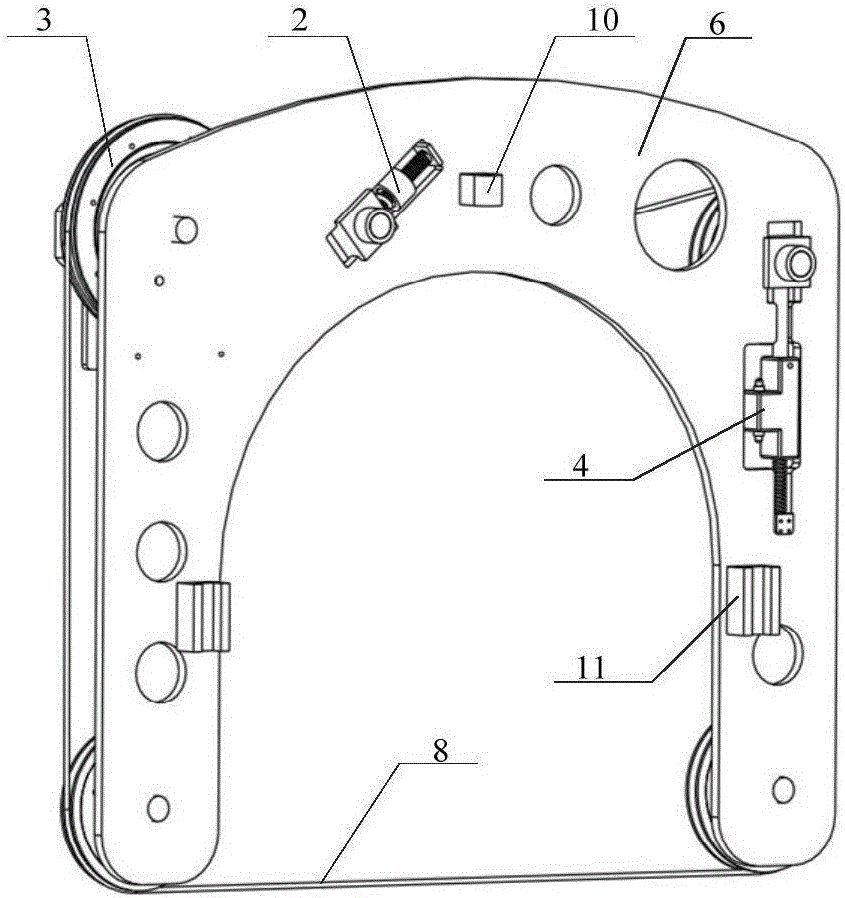

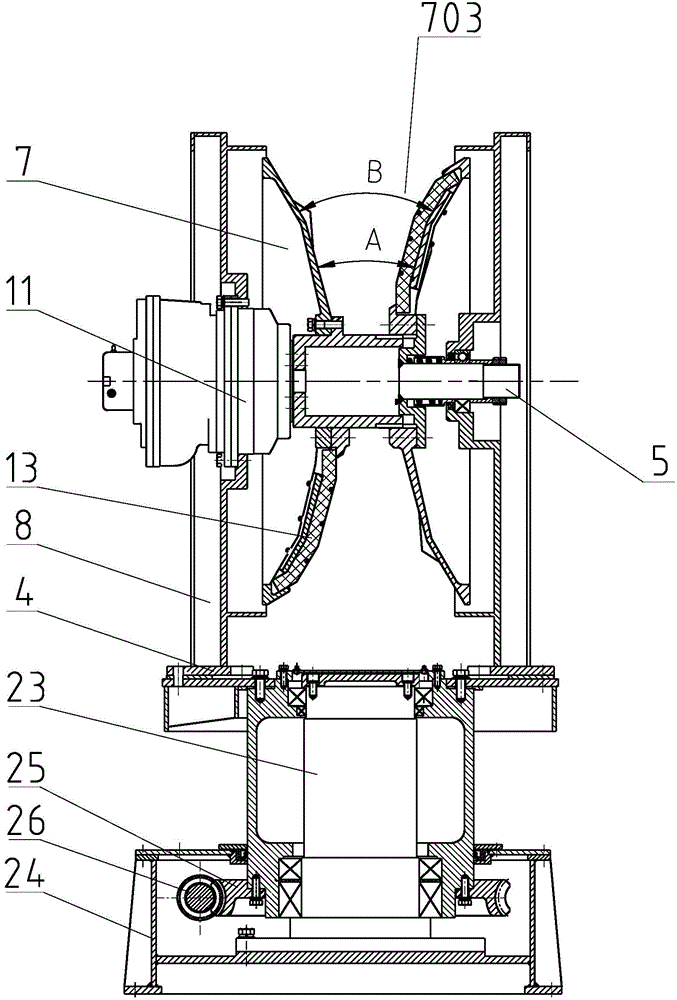

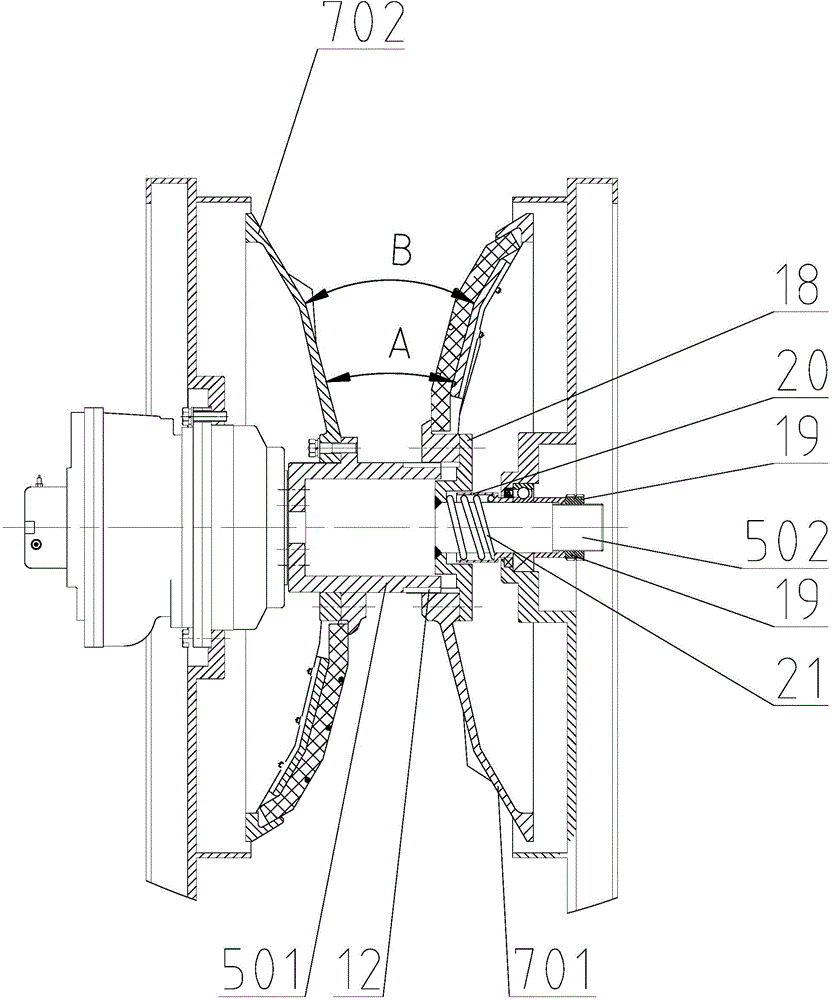

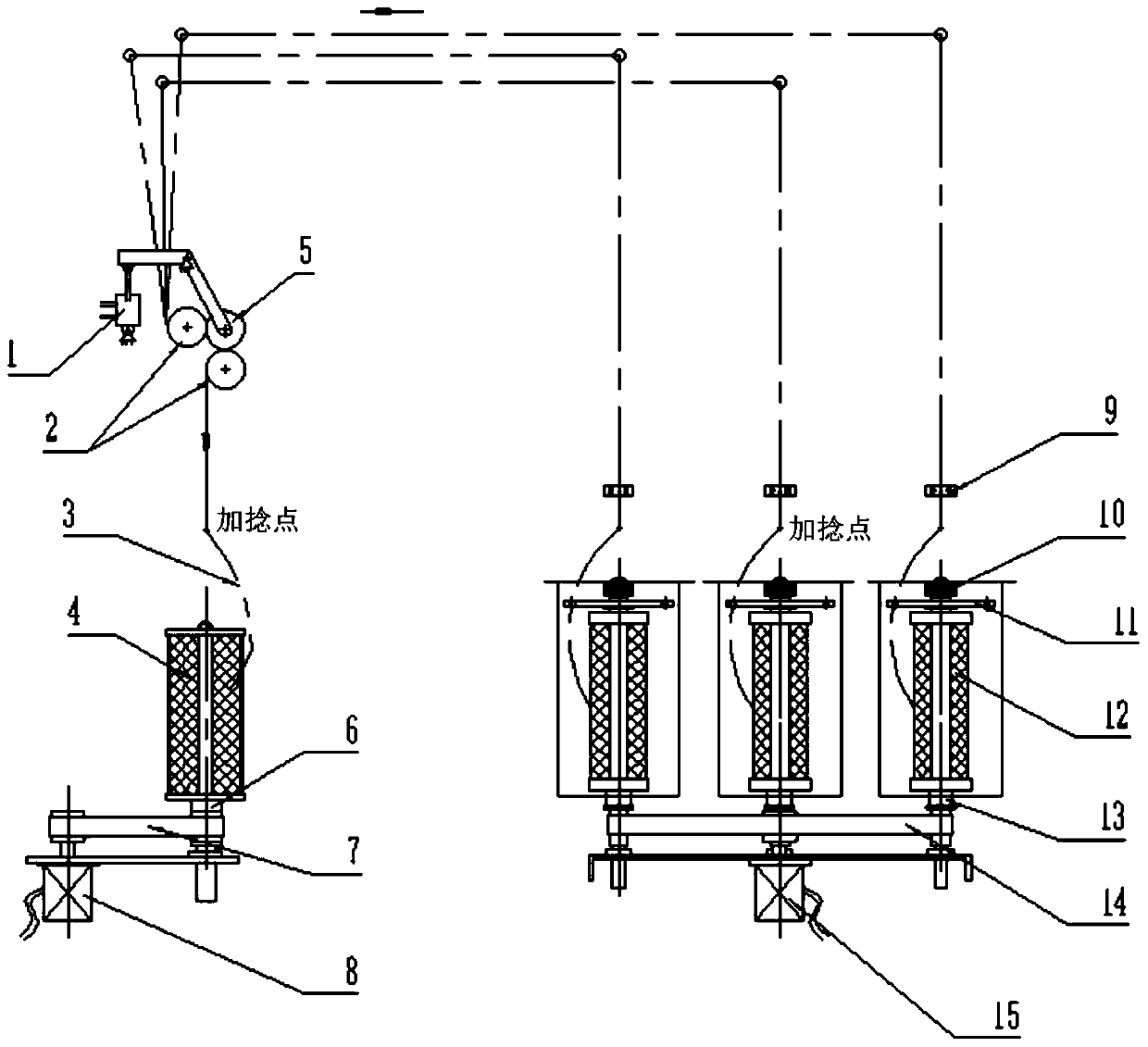

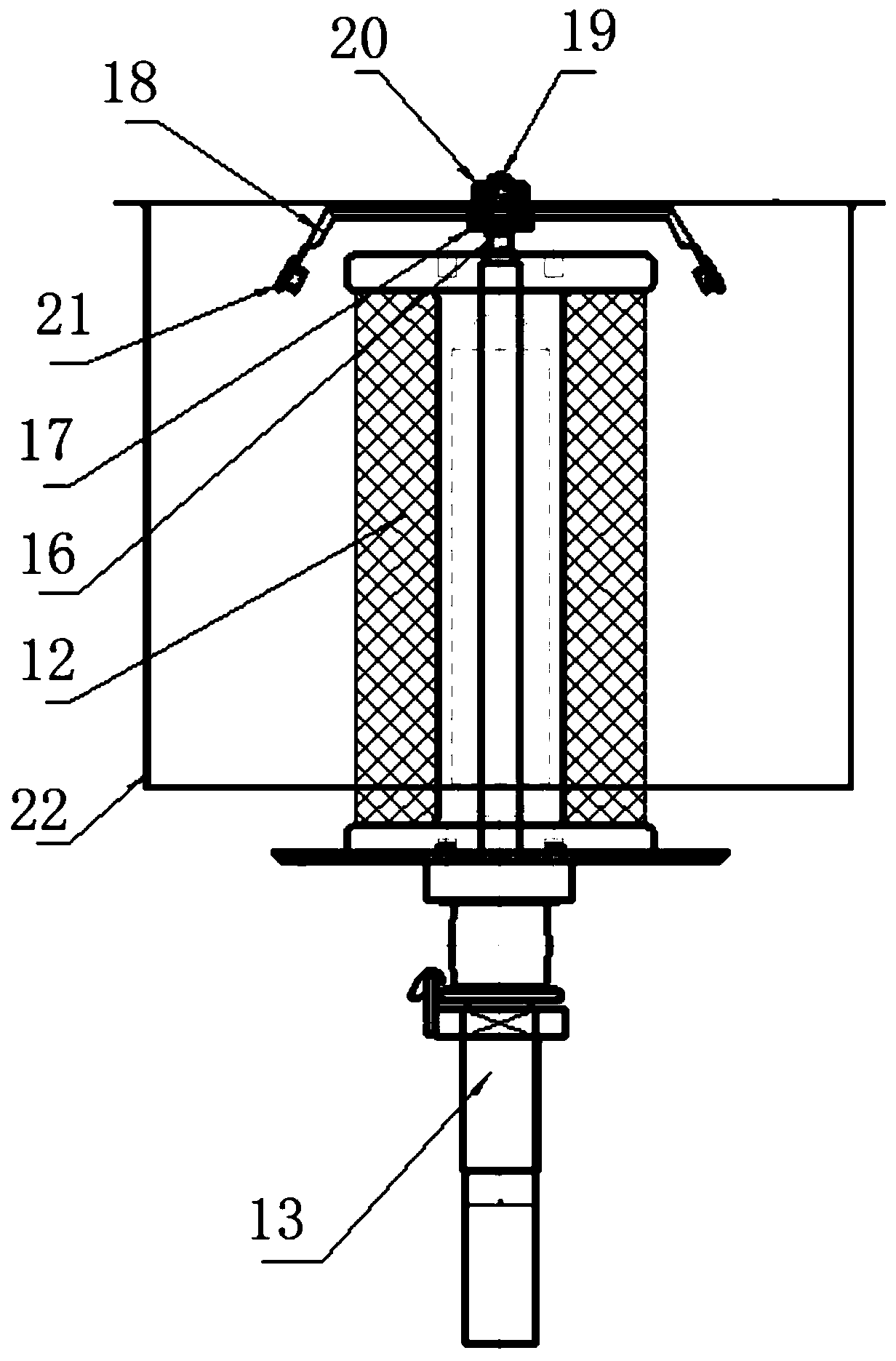

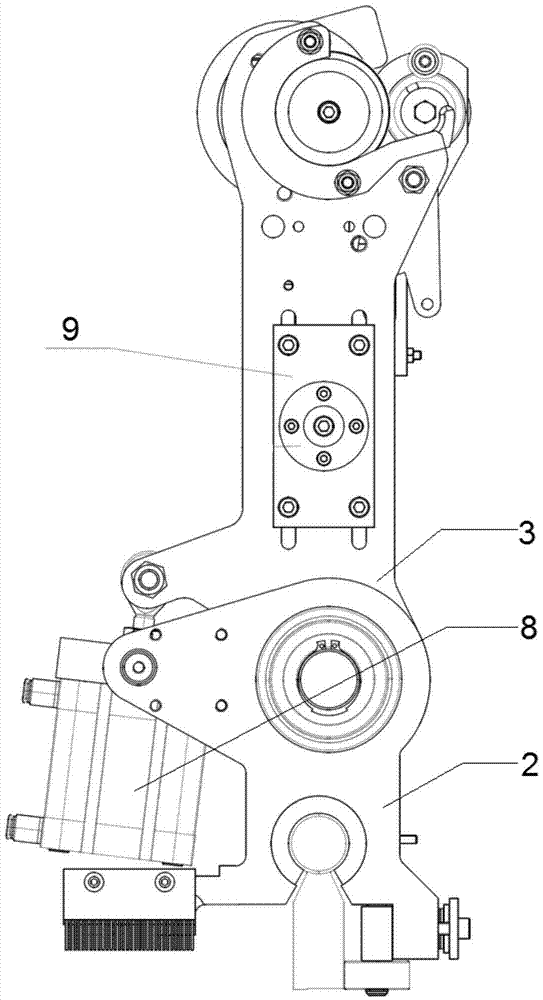

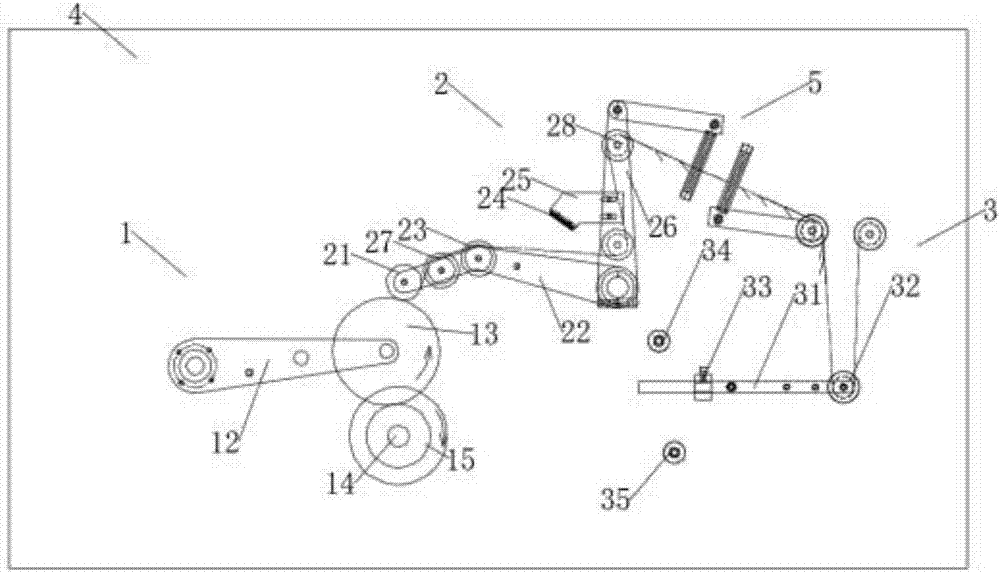

Deepwater diamond wire sawing machine

ActiveCN106141304AConvenient for underwater workGuaranteed lifeMetal sawing devicesMetal sawing accessoriesDiamond wire sawEngineering

The invention provides a deepwater diamond wire sawing machine which is majorly composed of a cutting drive mechanism, a feeding drive mechanism, a feeding speed regulating mechanism, a string bead wire tensioning mechanism and clamping mechanisms, and used for completing cutting repair of underwater structures. The feeding speed regulating mechanism is adopted for the deepwater diamond wire sawing machine, the feeding speed can be regulated along with the change of tension of a string bead wire in the operating process, and the service life of the string bead wire, the cutting efficiency of the machine and the reliability of cutting operation are effectively guaranteed. The feeding drive mechanism can promote transmission separation of a feeding motor and a lead screw, so that overload protection for the feeding drive mechanism is achieved; and meanwhile, under the condition that the machine does not have power, a handle can be rotated for feeding, and integrally automatic and manual drive feeding is achieved. A strong spring, a nut and a screw are adopted for tensioning of the string bead wire tensioning mechanism, and vibration of the string bead wire in the cutting process can be effectively reduced accordingly. The deepwater diamond wire sawing machine is provided with buoyancy materials and a deepwater valve box and suitable for deepwater environment operation.

