Traction sleeper device

A technology for pulling pillows and bolsters, which is used in transportation and packaging, transportation of passenger cars, tankers, etc., can solve the problems of stress concentration and low reliability of side tube struts, and achieves reduction of stress concentration level, increase of wrap angle, and increase of diameter. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

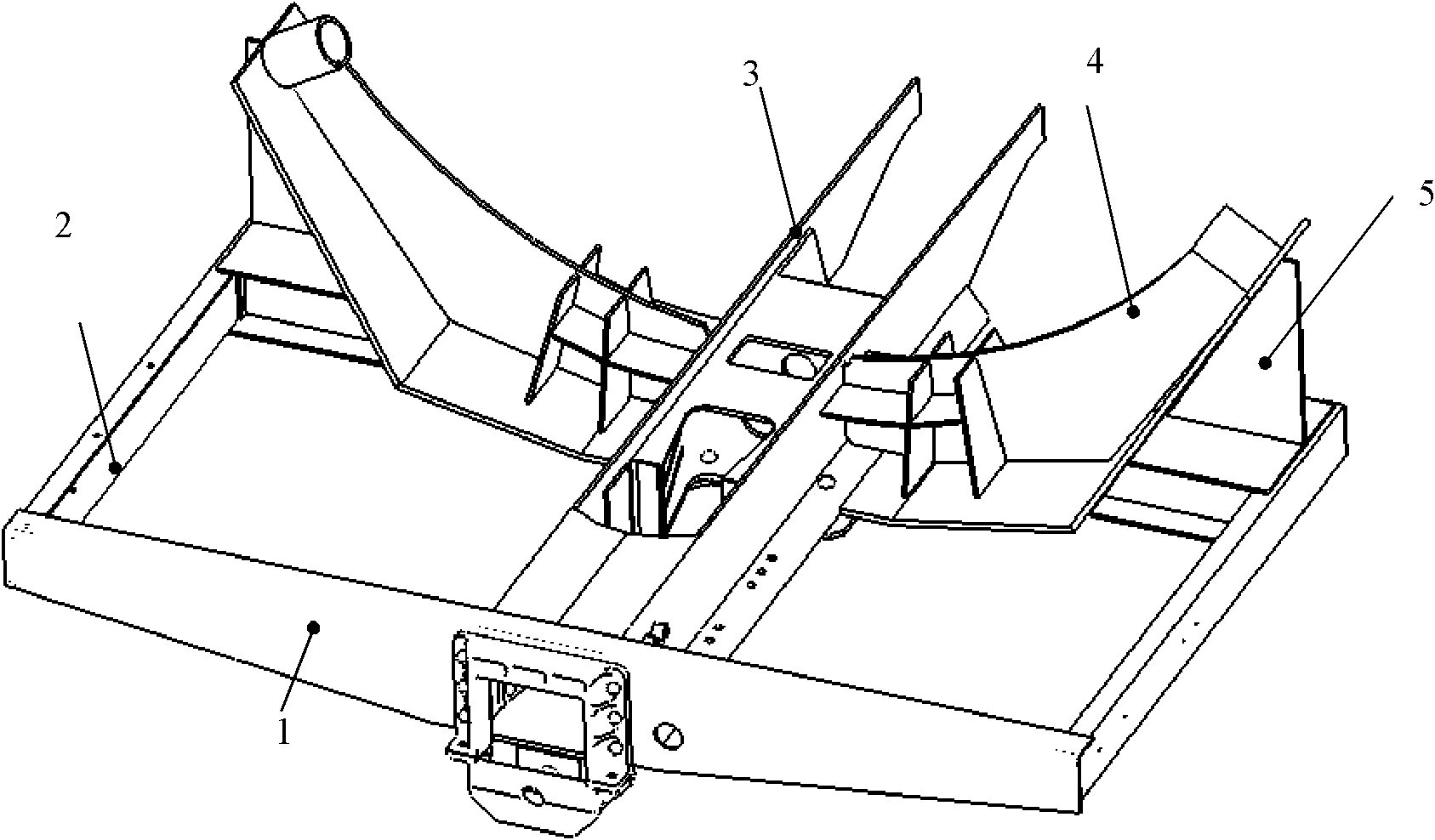

[0025] See figure 1 , The preferred embodiment of a pillow-traction device involved in the present invention is:

