A fish-breeding axial-flow paddle turbine

A water turbine and fish-shaped technology, which is applied in the direction of reaction engines, hydroelectric power generation, mechanical equipment, etc., can solve the problems of relatively large pressure drop, cavitation, fish damage, etc., to reduce the wedge-shaped gap, increase the work area, Increased wrap angle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

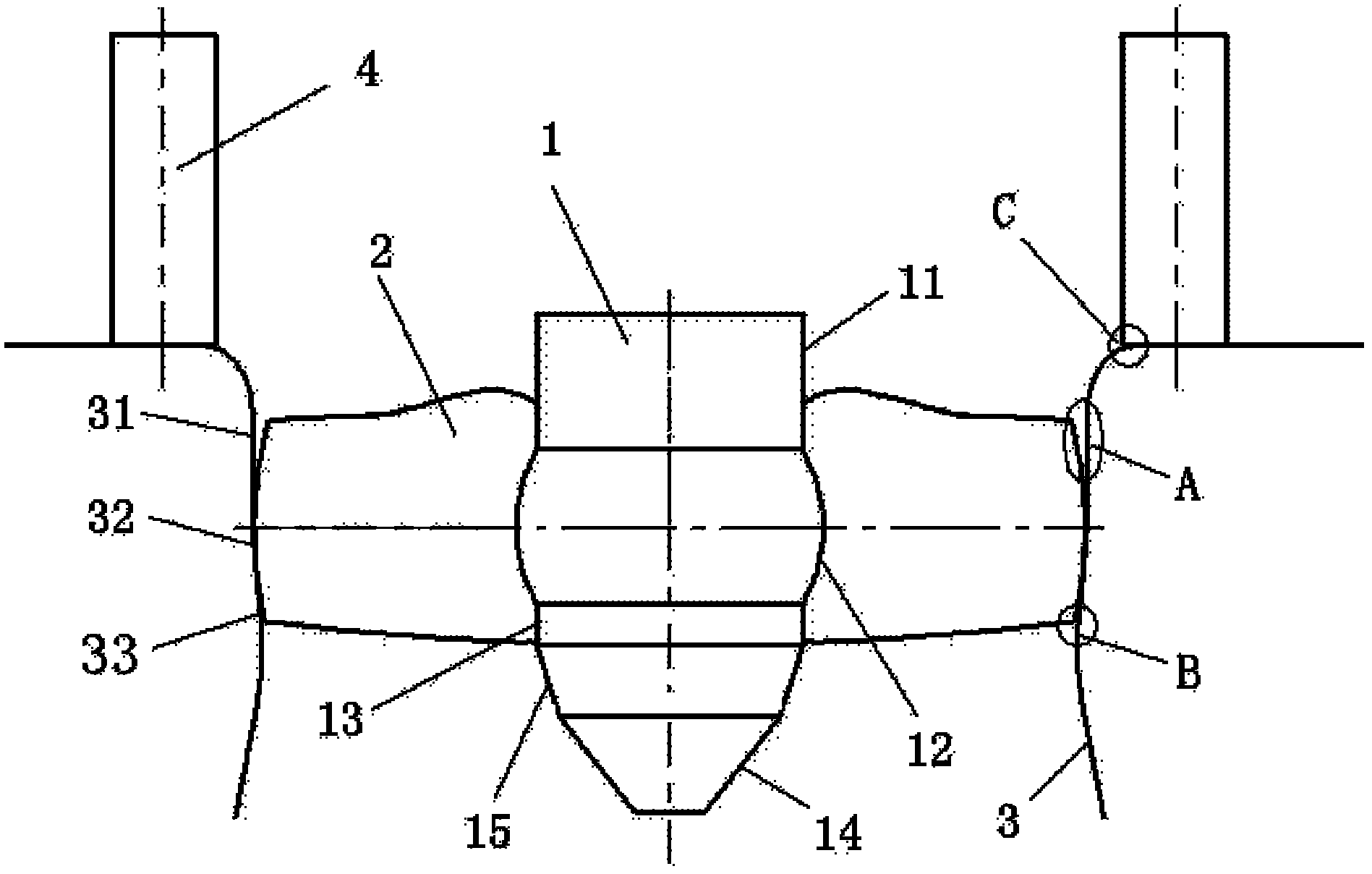

[0028] Below in conjunction with accompanying drawing and embodiment the present invention is further described