Owner:HARBIN ENG UNIV

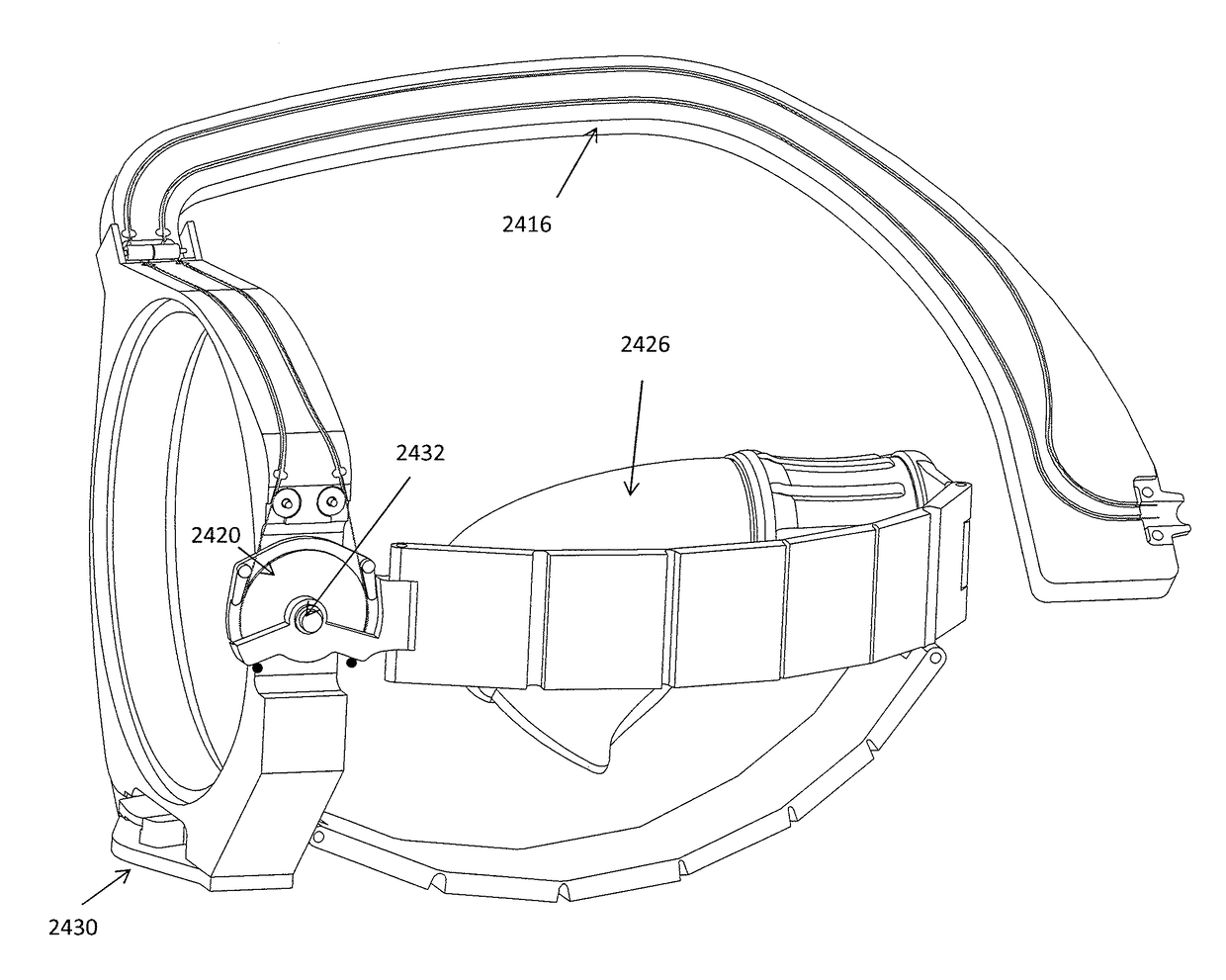

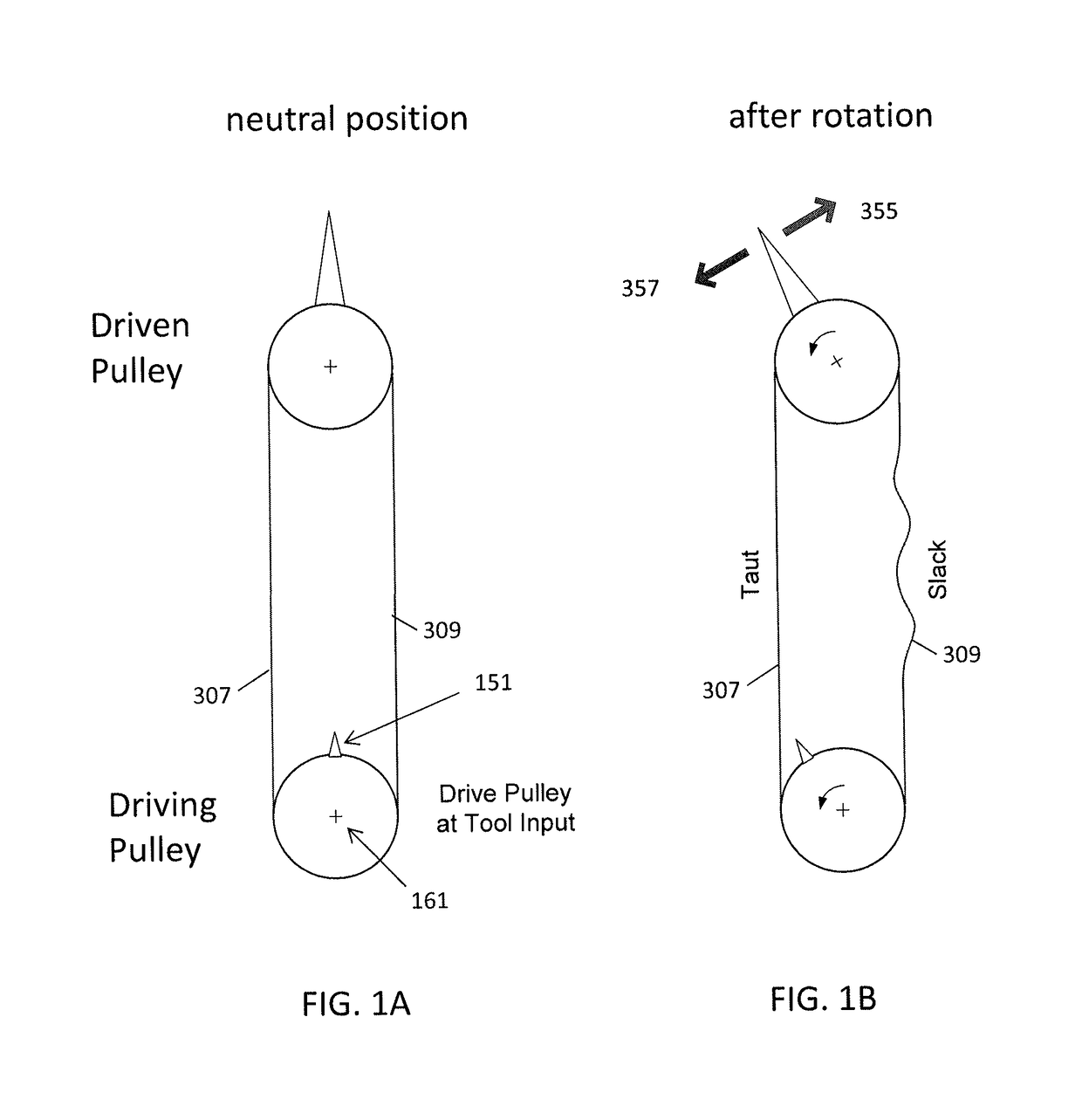

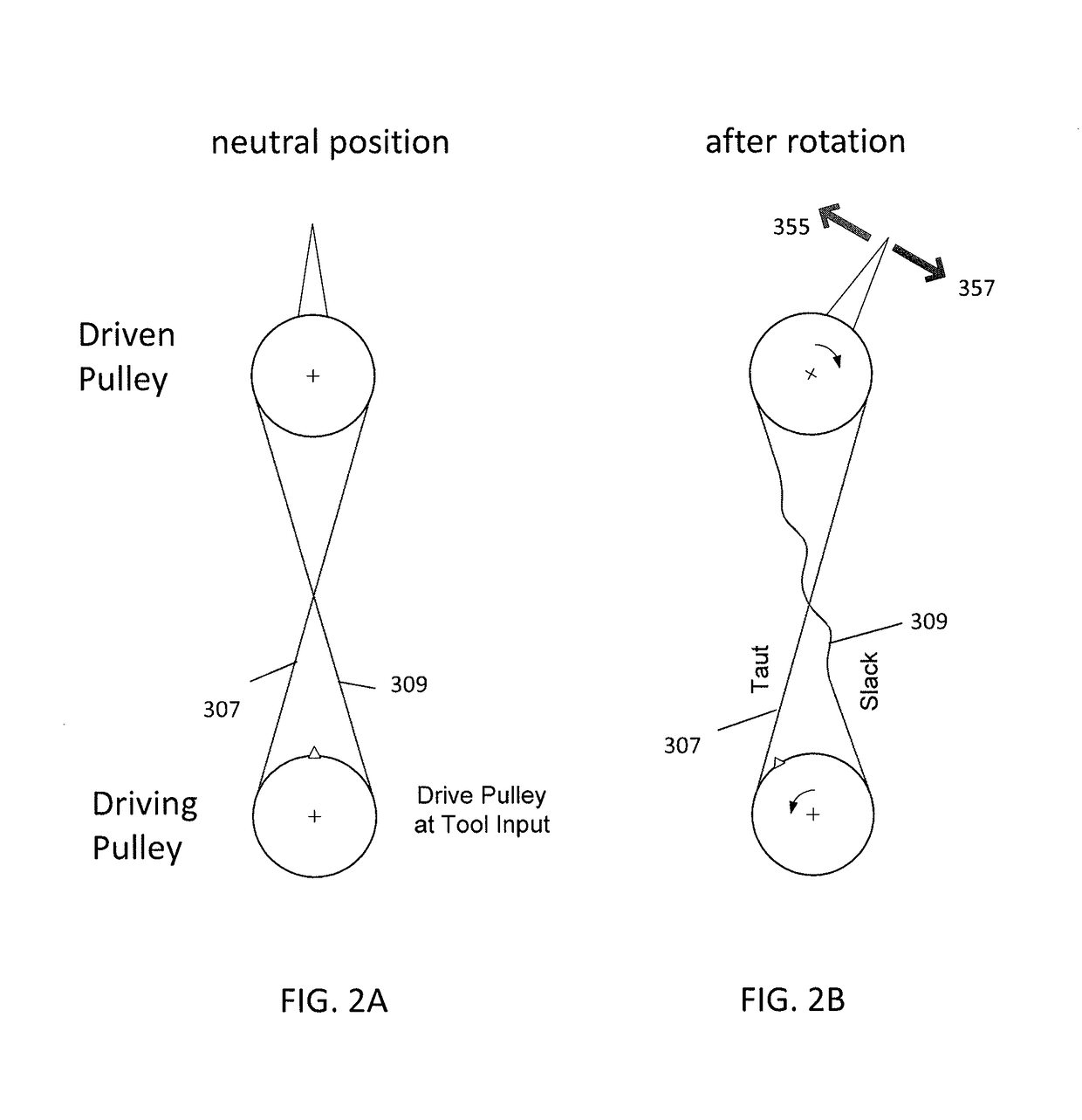

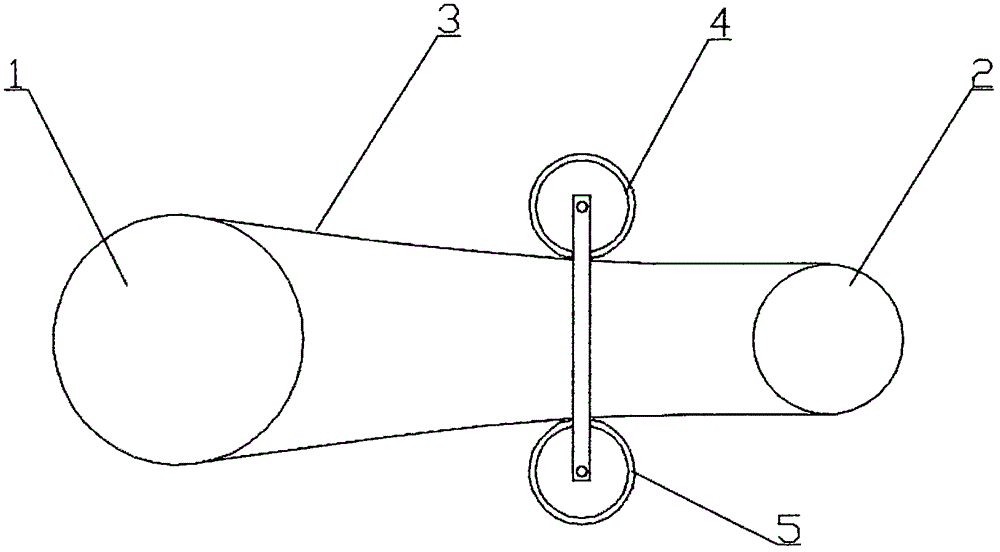

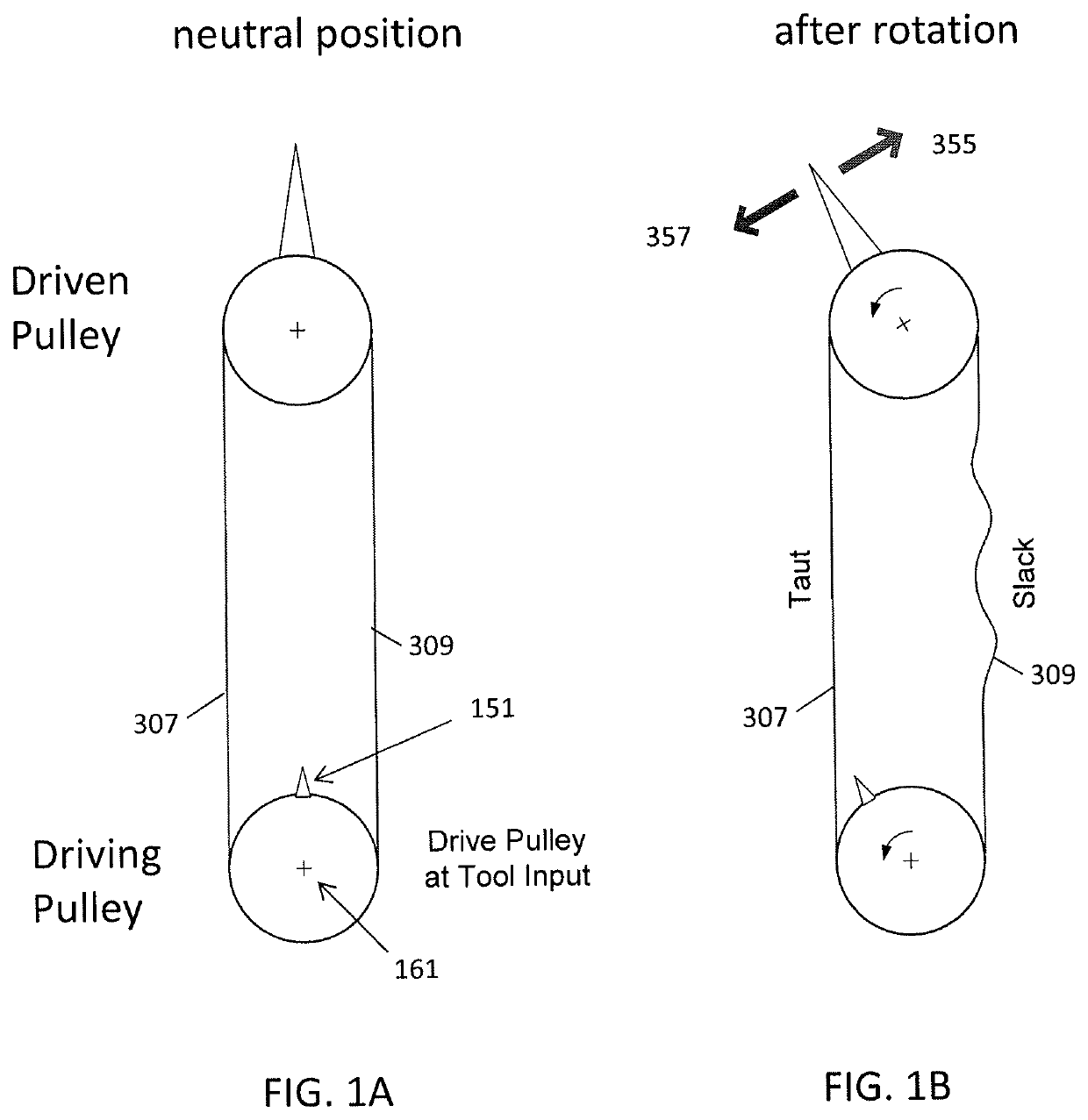

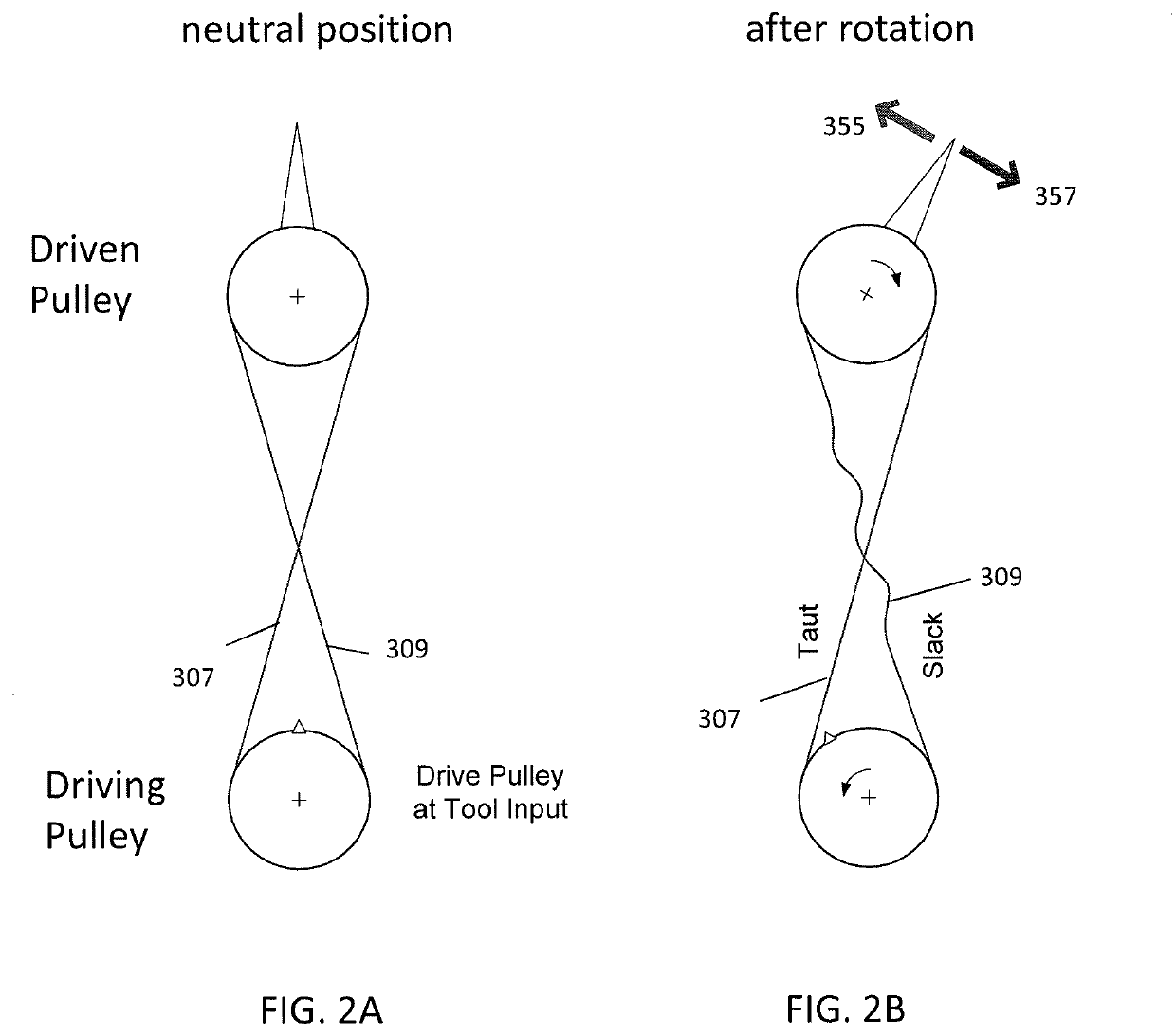

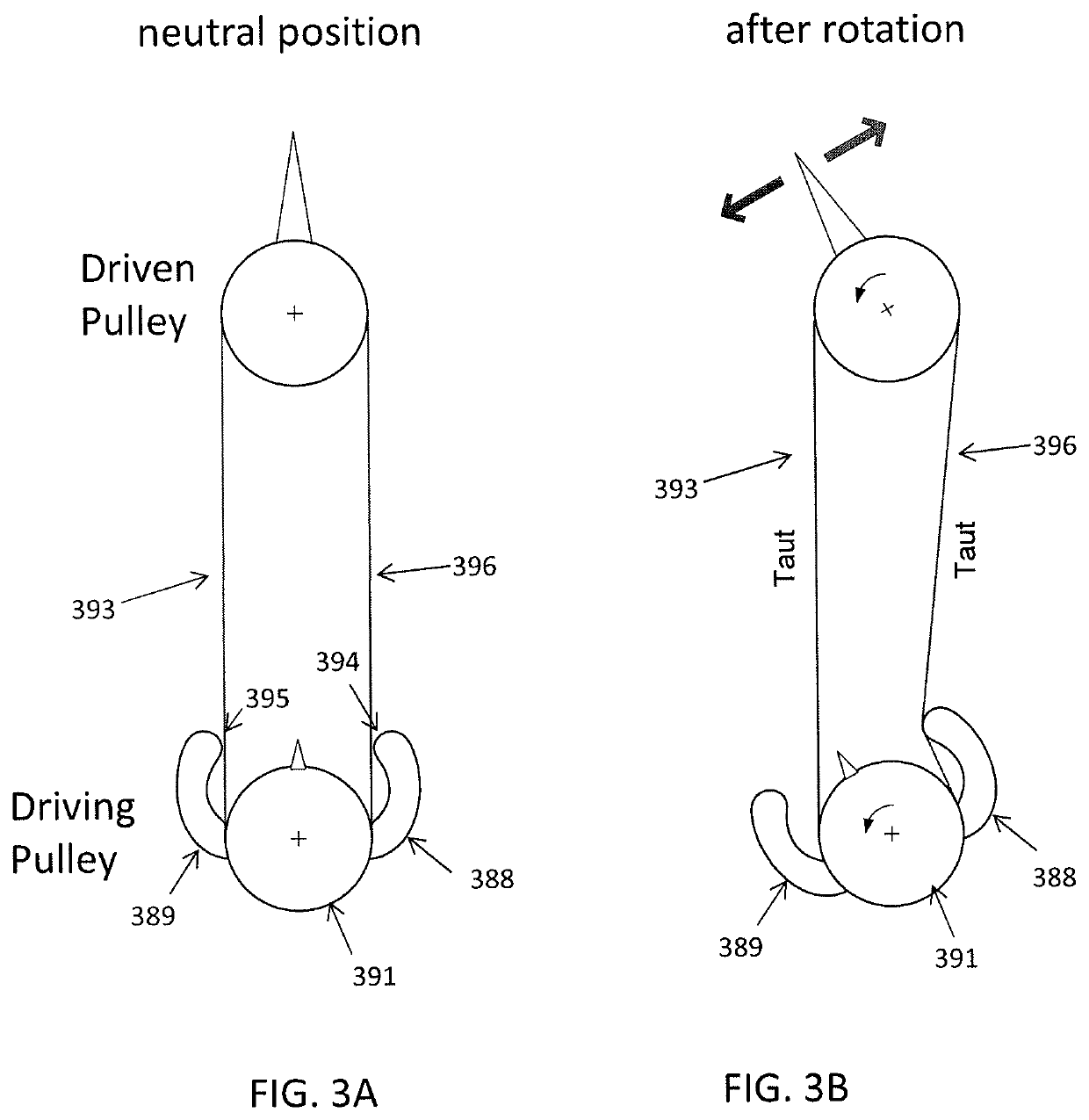

Tension management apparatus for cable-driven transmission

ActiveUS20180080533A1Reduce and eliminate slackIncrease wrap angleEndoscopesLaproscopesPath lengthEngineering

Slack-compensating pulleys, transmission systems including slack-compensating pulleys, and methods of operating these. In general, slack-compensating pulleys include a pulley body onto which a cable can wind, and one or more (e.g., two) slack take-up surfaces that rotate with the pulley body that are configured to remove slack form an outgoing length of cable by increasing the cable path length and wrap angle. In particular, described herein are minimal access tools having slack-compensating transmissions.

Owner:RGT UNIV OF MICHIGAN

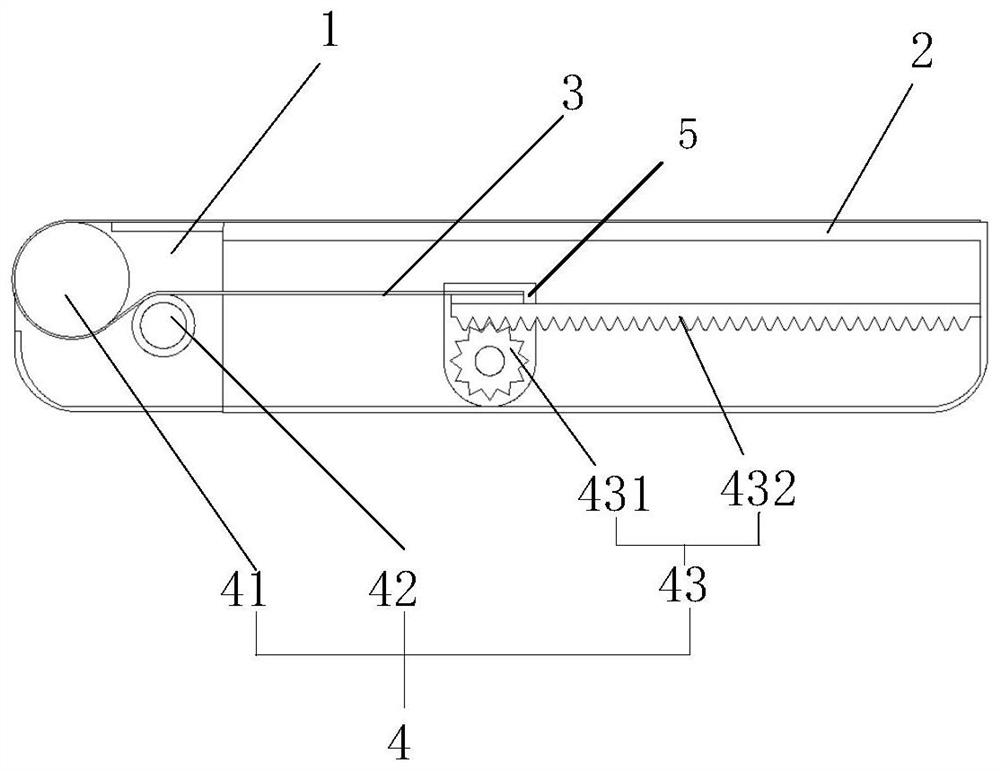

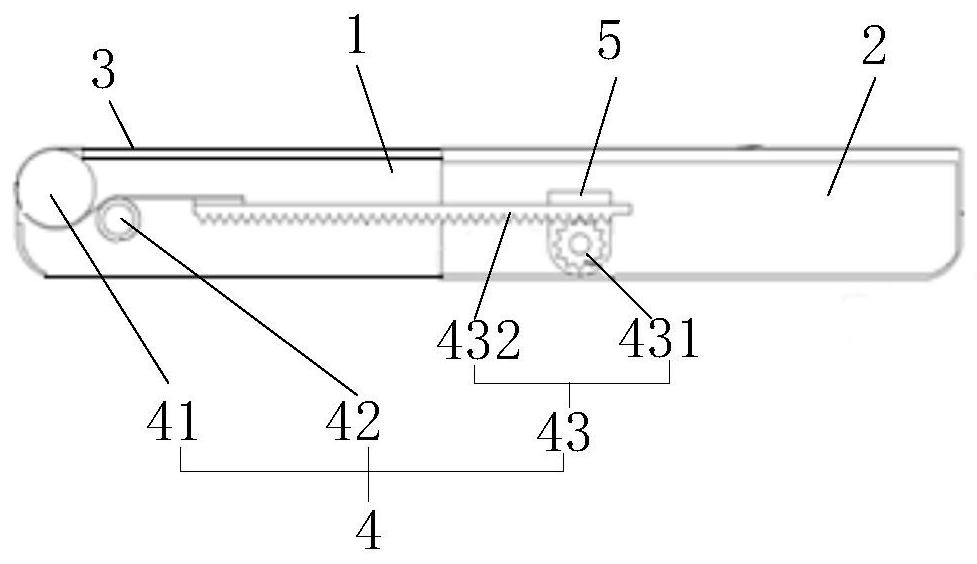

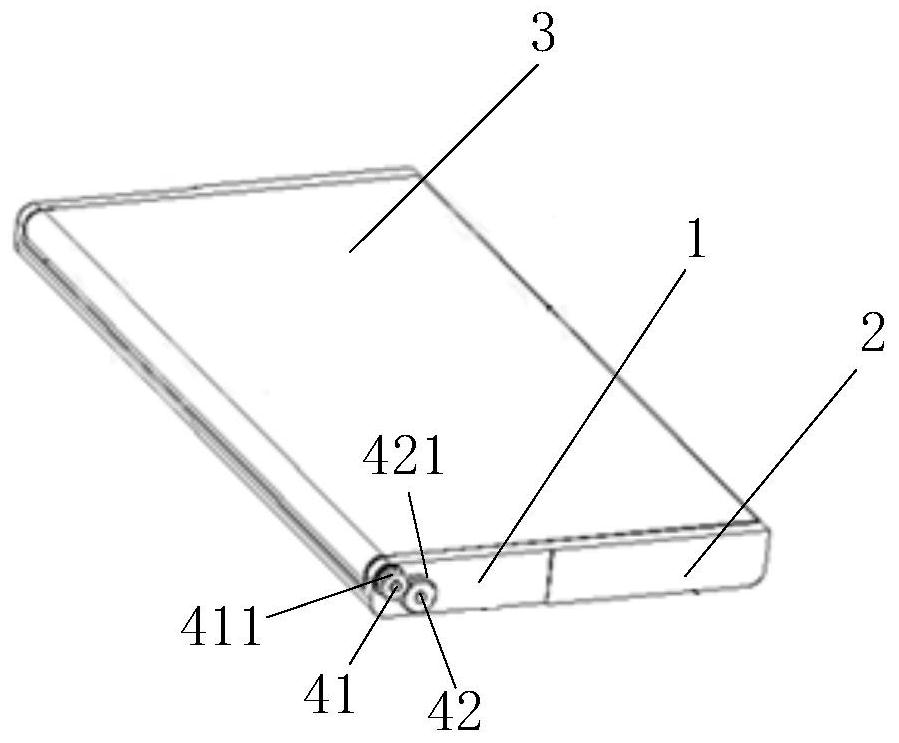

Display device and electronic equipment

PendingCN111768709AAvoid damageExtended useful lifeFriction gearingsIdentification meansDisplay deviceEngineering

The embodiment of the invention provides a display device and electronic equipment, and belongs to the technical field of display. The display device comprises a sliding machine shell, a fixed machineshell, a flexible screen and a conveying assembly. The sliding machine shell is in sliding connection with the fixed machine shell. The conveying assembly comprises a rolling shaft, a pre-tighteningshaft and a transmission part. The rolling shaft and the pre-tightening shaft are both hinged to the sliding machine shell. The transmission part is fixed in the fixed machine shell. A first end of the flexible screen is fixed to the fixed machine shell, the flexible screen covers the outer surface of the top of the fixed machine shell, and a second end of the flexible screen winds the rolling shaft and is fixed to the transmission part. The pre-tightening shaft is located between the rolling shaft and the transmission part, and the outer surface of the top of the pre-tightening shaft abuts against the flexible screen. Thus, the outer surface of the pre-tightening shaft abuts against the flexible screen all the time, the contact area between the flexible screen and the rolling shaft is increased, meanwhile, the flexible screen is always subjected to supporting force of the pre-tightening shaft, and the flexible screen can be always matched with the outer surface of the rolling shaft under the effect of the supporting force of the pre-tightening shaft.

