Engine accessory system

An accessory system and engine technology, which is applied in the direction of machines/engines, mechanical equipment, etc., can solve the problems of reducing the control effect of the tensioner on the generator, and achieve the effects of improving starting performance, increasing utilization rate, and improving work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

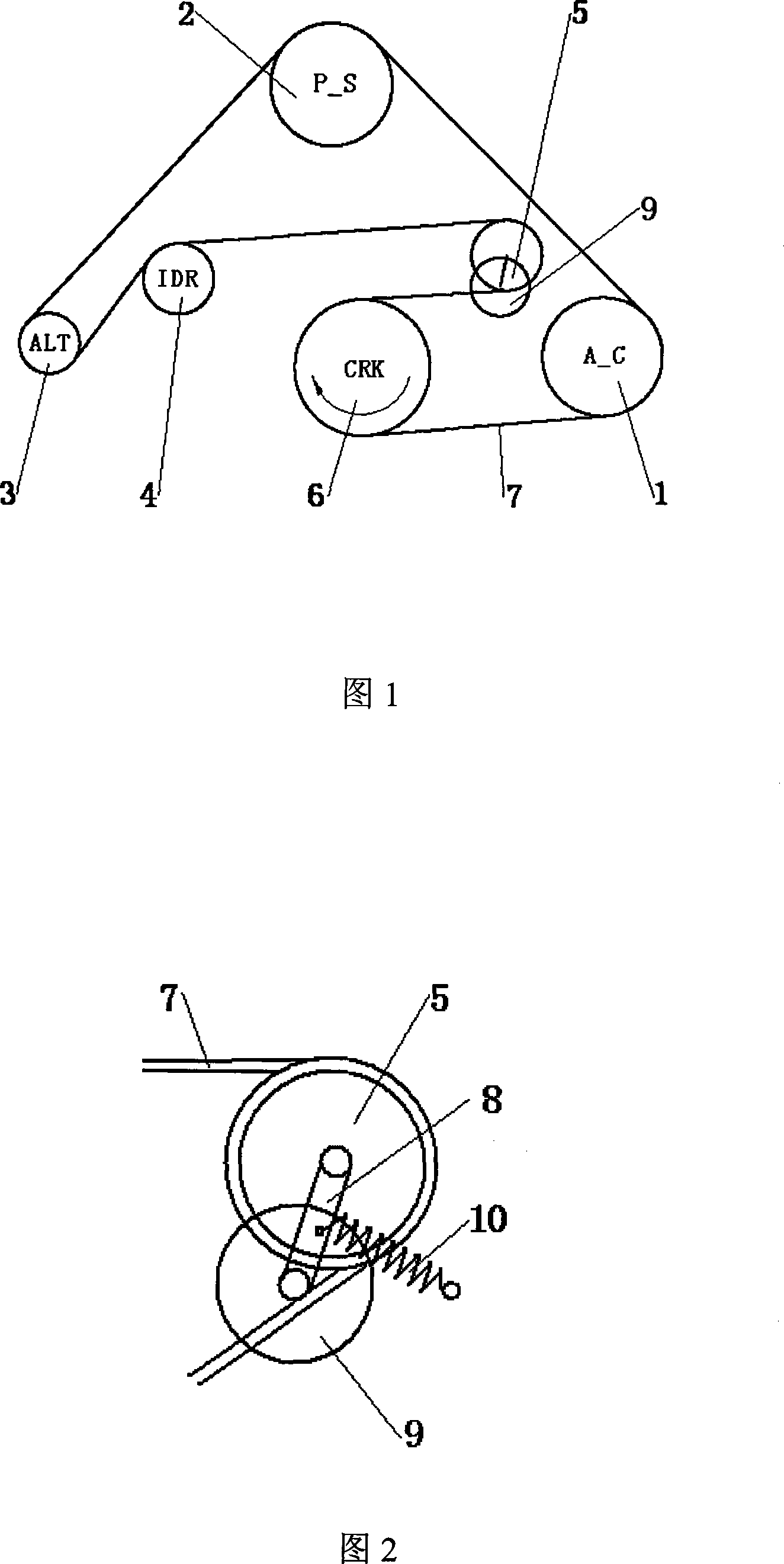

[0027] The pulley 1 of the air conditioner compressor in the transmission mechanism of the engine accessory system is arranged at a position close to the tight side of the pulley 6 of the crankshaft.

[0028] The air conditioner compressor is an accessory with a large static moment of inertia, and it is placed on the tightest side of the V-belt 7, which can improve the utilization rate of the V-belt 7 for the air-conditioner compressor, make the air-conditioner compressor enter the working state faster, and improve the The starting performance of the air conditioning system, while reducing the slip rate, thereby improving the performance of the air conditioning system.

Embodiment 2

[0030] Based on Embodiment 1, the transmission mechanism of the engine accessory system, from the loose side to the tight side of the crankshaft pulley 6, according to the tension pulley 5, idler pulley 4, generator pulley 3, power steering pump belt Set the order of wheel 2 and air conditioner compressor pulley 1.

[0031] An automatic tensioning mechanism is installed in the accessory system, and the automatic tensioning mechanism must be placed on the loosest side of the V-ribbed belt 7. The accessories next to the tensioning mechanism are generators, power steering pumps, air-conditioning compressors, and air-conditioning compressors. Be sure to place it on the tightest edge of the V-belt 7.

[0032] The moment of inertia of the power steering pump is in the middle of all accessories, so it is arranged between the generator and the air-conditioning compressor, which can meet the requirements of the steering system in general.

[0033] Arrange the automatic tensioning mech...

Embodiment 3

[0035] Based on Embodiment 1 and Embodiment 2, the tension pulley 5 is arranged on the outer circumference of the V-ribbed belt 7, so that the V-ribbed belt 7 forms an indentation there. Since the tension pulley 5 is arranged next to the crankshaft pulley 6 and is on the loosest side of the V-ribbed belt 7, the tensioning pulley 5 makes the wrap angle of the V-ribbed belt 7 larger on the crankshaft pulley 6 , making the transmission more efficient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com