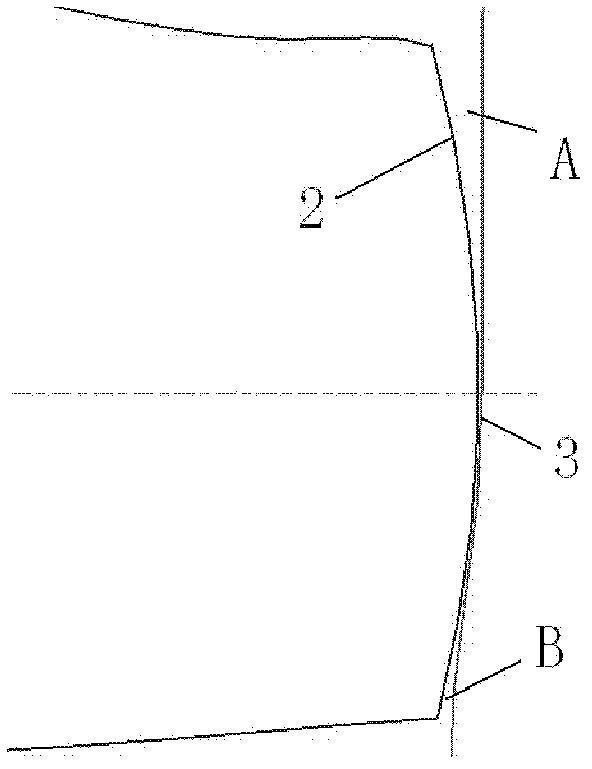

[0029] The improvement of the present invention to the conventional technology includes two main contents, one is to improve the runner body 1, increase the wrapping angle of the blade 2 to the runner body 1, and increase the blade 2 on the basis of avoiding the "wedge gap". 2; the second is to improve the runner chamber 3, increase the wrap angle of the runner chamber 3 to the blade 2, and increase the outer edge length of the blade 2 on the basis of avoiding the "wedge gap".

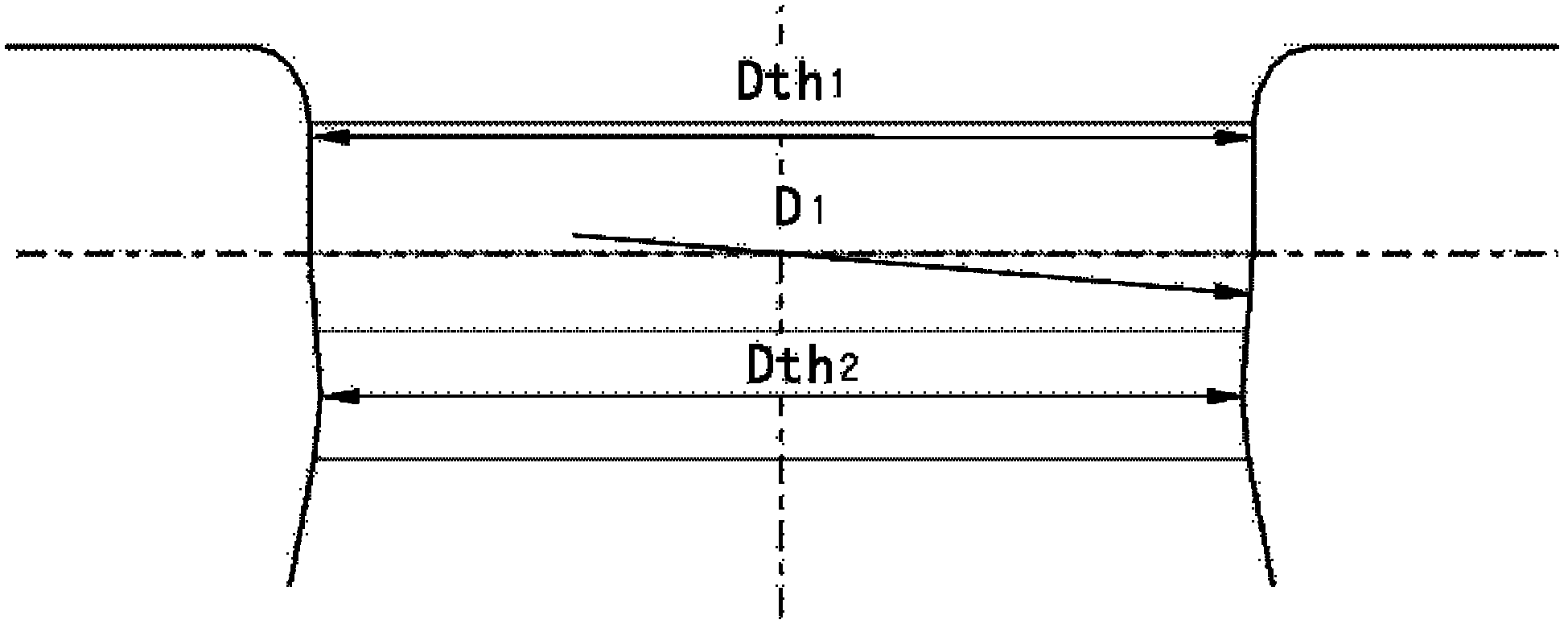

[0030] Such as Figure 8-10 As shown, the runner body 1 of the present invention also includes an upper cylindrical section 11 , a spherical section 12 , a lower cylindrical section 13 and two frustum sections 14 , 15 arranged in sequence, the same as the conventional technology. But the spherical segment 12 of the present invention adopts some eccentric spherical caps 16 (the present embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com