Owner:BOE TECH GRP CO LTD

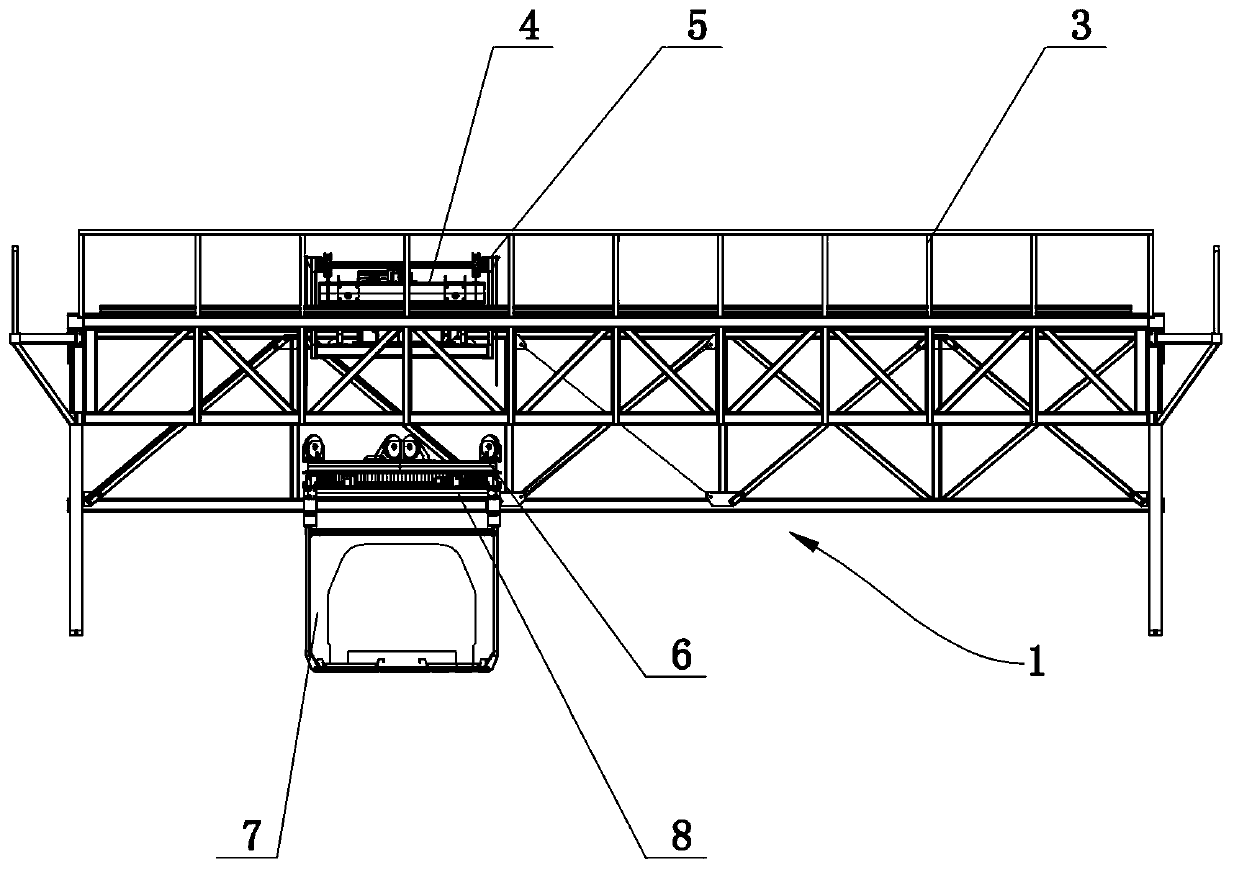

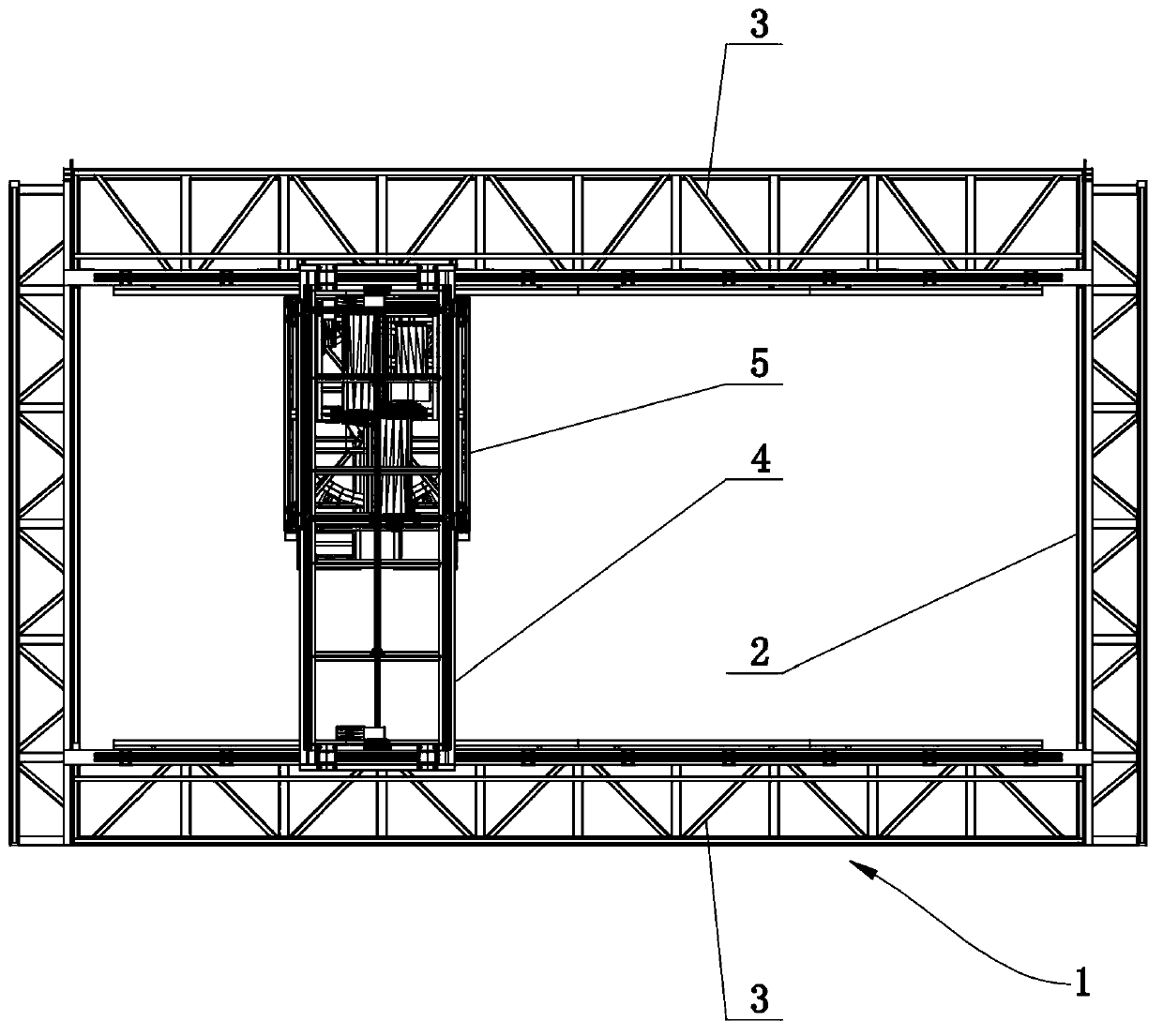

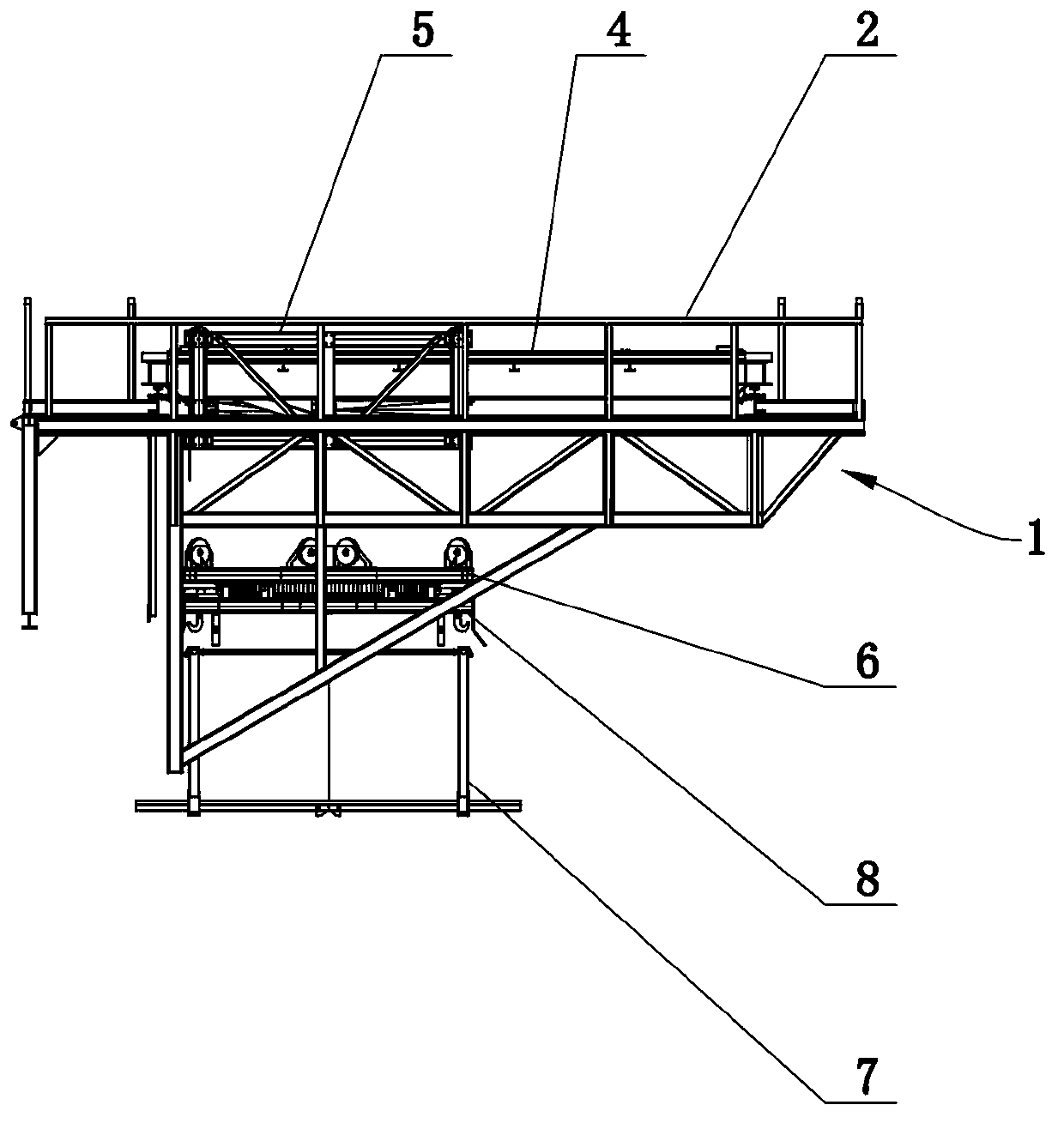

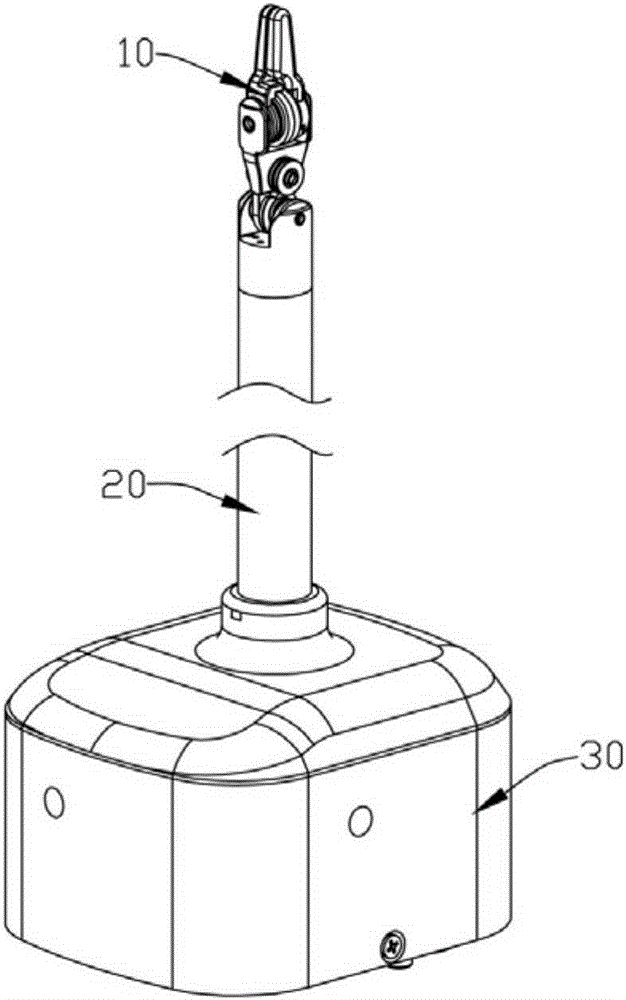

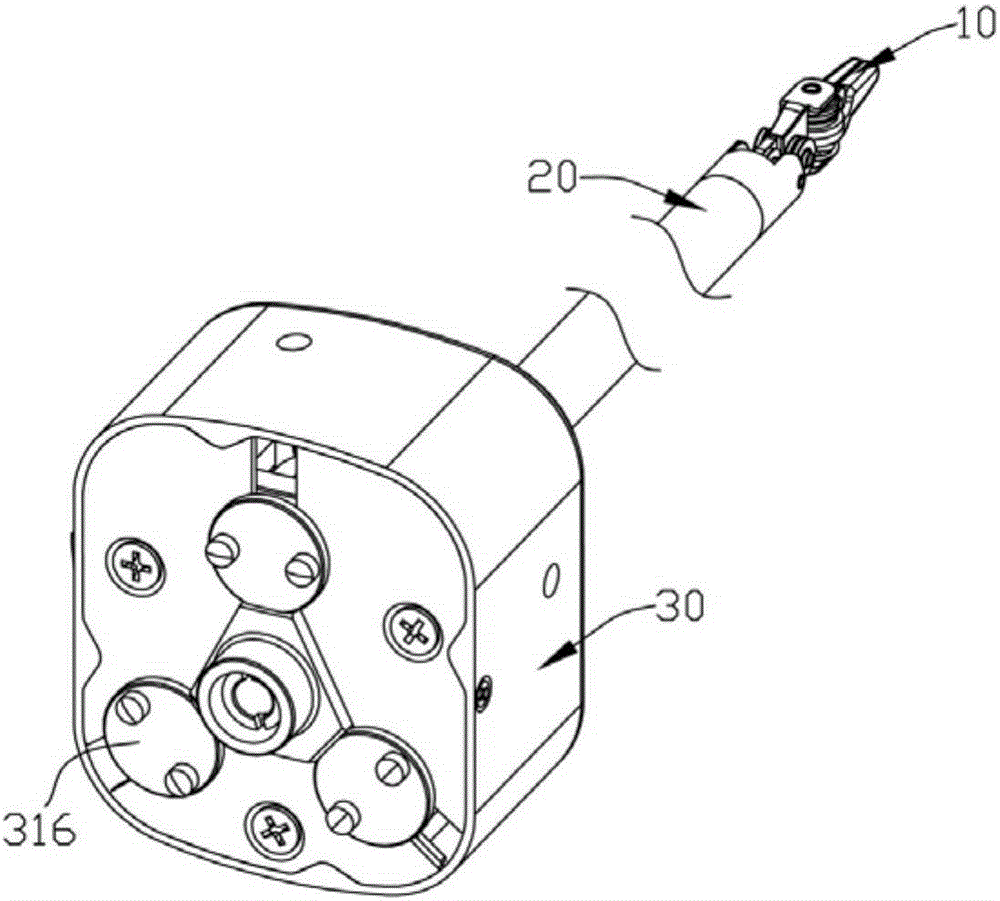

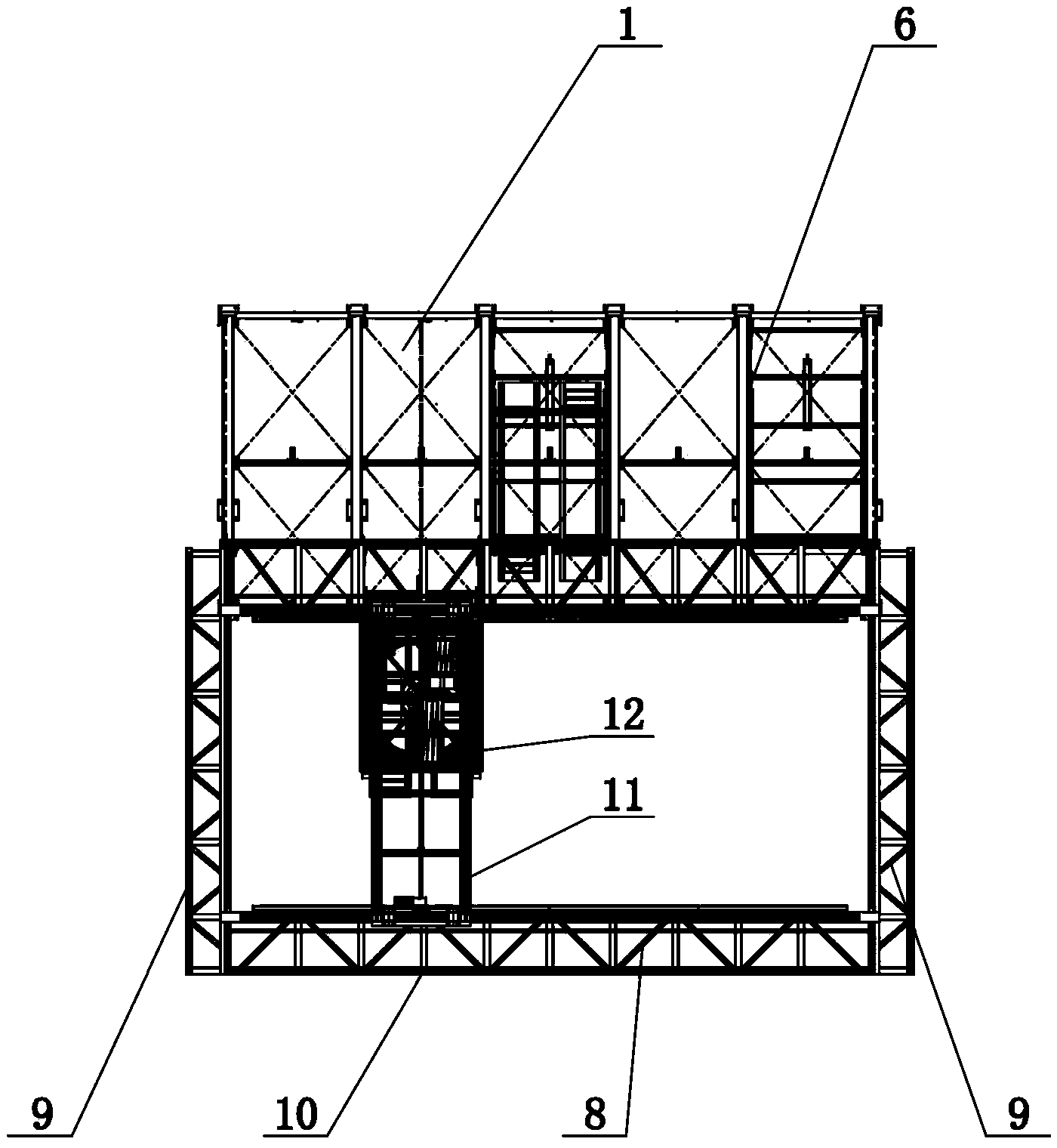

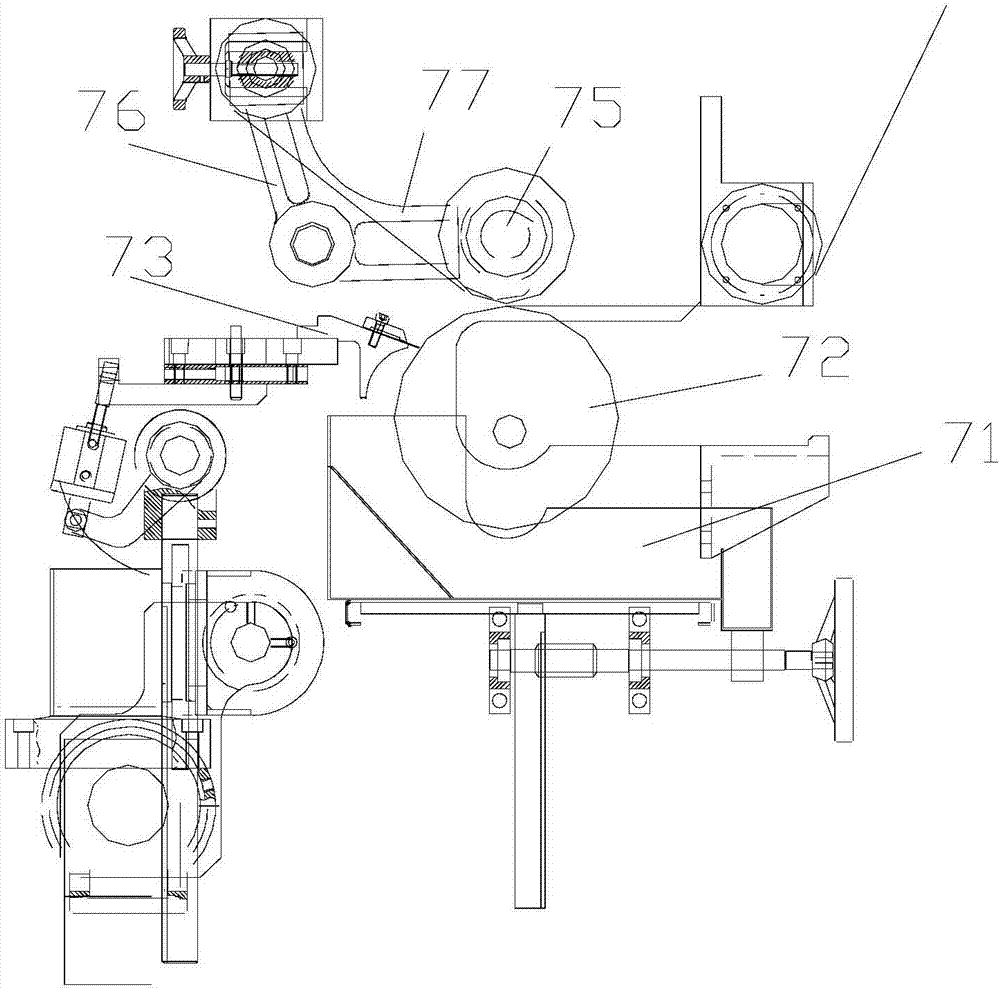

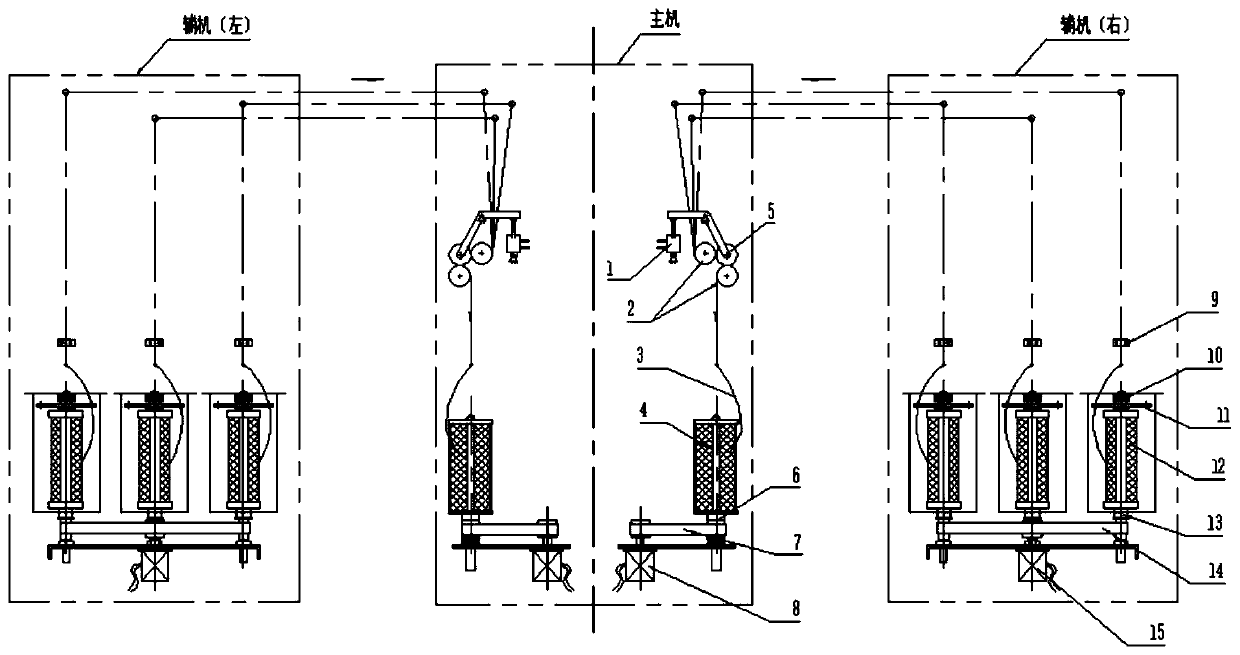

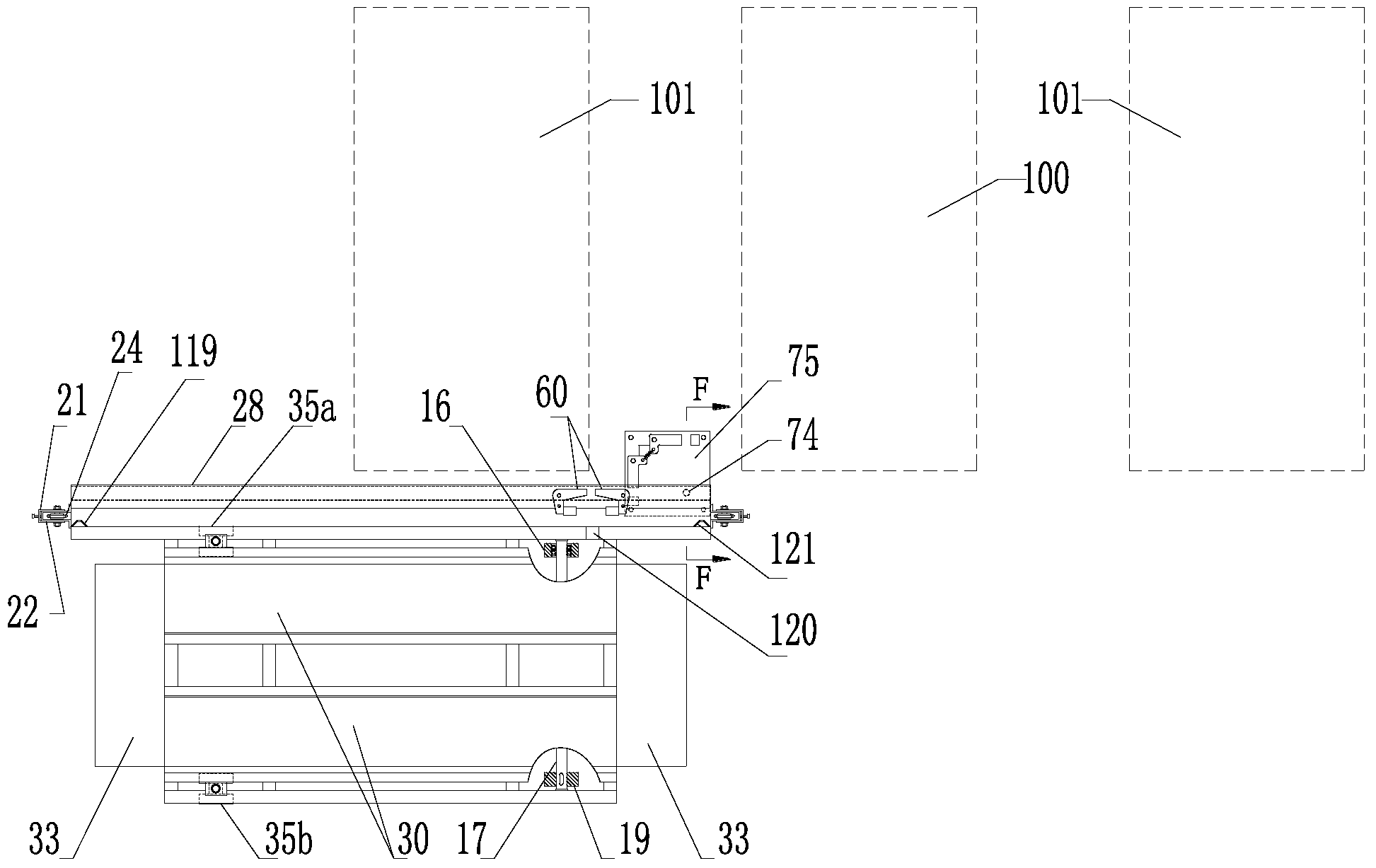

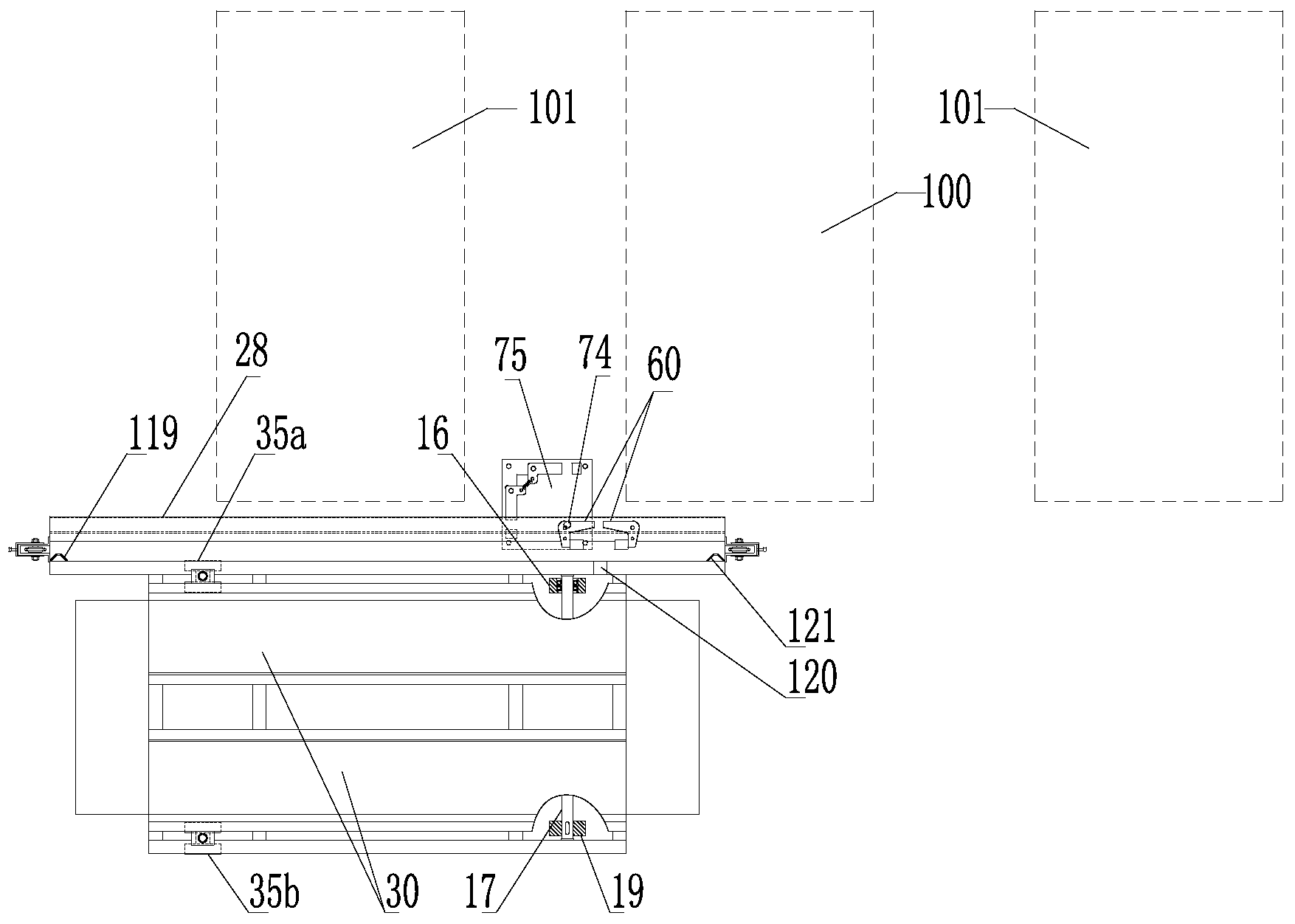

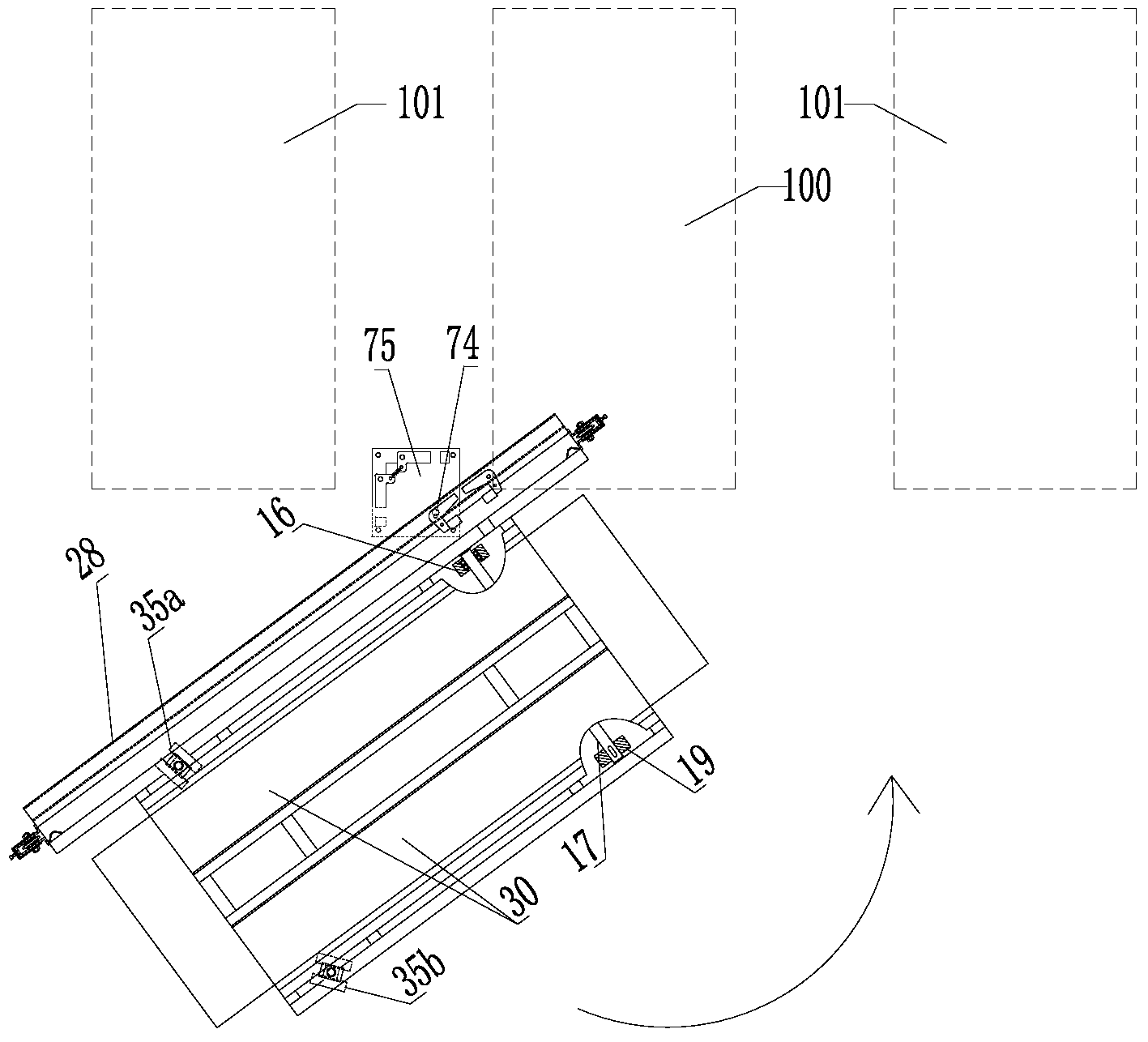

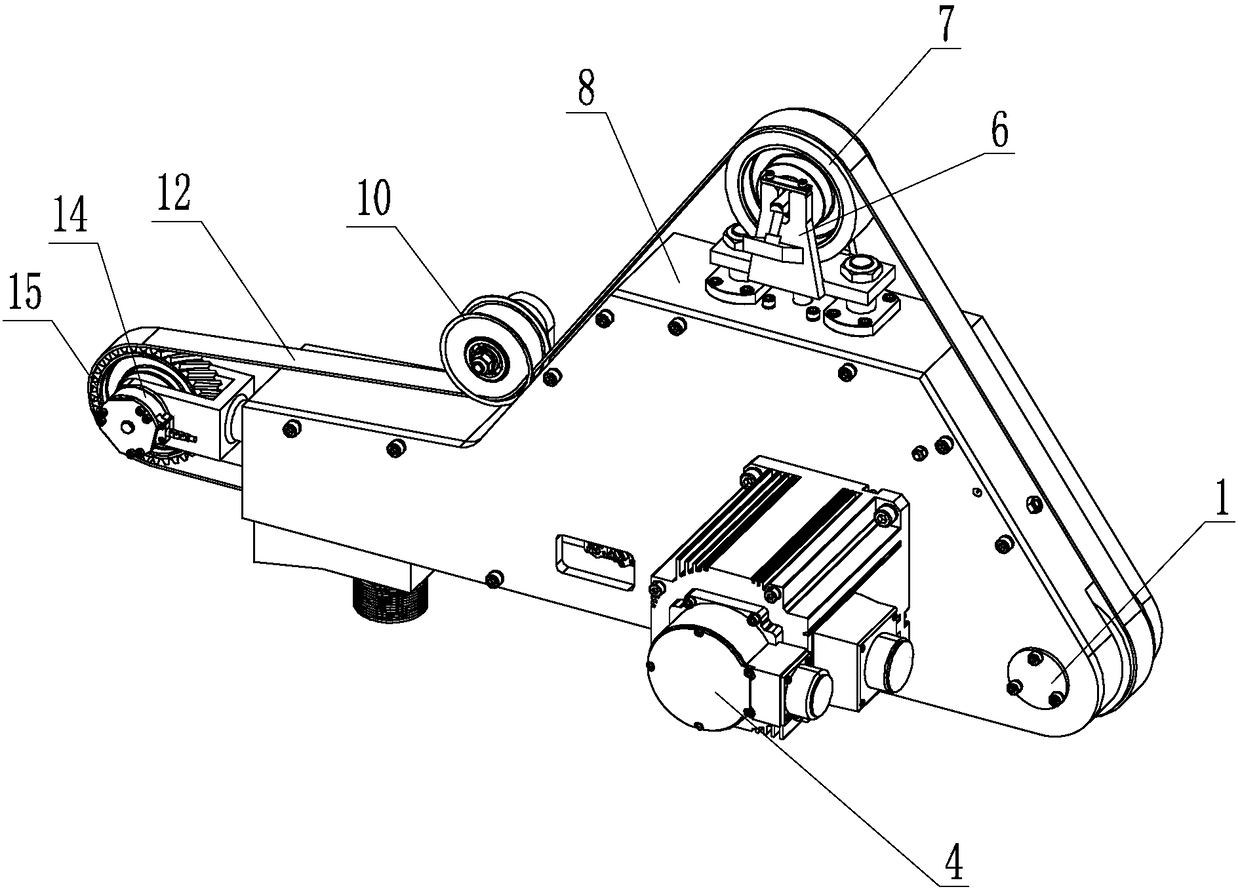

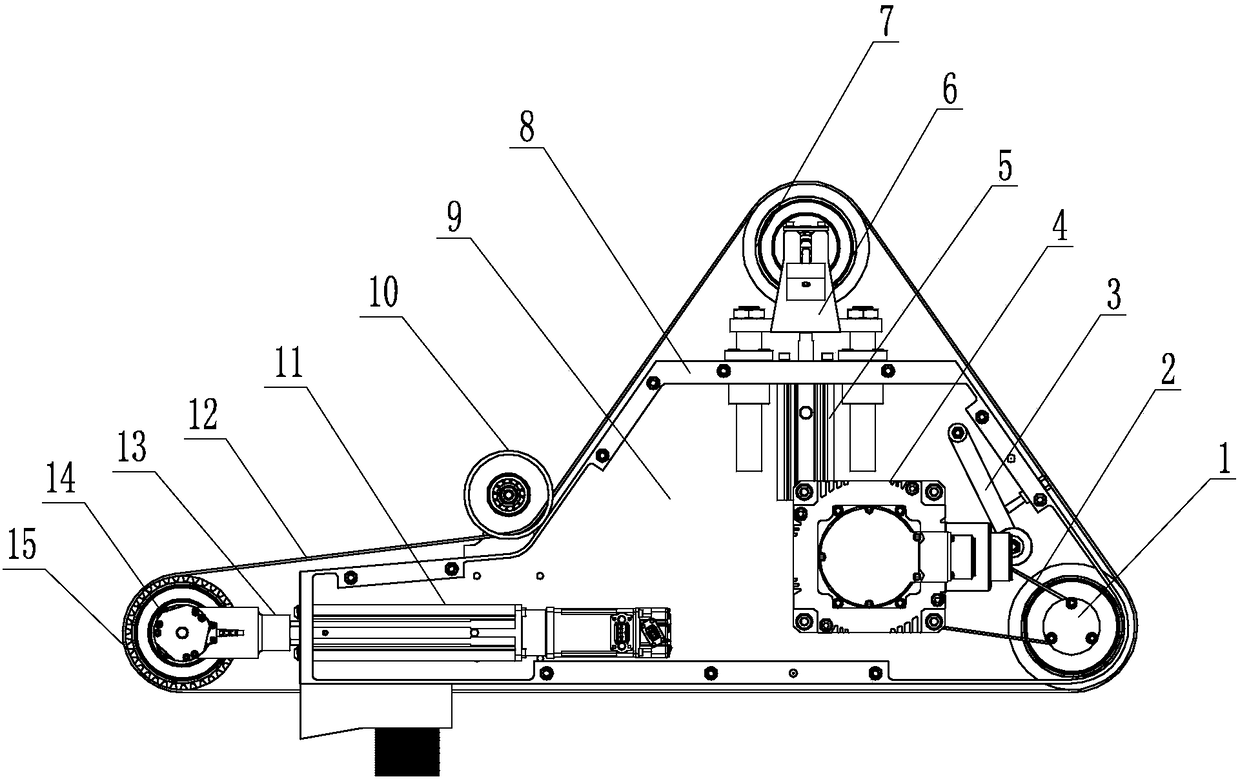

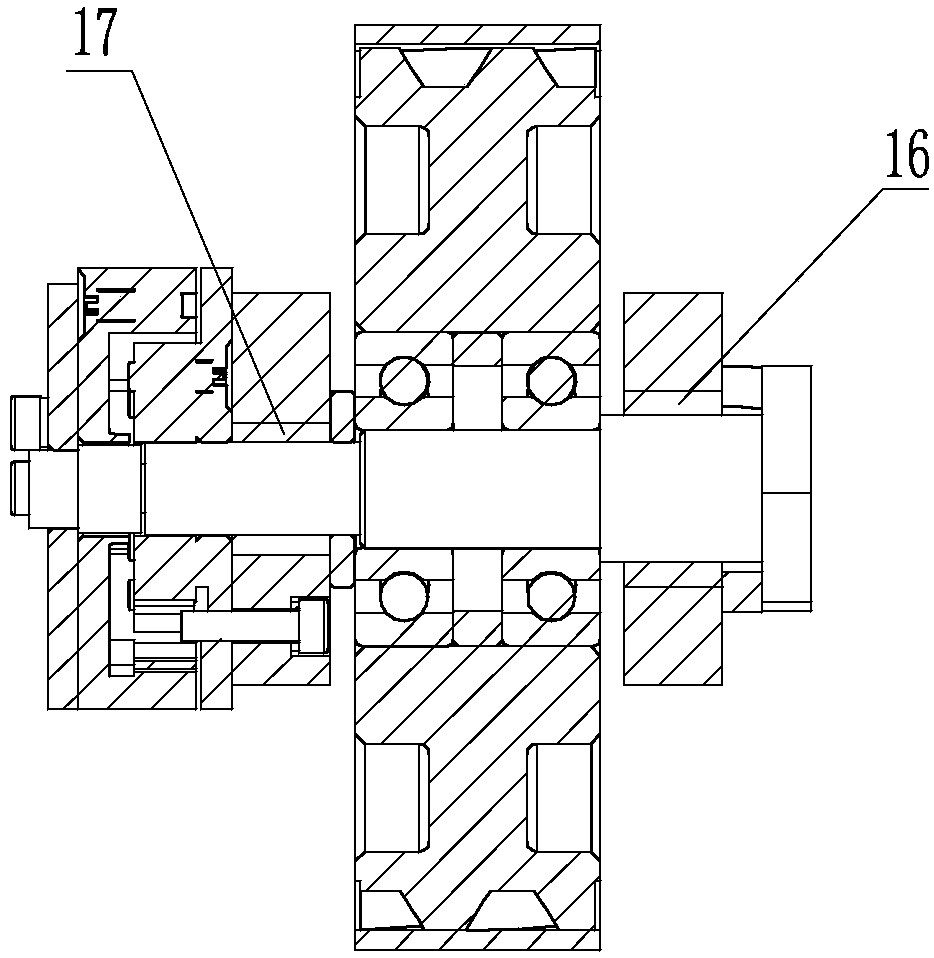

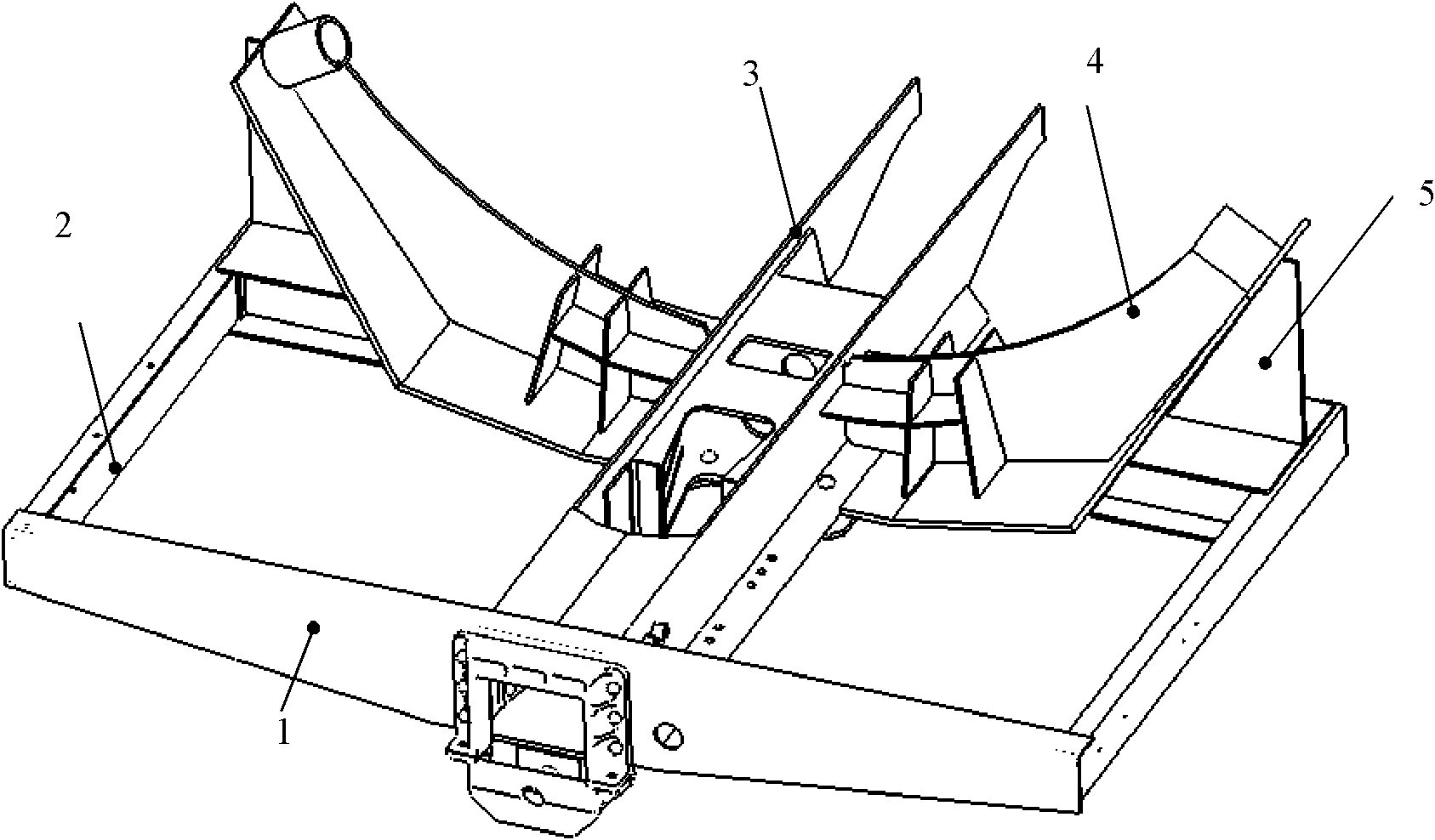

Four-freedom-degree vehicle carrier for three-dimensional parking equipment

The invention discloses a four-freedom-degree vehicle carrier for three-dimensional parking equipment and belongs to the technical filed of mechanical parking devices. The four-freedom-degree vehicle carrier comprises a cantilever support above a top-layer parking space, the cantilever support comprises two oppositely-arranged cantilever longitudinal beams and two oppositely-arranged cantilever cross beams, and the cantilever longitudinal beams and the cantilever cross beams are arranged in a rectangular mode. A transversely-moving mechanism driven by a first power plant is arranged on the cantilever support in a transversely-moving mode, and a longitudinally-moving mechanism driven by a second power plant is arranged on the transversely-moving mechanism in a longitudinally-moving mode. The longitudinally-moving mechanism is provided with a lifting transmission mechanism which is driven by a third power plant and capable of lifting in the vertical direction, and the lifting transmission mechanism is connected with a grabbing rotary mechanism which is driven by a fourth power plant and capable of rotating around a vertical axial line and used for grabbing lifting vehicle platforms. The four-freedom-degree vehicle carrier does not occupy ground space and enables arrangement of garage entrances and exits to be flexible; in the process of parking and taking vehicles, transverse moving, longitudinal moving, lifting and rotating of the vehicles and the lifting vehicle platforms can be finished at the same time, and working efficiency of parking and taking the vehicles is improved.