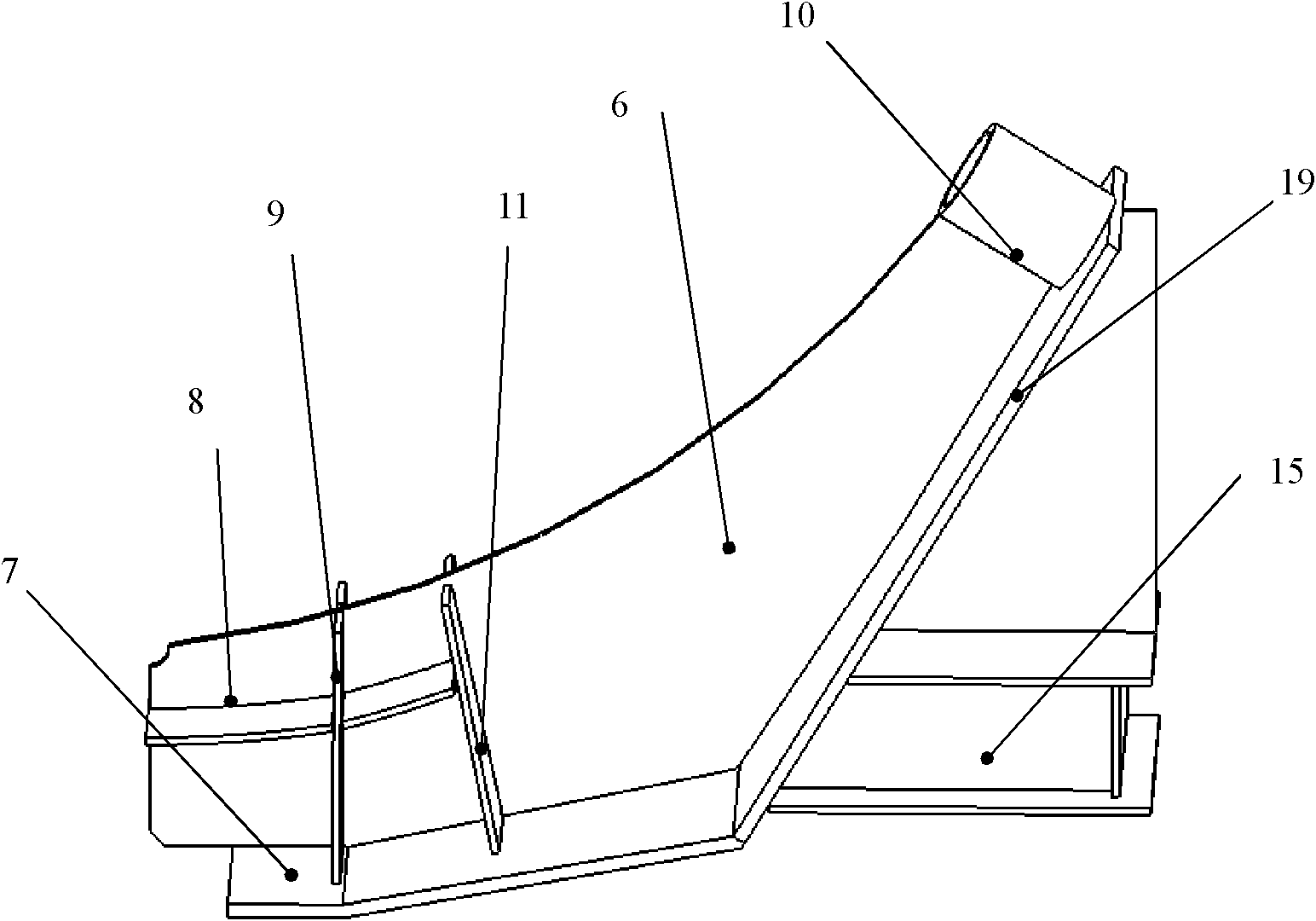

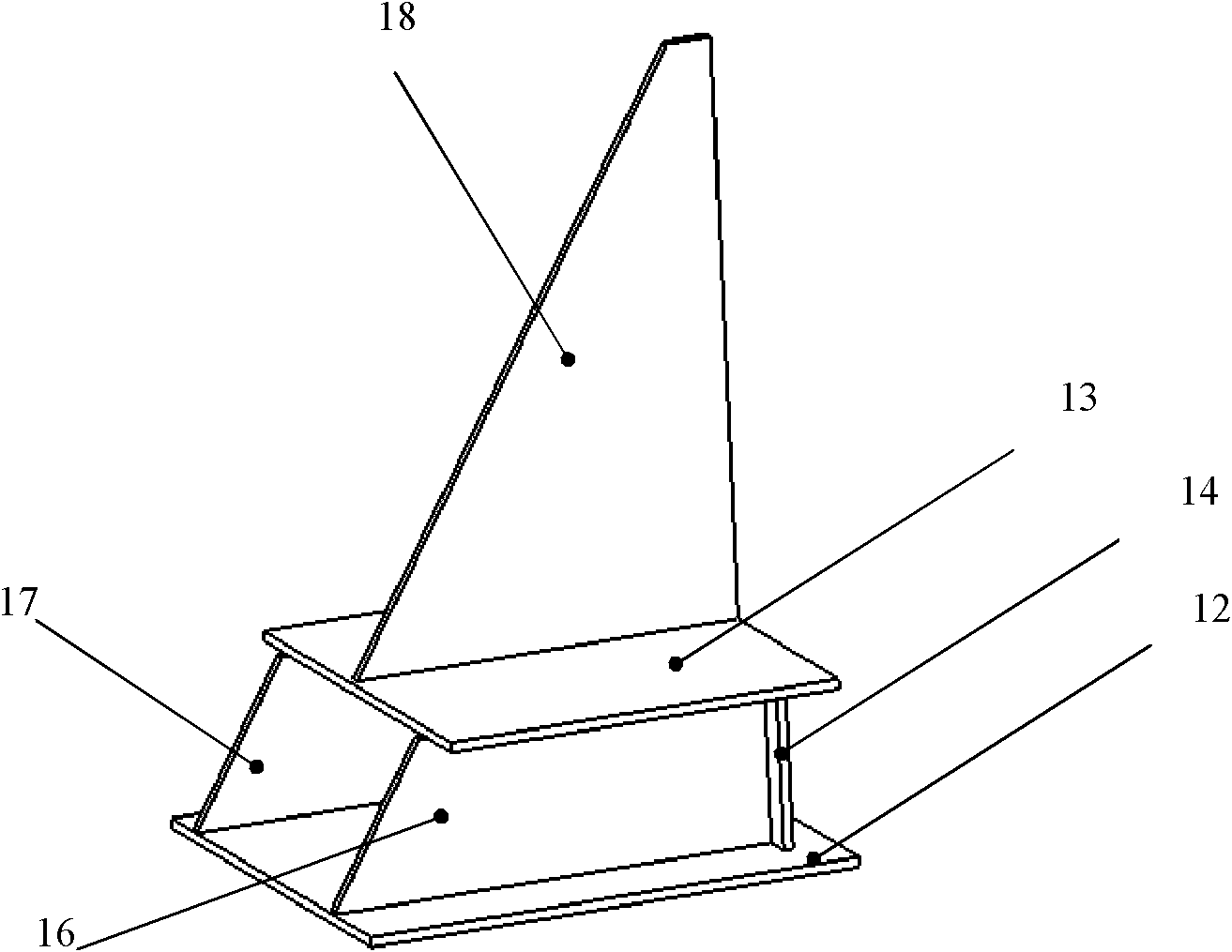

[0026] The device mainly includes an end beam 1, a side beam 2, a traction beam 3, and a corbel 4; the side beam 2 is vertically connected to both ends of the end beam 1; the traction beam 3 is vertically arranged in the middle of the end beam 1; the corbel 4 is symmetric It is arranged on both sides of the traction beam 3, and its other end is connected with the other end of the side beam 2. The end beam 1, the side beam 2, and the traction beam 3 can all adopt the structure in the prior art; the corbel 4 of the present invention includes a web The plate 6, the lower cover plate 7 arranged under the web 6 and the stiffener plate; the stiffener plate can be arranged vertically on the web 6, which can reduce the longitudinal and vertical load at the connection between the web 6 and the traction beam 3 Stress under working conditions.

[0027] The stiffener plate of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com