Owner:DAYANG PARKING CO LTD

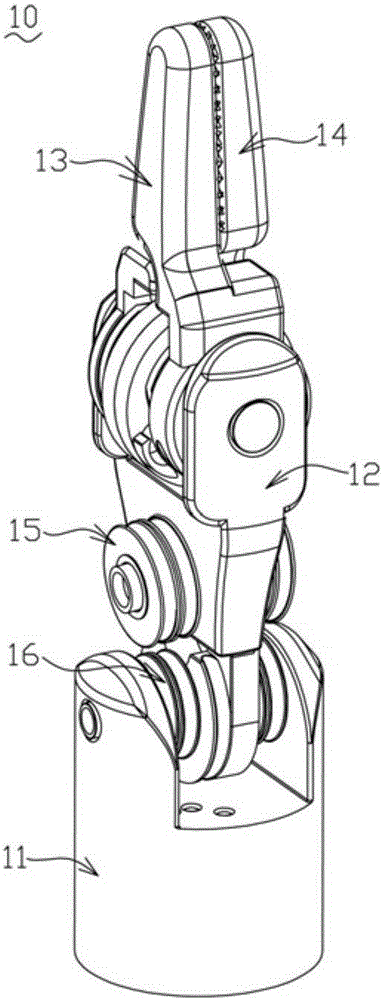

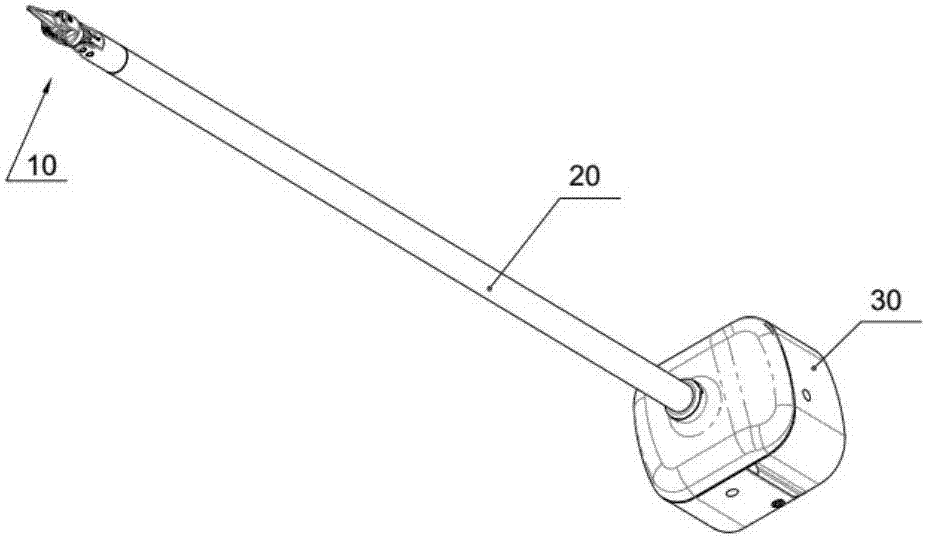

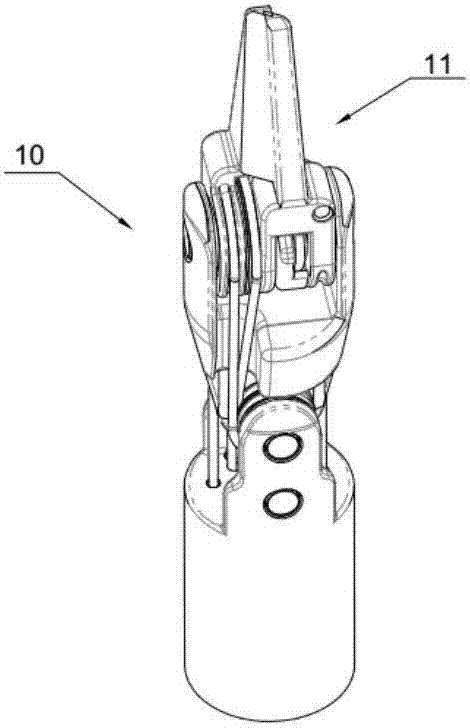

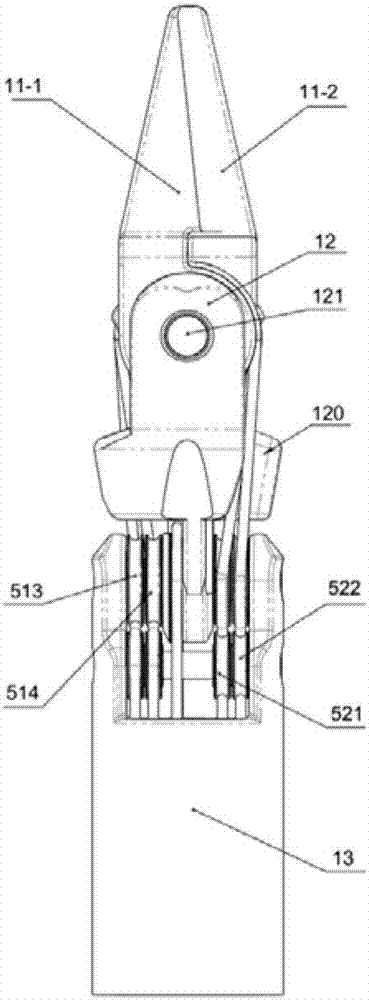

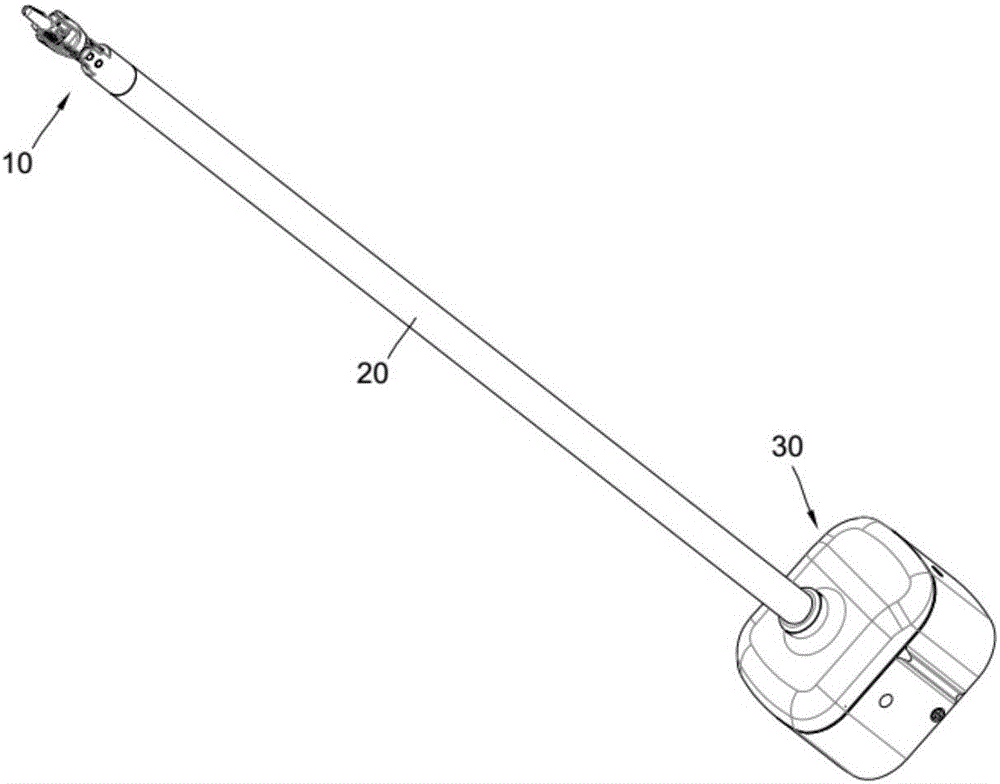

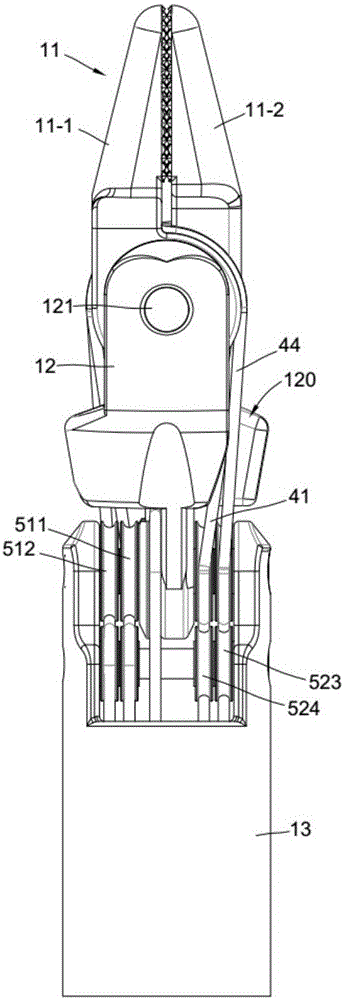

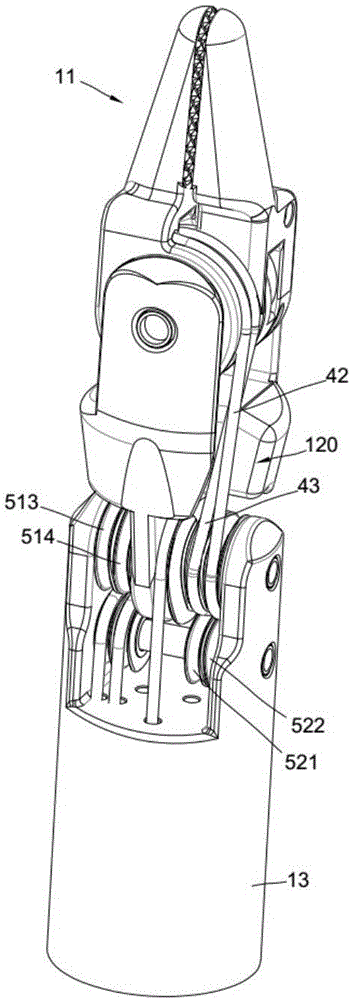

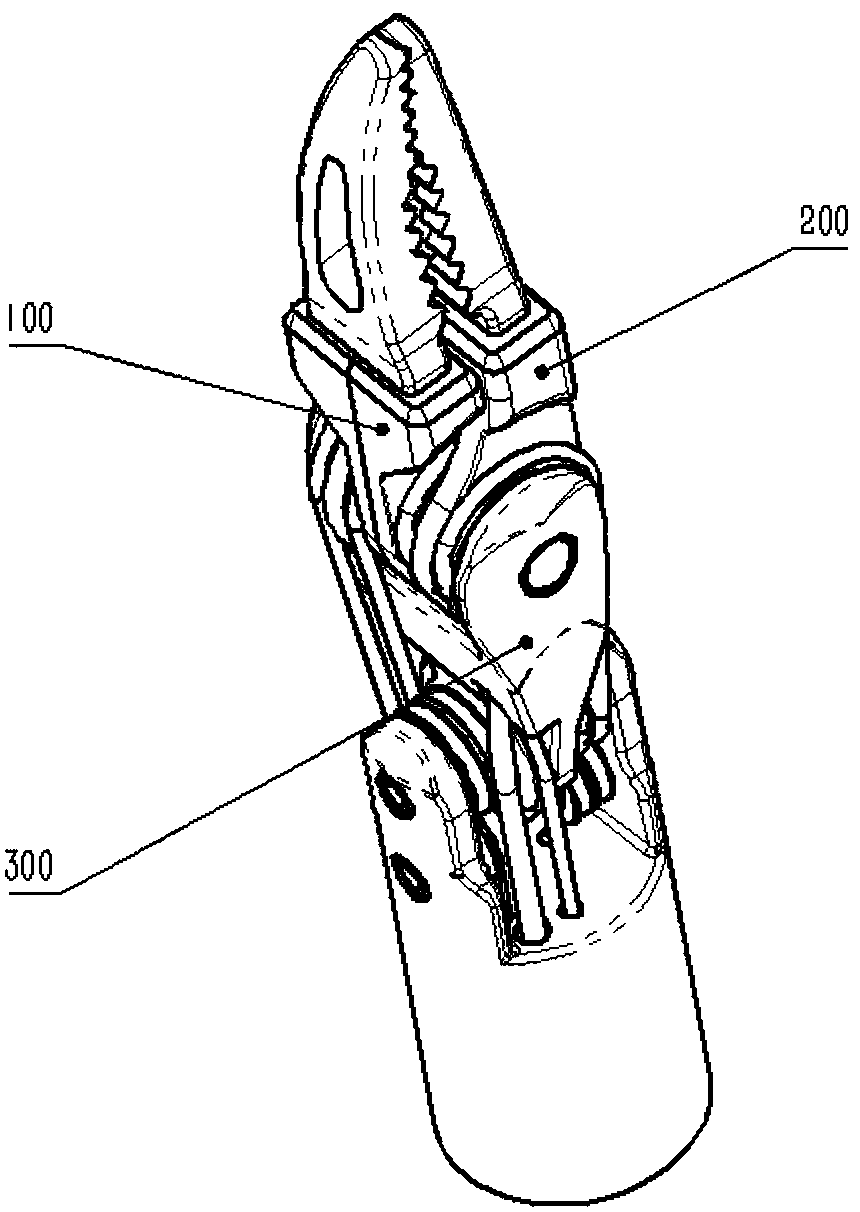

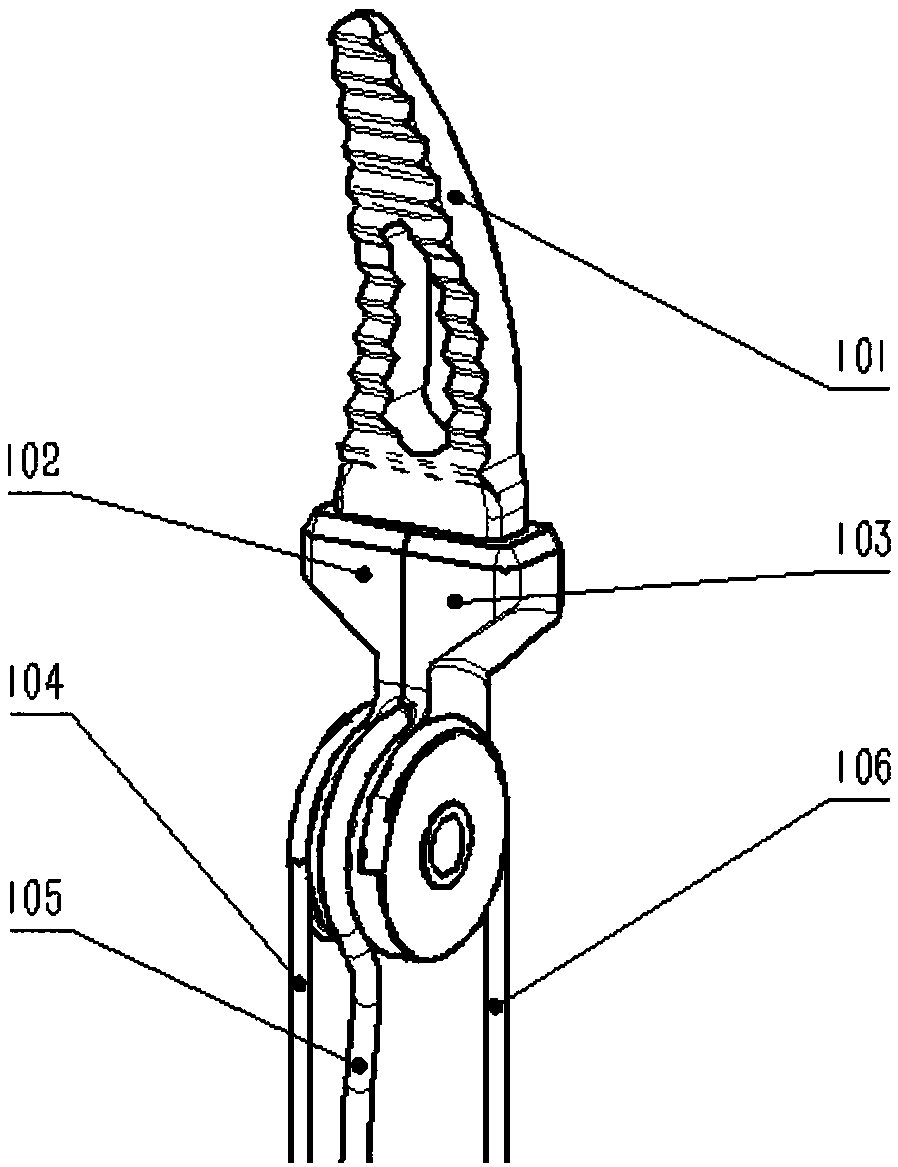

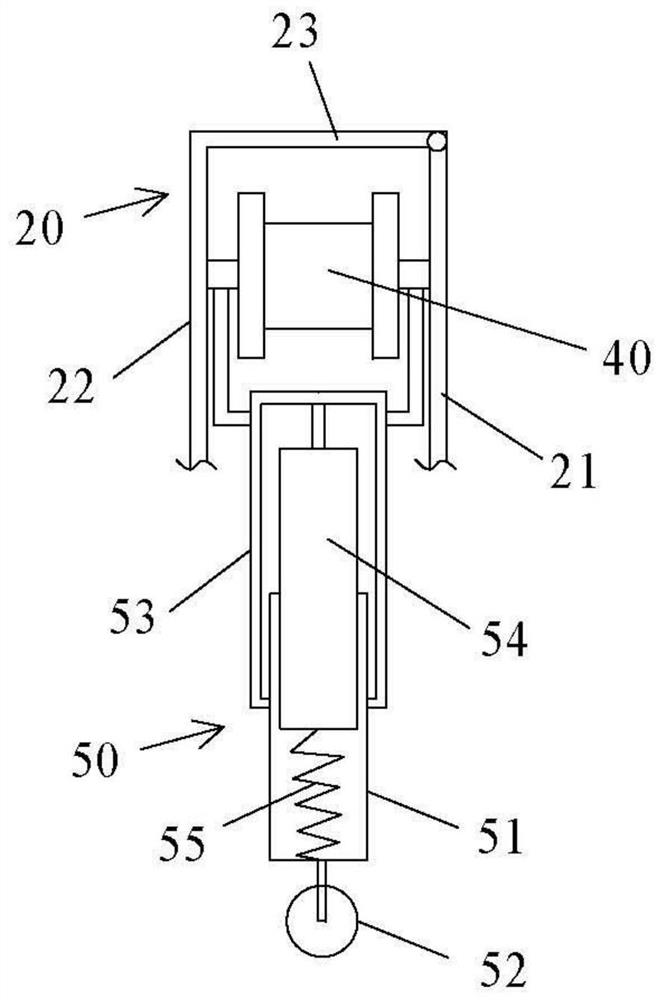

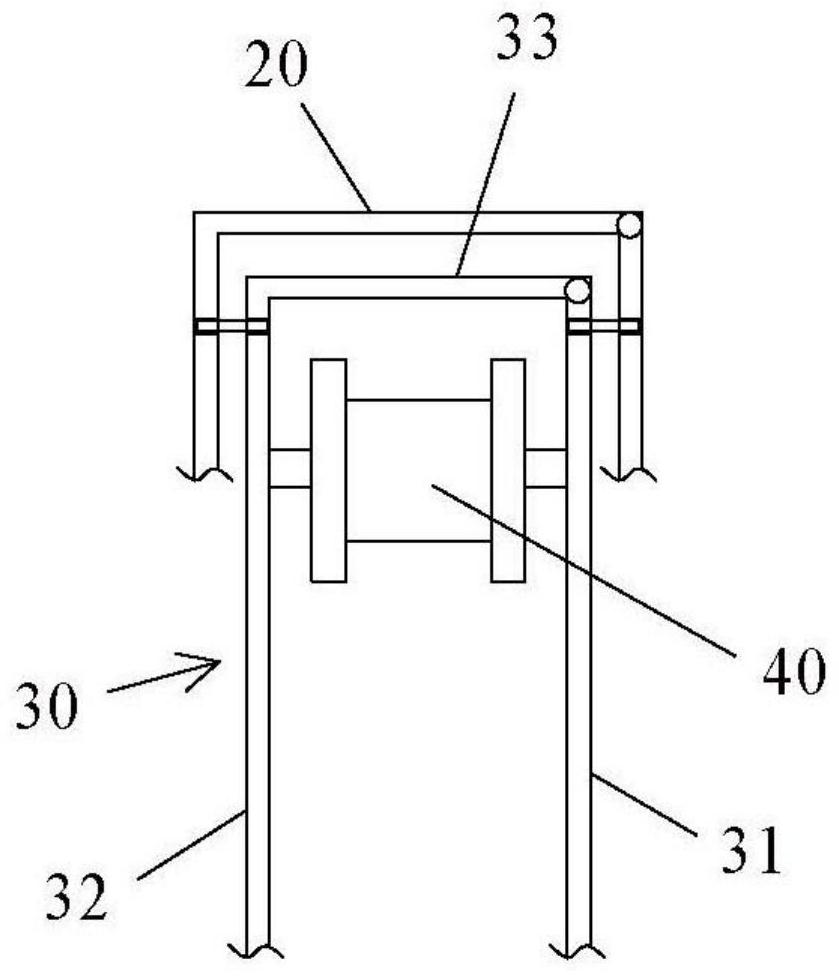

End effector mechanism of micro surgical instrument

ActiveCN105212987AIncrease wrap angleIncrease the equivalent allowable strengthSurgical forcepsFiberWrist

The invention discloses an end effector mechanism for a micro surgical instrument. The end effector mechanism comprises an interface board unit connected with a driving device, a carbon fiber tube connected with the interface board unit and adopting a hollow structure, an instrument tong head unit mounted at the far-end part of the carbon fiber tube and a plurality of wire cables used for controlling the instrument tong head unit to act according to preset commands, wherein the instrument tong head unit comprises a support part, a left side tong head, a right side tong head, a guiding wheel set and a wrist part guiding wheel set, a pair of second connecting arms are symmetrically arranged at the top of the support part, the left side tong head and the right side tong head are hinged to the second connecting arms in a crossed manner, the guiding wheel set and the wrist part guiding wheel set are symmetrically mounted in the middle and at the lower part of the support part; and an eccentric balance wheel groove is formed in the side wall of the lower part of the support part. The end effector mechanism can effectively increase both the accommodating space and the diameters of the guiding wheels, so that the winding wrap angles of the wire cables on the guiding wheels are correspondingly increased, accordingly, the equivalent allowable strength of the wire cables is improved, and the service lives of both the wire cables and the micro instrument are prolonged.

Owner:HARBIN SIZHERUI INTELLIGENT MEDICAL EQUIP CO LTD

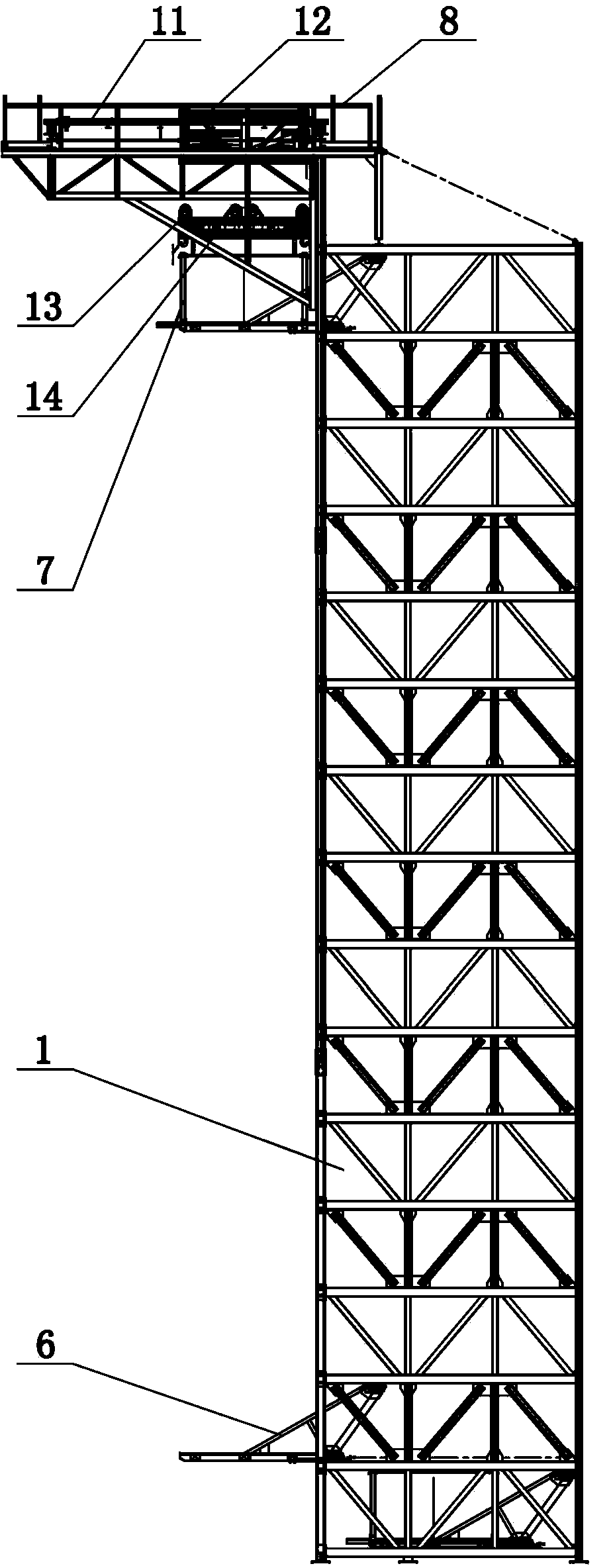

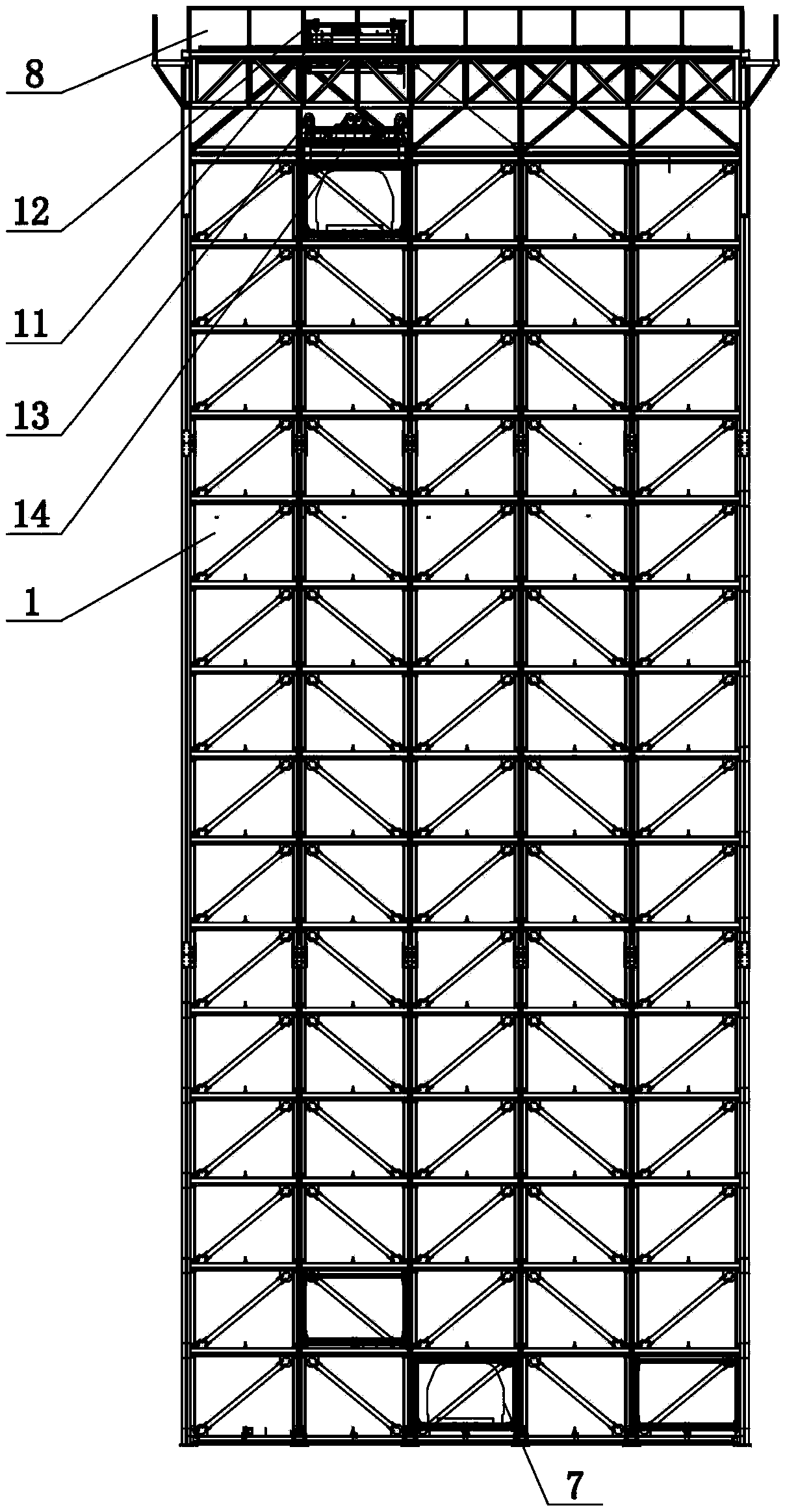

Lifting longitudinal-moving-type stereoscopic parking device

The invention discloses a lifting longitudinal-moving-type stereoscopic parking device, and belongs to the technical field of mechanical parking devices. The lifting longitudinal-moving-type stereoscopic parking device comprises a plurality of rectangular parking places arranged in an array mode. A longitudinal-moving storing and taking mechanism driven by a first power device is installed inside each parking place in a longitudinal-moving mode. A lifting truck platform is placed in each longitudinal-moving storing and taking mechanism. A cantilever support is installed above the top-layer packing place. A transverse-moving mechanism driven by a second power device is installed on the cantilever support in a transverse-moving mode. A longitudinal-moving mechanism driven by a third power device is installed on the transverse-moving mechanism in a longitudinal-moving mode. A lifting transmission mechanism driven by a fourth power device is installed on the longitudinal-moving mechanism. A grabbing swinging mechanism driven by a fifth power device is connected with the lifting transmission mechanism. According to the lifting longitudinal-moving-type stereoscopic parking device, the power devices are independent, the working efficiency of storing and taking trucks is improved, full stations are achieved, namely vacated parking places do not exist, the storage number of the trucks is increased, and the land utilization rate is improved.

Owner:DAYANG PARKING CO LTD

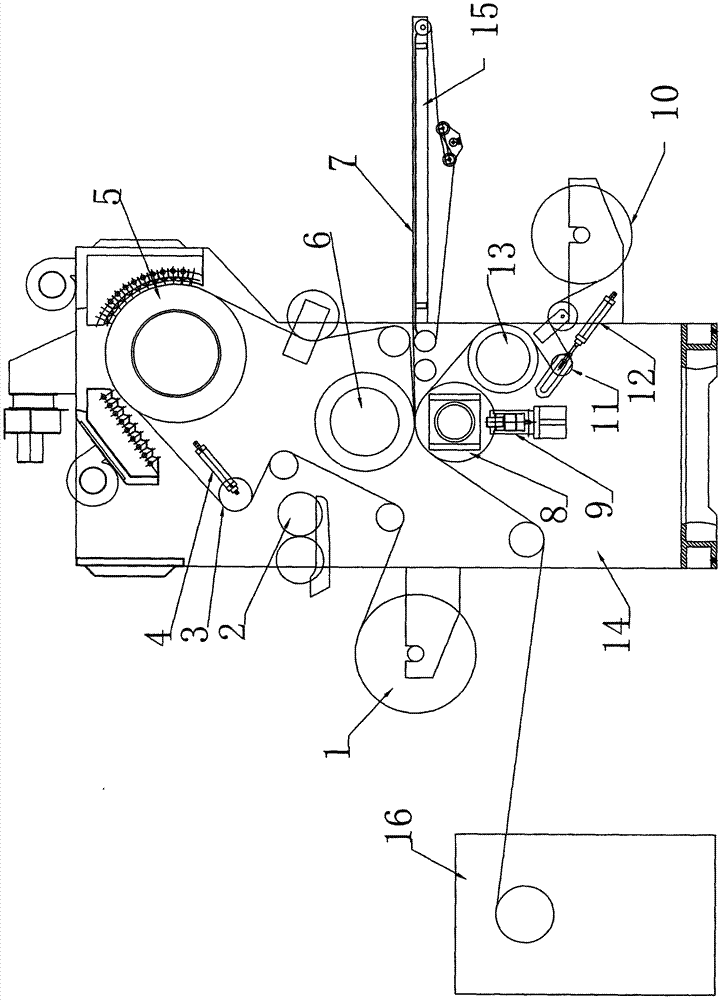

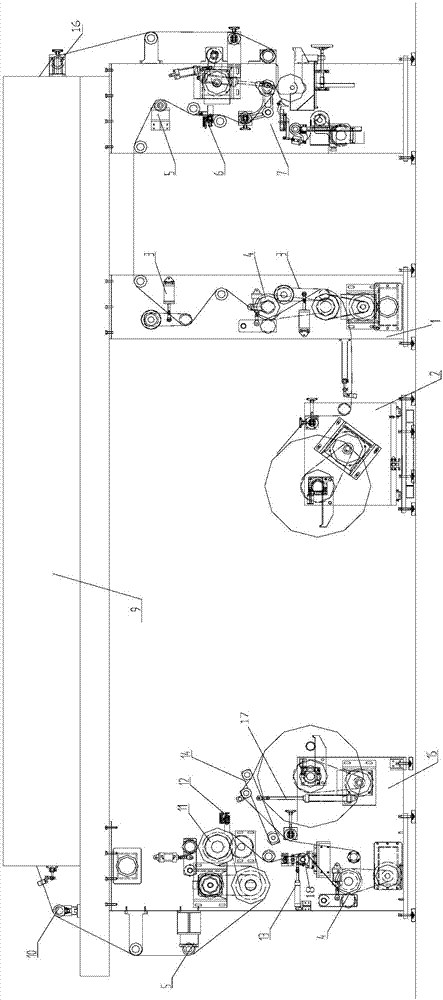

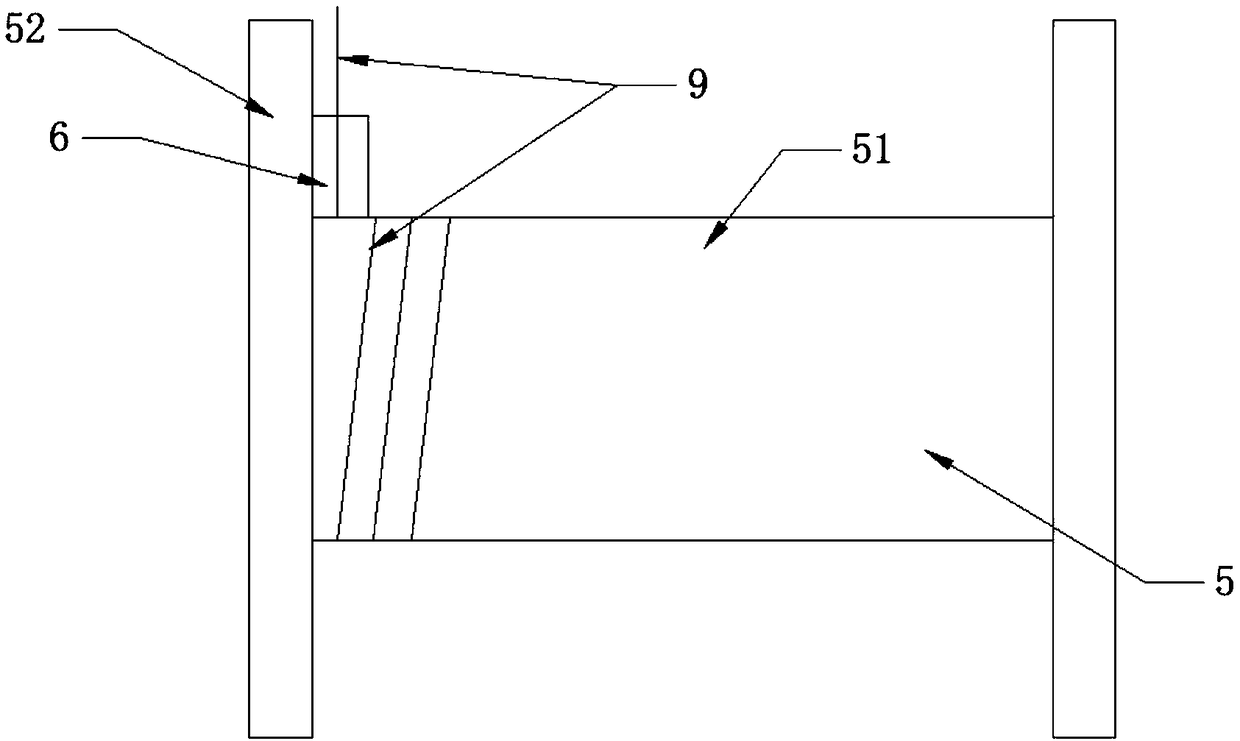

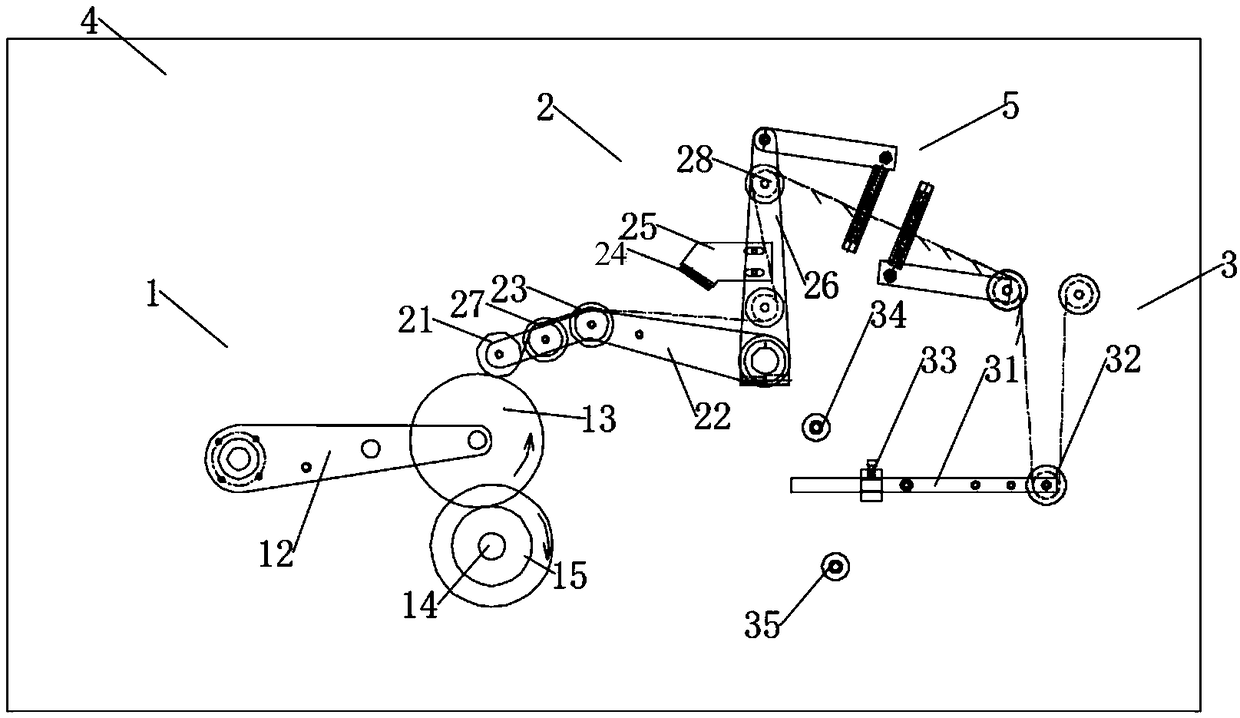

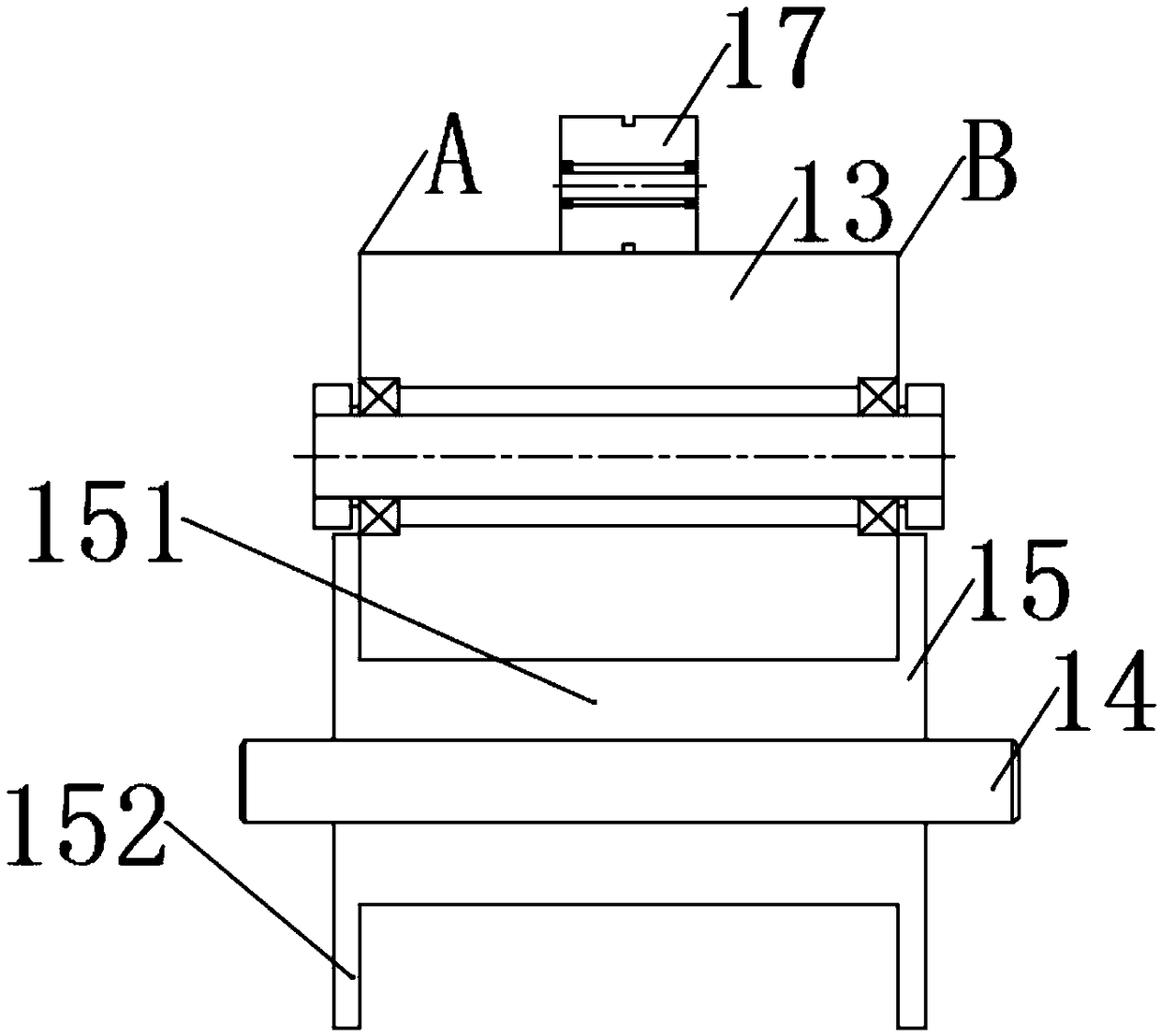

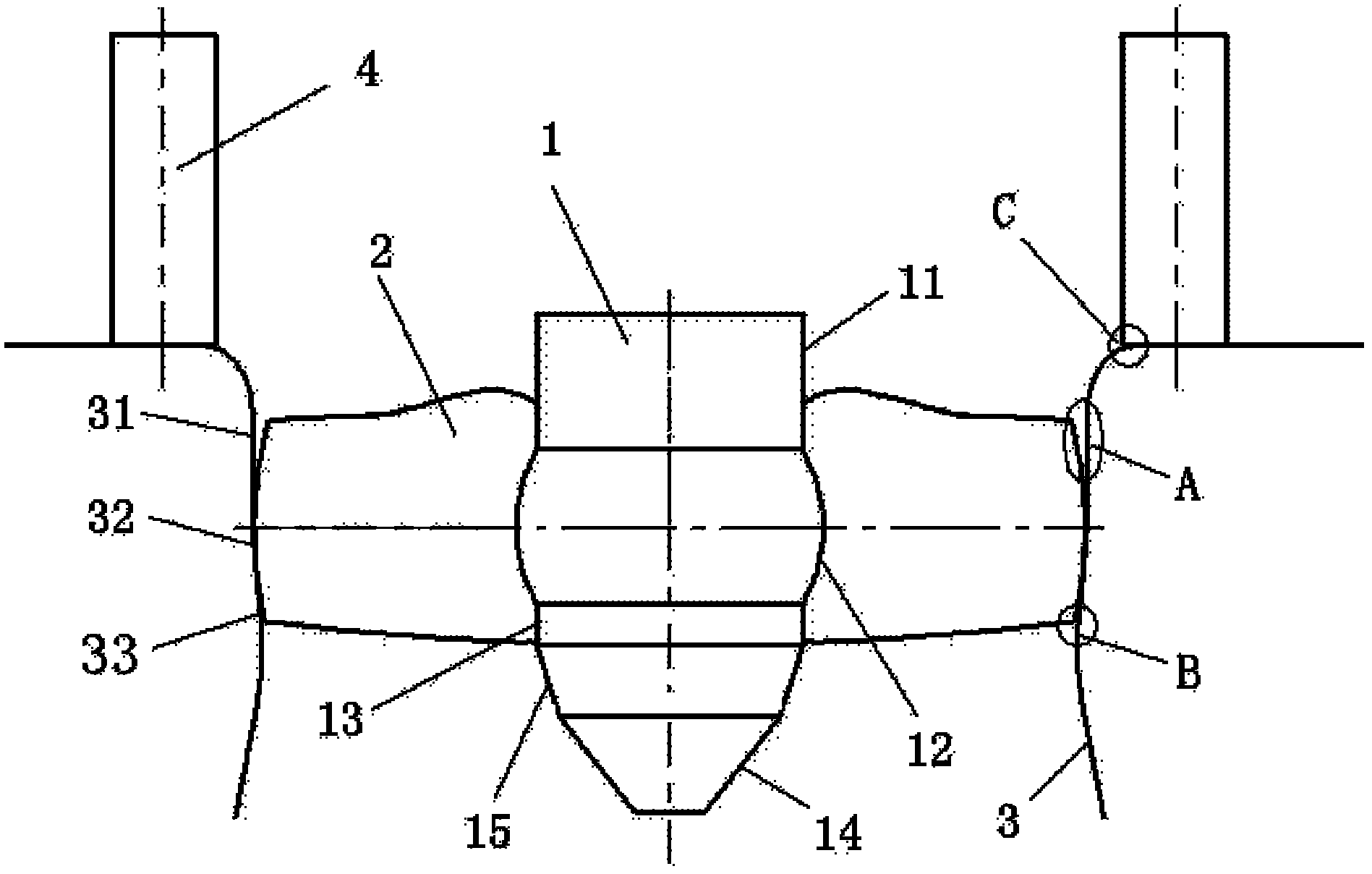

Multi-purpose type double-sided film laminating system

InactiveCN107160852AAvoid wrinklesFully warmed upLamination ancillary operationsLaminationMechanical engineeringEnergy conservation

The invention discloses a multi-purpose type double-sided film laminating system applied to a film laminating machine. The multi-purpose type double-sided film laminating system comprises a rack (14), an upper film roller (1) and a hot-pressing mechanism, wherein a gluing mechanism and a drying mechanism (5) are installed in sequence on the rack and above the hot-pressing mechanism, and a preheating roller (13) and a lower film roller (10) are installed in sequence on the rack and below the hot-pressing mechanism. An extension roller (11) is installed on the rack and between the preheating roller and the lower film roller, and the extension roller is connected with an extension power source (12).According to the multi-purpose type double-sided film laminating system, instant coating or precoating can be flexibly selected, so that the convenience is provided for the next processing procedure after a film is laminated on paper, the film can be effectively prevented from generating wrinkles during operation, a big enough wrap angle between the film and the preheating roller is guaranteed so as to be fully preheated, and the film laminating quality is high. The multi-purpose type double-sided film laminating system has the advantages of reasonable structure, simplicity in operation, energy conservation, environmental friendliness and high heat utilization rate, multiple purposes of one machine are realized, and the multi-purpose type double-sided film laminating system can be widely used for various paper materials.

Owner:RUIAN GREAT PRINTING & PACKAGING MACHINERY

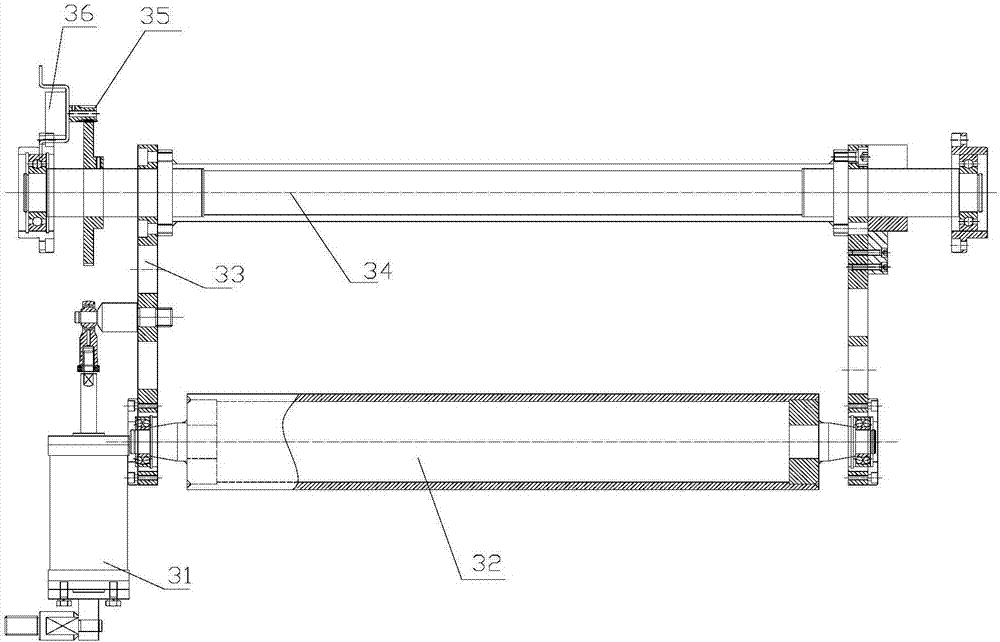

Floor type stern net hauling device for seine boat

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

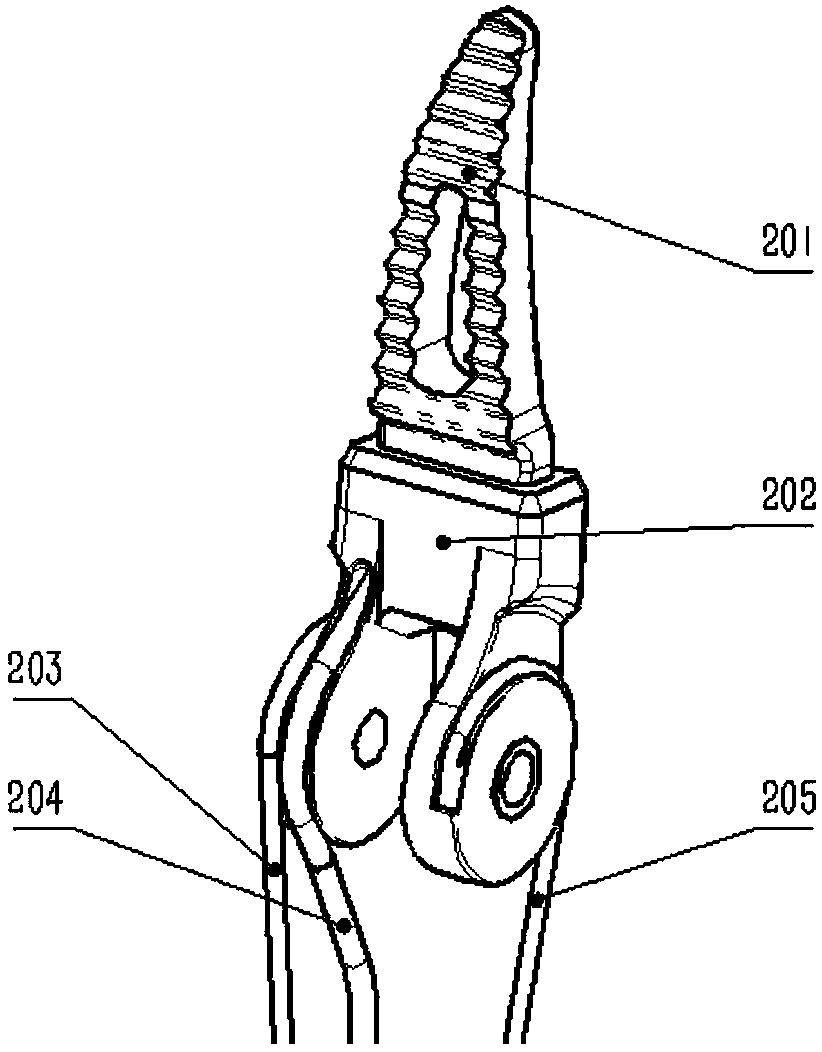

Localization guidance surgical electrocoagulation scissors

ActiveCN107049477AIncrease wrap angleExtended service lifeSurgical instruments for heatingSurgical forcepsElectrocoagulationBobbin

Localization guidance surgical electrocoagulation scissors comprise a front-end scissor mechanism and a control mechanism which are connected through a carbon fiber tube. The front-end scissor mechanism comprises a pair of scissor bodies, and a middle support with the top hinged to the pair of scissor bodies and the bottom hinged to a bobbin. The control mechanism controls the opening, closing and homodromous swinging of the pair of scissor bodies through steel wire ropes, and the control mechanism controls the swinging of the middle support through a steel wire rope. The middle support is conical, and a wiring groove is formed in the side wall of the middle support. The pair of scissor bodies is connected with an electrode through an electrocoagulation wire to form the single-pole electrocoagulation scissors, the electrocoagulation wire is fixedly connected to the bottom of the bobbin, and the electrocoagulation wire does not move along with the pair of scissor bodies. Wearing of the electrocoagulation wire is slight, the service life is long, and the service life of micro-equipment is prolonged overall.

Owner:HARBIN SIZHERUI INTELLIGENT MEDICAL EQUIP CO LTD

Micro instrument clamping mechanism for minimally invasive surgery

A micro instrument clamping mechanism for minimally invasive surgery comprises a gripper mechanism and a control mechanism which are connected through a carbon fiber tube. The gripper mechanism comprises a pair of grippers and a middle support with the top hinged to the pair of grippers and bottom hinged to a thread barrel, the control mechanism controls opening, closing and swinging in the same direction of the pair of grippers through a steel wire rope, and the control mechanism controls swinging of the middle support through a steel wire rope; the middle support is shaped like a cone, and a wiring groove is formed in the side wall of the middle support. Due to the fact that the middle support is shaped like the cone, the steel wire ropes are hidden in the wiring groove, and no other devices are arranged in the middle support, it is guaranteed that the whole gripper mechanism achieves smooth transition, no edge exists, and damage to the human body is avoided.

Owner:HARBIN SIZHERUI INTELLIGENT MEDICAL EQUIP CO LTD

Fixed length control system

PendingCN107235359AGood technical effectReduce tensionRotary pressesOther printing apparatusControl systemThin membrane

The invention discloses a fixed length control system. The fixed length control system comprises a rack, an unreeling device, traction devices, swing arm type tension adjusting devices, a coating device, a drying device and a take-up device. When the fixed length control system is in a debugging stage, a numerical value is set for the tension of an unreeled film between a traction mechanism and a coating mechanism, electric eyes are used for detecting the state of the film which is subjected to the tension, and if a pattern does not reach a standard length value, the tension of the film segment is improved through an operation interface; if the pattern length exceeds the standard value, the tension of the film segment is reduced through the operation interface till the pattern length is adjusted to the standard value; the tension of a film between a coating mechanism and a traction cooling mechanism is adjusted in a manner of the tension adjusting of the film segment; the length of the film is shaped when the film is in the drying device; and by means of cooling of the traction cooling mechanism, the situation that the film cannot be opened after being rolled up due to chilling shrink is prevented.

Owner:NANJING JIA XU MACHINERY MFG

One-step composite twisting frame

The invention provides a one-step composite twisting frame, and belongs to the technical field of textile machinery. By arranging an unwinding device on the top of a first twist spindle, the problemsthat in the yarn twisting process, uneven yarn twist, fuzzing, bubbling and the like are caused by unstable balloon tension can be effectively solved. The one-step composite twisting frame comprises afirst twisting mechanism, a roller transmission structure and the a second twisting mechanism; in the first twisting mechanism, single twisting is conducted through the first twisting spindle, and two or more yarns completing single twisting enter the roller transmission structure for monofilament stranding to form a twisted yarn; the second twisting mechanism is used for second twisting of the twisted yarn; the unwinding device is arranged on the top of the first twist spindle, that is to say, a bracket is additionally arranged in the middle of a twisting zone of the yarns, the size of a balloon formed through high-speed rotation of the yarns in the twisting zone is fixed, the balloon size is basically the same, and the yarn quality problem generated by colliding with other parts cannotbe caused; the problems of yarn fuzzing, bubbling, more white dots, more broken ends and the like of a traditional one-step twisting frame can be effectively solved.

Owner:HANGZHOU CHANGYI TEXTILE MACHINE

Parking system and method for taking vehicle

InactiveCN103321464AReduced motion precisionLower requirementParkingsRelative displacementEngineering

The invention discloses a parking system. The parking system comprises a bearing plate and a power head device, wherein multiple wheels are arranged at the lower side of the bearing plate; the power head device which is used for driving the bearing plate to move comprises a base, a swinging block, a driving motor and a control motor; the base is fixed on a floor; the swinging block is arranged on the base and is rotationally connected to the base; the driving motor and the control motor are fixed on the swinging block; the control motor is used for locking or releasing relative displacement of both the bearing plate and the driving motor; when the control motor releases the bearing plate, the driving motor drives the bearing plate to do translational motion, with respect to the driving motor per se; when the control motor locks the bearing plate, the driving motor drives the bearing plate to rotate around a rotating shaft line at a joint of the swinging block and the base, and the swinging block rotates synchronously along with the bearing plate. The invention also discloses a method for taking a vehicle.

Owner:佛山市南海区爱满亭机械有限公司

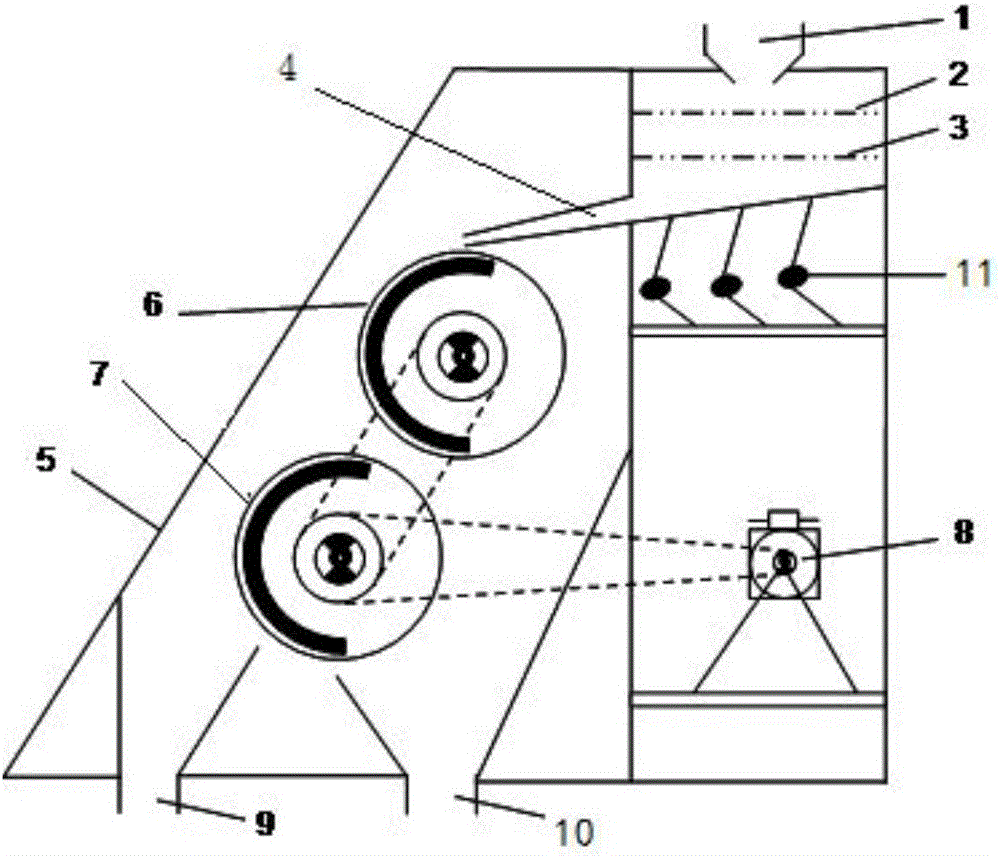

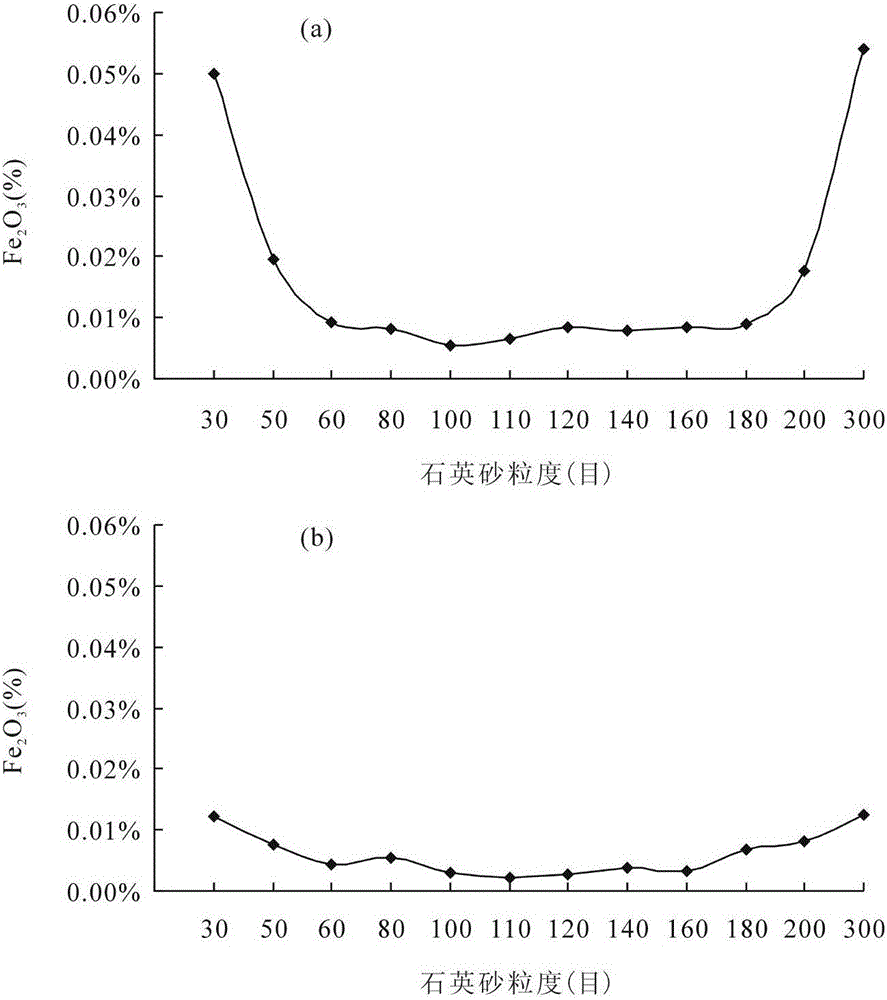

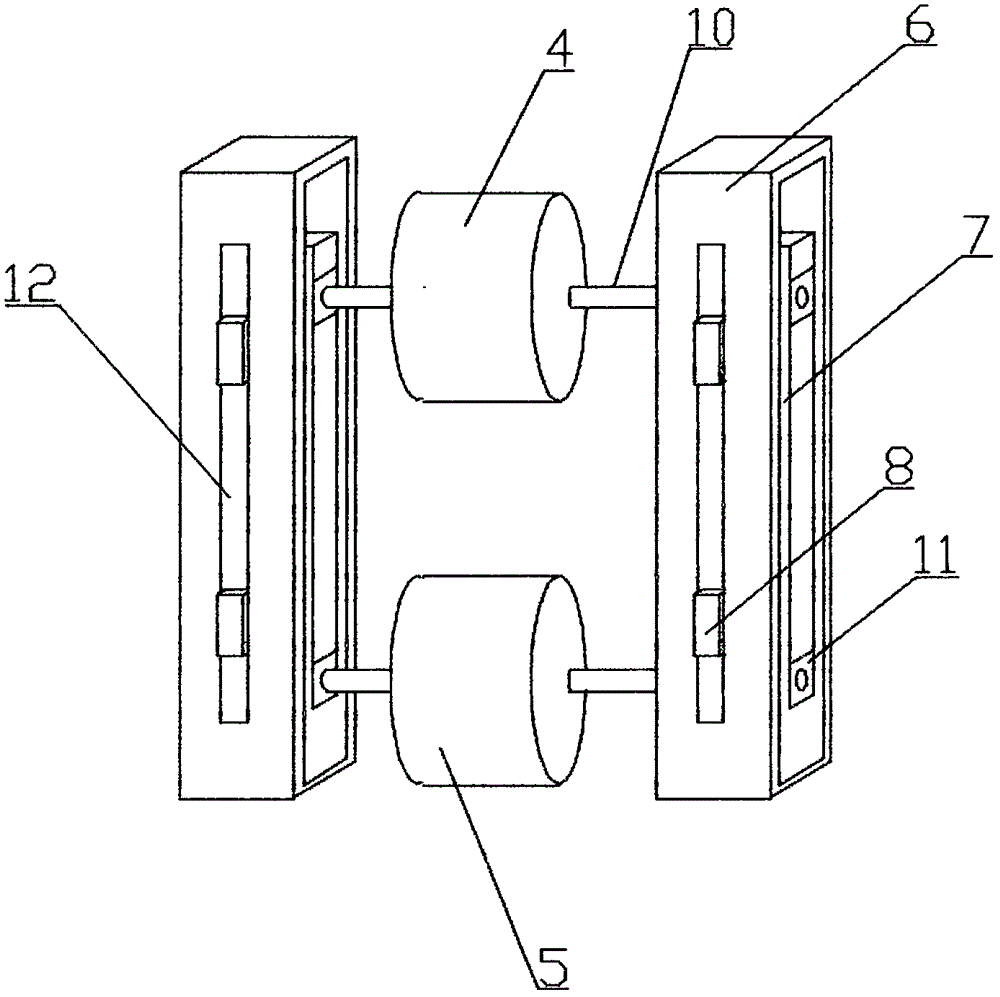

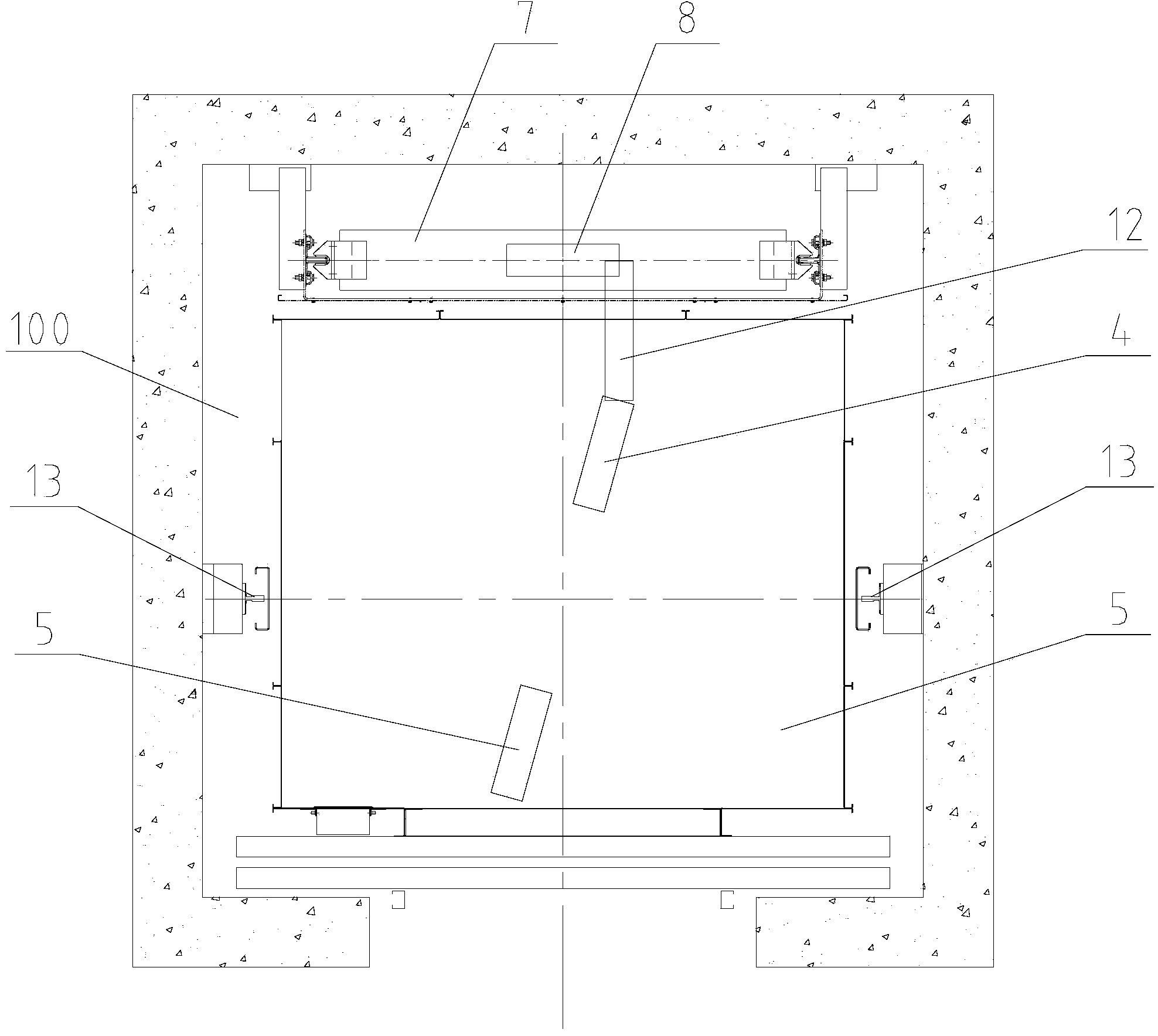

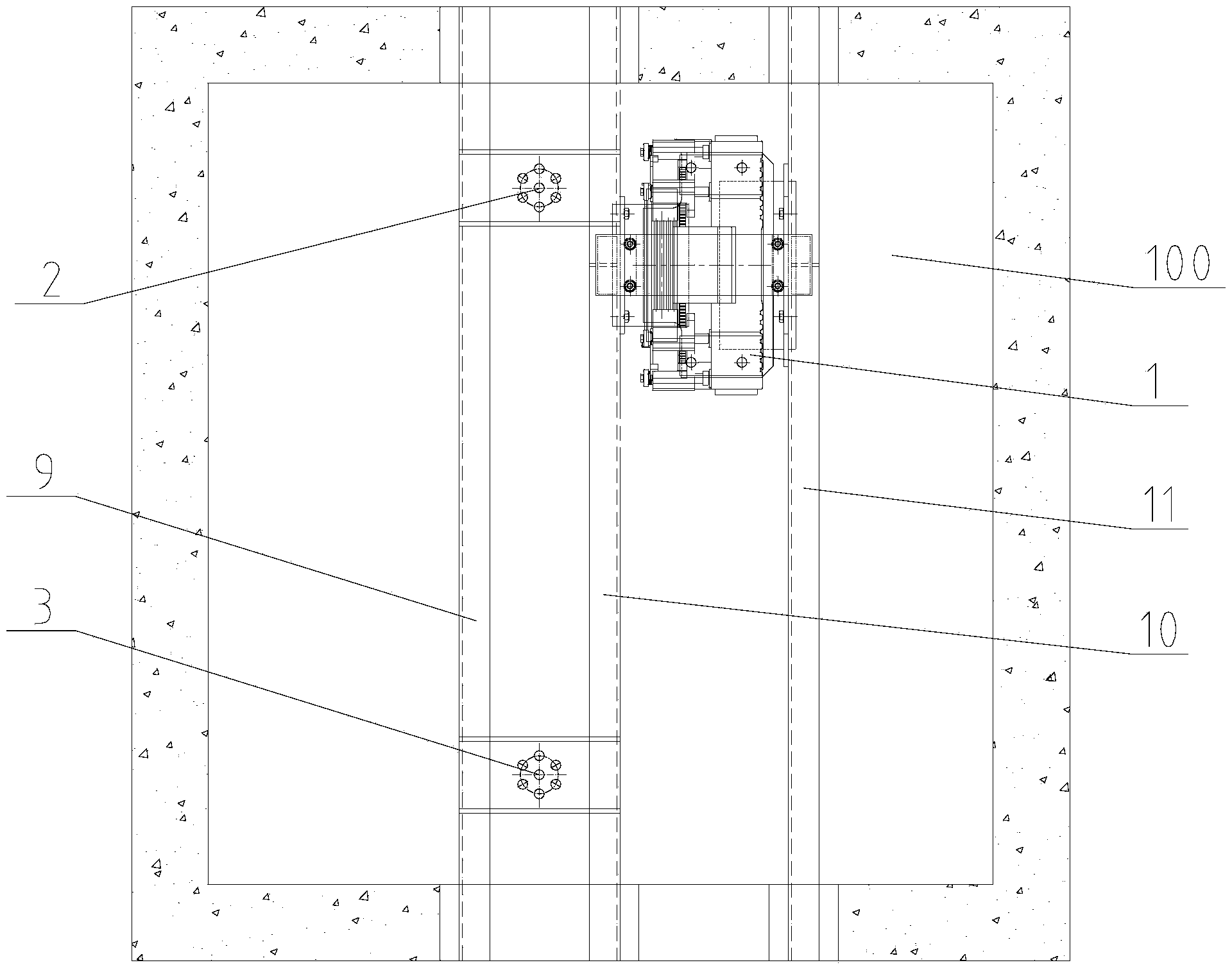

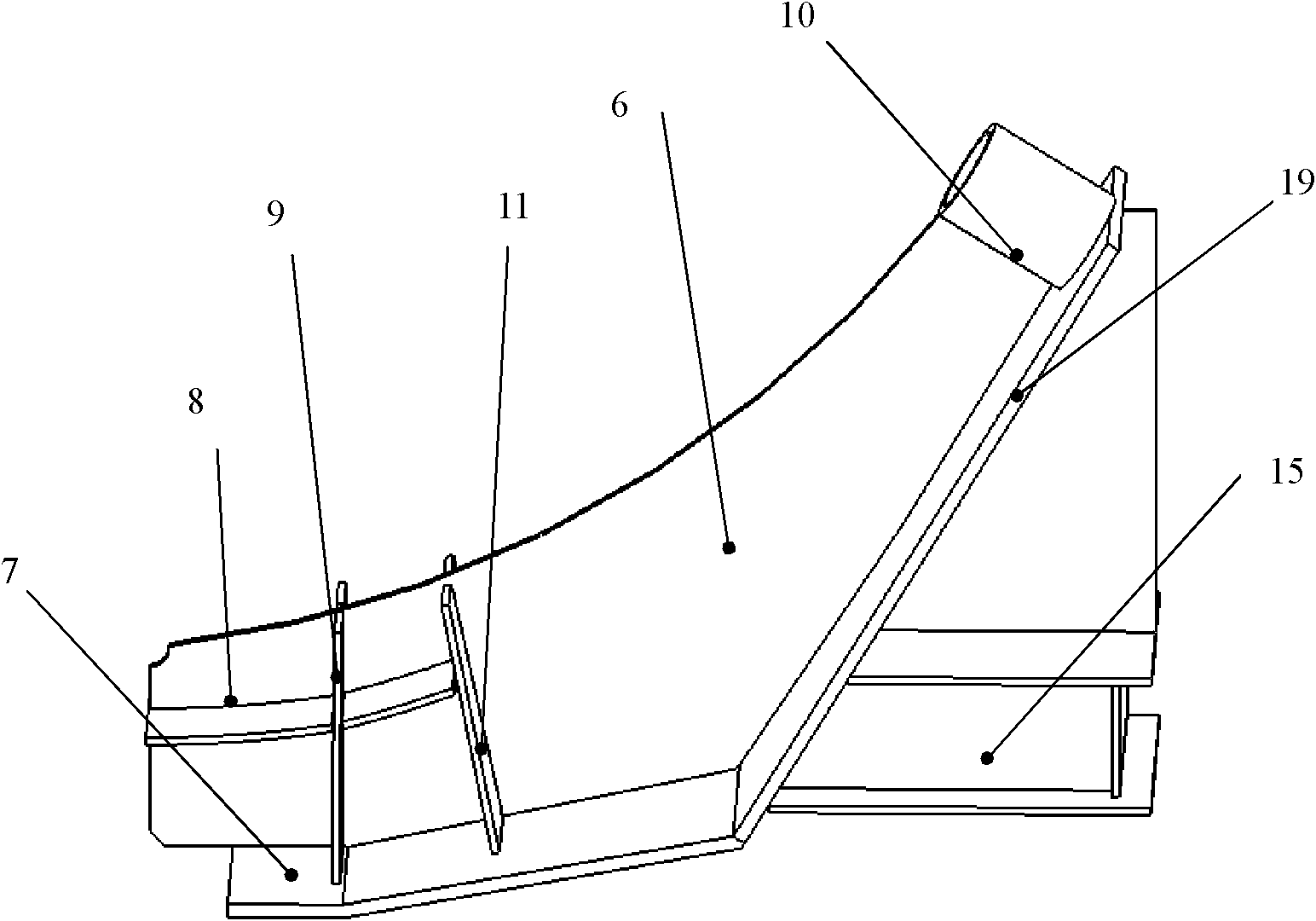

Method for carrying out classification magnetic separation according to particle sizes of quartz sand, and magnetic separator thereof

ActiveCN106733162AHigh iron removal efficiencyIncrease the magnetic field strengthMagnetic separationMagnetic separatorSieve

The invention discloses a method for carrying out classification magnetic separation according to the particle sizes of quartz sand, and a magnetic separator thereof, and relates to the technical field of quartz sand treatment. The method is characterized by comprising the following steps: crushing quartz stone at first; then carrying out grading screening by virtue of sieve screens, wherein the size of the first-stage sieve screen is 50-70 meshes, and the size of the second-stage sieve screen is 170-190 meshes; and then inputting the quartz sand subjected to the grading screening into the magnetic separator separately and carrying out magnetic separation. The magnetic separator comprises a screening device and a magnetic separator body, wherein the screening device is arranged at the upper side of the magnetic separator; a charge port is formed in the upper part of the screening device; the screening device comprises the first-stage sieve screen and the second-stage sieve screen; the second-stage sieve screen is arranged at the lower side of the first-stage sieve screen; charge channels connected to the magnetic separator body are formed in the screening layers of the first-stage sieve screen and the second-stage sieve screen; and the magnetic separator body comprises a rack, a first magnetic drum, a second magnetic drum and a transmission motor. The iron removal efficiency of the magnetic separation method and the magnetic separator is greatly increased.

Owner:ANHUI SCI & TECH UNIV

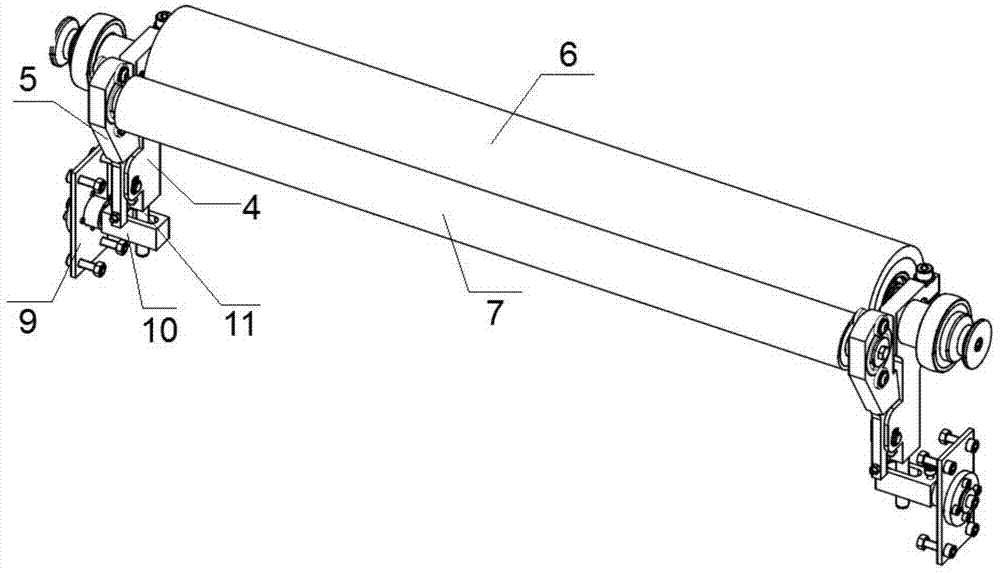

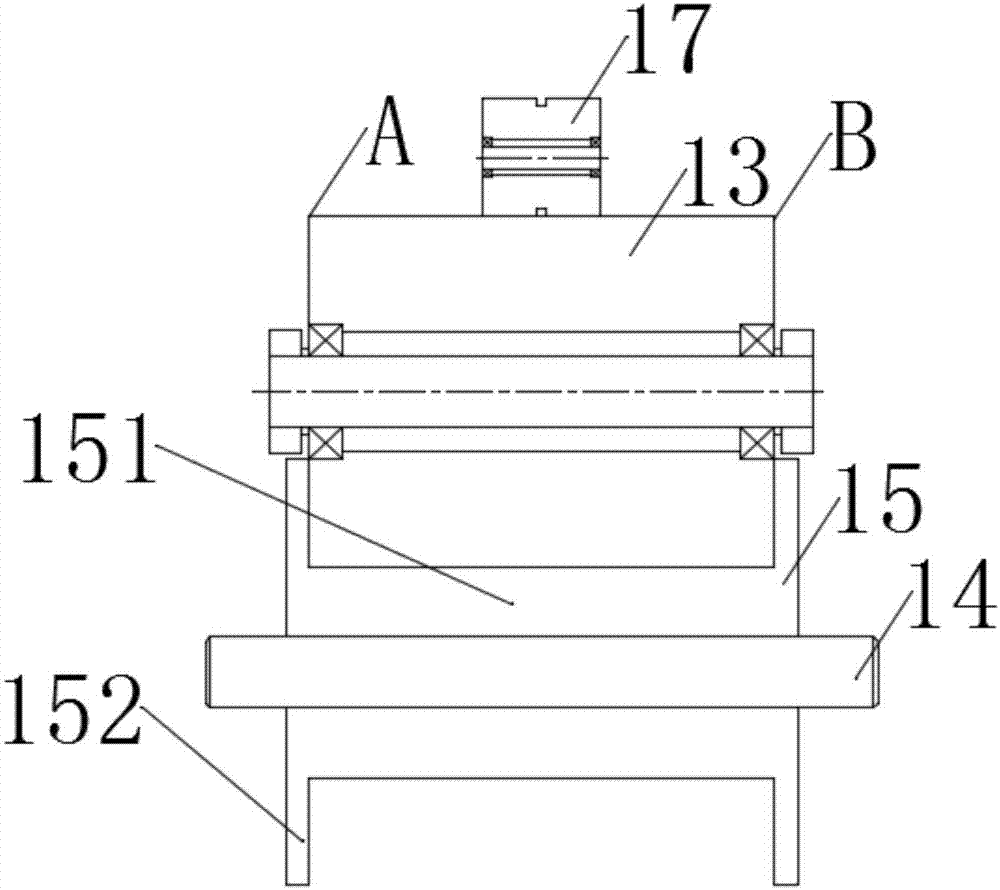

Slitting dual-pressure roll and winding method thereof

The invention discloses a slitting dual-pressure roll and a winding method thereof. The slitting dual-pressure roll comprises a base (1), supports (2), swing arms (3), clamping arms (4), rotating arms (5), a first pressure roll body (6) and a second pressure roll body (7). The supports (2) are fixedly installed on the base (1), one ends of the swing arms (3) are hinged to the supports (2), the clamping arms (4) and the swing arms (3) are connected, the rotating arms (5) and the clamping arms (4) are connected, the first pressure roll body (6) is rotationally installed on the clamping arms (4), the second pressure roll body (7) is rotationally installed on the rotating arms (5), and the diameter of the second pressure roll body (7) is smaller than that of the first pressure roll body (6). A thin film is flatly attached to the pressure roll bodies, and it is guaranteed that no excessive air is involved in the rolling process.

Owner:ANHUI GUOFENG PLASTIC

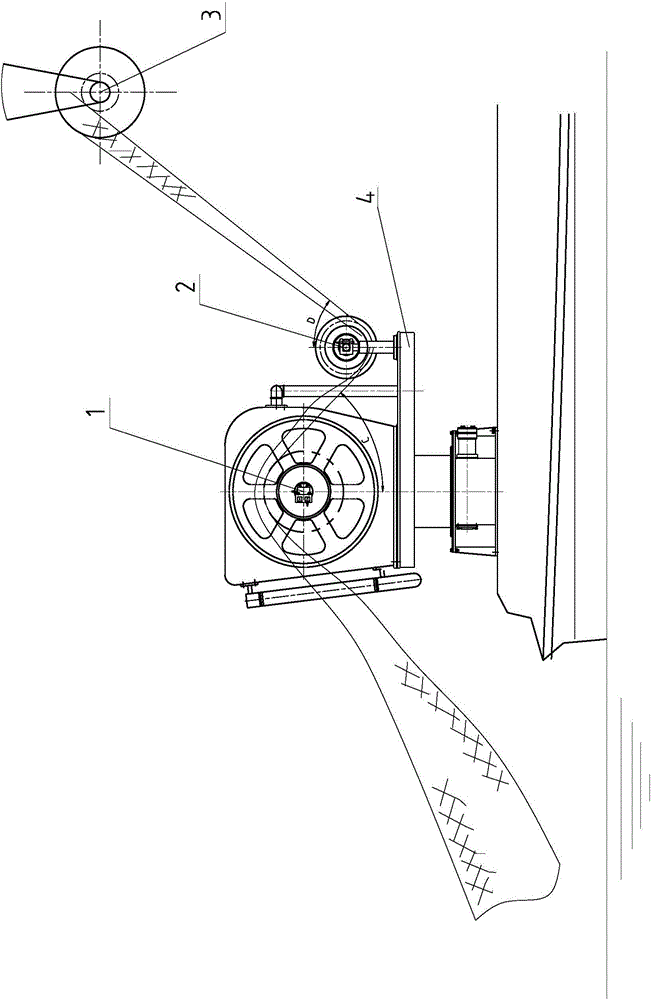

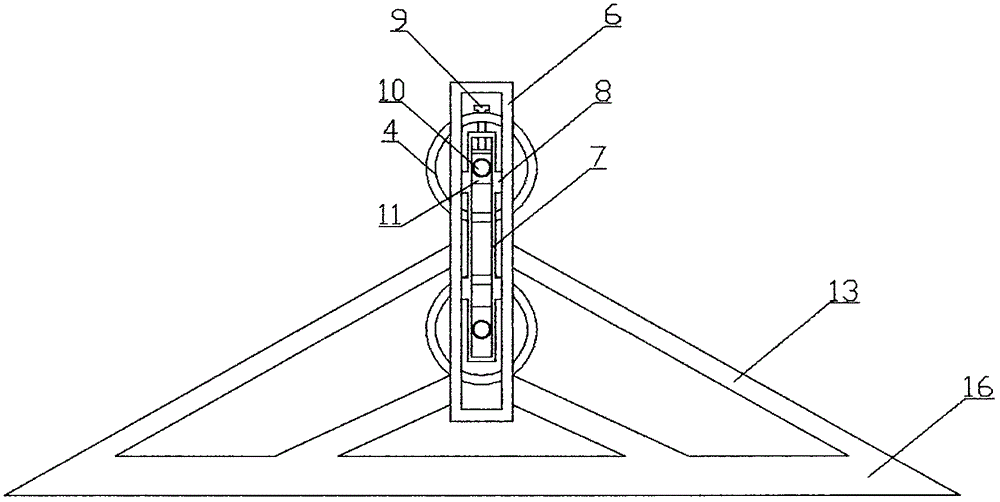

Belt wrap angle adjusting device for pumping unit

The invention discloses a belt wrap angle adjusting device for a pumping unit. The belt wrap angle adjusting device comprises a belt and a belt pressing device. The belt pressing device comprises an upper pressing wheel arranged on the upper side of the belt, and a lower pressing wheel arranged on the lower side of the belt. A wheel track adjusting device used for adjusting the distance between the upper pressing wheel and the lower pressing wheel is arranged between the upper pressing wheel and the lower pressing wheel. The tension degree of the belt is improved through extrusion of the upper pressing wheel and the lower pressing wheel, the wrap angle of the belt on a motor belt wheel and a speed reducer belt wheel is increased, the phenomenon of slippage of the belt is avoided, and oil well halt production due to belt damage caused by belt slippage is avoided.

Owner:东营市鑫瑞达工贸有限公司

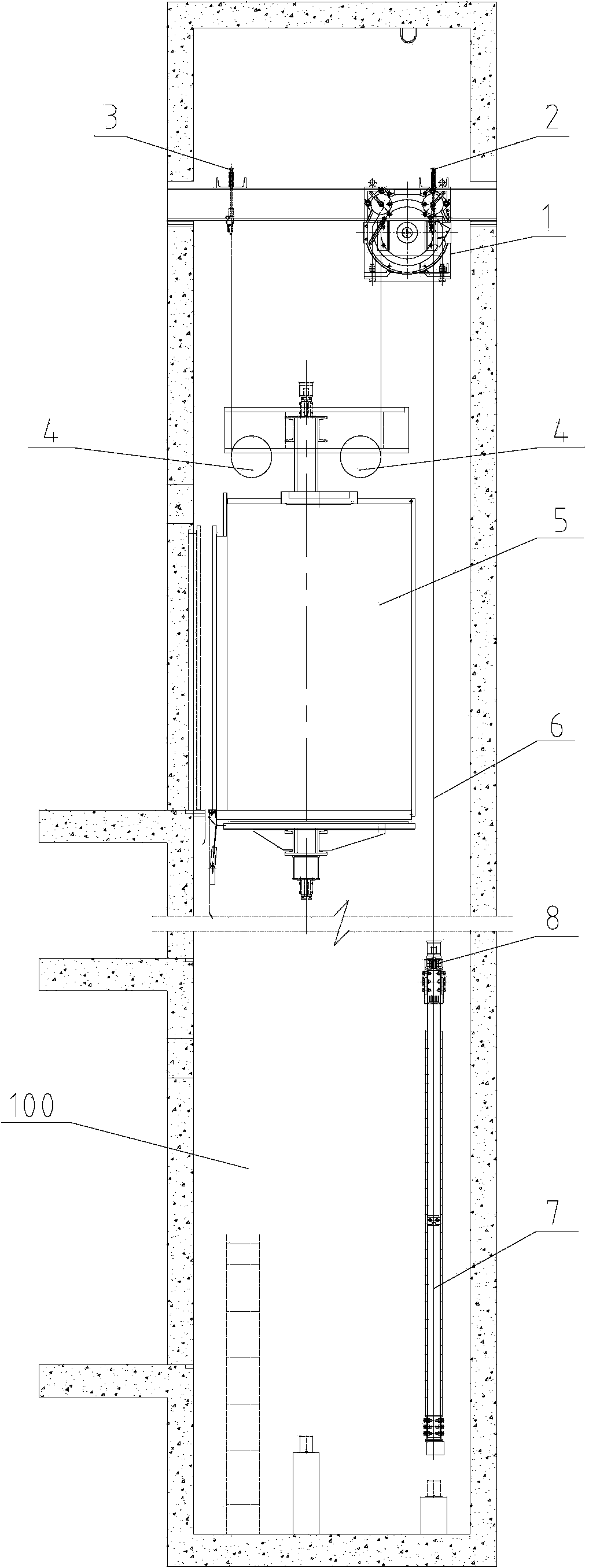

Machine-room-free elevator arrangement structure

InactiveCN104058321AGuaranteed uptimeReduce manufacturing costElevatorsBuilding liftsEngineeringWire rope

The invention provides a machine-room-free elevator arrangement structure, which comprises a lift car, a counterweight device, a traction machine and a steel wire rope, wherein the lift car, the counterweight device, the traction machine and the steel wire rope are arranged in a shaftway, the counterweight device is positioned at the back side of the lift car, a counterweight reverse rope wheel parallel to a transverse center line of the shaftway is arranged on the counterweight device, a load bearing beam parallel to the longitudinal center line direction of the shaftway is arranged above the lift car, the traction machine is arranged at the back side of the load bearing beam, a dragging wheel is parallel to the longitudinal center line of the shaftway, a lift car rope end and a counterweight rope end are also respectively arranged on the load bearing beam from the front side to the back side, two lift car reverse rope wheels are arranged on the top of the lift car from the front side to the back side, one end of the steel wire rope is fixedly arranged on the lift car rope end, the other end of the steel wire rope downwards and sequentially goes around the two lift car reverse rope wheels, upwards goes around a traction wheel, and then downwards goes around the counterweight reverse rope wheel, and finally, the end upwards extends and is fixedly arranged on the counter weight rope end. Compared with the prior art, the machine-room-free elevator arrangement structure has the advantages that the structure is simpler and neater, the shaftway space is saved, and the operation of an elevator is more stable.

Owner:SUZHOU FUSHI ELEVATOR

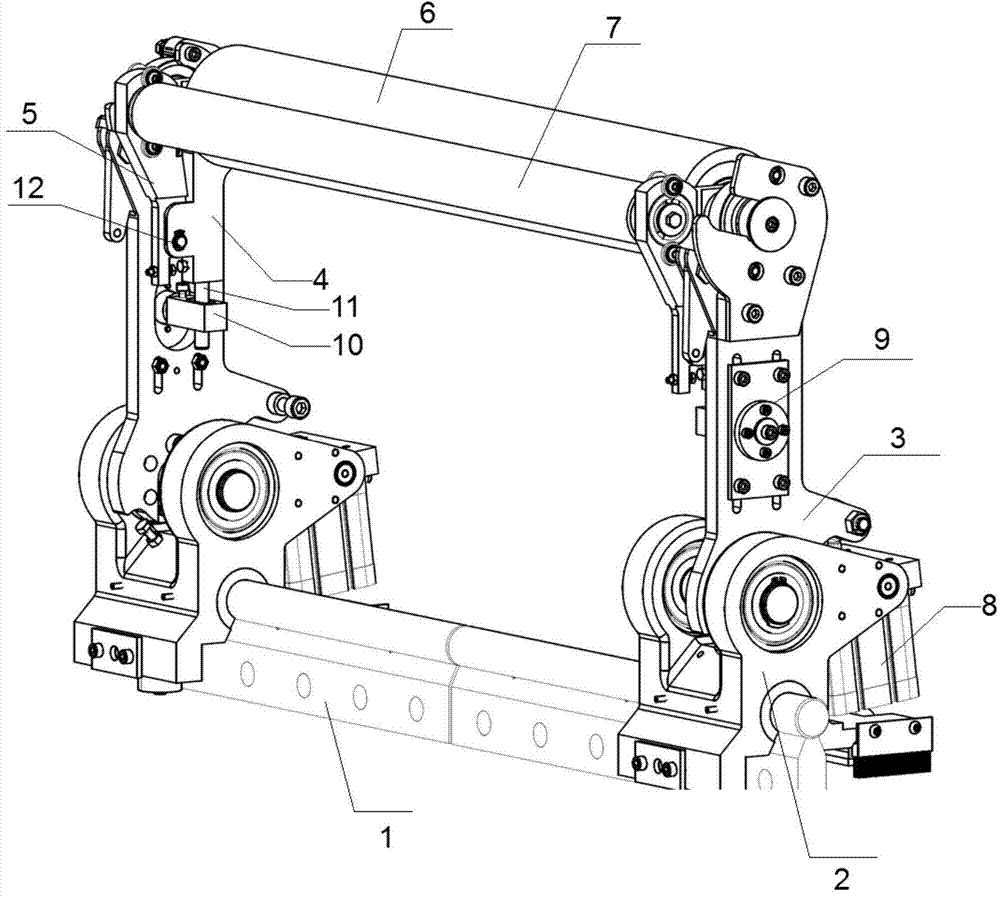

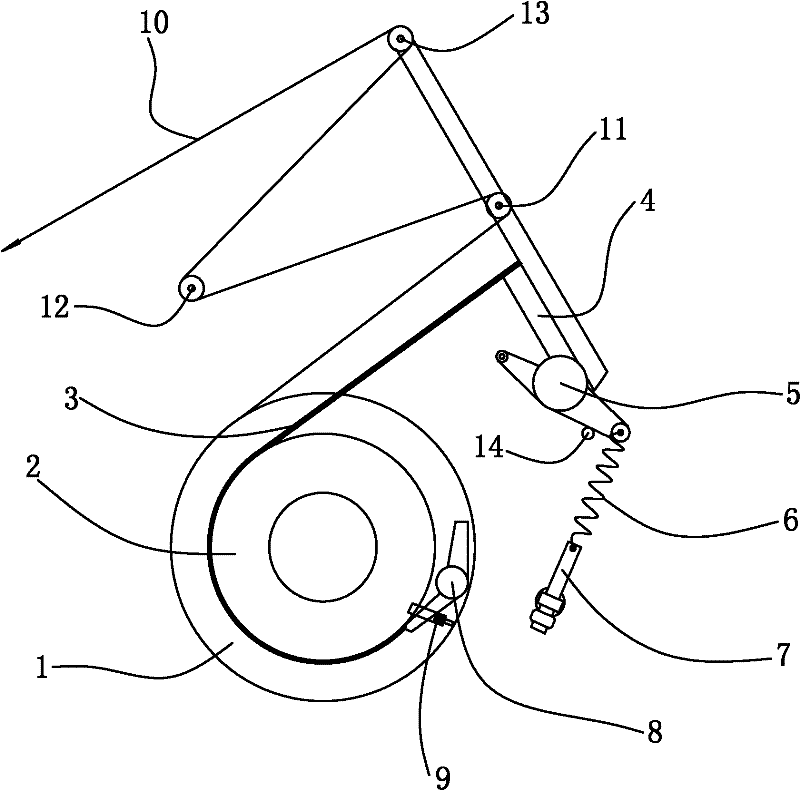

Belt sanding tool installed at tail end of robot

ActiveCN108436688AExtend the life cycleReduce grinding costsBelt grinding machinesAutomatic grinding controlCar manufacturingEngineering

The invention discloses a belt sanding tool installed at the tail end of a robot, and relates to a polishing tool. With the belt sanding tool installed at the tail end of the robot, the problem that an existing polishing tool for a robot is high in force control difficulty, requirement on control system performance, and cost is solved. A belt tensioner is installed on the upper end face of a framethrough a belt tensioner support. A low-friction air cylinder is fixedly installed on the frame and located below the belt tensioner support. A servo electric cylinder is horizontally installed at the bottom of the frame. A motor supporting plate is fixedly installed on the front end face of the frame. An output shaft of a servo motor is in transmission connection with a driving wheel through a synchronous belt. A contact wheel is connected to the servo electric cylinder through a contact wheel support. A high-precision sensor is installed on the contact wheel. The high-precision sensor is electrically connected with the servo electric cylinder. A transition wheel is installed in the middle of the frame. An abrasive belt is installed on the driving wheel, the belt tensioner and the contact wheel in sequence. The transition wheel is arranged on the part, between the belt tensioner and the contact wheel, of the abrasive belt in a pressing manner. The belt sanding tool installed at the tail end of the robot is used for aerospace product manufacturing and automobile making grinding.

Owner:HARBIN INST OF TECH

Double-electrode forceps structure for minimally invasive surgery

InactiveCN107789062AIncrease wrap angleExtended service lifeSurgical instruments for heatingSurgical manipulatorsInvasive surgeryEngineering

The invention provides a double-electrode forceps structure for minimally invasive surgery, comprising a first clamping end, a second clamping end and a multi-DOF (degree of freedom) joint. Driving force can be transmitted to a clamping mechanism through clamping wire ropes, pitching wire ropes and energy conductors, so that the clamping mechanism can provide the energy effect of pitching, deflecting and clamping free motions and operations. Compared with the prior art, the double-electrode forceps structure has the advantages that the two clamping ends are in embedded structure, and the functional and transmission needs and processing ends of the wire ropes and energy conductors can be satisfied in limited space; the clamping wire ropes are arranged close to one end, guide wheels are provided with large space for placement, the diameter of each guide wheel is enlarged, the service lives of the clamping wire ropes are extended, and equivalent allowable strength of each clamping wire rope is increased; the energy conductors are fixedly connected to the clamping mechanism and synchronously move with the clamping ends, the energy conductors experience less abrasion and have long service lives, and the service life of a micro instrument is prolonged accordingly.

Owner:HARBIN SIZHERUI INTELLIGENT MEDICAL EQUIP CO LTD

3D (three-dimensional) mechanical probe and rope transmission device

ActiveCN104224228AAvoid mutual interferenceIncrease wrap angleMedical imagingOrgan movement/changes detectionFixation pointDrive shaft

A 3D (three-dimensional) mechanical probe comprises a handheld portion and a penetrating portion. The size of the handheld portion is greater than that of the penetrating portion. The handheld portion comprises a rope transmission device. The rope transmission device comprises a driving shaft, a first rope and a second rope; the driving shaft is provided with a first fixation point and a second fixation point; the first fixation point and the second fixation point are arranged on different radial faces of the driving shaft; the first rope is connected to the first fixation point and wound on the driving shaft along the periphery of the driving shaft; the second rope is connected to the second fixation point and wound on the driving shaft along the periphery of the driving shaft; a first reversing pulley set comprises a first pulley and a second pulley; the penetrating portion comprises a driven shaft; the first rope and the second rope pass by the first pulley and the second pulley respectively and are then wound on the driven shaft. The driving shaft of the 3D mechanical probe allows large-range linear transmission.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD +1

Tension management apparatus for cable-driven transmission

ActiveUS10753439B2Reduce and eliminate slackIncrease wrap angleEndoscopesLaproscopesClassical mechanicsEngineering

Slack-compensating pulleys, transmission systems including slack-compensating pulleys, and methods of operating these. In general, slack-compensating pulleys include a pulley body onto which a cable can wind, and one or more (e.g., two) slack take-up surfaces that rotate with the pulley body that are configured to remove slack form an outgoing length of cable by increasing the cable path length and wrap angle. In particular, described herein are minimal access tools having slack-compensating transmissions.

Owner:RGT UNIV OF MICHIGAN

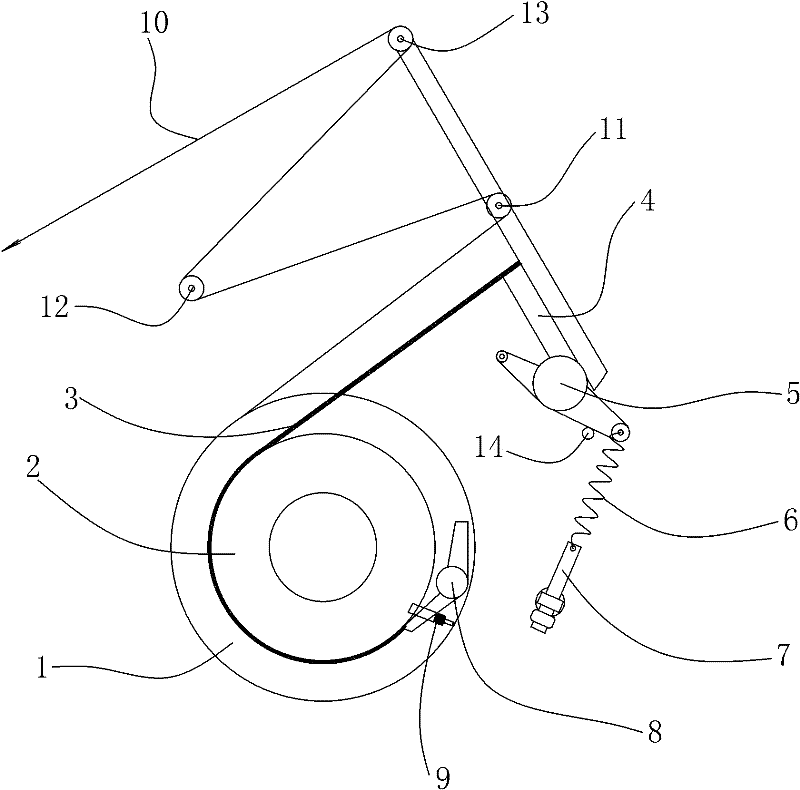

Braking device with transparent paper brake disc of cigarette packing machine

InactiveCN102530314AIncrease wrap angleIncrease friction areaWrapping material feeding apparatusDrum brakesCigarette packEngineering

The invention discloses a braking device with a transparent paper brake disc of a cigarette packing machine. The braking device comprises a bracket, a brake rack, the brake disc coaxially and fixedly connected with a transparent paper roll, and a brake band wound on the brake disc, wherein one end of the brake band is fixedly connected to the brake rack, and the other end of the brake band is fixedly connected to the bracket; the middle part of the bracket is rotatably arranged on a rotating shaft; one end of the bracket is also connected with a spring; the other end of the spring is connected with an adjusting bolt; and the connection points of the brake band and the spring on the bracket are respectively positioned on two sides of the rotating shaft. According to the invention, an original brake block is replaced by the soft brake band, so that a large package angle is realized, the frictional area is increased, the damping force for the swinging of the bracket is more uniform, and the dynamic stable swinging of a swinging arm is realized; and the braking device disclosed by the invention can be used for providing brake resistance for the spreading and transportation of transparent paper and the quality stability of related products, so that the equipment outage rate is reduced, the transparent paper consumption is reduced and the product cost is lowered.

Owner:CHINA TOBACCO GUIZHOU IND

Winding device

InactiveCN107128716ALarge diameterWinding wrap angle is largeFilament handlingWebs handlingFlangingConductor Coil

The invention discloses a winding device. The winding device comprises a winder, a pinch roller device, a tension adjusting device and a machine table. The winding device is characterized in that the winder, the pinch roller device and the tension adjusting device are sequentially arranged on the machine table, and a wire passes through the tensioning adjusting device and the pinch roller device and is wound by the winder; the winding device achieves pressing and winding through a large pressure roller and a winding plate, and winding at the edge can be effectively achieved; the opening and closing of a pinch roller can be conveniently controlled by the pinch roller device; the tension adjusting device is simple in structure and high in adjustment precision; and vertical guide wheels are additionally arranged, the winding is made to have tension in the horizontal direction, and the phenomena of flanging, puckering and the like of threading during winding are effectively prevented.

Owner:TAICANG HONGHAI PRECISION MACHINERY CO LTD

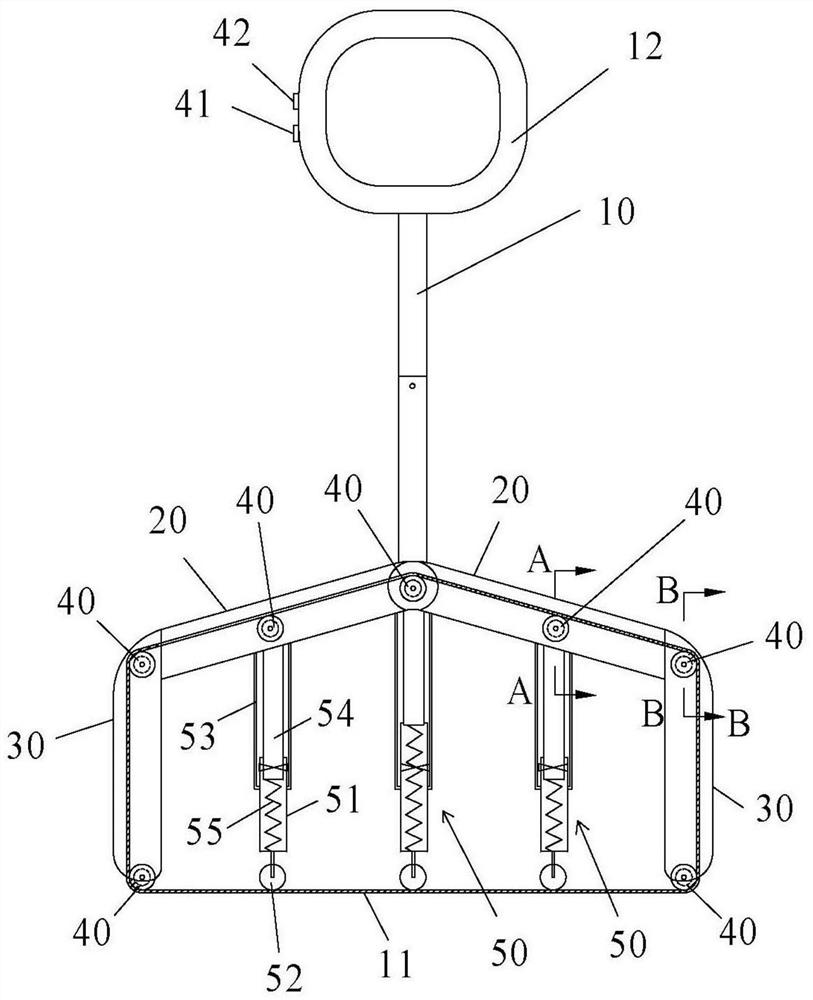

Adaptive grinding and polishing device for ship

PendingCN111730471AReduce elastic demandIncrease wrap angleBelt grinding machinesDrive wheelPolishing

The invention discloses an adaptive grinding and polishing device for ship. The device comprises a connecting rod and a polishing belt. The lower end of the connecting rod is connected with two rotating arms by shafts. The two rotating arms are respectively arranged on the left and right sides of the connecting rod. The left end of a rotating arm on the left side of the connecting rod and the right end of a rotating arm on the right side of the connecting rod are connected with vertical swinging arms by shafts. The two rotating arms and the two vertical swinging arms are provided with drivingwheels used for grinding and polishing belts. The belts after grinding and polishing is in closed loop shapes. Belt tensioning components are connected to both of the two rotating arms by shafts. Thebelt tensioning component comprise telescopic sleeves and rolling wheels connected with the telescopic sleeves by shafts. The rolling wheels abut on the inner surfaces of the belts after grinding andpolishing. The device can polish and grind shafts in the narrow space of a ship. Adaptive wrapping can be realized for the polished shaft during polishing and grinding. The device realizes self-adaptive grinding of shafts with different diameters and shaft surfaces with different curvatures.

Owner:SHANGHAI MERCHANT SHIP DESIGN & RES INST

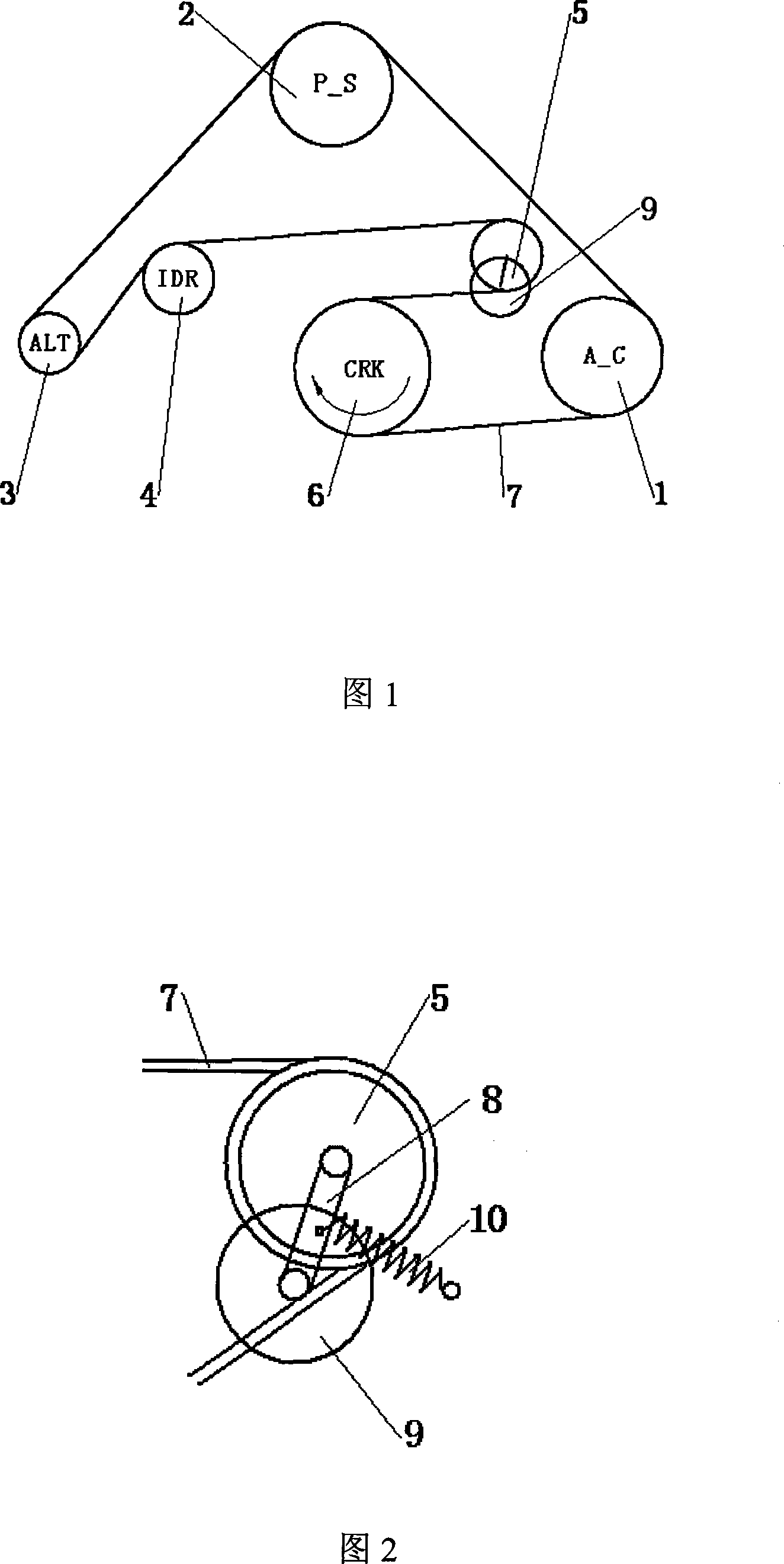

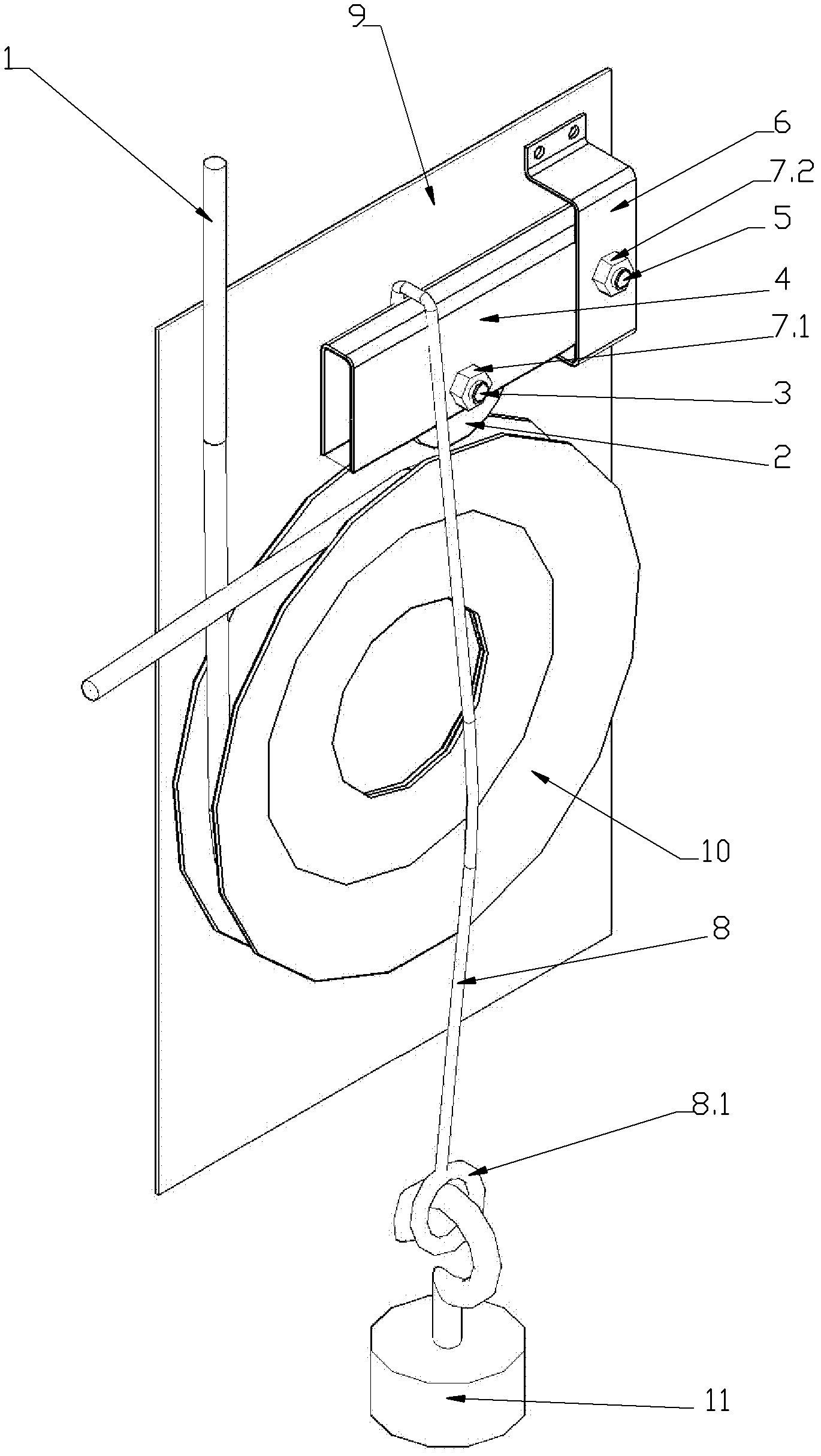

Engine accessory system

The invention discloses an engine accessory system. The transmission mechanism comprises an air condition compressor belt pulley, a power steering pump belt pulley, an electrical generator belt pulley, an idle pulley and a tightening pulley, and is connected with a crankshaft pulley through a multi-wedge belt, the crankshaft pulley as a driving pulley realizes the belt transmission, the tightening pulley is positioned on the casing body of the engine through an automatic tension mechanism, and is arranged at the position adjacent the loose side of the crankshaft pulley. By adopting the technical proposal, an electrical generator with a bigger dynamic rotation inertia is controlled perfectly while the tightening pulley maintaines a system overall tension force, thereby the utilization ratio of the tightening pulley is improved, the working stability of the electrical generator is improved, and the slip ratio is reduced; the air condition compressor is placed at the tightest side of the multi-wedge belt, the startability of the air conditioning system is improved, the utilization efficiency of the accessories is improved, the vibration quantity of the belt is reduced, the noise is lowered, and the stability, as well as the total life and the efficiency of the system are improved.

Owner:CHERY AUTOMOBILE CO LTD

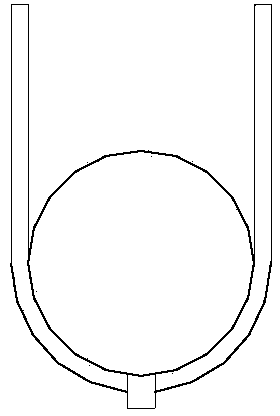

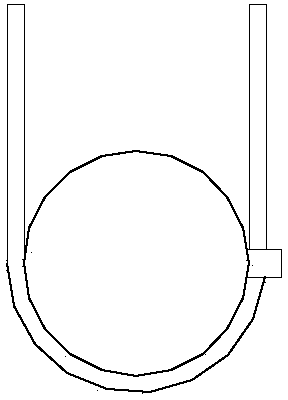

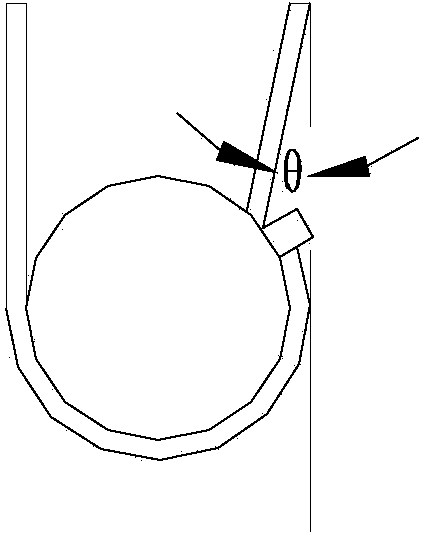

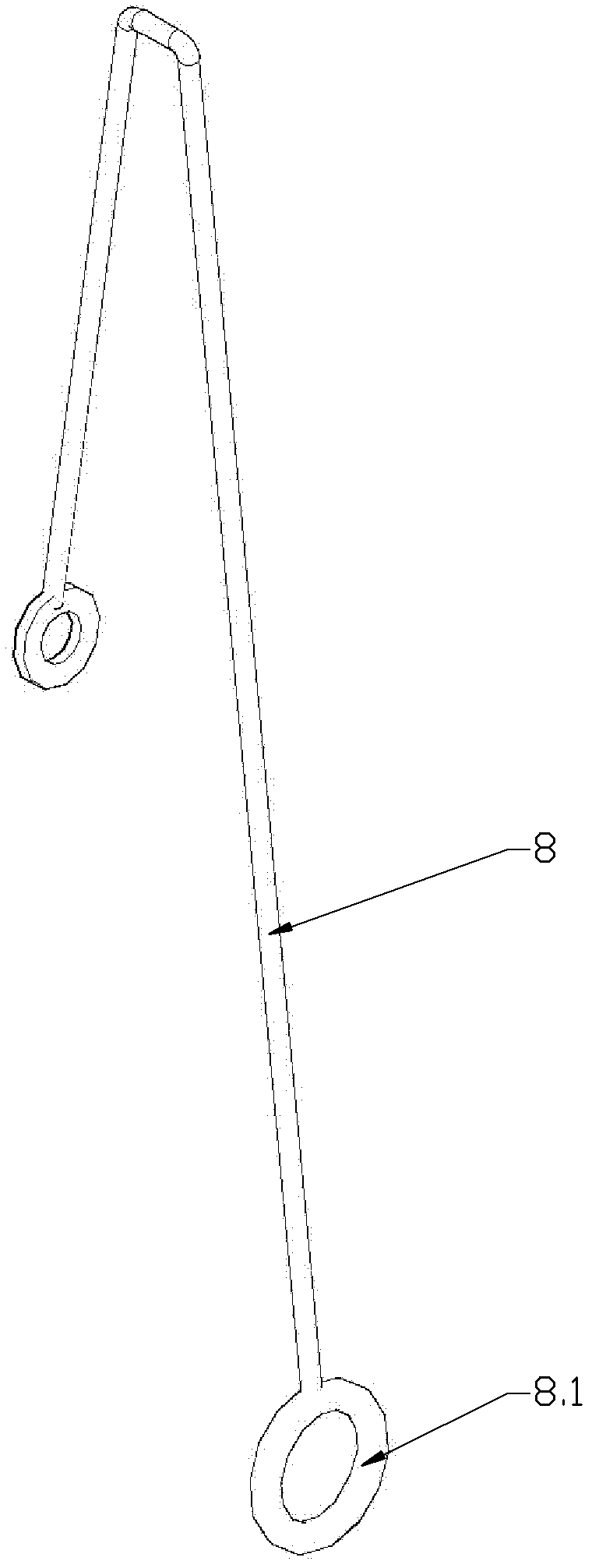

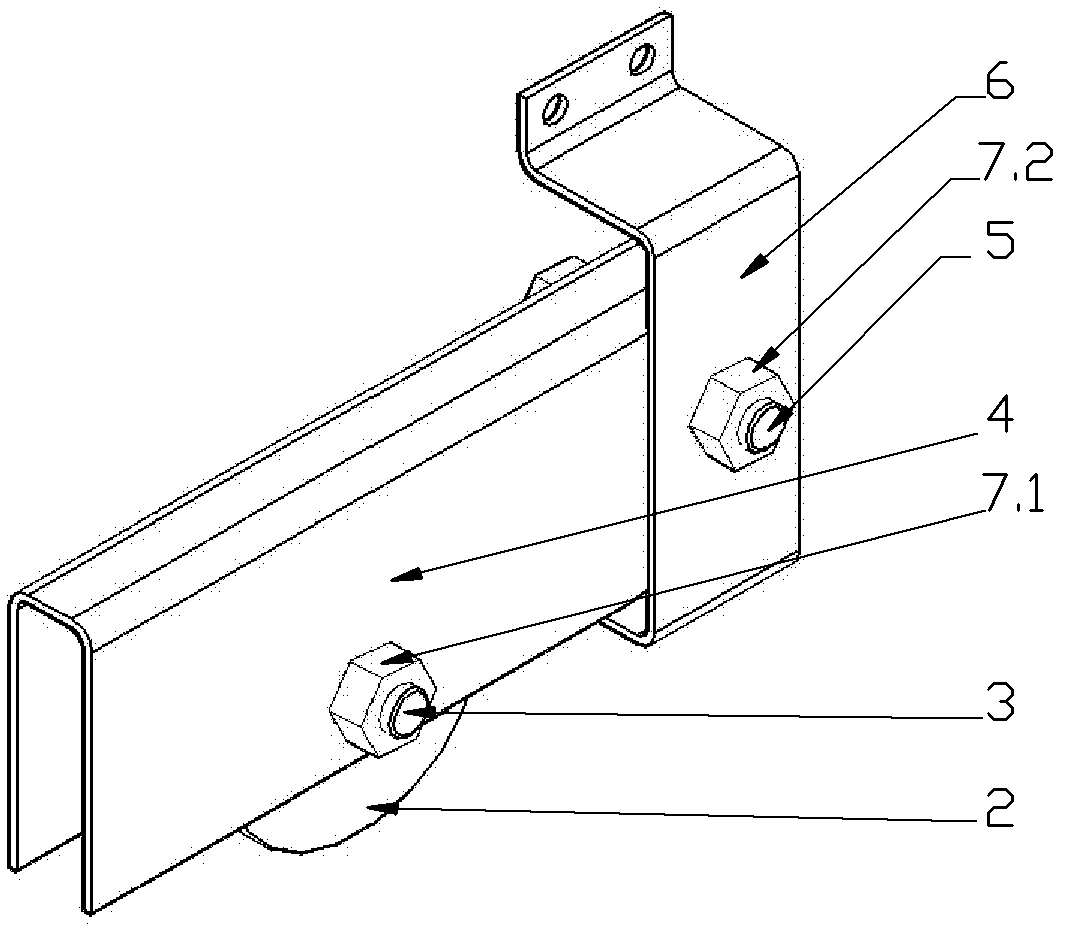

Rope pressing device of rope descent control device

InactiveCN102989090AIncrease the pressure rope wrap angleImprove the effect of pressing the ropeBuilding rescueEngineeringWheel and axle

The invention relates to a rope pressing device of a rope descent control device, which overcomes the problem that the rope pressing device of the rope descent control device in a rope through structure disclosed at present is small in rope pressing wrap angle and poor in rope pressing effect. The invention provides the rope pressing device of the rope descent control device. The rope pressing device of the rope descent control device mainly comprises a rope, a rope pressing wheel, a wheel shaft, a wheel shaft base, a supporting shaft, a supporting shaft base, a shaft end fixing piece, a pressing piece, a body, and a rope winded wheel. The rope is winded on the rope winded wheel, the rope pressing wheel is installed on the wheel shaft and fixed on the wheel shaft base through the shaft end fixing piece, and the wheel shaft base is installed on the supporting shaft base through the supporting shaft and fixedly installed on the body through the shaft end fixing piece. One end of the pressing piece is fixedly arranged on the body, while the other end of the pressing piece is further provided with a buckling piece. The rope pressing device of the rope descent control device is characterized in that the rope pressing wheel is installed above the rope winded wheel and placed in a rope slot of the rope winded wheel, and the pressing piece is tensioned and pressed on the wheel shaft base. The rope pressing device provided by the invention can be installed above the rope winded wheel, so that the rope pressing wrap angle can be increased, and therefore, the rope pressing effect is further improved.

Owner:何少敦

Winding device

ActiveCN108975055AIncrease wrap angleIncrease contact areaFilament handlingWebs handlingEngineeringAxial distance

The invention discloses a winding device. The winding device includes a roll-up device, a pressing wheel device, a tension adjusting device and a machine table; the roll-up device, the pressing wheeldevice and the tension adjusting device are sequentially arranged on the machine table, andafter passing through the tension adjusting device and then passing through the pressing wheel device, a wound wire is wound through the roll-up device; a large pressing wheel is arranged between a small pressing wheel and a roll-up disc to play a role of transition, therefore, the small pressing wheel getsaway from limit of the roll-up disc, the small pressing wheel does reciprocating movement on the surface of the large pressing wheel and can move to the very edge of the large pressing wheel, meanwhile, the axial distance of the large pressing wheel is the same as that of thecore of the roll-up disc so that the wound wire can be directly guided to the edge of the roll-up disc through cooperation of the small pressing wheel and the large pressing wheel, the problem of edge wire winding is solved, the end face is flat, the wound wire has the sense of layering, the accuracy of products is greatlyimproved, and the qualification rate of the products is greatly increased.

Owner:TAICANG HONGHAI PRECISION MACHINERY CO LTD

A fish-breeding axial-flow paddle turbine

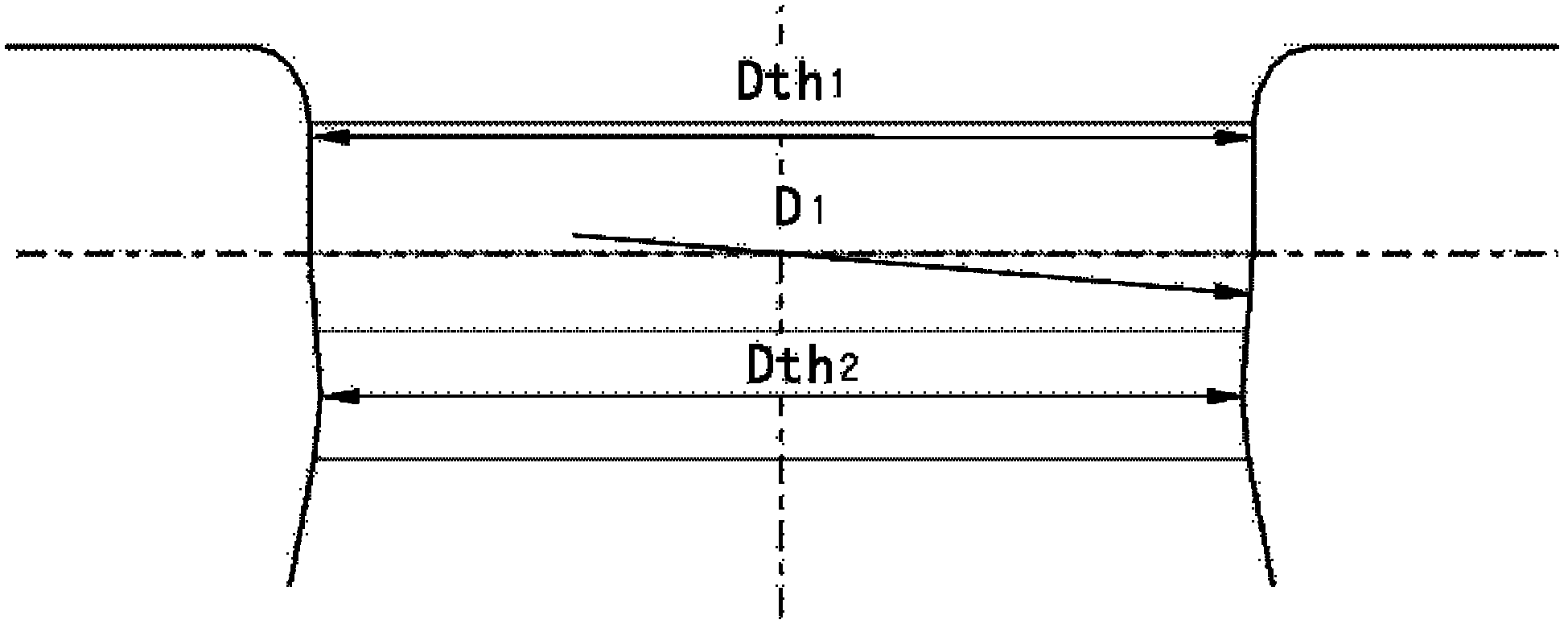

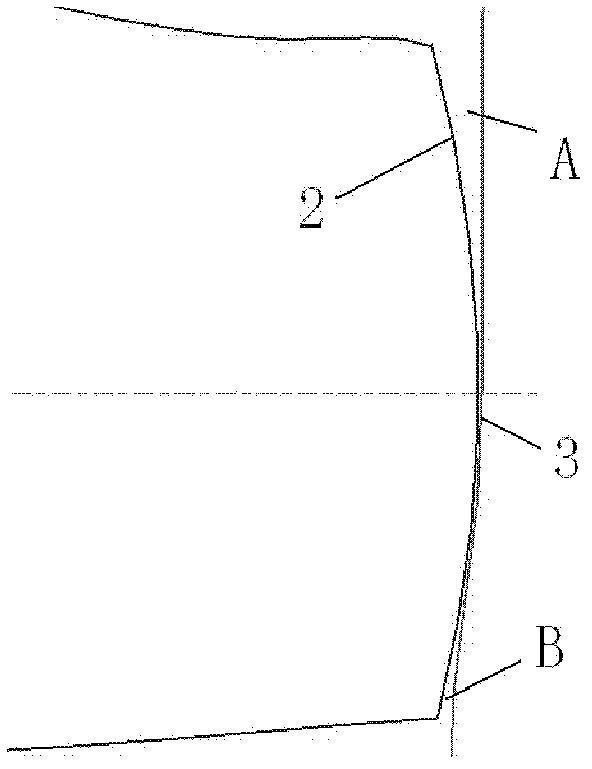

InactiveCN102278260AIncrease wrap angleSufficient lengthHydro energy generationReaction enginesBroodstockWater turbine

The invention relates to a parent-fish-type movable propeller turbine which comprises a runner chamber, a runner hub arranged in the runner chamber, blades connected with the periphery of the implemental runner hub and a guide vane connected with the top of the implemental runner chamber, wherein the runner hub comprises an upper cylindrical section, a spherical section, a lower cylindrical section and two frustum sections which are successively arranged; and the inner wall of the runner chamber successively comprises an cylindrical section, a middle spherical section and a lower throat section. The turbine is characterized in that the spherical section of the runner hub is composed of a plurality of projecting eccentric spherical crowns, and the quantity of the eccentric spherical crownsare same as that of the blades; each blade is respectively fixedly connected to the corresponding eccentric spherical crown on the runner hub, and the diameter of the cylindrical section of the runner chamber is lower than 0.98 times that of the spherical section; and the diameter of the throat section of the runner chamber is lower than 0.96 times that of the spherical section, the excircle arc semidiameter of the throat section is 0.02D1-0.1D1, the D1 represents the diameter of the runner chamber, and the spherical section of the runner chamber is a global section. The turbine provided by the invention can be widely used in hydroelectric installations.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES +1

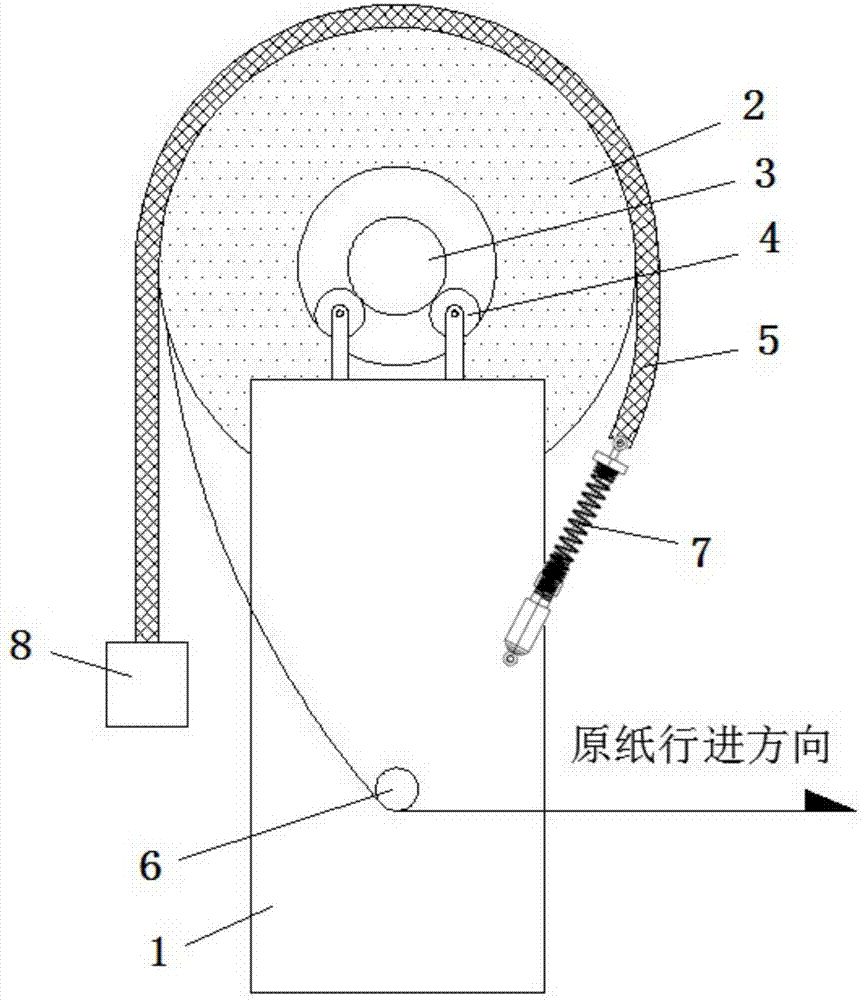

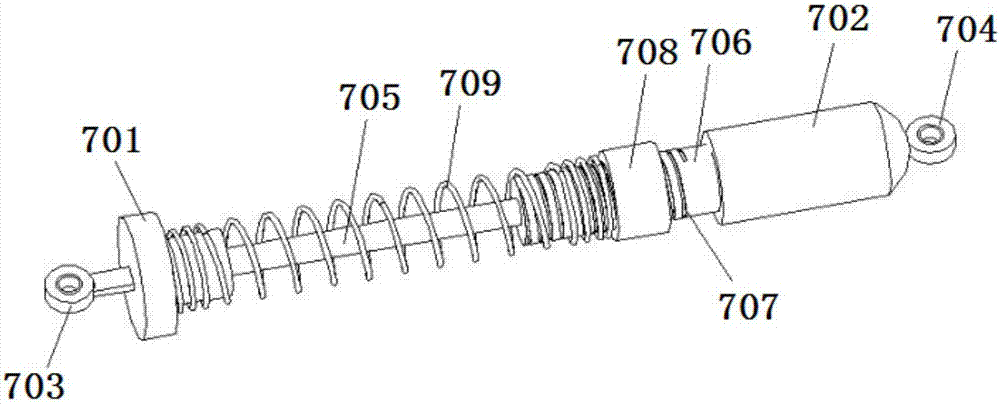

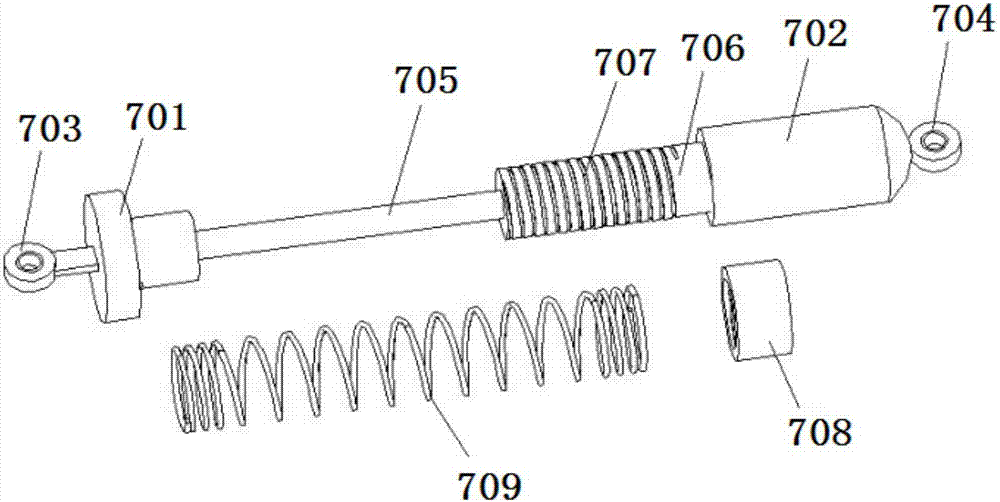

Tension stable type unrolling device for bag making machine

InactiveCN107010440AReduce frictional torqueIncrease wrap angleWebs handlingPeak valuePulp and paper industry

The invention discloses a tension stable type unrolling device for a bag making machine. The tension stable type unrolling device comprises a machine frame and a raw paper tube. A paper guide roller is fixed to the lower portion of the machine frame. The lower end of a paper rolling shaft of the raw paper tube is provided with a pair of rolling bearings. The outer side of the upper portion of the raw paper tube is provided with a damping belt. One end of the damping belt is fixedly connected with the lower portion of the machine frame through a damping shock absorber, and a balance weight hammer is hung to the other end of the damping belt. The damping shock absorber is composed of a columnar front bracket, a cylindrical rear bracket, a front pull ring, a rear pull ring, a piston rod, an adjusting column, a thread connection portion, an adjusting sleeve and a spring. The inner sides of the front bracket and the rear bracket are connected through the piston rod and the adjusting column. The adjusting column is rotationally connected with the adjusting sleeve through the thread connection portion. The spring is limited between the front bracket and the adjusting sleeve. The damping shock absorber is additionally arranged at the fixed end of the damping belt, the peak value of tension of raw paper can be reduced in the starting process, the raw paper can be prevented from being pulled apart, a paper roll can be rapidly braked in the stop process, and the damping shock absorber shrinks to enable the paper roll to rotate reversely, and looseness of the raw paper is reduced.

Owner:龙口思源塑业有限公司

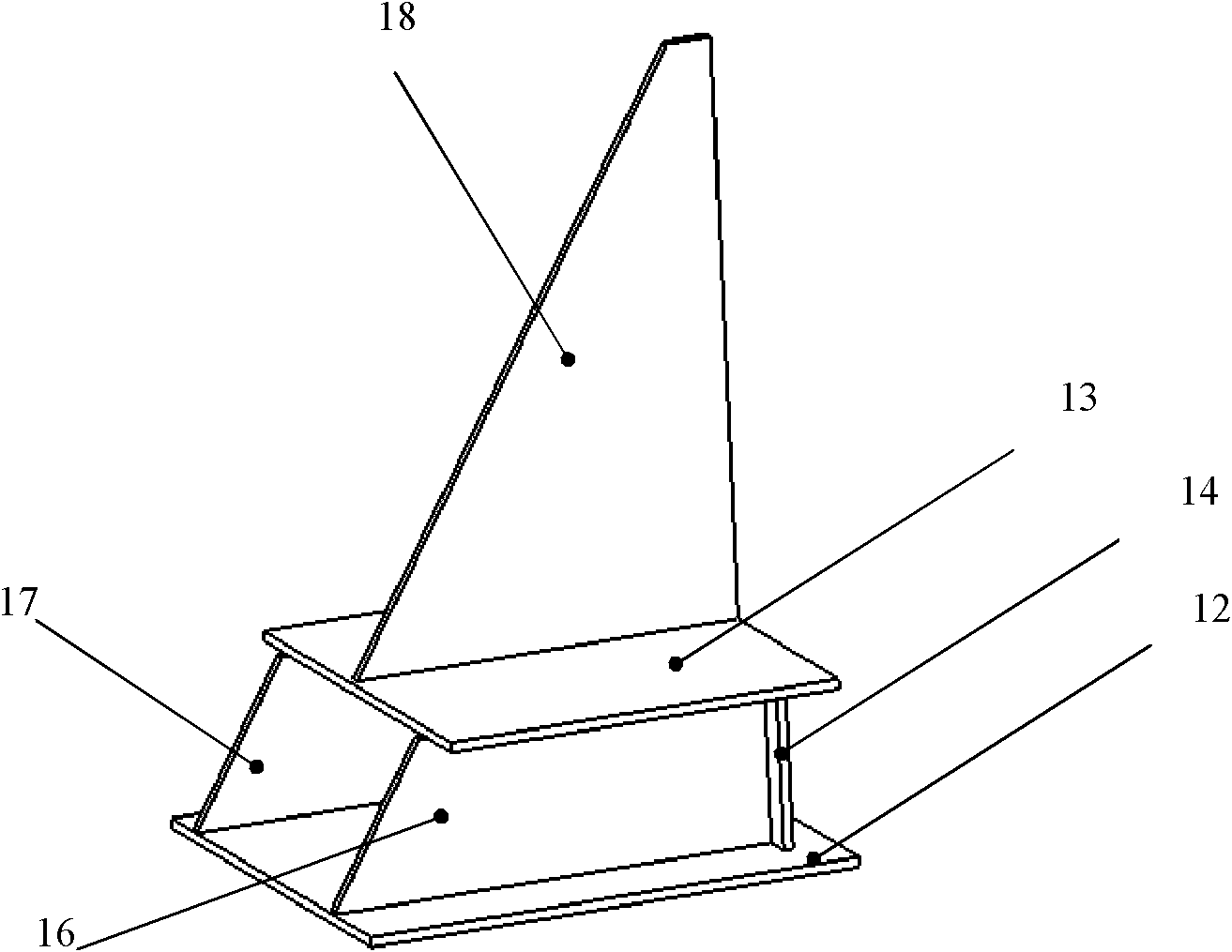

Traction sleeper device

The invention provides a traction sleeper device comprising a traction beam and sleeper beams; the sleeper beams are symmetrically arranged at both sides of the traction beam; the sleeper beams comprise web plates and lower cover plates arranged below the web plates; the traction sleeper device is characterized in that the sleeper beams also comprise reinforcing rib plates; the reinforcing rib plates are arranged on the web plates; transverse and longitudinal reinforcing rib plates and side-bearing reinforcing rib plates are added to the positions of the web plates of the sleeper beams of the traction sleeper device so as to form a box-shaped integral bearing structure, and the defect of high stress level of the joint of the web plates and a traction beam of a traction sleeper structure of a tank car of a traditional railway in China under the working condition of longitudinal and vertical loads is overcome; and moreover, a supporting post of a short side pipe is arranged, an original supporting post structure of a side pipe is changed, the center of the circle of the supporting post of the short side pipe is arranged along a radial direction, the wrap angle is increased, the diameter is increased, the stress concentration level of the nearby position of the upper end of the supporting post of the side pipe of an original structure is lowered, car jacking beams are arranged and are in grouped welding to form a box-shaped structure with favorable stress, and the stress concentration level of the nearby position of the upper end of the supporting post of the side pipe of the original structure is lowered.

Owner:XI AN RAILWAY TRANSPORTATION EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com